JULY 2011

Note: Installation and Glazing Manuals are product specific. FOR REVIEW ONLY!

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2 – 4

Outside Glaze

Non Thermal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 5 – 11

Inside Glaze Screw Spline

Non Thermal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 12– 17

Stack System Outside Glaze . . . . . . . . . . . . . . . . . . . . . . Page 18 – 23

FG-3000 Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 24– 27

Infill Thickness Options Chart . . . . . . . . . . . . . . . . . . . . . . Page 28

TABLE OF CONTENTS

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

JULY 2011

1

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

GENERAL INFORMATION

The Oldcastle BuildingEnvelope (2 x 4 1/2) system represents the latest in product

development technology complemented by dealer on-the-job input and experience. Proper use of these systems will assure optimum results in erection

and long term performance

Oldcastle BuildingEnvelope does not control the application nor selection of its product

configurations, sealant or glazing materials and assumes no responsibility

thereof. It is the responsibility of the owner, architect and installer to make

these selections in strict compliance with applicable laws and building codes.

PROTECTION AND STORAGE:

Handle the material carefully. Do not drop from the truck. Stack with adequate separation so that the material will not rub together. Store material off

the ground. Protect against the elements and other construction hazards by

using a well ventilated covering. Remove material from package if it is wet or

is located in a damp area.

CHECK MATERIAL:

Check all material upon arrival for quality and to assure against shipping

damage. Any visible damage must be noted on the freight bill at the time of

receipt. If a claim is required, then the receiving party must process a claim

with the freight company.

Completely check construction which will receive your materials against contract documents. Notify the general contractor by letter of any discrepancies

before proceeding with the work. Failure to do so constitutes acceptance of

work by other trades.

Check shop drawings and installation instructions to become familiar with the

project. The shop drawings take precedence and include specific details for

the project. The installation instructions are of a general nature and cover the

most common conditions. Due to varying job conditions, all sealants used

should be approved by the sealant manufacture, to insure they will function

for conditions shown on instructions and shop drawings. They must be compatible with all surfaces in which adhesion is required, including other sealant

surfaces. Use primers where directed by manufacturer of sealants. Be sure

to properly store sealants at recommended temperatures and check sealant

for remainder of shelf life before using.

FIELD CONDITIONS:

• Do not install wall if there is a walk way with a downslope towards an

entrance or a storefront

• All materials to be installed plumb, level, and true. Aluminum to be placed

in direct contact with the masonry or incompatible materials, should be isolated with a heavy coat of zinc-chromate or bituminous paint.

• After sealant is set and a representative amount of the wall has been

glazed (250 square feet or more), run a water hose to check installation. On

large jobs, hose test should be repeated during glazing operation. Test

should be conducted in accordance with AAMA 501.2 specifications.

• Coordinate protection of installed materials with general contractors and

other trades.

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

™

™

JULY 2011

2

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

GENERAL INFORMATION CONT.

CLEANING MATERIALS:

Cement, plaster, terrazzo, alkaline and acid based materials used to clean

masonry are very harmful to finishes and should be removed with water and

a mild soap immediately or permanent staining will occur. A spot test is recommended before any cleaning agent is used.

EXPANSION JOINTS:

Expansion joints and perimeter seals shown in these instructions and in the

shop drawings are shown at normal size. Actual dimensions may vary due to

perimeter conditions and/or differences in metal temperature between the

time of fabrication and time of installation. For example, a 12 foot unrestrained length of aluminum extrusion can expand or contract 3/32 of an inch

over a 50° F change. Any movement potential should be accounted for at the

time of the installation.

THERMAL IMPROVEMENT SUGGESTIONS:

To maintain or improve your wall installation, the following items should be

considered:

A. Blinds or drapes prevent warm air from washing the window.

B. Warm air ventilators too far from the window will not adequately wash

the window with air to prevent condensation.

C. In extreme conditions, the fan of the heating system should not cycle

on and off but should run continuously.

D. Some heating systems have a water injection feature that can raise

humidity levels. The higher the humidity level the more likely condensation or frost will form. Raising the temperature and reducing the

humidity will usually solve the problem.

E. On rare occasions, an extremely cold storm may cause frost to appear

on the glass or framing. A space heater and electric fan blowing along

the plane of the window wall can reduce or eliminate this temporary

condition.

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

JULY 2011

3

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

GENERAL INFORMATION CONT.

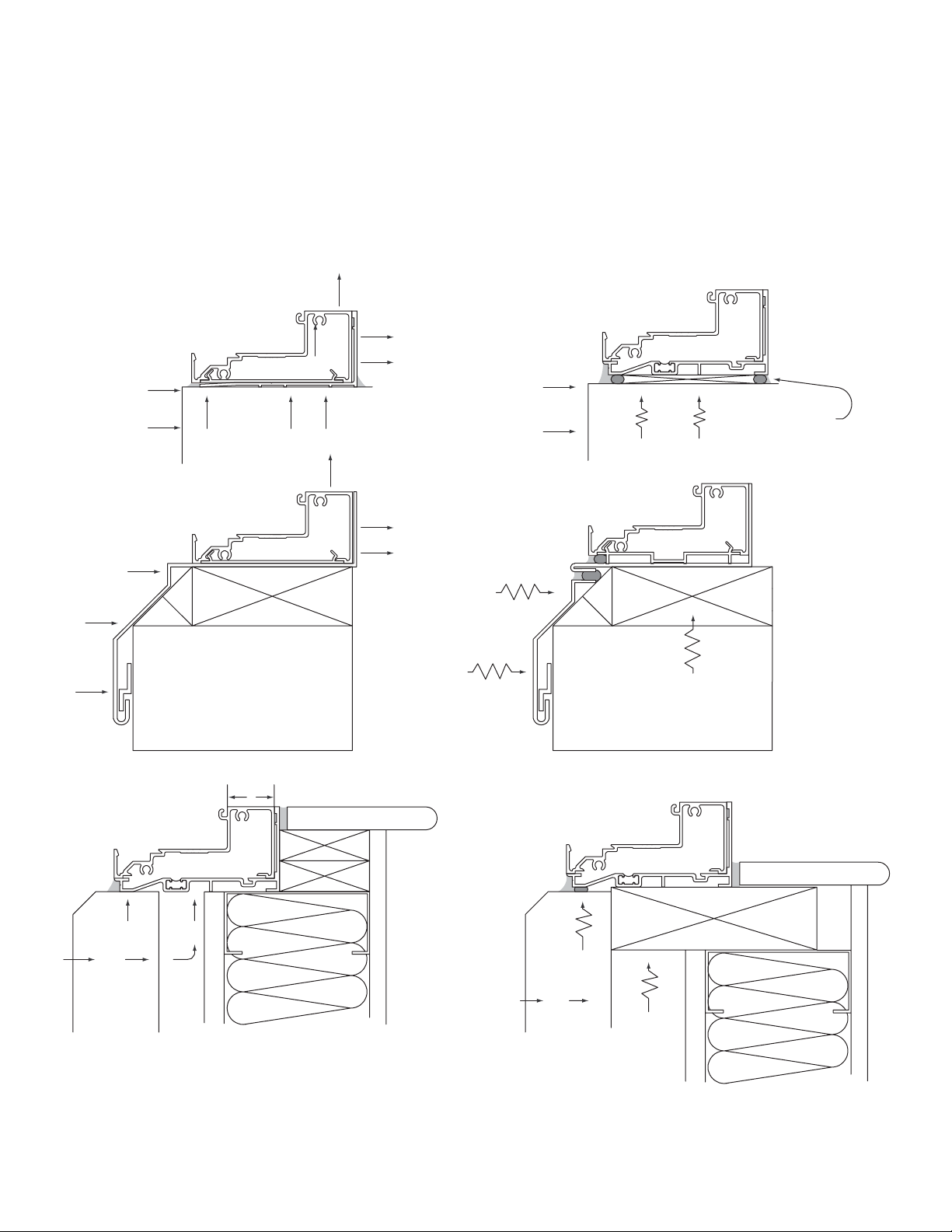

TO DERIVE THE GREATEST BENEFIT FROM YOUR STOREFRONT

INSTALLATION, WE RECOMMEND YOU REVIEW THE FOLLOWING.

NOT RECOMMENDED PREFERRED

SHIM & AIR SPACE.

MIN. 1/4" THICK.

JULY 2011

X

NOT ENOUGH METAL EXPOSED TO INTERIOR AT X.

4

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

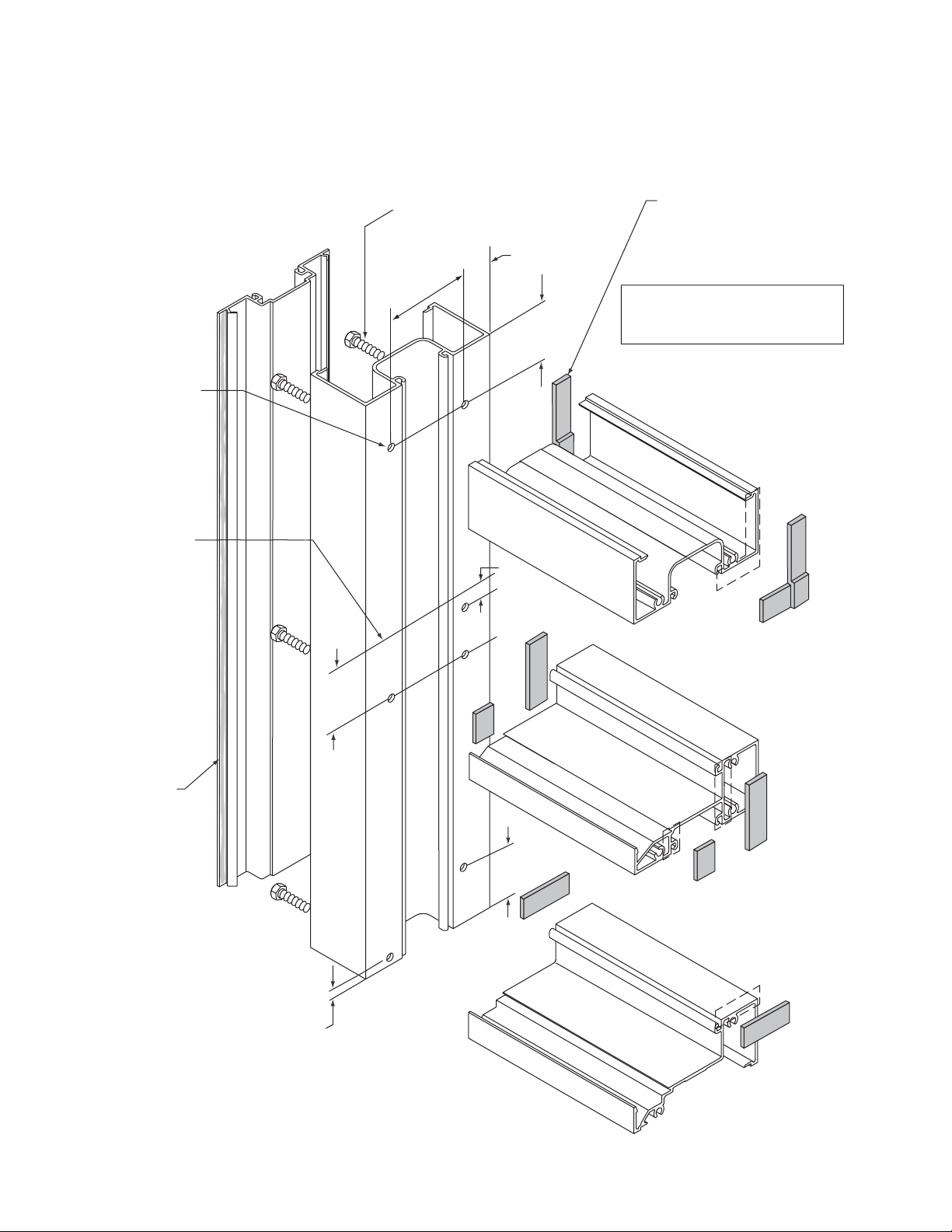

OUTSIDE GLAZE

SCREW SPLINE FRAME ASSEMBLY

SCHNEE-MOORHEAD

SM-5601 1/8"X1/2" TACKY TAPE.

PART # 4666 (OR EQUAL)

NOTE: KEEP TAPE AWAY FROM

SCREW SPLINES.

FS

-

8

(T

Y

P

.)

P

A

R

T #

: 1

0

2

23

(

T

YP

.

)

2

-

1

1/

1

6

"

1-3/4"

FG-3102

FG-3100

1/4"

1-3/4"

1-3/4"

1/4"

FG-3103

FG-3142

FG-3161

TOP 0F

HORIZONTAL

SEALANT

EXTERIOR ONLY

"F" (.257 DIA)

DRILL THRU TYP.

NOTE: USE RAZOR KNIFE TO

TRIM EXCESS SEALANT TAPE.

DO NOT PULL TAPE TO TRIM.

29/32" (TYP)

DJ-5 DRILL FIXTURE PART # 4562 IS ALSO AVAILABLE TO

AID FABRICATION FOR SCREW SPLINE FRAME ASSEMBLY.

FOR FASTER, MORE ACCURATE HOLE FABRICATION,

WE RECOMMEND THE EZ PUNCH FABRICATION TOOL.

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

JULY 2011

5

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

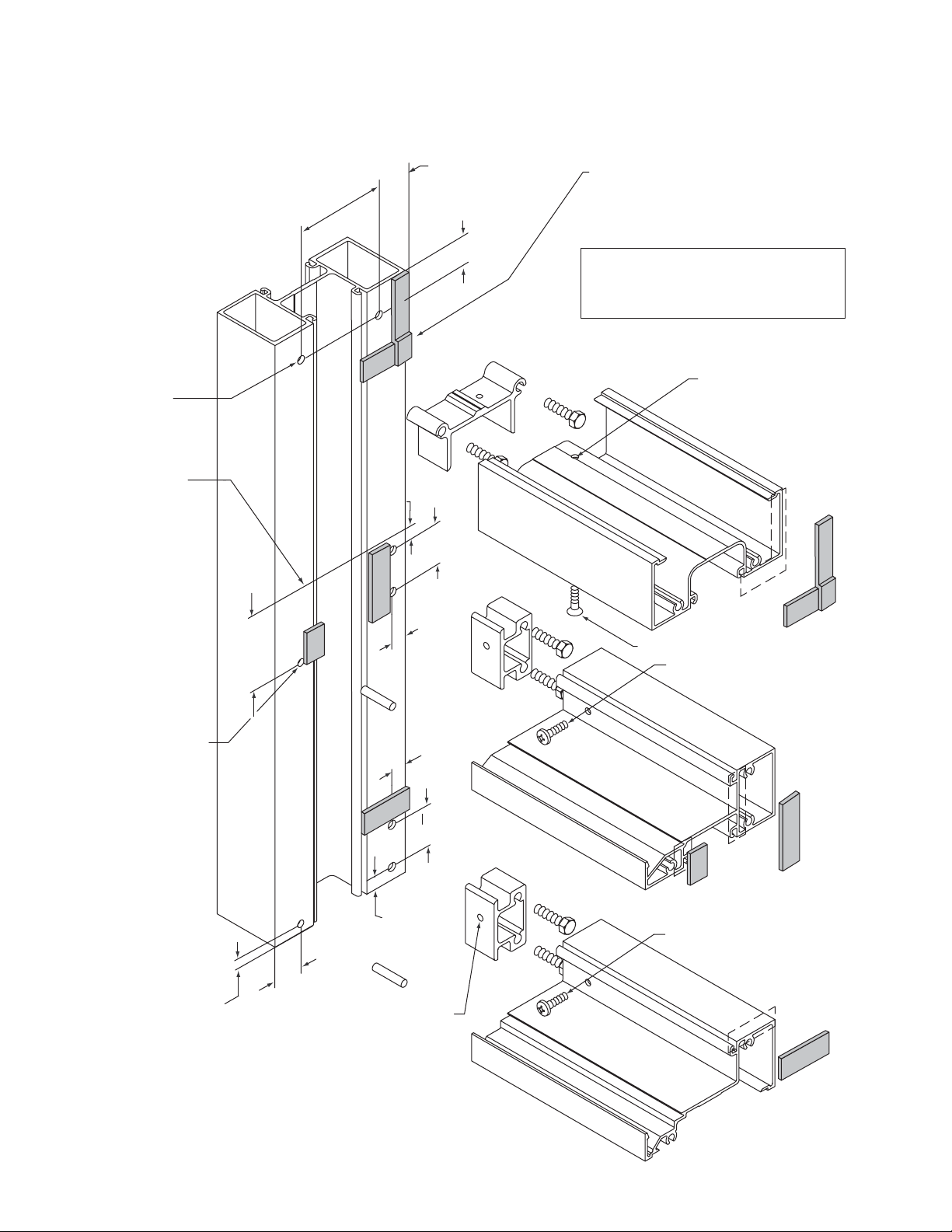

OUTSIDE GLAZE

SHEAR BLOCK FRAME ASSEMBLY

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

#11 TAP

HOLE TYP.

TOP 0F

HORIZONTAL

29/32"

"

16

/

11

-

2

9/16"

SCHNEE-MOORHEAD

SM-5601 1/8"X1/2" TACKY TAPE.

PART # 4666 (OR EQUAL)

NOTE: KEEP TAPE AWAY FROM

SCREW SPLINES.

NOTE: USE RAZOR KNIFE TO

TRIM EXCESS SEALANT TAPE.

DO NOT PULL TAPE TO TRIM.

*AC-108-1

PART #: 6533

TYP. #11 CLEAR HOLE

FG-3103

11/32"

1-1/4"

*AC-119-1

PART #: 6295

7/16"

1-3/4"

TYP.

.250 DIA. TYP.

FOR ROLL PIN

FG-3107

29/32"

1/4"

*PACKAGE INCLUDES SCREWS

TYP.

ROLL

PIN

7/16"

1-1/4"

*AC-119-1

PART #: 6295

11/32"

ROLL

PIN

TYP. #25

TAP HOLE

AND ROLL PIN

DJ-6 DRILL FIXTURE PART # 4563 IS ALSO AVAILABLE TO AID

FABRICATION FOR SCREW SPLINE FRAME ASSEMBLY.

FS-7

FS-6

FG-3142

FS-6

FG-3161

JULY 2011

6

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

OUTSIDE GLAZE

SILL FLASHING INSTALLATION

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

SEALANT

FG-2000-FP-4

PART #: 7949

FG-2169

NOTE: SILL FLASHING

SHOULD BE LEVEL AND

MAKE SURE IT IS NOT TILTED

TOWARD THE INTERIOR.

FLASHING ANCHORS MUST

BE CAP SEALED.

SHIM FLASHING AT

LOW SPOTS ONLY.

FLASHING SPLICE

FG-2000-FP-7

PART #: 7968

1/4" NOM.

JULY 2011

SEAL WITH A NON-SKINNING,

NON-HARDENING SEALANT.

FILL BREAK IN FLASHING

AND SEAL UNDER SPLICE.

7

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

OUTSIDE GLAZE

FRAME INSTALLATION

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

FG-1122 X 4" LONG

(PART SOLD IN STOCK LENGTHS.)

CLEAR HOLE

(SIZE DETERMIMED BY ANCHOR.)

FG-2188

PVC PROFILE

USED TO IMPROVE

INSTALLATION OF

BACKER ROD AND

PERIMETER SEALANT.

(OPTIONAL)

FG-2000-FP-3

PART #: 7944

1. ASSEMBLY WITHOUT FLASHING

IS NOT RECOMMENDED.

2. DO NOT ANCHOR WALL THRU

VERTICAL LEG OF FLASHING.

SEALANT

ACCESS HOLE AT ALL ANCHOR LOCATIONS.

(SIZE DETERMINED BY ANCHOR.)

DRILL CLEAR HOLE IN FLASHING THOUGH

ANCHOR CLIP. THEN INJECT SEALANT INTO

HOLE IN FLASHING AND UNDER ANCHOR CLIP.

JULY 2011

ANCHOR SIZE AND FREQUENCY SHOULD BE DETERMINED BY STRUCTURAL REQUIREMENTS.

SILL ANCHOR FG-2000-FP-3 AND HEAD ANCHOR FG-2122 SHOULD BE LOCATED SO THAT

THE ANCHOR IS NOT MORE THAN 4" FROM EACH SIDE OF THE MULLION.

8

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

OUTSIDE GLAZE SILL FLASHING

INSTALLATION AND PERIMETER SEAL

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

E

E

APPLY SEALANT ALONG LENGTH OF SUB SILL

AT AREAS A & B.

LAY FLASHING ON SLAB AND SHIM ONLY AT LOW

AREAS. RESEAL AT SHIM AREAS.

SPACE BETWEEN SILL AND FLASHING (C) TO BE

CONTINUOUSLY SEALED EXCEPT FOR 1/2"-3/4"

SPACE UNDER VERTICAL MULLIONS FOR WEEPAGE.

PRIOR TO INSTALLING FRAME, APPLY SEALANT

CONTINUOUSLY ALONG SILL FLASHING (D).

THIS WILL PROVIDE CONTINUOUS SEAL

BETWEEN SILL AND SILL FLASHING.

E

FG-2122

4" LONG

(PARTS SOLD IN

STOCK LENGTHS.)

E

NOTE: 1/2"- 3/4" WEEP HOLE

REQUIRED IN SEALANT AT

FLASHING (C)AT CENTER

LINE OF MULLION.

C

FG-2000-FP-3 PART #: 7944

THE QUALITY OF THE INSIDE AND OUTSIDE

PERIMETER SEALS (C AND E) MAY BE IMPROVED

BY USING FG-2188 RIGID PVC FILLER.

THE PART MAY BE USED IN FULL LENGTHS OR CUT

INTO PIECES. ITS PURPOSE IS TO PROVIDE

SUPPORT FOR THE BACKER ROD REGARDLESS

OF JOINT OR SIZE. PERIMETED SEAL (F) IS FOR

COSMETIC PURPOSES AND IS OPTIONAL.

A

B

D

F

JULY 2011

9

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

OUTSIDE GLAZE

SEALANT PROCEDURE FOR DOOR FRAME AT FLASHING

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

FG-3155

FG-2145

FG-3156

RUN SEALANT ONE INCH

ABOVE FLASHING.

JULY 2011

FLASHING IS BED IN

SEALANT AT DOOR JAMB.

LEAVE FRONT OF DOOR JAMB CLEAR OF

SEALANT FOR DRAINAGE PURPOSES.

*USE SHEAR BLOCKS AS SHOWN ON PAGE 6 TO SECURE TO TUBULAR FRAME.

DOOR FRAME IS ANCHORED BY FASTENERS THROUGH THRESHOLD

AND THROUGH DOOR FRAME HEADER.

DO NOT FABRICATE 2 PIECE DOOR FRAMES WITH POUR & DEBRIDGE PROFILES.

10

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

OUTSIDE GLAZE

GLAZING PROCEDURE

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

FG-1133

PART #: 364

VERTICAL GASKETS

RUN THRU.

NOTE:

FIRST, WET

BOTTOM OF SETTING

BLOCKS WITH SOAPY

WATER. ONCE GLASS IS SET,

PUSH AGAINST GASKET AT

SETTING BLOCK AREA.

FAILURE TO DO SO MAY CAUSE

DIAGONAL CRACKS TOWARDS

SETTING BLOCKS DUE TO GLASS

BENDING WHILE INSTALLING

GASKET(S) IN CORNERS.

FG-3144

GLAZING INSTALLATION INSTRUCTIONS

GLASS SIZE

7/8" OVER DAY LIGHT OPENING

SETTING BLOCK

SET AT 1/4 POINT OR 1/8 POINT OF HORIZONTAL LENGTH

DEPENDING ON LITE SIZE.

WATER DIVERTERS

GLAZE FROM BOTTOM TO TOP. INSTALL WATER DIVERTERS IN

HORIZONTAL ABOVE, AFTER LITE BELOW IS IN POSITION.

GLAZING GASKET

GASKET MAY BE INSTALLED ON ONE OR BOTH SIDES

SIMULTANEOUSLY. PROVIDE 3/8" ADDITIONAL GASKET

FOR EACH FOOT OF DAYLIGHT OPENING TO PROVIDE

ADEQUATE COMPRESSION FOR THE GLAZING INFILL.

NOTE: CLEAN GASKET WITH ISOPROPYL ALCOHOL PRIOR TO

SEALING CORNERS.

JULY 2011

11

FG-3146

PART #: 6471

FG-1000-FP-2

PART #: 6887

SET IN PLACE

WITH SEALANT.

0

15

MITER HORIZONTAL GASKET

TO FIT VERTICAL GASKET.

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

INSIDE GLAZE SCREW SPLINE FRAME ASSEMBLY

Most of the extrusions in this system are the same, only the

sill and its anchors are different. Note that the tapes used

for sealing the horizontals to mullions are located in a different manner.

The sill is designed so that sill anchors may be cap sealed

before the frame is installed. The frame is installed over the

the sill with twist-in anchors. This prevents any additional

screws from penetrating the sill and causing leaks under the

sill.

Multiple units require the use of split mullions. A minimum of

7/16" clearance between the jamb and sill end dam must be

provided. This will allow a minimum of 3/8" clearance to

move first unit sideways so the second unit with the same

clearance will clear the interlocking legs of the expansion

mull. Adjust frame locations before running perimeter seals.

OBE recommends using FG-2188 vinyl filler to improve

the perimeter seal.

OBE does not recommend the shear block or stack

method of assembly for inside glazing.

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

3/8"

MIN. CLEARANCE

5/16" CLEARANCE MIN. CLEARANCE

1/8" SPACE7/16"

JULY 2011

12

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

INSIDE GLAZE

SCREW SPLINE FRAME ASSEMBLY

SCHNEE-MOORHEAD

SM-5601 1/8"X1/2" TACKY TAPE.

PART # 4666 (OR EQUAL)

NOTE: KEEP TAPE AWAY FROM

SCREW SPLINES.

(

T

Y

P

.

)

2-1

1

/

1

6

"

29/32" (TYP)

FS

-

8

(

TY

P

.)

P

A

RT

#

:

1

0223

1-3/4"

1/4"

FG-3102

TOP 0F

HORIZONTAL

SEALANT

EXTERIOR ONLY

"F" (.257 DIA)

DRILL THRU TYP.

1-3/4"

1-3/4"

FG-3100

FG-3161

FG-3142

FG-3103

NOTE: USE RAZOR KNIFE TO

TRIM EXCESS SEALANT TAPE.

DO NOT PULL TAPE TO TRIM.

1/4"

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

FOR FASTER, MORE ACCURATE HOLE FABRICATION,

WE RECOMMEND THE EZ PUNCH FABRICATION TOOL.

DJ-5 DRILL FIXTURE PART # 4562 IS ALSO AVAILABLE TO

AID FABRICATION FOR SCREW SPLINE FRAME ASSEMBLY.

JULY 2011

13

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

INSIDE GLAZE

SILL FLASHING INSTALLATION

T

FLASHING SPLICE

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

SEALANT

FG-3000-FP-4

PART #: 7947

FG-3217

1. ANCHORS DESIGNED TO TWIST IN.

2. SPACE ANCHORS MAX. 4" FROM

EACH SIDE OF MULLION.

3. BENT LEG ALWAYS TO EXTERIOR.

4. NOTE: STAKE ANCHORS TO PREVEN

HORIZONTAL MOVEMENT.

ANCHORS MUST FACE EXTERIOR

AS SHOWN.

INTERIOR

FG-3000-FP-3

PART #: 7948

NOTE: SILL FLASHING

SHOULD BE LEVEL AND

MAKE SURE IT IS NOT TILTED

TOWARD THE INTERIOR.

FLASHING ANCHORS MUST

BE CAP SEALED.

A SHIM UNDER FLASHING

IS THE PREFERRED METHOD

FOR BEST THERMAL RESULTS.

FG-3000-FP-11

PART #: 7979

1/4" NOM.

JULY 2011

14

SEAL WITH A NON-SKINNING,

NON-HARDENING SEALANT.

FILL BREAK IN FLASHING

AND UNDER SPLICE.

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

INSIDE GLAZE

FRAME INSTALLATION

FG-3000-FP-3

PART #: 7948

FG-3217

FG-2188

PVC PROFILE

USED TO IMPROVE

INSTALLATION OF

BACKER ROD AND

(OPTIONAL)

FG-2122 X 4" LONG

(PART SOLD IN STOCK LENGTHS.)

CLEAR HOLE

(SIZE DETERMIMED BY ANCHOR.)

ANCHOR SIZE AND FREQUENCY SHOULD BE DETERMINED BY STRUCTURAL REQUIREMENTS.

SILL ANCHOR FG-3000-FP-3 AND HEAD ANCHOR FG-2122 SHOULD BE LOCATED

SO THAT THE ANCHOR SCREW IS NOT MORE THAN 4" FROM EACH SIDE OF THE MULLION.

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

JULY 2011

31

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

INSIDE GLAZE, NON THERMAL SILL FLASHING

INSTALLATION AND PERIMETER SEAL

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

C

FG-2122

4" LONG

(PARTS SOLD IN

STOCK LENGTHS.)

C

C

FG-3210

APPLY SEALANT ALONG LENGTH OF SUB SILL

AT AREA A.

PRIOR TO INSTALLING FRAME, APPLY SEALANT

CONTINUOUSLY ALONG SILL FLASHING (B).

THIS WILL PROVIDE CONTINUOUS SEAL

BETWEEN SILL AND SILL FLASHING.

THE QUALITY OF THE INSIDE AND OUTSIDE

PERIMETER SEALS (C ) MAY BE IMPROVED BY

USING FG-2188 RIGID PVC FILLER.

THE PART MAY BE USED IN FULL LENGTHS OR CUT

INTO PIECES. ITS PURPOSE IS TO PROVIDE

SUPPORT FOR THE BACKER ROD REGARDLESS

OF JOINT OR SIZE. PERIMETED SEAL (D) IS FOR

COSMETIC PURPOSES AND IS OPTIONAL.

C

JULY 2011

THIS LEG MUST BE

TO EXTERIOR.

NOTE: 1/4" WEEP HOLE

REQUIRED IN FLASHING (E)

AT MID-LITE.

E

A

B

16

B

D

FG-3000-FP-3

PART #: 7948

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

INSIDE GLAZE

GLAZING PROCEDURE

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

FG-1133

PART #: 364

VERTICAL GASKETS

RUN THRU.

NOTE:

FIRST, WET

BOTTOM OF SETTING

BLOCKS WITH SOAPY

WATER. ONCE GLASS IS SET,

PUSH AGAINST GASKET AT

SETTING BLOCK AREA.

FAILURE TO DO SO MAY CAUSE

DIAGONAL CRACKS TOWARDS

SETTING BLOCKS DUE TO GLASS

BENDING WHILE INSTALLING

GASKET(S) IN CORNERS.

GLAZING INSTALLATION INSTRUCTIONS

GLASS SIZE

7/8" OVER DAY LIGHT OPENING

SETTING BLOCK

SET AT 1/4 POINT OR 1/8 POINT OF HORIZONTAL LENGTH

DEPENDING ON LITE SIZE.

WATER DIVERTERS

GLAZE FROM BOTTOM TO TOP. INSTALL WATER DIVERTERS IN

HORIZONTAL ABOVE, AFTER LITE BELOW IS IN POSITION.

GLAZING GASKET

GASKET MAY BE INSTALLED ON ONE OR BOTH SIDES

SIMULTANEOUSLY. PROVIDE 3/8" ADDITIONAL GASKET

FOR EACH FOOT OF DAYLIGHT OPENING TO PROVIDE

ADEQUATE COMPRESSION FOR THE GLAZING INFILL.

NOTE: CLEAN GASKET WITH ISOPROPYL ALCOHOL PRIOR TO

SEALING CORNERS.

JULY 2011

17

HP-17

PART #: 10267

FG-1000-FP-2

PART #: 6887

SET IN PLACE

WITH SEALANT.

0

15

MITER HORIZONTAL GASKET

TO FIT VERTICAL GASKET.

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

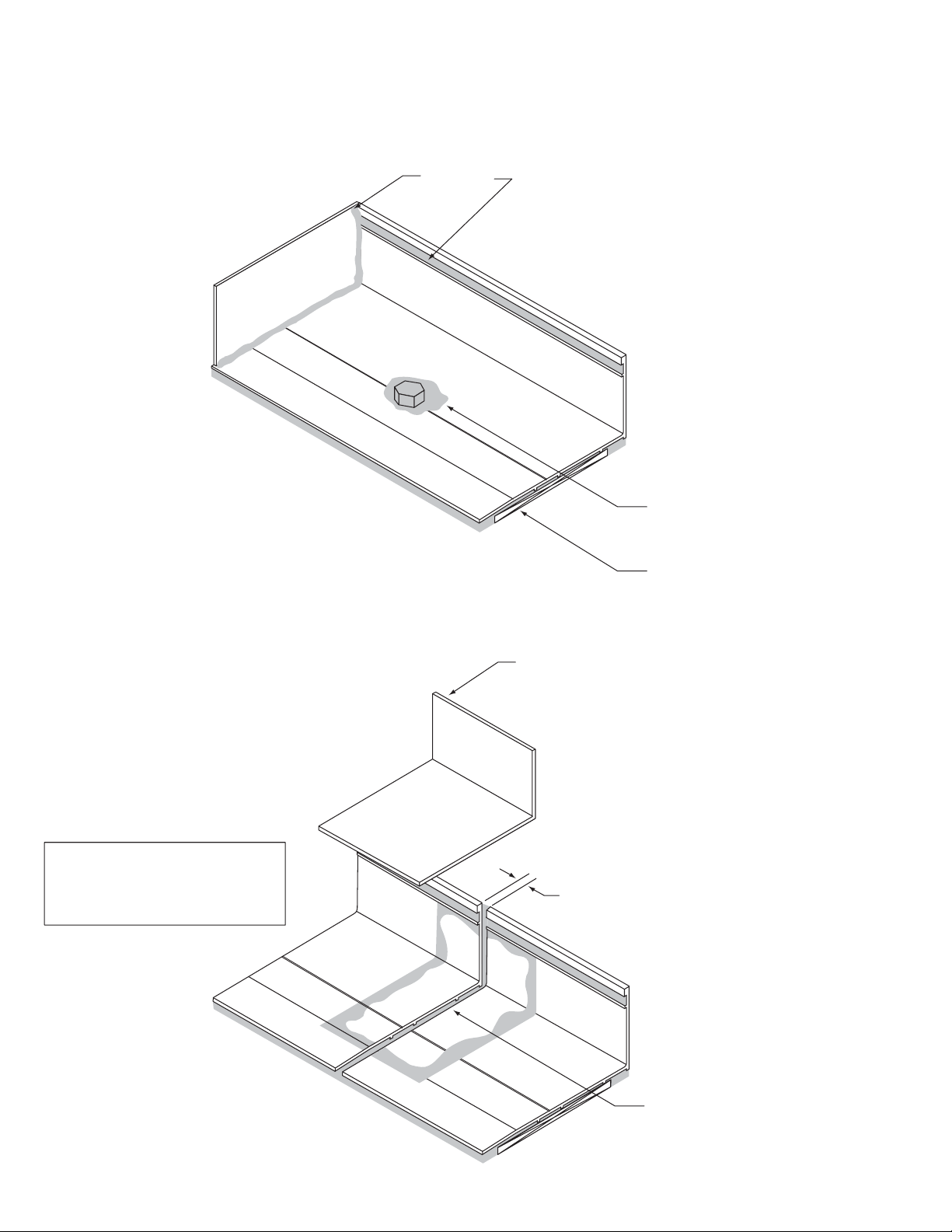

STACK SYSTEM

FRAME ASSEMBLY AND INSTALLATION

The assembly and sealant procedures are a part of the installation sequence

because of the stacking method.

HEAD CAN:

Anchor screws should be within 4" of each side of the intended mullion location. Head anchors AC-121-1 should be used if the height x width x design

load is 500 lbs. or more for one bay at the top of the mullion. Normally one

anchor screw at the middle of the lite or 24" O.C. is adequate for securing

the header. For unusual conditions, consult the OBE engineering department.

SILL CAN:

Shim can a minimum 1/4”

. Anchor sill can 24" O.C. and no more than 4" on

each side of intended mullion locations. Be sure weeps are located under

center line of mullion. Sill both sides of can.

HORIZONTAL HEAD AND SILL INSERT:

Members are cut 1/16” less than daylight opening to allow for incremental

expansion.

JAMB MEMBERS:

Remember all horizontals are cut 1/16” short. Do not over shim between jamb

and structure.

MULLIONS

Cut mullion length outside frame dimension 1-1/4 " . Install mullions by sliding

top end over anchor and rotating bottom into position.

RECOMMENDATION:

Prior to glazing, fill sill cavity with water to assure that end dams and anchors

are sealed. Then, run interior sill bead.

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

JULY 2011

46

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

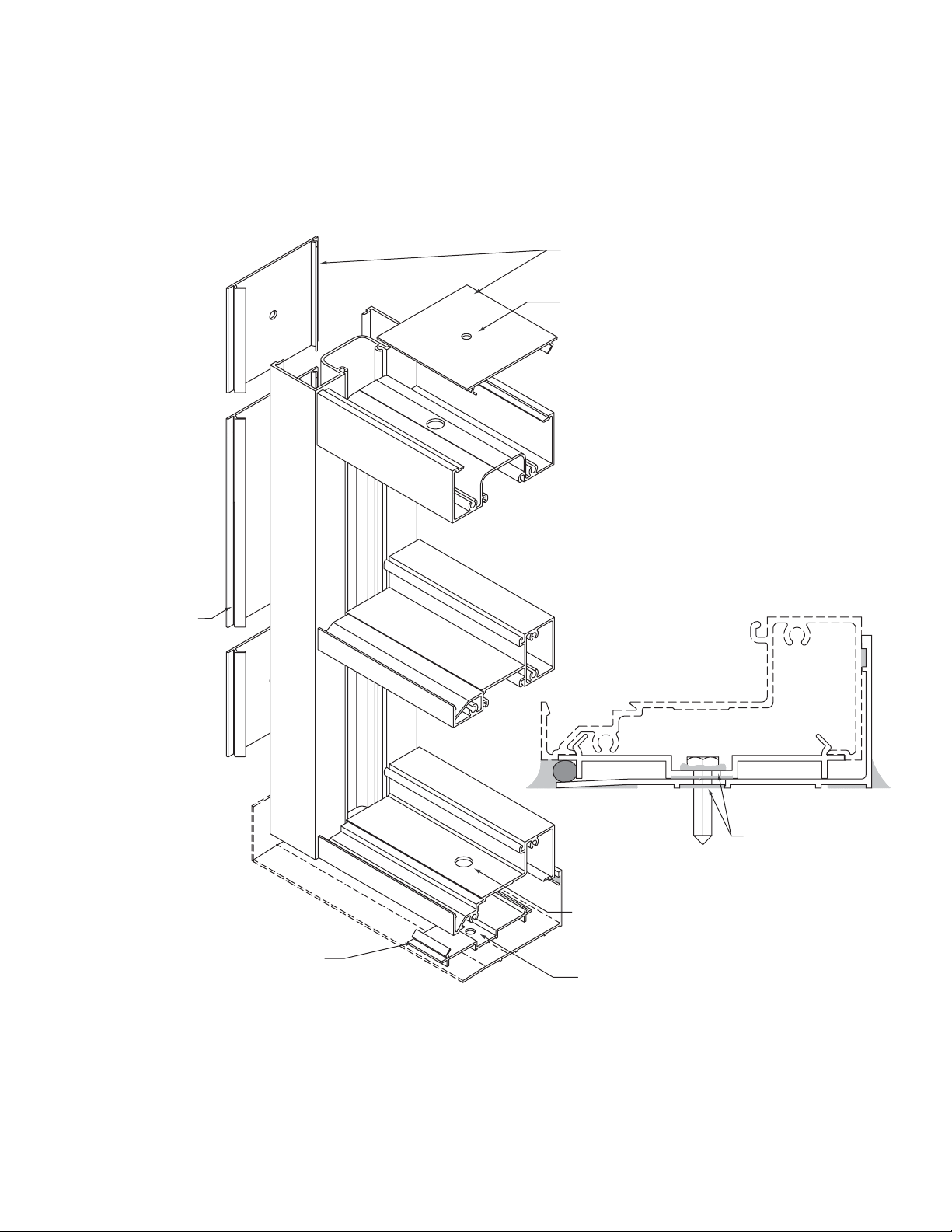

STACK SYSTEM ANCHORING

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

3/4"

FG-3203

FRAME

DIMENSION

MULLION

HEIGHT

AC-121-1

PART #: 5990

MULLION ANCHOR ROTATES

INTO HEAD CAN.

1/4" WEEP HOLE AT MID-LITE.

CAP SEAL ALL HEAD AND

SILL CAN ANCHORS.

FG-3205

JULY 2011

3/8"

19

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

STACK SYSTEM FRAME ASSEMBLY AND INSTALLATION

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

AC-121-1

PART #: 5990

TWIST IN ANCHOR

FITS INTO VERTICAL.

FG-3203

FG-3107

FG-2000-FP-2

PART #: 7165

TOP OF

HORIZONTAL

29/32"

1-11/16"

2-11/16"

5/16"

AC-122-1

PART #: 6647

FG-3204

FG-3192

FG-3144

FG-3164

FG-3191

JULY 2011

20

FG-3144

FG-3205

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

STACK SYSTEM, FRAME SEALANT PROCEDURES

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

STACK SYSTEM FRAME SEALANT PROCEDURE

AC-121-1

PART #: 5990

CONT. SEAL

SEAL BETWEEN SHEAR

BLOCK AND HORIZONTAL.

CONT. SEAL

NOTE: THE NATURE OF THE STACK SYSTEM REQUIRES CARE

WHEN APPLYING SEALANTS AS SHOWN TO ASSURE

PERFORMANCE LEVELS SHOWN IN THE TEST REPORT.

SEAL BETWEEN MULL

AND HORIZONTAL.

INSIDE HORIZONTAL

CONT. SEAL

JULY 2011

21

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

STACK SYSTEM

SEALANT PROCEDURE FOR DOOR FRAME AT FLASHING

FG-3155

FG-3156

FG-2145

LEAVE FRONT OF DOOR JAMB CLEAR OF

SEALANT FOR DRAINAGE PURPOSES.

*USE SHEAR BLOCKS AS SHOWN ON PAGE 44 TO SECURE TO TUBULAR FRAME.

DOOR FRAME IS ANCHORED BY FASTENERS THROUGH THRESHOLD

AND THROUGH DOOR FRAME HEADER.

DO NOT FABRICATE 2 PIECE DOOR FRAMES WITH POUR & DEBRIDGE PROFILES.

FLASHING IS BED IN

SEALANT AT DOOR JAMB.

RUN SEALANT ONE INCH

ABOVE FLASHING.

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

JULY 2011

22

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

STACK SYSTEM GLAZING PROCEDURE

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

FG-1133

PART #: 364

VERTICAL GASKETS

RUN THRU.

NOTE:

FIRST, WET

BOTTOM OF SETTING

BLOCKS WITH SOAPY

WATER. ONCE GLASS IS SET,

PUSH AGAINST GASKET AT

SETTING BLOCK AREA.

FAILURE TO DO SO MAY CAUSE

DIAGONAL CRACKS TOWARDS

SETTING BLOCKS DUE TO GLASS

BENDING WHILE INSTALLING

GASKET(S) IN CORNERS.

GLAZING INSTALLATION INSTRUCTIONS

GLASS SIZE

7/8" OVER DAY LIGHT OPENING

SETTING BLOCK

SET AT 1/4 POINT OR 1/8 POINT OF HORIZONTAL LENGTH

DEPENDING ON LITE SIZE.

WATER DIVERTERS

GLAZE FROM BOTTOM TO TOP. INSTALL WATER DIVERTERS IN

HORIZONTAL ABOVE, AFTER LITE BELOW IS IN POSITION.

GLAZING GASKET

GASKET MAY BE INSTALLED ON ONE OR BOTH SIDES

SIMULTANEOUSLY. PROVIDE 3/8" ADDITIONAL GASKET

FOR EACH FOOT OF DAYLIGHT OPENING TO PROVIDE

ADEQUATE COMPRESSION FOR THE GLAZING INFILL.

NOTE: CLEAN GASKET WITH ISOPROPYL ALCOHOL PRIOR TO

SEALING CORNERS.

JULY 2011

23

FG-3146

PART #: 6417

FG-1000-FP-2

PART #: 6887

SET IN PLACE

WITH SEALANT.

0

15

MITER HORIZONTAL GASKET

TO FIT VERTICAL GASKET.

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

ITEM DESCRIPTION

LENGTH

PCS./BOX

PART NO.

24'

5

FG3100_

24'

3

FG3101_

24'

10

FG3102_

24'

5

FG3103_

24'

4

FG3142_

24'

5

FG3161_

24'

10

FG3164_

24'

10

FG3144_

24'

5

FG3135_

24'

5

FG3108_

24'

5

FG3109_

24'

5

FG3180

_

24'

5

FG3181_

24'

10

FG3210_

Open back mullion

Heavy duty

open back mullion

Open back filler

Open back

head/mullion

Intermediate horizontal

Sill

(Use FG-3164 filler

for horizontal)

Open back filler

shallow pocket

maximum glass bite=3/8"

Glass stop for FG-3142

and FG-3161

Open back mullion

shallow pocket

maximum glass bite=3/8"

Expansion mullion/jamb

requires FG-3109

Expansion mullion

requires FG-3108

Adjustable mullion

20to 10

0

mates with FG-3181

Adjustable mullion

20to 10

0

mates with FG-3180

Heavy glass stop for

inside glazing

FG-3142

FG-3102

FG-3103

FG-3101

FG-3100

FG-3144

FG-3164

FG-3161

FG-3181

FG-3180

FG-3109

FG-3108

FG-3135

FG-3210

SERIES 3000 2" X 4-1/2" SCREW SPLINE

ITEM DESCRIPTION

LENGTH

PCS./BOX

PART NO.

24'

10

FG3164_

24'

10

FG3144_

24'

5

FG3100_

24'

3

FG3107_

24'

5

FG3203_

24'

5

FG3204_

24'

5

FG3191_

24'

5

FG3205_

24'

5

FG3192_

Horizontal filler

Stop for

FG-3191 and FG-3192

Jamb

Mullion

Head receptor

Head insert

Sill Insert

Sill receptor

Open back horizontal

(Use AC-122-1)

FG-3107

FG-3203

FG-3100

FG-3164

FG-3192

FG-3205

FG-3191

FG-3204

FG-3144

SERIES 3000 2" X 4-1/2" STACK SYSTEM

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

JULY 2011

24

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

ITEM DESCRIPTION

LENGTH

PCS./BOX

PART NO.

24'

5

FG2122_

24'

4

FG3110_

24'

4

FG3111_

24'

4

FG3201_

24'

4

FG2112_

24'

4

FG2138_

24'

10

FG3141_

24'

5

MO243_

24'

5

MO244_

24'

5

FG2139_

Open back flat filler

900Corner (self

mating for 180 post)

900Split corner

900Corner w/FG-2112

3-Way post w/FG-3111

Corner post

self mating

1350/450Corner

use FG-3141 or

FG-3102 filler

Deep pocket filler for

FG-2138

4-1/2" Head receptor

back

V-11 weathering

not included

Head receptor face

V-11 weathering

not included

Head receptor

V-11 weathering

not included

FG-3110

FG-3111

FG-2122

FG-2138

FG-2112

FG-3201

MO-244

MO-243

FG-3141

FG-2139

SERIES 3000 2" X 4-1/2” AUXILIARY EXTRUSIONS

ITEM DESCRIPTION

LENGTH

PCS./BOX

PART NO.

24'

10

FG2169_

24'

8

FG3217_

15'

1

923

24'

24

FG3126_

24'

12

FG3194_

24'

12

FG3236_

24'

12

FG3237_

Sub-Sill

(high back)

Sub-Sill

(inside glazed)

Steel reinforcement

for FG-3135 and

FG-3164 only

Snap-in pocket filler

Pocket reducer for

1/4" glass

Pocket reducer for

7/16" glass

Pocket reducer for

5/8" glass

RS-1

FG-3126

FG-3194

FG-2169

FG-3217

FG-3237

FG-3236

ITEM DESCRIPTION

LENGTH

PCS./BOX

PART NO.

24'

3

FG3155_

24'

3

FG3168_

24'

5

FG3156_

Tubular door jamb

Tubular double

door jamb

Open back door jamb

FG-3156

FG-3168

FG-3155

SERIES 3000 2" X 4-1/2" DOOR FRAME COMPONENTS

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

JULY 2011

25

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

SERIES 3000 2" X 4-1/2" DOOR FRAME COMPONENTS

ITEM DESCRIPTION

LENGTH

PCS./BOX

PART NO.

24'

12

FG3157_

24'

12

FG3158_

24'

3

FG3160_

24'

3

FG3163_

24'

5

FG3196_

24'

10

FG1129_

24'

10

FG1184_

21'-5"

18

FG2145_215

Door transom glazing

adaptor

Door transom glazing

adaptor stop

Tube door header

for OHCC

Door header for open

back frames

Door header

for OHCC

Snap-in filler for

FG-3196 header

Snap-in filler for

FG-3196 header

with weathering

1/2" X 1-1/16"

Snap-in door stop

with weathering

FG-3196

FG-3163

FG-3160

FG-3158

FG-3157

FG-2145

FG-1184

FG-1129

ITEM

DESCRIPTION

LENGTH

PCS./BOX

PART NO.

21'-5"

18

FG2120_215

24'

18

DS1_

24'

12

DS108__

24'

10

DS104_

21'-5"

24

FG1123_215

24'

3

FG3287_

24'

12

FG3324_

24'

12

FG3325_

1/2" X 1-5/8"

Snap-in door stop

with weathering

1/2" X 1-5/8" Door stop

with weathering

(use SC-1 clip)

3/4" X 1-5/8" Door stop

with weathering

(use SC-1 clip)

1 3/16" X 2" Door stop

with weathering

(use FS-201 screw)

Slide-in pocket filler

Door frame jamb

for front & back set

Transom glazing adaptor

mates with FG-3287

Transom glazing adaptor

stop mates with FG-3224

FG-1123

DS-104

DS-108

DS-1

FG-2120

FG-3325

FG-3324

FG-3287

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

JULY 2011

ITEM

FS-8

FS-10

FS-12

FS-15

FS-201

FS-6

DESCRIPTION

#14 X 1" H.H.S.T.S.

Assembly screw

#14 X 1-3/4"

P.F.H.W.S.

anchors FG thru

pocket

#14 X 1"

plastic plug

3/16" dia. X 7/16"

Drive rivet anchors

SC-1 clip

#10 X 2" PFH

attaches

DS-104

#10 X 3/4" P.P.H.

attaches sill to

sill anchor

FS-201

CLR.

FS-201

BRZ.

SEIROSSECCA 0003 SEIRES

PCS.

BOX

ITEM

DESCRIPTION

SEIROSSECCA 0003 SEIRES

PCS.

BOX

Shear block for

100

AC-108-1

FG-3103 header

(screws included)

20

Shear block for

100

AC-122-1

FG-3192 horizontal

(screws included)

20

Mullion anchor at

100

AC-121-1

head for FG-3190

and FG-3203

20

Sill anchor for

100

200

200

FG-2000-FP-3

FG-3000-FP-3

FG-3161

Sill anchor

for FG-3217

inside glazed

20

20

200

Phone: 1-866-OLDCASTLE (653-2278)

26

Web Address: www.oldcastlebe.com

ITEM

DESCRIPTION

PCS.

BOX

300'

300'

300'

300'

300'

500'

250'

100'

100'

100

100'

ITEM

DESCRIPTION

PCS.

BOX

Setting block for

FG-3157,

FG-3293, FG-3294

Water diverter for

center set outside

glazed

Water diverter for

center set

inside glazed

Splice for

FG-2169

Splice for

FG-3127

End dam

for FG-2169

End dam

for FG-3217

Joint sealant tape

1/8" X 1/2"

Vinyl filler for caulk

stop 12'

Vinyl pocket filler for

window applications

12'

200

50

100

10

10

20

20

30'

10

10

V-11

FL-66

FG-3129

FG-1134

FG-1133

WP-084

D-125

CW-998

WP-083

HP-92

FG-3146

FG-2000-FP-7

FG-1000-FP-4/5

FG-1000-FP-2

HP-17

SM-5601

FG-3000-FP-4

FG-2000-FP-4

FG-3000-FP-11

FG-3218

FG-2188

FG3000-FP-30

Butt Glaze

Horizontal

Shear Block

Butt Glaze

Horizontal

Water Diverter

50

20

FG3000-FP-33

Butt Glaze

Spacer

Heavy gasket

5/8"

Glazing gasket

Light gasket

Spacer gasket for slot/non-

thermal expansion mullion

& head receptors

Spacer gasket for

thermal expansion

mullion

Weathering gasket

for airtight applica-

tions

Weathering for

doorstops

Weathering for dou-

ble acting headers

Setting block

FG-3142 and 3161

Setting block for

FG-3155 and 3163

stacked

250'

SHP-30066

1"

Glazing gasket

SEIROSSECCA 0003 SEIRESSEIROSSECCA 0003 SEIRES

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

SC-1

DJ-5

DJ-6

SEIROSSECCA 0003 SEIRES

Spring clip for

DS-1 & DS-108

Drill fixture for screw

spline assembly

FG-3103, 3142, 3161

Drill fixture for shear

block assembly

AC-119-1 & AC-108-

100

1

1

JULY 2011

27

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

GLASS SIZE ADAPTOR GASKETS

1/4" FG-3194 FG-1133 BOTH SIDES

5/16" FG-3236 FL-66 BOTH SIDES

3/8" FG-3236 FG-1133 & FL-66

7/16" FG-3236 FG-1133 BOTH SIDES

1/2" FG-3237 FL-66 BOTH SIDES

9/16" FG-3237 FG-1133 & FL-66

5/8" FG-3237 FG-1133 BOTH SIDES

11/16" FG-3237 FG-1133 & FG-1134

3/4" FG-3237 FL-1134 BOTH SIDES

13/16" N/A NOT AVAILABLE

7/8" NONE FG-66 BOTH SIDES

15/16" NONE FL-1133 & FL-66

1" NONE FG-1133 BOTH SIDES

1-1/16" NONE FG-1133 & FG-1134

1-1/8" NONE FG-1134 BOTH SIDES

INFILL THICKNESS OPTIONS

F L U S H G L A Z E S E R I E S 3 0 0 0 I N S T A L L A T I O N M A N U A L

JULY 2011

28

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

Loading...

Loading...