Note: Installation and Glazing Manuals are product specific. FOR REVIEW ONLY!

February 2012

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

TABLE OF CONTENTS

General Information…………………………………………………………………… . . . . . . 4 & 5

General Installation…………………………………………………………………. . . . . . . . 6 thru 9

Mullion Fabrication and Shear Block Installation…………………………………..………… 10 & 11

Head Anchor Install.……………………………………………………………………….………….. ….. 12

Intermediate Horizontal Install …………………………………….. . . . . . . . . . . . . . . . . . . . . 13

Sill Install…………………………………………………………………………………………… 14

Roll Over Horiz Install………………………………………………………………………………….. 15

Jamb Installation…………………………………………………………………………………… 16

Glazing Instructions……………………………………………………………………………….. 17

Pressure Plate Installation…………………………………………………………………………. 18

1” Glazing Detail………………………………………………………………………………….. 19

1 / 4” Glazing Detail………………………………………………………………………………. 20

1 / 4” Adaptor Fabrication and Installation………………………………………………………. 21

Door Installation…………………………………………………………………………………. 22 thru 25

Splice Installation Option……………………………………………………………………………. 26

Fixed Splice Installation …………………………………………………………................. 27

Live Load Splice Installation ……………………………………………….……................ 28

Splice Sealant Instructions ……………………………………………….……................ 29-30

CORNERS

Outside 90 Corner Mullion Fabrication and Shear Block Installation…………………….…. 31

Outside 90 Corner Assembly…………………………………………………………………… 32

Outside 90 Corner Glazing………………………………………………………………………… 33

Inside 90 Corner Mullion Fabrication and Shear Block Installation………………………… 34

Inside 90 Corner Assembly………………………………………………………………………… 35

Inside 90 Corner Glazing………………………………………………………………………….. 36

Outside 135 Corner Mullion Fabrication and Shear Block Installation…………………….… 37

Outside 135 Corner Assembly…………………………………………………………………….. 38

Outside 135 Corner Glazing………………………………………………………………………. 39

Inside 135 Corner Mullion Fabrication and Shear Block Installation……………………….……. 40

Inside 135 Corner Assembly………………………………………………………………………. 41

Inside 135 Corner Glazing…………………………………………………………………………. 42

SSG (STRUCTURAL SILICONE GLAZED)

Mullion Fabrication and Shear Block Installation……………………………………………..43 & 44

Head Install…………………………………………………………………….………….. …...... 45

Intermediate Horizontal Install…………………………………………………………………….. 46

Sill Install…………… …………………………………………………………………………… 47

Bridge Installation…………………………………………………………………………………… 48-49

Pressure Plate Install……………………………………………………………………………….. 50

Glazing Instructions ……………………………………………………………………….. 51

1” Glazing Detail… ………………………………………………………………………….…....52

Glass Joint Seals ………………………………………………………………………….…....53

1 / 4” Glazing Detail………………………………………………………………………………. ...54

February 2012

2

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

TABLE OF CONTENTS -contd-

SSG CORNERS

Outside 90 Corner Mullion Fabrication and Shear Block Installation 55

Outside 90 Corner Assembly 56

Outside 90 Corner Glazing 57

Inside 90 Corner Mullion Fabrication and Shear Block Installation 58

Inside 90 Corner Assembly 59

Inside 90 Corner Glazing 60

Outside 135 Corner Mullion Fabrication and Shear Block Installation 61

Outside 135 Corner Assembly 62

Outside 135 Corner Glazing 63

Inside 135 Corner Mullion Fabrication and Shear Block Installation 64

Inside 135 Corner Assembly 65

Inside 135 Corner Glazing 66

MULLION REINFORCING

Steel Reinforcement Install 67-68

Parts List 69

February 2012

3

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

GENERAL INFORMATION

The CW-250 curtain wall system is intended to be used by glazing professionals with appropriate

experience. Subcontractors without this experience should employ a qualified person to provide field

instruction and project management.

Oldcastle BuildingEnvelope

or glazing material and assumes no responsibility thereof. It is the responsibility of the owner, architect and installer to

make these selections in strict compliance with applicable laws and building codes.

Variations on the details shown are inevitable and are not the responsibility of

drawn by others.

for calculations and shop drawings.

PROTECTION AND STORAGE:

Handle the material carefully. Do not drop from the truck. Stack with adequate separation so that the

material will not rub together. Store material off the ground. Protect against the elements and other

construction hazards by using a well- ventilated covering. Remove material from package if it is wet or is

located in a damp area. Please also reference AAMA publication “Care and Handling of Architectural

Aluminum From Shop to Site.”

CHECK MATERIAL:

Check glass dimensions for thickness. Some glass manufacturers are very liberal with their quality control

standards.

extreme glazing tolerances. However, given advance notice,

to provide an alternate gasket for a nominal charge.

Check all material upon arrival for quality and to assure against shipping damage. Any visible damage must

be noted on the freight bill at the time of receipt. If a claim is required, then receiving party must process a

claim with the freight company.

Completely check construction that will receive your material against contract documents. Notify the

general contractor by letter of any discrepancies before proceeding with the work. Failure to do so

constitutes acceptance of work by other trades.

Check shop drawings and installation instructions to become familiar with the project. The shop drawings

take precedence and include specific details for the project. The installation instructions are of a general

nature and cover the most common conditions. Due to varying job conditions; all sealant used should be

approved by the sealant manufacturer to insure they will function for conditions shown on instructions and

shop drawings. They must be compatible with all surfaces in which adhesion is required, including other

sealant surfaces. Use primers where directed by manufacturer of sealant. Be sure to properly store sealant at

the recommended temperatures and check sealant for remainder of shelf life before using.

Oldcastle BuildingEnvelope

Oldcastle BuildingEnvelope

™

does not control the application nor selection of its product configurations, sealant

Oldcastle BuildingEnvelope

™

strongly encourages its customers to use its Engineering department

™

cannot be held responsible for gaskets that are not water tight due to

Oldcastle BuildingEnvelope

™

will attempt

™

when

February 2012

4

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

GENERAL INFORMATION

FIELD CONDITIONS:

All material to be installed must be plumb, level and true. Aluminum to be placed in direct contact with

masonry or incompatible material should be isolated with a heavy coat of zinc-chromate,

or non -metallic materia l.

After sealant is set and a representative amount of the wall has been glazed ( 250 square feet of more ) run

a water hose test to check installation. On large jobs hose test should be repeated during glazing operation.

Test should be conducted in accordance with AAMA 501.2 specifications.

Coordinate protection of installed materials with general contractors and other trades.

CLEANING MATERIALS:

Cement, plaster, terrazzo, alkaline and acid based materials used to clean masonry are very harmful to

finishes and should be removed with water and mild soap immediately or permanent staining will occur. A

spot test is recommended before any cleaning agent is used.

EXPANSION JOINTS:

Expansion joints and perimeter seals shown in these instructions and in the shop drawings are shown at

nominal size. Actual dimensions may vary due to perimeter conditions and/or differences in metal

temperature between the time of fabrication and the time of installation. For example, a 12 foot unrestrained

length of aluminum can expand or contract 3/32 of an inch over a 50 F change. Any movement potential

should be accounted for at the time of the installation.

THERMAL IMPROVEMENT SUGGESTIONS:

To maintain or improve your wall installation the following items should be considered.

A. Blinds or drapes prevent warm air from washing the window.

B. Warm air ventilators too far from the window will not adequately wash the window with air to

prevent condensation.

C. In extreme conditions the fan of the heating system should not cycle on and off, but should run

continuously.

D. Some heating systems have a water injection feature that can raise humidity levels. The higher

the humidity level the more likely condensation or frost will form. Raising the temperature and

reducing humidity will usually solve the problem.

E. On rare occasions an extremely cold storm may cause frost to appear on the glass framing. A

space heater and electric fan blowing along the plane of the window wall can reduce or

eliminate this temporary condition.

Please note:

Some portions of this product are covered by patent pending.

bituminous paint

February 2012

5

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

GENERAL INSTALLATION

Please note that

Oldcastle BuildingEnvelope™

does not control the application, nor the selection of its

product configurations, sealant or glazing materials and assumes no responsibility; therfore, it is the

responsibility of the owner, architect and installer to make these selections in strict compliance

with applicable laws and building codes.

The air and water performance of the outside glazed CW-250 system is directly related to the

completeness and integrity of both the seal installed at the shear blocks, and the glazing gasket

installed at the interior side of the glass, as well as, proper installation of all pressure plates. To

insure top performance for this system, particular note should be made by the following

procedures:

Surfaces to be sealed should be cleaned with isopropyl alcohol or solvent as recomended by

sealant manufacturer to remove all dirt and cutting oils, then dried completely. sealant at shear

blocks should be a minimum nominal 3/16" dia., placed completely around top, face and bottom of the

shear block, without misses or skips. wipe exposed surfaces clean after installing horizontal.

Inspect joint for complete sealant contact, especially where the horizontal intersects the face of

the vertical member and repair as required. consult sealant manufacturer for review and

recommendation of sealant application. follow sealant manufacturers recommendations and

literature for proper installation.

The interior glazing gasket should be installed flat and true to the vertical and horizontal

surfaces without stretching, folds, buckles or tears. corners must be cut square, sealed and

butted. to avoid damage to gasket when glazing; glass should be level and straight when setting

glass against gasket.

Vertical movement of mullions at intermediate floors requires special expansion joints and glazing

materials. See pg. 29 for details which permit ± 1/4" movement.

For designs which may require greater movement or special considerations; please contact

engineering.

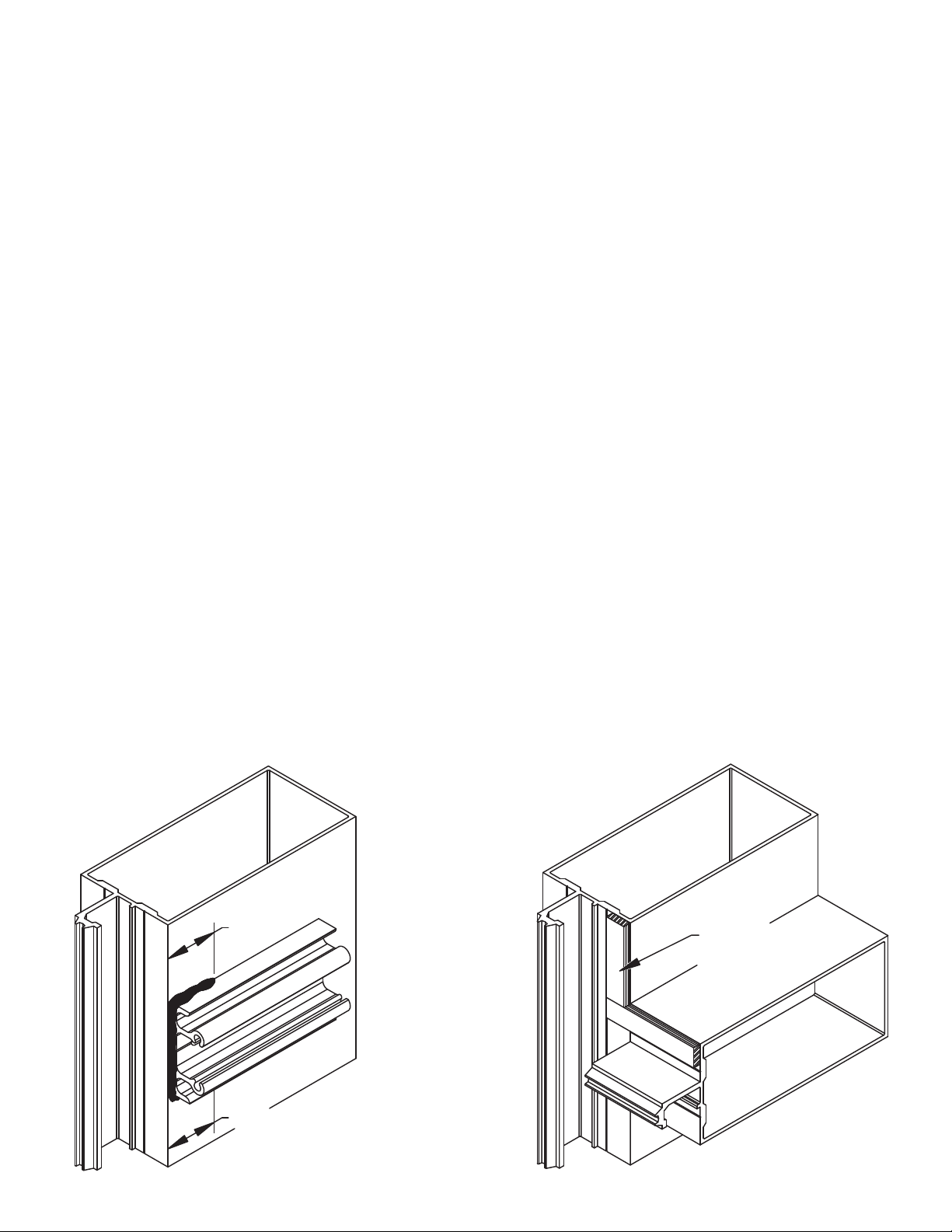

3/4”

CW-1636

FOAM GASKET

February 2012

3/4”

6

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

GENERAL INSTALLATION

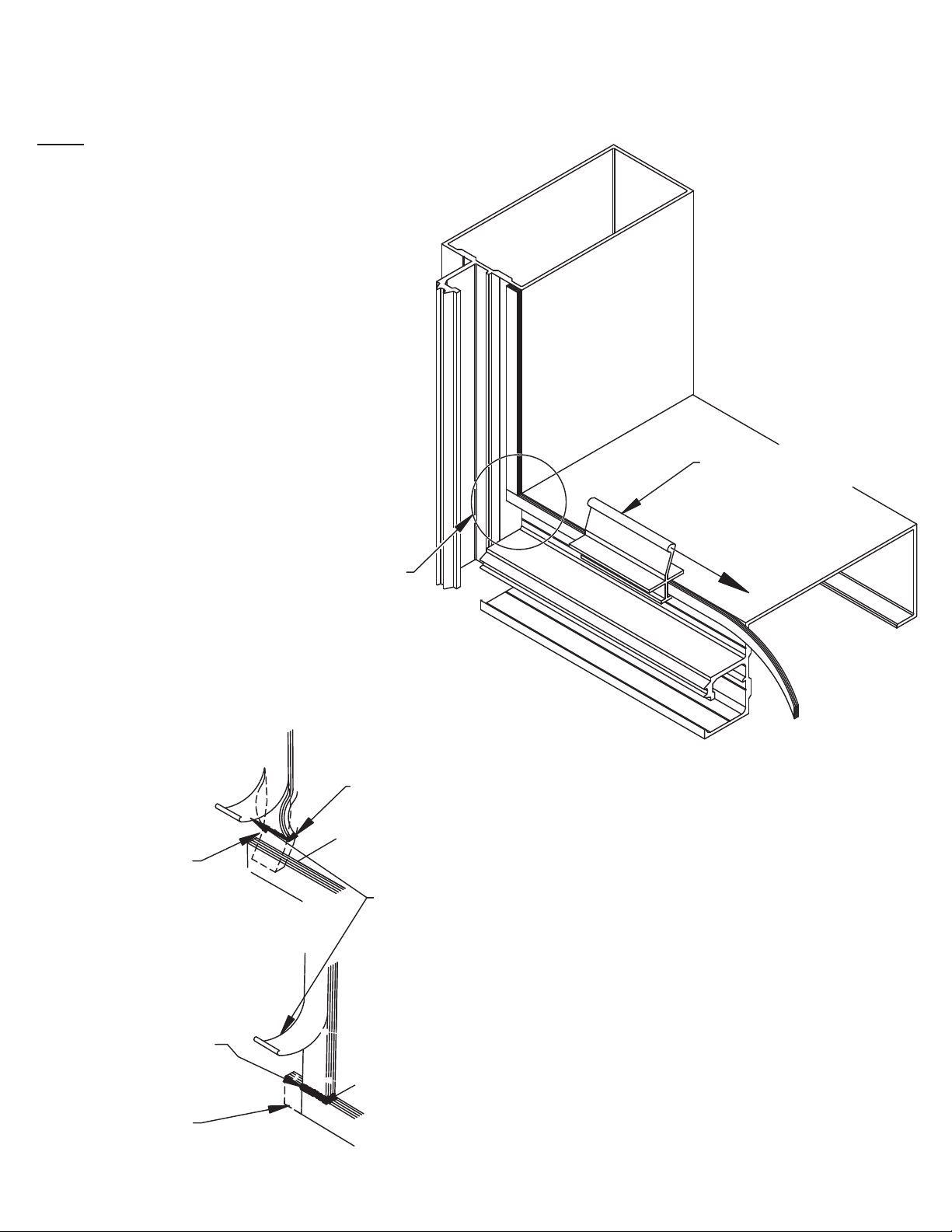

NOTE:

1) CLEAN FACE OF MULLION AND

HORIZONTALS WITH ISOPROPYL

ALCOHOL PRIOR TO INSTALLATION

OF GLAZING GASKETS TO REMOVE

ALL DIRT AND CUTTING OILS.

2) PROTECTIVE LINER TO BE LEFT

ON GLAZING GASKETS UNTIL GLASS

IS INSTALLED.

3) IT IS RECOMMENDED THAT THE INTERIOR

GLAZING GASKET BE PLACED

JUST PRIOR TO INSTALLATION OF THE GLASS,

SINCE LINER WILL ADHERE TO GASKET IF

ALLOWED TO DRY AFTER BECOMING WET.

4) IF DIRTY OR DUSTY FACE OF GASKET

SHOULD BE CLEANED WITH 50/50 SOLUTION

OF ISOPROPYL ALCHOHOL AND WATER

PRIOR TO GLAZING.

5) PROPER SEALING OF GASKET CORNERS

IS CRITICAL TO SYSTEM PERFORMANCE.

THIS PROCEDURE SHOULD BE PERFORMED

AT THE

SEE DETAILS BELOW.

TIME OF INSTALLATION OF GLASS.

CW250-FP-5

GASKET APPLICATOR

CUT OFF GASKET

APPROX. 1/4” OVERLAP

DETAIL SHOWN BELOW

APPLY SEALANT TO END OF VERTICAL

NOTE: DO NOT ENTIRELY REMOVE PROTECTIVE

LINER UNTIL READY TO GLAZE.

PUSH VERTICAL

GASKET INTO PLACE

TRIM SIDE OF

HORIZONTAL GASKET FLUSH

WITH VERTICAL GASKET

February 2012

7

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

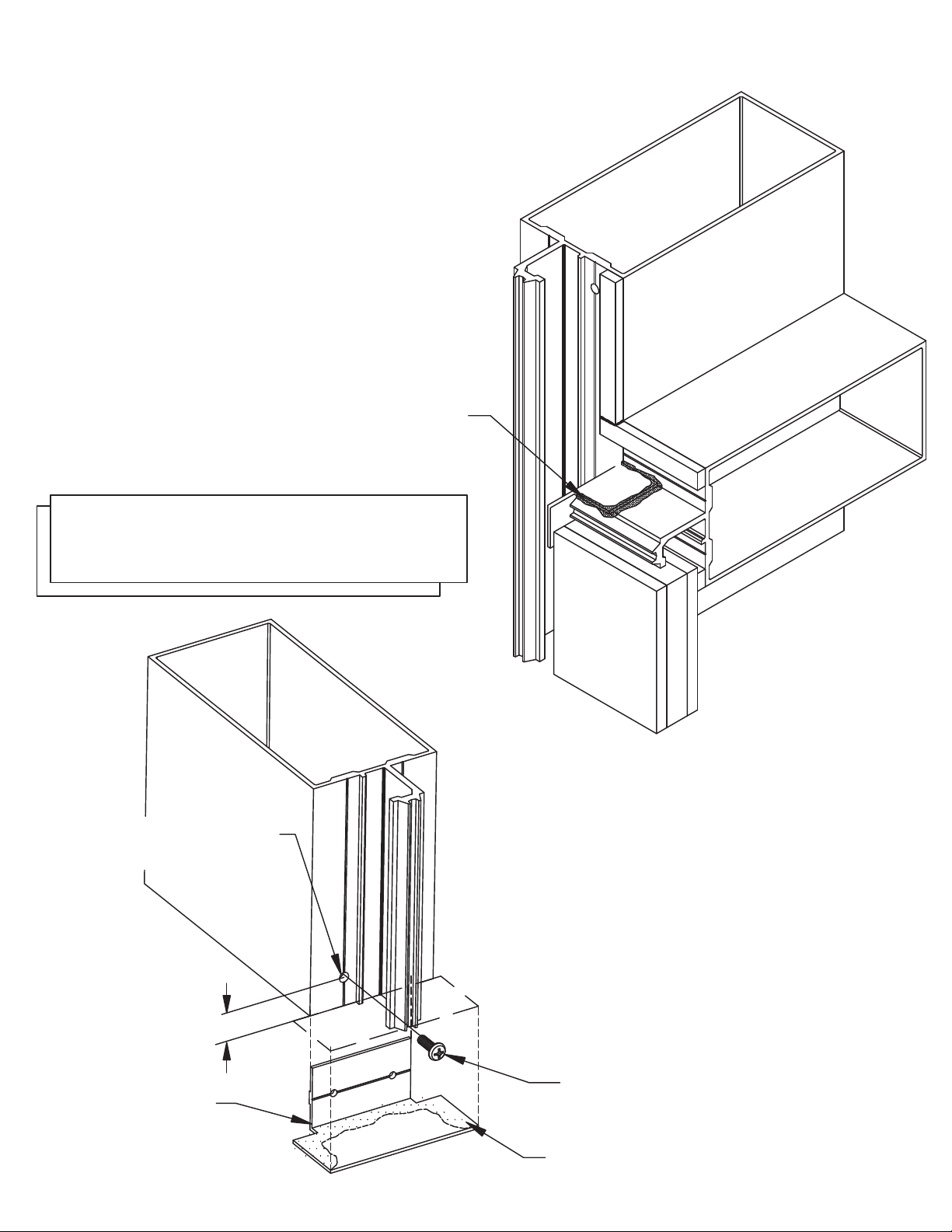

GENERAL INSTALLATION REQUIREMENTS

CW250-FP-108

WATER DIVERTER

BED IN SEALANT

NOTE:

GLAZE FROM BOTTOM TO TOP. INSTALL WATER

DIVERTERS ON HORIZONTAL ABOVE, AFTER LITE

BELOW IS IN POSITION.

#17 (.173 dia.) DRILL THRU

FOR #8 FASTENER.

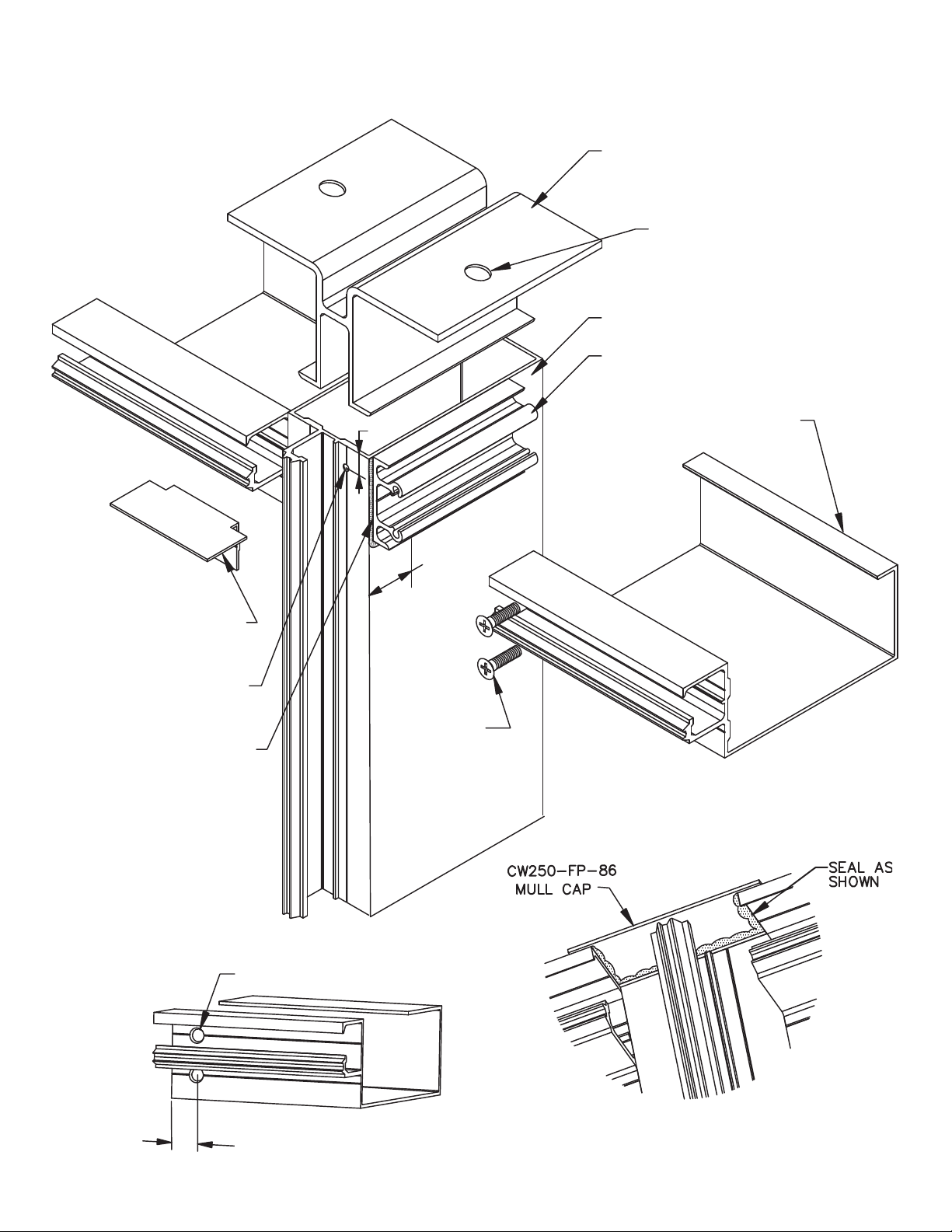

NOTE: LOCATE MULL CAPS

AT HEAD & SILL.

February 2012

CW250-FP-86

(MRP# 6541)

9/16"

FS-202

BED MULL CAP

IN SEALANT &

CAP SEAL

FASTENER

8

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

GENERAL INSTALLATION

The CW-250 SYSTEM for 1-inch glazing

is designed to accomodate glass or

panels with thickness ranging from

.969 to 1.031 inches. 1/4" spandrel

glass or panels may be .219 to .281

inches in thickness.

All

Oldcastle BuildingEnvelope

based on the use of glass as the

other than glass are to be installed

of the owner, architect, and installer

TM

Performance Tests are

infill glazing material. If materials

in this system, it is the responsibility

to verify compatibility of the glazing

materials to be used.

For Thermal Expansion considerations, pressure plates are

Oldcastle BuildingEnvelope

from

TM

in 12'-3". Butt joints are used between pressure

designed for a maximum length of 15'-3", and are available

plate installation on sheet 18. Please note that long face caps may span across

.969-1.031

plates in long runs. See Typical Pressure

a pressure plate butt joint.

.219-.281

Accessory parts required for the CW-250 SYSTEM are indicated on sheet 69, cross-referenced to

their Order Numbers, with available quantities and description.

Oldcastle BuildingEnvelope

or modify its products without prior notice.

local dealer or

February 2012

's reputation as a product innovator

For further assistance please contact your

Oldcastle BuildingEnvelope

TM

implies that it reserves the right to change

Sales Representitive.

9

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

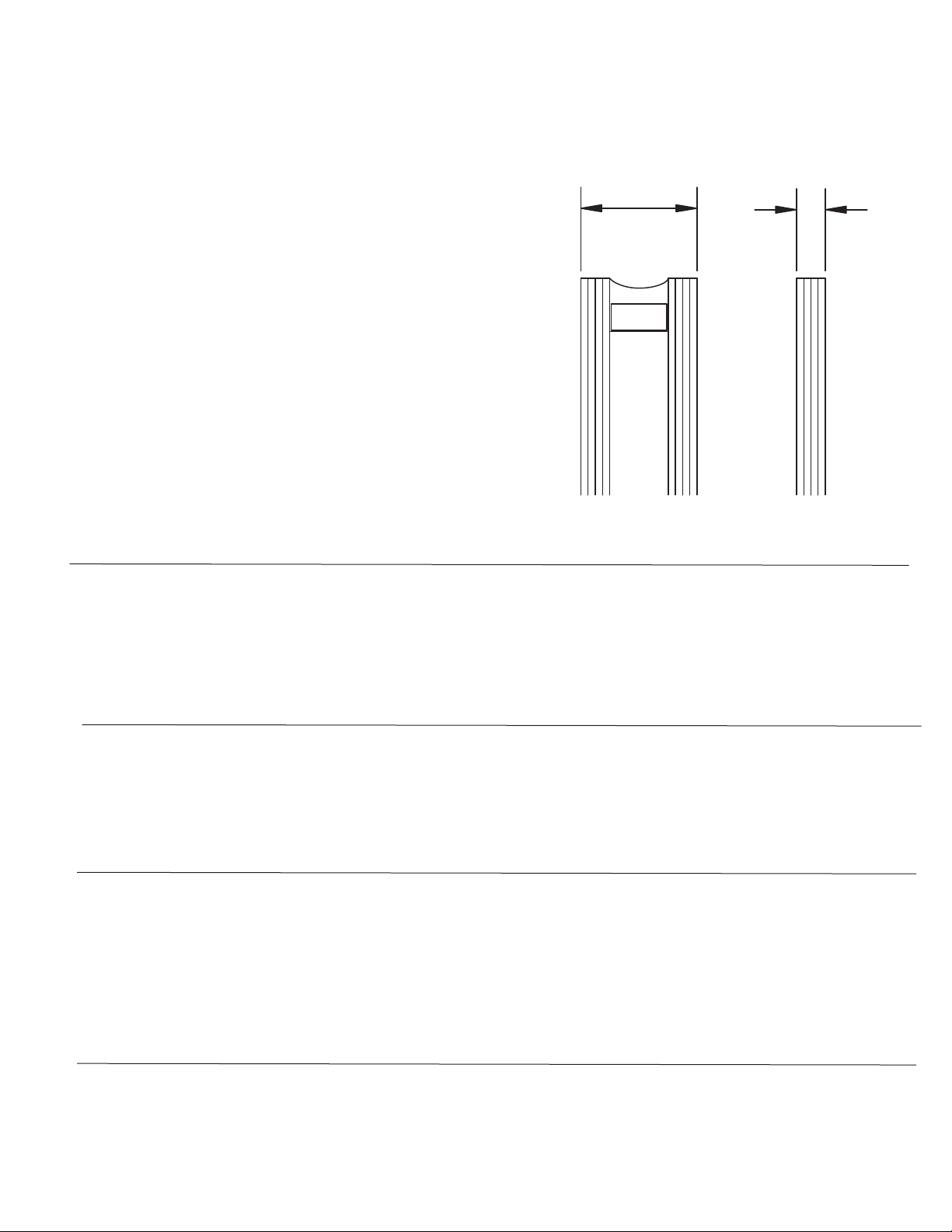

MULLION FABRICATION AND SHEAR

#17 (.173 dia.) DRILL THRU

FOR #12 FASTENER.

1-1/4”

1-1/2”

3/4”

1-1/2”

BLOCK INSTALLATION

CW-21

ALTERNATE

HEAVY MULLION

CW-250-FP-2

1-1/4”

1-1/4”

CW-250-FP-1. USE SMALL PIECE OF CW-1

W/SHEAR BLOCK TO ALIGN SHEAR BLOCK

FOR FASTENING

FS-43 (TYP)

CW-250-FP-2

FSW-324 LOCK WASHER

LOCATED @ HEAD & SILL

February 2012

CW-1

10

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

TOP OF

HORIZONTAL

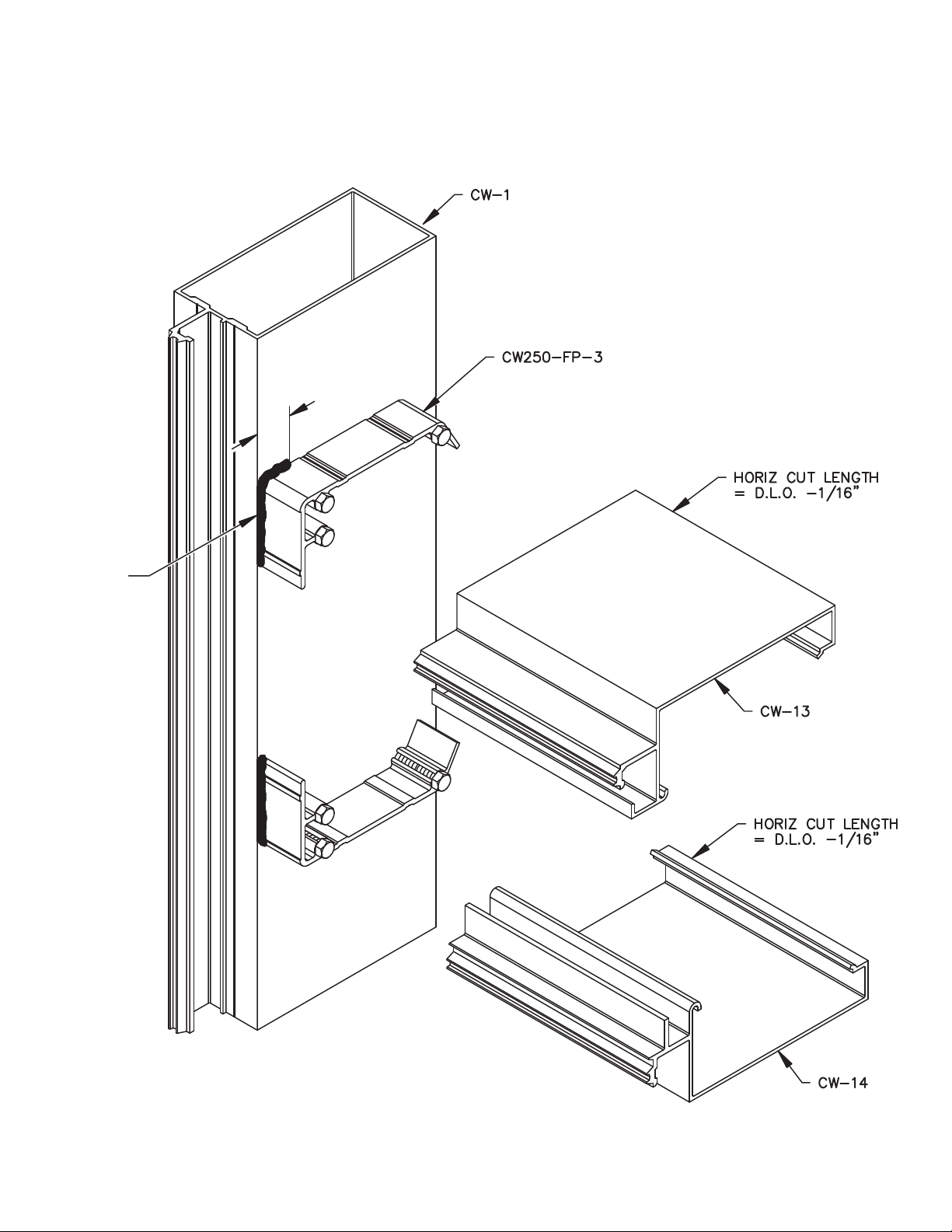

MULLION FABRICATION AND SHEAR

3 1/2”

3/4”

CW-1

7/8”

BLOCK INSTALLATION

NOTE: WHEN USING CW250-FP-3

SHEAR BLOCK. OPEN BACK HORIZONTAL

CUT LENGTH = D.L.O. MINUS 1/16”

#11 (.191 dia.) DRILL THRU

FOR #14 FASTENER

3/8”

CW250-FP-3

BOTTOM OF

HORIZONTAL

FS-9

7/8”

3/8”

CW250-FP-3

FS--9

February 2012

11

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

HEAD INSTALLATION

CW250-FP-148

INSTALLED PRIOR

TO ATTACHING

SHEAR BLOCKS

ANCHOR HOLES (BY OTHERS)

CW-1

CW250-FP-1

HORIZONTAL CUT LENGTH

9/16"

= D.L.O. - 1/16"

CW250-FP-86 MULL CAP

ATTACH W/ FS-202

#17 (.173 dia.) DRILL

THRU FOR #8 FASTENER.

TYP. SEAL FACE

AND UNDER SHEAR

BLOCK PRIOR TO

INSTALLING HORIZ.

"

4

/

3

FS-323

CAP SEAL

DRILL 7/32" CLEAR HOLE AND

C'SINK 7/16" DIA. FOR #12 PFH.

February 2012

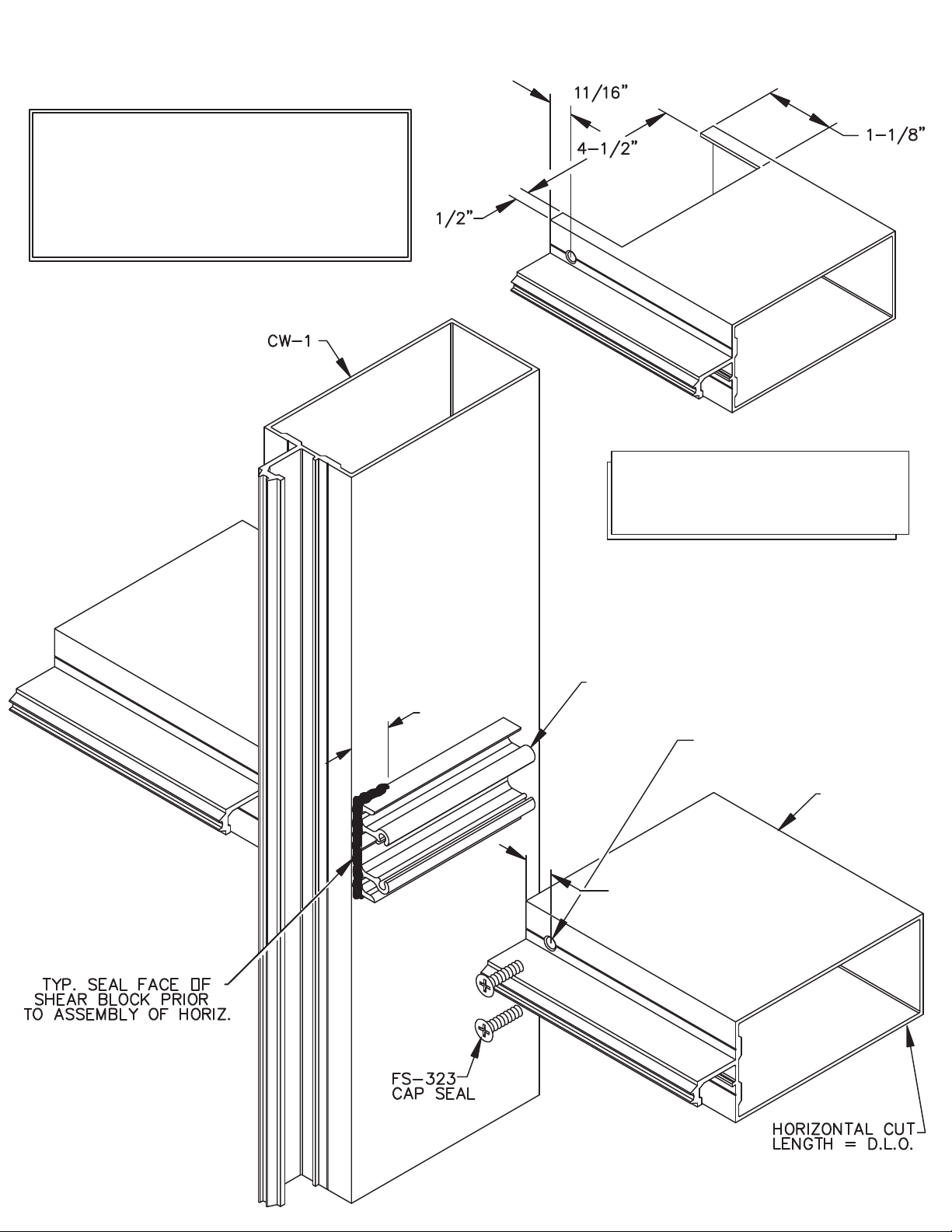

11/16"

12

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

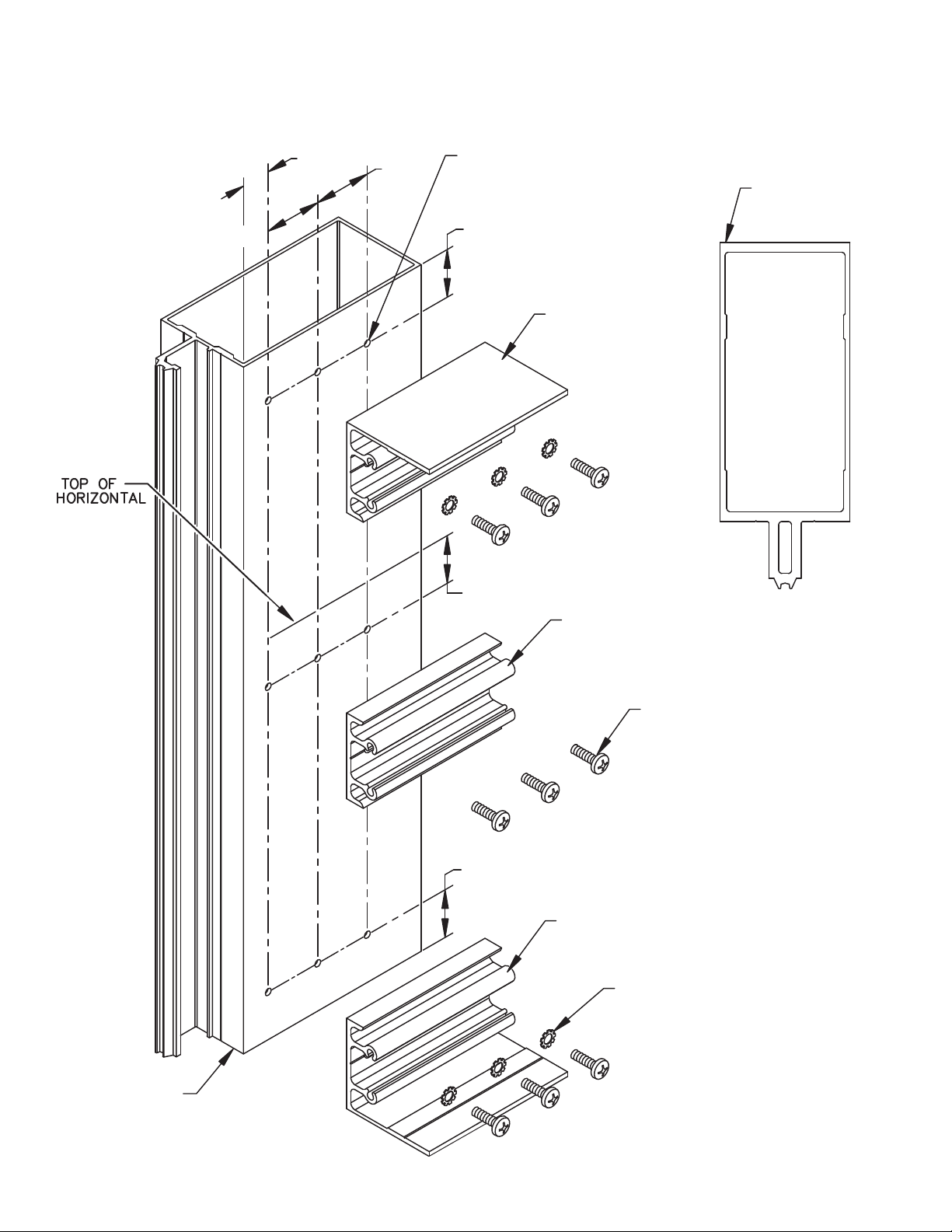

INTERMEDIATE HORIZONTAL INSTALLATION

NOTE: CW-1 HORIZONTAL IS NOTCHED AT

TOP WHEN ABOVE EYE LEVEL. NOTCHED

AT BOTTOM WHEN BELOW EYE LEVEL. THIS

METHOD OF INSTALLING HORIZONTALS

SHOULD BE USED AT THE END OF A RUN.

CONVENTIONAL METHODS MAY BE USED

FOR THE REMAINING WALL.

3/4"

CW250-FP-1

DRILL 7/32" CLEAR HOLE

AND C'SINK 7/16" DIA. FOR

#12 PFH.

WHEN HORIZONTAL

3/4"

IS NOT NOTCHED

CW-1

February 2012

13

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SILL INSTALLATION

9/16"

#17 (.173 dia.) DRILL

THRU FOR #8 FASTENER.

DRILL 7/32" CLEAR HOLE AND

C'SINK 7/16" DIA. FOR #12 PFH.

"

4

/

3

February 2012

14

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

HORIZONTAL INSTALLATION 1” OVER 1/4” & 1/4” OVER 1”

NOTE: HORIZONTAL DESIGN PROVIDES

FOR ITS OWN THERMAL EXPANSION.

DO NOT SCREW HORIZONTALS TO

SHEAR BLOCKS.

3/4”

TYP SEAL

AROUND SHEAR

BLOCK PRIOR

TO INSTALLING

HORIZONTAL

February 2012

15

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

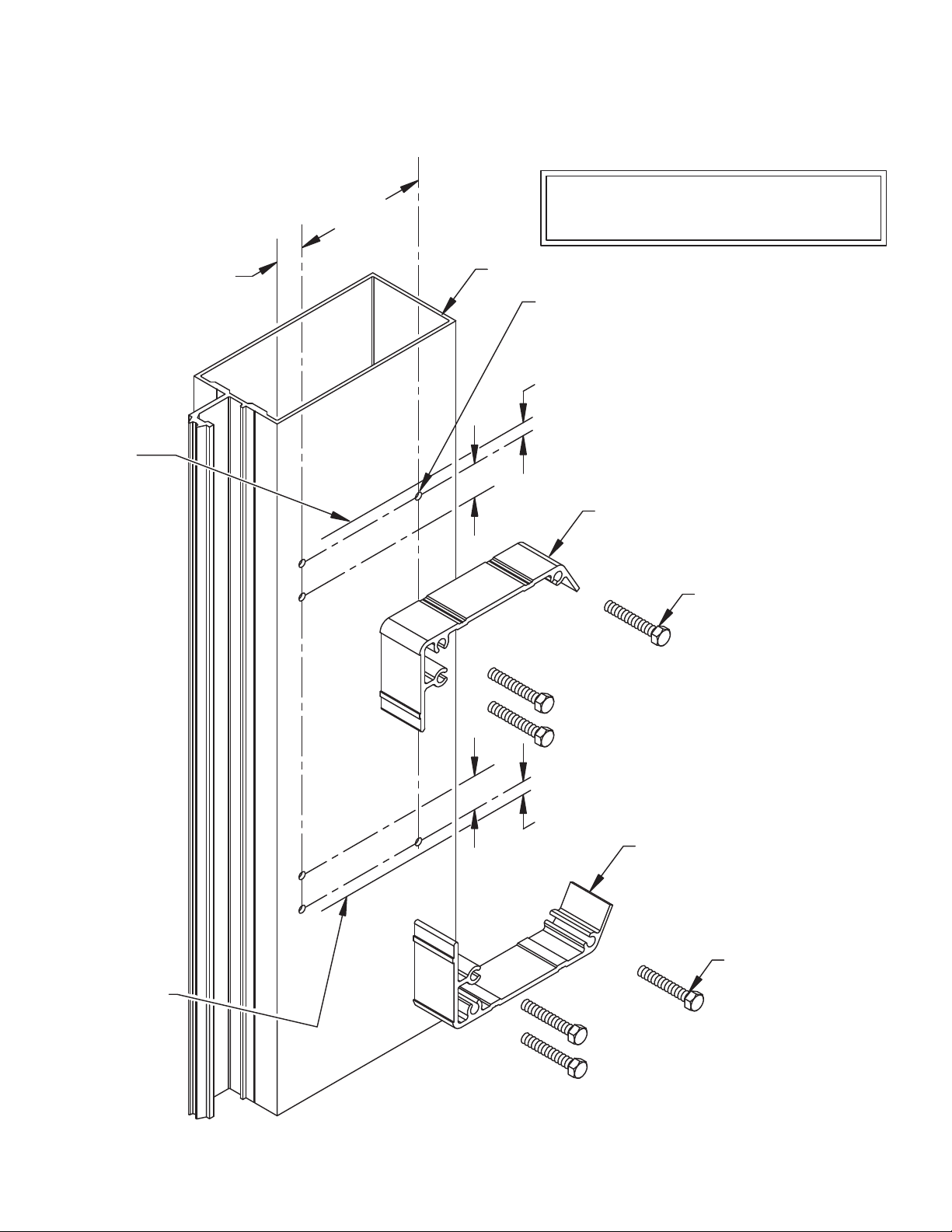

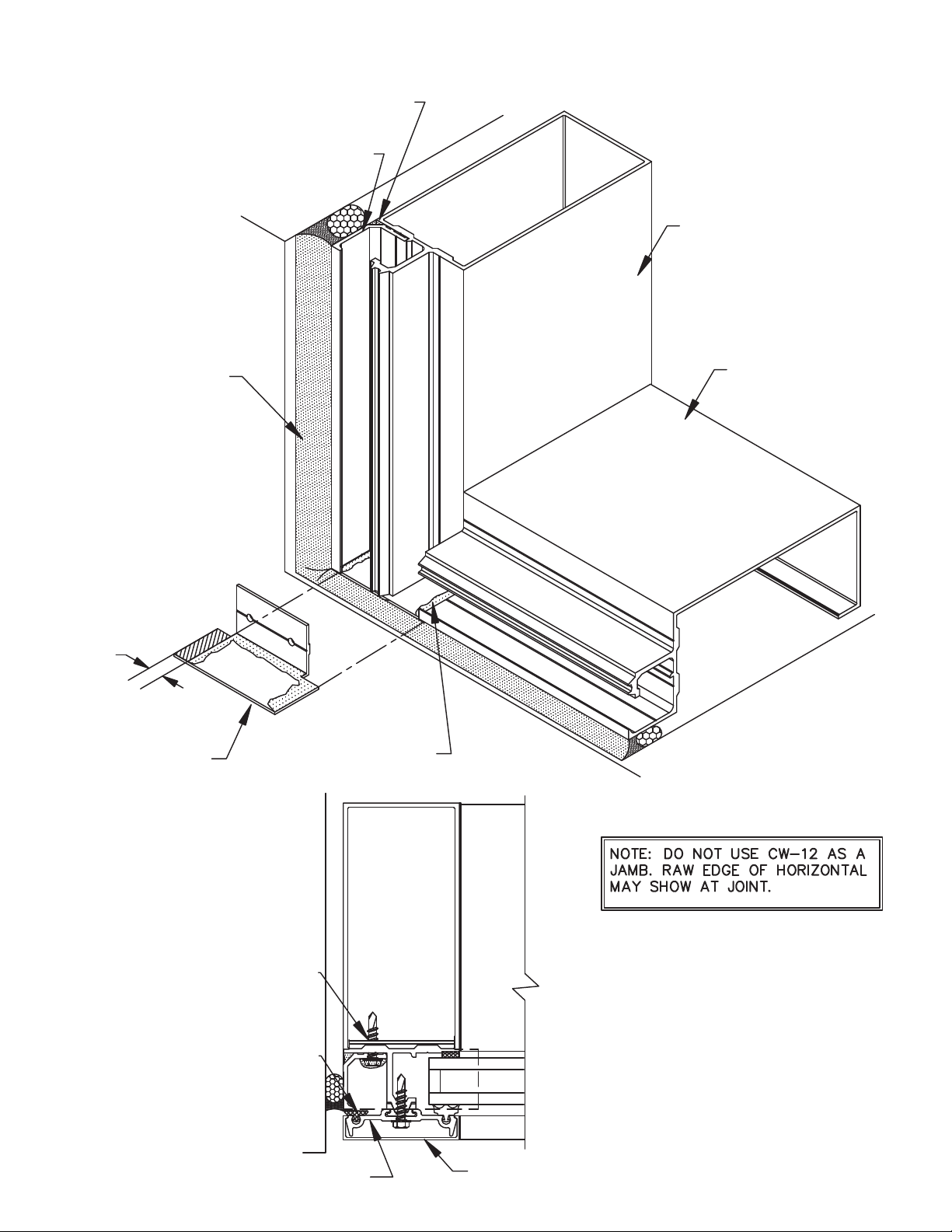

JAMB INSTALLATION

SEAL BETWEEN FILLER

AND MULLION

CW-1195 POCKET FILLER

PREATTACH TO MULL AND

SEAL PRIOR TO INSTALLATION.

CW-1

PERIMETER SEAL

APPLY PRIOR TO

GLAZING

7/16"

CW250-FP-86

FIELD MODIFY

AS SHOWN

CW-12

BED MULL CAP IN

SEALANT

February 2012

FS-322

@ 18" O.C.

CW-187

CW-3

16

CW-2

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

GLAZING INSTRUCTIONS

CW250-FP-108

WATER DIVERTER

BED IN SEALANT

CW-9 SETTING BLOCK

FS-322

(1) PER RETAINER

CW250-FP-4

TEMP. GLAZING RETAINER

February 2012

17

NOTE: GLAZE FROM BOTTOM TO TOP,

INSTALL WATER DIVERTER ON

HORIZONTAL ABOVE, AFTER LITE

BELOW IS IN POSTION.

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

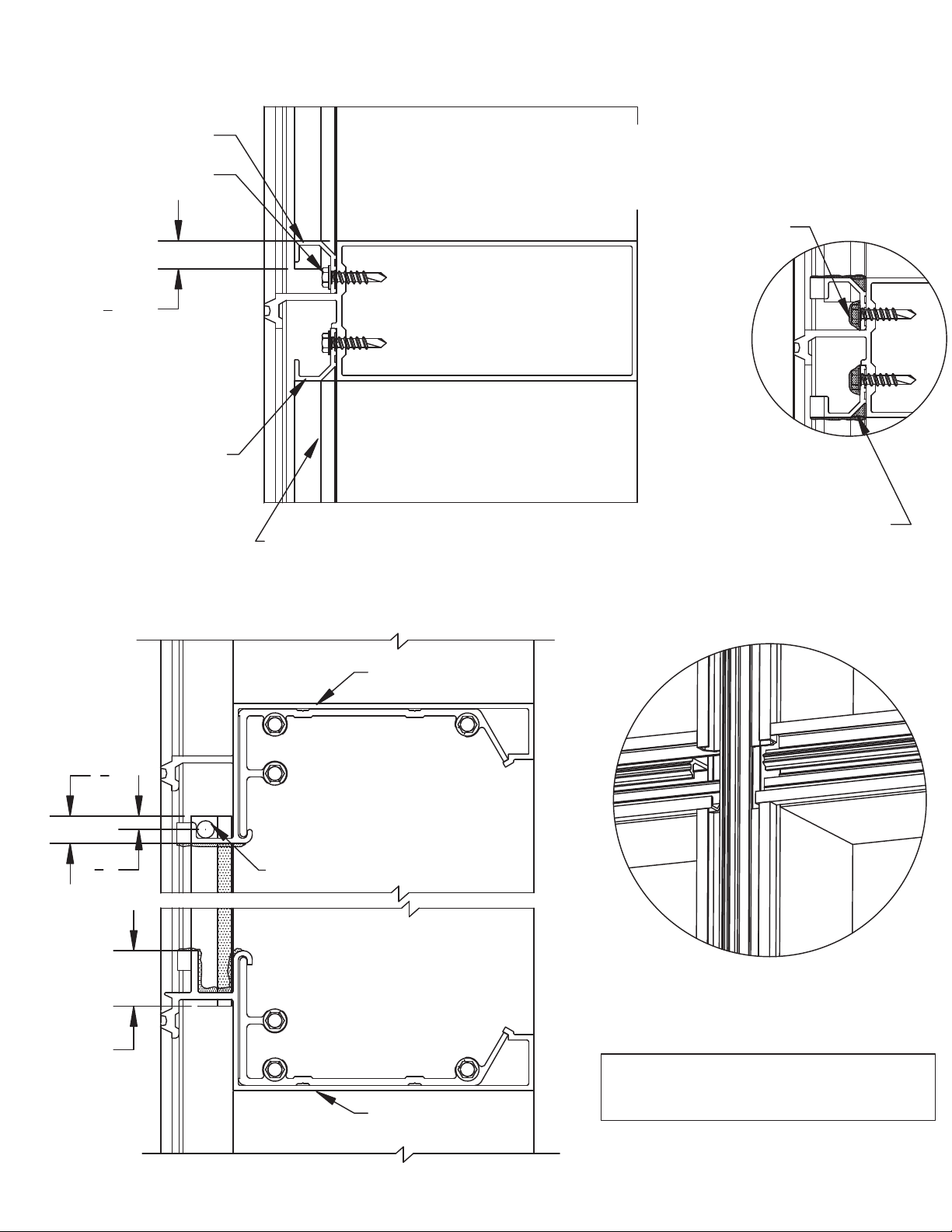

PRESSURE PLATE INSTALLATION

1/8" GAP BETWEEN

PRESSURE PLATESFILL W/ SEALANT

DRILL 7/32" CLEARANCE

HOLE AT END OF PRESSURE

PLATE FOR FS-322

4"

MAX

CW-3

NOTE: DO NOT ATTACH PRESSURE

PLATE TO MULLION STEM DIRECTLY W/ FS-322. A

CLEAR HOLE IS REQUIRED IN PRESSURE PLATE.

12"

12"

FACTORY PUNCHED SLOTS

@ 12" O.C.

FS-322 SELF-DRILLING

FASTENER (NOTE:

CENTERED IN SLOT TO ALLOW

FOR EXPANSION.)

TORQUE TO MINIMUM 60. IN LBS.

AND MAXIMUM 80 IN LBS

FASTENER

NOTE: VERTICAL APPLICATION

SHOWN: HORIZONTAL

APPLICATION SIMILAR

NOTE: ALL STANDARD PRESSURE

PLATES ARE PRE-PUNCHED WITH

CW-6 ISOLATOR:

STOCK LENGTH=12'-3"

February 2012

1/2"

TYP.

18

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

CW-1636 REF. SHT 7

FOR INSTALLATION

CW-1

CW-3

CUT LENGTH =

D.L.O. - 1/4"

4

CW-2

1/4" SHORT

2

1) GLASS BITE = 1/2" TYPICAL

2) CUT VERTICAL PRESSURE PLATE

1/4" SHORT AT SILL FOR WEEPAGE

(DO NOT BLOCK WITH WEATHERSEAL)

3) GLAZING GASKET: PROVIDE 1/4” ADDTIONAL GASKET FOR EACH FOOT OF

DAYLIGHT OPENING OT ALLOW FOR

RELAXATION OF GASKET.

February 2012

@ SILL

SEE NOTE 4 FOR PRESSURE PLATE

& FACE CAP INSTALLATION.

CW250-FP-108

WATER DIVERTER

CW-17

CW-2

CUT LENGTH =

D.L.O. - 1/16"

4) OPTION 1: INSTALL VERTICAL PRESSURE

PLATE AND FACE CAP PRIOR TO INSTALLATION

OF HORIZONTAL PRESSURE PLATES. SEAL HORIZONTAL

PRESSURE PLATE TO VERTICAL FACE CAP PRIOR

TO INSTALLING HORIZONTAL FACE CAP.

OPTION 2:

AND MAINTAIN A MINIMUM 1/8" SPACE BETWEEN

VERT. AND HORIZ. PRESSURE PLATES. INSTALL

VERTICAL FACE CAP AND SEAL HORIZONTAL

PRESSURE PLATE TO VERTICAL FACE CAP

PRIOR TO INSTALLING HORIZ. FACE CAP.

19

INSTALL ALL PRESSURE PLATES

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

1/4” GLAZING DETAIL

CW-1636 REF. SHT 7

FOR INSTALLATION

CW-1

CW-3

CUT LENGTH =

D.L.O. - 1/4"

4

CW-2

1/4" SHORT

2

1) GLASS BITE = 1/2" TYPICAL

2) CUT VERTICAL PRESSURE PLATE

1/4" SHORT AT SILL FOR WEEPAGE

(DO NOT BLOCK WITH WEATHERSEAL)

3) GLAZING GASKET: PROVIDE 1/4” ADDTIONAL GASKET FOR EACH FOOT OF

DAYLIGHT OPENING OT ALLOW FOR

RELAXATION OF GASKET.

@ SILL

SEE NOTE 4 FOR PRESSURE PLATE

& FACE CAP INSTALLATION.

CW-10 1/4" ADAPTOR

REFERENCE SHEET 21

FOR FABRICATION &

INSTALLATION.

CW250-FP-108

WATER DIVERTER

CW-17

CW-2

CUT LENGTH =

D.L.O. - 1/16"

4) OPTION 1:

PLATE AND FACE CAP PRIOR TO INSTALLATION

OF HORIZONTAL PRESSURE PLATES. SEAL HORIZONTAL

PRESSURE PLATE TO VERTICAL FACE CAP PRIOR

TO INSTALLING HORIZONTAL FACE CAP.

OPTION 2:

AND MAINTAIN A MINIMUM 1/8" SPACE BETWEEN

VERT. AND HORIZ. PRESSURE PLATES. INSTALL

VERTICAL FACE CAP AND SEAL HORIZONTAL

PRESSURE PLATE TO VERTICAL FACE CAP PRIOR

TO INSTALLING HORIZONTAL FACE CAP.

INSTALL VERTICAL PRESSURE

INSTALL ALL PRESSURE PLATES

February 2012

20

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

1/4” ADAPTOR FABRICATION & INSTALLATION

CW-10 CUT LENGTH

= D.L.O. TYPICAL

FS-322 @ 18" O.C.

1

" TYP.

2

CW-10 CUT LENGTH

= D.L.O. + 1"

NOTE: CUT LENGTH OF CW-10

AT CORNER VARIES. REFERENCE

CORNER DETAILS.

WHEN USING CW-1; THE VERTICAL CW-10

WILL BE CUT D.L.O. + 1/2" AND WILL RUN

THRU AT THE BOTTOM OF THE LITE

AND THE HORIZONTAL CW-10 WILL RUN

THRU AT THE TOP OF THE LITE.

CW-10 CUT LENGTH = D.L.O. + 1/2"

TYPICAL.

CAP SEAL ALL

FASTENERS

USE COMPATIBLE SEALANT TO

MARRY JOINT BETWEEN SEALANT

AT GLASS, VERTICAL SEALANT

AT MULLION ADAPTOR, SEALANT

AT SHEAR BLOCK, AND HORIZONTAL

SEALANT AT ADAPTOR.

1"

CW-13

1

"

2

1

"

4

DRILL 5/16" Ø

WEEP HOLE

WHEN USING CW-13 & CW-14;

THE CW-10 TO BE CUT D.L.O.

+ 1 1/2" AND WILL RUN THRU

VERTICALLY AT BOTH THE TOP

AND BOTTOM OF THE OPENING.

CW-14

DETAIL FOR INSTALLATION

OF CW-10 AT CW-1 HORIZ.

NOTE: CW-10 ADAPTOR IS SPLICED

AT MULLION SPLICE. REFERENCE

SHEET 31

February 2012

21

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

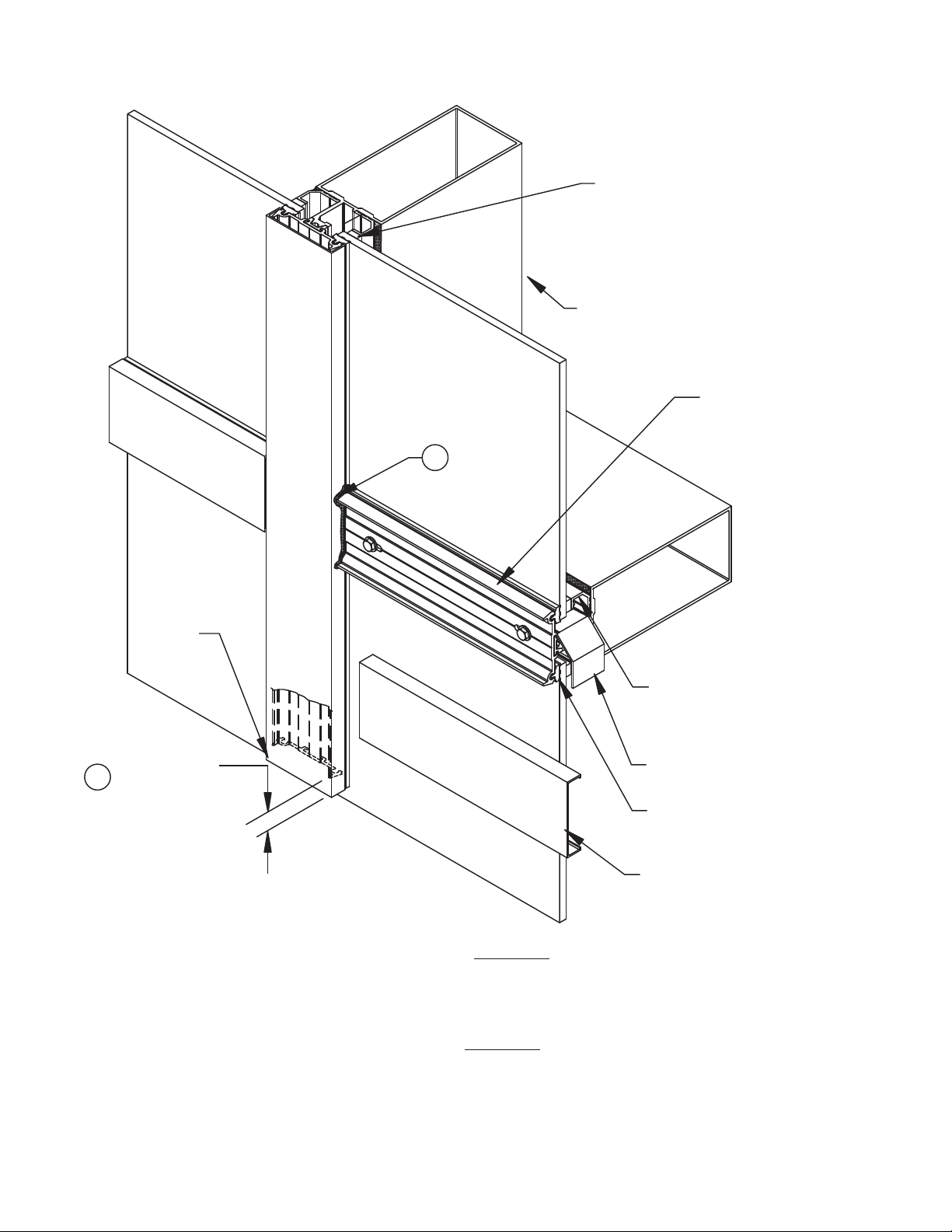

DOOR FRAME INSTALLATION - SUB-FRAME AT HEAD & JAMB

BED DOOR JAMB &

HEAD IN SEALANT

CUT AWAY FOR

CLARITY

CW-20 DOOR JAMB

CUT LENGTH =

DOOR OPENING + 1"

ATTACH W/ FS-322

@ 18" O.C.

TOP OF CW-20

DOOR JAMB

CW-20 DOOR JAMB

ATTACH W/ FS-322

@ 18" O.C.

FG-2145

FILL HOLE AT TOP OF

DOOR JAMB WITH BACKER ROD

AND SEAL.

CW-1636 GLAZING

GASKET (V788)

CW-9 SETTING BLOCK

CAP SEAL

FASTENERS

February 2012

1"

SEAL BETWEEN DOOR

JAMB & HEADER

22

FS322 @ 18" O.C.

(2 PLACES)

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

DOOR FRAME ASSEMBLY - SUB-FRAME AT THRESHOLD

CW-1 MULLION

BED DOOR JAMB

IN SEALANT

FS-322 (#12 X 1" HHSTS)

@ 18" O.C.

CW-3 CUT 1/4" SHORT

AT SILL. SEE NOTE 2

CW-20 DOOR JAMB

TH-44 CLIP

FG-2145

TH-43

FS-42

BED THRESHOLD

IN SEALANT

NOTES:

1) CW-20 DOOR JAMB TO RUN THRU AT

SILL TO FINISHED FLOOR

2) CW-3 PRESSURE PLATE TO BE CUT

1/4" SHORT AT SILL FOR WEEPAGE.

February 2012

SET DOOR JAMB IN SEALANT

AT SILL AND MARRY INTO

THRESHOLD & PRIMARY WEATHERSEAL.

CAP SEAL FASTENERS

23

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

DOOR FRAME ASSEMBLY AT HEAD & JAMB - NO SUB-FRAME

CW-3 PRESSURE PLATE

CW-2 FACE CAP

BUTT TO CW-150

FACE CAP BELOW

FS-322 @ 12" O.C.

CW-150 FACE CAP

CUT LENGTH = DOOR

OPENING + 2 1/2" -

SEALANT JOINT @ SILL

CW-1

APPLY CONTINUOUS

SEALANT BEFORE

INSTALLATION

CW-151 PRESSURE PLATE

CW-150 FACE CAP

CW-151 PRESSURE PLATE

CUT LENGTH = DOOR OPENING

+ 1 1/2". BED IN SEALANT

AT SILL.

DRILL 1/2" ACCESS HOLE IN

CW-151 AND INSTALL FS-43

@ 12" O.C.

February 2012

24

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

DOOR FRAME INSTALLATION AT HEAD & JAMB - NO SUB-FRAME

TOP OF HORIZ.

& CW-150

BOTTOM OF

CW-3

3/4"

1/4"

2 1/2"

1 1/2"

TOP OF

DOOR

OPENING

CW-151

1/2" DIA.

ACCESS HOLE

INSTALL BACKER ROD INTO TOP

OF CW-151 AND SEAL TO

MULL AND HORIZONTAL

NOTCH LEG OF CW-150 FACE CAP

X 7/8" LG. TO CLEAR CW-3

PRESSURE PLATE ABOVE.

DS-1 DOOR STOP

ATTACH W/ SC-1

CLIP @ 18" O.C.

February 2012

LEAVE GAP IN

SEALANT FOR

DRAINAGE

1/2" DIA. ACCESS HOLE

25

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

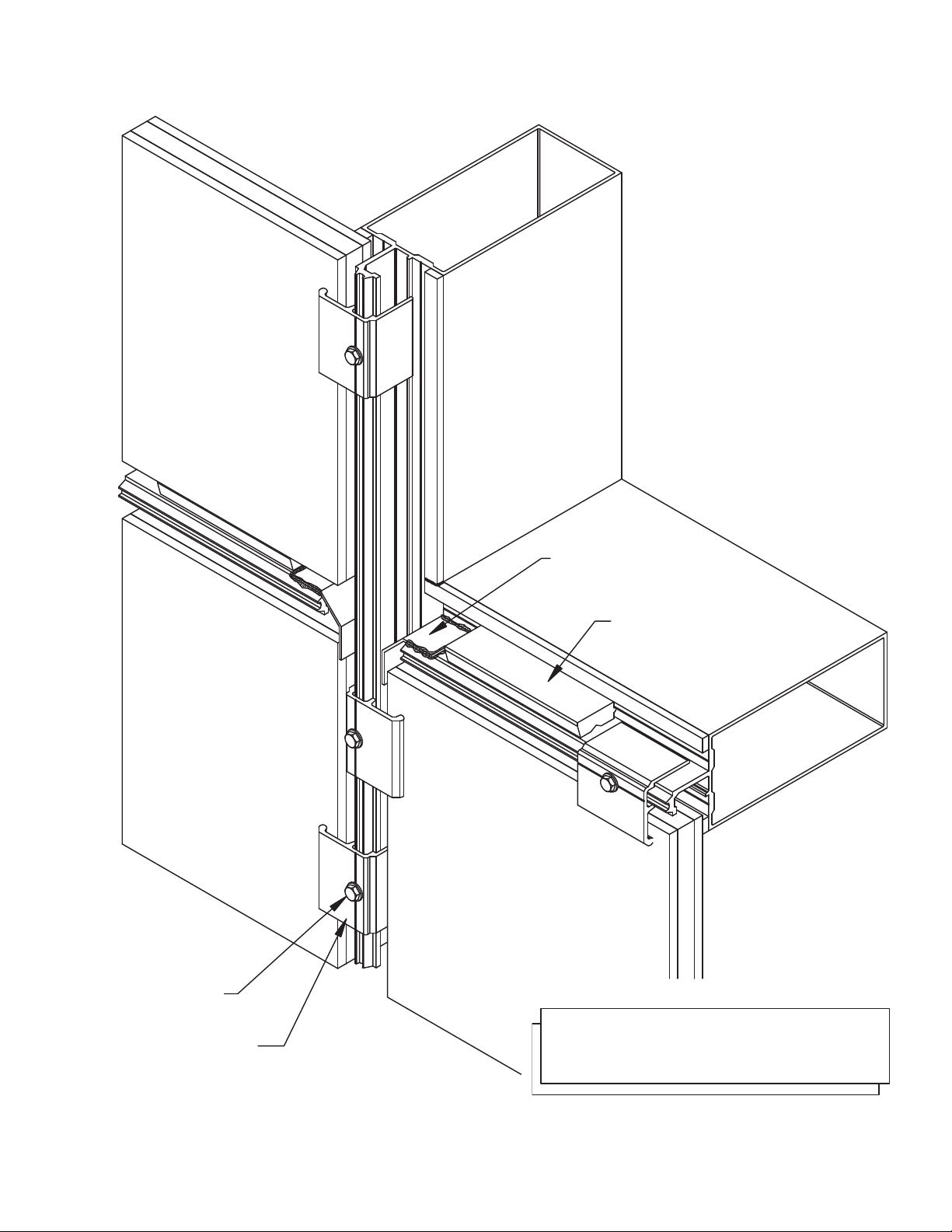

FIXED SPLICE INSTALLATION - RETRACTABLE SLEEVE OPTION

RETRACTABLE

SPLICE SLEEVE

1/4" X 3 1/4" LONG SLOT

EACH SIDE OF MULLION

FS-8 (#14 X 1" H.H)

(2) PER SIDE)

SHOP APPLY CW-65 SPLICE SLEEVE

TO EACH SIDE OF UPPER MULL USING

ONE FASTENER AT EACH SLOT. FIELD

DRILL AND INSTALL SECOND FASTENER

AFTER ASSEMBLY WITH LOWER MULL.

NOTE: SPLICED ASSEMBLY SHOULD BE DESIGNED FOR MULLION TO

ACT AS A SINGLE, NON-JOINTED MEMBER.

1 1/2"

3"

3/4"

4 1/2"

1 1/2"

3"

3/4"

3"

SHOP APPLY CW-65 SPLICE SLEEVE

TO EACH SIDE OF LOWER MULLION.

SPLICE SLEEVE

FS-8 (#14 X 1" H.H)

(2) PER SIDE)

SPLICE TABLE

EXTRUSION SPLICE (2) REQ'D

CW-1 CW-65

CW-7 CW-66

CW-21 CW-67

CW-63/64 CW-68

CW-22 CW-71

CW-161 CW-163

February 2012

26

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

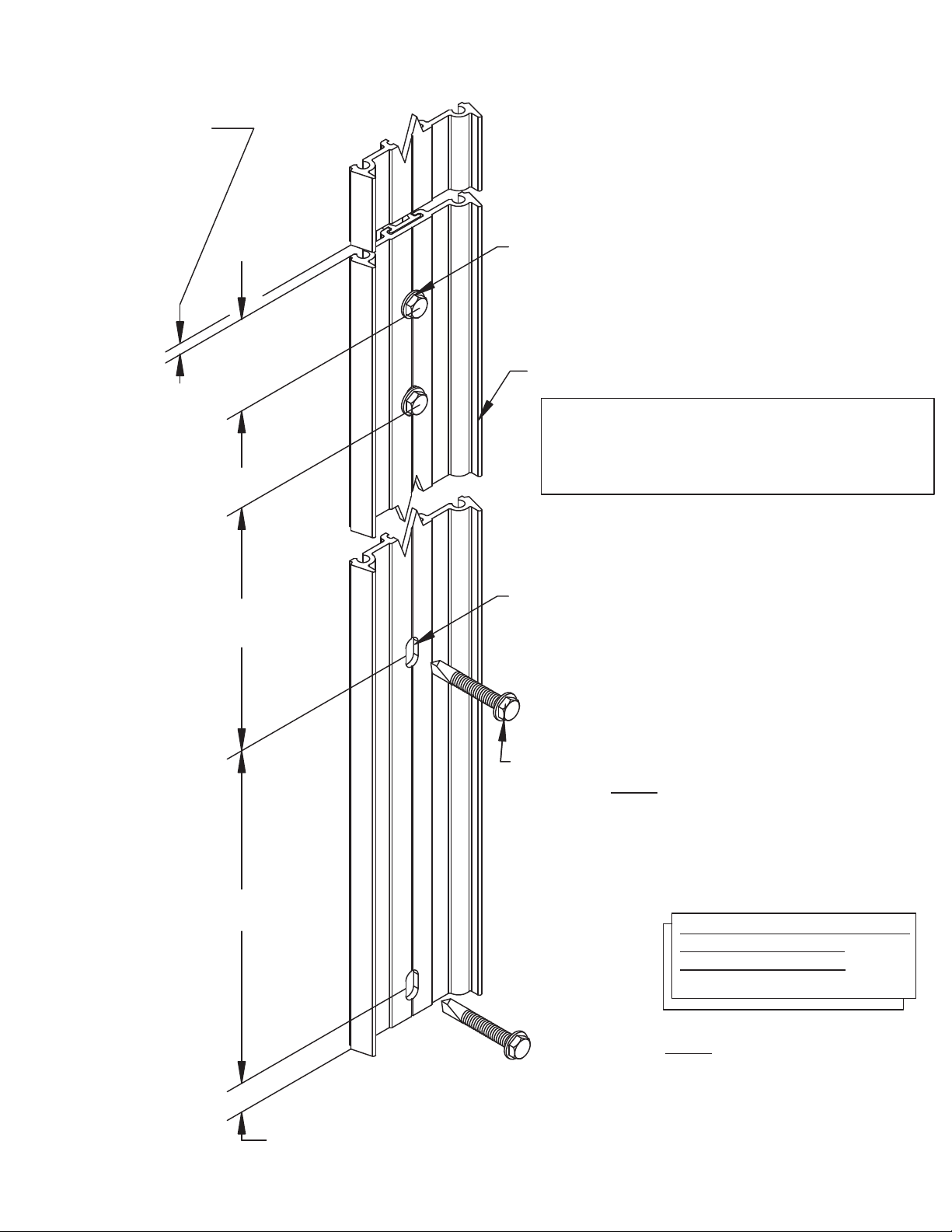

FIXED SPLICE INSTALLATION

NOTES:

1) REFERENCE SHEETS 26 THRU 30 FOR

FABRICATION, ASSEMBLY AND SEALANT

OF TYPICAL SPLICE CONNECTION.

2) DO NOT APPLY BOND BREAKER TAPE TO SPLICE

JOINT FOR FIXED SPLICE APPLICATIONS.

3) ASSEMBLE MULLIONS USING EITHER

RETRACTABLE OR FIXED CONNECTION AND SECURE

OPPOSITE HALF OF ASSEMBLY USING (4) FS-8

FASTENERS AS SHOWN BELOW.

4) 1/2" JOINT TO PROVIDE FABRICATION

CONTINUITY WITH LIVE LOAD SPLICES.

FOR FIXED SPLICE: FASTEN

OTHER MULL HALF AFTER

ASSEMBLY W/ (4) FS-8

1 1/2"

1 1/2"

1/2"

3"

3/4"

February 2012

27

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

LIVE LOAD SPLICE INSTALLATION

APPLY BOND BREAKER

TAPE TO SPLICE AT

LIVELOAD SPLICES ONLY.

SEAL BETWEEN MULL

AND SPLICE SLEEVES

SEAL JOINT BETWEEN MULLS

AT FACE AND SIDES

NOTES:

1) APPLY BOND BREAKER TAPE

AS SHOWN IN DETAIL 1 FOR LIVE

LOAD SPLICES ONLY.

2) SEAL SPACES BETWEEN SPLICE AND

MULLION AS SHOWN IN DTL 1

3) CLEAN (& PRIME IF REQ'D) FOR

CURING-TYPE SEALANT BETWEEN MULL

HALVES. AS SHOWN

IN DETAIL 2.

DETAIL 1

DETAIL 2

February 2012

28

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SPLICE SEALANT INSTRUCTIONS

1" DIA. X 3 3/4" LONG

"DENVER" FOAM ROD

3 3/4"

2" DIA. X 3 3/4" LONG

"DENVER" FOAM ROD

1/2" MULL SPLICE

SEE NOTE "C"

2"

SEE NOTE "A"

FOR SPECIAL

GLAZING TAPE

DETAIL 3

GENERAL NOTES:

A) NORTON "NORPRENE" P3247, 1/4" X 3/8" FOAM

GLAZING GASKET TO BE USED FOR LIVE-LOAD SPLICE

CONDITIONS IN LIEU OF CW-1636 FOAM TAPE INDICATED

ON STANDARD CW-250 DETAILS.

B) MULLION NORMALLY SPLICED IN 1/4" SPANDREL GLASS AREA.

C) MAXIMUM MOVEMENT OF ± 1/4" AT TYPICAL SPLICE

JOINT

1/4" GLASS

SEE NOTE "B"

February 2012

29

DETAIL 4

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SPLICE SEALANT INSTRUCTIONS

4 1/2"

2 1/2"

6

SEALANT INSTRUCTIONS:

1) SEAL MULLION AND SPLICE AS SHOWN IN

DETAILS 1 & 2, SHEET 28

2) INSTALL "DENVER" FOAM ROD AS SHOWN IN

DETAIL 3, SHT 29

3) APPLY NON-HARDENING NON-SKINNING

SEALANT ON TOP AND FRONT SURFACES

OF "DENVER" FOAM AS SHOWN IN

DETAIL 4, SHT. 29

4) INSTALL LOWER PRESSURE PLATE AND FILL

VOID INSIDE GLAZING CAVITY TO TOP OF

PRESSURE PLATE.

SEE DETAIL 5.

5) APPLY PREFERRED SEALANT BETWEEN

1/4" GLAZING ADAPTOR AND MULLION IN SPLICE

AREA.

6) INSTALL LOWER FACE CAP AND SEAL TO FACE

OF PRESSURE PLATE.

7) NOTE: UPPER PRESSURE PLATE AND FACE CAP

NOT SHOWN FOR CLARITY.

DETAIL 5

1/2" PRES. PLT.

SPLICE

1/2" FACE CAP

SPLICE

6

NOTE: SEALANT SLOPE AND

DRAIN AREA BETWEEN PRES.

PLATES AND AT LOWER FACE

CAP.

SEE NOTE #5

February 2012

30

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

O

90 OUTSIDE CORNER FABRICATION

1 17/32"

#17 (.173 DIA.)

DRILLTHRU FOR

#12 FASTENER

TOP OF

HORIZONTAL

CW-22

2 3/4"

1 1/4"

CW250-FP-13

CW250-FP-14 (OPP SIDE)

ANCHOR HOLE (NBV)

FS-43 (TYP)

FSW-324

@ HEAD &

SILL ANCHORS

1 1/4"

1 23/32"

REF.

CW250-FP-92

USE TOP & BOTTOM OF

MULL. ATTACH W/ FS-202

1 1/4"

CW250-FP-7

CW250-FP-14

CW250-FP-13 (OPP SIDE)

DRILL #17 (.173 dia)THRU

HOLE FOR #8 FASTENER

1/2"

FS-202

/

1

"

4

February 2012

31

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

O

90 OUTSIDE CORNER ASSEMBLY

CW-26

CW250-FP-13

CW-22

CW250-FP-14 (OPP SIDE)

(2) CW-34

CW-31

w/ CW-6

CW-12

CW250-FP-7 (TYP)

NOTE:

DO NOT USE CW-13 OR CW-14

HORIZONTALS AT CORNERS.

CW-1

3/4"

February 2012

FS-322

@ 12" O.C.

DRILL 7/23" CLEAR HOLE

& C'SINK 7/16" DIA. FOR #12 PFH.

CW250-FP-14

CW250-FP-13 (OPP SIDE)

* USE HOLES IN HORIZONTAL TO

MATCH DRILL (#17 (.173 dia) HOLES

IN SHEAR BLOCK

32

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

FS-42 (TYP)

CAP SEAL

CW-12

1" TYP.

*

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

O

90 OUTSIDE CORNER GLAZING

CONTINUOUS SEAL BETWEEN

(#10 X 1 3/8" PFH

SEAL ADAPTORS @

BOTH ENDS & FULL

LENGTH (SEE NOTE #1)

CW-17 GASKET

(SQUARE, BUTT

ENDS)

CW-2 FACE CAP

CW-3 PRESSURE

PLATE

ADAPTOR & MULLION

FS-119

STS) @ 18" O.C.

CW-37

2 1/2"

FS-322

@ 12" O.C.

CW-1636

NOTE: HORIZONTAL

FLUSH TO FACE

OF MULL

1 3/8"

CW-17

CW-31

W/ CW-6

1/2"

1/32"

(FACE CAP)

1/8"

(PRES. PLT.)

1/2"

WEATHER SEALANT

1 3/16"

NOTE:

HORIZONTAL CUT LENGTH =

WORKPOINT - 3 11/16"

HEAD AND SILL CUT LENGTH =

HORIZ. LENGTH - 1/16"

NOTE:

1) COMPLETELY SEAL BOTH ENDS OF ADAPTOR TO HORIZONTALS;

MARRY SEALANT TO ADAPTOR LONGITUDINAL SEALS TO GLASS

SEALS.

2) REFERENCE SHEETS 31 THRU 32 FOR SHEARBLOCK, ANCHOR AND HORIZONTAL

DETAILS.

CW-34

3 11/16"

February 2012

33

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

O

90 INSIDE CORNER FABRICATION

1 11/16"

2 3/4"

1 1/4"

CW-22

CW250-FP-14

CW250-FP-13 (OPP SIDE)

ANCHOR HOLE (NBV)

#17 (.173 dia)

DRILL THRU FOR

#12 FASTENER

TOP OF

HORIZONTAL

1 1/4"

FS-43 (TYP)

FSW-324

@ HEAD &

SILL ANCHORS

CW250-FP-7

1 1/4"

CW250-FP-13

CW250-FP-14 (OPP SIDE)

1 9/16"

REF.

February 2012

CW250-FP-92 MULL CAP

USE TOP & BOTTOM OF

MULL. ATTACH W/ FS-202

REF. SHT. 33 FOR ATTACHMENT

34

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

O

90 INSIDE CORNER ASSEMBLY

CW-24

CW250-FP-7 (TYP)

CW-33

CW-22

CW-30

W/ CW-6

SEAL TYPICAL

CW250-FP-14

CW250-FP-13 (OPP SIDE)

CW-12

NOTE:

DO NOT USE CW-13 OR CW-14

HORIZONTALS AT CORNERS.

February 2012

FS-322

@ 12" O.C.

CW250-FP-13

CW250-FP-14 (OPP SIDE)

FS-42

CAP SEAL

35

CW-1

CW-12

3/4" TYP.

*

DRILL 7/32" CLEAR HOLE

AND C'SINK 7/16" DIA. FOR #12 PFH.

* USE HOLES IN HORIZONTAL TO

MATCH DRILL (#17 (.173 dia) HOLES

IN SHEAR BLOCKS

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

O

90 INSIDE CORNER GLAZING

FS-322

@ 18" O.C.

SEAL ADAPTORS @

CW-27

V2110

BOTH ENDS & FULL

LENGTH

(SEE NOTE #1,SHT. 33)

CW-36

5 17/32"

(NTS)

CW-17 GASKET

CW-3 PRESSURE PLATE

CW-2 FACE CAP

1 1/8"

REF.

SEAL END OF HORIZONTAL

AND ADAPTOR TO FACE OF

MULLION.

MARRY SEALANT AT ENDS OF HORIZ.

ADAPTOR TO END SEAL AND VERT.

ADAPTOR SEALS.

February 2012

36

HORIZONTAL CUT LENGTH =

WORKPOINT + 5 17/32"

HEAD AND SILL CUT LENGTH =

HORIZ. LENGTH - 1/16".

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

O

135 OUTSIDE CORNER FABRICATION

"

3

/4

2 3/4"

CW-161

CW250-FP-50

CW250-FP-51 (OPP SIDE)

1 1/4"

FS-43 (TYP)

FSW-324

@ HEAD &

(

.

1

#

1

7

R

H

T

L

I

R

D

L

S

A

F

#

1

2

)

d

ia

7

3

R

O

F

U

R

E

N

E

T

SILL ANCHORS

TOP OF

HORIZONTAL

1 1/4"

DRILL #17 (.173 dia)

CLEAR HOLE FOR

#8 FASTENER

5

W

C

2

CW250-FP-51

CW250-FP-50 (OPP SIDE)

6

"

1

5

/

1

.

F

E

R

1/2"

1/4"

1 1/4"

2

0

-

-

P

F

5

February 2012

CW250-FP-94 MULL CAP

USE AT TOP & BOTTOM

OF MULL. ATTACH W/ FS-202

37

ANCHOR HOLE

(BY OTHERS)

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

O

135 OUTSIDE CORNER ASSEMBLY

(2) CW-167

CW-166

w/ CW-6

CW-161

CW-23

3/4"

CW250-FP-52 (TYP)

CW250-FP-50

CW250-FP-51 (OPP SIDE)

CW-12

NOTE:

DO NOT USE CW-13 OR CW-14

HORIZONTALS AT CORNERS.

CW-1

FS-322

@ 12" O.C.

USE HOLES IN HORIZONTAL

*

TO MATCH DRILL (#17 (.173 dia)

HOLES IN SHEAR BLOCKS.

SEAL TYP.

FS-42 (TYP)

CAP SEAL

CW250-FP-51

CW250-FP-50 (OPP SIDE)

CW-12

1" TYP.

*

DRILL 7/32" CLEAR HOLE AND

C'SINK 7/16" DIA. FOR #12 PFH.

February 2012

38

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

O

135 OUTSIDE CORNER GLAZING

FS-119

(#10 X 1 3/8"

PFH STS) @ 18" O.C.

CW-1636

CONTINUOUS SEAL BETWEEN

ADAPTOR & MULLION

2

1

7

-

CW

SEAL ADAPTORS @

BOTH ENDS & FULL

LENGTH (SEE

NOTE #1, SHT 33)

FS-322 @ 12" O.C.

WEATHER SEALANT

13/16"

CW-17

CW-3 PRESSURE

PLATE

CW-2 FACE CAP

1/32"

(FACE CAP)

1/8"

(PRES. PLT.)

February 2012

"

1

1

3

/

8

"

2

5

/

3

E:

NOT

Z

HORI

RK

O

W

D

A

HE

Z

HORI

39

/2

2

"

=

H

NGT

E

L

CUT

L

A

ONT

"

2

3

/

5

2

-

NT

OI

P

=

H

NGT

E

L

CUT

L

L

I

S

AND

"

6

1

/

1

-

H

T

NG

E

.

L

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

O

135 INSIDE CORNER FABRICATION

7

/

8

"

2 3/4"

CW-161

CW250-FP-51

CW250-FP-50 (OPP SIDE)

1 1/4"

FS-43 (TYP)

FSW-324

.

)

d

ia

7

(

3

.1

#

1

7

R

O

F

U

R

H

T

L

IL

R

D

R

E

N

E

T

S

A

F

#

1

2

@ HEAD &

SILL ANCHORS

TOP OF

HORIZONTAL

1 1/4"

DRILL #17 (.173 dia)

CLEAR HOLE FOR

#8 FASTENER

1

1/2"

5

W

C

2

1

6

"

3

/

1 1/4"

2

0

-

-

P

F

5

CW250-FP-50

CW250-FP-51 (OPP SIDE)

February 2012

1/4"

CW250-FP-94 MULL CAP

USE AT TOP & BOTTOM

OF MULL. ATTACH W/ FS-202

40

ANCHOR HOLE (NBV)

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

O

135 INSIDE CORNER ASSEMBLY

CW-23

CW-165

CW-164

w/ CW-6

CW-161

3/4"

CW250-FP-51

CW250-FP-50 (OPP SIDE)

CW-12

CW250-FP-52 (TYP)

NOTE:

DO NOT USE CW-13 OR CW-14

HORIZONTALS AT CORNERS.

SEAL TYP.

CW-1

FS-322 @ 12" O.C.

FS-42 (TYP)

CAP SEAL

CW250-FP-50

CW250-FP-51 (OPP SIDE)

CW-12

3/4" TYP.

*

February 2012

DRILL 7/32" CLEAR HOLE AND

C'SINK 7/16" DIA. FOR #12 PFH.

USE HOLES IN HORIZONTAL TO

*

MATCH DRILL (#17 (.173 dia) HOLES

IN SHEAR BLOCKS.

41

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

O

135 INSIDE CORNER ASSEMBLY

FS-322 @ 18" O.C.

SEAL ADAPTORS @

BOTH ENDS & FULL

LENGTH (SEE

NOTE #1, SHT #33)

CW-173 1/4" ADAPTOR

CW-1636

1/32"

(FACE CAP)

1/8"

(PRES. PLT.)

1/2"

MATCH DRILL MULL

THROUGH HOLES IN

ADAPTORS W/ #17

(.173 dia.) FOR

#12 HH DRILL-FLEX

CW-175 1" ADAPTOR

CW-164 PRESSURE PLATE

CW-165 FACE CAP

CW-17

GASKET

CW-3 PRESSURE

PLATE

CW-2 FACE CAP

1 21/32"

TO BACK OF

HORIZONTAL

"

2

3

/

1

1

1

.

F

RE

February 2012

3/4"

SEAL END OF HORIZONTAL

AND ADAPTOR TO FACE OF

MULLION.

:

E

T

NO

CUT

L

A

NT

O

Z

RI

42

HO

W

HE

HO

NT

I

O

P

RK

O

ND

A

D

A

NG

E

L

.

Z

RI

2

1

+

CUT

L

L

I

S

-

H

T

=

H

T

NG

E

L

"

2

3

/

1

=

H

T

NG

E

L

"

6

1

/

1

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG MULL FABRICATION

#17 (.173 dia.)

DRILLTHRU FOR

#12 FASTENER

February 2012

43

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG MULL FABRICATION

#11 (.191 dia.) DRILL THRU

FOR #14 FASTENER.

February 2012

44

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG MULL - HEAD INSTALLATION

CW250-FP-2

ANCHOR HOLES (BY OTHERS)

HORIZONTAL CUT LENGTH

9/16"

= D.L.O. - 1/16"

FS-202

CW250-FP-86

MULL CAP

#17 (.173 dia)

DRILL THRU FOR

#8 FASTENER

TYP. SEAL FACE

AND UNDER SHEAR

BLOCK PRIOR TO

INSTALLING HORIZ.

NOTE: FACE OF HORIZONTALS AND

SSG MULLION DO NOT ALIGN

DUE TO SILICONE SPACE

REQUIREMENTS. SEAL

OFFSET AFTER ASSEMBLY.

DRILL 7/32" CLEAR HOLE AND

C'SINK 7/16" DIA. FOR #12 PFH

3/4"

FS-323

CAP SEAL

February 2012

11/16"

45

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG MULL - HORIZONTAL INSTALLATION

NOTE: CW-1 HORIZONTAL IS NOTCHED AT

TOP WHEN ABOVE EYE LEVEL. NOTCHED

AT BOTTOM WHEN BELOW EYE LEVEL. THIS

METHOD OF INSTALLING HORIZONTALS

SHOULD BE USED AT THE END OF A RUN.

CONVENTIONAL METHODS MAY BE USED

FOR THE REMAINING WALL.

CW-7

*NOTE:

SSG MULLION DO NOT ALIGN

DUE TO SILICONE SPACE

REQUIREMENTS. SEAL

OFFSET AFTER ASSEMBLY.

FACE OF HORIZONTALS AND

11/16"

1/2"

4-1/2"

NOTE:

HORIZONTAL CUT LENGTH TO BE

D.L.O. - 1/16" WHEN HORIZONTAL IS

NOTCHED.

1-1/8"

*1/8

TYP. SEAL AROUND

SHEAR BLOCK PRIOR

TO ASSEMBLY OF HORIZ.

3/4"

FS-323

CAP SEAL

CW250-FP-1

3/4"

WHEN HORIZONTAL

IS NOT NOTCHED

DRILL 7/32" CLEAR HOLE AND

C'SINK 7/16" DIA. FOR #12 PFH

CW-1

HORIZONTAL CUT

LENGTH = D.L.O.

February 2012

46

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

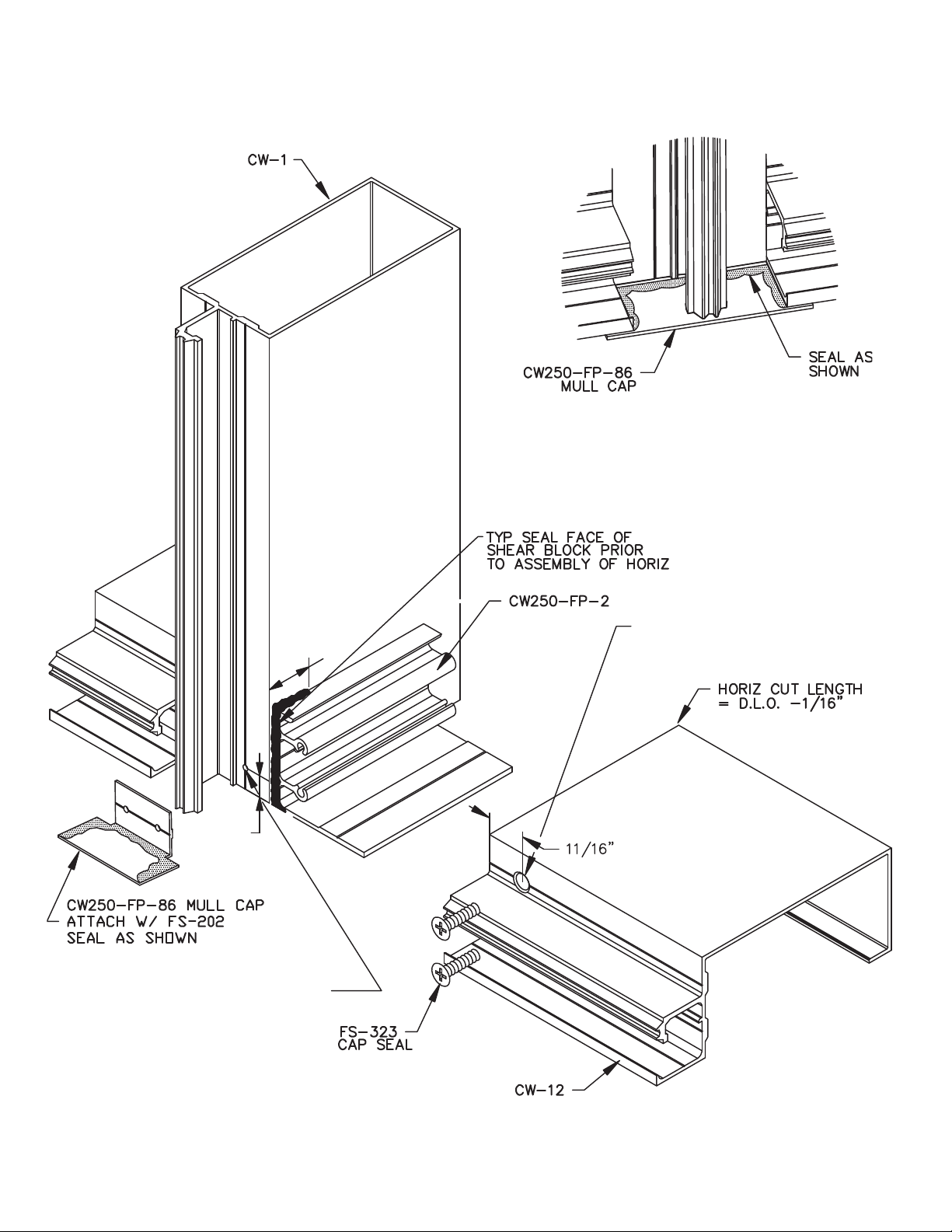

SSG MULL - SILL INSTALLATION

CW-7

*1/8"

3/4"

CW250-FP-86

MULL CAP

TYP SEAL FACE

SHEAR BLOCK PRIOR

TO ASSEMBLY OF HORIZ

CW250-FP-2

ANCHOR HOLES (NBV)

SEAL AS

SHOWN

HORIZ CUT LENGTH

= D.L.O. -1/16"

9/16"

CW250-FP-86

FS-202

*NOTE: FACE OF HORIZONTALS AND

BUTT GLAZE MULLION DO NOT ALIGN

DUE TO STRUCTURAL

SILICONE SPACE REQUIREMENTS.

SEAL OFFSET AFTER ASSEMBLY.

February 2012

MULL CAP

#17 (.173 dia) DRILL

THRU FOR #8 FASTENER

FS-323

CAP SEAL

DRILL 7/32" CLEAR HOLE AND

C'SINK 7/16" DIA. FOR #12 PFH

47

11/16"

CW-12

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

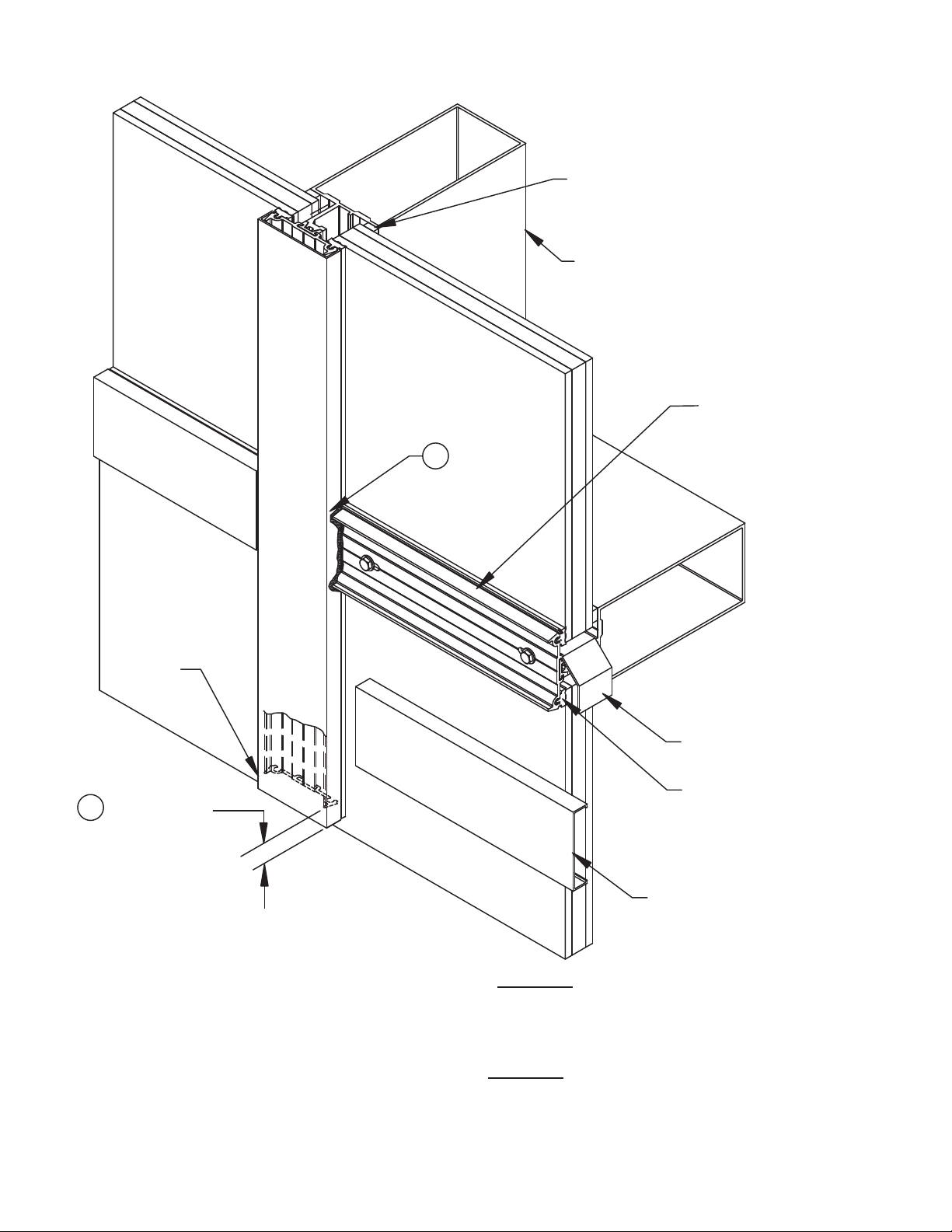

BRIDGE INSTALLATION

PRIOR TO INSTALLING BRIDGE

APPLY SILICONE ACROSS FACE

OF MULL, ALONG TONGUE OF

HORIZONTAL AND ALONG INSIDE

OF HORIZONTAL TONGUE.

LOWER LITES OF GLASS

MUST BE INSTALLED PRIOR

STEP 1

LOWER LEG BENEATH

BRIDGE SHOULD BE

ENGAGED UNDER

HORIZONTAL TONGUE.

2"-3"

4"

INSTALL A TEMPORARY CLIP 4"

FROM THE TOP OF THE GLASS,

INSTALL BACKER ROD AND

APPLY A WEATHERSEAL DOWN

2"-3" FROM THE TOP OF THE GLASS,

PRIOR TO INSTALLING BRIDGE.

TO INSTALLING BRIDGE

STEP 2

SLIDE CW250-PP-164

BRIDGE INTO POSITION

OVER HORIZONTAL TONGUE.

INSTALLING FROM LEFT

TO RIGHT.

STEP 3

February 2012

48

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

BRIDGE INSTALLATION

STEP 4

ONCE FACE OF BRIDGE

ALIGNS WITH LEFT HORIZONTAL

TONGUE, BEGIN TO ROTATE INTO

FINAL POSITION.

AFTER BRIDGE IS ROTATED INTO

POSITION, THE SNAP LEG ON

RIGHT SIDE OF BRIDGE WILL

BE LOCATED ABOVE THE

HORIZONTAL TONGUE. FLEX BRIDGE

AT CENTER AND SNAP ONTO TONGUE.

STEP 5

TOOL SEALANT ALONG BACK LEG,

SIDE AND ALONG FACE JOINT

AFTER INSTALLATION. MARRY SEAL

INTO JOINT BETWEEN HORIZONTAL

AND MULLION.

STEP 6

AFTER BRIDGE IS INSTALLED

RUN BEAD OF SEALANT

ALONG FACE JOINT JUST

PRIOR TO INSTALLING

PRESSURE PLATE.

February 2012

49

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

PRESSURE PLATE INSTALLATION AT BRIDGE

MARK LOCATION OF DIVERTER

BRIDGE CENTERLINE BY

TEMPORARILY ALIGNING

PRESSURE PLATE, CUT LOWER

PRESSURE PLATE GASKET AT

BRIDGE LOCATION AND SPREAD

GASKETS TO ALLOW 3/4" GAP.

INSTALL PRESSURE PLATE

ONTO HORIZONTAL AND ALLOW

GAP TO CLOSE AS SHOWN

IN DETAIL ON PAGE 53.

3/4"

IF PRE-PUNCHED SLOT

FALLS WITHIN 2" OF

CENTERLINE OF MULL.

SEAL SLOT WITH

SILICONE AND DRILL

ADDITIONAL 7/32" HOLE AT

2" OFF CENTERLINE

OF MULLION.

NOTE:

WHEN INSTALLING PRESSURE

PLATE FASTENERS, THEY SHOULD

BE WITHIN 2" TO 4" FROM

THE CENTERLINE OF MULLION.

ADDITIONAL 7/32" HOLES SHOULD

BE ADDED IF STANDARD SLOTS

ARE NOT WITHIN THIS AREA.

2"

2"

MIN.

MIN.

February 2012

INSTALL PRESSURE PLATE

WITH GAP IN LOWER GASKET.

FILL GAPS WITH SILICONE

BETWEEN ENDS OF GASKET

AND WEEP LEG OF DIVERTER.

50

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

GLAZING INSTRUCTIONS

NOTE: WIDTH OF STRUCTURAL SILICONE JOINT

AND PLACEMENT OF V2110 TO BE DETERMINED

BY PROJECT REQUIREMENTS.

CW-7

V2110 FOAM SPACER

(5/16" X 5/16" DSA TAPE)

FILL VOID WHEN APPLYING

STRUCTURAL SILICONE SEAL

CW-1

FS-322

(1) PER RETAINER

CW250-FP-4

TEMP. GLAZING

RETAINER

CW250-FP-164 BRIDGE

REF. SHEETS 48 THRU 50

FOR INSTALLATION.

FS-214

(1) PER RETAINER

CW250-FP-19

TEMP. GLAZING RETAINER

CW-1636 FOAM GASKET

(5/16" X 3/8" SSA)

CW-9 SETTING BLOCK

REFERENCE SHEET 73

FOR LOAD CHART/LOCATION

February 2012

51

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

A

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG GLAZING DETAIL AT 1” GLASS

NOTE: 1” GLASS BITE

AT SSG MULLION

CW-7

STRUCTURAL GLAZING SEALANT

(CLEAN & PRIME SURFACES PER

SEALANT MFG. RECOMMENDATIONS)

WEATHER SEAL

REF. SHEET 53 FOR

DDITIONAL SEALANT

INSTRUCTIONS

CW-1

FACE CAP SEAL

REF. SHEET 53

February 2012

52

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG WEATHER SEALS AT GLASS & FACE CAP

OPEN CELL

BACKER ROD

MARRY WEATHER SEAL

@ GLASS TO WEATHER

SEAL @ FACE CAP

NOTE: LEAVE SPACE IN

GASKET & SEALANT AT

BOTTOM FOR WEEPAGE

WEATHER SEAL

NOTE: 1/8” MIN FACE CAP JOINT

GLASS JOINT

(SPLICE IN CAP)

WITH SEALANT, MARRY WEATHER

SEAL TO GASKET AT TOP

February 2012

NOTE: LEAVE SPACE IN

GASKET AT BOTTOM FOR

WEEPAGE

53

GLASS JOINT

(NO SPLICE IN CAP)

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG DETAIL AT 1/4” GLAZING ADAPTOR

CW-11 ADAPTOR

ATTACH W/ FS-322

@ 18" O.C.

K

B

A

C

STRUCTURAL

SEALANT

E

IV

D

F

O

E

S

A

E

S

L

W

O

T

R

A

R

E

T

R

N

A

L

A

T

T

T

N

A

S

D

X

E

.

O

E

T

E

B

O

L

S

R

D

I

R

1/32"

TYP.

D

A

E

P

I

A

N

.

R

O

E

R

R

O

SILICONE

D -

V2110 FOAM SPACER

-

W

C

7

CW-14

CUT AWAY FOR

CLARITY

February 2012

* NOTE: WIDTH OF STRUCTURAL SILICONE SEAL

AND PLACEMENT OF V2110 TO BE DETERMINED

BY PROJECT REQUIREMENTS.

STRUCTURAL SEALANT WITH

V2110 (5/16" X 5/16" DSA)

FOAM SPACER

*

1/8” MIN FACE CAP JOINT

OPEN CELL BACKER ROD

AND WEATHER SEAL

Phone: 1-866-OLDCASTLE (653-2278)

54

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG 90 OUTSIDE CORNER FABRICATION

1 11/16"

#17 (.173 DIA.)

DRILLTHRU FOR

#12 FASTENER

TOP OF

HORIZONTAL

CW-22

2 3/4"

1 1/4"

CW250-FP-13

CW250-FP-14 (OPP SIDE)

ANCHOR HOLE (by others)

FS-43 (TYP)

FSW-324

@ HEAD &

SILL ANCHORS

1 1/4"

1 9/16"

REF.

CW250-FP-92

USE TOP & BOTTOM OF

MULL. ATTACH W/ FS-202

1 1/4"

CW250-FP-7

CW250-FP-14

CW250-FP-13 (OPP SIDE)

DRILL #17 (.173 dia)THRU

HOLE FOR #8 FASTENER

1/2"

1

FS-202

/

"

4

February 2012

55

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG 90 OUTSIDE CORNER ASSEMBLY

CW-24

CW250-FP-13

CW250-FP-14 (OPP SIDE)

w/ CW-6

CW-32

CW-29

CW-22

ANCHOR HOLES (by others)

CW-12

NOTE:

DO NOT USE CW-13 OR CW-14

HORIZONTALS AT CORNERS.

CW250-FP-7 (TYP)

CW-1

3/4"

FS-322

@ 12" O.C.

NOTE: SURFACES TO

BE FLUSH

CW250-FP-14

CW250-FP-13 (OPP SIDE)

MULL END CAP NOT

SHOWN FOR CLARITY

FS-42 (TYP)

CAP SEAL

CW-12

1" TYP.

*

DRILL 7/32" CLEAR HOLE AND

C'SINK 7/16" DIA. FOR #12 PFH.

* USE HOLES IN HORIZONTAL TO MATCH

DRILL (#17 (.173 dia) HOLES IN SHEAR

BLOCKS

February 2012

56

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG 90 OUTSIDE CORNER WEATHERSEAL

CONTINUOUS SEAL BETWEEN

ADAPTOR & MULLION

(#10 X 1 3/8"

PFH STS) @ 18" O.C.

SEAL ADAPTORS @

BOTH ENDS & FULL

LENGTH

(SEE NOTE #1)

CW-37

STRUCTURAL GLAZING

SEALANT (CLEAN & PRIME

SURFACE AS REQ'D)

FS-119

WEATHER SEAL

FS-322 @ 12" O.C.

NOTE: HORIZONTAL OFFSET 1/8"

TO VERTICAL. SEAL OFFSET

OF HORIZONTAL TO VERTICAL.

V2110

1/8"

1 5/16"

CW-3

(PRES.PLT.)

CW-2

(FACE CAP)

1/2"

NOTE:

1) COMPLETELY SEAL BOTH ENDS OR ADAPTOR TO HORIZONTALS;

MAARY SEALANT TO ADAPTOR LONGITUDINAL SEALS AND GLASS

SEALS.

2) REFERENCE SHEETS 55 & 56 FOR SHEARBLOCK, ANCHOR AND

HORIZONTAL DETAILS.

February 2012

1/16"

NOTE:

HORIZONTAL CUT LENGTH =

HEAD AND SILL CUT LENGTH =

CW250-FP-19

TEMP. GLAZING

RETAINER. ATTACH

W/ FS-214

57

9/16"

2 3/8"

3"

WORKPOINT - 2 3/8"

HORIZ. LENGTH - 1/16"

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG 90 INSIDE CORNER FABRICATION

2 1/8"

2 3/4"

1 1/4"

CW-22

CW250-FP-14

CW250-FP-13 (OPP SIDE)

ANCHOR HOLE (by others)

#17 (.173 dia)

DRILL THRU FOR

#12 FASTENER

TOP OF

HORIZONTAL

1 1/4"

FS-43 (TYP)

FSW-324

@ HEAD &

SILL ANCHORS

CW250-FP-7

1 1/4"

CW250-FP-13

CW250-FP-14 (OPP SIDE)

1 1/8"

REF.

February 2012

CW250-FP-92 MULL CAP

USE TOP & BOTTOM OF

MULL. ATTACH W/ FS-202

REF. SHT. 55 FOR ATTACHMENT

58

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG 90 INSIDE CORNER ASSEMBLY

CW-23

CW250-FP-7 (TYP)

CW250-FP-14

CW-22

CW250-FP-13 (OPP SIDE)

CW-12

SEAL TYP., ALSO

SEAL OFFSET OF

HORIZONTAL TO

MULL ASSEMBLY.

NOTE: MULL CAP

NOT SHOWN FOR

CLARITY.

FS-42

CAP SEAL

NOTE:

DO NOT USE CW-13 OR CW-14

HORIZONTALS AT CORNERS.

CW-1

CW-12

3/4" TYP.

*

February 2012

CW250-FP-13

CW250-FP-14

(OPP SIDE)

DRILL 7/32" CLEAR HOLE AND

C'SINK 7/16" DIA. FOR #12 PFH

59

* USE HOLES IN HORIZONTAL TO

MATCH DRILL (#17 (.173 dia.) HOLES

IN SHEAR BLOCK

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG 90 INSIDE CORNER WEATHERSEALS

HORIZONTAL CUT LENGTH =

WORKPOINT + 5 11/16"

HEAD AND SILL CUT LENGTH =

HORIZ. LENGTH - 1/16".

FS-322

V2110

CW-27

@ 18" O.C.

SEAL ADAPTORS @

BOTH ENDS & FULL

LENGTH

(SEE NOTE #1,SHT 57)

CW-36

5 11/16"

(NTS)

1 5/16"

1/4"

15/16"

REF.

MARRY SEALANT AT ENDS OF HORIZ.

ADAPTOR TO END SEAL AND VERT.

ADAPTOR SEALS.

SEAL BETWEEN PRESSURE

PLATES/FACE CAPS

CW-3 (PRES. PLT)

CW-2 (FACE CAP)

1/8"

February 2012

SEAL END OF HORIZONTAL

AND ADAPTOR TO FACE OF

MULLION.

60

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG 135 OUTSIDE CORNER FABRICATION

7/8"

2 3/4"

CW-161

CW250-FP-50

CW250-FP-51 (OPP SIDE)

1 1/4"

FS-43 (TYP)

FSW-324

@ HEAD &

(

.

1

#

1

7

R

H

T

L

I

R

D

L

S

A

F

#

1

2

)

d

ia

7

3

R

O

F

U

R

E

N

E

T

SILL ANCHORS

TOP OF

HORIZONTAL

1 1/4"

DRILL #17 (.173 dia)

CLEAR HOLE FOR

#8 FASTENER

1 3/16"

REF.

1/2"

1 1/4"

5

0

W

C

2

CW250-FP-51

CW250-FP-50 (OPP SIDE)

2

-

-

P

F

5

February 2012

1/4"

CW250-FP-94 MULL CAP

USE AT TOP & BOTTOM

OF MULL. ATTACH W/ FS-202

61

ANCHOR HOLE (by others)

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG 135 OUTSIDE CORNER ASSEMBLY

CW-23

CW250-FP-50

1

6

C

1

W

-

1

7

C

0

W

W

-

w

6

/

C

1

7

C

1

W

-

CW250-FP-51 (OPP SIDE)

CW-12

NOTE:

DO NOT USE CW-13 OR CW-14

HORIZONTALS AT CORNERS.

3/4"

CW250-FP-52 (TYP)

CW-1

FS-42 (TYP)

SEALANT, ALSO SEAL OFFSET OF

HORIZONTAL TO MULL ASSEMBLY.

CW250-FP-51

CW250-FP-50 (OPP SIDE)

1" TYP.

*

CW-12

February 2012

FS-322

@ 12" O.C.

* USE HOLES IN HORIZONTAL TO

MATCH DRILL (#17 (.173 dia) HOLES

IN SHEAR BLOCK

62

DRILL 7/32" CLEAR HOLE AND

C'SINK 7/16" DIA. FOR #12 PFH

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG 135 OUTSIDE CORNER WEATHERSEALS

FS-119

(#10 X 1 3/8"

PFH STS) @ 18" O.C.

CONTINUOUS SEAL BETWEEN

ADAPTOR & MULLION

CW-172

SEAL ADAPTORS @

BOTH ENDS & FULL

LENGTH (SEE

NOTE #1, SHT 57)

V2110

STRUCTURAL GLAZING

SEALANT (CLEAN & PRIME

SURFACE AS REQ'D)

WEATHER SEALANT

FS-322 @ 12" O.C.

CW-3

(PRES. PLT)

CW-2

(FACE CAP)

1/32" FACE CAP

1/8" PRES. PLT.

1 3

8

/

"

1

/

2

"

1

3

/

1

6

"

1

19

/

3

2

"

1/8"

NOTE:

HORIZONTAL CUT LENGTH =

WORKPOINT - 1 19/32"

HEAD AND SILL CUT LENGTH =

HORIZ. LENGTH - 1/16"

February 2012

SEAL BETWEEN HORIZONTAL

AND MULLION.

MARRY SEAL AT HORIZONTAL ADAPTOR

INTO SEAL BETWEEN HORIZONTAL AND

MULLION.

63

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG 135 INSIDE CORNER FABRICATION

1 1/32"

2 3/4"

CW-161

CW250-FP-51

CW250-FP-50 (OPP SIDE)

1 1/4"

FS-43 (TYP)

FSW-324

(

.

1

#

1

7

L

R

H

T

I

R

D

L

S

A

F

#

1

2

.)

7

3

d

ia

R

O

F

U

R

E

N

E

T

@ HEAD &

SILL ANCHORS

TOP OF

HORIZONTAL

1 1/4"

DRILL #17 (.173 dia)

CLEAR HOLE FOR

#8 FASTENER

1 1/32"

1/2"

1 1/4"

5

W

C

2

2

0

-

-

P

F

5

CW250-FP-50

CW250-FP-51 (OPP SIDE)

February 2012

1/4"

CW250-FP-94 MULL CAP

USE AT TOP & BOTTOM

OF MULL. ATTACH W/ FS-202

64

ANCHOR HOLE (by others)

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG 135 INSIDE CORNER ASSEMBLY

CW-23

CW250-FP-51

CW-161

CW-169

CW-168 ADAPTOR

CUT DLO - 1/16"

CW250-FP-50 (OPP SIDE)

CW-12

CW250-FP-52 (TYP)

SEAL TYP. , ALSO

SEAL OFFSET OF

HORIZONTAL TO

MULL ASSEMBLY.

NOTE:

DO NOT USE CW-13 OR CW-14

HORIZONTALS AT CORNERS.

CW-1

FS-42 (TYP)

CAP SEAL

CW250-FP-50

CW250-FP-51 (OPP SIDE)

CW-12

3/4" TYP.

*

February 2012

DRILL 7/32" CLEAR HOLE AND

C'SINK 7/16" DIA. FOR #12 PFH

* USE HOLES IN HORIZONTAL TO MATCH

DRILL (#17 (.173 dia) HOLES IN SHEAR BLOCK

65

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

SSG 135 INSIDE CORNER WEATHERSEALS

MATCH DRILL MULL

SEAL ADAPTORS @

BOTH ENDS & FULL

LENGTH (SEE

NOTE #1, SHT 57)

THROUGH HOLES IN

ADAPTORS W/ #17 (.173 dia)

FOR #12 HH DRILL-FLEX.

FS-322 @ 12" O.C.

CW-174 1/4" ADAPTOR

STRUCTURAL GLAZING

SEALANT (CLEAN & PRIME

SURFACE AS REQ'D)

WEATHER SEALANT

1/32"

FACE CAP

1/8"

PRES. PLT.

1/2"

CW-168 1" ADAPTOR

CUT DLO - 1/16"

V2110

CW-169 FACE CAP

CW-3

(PRES. PLT)

CW-2

(FACE CAP)

13/16"

1 21/32"

1 1/8"

REF.

February 2012

SEAL END OF HORIZONTAL

AND ADAPTOR TO FACE OF

MULLION.

NO

HO

W

HE

HO

66

:

E

T

RI

RK

O

D

A

RI

L

A

NT

O

Z

NT

I

O

P

S

ND

A

NG

E

L

.

Z

L

I

CUT

1

+

CUT

L

H

T

E

L

3

/

1

2

1

/

1

-

NG

2

L

6

=

H

T

"

E

"

NG

=

H

T

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

MULLION REINFORCING DETAIL

CW-21 MULLION

(CW-1 & CW-7 SIM.)

3/8"

FS-27 TYP.

(#12 X 1/2" PPHSTS)

NOTE: INSTALL FASTENERS

AFTER REINF. STEEL IS

IN PLACE INSIDE MULL.

(SEE NOTE #3)

CW250-FP-1

SHEAR BLOCK

(SEE NOTE #1)

5/16"

SEE NOTE#5

CW250-PP-15

CW250-PP-16

CW250-PP-17

February 2012

INTERMEDIATE HORIZONTAL SECTION

NOTES:

1) SEE SHEET 15 FOR TYPICAL DETAILS AT OPEN-BACK

INTERMEDIATE HORIZONTALS WITH CW250-FP-3 SHEARBLOCKS.

2) TO AVOID INTERFERENCE WITH SHEARBLOCK FASTENERS, INSTALL

ALL STEEL REINFORCING CHANNELS PRIOR TO SECURING SHEAR

BLOCKS TO MULLIONS.

3) THE USE OF REINFORCING CHANNELS REQUIRES THAT THE

CW250-FP-1&2 SHEARBLOCKS BE SECURED WITH FS-27

IN LIEU OF THE FS-43 FASTENERS TYPICALLY USED WHEN THE

MULLION IS NOT REINFORCED. (SEE SHEET 10 FOR THE TYPICAL

UNREINFORCED CONDITION)

4) CW250-PP-15 REINFORCING CHANNEL MAY BE USED ALONE, OR IN

COMBINATION WITH CW250-PP-16 OR CW250-PP-17

5) SEE SHEETS 10 & 11 FOR FABRICATION OF MULLION AND SHEET

68 FOR LOCATION OF BOLT FO

R ATTACHMENT OF REINFORCING CHANNELS.

67

FASTENERS

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

MULLION REINFORCING DETAIL

CW-21 MULLION

CW-12

SILL

SHIM CHANNELS

SNUG (by others)

(2) 3/8"-16 x 1 1/2"

ASSEMBLY BOLT W/

WASHERS. (by others)

(NOTE: ENLARGE HOLE

IN ANCHOR TO FIT.)

CW250-FP-2

SHEAR BLOCK

(SEE NOTE #1)

3/8"

SEE NOTE#5

5/16"

(CW-1 & CW-7 SIM.)

CW250-PP-15

CW250-PP-16

CW250-PP-17

7/16" Ø HOLES

IN MULLION & REINF.

CHANNELS (by others)

CW-13/14

HORIZONTAL

FS-9 TYP.

(#14 X 1 1/2" HH)

INSTALL ALL FASTENERS

AFTER REINF. STEEL IS

IN PLACE INSIDE MULL.

SILL SECTION (HEAD SIMILAR)

FS-114 @ 18" O.C.

(#8 X 3/8" PPHSMS)

DRILL CLEAR HOLE IN

CW-10 ADAPTOR. USE

WASHER (NBV) IF REQ'D

TO PREVENT SCREW

FROM TOUCHING STEEL.

February 2012

SPANDREL SECTION

68

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

CATALOG NO.

ORDER NO.

STOCKED QTY.

DESCRIPTION

CW250-FP-1

6450

20/BOX

SHEAR BLOCK, CW-1 INTERMEDIATE HORIZONTAL

CW250-FP-2

6451

20/BOX

SHEAR BLOCK, CW-12 HEAD/SILL

CW250-FP-3

6452

20/BOX

SHEAR BLOCK, CW-13 & CW-14 HORIZONTALS

CW250-FP-4

6459

20/BOX

CAPTURED GLAZING TEMPORARY RETAINER

CW250-FP-5

1201

EACH

GLAZING GASKET APPLICATION TOOL

CW250-FP-7

6465

20/BOX

SHEAR BLOCK , CW-22 (90 DEG.) CORNER MULL

CW250-FP-13

6467

10/BOX

90 DEG. CORNER MULL ANCHOR

CW250-FP-14

6468

10/BOX

90 DEG. CORNER MULL ANCHOR (OPP. HAND)

CW250-PP-15

302

EACH

REINFORCEMENT CHANNEL 4 ¾” x1 7/8”

CW250-PP-16

297

EACH

REINFORCEMENT CHANNEL 4 ¼” x 1 ½”

CW250-PP-17

296

EACH

REINFORCEMENT CHANNEL 3 ¾” x 1 5/16”

CW250-FP-19

4169

100/BOX

BUTT GLAZE TEMPORARY RETAINER

CW250-PP-25

295

EACH

REINFORCEMENT CHANNEL 4 5/8” x 1 5/8”

CW250-FP-50

4897

10/BOX

135 DEG. CORNER MULLION ANCHOR

CW250-FP-51

4898

10/BOX

135 DEG. CORNER MULLION ANCHOR (OPP HAND)

CW250-FP-52

4899

20/BOX

SHEAR BLOCK, CW-161 (135 DEG) CORNER MULLION

CW250-FP-86

6540

20/BOX

MULL END CAP

CW250-FP-92

6257

20/BOX

MULL END CAP 90 DEG. CORNER

CW250-FP-94

6562

20/BOX

MULL END CAP 135 DEG. CORNER

CW250-FP-108

6889

50/BOX

HORIZONTAL WATER DIVERTER

CW250-FP-148

727

10/BOX

HEAD ANCHOR FOR CW-1

CW-9

6456

100/BOX

EPDM SETTING BLOCK

SCW-9

6457

100/BOX

SILICONE SETTING BLOCK

HP-17

10267

200/BOX

SETTING BLOCK ¼” GLAZING ONLY

CW-17

501

500 FT/ROLL

EPDM EXTERIOR GLAZING GASKET

CW-187

4948

250 FT/ROLL

EPDM HEAD/SILL PRESSURE PLATE SPACER

CW-998

600

2000/FT/ROLL

BULB GASKET FOR EXPANSION MULLS

CW-1636

734

50 FT/ROLL

INTERIOR GLAZING GASKET

P3247

209

100 FT/ROLL

INTERIOR GLAZING GASKET AT LIVELOAD

V2100

235

25 FT/ROLL

INTERIOR BUTT GLAZE SPACER GASKET

CW-65

4723

20/BOX

SPLICE; CW-1 MULLION

CW-66

4724

20/BOX

SPLICE; CW-7 MULLION

CW-67

4725

20/BOX

SPLICE; CW-21 MULLION

CW-68

4735

20/BOX

SPLICE; CW-63 & CW- 64 EXPANSION MULLS

CW-71

4736

20/BOX

SPLICE; CW- 22 (90 DEG) CORNER MULLION

CW-163

4900

20/BOX

SPLICE; CW- 161 (135 DEG) CORNER MULLION

FS-7 CLR

10220

200/BOX

OPTIONAL FASTENER-HORIZ. TO SHEAR BLOCK

FS-7 BRZ

10221

200/BOX

OPTIONAL FASTENER-HORIZ. TO SHEAR BLOCK

FS-8

10223

100/BOX

FASTENERS; SPLICES TO MULLION

FS-9

6495

100/BOX

FASTENERS; SHEAR BLOCK TO MULLION

FS-27

10208

200/BOX

FASTENERS; SHEAR BLOCK TO MULLION

FS-41

6317

200/BOX

FASTENERS; ADAPTOR TO MULLION

FS-42

6469

200/BOX

FASTENERS; HORIZONTAL TO CORNER SHEAR BLOCK

FS-43

10211

200/BOX

FASTENERS; ADAPTOR TO MULLION

FS-114

6318

200/BOX

FASTENERS; ADAPTOR TO MULLION

FS-119

6493

100/BOX

FASTENERS; CW-37 ADAPTORS

FS-202

4910

100/BOX

FASTENERS; END CAP TO MULLION

FS-214

10205

200/BOX

FASTENERS; CW250 -FP-19 GLAZING RETAINER

FS-322

6453

200/BOX

FASTENERS; PRES. PLATE, DOOR FRAME, ADAPTORS

FS-323

6455

200/BOX

FASTENERS; HORIZONTAL TO SHEAR BLOCK

FSW-324

6454

100/BOX

LACK WASHER; USE W/ FS-43 @ CW250-FP-2 SHR. BLOCK

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

CW-250 1” PARTS CROSS-REFERENCE

February 2012

69

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

Loading...

Loading...