MAY 2013

Note: Installation and Glazing Manuals are product specific. FOR REVIEW ONLY!

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

AD-375 THERMAL DOOR

TABLE OF CONTENTS

General Information Sheet

Product Use 1

Protection and Storage 1

Preparation of Opening 1

Check Material 2

Field Conditions 2

Cleaning Materials 2

Suggestions for Improving System Thermal Performance 2

Door Size Warranty Guidelines 2

Door & Frame Checklist 3

Glass Sizing 4

Standard Hardware Locations 5

Door Handing 6

Frame Assembly 7-12

Door Frame Installation 13 -16

Door Glass Installation 17

Installation of Butt & Gear Hinges 18

Final Adjustments to Door 19

Adjustments to Pair of Doors (Astragal adjustment) 20

Parts List 21

MAY 2013

Phone: 1-866-OLDCASTLE (653-2 278)

Web Address: www.oldcastlebe.com

AD-375 THERMAL DOOR

GENERAL INFORMATION

PRODUCT USE

The AD-375 Thermal Doors are intended for installation by glazing professionals with appropriate experience.

Subcontractors without experience should employ a qualified person to provide field instruction and project

management.

Oldcastle BuildingEnvelope does not control the application or selection of its product configurations,

sealant or glazing material and assumes no responsibility thereof. It is the responsibility of the owner,

architect and installer to make these selections in strict compliance with applicable laws and building codes.

Consult sealant manufacturer for review and recommendation of sealant application. Follow sealant

manufacturer's recommendations and literature for proper installation.

The air and water performance of the AD-375 Thermal Door system is directly related to the completeness

and integrity of the installation process of both the seal installed at the horizontal to vertical connections

the glazing gasket installed at the interior side of the glass. To insure top performance of this system,

particular attention should be given to the following procedures:

1. Surfaces to be sealed should be cleaned with isopropyl alcohol or solvent and dried as

recommended by sealant manufacturer to remove dirt and cutting oils. Sealant at horizontal to

vertical connections should be a minimum 3/16" diameter bead on surfaces where horizontal

abuts vertical per glazing instructions herein. No gaps should be visible in the sealant. Exposed

surfaces should be cleaned after installing the horizontal. Inspect joint for complete sealant

contact, especially where the horizontal meets the face of the vertical member. Repair joint as

required.

2. The glazing gasket should be installed so as to avoid stretching, buckles or tears.

Corners must be cut to form a tight joint. To avoid damage to gasket and corner joints

during glazing, glass should be level and straight during installation.

Variations on the details shown are inevitable and are not the responsibility of Oldcastle BuildingEnvelope

when drawn by others. Oldcastle BuildingEnvelope strongly encourages its customers to use its

Engineering department for calculations and shop drawings.

TM

TM

TM

Consult glass manufacturer for correct setting block location and length for glass sizes in excess of 40 sq.ft.

PROTECTION AND STORAGE

Handle all material carefully. Do not drop from the truck. Stack with adequate separation so the material will

not rub together. Store material off the ground, protecting against the elements and other construction

hazards by using a well ventilated covering. Remove material from package if wet or located in a damp area.

For further guidelines consult AAMA publication "Care and Handling of Architectural Aluminum From Shop to

Site."

PREPARATION OF OPENING

Prior to installation of a door and frame, it is important to consider your surrounding construction.

Is the opening large enough to handle the door and frame that was ordered?

Allow for at least 1/4" shim space all around the frame.

Are there any obstructions present within the opening?

Is there sufficient structure to anchor the frame?

Is the support in the proper location?

What is the sill condition?

Is there a ledge?

Is there enough space to get anchorage into the floor slab?

Is the floor slab sloping away from the door so that it may operate properly?

Be sure the slab is level from side to side at door area.

Threshold will be standard 4 1/2" wide, 1/2" tall sloped from back to front.

If there is a problem with location of opening or slab level, please contact your general contractor, in writing

requesting a correction. DO NOT begin installation until problems are resolved.

1MAY 2013

Phone: 1-866-OLDCASTLE (653-2 278)

Web Address: www.oldcastlebe.com

AD-375 THERMAL DOOR

GENERAL INFORMATION

CHECK MATERIAL

Check glass dimensions for overall size as well as thickness. Oldcastle BuildingEnvelope cannot be held

TM

responsible for gaskets that are not water tight due to extreme glass tolerances. The AD-375 Thermal Door

wall system is designed to accommodate glass or panels measuring 1" or 1-9/16" in thickness (+/- 1/32").

Check all material upon arrival at job site for quality and to determine any shipping damage.

Check doors upon arrival to insure top and bottom seals are in place and not damaged in shipping. (ref.pg.3)

Using the contract documents, completely check the surrounding conditions that will receive your materials.

Notify the general contractor by letter of any discrepancies before proceeding with the work. Failure to do so

constitutes acceptance of work by other trades.

Check shop drawings, installation instructions, architectural drawings and shipping lists to become familiar

with the project. The shop drawings take precedence and include specific details for the project. The

installation instructions are of a general nature and cover the most common conditions. Due to varying job

conditions all sealant must be approved by the sealant manufacturer to insure it will perform per the

conditions shown on the instructions and shop drawings. The sealant must be compatible with all surfaces in

which adhesion is required, including other sealant surfaces. Use primers where directed by sealant

manufacturer. Properly store sealant at the recommended temperatures and check sealant for remainder of

shelf life before using.

FIELD CONDITIONS

All material to be installed must be plumb, level and true. Aluminum to be placed in direct contact with

masonry or incompatible material should be isolated with a heavy coat of zinc chromate, bituminous paint or

non-metallic material.

After sealant is set and a representative amount of the wall has been glazed (250 sq.ft. or more), perform a

water hose test in accordance with AAMA 501.2 specifications to check installation. On large projects the

hose test should be repeated during the glazing operation.

CLEANING MATERIALS

Cement, plaster terrazzo, alkaline and acid based materials used to clean masonry are very harmful to

finishes. Any residue should be removed with water and mild soap immediately or permanent staining will

occur. A spot test is recommended before any cleaning agent is used. Refer to the Architectural Finish

Guide in the Detail Catalog.

SUGGESTIONS FOR IMPROVING SYSTEM THERMAL PERFORMANCE

To maintain or improve your wall installation the following items should be considered.

A. Blinds or drapes prevent warm air from adequately flowing over the window surface.

B. Warm air ventilators too far from the window will not adequately wash the window with air to

prevent condensation.

C. In extreme conditions the fan of the heating system should not cycle on and off, but should run

continuously.

D. Some heating systems have a water injection feature that can raise humidity levels. The higher

the humidity levels the more likely condensation or frost will form. Raising the temperatures and

reducing humidity will usually solve the problem.

E. On rare occasions an extremely cold storm may cause frost to appear on the glass framing. A

space heater and electric fan blowing along the plane of the window wall can reduce or eliminate

this temporary condition.

DOOR SIZE WARRANTY GUIDELINES

The following are Oldcastle BuildingEnvelope standard warranty guidelines and recommendations for

TM

special size doors (all sizes are maximums):

1. Doors with 1" glass = 4'-0" x 9'-0" / Minimum 1 1/2 pair of butt hinges

2MAY 2013

Phone: 1-866-OLDCASTLE (653-2 278)

Web Address: www.oldcastlebe.com

AD-375 THERMAL DOOR

DOOR & FRAME CHECKLIST

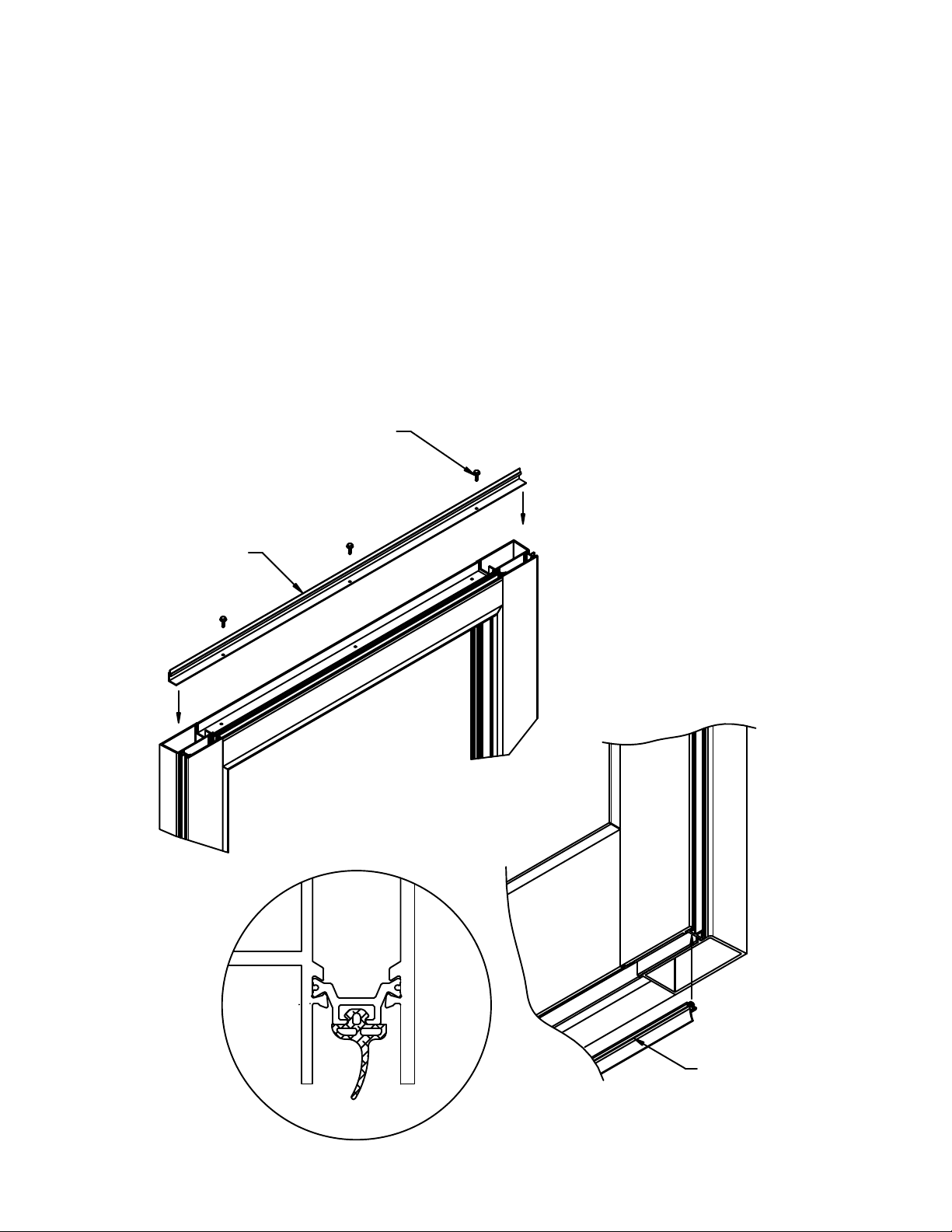

Inspect door to make sure no damage occurred in shipping. The door should have a seal installed in the

top rail and also a sweep gasket at the bottom rail see details below. If these are not in place or have

been damaged, install as shown below or contact your dealer for replacement. The door package should

also contain the door glass stops hooked in place, a roll of FG-1133 gasket, hinge hardware and your

push pull or panic hardware as required for your project.

Remove door frame from package and inspect for damage. The door package should contain a package

of shear blocks and fasteners for frame assembly. There will also be a threshold, threshold clip package

and various fasteners for attachment of threshold to frame. A standard package of anchor screws and

inserts may also be in the frame packaging, but project requirements may require use of other fasteners

at this area. Packaging does not contain any fasteners for securing your door frame to the opening of

your wall system or building.

60705 (#10 X 3/4" hh tek)

(3) places

AD-114 with

GP-157 gasket

GP-156

Bottom Rail Seal

3MAY 2013

Phone: 1-866-OLDCASTLE (653-2 278)

Web Address: www.oldcastlebe.com

AD-375 THERMAL DOOR

GLASS SIZING

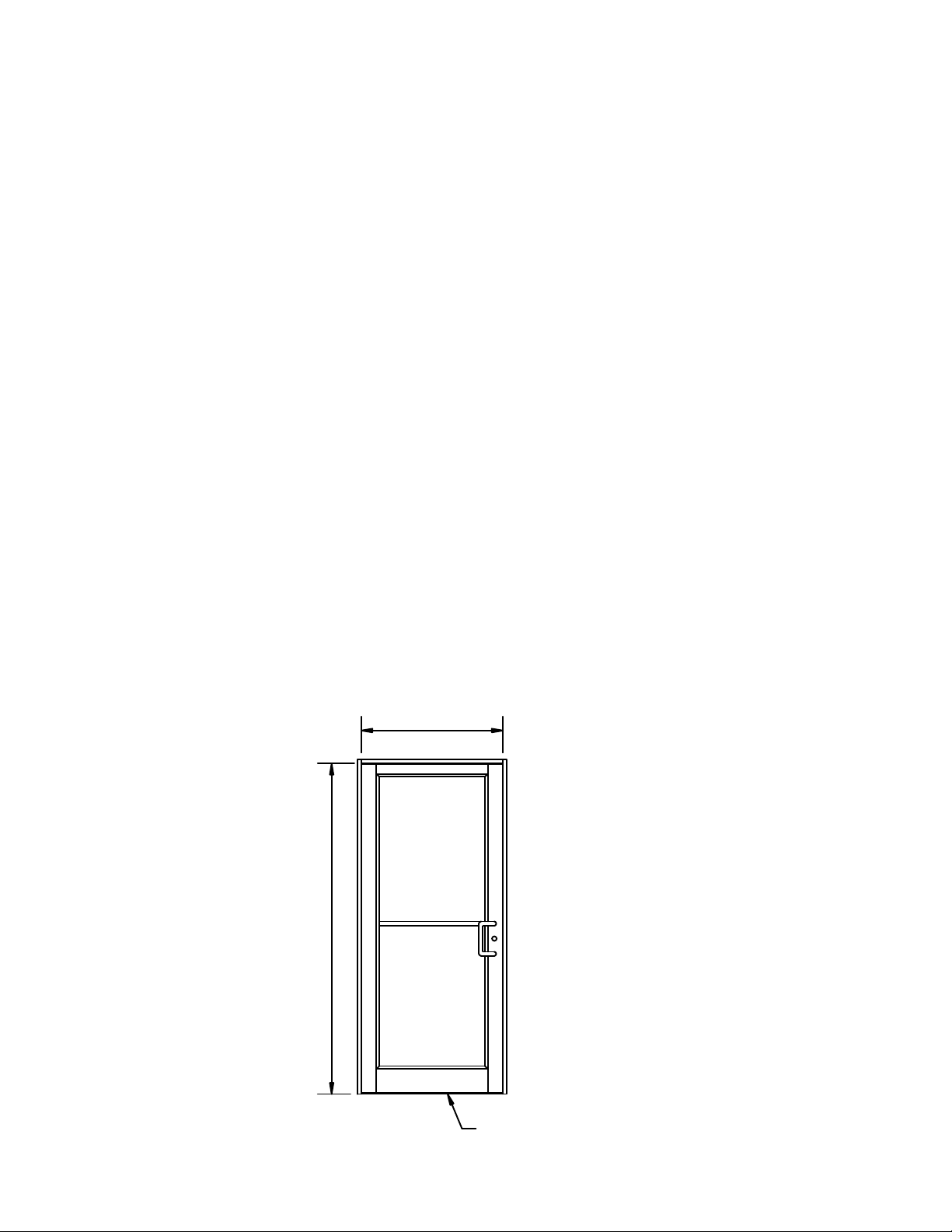

Thermal doors are available as a single, pair or sets of single doors that are separated by a 2" common

lock or 5 1/2" hinge jamb. Two optional bottom rails are available; 6" or 10". Muntins are not available for

the AD-375 Thermal Door. Size glass as listed below.

Calculate glass size based on Door Opening as shown below.

Standard Size

6" Bottom Rail 10" Bottom Rail

36 x 84 = 27 7/8" x 74 9/16" 27 7/8" x 70 9/16"

36 x 96 = 27 7/8" x 86 9/16" 27 7/8" x 82 9/16"

42 x 84 = 33 7/8" x 74 9/16" 33 7/8" x 70 9/16"

42 x 96 = 33 7/8" x 86 9/16" 33 7/8" x 82 9/16"

Non-Standard Sizes:

Horizontally: Door Opening minus 8 1/8"

Vertically: 6" bottom rail = Door Opening minus 9 7/16"

10" bottom rail = Door Opening minus 13 7/16"

AD-375 Thermal Doors will use the AD-450 sub-frame standard. This sub-frame is 1" wide x 4 1/2"

deep. Opening in wall should be Door Opening plus 2 1/2" horizontally and door opening plus 1 1/4"

vertically minimum. Optional 2" common lock jamb may be used as jamb and head. Center hung doors

are not available. All doors shall use a minimum of 1 1/2 pair of butt hinges or FM-SLI continuous gear

hinge, Offset pivots are not available.

Door Opening

Door Opening

Finished Floor

4MAY 2013

Phone: 1-866-OLDCASTLE (653-2 278)

Web Address: www.oldcastlebe.com

AD-375 THERMAL DOOR

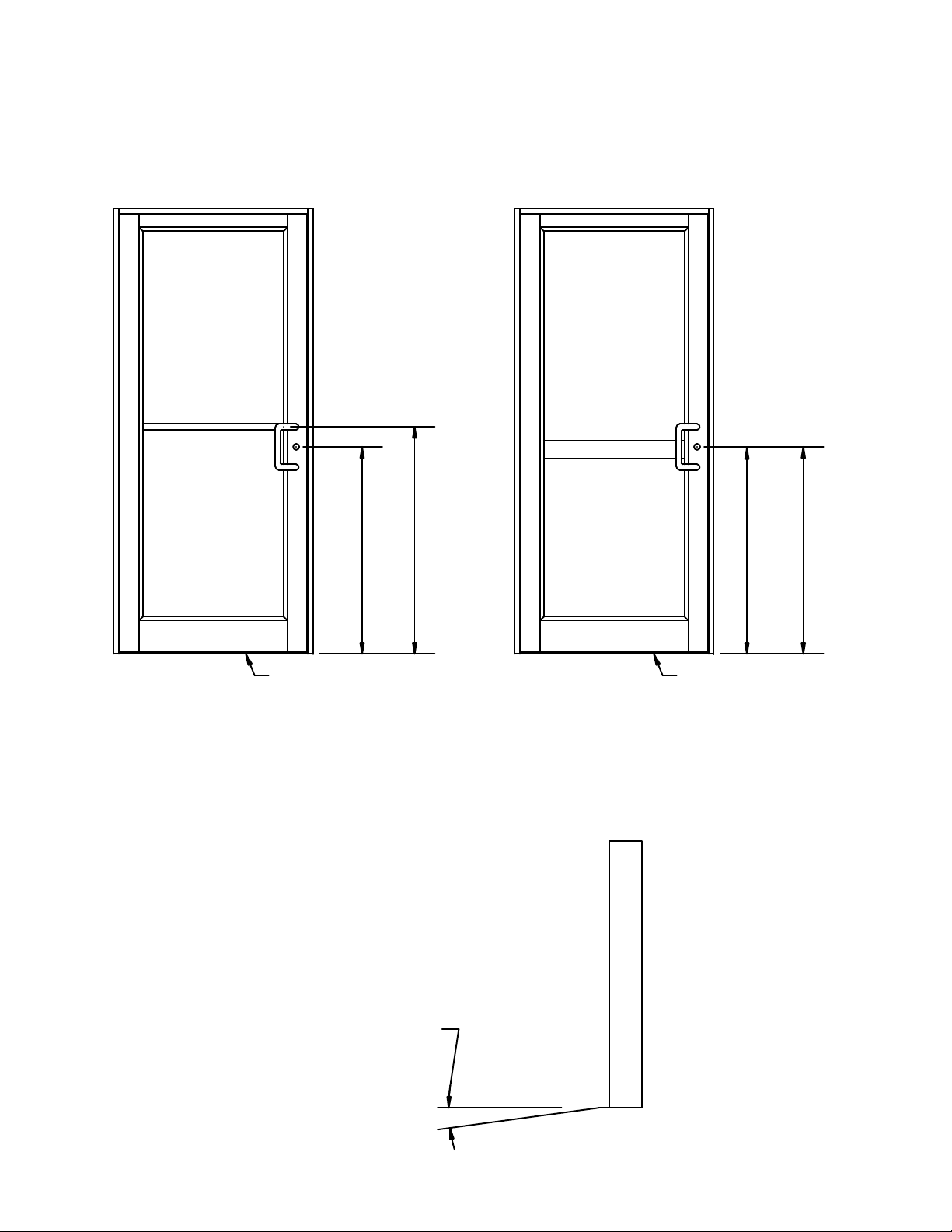

STANDARD HARDWARE LOCATIONS

39 3/8"

Finished Floor

Standard Door w/ AR1853 Lock Door w/ Rim Panic

44 1/8"

Center Line of Cylinder

Center Line of Push Bar

FLOOR SLAB SLOPE GUIDELINES

In order to insure proper operation and drainage

of water from face of door the substrate at the

exterior of door must slope at a minimum of 1

degree. If substrate slopes upwards door will not

open and water will flow into building.

Exterior

of Door

41 11/16"

Center Line of Panic

Finished Floor

41 15/16"

Center Line of Cylinder

M

°

1

m

u

i

m

n

i

5MAY 2013

Phone: 1-866-OLDCASTLE (653-2 278)

Web Address: www.oldcastlebe.com

Loading...

Loading...