MAY 2013

Note: Installation and Glazing Manuals are product specific. FOR REVIEW ONLY!

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

Table of Contents

General Information

Frame Fabrication

Sill Flashing Installation:

Thermal Performance Recommendations

Sill Receptor Installation

Outside Glazed Systems Fabrication and Assembly:

Screw Spline Assembly

Shear Block Assembly

Glazing Guidelines

Glazing Details

Inside Glazed Systems Fabrication and Assembly:

Glazing Details

Mullion Fabrication using Drill Fixtures

Outside Glazed, Screw Spline or Shear Blocks

Inside Glazed, Screw Spline or Shear Blocks

Frame Installation

Frame Installation Detail and Notes

Outside Glazed Anchorage and Perimeter Seal

Screw Spline Assembly

Shear Block Assembly

Glazing Guidelines

Inside Glazed Anchorage and Perimeter Seal

Glazing Adaptor Installation

Expansion Mullion Installation

Corner Details

Door Frame Installation

Pages 3- 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

MAY 2013

Phone: 1-866-OLDCASTLE (653-2278)

2

Web Address: www.oldcastlebe.com

The Oldcastle BuildingEnvelope Series 3000 XT (2 x 4 ½) system represents the latest in product

development technology complemented by dealer on -the -job input and experience. Proper use of this

system will assure optimum results in erection and long -term performance.

Oldcastle BuildingEnvelope does not control the application nor selection of its product configurations,

sealant, or glazing materials and assumes no responsibility thereof. It is the responsibility of the owner,

architect and installer to make these selections are in strict compliance with applicable laws and

building codes.

Over the years many components were added to our flush glaze systems. In addition, there are many

ways to install storefront products. This manual represents recommendations for the best results.

PROTECTION AND STORAGE:

Handle the material carefully. Do not drop from the truck. Stack with adequate separation so that the

material will not rub together. Store material off the ground. Protect against the elements and other

construction hazards by using a well -ventilated coveri ng. Remove material from package if it is wet or

is located in a wet area.

CHECK MATERIAL:

Check all material upon arrival for quality and to assure against shipping damage. Any visible damage

must be noted on the freight bill at the time of receipt. If a claim is required, then the receiving party

must process a claim with the freight company.

Completely check construction, which will receive your materials against contract documents. Notify

general contractor by letter of any discrepancies before proceeding with work. Failure to do so

constitutes acceptance of work by other trades.

Check shop drawings and installation instructions to become familiar with the project. The shop

drawings take precedence and include specific details for the project. The i nstallation instructions are

of a general nature and cover the most common conditions. Due to varying job conditions, all sealants

used should be approved by the sealant manufacturer, to insure they will function for conditions shown

on instructions and shop drawings. They must be compatible with all surfaces in which adhesion is

required, including other sealant surfaces. Use primers where directed by manufacturer of sealant. Be

sure to properly store sealants at recommended temperatures and check sealant for remainder of shelf

life before using.

FIELD CONDITIONS:

•

Do not install wall if there is a walkway with a down slope towards an entrance or a storefront.

•

All materials to be installed plumb, level and true. Aluminum to be placed in direct contact

with the masonry or incompatible materials should be isolated with a heavy coat of zinc chromate or bituminous paint.

•

After sealant is set and a representative amount of wall has been glazed (250 square feet of

more), run a water hose to check installation. On large jobs, hose test should be repeated

during glazing operation. Test should be conducted in accordance with AA MA 501.2

specifications.

•

Coordinate protection of installed materials with general contractors and other trades.

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

GENERAL INFORMATION

MAY 2013

3

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

CLEANING MATERIALS:

Cement, plaster, terrazzo, alkaline and acid based materials used to clean masonry are v ery harmful to

finishes and should be removed with water and a mild soap immediately or permanent staining will

occur. A spot test is recommended before any cleaning agent is used.

EXPANSION JOINTS:

Expansion joints and perimeter seals shown in these in structions and in the shop drawings are shown at

normal size. Actual dimensions may vary due to perimeter conditions and/or differences in metal

temperature between the time of fabrication and time of installation. For example, a 12 foot

unrestrained lengt h of aluminum extrusion can expand or contract 3/32 of an inch over a 50 degree

Fahrenheit change. Any movement potential should be accounted for at time of the installation.

THERMAL IMPROVEMENT SUGGESTIONS:

To maintain or improve your wall installation, the following items should be considered:

1. Blinds or drapes prevent warm air from washing the window.

2. Warm air ventilators too far from window will not adequately wash the window with air to

prevent condensation.

3. In extreme conditions, the fan of the heating systems should not cycle on and off, but run

continuously.

4. Some heating systems have a water injection feature that can raise humidity levels. The higher

the humidity levels the more likely condensation or frost will form. Raising the temperature

and reducing humidity will usually solve this problem.

5 .

On rare occasions, an extremely cold storm may cause frost to appear on the glass or framing.

A space heater and electric fan blowing along the plane of th e window wall can reduce or

eliminate this temporary condition.

FABRICATION SUGGESTIONS:

Oldcastle BuildingEnvelope recommends the use of our EZ Punch tooling for faster

and more accurate fabrication of wall systems. If hand fabricating the

mullions; drill fixtures are available to improve accuracy. Fabrication instructions

for use of these drill fixtures are described within this manual on pages 35

through 39.

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

GENERAL INFORMATION CONT.

MAY 2013

Phone: 1-866-OLDCASTLE (653-2278)

4

Web Address: www.oldcastlebe.com

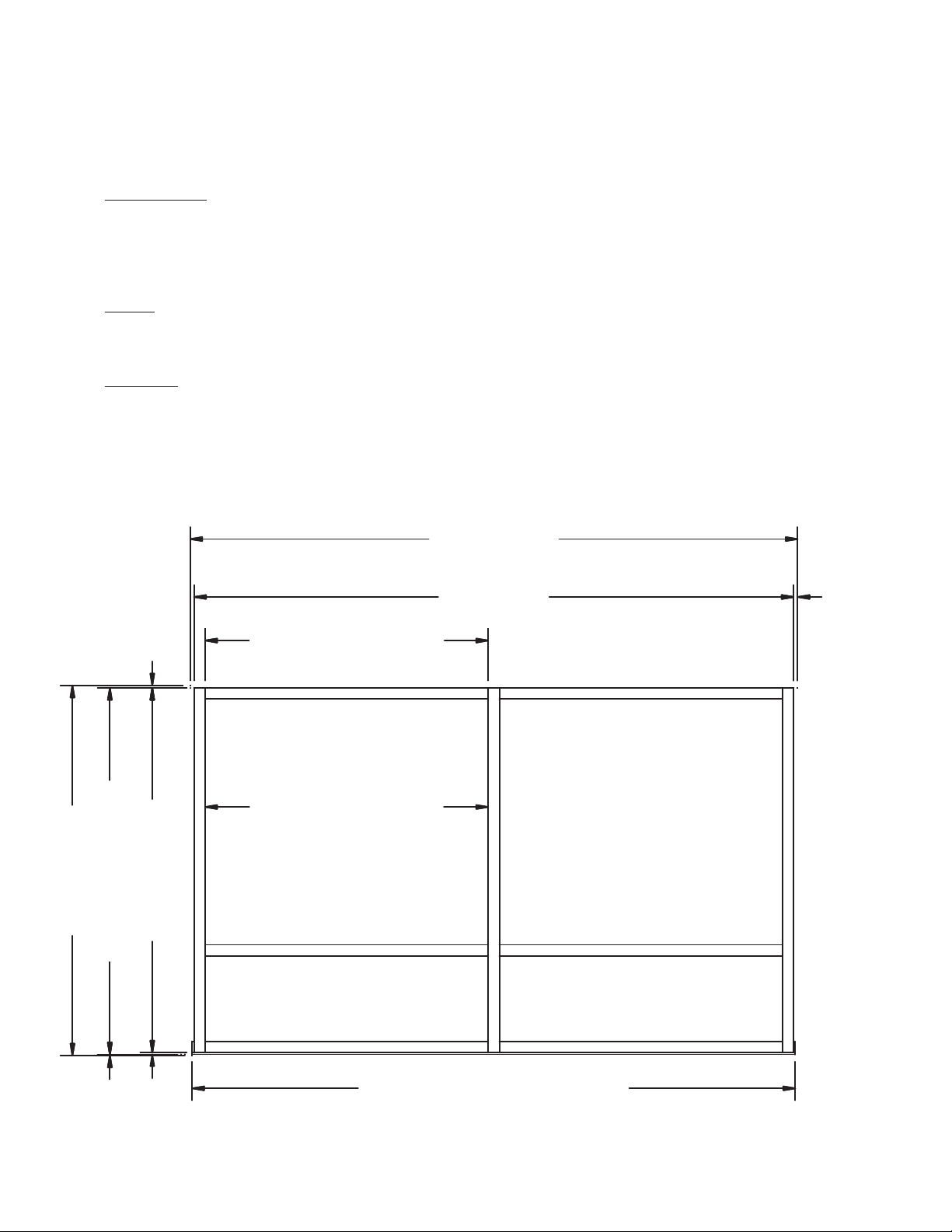

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

OUTSIDE GLAZED FRAME FABRICATION

Measure ROUGH OPENING to determine

FRAME WIDTH and FRAME HEIGHT dimensions. Allow 1/2" minimum clearance at

head and 1/4"minimum clearance at jambs and sill for shimming and caulking around perimeter frame.

Cut material to size per dimensions given below:

Frame Members

Mullions and Mullion Fillers: Frame Height (R

ough Opening - Head & Sill Joints - 1/2")

Sill Receptor: Frame Width + 1/4"

Horizontal, Head & Sill: Day Light Opening (DLO)

s

otS

s

alG

p

s

D:

L

6

O

"

1/1 -

Gaskets

Horizontal Gaskets: DLO + 3/8" per foot

a

sa

citreV

G l

toof rep "8/3 + "1 + OLD:s

t

ek

Accessories

Horizontal Glazing Adaptors: DLO - 1/16"

Vertical Glazing Adaptors: DLO + 7/8"

m

a

:s

J rooD

b

u

R

o

n

g

n

epO h

i

ROUGH OPENING

ROUGH OPENING

e

- g

H

tnioJ da

JAMB JOINT

FRAME WIDTH

FRAME WIDTH

HEAD, SILL & HORIZONTAL

( > 1/2")

( > 1/2")

HEAD JOINT

HEAD JOINT

(FRAME HEIGHT)

ROUGH OPENING

ROUGH OPENING

OVERALL FRAME HEIGHT

OVERALL FRAME HEIGHT

(FRAME HEIGHT)

MULLION & FILLER

MULLION & FILLER

WITH SILL RECEPTOR

WITH SILL RECEPTOR

HEAD, SILL & HORIZONTAL

(D.L.O.)

(D.L.O.)

HORIZONTAL GLASS STOPS

HORIZONTAL GLASS STOPS

(D.L.O. - 1/16")

(D.L.O. - 1/16")

JAMB JOINT

( > 3/8"

( > 3/8"

MAY 2013

SILL JOINT

SILL JOINT

( > 1/4")

( > 1/4")

SILL OFFSET

1/2"

SILL RECEPTOR (FRAME WIDTH + 1/4")

SILL RECEPTOR (FRAME WIDTH + 1/4")

5

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

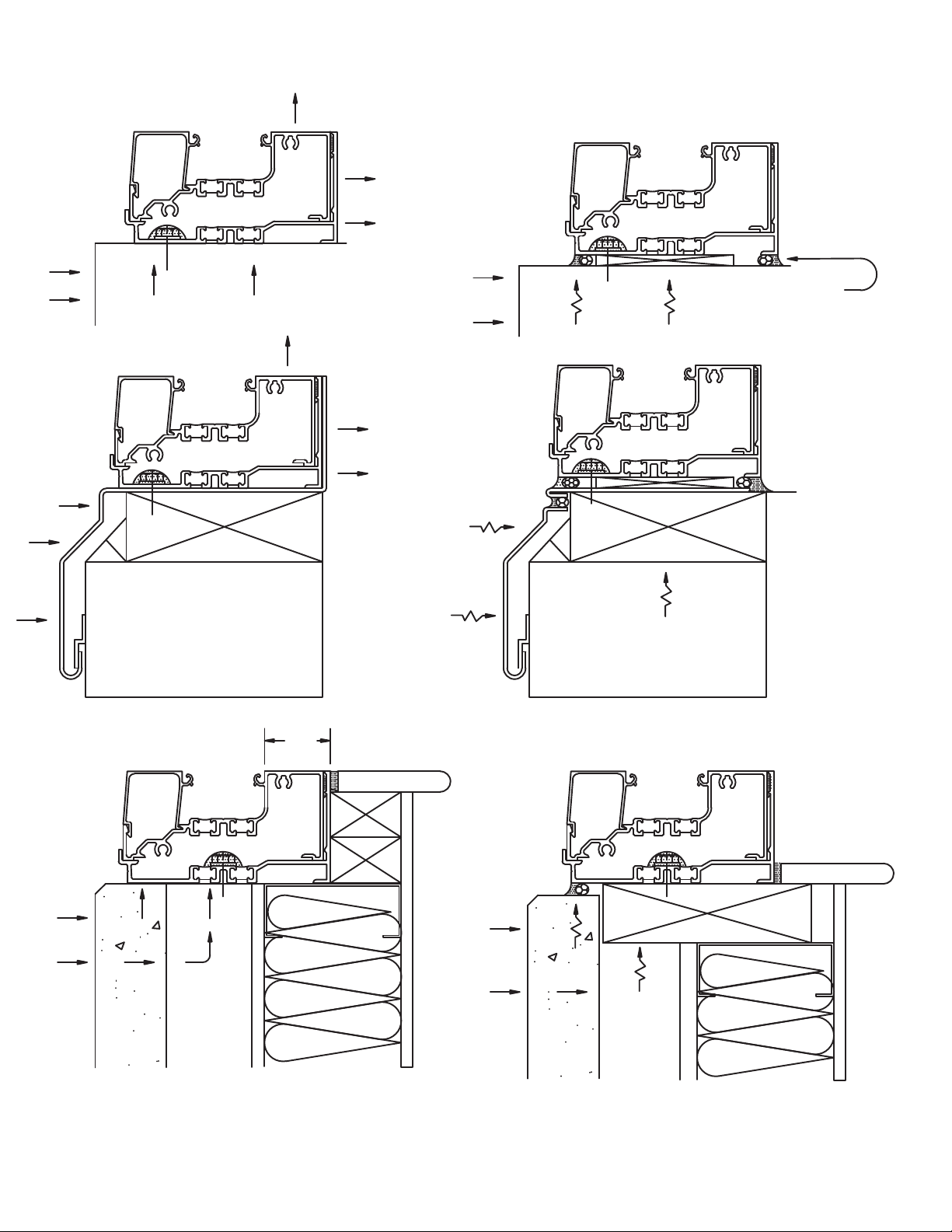

INSTALLATION FOR THERMAL PERFORMANCE

M

E

N

O

R

C

TO

EDN

D

EM

ER

P

DERREF

SHIM & AIR SPACE

MINIMUM 1/4" THICK

MAY 2013

X

NOT ENOUGH METAL SHOWING AT "X"

TO DERIVE THE GREATEST BENEFIT FROM YOUR STOREFRONT INSTALLATION,

WE RECOMMEND YOU REVIEW THE DETAILS ABOVE.

Phone: 1-866-OLDCASTLE (653-2278)

6

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

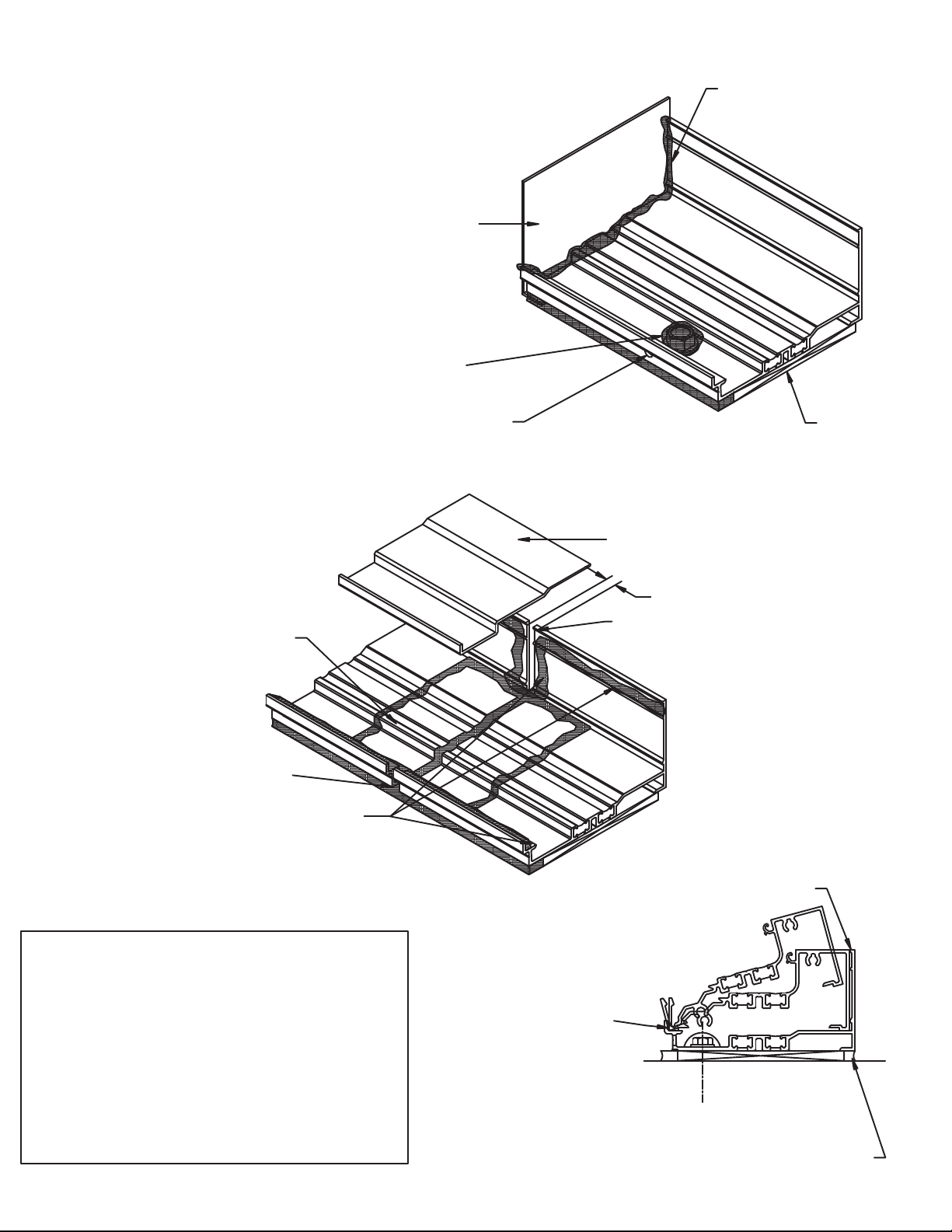

SILL RECEPTOR INSTALLATION

INSTALL SILL RECEPTOR AND END DAM

NOTE: IF A TWO PIECE HEAD RECEPTOR

IS NOT USED, A 1/4" MINIMUM CLEARANCE

IS REQUIRED AT THE HEAD CONDITION TO

ALLOW FRAME INSTALLATION.

ANCHOR SILL RECEPTOR WITHIN 4" FROM EITHER

SIDE OF INTERMEDIATE MULLIONS. ANCHOR

SIZE AND FREQUENCY SHOULD BE

DETERMINED BY STRUCTURAL REQUIREMENTS.

CAP SEAL FLASHING ANCHORS AS SHOWN.

FG3000-FP-46

DRILL 1/4" WEEP HOLES

LOCATE AT MID-LITE

SEAL END DAM TO

SILL RECEPTOR.

FG-3511

SHIM UNDER

SILL RECEPTOR.

INSTALL SPLICE SLEEVE

NOTE: INSTALL SILL RECEPTOR LEVEL.

SEAL WITH A NON-SKINNING

NON-HARDENING SEALANT.

FILL BREAK IN FLASHING

AND UNDER SPLICE.

SEAL SILL RECEPTOR

VERTICAL SPLICE JOINT

JUST PRIOR TO FRAME INSTALLATION,

APPLY CONTINUOUS SEALANT ALONG

GROOVE IN FRONT AND BACK LEGS OF

SILL RECEPTOR AND AROUND JOINT AS

SHOWN. IMMEDIATELY INSTALL FRAME

INTO SILL.

NOTE:

1) SILL RECEPTOR SHALL BE INSTALLED

LEVEL AND SHOULD NEVER TILT

TOWARDS INTERIOR OF BUILDING.

2) THE FG-3511 SILL RECEPTOR IS DESIGNED TO

WITHSTAND A MAXIMUM END REACTION

OF 600 LBS.

3) SPLICE SILL RECEPTOR AT MID-LITE.

4) LOCATE SPLICE JOINT AT DISTANCE OF NO

MORE THAN EVERY 12 FEET.

FG-3511

SET FRONT OF FRAME IN

SILL RECEPTOR AND TILT

BACK INTO PLACE.

FG3000-FP-57

1/4" NOMINAL

REFERENCE DETAIL "A"

PAGE 6 FOR ADDITIONAL

SEALANT INFORMATION

CLEAN EXCESS

SEALANT AWAY.

INTERIOR PERIMETER SEAL

AT SILL IS OPTIONAL AND FOR

COSMETIC PURPOSES ONLY.

MAY 2013

Phone: 1-866-OLDCASTLE (653-2278)

7

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

OUTSIED GLAZED SCREW SPLINE FRAME ASSEMBLY

FG-3514

FG-3506

1 3/4"

TOP OF

HORIZONTAL

FS-8 TYP

PART#: 10223

2-11/16"

TYP

29/32"

TYP

APPLY SILICONE SEALANT IN

GLAZING REGLET OF VERTICAL

WHERE IT MARRIES WITH SEALANT

APPLIED TO THE HORIZONTALS

FG-3506

1/4"

APPLY SILICONE

SEALANT 4" UP

INTERIOR SNAP

JOINT

4"

"F" (0.257 DIA)

DRILL TYPICAL

1 3/4"

1/4"

1 3/4"

FG-3509

FG-3220

PART# 1122

APPLY SILICONE

SEALANT TO END

OF HORIZONTALS

AS SHOWN

FG-3510

REFERENCE PAGE 16 FOR USE OF DJ-8 DRILL FIXTURE.

MAY 2013

FG-3220

PART# 1122

Phone: 1-866-OLDCASTLE (653-2278)

8

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

OUTSIDE GLAZED SHEAR BLOCK FRAME ASSEMBLY

FG-3514

TOP OF

HORIZONTAL

#11 (.191)

TAP HOLE

(TYP)

FG-3506

1"

2-11/16"

29/32"

11/32"

1 1/4"

#11 (0.191Ø)

TAP HOLE

(TYP.)

APPLY SILICONE SEALANT

IN GLAZING REGLET OF

VERTICAL WHERE IT MARRIES

WITH SEALANT APPLIED TO

THE HORIZONTALS

*FG3000-FP-60 (pART# 34996)

FS-9 (TYP)

#11 (.191)

CLEAR HOLE

FG-3506

1 3/4"

4"

APPLY SILICONE

SEALANT 4" UP

INTERIOR SNAP

JOINT

29/32"

1/4"

DRILL 1/4" DIA.

HOLE FOR

ROLL PIN

NOTE:

*SHEAR BLOCK PACKAGES INCLUDE

FASTENERS AND ROLL PINS

ROLL PIN

TYP. #25 (.149)

TAP HOLE

11/32"

1 1/4"

7/16"

FS-7

*AC-119-1 (PART#:6295)

FS-6

FG-3220

PART# 1122

FG-3509

APPLY SILICONE

SEALANT TO END

OF HORIZONTALS

AS SHOWN

FS-6

FG-3510

FG-3220

PART# 1122

MAY 2013

REFERENCE PAGE 16 FOR USE OF DJ-8 DRILL FIXTURE.

9

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

OUTSIDE GLAZED GLAZING GUIDELINES

1) REMOVE GASKETS FROM ROLL AND ALLOW TO RELAX OVERNIGHT.

ALL GASKETS TO BE CUT D.L.O. + 3/8" PER FOOT.

2) VERTICAL GASKETS RUN THRU, HORIZONTAL GASKETS SHOULD BE

MITERED ON ENDS AS SHOWN IN DETAIL "A"

3) INSTALL INTERIOR GASKETS PRIOR TO GLAZING. CORNERS OF INTERIOR GASKETS TO BE

SET IN SEALANT (DTL."B") AND CORNERS SEALED JUST PRIOR TO SETTING GLASS (DTL."A").

NOTE: CLEAN GASKETS AND SURFACES WITH ISOPOPYL ALCOHOL PRIOR TO

SEALING CORNERS.

4) LOCATE SETTING BLOCKS AT EITHER 1/4 POINTS OR 1/8 POINTS, DEPENDENT ON

SIZE OF GLASS.

5) GLASS IS CUT DAYLIGHT OPENING PLUS 7/8".

6) GLAZE OPENINGS FROM BOTTOM TO TOP. INSTALLING WATER DIVERTERS IN HORIZONTAL

ABOVE, AFTER LITE BELOW IS IN POSITION.

7) WATER DIVERTERS (FG1000-FP-2) MUST BE LOCATED ON EACH END OF HORIZONTALS

AND SET IN SEALANT.

8) WHEN INSTALLING GLASS: FIRST, WET TOP OF SETTING BLOCK WITH SOAPY WATER.

ONCE GLASS IS SET IN PLACE, PUSH GLASS AGAINST INTERIOR GASKET AT SETTING BLOCK

AREA. FAILURE TO DO SO MAY CAUSE DIAGONAL CRACKS TOWARDS SETTING BLOCKS DUE

TO GLASS BENDING WHILE INSTALLING GASKET(S) IN CORNERS.

SEAL CORNERS AT

GLAZING TRACK PRIOR

TO SETTING GLASS.

15°

SEAL CORNERS GASKET

RACE AT WATER

DIVERTER.

MAY 2013

DETAIL "A"

MITER HORIZONTAL GASKET TO

VERTICAL GASKET

10

DETAIL "B"

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

OUTSIDE GLAZED GLAZING DETAIL

FG-1133 PART# 364

VERTICAL GASKETS

RUN THROUGH

FG-3144

MAY 2013

11

FG-3220

PART#: 1122

FG1000-FP-2

PART#: 6887

SET IN PLACE

WITH SEALANT

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

FG-3514

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

INSIDE GLAZED SCREW SPLINE FRAME ASSEMBLY

FS-8 TYP

PART# 10223

2-11/16"

TYP

FG-3506

1 3/4"

TOP OF

HORIZONTAL

1/4"

29/32"

TYP

APPLY SILICONE SEALANT

IN GLAZING REGLET OF

VERTICAL WHERE IT MARRIES

WITH SEALANT APPLIED TO

THE HORIZONTALS

FG-3510

APPLY SILICONE

SEALANT 4" UP

INTERIOR SNAP

JOINT

1/4"

1 3/4"

4"

FG-3509

FG-3523

PART#: 34998

APPLY SILICONE

SEALANT TO END

OF HORIZONTALS

AS SHOWN

1 3/4"

"F" (0.257 DIA)

DRILL TYPICAL

REFERENCE PAGE 17 FOR USE OF DJ-8 DRILL FIXTURE.

MAY 2013

12

FG-3506

FG-3278

PART#: 841

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

INSIDE GLAZED SHEAR BLOCK FRAME ASSEMBLY

FG-3514

DRILL 1/4" DIA.

HOLES FOR

ROLL PIN

7/16"

FG-3506

11/32"

1 1/4"

TOP OF

HORIZONTAL

11/32"

29/32"

TYP

1/4"

APPLY SILICONE SEALANT

IN GLAZING REGLET OF

VERTICAL WHERE IT MARRIES

WITH SEALANT APPLIED TO

THE HORIZONTALS

*AC-119-1 (PART#:6295)

ROLL PIN

FS-9 (TYP)

FG-3510

1/4"

*AC-119-1 (PART#:6295)

APPLY SILICONE

SEALANT 4" UP

INTERIOR SNAP

JOINT

1 1/4"

4"

#11 (0.191 DIA)

TAP HOLE TYP.

1"

"

6

1

/

1

1

-

2

#25 (0.149 DIA)

TAP HOLE TYP.

FS-9 (TYP)

FS-6

FS-6

*FG3000-FP-60 (PART#: 34996)

FG-3523

PART#: 34998

FG-3512

APPLY SILICONE

SEALANT TO END

OF HORIZONTALS

AS SHOWN

FG-3506

NOTE:

* SHEAR BLOCK PACKAGES INCLUDE

FASTENERS AND ROLL PINS

REFERENCE PAGE 17 FOR USE OF DJ-8 DRILL FIXTURE.

MAY 2013

13

FG-3278

PART#: 841

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

INSIDE GLAZED GLAZING GUIDELINES

1) REMOVE GASKETS FROM ROLL AND ALLOW TO RELAX OVERNIGHT.

ALL GASKETS TO BE CUT D.L.O. + 3/8" PER FOOT.

2) VERTICAL GASKETS RUN THRU, HORIZONTAL GASKETS SHOULD BE

MITERED ON ENDS AS SHOWN IN DETAIL "A"

3) INSTALL EXTERIOR GASKETS PRIOR TO GLAZING. CORNERS OF EXTERIOR GASKETS

TO BE SET IN SEALANT (DTL."B") AND CORNERS SEALED JUST PRIOR TO SETTING

GLASS (DTL."A").

NOTE: CLEAN GASKETS AND SURFACES WITH ISOPOPYL ALCOHOL PRIOR TO

SEALING CORNERS.

4) LOCATE SETTING BLOCKS AT EITHER 1/4 POINTS OR 1/8 POINTS, DEPENDENT ON

SIZE OF GLASS.

5) GLASS IS CUT DAYLIGHT OPENING PLUS 7/8".

6) GLAZE OPENINGS FROM BOTTOM TO TOP. INSTALLING WATER DIVERTERS IN

HORIZONTAL ABOVE, AFTER LITE BELOW IS IN POSITION.

7) WATER DIVERTERS (FG1000-FP-4&5) MUST BE LOCATED ON EACH END OF HORIZONTALS

AND SET IN SEALANT.

8) WHEN INSTALLING GLASS: FIRST, WET TOP OF SETTING BLOCK WITH SOAPY WATER.

ONCE GLASS IS SET IN PLACE, PUSH GLASS AGAINST GASKET AT SETTING BLOCK AREA.

FAILURE TO DO SO MAY CAUSE DIAGONAL CRACKS TOWARDS SETTING BLOCKS DUE TO

GLASS BENDING WHILE INSTALLING GASKET(S) IN CORNERS.

SEAL CORNERS GASKET

RACE AT WATER

DIVERTER.

15°

SEAL CORNERS AT

GLAZING TRACK PRIOR

TO SETTING GLASS.

MAY 2013

DETAIL "A"

MITER HORIZONTAL GASKET TO

VERTICAL GASKET

14

DETAIL "B"

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

INSIDE GLAZED GLAZING DETAIL

FG-1133

PART#: 364

VERTICAL GASKETS

RUN THRU.

CW-552

PART#: ????

FG1000-FP-2

PART#: 6887

SET IN PLACE

WITH SEALANT

MAY 2013

15

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

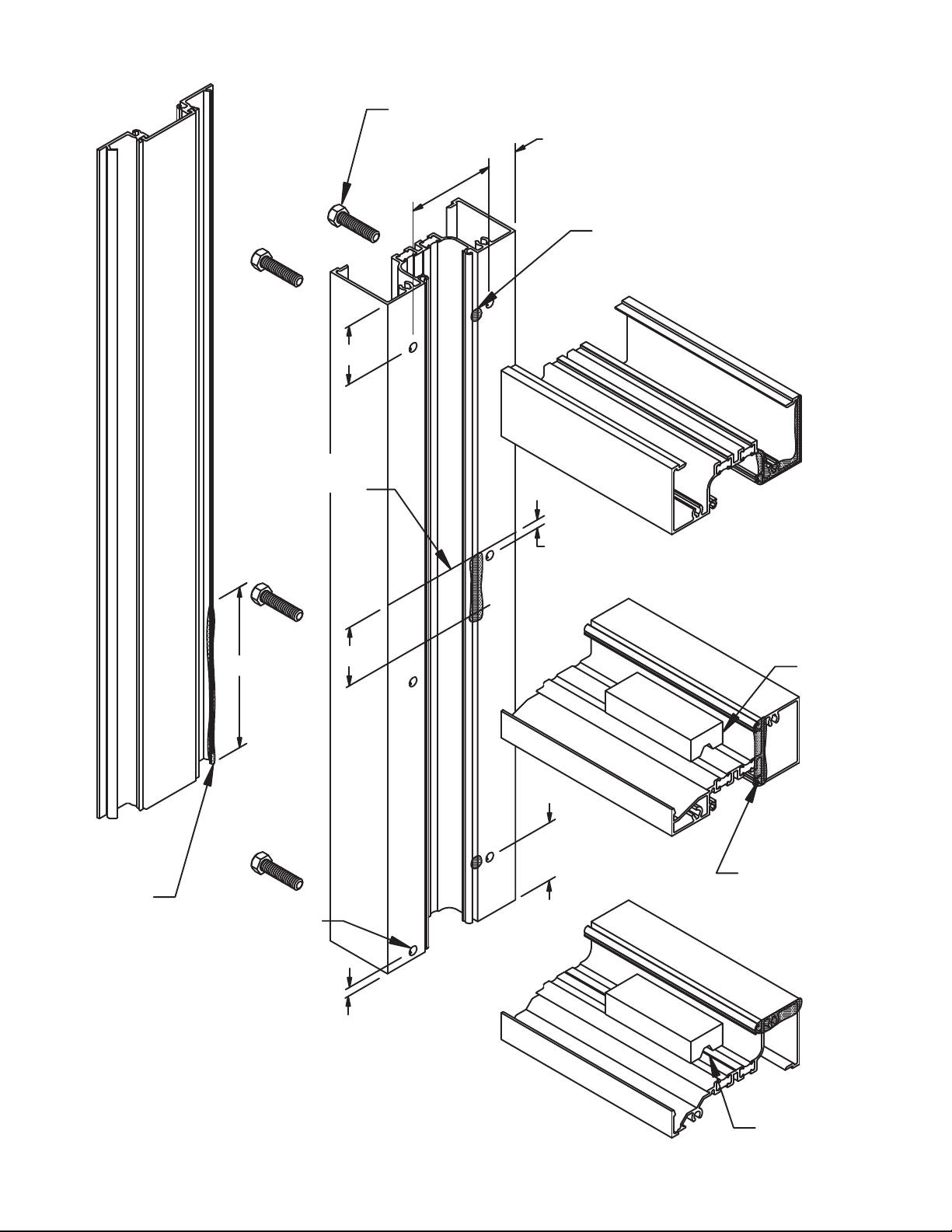

OUTSIDE GLAZED FABRICATION USING DRILL FIXTURE

FG-3198 (C-K)

ALIGN WITH TOP

OF MULLION

D

C

F

H

B

A

E

G

K

J

M

L

AC-108-1 (E-F)

FG-3506 (K-L)

FG-3197 (C-K-L)

ALIGN WITH TOP

OF HORIZONTAL

B

A

E

G

K

J

B

A

E

G

K

J

ROLL PIN USING

AC-119-1 (K)

D

C

F

H

M

L

AC-119-1 (D-M)

ROLL PIN USING

AC-119-1 (K)

FG-3198 (C-K)

D

C

F

H

M

L

AC-119-1 (D-M)

ALIGN WITH

BOTTOM OF MULLION

DJ-8 DRILL

FIXTURE

MAY 2013

REFERENCE FRONT SET ASSEMBLY

DRAWINGS FOR ADDITIONAL

INFORMATION, SEALANT APPLICATION

AND EXTRUSIONS.

NOTES:

1) DRILL HOLES FOR SCREWSPLINES

USING A "F" (.257 Ø) DRILL

2) DRILL HOLES FOR ROLL PINS USING A "F" (.257 Ø) DRILL

3) DRILL HOLES FOR SHEAR BLOCKS USING #11 (.191Ø) DRILL

16

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

INSIDE GLAZED FABRICATION USING DRILL FIXTURE

FG-3198 (C-K)

ALIGN WITH TOP

OF MULLION

D

C

F

H

B

A

E

G

K

J

M

L

ROLL PIN USING

AC-119-1 (C)

FG-3197 (B-C-K)

AC-119-1 (A-J)

ALIGN WITH TOP

OF HORIZONTAL

AC-119-1

ROLL PIN USING

AC-119-1 (C)

D

C

F

H

B

A

E

G

K

J

M

L

FG-3231 (B-C)

D

C

F

H

B

A

E

G

K

J

AC-108-1 (G-H)

M

L

ALIGN WITH

BOTTOM OF MULLION

MAY 2013

REFERENCE FRONT SET ASSEMBLY

DRAWINGS FOR ADDITIONAL

INFORMATION, SEALANT APPLICATION

AND EXTRUSIONS.

NOTES:

1) DRILL HOLES FOR SCREWSPLINES USING A "F" (.257 Ø) DRILL

2) DRILL HOLES FOR ROLL PINS USING A "F" (.257 Ø) DRILL

3) DRILL HOLES FOR SHEAR BLOCKS USING #11 (.191Ø) DRILL

17

DJ-8 DRILL

FIXTURE

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

FG-2188 PVC FILLER

MAY BE USED TO IMPROVE

INSTALLATION OF

PERIMETER SEALS.

(OPTIONAL)

FRAME INSTALLATION

FG3000-FP-58 OR FG3000-FP-59

ANCHOR FG-2188 PVC FILLER

IN BETWEEN

NOTES:

1) WHEN USING OPTIONAL FG-3511 SILL RECEPTOR, SILL ANCHORS ARE NOT REQUIRED.

2) MAXIMUM END REACTION AT MULLION WHEN USING FG-3511 SILL RECEPTOR IS 600 LBS.

3) HEAD ANCHORS SHOULD BE LOCATED SO THAT THE ANCHOR IS NOT MORE THAN 4" AWAY FROM

EACH SIDE OF MULLION.

4) ASSEMBLY WITHOUT FLASHING IS NOT RECOMMENDED.

5) ASSEMBLY USING A NON-THERMAL OR SHEET METAL FLASHING WILL RESULT IN LOSS OF

THERMAL CONTINUITY AND IS NOT RECOMMENDED.

Phone: 1-866-OLDCASTLE (653-2278)

MAY 2013

18

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

ANCHOR AND PERIMETER SEAL

C

FG-3506 HEAD WITH FG3000-FP-58 ANCHOR

C C

FG-3510 HEAD WITH FG3000-FP-59 ANCHOR

C

FG3000-FP-58 AND FG3000-FP-59

ANCHORS ARE DESIGNED TO

CARRY A MAXIMUM END

REACTION OF 600LBS.

C

OPTIONAL MO-678/MO-244

HEAD RECEPTOR

MAXIMUM END REACTION

OF 450 LBS.

C

C

C

FG3000-FP-58

ANCHOR

APPLY SEALANT ALONG LENGTH OF SILL FLASHING AT

POINT (A).

APPLY FILLET SEAL BETWEEN SILL FLASHING AND FRONT OF SILL (B).

THE QUALITY OF THE INSIDE AND OUTSIDE PERIMETER SEALS (C) MAY

BE IMPROVED BY USING FG-2188 RIGID PVC FILLER. THE PART MAY BE

USED IN FULL LENGTHS OR CUT INTO PIECES. ITS PURPOSE IS TO

PROVIDE SUPPORT FOR THE BACKER ROD REGARDLESS OF JOINT SIZE.

INTERIOR PERIMETER SEAL AT SILL (D) IS OPTIONAL AND FOR COSMETIC

PURPOSES ONLY.

A

B

E

A

D

MAY 2013

19

NOTE: 5/16" WEEP HOLES REQUIRED

IN FLASHING (E) AT CENTERLINE OF

D.L.O.

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

GLAZING ADAPTOR INSTALLATION

BED ADAPTORS IN CONTINUOUS

BEAD OF SEALANT

SEE CHART BELOW FOR CORRECT

GASKET AND ADAPTOR FOR

SPECIFIC APPLICATIONS

SEAL CORNERS OF ADAPTORS. MARRY

ADAPTOR SEAL INTO SEALANT AT

CORNER OF GASKETS.

MAY 2013

NOTE:

ADAPTORS SHOULD BE INSTALLED ON INTERIOR

SIDE OF ALL GLAZING OPTIONS.

GLASS

1/4"

5/16"

3/8"

7/16"

1/2"

9/16"

5/8"

5/8"

ADAPTOR

FG-3194

FG-3236

FG-3236

FG-3236

FG-3237

FG-3237

FG-3237

NONE

GASKETS

FG-1133 Both Sides

FL-66 Both Sides

FG-1133 & FL-66

FG-1133 Both Sides

FL-66 Both Sides

FG-1133 & FL-66

FG-1133 Both Sides

FG-3129 Both Sides

20

GLASS

11/16"

3/4"

13/16"

7/8"

15/16"

1"

1 1/16"

1 1/8"

ADAPTOR

FG-3237

FG-3237

N/A

None

None

None

None

None

GASKETS

FG-1133 & FG-1134

FG-1134 Both Sides

Not Available

FL-66 Both Sides

FG-1133 & FL-66

FG-1133 Both Sides

FG-1133 & FG-1134

FG-1134 Both Sides

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

EXPANSION MULLION INSTALLATION

MULTIPLE UNITS MAY REQUIRE THE USE OF AN EXPANSION MULLION IF THE TOTAL WIDTH OF THE OPENING EXCEEDS 24 FEET. IN

THESE CASES, LOCATE EXPANSION MULLIONS NO GREATER THAN 20 FEET ON CENTER. LOCATE SPLICE IN SILL RECEPTOR NO

MORE THAN 12 FEET ON CENTER. A MINIMUM OF 7/16" CLEARANCE BETWEEN THE JAMB AND THE SILL RECEPTOR END DAM MUST

BE PROVIDED TO ALLOW FOR FRAME INSTALLATION WHEN USING EXPANSION MULLIONS. THIS WILL ALLOW THE MINIMUM 3/8"

CLEARANCE NEEDED FOR THE NEXT FRAME ASSEMBLY TO BE ROTATED INTO POSITION AND INTERLOCKED WITH THE FRAME

ASSEMBLY ALREADY INSTALLED. ONCE IN POSITION, UNITS SHOULD BE CENTERED INTO THE OPENING TO PROVIDE EQUAL

CLEARANCE A THE JAMBS. OLDCASTLE BUILDINGENVELOPE RECOMMENDS THE USE OF THE FG-2188 FILLER IN THE HEAD AND

JAMBS TO IMPROVE THE PERIMETER SEAL.

MAY 2013

1/16"

7/16"

3/8"

3/8"

21

1/4"

1/4"

2 1/2"

3/8"

1/16"

3/8"

7/16"

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

CORNER DETAILS

FG-3515

FG-3516

INSIDE OR OUTSIDE 90 DEGREE CORNER

MAY 2013

INSIDE OR OUTSIDE 135 DEGREE CORNER

Phone: 1-866-OLDCASTLE (653-2278)

22

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

DOOR FRAME INSTALLATION

FG-3156

RUN SEALANT MINIMUM 1"

ABOVE BACK OF SUB-SILL

FG-3155

FG-2145

1"

BED SUB-SILL IN

SEALANT AT DOOR JAMB

LEAVE FRONT OF DOOR JAMB

CLEAR OF SEALANT FOR DRAINAGE

NOTES:

1) USE SHEAR BLOCKS AS SHOWN IN FRAME ASSEMBLY SECTION OF THIS MANUAL TO SECURE

HORIZONTALS TO TUBULAR FRAMES.

2) DOOR FRAME IS ANCHORED BY FASTENERS THROUGH THRESHOLD AND DOOR FRAME HEADER.

3) DO NOT FABRICATE STANDARD 2 PIECE POUR & DEBRIDGED FRAME EXTRUSIONS FOR DOOR

FRAMES. IF THERMAL FRAME IS REQUIRED,OPTIONAL THERMAL DOOR FRAME FG-3389 MAY BE

USED IN CONJUNCTION WITH OLDCASTLE BUILDINGENVELOPE THERMAL DOORS.

4) WHEN USING THE CENTER SET SYSTEM, THE TWO-PIECE OR TUBULAR FRAMING OPTION ARE

AVAILABLE AS SHOWN ABOVE. WHEN USING EITHER THE FRONT SET OR BACK SET SYSTEM ONLY

THE TUBULAR OPTION IS AVAILABLE. THE VERTICAL FOR THE FRONT OR BACK SET OPTIONS

IS FG-3287.

MAY 2013

23

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

SERIES 3000 MULTIPLANE CENTER SET

PARTS LIST

SERIES 3000 MULTIPLANE

AUXILARY EXTRUSIONS

FG-3506

FG-3517

FG-3520

FG-3519

FG-3514

FG-3509

Open Back

Head / Jamb / Mullion

Open Back

Heavy Mullion

Expansion

Mullion

(mates w/ FG-3519)

Expansion

Mullion

(mates w/ FG-3520)

Open Back

Filler

Outside Glazed

Intermediate

Horizontal

MO-678

MO-244

FG-3515

FG-3516

FG-3322

FG-3321

Head Receptor

Receptor Face

Center Set

90° Corner

Center Set

90° Corner

(Self-Mating 180°)

Center Set 135° Corner

Center Set 135°

Corner Filler

(2 per corner)

Inside Glazed

Intermediate

FG-3512

FG-3510

FG-3144

FG-3210

SERIES 3000 MULTIPLANE SILL FLASHING

FG-3511

Horizontal

Sill

Glass Stop

for Outside Glazing

Heavy Glass Stop

for Inside Glazing

Sill Receptor

FG-2188

FG-3218

FG-3194

FG-3237

FG-3236

Vinyl Filler

for Caulk Stop

12' lg.

Vinyl Pocket Filler

for Window

Applications

12' lg.

Glazing Adaptor for

1/4" glass

Glazing Adaptor for

1/2", 9/16",5/8",

11/16" & 3/4"

Glazing Adaptor for

5/16", 3/8" & 7/16"

MAY 2013

24

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

S E R I E S 3 0 0 0 X T - I N S T A L L A T I O N M A N U A L

SERIES 3000 MULTIPLANE ACCESSORIES

PARTS LIST

SERIES 3000 MULTIPLANE ACCESSORIES

GASKETS & SETTING BLOCKS

FG1000-FP-2

FG3000-FP-57

FG3000-FP-46

FG3000-FP-60

AC-119-1

FG3000-FP-58

Water Diverter

Splice for

FG-3511

End Dam for

FG-3511

Shear Block for

FG-3506

Shear Block for

FG-3509, FG-3512

& FG-3510

Head Anchor for

FG-3506

FG-1133

FG-1134

FG-3129

FL-66

CW-998

V-11

1" Glazing

Gasket

Light Gasket

5/8" Glazing

Gasket

Heavy Gasket

Gasket for

Expansion Mullions

Gasket for

Head Receptor

Head Anchor for

FG-3510

FG3000-FP-59

SERIES 3000 MULTIPLANE ACCESSORIES

FASTENERS & DRILL JIGS

#14 X 1" H.H.S.T.S.

Screw Spline

FS-8

FS-9

FS-55

DJ-8

Assembly Screw

#14 X 1-1/2" H.H.S.T.S.

Shear Block

Attachment Screw

#10 x 1/2" P.R.H.

Attachment of

Shear Blocks at

Horizontals

Drill Fixture for

Center Set

Shear Block or

Screwspline Assembly

FG-3220

FG-3278

FG-3523

Setting Block

for FG-3509 horizontal

and FG-3510 sill

Setting Block

for FG-3512ddinsert

Setting Block

for FG-3293, FG-3294

& FG-3334

MAY 2013

25

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

Loading...

Loading...