Page 1

PF-650(B)

Option Copier

SERVICE MANUAL

Code Y110900-9

Page 2

PUBLICATION ISSUED BY:

Olivetti S.p.A.

77, Via Jervis - 10015 Ivrea (TO)

Italy

Copyright © 2009, Olivetti

All rights reserved

Page 3

CAUTION

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE. DISPOSE OF

USED BATTERIES ACCORDING TO THE INSTRUCTIONS.

It may be illegal to dispose of this battery into the municipal waste stream. Check with your local

solid waste officials for details in your area for proper disposal.

ATTENTION

IL Y A UN RISQUE D’EXPLOSION SI LA BATTERIE EST REMPLACEE PAR UN MODELE DE

TYPE INCORRECT. METTRE AU REBUT LES BATTERIES UTILISEES SELON LES INSTRUCTIONS DONNEES.

Il peut être illégal de jeter les batteries dans des eaux d’égout municipales. Vérifiez avec les fonctionnaires municipaux de votre région pour les détails concernant des déchets solides et une mise

au rebut appropriée.

Page 4

This page is intentionally left blank.

Page 5

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Page 6

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING: Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION: Bodily injury or damage to property may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point

of attention is shown inside the symbol.

General warning.

Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action.

Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required.

Remove the power plug from the wall outlet.

Always ground the copier.

Page 7

1.Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check

that it is adequate for the rated current. .............................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the copier may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes,

lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the

proper authorities. ............................................................................................................................

CAUTION:

• Do not place the copier on an infirm or angled surface: the copier may tip over, causing injury. .......

• Do not install the copier in a humid or dusty place. This may cause fire or electric shock. ................

• Do not install the copier near a radiator, heater, other heat source or near flammable material.

This may cause fire. .........................................................................................................................

• Allow sufficient space around the copier to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance. ...........

• Always handle the machine by the correct locations when moving it. ...............................................

• Always use anti-toppling and locking devices on copiers so equipped. Failure to do this may cause

the copier to move unexpectedly or topple, leading to injury. ...........................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is accidentally ingested, drink a lot of water to dilute it in the stomach and obtain medical attention immediately. If it gets into the eyes, rinse immediately with copious amounts of water and obtain medical

attention. ......................................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the copier’s

instruction handbook. .....................................................................................................................

Page 8

2.Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly. ...............

• Always follow the procedures for maintenance described in the service manual and other related

brochures. .......................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety mechanisms

and protective circuits. .....................................................................................................................

• Always use parts having the correct specifications. ..........................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related brochure when replacing them. Using a piece of wire, for example, could lead to fire or other serious

accident. ..........................................................................................................................................

• When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ................................................................

• Always check that the copier is correctly connected to an outlet with a ground connection. .............

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If it

is dirty, clean it to remove the risk of fire or electric shock. ..............................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight. ...........................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause electric

shock if handled improperly. ............................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are

safely secured so they will not be caught in rotating sections. ..........................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts. ........

• Handle the fixing section with care to avoid burns as it can be extremely hot. ..................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures. ........................................................................................................

Page 9

• Do not remove the ozone filter, if any, from the copier except for routine replacement. ....................

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. .....................................................................................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. .............................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks. ........

• Remove toner completely from electronic components. ...................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ....................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten connector,

trapped wire and missing screws. ...................................................................................................

• Check that all the caution labels that should be present on the machine according to the instruction

handbook are clean and not peeling. Replace with new ones if necessary. ......................................

• Handle greases and solvents with care by following the instructions below: .....................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the power

switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc. .......................................................................................................................

• Should smoke be seen coming from the copier, remove the power plug from the wall outlet imme-

diately. ............................................................................................................................................

3.Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than the

specified refiner; it may generate toxic gas. .....................................................................................

Page 10

This page is intentionally left blank.

Page 11

3MV

CONTENTS

1-1 Specifications

1-1-1 Specifications..........................................................................................................................................1-1-1

1-1-2 Parts names............................................................................................................................................1-1-2

1-1-3 Machine cross section ............................................................................................................................1-1-3

1-2 Installation

1-2-1 Installation environment ..........................................................................................................................1-2-1

1-2-2 Unpacking ...............................................................................................................................................1-2-2

(1) Unpacking .........................................................................................................................................1-2-2

(2) Removing tapes and spacers............................................................................................................1-2-3

1-3 Maintenance mode

1-3-1 Maintenance mode .................................................................................................................................1-3-1

(1) Executing a maintenance item ..........................................................................................................1-3-1

(2) Contents of the maintenance mode items .........................................................................................1-3-2

1-4 Troubleshooting

1-4-1 Paper misfeed detection .........................................................................................................................1-4-1

(1) Paper misfeed detection....................................................................................................................1-4-1

(2) Paper misfeed detection condition ....................................................................................................1-4-1

(3) Paper misfeeds .................................................................................................................................1-4-2

1-4-2 Self-diagnosis .........................................................................................................................................1-4-3

(1) Self-diagnostic function .....................................................................................................................1-4-3

(2) Self diagnostic code ..........................................................................................................................1-4-3

1-4-3 Electrical problem ...................................................................................................................................1-4-5

1-5 Assembly and Disassembly

1-5-1 Precautions for assembly and disassembly............................................................................................1-5-1

(1) Precautions .......................................................................................................................................1-5-1

1-5-2 Procedure for assembly and disassembly ..............................................................................................1-5-2

(1) Adjusting the center line ....................................................................................................................1-5-2

2-1 Mechanical construction

2-1-1 Mechanical construction .........................................................................................................................2-1-1

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout..............................................................................................................................2-2-1

(1) PWBs, motors and clutches ..............................................................................................................2-2-1

(2) Switches ............................................................................................................................................2-2-2

2-3 Operation of the PWBs

2-3-1 Side feeder main PWB............................................................................................................................2-3-1

2-4 Appendixes

Maintenance parts list .............................................................................................................................2-4-1

Periodic maintenance procedures ..........................................................................................................2-4-2

Wiring diagram........................................................................................................................................2-4-3

Page 12

3MV

This page is intentionally left blank.

Page 13

3MV

1-1-1

1-1 Specifications

1-1-1 Specifications

Paper capacity ................................ 4000 sheets (80 g/m2)

Paper size.......................................A4, B5, 11 × 8 1/2"

Paper weight...................................60 to 160 g/m

2

Paper type ......................................Plain, recycled and colored paper

Power source..................................Electrically connected to the machine

Dimensions .....................................371 (W) × 589 (D) × 693 (H) mm

14 5/8" (W) × 23 3/16" (D) × 27 5/16" (H)

Weight.............................................41 kg or less/90.2 lbs. or less

NOTE: These specifications are subject to change without notice.

Y110900-9 Service Manual

Page 14

3MV

1-1-2

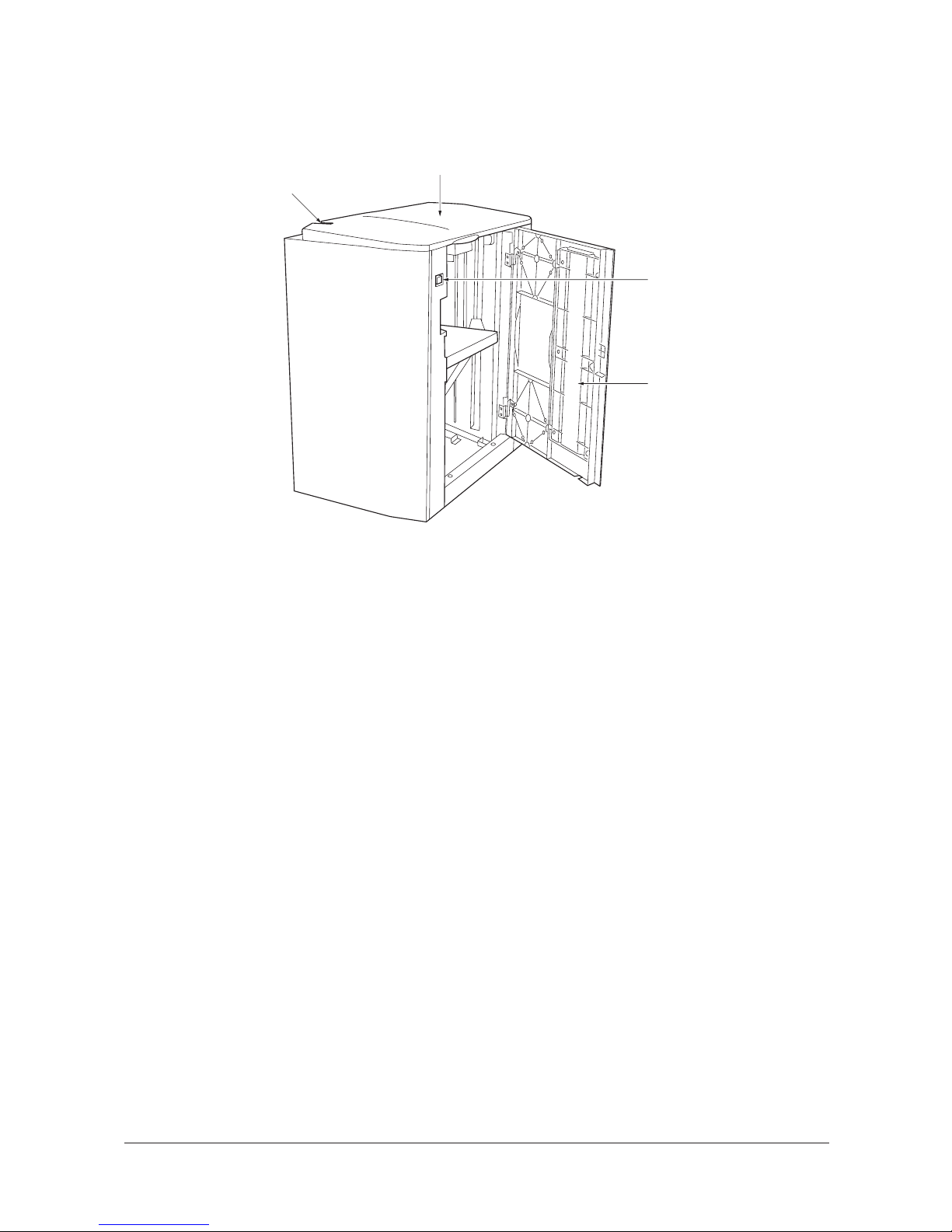

1-1-2 Parts names

Figure 1-1-1 Parts names

1

4

3

2

1. Upper cover

2. Right cover

3. Right down switch

4. Side feeder release button

Service Manual Y110900-9

Page 15

3MV

1-1-3

1-1-3 Machine cross section

Figure 1-1-2 Cross section

Figure 1-1-3

Papaer path

Y110900-9 Service Manual

Page 16

3MV

1-1-4

This page is intentionally left blank.

Service Manual Y110900-9

Page 17

3MV

1-2-1

1-2Installation

1-2-1 Installation environment

Installation location (Be based on the machine establishment place.)

Avoid direct sunlight or bright lighting. Ensure that the photo-conductor will not be exposed to direct sunlight or other

strong light when removing paper jams.

Avoid extremes of temperature and humidity, abrupt ambient temperature changes, and hot or cold air directed onto the

machine.

Avoid dust and vibration.

Choose a surface capable of supporting the weight of the machine.

Place the machine on a level surface (maximum allowance inclination: 1°).

Avoid air-borne substances that may adversely affect the machine or degrade the photo-conductor, such as mercury,

acidic of alkaline vapors, inorganic gasses, NOx, SOx gases and chlorine-based organic solvents.

Select a room with good ventilation.

Y110900-9 Service Manual

Page 18

3MV

1-2-2

1-2-2 Unpacking

(1) Unpacking

Figure 1-2-1 Unpacking

Caution: Place the machine on a level surface. See the Installation Guide for installation.

(1) Side feeder

(2) Guide plate

(3) Switch contact plate

(4) M4 × 12 dish screw

(5) M3 × 6 Tap Tight S screw

(6) M4 × 6 TP screws

(7) Clamp

(8) Plastic bag (70 × 110 mm)

(9) Air padded bag (400 × 500 mm)

(10) Bottom pad

(11) Top pad

(12) Lift spacer

(13) Installation guide

(14) Plastic bag

(15) Machine cover

(16) Outer case

(17) Bar code labels

(18) Skids

(19) Joint hinges

(20) Inner frame

Service Manual Y110900-9

Page 19

3MV

1-2-3

(2) Removing tapes and spacers

Remove the tapes and spacers as follows before machine installation.

1. Remove the tape securing the hook.

2. Remove two tapes and then remove the

sheet.

3. Remove two tapes securing the signal cable

and base retainer.

4. Remove two tapes and then remove the air

padded bag.

Figure 1-2-2

5. Remove two tapes securing the upper and

right covers.

Figure 1-2-3

A

ir padded

bag

Ta pe s

Signal cable

Base retainer

Ta pe s

Ta pe

Ta pe

Ta pe

Sheet

Hook

Right cove

r

Upper cover

Ta pe

Ta pe

Y110900-9 Service Manual

Page 20

3MV

1-2-4

6. Open the upper cover.

7. Remove the tape securing each of the two

lift spacers and then the spacers.

8. Remove the paper on the lift plate.

Figure 1-2-4

9. Open the right cover.

10. Remove two screws and then remove the

feeder support.

Figure 1-2-5

Lift spacer

Paper

Upper cover

Ta pe

Lift spacer

Ta pe

Screw

Screw

Right cove

r

Feeder support

Service Manual Y110900-9

Page 21

3MV

1-3-1

1-3Maintenance mode

1-3-1 Maintenance mode

(1) Executing a maintenance item

Enter “10871087” using

the numeric keys.

Enter “001” using the cursor

up/down keys or numeric keys

and press the start key.

Enter the maintenance item

number using the cursor up/down keys

or numeric keys.

The selected maintenance item is run.

Press the stop/clear key.

Press the start key.

Start

End

Maintenance mode is entered.

The maintenance item is

selected.

Maintenance mode is exited.

Repeat the same

maintenance item?

Run another maintenance

item?

No

No

Yes

Yes

Y110900-9 Service Manual

Page 22

3MV

1-3-2

(2) Contents of the maintenance mode items

Maintenance

item No.

Description

U019

Displaying the ROM version

Description

Displays the part number for the ROM fitted to each PWB.

Purpose

To check the part number or to decide, based on the last digit of the number, if the newest version of ROM is

installed.

Method

1. Press the start key. The ROM version (the last 6 digits of the part number) is displayed.

2. Change the screen using the * or # keys.

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

Display Description

MAIN Main PWB ROM IC

ENGINE Engine PWB ROM IC

SCANNER Scanner PWB ROM IC

LANGUAGE (Stand.) Standard language ROM IC

LANGUAGE(Option) Optional language ROM IC

MAIN BOOT Main PWB booting

PRINTER Optional printer board booting

NETWORK SCANNER Optional network scanner ROM IC

DP DP ROM IC

FINISHER Optional document finisher main PWB ROM IC

ENGINE BOOT Engine PWB booting

FINISHER BOOT Optional document finisher main PWB booting

CASSETTE1 Deck PWB ROM IC

CASSETTE2 Cassette PWB ROM IC

DUPLEX Duplex PWB ROM IC

SIDE FEEDER Side feeder main PWB ROM IC

Service Manual Y110900-9

Page 23

3MV

1-3-3

U031

Checking switches for paper conveying

Description

Displays the ON/OFF status of each paper detection switch on the paper conveying path.

Purpose

To check the operation of the switches for paper conveying.

Method

1. Press the start key. A list of switches, the on-off status of which can be checked, are displayed.

2. Turn each switch on and off manually to check the status.

When the on-status of a switch is detected, that switch is displayed in reverse.

*Optional.

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

Maintenance

item No.

Description

Display Sensor

REG SW Registration switch (RSW)

FEED-A SW Feed switch 1 (FSW1)

FEED-B SW E Feed switch 2 (FSW2)

FD EJ SW Switchback exit switch (SBESW)

EJECT SW Exit switch (ESW)

FEED-B SW D Feed switch 2 (FSW2)

LCF SW A Deck conveying switch 1 (DKCSW1)

LCF SW B Deck conveying switch 2 (DKCSW2)

FEED-C SW Feed switch 3 (FSW3)

FEED-D SW Feed switch 4 (FSW4)

FEED-E SW Feed switch 5 (FSW5)

LDECK FD SW Side feeder feed switch (SFFSW)*

FS SW Feedshift switch (FSSW)

DUP JAM SW Duplex jam detection switch (DUPJSW)

DUP FEED SW Duplex feed switch (DUPFSW)

DUP CV SW A Duplex conveying switch 1 (DUPCSW1)

DUP CV SW B Duplex conveying switch 2 (DUPCSW2)

DUP CV SW C Duplex conveying switch 3 (DUPCSW3)

PE SW1 Paper empty switch 1 (PESW1)

PE SW2 Paper empty switch 2 (PESW2)

PE SW3 Paper empty switch 3 (PESW3)

PE SW4 Paper empty switch 4 (PESW4)

LDECK PE SW Side feeder paper empty switch (SFPESW)*

LIM SW1 Lift limit switch 1 (LILSW1)

LIM SW2 Lift limit switch 2 (LILSW2)

LIM SW3 Lift limit switch 3 (LILSW3)

LIM SW4 Lift limit switch 4 (LILSW4)

LCF-A-1 SW Timing switch 1 (TIMSW1)

FEED-D-1 SW Timing switch 2 (TIMSW2)

FEED-E-1 SW Timing switch 3 (TIMSW3)

Y110900-9 Service Manual

Page 24

3MV

1-3-4

U208

Setting the paper size for the side feeder

Description

Sets the sizes of paper placed in cassette1, cassette 2 and side feeder respectively.

Purpose

To set the size when the size of paper placed in cassette 1, cassette 2 or side feeder is changed.

Setting: Paper size for cassettes 1 and 2, and the side feeder

1. Press the start key.

2. Select paper size.

Cassette 1, 2: 11 x 8.5, A4, B5 or 16K

Side feeder: 11 x 8.5, A4 or B5

Initial setting: A4 (220-240 V specifications)/11 x 8.5 (120 V specifications)

3. Press the start key. The setting is set.

Setting: Paper size for the large size side feeder

1. Press the start key.

2. Select SIDE FEEDER.

3. Select paper size.

Side feeder: 11 x 17, 8.5 x 14, 11 x 8.5, 8.5 x 11, A3, A4, or A4R

Initial setting: A4 (220-240 V specifications)/8.5 x 11 (120 V specifications)

4. Press the start key. The setting is set.

Completion

To exit this maintenance item without changing the current setting, press the stop/clear key. The screen for

selecting a maintenance item No. is displayed.

U212

Setting the feeder lift operation

Description

Sets the operation of the side feeder lift motor for when paper in the side feeder is exhausted.

Purpose

To be set according to the paper loading method.

Method

Press the start key. The screen for selecting an item is displayed.

Setting

1. Select the method to load paper.

Initial setting: SIDE FEED

2. Press the start key. The setting is set.

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

Maintenance

item No.

Description

Display Description

SIDE FEED Load paper through the right cover

UPPER FEED Load paper through the upper cover

Service Manual Y110900-9

Page 25

3MV

1-3-5

U247

Setting the paper feed device

Description

Drives each motor of the side feeder.

Purpose

To check the operation of the side feeder.

Method

1. Press the start key. The screen for selecting an item is displayed.

2. Select the motor to be operated.

When checking the side feeder lift motor (SFLM) operation, set the paper to the side feeder.

The selected item is displayed.

Side feeder

Large size side feeder

3. To stop operation, press the stop/clear key.

If this maintenance item is executed with the upper cover of the side feeder open, detection of the upper

limit is not possible and thus the side feeder lift motor overruns.

Completion

Press the stop key after operation stops. The screen for selecting a maintenance item No. is displayed.

U327

Setting the drawer heater ON/OFF

Description

Sets ON/OFF of the drawer heater and optional side feeder dehumidifier.

Purpose

To change the setting when dew condensation on the drum is heavy.

Method

Press the start key. The screen for selecting an item is displayed.

Setting

1. Select ON or OFF. The selected item is displayed in reverse.

Initial setting: Drawer heater OFF, side feeder dehumidifier OFF

2. Press the start key. The setting is set, and the screen for selecting a maintenance item No. is displayed.

Completion

To exit this maintenance item without changing the current setting, press the stop/clear key. The screen for

selecting a maintenance item No. is displayed.

Maintenance

item No.

Description

Display Operation

SDECK MOT Side feeder drive motor (SFDM)

SDECK FAN Separation fan motor (SPFM) and suction fan motor (IFM)

SDECK LIFT Side feeder lift motor (SFLM)

SDECK CVCL Side feeder conveying clutch (SFCCL)

SDECK FDCL Side feeder paper feed clutch (SFPFCL)

Display Operation

FEED MOT H Side feeder paper feed motor (SFPFM) is turned on at high speed

FEED MOT L Side feeder paper feed motor (SFPFM) is turned on at low speed

CONV MOT H Side feeder paper conveying motor (SFPCM) is turned on at high

CONV MOT L Side feeder paper conveying motor (SFPCM) is turned on at low

LIFT UP-DOWN Side feeder lift motor (SFLM)

Display Description

CASSETTE ON Drawer heater ON

CASSETTE OFF Drawer heater OFF

SIDE FEEDER ON Side feeder dehumidifier heater ON

SIDE FEEDER OFF Side feeder dehumidifier heater OFF

Y110900-9 Service Manual

Page 26

3MV

1-3-6

U901

Checking/clearing copy counts by paper feed locations

Description

Displays or clears copy counts by paper feed locations.

Purpose

To check the time to replace consumable parts. Also to clear the counts after replacing the consumable parts.

Method

1. Press the start key. The counts by paper feed locations are displayed.

When an optional paper feed device is not installed, the corresponding count is not displayed.

Clearing

1. Select the count to be cleared. The selected item is displayed in reverse.

To clear the counts for all paper feed locations, press the reset key.

2. Press the start key. The count is cleared.

When clearing all counts, the screen for selecting a maintenance item No. is displayed.

Completion

To exit this maintenance item without changing the count, press the stop/clear key.

The screen for selecting a maintenance item No. is displayed.

Maintenance

item No.

Description

Display Paper feed locations

BYPASS MP tray

CASSETTE 1 Cassette 1

CASSETTE 2 Cassette 2

CASSETTE 3 Cassette 3

CASSETTE 4 Cassette 4

SIDE FEEDER Side feeder

DUPLEX Duplex unit

Service Manual Y110900-9

Page 27

3MV

1-3-7

U905

Checking/clearing counts by optional devices

Description

Displays or clears the counts of the DP, document finisher or side feeder.

Purpose

To check the use of the DP, document finisher and side feeder. Also to clear the counts after replacing consumable parts.

Method

1. Press the start key. The screen for selecting an item is displayed.

2. Select the device, the count of which is to be checked. The count of the selected device is displayed.

DP

Document finisher

Side feeder

Clearing

1. Select the item to be cleared. The selected item is displayed in reverse.

To clear the counts for all, press the reset key.

2. Press the start key. The count is cleared.

To return to the screen for selecting an item, press the stop/clear key.

Completion

Press the stop/clear key at the screen for selecting an item.

The screen for selecting a maintenance item No. is displayed.

Maintenance

item No.

Description

Display Description

DP Document processor

FINISHER Ducument finisher

FEEDER Side feeder

Display Description

ADP Number of single-sided originals that has passed through the DP

RADP Number of double-sided originals that has passed through the DP

Display Description

CP CNT Number of copies that has passed

STAPLE Frequency the stapler has been activated

PUNCH Frequency the punch has been activated

STACK Frequency the stacker has been activated

SADDLE Frequency the center holding has been activated

Display Description

LCT COUNTER Number of copies that has passed through the side feeder

Y110900-9 Service Manual

Page 28

3MV

1-3-8

This page is intentionally left blank.

Service Manual Y110900-9

Page 29

3MV

1-4-1

1-4 Troubleshooting

1-4-1 Paper misfeed detection

(1) Paper misfeed detection

When a paper jam occurs, the machine stops operating immediately. The machine operation panel shows a jam message

and the jam location. To remove the jammed paper, detach the side feeder from the machine.

Figure 1-4-1

(2) Paper misfeed detection condition

Section Jam code Description Conditions

Side feeder 14 No paper feed from side

feeder

Side feeder feed switch (SFFSW) does not turn on within 2000

ms of the side feeder drive motor (SFDM) turning on.

30 Multiple sheets in side

feeder paper feed section

Side feeder feed switch (SFFSW) does not turn off within 700

ms of its turning on.

32 Misfeed in registration Feed switch 1 (FSW1) does not turn on within specified time

(909 ms for 82 cpm/1170 ms for 62 cpm) of side feeder feed

switch (SFFSW) turning on.

SFFSW

SFPFCL

Y110900-9 Service Manual

Page 30

3MV

1-4-2

(3) Paper misfeeds

Problem

Causes/check procedures

Corrective measures

(1)

A paper jam in the

paper feed section is

indicated during

copying (no paper

feed from side

feeder).

Jam code 14

Broken side feeder feed

switch actuator.

Check visually and replace the side feeder feed switch if its actuator is broken.

Defective side feeder feed

switch.

Run maintenance item U031 and turn the side feeder feed switch

on and off manually. Replace the side feeder feed switch if indication of the corresponding sensor on the touch panel is not displayed in reverse.

Check if the side feeder

drive motor malfunctions.

Run maintenance item U247 and select the side feeder drive

motor on the touch panel to be turned on and off. Check the status

and remedy if necessary.

Electrical problem with the

side feeder drive motor.

Check.

(2)

A paper jam in the

paper feed section is

indicated during

copying (multiple

sheets in side

feeder).

Jam code 30

Broken side feeder feed

switch actuator.

Check visually and replace the side feeder feed switch if its actuator is broken.

Defective side feeder feed

switch.

Run maintenance item U031 and turn the side feeder feed switch

on and off manually. Replace the side feeder feed switch if indication of the corresponding sensor on the touch panel is not displayed in reverse.

Check if the side feeder

drive motor malfunctions.

Run maintenance item U247 and select the side feeder drive

motor on the touch panel to be turned on and off. Check the status

and remedy if necessary.

Electrical problem with the

side feeder drive motor.

Check.

(3)

A paper jam in the

paper conveying section is indicated during copying (jam in

registration/transfer

section).

Jam code 32

Defective feed switch 1. Run maintenance item U031 and turn feed switch 1 on and off

manually. Replace feed switch 1 if indication of the corresponding

sensor on the touch panel is not displayed in reverse.

Broken side feeder feed

switch actuator.

Check visually and replace the side feeder feed switch if its actuator is broken.

Defective side feeder feed

switch.

Run maintenance item U031 and turn the side feeder feed switch

on and off manually. Replace the side feeder feed switch if indication of the corresponding sensor on the touch panel is not displayed in reverse.

The vertical feed roller or

feed B roller is dirty with

paper powder.

Check and, if it is dirty, clean it.

The vertical feed roller or

feed B roller is deformed or

worn.

Check and, if it is deformed or worn, fix or replace it.

Service Manual Y110900-9

Page 31

3MV

1-4-3

1-4-2 Self-diagnosis

(1) Self-diagnostic function

When a problem is detected in the side feeder, copying is disabled and the machine operation section displays a code

consisting of “C” followed by a number, indicating the nature of the problem.

After removing the problem, the self-diagnostic function can be reset by reattaching the side feeder.

(2) Self diagnostic code

Code Contents

Remarks

Causes Check procedures/corrective measures

C0420 Side feeder communication error

• A communication error from side

feeder is detected 10 times in succession.

Poor contact in the

connector terminals.

Check the connection of connector YC15 on

the engine PWB and the connector YC3 on

the side feeder main PWB, and the continuity across the connector terminals. Repair or

replace if necessary.

Defective engine

PWB.

Replace the engine PWB.

Defective side

feeder main PWB.

Replace the side feeder main PWB.

C0700 Side feeder EEPROM error

• An error occurs in EEPROM (U4) data

read or write for the side feeder main

PWB.

Defective side

feeder main PWB.

Replace the side feeder main PWB.

C1140 Side feeder lift motor going up error

(optional side feeder)

• Upper limit detection switch does not

turn off within 15 s of the side feeder

lift motor starting (within 200 ms during

paper feeding). This error is detected

four times successively.

Poor contact of

upper limit detection switch connector terminals.

Reinsert the connector. Also check for continuity within the connector cable. If none,

repair or replace the cable.

Defective side

feeder main PWB.

Replace the side feeder main PWB.

Defective side

feeder lift motor.

Run maintenance mode U247 and measure

the voltage between terminals YC5-A12

(side feeder main circuit board) and YC6B11. (Make sure all of LUSSW, UCSSW,

LLSSW and RCSSW are off.)

Despite either DC24V or DC-24V is

observed but if the side feeder lift motor

does not operate, replace the side feeder lift

motor.

Y110900-9 Service Manual

Page 32

3MV

1-4-4

C1150 Side feeder lift motor going down

error (optional side feeder)

• Lower limit detection switch does not

turn off within 15 s of the side feeder

lift motor starting (within 200 ms during

paper feeding). This error is detected

four times successively.

Poor contact of

lower limit detection switch connector terminals.

Reinsert the connector. Also check for continuity within the connector cable. If none,

repair or replace the cable.

Defective side

feeder main PWB.

Replace the side feeder main PWB.

Defective side

feeder lift motor.

Run maintenance mode U247 and measure

the voltage between terminals YC5-A12

(side-feeder main circuit board) and YC6B11. (Make sure all of LUSSW, UCSSW,

LLSSW and RCSSW are off.)

Despite either DC24V or DC-24V is

observed but if the side-feeder lift motor

does not operate, replace the side-feeder lift

motor.

C2640 Side feeder drive motor error Overloaded side

feeder drive motor

Verify that the side feeder motor or the paper

feeding mechanism is not interrupted by any

objects.

Defective side

feeder drive motor.

Replace the side feeder drive motor.

Defective side

feeder main PWB.

Replace the side feeder main PWB.

Code Contents

Remarks

Causes Check procedures/corrective measures

Service Manual Y110900-9

Page 33

3MV

1-4-5

1-4-3 Electrical problem

Problem Causes Check procedures/corrective measures

(1)

The side feeder

paper feed clutch

does not operate.

Poor contact of the side

feeder paper feed clutch

connector terminals.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Broken side feeder paper

feed clutch coil.

Check for continuity across the coil. If none, replace the side

feeder paper feed clutch.

Defective side feeder paper

feed clutch.

Run maintenance item U247 and check if the side feeder paper

feed clutch does not operate when YC5-A10 on the side feeder

main PWB goes low. If so, replace the side feeder paper feed

clutch.

Defective side feeder main

PWB.

Run maintenance item U247 and check if YC5-A10 on the side

feeder main PWB goes low. If not, replace the side feeder main

PWB.

(2)

The side feeder

paper conveying

clutch does not operate.

Poor contact of the side

feeder paper conveying

clutch connector terminals.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Broken side feeder paper

conveying clutch coil.

Check for continuity across the coil. If none, replace the side

feeder paper conveying clutch.

Defective side feeder paper

conveying clutch.

Run maintenance item U247 and check if the side feeder paper

conveying clutch does not operate when YC6-B7 on the side

feeder main PWB goes low. If so, replace the side feeder paper

conveying clutch.

Defective side feeder main

PWB.

Run maintenance item U247 and check if YC6-B7 on the side

feeder main PWB goes low. If not, replace the side feeder main

PWB.

(3)

The separation fan

motor does not operate.

Poor contact of the separation fan motor connector

terminals.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective separation fan

motor.

Run maintenance item U247 and check if the separation fan

motor does not operate when YC6-A1 on the side feeder main

PWB goes low. If so, replace the separation fan motor.

Defective side feeder main

PWB.

Run maintenance item U247 and check if YC6-A1 on the side

feeder main PWB goes low. If not, replace the side feeder main

PWB.

(4)

The suction fan

motor does not operate.

Poor contact of the suction

fan motor connector termi

-

nals.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective suction fan motor. Run maintenance item U247 and check if the suction fan motor

does not operate when YC6-A2 on the side feeder main PWB

goes low. If so, replace the side feeder main PWB.)

Defective side feeder main

PWB.

Run maintenance item U247 and check if YC6-A2 on the side

feeder main PWB goes low. If not, replace the side feeder main

PWB.

Y110900-9 Service Manual

Page 34

3MV

1-4-6

(5)

The side feeder lift

motor does not operate.

Poor contact of the side

feeder lift motor connector

terminals.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Broken side feeder lift

motor coil.

Check for continuity across the coil. If none, replace the feeder lift

motor.

Defective side feeder lift

motor or side feeder main

PWB.

Run maintenance item U247 and measure the voltage between

side feeder main PWB terminal YC5-A12 and YC6-B11.

Each of LUSSW, UCSSW, LLSSW, and RCSSW should be turned

off.

Although 24 V DC or -24 V DC are measured, if a side feeder lift

motor does not operate, replace the side feeder lift motor.

When change of voltage is not measured, (0V), replace the side

feeder main PWB.

(6)

The side feeder drive

motor does not operate.

Poor contact of the side

feeder drive motor connector terminals.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Broken side feeder drive

motor coil.

Check for continuity across the coil. If none, replace the feeder lift

motor.

Defective side feeder drive

motor.

Run maintenance item U247 and check if the side feeder drive

motor does not operate when YC4-4 on the side feeder main

PWB goes low. If so, replace the side feeder drive motor.

Defective side feeder main

PWB.

Run maintenance item U247 and check if YC6-A1 on the side

feeder main PWB goes low. If not, replace the side feeder main

PWB.

Problem Causes Check procedures/corrective measures

24V DC

SFMPWB

GND

Fwd./

rev.

motor

driver

SFLM+

SFLM-

ULSSW

UCSSW

RCSSW

LLSSW

YC6-B11

YC5-A12

SFLM

SFLM Wiring Diagram

C

P

U

Off

Off

Off

Off

On

On

On

On

GND

GND

24V DC

24V DC

Service Manual Y110900-9

Page 35

3MV

1-5-1

1-5 Assembly and Disassem bly

1-5-1 Precautions for assembly and disassembly

(1) Precautions

Before starting disassembly, press the Power key on the operation panel to off. Make sure that the Power lamp is off

before turning off the main power switch. And then unplug the power cable from the wall outlet. Turning off the main power

switch before pressing the Power key to off may cause damage to the equipped hard disk.

When handling PWBs (printed wiring boards), do not touch parts with bare hands. The PWBs are susceptible to static

charge.

Do not touch any PWB containing ICs with bare hands or any object prone to static charge.

When removing the hook of the connector, be sure to release the hook.

Take care not to get the cables caught.

To reassemble the parts, use the original screws. If the types and the sizes of screws are not known, refer to the PARTS

LIST.

Y110900-9 Service Manual

Page 36

3MV

1-5-2

1-5-2 Procedure for assembly and disassembly

(1) Adjusting the center line

Make the following adjustment if there is a regular error between the center lines of the original and the copy image when

paper is fed from the side feeder.

Note: Before performing this adjustment, be sure to perform the center line adjustment of the machine.

<Procedure>

1. Run maintenance item U034 and output a

test pattern.

2. Measure the discrepancy L (mm) between

the center lines of the paper and test pattern.

3. Open the lower vertical conveying cover of

the machine. Loosen the two screws securing the feeder retainer and move the Vshaped groove on the feeder retainer by the

measured amount L and retighten the

screws.

* If the center line of the sample is shifted to

the paper front, move the V-shaped groove

of the feeder retainer toward the machine

front (example 1).

* If the center line of the sample is shifted to

the paper rear, move the V-shaped groove

of the feeder retainer toward the machine

rear (example 2).

Figure 1-5-1

Figure 1-5-2

Screw

Feeder retainer

Feeder retainer

V-shaped groove

Screw

Vertical

conveying

cover

Scale

Sample 1

Sample 2

L

L

Center of pape

r

Eject

Eject

Center of test

pattern

Center of pape

r

Center of test

pattern

Service Manual Y110900-9

Page 37

3MV

2-1-1

2-1 Mechanical construction

2-1-1 Mechanical construction

The side feeder consists of the paper lifting mechanism, which winds up paper with the wire of the side feeder lift motor

(SFLM), and the paper feed and conveying mechanism, which conveys paper with the drive of the paper conveying belt,

feed roller and left feed roller.

The side feeder lift motor (SFLM) raises the lift by winding up the wire engaged with the pulley. The lift is stopped at the

upper and lower limit by the control of the upper limit detection switch (ULPSW) and lower limit detection switch (LLPSW).

Paper is fed by controlling currents of air. The top sheet of the paper loaded on the lift is floated by the separation fan

motor (SPFM) and then induced onto the paper conveying belt by the suction fan motor (IFM). The sheet thus attracted to

the paper conveying belt is then conveyed to the feed roller and left feed roller by the drive of the side feeder drive motor

(SFDM).

Figure 2-1-1 Side feeder (1)

(1) Upper paper conveying guide

(2) Lower paper conveying guide

(3) Paper guide

(4) Paper conveying belt retainer

(5) Left side feeder guide

(6) Upper limit switch mount

(7) Switch cover

(8) Paper level detection switch mount

(9) Lower separation duct mount

(10) Lower suction duct

(11) Upper separation duct

(12) Upper suction duct

(13) Left feed roller

(14) Feed roller

(15) Paper conveying pulley

(16) Paper conveying belt pulley

(17) Paper conveying belt

(18) Side feeder paper conveying clutch

(SFCCL)

(19) Side feeder paper feed clutch (SFPFCL)

(20) Side feeder drive motor (SFDM)

(21) Suction fan motor (IFM)

(22) Separation fan motor (SPFM)

(23) Side feeder feed switch (SFFSW)

(24) Upper cover safety switch (UCSSW)

(25) Upper cover open/close switch (UCOSW)

(26) Upper down switch (UDSW)

(27) Upper limit detection switch (ULPSW)

(28) Upper limit safety switch (ULSSW)

(29) Paper level detection switch (PRDSW)

(30) Right cover open/close switch (RCOSW)

(31) Right cover safety switch (RCSSW)

(32) Right down switch (RDSW)

Y110900-9 Service Manual

Page 38

3MV

2-1-2

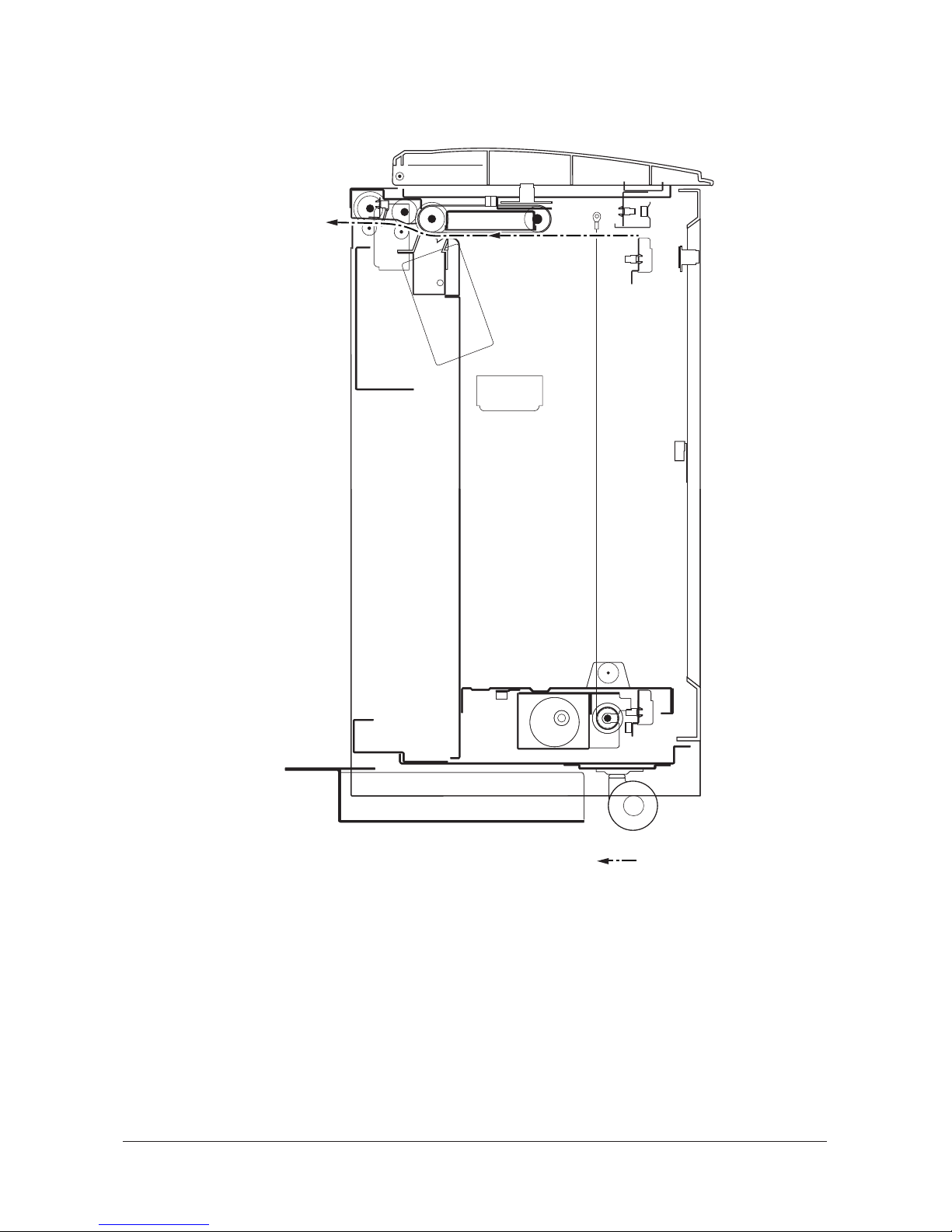

Figure 2-1-2 Side feeder (2)

(1) Lift

(2) Side feeder lift motor cover

(3) Lower limit detection switch mount

(4) Lift wire

(5) Wire lift pulley

(6) Wire holding plate

(7) Mirror pulley

(8) Side feeder lift motor (SFLM)

(9) Side feeder paper empty switch (SFPESW)

(10) Lower limit detection switch (LLPSW)

(11) Lower limit safety switch (LLSSW)

Service Manual Y110900-9

Page 39

3MV

2-1-3

Figure 2-1-3 Side feeder block diagram

Figure 2-1-4 Timing chart

1. In case the separation fan motor (SPFM) and the suction fan motor (IFM) is not activated when receiving Command 2

(start feeding) from the machine, waits for 1000 ms until the fan rotation becomes stable.

2. After turning the side feeder feed switch (SFFSW) on, feeds the 35 mm paper and turns off the side feeder paper feed

clutch (SFPFCL). The stop time varies along with the feeding speed 600 mm/s = 58 ms.

3. When the side feeder fee switch (SFFSW) turns on, feeds the paper and turns the side feeder conveying clutch

(SFCCL) off unless Command 3 (allows the next paper to be fed) is received. The stop time varies along with the feeding

speed 600 mm/s = 58 ms.

4. Restarts the feeding when receiving Command 3 (allows the next paper to be fed).

5. When the side feeder feed switch (SFFSW) is turned off, stops the feeding unless Command 3 (starts the feeding) is

received.

SFMPWB

IFM

SFLM

SFDM

SFCCL

ULPSW

SFFSW

LLPSW

SPFM

SFPFCL

CN6-B1

CN6-A1

CN6-B7

CN4-4

CN6-A2

CN6-B6CN5-A8

CN5-A12

CN6-B11

CN5-A10

Paper feed

starts

Allows the next

paper to be fed

Allows the next

paper to be fed

Paper feed

starts (second)

SFFSW

SFPFCL

SFM

IFM

SFDM

SFCCL

OFF

10000 ms

OFF

OFF

OFF

OFF

100 ms 300 ms

58 ms

58 ms

1000 ms

100 ms

Command

Status

Command2 Command3 Command3Command2

Status1

Status1

Status1 Status1

Paper feed (second)

Paper feed ends

Y110900-9 Service Manual

Page 40

3MV

2-1-4

This page is intentionally left blank.

Service Manual Y110900-9

Page 41

3MV

2-2-1

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout

(1) PWBs, motors and clutches

Figure 2-2-1 PWBs, motors and clutches

1. Side feeder main PWB (SFMPWB) ............. Controls electrical components in the side feeder and communications

with the machine.

2. Side feeder drive motor (SFDM) .................. Drives the paper feed and conveying mechanism in the side feeder.

3. Side feeder lift motor (SFLM)....................... Drives the paper lift mechanism of the side feeder.

4. Side feeder paper feed clutch (SFPFCL)..... Transfers drive from the paper conveying belt.

5. Side feeder paper conveying clutch

(SFCCL)....................................................... Transfers drive from the left feed roller and feed roller.

6. Separation fan motor (SPFM) ...................... Separates the uppermost sheet in the side feeder.

7. Suction fan motor (IFM) ............................... Attracts paper to the paper conveying belt.

8. Side feeder dehumidifier heater (SFDH)...... Dehumidifies paper in the side feeder.

4

5

2

6

7

8

1

3

Machine front Machine inside Machine rear

Y110900-9 Service Manual

Page 42

3MV

2-2-2

(2) Switches

Figure 2-2-2 Switches

1. Side feeder feed switch (SFFSW)................ Detects a paper misfeed.

2. Side feeder paper empty switch

(SFPESW) ................................................... Detects the presence of paper in the side feeder.

3. Upper limit detection switch (ULPSW) ......... Detects the lift reaching the upper limit.

4. Paper level detection switch (PRDSW)........ Detects the paper level in the side feeder.

5. Lower limit detection switch (LLPSW).......... Detects the lift reaching the lower limit.

6. Upper limit safety switch (ULSSW) .............. Breaks the safety circuit when the lift overruns the upper limit.

7. Lower limit safety switch (LLSSW)............... Breaks the safety circuit when the lift overruns the lower limit.

8. Upper down switch (UDSW) ........................ For the controlling of the descending of the lift when the upper cover is

opened.

9. Right down switch (RDSW).......................... For the controlling of the descending of the lift when the right cover is

opened.

10. Side feeder set switch (SFSETSW) ............. Detects the side feeder attached to the machine; breaks the safety circuit

when the feeder is detached from the machine.

11. Upper cover safety switch (UCSSW) ........... Breaks the safety circuit when the upper cover is opened.

12. Upper cover open/close switch (UCOSW)... Detects whether the upper cover is open or closed.

13. Right cover safety switch (RCSSW) ............ Breaks the safety circuit when the right cover is opened.

14. Right cover open/close switch (RCOSW) .... Detects whether the right cover is open or closed.

2

4

6

9

3

8

11

12

5

7

10

13

14

1

Machine front Machine inside Machine rear

Service Manual Y110900-9

Page 43

3MV

2-3-1

2-3 Operation of the PWBs

2-3-1 Side feeder main PWB

Figure 2-3-1 Side feeder main PWB block diagram

The main component of the side feeder main PWB (SFMPWB) is the CPU U1. It controls the overall operation of the side

feeder by receiving detection signals from switches as inputs and outputting drive signals to motors and clutches.

Communication of control signals with the machine is performed by 3-line type serial communication method.

With the control signal received from the CPU U1, the SFLM driver circuit U6 drives the side feeder lift motor (SFLM). A

safety circuit consisting of the side feeder set switch (SFSETSW), upper cover safety switch (UCSSW) and right cover

safety switch (RCSSW) ensures the security by cutting 24 V DC supply for the SFLM driver circuit U6 and drive output for

the side feeder lift motor (SFLM) when the side feeder is detached from the machine or when the upper or right cover is

opened.

The reset IC U2 monitors the 5 V DC power supply. When the power is turned on and when the supply voltage becomes

low, the reset IC U2 outputs a RESET signal to the CPU U1 to reset the system for the prevention of malfunctions.

SFSETSW

24 V DC

24 V DC

24 V DC

24 V DC

24 V DC

24 V DC

24 V DC

5 V DC

5 V DC

5 V DC

5 V DC

5 V DC

UCOSW

EH SDI

SFMPCB

EH SDO

EH CLK

EF SEL

SF READY

SFFSW

ULPSW

RCOSW

UDSW

RDSW

PRDSW

LLPSW

SDA

SCL

R

R

S

S

S

Reset IC

(U2)

EEPROM

(U4)

SFLM

driver

circuit

(U6)

SFLM

ULSSW

UCSSW

SFM

RCSSW

LLSSW

SFCCL

SFPFCL

SFDH

SPFM

IFM

Machine

CPU

(U1)

Serial communication

Y110900-9 Service Manual

Page 44

3MV

2-3-2

Figure 2-3-2 Side feeder main PWB silk-screen diagram

YC3

YC2

YC1

YC6

YC7

YC4

101

71

A1

B1

A11

B11

YC5

A1

B1

A12

B12

2

1

1

1

3

3

2

4

14

13

Service Manual Y110900-9

Page 45

3MV

2-3-3

Connector Pin No. Signal I/O Voltage Description

YC1 1 24V O 24 V DC 24 V DC power

Connected

to the side

feeder set

switch and

upper cover

open/close

switch.

2 SFSETSW I 0/24 V DC SFSETSW: On/Off

3 SFLM 24V I 24 V DC 24 V DC power (Via SFSETSW)

4 R24V I 24 V DC 24 V DC power (Via SFSETSW, UCOSW)

YC2 1 5V I 5 V DC 5 V DC power

Connected

to the

machine.

2 G(24V) - - Ground

3 24V I 24 V DC 24 V DC power

YC3 1 G(5V) - - Ground

Connected

to the

machine.

2 G(5V) - - Ground

3 EH SDI I 0/5 V DC (pulse) Serial communication data signal

4 G(5V) - - Ground

5 EH SDO O 0/5 V DC (pulse) Serial communication data signal

6 G(5V) - - Ground

7 SF RDY O 0/5 V DC Ready signal

8 G(5V) - - Ground

9 SF SEL I 0/5 V DC Select signal

10 G(5V) - - Ground

11 EH CLK 0/5 V DC (pulse) Clock signal for serial communication

12 G(5V) - - Ground

13 EH STOP - - Not used

14 G(5V) - - Ground

YC4 1 N.C. - - Not used

Connected

to the side

feeder drive

motor.

2 SFDM CLK O 0/5 V DC(pulse) Clock signal for SFDM

3 SFDM ALM I 0/5 V DC SFDM alarm signal

4 SFDM REM O 0/5 V DC SFDM: On/Off

5 5V O 5 V DC 5 V DC power supply for SFDM

6 G(5V) - - Ground

7 G(24V) - - Ground

8 G(24V) - - Ground

9 R24V O 24 V DC 24 V DC power supply for SFDM

10 R24V O 24 V DC 24 V DC power supply for SFDM

Y110900-9 Service Manual

Page 46

3MV

2-3-4

YC5 A1 LLSSW - - LLSSW

Connect to

the right

down

switch,

upper down

switch,

paper level

detection

switch,

lower limit

detection

switch, right

cover safety

switch, side

feeder paper

feed clutch

and side

feeder

dehumidifier heater.

A2 LED REM O 0/5 V DC RDSW LED: On/Off

A3 LED REM O 0/5 V DC UDSW LED: On/Off

A4 RDSW I 0/5 V DC RDSW: On/Off

A5 UDSW I 0/5 V DC UDSW: On/Off

A6 5V O 5 V DC 5 V DC power supply for PRDSW

A7 PRDSW I 0/5 V DC PRDSW: On/Off

A8 LLPSW I 0/5 V DC LLPSW: On/Off

A9 RCOSW I 0/5 V DC RCOSW: On/Off

A10 SFPFCL O 0/24 V DC SFPFCL: On/Off

A11 SFDH REM O 0/24 V DC SFDH: On/Off

A12 SFLM- O -24/0/+24 VDC SFLM: Fwd/Stop/Rev

B1 G(5V) - - Ground

B2 R24V O 24 V DC 24 V DC power supply for SFDH

B3 R24V O 24 V DC 24 V DC power supply for SFPFCL

B4 G(5V) - - Ground

B5 G(5V) - - Ground

B6 G(5V) - - Ground

B7 5V O 5 V DC 5 V DC power supply for LLPSW

B8 5V O 5 V DC 5 V DC power supply for UDSW

B9 5V O 5 V DC 5 V DC power supply for RDSW

B10 G(5V) - - Ground

B11 G(5V) - - Ground

B12 LLSSW - - LLSSW

YC6 A1 SPFM REM O 0/5 V DC SPFM: On/Off

Connect to

the

separation

fan motor,

suction fan

motor, side

feeder paper

empty

switch, side

feeder paper

feed switch,

upper limit

safety

switch and

side feeder

conveying

clutch.

A2 IFM REM O 0/5 V DC IFM: On/Off

A3 R24V O 24 V DC 24 V DC power supply for SPFM

A4 R24V O 24 V DC 24 V DC power supply for IFM

A5 G(24V) - - Ground

A6 G(24V) - - Ground

A7 5V O 5 V DC 5 V DC power supply for SPFM

A8 5V O 5 V DC 5 V DC power supply for IFM

A9 5V O 5 V DC 5 V DC power supply for SFPESW

A10 G(5V) - - Ground

A11 SFPESW I 0/5 V DC SFPESW: On/Off

B1 SFFSW I 0/5 V DC SFFSW: On/Off

B2 5V O 5 V DC 5 V DC power supply for SFFSW

B3 G(5V) - - Ground

B4 G(5V) - - Ground

B5 5V O 5 V DC 5 V DC power supply for ULPSW

B6 ULPSW I 0/5 V DC ULPSW: On/Off

B7 SFCCL O 0/24 V DC SFCCL: On/Off

B8 R24V O 24 V DC 24 V DC power supply for SFCCL

B9 ULSSW - - ULSSW

B10 ULSSW - - ULSSW

B11 SFLM+ O +24/0/-24 V DC SFLM: Fwd/Stop/Rev

Connector Pin No. Signal I/O Voltage Description

Service Manual Y110900-9

Page 47

3MV

2-4-1

2-4 Appendixes

Maintenance parts list

Maintenance part name

Part No.

Alternative

part No.

Fig.

No.

Ref.

No.

Name used in service manual Name used in parts list

Paper feed belts BELT LCF,PAPER FEED 909708Y

Paper feed blades BLADE PAPER FEED ASS'Y AVGR03584L

Paper guide GUIDE,PAPER No code

Upper paper conveying guide UPPER GUIDE,CONVEYING No code

Lower paper conveying guide LOWER GUIDE,CONVEYING No code

Feed left roller LEFT ROLLER,FEED AVGR04803F

Feed roller ROLLER,FEED AVGR04804U

Side feeder paper conveying

clutch

CLUTCH 20,CONVEYING AVGR11228E

Side feeder paper feed clutch CLUTCH 36,PAPER FEED AVGR11227R

Y110900-9 Service Manual

Page 48

3MV

2-4-2

Periodic maintenance procedures

Section

Maintenance

part/location

Method

Maintenance cycle

Points and cautions Page

Paper feed

section

Paper feed belts Clean and

Check

Every service

Clean with alcohol or a dry

cloth.

Replace if the belt is damaged.

Paper feed blades Clean and

Check

Every service

Clean with alcohol or a dry

cloth.

Replace if the edge of blade

is damaged.

Paper guide Clean Every service Clean with alcohol or a dry

cloth.

Upper paper conveying

guide

Clean Every service Clean with alcohol or a dry

cloth.

Lower paper conveying

guide

Clean Every service Clean with alcohol or a dry

cloth.

Feed left roller Clean Every service Clean with alcohol or a dry

cloth.

Feed roller Clean Every service Clean with alcohol or a dry

cloth.

Side feeder paper conveying clutch

Clean Every service Clean with alcohol or a dry

cloth.

Side feeder paper feed

clutch

Clean Every service Clean with alcohol or a dry

cloth.

Service Manual Y110900-9

Page 49

3MV

2-4-3

Wiring diagram

13 524678132

11 910

1352

132

4

54

678

678

123

13524678910

13524678910

13524678910

56

8

9

10

3

2

8

9

11

3

54

78

10 6

7

1011 3

52

4

6

7

11

11

12

3

24

6

7810

12

1321321213241324

132

RCSSW RCOSW LLSSW

UDSW RDSW

SFPFCL

PRDSW LLPSW

SFDH

SFDM

13524

1

12

2

4

13

1

5

1

12 9

129

132

4

132

4

UCSSW

UCOSW

13524

SFSETSW

132

SFPESW

132

12

SFLM

13524

132

1324

321

1324

10 84611 957

ULSSW

SPFM IFM

SFMPWB

13212

SFCCL

ULPSW

132

SFFSW

132

A12

A4

B125-B1

5-A1

6-A9

6-A6

6-A4

6-A8

6-A2

6-A5

6-A3

6-A7

6-A1

6-B11

6-B10

6-B9

6-B8

6-B7

6-B6

6-B5

6-B4

6-B3

6-B2

6-B1

G(5V)

G(5V)

G(5V)

G(5V)

G(5V)

G(5V)

G(5V)

G(5V)

G(5V)

G(5V)

EH SDI

EH CLK

EH STOP

EH SDO

SF RDY

SF SEL

G(5V)

G(5V)

G(5V)

G(5V)

G(5V)

SFPESW

LLSSW

LLSSW

LED REM

UDSW

RCOSW

SFLM-

G(24V)

G(24V)

5V

5V

24V

5V

R24V

R24V

R24V

R24V

R24V

SFDM REM

SFDM ALM

SFDM CLK

N.C.

R24V

SFDH REM

R24V

SFPFCL

SPFM REM

5V

5V

5V

G(5V)

LED REM

RDSW

PRDSW

5V

5V

G(5V)

G(5V)

G(24V)

G(24V)

LLPSW

5V

5V

G(24V)

R24V

IFM REM

5V

24V

SFLM 24V

SFSETSW

ULSSW

ULSSW

SFLM+

SFFSW

ULPSW

SFCCL

1-4

1-2

1-3

1-1

2-1

C1

B1 B1

B2 B2

B5 B4

B4 B5

B6 B6

B7 B7

B8 B8

B3 B3

A1 A6

A2 A5

A3 A4

A4 A3

A5 A2

A6 A1

C2

C3

C4

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

3-11

3-12

3-13

3-14

2-2

2-3

6-A11

6-A10

5-B4

5-B9

5-B3

5-B8

5-A9

5-A3

5-A6

5-A7

5-A8

5-B7

5-B5

5-B2

5-B6

5-A5

5-A2

5-A4

5-B12

5-B10

5-A10

5-B11

5-A11

5-A12

B9

B1

B3

B2

B4

B7

B6

B5

A1

A8

A3

A6

A5

A2

A9

A7

B5

A10

A11

B10

B11

4-10

4-9

4-8

4-7

4-6

4-5

4-4

4-3

4-2

4-1

Machine

Y110900-9 Service Manual

Page 50

3MV

2-4-4

This page is intentionally left blank.

Service Manual Y110900-9

Page 51

UPDATING STATUS

DATE UPDATED PAGES PAGES CODE

07/2009 1ST EDITION 51 Y110900-9

Loading...

Loading...