Page 1

d-Color 201MF

Color Printer

THEORY OF OPERATION

Code Y109670-2

Page 2

PUBLICATION ISSUED BY:

Olivetti S.p.A.

77, Via Jervis - 10015 Ivrea (TO)

Italy

Copyright © 2008, Olivetti

All rights reserved

Page 3

Revision history

After publication of this service manual, the parts and mechanism may be subject to change for

improvement of their performance.

Therefore, the descriptions given in this service manual may not coincide with the actual machine.

When any change has been made to the descriptions in the service manual, a revised version will be

issued with a revision mark added as required.

Revision mark:

• To indicate clearly a section revised, show to the left of the revised section.

A number within represents the number of times the revision has been made.

• To indicate clearly a section revised, show in the lower outside section of the corresponding page.

A number within represents the number of times the revision has been made.

NOTE

Revision marks shown in a page are restricted only to the latest ones with the old ones deleted.

• When a page revised in Ver. 2.0 has been changed in Ver. 3.0:

The revision marks for Ver. 3.0 only are shown with those for Ver. 2.0 deleted.

• When a page revised in Ver. 2.0 has not been changed in Ver. 3.0:

The revision marks for Ver. 2.0 are left as they are.

1

1

1

1

Page 4

bizhub C200

OutlineComposition/Operation

Theory of operation Ver. 1.0 Sep. 2008

i

CONTENTS

d-Color MF201 Main body

Outline

1. System configuration............................................................................................... 1

2. Product specifications ............................................................................................. 3

3. Section configuration............................................................................................... 8

4. Paper path............................................................................................................... 9

5. Image creation process......................................................................................... 10

Composition/Operation

6. Overall composition............................................................................................... 13

6.1 Control block diagram......................................................................................... 13

7. Scanner section (IR section) ................................................................................. 14

7.1 Composition........................................................................................................ 14

7.2 Drive ................................................................................................................... 15

7.3 Operation ............................................................................................................ 16

7.3.1 When the power is ON ................................................................................ 16

7.3.2 When the Start key is pressed .................................................................... 17

7.3.3 Exposure unit .............................................................................................. 19

7.3.4 Original size detection control ..................................................................... 20

8. Write section (PH section)..................................................................................... 21

8.1 Composition........................................................................................................ 21

8.2 Operation ............................................................................................................ 22

8.2.1 Exposure path ............................................................................................. 22

8.2.2 Write control ................................................................................................ 23

8.2.3 Writing area................................................................................................. 24

8.2.4 Color registration control ............................................................................. 25

8.2.5 Protection shutter mechanism .................................................................... 29

9. Imaging unit section (IU section)........................................................................... 30

9.1 Composition........................................................................................................ 30

9.2 Drive ................................................................................................................... 31

9.3 Operation ............................................................................................................ 32

9.3.1 IU life control ............................................................................................... 32

10. Photo conductor section........................................................................................ 34

10.1 Composition........................................................................................................ 34

10.2 Drive ................................................................................................................... 34

10.3 Operation ............................................................................................................ 35

d-Color MF201

Page 5

bizhub C200

OutlineComposition/Operation

Theory of operation Ver. 1.0 Sep. 2008

ii

10.3.1 PC drum drive mechanism ......................................................................... 35

10.3.2 PC drum phase control............................................................................... 37

10.3.3 PC drum small amount rotation control ...................................................... 38

11. Charge corona section.......................................................................................... 39

11.1 Operation............................................................................................................ 40

11.1.1 PC drum charge corona ON/OFF control ................................................... 40

11.1.2 Cleaning/main erase mechanism ............................................................... 40

12. Developing section................................................................................................ 41

12.1 Composition ....................................................................................................... 41

12.2 Drive ................................................................................................................... 42

12.3 Transfer belt pressure retraction clutch .............................................................. 46

12.3.1 Developing drive control ............................................................................. 46

12.3.2 Developer flow ............................................................................................ 47

12.3.3 Developing bias .......................................................................................... 48

12.3.4 TCR sensor control..................................................................................... 49

13. Toner supply section ............................................................................................. 50

13.1 Composition ....................................................................................................... 50

13.2 Drive ................................................................................................................... 51

13.3 Operation............................................................................................................ 52

13.3.1 Toner replenishing mechanism/control ....................................................... 52

13.3.2 Toner cartridge detection ............................................................................ 53

13.3.3 Toner remainder amount detection ............................................................. 54

13.3.4 Shutter mechanism ..................................................................................... 55

14. Transfer corona section......................................................................................... 56

14.1 Composition ....................................................................................................... 56

14.1.1 1st image transfer section........................................................................... 56

14.1.2 2nd image transfer section.......................................................................... 57

14.2 Transfer belt pressure retraction clutch .............................................................. 58

14.2.1 1st image transfer section........................................................................... 58

14.2.2 2nd image transfer section.......................................................................... 59

14.3 Operation............................................................................................................ 60

14.3.1 Transfer belt drive mechanism.................................................................... 60

14.3.2 1st image transfer roller mechanism........................................................... 60

14.3.3 2nd image transfer roller pressure mechanism........................................... 63

14.3.4 IDC sensor shutter mechanism .................................................................. 64

14.3.5 ATVC (Auto transfer voltage control)........................................................... 65

14.3.6 Transfer belt cleaning.................................................................................. 66

14.3.7 Reversing control of the transfer belt .......................................................... 66

d-Color MF201

Page 6

bizhub C200

OutlineComposition/Operation

Theory of operation Ver. 1.0 Sep. 2008

iii

14.3.8 2nd image transfer roller cleaning............................................................... 67

14.3.9 Charge neutralization and separation of paper........................................... 68

14.3.10 Detection of new transfer belt unit............................................................... 68

14.3.11 New unit detection timing/operation ............................................................ 68

14.3.12 Pressure/retraction control during ACS mode............................................. 69

14.3.13 ASC mode control change with the software SW ....................................... 71

15. Toner collecting section ......................................................................................... 72

15.1 Composition........................................................................................................ 72

15.2 Drive ................................................................................................................... 73

15.3 Operation ............................................................................................................ 74

15.3.1 Toner collecting mechanism........................................................................ 74

15.3.2 Waste toner box-in-position detection......................................................... 74

15.3.3 Waste toner near-full/full detection control.................................................. 75

16. Paper feed section................................................................................................. 79

16.1 Tray1 ................................................................................................................... 79

16.1.1 Composition ................................................................................................ 79

16.1.2 Drive............................................................................................................ 80

16.1.3 Paper Take-up control ................................................................................. 80

16.1.4 Paper Near-Empty/Paper Empty detection ................................................. 81

16.1.5 Paper Interval Control (PPM Control) ......................................................... 81

16.1.6 Paper size detection control........................................................................ 82

17. Timing roller section .............................................................................................. 84

17.1 Composition........................................................................................................ 84

17.2 Drive ................................................................................................................... 84

17.3 Operation ............................................................................................................ 85

17.3.1 Timing roller control .................................................................................... 85

18. Fusing section ....................................................................................................... 86

18.1 Composition........................................................................................................ 86

18.2 Drive ................................................................................................................... 87

18.3 Operation ............................................................................................................ 88

18.3.1 Fusing roller drive control............................................................................ 88

18.3.2 Fusing loop control...................................................................................... 88

18.3.3 Fusing pressure roller pressure/retraction mechanism ............................... 90

18.3.4 Fusing temperature control ......................................................................... 91

18.3.5 Fusing temperature control during a print job ............................................. 92

18.3.6 Temperature control during stand-by .......................................................... 92

18.3.7 Temperature control during low power mode .............................................. 92

18.3.8 Protection from abnormally high temperature............................................. 93

d-Color MF201

Page 7

bizhub C200

OutlineComposition/Operation

Theory of operation Ver. 1.0 Sep. 2008

iv

18.3.9 Detection of a new fusing unit..................................................................... 93

18.3.10 PPM control ................................................................................................ 93

18.3.11 Delay control............................................................................................... 93

19. Paper exit/switchback section ............................................................................... 94

19.1 Composition ....................................................................................................... 94

19.2 Drive ................................................................................................................... 95

19.3 Operation............................................................................................................ 96

19.3.1 Paper exit control........................................................................................ 96

20. Image stabilization control .................................................................................... 97

20.1 Overview ............................................................................................................ 97

20.2 Operation............................................................................................................ 98

20.2.1 IDC registration sensor adjustment control................................................. 98

20.2.2 Max. density adjustment control ................................................................. 98

20.2.3 LD (laser diode) intensity adjustment control.............................................. 98

20.2.4 Gamma correction control .......................................................................... 98

20.3 Operation sequence ........................................................................................... 99

20.4 Operation timing ............................................................................................... 100

21. Image processing................................................................................................ 103

21.1 Scanner section image processing block diagram ........................................... 103

21.2 Write section image processing block diagram ................................................ 104

22. Other control ....................................................................................................... 106

22.1 Fan control........................................................................................................ 106

22.1.1 Construction.............................................................................................. 106

22.1.2 Operation .................................................................................................. 107

22.2 Counter control................................................................................................. 110

22.2.1 Construction.............................................................................................. 110

22.3 Parts operated when the main power switch and sub power switch are

turned ON......................................................................................................... 111

22.3.1 Parts operated when the main power switch and sub power switch are

turned ON ................................................................................................. 111

d-Color MF201

Page 8

Theory of operation Ver. 1.0 Sep. 2008 1. System configuration

1

bizhub C200

Outline

Outline

1. System configuration

1/2 System front view

*1: Option of OC-508

[1] Main body [8] Desk DK-504

[2] Original cover OC-508 [9] Paper feed cabinet PC-104

[3] Automatic document feeder

DF-612

[10] Paper feed cabinet PC-204

[4] Working table WT-503 [11] Paper feed cabinet PC-405

[5] Automatic duplex unit AD-505 [12] Job separator JS-505

[6] Multi bypass tray MB-502 [13] Assist handle AH-101 *1

[7] Paper feed cabinet (2nd) PC-105

[2]

[6]

[8][10]

[11]

[12]

[1]

[3]

[13]

A02FT1E007AA

[4]

[7]

[5]

[9]

Y109670-2 Theory of Operation

d-Color MF201

Page 9

1. System configuration Theory of operation Ver. 1.0 Sep. 2008

2

bizhub C200

Outline

2/2 System rear view

[1] Main body [4] Fax multi line ML-504

[2] Stamp unit SP-503 [5] Fax kit FK-507

[3] Expanded memory unit EM-310

[2]

[1]

[4]

[5]

A02FT1E008AA

[3]

Theory of Operation Y109670-2

d-Color MF201

Page 10

Theory of operation Ver. 1.0 Sep. 2008 2. Product specifications

3

bizhub C200

Outline

2. Product specifications

A. Type

*1: Only when the optional paper feed cabinet/desk is installed.

Type Desktop/console *1 scanner/printer

Printing process Laser electrostatic printing system

PC drum type OPC drum: KM-12 (OPC with high mold releasability)

Scanning resolution 600 dpi

File memory 64 MB + 512 MB (Option)

Exposure lamp White rare-gas fluorescent lamp

Platen Stationary (Unit scan)

Original scanning

Unit scanning CCD optical system

* Sheet through system when DF-612 is used

Registration Rear left edge

Paper feeding

separation system

Tray 1 : Small roller separation system with torque limiter

Exposure system

• Four-multi array PH unit system

• Polygon mirror scan system

Exposure resolution 600 dpi u 600 dpi

Developing system Dry 2 components developing method, HMT developing system

Charging system DC comb electrode scorotron system

Neutralizing system Red LED system

Image transfer system Belt image transfer system (1st)/roller image transfer system (2nd)

Paper separating

system

Combination of curvature, separating claws, and bias system

Fusing system Belt fusing

Heating system Halogen lamp

Y109670-2 Theory of Operation

d-Color MF201

Page 11

2. Product specifications Theory of operation Ver. 1.0 Sep. 2008

4

bizhub C200

Outline

B. Functions

Types of original Sheets, books, and three-dimensional objects

Max. original size Book scanner A3 or 11 x 17

Max. original weight Book scanner Max. 2 kg

Multiple copies 1 to 999

Warm-up time

(at ambient temperature of 23 °C/73.4 °F

and rated source voltage)

*Without FK-507 and

EM-310

When the sub power switch is turned ON at any timing while the main power

switch remains ON for a predetermined period of time or more:

37 sec. or less (Monochrome print)

40 sec. or less (Color print)

When the sub power switch is turned ON immediately after the main power

switch is turned ON:

90 sec. or less (Monochrome print and Color print)

Image loss Copy Leading edge: 4.2 mm (3/16 inch),

Trailing edge: 3 mm (1/8 inch),

Rear edge: 3 mm (1/8 inch),

Front edge: 3 mm (1/8 inch)

PC Print Leading edge: 4.2 mm (3/16 inch),

Trailing edge: 4.2 mm (3/16 inch),

Rear edge: 4.2 mm (3/16 inch),

Front edge: 4.2 mm (3/16 inch)

First copy time

(Tray1 A4 or 8

1

/2 x 11,

full size)

Monochrome print 10.0 sec. or less

Color print 13.5 sec. or less

Processing speed 92.4 mm/s Plain paper (monochrome, full color), OHP film

46.2 mm/s Thick 1, Thick 2, Thick 3,

Envelope, Label sheet

Copying speed for

multi-copy cycle

1-sided 20 copies/min (A4 or 8

1

/2 x 11, plain paper)

2-sided 18 copies/min (A4 or 8

1

/2 x 11, plain paper)

Fixed zoom ratios Full size x1.000

Reduction Metric area x0.500, x0.707, x0.816, x0.866

Inch area x0.500, x0.647, x0.772, x0.785

Enlargement Metric area x1.154, x1.224, x1.414, x2.000

Inch area x1.214, x1.294, x1.545, x2.000

Zoom ratios memory 3 memories

Variable zoom ratios u0.250 to u4.000 in 0.001 increments

Paper size Tray 1 Metric area B6S, A5, A5S, B5, B5S, A4, A4S, A3,

A3 Wide, 8K, 16K, 16KS, FLS,

A6S (Thick paper only)

Inch area 5-

1

/2 x 8-1/2, 5-1/2 x 8-1/2S, 7-1/4 x 10-1/2,

7-

1

/4 x 10-1/2S, 8-1/2 x 11, 8-1/2 x 11S,

8-

1

/2 x 14, A3 Wide (12 x 18)

4 x 6 (Thick paper only)

Copy exit tray capacity Plain paper 250 sheets

Thick paper 10 sheets

OHP film 1 sheet

Theory of Operation Y109670-2

d-Color MF201

Page 12

Theory of operation Ver. 1.0 Sep. 2008 2. Product specifications

5

bizhub C200

Outline

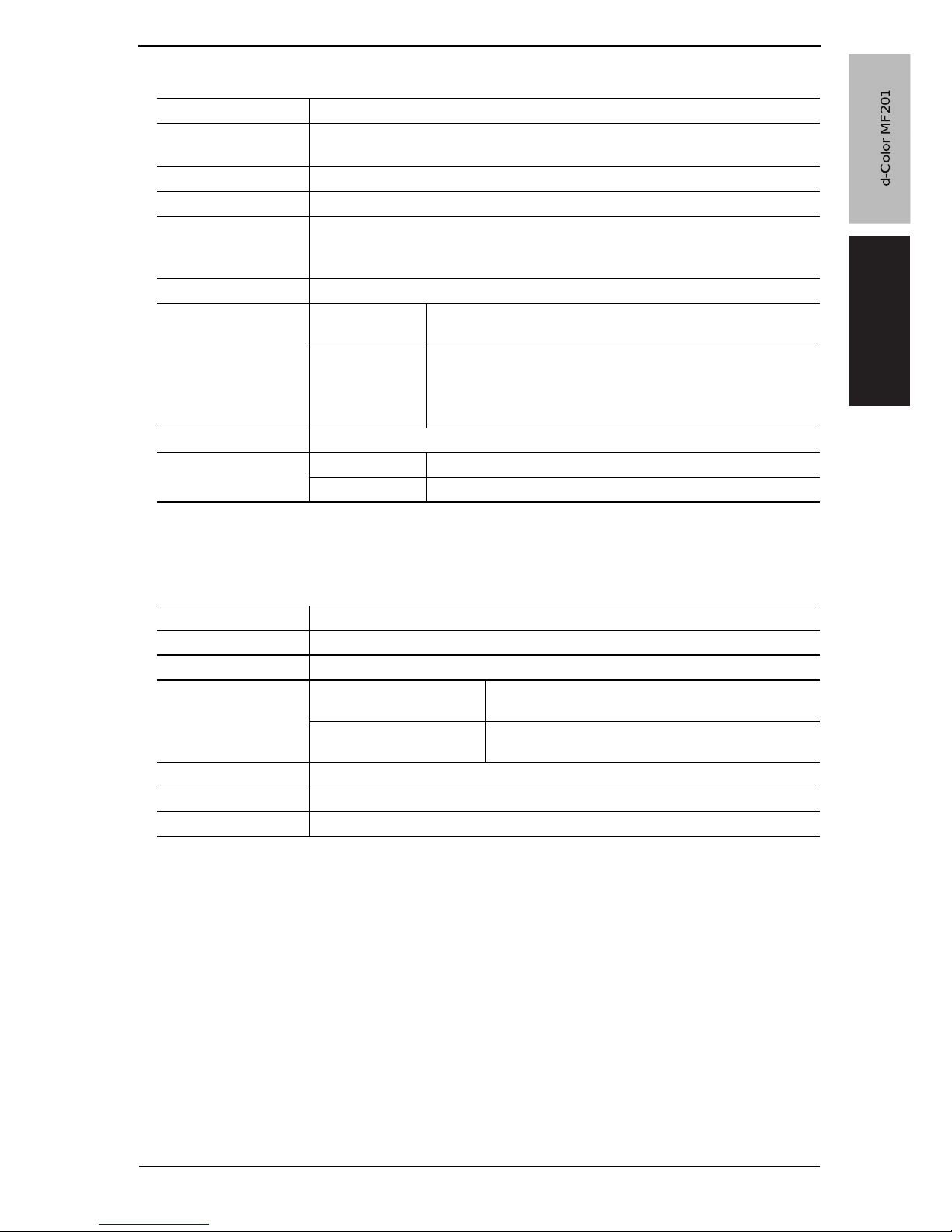

C. Paper

*1: Image is not guaranteed when thick paper 3 is used.

*2: Monochrome print only.

Automatic duplex unit : Only the plain paper weighing 64 to 90 g/m

2

(17 to 24 lb) or

thick paper weighing 91 to 256 g/m

2

(24.2 to 68 lb) are

reliably fed.

Ty pe

Paper source (maximum tray capacity)

Tra y 1

Tra y 2

(Option)

Multiple bypass

(Option)

Copy paper

type

Plain paper

(60 to 90 g/m

2

/ 16 to 24 lb)

250 sheets 500 sheets 100 sheets

Thick paper 1

(91 to 150 g/m

2

/

24.2 to 40 lb)

20 sheets

150 sheets

20 sheets

Thick paper 2

(151 to 209 g/m

2

/

40.2 to 55.6 lb)

Thick paper 3

(210 to 256 g/m

2

/

55.9 to 68.1 lb) *1

OHP film

(crosswise feeding only) *2

Label sheets

Envelopes 10 sheets

Postcards

Translucent paper

Copy paper

dimensions

Width

90 to 311.1 mm

3.6 to 12.3 inch

139.7 to 297 mm

5.5 to 11.7 inch

90 to 311.1 mm

3.6 to 12.3 inch

Length

139.7 to 457.2 mm

5.5 to 18 inch

182 to 431.8 mm

7.2 to 17 inch

139.7 to 457.2 mm

5.5 to 18 inch

Y109670-2 Theory of Operation

d-Color MF201

Page 13

2. Product specifications Theory of operation Ver. 1.0 Sep. 2008

6

bizhub C200

Outline

D. Maintenance

E. Machine specifications

*1: Width when the manual bypass tray is closed

*2: Height up to the original glass

*3: The paper feed tray is slide out, and the upper right door is open.

F. Operating environment

No. of pages printed

per month (average)

Color print 500 prints

Monochrome print 2,300 prints

Standard copy mode

Color print 2 pages/job

Monochrome print 2 pages/job

Standard original

density

Color print C, M, Y, K : 5%

Monochrome print K : 5%

Power requirements

Voltage: AC 100 V, 120 V, 220-240 V

Current: 100 V 12 A

110 V 12 A

120 V 11 A

127 V 11 A

230 V 6 A

Frequency: 50/60 Hz r 3 Hz

Max power consumption 1,250 W or less

Dimensions *2

620 *1 (W) x 688 (D) x 648 (H) mm

24.5 *1 (W) x 27.0 (D) x 25.5 (H) inch

Space requirements

650 (W) x 688 (D) mm *2

25.6 (W) x 270 (D) inch *2

1117 (W) x 1061 (D) mm *3

44.0 (W) x 41.8 (D) inch *3

Weight

Machine Approx. 68 kg / 150 lb (without IU and TC)

IU and TC Approx. 6.8 kg / 15 lb

Temperature 10 to 30qC / 50 to 86 qF (with a fluctuation of 10 qC / 18 qF or less per hour)

Humidity 15 to 85% (Relative humidity with a fluctuation of 10%/h)

Levelness Difference between front and back, right and left should be 1 degree or under.

Theory of Operation Y109670-2

d-Color MF201

Page 14

Theory of operation Ver. 1.0 Sep. 2008 2. Product specifications

7

bizhub C200

Outline

G. Print functions

• When the optional automatic duplex unit AD-505 is mounted, the optional expanded

memory unit EM-310 is required for duplex printing from the PC.

H. Scan functions

NOTE

• These specifications are subject to change without notice.

Type Built-in type controller

Host interface

Ethernet (10Base-T or 100Base-TX),

USB 2.0/1.1

Print speed 20 prints/min (color/monochrome, A4, 1-sided)

Resolution 600 dpi x 600 dpi

Printer language

PCL5e/c emulation

PCL XL Ver. 2.1 emulation

PostScript 3 emulation (3015)

Network protocol TCP/IP, LPD

Support OS

Server

Windows 2000/2003

Windows 2003server x64 Edition

Client

Windows 2000, Windows XP, Windows Vista

Windows XP x64 Edition, Windows Vista x64 Edition

Macintosh OS 9.x, Macintosh OS X Ver. 10.2 or later,

Macintosh Intel OS X 10.4 or later

Compatible paper size Max. standard paper size A3 Wide

Fonts

PCL Latin 80 fonts

PS Latin 136 fonts

Type Full-Colour Scanner

Protocol TCP/IP(SMTP)

Output format JPEG, PDF(V1.3 standrads), TIFF

Scan speed

/ DF-612

Monochrome

(Resolution 300 dpi)

40 pages/min : A4

40 pages/min : 8

1

/2 x 11

Full color

(Resolution 300 dpi)

20 pages/min : A4

20 pages/min : 8

1

/2 x 11

Scannable range Same as the copier (Max. A3)

Functions Scan to E-mail

Resolution 200/300/400/600 dpi

Y109670-2 Theory of Operation

d-Color MF201

Page 15

3. Section configuration Theory of operation Ver. 1.0 Sep. 2008

8

bizhub C200

Outline

3. Section configuration

A02FT1C003AA

Scanner section (IR section)

Fusing section

Timing roller section

Write section

(PH section)

Manual bypass section

(Option)

Paper feed section

(Tray1)

Paper feed section

(Tray2, Option)

Toner collecting section

Imaging unit section

(IU section)

Toner supply section

Duplex section

(Option)

Paper exit/

switchback section

Transfer section

Theory of Operation Y109670-2

d-Color MF201

Page 16

Theory of operation Ver. 1.0 Sep. 2008 4. Paper path

9

bizhub C200

Outline

4. Paper path

A02FT1C004AA

Y109670-2 Theory of Operation

d-Color MF201

Page 17

5. Image creation process Theory of operation Ver. 1.0 Sep. 2008

10

bizhub C200

Outline

5. Image creation process

[1] Photoelectric

conversion

• The light reflected off the surface of the original is separated into different

colors using the color filters (R, G, and B); CCD then converts it into a corresponding electric signal and outputs the signal to the IR imaging processing section.

[2] IR image

processing

• The electric signal is converted to 8-bit digital image signals. After going

through some corrections, video signals (C, M, Y, and K) are output to the

printer image processing section.

[3] Printer image

processing

• D/A conversion will be performed after the VIDEO signals (Y, M, C, Bk) are

corrected. This data will control the emission of the laser diode.

[4] PC drum • The image of the original projected onto the surface of the PC drum is

changed to a corresponding electrostatic latent image.

[5] PC drum charging • Supply DC ( - ) charge on the PC drum.

[6] Laser exposure • Expose photo conductor to a laser beam to develop electrostatic latent

image.

[7] Developing

• The toner, agitated and negatively charged in the developer mixing chamber, is attracted onto the electrostatic latent image formed on the surface of

the PC drum. It is thereby changed to a visible, developed image.

• AC and DC negative bias voltages are applied to the developing roller,

thereby preventing toner from sticking to the background image portion.

[8] 1st image transfer • A DC positive voltage is applied to the backside of the transfer belt,

thereby allowing the visible, developed image on the surface of each of the

PC drums (Y, M, C, and K) to be transferred onto the transfer belt.

A02FT1C007AA

[4] PC drum

[5] PC drum

charging

[1] Photoelectric

conversion

[2] IR image

processing

[3] Printer image

processing

[6] Laser exposure

[7] Developing

[8] 1st image transfer

[9] 2nd image

transfer

[11] Transfer belt cleaning

[13] Main erase

[12] PC drum cleaning

[10] Paper

separation

Theory of Operation Y109670-2

d-Color MF201

Page 18

Theory of operation Ver. 1.0 Sep. 2008 5. Image creation process

11

bizhub C200

Outline

[9] 2nd image transfer • A DC positive voltage is applied to the backside of the paper, thereby

allowing the visible, developed image on the surface of the transfer belt to

be transferred onto the paper.

[10] Paper separation • The paper, which has undergone the 2nd image transfer process, is neu-

tralized so that it can be properly separated from the transfer belt by the

paper separator claws.

[11] Transfer belt

cleaning

• Residual toner on the surface of the transfer belt is collected for cleaning

by cleaning blade.

[12] PC drum cleaning • The residual toner left on the surface of the PC drum is scraped off.

[13] Main erase • The surface of the PC drum is irradiated with light, which neutralizes any

surface potential remaining on the surface of the PC drum.

Y109670-2 Theory of Operation

d-Color MF201

Page 19

5. Image creation process Theory of operation Ver. 1.0 Sep. 2008

12

bizhub C200

Outline

Blank Page

Theory of Operation Y109670-2

d-Color MF201

Page 20

Theory of Operation Ver. 1.0 Sep. 2008 6. Overall composition

13

bizhub C200

Composition/Operation

Composition/Operation

6. Overall composition

6.1 Control block diagram

Exposure lamp (FL201)

Inverter board (INVB)

CCDU board (CCDUB)

BCRU bozrd

(BCRUB)

MFBU board (MFBUB)

Image

processing

PH relay board

(REYB/PH)

PH unit

Y/M/C/K

Control line

Image path line

Scanner motor (M201)

Printer control board

(PRCB)

Mechanical

control (CPU)

Finisher option

(JS-505)

Process

Fusing

Automatic

document

feeder

(DF-612)

Paper feed,

Transport,

Duplex feed

Paper feed option

(PC-104/105/204/405/

MB-502/AD-505

RAMU board

Fax part

Scanner part

Printer part

Operation panel (OPEUB)

ADCU

board

FAX board

(FAXUB,

Basis,

Option )

FAX board

(FAXUB,

Extension,

Option )

ACRU

board

A02FT2E100AA

Y109670-2 Theory of Operation

d-Color MF201

Page 21

7. Scanner section (IR section) Theory of Operation Ver. 1.0 Sep. 2008

14

bizhub C200

Composition/Operation

7. Scanner section (IR section)

7.1 Composition

A02FT2C061AA

18 degree sensor (PS202)

Scanner motor (M201)

Original size detection sensor/1 (PS203)

Lens

CCDU board (CCDUB) Original cover sensor (PS205)

Home position sensor (PS201)

Inverter board (INVB)

A02FT2C060AA

Speaker (SP)

Original size detection sensor/2

(PS204)

ADCU board (ADCUB)

MFBU board (MFBUB)

BCRU board (BCRUB)

Exposure lamp (FL201)

Theory of Operation Y109670-2

d-Color MF201

Page 22

Theory of Operation Ver. 1.0 Sep. 2008 7. Scanner section (IR section)

15

bizhub C200

Composition/Operation

7.2 Drive

A02FT2C062AA

Scanner drive wire /R

Exposure unit

Scanner motor (M201)

Scanner drive wire /F

Home position sensor (PS201)

Front

Pulley shaft

Rear

Pulley

Pulley

Y109670-2 Theory of Operation

d-Color MF201

Page 23

7. Scanner section (IR section) Theory of Operation Ver. 1.0 Sep. 2008

16

bizhub C200

Composition/Operation

7.3 Operation

7.3.1 When the power is ON

1. The exposure unit is first returned to its home position, since it might have been

moved out of the home position while the main power switch remains OFF.

2. The exposure unit moves from the home position to the exposure lamp ON position.

3. After the exposure lamp has been turned ON, the exposure unit moves up to the

shading position (under the shading correction sheet).

4. The shading correction is made while the exposure unit is moving.

5. After the adjustment has been made, the exposure unit moves from the shading

position to the home position.

A02FT2C065AA

A02FT2C063AA

Home position

Home position

Shading position

Shading position

Shading correction

Standby position

Exposure lamp (FL201) ON

Exposure unit movement

Exposure unit

Exposure lamp ON

Theory of Operation Y109670-2

d-Color MF201

Page 24

Theory of Operation Ver. 1.0 Sep. 2008 7. Scanner section (IR section)

17

bizhub C200

Composition/Operation

7.3.2 When the Start key is pressed

A. Document read mode

• The document is read in either of the following two modes: the original cover mode, in

which the original is directly placed on the original glass; and the DF mode, in which the

document is loaded in the automatic document feeder.

(1) Original cover mode

1. The press of the Start key turns ON the exposure lamp.

2. The exposure unit moves from the home position to the shading position to make a

shading correction.

3. The exposure unit moves from the shading position to the scan start position.

4. The exposure unit moves from the scan start position toward the image trailing

edge direction.

Reading of the image of the original is started with the image leading edge position.

Reading of the image of the original is completed at the image trailing edge position.

5. After the image of the original has been read, the exposure lamp turns OFF.

6. The exposure unit moves from the image trailing edge position to the home position.

The R, G, and B data are stored in memory through a single scan motion, so the

scan sequence is carried out only once even for color copying.

A02FT2C067AA

A02FT2C066AA

Exposure lamp (FL201) ON

Shading position

Home position

Scan start position

Leading edge of the image

Original

Back edge of the image

Exposure unit

Shading position

Home position

Back edge of the image

Scan

Return

Shading correction

Y109670-2 Theory of Operation

d-Color MF201

Page 25

7. Scanner section (IR section) Theory of Operation Ver. 1.0 Sep. 2008

18

bizhub C200

Composition/Operation

(2) DF mode

1. The press of the Start key turns ON the exposure lamp.

2. The exposure unit moves from the home position to the shading position to make a

shading correction.

3. The exposure unit moves from the shading position to the DF document read position.

4. The document in the automatic document feeder is fed up to the document read

position and the exposure unit reads the image of the document.

5. After the image of the document has been read, the exposure lamp turns OFF.

6. The exposure unit moves from the document read position to the home position.

7. The R, G, and B data are stored in memory through a single scan motion, so the

scan sequence is carried out only once even for color copying.

A02FT2C068AA

A02FT2C069AA

Reading of the image of the document

Automatic document feeder (DF-612)

Exposure lamp (FL201) ON

Shading position

Home position

Return

Shading correction

Home position

Original

Image reading

position

Theory of Operation Y109670-2

d-Color MF201

Page 26

Theory of Operation Ver. 1.0 Sep. 2008 7. Scanner section (IR section)

19

bizhub C200

Composition/Operation

7.3.3 Exposure unit

• This model has the exposure lamp, lens, CCD, and inverter board mounted in the exposure unit.

A02FT2C064AB

Exposure unit

Original glass

Exposure Lamp

LensCCD

1st mirror

4th mirror

3rd mirror2nd mirror

5th mirror

Y109670-2 Theory of Operation

d-Color MF201

Page 27

7. Scanner section (IR section) Theory of Operation Ver. 1.0 Sep. 2008

20

bizhub C200

Composition/Operation

7.3.4 Original size detection control

A. Detection method

• The reflective original size detection sensors detect the length of an original in the sub scan direction

and the CCD detects the length in the main scan direction.

*1: Size detectable only if the optional original size detection sensor 2 is mounted

Original size CCD width (mm)

Original size detection

sensor 1

(PS203, Standard)

Original size detection

sensor 2

(PS204, option)

Small size original 0 to 135 OFF Unset/OFF

5-

1

/2 x 8-1/2S

135 to 144 OFF Unset/OFF

A5S 144 to 163 OFF Unset/OFF

B5S 163 to 188 OFF Unset/OFF

16KS *1 188 to 199 OFF OFF

A4S 199 to 213 OFF Unset/OFF

8-

1

/2 x 11S

213 to 226

OFF Unset/OFF

8-

1

/2 x 13 *1

ON OFF

8-

1

/2 x 14

ON Unset/ON

B5

226 to 262

OFF Unset/OFF

B4 ON Unset/OFF/ON

16K *1

262 to 275

OFF OFF

8K *1 OFF ON

8-

1

/2 x 11

275 to 289

OFF Unset/OFF

11 x 17 ON Unset/OFF/ON

A4

289 to 301

OFF Unset/OFF

A3 ON Unset/OFF/ON

(non original) 301 or more OFF OFF

Original size detection sensor 1

(PS203, Standard)

A02FT2C060AA

Original size detection sensor 2

(PS204, option)

Theory of Operation Y109670-2

d-Color MF201

Page 28

Theory of Operation Ver. 1.0 Sep. 2008 8. Write section (PH section)

21

bizhub C200

Composition/Operation

8. Write section (PH section)

8.1 Composition

4038T2C034AA

SOS mirror

Laser diode

Polygon motor

SOS sensor

A02ET2C591AB

Y109670-2 Theory of Operation

d-Color MF201

Page 29

8. Write section (PH section) Theory of Operation Ver. 1.0 Sep. 2008

22

bizhub C200

Composition/Operation

8.2 Operation

8.2.1 Exposure path

• 4 units of the printer head are used for exposure process.

• The surface of the photo conductor is irradiated with a laser light and an electrostatic

latent image is thereby formed.

• The polygon mirror, which has only four faces.

• The laser light emitted from the laser diode scans one line for each face of the polygon

mirror.

YMC K

Transfer belt

2nd image transfer roller

LD/KLD/Y LD/M LD/C

PC drum Y

Direction of

rotation of

the PC drum

Beam

One lines

One scan

Surface of the PC drum

A02FT2E101AA

PC drum

Polygon

mirror

Laser diode

Direction

of rotation

of the PC

drum

Beam

Return mirror 2

G2 lens

G1 lens

Return mirror 1

Theory of Operation Y109670-2

d-Color MF201

Page 30

Theory of Operation Ver. 1.0 Sep. 2008 8. Write section (PH section)

23

bizhub C200

Composition/Operation

8.2.2 Write control

(1) Laser exposure process

1. Laser beam irradiated by the laser diode is reflected on the polygon mirror.

2. The polygon mirror is a four-faced mirror that rotates at high speed motored by the

polygon motor. The polygon mirror reflects the incoming laser beam in the main

scanning direction and reflects it on the G1 lens.

3. The G1 lens corrects the converging angle of the incoming laser beam and reflects

it on the return mirror 1.

4. Return mirror 1 reflects the laser beam collected by the G1 lens to the G2 lens.

5. G2 lens reflects the laser beam collected by the return mirror 1 on the return mirror

2.

6. The return mirror 2 irradiates the laser beam came from G2 lens to the PC drum.

(2) Laser emission timing

• When a ready signal is detected after the lapse of a given period of time after a print

cycle has been started, a laser ON signal is output from the printer control board.

• The laser ON signal triggers the firing of each laser light which illuminates the SOS sensor via the polygon mirror, G1 lens, and SOS mirror to generate a SOS (Start of Scan)

signal.

• This SOS signal unifies the timing at which laser light is irradiated to each main scan line.

4038T2C028AA

G1 lens

SOS mirror

Laser diode

Polygon motor

SOS sensor

Return mirror 1

Return mirror 2

G2 lens

PC drum

Y109670-2 Theory of Operation

d-Color MF201

Page 31

8. Write section (PH section) Theory of Operation Ver. 1.0 Sep. 2008

24

bizhub C200

Composition/Operation

8.2.3 Writing area

A. Main scan direction (CD)

• The writing area is determined by the paper size.

• When the copy mode, writing area except for a 3.0 mm band at both paper sides.

• When the PC print mode, writing area except for a 4.2 mm band at both paper sides.

B. Sub scan direction (FD)

• The writing area is determined by the paper size.

• When the copy mode, writing area except for a 4.2 mm band at the leading edge and a

3.0 mm band at the trailing edge.

• When the PC print mode, writing area except for a 4.2 mm band at the leading edge and

a 4.2 mm band at the trailing edge.

A02ET2C501AA

3.0 mm/0.118 inch

4.2 mm/0.165 inch

3.0 mm/0.118 inch

Writing area in the main scan direction

3.0 mm/0.118 inch

Paper path direction

Writing area in the

sub scan direction

Example: Copy mode

Theory of Operation Y109670-2

d-Color MF201

Page 32

Theory of Operation Ver. 1.0 Sep. 2008 8. Write section (PH section)

25

bizhub C200

Composition/Operation

8.2.4 Color registration control

• In a tandem engine, in which an independent image reproduction process is provided for

different colors, incorrect color registration, or color shift, is more likely to occur due to

individual PH assemblies being out of correct position or the relevant parts being out of

accuracy. Due to the registration control system that automatically detects the color shift,

the color shift in both main scan and sub scan directions can be corrected.

• The color shift detection sequence proceeds as follows. A color shift detection pattern in

the sub scan direction is created at the front and rear sides on the transfer belt. The IDC

registration sensor/YC and IDC registration sensor/MK read the corresponding pattern to

calculate the amount of color shift in the sub scan direction and save the data. A color

shift detection pattern in the main scan direction is created at the front and rear sides on

the transfer belt. The IDC registration sensor/YC and IDC registration sensor/MK read

the corresponding pattern to calculate the amount of color shift in the main scanning

direction and save the data. Based on the data representing the amounts of color shift,

the machine calculates how much each of the different colors should be corrected. The

correction data is further stored in memory. Based on the data stored in memory, the

machine controls each dot during production of image outputs, thereby correcting the

color shift (varying the timing at which the LD is turned ON).

• The color registration control system is activated at the timing when the image stabilization sequence gets started.

4038T2C007AA

Transfer belt

IDC registration sensor /YC

(IDCS/YC)

Detection pattern for main

scanning direction

IDC registration sensor /MK

(IDCS/MK)

Detection pattern for sub

scanning direction

Y109670-2 Theory of Operation

d-Color MF201

Page 33

8. Write section (PH section) Theory of Operation Ver. 1.0 Sep. 2008

26

bizhub C200

Composition/Operation

A. Types of color registration control

• Color shift is misalignment of the images of three different colors, yellow (Y), magenta

(M), and cyan (C), with respect to the image of black (K).

• Four different types of color shift can occur: the color shift in the main scan direction, the

color shift due to overall scaling error in the main scan direction, the color shift in the sub

scan direction, and image skew.

(1) The color shift in the main scan direction

• If the image of each color (Y, M, C) is misaligned with respect to the image of black (K) in

the main scan direction, changing the write start timing in the main scan direction can

correct the color shift. Color shift correction needs to be performed separately for the

respective colors (Y, M, C).

• Color shift correction control is activated when the image stabilization sequence is

started.

A02ET2C630AA

Rotational

direction of the

transfer belt

Color shift

Before correction After correction

Transfer belt

Black (K) Magenta (M) No color shift

* When the image of magenta is misaligned with respect to the image of black (K)

Theory of Operation Y109670-2

d-Color MF201

Page 34

Theory of Operation Ver. 1.0 Sep. 2008 8. Write section (PH section)

27

bizhub C200

Composition/Operation

(2) Color shift due to overall scaling error in the main scan direction

• If the image of each color (Y, M, C) and the image of black (K) vary in length in the main

scan direction, changing the clock frequency of the laser diode can correct the length difference in the main scan direction. Color shift correction needs to be performed separately for the respective colors (Y, M, C).

• Color shift correction control is activated when the image stabilization sequence is

started.

(3) The Color shift in the sub scan direction

• If the image of each color (Y, M, C) is misaligned with respect to the image of black (K) in

the sub scan direction, changing the write start timing in the sub scan direction can correct the color shift. Color shift correction needs to be performed separately for the

respective colors (Y, M, C).

• Color shift correction control is activated when the image stabilization sequence is

started.

A02ET2C631AA

Rotational

direction of the

transfer belt

Color shift

Before correction After correction

Transfer belt

No color shift

Black (K)

Magenta (M)

* When the image of magenta is longer than the image of black (K)

Color shift

A02ET2C632AA

Rotational

direction of the

transfer belt

Color shift

Before correction After correction

Transfer belt

No color shift

Black (K)

Magenta (M)

* When the image of magenta is misaligned with respect to the image of black (K) in the sub

scan direction

Y109670-2 Theory of Operation

d-Color MF201

Page 35

8. Write section (PH section) Theory of Operation Ver. 1.0 Sep. 2008

28

bizhub C200

Composition/Operation

(4) Image skew

• If the image of each color (Y, M, C) is tilted against the image of black (K), the image

skew can be corrected by changing the angle at which the printer head is mounted on

the main body installation plate. Image skew correction needs to be performed separately for the respective colors (Y, M, C).

• The image skew correction is mechanically accomplished and the adjustment is made

manually. (Image stabilization control does not make the skew correction.)

• The timing at which the image skew adjustment is made is when the printer head is

replaced with a new one or a skewed image occurs.

B. Skew control mechanism

• When the printer head is mounted on the main body installation plate, image distortion

(skew) occurs due to mounting error. Therefore the printer head adopts the correction

system.

• The main body skew can be corrected by adjusting the dial of the corresponding printer

head (Y, M, C.)

For the detailed adjustment method, refer to PH mechanical adjustment in the Adjustment/Setting section described in Field Service manual.

A02ET2C633AA

Rotational

direction of the

transfer belt

Color shift

Before correction After correction

Transfer belt

No color shift

Black (K)

Magenta (M)

* When the image of magenta is tilted against the image of black (K)

4038T2C038AB

Theory of Operation Y109670-2

d-Color MF201

Page 36

Theory of Operation Ver. 1.0 Sep. 2008 8. Write section (PH section)

29

bizhub C200

Composition/Operation

C. Timing of color registration control

• The “color shift in the main scan direction”, “color shift due to overall scaling error in the

main scan direction”, and the “color shift in the sub scan direction” are corrected when

the image stabilization sequence is executed.

• The “image skew” is corrected when the printer head is replaced with a new one or a

skewed image occurs.

8.2.5 Protection shutter mechanism

• There is a shutter mechanism provided to prevent the PH from being contaminated with

foreign matter such as dust when the front cover is opened or closed, or prevent the

emission laser from leaking outside for any reason.

• The shutter opens by pressing shutter guide at insertion of the imaging unit.

Shutter

Shutter guide

Y109670-2 Theory of Operation

d-Color MF201

Page 37

9. Imaging unit section (IU section) Theory of Operation Ver. 1.0 Sep. 2008

30

bizhub C200

Composition/Operation

9. Imaging unit section (IU section)

9.1 Composition

#(6%##

Imaging unit/Y, M, C, K

Cleaning blade

PC drum/Y, M, C, K

Toner collecting screw

PC drum charge corona/

Y, M, C, K

Developing unit/Y, M, C, K

Theory of Operation Y109670-2

d-Color MF201

Page 38

Theory of Operation Ver. 1.0 Sep. 2008 9. Imaging unit section (IU section)

31

bizhub C200

Composition/Operation

9.2 Drive

A02FT2C054AA

Developing clutch/K (CL4)

Color PC motor (M3)

Color dev. unit engaged motor (M4)

Transport motor (M1)

Y109670-2 Theory of Operation

d-Color MF201

Page 39

9. Imaging unit section (IU section) Theory of Operation Ver. 1.0 Sep. 2008

32

bizhub C200

Composition/Operation

9.3 Operation

9.3.1 IU life control

• Each IU has EEPROM board that detects a new IU and keeps track of the service life of

the IU.

A. New IU detection control

• New IU detection control is activated under the following conditions

While the front door is closed, the main and sub power switch is turned ON.

The front door is opened and closed during normal operation.

The machine is reactivating from the sleep mode.

B. Operation after a new IU detection

• When a new IU is detected, an automatic adjustment is made of TCR sensors.

C. When life is reached

• The IU life counter is used to keep track of IU life.

• When the life value is reached, a warning screen appears to prompt the user to replace

the imaging unit.

• After the life value is reached, when a predetermined number of pages is printed, the

machine stops printing and displays IU replacement screen to request the unit replacement.

D. Warning screen display

• The warning screen display that appears when the IU life value is reached can be

changed in Consumable life reminder in the service mode.

• When Consumable life reminder is set to YES, the full-screen message that requests IU

replacement is displayed when the life value is reached.

• When Consumable life reminder is set to NO, the message that requests IU replacement

is displayed when the life value is reached.

#(6%##

4038T2C012AA

EEPROM board

Theory of Operation Y109670-2

d-Color MF201

Page 40

Theory of Operation Ver. 1.0 Sep. 2008 9. Imaging unit section (IU section)

33

bizhub C200

Composition/Operation

E. IU life setting

• Comparing the “PC drum rotation time” with the “PC drum rotation time calculated based

on the number of printed pages”, the machine detects the end of unit life when either of

them reaches the set value.

• By changing “IU life setting” in the “system setting - 2/2” in the “service mode”, a desired

threshold for “PC drum rotation time” can be selected.

• When IU life is set to “normal”, the standard life value is used as the threshold for “PC

drum rotation time”. Selecting “Normal” is appropriate when the machine is under normal

use (Default setting).

• When IU life is set to “Long”, the longer life value is used as the threshold for “PC drum

rotation time”.

• If the machine is under the following conditions, the number of pages that can be printed

by one imaging unit can be increased in some cases by setting IU life to long.

“Page/Job value is low”.

“PV/M value is low”.

“Color print ratio is low”.

NOTE

• Setting IU life to Long cannot always increase the number of pages that can be

printed by one imaging unit.

• When IU life is set to Long, print images are out of guarantee if they are produced

after the IU life counter goes beyond the number described in the product specifications.

• Before changing the IU life setting, be sure to check that any warning message is

not displayed to let the user know that the imaging unit, fusing unit, or transfer

belt unit reaches the end of life. If the IU life setting is changed while a warning

message is displayed, unit change screen may appear and printing can be

stopped.

• After changing the IU life setting, be sure to turn OFF the main power switch and

turn it ON again more than ten seconds later.

Y109670-2 Theory of Operation

d-Color MF201

Page 41

10. Photo conductor section Theory of Operation Ver. 1.0 Sep. 2008

34

bizhub C200

Composition/Operation

10. Photo conductor section

10.1 Composition

10.2 Drive

#(6%##

4036ma2338c0

Charge transport

layer (CTL)

Charge generating

layer (CGL)

Aluminum

cylinder

PC drum

A02ET2C512AA

PC drum/K

PC drum/C

PC drum/M

Color PC motor (M3)

PC drum/Y

Transport motor (M1)

Theory of Operation Y109670-2

d-Color MF201

Page 42

Theory of Operation Ver. 1.0 Sep. 2008 10. Photo conductor section

35

bizhub C200

Composition/Operation

10.3 Operation

10.3.1 PC drum drive mechanism

• Two independent PC drum motors (for color and monochrome) are used for the drive

mechanism to suppress incorrect color registration and uneven pitch.

A. PC drum/K drive mechanism

• The transport motor drives the PC drum/K.

• The transport motor is the common source that provides drive to manual feed, paper tray

feed, timing roller, transfer belt, and others.

• Drive is transmitted to each of the PC drums when the triangular-prism-shaped shaft is

engaged with the mating coupling part.

A02ET2C513AA

Shaft

Coupling

Transport motor (M1)

PC drum/K

Y109670-2 Theory of Operation

d-Color MF201

Page 43

10. Photo conductor section Theory of Operation Ver. 1.0 Sep. 2008

36

bizhub C200

Composition/Operation

B. PC drum/Y, M, C drive mechanism

• The PC drums/Y, M, C are driven by the Color PC motor.

• Drive is transmitted to each of the PC drums when the triangular-prism-shaped shaft is

engaged with the mating coupling part.

A02ET2C514AA

Shaft

Coupling

Color PC motor (M3)

PC drum/C

PC drum/M

PC drum/Y

Theory of Operation Y109670-2

d-Color MF201

Page 44

Theory of Operation Ver. 1.0 Sep. 2008 10. Photo conductor section

37

bizhub C200

Composition/Operation

10.3.2 PC drum phase control

• The drive source of the PC drum/K is the transport motor.

• The drive source of the PC drums/Y, M, C is the PC motor. The three PC drum drive

gears/Y, M, C are connected by gears to each other and the PC drums/Y, M, C is always

in the same phase.

• The PC drum/K and the PC drums/Y, M, C use a different drive source to rotate themselves.

• Drive to the PC drums is provided by PC drum drive gears/Y, M, C and the PC drum drive

gear/K. If these eccentric gears can not synchronize with each other in their eccentric

rotation, rotational speed variations between the PC drums may happen. By synchronizing the eccentric rotation of the PC drum drive gears/Y, M, C with that of the PC drum

drive gear/K, rotational speed variations between the PC drums/Y, M, C and the PC

drum/K can be eliminated.

• The PC drum phase control system synchronizes the phase of all PC drum drive gears

by adjusting the rotation start timing of the drive gears/Y, M, C and the PC drum drive

gear/K when the PC drums start rotating.

• The phases of the gears are detected by Color PC drive sensor (Main/Sub) and the

monochrome PC drive sensor (Main/Sub) which are located on the PC drum drive gear/

C and PC drum drive gear/ K, respectively.

A02ET2C524AA

* Back view

PC drum drive gear/K

PC drum drive gear/C

Color PC drive main sensor (PS15)

Black PC drive main sensor (PS16)

Color PC drive sub sensor (PS17)

Black PC drive sub sensor (PS18)

Y109670-2 Theory of Operation

d-Color MF201

Page 45

10. Photo conductor section Theory of Operation Ver. 1.0 Sep. 2008

38

bizhub C200

Composition/Operation

10.3.3 PC drum small amount rotation control

• Humidity around the imaging unit can cause variations in sensitivity among different PC

drums, allowing black bands to occur on images. In addition, ozone stagnant in areas

near the PC drum charge corona reduces sensitivity of the PC drums, causing white

bands to occur in the image.

• To prevent these image problems, that the PC drum is turned at regular intervals to keep

the surface sensitivity uniform as temperature and humidity change.

A. PC drum small amount rotation timing

• This operation is performed during the standby condition after the completion of a print

cycle.

• Small amount rotation time changes according to accumulated time of the PC drum rotation and interior temperature.

• The small amount rotation is carried out when the PC drum stop hour counter reaches

the specified value. PC drum stop hour counter value is determined by the humidity measured when the PC drums are stationary and by how long IU has been operated.

Theory of Operation Y109670-2

d-Color MF201

Page 46

Theory of Operation Ver. 1.0 Sep. 2008 11. Charge corona section

39

bizhub C200

Composition/Operation

11. Charge corona section

A02FT2C055AA

4038T2C027AA

Comb electrode

Grid mesh

Grid mesh

Cleaning blade

Comb electrode/Y, M, C, K

Comb electrode

Y109670-2 Theory of Operation

d-Color MF201

Page 47

11. Charge corona section Theory of Operation Ver. 1.0 Sep. 2008

40

bizhub C200

Composition/Operation

11.1 Operation

11.1.1 PC drum charge corona ON/OFF control

• The grid voltage (Vg) value applied to the grid mesh is determined through the image

stabilization control.

11.1.2 Cleaning/main erase mechanism

A. Cleaning/main erase operation

1. The cleaning blade is pressed up against the surface of the PC drum, scraping

residual toner off the surface (forward blade system).

2. Toner, which has been scraped off the surface of the PC drum, is fed by the toner

collecting screw back toward to the conveying screw in the rear of the machine. It is

then collected in the waste toner collecting box.

3. The surface of the PC drum after the image transfer process is irradiated with light

from the main erase lamp. This neutralizes any potential left on the surface of the

PC drum.

4038T2C024AA

Drum charge corona bias Y, M, C

Drum charge corona bias K

Developing clutch/K (CL4)

Color PC motor (M3)

Transport motor (M1)

Color dev. unit engaged motor

(M4)

4038T2C030AA

Cleaning blade

Cleaning blade

Toner collecting screw

Theory of Operation Y109670-2

d-Color MF201

Page 48

Theory of Operation Ver. 1.0 Sep. 2008 12. Developing section

41

bizhub C200

Composition/Operation

12. Developing section

12.1 Composition

A02FT2C054AA

4038to503c0

Doctor blade

Developing roller

Toner supply screw

Developing drive coupling/K

PC drum/K

PC drum/Y

Developing roller/K

Supply screws

Toner conveying screw

Imaging unit

Developing drive coupling/C

Developing drive coupling/M

Developing drive coupling/Y

PC drum/M

PC drum/C

Y109670-2 Theory of Operation

d-Color MF201

Page 49

12. Developing section Theory of Operation Ver. 1.0 Sep. 2008

42

bizhub C200

Composition/Operation

12.2 Drive

A02FT2C012AB

Developing clutch/K (CL4)

PC drum/K

Color PC motor (M3)

Developing roller/K

Supply screws

Transport motor (M1)

Imaging unit

Color dev. unit engaged motor (M4)

PC drum/Y

PC drum/M

PC drum/C

Theory of Operation Y109670-2

d-Color MF201

Page 50

Theory of Operation Ver. 1.0 Sep. 2008 12. Developing section

43

bizhub C200

Composition/Operation

A. Developing section/K drive mechanism

• Drive force from the transport motor is transmitted to the developing clutch so that the

developing section/K is driven

• The transport motor is the common source that provides drive to the manual feed, paper

tray feed, timing roller, and transfer belt.

A02FT2C013AA

A02ET2C519AA

Supply screws

Developing clutch/K (CL4)

PC drum/K

Developing roller

Transport motor (M1)

Developing section/K

Developing drive coupling

Transport motor (M1)

Developing clutch/K (CL4)

Transport motor shaft

Developing drive coupling

Y109670-2 Theory of Operation

d-Color MF201

Page 51

12. Developing section Theory of Operation Ver. 1.0 Sep. 2008

44

bizhub C200

Composition/Operation

B. Developing section/Y, M, C drive mechanism

• Drive force from the color PC motor is transmitted to the color dev. unit engaged motor so

that the developing section/Y, M, C is driven.

• When the color dev. unit engaged motor starts running, the color dev. unit engaged gear

is engaged with the color dev. unit drive transmission gear and the drive force of the color

PC motor is transmitted to the developing section/Y, M, C.

• The state of the coupling operated by the color dev. unit engaged motor is detected by

the color dev. unit engaged position sensor.

A02ET2C523AA

A02FT2C056AA

Supply screws

Color PC motor (M2)

PC drum/Y

Color dev. unit engaged motor (M10)

Developing roller/M

PC drum/C

PC drum/M

Developing roller/C

Developing roller/Y

Color PC motor (M3)

Color dev. unit engaged motor (M4)

Developing drive coupling

Coupling released

Coupled

Color dev. unit

engaged gear

Color drive

transmission

gear

Developing section/Y, M, C

Theory of Operation Y109670-2

d-Color MF201

Page 52

Theory of Operation Ver. 1.0 Sep. 2008 12. Developing section

45

bizhub C200

Composition/Operation

C. Color dev. unit engaged position detection

• The color PC motor is the drive source of the developing section/Y, M, C

• When the color dev. unit engaged motor rotates the coupling detection gear, the color

dev. unit engaged gear is engaged with the color drive transmission gear. In this condition, rotation of the color PC motor is transmitted to the developing section/Y, M, C via the

color drive transmission gear.

• While the gears are engaged with each other, when the color dev. unit engaged motor

starts running again, the color dev. unit engaged gear is disengaged and the developing

section/Y, M, C stops rotating.

• The engaged position of the color dev. unit engaged gear is detected by the color dev.

unit engaged position sensor and the light blocking plate of the coupling detection gear.

.

A02ET2C528AA

A02ET2C525AA

A02ET2C527AA

A02ET2C526AA

*Back view

Unblocked

Color drive transmission gear

Coupling released

Coupled

Color dev. unit engaged position sensor (PS19)

Coupling detection gear

Blocked

Color dev. unit engaged motor (M4)

Color dev. unit engaged gear

Color dev. unit engaged gear

Y109670-2 Theory of Operation

d-Color MF201

Page 53

12. Developing section Theory of Operation Ver. 1.0 Sep. 2008

46

bizhub C200

Composition/Operation

12.3 Transfer belt pressure retraction clutch

12.3.1 Developing drive control

A02FT2C050AA

Color PC motor (M3)

Color dev. unit engaged motor (M4)

Developing clutch/K (CL4)

Drum charge corona bias/K

Drum charge corona bias/Y, M, C

Developing bias/K (DC)

Developing bias/K (AC)

Developing bias/Y, M, C (DC)

Developing bias/Y, M, C (AC)

Transfer belt pressure retraction

clutch (CL3)

2nd image transfer pressure

retraction motor (M5)

Transport motor (M1)

Theory of Operation Y109670-2

d-Color MF201

Page 54

Theory of Operation Ver. 1.0 Sep. 2008 12. Developing section

47

bizhub C200

Composition/Operation

12.3.2 Developer flow

1. Toner supplied from the rear end of the developing unit is fed to the lower screw. It

is then fed to the front of the unit, while being mixed with developer and electrically

charged by the Supply screws.

2. The TCR sensor installed on the underside of the developing unit detects toner-tocarrier ratio during this time.

3. The developer, fed to the front of the developing unit, is conveyed further to the

upper supply screw.

4. The developer is conveyed onto the developing roller. The doctor blade then controls the height of the developer brush to ensure that the developer on the developing roller levels out.

5. The toner sticks to the electrostatic latent image on the surface of the PC drum.

6. The developer that is left on the sleeve is returned to the lower supply screw by the

magnetic pole positioning of the developing roller.

7. It is then conveyed to the rear side of the imaging unit.

A02ET2C529AA

Supply screws

PC drum

Developing roller

Toner supplied from hopper

Doctor blade

1

7

2

5

6

PC drum

TCR sensor

3

4

Y109670-2 Theory of Operation

d-Color MF201

Page 55

12. Developing section Theory of Operation Ver. 1.0 Sep. 2008

48

bizhub C200

Composition/Operation

12.3.3 Developing bias

• The developing bias voltage (Vdc) is applied to the developing roller so that an adequate

amount of toner is attracted onto the surface of the PC drum.

• In addition to the negative DC component, AC voltage is applied during development to

help toner to be attracted more easily to the surface of the PC drum. This AC component

is applied only while development is taking place. At any other timing, only the DC(-) Vdc

is applied.

• The developing bias (Vdc) is supplied from high voltage unit (HV1).

A02ET2C530AA

Developing roller

* Back view

Developing bias is applied to the pressure plate

PC drum/Y

Theory of Operation Y109670-2

d-Color MF201

Page 56

Theory of Operation Ver. 1.0 Sep. 2008 12. Developing section

49

bizhub C200

Composition/Operation

12.3.4 TCR sensor control

• The TCR sensor is mounted on the underside of each of the developing sections.

• The sensor for C, M, Y and K is a magnetic type.

• Each of these sensors detects toner-to-carrier ratio (T/C) of the developer. The reading is

used for determining the amount of toner supplied.

• Only when a new imaging unit is installed in the machine, an automatic adjustment is

made of each of these TCR sensors. The automatic adjustment of TCR sensors cannot

be done at your own discretion.

• The target T/C ratio is 7%.

• The magnetic permeability (powder density) of the carrier in the developer is measured

to determine the T/C.

• A mylar is provided for the conveying screw portion to scrape toner off the surface of the

TCR sensor.

• The TCR sensor is integrated with the imaging unit. When the TCR sensor is to be

replaced with a new one, the entire imaging unit must be replaced.

4038to503c0

4038T2C031AA

TCR sensor

Mylar

TCR sensor

TCR sensor

Y109670-2 Theory of Operation

d-Color MF201

Page 57

13. Toner supply section Theory of Operation Ver. 1.0 Sep. 2008

50

bizhub C200

Composition/Operation

13. Toner supply section

13.1 Composition

A02ET2C534AA

A02ET2C623AA

A02ET2C624AA

Toner cartridge/Y, M, CToner cartridge/K

TC drive unit/YM

Toner cartridge/K

Toner cartridge/Y

TC drive unit/CK

Toner cartridge/C

Toner cartridge/M

Theory of Operation Y109670-2

d-Color MF201

Page 58

Theory of Operation Ver. 1.0 Sep. 2008 13. Toner supply section

51

bizhub C200

Composition/Operation

13.2 Drive

A02ET2C535AA

Toner supply motor CK (M7)

Toner supply motor YM (M6)

Agitating blade/K

Agitating blade/C

Agitating blade/M

Agitating blade/Y

Y109670-2 Theory of Operation

d-Color MF201

Page 59

13. Toner supply section Theory of Operation Ver. 1.0 Sep. 2008

52

bizhub C200

Composition/Operation

13.3 Operation

13.3.1 Toner replenishing mechanism/control

A. Toner replenishing mechanism

• Two toner supply motors are used to supply toner of four different colors.

• By changing the rotating direction of the toner supply motor/YM and toner supply motor/

CK, Y or M and C or K can be supplied, respectively.

* The above shows the rotating direction viewed from the motor drive shaft side.

• Replenishing operation

1. Drive of the toner supply motor is transmitted through a gear train to the toner cartridge drive gears for two different colors.

2. The shaft of the drive gears has a one way clutch that turns only in one direction.

Depending on whether the toner supply motor turns right or left, only one corresponding drive gear turns. Structurally, the two colors of toner (Y and M or C and K)

cannot be supplied at one time.

3. When the drive gear turns, the screw installed inside the toner cartridge rotates to

convey the toner to the toner cartridge replenishing port.

4. Then the toner goes through the carrier pipe of the main body and drops into the

imaging unit port to be supplied to the imaging unit.

Toner supply

motor/ CK (M7)

K toner C toner

Toner supply

motor/ YM (M6)

Y toner M toner

Right turn Not supplied Supplied Right turn Not supplied Supplied

Left turn Supplied Not supplied Left turn Supplied Not supplied

A02ET2C533AA

One-way clutch

Toner supply motor/ CK (M7)

Toner supply motor/ YM (M6)

Drive gears

Theory of Operation Y109670-2

d-Color MF201

Page 60

Theory of Operation Ver. 1.0 Sep. 2008 13. Toner supply section

53

bizhub C200

Composition/Operation

B. Toner replenishing control

• T/C is detected by TCR sensor when the developing section of the imaging unit is being

operated. (TCR sensor is located in the imaging unit.)

• Based on T/C ratio detected by the TRC sensor and amount of consumption calculated

by the dot counter, toner replenishing time (amount) is determined.

• When the machine determines the toner replenishing, sometime it detects the toner

amount that surpasses the maximum volume for one replenishing control. If it is not possible to replenish the supply of the required amount of toner within this maximum replenishing time, the reminder time is stored in memory and added to the replenishing time for

the next replenishing sequence.

13.3.2 Toner cartridge detection

A. Detection of toner cartridge mounted in place

• When the front door is closed, the machine accesses the EEPROM board of each toner

cartridge to determine whether or not the corresponding toner cartridge is loaded.

B. Detection of new toner cartridge

• After the toner cartridge in the loaded position has been detected, the machine determines if the toner cartridge is new or not using the EEPROM data.