Page 1

Cash Register

CMS 140 euro / CMS 240 euro

SERVICE MANUAL

Code 686711S-00

Page 2

Page 3

PREFACE

This manual is addressed to the field engineers who will install and service the CMS 140/240 cash register.

It provides all the information needed for a correct product maintenance.

SUMMARY

This manual is divided into six chapters.

The first three chapters describe the operating, functional checks, and maintenance and repair procedures.

Chapter 4 describes the disassembly and adjustment procedures. Chapters 5 and 6 describe the electronic

circuitry and provide the schematics.

The appendix holds the SPARE PARTS CATALOGUE.

PREREQUISITES

The topics described in this manual require knowledge of similar products.

REFERENCE DOCUMENTA TION

Instruction Manual - (provided with the product)

DISTRIBUTION: General

FIRST EDITION: November 1998

NEWSLETTER: September 1999

686710D Service Manual iii

686711S

.

Page 4

Page 5

CONTENTS

1. OVERVIEW

1.1 TECHNICAL SPECIFICATIONS ... 1-1

2. SPECIFICATIONS AND OPERATING

PRINCIPLES

2.1 SPECIFICATIONS......................... 2-1

2.1.1 Features ................................... 2-1

2.1.2 Specifications........................... 2-1

2.1.3 Mechanisms............................. 2-2

2.2 OPERATING PRINCIPLES........... 2-3

2.2.1 Transmission/SelectMechanism 2-3

2.2.2 Detector Mechanism ................ 2-6

2.2.3 Printing Mechanism ................. 2-7

2.2.4. Inking Mechanism .................... 2-9

2.2.5 Paper Feeding Mechanism ..... 2 -9

2.2.6 Printer Operation During One Print

Cycle Initialization .................... 2-10

3. HANDLING, MAINTENANCE, AND

REPAIR

3.1 HANDLING THE PRINTER .......... 3-1

3.1.1 Precautions on Printer

Handling ................................... 3-1

3.1.2 Paper Setting ........................... 3-1

3.1.3 Installating the Ink Roll Assembly 3-2

3.2 MAINTENANCE ............................. 3-2

3.2.1 Cleaning ................................... 3-2

3.2.2 Inspection................................. 3-2

3.3 APPLICATION OF LUBRICANTS. 3-4

3.3.1 Lubricant Types ....................... 3- 4

3.3.2 Lubricating Requirements ....... 3 -4

3.3.3 Lubrication Points .................... 3-4

3.4 TOOLS AND LUBRICANTS .......... 3-5

3.4.1 List of Tools.............................. 3-5

3.4.2 List of Lubricants ..................... 3-5

3.5 REPAIR.......................................... 3-5

3.5.1 Repair Levels ........................... 3 -5

3.5.2 Repair Procedures................... 3- 5

3.5.3 Repair Guidelines .................... 3-6

4. ASSEMBLY AND DISASSEMBLY

4.1 GENERAL...................................... 4-1

4.2 MACHINE DISASSEMBLY -

REASSEMBLY ............................... 4-2

4.2.1 Machine Case .......................... 4- 2

4.2.2 Printer Unit ............................... 4- 2

4.2.3 Main Board and Display .......... 4 -3

4.2.4 Paper Feed Motor.................... 4-3

4.2.5 Power Supply ........................... 4-4

4.2.6 Keypad ..................................... 4-4

4.3 PRINTER DISASSEMBLY -

REASSEMBLY ............................... 4-5

4.3.1 Ink Roller .................................. 4- 5

4.3.2 Electrical Connections ............. 4-6

4.3.3 Return Spring........................... 4-7

4.3.4 Snap Ring ............................... 4 -7

4.3.5 Gear ......................................... 4 -8

4.3.6 Motor ........................................ 4-10

4.3.7 Detection Wheel ...................... 4-11

4.3.8 Platen Assembly Removal ....... 4-12

4.3.9 Printer Carriage ....................... 4-1 3

4.3.10 Printer Carriage ....................... 4-14

4.3.11 Machine Case .......................... 4-1 6

5. CIRCUITRY

5.1 GENERAL ...................................... 5-1

5.1.1 Block Diagram.......................... 5-1

5.2 POWER SUPPLY CIRCUIT .......... 5-2

5.3 TRANSFORMER WIRING DIAGRAM 5-3

5.4 POWER SUPPLY SPECIFICATIONS 5-3

5.5 RESET CIRCUIT ........................... 5-4

5.6 POWER FAIL CIRCUIT................. 5-4

5.7 DISPLAY CIRCUIT........................ 5-5

5.8 DISPLAY TUBE INFORMATION .. 5-6

5.9 KEYBOARD CIRCUIT .................. 5-7

5.10 PRINTER CIRCUIT ....................... 5-8

5.11 DRAWER CIRCUIT ....................... 5-9

5.12 BATTERY CIRCUIT ...................... 5-9

5.13 BUZZER CIRCUIT ......................... 5-9

6. SCHEMATIC AND DIAGRAM...... 6-1

SPARE PARTS CATALOGUE ......... A-1

686710D Service Manual v

.

Page 6

Page 7

1. OVERVIEW

1.1 TECHNICAL SPECIFICATIONS

Type:

Display:

Capacity:

Printer:

Paper supply:

Memory battery protection:

Technology:

Voltage:

Power consumption:

Fig. 1-1

Electronic cash register with printer and eight

departments

Fluorescent display , symbols f or error , change,

minus, total and program mode

Input 7 digits and readout

Serial printer with ink roller

57-mm single ply register tape

Approx. 3 months after power interruption via

4 AA batteries

CMOS RAM

220-240V 50/60 Hz ~ 115V 50/60 Hz

0.07A; operating 0.22A

Operating temperature:

Dimensions:

Weight:

686710D Service Manual 1-1

686711S

0° to 40°C

Depth 425 mm, width 324 mm, height 220 mm

Approx. 6 kg

.

Page 8

Page 9

2. SPECIFICATIONS AND

OPERATING PRINCIPLES

2.1 SPECIFICA TIONS

2.1.1 Features

The Micro Printer was designed and developed as a

printer for use with calculators. It offers the following

features:

• Ultra-compact and lightweight design.

• Use of movable type for sharp printing quality.

• High printing speed due to a carriage return

mechanism that can return the carriage from any

column position.

• Silent operation and printing.

• Provided with quick feeding and paper free

functions.

• Use of ordinary calculator paper.

• Requires no control of the motor speed.

2.1.2 Specifications

The main specifications are listed as follows.

Print method

Type-printing serial printing

Carriage width

Max. 19 printable columns (including one column of

symbols)

Character position

On symbol column side: 13 positions +1 empty

positions

On numeric column side: 14 positions

Character size

1.6 (W) x 2.5 (H) mm

Intercharacter intervals

Between numerics: 2.1 mm

Between a numeric and symbol: 2.6 mm

Line spacing: 4.6 mm

Paper (Supplied by the user)

Type: Regular paper

Size: Width 57.5 mm +/- 0.5 mm

Roll diam.: 80 mm or less

Thickness: 0.06 - 0.085 mm

Aver age weight: 47 g/m2 - 64 g/m

(40 - 55 kg/1000 sheets/1091 x

788 mm)

Paper feed

TYP 8 lps. Fast paper feeding is also possible and a

paper release mechanism is provided.

Inking

Ink roll method

Colors : Purple or black

Ink roll life: Purple 1,000,000 characters

Black 350,000 characters

Standard: IR-40

Motor

Terminal voltage: 6.0 +0.5 -2.0 VDC

Average current: Approx. 0.25 A (during 19

columns 7 character shift

printing at 6.0 VDC, 25°C)

Detector

Mechanical point of contact

Reset signal "R", Timing signal "T", and a Sub-Timing

signal "t"

D .C. resistance: Approx. 20 Ohm +/- 2 ohm (at 25°C)

Connection method

Jumper Wire on printer side

Guaranteed operating temperature

0°C - 50°

External dimensions

86 (W) x 58.4 (D) x 19 (H) mm

Weight

Approx. 90 g.

2

Print speed

Average printing speed at 6.0 VDC

19-column printing: TYP 0.9 l/s

7-column printing: TYP 2.2 l/s

686710D Service Manual 2-1

Page 10

2.1.3 Mechanisms

This printer consists of two print wheels, a hammer,

and a carriage equipped with an ink roll. It is a serial

printer with movable type, and performs printing by

sequentially moving across from the lowest-order

column.

When the motor is activated, the gear trains rotate

and cause the print wheels and detection wheel to

rotate. When the trigger coil is charged according to a

signal (which corresponds to a character) output from

the detector, character selection is perf ormed, the print

wheel stops, the print gear is rotated by the action of

the planet gear, a character is printed then the carriage

shifts to the next column (column-shift operation).

When the charge to the trigger coil is lengthened

during character selection performed at the end of

line, printing is performed then the carriage is returned

to the initial column and the paper is fed forward,

thereby completing the printing of one line.

This printer consists of five mechanisms: the

transmission and selective mechanism, detection

mechanism, print mechanism, inking mechanism, and

paper feeding mechanism.

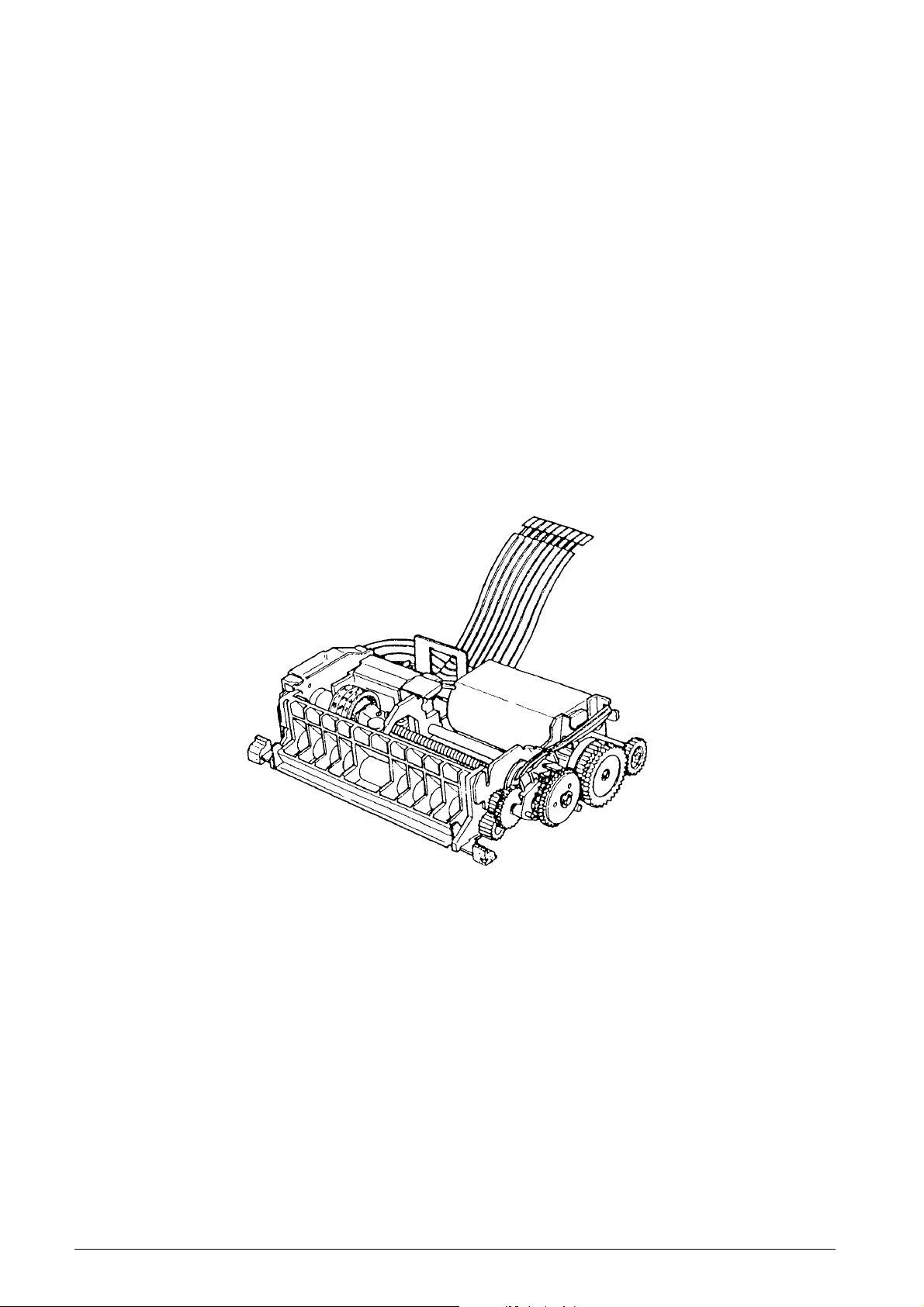

Fig. 2-1 shows an external view of the Micro Serial

Printer. For details on the operating principles and

handling of each mechanism, see section 2.2,

“OPERATING PRINCIPLES”, and Chapter 3,

“HANDLING, MAINTENANCE, AND REPAIR”.

Fig. 2-1 Exterior View

2-2 Service Manual 686710D

Page 11

2.2 OPERATING PRINCIPLES

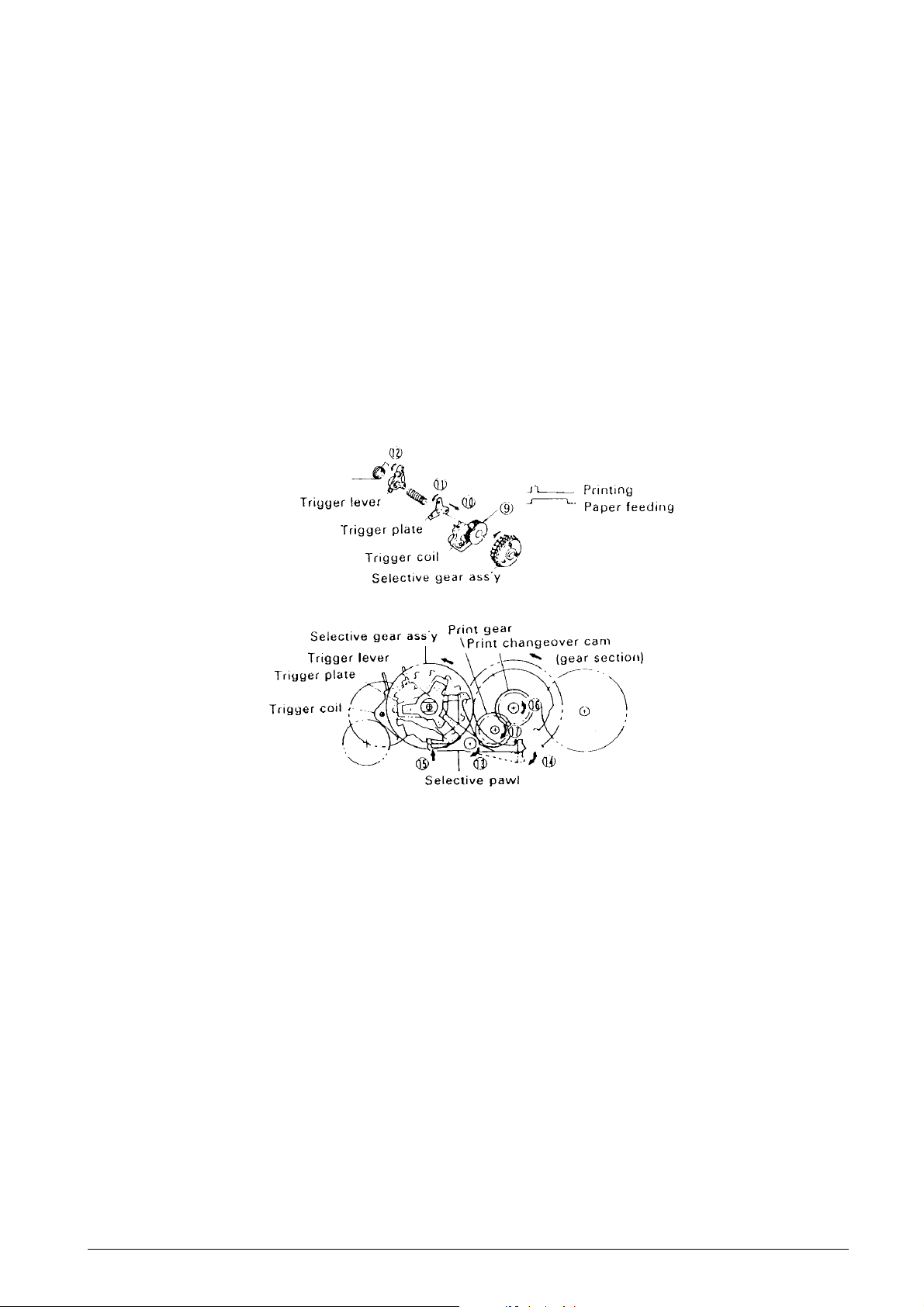

2.2.1 Transmission/Select Mechanism

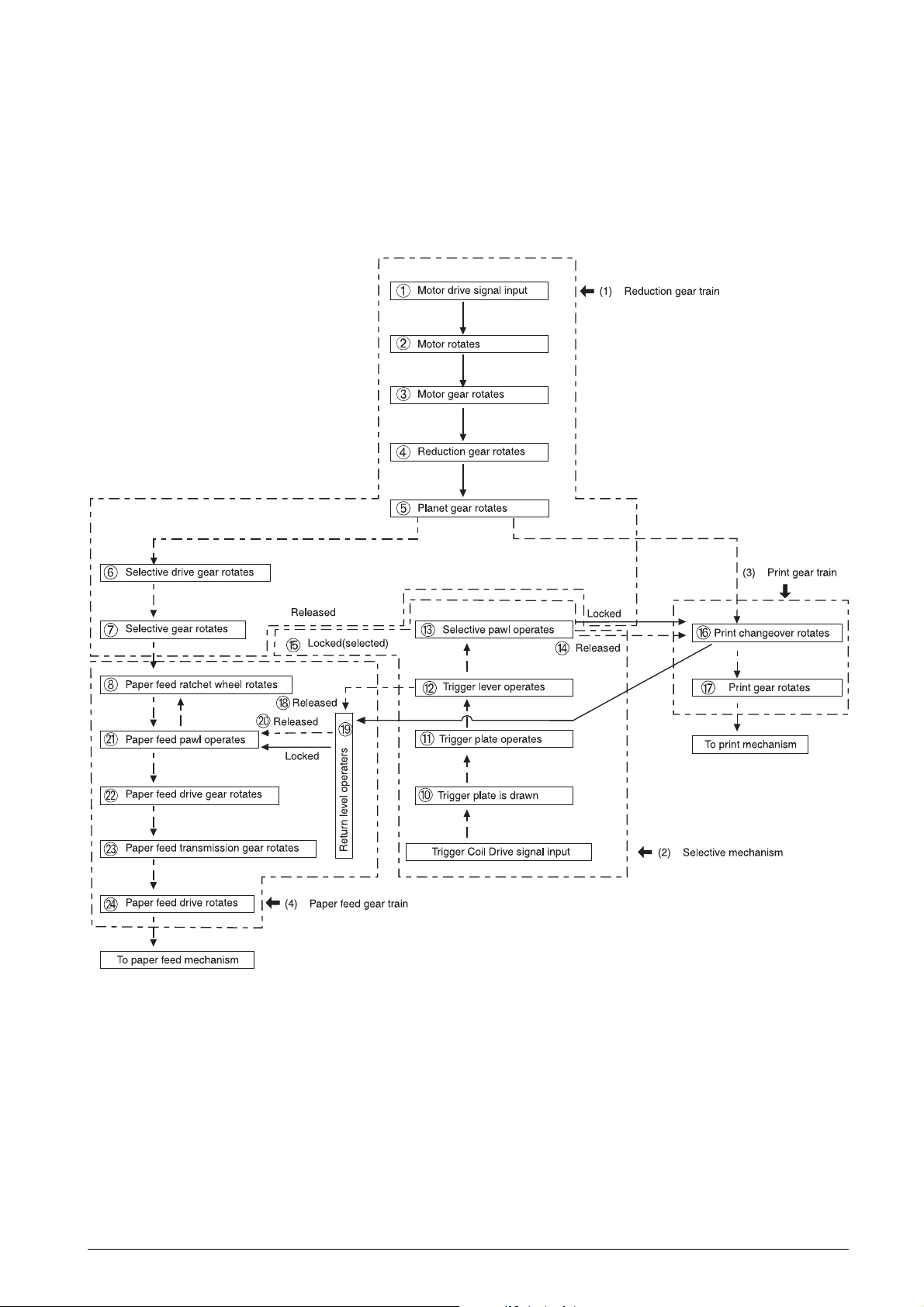

As shown in Fig. 2-2, this mechanism consists of the

reduction gear train, selective mechanism, print gear

train, and paper feed gear train.

➈

Fig. 2-2 Transmission/Select Mechanism

686710D Service Manual 2-3

Page 12

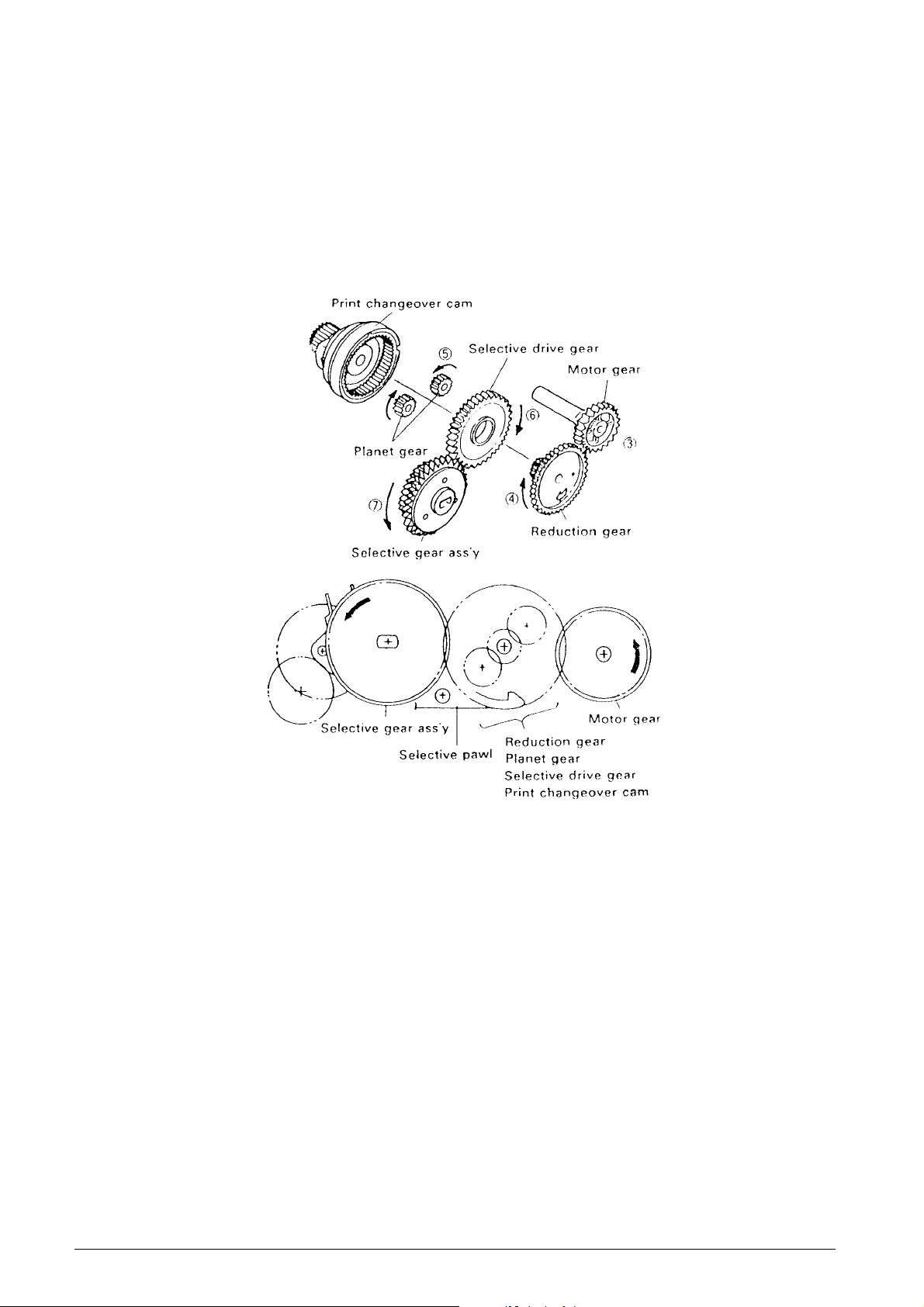

Reduction gear series (See Figs. 2-2 and 2-3.)

The reduction gear train consists of the motor gear,

reduction gear, planet gear, selective drive gear,

selective gear assembly, selective pawl, and print

changeover cam. When the motor rotates 2, the

rotation force is sequentially reduced from the motor

gear 3 on the same shaft through the gear tr ain to the

selective gear assembly 7.

The rotation of the print changeover cam is lock ed by

the action of the selective pawl, so the paper feed

ratchet wheel 8 on the same shaft as the selective

gear assembly, the print wheel, and detection wheel

also rotate at the same time.

Fig. 2-3 Reduction Gear Series

2-4 Service Manual 686710D

Page 13

Select mechanism (See Figs. 2-2 and 2-4.)

As shown in Fig. 1-4, the select mechanism consists

of the selective gear assembly, trigger coil, trigger

plate, and selective pawl. During rotation of the

reduction gear series, when a Drive signal is input 9

to the trigger coil in conformance with the Timing signal

output from the detector, the trigger plate is drawn 10

to the yoke fixed onto the selective gear assembly so

that the trigger plate 11, trigger lever 12, and selectiv e

pawl 13 rotate together with the rotation of the selective

gear assembly. At the same time as the print

changeover cam is unlocked, the selectiv e pawl loc ks

15 the tooth section corresponding to the character

of the selective gear assembly. When the selective

gear assembly is stopped, the print wheel mounted

on the same shaft is stopped also, and character

selection is performed.

Print gear series (See Figs. 2-2 and 2-4.)

The print gear series consists of the print changeover

cam and print gear. When the selectiv e gear assembly

is stopped by the select mechanism, the interlocked

selective drive gear is also stopped. At the same time,

the unlocked 14 print changeover cam is coupled and

is rotated 16 by the planet gear of the rotating reduction

gear series. The print gear thus rotates 17 which is

transmitted to the printing mechanism.

Fig. 2-4 Select Mechanism and Print Gear Series

686710D Service Manual 2-5

Page 14

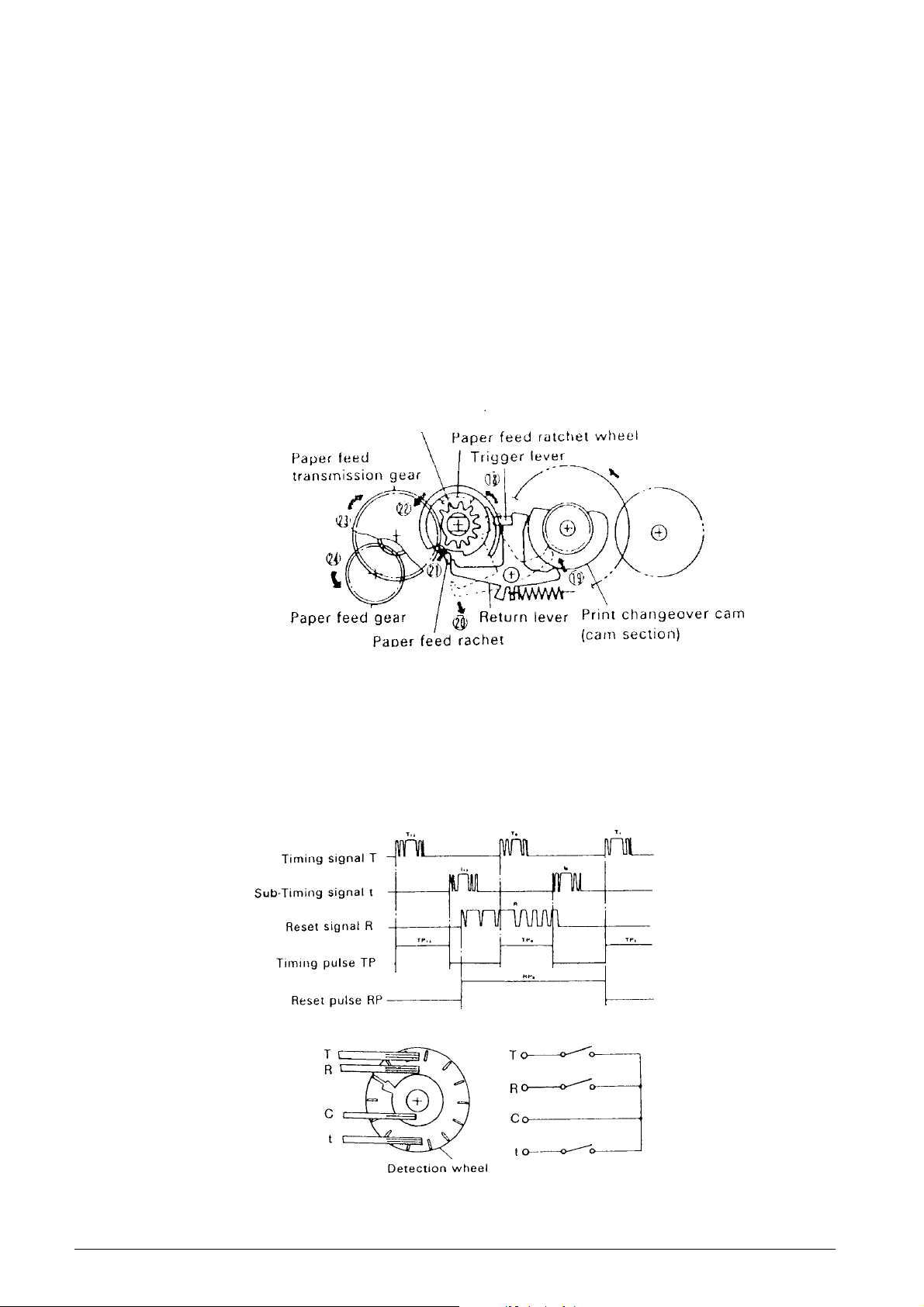

Paper feeding gear series (See Figs. 2-2 and 2-5.)

As shown in Fig. 2-5, the paper feeding gear series

consists of the paper feed ratchet wheel, paper feed

drive gear assembly, paper feed transmission gear,

and paper feed gear.

During column selection or consecutive paper feeding,

although the select mechanism and printing gear

series will operate through lengthening the Trigger Coil

Drive signal at the first column during space selection,

the return lever and trigger lever are in the unlocked

status 18 in order to maintain a long operating status

of trigger plate and trigger lever.

When the print changeover cam rotates, because the

cam controlling the return lever reaches a notched

section, the return lever is released and begins

operating 19 due to spring force, and its interlocking

with the paper feed ratchet in the paper feed drive

gear assembly is cancelled 20.

Selective gear assembly

The paper feed ratchet operates 21 due to spring force,

and meshes with the teeth of the paper feed ratchet

wheel which is on the same shaft as the selective gear .

When the printing operation is completed, the print

changeover cam causes the selective pawl to return

to its pre-selection status, and the print changeover

cam is stopped. When the selection gear begins

rotation, the paper feed driver gear assembly 22, paper

feed transmission gear 23 and paper feed gear 24 all

rotate together with the paper feed ratchet wheel, which

is transmitted to the paper feeding mechanism.

Fig. 2-5 Paper Feeding Gear Series

2.2.2 Detector Mechanism

(See Fig. 2-6.)

The detector mechanism consists of the detector

assembly and the detector gear. The detector employs

a mechanical contact-point system and generates a

Timing signal "T" and Sub-Timing signal "t" in

correspondence to each character position on the print

wheel.

The detector also generates a signal Reset signal at

each rotation of the print wheel. W av eform rectification

of these signals is to be performed by the user to use

as Timing pulses or Reset pulses.

Fig. 2-6 Detector Mechanism

2-6 Service Manual 686710D

Page 15

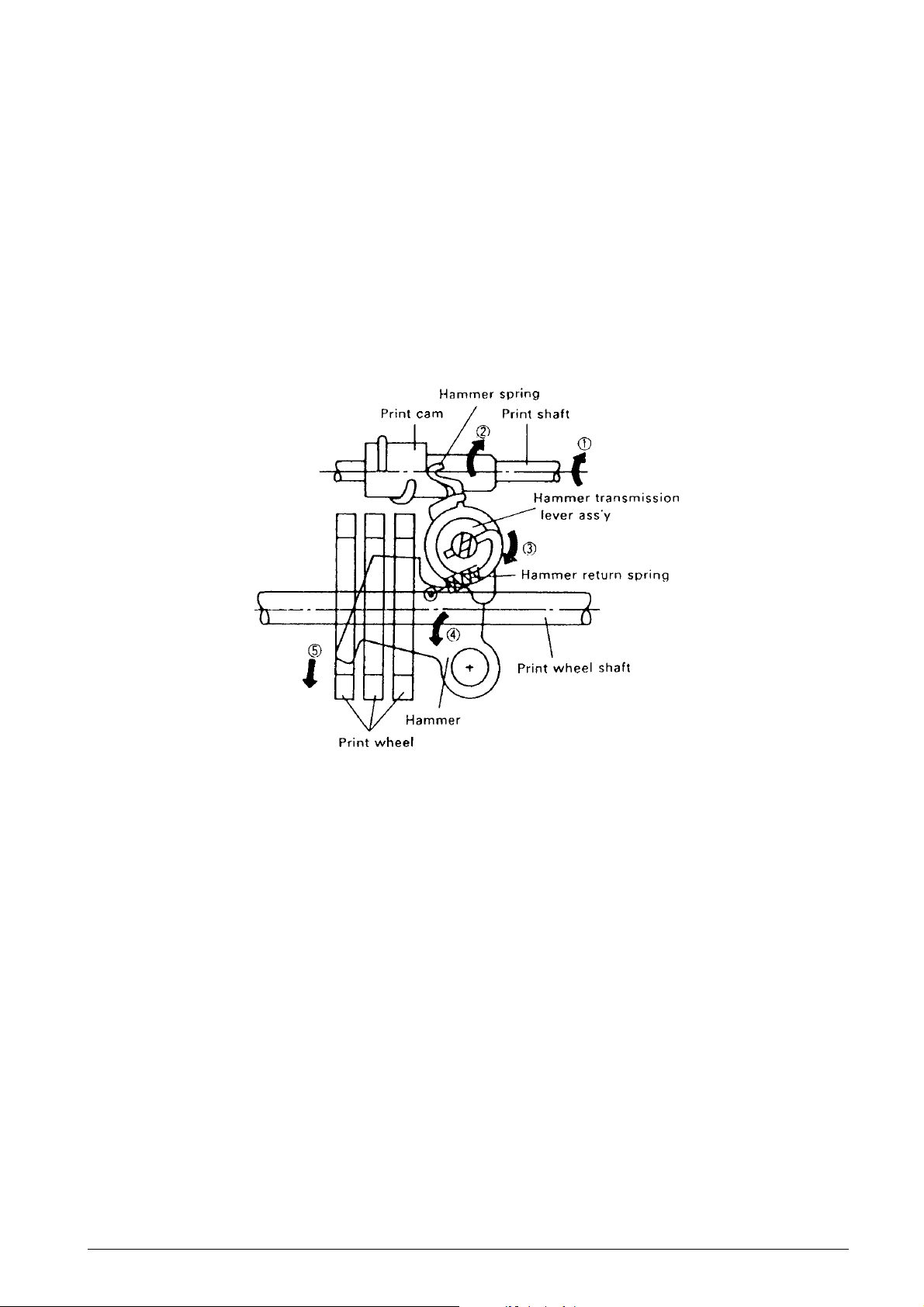

2.2.3 Printing Mechanism

The printing mechanism performs two functions: the

printing operation and carrying operation.

Printing operation (See Fig. 2-7.)

When the print gear series (see subsection 2.2.1,

Transmission/Select Mechanism) causes the print

shaft and print cam to rotate in the ➡ arrow 1 and 2

directions, the hammer transmission lever assembly

and hammer rotates in the ➡ arrow 3 and 4 directions;

therefore, the print wheel is pressed in the ➡ arrow 5

direction by the hammer, and printing is performed.

The hammer return spring moderates the pressure of

printing and also functions to restore the hammer and

hammer transmission lever assembly to standby

status at the completion of printing. The print wheel,

similar to the print changeover cam, makes one

rotation with each printing operation, and the printing

operation is performed during the first half of the

rotation.

Fig. 2-7 Printing Operation

686710D Service Manual 2-7

Page 16

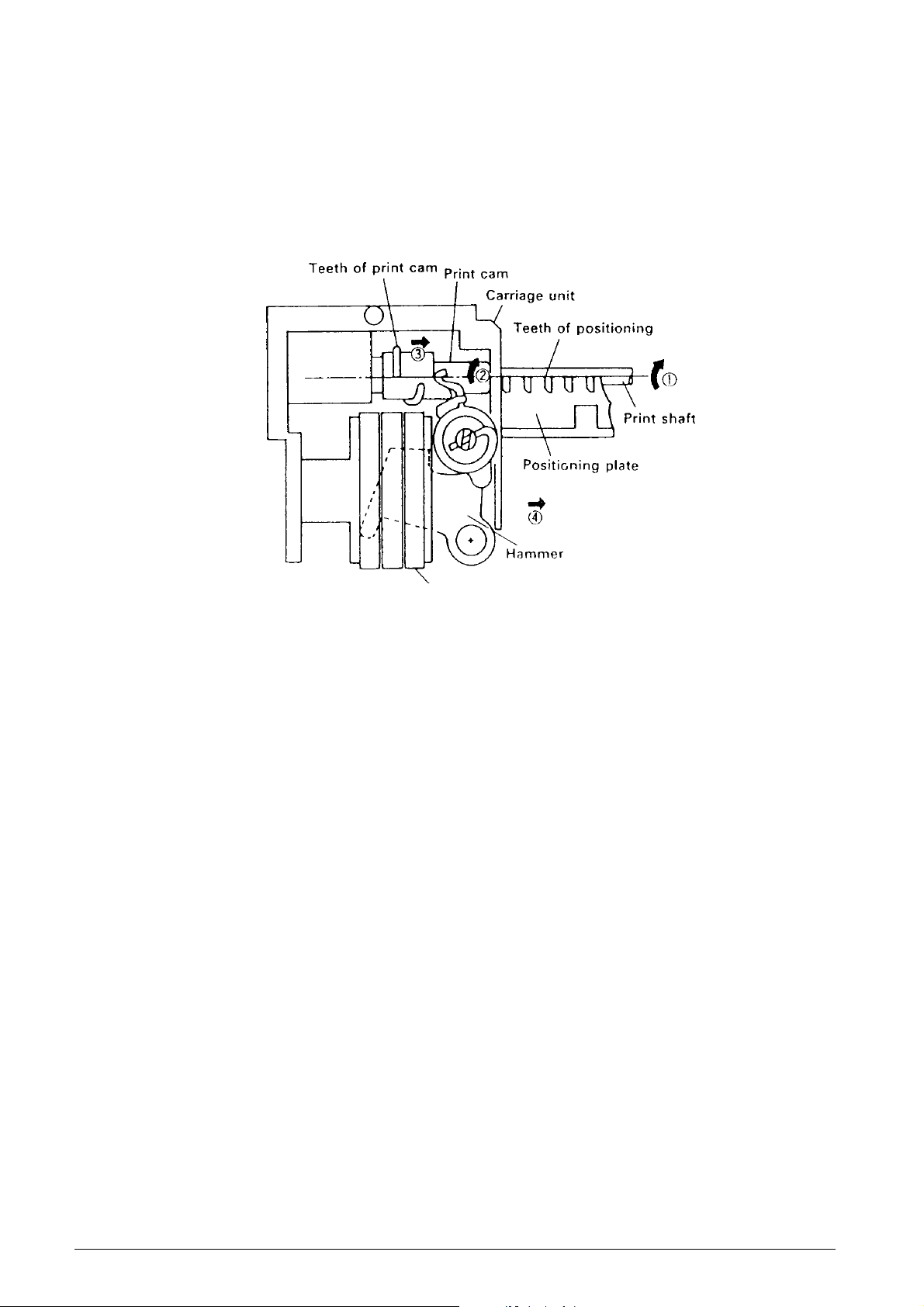

Carrying operation (See Fig. 2-8.)

The carrying operation is performed after the printing

operation during the last half of the print shaft rotation.

As soon as the positioning plate causes the print gear

to begin rotating, the cam section of the print gear

causes its meshing with the return lever to be

unlocked, and the print gear meshes with the print

cam.

When the print shaft rotates in the ➡ arrow 1 direction,

the meshing between the teeth of the print cam and

positioning plate causes the print shaft to slide to the

➡ arrow 2 direction while rotating in the ➡ direction

while in the ➡ arrow 3 direction. Sim ultaneously with

this sliding action, the carrying operation of the

carriage unit is performed (➡ arrow 4).

Print wheel assembly

Fig. 2-8 Carrying Operation

2-8 Service Manual 686710D

Page 17

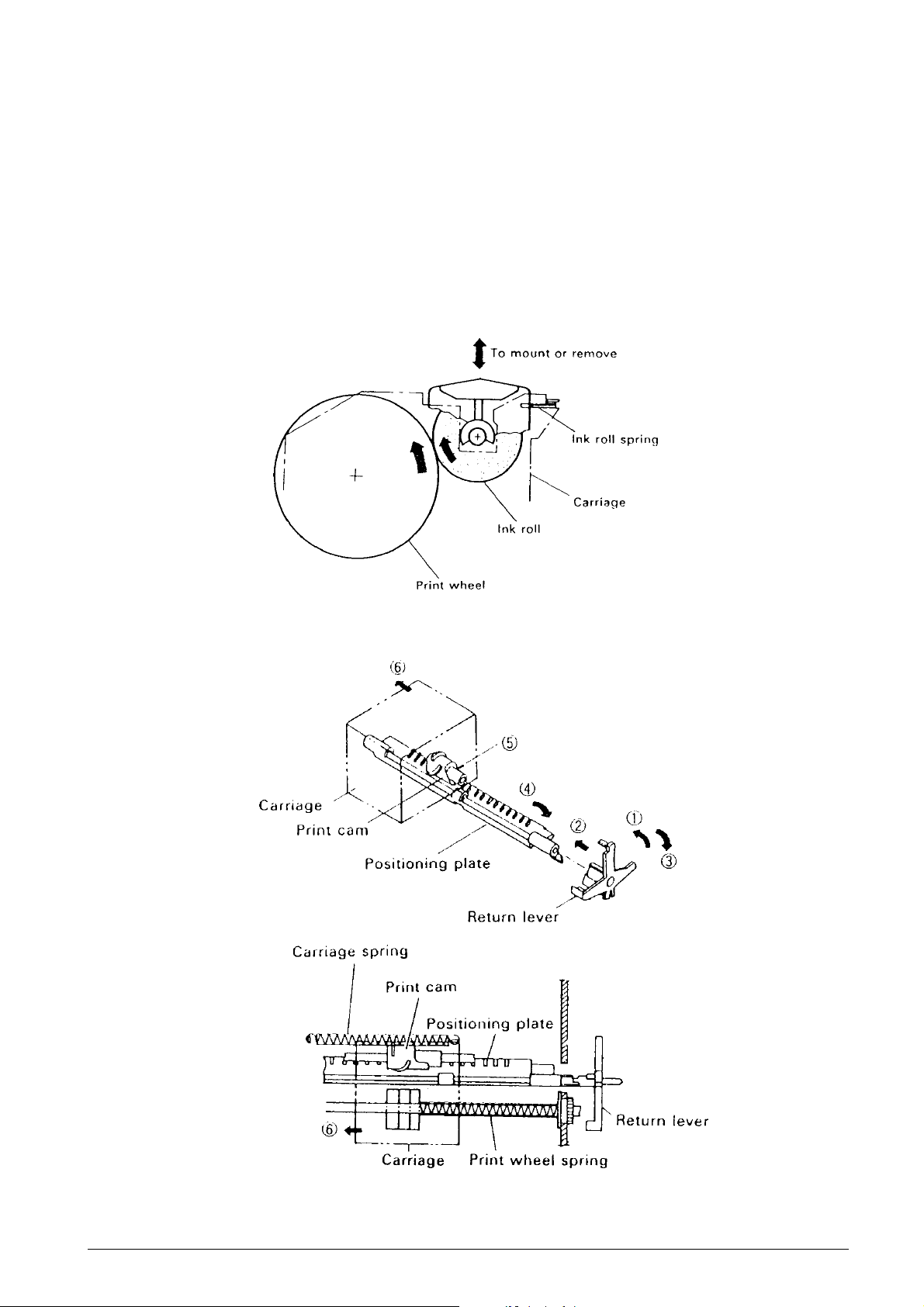

2.2.4 Inking Mechanism

(See Fig. 2-9.)

The ink roll assembly is constantly pressed lightly

against the outer periphery of the pr int wheel due to

the operation of the ink roll spring.

When the print wheel rotates, the ink roll also rotates

and the ink is supplied.

2.2.5 Paper Feeding Mechanism

The paper feeding mechanism performs two functions:

the carriage return operation and the paper feeding

operation.

Carriage return operation (See Fig. 2-10.)

The paper feeding gear series (see subsection 2.2.1,

“Transmission/Select Mechanism”) causes the return

lever to drop into the cam section of the print changeover cam so that it meshes with the positioning plate

(➡ arrows 1 and 2). The rotation of the print

changeover cam restores the return lev er to its original

position (➡ arrow 3) and rotates the positioning plate

with which it is meshed (➡ arrow 4). As a result, the

teeth of the positioning plate and print cam become

disengaged (5), and the spring force of the print wheel

spring and carriage spring causes the carriage to be

returned (➡ arrow 6).

Fig. 2-9 Inking Mechanism

Fig. 2-10 Carriage Return Operation

686710D Service Manual 2-9

Page 18

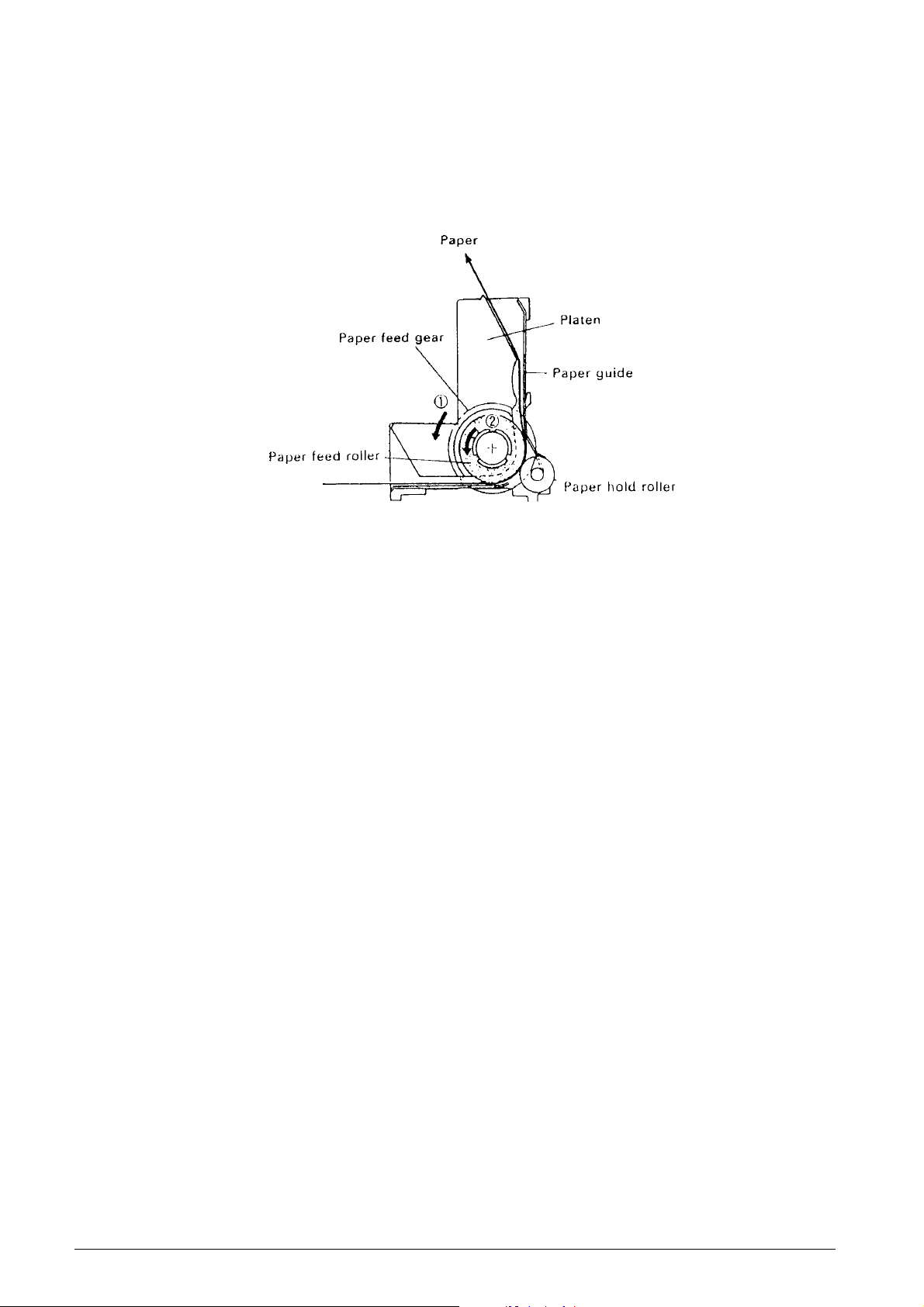

Paper feeding operation (See Fig. 2-11.)

Paper feeding is executed while the paper feed drive

gear assembly performs one rotation. When the paper

feeding gear series (see subsection 2.2.1,

"Transmission/Select Mechanism") causes the paper

feed gear to rotate in the ➡ arrow 1 direction, the paper

feed rubber within the platen also rotates in the ➡

arrow 2 direction, and the paper is f ed by friction from

Fig. 2-11 Paper Feeding Operation

the paper hold roller, which is in contact with the paper

feed rubber.

When the paper feed ratchet within the paper feed

drive gear assembly strikes the return lever, it

becomes disengaged with the paper feed ratchet

wheel, the rotation of the paper feed drive gear

assembly is stopped, and paper feeding is terminated.

2.2.6 Printer Operation During One Print

Cycle Initialization

To confir m that the carriage is in standby status (at

the first column), initialization must be performed prior

to printing and paper feeding. Initialization is completed

performing line feed.

Printing of the first line

1

The Timing pulses

Motor Drive signal is applied and the motor is

activated. The Reset pulse "RP" appearing 8 Timing

pulses shall be regarded as "RPo" and the first

Timing pulse "TP" after the rising of "RPo" shall be

regarded as "TPo".

2

Character selection (First column)

The Trigger Coil drive pulse is applied to the trigger

coil during the interval from Timing pulse "TPn" to

"TPn+1” which correspond to the desired character.

At such time, the Timing pulse interval ("TPn" to

"TPn+1”) is measured to obtain "TW1”. Following

character selection, the print wheel stops (the

timing pulse retains the "TPn+1” status), then print

and carrying are automatically executed.

3

Character selection (second column)

The print wheel starts rotating again and the first

Timing pulse is TP12. Character selection can be

performed from the next Timing pulse TP13. The

rest of this character selection operation is identical

to that described in Step (2) above.

"TP" are counted after the

4

Carriage return and paper feeding

During character selection for the highest-order

column of a line of print, printing, carriage return,

and paper feed are performed by adding: [the

width of the drive pulse to the trigger coil] + [the

timing pulse interval TW2 (TPn to TPn+1) at the

time] + [(the TP interval TW1 measured during

selection of the 1st column) x 6].

5

Motor OFF

After completing the printing of the highest-order

printing is one line of printing, the print wheel

begins rotation and the Timing pulse "TP" is

generated. Counting from this initial rising pulse,

the Motor Drive signal is cut off at the rising of the

fourteenth Timing pulse "TP".

NOTES:

• During a one-line print cycle, confirm the Reset

pulse "RP" between Timing pulses "TP13" and

"TPo" or "TPo" and "TP1”.

• The first Timing pulse that is generated after the

print column-shift process (TPn"2) cannot be used

for character selection.

2-10 Service Manual 686710D

Page 19

Consecutive printing

Fast paper feeding

1 The process for the initial line is similar to that for

"Printing of the first line".

2 Printing of the second and later lines begins as

follows: After completing the printing of the highestorder column for printing of the first line, with the

motor remaining driven, count the following Timing

pulses "TP". From the rising of the 29th Timing

pulse, pinting of the first column of the second line

becomes possible. Next, follow Steps 2 to 4 of

"Printing of the first line".

3 Consecutive printing is performed by repeating

Step 2 above.

4 Motor OFF

Perform Step 5 of "Printing of the first line".

Paper feeding of the first line

1 The Timing pulses "TP" are counted after the

Motor Drive signal is applied and the motor is

activated. The Reset pulse "RP" appearing 8

Timing pulses shall be regarded as "RPo" and the

first Timing pulse "TP" after the rising of "RPo"

shall be regarded as "TPo".

1 The process for feeding the initial line is similar to

that for "Paper feeding of the first line".

2 Paper feeding of the second and later lines begins

as follows: After completing the paper feeding of

the first line, with the motor remaining driven,

count the following Timing pulses "TP". From the

rising of the 21st Timing pulse, selection of the

empty character "TP10" becomes possible. Next,

follow Step 2 of "Paper feeding of the first line".

3 Fast paper feeding is performed by repeating Step

2 above.

4 Motor OFF

Perform step 3 of "Paper feeding of the first line".

2 Paper feeding

Select the empty character "TP10". At such time,

measure the Timing pulse interval "TP10" to "TP11”

to obtain TW1. When the width of the Trigger Coil

Drive pulse equals the measured "TW1” plus six

times "TW1”, the empty character on the print

wheel is selected and paper feeding is performed.

3 Motor OFF

After completing the paper feeding of one line, the

print wheel begins rotation. Counting from the

initial rising Timing pulse, the Motor Drive signal is

cut off at the rising of the fourteenth Timing pulse

"TP".

NOTE:

• During a one-line print cycle, confirm the Reset

pulse "RP" between Timing pulse "TP13" and

"TPo" or "TPo" and "TP1”.

686710D Service Manual 2-11

.

Page 20

Page 21

3. HANDLING, MAINTENANCE, AND

REP AIR

3.1 HANDLING THE PRINTER

3.1.2 Paper Setting

Loading the Paper

When loading the paper into the printer, note the

following points.

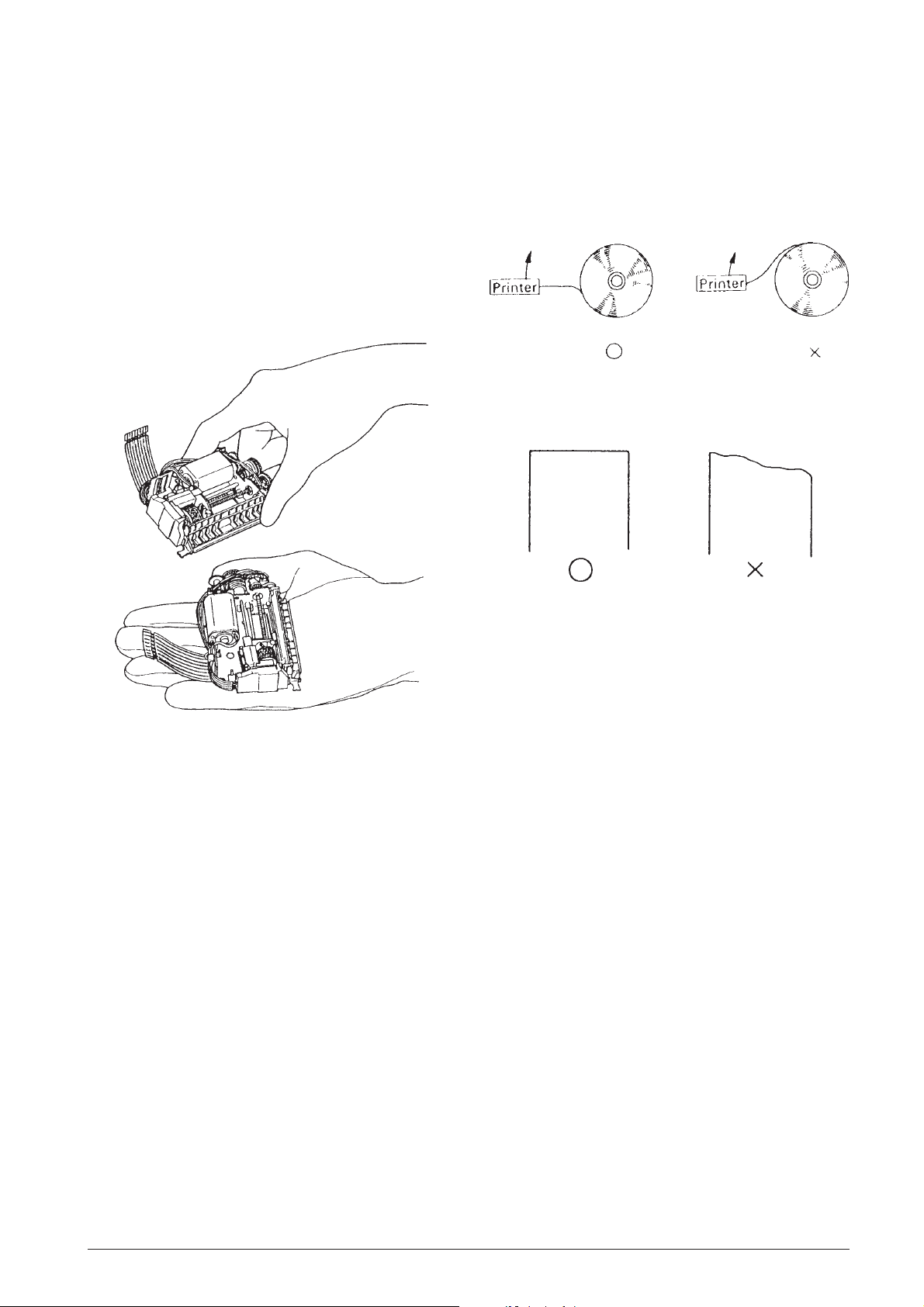

3.1.1 Precautions on Printer Handling

Precautions on transport (See Fig. 3-1.)

(1)When transporting this printer, never carry it by

grasping only the jumper lead.

(2)Never expose the printer to impact by dropping or

striking it, placing two printers into contact or

similar means.

Paper Setting Procedures (See Fig. 3-2.)

Fig. 3-2 Paper Setting Procedures

The Leading Edge of Rolled Paper (See Fig. 3-3.)

Fig. 3-3 The Leading Edge or Rolled Paper

Fig. 3-1 Proper Handling of Printer

Precautions on storage

• Avoid storage in locations exposed to excessive

dirt or dust, direct sunlight or excessive moisture.

• In the case of long-term storage (over 1 month),

place the printer a polyethylene bag after wrapping

it in anti-rust (VPI) paper, then store it in a dry

location.

Precautions on use

• Since this printer employs a permanent magnet

(motor section), avoid using it in locations exposed

to excessive iron filings, dirt, dust or other foreign

particles.

• Never perform a printing operation without the

paper and ink roller installed.

• Make sur you use only the paper and ink roll

assembly that are stipulated in the specifications.

• The ink roll assembly is a disposable part; do not

attempt to refil its ink supply.

Precautions on paper insertion

• Insert the paper straight into the paper entrance

section. Never insert paper having an uneven

leading edge at a slant.

• If the paper is pushed in the direction of feeding,

paper insertion will be simplified.

Removing the Paper

Remove the paper by following on the two methods

below.

• Perform paper feed using an electrical operation

(switch the printer power to ON, then press the

Paper Feed button), then remove the paper.

• Although the paper release mechanism in standby

status allows the paper to be freely removed by

pulling it out towards the front or back, make sure

to pull it straight out of the printer. Pulling the

leading edge out at a slant causes paper

jamming.

686710D Service Manual 3-1

Page 22

3.1.3 Installating the Ink Roll Assembly

3.2 MAINTENANCE

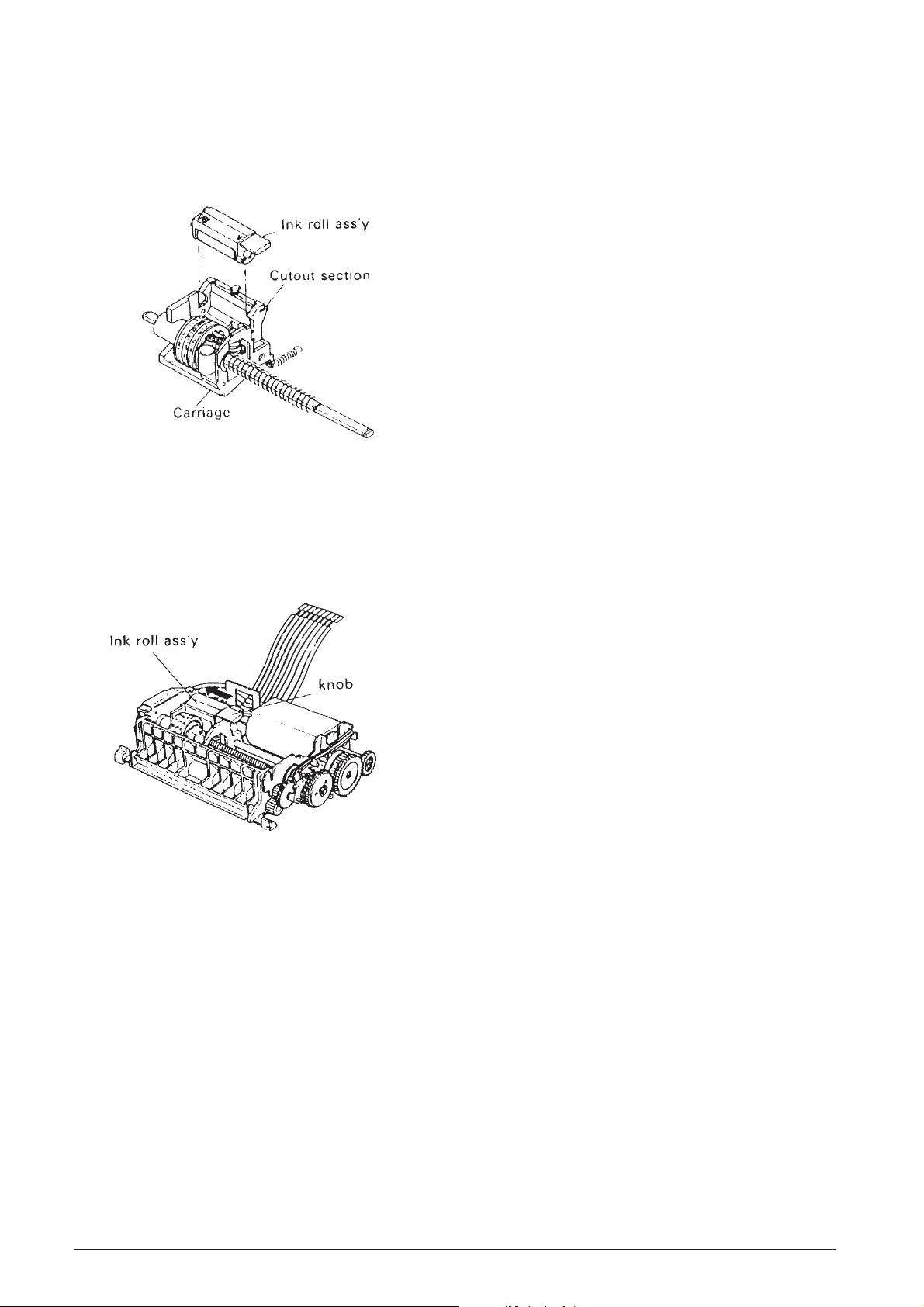

Fiting the Ink Roll Assembly (See Fig. 3-4.)

• Set the ink roll assembly in the cutout sections of

the carriage, then press it down gently until it clicks

into place.

Fig. 3-4 Installation of Ink Roll Assembly

Replacement of ink roller assembly

(See Fig. 3-5.)

• Press the knob of the ink roll assembly in the ➡

arrow direction, then lift the ink roll assembly up

and out of the carriage.

To ensure this printer retains its initial performance

level throughout a long product life, and to prevent

potential troubles, be sure to perform maintenance

and management according to the points described

in the following subsections.

3.2.1 Cleaning

Eliminating dirt or stains

Wipe off the soiled sections using alcohol or benzene.

Eliminating dust, scraps, and other foreign

particles

Use a vacuum cleaner to carefully draw out all f oreign

particles from every par t of the printer.

NOTES:

Never use thinner , tricholyene nor k etone solvents as

they may deteriorate or damage the plastic parts.

Check the remaining lubricant of each cleaned section

and perform lubrication as required. (See subsection

3.3.3, “Lubrication Points”.)

3.2.2 Inspection

Fig. 3-5 Replacement of Ink Roller Assembly

The maintenance and check-up procedures for this

printer are grouped into two types:

1) Daily checks that can be easily performed by the

operator of the printer during the course of daily

work, and

2) Periodic checks that can be performed only by

persons having a thorough understanding of the

printer mechanisms. These maintenance and

check procedures should be implemented

according to the technical level of the person

conducting them.

3-2 Service Manual 686710D

Page 23

Periodic Check

Every six months, periodic maintenance and inspection

of the points below should be conducted:

Check Item

Adhesion/penetration

of dirt, paper scraps,

or dust to the printer

interior.

Shape of the springs.

Lubrication status.

Printing and paper

feeding.

Standard

• No excessive adhesion

of dirt, paper scraps or

dust.

• No deformed springs.

• See subsection 3.3.1,

“Lubrication

Requirements”.

• No defects in the printed

results.

• No defects in the paper

feeding.

• Observe each function

and confirm the

absence of worn or

deformed parts, paper

jams, and other defects.

Repair Method

• Use a vacuum

cleaner to carefully

remove all foreign

matter from the

printer.

• Replace any

deformed springs.

• See subsection

3.3.3, “Lubrication

Points”.

• See subsection

3.5.3, “Repair

Guidelines”.

Daily check

The printer and printer operation are checked to see

if the printer is being operated in the proper manner

and if it is being maintained in optimum condition.

If any unsatisfactory points are discovered, they should

be remedied.

• Check that the ink roller ass’y is securely installed

in the carriage.

• Check the ink roller in use conforms to the

specifications (IR-40). Check the ink roller for

damage, replacing the ink roller if the ink roller

status is affecting printing quality.

686710D Service Manual 3-3

Page 24

3.3 APPLICATION OF LUBRICANTS

3.3.2 Lubricating Requirements

Lubrication plays an important role in maintaining this

printer at its initial performance level throughout a long

product life as well as preventing potential troubles.

Make sure to apply the specified lubrificants in the

appropriate amounts at the specified intervals.

3.3.1 Lubricant Types

The type of oil used greatly influenoes performance

and durability, and special attention is required to its

low temperature characteristics. Consequently , the oils

to be used with this printer are specified by us on the

basis of the results of the thorough analyses of data

for many types of oils and various experiments.

Note that our specified oils are availab le in 40cc (gm)

containers (minimum supply unit).

The three types of oils to be use with this printer are:

G-20, G-34 and 0-3.

No.

Lubrication Point

Prior to lubricating a part during assembly or

disassembly, that par t must be thoroughly cleaned.

The points requiring lubrification and the

corresponding lubricant types are listed in subsection

3.3.3, “Lubrication Points”, and shown in Fig.4-2,

“Lubrication Points” (Note that corresponding numbers

are used in the table and figure).

Lubrication should be periodically performed after

every six months, every overhaul, or every 700,000

printed lines. If lubrication becomes deficient due to

cleaning, disassembly or parts replacement, be sure

to perform lubrication regardless of the actual

lubrication interval.

3.3.3 Lubrication Points

(See also Fig. 4-2)

* (1), (2), (3), (11), (12) and (13) require lubrication

during assembly.

Oil Type

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

Flanged section of paper feeding ratchet wheel

(contact point between frame and teeth).

Contact point of detection wheel with frame.

Contact point between selective gear ass’y and trigger

plate.

Contact point between print shaft and frame (2 points).

Outer surface of print shaft.

Outer surface of print wheel shaft.

Contact point between print cam and hammer spring.

Teeth of positioning plate (3 points from the T side).

Contact point of positioning shaft with frame and

return lever (3 points).

Print gear cam.

Planet gear (teeth and shaft entrance section) (2

points).

Contact point of the selective drive gear with the

reduction gear.

Entire outer surface of detection wheel.

G-34

G-34

0-3

0-3

0-3

0-3

G-34

0-3

0-3

0-3

0-3

0-3

G-20

(14)

(15)

(16)

Contact point of selective pawl with print changeover

cam.

Contact point between print wheel ass’y and carriage.

Contact point between guide shaft with frame and

carriage.

0-3

0-3

0-3

3-4 Service Manual 686710D

Page 25

3.4 TOOLS AND LUBRICANTS

3.5.2 Repair Procedures

3.4.1 List of Tools

Tool Designation

Electric soldering iron

Round-nosed pliers

Diagonal-blade nippers

T weezers

Brush-Medium # 1

Brush-Thin # 2

Phillips screwdriver No. 1

ET holder # 1.5

O

Commercially available

Availability

O

O

O

O

O

O

O

O

3.4.2 List of Lubricants

Item

Oil

Grease

Designation

0-3

G-20

G-34

Volume

40 gm

40 gm

40 gm

3.5 REPAIR

In consideration of the level of expertise required for

implementation of after-service and repair procedures

for this printer, such procedures have been grouped

into two rankings: Le vel A and Level B . The person in

charge of repair, theref ore , should perform the repair

procedures appropriate to the repair level and to his/

her own level of expertise.

If of problem occurs, check its symptoms and status

and clarify the source of the problem with reference

to subsection 3.5.3, “Repair Guidelines” then repair

the damaged area. Note that the tab les of subsection

3.5.K3, “Repair Guidelines”, consist of the five items

listed below, enabling troubleshooting and repair to

be performed with speed and efficiency with minimum

error.

Phenomenon

Check the symptoms of the trouble.

Condition

Compare the trouble status of the problem with the

description in this column and locate the matching

status.

Cause

This columns lists the potential causes on the basis

of the trouble status, allowing the location of the trouble

to be checked.

Check-Point & Method

In correspondence to the cause, this column lists what

parts to check as well as the checking procedure to

be used. Be sure to inspect the chec k-points according

to the method describe here.

Repair Method

Repair the trouble area according to the description

in this column. If the identical phenomenon and

condition remain unchanged after performing the

rapair, chec k another item of the “Cause” column, then

perform the relative repair.

NOTE:

If you wish to carefully check the operation of such

parts as the gears, manually rotate the motor gear in

the counter-clockwise direction to perform such check.

3.5.1 Repair Levels

LEVEL A:

Requires general knowledge and technical skills

regarding the operating principles and structure of the

printer, but does not require previous repair

experience.

LEVEL B:

Requires full knowledge and technical skills regarding

the structure and operating principles of the pr inter

as well as previous repair experience.

686710D Service Manual 3-5

Page 26

3.5.3 Repair Guidelines

PHENOMENON CONDITION CAUSE LEVEL

1. Motor doesn't

rotate.

Motor doesn't

rotate despite

issuing of print

istruction or its

rotation becomes

locked.

(1) Defect of

power input

to motor.

(2) Defective

conductivity

of jumper

wire.

(3) Locking of

hammer and

print wheel

ass'y.

(4) Adhesion

of foreign

matter to the

rotating

mechanism

- - Check the input

A - Check the

B - Manually rotate the

(B) - Manually rotate the

CHECK POINT AND

METHOD

power. Use a tester or

oscilloscope to check

the input voltage

between the motor

terminals.

conductivity between

the motor terminals.

motor gear and check

whether the operation

of the print wheel ass'y

and other mechanisms

is normal.

motor gear in the

counter-clock-wise

direction and check for

the adhesion of foreign

matter. Remove any

foreign matter.

REPAIR METHOD

- Inspect and repair

the power supply

circuit.

- Perform resoldering

or replace the jumper

wire.

- Replace the hammer.

- Remove any foreign

matter.

2. No column

printing is

performed.

Motor rotates

normally, but no

printing is

performed.

(5) Improper

mounting

position of

the print

changeover

cam.

(6) Defective

motor.

(1) Defective

conductivity

of jumper

wire.

(2) Broken

coil lead of

trigger coil.

- See Main Assembly

B in the chapter 4 and

check.

B - Check the above

Cause (1) to (5) to see

if they are applicable.

A - Check the

conductivity between

across the terminals of

detector ass'y and

trigger coil.

B - Measure the

resistance value of the

trigger coil.

Rating: 20 +/- 2 Ohm

(at 25°C).

- Properly re-position

the print changeover

cam.

- Replace the motor.

- Perform resoldering

or replace the jumper

wire.

- Replace the triggle

coil.

3-6 Service Manual 686710D

Page 27

PHENOMENON CONDITION CAUSE LEVEL

CHECK POINT AND

METHOD

REPAIR METHOD

2. No column

printing is

performed.

Motor rotates

normally, but no

printing is

performed

(3) Improper

position of

print

changeover

cam.

(4) Broken

hammer

spring

(hammer

transmission

lever ass'y).

(5) Faulty

engagement

between the

print cam and

hammer

spring

(hammer

transmission

lever ass'y).

(6) Abnormal

charge pulses

to the trigger

coil.

B - See CAUSE (5) of

PHENOMENON !

B - Remove the ink roll

ass'y and check if the

spring is broken.

B - See Main Assembly

A in chapter 4 and

check.

B - Check if the charge

pulsewidth are within

rated values.

- Replace the hammer

transmission lever

ass'y.

- Properly engage the

print cam and hammer

spring.

- If they easily become

disengaged, bend the

hammer spring to

ensure engagement.

- Perform repair on the

circuit side.

3. Incomplete

printing.

Top, bottom or

sides of printed

characters are

missing.

(1) Faulty

mounting of

the platen

ass'y.

(2) Wear to

the print cam,

hammer

transmission

lever ass'y or

hammer.

(3) Wear or

adhesion of

foreign

particles to

positioning

plate.

(4) Foreign

particles

adhered to

print wheel

ass'y or

hammer.

A - Check if the platen

ass'y is firmly mounted

in the frame.

B - Manually set the

trigger lever into drawn

status, then perform a

printing operation to

check the hammer

stroke.

B - Check the

column-shift teeth of

the positioning plate

for wear and for the

adhesion of foreign

matter.

A - Check if foreign

matter is adhered to

front or back of the

hammer tip and print

wheel.

- Properly re-mount it.

- Replace any worn

parts.

- Replace the

positioning plate.

- Remove any foreign

matter.

- Remove particles.

686710D Service Manual 3-7

Page 28

PHENOMENON CONDITION CAUSE LEVEL

CHECK POINT AND

METHOD

REPAIR METHOD

3. Incomplete

printing.

4. Missing

characters or

missing printing.

Top, bottom or

sides of printed

character are

missing.

Missing characters

occur in all

columns.

Printing of

characters other

than those that

should be printed.

(5) Stretched

print wheel

ass'y or worn

characters.

(1) Defective

mounting of

trigger lever

spring.

(2) Disengage

or stretch of

selective pawl

spring.

(3) Stretching

of hammer

spring of the

hammer

transmission

lever ass'y.

(4)

Malfunction

of print wheel

ass'y

B - Check for stretching

at the frame of the

print wheel and worn

typefaces.

A - See Main Assembly

B in chapter 4 and

check.

A - Check the selecting

ratchet spring for

disengaged or stretch.

B - Check the hammer

spring for stretching.

B - Return the print

wheel ass'y and

carriage to standby

status and release the

positioning plate. Next,

manually slide the

carriage to check if the

print wheel ass'y slides

smoothly.

- Replace the print

wheel ass'y.

- Properly re-mount it.

- Replace the selective

pawl spring.

- Replace the hammer

transmission lever

ass'y.

- Replace the print

wheel ass'y.

(5) Bent

flange of the

detector

ass'y.

(6) Foreign

particles

adhered to

the trigger

plate and the

trigger yoke

of the

selective gear

ass'y.

B - Check if the flange is

bent.

A - Check for the

adhesion of foreign

matter.

- Check for the

adhesion of paper

dust.

- Replace the detector

ass'y.

- If foreign particles

are adhered, remove

them.

3-8 Service Manual 686710D

Page 29

PHENOMENON CONDITION CAUSE LEVEL

CHECK POINT AND

METHOD

REPAIR METHOD

4. Missing

characters or

missing printing.

5. Smudged or

faint printing.

Missing characters

occur in all

columns.

Printing of

characters other

than those that

should be printed.

Generation of

smudged or faint

printing

(7) Scratches

or burrs on

the trigger

plate or

trigger yoke

section

(selective

gear ass'y).

(8) Improper

mounting

position of

the print

gear.

(9) Defective

carryng.

(10) Defective

carriage

return.

(1) Improper

position of ink

roll ass'y.

B - Check the trigger

plate and trigger yoke

section for scratches

and burrs.

B - See Main Assembly

A in the chapter 4 and

check.

B - See PHENOMENON

8.

B - See PHENOMENON

8.

A - See Installation of

Ink Roller Ass'y in

chapter 2 and check.

- Replace the trigger

plate and/or selective

gear ass'y.

- Properly re-mount it.

- Properly re-mount it.

(2) Use of

improper ink

roll ass'y.

(3) Stretching

of the ink roll

spring.

(4) No ink

supply.

(5) Wear to

the print cam,

hammer

transmission

lever ass'y

and hammer.

(6) Dirt

adhered to

the print

wheel ass'y or

platen ass'y.

A - Check if the specified

ink roll ass'y is being

used. Rated pulse

width: IR 40.

A - Remove the ink roll

ass'y to check if the

springs stretched.

A - Check the ink supply

status.

B - See CAUSE (2) of

PHENOMENON 3

A - Check for the

adherence of ink

clumps, paper dust,

etc.

- Properly re-mount it.

Use only the specified

part.

- Replace the ink roll

spring.

- Replace the ink roller

ass'y

- Remove any dirt.

686710D Service Manual 3-9

Page 30

PHENOMENON CONDITION CAUSE LEVEL

CHECK POINT AND

METHOD

REPAIR METHOD

5. Smudged or

faint printing.

6. Paper is not

fed.

Generation of

smudged or faint

printing

The motor rotates

normally, but

paper not fed.

(7) Bent

platen ass'y

(the metal

section at the

paper outlet).

(1) Defective

conductivity

of jumper

wires.

(2) Broken

coil lead or

trigger coil.

(3) Abnormal

charge pulses

to the trigger

coil.

(4) Foreign

matter has

entered the

paper guide

of the platen

ass'y.

A - From the top of the

printer, check if the

platen ass'y is bent.

A - See CAUSE (2) of

PHENOMENON 1.

B - See CAUSE (2) of

PHENOMENON 2.

- - See CAUSE (6) of

PHENOMENON 2.

A - Check the paper

guide path.

- Repair the metal

section or replace the

platen ass'y.

- Remove any foreign

matter.

7. Uneven paper

feeding pitch.

The line spacing

of printed

character is

uneven

(5) Worn or

scratched

paper feed

gear train.

(6) Loose or

damaged

paper hold

roller in the

platen ass'y.

(1) Use of

improper

paper.

B - Manually set the

trigger lever to drawn

status then feed the

paper to check if any

of the below gears are

scratched or worn.

- Paper feed ratchet

wheel, paper feed

drive gear ass'y, paper

feed transmission

gear, or paper feed

gear.

A - Check if the platen

ass'y is improperly

mounted and if the

paper hold roller is

damaged.

A - Check that the

specified paper is

being used. Standard:

See subsection 2.2

Specification.

- Replace any faulty

parts.

- Properly re-mount

the platen ass'y or

replace it.

- Use the spacified

paper.

3-10 Service Manual 686710D

Page 31

PHENOMENON CONDITION CAUSE LEVEL

CHECK POINT AND

METHOD

REPAIR METHOD

7. Uneven paper

feeding pitch.

8. Defective

carrying.

The line spacing

of printed

character is

uneven.

The carriage does

not perform

carrying.

(2)

Processing

installation of

the platen

ass'y.

(3) Defective

platen ass'y.

(4) Defective

paper feed

drive gear

ass'y.

(5) Wear or

damage to

the gears.

(6) Defective

supplying of

paper.

(1) Wear of

the trigger

lever.

A - See CAUSE (1) of

PHENOMENON 3.

B - Check the paper

feeding rubber for

wear.

B - Check if any of the

internal springs are

bent.

B - See CAUSE (5) of

PHENOMENON 6.

A - Check the paper

supply path for

obstructions.

B - Check the trigger

lever for wear

(interlocking section

with selecting ratchet).

- Replace the platen

ass'y.

- Replace the paper

feed drive gear ass'y.

- Repair each paper

supply mechanism.

- Replace the trigger

lever.

(2) Wear of

the selective

pawl.

B - Check the selective

pawl for wear.

- Replace the seective

pawl.

686710D Service Manual 3-11

Page 32

PHENOMENON CONDITION CAUSE LEVEL

CHECK POINT AND

METHOD

REPAIR METHOD

8. Defective

carrying.

The carriage does

not perform

carrying.

(3) Wear or

broken teeth

of the print

cam and

positioning

plate.

(4) Abnormal

input pulse to

the trigger

coil.

(5)

Malfunction

of the

positioning

plate.

B - Check each part for

wear and missing

teeth.

- - Check the circuit to

see if the pulsewidth

of the carrying charge

pulses is correct.

B - With the positioning

plate in its unlocked

status, check for

stretching of the return

lever spring and for

foreign matter adhered

between the

positioning shaft and

positioning plate.

- Replace the print

cam and positioning

plate.

- Perform repair on the

circuit side.

- Replace the return

spring.

- Remove any foreign

matter.

9. Defective

carriage return.

The carriage

doesn't return.

(1) Wear of

the return

lever.

(2) Stretching

of the return

lever spring.

(3) Stretching

of the

carriage

spring and

print wheel

spring.

B - Check the return

lever for wear.

A - Check the return

lever spring for

stretching.

B - Check the carriage

spring and print wheel

spring for stretching.

- Replace the return

lever.

- Replace the return

lever spring.

- Replace the faulty

part.

3-12 Service Manual 686710D

Page 33

PHENOMENON CONDITION CAUSE LEVEL

CHECK POINT AND

METHOD

REPAIR METHOD

9. Defective

carriage return.

The carriage

doesn't return.

(4) Wear of

the point

where the

cam section

of the

positioning

plate contacts

the frame.

(5) Abnormal

input pulse to

the trigger

coil.

(6) Carriage

malfunction.

B - Check the point

where the cam section

of the positioning plate

contacts the frame.

- - Check the circuit to

see if the pulse width

of the return charge

pulses is normal.

A - Check if dirt has

adhered to section

where the carriage

rubs against the print

wheel ass'y

- Replace positioning

plate.

- Perform repair on the

circuit side.

- Remove any dirt.

Fig. 3-6 Pin Assignment Diagram

686710D Service Manual 3-13

Page 34

Fig. 3-7 Timing Chart

3-14 Service Manual 686710D

Page 35

4. ASSEMBLY AND DISASSEMBLY

4.1 GENERAL

• Assembly and Disassembly are performed using procedures described in figure 4-1.

• The presence in the assembly procedure column of a “✭” mark signifies that a <CHECK> is necessary; the

presence an “✦” in the assembly procedures means there is a <DISASSEMBLY POINT> in the Assembly

Points. It will be useful to refer to Assembly Points to confirm reassembling methods of reassembling as the

components are disassembled.

• Underlined words in the Reassembly Step indicate that lubrication is required before fiting that component and

that such lubrication would be very difficult if attempted after fiting is completed.

• A detailed description of lubrication, including points requiring lubrication upon completion of assembly, is given

in section 3.3.3, “Lubrication Points”. Perform lubrication also with reference to Fig. 4-2, “Lubrication Points”

at the back of this Chapter.

• Small parts are all represented by abbreviations.

List of Abbreviations for Small Parts

Symbol

S-1

S-2

R-1

R-2

Actual Size of Small Parts

Designation

Cup screw

Cup screw

Retaining ring TYPE-E

Retaining ring TYPE-E

Standard

M2 x 2.9

M2 x 3.5

1.2

1.5

686710D Service Manual 4-1

Page 36

4.2 MACHINE DISASSEMBLY - REASSEMBLY

4.2.1 Machine Case

Disassembly

• Unplug the machine power cord from the electrical wall outlet.

• Push the case of the machine (1) in the direction of the arrow (2).

• Remove the case (1) by lifting it the direction of arrow (3).

Reassembly

• Correctly position the case on the machine (1).

• Push the case (1) in the direction of arrow (4).

• Plug the machine power cord into the electrical wall outlet.

4.2.2 Printer Unit

Disassembly

• Remove the printer compartment cover (1).

• Remove the machine case (2).

• Disconnect connector (3).

• Using a screwdriver, remove screw (4) that secures the paper support (5) and remove this support.

• Remove the printer (6) in the direction of the arrow shown being careful to avoid damaging the connection

cables.

Reassembly

• Correctly position the printer (6) as shown in the figure.

• Correctly position the paper support (5) and tighten its related securing screw (4).

• Reattach the connector (3).

• Refit the case of the machine (2) and the printer compartment cover (1).

4-2 Service Manual 686710D

Page 37

4.2.3 Main Board and Display

Disassembly

• Remove the machine case.

• Disconnect the printer connector (1).

• Disconnect the paper feed motor connector (2).

• Disconnect the keypad connectors (3).

• Disconnect the battery supply connectors (4).

• Disconnect the drawer open control mechanism connector (5).

• Disconnect the power supply connector (6).

• Using a screwdriver, remove the securing screws (7).

• Remove the main board (8).

Reassembly

Perform the disassembly procedure in reverse order.

4.2.4 Paper Feed Motor

Disassembly

• Remove the machine case.

• Disconnect the motor power supply connector (1).

• With a screwdriver, remove securing screws (2).

• Remove motor (3) with its related support (4).

Reassembly

• Correctly position motor (3).

• Tighten securing screws (2).

• Reconnect the motor power supply connector (1).

• Refit the machine case.

686710D Service Manual 4-3

Page 38

4.2.5 Power Supply

Disassembly

• Remove the machine case.

• Disconnect the power supply - main board connector (1a) and the drawer open mechanism - main board

connector (1b).

• Slightly pull back the protection sheath (2).

• Using the appropriate tool, cut the junctions between the power cord (3) and the power supply cables.

• Remove the power supply securing screws (4).

• Remove the power supply (5).

Reassembly

• Correctly position the power supply (5) into its seat.

• Tighten the securing screws (4).

• Using the appropriate tool, restore the connections that were previously cut.

• Replace the protection sheaths (2).

• Reconnct the power supply - main board connector (1) and the drawer open mechanism - main board

connector.

• Refit the machine case.

4.2.6 Keypad

Disassembly

• Remove the machine case.

• Disconnect the keypad - main board connectors (1).

• Using a screwdriver, remove securing screws (2).

• Remove the keypad (3) together with the machine’s ON/OFF switch (4).

Reassembly

• Correctly position the keypad (3) and the ON/OFF switch (4).

• Tighten the securing screws (2).

• Restore connection (1).

• Refit the machine case.

4-4 Service Manual 686710D

Page 39

4.3 PRINTER DISASSEMBLY - REASSEMBLY

4.3.1 Ink Roller

• Grasp the tab of the ink roller and lift it out of its slot.

Refitting the Ink Roller

• Position the ink roller in its slot and then press it until it snaps into place.

686710D Service Manual 4-5

Page 40

4.3.2 Electrical Connections

Disconnecting

• With the appropriate tool, cut the electrical connections and remove the connection cables.

Reconnecting

• With the appropriate tool, restore the electrical connections that were previously cut.

4-6 Service Manual 686710D

Page 41

4.3.3 Return Spring

Disassembly

• Using the appropriate tool, release the spring at its ends and remove it.

Reassembly

• Position the spring and hook it in place by placing its ends into the corresponding slots.

4.3.4 Snap Ring

DisassemblyDisassembly

Disassembly

DisassemblyDisassembly

• Using tweezers, remove the snap rings from the gears.

Reassembly

• Position the snap ring in place and secure it using tweezers.

686710D Service Manual 4-7

Page 42

4.3.5 Gear

Disassembly

• Being careful to avoid loosing and/or damaging any part, remove the printer reduction gear - movement

assembly as shown in the figure.

(a)

(b)

(c)

assembly

Reassembly

• Fit onto the print wheel shaft.

• Fit onto the paper feeding transmission gear shaft.

• Fit onto the positioning shaft.

• Assemble the trigger lever and trigger lever spring, then fit the assembled piece onto the print wheel shaft.

• After aligning the trigger lever with the stage-change section of the return lever, attach the hook of the trigger

lever spring to the groove in the paper feed transmission gear shaft.

• Fit the positioning shaft then engage it with the selective pawl spring.

4-8 Service Manual 686710D

Page 43

✭ CHECK

• Check that its phase matches the trigger lever phase.

• Make sure that the phase of the print gear is properly aligned.

• Fit the print changeover cam so that the stopper of the selective pawl spring engages with the cam track on

the outer periphery of the print shift cam.

• Make sure that the chamfered side faces outward.

• Fit onto the print wheel shaft and paper feeding transmission gear shaft.

• While matching the three dowels of the trigger lever to the openings of the trigger plate, press the opposite end

of the print wheel shaft and press on the selecting gear assembly, then secure it with R-2.

• Push the tip of the print wheel shaft from the T side toward the T side so that the selective gear assembly

contacts R-2.

✭ CHECK

• Before re-fiting the selective gear assembly during parts replacement or other occasions, make sure that the

detection wheel and detector assembly have been removed (otherwise, the detection wheel and detector

assembly may be damaged).

• Assemble parts a through c, fit the assembled piece onto the reduction shaft, then secure by R-1.

686710D Service Manual 4-9

Page 44

4.3.6 Motor

Disassembly

• Using a screwdriver, remove the securing screws.

• Remove the selection lever, related spring and then remove the motor.

Reassembly

• Fit the motor with the round hole on its screw-hole side closest to the bottom, then secure section E by screw.

• Fit the spring onto the tab on the M side of the frame assembly.

• Fit the selective pawl spring holder, then secure by screw in the position where the selective pawl spring holder

contacts the outer periphery of the motor shaft holder (~).

4-10 Service Manual 686710D

Page 45

4.3.7 Detection Wheel

Disassembly

• Remove the detector assembly with related brushes.

• Slide the wheel off the guide shaft.

Detector assembly

Reassembly

• Align the blank character of the print wheel with the print position of the platen.

• The rotation of the print wheel causes the motor gear to rotate in the counter-clockwise direction.

• Press the detection wheel onto the print wheel shaft.

✭ CHECK

• Position the R pattern of the detection wheel towards the upper left diagonal direction.

• Pass the shaft along the track in the carriage from the frame T side to the frame M side.

• Match the tabs of the detector assembly to the related positions of the frame assembly, then fit the detector

assembly.

✭ CHECK

• Make sure you do not deform the detection brush of the detector assembly.

✦ DISASSEMBLY POINT

• To remove the detector assembly, release the hooks.

686710D Service Manual 4-11

Page 46

4.3.8 Platen Assembly Removal

• Remove the assembly in the direction of the arrow and lift it off.

Platen assembly

Frame assembly

• Fit section C of the platen assembly into the frame assembly, then press the platen assembly in the ➡ arrow

direction.

Platen assembly

Frame assembly

✭ CHECK

• Make sure there is no gap between the platen assembly and frame assembly (at the section indicated by).

Platen assembly

Frame assembly

✦ DISASSEMBLY POINT

• To remove the platen assembly, insert tweezers into the gap between the bottom of the platen assembly and

the frame assembly and then release section D.

Platen assembly

Frame assembly

4-12 Service Manual 686710D

Page 47

4.3.9 Printer Carriage

Removal

• Release the printer carriage spring from the structure and then slide the carriage off.

Reassembly

• Fit the carriage unit onto the frame assembly, making sure not to squash the carriage spring.

• Hook the carriage spring to section B of the frame assembly.

• Fit the print gear onto the print shaft.

• Pass the print shaft through the carriage unit from the M side of the frame assembly, engage the print cam

and the hammer spring, then align the phase of the print gear so that its cam section is at the bottom.

686710D Service Manual 4-13

Page 48

4.3.10 Printer Carriage

Disassembly

• Remove the paper feed wheel and then remove the R-2 ring from its position A.

• Remove the spring.

• Remove the printer shaft.

• Remove the ink roller securing spring from the carriage.

• Remove the hammer return spring.

• Remove the print wheel assembly - hammer from the carriage.

Print wheel assembly

4-14 Service Manual 686710D

Page 49

Reassembly

• Fit the hammer onto the print wheel assembly, then fit the assembled piece in the carriage.

• Fit from the bottom of the carriage.

• Attach the spring to the hammer and the carriage.

• Make sure you fit the ink roll spring so that it is properly oriented.

• Secure R-2 to section A of the print wheel shaft, then fit the print wheel spring and paper feed ratchet wheel.

• Pass the shaft through the hammer and print wheel assembly which the print wheel are fited onto the carriage.

Hammer transmission lever assembly

Print wheel assembly

686710D Service Manual 4-15

Page 50

4.3.11 Machine Case

Disassebly

• Remove the positioning shaft with related positioning plate.

• Remove the mounting rubber.

Frame assembly

Reassebly

• To reassemble follow the disassembly procedure in reverse order.

4-16 Service Manual 686710D

Page 51

Fig. 4-1 Exploded View

686710D Service Manual 4-17

Page 52

Fig. 4-2 Lubrification Points

4-18 Service Manual 686710D

Page 53

5. CIRCUITRY

5.1 GENERAL

The terminal uses a 8-bits single chip microcomputer The CPU has 24K bytes of internal ROM and 512 bytes of

internal RAM , and used 2K bytes S-RAM of external memory. The terminal also has a battery-backed up clock

that keeps track of the month, day of the week, date, hour and minute.

5.1.1 Block Diagram

686710D Service Manual 5-1

Page 54

5.2 POWER SUPPLY CIRCUIT

+17 V

+6 V, the printer motor voltage, is generated using the

15.6 VAC input across Pins 1 and 2 of CN5. This AC

voltage is rectified by the bridge rectifier and filtered

by EC3, a 4700 uF capacitor . The resulting DC voltage

is about +17 V.

+6 V

The circuit generating the +6 V uses the 17 V. It applies

to the collector of T10, a D837B transistor. It is also

dropped across R26, a 2.2 KOhm resistor, and D24,

rated at 6.8 V. This provides a bias voltage of about

6.8 VDC on the base of T5. This output voltage is

filtered by capacitor EC4 and supplied to the emitter

of transistor T5. This voltage is used by the printer.

+5 V

The circuit generating the +5 V uses the 17 V. It applies

to the collector of T6, a C3242A transistor. It is also

dropped across R27, a 2.2 KOhm resistor, and D25,

rated at 6.2 V. This provides a bias voltage of about

6.2 VDC on the base of T6. This output voltage is

filtered by capacitor EC5 and supplied to the emitter

of transistor T6. This voltage is through the D15 diode,

output voltage is 5.3 V.

-30 V

The -30 V circuit uses 27.5 VAC across Pins 3 and 4

of CN5. This AC voltage is rectified by D5, a diode,

and filtered by EC2; output voltage is approximately 30V DC. This voltage is used by the display.

Filament Voltage

The filament voltage F1.F2 is used by the displa y tube.

Its AC input is 4.0 V, and uses a ground reference -25

V from the -30 V circuit dropped across R28, R30, an

470 Ohm resistor.

5-2 Service Manual 686710D

Page 55

5.3 TRANSFORMER WIRING DIAGRAM

5.4 POWER SUPPLY SPECIFICATIONS

Input - Power Consumption

Standing by: Maximum 9 Watts

Printing: Maximum 16 Watts

Output - Rated Voltage

+5V to GND

Voltage: 5 V +/- 0.25 V Standing by

Ripple: Less than 0.4 V p-p Printing

Stability: Line regulation - less than 0.3 V Viac -10% to +10%

Temp. regulation - less than 0.3 V Temp. 0°C to 40°C

+6V to GDN

Voltage: 6.0 V +/- 0.5 V Standing by

Ripple: Less than 1.0 V p-p Printing

Stability: Line regulation - less than 1.0 V Viac -10% to +10%

Temp. regulation - less than 1.2 V Temp. 0°C to 40°C

-30 to GDN

Voltage: -30 V +/- 2.0 V Standing by

Ripple: Less than 5.5 V p-p Standing by

Stability: Line regulation - less than 8.5 V Viac -10% to +10%

Temp. regulation - less than 2 V Temp. 0°C to 40°C

F1 to F2

Voltage: 4.0 +/- 0.2 Vac

Stability: Line regulation - less than 1.0 V Viac -10% to +10%.

686710D Service Manual 5-3

Page 56

5.5 RESET CIRCUIT

The reset circuit prevents the CPU from starting to operate before the system is fully powered-up and initialized.

Then 2uS after power is applied, reset goes high and the CPU can begin functioning.

When power is first applied to the circuit, the VBB begins charging EC1, a capacitor. While EC1 is charging.

Once EC1 is fully charged, the voltage drops across the capacitor.

5.6 POWER FAIL CIRCUIT

Power fail is generated by a circuit using the +6 V voltage.

When power is on and the system is operating normally, the power fail signal stays at a high level.

5-4 Service Manual 686710D

Page 57

5.7 DISPLAY CIRCUIT

Display control is done by timer interrupt routine of CPU. Cycle of the timer is about 680 usec. P00 through

P07,P23 indicates scan signal of displayed digit and displa yed digit of scan is done from G1 to G10 and each digit

is turned on sequentially.

P10 through P17,P22 indicates segment signal and these are connected to each segment of the digit. Along with

Segment signal and Grid signal, High level segment is turned on. I/O port of the CPU, which controls Segment

and Grid, is high-voltage port and directly drives fluorescent display . High-voltage port is special I/O port designed

for fluorescent display and VEE level (-30 V) will be output as a low level.

Front display and Rear display are connected in parallel.

686710D Service Manual 5-5

Page 58

5.8 DISPLA Y TUBE INFORMA TION

8.8.8.8.8.8.8.8.8.8

G10 G9 G8 G3 G2 G1G7 G6 G5 G4

G1-G7 AMOUNT

G8 REPEA T/DEPT#

G9 SIGN/DEPT#

G10 NOT USED

Display Symbols

Discount

Minus amount Error Change Total Subtotal Prg. mode

Clerk1 (G9)

-Clerk6 (G4)

<

- E C = S P

Display specification

- Display tube front 10LT-50G

rear 11LT-13G

- Character size front 4 mm (H) x 4.9 (W)

rear 12 mm (H) x 3.4 (W)

5-6 Service Manual 686710D

Page 59

5.9 KEYBOARD CIRCUIT

Keyboard scan is done b y CPU interrupt routine as same as one for displa y. P00 through P07, P23 are commonly

used with scan signal displayed by Strobe line. P54 through P57 are return line of Keyboard matrix.

It is consist of matrix of strobe line (8) x Return line (4) and total of 32 keys are assigned.

In order to remove chattering, key entry is confirmed when two sequential entry of a key.

P25 is used for Mode lock s witch, Feed ke y. Mode lock s witch is connected to strobe line (P00 through P04), Feed

key is connected to P07.

686710D Service Manual 5-7

Page 60

5.10 PRINTER CIRCUIT

Motor

The printer motor is activated using the signal P51 from the CPU.

This signal is normally low, and goes high to cause the motor to run.

Printer Magnets

The signals P50 from the CPU are the input for the printer magnets.

These normally low signals drop high with a print signal.

Timing Signal

The printer generates, through the use of a mecanical switch assembly, a timing signal that is returned to the CPU

through the INT1 line.

A secter wheel passes through the nor gate M2, creating a square wave.

The CPU uses this signal from the printer as the basis for timing the printer magnet signals, the motor drive and

feed.

5-8 Service Manual 686710D

Page 61

5.11 DRAWER CIRCUIT

5.13 BUZZER CIRCUIT

The drawer is activated using the signal P26 from the

CPU. This signal is normally low, and goes high to

cause the drawer to run. When P26 is high, T9 is on.

Current flow through the transistor cause the collector

to be held low, near high potential.

5.12 BATTERY CIRCUIT

When the +5 V supply starts dropping, as in a power

fail condition, the voltage through the divider network

drops accordingly.

The buzzer circuit uses signal P24 from the CPU.

This normally low signal goes high on 2 conditions.

First, on a error tone, P24 goes high until the error

condition is cleared. For a key entry tone, P24 goes

high and then returns to its low state. This pulse is of

extremely short duration.

When the voltage at +5 V has dropped, voltage bac kup is provided by the battery.

The battery voltage B+5V goes to the CPU and

external RAM.

When +5 V novoltage, D17 is shut off current B+5 V

is through the D20 and D21 from battery.

Battery specification:

Type: SUM-3 x 4

V oltage: 6.0 V

Rating: 500 mAh

686710D Service Manual 5-9

.

Page 62

Page 63

6. SCHEMATIC AND DIAGRAM

220V Model

686711S

686710D Service Manual 6-1

Page 64

115V Model

686710D Service Manual 6-26-2 686710D

686711S

Page 65

REF. CODE DESCRIPTION

SPARE PARTS CATALOGUE

IMPORTANT

THIS PUBLICATION IS WRITTEN BY OLIVETTI LEXIKON (SPARE PARTS DEPARTMENT).

THIS CATALOGUE IS THE ONLY DOCUMENT TO WHICH REFERENCE MAY BE MADE

FOR ORDERING SPARE PARTS.

686711S

Spare parts catalogue

A - 1

Page 66

EXPLODED PARTS

REF. CODE DESCRIPTION

128703 B

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

128704 C

128705 D

128839 T

128707 F

128708 Q

128709 R

128710 D

128711 S

128834 N

128835 P

128836 Q

128837 R

128838 S

128717 Y

MAIN BOARD

LSI 225 CX - M38123 M4

DISPLAY 10 LT - 50G

COMPLETE KEYBOARD ASSY

TRANSFORMER

AC CORD AOBA EP307

PRINTER END CASSETTE KEY

MOTOR

PRINTER M42 - V

CASSETTE

COVER ASSEMBLY

PRINTER COVER

FRONT COVER

DEPOSIT DRAWER

WINDING REEL

CMS 140

A - 2

Spare parts catalogue

686711S

Page 67

EXPLODED PARTS

REF. CODE DESCRIPTION

7

12

CMS 140

4

13

15

11

3

9

1

2

7

8

5

6

14

686711S

10

Spare parts catalogue

A - 3

Page 68

EXPLODED PARTS CMS 240

REF. CODE DESCRIPTION

417168 U

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

128718 H

128704 C

128705 D

128721 U

128722 V

128723 W

128710 D

128707 F

128708 Q

128840 G

128709 R

128842 W

128717 Y

128711 S

128843 X

128844 Y

128841 V

128845 Z

MAIN BOARD 115V

MAIN BOARD 220V

LSI 225 CX - M38123 M4

DISPLAY 10 LT - 50G

DISPLAY 11 LT - 13G

FRONT SUPPORT

REAR SUPPORT

MOTOR

TRANSFORMER

AC CORD AOBA EP307

CASSETTE

PRINTER END CASSETTE KEY

PRINTER COVER

WINDING REEL

PRINTER M42 - V

FRONT COVER

DEPOSIT DRAWER

COVER ASSEMBLY

COMPLETE KEYBOARD ASSY

A - 4

Spare parts catalogue

686711S

Page 69

EXPLODED PARTS

REF. CODE DESCRIPTION

CMS 240

11

15

13

14

12

11

18

17

7

6

4

3

1

2

5

8

16

686711S

10

Spare parts catalogue

9

A - 5

.

Page 70

Page 71

UPDUPD

AA

UPD

UPDUPD

DATE UPDATED PAGES PAGES CODE

11/1998 1stEDITION 65 686710D-00

09/1999 1stNEWSLETTER 15 686711S-00

TING STTING ST

A

TING ST

AA

TING STTING ST

AA

TUSTUS

A

TUS

AA

TUSTUS

Loading...

Loading...