Page 1

Cash Register

CMS 140 B

SERVICE MANUAL

Page 2

PUBLICATION ISSUED BY:

Olivetti Lexikon, S.p.A.

Documentazione

77, Via Jervis - 10015 Ivrea (Italy)

Copyright © 1998, by Olivetti

All rights reserved

Page 3

PREFACE

This manual is addressed to the field engineers who will install and service the CMS 140B cash register.

It provides all the information needed for a correct product maintenance.

SUMMARY

This manual is divided into seven chapters.

The first three chapters describe the operating, functional checks, and maintenance and repair procedures.

Chapter 4 describes the disassembly and adjustment procedures. Chapters 5, 6 and 7 describe the electronic

circuitry, schematics and diagram and assembly construction.

PREREQUISITES

The topics described in this manual require knowledge of similar products.

REFERENCE DOCUMENTA TION

Instruction Manual - (provided with the product)

Spare Parts Catalogue

DISTRIBUTION: General

FIRST EDITION: December 1998

686770R Service Manual iii

Page 4

Page 5

CONTENTS

1.OVERVIEW.................................. 1-1

1.1 TECHNICAL SPECIFICATIONS..... 1-2

2.SPECIFICATIONS AND

OPERATING PRINCIPLES......... 2-1

2.1 SPECIFICATIONS......................... 2-1

2.1.1 Features................................... 2-1

2.1.2 Specifications........................... 2-1

2.1.3 Mechanisms............................. 2-2

2.2 OPERATING PRINCIPLES........... 2-3

2.2.1 Transmission/Select Mechanism 2-3

2.2.2 Sensor Mechanism................... 2-7

2.2.3 Printing Mechanism.................. 2-8

2.2.4 Inking Mechanism..................... 2-9

2.2.5 Paper Feeding Mechanism....... 2-10

2.2.6 Print Cycle Initialization............. 2-12

3.HANDLING, MAINTENANCE....... 3-1

3.1 HANDLING THE PRINTER........... 3-1

3.1.1 Precautions on Printer Handling 3-1

3.1.2 Paper Installation...................... 3-2

3.1.3 Ink Roller Installation................ 3-3

3.2 MAINTENANCE............................. 3-4

3.2.1 Cleaning.................................. 3-4

3.2.2 Inspection................................. 3-4

3.3 LUBRICATION............................... 3-4

3.3.1 Lubricant Types....................... 3-4

3.3.2 Lubrication Points.................... 3-4

3.3.3 List of lubricants....................... 3-4

3.4 PROBLEM RESOLUTION.............. 3-5

3.5 PRINTER PIN ASSIGNMENTS...... 3-7

3.6 TIMING CHART.............................. 3-9

4.DISASSEMBLY PROCEDURE/HOW

TO LOCATE THE ASSEMBLIES 4-1

4.1 HOW TO LOCATE THE POWER

ASSEMBLY.................................... 4-1

4.2 THE REMOTE BATTERIES/

LOCATION OF ON/OFF SWITCH. 4-2

4.3 MACHINE DISASSEMBLY -

REASSEMBLY............................... 4-3

4.3.1 Machine Case........................... 4-3

4.3.2 Printer Unit............................... 4-3

4.3.3 Main Board and Display.......... 4-4

4.3.4 Paper Feed Motor.................... 4-4

4.3.5 Battery Compartment............... 4-5

4.3.6 Keypad..................................... 4-5

5.BLOCK STRUCTURE CHART... 5-1

5.1 CIRCUITRY.................................... 5-1

6.SCHEMATICS AND DIAGRAMS 6-1

6.1 SYSTEM BLOCK DIAGRAM.......... 6-1

6.2 POWER SUPPLY CIRCUIT............ 6-2

6.3 RESET CIRCUIT............................ 6-3

6.4 POWER FAIL CIRCUIT.................. 6-3

6.5 DISPLAY CIRCUIT......................... 6-4

6.6 KEYBOARD CIRCUIT.................... 6-5

6.7 BUZZER CIRCUIT.......................... 6-6

6.8 BATTERY CIRCUIT....................... 6-6

6.9 PRINTER CIRCUIT........................ 6-7

6-10 SCHEMATIC DIAGRAM................. 6-9

7.ASSEMBLY CONSTRUCTION... 7-1

686770R Service Manual v.

Page 6

Page 7

1. O VERVIEW

Fig. 1-1 Overall View of the Cash Register

686770R Service Manual 1-1

Page 8

1.1 TECHNICAL SPECIFICATIONS

Type: Electronic cash register with 8 departments

Display: Bright double display with 16x6 mm numbers, error symbol, change, subtotal, minus,

total and quantity

Display capacity: 9 digits

Printer: ECR exclusive serial printer

Paper supply: 57 mm wide wood-free single ply tape

Memory protection: Approx. 3 months after power interruption with 4 1.5 V Mignon batteries

Technology: CMOS RAM

Power supply: AC Adapter

Internal Battery

Line voltage: 220 V

Power consumption: Stand-by 2.2 W; operating 4 W

Operating temperature: 0° to 40° C

Dimensions: Depth 425 mm, Width 325 mm, Height 210 mm

Weight: Approx. 6 Kg

1-2 Service Manual 686770R

Page 9

2. SPECIFICA TIONS AND

OPERATING PRINCIPLES

2.1 SPECIFICATIONS

2.1.1 FEATURES

Paper (supplied by the user)

Type: Regular paper roll

Size: Width 57.5 mm ± 0.5 mm

Roll diameter: 80 mm or less

Thickness: 0.06 ~ 0.085 mm

Average weight: 47 g/m2 ~ 64 g/m2 (40 ~ 55 kg/

1000 sheets/1091 x 788 mm)

The Micro Printer is designed for use with calculators.

It offers the following features:

• Ultra-compact and lightweight design.

• Movable type for sharp printing quality.

• High printing speed using a mechanism that can

return the carriage from any column position.

• Silent printing.

• Quick feeding and paper free functions.

• Can run on size AAA manganese batteries (low-

power drive).

• Uses ordinary paper.

• Requires no motor speed control.

2.1.2 SPECIFICATIONS

The main printer specifications are listed below.

Print method

Serial printing with movable type

Carriage width

Maximum of 13 printable columns (including 2 symbol

columns)

Character position

On symbol column side: 12 positions + 2 empty

positions

On numeric column side: 14 positions

Character size

1.6 (W) x 2.8 (H) mm

Intercharacter intervals

Between numerics: 2.1 mm

Between a numeric and a symbol: 2.6 mm

Paper feeding

Typically 4.3 Ips. Fast paper feeding is also possible,

and a paper release mechanism is provided.

Inking

Ink roller method

Ink roller life: 700,000 characters

Standard: IR-30 (IR-40 is also applicable)

Motor

Terminal voltage: 6.0 VDC

Average current: Approximately 0.14 A

(during 13-column, 7-character

shift printing at 6.0 VDC,

25°C/77°F)

Sensor

Mechanical point of contact

Reset signal R, Timing signal T, and Sub-timing

signal t

Trigger coil (electromagnet)

Terminal voltage: 6.0 VDC

D.C. resistance: 16.7 Ω (at 25°C/77°F)

Connection method

Jumper wire on printer side

Guaranteed operating temperature

0° - 40°C / 32° - 104°F

(guaranteed printing temperature:

5° - 40°C/41° - 104°F)

Reliability

MCBF: 300,000 columns

Line spacing

4.6 mm

Print speed

Average printing speed at 6.0 VDC, 13-column printing:

Typically 0.7 I/s

6-column printing: Typically 1.4 I/s

686770R Service Manual 2-1

External dimensions

86 (W) x 58.4 (D) x 19 (H) mm

(3.39 (W) x 2.30 (D) x 0.75 (H) inch)

Weight

Approximately 80 g (0.21Ib)

Page 10

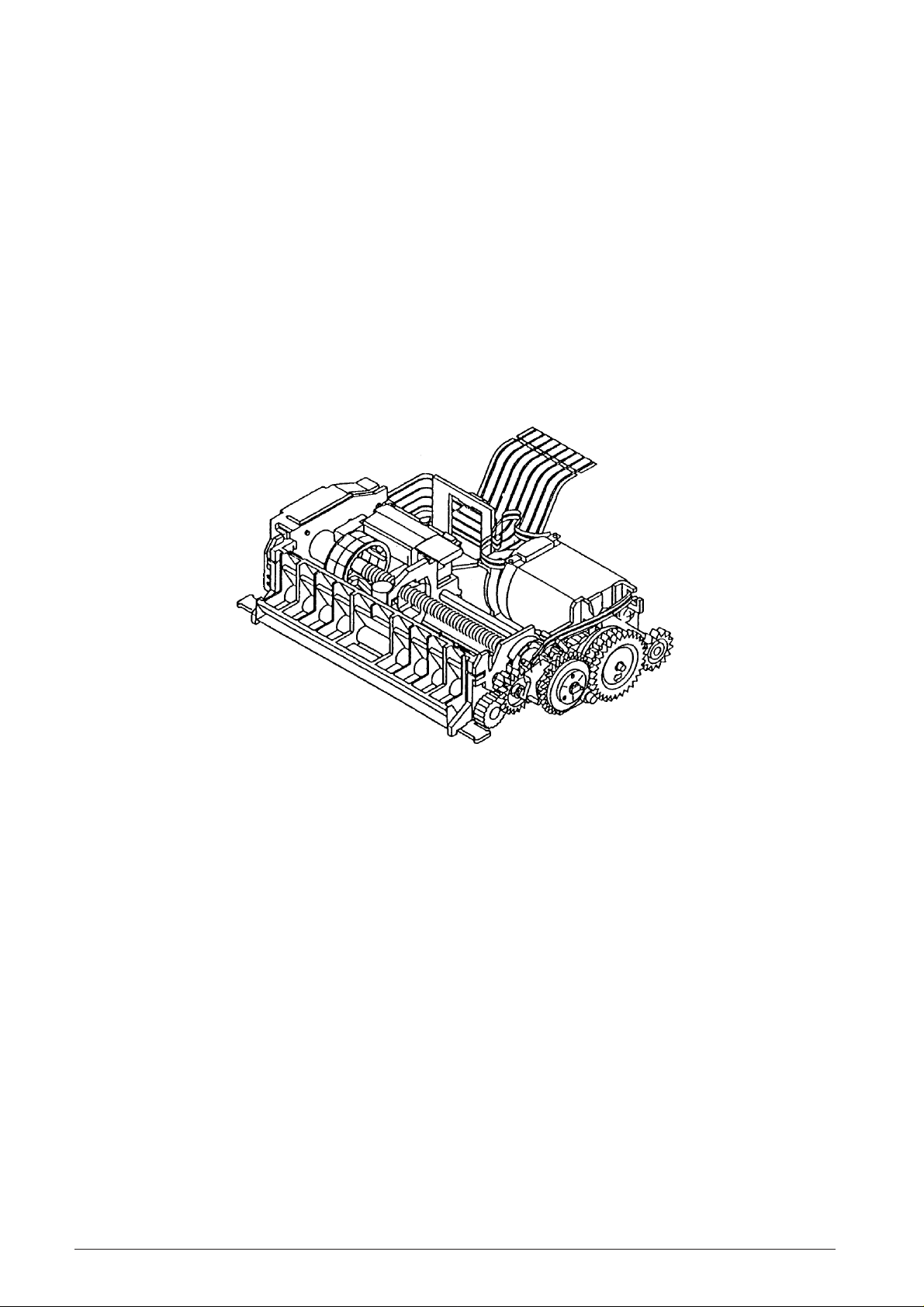

2.1.3 MECHANISMS

This printer consist of two print wheels, a hammer, and

a carriage equipped with an ink roll. It is a serial printer

with movable type, and it prints by sequentially moving

the carriage across from the lowest-order column.

When the motor is activated, the gear trains rotate and

cause the print wheels and detection wheel to rotate.

When the trigger coil charged by a signal (corresponding

a character) output from the sensor, a character is

selected, the print wheel stops, the print gear is rotated

by the action of the planet gear, and a character is

printed.

The carriage then shifts to the next column (columnshift operation). When charge to the trigger coil is

extended during character selection at the end of a line,

printing is performed and the carriage is returned to the

initial column. The paper is then fed forward to complete

the printing of one line.

This printer consist of five mechanism: the transmission

and select, defection, print, inking, and paper feeding.

Fig. 2-1 shows an external view of the Micro serial

Printer. For details on the operating principles and

handling of each mechanism, see Subsection

2.2

Operating Principles

and Maintenance

.

, and Chapter 3

Handling

Fig. 2-1 Exterior View

2-2 Service Manual 686770R

Page 11

2.2 OPERATING PRINCIPLES

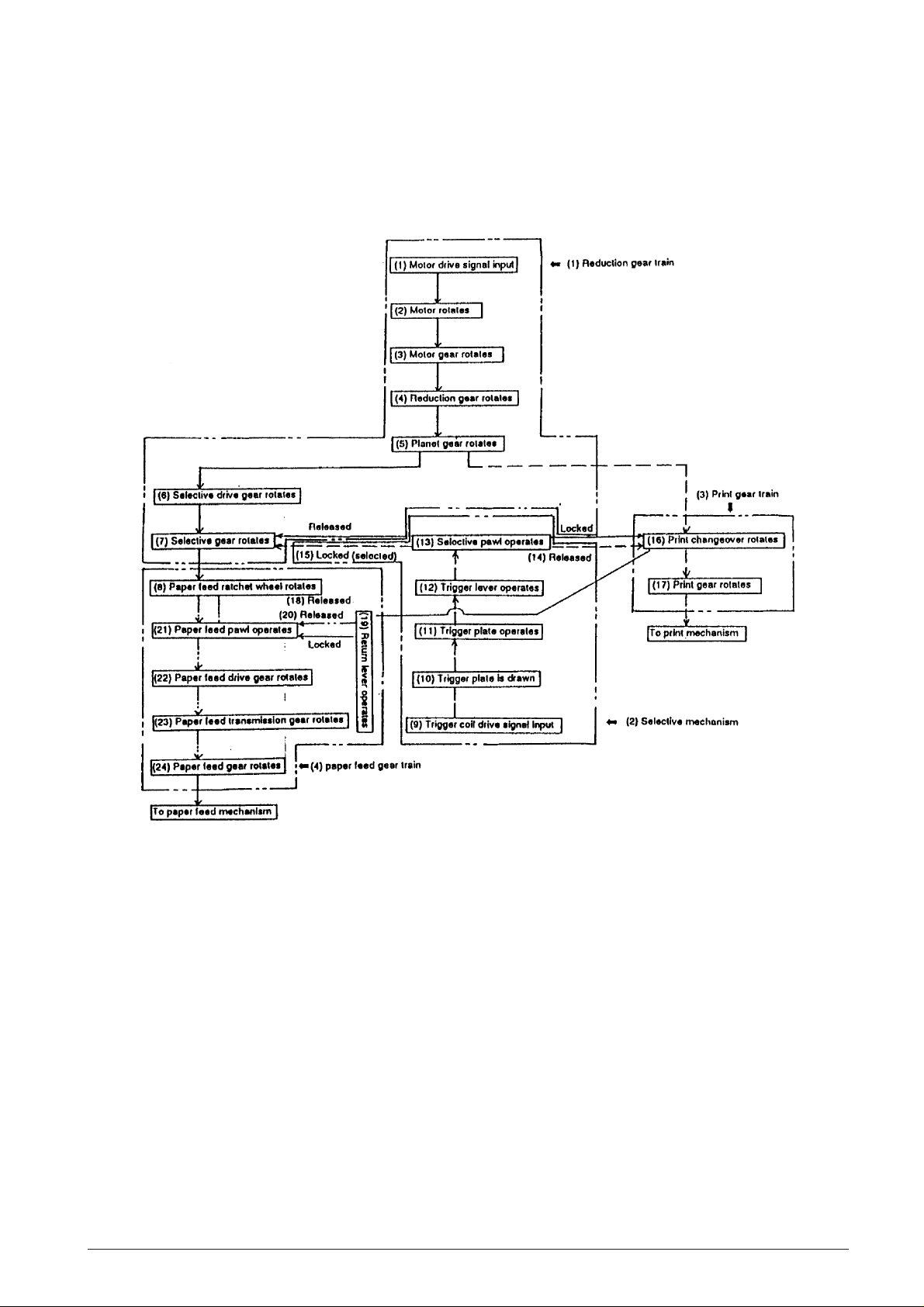

2.2.1 TRANSMISSION/SELECT MECHANISM

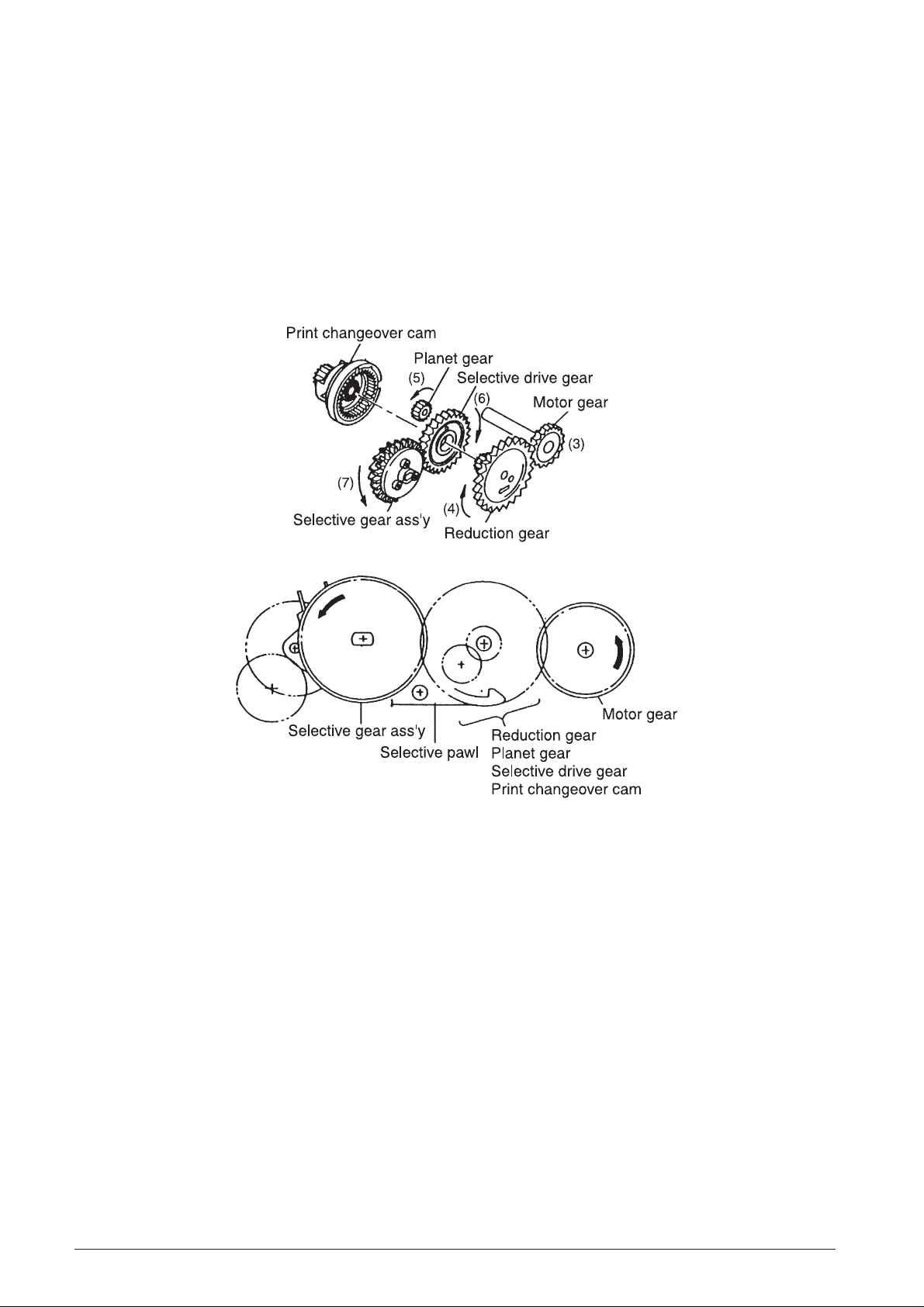

As shown in Fig. 2-2, this mechanism consists of the reduction gear train, and paper feed gear train.

Fig. 2-2 Transmission/Select Mechanism

686770R Service Manual 2-3

Page 12

Reduction gear series

(See Fig. 2-2 and 2-3)

The reduction gear train consists of the motor gear,

reduction gear, planet gear, selective drive gear,

selective gear assembly, selective pawl, and print

changeover cam. When the motor rotates (2), the

rotational force is sequentially reduced from the motor

gear (3) on the same shaft through the gear train to the

selective gear assembly (7).

The rotation of the print changeover cam is locked by

the action of the selective pawl, so the paper feed

ratchet wheel (8) on the same shaft as the selective

gear assembly, the print wheel, and the detection

wheel also rotate at the same time.

Fig. 2-3 Reduction Gear Series

2-4 Service Manual 686770R

Page 13

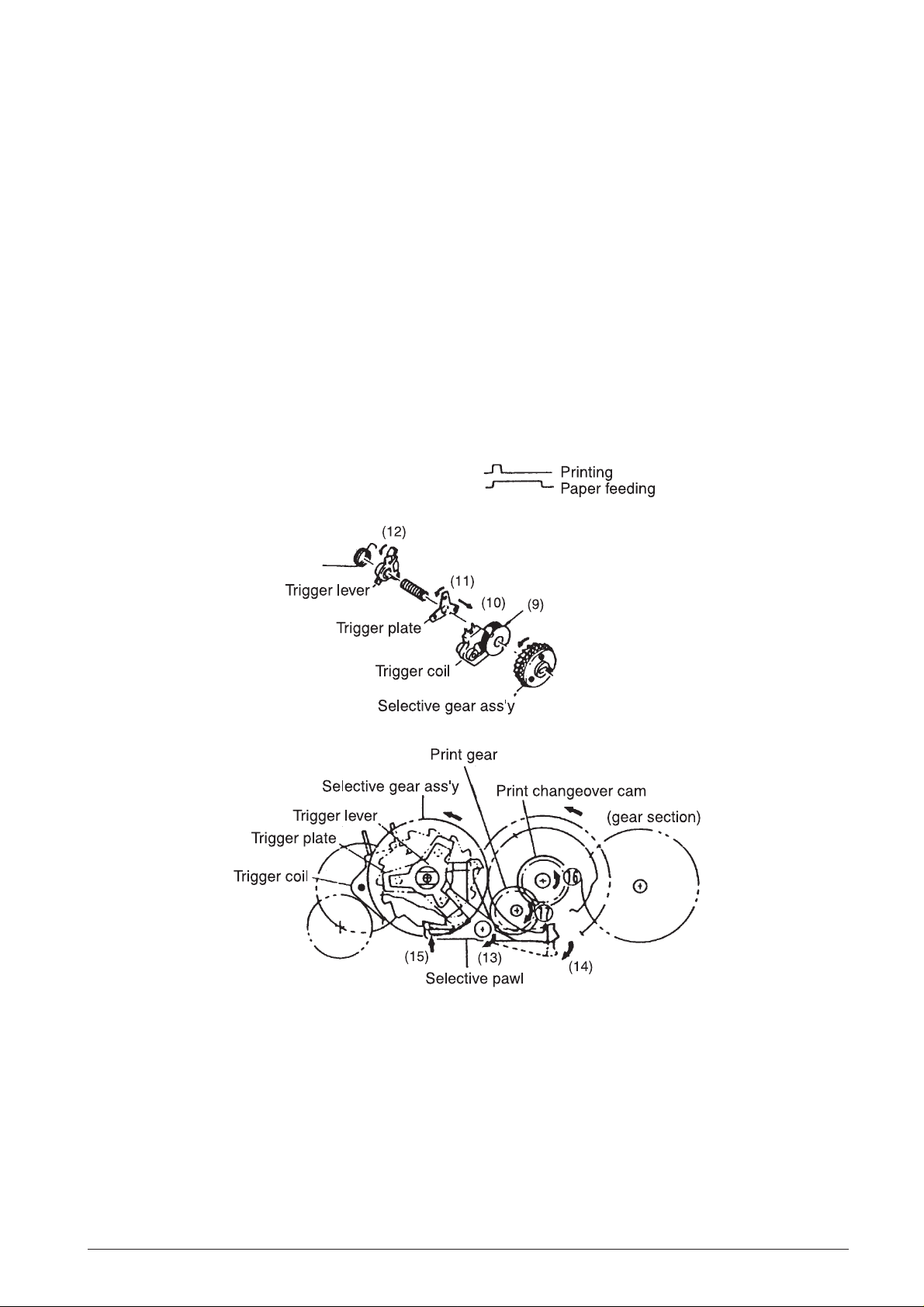

Select mechanism

(See Fig. 2-2 and 2-4)

As shown in Fig. 1-4, the select mechanism consists

of the selective gear assembly, trigger coil, trigger

plate, trigger lever, and selective pawl. The select

mechanism operates during rotation of the reduction

gear series. When a drive signal is input (9) to the

trigger coil in conformance with the timing signal output

from the sensor, the trigger plate is drawn (10) to the

yoke fixed on the selective gear assembly so that the

trigger plate (11), trigger lever (12), and selective pawl

(13) rotate together with the selective gear assembly.

At the same time as the print changeover cam is

unlocked, the selective pawl locks (15) the tooth

section corresponding to the character of the selective

gear assembly. When the selective gear assembly is

stopped, the print wheel mounted on the same shaft

also is stopped, and the character selected.

Print gear series

(See Fig. 2-2 and 2-4)

The print gear series consists of the print changeover

cam and the print gear. When the selective gear

assembly is stopped by the select mechanism, the

interlocked selective drive gear is also stopped. At the

same time, the unlocked (14) print changeover cam is

coupled and is rotated (16) by the planet gear of the

totalling reduction gear series. The print gear thus

rotates (17) and transmits its movement to the printing

mechanism.

Fig. 2-4 Select Mechanism and Print Gear Series

686770R Service Manual 2-5

Page 14

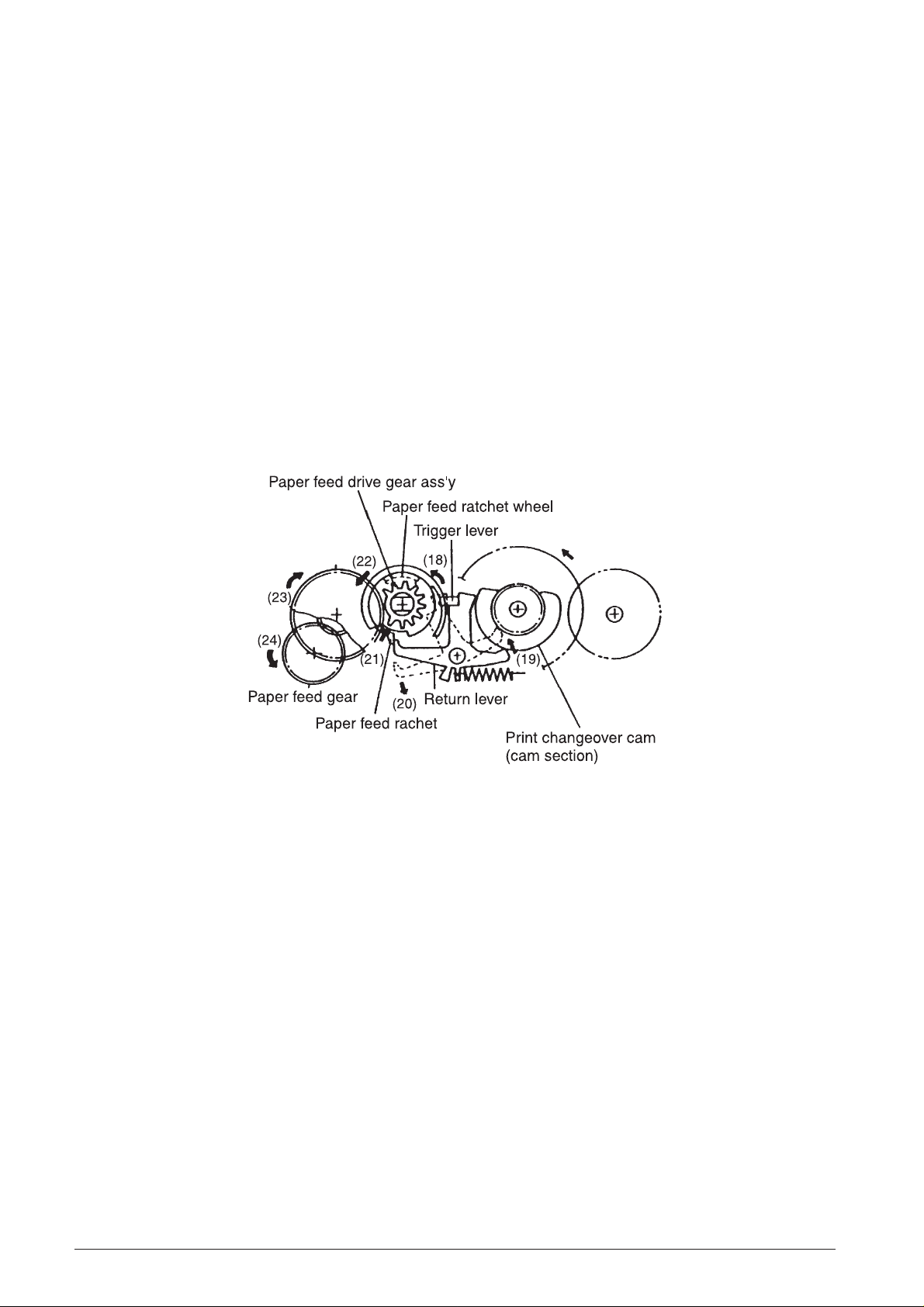

Paper feeding gear series

(See Fig. 2-2 and 2-5)

As shown in Fig. 2-5, the paper feeding gear series

consists of the paper feed ratchet wheel, paper feed

ratchet, paper feed drive gear assembly, paper feed

transmission gear, and paper feed gear.

During column selection or consecutive paper feeding,

the select mechanism and printing gear series operate

by extending the trigger coil drive signal at the first

column during space selection. However, the return

lever and trigger lever are unlocked (18) to maintain the

operation of the trigger plate and trigger lever. When the

print changeover cam rotates, the cam controlling the

return lever reaches a notched section. The return

lever is thereby released and beings operating (19) due

to spring force, and its interlocking with the paper feed

ratchet is cancelled (20).

The paper feed ratchet on the paper feed drive gear

assembly operates (21) due to spring force and

meshes with the teeth of the paper feed ratchet wheel

on the same shaft as the selective gear.

When printing operation is completed, the print

changeover cam causes the selective pawl to return to

its pre-selection status, and the print changeover cam

is stopped. When the selection gear begins rotation,

the paper feed drive gear assembly (22), paper feed

transmission gear (23), and paper feed gear (24) all

rotate together with the paper feed ratchet wheel. This

movement is then transmitted to the paper feeding

mechanism.

Fig. 2-5 Paper Feeding Gear Series

2-6 Service Manual 686770R

Page 15

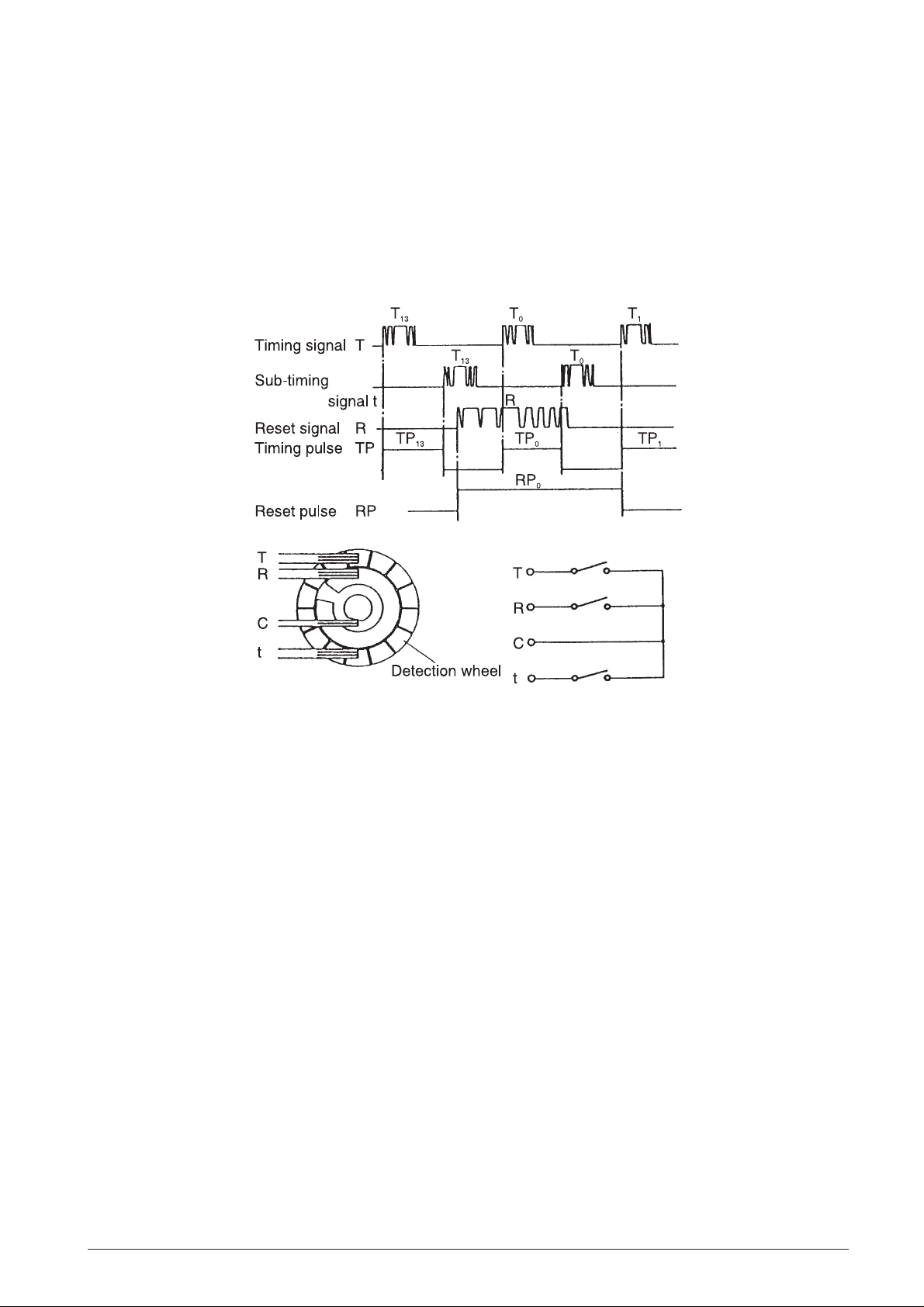

2.2.2 SENSOR MECHANISM

(See Fig. 2-6)

The sensor mechanism consists of the sensor as-

sembly and the sensor gear. The sensor employs a

mechanical contact-point system and generates a

timing signal T and a sub-timing signal t in correspondence to each character position on the print

wheel.

The sensor also generates a reset signal at each

rotation of the print wheel. Waveform rectification of

these signals should be performed by the user, as

timing or reset pulses.

Fig. 2-6 Sensor Mechanism

686770R Service Manual 2-7

Page 16

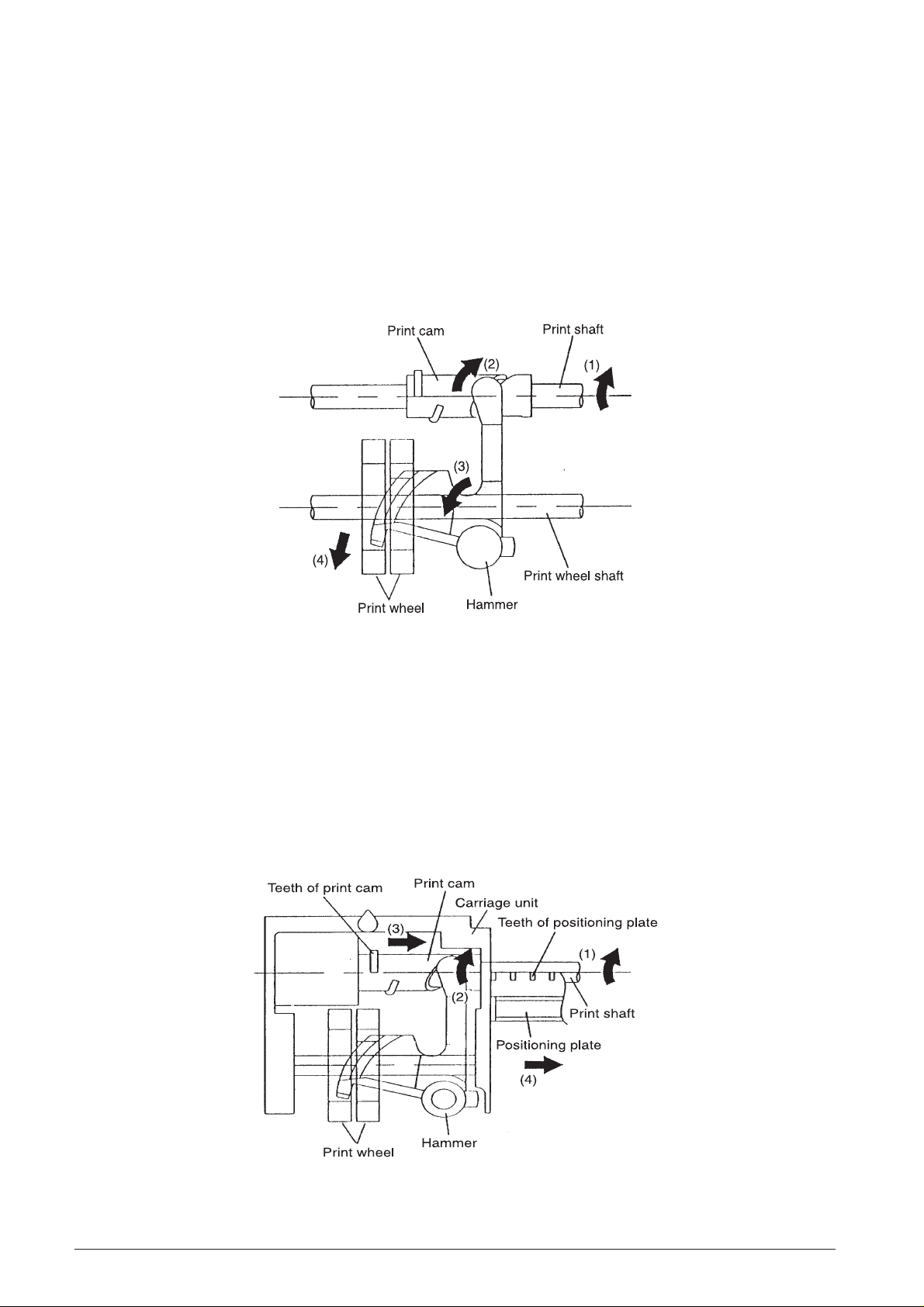

2.2.3 PRINT ING MECHANISM

The printing mechanism performs two operations:

printing and carriage movement.

Printing operation

(See Fig. 2-7)

When the print gear series (see Subsection 2.2.1,

Transmission/Select Mechanism)

shaft and print cam to rotate in the direction of a

arrows (1) and (2), the hammer rotates in the direction

of ➡ arrow (3).

causes the print

Thus, the print wheel is pressed in the direction of ➡

arrow (4) by the hammer, and printing is performed.

The print wheel, similar to the print changeover cam,

rotates once with each printing operation, and printing

is performed during the first half of the print shaft

rotation.

Fig. 2-7 Printing Operation

Carrying operation

(See Fig. 2-8)

Carrying is performed after printing, during the sec-

ond half of the print shaft rotation. As soon as the

positioning plate begins rotating the print gear, the

cam section of the print gear unlock its meshing the

return lever, and the print gear meshes with the print

cam.

When the print shaft rotates in the direction of ➡ arrow

(1), the meshing between the teeth of the print cam

and the teeth of the positioning plate causes the print

shaft to slide in the direction of ➡ arrow (2) while

rotating in the direction of ➡ arrow (3). The simultaneously with this carriage unit is carried sliding action

(➡ arrow (4))

Fig. 2-8 Carrying Operation

2-8 Service Manual 686770R

Page 17

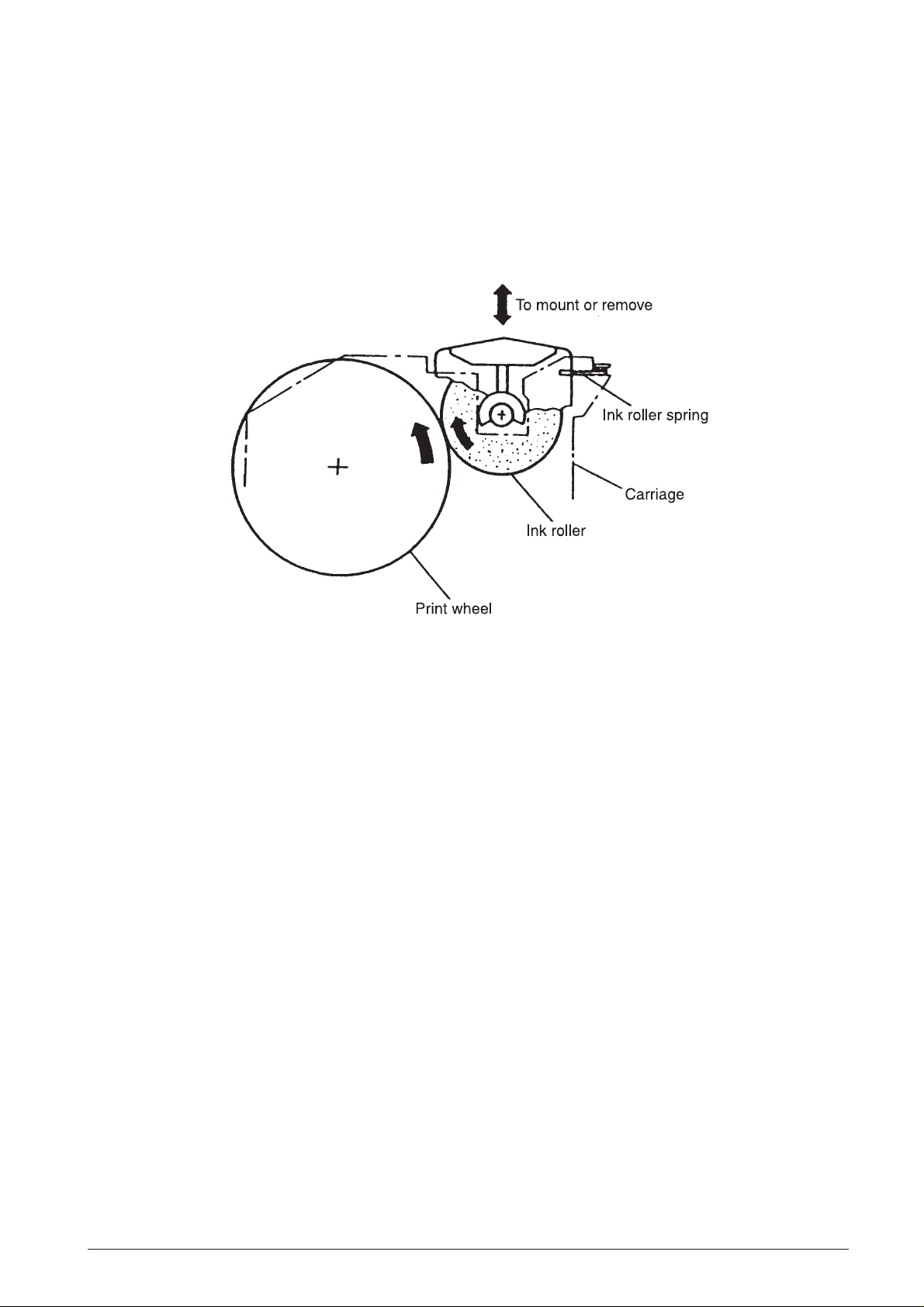

2.2.4 INKING MECHANISM

(See Fig. 2-9)

The ink roller is held lightly against the other periphery

of the print wheel by the force of the ink roller spring.

When the print wheel rotates, the ink roller also

rotates and supplies ink to the wheel.

Fig. 2-9 Inking Mechanism

686770R Service Manual 2-9

Page 18

2.2.5 PAPER FEEDING MECHANISM

The paper feeding mechanism performs two operations: carriage return and paper feeding.

Carriage return operation

(See Fig. 2-10)

The paper feeding gear series (see Subsection 2.2.1,

Transmission/Select Mechanism

lever to drop into the cam section of the print

changeover cam so that it meshes with the positioning plate (➡ arrow (1) and (2)).

) causes the return

The rotation of the print changeover cam restores the

return lever to its original position (➡ arrow (3)) and

rotates the positioning plate with which it is meshed

(➡ arrow (4)).

As a result, the teeth of the positioning plate and print

cam are disengaged (5), and the force of the print

wheel spring and carriage spring returns the carriage

(➡ arrow (6)).

Fig. 2-10 Carriage Return Operation

2-10 Service Manual 686770R

Page 19

Paper feeding operation

(See Fig. 2-11)

Paper is feed while the paper feed drive gear assem-

bly performs one rotation. When the paper feeding

gear series (see Subsection 2.2.1,

Select Mechanism

rotate in the direction of ➡ arrow (1), the paper feed

roller within the platen also rotates in the direction of

➡ arrow (2), and the paper is fed by friction between

the paper hold roller and the paper feed roller.

) causes the paper feed gear to

Transmission/

When the paper feed ratchet within the paper feed drive

gear assembly strikes the return lever, it disengages

from the paper feed ratchet wheel, the rotation of the

paper feed drive gear assembly stops, and paper

feeding terminates.

Fig. 2-11 Paper Feeding Operation

686770R Service Manual 2-11

Page 20

2.2.6 PRINT CYCLE INITIALIZATION

To confirm that carriage is in stand-by status (at the

first column), initialization must be performed prior to

printing and paper feeding. Initialization is completed

by performing a line feed. The following paragraphs

describe printer timing operations for printing and

paper feeding.

Printing of the first line

1) The Timing pulses TP are counted after the motor

drive signal is applied and the motor is activated.

The reset pulse RP appearing after eight timing

pulses is regarded as RPo, and the first timing

pulse TP after RPo rises is regarded as TPo.

2) Character selection (first column)

The trigger coil drive pulse is applied to the trigger

coil during the interval from timing pulse TPn to

TPn + 1 which corresponds to the desired character. At that time, the timing pulse interval (TPn to

TPn +1) is measured to obtain TW1. Following

character selection, the print wheel stops (the

timing pulse retains the TPn + 1 status). Printing

and carrying are then automatically executed.

3) Character selection (second column and onward)

The print wheel starts rotating again and the first

timing pulse is TPn +2. Character selection can be

performed from next timing pulse TPn + 3. The

rest of the character selection operation is identical to that described in step 2) above.

4) Carriage return and paper feeding

During character selection for the highest-order

column of a line of print, printing, carriage return,

and paper feeding are performed by adding: [the

width of the drive pulse to the trigger coil] + [the

timing pulse interval TW2 (TPn to TPn + 1) at that

time] + [(the TP interval TW1 measured during the

selection of the first column) x 6].

5) Motor off

After completing the highest order printing in one

line, the print wheel begins to rotate and timing

pulse TP is generated. Counting from this initial

rising pulse, the motor drive signal is cut off at the

rise of the 14th timing pulse TP.

NOTE:

• The first timing pulse generated after the print

column-shift process (TPn + 2) cannot be used for

character selection.

Consecutive printing

1) The process for printing the initial line similar to

that for “Printing the first line” above.

2) Printing of second and later lines begins as

follows:

After printing the first line, the following pulses TP

are counted with the motor still driven. Printing of

the first column of the second line then begins at

the rise of the 14th timing pulse in cases where the

number of columns in the first line is 7 or less,

otherwise, printing begins at the 21st timing pulse.

The same procedures as those in steps 2) to 4) of

“Printing the first line” above are then performed.

3) Consecutive printing is performed by repeating

step 2) above.

4) Motor off

Step 5) of “Printing the first line” above is per-

formed.

Paper feeding for the first line

1) The timing pulses TP are counted after the motor

drive signal is applied and the motor is activated.

The reset pulse RP appearing after eight timing

pulses is regarded as RPo, and the first timing

pulse TP after RPo rises is regarded as TPo.

2) Paper feeding

The empty character TP10 is selected. At that

time, the timing pulse interval TP10 to TP11 is

measured to obtain TW1. When the width of the

trigger coil drive pulse equals the measured TW1

plus six times TW1, the empty character on the

print wheel is selected and the paper is fed.

3) Motor off

After the paper is fed for one line, the print wheel

begins to rotate. Counting from the initial rising

timing pulse, the motor drive signal is cut off at the

rise of the 14th timing pulse TP.

Fast paper feeding

1) The process for feeding the initial line is similar to

that for “Paper feeding for the first line” above.

2) Paper feeding for the second and later lines begins

as follows: after completing the paper feeding for

the first line, with the motor remaining driven, the

following timing pulses TP are counted. From the

rise of the 21st timing pulse, selection of the empty

character TP10 becomes possible. Step 2) of

“Paper feeding for the first line” above is then

performed.

3) Fast paper feeding is performed by repeating step

2) above.

4) Motor off

Step 3) of “Paper feeding for the first line” above

is performed.

2-12 Service Manual 686770R

Page 21

3. HANDLING, MAINTENANCE

3.1 HANDLING THE PRINTER

3.1.1 PRECAUTIONS ON PRINTER

HANDLING

Transport precautions

(See Fig. 3-1)

1 ) When transporting the printer, never carry it by the

jumper lead only.

2 ) Avoid impact to the printer by dropping, striking it,

or collision with another printer.

Fig. 3-1 Proper Handling of Printer

Storage precautions

• Avoid storage in locations exposed to excessive

dirt, dust, moisture, or in direct sunlight.

• For long-term storage (over one month), place the

printer in a polyethylene bag after wrapping it in

anti-rust (VPI) paper, then store it in a dry location.

686770R Service Manual 3-1

Page 22

Use precaution

• Since the printer employs a permanent magnet (in

the motor section), avoid using it in locations

exposed to excessive iron filings, dirt, dust, or

other foreign particles.

• Never use the printer without the paper and ink

roller installed.

• Make sure to use only the specified paper and ink

roller.

• The ink roller is a disposable part; do not attempt

to refill its ink supply.

3.1.2 PAPER INSTALLATION

Loading the Paper

When loading the paper into the printer, make sure to

heed the following points.

Paper insertion

Insertion the paper into the printer with the paper roll

positioned as shown in Fig. 3-2.

Paper insertion precautions

• Insert the paper straight into the paper entrance.

Never insert paper having an uneven leading

edge; never insert paper at a slant.

• Push the paper in the feeding direction to make

insertion easier.

Removing the paper

Remove the paper by following one of the two methods below:

• Perform paper feed using an electrical operation:

Switch on the printer, press the Paper Feed button,

and remove the paper.

• The paper release mechanism in stand-by status

allows the paper to be freely removed by pulling it

out the printer. Pulling out the leading edge of

the paper at a slant may cause jamming.

Fig. 3-2 Paper Insertion

Leading edge of the paper roll

The leading edge of the paper from the paper roll should

be cut straight as shown in Fig. 3-3.

Fig. 3-3 Leading Edge of the Paper Roll

3-2 Service Manual 686770R

Page 23

3.1.3 INK ROLLER INSTALLATION

Mounting the Ink roller

(See Fig. 3-4)

• Place the ink roller in the cutout sections of the

carriage, then press down gently until it clicks into

place.

Fig. 3-4 Ink Roller Installation

Replacing the ink roller

(See Fig. 3-5)

• Press the knob of the ink roller in the direction of

the ➡ arrow, then lift the ink roller up and out of the

carriage.

Fig. 3-5 Ink Roller Replacement

686770R Service Manual 3-3

Page 24

3.2 MAINTENANCE

3.2.2 INSPECTION

To prevent potential trouble, make sure cleaning and

inspection is carried out according to the points described in the following subsections, depending on the

environment in which the printer is used.

3.2.1 CLEANING

Eliminating dirt or stains

Wipe off soiled areas using alcohol or benzene.

Eliminating dust, scraps, and other foreign particles

Use a vacuum cleaner to carefully draw out all foreign

particles from every area of the printer.

NOTES:

Never use thinner, tricholyene, or ketone solvent as

they may deteriorate or damage plastic parts. Check

the lubricant remaining in each cleaned area and

perform lubrication as required (see Subsection 3.3.2,

Lubrication Points

).

3.3.2 LUBRICATION POINTS

Check the printer to see if it is being operated properly

and if it is being maintained in optimum condition. If

any unsatisfactory points are discovered, they should

be remedied. In particular:

• Make sure that the ink roller is securely installed

in the carriage.

• Make sure that the ink roller in use conforms to the

specifications. Check the ink roller for damage,

and replace it if it is affecting print quality.

3.3 LUBRICATION

3.3.1 LUBRICANT TYPES

The types of oil used greatly influence the performance and durability of the printer, especially at low

temperatures.

No. Lubrication Point Oil Type

(1) Contact point between selective gear assembly and trigger plate O-3

(2) Contact point between print shaft and frame (2 points) O-3

(3) Outer surface of print shaft O-3

(4) Outer surface of print wheel shaft O-3

(5) Contact point between print cam and hammer spring O-3

(6) Contact point between print cam and the positioning plate O-3

(7) Contact point between positioning shaft, frame, and return lever (3 points) O-3

(8) Contact point between reduction gear and the E-ring O-3

(9) contact point between selective drive gear and reduction gear O-3

(10) Contact point between selective pawl and print changeover cam O-3

3.3.3 LIST OF LUBRICANTS

Item Designation Volume

Oil O-3 40 gm

Grease G-34 40 gm

3-4 Service Manual 686770R

Page 25

3.4 PROBLEM RESOLUTION

In general, the printer should be replaced when problems arise. Depending on the particular problem, however,

the printer may be easily repaired. Therefore, take necessary corrective actions according to the following table.

In the case of problems for which no corrective actions exist in this table, the printer should be replaced.

686770R Service Manual 3-5

Page 26

3-6 Service Manual 686770R

Page 27

3.5 PRINTER PIN ASSIGNMENTS

Fig. 3-6 illustrates the pin assignments of the printer

circuitry.

NOTE:

The printer sensor side is regarded as “1”.

Fig. 3-6 Pin Assignment Diagram

686770R Service Manual 3-7 .

Page 28

Page 29

3.6 TIMING CHART

686770R Service Manual 3-9.

Page 30

Page 31

4. DISASSEMBLY PROCEDURE/HOW TO LOCATE THE ASSEMBLIES

Fig. 4-1 Cash Register Front View

4.1 HOW TO LOCATE THE POWER ASSEMBLY

Fig. 4-2 Cash Register Rear View

686770R Service Manual 4-1

Page 32

4.2 THE REMOTE BATTERIES/

LOCATION OF ON/OFF SWITCH

• Remove the cover (1).

• Remove the paper roll and roll holder.

• Remove the battery housing cover (2) in the direc-

tion of the arrow.

Fig. 4-3 Locating the Battery Compartment and Printer Cover

Fig. 4-4 Locating the ON/OFF Switch

4-2 Service Manual 686770R

Page 33

4.3 MACHINE DISASSEMBLY REASSEMBLY

4.3.1 MACHINE CASE

Disassembly

• Unplug the machine power cord from the electrical

wall outlet.

• Loosen screw (1)

• Push the case of the machine (2) in the direction of

the arrow (3).

• Remove the case (2) by lifting it the direction of

arrow (4).

Reassembly

• Correctly position the case on the machine.

• Push the case (1) in the direction of arrow (5).

• Tighten screw (1).

• Plug the machine power cord into the electrical wall

outlet.

Fig. 4-5 Machine Case Disassembly/Reassembly

4.3.2 PRINTER UNIT

Disassembly

• Remove the printer compartment cover (1).

• Remove the machine case (2).

• Disconnect connector (3).

• Using a screwdriver, remove screw (4) that secures

the paper support (5) and remove this support.

• Remove the printer (6) in the direction of the arrow

shown being careful to avoid damaging the

connection cables.

Reassembly

• Correctly position the printer (6) as shown in the

figure.

• Correctly position the paper support (5) and tighten

its related securing screw (4).

• Reattach the connector (3).

• Refit the case of the machine (2) and the printer

compartment cover (1).

Fig. 4-6 Printer Unit Disassembly/Reassembly

686770R Service Manual 4-3

Page 34

4.3.3 MAIN BOARD AND DISPLAY

Disassembly

• Remove the machine case.

• Disconnect the printer connector (1).

• Disconnect the paper feed motor connector (2).

• Disconnect the keypad connectors (3).

• Disconnect the battery supply connectors (4).

• Disconnect the power supply connector (5).

• Disconnect the battery supply

connector (6).

• Using a screwdriver, remove the securing

screws (7).

• Remove the main board (8).

Reassembly

Perf orm the disassembly procedure in reverse order .

Fig. 4-7 Main Board and Display Disassembly/Reassembly

4.3.4 PAPER FEED MOTOR

Disassembly

• Remove the machine case.

• Disconnect the motor power supply connector (1).

• With a screwdriver, remove securing screws (2).

• Remove motor (3) with its related support (4).

Reassembly

• Correctly position motor (3).

• Tighten securing screws (2).

• Reconnect the motor power supply connector (1).

• Refit the machine case.

Fig. 4-8 Paper Feed Motor Disassembly/Reassembly

4-4 Service Manual 686770R

Page 35

4.3.5 BATTERY COMPARTMENT

Disassembly

• Remove the machine case.

• Remove the securing screws (1).

• Remove the battery compartment.

Fig. 4-9 Battery Compartment Disassembly/Reassembly

4.3.6 KEYP AD

Reassembly

• Perform the disassembly procedure in reverse

order.

Disassembly

• Remove the machine case.

• Disconnect the keypad - main board connectors (1).

• Using a screwdriver, remove securing screws (2).

• Remove the keypad (3) together with the machine’s

ON/OFF switch (4).

Reassembly

• Correctly position the keypad (3) and the ON/OFF

switch (4).

• Tighten the securing screws (2).

• Restore connection (1).

• Refit the machine case.

Fig. 4-10 Keypad Disassembly/Reassembly

686770R Service Manual 4-5

Page 36

Page 37

5. BLOCK STRUCTURE CHART

As illustrated in the Chapter 6.

5.1 CIRCUITRY

Functions in each circuit is explained below block by

block.

• Block A: Display Control

LCD driver is included in the main CPU and is

directly driven by ports below.

* COM 0 - COM 1 - COM 2

* SEG 0 - SEG 25 - SEG 32 - SEG 33

LCDs are 1/3 duty,1/2bias.

• Block B: Scan Signal for Key switch, Mode

switch and Paper feed key:

Scan Signal Output Ports: from ports P07 - P12P60 and P61 , by High-active scan output.

Key switch: when P54 - P57 are depressed, they

are accepted as return input of the key matrix.

Mode lock switch and Feed key: P53 is read in as

a return input.

* To prevent input errors caused by chattering,

data will be read twice before accomplishing key

input.

• Block E: Buzzer:

When Port P45 gets high, oscillating signals programmed at NAND gate make transistor 2SA2603

on/off and make the buzzer buzz.

• Block F: Reset Circuit:

Reset IC works to reset main CPU.

• Block G: Black-Out Detection Signal:

Blackout signal is generated when voltage in Vcc

line drops to 3.0 V. This signal gets “low” at the

time of blackout and is transferred to Port 42 for

CPU to dispose it. Once blackout is detected, X

IN halts and only X CIN oscillates to turn the cash

register for electric consumption mode. Backup

currency at this time is about 10-40 uA.

• Block H: Printer Control:

• Motor Drive: P51 (low active)

• Printing Trigger: P50 (low active)

• Timing Signal: P43

• Reset: P44

NOTE:

Waveforms for timing signals and reset signals

are shaped by flip-flop at NAND gate.

• Block I: Circuitry:

This machine operates both by dry batteries and

with use of AC adaptor. Inserting an adaptor jack

automatically disconnect the battery circuit.

Voltage at each power line is as follows (at rated

voltage input).

VBB: 6.0 V (with backup)

Vcc: 6.0 V

Vprm: 6.0 V (when printer is not working)

V BB / V cc are provided via a stable circuit that

uses 3-terminal regulator (S81250HG).

NOTE:

1 ) Reset does not work when backup function is

working.

2) CPU needs to be reset at the first setting up,

otherwise normal operation would be hindered.

To secure normal operation, first install operation batteries worth OFF mode. Next turn the

key to REG1 mode, then place memory backup

batteries.

686770R Service Manual 5-1

Page 38

Page 39

6. SCHEMATICS AND DIAGRAMS

6.1 SYSTEM BLOCK DIAGRAM

Fig. 6-1 System Block Diagram

686770R Service Manual 6-1

Page 40

6.2 POWER SUPPLY CIRCUIT

Fig. 6-2 Power Supply Circuit

6-2 Service Manual 686770R

Page 41

6.3 RESET CIRCUIT

Fig. 6-3 Reset Circuit

6.4 POWER FAIL CIRCUIT

Fig. 6-4 Power Fail Circuit

686770R Service Manual 6-3

Page 42

6.5 DISPLAY CIRCUIT

Fig. 6-5 Display Circuit

6-4 Service Manual 686770R

Page 43

6.6 KEYBOARD CIRCUIT

Fig. 6-6 Keyboard Circuit

686770R Service Manual 6-5

Page 44

6.7 BUZZER CIRCUIT

Fig. 6-7 Buzzer Circuit

6.8 BATTERY CIRCUIT

Fig. 6-8 Battery Circuit

6-6 Service Manual 686770R

Page 45

6.9 PRINTER CIRCUIT

Fig. 6-9 Printer Circuit

686770R Service Manual 6-7 .

Page 46

Page 47

6.10SCHEMATIC DIAGRAM

686770R Service Manual 6-9.

Page 48

Page 49

7. ASSEMBLY CONSTRUCTION

686770R Service Manual 3-11

7-1.

Page 50

Page 51

REF. CODE DESCRIPTION

SPARE PAR TS CATALOGUE

IMPORTANT

This publication is written by TA TRIUMPH-ADLER Vertriebs GmbH (Service Department).

This document is the only document to which reference may be made for ordering spare

parts

Spare parts should be ordered at the following address: TA Triumph-Adler Vertriebs GmbH

Service Department

Fürther Straße 212

Nuremberg

November 1998

Subject to Alterations

686770R

Spare parts catalogue

TA Triumph-Adler Vertriebs GmbH

Fürther Straße 212

90429 Nürnberg

A - 1

Page 52

EXPLODED PARTS

REF. CODE DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

037498 N

037499 P

037500 U

037502 J

037503 K

037504 L

128710 D

037505 M

037506 N

037507 P

037508 Y

037509 Z

037510 M

037511 A

037512 B

037513 C

037514 D

037515 E

MAIN BOARD

M38203M4-374FP

DISPLAY LCO- B5180A

COMPLETE KEYBOARD ASSEMBLY

KEY DRAWER

PRINTER M31-041

MOTOR

DRAWER GROUP

COVER ASSEMBLY

PRINTER COVER

FRONT COVER

DEPOSIT DRAWER

WINDING REEL

BATTERY BOX

BATTERY COVER

DISPLAY FILTER

CAM LOCK KEYSET

AC ADAPTOR

A - 2

Spare parts catalogue

686770R

Page 53

EXPLODED PARTS

REF. CODE DESCRIPTION

17

10

16

9

3

4

15

2

14

1

18

13

7

11

5

6

686770R

12

Spare parts catalogue

8

A - 3

.

Page 54

Page 55

STST

AA

TT

A

AA

T

TT

UPDUPD

UPD

UPDUPD

O DI AO DI A

O DI A

O DI AO DI A

ST

STST

DATA PAGINE AGGIORNATE PAGINE CODICE

DATE UPDATED PAGES PAGES CODE

2/1999 1aEDIZIONE - 1st EDITION 55 686770R-00

GGIORNAMENTGGIORNAMENT

GGIORNAMENT

GGIORNAMENTGGIORNAMENT

AA

TING STTING ST

A

TING ST

AA

TING STTING ST

AA

TUSTUS

A

TUS

AA

TUSTUS

OO

O

OO

Loading...

Loading...