Page 1

HCT-1000

HCT-1000

User Guide

HCT-1000用户指南

HCT-1000使用者指南

HCT-1000ユーザーガイド

HCT-1000 사용설명서

Page 2

1

INTRODUCTION

The HCT-1000 is a hand-held convection rework tool. It features digital controls, multiple

modes of operation, internal or external feedback control and integrated vacuum pick-up

for component placement and removal. Additionally, this unit may be connected to the

PCT-1000 as part of the Modular Rework System.

CONTENTS

1. Safety & Warranty 1

2. Specifications 2

3. Unit identification 3

4. Setup and unit operation 4, 5 & 6

5. Additional Features 6

6. Nozzle Information 7

7. Operation 8

8. Troubleshooting 8

9. Maintenance 9

SAFETY

Intended Use:

WARNING: Use of this equipment in ways other than those described in this User Guide

may result in injury to persons or damage to property. Use this equipment only as

described in this User Guide.

OK International cannot be responsible for injuries or damages resulting from unintended

applications of its equipment. Unintended uses may result from taking the following

actions:

• Making changes to equipment that has not been recommended in the User Guide

• Using incompatible or damaged replacement parts

• Using unapproved accessories or auxiliary equipment

Safety Precautions:

• Do not operate this unit in excess of maximum ratings/settings

• Always wear appropriate personal protective clothing or apparel

• This equipment is for indoor use only

Warranty

OK International warrants the HCT-1000 hand-held convection rework tool power supply

against any defects in materials or workmanship for one (1) year from the date of

purchase by the original owner.

OK International warrants the HCT-1000 hand-held convection rework tool hand-piece

(HCT-HV1) against any defects in materials or workmanship for one (1) year from the

date of purchase by the original owner.

OK International warrants the HCT-1000 heater assembly (HCT-HTRASSY) against any

defects in materials or workmanship for ninety (90) days from the date of purchase by

the original owner.

This Warranty excludes normal maintenance and shall not apply to any opened,

misused, abused, altered or damaged items. If the product should become defective

within the warranty period, OK International will repair or replace it free of charge at its

sole option. The replacement item(s) will be shipped, freight prepaid, to the original

purchaser. The warranty period will start from the date of purchase. If the date of

purchase cannot be substantiated the date of manufacture will be used as the start of

the warranty period

!

Page 3

2

2. HCT-1000 SPECIFICATIONS

Size

9” x 7” x 6” (229 mm x 178 mm x 152 mm)

Weight

12lbs

Input Voltage

100-240 VAC, 50/60 Hz

Rated Power

600W

Pollution Degree Category

II

Storage Temperature

-10°C to 60°C (14°F to 140°F)

Operating Temperature

0°C to 50°C (32°F to 122°F)

Air Pump Type

Diaphragm

Air Flow

5-25 l/min

Vacuum Pump

15” Hg (381 mm Hg)

Control Temperature

450°C

Surface Resistivity

107Ω to 1011Ω

Noise Level

< 55 dB

Certifications

TUV

Max. Relative Humidity

80% for temperature up to 31°C (87.8°F) Decreasing

linearly to 50% relative humidity at 40°C (104°F)

System Modes

HCT, MRS

Operational Modes

Setup, Run, Manual, Active Setup

Memory Locations

50

Display

LCD 20 X 4 display segments

Description

HCT-PS1000

HCT-1000 Power Supply

HCT-HV1

Hand-piece with integral vacuum, cord and connector

HCT-FS2

Footswitch, Dual, HCT-1000

HCT-NC

Nozzle Carrier, HCT-1000 nozzles

HCTA-TH1

Hand-piece tool Holder

HNA-1

Nozzle Adapter

HCTA-NW1

Nozzle Wrench

HCTA-VCT1

Vacuum Cup Tool

Accessories

HCTA-VC24

Vacuum Cup, 3/32” (2.38mm)

HCTA-VC50

Vacuum Cup, 3/16” (5.00mm)

HCTA-VC64

Vacuum Cup, ¼” (6.4mm)

HCTA-VC80

Vacuum Cup, 5/16” (8mm)

HCTA-VC11

Vacuum Cup, 7/16” (11mm)

HCTA-ASC

Anti-seize Compound

AC-TCK-24-36

Thermocouple

HCTA-CC

Communications Cable

HCT-HTRASSY

Heater Assembly

Page 4

3

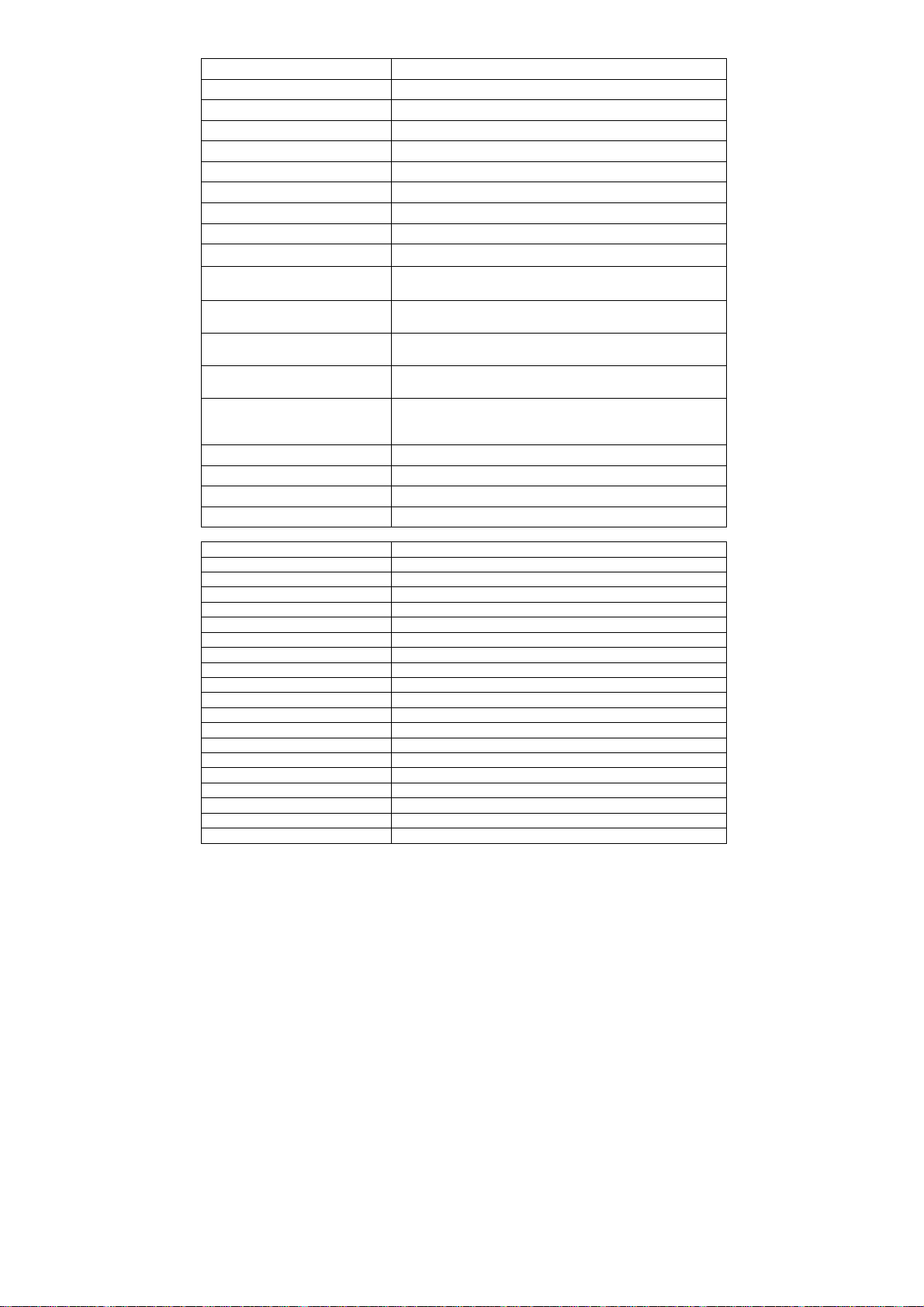

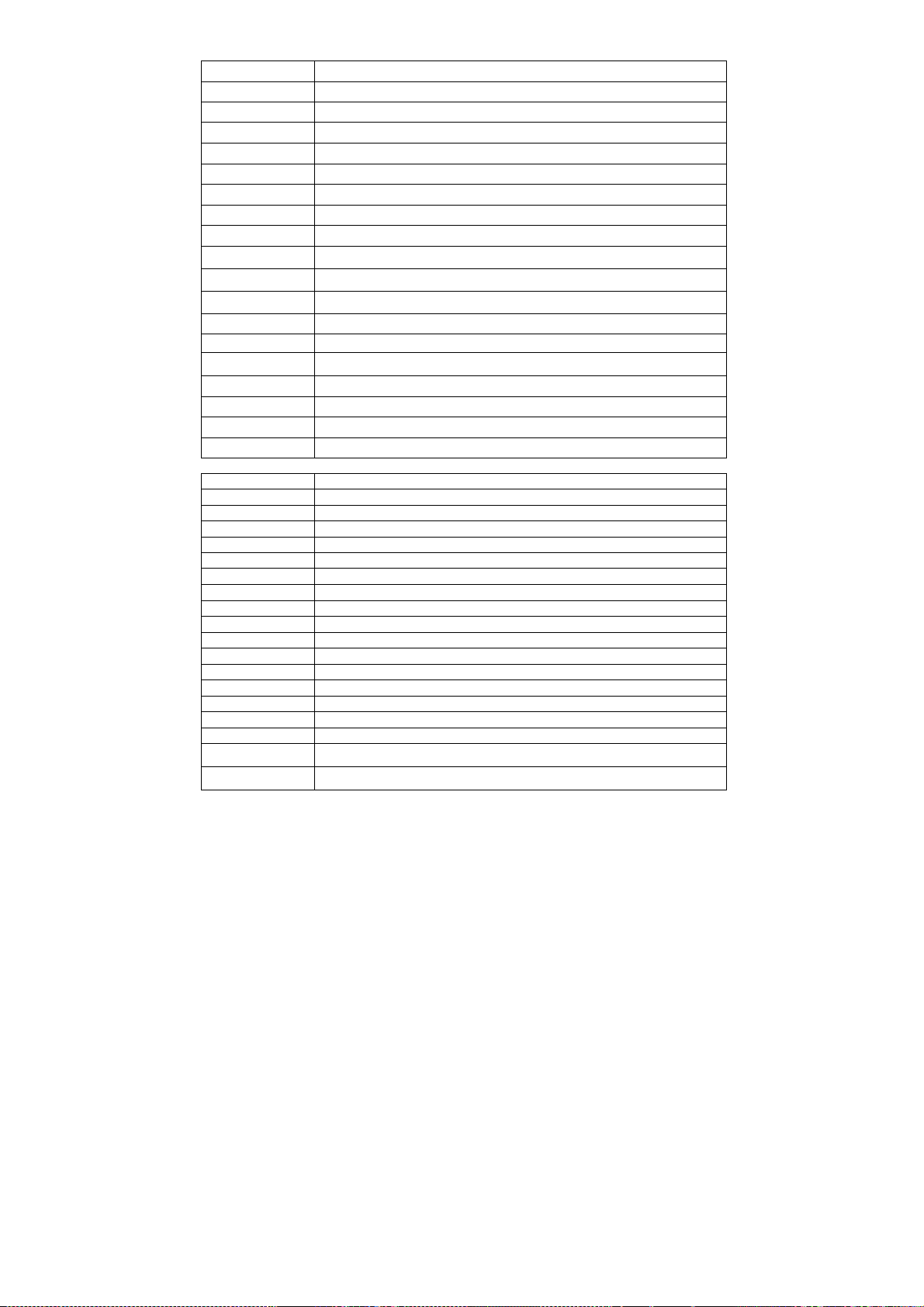

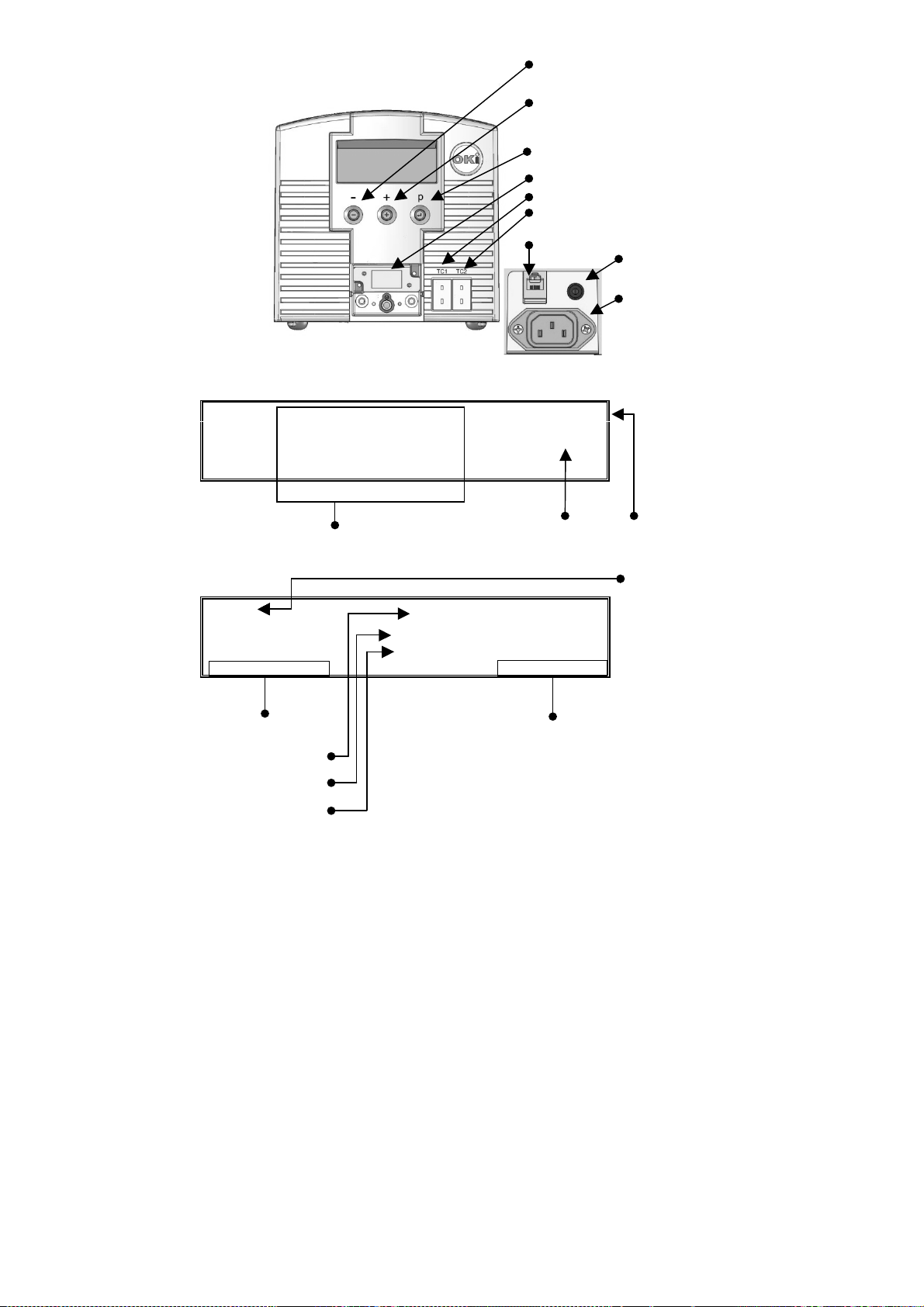

3. Unit Identification

Figure 1 HCT-PS1000 Power Supply

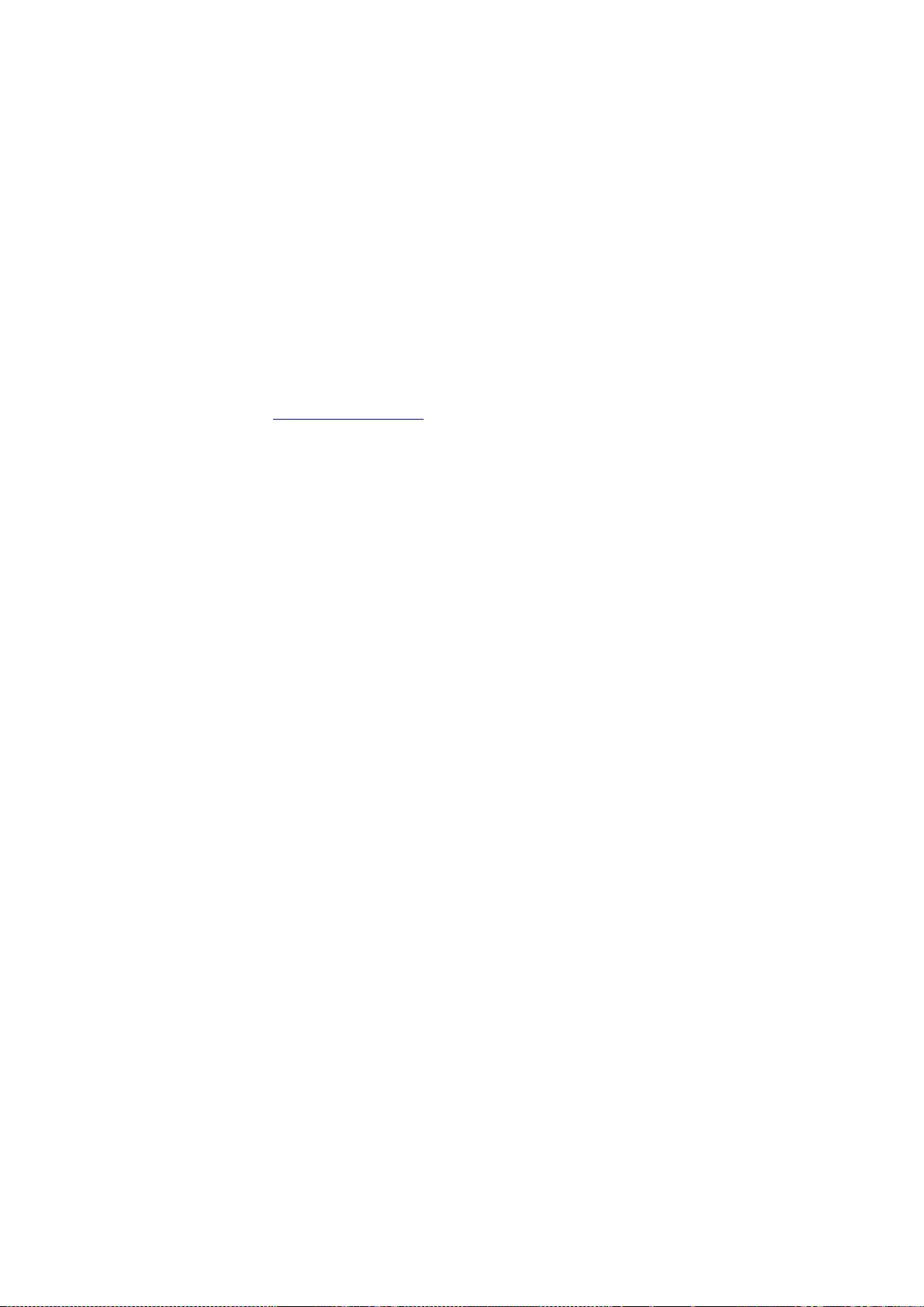

Figure 3: Run Mode, Before Profile Start

Figure 4: Run Mode, After Profile Start, MRS Mode

Z 1 : 1 5 0

°c 6 5 s P

0

6

Z 2 : 2 0 0

°c 5 5 s T C : I N T

Z 3 : 2 5 0

°c 4 5 s

Z 4 : 3 0 0

°c 3 0 s

Z 1 :

5 5 s P 0 6

T - S E T

: 1 5 0

°c T C : I N

T

T

- H t r : 1 3 6

°c

1 2 5 °c R E M O V E

(↵) Enter/Profile Select

Power On/Off

Timer/Temperature Adjust Down

⊕ Timer/Temperature Adjust Up

and Profile start/abort

Thermocouple (TC1)

Hand-piece Connector

Communications Connector

Figure 2

Back Panel Detail

T

C

1:

Active Zone

Zone Set Point

Actual Heater Reading

Temperature Monitor

Thermocouple

Control

Selected Profile

Place/Remove Option

(Only Available in

MRS Mode)

Zone Target Temperature

Profile Parameters

Power Connector

Footswitch Connector

Thermocouple (TC2)

Page 5

4

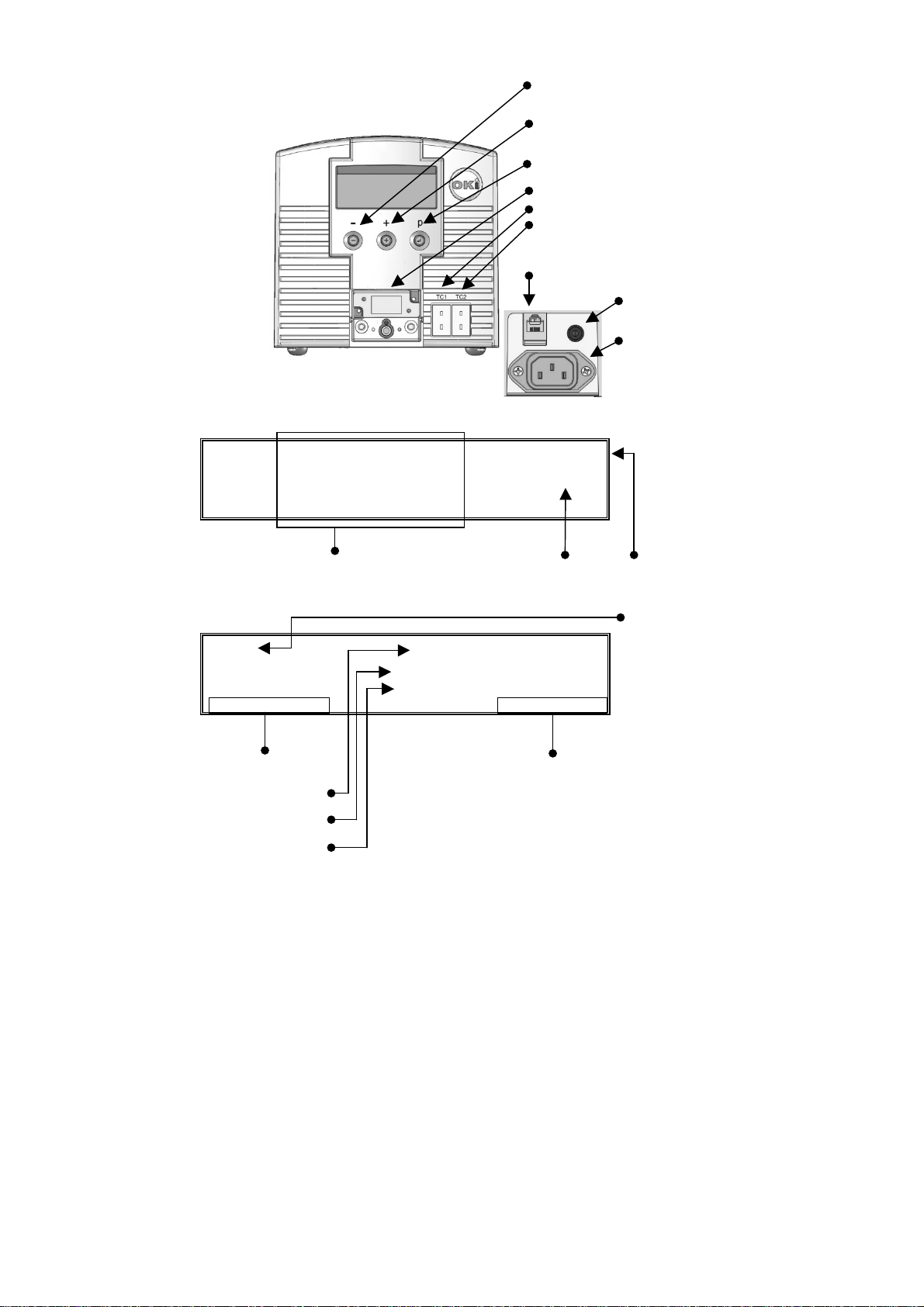

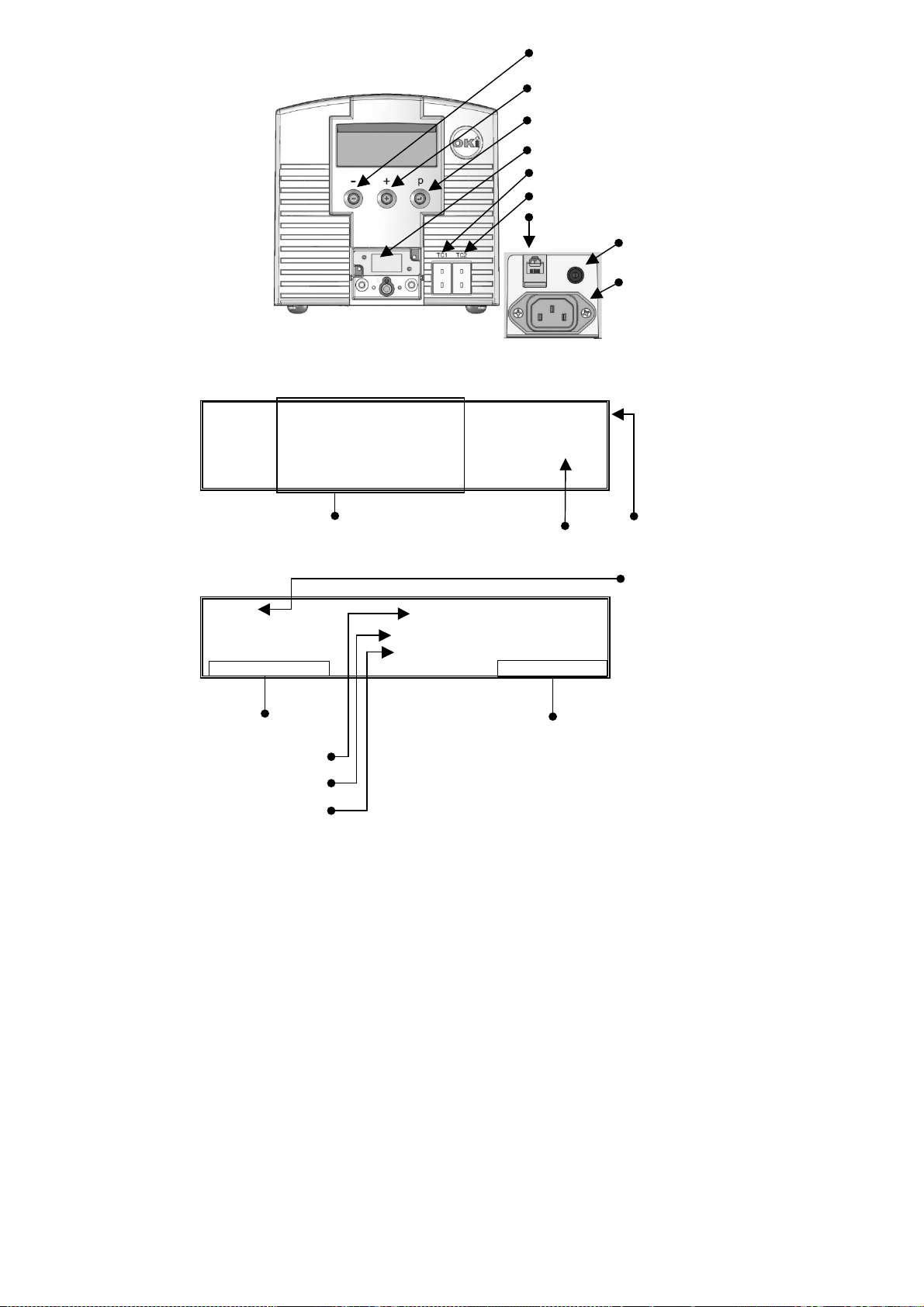

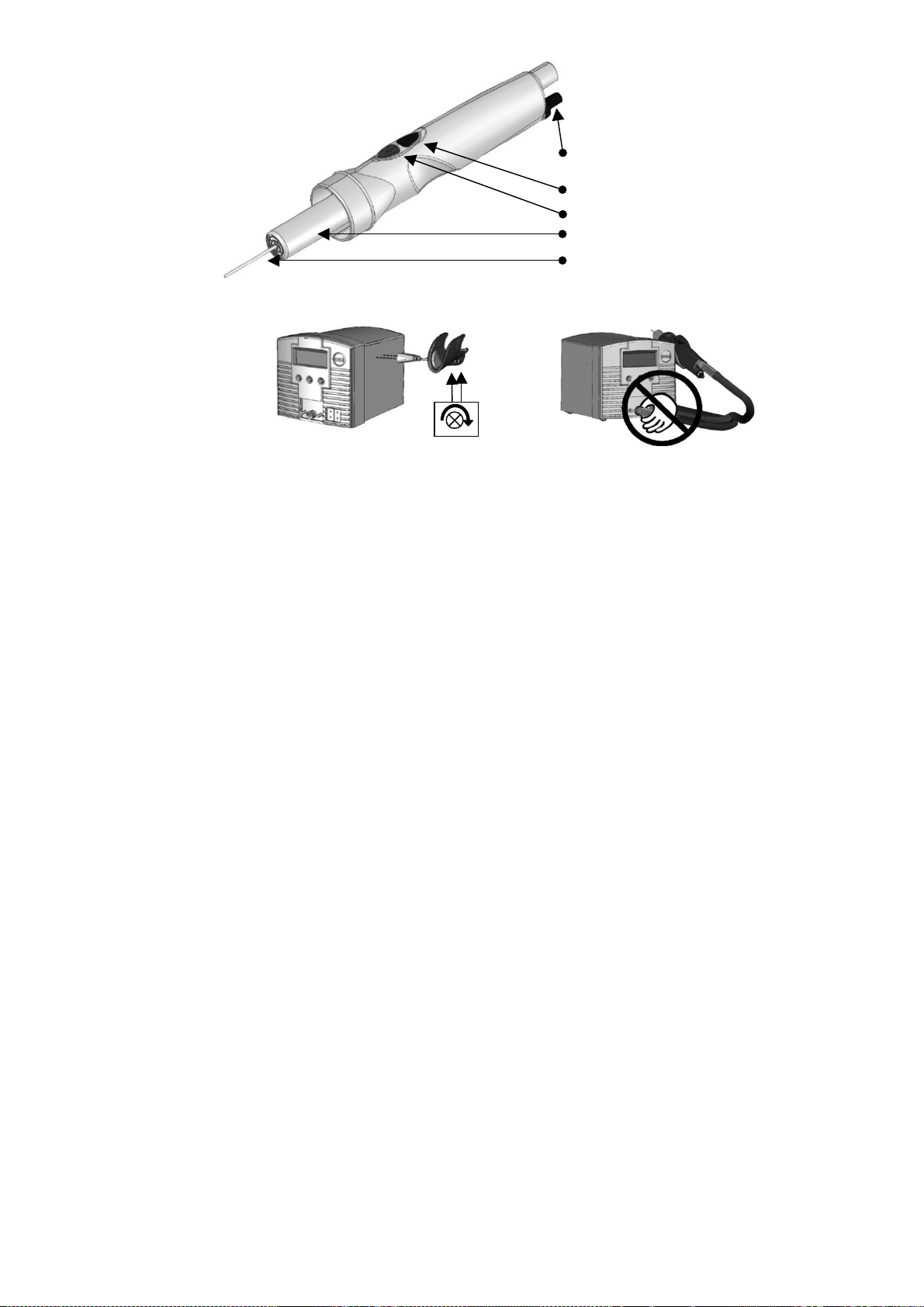

Figure 5 HCT-HV1 Hand-piece Assembly

4. Setup and unit operation

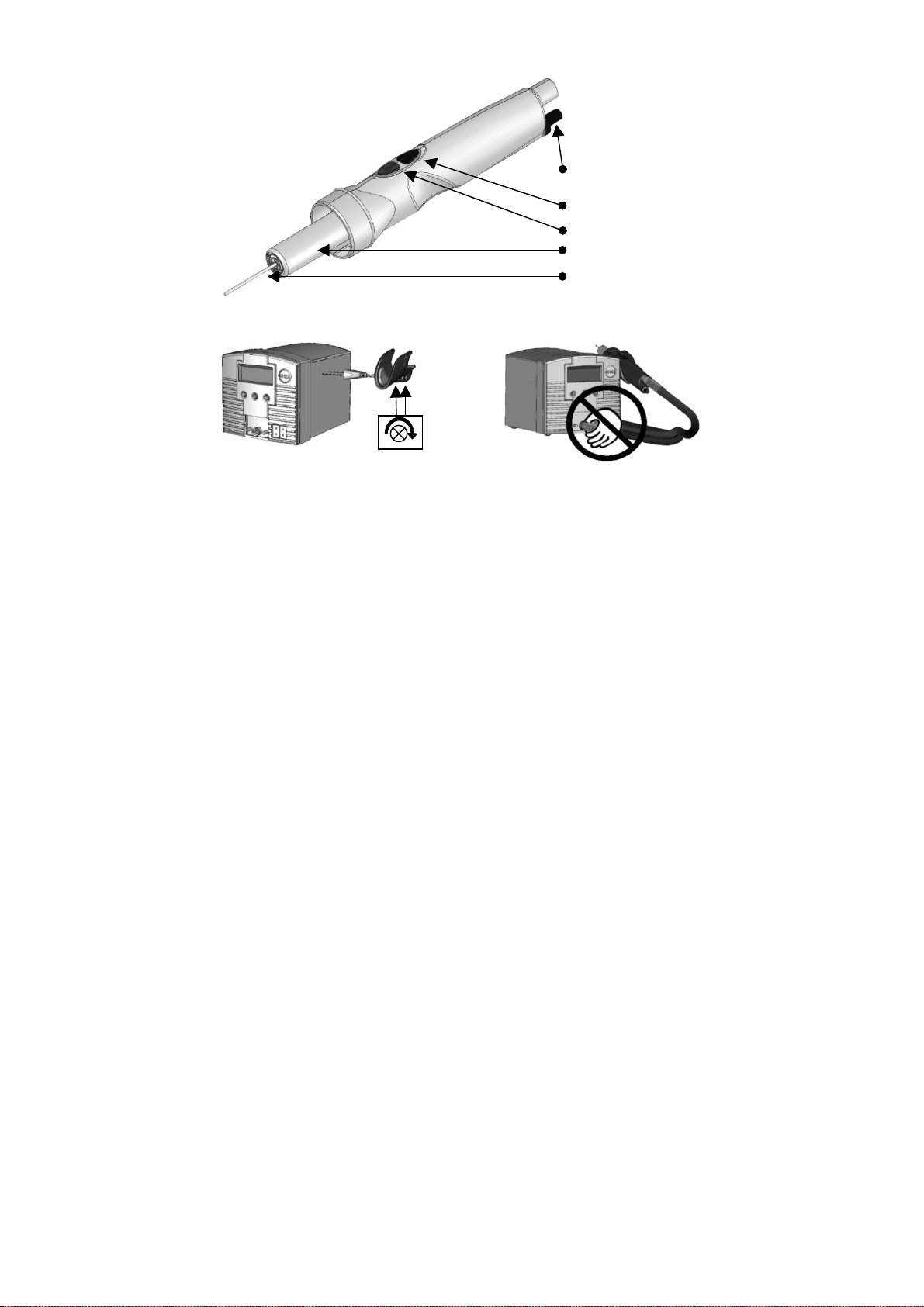

1. Basic unit setup

1. Connect the hand-piece assembly, HCT-HV1, to the power supply.

2. Plug the power cord into the power connector (Figure 2). Plug the power cord

into a grounded wall socket of the rated input line voltage.

3. Connect the dual footswitch, HCT-FS2, to the unit (Figure 2).

4. Turn On the unit by pressing the Power button momentarily.

5. To Abort a Profile (to the Cool-Down zone*) press and hold the (red) on the

footswitch or (red) on the hand-piece down while in Run Mode.

6. *Note: Depressing the (red) on the footswitch or (red) on the hand-piece

a second time will decrease the cool down time to a minimum of 60 seconds.

7. Turn Off the unit by pressing the Power button momentarily. Note ~ you

must be out of set-up mode in order to do this. I.e. no flashing numbers on the

display.

2. System Mode Selection

The HCT-1000 has two system modes of operation.

• The first mode is HCT. In this mode, the HCT-1000 is used as a standalone

handheld convection rework tool.

• The second mode is MRS. In this mode, the HCT-1000 is used as part of a

Modular Rework System. The unit is connected via cable to a PCT-1000 and

may be used with the ATH-1000 Adjustable Tool Holder. In this mode the

HCT-1000 provides timing control for both units and the ATH-1000 allows

repeatable place and remove operations.

• Plug the Communications Cable into the Communication Connector (Figure 2

above) on the HCT-1000 and the PCT-1000. When connected in MRS mode

the time setting on the PCT-1000 will display “- -“.

Vacuum Pick-up Tube

(red) Profile Start/Abort

(blue) Vacuum Activation

Vacuum Pick-up Tube

Adjustment

Heater Assembly

Figure 6 HCTA-TH1

Figure 7

Page 6

5

• Selection of the System mode is made in Setup mode, refer to section 3.1.

Additional operational options are available, refer to section 3.5.

3. Operational Mode Selection

The HCT-1000 has four operational modes. The operational modes are Setup, Run,

Manual and Active Setup. The Setup mode is for modifying system or profile

parameters. The Run mode is for operating the unit with a profile that uses four

zones of heating. The Manual mode is for operating the unit with a single zone of

heat and no time limit. The Active Setup mode allows for the changing of

parameters within a running profile.

1. Setup Mode

1. Press the Mode button (↵ ) once to start “P:” flashing

2. Use the ⊕ / buttons to scroll through the profiles

3. Press (↵ ) to select the desired profile

4. Press and hold (↵) for 3 seconds to activate program mode (first

temperature in zone 1 will flash).

5. Run Mode setup; proceed to step 3.1.6.1; Manual Mode setup

proceed to step 3.1.7.1.

6. Run Mode Setup

1. Use the ⊕ / buttons to change the temperature to the desired

value. (Note: continually pressing either the ⊕ or buttons for

5 seconds will change the count up/down in an accelerated

mode)

2. When the value is set, press (↵ ) to move to the next parameter.

3. Repeat steps 3.1.6.1 & 3.1.6.2 until profile is programmed.

Note: In the Cool-Down Zone you can only modify the Time

parameter

4. Proceed to step 3.1.8.

7. Manual Mode Setup

1. Use the ⊕ / buttons to change the temperature to the

desired value. (Note: continually pressing either the ⊕ or

buttons for 5 seconds will change the count up/down in an

accelerated mode)

2. Set the Time for Zone 1 to a value greater than 300 seconds.

The display will now show the word MANUAL and Z2, Z3, Z4

will no longer be shown on the display.

Note: Manual mode profiles do not have a time requirement and

once activated will run until the profile is stopped.

3. Once required changes have been made, press and hold (↵ ) for

3 seconds until the LCD tops flashing, to set the profile to

memory and exit setup mode.

8. Press (↵) to move to the next parameter. This is the HCT or MRS

option. Use ⊕ or to switch between HCT or MRS or press (↵ ) to

skip

9. Press (↵) to move to the next parameter. This is the Internal or

External TC option. Use ⊕ or to switch between Int or Ext or press

(↵) to skip.

Note: When EXT is selected, TC1 becomes the master thermocouple

and provides feedback to the power supply.

10. Press (↵ ) to move to the next parameter. This is the Airflow option

(AF). Use ⊕ to increase or to decrease the airflow. The range is

adjustable from 1-10. Note the Air Pump will turn on will adjusting the

Airflow. Press (↵ ) to skip.

11. Once required changes have been made, press and hold (↵) for 3

seconds until the LCD stops flashing, to set the profile to memory and

exit setup mode. (see Figure 1 above)

Page 7

6

2. Run & Manual Mode

1. Turn on the unit by pressing the Power button .

2. HCT start-up message and Software Rev # are momentarily displayed

before displaying last-used profile settings. Note: The unit may display

MRS-1000 if that was the last operational state.

3. IMPORTANT ~ If “TC: Ext” is displayed on the panel (see Figure 4

above) ensure that the external thermocouple is suitably positioned in the

heat path. Neglecting to do this could result in premature heater failure

4. Select the desired profile.

5. When the chosen profile is shown, press (↵) to select the desired profile

6. To start the profile, depress the (red) on the footswitch or (red) on

the hand-piece once

7. As the profile runs you will see the current zone, time remaining, heater

value and temperature set point. Manual mode profiles will display

“Manual” and will not display time remaining.

8. To quit the profile, simply depress the (red) on the footswitch or

(red) on the hand-piece continually for 3 seconds. The profile will skip to

the Cool-Down Zone. Note: Repeating step 8 turns off the Cool-Down

Zone after a minimum of 60 seconds of cooling.

3. Active Setup Mode

1. Select Profile to be modified as per steps 1 3 above

2. To activate Active Setup Mode press (↵ ) for 3 seconds then depress the

(red) on the footswitch or (red) button on the hand-piece once the

temperature in Z1 has started to flash

3. Profile will start to run and ‘SETUP’ will be displayed on LCD

4. To modify the current zone set-temperature use the ⊕ / buttons

5. To increase the time of the current zone press and hold the (↵) button as

the zone ends. Instead of stepping onto the next zone the current zone

time-setting will increment the original setting for as long as you keep the

(↵) button depressed. Releasing the button will allow the profile to

progress onto the next Zone.*

6. To decrease the zone time, depress the (red) on the footswitch or

(red) button on the hand-piece at the desired time. This will set the time

to memory and advance the profile into the next zone.* Note: Steps 3.4.5

& 3.4.6 can be carried out simultaneously

7. Once required changes have been made, allow the profile to finish. Press

and hold (↵ ), until the LCD tops flashing, to set the profile to memory and

exit setup mode

8. *Note: feature not available in Cool-Down Zone

5. Additional Features

1. Integrated Vacuum Pick-up

The vacuum pick-up tube has 1.0” (25.4 mm) of travel and is spring loaded

to prevent damage to components during attachment.

Use an appropriate sized vacuum cup to make a seal on the component.

2. HCT System Mode

1. Press the (blue) on the footswitch or (blue) on the hand-

piece once to activate the vacuum pump and again to deactivate.

3. MRS System Mode – Place or Remove selection

Page 8

7

1. To toggle between Place and Remove; press and hold the

(blue) on the footswitch or (blue) button on the hand-piece for 3

seconds.

4. MRS System Mode - Place

1. Press the (blue) on the footswitch or (blue) button on the

hand-piece once to activate the vacuum pump and again to

deactivate.

5. MRS System Mode - Remove

1. The integrated vacuum pick-up will automatically activate the

vacuum and retract the vacuum pick-up tube at the completion of

Zone 4 (Z4) in Run mode. The vacuum will be active for the

duration of the ZC (Cool-Down Zone).

6. MRS System Mode – Positive Vacuum Indicator

1. VAC will be displayed when the vacuum has been activated while

in Setup or Run Mode (Figure 4). VAC will blink when a positive

seal has been achieved with the component.

7. External Thermocouple Control

1. When using the HCT-1000 with the external thermocouple (EXT

see Figure 4 above), TC1 is used to provide external feedback

control. Ensure that the thermocouple is placed in the heat path.

Failure to do so may result in an error or damage to the

component. TC2 can be used for temperature monitoring (refer to

1.5.7)

2. When using the HCT-1000 with external thermocouples in MRS

mode, TC1 on the HCT-1000 becomes the master thermocouple

and is used to provide external feedback for the entire system.

TC2 on the HCT-1000 and TC1 & TC2 on the PCT-1000 can be

used for temperature monitoring only (refer to 1.9 and PCT-1000

User Guide 7000-2420, section 4.4).

8. Temperature Monitoring

1. While using the HCT-1000 with the internal thermocouple (INT

see Figure. 3 above), TC1 and TC2, the external thermocouples,

may be used to monitor temperature.

2. Attach a thermocouple to TC1 and/or TC2 and attach to the area

to be monitored. When attached, the appropriate thermocouple

will be displayed (see Figure 4 above).

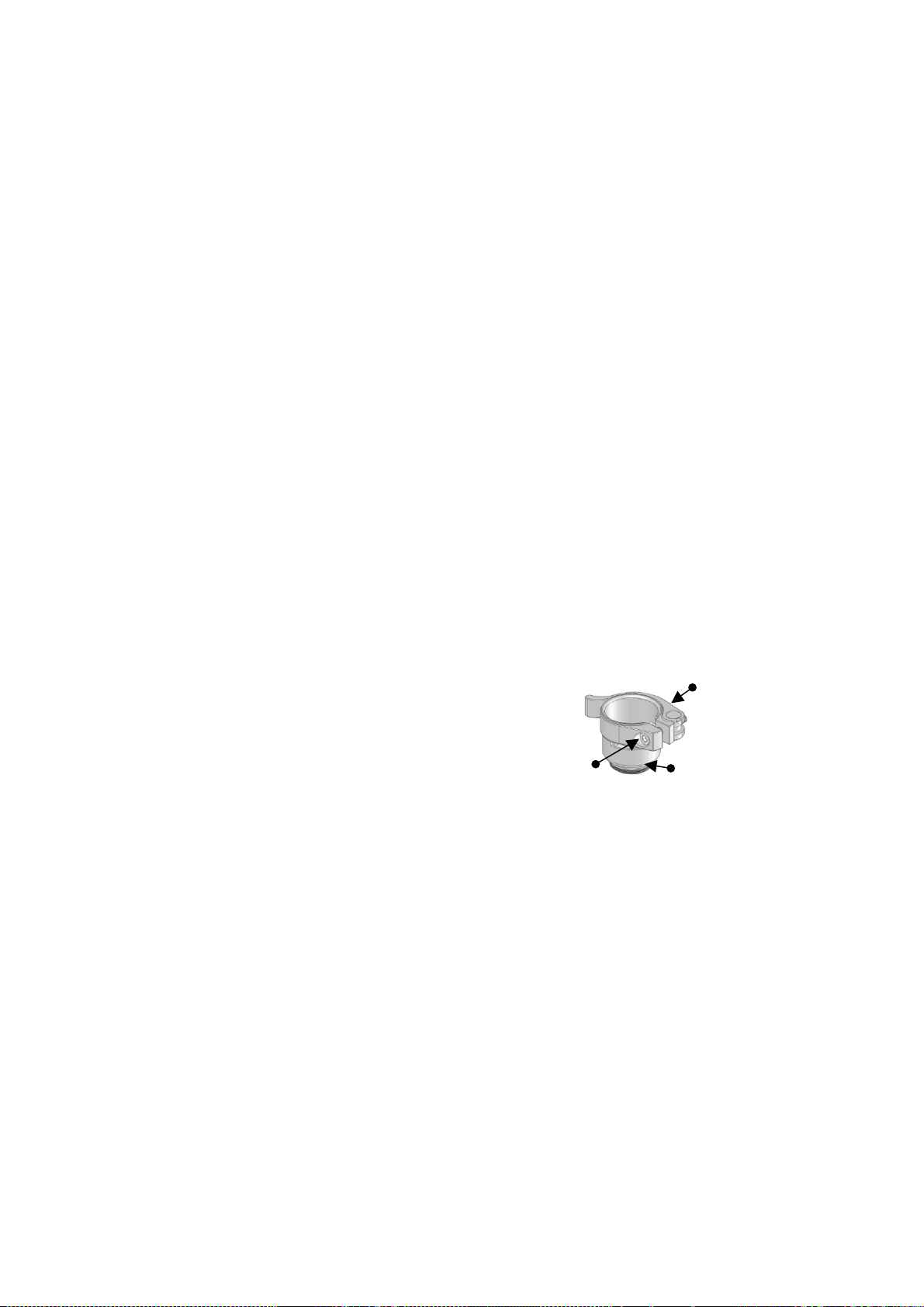

6. Nozzle Attachment

1. Secure the Nozzle Adapter (HNA-1) to Heater

Assembly

1. Loosen clamp screw counterclockwise (Figure

6, 1)

2. Close the clamp (Figure 6, 2).

3. Slide the Nozzle Adapter up the heater

assembly (Figure 5) until it stops.

4. Tighten the clamp screw clockwise (Figure 6,

1) for firm fit of the adapter to the heater

assembly. Once adjusted, removing the

adapter is done by opening the clamp and

sliding the adapter off the heater assembly.

2. Nozzle to Nozzle Adapter

1. Select the proper nozzle for the application.

Figure 6: Nozzle Adapter

(HNA-1)

1 2 3

Page 9

8

2. To attach; screw the nozzle to the nozzle adapter (Figure 6, 3); tighten

clockwise with Nozzle Wrench.

3. To remove; unscrew the nozzle from the adapter (Figure 6, 3); loosen

counterclockwise with Nozzle Wrench.

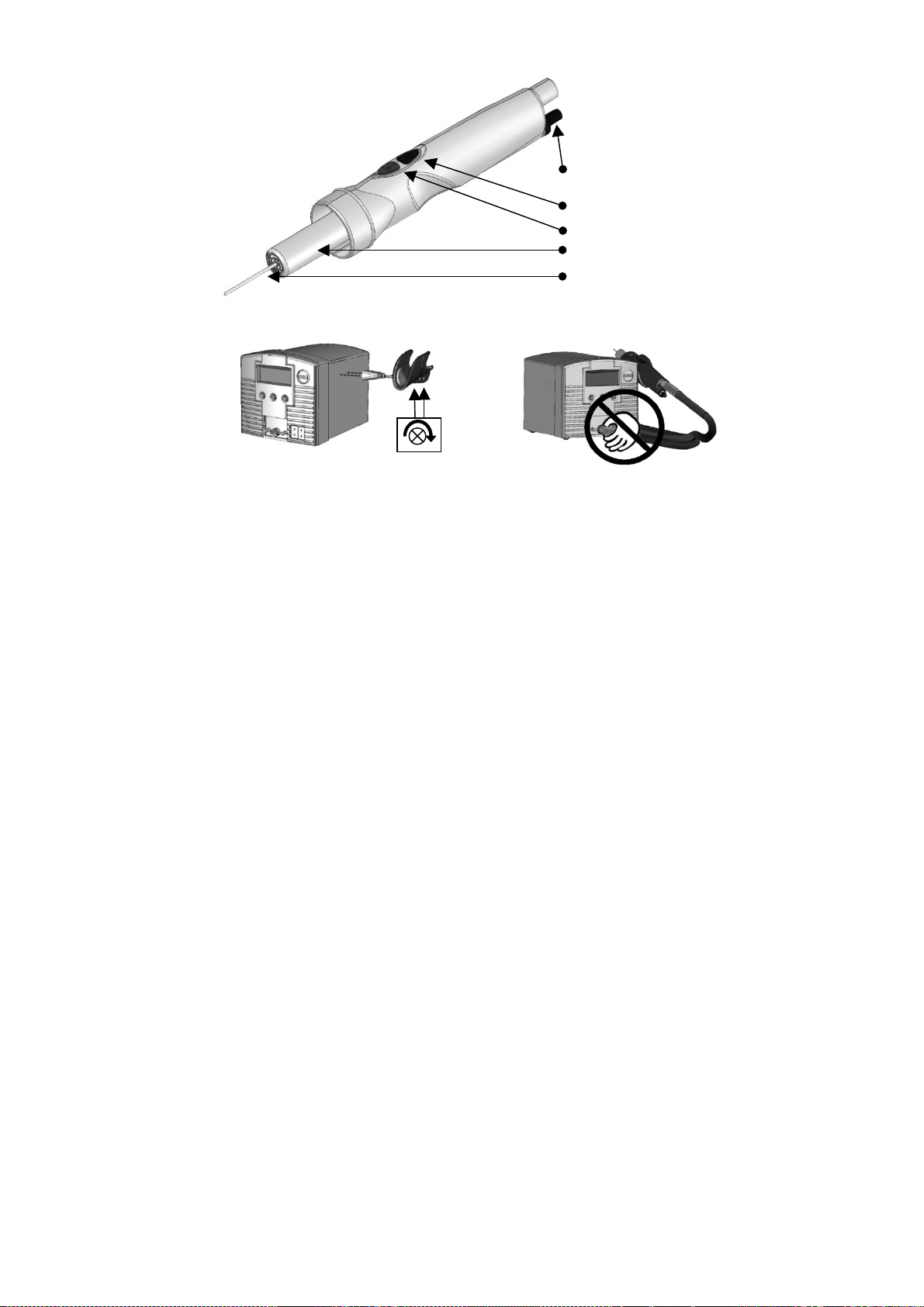

3. Nozzle Selection

1. Select the appropriate sized nozzle for the application. This is only a

sample of the available nozzles. Please refer to the HCT-1000 Nozzle

Selection Guide or visit our website www.okinternational.com for the

complete selection.

7. Operation

1. De-Soldering Components using convection heat

1. Select the proper nozzle, and secure it to the adapter.

2. Set the desired profile.

3. Move the nozzle close to the component leads; maintain 3-5 mm

distance. Use the hot air to melt the solder

4. When solder is molten, use the integrated vacuum, tweezers or other

suitable tool to remove the component from the circuit board

2. Soldering Components using convection heat

1. Choose the proper nozzle, secure it to the adapter.

2. Apply the right amount of solder to the circuit board; position the

component on the circuit board.

3. Set the desired profile.

4. Move the nozzle closer to the component leads, blow hot air onto the

leads and melt the solder.

8. Troubleshooting

1. Unit does not power ON

• Check the power cord

• Check to see that you have mains voltage

2. OH displayed on the LED screen

• Unit has exceeded the internal safety cut-off

• Allow unit to cool

• Check placement of thermocouple (if used)

• Reset the unit by cycling the power

3. TCFAULT displayed on LED screen

• Check location of thermocouple

• Ensure the thermocouple is firmly inserted into the correct TC

connector

• Replace thermocouple if problem persists

4. Flashing zone and temperature parameters while in Run Mode

• Indicates the unit cannot meet the programmed time and

temperature as set

9. Maintenance

The Hand-piece (HCT-HV1) will be part of OK International’s Service Exchange Program

or the heater assembly (HCT-HTRASSY) can be purchased separately as a replacement

part.

HN-J0005

5.0MM

HN-B1818

18MM x 18MM

HN-B1010

10MM x 10MM

HN-B4040

40MM x 40MM

Page 10

9

Please!visit!OK!Int ernational’s!web!page!(www.okinternational.com)!where!you!will!

find!additional!information!on!systems,!accessories,!technical!notes,!and!more.!

Page 11

1

简介

HCT-1000 是一种手持式热风返修工具。 该设备的特色是:采用数字控制、包含多种操作

模式、具有内部或外部反馈控制、通过集成式真空吸放功能对组件进行放置和移取操作。

此外,此设备还可作为模块化返修系统的一部分与 PCT-1000 进行连接。

目录

1. 安全和保修 1

2. 规格 2

3. 设备标识 3

4. 设置与设备操作 4、5和6

5. 其它功能 6

6. 管口信息 7

7. 操作 8

8. 故障排除 8

9. 维护 9

安全信息

用途:

警告: 除“用户指南”中介绍的使用方法之外,以其它任何方式使用此设备均可能会造成

人身伤害或财产受损。 请务必按照“用户指南”中的方法使用此设备。

OK International 对因设备的非规定应用所造成的人身伤害或财产受损概不负责。 以下行

为可能导致非规定应用:

• 对设备进行改动,而这些改动并不是“用户指南”中推荐的

• 使用不兼容的或损坏的更换件

• 使用未经许可的附件或辅助设备

安全注意事项:

• 操作此设备时切勿超过最大额定值/设置

• 务必穿上适当的个人防护衣

• 该设备仅可在室内使用

保修

自第一个买主购买之日起的一 (1) 年内,OK International 对 HCT-1000 手持式热风返修工

具电源在材料或工艺方面的缺陷提供保修。

自第一个买主购买之日起的一 (1) 年内,OK International 对 HCT-1000 手持式热风返修工

具手柄 (HCT-HV1) 在材料或工艺方面的缺陷提供保修。

自第一个买主购买之日起的九十 (90) 天内,OK International 对 HCT-1000 加热器装置

(HCT-HTRASSY) 在材料或工艺方面的缺陷提供保修。

此保修不包含正常的维护,且不保修任何打开、误用、滥用、改动或受损的零件。 如果产

品在保修期内出现故障,OK International 将自行决定进行修理或免费更换。 更换件将寄送

到第一个买主手中,并预付运费。 保修期从购买之日开始算起。 如果无法确定购买日期,

生产日期将作为保修期的起始日期。

Page 12

2

2. HCT-1000 规格

尺寸

9” x 7” x 6”(229 mm x 178 mm x 152 mm)

重量

12lbs

输入电压

100-240 VAC, 50/60 Hz

额定功率

600W

污染程度类别

II

储藏温度

-10°C 到 60°C(-10.00°C 到 60.00°C)

操作温度

0°C 到 50°C(32°F 到 122°F)

气泵类型

隔膜

气流

5-25 l/min

真空泵

15” 汞柱(381 mm 汞柱)

控制温度

450°C

表面电阻率

107Ω 到 1011Ω

噪音级别

< 55 分贝

证书

TUV

最大相对湿度

达到 31°C (87.8°F) 时为 80%,温度为 40°C (104°F) 时会线性降至 50%

系统模式

HCT、MRS

操作模式

设置、运行、手动、活动设置

存储单元

50

显示屏

LCD 20 X 4 显示段

说明

HCT-PS1000

HCT-1000 电源

HCT-HV1

配有整成式真空吸放管、电线和接头的手柄

HCT-FS2

HCT-1000 的双脚踏开关

HCT-NC

HCT-1000 管口的管口托架

HCTA-TH1

手柄工具固定器

HNA-1

管口接头

HCTA-NW1

管口扳手

HCTA-VCT1

真空杯工具

附件

HCTA-VC24

真空杯,3/32” (2.38mm)

HCTA-VC50

真空杯,3/16” (5.00mm)

HCTA-VC64

真空杯,¼” (6.4mm)

HCTA-VC80

真空杯,5/16” (8mm)

HCTA-VC11

真空杯,7/16” (11mm)

HCTA-ASC

防卡润滑物

AC-TCK-24-36

热电偶

HCTA-CC

通讯电缆

HCT-HTRASSY

加热器装置

3. 设备标识

电源开关

计时器/调低温度

Page 13

3

图 1 HCT-PS1000 电源

图 3: 运行模式,配置启动后,MRS 模式

图 4: 运行模式,配置启动后,MRS 模式

Z

1 : 1 5 0 °c 6 5 s P

0

6

Z 2 : 2 0 0

°c 5 5 s T C : I N T

Z 3 : 2 5 0

°c 4 5 s

Z 4 : 3 0 0

°c 3 0 s

Z 1 :

5 5 s P 0 6

T - S E T

: 1 5 0

°c T C : I N

T

T

- H t r : 1 3 6

°c

1 2 5 °c R E M O V E

T

C

1:

区域设定点

加热器实际温度读数

温度监测

热电偶控制

所选配置

放置/移取选项

(仅在 MRS 模式下可用)

区域目标温度

配置参数

(↵) 进入/配置选择

⊕ 计时器/调高温度以及配置启动/中止

热电偶 (TC1)

热电偶 (TC2)

手柄接头

电源插头

脚踏开关接头

通讯接口

图 2

背板详细视图

活动区域

Page 14

4

图 5 HCT-HV1 手柄组件

4. 设置与设备操作

1. 基本设备设置

1. 将手柄组件 HCT-HV1 连接到电源。

2. 将电源线插入电源插头(图 2)。 将电源线插入具有额定输入线电压的接地壁

装插座中。

3. 将双脚踏开关 HCT-FS2 与设备连接(图 2)。

4. 短暂按下电源按钮 打开设备。

5. 要中止配置(进入冷却区*),请在运行模式下按住脚踏开关或手柄上的(红

色)按钮。

6. *注意: 再次按下脚踏开关或手柄上的(红色)按钮将会使冷却时间缩短到最

短时间 60 秒。

7. 短暂按下电源按钮 关闭设备。 注意 ~ 进行此操作必须退出设置模式,即显

示屏上不显示闪烁的数字。

2. 系统模式选择

HCT-1000 有两种系统操作模式。

• 第一种模式是 HCT。 在该模式下,HCT-1000 用作独立的手持式热风返修工具。

• 第二种模式是 MRS。在该模式下,HCT-1000 用作模块化返修系统的一部分。

该设备通过电缆连接到 PCT-1000,并且可以与 ATH-1000 可调节工具固定器一

起使用。 在该模式下,HCT-1000 为两个设备提供定时控制,而且 ATH-1000 允

许进行可重复的放置和移取操作。

• 将通讯电缆插入 HCT-1000 和 PCT-1000 上的通讯接口(见上图 2)。如果在

MRS 模式下进行连接,则 PCT-1000 上的时间设置将显示为“- -”。

• 在设置模式下选择系统模式,请参阅 3.1 节。 另外,还提供了其它的操作选项,

请参阅 3.5 节。

真空吸放管

(红色)配置启动/中止

(蓝色)真空激活

真空吸放管调整

加热器装置

图6 HCTA-TH1

图7

Page 15

5

3. 操作模式选择

HCT-1000 有四种操作模式。 这些操作模式分别是:设置、运行、手动和活动设置。

“设置”模式用于修改系统或配置参数。 “运行”模式用于通过配置(该配置使用

四个加热区域)运行设备。 “手动”模式用于通过一个加热区且不受时间限制地运

行设备。 “活动设置”模式可用于在运行配置中更改参数。

1. 设置模式

1. 按一次模式按钮 (↵) 使“P:” 开始闪烁

2. 使用 ⊕ / 按钮浏览各个配置

3. 按 (↵) 选择所需的配置

4. 按住 (↵)#3#秒,激活编程模式(区域1 的第一个温度开始闪烁)。

5. 对于“运行”模式设置,请转到步骤 3.1.6.1;对于“手动”模式设

置,请转到步骤 3.1.7.1。

6. “运行”模式设置

1. 使用 ⊕ / 按钮将温度更改为所需的值。 (注意: 持续按 ⊕ 或

按钮 5 秒,将以加速模式增加/减少计数)

2. 该值设定后,按 (↵ ) 移动到下一个参数。

3. 重复步骤 3.1.6.1 和 3.1.6.2,直到完成配置的编程。 注意: 对于冷

却区,只能修改时间参数

4. 转到步骤 3.1.8。

7. “手动”模式设置

1. 使用 ⊕ / 按钮将温度更改为所需的值。 (注意: 持续按 ⊕ 或

按钮 5 秒,将以加速模式增加/减少计数)

2. 将区域 1 的时间设为大于 300 秒的值。 显示屏即会显示 MANUAL

(手动),并且不再显示 Z2、Z3、Z4。

注意: 手动模式配置没有时间要求,一旦激活,将会一直运行到该配

置被停止。

3. 进行所需的更改后,按住 (↵) 3 秒,直到 LCD 停止闪烁,这样此配

置就会存入内存并退出设置模式。

8. 按 (↵ ) 移动到下一个参数。 这是 HCT 或 MRS 选项。 使用 ⊕ 或

在 HCT 与 MRS 间切换,或按 (↵ ) 跳过

9. 按 (↵) 移动到下一个参数。 这是内部或外部 TC 选项。 使用 ⊕ 或

在 Int(内部)或 Ext(外部)间切换,或按 (↵ ) 跳过。

注意: 如果选择 EXT(外部),则 TC1 将变为主热电偶,并提供电源

反馈。

10. 按 (↵) 移动到下一个参数。 这是气流选项 (AF)。 使用 ⊕ 增加气流,

或使用 减小气流。 可调节的范围为 1-10。请注意,调节气流时,气

泵将打开。 按 (↵ ) 跳过。

11. 进行所需的更改后,按住 (↵ ) 3 秒,直到 LCD 停止闪烁,这样此配置

就会存入内存并退出设置模式。 (请参见上图 1)

2. 运行模式和手动模式

1. 按电源按钮 打开设备的电源。

2. HCT 开机信息和软件版本号将短暂显示,然后将显示上次使用时的配置设

置。 注意: 如果上次的操作状态为 MRS,设备会显示 MRS-1000。

3. 重要说明 ~ 如果面板上显示“TC: Ext”(TC:外部)(请参见上图 4)

,请确保外部热电偶位于热路的正确位置上。否则,可能导致加热器永久

损坏

4. 选择所需的配置。

5. 当所选配置出现在显示屏上时,按 (↵) 即可选择所需配置

6. 要启动配置,请按一次脚踏开关或手柄上的(红色)按钮

7. 当配置运行时,您将看到当前区域、剩余时间、加热器值和温度设定点。

手动模式配置将显示“Manual”(手动),而不显示剩余时间。

Page 16

6

8. 要退出配置,只需持续按住脚踏开关或手柄上的(红色)按钮 3 秒钟即

可。 配置将跳到冷却区。

注意:

在经过 60 秒的最短冷却时间后,重复

步骤 8 会关闭冷却区。

3. 活动设置模式

1. 按照上述步骤 1 3 选择要修改的配置

2. 要激活“活动设置”配置,请在 Z1 中的温度开始闪烁后,按 (↵ ) 持续 3

秒钟,然后按一次脚踏开关或手柄上的(红色)按钮

3. 配置将开始运行,LCD 上将显示“SETUP”(设置)

4. 要修改当前区域设置温度,请使用 ⊕ / 按钮

5. 要增加 当前区域的时间,请按住 (↵) 按钮直到达到该区域的限值。 在您

按下 (↵) 按钮的期间,当前的区域时间设置将在原始设置的基础上增加,

而不会进入下一个区域。 松开该按钮,配置将进入下一个区域。*

6. 要缩短 区域时间,请在时间减至所需时间后,按下脚踏开关或手柄上的

(红色)按钮。 这样会将时间存入内存,配置将进入下一个区域。* 注意

: 步骤 3.4.5 和步骤 3.4.6 可同时执行

7. 进行所需的更改后,配置可完成。 按住 (↵), 直到 LCD 停止闪烁,这样

此配置就会存入内存并退出设置模式

8. *注意: 无法在冷却区中使用此功能

5. 其它功能

1. 集成式真空吸放功能

真空吸放管具有 1.0” (25.4 mm) 的行程,装有弹簧,可以防止在连接过程中

损坏组件。

利用大小适当的真空杯对该组件进行密封。

2. HCT 系统模式

1. 按脚踏开关或手柄上的(蓝色)按钮一次将激活真空泵,再按一

次该按钮将禁用真空泵。

3. MRS 系统模式 – 放置或移取选择

1. 要在放置和移取之间切换,请按住脚踏开关或手柄上的(蓝色)

按钮 3 秒钟。

4. MRS 系统模式 - 放置

1. 按脚踏开关或手柄上的(蓝色)按钮一次将激活真空泵,再按一

次该按钮将禁用真空泵。

5. MRS 系统模式 - 移取

1. 在运行模式下,完成了区域 4 (Z4) 中的操作后,集成式真空吸放功

能将自动激活真空并收缩真空吸放管。 在处于 ZC(冷却区域)期间

,真空吸放管处于活动状态。

6. MRS 系统模式 – 实际真空指示器

1. 当在“设置”或“运行”模式下激活真空(图4)时,VAC 将会显

示。当对元件实现了实际密封时 VAC 会闪烁。

7. 外部热电偶控制

1. 将 HCT-1000 与外部热电偶(EXT,请参见上图 4)一起使用时,

TC1 用于提供外部反馈控制。 请确保将该热电偶置于热路中。否则,

可能导致组件故障或损坏。 TC2 可用于温度监测(请参阅 1.5.7 节)

Page 17

7

2. 在 MRS 模式下将 HCT-1000 与外部热电偶一起使用时,HCT-1000

上的 TC1 将变为主热电偶,用于为整个系统提供外部反馈。 HCT-

1000 上的 TC2 以及 PCT-1000 上的 TC1 和 TC2 只能用于监测温

度(请参阅 1.9 节,以及《PCT-1000 用户指南 7000-2420》中的

4.4 节)。

8. 温度监测

1. 如果使用的 HCT-1000 带有内部热电偶(INT,请参见上图 3),

则外部热电偶 TC1 和 TC2 可用于监测温度。

2. 将一个热电偶与 TC1 和/或 TC2 相连,并连接到要监测的区域。 连

接后将显示相应的热电偶(请参见上图 4)。

6. 管口固定

1. 将管口接头 (HNA-1) 固定到加热器装置上

1. 逆时钟松开夹紧螺钉(图 6-1)

2. 合上夹子(图 6-2)。

3. 将管口接头向上滑动到加热器装置(图 5)直

到停止。

4. 顺时针拧紧夹紧螺钉(图 6-1),使接头与加

热器装置牢固配合。 调整后,打开夹子并从

加热器装置上将接头滑出,取下接头。

2. 管口到管口接头

1. 根据应用需要,选择合适的管口。

2. 要进行连接,将管口拧到管口接头上(图 7-3),使用管口扳手顺时针拧紧。

3. 要进行拆卸,将管口从接头上拧松(图 7-3),使用管口扳手逆时针松开。

3. 管口选择

1. 根据应用需要,选择大小合适的管口。 这只是可用管口的一个示样。 有

关完整的选择列表,请参阅《HCT-1000 管口选择指南》,或访问我们

的网站,网址为:www.okinternational.com。

7. 操作

1. 使用对流热脱焊组件

1. 选择合适的管口,并将其固定到接头上。

2. 设置所需的配置。

3. 移动管口靠近元件引线;保留 3-5 mm 的距离。 利用热风熔化焊料

4. 焊料熔化后,使用集成式真空吸放管、镊子或其它适合的工具将组件从

电路板上取下

2. 使用对流热焊接组件

1. 选择合适的管口,并将其固定到接头上。

2. 在电路板上加适量的焊料,将组件定位到电路板上。

3. 设置所需的配置。

4. 移动管口靠近元件引线,将热风吹到引线上并熔化焊料。

2

图 6: 管口接头

(HNA-1)

1

3

HN-J0005

5.0MM

HN-B1818

18MM x 18MM

HN-B1010

10MM x 10MM

HN-B4040

40MM x 40MM

1

Page 18

8

8. 故障排除

1. 设备电源无法打开

• 检查电源线

• 检查电力线路是否有电

2. LED 屏幕上显示 OH

• 设备超过了内部安全切断值

• 使设备冷却

• 检查热电偶(如果使用)的放置位置

• 关闭并重新打开电源以重置设备

3. LED 屏幕上显示 TCFAULT

• 检查热电偶的位置

• 确保热电偶已牢固插入正确的 TC 接头

• 如果问题仍然存在,请更换热电偶

4. 在运行模式下区域和温度参数闪烁

• 说明设备无法达到所设的编程时间和温度

9. 维护

手柄 (HCT-HV1) 将作为 OK International 的“服务交换程序”的一部分,加热器装置

(HCT-HTRASSY) 可作为更换件单独购买。

请访问 OK International 的网页 (www.okinternational.com),您将获得有关系统、

附件、技术说明等的更多信息。

Page 19

1

簡介

HCT-1000為手持式對流重工工具。 其功能包括數位控制、多模式操作、內部及外部

迴授控制及零件放置及移除之整合式真空檢取。 此外,本裝置可連接至 HCT-1000作

為「模組重工系統」(MRS) 的一部分。

目錄

1. 安全及保固 1

2. 規格 2

3. 裝置識別 3

4. 設定及裝置操作 4, 5 & 6

5. 外加功能: 6

6. 噴嘴資訊 7

7. 操作 8

8. 疑難排解 9

9. 維護 9

安全性

預期用途:

警告: 以本「使用者指南」所述以外之方式使用本設備時,可能導致人身傷害或財產損

失。 請依本「使用者指南」所述之方式使用本設備。

OK International 對於非本設備之預期用途所導致的傷害或損壞,不負擔任何責任。

所謂的非預期用途,可能發生於下列行為:

• 以使用指南未建議之方式修改設備。

• 使用不相容或受損之更換件。

• 使用未經核准的附件或輔助設備

安全預防措施:

• 本裝置之操作,不得超出最大額定功率/設定。

• 應隨時穿著合適的個人防護衣物或服裝

• 本設備僅限室內使用。

保固

OK International 提供原始擁有人自購買 HCT-1000 手持式對流重工工具之日起一年內,

任何材料或工藝缺陷相關之保固。

OK International 提供原始擁有人自購買 HCT-1000 手持式對流重工工具手柄 (HCTHV1) 之日起一年內,任何材料或工藝缺陷相關之保固。

OK International 提供原始擁有人自購買 HCT-1000 加熱器組 (HCT-HTRASSY) 之日起

90 天內,任何材料或工藝缺陷相關之保固。

本保固不含裝置之正常維護,亦不適用於敞開、誤用、濫用、修改或損壞之零組件。

如果產品在保固期內出現故障,OK International 將可自行斟酌免費修理或更換產品。

更換件將以預付運費之方式寄達原始購買人。 保固期自購買之日起生效。 購買日期無

法確定者,以生產日為保固起始日。

!

2. HCT-1000 規格

尺寸

9” x 7” x 6” (229 mm x 178 mm x 152 mm)

重量

12 磅

輸入電壓

100-240 VAC, 50/60 Hz

額定功率

600W

污染程度分類

II

儲存溫度

-10°C 至 60°C (-14°F 至 140°F)

操作溫度

0°C 至 50°C (32°F 至 122°C)

空氣泵類型

隔膜

空氣流量

5-25 公升/分鐘

Page 20

2

真空泵

15” Hg (381 mm Hg)

控制溫度

450°C

表面電阻係數

107Ω至 1011Ω

噪音程度:

< 55 dB

認證

TUV

最大相對溼度

溫度 31°C (87.8°F) 以下時 80%,40°C (104°F) 時線性減少至 50%

系統模式

HCT, MRS

操作模式

設定、執行、手動、主動設定

記憶體位置

50

顯示器

LCD 20 X 4 螢幕區塊

說明

HCT-PS1000

HCT-1000 電源

HCT-HV1

手柄,附整合真空吸氣、電線及連接器

HCT-FS2

腳踏開關、雙動、 HCT-1000

HCT-NC

噴嘴托架、 HCT-1000 噴嘴

HCTA-TH1

手柄工具固定架。

HNA-1

噴嘴接頭

HCTA-NW1

噴嘴扳手

HCTA-VCT1

真空杯工具

附件

HCTA-VC24

真空杯,3/32” (2.38mm)

HCTA-VC50

真空杯,3/16” (5.00mm)

HCTA-VC64

真空杯,¼” (6.4mm)

HCTA-VC80

真空杯,5/16” (8mm)

HCTA-VC11

真空杯,7/16” (11mm)

HCTA-ASC

防卡死化合物

AC-TCK-24-36

熱電偶

HCTA-CC

通訊纜線

HCT-HTRASSY

加熱器組

Page 21

3

3. 裝置識別

圖 1 HCT-PS1000 電源

圖 3: 執行模式,設定檔開始前

圖4: 執行模式,設定檔開始後,MRS模式

Z 1 : 1 5 0

°c 6 5 s P

0

6

Z 2 : 2 0 0

°c 5 5 s T C : I N T

Z 3 : 2 5 0

°c 4 5 s

Z 4 : 3 0 0

°c 3 0 s

Z 1 :

5 5 s P 0 6

T - S E T

: 1 5 0

°c T C : I N

T

T

- H t r : 1 3 6

°c

1 2 5 °c R E M O V E

T

C

1:

零設定點

加熱區實際讀數

溫度監控器

熱電偶控

選取之設定檔

放置/移除選項

(僅限MRS模式)

目標區溫度

設定檔參數

電源 開/關

計時器/溫度向下調整

(↵) 輸入/設定檔

⊕ 計時器/溫度向上調整及

設定檔開始/中斷

熱電偶 (TC2)

手柄連接器

電源接頭

腳踏開關連接器

通訊連接器

圖2面板背部詳圖

Active Zone

Active Zone主動

Active Zone

主動區

熱電偶 (TC1)

Page 22

4

圖 5 HCT-HV1 手柄組

4. 設定及裝置操作

1. 基本裝置設定

1. 將手柄組 HCT-HV1 連接至電源。

2. 將電源線插入電源接頭 (圖2)。 將電源線插入電流為額定輸入電壓的接地牆

壁插座。

3. 將雙動腳踏開關 HCT-FS2 連接至裝置 (圖 2)。

4. 短暫地按下電源按鈕 ,開啟裝置電源。

5. 欲中斷設定檔 (至冷卻區*) 時,於執行模式下按住腳踏開關的 (紅色),或按

住手柄上的 (紅色) 。

6. *注意: 第二次按下腳踏開關的(紅色) 或手柄的 (紅色) 時,冷卻時間會

減少至最少60秒。

7. 短暫地按下電源按鈕 ,即可關閉裝置。 注意 ~ 執行上列步驟時應先退出

設定模式,即螢幕上無閃爍數字時。

2. 系統模式選擇

HCT-1000 共有兩種操作模式。

• 第一種模式為 HCT。 本模式中,HCT-1000 用作為獨立的手持式對流重

工工具。

• 第二種模式為 MRS。 本模式中,HCT-1000 用作為模組化重工系統的一

部份。 本裝置以纜線連接至 PCT-1000,亦可搭配 ATH-1000 可調式工具固

定架使用。 本模式中,HCT-1000 提供裝置及 ATH-1000 計時控制功能,

可重覆執行放置及移除作業。

• 將通訊纜線插入 HCT-1000 及 PCT-1000 的通訊連接器 (如圖 2)。連接至

MRS 模式時,PCT-1000 的時間設定會顯示 “- -”。

輸入/設定檔

(紅)設定檔開始/中斷

(藍)真空啟動

真空管檢取管調整

加熱器組

圖6 HCTA-TH1

圖7

Page 23

5

• 系統模式選擇於設定模式中執行,請參考 3.1 節。 其它可用的操作選項,

請參考3.5.節。

3. 操作模式選擇

HCT-1000 共有四種操作模式。 這些操作模式分別為設定、執行、手動、及主動設

定。 設定模式用於修改系統或設定檔參數。 執行模式用於搭配設定檔進行裝置操

作,設定檔可使用四組加熱區。 手動模式用於設備之單區加熱操作,且無時間

限制。 主動設定模式可用於修改執行中設定檔的參數。

1. 設定模式

1. 按下模式按鈕 (↵) 一次,即可啟動 “P:” 開始閃爍

2. 使用 ⊕ / 按鈕可在整個設定檔中捲動

3. 按下 (↵),選取所要的設定檔

4. 按下 (↵ ) 3 秒鐘不放,以啟動程式模式 (第一區的第一個溫度會開始

閃爍)。

5. 若要執行模式設定;請繼續步驟 3.1.6.1;若要執行手動模式設

定,請繼續步驟 3.1.7.1.。

6. 執行模式設定

1. 使用 ⊕ / 按鈕將溫度修改至所要的數值。 (注意: 持續按

住 ⊕ 或 按鈕 5 秒鐘後,向上/向下計數會變為加速模式。

2. 數值設定完畢後,按下 (↵) 可移至下一個參數。

3. 重覆步驟 3.1.6.1 及 3.1.6.2,直到設定檔完成設定為止。 注

意: 冷卻區內只能修改時間參數。

4. 繼續步驟 3.1.8。

7. 手動模式設定

1. 使用!⊕ /!!按鈕,將溫度修改至所要的數值。 (注意: 持續

按住 ⊕ 或 按鈕 5 秒鐘後,向上/向下計數會變為加速模式

2. 將第一區的時間數值設定為大於 300 秒。 此時螢幕會顯示

MANUAL (手動) 字樣, Z2、Z3、Z4 則不再出現於顯示螢幕上。

注意: 手動模式設定檔無時間要求,一旦啟動後將執行至設

定檔停止為止。

3. 完成所需的修改後,按住 (↵) 3 秒鐘不放直到 LCD 停止閃爍為

止,讓設定檔存入記憶體後退出設定模式。

8. 按下 (↵ ) 移至下一個參數。 此即 HCT 或 MRS 選項。 使用 ⊕ 或

在 HCT 或 MRS 之間切換,或按 (↵ ) 跳過。

9. 按下 (↵ ) 移至下一個參數。 此即內部或外部 TC 選項。 使用 ⊕ 或

在Int (內部) 或 Ext (外部) 之間切換,或按 (↵) 跳過。

注意: 選取 EXT 後,TC1 會變為主熱電偶,並提供迴授至電源。

10. 按下 (↵) 移至下一個參數。 此即氣流量選項 (AF)。 使用 ⊕ 增加或

降低氣流量。可調範圍介於 1-10 之間。請注意,調整氣流量時

會啟動空氣泵。 按 (↵ ) 可跳過本選項。

11. 完成所需的修改後,按住 (↵)3 秒鐘不放直到 LCD 停止閃爍為止,

將設定檔存入記憶體後退出設定模式。 (請參考圖 1 如上)

2. 執行及手動模式

1. 按下電源按鈕 ,開啟裝置電源。

2. 顯示上次使用的設定檔設定值之前,HCT 啟動訊息及軟體版本號碼

會短暫的出現於螢幕上 。 注意: 假如為最後一次操作狀態,裝置會

顯示 MRS-1000。

3. 重要 ~ 假如面板上顯示 “TC: Ext” (參見上方圖 4)時,請確認外部熱

電偶己經適當的固定於加熱路徑中。 疏忽執行此動作,可能會導致

加熱器提前失效。

4. 選取所要的設定檔。

Page 24

6

5. 螢幕上出現選取的設定檔後,按 (↵) 選取所要的設定檔。

6. 啟動設定檔時,壓下腳踏開關之 (紅色) 或手柄上的 (紅色)。

7. 執行設定檔時,您會看到目前區域、剩餘時間、加熱器值及溫度設定點

等數據。 手動模式設定檔會顯示 “Manual (手動)” 字樣,但不會顯示剩

餘時間。

8. 若要結束設定檔,只需持續壓住腳踏開關之 (紅色) 或手柄上的 (紅

色) 3秒鐘。 隨後,設定檔會跳至冷卻區。

注意:

請在至少冷卻 60

秒後,重覆步驟 8 以關閉冷卻區。

3. 主動設定模式

1. 依據上述 1 3 步驟,選取待修改之設定檔。

2. 開啟主動設定模時,按住 (↵) 3 秒鐘後,再壓下腳踏開關的 (紅色)

或手柄的 (紅色) 一次,Z1 之溫度即開始閃動。

3. 隨後即開始執行設定檔,LCD 則會顯示「SETUP」(設定) 字樣。

4. 若要修改目前區域之設定溫度,請使用 ⊕ / 按鈕。

5. 若要增加目前區域的時間,請在區域底端時按住 (↵) 按鈕不放。 按

住 (↵ ) 不放時,目前區域時間的原始設定值會增加,但不會跳到下一

區。 放開按鈕,即可讓設定檔移至下一個區域*。

6. 若要減少區域時間,請於所要的時間,壓下腳踏開關之 (紅色) 或

手柄上的 (紅色) 即可。 這個動作可將時間設定於記憶體,並讓設

定檔移至下一區*。注意: 可同時執行步驟 3.4.5 及 3.4.6。

7. 完成所要的修改後,讓設定檔結束作業。 按住 (↵ ) 不放直到 LCD 不

再閃爍,將設定檔儲存於記憶體並退出設定模式。

8. *注意: 冷卻區無法使用本功能

5. 外加功能

1. 整合式真空檢取

真空檢取管之行程為 1.0” (25.4 mm),且有裝置彈簧以防連接時零組

件受損。

請使用適當尺寸的真空杯將零件密封。

2. HCT 系統模式

1. 按下腳踏開關之 (藍) 或手柄上的 (藍色) 啟動真空泵,再

按下一次即可關閉。

3. MRS 系統模式 – 放置或移除選擇

1. 若要在放置及移除之間切換,請壓下腳踏開關之 (藍色) 或

手柄上的 (藍色) 3秒鐘不放。

4. MRS 系統模式 – 放置

1. 按下腳踏開關之 (藍) 或手柄上的 (藍色) 可啟動真空泵,

再按下一次即可關閉。

5. MRS 系統模式 – 移除

1. 執行模式下完成第四區 (Z4) 時,整合式真空檢取會自動啟動

真空,並縮回真空檢取管。 ZC 區 (冷卻區) 持續時間中,真

空檢取管呈啟動狀態。

6. MRS 系統模式 – 正真空指示燈

1. 當為「設定」或「執行」模式時,如果已啟用真空功能,將顯

示 VAC (圖 4)。當使用該零件達成正密封時,VAC 會閃爍。

7. 外部熱電偶控制

1. 搭配外部熱電偶使用 HCT-1000 時(EXT,請參閱上方圖 4),

TC1 可用於提供外部迴授控制。 確認熱電偶放置於加熱路徑

中。 熱電偶如未放入加熱路徑中,可能導致錯誤或損壞零件。

TC2 可用於溫度監控 (請參閱 1.5.7 節)。

Page 25

7

2. MRS 模式中,搭配外部熱電偶使用 HCT-1000 時,HCT-1000

上的TC1 會變為主熱電偶,可用於提供全系統的外部迴授。

HCT-1000 的 TC2 及 PCT-1000 的 TC1 與 TC2 僅能用於溫

度監控 (請參閱 1.9 節及 PCT-1000 使用指南 7000-2420,第

4.4 節)。

8. 溫度監控

1. 使用配備內部電熱偶的 HCT-1000 時 (INT,請參閱上方圖 3),

外部電熱偶 TC1 及 TC2 可用於溫度監控。

2. 將電熱偶連接到 TC1 及/或 TC2,隨後再連接至待監控的區域。

接妥後,即會顯示適當的電熱偶 (請參閱上方圖 4)。

6. 噴嘴連接

1. 將噴嘴接頭 (HNA-1) 穩固接在加熱器組上

1. 逆時針鬆開夾鉗螺絲 (圖6, 1)

2. 關閉夾鉗 (圖6, 2)

3. 將噴嘴接頭向上滑動至加熱器組 (圖5),直到停

止為止。

4. 順時針上緊夾鉗螺絲 (圖6, 1),讓接頭與加熱器

組穩固密合。 調整完畢後,打開夾鉗,拆除

接頭,並將接頭滑離加熱器組。

2. 噴嘴及噴嘴接頭

1. 選取符合用途的噴嘴。

2. 連接時,請將噴嘴旋入噴嘴接頭 (圖6, 3);再以噴嘴扳手順時針上緊。

3. 拆除時,請將噴嘴旋出噴嘴接頭 (圖6, 3);再以噴嘴扳手逆時針鬆開。

3. 噴嘴選擇

1. 請選擇適當尺寸之噴嘴。 這只是可用之噴嘴的部份樣品。 完整的噴

嘴選擇資料,請參考 HCT-1000 噴嘴選擇指南或造訪本公司網頁

www.okinternational.com。

7. 操作

1. 利用對流加熱去除零件銲料

1. 選取合適的噴嘴,並固定於接頭處。

2. 設定所要的設定檔。

3. 移動噴嘴接近零件導線;並維持 3-5 mm 距離。 以熱空氣融解銲料。

4. 待銲料融解後,以整合式真空抽氣、鑷子或其它合適的工具將零件

移離電路板。

2. 利用對流加熱銲接零件

1. 選取合適的噴嘴,並固定於接頭處。

2. 於電路板上塗上適量的銲料;將零件固定於電路板。

3. 設定所要的設定檔。

4. 移動噴嘴靠近零件導線,讓熱空氣吹到導線上融解銲料。

2

圖6:噴嘴接頭(HNA-1)

1

3

HN-J0005

5.0MM

HN-B1818

18MM x 18MM

HN-B1010

10MM x 10MM

HN-B4040

40MM x 40MM

Page 26

8

8. 疑難排解

1. 設備電源未開啟

• 檢查電源線

• 檢查有否有主電源電壓。

2. LED 螢幕是否顯示 OH

• 設備超出內部安全斷電標準

• 靜待設備冷卻

• 檢查熱電偶是否放置妥當 (如使用電熱偶)

• 關閉然後重新開啟電源,重新啟動設備

3. LED 螢幕顯示 TCFAULT (TC 故障)

• 檢查電熱偶之位置

• 確認電熱偶已經牢固的插入到正確的 TC 連接器

• 如果問題仍無法解決,請更換電熱偶

4. 執行模式時,區域及溫度參數閃爍不停

• 這表示設備無法符合設定的時間及溫度。

9. 維護

手柄 (HCT-HV1) 可列為 OK International 之服務交換計畫 (Service Exchange

Program) 的一部份,加熱器組 (HCT-HTRASSY) 視為更換件需另行購買。

如需系統、附件、技術說明及其它事項的進一步資訊,請造訪 OK International

公司網頁 (www.okinternational.com) 。

Page 27

1

はじめに

HCT-1000 は、ハンドヘルド対流熱式再加工用ツールです。HCT-1000 は、デジタル制御

、マルチ操作モード、内部または外部フィードバック制御、部品の取り付けおよび取り

外し 用の内 蔵吸引ピ ックアッ プが装 備されて います。 さらに 、この装 置は、Modular

Rework System の一部として PCT-1000 に接続することもできます。

目次

1. 安全に関する情報と保証 1

2. 仕様 3

3. 装置各部の名称 4

4. 設定および装置の操作 5

5. 追加機能 9

6. ノズルに関する情報 10

7. 操作 11

8. トラブルシューティング 11

9. 保守 11

安全に関する情報

使用目的 :

警告 : この装置を本書に記載されている以外の方法で使用した場合、人体の負傷、また

は装置の損傷を引き起こす恐れがあります。この装置は、本書に記載されている説明に

従って使用してください。

OK インターナショナルは、この装置を本来の目的以外に使用したことによる負傷また

は損傷に関して、一切の責任を負いかねます。本来の目的以外の使用とは、次のような

ことが含まれます。

• 本書で推奨されていない変更を装置に対して行う。

• 互換性がない、または損傷している交換部品を使用する。

• 承認されていないアクセサリーまたは補助装置を使用する。

安全に関する予防措置 :

• 最大定格/設定を超えた状態で本装置を操作しないでください。

• 適切な個人用防護服または防護衣を必ず着用してください。

• 本装置は、室内での使用に限られています。

保証

OK インターナショナルは、HCT-1000 ハンドヘルド対流熱式再加工用ツール電源に関し

て、最初の所有者による購入日から 1 年間にわたり、素材または製造上の作業不良に

起因する欠陥について保証します。

OK インターナショナルは、HCT-1000 ハンドヘルド対流熱式再加工用ツールのホルダー

(HCT-HV1)に関して、最初の所有者による購入日から 1 年間にわたり、素材または製

造上の作業不良に起因する欠陥について保証します。

OK インターナショナルは、HCT-1000 ヒーターアセンブリ(HCT-HTRASSY)に関して、最

初の所有者による購入日から 90 日間にわたり、素材または製造上の作業不良に起因す

る欠陥について保証します。

本保証は、通常の保守を含まず、かつ開放された、誤用された、乱用された、改造され

たまたは破損されたものには一切適用されないものとします。本製品が保証期間内に故

障した場合、OK インターナショナル社は唯一のオプションとして故障した製品を無償で

修理または交換します。交換品は、送料を OK インターナショナルが支払い、お客様の

元へ届けられます。保証期間は、購入日から起算されます。購入日を証明できない場合

、製造日が保証期間の開始日として用いられます。

Page 28

2

2. HCT -1000 の仕様

サイズ

9” x 7” x 6”(229 mm x 178 mm x 152 mm )

重量

12 lbs

入力電圧

100-240 VAC、50/60 Hz

定格出力

600W

汚染度カテゴリー

II

保存温度

-10C 〜 60C(14F 〜 140F)

動作温度

0C 〜 50C(32F 〜 122F)

エアポンプタイプ

ダイアフラム

エアフロー

5 〜 25 l/分

吸引ポンプ

15” Hg(381 mm Hg)

制御温度

450°C

表面抵抗率

107Ω 〜 1011Ω

騒音レベル

55 dB 未満

適合規格

TUV

最大相対湿度

31C(87.8F)までは 80%、40C(104F)で 50% まで直線的に低下

システムモード

HCT、MRS

操作モード

設定、実行、手動、アクティブ設定

メモリ位置

50

ディスプレイ

LCD 20 X 4 ディスプレイセグメント

説明

HCT-PS1000

HCT-1000 電源

HCT-HV1

吸引ツール、コード、コネクタ内蔵のホルダー

HCT-FS2

フットスイッチ、デュアル、HCT-1000

HCT-NC

ノズルキャリア、HCT-1000 ノズル

HCTA-TH1

ホルダーツール

HNA-1

ノズルアダプタ

HCTA-NW1

ノズルレンチ

HCTA-VCT1

吸引キャップツール

アクセサリー

HCTA-VC24

吸引キャップ、3/32”(2.38mm)

HCTA-VC50

吸引キャップ、3/16”(5.00mm)

HCTA-VC64

吸引キャップ、¼”(6.4mm)

HCTA-VC80

吸引キャップ、5/16”(8mm)

HCTA-VC11

吸引キャップ、7/16”(11mm)

HCTA-ASC

焼付防止剤

AC-TCK-24-36

熱電温度計

HCTA-CC

通信ケーブル

HCT-HTRASSY

ヒーターアセンブリ

3. 装置各部の名称

電源のオン/オフ

タイマー/温度値を下げる

Page 29

3

図 1 HCT-PS1000 電源

図 3:実行モード、プロファイル開始前

図 4:実行モード、プロファイル開始後、MRS モード

Z

1 : 1 5 0 °c 6 5 s P

0

6

Z 2 : 2 0 0

°c 5 5 s T C : I N T

Z 3 : 2 5 0

°c 4 5 s

Z 4 : 3 0 0

°c 3 0 s

Z 1 :

5 5 s P 0 6

T - S E T

: 1 5 0

°c T C : I N

T

T

- H t r : 1 3 6

°c

1 2 5 °c R E M O V E

T

C

1:

ゾーン設定ポイント

実際のヒーター温度

温度モニター

熱電温度計

コントロール

選択したプロファ

イル

配置/取り外しオプション

(MRS モードのみで使用可)

ゾーンターゲット

プロファイルパラ

メータ

Active Zone

アクティブゾーン

(↵) 入力/プロファイル選択

⊕ タイマー/温度値を上げる、プ

ロファイルの開始/中止

熱電温度計(TC1)

熱電温度計(TC2)

ホルダーコネクタ

電源コネクタ

フットスイッチ

コネクタ

通信コネクタ

図 2

背面パネルの説

Page 30

4

図 5 HCT-HV1 ホルダーアセンブリ

4. 設定および装置の操作

1. 装置の基本設定

1. ホルダーアセンブリ、HCT-HV1 を電源に接続します。

2. 電源ケーブルを電源コネクタに接続します(図 2)。入力電圧の接地済みの

コンセントに電源ケーブルを接続します。

3. デュアルフットスイッチ、HCT-FS2 を装置に接続します(図 2)。

4. 電源ボタン を押して、装置の電源を入れます。

5. プロファイルを中止(冷却ゾーンに移行*)するには、実行モードでフットス

イッチの(赤)またはホルダーの(赤)を押し続けます。

6. *注記 :フットスイッチの(赤)またはホルダーの(赤)を 2 回押した

ままにすると、冷却時間が最小の 60 秒間に減ります。

7. 電源ボタン を押して、装置の電源を切ります。注記 : 電源を切るには

、設定モードを無効(ディスプレイに数値が表示されていない状態)にする

必要があります。

2. システムモード選択

HCT-1000 には、次の 2 種類のシステム操作モードがあります。

• HCT モード : HCT-1000 は、スタンドアロンのハンドヘルド対流熱式再加工

用ツールとして使用されます。

• MRS モード : HCT-1000 は、M odular R ework S ystem(モジュール式再加工

システム)の一部として使用されます。この装置は、ケーブルを介して PCT1000 に接続し、ATH-1000 Adjustable Tool Holder と使用できます。また、

このモードでは、HCT-1000 は、両方の装置のタイミングを制御できるので、

ATH-1000 を使用して、取り付け/取り外し操作を繰り返すことができます。

吸引ピックアップチ

(赤)プロファイル開始/

(青)吸引ツールアク

吸引ピックアップチュー

ヒーターアセン

図6 HCTA-TH1

図7

Page 31

5

• 通信ケーブルを HCT-1000 および PCT-1000 の通信コネクタ(上記の図 2)

に差し込みます。MRS モードで接続した場合、PCT-1000 の時間設定は「-

-」と表示されます。

• システムモードは、設定モードで選択します。セクション 3.1 を参照してく

ださい。別の操作オプションも使用できます。セクション 3.5 を参照してく

ださい。

3. 操作モード選択

HCT-1000 には、4種類の操作モードがあります。使用できる操作モードは、設定

、実行、手動、アクティブ設定です。設定モードでは、システムまたはプロファイ

ルパラメータを変更します。実行モードでは、4 種類の加熱ゾーンを使用するプロ

ファイルにより、装置を操作します。手動モードでは、1 つの加熱ゾーンで装置を

操作します。時間の制限はありません。Active Setup モードでは、プロファイル実

行中にパラメータを変更できます。

1. 設定モード

1. モードボタン (↵) を一度押します。「P:」が点滅します。

2. ⊕ / ボタンを使用して、プロファイルをスクロールします。

3. (↵) を押して、目的のプロファイルを選択します。

4. (↵) ボタンを 3 秒間押し続け、プログラムモードをアクティブにし

ます(ゾーン 1 の最初の温度が点滅します)。

5. 実行モードを設定するには、ステップ 3.1.6.1 に進んでください

。手動モードを設定するには、ステップ 3.1.7.1 に進んでくださ

い。

6. 実行モードの設定

1. ⊕ / ボタンを使用して、温度を目的の値に変更します。(

注記 :⊕ または のいずれかのボタンを 5 秒間押したまま

にすると、数値の増加または減少が速くなります。)

2. 値が設定されたら、(↵) を押して、次のパラメータに移動します

。

3. プロファイルがプログラムされるまで、ステップ 3.1.6.1 および

3.1.6.2 を繰り返します。注記 :冷却ゾーンでは、温度のみを修正

できます。

4. ステップ 3.1.8 に進みます。

7. 手動モードの設定

1. ⊕ / ボタンを使用して、温度を目的の値に変更します。(注

記 :⊕ または のいずれかのボタンを 5 秒間押したままに

すると、数値の増加または減少が速くなります。)

2. ゾーン 1 の時間を 300 秒より大きい値に設定します。ディスプレイ

に「MANUAL」と表示されます。Z2、Z3、Z4 は表示されなくなりま

す。

注記 :手動モードプロファイルには、時間制限がありません。一度開

始されると、プロファイルが停止されるまで実行できます。

3. 必要な変更が終了したら、LCD の点滅が停止するまで ( ↵ ) を 3

秒間押し続けます。プロファイルがメモリに保存され、設定モード

が終了します。

8. (↵ ) を押して、次のパラメータに移動します。これは、HCT または

MRS オプションです。⊕ または を使用して HCT または MRS を

選択するか、(↵) を押して次に進みます。

9. (↵) を押して、次のパラメータに移動します。これは、内部または外

部 TC オプションです。⊕ または を使用して Int(内部)または

Ext(外部)を選択するか、(↵ ) を押して次に進みます。

Page 32

6

注記 :EXT が選択されている場合、TC1 は、マスター熱電温度計とな

り、電源のフィードバックを表示します。

10. (↵ ) を押して、次のパラメータに移動します。これは、エアフローオ

プション(AF)です。⊕ または を使用するとエアフローを増加ま

たは減少できます。範囲は、1 〜 10 で調整できます。エアフローの

調整中に、エアポンプが起動しますので注意してください。スキップ

するには、(↵) を押します。

11. 必要な変更が終了したら、LCD の点滅が停止するまで (↵) を 3 秒間

押し続けます。プロファイルがメモリに保存され、設定モードが終了

します。(上記の図 1 を参照してください。)

2. 実行および手動モード

1. 電源ボタン を押して、装置に電源を入れます。

2. HCT スタートアップメッセージおよびソフトウェアのリビジョン番号

が一瞬表示され、その後、最後に使用したプロファイル設定が表示さ

れます。注記 : MRS-1000 が最後の操作状態であった場合、これが表

示されます。

3. 重要 : 「TC: Ext」がパネルに表示された場合(上記の図 4 を参照)

、外部熱電温度計が加熱パスに正しく配置されているか確認してくだ

さい。正しく配置されていない場合、ヒーターに不慮の故障が発生す

る可能性があります。

4. 目的のプロファイルを選択します。

5. 目的のプロファイルが表示されたら、(↵) を押して、そのプロファイ

ルを選択します。

6. プロファイルを開始するには、フットスイッチの(赤)またはホル

ダーの(赤)を一度押します。

7. プロファイルを実行すると、現在のゾーン、残り時間、ヒーター値、

温度設定ポイントが表示されます。手動モードプロファイルには、「

Manual」と表示され、残り時間は表示されません。

8. プロファイルを停止するには、フットスイッチの(赤)またはホル

ダーの(赤)を 3 秒間押し続けます。プロファイルは、冷却ゾーン

に移行します。

注記 :

ステップ 8 繰り返すと、1 分間の冷却時間の

後に冷却ゾーンが終了します。

3. アクティブ設定モード

1. 上記のステップ 1 3 に従って、修正するプロファイルを選択しま

す。

2. アクティブ設定モードを開始するには、(↵) を 3 秒間押し続け、Z1 の

温度が点滅したら、フットスイッチの(赤)ボタンまたはホルダー

の(赤)ボタンを押します。

3. プロファイルが実行を開始し、LCD に「SETUP」と表示されます。

4. 現在のゾーンに設定されている温度を修正するには、⊕ / ボタンを

使用します。

5. 現在のゾーンの時間を増加するには、ゾーンが終了するときに、( ↵ )

ボタンを押し続けます。(↵) ボタンを押し続けると、次のゾーンに移

行せずに、現在のゾーンの時間設定が元の時間設定より大きくなりま

す。ボタンを放すと、プロファイルが次のゾーンに進みます。*

6. ゾーンの時間を減少するには、フットスイッチの(赤)ボタンまたは

ホルダーの(赤)ボタンを押して目的の時間に設定します。これによ

り、時間がメモリに保存され、プロファイルが次のゾーンに進みます

。*注記 :ステップ 3.4.5 と 3.4.6 は同時に実行できます。

Page 33

7

7. 必要な変更が終了したら、プロファイルを終了できます。LCD の点滅

が停止するまで (↵ ) を押し続けます。プロファイルがメモリに保存さ

れ、設定モードが終了します。

8. *注記 :冷却ゾーンでは使用できません。

5. 追加機能

1. 内蔵吸引ピックアップチューブ

この吸引ピックアップには、長さ 1.0”(25.4 mm)のチューブが装備

されています。また、取り付け中に部品を傷付けないようにバネが付

けられています。

用途に適したサイズの吸引キャップを部品に被せます。

2. HCT システムモード

1. フットスイッチの(青)またはホルダーの(青)を 1 回押す

と、吸引ポンプが起動します。もう一度押すと、停止します。

3. MRS システムモード – 取り付けまたは取り外しの選択

1. 取り付けと取り外しを切り替えるには、フットスイッチの(青

)またはホルダーの(青)を 3 秒間押し続けます。

4. MRS システムモード – 取り付け

1. フットスイッチの(青)ボタンまたはホルダーの(青)ボタ

ンを 1 回押すと、吸引ポンプが起動します。もう一度押すと、停

止します。

5. MRS システムモード – 取り外し

1. 内蔵吸引ピックアップは、自動的に吸引を開始し、実行モードで

のゾーン 4(Z4)の完了時に吸引ピックアップチューブを縮めま

す。吸引は、ZC(冷却ゾーン)の間アクティブになります。

6. MRSシス テ ム モ ー ド – ポ ジ テ ィ ブ 吸 引 表示

1. VACは、設定または実行モード(図4)で吸引が開始されたときに表示さ

れます。VACは、コンポーネントにポ ジテ ィブシールが達したときに点

滅します。

7. 外部熱電温度計コントロール

1. HCT-1000 で外部熱電温度計(上記の図 4 の EXT)を使用している

場合、TC1 は、外部フィードバックコントロールに使用されます。

熱電温度計が加熱パスに正しく配置されていることを確認してく

ださい。正しく配置されていない場合、エラーが発生したり、コ

ンポーネントが損傷したりします。TC2 は、温度の監視に使用で

きます(1.5.7 を参照してください)。

2. MRS モードで HCT-1000 と外部熱電温度計を使用する場合、

HCT-1000 の TC1 がマスター熱電温度計になり、システム全体の

外部フィードバックに使用されます。HCT-1000 の TC2 および

PCT-1000 の TC1 & TC2 は、温度の監視のみに使用できます(

1.9 および『PCT-1000 User Guide 7000-2420』のセクション 4.4

を参照してください)。

8. 温度の監視

1. HCT-1000 で内部熱電温度計(上記の図 3 の INT)を使用してい

る場合、TC1 と TC2 および外部熱電温度計を温度の監視に使用

できます。

2. 熱電温度計を TC1 または TC2 あるいはその両方に接続し、監視

する領域に熱電温度計を取り付けます。熱電温度計を取り付けた

ら、該当する熱電温度計が表示されます(上記の図 4 を参照して

ください)。

6. ノズルの取り付け

Page 34

8

1. ノズルアダプタ(HNA-1)をヒーターアセンブリに

固定します。

1. クランプネジを半時計回りに回して緩めます(

図 6、1)。

2. クランプを閉じます(図 6、2)。

3. ノズルアダプタを停止するまで上側にスライ

ドさせ、ヒーターアセンブリ(図 5)に固定

します。

4. クランプネジを時計回りに回して締めて(図 6

、1)、アダプタとヒーターアセンブリをしっかりと密着させます。調整

後アダプタを取り外すには、クランプを開いて、アダプタをスライドさ

せ、ヒーターアセンブルから取り外します。

2. ノズルとノズルアダプタを装着します。

1. 用途に適したノズルを選択します。

2. ノズルを取り付けるには、ノズルレンチを使用して、ネジを時計回り

に回して締め、ノズルとノズルアダプタを固定します(図 6、3)。

3. ノズルを取り外すには、ノズルレンチを使用して、ネジを反時計回り

に回して緩め、ノズルをノズルアダプタから取り外します(図 6、3)

。

3. ノズルを選択します。

1. 用途に適したサイズのノズルを選択します。以下は、使用できるノズル

の一例です。使用できるすべてのノズルについては、『HCT-1000

Nozzle Selection Guide

(HCT-1000 ノズル選定ガイド)』を参照するか、弊社 Web サイト

www.okinternational.com をご覧ください。

2

図 6:ノズルアダ

プタ(HNA-1)

1

3

HN-J0005

5.0MM

HN-B1818

18MM x 18MM

HN-B1010

10MM x 10MM

HN-B4040

40MM x 40MM

Page 35

9

7. 操作

1. 対流熱を使用して部品のはんだを吸い取る

1. 正しいノズルを選択して、アダプタに固定します。

2. 目的のプロファイルを設定します。

3. ノズルを部品リードに近付けます。部品リードとの距離は 3 〜 5 mm

に保ってください。熱風を使用して、はんだを溶かします。

4. はんだが溶けたら、内蔵の吸引チューブ、ピンセットまたはその他の

適切なツールを使用して、回路基板から部品を取り外します。

2. 対流熱を使用して部品をはんだ付けする

1. 正しいノズルを選択して、アダプタに固定します。

2. 適量のはんだを回路基板に付け、部品の位置を決めます。

3. 目的のプロファイルを設定します。

4. ノズルを部品リードに近付け、リードに熱風を吹きかけて、はんだを

溶かします。

8. トラブルシューティング

1. 装置に電源が入らない。

• 電源ケーブルを確認する。

• 電源電圧が正しいか確認する。

2. LED 画面に OH と表示される。

• 装置が内部セイフティカットオフを超えている。

• 装置を冷却する。

• (使用している場合) 熱電温度計の位置を確認する。

• 電源を切り、再び電源を入れて、装置をリセットする。

3. LED 画面に TCFAULT と表示される。

• 熱電温度計の位置を確認する。

• 熱電温度計が正しい TC コネクタにしっかりと挿入されているか確

認する。

• 問題が解決しない場合、熱電温度計を交換する。

4. 実行モード中にゾーンおよび温度パラメータが点滅する。

• プログラムされた時間および温度に装置が設定されない。

9. 保守

ホルダー (HCT-HV1) は、OK International 社のサービス交換プログラムに含まれます

。または、ヒーターアセンブリ (HCT-HTRASSY) は、交換部品として個別に購入できま

す。

OK International 社の Web ページ (www.okinternational.com) をご覧ください。この

Web ページには、システム、付属品、技術解説などの追加情報が記載されていま

す。

Page 36

1

소개

HCT-1000은 손잡이형 컨벡션 리워크 도구로, 디지털 제어, 다중 작동 모드, 내부 또는 외부

피드백 제어, 부품 배치 및 제거를 위한 통합형 진공 픽업이 장착되어 있습니다. 뿐만 아니

라, 이 장치는 MRS(Modular Rework System)의 부분으로 PCT-1000에 연결될 수 있습니다.

목차

1. 안전 및 보증 1

2. 규격 2

3. 장치 식별자 3

4. 설정 및 장치 작동 4

5. 추가 기능 7

6. 노즐 정보 9

7. 작동 10

8. 문제 해결 10

9. 유지보수 10

안전

용도:

경고: 본 장비를 사용설명서에 명시된 것과 다른 방법으로 사용할 경우 인명 또는 재산 피해를

초래할 수도 있습니다. 반드시 사용설명서에 명시된 대로만 사용하여 주십시오.

OK International은 본 장비를 본래 용도 이외의 용도에 사용한 데 따른 일체의 인적, 물적 피해에

대하여 책임을 지지 않습니다. 다음과 같은 행위를 할 경우 오용으로 이어질 수 있습니다.

• 사용 설명서에서 권장되지 않은 장비 변경

• 호환이 되지 않거나 파손된 교체 부품 사용

• 허가되지 않은 액세서리나 보조 장비 사용

안전 예방조치:

• 최대 정격/설정을 초과하여 본 장치를 가동시키면 안 됩니다.

• 항상 적합한 개인 보호복을 착용해야 합니다.

• 본 장비는 실내 전용입니다.

보증

OK International은 원래 소유자의 구매일로부터 1년 동안 HCT-1000 손잡이형 컨벡션 리워크 도

구 전원 공급장치의 자재 또는 제조 기술 결함에 대해 보증합니다.

OK International은 원래 소유자의 구매일로부터 1년 동안 HCT-1000 손잡이형 컨벡션 리워크 도

구 핸드피스(HCT-HV1)의 자재 또는 제조 기술 결함에 대해 보증합니다.

OK International은 원래 소유자의 구매일로부터 90년 동안 HCT-1000 히터 어셈블리(HCTHTRASSY)의 자재 또는 제조 기술 결함에 대해 보증합니다.

이 보증에는 일반적인 정비사항이 포함되지 않습니다. 본 제품을 오용, 남용, 변경 및 손상을 준

경우에도 적용되지 않습니다. 보증 기간 내에 본 제품에 하자가 생긴 경우에는 OK International사

는 무상으로 수리 또는 교환해 드립니다. 수리 또는 교체 품목은 운송료 선불로 원구매자에게 배

송됩니다. 보증기간은 구매날짜로부터 시작합니다. 구매일을 입증할 수 없는 경우 제조일을 보

증 기간의 시작으로 하여 적용됩니다.

2. HCT-1000 규격

크기

229mm x 178mm x 152mm(9” x 7” x 6”)

중량

12lbs

입력 전압

100-240 VAC, 50/60 Hz

정격 전압

600W

오염도 범주

II

보관 온도

-10°C - 60°C(14°F - 140°F)

작동 온도

0°C ~ 50°C (32°F ~ 122°F)

공기 펌프 유형

다이아프램

기류

5-25 l/min

진공 펌프

15” Hg(381 mm Hg)

Page 37

2

제어 온도

450°C

표면 저항

107Ω - 1011Ω

소음 수준

55 dB 미만

인증

TUV

최대 상대 습도

최대 31°C까지 80% (87.8°F) 40°C(104°F)에서 상대 습도 50%까지 선형으로 감소

시스템 모드

HCT, MRS

작동 모드

설정, 실행, 수동, 활성 설정

메모리 위치

50

디스플레이

LCD 20 X 4 디스플레이 세그먼트

설명

HCT-PS1000

HCT-1000 전원 공급장치

HCT-HV1

전체 진공, 코드 및 커넥터가 포함된 핸드피스

HCT-FS2

페달 스위치, 이중, HCT-1000

HCT-NC

노즐 캐리어, HCT-1000 노즐

HCTA-TH1

핸드피스 도구 홀더

HNA-1

노즐 어댑터

HCTA-NW1

노즐 렌치

HCTA-VCT1

진공 컵 도구

부속품

HCTA-VC24

진공 컵, 2.38mm(3/32”)

HCTA-VC50

진공 컵, 5.00mm(3/16”)

HCTA-VC64

진공 컵, 6.4mm(¼”)

HCTA-VC80

진공 컵, 8mm(5/16”)

HCTA-VC11

진공 컵, 11mm(7/16”)

HCTA-ASC

고착 방지제

AC-TCK-24-36

열전대

HCTA-CC

통신 케이블

HCT-HTRASSY

히터 어셈블리

Page 38

3

3. 장치 식별자

그림 1 HCT-PS1000 전원 공급장치

그림 3: 실행 모드, 프로파일 시작 전

그림 4 실행 모드, 프로파일 시작 후, MRS 모드

Z 1 : 1 5 0

°c 6 5 s P

0

6

Z 2 : 2 0 0

°c 5 5 s T C : I N T

Z 3 : 2 5 0

°c 4 5 s

Z 4 : 3 0 0

°c 3 0 s

Z 1 :

5 5 s P 0 6

T - S E T

: 1 5 0

°c T C : I N

T

T

- H t r : 1 3 6

°c

1 2 5 °c R E M O V E

(↵) 입력/프로파일 선택

⊕ 타이머/온도 상향 조정 및

프로파일 시작/중지

열전대(TC1)

열전대(TC2)

핸드피스 커넥터

전원 커넥터

페달 스위치 커넥터

통신 커넥터

그림 2 후면 패널 세부사항

T

C

1:

지대 설정점

실제 히터 계기

온도 모니터

열전대 제어

선택된 프로파일

옵션 배치/제거

(MRS 모드에서만 사용할 수 있음)

지대 목표 온도

프로파일 매개변수

활성 지대

전원 On/Off

타이머/온도 하향 조정

Page 39

4

그림 5 HCT-HV1 핸드피스 어셈블리

4. 설정 및 장치 작동

1. 기본 장치 설정

1. 핸드피스 어셈블리 HCT-HV1을 전원 공급장치에 연결합니다.

2. 전원 코드를 전원 커넥터에 연결합니다(그림 2). 파워선을 접지가 되고, 정격입

력 전압규격을 충족시키는 벽면소켓에 꽂으십시오.

3. 이중 페달 스위치 HCT-FS2를 장치에 연결합니다(그림 2).

4. 전원 버튼 를 잠시 눌러 장치를 가동시킵니다.

5. (냉각 지대에 대한) 프로파일을 중지하려면 실행 모드에서 페달 스위치의

(빨강) 또는 핸드피스의 (빨강)를 꾹 누릅니다.

6. *참고: 페달 스위치의 (빨강) 또는 핸드피스의 (빨강)를 다시 누르면 냉각

시간이 최소 60초로 감소합니다.

7. 전원 버튼 를 잠시 눌러 장치를 끕니다. 참고 ~ 즉, 디스플레이에 깜박이는 숫

자가 없도록 하려면 설정 모드에서 나가야 합니다.

진공 픽업 튜브

(빨강) 프로파일 시작/중지

(파랑) 진공 활성화

진공 픽업 튜브 조정

히터 어셈블리

그림6 HCTA-TH1

그림7

Page 40

5

2. 시스템 모드 선택

HCT-1000에는 두 가지 시스템 작동 모드가 있습니다.

• 첫 번째 모드는 HCT입니다. 이 모드에서 HCT-1000은 독립형의 손잡이형 컨벡

션 리워크 도구로 사용됩니다.

• 두 번째 모드는 MRS입니다. 이 모드에서 HCT-1000은 MRS(Modular Rework

System)의 일부로서 사용됩니다. 이 장치는 케이블로 PCT-1000에 연결하여

ATH-1000 Adjustable Tool Holder와 함께 사용할 수 있습니다. HCT-1000은 이

모드에서 두 장치에 타이밍 제어를 제공하므로 ATH-1000은 작동을 반복적으

로 배치하거나 제거할 수 있습니다.

• HCT-1000과 PCT-1000에 있는 통신 커넥터(위의 그림 2)에 통신 케이블을 연결

합니다. MRS 모드에서 연결하면 PCT-1000의 시간 설정에 “- -”가 표시됩니다.

• 설정 모드에서 시스템 모드를 선택합니다. 3.1절을 참조하십시오. 추가 작동 옵

션을 사용할 수 있습니다. 3.5절을 참조하십시오.

3. 작동 모드 선택

HCT-1000에는 설정, 실행, 수동 및 활성 설정의 4가지 작동 모드가 있습니다. 설정 모

드는 시스템 또는 프로파일 매개변수를 수정하는 경우, 실행 모드는 가열 지대 4개를

사용하는 프로파일이 포함된 장치를 작동하는 경우, 수동 모드는 가열 지대가 1개이

고 시간 제한이 없는 장치를 작동하는 경우, 활성 설정 모드는 실행 중인 프로파일 내

에서 매개변수를 변경하는 경우에 사용됩니다.

1. 설정 모드

1. 모드 버튼 (↵)을 한 번 눌러 “P:” 깜박임을 시작합니다.

2. ⊕ / 버튼을 사용하여 프로파일을 이동합니다.

3. (↵)를 눌러 원하는 프로파일을 선택합니다.

4. (↵)를 3초 간 눌러 프로그램 모드를 활성화합니다(지대 1의 온도가 먼저

깜박입니다).

5. 실행 모드 설정은 3.1.6.1단계로 진행하고, 수동 모드 설정은 3.1.7.1단

계로 진행합니다.

6. 실행 모드 설정

1. ⊕ / 버튼을 사용하여 온도를 원하는 값으로 변경합니다. (참고:

⊕ 또는 버튼을 5초 간 계속 누르고 있으면 숫자가 가속화된 모

드에서 증가/감소합니다.)

2. 값이 설정되면 (↵)를 눌러 다음 매개변수로 이동합니다.

3. 프로파일이 프로그래밍될 때까지 3.1.6.1단계와 3.1.6.2단계를 반복

합니다. 참고: 냉각 지대에서는 시간 매개변수만 수정할 수 있습니

다.

4. 3.1.8단계로 진행합니다.

7. 수동 모드 설정

1. ⊕ / 버튼을 사용하여 온도를 원하는 값으로 변경합니다. (참고

: ⊕ 또는 버튼을 5초 간 계속 누르고 있으면 숫자가 가속화된

모드에서 증가/감소합니다.)

2. 지대 1의 시간을 300초 이상의 값으로 설정합니다. 이제 디스플레

이에 MANUAL(수동) 단어가 표시되고 Z2, Z3, Z4는 더 이상 표시

되지 않습니다.

참고: 수동 모드 프로파일에는 시간 요구사항이 없으며, 일단 활성

화되면 프로파일이 중지될 때까지 실행됩니다.

3. 필요한 변경사항을 변경했으면 (↵ )를 3초 간 누릅니다. LCD가 깜

박임을 중지합니다. 프로파일을 메모리로 설정하고 설정 모드를

종료합니다.

Page 41

6

8. (↵)을 눌러 다음 매개변수로 이동합니다. 이것은 HCT 또는 MRS 옵션입

니다. ⊕ 또는 를 사용하여 HCT 또는 MRS로 전환하거나 (↵ )를 눌러

건너뜁니다.

9. (↵)을 눌러 다음 매개변수로 이동합니다. 이것은 내부 또는 외부 TC 옵션

입니다. ⊕ 또는 을 사용하여 Int 또는 Ext로 전환하거나 (↵)를 눌러 건

너뜁니다.

참고: EXT를 선택하는 경우 TC1이 마스터 열전대가 되고 전원 공급장치

에 피드백을 제공합니다.

10. (↵)을 눌러 다음 매개변수로 이동합니다. 이것은 기류 옵션입니다(AF).

기류를 증가시키려면 ⊕ 를 사용하고 기류를 감소시키려면 를 사용합

니다. 1-10 범위에서 조정할 수 있습니다. 공기 펌프가 가동되면서 기류가

조정됩니다. (↵)를 눌러 건너뜁니다.

11. 일단 필요한 변경사항을 변경했으면 (↵ )를 3초 간 눌러 LCD의 깜박임을

멈추고 프로파일을 메모리에 설정한 다음 설정 모드를 종료합니다. (위의

그림 1 참조)

2. 실행 및 수동 모드

1. 전원 버튼 을 눌러 장치를 가동시킵니다.

2. 마지막으로 사용된 프로파일 설정을 표시하기 전에 HCT 시작 메시지 및

소프트웨어 개정 번호가 잠시 표시됩니다. 참고: 이것이 마지막 작동 상

태일 경우 장치에는 MRS-1000이 표시될 수 있습니다.

3. 중요 ~ “TC: Ext”가 패널에 표시되는 경우(위의 그림 4 참조)에는 외부 열

전대가 가열 경로에 적절하게 배치되었는지 확인하십시오. 이렇게 하지

않으면 히터가 조기에 고장 날 수 있습니다.

4. 원하는 프로파일을 선택합니다.

5. 선택한 프로파일이 표시되면 (↵)를 눌러 원하는 프로파일을 선택합니다.

6. 프로파일을 시작하려면, 페달 스위치의 (빨강) 또는 핸드피스의 (빨

강)을 한 번 누릅니다.

7. 프로파일이 실행되면 현재 지대, 남은 시간, 히터 값 및 온도 설정점이 표

시됩니다. 수동 모드 프로파일에는 “Manual(수동)”이 표시되고 남은 시간

은 표시되지 않습니다.

8. 프로파일을 종료하려면, 간단히 페달 스위치의 (빨강) 또는 핸드피스의

(빨강)을 누릅니다. 프로파일이 냉각 지대로 건너뜁니다. 참고: 8단계를

반복하면 냉각 후 최소 60초 이후에 냉각 지대가 켜집니다.

3. 활성 설정 모드

1. 위의 1 3단계를 진행하면서 수정할 프로파일을 선택합니다.

2. 활성 설정 모드를 활성화하려면 Z1의 온도가 깜빡이기 시작할 때 (↵ )를 3

초 간 누르고 나서 페달 스위치의 (빨강) 또는 핸드피스의 (빨강) 버

튼을 누릅니다.

3. 프로파일이 실행되기 시작하고 ‘SETUP’이 LCD에 표시됩니다.

4. 현재 지대에 설정된 온도를 수정하려면 ⊕ / 버튼을 사용합니다.

5. 현재 지대의 시간을 증가시키려면 지대가 종료될 때까지 (↵) 버튼을 누릅

니다. (↵ ) 버튼을 누르고 있는 동안에는 다음 단계로 이동하지 않고, 현재

지대 시간 설정이 원래 설정을 증분시킵니다. 버튼을 놓으면 프로파일이

다음 지대로 진행될 수 있습니다.*

6. 프로파일을 감소시키려면 원하는 시간에 간단히 페달 스위치의 (빨강)

또는 핸드피스의 (빨강) 버튼을 누릅니다. 그러면 시간이 메모리에 설정

되고 프로파일이 다음 지대로 이동합니다.* 참고: 3.4.5단계와 3.4.6단계

를 동시에 수행할 수 있습니다.

Page 42

7

7. 필요한 변경사항을 변경했으면 프로파일을 마칠 수 있습니다. LCD가 깜

박일 때까지 (↵ )을 눌러 프로파일을 메모리에 설정하고 설정 모드를 종료

합니다.

8. *참고: 냉각 지대에서는 이 기능을 사용할 수 없습니다.

5. 추가 기능

1. 통합형 진공 픽업

진공 픽업 튜브에는 25.4mm(1.0”)의 트래블이 있고 장착 중 부품 손상을 방지

하기 위해 스프링이 고정되어 있습니다.

적절한 크기의 진공 컵을 사용하여 부품을 밀봉합니다.

2. HCT 시스템 모드

1. 진공 펌프를 활성화하려면 페달 스위치의 (파랑) 또는 핸드피스의

(파랑) 를 한 번 누르고 비활성화하려면 다시 한 번 누릅니다.

3. MRS 시스템 모드 – 선택 배치 또는 선택 제거

1. 배치 또는 제거로 전환하려면 페달 스위치의 (파랑) 또는 핸드피

스의 (파랑) 버튼을 3초 간 누릅니다.

4. MRS 시스템 모드 – 배치

1. 진공 펌프를 활성화하려면 페달 스위치의 (파랑) 또는 핸드피스의

(파랑) 버튼을 한 번 누르고 비활성화하려면 다시 한 번 누릅니다.

5. MRS 시스템 모드 – 제거

1. 통합형 진공 픽업은 실행 모드에서 지대 4(Z4)가 완료되면 진공을 자

동으로 활성화하고 진공 픽업 튜브를 집어 넣습니다. 진공은 ZC(냉

각 지대) 지속 시간 동안 활성화됩니다.

6. MRS 시스템 모드 – 포지티브 진공 표시기

1. 설정 또는 실행 모드(그림 4)에서 진공이 활성화된 경우 VAC가 표

시됩니다. 부품으로 포지티브 씰이 확보된 경우 VAC가 깜빡입니다

.

7. 외부 열전대 제어

1. 외부 열전대(EXT, 위의 그림 4 참조)에서 HCT-1000을 사용하는 경

우 TC1은 외부 피드백 제어를 제공하는 데 사용됩니다. 열전대가 가

열 경로에 배치되어 있는지 확인하십시오. 열전대가 가열 경로에 배

치되어 있지 않으면 부품에 오류나 손상이 발생할 수 있습니다. TC2

는 온도 모니터링에 사용될 수 있습니다(1.5.7 참조).

2. MRS 모드에서 외부 열전대와 함께 HCT-1000을 사용하는 경우

HCT-1000의 TC1은 마스터 열전대가 되고 전체 시스템에 외부 피드

백을 제공하는 데 사용됩니다. HCT-1000의 TC2와 PCT-1000의 TC1

및 TC2는 온도 모니터링에만 사용할 수 있습니다(1.9와 PCT-1000 사

용 설명서 7000-2420 4.4절 참조).

8. 온도 모니터링

1. 내부 열전대가 포함된 HCT-1000을 사용하는 동안(INT 위의 그림. 3

참조) 외부 열전대 TC1과 TC2를 사용하여 온도를 모니터할 수 있습

니다.

2. 열전대를 TC1 및/또는 TC2에 부착하고 모니터할 영역에 부착합니

다. 부착했으면 해당 열전대가 표시됩니다(위의 그림 4 참조).

Page 43

8

그림 6: 노즐 어댑

터(HNA-1)

6. 노즐 장착

1. 노즐 어댑터(HNA-1)를 히터 어셈블리에 고정합니다.

1. 고정 나사를 반시계 방향으로 풉니다(그림 6, 1).

2. 클램프를 닫습니다(그림 6, 2).

3. 노즐 어댑터를 히터 어셈블리(그림 5)로 완전히

밀어 올립니다.

4. 어댑터와 히터 어셈블리가 단단히 고정되도록

고정 나사를 시계 방향으로 조입니다(그림 6, 1).

조정 후 클램프를 열고 어댑터를 밀고 히터 어

셈블리에서 분리하여 어댑터를 제거합니다.

2. 노즐-노즐 어댑터

1. 용도에 적합한 노즐을 선택합니다.

2. 부착하려면 노즐-노즐 어댑터(그림 6, 3)를 나사로 고정하고 노즐 렌치로

시계 방향으로 조입니다.

3. 제거하려면 어댑터(그림 6, 3)에서 노즐 나사를 풀고 노즐 렌치로 반시계

방향으로 풉니다.

3. 노즐 선택

1. 용도에 적합한 노즐을 선택합니다. 이것은 사용 가능한 노즐의 샘플입니

다. 가장 적절한 선택을 위해서는 HCT-1000 노즐 선택 설명서를 참조하

거나 웹사이트 www.okinternational.com을 방문하십시오.

1 2 3

HN-J0005

5.0MM

HN-B1818

18MM x 18MM

HN-B1010

10MM x 10MM

HN-B4040

40MM x 40MM

Page 44

9

7. 작동

1. 대류열을 사용하여 부품 납땜 제거

1. 적절한 노즐을 선택하여 어댑터에 고정합니다.

2. 원하는 프로파일을 선택합니다.

3. 부품 납 가까이로 노즐을 이동하고 3-5mm 거리를 유지합니다. 뜨거운 공

기를 사용하여 납땜을 녹입니다.

4. 납땜이 녹으면 통합형 진공, 핀셋 또는 기타 적절한 도구를 사용하여 회

로 보드에서 부품을 떼어냅니다.

2. 대류열을 사용하여 부품 인두

1. 적절한 노즐을 선택하여 어댑터에 고정합니다.

2. 적절한 양의 인두를 회로 보드에 바르고 회로 보드에 부품을 놓습니다.

3. 원하는 프로파일을 설정합니다.

4. 노즐을 부품 납 가까이로 더 이동하고 뜨거운 바람을 이 납에 내뿜어 인

두를 녹입니다.

8. 문제 해결

1. 장치의 전원이 켜지지 않음

• 전원 코드를 점검합니다.

• 주 전압을 사용하는지 점검합니다.

2. OH가 LED 화면에 표시됨

• 장치가 내부 안전 차단을 초과했습니다.

• 장치를 냉각시킵니다.

• 열전대의 위치를 확인합니다(사용된 경우).

• 전원을 껐다가 다시 켜서 장치를 초기화합니다.

3. TCFAULT가 LED 화면에 표시됨

• 열전대의 위치를 확인합니다.

• 열전대가 올바른 TC 커넥터에 단단히 꽂혔는지 확인합니다.

• 문제가 계속되면 열전대를 교체합니다.

4. 실행 모드에서 지대 및 온도 매개변수가 깜박임.

• 장치가 프로그래밍된 시간 및 온도를 설정대로 충족시킬 수 없음을 나

타냅니다.

9. 유지보수

핸드피스(HCT-HV1)는 OK International의 서비스 교환 프로그램(Service Exchange Program)

의 일부이며, 히터 어셈블리(HCT-HTRASSY)는 교체 부품으로서 별도로 구입할 수 있습니

다.

OK International 웹페이지(www.okinternational.com)를 방문하시면 시스템, 액세서리,

기술 정보에 관하여 자세한 정보를 얻으실 수 있습니다.

Loading...

Loading...