OK International DX-350, DX - 355 User Manual

OK International

DX-350 / 355

Precision Dispensers

User Guide

English, German, French, Italian and Spani sh version

DX-350 / 355

PräzsionsDosiergeräte

Benutzerhandbuch

DX-350 / 355

Doseurs de

précision

Guide de

l'utilisateur

DX-350 / 355

Dosatore di

precisione

Manuale dell’utente

Copyright © OK International

DX-350 / 355

Dosificadores de

precisión

Guía del usuario

CONTENTS

Page Number

1. Safety ……………………………………………………………2

2. Symbol Definitions …………………………………………………3

3. Specifications ……………………………………………….…………...3

4. Features ……………………………………………………………4

5. Connecting the Unit ……………………….…….………..…………5

6. Setup Instructions …………………………………………………5 - 6

7. Troubleshooting …………………………………………………7

8. Maintenance ……………………………………………………………8

9. Spare Parts and Accessories ………………………………………8

10. Warranty ……………………………………………………………8

11. I/O Configuration and End of Cycle Switch ……………………….…...8

1 SAFETY

1.1 Intended Use:

WARNING: Use of this equipment in ways other than those described in this User

Guide may result in injury to persons or damage to property. Use this equipment

only as described in this User Guide.

OK International cannot be responsible for injuries or damages resulting from

unintended applications of its equipment. Unintended uses may result form taking

the following actions:

• Making changes to equipment that has not been recommended in the User

Guide

• Using incompatible or damaged replacement parts

• Using unapproved accessories or auxiliary equipment

1.2 Safety Precautions:

• Do not operate this unit in excess of maximum ratings/settings

• Always wear appropriate personal protective clothing or apparel

• Use only the following power adaptor models: PSA15R-240P(ZJ) or

PW118RA2403B01, PW118RA2403H01, PW118RA2403M01,

PW118RA2403G01

• Care must be taken to prevent the ingress of corrosive or flammable fluid back

into the unit. If corrosive or flammable fluids are used, an inline filter (881000-000) must be installed on the dispenser to help prevent the fluids from

being sucked back into the unit

• The fluid being dispensed may be toxic and/or hazardous. Refer to Material

Safety Data Sheet for proper handling and safety precautions

• If a piston is not used with the barrel, an inline filter (881-000-000) must be

installed on the receiver head to help prevent fluids from being sucked back

into the unit. Also do not overfill the barrel and to lay the barrel on its side

• Do not smoke or use open flame when flammable materials are being dispensed

2

• This equipment is for indoor use only

2 SYMBOL DEFINITIONS

Symbol Definition

Power On/Off

Cycle Mode

Timer

Vacuum

3 SPECIFICATIONS

Size

Weight 1.2 kg (2.6 lbs)

Input Voltage 24VDC

Rated Power 10W

Air Input 100 psi (6.9 bar) Max.

Pollution Degree II

Installation Category I

Indoor Use Altitude up to 2,000m (6,562ft)

Operating Temperature 0˚C to 50˚C (32˚F to 122˚F)

Storage Temperature -10˚C to 60˚C (14˚F to 140˚F)

Max. Relative Humidity

Air Output

Vacuum 406mm (16”) of Hg

Timer 0.008-60.000 seconds

Cycle Mode Timed, Interrupt, Teach, Purge

Timing Repeat Tolerance +/- 0.001%

Cycle Rate 1,200 cycles/min.

LCD 20 X 4 display segments

Pressure

152mm X 165mm X 178mm

(6” X 6.5” X 7”)

80% for temperature up to 31˚C (87.8˚F) Decreasing

linearly to 50% relative humility at 40˚C (104˚F)

DX-350 = 0-100 psi (0-6.9 bar)

DX-355 = 0-15 psi (0-1.03 bar)

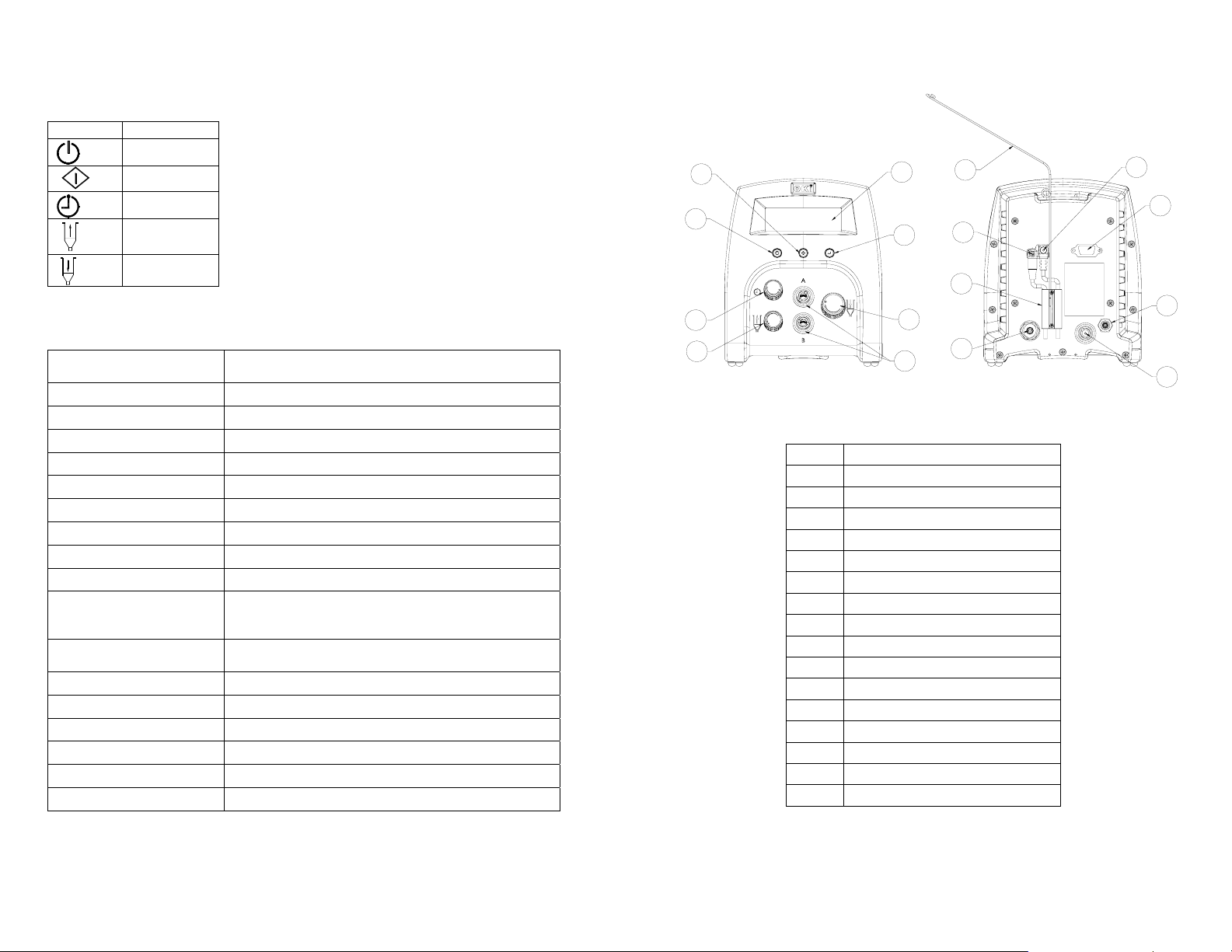

4 FEATURES

2

4

10

11

12

1

3

9

16

13

8

7

5

6

15

14

Figure 1.0

Items Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Power Button

Mode Button

Reset Button

Display

Air Pressure Regulator

Pulsed Air Outlet

Vacuum Control

Setup Control Knob

Foot Switch Receptacle

Receiver Head air hose holder

Power Receptacle

I/O Connection

Exhaust Port

Accessory Air Outlet

Air Inlet

Cord Lock

3

4

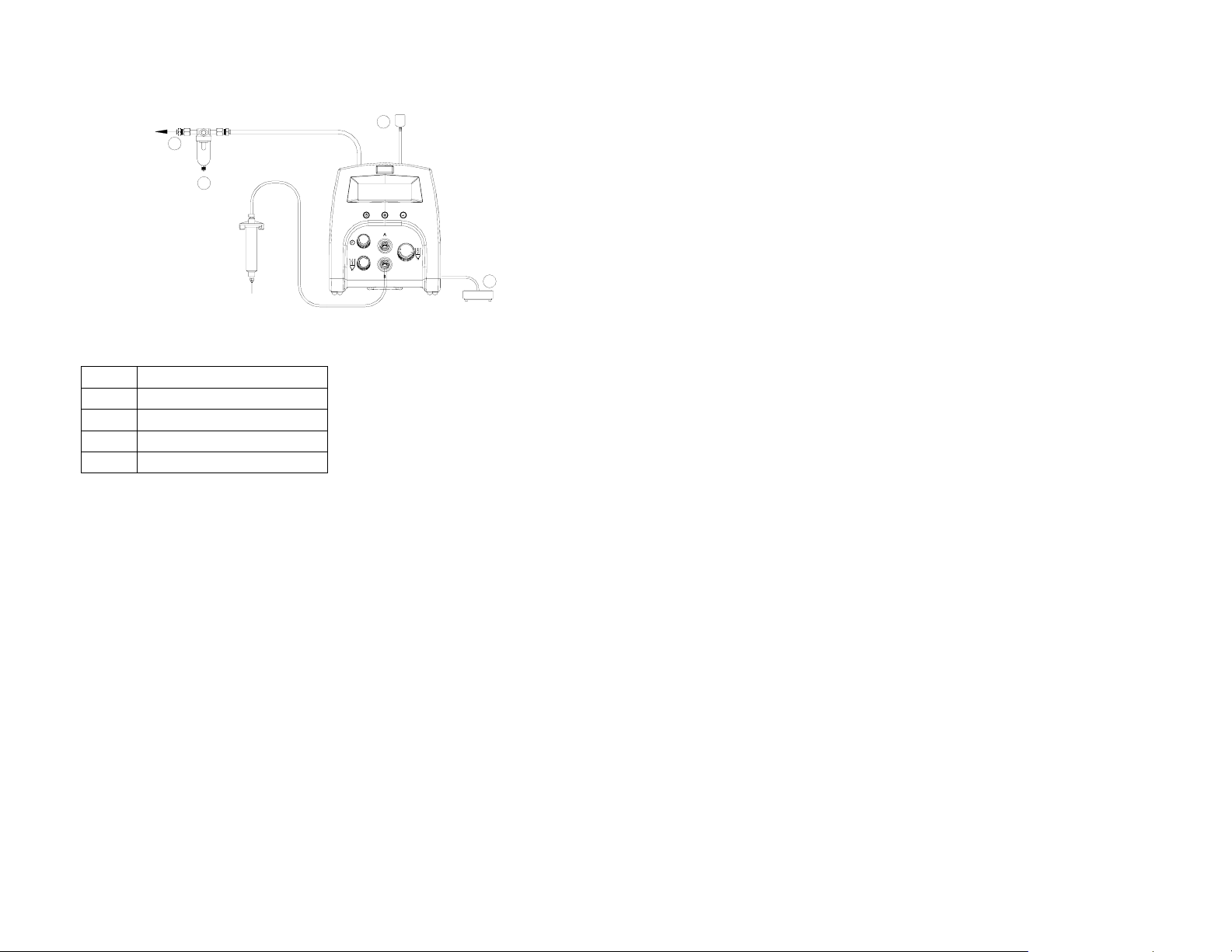

5 CONNECTING THE UNIT

CAUTION: A 5-micron filter (TSD800-6) ,not included, must be installed with the unit to

ensure proper air filtration.

1

2

3

B

Figure 2.0

Items Description

1 To Air Source

2 Air Filter (not included)

3 Power Adapter

4 Foot Switch

6 SETUP INSTRUCTIONS

Refer to Figure 1.0

6.1 Manual/Purge Dispense Cycle Setting:

1. Turn on the unit by pressing the Power button (1).

2. Press the Mode button (2) until “PURGE” appears on the Display.

3. Turn up the air pressure by rotating the Air pressure regulator knob (5) until

the desired pressure is indicated on the Display.

4. After filling the barrel or using pre-packaged adhesive, attach syringe to

receiver head assembly. Make certain that the syringe locks into place.

5. Connect the plug end of the receiver head assembly to one of the air

dispense outlet (6).

6. If vacuum “suck back” is needed, rotate the Vacuum regulator (7) counter

clockwise until the desired vacuum pressure is indicated on the Display.

7. Press and hold the Foot switch to activate dispensed cycle. (The

Manual/Purge Mode is now activated)

6.2 Automatic Dispense Cycle Setting

6.2.1 Program selection

1. Press the reset button (3) until “P:” is flashing

2. Rotate the Setup Control Knob (8) to select desired program

6.2.2 Timed Mode setting

1. Press the Mode button (2) to select “TIMED” mode

2. Press and release the reset button (3) until the colon (:) in the

“TIME:” is flashing

3. Rotate the Setup control knob (8) to set the desired dispense time

4. Depress Foot switch to activate timed dispensed cycle

6.3 Teach Mode Setting

In the teach mode, the unit will accumulate time as long as the foot switch is

depressed. This is helpful in determining dispense time required when

dispense output is unknown.

1. Press the Mode button (2) to select “TEACH” mode

2. Press and release the reset button (3) until the dispense time = 0.000S

3. Press and hold down Foot switch. Dispense time will accumulate

during this time

4. Release Foot switch when proper amount of fluid is dispensed

5. Press the Mode button (2) to switch the “TIMED” mode

4

6. The dispenser is now set to repeat this time cycle.

6.4 Multiple Shots Setting:

Up to ten separate individual or sequenced shots can be stored in the DX350/DX-355.

1. Follow steps in section “6.2 Automatic Dispense Cycle Setting” to set

dispense time in desired programs

2. Press both the Reset button (3) and the Power button (1)

simultaneously to activate sequence program mode

3. Rotate the Setup Control knob to select total number of program to be

dispensed in sequence

4. Press both the Reset button (3) and Power button (1) to exit Multiple

Shots mode

6.5 Cycle Counter

The cycle counter records the numbers of automatic dispense cycle being

activated. Up to 65,535 cycles can be recorded. This number is shown at

the lower right hand corner of the LCD. To reset the counter, press and hold

the Reset button (3) and the Mode button (2) simultaneously until the

counter shows “0”.

6.6 Change Pressure and Vacuum Unit Display

1. Press and release the reset button (3) until the colon (:) in the

“PRESSURE:” or “VACUUM:” is flashing

2. Rotate the Setup control knob (8) to select desired unit display

5

6

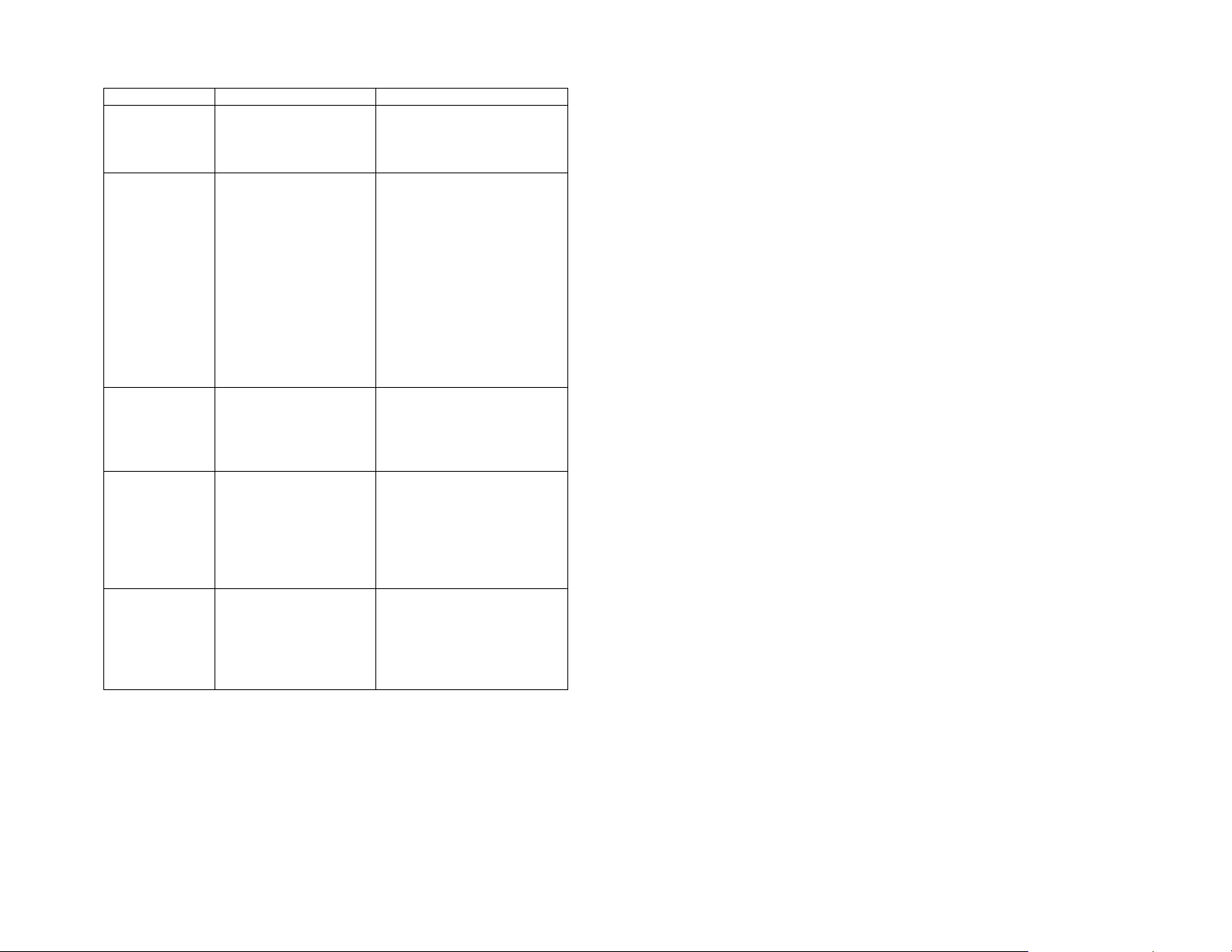

7 TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTION

LCD does not

light

System will not

actuate

System will not

pressurize

System will not

pull vacuum

Inconsistent

dispensing

• No power input

• Foot switch not

plugged in or

improperly plugged

in

• Defective foot switch

• Broken wire or loose

connection inside

unit

• Defective solenoid

• Defective PC board

• Insufficient air

pressure

• Air hoses not

plugged in

• Regulator defective

• Vacuum setting is

too low

• Defective solenoid

• Defective vacuum

venturi

• Defective vacuum

needle valve

• Air bubbles in

adhesive

• Dispense time is too

low

• Dispense needle

started to clog

• Check power cord

connections

• Turn on power

• Check foot switch

connection

• Foot switch needs to be

repaired or replaced

• Unplug power cord and

disconnect air supply.

Remove cover and check

for broken wires or loose

connections

• Replace solenoid

• Replace PC board

• Increase air supply

pressure

• Check connection

• Replace regulator

• Increase vacuum setting

• Replace solenoid valve

• Replace venture

• Replace needle valve

• Reduce vacuum setting

• Increase dispensing time

• Replace needle

8 MAINTENANCE

The dispenser is designed and built to be relatively maintenance free. To assure

trouble free operation, the following recommendations should be followed:

1. Make certain air supply is clean and dry

2. Avoid turning barrels upside down or laying barrel so that material may

run through air line to internal components

3. Avoid connecting the unit to excessive moisture or solvent saturation.

4. Avoid connecting air supply exceeding 100 psi (6.9 bar) for the DX-350

and 15 psi (1.03 bar) for the DX-355

5. Use only Amyl Alcohol to clean outside surface of the main housing.

6. Use only soft cloth to clean the LCD

9 SPARE PARTS AND ACCESSORIES

For DX-3xx/2xx spare parts and accessories information, please visit the DX3xx/2xx User Guide webpage at http://www.okinternational.com

10 LIMITED WARRANTY

OK International warrants this product to the original purchaser for a period of one

(1) year from date of purchase to be free from material and workmanship defects but

not normal wear-and-tear, abuse and faulty installation. Defective product or

subassembly and components under warranty will be repaired or replaced (at OK

International's option) free of charge. Customer with defective product under

warranty must contact the nearest OK International office or distributor to secure a

return authorization prior to shipping the product to the assigned OK International

authorized service center. For nearest OK International office or distributor contact

information, please visit www.okinternational.com. OK International reserves the

right to make engineering product changes without notice.

11 I/O Configuration and End of Cycle Switch

For DX3xx/2xx I/O Configuration and End of Cycle Switch information, please visit

the DX-3xx/2xx User Guide webpage at http://www.okinternational.com

7

8

INHALTSVERZEICHNIS

Seite

1 Sicherheitshinweise .......................... ........................... ........................... ........2 - 3

2 Erläuterung der Symbole................................................................................3

3 Spezifikationen………………………......................…………………...…..4

4 Hauptkomponenten.........................................................................................5

5 Anschluss des Gerätes...................................... ........................... ....................6

6 Setup-Anleitung................................................................... ........................... .6 - 7

7 Fehlerbeseitigung............................................................................................9

8 Wartung...........................................................................................................10

9 Ersatzteile und Zubehör..................................................................................10

10 Garantie...........................................................................................................10

11 I/O Konfiguration und Schalter zum Beenden des Zyklus.............................10

1 SICHERHEITSHINWEISE

1.1 Bestimmungsgemäßer Gebrauch

WARNUNG: Wird dieses Gerät für andere Zwecke eingesetzt als in diesem

Benutzerhandbuch beschrieben, kann es zu Personen- oder Sachschäden

kommen. Setzen Sie das Gerät nur gemäß der Anleitung ein.

OK International ist nicht haftbar für Personen- oder Sachschäden, die auf nicht

zweckgemäßen Einsatz der Geräte zurückzuführen sind. Zu nicht

bestimmungsgemäßem Gebrauch zählen:

• Änderungen am Gerät, die nicht ausdrücklich im Benutzerhandbuch

empfohlen werden

• Einsatz nicht kompatibler oder beschädigter Ersatzteile

• Verwendung nicht zugelassenen Zubehörs oder Hilfsgeräte

1.2 Sicherheitsvorkehrungen

• Betreiben Sie das Gerät ausschließlich mit den maximal zugelassenen

Nennleistungen/Einstellungen.

• Tragen Sie immer geeignete Schutzkleidung.

Verwenden Sie nur die folgenden Adaptertypen: PSA15R-240P(ZJ) oder

•

PW118RA2403B01, PW118RA2403H01, PW118RA2403M01,

PW118RA2403G01

• Achten Sie darauf, dass korrosive oder brennbare Medien nicht in das Gerät

zurückfließen. Wenn korrosive oder brennbare Medien eingesetzt werden,

muss ein Inline-Filter (881-000-000), nicht im Lieferumfang enthalten, am

Dosiersystem installiert werden, so dass die Medien nicht in das Gerät

zurück gesaugt werden können.

• Das dosierte Medium kann giftig und/oder gefährlich sein. Weitere

Einzelheiten bezüglich ordnungsgemäßer Handhabung und

Sicherheitsvorkehrungen finden Sie im Sicherheitsdatenblatt.

• Wird kein Stopfen mit der Kartusche eingesetzt, ist am Schlauch des

Kartuschenadapters ein Inline-Filter (881-000-000), nicht im Lieferumfang

enthalten, zu montieren, so dass die Medien nicht in das Dosiergerät zurück

gesaugt werden. Die Kartusche darf nicht überfüllt oder auf die Seite gelegt

werden.

• Rauchen oder offenes Feuer sind bei der Dosierung brennbarer Medien

untersagt.

• Dieses Gerät ist nur für den Gebrauch in geschlossenen Räumen geeignet.

2 ERLÄUTERUNG DER SYMBOLE

Symbol

Ein / Aus

Zyklusbetrieb

Timer

Vakuum

Druckluft

2

3

3 SPEZIFIKATIONEN

Abmessungen

Gewicht 1,2 kg (2,6lbs)

Eingangs-

spannung

Nennleistung 10 W

Drucklufteingang 100 psi ( 6,9 bar) max.

Verunreinigungsgrad

Installationskategorie

Einsatz in

Innenräumen

Betriebstemperatur 0 °C bis 40 °C (32 °F bis 104°F)

Lagertemperatur -10 °C bis 60 °C (14 °F bis 140 °F)

Max. relative

Feuchtigkeit

Druckluftausgang

Rückhaltevakuum 406 mm (16”) Hg

Timer 0,008-60,0 Sekunden

Zyklusbetrieb

Wiederholtoleranz +/- 0,001%

Zyklen-

geschwindigkeit

LCD 20 X 4 Displaysegmente

152 X 165 X 178mm

(6” X 6,5” X 7”)

24 VDC

II

I

Aufstellungshöhe bis zu 2.000 m (6.562 ft)

80 % für Temperaturen bis 31 °C (87,8 °F), linear

abnehmend bis auf 50 % bei 40 °C (104 °F)

DX-350 = 0-100 psi (0- 6,9 bar)

DX-355 = 0-15 psi (0-1,03 bar)

Zeiteinstellmodus , mit Unterbrechung, Spülen, (Lern)-

Modus

1.200 Zyklen/Minute;

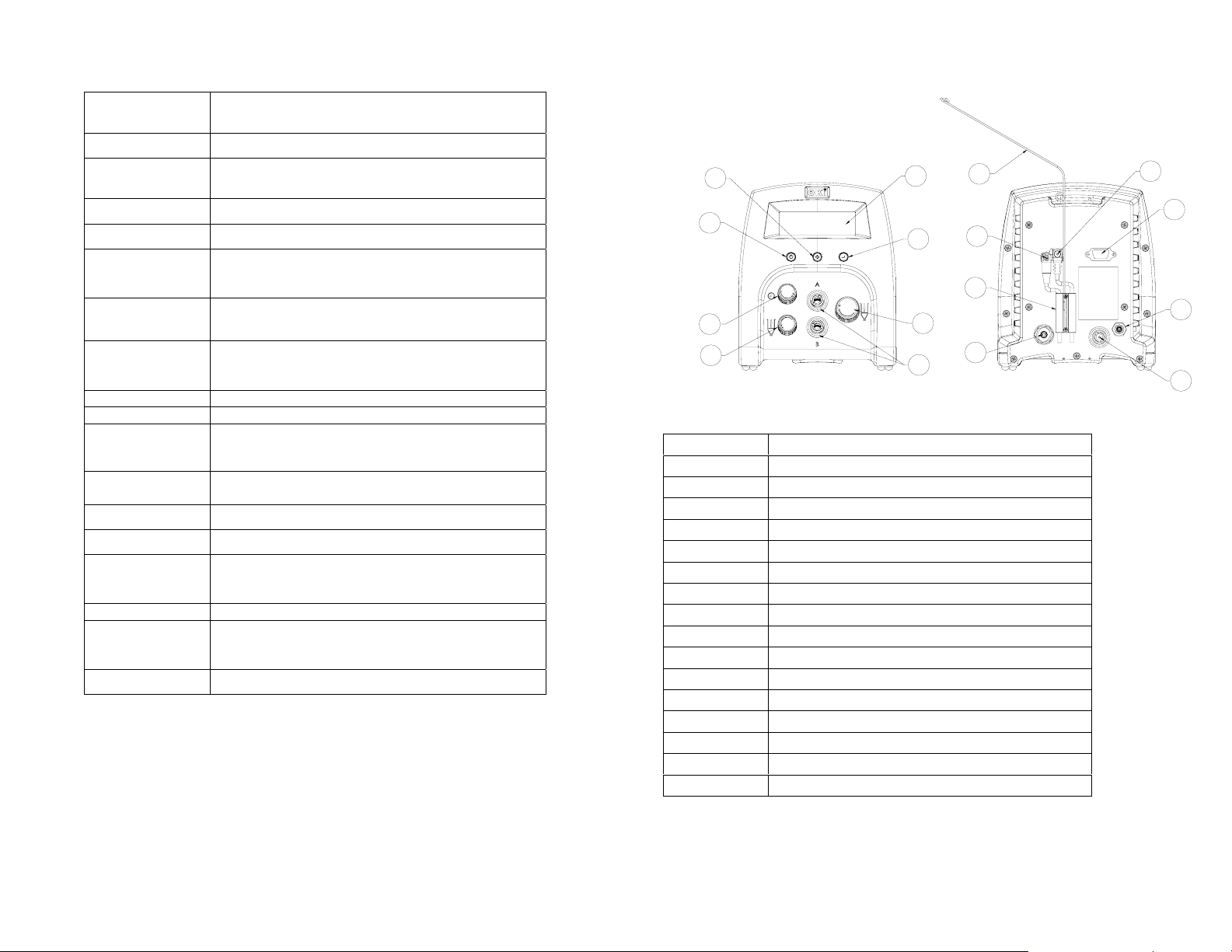

4 HAUPTKOMPONENTEN

2

4

10

1

3

9

16

8

7

5

6

15

Abb. 1.0

Positionen Beschreibung

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Ein-/Aus-Taste

Modustaste

Programmauswahl-Taste

Display

Druckluftregler

Ausgang für gepulste Luft

Einstellung Rückhaltevacuum

Regler zur Einstellung des ausgewählten Programms

Fußschalterbuchse

Schlauchhalter für Kartuschenadapter

Netzbuchse

I/O Anschluss

Abluftöffnung

Zusätzlicher Druckluftausgang

Drucklufteingang

Kabelsicherung

11

12

13

14

4

5

Loading...

Loading...