OK International DX-200, DX-215 User Manual

CONTENTS

OK International

1 Safety....................................................................................................2 - 3

DX-200 / 215

Precision Dispensers

User Guide

English, Simplified Chinese, Traditional Chinese and Korean Version

DX-200 / 215

精密点胶机

用户指南

DX-200 / 215

精密點膠機

使用者指南

Copyright © OK International

DX-200 / 215

정밀 디스펜서

사용설명서

2 Symbol Definitions...............................................................................3

3 Specifications .......................................................................................3

4 Features ................................................................................................4

5 Connecting the Unit..............................................................................5

6 Setup Instructions.................................................................................5 - 6

7 Operational Diagram............................................................................6

8 Troubleshooting ...................................................................................7

9 Maintenance .........................................................................................8

10 Spare Parts and Accessories.................................................................8

11 Warranty...............................................................................................8

12 I/O Configuration and End of Cycle Switch ........................................8

1 SAFETY

1.1 Intended Use:

WARNING: Use of this equipment in ways other than those described in this User

Guide may result in injury to persons or damage to property. Use this equipment

only as described in this User Guide.

OK International cannot be responsible for injuries or damages resulting from

unintended applications of its equipment. Unintended uses may result form taking

the following actions:

• Making changes to equipment that has not been recommended in the User

Guide

• Using incompatible or damaged replacement parts

• Using unapproved accessories or auxiliary equipment

1.2 Safety Precautions:

• Do not operate this unit in excess of maximum ratings/settings

• Always wear appropriate personal protective clothing or apparel

• Use only the following power adaptor models: PSA15R-240P(ZJ) or

PW118RA2403B01, PW118RA2403H01, PW118RA2403M01,

PW118RA2403G01

• Care must be taken to prevent the ingress of corrosive or flammable fluid back

into the unit. If corrosive or flammable fluids are used, an inline filter (881000-000) must be installed on the dispenser to help prevent the fluids from

being sucked back into the unit

• The fluid being dispensed may be toxic and/or hazardous. Refer to Material

Safety Data Sheet for proper handling and safety precautions

Page Number

2

• If a piston is not used with the barrel, an inline filter (881-000-000) must be

installed on the receiver head to help prevent fluids from being sucked back

into the unit. Also do not overfill the barrel and to lay the barrel on its side

• Do not smoke or use open flame when flammable materials are being dispensed

• This equipment is for indoor use only

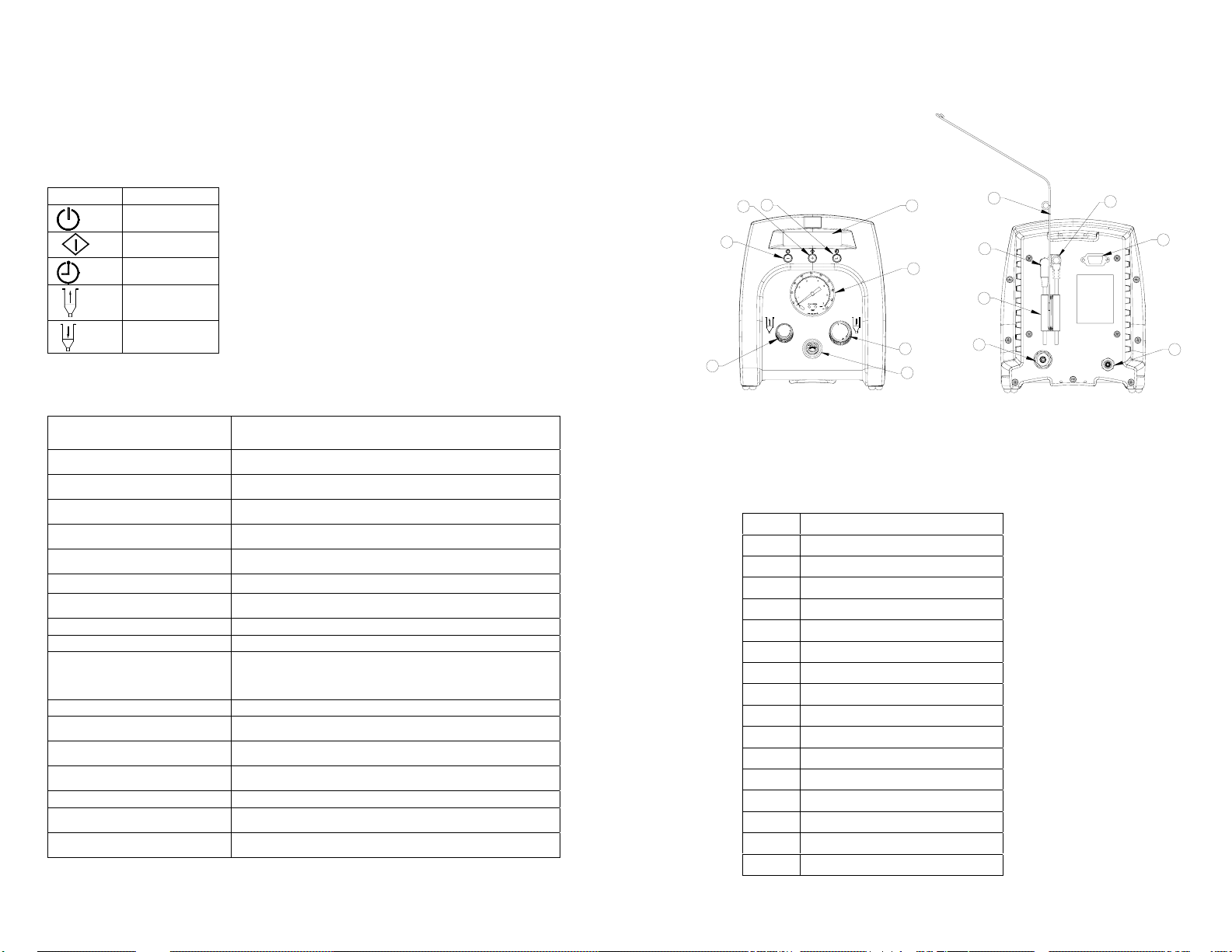

2 SYMBOL DEFINITIONS

Symbol Definition

Power On/Off

Cycle Mode

Timer

Vacuum

Pressure

3 SPECIFICATIONS

Size

Weight 1.2 kg (2.6lbs)

Input Voltage 24VDC

Rated Power 10W

Air Input 100 psi (6.9 bars) Max.

Pollution Degree II

Installation Category I

Indoor Use Altitude up to 2,000m (6,562ft)

Operating Temperature 0˚C to 50˚C (32˚F to 122˚F)

Storage Temperature -10˚C to 60˚C (14˚F to 140˚F)

Max. Relative Humidity

Air Output 0-100 psi (0-6.9 bars)

Vacuum 406mm (16”) of Hg

Timer 0.020-99.999 seconds

Cycle Mode Manual, Timed

Timing Repeat Tolerance +/- 0.001%

Cycle Rate 600 cycles/min

LCD 16 X 2 display segments

152mm X 165mm X 178mm

(6” X 6.5” X 7.0”)

80% for temperature up to 31˚C (87.8˚F) Decreasing

linearly to 50% relative humility at 40˚C (104˚F)

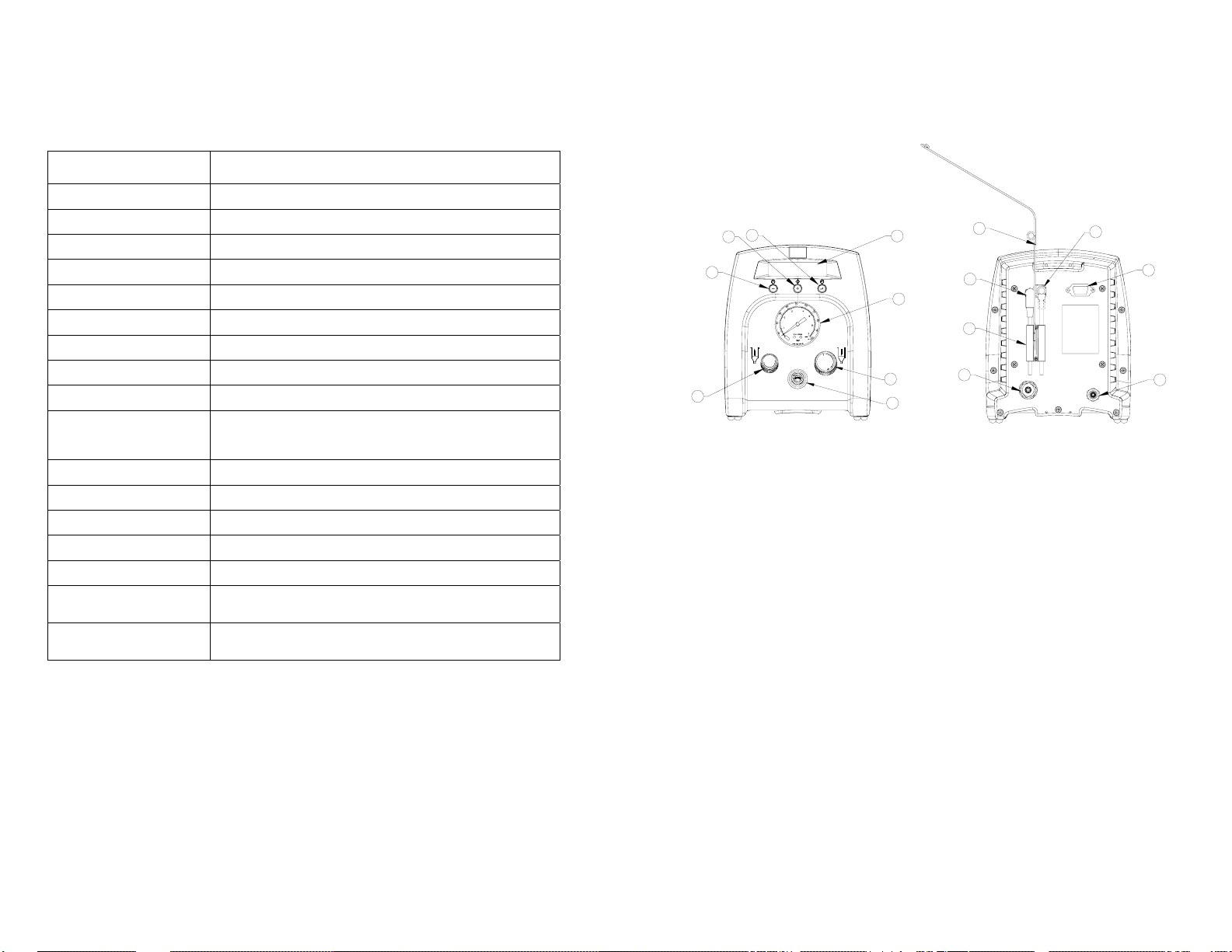

4 FEATURES

3

2

4

9

11

1

5

10

16

12

8

6

7

15

14

Figure 1.0

Items Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Power Button

Mode Button

Set up/Save Button

Display

Air Pressure Gauge

Air Pressure Regulator

Pulsed Air Outlet

Vacuum Control

Receiver head air hose holder

Foot Switch Receptacle

Power Receptacle

I/O Connection

Accessory Air Outlet

Exhaust Port

Air Inlet

Cord Lock

3

4

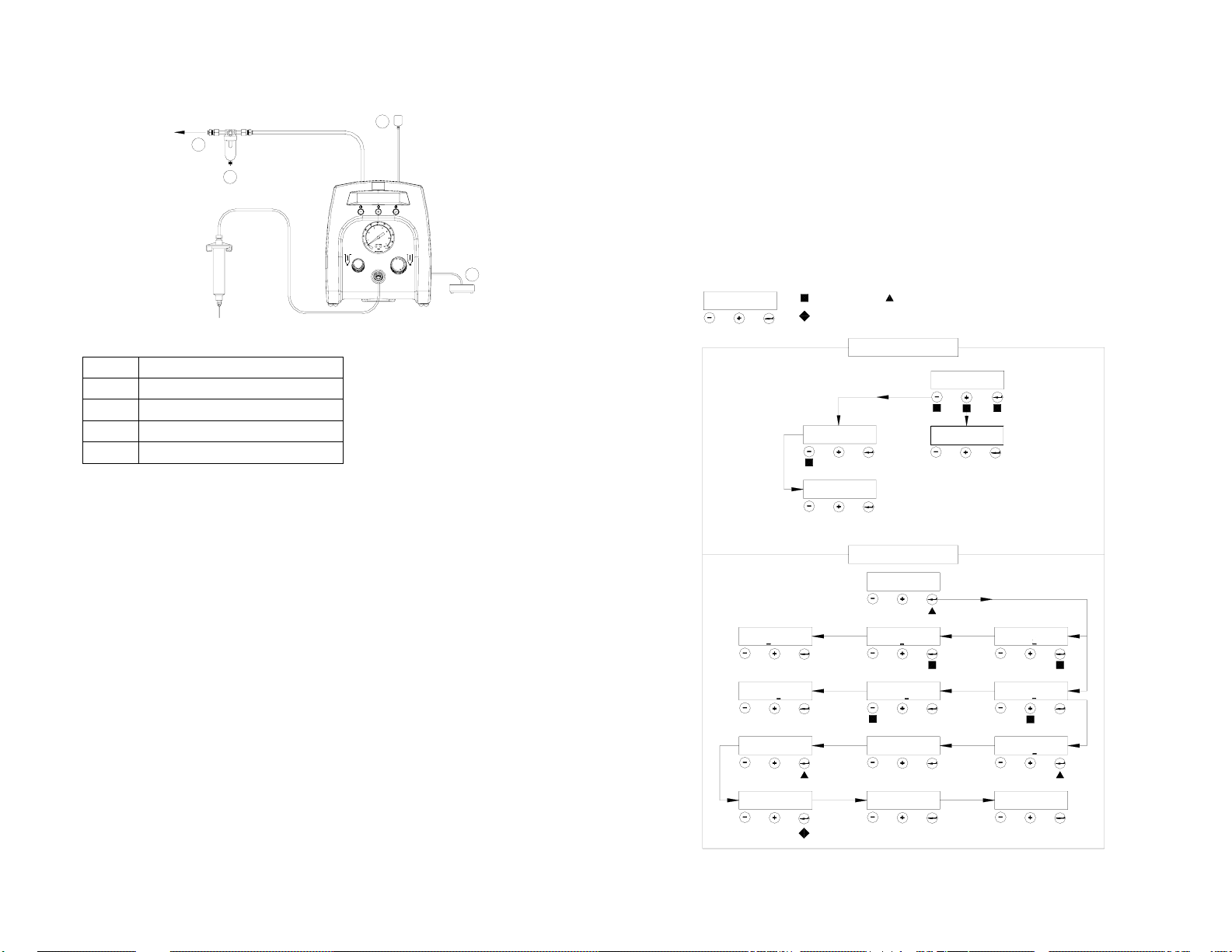

5 CONNECTING THE UNIT

P

CAUTION: A 5-micron filter (TSD800-6), not included, must be installed with the unit

to ensure proper air filtration.

1

2

Items Description

1 To Air Source

2 Air Filter (Not Included)

3 Power Adapter

4 Foot Switch

6 SETUP INSTRUCTIONS

Refer to Figure 1.0

6.1 Manual Dispense Cycle Setting:

1. Turn on the unit by pressing the Power button (1).

2. Press the Mode button (2) until “MANUAL MODE” appears on the

Display.

3. Turn up the air pressure by rotating the Air pressure regulator knob (6)

until the desired pressure is indicated on the Air pressure gauge (5).

4. After filling the barrel or using pre-packaged Adhesives, attach syringe

to receiver head assembly. Make certain that the syringe locks into

place.

5. Connect the plug end of the receiver head assembly to one of the air

dispense outlet (7).

6. If vacuum “suck back” is needed, rotate the Vacuum regulator (8)

counter clockwise until the desired vacuum pressure is obtained

7. Press and hold the Footswitch to activate dispensed cycle. (The Manual

Mode is now activated)

6.2 Automatic Dispense Cycle Setting

1. Push the Mode button (2) to select “TIMED MODE”.

2. Press and hold the Set button (3) for two seconds to enter set up

screen. The last digit of the dispense time will be highlighted.

3. Press the Set button (3) to move the cursor to the next position.

4. Press the (+) and (-) button to set the time

5. Press and hold the Set button (3) for two seconds to save the data.

6. Depress Foot switch to activate timed dispensed cycle.

6.4 Cycle Counter

3

The cycle counter records the numbers of automatic dispense cycle being

activated. Up to 65,535 cycles can be recorded. This number is shown at

the lower right hand corner of the LCD. To reset the counter, press and

hold the Set button (3) for two seconds to enter the set mode. Then press

and hold the Set button (3) for four seconds to reset the counter.

7 OPERATION DIAGRAM

4

Figure 2.0

MODE

Prog

Counter

Time

OWER MODE SET

SETUP MODE

2.2

P1 00004

SETUP MODE

P1 00004

TIMED MODE

P1 00004

SETUP MODE

P1 00004

22.25

2.25

22.251

:Press then release :Press and hold for approximately 2 seconds then release

:Press and hold for approximately 4 seconds then release

Normal Operation

TIMED MODE

P1 2.250 00004

*************************

0

1

MANUAL MODE

Change Mode

Time setting

in TIMED MODE

50

0

1

OFF

TIMED MODE

P1 2.250 00004

Power ON/OFF

Setup

TIMED MODE

P1 2.250 00004

SETUP MODE

P1 00004

22.25

TIME SETTING

SETUP MODE

P1 00004

Save and Exit...

COUNTER RESET

Save and Exit...

SETUP MODE

P1 00004

22.250

SETUP MODE

P1 00004

22.25022.25

SETUP MODE

P1 00004

22.251

TIMED MODE

P1 2.251 00000

5

6

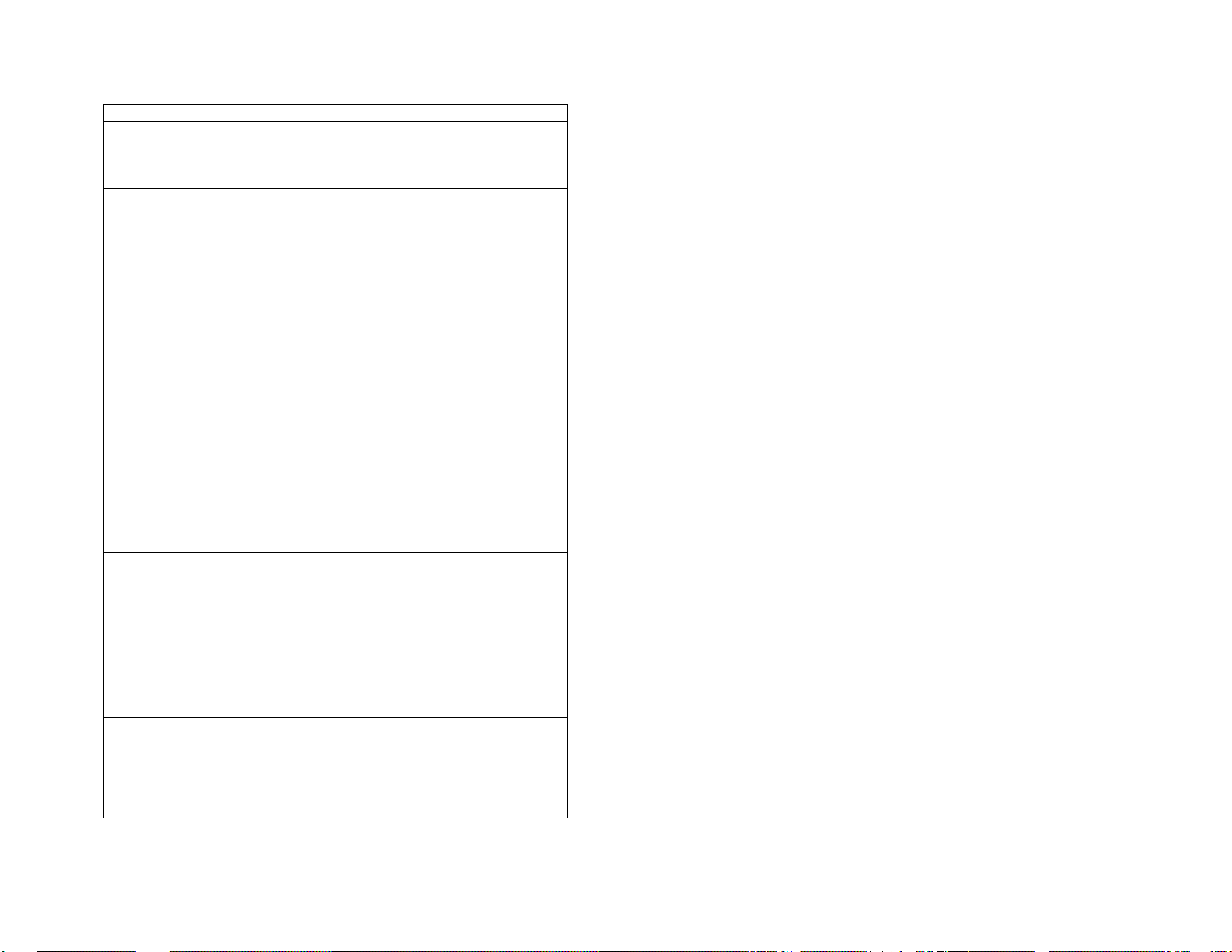

8 TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTION

LCD does not

light

System will not

actuate

System will not

pressurize

System will not

pull vacuum

Inconsistent

dispensing

• No power input

• Foot switch not

plugged in or

improperly

plugged in

• Defective foot

switch

• Broken wire or

loose connection

inside unit

• Defective

solenoid

• Defective PC

board

• Insufficient air

pressure

• Air hoses not

plugged in

• Regulator

defective

• Vacuum setting is

too low

• Defective

solenoid

• Defective

vacuum venturi

• Defective

vacuum needle

valve

• Air bubbles in

Adhesives

• Dispense time is

too low

• Dispense needle

started to clog

• Check power cord

connections

• Turn on power

• Check foot switch

connection

• Foot switch needs

to be repaired or

replaced

• Unplug power cord

and disconnect air

supply. Remove

cover and check

for broken wires or

loose connections

• Replace solenoid

• Replace PC board

• Increase air supply

pressure

• Check connection

• Replace regulator

• Increase vacuum

setting

• Replace solenoid

valve

• Replace venturi

• Replace needle

valve

• Reduce vacuum

setting

• Increase

dispensing time

• Replace needle

9 MAINTENANCE

The dispenser is designed and built to be relatively maintenance free. To assure

trouble free operation, the following recommendations should be followed:

1. Make certain air supply is clean and dry.

2. Avoid turning barrels upside down or laying barrel so that material may

run through air line to internal components.

3. Avoid connecting the unit to excessive moisture or solvent saturation.

4. Avoid connecting air supply exceeding 100 psi (6.9 bars)

5. Use only Amyl Alcohol to clean outside surface of the main housing.

6. Use only soft cloth to clean the LCD.

10 SPARE PARTS AND ACCESSORIES

For DX-3xx/2xx spare parts and accessories information, please visit the DX3xx/2xx User Guide webpage at http://www.okinternational.com

11 LIMITED WARRANTY

OK International warrants this product to the original purchaser for a period of one

(1) year from date of purchase to be free from material and workmanship defects but

not normal wear-and-tear, abuse and faulty installation. Defective product or

subassembly and components under warranty will be repaired or replaced (at OK

International's option) free of charge. Customer with defective product under

warranty must contact the nearest OK International office or distributor to secure a

return authorization prior to shipping the product to the assigned OK International

authorized service center. For nearest OK International office or distributor contact

information, please visit www.okinternational.com. OK International reserves the

right to make engineering product changes without notice.

12 I/O Configuration and End of Cycle Switch

For DX-3xx/2xx I/O Configuration and End of Cycle Switch information, please

visit the DX-3xx/2xx User Guide webpage at http://www.okinternational.com

7

8

目录

页码

1 安全信息.....................................................................................2 - 3

2 符号定义.....................................................................................3

3 规格说明.....................................................................................4

4 特色............................................................................................5

5 连接设备.....................................................................................6

6 设置说明.....................................................................................7

7 操作图 ........................................................................................8

8 故障排除.....................................................................................9

9 维护............................................................................................10

10 备件和附件 .................................................................................10

11 保修............................................................................................10

12 I/O 配置和循环结束开关 .............................................................10

1 安全信息

1.1 用途:

警告:除“用户指南”中介绍的使用方法之外,以其它任何方式使用此设备均可

能会造成人身伤害或财产受损。请务必按照“用户指南”中的方法使用此设备。

OK International 对因设备的非规定应用所造成的人身伤害或财产受损概不负

责。以下行为可能导致非规定应用:

• 更换为“用户指南”中并未推荐的设备

• 使用不兼容或已损坏的更换件

• 使用未经验证的附件或辅助设备

1.2 安全注意事项:

• 操作此设备时切勿超过最大额定功率/设置

• 务必穿上适当的个人防护衣

• 仅可使用以下电源适配器型号:PSA15R-240P(ZJ) 或

PW118RA2403B01、PW118RA2403H01、PW118RA2403M01、

PW118RA2403G01

• 务必小心防止入口处的腐蚀性或易燃液体回流入设备。如果使用腐蚀性或

易燃液体,则在点胶机上必须要安装进气管过滤器 (881-000-000),防止

液体倒吸入设备

• 点胶液可能是有毒和/或危险物质。请仔细阅读用“材料安全数据表”和安全

注意事项

• 如果活塞没有配合针筒使用,则在接收器磁头上必须要安装进气管过滤器

(881-000-000),防止液体倒吸入设备。切勿将该针筒装得太满并且要以其

侧面放置

• 使用易燃液料点胶时,切勿吸烟或使用明火

• 该设备仅可在室内使用

2 符号定义

符号 定义

电源开关

循环模式

计时器

真空装置

压力装置

2

3

3 规格说明

尺寸

重量

输入电压

额定功率

152mm X 165mm X 178mm

(6" X 6.5" X 7.0")

1.2 kg (2.6lbs)

24VDC

10W

进气量 最大 100 psi(6.9 巴)

污染程度

安装类别

II

I

室内使用 海拔可达 2000m (6562ft)

操作温度 0°C 到 50°C(32°F 到 122°F)

储藏温度 -10°C 到 60°C(-10.00°C 到 60.00°C)

最大相对湿度

温度是 31°C (87.8°F) 时为 80%,达到 40°C (104°F) 时

会线性降至 50%

排气量 0-100 psi(0-6.9 巴)

真空 406mm (16")(水银汞柱)

计时器 0.020-99.999 秒

循环模式 自动模式, 手动模式

定时重复容限

+/- 0.001%

循环率 600 次/分

液晶显示器 (LCD) 16 X 2 显示段

4 功能

2

1

8

3

4

5

6

7

9

10

16

15

11

12

14

图 1.0

4

5

Loading...

Loading...