Thank You for purchasing this

Click Here for more Factory Service

Manuals for other Computer and

Printer / Copier Manufacturers

from PCTECHINFO!

Page: 1

Service Guide OL810e

Chapter 0 About This Manual

OL810e

LED Page Printer

Adobe Acrobat printable reference

copy of the OKIDATA Service Training Manual.

09/17/97

Note: This Adobe Acrobat version of the Okidata Service Training Manual was built with the

pictures rendered at 300 dpi, which is ideal for printing, but does not view on most

displays well.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Table of Contents Page

Service Guide OL810e

0 About This Manual

Front Cover 1

Manual Copyright 2

1 Configuration

1.1 System Configuration 3

1.2 Printer Configuration 4

1.3 Options available for use with OL810e 5

1.4 Specification 6

1.5 Safety Standards - Certification & Warning Labels 7

....1.5.3 Warning/Caution Marking 8

2 Operation Description

Operation Description 9

2.1 Main Control Board 10

2.2 Power Supply/Sensor Board 11

2.3 Electrophotographic Process 12

....2.3.2 Electrophotographic Process 13

....2.3.3 Process Operation Descriptions 14

....2.3.4 Revision of LED Head Illumination 15

2.4 Paper Jam Detection 16

2.5 Cover Open 17

2.6 Toner Low Detection 18

3 Parts Replacement

Parts Replacement 19

3.1 Precautions for Parts Replacement 20

3.2 Parts Layout 21

3.3 How to Change Parts 22

....3.3.1 Upper Cover Assy 23

....3.3.2 IC Card Cover 24

....3.3.3 LED Head 25

....3.3.4 Operator Panel Assy 26

....3.3.5 Pulse Motor (Main/Drum) 27

....3.3.6 Pulse Motor (Registration) 28

....3.3.7 Face Up Stacker Assy 29

....3.3.8 Lower Base Unit 30

....3.3.9 Eject Roller Assy 31

....3.3.10 Motor Assy 32

....3.3.11 Hopping Roller Shaft Assy 33

....3.3.12 Stacker Cover Assy 34

....3.3.13 Registration Roller 35

....3.3.14 Transfer Roller 36

....3.3.15 Fusing Unit 37

....3.3.16 Back-up Roller 38

Table of Contents Page

....3.3.17 Sensor Plate (Inlet) 39

....3.3.18 Sensor Plate (Outlet) 40

....3.3.19 Manual Feed Guide Assy 41

....3.3.20 Sensor Plate (Paper Supply) 42

....3.3.21 TQCB-PCB 43

....3.3.22 Transformer 44

....3.3.23 Power Supply/Sensor Board and Contact Assy 45

....3.3.24 Cassette Guide L Assy 46

....3.3.25 Cassette Guide R Assy 47

4 Adjustments

Adjustment 48

....4.1.1 User Maintenance Mode 49

....4.1.2 System Maintenance Mode 50

....4.1.3 Engine Maintenance Mode 51

....4.1.4 EEPROM initialization 52

4.2 Adjustment When Replacing a Part 53

....4.2.1 Setting of LED Head Drive Time 54

5 Periodical Maintenance

5.1 Periodical Replacement Parts 55

5.2 Cleaning 56

....5.2.1 Cleaning of LED Lens Array 57

........Cleaning Page Function 58

5.3.1 Lubrication 59

6 Troubleshooting

6. Troubleshooting Procedures 60

6.1 Troubleshooting Tips 61

6.2 Points to Check before Correcting Image Problems 62

6.3 Tips for Correcting Image Problems 63

6.4 Preparation for Troubleshooting 64

6.5 Troubleshooting Flow 65

....6.5.1 LCD status message/problem list 66

....6.5.2 LCD message troubleshooting 67

........1 Printer doesn't work normally after the power is turned

on.

........2 - 1 Paper input jam 69

........2 - 2 Paper feed jam 70

........2 - 3 Paper exit jam 71

........3 Paper size error 72

........4 Fusing unit error (ERROR 71) (ERROR 72) (ERROR

73)

........5 Synchronous serial I/O error (ERROR 74) or I/F timeout

between printer and optional tray (ERROR 81)

........6 Fan error (ERROR 70) 75

....6.5.3 Image troubleshooting 76

68

73

74

Table of Contents Page

........1 Images are light or blurred entirely. 77

........2 Dark background density 78

........3 Blank paper is output. 79

........4 Black vertical belts or stripes 80

........5 Cyclical defect 81

........6 Prints voids 82

........7 Poor fusing (images are blurred or peels off when the

printed characters and images on the paper are touched by

hand)

........8 White vertical belts or streaks 84

7 Wiring Diagrams

7.1 Interconnect Signal Diagram 85

7.2 PCB Layout and Connector Signal List 86

....FAN Pin Assignment (To fan motor) 87

....DM Pin Assignment (To main/drum motor) 88

....RM Pin Assignment (To registration motor) 89

....HEAD1 Pin Assignment (To LED head) 90

....HEAD2 Pin Assignment (To LED head) 91

....PANEL Pin Assignment (To operator panel) 92

....2ND TRAY Pin Assignment (To option feeder I/F) 93

....Power Pin Assignment 94

....CENT Pin Assignment 95

....SERIAL Pin Assignment (To RS232C) 96

....CARD Pin Assigment 97

....OPTION Pin Assignment 98

....7.3 Resistance Check 99

7.4 Short Plug Setting 100

8 Parts List

Lower Base Unit 101

............Part #25 Face down Stacker Assy : Jim

Homeuser/Okidata; 10/14/96

Upper cover unit 103

Base Unit 2 104

A RS-232 Interface

Rs-232C Serial Interface 105

....Interface Parameter Setting 106

B Centronics Parallel Interface

Centronics Parallel Interface 107

....Interface Parameter Setting 108

C Loop Test (RS-232C Interface)

Loop Test (Rs-232C Interface) 109

D Diagnostic Tests

1. Maintenance Modes 110

....1.1 User Maintenance Mode 111

83

102

Table of Contents Page

....1.2 System Maintenance Mode 112

....1.3 Engine Maintenance Mode 113

....1.4 User Factory Set Operation 114

E Option: Multi-Purpose Feeder

Multi-Purpose Feeder Paper Specifications 115

....External View and Component Names 116

....Mechanism Description 117

....Parts Layout 118

....Parts Replacement Methods 119

........3.3.1 Link 120

........3.3.2 Separator 121

........3.3.3 OLEV-11-PCB 122

........3.3.4 Pulse Motor 123

........3.3.5 Planet Gear 124

........3.3.6 Roller-A and B 125

....Troubleshooting Problems with the Multi-Purpose Feeder 126

....Multi-Purpose Feeder Connection Diagram 127

....Multi-Purpose Feeder Parts List 128

F Option: Second Paper Mech.

Second Paper Mech. Paper Specifications 129

....External View and Component Names 130

....Mechanism Description 131

Parts Replacement 132

....Parts Layout 133

....Parts Replacement Methods 134

........3.3.1 Pulse Motor (Hopping) 135

........3.3.2 TQSB-PCB 136

........3.3.3 Hopping Roller Assy and One-way Clutch Gear 137

Troubleshooting the 2nd Paper Tray Mech. 138

Second Paper Mech. Connection Diagram 139

....Second Paper Mech. PCB Layout TQSB-PCB 140

Second Paper Mech. Parts List 141

Page: 2

Service Guide OL810e

Chapter 0 About This Manual

OKIDATA is a registered trademark of Oki America, Inc.

OKIDATA est une marque déposée de Oki America, Inc.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

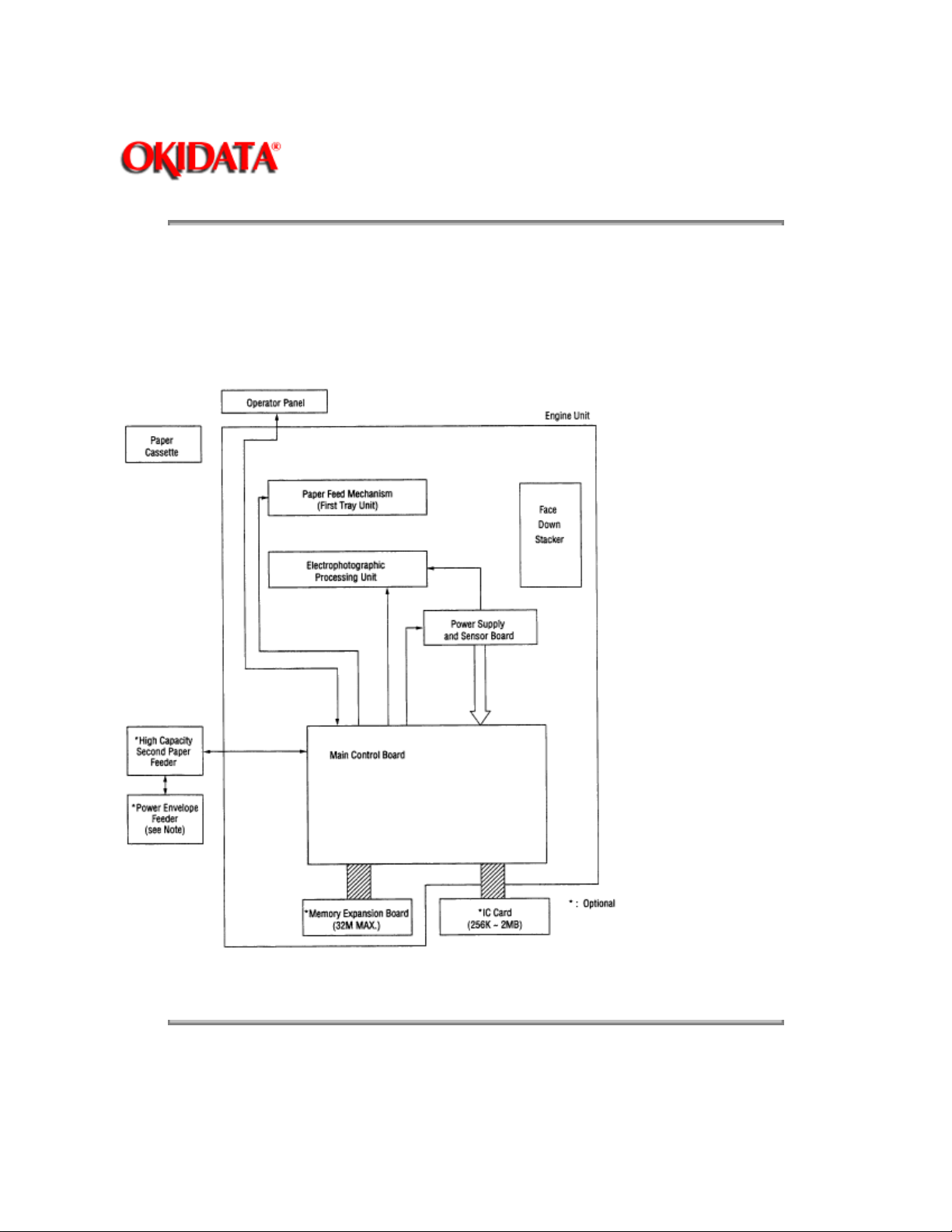

Service Guide OL810e

Chapter 1 Configuration

1.1 System Configuration

OL810e consists of control and engine blocks in the standard configuration, as shown in Figure 1-1.

In addition, the options marked with asterisk (*) are available.

Figure 1-1

Page: 3

Note:

Power Envelope Feeder is compatible with OL400e series printers.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

Chapter 1 Configuration

1.2 Printer Configuration

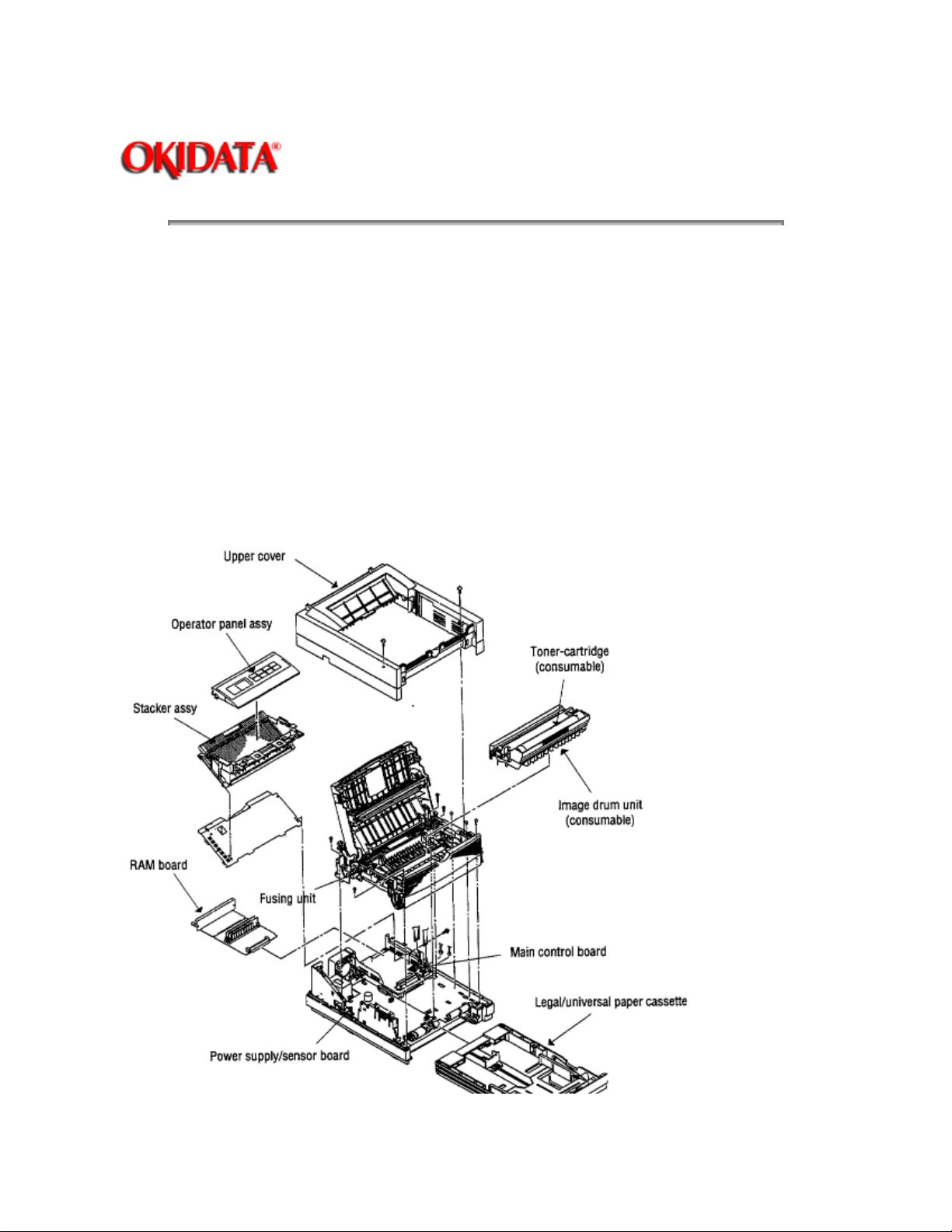

The printer unit consists of the following hardware components:

- Electrophotographic Processor

- Paper Feeder

- Controller

- Operator Panel

- Power Supply Unit

The printer unit configuration is shown in Figure 1-2.

Page: 4

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

Chapter 1 Configuration

1.3 Optional Configuration

The options shown below are available for use with OL810e. These are available separately from

the printer unit.

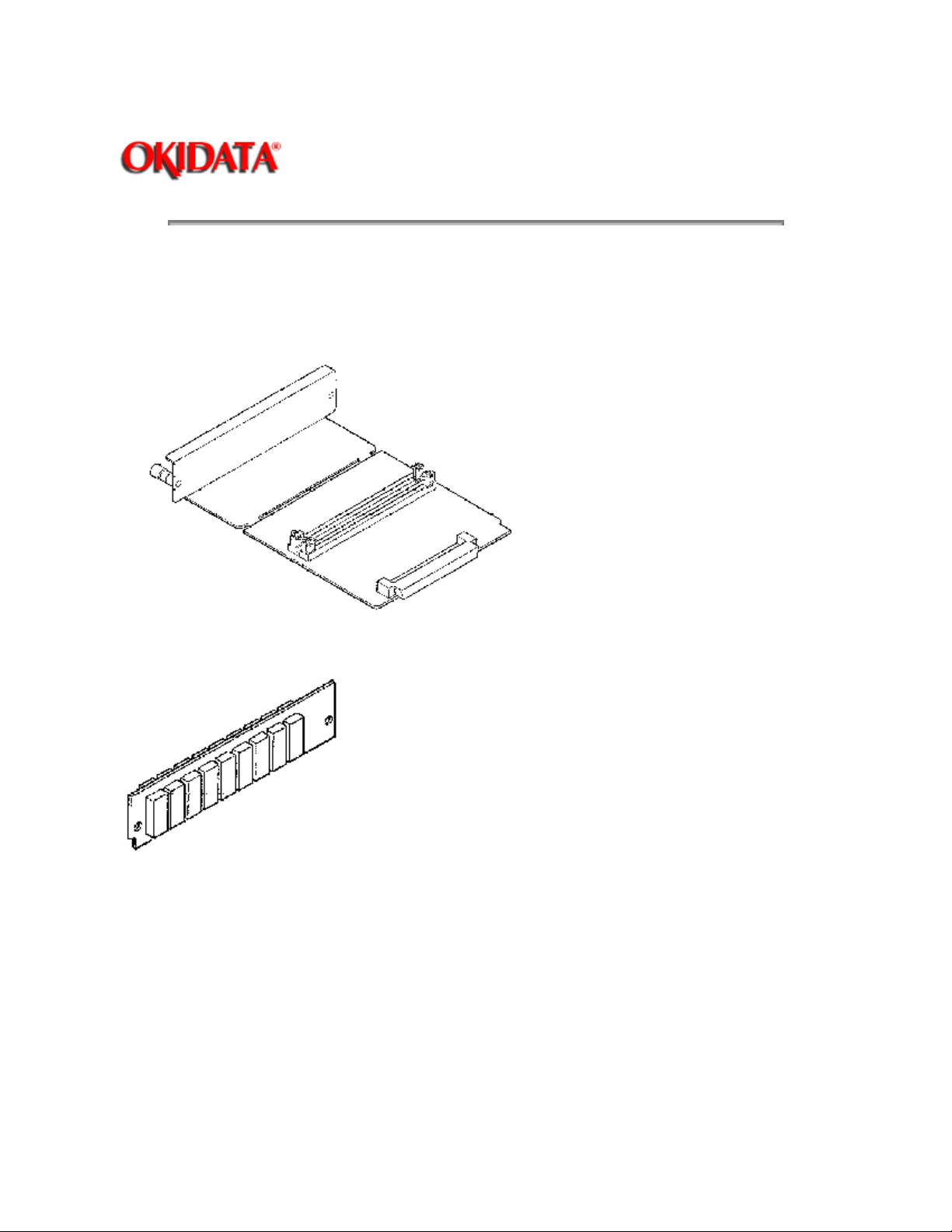

(1) Memory Expansion Board (1MB to 32MB)

Page: 5

(2) SIMM Memory SIMM memory is available with memory of 1MB (min.) to 16MB (max.). The

access time of SIMM memories are 60ns, 70ns, 80ns, and 100ns.

(3) IC Card

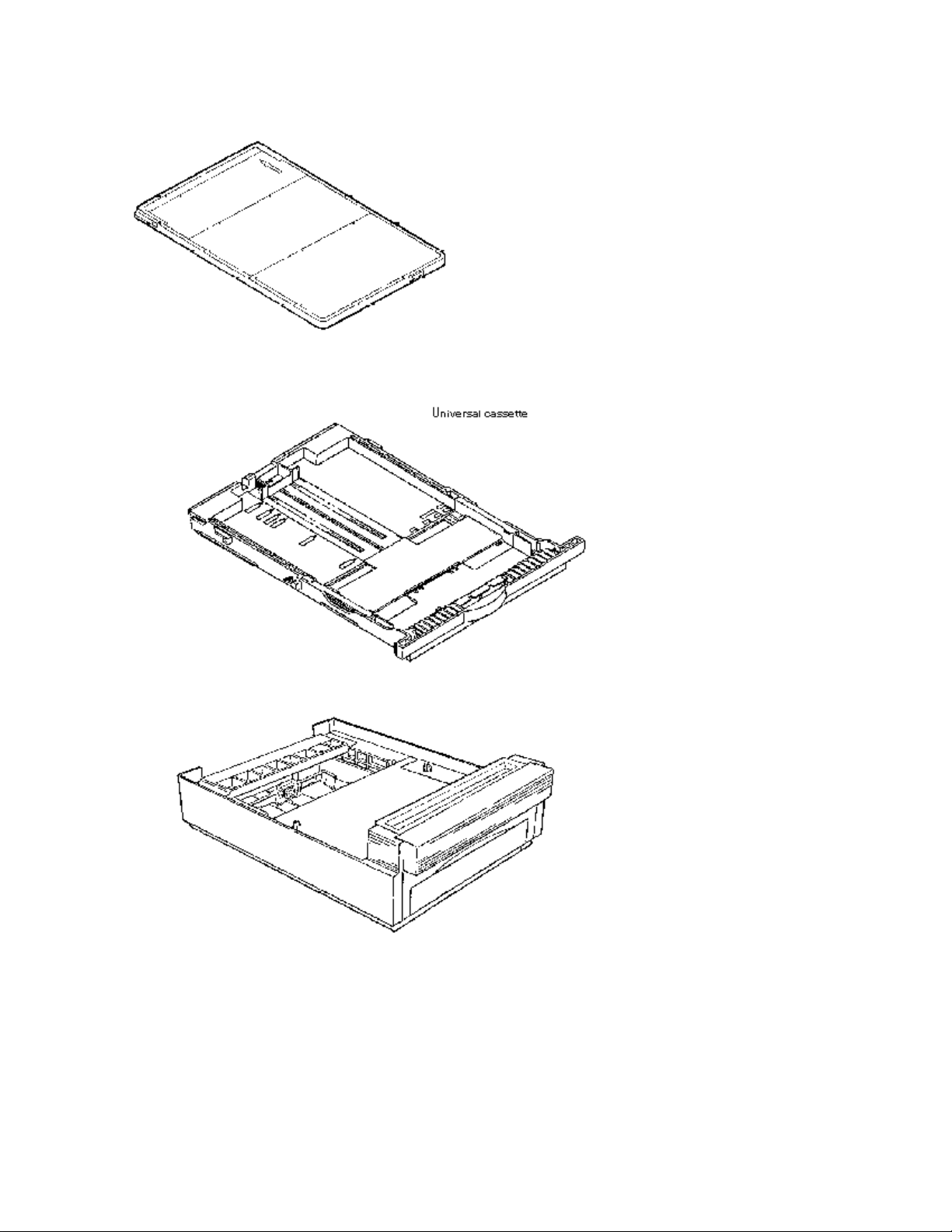

(4) Universal Paper Cassette

(5) High Capacity Second Paper Feeder

(6) Power Envelope Feeder

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 6

Service Guide OL810e

Chapter 1 Configuration

1.4 Specification

(1) Type Desktop

(2) External dimensions Height 7.9 (200 mm) (excludes protruding Width 12.8 (370 mm) portion) Depth

14.6 (370 mm)

(3) Weight 10 kg

(4) Developing method Dry electrophotography Exposing method LED stationary head

(5) Paper used

<Type>

- Standard paper Xerox 4200 (20 lbs)

- Application paper (manual face-up feed) Label Envelope OHP paper (transparency)

<Size>

- Standard sizes Letter Legal Executive CON-10 Monarch DL C5 COM-9 Envelope A4 A5 B5

(JIS) A6

- Applicable sizes Width: 3.87 to 8.5 (116 to 216 mm) Length: 5.83 to 14 (148 to 355.6 mm)

<Thickness> Automatic feed: 16 to 36 lbs (60 to 135 g/m 2 ) Manual feed: Label, OHP paper

(transparency) Envelope

(6) Printing speed First print: 25 sec. Continuous print: 8 sheets/min. for letter size paper Warm-up time:

60 sec. [at room temperature 77°F (25°C) and rated voltage (120 VAC)]

(7) Paper feeding method Automatic feed or manual feed

(8) Paper delivery method Face down/face up

(9) Resolution 600 x 600 dots/inch

(10) Power input 120 VAC + 5.5%, -15% 230 VAC + 6%, -14% 230 VAC + 10%, -10%

(11) Power consumption Peak: Approx. 600W Typical operation: Approx. 130W Idle: Approx. 41W

Power save mode: Approx. 13W

(12) Temperature and humidity During operation: 50 to 90°F (10 to 32°C) In storage: -14 to 112°F (-20 to

50°C)

(13) Noise During operation: 48 dB (A) or less Standby: 36 dB (A) or less Quiet mode: 32 dB (A) or less

(14) Consumables Toner cartridge kit 2,000 (5% duty) Image drum cartridge 20,000 (at continuous

printing) 15,000 (3 page/job) 10,000 (1 page/job)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

Chapter 1 Configuration

1.5 Safety Standards

1.5.1 Certification Label

The safety certification and serial number labels are affixed to the printer in the positions

described below.

Page: 7

1.5.2 Warning Label

The warning labels are affixed to the sections which may cause bodily injury.

Follow the instructions on warning labels during maintenance.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

Chapter 1 Configuration

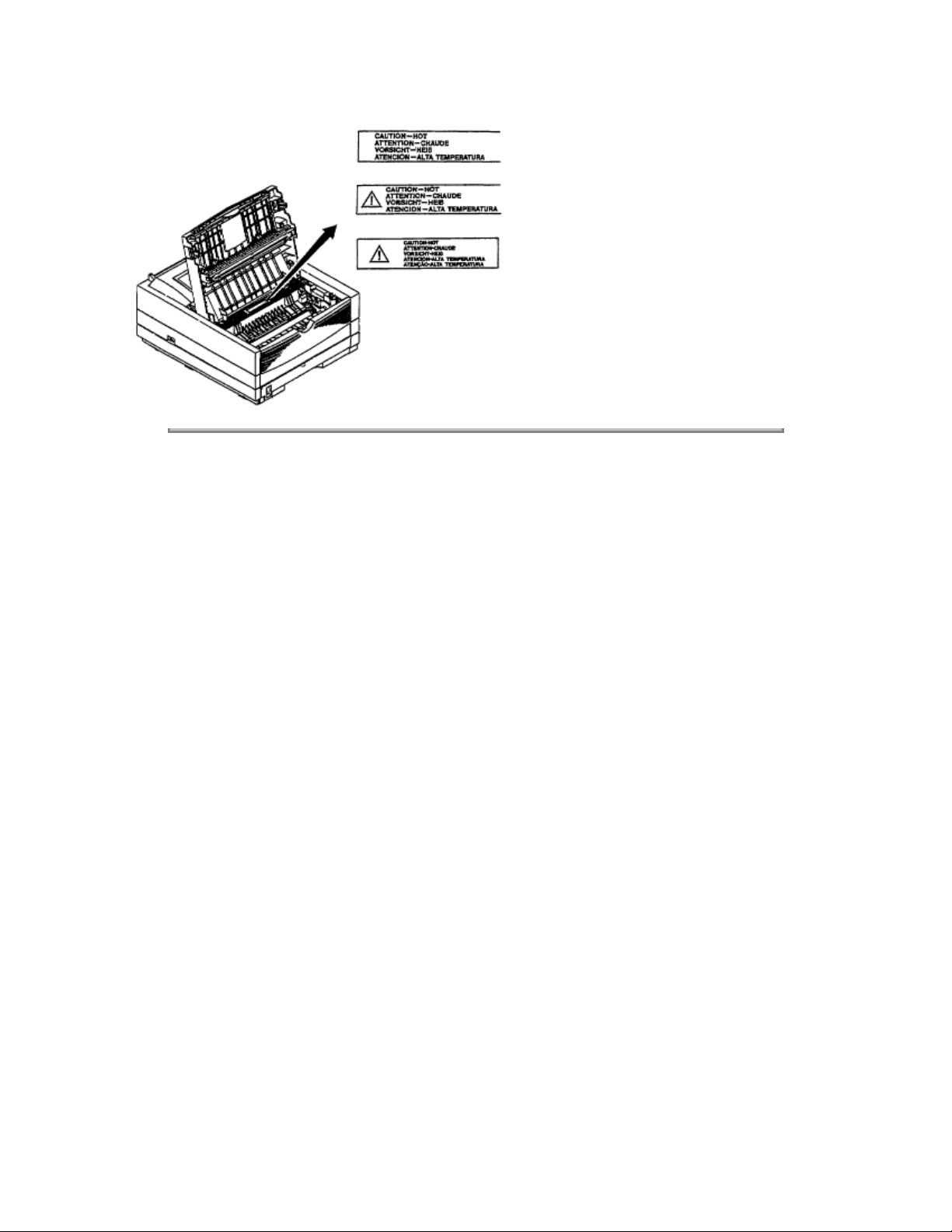

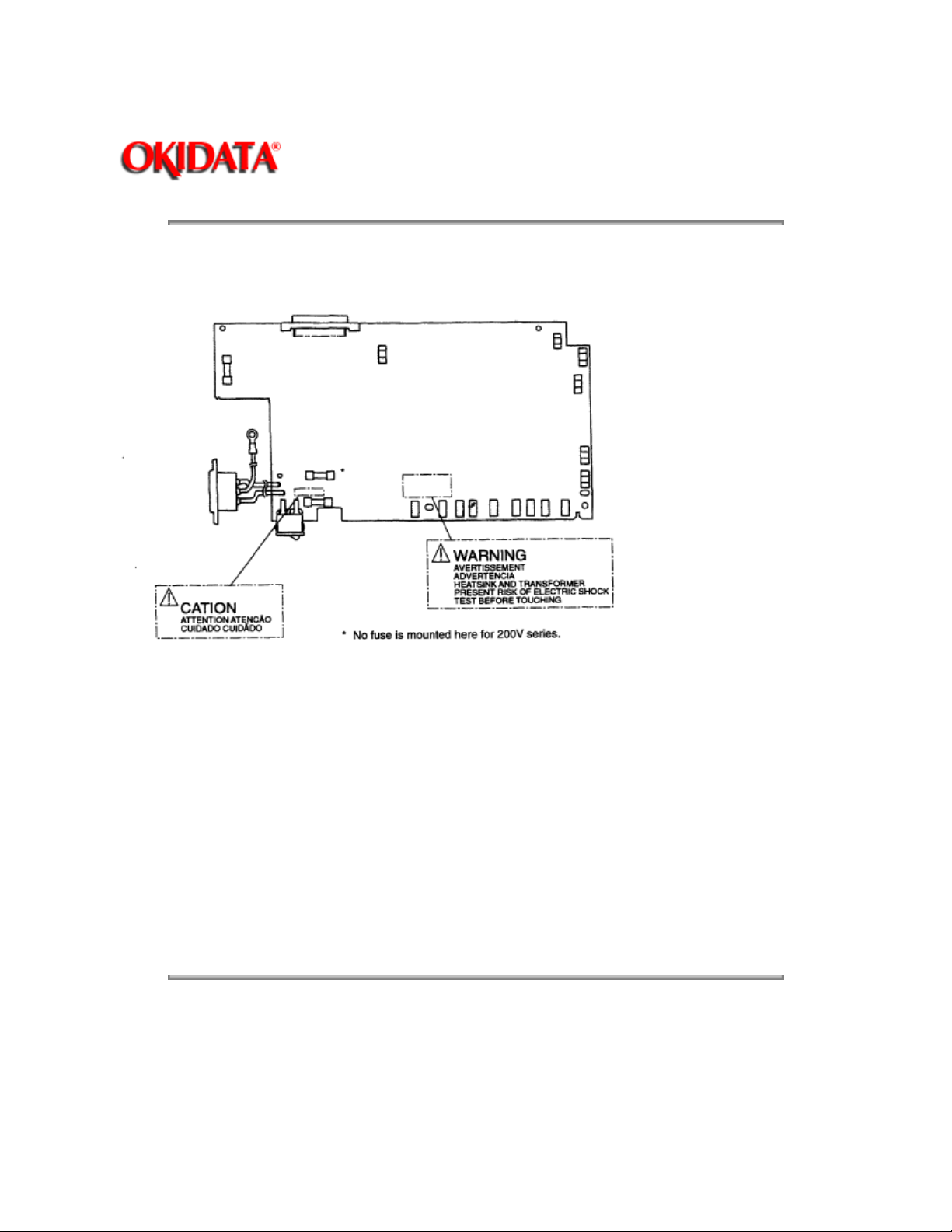

1.5.3 Warning/Caution Marking

The following warning and caution markings are made on the power supply/sensor board.

Page: 8

ENGLISH Heatsink and transformer core present risk of electric shock. Test before touching.

FRENCH Le dissipateur thermique et le noyau du transformateur présentent des risques de choc

électrique. Testez avant de manipuler.

SPANISH Las disipadores de color el núcel del transformador pueden producir un choque

eléctrico. Compruebe antes de tocar. PORTUGUESE O dissipador de calor e o núcleo do

fransiormador apresentam risco de choque elétrico. Teste antes de focar.

ENGLISH Circuits maybe live after fuses open.

FRENCH Il se peut que les circuits soient sous tension une fois que les fusibles ont éfé rerirés.

SPANISH Las circuitos pueden estar activos una vez que se hayan abierio los fusibles.

PORTUGUESE Os circuitos podem estar energizados após os fusiveis se queimarem.*

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

Chapter 2 Operation Description

2. OPERATION DESCRIPTION

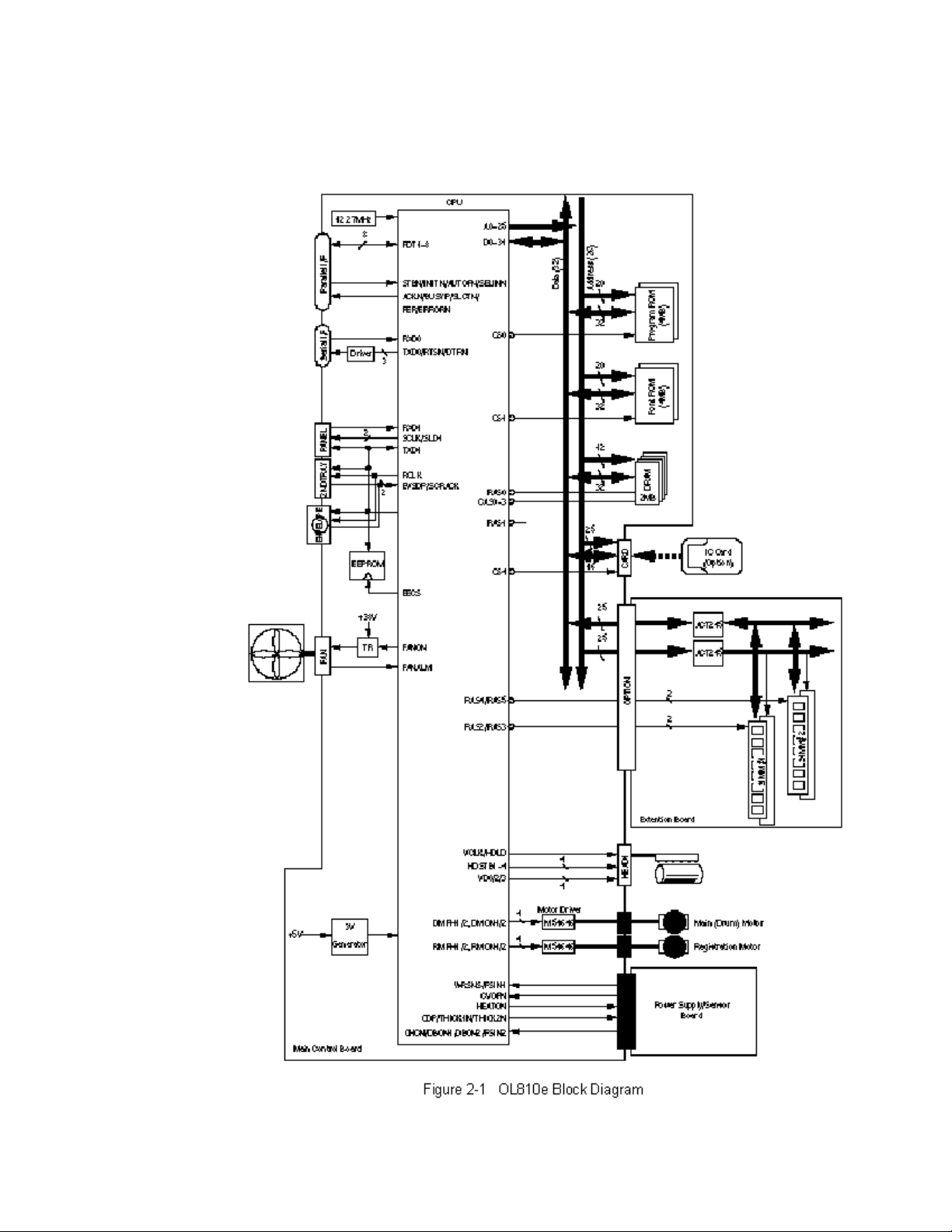

OL810e consists of a main control board, a power supply/sensor board, an operator panel, an

electrophotographic process mechanism, and revision for illumination of LED head.

The main control board receives data via the host I/F, it then decodes, edits and stores the data in

memory. After completing the editing of a single page of data, it references the font memory and

generates bit image data, which is transferred to the LED head in one dot line units.

Through the electrophotographic process mechanism, the data is printed on the paper.

The operator panel is used for operations and status display.

OL810e block diagram is shown in Figure 2-1.

Page: 9

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 10

Service Guide OL810e

Chapter 2 Operation Description

2.1 Main Control Board

The main control board consists of a single chip CPU, a program ROM, a font ROM, four DRAMs, an

EEPROM, a host interface circuit, and a mechanism driving circuit.

(1) Single chip CPU

The single chip CPU is a custom CPU (32-bit internal bus, 32-bit external bus, 25.54-MHz clock, with input

frequency from a 12.27-MHz clock) which incorporates the RISC CPU and its peripheral devices, and has

the following functions:

Built-in device

Chip select controller Control of ROM, DRAM and I/O device Bus controller

DRAM controller

DMA controller Transfer of image data from DRAM to video output port

Parallel interface controller Control of Centronics parallel interface

Serial interface controller Control of RS-232C serial interface

Video output port Control of LED head

LED STB output port

Timer Generation of various control timing

Serial I/O port Control of operator panel, EEPROM, and options

I/O port Input and output of sensor and motor signals

(2) Program and Font ROMs

The Program and Font ROMs store the equipment program and various types of fonts. EPROM or Mask

ROM is used as Program and Font ROMs. The mounting locations of these Program and Font ROMs vary

depending on the type of the ROMs (for the mounting location see Section 7.4).

Function

Monitoring of paper running and paper size

(3) DRAM

The DRAM is a 2MB resident memory which is used as a buffer, that stores edited data, image data, DLL

data and macro data.

(4) EEPROM

1,024-bit Electrically Erasable PROM (EEPROM), is loaded with the following kinds of data:

- Menu data

- Various counter data (page counter, drum counter)

- Adjusting parameters (LED head drive time, print start position, paper feed length)

(5) Parallel Interface

Parallel data is received from a host system via parallel interface which conforms to the Centronics

specification.

(6) RS232C Serial Interface

Serial data is sent to and received from a host system via serial interface which conforms to EIA RS232C.

Following items are selectable:

Flow control: DTR HI/DTR LO/XONXOFF/RBSTXON

Baud rate: 300/600/1200/2400/4800/9600/19200

Data bits: 7 BITS/8 BITS

Parity: NONE/EVEN/0DD

Minimum busy: 200 mSEC/1 SEC

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 11

Service Guide OL810e

Chapter 2 Operation Description

2.2 Power Supply/Sensor Boar

The power supply/sensor board consists of an AC filter circuit, a low voltage power supply circuit, a high

voltage power supply circuit, heater drive circuit, and photosensors.

(1) Low Voltage Power Supply Circuit

This circuit generates the following voltages.

Output voltage Use

+5 V Logic circuit supply voltage

+30 V Motor and fan drive voltage and source voltage for high-voltage supply

+8 V RS-232C line voltage

+8 V RS-232C line voltage and PS board supply voltage

+3.3V LED head supply voltage

(2) High Voltage Power Supply Circuit

This circuit generates the following voltages required for electrophotographic process from +5 V,

according to the control sequence from the main control board. When cover open state is detected, +5 V

supply is interrupted automatically to stop the supply of all high-voltage outputs.

Output

CH -1.35 KV Voltage applied to charging roller

DB -300 V/+300 V Voltage applied to developing roller

SB -450 V/ 0 V Voltage applied to toner supply roller

TR +500 V to +4 KV/-750 V Voltage applied to transfer roller Variable

CB +400 V Voltage applied to clearing roller

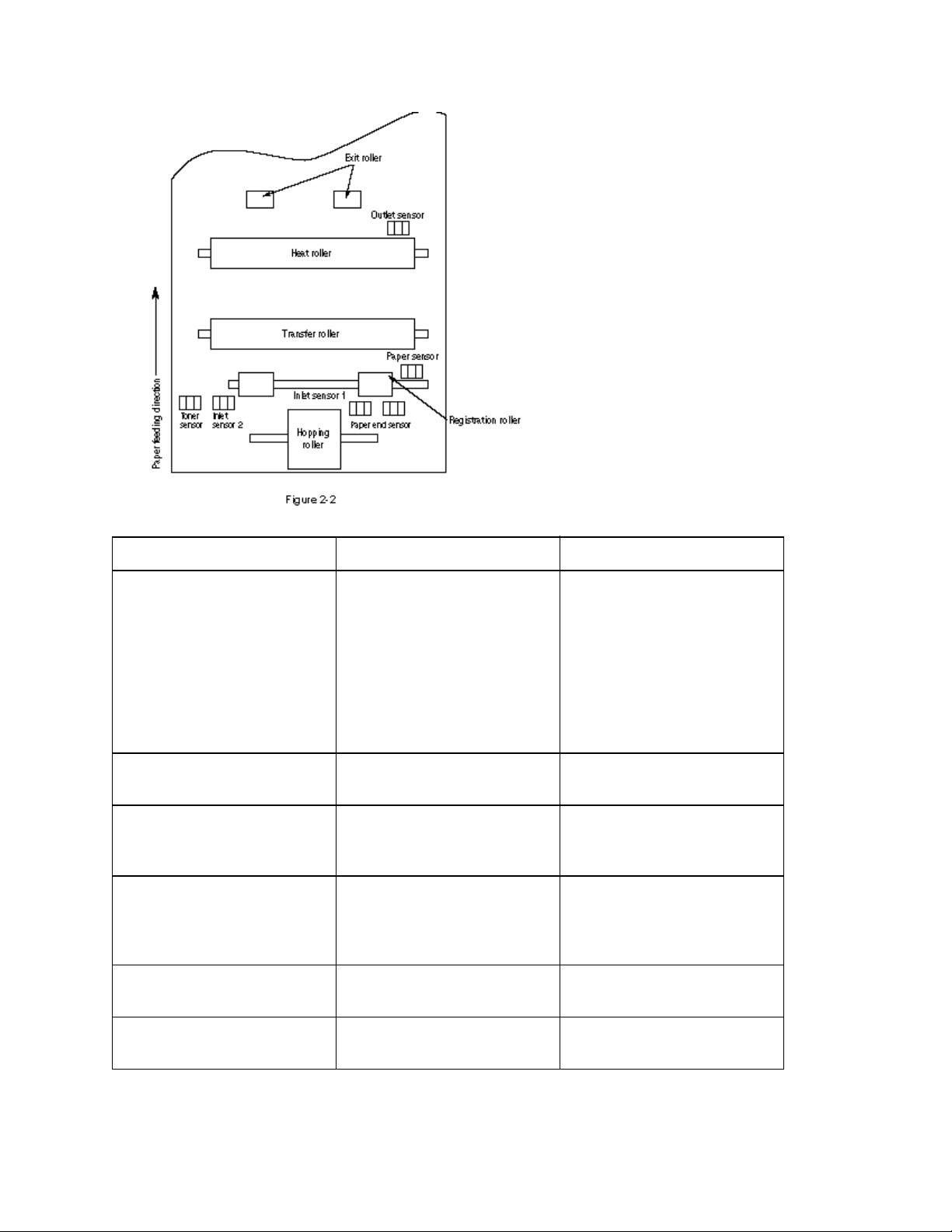

(3) Photosensor

The photosensor mounted on this power supply/sensor board monitors the status of paper being fed

through the printer during printing.

Voltage Use Remarks

The sensor layout diagram is shown in Figure 2-2.

Function Sensing state

Inlet sensor 1 Detects the leading part of

the paper and gives the

monitor timing for switching

from hopping operation to

feeding operation. Monitors

paper feeding situation and

paper size based on the

paper arrival time and

running time.

Intel sensor 2 Detects the paper width. ON: A4 or larger OFF:

Paper sensor Detects the leading portion of

the paper. Monitors the paper

feeding situation.

Outlet sensor Monitors the paper feeding

and size according to the

time of arrival to and leaving

past the sensor.

Paper end sensor Detects the end of the paper. ON: Paper exists. OFF: No

Toner low sensor Detects the lack of toner

Sensor

ON: Paper exists. OFF: No

paper exists.

Smaller than A4

ON: Paper exists. OFF: No

paper exists.

ON: Paper exists. OFF: No

paper exists.

paper exists.

- - - - -

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 12

Service Guide OL810e

Chapter 2 Operation Description

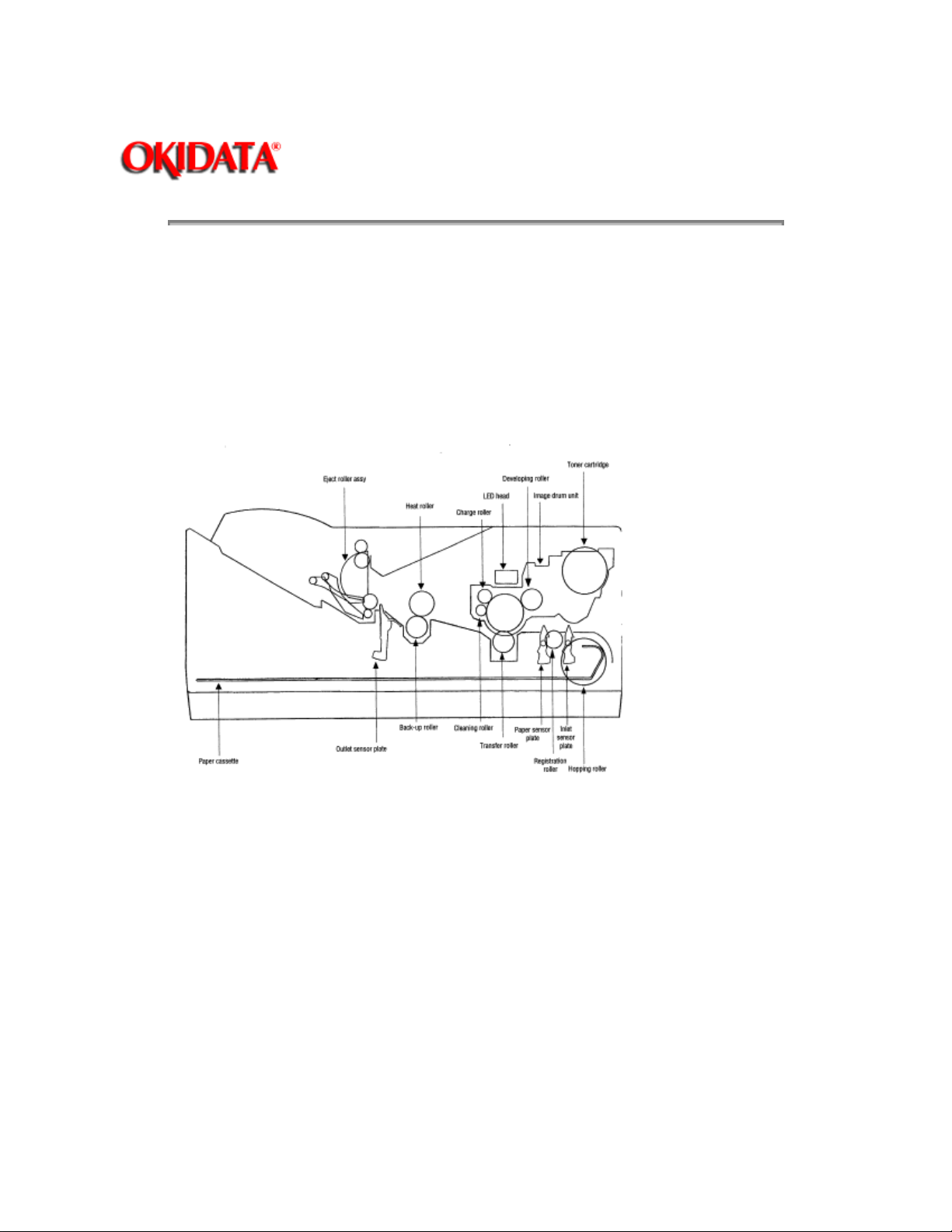

2.3 Electrophotographic Process

2.3.1 Electrophotographic Process Mechanism

This mechanism actuates the printing of image data supplied by the main control board on the paper by

electrophotographic process.

The layout of the electrophotographic process mechanism is shown in Figure 2-3.

(1) Image Drum Unit

The image drum unit consists of a sensitive drum, a charger, and a developer. The unit forms a toner

image on the sensitive drum, using a electrostatic latent image formed by the LED head.

(2) Registration Motor

The registration motor is a pulse motor of 48 steps/rotation with two-phase excitement by the signal from

the main control board. It drives the hopping and registration rollers via two one-way clutches according to

the direction of rotation.

(3) Main (Drum) Motor

The main or drum motor is a pulse motor of 48 steps/rotation with two-phase excitement by the signal

from the main control board and is the main motor of this mechanism.

(4) LED Head

Image data for each dot line from the main control board is received by the shift register and latch register.

The 4992 LED's are driven to radiate the image data on the image drum.

(5) Fuser

The fuser consists of a heater, a heat roller, a thermistor and a thermostat.

The AC voltage from the power supply/sensor board is applied to the heater controlled by the HEATON

signal from the main control board. This AC voltage heats the heater. The main control board monitors the

heat roller temperature via the thermistor, and regulates the heater roller to keep it at a designated

temperature in the menu, depending on the thickness of the paper (tray 1&2: light=165°C, medium

light=170°C, medium=175°C, medium heavy and heavy=195°C; manual feeding and power envelope

feeder: light=175°C, medium light=180°C, medium=185°C, medium heavy=190°C, heavy=195°C) by

connecting or disconnecting the AC voltage supply to the heater.

When an abnormal rise of the heater roller temperature takes place, the thermostat of the heater voltage

supply circuit becomes active and forcibly cuts the AC voltage supply.

The temperature setting of the fuser can be changed through operator panel setting.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 13

Service Guide OL810e

Chapter 2 Operation Description

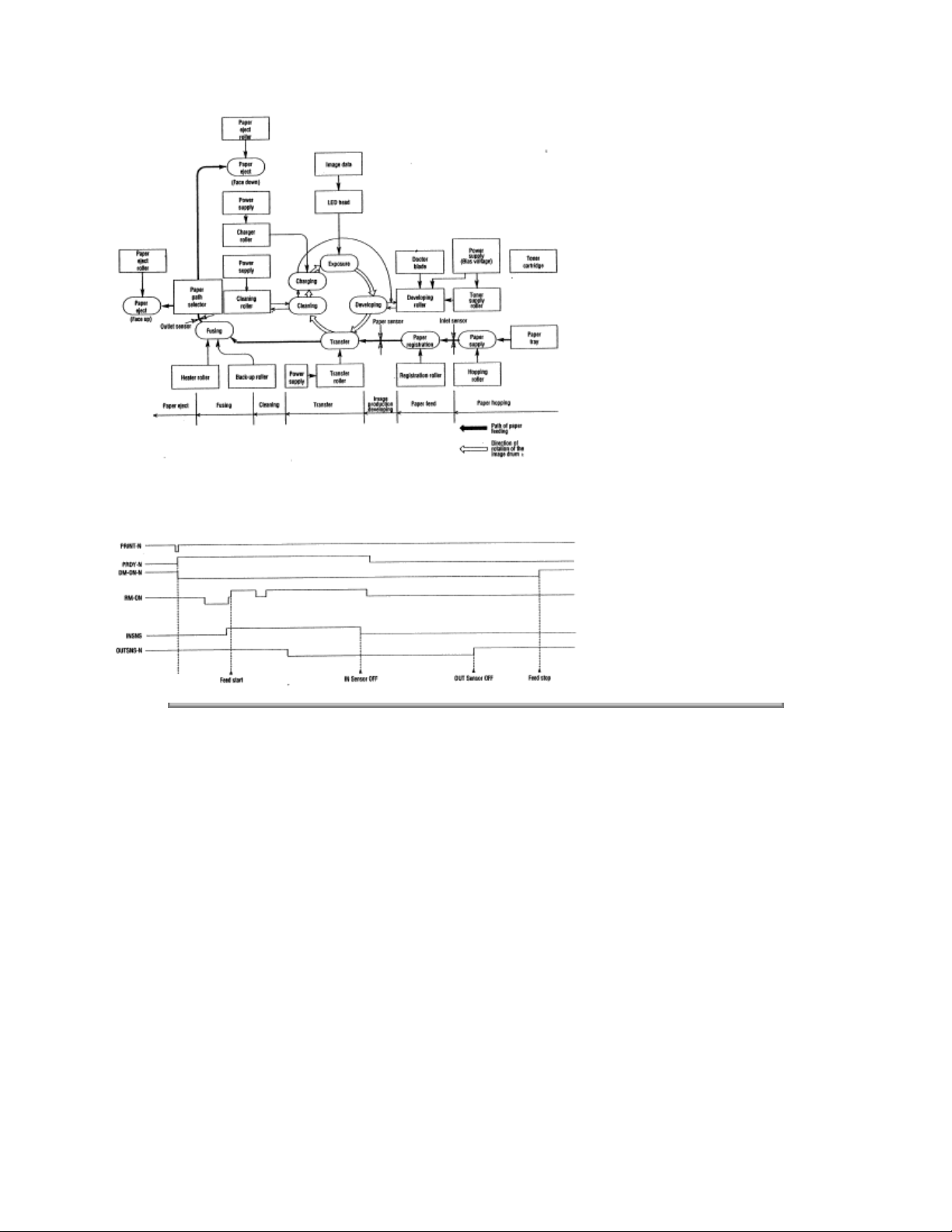

2.3.2 Electrophotographic Process

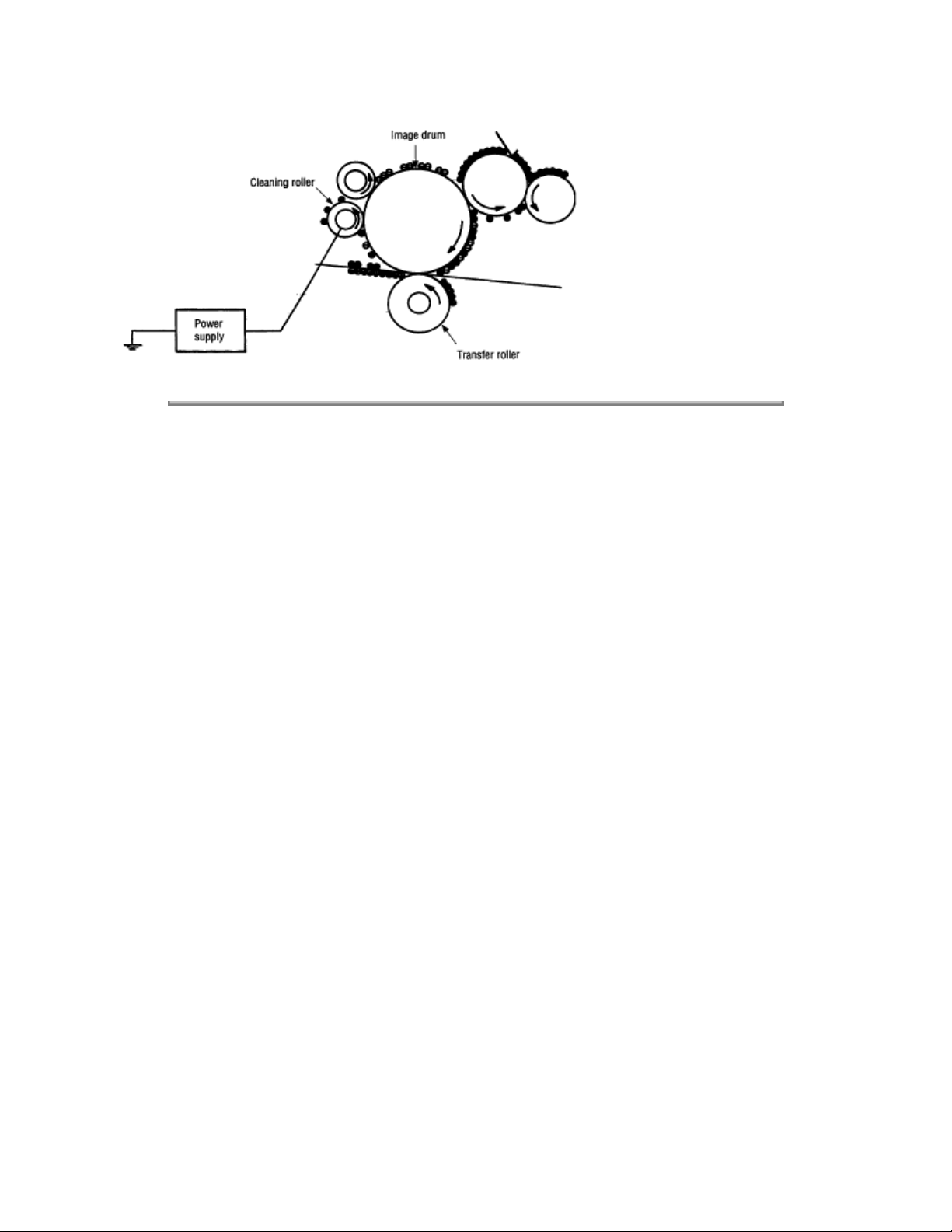

The electrophotographic processing is outlined below. The electrophotographic printing process is shown

in Figure 2-4.

1 Charging

The surface of the image drum is charged uniformly with a negative charge by applying the negative

voltage to the charge roller.

2 Exposure

Light emitted from the LED head irradiates the negatively charged surface of the image drum. The surface

potential of the irradiated portion of the image drum surface becomes lower, forming the electrostatic

latent image associated with the print image.

3 Developing and toner recovery

When the negatively charged toner is brought into contact with the image drum, it is attracted to the

electrostatic latent image by static electricity, making the image visible.

At the same time, the residual toner on the image drum is attracted to the developing roller by static

electricity.

4 Transfer

When paper is placed over the image drum surface, the positive charge which is opposite in polarity to

that of the toner, is applied to the reverse side of the paper by the transfer roller. The toner is attracted by

the positive charge and is transferred onto the paper. This results in the transfer of the toner image formed

on the image drum onto the paper.

5 Temporary cleaning

Residual toner which remains on the image drum without being transferred is evened out by the cleaning

roller and is temporarily attracted to the cleaning roller by static electricity.

6 Fusing

The toner image transferred onto the paper is fused to the paper by heat and pressure.

An electrophotographic process timing chart is shown in Figure 2-5.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 14

Service Guide OL810e

Chapter 2 Operation Description

2.3.3 Process Operation Descriptions

(1) Hopping and Feeding

Hopping and feeding motions are actuated by a single registration motor in the mechanism as shown

below:

The registration motor turning in direction "a" drives the hopping roller. The registration motor turning in

direction "b" drives the registration roller. The registration and hopping gears have one-way bearing, so

turning any of these gears in the reverse direction will not transmit the motion to the corresponding roller.

(a) Hopping

1 For hopping, the registration motor turns in direction "a" (clockwise direction) and drives the hopping

roller to advance the paper until the inlet sensor turns on (in this case, the registration gear also turns, but

the registration roller is prevented from turning by the one-way bearing).

2 After inlet sensor is turned on by the paper advance, the paper is further advanced to a predetermined

distance until the paper hits the registration roller (the skew of the paper can thus be corrected).

(b) Feeding

1 When hopping is completed, the registration motor turning in direction "b" (counter-clockwise direction)

drives the registration roller to advance the paper (in this case, the hopping gear also turns, but the

hopping roller is prevented from turning by the one-way bearing).

2 The paper is further advanced in synchronization with the print data.

(2) Charging

Charging is actuated by the application of the DC voltage to the charge roller that is in contact with the

image drum surface.

The charge roller is composed of two layers, a conductive layer and a surface protective layer, both

having elasticity to secure good contact with the image drum. When the DC voltage applied by the power

supply exceeds the threshold value, charging begins. The applied voltage is proportional to the charge

potential, with offset of approximately 550V.

(3) Exposure

Light emitted by the LED head irradiates the image drum surface with a negative charge. The surface

potential of the irradiated portion of the image drum drops, forming an electrostatic latent image

associated with the image signal.

The image drum is coated with an underlayer (UL), a carrier generation layer (CGL), and carrier transfer

layer (CTL) on aluminum base. The organic photo conductor layer (OPC), comprising CTL and CGL, is

about 20 µm thick.

The image roller surface is charged to about 750 V by the contact charge of the charge roller.

When the light from the LED head irradiates the image drum surface, the light energy generates positive

and negative carriers in the CGL. The positive carriers are moved to the CTL by an electrical field acting

on the image drum. Likewise, the negative carriers flow into the aluminum layer (ground).

The positive carriers moved to the CTL combine with the negative charges on the image drum surface

accumulated by the contact charge of the charge roller, lowering the potential on the image drum surface.

The resultant drop in the potential of the irradiated portion of the image drum surface forms an

electrostatic latent image on it. The irradiated portion of the image drum surface is kept to about 100 V.

(4) Developing

Toner is attracted to the electrostatic latent image on the image drum surface, converting it into a visible

toner image. Developing takes place through the contact between the image drum and the developing

roller.

1 As the toner supply roller rotates while rubbing on the developing roller, a friction charge is generated

between the developing roller and the toner, allowing the toner to be attracted to the developing roller (the

developing roller surface is charged positive and the toner, negative).

2 The toner attracted to the developing roller is scraped off by the doctor blade, forming a thin coat of

toner on the developing roller surface.

3 Toner is attracted to the exposed portion (low-potential part) of the image drum at the contact of the

image drum and the developing roller, making the electrostatic latent image visible.

Note: The bias voltage required during the developing process is supplied to the toner supply roller and

the developing roller, as shown below. 450 VDC is supplied to the toner supply roller, 300 VDC to the

developing roller.

(5) Transfer

The transfer roller is composed of conductive sponge material, and is designed to get the image drum

surface and the paper in a close contact.

Paper is placed over the image drum surface, and the positive charge, opposite in polarity to that of the

toner, is applied to the paper from the reverse side.

The application of a high positive voltage from the power supply to the transfer roller causes the positive

charge inducement on the transfer roller surface, transferring the charge to the paper as it contacts the

transfer roller. The toner with negative charge is attracted to the image drum surface, and it is transferred

to the upper side of the paper due to the positive charge on the reverse side of the paper.

(6) Fusing

When the transfer is completed, the toner image is fused to the paper by heat and pressure as the paper

with unfused toner image passes between the heater roller and the back-up roller. The heater roller with

Teflon coating incorporates a 400W heater (Halogen lamp), which generates heat.

A thermistor which is in contact with the heater roller regulates the temperature of the heater roller to a

designated temperature in the menu, depending on the thickness of the paper (tray 1&2: light=165°C,

medium light=170°C, medium=175°C, medium heavy and heavy=195°C/ manual feeding and power

envelope feeder: light=175°C, medium light=180°C, medium=185°C, medium heavy=190°C,

heavy=195°C). A safety thermostat cuts voltage supply to the heater off by opening the thermostat in the

event of abnormal temperature rises.

The back-up roller is held under a pressure of 7.52 kg applied by the pressure spring on each side.

(7) Cleaning

When the transfer is completed, the residual toner left on the image drum is attracted to the cleaning roller

temporarily by static electricity, and the image drum surface is cleaned.

(8) Cleaning of rollers

The charge, transfer and cleaning rollers are cleaned for the following cases:

- Warming up when the power is turned on.

- Warming up after the opening and closing of the cover.

- When the number of sheets accumulated reaches 10 or more, and the printout operation ends.

Changes in bias voltage applied to each roller move the attaching toner off the roller to the image drum

and return it to the developer.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 15

Service Guide OL810e

Chapter 2 Operation Description

2.3.4 Revision of LED Head Illumination

An LED correcting head, which is capable of correcting the illumination of the LED for each dot, is being

used in this printer. LED illumination correction function of 16 steps is carried out by using an EEPROM

which is installed in the LSI that maintains the LED illumination correction values, and an LED correction

drivers (MSM6731BWAF) together as a pair.

The LED correcting head consists of the correction control LSI (MSM6730WAF), LED drivers

(MSM6731BWAF), and an LED array. The block diagram of the LED correcting head is shown below.

The existing LED head receives the printing data from the CPU directly at its LED drivers. With the LED

correcting head, a correction control LSI (MSM6730WAF) is connected between the CPU and LED

drivers, so the printing data is input to the LED drivers through the correction control LSI. In order to

maintain compatibility with the existing LED head, the printing operation of the LED correcting head is

carried out through identical sequence.

The LED correcting head is a 600 dpi head, with the LED drivers located on both sides of the LED array

with a 300 dpi pitch spacing. The printing and correction data obtained from the CPU through four signal

lines are sent to the LED array.

The printing operation timing chart is shown below.

The printing operation is carried out in normal mode. Under ordinary circumstances such as when the

power is turned on or when LOADI, signal level is low, the normal mode is enabled.

The printing operation is carried out in the following sequence. First, the printing data DATAI3 through

DATAI0 are stored, sequentially shifted, in the shift registers of the LED drivers, by the printing data

synchronous clock, CLOCKI. Then the printing data stored in shift registers are latched by the high level

pulse of LOADI. The latched printing data turns the LEDs on by STRB1I-N through STRB4I-N and

actuates printing.

The mode setting timing chart during illumination correction is shown below.

The mode setting is carried out in the following manner. LOADI is fixed at high level, and DATAI0 which

comes up following this is 4-data latched with the timing of the fall of CLOCKI. The illumination correction

mode is selected based on the latched 4-data combination. Then the mode becomes valid at the fifth fall

of CLOCKI.

The period during which the illumination correction mode is valid is from the fall of the fifth CLOCKI and

while the level of LOADI is high. When the level of LOADI becomes low, the illumination correction mode

is terminated, and the head returns to the normal mode, which is mode with which the printing is normally

carried out.

The LED driver (MSM6731BWAF) corrects the LED illumination by controlling the LED current. The LED

illumination can be set in 16 steps, with 7 steps in the direction of illumination increase in relation to the

standard value, and 8 steps in the direction of decrease. For this reason, the LED correction data is a 4-bit

data for each dot.

The relationship between the LED correction data and LED current correction steps with the LED driver

(MSM6731BWAF) used in an LED head is shown below.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 16

Service Guide OL810e

Chapter 2 Operation Description

2.4 Paper Jam Detection

The paper jam detection function monitors the paper condition when the power is turned on and during

printing. When any of the following conditions arises, this function interrupts the printing process. If any of

the following errors is encountered, printing can be recovered by removing the jammed paper (by opening

the upper cover, removing the jammed paper and closing the upper cover).

Error

Paper input jam - The paper is in contact with the inlet sensor when the

Paper feed jam - The paper is in contact with the paper sensor when the

Paper exit jam - The paper is in contact with the outlet sensor when the

Cause of error

power is turned on.

- After hopping operation is attempted three times, the

leading edge of the paper does not reach the inlet sensor.

power is turned on.

- The leading edge of the paper does not reach the paper

sensor within a predetermined feeding distance since the

paper has reached the inlet sensor.

- The trailing edge of the paper does not pass over the

paper sensor within a predetermined feeding distance after

the same has passed over the inlet sensor.

- The leading edge of paper does not reach the outlet

sensor within a predetermined feeding distance after the

paper has reached the paper sensor.

power is turned on.

- The paper does not pass over the outlet sensor within a

predetermined feeding distance after the leading edge of

the paper has reached the outlet sensor.

- The paper size check for manual feeding finds that the

paper size is free size.

Paper size error Paper size error - The size of the paper is monitored by the

inlet sensor 1. The paper is not detected by the inlet

sensor 1 within predetermined feeding distance.

- The inlet sensor 2 detects that the size of the loaded

paper is A4 or larger, or smaller than A4. The detected

paper size differs from the paper size set by command or

menu.

- The paper size check for manual feeding finds that the

paper size is free size.

Paper Feed Check List

ERROR

Type of error

Paper feed

error

Paper feed jam In sensor on

Paper feed jam Write sensor on

Paper size

error

Paper exit jam Out sensor on

Paper feed jam In sensor off

Monitor Standard value Pulse Minus

Hopping start

to

In sensor on

to

Write sensor on

to

Out sensor on

In sensor on

to

Out sensor on

to

Out sensor off

to

Write sensor off

72.0 36.0 _

20.0 20.0 _

138.0 69.0 _

Depends on the paper

length

Depends on the paper

length

22.0 22.0 -

45.0 45.0

45.0 45.0

Note: Hyphen "-" in the table represents "not checked." Paper Length List

Unit : mm

Check range

Type Paper length Min. Max.

A4 297.0 252.0 342.0

A5 210.0 165.0 255.0

B5 257.0 212.0 302.0

LETTER 279.4 234.4 324.4

LEGAL 13 330.2 285.2 400.6

LEGAL 14 355.6 285.2 400.6

EXEC 266.7 221.7 311.7

A6 148.0 103.0 193.0

Monarch 190.5 145.5 235.5

COM-9 225.4 180.4 270.4

COM-10 241.3 196.3 286.3

DL 220.0 175.0 265.0

C5 229.0 184.0 274.0

Free 148.0 ~ 355.6 103.0 400.6

Unit : mm

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 17

Service Guide OL810e

Chapter 2 Operation Description

2.5 Cover Open

When the stacker cover is opened, the cover open microswitch on the power supply/sensor board is

turned off to cut +5V supply to the high voltage power supply circuit. This results in the interruption of all

high-voltage outputs. At the same time, the CVOPN signal is sent to the main control board to notify that

the microswitch is off, and the main control board carries out the cover open process.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 18

Service Guide OL810e

Chapter 2 Operation Description

2.6 Toner Low Detection

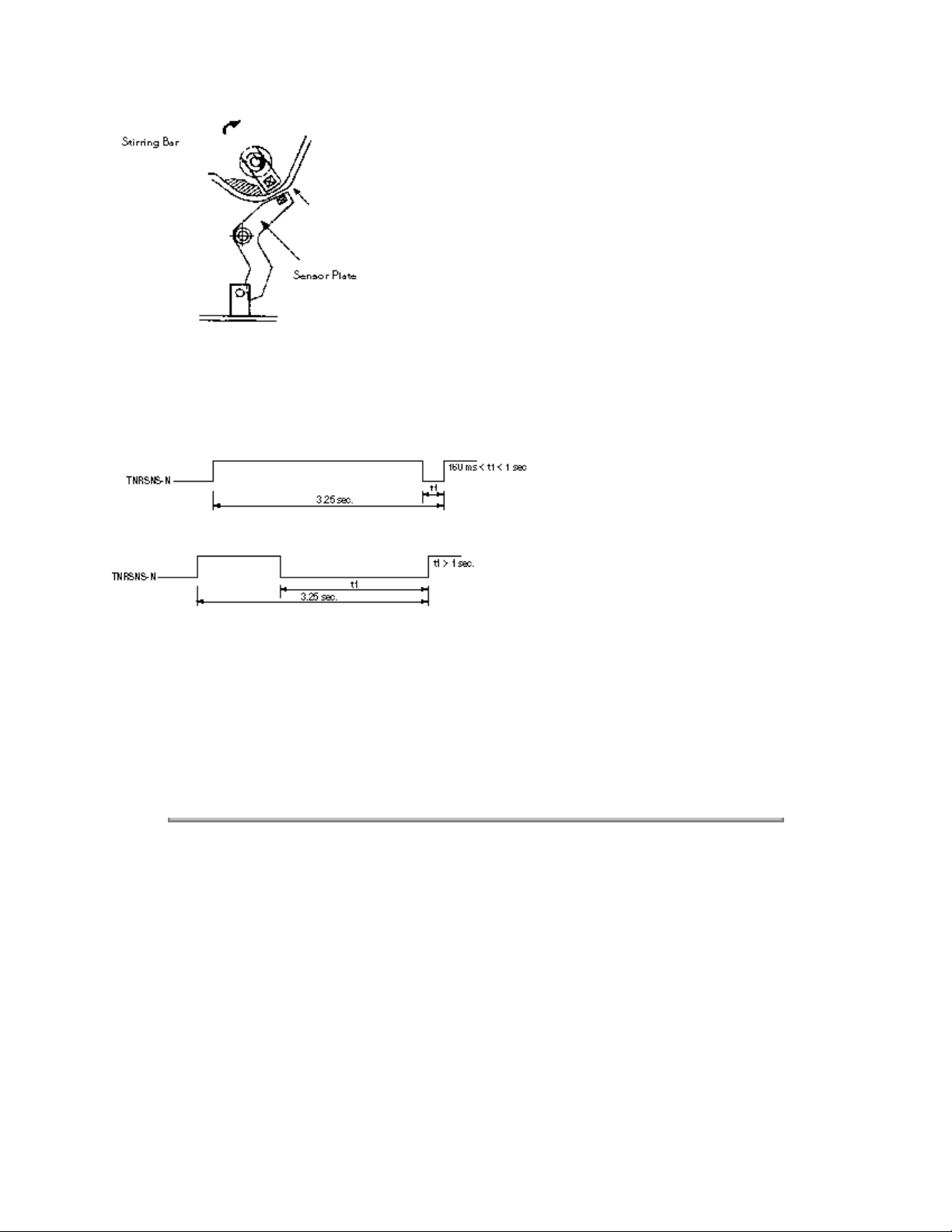

- Device The Toner Low Detection device consists of a stirring gear which rotates at a constant rate, a

stirring bar and a magnet on the stirring bar. The stirring bar rotation is driven by the link to the gouged

portion in the stirring gear.

- Operation Toner Low is detected by monitoring the time interval of the encounter of the magnet set on

the sensor plate and the magnet on the stirring bar.

Operation during Toner Full state

- The stirring bar rotates due to the mechanical transmission of energy originating from the interlocking

with the stirring gear.

- Even when the magnet on the stirring bar reaches the maximum height, the stirring bar is pushed by the

stirring gear, since the other side is being dipped in the toner.

Operation during Toner Low state

- When the stirring bar reaches the maximum height, it falls to the minimum height due to its own weight,

since there is no resistance provided by the toner on the other side. Because of this, the time interval

during which it is in encounter with the magnet of the sensor plate becomes longer. By monitoring this time

interval, Toner Low state can be detected.

TONER FULL state

TONER LOW state

- When the Toner Low state is detected 2 times consecutively, Toner Low is established.

- When the Toner Full state is detected 2 times consecutively, Toner Low is cancelled.

- When there is no change with the toner sensor for 2 cycles (3.25 sec. x 2) or more, then the Toner

Sensor Alarm is activated.

- The toner sensor is not monitored while the main (drum) motor is in a halt.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 19

Service Guide OL810e

Chapter 3 Parts Replacement

PARTS REPLACEMENT

The section explains the procedures for replacement of parts, assemblies, and units in the field. Only the

disassembly procedures are explained here. For reassembly, reverse the disassembly procedure.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

Chapter 3 Parts Replacement

3.1 Precautions for Parts Replacement

(1) Before starting to replace parts, remove the AC cord and interface cable.

(a) Remove the AC cord in the following sequence:

i) Turn off ("o") the power switch of the printer

ii) Disconnect the AC inlet plug of the AC cord from the AC receptacle.

iii) Disconnect the AC cord and interface cable from the printer.

(b) Reconnect the printer in the following procedure.

i) Connect the AC cord and interface cable to the printer.

ii) Connect the AC inlet plug to the AC receptacle.

Page: 20

iii) Turn on ("l") the power switch of the printer.

(2) Do not disassemble the printer as long as it is operating normally.

(3) Do not remove parts which do not have to be touched; try to keep the disassembly to a minimum.

(4) Use specified service tools.

(5) When disassembling, follow the laid out sequences. Parts may be damaged if these sequences are

not followed.

(6) Since screws, collars and other small parts are likely to be lost, they should temporarily be attached

to the original positions during disassembly.

(7) When handling ICs such as microprocessors, ROMs and RAMs, or circuit boards, use proper

anti-static procedures.

(8) Do not place printed circuit boards directly on the equipment or floor.

[Service Tools]

The tools required for field replacement of printed circuit boards, assemblies and units are listed in Table

3-1.

Table 3-1 Service Tools

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

Chapter 3 Parts Replacement

3.2 Parts Layout

This section explains the layout of main components of the equipment.

[Lower base unit]

Page: 21

[Upper cover unit]

[Base unit]

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 22

Service Guide OL810e

Chapter 3 Parts Replacement

3.3 How to Change Parts

This section explains how to change parts and assemblies listed in the disassembly diagram below.

In the parts replacement procedure, those parts marked with the part number inside l with white letters are

RSPL parts.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 23

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.1 Upper Cover Assy

(1) With the power switch turned off, unplug the AC power cord from the outlet.

(2) Disconnect the interface cable 1.

(3) Open the IC card cover 2, and remove the IC card (option) 3.

(4) Press the knobs 4 on left and right sides and open the stacker cover assy 5.

(5) Take out the image drum unit 6.

(6) Remove two screws 7, and open the manual feed guide assy 8. Lift the front side of the upper cover 9

up and unlock the latches at two locations on the back side. Lift and remove the upper cover assy 9.

Notes :

1. When removing or reinstalling the upper cover, be careful not to get the motor cables tangled or caught.

2. When reinstalling the screws 7, be sure to direct the screws into preexisting threads.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 24

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.2 IC Card Cover

(1) Open the IC card cover 1, press it from both sides at the hinges in the directions of arrows shown

below and remove it.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.3 LED Head

(1) Press the buttons on the left and right sides of the stacker cover 1 and open assy.

(2) Open the hook section on the left side of the stacker cover and remove the LED head 2.

Note:

Be sure not to touch directly or push on the SLA part of the LED head.

(3) Remove the PC Connector 4 from the LED Head. Do not remove the LED cable 3 from the PC

connector.

(4) After mounting the new LED head, re-attach the PC Connector and LED cable.

Note:

Set the drive time of the LED head according to the marking on the LED head (see 4.2.1).

Page: 25

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 26

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.4 Operator Panel Ass

(1) Use a flat blade screwdriver to unlock the two latches on the Operator Panel from the rear. Lift the

operator panel assy 1 from the back and remove it.

y

NOTE:

(2) Remove the Sumi card (operator panel cable) 2 from the connector (CN1) 3.

Note:

Use great care as the Operator Panel cable is very short and can be easily damaged.

You can remove the operator panel assy while the upper cover remains installed on the unit.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.5 Pulse Motor (Main/Drum)

(1) Remove the Operator Panel (see 3.3.4)

(2) Remove the upper cover assy (see 3.3.1).

(3) Remove the connector 3 from the connector (DM) 2 of the TQCA-PCB 1.

(4) Remove two screws 4 and remove the pulse motor (main/drum) 6 from the motor bracket 5.

Page: 27

NOTE:

the right side of the base unit.

To ease access to the bottom screw holding the motor(s) to the bracket, loosen the screws holding

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.6 Pulse Motor (Registration)

(1) Remove the Operator Panel (see 3.3.4)

(2) Remove the upper cover assy (see 3.3.1).

(3) Remove the connector 3 from the connector (RM) 2 of the TQCA-PCB 1.

(4) Remove two screws 4 and remove the pulse motor (registration) 6 from the motor bracket 5.

Page: 28

NOTE:

the right side of the base unit.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

To ease access to the bottom screw holding the motor(s) to the bracket, loosen the screws holding

Page: 29

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.7 Face Up Stacker Assy

(1) Remove the operator panel assy (3.3.4).

(2) Remove the upper cover assy (see 3.3.1).

(3) Remove the screw 1 and remove the Sumi card (operator panel cable) 2 off the latch section of face

up stacker 4. Remove both the shield plate 3 and face up stacker 4 together.

(4) Unlock the latches at two locations, and remove the face up stacker 4.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.8 Lower Base Unit

(1) Remove the operator panel assy (see 3.3.4).

(2) Remove the upper cover assy (see 3.3.1).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the connecting cables 2 and 3 of the pulse motors from the connectors (DM, RM) of the

TQCA-PCB 1. NOTE: Mark the cables with the correct re-installation order and location to ease

re-assembly.

(5) Remove the LED head cables 4 and 5 from the connectors (HEAD1, HEAD2).

(6) Open the manual feed guide assy, remove seven screws 7, then remove the lower base unit

Page: 30

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.9 Eject Roller Assy

(1) Remove the operator panel assy (see 3.3.4).

(2) Remove the upper cover assy (see 3.3.1).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the lower base unit (see 3.3.8).

(5) Disengage the eject roller assy 1 from the lower base 2 by pressing the latch section of the eject

roller assy 1 in the direction of the arrow shown below, and remove the eject roller assy 1.

Page: 31

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 32

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.10 Motor Assy

(1) Remove the operator panel assy (see 3.3.4).

(2) Remove the upper cover assy (see 3.3.1).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the lower base unit (see 3.3.8).

(5) Stand the lower base unit on its side as shown, and unlock two latches, then remove the motor assy

1.

NOTE:

remove motor cables making careful note of orientation and placement.

Use care as the gears are not permanently mounted onto the mounts/ shafts. Mark and

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 33

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.11 Hopping Roller Shaft Assy

(1) Remove the operator panel assy (see 3.3.4).

(2) Remove the upper cover (see 3.3.1).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the lower base unit (see 3.3.8).

(5) Remove the motor assy (see 3.3.10).

(6) With the lower base unit 1 standing on its side, remove the hopping roller gear 2 and the bearing (A)

3.

(7) Remove the hopping roller shaft assy 4 (the bearing (B) 5 comes off, so be careful not to lose it).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 34

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.12 Stacker Cover Assy

(1) Remove the operator panel assy (see 3.3.4).

(2) Remove the upper cover assy (see 3.3.1).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Release the stacker cover assembly from the reset Lever R 1 by gently prying the cover from the

reset lever. Remove the reset lever R 1 from the machine.

(5) Release the stacker cover assembly from the reset Lever L. Detach the reset spring 2 from the lower

base unit 3, turn the reset lever L 4 in the direction of arrow until it stops, and remove it in the direction

of arrow .

(6) Remove the LED Cable from the connector on the Main Logic Board. Unlock the two posts of the

lower base unit 3, then remove the stacker cover assy 5.

Note:

Use care when removing the Stacker Cover Assembly as the cover close damper is not

permanently attached.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 35

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.13 Registration Roller

(1) Remove the operator panel assy (see 3.3.4).

(2) Remove the upper cover (see 3.3.1).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the lower base unit (see 3.3.8).

(5) Remove the motor assy (see 3.3.10).

(6) With the lower base unit standing on its side, remove the Registration Roller gear 1.

(7) Press the registration roller 2 in the direction of arrow and lift up the left side of it, then remove the

registration roller 2 and the bearing (registration) 3.

(8) Pull out the registration roller 2 in the direction of arrow B.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

3.3.14 Transfer Roller

Page: 36

Service Guide OL810e

Chapter 3 Parts Replacement

Special Note:

surface of roller.

(1) With the power switch turned off, unplug the AC cord from the outlet.

(2) Open the stacker cover.

(3) Release the transfer roller gear 1 by unlocking the latch of the main unit (never apply excessive force

when unlocking the latch).

(4) Lift the right side of the transfer roller 2, and shift it to the right side, then pull it out from the main unit

(at this time, the bearings 3 of the left and right sides of the transfer roller 2 will come off also).

Use great care. The bearings are not permanently attached.

Handling the Transfer Roller unnecessarily will cause poor print quality. Do not touch the

NOTE:

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 37

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.15 Fusing Unit

(1) Remove the operator panel assy (see 3.3.4).

(2) Remove the upper cover (see 3.3.1).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the stacker cover assy (see 3.3.12).

(5) Remove four screws 1, lift and remove the fusing unit 2.

Caution: Fusing unit may be hot. Use care when handling.

Notes:

1. When reinstalling or removing the fusing unit, tighten or loosen the screws while holding the fusing

unit assy 2 down with your hand (it is being pushed up by the fuser pressure roller).

2. When reinstalling the screws 1, be sure to direct the screws into preexisting thread and avoid

damaging the threads.

3. Do not apply excessive torque when tightening the screws 1. Stripping these screws will require

replacing the entire lower base unit.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.16 Back-up Roller

(1) Remove the fusing unit assy (see 3.3.15).

(2) Remove the Lower Base Unit Assembly (see 3.3.8)

(3) Remove the Motor Assembly (see 3.3.10)

(4) Remove the Reset Lever R (see 3.3.12)

(5) Lift the left side of the back-up roller 1, and pull it out to the left side (at this time, two bushings

(back-up) 2 and the bias springs (back-up) 3 will also come off).

Page: 38

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.17 Sensor Plate (Inlet)

(1) Remove the operator panel assy (see 3.3.4).

(2) Remove the upper cover (see 3.3.1).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the lower base unit (see 3.3.8).

(5) Press the clamps of three sensor plates (inlet and paper) 1, and remove them by pressing them

upward from the bottom.

Page: 39

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.18 Sensor Plate (Outlet)

(1) Remove the operator panel assy (see 3.3.4).

(2) Remove the upper cover assy (see 3.3.1).

(3) Remove the eject roller assy (see 3.3.9).

(4) Remove the face up stacker assy (see 3.3.7).

(5) Remove the lower base unit (see 3.3.8).

(6) Remove the fusing unit assy (see 3.3.15).

(7) Press the clamps of the sensor plate (outlet) 1, and remove the sensor plate by pushing it up.

Page: 40

NOTE:

This is a two part sensor. Use great care when handling.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 41

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.19 Manual Feed Guide Assy

(1) Remove the Operator Panel Assembly (see 3.3.4)

(2) Remove the upper cover assy (see 3.3.1).

(3) Open the manual feed guide assy 1, and release the engagement on both sides with the main unit by

carefully bending the manual feed guide assy 1.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.20 Sensor Plate (Paper Supply)

(1) Remove the operator panel assy (see 3.3.4).

(2) Remove the upper cover assy (see 3.3.1).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the lower base unit (see 3.3.8).

(5) Press the clamps of the sensor plate (paper supply) 1 to unlock the latch, and remove it from

Note:

When remounting, verify the proper the engagements as shown in the diagram.

Page: 42

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 43

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.21 TQCB-PCB

(1) Remove the operator panel assy (see 3.3.4).

(2) Remove the upper cover assy (see 3.3.1).

(3) Remove the face up stacker assy (see 3.3.7), and shield plate.

(4) Remove the connector (PSIZE) (2NDTRAY) 5 and 6, LED Head cables, and motor connectors.

(5) Remove three screws 1.

(6) Move the TQCB-PCB 2 in the direction of arrow to disconnect it from the power supply/sensor board

3.

(7) Remove the TQCB-PCB 2, together with the PCB guide plate (remove the fan motor 4 at the same

time).

(8) Remove the connector CN1, and disconnect the fan motor 4.

(9) Remove three screws 8 and two nuts 9, and remove the PCB guide plate 7 from the TQCB-PCB 2.

Note:

When reinstalling the TQCB-PCB 2 onto the base plate 7, be careful not to bend the base plate (it is

desirable to place a block underneath it to prevent bending).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

3.3.22 Transformer

(1) Remove the operator panel assy (see 3.3.4).

(2) Remove the upper cover assy (see 3.3.1).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the connectors (CN1 and CN2).

(5) Remove two screws 1, and remove the transformer 2.

Page: 44

Chapter 3 Parts Replacement

Note:

When reinstalling the transformer, be sure to lay the AC and transformers primary side cables

under the divider (see view A diagram below)

.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 45

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.23 Power Supply/Sensor Board and Contact Assy

(1) Remove the Operator Panel assembly (3.3.4), then remove the upper cover assy (see 3.3.1).

(2) Remove the lower base unit (see 3.3.8).

(3) Remove the TQCA-PCB (See 3.3.21).

(4) Remove the transformer (see 3.3.22).

(5) Remove the AC inlet 1 from the base plate 2.

(6) Remove the screw 4 and remove the grounding (earth) wire 5.

(7) Remove three screws 6, and remove the power supply/sensor board 7 and contact assy 8 together.

(8) Unlock two latches 9, and remove contact assy 8 from the power supply/sensor board 7.

Notes :

1. Be careful about the sensor (paper supply) when reinstalling the lower base.

2. Make sure that no excessive force is applied to the power supply switch.

3. When installing the power supply/sensor onto the base plate, be careful not to bend the base plate (it

is desirable to place a block underneath it to prevent bending).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 46

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.24 Cassette Guide L Assy

(1) Remove the paper cassette.

(2) Remove the Operator Panel Assembly (3.3.4), then remove the upper cover assy (see 3.3.1).

(3) Remove the lower base unit (see 3.3.8).

(4) Remove the TQCA-PCB (see 3.3.22).

(5) Remove the transformer (see 3.3.23).

(6) Remove the power supply/sensor board (see 3.3.24).

(7) Remove two screws 1, and remove the guide rails 2.

(8) Remove the screw 3, and remove the cassette guide L 9 by shifting it in the direction of the arrow as

shown below.

(9) Remove cassette lock lever 4 and torsion spring 5.

(10) Remove cassette lock lever spring 8 then remove the sheet link (L) 6 and link pull lock 7.

Special Note:

number sticker must be transfered from the old assembly to the new one.

The serial number sticker is attached to the Cassette Guide Right, Assembly. The serial

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OL810e

Chapter 3 Parts Replacement

3.3.25 Cassette Guide R Assy

(1) Remove the paper cassette.

(2) Remove the Operator Panel Assembly (3.3.4), then remove the upper cover assy (see 3.3.1).

(3) Remove the lower base unit (see 3.3.8).

(4) Remove the TQCA-PCB (see 3.3.22).

(5) Remove two screws 1, and remove the guide rails 2.

(6) Remove the screw 3, and remove the cassette guide R 4 by shifting it in the direction of arrow.

(7) Remove the cassette lock lever 5 and torsion spring 6.

(8) Remove the cassette lock lever spring 9, then remove the sheet link (R) 7 and link pull block 8.

Page: 47

(9) Remove two screws 0, and remove the square-shaped connector A.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 48

Service Guide OL810e

Chapter 4 Adjustments

ADJUSTMENT

This chapter provides explanations concerning the adjustment necessary when replacing a part. The

adjustment is made by changing the parameter value set in EEPROM on the main control board. The

parameter can be set by the key operation from the operator panel. This printer has three kinds of

maintenance modes, and it is necessary to select one of the modes when replacing any parts.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 49

Service Guide OL810e

Chapter 4 Adjustments

4.1.1 User Maintenance Mode

To enter into the user maintenance mode, turn the POWER switch on while holding the MENU key down.

Function

There are five functions as follows:

- Menu reset

- Opepane menu disable

- Hex dump

- X-adjust / Y-adjust

- Drum counter reset

Detailed descriptions of these functions are provided in Appendix D, DIAGNOSTICS TEST.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Loading...

Loading...