Chapter 0

General Manual Information

OL400/410ex (96-01-30)

Chapter 1

1.1 General Description

General Information

The OL400e, OL410e, and the OL410e/PS are compact Light Emitting Diode (LED) page

printers. The printers utilize an LED head for the exposure method. Dry electrophotography is

used as the development method. The print resolution is 300 x 300 dots per inch. The OL410e

and the OL410e/PS (in PCL Mode) can print at 300 x 1200 dots per inch. The printers have

a continuous print speed of up to 4 sheets per minute.

All three products include both a Centronics parallel interface and a 9-pin RS232 serial interface

as standard features. The OL410e/PS includes an LocalTalk interface, which can only be used

in PostScript mode. Theprinters have automatic interface switching capabilities, a power-saving

standby mode, free-paper sizing (which allows printing on custom size paper), and graphic

compression capabilities (for full-page business graphics).

The OL400e utilizes 512 Kbyte of standard Random Access Memory (RAM). An optional

expansion memory board can be installed. Up to 4 Mbyte of RAM (in 1 Mbyte increments)

can be installed on the expansion board, providing up to 4.5 Mbyte of total RAM in the OL400e.

The OL410e utilizes 2 Mbyte of standard Random Access Memory (RAM). The main controller

board contains 1 Mbyte of RAM. The standard expanded memory board contains 1 Mbyte.

An optional expansion memory board can be installed in place of the standard expanded memory

board. The optional board contains 2 Mbyte of RAM. However, up to 4 Mbyte of RAM (in 1 Mbyte

increments) can be installed, providing up to 5 Mbyte of total RAM in the OL410e.

The OL410e/PS utilizes 2 Mbyte of standard Random Access Memory (RAM). 1 Mbyte is on the

main control board. 1 Mbyte is on the PostScript Board. The PostScript board will accept and

additional 3 Mbytes of RAM, providing up to 5 Mbyte of total RAM in the OL410e/PS.

A universal / letter cassette is included with each printer. Legal, executive, and A4 trays are

available.

The printers will print on a variety of paper types, labels, and transparencies.

OL400/410ex (96-01-30)

1.2 Product Specifications

1.2 PRODUCT SPECIFICATIONS

1.2.01 Print Specifications

Exposure Method

Stationary LED Head

Development Method

Dry Electrophotography

1.2.02 Print Speed

Continuous Print

4 sheets per minute

Warm-up Time

Approximately 60 seconds with standard memory

Approximately 90 seconds with the memory expansion board installed

1.2.03 Print Resolution

Standard Printing Mode

300 x 300 dots/inch

Enhanced Printing Mode(OL410e and OL410e/PS in HP LaserJet III mode)

300 x 1200 dots/inch (600 dpi Class Printing)

1.2.04 Symbol Sets

40 Symbol Sets

1.2.05 Paper Feed Method

Automatic Feed

Manual Feed

1

.2.06 Paper Delivery Methods

Face down

Face up

1.2.07 Interface Capabilities

OL400e/OL410e Interfaces

Centronics Parallel Interface

RS232 Serial Interface

OL410e/PS Interfaces (with Auto-switching)

RS232 Serial Interface

Centronics Parallel Interface

LocalTalk (PostScript only)

1.2.08 Emulations

OL400e

HP LaserJet IIP

OL410e

HP LaserJet III (HP PCL 5)

OL410e/PS

HP LaserJet III (HP PCL 5)

Adobe PostScript Level 2

NOTE: When operating under the DOS environment, the OL410e/PS supports auto-emulation

switching by means of the Oki-Switch software, which is included with the printer.

1.2.09 Available Fonts

OL400/410ex (96-01-30)

The OL400e and OL410e printers contain four resident bit mapped typefaces which can be printed

in both landscape and portrait orientations.

Courier

Swiss

Line (LN) Printer

Dutch

The OL410e contains three scalable typefaces, in addition to the four bitmapped typefaces.

CG Times

Univers

Courier

The OL410e/PS contains the following fonts.

Resident Fonts

Adobe PostScript

35 (Type 1 Fonts)

2 (Multiple Master Fonts) - for use with Adobe ATM 3.0 and Adobe Acrobat

PCL5

12 Scalable Fonts

Bit mapped Fonts/Typefaces

2 Line Printer Fonts

USPS Barcode Fonts

The OL400e and OL410e use twenty bit mapped fonts from the four typefaces.

Courier 10 cpi

Courier Bold 10 cpi

Courier Italic 10 cpi

Courier 12 cpi

Courier Bold 12 cpi

Courier Italic 12 cpi

LN Printer 16.67 cpi

Swiss Bold Proportional (B)

Swiss Bold Proportional (F)

Dutch Proportional (B)

Dutch Bold Proportional (B)

Dutch Italic Proportional (B)

Dutch Compressed (B)

Dutch Bold Compressed (B)

Dutch Italic Compressed (B)

Dutch Proportional (F)

Dutch Bold Proportional (F)

Dutch Italic Proportional (F)

Dutch Proportional (B)

Dutch Compressed (B)

NOTE: cpi = Characters Per Inch

OL400/410ex (96-01-30)

1.3 Paper Specifications

1.3 PAPER SPECIFICATIONS

CAUTION: All paper (all types) should be designed for xerographic printing.

Envelopes, labels, and transparencies should only be fed from the top paper tray or manually.

Use the face-up paper ejection path. DO NOT use the optional second paper feed mechanism for

these items.

1.3.01 Paper Types

Letter

Size: 8.5" x 11" (216 mm x 279 mm)

Feed: Automatic or Manual

Weight

Minimum: 16 lbs. (60 g / m2)

Maximum: 24 lbs. (90 g / m2)

Recommended: 20 lbs. (75 g / m2)

Legal

Size:8.5" x 13" (216 mm x 330 mm) 8.5" x 14" (216 mm x 356 mm)

Feed: Automatic (with optional paper tray)

Executive

A4

A5

Weight

Minimum: 16 lbs. (60 g / m2)

Maximum: 24 lbs. (90 g / m2)

Recommended: 20 lbs. (75 g / m2)

Size: 7.25" x 10.5" (184 mm x 267 mm)

Feed: Automatic (with optional paper tray) or Manual

Weight

Minimum: 16 lbs. (60 g / m2)

Maximum: 24 lbs. (90 g / m2)

Recommended: 20 lbs. (75 g / m2)

Size: 8.27" x 11.69" (210 mm x 297 mm)

Feed: Automatic (with optional paper tray)

Weight

Minimum: 16 lbs. (60 g / m2)

Maximum: 24 lbs. (90 g / m2)

Recommended: 20 lbs. (75 g / m2)

Size: 5.83 " x 8.27" (148 mm x 210 mm)

Feed: Automatic (with optional paper tray)

Weight

Minimum: 16 lbs. (60 g / m2)

Maximum: 24 lbs. (90 g / m2)

OL400/410ex (96-01-30)

A6

B6

Envelope

Recommended: 20 lbs. (75 g / m2)

Size: 4.13" x 5.83" (105 mm x 148 mm)

Feed: Automatic (with optional paper tray)

Weight

Minimum: 16 lbs. (60 g / m2)

Maximum: 24 lbs. (90 g / m2)

Recommended: 20 lbs. (75 g / m2)

Size: 7.17" x 10.12" (182 mm x 257 mm)

Feed: Automatic (with optional paper tray)

Weight

Minimum: 16 lbs. (60 g / m2)

Maximum: 24 lbs. (90 g / m2)

Recommended: 20 lbs. (75 g / m2)

Size

Minimum: 3.5" x 7.5" (89 mm x 191 mm)

Maximum: 7.2" x 10.1" (183 mm x 257 mm)

Feed: Automatic (with optional paper tray) or Manual

Weight

Minimum: 16 lbs. (60 g / m2)

Maximum: 24 lbs. (90 g / m2)

Recommended: 20 lbs. (75 g / m2)

Labels

Manual feed / Face up delivery only

Use labels designed specifically for xerographic printing

Transparencies

Manual feed / Face up delivery only

Must be able to withstand the heat of the fusing process

1.3.02 Free Paper Size

The Free Paper Size menu feature allows the end user to print on custom size paper without

a paper size error.

Normally, if the paper is loaded in the paper tray is NOT the same size selected in the software,

a PAPER SIZE error will be displayed when a print job is sent. Enabling the Free Paper Size menu

feature will override this operation.

Free Paper Size Dimensions

Width

Size: 3.4" x 8.5" (86.4 mm x 216 mm)

Length

Size: 5.5" x 14" (140 mm x 355.6 mm)

Feed

Automatic (with optional paper tray)

OL400/410ex (96-01-30)

Manual

Weight

Minimum: 16 lbs. (60 g / m2)

Maximum: 24 lbs. (90 g / m2)

Recommended: 20 lbs. (75 g / m2)

To enable Free Paper Size, follow this procedure.

- Place the printer OFF-LINE.

- Press LAST / Paper Size for two seconds.

- Press NEXT + repeatedly until FREE is displayed on the operator panel.

- Press ENTER to select FREE as the default setting.

- Press ON-LINE to exit the menu.

- Place the custom size paper stock in Tray 1, the Manual Feed Tray, Tray 2,

or the Multi-Purpose Feeder.

- Run the print job.

OL400/410ex (96-01-30)

1.4 Physical Specifications

1.4 PHYSICAL SPECIFICATIONS

1.4.01 Outside Dimensions

Width: 12.6 inches (320 mm)

Height: 6.3 inches (160 mm)

Depth: 14.17 inches (360 mm)

1.4.02 Printer Weight

24 lbs. (11 kg)

1.4.03 LED Array

1.4.03 LED Array

Number of LED Elements: 2560

OL400/410ex (96-01-30)

1.5 Power Requirements

1.5 POWER REQUIREMENTS

1.5.01 Input Power

120 VAC + 5.5% - 15%

220/240 VAC +/- 10%

1.5.02 Power Consumption

Peak

Approximately 600 Watts

Operation (typical)

Approximately 80 Watts

Idle

Approximately 40 Watts

Power Save

Approximately 15 Watts

OL400/410ex (96-01-30)

1.6 Environmental Conditions

1.6 ENVIRONMENTAL CONDITIONS

1.6.01 Ambient Temperature

Operation

50 to 90 degrees Fahrenheit

10 to 32 degrees Celsius

Storage

14 to 110 degrees Fahrenheit

-10 to 43 degrees Celsius

1.6.02 Printer Noise Level

Operation

50 dBA (A) or less

Standby

45 dBA (A) or less

OL400/410ex (96-01-30)

1.8 Options

1.8 OPTIONS

1.8.01 Memory Expansion

OL400e

Expansion RAM Board: contains 1 Mbyte. Can be expanded up to 4.5 Mbyte

in 1 Mbyte increments

OL410e

Expansion RAM Board: Contains 2 Mbyte. Can be expanded up to 5 Mbyte

in 1 Mbyte increments

OL410e/PS

Resident RAM - 2 MByte

Optional RAM - 3 MByte (in 1 Mbyte increments)

Maximum RAM - 5 Mbyte

1.8.02 Font Cards

Bit mapped (OL400e and OL410e)

OKIPRO 65

Bar Codes Plus

MICRO DOCS

Tax

Scalable (OL410e and OL410e/PS in PCL5 emulation)

Distinctive Documents

Perfect Presentations

Wordperfect II Scalable

1.8.03 Paper Trays

100 Sheet Letter Tray

100 Sheet Legal Tray

OL400/410ex (96-01-30)

1.9 Consumables

1.9 Consumables

1.9.01 Image Drum Cartridge Kit

Contents

Image Drum Cartridge

1.9.02 Toner Cartridge Kit

Contents

Toner Cartridge

LED Lens Cleaner

Toxicity

No carcinogens are contained.

OL400/410ex (96-01-30)

1.10 Memory Specifications

1.10 Memory Specifications

1.10.01 ROM

Main Controller Program ROM

OL400e

512 Kbyte

OL410e

1 Mbyte

1.10.02 RAM

OL400e

Standard: 512 Kbyte

Expansion: Up to 4.5 Mbyte (in 1 Mbyte increments)

OL410e

Standard: 2 Mbyte (1 Mbyte on the main controller

and 1 Mbyte on the expanded memory board)

Expansion (on the expansion memory board, which replaces the

1 Mbyte expanded memory board)

Up to 5 Mbyte (in 1 Mbyte increments)

OL410e/PS

Standard - 2 MByte (1 Mbyte on the main controller and 1 Mbyte

on the PostScript board)

Expansion - 3 MByte (in 1 Mbyte increments) on the PostScript board

Maximum RAM - 5 Mbyte

1.10.03 EEPROM

NOTE: EEPROM = Electrically Erasable Programmable Read Only Memory

Main Controller EEPROM

1024 x 1 bit serial input/output

OL400/410ex (96-01-30)

1.11 Reliability Specifications

1.11 Reliability Specifications

1.11.01 Mean Pages Between Failure (MPBF)

Approximately 24,000 pages

1.11.02 Mean Time To Repair (MTTR)

Approximately 20 minutes

1.11.03 Estimated Toner Cartridge Life

Approximately 2,000 pages at 5% density

1.11.04 Image Drum Life

Approximately 20,000 pages: Continuous print at 5% density

Approximately 18,000 pages: at 7 pages per print job

1.11.05 Printer Duty Cycle

Approximately 6,000 pages per month

OL400/410ex (96-01-30)

2.1 Printer Overview

2.1 PRINTER OVERVIEW

2.1.01 General Information

This section describes the operation of the product in the order listed below.

Control Process

Mechanical Operation

Printing Process

Sensors and Switches

OL400/410ex (96-01-30)

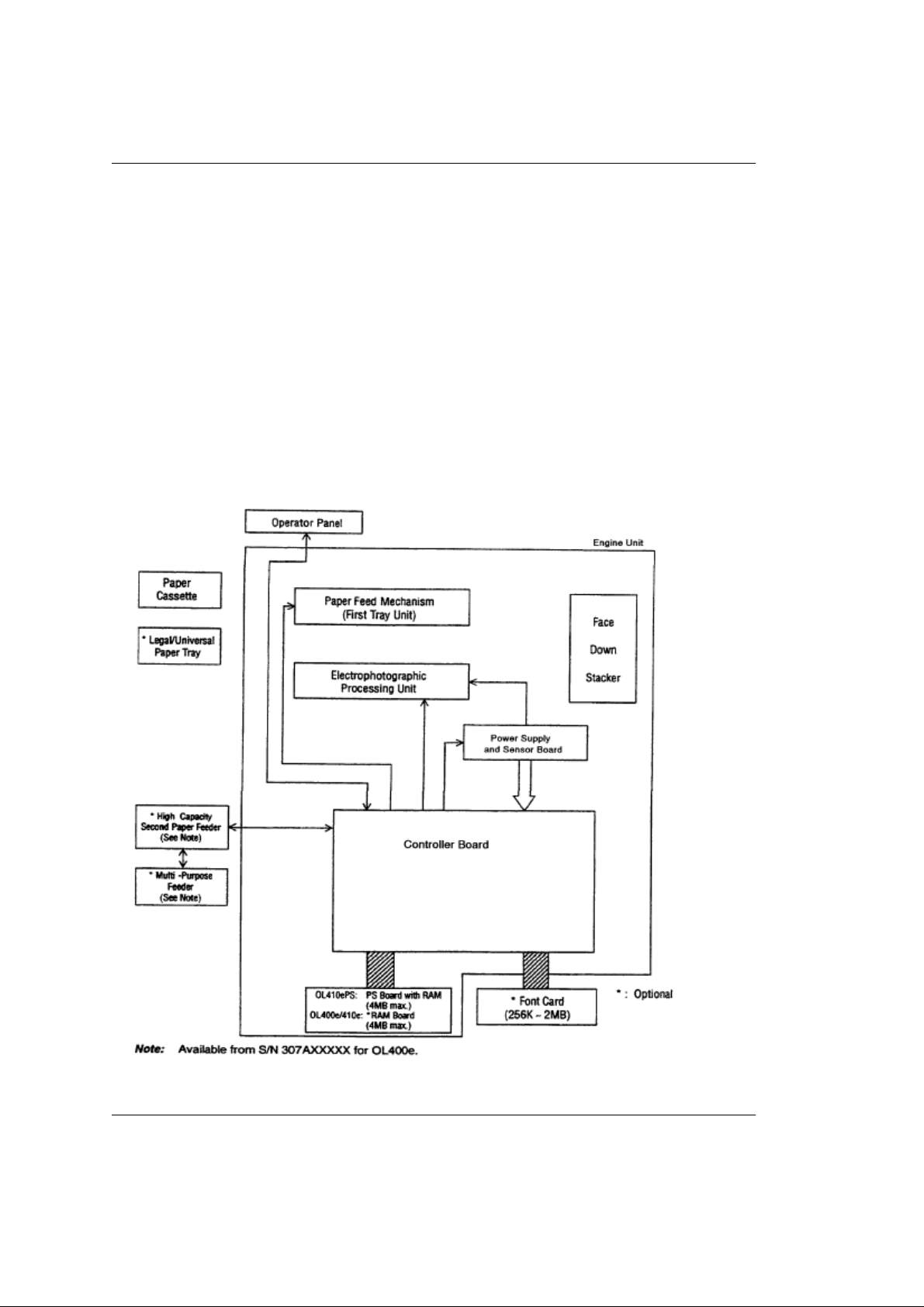

2.2 Control Process

2.2 CONTROL PROCESS

2.2.01 General Information

The control process involves regulating the reception of data from the host system interface,

receiving data and commands from the host system, and generating bit-image data. The control

process also includes sending data and commands to the print engine where the print process is

performed.

The control process is performed by the following hardware components.

Main Controller Board

Expanded RAM Board (OL410e ONLY)

Expansion RAM Board Option

Font Card Option

Configuration Diagram

OL400/410ex (96-01-30)

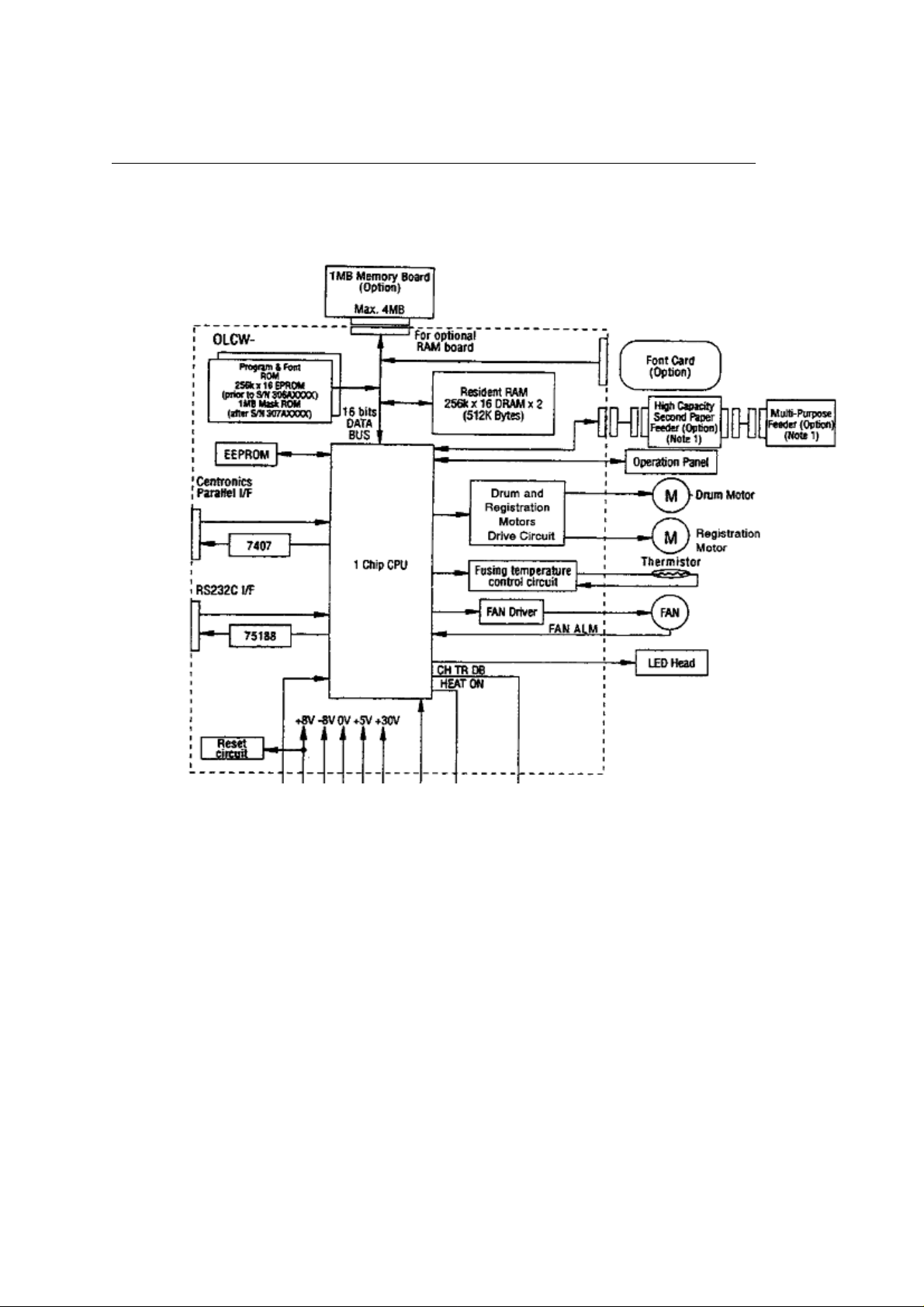

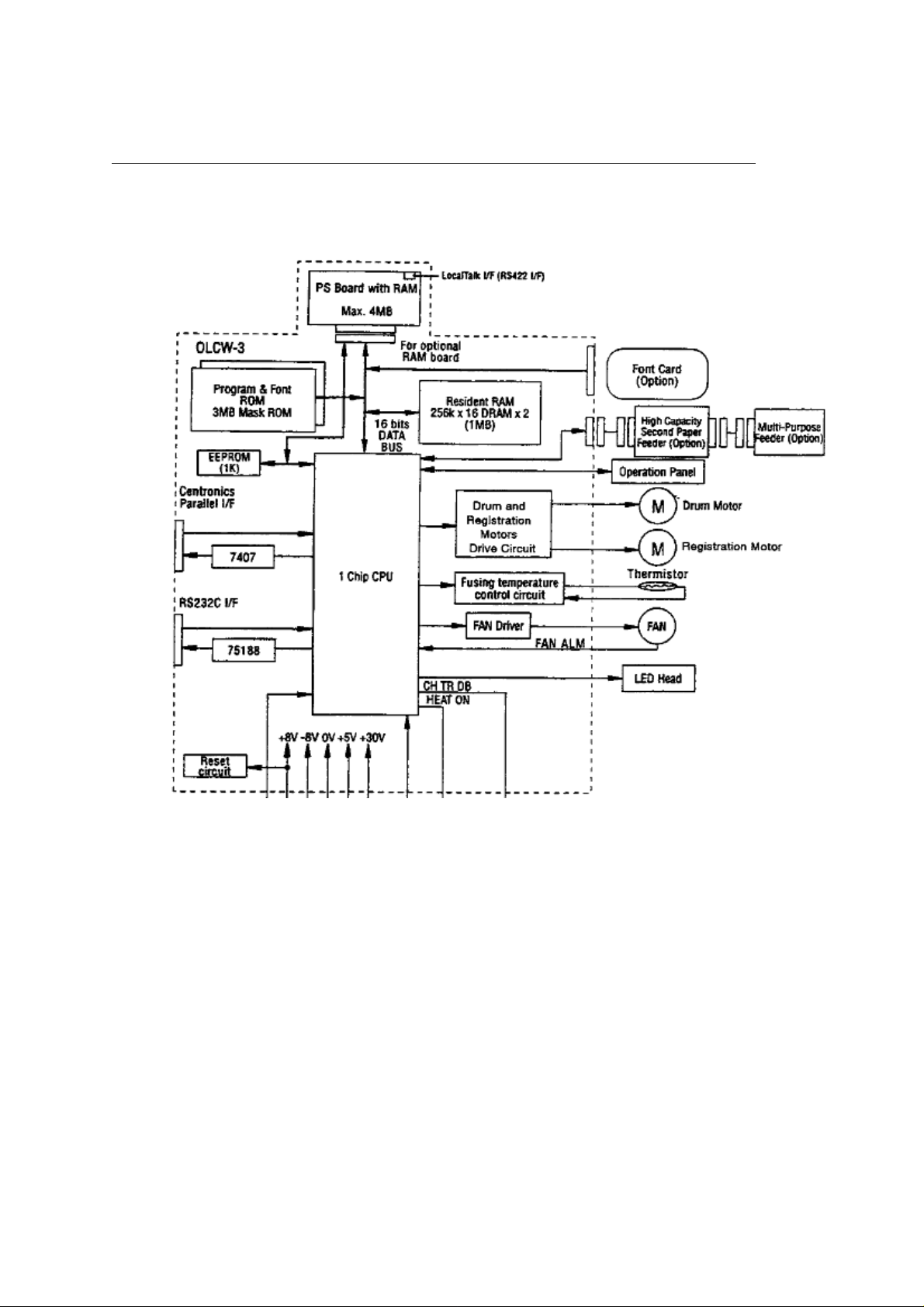

2.2.02 Block Diagrams 400E

2.2.02 Block Diagrams

OL400e

OL400/410ex (96-01-30)

OL400/410ex (96-01-30)

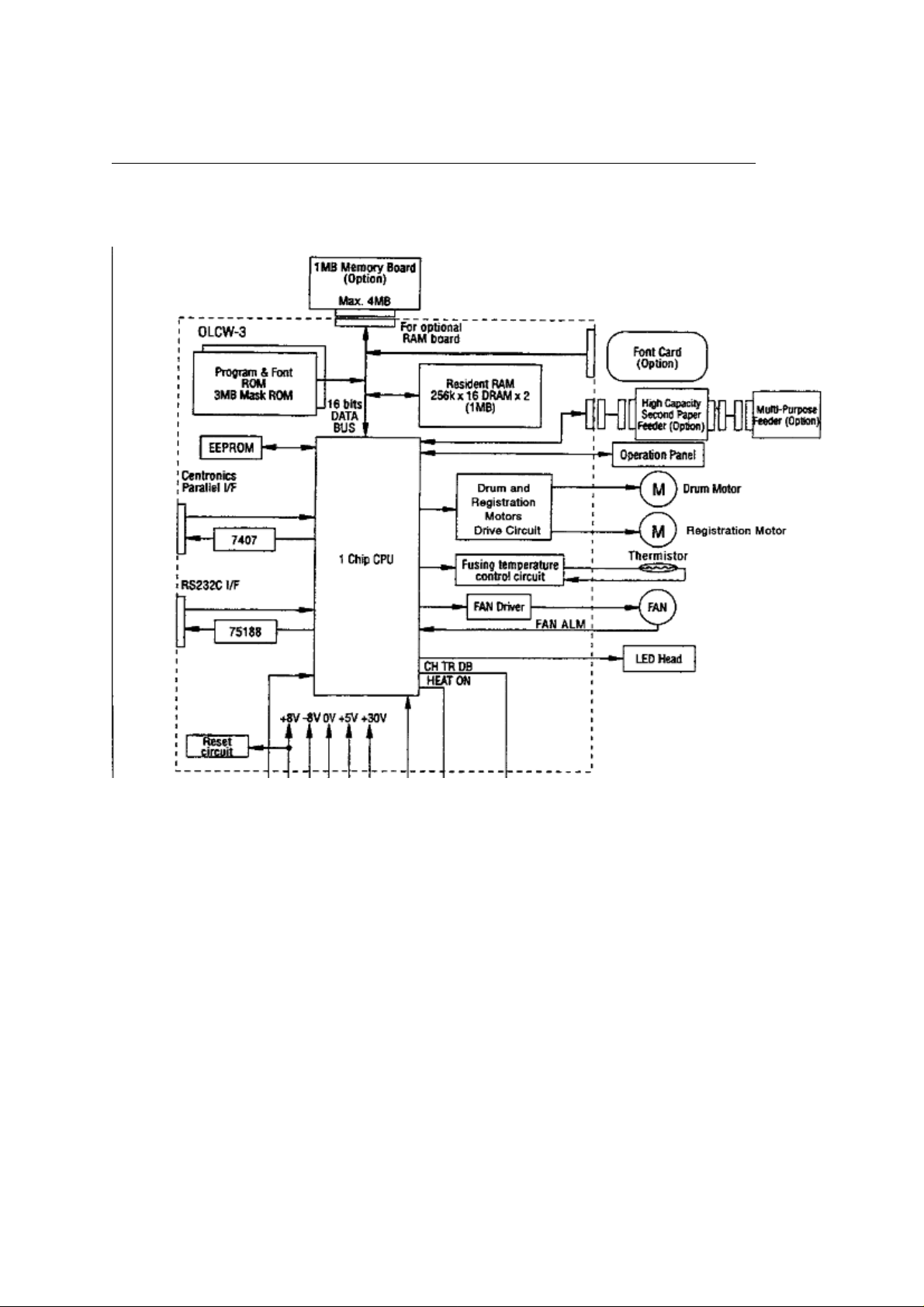

2.2.02 Block Diagrams 410E

2.2.02 Block Diagrams

OL410e

OL400/410ex (96-01-30)

OL400/410ex (96-01-30)

2.2.02 Block Diagrams 410E/PS

2.2.02 Block Diagrams

OL410eps

OL400/410ex (96-01-30)

OL400/410ex (96-01-30)

2.2.03 Main Controller Board (OLCW) Overview

2.2.03 Main Controller Board

Overview

The principal components of the main controller board are listed below.

- 16 Mhz Oscillator

- ASIC (with a built-in RISC microprocessor)

- PROM (contains printer control program)

- ROM (contains the bit-mapped fonts)

- EEPROM

- Dynamic RAM (DRAM)

OL400e

512 Kbyte

OL410e

1 Mbyte with an additional 1 Mbyte contained on the Expanded RAM Board

OL410e

1 Mbyte with an additional 1 Mbyte contained on the PostScript Board

Driver Circuitry

RS232 Serial Interface Port

Centronics Parallel Interface Port

Both the print engine functions and the control functions are integrated on the main controller

board. Most of the logic needed to perform print engine functions and control functions is

integrated internally in the microprocessor.

OL400/410ex (96-01-30)

Main Controller Board Functions

Main Controller Board Functions

General Information

The functions of the main controller board are listed below.

- Reception Control..................................... (

- Command Analysis Processing................... (

- Font Processing....................................... (

- Buffer Read Operation.............................. (

- Engine Control......................................... (

- Operation Panel Control...................... (

- Operation Panel Functions.................. (

- Sensor Control......................................... (

- Print Operation........................................ (

- Electrophotographic Processing Action........ (

- LED Array Operation................................. (

- Fuser Lamp Operation.............................. (

- Registration Motor Operation..................... (

- Drum Motor Operation.............................. (

- DC Fan Operation

)

)

)

)

)

)

)

)

)

)

)

)

)

)

OL400/410ex (96-01-30)

Reception Control

Main Controller Board Reception Control

As data is received from the host system, the CPU sets the BUSY-P signal to ON and reads

the parallel data lines (DATA 1 - DATA 8). The I-PRIME signal (Enable/Disable) of the parallel

interface port can be specified through the menu.

The serial data from the host system is received by the built-in serial controller of the

microprocessor.

Both the parallel and serial interface ports can receive data. The port that receives data first

will be activated.

OL400/410ex (96-01-30)

Command Analysis Processing

Main Controller Board Command Analysis Processing

- The OL400e emulates the HP LaserJet Series IIP.

- The OL410e emulates the HP LaserJet Series III.

- The OL410e/PS emulates the HP LaserJet Series III

and also contains a PostScript (Level 2) Interpreter

OL400/410ex (96-01-30)

Font Processing

Main Controller Board Font Processing

OL400e

- Bit mapped fonts are available for the HP LaserJet Series IIP emulation.

OL410e

- Bit mapped and scalable fonts are available for the HP LaserJet Series III emulation.

OL410e/PS

- Scalable fonts are available for the HP LaserJet Series III emulation.

- PostScript Fonts are contained on the PostScript Board.

OL400/410ex (96-01-30)

Main Controller Board Buffer Read Operation

Main Controller Board Buffer Read Operation

Bit images written in the raster buffer (registers) are converted to serial data. The contents

of the registers are transferred to the engine control section of the microprocessor (MPU)

on the main controller board.

OL400/410ex (96-01-30)

Engine Control Functions

Main Controller Board Engine Control Functions

Engine control functions are executed when the CPU receives a print request signal.

OL400/410ex (96-01-30)

Operation Panel Control

Main Controller Board Operation Panel Control

General Information

The operation panel consists of the following circuits.

- MPU Interface Integrated Circuit

- LCD Control Driver

- LCD Display

- LED

- Operation Panel Sheet

- Contact Switches (There are eight contact switches).

OL400/410ex (96-01-30)

Operation Panel Functions

Main Controller Board Operation Panel Functions

The operation panel LCD displays the printer's operational status and error messages. The

operation panel is also used to modify the printer menu.

The operation panel is connected to the main controller board through connector CN1 of

the contact switch board and CN5 of the main controller board.

The LCD control driver board is connected to the contact switch board. The connector on

the contact switch board is CN2, and the connector on the control drive board is CN3.

The operation panel is controlled by the CPU of the main controller board. The LSI chip on

the contact switch board is connected to a clock-synchronous serial port of the CPU. This

port controls the switch data input, LED data output, and LCD data. The CPU sends a 2-byte

(16-bit) command to the LSI. Upon receiving a command from the CPU, the LSI returns a

2-byte command response to the CPU.

OL400/410ex (96-01-30)

Sensor Control & Location Diagrams

Sensor Control & Location Diagrams

General Information

There are six sensors in the printer.

- Inlet Sensor 1.............. (

- Inlet Sensor 2.............. (

- Inlet Sensor 3.............. (

- Outlet Sensor.............. ( )

- Paper Supply Sensor.... (

- Toner Sensor..............(

The same part is used in three locations for the three inlet sensors.

)

)

)

)

(also known as the Paper Sensor)

)

OL400/410ex (96-01-30)

OL400/410ex (96-01-30)

Inlet Sensor 1

Inlet Sensor 1

Inlet sensor 1 detects the leading edge of the paper and regulates the timing of switching

from the hopping operation to the feeding operation.

This sensor also controls the timing of the paper feed process and the paper size according

to the paper detection time and running time.

Refer to Sensor Diagram (

) for exact location.

OL400/410ex (96-01-30)

Inlet Sensor 2

Inlet Sensor 2

Inlet sensor 2 detects the form width.

Refer to Sensor Diagram (

) for exact location.

OL400/410ex (96-01-30)

Inlet Sensor 3 / Paper Sensor

Inlet Sensor 3 / Paper Sensor

Inlet sensor 3 detects the leading edge of the paper and controls the timing of the paper

feed process. This sensor is also referred to as the paper sensor.

Refer to Sensor Diagram (

) for exact location.

OL400/410ex (96-01-30)

Outlet Sensor

Outlet Sensor

The outlet sensor controls the paper feed and size based on the time the sensor

detects the paper and the time of passage of the paper.

Refer to Sensor Diagram (

) for exact location.

OL400/410ex (96-01-30)

Paper Supply Sensor

Paper Supply Sensor

The paper end sensor detects an out-of-paper condition.

Refer to Sensor Diagram (

) for exact location.

OL400/410ex (96-01-30)

Toner Sensor

Toner Sensor

The toner sensor detects a low-toner condition.

Refer to Sensor Diagram (

) for exact location.

OL400/410ex (96-01-30)

Print Operation

Print Operation

Both the control function (data reception and bit-image data generation) and the print

engine function (LED head, registration motor, and drum motor) are integrated. Both

functions are controlled by the main controller board. The peripheral logic is integrated

into one chip, an ASIC microcomputer (RISC-based microprocessor) chip.

Data is received through either the Centronics parallel interface or the RS232 serial interface.

These two interfaces are located on the main control board.

The LocalTalk interface is located on the PostScript Board.

The data is then stored in the receive buffer. The data is transferred from the receive buffer

to a processing section of the main controller. In this processing section, control codes and

printing codes are assigned. Once the font is determined, the data is written to the page buffer.

The microprocessor then executes the print routine. The data is extracted from the page buffer,

synchronized to the printing operation, and written to the band buffer. While performing the

engine functions, the microprocessor sends the data from the band buffer to the LED array

head.

OL400/410ex (96-01-30)

2.2.04 Expanded Ram Board(410E Only)

2.2.04 Expanded RAM Board(OL410e Only)

The expanded RAM board contains 1 Mbyte of RAM and along with the 1 Mbyte of

RAM on the main controller board, increases the standard RAM capacity to 2 Mbyte.

The RAM capacity is identified during power-ON. It can be verified by requesting a

MENU PRINT operation.

OL400/410ex (96-01-30)

2.2.05 Expansion Ram Board(400E)

2.2.05 Expansion RAM Board(OL400e)

The expansion RAM board can contain up to 4 Mbyte of RAM in 1 Mbyte increments. This

board can increase the OL400e RAM capacity up to 4.5 Mbyte. The RAM capacity is identified

during power-ON. It can be verified by requesting a MENU PRINT operation.

OL400/410ex (96-01-30)

2.2.06 Expansion Ram Board(410E)

2.2.06 Expansion RAM Board(OL410e)

The expansion RAM board is an option installed in place of the expanded RAM board.

This board can contain up to 4 Mbyte of RAM in 1 Mbyte increments. This board can

increase the OL410e RAM capacity up to 5 Megabyte. The RAM capacity is identified

during power-ON. It can be verified by requesting a MENU PRINT operation.

OL400/410ex (96-01-30)

2.2.07 Font Cards

2.2.07 Font Cards

An optional font card can be used with the printer. The printer must be OFF-LINE (the

READY lamp is OFF) when the card is either inserted or removed. If the font card is inserted

or removed while the printer is ON-LINE (the READY lamp is ON), a CARD REMOVED

ON-LINE message will appear on the operator panel display.

OL400/410ex (96-01-30)

2.2.08 Postscript Board

2.2.08 PostScript Board

The PostScript Board contains the LocalTalk interface, a program ROM and Font Rom

(2 MB each), 1 MByte of Dynamic RAM, and a 4 KBit EEPROM. Sockets are provided for

an additional 3 Mbyte of DRAM.

OL400/410ex (96-01-30)

2.3.01 Basic Principals - Electrostatic Printing

2.3.01 Basic Principals - Electrostatic Printing

A -1.3 Kvdc charge is placed on the charge roller. The charge roller is in direct contact

with the surface of the image drum. The printer engine section enables the LED array in

conformance with the data received from the host via the interface on the main controller

board. Once the charged drum is exposed to this light, an electrostatic image is formed

on the drum surface. This latent image is developed with toner.

Charging

The surface of the image drum is uniformly negatively charged by the application of a negative

charge to the charge roller.

Exposure

Light emitted from the LED head irradiates the negatively charged surface of the image drum.

The electrostatic potential of the irradiated part of the image drum surface is lowered, so that

an electrostatic latent image associated with the print image is formed.

Developing

When the negatively charged toner is brought into contact with the image drum surface, it is

attracted to the electrostatic latent image by static electricity, making the latent image visible.

At the same time, the residual toner on the image drum is attracted to the developing roller by

static electricity.

Transfer

OL400/410ex (96-01-30)

Paper is placed over the image drum surface. A positive charge (opposite in polarity to the toner)

is applied to the reverse side of the paper by the transfer roller. The toner is attracted by the positive

charge. The image formed on the image drum is transferred to the paper.

Cleaning

The toner remaining on the image drum after transfer is temporarily attracted to the cleaning roller

by static electricity. This residual toner is accumulated in the image drum cartridge until the drum is

replaced.

Fusing

The toner image transferred to the paper is fused to the paper by heat and pressure.

OL400/410ex (96-01-30)

2.3.02 Engine Functions

2.3.02 Engine Functions

The engine control section of the microprocessor on the main controller board enables

the fuser lamp and activates the preliminary print circuits. Upon completion of the

preliminary print functions, the engine control section enables the LED array in conformance

with the signals received from the host, and commands output from the control section of the

CPU. The LED illuminates, leaving a latent image on the photosensitive drum. The engine

control section also controls paper feed, paper transfer and the electrophotographic printing

process.

OL400/410ex (96-01-30)

2.3.03 Eeprom Operation

2.3.03 EEPROM Operation

The 1024 x 1 bit Electrically Erasable Programmable Read-Only-Memory (EEPROM)

is loaded with the data listed below.

- Menu Data

- Various Counter Data

- LED Head Drive Time

- Print Start Position

- Paper Feed Duration

OL400/410ex (96-01-30)

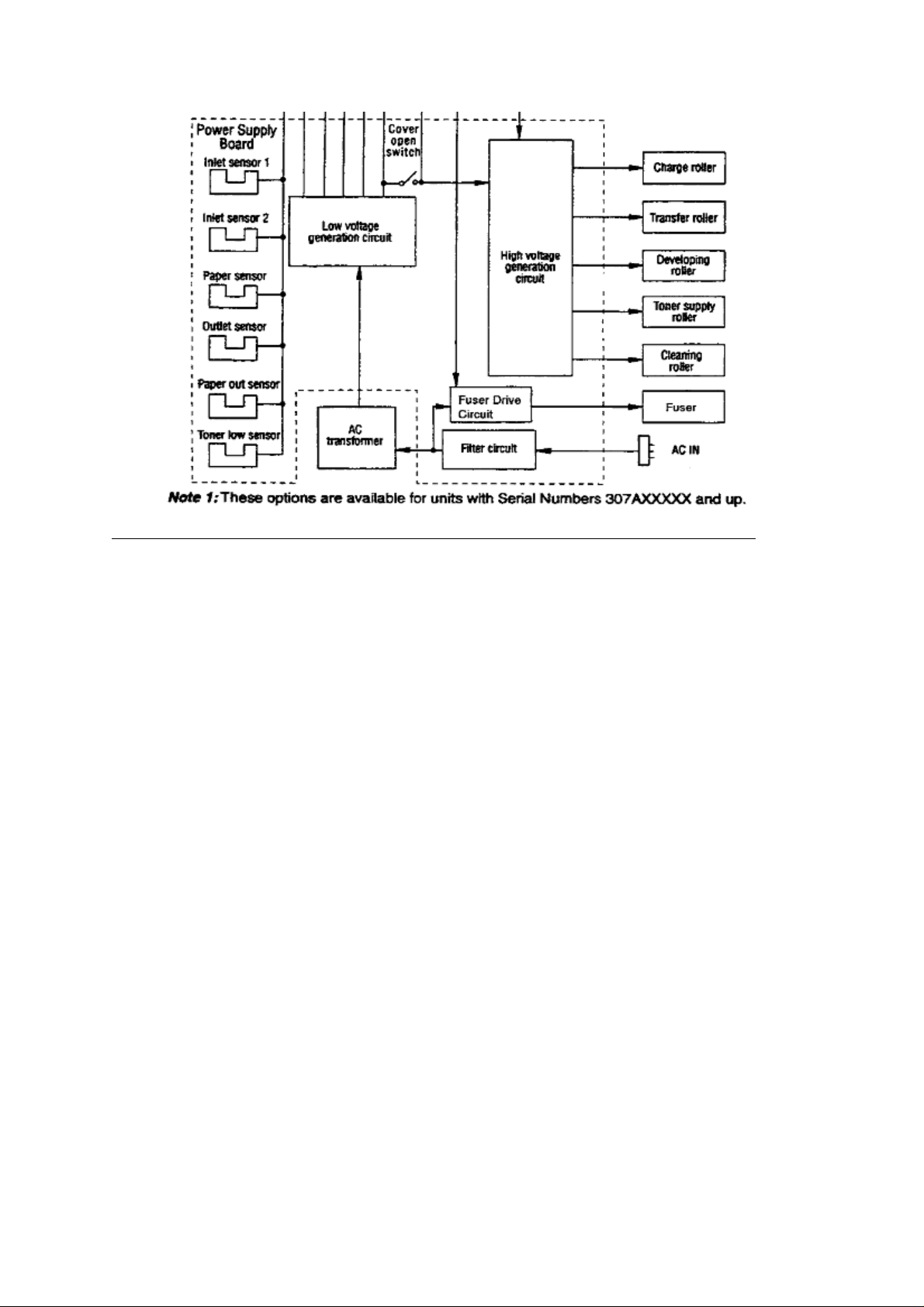

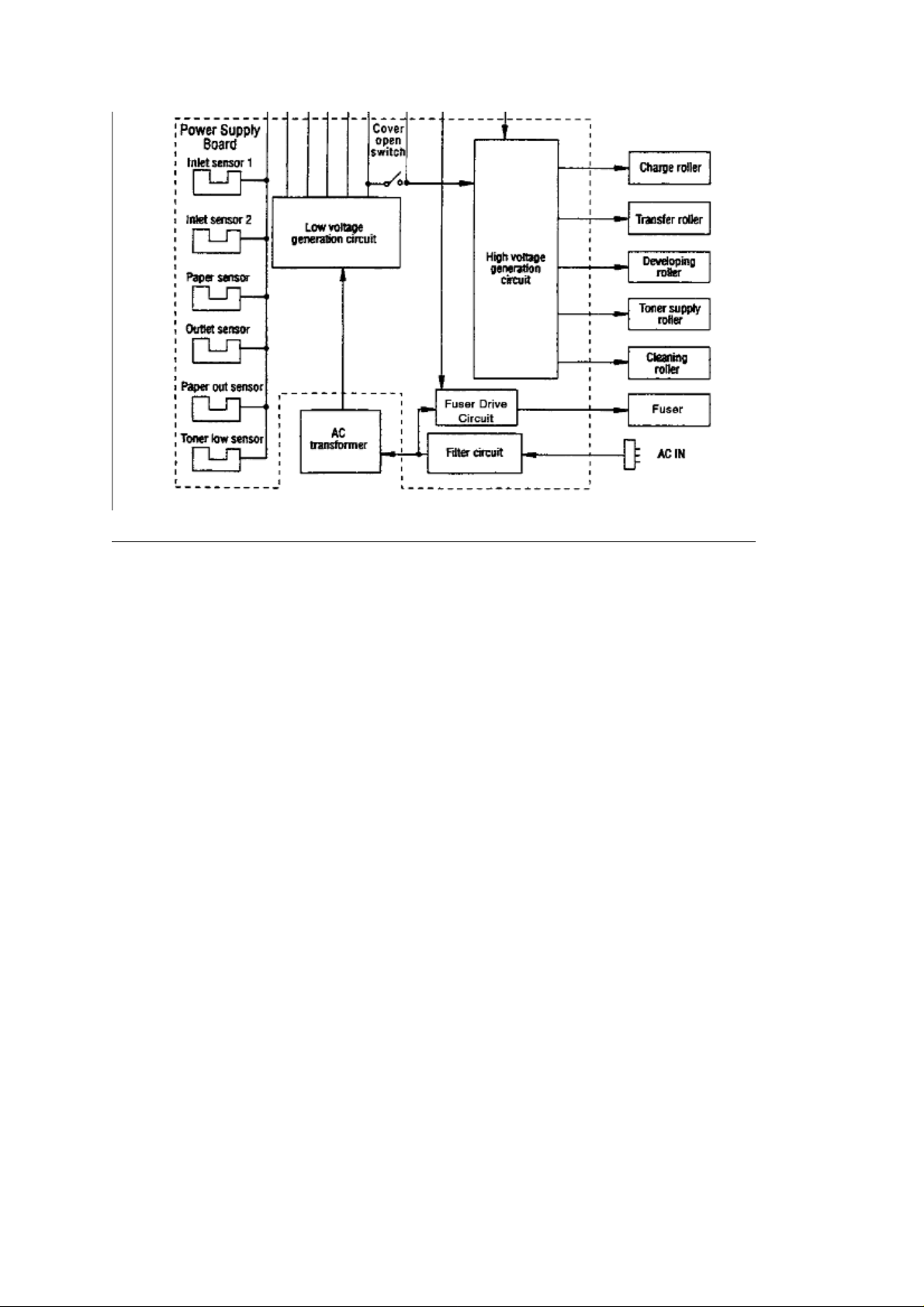

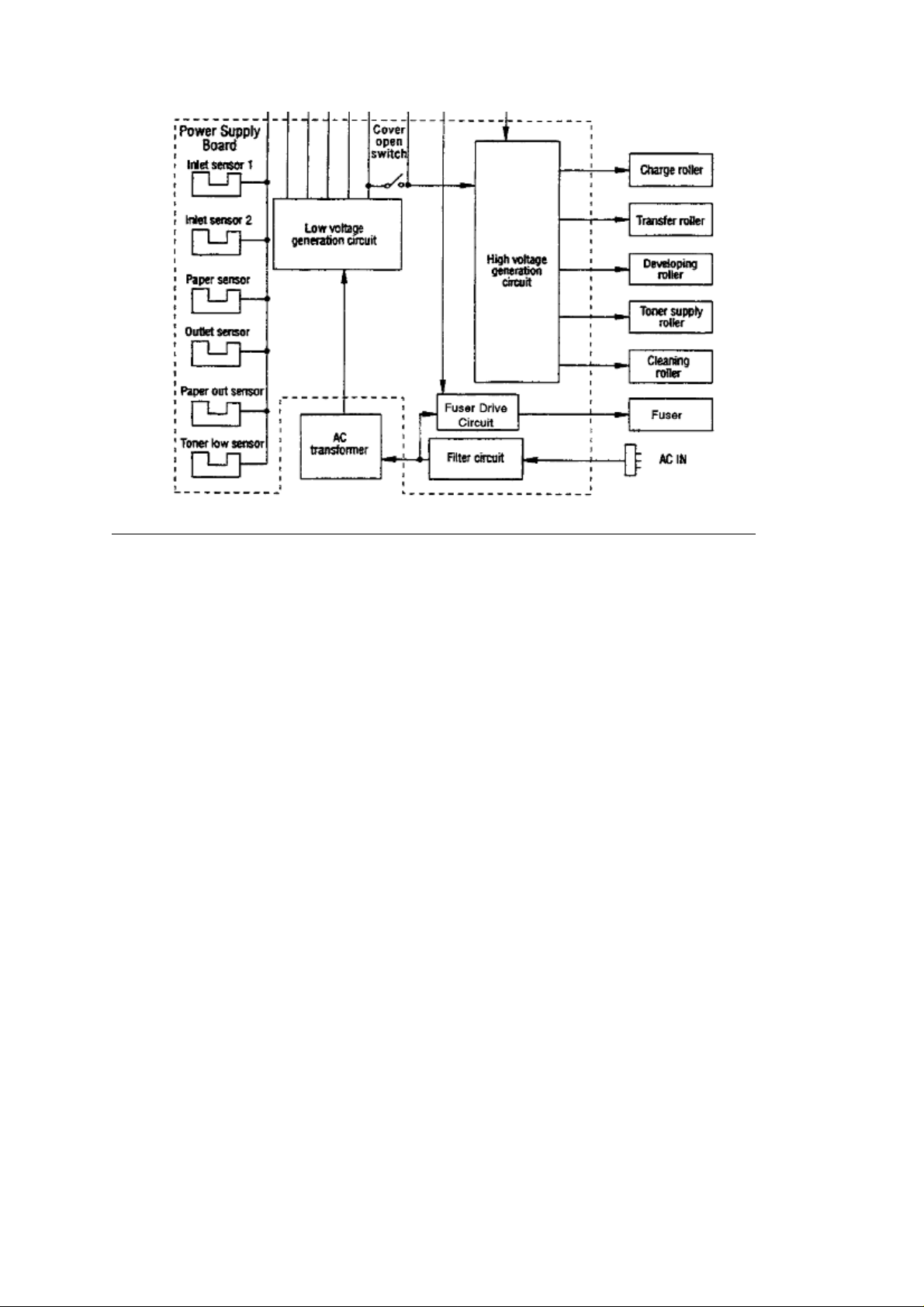

2.3.04 Power Supply Board

2.3.04 Power Supply Board

The power supply board consists of an AC filter circuit, a low-voltage power supply circuit,

a high-voltage power supply circuit, a fuser drive circuit and photosensors.

Low-Voltage Power Supply Circuit

The following voltages are generated by the low-voltage power supply circuit.

+ 5 vdc: Logic circuit supply voltage

+ 38 vdc: Motor / fan drive voltage and source voltage for the high-voltage supply

+ 8 vdc: RS232 line voltage

- 8 vdc: RS232 line voltage and analog circuit voltage

High-Voltage Power Supply Circuit

This circuit uses the + 38 vdc to generate voltages for the electrophotographic process.

The control sequence for enabling these voltages is issued by the main controller board.

When the cover-open state is detected, the + 38 vdc is turned off. Turning the +38 vdc

off disables all high-voltage outputs. The high-voltage power circuit generates the voltages

listed below.

- 1.3 Kvdc: applied to the charging roller

- 300 vdc: applied to the developing roller

- 450 vdc: applied to the toner supply roller

+ 1.6 Kvdc: applied to the transfer roller

+ 500 vdc: applied to the cleaning roller

OL400/410ex (96-01-30)

2.3.05 Fusing Unit

2.3.05 Fusing Unit

The fusing unit consists of a halogen lamp, a fusing roller, a thermistor and a thermostat.

An AC voltage from the power supply board is applied to the halogen lamp under the control

of the HEAT ON signal from the main controller board. This AC voltage is applied to the 400

watt halogen lamp. The main controller board controls the fusing roller temperature via the

thermistor, and regulates the fusing roller temperature at 150 degrees Celsius by switching

the lamp ON/OFF. If the roller temperature rises abnormally, the thermostat in the fusing unit

will cut the AC voltage supply OFF.

OL400/410ex (96-01-30)

2.3.06 Registration Motor

2.3.06 Registration Motor

The registration motor is a DC stepping motor (48 steps/rotation). This motor drives

the hopping roller and the registration roller via two one-way clutches. The direction

that the motor turns determines which clutch is activated.

OL400/410ex (96-01-30)

2.3.07 Drum Motor

2.3.07 Drum Motor

The drum motor is a DC stepping motor (48 steps/rotation).

This motor is the main drive motor of the printer.

OL400/410ex (96-01-30)

2.3.08 LED Head

2.3.08 LED Head

Image data for each dot line is received by shift registers and latch registers.

The 2,560 LEDs are activated to radiate the image data onto the image drum.

OL400/410ex (96-01-30)

**2.4 Printing Process General Information

2.4.01 PRINTING PROCESS General Information

Hopping and feeding are controlled by a single registration motor.

Turning the registration motor in the "A" direction drives the hopping roller.

Turning the registration motor in the "B" direction drives the registration roller.

The registration gear and hopping gear contain one-way bearings. Turning each

of these gears in the reverse direction will NOT turn the corresponding roller.

The following is too big!!!!

OL400/410ex (96-01-30)

OL400/410ex (96-01-30)

2.4.02 Hopping

2.4.02 Hopping

Hopping loads paper from the paper cassette.

During the hopping operation, the registration motor turns in a clockwise direction.

This motor drives the hopping roller, which in turn advances the paper until the inlet

sensor 1 switches ON. The registration gear turns, but the one-way bearing does not

allow the registration roller to turn.

After inlet sensor 1 switches ON, the paper is advanced a predetermined length (until

the paper reaches the registration roller).

OL400/410ex (96-01-30)

2.4.03 Feeding

2.4.03 Feeding

Feeding transports paper through the printer.

After the completion of hopping, the registration motor turns in a counter-clockwise

direction. This counter-clockwise motion drives the registration roller and advances

the paper. The hopping gear turns, but the one-way bearing does not allow the hopping

roller to turn.

OL400/410ex (96-01-30)

2.4.04 Charging

2.4.04 Charging

Charging applies -1.3 Kvdc to the charge roller. The charge roller contacts the image drum

surface.

The charge roller has two layers: a conductive layer and a surface protective layer. The

surface layer is flexible, which assures proper contact with the photosensitive drum.

The drum surface charges to approximately -750 vdc.

OL400/410ex (96-01-30)

2.4.05 Exposing

2.4.05 Exposing

The image drum has four layers.

- Carrier Transfer Layer (CTL)

- Carrier Generation Layer (CGL)

- Underlayer (UL)

- Aluminum Base

The CTL and CGL make up the organic photo conductor layer (OPC), which is about 20

micrometers (mm) thick.

When light from the LED head irradiates the image drum surface, the light energy generates

positive and negative carriers in the CGL. The positive carriers are moved to the CTL by an

electrical field acting on the image drum. The negative carriers flow into the aluminum layer

(ground).

OL400/410ex (96-01-30)

The positive carriers moved to the CTL combine with the negative charges on the image surface

(accumulated by the contact charge of the charge roller), lowering the potential on the image

drum surface. The resultant drop in the potential of the irradiated part of the image drum surface

forms an electrostatic latent image on it. The surface potential on this irradiated part of the image

drum is approximately -100 vdc.

OL400/410ex (96-01-30)

OL400/410ex (96-01-30)

2.4.06 Developing

2.4.06 Developing

The electrostatic latent image formed on the image drum surface is developed into a

visible image. Developing takes place when contact is made between the image drum

and the developing roller.

As the toner supply roller rotates, toner is absorbed into the sponge type roller material.

A charged particle will be attracted to a particle having a MORE POSITIVE charge than its own.

The developing roller surface is charged to -300 vdc and the toner supply roller is charged

to -450 vdc. Since the development roller is charged more positive than the toner supply roller,

the toner on the toner supply roller is attracted to the developing roller. The toner on the

developing roller contacts the doctor blade, forming a thin coat of toner on the developing

roller surface.

The exposed portion of the image drum contains a more positive charge than the development

roller (-100 vdc vs. -300 vdc). Therefore, toner is attracted to the exposed areas of the image

OL400/410ex (96-01-30)

drum, making the electrostatic latent image visible.

NOTE: The toner supply roller and the developing roller are supplied with the bias voltages

required during the developing process. The toner supply roller is charged to -450 vdc.

The developing roller is charged to -300vdc.

OL400/410ex (96-01-30)

2.4.07 Transfer

2.4.07 Transfer

The transfer roller is made of a conductive sponge material. The roller keeps the paper in

constant contact with the image drum. Paper is placed over the image drum surface. A

positive charge (opposite in polarity to the toner) is applied to the paper from the reverse

side.

A charged particle will be attracted to a particle having a MORE POSITIVE charge than

its own.

A high positive charge is applied to the transfer roller by the power supply board. This

induced charge (on the surface of the transfer roller) is transferred to the paper when

contact is made between the transfer roller and the paper. The lower side of the paper

is positively charged. The negatively charged toner (on the image drum) is transferred to

the upper side of the paper because of the positive charge on the lower side of the paper.

OL400/410ex (96-01-30)

2.4.08 Fusing

2.4.08 Fusing

After transfer, the toner image is fused to the paper by heat and pressure. The paper

passes between the fusing roller and the pressure roller. The fusing roller has a teflon

coating and contains a 400 watt halogen lamp. A thermistor (which contacts the fusing roller)

maintains the fusing roller temperature at approximately 150 degrees Celsius. A thermostat

cuts off the voltage supply to the lamp if there is an abnormal temperature rise.

The pressure roller provides 2.5 Kg of pressure. This is generated by the pressure springs at

each side of the roller.

OL400/410ex (96-01-30)

2.4.09 Cleaning

2.4.09 Cleaning

The image drum is cleaned at the end of transfer. The residual toner on the image

drum is attracted to the cleaning roller, which has a + 500 vdc static charge. This residual

toner is accumulated in the image drum cartridge until the drum is replaced.

OL400/410ex (96-01-30)

2.4.10 Printing

2.4.10 Printing

Refer to the Printing Process Diagram.

Printing is accomplished as follows.

Approximately - 1.3 Kvdc is supplied to the charge roller. This causes the drum to charge

to approximately - 750 vdc.

The LED head is turned ON by the printer control board in accordance with signals from the

main control board. This causes a latent electrostatic image to be formed on the surface of

the drum.

Through the development process, a toner image replaces the electrostatic image.

A + 1 Kvdc charge is applied to the transfer roller. This causes the toner image to be transferred

to the receive paper.

Heat and pressure cause the toner image to become fused to the receive paper. The 150

degree Centigrade fusing temperature is attained by turning a 400 watt halogen lamp ON.

The fusing temperature is controlled by a thermistor. In the event of a thermistor failure, a

temperature fuse will OPEN, turning off the quartz lamp, and preventing equipment damage.

The residual toner is removed from the drum.

OL400/410ex (96-01-30)

2.5 Sensors And Switches

2.5 SENSORS AND SWITCHES

OL400/410ex (96-01-30)

Sensor Location Diagram

Sensor Location Diagram

Top View

Side View

OL400/410ex (96-01-30)

OL400/410ex (96-01-30)

2.5.01 Paper Jam Detection

2.5.01 Paper Jam Detection

Paper jam detection monitors the location of paper when the printer is powered ON and during

printing. If any of the following jams are present, the printing process is interrupted and the

message PAPER JAM will be displayed on the LCD.

To return to the printing process, the paper jam condition MUST be cleared. This is accomplished

by opening the upper cover, clearing the jam, and closing the cover.

Paper Outlet Jam

This jam occurs if the paper does NOT pass over the outlet sensor within a pre-determined period

of time. However, the paper has already passed over the paper sensor.

Paper Size Error

The time interval between when the paper contacts the paper sensor and the outlet sensor

determines which size (length) paper is being used.

This error occurs if the paper size of the loaded paper differs by + 45 mm or more from the paper

size set by the menu.

Cover Open Switch

When the stacker cover is opened, the cover open microswitch on the power supply unit is

deactivated. This disables the + 38 vdc and the high voltage power supply circuit. As a result,

all high voltage outputs are interrupted. At the same time, the CVOPN signal is sent to the

main control board to notify it of the OFF state of the microswitch. The main control board

executes the cover open routine. The operation panel displays the message COVER OPEN.

OL400/410ex (96-01-30)

Paper Inlet Jam

Paper Inlet Jam

This jam occurs when either of the following situations occur.

When the printer is powered ON, paper is at inlet sensor 1.

After the hopping operation is attempted three times, the leading edge of the paper

does NOT reach inlet sensor 1.

Paper Inlet Jam Timing Diagram

OL400/410ex (96-01-30)

Paper Feed Jam

Paper Feed Jam

This jam occurs when either of the following conditions occur.

The paper does not pass over the paper sensor within a pre-determined period of time.

The leading part of the paper does not reach the outlet sensor within a pre-determined

period of time after the paper has passed over the paper sensor.

Paper Feed Jam Timing Diagram

OL400/410ex (96-01-30)

2.5.02 Toner Low Sensor

2.5.02 Toner Low Sensor

The toner well of the image drum cartridge contains a toner agitator. Whenever the image

drum rotates, the toner agitator attempts to turn. A spring clip in the bottom of the toner well

(along with the proper amount of toner) holds the agitator at the bottom of the well. However,

when toner is distributed unevenly or an insufficient amount of toner is in the well, the toner

agitator will rotate. Therefore, as long as the toner well contains an adequate supply of evenly

distributed toner, the toner agitator will not rotate.

The toner sensor plate has a magnet embedded in it. Whenever the toner agitator is positioned

at the bottom of the toner well, the toner sensor plate is magnetically attracted to the toner

agitator. This causes the toner sensor plate to be lifted from the path of the toner sensor.

During a low toner condition, the toner agitator will rotate continuously. This causes the toner

sensor to turn ON / OFF as the image drum rotates. The operator panel will then display the

TONER LOW message.

During an unevenly distributed toner condition, the toner agitator will rotate until the toner is

distributed sufficiently. This causes the toner sensor to turn ON / OFF for only a few image

drum rotations. The operator panel will not display an error message since this is normal printer

operation.

If the toner sensor remains activated (ON), the operator panel will display the TONER SNS

message.

Customers may experience a "TONER SNS" or "TONER LOW" message with a brand new printer.

This may occur even though a new toner cartridge and drum have been installed.

This can occur for the first 30 pages. Between 30 and 200 pages, the CPU will turn OFF the

toner sensor. This will eliminate the message on the LCD. After 200 pages, the printer will

begin checking for proper operation of the toner sensor flag.

Customers should use the printers for at least 30 pages. The "TONER SNS" or "TONER LOW"

messages do not cause any print quality problems. The unit is in NO danger of suffering any

damage. If the problem persists for more than thirty pages, customers are directed to contact

a service center for warranty repair. This information is documented in TSB 5604(

).

OL400/410ex (96-01-30)

2.5.03 Paper Path

2.5.03 Paper Path

General Information

The automatic and manual feed paths are different. In addition, the path will change if the

paper is ejected face up or face down. Paper fed from the paper tray (automatic feed) and

ejected face down will follow an "S" path. The path with the least amount of turns is a

manual feed, face up ejection.

Automatic Feed

Load paper into the tray. The side to be printed on should be facing DOWN.

The leading edge of the paper should face the FRONT of the printer. Refer to either the

face down or the face up section for further paper path details.

Manual Feed

Manually load the paper into the unit. The side to be printed on should be facing UP.

The leading edge of the paper should face the BACK of the printer. Refer to either the

face down or the face up section for further paper path details.

Face Down

The hopping roller picks up the paper. The hopping roller transports the paper to the registration

roller. The registration roller transports the paper to the image drum. Then, the paper passes

between the fusing roller (on top) and the pressure roller (on the bottom). The paper is then

routed upward and is ejected from inside the unit.

Face Up

The hopping roller picks up the paper. The hopping roller transports the paper to the registration

roller. The registration roller transports the paper to the image drum. Then, the paper passes

between the fusing roller (on top) and the pressure roller (on the bottom). The paper is then

ejected from the inside of the unit.

OL400/410ex (96-01-30)

OL400/410ex (96-01-30)

Chapter 3

3.1.01 Maintenance General Information

3.1.01 General Information

This section lists the parts replacement, adjustment, cleaning, lubrication, and shipping

procedures.

Disassembly should not be performed unless absolutely necessary. NEVER perform

disassembly on a malfunctioning unit until you have followed the failure analysis

procedures in Section Four of this Service Handbook.

Follow the procedures listed in Adjustments and Service Settings. Adjustments may be

required when either consumables or parts are replaced. Failure to perform these

procedures could result in unnecessary service calls.

Cleaning procedures must be performed correctly if high print quality is to be achieved.

OL400/410ex (96-01-30)

3.3 Adjustments And Service Settings

3.3 ADJUSTMENTS AND SERVICE SETTINGS

General Information

This section contains the procedures for checking and resetting counters and performing

adjustments and service settings. These procedures may be required when replacing either

consumables or parts. The disassembly / assembly procedures list the required adjustments

and refer you to this section. Failure to perform these procedures may result in unnecessary

service calls.

The adjustments and service settings are accomplished through the operator panel. Three

different maintenance modes are used: user, system, and engine. Service setting changes

are saved in the EEPROM located on the main controller board.

NOTE: End users should NOT access the system or engine maintenance modes.

OL400/410ex (96-01-30)

3.3.01 User's Maintenance Mode

3.3.01 User's Maintenance Mode

General Information

This maintenance mode allows the user to access the following functions.

- Menu Reset..................................... (

- Hex Dump....................................... (

- Drum Counter Reset......................... (

- Op Menu......................................... (

- X-Adjust (OL410e / OL410e-PS)......... (

- Y-Adjust (OL410e / OL410e-PS)......... (

User's Maintenance Mode Procedure

To enter user maintenance mode, perform the following procedure.

- Close the stacker cover.

- Install the paper cassette tray.

- Clear all error messages displayed on the operator panel.

- Power OFF the unit.

- Press and hold MENU 1 / Menu 2 while powering ON the unit.

Continue to hold through both panel message displays.

The operator panel displays the following for approximately two seconds.

88888888

88888888

- Release MENU 1 / Menu 2 once the operator panel displays

USER MNT

- Press MENU 1 / Menu 2.

The operator panel displays the following message.

MENU

RESET

)

)

)

)

)

)

7) Press MENU 1 / Menu 2.

The operator panel displays the following message.

8) Press MENU 1 / Menu 2.

The operator panel displays the following message.

9) Press MENU 1 / Menu 2.

The operator panel displays the following message.

For OL410 / OL410e-PS models only

10) Press MENU 1 / Menu 2.

The operator panel displays the following message.

11) Press MENU 1 / Menu 2.

OL400/410ex (96-01-30)

HEX DUMP

DRUM CNT

RESET

OP MENU

ENABLE

X ADJUST

0 mm *

The operator panel displays the following message.

Y ADJUST

0 mm *

NOTE:

- To work with any of the user maintenance mode items, press ENTER / Copies.

- Press LAST - / Paper Size or NEXT + / Demo to move through the settings for

the user maintenance mode items.

OL400/410ex (96-01-30)

Menu Reset / Menu Print

Menu Reset / Menu Print

CAUTION:

Menu Reset returns ALL menu level 1 settings to factory defaults.

ALL customized menu level 1 settings will be lost.

ALWAYS print the menu before doing a menu reset.

Double Click to see Menu Settings Level 1................ (

Menu Settings Level 2................ (

Sample Page OL400e................ (

Sample Page OL410e................ (

Sample Page OL410e-PS........... (

Procedure - Menu Print

To print the menu, follow this procedure.

1) Press ON-LINE to take the printer OFF-LINE.

2) Press PRINT MENU / Print Fonts to print the menu.

Procedure - Menu Reset

To reset the menu, perform the following procedure.

CAUTION:

Menu Reset returns ALL menu level 1 settings to factory defaults.

ALL customized menu level 1 settings will be lost. ALWAYS print

the menu before doing a menu reset.

1) Close the stacker cover.

2) Install the paper cassette tray.

3) Clear all error messages displayed on the operator panel.

4) Power OFF the unit.

5) Press and hold MENU 1 / Menu 2 while powering ON the unit.

The operator panel displays the following for approximately two seconds.

88888888

88888888

The operator panel displays the following message.

USER MNT

)

)

)

)

)

6) Press MENU 1 / Menu 2.

The operator panel displays the following message.

MENU

RESET

7) Press ENTER / Copies.

The operator panel displays the following message for approximately 15 seconds.

WARM UP

8) The unit will then go ON-LINE.

The operator panel displays the following message.

ON-LINE ON-LINE ON-LINE

HPIIP HPIII ADOBE PS

(OL400e) (OL410e) (OL410e/PS)

OL400/410ex (96-01-30)

Menu Settings - Level 1

Menu Settings - Level 1

Factory defaults are printed in

Category Items Options Explanation

PRINTER

LANGUAGE

(OL400e only)

PRINTER

LANGUAGE

(OL410e only)

PRINTER

LANGUAGE

(OL410e-PS only)

TRAY SELECT PAPER IN

EMULATE HPIIP

EMULATE HPIII (OL410e)

EMULATE Adobe PS

.

bold

(OL410e-PS)

TRAY 1

TRAY 2

Appears if

installed

MANUAL Select manual paper

Select paper tray.

Select second paper

tray

feed.

AUTOTRAY

if tray 2 installed

PAPER SIZE TRAY 1

Appears

FEEDER

installed

, OFF

ON

Appears if

LETTER

EXEC

LEGAL 14

LEGAL 13

A4 SIZE

A5 SIZE

A6 SIZE

B5 SIZE

FREE

Select feeder.

Set On, printer will

switch to second tray

when first tray is

empty.

Select paper size in

tray 1.

8.5" X 11"

7.25" X 10.5"

8.5" X 14"

(with optional legal

tray)

8.5" X 13"

(with optional legal

tray)

210 mm 297 mm

148 mm 210 mm

105 mm X 148 mm

176 mm X 250 mm

Allows printing on

custom size paper

OL400/410ex (96-01-30)

TRAY 2

installed

Appears if

LETTER

LEGAL 14, LEGAL

13, A4 SIZE, A5

SIZE, A6 SIZE, B5

SIZE, FREE

, EXEC,

Select paper size in

tray 2 if installed.

MANUAL

FEEDER

installed

MEDIA TYPE TRAY 1

MANUAL

Appears if

LETTER

LEGAL 14, LEGAL

13, A4 SIZE, A5

SIZE, A6 SIZE, B5

SIZE, FREE

COM-10

MONARCH, DL ENV,

C5 ENV, LETTER,

EXEC, LEGAL 14,

LEGAL 13, A4 SIZE,

A5 SIZE, A6 SIZE,

B5 SIZE, FREE

MEDIUM,

LIGHT

, EXEC,

COM-10

MONARCH

DL ENV

,

Select paper size for

manual feed.

4.12" X 9.50"

Envelope

3.87" X 7.50"

Envelope

110 mm X 220 mm

Envelope

Select

envelope/paper size

in feeder if installed

Normal setting for

20-28lb paper.

Select LIGHT if

16-20lb paper

wrinkles or curls

COPIES 1 to 99 Select number of

copies to print for

each document

FONTS & SYMBOLS FONT SRC

RESDENT

Appears if installed,

DLLSOFT

, CARD

Appears if

Select font source.

loaded

FONT NO

I000

to I013,

I020 (OL410e)

I000

to

Select font by ID

number (see font print

sample). Prefix

indicates font source:

I=internal (resident);

C=card; S=soft font.

OL400/410ex (96-01-30)

FONT CPI

Appears if selected

font is scalable/fixed

spaced

(OL410e)

10.00

, 0.44 to 99.99

Select number of

characters printed in

a horizontal inch

(pitch) when scalable

font with fixed

spacing is selected.

(0.01 mm

increments).

Character height

(point size) adjusts

accordingly.

FONT HGT

Appears if selected

font is

scalable/proportional

spaced

SYMBOL ROMAN-8 Roman-8 is the

HP CART

410e-PS)

PAGE LAYOUT ORIENT

LINES/PG

(OL410e)

(OL410E &

12.00

, 4.00 to 999.75

NONE

, F,B

PORTRT

60 LNS

LNS

, 5 to 128

Select point size

(height) of characters

when scalable font

with proportional

spacing is selected.

(0.25 mm

increments).

Horizontal spacing

adjusts accordingly.

standard HP set.

HP font cartridge

designations. Select

F or B to agree with

software or select

NONE.

, LANDSCP

Select number of

lines on page.

A4 WIDTH

BLNKSKIP

OL400/410ex (96-01-30)

78 COL

OFF

, ON

, 80 COL

Use this option for A4

size paper to select

78 columns or

condense 80 columns

so characters will fit

on a line.

Set ON printer will

ignore FF code when

buffer is empty.

(Sometimes Word for

Windows will print an

extra blank page.)

HOST I/F AUTO I/F,

PARALLEL, RS232C

Adobe-PS

Local Talk

or RS-422

Select active

interface.

OL400/410ex (96-01-30)

Menu Settings - Level 2

Menu Settings - Level 2

Factory defaults are printed in

Category Items Options Explanation

PRINT MODE

bold.

Select printing mode.

(OL410e and

OL410e-PS)

OKI600 requires

OL410e driver. HPIII

Emulation supports

OKI300

widens/blackens

characters and

graphic dots so edges

appear more crisp and

less jagged

Reserves area in

memory for page size

selected; eliminates

print overuns

MEMORY USAGE

(OL400e and

OL410e-PS Only)

SMOOTHNG Appears

if PRINT MODE is

OKI600

PAGEPROT Appears

if optional RAM is

installed

OKI600,

OKI300

MEDIUM, DARK Smoothing

Off

, Letter, Legal, A4

PAGE BUF (OL410e),

OKI600

300DPI

, 360KB to

AUTO

3.96MB, FUL LTR

Requires 5MB RAM,

FUL A4 Requires 5MB

RAM

, 180KB to

AUTO

900KB, FUL LTR, FUL

A4, FUL LGL

Reserve work area in

memory for building

image insuring that

entire page prints;

eliminates print

overuns. AUTO allows

printer to maximize

RAM areas for best

results. Other areas

may be customized if

file size of graphic

image is known

OL400/410ex (96-01-30)

REC BUFF AUTO (OL410e), 8KB,

20KB, 50KB, 100KB,

1MB

Select amount of

memory devoted to

holding received data;

larger setting improves

computer return to

application time.

OL400e requires

optional RAM for 1 MB

setting

AUTO

OPERATION

FONT PROT OKI600

AUTO

, OFF, 100 KB

to 3.1MB

300DPI AUTO, OFF, 100KB to

3.6MB

AUTOCONT

OFF

, ON

Reserves a section of

memory for

downloading fonts;

improves printing

speed by saving

previously created

fonts. Will take

memory away from

total print buffer and

REC BUFF

If ON, software or

data error will cause

printer to display error

message then

continue to print; Set

Off, printer will stop

printing; press

RECOVER to

continue.

DARKNESS

CONTROL

AUTOEJCT

DARKNESS

OFF

, 15 SEC, 30

SEC, 1 MIN

0

, +1, +2, -2, -1

When set to other

than Off: if printer

doesn't receive data

within the set time (15

Sec, 30 Sec, or 1

Min), current page will

print and eject. Meant

for use with software

that doesn't issue

Form Feed command

at end of last page.

When Off, printer

won't print last page

without a Form Feed

Control print density.

Negative values

lighten, positive values

darken.

OL400/410ex (96-01-30)

POWER SAVING PWR SAVE

ENABLE

, DISABLE

Enable: reduces

power consumption. 8

minutes after printer

stops receiving data

fuser heating element

shuts off; after 12

additional minutes fan

shuts off. When printer

receives more data,

fuser warms up before

printing begins.

Disable: fuser and fan

are always on, printer

is ready to print at all

times

TONER SAVING

(OL400e)

PARALLEL I/F I-PRIME

RS232C SERIAL FLOW CTL

BAUDRATE

TNR SAVE DISABLE

MEDIUM, LIGHT

OFF

, ON

DTR HI

, DTR LO,

XONXOFF,

RBSTXON

9600

, 19200, 300,

600, 1200, 2400, 4800

Use this feature to

,

conserve toner and

reduce printing costs

when you are printing

rough drafts or proof

copies.

Medium reduces toner

by 30%, light reduces

toner by 50%

Set On, I-Prime signal

resets printer. Set

OFF, or HOST I/F is

AUTO IF, printer

ignores signal

Select serial protocol.

Select transmission

rate in bits per second

(bps)

DATABITS

PARITY

MIN BUSY

OL400/410ex (96-01-30)

8 BITS

NONE,

, 7 BITS

EVEN, ODD

200 mSEC

, 1 SEC

Select serial interface

data bit format.

Select serial interface

parity type.

Set length of busy

signal when

Ready/Busy (DTR)

protocol is selected.

LANGUAGE ENGLISH,

DEUTSCH,

FRANCIS,

ITLIANO,

CASTLAN,

SVENSKA,

NORSK,

DANSK,

NEDERL,

PORTUGUÊS

Select language

displayed.

German

French

Italian

Spanish

Swedish

Norwegian

Danish

Dutch

Portuguese

OL400/410ex (96-01-30)

Sample Menu - OL400E

Sample Menu - OL400e

OL400/410ex (96-01-30)

Sample Menu - OL410E

Sample Menu - OL410e

OL400/410ex (96-01-30)

Sample Menu - OL410E/PS

Sample Menu - OL410e/PS

OL400/410ex (96-01-30)

OL400/410ex (96-01-30)

Hex Dump

Hex Dump

General Information

Data received by the printer is converted to hexadecimal codes and printed

when the printer is in HEX DUMP mode.

If the amount of data received is more than one page, printing will

automatically activate.

If the amount of data received is less than one page, you may have to manually

activate printing.

To print the page, you can do one of the following procedures.

- Press ON-LINE to place the printer OFF-LINE.

- Press FORM FEED / Tray Select.

or

- Set AUTO EJECT to ON in the menu.

Procedure

To enter hex dump mode, perform the following procedure.

- Close the stacker cover.

- Install the paper cassette tray.

- Clear all error messages displayed on the operator panel.

- Power OFF the unit.

- Press and hold MENU 1 / Menu 2 while powering ON the unit.

The operator panel displays the following for approximately two seconds.

88888888

88888888

- Release MENU 1 / Menu 2 once the operator panel displays the following message.

- Press MENU 1 / Menu 2.

The operator panel displays the following message.

- Press MENU 1 / Menu 2.

The operator panel displays the following message.

- Press ENTER / Copies

The operator panel displays the following message for approximately 15 seconds.

- The unit will go ON-LINE.

The operator panel displays the following message.

To exit Hex Dump, power OFF the unit.

Hexadecimal Codes (US ASCII)

USER MNT

MENU

RESET

HEX DUMP

WARM UP

ON-LINE

HEX DUMP

OL400/410ex (96-01-30)

OL400/410ex (96-01-30)

Drum Counter Reset

Drum Counter Reset

General Information

The drum counter should be reset when the image drum is replaced.

This message will be displayed on the operator panel when the image drum

should be replaced.

CHG DRUM

The counter MUST be reset to clear this message.

The drum count is NOT the same as the page count or the drum count total.

Procedure

To view the drum count, perform the following procedure.

- Close the stacker cover.

- Install the paper cassette tray.

- Clear all error messages displayed on the operator panel.

- Power OFF the unit.

- Press and hold MENU 1 / Menu 2 while powering ON the unit.

The operator panel displays the following for approximately two seconds.

88888888

88888888

- Release MENU 1 / Menu 2 once the operator panel displays the following message.

USER MNT

- Press MENU 1 / Menu 2.

- The operator panel displays the following message.

MENU

RESET

- Press MENU 1 / Menu 2.

The operator panel displays the following message.

HEX DUMP

- Press MENU 1 / Menu 2.

The operator panel displays the following message.

DRUM CNT

RESET

- Press ENTER / Copies.

The operator panel displays the following message.

DRUM CNT

RESETTING

- The unit will go ON-LINE.

- The operator panel displays the following message.

OL400/410ex (96-01-30)

ON-LINE ON-LINE ON-LINE

HPIIP HPIII ADOBE PS

(OL400e) (OL410e) (OL410e/PS)

OL400/410ex (96-01-30)

Operator Panel Menu Enable / Disable

Operator Panel Menu Enable / Disable

General Information

This function enables or disables the operator panel menu functions.

When this function is DISABLED, all control panel buttons except ON-LINE are disabled.

The default is for the operator panel to be enabled.

Procedure

To enable or disable the operator menu, perform the following procedure.

- Close the stacker cover.

- Install the paper cassette tray.

- Clear all error messages displayed on the operator panel.

- Power OFF the unit.

- Press and hold MENU 1 / Menu 2 while powering ON the unit.

The operator panel displays the following for approximately two seconds.

88888888

88888888

- Release MENU 1 / Menu 2 once the operator panel displays the following message.

USER MNT

- Press MENU 1 / Menu 2.

The operator panel displays the following message.

MENU

RESET

- Press MENU 1 / Menu 2.

The operator panel displays the following message.

HEX DUMP

- Press MENU 1 / Menu 2.

The operator panel displays the following message.

DRUM CNT

RESET

- Press MENU 1 / Menu 2.

The operator panel displays the following message.

OP MENU

ENABLE

- Press ENTER / Copies

The operator panel displays the following message.

OP MENU

ENABLE

An asterisk will follow the word ENABLE if the op menu is enabled.

- Press LAST - / Paper Size or NEXT + / Demo to toggle between ENABLE and DISABLE.

The operator panel displays the following message.

OL400/410ex (96-01-30)

OP MENU OP MENU

ENABLE or DISABLE

An asterisk will follow the word ENABLE or DISABLE to show the selection.

- Press ENTER / Copies to select the setting.

An asterisk will follow the word ENABLE or DISABLE to show the selection.

- Press ON-LINE to save the setting and exit the user maintenance mode.

The operator panel displays the following message for approximately 15 seconds.

WARM UP

The operator panel displays the following message.

ON-LINE ON-LINE ON-LINE

HPIIP HPIII ADOBE PS

(OL400e) (OL410e) (OL410e/PS)

OL400/410ex (96-01-30)

Loading...

Loading...