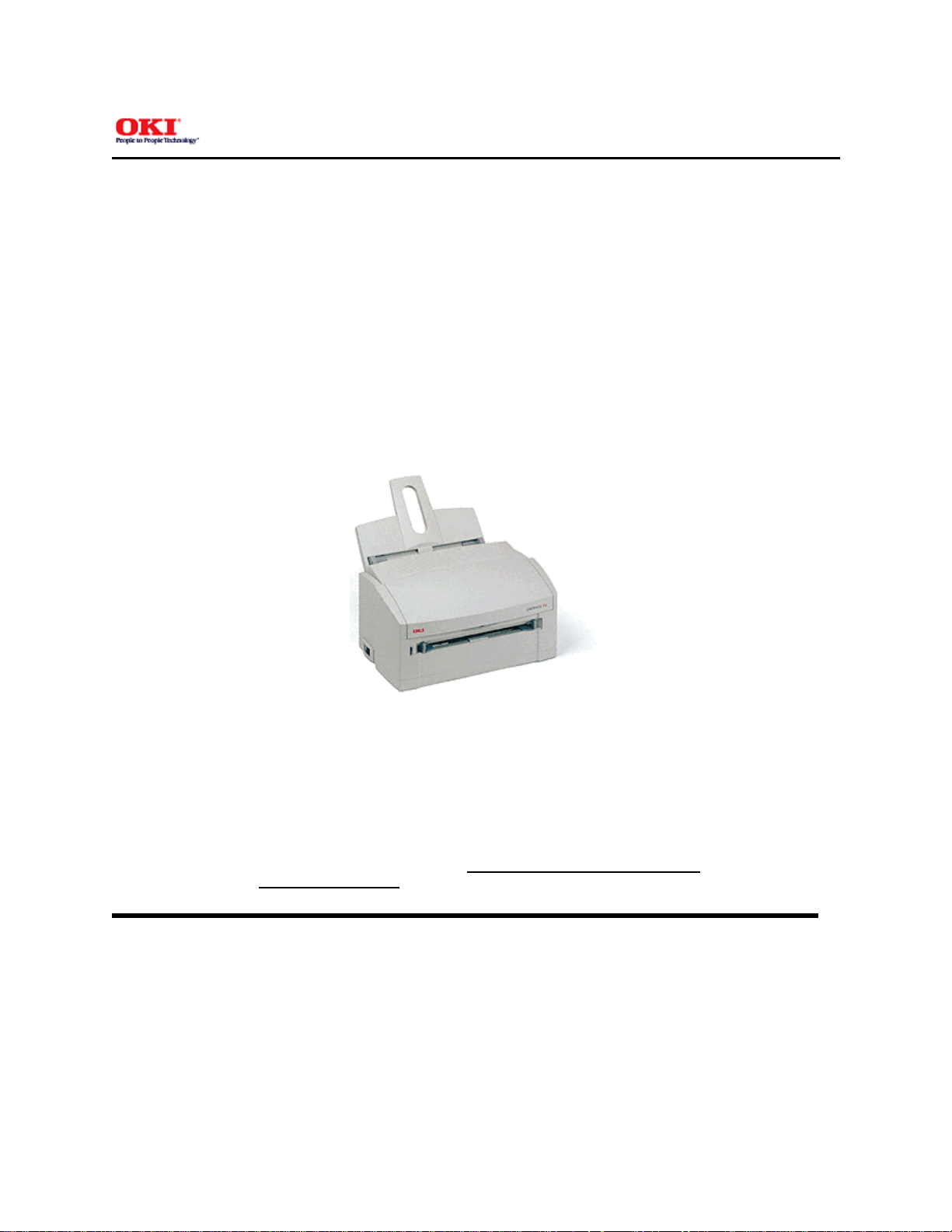

Okidata OKIPAGE 8z Service Manual

Thank You for purchasing this

Click Here for more Factory Service

Manuals for other Computer and

Printer / Copier Manufacturers

from PCTECHINFO!

Front Cover

Service Manual for OKIPAGE 8z

Chapter 0 Introduction

Service Guide

OKIPAGE 8z

Digital LED Page Printer

Page: 1

Adobe Acrobat printable reference copy

of the OKIDATA Service Training Manual.

07/18/2000

Note: This Adobe Acrobat version of the Okidata Service Training Manual was built with the pictures

rendered at 72 dpi, which is ideal for screen viewing. For future updates to this manual, and

more on-line information visit our Business Partner Exchange (BPX) at

http://bpx.okidata.com.

Copyright 2000, Oki Data, Division of OKI America, Inc. All rights reserved. See the Oki Data Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Table of Contents Page

....4.1 Adjustment Types and Functions 45

........4.1.1 Printer Driver 46

........4.1.2 Engine Maintenance Utility 47

....4.2 Adjustment When Replacing a Part 48

........4.2.1 Setting LED Head Drive Time 49

........4.2.2 Uploading and Downloading EEPROM Data 50

5 Periodical Maintenance

5.1 Periodical Replacement Parts 51

5.2 Cleaning 52

....5.2.1 Cleaning the LED Lens Array 53

6 Troubleshooting Procedures

6.1 Troubleshooting Tips 54

6.2 Check Points Before Correcting Image Problems 55

6.3 Notes When Correcting Image Problems 56

6.4 Preparation Before Troubleshooting 57

6.5 Troubleshooting 58

....6.5.1 Status Monitor Message List 59

....6.5.2 Status Message Troubleshooting 60

....6.5.3 Image Troubleshooting 61

........(1) An image is light or blurred entirely 62

........(2) Dark background density 63

........(3) A blank paper is output 64

........(4) Vertical black belt/stripe 65

........(5) Cyclic defect 66

........(6) A blank paper is output 67

........(7) Poor fusing 68

........(8) Vertical white belt/stripe 69

........Contents - Figure 6-4 70

........Contents - Figure 6-5 71

7 Wiring Diagram

7.1 Interconnect Signal Diagram 72

7.2 PCB Layout 73

....7.2.1 Main Control Board (U8S PCB) 74

....7.2.2 High-Voltage Power Supply Board 75

8 Parts List

Cover Assy Upper 76

Base Frame Unit 77

Heat Assy 78

Base Plate Unit 79

A Local Printing

Local Printing 80

B Parallel Interface

Parallel Interface 81

C Maintenance Utility

Outline of Maintenance Utility 82

Detail of Each Function 83

....4.1 Engine Menu Setting 84

....4.2 Engine Counter 85

....4.3 Printer Status 86

....4.4 Test Print 87

....4.5 Option 88

Table of Contents Page

....4.6 About 89

....4.7 Reload 90

.... 4.8 Exit 91

D Universal Serial Bus (USB)

USB Specifications 92

Page: 1

Service Manual for OKIPAGE 8z

Chapter 0 Introduction

Preface

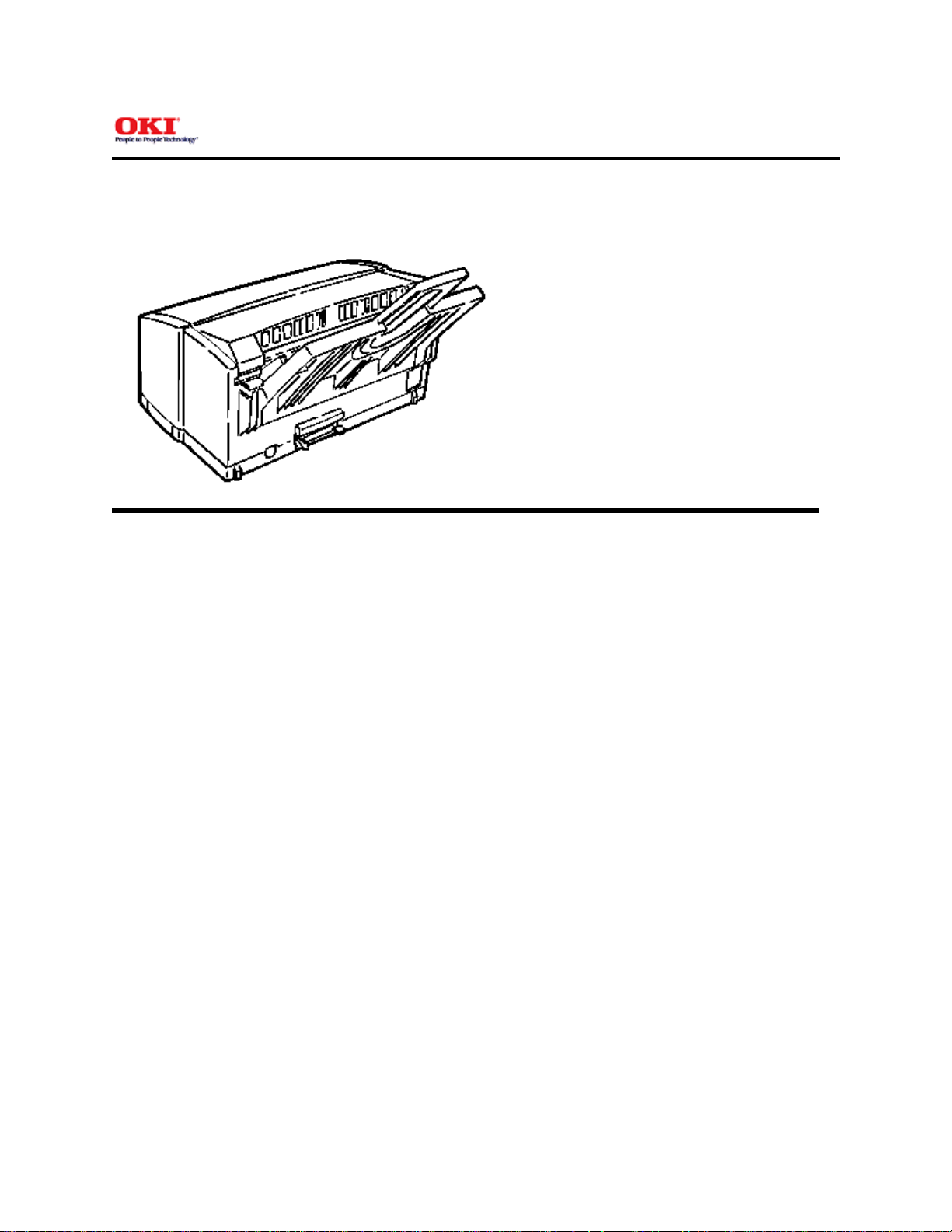

This Service Handbook describes the field maintenance procedures for the OKIPAGE 8z.

This manual is written for use by service persons. Please note that you should refer to the Printer User's Manual for

operating procedures.

Copyright 2000, Oki Data, Division of OKI America, Inc. All rights reserved. See the Oki Data Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 2

Service Manual for OKIPAGE 8z

Chapter 1 Configuration

Configuration

System Configuration

Printer Configuration

Specification

Safety Standards

Copyright 2000, Oki Data, Division of OKI America, Inc. All rights reserved. See the Oki Data Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 3

Service Manual for OKIPAGE 8z

Chapter 1 Configuration

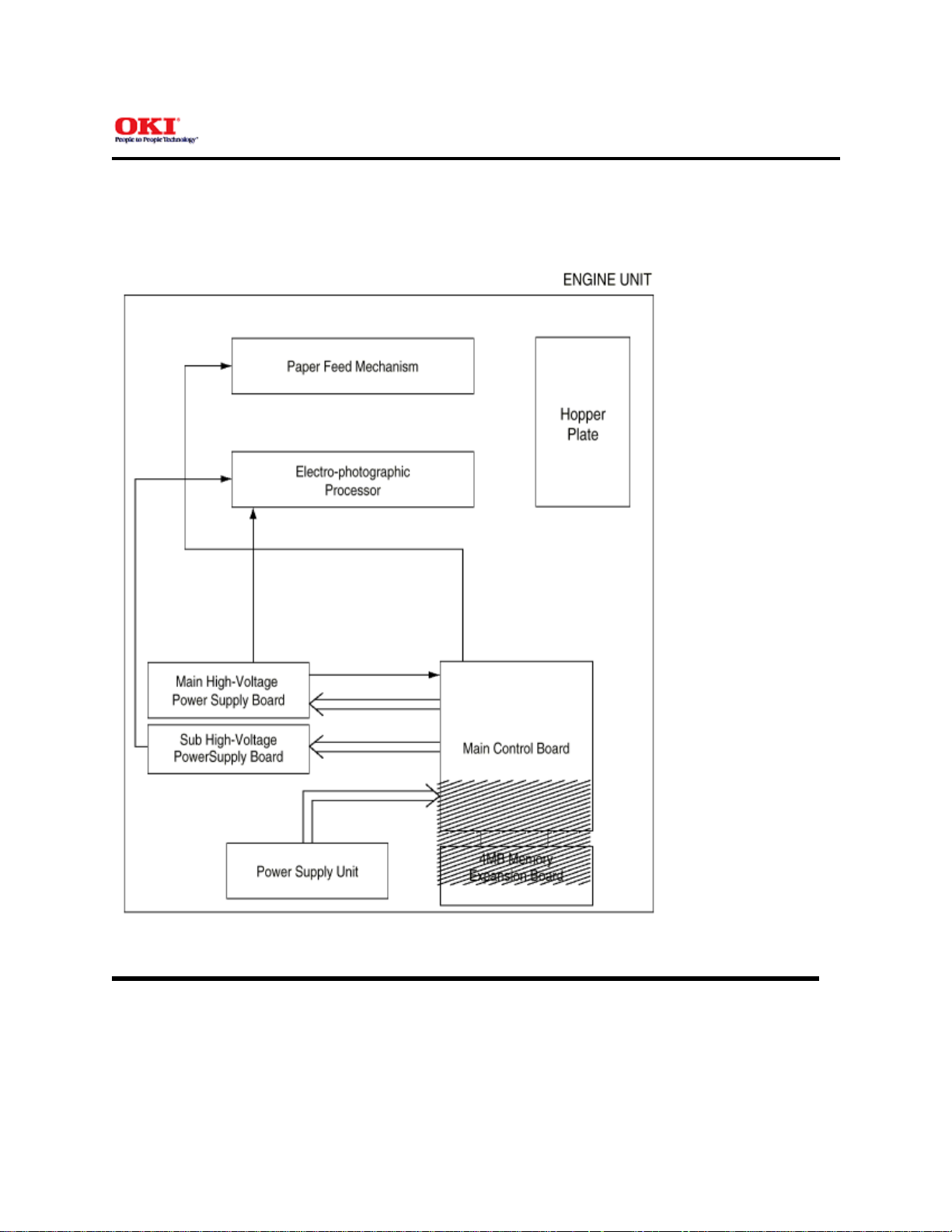

1.1 System Configuration

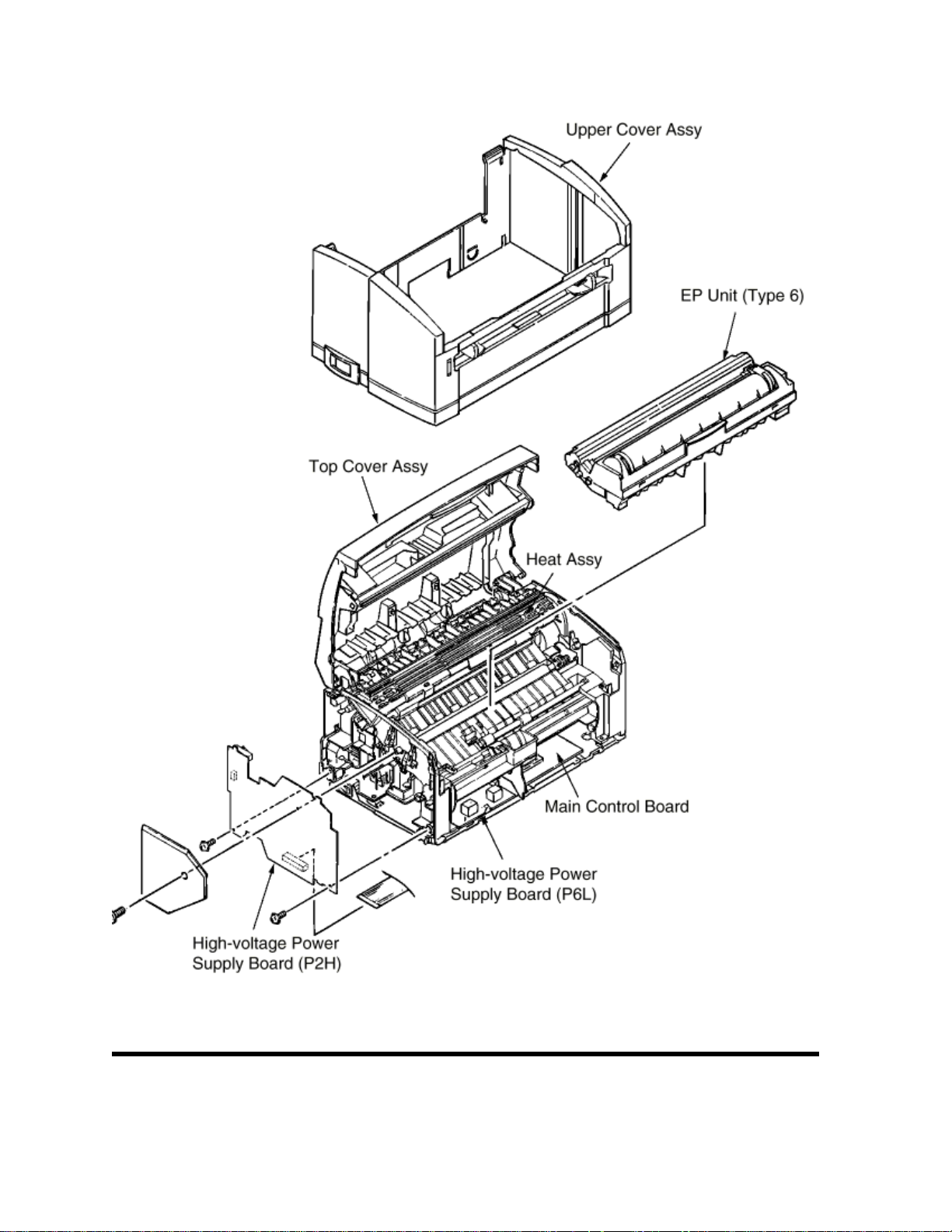

The OKIPAGE 8z consists of a control block, a power supply unit, and an engine block. (See Figure 1-1

below.)

Figure 1-1

Copyright 2000, Oki Data, Division of OKI America, Inc. All rights reserved. See the Oki Data Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual for OKIPAGE 8z

1.2 Printer Configuration

The printer unit consists of the following five hardware components:

Electro-Photographic Processor l

Paper Feeder l

Main Control Board l

High-Voltage Power Supply Board l

Power Supply Unitl

Figure 1-2 is the configuration of the printer unit.

Chapter 1 Configuration

Page: 4

Figure 1-2

Copyright 2000, Oki Data, Division of OKI America, Inc. All rights reserved. See the Oki Data Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual for OKIPAGE 8z

1.3 Specification

(1) Type: Desktop

Chapter 1 Configuration

Page: 5

(2) Outside dimensions

(excludes protruding

portion)

Height: 5.9" (150 mm)

Width 12.2" (310 mm)

Depth 7.5" (191mm)

(3) Weight 8.4 lbs. (3.8kg)

(4) Development

method

Dry non-magnetic development system

LED stationary head

Exposure method

(5) Paper used <Type>

Standard paperl

- Xerox 4200 (20 lbs)

Application paper (manual face-up feed)l

- Label

- Envelope

- OHP paper (Transparency)

<Size>

14" (355.6 mm) (Max.) x 8.5" (215.9 mm)

<Thickness>

Automatic feed: 16 to 28 lbs (60 to 105 g/m2)

- Manual feed: Label, Envelope, OHP paper (transparency)

(6) Printing speed: First print: 23 seconds (A4) (after warm-up)

Continuous print: 8 sheets/minute (A4)

Warm-up time: 40 seconds (120 VAC for ODA, 230 VAC for

OEL/INT) (at room temperature 77o F (25o C)

(7) Paper feeding

Automatic paper feed or manual paper feed

method

(8) Paper delivery

Face down

method

(9) Resolution 600 dpi x 600 dpi (true)

(10) Power input 230 VAC +/-10% (for OEL/INT)

120 VAC +/-15% for (ODA)

(11) Power consumption Peak: Approx. 450W

Typical operation: Approx. 100W

Idle: Approx. 30W

Power save mode: Approx. 5W

(12) Temperature and

humidity

Temperature Humidity

During operation

In storage

10 to 32o C

-10 to +43o C

20 to 80% RH (relative humidity)

10 to 90% RH (relative humidity)

No condensation is permissible.

Caution: Temperature and humidity in storage are measured with the OKIPAGE 8z being packed; they

are valid for one year.

(13) Noise During operation: 48 dB (A) or less

Standby: 38 dB (A) or less

(14) Consumables Toner cartridge kit - 1,500 (5% duty) ---- 45g cartridge kit

Image drum cartridge - 10,000 (at continuous printing)

Copyright 2000, Oki Data, Division of OKI America, Inc. All rights reserved. See the Oki Data Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 6

Service Manual for OKIPAGE 8z

Chapter 1 Configuration

1.4 Safety Standards

1.4.1 Certification Label

1.4.2 Warning Label

Copyright 2000, Oki Data, Division of OKI America, Inc. All rights reserved. See the Oki Data Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 7

Service Manual for OKIPAGE 8z

Chapter 1 Configuration

1.4.1 Certification Label

The safety certification label is affixed to the following location of the OKIPAGE 8z:

Copyright 2000, Oki Data, Division of OKI America, Inc. All rights reserved. See the Oki Data Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual for OKIPAGE 8z

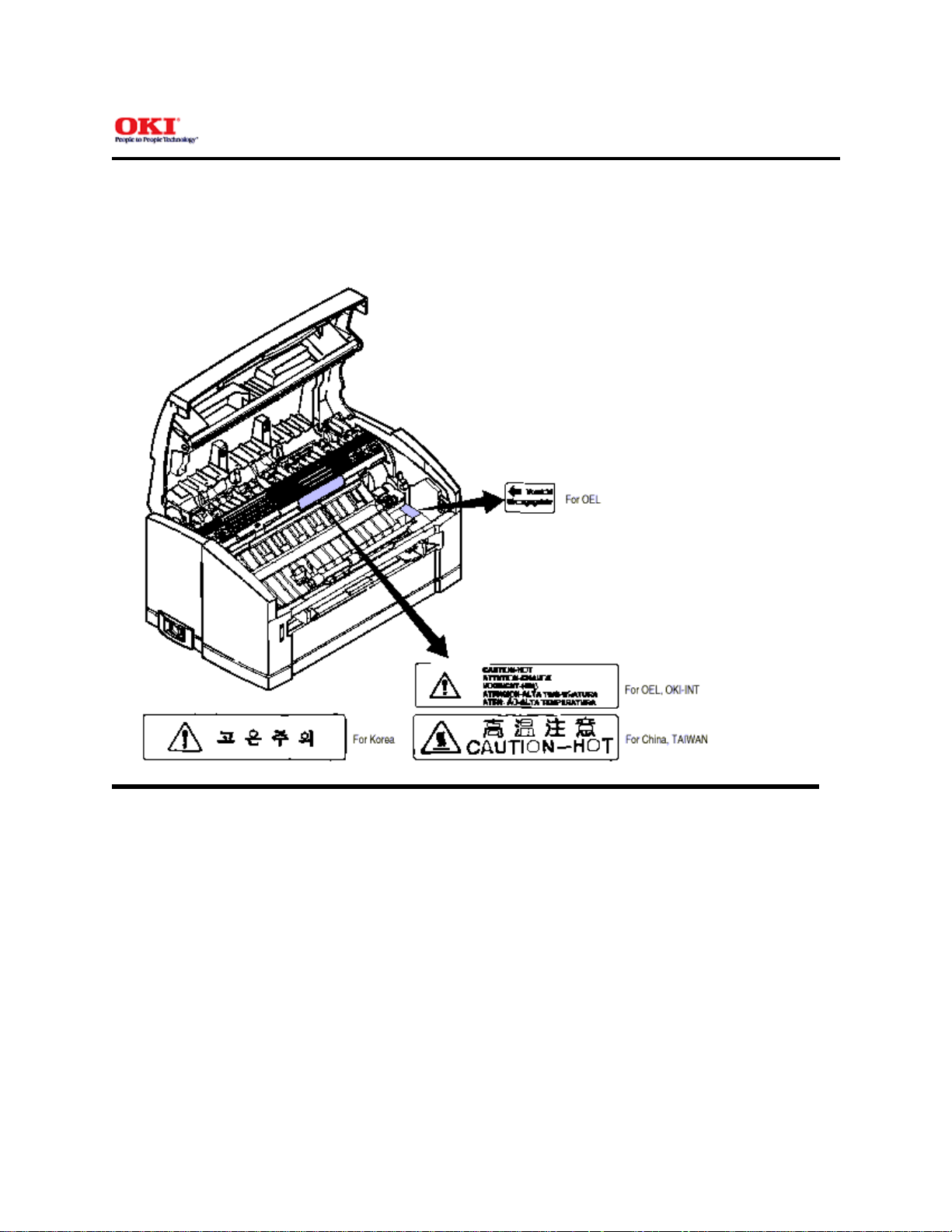

1.4.2 Warning Label

Warning labels are affixed to the locations that may cause bodily injury.

During maintenance, do work with enough care while following instructions on these warning labels.

Chapter 1 Configuration

Page: 8

Copyright 2000, Oki Data, Division of OKI America, Inc. All rights reserved. See the Oki Data Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 9

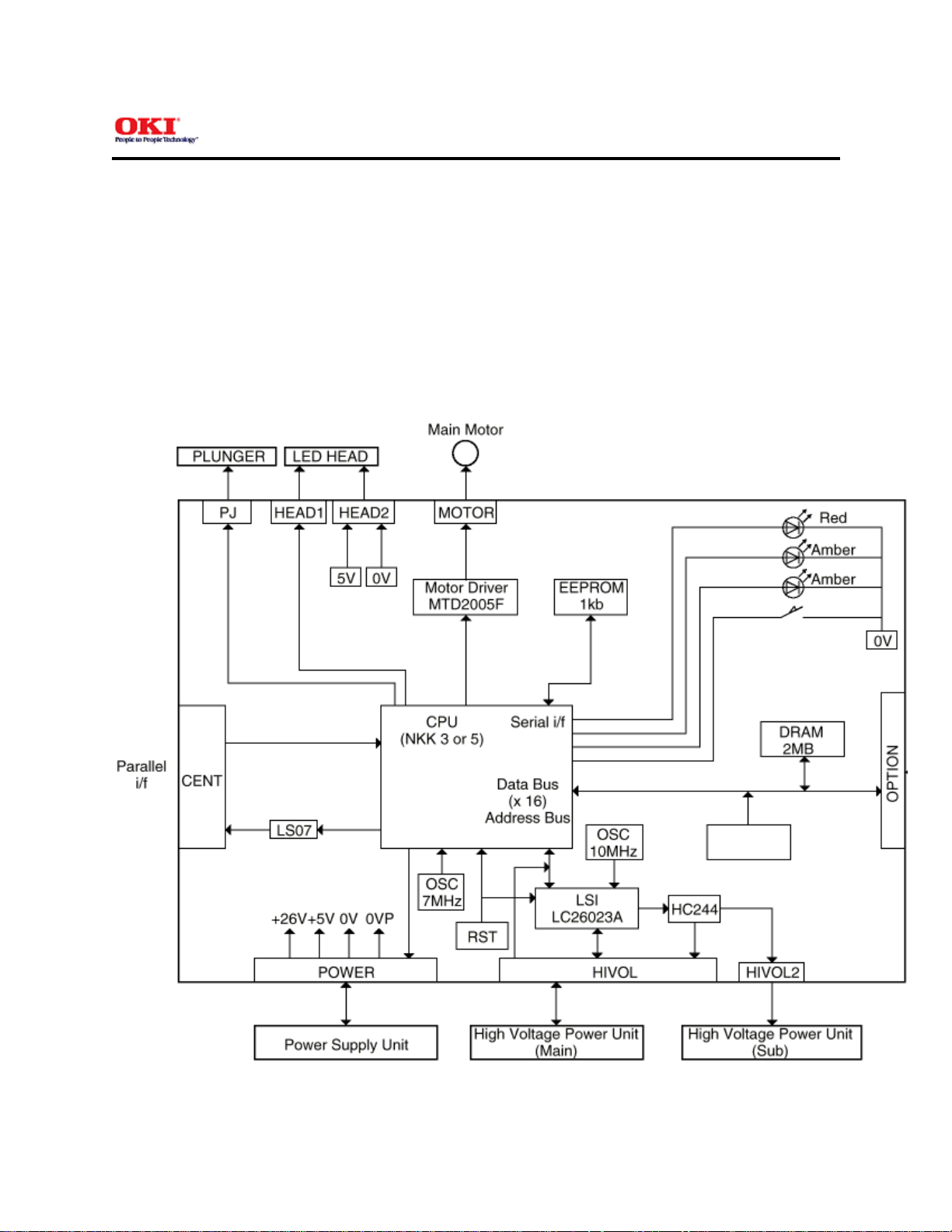

2.0 Operation Description

Service Manual for OKIPAGE 8z

Chapter 2 Operation Description

The OKIPAGE 8z consists of a main control board, a high-voltage power supply board, a power supply

unit, and an electro-photographic processor. The OKIPAGE 8z receives print data from a higher-level

interface and sequentially stores it in memory. The OKIPAGE 8z decodes and edits the received data

while storing print data from the interface in memory. It sequentially transfers the edited data to the LED

head for each dot line. The electro-photographic processor then prints the data on sheets of paper.

The display of the higher-level host is used for device operation and status display.

Figure 2-1 is the block diagram of the OKIPAGE 8z.

Figure 2-1 Block Diagram

Copyright 2000, Oki Data, Division of OKI America, Inc. All rights reserved. See the Oki Data Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 10

2.1 Main Control Board

Service Manual for OKIPAGE 8z

Chapter 2 Operation Description

The main control board consists of a one-chip CPU, a program ROM, a DRAM, an EEPROM, a host

interface circuit, and a mechanism driving circuit. The mechanism driving circuit consists of an LED head,

a main motor, and an electromagnetic clutch.

(1) One-chip CPU

The one-chip CPU is a custom CPU (8-bit internal bus, 8-bit external bus, 16-MHz clock) incorporating

mask ROM and CPU peripheral devices. This CPU has the functions listed in the table below.

Built-in Device Function

DRAM controller Controls DRAM.

DMA controller Transfers image data from Parallel I/F to DRAM, from

DRAM to a video output port and between CPU and

DRAM.

Parallel interface controller Controls the parallel interface.

Video output port

Controls LED head.

LED STB output port

Timer Generates various control timings for monitoring paper

feeding and a paper size.

I/O Port Inputs and outputs the sensor signals and motor

signals, etc. Also performs I/O for EEPROM.

A/D converter Inputs the feedback signals from a high-voltage

generation circuit and thermistor signal.

(2) Program ROM

Program ROM contains a program for the equipment. EPROM is used as program ROM. When mask

ROM in the one-chip CPU explained in (1) above is valid, the EPROM is not mounted. (For details on

short wiring setting, see Section 7.2.)

(3) DRAM

DRAM is used as resident memory.

(4) EEPROM

EEPROM holds the following data:

Menu data l

Counter value l

Adjustment valuel

(5) Parallel interface

The parallel interface receives parallel data from the host; it conforms to the IEEE1284 specification.

Copyright 2000, Oki Data, Division of OKI America, Inc. All rights reserved. See the Oki Data Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 11

Service Manual for OKIPAGE 8z

Chapter 2 Operation Description

2.2 Power Supply Unit

The power supply unit supplies +5 V and +26 V to the main control board according to 230 VAC / 120 VAC.

Output voltage Application

+5 V Used to generate a logic circuit and a high voltage.

+26 V Used to drive the motor and electromagnetic clutch.

Copyright 2000, Oki Data, Division of OKI America, Inc. All rights reserved. See the Oki Data Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual for OKIPAGE 8z

2.3 High-Voltage Power Supply Board

Chapter 2 Operation Description

Page: 12

(1) High-Voltage power supply circuit

The high-voltage power supply circuit generates the following voltages required for the electro-photographic

processor from +5 V according to the control sequence from the main control board. When the cover is open, +5 V

supply is automatically interrupted to stop high-voltage output.

Output Voltage Application

CH -1.3 KV Voltage to be applied to charge roller.

DB -265 V/+265 V Voltage to be applied to a developing roller.

SB -520 V/ 0 V Voltage to be applied to a sponge roller.

CB +400 V/-1.3 KV Voltage to be applied to a cleaning roller.

TR +500 V ~ +3.5 KV/-750 V Voltage to be applied to a transfer roller.

Caution: The TR voltage varies with medium and transfer roller impedance.

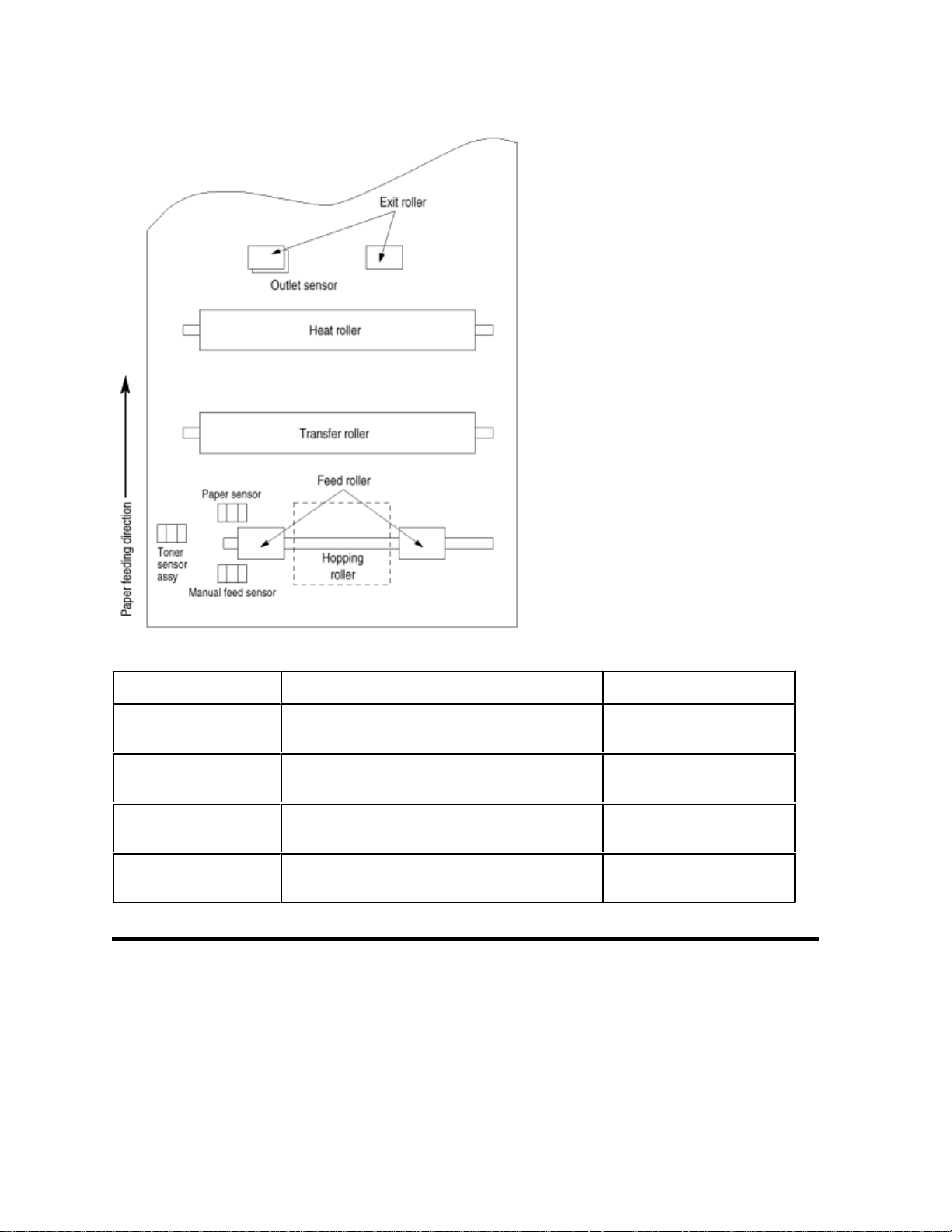

(2) Sensors

The high-voltage power supply board consists of the high-voltage power supply circuit that supplies power to the

electro-photographic processor system and the photosensor that detects a paper feeding system and toners.

Figure 2-2 shows the sensor layout drawing.

Sensor Function Sensing State

Manual feed sensor Monitors whether paper was inserted into the

manual feed sensor section.

Paper sensor Detects the leading part of the paper. Monitors

paper feeding.

Output sensor Monitors paper feeding and the paper size

according to the paper sensor arrival and

ON: Paper exists.

OFF: No paper exists.

ON: Paper exists.

OFF: No paper exists.

ON: Paper exists.

OFF: No paper exists.

passing time.

Toner sensor Detects the low toner status. ON (long): Toner low.

OFF (short): Toner high.

Copyright 2000, Oki Data, Division of OKI America, Inc. All rights reserved. See the Oki Data Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual for OKIPAGE 8z

2.4 Electro-Photographic Processor

Chapter 2 Operation Description

Page: 13

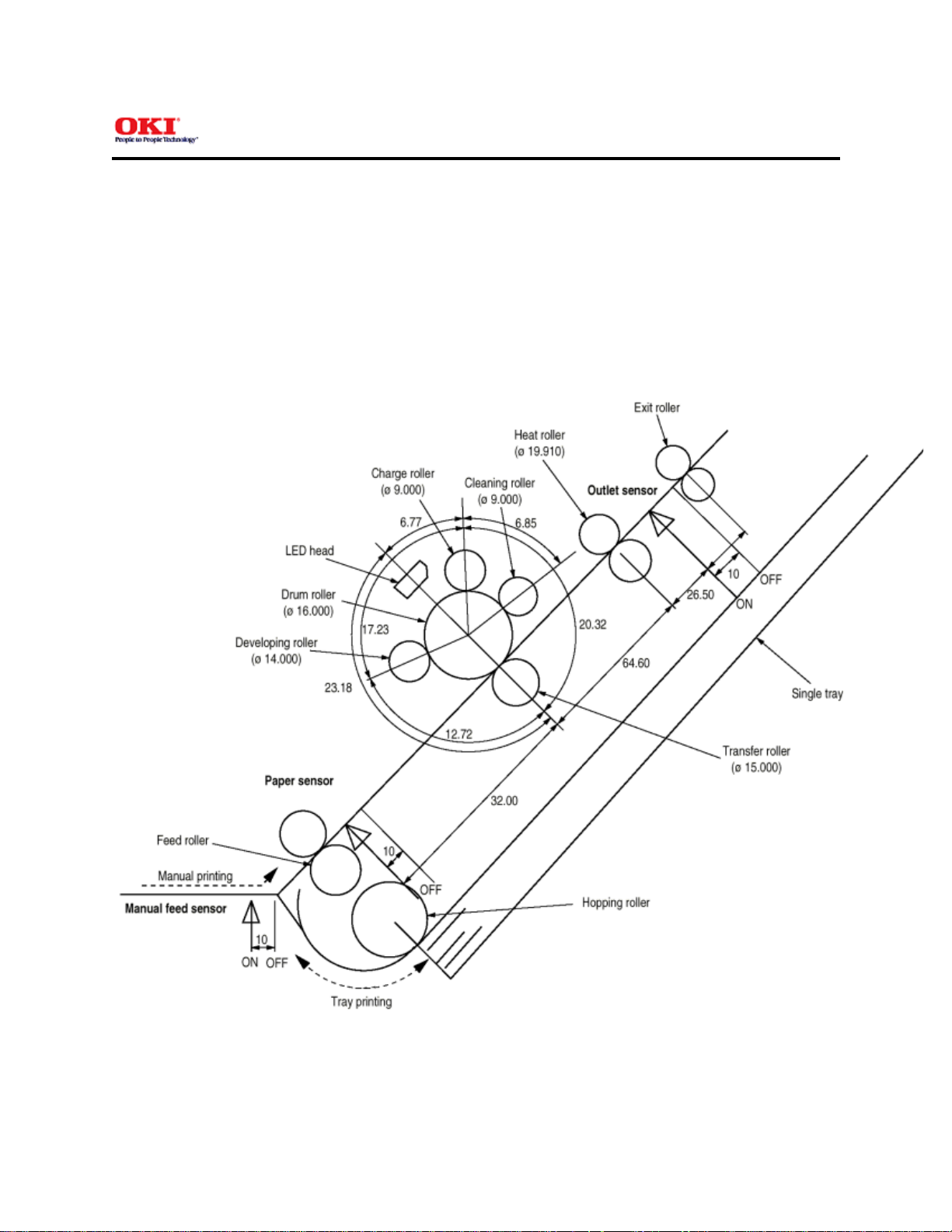

The electro-photographic processor prints out the image data to be sent from the main control board on sheets of

paper. Figure 2-3 shows the layout drawing of the electro-photographic processor.

(1) Image drum unit

The image drum unit makes a toner adhere to the formed electrostatic latent image with static electricity. This

electrostatic latent image is formed by the lights irradiated from LED heads.

(2) Electromagnetic clutch

The electromagnetic clutch controls the rotation of the hopping roller according to signals from the control block.

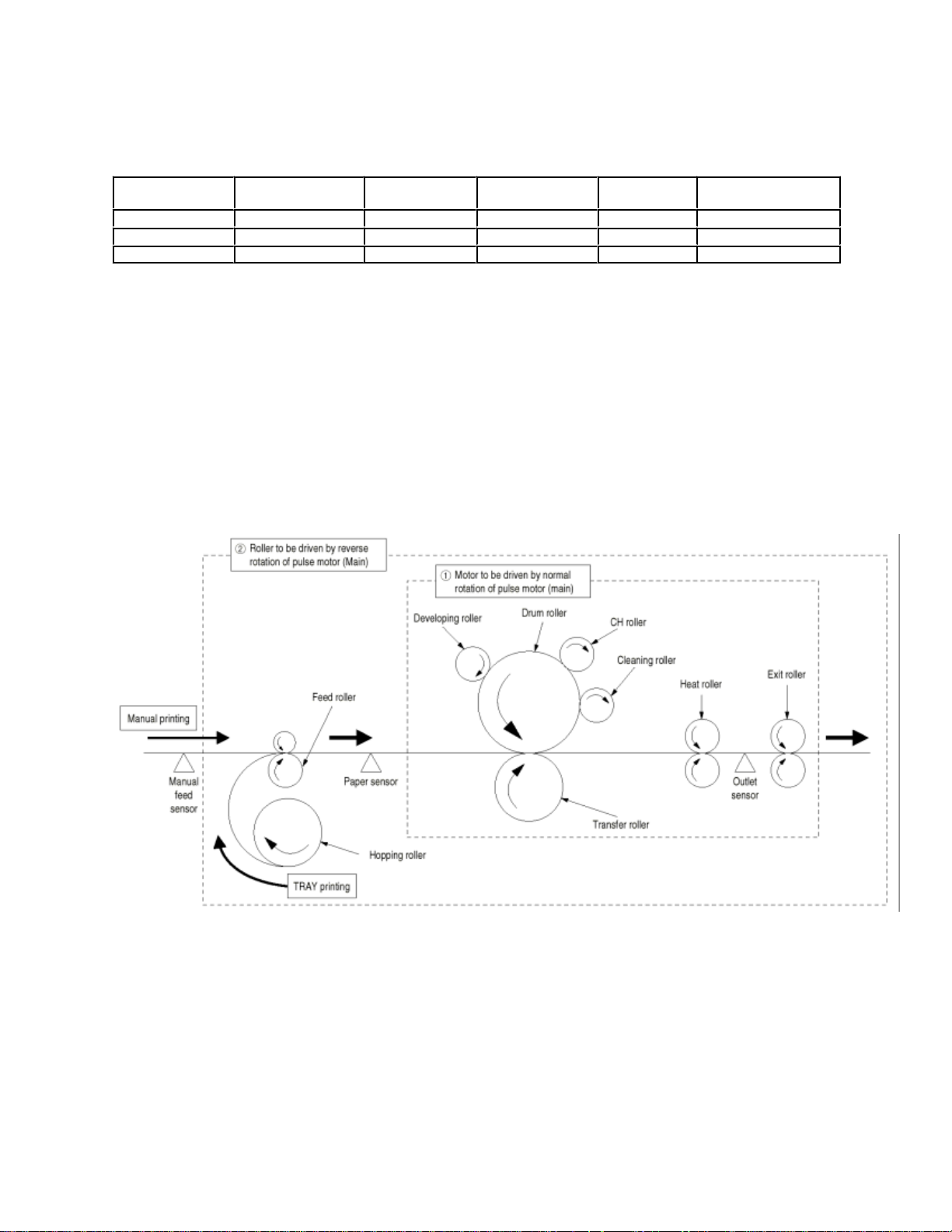

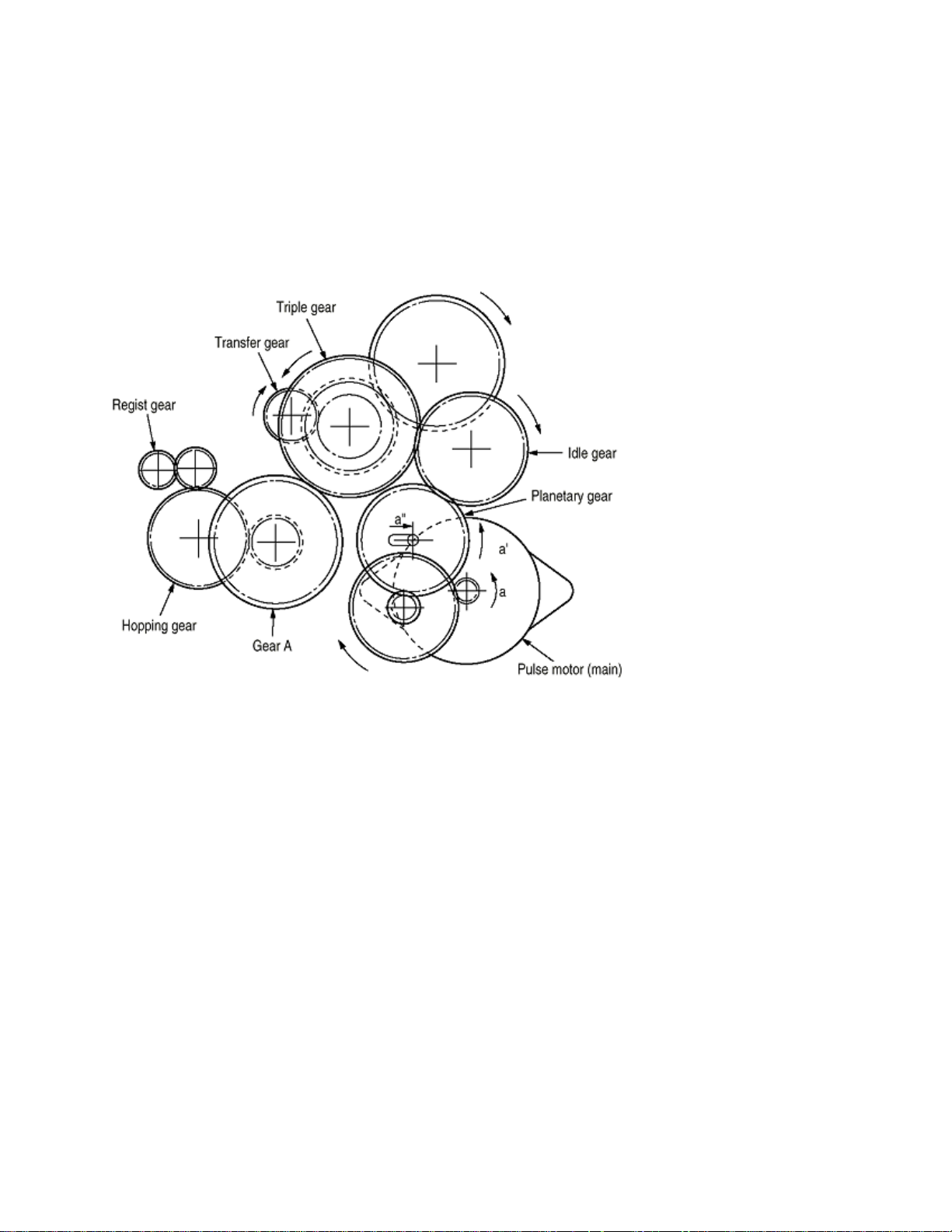

(3) Pulse motor (Main)

This pulse motor of 48 steps/rotation is two-phase excited by the signal from the main control board; it performs

feeding control by switching normal rotation to reverse rotation or vice versa and turning on/off the electromagnetic

clutch. The relationship between the main motor, electromagnetic clutch, resist gear, drum gear, hopping roller is

shown in the table

below and on the subsequent pages.

Main Motor Electromagnetic

Clutch

Hopping Roller Regist Gear Drum Gear Operation

Normal rotation OFF Non-rotation Non-rotation Rotation Warm-up

Reverse rotation ON Rotation Rotation Rotation Hopping

Reverse rotation OFF Non-rotation Rotation Rotation Printing

(4) LED head

The shift and latch registers receive image data from the main control board for each dot line. 4,992 LEDs are driven

to radiate the image drum.

(5) Heat Assy

The heat Assy consists of a heater, a heat roller, a thermistor, and a thermostat.

The power supply unit supplies AC voltage to the heater according to the HEATON signal from the main control

board to heat the heat roller. The main control board monitors the heat roller temperature via the thermistor and

keeps the temperature constant by turning on/off the heater AC voltage supply.

If the heat roller temperature rises abnormally, the thermostat of the heater voltage supply circuit functions to forcibly

suspend the AC voltage supply.

(1)

(2)

Roller control by pulse motor (main)

Normal rotation of pulse motor (main): Drum roller, transfer roller, cleaning roller, CH

roller, developing roller, heat roller, exit roller

rotation.

Reverse rotation of pulse motor (main): Drum roller, transfer roller, cleaning roller, CH

roller, developing roller, heat roller, exit roller,

feed roller, hopping roller rotation.

Hopping operation from the tray, however, is

performed when the electromagnetic clutch is

turned on.

Copyright 2000, Oki Data, Division of OKI America, Inc. All rights reserved. See the Oki Data Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual for OKIPAGE 8z

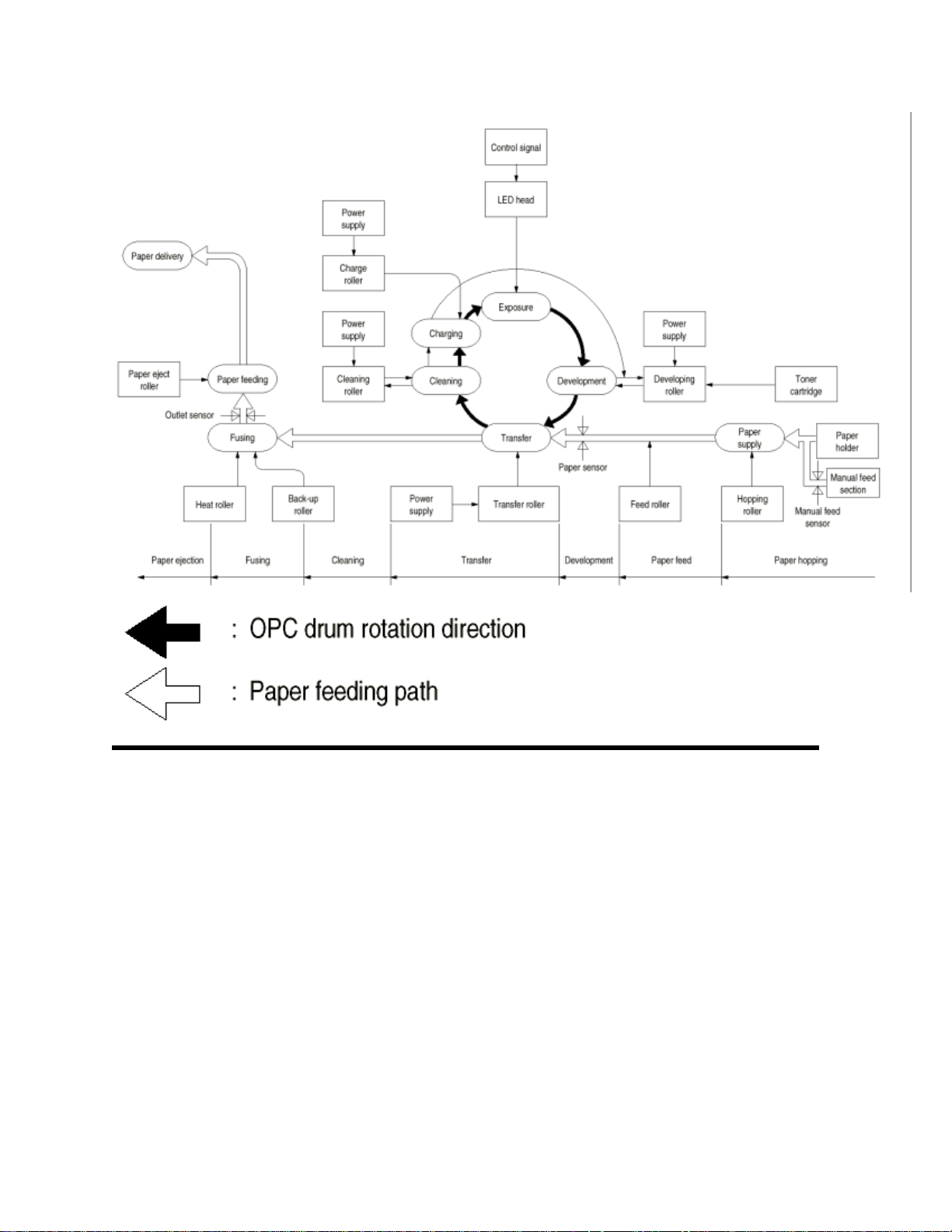

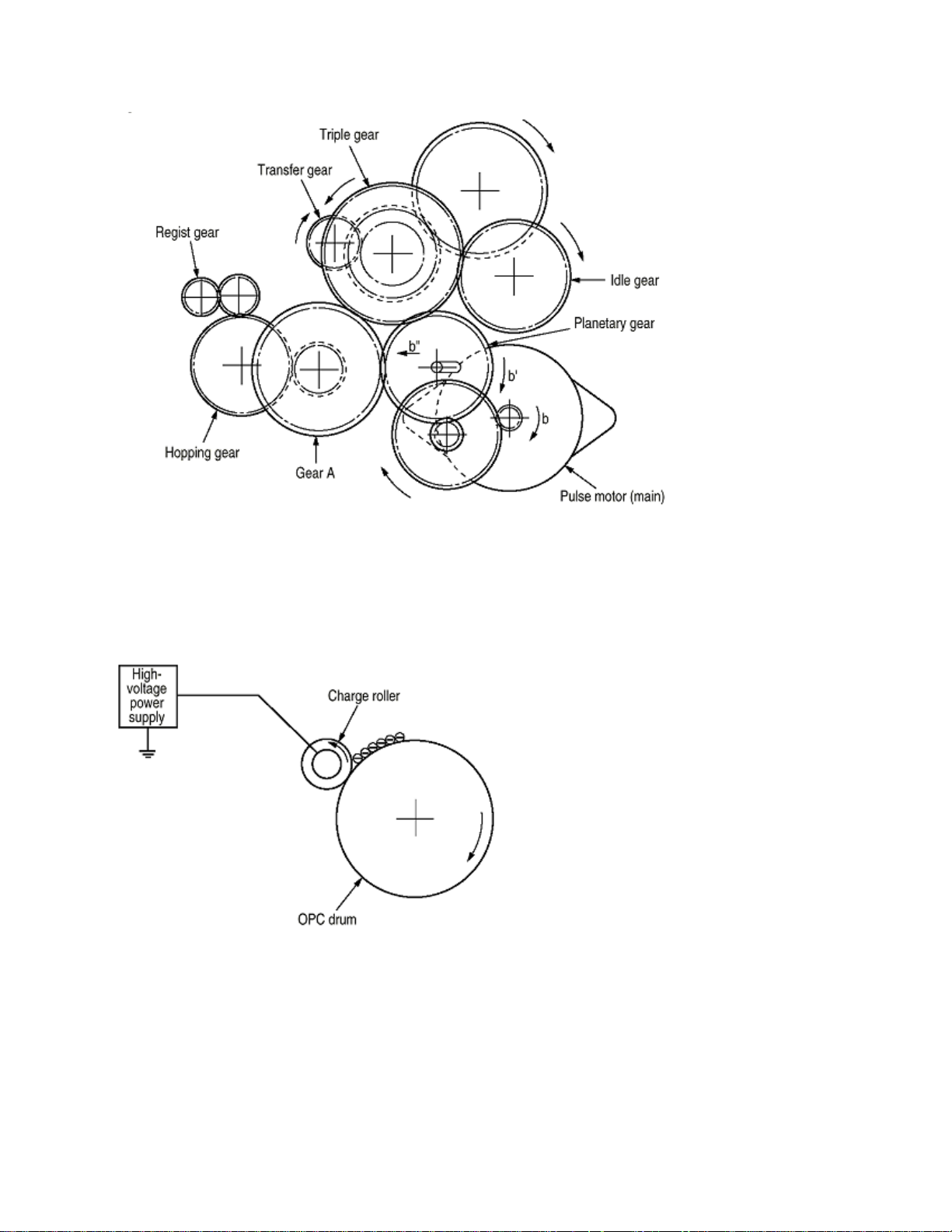

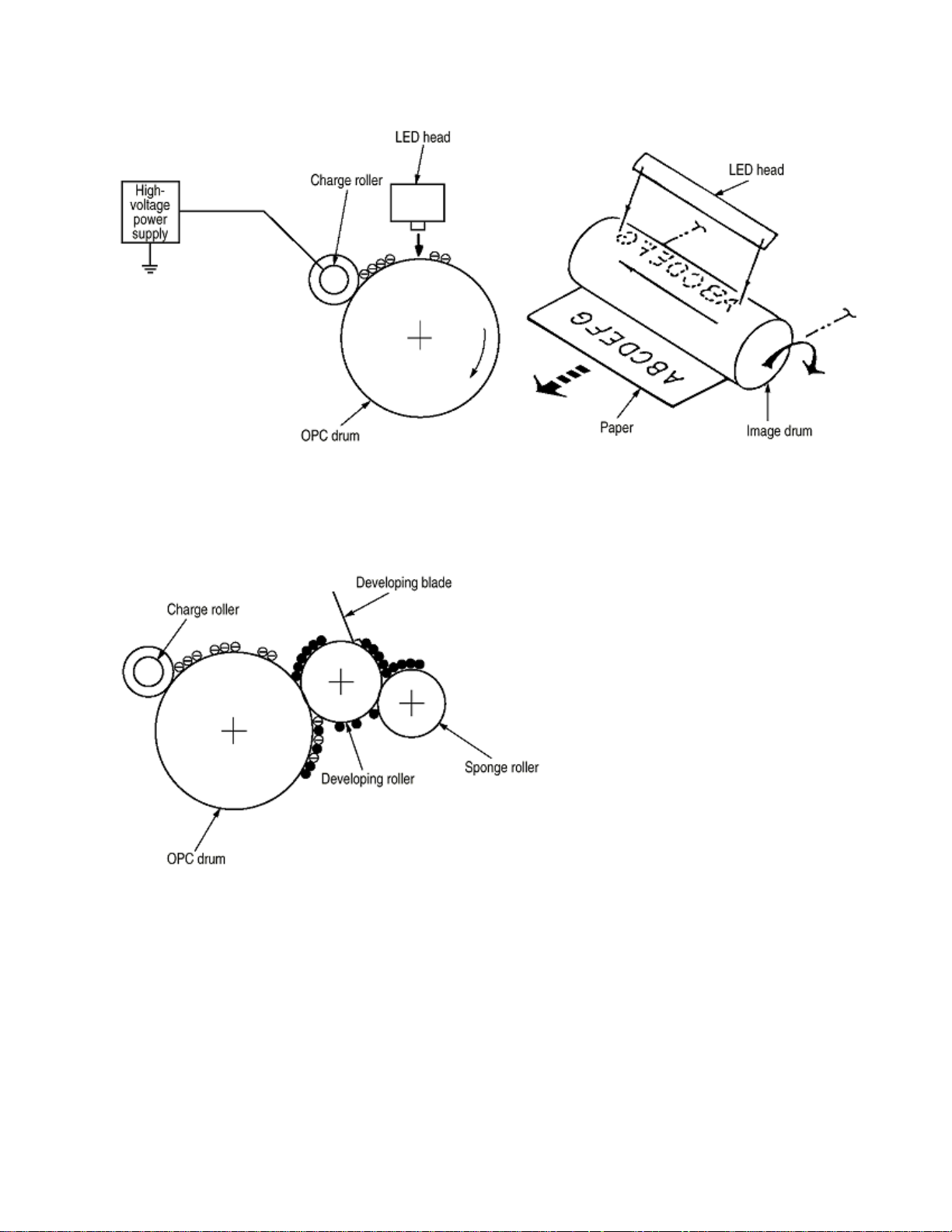

2.5 Electro-Photographic Process

The electro-photographic process is outlined below:

(1) Charging - The surface of the OPC drum is charged negatively and uniformly by

applying the DC voltage to the CH roller.

(2) Exposure - Light emitted from the LED head irradiates the negatively charged surface of

the OPC drum. The surface potential of the irradiated surface attenuates to form the

electrostatic latent image corresponding to the image signal.

(3) Development and residual toner recovery - The negatively charged toner is brought into

contact with the OPC drum, adhering to the electrostatic latent image on the OPC drum

by static electricity. This adhesion causes the electrostatic latent image to change to a

visible image. At the same time, the residual toner on the OPC drum is attracted to the

developing rollerby static electricity.

(4) Transfer - When paper is placed over the image drum surface, the positive charge

which is opposite in polarity to that of the toner, is applied to the reverse side by the

transfer roller. The toner is attracted by the positive charge and is transferred onto the

paper. This results in the transfer of the toner image formed on the image drum onto the

paper.

(5) Cleaning - The cleaning roller temporarily attracts the residual toner on the transferred

OPC drum with static electricity, then returns the toner to the OPC drum.

Chapter 2 Operation Description

Page: 14

(6) Fusing - The transferred unfused toner image is fused to a sheet of paper by applying

heat and pressure to the image.

Figure 2-5 shown below is a flow for the electro-photographic process.

Copyright 2000, Oki Data, Division of OKI America, Inc. All rights reserved. See the Oki Data Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual for OKIPAGE 8z

2.5.1 Explanation of Each Process Operation

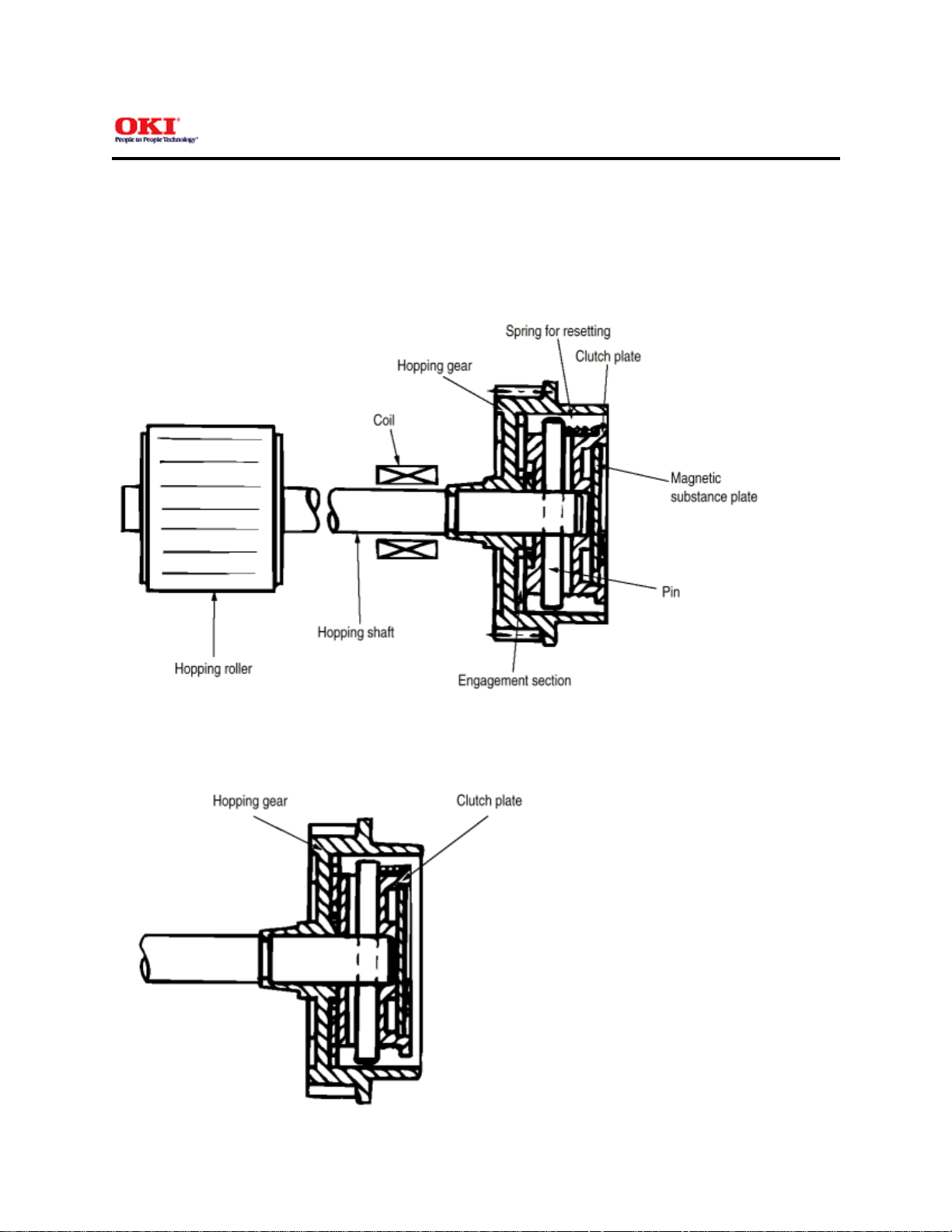

(1) Hopping

As shown in the figure below, the clutch for hopping is turned on/off according to current ON/OFF to a coil.

When the clutch is OFF

Chapter 2 Operation Description

Page: 15

When the clutch is ON

When the clutch is on, the hopping gear engages with the clutch plate to rotate the hopping roller.

When the clutch is off, the hopping gear is separated from the clutch plate by the spring for resetting, disabling the

rotation of the hopping roller.

(2) Printing and warm-up

At warm-up

Rotate the pulse motor (main) in the a direction. The planetary gear rotates in the a' direction, dislocating its position

in the a" direction. This causes the planetary gear to be separated from gear A. The hopping gear will not rotate. The

triple gear and transfer gear rotate via the idle gear to drive the EP unit.

At printing

The paper is further advanced in synchronization to the print data.

(3) Charging

Charging is performed by applying DC voltage to the charge roller that is in contact with the surface of the OPC

drum.

(4) Exposure

Light emitted from the LED head irradiates the negatively charged surface of the OPC drum. The surface potential of

the irradiated surface attenuates to form the electrostatic latent image corresponding to the image signal.

(5) Development

The electrostatic latent image on the surface of the OPC drum is changed to a visible toner image by applying a

toner to it. Development is performed in the contact part between the OPC drum and developing roller.

1 The sponge roller negatively charges a toner and applies it to the developing roller.

2 The toner applied to the developing roller is thin-coated by the developing blade.

3 A toner adheres to the exposure part of the OPC drum in the contact part between the OPC drum and

developing roller. This causes the electrostatic latent image to be changed to a visible image.

(6) Transfer

The transfer roller is composed of conductive sponge material. This roller is set so that the surface of the OPC drum

and sheets of paper will adhere closely.

A sheet of paper is placed on the surface of the OPC drum and the positive charge opposite to the negative charge

of a toner is applied from the reverse side by the transfer roller.

When a high negative voltage is applied from the power supply to the transfer roller, the positive charge induced on

the surface of the transfer roller moves to the paper side at the contact part between the transfer roller and the sheet

Loading...

Loading...