Okidata OKIPAGE 8cn, OKIPAGE 8c Service Manual

Front Cover

Service Guide - OKIPAGE 8c

Chapter

0 Introduction

OKIPAGE 8c / OKIPAGE 8cn

LED PAGE COLOR PRINTER PRODUCTS

Adobe Acrobat printable reference copy

of the OKIDATA Service Training Manual.

11/02/98 Rev. 2.0

Note: This Adobe Acrobat version of the Okidata Service Training Manual was built with

the pictures rendered at 72 dpi, which is ideal for screen viewing. For future updates

to this manual, and more on-line information visit our

(BPX) at http://bpx.okidata.com

.

Business Partner Exchange

Table of Contents Page

Service Guide - OKIPAGE 8c

0 Introduction

Preface 2

1 Specifications

1.1 Basic System Configuration 3

1.2 Printer Specifications 4

1.3 Option Specifications 5

1.4 Basic Specifications 6

2 Operation

2. Operation 7

2.1 Main Control Board (PCR PCB) 8

2.2 Engine Control Board (PX4 PCB) 9

2.3 Power/Board 10

2.4 Mechanical Processes 11

....2.4.1 Electrophotographic processing mechanism 12

....2.4.2 Paper running process 13

2.5 Sensors 14

....2.5.1 Paper Related Sensors 15

....2.5.2 Other sensors 16

2.6 Correction of Color Deviation 17

2.7 Transfer Control according to Environmental Changes 18

2.8 Form Jam Detection 19

2.9 Cover Opening 20

2.10 Toner Lower Detection 21

2.11 Page Size Detection 22

2.12 Power-on Processing 23

3 Disassembly

3.0 Parts Replacement 24

3.1 Precautions for Parts Replacement 25

3.2 Parts Layout 26

3.3 How to Change Parts 27

....3.3.1 Cover Assy Rear 28

....3.3.2 Motor-Fan (80-25) 29

....3.3.3 Paper Eject Assy 30

....3.3.4 Cover Assy Stacker, Guide Eject FD Assy 31

....3.3.5 Upper Frame Assy 32

....3.3.6 Plate Support Assemblies 33

....3.3.7 Limiter 2way (L), (R) / Plate Guide (L), (R) 34

....3.3.8 Cover 35

....3.3.9 PCR PCB Assy 36

....3.3.10 Motor Fan 37

....3.3.11 PXF PCB/PX4 PCB 38

....3.3.12 Gear Heat Assy 39

Table of Contents Page

....3.3.13 Main Motor (A), (B) Assy 40

....3.3.14 Gear One-way (Z30) 41

....3.3.15 Motor Assy Belt 42

....3.3.16 Power Supply Unit, Holder Inlet, Sheet Insulation 43

....3.3.17 Sensor Assy Box Toner 44

....3.3.18 Square-shaped Connector 45

....3.3.19 Motor - Pulse (ID) 46

....3.3.20 One-way Gears 47

....3.3.21 Feeder Unit Front 48

....3.3.22 Manual Feed Hopper Assy 49

....3.3.23 Guide Paper Input Assy 50

....3.3.24 Two Lever Input Sensors, Lever 2nd Feed Sensor 51

....3.3.25 Roller Registration, Roller Assy Hopping 52

....3.3.26 Hopping Roller Assy 53

....3.3.27 PXU PCB/PXM PCB, Lever Resist Sensor 54

....3.3.28 Paper End Lever 55

....3.3.29 PCO PCB (Operator Panel) 56

....3.3.30 Holder Gear Toner Assy 57

....3.3.31 Plate Latch Lever (FD), Spring Latch Lever (FD) 58

....3.3.32 Transfer Belt 59

....3.3.33 High Voltage Power Supply Unit, Bracket HV (BT)

Assy

....3.3.34 Eraser Bracket Assy, Eraser Bracket (KCM) Assy 61

....3.3.35 Shaft Link 62

....3.3.36 Contact Bracket (BL-R) Assy, Contact Bracket (CL-R)

Assy

....3.3.37 Contact (BL-L) Assy, Contact (CL-L) Assy 64

....3.3.38 Contact SB Assy 65

....3.3.39 PXC PCB 66

....3.3.40 Heat Unit Assy (Fuser unit and oil roller) 67

....3.3.41 Oil Roller Kit 68

....3.3.42 Lever Lock Heat (L)/(R), Guide Side Heat, Spring Lock 69

....3.3.43 PXL PCB 70

....3.3.44 Heat Unit Guide Assy 71

....3.3.45 Holder LED Assy, LED Head 72

4 Adjustments

4. Adjustments 73

4.1 Maintenance Modes and Their Functions 74

....4.1.1 User maintenance mode 75

....4.1.2 System maintenance mode 76

....4.1.3 Engine maintenance mode 77

4.2 Adjustments after Parts Replacement 78

....4.2.1 Confirm the LED head driving time 79

60

63

Table of Contents Page

....4.2.2 Color Registration Using the Operator Panel (Color

deviation correction)

5 Maintenance

Preventive Maintenance 81

....5.1 Periodically Replaced Parts 82

....5.2 Cleaning 83

....5.4 Cleaning the Pickup Roller 84

6 Troubleshooting Procedures

6.0 Troubleshooting Procedures 85

....6.1 Troubleshooting Tips 86

....6.2 Points to Check before Correcting Image Problems 87

....6.4 Preparation for Troubleshooting 88

....6.5 Troubleshooting Flow 89

........6.5.1 LCD status message/problem list 90

........6.5.2 LCD message troubleshooting 91

........6.5.3 Image Troubleshooting 92

............Blank paper 93

............Vertical black 94

............Vertical white 95

............Poor fusing (Images are blurred or peeled off when

touched)

............Evenly spaced, repeating marks 97

............Missing characters or colors 98

............Poor synthesization Color 99

............Printout colors different from original colors

7 Wiring Diagram

7.1 Resistance Check 100

7.2 Program/Font ROM Location 101

8 Centronics Parallel Interface

Centronics Parallel Interface 102

A Illustrated Parts List

Diagram A1: Covers (Top & Sides) 103

Diagram A2: Printer Unit 104

Diagram A3: Main Chassis Unit (1) 105

Diagram A4: Main Chassis Unit (2) 106

Diagram A5: Main Chassis Motor/PCB 107

Diagram A6: Frame Upper Assy 108

Diagram A7: Guide Cassette (R) Assy 109

Diagram A8: Main Motor (A) Assy 110

Diagram A9: Main Motor (B) Assy 111

Product Accessory: I. Second Paper Feed

Preface 112

1.0 Outline 113

80

96

Table of Contents Page

....1.1 Functions 114

....1.2 External View and Component Names 115

2.0 Mechanism Description 116

....2.1 General Mechanism 117

....2.2 Hopper Mechanism 118

3.0 PARTS REPLACEMENT 119

....3.1 Precautions Concerning Parts Replacement 120

....3.2 Parts Layout 121

....3.3 Parts Replacement Methods 122

........3.3.1 Idle rollers 123

........3.3.2 AOLT-PCB 124

........3.3.3 Hopping motor 125

........3.3.4 Feed roller 126

........3.3.5 Hopping roller 127

........3.3.6 Side frame (L) assy 128

........3.3.7 Side frame (R) assy 129

4.0 Troubleshooting 130

....4.1 Precautions Prior to the Troubleshooting 131

....4.2 Preparations Prior to the Troubleshooting 132

....4.3 Troubleshooting Method 133

........4.3.1 LCD Status Message List 134

........4.3.2 Troubleshooting Flow 135

5.0 CONNECTION DIAGRAM 136

....5.1 Interconnection Diagram 137

....5.2 PCB Layout 138

6. PARTS LIST 139

....High Capacity Second Paper Feeder 140

....2nd Tray Assembly 141

Page: 2

Service Guide - OKIPAGE 8c

Chapter 0 Introduction

Preface

This manual provides procedures and techniques for the troubleshooting, maintenance, and repair of

OKIPAGE 8c.

This manual is written for maintenance personnel, but it should always be accompanied with the

OKIPAGE 8c User's Manual for procedures for handling and operating OKIPAGE 8c. For repairing each

component of OKIPAGE 8c, see the Troubleshooting Manual.

[Notices]

The contents of this manual are subject to change without prior notice. Although reasonable efforts have

been taken in the preparation of this manual to assure its accuracy, this manual may still contain some

errors and omissions. OKI will not be liable for any damage caused or alleged to be caused, by the

customer or any other person using this maintenance manual to repair, modify, or alter OKIPAGE 8c in

any manner.

[Warning]

Many parts of OKIPAGE 8c are very sensitive and can be easily damaged by improper servicing. We

strongly suggest that OKIPAGE 8c be serviced by OKI's authorized technical service engineers.

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide - OKIPAGE 8c

Chapter 1 Specifications

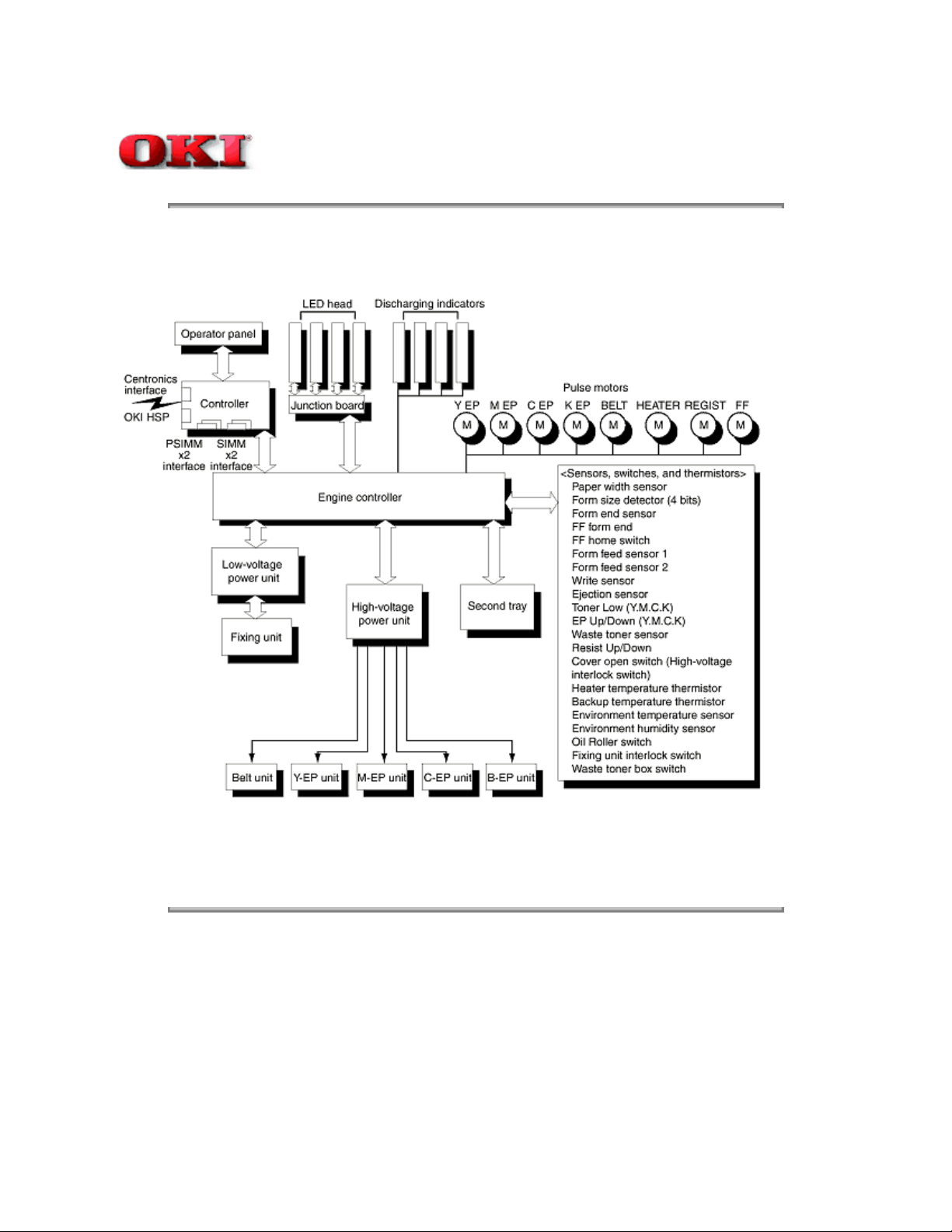

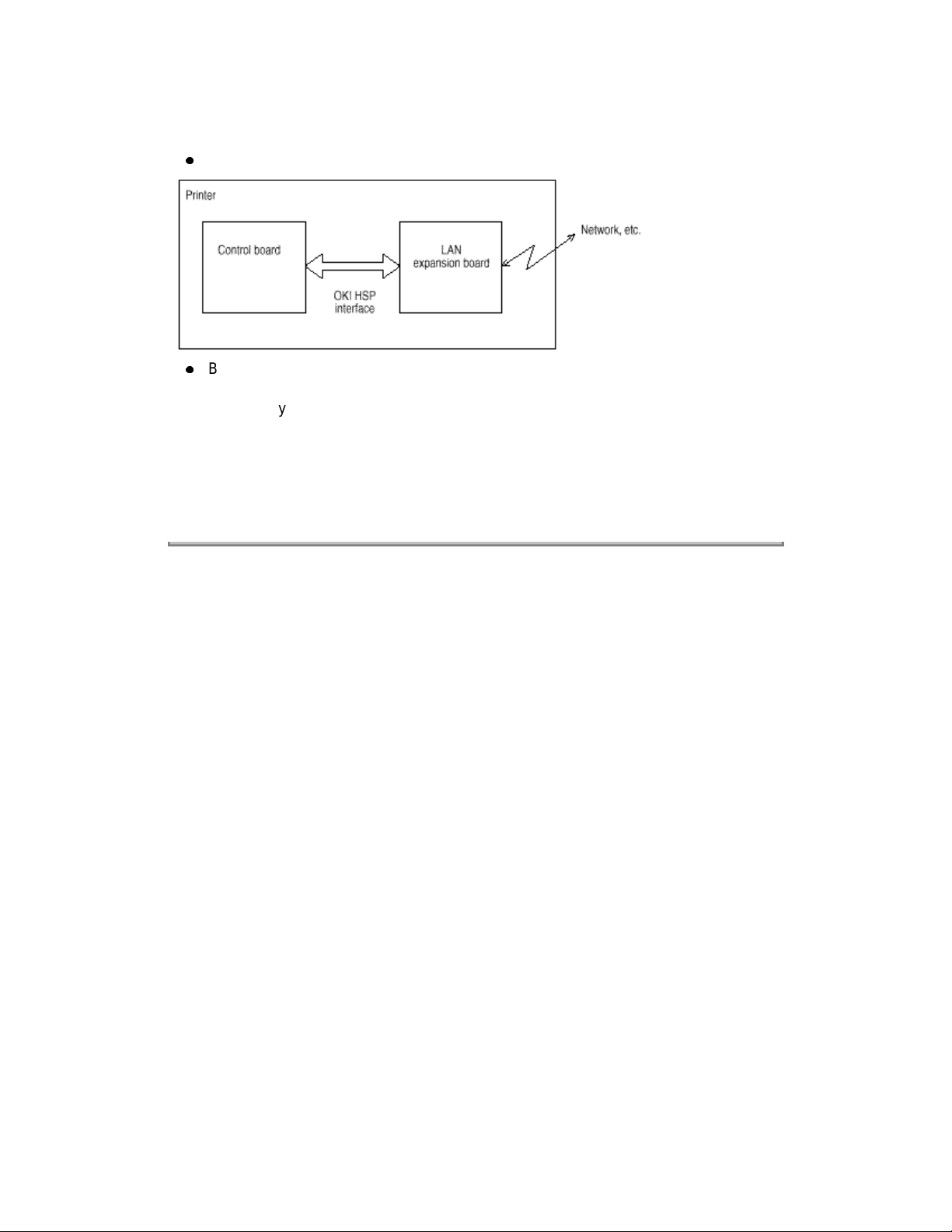

1.1 Basic System Configuration

This diagram shows the basic system configuration of OKIPAGE 8c.

Page: 3

Basic System Configuration Diagram

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide - OKIPAGE 8c

Chapter 1 Specifications

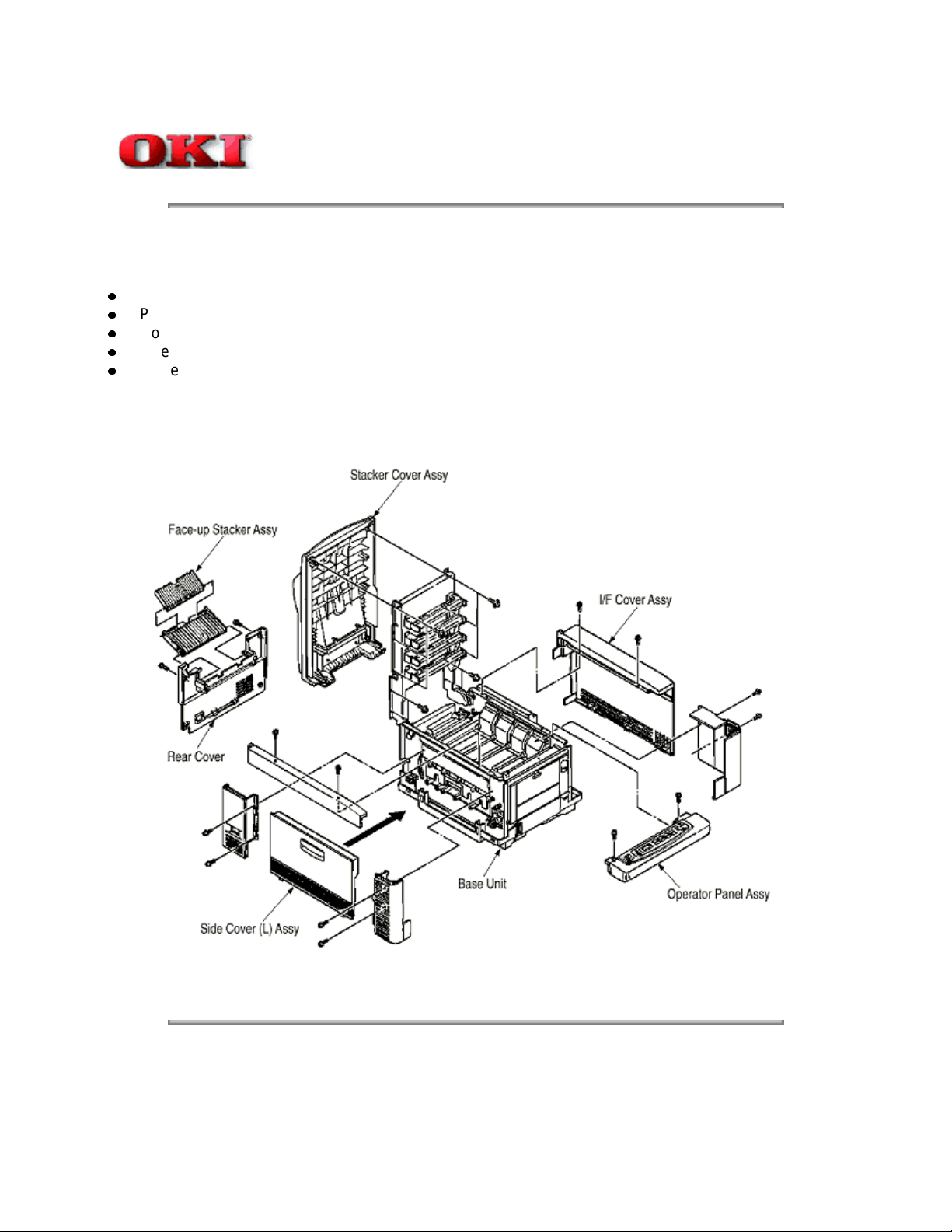

1.2 Printer Specifications

This printer unit is composed of the following hardware.

Electro-photographic processor

z

z

Paper feeder

z

Controller (CU part / PU Part)

z

Operator panel

z

Power board (High voltage part / PU part)

This diagrams shows the printer unit configuration.

Page: 4

Printer Unit Configuration Diagram

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide - OKIPAGE 8c

Chapter 1 Specifications

1.3 Option Specifications

The OKIPAGE 8c options are listed below.

(1) Second Paper Feeder

(2) RAMM SIMM module (72 pin SIMM, 4MB/8MB/16MB/32MB)

Page: 5

Make sure to use a set of 2 of the same volume size modules.

z

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

1.4 Basic Specifications

Page: 6

Service Guide - OKIPAGE 8c

Chapter 1 Specifications

(1) Dimensions

(2) Weight

(3) Form

Type:

Sizes:

Reams:

(4) Printing speed:

(5) Resolution

(6) Input voltage

(7) Power

consumption

(8) Frequency

(9) Noises

(10) Expendables and

service life

(11) Periodically

replaced parts

Width: 18.8"

Approx. 91 lbs. without box

Ordinary paper (Hammermill xx lb.) and Transparency (Only CG3710)

Recommended paper (for color printing)

Note: the printout color tones are dependent upon the whiteness of the

print paper.

Letter, Legal (13" or 14"), Executive, A4, A5, B5, and B6 (1st tray and front

feeder)

1st tray - 20 lbs. to 28 lbs.

2nd tray - 20 lbs. to 28 lbs.

Front feeder - 20 lbs. to 44 lbs.

8 pages per minute (5 pages per minute: Transparency / 34 lb. ~ 44 lb.,

123g/m

2

~ 166g/m2)

600 dots per inch x 600 dots per inch

120VAC +5.5%, -15%

230VAC to 240VAC +10%, -14%

Peak: Approx. 980W

Typical operation: Approx 230W

Idle: Approx 70W

Power save mode: Approx 32W

50Hz or 60Hz +2%, -2%

Operating: 54 decibels (without 2nd tray), 55 decibels (with 2nd tray)

Standby: 45 decibels

Power-saving: 43 decibels

Toner Cartridge: Approx. 1800 pages (5% density) (each of Y, M, C, and

K)

Image Drum: Up to 12,000 pages (5% density, continuous) (each of Y, M,

C and K)

Waste Toner Box: Up to 25,000 sheets (under typical printout conditions:

Single images of 5% density, equivalent to printout using 14 toner

cartridges)

Oil Roller Unit: Up to 10,000 sheets (Life defined in the number of actual

printed paper sheets)

Y=Yellow, M=Magenta, C=Cyan, K=Black

Note:

Fuser Heat Unit Assy: 60,000 pages

Transfer Belt Cassette Assy: 50,000 pages

(12) Temperatures and relative humidities

Temperature

Temperature conditions

Fahrenheit Celsius Remarks

Operating 50 to 89.6 10 to 32 17 Celsius to 27 Celsius (for assurance of

full-color printout quality)

Non-operating 32 to 109.4 0 to 43 Power off

Storage (1 year max.) -14 to 109.4 -10 to 43 with drum and toner

Delivery (1 month max.) -20 to 122 -29 to 50 without drum and toner and Belt Cassette

Assy

Delivery (1 month max.) -20 to 122 -29 to 50 with drum and toner

Humidity

Humidity condition

Fahrenheit Celsius Remarks

Operating 20 to 80 5 50% to 70% (for assurance of full-color

printout quality)

Non-operating 10 to 90 26.8 Power off

Storage 10 to 90 35

Delivery 10 to 90 40

(13) Printer life - 3,000,000 (A4) pages or 5 years

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 7

Service Guide - OKIPAGE 8c

Chapter 2 Operation

2. Operation

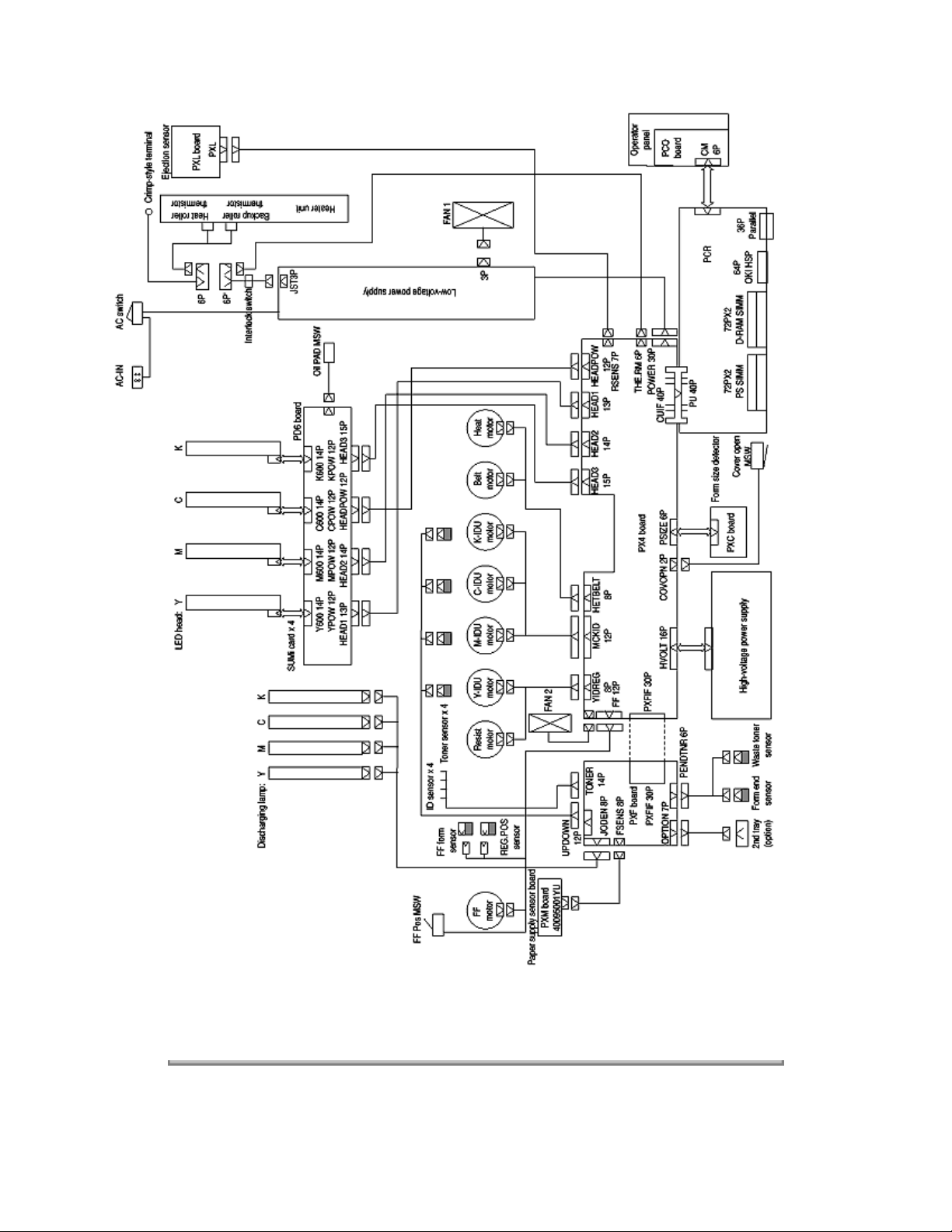

OKIPAGE 8c is a tandem color electrophotographic page printer, using 4992 Pixel-LED technologies,

OPC, dry single-component non-magnetic developing, roller transfer, heat-compression fixing (fusing).

The printing method used is a Black Writing method which applies light beams to printout areas.

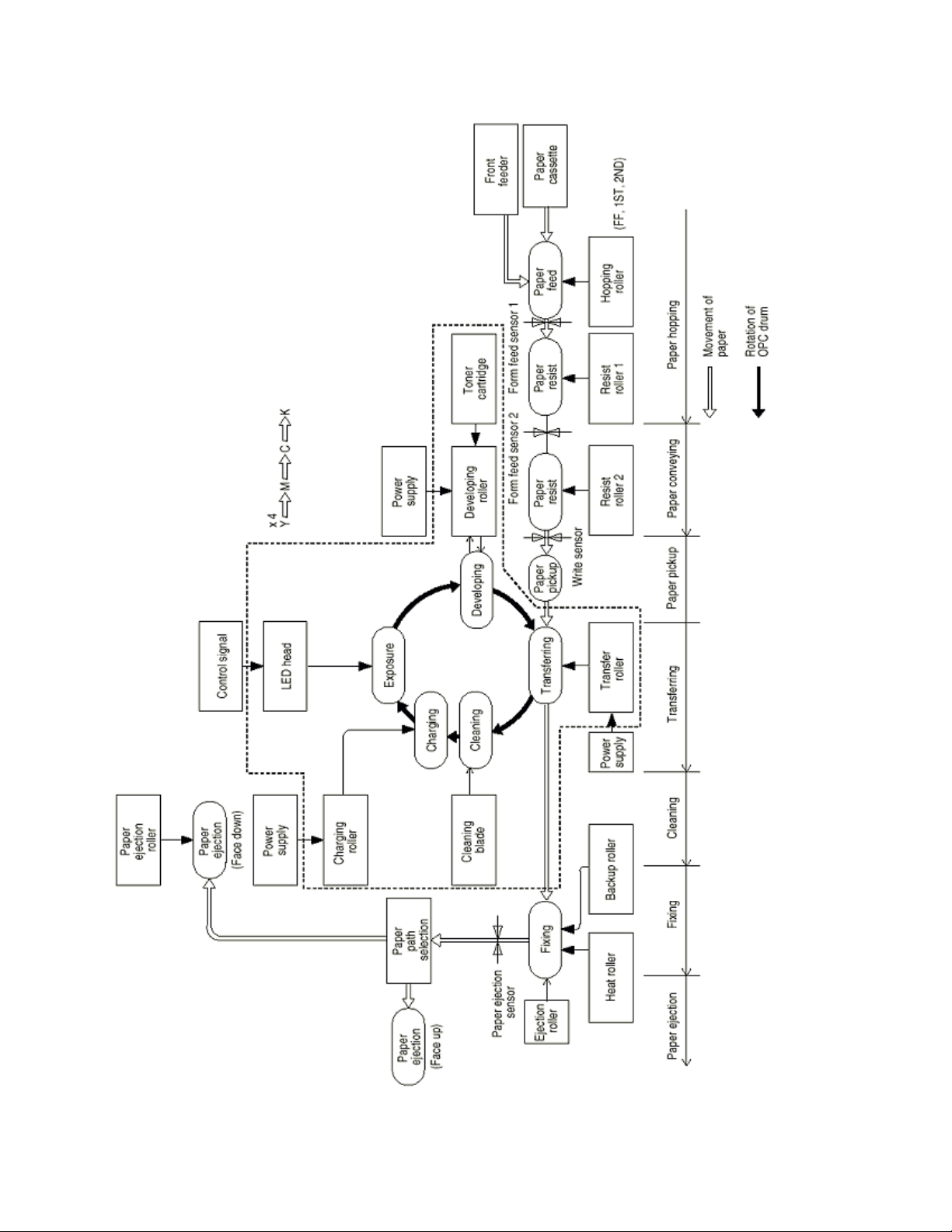

Here is the Functional Block Diagram of OKIPAGE 8c.

Functional Block Diagram

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 8

Service Guide - OKIPAGE 8c

Chapter 2 Operation

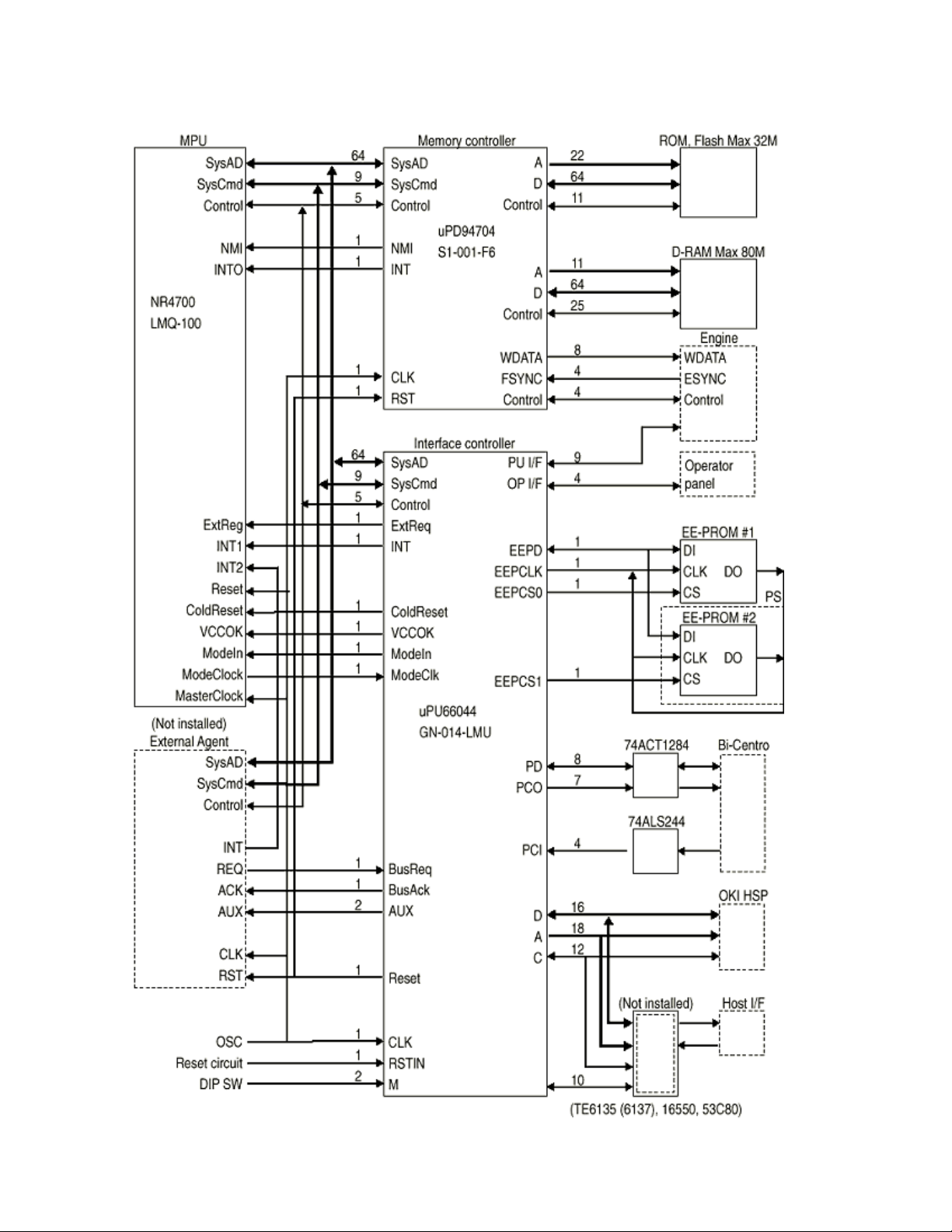

2.1 Main Control Board (PCR PCB)

The control board consists of a CPU (NR4700) block, a memory control LSI block, an interface control

LSI block, a DRAM block, an EEPROM block, a mask ROM block, and an interface block.

Here is the Functional Block Diagram of the main control board (PCR PCB).

Functional Block Diagram of Main Control Board

(1) CPU

The CPU is a 64-bit RISC architecture processor (provided y NKK). It inputs a frequency

of 50 MHz and runs at 100 MHz. It transfers data to a from memory at 50 MHz.

(2) Mask ROM

The mask ROM block consists of four 16 Mbit (1M x 16 bits) chips and its total size is 8M

bytes. The chips are mounted on the PCR-PCB by means of IC sockets and store

programs and character fonts.

(3) DRAM

The DRAM block consists of eight 16 Mbit (1M x 16bits) chips and its total size is 16M

bytes. The chips are mounted on the PCR-PCB and can be expanded up to 80M bytes

by adding the 32M byte SIMMs to the SIMM slots on the PCR-PCB.

(4) EEPROM

The EEPROM block consists of 1K-bit chips mounted on a board by means of IC sockets

and stores the following:

z

Menu data

z

Counter values

z

Adjustment values

(5) Flash ROM

The Flash ROM block consists of four 4M bit (256K x 16bits) chips and its total size is 2M

bytes. The chips are mounted on the PCR-PCB and are used for storing fonts, macro

and demo pages.

(6) Memory control LSI

This block mainly consists of memory control, CPU control, compression and

decompression, and video interface functions.

(7) Interface control LSI

This block mainly consists of PU interface control, operator panel interface control,

EEPROM control, parallel interface control, and HSP control functions.

(8) Host interface

The printer has the following interfaces to the host.

Centronics bi-directional parallel interface

OKI HSP interface (Option)

The single effective interface or the automatic interface select mode can be selected

using the menu. If the busy state of the printer continues for a long time period, the buffer

near-full control releases the busy status at constant intervals even if the host side is

busy so as not to cause interface time-out at the host side.

(a) Centronics bi-directional parallel interface

This is an interface confirming to IEEE-1284 and provides either unidirectional ad

bi-directional communications according to each of the following communication modes.

Compatibility mode - Unidirectional communications from the host to the printer.

z

z

Nibble mode - This mode transfers 4-bit wide data from the printer to the host. In

z

z

this mode, each bit of 1-byte data transmits in the form of two nibbles using

ERROR, BUSY, FAULT, and SELECT signal leads. This mode can provide

bi-directional operation in combination with the compatibility mode.

ECP mode - This mode provides the asynchronous bi-directional interface and

z

z

transmits and receives 1-byte data using eight data signal leads under semi-duplex

control by the host.

When the power is turned on, the compatibility mode is automatically selected. The

change to another mode form the compatibility mode is made through negotiation. (When

the BI-DIRECTION is set to ENABLE in the menu, this change can be performed.) (For

the electrical/physical characteristics of this interface, see APPENDIX B).

(b) OKI HSP interface (Option)

This interface (slot) is an OKI unique universal interface that provides the platform to

connect various boards (including those supplied by third vendors) such as the LAN

connection expansion board and SCSI expansion board.

Any expansion boards compatible with this interface can be mounted on the Control

board the piggyback board from without modifying the program at the printer side. Refer

to the Conceptual Diagram of the OKI HSP interface.

Conceptual Diagram of OKI HSP Interface

(9) RAM module

z

Pin layout

z

Basic specification

Type:

Access time: 72 pins SIMM (32 bits buss width)

Capacity: 60ns, 70ns, 80ns

Parity: 4, 8, 16 32 or 64MB

None

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide - OKIPAGE 8c

Chapter 2 Operation

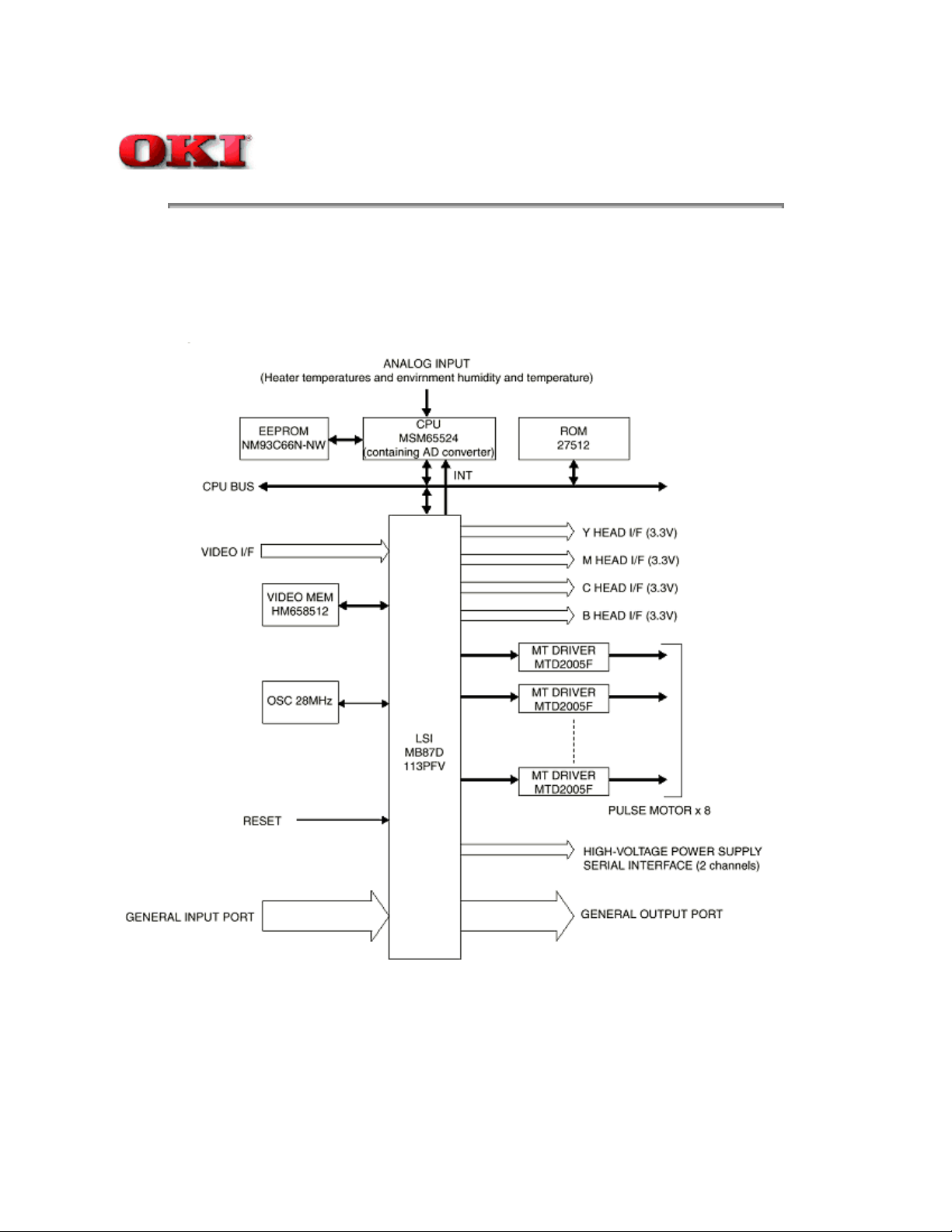

2.2 Engine Control Board (PX4 PCB)

ANALOG INPUT

(Heater temperatures and environmental humidity and temperature)

Yellow (Y), Magenta (M), Cyan (C), Black (B)

Page: 9

Engine Control Board Block Diagram

The engine control block (PU) is controlled by the engine control board (PX4 PCB) which consists of a

CPU (MSM65524), general purpose LSI chips, EPROM, EEPROM, pulse motor drivers, and video

memory. Refer to the Engine Control Board Block Diagram.

(1) CPU

This is an 8-bit CPU (OKI MSM65524) containing the AD converter and controls the whole

system.

(2) General-purpose LSI

This LSI (MB87D113PFV) is provided in the printer engine control block and has

controller-engine video interface, LED interface, motor control, sensor input, video memory

control, main scanning color correction, skew correction, high-voltage power control, and

OST-EX2 functions.

(3) EPROM

This EPROM (275C512-150) has a storage capacity of 512K bits and stores programs for

the PU block.

(4) EEPROM

This EEPROM (NM93C66N-NW) has a storage capacity of 4K bits. It is mounted on the

board by means of IC socket and stores adjustment values.

(5) Pulse motor drivers

These drivers (MTD2005F) drive eight pulse motors for moving up and down the image

drum (EP) and transferring medium.

(6) Video memory

This SRAM received print data through video interface and stores it.

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 10

Service Guide - OKIPAGE 8c

Chapter 2 Operation

2.3 Power/Board

The power board consists of an AC filter circuit, a low voltage power supply circuit, a high voltage power

supply circuit, and heater drive circuit, and photo sensors.

(1) Low voltage power supply circuit.

This circuit generates the following voltages.

Output voltage

+3.3 V CU Unit CPU, LED HEAD

+5 V Logic circuit supply voltage

+32 V Motor and fan drive voltage and source voltage for high-voltage supply,

discharge lamp

+12 V HSP, OP Amp, high voltage power supply

-12 V HSP

(2) High voltage power supply circuit

This circuit generates the following voltages necessary for electro-photographic processing from +32 V in

accordance with the control sequence from the control board. When cover open state is detected, +32 V

supply is automatically interrupted to stop the supply of all high-voltage outputs.

YMCK = Yellow, Magenta, Cyan, Black

Output

CH -1.35 KV ±50V Voltage applied to charging

DB Normal paper

Y.M.C.K.: -250V/+300V, -232V/+300V

(First paper: Y only)

Voltage Use Remarks

Use

roller

Voltage applied to

developing roller

K.: -270V/+300V

Transparency

Y.M.C.: -200V/+300V, K.:

-250V/+300V

SB Y.M.C.K.: -650V/0V Voltage applied to toner

supply roller

TR 0 to 4 KV Voltage applied to transfer

roller

FIX 0 to 2.5 KV Voltage applied to transfer

roller

Variable

Variable

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide - OKIPAGE 8c

Chapter 2 Operation

2.4 Mechanical Processes

Here is the Mechanical Process Diagram of OKIPAGE 8c.

Page: 11

Mechanical Process Diagram (Figure 2.5)

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide - OKIPAGE 8c

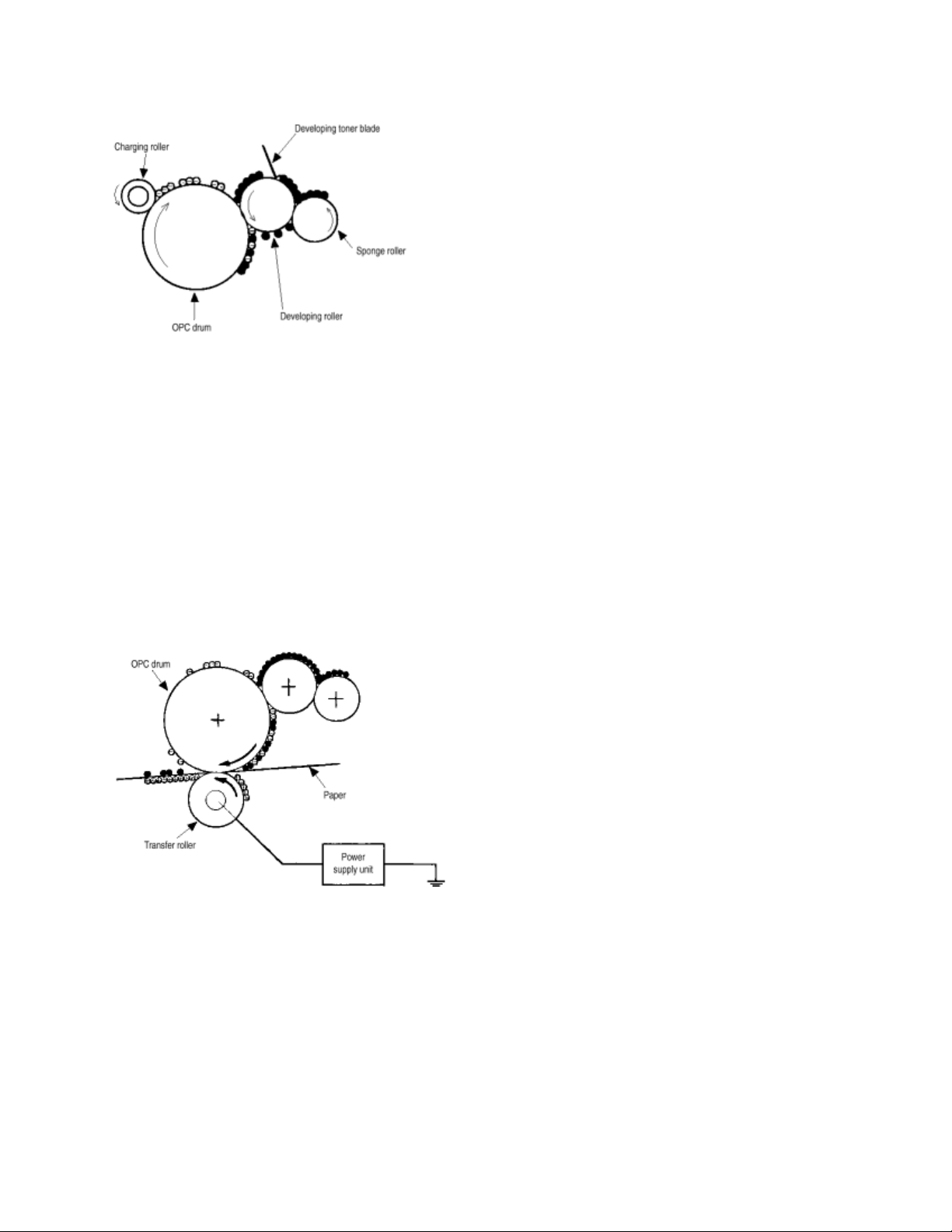

2.4.1 Electrophotographic processing mechanism

Page: 12

Chapter 2 Operation

(1) Electrophotographic processed

mechanism is outlined below.

(1) Paper pickup

resulting in a negative charge. With this negative charge, the paper is electrostatically

attracted to the roller.

(2) Charging

drum may have a uniform negative charge on its surface.

(3) Exposure

image signals to the negatively-charged surface of the image drum. The negative charge

on the illuminated surface of the image drum is reduced according to magnitudes of the

light beams. Thus, a latent image is formed on the surface of the image drum according

to the resulting surface potentials.

(4) Developing and recovery of excessive toner

negatively-charged toner to the surface of the image drum. The toner is electrostatically

attracted to the latent image to form a visible image on the surface of the image drum.

Simultaneously, this process electrostatically transfers excessive toner from the image

drum to the developing roller.

(5) Transferring

positive charge (opposite to the charge of the toner) to the back side of the paper from

the transfer roller. The toner image is transferred to the paper.

(6) Cleaning

has been used to transfer the image drum the drum to the paper.

(7) Fixing

image.

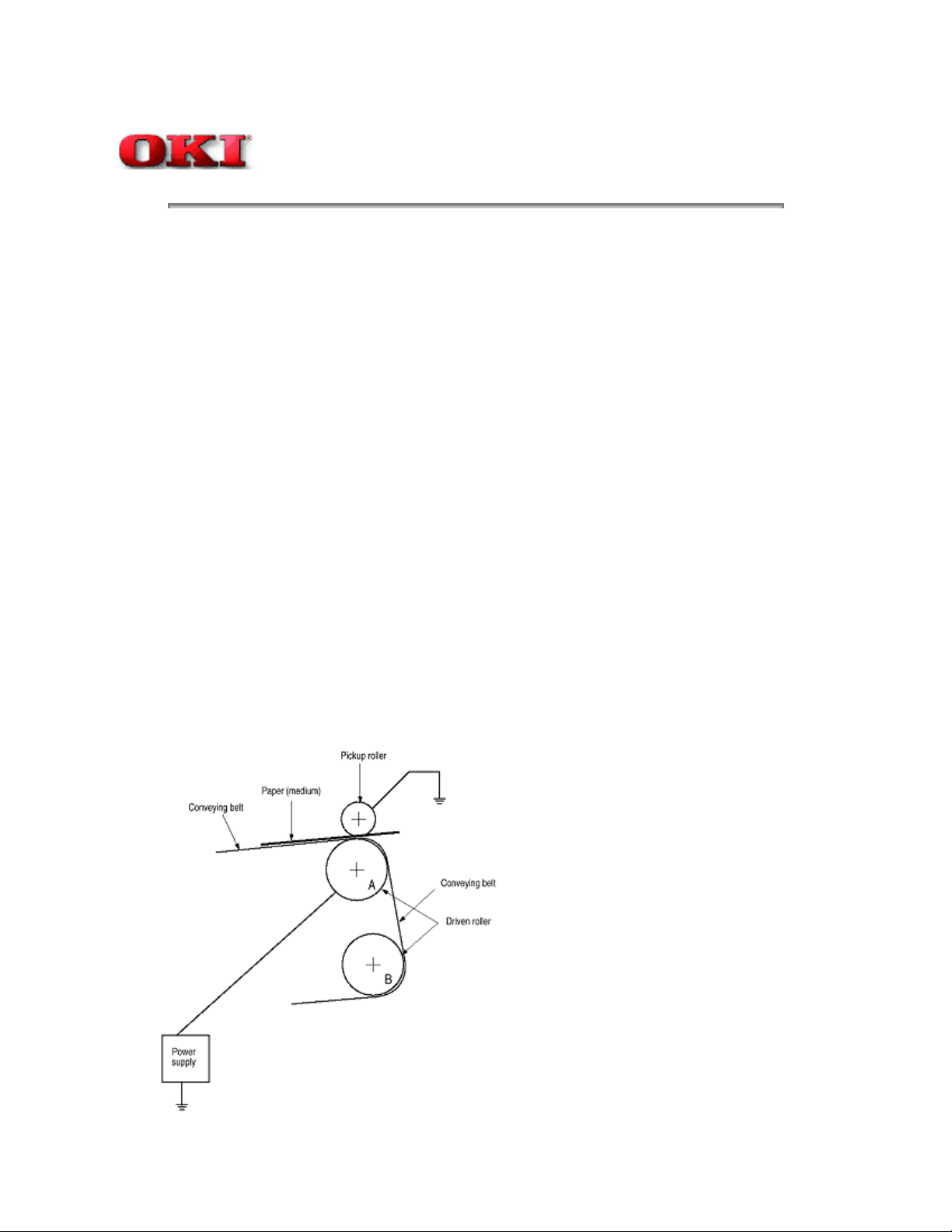

(2) Paper pickup

- This process fixes the toner image on the paper by pressing the fusing the

- This process causes the roller to give a DC voltage to the paper,

- This process gives a DC voltage to the charge roller so that the image

- This process causes the LED head to apply light beams according to

- This process fits paper to the surface of the image drum and applies

- Cleaning blade scrapes off the remaining toner of any image drum, which

- Each process of the electrophotographic processing

- This process applies

A DC voltage (0V to 2KV) is applied to the driven roller A, to create a positive charge on the lower surface

of the paper. The

kept in charged paper is electrostatically attracted to the pickup roller. The paper is in close contact with

the conveying Belt

and moves steadily.

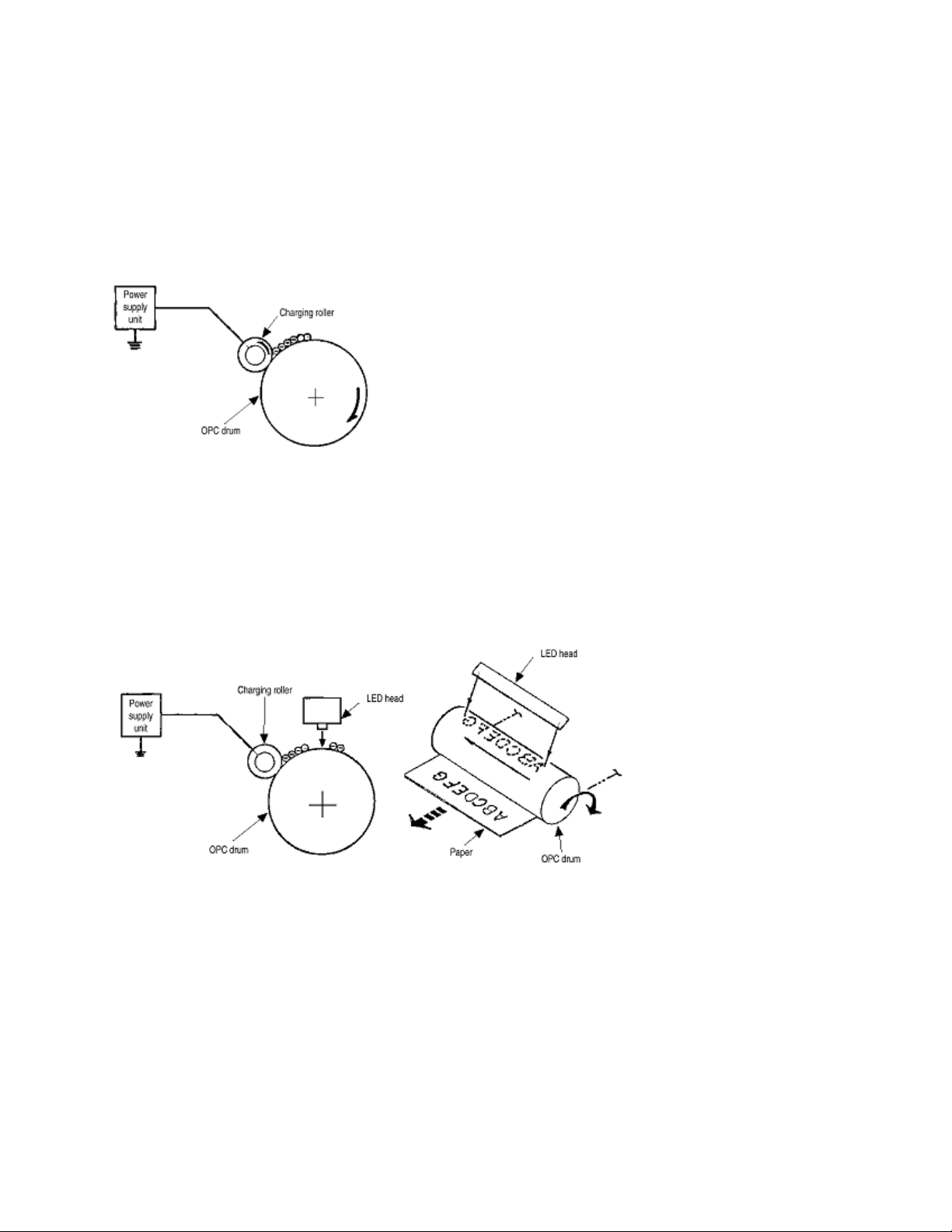

(3) Charging - This process applies a DC voltage to the charging roller in contact with the surface of the

image drum.

(4) Exposure - The light beams from the LED head are applied to the surface of the image drum which is

charged

negatively. The negative charge on the illuminated surface f the image drum is reduced according to the

magnitude of the

light beams and a latent image is formed on the surface of the image drum according to the resulting

surface potentials.

(5) Developing - This process applies toner to the latent image on the surface of the drum to create a

toner image.

Developing is carried out on the surface of the image drum at where the image contacts with the

developing roller.

(1) The sponge roller transfers toner to the developing roller. The toner is charged negatively.

(2) The toner blade scrapes away excess toner from the developing roller, leaving a thin film of toner

on the surface of

the developing roller.

(3) The toner is attracted to the latent image on the surface of the image drum, where the image

drum contacts the

developing roller. The latent image on the surface of the image drum is made visible with the toner.

(6) Transferring - The transfer roller made of conductive sponge presses the paper against the surface

of the image drum. The paper will make close contact with the surface of the image drum. This process

fits the paper to the surface of the image drum (using the transfer roller) and applies a positive charge

(opposite to the charge of the toner) from under the paper. When a positive high voltage is applied to the

transfer roller from the power supply, the positive charge induced on the transfer roller jumps to the upper

surface of the paper (where the transfer roller touches the paper) and attracts the negatively-charged

toner from the surface of the image drum onto the surface of the paper.

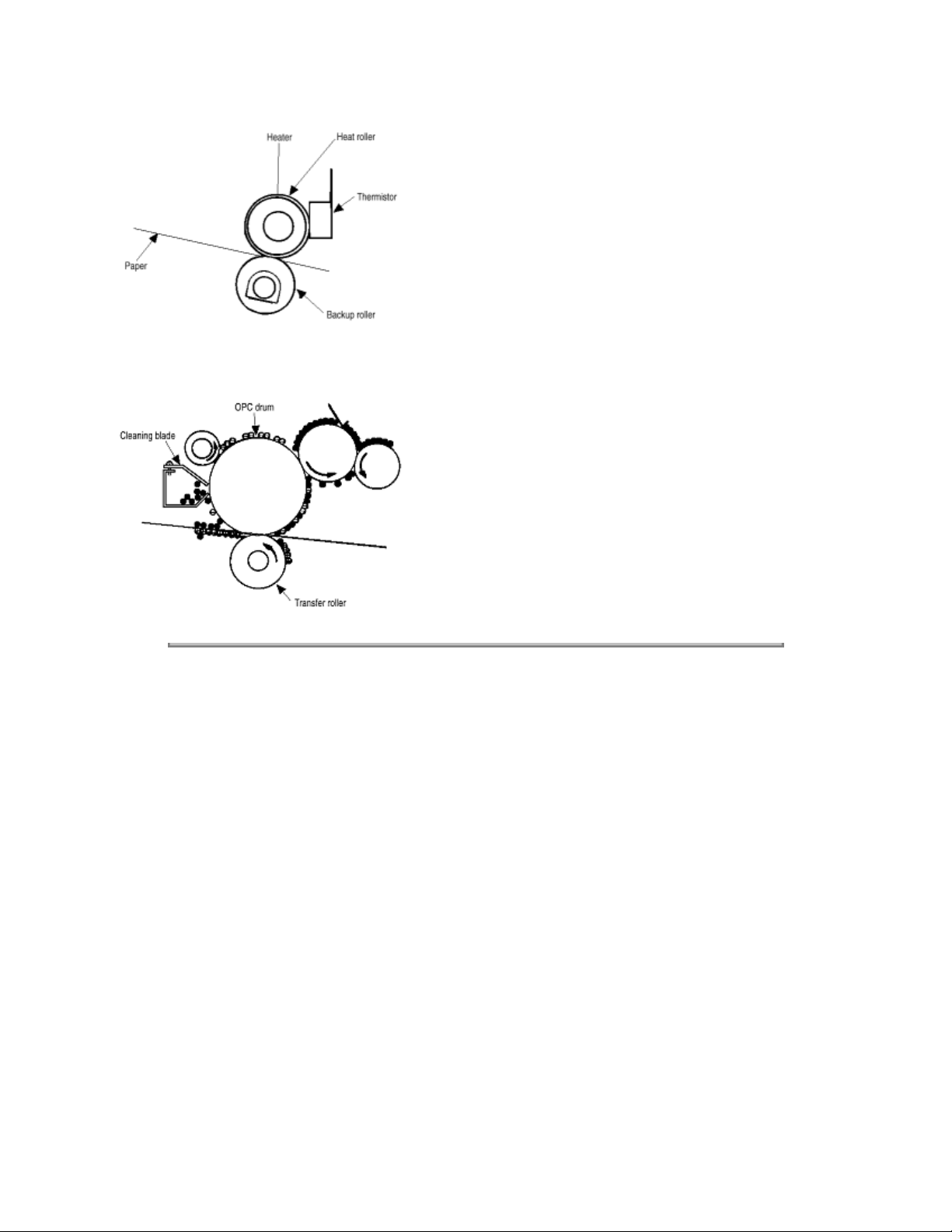

(7) Fixing - The toner image just transferred to the paper is fused and fixed to the paper while the paper

is passing through the gap between the heat roller and the backup roller. The teflon-coated surface of

the heat roller is heated by the 800-watt heater (or a halogen lamp) in the heat roller. The temperature of

the heat roller surface is controlled by a thermistor in contact with the surface of the heat roller. A

thermostat is provided for safety. When the heat roller temperature rises above the preset temperature,

the thermostat opens and shuts off power to the heater in the heat roller. The backup roller is evenly

pushed against the heat roller by two end springs.

(8) Cleaning - The toner which remains on the (OPC) Image Drum without being fused is scraped by a

cleaning blade and discarded in the waste toner tank.

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide - OKIPAGE 8c

Chapter 2 Operation

2.4.2 Paper running process

How paper moves through the OKIPAGE 8c is shown in the Paper Route Diagram.

Y=Yellow; M=Magenta; C=Cyan; K=Black

Page: 13

Loading...

Loading...