Thank You for purchasing this

Click Here for more Factory Service

Manuals for other Computer and

Printer / Copier Manufacturers

from PCTECHINFO!

Page: 1

Service Manual - OKIPAGE20

Chapter 0 Introduction

OKIPAGE 20 / OKIPAGE 20 DX / OKIPAGE 20 DXn

LED PAGE PRINTER PRODUCTS

Adobe Acrobat printable reference copy

of the OKIDATA Service Training Manual.

03/20/98

Note: This Adobe Acrobat version of the Okidata Service Training Manual was built with

the pictures rendered at 300 dpi, which is ideal for printing, but does not display well

on most displays.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Table of Contents Page

Service Manual - OKIPAGE20

0 Introduction

Copyright 1

Preface 2

1 Configuration

1.1 System Configuration 3

1.2 Printer Configuration 4

1.3 Optional Configuration 5

1.4 Specification 6

1.5 Safety Standards 7

....1.5.1 Certification Label 8

....1.5.2 Warning label 9

2 Operation Description

2.0 Operation Description 10

2.1 Main Control Board (BOARD-AAA) 11

2.2 Power Supply Unit 12

2.3 Electro-photographic Process 13

....2.3.1 Electro-photographic process mechanism 14

....2.3.2 Electro-photographic process 15

....2.3.3 Process operation descriptions 16

....2.3.4 Revision of LED Head Illumination 17

2.4 Paper Jam Detection 18

2.5 Cover Open 19

2.6 Toner Low Detection 20

2.7 Stacker-full Detection 21

2.8 Paper Size Detection 22

2.9 PostScript ROM module (BOARD-MSM or BOARD-FSL) 23

3 Parts Replacement

3.0 Parts Replacement 24

3.1 Precautions for Parts Replacements 25

3.2 Parts Layout 26

3.3 How to Change Parts 27

....3.3.1 Face -up Stacker Assy 28

....3.3.2 Contact Assy 29

....3.3.3 DC Fan Motor 30

....3.3.4 OP Panel Assy 31

....3.3.5 Board-AAA 32

....3.3.6 Stacker Assy, Damper Arm, Cover Rear 33

....3.3.7 Sensor Stacker Full 34

....3.3.8 Cable cover (guide film) 35

....3.3.9 Damper 36

....3.3.10 Feeder Unit-Front 37

....3.3.11 Roller Assy-Regist 38

Table of Contents Page

....3.3.12 Motor -Main 39

....3.3.13 Guide Assy-Eject 40

....3.3.14 Heat Assy 41

....3.3.15 Roller feed (C) 42

....3.3.16 Roller Assy-BK 43

....3.3.17 Roller Assy-Feed 44

....3.3.18 LED Head 45

....3.3.19 Paper cassette, ROLLER Ass-Feed,

ROLLER-Assy-Hopping

....3.3.20 Frame Assy-Separation 47

....3.3.21 Transfer Roller/TR Gear/TR Bearing 48

....3.3.22 EP lock shaft 49

....3.3.23 LEVER Assy- Out Sensor 50

....3.3.24 Toner sensor lever 51

....3.3.25 Paper sensor lever 52

....3.3.26 Inlet sensor lever 53

....3.3.27 Power supply unit 54

....3.3.28 Lever-Paper end & Lever-Paper near end 55

....3.3.29 Guide Assy-Cassette (L) 56

....3.3.30 Guide Assy-Cassette (R) 57

4 Adjustment

4.0 Adjustment 58

....4.1 Maintenance Mode and Functions 59

........User maintenance mode 60

........System maintenance mode 61

........Engine maintenance mode 62

........4.1.1 User maintenance mode 63

........4.1.2 System maintenance mode 64

........4.1.3 Engine maintenance mode 65

........4.1.4 EEPROM Initialization 66

....4.2 Adjustment When Replacing a Part 67

........4.2.1 Resetting the fuser counter 68

........4.2.2 Destination setting 69

5 Periodic Maintenance

5.1 Period Replacing Part 70

5.2 Cleaning 71

....5.2.1 Cleaning of LED lens array 72

....5.2.2 Cleaning the Plastic Film 73

6 Troubleshooting Procedures

6.1 Troubleshooting Tips 74

6.2 Points to Check before Correcting Image Problems 75

6.3 Tips for Correcting Image Problems 76

6.4 Preparation for Troubleshooting 77

6.5 Troubleshooting Flow 78

46

Table of Contents Page

....6.5.1 LCD status message/trouble list 79

....6.5.2 LCD message troubleshooting 80

....6.5.3 Image troubleshooting 81

7 Wiring Diagram

7.1 Interconnect Signal Diagram 82

7.2 PCB Layout 83

7.3 Resistance Check 84

7.4 Program/Font ROM Location 85

8 Parts List

Figure 8-1 Printer Unit 86

Table 8-1 Printer Unit 87

Figure 8-2 Frame-Main Unit 88

Table 8-2 Frame-Main Unit 89

Figure 8-3 Base Unit 90

Table 8-3 Base Unit 91

A Centronics Parallel Interface

Centronics Parallel Interface 92

B RS-232C Serial Interface

RS-232C Serial Interface 93

C Duplex Unit

1. OUTLINE 94

....1.1 Functions 95

....1.2 External View and Component Names 96

2.0 Mechanism Description 97

....2.1 General Mechanism 98

....2.2 JAM Release Mechanism 99

....2.3 Removing/Installing Duplex Unit 100

3.0 Parts Replacement 101

....3.1 Precautions Concerning Parts Replacement 102

....3.2 Parts Layout 103

....3.3 Parts Replacement Methods 104

........3.3.1 Board-LEX 105

........3.3.2 Connector (IMSA-9714N-14A) 106

........3.3.3 Photo Sensor 107

........3.3.4 SOLENOID Assy 108

........3.3.5 Motor 109

4.0 Troubleshooting 110

....4.1 Precautions Prior to the Troubleshooting 111

....4.2 Preparations for the Troubleshooting 112

....4.3 Troubleshooting Method 113

........4.3.1 LCD Status Message List 114

........4.3.2 Troubleshooting Flow 115

5.0 Connection Diagram 116

....5.1 Interconnection Diagram 117

Table of Contents Page

....5.2 PCB Layout 118

6.0 Parts List 119

Table 6-1 Duplex Unit 120

D Second / Third Paper Feeder

1.0 Outline 121

....1.1 Functions 122

....Appearance and Parts Name 123

2.0 Description of operation 124

....2.1 Driving Mechanism 125

....2.2 Hopper Mechanism 126

3.0 Parts Replacement 127

....3.1 Precautions Concerning Parts Replacement 128

....3.2 Parts Layout 129

....3.3 Parts Replacement Methods 130

........3.3.1 Roller assy hopping, Roller assy feed 131

........3.3.2 Cover front assy 132

........3.3.3 Board-BBB 133

........3.3.4 Lever paper end, Lever paper near end 134

........3.3.5 Motor 135

........3.3.6 Connector (IMSA-9714N-14B), Connector

(IMSA-9714N-14A)

........3.3.7 Frange pulley, pulley Idle, Mini pitch belt, Plate Earth

shaft, Gear double, Tray switch assy

........3.3.8 Roller feed 138

........3.3.9 Bracket sub roller 139

........3.3.10 Frame side (L) assy 140

........3.3.11 Frame side (R) assy 141

4.0 Troubleshooting 142

....4.1 Precautions Prior to the Troubleshooting 143

....4.2 Preparations for the Troubleshooting 144

....4.3 Troubleshooting Method 145

........4.3.1 LCD Status Message List 146

........4.3.2 Troubleshooting Flow 147

5.0 Connection Diagram 148

....5.1 Interconnection Diagram 149

....5.2 PCB Layout 150

6.0 Parts List 151

E Multi-Feeder

1.0 Outline 152

....1.1 Functions 153

....1.2 External View and Component Names 154

2.0 Mechanism Description 155

....2.1 General Mechanism 156

....2.2 Hopper Mechanism 157

136

137

Table of Contents Page

3.0 Parts Replacement 158

....3.1 Precautions Concerning Parts Replacement 159

....3.2 Parts Layout 160

....3.3 Parts Replacement Methods 161

........3.3.1 Separator 162

........3.3.2 AOLE-PCB 163

........3.3.3 Square-shaped connector 164

........3.3.4 Hopping Motor 165

........3.3.5 Planet gear 166

........3.3.6 Roller B 167

........3.3.7 Roller A 168

........3.3.8 Mini pitch belt & Feed roller 169

4.0 Troubleshooting 170

....4.1 Precautions Prior to the Troubleshooting 171

....4.2 Preparations for the Troubleshooting 172

....4.3 Troubleshooting Method 173

........4.3.1 LCD Status Message List 174

........4.3.2 Troubleshooting Flow 175

5.0 Connection Diagram 176

....5.1 Interconnection Diagram 177

....5.2 PCB Layout 178

@6.0 Parts List 179

Page: 1

Service Manual - OKIPAGE20

Chapter 0 Introduction

All specifications are subject to change without notice.

PostScript, Adobe and the PostScript logo are trademarks of Adobe Systems Incorporated, registered in

the U.S.A.

*Times, Helvetica and Palatino are trademarks of Linotype AG and/or its subsidiaries.

ITC Avant Garde Gothic, ITC Zapf Chancery, ITC Zapf Dingbats and ITC Bookman are registered

trademarks of International Typeface Corporation.

HP and LaserJet are registered trademarks of Hewlett-Packard Company.

Diablo 630 is a registered trademark of Xerox Corporation.

AppleTalk is a registered trademark of Apple Computer, Inc.

LocalTalk is a trademark of Apple Computer, Inc.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 2

Service Manual - OKIPAGE20

Chapter 0 Introduction

This Service Handbook describes the field maintenance procedures for the OKIPAGE20/20n and 20DX.

This handbook was written for use by maintenance personnel. Note, however, that the user should refer to

the USER'S MANUAL for operating instructions for the equipment.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 3

Service Manual - OKIPAGE20

Chapter 1 Configuration

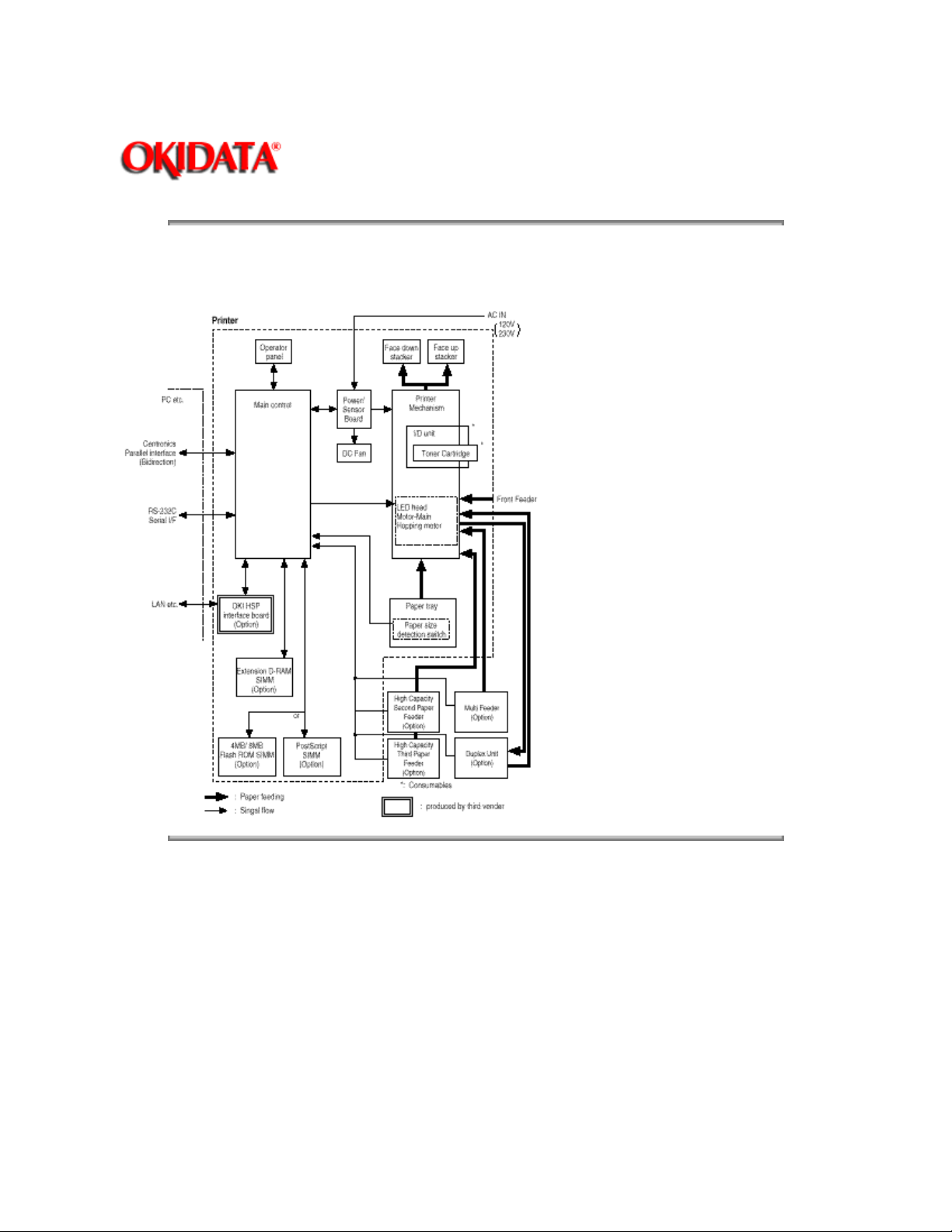

The OKIPAGE20 Series printers consist of control and engine blocks as the standard configuration (See

Figure 1-1.)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 1 Configuration

The printer unit consists of the following hardware components:

Electro-photographic processor

Paper feeder

Controller

Operator panel

Power/sensor board

Figure 1-2 shows the printer unit configuration.

Page: 4

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 1 Configuration

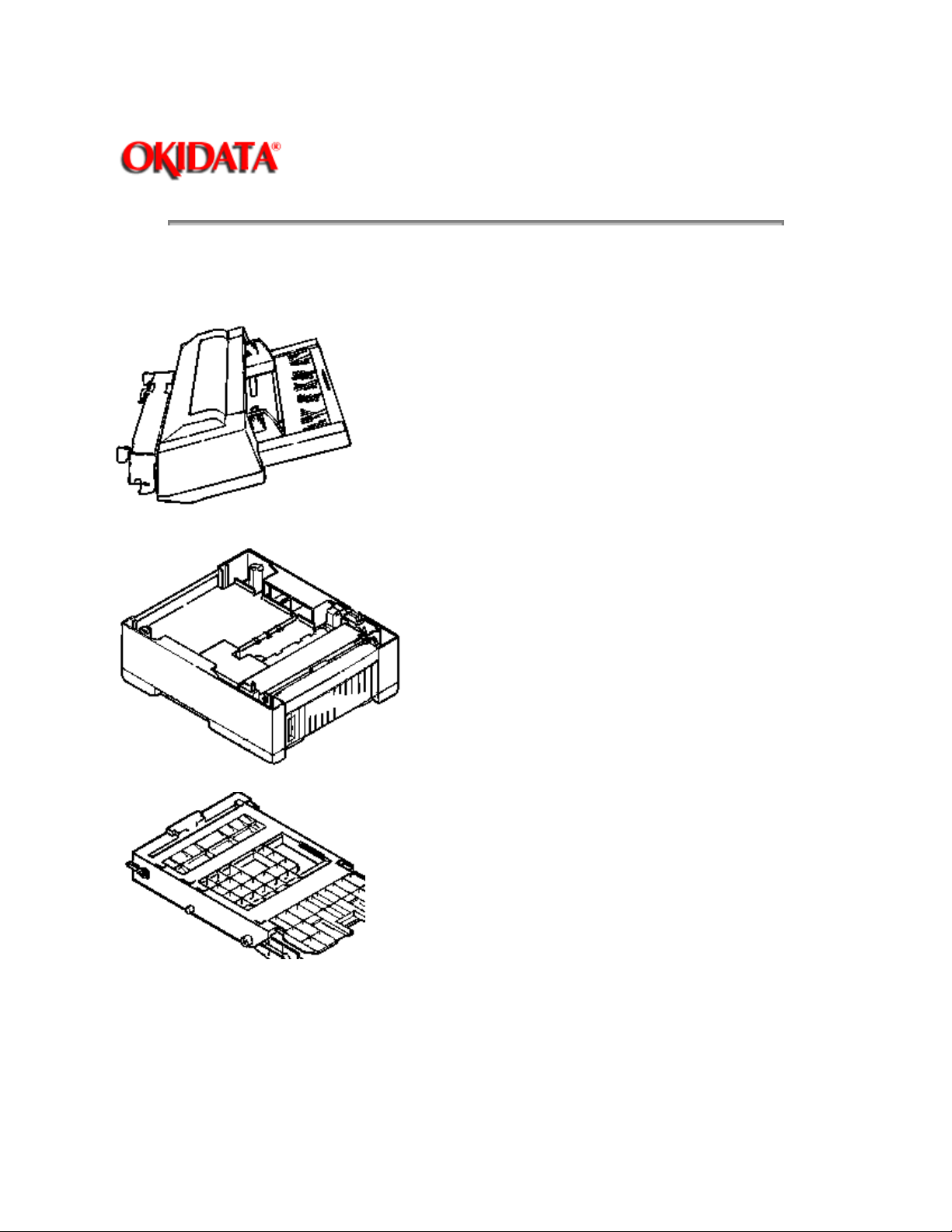

The options below are available for use with the OKIPAGE20 Series Printer. They are sold

separately from the printer unit.

(1) Multi Feeder

(2) Second / Third Paper Feeder

Page: 5

(3) DUPLEX Unit

(4) Flash ROM module (72 pin SIMM, 4MB/8MB)

(5) PostScript ROM module (72pin SIMM)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

(1) Type Desktop

Page: 6

Service Manual - OKIPAGE20

Chapter 1 Configuration

(2) External dimensions (excludes

protruding portion)

Height 13.0" (331 mm)

Width 14.4" (336 mm)

Depth 18.2" (378 mm)

(3) Weight 42 lbs. (19 kg) If Installed Duplex 47 lbs. (21.3 kg)

(4) Developing method

Exposing method

Dry electrophotography

LED stationary head

(5) Paper used <Type>

Standard paper

- Xerox 4200 (20 lbs.)

Application paper (manual face-up feed)

- Label

- Envelope

- OHP paper (transparency)

<Size>

Standard sizes

- Letter

- Legal

- Legal-13

- Executive

- COM-10

- Monarch

- DL

- C5

- COM-9

- A4

- A5

- B5 (JIS)

- A6

Applicable sizes

- Width: 3.4" to 8.5" (86 to 216 mm)

- Length: 5.5" to 14" (140 to 355.6 mm)

<Thickness>

- Automatic feed: 16 to 28 lbs. (60 to 105 g/m

2

)

- Manual feed: label, OHP paper (transparency)

Envelope, 16-36 lb.

(6) Printing speed First print: 8 sec.

Continuous printing: 20 sheets/min. [at duplex print: 10

sheet/min.]

Warm-up time: 90 seconds, [at room temperature 77o F

o

C), and rated voltage (120 VAC)]

(25

(7) Paper feeding method Automatic feed or manual feed

(8) Paper delivery method Face down/face up

(9) Resolution 600 x 600 dots/inch

600 x 1200 dots/inch

(10) Power input 120 VAC + 5.5%, -15% (ODA)

230V + 10%

(11) Power consumption Peak: Approx. 820W

Typical: Approx. 350W

Idle: Approx. 95W

Power save mode: Approx. 25W

(12) Temperature and humidity

In operation Power off mode During Storage Unit

Temperature 50-90

(10-32)

32-110

(0-43)

14-110

(-10-43)

Humidity 2-80 10-90 10-90 %RH

Maximum wet bulb

temperature

Minimum

difference between

77

(25)

35.6

(2)

80.4

(26.8)

35.6

(2)

--------------

________

o

F

o

C)

(

o

F

o

C)

(

o

F

o

C)

(

wet and dry bulb

temperature

Notes:

1. Storage conditions specified above apply to printers in packed condition.

2. Temperature and humidity must be in the range where no condensation occurs.

(13) Noise During operation: 50 dBA or less (without second tray)

55 dBA or less (with second tray)

At standby: 45 dBA or less

Power save mode: 43 dBA or less

(14) Consumables Toner cartridge kit 5,000 (5% duty)*

Image drum cartridge 30,000 at continuous printing*

19,000 (3 page/job) (Simplex printing)*

*Simplex printing without Power Save.

10,000 (1 page/job)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 7

Service Manual - OKIPAGE20

Chapter 1 Configuration

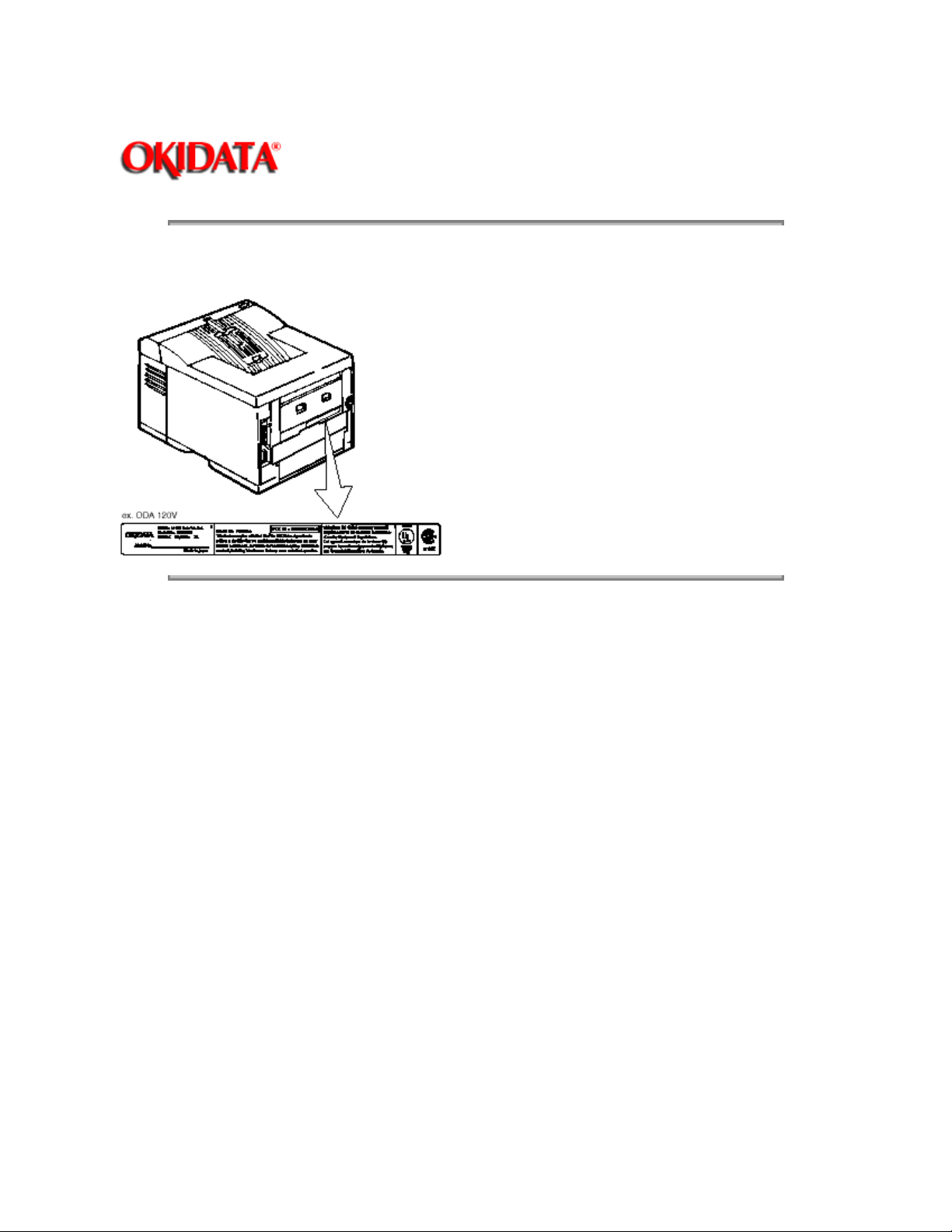

1.5.1 Certification label

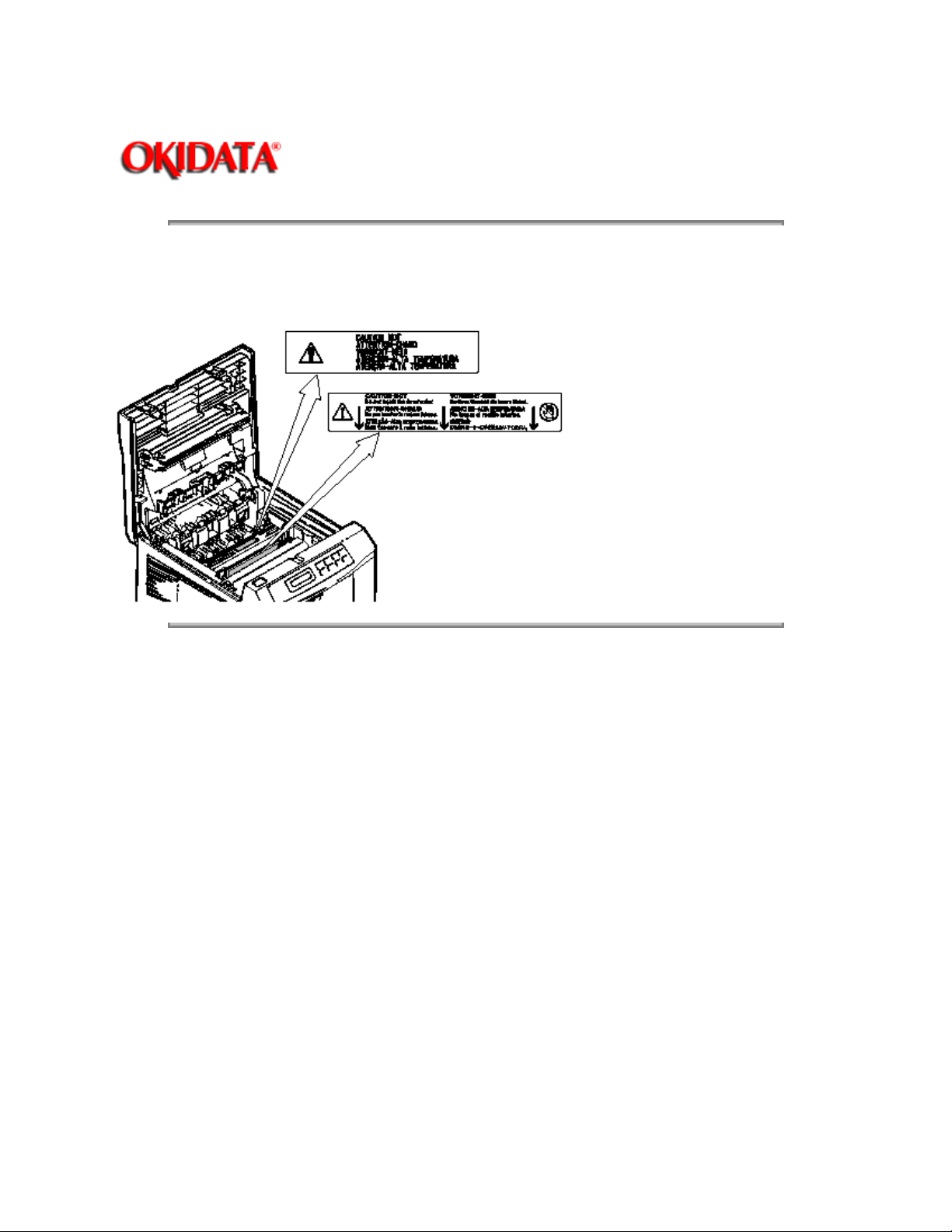

1.5.2 Warning label

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 1 Configuration

The safety certification label is affixed to the printer in the position below.

Page: 8

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 9

Service Manual - OKIPAGE20

Chapter 1 Configuration

he warning label is affixed to the portion which may cause an injury to human body. Follow the instructions

on warning labels during maintenance.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 10

Service Manual - OKIPAGE20

Chapter 2 Operation Description

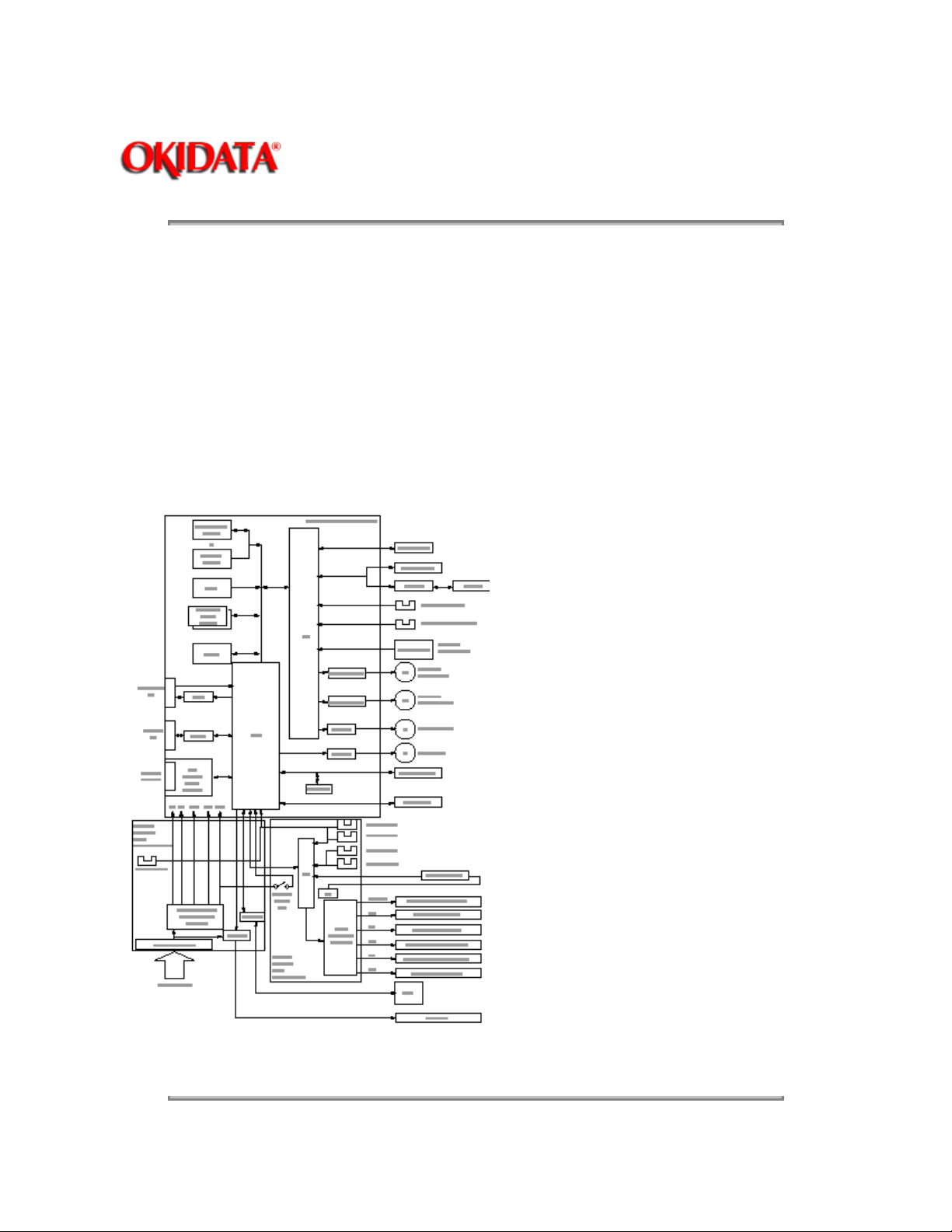

The OKIPAGE20 Series Printers consist of a main control board, a power supply unit (120V/230V), a

power supply unit (high voltage), an operator panel and an electro-photographic process mechanism.

The control board receives data through a host I/F, decodes and edits the data, and stores the edited data

in a memory. After completing edition of one page of data, it references the font memory and generates bit

data on the same memory. At the same time, it transfers the bit image data to an LED head in units of one

dot line.

The electro-photographic process mechanism prints data on paper.

The operator panel is used for operations and status display.

Fig. 2-1 shows an OKIPAGE20 Series Printer block diagram.

Figure 2-1 OKIPAGE 20 Series Printer block diagram

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 11

Service Manual - OKIPAGE20

Chapter 2 Operation Description

The control board consists of an one chip CPU, a LSI program/font ROMs, four DRAMs, an EEPROM, a

host interface circuit, and a mechanism driving circuit.

(1) One-chip CPU

The one-chip CPU is a custom CPU (32-bit internal bus, 32-bit external bus, 40-MHz clock, that

incorporates and RISC CPU and its peripheral devices, and has the following functions.

Built-in device

Chip select controller

Bus controller

DRAM controller

DMA controller Transfer of data from Host I/F to RAM

Serial interface controller Control of RS-232C serial interface

Parallel interface controller Control of Centronics parallel interface

Timer Generation of various control timing

Serial I/O Port Control of serial interface between controller and operator panel,

I/O Port Input and output of sensor and motor signals.

Motor driver controller Control of Main Motor

Compression/extension circuit Compressed frame buffer is produced by compressing the data

Function

Control of peripheral LSI, ROM, RAM and I/O device

Monitoring of paper running and paper size

EEPROM Control of a serial interface between controller and

power supply board.

Outputting of various control signals

of temporary band buffer.

Extension printing operation is executed by extending the data

of compressed frame buffer.

(2) Program and Font ROMs

The program/font ROM's store the HP LJ5 emulation program and various types of font. MASK ROM is

used as the program/font ROM's.

(3) DRAM's

4-Megabyte DRAM (16 Mbit DRAM x 2) is mounted as resident memory to be used for storing

the program and providing various buffers. This DRAM is expandable up to 68 Mbytes by

adding expansion memory (SIMMs). This DRAM provides the areas shown in the following

table.

Memory capacity setting

Memory area Use MENU Expansion RAM

System area Working area used for the program Fixed Fixed

Raster buffer Stores converted bit image data Enable Expandable

Receive buffer Stores temporarily the data received from

Enable Expandable

the host interface

Page buffer Adds print information to the analyzed

-- Expandable

receive data and stores the resulted data.

DLL/macro buffer Stores soft fonts and macro data -- Expandable

Font cache buffer Stores bit map fonts generated by the font

Enable Expandable

rasterizer based on scalable font

information

(4) EEPROM

The EEPROM has a 1-kbit capacity and stores the following data:

Menu data

Various counter data (page counter, drum counter, fuser counter, etc)

Adjusting parameters (LED head drive time, print start position, etc)

(5) LSI (LZ9FF22)

Built in device

Function

Serial I/O port Control of serial interface between controller and 2nd tray, 3rd tray, Multi-purpose feeder

Control of serial interface between controller and Duplex unit

Motor driver controller Control of Hopping motor

I/O port Inputting of various sensor signals

Output of various control signals

(6) Host interface

Centronics bi-directional parallel interface

RS232C interface

OKI HSP interface (Option)

The single effective interface or the automatic interface select mode can be selected using the menu. If

the busy state of the printer continues for a long time period, the buffer near-full control releases the busy

status at constant intervals even if the host side is busy so not to cause the interface time-out at the host

side.

(a) Centronics bi-directional parallel interface

This is an interface conforming to IEEE-1284 and provides either of unidirectional and bi-directional

communications according to each of the following communication modes.

Compatibility mode - Unidirectional communications from the host to the printer.

Nibble mode - This mode transmits 4-bit wide data from the printer to the host. In this mode, each

1-byte data is transferred in the form of two nibbles using ERROR, BUSY, FAULT, and SELECT

signal leads. This mode can provide the bi-directional operation in combination with the compatibility

mode.

ECP mode - This mode provides the asynchronous bi-directional interface and transmits and receives

1-byte data using eight data signal leads under the semi-duplex control by the host.

When the power is turned on, the compatibility mode is automatically selected. The change to another

mode from the compatibility mode is made through negotiation. (When the BI DIRECTION is set to

ENABLE in the menu, this change can be performed.) (For the electrical/physical characteristics of this

interface, see APPENDIX B)

(b) RS232C serial interface

The following protocol is supported for the serial interface conforming to EIA RS232C.

READY/BUSY (DTR HI or DTR LO)

X-ON/X-OFF

RBST X-ON

(For the electrical/ physical characteristics of the interface, see APPENDIX B)

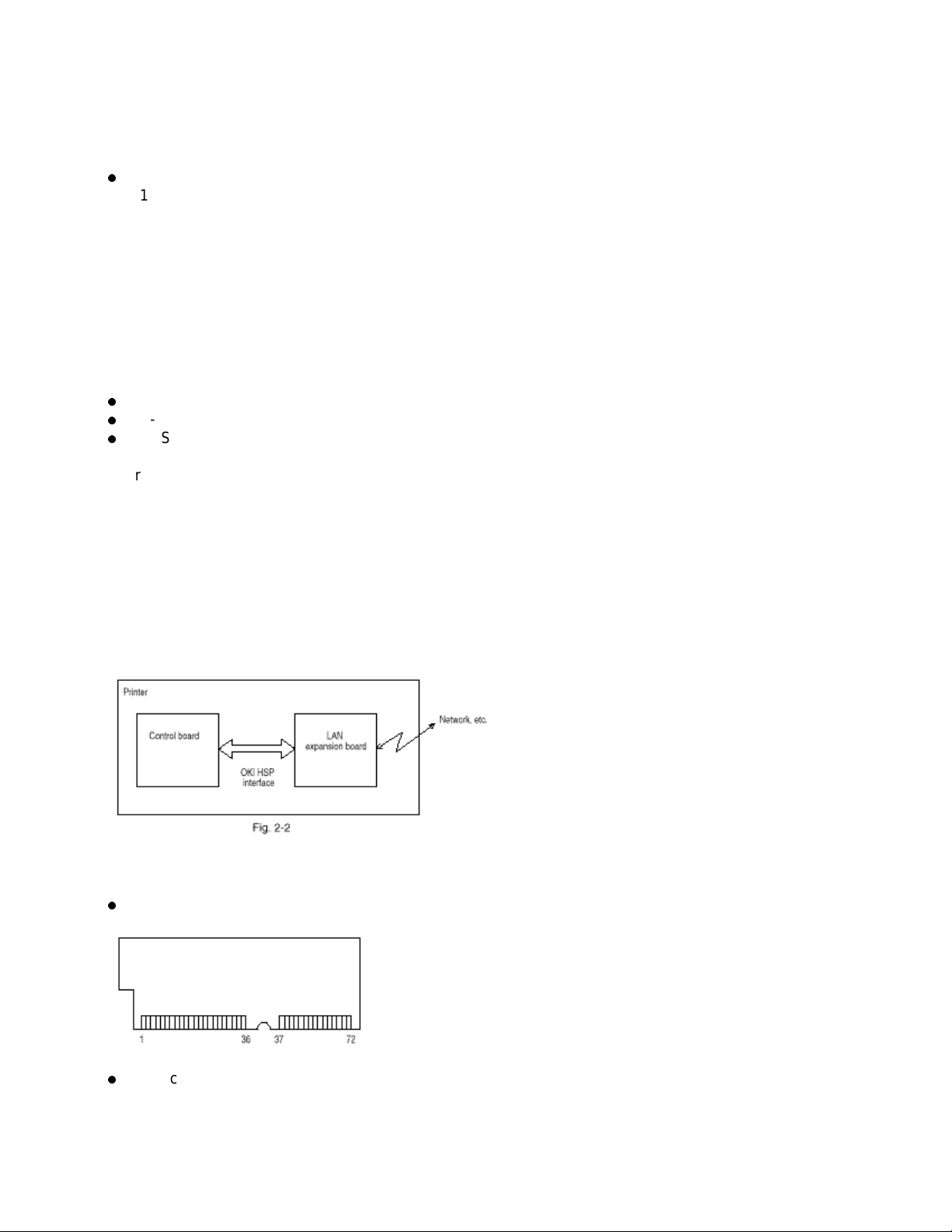

(c) OKI HSP interface (Option)

This interface (slot) is an OKI proprietary universal interface that provides the platform to connect various

boards (including those supplied by third party vendors) such as the LAN connection expansion board and

SCSI expansion board. Any expansion boards compatible with this interface can be mounted on the

Control board in the piggyback connector without modifying the program at the printer side. The

conceptual diagram of the OKI HSP interface is shown in Fig. 2-2. (For the electrical/physical

characteristics of the OKI HSP interface, see the OKI HSP interface technical manual.)

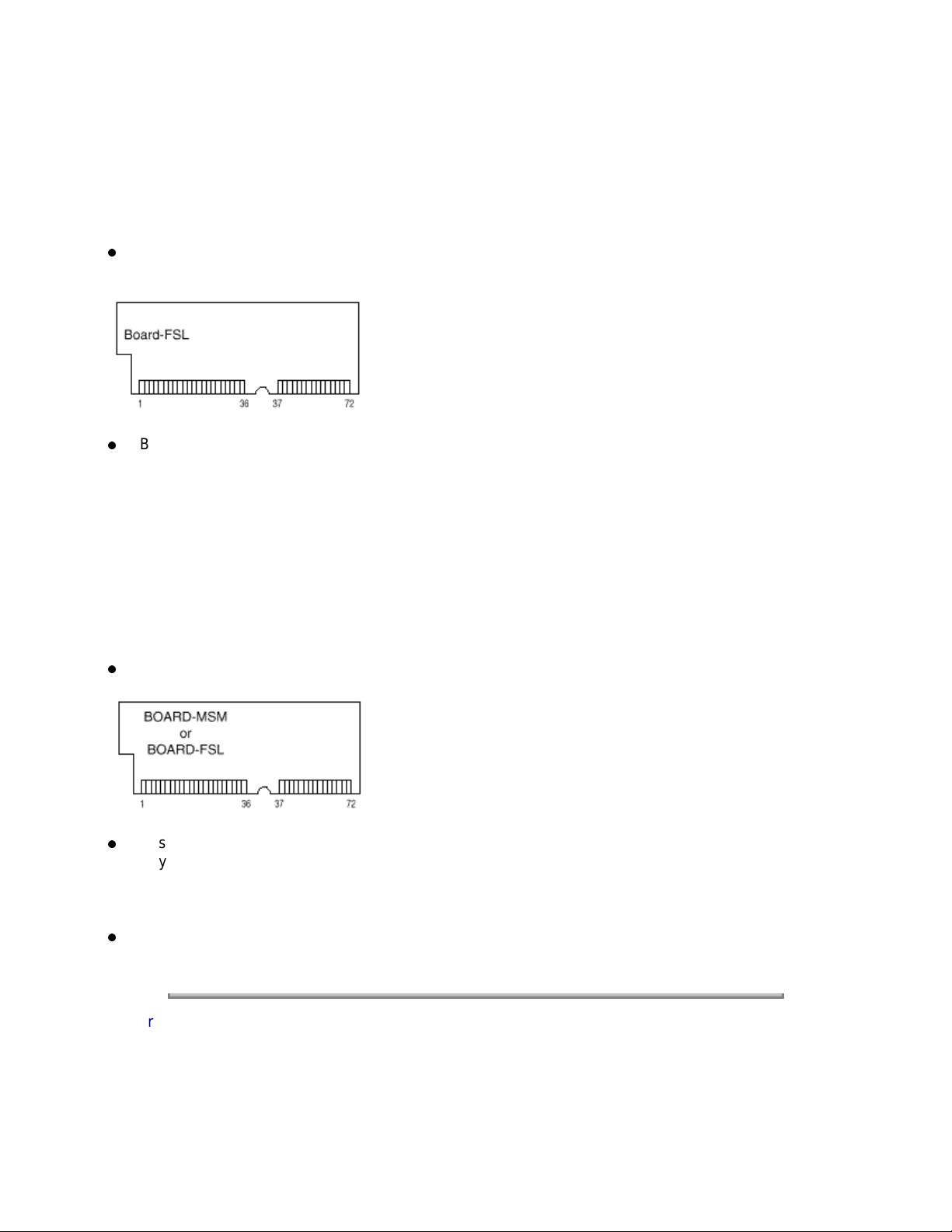

(7) RAM module

Pin layout

Basic specification

- Type: 72 pins Standard SIMM (32 bits buss width) [

- Access time: 60ns, 70ns, 80ns, 100ns

- Capacity: 4, 8, 16 or 32MB

- Parity: None

(8) Flash ROM module

Pin layout

Basic specification

- Type: 72 pins SIMM (32 bits buss width)

- Access time: 90ns

- Capacity: 4 or 8MB

(9) PS ROM module

PS ROM module is BOARD-MSM or BOARD-FSL

Note:

EDO SIMM type cannot be used.]

BOARD MSM consists of MASK ROM

BOARD FSL consists of Flash ROM (8MB).

Pin layout

Basic specification

- Type: 72 pins SIMM (32 bits buss width)

- Access time: 100ns (Board-MSM), 90n (Board-FSL)

- Capacity: 6MB (Board-MSM), 8MB (Board-FSL)

Emulation : PostScript Level 2

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 12

Service Manual - OKIPAGE20

Chapter 2 Operation Description

The power supply/sensor board consists of an AC filter circuit, a low voltage power supply circuit, a high

voltage power supply circuit, heater drive circuit, and photosensors.

(1) Low Voltage Power Supply Circuit

This circuit generates the following voltages.

Output voltage

+5 V Logic circuit supply voltage

+30 V Motor and fan drive voltage and source voltage for high-voltage supply

+8 V Reset circuit, RS232C Line voltage

-8 V RS232C Line voltage

+3.8V LED head supply voltage

(2) High Voltage Power Supply Circuit

This circuit generates the following voltages necessary for electrophotographic process from +30 V,

according to the control sequence from the main control board. When cover open state is detected, +30 V

supply is automatically interrupted to stop the supply of all high-voltage outputs.

Output

Sub-CH -15 Microline Voltage applied to Sub charging roller

CH -1.3 KV Voltage applied to charging roller

DB -220V/+300V Voltage applied to developing roller

SB -450 V Voltage applied to toner supply roller

TR +4 KV/-1.3 kV Voltage applied to transfer roller Variable + only

CB +450 V/-1350V Voltage applied to cleaning roller

(3) Photosensor

The photosensor mounted on this power supply/sensor board monitors the status of paper being fed

through the printer during printing.

Voltage Use Remarks

Use

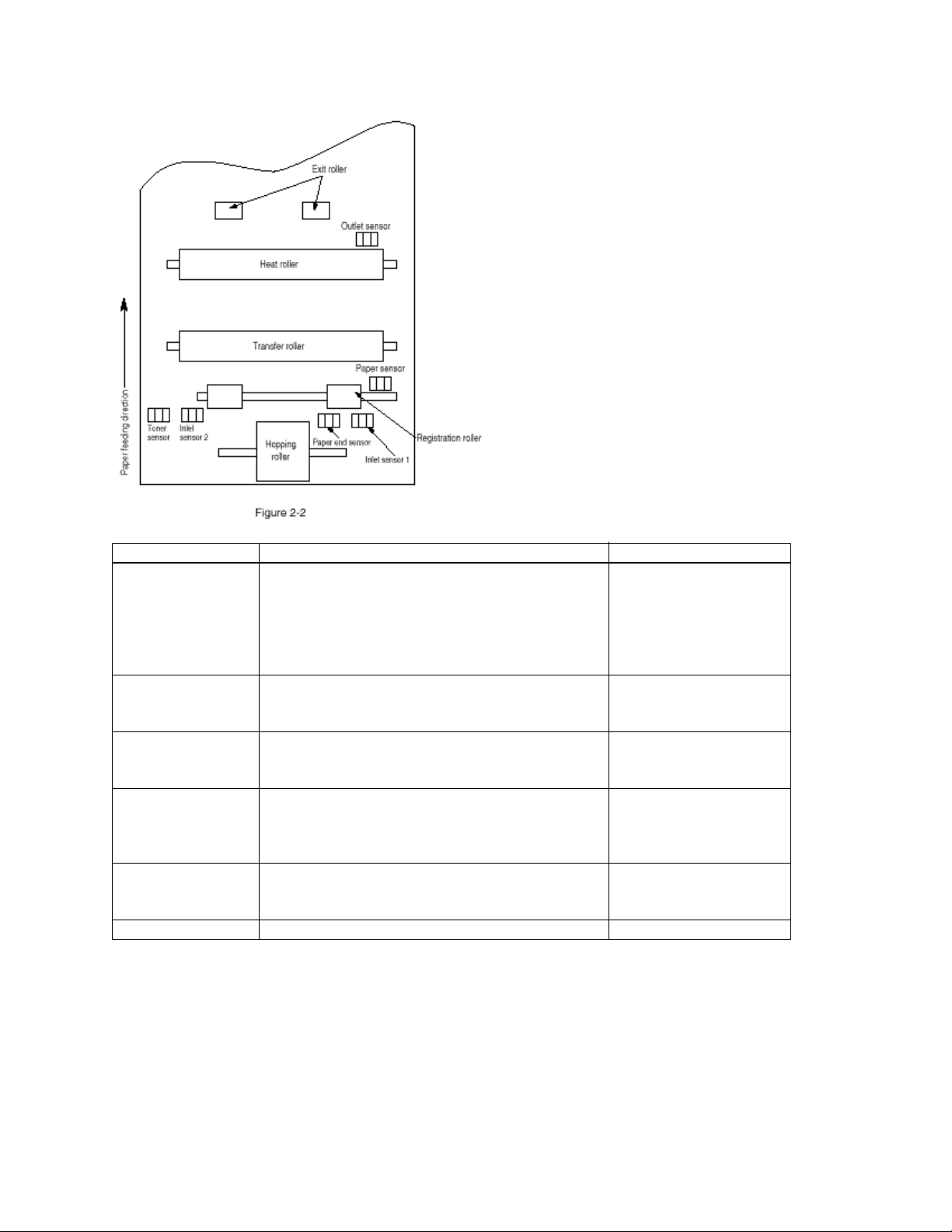

The sensor layout diagram is shown in Figure 2-2.

Sensor Function Sensing state

Inlet sensor 1 Detects the leading part of the paper and gives

the monitor timing for switching from hopping

operation to feeding operation. Monitors paper

feeding situation and paper size based on the

paper arrival time and running time.

Inlet sensor 2 Detects the paper width ON: A4 or larger

ON: Paper exists.

OFF: No paper exists.

OFF: Small than A4

Paper sensor Detects the leading portion of the paper. Monitors

the paper feeding situation.

Outlet sensor Monitors the paper feeding and size according to

the time of arrival to and leaving the past the

sensor.

Paper and sensor Detects the end of the paper. ON: Paper exits.

Toner low sensor Detects the lack of toner. - - - - -

-----The power supply unit consists of an AC filter circuit, a low voltage power supply circuit, a high

voltage power supply circuit, heater drive circuit, and photosensors.

(1) Low voltage power supply circuit

This circuit generates the following voltages.

ON: Paper exists.

OFF: No paper exists.

ON: Paper exists.

OFF: No paper exists.

OFF: No paper exists.

(2) High voltage power supply circuit

This circuit generates the following voltages necessary for electro-photographic processing

from +30 V according to the control sequence from the control board. When cover open state

is detected, +30 V supply is automatically interrupted to stop the supply of all the high-voltage

outputs.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 13

Service Manual - OKIPAGE20

Chapter 2 Operation Description

2.3.1 Electro-photographic process mechanism

2.3.2 Electro-photographic process

2.3.3 Process operation descriptions

2.3.4 Revision of LED Head Illumination

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 14

Service Manual - OKIPAGE20

Chapter 2 Operation Description

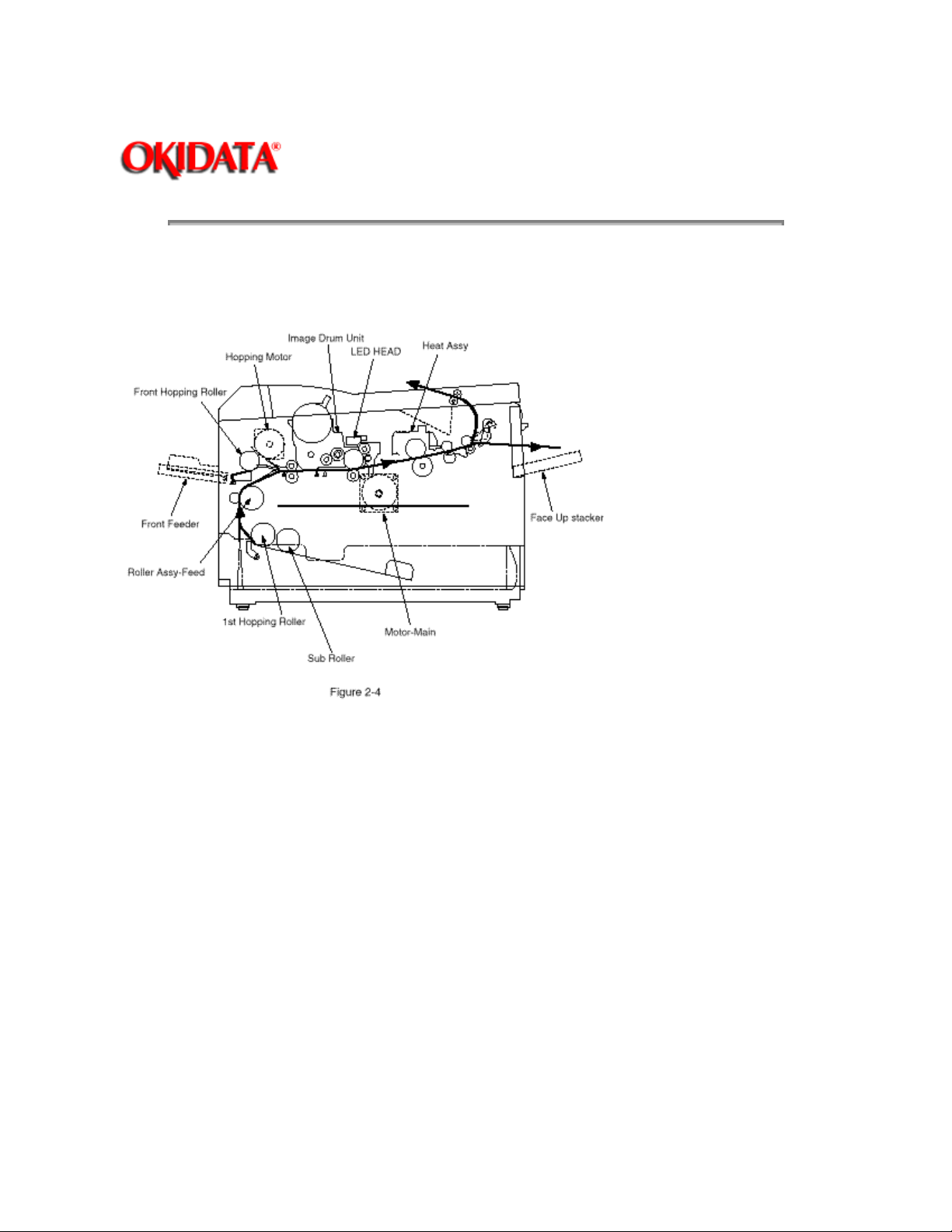

This mechanism prints image data from the control board on the paper by electro-photographic process.

The Figure 2-4 shows the layout of the electro-photographic process mechanism.

(1) Image drum unit

The image drum unit consists of a sensitive drum, a charger, and a developer. The unit forms a toner

image on the sensitive drum, using a electrostatic latent image formed by the LED head.

(2) Hopping motor

This motor is a pulse motor of 48 steps/rotation that is two-phase excited by the signal from the control

board. It drives the hopping roller of the first tray and the front feed roller via two one-way clutches

according to the direction of rotation.

(3) Motor-Main

This motor is a pulse motor of 72 steps/rotation that is two-phase excited by the signal from the control

board and is the main motor of this mechanism.

(4) Clutch (for Roller-Regist)

(5) Clutch (for Feed Roller)

(6) LED head

Image data for each dot line from the control board is received by the shift register and latch register. The

4992 LEDs are driven to radiate the image data to the image drum.

(7) Fuser

The fuser consists of a heater, a heat roller, a thermistor and a thermostat. An AC voltage from the power

supply board is applied to the heater under the control of the HEATON signal from the control board. This

AC voltage heats the heater. The control board supervises the heat roller temperature via the thermistor,

and regulates the heater roller at a predetermined temperature (185 °C : Normal paper, MEDIA TYPE =

MEDIUM) by connecting or disconnecting the AC voltage supply to the heater. If the heater roller

temperature rises abnormally, the thermostat of the heater voltage supply circuit is activated to cut the AC

voltage supply forcibly.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 15

Service Manual - OKIPAGE20

Chapter 2 Operation Description

The electro-photographic processing is outlined below. Figure 2-5 shows the electro-photographic printing

process.

(1) Charging

The surface of the image drum is uniformly charged with negative charges by applying a negative voltage

to the charge roller.

2) Exposure

(

Light emitted from the LED head irradiates the negatively charged surface of the image drum. The surface

potential of the irradiated part of the image drum surface is lowered, so that an electrostatic latent image

associated with the print image is formed.

(3) Developing and toner recovery

When the negatively charged toner is brought into contact with the image drum, it is attracted to the

electrostatic latent image by static electricity, making the image visible. At the same time, the residual

toner on the image drum is attracted to the developing roller by static electricity.

(4) Transfer

When paper is placed over the image drum surface and a positive charge, opposite in polarity to the toner,

is applied to the reverse side of the paper from the transfer roller, the toner is attracted by the positive

charge and is transferred to the paper. As a result, the toner image formed on the image drum is

transferred to the paper.

(5) Temporary cleaning

Residual toner that remains on the image drum without being transferred is made uniform

by the cleaning roller and is temporarily attracted to the cleaning roller by static electricity.

(6) Fusing

The toner image transferred to the paper is fused under heat and pressure. Figure 2-6 shows an

electro-photographic process timing chart.

Figure 2-5

Figure 2-6

Figure 2-7

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 16

Service Manual - OKIPAGE20

Chapter 2 Operation Description

(1) Hopping

Hoppings from the first tray and the front feeder are effected by a single hopping motor in the mechanism

shown below.

Turning the Hopping motor in direction a (CW) drives the 1st Hopping Roller. Turning the Hopping motor in

direction b (CCW) drives the Front Hopping Roller. Gear C and Hopping roller build-in one-way bearing,

so that turning each of these gears in reverse direction will not be transmitted to the corresponding roller.

(a) Hopping from the 1st Tray

(

1) Hopping

Rotating the Hopping Motor in direction a (CW) drives the 1st Hopping Roller and the Sub Roller then pick

up a sheet of paper in the 1st tray. The Main Motor is always driven in direction c (CCW) on printing. After

the paper fed approx. 30mm from the tray, the Clutch (Feed) drives the Align Roller to advance the paper

until the Inlet Sensor turns off.

(2) Aligning

After turning on the Inlet Sensor, the paper fed by a predetermined length and choked up to the wedge

space formed by the Regist Roller and the Pressure Roller so that to align the skew of paper.

(3) During the paper fed from the 1st tray, the build in clutch of Gear C is idled and not to drive the Front

Hopping Roller.

(4) Feeding

After aligned the paper, the Hopping Motor turned off and stop hopping. Also the Clutch (Feed) turned off

and the Align Roller idled freely. Then Clutch (Regist) turned on and the Regist Roller start to feed the

paper. After the paper fed, the 1st Hopping Roller is freely idled by releasing build in one way clutch, also

the Sub Roller is freely idled by escaping the Planet Gear.

(5) Start printing. after the paper turns off the Write Sensor.

(b) Hopping from the Front Feeder

(1) Hopping

The Front Feeder Plate is normally locked at the lower position by the Release Lever and turn the Micro

SW on. Top of the FF Cam which attached on end of the Front Hopping Shaft is normally located Upper

position (0 to 30 degree : home position). Rotating the Hopping Motor in direction b (CCW) drives the

Front Hopping Shaft and then attached the FF Cam and the Front Hopping Roller are driven. During the

FF Cam rotated approx. 60 degree, the Release Lever was pushed and

the Front Feeder Plate lifts up, then the Front Hopping Roller picks up a sheet of paper. At the FF Cam

rotated approx. 180 degree, the Front Feeder Plate is pushed down and locked by the Release Lever

again. At the FF Cam rotated approx. 275

degree the paper fed until the Inlet Sensor turns off.

(2) Aligning

After turning on the Inlet Sensor, the paper fed by a predetermined length and choked up to the wedge

space formed by the Regist Roller and the Pressure Roller so that to align the skew of paper.

(3) During the paper fed from the Front Feeder Plate, the one way clutch of 1st Hopping Roller is idled and

not to drive the 1st Hopping Roller and the Sub Roller.

(4) Feeding

After aligned the paper, the Hopping Motor turned off and stop hopping. Then Clutch (Regist) turned on

and the Regist Roller start to feed the paper. After the paper fed, the Front Hopping Roller drives the Front

Hopping Shaft and attached the FF Cam with small idle torque of build in one way clutch and when comes

into the Release Lever, the one way clutch is slipped and the FF Cam is stopped at the upper position

(home position). The Front Hopping Roller continuously idled up to the paper away.

(5) Start printing. after the paper turns off the Write Sensor.

(2) Feeding

After the end of hopping, the pulse motor dedicated for driving the registration roller rotates to drive the

registration roller. The driven registration roller advances the paper until it comes out of the registration

roller.

When leading edge of the paper causes the paper sensor to turn on, the printing is started synchronously.

Although Gear D is always rotating due to an all-time rotation of the main motor in direction c, the regist

roller would not rotate because the clutch (regist) is turned off.

After the completion of hopping, turn on the clutch (regist) to drive the regist roller. The regist roller would

drive a paper until the paper has passed.

(3) Charging

Charging is effected by applying a DC minus voltage to the charge roller that is in contact with the image

drum surface.

(4) Exposure

Light emitted from the LED head irradiates the image drum surface with negative charges. The surface

potential of the irradiated part of the image drum drops, thereby forming an electrostatic latent image

associated with the image signal.

(5) Developing

Toner is attracted to the electrostatic latent image on the image drum surface to convert it into a visible

toner image. Developing takes place at the contact between the image drum and the developing roller.

(1) As the toner supply roller rotates while rubbing on the developing roller, a friction charge is generated

between the developing roller and the toner, allowing the toner to be attracted to the developing roller.

(The developing roller surface is charged positive and the toner, negative.)

(2) The toner attracted to the developing roller is scraped off by the doctor blade, forming a thin coat of

toner on the developing roller surface.

(3) Toner is attracted to the exposed part (low-potential part) of the image drum at the contact between the

image drum and the developing roller, making the electrostatic latent image visible.

(6) Transfer

The transfer roller is composed of conductive sponge material and is designed to make the image drum

surface and the paper closely into contact.

Paper is placed over the image drum surface, and a positive charge, opposite in polarity to the toner, is

applied to the paper from its reverse side.

The application of a high positive voltage from the power supply to the transfer roller causes the positive

charge induced to the transfer roller surface to be transferred to the paper at the contact between the

transfer roller and the paper. As a results, toner charged negative that is attracted to the image drum

surface is transferred to the upper side of the paper by the positive charge on the lower side of the paper.

(7) Fusing

After the end of the transfer, the unfused toner image is fused on the paper under heat and pressure as it

passes between the heater roller and the back-up roller. The heater roller with a Teflon coating

incorporates a 750W heater (Halogen lamp), which heats the heat roller.

A thermistor which is in contact with the heater roller regulates the heater roller at a predetermined

temperature (about 180 ~ 200°C). A safety thermostat cuts off voltage supply to the heater by opening the

thermostat in the event of abnormal temperature rises.

The back-up roller is held under a pressure of 5 kg from the pressure spring at each side.

(8) Cleaning

After the end of the transfer, residual toner on the image drum is attracted to the cleaning roller temporarily

by static electricity to clean the image drum surface.

(9) Cleaning of rollers

The charge roller, transfer roller and cleaning roller are cleaned in the following cases:

In warming up at power-on time

In warming up after the cover is opened and closed

When the number of accumulated sheets is 10 or more and the printout operation ends

Changes in bias voltage applied to each roller move adhesive toner from the roller to the image drum and

return it to the developer.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 17

Service Manual - OKIPAGE20

Chapter 2 Operation Description

An LED correcting head, which is capable of correcting the illumination of the LED for each dot, is being

used in this printer. LED illumination correction function of 16 steps is carried out by using an EEPROM

which is installed in the LSI that maintains the LED illumination correction values, and an LED correction

drivers together as a pair.

The LED correcting head consists of the correction control LSI , LED drivers , and an LED array. The

block diagram of the LED correcting head is shown below.

The LED correcting head is a 600 dpi head, with the LED drivers located on both sides of the LED array

with a 300 dpi pitch spacing. The printing and correction data obtained from the CPU through four signal

lines are sent to the LED array.

In the OKIPAGE 20 Series Printer, the correction control of LED head is executed by CPU. The procedure

is as follows

(1) LED head is set to the correction control read mode and all correction data stored in EEPROM within

the correction control LSI are read by CPU, and stored temporarily in the memory.

(2) Next, LED head is set to the correction control direct mode and the correction data stored temporarily

in the memory is transferred directly to the LED driver.

(1) Read of correction data

(2) Transfer of correction data to head driver correction data

The LED driver corrects the LED illumination by controlling the LED current. The LED illumination can be

set in 16 steps, with 7 steps in the direction of illumination increase in relation to the standard value, and 8

steps in the direction of decrease. For this reason, the LED correction data is a 4-bit data for each dot.

The relationship between the LED correction data and LED current correction steps with the LED driver

used in an LED head is shown below.

Correction Data

msb b3 b2 b1 lsb b0

1 0 0 0 +16%

0 1 1 1 +14%

0 1 1 0 +12%

0 1 0 1 +10%

0 1 0 0 +8%

0 0 1 1 +6%

0 0 1 0 +4%

0 0 0 1 +2%

0 0 0 0 +0% No correction

1 1 1 1 -2%

1 1 1 0 -4%

1 1 0 1 -6%

1 1 0 0 -8%

1 0 1 1 -10%

Correction

Step

Correction

Mode

Correction

by increasing

Illumination

Correction

by decreasing

1 0 1 0 -12%

1 0 0 1 -14%

The printing operation timing chart is shown below.

Normal Mode Printing Timing Chart

The printing operation is carried out in normal mode. Under ordinary circumstances such as when the

power is turned on or when LOAD signal level is low, the normal mode is enabled.

Illumination

The printing operation is carried out in the following sequence. First, the printing data DATA3 through

DATA0 are stored, sequentially shifted, in the shift registers of the LED drivers, by the printing data

synchronous clock, CLOCK. Then the printing data stored in shift registers are latched by the high level

pulse of LOAD. The latched printing data turns the LEDs on by STRB1-N through STRB4-N and actuates

printing.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 18

Service Manual - OKIPAGE20

Chapter 2 Operation Description

The paper jam detection function supervises the paper state at power-on time and during printing. In the

event that the following state occurs, this function interrupts the printing process. If any of the following

errors is presented, recovery printing will be performed by removing the jammed paper (namely by

opening the upper cover, removing the jammed paper and closing the upper cover).

Error

Paper Input jam At power-on time, the paper is placed at the inlet

Cause of error

sensor.

After hopping operation is attempted three times, the

leading part of the paper does not reach the inlet

sensor.

Paper feed jam At power-on time, the paper is placed at the paper

sensor.

The leading part of the paper does not reach the paper

sensor within a predetermined distance after the paper

has reached the inlet sensor.

The trailing part of the paper does not pass over the

paper sensor within a predetermined leading edge of

the paper has passed over the paper sensor.

The leading part of paper does not reach the outlet

sensor within a predetermined distance after the paper

has reached the paper sensor.

Paper exit jam At power-on time, the paper is placed on the outlet

sensor.

The paper does not pass over the outlet sensor within a

predetermined after the leading part of the paper has

reached the outlet sensor.

The paper size check for manual feed specified

considers the reference size as free size.

Paper size error The size of the paper is supervised by the inlet sensor

1. It is detected that the paper does not pass over the

inlet sensor 1 within predetermined range of distance.

The inlet sensor 2 detects that the size of the loaded

paper is A4 or larger, or smaller than A4. The detected

paper size differs from the paper size set by command

or menu.

The paper size check for manual feed specified

considers the reference size is free size.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 19

Service Manual - OKIPAGE20

Chapter 2 Operation Description

When the stacker cover is opened, the cover open microswitch on the Power Supply Unit (High voltage) is

turned off to cut the supply of +30V to the high voltage power supply circuit. As a result, all high-voltage

outputs are interrupted. At the same time, the CVOPN signal is sent to the control board to notify it of the

off state of the microswitch, and the Main board performs the cover open processing.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 20

Service Manual - OKIPAGE20

Chapter 2 Operation Description

Composition

The device consists of the stirring gear which rotates at a constant rate, the stirring bar and the magnet on

the stirring bar. The stirring bar rotates through the link on the protrusion in the stirring gear.

Operation

Toner Low is detected by monitoring the time interval of the encounter of the magnet set on the

sensor lever and the magnet on the stirring bar.

Operation during toner full state

The stirring bar rotates due to the

interlocking with the stirring gear.

Even when the magnet on the

stirring bar reaches the maximum

height, since the other side is

being dipped in the toner, the

stirring bar is pushed by the

stirring gear.

Operation during Toner Low State

When the stirring bar reaches the maximum

height, since there is no resistance provided by the toner on the

other side, it falls to the minimum height due to its own weight.

Because of this, the time interval during which it is in encounter with

the magnet of the sensor lever becomes long. By monitoring this

time interval, toner low can be detected.

When the toner low state is detected 2 times consecutively, Toner Low is established.

When the toner full state is detected 2 times consecutively, Toner Low is canceled.

When there is no change with the toner sensor for 2 cycles (2.77 sec. x 2) or more, then the Toner

Sensor Alarm is activated.

The toner sensor is not monitored while the drum motor is in a halt.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 21

Service Manual - OKIPAGE20

Chapter 2 Operation Description

The sensor (interlocked with the lever) at the paper outlet to the stacker detects a stacker-full state (about

250 sheets) and stops printing of the ensuing pages.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 2 Operation Description

The four tab pieces are driven according to the setting position of the paper guide through the cam

interlocked with the paper guide of the paper cassette.

When the paper cassette is inserted into the printer, the state of the tab pieces is detected by the

microswitch to recognize the paper size.

Page: 22

State of Microswitches

SW1 SW2 SW3 SW4

0 1 1 1 Letter

0 1 0 1 Executive

0 0 1 1 A4

1 1 1 0 Legal 14

1 0 1 1 Legal 13

1 1 0 1 B5

1 1 0 0 A5

1 0 0 1 A6 (Not available)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Paper size

Service Manual - OKIPAGE20

Chapter 2 Operation Description

PostScript ROM module is mounted on SIMM socket (FSIMM1).

The PostScript ROM module consists of program/font ROM's, an EEPROM.

(1) Program/font ROM's

The program/font ROM's store the PostScript Level II program and its fonts.

BOARD-MSM consists of Mask ROM.

BOARD-FSL consists Flash ROM.

Mask ROM and Flash ROM is used as the program/ font ROM's.

(2) EEPROM

The EEPROM has a 4-kbit capacity and stores the PostScript's menu settings.

(3) Emulation

Page: 23

PostScript Level 2.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 24

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

This section explains the procedures for replacement of parts, assemblies, and units in the field.

Only the removal procedures are explained here. Reverse the procedure for the installation.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Before starting to replace parts, remove the AC cord and interface cable.

(a) Remove the AC cord in the following sequence:

i) Turn off ("o") the power switch of the printer.

ii) Disconnect the AC inlet plug of the AC cord from the AC

receptacle.

iii) Disconnect the AC cord and interface cable from the printer

(b) Reconnect the printer in the following procedure.

i) Connect the AC cord and interface cable to the printer.

ii) Connect the AC inlet plug to the AC receptacle.

iii) Turn on ("I") the power switch of the printer.

Page: 25

(2) Do not try disassembly as long as the printer is operating normally.

(3) Do not remove unnecessary parts: try to keep the disassembly to a minimum.

(4) Use specified service tools.

(5) When disassembling, follow the determined sequence. Otherwise, parts may be damaged.

(6) Since screws, collars and other small parts are likely to be lost, they should temporarily be attached to

the original positions.

(7) When handling IC's such as microprocessors, ROM and RAM, and circuit boards, do not wear gloves

that are likely to generate static electricity.

(8) Do not place printed circuit boards directly on the equipment or floor.

[Service Tools]

The tools required for field replacement of printed circuit boards, assemblies and units are listed in Table

3-1.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 26

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

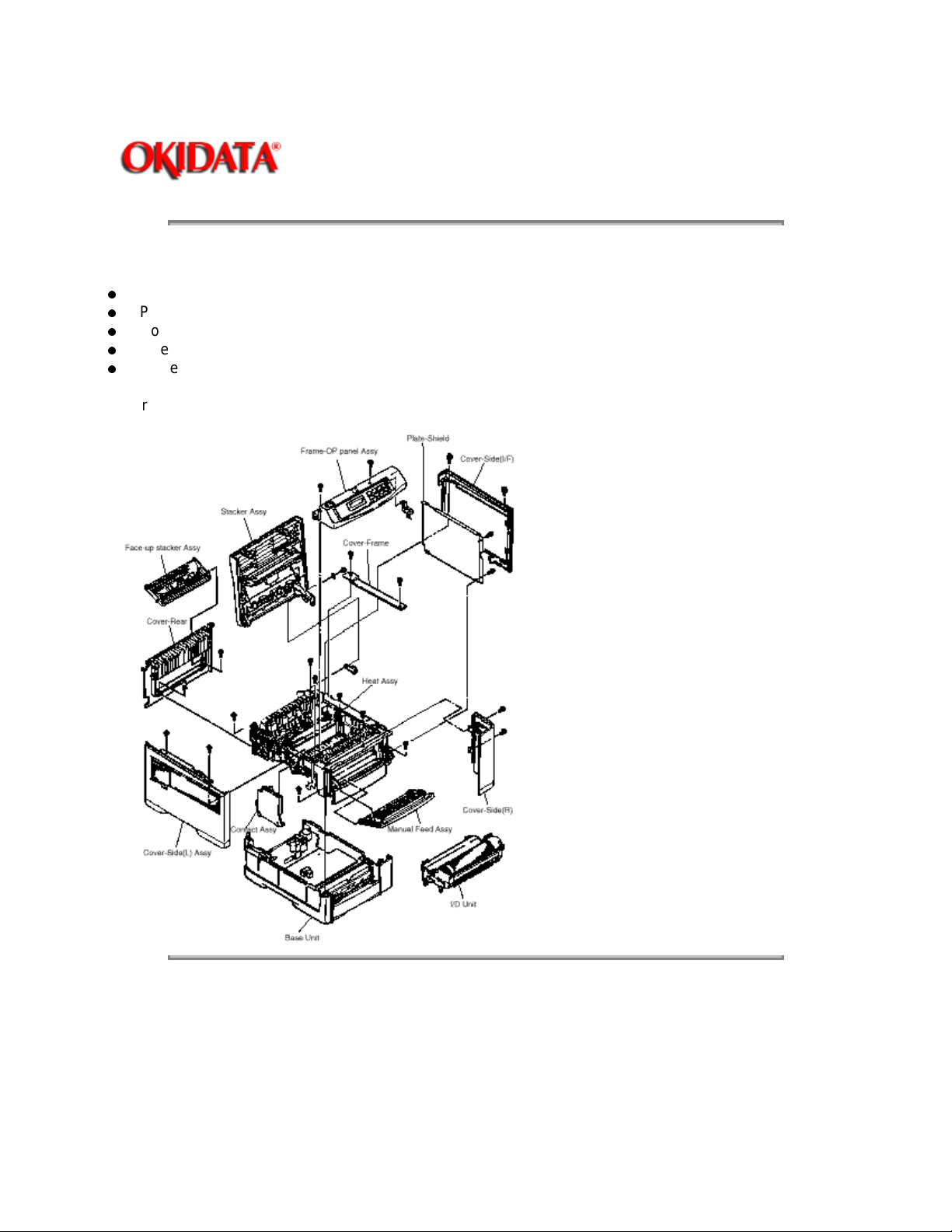

Page: 27

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

This section explains how to change parts and assemblies appearing in the disassembly diagram below.

3.3.1 Face-up Stacker Assy

3.3.2 Contact Assy

3.3.3 DC Fan Motor

3.3.4 OP Panel Assy

3.3.5 Board-AAA

3.3.6 Stacker Assy, Damper Arm, Cover Rear

3.3.7 Sensor Stacker Full

3.3.8 Cable cover (guide film)

3.3.9 Damper

3.3.10 Feeder Unit - Front

3.3.11 Roller Assy - Regist

3.3.12 Motor - Main

3.3.13 Guide Assy - Eject

3.3.14 Heat Assy

3.3.15 Roller feed (C)

3.3.16 Roller Assy - Bk

3.3.17 Roller assy - Feed

3.3.18 LED Head

3.3.19 Paper cassette, ROLLER Assy - Feed, ROLLER - Assy - Hopping

3.3.20 Frame Assy - Separation

3.3.21 Transfer Roller / TR Gear / TR Bearing

3.3.22 EP lock shaft

3.3.23 LEVER Assy - Out Sensor

3.3.24 Toner sensor lever

3.3.25 Paper sensor lever

3.3.26 Inlet sensor lever

3.3.27 Power supply unit

3.3.28 Lever - Paper end & Lever - Paper near end

3.3.29 Guide Assy - Cassette (L)

3.3.30 Guide Assy - Cassette (R)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 28

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Turn off the AC Power Switch and unplug the AC Power Cord from the outlet.

(2) Disconnect the Interface Cable (1).

(3) Open the face-up stacker assy (2), unhook the right and left projections, and then remove the face-up

stacker assy (2).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Open the stacker assy (1) and unscrew 2 screw (2) to remove the assy -side (L) (3).

(2) Unscrew 2 screws (4) and remove the plate (contact) (5) and contact Assy (6).

Note!

Don't deform the electrode plates of the contact assy (6).

Page: 29

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Remove the cover assy-side (L). [See 3.3.2 (1)]

(2) Remove the DC fan motor (1) by pulling out the connector of DC fan motor (1).

Page: 30

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Disconnect the Interface cable (1).

(2) Open the stacker assy (2), unscrew 2 screws (3) and remove the cover side (I/F) (4).

(3) Remove 2 screws (5) and flexible cable (6) to remove the operator panel assy (7).

Page: 31

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 32

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Remove the operator panel assy and cover side (I/F). [See 3.3.4]

(2) Unscrew 2 screws (1) and remove the cover side (R) (2).

(3) Unscrew 2 screws (3) and remove plate-shield (4).

(4) Unscrew 3 screws (5) and 2 screws (6), unplug all the connectors (7) , and remove Board-AAA (8).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 33

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Remove the face-up stacker assy. [See 3.3.1]

(2) Remove the cover-side (L). [See 3.3.2 (1)]

(3) Remove the OP panel assy. [See 3.3.4]

(4) Remove the Board-AAA. [See 3.3.5]

(5) Loosen 2 screws, unlock the both sides latches and remove the cover rear (A).

(6) Unscrew 2 screws (1) and cover frame (2).

(7) Unscrew 3 screws (3) and remove the plate assy-side (R) (4).

(8) Remove the lever back up release (5) and unlock the engagement of the projection on the right side of

gear at the right side of stacker cover.

(9) Remove a screw (6) and washer (7), and then remove the stacker assy (8). (At this time, the damper

arm 9 can also be detached simultaneously.)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 34

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Turn the AC power switch off. Unplug the AC power cord from the outlet.

(2) Remove the Stacker assy. [See 3.3.6]

(3) Remove four screws (1). Remove stacker mount 2 by releasing the tabs at position (2A) .

(4) Remove Sensor stacker full (3) by releasing spreading the plastic tabs on each side of sensor Assy (3)

and lifting switch from cover.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Turn the AC power switch off. Unplug the AC power cord from the outlet.

(2) Remove the stacker Assy. [See 3.3.6]

(3) Unscrew 2 screws (1) release tabs at portion (1A) . Remove cable cover (2), guide film (3).

Page: 35

Note:

Use care when replacing cable cover. Do not pitch, crimp, or cut cables or protective sheet.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Remove the damper arm.[See 3.3.6]

(2) Unscrew 2 screws (1) and remove the two damper (2).

Page: 36

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 37

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Open the manual feed assy (1) and release both right and left parts by pulling out the engagements on

the lower part.

(2) Stand the manual feed assy (1) on end and unhook the engagements with both right and left manual

feed hopper stays.

(3) Remove the OP panel assy. [See 3.3.4]

(4) Unscrew 5 screws (2) and remove the feeder unit-front (3).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 38

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Remove the feeder unit-front. [See 3.3.10]

(2) Remove an E-ring (3), gear assy-clutch (4), and four screws (1) in this order, and lifting out the roller

assy-regist (2).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Remove the stacker assy. [See 3.3.6]

(2) Remove the feeder unit-front. [See 3.3.10] (At this point, the manual feed assy has not to be

removed.)

(3) Remove the DC fan motor. [See 3.3.3]

(4) Remove the contact assy. [See 3.3.2]

(5) Remove the plate-FG (F) (1).

(6) Remove the TR gear (2) and roller transfer (3).

(7) Unscrew 7 screws (4) and remove the main frame (5).

(8) Unlock latches at two points of the lever back up release (6) and pull out it in right direction.

Page: 39

(9) Unhook the EP lock spring (7) and remove the EP lock lever (8).

(10) Take off the E ring (9) and remove the plate-FG (1st ) (10) and gear assy-clutch (A).

(11) Unlock 2 latches to remove the motor assy-main (12) and idle gear (13).

(12) Unscrew 2 screws (14) and remove the motor -main (15).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 40

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Remove the lever back up release. [See 3.3.12(8)] (But the roller transfer/feeder unit front/plate-FG

have not be removed)

(2) Remove the cover rear (2). [See 3.3.6(5)]

(3) Loosen 2 screws (1), unlock the both side's latches and remove the cover rear (2).

(4) Unlock the latches on both sides of the guide assy-eject (3) and lifting it out.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 41

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Remove the cover assy-side (L). [See 3.3.2 (1)]

(2) Unplug the connectors (1), (2).

(3) Unscrew 4 screws (3) and remove the heat assy (4) in the direction of the arrow by lifting the right side

first.

Note !

As the heat assy (4) becomes high temperature soon after the power is turned off, start the work after

it cools off sufficiently.

Carry out a reset of the counter after the replacement. (See Section 4.2)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 42

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Remove the guide assy-eject. (See 3.3.13) (But roller transfer/feeder unit-front/plate-FG(F) have not

be removed)

(2) Remove the gear roller (C) (1) and bush (2), warp (a) part of the plate-FG (BK) (3). Take off the carrier

bearing (4) and remove the roller feed (c) (5) in the direction of the arrow.

Note !

Be careful not to deform (a) part of the plate-FG (BK) (3).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Remove the heat Assy. [See 3.3.14]

(2) Remove the lever back up release. [See 3.3.12 (8)]

(3) Unlock the engagement with the plate-FG (BK) (1) and lift out the roller heat assy (2).

Page: 43

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Remove the feeder unit -front. [See 3.3.10]

(2) Remove the roller assy-feed (1) by unlocking a latch.

Page: 44

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 45

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Remove the stacker assy 1. [See 3.3.6]

(2) Unplug the PC connector (2) and (2) LED cables (3) from the LED head (4).

(3) Open the hooks of the cover stacker (1) in the direction of the arrow and remove the LED head (4).

(4) Pull out the head spring (5) from the post.

Note:

Don't remove two LED cable (3) from the PC connector (2).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Pull out the case assy -cassette (1) from the printer.

(2) Remove the ROLLER Ass-Feed (2) and remove the ROLLER-Assy-Hopping (3).

Page: 46

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 47

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Turn the AC power switch off. Unplug the AC power cord from the outlet.

(2) Pull out the case Assy-Cassette (1) from the printer.[See 3.3.19(1)]

(3) Release two locks and remove frame assy-separation (2). (At this time, coil spring (3) is also remove.

Be careful not to lose this spring.)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Open the stacker cover .

(2) Unlock the lock by lifting the TR gear (1) to remove the TR gear (1) and roller transfer (2).

Page: 48

Note !

and the like under it.

(3) Remove right and left, 2 bearings (3) from the frame-main by sliding them inside while pushing them.

At this time, 2 transfer springs R (4) would be detached simultaneously.

Don't place the removed roller transfer directly on the desk and so on. When placing it, lay a paper

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Turn the AC power switch off. Unplug the AC power cord from the outlet.

(2) Remove Frame-Main [See.3.3.12(7)]

(3) Remove screw (1). Turn EP lock lever (L) Assy (2) in the direction of arrow (A) .

(4) Remove spring (3).

(5) Drop EP lock shaft (4) down and turn in the direction of arrows (B) and remove it.

Page: 49

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 50

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Turn the AC power switch off. Unplug the AC power cord from the outlet.

(2) Remove the frame main [See 3.3.12(7)]

(3) Press the clamp part of LEVER Assy.- Out Sensor (1). Remove the LEVER Assy.-Out Sensor (1) by

pushing it upward from the lower side.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 51

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Turn the AC power switch off. Unplug the AC power cord from the outlet.

(2) Remove the frame main [See.3.3.12(7)].

(3) Squeeze the clamp part of toner sensor lever (1) and remove the toner sensor lever (1) by pushing it

upward from the lower side.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Turn the AC power switch off. Unplug the AC power cord from the outlet.

(2) Remove the frame main [See 3.3.12(7)]

(3) Squeeze the clamp part of the paper sensor lever (1) and remove the paper sensor lever (1) by

pushing it upward from the lower side.

Page: 52

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 53

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Turn the AC power switch off. Unplug the AC power cord from the outlet.

(2) Remove the frame main [See 3.3.12(7)]

(3) Squeeze the clamp part of two inlet sensor levers (1). Remove the inlet sensor levers (1) by pushing

them downward.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Turn the AC power switch off. Unplug the AC power cord from the outlet.

(2) Remove the frame main [See 3.3.12(7)]

(3) Unscrew 2 screws (1) and remove the BRACKET-AC (2).

(4) Unscrew 10 screws (3) and remove the connector (6) remove the Power supply unit

[AC-DC(120/230V)] (4) and Power supply unit (High voltage) (5).

Page: 54

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 55

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Turn the AC power switch off. Unplug the AC power cord from the outlet.

(2) Remove the frame main [See 3.3.12(7)]

(3) Remove screw (1) and then remove the PLATE-Base (2).

(4) Remove two Spacer-Cord (KGPS-5RF (4) and then remove FILM-Insulation (4).

(5) Remove four screws (5) and then remove the FRAME ASS-Hopping (6).

(6) Remove the GEAR-Z58 (9) and GEAR-Z42 (8). (At this time, the ADF Bearing (10) can also be

detached simultaneously.)

(7) Remove the GEAR-Z38 (14), ADF Bearing (15), ROLLER-Guide (16) and SHAFT Hopping (17) and

Bracket-Sub roller (28). (At this time, the Kock Pin (18) can also be detached simultaneously.)

(8) Remove two screws (7) and then remove the SPRING-Release (11) and then remove the LEVER-Sub

roller (12) and PLATE-Hopping (13).

(9) Remove the GEAR-Planet (Z28 (19), Plate-Planet (20), BRACKET-Spring (Sub) (21) and

SPRING-Sub ROLLER (22).

(10) Press the clamp part of Lever-Paper end (23) and Lever-Paper near end (24). Remove the

Lever-Paper end (23) and Lever-Paper near end (24) by pushing it upward from the FRAME Hopping (28).

(11) Remove the Connection Cord-Wire (25) and TR-23-11-14 R CORE (26) together.

(12) Remove two Photo Sensor (27).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 56

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Turn the AC power switch off. Unplug the AC power cord from the outlet.

(2) Remove Frame Main [See 3.3.12(7)]

(3) Remove PLATE-Base and FRAME Assy Hopping [See 3.3.28 (5)]

(4) Unscrew two screw (1) and then remove Guide Assy-Cassette (L) (2).

(5) Remove SPRING-Sheet (3) and then remove LINK-Sheet (4) and pull block (5). (Pay attention the

direction of hook of SPRING-Sheet (3).)

(6) Remove spring (6) and then remove cassette stopper (7).

(7) Remove screw (8) from LINK-Sheet (4) and then remove link support (9) and Roller-link (10).

(8) Remove Earth Plate L (11) and Plate-Earth (link) (12).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 57

Service Manual - OKIPAGE20

Chapter 3 Parts Replacement

(1) Turn the AC power switch off. Unplug the AC power cord from the outlet.

(2) Remove Frame Main [See 3.3.12(7)]

(3) Remove PLATE-Base and FRAME Assy Hopping [See 3.3.28 (5)]

(4) Unscrew two screw 1 and then remove Guid Assy-Cassette (R) (2).

(5) Remove SPRING-Sheet (3) and then remove LINK Sheet (4) and pull block (5). (Pay attention the

direction of hook of SPRING-Sheet (3).)

(6) Remove spring (6) and then remove cassette stopper (7).

(7) Remove screw (8) from LINK-Sheet (4) and then remove link support (9) and Roller-link (10).

(8) Unscrew two screws (11) and remove the Square shaped connector (176496-1) (12) and Nylon

Connector Cord (13) and TR-23-11-R CORE (14).

(9) Unscrew two screws (15) and remove the two Plate Earth (Bottom) (16).

(10) Unscrew two screws (17) and remove the Square shaped connector (5-176496-1) (18) and

Connection Cord Wire (19) and TR-23-11-R CORE (20).

(11) Unscrew a screw (21) and remove the Detector spring (22).

(12) Unscrew a screw (23) and remove the Board PXC (24).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 58

Service Manual - OKIPAGE20

Chapter 4 Adjustment

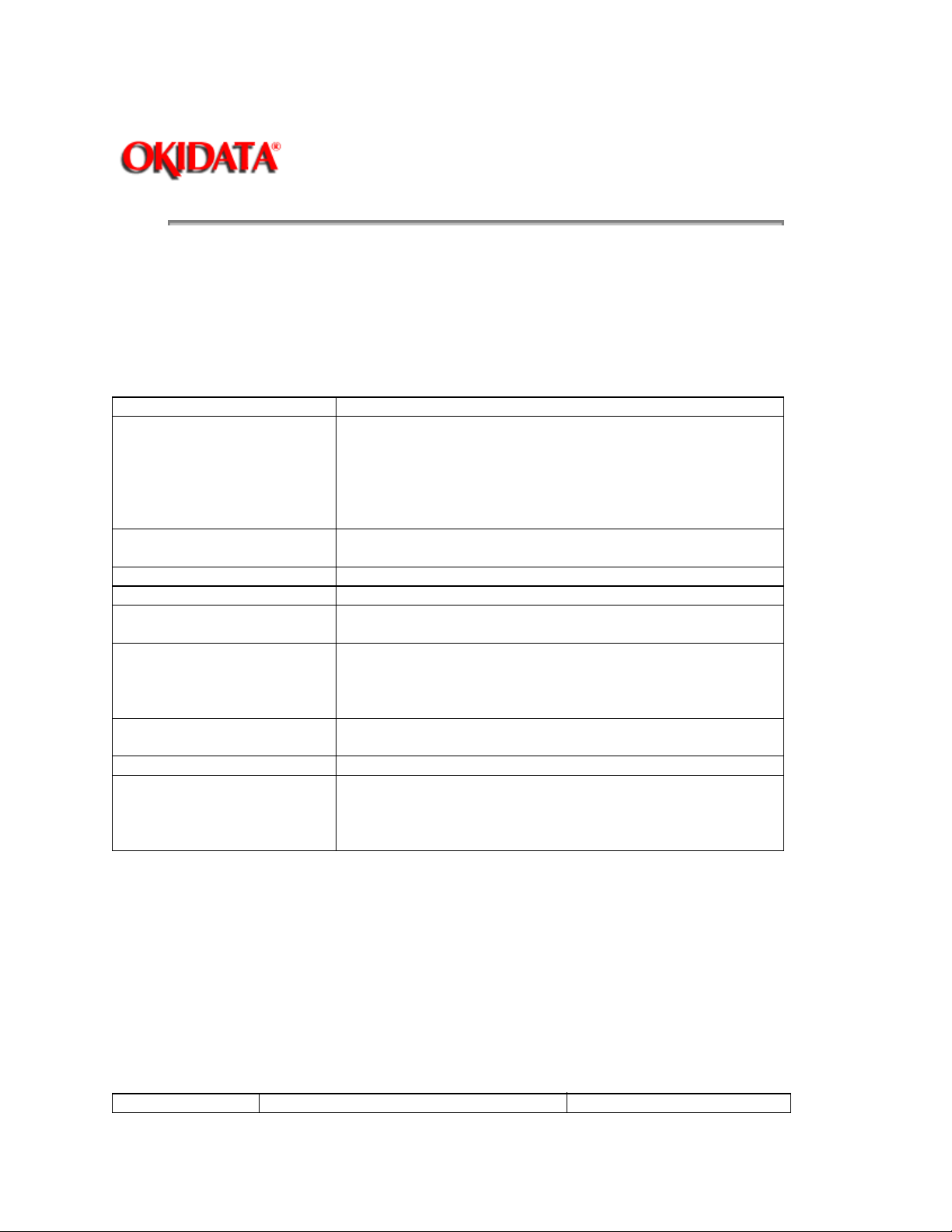

This chapter explains the adjustment necessary when replacing a part. Adjustment is made by changing a

parameter value set in EEPROM on the controller PCB. A parameter is able to set with the key operation

on the operator panel. This printer has three kinds of the maintenance mode, it is required to select one of

the maintenance mode necessary when replacing a part.

4.1 Maintenance Modes and Functions

4.2 Adjustment When Replacing a Part

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 59

Service Manual - OKIPAGE20

Chapter 4 Adjustment

User maintenance mode

System maintenance mode

Engine maintenance mode

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE20

Chapter 4 Adjustment

To enter the user maintenance mode, turn on the POWER switch while pressing the MENU key.

[Function]

There are 13 functions as follows.

Menu reset

Hex dump

Drum counter reset

Resource Save (Second, Third, Front Tray)

Receive Buffer Size

Operator panel menu disable

X adjust

Y adjust

Duplex Adjust

Select paper source command parameter

Page placement

Setting

Cleaning cycle

Page: 60

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 61

Service Manual - OKIPAGE20

Chapter 4 Adjustment

Note:

This mode is used only by service persons and it should not be released to the end-users.

To enter the system maintenance mode, turn on the POWER switch while pressing the RECOVER key.

[Function]

There are 8 functions as follows.

Page count display

Page count printing enable/disable

Rolling ASCII continuous printing

RS232C LOOP TEST

EEPROM reset

HSP ERROR recovery

HSP ERROR count display

HSP ERROR count reset

SIDM enable/disable

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 62

Service Manual - OKIPAGE20

Chapter 4 Adjustment

Note: This mode is used only by service persons and it should not be released to the end-users.

To enter the engine maintenance mode, turn on the POWER switch while pressing the FORM FEED key

and ENTER key.

[Function]

There are 19 functions as follows.

Head type setting

Head drive time setting.

Head drive time setting at Auto head type

Head strobe time at 600 x 1200 dpi

Printing start position setting

Drum counter total display

Drum count display

Setting of standard paper feed length

Setting of front feeder paper feed length

Setting of second tray paper feed length

Selection of second tray feeder download table

Setting of third tray paper feed length

Selection of third tray feed download table

Setting of Multi-purpose feeder paper feed length

Selection of Multi-purpose feeder download table

Setting of duplex feed length

Fuser count indication

Fuser count reset

Engine reset

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Loading...

Loading...