Okidata OKIPAGE 10i, OKIPAGE 10in Service Manual

Thank You for purchasing this

Click Here for more Factory Service

Manuals for other Computer and

Printer / Copier Manufacturers

from PCTECHINFO!

Page: 1

Service Manual - OKIPAGE10i

Chapter 0 Introduction

OKIPAGE 10i / OKIPAGE 10i/n

LED PAGE PRINTER PRODUCTS

Adobe Acrobat printable reference copy

of the OKIDATA Service Training Manual.

03/20/98

Note: This Adobe Acrobat version of the Okidata Service Training Manual was built with

the pictures rendered at 300 dpi, which is ideal for printing, but does not display well

on most displays.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Table of Contents Page

Service Manual - OKIPAGE10i

0 Introduction

Disclaimer 1

Copyright Listing 2

1 Configuration

1.1 System Configuration 3

1.2 Printer Configuration 4

1.3 Optional Configuration 5

1.4 Specification 6

1.5 Safety Standard 7

....1.5.1 Certification Label 8

....1.5.2 Warning Label 9

....1.5.3 Warning/Caution Marking 10

2 Operation Description

Operation Description 11

2.1 Main Control Board 12

2.2. Power Supply/Sensor Board 13

2.3 Electrophotographic Process 14

....2.3.1 Electrophotographic Process Mechanism 15

....2.3.2 Electrophotographic Process 16

....2.3.3 Process Operation Descriptions 17

2.4 Paper Jam Detection 18

2.5 Cover Open 19

2.6 Toner Low Detection 20

3 Parts Replacement

3.0 Parts Replacement 21

3.1 Precautions for Parts Replacement 22

3.2 Parts Layout 23

3.3 How to Change Parts 24

....3.3.1 Upper Cover Assy 25

....3.3.2 IC Card Cover 26

....3.3.3 LED Head 27

....3.3.4 Operator Panel Assy 28

....3.3.5 Lower Base Unit 29

....3.3.6 Pulse Motor (Main/Drum) 30

....3.3.7 Pulse Motor (Registration) 31

....3.3.8 Face Up Stacker Assy 32

....3.3.9 Eject Roller Assy 33

....3.3.10 Motor Assy 34

....3.3.11 Hopping Roller Shaft Assy 35

....3.3.12 Stacker Cover Assy 36

....3.3.13 Registration Roller 37

....3.3.14 Roller Transfer Assy 38

Table of Contents Page

....3.3.15 Fusing Unit 39

....3.3.16 Back-up Roller 40

....3.3.17 Sensor Plate (Inlet) 41

....3.3.18 Sensor Plate (Outlet) 42

....3.3.19 Manual Feed Guide Assy 43

....3.3.20 Sensor Plate (Paper Supply) 44

....3.3.21 M5B-PCB 45

....3.3.22 Transformer 46

....3.3.23 Power Supply/Sensor Board and Contact Assy 47

....3.3.24 Cassette Guide L Assy 48

....3.3.25 Cassette Guide R Assy 49

....3.3.26 Spacer Bearing (L/R) 50

4 Adjustment

4.0 Adjustment 51

4.1 Maintenance Modes and Functions 52

....4.1.1 User Maintenance Mode 53

....4.1.2 System Maintenance Mode 54

....4.1.3 Engine Maintenance Mode 55

....4.1.4 EEPROM Initialization 56

4.2 Adjustment When Replacing a Part 57

....4.2.1 Setting of LED Head Drive Time 58

....4.2.2 Uploading/Downloading EEPROM data 59

5 Periodical Maintenance

5.1 Periodical Replacement Parts 60

5.2 Cleaning 61

....5.2.1 Cleaning of LED Lens Array 62

....5.2.2 Cleaning Page Function 63

6 Troubleshooting Procedures

6.1 Troubleshooting Tips 64

6.2 Points to Check before Correcting Image Problems 65

6.3 Tips for Correcting Image Problems 66

6.4 Preparation for Troubleshooting 67

6.5 Troubleshooting Flow 68

....6.5.1 LCD Status Message/Problem List 69

........6.5.1 Table 6-1 (1 of 10) 70

........6.5.1 Table 6-1 (2 of 10) 71

........6.5.1 Table 6-1 (3 of 10) 72

........6.5.1 Table 6-1 (4 of 10) 73

........6.5.1 Table 6-1 (5 of 10) 74

........6.5.1 Table 6-1 (6 of 10) 75

........6.5.1 Table 6-1 (7 of 10) 76

........6.5.1 Table 6-1 (8 of 10) 77

........6.5.1 Table 6-1 (9 of 10) 78

........6.5.1 Table 6-1 (10 of 10) 79

Table of Contents Page

....6.5.2 LCD Message Troubleshooting 80

........6.5.2 (1) The printer does not work normally after the

power is turned on

........6.5.2 (2) Jam alarm 82

........6.5.2 (3) Paper size error 83

........6.5.2 (4) Fusing unit error (ERROR 71) (ERROR 72)

(ERROR 73)

........6.5.2 (5) Synchronous serial I/O error (ERROR 74) 85

........6.5.2 (6) Fan error (ERROR 70) 86

....6.5.3 Image Troubleshooting 87

........6.5.3 (1) Images are light or blurred entirely 88

........6.5.3 (2) Dark background density 89

........6.5.3 (3) Blank paper is output 90

........6.5.3 (4) Black vertical belts or stripes 91

........6.5.3 (5) Cyclical defect 92

........6.5.3 (6) Missing Print 93

........6.5.3 (7) Poor fusing 94

........6.5.3 (8) White vertical lines or streaks 95

7 Wiring Diagram

7.1 Interconnect Signal Diagram 96

7.2 PCB Layout and Connector Signal List 97

7.3 Resistance Check 98

7.4 Short Plug Setting 99

8 Parts List

Lower Base Unit - Figure 8-1 100

Lower Base Unit - Table 8-1 101

Upper cover unit - Figure 8-2 102

Upper cover unit - Table 8-2 103

Base Unit - Figure 8-3 104

Base Unit - Table 8-3 105

A RS-232C Serial Interface (Option)

RS-232C Serial Interface (Option) 106

B Centronics Parallel Interface

Centronics Parallel Interface 107

C Loop Test (RS-232C Interface)

Loop Test (RS-232C Interface) 108

D Diagnostics Test

1.0 Maintenance Modes 109

1.1 User Maintenance Mode 110

1.2 System Maintenance Mode 111

1.3 Engine Maintenance Mode 112

E Multi-Purpose Feeder Maintenance

Preface 113

1.0 Outline 114

81

84

Table of Contents Page

....1.1 Functions 115

....1.2 External View and Component Names 116

2.0 Mechanism Description 117

....2.1 General Mechanism 118

....2.2 Hopper Mechanism 119

3.0 Parts Replacements 120

....3.1 Precautions Concerning Parts Replacement 121

....3.2 Parts Layout 122

....3.3 Parts Replacement Method 123

........3.3.1 Link 124

........3.3.2 Separator 125

........3.3.3 OLEV-11-PCB 126

........3.3.4 Pulse Motor 127

........3.3.5 Planet Gear 128

........3.3.6 Roller-A 129

4.0 Troubleshooting 130

....4.1 Precautions Prior to the Troubleshooting 131

....4.2 Preparations for the Troubleshooting 132

....4.3 Troubleshooting Method 133

........4.3.1 LCD Status Message List 134

5.0 CONNECTION DIAGRAM 135

....5.1 Interconnection Diagram 136

....5.2 PCB Layout 137

6.0 Parts List 138

F High Capacity Second Paper Feeder M/M

Preface 139

1.0 Outline 140

....1.1 Functions 141

....1.2 External View and Component Names 142

2.0 Mechanism Description 143

....2.1 General Description 144

....2.2 Hopper Mechanism 145

3.0 PARTS REPLACEMENT 146

....3.1 Precautions Concerning Parts Replacement 147

....3.2 Parts Layout 148

....3.3 Parts Replacement Methods 149

........3.3.1 Stepping Motor (Hopping) 150

........3.3.2 TQSB-2 PCB 151

........3.3.3 Hopping shaft etc. 152

4.0 Troubleshooting 153

....4.1 Precautions Prior to the Troubleshooting 154

....4.2 Precautions Prior to the Troubleshooting 155

....4.3 Troubleshooting Method 156

........4.3.1 LCD Status Message List 157

Table of Contents Page

5.0 CONNECTION DIAGRAM 158

....5.1 Interconnection Diagram 159

....5.2 PCB Layout 160

6. PARTS LIST 161

....High Capacity Second Paper Feeder 162

....2nd Tray Assembly 163

G Network Interface (Option)

Network Interface (Option) 164

Service Manual - OKIPAGE10i

Chapter 0 Introduction

This document may not be reproduced without the written permission of Okidata Training and

Publications. Every effort has been made to ensure the accuracy of the information contained in this

training course. Okidata is not responsible for errors beyond its control.

Copyright 1997 OKIDATA All rights reserved.

Edited by: Okidata Training and Publications

Please address any comments on this publication to:

Mailing Address: OKIDATA

532 Fellowship Road

Mount Laurel, NJ 08054-3499

Website: www.okidata.com

Telephone: 609-235-2600

Page: 1

Facsimile: 609-222-5320

OkiLink (BBS) Technical Training

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 2

Service Manual - OKIPAGE10i

Chapter 0 Introduction

OKIDATA is a registered trademark of Oki Electric Industry Company, Ltd.; marques deposee de Oki

Electric Industry Company, Ltd.; marca registrada, Oki Electric Industry Company, Ltd.

Notice

All service documentation is supplied for informational purposes only. Okidata service documentation is

intended for use by certified, product trained service personnel only. Okidata does not warrant or

represent that such documentation is complete, nor does Okidata represent or warrant that it will notify or

provide to such customer any future changes to this documentation. Customer performed service of

equipment, or modules, components or parts of such equipment may affect the warranty offered by

Okidata with respect to such equipment. You should consult the applicable warranty for its terms

regarding customer or third party provided service. If the customer services such equipment, modules,

components or parts thereof, the customer releases Okidata from any and all liability for the customer

actions, and the customer agrees to indemnify, defend and hold Okidata harmless from any third party

claims which arise directly or indirectly from such service.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 3

Service Manual - OKIPAGE10i

Chapter 1 Configuration

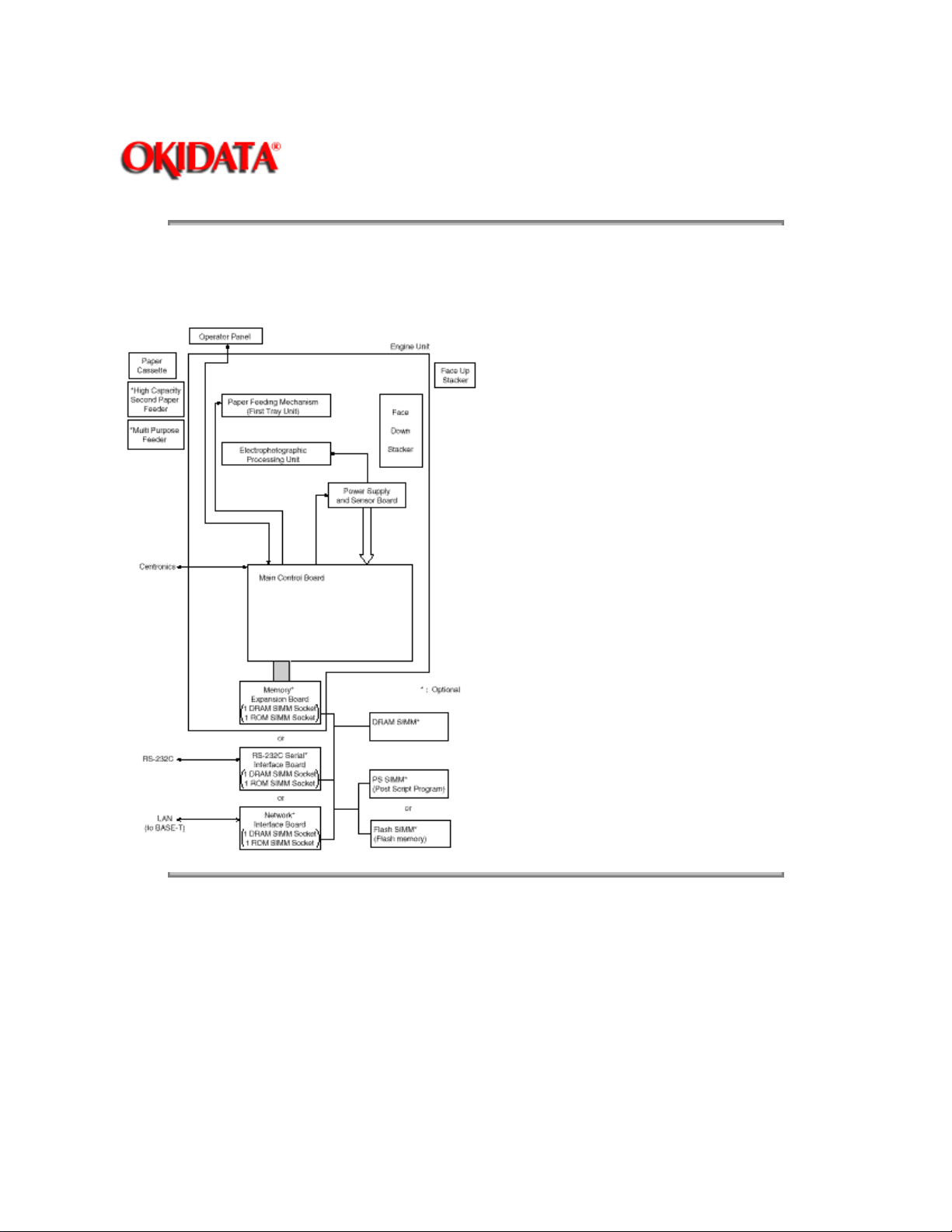

OKIPAGE 10i consists of control and engine blocks in the standard configuration, as shown in Figure 1-1.

In addition, the options marked with asterisk (*) are available.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE10i

Chapter 1 Configuration

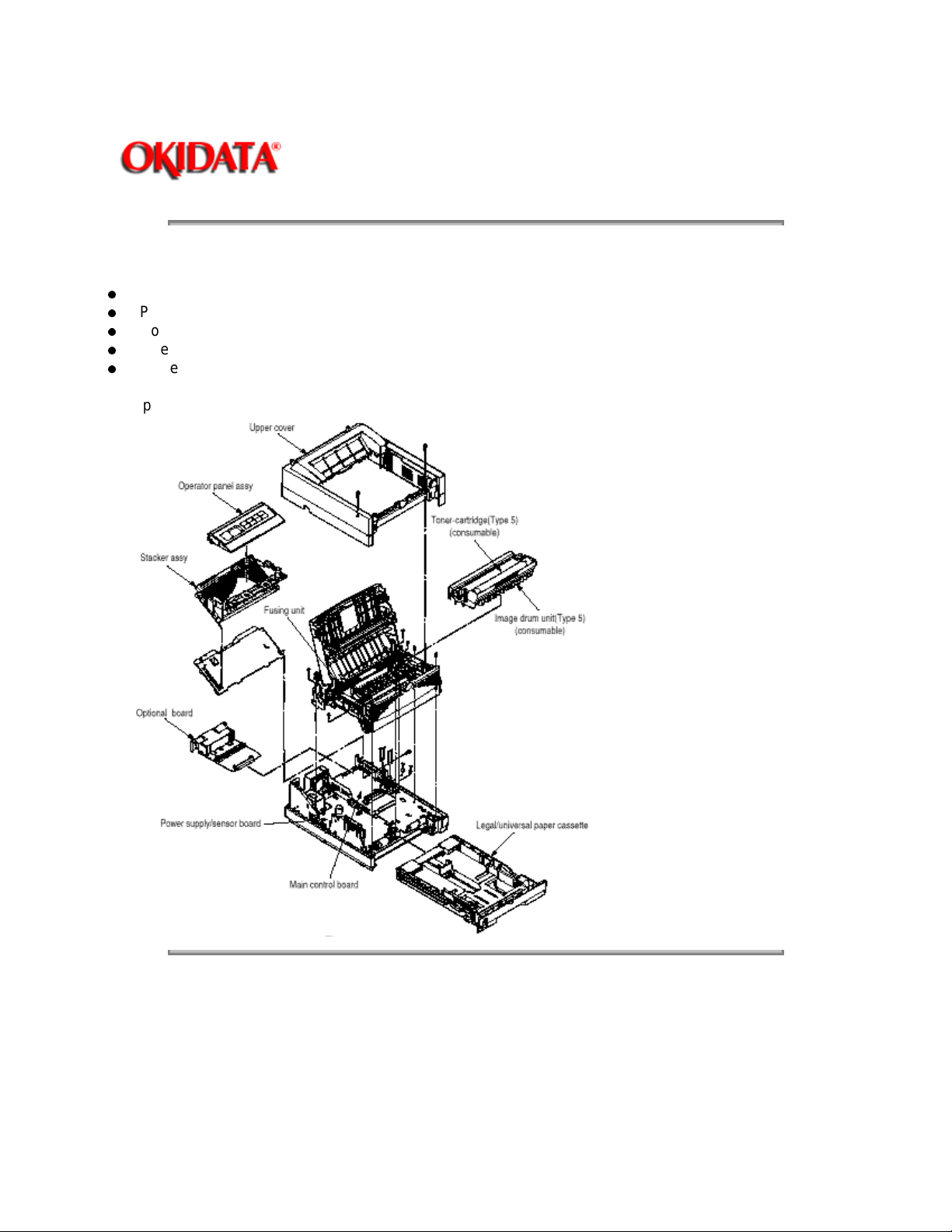

The printer unit consists of the following hardware components:

Electrophotographic Processor

Paper Feeder

Controller

Operator Panel

Power Supply Unit

The printer unit configuration is shown in Figure 1-2.

Page: 4

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 5

Service Manual - OKIPAGE10i

Chapter 1 Configuration

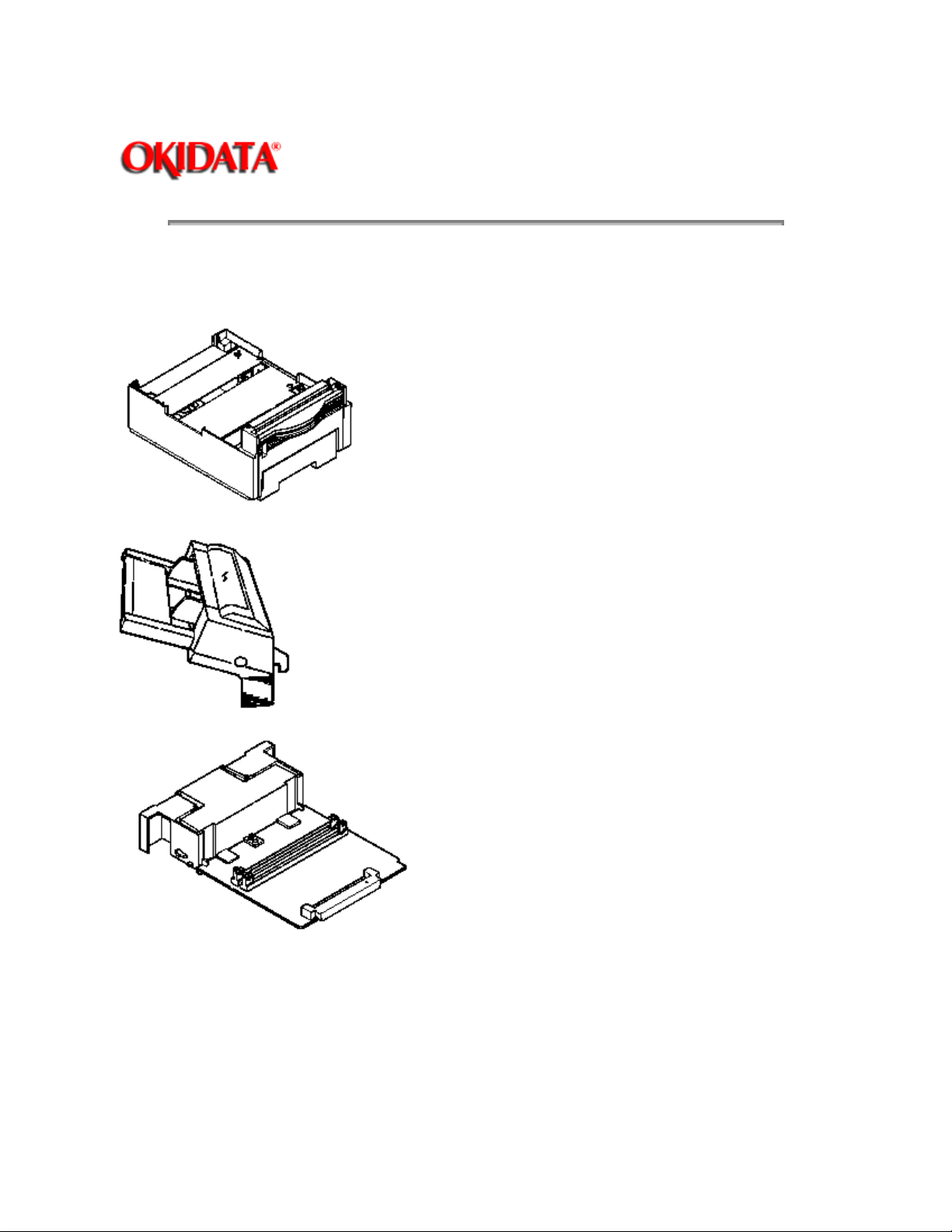

The options shown below are available for use with OKIPAGE 10i. These are available separately from

the printer unit.

(1) High Capacity Second Paper Feeder

(2) Power Envelope Feeder

(3) 1MB Memory Expansion Board

(4) RS-232C Serial Interface Board

(5) Network Interface Board

(6) DRAM SIMM Memory

Dram SIMM is available in increments of 1MB (min.) to 16MB (max.) on each SIMM. The access time of

SIMM memories are 60ns, 70ns, 80ns, and 100ns.

(7) PostScript program SIMM

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

(1) Type Desktop

Page: 6

Service Manual - OKIPAGE10i

Chapter 1 Configuration

(2) External dimensions (excludes

protruding portion)

Height 7.9" (200 mm)

Width 13.0" 9330 mm)

Depth 14.9" (378 mm)

(3) Weight 26 lbs. (10 kg)

(4) Developing method

Exposing method

Dry electrophotography

LED stationary head

(5) Paper used <Type>

Standard paper

- Xerox 4200 (20 lbs.)

Application paper (manual face-up feed)

- Label

- Envelope

- OHP paper (transparency)

<Size>

Standard sizes

- Letter

- Legal

- Legal-13

- Executive

- COM-10

- Monarch

- DL

- C5

- COM-9

- A4

- A5

- B5 (JIS)

- A6

Applicable sizes

- Width: 3.87" to 8.5" (116 to 216 mm)

- Length: 5.83" to 14" (148 to 355.6 mm)

<Thickness>

- Automatic feed: 16 to 28 lbs. (60 to 135 g/m

- Manual feed: 5.83" to 14" (148 to 355.6 mm)

2

)

(6) Printing speed Continuous printing: 10 pages per minute with Letter

size paper. [Except Second Paper Feeder 8.8PPM),

Multi-Purpose Feeder (8.3PPM)].

Warm-up time: 80 seconds, typical at room

temperature [77

o

F (25o C), AC120/230 V].

First page print time: 14 seconds typical for the Letter

size paper after warm-up.

(7) Paper feeding method Automatic feed or manual feed

(8) Paper delivery method Face down/face up

(9) Resolution 600 x 600 dots/inch

600 x 1200 dots/inch

(10) Power input 120 VAC + 5.5%, -15%

230V + 10%

(11) Power consumption Peak: Approx. 460W

Typical: Approx. 215W

Idle: Approx. 61W

Power save mode: Approx. 18W

(12) Temperature and humidity

In operation Power off mode During Storage Unit

Temperature 50-90

(10-320

32-110

(0-43)

14-110

(-10-43)

Humidity 2-80 10-90 10-90 %RH

Maximum wet bulb

temperature

Minimum

difference between

77

(25)

35.6

920

80.4

(26.8)

35.6

(2)

--------------

________

o

F

o

C)

(

o

F

o

C)

(

o

F

o

C)

(

wet and dry bulb

temperature

1. Storage conditions specified above apply to printers in packed condition.

2. Temperature and humidity must be in the range where no condensation occurs.

(13) Noise During operation: 50 dB (A) or less

Standby: 38 dB (A) or less

Quiet mode: Background level

(14) Consumables Toner cartridge 2,000 (5% duty)

Image drum cartridge 20,000 at continuous printing

16,000 (3 page/job)

10,000 (1 page/job)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 7

Service Manual - OKIPAGE10i

Chapter 1 Configuration

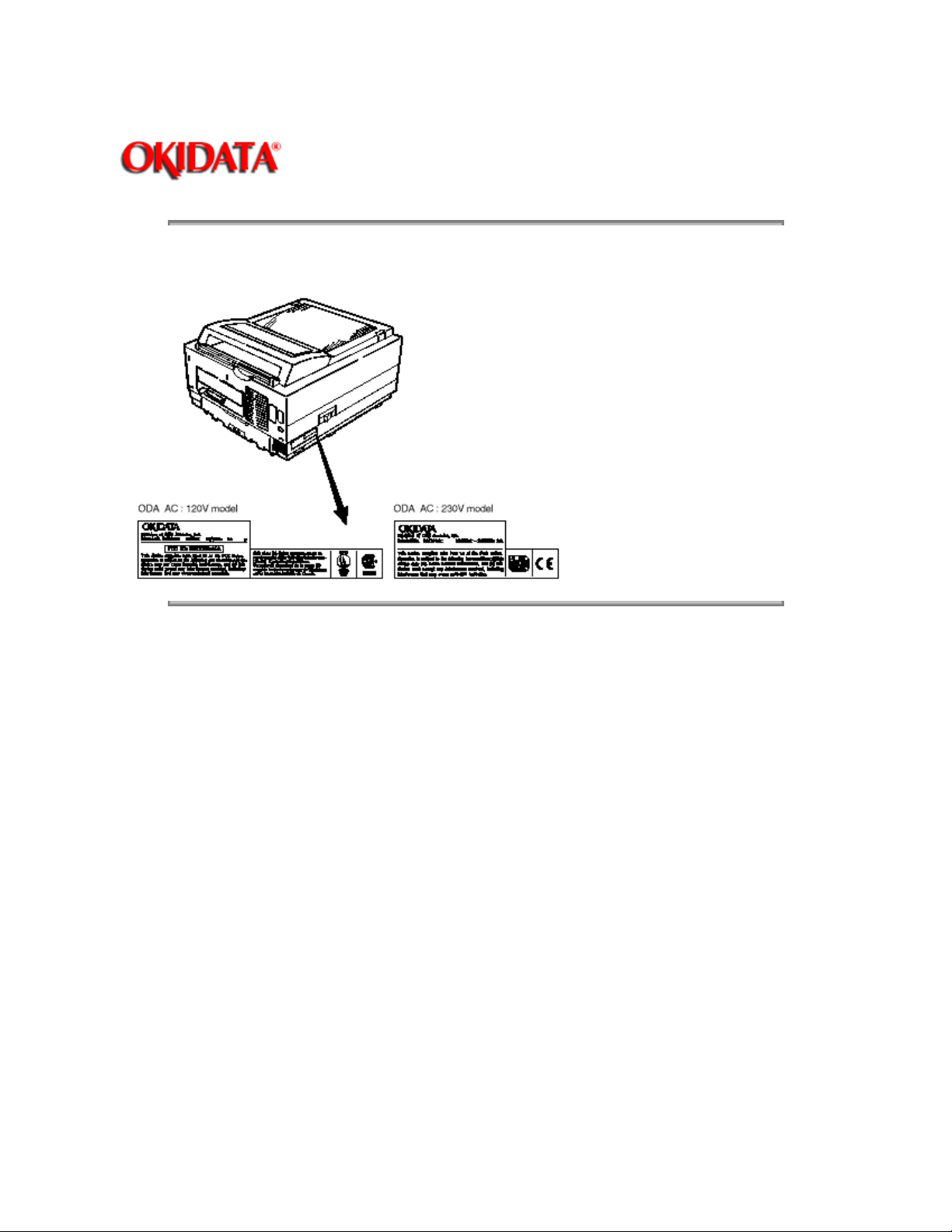

1.5.1 Certification Label

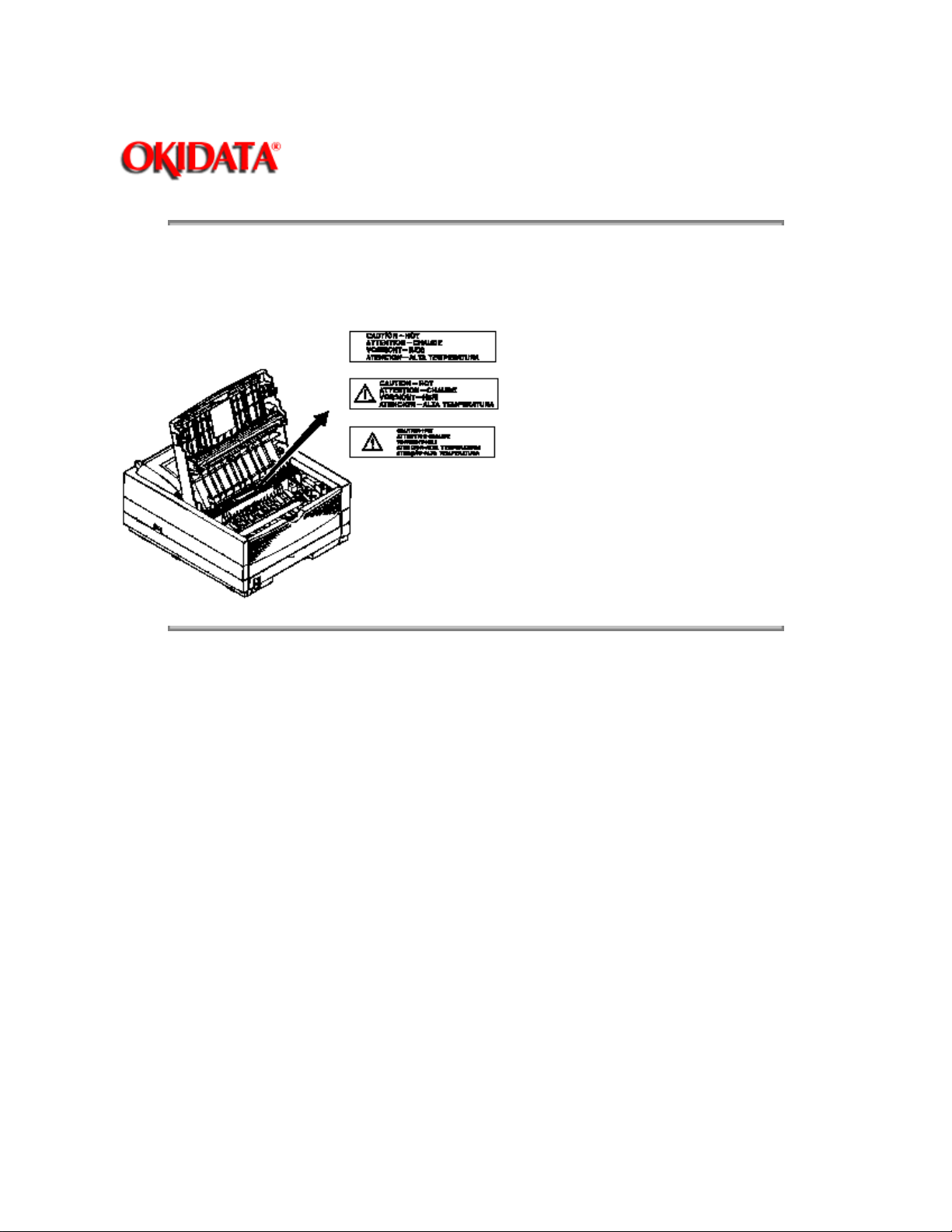

1.5.2 Warning Label

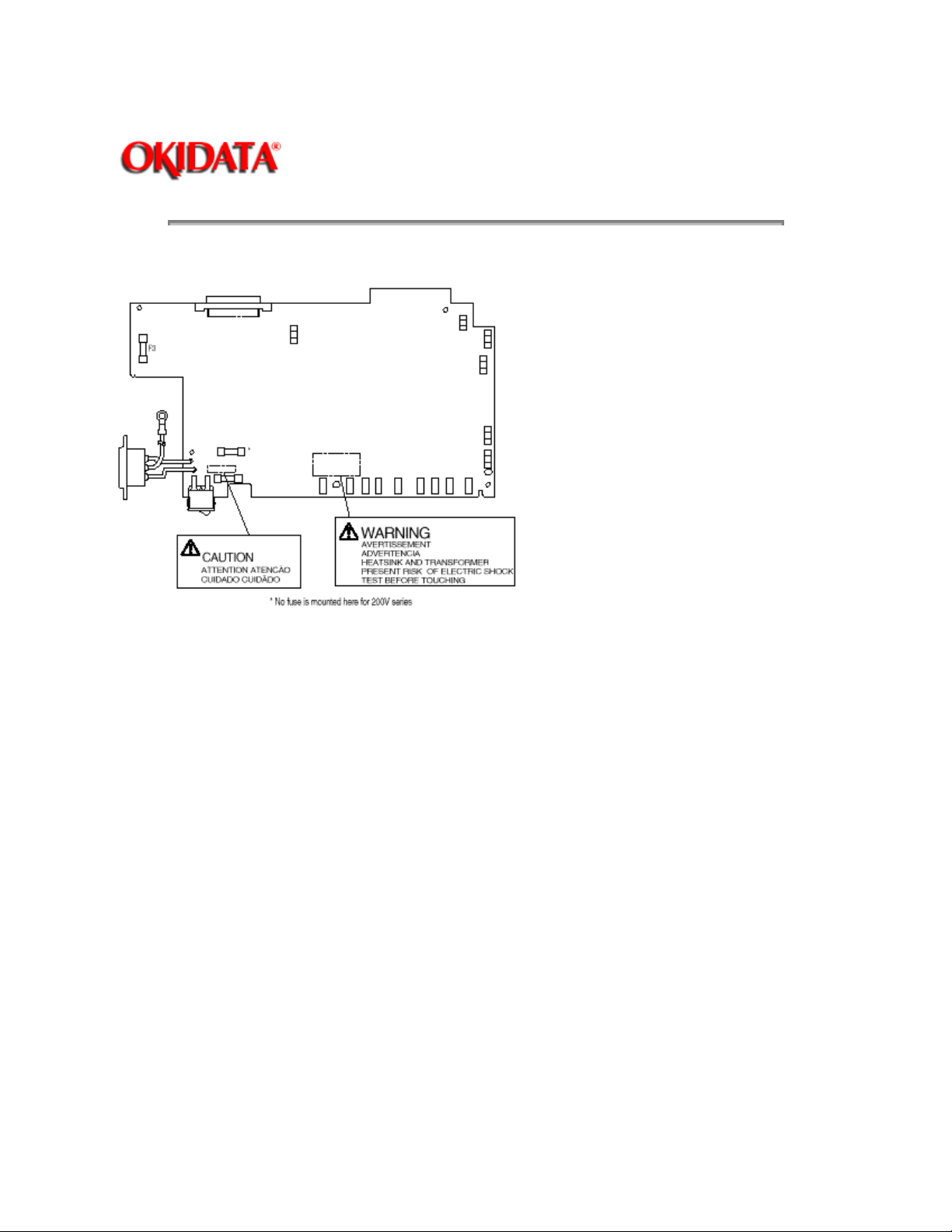

1.5.3 Warning/Caution Marking

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE10i

Chapter 1 Configuration

The safety certification label is affixed to the printer in the position described below.

Page: 8

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE10i

Chapter 1 Configuration

The warning labels are affixed to the sections which may cause bodily injury.

Follow the instructions on warning labels during maintenance.

Page: 9

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Manual - OKIPAGE10i

Chapter 1 Configuration

The following warning and caution markings are made on the power supply/sensor board.

Page: 10

ENGLISH

Heatsink and transformer core present risk of electric shock. Test before touching.

FRENCH

Le dissipateur thermique et le noyau du transformateur présentent des risques de choc électrique. Testez

avant de manipuler.

SPANISH

Las disipadores de color el núcel del transformador pueden producir un choque eléctrico. Compruebe

antes de tocar.

PORTUGUESE

O dissipador de calor e o núcleo do fransiormador apresentam risco de choque elétrico. Teste antes de

focar.

ENGLISH

Circuits maybe live after fuses open.

FRENCH

Il se peut que les circuits soient sous tension une fois que les fusibles ont éfé rerirés.

SPANISH

Las circuitos pueden estar activos una vez que se hayan abierio los fusibles.

PORTUGUESE

Os circuitos podem estar energizados após os fusiveis se queimarem.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 11

Service Manual - OKIPAGE10i

Chapter 2 Operation Description

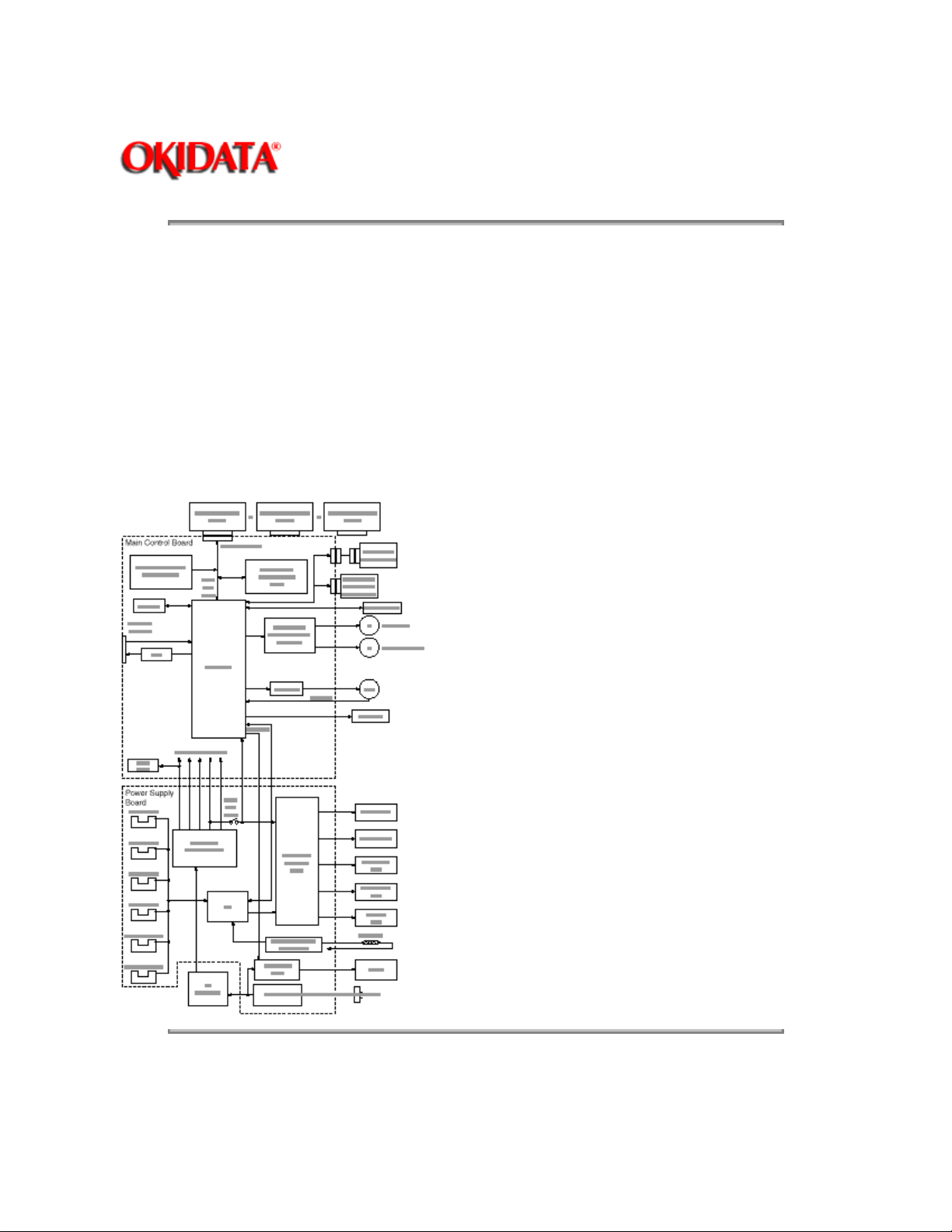

OKIPAGE 10i consists of a main control board, a power supply/sensor board, an operator panel, an

electrophotographic process mechanism, and revision for illumination of LED head.

The main control board receives data via the host I/F, it then decodes, edits and stores the data in

memory. After completing the editing of a single page of data, it references the font memory and

generates bit image data, which is transferred to the LED head in one dot line units.

Through the electrophotographic process mechanism, the data is printed on the paper.

The operator panel is used for operations and status display.

OKIPAGE 10i block diagram is shown in Figure 2-1.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 12

Service Manual - OKIPAGE10i

Chapter 2 Operation Description

The main control board consists of a single chip CPU, two program/font ROMs, four DRAMs, an

EEPROM, a host interface circuit, and a mechanism driving circuit.

(1) Single chip CPU

The single chip CPU is a custom CPU (32-bit internal bus, 32-bit external bus, 28.24-MHz clock, with input

frequency from a 7.06-MHz clock) which incorporates the RISC CPU and its peripheral devices, and has

the following functions:

Built-in device

Chip select controller

Bus controller

DRAM controller

DMA controller Transfer of image data from DRAM t video output port

Parallel interface controller Control of Centronics parallel interface

Serial interface controller Control of RS-232C serial interface

Video output port

LED STB output port

Timer Generation of various control timing

Serial I/O Port Control of operator panel, EEPROM, and options

I/O Port Input and output of sensor and motor signals.

Function

Control or ROM, RAM and I/O device

Control of LED head

Monitoring of paper running and paper size

(2) Program and Font ROMs

The Program and Font ROMs store the equipment program and various types of fonts. EPROM or Mask

ROM is used as Program and Font ROMs. The mounting locations of these Program and Font ROMs vary

depending on the type of the ROMs (for the mounting location see Section 7.4).

(3) DRAM

The DRAM is a 2MB resident memory on the main control board that stores edited data, image data, DLL

data and macro data.

(4) EEPROM

1,024-bit Electrically Erasable PROM (EEPROM), is loaded with the following kinds of data:

Menu data

Various counter data (page counter, drum counter)

Adjusting parameters (LED head drive time, print start position, paper feed length)

(5) Parallel Interface

Parallel data is received from a host system via parallel interface which conforms to the IEEE1284

specification.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 13

Service Manual - OKIPAGE10i

Chapter 2 Operation Description

The power supply/sensor board consists of an AC filter circuit, a low voltage power supply circuit, a high

voltage power supply circuit, heater drive circuit, and photosensors.

(1) Low Voltage Power Supply Circuit

This circuit generates the following voltages.

Output voltage

+5 V Logic circuit supply voltage

+ 30 V Motor and fan drive voltage and source voltage for high-voltage supply

+8 V RS-232C line voltage

-8 V RS-232C line voltage and PS board supply voltage

_3.3V LED head supply voltage

(2) High Voltage Power Supply Circuit

This circuit generates the following voltages required for electrophotographic process from +5 V,

according to the control sequence from the main control board. When cover open state is detected, +5 V

supply is interrupted automatically to stop the supply of all high-voltage outputs.

Output

CH -1.3 KV Voltage applied to charging roller

DB -265 V/+300 V Voltage applied to developing roller

SB -500 V/ 0 V Voltage applied to toner supply roller

TR +500 V to +3.5

CB +400 V/-1350 V Voltage applied to clearing roller

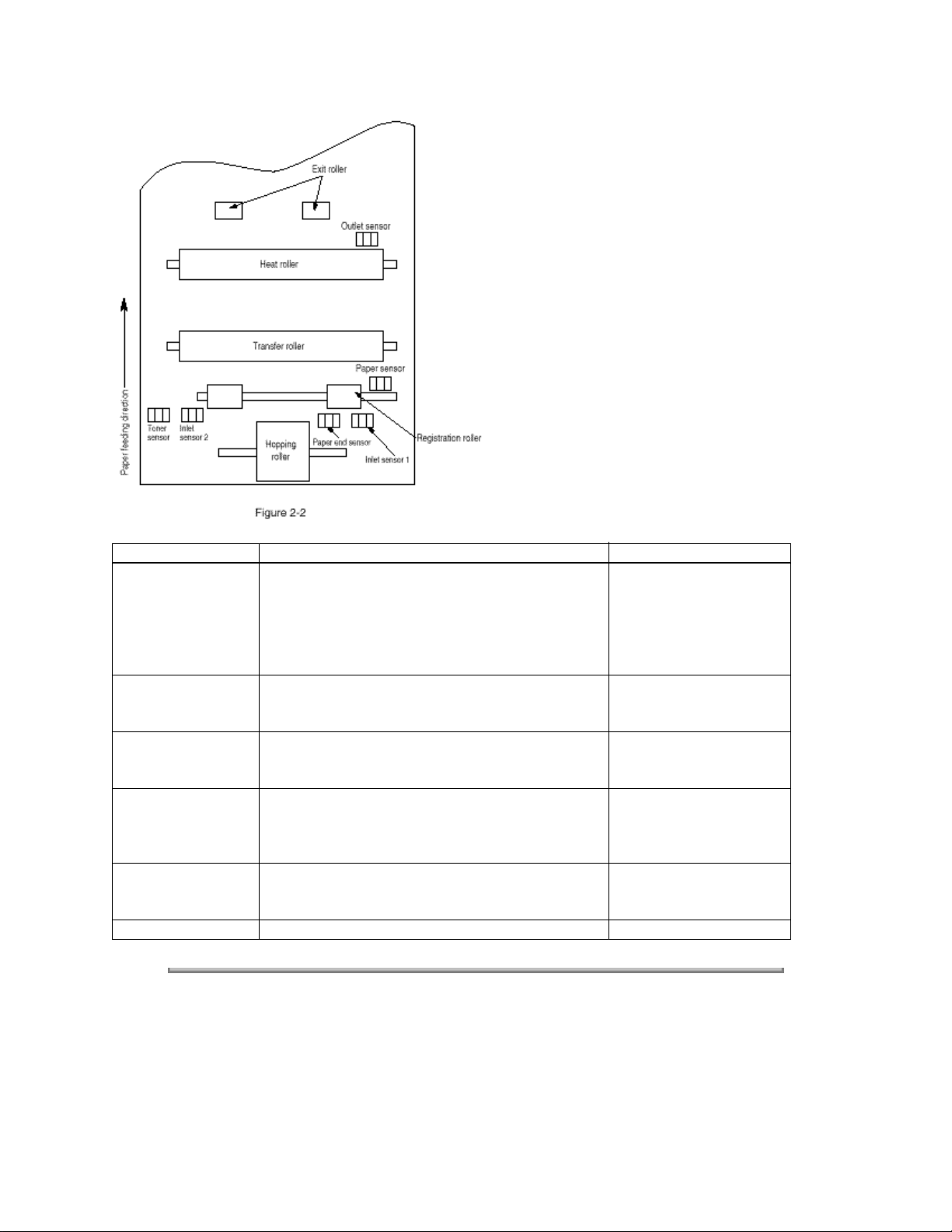

(3) Photosensor

The photosensor mounted on this power supply/sensor board monitors the status of paper being fed

through the printer during printing.

Voltage Use Remarks

KV/-1100 V

Use

Voltage applied to transfer roller Variable

The sensor layout diagram is shown in Figure 2-2.

Sensor Function Sensing state

Inlet sensor 1 Detects the leading part of the paper and gives

the monitor timing for switching from hopping

operation to feeding operation. Monitors paper

feeding situation and paper size based on the

paper arrival time and running time.

Inlet sensor 2 Detects the paper width ON: A4 or larger

ON: Paper exists.

OFF: No paper exists.

OFF: Small than A4

Paper sensor Detects the leading portion of the paper. Monitors

the paper feeding situation.

Outlet sensor Monitors the paper feeding and size according to

the time of arrival to and leaving the past the

sensor.

Paper and sensor Detects the end of the paper. ON: Paper exits.

Toner low sensor Detects the lack of toner. - - - - -

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

ON: Paper exists.

OFF: No paper exists.

ON: Paper exists.

OFF: No paper exists.

OFF: No paper exists.

Page: 14

Service Manual - OKIPAGE10i

Chapter 2 Operation Description

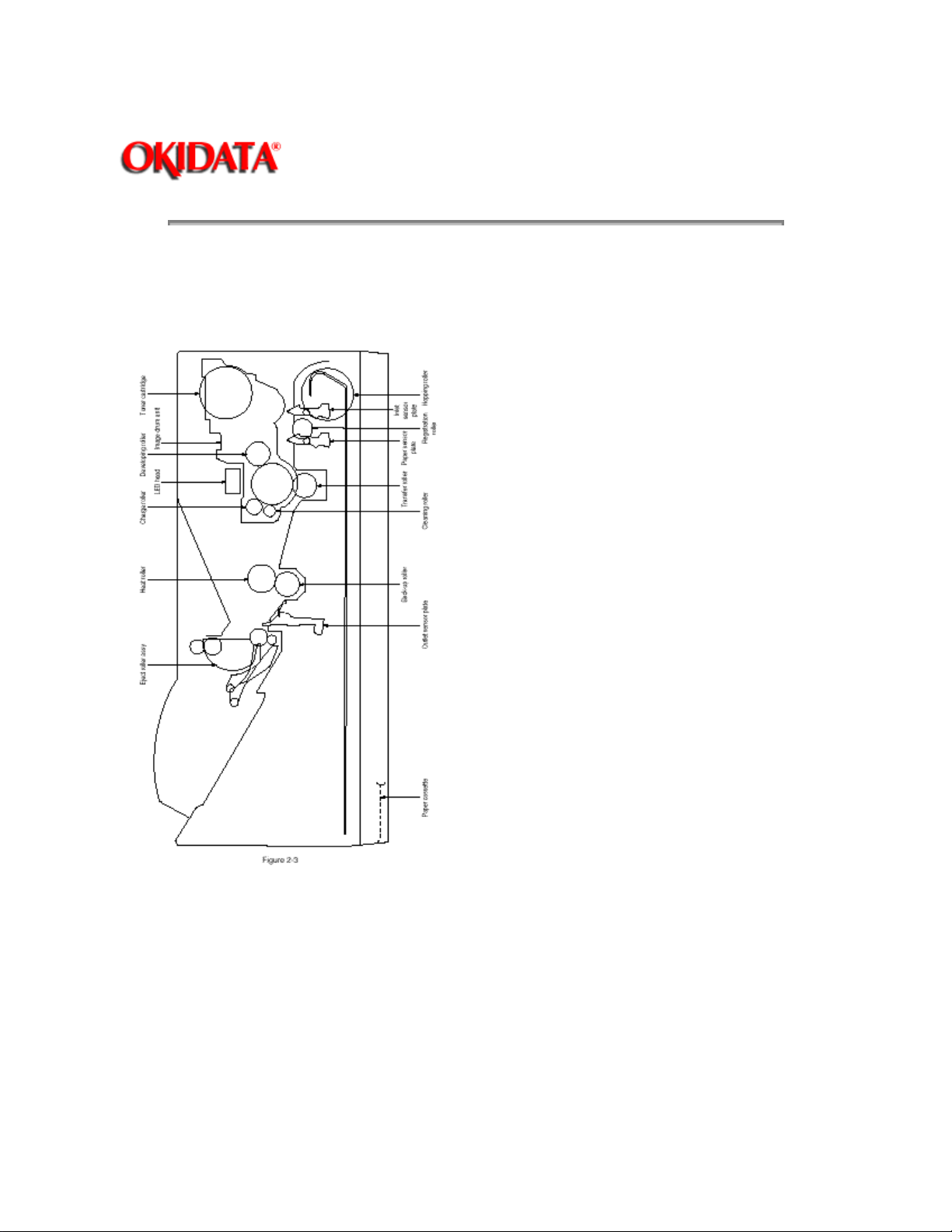

2.3.1 Electrophotographic Process Mechanism

2.3.2 Electrophotographic Process

2.3.3 Process Operation Descriptions

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 15

Service Manual - OKIPAGE10i

Chapter 2 Operation Description

This mechanism actuates the printing of image data supplied by the main control board on the paper by

electrophotographic process.

The layout of the electrophotographic process mechanism is shown in Figure 2-3.

(1) Image Drum Unit

The image drum unit consists of a sensitive drum, a charger, and a developer. The unit forms a toner

image on the sensitive drum, using a electrostatic latent image formed by the LED head.

(2) Registration Motor

The registration motor is a pulse motor of 48 steps/rotation with two-phase excitement by the signal from

the main control board. It drives the hopping and registration rollers via two one-way clutches according to

the direction of rotation.

(3) Main (Drum) Motor

The main or drum motor is a pulse motor of 48 steps/rotation with two-phase excitement by the signal

from the main control board and is the main motor of this mechanism.

(4) LED Head

Image data for each dot line from the main control board is received by the shift register and latch register.

The 4992 LED's are driven to radiate the image data on the image drum.

(5) Fuser

The fuser consists of a heater, a heat roller, a thermistor and a thermostat.

The AC voltage from the power supply/sensor board is applied to the heater controlled by the HEATON

signal from the main control board. This AC voltage heats the heater. The main control board monitors the

heat roller temperature via the thermistor, and regulates the heater roller to keep it at a designated

temperature in the menu, depending on the thickness of the paper (tray 1&2: light=165°C, medium

light=170°C, medium=175°C, medium heavy and heavy=195°C; manual feeding and power envelope

feeder: light=175°C, medium light=180°C, medium=185°C, medium heavy=190°C, heavy=195°C,

transparency = 160°C) by connecting or disconnecting the AC voltage supply to the heater.

When an abnormal rise of the heater roller temperature takes place, the thermostat of the heater voltage

supply circuit becomes active and forcibly cuts the AC voltage supply.

The temperature setting of the fuser can be changed through operator panel setting.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 16

Service Manual - OKIPAGE10i

Chapter 2 Operation Description

The electrophotographic processing is outlined below. The electrophotographic printing process is shown

in Figure 2-4.

1 Charging

The surface of the image drum is charged uniformly with a negative charge by applying the negative

voltage to the charge roller.

2 Exposure

Light emitted from the LED head irradiates the negatively charged surface of the image drum. The surface

potential of the irradiated portion of the image drum surface becomes lower, forming the electrostatic

latent image associated with the print image.

3 Developing and toner recovery

When the negatively charged toner is brought into contact with the image drum, it is attracted to the

electrostatic latent image by static electricity, making the image visible. At the same time, the residual

toner on the image drum is attracted to the developing roller by static electricity.

4 Transfer

When paper is placed over the image drum surface, the positive charge which is opposite in polarity to

that of the toner, is applied to the reverse side of the paper by the transfer roller. The toner is attracted by

the positive charge and is transferred onto the paper. This results in the transfer of the toner image formed

on the image drum onto the paper.

5 Temporary cleaning

Residual toner which remains on the image drum without being transferred is evened out by the cleaning

roller and is temporarily attracted to the cleaning roller by static electricity.

6 Fusing

The toner image transferred onto the paper is fused to the paper by heat and pressure.

An electrophotographic process timing chart is shown in Figure 2-5.

Loading...

Loading...