Okidata OKIOFFICE 1200, OKIOFFICE 1600 Parts list

OKIOFFICE 1200 1600

FIELD ENGINEERING MANUAL

Version 2.0

(11 June 2002)

Safety Information

LED Safety Label

A LED safety label is attached to the outside of the machine as shown below.

Battery Precautions

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer’s instructions.

Important: Muratec does not recommend the independent replacement of this battery.

The battery is sold only as a component part of the main control PCB and Battery

PCB, and cannot be purchased separately from Muratec.

Il y a un danger d'explosion s'il y a un remplacement incorrect de la batterie.

Remplacer uniquement avec une batterie du même type ou d'un type recommandé par le

constructeur. Mettre au rebut les batteries usagées conformement aux instructions du fabricant.

Germany only

VORSICHT!

Explosinsgefahr bei unsachgemäßen austausch der batterie.

Ersatz nur durch denselben oder einen vom hersteller empfohlenen ähnlichen typ. Entsorgung

gebrauchter batterien nach angaben des herstellers.

Denmark only

ADVARSEL!

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering

Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

Norway only

ADVARSEL

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens instruksjoner.

Sweden only

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens instruktion.

Finland only

ALL Areas

“Replace only with the same or equivalent type recommended by the manufacturer.

Germany only

gleichwertigen typ. Entsorgung gebrauchter Batterien nach Angaben des Herstellers.

VAROlTUS

Paristo voi räjähtää, los se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin.

Hävitä Käytetty paristo valmistajan ohjeiden mukaisesti.

CAUTION

Dispose of used IC Package according to the manufacturer’s instructions.”

VORSICHT!

⇒”Austausch nur durch denselben oder einen vom Hersteller empfohlenen,

Table of Contents

Safety Information..........................................................................................................................................1

LED Safety Label.................................................... .................................. .................................................1

Battery Precautions...................................................................................................................................1

Section 1 General Description

1.1 Product Description..............................................................................................................................1-1

1.2 Specifications....... .................................. ................................. ..............................................................1-2

Section2 Machine Composition

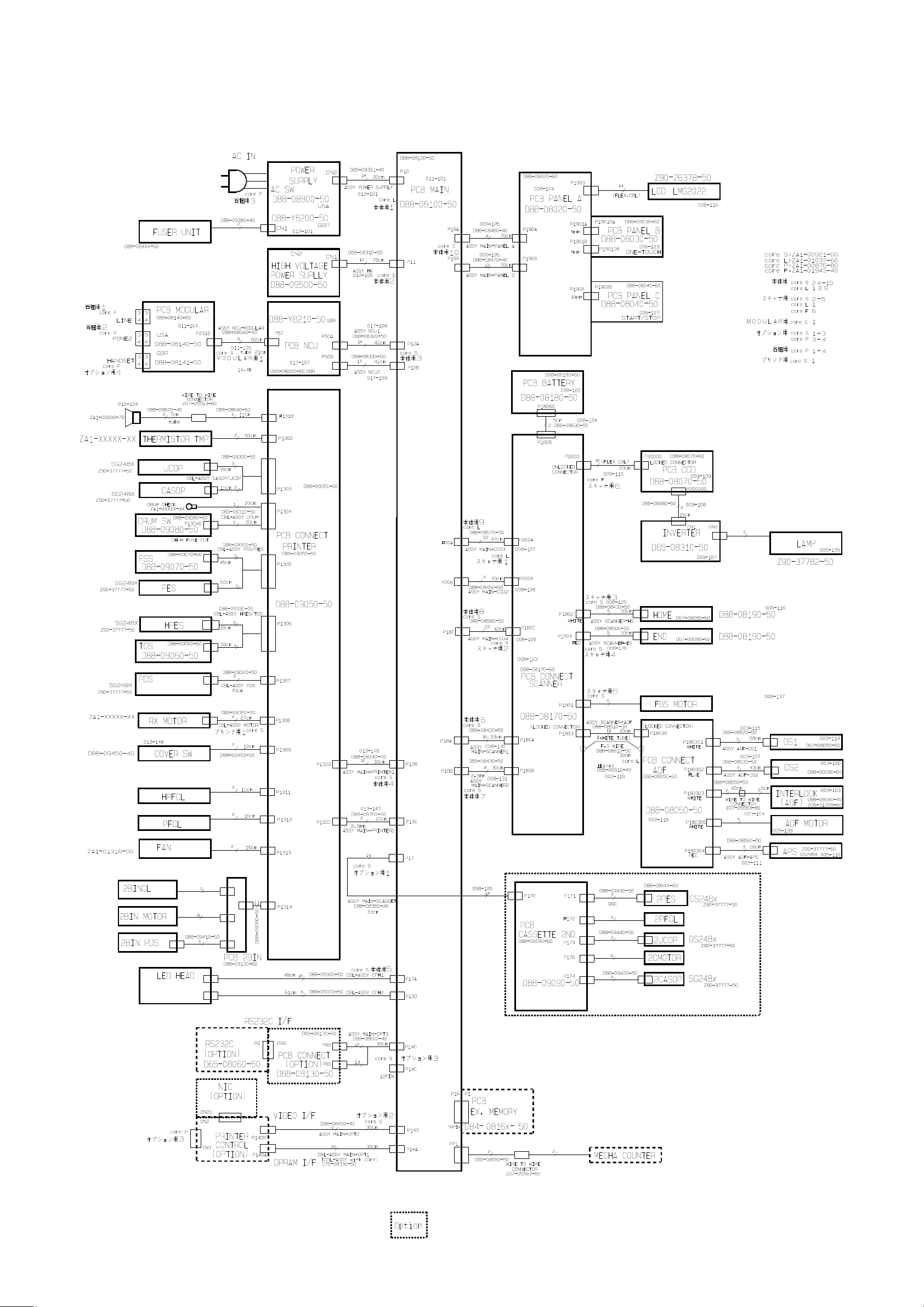

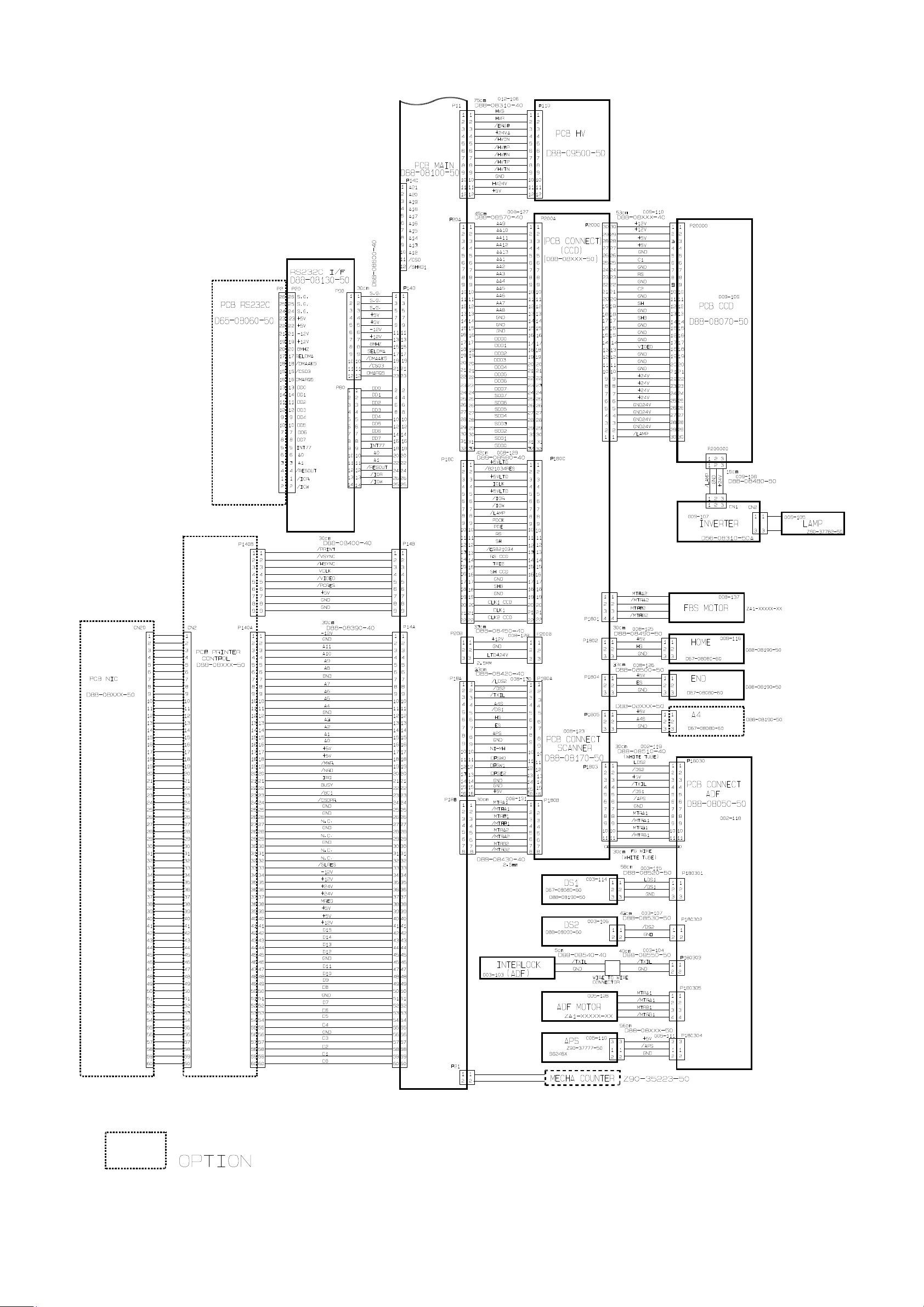

2.1 OKIOFFICE 1200 In te r connect Block Diagra m ( 1 /2 )........................................ .................................. ..2-1

OKIOFFICE 1600 Interconnect Block Diagram (1/2).......................................................... ... ..... ..... .. . ..... ...2-3

2.2 Main Control PCB... .. ................................................. .................................. .........................................2-5

2.3 Network Control Unit (NCU) PCB............ .................................. ................................. ..........................2-7

2.4 Power Supply Unit (PSU) .....................................................................................................................2-8

2.5 Sensors ................................ ................................................. ................................. .. .............................2-9

2.5.1 Sensor Locations...........................................................................................................................2-9

2.5.2 Sensor Descriptions ....................................................................................................................2-10

2.6 Document Scanning Sequence....................................................................................... ..... ..... .........2-11

2.6.1 Document Detection....................................................................................................................2-11

2.6.2 Document Separation..................................................................................................................2-11

2.6.3 Document Transport....................................................................................................................2-11

2.6.4 Document Scanning....................................................................................................................2-11

2.6.5 Document Discharge...................................................................................................................2-12

2.7 Recording Section .............. ... ................................................. .................................. ..........................2-13

2.7.1 Recording Paper Feed Path........................................................................................................2-13

2.8 Image Processing...............................................................................................................................2-13

2.8.1 Drum Charge...............................................................................................................................2-14

2.8.2 Drum Exposure ...........................................................................................................................2-14

2.8.3 Development ...............................................................................................................................2-14

2.8.4 Image Transfer............................................................................................................................2-15

2.8.5 Residual toner distribute............................................ ... .. ... ......................................... ... ..............2-15

2.8.6 Fusing..........................................................................................................................................2-16

Section3 Adjustment Procedures

3.1 Field Service Program Modes .......................... . ..... ..... ... .... . ..... ..... ... .... . ..... ... ..... .... . ..... ... ..... ................3-1

3.2 Machine Parameter Ad j us tment .............. .................................. ................................. ..........................3-2

3.2.1 Setting the Machine Parameters...................................................................................................3-2

3.2.2 Clearing the Machine Parameters.................................................................................................3-2

3.3 Memory Switch Adjustment ................................................................................................................3-18

3.3.1 Setting the Memory Switches......................................................................................................3-18

3.3.2 Clearing the Memory Switches....................................................................................................3-18

3.4 Clear Programmed D a ta / Use r Settings..................................... .................................. .....................3-35

3.5 All RAM Clear .................................................. .................................. .................................................3-36

3.6 Setting Individual Autodialer Attributes...............................................................................................3-36

3.7 Unique Switch Adjustment............................................................. ... .......... ... ..... ..... ..... ... ...................3-40

3.7.1 Setting the Unique Switches........................................................................................................3-40

3.7.2 Clearing the Unique Switches............................................................................. ..... ..... ..... .........3-40

Unique Switch a:0 — Dialer...................................... .. ... ..... ... ..... ..... ... .... . ..... ... ..... ..... ..... .. . ..... ..............3-41

3.8 Printer maintenance mode..... .................................. ................................. ..........................................3-62

3.9 Print Program Mode List ....................................... .................................. ............................................3-63

3.10 Test Modes.......................................................................................................................................3-63

3.10.1 Life Monitor................................................................................................................................3-64

i

3.10.2 Printer Test................................................................................................................................3-65

3.10.3 Feeder test............................................................ ..... .. ... ..... .. . ..... .... . ... .... . ..... ...........................3-66

3.10.4 Backgrou nd Level Test. .................. ................................................. ..........................................3-66

3.10.5 Set Background Level ...............................................................................................................3-66

3.11 Print Machine Parameters, Memory Switch and Unique Switch Settings........................................ .3-67

3.12 Factory Functions .............................................................................................................................3-67

3.12.1 Function List..............................................................................................................................3-67

3.12.2 LED Test....................................................................................................................................3-67

3.12.3 LCD Test ...................................................................................................................................3-68

3.12.4 Key Panel Test..........................................................................................................................3-68

3.12.5 SRAM Check.............................................................................................................................3-69

3.12.6 DRAM Check.............................................................................................................................3-69

3.12.7 RTC(real time clock) Test..........................................................................................................3-70

3.12.8 RS-232C Test............................................................................................................................3-70

3.13 Line Tests .........................................................................................................................................3-71

3.13.1 Relay Test .................................................................................................................................3-71

3.13.2 Tonal Signal Test.......................................................................................................................3-72

3.13.3 DTMF Output Test.....................................................................................................................3-74

3.14 Mirror Carriage Transfer Mode...................................................................... ... ..... ..... ... ...................3-75

3.15 Consumable order sheet ..................................................................................................................3-75

3.15.1 Set consumable order sheet .....................................................................................................3-75

3.15.2 Print consumable order sheet ............................ .. ... ... ..... .... . ... ..... .... . ..... ... ................................3-76

3.15.3 Clear consumable order sheet ..................................................................................................3-76

3.16 DRAM Clear......................................................................................................................................3-77

3.17 Clear Life Monitor .............................................................................................................................3-77

3.18 Clear Optional Data..........................................................................................................................3-77

3.19 Set Service Code.............. .................................................. ................................. .............................3-78

3.20 Life monitor maintenance .................................................................................................................3-78

3.21 JP1, JP2 Battery Backup..................................................................................................................3-79

3.22 Update the software..........................................................................................................................3-80

Section4 Troubleshooting Procedures

4.1 Troubleshoot in g O ut line......... .................................. ................................................. ............................4-1

4.2 Recording Paper Jam...........................................................................................................................4-2

4.3 Document Feeder Jam.......................................................................... ..... ..........................................4-2

4.4 Document Feeder Multi-feeding or Skew ............................................................................. .. ... ... ........4-3

4.5 Mirror Carriage Error...................................................................... ... ..... ..... ... ..... ..... ..... ........................4-3

4.6 Transmit Erro r............................................... .................................. ......................................................4-3

4.7 Transmit Black Lines ............................................................................................................................4-3

4.8 Cannot transmi t ................... ................................. ................................................. ...............................4-4

4.9 Receive Erro r s..... .................................. ................................. ..............................................................4-4

4.10 Will not Auto-Answer ..........................................................................................................................4-4

4.11 Clearing Jammed Pap er ................ .................................. .................. .................................................4-5

If the original document jams..................................................................................................................4-5

To remove the document: ............... .................................. ................................. .................. ..................4-6

If a printout jams inside your machine....................................................................................................4-7

4.12. The Image Quality Problems . ................................. .................................. .........................................4-9

4.12.1 Blank pages.................................................................................................................................4-9

4.12.2 Black pages.................................................................................................................................4-9

4.12.3 Printout too light.........................................................................................................................4-10

4.12.4 Printout too dark........................................................................................................................4-10

4.12.5 Blurred background...................................................................................................................4-10

4.12.6 Uneven print density .................. .................................. ................................. .............................4-11

4.12.7 Irregularities...............................................................................................................................4-11

4.12.8 White (Black) Line .....................................................................................................................4-12

ii

4.12.9 Toner Smudges....................................... . ..... .... . ..... .. . ..... .... . ... ..................................................4-12

4.13 LCD Error Messages ........................................................................................................................4-13

LCD error messa g es ( Alp h ab e tic list)...... ................................................. ................................. ...........4-13

4.14 Error Codes ....................................... . ..... ..... ... ..... ..... .. . ..... ..... ..... ... ..... .. ... ... ..... ..... ...........................4-18

Dialing errors ........................................................................................................................................4-18

Reception errors...................................................................................................................................4-18

Transmission errors..............................................................................................................................4-19

Communication Error Messages......................................... .................. .................................. .............4-20

4.15 Service Call Error..............................................................................................................................4-21

4.15.1 Call For Service......................... .................................. ................................. .............................4-21

4.15.2 Please Call Service ...................................................................................................................4-21

4.16 LCD Failure.......................................................................................................................................4-24

4.17 General Power Failure......................................................................................................................4-24

4.18 Cleaning the Unit.................................................. ..... .. ... ... .... . ..... .. . ..... .... . ..... ...................................4-25

Curing frequent jams in the ADF..........................................................................................................4-25

Cleaning the FBS glass, Contact glass and white pad.........................................................................4-26

Cleaning the LED print head ........................ ................................. ................... ....................................4-26

Section5 Maintenance & Adjustment

5.1 Maintenance schedule..........................................................................................................................5-2

5.2 Re/Disass embl e........... .................. ................................. .................................. ....................................5-3

5.2.1 Covers ...........................................................................................................................................5-5

5.2.2 PCBs ...........................................................................................................................................5-13

5.2.3 Sensors .......................................................................................................................................5-24

5.2.4 Scanning section.........................................................................................................................5-25

5.2.5 Printer section..............................................................................................................................5-37

5.3 Adjustment................ .................................. ................................................. .......................................5-49

5.3.1 Adjustment of Retard roller pressure...........................................................................................5-49

Section 6 Options

6.1 Memory Upgrade.... .................. ................................. .................. .................................. .. .....................6-1

Packaging contents:........... .................................. ................................. .................................................6-1

Installation ..............................................................................................................................................6-1

6.2 Attaching an optional handset ..............................................................................................................6-3

Packaging contents:........... .................................. ................................. .................................................6-3

Installation ..............................................................................................................................................6-3

6.3 RS-232C interfa ce...................................... ................................. .................................. . ......................6-4

Packaging contents:........... .................................. ................................. .................................................6-4

Installation ..............................................................................................................................................6-4

RS-232C interface cable ........................................................................................................................6-6

Signal direction.......................................................................................................................................6-6

RS-232C Test.........................................................................................................................................6-6

6.3 Page Counter........................................................................................................................................6-7

Packaging contents:........... .................................. ................................. .................................................6-7

Installation ..............................................................................................................................................6-7

6.4 AL-200 (only for OKIOFFICE 1600)......................................................................................................6-8

Packaging contents:........... .................................. ................................. .................................................6-8

Installation ..............................................................................................................................................6-8

6.5 OP-100/NP- 200 ............. .................................. .................................. .................................................6-12

Packaging contents:........... .................................. ................................. ...............................................6-12

Attaching the OP-100 (and NP-200) ........................ ..... ... .. ... ..... ..........................................................6-13

Installing the Printer driver............ ... ................................................. ....................................................6-16

6.6 Attaching the 2-Bin tr a y ................................ .................................. ....................................................6-17

Packaging contents:........... .................................. ................................. ...............................................6-17

Installation ............................................................................................................................................6-17

6.7 Second paper cassette.......................................................................................................................6-22

iii

Packaging contents:........... .................................. ................................. ...............................................6-22

Installation ............................................................................................................................................6-22

Setting of the Paper Size......................................................................................................................6-25

iv

Section 1

General Description

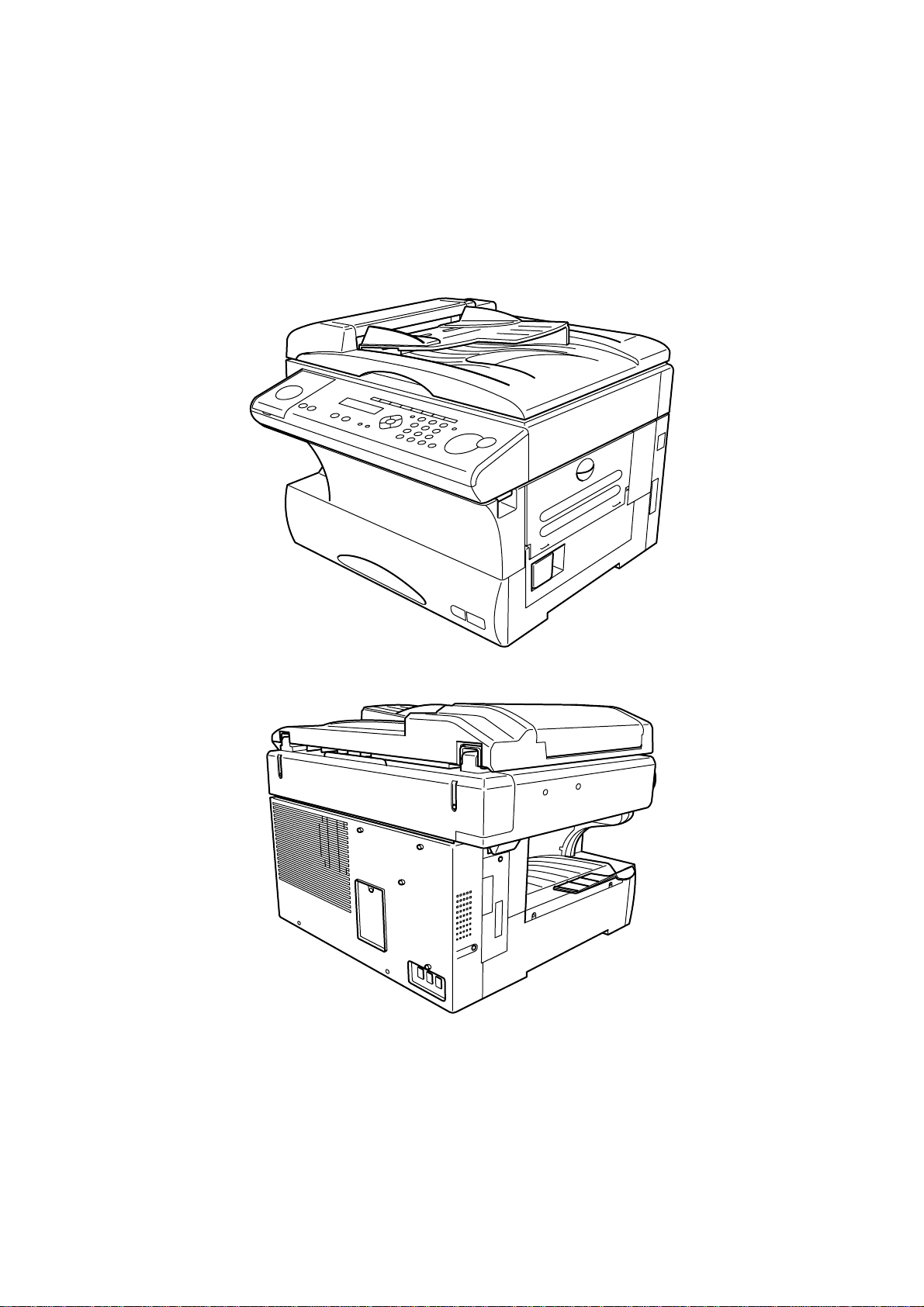

1.1 Product Description

The OKIOFFICE 1200 and OKIOFFICE 1600 is Multi-function product with flat bed scanner and Group

3 and V.34 HDX modem facsimile machine. Documents are printed on plain paper using dry

electrophotographic printing.

1-1

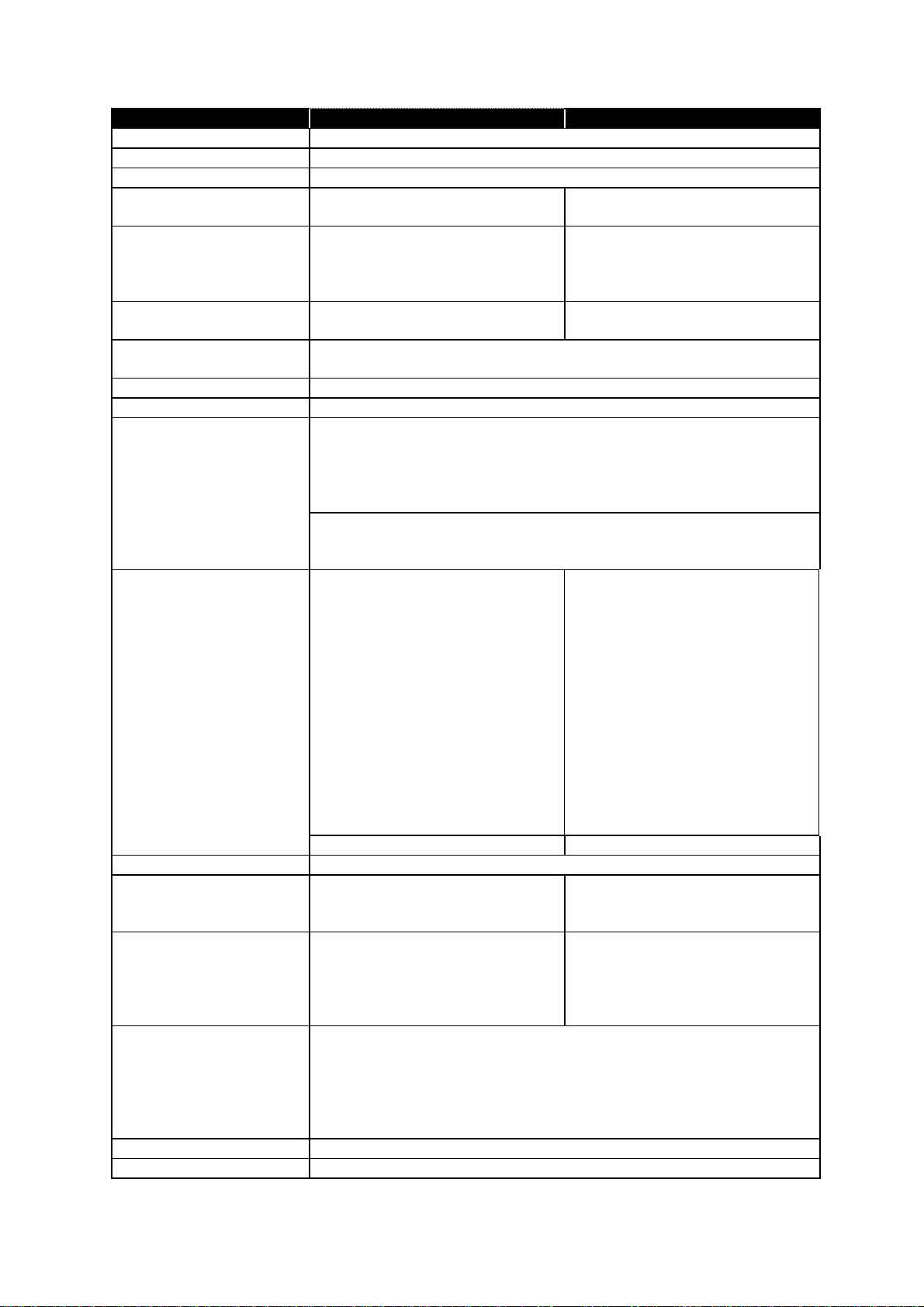

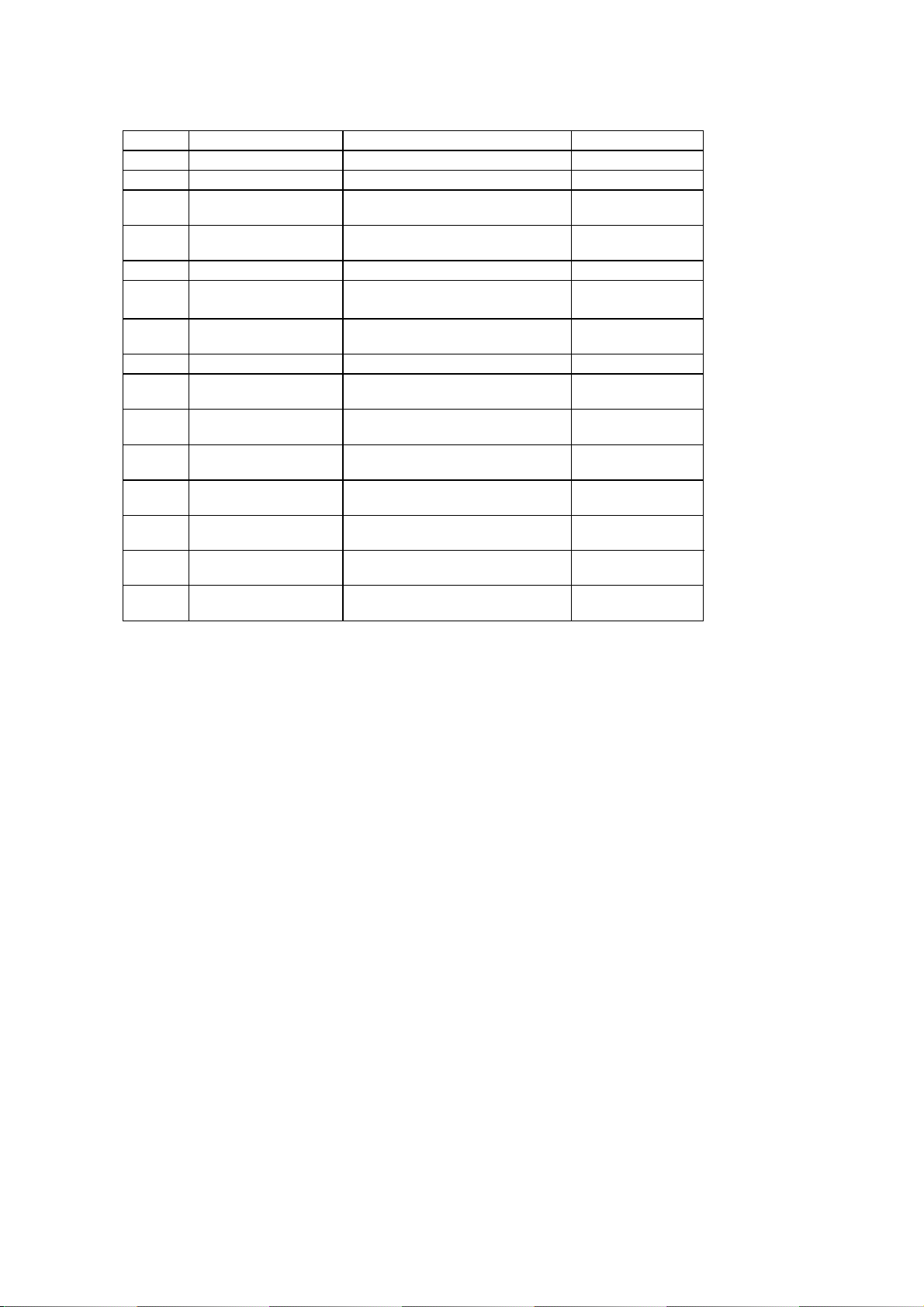

1.2 Specifications

Item 1200 1600

Type Desktop type

Telephone network PSTN (Public Switched Telephone Network) or equivalent.

Compatibility ITU-T T.4 and T.30

Coding method ITU-T-standard MH, MR, MMR and

Murata-proprietary MSE.

Modem speed 14400, 12000, 9600, 7200, 4800

and 2400 bps

Dual Access Allows up to two simultaneous

operations.

Display LCD: 2 lines, 20 characters per line.

Language: English, French, Spanish, Germany

Scanning method Flatbed CCD

Recording method Dry electrophotographic (LED) printer

Acceptable document size

Scanning resolution <Transmission>

<Copy> 300 dpi 400 dpi

Effective Scanning width 208 mm(Fax), 210 mm(Copy)

Transmission speed Approx. 6 seconds

Document Memory Standard:

Document memory backup (Total memory capacity : Backup time)

Printing resolution 600 dpi

Warm-up time Less than 20 seconds at 68° F (20° C)

<ADF>

Single sheet Two or more sheets

Max: 216 mm (W) × 900 mm (L) 210 mm (W) × 330 mm (L)

Min: 120 mm (W) × 100 mm (L) 148 mm (W) × 105 mm (L)

Paper weight: 30.2 – 104.7g/m2 52.3 – 80 g/m2

<FBS glass>

Max: 210 mm (W) × 330 mm (L)

Min: No limit

horizontal × vertical

(in dots/mm × in lines/mm)

Normal: 8 × 3.85

Fine: 8 × 7.7

Super fine: 8 × 15.4

Greyscale: 8 × 7.7

Based on transmission of ITU-T

Test Document 1.

8 MB (630 pages)

Upgrade option:

plus 8MB (680 pages)

8 MB: 72 hours

16 MB: 36 hours

32 MB: 18 hours (1600 only)

The backup battery requires about 24 hours to reach full charge after

power to the fax unit is restored.

ITU-T-standard MH, MR, MMR,

JBIG and Murata-proprietary MSE.

33600, 31200, 28800, 26400,

24000, 21600, 19200, 16800,

14400, 12000, 9600, 7200, 4800

and 2400 bps

Allows up to three simultaneous

operations.

<Transmission>

horizontal × vertical

(in dots/mm × in lines/mm)

Normal: 8 × 3.85

Fine: 8 × 7.7

Super fine: 16 × 15.4*

Greyscale: 8 × 7.7(Memory Tx)

16 × 15.4*(Rea l t i m e T x )

*: In the case that the remote fax

has the ability of “16 × 15.4”.

If not, the superfine resolution is

“8 × 15.4“, and the greyscale

resolution in real time transmission

is “8 × 7.7”.

Approx. 2 seconds

Based on transmission of ITU-T

Test Document 1.

Standard:

8 MB (630 pages)

Upgrade option:

plus 8MB (680 pages)

plus 24MB (2040 pages)

1-2

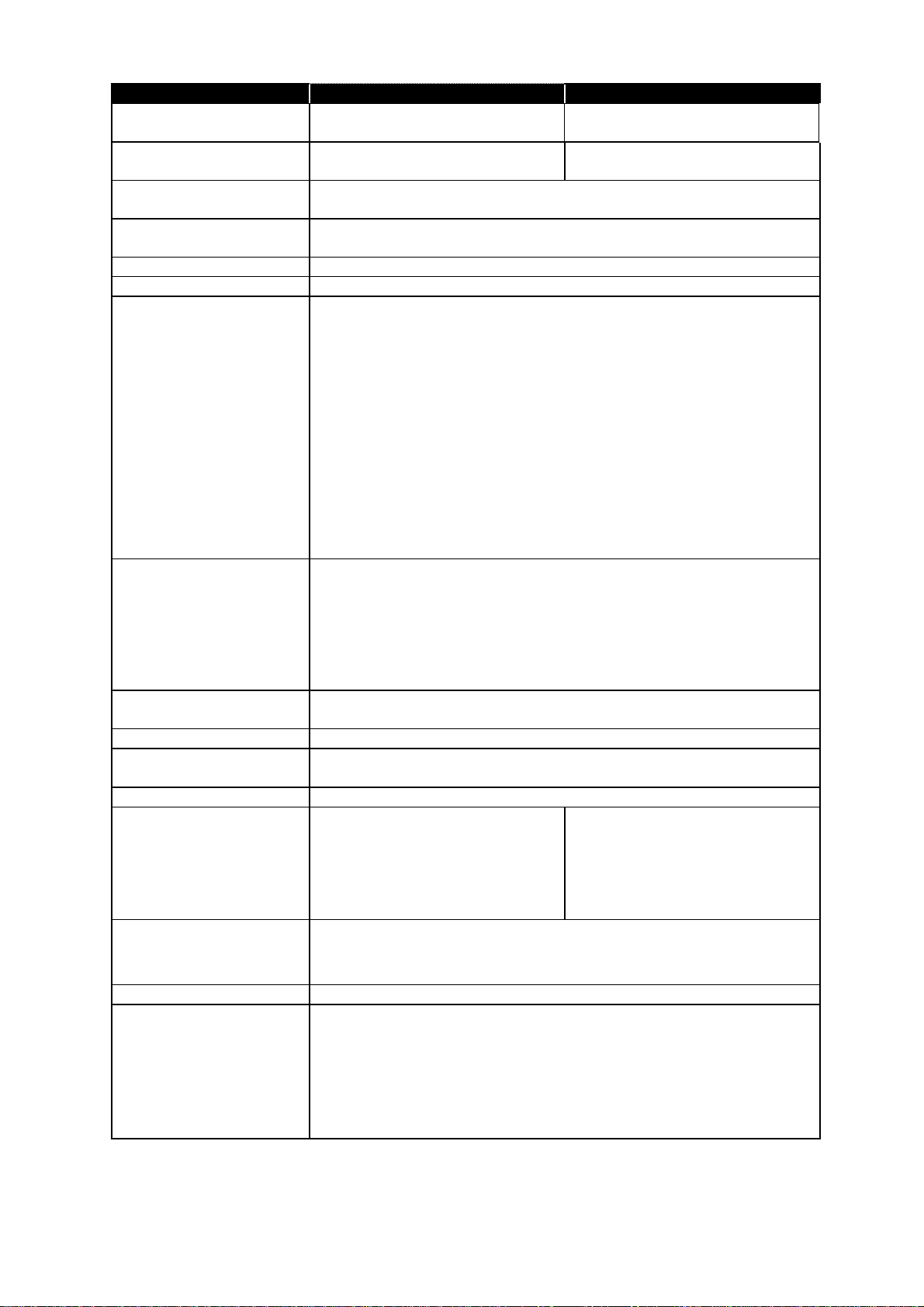

Item 1200 1600

First copy time 12 seconds (using A4-sized paper

in 1st paper cassette)

Printing speed 12 ppm (When loading A4-sized

paper from 1st paper cassette.)

10 seconds (using A4-sized paper

in 1st paper cassette)

16 ppm (When loading A4-sized

paper from 1st paper cassette.)

Toner yield Approx. 8,000 pages (A4, 6 % document coverage under 2-pages

interval printing.)

Drum yield Approx. 16,000 pages (A4, 6 % document coverage under 2-pages

interval printing.)

Smoothing Yes

Print margin Reading edge, Trailing edge, Left edge and Right edge: 3 ± 2 mm

Acceptable recording

paper size

<Paper cassette>

Plain paper: A4(SEF), A5(LEF), F4(SEF)

Paper weight: 60 – 90g/m

2

<Bypass tray>

Plain paper: A4(SEF), A5(LEF)(SEF), A6(SEF), F4(SEF),

Letter(SEF), Legal(SEF), Half letter(LEF),

Executive(SEF)

Envelopes: DL(SEF), COM10(SEF), Monarch(SEF)

Postcard: 100 mm (W) × 148 mm (L)

Transparency: A4(SEF)

Custom size*: (105 – 216 mm) × (148 – 356 mm) (Width × Length)

*Custom sized paper is available only when the optional printer controller

kit has been installed.

Recording paper capacity <Paper cassette>

1st cassette: 500 sheets

2nd cassette (option): 500 sheets

<Bypass tray>

Plain paper: 50 sheet

Postcard/Transparency: 20 sheets

Envelopes 1 sheet

Receive paper tray

capacity

Approx. 300 sheets

with optional 2-bin tray: Upper approx. 100, Lower approx. 150 sheets

Printouts exit Face up

Environmental conditions

Ambient temperature: 10 °C to 32 °C (50 °F to 89.6 °F)

Relative humidity: 20 % to 80 % with no condensation

Power requirements 230 VAC ± 10 %; 50/60 Hz

Power consumption Sleep mode (Heater off) 19.8 W

Standby: 20.6 W

Memory Transmission: 21.3 W

Reception: 21.5 W

Copying: 1020 W

Maximum: 1060 W

Dimensions

2WAY: 510 (W) × 492 (D)

3WAY: 510 (W) × 492 (D)

× 376 (H) mm

× 483 (H) mm

Sleep mode (Heater off) 22.2 W

Standby (Heater off): 24.2 W

Memory Transmission: 25.0 W

Reception: 25.2 W

Copying: 1200 W

Maximum: 1210 W

When the Extension paper tray and Bypass tray are retracted.

Weight Approx. 23.3 Kg (51.4 lbs) without consumables and trays.

Optional products

• Optional telephone handset

• 2nd paper cassette

• Printer controller kit

• Network interface card

• Second phone line kit (only for OKIOFFICE 1600)

• RS-232C interface kit

• Mechanical page counter

1-3

Section2

Machine Composition

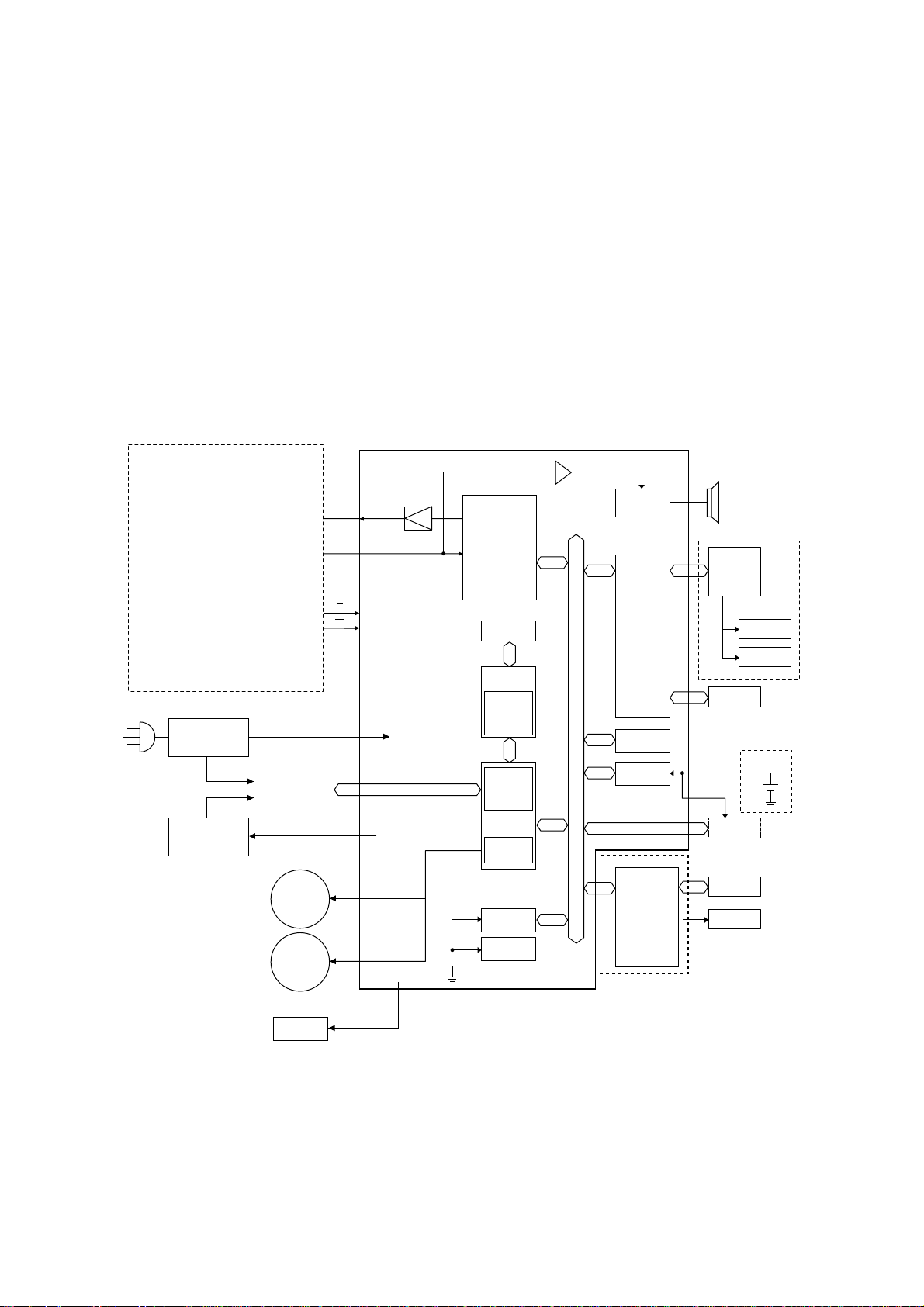

2.1 OKIOFFICE 1200 Interconnect Block Diagram (1/2)

2-1

OKIOFFICE 1200

Connection Diagram (1/2)

OKIOFFICE 1200 Interconnect Block Diagram (2/2)

OKIOFFICE 1200

Connection Diagram (2/2)

2-2

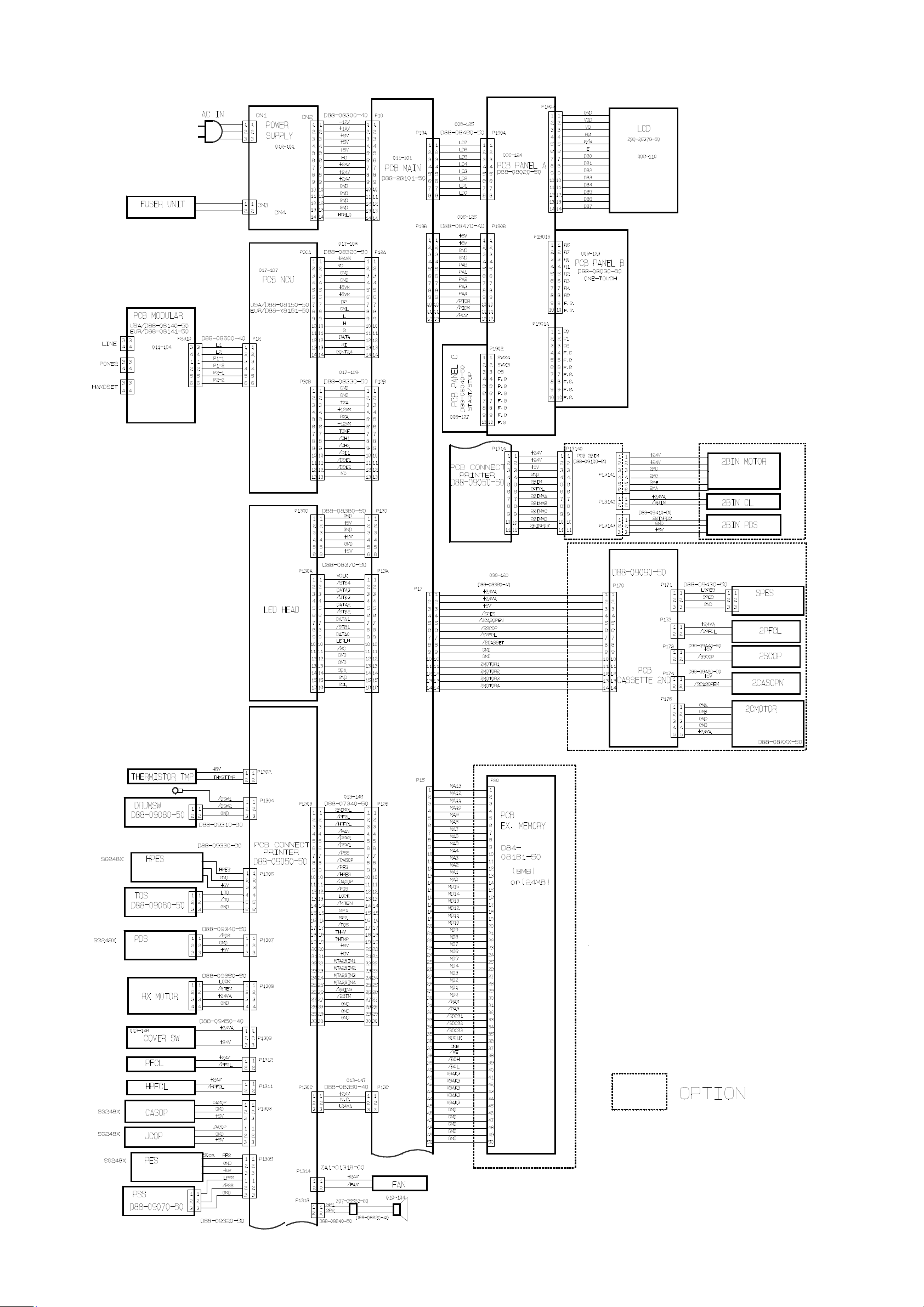

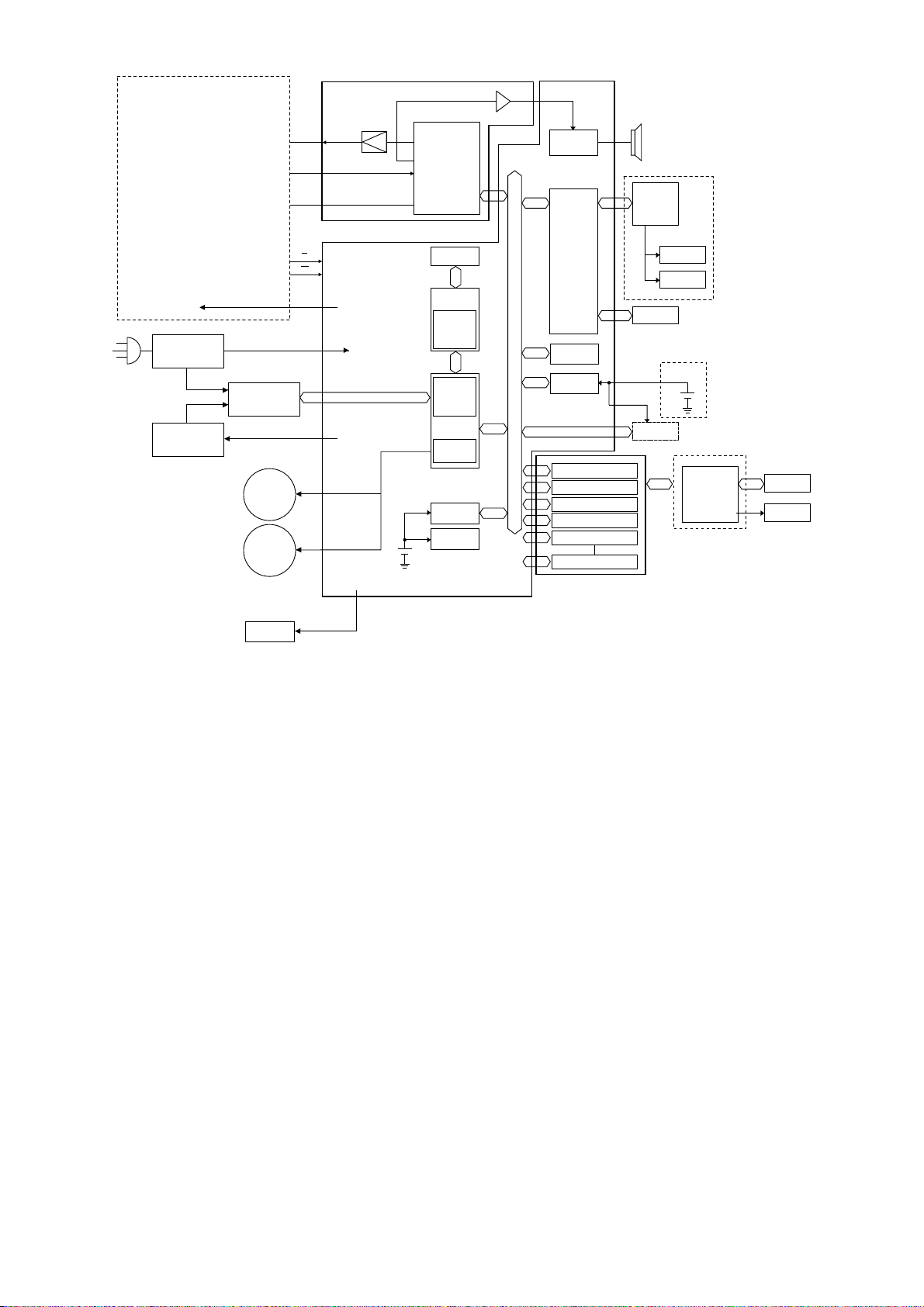

OKIOFFICE 1600 Interconnect Block Diagram (1/2)

2-3

OKIOFFICE 1600

Connection Diagram (1/2)

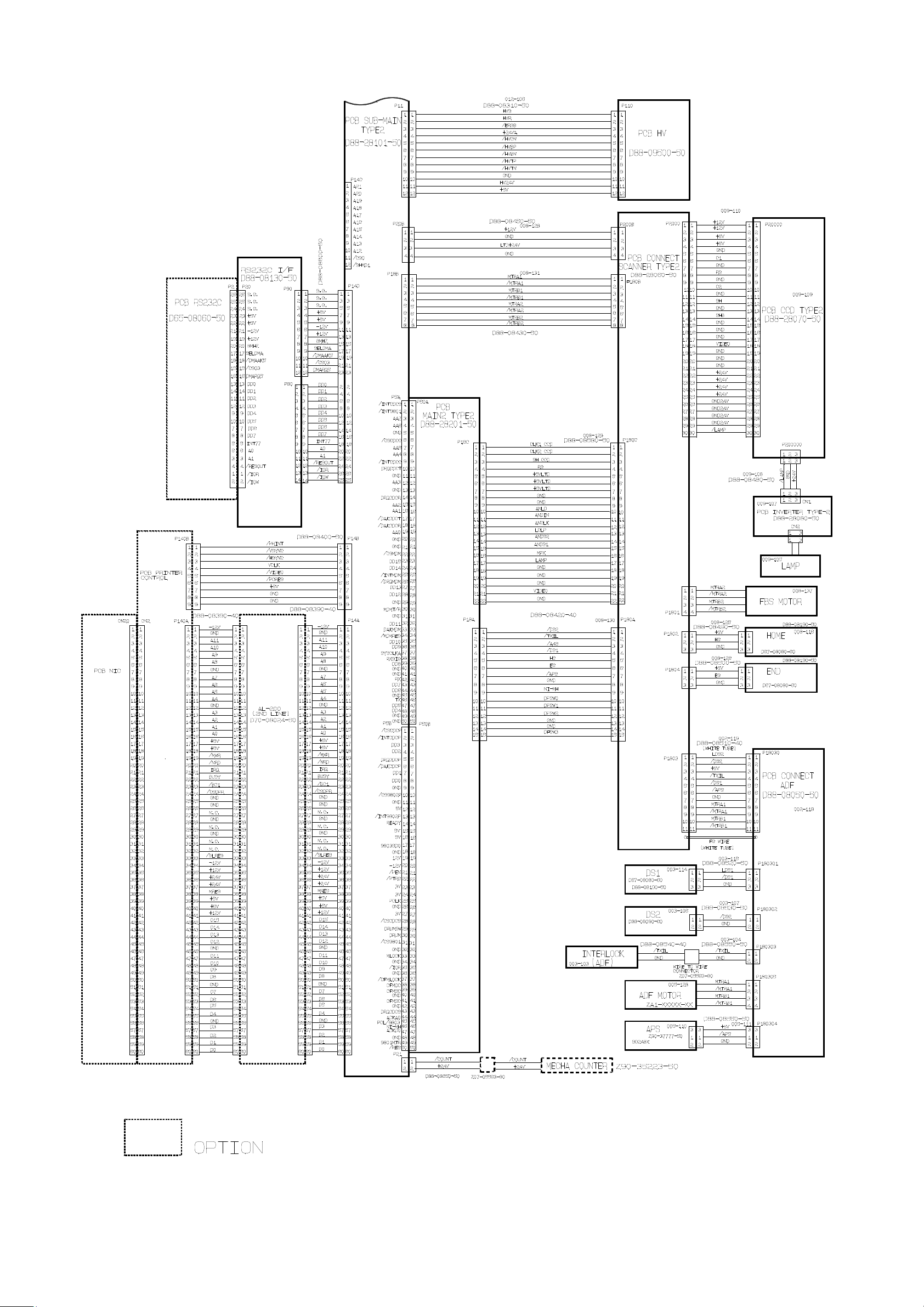

OKIOFFICE 1600 Interconnect Block Diagram (2/2)

OKIOFFICE 1600

Connection Diagram (2/2)

2-4

2.2 Main Control PCB

The main control PCB controls the operations of all machine functions.

Jumper JP2 on the main control PCB is used for battery back-up of the SDRAM. Removing JP2 will

initialize the SDRAM. If the power is turned off, the battery will provide up to 72 hours (8MB) of backup when fully charged.

Jumper JP1 on the main control PCB is used for battery back-up of the SRAM. All user programmed

data and internal memory switch settings are held in SRAM. Removing JP1 will initialize the SRAM.

If the power is turned off, the battery will provide up to five years of back-up when fully charged.

NOTE: JP1, JP2 should remain in the "ON" position at all times.

Memory (FLASH MEMORY, SRAM, SDRAM)

FLASH MEMORY --- T he FL A SH ME M OR Y co n t a in s al l p r og r am in s tr u c t io n s f o r u ni t operation.

SRAM --- T he S RA M, w hi c h i s b a ck e d- u p b y a l it hi u m b at t er y is us e d t o st o re us e r p r og r am me d

information.

SDRAM --- T he S DR AM i s u s ed fo r bu f fe r, w hi c h i s b a ck e d- u p b y a b at t er y i s us e d t o s t or e

memorized documents.

MAIN CONTROL PCB

NCU PCB

POWER SUPPLY

UNIT

AC 220V

HIGHT VOLTAGE

POWER SUPPLY

UNIT

TXA

RXA

TONE

OH

+24V, +12V, -12V,

+5V, GND

PRINTER

UNIT

+24V, +5V, GND

ADF MOTOR

FBS MOTOR

BUFFER

LPF

MODEM

IC

CI

SRAM

SYSTEM

G/A2

PRINTER

CONTROL

2

PRINTER

CONTROL

1

SYSTEM

G/A1

MOTOR

CONTROL

SDRAM

SDRAM

Lithium Battery

Monitor

Control

CPU

FLASH ROM

SDRAM

IMAGE

PROCESSING

IC

CONNECTOR (SCANNER) PCB

Speaker

PANEL PCB

LOGIC IC

RS232C

Battery PCB

SDRAM

Extension Memory

CCD

LED LAMP

LCD

KEY

Ni-MH

Battery

SDRAM

OKIOFFICE 1200 Main control PCB block diagram

2-5

NCU PCB

POWER SUPPLY

UNIT

AC 220V

HIGHT VOLTAGE

POWER SUPPLY

UNIT

+24V, +5V, GND

+12V, -12V

+24V, +12V, -12V,

+5V, GND

PRINTER

UNIT

+24V, +5V, GND

ADF MOTOR

FBS MOTOR

PCB MAIN 2 for MFX-1600

TXA

RXA

TONE

LPF

PCB MAIN 1 for MFX-1600

CI

OH

MODEM

IC

SRAM

SYSTEM

G/A2

PRINTER

CONTROL

2

PRINTER

CONTROL

1

SYSTEM

G/A1

MOTOR

CONTROL

SDRAM

SDRAM

Lithium Battery

BUFFER

Monitor

Control

PANEL PCB

LOGIC IC

CPU

RS232C

FLASH ROM

SDRAM

SDRAM

Extension Memory

Image Processing IC

CODEC

CODEC

CODEC

Memory CTR IC

SDRAM

PCB MAIN 2 for MFX-1600

Speaker

LCD

KEY

Battery PCB

Ni-MH

Battery

AFG

CONNECTOR (SCANNER) PCB

CCD

LED LAMP

SDRAM

OKIOFFICE 1600 Main control PCB block diagram

2-6

2.3 Network Control Unit (NCU) PCB

The NCU PCB provides the connection to the telephone line. It consists of the interface circuit, dial

pulse generator, ring signal detector and telephone control circuit.

MODULAR

PCB

Major components of the NCU

CML relay

Connects the telephone line to the phone or fax.

S relay

Used to send dial pulse signals in pulse dialing.

OH & Tone detector

Detects the On-hook condition of the second telephone unit.

H relay

Connects the Tel1 and Tel2 line to the fax machine.

24V generator

Supplies 24 volts to the relays.

Ring signal detector

A photo coupler that detects an incoming ring.

NCU PCB

TXA

RXA

S

DP

GENERATOR

TONE

OH

CI

+24V, +5V, GND

+12V, -12V

NCU PCB block diagram

2-7

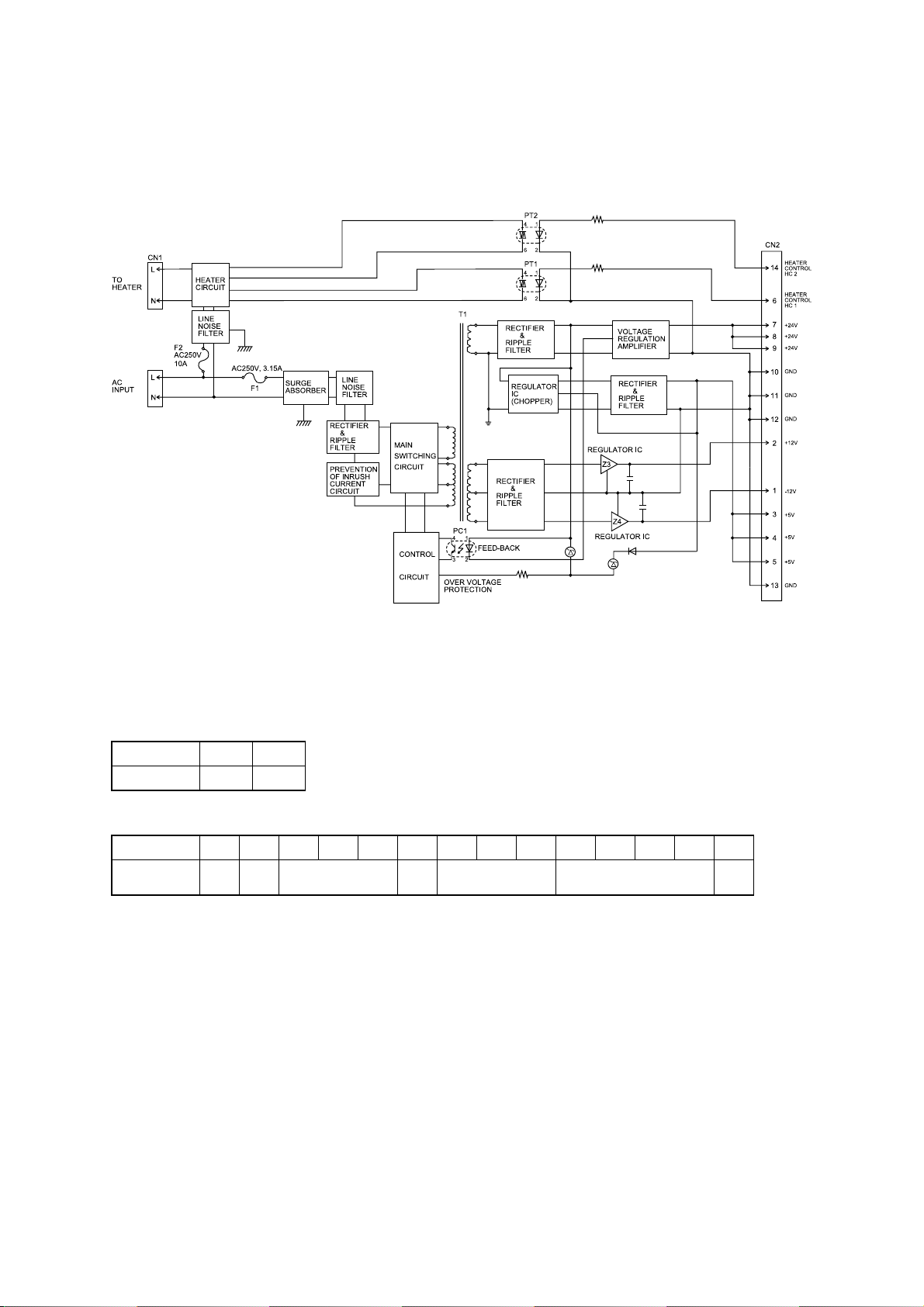

2.4 Power Supply Unit (PSU)

The power supply unit receives the input line voltage and currents it to output voltages of +5 VDC, +24

VDC, +12 VDC, and -12 VDC.

The heater circuit controls output voltage to the fuser heater according to instructions received from

the heater control circuit.

If an over-current is sensed in the secondary circuit, power is interrupted.

Power supply unit block diagram

The power supply unit has two output connectors.

The following table shows the connector outputs:

CN1 -- to the Fuser Heater

Pin No. 1 2

Output L N

CN2 -- to the Main Control PCB.

Pin No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14

Output

voltage

–12V +12V +5V HC1 +24V GND HC2

2-8

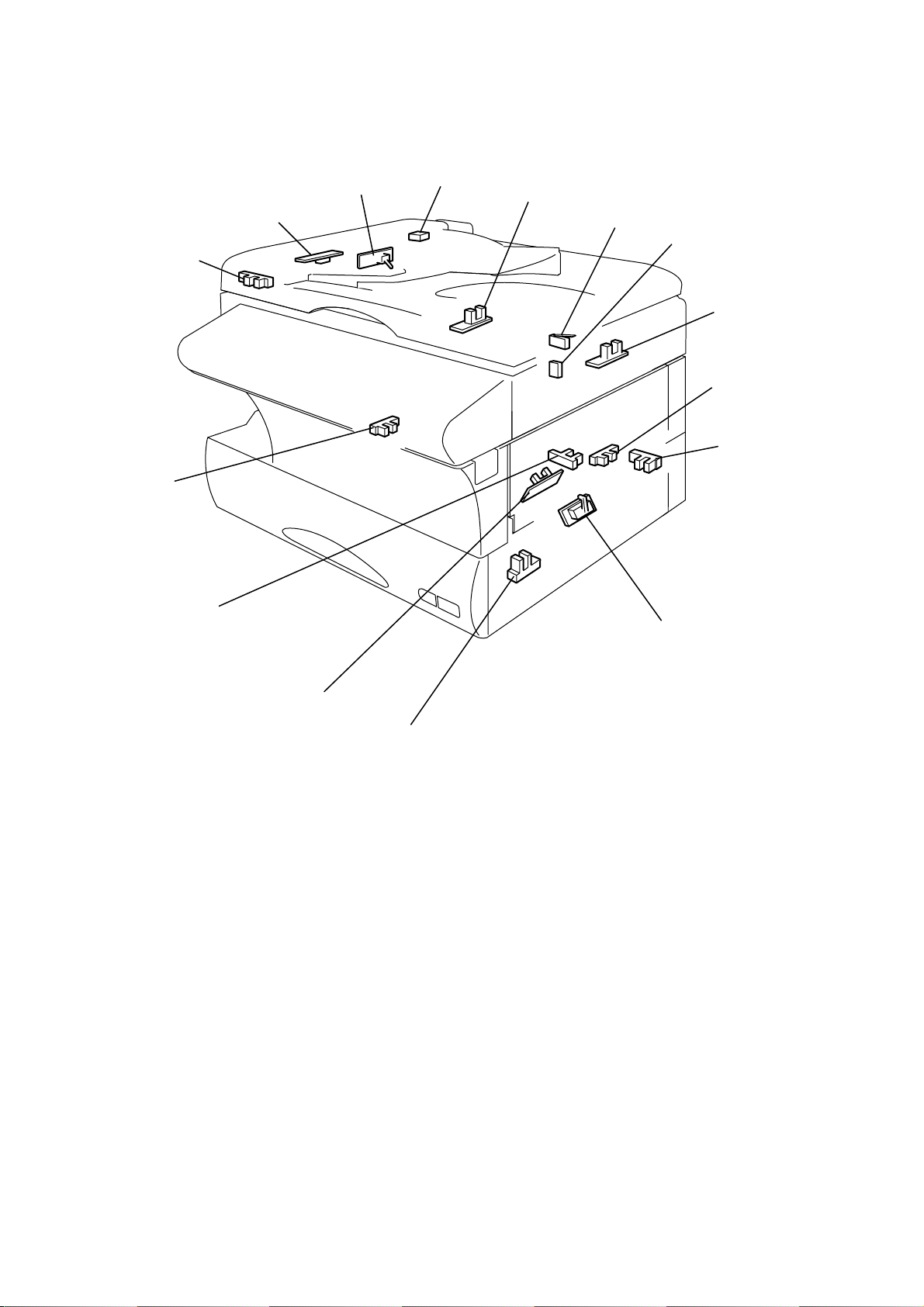

2.5 Sensors

2.5.1 Sensor Locations

The following illustration shows the relative positions of the machine’s sensors.

DS2

DS1

APS

PDS

TXIL

END

COVER SW

DRUM SW

HOME

HPES

CASOP

PES

PSS

TOS

JCOP

2-9

2.5.2 Sensor Descriptions

The following table gives a brief description of each sensor and its function.

Code Name Detects Sensor Type

DS1 Document sensor 1 P res ence of document in feeder Photo interrupter

DS2 Document sensor 2 Leading and trailing edge of doc ument Mechanical Switch

HOME Mirror carriage home

position sensor

END Mirror carriage end

position sensor

APS ADF permit sensor Platen c over quite close or not Photo interrupter

TXIL

(ADF)

PSS Paper set sensor Detects paper feeding out of

PDS Paper disc harge sensor Detects paper pass at paper ex i t . P hoto interrupter

PES Paper empty sensor Detect s presence of recording paper in

HPES Hand paper empty

TOS Toner sensor Detects the toner empty and toner

CASOP Paper cassette open

JCOP Jam access cover (side

COVERSW

DRUM

SW

Interlock switc h (A DF) Scanner cover open or close Micro switch

sensor

sensor

cover) open sensor

Cover switch Detects top cover open or c l ose Micro swit ch

Drum switch Detects drum cartridge is set or not Electrical terminal

Mirror carriage position Photo interrupter

Mirror carriage position Photo interrupter

Photo interrupter

cassette/tray.

Photo interrupter

the 1st paper cassette

Detects presence of rec ordi ng paper i n

the bypass tray

cartridge set.

Detects the 1st paper c as sette open or

close

Detects the side cover open or close Photo interrupter

Photo interrupter

Photo interrupter

Photo interrupter

2-10

2.6 Document Scanning Sequence

2.6.1 Document Detection

When a document is placed into the document feeder, Document Sensor 1 (DS1) is activated and you

will hear the short beep.

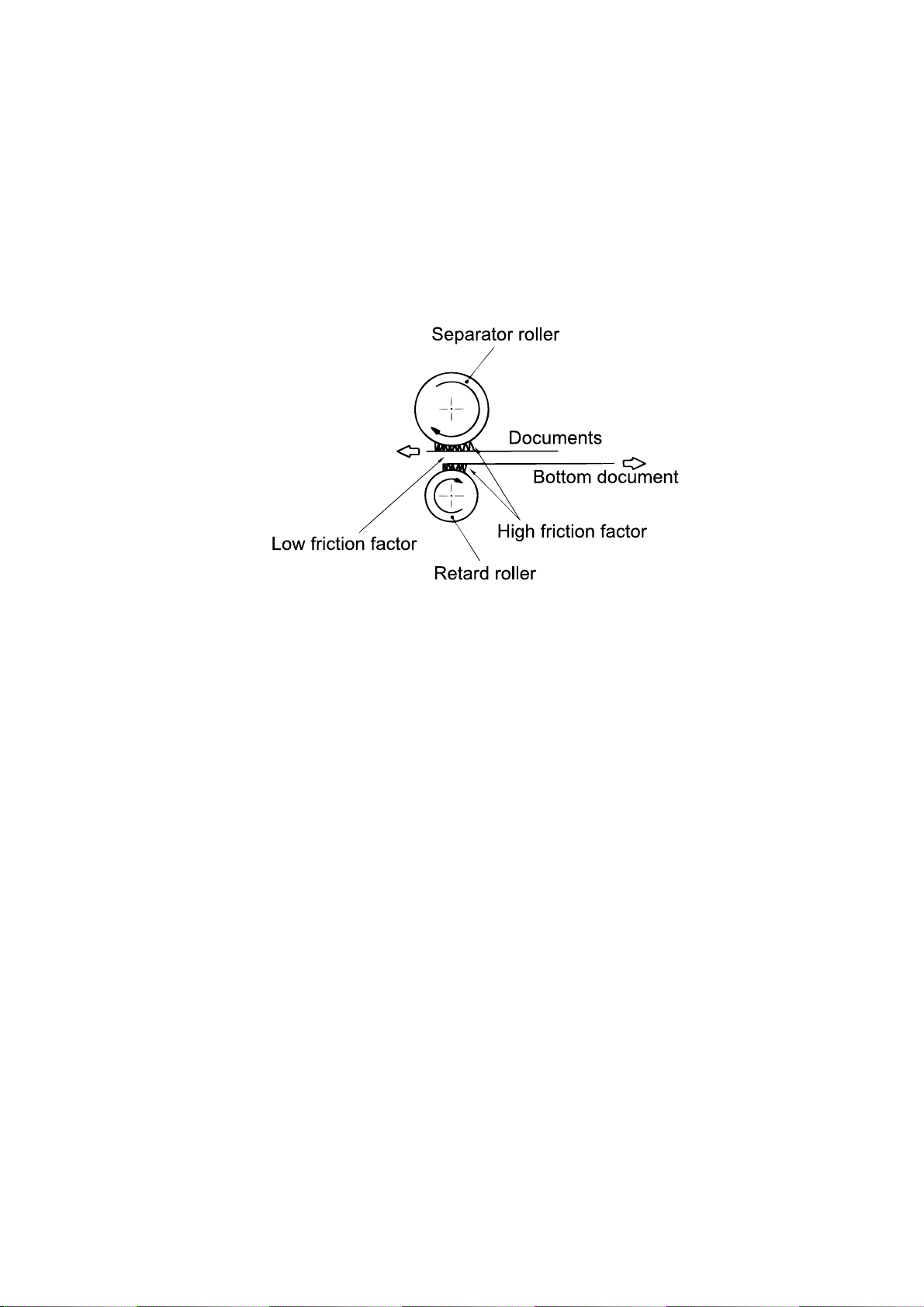

2.6.2 Document Separation

Document separation is the process that allows a multi-page document to go through the scanner one

page at a time. Separation occurs through the action of the separator roller and retard roller.

As shows in the illustrations, documents in the feeder are pressed against the separator roller. The

bottom document is separated from the remaining documents by the friction of the retard roller.

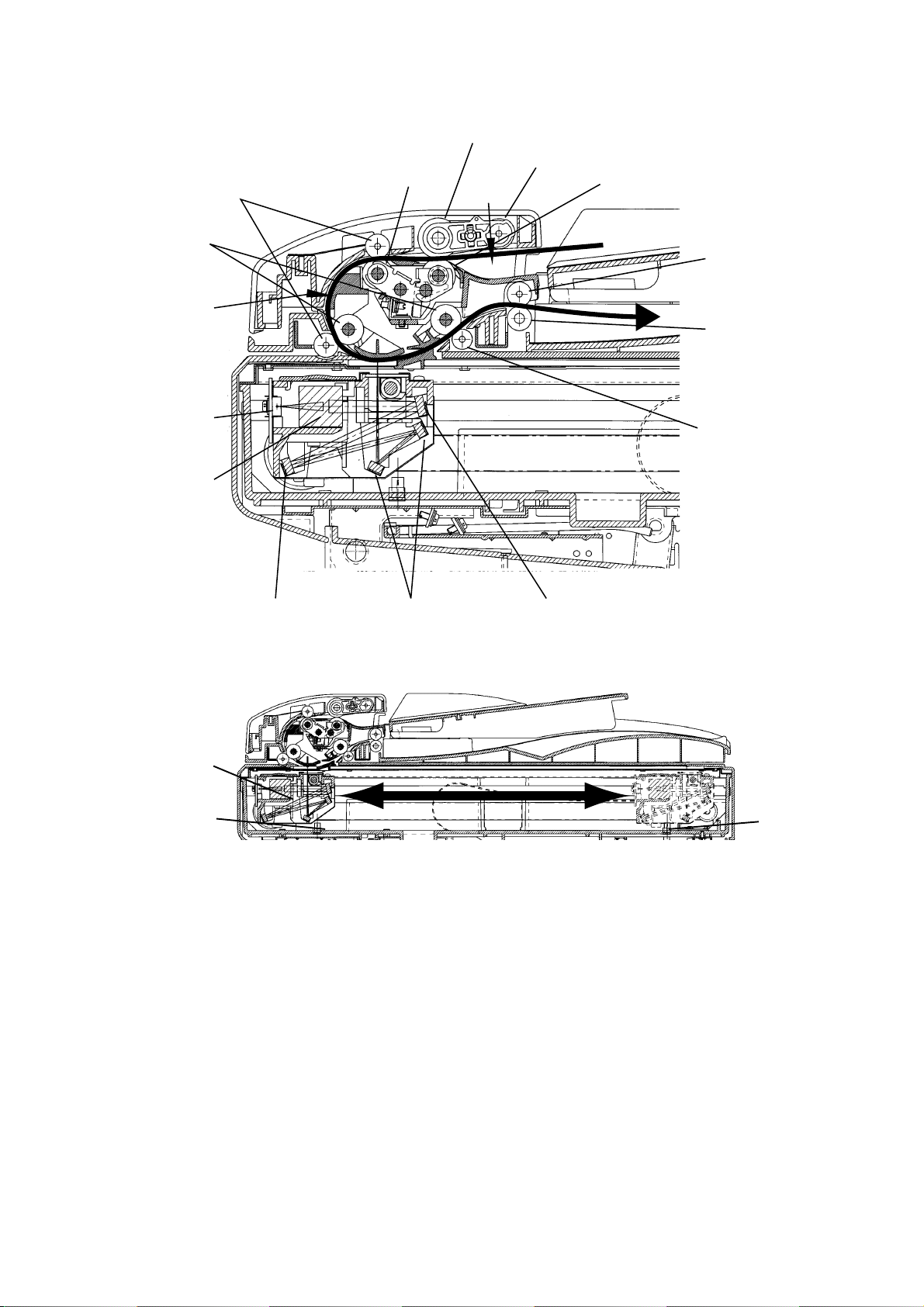

2.6.3 Document Transport

Following document separation, the feed roller causes the document to advance. As it advances, the

leading edge of the document activates the Document Sensor 2 (DS2) sensor. Once DS2 is activated,

the feed roller continues to rotate until the document reaches the scan wait position. The machine

uses the distance from DS2 to the scan wait position and the diameter of the feed roller to determine

the number of rotations necessary to feed the document to the scan wait position.

2.6.4 Document Scanning

When the document reaches the scan wait position, the machine waits for the next command. It will

start scanning the document when either the START key is pressed. The light from the scanner lamp

strikes the face of the document and is reflected into the lens through mirrors A, B, and C. In case the

light intensity along the length of the scanner lamp is not uniform, shading compensation is provided to

ensure even illumination.

As the reflected image passes through the lens, it is focused onto the charged coupled device(CCD).

The CCD then converts the dark and light areas of the image into electrical impulses, or image data.

Circuits on the main control PCB encode the image data and send it to the modem where it is

modulated. The modulated signal is then placed onto the telephone line by the NCU.

2-11

When DS2 detects the trailing edge of the document, the image signal output is turned off. The

scanner continues to remain active for a few more seconds in case there is another document to

follow.

Separator roller

Pick up roller

Press roller A

Feed roller B

DS2

Feed roller A

DS1

Retard roller

Press roller A

Exit roller

CCD

Lens

Scanner unit

End sensor

Mirror AMirror B Mirror C

Document scanning in ADF section

Document scanning in FBS section

Press roller B

Home sensor

2.6.5 Document Discharge

The scanned document is discharged through the document exit by the exit roller

2-12

2.7 Recording Section

2.7.1 Recording Paper Feed Path

A sheet of the recording paper is separated from the remaining paper by the friction of the pickup

roller.

The paper is moved along the paper guide until it reaches the platen roller. Is then fed by the rotation

of the platen roller.

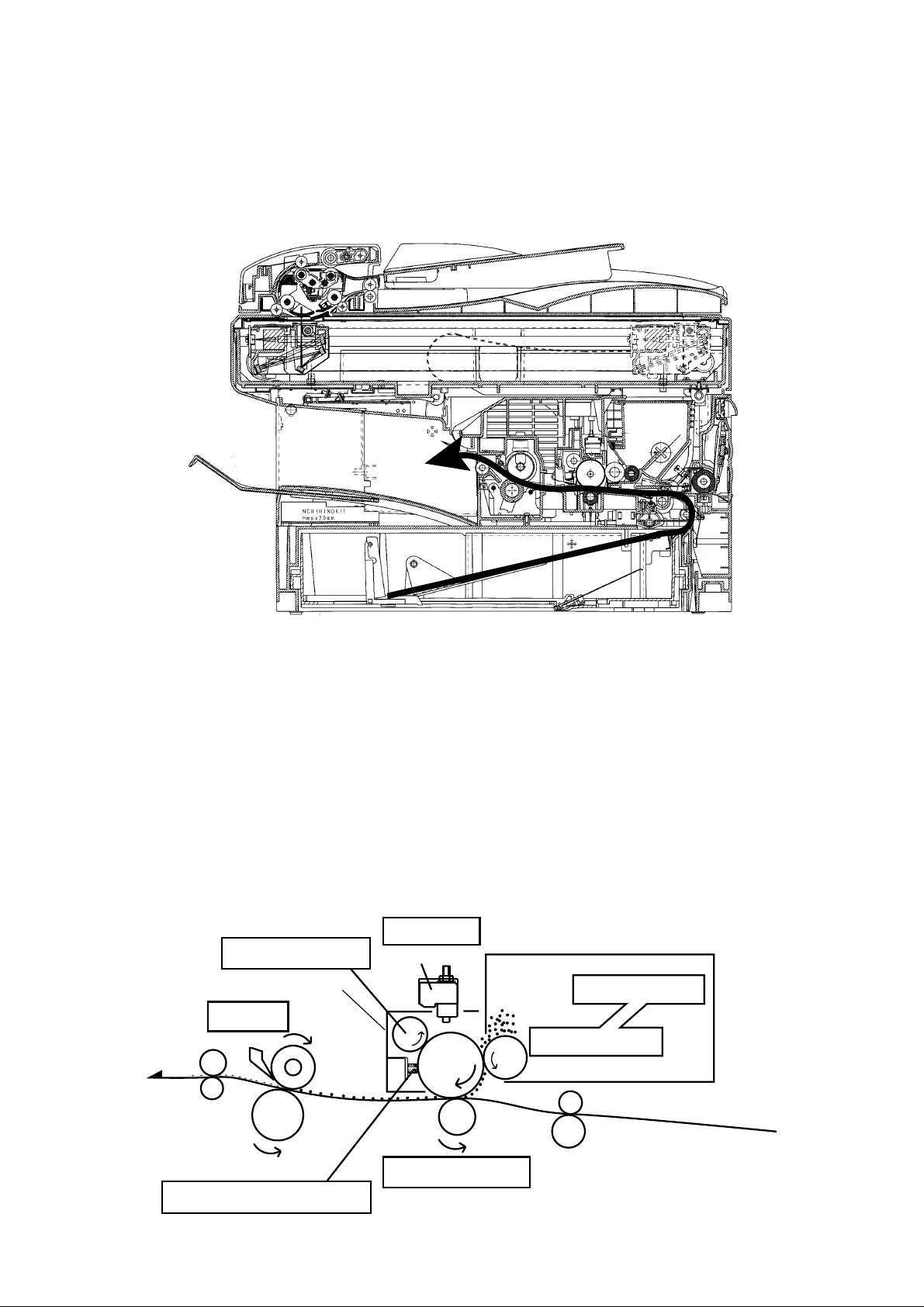

2.8 Image Processing

Incoming data is received from the telephone line by the NCU and sent to the main control PCB. The

modem, located on the main control PCB, demodulates the data.

The data is then sent to the printer for image processing.

The image processing is roughly divide into the following steps:

1. Drum Charging

2. Drum Exposure

3. Development

4. Image transfer

5. Fusing

6. Distributing the toner

Drum charging

Drum cartridge

Fusing

Exposure

LED print head

Development

Toner cartridge

Toner agitate

Image transfer

Distributing the toner

2-13

2.8.1 Drum Charge

• The Drum is charged with static electricity before LED exposure. The Rotating Charge Brush is

used for the charging method.

• The rotating brush charging generate little ozone in the printer. Because the charge is directly given

to the Drum, the Drum can be charged by low voltage. At the same time, the Drum can be charged

stably and evenly.

2.8.2 Drum Exposure

An invisible static image is made by the light from the LED print head.

The LED print head, located inside the printer cover, closes down over the drum and projects light

onto the drum surface. When the document is to be printed, individual elements in the LED print head

turn on and expose the drum where ever a dark area should appear in the document.

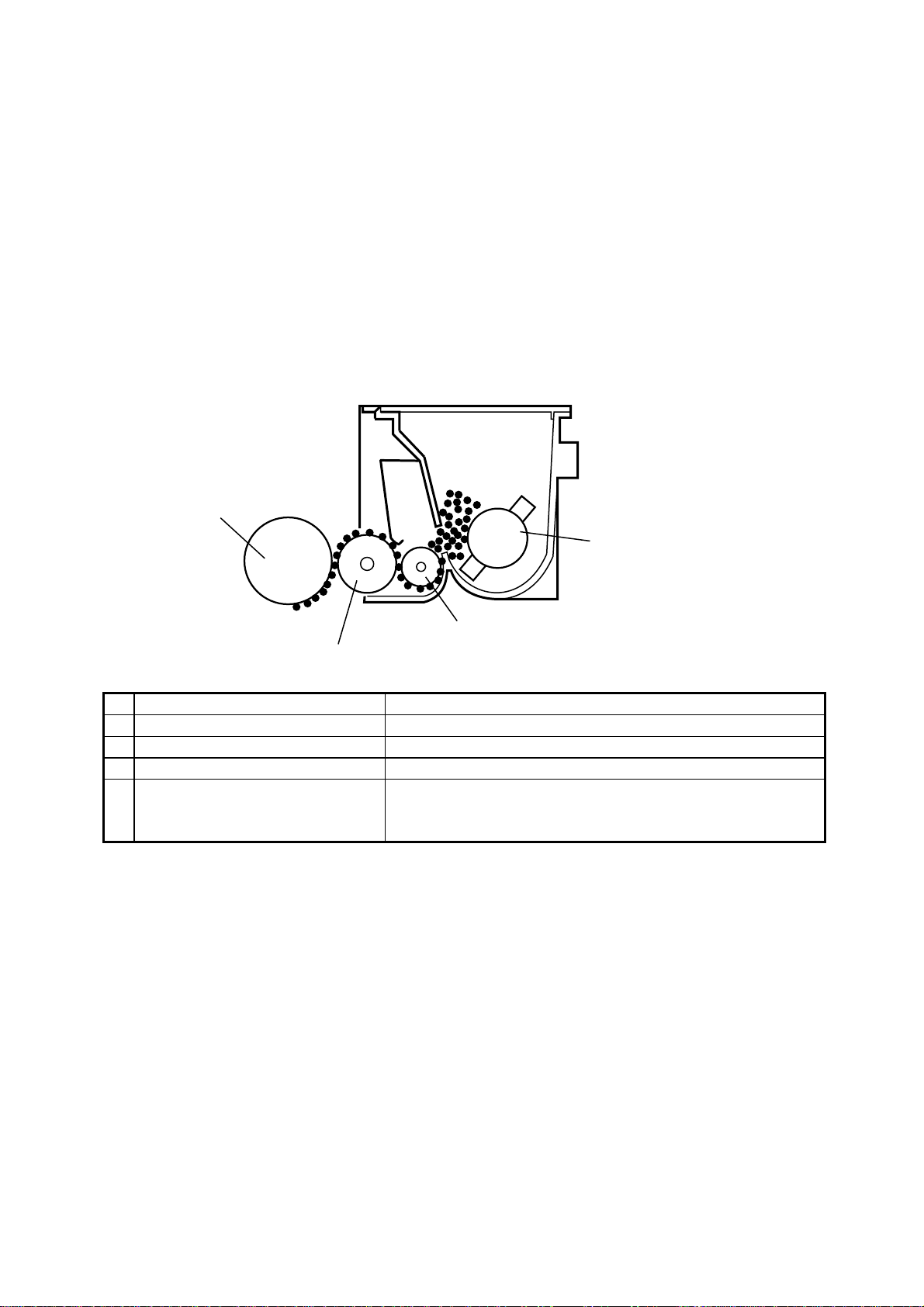

2.8.3 Development

Toner is applied to the invisible static image on the Drum and a toner image is created on the surface.

Drum

Toner agitator

Toner supply roller

Developing roller

Part Name Function

1 Toner Agit at or Contains toner.

2 Toner supply Roller Transports the toner to t he developing r oller.

3 Developing Roller Carries the toner to the Drum surf ace for development.

4 Dr um Exposed to LED right to create an invisible image and

rotates to carry the developed image to t he paper

surface.

2-14

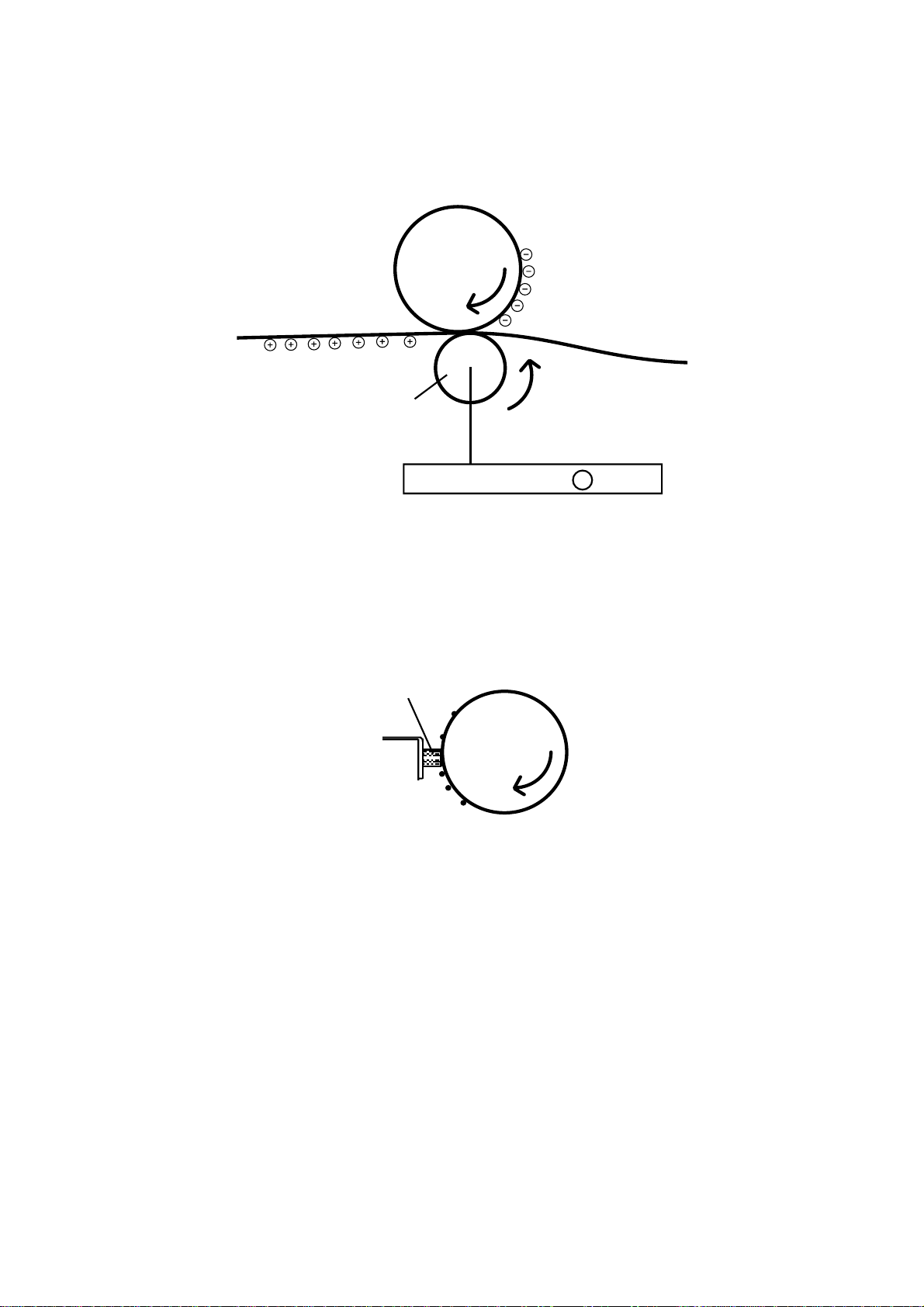

2.8.4 Image Transfer

Image transfer is the process of transferring the toner image created on the Drum in the developing

process to paper. We use the Roller Image Transfer instead of the Corona Image Transfer, as the

image transfer method. In the Roller Image Transfer, there is little generation of ozone due to corona

discharge. Also, there is no blur of toner because the paper is always pressed by the Drum and the

Image Transfer Roller.

PC Drum

Image transfer roller

Hight voltage unit + output

2.8.5 Residual toner distribute

The residual toner must be removed from the drum. This step does not actually remove the residual

toner from the drum surface. Instead, a “Eraser brush” is used to evenly distribute the remaining toner

over the drum surface. When the drum surface is charged in preparation for printing the next

document the remaining toner is also charged. Any residual toner that is not exposed in the

subsequent drum exposure process is attached back onto the developing roller.

Eraser brush

PC drum

2-15

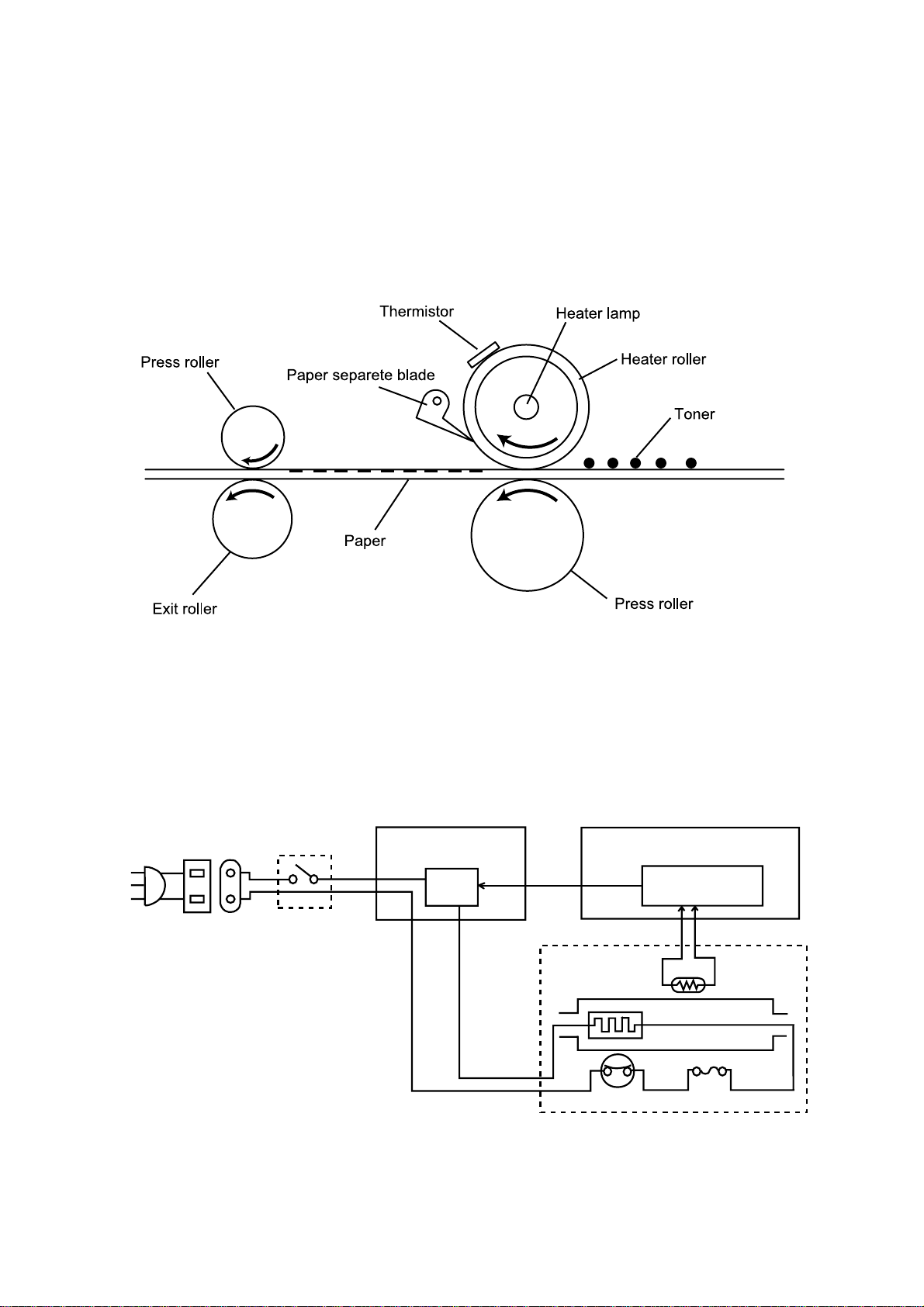

2.8.6 Fusing

An Overview

The toner image transferred on to the paper is securely fixed.

A heat roller system is used as the fusing system. The toner image is fused by Heater Roller heated

by the Heater Lamp, and securely fixed by the pressure between the Heater roller and Press rollers.

A Thermistor detects and controls the Heater Roller temperature.

The Thermostat functions when the Heater Lamp is not turned OFF even if the Thermistor detects a

high temperature malfunction.

Fusing Temperature Control Circuit

The Thermistor detects the surface temperature of the Heater Roller and inputs that analog voltage

into the Main Control PCB. Corresponding to this data, the Heater Lamp ON/OFF signal is output to

the Heater ON/OFF switch of the power supply unit, causing the Heater Lamp to turn ON or OFF to

control the fusing temperature.

When the Heater Lamp is not turned OFF even if the Thermistor detects a high temperature

malfunction, the thermostat shuts down the power to the heater lamp. When the thermostat is

malfunction, the thermal cut-off shuts down the power to the heater lamp.

AC Inlet

L

N

Main switch

Power supply unit

Heater

on/off

switch

Main Control PCB

Fusing unit

Fusing temperture

control circuit

Thermistor

Heater Lamp

Thermostat Thermal cut-off

2-16

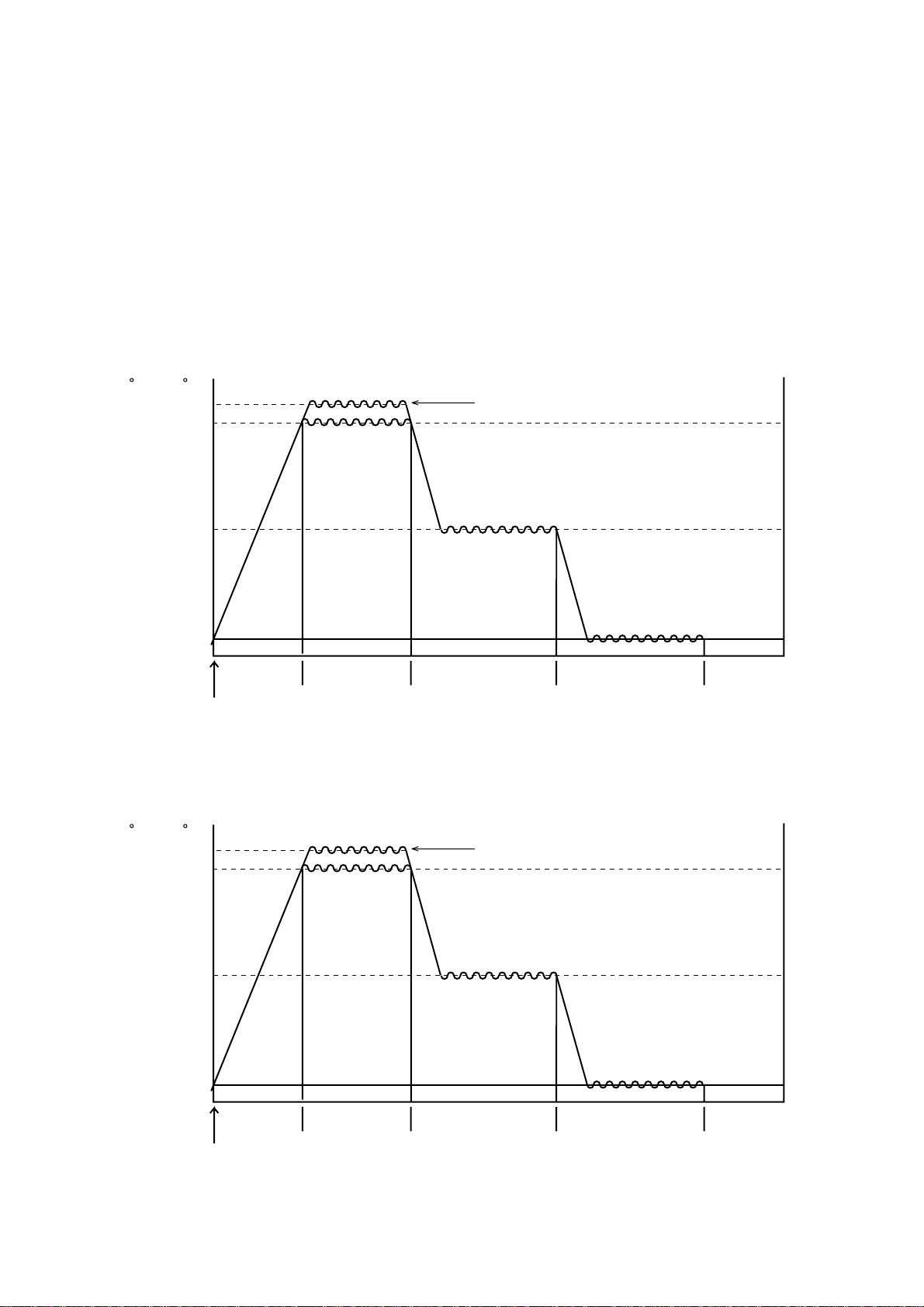

Fusing temperature

1) Warming Up After the initialization of the printer, warming up of the printer starts and the

Heater Lamp turns ON until the temperature of the Heater Roller reaches

approx. 185 °C.

2) Printing When the printer obtains the printing command from its controller, the Heater

Roller is maintained at 185 °C.

After printing, the printer turns to standby mode. The fuser kept at low

temperature.

3) Standby mode The Heater Roller maintained at approx. 100 °C.

4) Sleep mode In this mode, saving the power.

OKIOFFICE 1200:

Temperature

( F) ( C)

392

356

200

180

Post card printing only

320

160

Warming up

Power ON

OKIOFFICE 1600:

Temperature

( F) ( C)

401

374

338

205

190

170

Printing

Standby mode

Post card printing only

Sleep mode

Time

Warming up

Power ON

Printing

Standby mode

Sleep mode

Time

2-17

Section3

Adjustment Procedures

3.1 Field Service Program Modes

The fax machine feature maintenance modes for machine adjustment. Each mode is listed below

along with the command used to activate the mode and a brief functional description.

Note: When you press “ * ”, you will hear short beeps. However continue the operation, as it is no

problem.

Set or Clear Machine Parameters.............................................................................. Program key, *, 0

Used to set or clear machine parameters.

Set or Clear Memory Switches.................................................................................. Program key, *, 1

Used to set or clear memory switches.

Clear Programmed Data / User Se ttings.................................................................. Program key, *, 2

Erases user-programmed information (date, time, TTI, autodialer, etc.) and any documents

stored in memory.

All RAM Clear.............................................................................................................. Program key, *, 3

Erases same information as “Clear Programmed Data / User Settings” function along with

resetting all of the machine parameters, memory switches and unique switches to factory

defaults.

Set or Clear Unique Switches.................................................................................... Program key, *, 4

Used to set or clear Unique switches.

Printer maintenance mode........................................................................................ Program key, *, 6

Access the printer maintenance mode.

Print Program Mode List............................................................................................ Program key, *, 8

Prints a list of the unit’s programming modes.

Test Modes.................................................................................................................. Program key, *, 9

Allows the technician to perform a series of diagnostic tests.

Print Machine Parameters, Memory Switches and

Unique Switches List ......................................................................................... Program key, *, A (01)

Prints a list of the machine switch settings showing the default settings and current

settings.

Factory Functions .............................................................................................. Program key, *, B (02)

Allows the technician to perform a series of diagnostic tests.

Telephone Circuit Test Modes .......................................................................... Program key, *, C (03)

Allows the technician to perform a series of diagnostic tests.

Mirror Carriage Transfer Mode...........................................................................Program key, *, E (05)

Perform it before installing the fax machine.

Set or clear the consumable order sheet..........................................................Program key, *, F (06)

Used to set or clear the consumable order sheet.

DRAM Clear......................................................................................................... Program key, *, G (07)

Used to clear a DRAM.

Clear Life Monitor............................................................................................... Program key, *, H (08)

Used to clear a Life monitor keeps a count of the pages scanned, etc.

Clear option module’s SRAM..............................................................................Program key, *, I (09)

Used to clear a SRAM of option module.

Set Service Code .................................................................................................Program key, *, J (10)

Used to protect to clear a Life monitor.

Life Monitor Maintenance ...................................................................................Program key, *, K (11)

Used to protect to clear a Life monitor.

3-1

3.2 Machine Parameter Adjustment

3.2.1 Setting the Machine Parameters

These switches are used to program internal machine parameters. The primary back up battery maintains

these settings if power is lost.

1. From standby, press Program key, *, 0.

Set Parameters

/ /Enter

2. Press ENTER.

A0: 00000000

/ /Enter

3. Select the desired parameter by pressing a one-touch key plus a number on the keypad. For example,

to access parameter B:1, press one-touch “B” plus the number “1” on the numeric keypad.

B1: 00101011

/ /Enter

4. Press ENTER.

Set Parameters

B1 0

Bit No. 76543210

(The bits are numbered 7 through 0 --- b it 7 i s l ef t m os t. )

5. To navigate through the machine parameter settings:

• Press

• Press

• Press the 0 or 1 on the numeric keypad to change the bit value.

• Press ENTER to save the setting of the displayed parameter and advance to the next

parameter.

(Continue pressing ENTER until the desired parameter is shown in the display. Be sure to press

ENTER after each parameter is programmed to save the new setting.)

• Press STOP to return the unit to standby.

Note: You can confirm the initial setting of each Machine parameter by the Machine Parameters List.

The Machine Parameters List will be printed by pressing Program key, *, A(01).

key to move the cursor to the left.

to move the cursor to the right.

0101011

3.2.2 Clearing the Machine Parameters

Resets the machine parameters to factory defaults.

1. From standby, press Program key, *, 0,

.

Clear Parameters

/ /Enter

2. Press ENTER.

Clear Parameters

Check Enter/Cancel

3. Press ENTER. The machine parameters will reset to factory defaults.

Note: To finish the operation without clearing the parameters, press CANCEL.

3-2

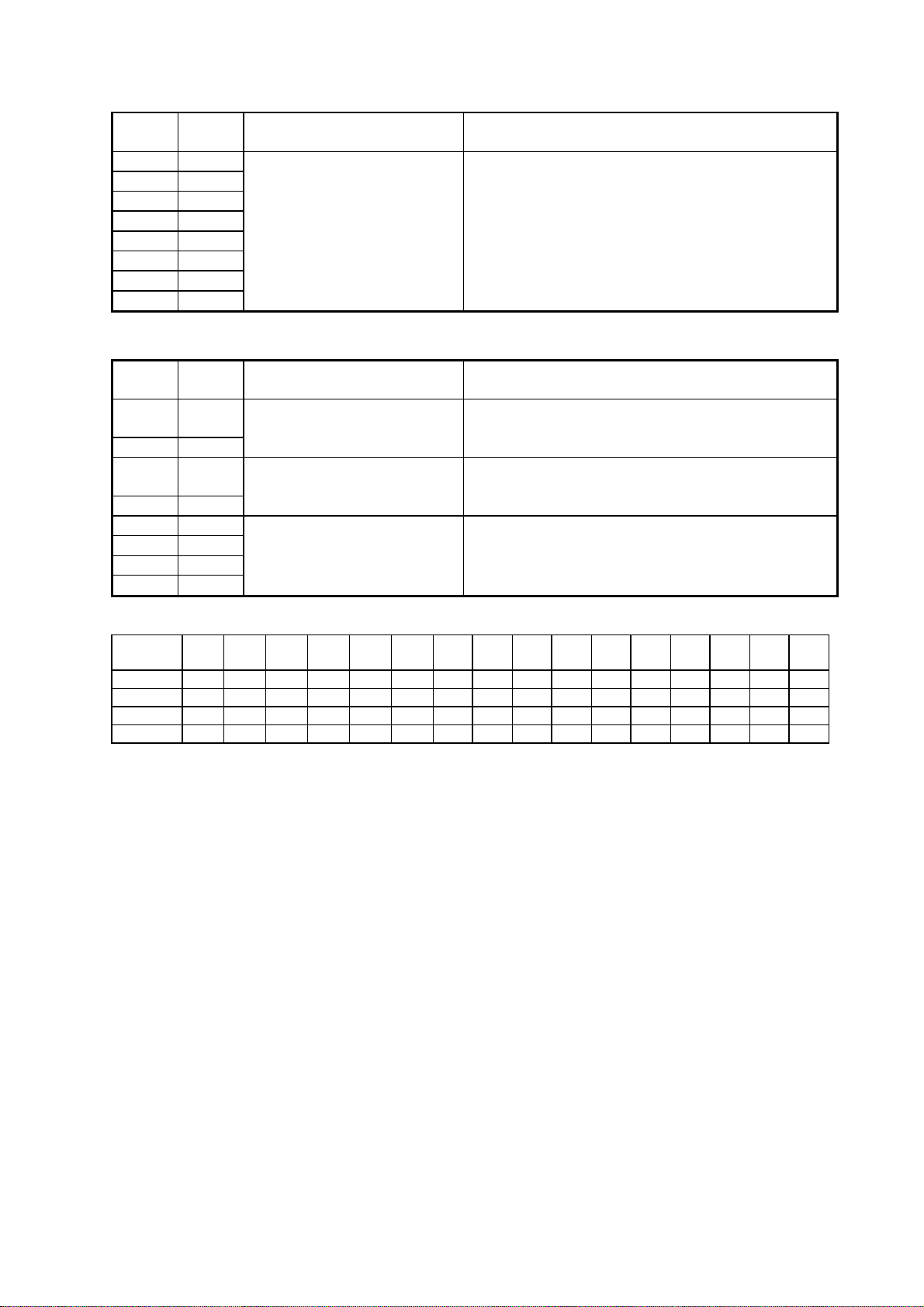

Machine Parameter A:0

Switch

7 0

6 0

5 0

4 0

3 0

2 0

1 0

0 0

Initial

Setting

Adjust Usage/Comments

Country code The country code enables the ROM to output the

correct programming information for the respective

country.

Machine Parameter A:1

Switch

7 0 Non-loaded cable

6 1 0: 1: 0: 1:

5 0 Non-loaded cable

4 1 0: 1: 0: 1:

3 *

2 *

1 *

0 *

Machine Parameter A:1…Output attenuation

Switch -15

3 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

2 1 1 1 1 0 0 0 0 1 1 1 1 0 0 0 0

1 1 1 0 0 1 1 0 0 1 1 0 0 1 1 0 0

0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0

Initial

Setting

dB

Adjust Usage/Comments

0: 0: 1: 1:

compensation (TX)

0 db 4 db 8 db 12 db

0: 0: 1: 1:

compensation (RX)

0 db 4 db 8 db 12 db

Output attenuation See table below

Note: The setting of this switch is available only

when setting other than 0 dB and this setting is

used instead of Memory Switch B:1, bit 3-0.

-14

-13

-12

-11

-10

-9

-8

-7

dB

dB

dB

dB

dB

dB

dB

dB

-6

dB

-5

dB

-4

dB

-3

dB

-2

dB

-1

dB

-0

dB

3-3

Loading...

Loading...