Page 1

PT340/341

Page 2

Every effort has been made to ensure that the information in this document is complete, accurate, and

up-to-date. The manufacturer assumes no responsibility for the results of errors beyond its control. The

manufacturer also cannot guarantee that changes in software and equipment made by other

manufacturers and referred to in this manual will not affect the applicability of the information in it.

Mention of software products manufactured by other companies does not necessarily constitute

endorsement by the manufacturer.

While all reasonable efforts have been made to make this document as accurate and helpful as possible,

we make no warranty of any kind, expressed or implied, as to the accuracy or completeness of the

information contained herein.

All rights are reserved by Oki Data Corporation. Unauthorized copying, transferring, translating, or

related actions are prohibited. You must obtain written permission from Oki Data Corporation before

doing any of the above.

© 201 Oki Data Corporation

OKI is a registered trademark of Oki Electric Industry Co., Ltd.

Energy Star is a trademark of the United States Environmental Protection Agency.

Microsoft, Windows, Windows Server and Windows Vista are registered trademarks of Microsoft

Corporation.

Apple, Macintosh, Rosetta, Mac and Mac OS are registered trademarks of Apple Inc.

Other product names and brand names are registered trademarks or trademarks of their proprietors.

As an Energy Star Program Participant, the manufacturer has determined that this product

meets the Energy Star guidelines for energy efficiency.

This product complies with the requirements of the Council Directives 2014/30/EU (EMC) and

2014/35/EU (LVD), 2014/53/EU (RED) and 2011/65/EU(RoHS) as amended where

applicable, on the approximation of the laws of the member states relating to Electromagnetic

Compatibility, Low Voltage, Radio & Telecommunications Terminal Equipment, Energy

related Products and Restriction on the use of certain Hazardous Substances in electrical

and electronic equipment.

The following cables were used to evaluate this product to achieve EMC directive

2014/30/EU compliance and configurations other than this may affect that compliance.

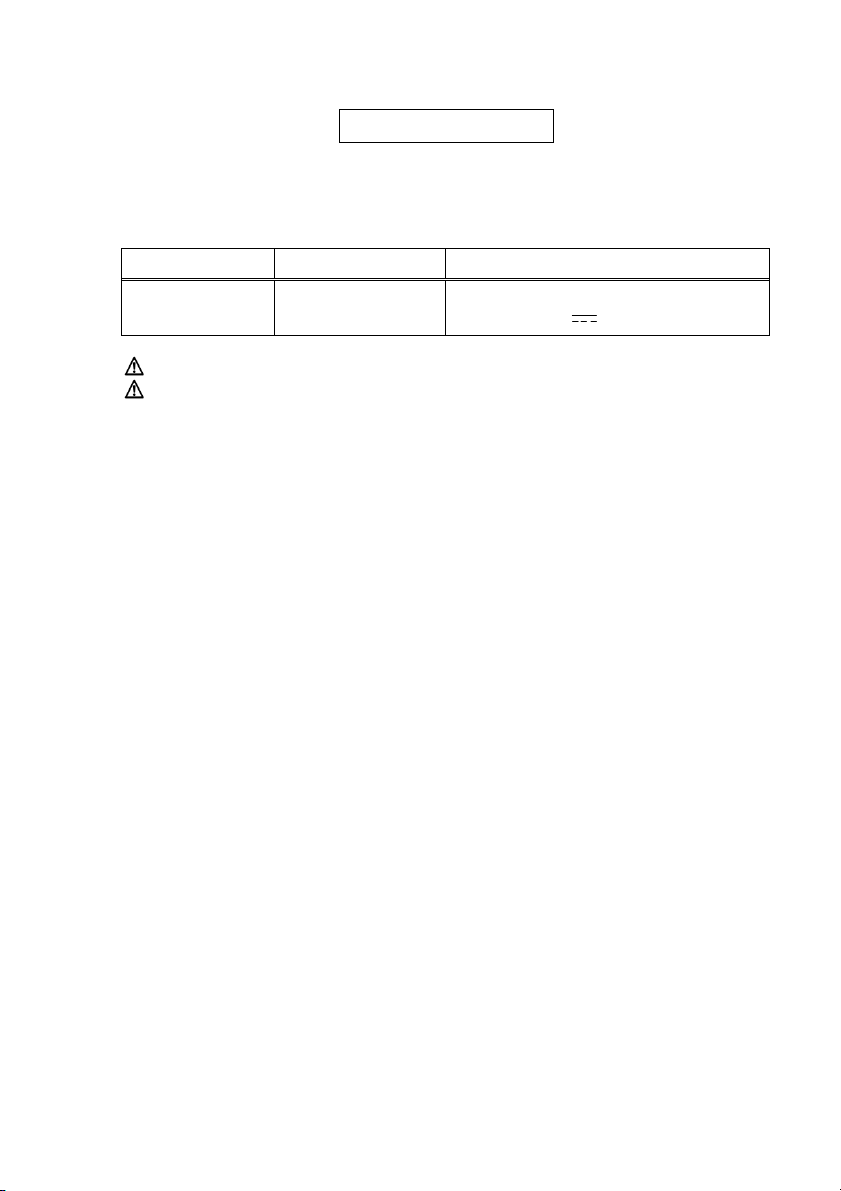

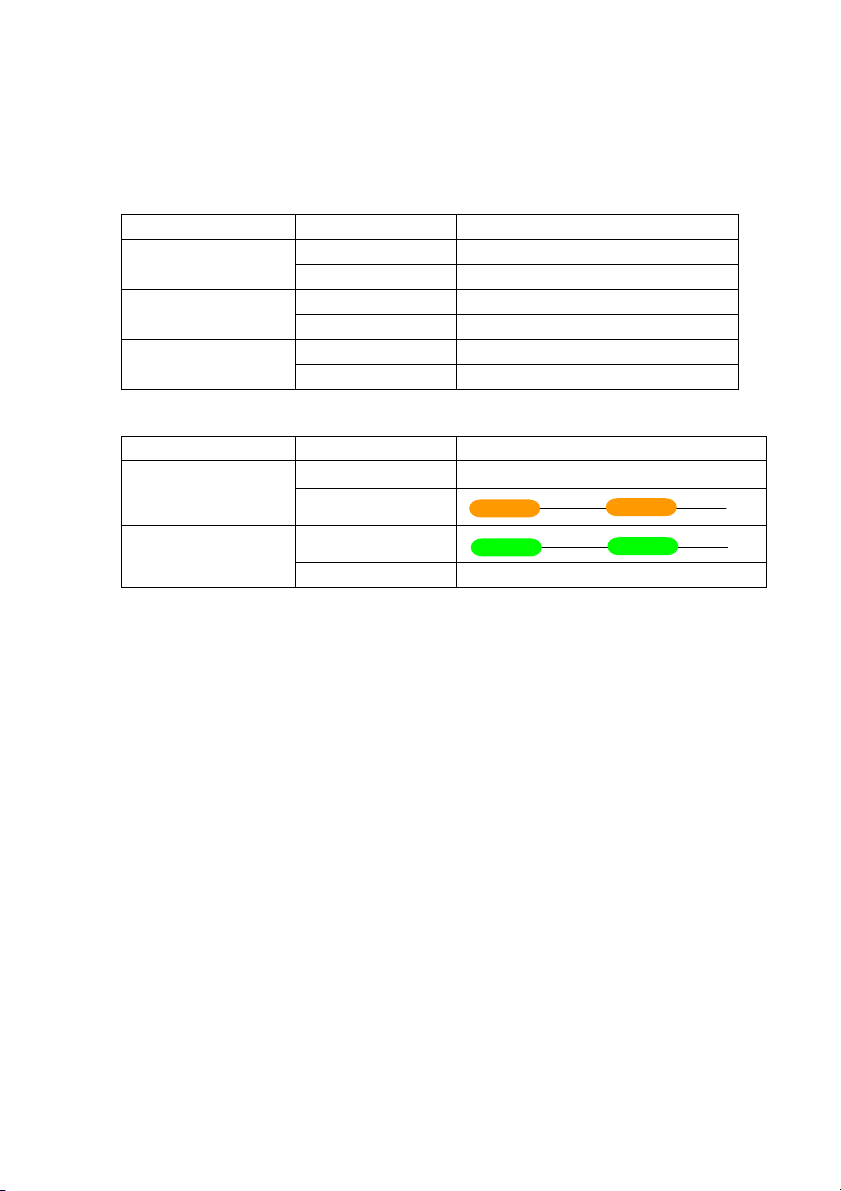

&$%/(7<3( &25(CORE

CABLE TYPE

Power 2.0

USB 5.0

Serial (25pin)

Serial (9pin) 15.0

LAN 5.0

Drawer 1.8

This is a class A product as defined in EN55022. In a domestic environment

this product may cause radio interference, in which case the user may be required to

take adequate measures.

LENGTH

(METRE)

15.0

CORE SHIELD

88

89

89

89

88

88

Page 3

M

ANUFACTURER

Oki Data Corporation,

4-11-22 Shibaura, Minato-ku,

Tokyo 108-8551,

Japan

For all sales, support and general enquiries contact your local distributor.

I

MPORTER TO THE

OKI Europe Limited (trading as OKI Printing Solutions)

Blays House

Wick Road

Egham

Surrey, TW20 0HJ

United Kingdom

For all sales, support and general enquiries contact your local distributor.

E

NVIRONMENTAL INFORMATION

EU/A

UTHORISED REPRESENTATIVE

!"#$!"%

!"#$%

'*+%

#3$7:;

%'

Page 4

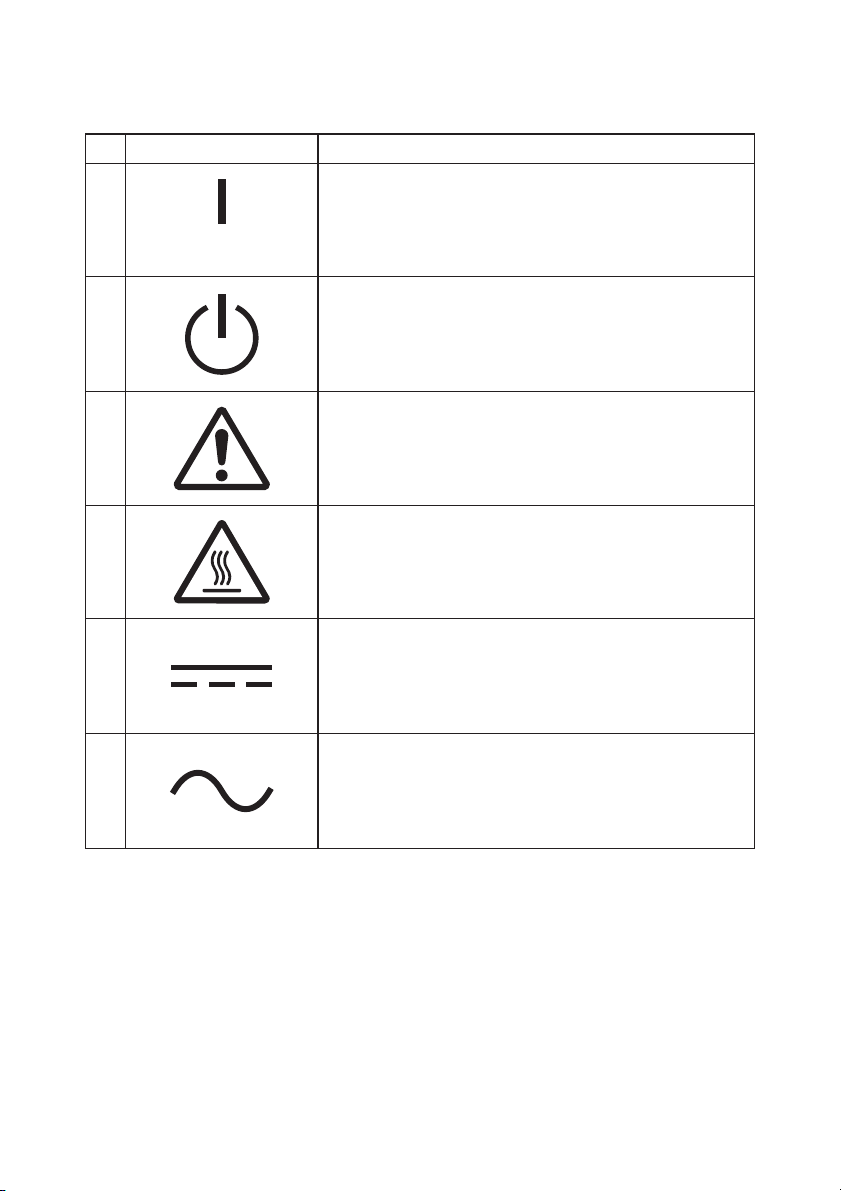

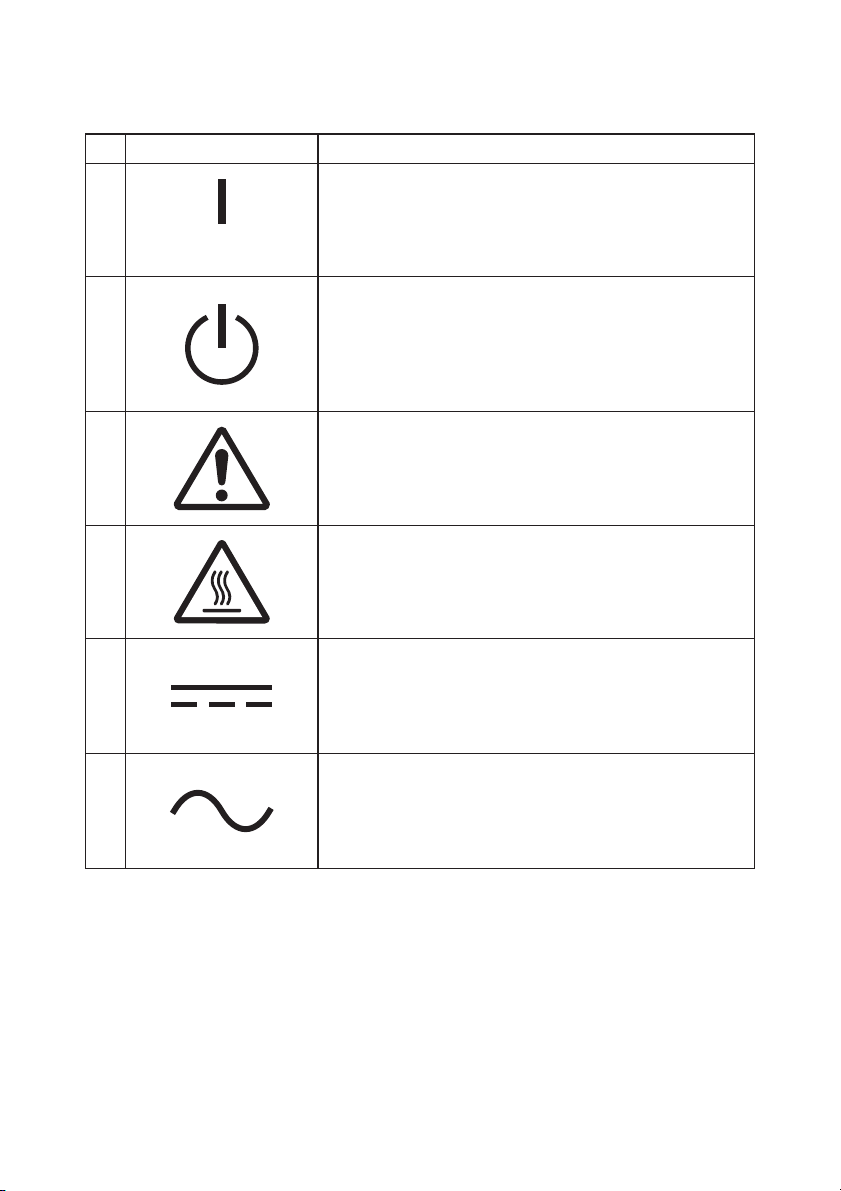

Description of Safety symbols displayed on the equipment

No. Symbol Description

1

"ON" (power)

To indicate connection to the mains, at least for

mains switches or their positions.

2

3

4

5

6

Stand-by

To identify the switch or switch position by means of

which part of the equipment is switched on in order

to bring it into the stand-by condition.

General warning/caution

To identify a general warning/caution.

Caution, hot surface

To indicate that the marked item can be hot and

should not be touched without taking care.

Direct current

To indicate on the rating plate that the equipment is

suitable for direct current only; to identify relevant

terminals.

Alternating current

To indicate on the rating plate that the equipment

is suitable for alternating current only; to identify

relevant terminals.

Page 5

Table of Contents

1. Appearance and Name of Components ············································· 5

1-1. Names of Components ······················································· 5

1-2. Package Contents ····························································· 6

2. AC Adapter ·············································································· 7

3. Paper Specifications ···································································· 8

3-1. Paper Width ··································································· 8

3-2. Paper Thickness ······························································ 8

3-3. Paper Roll ······································································ 8

3-4. Recommended Thermal Paper ············································ 9

4. Preparation ············································································ 10

4-1. Connecting the Interface Cable (to the printer) ····················· 11

4-2. Connecting the Interface Cable (to the PC)··························· 13

4-3. Connecting the Drawer Kick Cable ···································· 15

4-4. Connecting the AC Adapter and Cable ································ 16

4-5. Removing the AC Adapter ··············································· 19

4-6. Installing the Printer ······················································· 20

4-7. Power On ····································································· 24

4-8. Installing the Printer Software ·········································· 25

5. Inserting Paper ········································································ 26

5-1. Opening the Top Cover ··················································· 26

5-2. Paper Width Setting (Width: 58mm / 80mm) ························ 28

5-3. Setting the Paper ··························································· 30

5-4. Closing the Top Cover ····················································· 32

6. Control Panel ·········································································· 33

6-1. Control Panel ································································ 33

6-2. Error Indications ··························································· 34

7. Paper Jam Prevention and Removal ·············································· 36

7-1. Paper Jam Prevention ····················································· 36

7-2. Paper Jam Removal ························································ 36

7-3. If the Top Cover Does Not Open ········································ 37

8. Troubleshooting ······································································· 40

8-1. Problems at Power-on and Other Errors ····························· 40

8-2. Cutter Problems ···························································· 40

8-3. Printing Problems ·························································· 41

9. Special Mode (Test Print, Setup Menu...) ········································ 42

9-1. Test Print ····································································· 42

9-2. Changing the Setup ························································ 44

9-3. Setup Settings ······························································· 54

9-4. LAN Setup Settings (Printer with triple interface model) ········· 60

3

Page 6

9-5. HEX Dump·························································································63

9-6. Command Trace················································································64

9-7. Sample Print······················································································65

10. Regular Cleaning······························································································ 70

10-1. Cleaning Paper Holder and Paper Transport······························70

10-2. Cleaning the Platen Roller······························································71

10-3. Cleaning the Thermal Head···························································72

11. Interface ············································································································ 73

11-1. Serial Interface················································································73

11-2. USB Interface···················································································76

11-3. LAN Interface·················································································· 76

11-4. Drawer Kick Connector··································································77

11-5. Power Specifications········································································79

12. Specifications ····································································································80

12-1. General Specifications·····································································80

12-2. Cutter Specifications·······································································83

12-3. Paper Roll Supply Specifications···················································83

12-4. Interface Specifications···································································83

12-5. Environment Specifications····························································84

12-6. Reliability Specifications·································································85

13. Usage Precautions ···························································································· 86

13-1. Paper Related Precautions ·····························································86

13-2. Cutter Related Precautions····························································87

13-3. Barcode/2D Code Printing Precautions·········································87

13-4. USB Interface Usage Precautions··················································88

13-5. LAN Interface Usage Precautions··················································88

13-6. Installation Precautions··································································89

13-7. Modular Type Connector Usage Precautions·······························89

4

Page 7

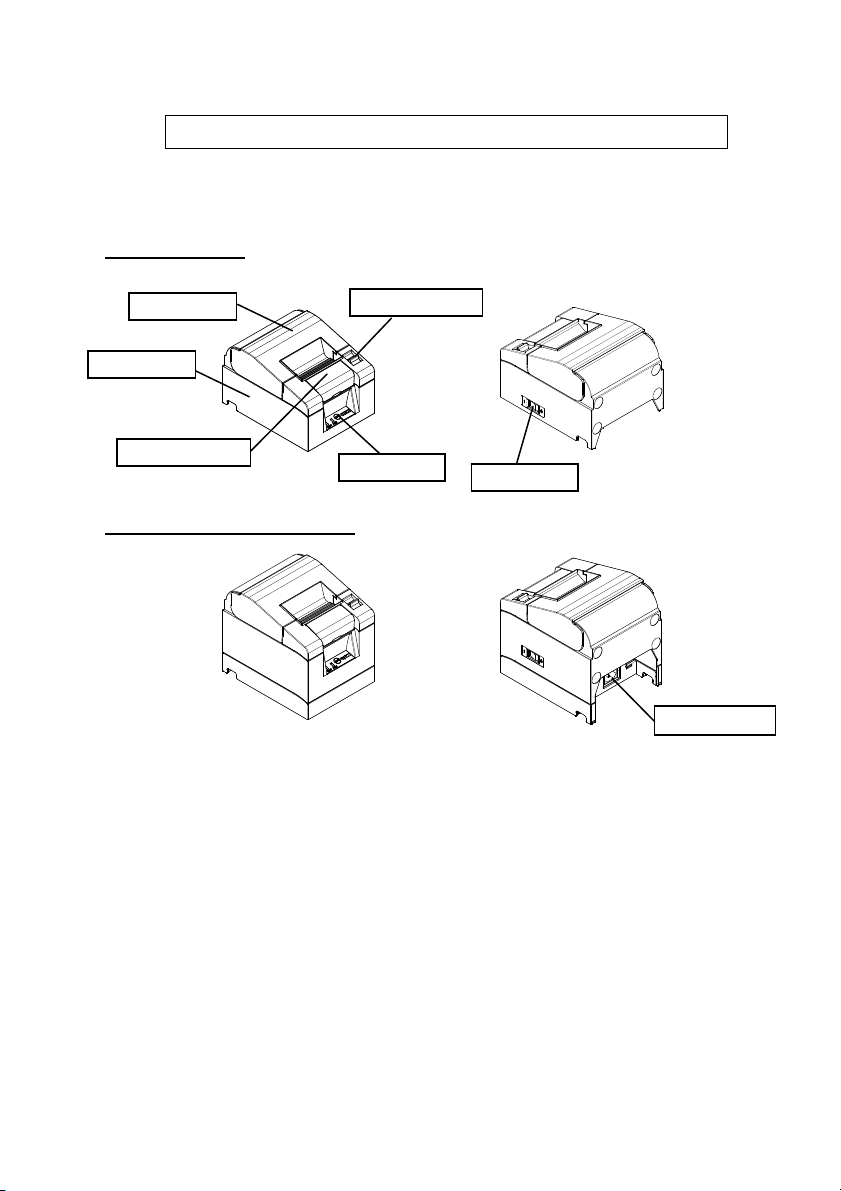

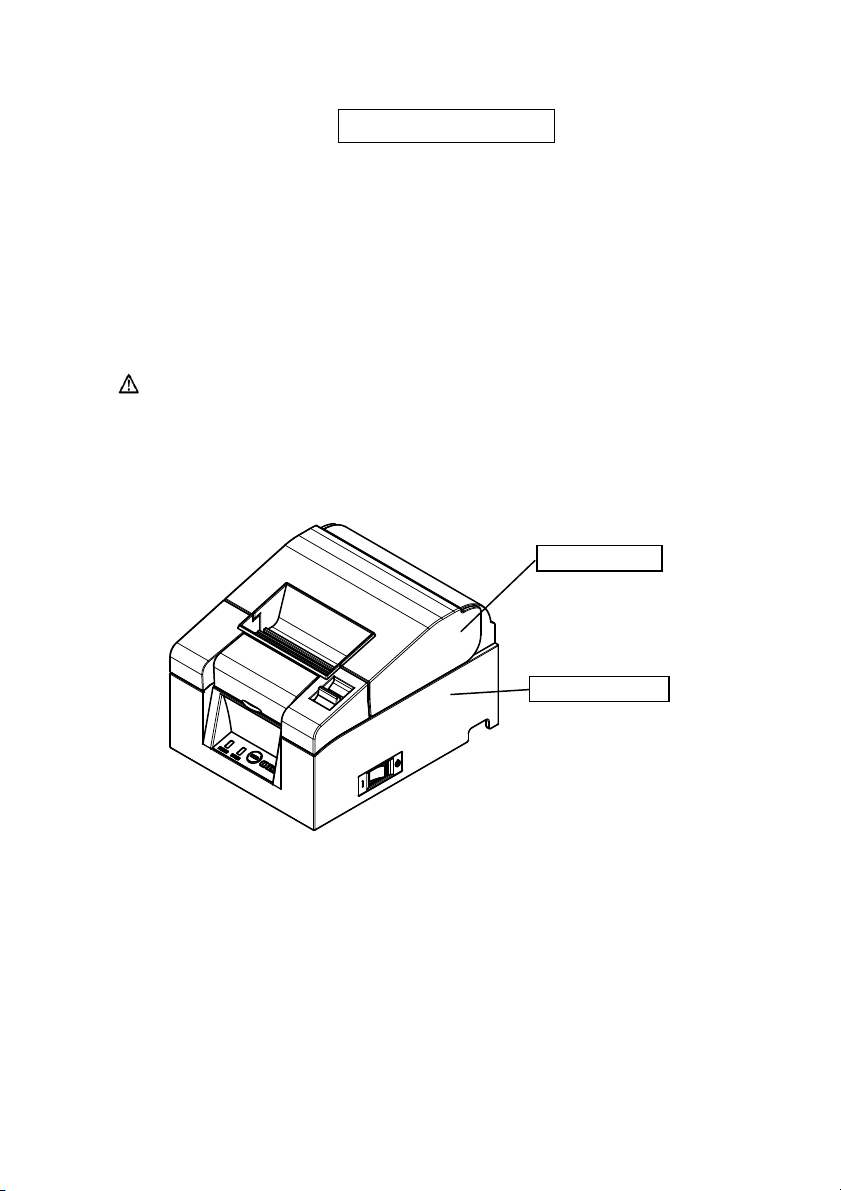

1. Appearance and Name of Components

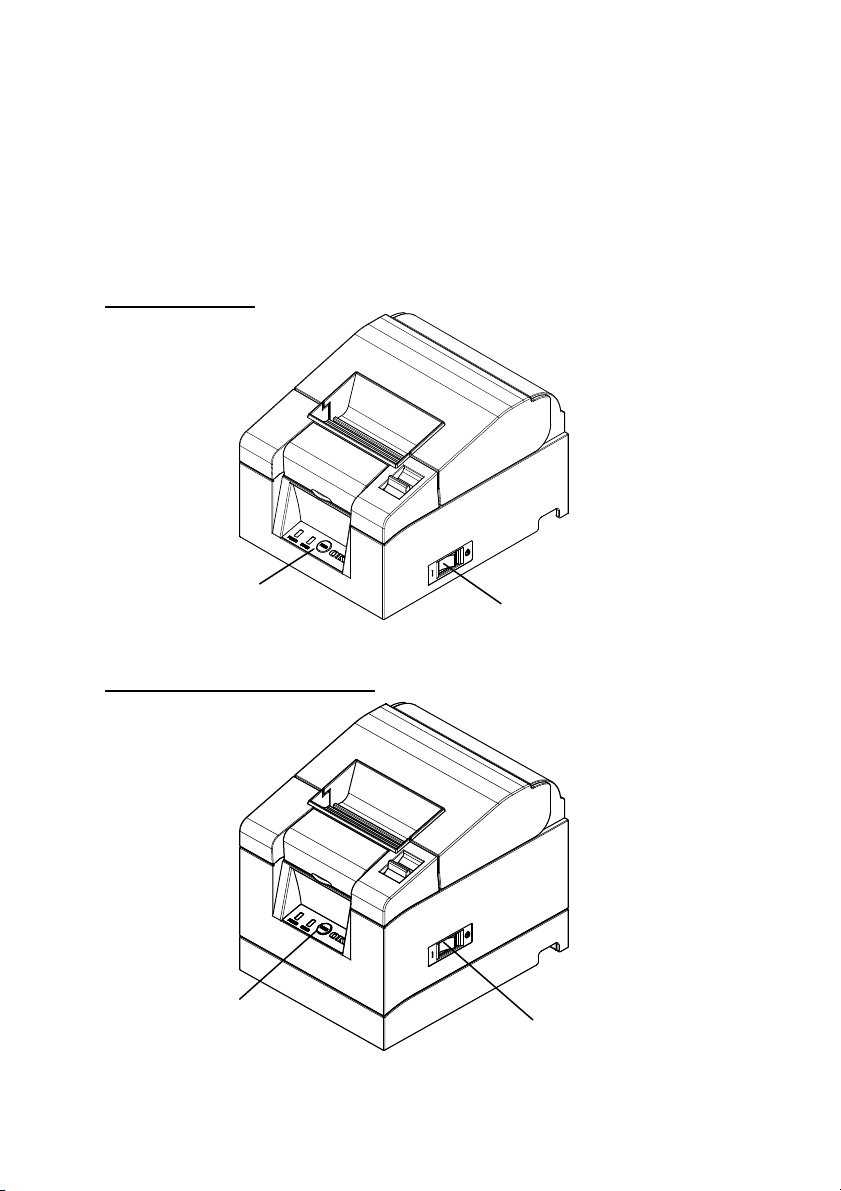

1-1. Names of Components

Standard Model

Top Cover

Middle Cover

Front Cover

Built-in Power Supply Model

• Top Cover

Open

• Release Lever

• Power Switch

• Control Panel

s to replace paper.

Used for opening the top cover.

Turns the printer power ON/OFF.

Contains switches for operating the printer and LEDs that indicate the printer

status.

• Front Cover

This can be removed in case of cutter jam or when the top cover does not open.

• AC Inlet

Plug in the AC power supply cable here.

Release Lever

Control Panel

Power Switch

5

AC Inlet

Page 8

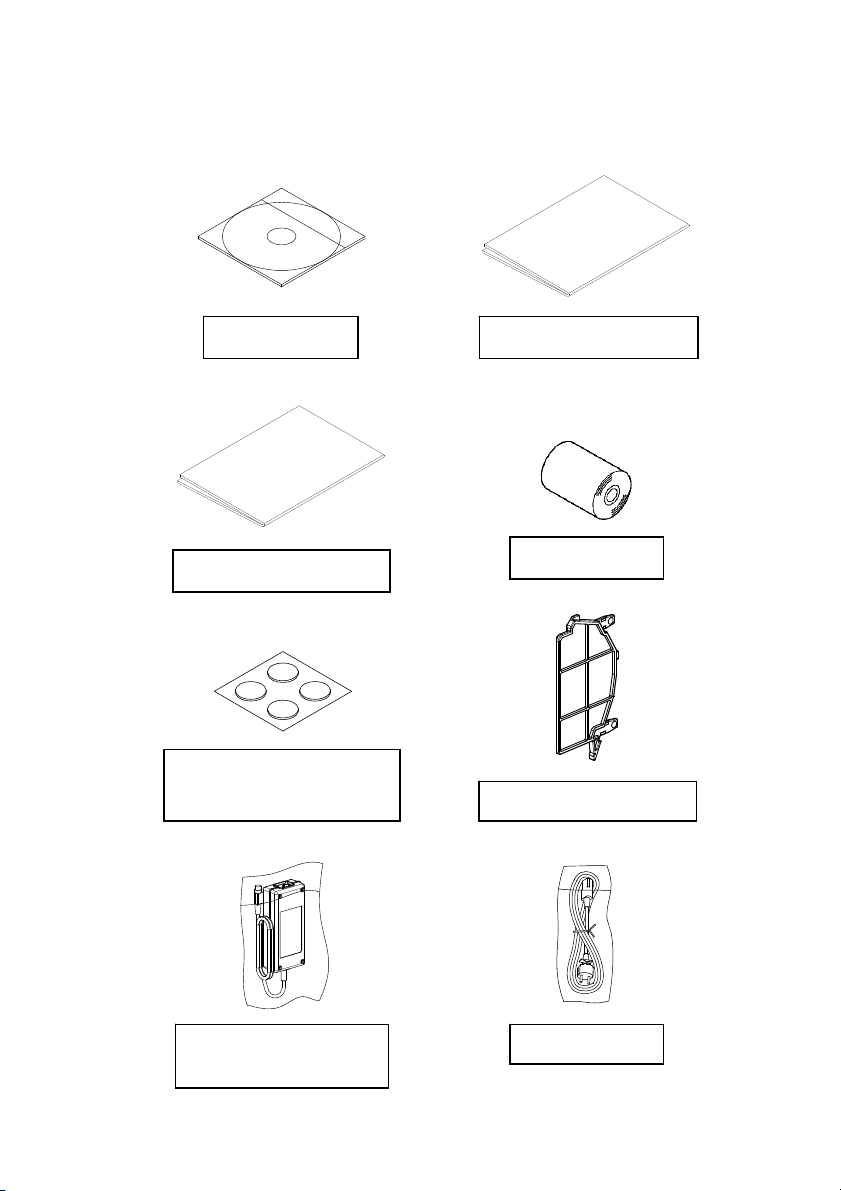

1-2. Package Contents

Safety warranty sheet

(For vertical installation)

CD Instruction sheet

Rubber Feet

AC Adapter

(Standard Model)

Thermal Paper

58mm Width Separator

Power cable

6

Page 9

2. AC Adapter

Only use the AC adapter specified below.

Item No. Remarks

AC Adapter

Caution: Only use authorized AC adapters.

Caution: Do not use any other bundled AC adapter other than designed

KA02951-0120

for this printer.

Input : 100 to 240V AC, 50-60Hz

Output : 24V ±5%,1.5A

7

Page 10

3. Paper Specifications

Only use the thermal paper roll specified below.

3-1. Paper Width

• 80mm paper

• 58mm

paper

80mm

58mm

3-2. Paper Thickness

• 65 - 85μm

3-3. Paper Roll

• Outside diameter: φ83mm or less

• Core diameter: φ12±0.5mm (inside) / φ18±0.5mm (outside)

0

0.1

0

0.1

• Printing surface:

outer surface of the roll

• Treatment of end of paper: The roll paper must not be glued to the core.

The end of the paper must also not be folded

back.

Caution: Do not use rolls that have rough sides or sides from which

pieces of paper extrude. Such paper may cause unstable

paper feeding, resulting in printer trouble.

8

Page 11

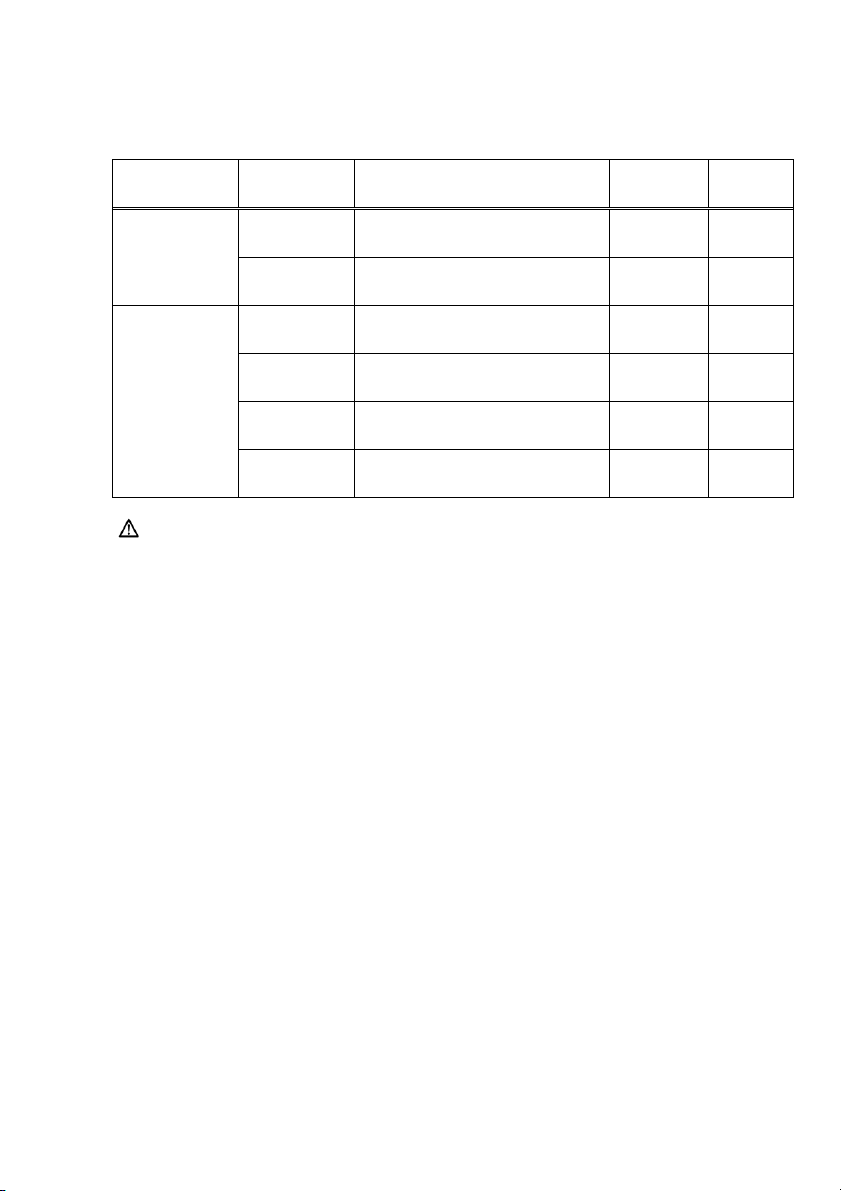

3-4. Recommended Thermal Paper

Manufacturer Product

Name

Oji Paper Co.,

Ltd.

PD160R

PD190R

Nippon Paper

Industries

Co., Ltd.

TF60KS-E

TP60KS-F1

TF50KS-E

TF62KS-E

Caution: Using non-recommended paper may cause printer head

damage, bad printing quality, etc.

Quality Characteristic Paper

Monochrome thermal paper

(high-grade preservation type )

Monochrome thermal paper

(mid-grade preservation type )

Monochrome thermal paper

(normal type)

Monochrome thermal paper

(mid-grade preservation type)

Monochrome thermal paper

(normal type)

Monochrome thermal paper

(normal type)

Density

Thickness

75μm 100%

75μm 100%

75μm 100%

75μm 100%

65μm 100%

85μm 100%

9

Page 12

4. Preparation

No printer cable is provided with the product. Obtain a printer cable suitable for

the product interface. If you have any question, consult your dealer. Before

connecting or disconnecting cables, make sure of the following:

(1) The power to the printer and all other devices connected to the printer is

turned off.

(2) The AC adapter power cable has been unplugged from the outlet.

Caution: When connecting cables or moving the printer, hold the

middle part of the printer cover on both sides. Holding the top

cover may cause it to open.

Top Cover

Middle Cover

10

Page 13

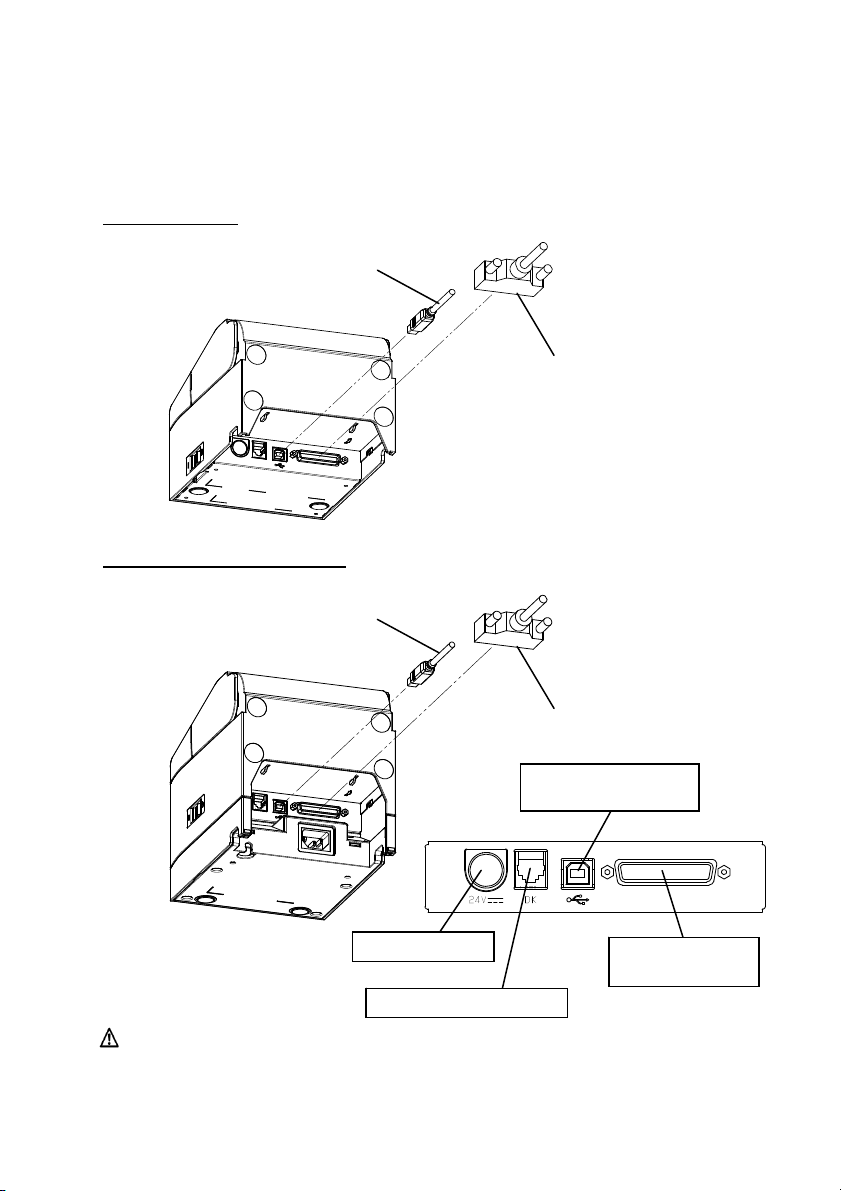

4-1. Connecting the Interface Cable (to the printer)

4-1-1 Printers with serial and USB interfaces

Standard Model

Built-in Power Supply Model

USB Interface Cable Type-B

* Connect the printer to a PC through this connector.

USB Interface Cable Type-B

* Connect the printer to a PC through this connector.

Power Connector

Drawer Kick Connector

Caution: Do not connect both the serial and USB interfaces at the same

time.

Serial Interface Cable

* Use the screws to secure it in place after connection.

Serial Interface Cable

* Use the screws to secure it in place after connection.

USB Interface

Type-B Connector

Serial Interface

Connector

11

Page 14

r

r

r

r

p

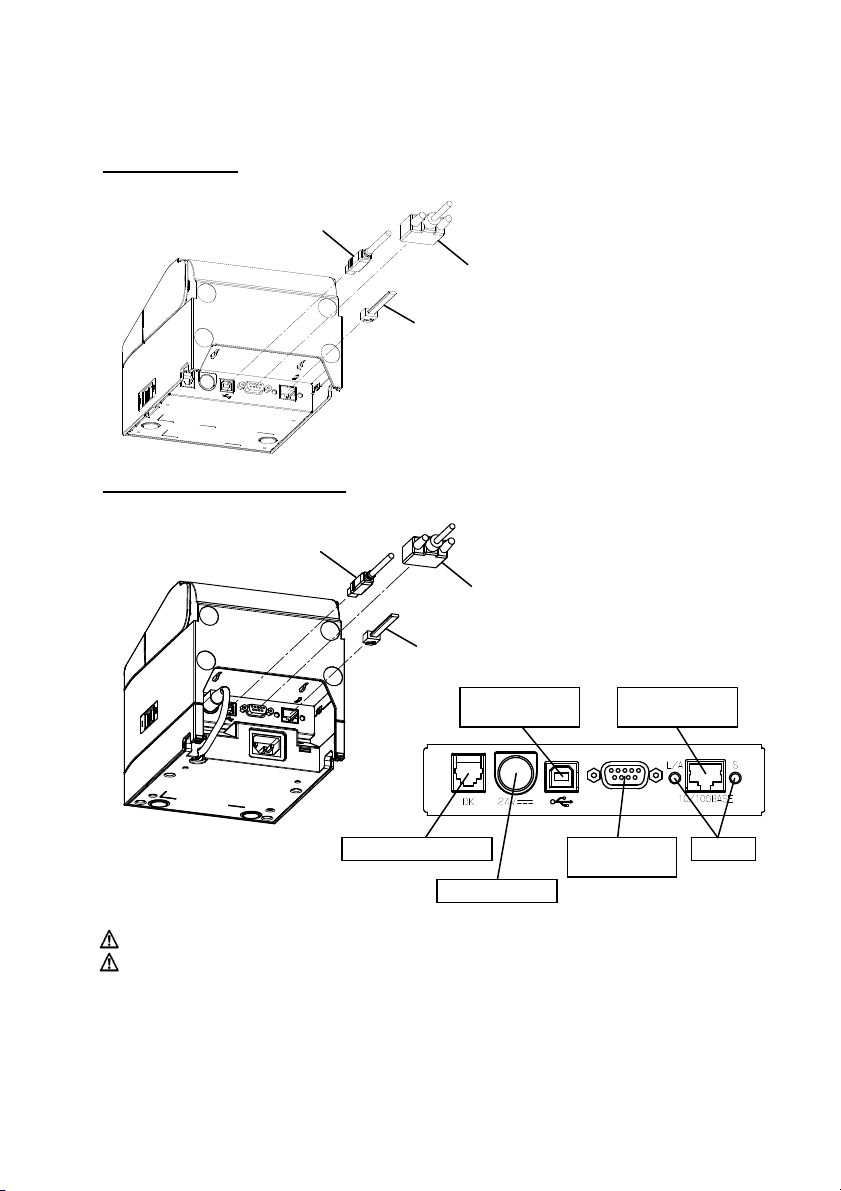

4-1-2 Printers with serial, USB and LAN interfaces

Standard Model

USB Interface Cable Type-B

* Connect the printer to a PC through this connector.

Serial Interface Cable

* Use the screws to secure it in place after connection.

LAN Interface Cable

Built-in Power Supply Model

USB Interface Cable Type-B

* Connect the

rinter to a PC through this connector.

Serial

Interface Cable

e the screws to secure it in place after connection.

* Us

LAN Interface Cable

USB Interface

Type-B Connecto

LAN Interface

Drawer Kick Connector

Power Connecto

Serial Interface

Connecto

Caution: Do not connect the multiple interfaces at the same time.

Caution: While this printer supports 3 different interfaces, it is set to LAN

Settings at time of shipment, so if you intend on using the USB or

serial interfaces, please make sure to change settings prior to use.

For more details on how to change setup se ttings, plea s e refe r to “9-4.

LAN Setup Settings".

Connecto

LED

12

Page 15

4-2. Connecting the Interface Cable (to the PC)

4-2-1 Serial Interface

(1) Connect the connector of serial interface cable to the serial port on the

computer as shown in the figure.

2 USB Interface

-

4-2

(1) Connect the connector of USB interface cable to the USB port on the

computer as shown in the figure.

13

Page 16

4-2-3 LAN Interface

(1) Connect the connector of LAN interface cable to the LAN port on the

computer as shown in the figure.

14

Page 17

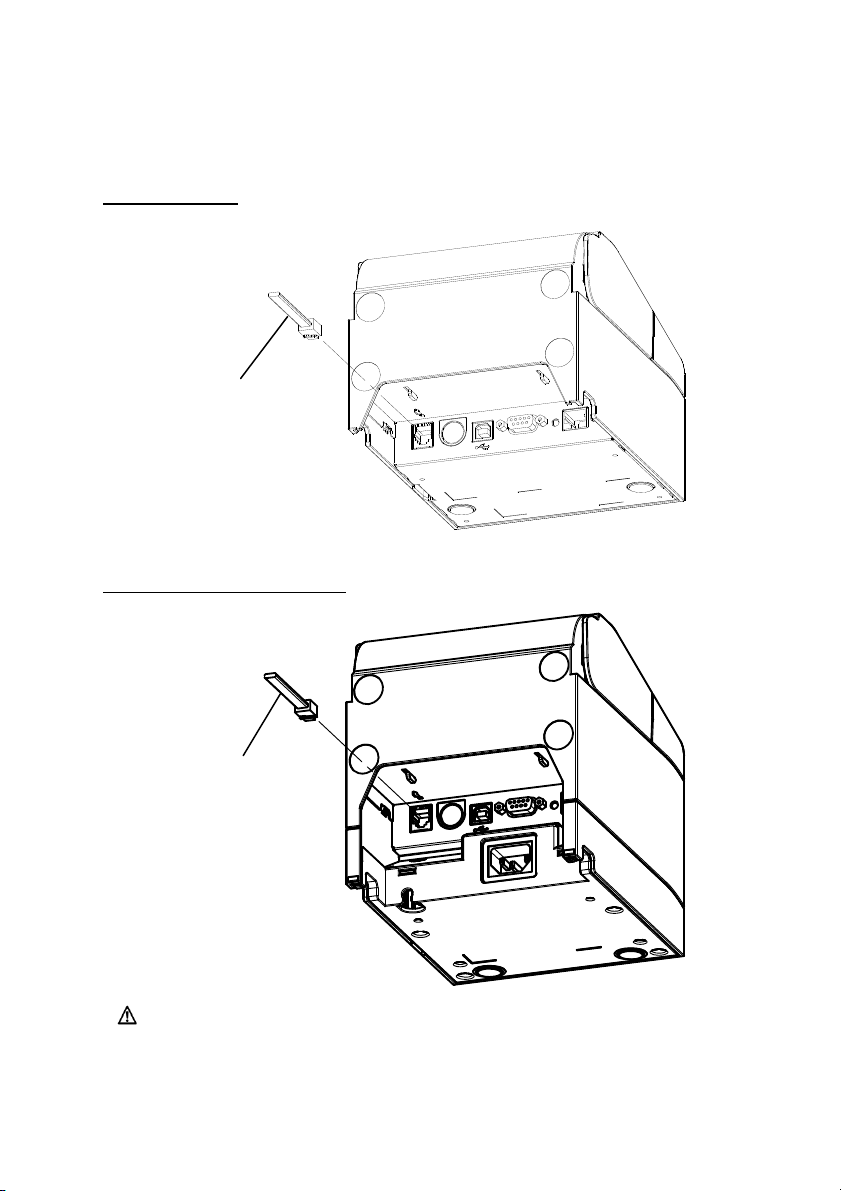

4-3. Connecting the Drawer Kick Cable

Standard Model

Drawer Kick Cable

Built-in Power Supply Model

Drawer Kick Cable

Caution: This product uses a special-purpose modular connector for the

cash drawer. Do not attempt to use other types of connectors

such as public telephone connectors.

15

Page 18

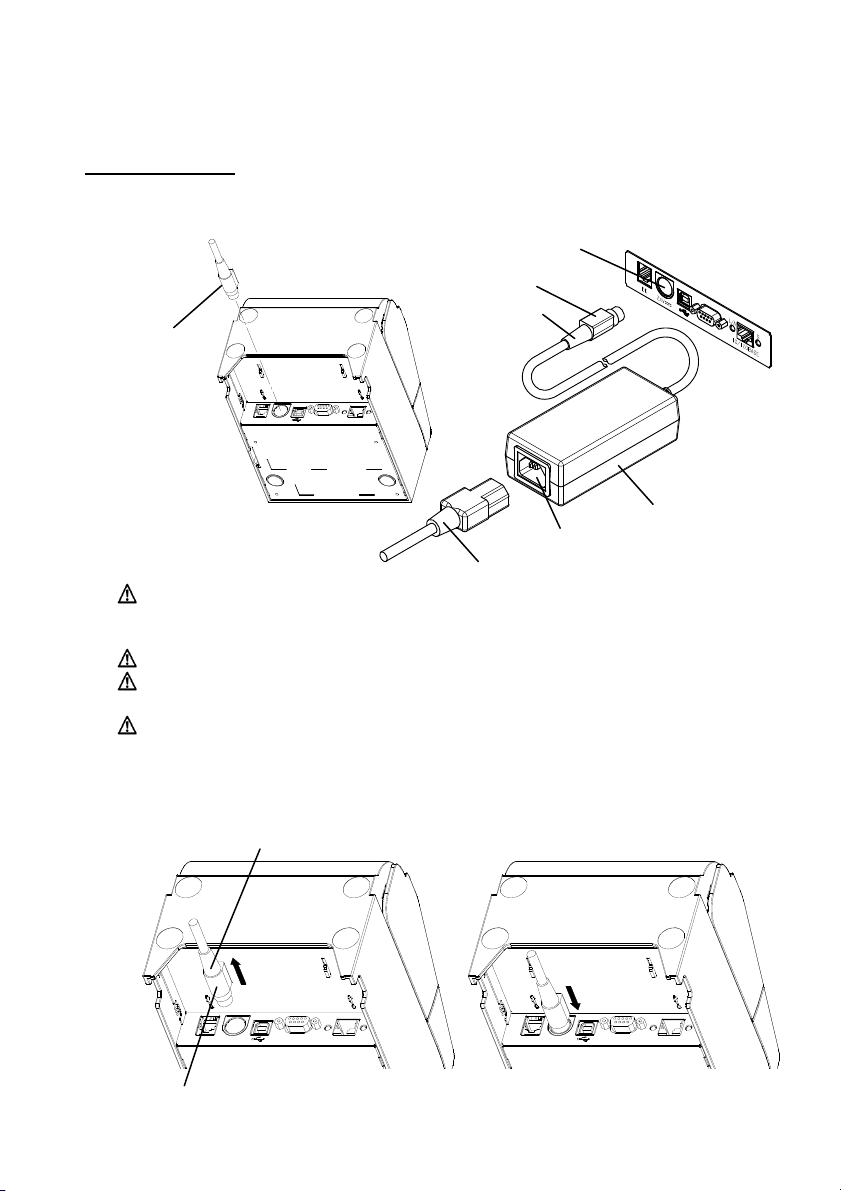

4-4. Connecting the AC Adapter and Cable

Standard Model

(1) Connect the cable connector of the AC adapter to the power connector.

AC Adapter

Connector

Caution: Before connecting the AC adapter, turn off the power switches

Caution: Use the specified AC adapters.

Caution: Perform the adapter connection with the device placed vertically

Caution: As the connector is clipped in place after insertion in order to

Th

e Outer Section of the Connector

Power Connector

Flat Side

Cable Connector

AC Adapter

AC Inlet

Power Cable

on the printer and all the devices connected to the printer. Also,

remove the plug of the AC adapter power cable from the outlet.

for easy operation.

prevent it from falling off, when performing insertion, (1) grip the

cable base with one hand, (2) slide the outer part of the

connector upwards with the other hand (3) and push in until it

locks into place.

Cable Base

(1)

(2)

16

(3)

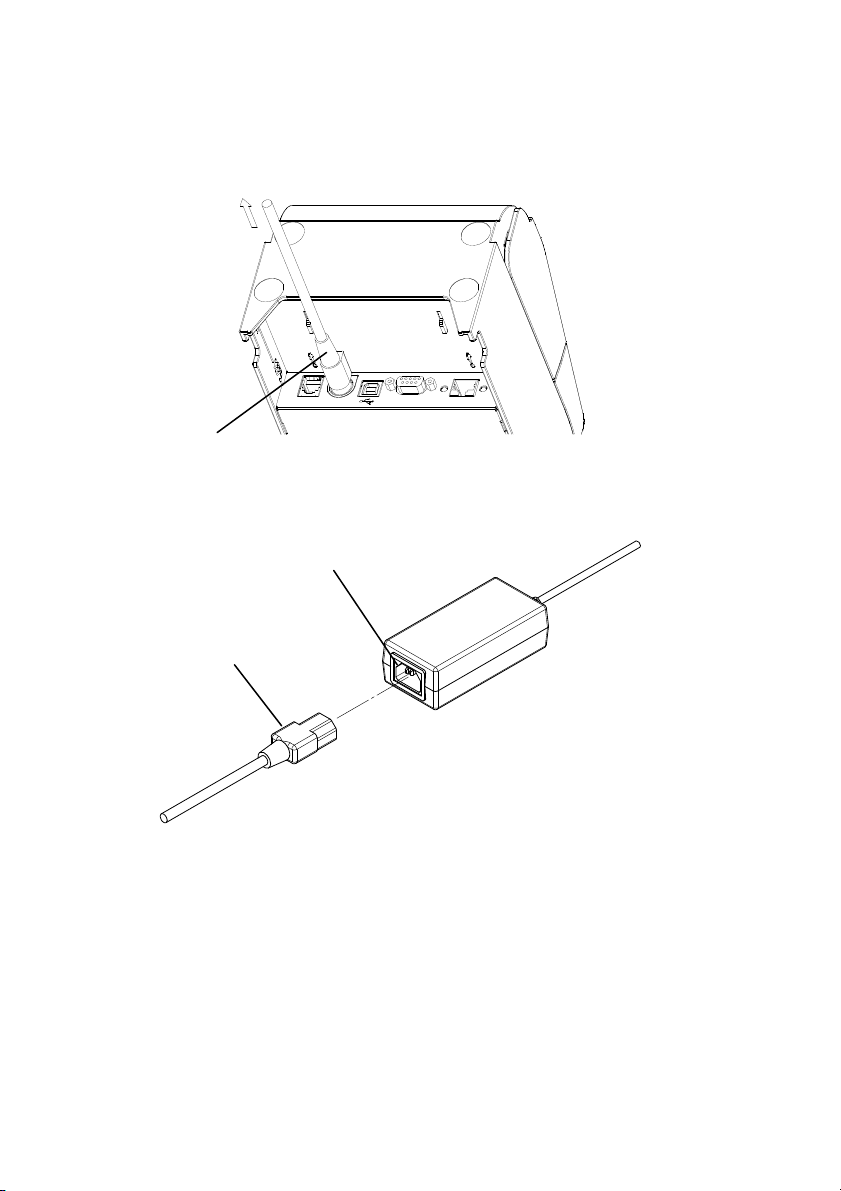

Page 19

(2) Confirm that the cable is locked in place by gently pulling on the cable base

after connection.

Cable Base

Co

nnect the power connector to the AC inlet of the AC adapter.

(3)

The AC Inlet of the AC Adapter

Power Cable

sert the plug of the power cable into the outlet.

In

(4)

17

Page 20

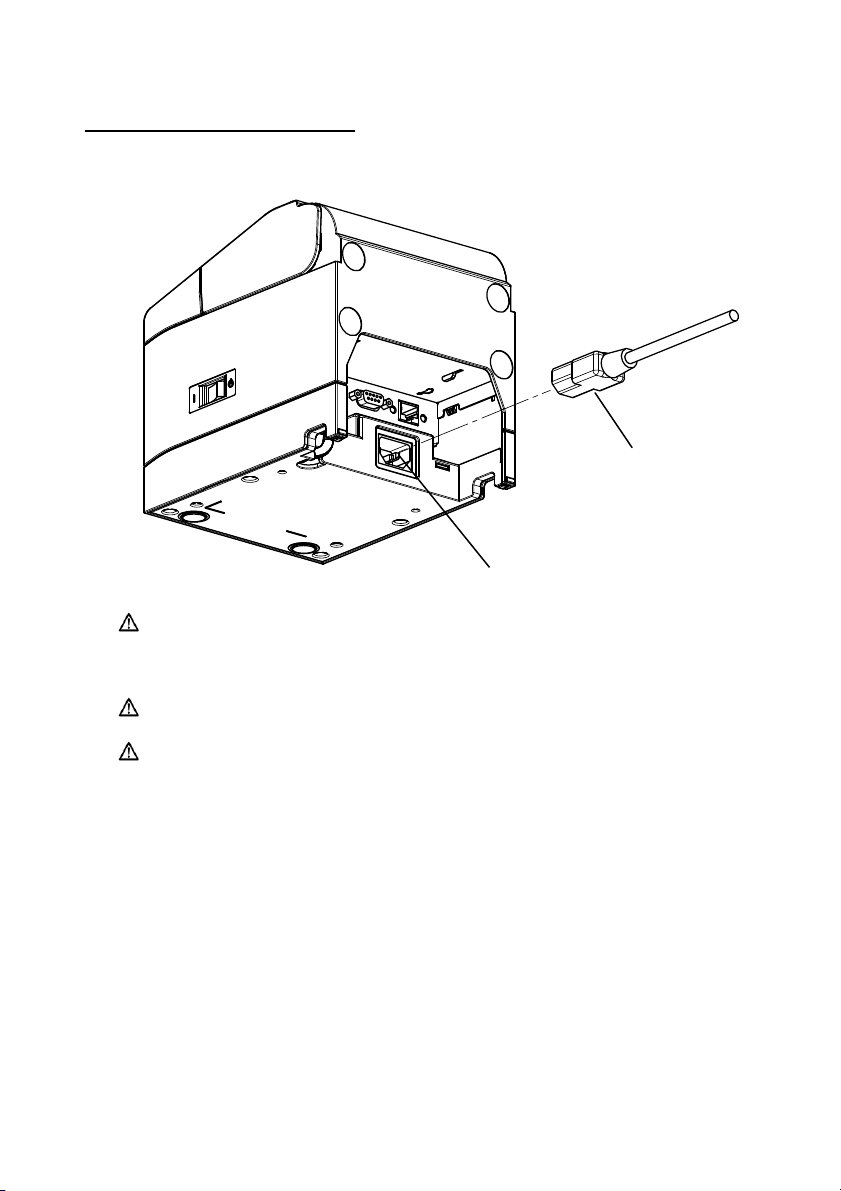

Built-in Power Supply Model

(1) Connect the power connector to the AC inlet.

Power Cable

Caution: Before connecting the power cable, turn off the power

switches on the printer and all the devices connected to the

printer. Also, remove the plug of the power cable from the

outlet.

Caution: Perform power cable connection with the device placed

vertically for easy operation.

Caution: If the device is installed vertically, use a right-angled power

cable.

AC Inlet

(2) Insert the plug of the power cable into the outlet.

18

Page 21

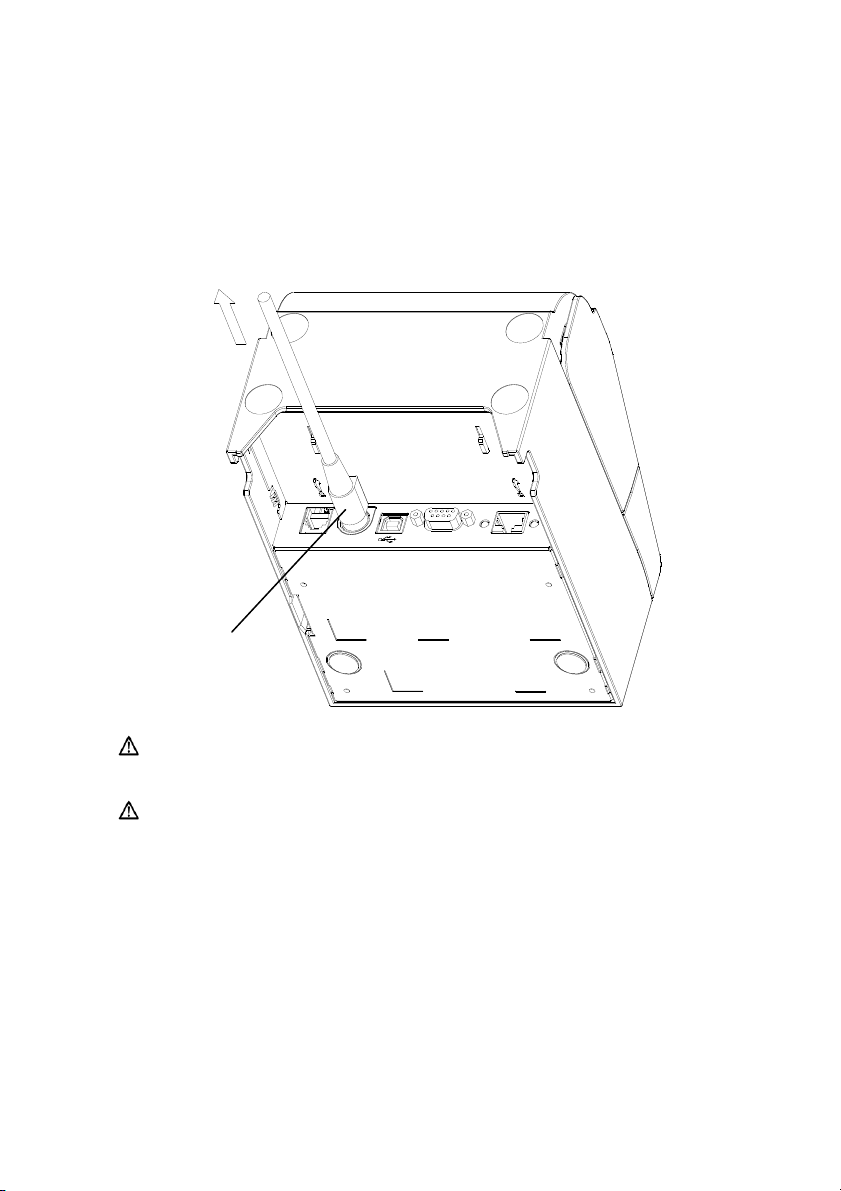

4-5. Removing the AC Adapter

To remove the cable of the AC adapter, pull it while gripping the connector

section on the cable side as shown in the following figure. The lock is

released, making it easy to remove. Forcibly pulling the cable will damage

the connector section.

The Cable Connector

Caution: Before removing the AC adapter, turn off the power switches

on the printer and all the devices connected to the printer. Also,

remove the plug of the AC adapter power cable from the outlet.

Caution: Perform adapter removal with th e d evice placed vertically for

easy operation.

19

Page 22

t

4-6. Installing the Printer

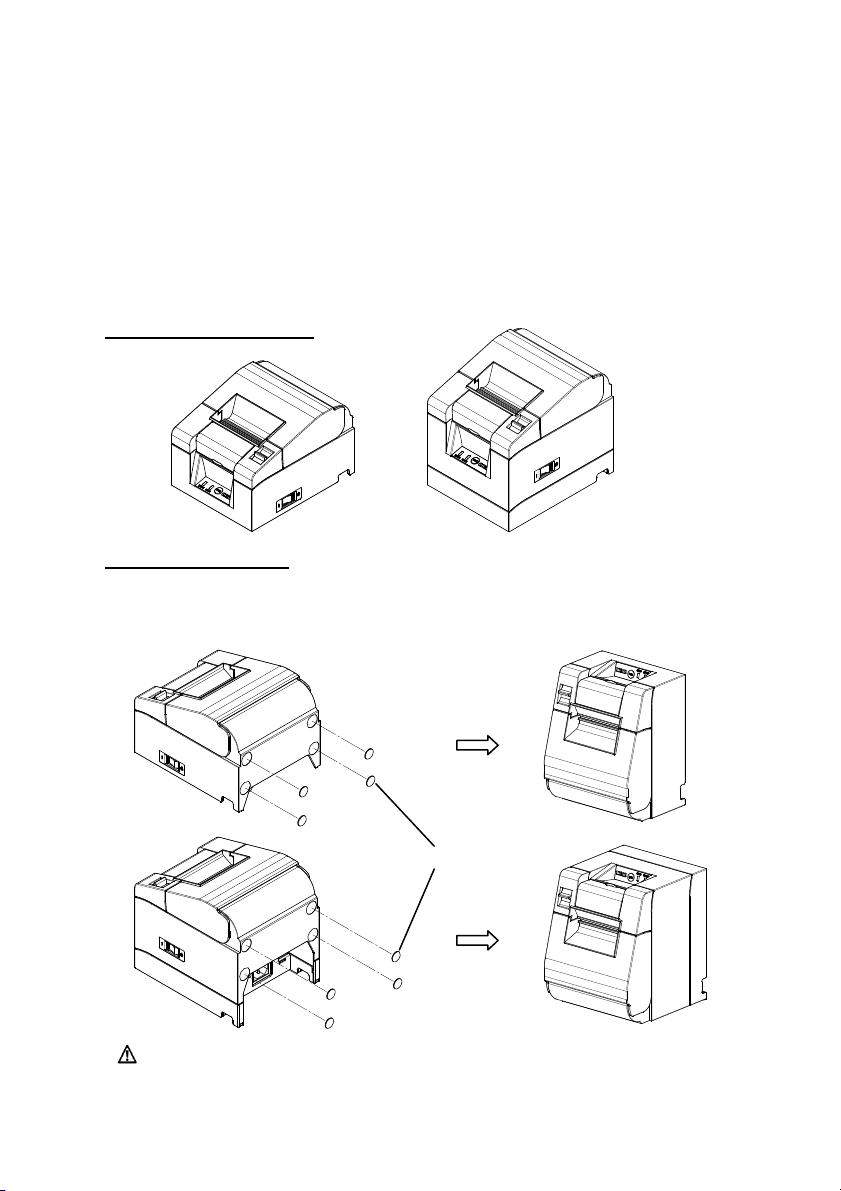

Both horizontal installation (the paper exit is on the topside) and vertical

installation (the paper exit is on the front side) orientations are available.

In the case of vertical installation, attaching the optional splash-proof cover can

protect the printer from water.

The printer can also be fixed to the wall by using the optional wall-hanging

bracket.

Horizontal Installation

Vertical Installation

If the printer is installed vertically, stick the rubber feet (included in the package)

into the round indents on the printer rear cover.

Caution: Before sticking on the rubber feet, wipe off any dirt inside the

indents.

Rubber Fee

20

Page 23

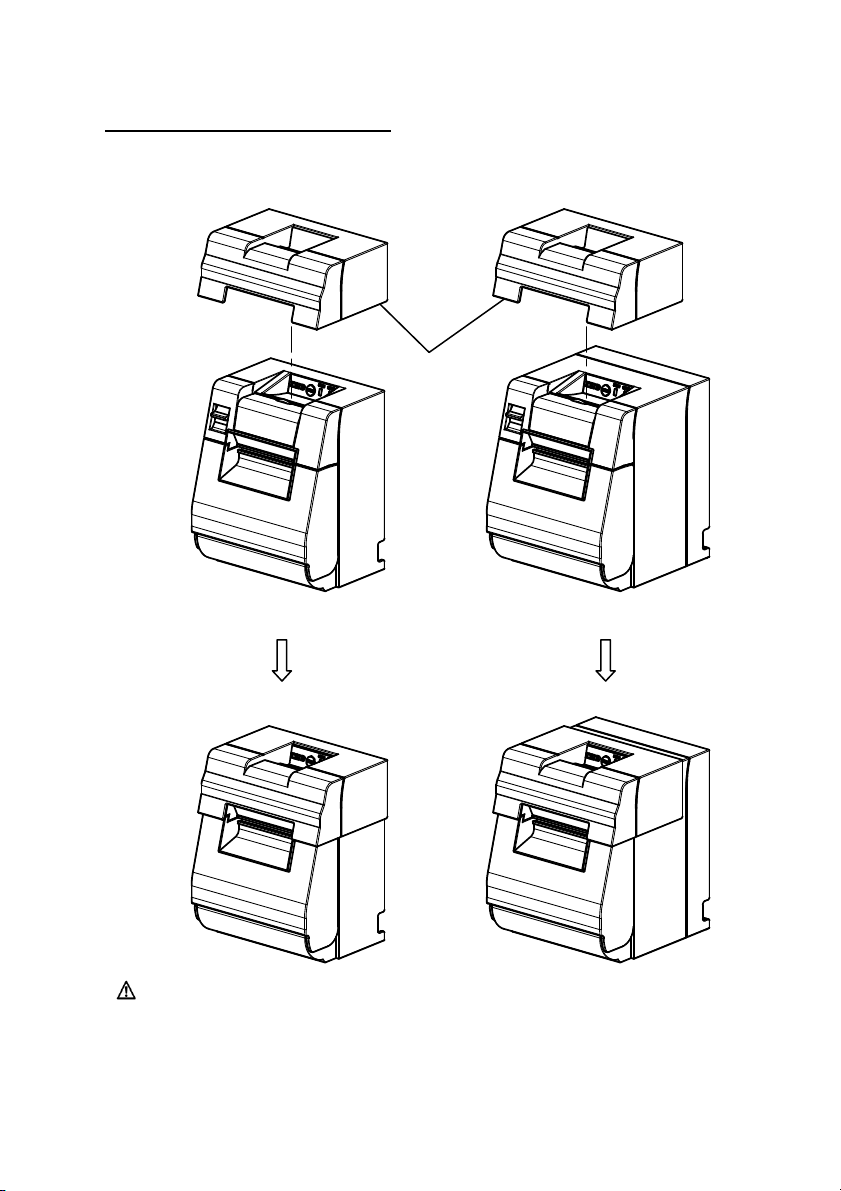

Splash-proof Cover (Optional)

Mount the splash-proof cover at the top when the printer is installed vertically.

Splash-proof Cover

Caution: The splash-proof cover is used only for vertical installation.

21

Page 24

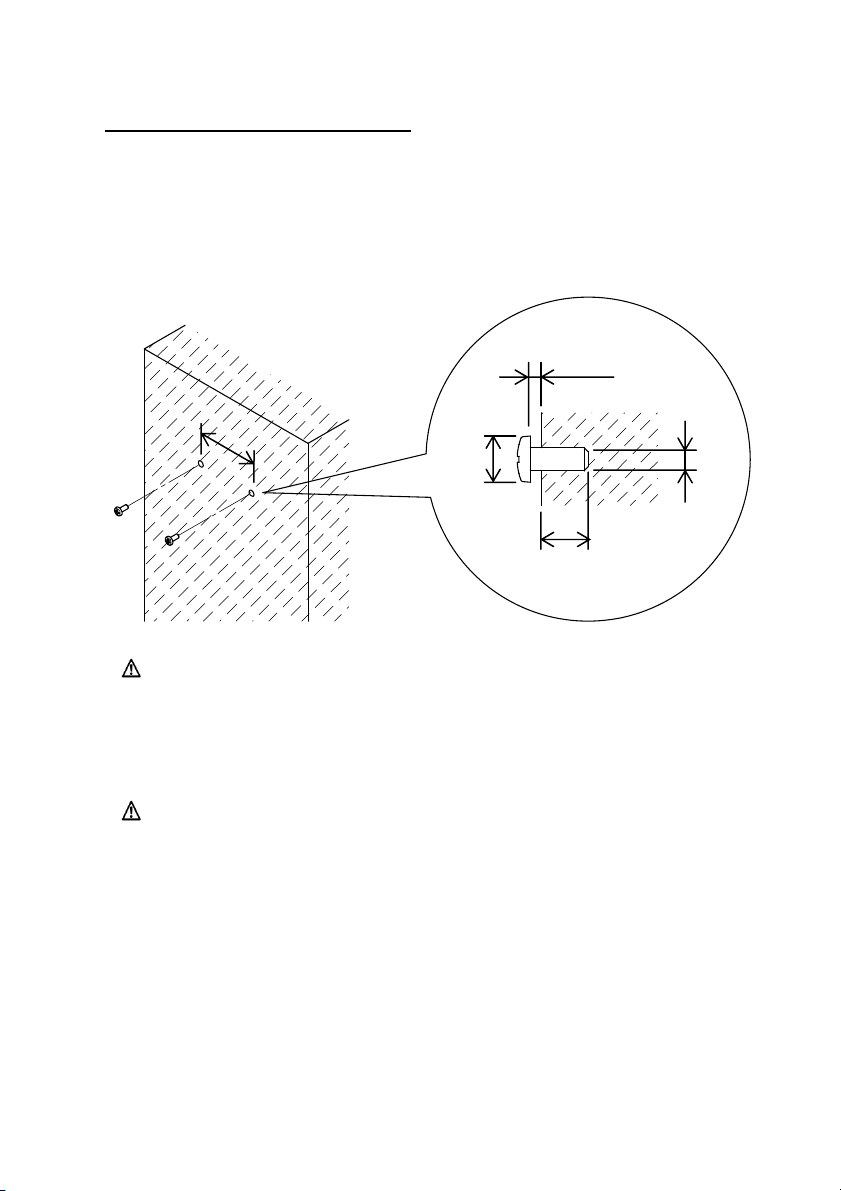

Wall Hanging Bracket (Optional)

To fix the printer to a wall, follow the procedures below:

(1) Mount two metal screws (thread diameter: Φ4, head diameter: Φ7) on the wall,

spaced 62mm apart in a horizontal line, such that the length of each screw

entering the wall is at least 10mm and the length protruding outside is 2-4mm.

2~4mm

62mm

7~9mm

4mm

More than or

equal to 10mm

Caution: In order to firmly fix the printer, mount the wall hanging bracket

onto a wooden, concrete or metal wall. It is recommended that the

wall thickness should be 10mm or more.

Use metal screws.

The screws mounted on the wall are required to have a pull-out

strength of 150N (15.3kgf) or more.

Caution: The wall hanging bracket can be used only for printers that use

an external AC adapter (Standard Model).

22

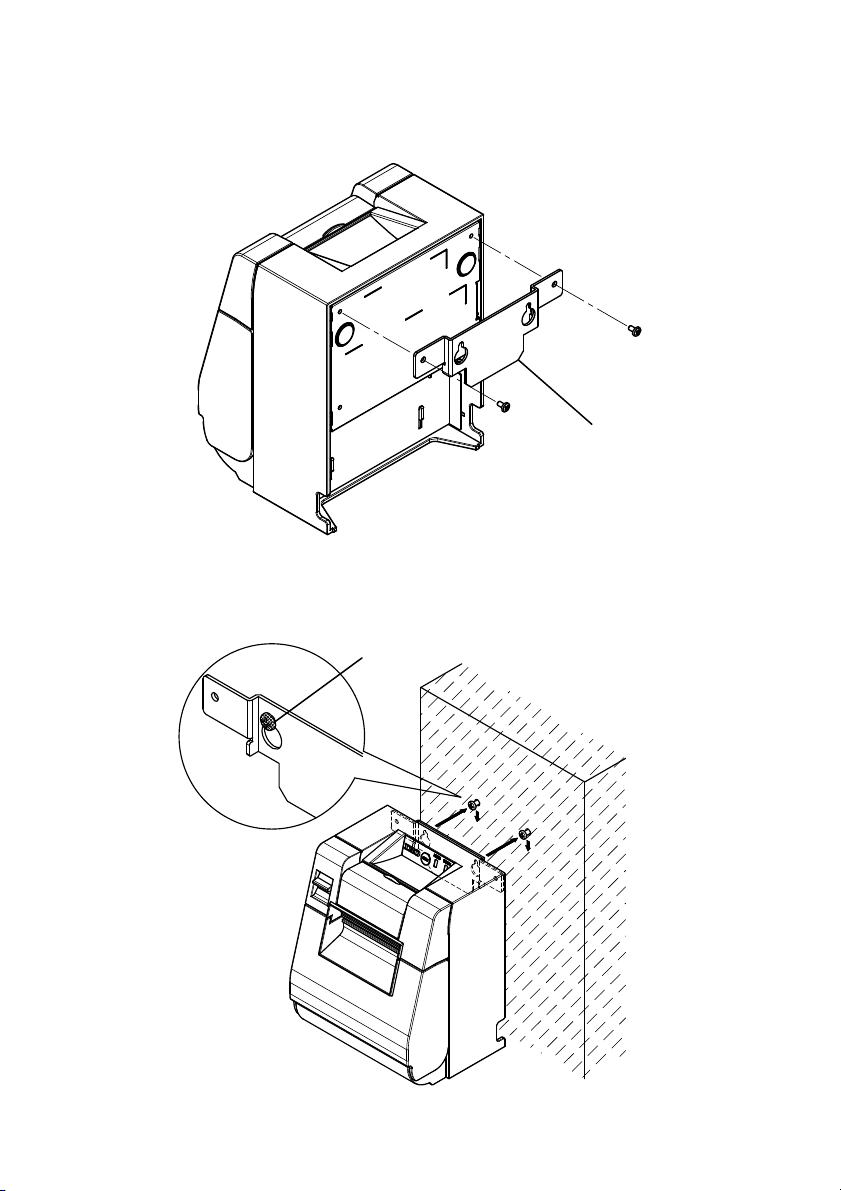

Page 25

(2) Attach the wall hanging bracket to the printer and fix it securely with the

enclosed screws.

Wall Hanging Bracket

Align the holes of the wall hanging bracket with the screws mounted to the

)

(3

wall and hang the printer securely.

Screw Head Section

23

Page 26

4-7. Power On

(1) Connect to the power cable according to 4-4 above.

(2) Turn on the power switch at the side of the printer.

After turning the power on, the POWER LED on the control panel will light

up.

Standard Model

Control Panel

Built-in Power Supply Model

Control Panel

Power Switch

Power Switch

24

Page 27

4-8. Installing the Printer Software

Refer to the "Installation Guide"(*1) in the enclosed CD for instructions on

installing the printer driver and utility software.

*1: \Manuals\PT340-341_InstallGuide_en.pdf

The "Installation Guide" can also be viewed by loading the CD in your PC's

CD drive and selecting "Manuals" on the "Setup" screen that appears.

25

Page 28

5. Inserting Paper

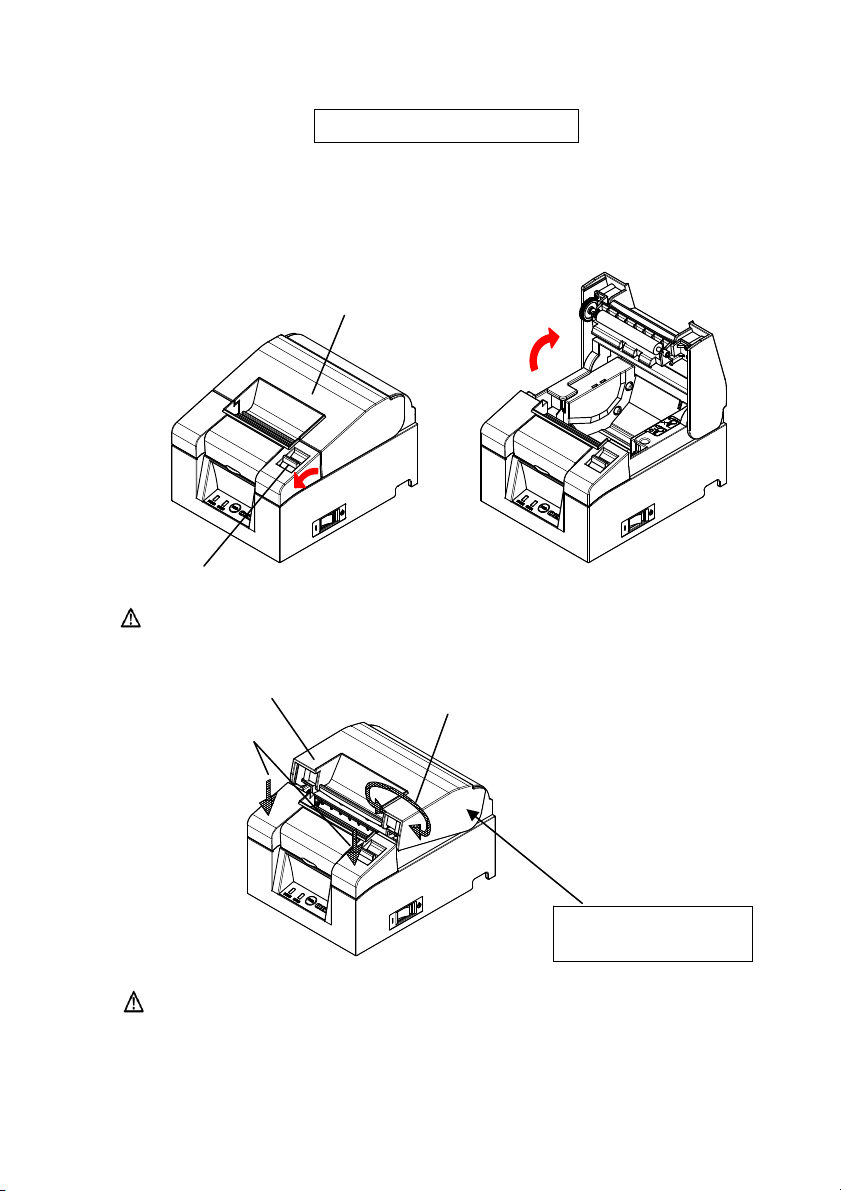

5-1. Opening the Top Cover

(1) Pull the release lever in the direction of the arrow, and then open the top

cover.

Release Lever

Caution: Lift the cover until it is vertical so that it will stay open.

Part C

Caution: To open the cover, use either side of part C to hold the

printer steady and use part A or part B to lift the cover. To

prevent your fingers being pinched, please do not touch the

area around the top cover hinge.

Top Cover

Part A

Part B

The fulcrum point

of top cover

26

Page 29

Front part of Printer

(Shaded part)

Caution: When using printer vertically, steady the front part of the printer

(shaded part in the above picture) to open the top cover.

27

Page 30

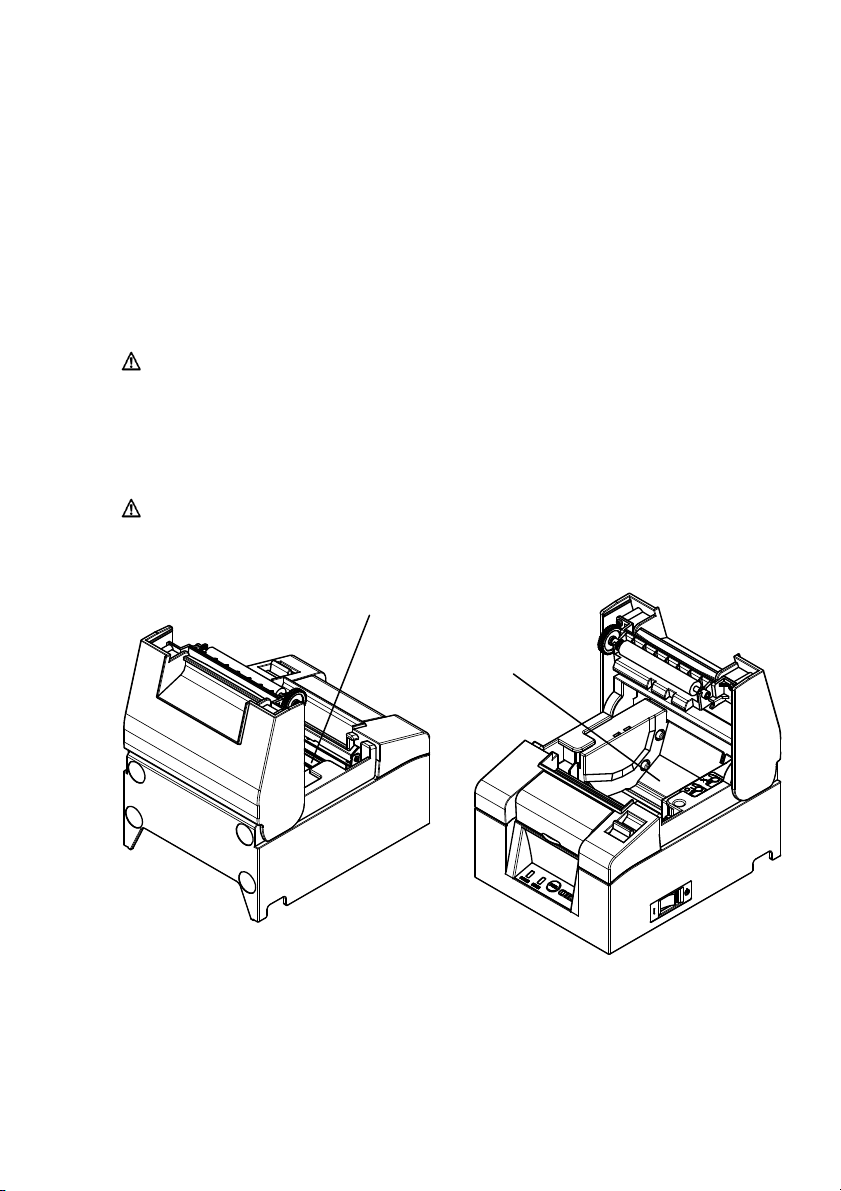

5-2. Paper Width Setting (Width: 58mm / 80mm)

As the factory setting for paper width is 80mm, follow the instructions in "5-3.

Setting the Paper" to set the paper roll when using 80mm paper.

When using 58mm paper, first attach the separator in accordance with the

instructions in "5-2-1. Attaching the Separator" and then set the paper roll.

Also, follow the instructions in "9-2. Changing the Setup" to set the "Paper

Width" in the printer setup to "58mm/35columns" or "58mm/32columns".

Caution: Do not switch from the 58mm width paper to 80mm width

paper when printing is in progress. When using narrow-width

paper, a part of the thermal head may directly come in contact

with the platen roller without any paper present. This causes

the head to wear down, resulting in poor printing quality.

In addition, as the cutter blade also works on sections without

paper, the cutter blade may wear down, resulting in a bad cut.

Caution: As the thermal head may be damaged by static electricity, do

not touch the thermal head except for cleaning.

Thermal Head

Roll Holder

28

Page 31

5-2-1 Attaching the Separator

(1) Align the three lugs of the supplied 58mm width separator with the

corresponding holes on the printer body, then push it into place.

58mm Width Separator

Setting Hole

Caution: Push the plate until it locks with a clicking sound and confirm

that the top side of the separator is horizontal.

Caution: When moving the separator follow the instructions in the

Special Mode section to set the paper width and align it with

the printing area.

(Refer to 9 Special Mode: 9-2. Changing the Setup.)

29

Page 32

5-3. Setting the Paper

(1) In the case of a new roll of paper, remove the glued portion and tape on the

paper roll.

When replacing the roll paper, first remove the old paper core.

Caution: Since the glued portion of the paper should not be printed on,

remove about one turn (about 30 cm) of the roll paper from the

beginning so that none of the remaining paper has glue on it.

Any adhesive or other matter remaining from the glue may

adhere to the thermal head and cause a problem, such as

voids on printouts. Therefore, do not forget to remove the

glued portion of the paper.

(2) After inserting the new roll of paper with the orientation shown, pull the end

of the paper in the direction indicated by the arrow [1].

Top of Cover

Caution: Pull the end of the paper so that it passes over the top of the

cover.

Caution: Do not damage or dent the platen roller.

Dents on the platen roller will cause gaps in the printing

and/or line feed failure.

Platen Roller

[1]

30

Page 33

Caution: Setting the paper as shown in the following figures may cause

paper or printing jams.

The paper does not pass over

the top of the cover.

The paper has been set incorrectly.

Caution: Do not use deformed roll paper. Using rolls such as those

shown below may cause trouble such as paper or printing

jams.

Caution: If the roll paper is loose (slack) as shown b elow, remove the

slack before using the roll. Using without removing the slack

may cause paper or printing jams, or result in failure to detect

the paper near end condition.

31

Page 34

5-4. Closing the Top Cover

Set the paper correctly and carefully close the top cover.

Caution: Set the paper correctly. Closing the top cover while the paper

is skewed may cause a paper jam or messy printing.

Caution: When clo sing the top cover, close it securely by pressing

around the central position (shown by the arrow in the figure)

until you hear a clicking sound. If the cover has not locked

into place, the printer may not function.

Caution: When the printer is mounted vertically, use the front of the

printer (shaded part in the above picture) to hold it steady when

opening the top cover.

Push

Top Cover

Front part of Printer

(Shaded part)

32

Page 35

6. Control Panel

6-1. Control Panel

)

POWER LE

If the power switch is turned on and the printer is supplied with power, this

LED will light up.

ERROR LED()

This LED lights up or blinks to indicate an error.

FEED Button

Pressing this button once causes the printer to feed the paper by an amount

equivalent to one line.

Holding it down feeds the paper continuously.

Caution: When the printer is mounted vertically, always hold the rear of

D(

the printer when you press the FEED button to keep the printer

steady and prevent it from falling over.

Rear of the Printer

33

Page 36

6-2. Error Indications

Recoverable errors

Error State LED Lamp Blinking Pattern

No paper

Paper end

Error State LED Lamp Blinking Pattern

Paper near end

Head hot

POWER () Constantly on

ERROR () Constantly on

POWER () Constantly on Cover open

ERROR () Constantly on

POWER () Constantly on Cutter jam

ERROR () Constantly on

POWER () Constantly on

ERROR ()

POWER ()

ERROR ()

Remains unchanged.

34

Page 37

Unrecoverable errors

Error State LED Lamp Blinking Pattern

Internal error

Head not

installed

Low voltage

Over voltage

Watchdog timer

error

SPI Flash ROM

error

POWER()

ERROR()

POWER()

ERROR()

POWER()

ERROR()

POWER()

ERROR()

POWER()

ERROR()

POWER()

ERROR()

————

—————

Repetition of two blinks of the lamp

and one blink of the lamp

—————

———————

Repetition of three blinks of the lamp

and one blink of the lamp

——————

——————————

Repetition of four blinks of the lamp

and one blink of the lamp

———————

————————————

Repetition of five blinks of the lamp

and one blink of the lamp

——————————

——————————————————

Repetition of eight blinks of the lamp

and one blink of the lamp

—————————

——

———————————————

———

Repetition of nine blinks of the lamp

and one blink of the lamp

35

Page 38

7. Paper Jam Prevention and Removal

7-1. Paper Jam Prevention

Do not touch the paper while it is coming out or before cutting is complete.

Pressing or pulling the paper with your hand while it is coming out may cause

a paper jam, bad cut, or bad line feed.

7-2. Paper Jam Removal

In case of a paper jam, remove the paper as follows:

(1) Turn off the power switch to disconnect the printer from the power.

(2) Pull the release lever towards you, and then open the top cover.

If the top cover does not open, refer to the instructions in "7-3. If the Top

Cover Does Not Open" to remove the cutter jam.

(3) Press the printer and remove the jammed paper.

Caution: When removing paper, remove the paper slowly without

pulling it forcibly.

Caution: As the thermal head may be damaged by static electricity, do

not touch the thermal head. Also, do not touch the thermal

head as it may still be hot after printing.

(4) Set the paper correctly and carefully close the top cover.

Caution: Set the paper correctly. Closing the top cover while the paper

is skewed may cause a paper jam or messy printing.

Caution: When closing the top cover, close it securely by pressing

around the central position until you hear a clicking sound. If

the cover has not locked into place, the printer may not

function.

(5) Turn on the power switch . Also, at this time confirm that the ERROR

lamp has turned off.

Caution: As printing data cannot be received while the ERROR lamp is

on, firmly close the top cover.

36

Page 39

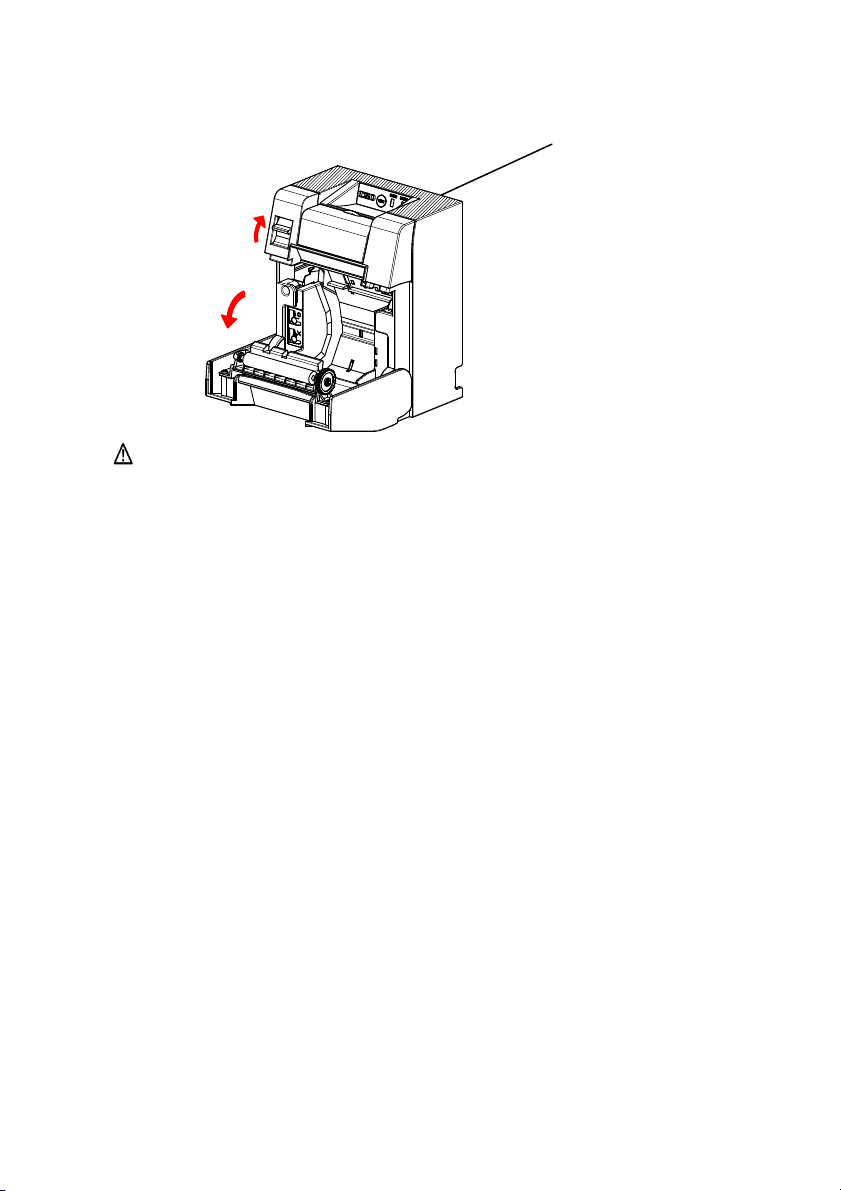

7-3. If the Top Cover Does Not Open

When the printer has stopped with the cutter blade exposed due to some

abnormality such as a paper jam, the top cover will not open.

In such a case, instead of opening it forcibly, perform the following steps:

(1) Turn off the power switch to disconnect the printer from the power.

(2) Turn the power on again. This causes the cutter to operate and may clear

the paper jam.

(3) Pull the release lever toward you to check whether the top cover opens. If

so, turn the power off again and follow the instructions from step (6) to

clear the paper jam.

If the top cover still cannot be opened after the power is turned on, turn the

power off again and follow the instructions from step (4) to clear the paper

jam.

(4) Remove the front cover by lifting it as shown by the arrow.

Top Cover

Front Cover

37

Page 40

(5) Lift the protective sheet as indicated by arrow A and rotate the cutter gear

in the direction indicated by arrow B while pulling the release lever

toward you.

If the auto-cutter blade fails to move despite rotating the cutter gear and

the top cover still will not open, pull the release lever toward you and

rotate the cutter gear in the opposite direction (indicated by arrow C) until

the top cover is able to open.

Protective Sheet

Top Cover

A

B

Cutter Gear

C

Cutter Motor

Release Lever

Auto-cutter blade is

protruding

Top cover cannot open

Auto-cutter blade is

retracted

Top cover can open

Caution: Do not the touch the cutter motor, as it may still be hot after

printing.

Caution: Do not touch the auto cutter, as its blade end is sharp an d

dangerous.

Caution: When you cannot open Top Cover with rotating Cutter Gear to

either direction, call your service provider.

38

Page 41

(6) Open the top cover and remove the jammed paper while holding the

printer steady.

Caution: When removing paper, remove the paper slowly without

pulling it forcibly.

Caution: As the thermal head may be damaged by static electricity, do

not touch the thermal head. Also, do not touch the thermal

head as it may still be hot after printing.

(7) Set the paper correctly and carefully close the top cover.

Caution: Set the paper correctly. Closing the top cover while the paper

is skewed may cause a paper jam or messy printing.

Caution: When closing the top cover, close it securely by pressing

around the central position until you hear a clicking sound. If

the cover has not locked into place, the printer may not

function.

(8) Turn on the power switch. Also, at this time confirm that the ERROR lamp

has turned off.

Caution: As printing data cannot be received while the ERROR lamp is

on, firmly close the top cover.

39

Page 42

8. Troubleshooting

This section provides solutions for printer malfunctions and print quality

problems.

8-1. Problems at Power-on and Other Errors

Symptom Cause Solution

Although the power has

been turned on, the

POWER lamp on the

control panel does not

light up and the printer

does not start.

The ERROR lamp on the

control panel lights up

and the printer does not

work.

8-2. Cutter Problems

Symptom Cause Solution

The paper is not cut. (1) The cutter blade is

The cutter does not return

to its correct position.

(1) The power cable is

disconnected.

(2) The AC adapter is not

plugged in.

(1) There is no paper in the

printer .

(2) The top cover is not

completely closed.

(3) The thermal head is

excessively hot.

damaged or worn out.

(2) Paper fragments or other

foreign matter are stuck

around the cutter or the

sliding section.

Paper fragments or other

foreign matter are stuck

around the cutter or the

sliding section.

(1) Connect the power cable.

* Refer to 4-4. Connecting the AC

Adapter and Cable.

(2) Connect the connector of the AC

adapter.

* Refer to 4-4. Connecting the AC

Adapter and Cable.

(1) Set the paper.

* Refer to 5. Inserting Paper.

(2) Close the top cover completely.

* Refer to 5. Inserting Paper.

(3) Wait for the thermal head to cool

down.

(1) Turn off the power and request

repair.

(2) Remove the paper fragments or

other foreign matter.

Remove the paper fragments or other

foreign matter.

40

Page 43

8-3. Printing Problems

Symptom Cause Solution

The printer does not

print.

Print is too dark or

blurred.

Print is too faint.

Printing is uneven.

Vertical marks

appear on the

printout.

(1) The interface cable is

disconnected or broken.

(2) The printer setup is not correct.

(1) Print density setting in the

printer setup is incorrect.

(2) The thermal head is damaged.

(1) Print density setting in the

printer setup is incorrect.

(2) The thermal head is damaged.

(1) Paper fragments or other

foreign matter are stuck to the

heating elements of the thermal

head.

(2) The setting of the printer setup

is incorrect.

(3) Foreign matter is stuck on the

platen roller.

(4) The thermal head is damaged.

(1) Foreign matter is stuck in or

dropped into the paper

transport.

(2) Foreign matter is stuck on the

thermal head.

(3) The thermal head is damaged.

(1) Connect the interface cable

correctly, or replace it.

* Refer to 4-1. Connecting the

Interface Cable

(2) Amend the setting.

Example: Baud rate mismatch

* Refer to 9-2,9-4. Changing the

Setup.

(1) Set the printer at the suitable print

density and/or print speed for the

print paper.

* Refer to 9-2. Changing the Setup.

(2) Turn off the power and request

repair.

(1) Set the printer at the suitable print

density and/or print speed for the

print paper.

* Refer to 9-2. Changing the Setup.

(2) Turn off the power and request

repair.

(1) Check and clean the thermal head.

* Refer to 10-3. Cleaning the

Thermal Head

(2) Set the printer at the suitable print

density and/or print speed for the

print paper. Amend the setting.

* Refer to 9-2. Changing the Setup.

(3) Remove the foreign matter from

the platen roller.

* Refer to 10-2. Cleaning the Platen

Roller

(4) Turn off the power and request

repair.

(1) Clean the paper transport.

* Refer to 10-1. Cleaning Paper

Holder and Paper transport

(2) Clean the thermal head.

* Refer to 10-3. Cleaning the

Thermal Head

(3) Turn off the power and request

repair.

41

Page 44

9. Special Mode (Test Print, Setup Menu...)

9-1. Test Print

Ensure that paper is set in the printer. Turn off the power switch on the printer,

then turn it on again while pressing the FEED button on the control panel. This

outputs the following printout.

Caution: Press and hold the FEED button until the printer starts

printing.

Special Mode

1.Test Print

2.Setup Menu

3.Hex Dump

4.Command Trace

5.Sample Print

6.End

<Set>

Press FEED button for the number of times

as the same as your selecting item, and

wait more than 1 second.

Dual interface model Triple interface model

Then Press the FEED button once (select 1. Test Print) to start a test print.

The printer automatically cuts the paper and stops after performing a set amount

of printing. To terminate the test print while in progress, press the FEED button.

This cuts the paper and terminates printing.

Paper feed direction

Special Mode

1.Test Print

2.Setup Menu

3.LAN Setup Menu

4.Hex Dump

5.Command Trace

6.Sample Print

用紙送り方向

7.End

<Set>

Press FEED button for the number of times

as the same as your selecting item, and

wait more than 1 second.

Paper feed

用紙送り方向

42

Page 45

Test Print (Example)

The Firmware Number and Firmware Version vary according to the model.

“123456”is an example serial number.

PT340-341 Ver1.0

123456

Memory Switch 1

Power On Status Enable

Receive Buffer 4KByte

Busy Condition Bufferfull

Receive Error ? Print

Auto LF Disable

DSR(#6)Reset Disable

INIT(#25)Reset Disable

USB Soft Reset Enable

Memory Switch 2

Cover Open Error Auto Recovery

Error Auto Recovery

Batch (COM IF) Enable

Batch (Other IF) Disable

Serial Number D isable

ASB Enable

Font-B Mode1

Print

Paper Width 80mm/48columns

Max Speed 220mm/s

Print Density 1 00%

Hardware

Error Alert None

Buzzer Interval Pattern 2

Buzzer Repetition Three

Graph/User NV-MEM 384KB/192KB

Cut at CoverClose Disable

PNE Detect Enable

Interface

Baudrate 115200BPS

Format 8NONE1

Protocol DSR/DTR

USB Printer

!"#$%&'()*+,-./0 1234

56789:;<=>?@ABCDEFG HI

JKLMNOPQRSTUVWXYZ[\ ]^

_~abcdefghIjklmnopq rs

∬

Dual interface model

∬

Paper feed direction

用紙送り方向

PT340-341 Ver2.0

123456

Memory Switch 1

Power On Status Enable

Receive Buffer 4KByte

Busy Condition Bufferfull

Receive Error ?Print

Auto LF Disable

DSR(#6)Reset Disable

USB Soft Reset Enable

Memory Switch 2

Cover Open Error Auto Recovery

Error Auto Recovery

Batch (COM IF) Enable

Batch (Other IF) Disable

Serial Number Disable

ASB Enable

Font-B Mode1

Print

Paper Width 80mm/48columns

Max Speed 220mm/s

Print Density 100%

Hardware

Error Alert None

Buzzer Interval Pattern 2

Buzzer Repetition Three

Graph/User NV-MEM 384KB/192KB

Cut at CoverClose Disable

PNE Detect Enable

Interface

Baudrate 115200BPS

Format 8NONE1

Protocol DSR/DTR

USB Printer

LAN Enable

Mac Address [xx:xx:xx:xx:xx:xx]

root Password "*******"

Printer Name "PT340-341"

DHCP Enable

IP Address 192.168. 1. 1

Subnet Mask 255.255.255. 0

Default Gateway 0. 0. 0. 0

SNMP

Authentic Community "***************"

Trap Community "public"

Trap Address(IP) 0. 0. 0. 0

SysContact ""

SysName ""

SysLocation ""

EnableAuthenTrap Disable(2)

!"#$%&'()*+,- ./012 34

56789:;<=>?@ABCDEFGHI

JKLMNOPQRSTUVWXYZ[\]^

_~abcdefghIjklmnopqrs

∬

用紙送り方向

∬

43

Triple interface model

Page 46

9-2. Changing the Setup

This section explains how to setup the printer without using a PC.

Alternatively, when the printer is connected to a Windows PC, the settings can

be changed using the utility software on the enclosed CD.

For instructions on installing and using the utility software, refer to the

"Installation Guide" and "Utility User's Guide" located in the Manuals folder

of the CD.

• Installation Guide : PT340-341_InstallGuide_en.pdf

• Utility User's Guide : PT340-341_UtilityGuide_en.pdf

The "Installation Guide" and "Utility User's Guide" can also be viewed by

loading the CD in your PC’s CD drive and selecting "Manuals" on the "Setup"

screen that appears.

Setting Example Select a higher print density

Print Density Changed from 100% to 130%

Perform setup as follows:

1. Check the printer state prior to setting.

(1) The power is off.

(2) The paper roll is set.

(3) The cover is closed.

44

Page 47

2. Ensure that paper is set in the printer. Turn off the power switch on the printer, then

turn it on again while pressing the FEED button on the control panel. This outputs

the printout shown in section 9-1.

Then Press the FEED button twice (to select 2. Setup Menu) enters setup

mode and prints the following menu.

Setup Menu

1.Setting

2.Setup Print

3.Save & End

4.Default Set

<Set>

Press FEED button for the number of times

as the same as your selecting item, and

wait more than 1 second.

<Return>

Continue to press FEED button more than

1 second.

Paper feed direction

用紙送り方向

45

Page 48

3. Then Press the FEED button once (to select 1. Setting) enters setting

mode and prints the following setting groups.

Setting

1.Memory Switch 1

2.Memory Switch 2

3.Print

4.Hardware

5.Interface

<Set>

Press FEED button for the number of times

as the same as your selecting item, and

wait more than 1 second.

<Return>

Continue to press FEED button more than

1 second.

Paper feed direction

用紙送り方向

46

Page 49

4. Then Press the FEED button three times (to select 3. Print) selects the

Print group and prints the following setting options.

Print

1.Paper Width 80mm/48columns

2.Max Speed 220mm/s

3.Print Density 100%

<Set>

Press FEED button for the number of times

as the same as your selecting item, and

wait more than 1 second.

<Return>

Continue to press FEED button more than

1 second.

<Setup Menu>

Continue to press FEED button more than

3 seconds.

Paper feed direction

用紙送り方向

47

Page 50

5. Then Press the FEED button three times (select 3.Print Density) selects

the Print Density setting and prints the following Print Density settings.

Print Density 100%

1.70%

2.80%

3.90%

4.100%

5.110%

6.120%

7.130%

<Set>

Press FEED button for the number of times

as the same as your selecting item, and

wait more than 1 second.

<Return>

Continue to press FEED button more than

1 second.

<Setup Menu>

Continue to press FEED button more than

3 seconds.

Paper feed direction

用紙送り方向

48

Page 51

6. Then Press the FEED button seven times (to select 7. 130%) returns to

the Print settings group.

Changed items are displayed in bold and underlined.

Print

1.Paper Width 80mm/48columns

2.Max Speed 220mm/s

3.Print Density 130%

<Set>

Press FEED button for the number of times

as the same as your selecting item, and

wait more than 1 second.

<Return>

Continue to press FEED button more than

1 second.

<Setup Menu>

Continue to press FEED button more than

3 seconds.

it t

To ex

o the previous level (<Return>)

⇒ Go to Section 7-1

To exit directly to the setup menu (<Setup Menu>)

⇒ Go to Ssection 7-2

Paper feed direction

用紙送り方向

49

Page 52

7-1. Exiting to Previous Level

Hold the FEED button down for 1 second or more until the buzzer

sounds twice.

Release the FEED button after the buzzer sounds.

This returns to the previous level and prints the Setting group

options.

Setting

1.Memory Switch 1

2.Memory Switch 2

3.Print

4.Hardware

5.Interface

<Set>

Press FEED button for the number of times

as the same as your selecting item, and

wait more than 1 second.

<Return>

Continue to press FEED button more than

1 second.

Paper feed direction

用紙送り方向

50

Page 53

Hold down the FEED button again for 1 second or longer until the

buzzer sounds twice. Release the FEED button after the buzzer

sounds.

This returns to the previous level and prints the Setup Menu.

Setup Menu

1.Setting

2.Setup Print

3.Save & End

4.Default Set

Paper feed direction

Proceed to step

<Set>

Press FEED button for the number of times

as the same as your selecting item, and

wait more than 1 second.

<Return>

Continue to press FEED button more than

1 second.

8.

用紙送り方向

51

Page 54

7-2. Exiting Directly to Setup Menu

Hold the FEED button down for 3 seconds or more to return to the Setup

Menu.

Although holding down the FEED button for a long time causes the buzzer

to sound twice after 1 second, ignore this and continue to press the FEED

button.

After about 3 seconds, the buzzer sounds three times and the following

menu is printed.

Setup Menu

1.Setting

2.Setup Print

3.Save & End

4.Default Set

Paper feed direction

Proceed to step

<Set>

Press FEED button for the number of times

as the same as your selecting item, and

wait more than 1 second.

<Return>

Continue to press FEED button more than

1 second.

8.

52

用紙送り方向

Page 55

8. Pressing the FEED button three times (to select 3. Save & End) saves the

settings, cuts the paper, and then exits setup mode.

Caution: If the power switch of the printer is turned off without

selecting "Save & End", any changes made will not be saved.

Checking the Settings

To check that the settings have been applied, follow the instru ctions in

section 9.1 to perform a test print.

The test print includes a list of printer settings. Use this to

confirm your changes.

53

Page 56

9-3. Setup Settings

Setting Groups

Settings Group Description

1

Memory Switch 1

2

Memory Switch 2

3 Print

4 Hardware

5 Interface Serial and USB interface settings

Setting Items and Detailed Setting Items

(Note) Setup items and the default values depend on the printer model and/or area.

(1) Memory Switch 1 Group

Item Description Setting Value

1

Power On Status

2

Receive Buffer

3 Busy Condition

4 Receive Error

5 Auto LF

6 DSR(#6)Reset

INIT(#25)Reset

7

*1

Memory Switch 1 settings

Memory Switch 2 settings

Print settings

Hardware settings

(This group is not displayed on printers with a LAN interface.)

Specifies Power ON notification.

Specifies receiver buffer size.

Sets the printer as BUSY (data

reception not available).

Specifies what to do when a receive

error occurs using the serial interface.

Specifies whether the CR code

generates an automatic line feed.

Specifies whether receiving DSR

(#6) via the serial interface triggers a

hardware reset.

Specifies whether receiving INIT

(#25) via the serial interface triggers

a hardware reset.

Enable

1

Disable

2

1245bytes

4Kbytes

12Buffer full

Offline/Buffer full

12?Print

Ignore

12Enable

Disable

12Enable

Disable

12Enable

Disable

54

Page 57

Item Description Setting Value

Specifies whether a USB Soft Reset

8 USB Soft Reset

triggers a hardware reset when using

printer class USB.

*1 " INIT(#25)Reset "

Only Dual interface model.

(2) Memory Switch 2 Group

Item Description Setting Value

1

Cover Open Error

2

Error

3 Batch (COM IF)

4 Batch (Other IF)

5 Serial Number

6 ASB

7 Font-B

Recovery method for Cover Open Error

during print

What to do at power on or after recovery

from error

"Auto Recovery": Perform auto recovery

to enable data reception.

"Recovery by CMND": Discard any

received data until a reset command is

received.

Specifies whether to use batch printing

for the serial interface

Specifies whether to use batch printing

for the USB or LAN interface

Specifies iSerial Number notification for

USB

"Disable": Returns “0” as the iSerial

"Enable": Returns the manufacturing

Specifies whether to enable the automatic

status transmission function

(ASB: Automatic Status Back)

Specifies the number of columns for font

B (horizontal x vertical)

"Mode1" 10x24

"Mode2" 9x24

Number.

serial number as the iSerial

Number

12Enable

Disable

Auto Recovery

1

Recovery by CMND

2

12Auto Recovery

Recovery by CMND

12Enable

Disable

12Enable

Disable

12Enable

Disable

12Enable

Disable

12Mode1

Mode2

55

Page 58

(3) Print Group

1

2

3 Print Density

Item Description Setting Value

80mm/48columns

1

Paper Width

Max Speed

Paper width and number of

characters per line

Maximum print speed

The maximum for printing ladder

barcodes and two-dimensional codes

is 120mm/s.

Print density

The smaller the value the lower the

print density.

The higher the value the higher the

print density.

80mm/42columns

2

58mm/35columns

3

58mm/32columns

4

100mm/s

1

110mm/s

2

120mm/s

3

130mm/s

4

140mm/s

5

150mm/s

6

160mm/s

7

170mm/s

8

180mm/s

9

190mm/s

10

200mm/s

11

210mm/s

12

220mm/s

13

250 mm/s

14

270 mm/s

15

300 mm/s

16

70%

1

80%

2

90%

3

100%

4

110%

5

120%

6

130%

7

56

Page 59

(4) Hardware Group

Error Alert

1

*1

Buzzer Interval

2

*2

Buzzer Repetition

3

*2

Graph/User

4

NV-MEM

Cut at Cover

5

Close

6 PNE Detect

Item Description Setting Value

Whether to sound a buzzer when an

error occurs

"None":

Does not beep.

"One Time":

"Continuous":

Beeps four times.

Beeps continuously.

None

1

One Time

2

Continuous

3

The buzzer tone to use during printing

The buzzer beeps in the following cases

during printing:

• FEED button pressed while cover

open

• Buzzer command received

1

2

3

4

5

Pattern 1

Pattern 2

Pattern 3

Pattern 4

Pattern 5

(ESC p 03h t1 t2 t3)

The number of buzzer beeps during

printing

Zero specifies no buzzer.

The buzzer beeps in the following cases

during printing:

• FEED button pressed while cover

open

• Buzzer command received

Zero

1

One

2

Two

3

Three

4

Four

5

Five

6

(ESC p 03h t1 t2 t3)

NV graphic memory size and user NV

memory size

Specifies the size of the registration

area for graphics images and NV bit

images, and the size of the area for

384KB/192KB

1

448KB/128KB

2

512KB/64KB

3

576KB/0B

4

storing any user data.

Whether to trigger the cutter when the

cover is closed.

Whether to notify when near the paper

end

12Enable

Disable

12Enable

Disable

57

Page 60

*1 "Error Alert"

The operation when a "continuous" buzzer tone is output is as follows:

(Note) To stop the buzzer during continuous beeping, press the FEED button.

• Recoverable Error (Excluding Paper Near End)

• Hardware Error

*2 "Buzzer Interval"

The buzzer patterns are as follows:

• Pattern 1 40msON / 120msOFF

• Pattern 2 140msON / 140msOFF

• Pattern 3 200msON / 200msOFF

• Pattern 4 10msON / 50msOFF

• Pattern 5 30msON / 50msOFF

Continuous beeping of 500mSecON/200mSecOFF

Continuous beeping of 1000mSecON/500mSecOFF

58

Page 61

(5) Interface Group

Item Description Setting Value

1

Baud rate Baud rate for the serial interface

2

Format Data format for the serial interface

3 Protocol

4 USB Class for USB interface

Buffer control protocol for the serial

interface

2400BPS

1

4800BPS

2

9600BPS

3

19200BPS

4

38400BPS

5

57600BPS

6

115200BPS

7

7EVEN1

1

7ODD1

2

8NONE1

3

8ENEN1

4

8ODD1

5

12DSR/DTR

XON/XOFF

12Printer

V-COM

59

Page 62

9-4. LAN Setup Settings (Printer with triple interface model)

Ensure that paper is set in the printer. Turn off the power switch on the p rinter,

then turn it on again while pressing the FEED button on the control panel. This

outputs the printout shown in section 9-1.

Then Press the FEED button three times (to select 3. LAN Setup Menu)

enters setup mode and prints the following menu.

Settings have the same operation method as described in paragraph 9-2.

LAN Setup Menu

1.Setting

2.Setup Print

3.Save & End

4.Default Set

5.DHCP IP Address Print

<Set>

Press FEED button for the number of times

as the same as your selecting item, and

wait more than 1 second.

<Return>

Continue to press FEED button more than

1 second.

Paper feed direction

用紙送り方向

60

Page 63

Setting Item

Item Description Setting Value

Specify interface

"Enable":

Runs on LAN interface.

1

LAN

"Disable":

Runs on either USB or serial interface. If both USB

and serial interfaces are connected, USB will be

prioritized.

1 2 Enable

Disable

61

Page 64

DHCP IP Address Print

1) Select “DHCP IP Address Print” to enter the IP Address Print Mode as shown

below. Wait several tens of seconds.

Please wait...

Acquiring IP address via DHCP.

If you need to finish,

please press FEED button.

2) When the IP

successfully acquired, the acquired values will be printed out and the Print

Mode will be closed.

Please wait...

Acquiring IP address via DHCP.

If you need to finish,

please press FEED button.

Completed to acquire IP address.

DHCP IP Address Print mode finished.

3) If the FEED button is pressed while the values are being acquired, the Print

Mode will be immediately closed with the following message printed out:

“ DHCP IP Address Print mode finished. ”

Paper feed direction

用紙送り方向

Address, Subnet Mask, and Default Gateway have been

Paper feed direction

用紙送り方向

IP Address 10. 50.138.100

Subnet Mask 255.255.255. 0

Default Gateway 10. 50.138. 1

62

Page 65

9-5. HEX Dump

Ensure that paper is set in the printer. Turn off the power switch on the printer,

then turn it on again while pressing the FEED button on the control panel. This

outputs the printout shown in section 9-1.

Pressing the FEED button three times (Dual interface model:select 3. Hex

Dump) or four times (Triple interface model:select 4. Hex Dump) enters HEX

dump mode.

This mode prints all the data sent to the printer as hex code. It is useful for

checking whether the control codes being sent to the printer by the PC program

are correct.

To clear this mode, turn the power switch off and on again.

HEX Dump Print (Example)

Hex Dump

000000 1B 40 1B 4D 02 1B 74 01 .@.M..t.

Addres s ASCII

Hex

∬

∬

63

Page 66

9-6. Command Trace

Ensure that paper is set in the printer. Turn off the power switch on the printer,

then turn it on again while pressing the FEED button on the control panel. This

outputs the printout shown in section 9-1.

Pressing the FEED button four times (Dual interface model:select 4.

Command Trace) or five times (Triple interface model:select 5. Command

Trace) enters command trace mode.

This mode prints all the data sent to the printer in ASCII format (with

ESC/POS command explanations). It can be used to analyze the ESC/POS

commands sent to the printer by the PC program.

To clear this mode, turn the power switch off and on again.

Command Trace Print (Example)

Command Trace

<1B40:Initialize printer (ESC @)>

<1B4D02:Set ANK font C (ESC M n)>

<1B7480:Set character code table (ESC t n)>

<

1D4200:Disable reverse printing (GS B n)>

<1B6102:Set justification RIGHT (ESC a n)>

<1C2E:Reset kanji mode (FS .)>

ABC

<0A:Print and line feed (LF)>

∬

a. Undefined commands or commands with abnormal command parameters are treated

as errors and printed with background and foreground reversed.

b. Meaningless and unnecessary commands are printed with an underline as a warning.

c. Command codes are printed in bold.

∬

64

Page 67

9-7. Sample Print

Ensure that paper is set in the printer. Turn off the power switch on the printer,

then turn it on again while pressing the FEED button on the control panel. This

outputs the printout shown in section 9-1.

Pressing the FEED button five times (Dual interface model:select 5. Sample

Print) or six times (Triple interface model:select 6. Sample Print) enters

sample print mode.

This mode prints an explanation of FEED button operation, performs a paper

cut, and then prints sample patterns. (The FEED button explanation is only

printed at the first time.)

" Press FEED button.

Short : Next pattern

Long : Same pattern"

After printing, pressing the FEED button briefly (less than one second) prints

the following samples, one at a time.

* "Receipt" "Coupon" "Bar Code" "Receipt" in turn. (Printing

pauses after each sample. Press the FEED button to print the next

sample.)

Pressing the FEED button for a long time (one second or longer) prints the

previous sample again.

65

Page 68

To clear sample print mode, turn the power switch off and on again.

Sample print mode performs a cut after each sheet is printed.

Sample print mode uses the 80mm or 58mm pattern depending on the paper

width setting in setup.

If a recoverable error occurs, the sample print resumes after recovery.

The following page shows examples printouts.

66

Page 69

<Printing Results of Sample Print, 80mm Pattern>

"Receipt" Pattern "Coupon" Pattern

67

Page 70

"Bar Code" Pattern

68

Page 71

<Printing Results of Sample Print, 58mm Pattern>

"Receipt" Pattern "Barcode" Pattern

"Coupon" Pattern

69

Page 72

10. Regular Cleaning

The print quality may be impaired by paper parti cl es, du st , or ot her material.

To avoid this problem, remove any paper particles or dust from the paper

holder, the paper transport, the platen roller, and the thermal head as

described below.

Perform cleaning every six months.

10-1. Cleaning Paper Holder and Paper Transport

(1) Be sure to turn off the printer power.

(2) Open the top cover.

(3) Wipe off any dust, paper particles, glue, or other foreign material from

the paper holder and paper transport using a soft, dry cloth.

Paper Holder and Paper Transport

70

Page 73

r

10-2. Cleaning the Platen Roller

(1) Be sure to turn off the printer power.

(2) Open the top cover.

(3) Wipe off any dust, paper particles, glue, or other foreign material from

the platen roller using a soft, dry cloth.

Platen Rolle

Caution: Do not damage or dent the platen roller.

Dents on the platen roller will cause incomplete printing

and/or line feed failure.

71

Page 74

10-3. Cleaning the Thermal Head

(1) Be sure to turn off the printer power.

(2) Open the top cover.

(3) Using an alcohol solvent, remove black paper particles and other residue

from the surface of the thermal head.

Thermal Head

Caution: The thermal head can easily be damaged. Clean it carefully

using a soft cloth to avoid any damage.

Caution: The thermal head is still hot immediately after printing. Leave

it to cool for about ten minutes before cleaning.

Caution: The thermal head may be damaged by static electricity. Take

care to avoid exposing it to static electricity.

Caution: Wait until alcohol from the cleaning solvent has thoroughly

dried before turning on the printer power.

Caution: Use only alcohol or isopropyl alcohol solvents.

72

Page 75

11. Interface

11-1. Serial Interface

(1) Transmission Interface Specifications

Transmission

Method

Line Type

Input/Output

Circuit

Baud Rate

Transmission

Code Type

Transmission

Code Format

Transmission

Sequence

Transmission

Code

Error Control Parity check (Setup Settings)

Connection Line

Length

Protocol DSR/DTR, XON/XOFF (Setup Settings)

Asynchronous

Full duplex

Input: MAX211 Equivalent

Output: MAX211 Equivalent

2400, 4800, 9600, 19200, 38400, 57600, 115200BPS

(Setup Settings)

7 or 8 bits

Start bits: 1 bit

Stop bits: 1 bit

Data bits: 7 or 8 bits (Setup Settings)

Parity: NONE, ODD, EVEN (Setup Settings)

Mark(1)

ST b0 b1 b2 b3 b4 b5 b6 b7 PT SP

Space(0)

LSB to MSB

JIS code

Max. 15m: (When power is sup pl i e d fr o m the power

connector)

73

Page 76

(2) Serial Interface Connector (Dual interface model)

Pin N o . S i g na l N ame Direction Signal Line Name

1

SG - Signal Ground

2 TXD Output Transmit Data

3 RXD Input Receive Data

4 RTS Output Request to Send

5 CTS Input Clear to Send

6 DSR Input Data Set Ready

7 SG - Signal Ground

8~19 N.C - No Connection

20 DTR Output Data Terminal Ready

21~24 N.C - No Connection

25 INIT Input Forcible Reset Signal

Caution: Use a lock screw with an imperial thread on the connector.

Caution: Please use a RS232C 9 Pin – 25 Pin crossover cable for your

interface cable.

(3) Connection Cable (Dual interface model)

The connection setup shown in the following figure is recommended.

Host Printer

FG < > FG

1DCD< >SG 1

2RXD< >TXD2

3TXD< >RXD3

4DTR< >RTS 4

5SG< >CTS5

6DSR< >DSR6

7RTS< >SG 7

8CTS< >N.C 8

>DTR 20

9RI< >N.C22

Caution: Supplying power from the interface connector is prohibited.

74

Page 77

(4) Serial Interface Connector (Triple interface model)

Pin N o . Signal Na m e Direction Signal Line Name

1 N.C - No Connection

2 TXD Output Transmit Data

3 RXD Input Receive Data

4 DSR Input Data Set Ready

5

SG - Signal Ground

6

DTR Output Data Terminal Ready

7

CTS Input Clear to Send

8

RTS Output Request to Send

9 N.C - No Connection

Caution: Use a lock screw with an imperial thread on the connector.

Caution: Please use a RS232C 9 Pin straight cable for your interface

cable.

(5) Connection Cable(Triple interface model)

The connection setup shown in the following figure is recommended.

Host Printer

<

DCD1

<

2

RXD

<

3

TXD

<

4

5

6

7

8

SG <

DSR

RTS

CTS

<

<

<

<

<

>

>

>

>

>

>

>

>

>

>

FGFG

TXD

RXD

DSRDTR

SG

DTR

CTS

RTS

1N.C

2

3

4

5

6

7

8

9N.CRI9

Caution: Supplying power from the interface connector is prohibited.

75

Page 78

11-2. USB Interface

(1) Type-B Connector: 4 Pins

Pin No. Signal Name Direction Signal Line Name

1

2

3

4

VBUS Input VBUS

D-inB Input/Output DD+inB Input/Output D+

SG - Signal Ground

Caution: Use a shielded USB cable.

11-3. LAN Interface

(1) LAN Interface Connector

Pin No. Signal Name Direction Signal Line Name

1

2 TX- Output Output data

3 RX+ Input Input data

4 N.C - 5 N.C - 6 RX- Input Input data

7 N.C - 8 N.C - -

Caution: Use a straight LAN cable for the interface cable and co nnect it

TX+ Output Output data

to the network via a HUB.

76

Page 79

(2) LED

2

1

No. Meaning Description

1 S

(Speed)

2 L/A

(Link/Act)

Lights up when the connection is recognized as

100BASE-TX

Turns off when not connected or when it recognizes being

connected to 10BASE-T.

Lights up when the link is established with 100BASE-TX

or 10BASE-T

Flashes when sending and receiving packets.

11-4. Drawer Kick Connector

Pin No. Signal Name Direction Signal Line Name

1

2 *DRD1 Output Drawer Kick Drive Signal 1

3 DRSNS1 Input Drawer Sense Signal 1

4 +24V - Drive Power

5 *DRD2 Output Drawer Kick Drive Signal 2

6 SG -

FG - Frame Ground

Signal Ground

1

<Connecting side>

6

77

Page 80

<Connection>

Printer

1

Cable

3

2

6

Drawer 1

Drawer

Open/Close

3

4

5

2

Drawer Kick

4

Solenoid

(24Ω or bigger)

6

Drawer 2

5

Drawer Kick

4

Solenoid

Ω or bigger)

(24

Caution: The drawer connection cable should be of the shielded type.

Caution: Simultaneous drive from the two drives is not available.

Caution: Specify the ON time and OFF time (t1 and t2) for the drawer

using the pulse generation command (ESC p m t1 t2).

Caution: Set the drive duty cycle for the drawer in accordance with the

following formula: ON time/(ON time + OFF time) ≤ 0.2

Caution: Always use printer power (connector pin 4) for the drawer

power.

Caution: Use a drawer kick solenoid with a resistance value of at least

24Ω. If it is under 24Ω, the solenoid may be damaged by

excess current.

Caution: This product uses a special-purpose modular connector for

the cash drawer and customer display connector. Do not

attempt to use other types of connectors such as public

telephone connectors.

78

Page 81

11-5. Power Specifications

(1) Rated Input Voltage: 100-240V, 50-60Hz

(2) Rated Input Current: 1.1A

(3) Operating Voltage: 24V ±10%

(4) Power Consumption: During standby : 3.0W or less/0.1A on average

During operation : About 38W/1.5A on average

(at 24V, 25°C, print density setting 100%, paper

width 80mm, print duty 9%)

Note: Drawer Kick Drive Current: Max. 1A

However, do not operate two drawer kick at the

same time.

Power C

Caution: Use the specified AC adapter for the power supply.

Caution: If our AC adapter is not used (power supply is supplied by the

onnector Pin Assignment

Pin No. Signal Name

1

+24V

3

1

2 SG

3 N.C

user), problems such as bad print quality, electromagnetic

interference, or circuit noise may occur. In such cases, take

note of the following points:

· Use an AC adapter whose capacity corresponds to the printing

rate that will actually be used.

· Ensure in advance that there are no problems such as static

electricity, electromagnetic interference, circuit noise, etc.

2

79

Page 82

12. Specifications

12-1. General Specifications

(1) Printing Method: Direct Line Thermal Printing

(2) Print Speed: Maximum 300 mm/s (Monochrome only)

(3) Print Resolution: 8dot/mm (0.125mm)

(4) Relationship between Number of Print Column and Character Size

Body face ((Width)x(Height) dot)

ANK: Font A

ANK: Font B

ANK: Font C 48 columns: 8x16 52 columns: 8x16

ANK: Font A

Extension Font

ANK: Font B

Extension Font

ANK: Font A

ANK: Font B

ANK: Font C 64 columns: 8x16 72 columns: 8x16

ANK: Font A

Extension Font

ANK: Font B

Extension Font

32 column printing 35 column printing

32 columns: 12x24 35 columns: 12x24

38 columns: 10x24

42 columns: 9x24

32 columns: 12x24 35 columns: 12x24

38 columns: 10x24

42 columns: 9x24

Body face ((Width)x(Height) dot)

42 column printing 48 column printing

42 columns: 12x24 48 columns: 12x24

51 columns: 10x24

56 columns: 9x24

42 columns: 12x24 48 columns: 12x24

51 columns: 10x24

56 columns: 9x24

Paper width: 58mm

42 columns: 10x24

46 columns: 9x24

42 columns: 10x24

46 columns: 9x24

Paper width: 80mm

57 columns: 10x24

64 columns: 9x24

57 columns: 10x24

64 columns: 9x24

80

Page 83

(5) Character Sets

Alphanumeric character (95)

International character (16 sets : Gothic)

Enlarged graphics (128 x 20 pages : Gothic)

Down-loaded registration (9 6)

User-defined Kanji (94)

(6) Character Size

Body face Letter face

ANK: Font A

ANK: Font B

ANK: Font C 8 x 16 1.0 x 2.0 8 x 13 1.0 x 1.625

ANK: Font A

Extension Font

ANK: Font B

Extension Font

(Width)x(Height)

dot

12 x 24 1.5 x 3.0 11 x 22 1.375 x 2.75

10 x 24

9 x 24

12 x 24 1.5 x 3.0 12 x 24 1.5 x 3.0

10 x 24

9 x 24

(Width)x(Height)

mm

1.25 x 3.0

1.125 x 3.0

1.25 x 3.0

1.125 x 3.0

(Width)x(Height)

dot

9 x 17

9 x 22

9 x 22

9 x 22

(Note) Print Column, Character Size and Character Sets depend on the printer

model and/or area.

(Width)x(Height)

mm

1.125 x 2.125

1.125 x 2.75

1.125 x 2.75

1.125 x 2.75

81

Page 84

(7) Outline View

Standard Model

Built-in Power Supply Model

82

Page 85

12-2. Cutter Specifications

(1) Cutting Method: Partial cut (the paper remains connected at one point)

Caution: Do not use the cutter continuously at a rate exceeding 10 cuts

per minute (1 cut per 6 seconds or more). Excessive use may

cause a malfunction.

12-3. Paper Roll Supply Specifications

(1) Loading Method: Rolls are loaded manually.

(2) Paper Near End: Detected when the remaining pape r length is inadequate.

Caution: Core diameter φ18mm is supported.

12-4. Interface Specifications

(1) Serial (RS-2332C)

(2) USB (USB 2.0 Full-speed)

(3) LAN (10BASE/100BASE-T)

83

Page 86

12-5. Environment Specifications

(1) Temperature

Operating Operation Guaranteed at: 0°C - 40°C

Print Quality Guaranteed at: 5°C - 35°C

Non-operating -5°C - 60°C

Transportation or storage (packaging) -20°C - 60°C

(2) Humidity

Operating Operation Guaranteed at: 10%-95%RH (no condensation)

Print Quality Guaranteed at: 10%-85%RH (no condensation)

Non-operating 8%-95%RH (no condensation)

Transportation or storage (packaging) 5%-95%RH (no condensation)

(3) Maximum Wet Bulb Temperature 29°C or less

Relative Humidity %

100

90

80

70

60

50

40

30

20

10

30°C /95%

Guaranteed

Operating

Range

0

0 10 20 30 40 50

Ambient Temperature °C

40°C /65%

84

Page 87

12-6. Reliability Specifications

(1) Printer Life 20 million line-feed

(When the recommended paper of 75μm is used)

(2) Head Life Running Life: 100km

(When the recommended paper of 75μm is used)

Pulse Life: 100 million pulses

(When the recommended paper of 75μm is used)

(3) Cutter Life

Paper Thickness 75μm: 1.5 million cuts

(When the recommended paper of 75μm is used)

65μm/85μm: 1.0 million cuts

Note: When a setup of the maximum printing speed is 220 mm/s.

85

Page 88

13. Usage Precautions

13-1. Paper Related Precautions

(1) High printing rates may cause b lurred printing. Choose a suitable printing