OKI Semiconductor

PEDL87V21071-01

Issue Date: Nov. 15, 2005

ML87V21071

Video Signal Noise Reduction IC with a Built-in Frame Memory

Preliminary

GENERAL DESCRIPTION

The ML87V21071, which comprises a frame memory and signal processing and memory control logic circuits, has

achieved motion-adaptive 3D noise reduction.

To perform noise reduction with afterimage suppression, the ML87V210 71 also enables noise reduction using the

edge-adaptive 2D noise reduction filter.

Each noise reduction function allows setting an automatic mode. In automatic mode, noise of a vertical blanking

period and a valid data peri od is detected t o reduce noi se accordin g to the noise status fro m which t he noise reduct ion

setting value is detected.

The ML87V21071 also has a cross-color cancellation function that uses the motion-adaptive 3D comb filter method

that removes cross colors occurring at two-dimensional YC separation in the NTSC/PAL system.

Since the same format as the input can be selected for outpu t, n oise re ducti on can ea sil y be achie ved by i nsertin g t he

IC into the conventional system.

FEATURES

• Built-in memory:

Frame memory (78 × 608 × 16-bit) × 1 unit

• Maximum input and output operating frequencies (16-bit/8-bit, ITU-R BT.656):

14.75/29.5 MHz

* For 525p/625p, only 16-bit input mode is supported (Max.: 29.5 MHz).

• Power supply voltage:

3.3 V ± 0.3 V

• Input/ouput pin:

LVCMOS (3.3 V)

• Input/ouput data format:

YCbCr (8 bit (Y) + 8 bit (CbCr))(4:2:2): 16-bit mode

YCbCr (8 bit (YCbCr))(4:2:2): 8-bit mode

ITU-R656 (8 bit (YCbCr)): ITU-R BT.656 mode

* In 16-bit input mode, neither 8-bit mode nor ITU-R BT.656 mode can be selected for output.

• Serial bus:

2

C-bus interface: (400 kHz, 100 kHz)

I

• Memory controller:

Compatible with 625/50Hz 2:1(625i), 525/60Hz 2:1(525i), 625/50Hz 1:1(625p), and 525/60Hz 1:1(525p)

• Motion-adaptive 3D noise reduction:

Frame-field-line-correlation noise detection and noise subtraction method

Supports automatic noise reduction setting

• Edge-adaptive 2D noise reduction:

Edge-adaptive space filter used

• Chrominance signal cross color cancelling:

Motion-adaptive 3D comb filter used

Compatible with 525i (NTSC decode signal)/625i (PAL decode signal)

• Package:

100-pin TQFP (TQFP100-P-1414-0.50-K) (ML87V21071TB)

1/123

PEDL87V21071-01

OKI Semiconductor

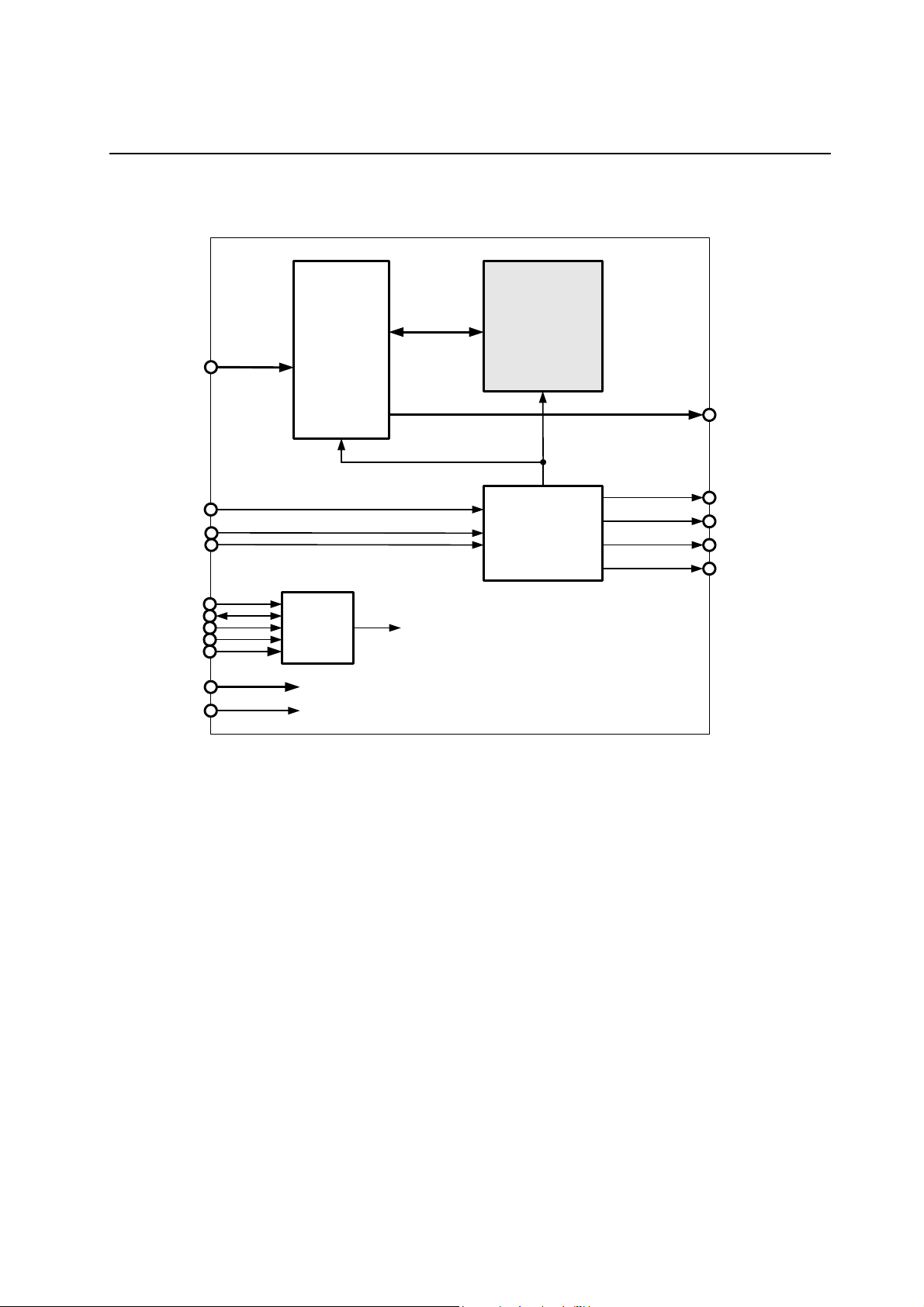

BLOCK DIAGRAM

YI0-7

CI0-7

ICLK

IVS

IHS

x16

Input/Output

Process

Block

+

3D NR

+

2D NR

+

CC

x16

Frame

Memory

Memory

Controller

x16

ML87V21071

YO0-7

CO0-7

OVS

OHS

HREF

CLKO

SCL

SDA

SLA1

SLA2

MODE0-4

TEST0-5

RESET

I2C-bus

I/F

Register

Control

Signal

2/123

PEDL87V21071-01

OKI Semiconductor

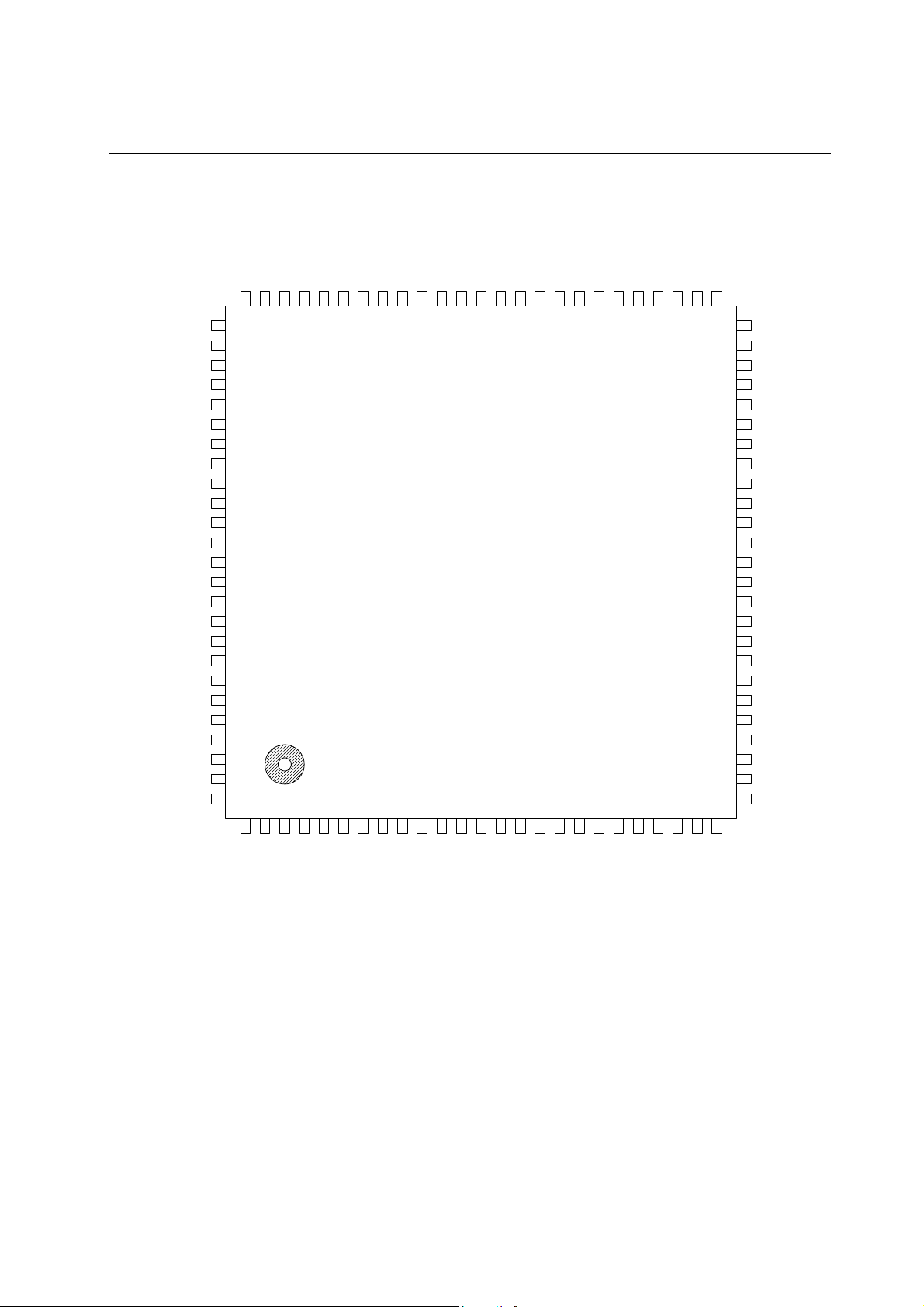

PIN CONFIGURATION (TOP VIEW)

VDD

N.C.

V

MODE3

MODE4

N.C.

OE

N.C.

N.C.

N.C.

N.C.

TEST5

VDD

TEST4

TEST3

TEST2

TEST1

TEST0

N.C.

N.C.

TESTM

TSELF

VSS

N.C.

V

SS

TEST6

RESET

74

75

76

77

78

SS

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

DD

YO7

TEST7

V

71

72

73

YO4

YO6

YO5

68

69

70

VDD

YO3

YO2

65

66

67

SS

N.C.

V

YO1

YO0

63

64

VDD

60

61

62

ML87V21071TB

(TQFP100-P-1414-0.5-K)

CO7

59

CO6

58

CO5

57

CO4

56

ML87V21071

VSS

CO3

CO2

CO1

CO0

51

52

53

54

55

50

VDD

49

N.C.

48

SS

V

47

HREF

46

OVS

45

OHS

44

N.C.

43

N.C.

42

N.C.

41

N.C.

40

V

DD

39

N.C.

38

N.C.

37

VSS

36

VDD

35

CLKO

34

MODE2

33

N.C.

32

MODE1

31

MODE0

30

IHS

29

IVS

28

VSS

27

N.C.

26

V

DD

1

YI7

YI6

VSS

N.C.

SCL

SDA

SLA1

SLA2

YI5

12

11

10

YI3

YI2

YI4

15

14

13

DD

YI1

YI0

V

16

ICLK

18

17

CI7

VSS

21

20

19

CI6

CI5

CI4

24

23

22

CI3

25

CI2

CI1

CI0

9

8

7

6

5

4

3

2

3/123

PEDL87V21071-01

OKI Semiconductor

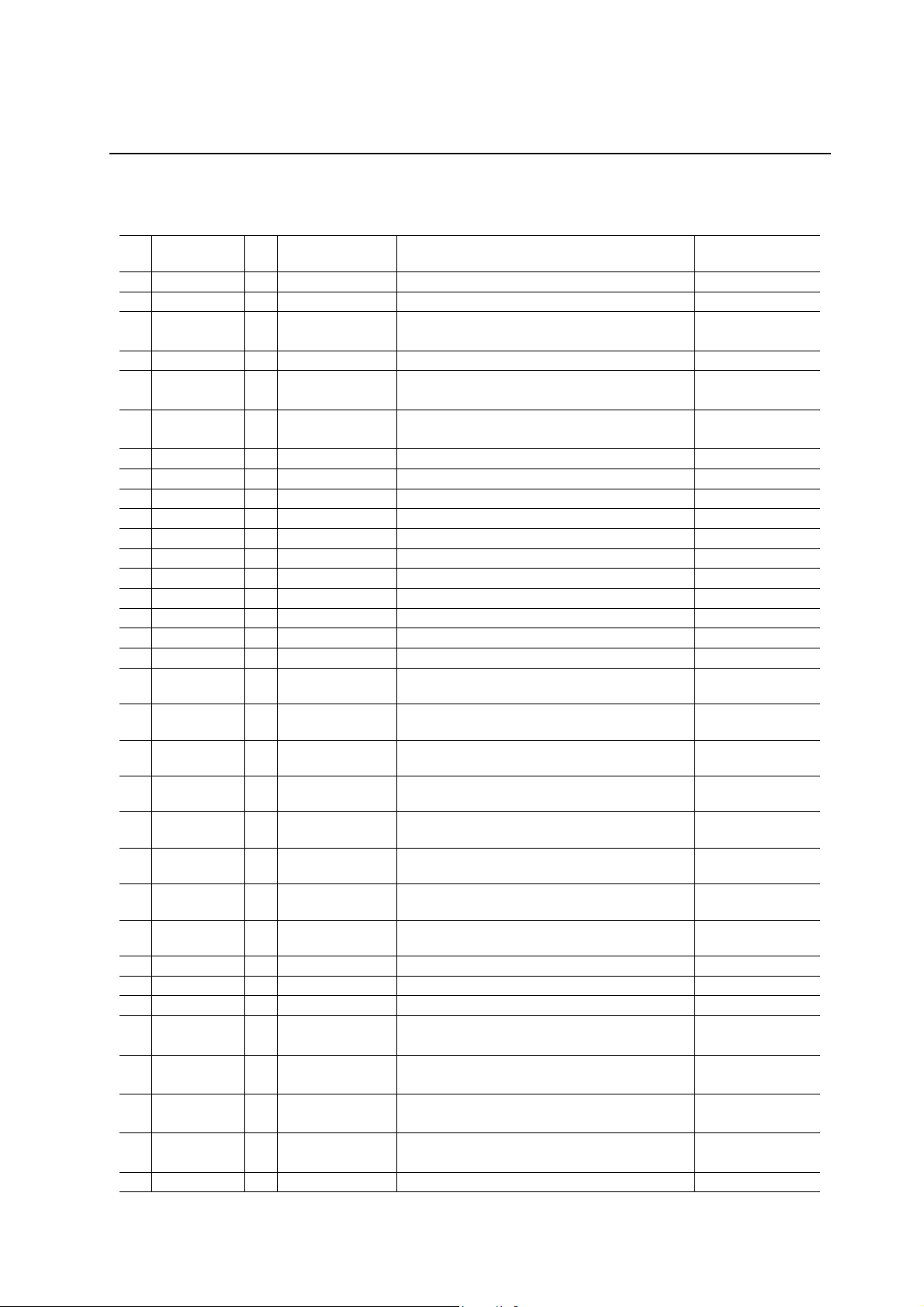

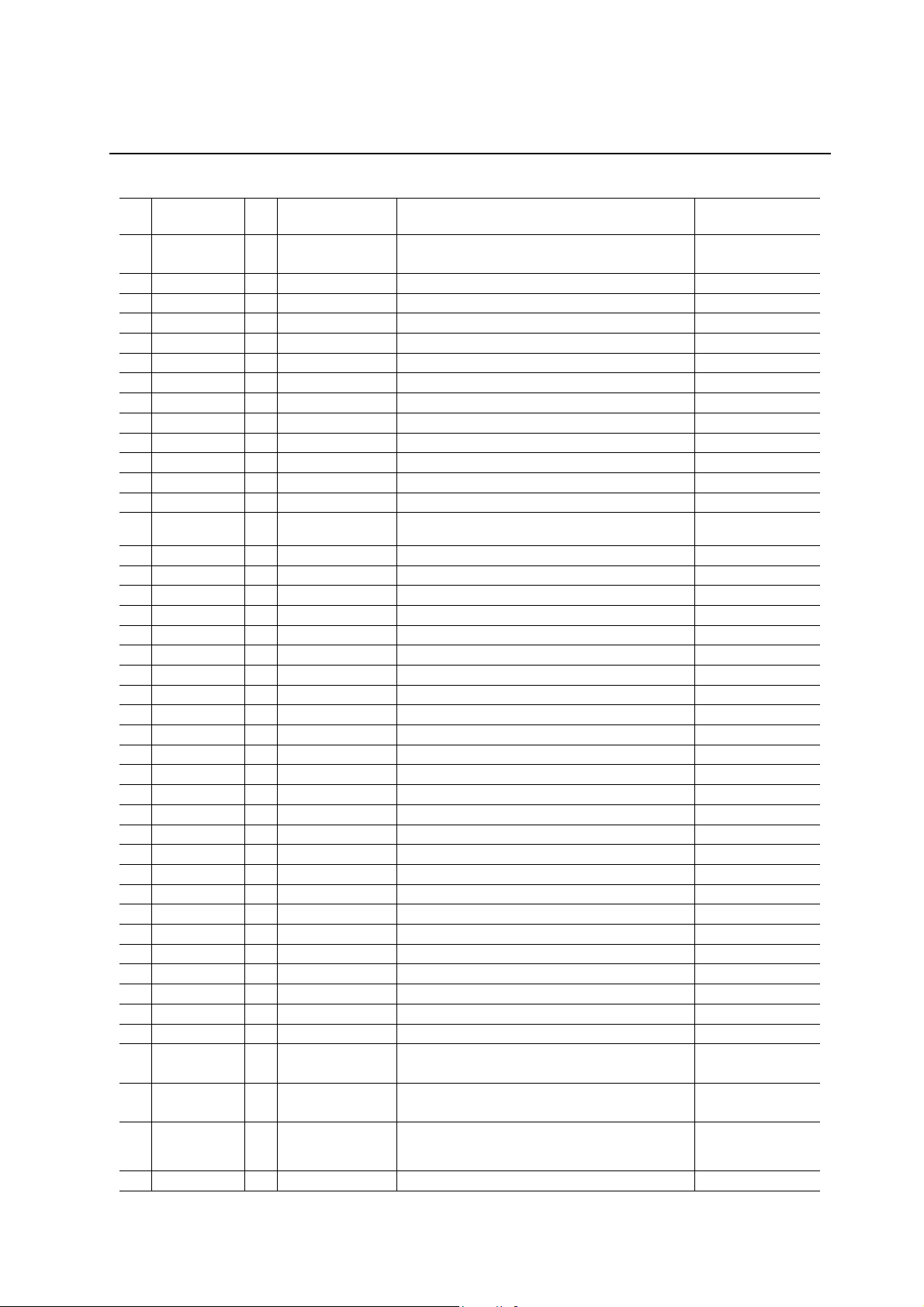

PIN DESCRIPTIONS

No. Symbol I/O Pad Remarks Pin Description

1 N.C. —

2 VSS —

3 SDA I/O

4 SCL I Schmitt

5 SLA1 I

6 SLA2 I

7 YI7 I

8 YI6 I

9 YI5 I

10 YI4 I

11 YI3 I

12 YI2 I

13 YI1 I

14 YI0 I

15 VDD —

16 ICLK I

17 VSS —

18 CI7 I pull-down 50k

19 CI6 I pull-down 50k

20 CI5 I pull-down 50k

21 CI4 I pull-down 50k

22 CI3 I pull-down 50k

23 CI2 I pull-down 50k

24 CI1 I pull-down 50k

25 CI0 I pull-down 50k

26 VDD —

27 N.C. —

28 VSS —

29 IVS I

30 IHS I

31 MODE0 I

32 MODE1 I

33 N.C. —

Schmitt(IN)/

OpenDrain(OUT)

Schmitt

pull-down 50k

Schmitt

pull-down 50k

Schmitt

pull-down 50k

Schmitt

pull-down 50k

Schmitt

pull-down 50k

Schmitt

pull-down 50k

Unused pin

Ground

2

I

C-bus data pin

2

C-bus clock pin

I

Slave address setting pin bit 1

Slave address setting pin bit 2

Luminance signal input pin bit 7 (MSB)

Luminance signal input pin bit 6

Luminance signal input pin bit 5

Luminance signal input pin bit 4

Luminance signal input pin bit 3

Luminance signal input pin bit 2

Luminance signal input pin bit 1

Luminance signal input pin bit 0 (LSB)

3.3 V power supply

System clock Input pin

Ground

Chrominance signal input pin bit 7 (MSB)

Chrominance signal input pin bit 6

Chrominance signal input pin bit 5

Chrominance signal input pin bit 4

Chrominance signal input pin bit 3

Chrominance signal input pin bit 2

Chrominance signal input pin bit 1

Chrominance signal input pin bit 0 (LSB)

3.3 V power supply

Unused pin

Ground

Input system vertical Sync. signal input pin

Input system horizontal Sync. signal input pin

Mode setting pin bit 0

(Equivalent to internal register VMD[0])

Mode setting pin bit 1

(Equivalent to internal register HMD[0])

Unused pin

ML87V21071

Termination of

unused pin

Not used

X

X

X

Not used or

connected to GND

Not used or

connected to GND

X

X

X

X

X

X

X

X

X

X

X

Not used or

connected to GND

Not used or

connected to GND

Not used or

connected to GND

Not used or

connected to GND

Not used or

connected to GND

Not used or

connected to GND

Not used or

connected to GND

Not used or

connected to GND

X

Not used

X

Not used or

connected to GND

Not used or

connected to GND

Not used or

connected to GND

Not used or

connected to GND

Not used

4/123

PEDL87V21071-01

OKI Semiconductor

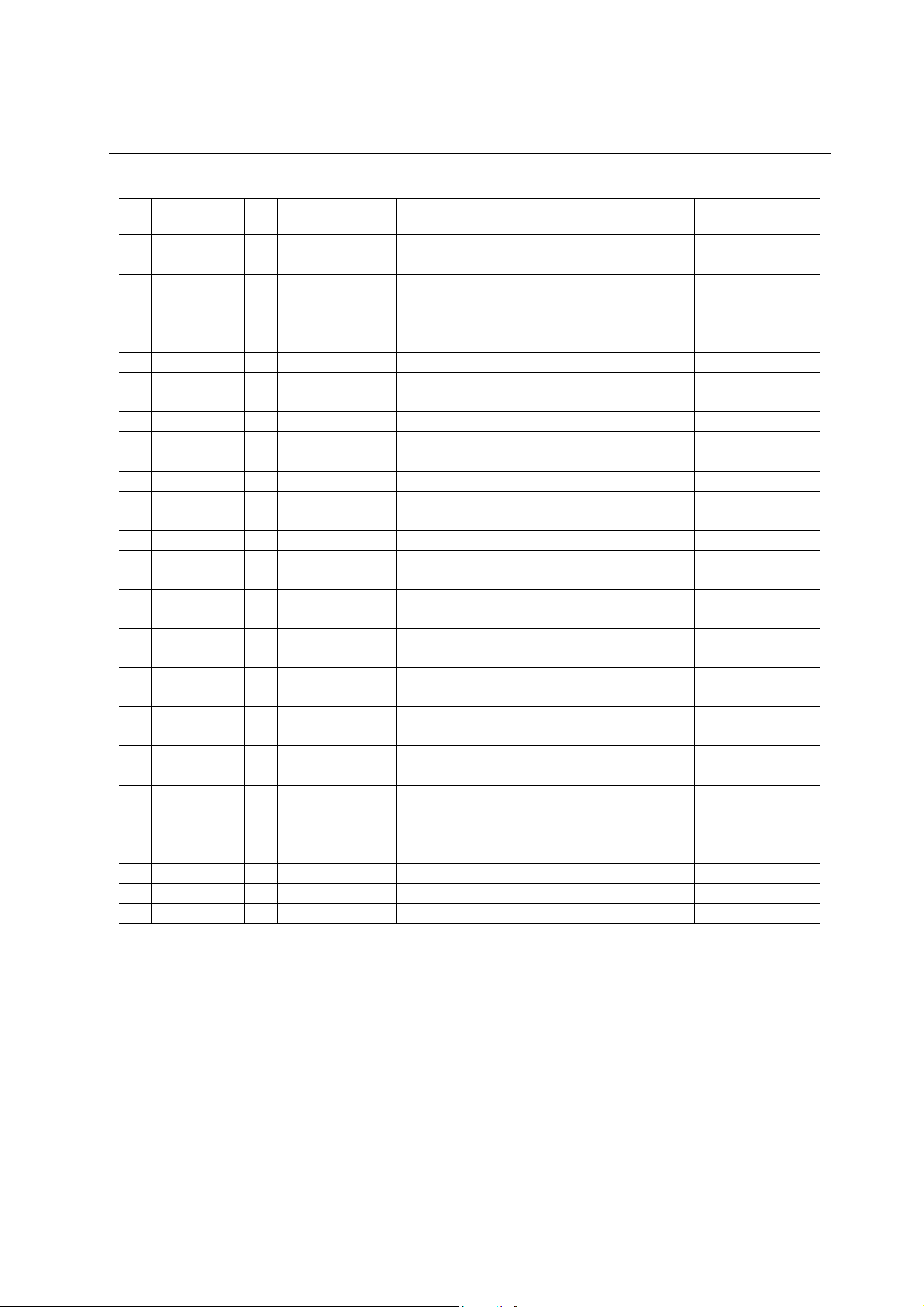

No. Symbol I/O Pad Remarks Pin Description

34 MODE2 I

35 CLKO O

36 VDD —

37 VSS —

38 N.C. —

39 N.C. —

40 VDD —

41 N.C. —

42 N.C. —

43 N.C. —

44 N.C. —

45 OHS O

46 OVS O

47 HREF O

48 VSS —

49 N.C. —

50 VDD —

51 CO0 O

52 CO1 O

53 CO2 O

54 CO3 O

55 VSS —

56 CO4 O

57 CO5 O

58 CO6 O

59 CO7 O

60 VDD —

61 N.C. —

62 VSS —

63 YO0 O

64 YO1 O

65 YO2 O

66 YO3 O

67 VDD —

68 YO4 O

69 YO5 O

70 YO6 O

71 YO7 O

72 VSS —

73 TEST7 I

74 TEST6 I

75

76 VDD —

RESET

I Schmitt

Schmitt

pull-down 50k

Schmitt

pull-down 50k

Schmitt

pull-down 50k

Mode setting pin bit 2

(Equivalent to internal register DISEL[0])

Clock output (I

3.3 V power supply

Ground

Unused pin

Unused pin

3.3 V power supply

Unused pin

Unused pin

Unused pin

Unused pin

Horizontal Sync. signal output pin

Vertical Sync. signal output pin

Data output horizontal reference signal output

pin

Ground

Unused pin

3.3 V power supply

Chrominance signal output pin bit 0 (LSB)

Chrominance signal output pin bit 1

Chrominance signal output pin bit 2

Chrominance signal output pin bit 3

Ground

Chrominance signal output pin bit 4

Chrominance signal output pin bit 5

Chrominance signal output pin bit 6

Chrominance signal output pin bit 7 (MSB)

3.3 V power supply

Unused pin

Ground

Luminance signal output pin bit 0 (LSB)

Luminance signal output pin bit 1

Luminance signal output pin bit 2

Luminance signal output pin bit 3

3.3 V power supply

Luminance signal output pin bit 4

Luminance signal output pin bit 5

Luminance signal output pin bit 6

Luminance signal output pin bit 7 (MSB)

Ground

Test input pin bit 7 (1: Test mode)

Test input pin bit 6 (1: Test mode)

System reset/input pin

0: System reset

1: Operation

3.3 V power supply

2

C-bus control possible)

ML87V21071

Termination of

unused pin

Not used or

connected to GND

Not used

X

X

Not used

Not used

X

Not used

Not used

Not used

Not used

Not used

Not used

Not used

X

Not used

X

Not used

Not used

Not used

Not used

X

Not used

Not used

Not used

Not used

X

Not used

X

X

X

X

X

X

X

X

X

X

X

Not used or

connected to GND

Not used or

connected to GND

X

X

5/123

PEDL87V21071-01

OKI Semiconductor

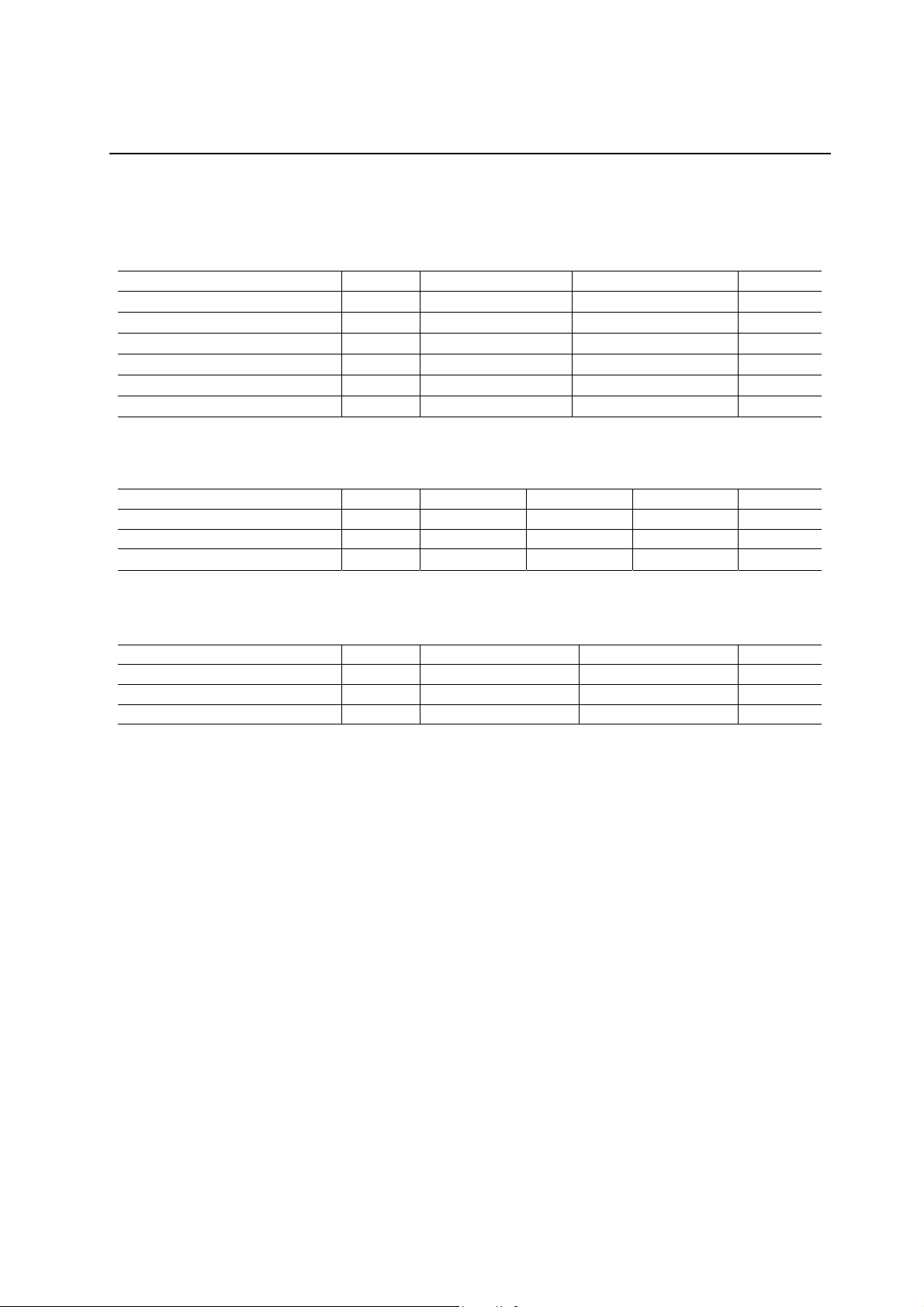

No. Symbol I/O Pad Remarks Pin Description

77 N.C. —

78 VSS —

79 MODE3 I

80 MODE4 I

81 N.C. —

82 OE —

83 N.C. —

84 N.C. —

85 N.C. —

86 N.C. —

87 TEST5 I

88 VDD —

89 TEST4 I

90 TEST3 I

91 TEST2 I

92 TEST1 I

93 TEST0 I

94 N.C. —

95 N.C. —

96 TESTM I

97 SELF I

98 VSS —

99 N.C. —

100 VDD —

Schmitt

pull-down 50k

Schmitt

pull-down 50k

Schmitt

pull-down 50k

Schmitt

pull-down 50k

Schmitt

pull-down 50k

Schmitt

pull-down 50k

Schmitt

pull-down 50k

Schmitt

pull-down 50k

Schmitt

pull-down 50k

Schmitt

pull-down 50k

Schmitt

pull-down 50k

Unused pin

Ground

Mode setting pin bit 3

(Equivalent to internal register R656I)

Mode setting pin bit 4

(Equivalent to internal register DOSEL)

Unused pin

Output enable input pin

Unused pin

Unused pin

Unused pin

Unused pin

Test input pin bit 5 (1: test mode)

3.3 V power supply

Test input pin bit 4 (1: test mode)

Test input pin bit 3 (1: test mode)

Test input pin bit 2 (1: test mode)

Test input pin bit 1 (1: test mode)

Test input pin bit 0 (1: test mode)

Unused pin

Unused pin

Memory test input pin (1: test mode)

Self refresh test input setting pin

Ground

Unused pin

3.3 V power supply

ML87V21071

Termination of

unused pin

Not used

X

Not used or

connected to GND

Not used or

connected to GND

Not used

Not used or

connected to GND

Not used

Not used

Not used

Not used

Not used or

connected to GND

X

Not used or

connected to GND

Not used or

connected to GND

Not used or

connected to GND

Not used or

connected to GND

Not used or

connected to GND

Not used

Not used

Not used or

connected to GND

Not used or

connected to GND

X

Not used

X

6/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

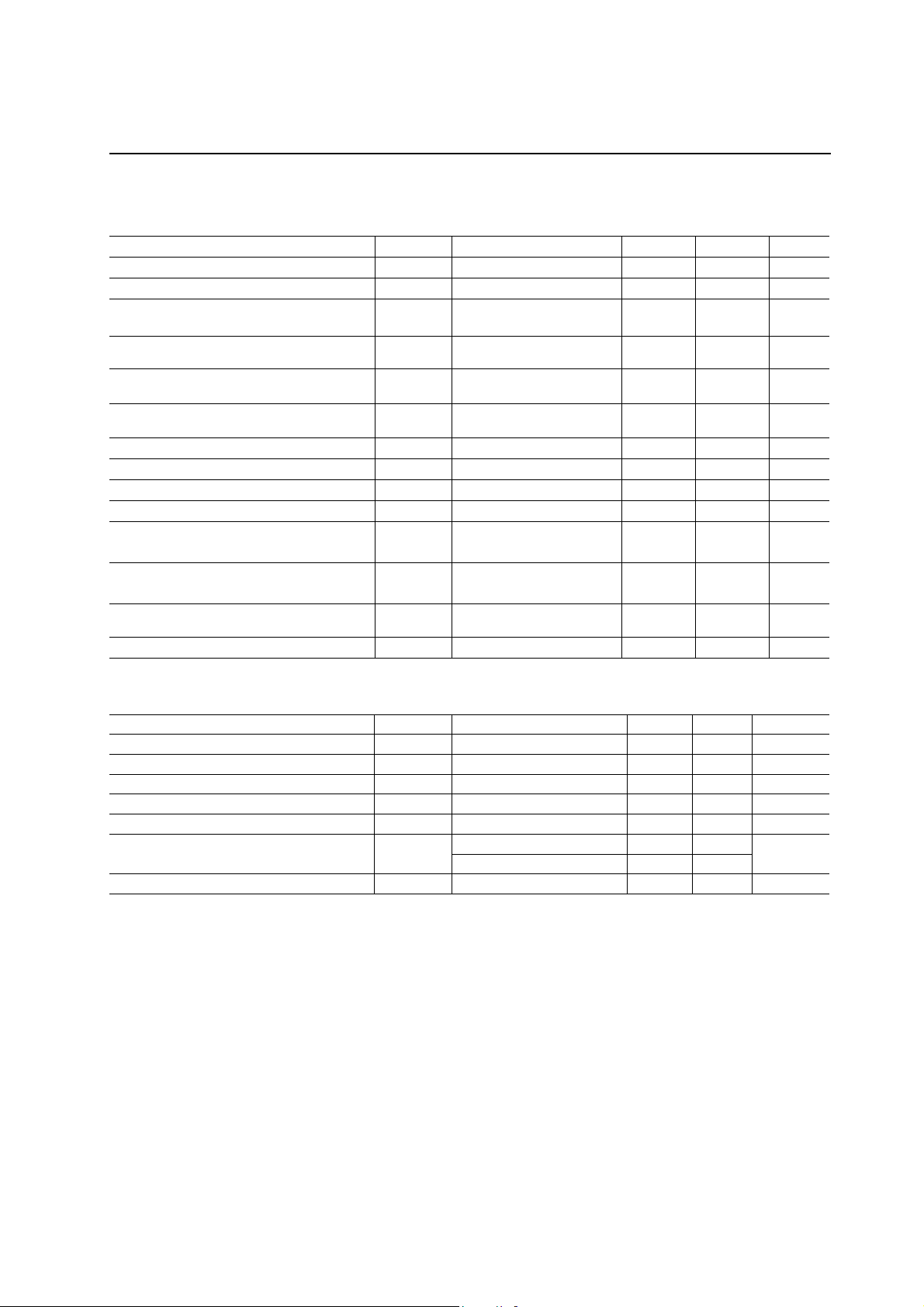

ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings

Parameter Symbol Condition Rating Unit

Power supply voltage

Input pin voltage

Output pin short-circuit current

Power dissipation

Operating temperature

Storage temperature

Recommended Operating Conditions

Parameter Symbol Min. Typ. Max. Unit

Power supply voltage VDD 3.0 3.3 3.6 V

Power supply voltage VSS 0 0 0 V

Operating temperature

Pin Capacitance

Parameter Symbol Min. Max. Unit

Input capacitance Ci — 7 pF

Input/output capacitance (SDA) Cio — 7 pF

Output capacitance Co — 7 pF

V

DD

V

I

I

OS

P

D

T

— 0 to 70

opr

T

— –50 to +150

stg

Ta = 25°C

Ta = 25°C –0.5 to V

Ta = 25°C

Ta = 25°C

–0.5 to +4.6 V

+ 0.5 ≤ 4.6

DD

50 mA

1 W

Ta 0 — 70

(VCC = 3.3 V ± 0.3 V, f = 1 MHz, Ta = 25°C)

V

°C

°C

°C

7/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

DC Characteristics

(Ta = 0 to 70°C)

Parameter Symbol Condition Min. Max. Unit

V

“H” level input voltage V

“L” level input voltage V

“H” level input voltage

(TEST1–TEST7, TESTM, SELF)

“L” level input voltage

(TEST1–TEST7, TESTM, SELF)

“H” level input voltage

(SDA, SCL, IVS, IHS, RESET)

“L” level input voltage

(SDA, SCL, IVS, IHS, RESET)

—

IH1

—

IL1

V

IH2

V

IL2

V

Schmitt

IH3

Schmitt –0.3

V

IL3

—

—

V

V

V

DD

–0.3

DD

–0.3

DD

× 0.7

× 0.75

× 0.75

+0.3 V

DD

× 0.3

V

DD

+0.3 V

V

DD

V

× 0.25

DD

+0.3 V

V

DD

V

× 0.25

DD

V

V

V

“H” level input current (pull-down) IIH 50 kΩ pull down 20 200 µA

Input leakage current IIL — –10 +10 µA

“H” level output voltage (other than SDA) VOH I

“L” level output voltage (other than SDA) VOL I

“L” level output voltage (N-Ch. OD)

(SDA)

V

I

OOL

Output leakage current IOL

Supply current (during operation) I

Supply current (during standby) I

DD1

Input pin = 0 V — 5 mA

DD2

= –4 mA 2.4 VDD V

OH

= 4 mA 0 0.4 V

OL

= 4 mA 0 0.4 V

OL

0 ≤ V

≤ VDD

out

Output disabled

ICLK: 29.5MHz

Output disabled

–10 +10 µA

— 100 (TBD) mA

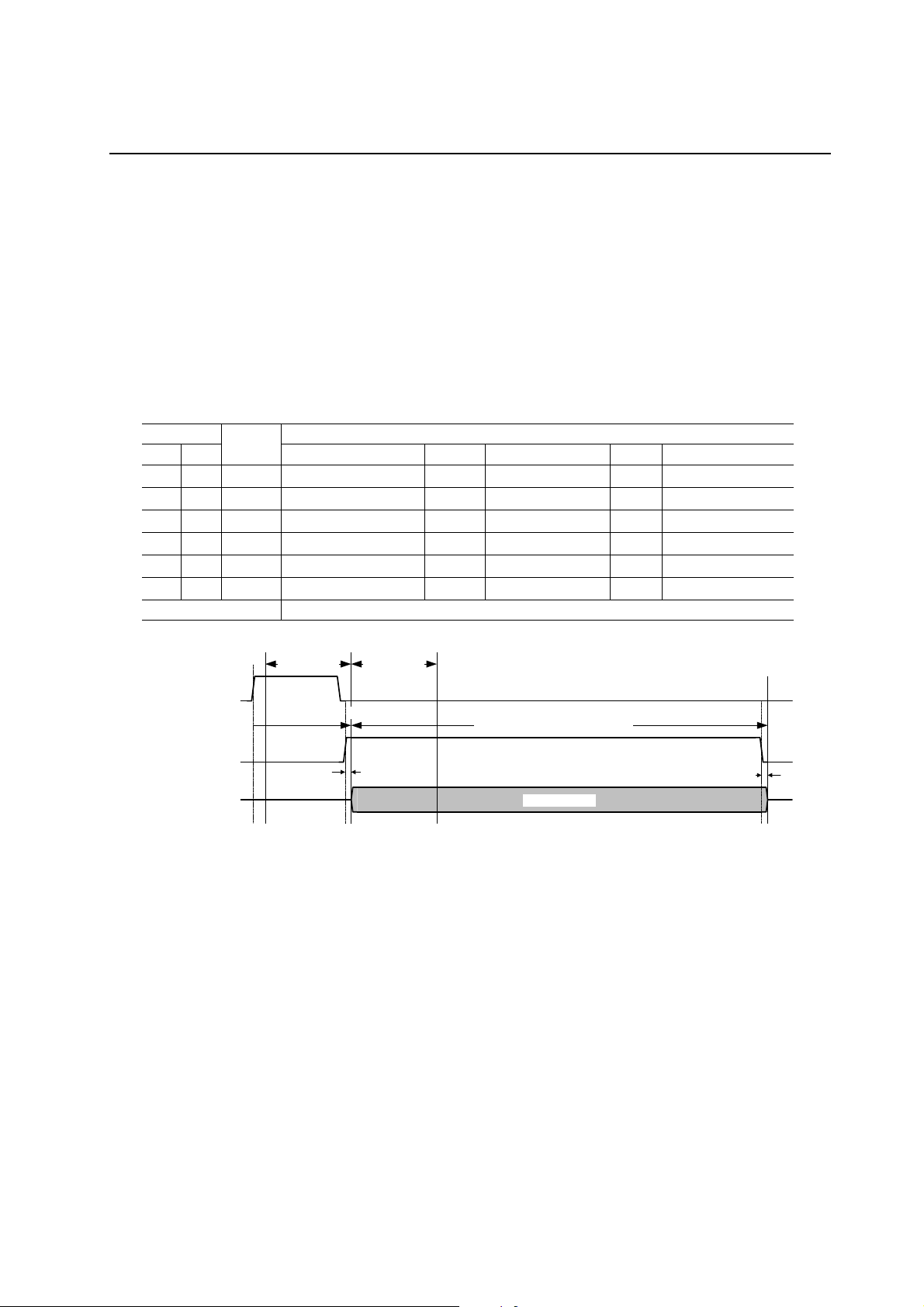

AC Characteristics

(Ta = 0 to 70°C)

Parameter Symbol Condition Min. Max. Unit

t

ICLK clock cycle time

ICLK clock duty ratio

ICLK input set-up time

ICLK input hold time

ICLK output delay time

CLKO delay time

Data through time

— 33 — ns

ICLK

dt

— 40 60 %

ICLK

t

— 5 — ns

IISU

t

— 3 — ns

IIH

t

C

IOD

t

CKD

t

DIDO

CL = 30 pF (IICLK output) 2 25

C

L

C

= 30pF 2 25 ns

L

= 30 pF (ICLK output) 2 17

= 30 pF 2 17 ns

L

ns

Note 1: Measurement conditions

Output comparison level: V

Input voltage level: V

IH

= VDD/2, VOL = VDD/2

OH

= VDD, VIL = 0.0 V

Note 2: Input/output data for the internal memory is guaranteed from the third input-system vertical synchronization

signal with RESET = 1 after V

reaches 3.0 V after the power is turned on. (Due to memory initialization,

DD

the first and second data for two fields is not guaranteed.)

8/123

PEDL87V21071-01

OKI Semiconductor

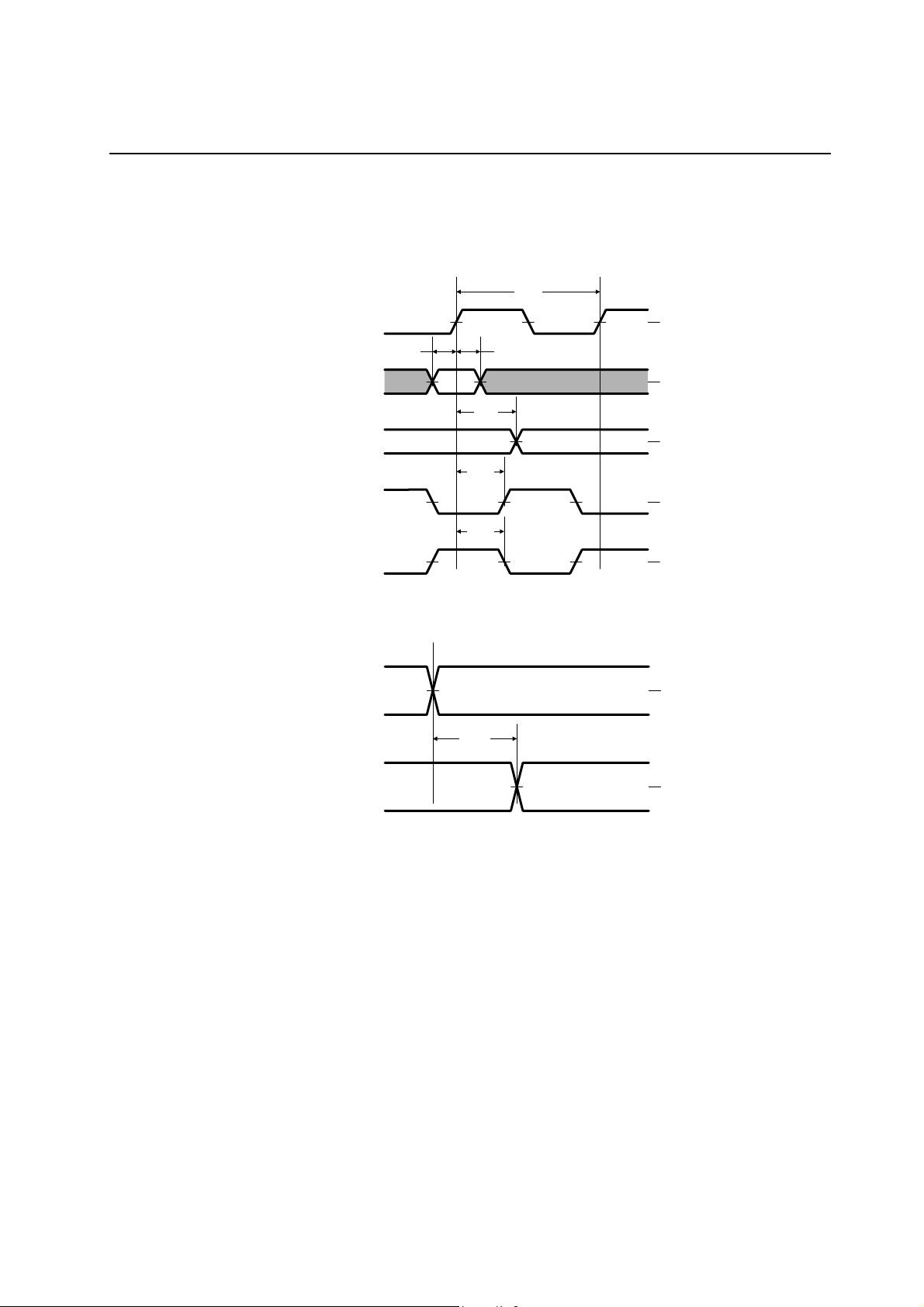

INPUT/OUTPUT TIMING

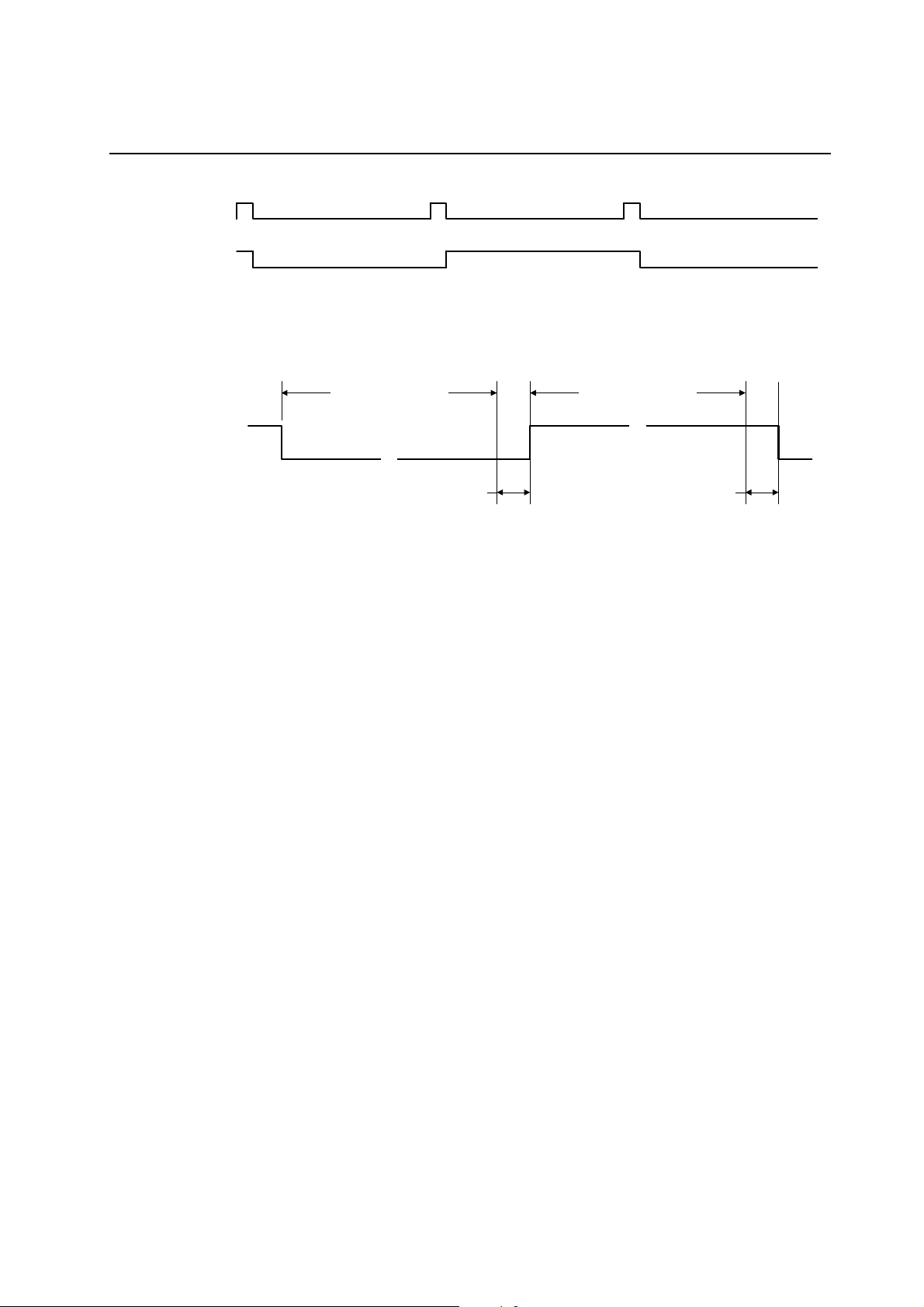

1. ICLK Input/Output Timing

ICLK

DATA &

CONTROL

INPUT (ICLK)

DATA &

CONTROL

OUTPUT (ICLK)

CLKO

(CKINV=0)

CLKO

(CKINV=1)

2. Data through Mode Input/Output Timing

t

IISU

t

CKD

t

CKD

t

IOD

ML87V21071

t

ICLK

50%

t

IIH

50%

50%

50%

50%

DATA &

CONTROL

INPUT

DATA &

CONTROL

OUTPUT

t

DIDO

50%

50%

9/123

PEDL87V21071-01

OKI Semiconductor

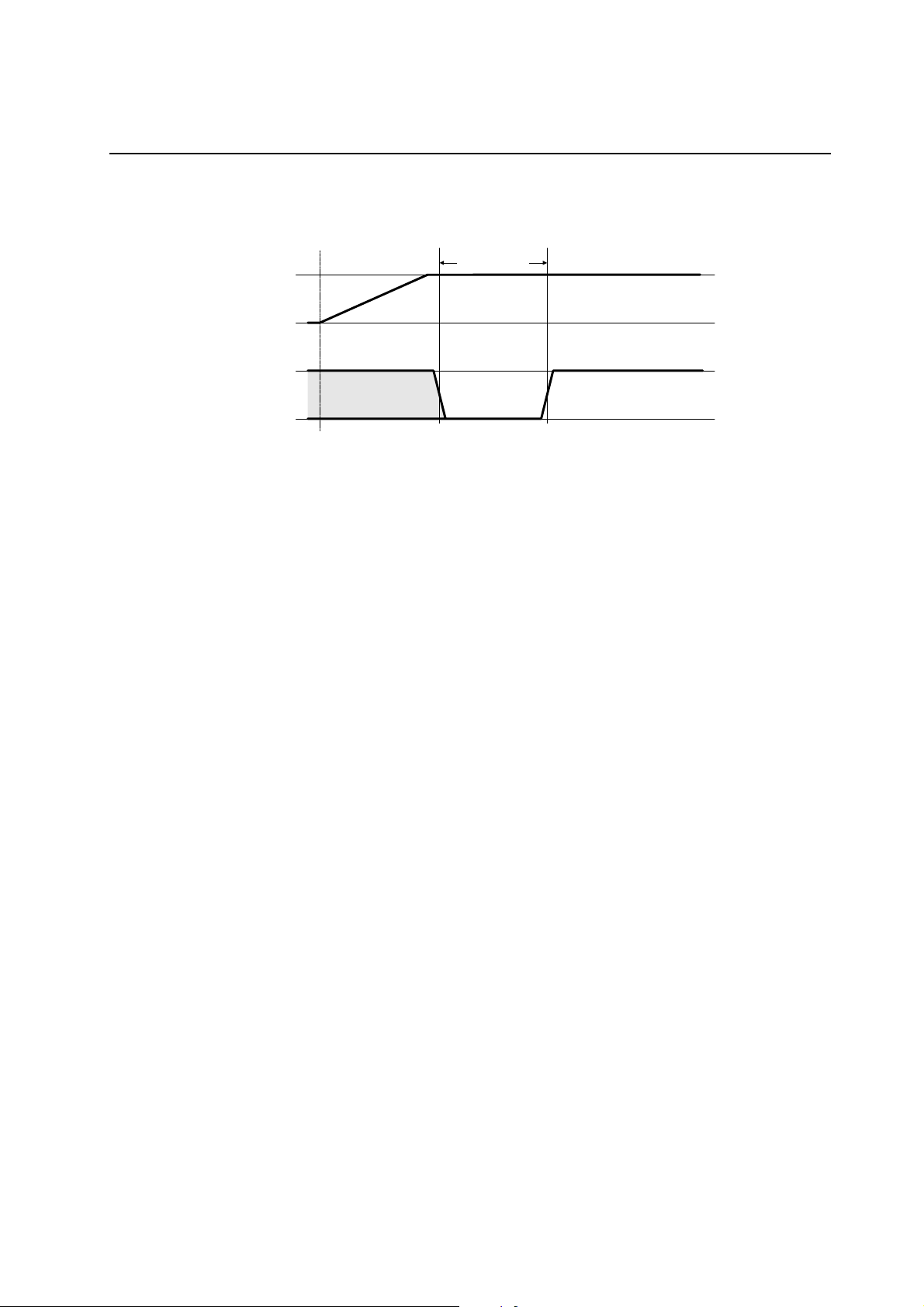

3. System Reset Timing

Power ON

1ms (Min.)

Power

supply

voltage

RESET

* When the power supply voltage reaches V

RESET pin for 1 ms or more to initialize the internal circuits.

* After the RESET pin goes to 1, the I

Don't care

(3.0 to 3.6 V) from 0 V after power is turned on, input 0 to the

DD

2

C-bus interface can be used while the input of ICLK is stable.

ML87V21071

V

DD

0 V

V

DD

0 V

10/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

FUNCTIONAL DESCRIPTION

1. Input/Output

1.1 Memory Control

The ML87V21071 accesses data to the input data frame memory by generating a line access type memory control

signal from Sync. signals of the IVS and IHS pin inputs or the Sync. signals separated from SAV and EAV, and

achieves noise reduction of frame/field/line adaptation recursive type.

1.1.1 Input Control Mode Settings

As shown in the table below, this IC offer s a choi ce of 12 i nput cont rol m odes includi ng the progressi ve m ode by

the INPR setting (SUB:44h-bit[7]), which can be selected by setting either the external setting pin mode (IRMON

= 0 (SUB: 40h–bit [7]) or internal register mode (IRMON = 1).

In ITU-R BT.656 input mode and i n the m ode of vali d 720 pixel s in the horizont al directi on (HM D[1:0] =0h), the

IC checks the mode by measuring the blanking period (between EAV and SAV) of the timing reference code of

the input data (YI[7:0]) and automatically sets VMD[0] by setting APN656 = 1 (SUB: 41h-bit[2]).

During APN656=1, do not set any value other than HMD[1:0]=1.

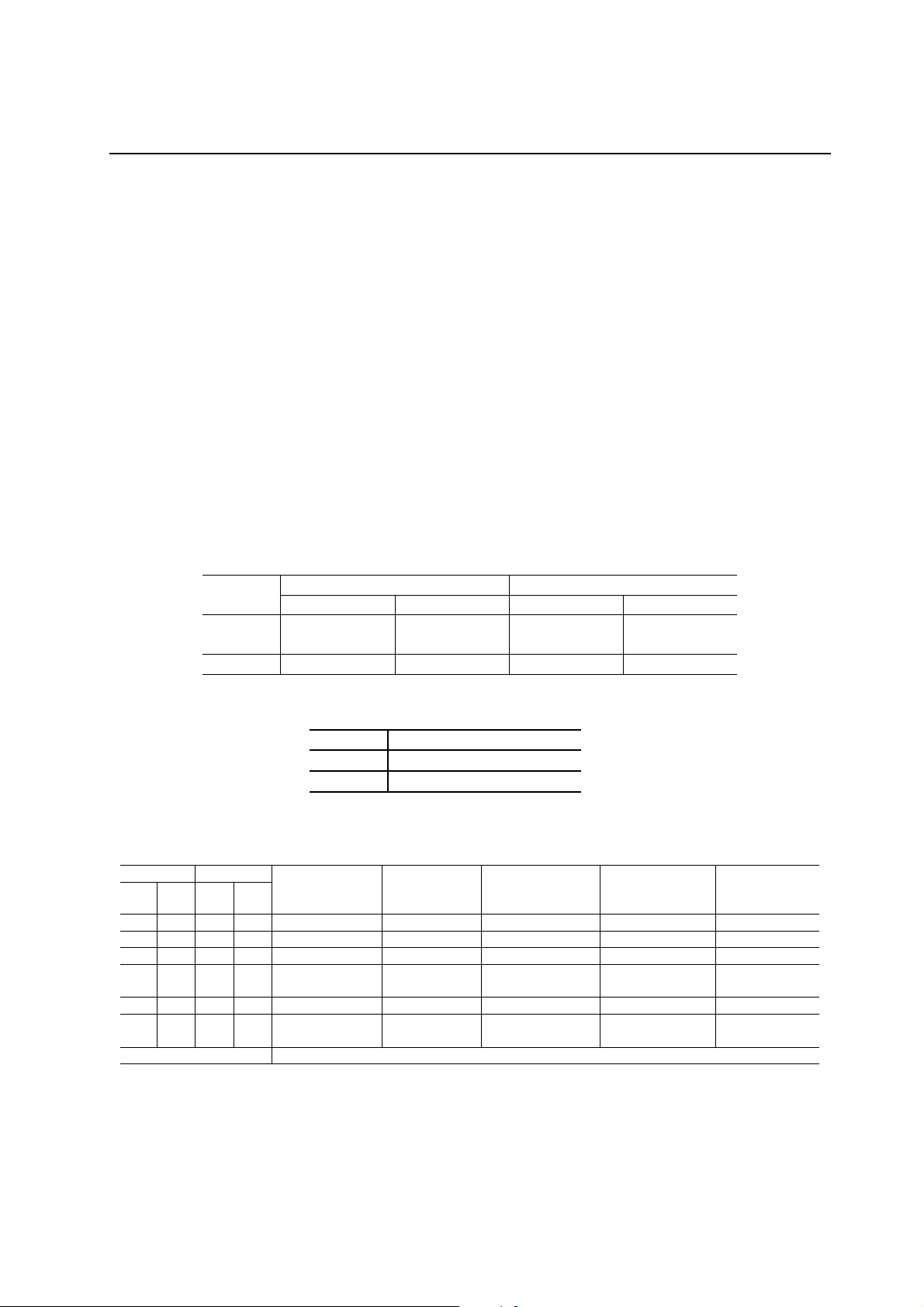

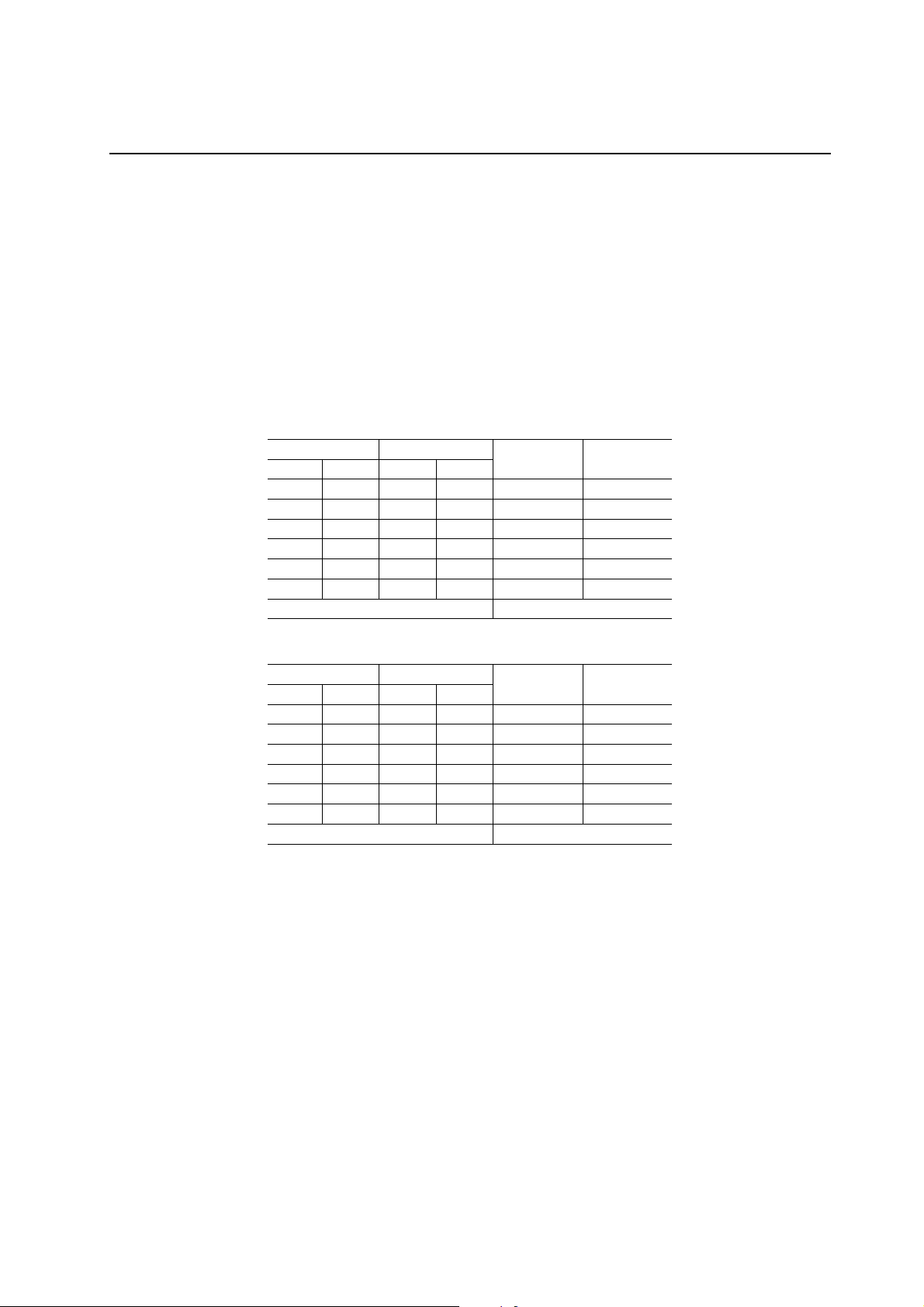

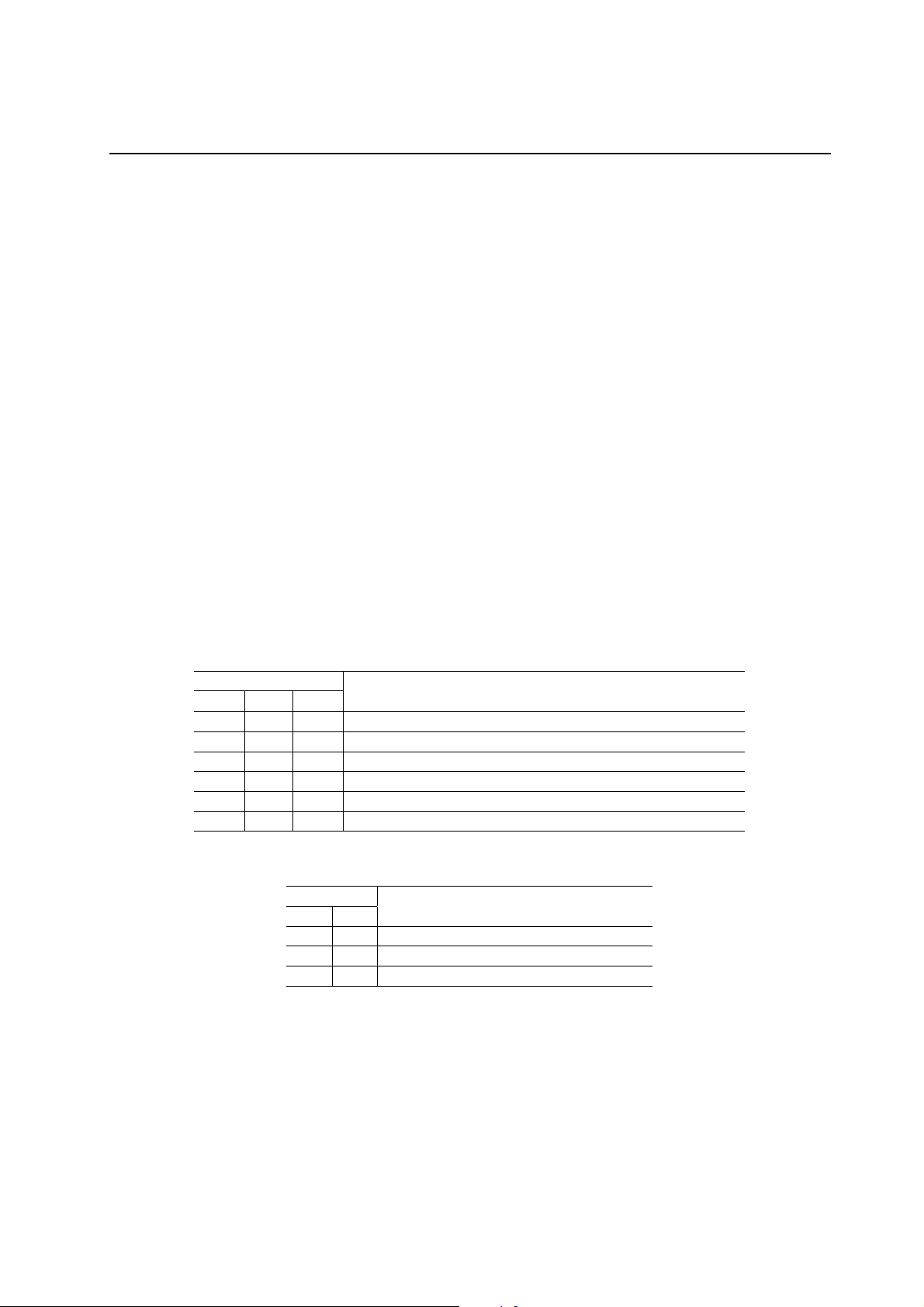

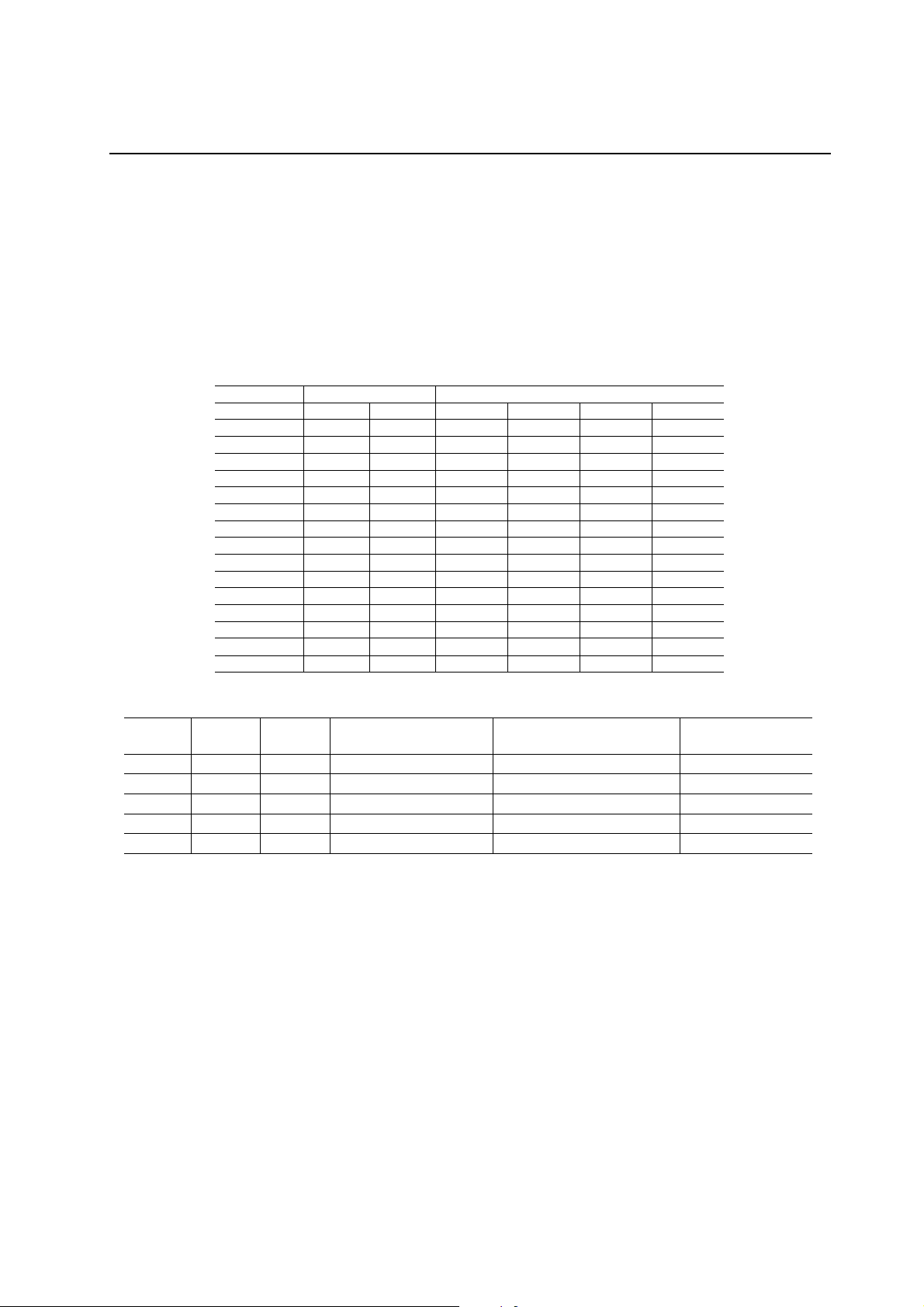

Table F1-1-1 (1) Input Control Mode Setting Allocation 1

IRMON

0 SUB:40h-bit[1]

1 SUB:40h-bit[1] SUB:40h-bit[0] SUB:40h-bit[3] SUB:40h-bit[2]

[1] [0] [1] [0]

VMD HMD

MODE 0

(External pin)

SUB:40h-bit[3]

MODE 1

(External pin)

Table F1-1-1 (2) Input Control Mode Setting Allocation 2

INPR Mode

0 Interlace (525i/625i)

1 Progressive (525p/625p)

* In progressive mode, neithe r 8-bit input m ode nor ITU-R BT.6 56 input mode can be

seected.

Table F1-1-1 (3) Input Control Mode Settings(INPR=0: Interlace)

VMD HMD

[1] [0] [1] [0]

0 0 0 0 625/50Hz 2:1 288 13.5/27 864 720

0 1 0 0 525/60Hz 2:1 243 13.5/27 858 720

0 0 0 1 625/50Hz 2:1 288 14.75/29.5 944 768

0 1 0 1 525/60Hz 2:1 243

0 0 1 0 625/50Hz 2:1 288 14.75/29.5 944 768

0 1 1 0 525/60Hz 2:1 243

Other than above Test modes

Vertical mode

The input system internal clock frequency f

16-bit input mode: f

IICLK

= f

ICLK

8-bit input mode/ITU-R BT.656 mode: f

Number of

valid lines

is as follows:

IICLK

= f

IICLK

Standard clock

frequency f

12.272727/

24.545454

14.31818/

28.63636

/2

ICLK

[MHz]

ICLK

Standard pixels

per line

780 640

910 768

Valid pixels

11/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

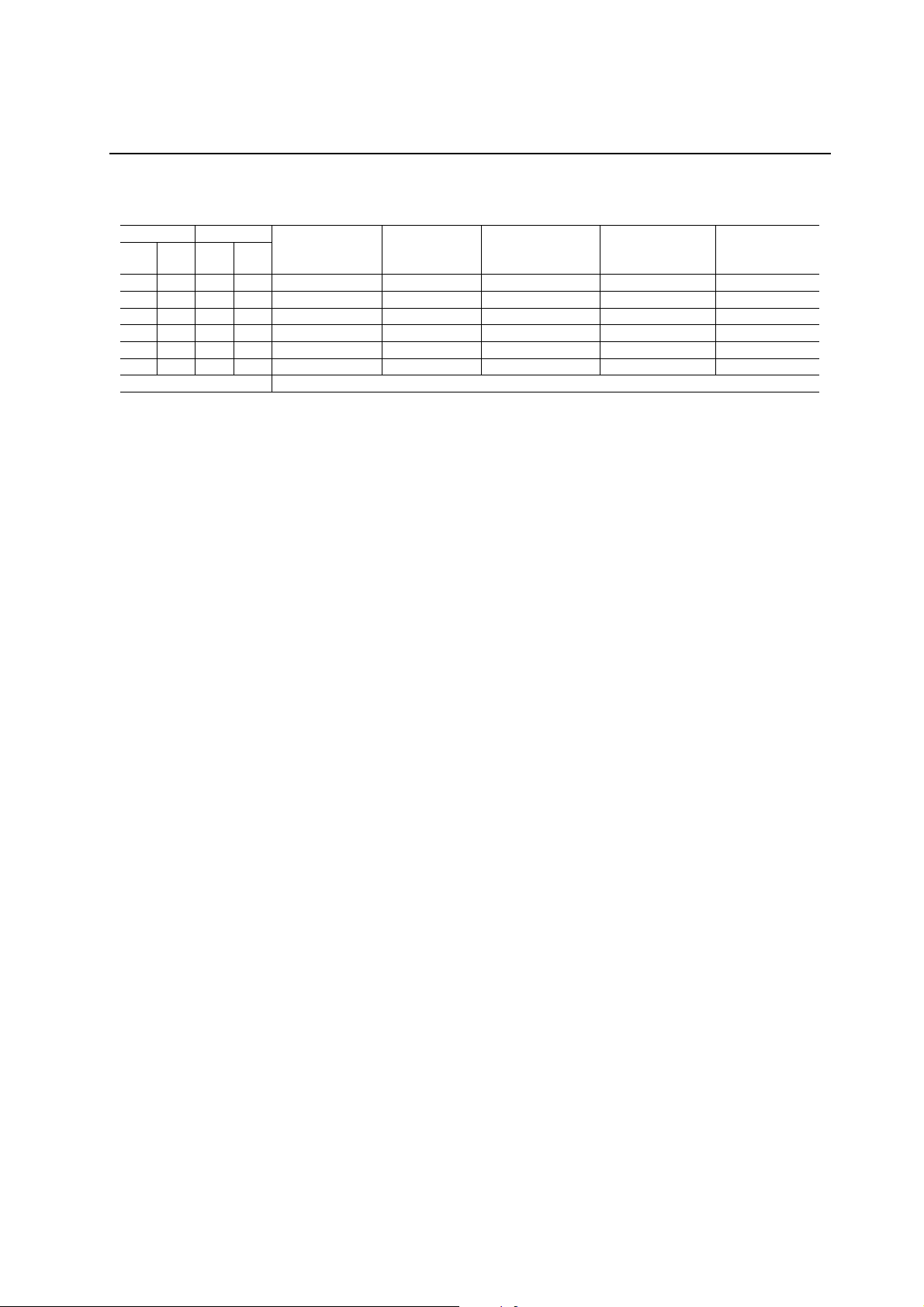

Table F1-1-1 (4) Input Control Mode Settings(INPR=1: Progressive)

VMD HMD

[1] [0] [1] [0]

Vertical mode

Number of

valid lines

0 0 0 0 625/50Hz 1:1 288 27 864 720

0 1 0 0 525/60Hz 1:1 243 27 858 720

0 0 0 1 625/50Hz 1:1 288 29.5 944 768

0 1 0 1 525/60Hz 1:1 243 24.545454 780 640

0 0 1 0 625/50Hz 1:1 288 29.5 944 768

0 1 1 0 525/60Hz 1:1 243 28.63636 910 768

Other than above Test modes

The input system internal clock frequency f

16-bit input mode: f

IICLK

= f

ICLK

is as follows:

IICLK

Standard clock

frequency f

ICLK

[MHz]

Standard pixels

per line

Valid pixels

12/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

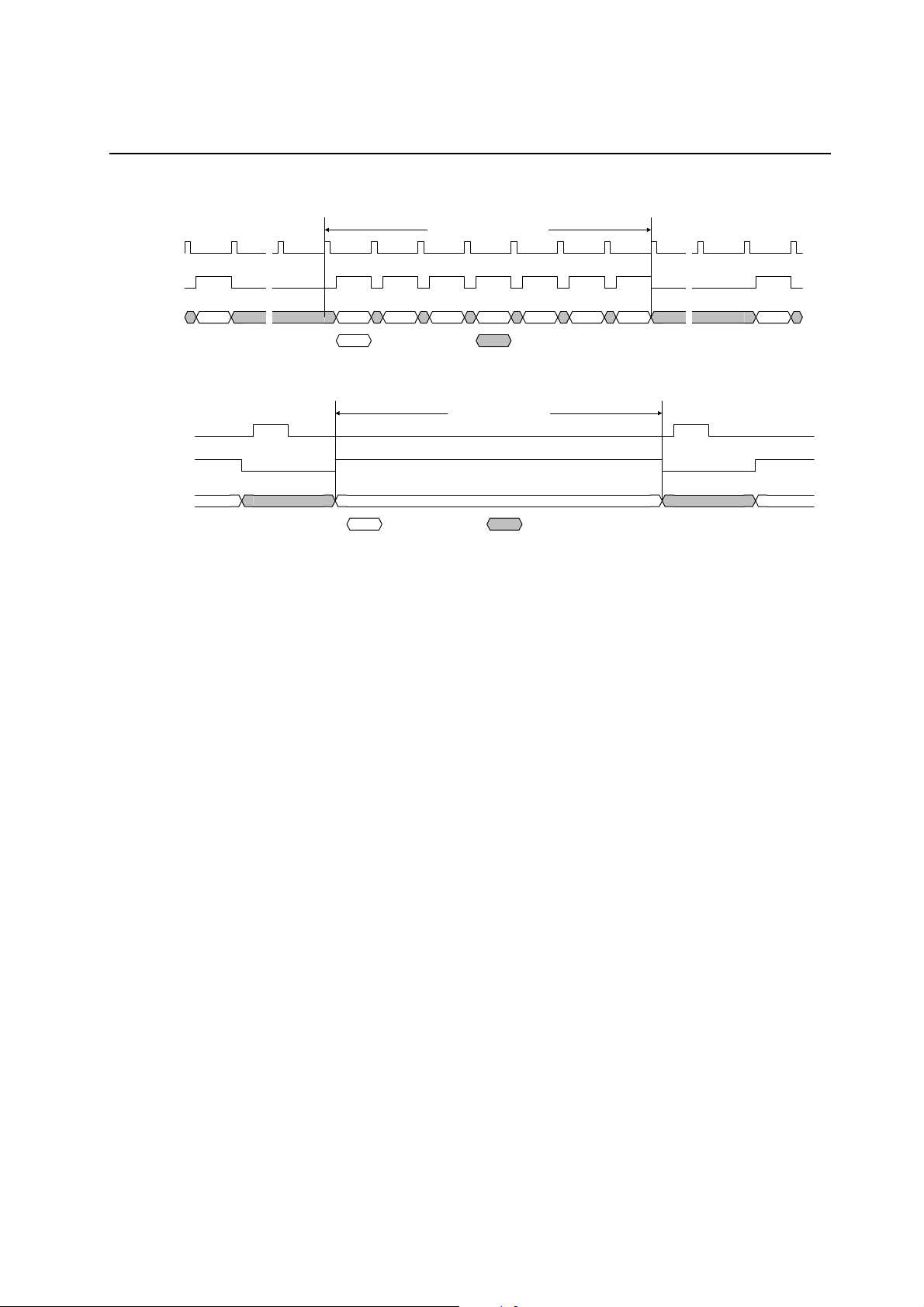

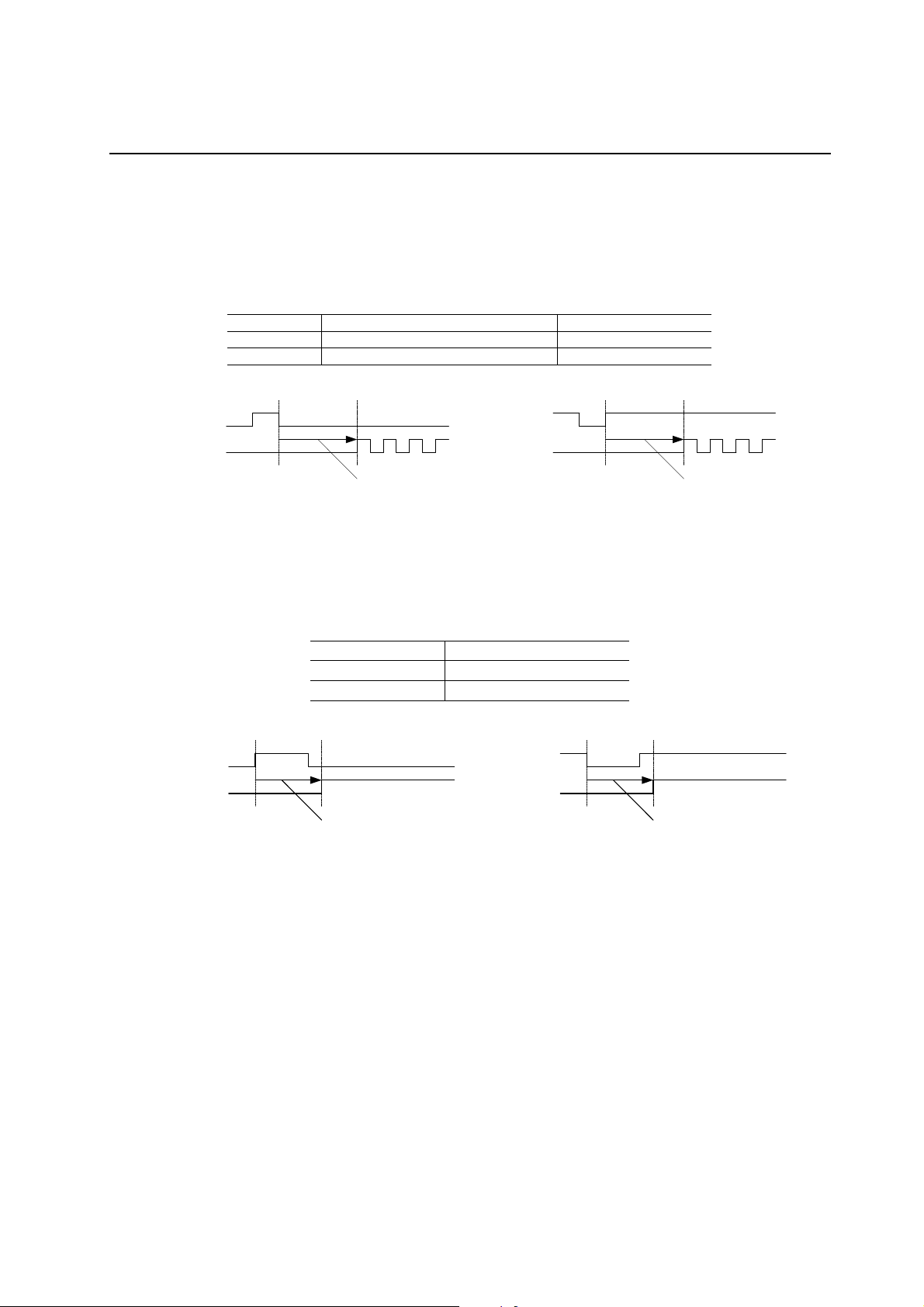

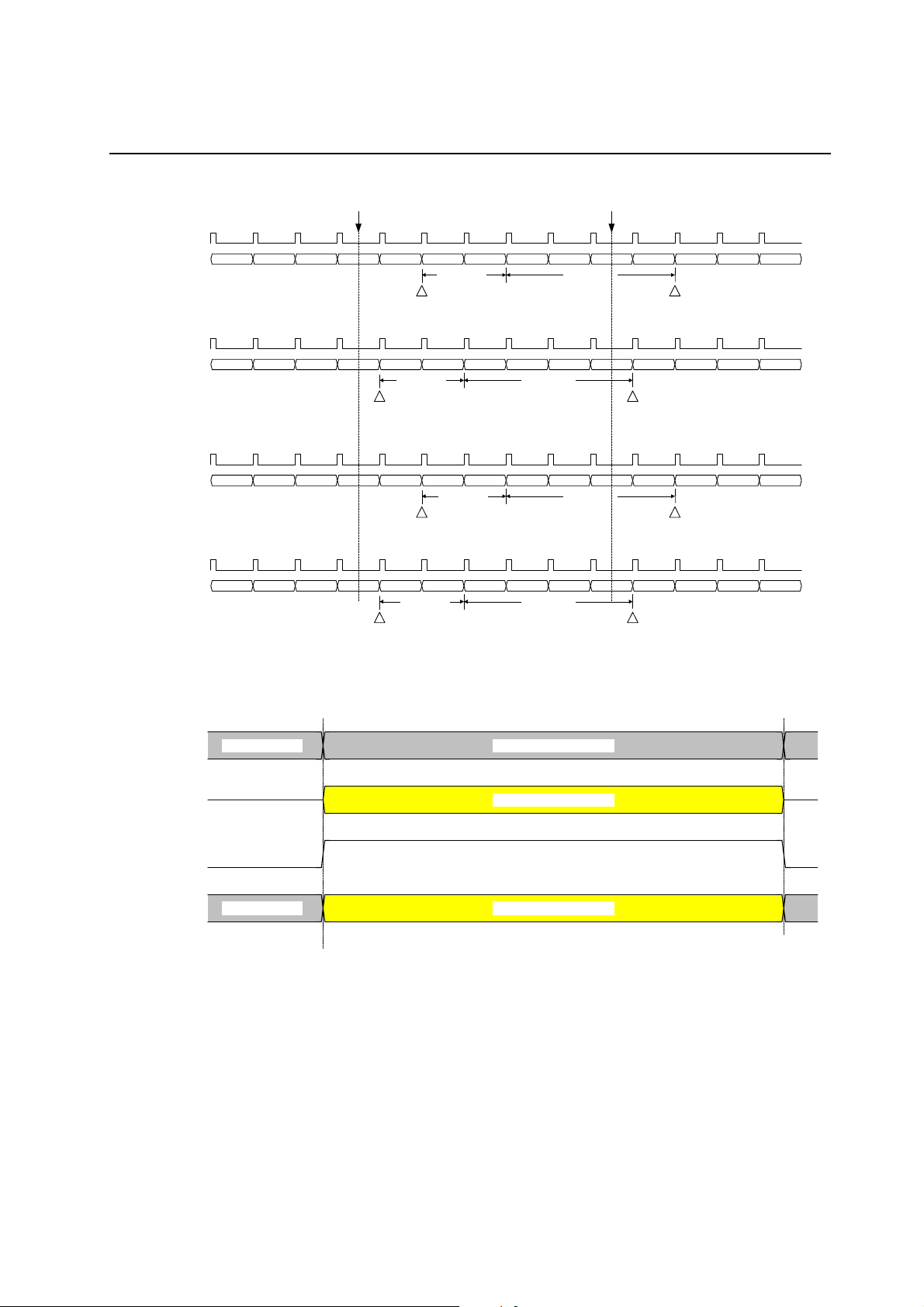

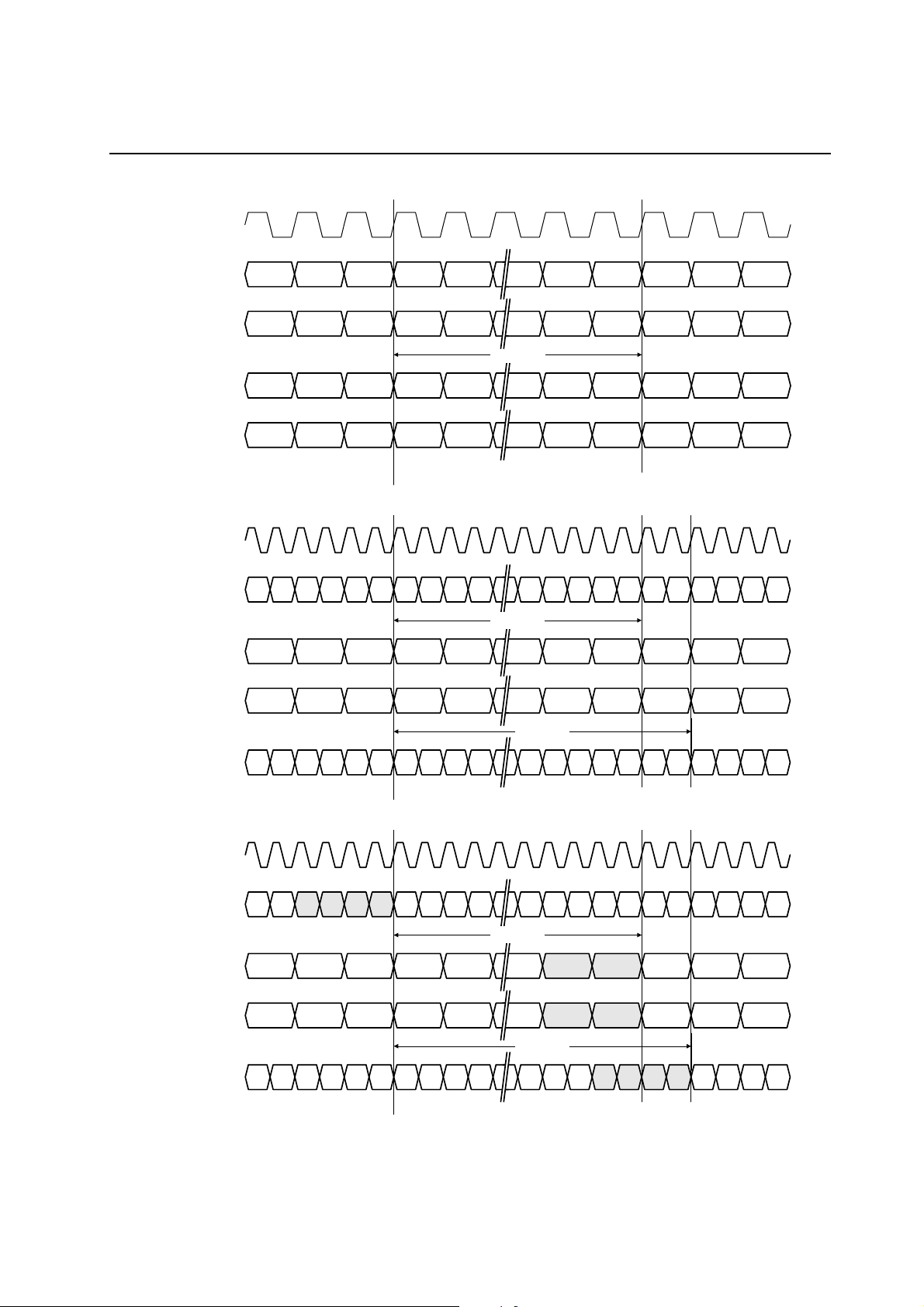

1.1.2 Input System Field Detection

The IC detects the input data field from the phase of IVS and IHS and generates the input field pulse (IF) to

control the internal memory.

The field detection pulse can be selected from the IHS (IFLS = 0) or from 0.5H pulse IHALF (IFLS = 1) by setting

2

the I

C-bus setting register IFLS (SUB:42h-bit[3]).

In the rear edge of judgment area, since the field ju dgm ent uncert ainty are a cont ains 10 c locks o f IICL K (inter nal

input system clock), external phase adjustment will be necessary if the phase of IVS lies in this area. (However,

there is no problem if the change of IVS and IHS is in the same phase.)

When a single field Sync. signal is input (8 fields or more) while the output is in progressive mode, the inter-frame

movement compensation stops.

The device also has the function to automatical ly generate a field pulse by judging a si ngle field Sync . signal input

(continuous for more than 8 fields) with the setting of FCON (SUB:42h-bit[7]) = 1. For example, if there is only

field A input, the pulse toggled by IVS is regarded as the field pulse.

IVS

Field A detection

phase

IHS

Field A detection

0.5H

phase

pulse

#IF

Figure F1-1-2 (1) Input System Field A Detection Timing

IVS

Field B detection

phase

IHS

Field B detection

0.5H

phase

pulse

#IF

Figure F1-1-2 (2) Input System Field B Detection Timing

13/123

PEDL87V21071-01

OKI Semiconductor

IVS

#IF

Figure F1-1-2 (3) Field Detection during Continuous Same Field Input (FCON = 1)

IHS

or

0.5H pulse

Field A Field A Field A

Field A Field B Field A

Field A judgment area

Field judgment margin (10 clocks)

Field judgment uncertainty area

Field B judgment area

Field judgment margin (10 clocks)

Field judgment uncertainty area

Figure F1-1-2 (4) Field Judgment Uncertainty Area

ML87V21071

14/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

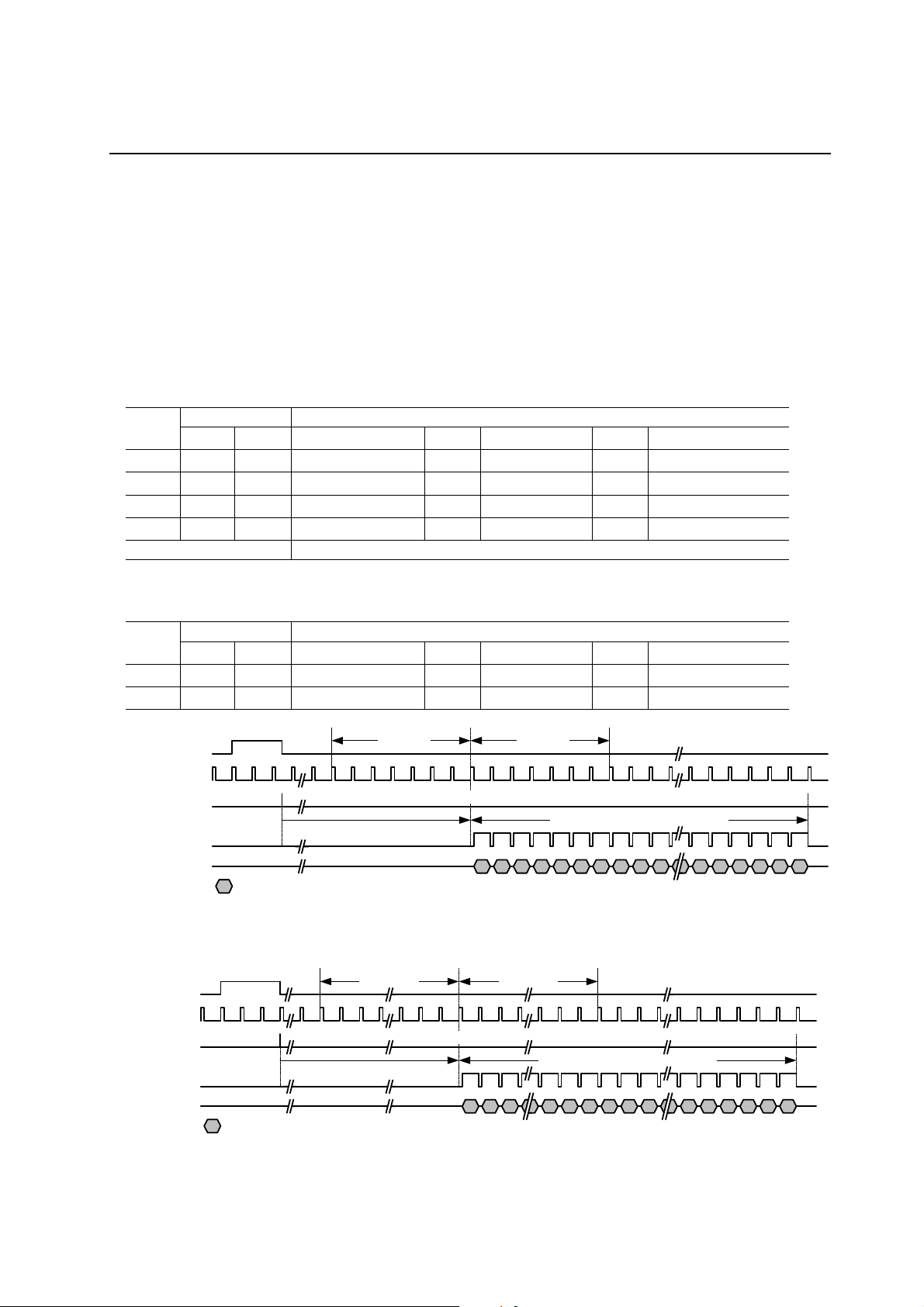

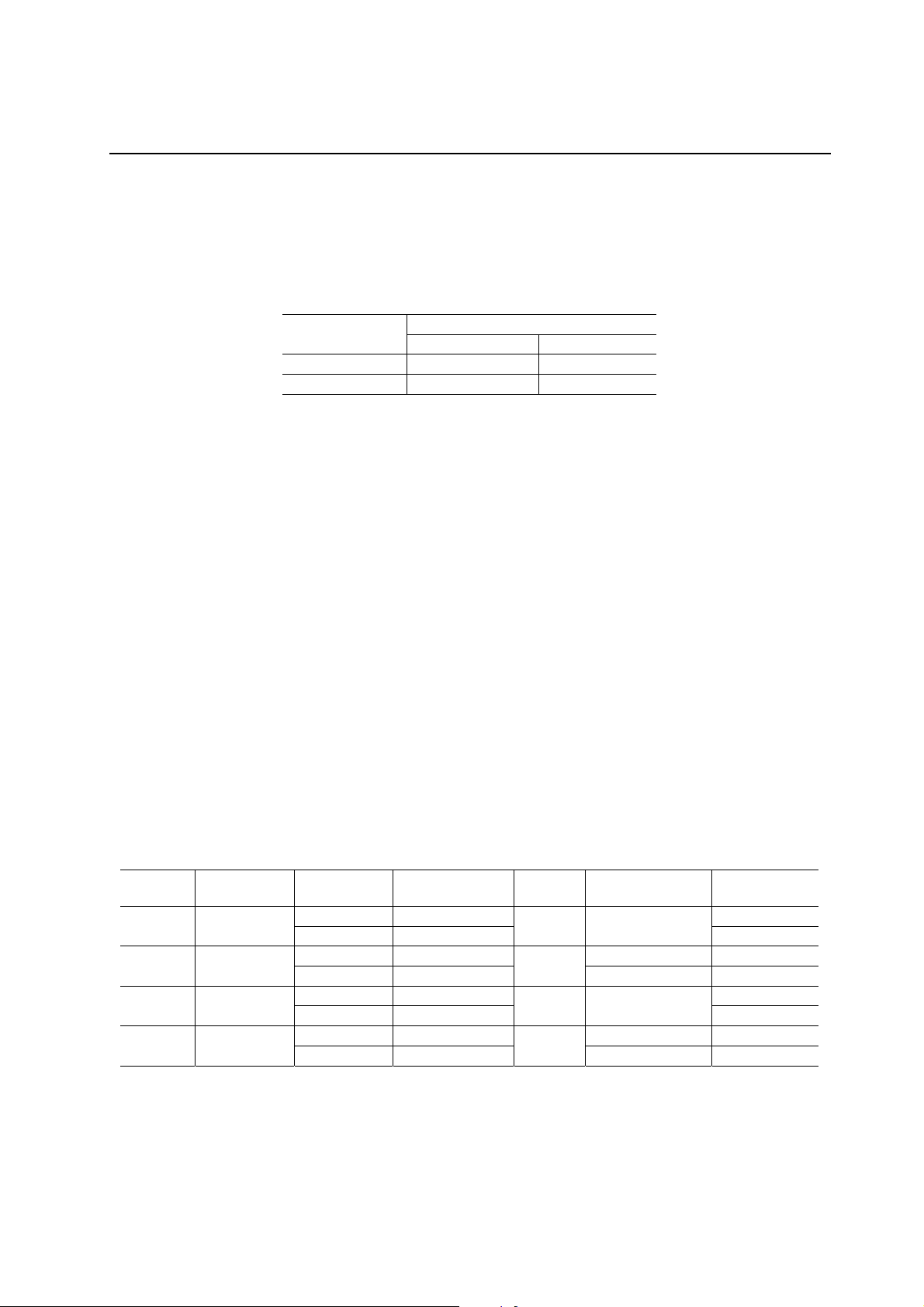

1.1.3 Setting Input System Write Enable and Read Enable

This IC generates the write enable signals (IWE) for writing data in the valid area made up of the valid vertical

lines and the valid horizontal pixels defined by the input control mode settings to the write port of the frame

memory.

With the write enable, it is possible to set the starting point in the vertical and horizontal directions. This setting

makes it possible to position the areas of valid lines and valid pixels with non-standard phase Sync. signals.

This IC also generates a Read Enable (IRE) signal for Read operation to establish recursive noise reduction.

By setting PAOS (SUB:72h-bit[4]) to 1, the valid start offset, which is 2 lines at the setting of INPR=0 and 4 lines

at the setting of INPR=1, is set and the number of valid lines is reduced by 2 lines or 4 lines from the normal

condition.

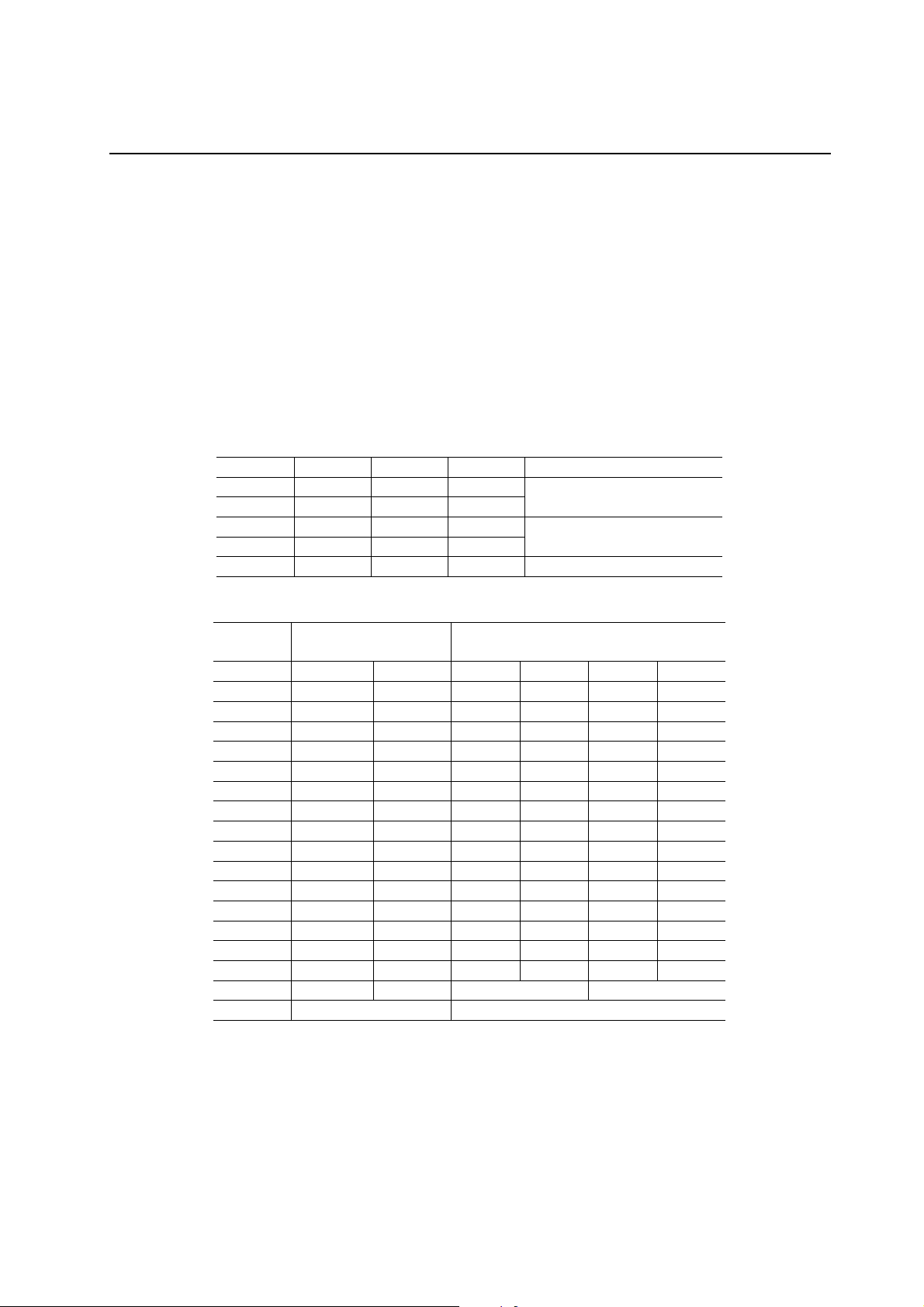

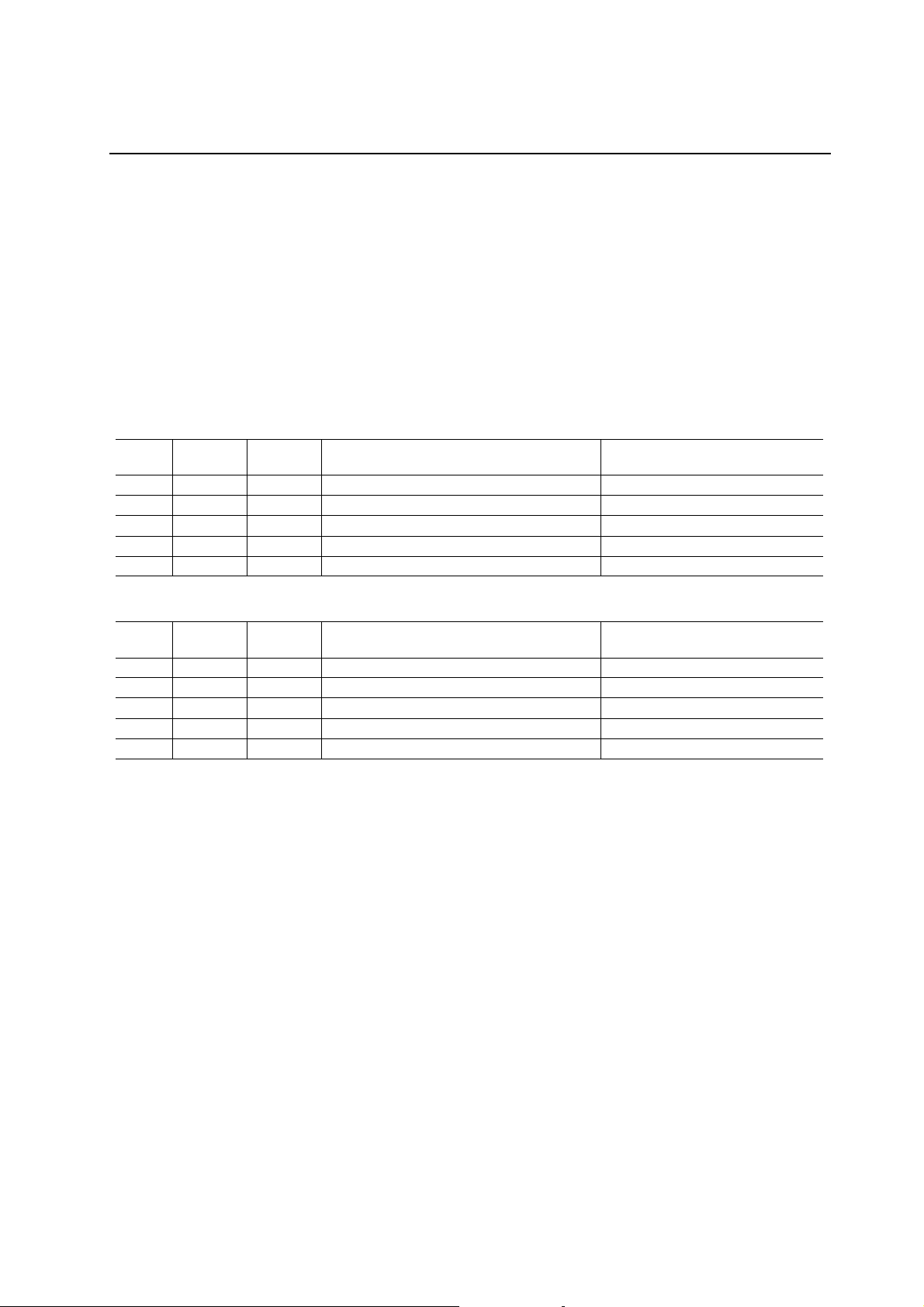

Table F1-1-3(1) Valid Input Data Area (INPR=0: Interlace)

VMD HMD

[1] [0] [1] [0]

0 0 0 0 288(286) 720

0 1 0 0 243(241) 720

0 0 0 1 288(286) 768

0 1 0 1 243(241) 640

0 0 1 0 288(286) 768

0 1 1 0 243(241) 768

Other than above Test modes (not settable)

Valid lines Valid pixels

Table F1-1-3(2) Valid Input Data Area (INPR=1: Progressive)

VMD HMD

[1] [0] [1] [0]

0 0 0 0 576(572) 720

0 1 0 0 486(482) 720

0 0 0 1 576(572) 768

0 1 0 1 486(482) 640

0 0 1 0 576(572) 768

0 1 1 0 486(482) 768

Other than above Test modes (not settable)

Valid lines Valid pixels

15/123

PEDL87V21071-01

OKI Semiconductor

IHS

IWE

IRE

YI

CI

IHS

IWE

IRE

YI

CI

243/288/486/576lines

: Valid data : Invalid data

Figure F1-1-3(1) Input Vertical Valid Lines

720/640/768pixels

: Valid data : Invalid data

Figure F1-1-3(2) Input Horizontal Valid Pixels

ML87V21071

16/123

PEDL87V21071-01

OKI Semiconductor

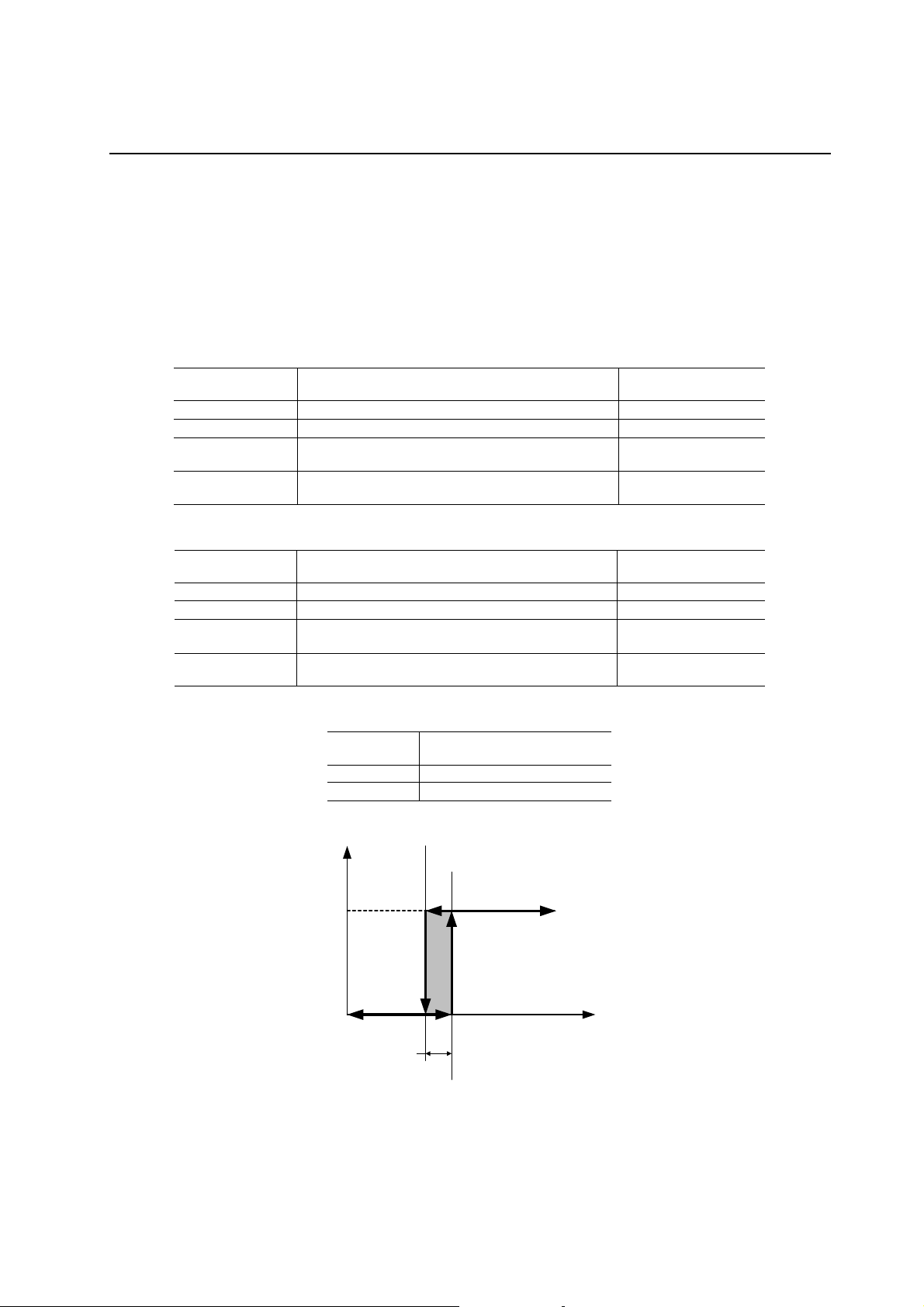

• Setting of Input System Vertical Valid Line Start Position

The input system vertical valid line start position (IVPS) is set in line unit with reference to the input system

vertical reset (IVR: internal signal ), generated from IVS, by setting N PVWE[4:0] (SUB :44h-bit[4:0]) . Data of

valid lines is written in the memory taking the input data subsequent to IVPS as valid data.

For this value, ±7 lines (15 stages) can be set for the reference position (NPVWE[3:0]=8h) in interlace mode

(INPR=0) and in progressive mode (INPR=1), ±15 lines (31 stages) can be set for the reference position

(NPVWE[4:0]=10h).

In interlace mode, NPVWE[4] is ignored.

Table F1-1-3 (3) Input System Vertical Valid Line Start Position (INPR=0: Interlace)

R656I

0 0 0 13 (–7 lines)

0 0 1 7 (–7 lines)

1 0 0 17 (–7 lines) (*1)

1 0 1 12 (–7 lines) (*1)

Other than above Test modes (not settable)

*1: In the case of field B, it is +1.

VMD IVPS position (number of IHS’s from IVR)

[1] [0] NPVWE=1h

……

……

……

……

……

NPVWE=8h

20 (default)

14 (default)

24 (default) (*1)

19 (default) (*1)

……

……

……

……

……

NPVWE=Fh

27 (+7 lines)

21 (+7 lines)

31 (+7 lines) (*1)

26 (+7 lines) (*1)

Table F1-1-3 (4) Input System Vertical Valid Line Start Position (INPR=1: Progressive)

R656I

0 0 0 24 (–15 lines)

0 0 1 12 (–15 lines)

VMD IVPS position (number of IHS’s from IVR)

[1] [0] NPVWE=1h

……

……

……

NPVWE=10h

49 (default)

27 (default)

……

……

……

NPVWE=1Fh

54 (+15 lines)

42 (+15 lines)

IVS

7 lines7 lines

ML87V21071

IHS

#IVR

#IWE/IRE

YI[7:0]

CI[8:0]

IVS

IHS

#IVR

#IWE/IRE

YI[7:0]

CI[8:0]

IVPS

288/243 lines

: Valid data #: Internal signal

Figure F1-1-3 (3) Input System Vertical Valid Line Start Timing (INPR=0)

15 lines15 lines

IVPS

576/486 lines

: Valid data #: Internal signal

Figure F1-1-3 (4) Input System Vertical Valid Line Start Timing (INPR=1)

17/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

• Setting of Input System Horizontal Valid Pixel Start Position

The input system horizontal valid pixel start position (IHPS) is set in pixel unit with reference to the input

system horizontal reset (IHR: internal signal), generated from IHS, by setting NPHWE[7:0]

(SUB:45h-bit[7:0]).

The data subsequent to IHPS is written in the data memory of valid pixels as the valid data.

This value can be set in 255 levels of ±127 pixels with regard to the initial value (NPHWE[7:0] = 80h).

In the ITU-R BT.656 mode, the value cann ot be set. Wri te enable with regard to valid data is generated on the

basis of detected SAV, EAV.

Table F1-1-3 (5) Input System Horizontal Valid Pixel Start Position

HMD IHPS position (Number of pixels from IHS)

[1] [0]

0 0 0 17 (–127 pixels)

0 0 1 11 (–127 pixels)

0 1 0 49 (–127 pixels)

0 1 1 13 (–127 pixels)

1 0 0 49 (–127 pixels)

1 0 1 15 (–127 pixels)

Other than above Test modes (Setting inhibited)

VMD

[0]

NPHWE=01h

……

……

……

……

……

……

……

NPHWE=80h

144 (default)

138 (default)

176 (default)

140 (default)

176 (default)

142 (default)

……

……

……

……

……

……

……

NHPWE=FFh

271 (+127 pixels)

265 (+127 pixels)

303 (+127 pixels)

267 (+127 pixels)

303 (+127 pixels)

269 (+127 pixels)

127 pixels127 pixels

IHS

IHPS

#IWE

1 pixel

YI[7:0]

CI[7:0]

640/720/768 pixels

1 pixel

Valid data

Figure F1-1-3 (5) Input System Horizontal Valid Pixel Start Timing

18/123

PEDL87V21071-01

[

]

[

]

OKI Semiconductor

ML87V21071

1.1.4 Input System Sync. Signal Polarity Inversion Setting

Negative polarity IVS can also be supported by setting the I

2

C-bus setting register IVSINV (SUB:42h-bit[0]).

Moreover, with regard to field detection, setting is possible even when setting the internal IVR generation edge.

Table F1-1-4 (1) IVINV Setting

IVSINV Recommended input IVS polarity IVR generation edge

0 Positive (default) Rising edge

1 Negative Falling edge

IVSINV=1IVSINV=0

IVS

IWE

Value set by

NPVWE[3:0]

IVS

IWE

Value set by

NPVWE[3:0]

Figure F1-1-4 (1) Support of Input System Vertical Sync. Signal Polarity Inversion

Negative polarity IHS can also be supported by setting the I

2

C-bus setting register IHSINV (SUB:42h-bit[1]).

Table F1-1-4 (2) IHSINV Setting

IHSINV Input IHS polarity

0 Positive (default)

1 Negative

IHSINV=1IHSINV=0

IHS

IWE

Value set by

NPHWE

7:0

IHS

IWE

Value set by

NPHWE

Figure F1-1-4 (2) Support of Input System Horizontal Sync. Signal Polarity Inversion

7:0

19/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

1.1.5 Input System Detection Field Inversion Setting

Inversion of input system internal field detection is possible by setting IFINV (SUB:42h-bit[2]) by I

interface. However, setting is not necessary if there is no problem in normal detection.

Table F1-1-5 IFIND Setting

IFINV

0 0 1

1 1 0

Field A Field B

Input field

* PAL : Field A = 1st, 3rd, 5th, 7th color field

Field B = 2nd, 4th, 6th, 8th color field

* NTSC : Field A = 2nd, 4th color field

Field B = 1st, 3rd color field

1.1.6 Input System Vertical Reset Compensation Mode Setting

In this IC, the rear edge (in the case of standard signal, 625 lines; A-3 line, 0.5H position, in between B-315 an d

B-316 lines, 525 lines; A-6 line, 0.5H position, in between B-6 and B-7 lines) of normally standard vertical Sync.

signal (IVS) is regarded as the reference position (IVR generating position) to perform field detection and

memory control.

If a Sync. signal with unspecified phase of the IVS rear edge and horizo n t al Sy nc. signal (IHS) is input, the front

edge can be used with the setting IVSINV = 1. But if the front edge is used in standard 626-line mod e, the

detection filed reverses in normal operation and field B gets written in the memory with one line earlier phase.

Therefore, by setting the I

2

C-bus setting register IVEM (SUB:42h-bit[4]), the detection field is inve rted (A→B,

B→A) and the vertical phase with regard to field B of the inverted result is delayed by 1H.

This allows compensation for field detection and IVR which is the typical front edge phase of IVS of 625-line

mode.

In practice, this allows compliance with the Sync. signal examples shown in Table F1-1-6 and Figure F1-1-6.

Note: Use it in case the phase of field-detecting IVS and IHS reverses in the IC standard setting.

Table F1-1-6 Input System Vertical Reset Compensation by IVEM Setting

Condition

Phase 1

Phase 2

Phase 3

Phase 4

Vertical

reference

Rear edge

IVSINV = 0

Rear edge

IVSINV = 0

Front edge

IVSINV = 1

Front edge

IVSINV = 1

Input

data field

A A n

B B

A B A n

B A

A A n

B B

A B A n

B A

Internal

decision field

IVEM

setting

0 No compensation

1

0 No compensation

1

Field after

compensation

B n + 1

B n + 1

Valid data start

position

n

n

2

C-bus

20/123

PEDL87V21071-01

OKI Semiconductor

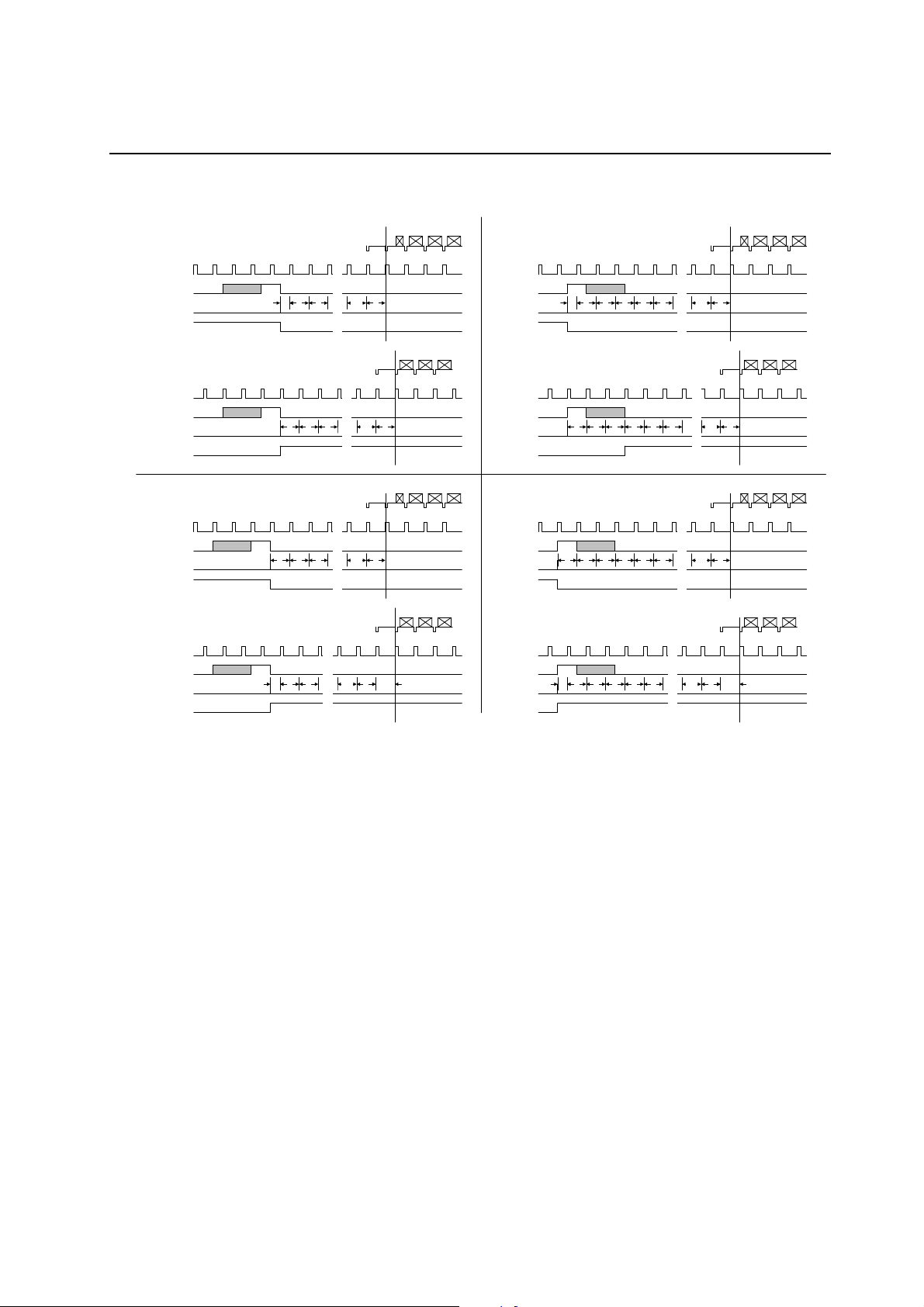

Input sync signal phase 1

Field A input

IHS

IVS

#IVR

#IF

Field B input

IHS

IVS

#IVR

#IF

Input sync signal phase 2

Field A input

IHS

IVS

#IVR

#IF

0 1 2 nn-1

0 1 2 nn-1

ML87V21071

Input sync signal phase 3

nn-10 1 2

Input sync signal phase 4

IHS

IVS

#IVR

#IF

IHS

IVS

#IVR

#IF

IHS

IVS

#IVR

#IF

Field A input

0 1 2 nn-1

Field B input

Field A input

0 1 2 nn-1

3 4 5

3 4 5

3 4 5

nn-10 1 2

IHS

IVS

#IVR

#IF

Field B input

nn-10 1 2 n+1

IHS

IVS

#IVR

#IF

Field B input

3 4 5

nn-10 1 2 n+1

Figure F1-1-6 Input System Vertical Reset Compensation by IVEM Setting

21/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

1.1.7 Stop Memory Write Setting (Freeze Function)

By setting the I

2

C-bus settings register STL[2:0] (SUB:43h-bit[2:0]), you can stop writing data to the memory.

When you do this, the noise reduction feature stops.

Further, by setting STLM[1:0] (SUB:43h-bit[4:3]), field still image output, frame still image output, or frame still

median) image output can be selected.

The still image data output is achieved by rewriting only the signals read from the memory for the valid data

period selected by the IBLK signal, which indicates the valid data. Therefore, it is necessary to input the input

Sync. signals as normal.

The data output as a field or frame (median) still image is based on the most recent data written to the memory

(before the writing was stopped).

The timing of the writing stop and restoration can be set in one of the following three modes: selected field A/B

timing, field A timing, and field B timing.

In the mode of selected field A/B timing, writing is stopped after data for the next frame (field A + field B) after

writing stop is set is written. Writing is restored from the next frame after writing restoration is set. In this mode,

the field still image output depends on the writing stop setting timing.

In the mode of field A timing, after data for one frame (field B + field A) is written from the field B after writing

stop is set, writing is stopped from the next field B vertical Sync. signal. Writing is restored with the field B

vertical Sync. signal. In this mode, field A is always output for the field still image output.

In the mode of field B timing, after data for one frame (field A + field B) is written from the field A after writing

stop is set, writing is stopped from the next field A vertical Sync. signal. Writing is restored with the field A

vertical Sync. signal. In this mode, field B is always output for the field still image output.

When INPR is set to 1, the setting of field timing STL[2:1] is ignored and only STL[0] stop operation is

performed.

Table F1-1-7(1) Writing Stop Settings

STL

[2] [1] [0]

0 0 0 Possible (field A restoration)

0 1 0 Possible (field B restoration)

1 X 0 Possible (either field restoration)

0 0 1 Stopped (field A maintained)

0 1 1 Stopped (field B maintained)

1 X 1 Stopped (either field output maintained)

Input data writing

Table F1-1-7 (2) Still Image Output Mode Settings

STLM

[1] [0]

0 X Field image

1 0 Frame image

1 1 Frame image (median)

Output still image

22/123

PEDL87V21071-01

OKI Semiconductor

[Field A timing setting example 1]

IVS

Field

[Field A timing setting example 2]

IVS

Field

[Field B timing setting example 1]

IVS

Field

[Field B timing setting example 2]

IVS

Field

Writing stop set

A B

A B

A B A B A B A B A B A B

Writing stop processing

A B

A B A B A B A B A B A B

A B A B A B A B A B AB

Writing stop processing

start position

Writing stop processing

A B A B A B A B A B A B

Writing stop processing

start position

start position

Frame for pre-stop

write processing

start position

Frame for pre-stop

write processing

Frame for pre-stop

write processing

Frame for pre-stop

write processing

Stopping period

Stopping period

Writing restoration set

Stopping period

Writing stop processing

end position

Stopping period

Writing stop processing

end position

Writing stop processing

Writing stop processing

Figure F1-1-7 (1) Writing Stop/Restoration Timing

ML87V21071

end position

AB

end position

Input data

Memory data

Valid dataBLK data

Valid data

#IBLK

Output data

BLK data Valid data

Figure F1-1-7(2) Output Data in Still Image Mode

* When MEM411 is set to 1, output data from the memory is converted to 4:2:2 data (pseudo conversion) through

linear interpolation of c hrom inance data si nc e the o utput da t a is 4:1: 1 data . The refore , t he ban d o f t he da ta on t he

chrominance side deteriorates from that of the normal data.

23/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

1.2 Input/Output Format

1.2.1 Input Data Format

The input of this IC complies with 16-bit 4:2:2 (YI[7:0] = Y-8bit, CI[7:0] = CbCr-8bit 4:2:2) format (input in

16-bit mode), 8-bit 4:2:2 (YI[7:0] = YCbCr-8bit 4:2:2, without SAV, EVA) format (input in 8-bit mode) and

ITU-R BT.656 conforming (YI[7:0] = YCbCr-8bit 4:2:2, with SAV, EAV) format (ITU-R BT.656 mode).

However, when INPR is set to 1, neither 8-bit input mode nor ITU-R BT.656 input mode can be selected.

The input format mode is set by an exte rnal pin MODE 2 or I

R656 (SUB:41h-bit[1]).

Switching of an external pin and a register is accomplished by setting the I

2

C-bus setting register DISEL (SUB: 4 1h -bit[0]), or

2

C-bus setting register IRMON

(SUB:40h-bit[7]).

Table F1-2-1 (1) Input Data Format Mode

IRMON MODE2 DISEL R656I Mode

0 0 X 0

1 X 0 0

0 1 X 0

1 X 1 0

X X X 1 ITU-R BT.656 mode

Input in 16-bit mode

Input in 8-bit mode

Table F1-2-1(2) Input Data Format

Input pin Input in 16-bit mode

YI7 Y07 Y17 Cb07 Y07 Cr07 Y17

YI6 Y06 Y16 Cb06 Y06 Cr06 Y16

YI5 Y05 Y15 Cb05 Y05 Cr05 Y15

YI4 Y04 Y14 Cb04 Y04 Cr04 Y14

YI3 Y03 Y13 Cb03 Y03 Cr03 Y13

YI2 Y02 Y12 Cb02 Y02 Cr02 Y12

YI1 Y01 Y11 Cb01 Y01 Cr01 Y11

YI0 Y00 Y10 Cb00 Y00 Cr00 Y10

CI7 Cb07 Cr07 — — — —

CI6 Cb06 Cr06 — — — —

CI5 Cb05 Cr05 — — — —

CI4 Cb04 Cr04 — — — —

CI3 Cb03 Cr03 — — — —

CI2 Cb02 Cr02 — — — —

CI1 Cb01 Cr01 — — — —

CI0 Cb00 Cr00 — — — —

Y point 0 1 0 1

C point 0 0

Input in 8-bit mode

ITU-R BT.656 mode

24/123

PEDL87V21071-01

OKI Semiconductor

Input in 8-bit mode or ITU-R BT.656 modeInput in 16-bit mode

ICLK

#IICLK #IICLK

YI[7:0]

CI[7:0]

#: Internal signal

Yn Yn+1 Yn+2 Yn+3

Cn Cn+1 Cn+2 Cn+3

ICLK

YI[7:0]

CI[7:0]

Cbn Yn Crn Yn+1

Figure F1-2-1 (1) Input Data Timing

The data and control signal interfaces according to input system modes are as follows.

• Input in 16-bit mode

Vertical Sync. signal: IVS

Horizontal Sync. signal: IHS

Data input pin: YI[7:0], CI[7:0] (YCbCr-4:2:2)

Input system clock frequency: f

= 12.2727272/13.5/14.31818/14.75 MHz

ICLK

Clip level: None

• Input in 8-bit mode

Vertical Sync. signal: IVS

Horizontal Sync. signal: IHS

Data input pin: YI[7:0], (YCbCr-4:2:2)

Input system clock frequency: f

= 24.545454/27/28.63636/29.5 MHz

ICLK

Clip level: None

• ITU-R BT.656 mode

Vertical Sync. signal: SAV, EAV split

Horizontal Sync. signal: SAV, EAV split

Data input pin: YI[7:0] (YCbCr-4:2:2)

Input system clock frequency: f

= 27 MHz

ICLK

Clip level: 00h → 01h, FFh → Feh

* By setting POFF (SUB:41h-bit[6]) to 1, the parity bits of SAV and EAV can be disabled.

ML87V21071

don't care (no connect)

25/123

PEDL87V21071-01

OKI Semiconductor

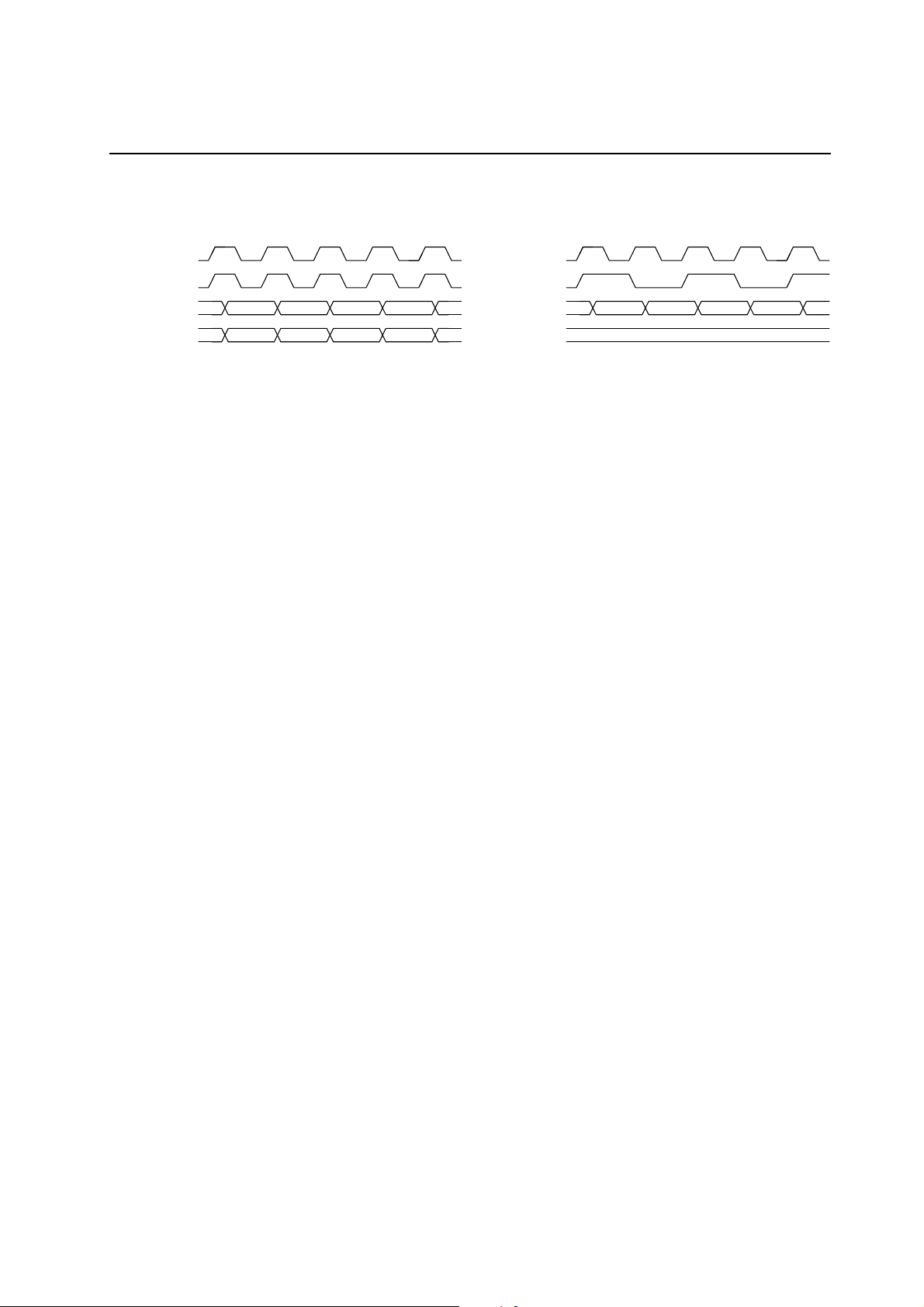

• Internal Input System Clock (IICLK)

The IICLK is IICLK = ICLK in 16-bit 4:2: 2 mode whereas in 8-bi t 4:2:2 mode and IT U-R BT.656 mode

it is the clock pulse obtained by internally frequency-dividing ICLK to 1/2.

In 8-bit 4:2:2 mode, the position which is two ICLK clocks delayed from the rise of IHS is used for

resetting and IICLK is generated by frequency-dividing ICLK to 1/2.

Normally reset of IICLK presumes the rise position of positive polarity IHS (IHSINV = 0), but by setting

IHES (SUB:41h-bit[5]) and IHSINV, selection of compliance with negative polarity IHS and fall

position is also possible.

In ITU-R BT 656 mode, ICLK is frequency-divided to 1/2 based on SAV.

In 8-bit 4:2:2 mode, if the p hase of IHS for l umina nce and chrominance d ata reverses (n umber of ICL Ks

from IICLK reset to initial chrominance data is odd), it is possible to avoid the reversal by setting ICINV

(SUB:41h-bit[4]).

Table F1-2-1 (4) Compliance with Luminance-Chrominance Phase Reversal

ICINV Usage conditions (8-bit 4:2:2 mode)

8-bit 4:2:2 mode

ICLK

IHS

IICLK

Reset

IICLK

YI[7:0]

Table F1-2-1 (3) IICLK Reset Position

IHES IHSINV Reset position

0 0

1 0

0 1

1 1

0 Number of ICLKs from IICLK reset to initial chrominance data is even.

1 Number of ICLKs from IICLK reset to initial chrominance data is odd.

Positive polarity IHS rise (horizontal Sync. signal front

edge)

Positive polarity IHS fall (horizontal Sync. signal rear

edge)

Negative polarity IHS fall (horizontal Sync. signal front

edge)

Negative polarity IHS rise (horizontal Sync. signal rear

edge)

Crn Yn Cbn Yn+1

Figure F1-2-1 (2) IICLK Phase Timing Example

ML87V21071

26/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

1.2.2 Output Data Format

Since internal signal processing is performed independently for luminance and chrominance signals, the output

data format of basic output of this IC is YCbCr 16bit 4:2:2.

However, in YCbCr 8bit 4:2:2 mode and ITU-R BT.656 mode, selection of YCbCr 8bit 4:2:2 (same format as

input) is enabled by setting DOSEL (SUB:60h-bit[1]) to 1. In this case, unused CO[7:0] becomes Hi-Z.

Table F1-2-2(2) shows the delay amount from input to output and the same delay amount occurs for all the data

and Sync. signals.

Table F1-2-2 (1) Output Data Format

Output Normal mode 8-bit input – 8-bit output mode (DOSEL =1)

YO7 Y07 Y07 Cr07 Y17 Cb07 Y17

YO6 Y06 Y06 Cr06 Y16 Cb06 Y16

YO5 Y05 Y05 Cr05 Y15 Cb05 Y15

YO4 Y04 Y04 Cr04 Y14 Cb04 Y14

YO3 Y03 Y03 Cr03 Y13 Cb03 Y13

YO2 Y02 Y02 Cr02 Y12 Cb02 Y12

YD1 Y01 Y01 Cr01 Y11 Cb01 Y11

YD0 Y00 Y00 Cr00 Y10 Cb00 Y10

CO7 Cb07 Cr07 — — — —

CO6 Cb06 Cr06 — — — —

CO5 Cb05 Cr05 — — — —

CO4 Cb04 Cr04 — — — —

CO3 Cb03 Cr03 — — — —

CO2 Cb02 Cr02 — — — —

CO1 Cb01 Cr01 — — — —

CO0 Cb00 Cr00 — — — —

Table F1-2-2(2) Combinations for Input/Output Data Format

DISEL R656I DOSEL Input Output

0 0 X 16-bit + Sync (H, V) 16-bit + Sync (H, V) 32 (ICLK)

1 0 0 8-bit + Sync (H, V) 8-bit + Sync (H, V) 64 (ICLK)

1 0 1 8-bit + Sync (H, V) 8-bit + Sync (H, V) 66 (ICLK)

X 1 0 ITU-R BT.656 16-bit + Sync (H, V) 64 (ICLK)

X 1 1 ITU-R BT.656 ITU-R BT.656 + Sync (H, V) 66 (ICLK)

Input/output delay

amount

* When input is ITU-R BT.656, Sync (H, V) on the output side is output to OVS and OHS as the Sync. signal

separated from SAV and EAV.

27/123

PEDL87V21071-01

OKI Semiconductor

ICLK

YI[7:0]

CI[7:0]

YO[7:0]

CO[7:0]

ICLK

YI[7:0]

ML87V21071

Y0 Y1

Cb0 Cr0

32(ICLK)

Y0 Y1 Y2

Cb0 Cr0 Cb1

Figure F1-2-2(1) Input/Output Delay in 16-Bit Input Mode

Cb0 Y0 Cr0 Y1

[DOSEL=0]

YO[7:0]

CO[7:0]

[DOSEL=1]

YO[7:0]

ICLK

YI[7:0]

[DOSEL=0]

YO[7:0]

CO[7:0]

[DOSEL=1]

64(ICLK)

Y0 Y1 Y2

Cb0 Cr0 Cb0

66(ICLK)

Cb0 Y0 Cr0 Y1

Figure F1-2-2(2) Input/Output Delay in 8-Bit Input Mode

FF 00 00 SAV Cb0 Y0 Cr0 Y1

64(ICLK)

00 SAV Y0 Y1 Y2

FF 00 Cb0 Cr0 Cb0

66(ICLK)

YO[7:0]

FF 00 00 SAV Cb0 Y0 Cr0 Y1

Figure F1-2-2(3) Input/Output Delay in ITU-R BT.656 Mode

28/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

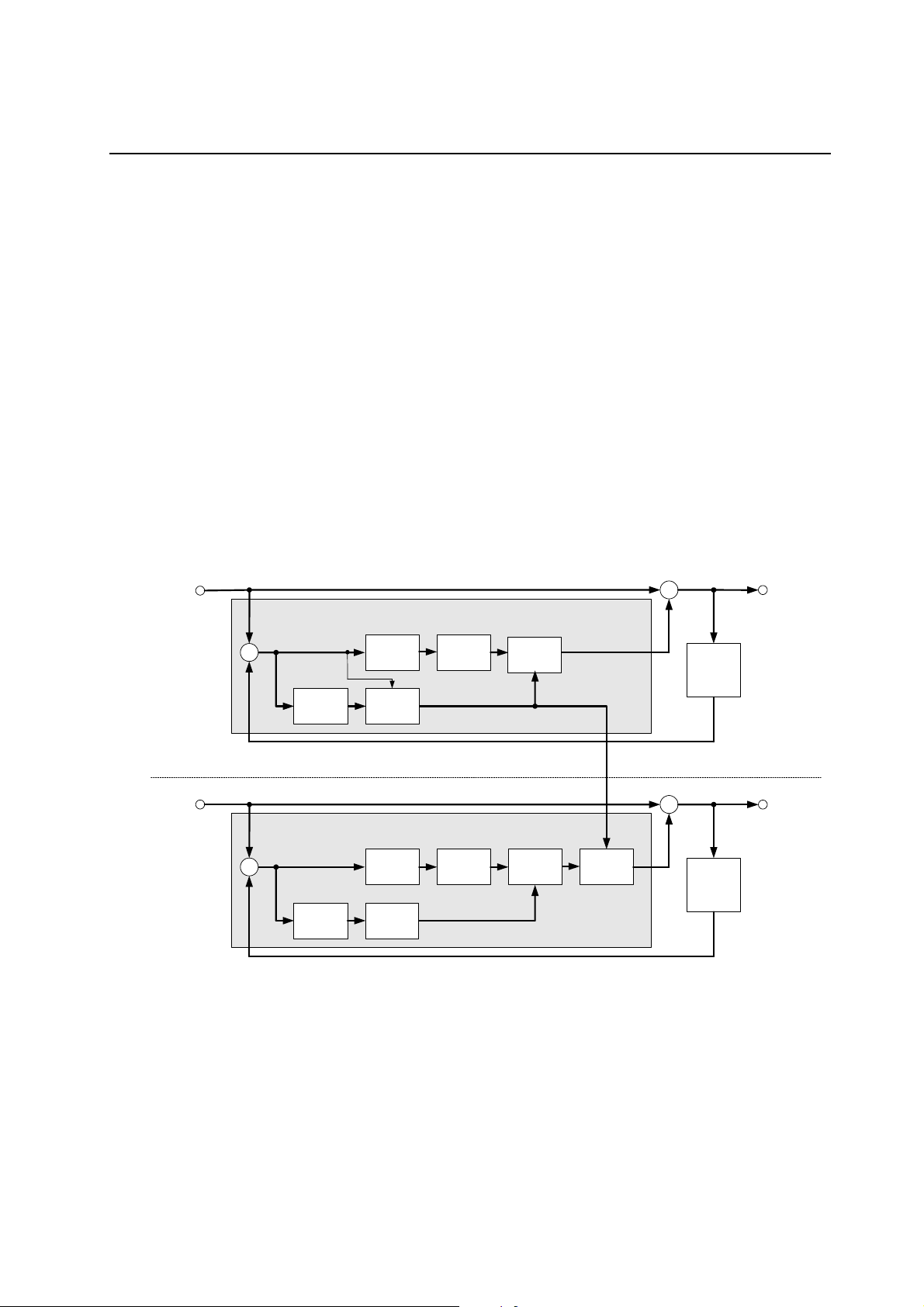

2. Video Signal Processing Functions

2.1 Motion-Adaptive 3D Noise Reduction

This IC performs noise reduction first by detecting noise and predicting motion using frame recursion, field

recursion, and line correlation, then by performing noise subtraction while performing motion compensation for

the detected noise. Moreover, it achieves adaptive noise reduction by synthesizing four NR data items based on

prediction of motion.

However, when INPR is set to 1, the field recursion stops and adaptive noise reduction is performed by the two

NR data items, frame recursion and line correlation.

• Principle of Noise Reduction

Difference between the current field data and the filed data preceding one frame, one field, or one line is

extracted as time motion and noise independently for luminance and chrominance signals.

The low gain portion of this data is judged to be noise and the high gain portion to be motion an d is extrac ted

as motion level detection noise.

The noise component extracted here is subjected to motion prediction by ad jacent motion level and adjacent

code, then further subjected to c om pensati on base d on m otion a nd i s regarde d as the fina l noi se component.

Finally, noise reduction is carried out by subtracting this final noise data from the current field data.

Luminance

input data

Luminance noise detection

+

-

-

LPF

MSB

Non-

linear filter

Motion

detection

Limiter

Motion

compen-

sation

+

-

-

Field

memory

NR recursive data

Luminance

output data

Chrominance

input data

+

-

-

Chrominance noise detection

+

-

-

LPF

Non-

linear filter

Motion

detection

Limiter

Chrominance

motion level

compen-

sation

Luminance

interlock

motion

compensation

Field

memory

Figure F2-1 (1) Noise Detection Type Noise Reduction Configuration

Chrominance

output data

NR recursive data

29/123

PEDL87V21071-01

Noi

OKI Semiconductor

Current field data

One preceding field data

–

–

se

–

–

detection

+

motion

compensation

Figure F2-1(2) Noise Reduction by Noise Detection

ML87V21071

Data after 3DNR

30/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

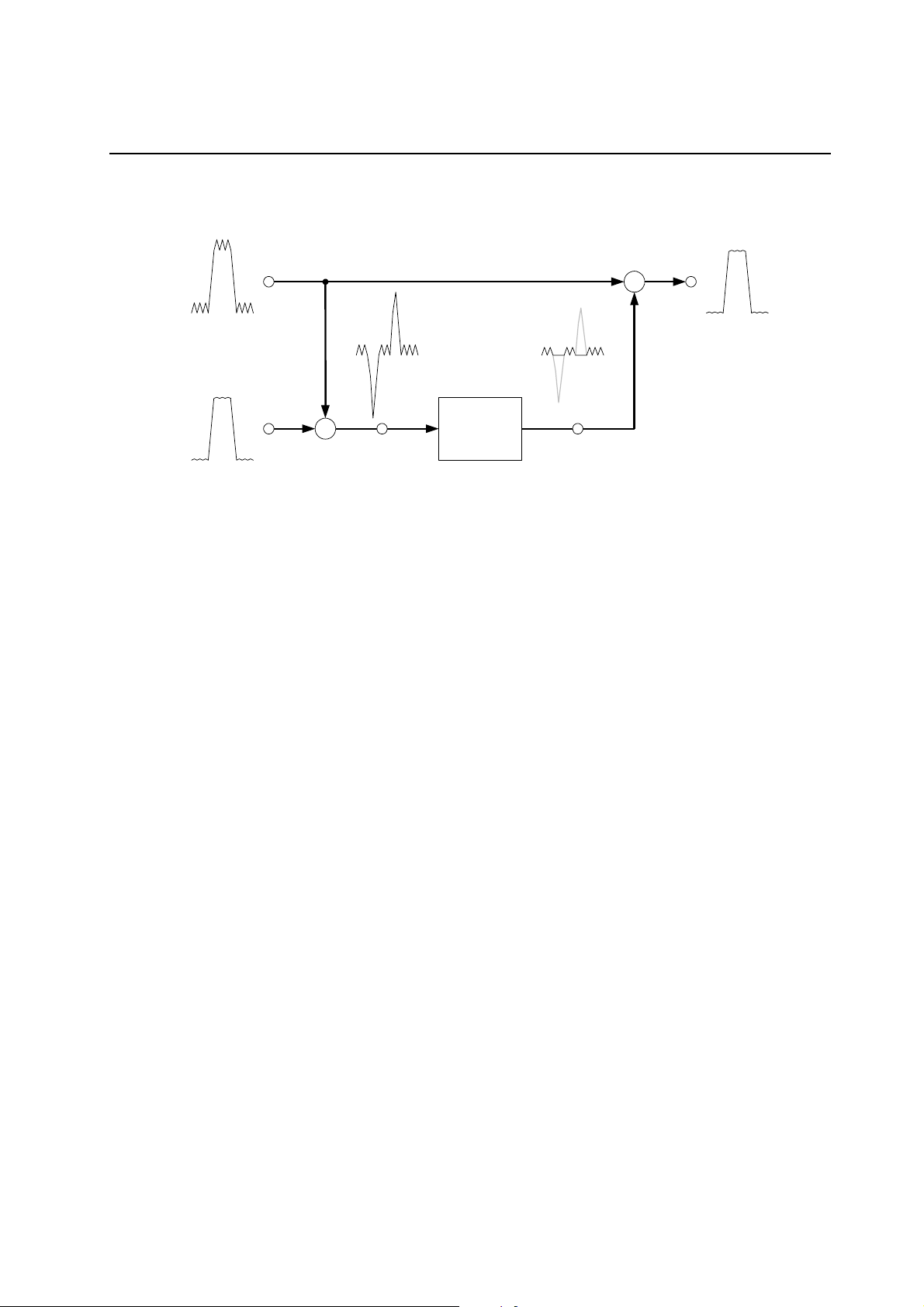

• Principles of Adaptive Noise Reduction

Adaptive noise reduction is achieved through the selection of noise reduction data, which utilizes the

correlative relationships between frames, fields, and lines for the pixels for which noise reduction is to be

performed, as shown in Figure F2-3 (3).

The distinguishing characteristics of each correlation are as shown below.

Between frames : Same position (most effective), time difference 2V (less effective)

→Effective for still images (good NR, substantial afterimage)

Between fields : Position 0.5H different (effective), time difference 1V(effective)

→More effective for moving images than frames, more effective for still images than

lines (medium NR, medium afterimage)

Between lines : Position 1H different (less effective), time difference 0 (most effective)

→Effective for moving images, but not effective for edges (medium NR, no

afterimage, no NR for edges)

This IC detects motions and e dges betwee n lines, f rames, and fields, ba sed on t he features described a bove, t o

select data after better correlated NR and achieve effective noise reduction.

Time axis

2V

Direction of V

1V 1V

1H

: NR-target pixel

: NR

Figure F2-1 (3) Noise Reduction Correlation

31/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

2.1.1 Noise Reduction Mode

The noise reduction mode is set by NR2OFF(SUB:48h-bit[4]), FNRM[1:0] (SUB:48h-bit[6:5]), and you can

select the noise reduction modes shown in Table F2-1-1.

Synthesis of an adaptive noise reduction mode is performed by checking motions that are predicted from the

motion detection signal and differe ntial sign al level that are detected at noi se reducti on between frames, fiel ds, or

lines.

For determining the motion difference level, weighting factor can be applied to frames by setting the adaptive

margin that is set by YFAM(SUB:4Ah-bit[1]), CFAM(SUB:4Bh-bit[1]). NR effect is improved by applying

weighting factor to frames (however, afterimage will be more likely to occur).

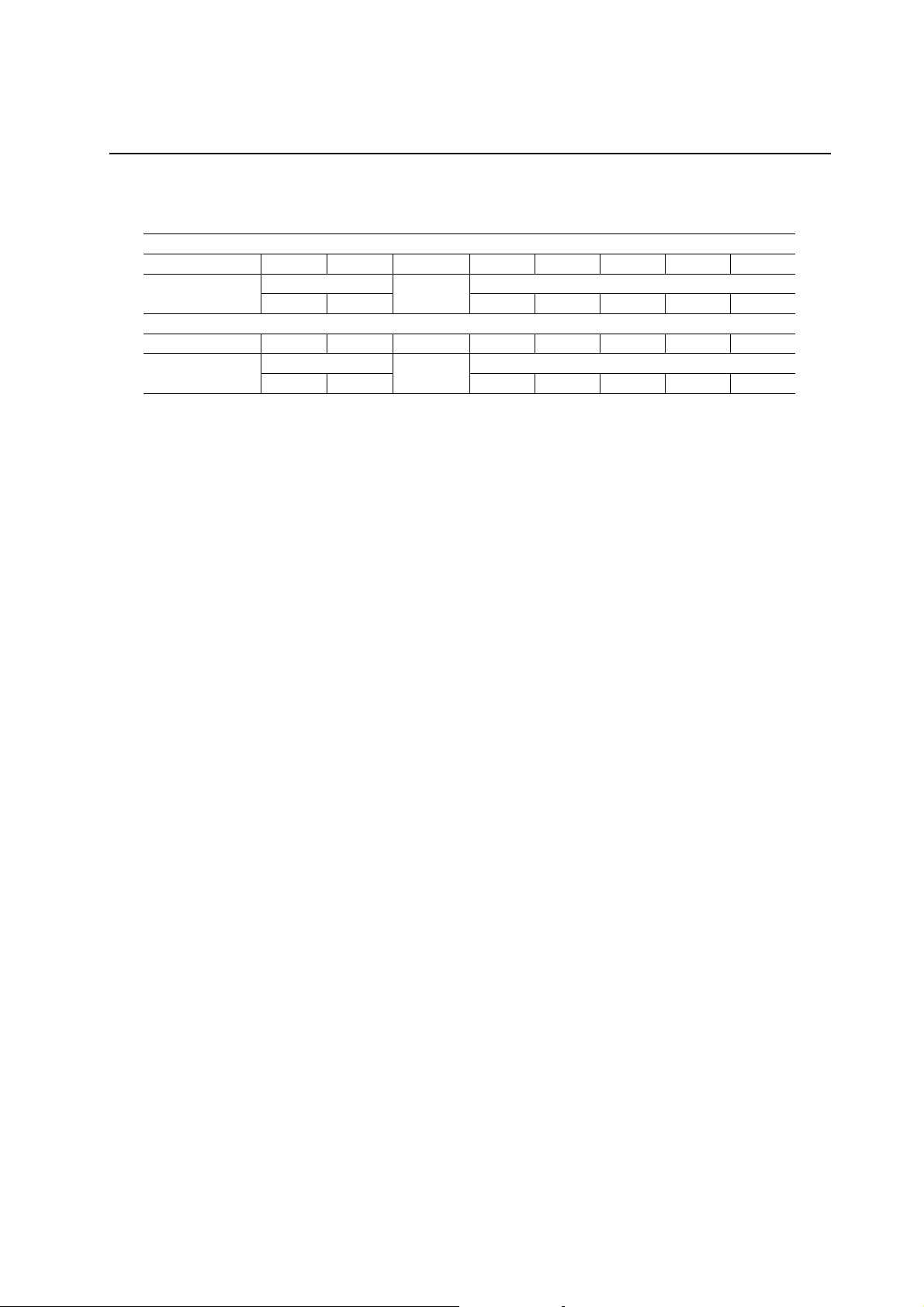

Table F2-1-1 (1) Noise Reduction Modes

FNRM

[1] [0]

0 0

0 0 1 3D adaptive frame-recursive NR (uses frames and fields)

0 1 0 2D adaptive frame-recursive NR (uses frames and lines)

0 1 1 Frame-recursive NR

1 X 0 2D adaptive field-recursive NR (uses fields and lines)

1 X 1 Field-recursive NR

NR2OFF Noise Reduction Mode

0

Fully adaptive frame-recursive NR (uses frames, fields, and

lines)

Table F2-1-1 (2) Luminance Adaptive Margin Settings

YFAM

0 0

1 –2

Luminance adaptive

margin

Remarks

Frame NR performance emphasized (larger

NR, larger afterimage)

F2-1-1 (3) Chrominance Adaptive Margin Settings

CFAM

0 0

1 –2

Chrominance adaptive

Margin

Remarks

Frame NR performance emphasized (larger

NR, larger afterimage)

32/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

2.1.2 Detected Noise Between Frames, Fields and Lines

The differences are calculated between

- one pixel in the current field and one pixel preceding by one frame,

- one pixel in the current field and two pixels by one field, and

- one pixel in the current field and one pixel preceding by one line.

Among the absolute values of these differences, the smallest value is selected.

From the differential values between frames and between fields (∆Y, ∆C), the signal with a low level of absolute

value for the differential values (|∆Y|, |∆C|) is judged to be the noise component and the signal with a high level is

judged to be the motion component. The data judged to be the noise is extracted as the motion level detection

noise.

The detected noise is output after being filtered by the area covered by the input noise detectio n line, the noise

convergence line, and the noise upper limit line. The inclination of the input noise detection line is set by

YSLT[1:0](SUB:4Ah-bit[5:4]) and CSLT[1:0](SUB:4Bh-bit[5:4]), the inclination and offset of the noise

convergence line are set by YSLT[3:2](SUB:4Ah-bit[7:6]), YNS[5:0] (SUB:4Ch-bit[5:0]), CSLT[3:2]

(SUB:4Bh-bit[7:6]) and CNS[5:0] (SUB:4Dh-bit[5:0]), and the offset of the noise upper limit line, which has 0

inclination, is set by YLM[4:0] (SUB:4Eh-bit[4:0]) and CLM[4:0] (SUB:4Fh-bit[4:0]). (Figure F2-1-1)

Table F2-1-2 Non-Linear Filter Noise Detection Area Settings

YSLT/CSLT Noise detection line Noise convergence line Noise upper limit line

[3] [1] [2] [0] Inclination Offset Inclination Offset Inclination Offset

0 0 0 0 1

0 0 0 1 7/8

0 1 0 0 3/4

–1

0 1 0 1 1/2

0 0 1 0 1

0 0 1 1 7/8

0 1 1 0 3/4

0 1 1 1 1/2

1 0 0 0 1

1 0 0 1 7/8

1 1 0 0 3/4

0

–3/4

–1/2

YNS[5:0]

CNS[5:0]

0

YLM[4:0]

CLM[4:0]

1 1 0 1 1/2

1 0 1 0 1

1 0 1 1 7/8

1 1 1 0 3/4

–3/2

1 1 1 1 1/2

Field-recursive

detection noise

output

31(MAX)

Noise convergence line

Input noise detection line inclination

1 or 7/8 or 3/4 or 1/2

Noise detection line

Non-noise detection area

Noise convergence line inclination

-1 or -3/4 or -1/2 or -3/2

Noise upper limit line

Noise upper limit

line offset:

YLM[4:0], CLM[4:0]

= 0 to 31

Noise detection area

(Differential absolute

0

Noise convergence line offset: YNS[5:0], CNS[5:0] = 0 to 63

63(MAX)

value of difference

between fields

|∆Y|, |∆C|) input

Figure F2-1-2 Field-Recursive Noise Motion Level Detection Noise Characteristics

33/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

2.1.3 Detection of Motion between Frames, Fields, and Lines

There are two types of luminance signal motion detection: level motion detection and continuous code motion

detection.

Chrominance signal motion detection includes level motion detection.

c Luminance Level Motion Detection

From the differential data between fields, including luminance signal motion and noise, the high frequency

component (∆HY) is filtered with the LPF, extracting only the low frequency differential data (∆LY).

Luminance LPF: F(z) = (1/8)z

-2

+ (1/8)z-1 + (1/2)z0 + (1/8)z1 + (1/8)z2

The low frequency differential data is assumed to have a large proportion of the motion component, so the

absolute value of that data (|∆LY|) is compared with the luminance noise convergence level set in YNS[5:0] to

determine the amount of motion.

If the result shows that the differential absolute value is greater than the noise convergence level, it is determined

that there is a lot of motion in the data, and the motion flag (YMT) = 1 is set.

If the differential absolute value is less than the noise convergence level, it is determined that there is not much

motion in the data, and the motion flag (YMT) = 0 is set.

Table F2-1-3 (1) Luminance Level Motion Detection

Motion Detection Conditions Motion Flag (YMT)

|∆LY| > 64

|∆LY| > YNS[5:0]

|∆LY| ≤ YNS[5:0]

1

1

0

d Luminance Continuous Code Motion Detection

This feature detects sequences of 3, 4, and 5 continuous codes in the differential data that includes the pixels for

which noise detection is being performed. Where continuity is detected, the absolute value of the low frequency

differential data and the continuous code motion detection level YMS[3:0]( SUB:50h-bit[3:0]) are compared to

determine the amount of motion.

• 3 Continuous Code Detection

If 3 continuous codes are detected to be the same and their low frequency differential data absolute values are

equal to or greater than the continuous code motion detection level (YMS[3:0]), the data is judged to have much

motion, and the 3 continuous code motion flag (YMT3) = 1 is set.

If the absolute value is less than the continuous motion detection level, the data is judged to have little motion, and

the 3 continuous code motion flag (YMT3) = 0 is set.

Table F2-1-3 (2) Luminance 3 Continuous Code Motion Detection

Motion detection condition Motion flag (YMT3)

|∆LY| > 16

|∆LY| ≥ YMS[3:0]

|∆LY| < YMS[3:0]

1

1

0

34/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

• 4 Continuous Code Detection

If 4 continuous codes are detected to be the same and their low frequency differential data absolute values are

equal to or greater than the continuous code motion detection level 1/2(YMS[3:1]), the data is judged to have

much motion, and the 4 continuous code motion flag (YMT4) = 1 is set.

If the absolute value is less than the continuous motion detection level, the data is judged to have little motion, and

the 4 continuous code motion flag (YMT4) = 0 is set.

By setting YMDM( SUB:50h-bit[4]) = 1, the detection precision of the 4-continu ous code motion flag can be

improved.

Table F2-1-3 (3) Luminance 4 Continuous Code Motion Detection

Motion detection condition Motion flag (YMT4)

|∆LY| > 8

|∆LY| ≥ YMS[3:1]

|∆LY| < YMS[3:1]

1

1

0

• 5 Continuous Code Detection

If 5 continuous codes are detected to be the same and their low frequency differential data absolute values are

equal to or greater than the continuous code motion detection level 1/4 (YMS[3:2]), the data is judged to have

much motion, and the 5 continuous code motion flag (YMT5) = 1 is set.

If the absolute value is less than the continuous motion detection level, the data is judged to have little motion, and

the 5 continuous code motion flag (YMT5)=0 is raised.

By setting YMDM( SUB:50h-bit[4]) = 1, the detection precision of the 5-continu ous code motion flag can be

improved.

Table F2-1-3 (4) Luminance 5 Continuous Code Motion Detection

Motion detection condition Motion flag (YMT5)

|∆LY| > 4

|∆LY| ≥ YMS[3:2]

|∆LY| < YMS[3:2]

1

1

0

e Chrominance Level Motion Detection

From the differential data between fields, including chrominance signal motion and noise, the high frequency

component (∆HC) is filtered with the LPF, extracting only the low frequency differential data (∆LC).

Chrominance LPF: F(z) = (1/4)z

-2

+ (1/2)z0 + (1/4)z2

The low frequency differential data is assumed to have a large proportion of the motion component, so the

absolute value of that data (|∆LC|) is compared with the chrominance noise convergence level set in CNS[5:0] to

determine the amount of motion.

If the result shows that the differential absolute value is greater than the noise convergence level, the data is

judged to have a lot of motion, and the chrominance motion flag (CMT) = 1 is set.

If the differential absolute value is less than the noise convergence level, it is determined that there is not much

motion in the data, and the motion flag (CMT) = 0 is set.

This motion flag is used in adjacent pixel motion compensation.

Table F2-1-3 (5) Chrominance Level Motion Detection

Motion detection condition Motion flag (CMT)

|∆LC| > 64

|∆LC| > CNS[5:0]

|∆LC| ≤ CNS[5:0]

1

1

0

35/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

2.1.4 Motion Compensation Processing

This IC performs the motion compensation descri bed below in c and d for the noise de tected in Section 2.1. 2 It

does this by creating the motion compensation flags YMA[3:0] and CMA[4:0] from the motion flags (YMT,

YMT3, YMT4, YMT5, and CMT) detected in Section 2.1.3, the motion compensation stop settings YMOFF[3:0]

(SUB:51h-bit[3:0]) and CMOFF[4:0](SUB:52h-bit[4:0]), and the luminance linked chrominance motion

compensation setting CMY (SUB:52h-bit[7]).

Table F2-1-4 (1) Motion Compensation Flags

Motion

compensation flag

YMA[0] YMT&YMOFF[0]

YMA[1] YMT&YMOFF[1]

YMA[2] YMT&YMOFF[2]

YMA[3] YMT&YMOFF[3]

CMA[0] CMT&CMOFF[0]

CMA[1] YMT&CMOFF[1]&CMY

CMA[2] YMT3&CMOFF[2]&CMY

CMA[3] YMT4&CMOFF[3]&CMY

CMA[4] YMT5&CMOFF[4]&CMY

Composite signal Remarks

Luminance adjacent pixel level luminance

motion compensation

Luminance 3 continuous codes luminance

motion compensation

Luminance 4 continuous codes luminance

motion compensation

Luminance 5 continuous codes luminance

motion compensation

Chrominance adjacent pixel level chrominance

motion compensation

Luminance adjacent pixel level chrominance

motion compensation

Luminance 3 continuous codes chrominance

motion compensation

Luminance 4 continuous codes chrominance

motion compensation

Luminance 5 continuous codes chrominance

motion compensation

c Luminance Signal Noise Motion Compensation

This feature performs motion compensation for the detected noise using the motion compensation flag

YMA[3:0].

As the method of motion compensati on , you can select the reductio n mode (YNRM = 0) o r the noise 0 mode with

YNRM(SUB:4Ah-bit[0]).

In the reduction mode, you can choose the normal reduction mode (YABN = 0) or the absolute noise reduction

mode (YABN = 1) in register YABN(SUB:4Ah-bit[2]).

Table F2-1-4 (2) Luminance Motion Compensation Modes

YNRM YABN

X X None Detected noise as is

0 0 Normal reduction

0 1 Absolute noise reduction

1 X Noise 0

Motion compensation

mode

Remarks

(Detected noise) x

(Reduction coefficient)

(Detected noise) x

(Reduction coefficient)

Noise 0 judgment

(NROFF)

36/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

Table F2-1-4 (3) Noise Reduction Coefficients

YMA Reduction coefficient

[3] [2] [1] [0] YABN = 0 YABN = 1

0 0 0 0 1 1

0 0 0 1 1/2 3/4

0 0 1 0 1/2 3/4

0 0 1 1 1/4 5/8

0 1 1 0 1/4 5/8

0 1 1 1 1/8 9/16

1 1 1 0 1/8 9/16

1 1 1 1 1/16 17/32

d Chrominance Signal Noise Motion Compensation

This feature performs mot ion compensation for t he detected noise using the motion com pensation flag CMA[ 4:0].

As the method of motion c ompensation , the reduct ion mode (CNRM = 0) or the noise 0 mode (CNRM = 1) can be

selected by CNRM (SUB:4Bh-bit[0]).

In the reduction mode, the normal reduction mode (CABN = 0) or the absolute noise reduction mode (CABN = 1)

can be selected by CABN (SUB:4Bh-bit[2]).

Table F2-1-4 (4) Chrominance Motion Compensation Mode

CNRM CABN Motion compensation mode Remarks

X X None Detected noise as is

0 0 Normal reduction

0 1 Absolute noise reduction

1 X Noise 0

(Detected noise) x

(Reduction coefficient)

(Detected noise) x

(Reduction coefficient)

Noise 0 judgment

(NROFF)

Table F2-1-4 (5) Chrominance Normal Reduction Mode Noise Reduction Coefficients

CMA Reduction coefficient

[4] [3] [2] [1] [0] CABN=0 CABN=1

0 0 0 0 0 1 1

0 0 0 0 1 1/2 3/4

0 0 0 1 0 1/2 3/4

0 0 0 1 1 1/4 5/8

0 0 1 0 0 1/2 3/4

0 0 1 0 1 1/4 5/8

0 0 1 1 0 1/4 5/8

0 0 1 1 1 1/8 9/16

0 1 1 0 0 1/4 5/8

0 1 1 0 1 1/8 9/16

0 1 1 1 0 1/8 9/16

0 1 1 1 1 1/16 17/32

1 1 1 0 0 1/8 9/16

1 1 1 0 1 1/16 17/32

1 1 1 1 0 1/16 17/32

1 1 1 1 1 0 1/2

37/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

2.1.5 Noise Reduction Stop Setting

Noise reduction can be forcibly stopped by setting NROFF (SUB:48h-bit[0]) on the I

2

C-bus interface.

However, data can be written into the memory even while noise reduction is stopped.

Table F2-1-5 NROFF Setting

NROFF Noise Reduction

0 Operated

1 Stopped

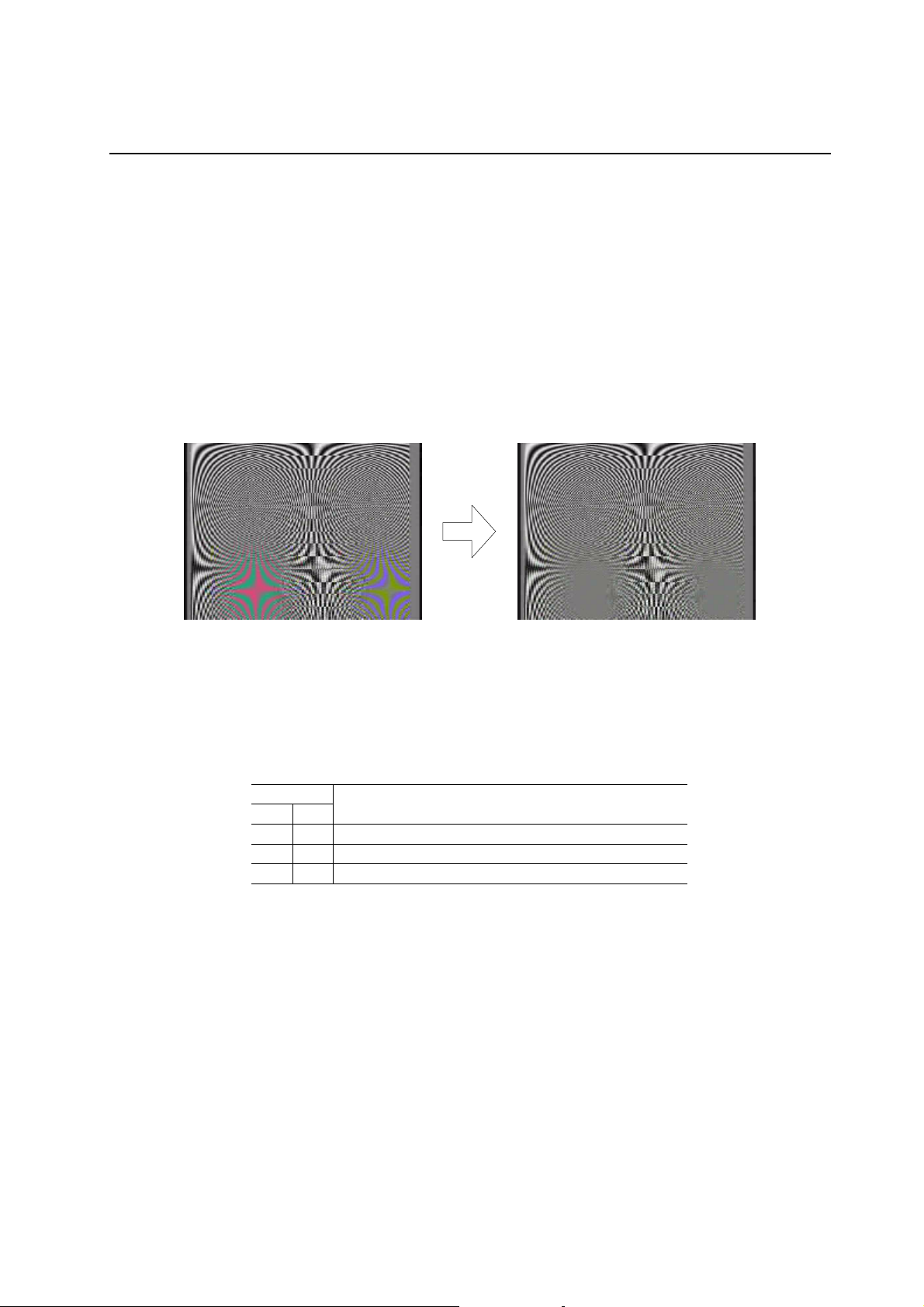

2.1.6 Noise Reduction Demo Mode Setting

By setting NRDEMO[2:0] (SUB:48h-bit[2:0]), a screen can be split as shown in Figure F2-1-6 and noise

reduction function can be confirmed as demo mode or the I

2

C-bus interface.

However, the demo mode does not work when noise reduction is stopped by setting NROFF = 1.

Table F2-1-6 NRDEMO Setting

NROFF

0 0 0 0 NR setting value NR setting value

1 X X X Stop NR Stop NR

0 X X 1 Stop NR NR setting value

0 X 1 0 NR Setting value Adaptive NR ON

0 1 0 0 NR Setting value

NRDEMO

[2] [1] [0]

Left side of screen Right side of screen

Adaptive line

correlation NR ON

Left side area

of screen

Right side area

of screen

Figure F2-1-6 Noise Reduction Demo Screen

38/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

2.1.7 Noise Status Detection

In order to automatically optimize noise reduction setting, this IC has a function for detecting the overall video

sample noise status during the motionless vertical blanking period.

• Detection of noise level (average and maximum values)

Set NRDTON (SUB:49h-bit[1]) = 1 to detect the blanking period noise level for one line (NDTC = 0) of a

vertical blanking period set by NRD TP[3:0] (SUB:57h -bit[4:2] ) and DT PSL (S UB:57h- bit[7]). Altern atively,

you can set the same register to detect the bl a nking noise (average and maxim um values) for one li ne ( NDTC

= 1) of the maximum noise level of multiple lines (a maximum of 16 lines not including valid lines) ending

with line NRDTP[2:0]. The detection of blanking period noise (average and maximum values) and the noise

on the line on which the average noise between fields for the valid data period is minimum can be performed

frame by frame.

The detection starting position is set in DTPSL. When DTPSL = 0, the starting position is immediately after

the end of the valid lines; when DTPSL = 1, the starting pos ition is one line after the end of the valid lines.

In a blanking period, one line is divided into two sections, the noise levels of the two sections are detected,

and the larger average noise value between the first 128 pixels and second 128 pixels is assumed as the

average value and maximum value of the line.

In a valid data period, one line is divided into four sections, the noise levels of the four 128-pixel periods are

detected, and the lowest average noise value is assumed as the a verage val ue a nd m axim um value of t he line.

During the valid data period, a luminance noise detection saturation level can be set through

PYST[1:0](SUB:52h-bit[6:5]), thereby preventing deterioration of the noise detection level by luminance

level saturation of CCD image input.

When NRDTON = 0, the final status data for NRDTON = 1 is preserved. Initially, the average and maximum

noise values are set at 0.

The fields for which detection is to be performed are set in NRDTF (SUB:49h-bit[5]). When NRDTF = 0,

field A vertical blanking period is set; when NRDTF = 1, field B vertical blanking period is set.

By setting YNMAS (SUB:57-bit[0]) and CNMAS (SUB:57h-bit[1]), it is possible to select either an 8-frame

average of the detected noise (YNMAS = 0, CNAMS = 0) or the level of detected noise in a single frame

(YNMAS = 1, CNAMS = 1).

For a noise detection area, a vertical blanking period, a valid data period, or a combination of both can be set

using PODT (SUB:49h-bit[4]) and PNON (SUB:49h-bit[7]).

39/123

PEDL87V21071-01

OKI Semiconductor

#Valid data

signal

NRDTP[3:0]

(DTPSL=0)

NRDTP[3:0]

(DTPSL=1)

#: Internal signal

Figure F2-1-7 (1) Vertical Blanking Noise Status Detection timing (NDTC = 0)

#Valid data

signal

NRDTP[3:0]

(DTPSL=0)

NRDTP[3:0]

(DTPSL=1)

IHS

IHS

1 2 3 4 5 14 15

0

1 2 3 4 5 13 14 150

NDTP[3:0]+1

NDTP[3:0]+1

ML87V21071

#: Internal signal

Figure F2-1-7 (2) Vertical Blanking Noise Status Detection timing (NDTC = 1)

40/123

PEDL87V21071-01

OKI Semiconductor

128pixels 128pixels

ML87V21071

Vertical blanking period

horizontal valid data

noize level detection per iod (2 x

128 pixels)

Vertical blanking

noise level detection

period (1 or 16 lines)

Vertical valid line

noise level detection period

128pixels128pixels128pixels128pixels

Valid data period

horizontal valid data

noize level detection per iod (2 x

128 pixels)

Figure F2-1-7(3) Noise Level Detection Area

41/123

PEDL87V21071-01

OKI Semiconductor

[NRDTF = 0: detection by field A]

Noise status

detection timing

[NRDTF = 1: detection by field B]

Noise status

detection timing

IVS

#IF

Field A

Field B

Field A

Figure F2-1-7 (4) Detection Field Based on NRDTF

Table F2-1-7 (1) Vertical Blanking Sample Noise Detection Settings

NRDTON Noise detection

0 Stopped (previously

detected data is maintained)

1 Operating

Table F2-1-7 (2) Noise Detection Field Settings

NRDTF Noise detection field

0 Field A

1 Field B

Table F2-1-7 (3) Blanking Period Noise Detection Line Settings

NDTC Noise detection line

0 1 line set at the NRDTP[3:0] position

1 Multiple lines (a maximum of 16 lines) from the line after the last

valid line to NRDTP[3:0]

Table F2-1-7 (4) Noise Detection Value Select Settings

YNAMS

CNAMS

0 Average of 8 frames

1 Single frame

Noise detection value

Table F2-1-7(5) Noise Detection Area Settings

PODT PNON Noise detection area

0 0 Vertical blanking only

0

1 X Valid data period only

Vertical blanking only + valid data

period

Table R2-1-7(6) Luminance Saturation Level Settings for Valid Data Area Noise Detection

PYST[1:0] Luminance saturation level

0h No saturation level

1h E0h

2h C0h

3h 80h

ML87V21071

Field B

42/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

c Detection of Basic Noise Status Signals

Detection of the basic noise status signal (YBDTO, CBDTO) involves comparing the average noise value

(YBAVRO[6:0], CBAVRO[6:0]) and the noise status comparison value (YAVR1[5:0] (SUB:53h-bit[5:0]),

CAVR1[5:0] (SUB:54h-bit[5:0] )) of the blanking period. The noise statu s is switched when the new status has

continued for four frames or more.

The detection of the noise status signal has the hysteresis characteristic shown in Figure F2-1-6(4). You can

select the characteristic with YAH1(SUB:53h-bit[7]) and CAH1 (SUB:54h-bit[7]).

Table F2-1-7 (5) Luminance Blanking Period Noise Status Detection

Before transition

YBDTO

0

0 YBAVRO[6:0] > YAVR1[5:0] 1

1

1

Condition

YBAVRO[6:0]

YBAVRO[6:0]

YBAVRO[6:0] > YAVR1[5:0] x (hysteresis

≤ YAVR1[5:0]

≤ YAVR1[5:0] x (hysteresis

coefficient)

coefficient)

After transition

YBDTO

0

0

1

Table F2-1-7 (6) Chrominance Blanking Period Noise Status Detection

Before transition

CBDTO

0

0 CBAVRO[6:0] > CAVR1[5:0] 1

1

1

Condition

CBAVRO[6:0]

CBAVRO[6:0]

CBAVRO[6:0] > CAVR1[5:0] x (hysteresis

≤ CAVR1[5:0]

≤ CAVR1[5:0] x (hysteresis

coefficient)

coefficient)

After transition

CBDTO

0

0

1

Table F2-1-7 (7) Noise Status Reduction Direction Detection Hysteresis Settings

YAH1

CAH1

0 3/4

1 7/8

Noise reduction direction

switching coefficient

Basic noise status judgment

Noise reduction direction judging threshold value

Noise increase direction judging threshold value

YBDTO=1,CBDTO=1

Basic average noise value

YBDTO=0,CBDTO=0

0

Set with YAH1, CAH1

YAVR1[6:0]

CAVR1[6:0]

YBAVRO[6:0]

CBAVRO[6:0]

Figure F2-1-7 (4) Basic Noise Status Judgment Transition Diagram

43/123

PEDL87V21071-01

OKI Semiconductor

ML87V21071

d Judgment Noise Level Selection

Select the judgment noise level based on the procedure for basic noise level detection described above.

When PODT = 0 and PNON = 0, the blanking period noise level is referen ced for the judgment noise level.

When PODT = 0 and PNON = 1, the overall noise status is referenced on the noise level of the valid data

period when the noise status of the blanking period is judged to be low noise (YBDTO1 = 0, CBDTO1 = 0).

When the noise status of the blanking period is judged to be high (YBDTO1 = 1, CBDTO1 = 1), the average

noise level of the blanking peri od and the average noise level of the valid period are com pared and the smal ler

value is referenced for the overall noise status.

Switching between the blanking period and the valid data period occurs when the noise average value

condition has continued for four frames or more.

When PODT = 1, the noise level of the valid data period is referenced for the judgment noise level.

Table F2-1-7 (8) Luminance Judgment Noise Level Selection

PODT PNON YBDTO1

0 0 X — Blanking period noise level

0 1 0 — Valid data period noise level

0 1 1

0 1 1 Blanking period > Valid data period Valid dat a period noise level

1 X X — Valid data period noise level

Luminance noise average value noise level

condition

Blanking period

≤ Valid data period

Luminance judgment noise level

Blanking period noise level

Table F2-1-7 (9) Chrominance Judgment Noise Level Selection

PODT PNON CBDTO1

0 0 X — Blanking period noise level

0 1 0 — Valid data period noise level

0 1 1

0 1 1 Blanking period > Valid data period Valid dat a period noise level

1 X X — Valid data period noise level

Chrominance noise average value noise

level condition

Blanking period

≤ Valid data period

Chrominance judgment noise

level

Blanking period noise level

44/123

PEDL87V21071-01

OKI Semiconductor

e Judging noise status detection

Judgment of the noise status is achieved by comparing t he average noise value (YAVRO[6:0], CAVRO[6:0]),

the noise status comparison value (I

2

C-bus setting registers YAVR1[5:0] (SUB:53h-bit[5:0]), CAVR1[5:0]

(SUB:54h-bit[5:0]), YAVR2 [6:0] (SUB:55h-bit[6:0]), CAVR2[6:0] (SUB:56h-bit[6:0])). Based on this

judgment, the noise status signals (YDTO1, CDTO1, YDTO2, CDTO2) are generated.

The detection of noise status signal has a hysteresis characteristic as shown in Figure F2-1-6 (5). Select the

characteristic with YAH1 (SUB:53h-bit[7]), CAH1 (SUB:54h-bit[7]), YAH2 (SUB:55h-bit[7]), and CAH2

(SUB:56h-bit[7]).