Page 1

ML6300

Technical reference guide

ML6300FB

Page 2

P

REFACE

Every effort has been made to ensure that the information in this document is

complete, accurate, and up-to-date. Oki Printing Solutions assumes no

responsibility for the results of errors beyond its control. Oki Printing Solutions also

cannot guarantee that changes in software and equipment made by other

manufacturers and referred to in this guide will not affect the applicability of the

information in it. Mention of software products manufactured by other companies

does not necessarily constitute endorsement by Oki Printing Solutions.

While all reasonable efforts have been made to make this document as accurate and

helpful as possible, we make no warranty of any kind, expressed or implied, as to

the accuracy or completeness of the information contained herein.

The most up-to-date drivers and manuals are available from the Oki Printing

Solutions web site:

http://www.okiprintingsolutions.com

Copyright © 2006 Oki Printing Solutions.

Oki, OKI Printing Solutions and Microline are registered trademarks of Oki Electric

Industry Company, Ltd.

ENERGY STAR is a trademark of the United States Environmental Protection Agency.

Microsoft, MS-DOS and Windows are registered trademarks of Microsoft

Corporation.

Other product names and brand names are registered trademarks or trademarks of

their proprietors.

As an ENERGY STAR Program Participant, the manufacturer has

determined that this product meets the ENERGY STAR guidelines

for energy efficiency.

This product complies with the requirements of the Council

Directives 89/336/EEC (EMC) and 73/23/EEC (LVD) as amended

where applicable on the approximation of the laws of the member

states relating to electromagnetic compatibility and low voltage.

Preface > 2

Page 3

C

ONTENTS

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Notes, cautions and warnings . . . . . . . . . . . . . . . 10

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Standard configuration . . . . . . . . . . . . . . . . . . . . 12

Identifying component parts . . . . . . . . . . . . . . . . 12

Front view. . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Rear view . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

About this guide . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Online usage . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Printing pages . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Interface specifications . . . . . . . . . . . . . . . . . . . . 18

IEEE1284 parallel interface specifications . . . . . . . 18

Connectors and cable . . . . . . . . . . . . . . . . . . . 18

Parallel interface signals . . . . . . . . . . . . . . . . . 19

Parallel interface levels. . . . . . . . . . . . . . . . . . 19

Parallel interface circuits . . . . . . . . . . . . . . . . . 20

Parallel interface timing chart . . . . . . . . . . . . . 20

Support mode . . . . . . . . . . . . . . . . . . . . . . . . 20

Universal Serial Bus (USB) . . . . . . . . . . . . . . . . . 21

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

USB interface signals . . . . . . . . . . . . . . . . . . . 21

Mode and class of device . . . . . . . . . . . . . . . . 22

Data signalling rate . . . . . . . . . . . . . . . . . . . . 22

Interface circuit . . . . . . . . . . . . . . . . . . . . . . . 22

Signal level . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Timing chart . . . . . . . . . . . . . . . . . . . . . . . . . 24

Option interface specifications . . . . . . . . . . . . . . . 25

Interface signals . . . . . . . . . . . . . . . . . . . . . . 25

Electrical characteristics . . . . . . . . . . . . . . . . . 26

Interface timing charts . . . . . . . . . . . . . . . . . . 28

Receiving margin . . . . . . . . . . . . . . . . . . . . . . 28

Description of communication procedures . . . . . 28

Interface control code . . . . . . . . . . . . . . . . . . 29

Local test function . . . . . . . . . . . . . . . . . . . . . 30

Operator interface . . . . . . . . . . . . . . . . . . . . . . . . 32

Operator panel functions. . . . . . . . . . . . . . . . . . . 32

Print mode . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Hex Dump mode, Menu mode, Test mode. . . . . 35

Preface > 3

Page 4

Maintenance mode 1 . . . . . . . . . . . . . . . . . . . 36

Maintenance mode 2 . . . . . . . . . . . . . . . . . . . 36

Lamp functions . . . . . . . . . . . . . . . . . . . . . . . . . 37

Alarm/error indications . . . . . . . . . . . . . . . . . . . . 37

Recoverable alarms . . . . . . . . . . . . . . . . . . . . 37

Unrecoverable alarms. . . . . . . . . . . . . . . . . . . 38

Menu selection. . . . . . . . . . . . . . . . . . . . . . . . . . 39

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Button switch functions . . . . . . . . . . . . . . . . . 40

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Menu items . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Registration menu . . . . . . . . . . . . . . . . . . . . . . . 54

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Registration details . . . . . . . . . . . . . . . . . . . . 55

Self test printing . . . . . . . . . . . . . . . . . . . . . . . . 55

Rolling ASCII self test printing . . . . . . . . . . . . . . . 56

Hexadecimal Dump mode . . . . . . . . . . . . . . . . . . 57

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Continuous paper auto-loading . . . . . . . . . . . . . . 58

Continuous paper auto-parking . . . . . . . . . . . . . . 58

Cut-sheet paper semi-auto-loading . . . . . . . . . . . 59

Form tear-off . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Action. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Command descriptions . . . . . . . . . . . . . . . . . . . . . 61

Horizontal control. . . . . . . . . . . . . . . . . . . . . . . . 61

Carriage return . . . . . . . . . . . . . . . . . . . . . . . 61

Horizontal tab set . . . . . . . . . . . . . . . . . . . . . 61

Horizontal tab . . . . . . . . . . . . . . . . . . . . . . . . 63

Reset tab settings to power-on default values . . 63

Execute absolute horizontal dot position . . . . . . 64

Execute relative dot position . . . . . . . . . . . . . . 64

Move right relative dot position . . . . . . . . . . . . 66

Move left relative dot position . . . . . . . . . . . . . 67

Left margin set . . . . . . . . . . . . . . . . . . . . . . . 67

Right margin set . . . . . . . . . . . . . . . . . . . . . . 68

Set left/right margin . . . . . . . . . . . . . . . . . . . 69

Auto justification . . . . . . . . . . . . . . . . . . . . . . 70

Set/reset unidirection printing . . . . . . . . . . . . . 71

Preface > 4

Page 5

One line unidirectional printing . . . . . . . . . . . . 72

Set/reset half speed printing . . . . . . . . . . . . . . 72

Backspace. . . . . . . . . . . . . . . . . . . . . . . . . . . 73

One character data delete. . . . . . . . . . . . . . . . 74

Vertical control . . . . . . . . . . . . . . . . . . . . . . . . . 74

Set 1/8 inch fixed line spacing. . . . . . . . . . . . . 74

Set 7/72 inch fixed line spacing. . . . . . . . . . . . 75

Start line spacing. . . . . . . . . . . . . . . . . . . . . . 75

Set 1/6 inch line spacing. . . . . . . . . . . . . . . . . 75

Set n/60 inch line spacing. . . . . . . . . . . . . . . . 76

Set n/180 inch line spacing . . . . . . . . . . . . . . . 77

Set n/360 inch fine line spacing. . . . . . . . . . . . 77

Set n/360 inch line spacing . . . . . . . . . . . . . . . 78

Line feed . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Set/reset automatic linefeed . . . . . . . . . . . . . . 79

Fine line feed (n/180 inch) . . . . . . . . . . . . . . . 79

Fine line feed (n/360 inch) . . . . . . . . . . . . . . . 80

Fine line feed (n/360 inch) . . . . . . . . . . . . . . . 81

Reverse line feed . . . . . . . . . . . . . . . . . . . . . . 81

Reverse line feed . . . . . . . . . . . . . . . . . . . . . . 82

Form feed . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Vertical tab . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Set vertical tab stops . . . . . . . . . . . . . . . . . . . 84

Set vertical format unit (VFU) . . . . . . . . . . . . . 85

Select vertical tab channel . . . . . . . . . . . . . . . 86

Form length set by inches. . . . . . . . . . . . . . . . 86

Form length set by lines . . . . . . . . . . . . . . . . . 87

Set perforation auto skip . . . . . . . . . . . . . . . . 88

Reset perforation auto skip . . . . . . . . . . . . . . . 88

Top of form set . . . . . . . . . . . . . . . . . . . . . . . 89

Set vertical units . . . . . . . . . . . . . . . . . . . . . . 89

Set n/360 inch fine line spacing. . . . . . . . . . . . 89

Set n/360 inch line spacing . . . . . . . . . . . . . . . 90

Set forward line spacing . . . . . . . . . . . . . . . . . 91

Set reverse line spacing . . . . . . . . . . . . . . . . . 91

Character set. . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Copies ROM CG to RAM CG . . . . . . . . . . . . . . . 91

Character definition . . . . . . . . . . . . . . . . . . . . 92

Load DLL character . . . . . . . . . . . . . . . . . . . . 94

DLL font select . . . . . . . . . . . . . . . . . . . . . . . 96

Foreign character set select . . . . . . . . . . . . . . 96

Select international character set. . . . . . . . . . . 99

Select character table. . . . . . . . . . . . . . . . . . . 99

Preface > 5

Page 6

Enable upper ASCII characters . . . . . . . . . . . .100

Select character set II . . . . . . . . . . . . . . . . . .100

Print continuously from all characters chart. . . .101

Print one character from all characters chart . . .101

Select character set I . . . . . . . . . . . . . . . . . . .101

Select character set II . . . . . . . . . . . . . . . . . .102

Code page select . . . . . . . . . . . . . . . . . . . . . .102

Assign character table . . . . . . . . . . . . . . . . . .105

Select character table. . . . . . . . . . . . . . . . . . .106

Select font . . . . . . . . . . . . . . . . . . . . . . . . . .106

Print quality – select HSD . . . . . . . . . . . . . . . .107

Print quality – select HSD . . . . . . . . . . . . . . . .108

Font description . . . . . . . . . . . . . . . . . . . . . . . . .108

Select character font . . . . . . . . . . . . . . . . . . .108

Select type styles . . . . . . . . . . . . . . . . . . . . .109

Set/reset proportional spacing. . . . . . . . . . . . .110

Set/reset proportional spacing. . . . . . . . . . . . .111

Set pica character pitch (10 CPI) . . . . . . . . . . .112

Set 10 CPI . . . . . . . . . . . . . . . . . . . . . . . . . .112

Set elite character pitch (12 CPI). . . . . . . . . . .112

Set 12 CPI . . . . . . . . . . . . . . . . . . . . . . . . . .113

Set 15 character per inch . . . . . . . . . . . . . . . .113

Set compressed character pitch (17.1/20 CPI) .114

Set compressed character pitch (17.1/20 CPI) .114

Reset compressed character pitch . . . . . . . . . .115

Set character spacing. . . . . . . . . . . . . . . . . . .115

Set italic characters . . . . . . . . . . . . . . . . . . . .116

Reset italic characters . . . . . . . . . . . . . . . . . .116

Set italic character . . . . . . . . . . . . . . . . . . . . .116

Reset italic characters . . . . . . . . . . . . . . . . . .117

Text print features . . . . . . . . . . . . . . . . . . . . . . .117

Set/reset underlining . . . . . . . . . . . . . . . . . . .117

Set subscript/superscript . . . . . . . . . . . . . . . .118

Reset super/subscript. . . . . . . . . . . . . . . . . . .119

Set emphasised print mode. . . . . . . . . . . . . . .119

Reset emphasised print mode . . . . . . . . . . . . .119

Set double strike print mode . . . . . . . . . . . . . .120

Reset double strike mode . . . . . . . . . . . . . . . .120

Set double or expanded characters . . . . . . . . .120

Set immediate double width characters . . . . . .121

Set immediate double width characters . . . . . .122

Reset immediate double width characters . . . . .122

Set/reset double height characters . . . . . . . . .122

Preface > 6

Page 7

Set/reset double height characters . . . . . . . . .123

Set/reset double height characters . . . . . . . . .124

Overscore set/reset . . . . . . . . . . . . . . . . . . . .124

Select character style . . . . . . . . . . . . . . . . . . .125

Set double width or expanded characters . . . . .125

Set/reset double height characters . . . . . . . . .126

Graphics mode. . . . . . . . . . . . . . . . . . . . . . . . . .127

Enter/exit bit image graphics . . . . . . . . . . . . .127

Single density graphics. . . . . . . . . . . . . . . . . .130

Double density graphics . . . . . . . . . . . . . . . . .130

Quasi-double-density graphics. . . . . . . . . . . . .131

Set quadruple density graphics . . . . . . . . . . . .132

Reassign alternate graphics codes . . . . . . . . . .133

Graphics resolution . . . . . . . . . . . . . . . . . . . .134

Select aspect ratio . . . . . . . . . . . . . . . . . . . . .135

Composite commands. . . . . . . . . . . . . . . . . . . . .136

Print mode select. . . . . . . . . . . . . . . . . . . . . .136

Print mode select. . . . . . . . . . . . . . . . . . . . . .137

General control . . . . . . . . . . . . . . . . . . . . . . . . .137

Printer initialisation . . . . . . . . . . . . . . . . . . . .137

Cancel code . . . . . . . . . . . . . . . . . . . . . . . . .138

Set bit 7 code to 1 . . . . . . . . . . . . . . . . . . . . .138

Set bit 7 code to 0 . . . . . . . . . . . . . . . . . . . . .138

Reset 8 bit mode . . . . . . . . . . . . . . . . . . . . . .139

Set print suppress . . . . . . . . . . . . . . . . . . . . .139

Print suppress . . . . . . . . . . . . . . . . . . . . . . . .139

Reset print suppress mode . . . . . . . . . . . . . . .140

Stop printing . . . . . . . . . . . . . . . . . . . . . . . . .140

Enable paper out sensor . . . . . . . . . . . . . . . . .140

Disable paper out sensor . . . . . . . . . . . . . . . .141

Select emulation . . . . . . . . . . . . . . . . . . . . . .142

Printer initialisation . . . . . . . . . . . . . . . . . . . .142

Printer initialisation . . . . . . . . . . . . . . . . . . . .143

Barcode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

Print barcode. . . . . . . . . . . . . . . . . . . . . . . . .143

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Physical specification . . . . . . . . . . . . . . . . . . . . .147

Power requirements . . . . . . . . . . . . . . . . . . . . . .147

Electrical insulation. . . . . . . . . . . . . . . . . . . . . . .148

Environmental conditions . . . . . . . . . . . . . . . . . .148

Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .149

Agency approvals. . . . . . . . . . . . . . . . . . . . . . . .149

Print specification. . . . . . . . . . . . . . . . . . . . . . . .149

Preface > 7

Page 8

Paper specification . . . . . . . . . . . . . . . . . . . . . . .152

Ribbon specification . . . . . . . . . . . . . . . . . . . . . .152

Appendix A – Command summary . . . . . . . . . . . 153

Command summary by initiator . . . . . . . . . . . . . .153

Command summary by function. . . . . . . . . . . . . .161

Appendix B – Print modes/features . . . . . . . . . . 168

IBM mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

EPSON mode . . . . . . . . . . . . . . . . . . . . . . . . . . .169

Appendix C – Code pages . . . . . . . . . . . . . . . . . . 170

Appendix D – Media specifications . . . . . . . . . . . 178

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

Unsuitable paper . . . . . . . . . . . . . . . . . . . . . .178

Pre-printed paper . . . . . . . . . . . . . . . . . . . . .179

Paper storage conditions. . . . . . . . . . . . . . . . .180

Usable paper types and assurance range . . . . .180

Continuous paper (continuous forms) . . . . . . . . . .181

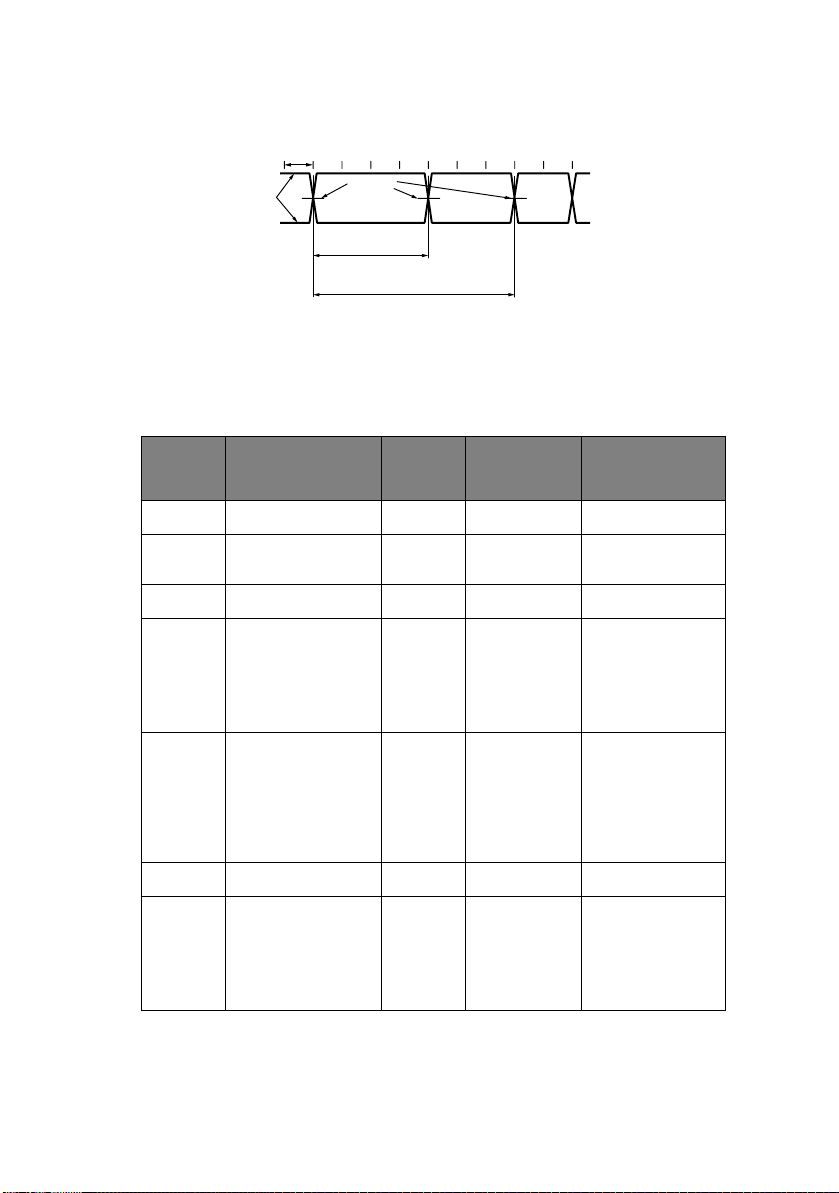

Vertical and horizontal dimensions. . . . . . . . . .181

Feed hole (sprocket hole) positions and sizes . .182

Perforation dimensions . . . . . . . . . . . . . . . . . .184

Paper size and printing areas . . . . . . . . . . . . .186

Paper quality. . . . . . . . . . . . . . . . . . . . . . . . .187

Paper weight and max. no. of form parts . . . . .188

Methods for joining parts of multipart forms . . .188

Horizontal perforation rising . . . . . . . . . . . . . .192

Misalignment between feed holes . . . . . . . . . .193

Binding holes . . . . . . . . . . . . . . . . . . . . . . . .193

Corner cuts . . . . . . . . . . . . . . . . . . . . . . . . . .194

Paper condition . . . . . . . . . . . . . . . . . . . . . . .195

Cut-sheet paper. . . . . . . . . . . . . . . . . . . . . . . . .196

Vertical and horizontal dimensions. . . . . . . . . .196

Paper size and printing areas . . . . . . . . . . . . .197

Paper quality. . . . . . . . . . . . . . . . . . . . . . . . .199

Paper weight and max. no. of form parts . . . . .199

Joining of parts of multipart forms . . . . . . . . . .200

Binding holes . . . . . . . . . . . . . . . . . . . . . . . .201

Perforations . . . . . . . . . . . . . . . . . . . . . . . . .202

Folds, bends and curls of cut-sheet paper . . . . .203

Envelopes (individual). . . . . . . . . . . . . . . . . . . . .204

Label paper . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

Package delivery slips. . . . . . . . . . . . . . . . . . . . .209

Recycled paper . . . . . . . . . . . . . . . . . . . . . . . . .210

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Preface > 8

Page 9

Oki Printing Solutions contact details . . . . . . . . 212

Preface > 9

Page 10

N

OTES, CAUTIONS AND WARNINGS

NOTE

A note provides additional information to supplement the main

text.

CAUTION!

A caution provides additional information which, if

ignored, may result in equipment malfunction or

damage.

WARNING!

A warning provides additional information which, if

ignored, may result in a risk of personal injury.

Notes, cautions and warnings > 10

Page 11

I

NTRODUCTION

The ML6300FB is designed to provide highly reliable letter quality

printing and high resolution graphics for the desktop/office

printing environment. It combines state-of-the-art, 24-pin, serial

impact dot matrix printing technology with advanced materials

and superior construction to provide high performance and

versatility in a desktop sized unit. Careful attention to

ergonomics and application needs provides user friendly

operation for operators of varying technical capabilities.

F

EATURES

ML6300FB features include:

> OKI smart Paper Handling

> Direct access control panel

> Structured direct access menu for easy set up

> Printhead life: 200M characters (average) in 10 CPI Utility

mode at normal 25% duty, 35% page density

> Bidirectional short-line-seeking printing

> Print speed:

400 CPS HSD (10 CPI)

300 CPS Utility (10 CPI)

100 CPS LQ (10 CPI)

> Paper feed

Rear path (with push tractor)

Front tray

> Paper handling

Automatic sheet loading

Short paper tear-off available by menu selection or TEAR

switch operation

Auto-loading for continuous paper

Auto park feature

> Paper copies: 9 – 11 lb, 5 part

> Cartridge ribbon

> Interfaces

Introduction > 11

Page 12

Standard IEEE1284 parallel interface

USB interface.

> 58 dBA noise

> 64 kbytes max. receive buffer

> Line feed resolution at 1/6 in, 1/8 in, n/60 in, n/72 in,

n/180 in, n/216 in, n/360 in

> Agency approved by:

200 V system: GE BSI

> Barcode data printing

> Postnet bar code data printing

> EMI approved 200 V system: EN55022 Class B

S

TANDARD CONFIGURATION

The ML6300FB consists of the following components:

> Printer mechanism

> Power supply unit

> Control board (including an IEEE1284 parallel interface)

> Acoustic covers

> Push tractor feed unit

> Option

• RS-232C Serial Interface Board

• OL7120e 100BASE-TX/10BASE-T Network Board

NOTE

It is not recommended that you use either the parallel or USB

port when the RS-232C or OL7120e option is installed in this

product.

I

DENTIFYING COMPONENT PARTS

The main parts of your printer are identified and briefly explained

below.

Introduction > 12

Page 13

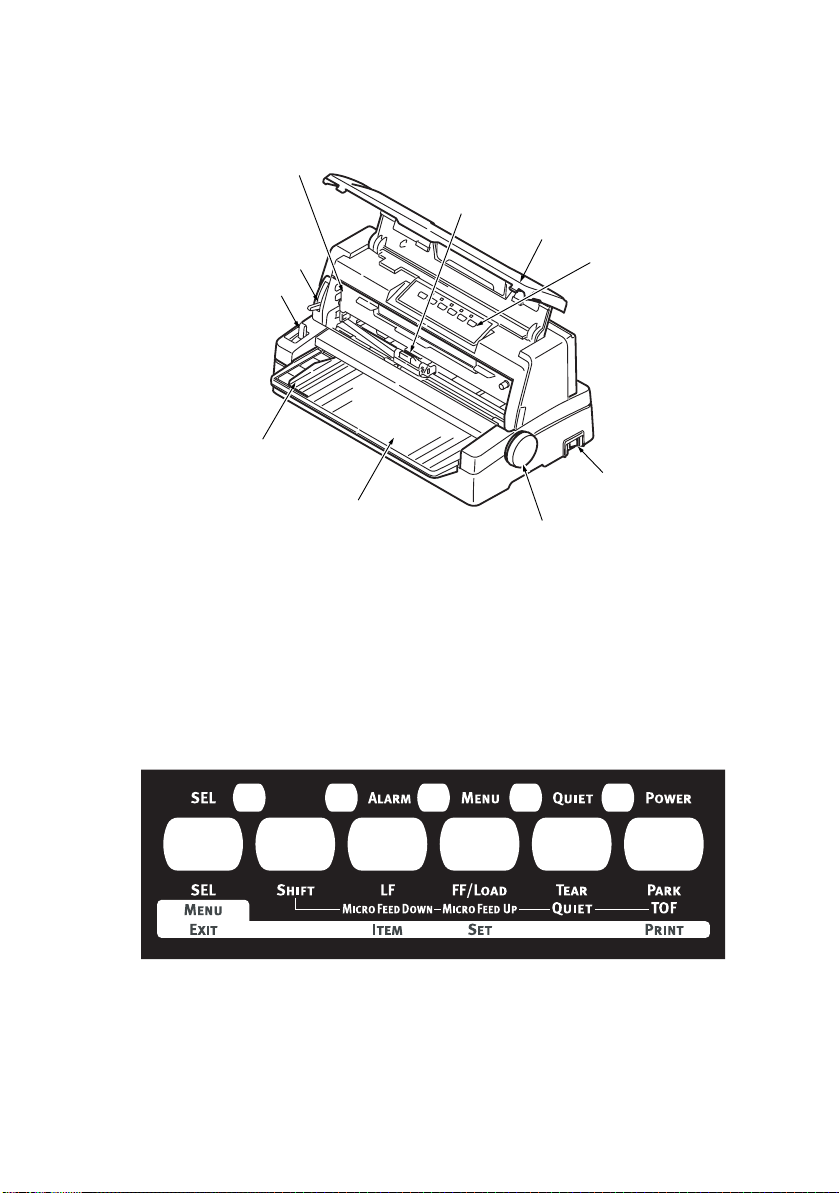

F

RONT VIEW

10

1

2

9

3

8

7

4

6

5

1. Print Head: prints the characters on the paper.

2. Top Cover: open and close for access, for example when

changing a ribbon cartridge. Keep closed for noise

reduction.

3. Control Panel: contains button switches and indicators

(described in detail later) that allow you to operate the

printer.

4. Power Switch: to turn the printer power ON/OFF.

5. Platen Knob: turn to move or eject the paper.

Introduction > 13

Page 14

6. Paper Tray: to hold cut sheet paper for use by the printer

(one sheet at a time).

7. Paper Guide: can be adjusted as required to locate the left

edge of cut sheet paper.

8. Paper Type Lever: set according to the type of paper used

– cut sheet or continuous forms.

9. Paper Thickness Lever: set according to the thickness of

the paper. There is also a setting to facilitate ribbon

replacement.

10. Ribbon Cartridge: holds the printer ribbon.

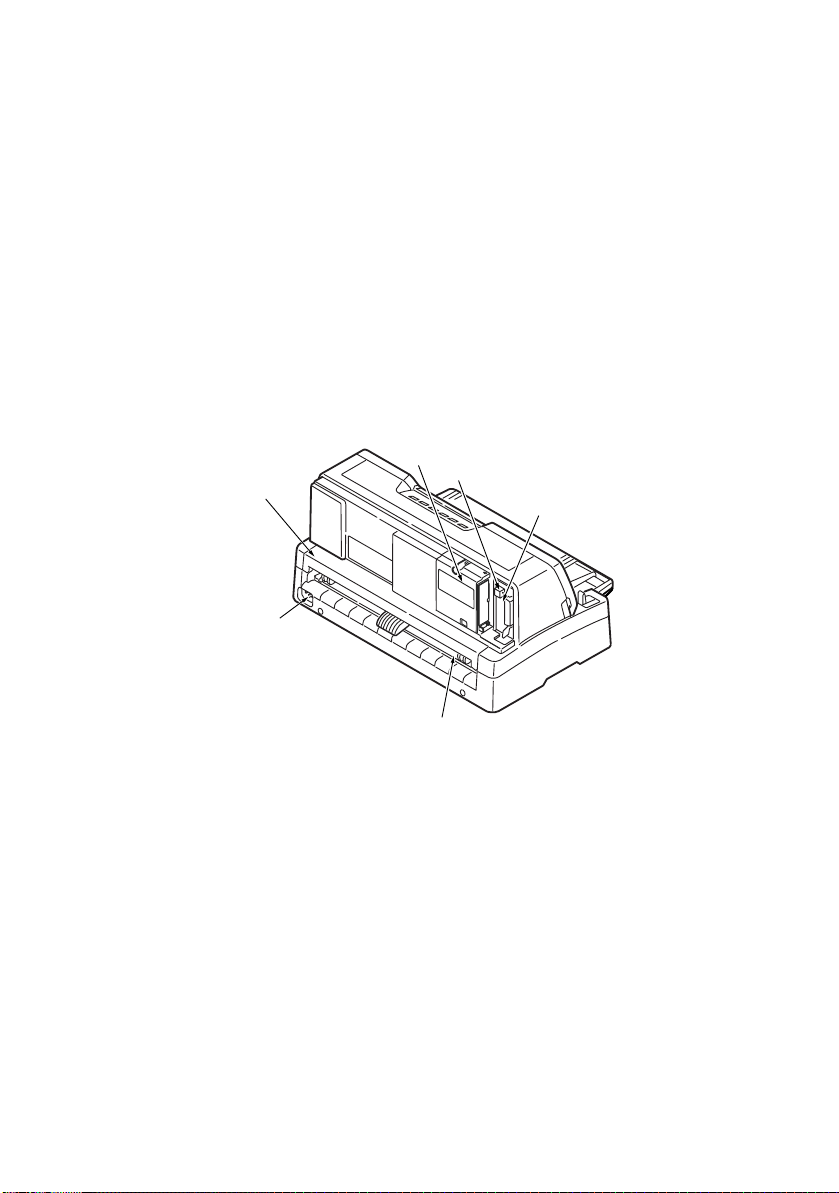

R

EAR VIEW

1

2

6

3

5

4

1. Optional connector position: connect to optional accessory

serial interface card or 100BASE-TX/10BASE-T network

card.

2. USB connector: connect to USB interface cable.

3. Parallel connector: connect to parallel interface cable.

4. Pin Tractor: to load and feed continuous forms.

5. Power connector: connect to printer power cable.

6. Rear Cover: open and close for access, for example when

loading continuous forms.

Introduction > 14

Page 15

A

BOUT THIS GUIDE

NOTE

Im a g e s used i n t h is man u a l may include optional features that

your printer does not have installed.

If required, you may wish to refer for basic information to the

User’s Guide which is stored on the manuals CD.

This manual is your Technical Reference guide (check the web

site, www.okiprintingsolutions.com, for the most up-to-date

version) for your printer and forms part of the overall user

support listed below:

> Installation Safety booklet: provides information as to

safe use of the printer.

This is a paper document that is packaged with the printer

and should be read before setting up your printer.

> Set-up guide: to describe how to unpack and set up your

printer.

This is a paper document that is packaged with the printer.

> This Technical Reference Guide: to provide detailed

technical information for programmers and more technical

users.

This is an electronic document available on the web site

www.okieng.com.

> User’s Guide: to help you to become familiar with your

printer and make the best use of its many features. Also

included are guidelines for troubleshooting and

maintenance to ensure that it performs at its best.

Additionally, information is provided for adding optional

accessories as your printing needs evolve.

This is an electronic document stored on the manuals CD.

> Network Configuration Guide: to provide detailed

technical information for network administrators to

configure the optional accessory network interface.

This is an electronic document stored on the CD that

accompanies the network interface card optional

accessory.

About this guide > 15

Page 16

> Installation Guides: accompany consumable items and

optional accessories to describe how to install them.

These are paper documents that are packaged with the

consumables and optional accessories.

> Online Help: online information accessible from the

printer driver and utility software.

O

NLINE USAGE

This guide is intended to be read on screen using an Adobe

Acrobat Reader. Use the navigation and viewing tools provided in

Acrobat.

You can access specific information in two ways:

> In the list of bookmarks down the left hand side of your

screen, click on the topic of interest to jump to the

required topic. (If the bookmarks are not available, use

the “Contents” on page 3.)

> In the list of bookmarks, click on Index to jump to the

Index. (If the bookmarks are not available, use the

“Contents” on page 3.) Find the term of interest in the

alphabetically arranged index and click on the associated

page number to jump to the page containing the term.

P

RINTING PAGES

The whole manual, individual pages, or sections may be printed.

The procedure is:

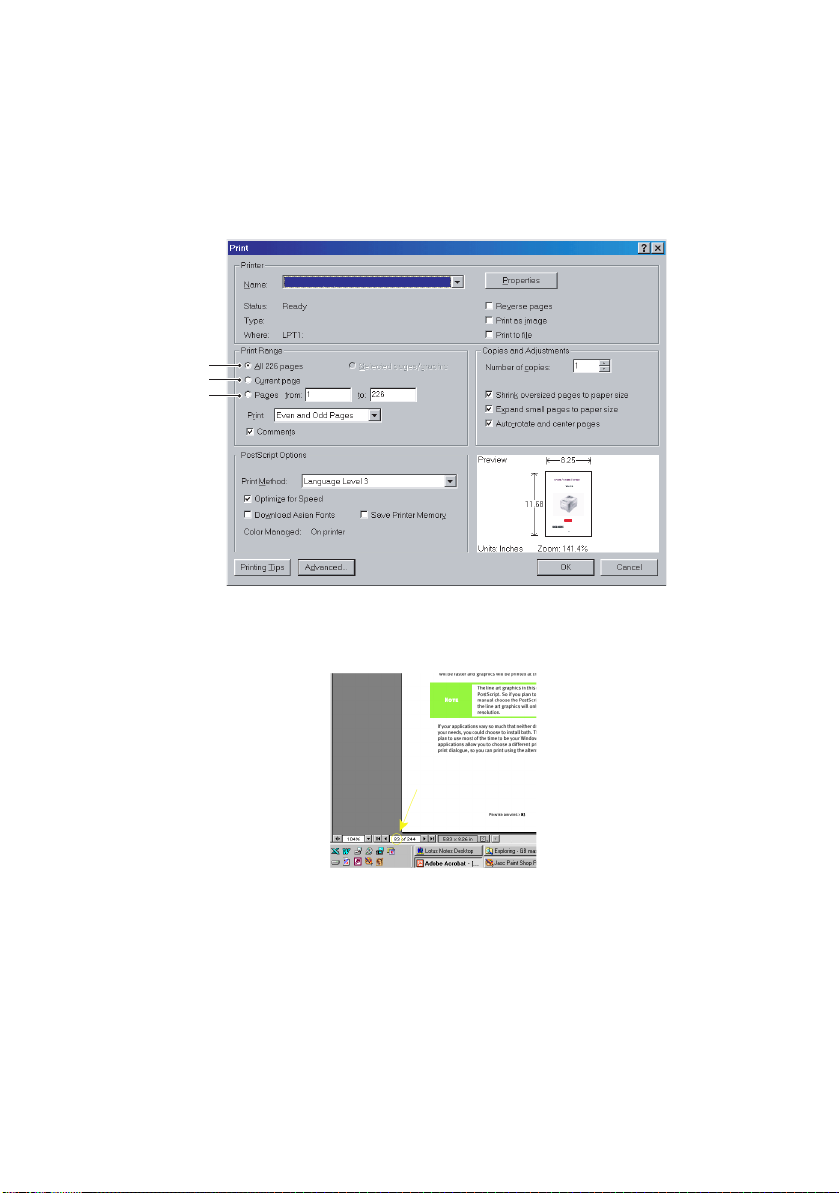

1. From the toolbar, select [File], then [Print] (or press the

Ctrl + P keys).

About this guide > 16

Page 17

2. Choose which pages you wish to print:

(a) [All pages], (1), for the entire manual.

(b) [Current page], (2), for the page at which you are

looking.

1

2

3

(c) [Pages from] and [to], (3), for the range of pages

you specify by entering their page numbers.

3. Click on [OK].

About this guide > 17

Page 18

I

NTERFACE SPECIFICATIONS

IEEE1284

C

ONNECTORS AND CABLE

Connectors

Cable

PARALLEL INTERFACE SPECIFICATIONS

Printer side:

36-pin receptacle 57-40360 (Amphenol or Daiichi

Electronics) or equivalent

Cable side:

36-pin plug 57-30360 (Amphenol or Daiichi Electronics) or

equivalent, or plug 552274-1 (Amphenol) and cover

552073-1 (Amphenol) or equivalent

Use a cable less than 6 ft (1.8 m) in total length.

(A shielded cable is required and use of twisted-pair wires

is recommended for noise prevention.)

The cable is not supplied with the printer.

Interface specifications > 18

Page 19

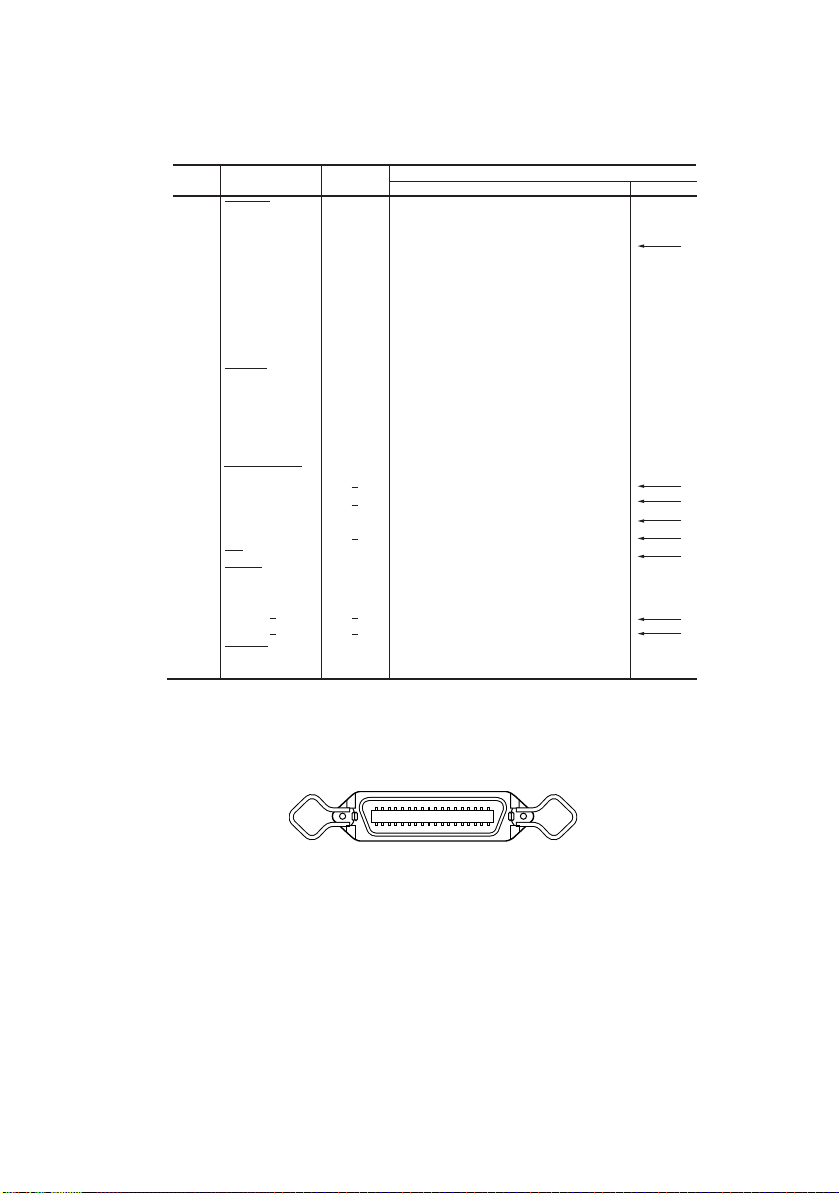

P

ARALLEL INTERFACE SIGNALS

PinNo. Direction

1

2

3

4

5

6

7

8

9

10

11

12

13

14

16, 33

17

18

19 to 30

31

32

15, 34

35

36

Signal

STROBE

DATA BIT 1

DATA BIT 2

DATA BIT 3

DATA BIT 4

DATA BIT 5

DATA BIT 6

DATA BIT 7

DATA BIT 8

ACKNLG

BUSY

PE

SEL

AUTO FEEDXT

GND

CHASSIS GROUND

+5 V

GND

INIT

ERROR

SLCT IN

To printer

To printer

From printer

From printer

From printer

From printer

To printer

From printer

To printer

From printer

To printer

Samples input data when changing from low

level to high level.

Input data: High level indicates 1 and low

level 0 .

Indicates character input completion, or function

operation end, at low level.

Indicates data cannot be received at high level.

Data can be input at low level.

High level indicates paper end.

High level indicates select (on line) condition.

Signal ground.

Frame ground.

+5 V supply (17 mA maximum)

Twisted pair return (for pin No. 1 to 12)

This signal goes from high to low level when

paper runs out.

(Possible to indicate error and Off Line state).

Unused

Fixed to High (Connected to +5 V via 3.3 K Ω)

Connected to input port

NOTE

Connector pin arrangement for above.

Description

Compatible Nibble

HostClk

PrtClk

PrtBusy

AckDataReq

Xflag

HostBusy

nDataAvail

IEEE1284

active

18

36

P

ARALLEL INTERFACE LEVELS

Low level: 0.0 V to + 0.8 V

High level: +2.3 V to +5.0 V

Interface specifications > 19

1

19

Page 20

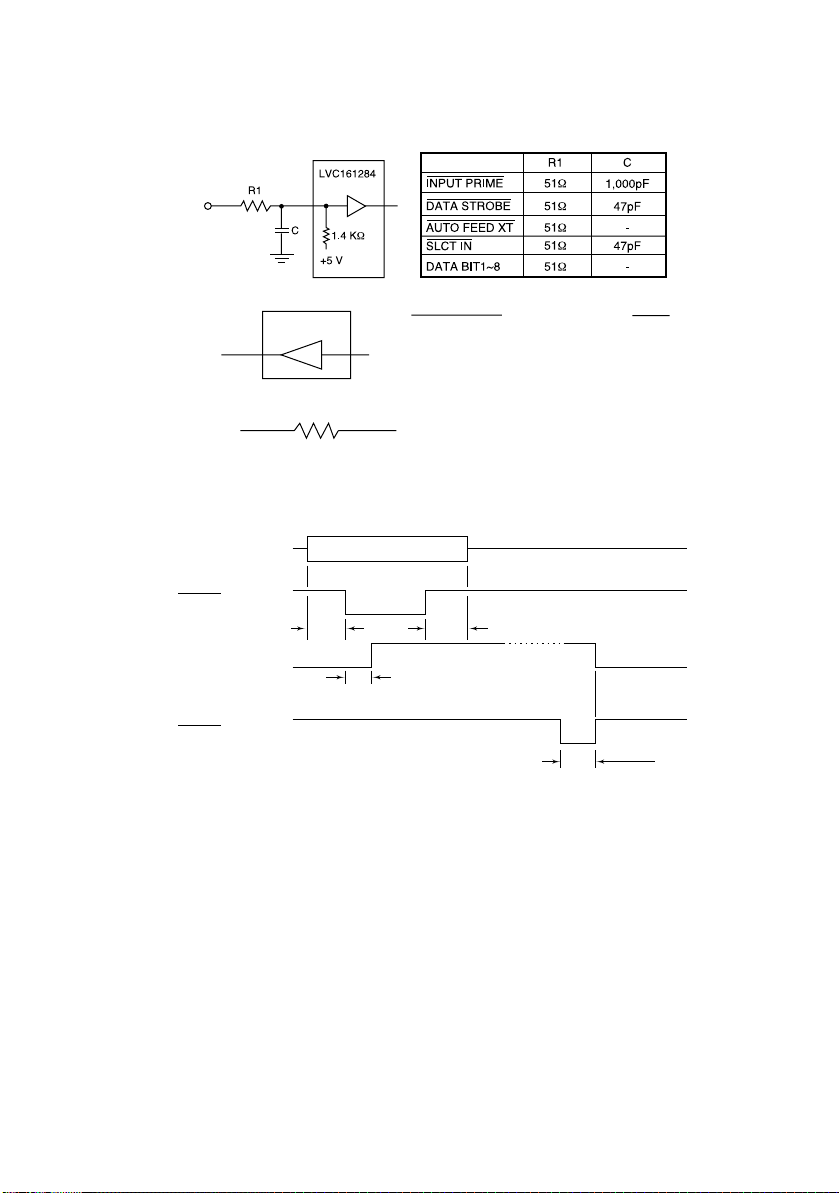

P

A

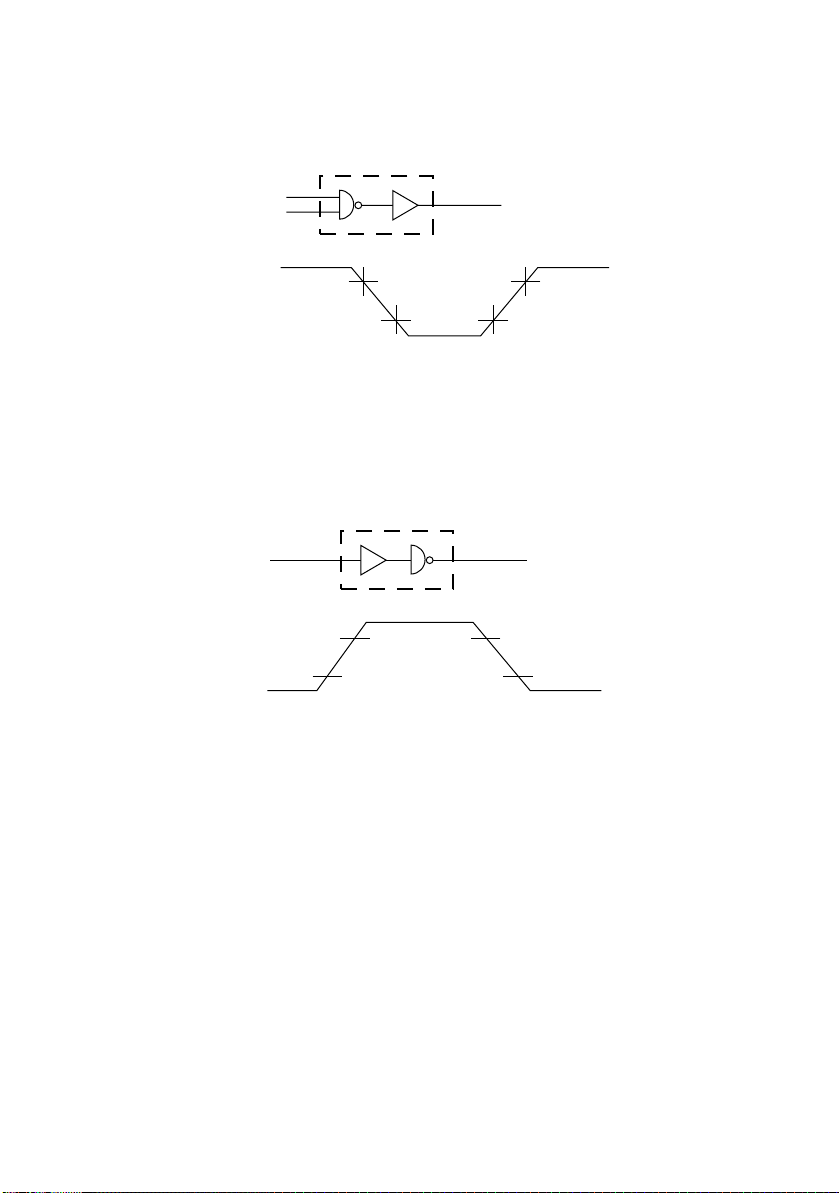

ARALLEL INTERFACE CIRCUITS

(a) Receiver

(b) Driver

1

LVC161284

BUSY, ACKNOWLEDGE, PAPER END, SLECT, FAULT

2 HL

P

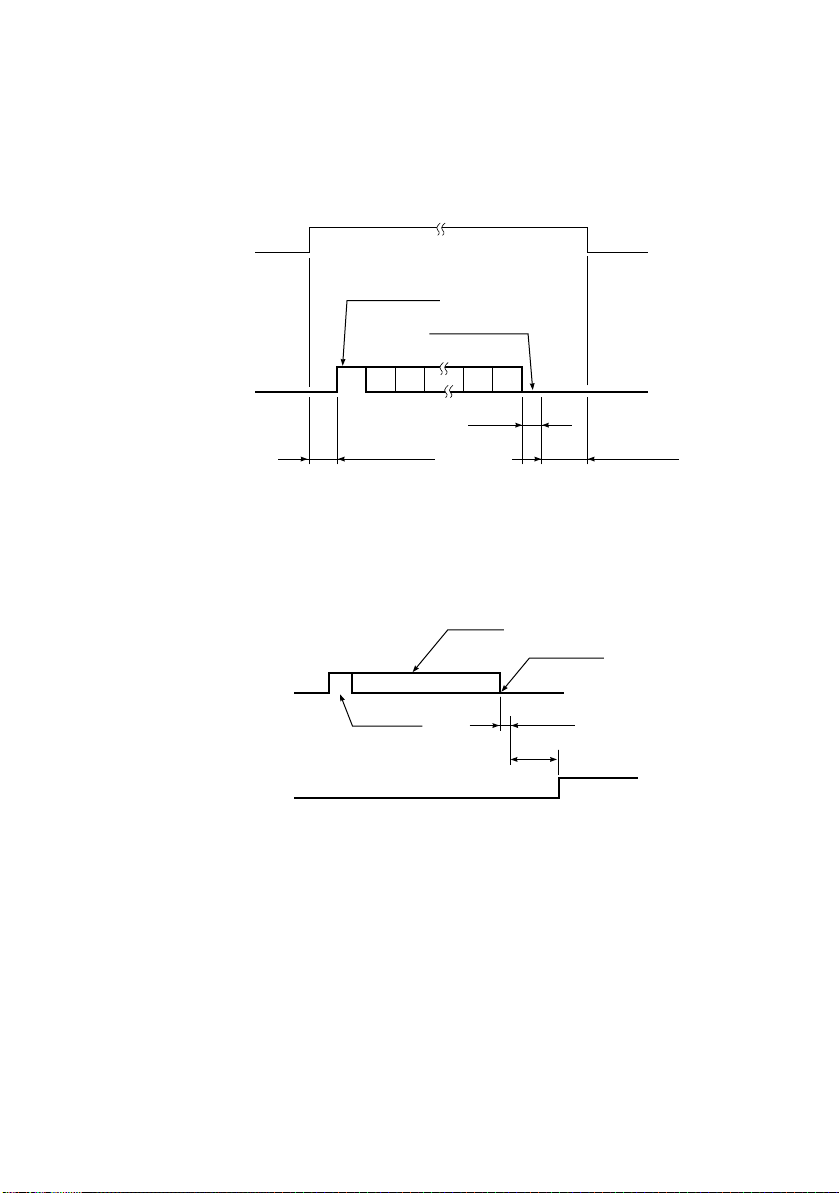

ARALLEL INTERFACE TIMING CHART

DATA BIT1 to

DATA BIT8

STROBE

BUSY

CKNLG

S

UPPORT MODE

240 Ω

DATA

(H)

(L)

0.5 µs

0.5 µs

min

1.0 µs

max

min

(H)

(L)

(H)

(L)

Compatible

Nibble (PnP Device ID only)

+5 V

0.5 µs

min

2.5 µs(TYP)

Interface specifications > 20

Page 21

U

NIVERSAL SERIAL BUS

(USB)

Universal Serial Bus Specification Revision 2.0 compliance.

C

ONNECTORS

Printer Side:

“B” Receptacle (Upstream Input to the USB Device)

Cable Side:

Series “B” Plug

C

ABLE

Length:

Max. 5 m (Cable must be shielded and meet the USB Spec

Rev 2.0 for normal operation.)

The cable is not supplied with the printer.

USB

INTERFACE SIGNALS

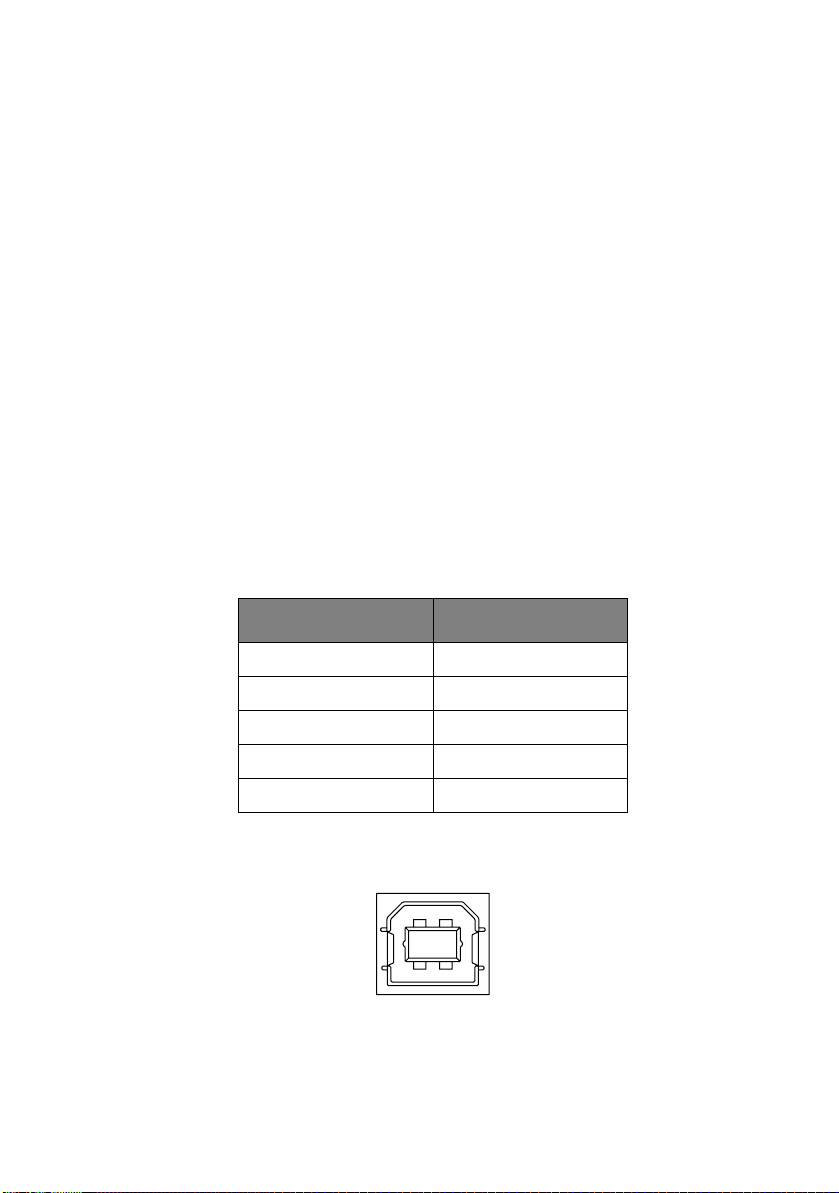

CONTACT NUMBER SIGNAL NAME

1 Vbus (Not Used)

2 D-

3 D+

4 GND

Shell Shield

NOTE

Connector pin arrangement for above:

2

1

34

Interface specifications > 21

Page 22

M

ODE AND CLASS OF DEVICE

Full-speed driver

Self-powered device

D

ATA SIGNALLING RATE

Full-speed function – 12 Mb/s

I

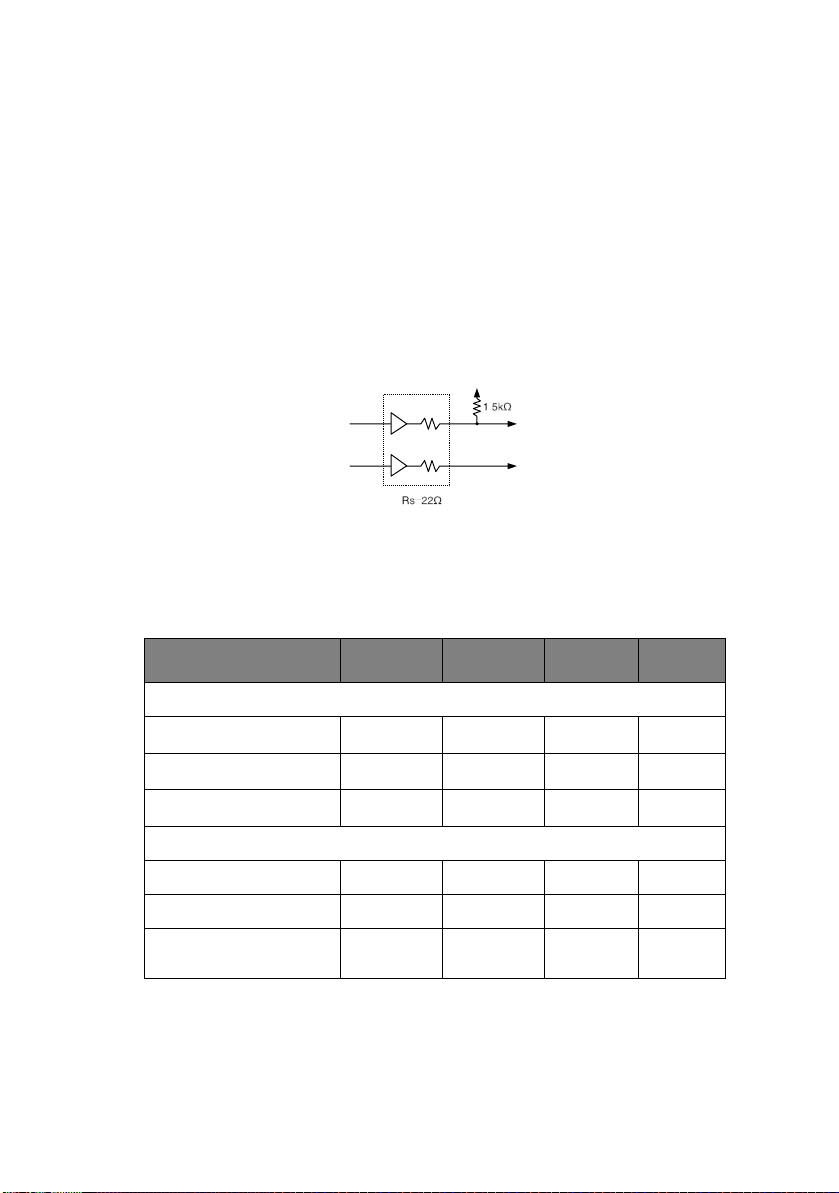

NTERFACE CIRCUIT

S

IGNAL LEVEL

TxD+

TxD-

Full-speed

Buffer

+ 3.3V

Rs

Rs

Input/output level

PARAMETER SYMBOL MIN. MAX. UNITS

Input levels:

High (driven) V

High (floating) V

Output levels:

High (driven) OH 2.8 3.6 V

Output signal crossover

voltage

IH

IHZ

Low V

Low OL 0.0 0.3 V

IL

V

CRS

2.0 V

2.7 3.6 V

0.8 V

1.3 2.0 V

Interface specifications > 22

Page 23

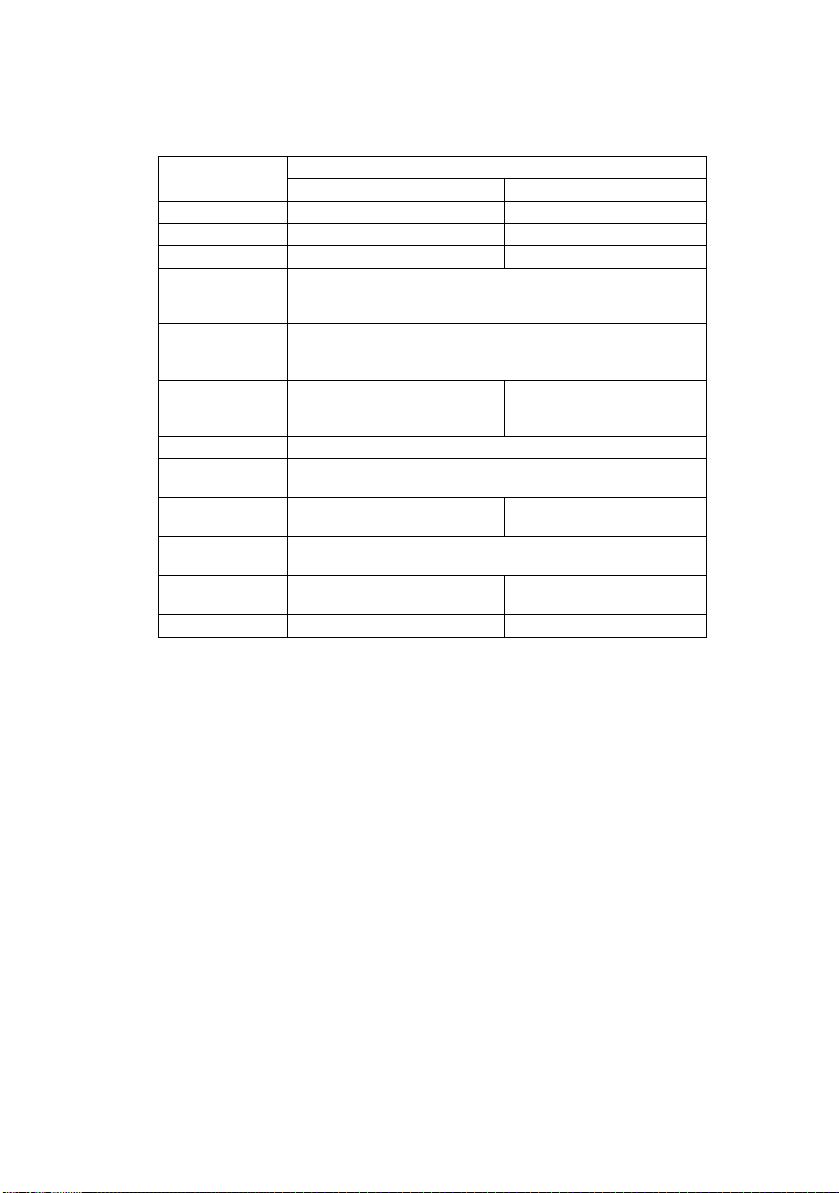

Signalling levels

Bus State

Required Acceptable

Differential “1” (D+)-(D-)> 200mV and D+ > V

Differential “0” (D-)-(D+)> 200mV and D- > V

Single-ended 0 (SE0) D+ and D- < V

(max) D+ and D- < VIH(min)

IL

Signalling Levels

(min) (D+)-(D-)> 200mV

IH

(min) (D-)-(D+)> 200mV

IH

Data J state:

Low-speed

Full-speed

Differential “0”

Differential “1”

Data K state:

Low-speed

Full-speed

Differential “1”

Differential “0”

Idle state:

Low-speed

Full-speed

D- > V

(min) and D+ < VIL(max)

IHZ

D+ > V

(min) and D- < VIL(max)

IHZ

D- > V

(min) and D+ < VIH(min)

IHZ

D+>V

(min) and D- < VIH(min)

IHZ

Resume state Data K state

Start-of-

Data lines switch from Idle to K state

Packet (SOP)

End-of-Packet (EOP)

Disconnect

SE0 for ≥ 1 bit time1followed by a J

state for 1 bit time

SE0 for ≥ 2.5µs

SE0 for ≥ 1 bit time1followed by a J

state

(at downstream port)

Connect

Idle for ≥ 2ms Idle for ≥ 2.5µs

(at downstream port)

Reset D+ and D- < V

(max) for ≥ 10ms D+ and D- < VIL(max) for ≥ 2.5µs

IL

NOTE

1. The width of EOP is defined in bit times relative to the

device type receiving the EOP. The bit time is

approximate.

Interface specifications > 23

Page 24

T

IMING CHART

Packet voltage levels

VOH(min)

VIH(min)

VIL(max)

VOL(max)

VSS

Bus Idle

SOP

VOH(min)

VIH(min)

VIL(max)

VOL(max)

VSS

Disconnect detection

First Bit

of Packet

Last Bit

of Packet

SE0

Portion

of EOP

Bus Driven to

J State at end

of EOP

Bus Floats

Bus Idle

VSS

D+/D-

VIL

D-/D+

Device

Connected

VIHZ(min)

Full-speed device connect detection

Device

Connected

D+

VIH

D-/D+

VSS

Interface specifications > 24

‡2.5

µs

‡2.5

µs

D-

Connect

Detected

Disconnect

Detected

Page 25

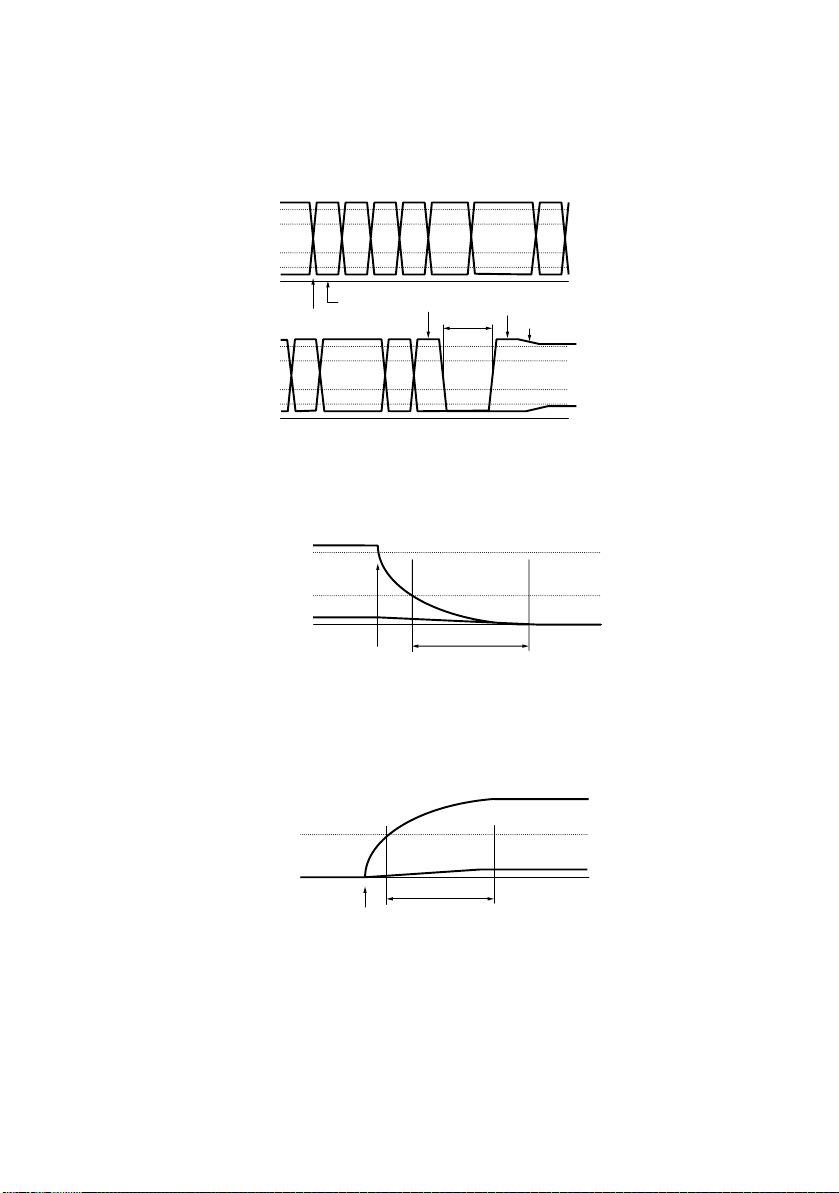

Differential data jitter

TPERIOD

Differential

Data Lines

(VCRS)

O

PTION INTERFACE SPECIFICATIONS

I

NTERFACE SIGNALS

PIN

SIGNAL CODE SIGNAL FUNCTION

Crossover

Points

Consecutive

Transitions

*

TPERIOD + TxDJ1

N

N

Paired

Transitions

*

TPERIOD + TxDJ2

TPERIOD = 12Mbps(–0.25%)

TxDJ1 = Min-3.5ns~Max3.5ns

TxDJ2 = Min-4ns~Max4ns

NO.

1 Protective Ground PG — Frame ground

2 Transmitted Data TD From printer Data from

3 Received Data RD To printer Data to printer

4

Request to Send RTS From printer Signal to

Note 2

printer

indicate printer

cannot receive

data in printer

Busy/Ready

protocol

6

Note 3

Data Set Ready DSR To printer Indicates that

data can be sent

(Printer receives

data after

confirming this

signal as a

SPACE.)

7 Signal Ground SG — Signal ground

11

Note 2

Supervisory Send

Data

SSD From printer Signal to

indicate printer

cannot receive

data in printer

Busy/Ready

protocol

Interface specifications > 25

Page 26

PIN

NO.

SIGNAL CODE SIGNAL FUNCTION

20

Note 2

5, 8 to

10, 12

to 19,

21 to 25

Data Terminal

Ready

— — — Unused

DTR From printer Signal to

indicate printer

cannot receive

data in printer

Busy/Ready

protocol

NOTE

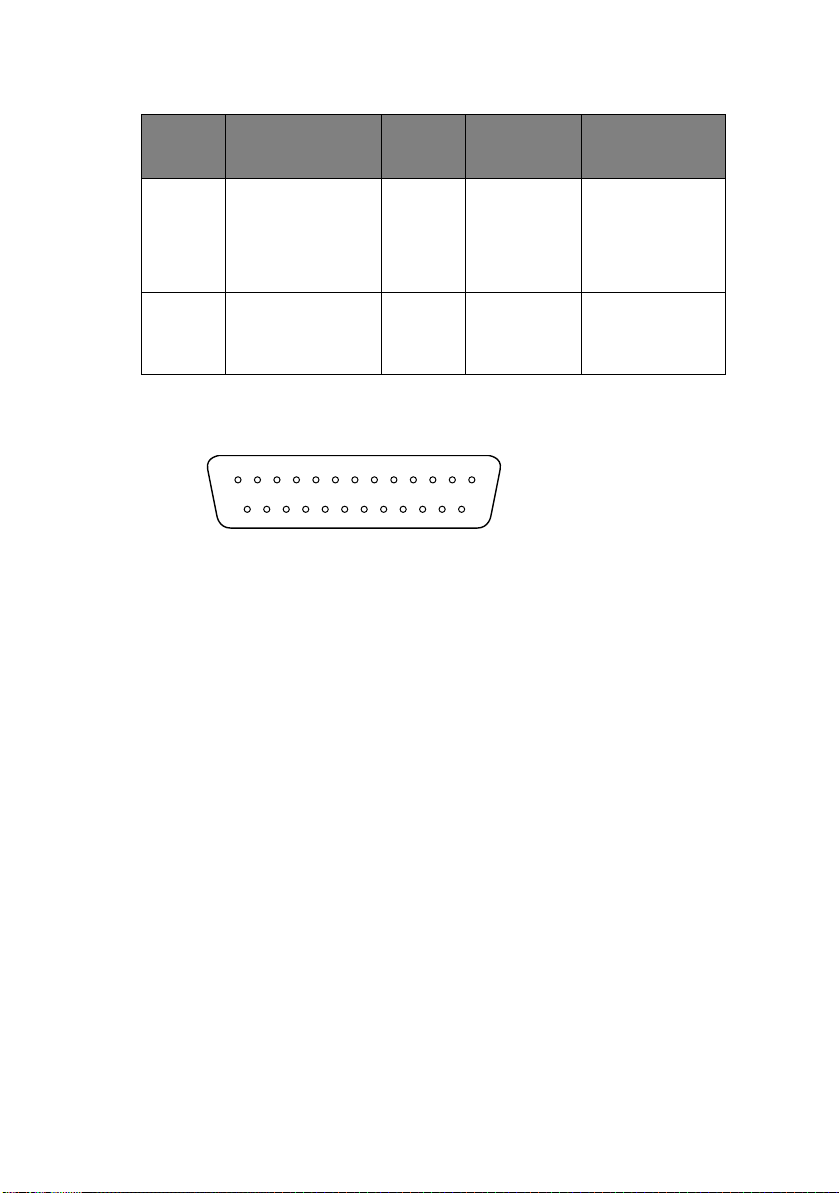

1. Connector pin arrangement for above:

13

25

1

14

(Viewed from interface cable side)

2. SSD signal output can be selected from pins 4, 11, 20 by

the Menu.

3. DSR signal valid/invalid can be set by Menu.

E

LECTRICAL CHARACTERISTICS

Signal levels

RS-232C interface signal levels are as specified below, and meet

the EIA Standard RS-232C:

–15 to –3 V: LOW = OFF = LOGIC “1”

+15 to + 3 V: HIGH = ON = LOGIC “0”

Interface specifications > 26

Page 27

Line driver

Equivalent to SN75188

INPUT

OUTPUT

OUTPUT

+3V

-3V

NOTE

The above figures are the standard values for a load of

3 Kohm, 15 pF and a driver source level of ±9 V.

Line receiver

Equivalent to SN75154

INPUT OUTPUT

+3V

INPUT

NOTE

If the power on the input side is OFF, the output of the receiver

becomes high (+2.4 V or more) at TTL level.

-3V

+9V

-9V

+12V

-12V

Interface specifications > 27

Page 28

I

NTERFACE TIMING CHARTS

Receiving timing chart

DSR signal

HIGH

LOW

Start bit

Stop bit

HIGH

RD

LOW

More than 0 µs More than 300 µs

NOTE

DSR signal valid/invalid can be set by the Menu.

SSD signal timing chart

RD

HIGH

LOW

SSD

BUSY

READY

0.5 bit

Data

Stop bit

0.5 bitStart bit

MAX 5 ms

R

ECEIVING MARGIN

Receiving margin is more than 37% at any baud rate.

D

ESCRIPTION OF COMMUNICATION PROCEDURES

Two types of protocol can be selected by menu communication

procedures: READY/BUSY and X-ON/X-OFF.

Interface specifications > 28

Page 29

I

NTERFACE CONTROL CODE

The following function codes are used in the high-speed serial

interface:

COMMAND CODE

DC1 (17)D (11)H

DC3 (19)D (13)H

NOTE

Characters to be printed according to the parity error

indication code (40)H will differ depending on the setting of the

printer character set. Refer to the printer User’s Guide.

Ready/Busy protocol

Block format Free

Error indication The parity error indication is printed as character

Busy state indication The busy signal turns on (becomes Busy) when the

40(H).

space in the interface buffer has become less than

256 bytes. The busy signal turns off (becomes

Ready) after 200 ms or 1 second has passed if 256

bytes have recovered within 200 ms or 1 second. If

the recovery time exceeds 200 ms or 1 second, the

busy signal turns off (becomes Ready) immediately

after the recovery has occurred.

Timing chart

RD DATA 1 DATA 2

Threshold of the

characters in

the buffer

SSD

8K

512

0

ON (BUSY)

OFF (READY

Interface specifications > 29

200 ms or 1 second minimum

Page 30

X-ON/X-OFF protocol

Block format Free

Error indication The parity error indication character is converted

into code 40(H).

Busy state indication The DC3 will be sent to the transmission side

immediately after the space in the interface buffer

has become less than 256 bytes to indicate that

receiving is impossible. The transmission of the

DC3 stops when data receiving has stopped. If the

recovery time for 256 bytes is within 200 ms or

1 second after the DC3 is sent, DC1 will be sent

200 ms or 1 second after the recovery to indicate

that receiving is possible. If the recovery time

exceeds 200 ms or 1 second, the DC1 is sent

immediately after the recovery has occurred.

Timing chart

256 characters or less

RD

TD PRINTING

BUSY state

ON

OFF

DATA 1

3

3-C

3

-

-CD

CD

D

200 ms or 1 second minimum

NOTE

If data is transferred when the printer is still BUSY, the printer

sends a DC3 code every time it receives data.

Waiting for BUSY

state to be free

DATA

1CD

L

OCAL TEST FUNCTION

Circuit Test mode setting

Diagnostic: Test set by menu

Interface specifications > 30

Page 31

Test connector: Connect the test connectors as shown below to

the interface connectors.

2

TD

3

RD

4

RTS

5

Equivalent to Cannon DB-25P

CTS

CD

SSD

DTR

DSR

8

11

20

6

Circuit Test mode function

After the settings outlined in Circuit Test mode setting are

completed and power is turned on, the serial interface checks the

message buffer memory and interface driver and receiver

circuits, then prints all characters. To start and stop this test,

press the SEL switch on the front of the printer. Details of this

test are explained below.

1. Print the program revision with two numerical characters.

2. Print “LOOP TEST.”

3. Check memory for message buffer.

Print “GOOD” if memory check is OK, and print “BAD” if

memory check fails.

4. Output LOW to DTR, RTS, and SSD signals. If a CTS, DSR,

or CD signal is HIGH, print “IF BAD”. If the CTS, DSR, and

CD signals are all LOW, print “IF GOOD”.

Output HIGH to DTR, RTS, and SSD signals. If a CTS, DSR,

or CD signal is LOW, print “IF BAD.” If the CTS, DSR and

CD signals are all HIGH, print “IF GOOD.”

5. Transmit characters from code 20H to 7FH by TD signals.

At the same time, characters are received from the RD

signal and stored in the message buffer.

6. Print the characters that were stored in the message

buffer as indicated in Step 5.

7. Repeat from Step 1.

Interface specifications > 31

Page 32

O

PERATOR INTERFACE

O

PERATOR PANEL FUNCTIONS

The operator panel button switches and lamps are located as

follows:

Button switch functions depend on the printer state which can be

any one of:

> Print Mode (for a summary of print modes and features

see “Appendix B – Print modes/features” on page 168.)

> Hex Dump Mode

> Menu Mode

> Tes t Mo d e

> Maintenance Mode 1 (not for use by general users)

> Maintenance Mode 2 (not for use by general users)

P

RINT MODE

> Without pressing the SHIFT switch:

PRINTER STATE

SWITCH

SEL Sets printer off line Sets printer off line

SHIFT Changes functions (see below)

LF Performs a line feed Performs a line feed

CONT. FORMS CUT-SHEET

Operator interface > 32

SELECT

Page 33

PRINTER STATE

SELECT

SWITCH

FF/LOAD Feeds forms or loads

TEAR Feeds paper to the tear

PARK Feeds paper in the

PRINTER STATE

SWITCH

SEL Sets printer on line Sets printer on line

SHIFT Changes functions (see below)

LF Performs a line feed Performs a line feed

FF/LOAD Feeds forms or loads

TEAR Invalid Invalid

PARK Feeds paper in the

CONT. FORMS CUT-SHEET

paper

or print position

reverse direction

Ejects paper

Invalid

Ejects paper

DESELECT

CONT. FORMS CUT-SHEET

paper

reverse direction

Feeds forms or ejects

paper

Ejects paper

> While pressing the SHIFT switch:

PRINTER STATE

SWITCH

SEL Switches between Menu

LF Adjusts the TOF position

FF/LOAD Adjusts the TOF position

CONT. FORMS CUT-SHEET

and Normal modes

(reverse fine

increments)

(fine increments)

Operator interface > 33

SELECT

Switches between Menu

and Normal modes

Adjusts the TOF position

(reverse fine

increments)

Adjusts the TOF position

(fine increments)

Page 34

PRINTER STATE

SELECT

SWITCH

TEAR Switches between

PARK Invalid Invalid

PRINTER STATE

SWITCH

SEL Switches between Menu

LF Adjusts the TOF position

FF/LOAD Adjusts the TOF position

TEAR Invalid Invalid

PARK Sets the TOF position

CONT. FORMS CUT-SHEET

quiet, high impact and

normal print modes

(Note 1)

Switches between

quiet, high impact and

normal print modes

(Note 1)

DESELECT

CONT. FORMS CUT-SHEET

and Normal modes

(reverse fine

increments)

(fine increments)

(Note 2)

Switches between Menu

and Normal modes

Adjusts the TOF position

(reverse fine

increments)

Adjusts the TOF position

(fine increments)

Sets the TOF position

(Note 2)

NOTE

1. Pressing TEAR while holding down SHIFT changes the

print mode.

Press TEAR once while holding down SHIFT: switches to

quiet print mode.

Press TEAR twice while holding down SHIFT: switches to

normal print mode (returns to the default).

2. PARK is used to set the TOF position.

Press PARK: The setting is valid until power off.

Hold down PARK: The setting is saved in the Flash-ROM.

Operator interface > 34

Page 35

HEX D

UMP MODE

, M

ENU MODE

, T

EST MODE

SWITCH

SEL SHIFT LF FF/LOAD TEAR PARK

XXO X XXActivates Self

XXO O XXPerforms skip/

X X X X X O Activates

O X X O X X Activates Hex

O X X X X X Activates Menu

OOX X XXSets Menu

O X O X X X Activates

OXO X OXActivates

MENU

TYPES

Test m o d e

continuous

pattern

Rolling ASCII

(1 page)

Dump mode

mode

factory default

setting

Maintenance

Mode 1

(Note 1)

Maintenance

Mode 2

(Note 1)

NOTE

1. When a Maintenance Mode is launched, the SEL lamp

lights and waits for the switch to be pressed.

Operator interface > 35

Page 36

M

AINTENANCE MODE

1

SWITCH

SEL SHIFT LF FF/LOAD TEAR PARK

ZXX X OXActivates

XXO X Z XActivates

M

AINTENANCE MODE

2

SWITCH

SEL SHIFT LF FF/LOAD TEAR PARK

XXZ X O XActivates

MENU

TYPES

Maintenance

Menu mode

Registration

Menu mode

MENU

TYPES

Flash Loading

mode

NOTE

The above mode appears by pressing the switch marked O,

releasing the switch marked X and then turning ON the power.

The switch is invalidated when pressed in any other

combination.

After launching each mode, temporarily release all switches

then press the switch marked Z and the switch marked O to

launch the local function.

Operator interface > 36

Page 37

L

AMP FUNCTIONS

LAMP COLOUR ON OFF BLINKING

SEL Green SELECT

ALARM Red Paper end

MENU Green MENU

QUIET Green Quiet print

POWER Green Power ON

NOTE

1. In recovery impossible alarm state, both SEL and ALARM

lamps are blinking.

A

LARM/ERROR INDICATIONS

R

ECOVERABLE ALARMS

LED

ALARM

(data

receiving

enable)

state

state

mode

mode

state

DESELECT

(data

receiving

impossible)

state

Paper

existing

state

Normal print

mode

Normal print

mode

Power OFF

state

Recovery impossible

alarm state (Note 1).

Keep printing data

state.

Cut sheet removal

standby state.

Recovery impossible

alarm state (Note 1).

Paper jam state.

Media switching

alarm state.

LF and SP motor

protecting alarm.

High multipart print

mode.

Power save mode

(1s ON/1s OFF).

SEL ALARM MENU

Paper End R O R

Paper Leve r B R

Paper Jam (Load jam,

Ejection jam)

Head Temperature R R B

SPACE/LF MOTOR

Tem p e ratu r e

RR B

Operator interface > 37

BR

Page 38

NOTE

O: LED continuously ON

B: LED blinking (500 ms ON, 500 ms OFF)

R: Current LED indication retained

Blank: LED OFF

U

NRECOVERABLE ALARMS

Unrecoverable alarms are shown below. The numbers of blinks of

the alarms indicate the states of the alarms.

Alarm indication consists of main blinking and sub-blinking. Main

blinking is the concurrent blinking of the SEL and ALARM LEDs

and sub-blinking is the blinking of only the SEL LED.

ALARM INDICATION

ALARM CONTENTS

MAIN BLINKING SUB-BLINKING

1 1 Head homing alarm

2 Spacing alarm

3 Roller alarm

2 1 Program ROM alarm

2 CG ROM alarm

3 Flash ROM alarm

3 1 DRAM alarm

Operator interface > 38

Page 39

ALARM INDICATION

MAIN BLINKING SUB-BLINKING

4 1 CPU (inside RAM) alarm

2 Manual reset alarm

3 NMI alarm

4 CPU address alarm

5 DMA address alarm

6General invalid

7 Slot alarm

8 Watchdog timer alarm

ALARM CONTENTS

instruction alarm

9 Invalid interrupting

5 1 F/W alarm

9 1 Head A/D error

alarm

LED blink time periods

SEL

ALARM

M

ENU SELECTION

O

VERVIEW

ON

OFF

ON

OFF

T1 T2

Main blinking

T1=T2=250 msec T3=T4=750 msec

T3

T1 T2

T4

Sub-blinking

1 Cycle

Features selected in Menu mode become the default features for

the printer each time it is powered on. The Menu function allows

Operator interface > 39

Page 40

features to be activated without the use of a software command

but software commands override Menu settings.

NOTE

Maintenance Menu items are not accessible to day-to-day

users.

B

UTTON SWITCH FUNCTIONS

SWITCH FUNCTION

LF Moves forward through the menu items.

SHIFT + LF Moves backward through the menu items.

FF/LOAD Moves forward through the values of a menu item.

SHIFT + FF/LOAD Moves backward through the values of a menu

SHIFT + SEL Exits the Menu mode.

PARK The first menu item is printed after all the menu

O

PERATION

When the last item is selected, the first one will

come up on pressing LF.

When the first item is selected, the last one will

come up on pressing LF.

When the last value is selected, the first one will

come up on pressing FF/LOAD.

item.

When the first value is selected, the last one will

come up on pressing SHIFT + FF/LOAD.

The printer enters the initial state as at power on.

items are printed.

1. To enter Menu Mode:

(a) If the printer power is OFF, while holding down the

SEL button turn the power ON.

(b) If the printer power is ON, press the SHIFT and SEL

buttons together.

To enter Maintenance Menu mode.

(a) Hold down the SEL and LF switches and turn the

power ON to activate Maintenance Mode.

(b) After Maintenance Mode is enabled, hold down the

SEL switch and press the TEAR switch.

Operator interface > 40

Page 41

2. On entering the Menu mode, “Menu Print?” is printed.

3. See “Button switch functions” on page 40 for a description

of how to navigate the menus.

4. To exit the Menu mode, hold down the SHIFT switch and

press the SEL switch.

5. The TOF position is not affected by Menu mode.

(However, TOF setting is executed if page length

changes.)

NOTE

When entering/exiting Menu Mode, the user is not prompted.

M

ENU ITEMS

In the menu settings tables below, factory default settings are

shown emboldened.

ITEM FUNCTION SETTING

Emulation Mode Select EPSON LQ mode,

Print Mode Select quality of ANK

Pitch Select character pitch. 10 CPI, 12 CPI, 15 CPI,

Proportional Spacing Select whether to use

Style Select either font style. Normal, Italics

Size Select the character

Character Set Select either ANK

IBM PPR mode, or IBM

X24 AGM mode.

characters.

proportional spacing or

not.

scale size.

character code table.

Operator interface > 41

IBM PPR

IBM AGM

EPSON LQ

LQ Courier

LQ Roman

LQ Swiss

LQ Swiss Bold

LQ Orator

LQ Gothic

LQ Prestige

LQ OCR-A

LQ OCR-B

Utility

HSD

17.1 CPI, 20 CPI

Yes

No

Single, Double

Set I

Set II

Page 42

ITEM FUNCTION SETTING

Language Set Select a language

Zero Character Select either print font

character set.

pattern to receive a

zero character located

at 30H in ANK code or

at AA30H in a singlebyte code.

ASCII, French,

German, British, Danish

I, Swedish I, Italian,

Spanish I, Japanese,

Norwegian, Danish II,

Spanish II, Latin

American, French

Canadian, Dutch,

Swedish II, Swedish III,

Swedish IV, Turkish,

Swiss I, Swiss II,

Publisher

Unslashed

Slashed

Operator interface > 42

Page 43

ITEM FUNCTION SETTING

Code Page Select a code page. USA

Slashed Letter 0 Set whether to convert

slashed 0 located at

9BH and 9DH in USA

code page or not.

Canada French

Multilingual

Portugal

Norway

Turkey

Greek_437

Greek_869

Greek_928

Grk_437 CYPRUS

Polska Mazovia

Serbo Croatic I

Serbo Croatic II

ECMA-94

Hungarian CWI

Windows Greek

Windows East Europe

Windows Cyrillic

East Europe Latin II852

Cyrillic I-855

Cyrillic II-866

Kamenicky (M JK)

ISO Latin 2

Hebrew NC (862)

Hebrew OC

Turkey_857

Latin 5 (Windows

Turkey)

Windows Hebrew

Ukrainian

Bulgarian

ISO Latin 6 (8859/10)

Windows Baltic

Baltic_774

KBL-Lithuanian

Cyrillic Latvian

Roman-8

Icelandic-861

Multilingual 858

ISO 8859-15

Greek_737

Asmo449+

Asom708

Arabic864

Windows Arabic

POL 1

Yes

No

Operator interface > 43

Page 44

ITEM FUNCTION SETTING

Multi Pass Select the printing

Rcv Buffer Select size of the

Print Suppress Effective Set whether to enable

Auto LF Select whether to

Auto CR

*IBM PPR only

SI Select Pitch (10CPI)

*IBM PPR/AGM only

SI Select Pitch (12CPI)

*IBM PPR/AGM only

Reset Inhibit Set whether to enable

direction when doubleheight print data exists

in a line.

received buffer.

or disable a print

suppress setup

command.

perform auto LF

operation or not upon

receiving a CR code.

Select whether to

perform auto CR

operation upon

receiving a carriage

return command.

Set how to handle an SI

command received in

10 CPI mode.

Set how to handle an SI

command received in

12 CPI mode.

or disable an initial

command.

Bi-directional

Uni-directional

0, 2 K, 32 K, 64 K

Yes

No

Yes

No

Yes

No

15 CPI

17.1 CPI

12 CPI

20 CPI

No

Yes

Select Language Set

*EPSON only

Impact Mode Select print mode on

Print Direction

Command

Set whether to enable

or disable a

combination of the code

page setting and the

language setting by

menu.

power on. (This item is

referred to on

initialisation only by IPRIME or power on but

not by an initialisation

command.)

Select the validity of a

one-way print setup

command.

Operator interface > 44

Combined

Code Page Only

Normal

Quiet

Hi Copy

Valid

Invalid

Page 45

ITEM FUNCTION SETTING

Power Save Time Set idle time to enter

PE Detection Select whether to

Table Print Set whether to divide a

Line Spacing Select line feed pitch. 6 LPI

Page Width Set width of a line to

Form Tear-Off Select manual or auto

Skip Over Perforation Select whether to skip

Page Length

(Continuous)

power save mode.

detect paper end or not.

path or not to print on

occasions when printing

by the same headpin

continues for 3 in or

more in the same print

block.

determine the number

of ANK (10CPI)

characters to be

printed. With this

setting, the right

margin is set. For

reduced-size prints, at

75 % or 50%, 136

characters are printed.

as the method to

advance a continuous

form to the form tearoff position.

over perforation or not.

(When a skip over

perforation setup

command is received,

the received command

is given priority.)

Select the length of a

continuous form.

5 min, 10 min, 15 min,

30 min, 60 min

OFF

ON

Standard

Special

8 LPI

10.6 in

8 in

Off

500 ms

1 sec

2 sec

Yes

No

3.5 in, 4 in, 5.5 in, 6 in,

7 in, 8 in, 8.5 in, 11 in,

11 2/3 in, 12 in, 14 in,

17 in, 5 in, 3 in, 3.25 in

Operator interface > 45

Page 46

ITEM FUNCTION SETTING

TOF (Continuous) Select the reference

Initial Position This is the position of

Auto Eject Position Select a printable area

Page Length (Cut

Sheet)

TOF (Cut Sheet) Select the reference

position for the TOF

position when auto

loading continuous form

paper from the rear of

the printer. (Up to the

mid-section of

characters in the first

line.)

“1Chr. Set Pos.” is

printed if the TOF

position is set by using

SHIFT + PARK switches.

the paper when the

paper is already loaded

at power on. (For

continuous form mode

only.)

at the bottom of cut

sheets of paper in cutpaper mode (the

character centre

position).

Select the page length

of cut-paper.

position for the TOF

position when feeding

cut-paper in manual

mode. (Up to the midsection of characters in

the first line.)

“1Chr. Set Pos.” is

printed if the TOF

position is set by using

SHIFT + PARK switches.

2.12 mm (1/12 in)

4.23 mm (1/6 in)

6.35 mm (1/4 in)

8.47 mm (1/3 in)

10.58 mm (5/12 in)

12.7 mm (1/2 in)

14.82 mm (7/12 in)

16.93 mm (2/3 in)

19.05 mm (3/4 in)

21.17 mm (5/6 in)

23.28 mm (11/12 in)

25.4 mm (1 in)

27.52 mm (13/12 in)

1Chr. Set Pos.

Print

Tear OFF

6.35 mm (1/4 in)

14.8 mm

3.5 in, 4 in, 5.5 in, 6 in,

7 in, 8 in, 8.5 in, 11 in,

11 2/3 in, 12 in, 14 in,

16.57 in, 5 in, 3 in,

3.25 in

2.12 mm (1/12 in)

4.23 mm (1/6 in)

6.35 mm (1/4 in)

8.47 mm (1/3 in)

10.58 mm (5/12 in)

12.7 mm (1/2 in)

14.82 mm (7/12 in)

16.93 mm (2/3 in)

19.05 mm (3/4 in)

21.17 mm (5/6 in)

23.28 mm (11/12 in)

25.4 mm (1 in)

27.52 mm (13/12 in)

1Chr. Set Pos.

Operator interface > 46

Page 47

ITEM FUNCTION SETTING

Wait Time Select the waiting time

I-Prime Select whether to print

Auto Feed XT

*EPSON only

I/F Bi-Direction Set whether to return a

Parity

*Displayed only when

connected to a serial

interface.

Serial Bits

*Displayed only when

connected to a serial

interface.

Protocol

*Displayed only when

connected to a serial

interface.

Diagnostic Test

*Displayed only when

connected to a serial

interface.

between setting paper

on the tray and feeding

it while the printer is

waiting for paper to be

fed in cut-paper manual

feed mode.

or clear buffer contents

upon initialisation by

receiving I-PRIME.

Set the validity of an

Auto Feed XT signal.

device ID or not in

accordance with

IEEE1284.

Select presence or

absence of parity bit

and whether even or

odd parity.

None: No parity bit

Odd: Odd parity

Even: Even parity

Select the data length.

7: Data length 7 bits

8: Data length 8 bits

Select an I/F Busy

control method.

Ready/Busy: Busy

control by a DTR signal

X-ON/X-OFF: Busy

control by a CD3/DC1

code

Select whether to

perform input/output

diagnosis of RS-232C

interface signals.

No: Do not execute the

self diagnostic function

Yes: Execute the self

diagnostic function

500 ms

1 sec

2 sec

Invalid

Buffer Clear

Buffer Print

Valid

Invalid

Enable

Disable

None

Odd

Even

7 Bits

8 Bits

Ready/Busy

X-ON/X-OFF

No

Yes

Operator interface > 47

Page 48

ITEM FUNCTION SETTING

Busy Line

*Displayed only when

connected to a serial

interface.

Baud Rate

*Displayed only when

connected to a serial

interface.

DSR Signal

*Displayed only when

connected to a serial

interface.

Set a Busy Line setting

of a serial interface.

Select the data baud

rate from the options.

300: Sets the data baud

rate to 300 BPS

600: Sets the data baud

rate to 600 BPS

1200: Sets the data

baud rate to 1200 BPS

2400: Sets the data

baud rate to 2400 BPS

4800: Sets the data

baud rate to 4800 BPS

9600: Sets the data

baud rate to 9600 BPS

19200: Sets the data

baud rate to 19200 BPS

38400: Sets the data

baud rate to 38400 BPS

Select the validity of the

received data.

Valid: Checks the status

of a DSR signal. The

data received while the

DSR signal is in the

SPACE state is

determined to be valid.

If data is received while

a DSR signal is in the

MARK state, the data is

determined to be invalid

and discarded.

Invalid: Regardless of

the status of a DSR

signal, all the received

data is determined to

be valid.

SSD-

SSD+

DTR

RTS

300 BPS

600 BPS

1200 BPS

2400 BPS

4800 BPS

9600 BPS

19200 BPS

38400 BPS

Valid

Invalid

DTR Signal

*Displayed only when

connected to a serial

interface.

Busy Time

*Displayed only when

connected to a serial

interface.

Set a method to switch

a DTR signal of a serial

interface, by select/

deselect or fix it to

power on.

Set the minimum time

between BUSY to

READY.

Operator interface > 48

Ready on Power UP

Ready on Select

200ms

1 sec

Page 49

ITEM FUNCTION SETTING

TOF Adjustment

(Cut Sheet)

Rear Load Adjustment Select an adjustment

Cut Position Adjust Select an adjustment

Registration Low Adjust the print starting

Select an adjustment

value for the reference

position in regard to the

TOF position of cutpaper/passbooks.

The position moves to

the rear of the form by

[+] and to the top of

the form by [-] in 1/

60 in increments.

value for the reference

position in regard to the

TOF position of a

continuous form.

The position moves to

the rear of the form by

[+] and to the top of

the form by [-] in 1/

60 in increments.

value for the position to

cut the end of a

continuous form. (In 1/

90 in increments)

position on printing in

the reverse direction.

(The position moves to

the right or left in 1/

720 in increments.)

-7 – -1

0

+7 – +1

-7 – -1

0

+7 – +1

-7 – -1

0

+7 – +1

-10 – -1

0

+10 – +1

Registration Normal Adjust the print starting

Registration High1 Adjust the print starting

position on printing in

the reverse direction.

(The position moves to

the right or left in 1/

720 in increments.)

position on printing in

the reverse direction.

(The position moves to

the right or left in 1/

720 in increments.)

Operator interface > 49

-10 – -1

0

+10 – +1

-10 – -1

0

+10 – +1

Page 50

ITEM FUNCTION SETTING

Registration High2 Adjust the print starting

LF Revise (Cut Sheet) Adjust a line feed

LF Revise (Continuous)

*Displayed in

Maintenance Menu only

Centring For Feed

*Displayed in

Maintenance Menu only

position on printing in

the reverse direction.

(The position moves to

the right or left in 1/

720 in increments.)

amount in cut-paper

mode.

Adjust by a line feed

amount when printing a

continuous form from

the rear.

Specify the centring

position for a line feed.

Mod e 1 : Centring to the

8th character position

to feed a continuous

form from the rear by 2

ranges or more and 2/

3-in and more.

Mod e 2 : Centring to the

5th character position

to feed a continuous

form from the rear by 2

ranges or more and 2/

3-in and more.

Mod e 3 : Centring to the

8th character position

to feed either

continuous form from

the rear or cut-paper.

Mode 4: No centring by

a line feed.

-10 – -1

0

+10 – +1

-14 – -1

0

+14 – +1

-2

-1

0

+1

+2

Mode1

Mode 2

Mode 3

Mode 4

Operator interface > 50

Page 51

ITEM FUNCTION SETTING

Position Check

*Displayed in

Maintenance Menu only

SP Check

*Displayed in

Maintenance Menu only

Slack Adjust

(Continuous)

*Displayed in

Maintenance Menu only

Centring For Paper Top

(Continuous)

*Displayed in

Maintenance Menu only

Switch settings for

position check of the

print head.

Check 1: Homing when

shifting from OFFLINE

to ONLINE by pressing a

switch with a standard

setting and when

exiting the power save

mode.

Check 2: Homing when

printing is started by

data reception after no

operation of

enhancement setting or

printing for more than 3

minutes, and at the

time of cut-paper

feeding or a continuous

form auto loading

(before loading).

Checking the starting

point of the head for a

continuous form.

Set whether to execute

slack adjustment for

paper or not when using

rear tractor.

Select whether to apply

centring or not to the

30th character before

inserting line feeds until

the top of form goes

over the rear feed roller

in continuous form

mode.

Valid: Apply centring

Invalid: Do not apply

centring

Check1

Check 2

Valid

Invalid

Valid

Invalid

Valid

Invalid

Image Print Speed

*Displayed in

Maintenance Menu only

Select image print

speed.

Normal: Image print at

speed DOWN (80%)

Special: Image print at

normal speed (100%)

Operator interface > 51

Normal

Special

Page 52

ITEM FUNCTION SETTING

CPU Compensation

*Displayed in

Maintenance Menu only

I/F Timing Set

*Displayed in

Maintenance Menu only

Time Out Print

*Displayed in

Maintenance Menu only

Set data latch timing

and ACK-BUSY signal

output timing with

regard to Centronics

interface signals.

Standard: Busy signal

output at the centre of

ACK

Special: Busy signal

output at the falling

edge of ACK

Set data latch timing

and STB-BUSY signal

output timing with

regard to Centronics

interface signals.

New: Busy signal output

and data latch at the

falling edge of STB

Old: Busy signal output

and data latch at the

rising edge of STB

Special: Busy signal

output at the falling

edge of STB and data

latch at the rising edge

of STB

This is to set or cancel

the 150 ms timeout

print mode.

Standard

Special

New

Old

Special

Valid

Invalid

NOTE

1. Cut sheet LF accuracy adjustment, as in the table below

with TOF position as a standard.

SET

CONTENTS

VALUE

-14 Add 1 pitch [0.035 mm (1/720 in)] every -3.88 mm (55/360 in)

-13 Add 1 pitch [0.035 mm (1/720 in)] every -7.83 mm (111/360 in)

-12 Add 1 pitch [0.035 mm (1/720 in)] every -8.46 mm (120/360 in)

-11 Add 1 pitch [0.035 mm (1/720 in)] every -9.10 mm (129/360 in)

-10 Add 1 pitch [0.035 mm (1/720 in)] every -10.01 mm (142/360 in)

-9 Add 1 pitch [0.035 mm (1/720 in)] every -11.00 mm (156/360 in)

Operator interface > 52

Page 53

SET

CONTENTS

VALUE

-8 Add 1 pitch [0.035 mm (1/720 in)] every -12.48 mm (177/360 in)

-7 Add 1 pitch [0.035 mm (1/720 in)] every -13.97 mm (198/360 in)

-6 Add 1 pitch [0.035 mm (1/720 in)] every -16.29 mm (231/360 in)

-5 Add 1 pitch [0.035 mm (1/720 in)] every -18.62 mm (264/360 in)

-4 Add 1 pitch [0.035 mm (1/720 in)] every -23.28 mm (330/360 in)

-3 Add 1 pitch [0.035 mm (1/720 in)] every -27.94 mm (396/360 in)

-2 Add 1 pitch [0.035 mm (1/720 in)] every -41.91 mm (594/360 in)

-1 Add 1 pitch [0.035 mm (1/720 in)] every -55.88 mm (792/360 in)

0 No LF pitch adjustment

+1 Remove 1 pitch [0.035 mm (1/720 in)] every +55.88 mm (792/360

+2 Remove 1 pitch [0.035 mm (1/720 in)] every +41.91 mm (594/

+3 Remove 1 pitch [0.035 mm (1/720 in)] every +27.94 mm (396/

+4 Remove 1 pitch [0.035 mm (1/720 in)] every +23.28 mm (330/

+5 Remove 1 pitch [0.035 mm (1/720 in)] every +18.62 mm (264/

+6 Remove 1 pitch [0.035 mm (1/720 in)] every +16.29 mm (231/

+7 Remove 1 pitch [0.035 mm (1/720 in)] every +13.97 mm (198/

+8 Remove 1 pitch [0.035 mm (1/720 in)] every +12.48 mm (177/

+9 Remove 1 pitch [0.035 mm (1/720 in)] every +11.00 mm (156/

+10 Remove 1 pitch [0.035 mm (1/720 in)] every +10.01 mm (142/

+11 Remove 1 pitch [0.035 mm (1/720 in)] every +9.10 mm (129/

in)

360 in)

360 in)

360 in)

360 in)

360 in)

360 in)

360 in)

360 in)

360 in)

360 in)

Operator interface > 53

Page 54

SET

VALUE

CONTENTS

+12 Remove 1 pitch [0.035 mm (1/720 in)] every +8.46 mm (120/360

+13 Remove 1 pitch [0.035 mm (1/720 in)] every +7.83 mm (111/360

+14 Remove 1 pitch [0.035 mm(1/720 in)] every +3.88 mm (55/360

R

EGISTRATION MENU

O

VERVIEW

in)

in)

in)

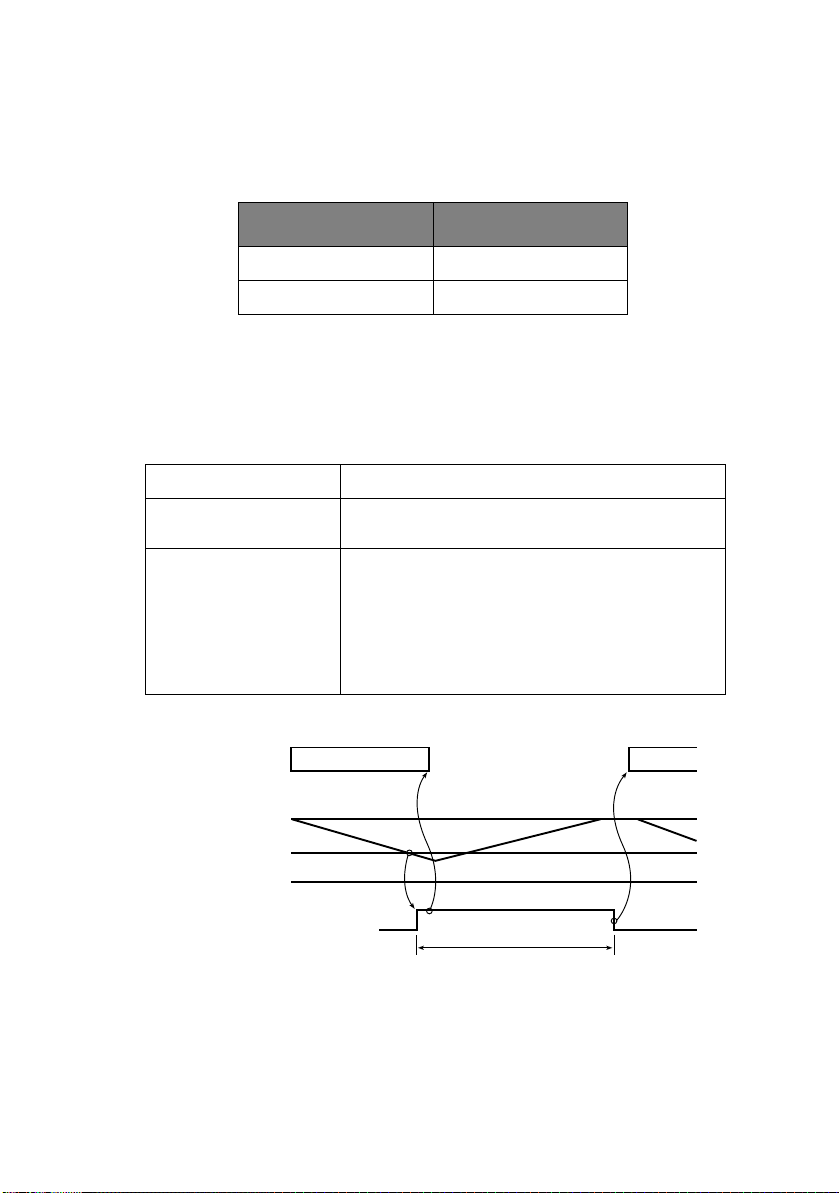

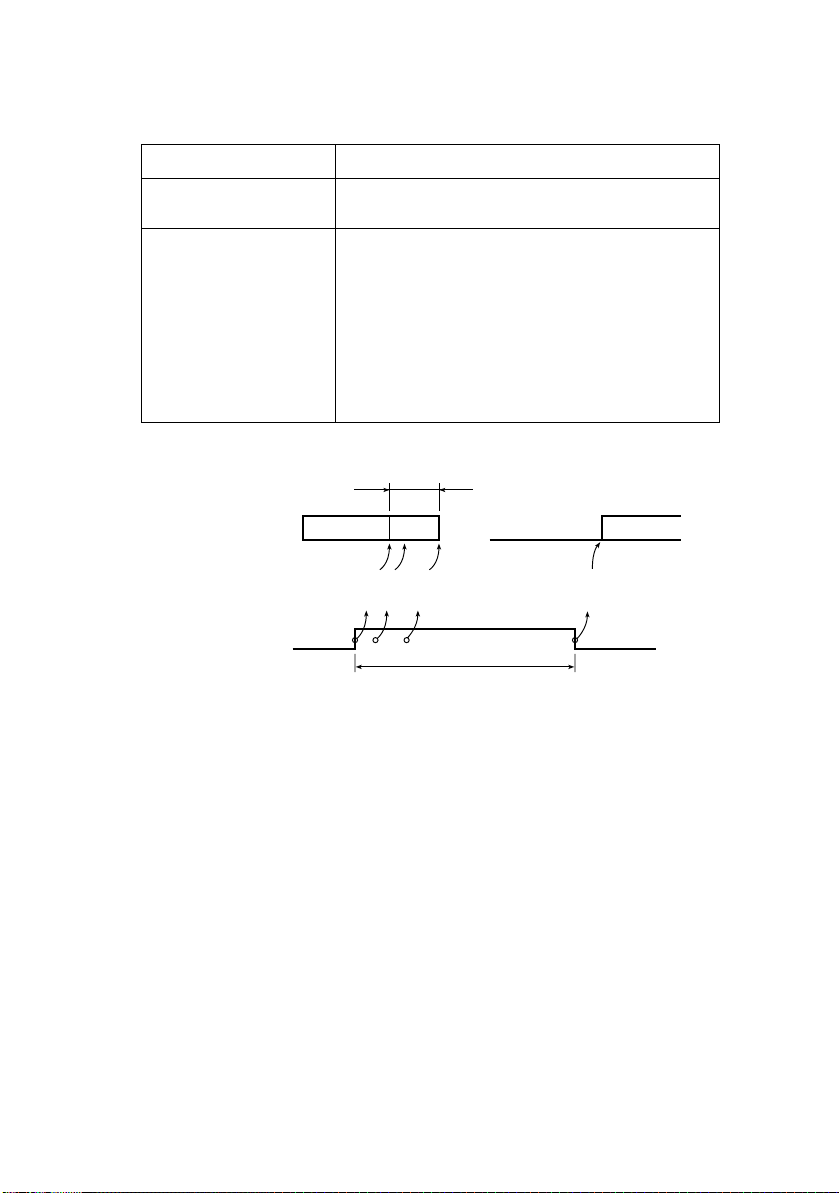

2. Ruled lines print pattern at level print position adjustment

is as follows:

FF SHIFT+FF

3. For details of the code pages see “Appendix C – Code

pages” on page 170.

This is a factory shipped configuration to adjust the horizontal

print position correction and is capable of setting the horizontal

print position (see “Menu selection” on page 39.)

O

PERATION

To enter registration menu mode:

1. Hold down the SEL + LF switches and turn on the power

to activate the maintenance mode.

2. After the maintenance mode is enabled, hold down the

TEAR switch and press the LF switch.

Operator interface > 54

Page 55

R

EGISTRATION DETAILS

NO ITEM SET REMARK

1 Registration

Low

2 Registration

Normal

3 Registration

High 1

4 Registration

High 2

S

ELF TEST PRINTING

+10, +9, ...0...-9, -10

Factory Shipped

Configuration:

+-10/720 in in increments

of 1/720 in.

1. Start:

While pressing the LF switch, turn on the power.

2. Stop:

Stop the test by pressing the SEL switch.

3. Print Pattern:

(a) Header:

aaaaa EI E F/W bb.cc

LD ff.gg

ddddddddYR-ee

as defined by:

POSITION &

CHAR. COUNT

aaaaa Model name ML6300FB

DESCRIPTION DATA

PRINTED

COMMENTS

bb.cc Revision no. 00.00 – 99.99 Firmware revision

dddddddd Part Number 43058201 YR Number

ee Part Number 01 – 99 ROM-FD Number

ff.gg Revision no. 00.00-99.99 Boot program

revision

(b) The first firmware revision is

‘01.xx’ (30)H(31)H(2E)H(x)H(x)H

Operator interface > 55

Page 56

(c) The test pattern is a consecutive printing of ASCII

R

OLLING

ASCII

1. Start:

Start the continuous rolling ASCII by pressing and holding

the PARK switch then turning the power on.

2. Stop:

Stop the test by pressing the SEL switch.

3. Print pattern:

(a) Header:

characters 20H to 7EH in all print quality and pitch

combinations

NUMBER OF CHARACTERS PRINTED PER LINE

80 at 10 CPI 136 CH

96 at 12 CPI 163 CH

120 at 15 CPI 204 CH

137 at 17.1 CPI 233 CH

160 at 20 CPI 272 CH

SELF TEST PRINTING

aaaaa EI E F/W bb.cc

LD ff.gg

ddddddddYR-ee

as defined by:

POSITION &

CHAR. COUNT

aaaaa Model name ML6300FB

bb.cc Revision no. 00.00 – 99.99 Firmware revision

dddddddd Part Number 43058201 YR Number

ee Part Number 01 – 99 ROM-FD Number

ff.gg Revision no. 00.00 - 99.99 Boot program

DESCRIPTION DATA

PRINTED

Operator interface > 56

COMMENTS

revision

Page 57

(b) Pattern will be continuous printing of all ASCII

characters.

(c) The test completes when one print pattern is printed

out.

H

EXADECIMAL DUMP MODE

O

VERVIEW

Normally a printer prints character patterns that correspond with

the input character code. The printer does not print function

codes or invalid codes. If the printer does not operate normally,

the data sent from the host computer must be checked to

determine if the commands are correct.

In this mode the printer converts input data into hexadecimal

data and prints all the input data, making it is easy to check all

the codes sent from the host computer to the printer.

O

PERATION

1. Entering Hexadecimal Dump mode:

While pressing the SEL+FF/LOAD switches, turn on the

power.

2. Exiting Hexadecimal Dump mode:

Turn the power OFF

3. Print pattern:

Hex Data Dump

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX ...................

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX ...................

4. Printing example:

The following is an example when data is input from the

host computer in the basic format:

Basic: LPRINT CHR$ (&H1B); “0 “; CHR$ (&H1E);

“01234567890 “; CHR$ (&0D); CHR$ (&H0A)

1B 30 1E 30 31 32 33 34 35 36 37 38 39 30 OD OA

.0.01234567890.

Operator interface > 57

Page 58

F

UNCTION

> Prints in 10 CPI Utility mode.

> Both parallel and USB interfaces are available.

> Paper auto Skip Over Perforation (SOP) by menu default

value continuous for both. If SOP is enabled, one inch

from the bottom of the paper will not be printed.

> Printing starts when more than 16 bytes of data are

received (line full).

C

ONTINUOUS PAPER AUTO-LOADING

Load continuous paper on the tractor (at a position such that the

paper does not cross the paper-end sensor).

In this situation, pressing the FF/LOAD switch starts autoloading.

When the paper does not cross the paper-end sensor within an

8-in feed of the paper, a paper-end state occurs.

The print position of the first data line can be set by menu

function or in first character setting mode.

NOTE

TOF is the position that is set when the operation was

completed properly.

C

ONTINUOUS PAPER AUTO-PARKING

With continuous paper loaded in continuous paper mode,

pressing the PARK switch starts auto-parking.

When the end of continuous paper is detected by the time the

paper is fed 22 in in reverse, auto-parking finishes and a paperend state is established.

If the end of continuous paper is not detected after a 22-in