Page 1

MICROLINE

ML184T+

Printer Handbook

Page 2

Oki Data Corporation

4-11-22 Shibaura, Minato-ku,

T okyo 108-8551, Japan

Tel : (81) 3 5445 6158

Fax: (81) 3 5445 6189

www.okidata.co.jp

Oki Data (Singapore) Pte Ltd.

78 Shenton Way, #09-01,

Singapore 079120

Tel : (65) 6221 3722

Fax: (65) 6421 1688

www.okidata.com.sg

Oki Systems (Thailand) Ltd.

956 Udomvidhya Building,

6th Floor, Rama IV Rd.,

Bangkok 10500, Thailand

Tel : (662) 636 2535

Fax: (662) 636 2536

www.okisysthai.com

The IPL Group

63-85 Victoria Street,

Beaconsfield NSW 2015, Australia

Tel : (61) 2 9690 8200

Fax: (61) 2 9690 8300

www.oki.com.au

Comworth Systems Ltd.

10 Constellation Drive Mairangi Bay ,

Auckland, New Zealand

Tel : (64) 9 477 0500

Fax: (64) 9 477 0549

www.comworth.co.nz

Page 3

IMPORTANT

You have just bought the best printer, so be sure to use the only ribbons

recommended for it. Original OKI ribbons are the only ones that the manufacturers recommend. Ask for them by name.

Please remember that if you buy any other ribbon your warranty may be

invalidated.

Purchasing inferior ribbons really does not make sense. They do not last as

long. What is more, they are prone to shredding, which can cause damage

to your printhead. Any short term savings on cheap ribbons are quickly

lost.

So do not waste your time and money... insist on OKI consumables for

your OKI printer.

You can order them from your printer supplier.

i

Page 4

CONTENTS

Chapter 1: Setting Up Your Printer ........................................... 1-1

Connecting to Your Computer................................................... 1-11

Chapter 2: Operating Your Printer............................................ 2-1

Buttons, Levers and Indicators.................................................. 2-1

Menu Mode................................................................................. 2-6

Sample Menu.............................................................................. 2-7

Summary of Menu Settings ....................................................... 2-8

Paper Loading............................................................................. 2-14

Installing and Using the Roll Paper Stand ............................... 2-19

Loading Single Sheets ............................................................... 2-22

Installing and Using the Tractor Feed Unit.............................. 2-24

Installation of the Cut-Sheet Feeder ......................................... 2-29

Chapter 3: Working with Software ............................................ 3-1

Basic Terminology ..................................................................... 3-1

Printer Drivers ............................................................................ 3-2

Appendix A: Printer Commands ................................................ A-1

Appendix B: Interface Cable....................................................... B-1

Appendix C: ASCII Character Codes........................................ C-1

Appendix D: Menu Selections ..................................................... D-1

Appendix E: Specifications.......................................................... E-1

ii

Page 5

SPECIAL NOTE

This manual will help you install and use your new IBM/EPSON/OKI ML

compatible MICROLINE 184 Turbo+ printer. It contains everything you

need to know to print with your MICROLINE’s special features. If you

still need assistance after reading this book, please contact your dealer for

fast personal service. If your dealer cannot answer your questions, please

ask us.

Every effort has been made to ensure that the information in this document

is complete, accurate, and up-to-date. OKI assumes no responsibility for

the results of errors beyond its control. OKI also cannot guarantee that

changes in software and equipment made by other manufacturers, and referred to in this book, will not affect the applicability of the information in

this book.

© Copyright 1992 by OKI.

All rights reserved, including the right to reproduce this book or portions

thereof in any form.

iii

Page 6

IMPORTANT

The wires in this mains lead are coloured in accordance with the following

code:

GREEN AND YELLOW EARTH

BLUE NEUTRAL

BROWN LIVE

As the colours of the wires in the mains lead of this apparatus may not

correspond with the coloured markings identifying the terminals in your

plug — PROCEED AS FOLLOWS:

The wire coloured GREEN AND YELLOW must be connected to the terminal in the plug marked with the letter E or by the safety earth symbol or

coloured GREEN or GREEN AND YELLOW. The wire coloured BROWN

must be connected to the terminal marked with the letter L or coloured

RED. The wire coloured BLUE must be connected to the terminal marked

with the letter N or coloured BLACK.

WARNING: THIS APPARATUS MUST BE EARTHED

Ensure that your equipment is connected correctly . If you are in any doubt

consult a qualified electrician.

iv

Page 7

Chapter 1

Setting Up Your Printer

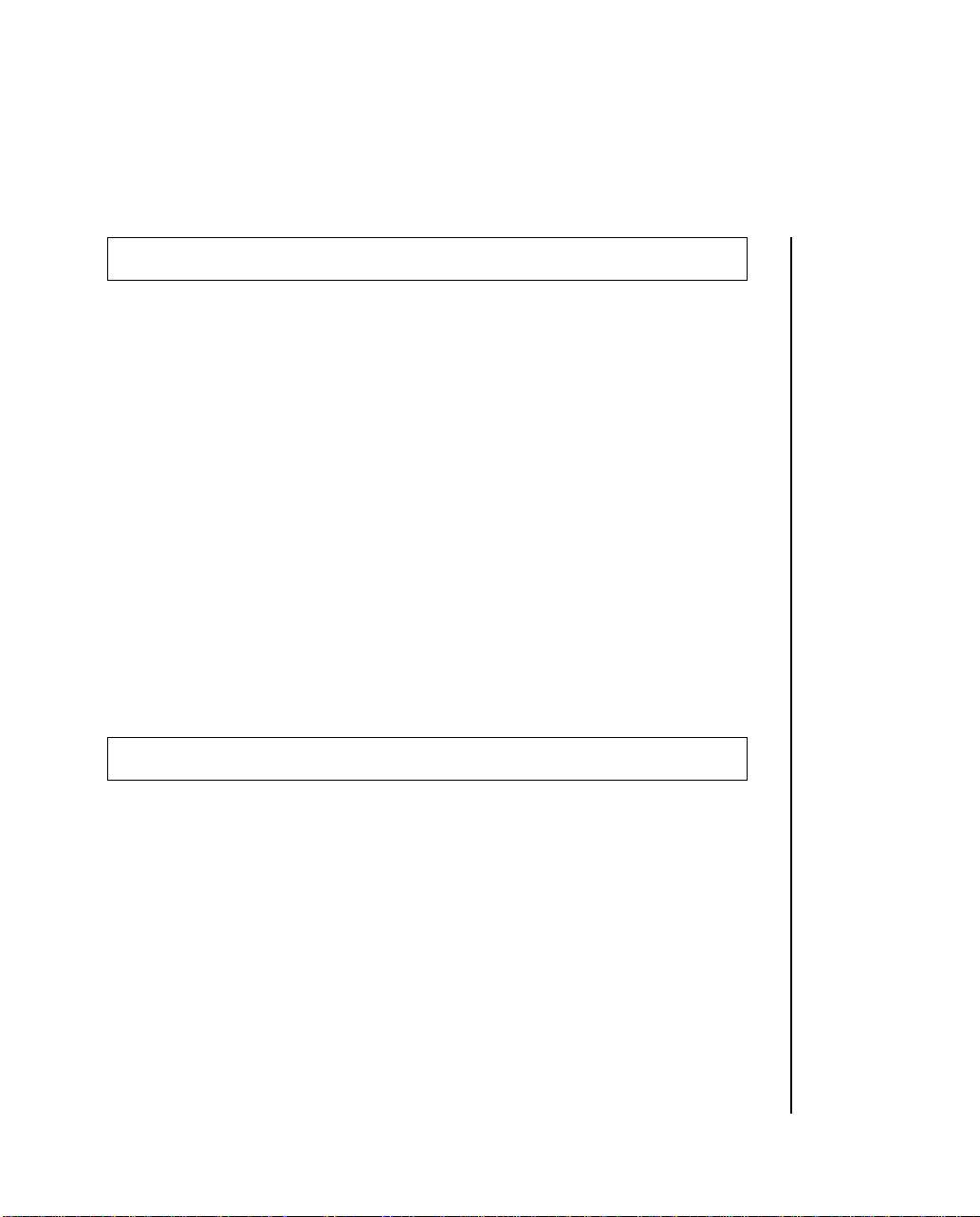

Your IBM/EPSON/OKI ML-compatible ML 184 Turbo+ printer is packed

in a protective container along with some extra items you need. These

items include:

Paper separator

Platen knob

Ribbon

cartridge

AC cable

Optional equipment available for your ML 184 Turbo+ printer includes:

Roll Paper stand

Setting Up 1 -- 1

Page 8

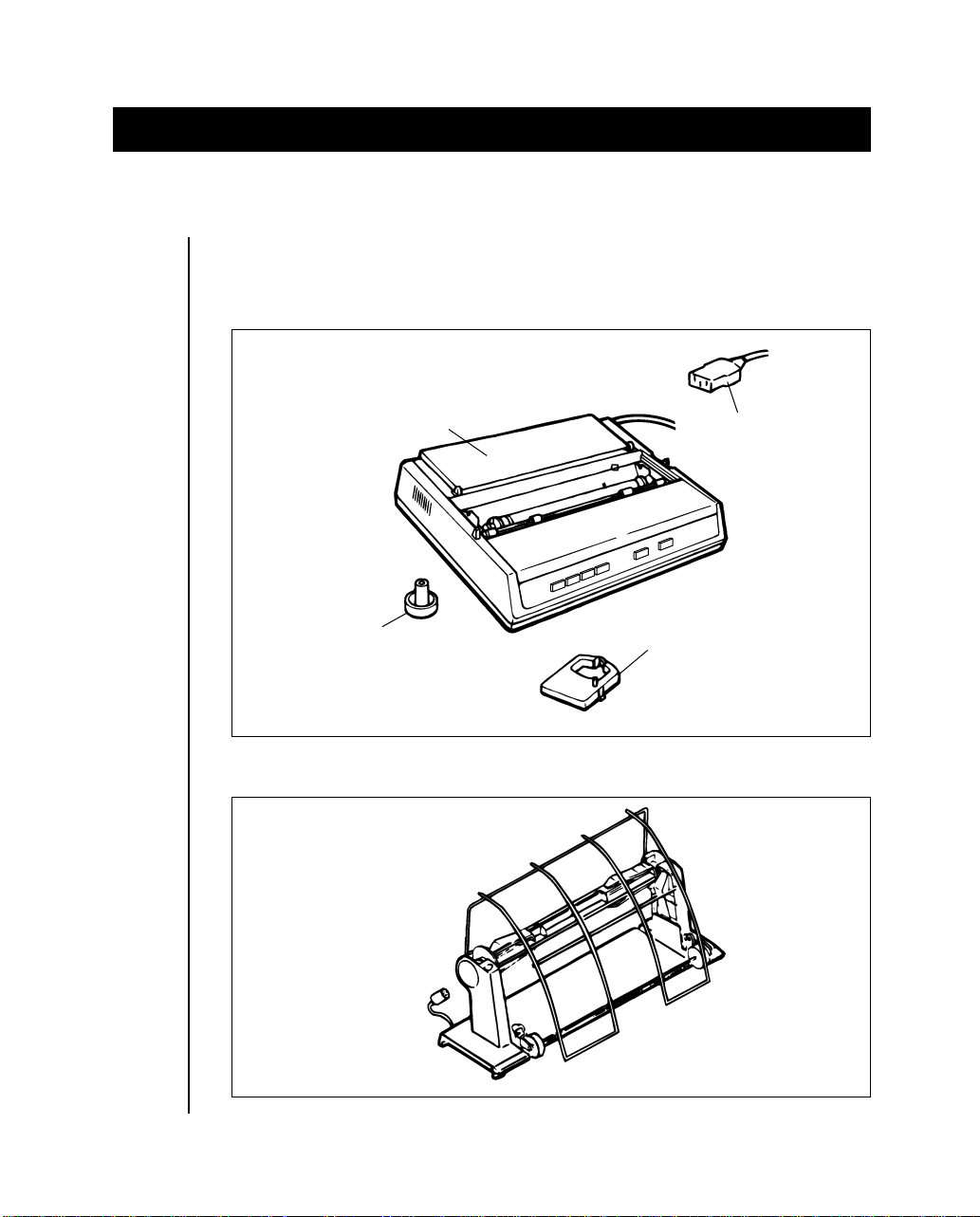

Tractor feed option kit

Tractor feed unit

Access cover

Acoustic cover

Cut-Sheet Feeder

Left paper guide

Paper test lever

Rear sheet support

Front sheet guide

Interface Equipment:

Super-Speed (19,200 baud) RS-232C serial board

1 -- 2 Setting Up

Front sheet support

Cut-Sheet Feeder unit

Page 9

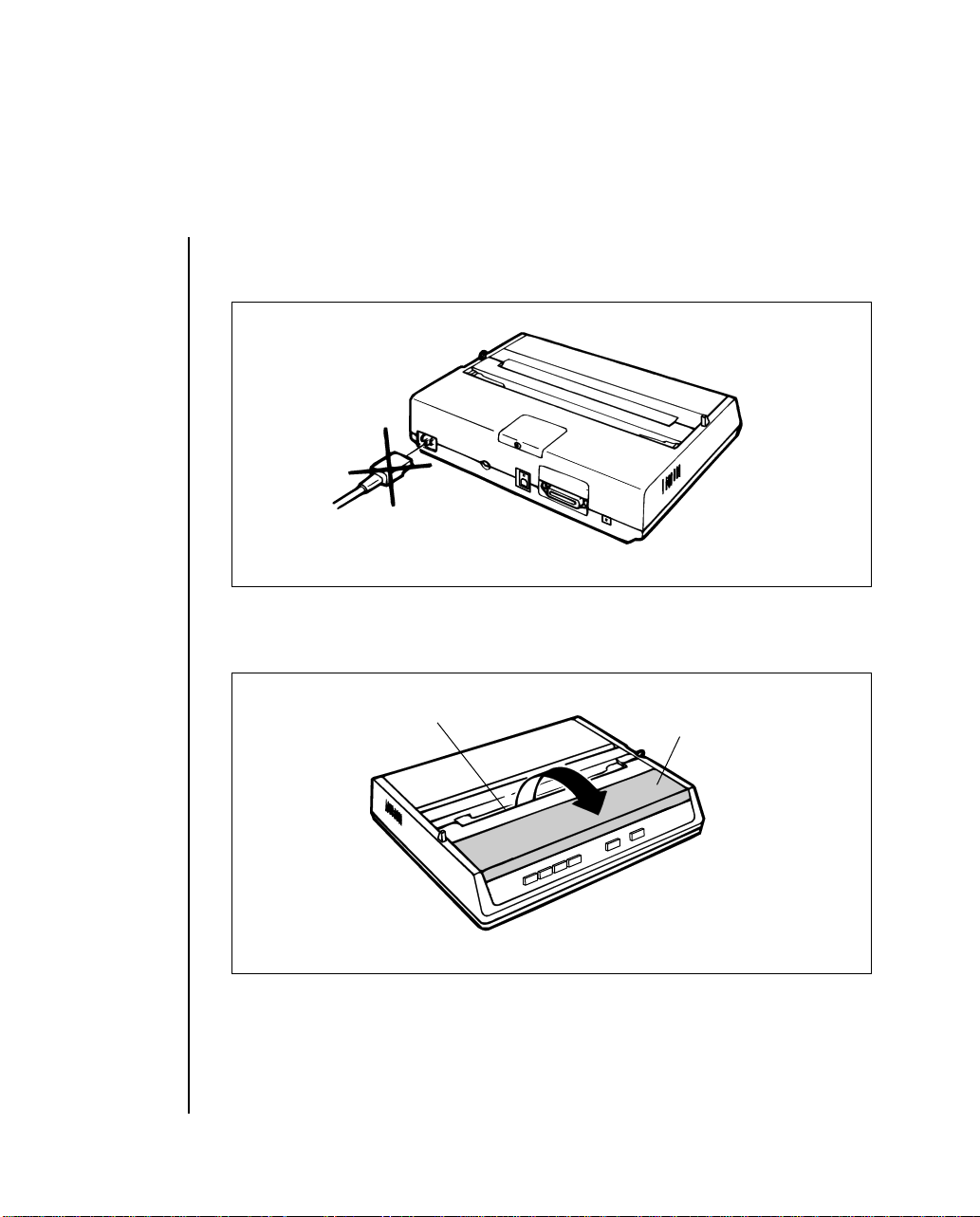

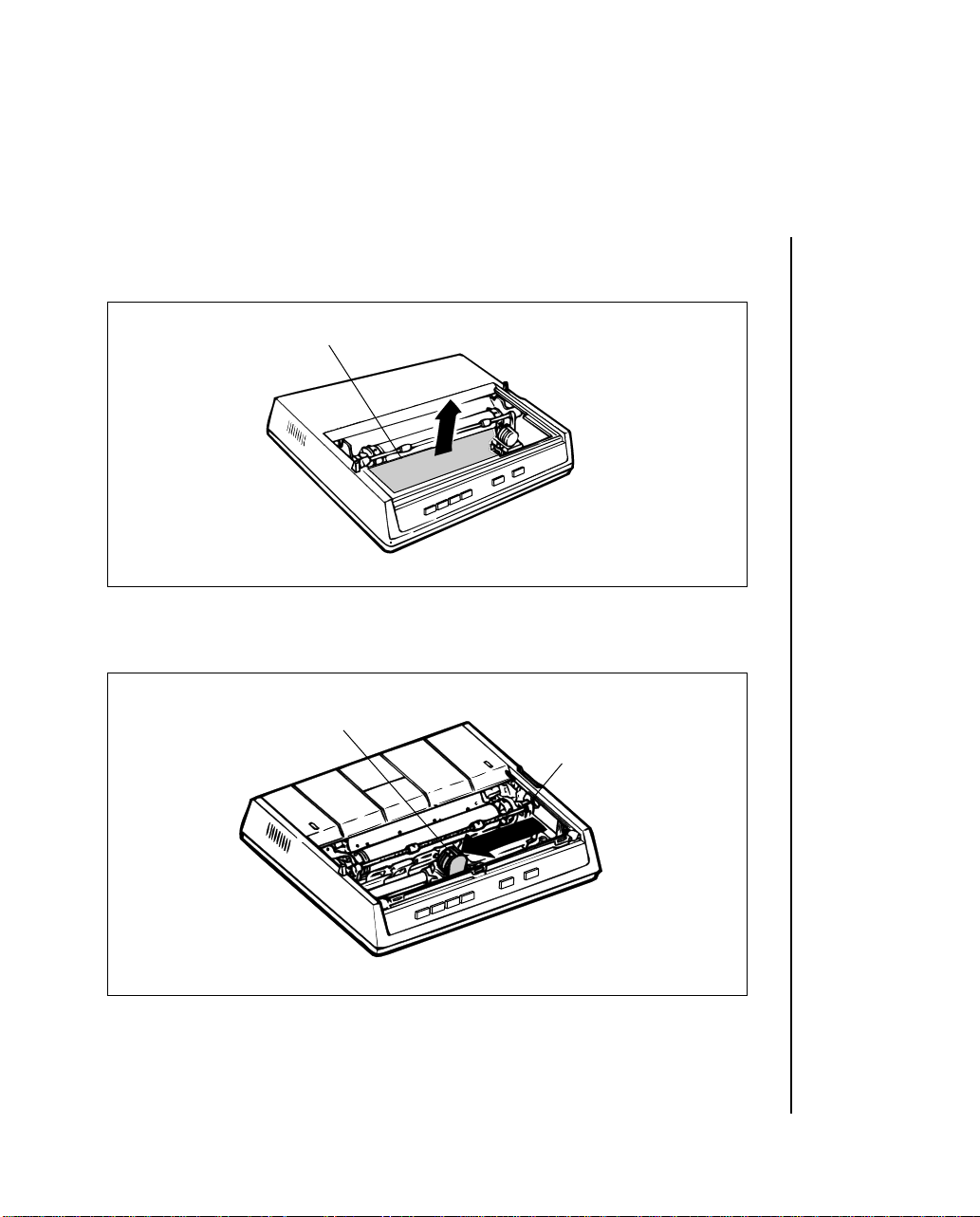

1. Do not plug in your printer until the following steps have been completed.

2. Remove the access cover by inserting your hand in the top cover slot

(see figure below) and lifting.

Slot

Access cover

Setting Up 1 -- 3

Page 10

3. Remove the carriage shipping restraint that keeps the print head in

place.

Carriage shipping restraint

4. Gently slide the print head to the middle of the printer or to the lefthand

side so that it is away from the rollers on the Bail bar.

Print head

Bail bar

1 -- 4 Setting Up

Page 11

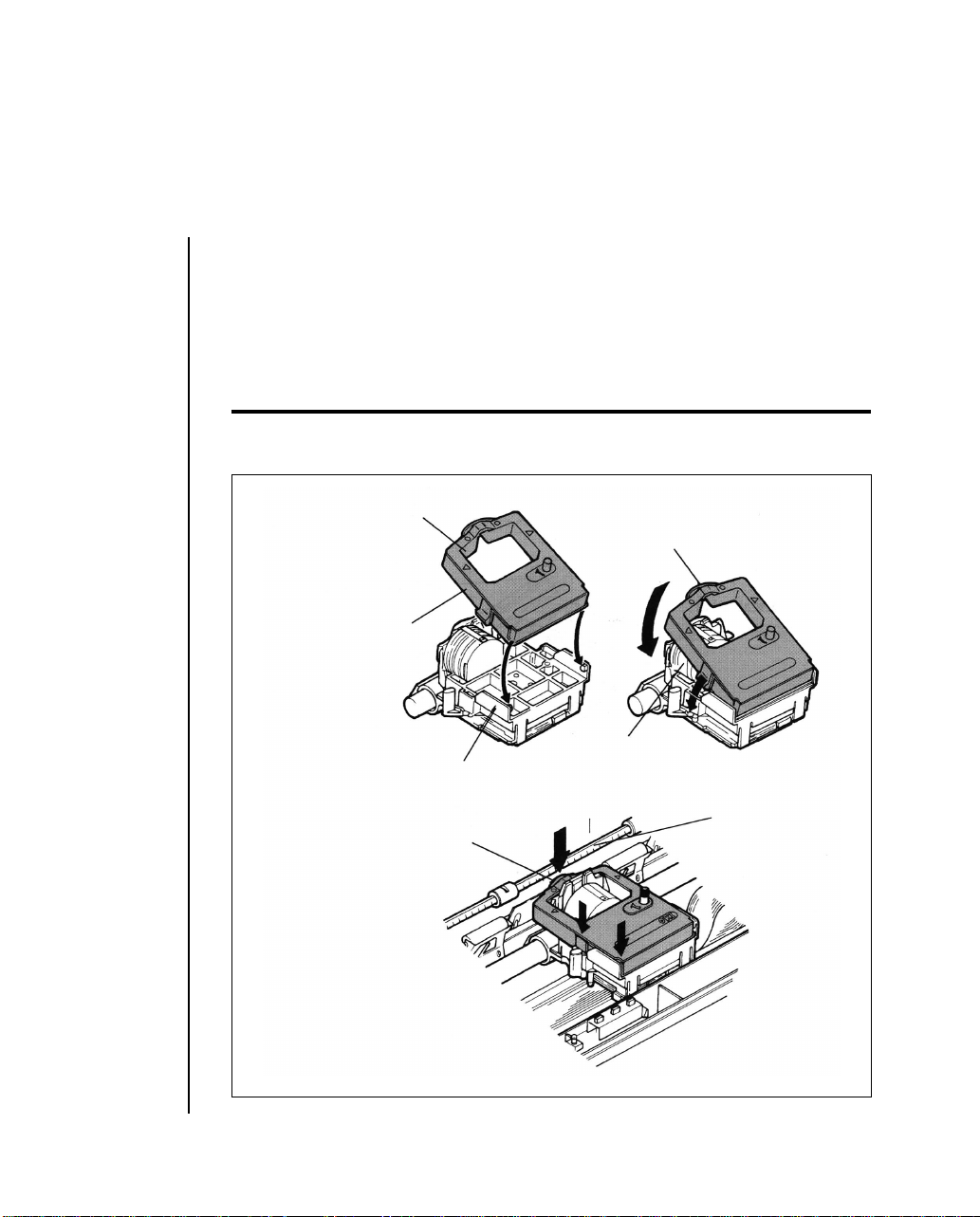

5. Place the black ribbon cartridge on the ribbon cartridge holder. The

easiest method is to tilt the back of the cartridge so that it slides into

the area of the plate that is nearest the front of the printer, then lower

the top of the cartridge (where the plastic ribbon shield is located)

over the print head. The tabs on both sides of the cartridge should

align perfectly with the inserts on the print head plate.

Important: Only use genuine OKI ribbon cartridges in your printer. Do not remove the

ribbon shield.

Ribbon cartridge

Ribbon shield

Holding position

Print head

Ribbon cartridge holder

Ribbon shield

Bail bar

Setting Up 1 -- 5

Page 12

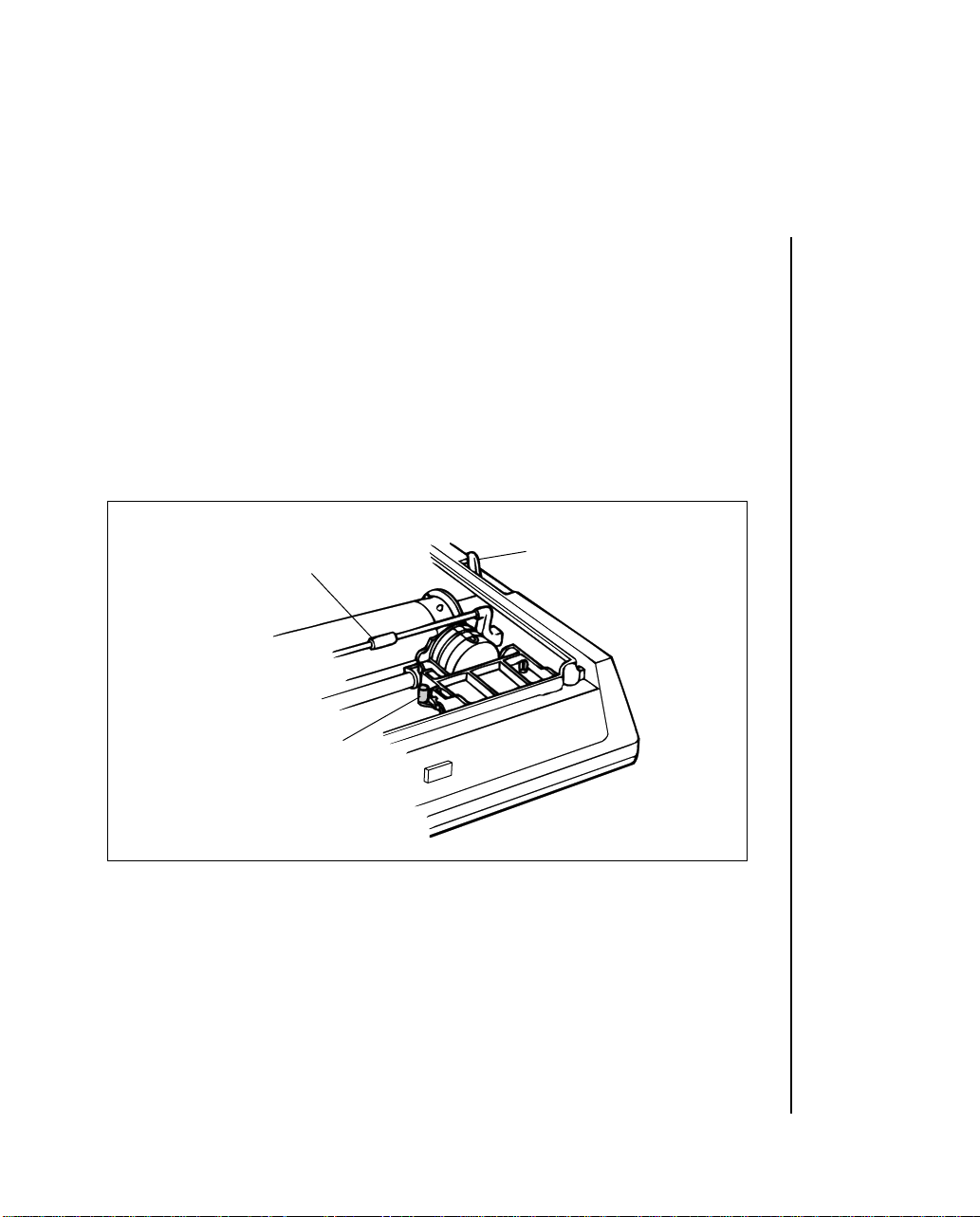

6. Press gently on the cartridge until you feel it snap into place. To remove the ribbon cartridge, make sure the print head is moved away

from the edge of the platen, then grasp the cartridge on both sides of

the print head and lift up.

7. The blue lever located to the left of the ribbon cartridge is used to

adjust the print head gap for single or multi-part paper. When single

part paper or two part paper is in the printer, slide the blue lever forwards towards the print head. To print on three or four part paper,

slide the lever towards the front of the printer.

Bail bar

Print head gap lever

Print release lever

1 -- 6 Setting Up

Page 13

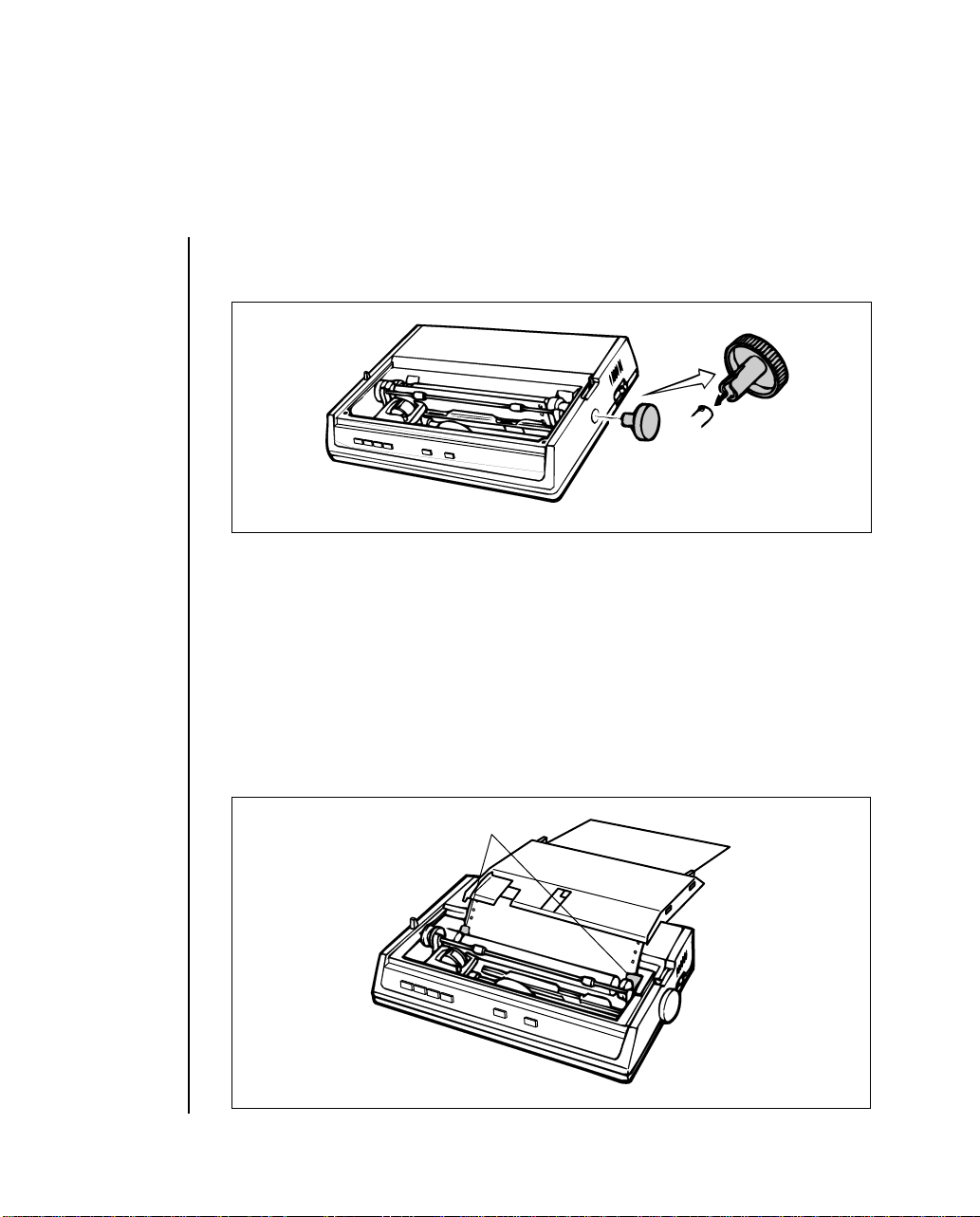

8. Put the platen knob shaft in the hole on the right-hand side of the

printer as shown.

9. Try running a self test to make sure your new printer is working correctly . Insert a piece of computer paper (with sprocket holes) or a single sheet of typing paper into the printer as you would insert it in a

typewriter. If you are unfamiliar with typewriters, here is the method:

a. Open the paper release lever by sliding it towards you.

b. After letting the slit of the paper separator pass, the paper as far

as you can into the slots provided by the black paper guides.

Paper guides

Setting Up 1 -- 7

Page 14

c. Close the paper release lever.

d. Turn the platen knob clockwise away from you to pull the paper

around the platen and behind the Bail bar.

e. Move the Bail bar back on to the platen so that the rollers rest on

the paper you have just inserted.

10. Advance the paper, using the platen knob, until 1 inch of paper appears above the Bail bar.

11. Replace the access cover:

a. Insert the three tabs in the edge of the access cover into the holes

on the top front edge of the printer.

b. Lower the access cover on to the printer.

12. Grasp the paper and pull it through the opening in the access cover.

Use the platen knob if you need more paper.

13. Insert the connector end of the power cord into the socket at the rear

of the printer.

14. Make absolutely certain that the ON/OFF power switch on the side of

the printer is OFF. (A sudden power surge can damage the printer.)

15. Plug the power cord into a earthed (three-pronged) electrical socket.

Important: The printer must be earthed at all times.

1 -- 8 Setting Up

Page 15

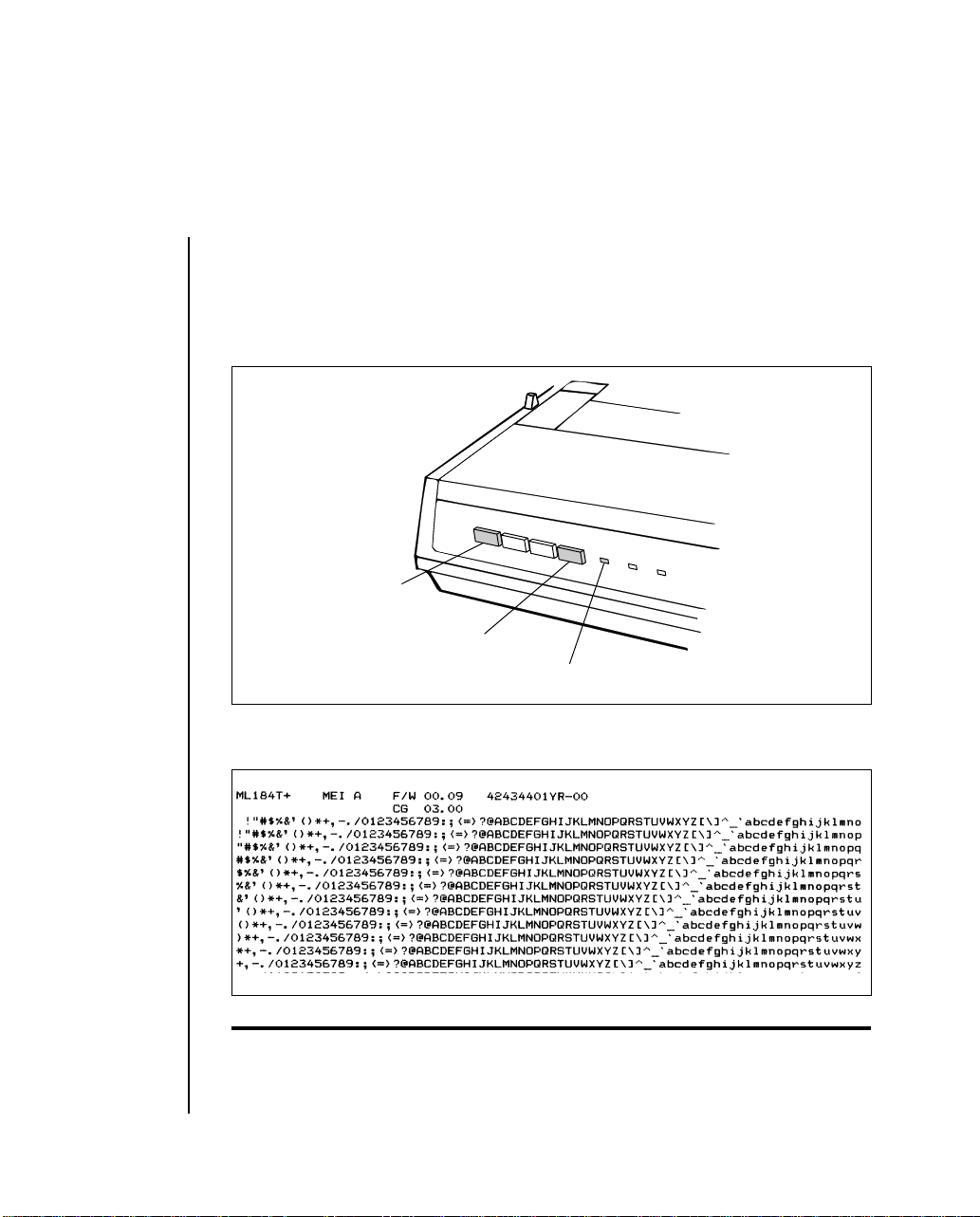

16. T o print the self test, hold down the LF (line feed) and SEL (SELECT)

button (located on the front panel) and turn the power switch ON.

When the printer is powered on (indicator lights), release the LF and

SEL button.

Line feed

SEL button

SELECT indicator

17. The following test pattern will be printed, beginning with a printer

revision number that is followed by a rolling character pattern.

Note: During self test printing the SELECT indicator is not lit.

Setting Up 1 -- 9

Page 16

18. To stop the test, press the SEL button (located on the front panel) or

turn the power switch OFF.

After the printer has shown that it is functioning correctly, you are ready

to connect your computer. First, you need an interface cable. If you do not

have one, see your computer dealer or, if you have the equipment and the

technical expertise, make your own cable using the instructions in Appendix C.

Attention: Install your printer away from a CRT. An electromagnetic field may create a

distortion on your computer screen.

1 -- 10 Setting Up

Page 17

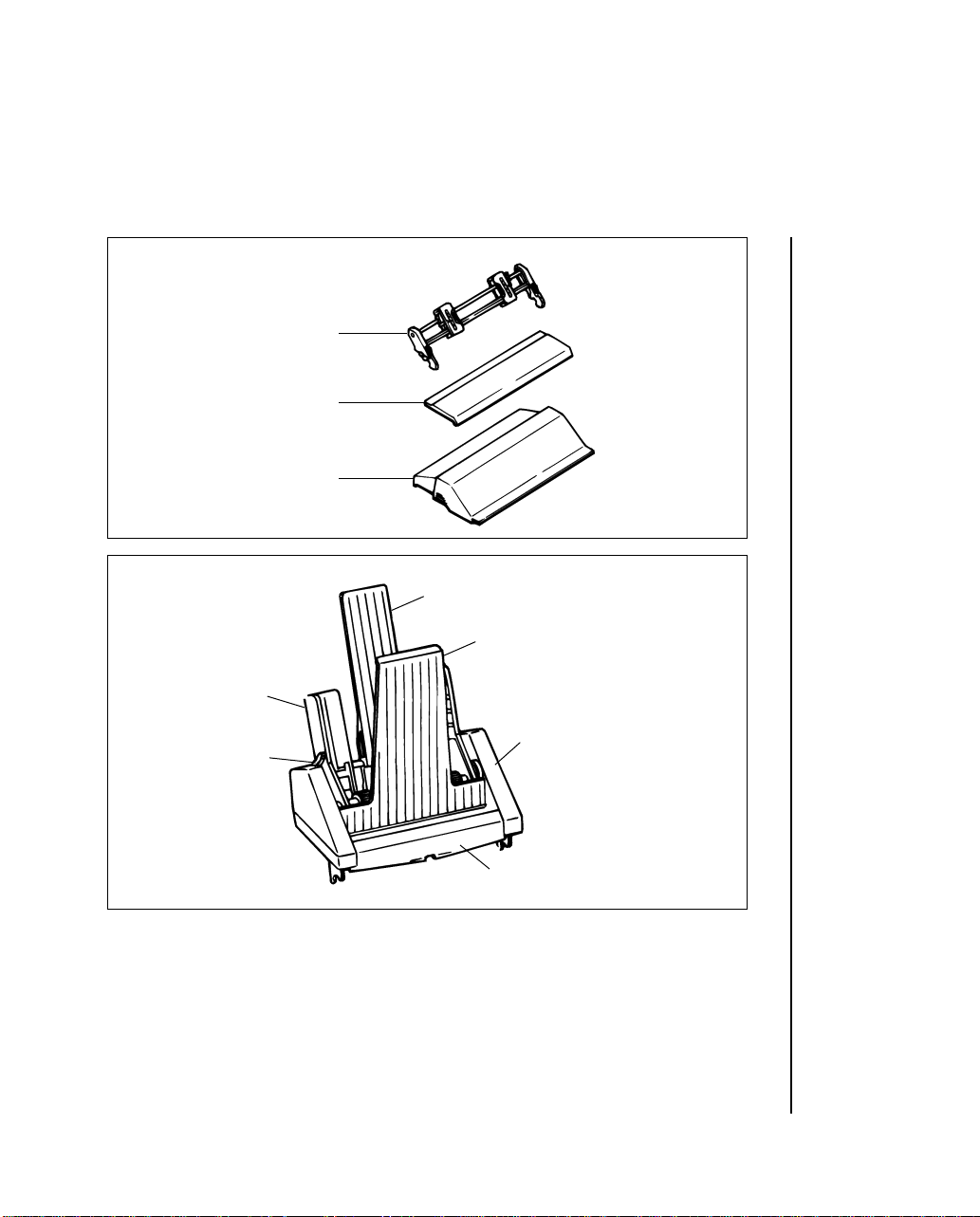

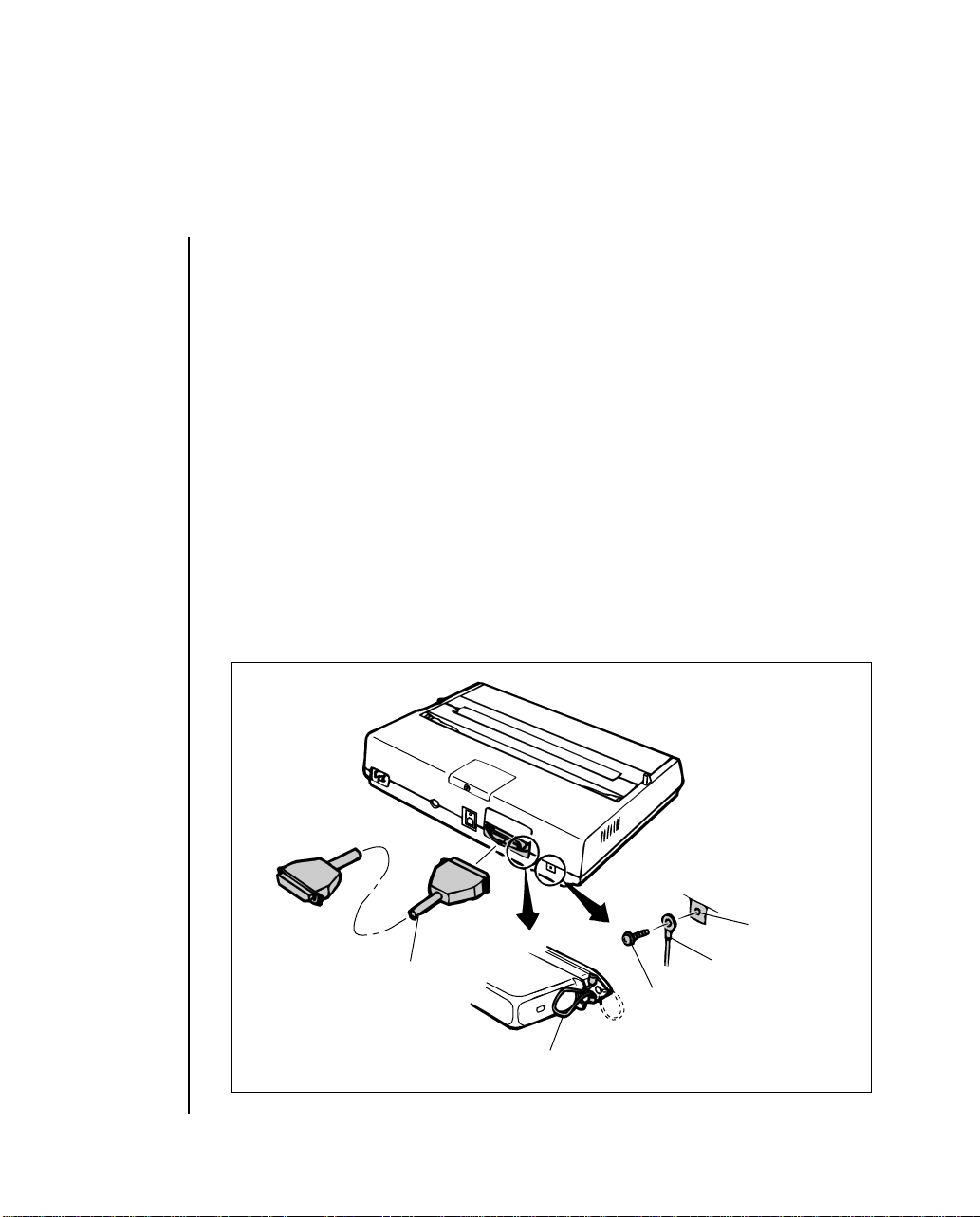

Connecting to Your Computer

Parallel interface cable

Locking tab

Frame

ground

screw

Frame

ground

wire

Frame

ground

Connector

hole

You will need either a parallel, usb or serial interface cable to connect

your computer to your ML 184 Turbo+ printer. Before you connect the

cable, make sure both printer and computer power is OFF.

* More than one interface cannot be connected simultaneously.

Connecting a Parallel Interface

1. Insert the 36-pin plug into the appropriate socket on the rear of the

printer.

If there is no frame ground (FG) included in your interface cable, connect a frame ground wire from the computer to the frame ground connection hole at the back of the printer.

Setting Up 1 -- 11

Page 18

2. Snap the two wire locking tabs on to the plug.

3. Insert the other end of the cable into your computer. You may also

connect it to another peripheral device, such as a disk drive, if your

equipment is designed for daisychain connection.

4. Turn on the equipment and try the one line BASIC program shown

below, using the proper print statement for your computer (the example uses LPRINT). Make sure you have paper and ribbon in the printer.

5. Type: LPRINT “Everything’s okay” and then run the program.

6. Y our printer should print “Everything’ s okay” at 10 characters per inch.

Note: If the printer did not print, make sure you entered the program correctly. Some computers require that you assign a number to the printer and specify that number in your print

statement; for example OPEN # 3 means the printer is on line # 3 to the computer.

7. Now try this BASIC program (change it, if necessary, to suit your

computer’s requirements):

10 LPRINT “EVERYTHING’S OKAY”

20 LPRINT “THIS LINE SHOULD BE SPACED 1/6“”;

CHR$(34);”UNDER THE FIRST”

8. The printout should look like this:

EVERYTHING’S OKAY

THIS LINE SHOULD BE SPACED 1/6” UNDER THE FIRST

1 -- 12 Setting Up

Page 19

If it is overprinted, make a small adjustment to the printer menu settings

so that a line feed is automatically inserted at the end of a line.

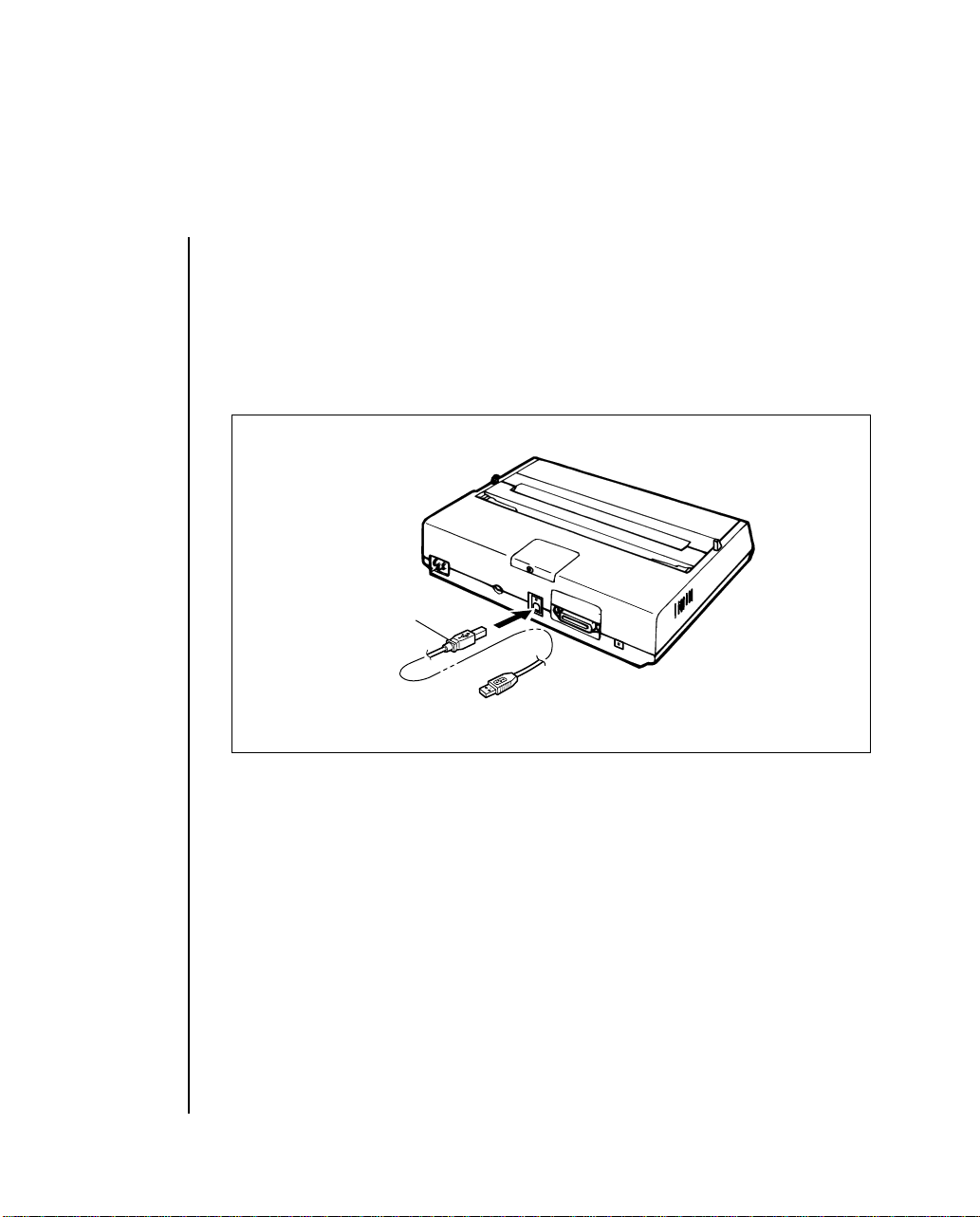

Connecting a USB Interface

1. Connect a USB cable to a USB port on the back of a printer.

USB cable

Serial Interfaces

The Super-Speed board has a maximum speed of 19,200 baud with a choice

of either printer Ready/Busy or XON/XOFF protocol.

Before connecting your interface cable, make sure both your printer and

computer are off. If you are using a serial cable, you are probably required

to use an OPEN and PR #1 statement in BASIC programming instead of

LPRINT. Consult your computer documentation for details.

Setting Up 1 -- 13

Page 20

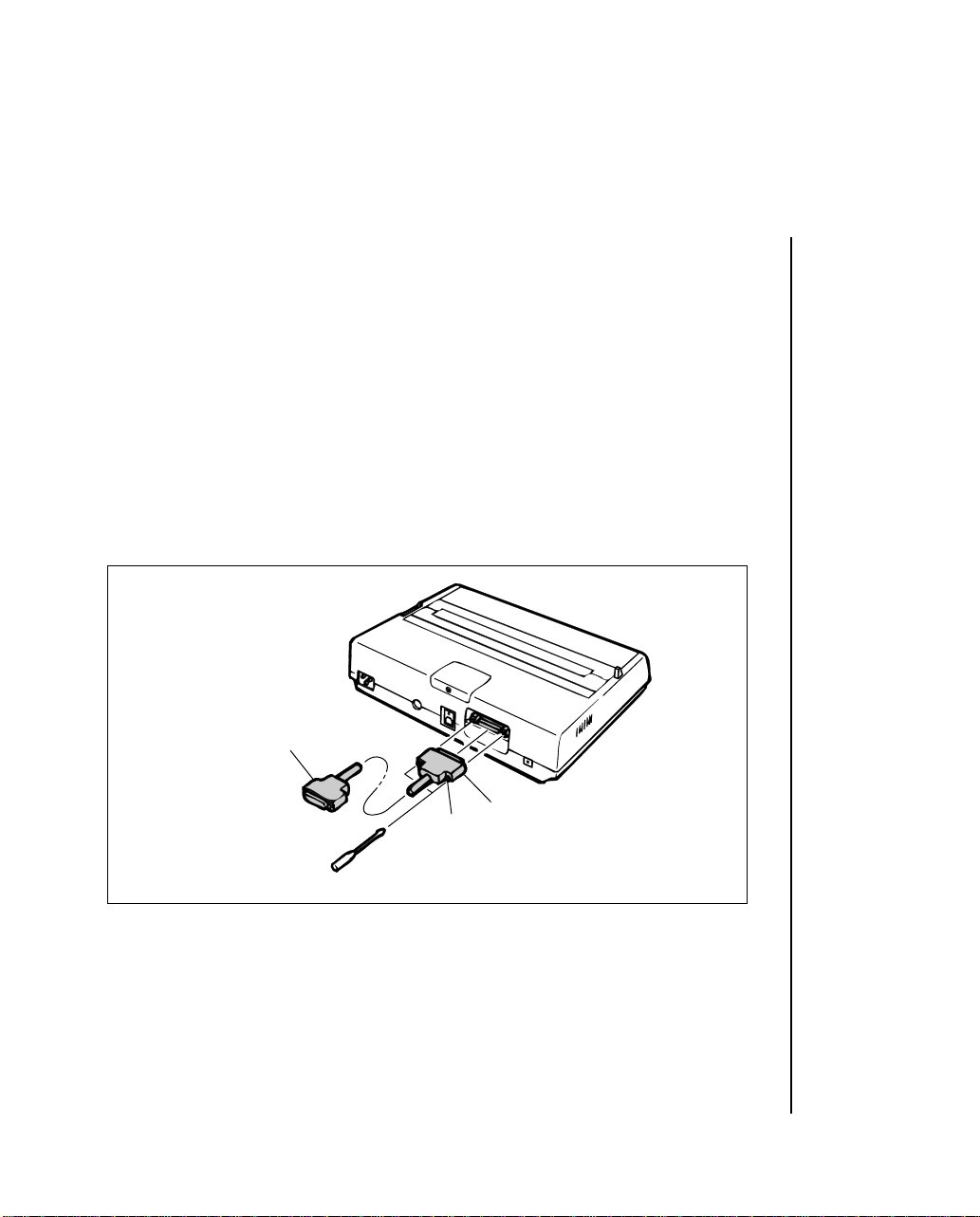

Connecting a Serial Interface

1. Insert the 25-pin plug in the socket on the rear of the printer.

2. Tighten the mounting screw on each side of the connector shell so that

it is securely attached to the printer.

3. Insert the other end of the cable into your computer. You may also be

able to connect the cable to another peripheral device, such as a disk

drive, if your equipment accommodates daisychain connection.

4. Make sure you have a ribbon cartridge and paper in the printer.

Serial interface cable

1 -- 14 Setting Up

Screw

25-pin plug

Page 21

5. Turn ON the power and try this one line BASIC program to make sure

the connection is correct:

LPRINT “Everything’s okay”

Note: Your computer may require a different print statement such as PRINT # 1 or PR #1.

Check your computer documentation for details.

6. Run the program. Your printer should print this at 10 characters per

inch:

Everything’s okay

7. Now try this BASIC program (modify it to suit your computer requirements):

10 LPRINT “Everything’s okay”

20 LPRINT “This line should be spaced 1/6”;

CHRS(34); “under the first”

8. The printout should look like this:

Everything’s okay

This line should be spaced 1/6” under the first

9. If the two lines of text have overprinted each other, you will have to

change the printer menu settings so that a line feed is automatically

inserted at the end of a line.

Setting Up 1 -- 15

Page 22

Page 23

Chapter 2

Operating Your Printer

Buttons, Levers and Indicators

Before using your printer, it is worth familiarising yourself with the buttons, levers and indicators on the printer and to understand the various

methods of loading paper.

The front panel of the printer has six buttons, two of which were briefly

introduced in the setup procedure. In addition, there are indicator lights

that show the status of the printer, mode and pitch selected.

LINE

FEED

FORM

FEED

TOF

SELECT MODE

SET

ALARM PITCH

POWER 10

NLQ

12

17

UTILITY

HSD

POWER Indicator: Indicates that the printer power is turned ON.

SEL Button: Pressing this button after the printer power is ON

places the printer in deselect mode. In this mode

the computer cannot communicate with the printer .

T o return to select mode, simply press this button

again. Pressing this button also stops the self test.

It is also used to enter into HEX-dump mode: turn

the printer ON while holding down the SEL and

FORM FEED buttons.

Operating Your Printer 2 -- 1

Page 24

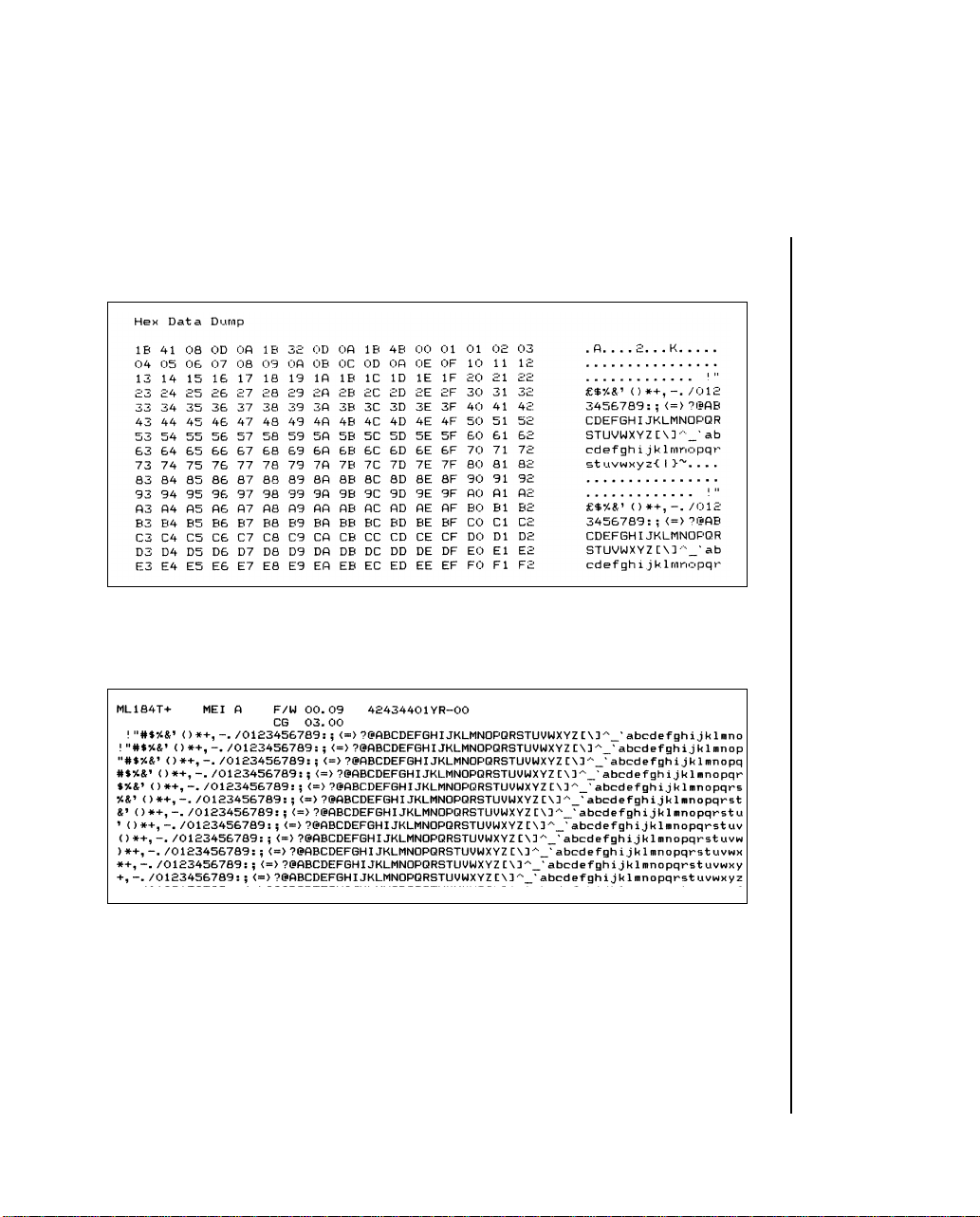

Hex mode generates data rather than text, and a sample is shown below . To

terminate this mode, switch the printer off and on again.

Switching on the printer while holding down the Select and Line Feed

buttons will generate a rolling ASCII character display. Reset the printer

to terminate. A sample is shown below.

TOF SET Button: To set the first line position on each page (Top of

Form), deselect the printer when the print head is

in the desired position. You can also select 17.1

character per inch printing by holding this button

down when turning printer power ON.

2 -- 2 Operating Your Printer

Page 25

SELECT Indicator: W orks together with the SEL button. Lights when

the printer is selected (ready to receive data from

the computer). The indicator is not lit when the

printer is deselected or during self tests. If an

abnormal status is detected during the self test,

the indicator flashes.

FORM FEED Button: To advance the paper to the next page (Top Of

Form), press this button while the printer is

deselected. You can also select NLQ (Near Letter Quality) with this button. Just hold down the

FORM FEED button while switching on the printer.

ALARM Indicator: Lights when paper supply is low or exhausted (un-

less you use the command to disable the alarm).

Printing stops until the paper supply is replenished. It is also lit when a jam is detected using

the CSF. The light flashes when high temperatures are detected in the printhead and space motor.

Allow the printer to cool down before re-using.

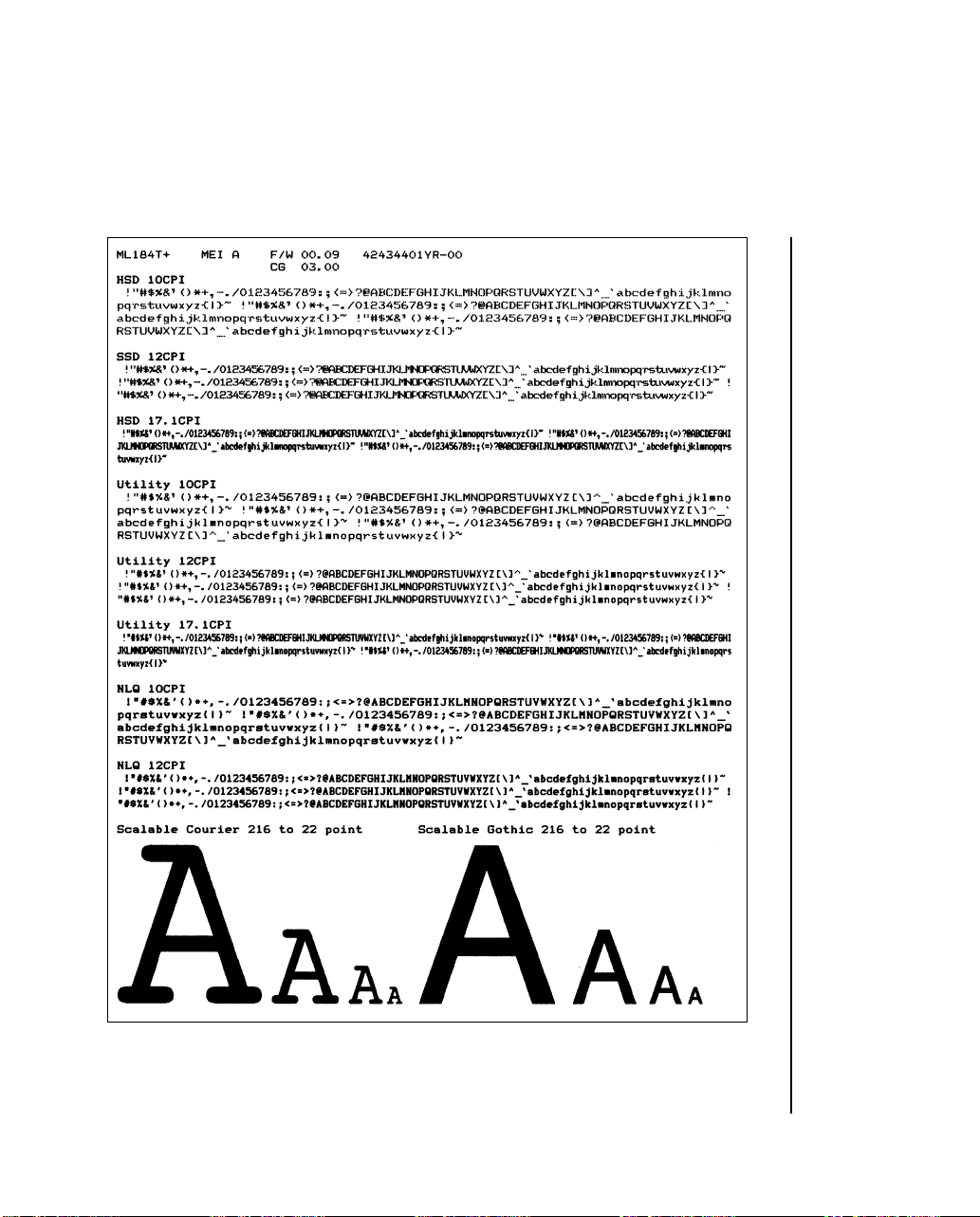

LINE FEED Button: If you want to advance the paper one line, press

this button while the printer is deselected. A DEMO

page print can be generated by switching on the

printer and holding down the Line Feed button.

This printout illustrates the various styles of printing

available from the ML 184 T urbo+. Once printed,

the printer automatically reverts to 10 cpi Utility

mode. An example of the DEMO page is on the

next page.

Operating Your Printer 2 -- 3

Page 26

2 -- 4 Operating Your Printer

Page 27

PITCH Button: This b utton allo ws you to manually select the char-

acter pitch. The appropriate lamp glows upon selection. The lamps also light as software changes,

for example, normal to condensed, are implemented.

MODE Button: Similar function to above, but this refers to the

print quality selected: NLQ, Utility or High Speed

Draft.

The levers on the printer allow you to adjust the paper.

PAPER LOCK/ Open (slide forwards) for inserting paper, and

RELEASE LEVER: adjusting paper, and when using tractor fed com-

puter paper. Close (slide back) for use with roll

paper and for single sheets.

PAPER GAP Slide towards the back of the printer when

ADJUSTMENT: inserting single sheets, and away when using

multipart paper.

Operating Your Printer 2 -- 5

Page 28

Menu Mode

When your printer is in the Menu Mode, you can use the front panel controls to change the defaults for the printer parameters, including emulation, page length, line spacing, typeface, pitch, etc. For example, you might

want to change the page length to 14 inches if you’re printing on legal-size

documents, or to 3 inches if you’re printing on labels or small cards.

T o place your printer in the Menu Mode, To place your printer in the Menu

Mode, turn on the power with pressing the SEL button.

To exit the Menu Mode, hold the PITCH button and press the MODE button. The MENU light will go out and the SEL light will come on.

2 -- 6 Operating Your Printer

Page 29

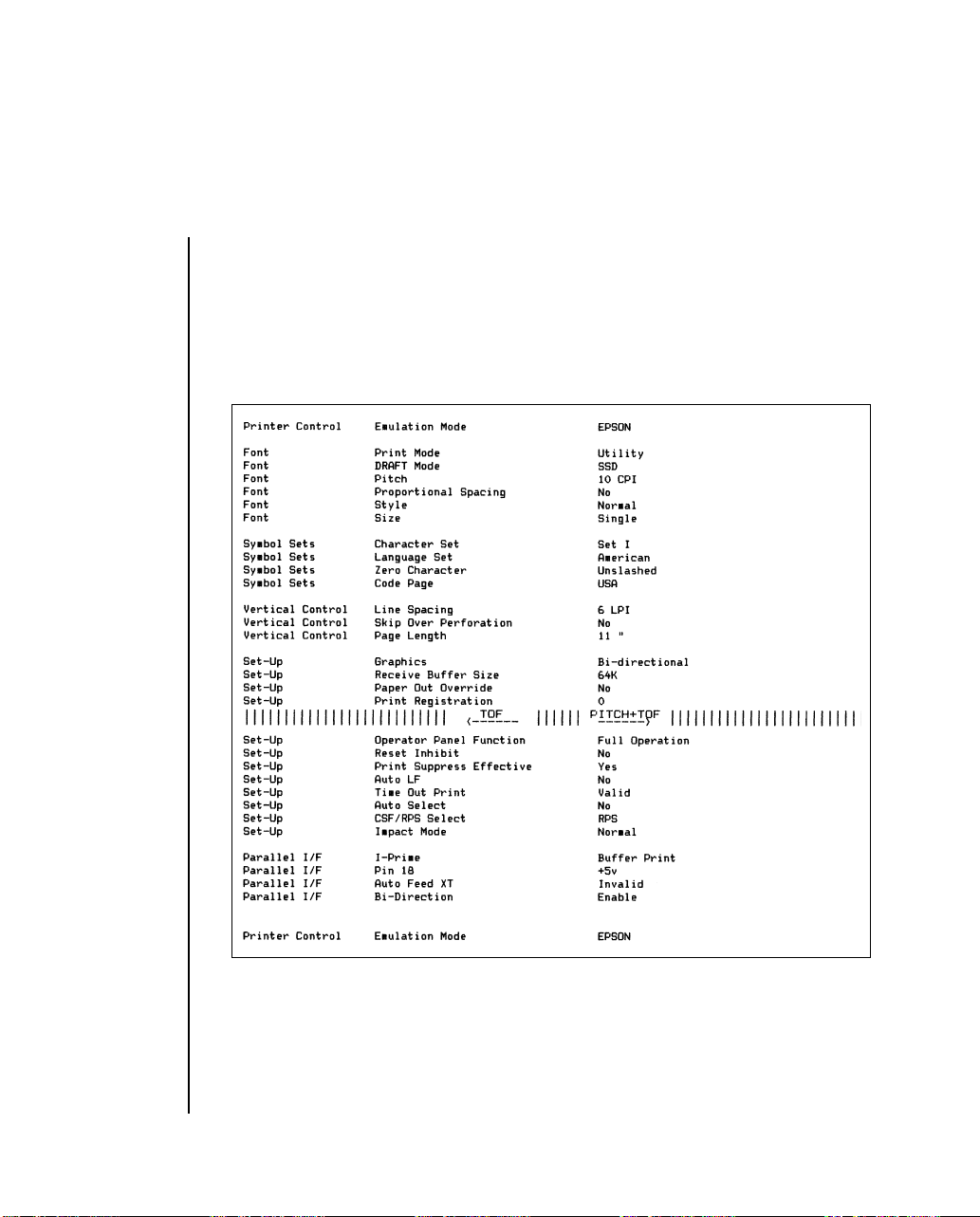

Sample Menu

The menu is made up of groups of parameters. Within each group is a list

of items and each of those items has several possible settings. Here’s a

sample Menu printout. The first column lists the groups; the second, items;

the third, settings:

Operating Your Printer 2 -- 7

Page 30

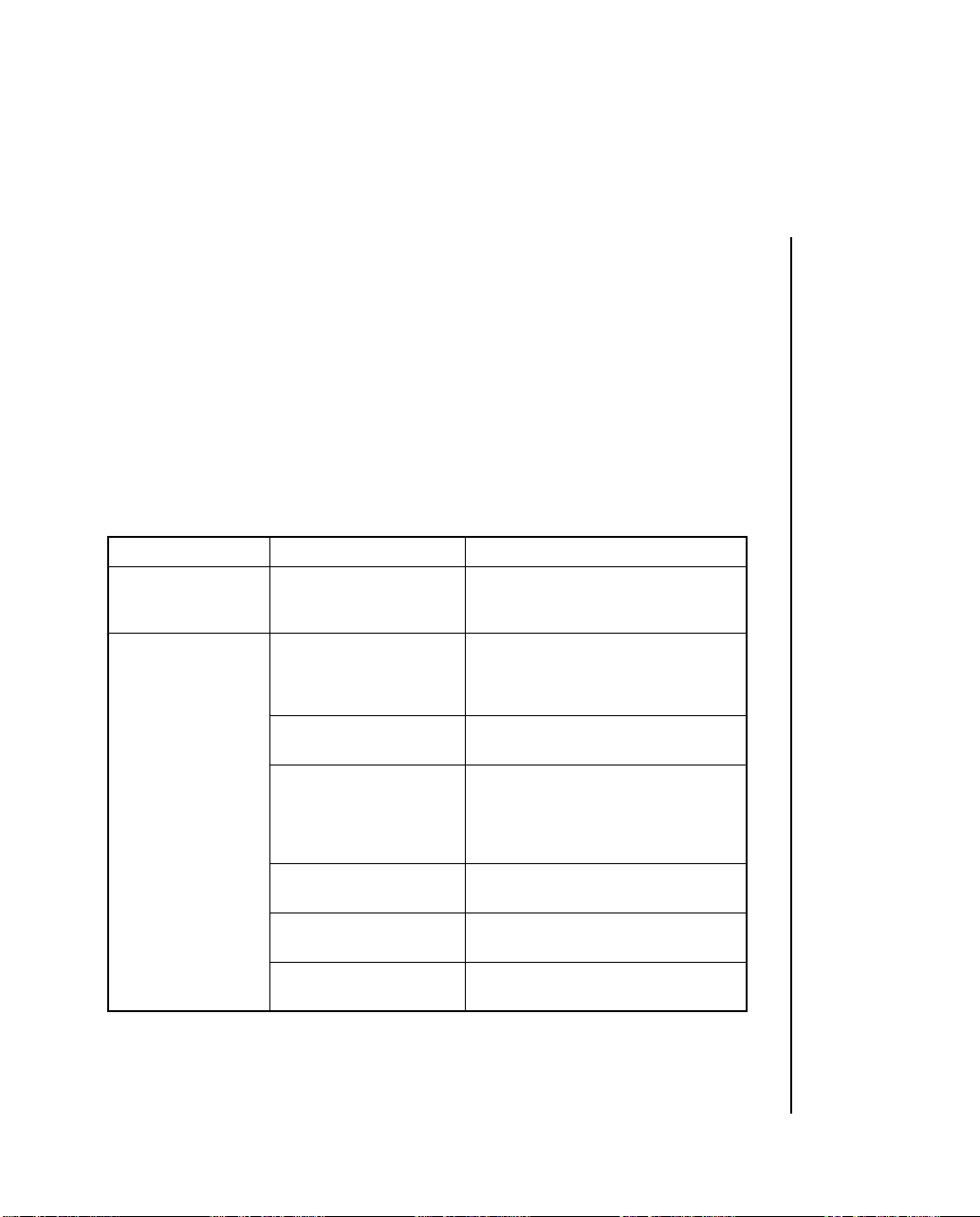

Summary of Menu Settings

The table below details the entries in the printer Menu as it comes from

the factory.

The factory defaults are marked with “*”.

Other entries will appear in the Menu depending on what options you have

installed and what emulation is engaged.

For a complete listing of all the available Menu selections, along with

explanations for each setting, see appendix D.

Group Item Sets

Printer Control Emulation Mode IBM *

Font Print Mode Utility *

DRAFT Mode HSD

Pitch 10CPI *

Proportional Spacing No *

Style Normal *

Size 1) Single *

2 -- 8 Operating Your Printer

Epson

ML

NLQ Courier

NLQ Gothic

DRAFT

SSD *

12 CPI

15 CPI

17.1 CPI

20 CPI

Yes

Italics

Double

Page 31

Group Item Sets

Symbol Sets Character Set Set I

*

Set II

Standard, Line Graphics, Block

Graphics (ML Mode only)

Language Set American *

Zero Character Slashed

Code Page USA * BRASCII

Slashed Letter O No *

Vertical Control Line Spacing 6 LPI *

Skip Over Perforation No *

French

German

British

Danish I

Swedish

Italian

Spanish I

Japanese

Norwegian

Danish II

Spanish II

Latin American

French Canadian

Dutch

Publisher

Unslashed *

Canada French Abicomp

Multilingual Multilingual 858

Portugal ISO8859-15

Norway

Yes

8 LPI

Yes

Operating Your Printer 2 -- 9

Page 32

Group Item Sets

Vertical Control Page Length 11"

11 2/3"

12" *

14"

17"

5"

3"

3.5"

4"

5.5"

6"

7"

8"

8.5"

Set-Up Graphics Bi-directional

Uni-directional *

7 or 8 Bits Graphics 4) 8

Receive Buffer Size 2) 1 Line

Paper Out Override No *

Print Registration 0.25 mm Right

7 or 8 Bits Data Word 4) 8 *, 7

Operator Panel Full Operation

Function 3) Semi Operation *

2 -- 10 Operating Your Printer

7 *

32K

64K *

128K

Yes

0.20 mm Right

0.15 mm Right

0.10 mm Right

0.05 mm Right

0 *

0.05 mm Left

0.10 mm Left

0.15 mm Left

0.20 mm Left

0.25 mm Left

Limited Operation

Page 33

Group Item Sets

Set-Up Reset Inhibit No *

Yes

Print Suppress Effective No

Auto LF No *

Auto CR 5) No

Print DEL Code 4) No

Yes *

Yes

Yes *

Yes *

Sl Select Pitch 15 CPI

(10 CPI) 5) 17.1 CPI *

Sl Select Pitch 12 CPI *

(12 CPI) 5) 20 CPI

Time Out Print Valid

Auto Select No *

ESC SI Pitch 5) 17.1 CPI *, 20CPI

CSF/RPS Select RPS *

Impact Mode Normal *

Invalid *

Yes

CSF

Quiet

Parallel I/F I-Prime Invalid

Buffer Print *

Buffer Clear

Pin 18 + 5V *

Open

Auto Feed XT 6) Valid

Invalid *

Bi-Direction Enable *

Disable

Operating Your Printer 2 -- 11

Page 34

Group Item Sets

CSF 7) Line Spacing 6 LPI *

Bottom Margin Valid

Page Length 11"

8 LPI

Invalid *

11 2/3"

12" *

14"

17"

5"

3.5"

4"

5.5"

6"

7"

8"

8.5"

Notes: 1. Selects both double width and double height characters OR single width and sin-

gle height characters.

2. When “1 Line” is selected, the receiving buffer size is set to 2K bytes.

3. When “Limited Operation” is selected, after exiting MENU, only the SEL, LF

and FF switches are valid. PRINT QUALITY, TOF and PITCH are invalid.

4. Displayed only for ML emulation.

5. Displayed only for IBM emulation.

6. Displayed only for EPSON emulation.

7. Displayed only when CFS is selected.

2 -- 12 Operating Your Printer

Page 35

Menu Mode Buttons

LINE

FEED

FORM

FEED

TOF

SET

SELECT MODE

ALARM PITCH

POWER 10

12

17

NLQ

UTILITY

HSD

Here is a summary of the buttons active in the Menu Mode:

1. LINE FEED button: Press to scan through groups of listings. Each

time you press the LINE FEED button, a line will print, showing the

next group in the Menu. T o go back one group, hold the PITCH button

while pressing the LINE FEED button.

2. FORM FEED button: Press to scan through items for a particular

group. Each time you press the FORM FEED button a line will print,

showing the next item within the group. To go back one item, hold the

PITCH button while pressing the FORM FEED button.

3. TOF SET button: Press to change setting for the items. Each time

you press the TOF SET button, a line will print across the page showing the next setting for that item. Keep pressing the button until the

setting you wish to engage appears. To go back one setting, hold the

PITCH button while pressing the TOF SET button.

4. SEL button: Press to print out listing of current settings for each items,

group by group.

Resetting Menu to Factory Defaults

T o reset your printer Menu to the factory settings, turn the printer of f, then

hold the LINE FEED and FORM FEED buttons while turning it back on

again.

Operating Your Printer 2 -- 13

Page 36

Paper Loading

You can load paper into the printer using several methods. If you have a

printer stand with a paper slot, you can load paper through the bottom of

the printer. If the printer is placed on a desk or table, paper can be loaded

from the top, like typewriter paper.

If you have the optional roll paper stand, tractor feed unit, or cut-sheet

feeder read the following instructions on how to install them and how to

load the paper.

When you use fanfold paper, adjust the distance between the sprocket pins

at the ends of the platen to correspond to the holes in the paper. You can

adjust the platen pin width by extending or compressing the platen ends.

To move the platen end: Unsnap the lever, move the platen end to the left

or right, then close the lever.

Bottom Feed Paper Loading

1. Place the printer on a slotted printer stand, carefully aligning the slot

in the stand with the opening in the base of the printer.

2. Place the box of paper under the printer stand.

3. Remove the access cover and lift the column indicator bar.

4. Open the paper release lever.

2 -- 14 Operating Your Printer

Page 37

5. Insert the first sheet of paper through the opening in the bottom of the

printer.

6. Slide the paper up until it appears in front of the platen.

7. Lower the column indicator bar.

8. Close the paper release lever.

9. Use the platen knob to advance the paper to the first printing line.

10. Replace the access cover.

Operating Your Printer 2 -- 15

Page 38

Rear Feed Paper Loading:

1. Put the printer on a desk or table.

2. Place the box of paper behind the printer.

3. Remove the access cover and lift the Bail bar.

4. Open the paper release lever.

5. Insert the first sheet of paper in the paper guide after letting a paper

pass to slit of the paper separator.

6. Push the paper in just enough so that its sprocket holes engage the

sprocket pins located on the platen ends.

7. Turn the platen knob to advance the paper until it appears in front of

the platen.

Paper guides

Bail bar

8. Lower the Bail bar.

9. Close the paper release lever.

2 -- 16 Operating Your Printer

Paper release lever

Page 39

11. Use the platen knob to advance the paper to the first printing line.

12. Replace the access cover.

Access cover

Operating Your Printer 2 -- 17

Page 40

Note: When the printed paper is involved in the platen, more the wire ahead.

Wire

If you adjust the printing position for the set paper by rotating the platen

knob in the reverse direction, the printing precision may fluctuate.

2 -- 18 Operating Your Printer

Page 41

Installing and Using the Roll Paper Stand

Select “RPS” at the “CSF/RPS Select” menu option.

1. Remove the access cover.

2. Insert the tabs on the roll paper stand into the holes on both sides of

the printer.

Roll Paper

Stand

3. Plug the roll paper stand plug into the socket on the rear of the printer .

Plug

Operating Your Printer 2 -- 19

Page 42

4. Pull the bail arm lever forwards to move the column indicator away

from the platen.

5. Place the paper release lever in the forward (open) position.

6. Insert the paper shaft in the roll paper core, and open the sheet guide

of the roll paper stand. Mount the shaft on the stands so that the grooved

end of the shaft fits into the groove on the left stand, and the paper

rolls from the bottom.

Paper shaft

Sheet guide

Bail arm lever

Roll Paper

Release lever

7. Insert the paper from the back of the platen over the paper bar, making

sure its edges lie within the platen ends. (The sprocket pins will tear

the paper if they come into contact with it.)

8. Push the paper in slightly. Close the paper release lever. Now turn the

platen knob to bring the paper to the front of the platen.

2 -- 20 Operating Your Printer

Page 43

9. Feed the paper supplied to the front of the platen in Step 8 through the

slit between the indicator and the platen. If necessary, align the edges

of the paper. You must open the paper release lever to do this.

10. Close the bail arm lever.

Align the ends

Bail arm lever

Sheet guide

Release lever

11. Replace the access cover. Fit the cover tabs into the slots at the printer

front. Lower the cover carefully , making sure the paper feeds through

the front slot in the access cover.

12. By turning the platen knob, move the paper to the point where you

want printing to start. (Many word processing packages automatically

allow for a top margin of 25.4 mm (1 inch).

Sheet guide

Operating Your Printer 2 -- 21

Page 44

Loading Single Sheets

The ML184 Turbo+ can accommodate standard single sheets of 216 by

297 or 355 mm (8.5 by 11-inch or 14-inch) paper. Only one copy, with no

carbons, can be printed at a time.

Remove the tractor feed unit and any other accessories before using the

paper separator.

Operation

1. Place the paper release lever in its rear (closed) position.

2. Place the printer OFF LINE. (Press the SEL switch.)

3. Close the paper bail lever (Place it in its rearward position.)

4. Raise the paper separator as shown in the figure. (The paper separator

remains raised to prevent the paper separator from falling.)

5. Adjust the cut sheet guide on the paper separator to the printing pattern to be used.

Cut sheet guide

Paper bail lever

2 -- 22 Operating Your Printer

Single sheet

Paper separator

Stay

Page 45

Line mark

Cut sheet guide

Note: When letter-size paper is used, set the cut sheet guide to the line mark on the paper

separator then 80-characters (10 CPI) width can be printed in the centre position of the paper.

6. Insert a single sheet along the cut sheet guide until it reaches the pinch

roller . Be sure to keep the paper inside the platen ends. Otherwise the

built-in sprocket pins will tear it.

7. Open the paper bail lever, place it in its forward position.

8. Close the paper bail lever after confirming that the single sheet has

been grasped. Be sure to throw the paper bail lever all the way; otherwise the paper will jam.

9. Press the SEL key after confirming that the paper is fed again up to

the first-line printing position. Then place the printer ON LINE.

Attention: Load paper properly in order for paper to be fed straight.

Operating Your Printer 2 -- 23

Page 46

Installing and Using the Tractor Feed Unit

1. Remove the access cover.

2. Insert the post on each end of the tractor feed unit around the ends of

the platen shaft.

Post

Tractor feed unit

Lever

Clamp

Side frame

3. Pull the tractor unit forwards until it clamps on to the platen ends.

4. Install the paper separator by placing its hooks in the slots provided

on the printer.

2 -- 24 Operating Your Printer

Page 47

5. Paper can be loaded from the top or bottom of the printer. Paper can

only be loaded from the bottom if you have a slotted printer stand.

Rear feed

Bottom feed

Operating Your Printer 2 -- 25

Page 48

6. Adjust the left tractor if necessary; make sure it is not more than 12.7

mm (1/2 inch) from the left-hand end of the tractor unit. To move the

tractor pull the lock lever forwards, slide the tractor to the desired

position, then push it backwards to lock it in place.

Lock lever

Sprocket cover

Tractor

7. Pull the paper under the column indicator and up to the level of the

tractor unit.

8. Adjust the right tractor to the paper width by pulling the lock lever

forwards, sliding the tractor to the right or left (depending on the paper size), and pushing the lock lever backwards to lock it in place.

2 -- 26 Operating Your Printer

Page 49

9. Open the sprocket covers and the paper release lever (slide forwards).

Tractors

Sprocket covers

10. Place the sprocket holes in the paper over the sprockets on the tractor

unit, making sure that the paper is flat.

Sprocket pins

Sprocket holes

Operating Your Printer 2 -- 27

Page 50

11. Close both the sprocket covers. (Leave the paper release lever open.)

Sprocket covers

12. Put the access cover supplied with the tractor feed unit on the printer.

Access cover

2 -- 28 Operating Your Printer

Page 51

Installation of the Cut-Sheet Feeder

Select “CSF” at the “CSF/RPS Select” menu option.

1. Remove the acoustic cover, tractor feed unit, and paper separator if

installed.

2. Remove the access cover.

3. Pull the column indicator away from the platen and push the pressure

rollers to the left and the right end of the bar.

4. Fit the cut-sheet feeder clamps over the platen collar and lower on to

the printer.

Notes: 1. Move the front sheet guide of the cut-sheet feeder under the column indicator.

Gently push the front sheet guide towards the platen, then close the column indicator. To engage it with the front sheet guide hook, pull it back to open position.

2. Turn the platen knob to make sure the coupling gear on the left-hand side of the

cut-sheet feeder are in line with the platen gear.

Clamp

Coupling gear

Platen gear

Platen collar

5mm

Pressure roller

Column indicator bar

Front sheet guide

Platen collar

Pressure roller

5. Insert the sheet supports. Fit the slotted ends of the narrow sheet support on to the square bar and paper chute on to either side of the middle paper guide at the rear of the cut sheet feeder. Slide the front sheet

support into the tracks between the feed rollers and the metal plate.

Operating Your Printer 2 -- 29

Page 52

6. Insert the feeder cable into the socket on the rear of the printer. The

arrow on the plug faces up.

Feed cable

Paper release lever

(Closed)

7. Make sure the printer’s paper release is closed.

Important: Be sure the paper release lever is closed whenever you are printing with the cutsheet feeder. If you do not close the paper release, the paper will not feed properly. The

printer could print an entire page without any paper, possibly damaging the platen and the

print head.

Loading paper into the hopper

1. Put the paper set level to the RESET position.

(a)

2 -- 30 Operating Your Printer

Paper set lever

(b)

Right paper guide

Paper guide fixing levers

Left paper guide

Page 53

2. Release the paper guides by pushing the fixing levers downwards.

3. Move the left paper guide to the position where you wish to set the

left-hand edge of the sheet. Make sure that this guide is not set to the

right of the paper out sensor (the groove in the platen).

Left paper guide

4. Flex the paper stack (not more than 170 sheets of 60g/m

12

Right paper guide

2

(161b) paper). Square the stack again, turn it over, and repeat the bending. The

paper stack should not exceed 16mm in total thickness.

Operating Your Printer 2 -- 31

Page 54

5. Insert the paper stack in the hopper, then push it against the left paper

guide. Make sure the paper fits under the corner separators. Adjust the

right paper guide to the width of the paper.

Paper stack

Left paper guide

Paper set lever

Right paper guide

6. Push the paper guide fixing levers upwards into the locked position.

Tuck the paper

stack under the

rollers

Roller

2 -- 32 Operating Your Printer

Stopper

Page 55

Rear sheet supporter

0.5~1mm

Right-hand

paper guide

7. Push the paper set lever gently backwards to the set position.

Paper set lever

Operating Your Printer 2 -- 33

Page 56

Manual paper loading with the cut-sheet feeder installed.

1. Gently insert the paper from directly above the front sheet support.

Front sheet

supporter

Slot for setting

manually

FORM FEED button

2. Use the FORM FEED button to feed the manually loaded paper.

3. Turn the platen knob clockwise/anticlockwise until the sheet is in the

desired position.

Notes: 1. The manually set sheet is printed automatically even when other sheets are

loaded in the hopper. (When the FORM FEED button is pressed, the manually

set sheet will be fed into the cut-sheet feeder.)

2. Do not manually feed paper if a sheet is being fed from the hopper. Simultaneously feeding paper may result in a paper jam.

3. To manually feed a sheet of paper, you must use the FORM FEED button, and

use the platen knob to adjust the papers position in the printer. If the paper is being

fed manually and is positioned using the platen knob rather than the FORM FEED

button it may be ejected just before printing begins.

2 -- 34 Operating Your Printer

Page 57

Cut-sheet feeder controls

The printer’s control switches also control the operation of the cut-sheet

feeder. The control switches, however, function only when the printer is

off-line or deselected (SELECT indicator is not lit).

Printing with the cut-sheet feeder

After the first sheet is inserted and the top of form is set, you can begin

printing with the cut-sheet feeder. Simply request a printout from your

word processing package as normal. When it receives the PRINT command, the printer starts printing on the inserted sheet until the amount of

lines that have been printed according to the appropriate page length, ejects

the printed page into the output tray, and inserts a new page. If a file is

several pages long, the printer ejects each printed page into the output

tray, inserts a new sheet from the hopper, then continues printing.

If you are printing program outputs using the cut sheet feeder, you must

include the cut-sheet feeder insert and eject commands. When the printer

receives the PRINT command, it inserts a sheet of paper and starts printing. Each time the printer receives the cut-sheet feeder insert command, it

ejects the printed sheet then inserts a new sheet. Use the cutsheet feeder

eject command at the end of your program if you want the printer to eject

the printed sheet without inserting a new sheet. For further information

consult the programming section in this handbook.

If you want to eject a sheet of paper you can do it using the FORM FEED

button.

Note: Make sure that the page length the printer is set to is no greater than the page length

that your word processing system uses.

The action of the LINE FEED button varies according to the status of the

cut sheet feeder.

Operating Your Printer 2 -- 35

Page 58

Page 59

Chapter 3

Working with Software

This chapter covers the fundamentals of setting up commercial software

packages for use with your printer. Be sure to read your software documentation

carefully for more details.

Basic Terminology

Before we start, let’s examine a few terms with which you may not be

familiar.

Printer Commands

If you’re using commercial software with an appropriate printer

driver (see “Printer Drivers” below), the printer commands will

normally be sent to the printer by your software and you won’t

even need to think about them.

Printer commands are signals sent by your PC to the printer which guide

and control its operation. Printer commands tell the printer what character

pitch to use, what font to use, what margins to use, whether to use single

or double spacing, when to engage/disengage double width or double height

printing, etc.

Printer commands can be sent in decimal, ASCII, or hexadecimal form.

The values (decimal/ASCII/hexadecimal) for each type of command depend

on which emulation is active (see Appendix A for a listing of printer commands

for each emulation).

With only a few exceptions, printer commands begin with the ESC character ,

decimal 27 (hexadecimal 1B), which serves as signal to the printer that

what follows is to be interpreted as a command rather than just a string of

characters. Some printer commands expect you supply a numerical value,

representing tab stops, line spacing, etc.

Working with Software 3 -- 1

Page 60

Emulations

In order to eliminate hundreds of different sets of printer commands, most

printers emulate, or imitate, one of several general printers; i.e., they accept

all of that printer’s commands and behave as though they were the emulated

printer.

Your printer has three emulations:

• IBM (factory default)

• Epson

• Oki Microline

Printer Drivers

Compatible Printer Drivers (DOS)

Many of the software packages you use will contain drivers 100% compatible

with your printer. For older software, however , it may be necessary to select

a driver that functions nearly the same as a driver specifically designed for

your printer. This generally means that you will be selecting a driver that

provides commands to access most, but not all of the available functions;

however, the commands that are available will perform properly with your

printer.

The table below summarizes the various drivers that will work with your

printer . They are listed in order by decreasing compatibility as you go down

the list: select one from as high up on the list as possible, based on what is

available from among the drivers supplied with your software. If you don’t

see one from near the top of the list, give the software manufacturer a call

to see if they have added any drivers to those supplied when you purchased

your software. Software manufacturers are constantly updating their lists

of drivers to keep up with the printer market and they may very well have

one which will give maximum compatibility with your printer.

3 -- 2 Working with Software

Page 61

IBM Emulation Epson Emulation

OKI ML Emulation

Oki ML 184 Turbo (IBM)

Oki ML 320 (IBM)

Oki ML 520 (IBM)

Oki ML 320 T (IBM)

Oki ML 720 (IBM)

IBM Graphics printer

IBM Proprinter

Oki ML 320 (EPSON)

Oki ML 520 (EPSON)

Oki ML 320 T (EPSON)

Oki ML 720 (EPSON)

Epson EX 800

Epson FX

Oki ML 184 Turbo (STD)

Oki ML 182 (STD)

Oki ML 192 (STD)

Oki ML 320 (STD)

Oki ML 520 (STD)

Oki ML 320 T (STD)

Oki ML 720 (STD)

Because there are some differences in characteristics such as speed or access

to various features, you may wish to experiment with several different

drivers. If you must select a driver that is not listed in the table, be sure to

check it thoroughly for print features such as boldface, underline and changes

in pitch. Don’t be surprised if boldfaced items are printed twice, underlines

are misplaced, wide spaces are left between lines or the printer behaves

chaotically (turn off the printer if the latter occurs). These are all characteristics

of an incompatible driver selection.

Windows Printer Drivers

To use this printer on a Windows operating system, install the Windows

printer driver, that is on the Printer Software CD-ROM provided with your

printer, on your computer.

For information about which Windows systems are compatible with the

printer drivers on the Printer Software CD-ROM and the installation procedure

open the Readme file on the Printer Software CD-ROM.

Working with Software 3 -- 3

Page 62

Page 63

Appendix A

Printer Commands

This appendix contains a listing of the printer commands for the IBM,

Epson, and OKI MICROLINE emulations, grouped by function.

IBM Printer Commands

IBM Function ASCII Code

Bar Code Commands

Select Bar Code Type

and Size

Print Bar Code Data

Print Postnet Bar Code

Select Bar Code Type

Print Bar Code

Character Sets

Select IBM Character Set I

Select IBM Character Set

Print from IBM

Character Set III

Print One Character from

IBM Character Set III

Select International

Character Set *

Select Code Page

Character Size/Spacing

Select 10 cpi Pitch

Select 12 cpi Pitch

Select 15 cpi Pitch *

Select 20 cpi Pitch *

Set Compressed Pitch

Superscript Printing On

Subscript Printing On

Super script/Subscript

ESC DLE A m n

ESC DLE B m n [data]

ESC DLE C n [data]

Data

ESC [ f L

L

v Hv Pc

ESC [ f Ln Hn DATA

ESC 7

ESC 6

II

ESC \ L

ESC n

ESC ! n

ESC [ TL

0

DC2

ESC :

ESC g

ESC SI

SI

ESC S 1

ESC S 0

ESC T

n

1

n Hn Pk Pm Ps

n Hn

0 0 Hcp Lcp

n Hn

Decimal Code

27 16 65 m n1 n

8

27 16 66 m n [data]

27 16 67 n [data]

27 91 102 L

P

m Ps Lv Hv Pc

27 91 112 Ln Hn

DATA

27 55

27 54

27 92 L

27 94 n

27 33 n

27 91 84 L

H

cp Lcp

18

27 58

27 103

27 15

15

27 83 1

27 83 0

27 84

n Hn

0

n Hn Pk

n Hn

Hexadecimal Code

1B 10 41 m n1 n

8

1B 10 42 m n [data]

1B 10 43 n [data]

1B 5B 66 L

P

m Ps Lv Hv Pc

1B 5B 70 Ln Hn

DATA

1B 37

1B 36

1B 5C L

1B 5E n

1B 21 n

0 0

1B 5B 54 L

H

cp Lcp

12

1B 3A

1B 67

1B 0F

0F

1B 53 01

1B 53 00

1B 54

n Hn

0

n Hn Pk

0 0

n Hn

8

Appendix A: Printer Commands A -- 1

Page 64

IBM Function ASCII Code

Character Size/Spacing

(cont.)

Start Double Width

SO

Printing Line by Line

End Double Width

DC4

Printing Line by Line

Double Width Printing

ESC W 1

On

Double Width Printing

ESC W 0

Off

Double Width and/or

ESC [ @ L

Height Printing On

Proportional Spacing On

Proportional Spacing Off

Set Intercharacter

ESC P1

ESC P0

ESC Vn

Spacing *

Character Style

HSD Print Mode On

Select Font

Italics On

Italics Off

Emphasized Printing On

Emphasized Printing Off

Enhanced Printing On

Enhanced Printing Off

Underline On

Underline Off

Overscore On

Overscore Off

Select font by Pitch and

ESC # 0

ESC I n

ESC % G

ESC % H

ESC E

ESC F

ESC G

ESC H

ESC - 1

ESC - 0

ESC 1

ESC 0

ESC DEL F P

Point

ESC [ I Ln Hn Hfid Lfid

Select Font

Select Print Quality

Hfwd Lfwd fa Nul H

ESC [ d Ln Hn P

Custom Characters

Down Line Load

Characters

Copy ROM Character Set

ESC = c1 c2 m n a1 a2 d1

d

k

ESC $

to RAM Character Set *

n Hn m1

n0 Pn Lp Hp

n

m

Decimal Code

14

20

27 87 1

27 87 0

27 91 64 L

k

m

k

27 80 1

27 80 0

27 86 n

27 35 48

27 73 n

27 37 71

27 37 72

27 69

27 70

27 71

27 72

27 45 1

27 45 0

27 95 1

27 95 0

27 16 70 P

H

p

27 91 73 Ln Hn Hfid

Lfid Hfwd Lfwd fa

c Lc

Nul H

c Lc

27 91 100 Ln Hn P

27 61c1 c2 m n a1 a2

d

d

1

k

27 36

n Hn m1

n0 Pn Lp

Hexadecimal Code

0E

14

1B 57 1

1B 57 00

1B 5B 40 L

m

1B 50 01

n Hn m1

k

1B 50 00

1B 56 n

1B 23 30

1B 49 n

1B 25 47

1B 25 48

1B 45

1B 46

1B 47

1B 48

1B 2D 01

1B 2D 00

1B 5F 01

1B 5F 00

1B 10 46 P

H

1B 5B 49 Ln Hn Hfid

n0 Pn Lp

p

Lfid Hfwd Lfwd fa

Nul H

c Lc

1B 5B 64 Ln Hn P

n

1B 3D c1 c2 m n a1 a2

d

d

1

k

1B 24

n

Cut-Sheet Feeder Control

Insert/Eject Paper *

ESC EM n

A -- 2 Appendix A: Printer Commands

27 25 n

1B 19 n

Page 65

IBM Function ASCII Code

Graphics

Single Density Graphics

Double Density Graphics

Double Speed/Double

ESC K L

ESC L L

ESC Y L

Density Graphics

Quadruple Density

ESC Z L

Graphics

Horizontal Control

Backspace

Carriage Return

Margin Setting, Left &

BS

CR

ESC X n m

Right

Horizontal Tab

Set Horizontal Tab

Clear Horizontal Tab

HT

ESC D n

ESC D 0 0

Settings

Set 4-column Tabulation *

Set Print Position *

Set Relative Dot Position *

Uni-directional Print On

Uni-directional Print Off

Set Relative Print Position

ESC % B n

ESC DLE @ Pn A1 A2 P1

P

2 P3 P4

ESC | Ln H

ESC U 1

ESC U 0

ESC d L

Vertical Control

Page Length, Set in n

ESC C 0 n

Inches

Page Length, Set in Lines

Skip Over Perforation On

Skip Over Perforation Off

Set Top of Form at

ESC C n

ESC N n

ESC O

ESC 4

Current Position

Form Feed

Line Feed

n

Perform

Perform

Auto Line Feed On

/

216

n

/

144

" Line Feed

" Line Feed

Auto Line Feed Off

Set Line Spacing to

Set Line Spacing to

7

1

/72"

/8"

FF

LF

ESC J n

ESC % 5 n

ESC 5 1

ESC 5 0

ESC 1

ESC 0

n Hn

n Hn

n Hn

n Hn

nk 0

1 n2

1 n2 n3 n4

n

n Hn

[data]

[data]

[data]

[data]

Decimal Code

27 75 Ln Hn [data]

n Hn

n Hn

n Hn

[data]

[data]

[data]

27 76 L

27 89 L

27 90 L

8

13

27 88 n m

9

27 68 n

1 n2

nk 0

27 68 0 0

27 37 66 n

1 n2 n3 n4

27 16 64 Pn A1 A2

P

1 P2 P3 P4

27 124 Ln H

n

27 85 1

27 85 0

27 100 L

n Hn

27 67 0 n

27 67 n

27 78 n

27 79

27 52

12

10

27 74 n

27 37 53 n

27 53 1

27 53 0

27 49

27 48

Hexadecimal Code

1B 4B Ln Hn [data]

n Hn

n Hn

n Hn

[data]

[data]

[data]

1B 4C L

1B 59 L

1B 5A L

08

0D

1B 58 n m

09

1B 44 n

1 n2

nk 0

1B 44 0 0

1B 25 42 n

1 n2 n3 n4

1B 10 40 Pn A1 A2 P1

P

2 P3 P4

1B 7C Ln H

n

1B 55 1

1B 55 00

1B 64 L

n Hn

1B 43 00 n

1B 43 n

1B 4E n

1B 4F

1B 34

0C

0A

1B 4A n

1B 25 35 n

1B 35 01

1B 35 00

1B 31

1B 30

Appendix A: Printer Commands A -- 3

Page 66

IBM Function ASCII Code

Vertical Control (cont.)

Set Line Spacing to n/

Set Line Spacing to 7/

Set Line Spacing to n/72"

Line feed compound

command

Perform Line Feed Set by

"

ESC 3 n

216

" *

ESC % 9 n

144

ESC A n

ESC DLE H Pno A1 A2

P1 P2 P3

ESC 2

ESC A n Command

Vertical Tab

Set Vertical Tab

Reset Vertical Tab to

VT

ESC B n1 n2 nk 0

ESC R

Defaults

Miscellaneous

Cancel

Change Emulation *

Paper-Out Sensor On

Paper-Out Sensor Off

Print Suppress Mode On

Print Suppress Mode Off

CAN

ESC { n

ESC 8

ESC 9

ESC Q STX

DC1

(either Model)

Set Initial Conditions

Software I-Prime *

Stop Printing

ESC [ K Ln Hn Init Id a1 a

ESC } 0

ESC j

* OKI-Unique command

Decimal Code

27 51 n

27 35 57 n

27 65 n

27 16 72 Pno A1 A2

P1 P2 P3

27 50

11

27 66 n1 n2 nk 0

27 82

24

27 123 n

27 56

27 57

27 81 2

17

27 91 75 Ln Hn Init

2

Id a1 a

2

27 125 0

27 106

Hexadecimal Code

1B 33 n

1B 25 39 n

1B 41 n

1B 10 48 Pno A1 A2

P1 P2 P3

1B 32

0B

1B 42 n1 n2 nk 0

1B 52

18

1B 7B n

1B 38

1B 39

1B 51 02

11

1B 5B 4BLn Hn Init Id

a1 a

2

1B 7D 00

A -- 4 Appendix A: Printer Commands

Page 67

Epson Printer Commands

Epson Function ASCII Code

Bar Code Commands

Select Bar Code Type

ESC DLE A m n

and Size *

Print Bar Code Data *

Print Postnet Bar Code

ESC DLE B m n [data]

ESC DLE C n [data]

Data *

Print Bar Code

ESC ( B Ln Hn Pk Pm Ps

Lv Hv Pc DATA

Character Sets

Select International

ESC R n

Character Set

Select Epson Character

ESC t n

Set

Permit Printing of Upper

ESC 6 or ESC I 1

Range Control Codes

Cancel Printing of Upper

ESC 7 or ESC I 0

Range Control Codes

Character table selection

ESC ( t Ln Hn Pn1 Pn2

Pn3

Character Size/Spacing

Select 10 cpi Pitch

Select 12 cpi Pitch

Select 15 cpi Pitch

Select 20 cpi Pitch

Cancel 20 cpi Pitch

Set Compressed Pitch

Superscript Printing On

Subscript Printing On

Superscript/Subscript

ESC P

ESC M

ESC g

ESC SI

DC2

SI

ESC S 1

ESC S 0

ESC T

Printing Off

Begin Double Width

ESC SO

Printing Line by Line

End Double Width

DC 4

Printing Line by Line

Double Width Printing

ESC W 1

On

Double Width Printing

ESC W 0

Off

1

n

Decimal Code

27 16 65 m n1 n

8

27 16 66 m n [data]

27 16 67 n [data]

27 40 66 Ln Hn Pk

Pm Ps Lv Hv Pc

DATA

27 82 n

27 116 n

27 54 or 27 73 1

27 55 or 27 73 0

27 40 116 Ln Hn Pn1

Pn2 Pn3

27 80

27 77

27 103

27 15

18

15

27 83 1

27 83 0

27 84

27 14

20

27 87 1

27 87 0

Hexadecimal Code

1B 10 41 m n1 n

8

1B 10 42 m n [data]

1B 10 43 n [data]

1B 28 42 Ln Hn Pk

Pm Ps Lv Hv Pc

DATA

1B 52 n

1B 74 n

1B 36 or 1B 49 01

1B 37 or 1B 49 00

1B 28 74 Ln Hn Pn1

Pn2 Pn3

1B 50

1B 4D

1B 67

1B 0F

12

0F

1B 53 01

1B 53 00

1B 54

1B 0E

14

1B 57 01

1B 57 00

8

Appendix A: Printer Commands A -- 5

Page 68

Epson Function ASCII Code

Character Size/Spacing

(cont.)

Double Height Printing On

Proportional Spacing On

Proportional Spacing Off

Set Intercharacter Spacing

ESC w n

ESC p 1

ESC p 0

ESC SP n

Decimal Code

27 119 n

27 112 1

27 112 0

27 32 n

Hexadecimal Code

1B 77 n

1B 70 01

1B 70 00

1B 20 n

Character Style

Select HSD Print Mode *

Select Utility or NLQ

Print Mode

Select Draft Font

Select font by Pitch and

Point

Select NLQ Type

Composite Command

Italics On

Italics Off

Emphasized Printing On

Emphasized Printing Off

Enhanced Printing On

Enhanced Printing Off

Underline On

Underline Off

Custom Characters

Down Line Load Custom

Characters

Copy ROM Character Set

to RAM Character Set

Custom Character Set On

Custom Character Set Off

Cut Sheet Feeder Control

Insert/Eject Paper

Graphics

Single Density Graphics

Double Density Graphics

Double Speed/Double

Density Graphics

Quadruple Density

Graphics

ESC ( n

ESC x n

ESC y Pn

ESC X Pn Lp Hp

ESC k n

ESC ! n

ESC 4

ESC 5

ESC E

ESC F

ESC G

ESC H

ESC - 1

ESC - 0

ESC & 0 n

1 n2

a [data]

ESC : 0 n 0

ESC % 0

ESC % 1

ESC EM n

ESC K L

ESC L L

ESC Y L

ESC Z L

n Hn

n Hn

n Hn

n Hn

[data]

[data]

[data]

[data]

27 40 n

27 120 n

27 40 85 Pn

27 88 Pn Lp Hp

27 107 n

27 33 n

27 52

27 53

27 69

27 70

27 71

27 72

27 45 1

27 45 0

27 38 0 n

1 n2

a [data]

27 58 0 n 0

27 37 0

27 37 1

27 25 n

27 75 L

27 76 L

27 89 L

27 90 L

n Hn

n Hn

n Hn

n Hn

[data]

[data]

[data]

[data]

1B 28 n

1B 78 n

1B 28 55 Pn

1B 58 Pn Lp Hp

1B 6B n

1B 21 n

1B 34

1B 35

1B 45

1B 46

1B 47

1B 48

1B 2D 01

1B 2D 00

1B 26 00 n

1 n2

a [data]

1B 3A 0 n 0

1B 25 00

1B 25 01

1B 19 n

1B 4B L

1B 4C L

1B 59 L

1B 5A L

n Hn

n Hn

n Hn

n Hn

[data]

[data]

[data]

[data]

A -- 6 Appendix A: Printer Commands

Page 69

Epson Function ASCII Code

Graphics (cont.)

Graphics Select/Print

Reassign Graphics

Select 9-pin Graphics

ESC * m L

ESC ? m n

ESC m L

Printing

Horizontal Control

Backspace

Carriage Return

Margin Setting, Left

Margin Setting, Right

Horizontal Tab

Set Horizontal Tab

Clear Horizontal Tab

BS

CR

ESC l n

ESC Q n

HT

ESC D n

ESC D 0 0

Settings

Set Print Position

Set Absolute Dot Position

Set Relative Dot Position

Uni-directional Print On

Uni-directional Print Off

Print Uni-directional for

ESC DLE @ P

P

2 P3 P4

ESC $ Ln H

ESC \ Ln H

ESC U 1

ESC U 0

ESC <

One Line

Vertical Control

Page Length, Set in n

ESC C 0 n

Inches

Page Length, Set in Lines

Skip Over Perforation Set

Skip Over Perforation

ESC C n

ESC N n

ESC O

Reset to Default

Form Feed

Line Feed

n

Perform

Perform

Set Line Spacing to

/

216

n

/

144

" Line Feed

" Line Feed *

Set Line Spacing to

Set Line Spacing to

Set Line Spacing to

Set Line Spacing to

FF

LF

ESC J n

ESC % 5 n

1

ESC 2

/6"

1

ESC 0

/8"

7

ESC 1

/72"

n

ESC A n

/72"

n

ESC % 9 n

/

" *

144

n Hn

n Hn

1 n2

n

n

[data]

[data]

nk 0

n A1 A2 P1

Decimal Code

27 42 m Ln Hn [data]

27 63 m n

27 94 m L

n Hn

8

13

27 108 n

27 81 n

9

27 68 n

1 n2

nk 0

27 68 0 0

27 16 64 P

P

27 36 Ln H

27 92 Ln H

n A1 A2

1 P2 P3 P4

n

n

27 85 1

27 85 0

27 60

27 67 0 n

27 67 n

27 78 n

27 79

12

10

27 74 n

27 37 53 n

27 50

27 48

27 49

27 65 n

27 37 57 n

Hexadecimal Code

1B 2A m Ln Hn [data]

1B 3F m n

1B 5E m L

[data]

08

0D

1B 6C n

1B 51 n

09

1B 44 n

1B 44 00 00

1B 10 40 P

P

2 P3 P4

1B 24 Ln H

1B 5C Ln H

1B 55 01

1B 55 00

1B 3C

1B 43 00 n

1B 43 n

1B 4E n

1B 4F

0C

0A

1B 4A n

1B 25 35 n

1B 32

1B 30

1B 31

1B 41 n

1B 25 39 n

n Hn

nk 00

1 n2

n A1 A2 P1

n

n

[data]

Appendix A: Printer Commands A -- 7

Page 70

Epson Function ASCII Code

Vertical Control (cont.)

Set Line Spacing to

Vertical Tab

Set Vertical Tab Stops

Line feed compound

Reset Vertical Tab to

n

/

216

command

"

ESC 3 n

VT

ESC B n

ESC DLE H Pno A1 A2

P1 P2 P3

ESC B 0

Defaults

Set Vertical Format Unit

ESC b m n

(VFU)

Set Vertical Tab Channel

Set Basic Unit

Set Page Length in

ESC/n

ESC ( U Ln Hn Pn

ESC ( C Ln Hn Lp Hp

Defined Unit

Set Page Format

ESC ( c Ln Hn Lt Ht Lb

Hb

Miscellaneous

Cancel

Change Emulation *

Delete One Character

Initialize Printer

Half-Speed Printing On

Half-Speed Printing Off

Paper-Out Sensor On *

Paper-Out Sensor Off *

Print Suppress Mode On

Print Suppress Mode Off

Set Most Significant Bit to

CAN

ESC { n

DEL

ESC @

ESC s 1

ESC s 0

ESC 9

ESC 8

DC3

DC1

ESC =

Zero

Set Most Significant Bit to

ESC >

One

Cancel Most Significant

ESC #

Bit Control

Software I-Prime *

ESC } 0

1 n2

nk 0

1 n2

nk 0

Decimal Code

27 51 n

11

27 66 n

27 16 72 Pno A1 A2

1 n2

nk 0

P1 P2 P3

27 66 0

27 98 m n

0

1 n2

nk

27 47 n

27 40 85 Ln Hn Pn

27 40 67 C Ln Hn

Lp Hp

27 40 99 Ln Hn Lt

Ht Lb Hb

24

27 123 n

127

27 64

27 115 1

27 115 0

27 57

27 56

19

17

27 61

27 62

27 35

27 125 0

Hexadecimal Code

1B 33 n

0B

1B 42 n

1B 10 48 Pno A1 A2

1 n2

nk 00

P1 P2 P3

1B 42 00

1B 62 m n

1 n2

nk 0

1B 2Fn

1B 28 55 Ln Hn Pn

1B 28 43 C Ln Hn Lp

Hp

1B 28 63 Ln Hn Lt

Ht Lb Hb

18

1B 7B n

7F

1B 40

1B 73 0

1B 73 00

1B 39

1B 38

13

11

1B 3D

1B 3E

1B 23

1B 7D 00

Justification

Left Justification

Center Justification

Right Justification

Within Line Justification

ESC a 0

ESC a 1

ESC a 2

ESC a 3

* OKI-Unique Command

A -- 8 Appendix A: Printer Commands

27 97 0

27 97 1

27 97 2

27 97 3

1B 61 00

1B 61 01

1B 61 02

1B 61 03

Page 71

OKI Microline (ML) Printer Commands

Microline Function ASCII Code

Bar Code Commands

Select Bar Code Type

and Size

Print Bar Code Data

Print Postnet Bar Code

Character Sets

Select Standard Character

Select Line Character Set

(comparable to IBM Set 2)

Block character set

Select International

Character Set

Select Code Page

Character Size/Spacing

Select 10 cpi Pitch

Select 12 cpi Pitch

Select 15 cpi Pitch

Select 17.1 cpi Pitch

Select 20 cpi Pitch

Superscript Printing On

Superscript Printing Off

Subscript Printing On

Subscript Printing Off

Double Width Printing

Double Height Printing

Double Height Printing

Select Print Mode

Proportional Spacing On

Proportional Spacing Off

Set Intercharacter Spacing

ESC DLE A m n1 n

ESC DLE B n [data]

ESC DLE C n [data]

Data

ESC ! 0

Set

ESC ! 2

ESC ! 1

ESC ! n

ESC [ T Ln Hn 0 0 Hcp

Lcp 0

RS

FS

ESC g

GS

ESC # 3

ESC J

ESC K

ESC L

ESC M

US

ESC US 1

On

ESC US 0

Off

ESC & n1 n2 n3 n4 :

ESC Y

ESC Z

ESC N n

Decimal Code

27 16 65 m n1 n

8

27 16 66 n [data]

27 16 67 n [data]

27 33 48

27 33 50

27 33 49

27 33 n

27 91 84 Ln Hn 0 0

Hcp Lcp 0

30

28

27 103

29

27 35 51

27 74

27 75

27 76

27 77

31

27 31 49

27 31 48

27 38 n1 n2 n3 n4 58

27 89

27 90

27 78 n

Hexadecimal Code

1B 10 41 m n1 n

8

1B 10 42 n [data]

1B 10 43 n [data]

1B 21 30

1B 21 32

1B 21 31

1B 21 n

1B 5B 54 Ln Hn 0 0

Hcp Lcp 0

1E

1C

1B 67

1D

1B 23 33

1B 4A

1B 4B

1B 4C

1B 4D

1F

1B 1F 31

1B 1F 30

1B 26 n1 n2 n3 n4 3A

1B 59

1B 5A

1B 4E n

8

Appendix A: Printer Commands A -- 9

Page 72

Microline Function ASCII Code

Character Style

HSD Print Mode On

Select Utility Print Mode

Select NLQ Courier Font

Select NLQ Gothic Font

Select Font by Pitch and

Italics On

Italics Off

Emphasized Printing On

Enhanced Printing On

Emphasized and

Point

ESC # 0

ESC 0

ESC 1

ESC 3

ESC DLE F Pn

Hp

ESC ! /

ESC ! *

ESC T

ESC H

ESC I

Enhanced Printing Off

Underline On

Underline Off

ESC C

ESC D

Custom Characters

Copy ROM Character Set

ESC $

to RAM Character Set

Download Custom

ESC % A m n

Ascender Characters

Download Custom

ESC % D m n1 n

Descender Characters

Select DLL Utility

ESC 2

Character Font

Select Down Line Load

ESC 7

NLQ Character Font

Pn Lp

0

n

1

Decimal Code

27 35 48

27 48

27 49

27 51

27 16 70 Pn

Pn Lp

0

Hp

27 33 47

27 33 42

27 84

27 72

27 73

27 67

27 68

27 36

11

11

27 37 65 m n

1

27 37 68 m n1 n

27 50

27 55

Hexadecimal Code

1B 23 30

1B 30

1B 31

1B 33

1B 10 46 Pn

Hp

1B 21 2F

1B 21 2A

1B 54

1B 48

1B 49

1B 43

1B 44

1B 24

1B 25 41 m n

n

11

1B 25 44 m n1 n

11

1B 32

1B 37

Pn Lp

0

n

1

11

11

Cut Sheet Feeder Control

Cut Sheet Feeder Insert

ESC S

Sheet

Cut Sheet Feeder Sheet

ESC V

Eject

Cut Sheet Feeder Bin 1 or

ESC EM n

Bin 2 Selection

Graphics

Single Density Graphics

Double Density Graphics

Double Speed/Quadruple

ESC P or ESC Q

ESC R

ESC # Q

Density Graphics

A -- 10 Appendix A: Printer Commands

27 83

27 86

27 25 n

27 80 or 27 81

27 82

27 35 81

1B 53

1B 56

1B 19 n

1B 50 or 1B 51

1B 52

1B 23 51

Page 73

Microline Function ASCII Code

Graphics (cont.)

Graphics Mode Selection

Graphics Print Mode

ESC * n

ETX

1 n2

Selection

Decimal Code

:

27 42 n1 n2 58

3

Hexadecimal Code

1B 2A n1 n2 3A

03

Horizontal Control

Backspace

Carriage Return

Horizontal Tab

Margin Setting, Left

Margin Setting, Right

Move to the Left

Move to the Right

Set Print Position

Set Multiple Print

Positions

Set Horizontal Tab by

Characters

Set Horizontal Tab by

Dot Columns

Uni-directional Print On

Uni-directional Print Off

Vertical Control

Page Length, Set in

Increments

Page Length, Set in Lines

Skip Over Perforation On

Skip Over Perforation Off

Set Top of Form

Form Feed

Skip Down Selected

Number of Lines

Line Feed

(with Carriage Return)

Line Feed (without

Carriage Return)

Carriage Return/Line

Feed Selection Command

BS

CR

HT

ESC % C n

ESC % R n1 n2 n3 n

ESC % F n1 n2 n3 n

ESC % E n1 n2 n3 n

ESC % B n1 n2 n3 n

ESC DEL @ Pn a1 a2 P1

P

2 P3 P4

ESC HT x y z CR

ESC HTX x y z w CR

ESC ESC =

1

/2"

ESC G H

ESC F Hn L

ESC % S n

ESC % S 0

ESC 5

FF

ESC VT H

LF

ESC DC2

ESC ? n :

1 n2 n3

n Ln

n Ln

8

13

9

4

4

4

4

27 37 67 n

27 37 82 n1 n2 n3 n

27 37 70 n1 n2 n3 n

27 37 69 n1 n2 n3 n

27 37 66 n1 n2 n3 n

1 n2 n3

27 16 64 Pn a1 a2 P1

P

2 P3 P4

27 9 x y z 13

27 3 x y z w 13

27 45

27 61

27 71 H

n Ln

n

27 70 Hn L

n

27 37 83 n

27 37 83 0

27 53

12

27 11 H

n Ln

10

27 18

25 63 n 58

08

0D

09

1B 25 43 n

1B 25 52 n1 n2 n3 n

4

1B 25 46 n1 n2 n3 n

4

1B 25 45 n1 n2 n3 n

4

1B 25 42 n1 n2 n3 n

4

1 n2 n3

1B 10 40 Pn a1 a2 P1

P

2 P3 P4

1B 09 x y z 0D

1B 03 x y z w 0D

1B 2D

1B 3D

1B 47 H

n Ln

1B 46 Hn L

1B 25 53 n

1B 25 53 00

1B 35

0C

1B 0B H

n Ln

0A

1B 12

1B 3F n 3A

4

4

4

4

n

Appendix A: Printer Commands A -- 11

Page 74

Microline Function ASCII Code

Vertical Control (cont.)

Perform n/

Set Line Spacing to 1/8"

Set Line Spacing to 1/6"

Set Line Spacing to n/

Vertical Tab

Execute VFU Vertical Tab

Set Vertical Tab Channels

Line feed compound

" Line Feed

144

command

ESC % 5 n

ESC 8

ESC 6

"

ESC % 9 n

144

VT

VT n

DC4 SP SP n SP SP?

ESC DLE H Pno A1 A2

P1 P2 P3

Miscellaneous

Cancel

Initialize Printer

Half-Speed Printing On

Half-Speed Printing Off

Change Emulation

Paper-Out Sensor On

Paper-Out Sensor Off

Print Suppress Mode On

Print Suppress Mode Off

Software I-Prime

CAN

ESC CAN

ESC <

ESC >

ESC { n

ESC E 0

ESC E 1

DC3

DC1

ESC } 0

Decimal Code

27 37 53 n

27 56

27 54

27 37 57 n

11

11 n

20 32 32 n 32 32 63

27 16 72 Pno A1 A2

P1 P2 P3

24

27 24

27 60

27 62

27 123 n

27 69 0

27 69 1

19

17

27 125 0

Hexadecimal Code

1B 25 35 n

1B 38

1B 36

1B 25 39 n

0B

0B n

14 20 20 n 20 20 3F

1B 10 48 Pno A1 A2

P1 P2 P3

18

1B 18

1B 3C

1B 3E

1B 7B n

1B 45 00

1B 45 01

13

11

1B 7D 00

A -- 12 Appendix A: Printer Commands

Page 75

Appendix B

Interface Cable

Cables and Connectors

This appendix is designed to help you make a cable to connect your printer

to your computer. Please do not attempt to make a cable unless you have

experience in doing so. In this section we explain the signals from the

printer end; you should read your computer documentation to determine

the requirements at the computer end.

Parallel Cable

The Microline 184 Turbo requires a Centronics-equivalent parallel cable

with the following:

• Amphenol 57-30360 or AMP 552274-1 plug (or equivalent) with 36

pins.

• AMP 552073-1 (or equivalent) cover.

• Beldon (or equivalent) shielded cable, maximum 1.8 metres with twisted-

pair conductors. It must be UL and CSA (equivalent to European standards)

approved.

• The printer has a 36-pin receptacle, Amphenol57-40360-12-D56, built

into the back.

The wiring requirements are detailed in the following tables.

Appendix B: Interface Cable B -- 1

Page 76

Pin# Signal Pin# Direction Description

Return

1

Data Strobe

19 To printer Strobe pulse to read data in.

Pulse width must be more

than 0.5 tis at receiving

terminal. The signal level

is normally high; read-in of

data is performed at the

low level of this signal.

2 Data 1 20 To printer These signals represent

3 Data 2 21 To printer information in the 1st to 8th

4 Data 3 22 To printer bits of parallel data

5 Data 4 23 To printer respectively. Each signal is

6 Data 5 24 To printer at high level when data is

7 Data 6 25 To printer logical 1 and low when

8 Data 7 26 To printer logical 0.

9 Data 8 27 To printer

10 ACKNOWLEDGE 28 From printer Approximately 2~8µs low

pulse. Low indicates

that data has been received

and that printer is now

ready to accept other data.

11 Busy 29 From printer A high signal indicates that

the printer cannot receive

data. The signal becomes

high in the following cases:

1. During data entry

2. During printing

3. In off-line state

4. During printer

error state.

12 Paper End 30 From printer A high signal indicates that

the printer is out of paper.

13 Select No From printer This signal indicates that

return the printer is ready to receive

data.

B -- 2 Appendix B: Interface Cable

Page 77

Pin# Signal Pin# Direction Description

Return