Page 1

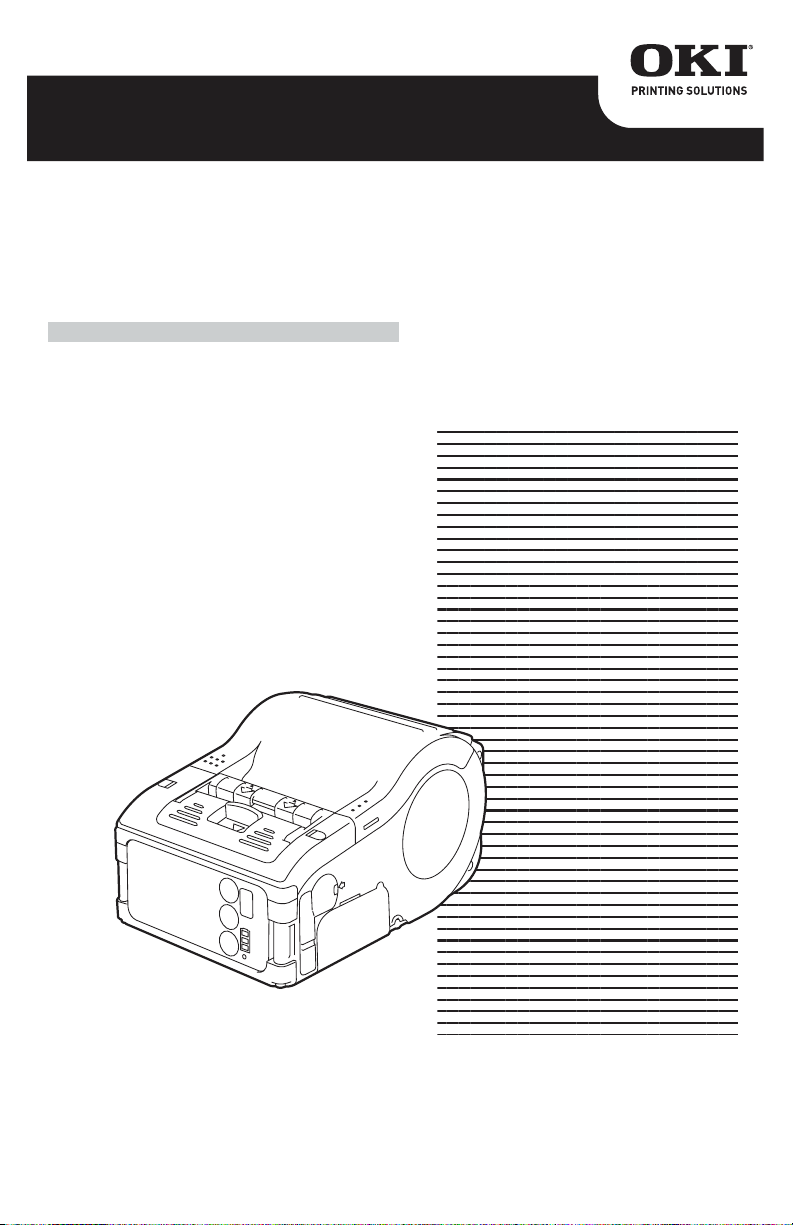

LP440, LP441

User’s Guide

59318201 my.okidata.com

Page 2

Contents

Safety, Warnings and Cautions . . . . . . . . . . . . . . . .5

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Notes on Bluetooth/Wireless Communication . . . . . . . . . . . .14

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Unpacking the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Part Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Description of Printer Parts . . . . . . . . . . . . . . . . . . . . . . . .20

The Battery Pack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Charging the Battery Pack . . . . . . . . . . . . . . . . . . . . . . .22

Installing the Battery Pack . . . . . . . . . . . . . . . . . . . . . . .25

Removing the Battery Pack. . . . . . . . . . . . . . . . . . . . . . .27

Powering the Printer using the Optional AC Adapter . . . . . . .29

Loading the Label Roll . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Loading the Label Roll: Continuous Mode . . . . . . . . . . . . .30

Loading the Label Roll: Dispense Mode. . . . . . . . . . . . . . .33

Operation and Configuration . . . . . . . . . . . . . . . . .37

Turning the printer ON. . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Turning the printer OFF . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Performing a Test Print . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Printing using the RS-232C Interface . . . . . . . . . . . . . . . .40

Printing using the IrDA Interface . . . . . . . . . . . . . . . . . . .41

Printing using the Bluetooth Interface . . . . . . . . . . . . . . .43

The LCD screen (Wireless LAN Model Only) . . . . . . . . . . . . .43

General Printing Procedure . . . . . . . . . . . . . . . . . . . . . . .46

Adjusting Printing for Non-Separate Labels. . . . . . . . . . . .47

The Label Dispensing mode . . . . . . . . . . . . . . . . . . . . . . . .49

Status LEDs for Printing Modes. . . . . . . . . . . . . . . . . . . . . .50

Status LEDs for the Test Print Mode. . . . . . . . . . . . . . . . .50

Status LEDs for the Head Check Setting Mode. . . . . . . . . .51

Status LEDs for the Online Command Compatibility Mode. .51

Interface Specifications . . . . . . . . . . . . . . . . . . . . .53

Cleaning and Maintenance . . . . . . . . . . . . . . . . . . .59

Cleaning the Print Head . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Cleaning the Platen and Peel Roller . . . . . . . . . . . . . . . . . . .61

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

2

Page 3

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . .69

3

Page 4

Copyright Information

Copyright © 2009 by Oki Data. All Rights Reserved

LP440/LP441 User’s Guide

P/N 59318201, Revision 1.0

Disclaimer

Every effort has been made to ensure that the information in

this document is complete, accurate, and up-to-date. The

manufacturer assumes no responsibility for the results of errors

beyond its control. The manufacturer also cannot guarantee that

changes in software and equipment made by other

manufacturers and referred to in this guide will not affect the

applicability of the information in it. Mention of software

products manufactured by other companies does not necessarily

constitute endorsement by the manufacturer .

While all reasonable efforts have been made to make this

document as accurate and helpful as possible, we make no

warranty of any kind, expressed or implied, as to the accuracy

or completeness of the information contained herein.

The most up-to-date drivers and manuals are available from the

web site: http://www.okiprintingsolutions.com

Trademark Information

Oki is a registered trademark of Oki Electric Industry Company Ltd.

Other product names and brand names are registered trademarks or

trademarks of their proprietors.

4

Page 5

Safety, Warnings and Cautions

Safety Precautions

As a preventive measure to ensure safe usage of this machine

so as to safeguard against damage to yourself, other people

or property, there are display diagrams used in this

instruction manual and on this machine.

The displays and their meanings are illustrated in the

following pages. Please take time to read and understand the

content

Warning

If this display and its warning is ignored, any

mishandling could result in death or serious injuries.

Attention

If this display and its warning is ignored, any mishandling

could result in serious injuries as well as property damage.

5

Page 6

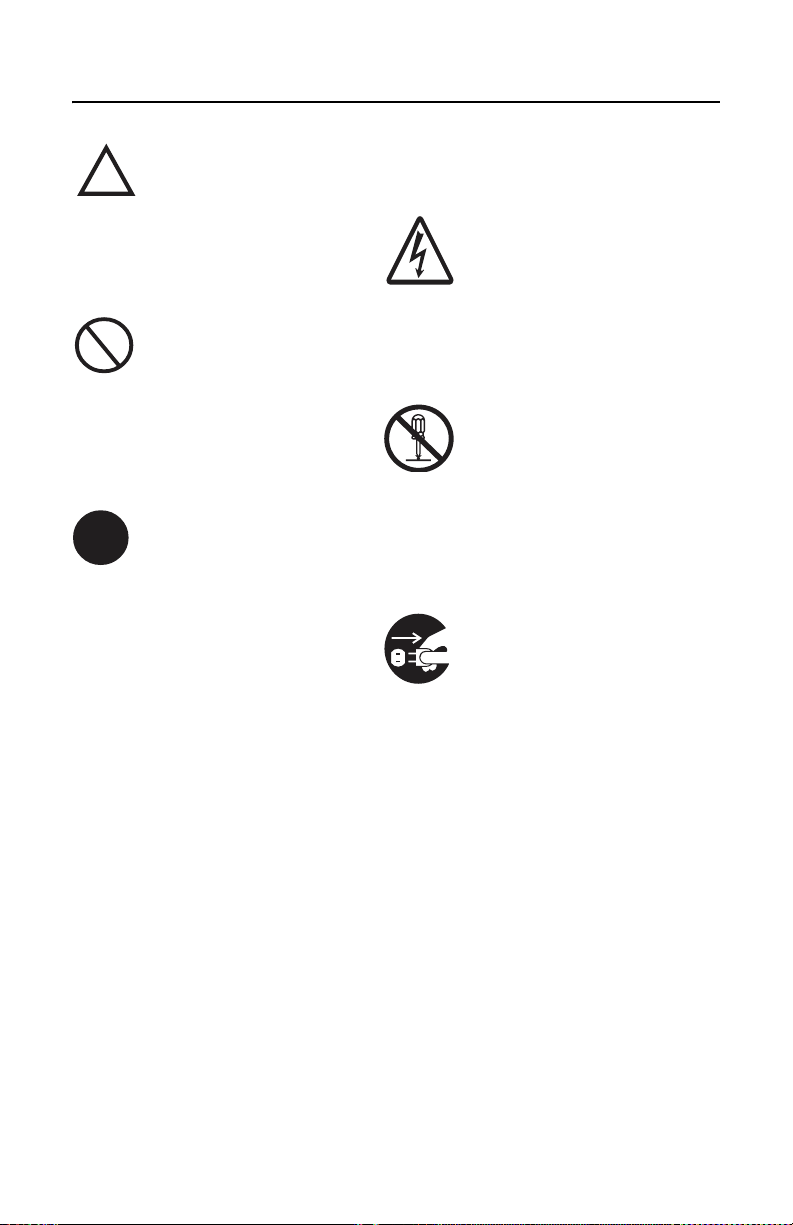

Basic Hazard Icons

The triangle sign means ‘Be careful’. The content within

the triangle illustrates specific hazards. In this case,

the sign on the below means ‘beware of electric shock’.

The circular sign means ‘prohibited’. The content

within the circle illustrates a specific prohibition. In this

case the sign below means ‘disassembly prohibited’.

The black circular sign means ‘must do’. The content

within the sign illustrates specific items that must be

carried out. In this case the sign on the left means ‘the

plug must be unplugged from the socket’. Warnings

6

Page 7

Hazard Warnings

Liquids

• Do not place any liquids or small metallic objects near the

printer. Should any of these fall into the printer,

immediately turn off the power and contact your nearest

dealer or service center. Continued use increases the risk of

fire or electric shocks.

Foreign Matter

• Do not insert or drop metallic or flammable objects into the

openings of the printer (such as outlets for cables). If this

happens, immediately turn off the power and contact your

nearest dealer or service center. Continued use increases

the risk of fire or electric shocks.

• Should the printer be dropped or become damaged,

immediately turn off the power and contact your nearest

dealer or service center. Continued use increases the risk of

fire or electric shocks.

7

Page 8

Abnormal Conditions

• Continued use of the printer while it is emitting smoke or

strange odors increases the risk of fire or electric shocks.

Immediately turn off the power and contact your nearest

dealer or service center. Do not try to service the printer by

yourself.

Disassembly

• Never try to take the unit apart or modify it in any way.

Doing so increases the risk of fire or electric shocks.

Contact your nearest dealer or service center for repairs.

Battery Care

• Never try to take apart the battery pack or modify it in any

way.

• Never expose the battery to direct heat or fire, or take any

actions that may lead to physical damage.

• When charging the battery pack, be sure to use the printer

or the specified battery charger.

8

Page 9

Power Supply Precautions

• Use only the specified voltage and use only the specified

battery charger.

• Never use the battery charger with any other battery pack

except for the specified type. Doing so can rupture the

battery, or cause leakage, fire or electric shocks.

• Never cut, damage or modify the power cord. Also, never

place heavy objects on the power cord or heat or pull the

power cord. Doing so may damage the cord.

• Should the power cord ever become seriously damaged

(internal wiring exposed or shorted), contact your nearest

dealer or service center for repair.

• Never modify, excessively bend, twist, or pull the power

cord.

Continued use of the printer in any of the above situations

can lead to increased risks of fire or electric shocks.

9

Page 10

Cautions

Location

Do not locate the printer in the area subjected to high humidity or dew. If dew

forms inside the printer, immediately turn off the printer and do not use it until

all moisture has dried up. Continued use creates the danger of electric

shock and can damage the printer.

Power

Do not use wet hands to operate the power switch, replace

the battery pack or unplug the AC adapter or battery charger.

Doing so increases the risk of electric shock.

Hazardous Parts

• The entire thermal head gets very hot after printing. Avoid

touching any part of it when replacing paper or cleaning the

printer.

• Do not try to replace the thermal head by yourself.

• The cutter contains a blade, so be careful not to get cut by

the sharp blade.

10

Page 11

Replacing the Battery Pack

• Use only specified replacement battery packs.

• Make sure to install the pack in the correct direction to

avoid the danger of injury or damage to surrounding areas.

• To replace small-size rechargeable (Lithium ion) batteries,

seal the old battery pack with tape and ask our sales

representative or service center about disposal methods. Do

not place the battery pack together with other batteries

such as dry batteries.

Storing the Printer

If you have no plan to use the printer for a long time, remove

the battery pack from the printer and unplug the AC adapter

from the wall outlet if you were using the AC adapter as the

power source.

Maintenance and Cleaning

For safe maintenance or cleaning of the printer, make sure to

remove the battery pack and the AC adapter from the printer

if you were using the AC adapter as the power source.

11

Page 12

Other Precautions

Avoid placement in extreme temperatures.

• Do not place the printer in highly humid areas or at outside

the -15°C to 50°C temperature range.

When the printer is being transported...

• The normal vibration encountered during transportation is

acceptable, but avoid dropping the printer or exposing it to

extreme vibrations.

Do not disassemble or modify the printer

• The printer has high-precision components inside requiring

e adjustments.

Use only the specified cables.

• Special cables are required to connect to external

equipment through the external input terminals. Contact

your nearest dealer or service center if necessary.

Use only specified options.

• Do not use a device not specified as option.

Use the specified paper.

• Use the specified paper to avoid printing errors and to avoid

damaging the print head.

12

Page 13

Overview

This manual is intended to familiarize you with the basic

features and operation of your printer in a short time.

Key Features:

• High speed CPU and printing speed

• Long battery life

• Supports Infrared, RS-32C and Bluetooth I/O

• Durable and rugged design

• Supports media up to 2.6 inches (67mm) in width

• Supports MB200 emulation or SBPL command compatibility

Please read this manual carefully to make full use of this

product.

13

Page 14

Notes on Bluetooth/Wireless

Communication

Compliance Statement

This product has been certified for compliance with the relevant

radio interference regulations of your country or region. To

ensure continued compliance, do not:

• Disassemble or modify this product

• Remove the certificate label (serial number seal) affixed to

this product

Note: Use of this product near microwave and/or other wireless

LAN equipment, or where static electricity or radio

interference is present, may shorten the communication

distance, or even disable communication.

“Bluetooth” is a trademark of Bluetooth SIG, Inc.,

USA., and is used herein under licence.

Caution! Before using the wireless LAN interface, make all the

security settings of the wireless LAN equipment are

configured in accordance with the instructions

supplied with the equipment.

14

Page 15

Setup

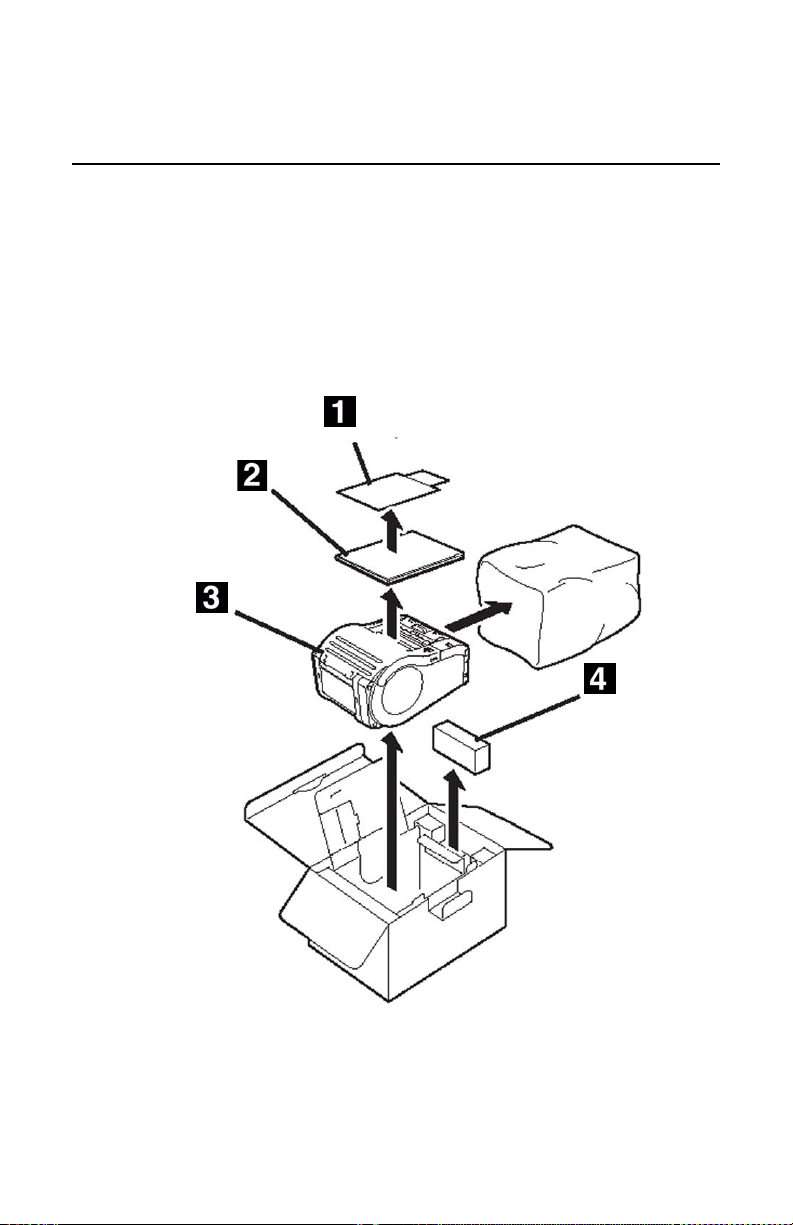

Unpacking the printer

If anything here is missing, contact your nearest Oki dealer or

service center.

1 Safety, Warranty and Regulatory Information

2 Quick Guide

3 Printer

Note: Battery Pack

Note: An external battery charger is available separately.

15

Page 16

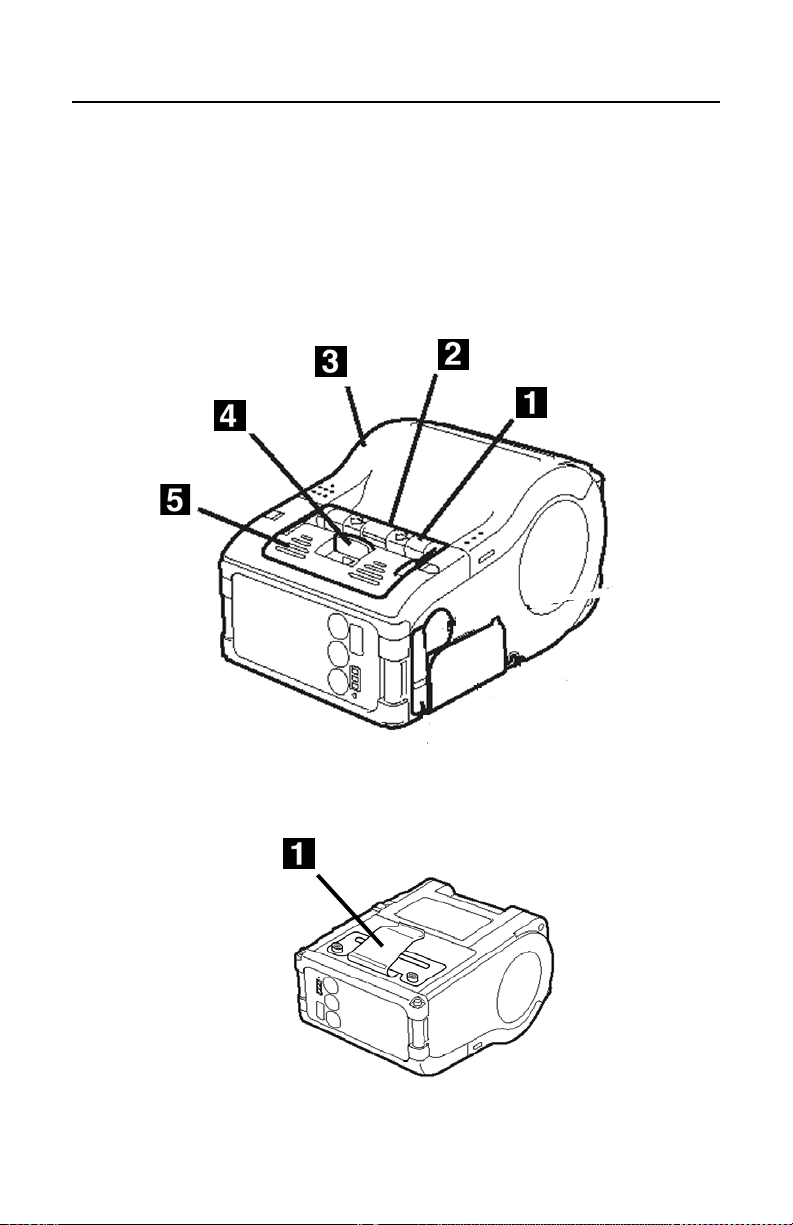

Part Names

Top View

1 Easy Cutter

2 Label Dispenser

3 Main Cover

4 Cover Release Lever

5 Dispenser Unit

Bottom View

1 Belt Clip

16

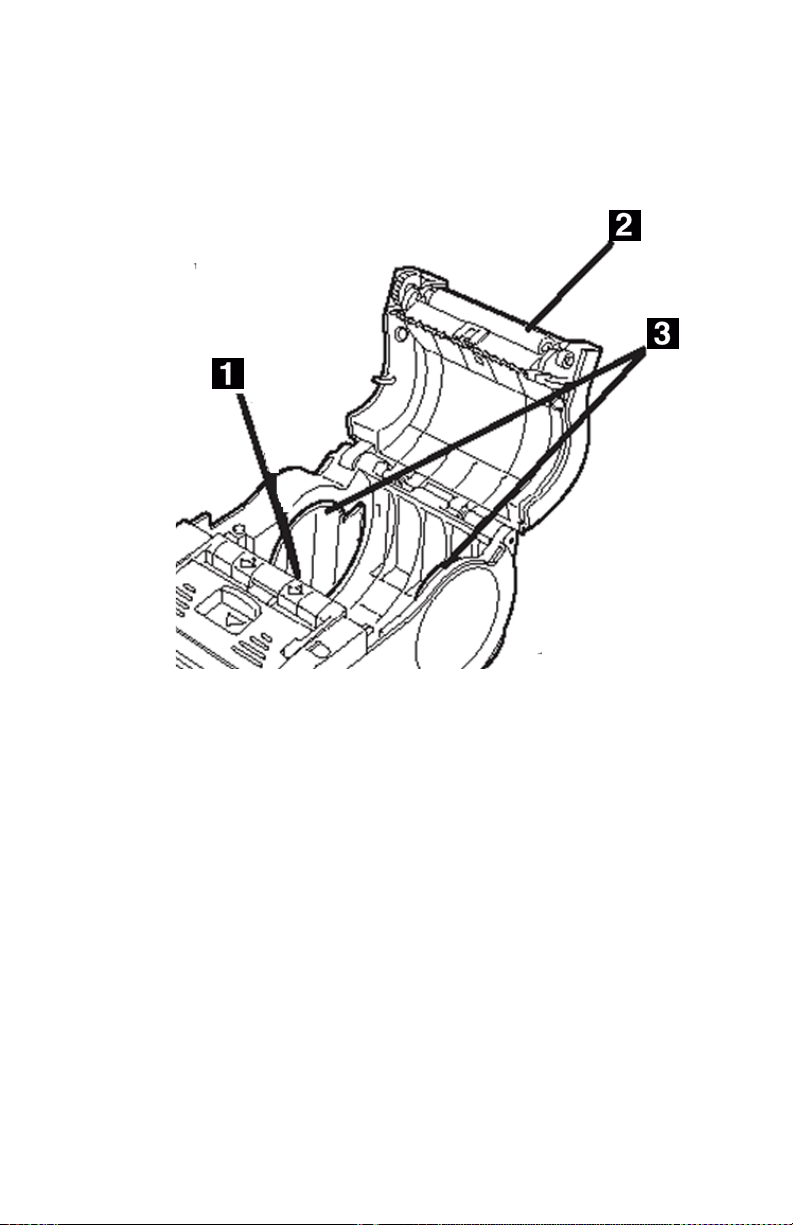

Page 17

Interior View

1 Label Width Markings

2 Platen

3 Label Guides

17

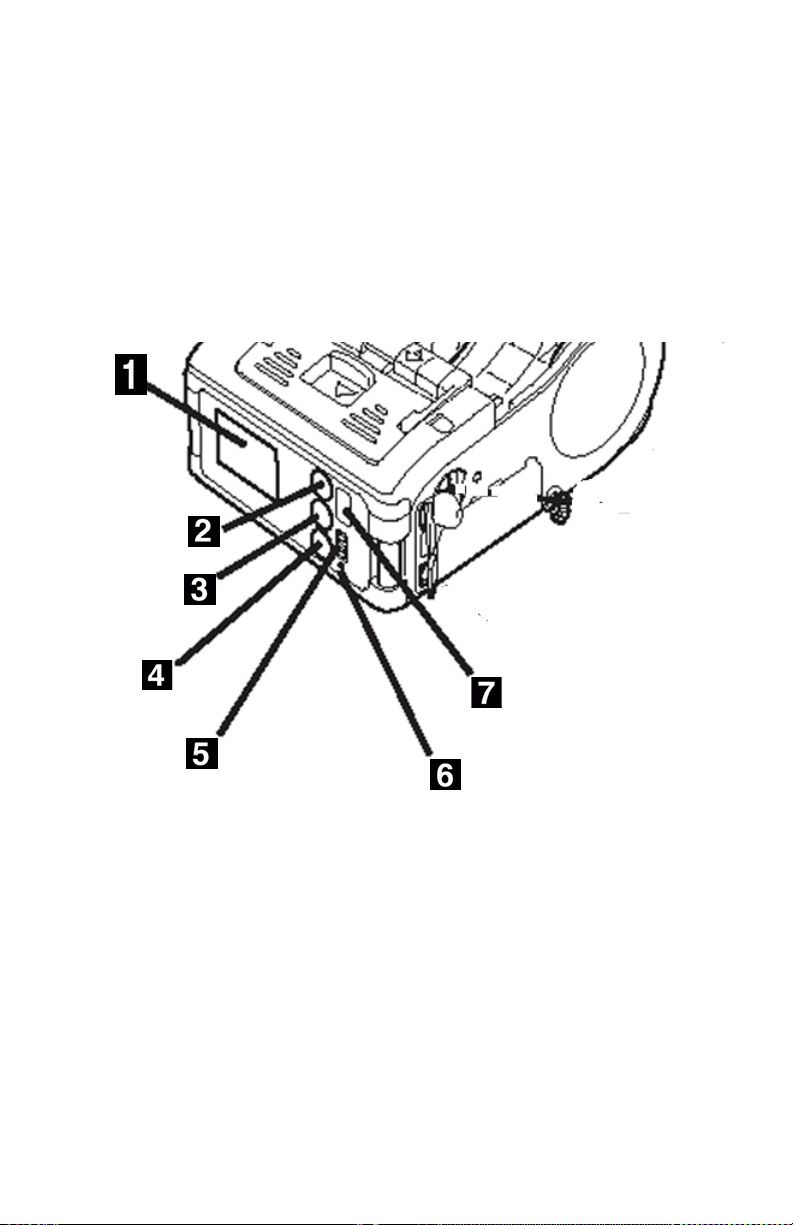

Page 18

Control Panel

1 LCD Display (WLAN Models only)

2 POWER button

3 PRINT button

4 FEED button

5 Battery Indicator (Charge Indictor on WLAN models)

6 Status LED

7 IrDA filter

18

Page 19

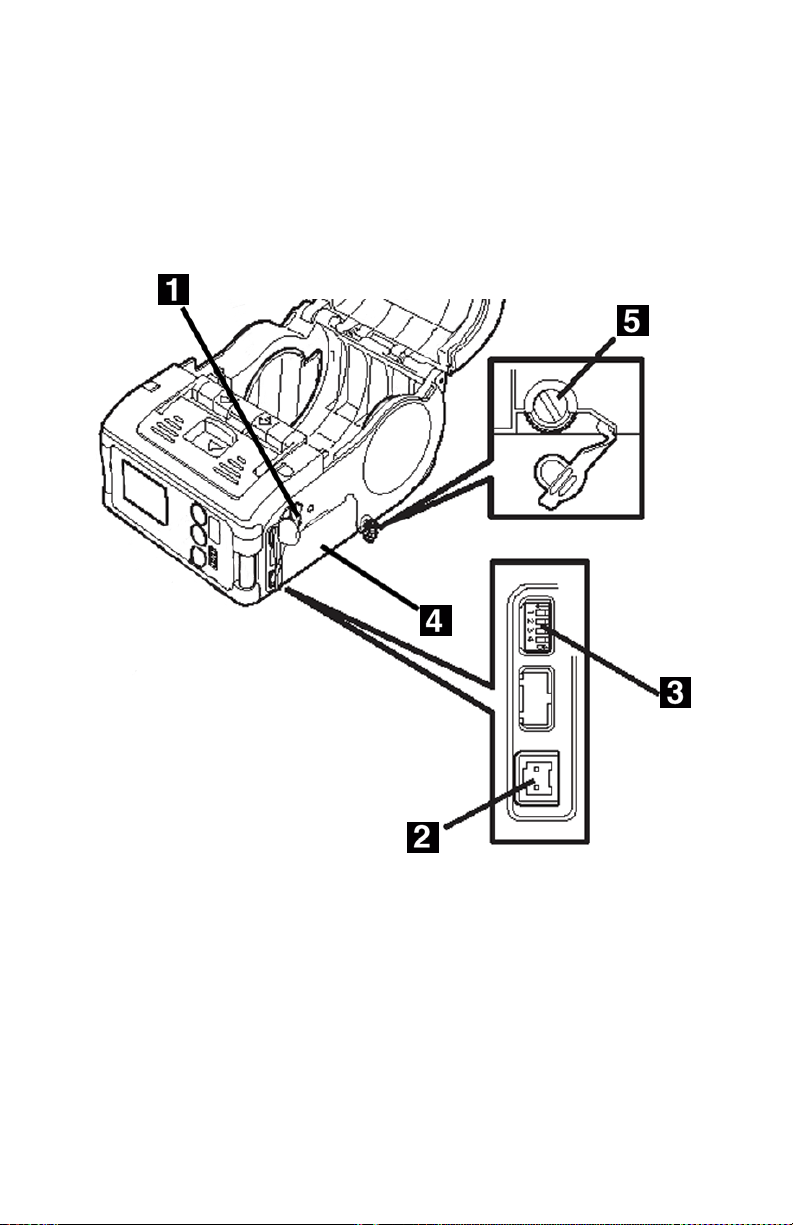

Side Panel

1 RS-232c Port

2 DC Input

3 DIP Switches

4. Battery Cover

5. Label Guide Adjust Dial

19

Page 20

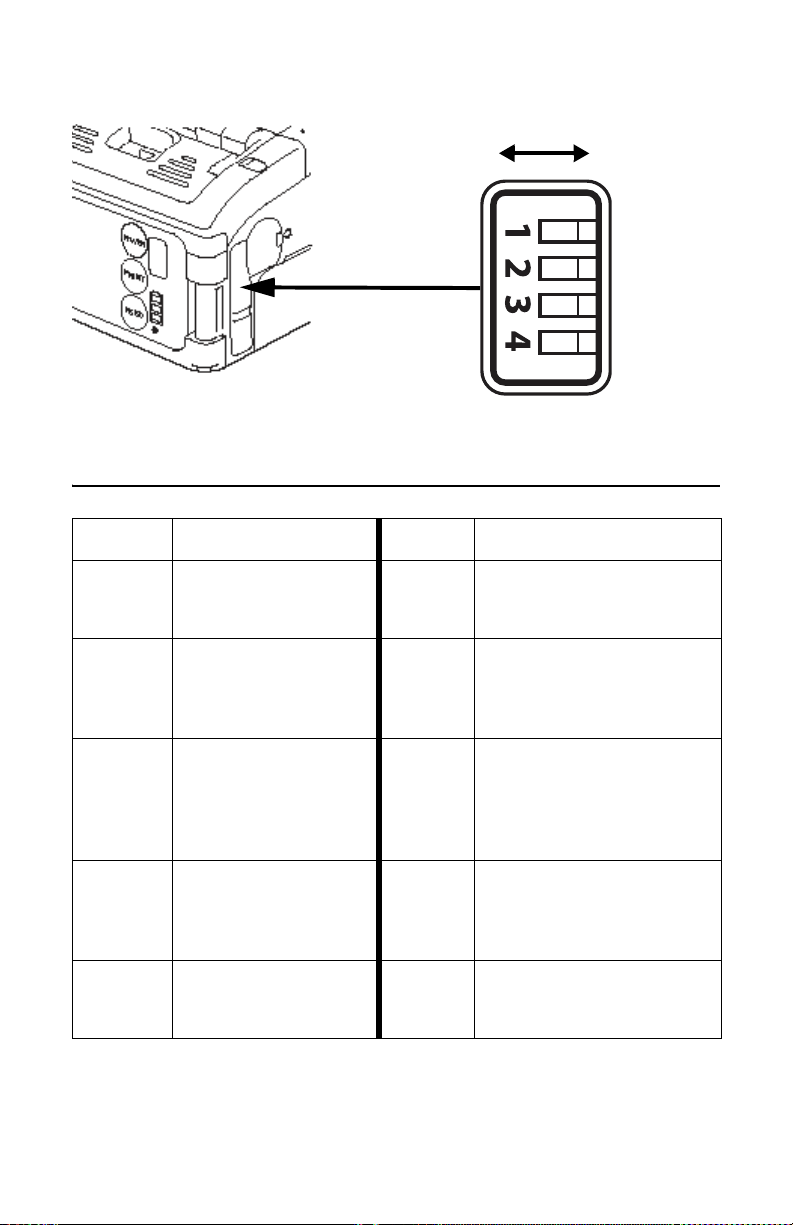

DIP Switches

Description of Printer Parts

Part Function Part Function

OFFON

RS-232C

Interface

RS-232C

cover

Cover Opens up to allow the

Cover

Open/

Close

lever

Easy

cutter

Allows connection to a

computer or

hand-held terminal

Protects the RS-232C

connector from dust

and damage

installation of labels

Enables the user to

releases the cover, or

to lock the cover shut

Cuts printed labels Label

Label

guide

Label

guide

adjust

dial

Cover for

Label

guide

adjust

dial

Label

output

area

width

markings

Set to meet the size of the

label used

Allows adjustment of the

label guide to fit the width

of an installed label roll

Protects the label guide

adjustment dial from dust

or damage

This is the area where the

printed label is output

Indicates the width of label

installed or in use.

20

Page 21

Part Function Part Function

IrDA filter Contains the IrDA

(infrared) sensor and

emitter

DIP

switch

Dispenser

unit

POWER

key

Battery

cover

Battery

indicator

(LED)

Sets the operation

mode of the printer.

(See page 4-1.)

Moved to select

Dispense mode

Allows the user to

turns ON/OFF the

printer

Cover for special

battery pack

Indicates the amount

of battery power

remaining.

DC input

jack

Cover for

DC input

jack

FEED key Press to feed label

PRINT

key

Status

LED

Belt clip Suspends the printer on a

Connects to AC adapter

which supplies direct

current to the printer

Protects the DC input

terminal and DIP switch fro

dust and damage

Takes the printer Online or

Offline

Indicates the status of the

printer. (S

Do not hang the

belt.

printer on anything but a

belt.

21

Page 22

The Battery Pack

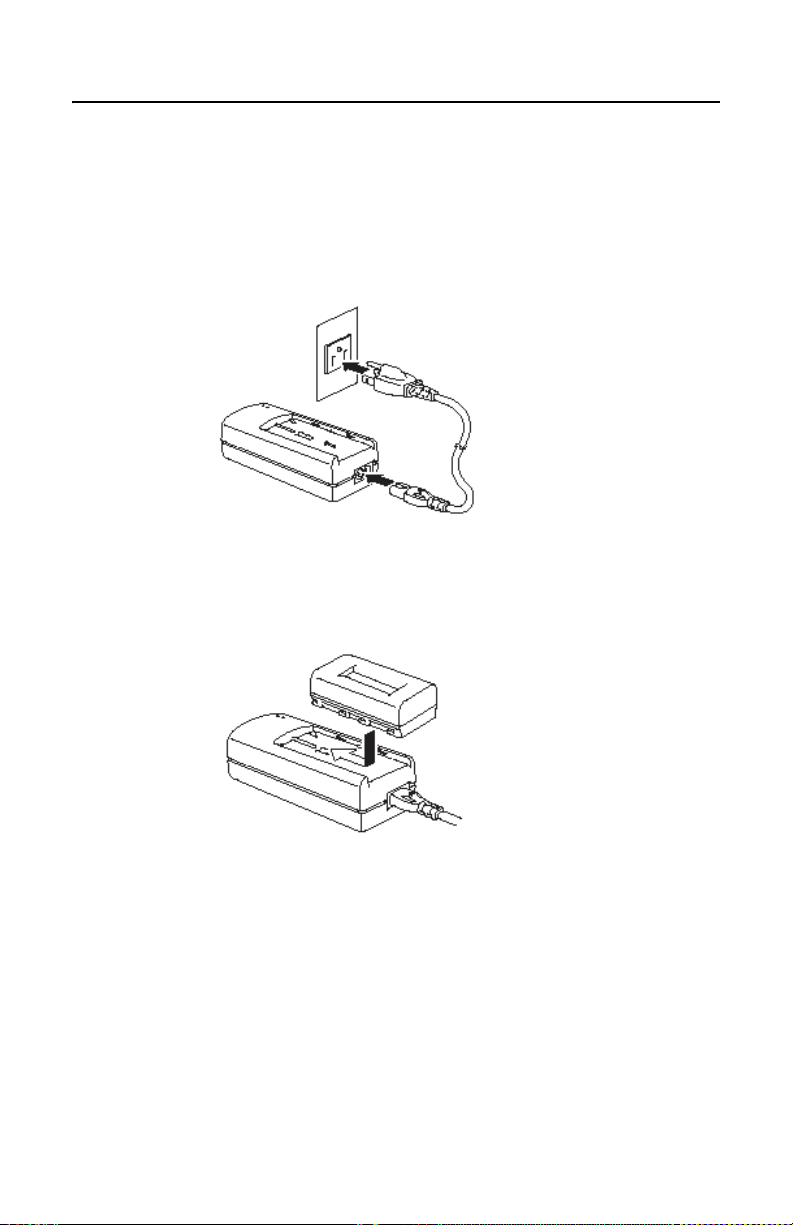

Charging the Battery Pack

Charging with the Optional Charger

If your printer comes with the optional battery charger, you ca use it to

charge the supplied battery pack. Follow the steps below:

1. Connect the charger to the wall outlet and turn on the power.

The POWER lamp lights red.

2. Align the battery pack with its metal contacts facing front,

and slide it forward into the charger.

The CHARGE lamp lights red when charging starts. It turns off

when the battery pack is fully charged. In the case of a five-

battery charger, when charging starts, the CHARGE lamp

22

Page 23

glows red. It then glows green when the battery packs are

fully charged.

3. Slide the battery pack out of the charger.

Notes

• If the POWER lamp does not light when you turn on the

power, check the power cord connection.

• If the CHARGE lamp does not light at the start of charging,

make sure the battery pack is firmly mounted into the

charger. Poor mounting of the battery pack may result in

faulty charging.

• When the fully charged battery pack is placed into the battery

charger, the CHARGE lamp turns on and then off. In the case

of the five-socket charger, the CHARGE lamp lights green.

• When charging a battery pack that has not been used for a

long time, the CHARGE lamp may blink for a while. This does

not indicate an error. You can continue charging.

• The battery pack can be recharged over about 300 times

(when used at normal temperatures). If the battery pack is

fully charged but runs out quickly, replace it with a new

battery.

Charging Time

It takes about 2.5 hours for a fully discharged battery pack to

return to a fully charged state.

Charging with the Optional AC Adapter

Note: These instructions assume that the battery is installed in

the printer (see “Installing the Battery Pack” below.

23

Page 24

1. Remove the cover of the printer’s DC input jack (1) and

connect the DC output terminal (2) on the AC adapter (3) to

it.

2. Connect the AC adapter to the wall outlet and turn on the

power.

The POWER lamp on the adapter lights green. Charging starts

and the battery indicator on the printer lights red.

When the battery pack is fully charged, the battery indicator

goes off.

Note: In the case of the Wireless LAN interface model, the

CHARGE LED on the LCD screen lights red when charging

starts, and goes off when charging is complete.

Charging Time

With the AC adapter, it takes about 5 hours for the battery pack

to reach full charge from a fully discharged state.

24

Page 25

Installing the Battery Pack

1. Press the POWER button to turn the printer off.

2. Reach under the printer and unlatch the battery

compartment cover.

25

Page 26

3. Align the battery pack so that its metal terminals (1) are

facing the printer and the tab (2) on the battery is up, then

insert the battery until it snaps in place.

4. Close the battery cover.

26

Page 27

Removing the Battery Pack

Important!: Remove the battery pack only when the printer is

turned off. Do not remove the battery while the

STATUS LED is on. Otherwise, the information

stored in the printer may not be updated.

1. Press the POWER button to turn the printer off.

2. Reach under the printer and unlatch the battery

compartment cover.

27

Page 28

3. Push aside the gray latch (1) in the compartment, grasp the

tab (2) on the top of the battery pack (3) and pull it out.

4. Close the battery cover.

28

Page 29

Powering the Printer using the Optional AC

Adapter

If your printer comes with the optional AC adapter, it can be

operated on AC power instead of the supplied battery pack.

1. Remove the cover of the printer’s DC input jack (1) and

connect the AC adapter’s (2) DC output terminal (3) to it.

2. Connect the AC adapter to the wall outlet (4) and turn on the

power.

The POWER lamp on the adapter lights green.

Important!: Be sure to turn the printer power off when

removing the DC output terminal of the AC

adapter or disconnecting the power source.

Otherwise, the information stored in the printer

may not be updated.

29

Page 30

Note: A battery pack is unnecessary when an AC adapter is

used. If a battery pack and an AC adapter are being used

at the same time, the printer will attempt to charge the

battery pack (if it is not already fully charged).

Loading the Label Roll

The method of installing label media varies with your choice of

print modes: continuous or dispense mode.

Loading the Label Roll: Continuous Mode

1. Make sure you can see the red platen roller. If not, lift the

edge (1) of the dispenser unit (2) slightly and slide it toward

the front of the printer.

30

Page 31

2. Push the black release lever (1) down and toward the front

of the printer to open the cover.

3. Place the label roll in the printer. Make sure it is placed with

the leading edge (1) feeding up from the bottom of the roll

and not down from the top.

Note: When replacing a label roll of the same width as that used

previously, adjustment of the label guide is not

necessary.

31

Page 32

4. Lift up the label guide adjust dial cover and turn the dial (1)

until the label guides press loosely against label roll.

5. Turn the label roll lightly by hand and confirm that it rotates

smoothly. Otherwise, paper may not be fed correctly during

operation.

6. Close the label guide adjust dial cover.

7. Close the printer cover after confirming that the leading edge

of the label is outside the printer.

32

Page 33

Loading the Label Roll: Dispense Mode

1 1. Make sure you can see the red platen roller. If not, slide

the dispenser unit down, by lifting its top edge upwards at

the two arrow marks.

2. Push the black release lever down and toward the front of the

printer to open the cover.

33

Page 34

3. Peel the first label on the top of the label. This step is

unnecessary when a non-separate label is used.

4. Place the label roll in the printer. Make sure it is placed with

the leading edge (1) feeding up from the bottom of the roll

and not down from the top.

Note: When replacing a label roll of the same width as that used

previously, The next step (adjustment of the label guide)

is not necessary

34

Page 35

5. Lift up the label guide adjust dial cover and turn the dial

(1) until the label guides press loosely against the label

roll.

6. Turn the label roll lightly by hand and confirm that it

rotates smoothly. Otherwise, paper may not be fed

correctly during operation.

7. Close the label guide adjust dial cover.

35

Page 36

8. Close the printer cover after confirming that the leading edge

(1) of the label is outside the printer by at least 1/2-inch (

10mm).

Note: When using non-separate labels, press the FEED button

to feed a piece of label and pull the label upward to cut

it along the perforation. If the label becomes jammed,

retry the label setting procedure.

9. Push the dispenser unit forward so that it covers the red

platen roller.

36

Page 37

Operation and Configuration

Turning the printer ON

1. Press and hold the POWER button (1).

2. When the STATUS LED (2) lights green, release the button

Turning the printer OFF

1. Press and hold the POWER button (1).

2. When the STATUS LED (2) goes off, release the button.

37

Page 38

Performing a Test Print

Important!: Overall print quality is readable and sharp.

Important!: A low battery condition may affect the print

quality. Make sure the printer is running on AC

or on a full battery during a test print.

Users can perform test prints to evaluate the print quality and

also diagnose problems.

1. Turn the printer off.

2. Press the POWER button (2) while pressing and holding

down the FEED button (1).

The printer powers up in the test mode.

38

Page 39

3. Press the FEED button (1) again to do a test print.

4. Verify the following using the output of the test printing.

• All printed characters are solid black.

• Overall print quality is sharp.

Note: If any fault is detected, contact your Oki dealer or

service center. Before asking for a repair, please read

the Troubleshooting section of this manual.

5. Press the POWER button to exit the Test Print Mode and

turn the printer off.

39

Page 40

Printing

Printing using the RS-232C Interface

1. Locate the RS-232C interface port cover (1) and lift it up to

expose the port.

2. Plug one end of the RS-232C cable (2) firmly into the port.

Make sure that the arrow mark on the connector of the

RS-232C cable matches with the arrow mark by the side of

the printer’s port.

3. Plug the other end of the RS-232C cable to the corresponding

RS-232C connector of the computer or hand-held terminal.

For information on the host device RS-232C connector, refer

to the relevant instruction manual.

40

Page 41

Printing using the IrDA Interface

1. Place the printer 20 cm away from the IrDA port of the

computer or hand-held terminal. Adjust the printer position

so that the center of its IrDA filter projects a 30° conical area

which contains the IrDA transceiver of the computer or

hand-held terminal.

• The IrDA communication range is limited to 5.9 to 7.9

inches (15 to 20 cm).

• The usable range may vary depending on the usage

environment, or the capabilities of other IrDA devices.

• Communication is compromised by direct sunlight or

ambient light. In such a case, block the strong light from

entering the IrDA filter, or reduce the distance between the

two IrDA ports.

41

Page 42

Printing using the Wireless LAN Interface

To print using the Wireless LAN model, you need to have a

properly configured wireless LAN set up. The next step is to

configure the printer to share the same network settings in

order to establish communication.

1. Check the DIP Switches:

• The printer’s DIP switches are factory set for WLAN

operation.

• Check that Dip switch 1 is OFF and Dip switch 2 is ON.

• If you need to reset other switches, refer to the full DIPSwitch table in the next chapter, “Interface

Specifications.”

2. Setup a connection to the Wireless Network

• Ensure that your printer is configured with the proper

- IP address

- Subnet mask

- Gateway

- SSID

-Channel

-WLAN mode

- Security settings

• Refer to your MIS personnel for details of your existing

wireless network settings.

Note: When printing with the WLAN interface, the usable

range between the printer and the host may vary

depending on the usage environment and the

capabilities of the connected devices.

42

Page 43

Printing using the Bluetooth Interface

To print using the Bluetooth-enabled version of MB200/201i,

you need to have a bluetooth-enabled computing device. Two

more steps are required.

1. Check the DIP Switches:

• The printer’s DIP switches are factory set for

bluetooth operation. Check that Dip switch 1 is OFF and

Dip switch 2 is ON. This is the main setting for Bluetooth

operation. In case you need to reset other switches, refer

to the full DIP-Switch table in the next chapter, Interface

Specifications.

2. Synchronize Bluetooth settings

• After setting the DIP-switches, the next step is to ensure

that both bluetooth devices are configured to operate with

the same PIN code and Authentication mode settings.

Refer to the instruction manual of the computing device for

details on how to set these parameters.

Note: When printing with the Bluetooth interface, the usable

range between the printer and the host may vary

depending on the usage environment and the

capabilities of the connected devices.

The LCD screen (Wireless LAN Model

Only)

The Wireless LAN version of the printer has a Liquid Crystal

Display (LCD). The screen can display the following

information:

1 Dispense Mode Status: Manual/Auto

2 Test Print

3 Signal Strength

4 Battery Strength

43

Page 44

5 Text Display

T

Battery strength

Three-segment indicator.

• When all segments are lit, voltage level is greater than

8.0 V.

• Two segments indicator a level of between 7.8V and

7.9 V.

• One segment indicates a level of between 7.6V and

7.7 V.

• When all segments are off (voltage level below 7.5 V,

printing is not possible.)

Signal strength

Three-segment indicator to indicate Minimum, Medium and

Maximum signal quality. An X indicates no reception.

Test Print indicator

Appears in Test Print mode.

Two-line text display

Displays the following:

• Various status messages: Firmware version, On-line

mode, Off-line mode, labels remaining in print queue, Test

Print status, Default Setting, Complete, Factory Clear,

Press Feed Key, Press Print Key, Hex Dump Mode, Set up

Display, Adjust LCD, Exit, Contrast, Back Light On

• Warning messages: Cover Open, Paper End, Sensor

Error, Buffer Near Full, Head Protect, Head Error, Module

Error,

44

Page 45

• WLAN information: Messages such as Adhoc mode,

Infrastructure mode, IP address, subnet mask, default

gateway, Socket Port Number.

45

Page 46

General Printing Procedure

After the proper setup and basic configuration procedures,

you are ready to print.

1. Make sure the host computer is ready to transmit data,

and ensure that the STATUS LED is lit. (Press the PRINT

button to take the printer ONLINE).

2. Start the print job from the computer.

3. When printing is finished, pinch either the left or right

corner of the printed roll of label(s) and tear it off in the

direction of the arrow in the diagram below.

Note: The number of sheets you can print is determined by

the printer’s mode (continuous or peel mode).

When you are printing non-separate labels and you

have torn the labels at a wrong place, stop the printing

and follow the instructions on the next page to correct

the print job.

46

Page 47

Adjusting Printing for Non-Separate Labels

When printing on a continuous label roll (non-separate), if

you tear off a label at the wrong place, proceed as follows.

1. Interrupt printing on the computer, or by pressing the

PRINT key (1) to take the printer OFFLINE. (STATUS LED

goes off) .

2. Press the FEED button (1) to feed a label.

3. When the feeding stops, tear off the label correctly by

pulling the label in the direction of the arrow shown in the

47

Page 48

diagram. The label is now aligned properly for printing to

resume.

4. Press the PRINT button to return to the on-line state

(STATUS LED lights green). You can now resume the print

job.

48

Page 49

The Label Dispensing mode

You can choose to dispense labels in Continuous Mode and

Dispense Mode. In either mode, test printing and online

printing are available.

Configuring Dispense mode

Dispense Mode can be set to Auto Print or Manual Print, as

described below.

Type Description

Auto Print Prints one label after receiving data and waits for

peeling. After the label is peeled off, the printer

automatically prints the next label.

Manual

Print

Prints one label after receiving data and goes off-line.

Press the PRINT key to print the next label. After the

specified number of labels are printed, printing

terminates. No printing occurs even when the PRINT

key is pressed.

To switch between Auto or Manual Print for the Dispense

Mode, set the DIP switches and then hold down the PRINT or

FEED button when turning the printer ON. The new settings

take effect when the printer is next turned ON.

Switching from Manual to Auto Print

1. Turn the printer off.

2. Make sure DIP switches 1-2-3-4 are set to

OFF-OFF-OFF-ON.

3. Open the cover.

4. Press and hold the PRINT button while turning the printer

on.

5. Close the cover.

Switching from Auto to Manual Print

1. Turn the printer off.

2. Make sure DIP switches 1-2-3-4 are set to

OFF-OFF-OFF-ON.

3. Open the cover.

49

Page 50

4. Press and hold the FEED button while turning the printer

on.

5. Close the cover.

When setting the dispense mode, the STATUS LED blinks

green, and turns into a steady green signal upon completion

of setting. Turn off the printer ONLY when the STATUS LED is

a steady green light.

Status LEDs for Printing Modes

Available modes include Normal, Test Print, Head Check

Setting and Online Command Setting mode.

Status LEDs for Normal Mode

Operational State STATUS LED LED Action

START OF PRINTING Orange Steady

ONLINE Green Steady

OFFLINE OFF NA

STANDBY (after 5

seconds of inactivity)

Green Blinks every 4

seconds

Note: The Battery indicator (only available on the Bluetooth/

WLAN model) remains lit even when the printer is

OFFLINE. During the Standby state, the printer

resumes normal operational status upon sensing any

incoming data or pressing of the buttons.

Status LEDs for the Test Print Mode

Enter Test Print mode by using the FEED and POWER buttons.

Operational State STATUS LED LED Action

ENTERING TEST

PRINT MODE

START OF TEST

PRINT

DURING TEST PRINT Green Steady

END OF TEST PRINT OFF NA

Orange Steady

Green Blinks

50

Page 51

Status LEDs for the Head Check Setting Mode

Head checking can be applied to one of two areas: the

normal print area and the barcode print area. To specify

the area subjected to a head check, follow the settings in the

table below (cover must be left open):

H.Check

setting

Normal Print

Area

Disable H.

Check

Barcode Print

Area

Disable H.

Check

DSW-1 DSW-2 DSW-3 DSW-4 Other keys

OFF ON OFF ON hold down

PRINT button

OFF ON OFF ON hold down

FEED button

ON OFF OFF ON hold down

PRINT button

ON OFF OFF ON hold down

FEED button

You can check the current setting with a test printout as

described in “Performing a Test Print” on page 38.

When setting the Head Check options, the STATUS LED blinks

green, and turns into a steady green signal upon completion

of setting. Turn off the printer ONLY when the STATUS LED is

a steady green light.

Status LEDs for the Online Command Compatibility Mode

The printer can be set for compatibility with SBPL commands

or with the older MB200 commands.

Compatibility DSW-1 DSW-2 DSW-3 DSW-4 Other keys

LP440compatible

online

commands

SBPL online

commands

ON ON ON ON hold down

PRINT button

ON ON ON ON hold down

FEED button

You can check the current setting with a test printout as

described in “Performing a Test Print” on page 38.

51

Page 52

When setting the online command compatibility options, the

STATUS LED blinks green, and turns into a steady green

signal upon completion of setting. Turn off the printer ONLY

when the STATUS LED is a steady green light.

52

Page 53

Interface Specifications

Through a combination of DIP switch settings and turning the printer ON with

certain buttons held down, you can enable or disable special functions and

features.

Warning: Never connect or disconnect interface cables

(or use a switch box) with power applied to

either the host or the printer. This may cause

damage to the interface circuitry in the printer/

host and is not covered by the warranty.

On-line Command Compatibility Settings

OFFON

DIP Switch

Settings

1234

ON ON ON ON

ON ON ON ON

Function

Procedure

Switch to MB200 emulation command

compatibility

With printer turned off:

•Open the cover.

• Press and hold PRINT button.

• Press the POWER button to turn the printer on.

Switch to SBPL command compatibility

With printer turned off:

•Open the cover.

• Press and hold FEED button.

• Press the POWER button to turn the printer on.

53

Page 54

RS-232C Settings

OFFON

DIP Switch

Settings

1234

OFF OFF OFF OFF

OFF OFF OFF OFF

OFF OFF OFF OFF

OFF OFF ON ON

OFF OFF OFF ON

Function

Procedure

RS-232C Normal mode

With printer turned off and cover closed:

• Press and hold the FEED button.

• Press the POWER button to turn on the printer

in the normal mode.

Test Print, RS-232C Mode

With printer turned off and cover closed:

• Press and hold the FEED button.

• Press the POWER button to turn the printer on

in the Test Print mode.

RS-232C Default Setting Mode

With printer turned off:

•Open the cover.

• Press and hold the PRINT button .

• Press the POWER button to turn the printer on.

RS-232C Hex Dump Mode

With the printer turned off and the cover closed:

• Press the POWER button to turn the printer on

with the hex dump mode engaged.

A small label may produce a large amount

Note:

of data when printing a Hex Dump.

RS-232C Font Download

With the printer turned off and the cover closed:

• Press the POWER button to turn the printer on

54

Page 55

RS-232C Settings (cont.)

OFFON

OFF OFF OFF ON

OFF OFF OFF ON

OFF OFF ON OFF

RS-232C Dispense Mode, Auto print

With the printer turned off:

•Open the cover.

• Press and hold the PRINT button.

• Press the POWER button to turn the printer on

in the dispense mode.

RS-232C Dispense Mode, Manual Print

With the printer turned off:

•Open the cover.

• Press the POWER button to turn the printer on

in the manual print dispense mode.

RS-232C Program Download

With the printer turned off:

•Open the cover.

• Press the POWER button to turn the printer on.

55

Page 56

IrDA Settings

OFFON

DIP Switch

Settings

1234

ON OFF OFF OFF

ON OFF OFF OFF

ON OFF ON ON

ON OFF OFF ON

ON OFF OFF ON

ON OFF ON OFF

Function

Procedure

IrDA Normal Mode

WIth printer turned off:

• Press the POWER button.

IrDA User Test Print Mode

With the printer off:

• Press and hold the FEED button.

• Press the POWER button.

IrDA Hex Dump Mode

With the printer turned off:

• Change the setting for dips switch 3 to ON.

• Press the POWER to turn the printer on.

A small label may produce a large amount

Note:

of data when printing a Hex Dump.

IrDA Head Check, Barcode Print Area

With the printer turned off:

•Open the cover.

• Press and hold the PRINT button.

• Press the POWER button.

Cancel IrDA Head Check

With the printer turned off:

•Open the Cover.

• Press and hold the FEED button.

• Press the POWER button to turn on the printer.

IrDA Reset to Factory Defaults

With the printer turned off:

•Open the cover.

• Press and hold the PRIONT and FEED buttons.

• Press the POWER button to turn on the printer.

56

Page 57

Bluetooth/WLAN Settings

OFFON

DIP Switch

Settings

1234

OFF ON OFF OFF

OFF ON OFF ON

OFFONONOMNBluetooth/WLAN Maintenance Mode

OFFONONON

Function

Procedure

Bluetooth/WLAN Normal Operation Mode

With the printer turned off and the cover closed:

• Press the POWER button to turn the printer on.

Bluetooth/WLAN Test Print Mode

With the printer turned off and the cover closed:

• Press and h old the FEED button.

• Press the POWER button to turn the printer on.

With the printer turned off:

•Open the cover.

• Press and hold the FEED button.

• Press the POWER button to turn the printer on.

Bluetooth/WLAN HEX Dump Mode

With the printer turned off:

•Open the cover.

• Press and hold the POWER button to turn the

printer on.

A small label may produce a large amount

Note:

of data when printing a Hex Dump.

57

Page 58

Bluetooth/WLAN Settings (cont.)

OFFON

OFF OFF OFF ON

OFF ON OFF ON

OFFONONOFF

Bluetooth/WLAN Enable CRC Check

With the printer turned off:

•Open the cover.

• Press and hold the PRINT button.

• Press the POWER button to turn the printer on.

Bluetooth/WLAN Disable CRC Check

With the printer turned off:

•Open the cover.

• Press and hold the FEED button.

• Press the POWER button to turn the printer on.

Bluetooth/WLAN Activate Head Check

With the printer turned off:

•Open the cover.

• Press and hold the PRINT button.

• Press the POWER button to turn the printer on.

Bluetooth/WLAN Deactivate Head Check

With the printer turned off:

•Open the cover.

• Press and hold the FEED button.

• Press the POWER button to turn the printer on.

Bluetooth/WLAN Factory Clear + Clear Head

Counter

With the printer turned off:

•Open the cover.

• Press and hold the PRINT and FEED buttons.

• Press the POWER button to turn the printer on.

Some hosts monitor the Request-To-Send (RTS) signal (pin 4 of

25) to determine if the printer is ready to receive data. Since the

printer does not generate this signal, the RTS pin must be

connected to the Clear-To-Send (CTS) pin (pin 5 of 25)

58

Page 59

Cleaning and Maintenance

Cleaning and maintaining the printer regularly will prolong its

durability and reliability.

Cleaning the Print Head

1. Press the POWER button to turn the printer off.

2. Push the black release lever (1) down and toward the front of

the printer to open the cover

59

Page 60

Note: If the red roller is not visible (lever cannot be pushed

down), lift the edge (1) of the dispenser unit (2) slightly

and slide it toward the front of the printer.

3. Wipe off any dirt on the print head (1) using a soft cloth

soaked with some rubbing alcohol.

Caution! Never use thinner, benzene, or kerosene. These

solvents can damage the printer.

Note: The illustration below is viewed from the rear of the

printer.

60

Page 61

4. Let the print head dry, then reinstall the label roll and close

the cover.

Cleaning the Platen and Peel Roller

Users can perform test prints to evaluate the print quality and also

diagnose problems.

1. Press the POWER button to turn the printer off.

2. Push the black release lever (1) down and toward the front

of the printer to open the cover

61

Page 62

3. If the lever is not accessible, first slide the dispenser unit

away by lifting the top edge where the arrow marks are

located. (see Step 1 of “Loading the Label Roll” on page 30).

4. Wipe off any dirt on the platen and peel roller (1) using a

cloth soaked in alcohol.

Caution! Never use thinner, benzene, or kerosene. These

solvents can damage the printer.

5. Let the platen and roller dry, then close the cover

62

Page 63

Troubleshooting

.

Print Fault Cause Remedy

Smudged

printing

Vertical

streaking in

printouts

Slanted text

characters

No printing RS-232C cable

Print head is dirty. Clean the print head.

Roller is dirty. Clean the platen and dispense roller

Print head is dirty. Clean the print head.

Print head is faulty. Replace the print head.

Paper guide is

positioned incorrectly.

Roller is dirty. Clean the platen and peel roller (see

connection is faulty.

IrDA Interface is

faulty.

Bluetooth/WLAN

interface is faulty.

Dip Switch setting is

incorrect.

(see page 61).

Retry with different label paper. Use

only certified media for best print

quality and minimal problems.

page 61).

Check the connection of the RS-232C

cable connector (see page 40).

The printer and IrDA host must be

within 5.9 to 7.9 inches (15 or 20 cm)

of each other. The host must be

located within a 30° conical area from

the center of the IrDA filter (com area)

on the printer (see “Printing using the

IrDA Interface” on page 41 ).

Check the communication protocol

settings.

Double-check Dip Switch settings

(see “Interface Specifications” on

page 53).

Print head is faulty. Replace the print head.

63

Page 64

Error Indicators

STATUS

(LED)

Light (Red) All

Blink (Red)

every 2s

Light (Red) After

Blink

GreenÌ Red

every 2s

Mode Description Cause Remedy

Low battery Battery charge

modes

Online Error in

Power

On

Online Head error Head wiring is

Bluetooth or

WLAN card

Program

illegal error

Flashromerror

level is low.

Interface module

error (Bluetooth,

wireless LAN).

Flash ROM read/

write error has

occurred.

disconnected.

Recharge the

battery.

Replace the

board,.

Replace Flash

ROM.

Retry

downloading

program.

Replace the head.

Warning: Never connect or disconnect interface cables (or use a

switch box) with power applied to either the printer or

the host. This may cause damage to the interface circuitry and the damageis not covered by warranty.

64

Page 65

Specifications

Basic Specifications

Attribute Description

Printing system Direct Thermal printing system

Head density 203 dpi (8 dots/mm)

Maximum print area 1.9 inches (48 mm) wide x 6.3 inches

(160 mm) pitch

Print speed 4.1 inches (103 mm) per sdecond max.

Note: The speed varies depending on

print duty and environment of use.

Dimensions LP440:

128 mm wide x 88 mm high x 73 mm

deep, excluding belt clip

LP441:

119 mm wide x 88 mm high x 64 mm

deep, excluding belt clip

Weight, with battery

pack

Power supply

(Battery)

Paper thickness 0.0025 to 0.0075-inch (0.064 to

Shape of paper Roll paper: Wound with surface out

Label size (Liner

sheet and eye mark

pitch)

LP440: 14.3 oz. (405 g)

LP441: 13.7 oz. (390 g)

Prints 4 rolls of thermal labels with full

charge. (equivalent of 18.9 yards (48

m)

Continuous printing is permitted

(provided print duty is 16% or less.)

0.190 mm).

Maximum diameter: 2.25 inches (57.5

mm)

Width: 1 to 2.2 inches (1.1 to 2.2

inches)

25.4 to 55 mm (28.4 to 57.5 mm)

Pitch: 0.5 to 6.3 inches (0.6 to 6.4

inches)

13 to 160 mm (16 to 163 mm)

65

Page 66

Media Roll Size, outer

diameter

Label printing modes Continuous, Dispense (peel)

Self-diagnosis Head check/Cover open/Paper end/

Outer Diameter

LP440: 67 mm (2.63”)

LP441: 8 mm (2.28”) outer diameter

Inner Diameter

Core: 0.75-inch (19 mm )

Creoles: 0.31-inch (7.9 mm)

Battery check/Test print

Power saving

features

Interfaces

RS-232C Mini DIN

Photo coupling • IrDA communication (Complies with

Bluetooth Bluetooth Specification Ver. 1.1 Class 2

Wireless LAN • Wireless LAN interface (IEEE802.11b)

Paper sensors Reflection type (eye mark),

Text Character

magnification

• Auto power off after non operation for

5 minutes.

• With Bluetooth or wireless LAN

specifications, default is no auto

power off.

• Auto power off time can be changed

via the printer operation register

command <PG>.

IrDA standard Ver. 1.2.

communication range: 5.9 to 7.9

inches [15 to 20 cm] max.)

• IrOBex/BHT protocol/Ir Comm

TCP/IP (FTP, LPR, SOCKET)

Transmission type (gap)

1 to 6 times

Character rotation 0°, 90°, 180°, 270°

Character type Standard font: XU, XS, XM, XL, OCR-A,

OCR-B, POP character Kanji: 16 x 16,

22 x 22, 24 x 24 Square Gothic (JIS

Level 1, Level 2)

66

Page 67

Barcode JAN8/13, UPC-E/UPC-A, NW-7,

CODE39, CODE93, CODE128,

INTERLEAVED2of5, POSTNET, RSS-14.

However, barcode shall be used with

the following.

• Parallel barcode: Thin bar width of 2

dots or more

• Serial barcode: Thin bar width of 3

dots or more

Two-dimensional

code

Application

standards

Protective feature • Overcharge protection

Environmental Condition, including battery pack (Does not

apply to label media)

Operating Temperature: (15 to 50°C)

Storage Temperature: (-25 to 60°C)Humidity:

Any one of PDF417 (ver 2.4), QR code

(ver 8.1 including micro QR), Data

matrix code (ECC200) ver 2.0, MAXI

code ver 3.0, Composite symbol usable

via downloads.

FCC 15 ClassB, EN55022, EN55024,

UL60950-1, CSA C22.2 No.60950-1-03,

GB9243, GB9254, GB4943, GB17625.1,

TUV EN60950-1, CE, R&TTE EN30328

v1.4, EN301489 v1.4, IDATSSSS.

• Head overheat protection

• Detection of Low Battery state

Humidity: 20 to 80% without

condensation

20 to 80% without condensation

Note: Before using a wireless interface with this equipment,

make sure that any radio transmission/reception

equipment on site, does not share the same frequency

range as this product’s wireless setup.

67

Page 68

Printer Radio Frequency Characteristics

2.4

FH1

Frequency band used 2.4 GHz

Modulation system Frequency Hopped - Spread

Spectrum system

Assumed distance of

interference

Availability of

frequency change

0.4-inch (10 mm) max.

All area is used and exclusion of the

band for equipment for mobile

object identification is impossible

68

Page 69

Optional Accessories

Spare Battery Pack, Oki 70061401

AC Adapter, Oki 70061301

Allows the printer to be operated via an AC outlet, and to charge

a battery pack loaded inside the printer.

Warning: Use only the specified AC Adapter designed for

your printer).

69

Page 70

Battery Chargers

Single-Slot Battery Charger Oki 70061403

Use to charge battery pack without using the printer connected

to an AC outlet.

Five-Slot Battery Charger, Oki 70061405

Use this to charge multiple spare battery packs at the same

time.

70

Page 71

Belt Holder, Oki 70061204

For hanging the printer on a waist belt.

Installation

1. Thread your belt (1) through the belt holder (2), with the

open end (3) of the clip mechanism up..

2. Using a screwdriver, replace the belt clip on the back of the

printer with the belt hook (4) included with the holder.

3. Insert the belt hook (4) into the belt holder until it clicks

securely into place.

Caution! If the belt hook is not inserted properly, the printer

may fall off.

71

Page 72

Detachment

Pull the printer sideways and upwards to remove it from the belt

hook.

72

Page 73

Shoulder Strap , Oki 70061201

Installation

1. Feed one end of the shoulder strap through one of the

channels at either side of the front of the printer.

2. Pass the end of the strap through the buckle.

3. Repeat for the other end of the strap.

4. Adjust the length of the strap.

Caution! If the shoulder strap is improperly secured, the

printer may fall off.

73

Page 74

Rainproof Shoulder Case, Oki 70061202

Includes a shoulder strap and cover to protect the printer during

wet weather.

Installation

Clip the belt clip on the back of the printer securely to the case.

Caution! If the printer is not firmly secured to the case, the

printer may fall off.

Waist Case, Oki 70061203

A protective case with a strap for hanging the printer from your

waist.

74

Page 75

Installation

1. Attach the belt clip (1) on the back of the printer securely to

the back of the case.

2. Feed the strap (1) through the hangers (2) on the case.

3. Attache the strap to your waist.

Caution! If the printer is not firmly secured to the case, the

printer may fall off.

75

Page 76

RS-232C Cable, Oki 70061101

76

Loading...

Loading...