Page 1

LE840/LE850

External Equipment Interface Manual

Technical Reference

Page 2

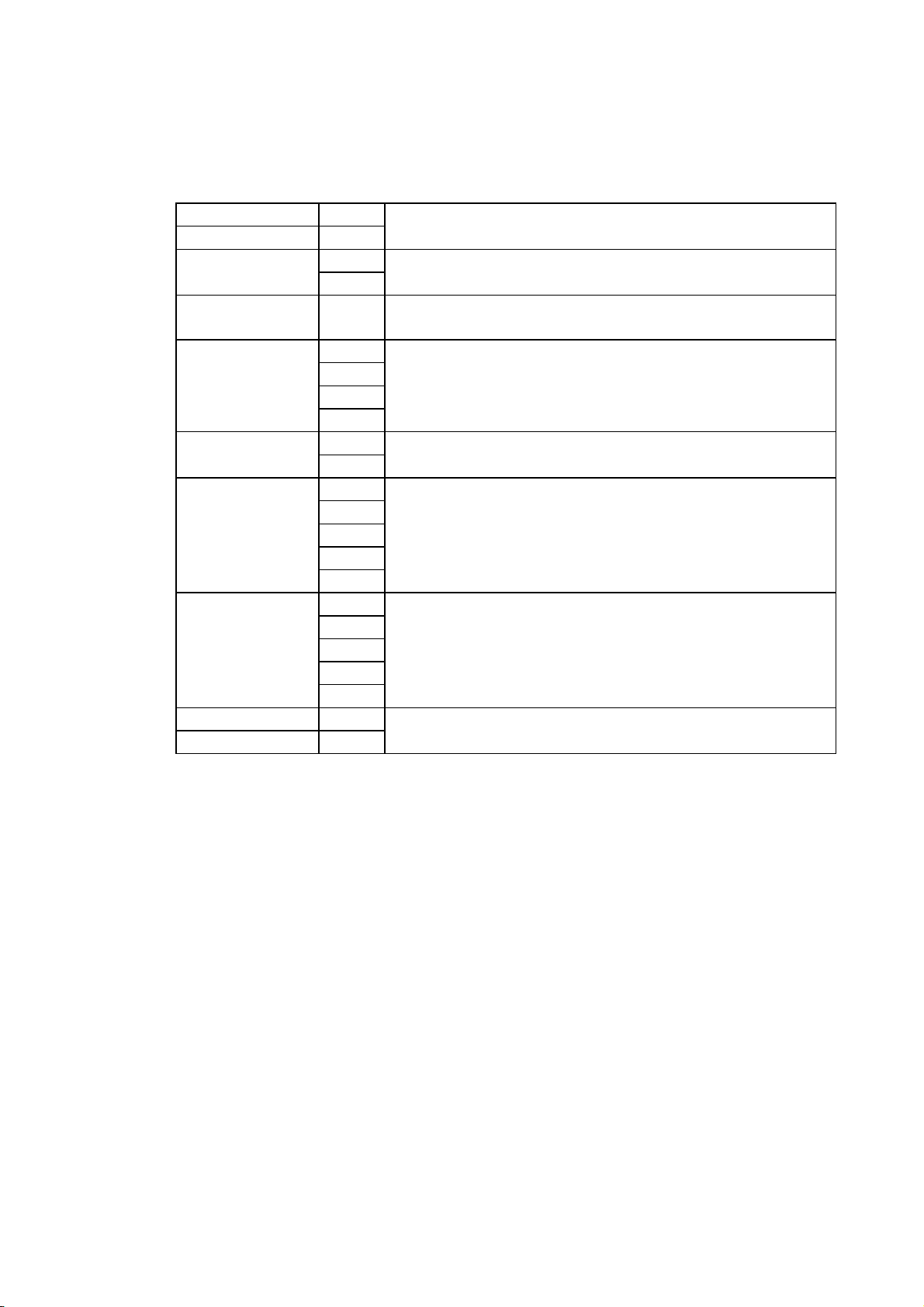

TABLE OF CONTENTS

Page

1. SCOPE AND GENERAL DESCRIPTION .................................................................................. 1-1

1.1 SCOPE .................................................................................................................................. 1-1

1.2 GENERAL DESCRIPTION......................................................................................................... 1-1

1.2.1 Contents of the Specification .......................................................................................... 1-1

2. OUTLINE OF THE SPECIFICATION......................................................................................... 2-1

2.1 MODEL CONFIGURATION AND DIFFERENCES BETWEEN THE MODELS........................ 2-1

2.1.2 LE840T/LE850T 203 dpi/300 dpi ......................................................................................... 2-2

2.1.4 LE840D 203 dpi.................................................................................................................... 2-3

2.2 PRINT METHOD ................................................................................................................... 2-3

2.3 PRINT HEAD SPECIFICATION ............................................................................................ 2-3

2.4 PAPER ALIGNMENT............................................................................................................. 2-3

2.5 PRINT SPEED....................................................................................................................... 2-3

2.6 CHARACTERS...................................................................................................................... 2-4

2.7 BAR CODES/TWO-DIMENSIONAL CODES........................................................................ 2-5

2.8 STORABLE FORMATS......................................................................................................... 2-5

2.9 WRITABLE CHARACTERS .................................................................................................. 2-5

2.10 INTERFACE .......................................................................................................................... 2-5

2.11 USB MEMORY (USB HOST) .............................................................................................. 2-5

2.12 SENSOR................................................................................................................................ 2-5

2.13 KEYS ..................................................................................................................................... 2-6

2.14 LED ........................................................................................................................................ 2-6

2.15 LCD........................................................................................................................................ 2-6

2.16 ISSUE MODE ........................................................................................................................ 2-6

2.17 MEDIA ................................................................................................................................... 2-6

2.18 CUT ....................................................................................................................................... 2-7

2.19 RIBBON SAVING FUNCTION............................................................................................... 2-7

2.20 AUTO CALIBRATION............................................................................................................ 2-7

2.21 MANUAL HOME POSITION DETECTION............................................................................ 2-7

3. INTERFACE ............................................................................................................................... 3-1

3.1 GENERAL DESCRIPTION.................................................................................................... 3-1

3.2 USB INTERFACE.................................................................................................................. 3-2

3.3 NETWORK INTERFACE....................................................................................................... 3-3

3.4 SERIAL INTERFACE............................................................................................................. 3-4

3.5 PARALLEL INTERFACE....................................................................................................... 3-9

3.6 USB HOST INTERFACE....................................................................................................... 3-18

3.7 WIRELESS LAN .................................................................................................................... 3-19

3.7.1 SPECIFICATION OF WIRELESS LAN MODULE............................................................ 3-19

i

Page 3

3.7.2 MAC ADDRESS ............................................................................................................... 3-19

3.7.3 CONNECTION SEQUENCE ............................................................................................ 3-19

3.7.4 RECEIVED DATA HANDLING WHEN THE PRINTER ENTERS

THE POWER SAVE MODE........................... 3-22

4. TRANSMISSION SEQUENCE................................................................................................... 4-1

4.1 PREPARATORY SETTING................................................................................................... 4-1

4.2 LABEL ISSUE OPERATION ................................................................................................. 4-3

5. INTERFACE COMMANDS......................................................................................................... 5-1

5.1 GENERAL DESCRIPTION.................................................................................................... 5-1

5.1.1 FORMAT OF INTERFACE COMMAND........................................................................... 5-1

5.1.2 HOW TO USE REFERENCE ........................................................................................... 5-1

5.1.3 PRECAUTIONS................................................................................................................ 5-2

5.1.4 LIST OF COMMANDS...................................................................................................... 5-3

5.2 COMMANDS RELATED TO SETTING................................................................................. 5-5

5.2.1 LABEL SIZE SET COMMAND ......................................................................................... 5-5

5.3 COMMANDS RELATED TO FINE ADJUSTMENT............................................................... 5-14

5.3.1 POSITION FINE ADJUST COMMAND............................................................................ 5-14

5.3.2 PRINT DENSITY FINE ADJUST COMMAND.................................................................. 5-24

5.3.3 RIBBON MOTOR DRIVE VOLTAGE FINE ADJUST COMMAND................................... 5-25

5.3.4 HEAD DOWN TIMING FINE ADJUST COMMAND ..................................................... 5-27

5.4 COMMANDS RELATED TO CLEAR .................................................................................... 5-28

5.4.1 IMAGE BUFFER CLEAR COMMAND ............................................................................. 5-28

5.4.2 CLEAR AREA COMMAND............................................................................................... 5-29

5.5 COMMANDS RELATED TO DRAWING FORMAT SETTING.............................................. 5-31

5.5.1 LINE FORMAT COMMAND ............................................................................................. 5-31

5.5.2 BIT MAP FONT FORMAT COMMAND............................................................................ 5-35

5.5.3 OUTLINE FONT FORMAT COMMAND........................................................................... 5-51

5.5.4 BAR CODE FORMAT COMMAND .................................................................................. 5-68

5.6 COMMANDS RELATED TO PRINT DATA...........................................................................5-125

5.6.1 BIT MAP FONT DATA COMMAND..................................................................................5-125

5.6.2 OUTLINE FONT DATA COMMAND ................................................................................5-130

5.6.3 BAR CODE DATA COMMAND ........................................................................................5-133

5.7 COMMANDS RELATED TO ISSUE AND FEED ..................................................................5-149

5.7.1 ISSUE COMMAND...........................................................................................................5-149

5.7.2 FEED COMMAND ............................................................................................................5-169

5.7.3 EJECT COMMAND ..........................................................................................................5-179

5.7.4 FORWARD/REVERSE FEED COMMAND......................................................................5-181

5.8 COMMANDS RELATED TO WRITABLE CHARACTERS....................................................5-184

5.8.1 STORAGE AREA ALLOCATE COMMAND .....................................................................5-184

5.8.2 FLASH MEMORY FORMAT COMMAND ........................................................................5-187

5.8.3 EXTERNAL MEMORY FORMAT COMMAND.................................................................5-188

5.8.4 2-BYTE WRITABLE CHARACTER CODE RANGE COMMAND ....................................5-189

5.8.5 BIT MAP WRITABLE CHARACTER COMMAND ([ESC] XD) .........................................5-190

5.8.6 BIT MAP WRITABLE CHARACTER COMMAND ([ESC] XA) .........................................5-192

5.9 COMMANDS RELATED TO GRAPHICS..............................................................................5-203

5.9.1 GRAPHIC COMMAND .....................................................................................................5-203

ii

Page 4

5.10 COMMANDS RELATED TO PC COMMAND SAVE.............................................................5-211

5.10.1 SAVE START COMMAND ([ESC] XO)............................................................................5-211

5.10.2 SAVE START COMMAND ([ESC] XV) ............................................................................5-212

5.10.3 SAVE TERMINATE COMMAND......................................................................................5-214

5.10.4 SAVED DATA CALL COMMAND ([ESC] XQ) .................................................................5-215

5.10.5 SAVED DATA CALL COMMAND ([ESC] XT) ..................................................................5-216

5.11 COMMANDS RELATED TO CHECK....................................................................................5-217

5.11.1 HEAD BROKEN DOTS CHECK COMMAND ..................................................................5-217

5.12 COMMANDS RELATED TO DISPLAY .................................................................................5-218

5.12.1 MESSAGE DISPLAY COMMAND ...................................................................................5-218

5.13 COMMANDS RELATED TO CONTROL...............................................................................5-220

5.13.1 RESET COMMAND..........................................................................................................5-220

5.13.2 BATCH RESET COMMAND ............................................................................................5-221

5.14 COMMANDS RELATED TO STATUS ..................................................................................5-222

5.14.1 STATUS REQUEST COMMAND.....................................................................................5-222

5.14.2 RECEIVE BUFFER FREE SPACE REQUEST COMMAND............................................5-223

5.14.3 VERSION INFORMATION ACQUIRE COMMAND .........................................................5-224

5.14.4 EXTERNAL MEMORY INFORMATION ACQUIRE COMMAND .....................................5-225

5.14.5 EXTERNAL MEMORY WRITABLE CHARACTER INFORMATION

ACQUIRE COMMAND......................5-227

5.14.6 PRINTER OPTION STATUS ACQUIRE COMMAND......................................................5-228

5.15 COMMANDS RELATED TO TCP/IP SETTING ....................................................................5-229

5.15.1 IP ADDRESS SET COMMAND........................................................................................5-229

5.15.2 SOCKET COMMUNICATION PORT SET COMMAND ...................................................5-230

5.15.3 DHCP FUNCTION SET COMMAND................................................................................5-231

5.16 COMMANDS RELATED TO INTERNAL SERIAL INTERFACE ...........................................5-232

5.16.1 PASS-THROUGH COMMAND ........................................................................................5-232

5.16.2 INTERNAL SERIAL INTERFACE PARAMETER SET COMMAND.................................5-233

5.17 COMMANDS RELATED TO PARAMETER SETTING .........................................................5-234

5.17.1 PARAMETER SET COMMAND .......................................................................................5-234

5.17.2 FINE ADJUSTMENT VALUE SET COMMAND ...............................................................5-238

5.17.3 RFID PARAMETER SET COMMAND..............................................................................5-240

5.18 COMMANDS RELATED TO RFID ........................................................................................5-242

5.18.1 RFID TAG POSITION ADJUSTMENT COMMAND.........................................................5-242

5.18.2 RFID TAG READ COMMAND..........................................................................................5-244

5.18.3 RFID VOID PATTERN PRINT COMMAND .....................................................................5-248

5.18.4 RFID DATA WRITE COMMAND......................................................................................5-249

5.19 COMMANDS RELATED TO REAL TIME CLOCK (RTC).....................................................5-255

5.19.1 REAL TIME CLOCK (RTC) SET COMMAND ..................................................................5-256

6. CONTROL CODE SELECTION................................................................................................. 6-1

6.1 AUTOMATIC SELECTION.................................................................................................... 6-1

6.2 MANUAL SELECTION (ESC.LF.NUL).................................................................................. 6-1

6.3 MANUAL SELECTION ({.|.}) ................................................................................................. 6-1

6.4 MANUAL SELECTION (ANY SET CODE)............................................................................ 6-2

iii

Page 5

7. ERROR PROCESSING.............................................................................................................. 7-1

7.1 COMMUNICATION ERRORS............................................................................................... 7-1

7.2 ERRORS IN ISSUING OR FEEDING ................................................................................... 7-1

7.3 ERRORS IN WRITABLE CHARACTER AND PC COMMAND SAVE MODES.................... 7-4

7.4 SYSTEM ERRORS................................................................................................................ 7-4

7.5 RTC LOW BATTERY ERROR .............................................................................................. 7-4

7.6 RESET PROCESSING.......................................................................................................... 7-4

7.7 RFID ERROR ........................................................................................................................ 7-5

8. STATUS RESPONSE ................................................................................................................ 8-1

8.1 FUNCTIONS.......................................................................................................................... 8-1

8.1.1 STATUS FORMAT ........................................................................................................... 8-3

8.1.2 DETAIL STATUS.............................................................................................................. 8-4

8.1.3 SUMMARY OF STATUS FORMAT.................................................................................. 8-6

8.2 PARALLEL INTERFACE SINGALS ...................................................................................... 8-7

8.2.1 COMPATIBILITY MODE .................................................................................................. 8-7

8.3 E-MAIL................................................................................................................................... 8-8

9. LCD MESSAGES AND LED INDICATIONS ............................................................................. 9-1

10. CHARACTER CODE TABLE .................................................................................................... 10-1

10.1 GENERAL DESCRIPTION.................................................................................................... 10-1

10.2 TIMES ROMAN, HELVETICA, LETTER GOTHIC, PRESTIGE ELITE,

COURIER, GOTHIC725 BLACK....... 10-1

10.3 PRESENTATION................................................................................................................... 10-8

10.4 OCR-A ...................................................................................................................................10-12

10.5 OCR-B ...................................................................................................................................10-19

10.6 OKI OUTLINE FONT 1 ..........................................................................................................10-25

10.7 PRICE FONT 1, 2, 3..............................................................................................................10-32

10.8 OKI OUTLINE FONT 2, 3, GOTHIC725 BLACK...................................................................10-33

10.9 GB2312-50 (CHINESE KANJI)..............................................................................................10-40

10.10 TrueType FONT.....................................................................................................................10-41

10.11 GB18030 (2-BYTE CODE) ....................................................................................................10-48

10.12 GB18030 (4-BYTE CODE) ....................................................................................................10-64

11. BAR CODES ............................................................................................................................ 11-1

11.1 BAR CODE TABLE................................................................................................................ 11-1

11.2 DRAWING OF BAR CODE DATA.........................................................................................11-21

11.3. AUTOMATIC ADDITION OF START/STOP CODES............................................................11-44

iv

Page 6

1. SCOPE AND GENERAL DESCRIPTION

1.1 SCOPE

This specification applies to the software for the LE840/LE850 industrial high-performance class

general-purpose label printers.

1.2 GENERAL DESCRIPTION

The external equipment interface connects a printer to the host computer through a serial interface (RS232C/USB), parallel interface (Centronics), or a network for making various settings and printing labels.

This specification describes how to use the external equipment interface.

This specification consists of the following chapters.

1.2.1 Contents of the Specification

Chapter 1: Scope and General Description

Chapter 2: Outline of the Specification

Chapter 3: Interface

Chapter 4: Transmission Sequence

Chapter 5 Interface Command

Chapter 6: Control Code Selection

Chapter 7: Error Processing

Chapter 8: Status Response

Chapter 9: LCD Message and LED Indications

Chapter 10: Character Code Table

Chapter 11 Bar Code Table

1-1

Page 7

2. OUTLINE OF THE SPECIFICATION

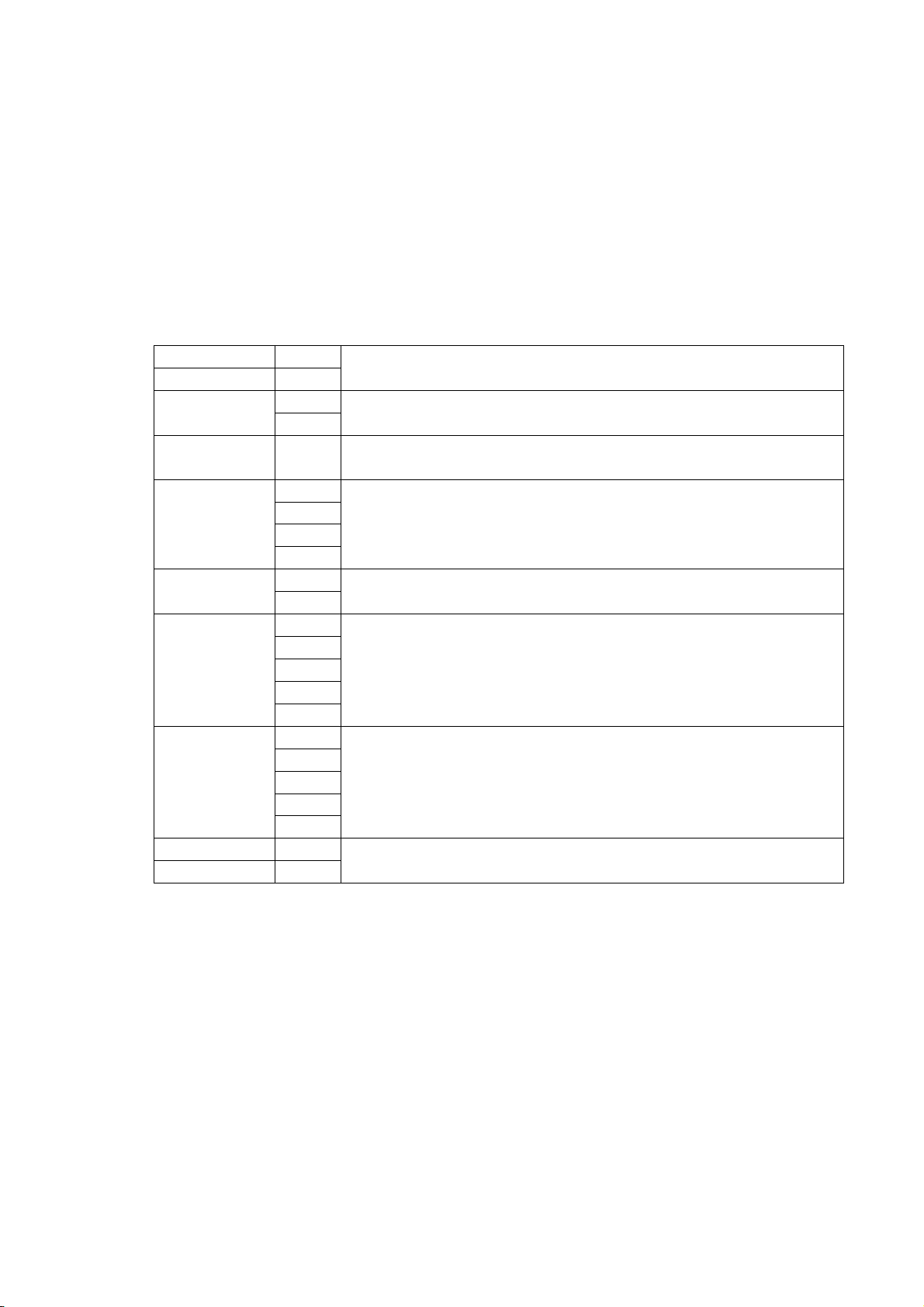

2.1 MODEL CONFIGURATION AND DIFFERENCES BETWEEN THE MODELS

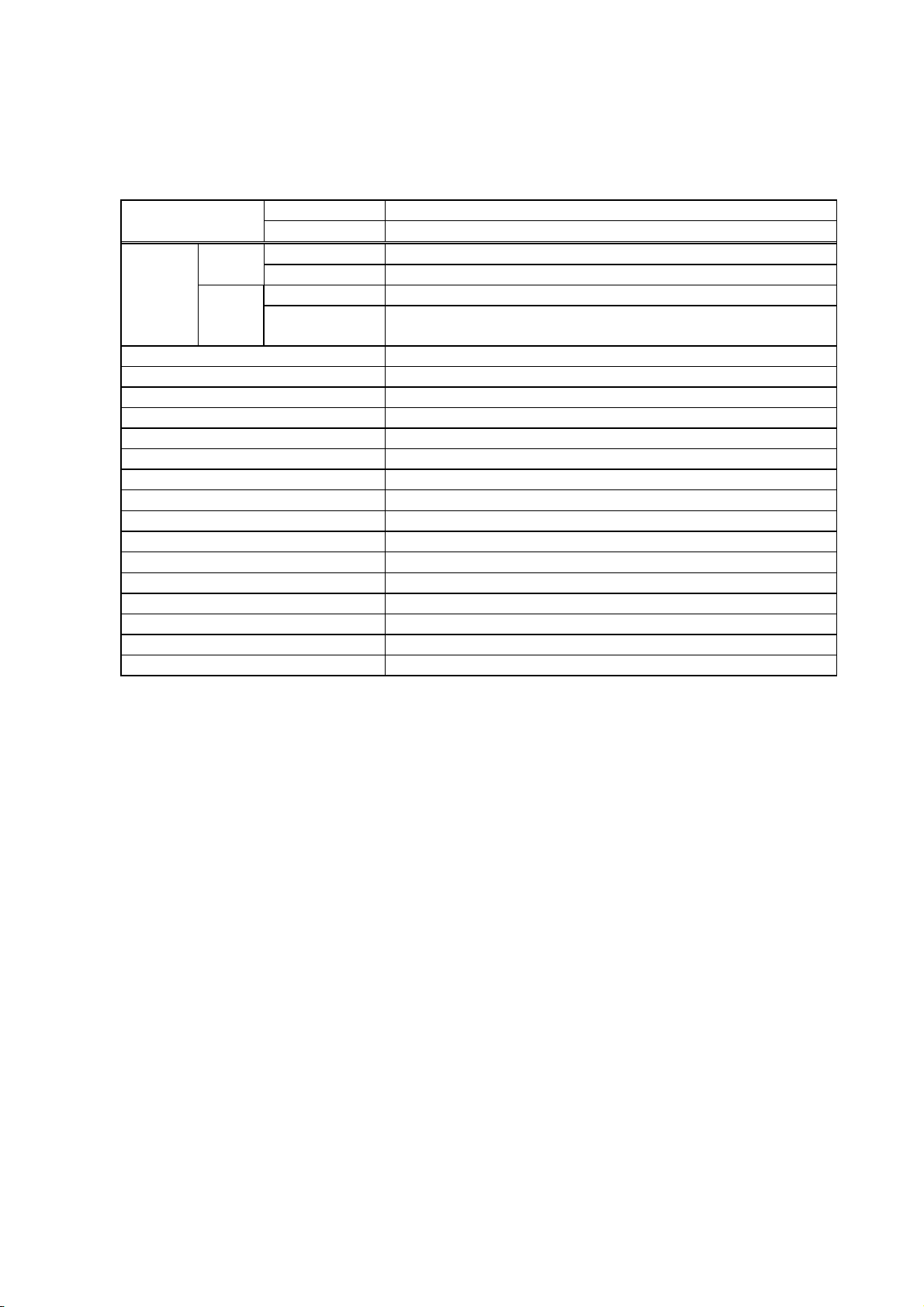

2.1.1 LE840T/LE850T 203 dpi/300 dpi

Model

Main 8 MB × 2 = 16 MB

Memory Whole 32 MB × 1 = 32 MB

Flash

ROM

SDRAM

Bitmap Kanji (Gothic)

Bitmap Kanji (Mincho)

Chinese

203 dpi LE840T

300 dpi LE850T

Font None

Image buffer of

whole SDRAM

203 dpi: 1.2 MB (Label length: 1500 mm)

300 dpi: 2.6 MB (Label length: 1500 mm)

None

None

None

RS-232C Option

Centronics Option

USB device (Function) Standard

100BASE wired LAN Standard

Wireless LAN Board Option

Ribbon save module None

Disc cutter module Option

Rotary cutter module None

Strip module Option

External rewinder None

Platen for narrow media None

Expansion I/O board Option

RTC+USB host Interface board Option

2-1

Page 8

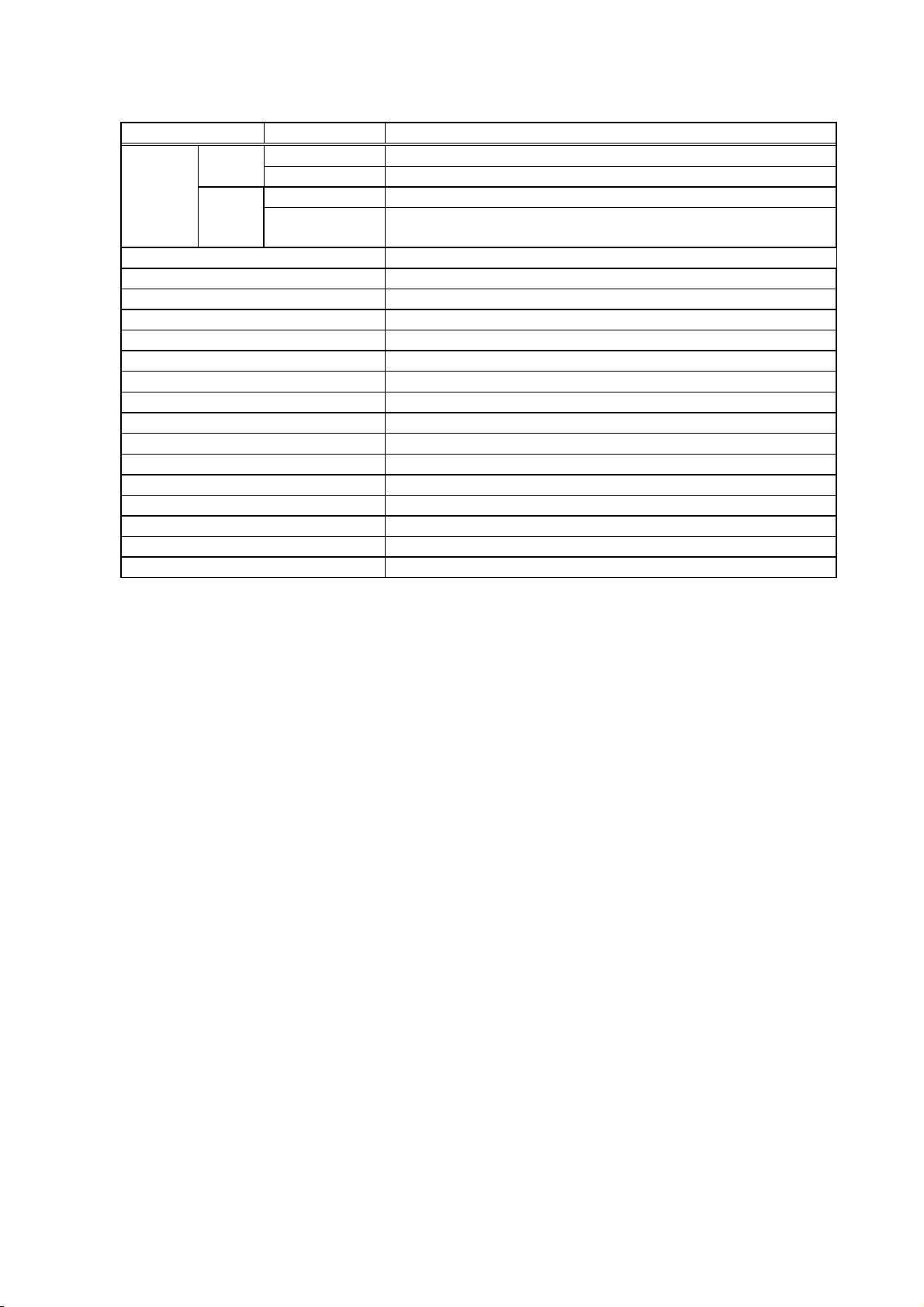

2.1.2 LE840D 203 dpi

Model 203 dpi LE840D

Main 8 MB × 2 = 16 MB

Flash

ROM

Font None

Memory Whole 32 MB × 1 = 32 MB

SDRAM

Bitmap Kanji (Gothic)

Bitmap Kanji (Mincho)

Chinese

Image buffer of

whole SDRAM

1.2MB (Label length: 1500 mm)

RS-232C Option

Centronics Option

USB device (Function) Standard

100BASE wired LAN Standard

Wireless LAN Board Option

Ribbon save module None

Disc cutter module Option

Rotary cutter module None

Strip module Option

External rewinder None

Platen for narrow media None

Expansion I/O board Option

RTC+USB host Interface board Option

None

None

None

2-2

Page 9

2.2 PRINT METHOD

Thermal transfer method

Direct thermal method

2.3 PRINT HEAD SPECIFICATION

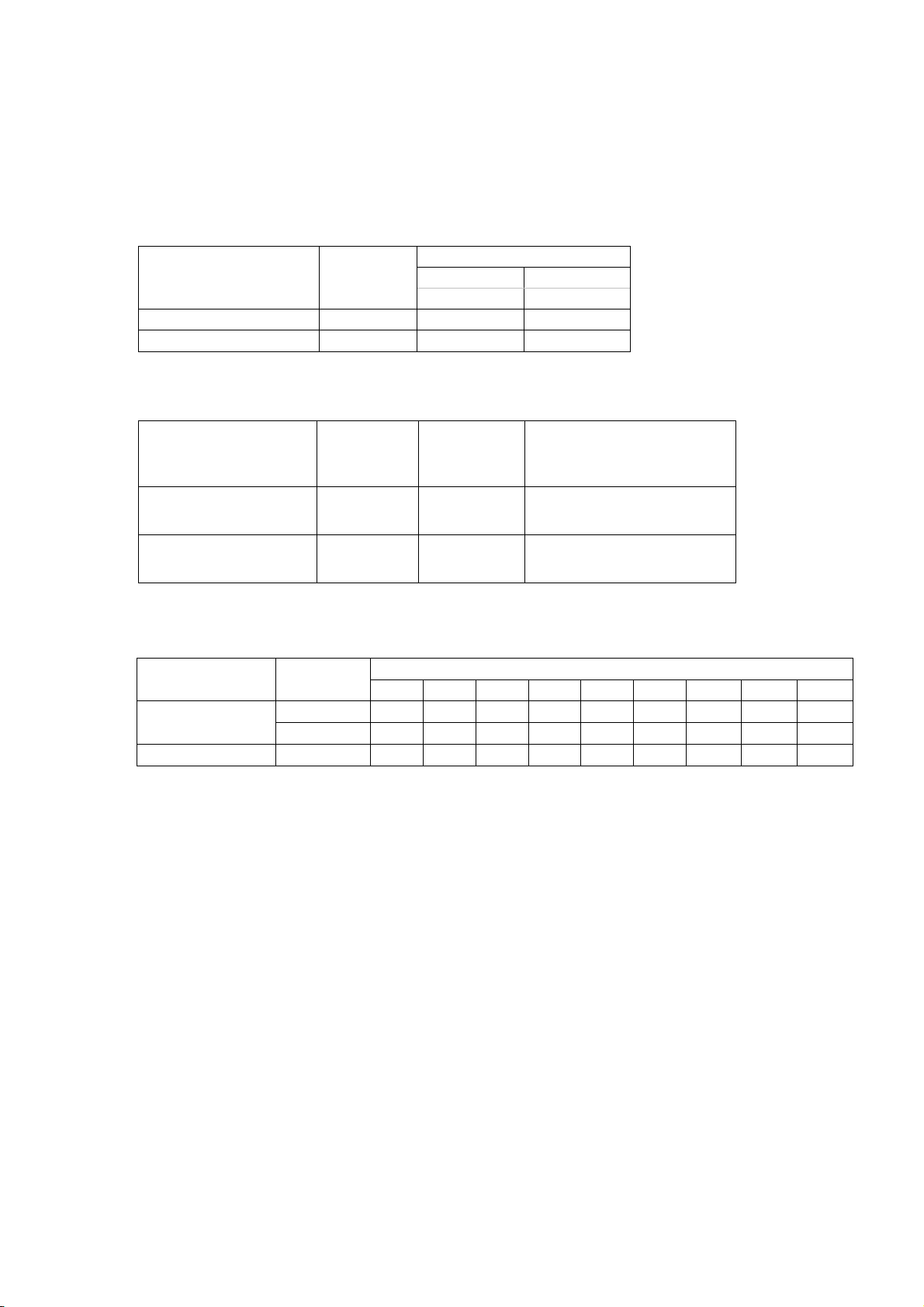

Model

LE840T/LE850T Flat

LE840D Flat

2.4 PAPER ALIGNMENT

Model Resolution

LE840T/LE850T

LE840D 203 dpi Flat Side

2.5 PRINT SPEED

Model Resolution

LE840T/LE850T

LE840D 203 dpi

203 dpi

300 dpi

Print head

type

203 dpi/

300 dpi

2”/s 3”/s 4”/s 5”/s 6”/s 8”/s 10”/s 12”/s 14”/s

Resolution

203dpi 300dpi

8 dots/mm 11.8 dots/mm

Print head

type

Flat Side

Paper alignment

Print speed

2-3

Page 10

2.6 CHARACTERS

<Bitmap font> 203 dpi

Times Roman (Medium) 12 point

Times Roman (Medium) 15 point

Times Roman (Bold) 15 point

Times Roman (Bold) 18 point

Times Roman (Bold) 21 point

Times Roman (Italic) 18 point

Helvetica (Medium) 9 point

Helvetica (Medium) 15 point

Helvetica (Medium) 18 point

Helvetica (Bold) 18 point

Helvetica (Bold) 21 point

Helvetica (Italic) 18 point

Presentation (Bold) 27 point

Letter Gothic (Medium) 14.3 point

Prestige Elite (Medium) 10.5 point

Prestige Elite (Bold) 15 point

Courier (Medium) 15 point

Courier (Bold) 18 point

OCR-A 12 point

OCR-B 12 point

Gothic725 Black 6 pint

Kanji/External character (Gothic) 16 x 16 dots

Kanji/External character (Gothic) 24 x 24 dots

Kanji/External character (Gothic) 32 x 32 dots

Kanji/External character (Gothic) 48 x 48 dots

Kanji (Mincho) 24 x 24 dots

Kanji (Mincho) 32 x 32 dots

Chinese*1 24 x 24 dots

*1: Chinese fonts need to be installed.

<Outline font>

Fonts other than TrueType

font

OKI FONT 1, OKI FONT 2, Price Fonts 1, 2 and 3, DUTCH801

Bold, BRUSH738 Regular, Gothic 725 Black

TrueType font BalloonPExtBol, BlacklightD, BrushScrD, CG Times, CG Times

Bold, CG Times Italic, Clarendon Condensed Bold, FlashPBol,

Garamond Kursiv Halbfett, GoudyHeaP, GilliesGotDBol,

GilliesGotDLig, NimbusSanNovTUltLigCon, Ryahd, Ryahd

Bold, CG Triumvirate, CG Triumvirate Condensed Bold,

Univers Medium, Univers Bold, Univers Medium Ilalic, add_on

TrueTypeFont 1, add_on TrueTypeFont 2, add_on

TrueTypeFont 3, add_on TrueTypeFont 4, add_on

TrueTypeFont 5, Kanji add_on TrueTypeFont 1, Kanji add_on

TrueTypeFont 2, Kanji add_on TrueTypeFont 3, Kanji add_on

TrueTypeFont 4, Kanji add_on TrueTypeFont 5

NOTE: TrueType fonts need to be installed separately.

2-4

Page 11

2.7 BAR CODES/TWO-DIMENSIONAL CODES

<Bar codes> JAN8/EAN8, JAN13/EAN13, UPC-A, UPC-E, Interleaved 2 of 5,

NW7, CODE39, CODE93, CODE128, EAN128, MSI, GS1 DataBar,

Customer Barcode, POSTNET, RM4SCC, KIX CODE, Industrial 2

of 5, MATRIX 2 of 5 for NEC

<Two-dimensional codes> QR CODE, MicroQR CODE, PDF417, DataMatrix, Maxicode,

MicroPDF417, CP CODE

2.8 STORABLE FORMATS

Max. 99 types

2.9 WRITABLE CHARACTERS

Free size: 224 characters x 40 types

16 x 16 dots: 188 characters

24 x 24 dots: 188 characters

32 x 32 dots: 188 characters

48 x 48 dots: 188 characters

2.10 INTERFACE

RS-232C

Centronics (IEEE1284 compatible mode, Nibble mode)

LAN (100base)

Wireless LAN (IEEE802.11b/g)

USB V2.0

2.11 USB MEMORY (USB HOST)

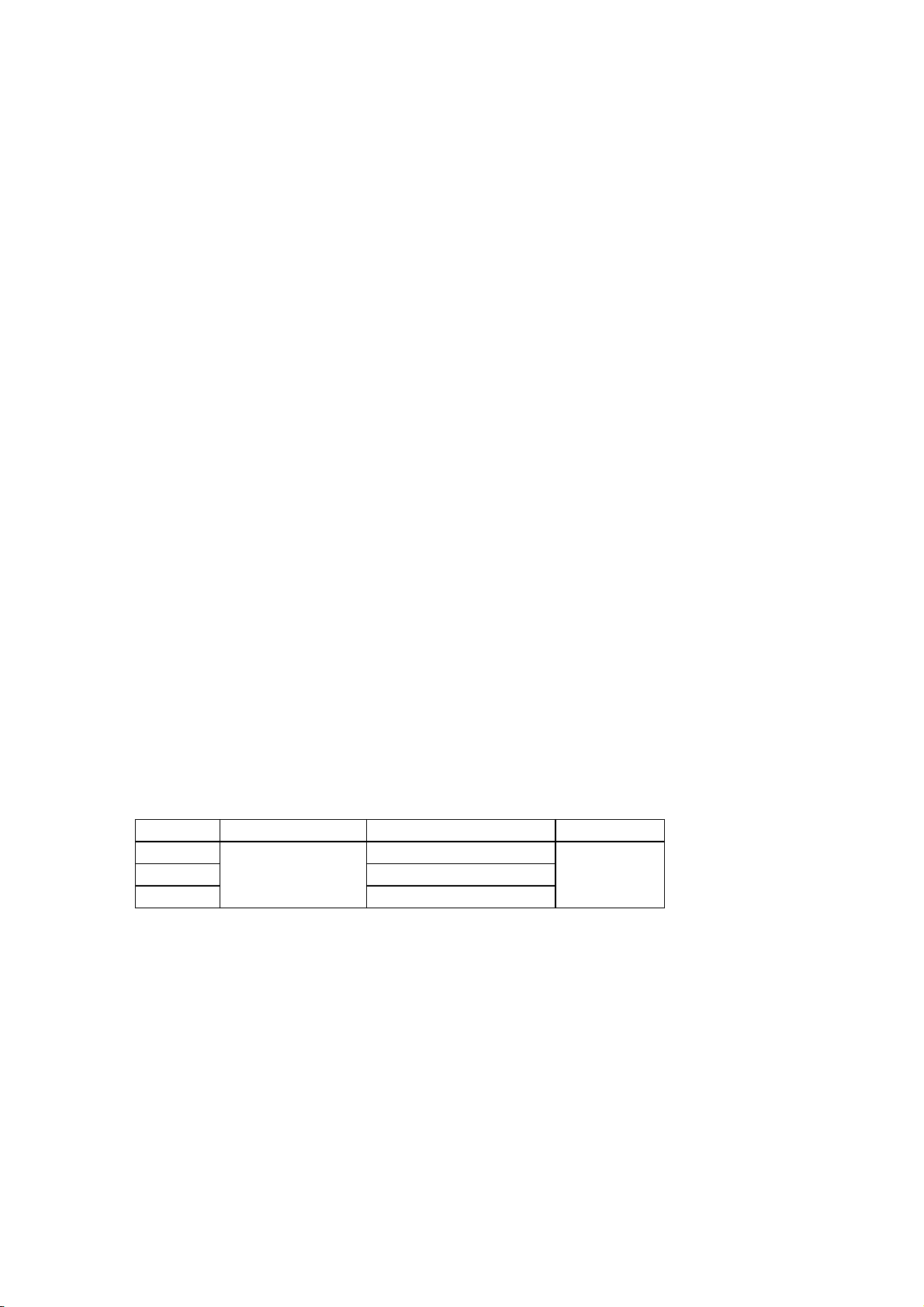

Recommended USB memories

Size Manufacturer Type Function

1GB SP001GBUF2M01V1K

2GB SP002GBUF2M01V1K

8GB

SILICON POWER

SP008GBUF2M01V1K

2.12 SENSOR

Head open sensor

Head up sensor (Head lock sensor)

Transmissive sensor

Reflective sensor

Ribbon take-up motor sensor

Ribbon feed (back tension) motor sensor

Rewinder overflow sensor

Backing paper overflow sensor

Peel-off sensor

Head thermistor

Ambient temperature sensor

Readable

and writable

2-5

Page 12

2.13 KEYS

FEED key

PAUSE key

RESTART key

MODE key

CANCEL key

ENTER key

Up (↑) key

Down (↓) key

Left (←) key

Right (→) key

2.14 LED

ONLINE LED: Green

ERROR LED: Red

2.15 LCD

Type: Graphic LCD

Size: 128 dots (W) x64 dots (H)

Max. No. of characters displayed: 21 digits x 5 lines

2.16 ISSUE MODE

Batch: The specified number of labels is continuously issued in a batch.

Cut: The specified number of labels is issued while being cut at the specified cut interval.

Cut issue will be ignored if the cut issue is specified while the printer is in the peel-off

mode.

Peel-off: Next label will not be printed until the current label is removed from the strip shaft.

However, when the application is programmed so that the applicator of a labeler ignores

the peel-off sensor, subsequent labels are printed regardless of whether the current label

is removed or not.

2.17 MEDIA

Size

Mode

LE840T/LE850T

203/300 dpi

LE840D

203 dpi

Label width

22 to 111mm 2 to 20mm 2 to 10mm 25 to 114mm

22 to 111 mm 2 to 20 mm 2 to 10 mm 25 to 114 mm

Gap between

labels

Black mark length

Backing paper

width

2-6

Page 13

2.18 CUT

Stop and cut with the disc cutter

Non-stop cut with the rotary cutter

2.19 RIBBON SAVING FUNCTION

When the ribbon saving function is enabled, the print head is raised when non-print area is detected

during printing. While the print head is raised, only the media is fed, causing ribbon loss to be

reduced. RIBBON save, Head up related parameter are included in system menu. However, this

function will not be supported by LE840/LE850. Therefore these parameter setting will be ignored and

no effect.

2.20 AUTO CALIBRATION

When the auto calibration function is enabled, the printer performs an auto calibration at a power on

time and the open/close of the print head. During the auto calibration, the threshold value, gap length,

label pitch, effective print length and whether the ribbon is used or not are automatically detected. The

printer performs subsequent printing based on the detected settings.

2.21 MANUAL HOME POSITION DETECTION

When the manual home position detection function is enabled, the printer feeds media to the print

start position after a power on, a batch reset (cause by Z0 command or W@ command), depression of

the FEED key which follows the closing of the print head block.

2-7

Page 14

3. INTERFACE

3.1 GENERAL DESCRIPTION

This chapter provides the detailed explanations of each interface between the host and the printer.

Interface types available to the LE840/LE850 series are as follows:

Standard: USB (FUNCTION) + LAN

Option: Wireless LAN

USB (HOST)

RS-232C

Centronics (IEEE1284)

NOTES: 1. When using RS-232C interface, the RS-232C cable shall be connected to the printer

before turning on the printer power.

2. The wireless LAN and the wired LAN cannot be used at the same time.

3-1

Page 15

3.2 USB INTERFACE

(1) Applicable standard: Conforming to USB Standard Rev. 2.0

(2) Data Transfer Type: Control transfer, Bulk transfer

(3) Transfer Rate: Full speed (12Mbps)

(4) Transfer Control Method: A status is sent along with the receive buffer free space information in

response to a read request immediately after [ESC]WB[LF][NUL], as

described below. Based on this status response, the host computer

can transmit data so that the receive buffer does not become full.

Status with the receive buffer free space information

SOH 01H

STX 02H

3XH Status

3XH

Status type 33H Indicates that this status includes the receive buffer free space

Remaining

count

Free space of

receive buffer

Receive buffer

capacity

CR 0DH

LF 0AH

3XH

3XH

3XH

3XH

32H Length

33H

3XH

3XH

3XH

3XH

3XH

30H

30H

35H

31H

32H

Indicates the header of the status block

Printer status

*Details are described later

information.

Remaining number of labels to be printed

“0000” (0 labels) to “9999” (9999 labels)

Total number of bytes of this status block

“23” (23 bytes)

Free space of the receive buffer

“00000” (0K bytes) to “00512” (512K bytes)

However, the maximum value shall be the receive buffer capacity.

Receive buffer capacity

“00512” (512K bytes)

Indicates the terminator of the status block.

3-2

Page 16

3.3 NETWORK INTERFACE

(1) Configuration

On board

(2) Protocol: TCP/IP

(3) Network Specifications

LPR server function

WEB printer function

Socket communication function

FTP server function

Mail transmission/reception function

3-3

Page 17

3.4 SERIAL INTERFACE

(1) Type: Conforming to RS-232C

(2) Mode of Communication: Full duplex

(3) Transmission Speed: 2400 bps

4800 bps

9600 bps

19200 bps

38400 bps

115200 bps

(4) Synchronization Method: Start-stop synchronization

(5) Start Bit: 1 bit

(6) Stop Bit: 1 bit

2 bits

(7) Data Length: 7 bits

8 bits

(8) Parity: None

Even

Odd

(9) Error Detection: Parity error Vertical parity error check

Framing error This error occurs if no stop bit is found in the frame

specified starting with the start bit.

(10) Protocol: No-procedure method

(11) Data Input Code: ASCII code

European character set 8 bit code

Graphics 8 bit code

JIS 8 code

Shift JIS Kanji code

JIS Kanji code

UTF-8

(12) Receive Buffer: 1 MB

* The receive buffer is shared with other interfaces.

3-4

Page 18

(13) Transmission Control: XON/XOFF (DC1/DC3) Protocol

READY/BUSY (DTR) Protocol

XON/XOFF (DC1/DC3) Protocol + READY/BUSY (DTR) Protocol

READY/BUSY (RTS) Protocol

XON/XOFF (DC1/DC3) Protocol

● When initialized after the power is turned on, this printer becomes ready to receive data

and sends an XON code (11H). (Transmission or non-transmission of the XON code is

selectable by means of the parameter setting.)

● The printer sends an XOFF code (13H) when the free space in the receive buffer become

10 Kbytes or less.

● The printer sends an XON code (11H) when the free space in the receive buffer become

512 Kbytes or more.

● When there are no free space in the receive buffer, the printer discards data received

exceeding the receive buffer capacity, without storing it in the buffer. (After detecting the

XOFF code, the host computer must stop transmission before the printer receive buffer

becomes full.)

● The printer sends an XOFF code (13H) when the power is off. (Transmission or nontransmission of the XOFF code is selectable by means of the parameter setting.)

● The DTR signal is always “High” (READY).

● The RTS signal is always “High”.

READY/BUSY (DTR) Protocol

● When initialized after the power is turned on, this printer becomes ready to receive data

and turns the DTR signal to “High” level (READY).

● The printer turns the DTR signal to “Low” level (BUSY) when the free space in the receive

buffer become 10 Kbytes or less.

● The printer turns the DTR signal to “High” level (READY) when the free space in the

receive buffer become 512 Kbytes or more.

● When there are no free space in the receive buffer, the printer discards data received

exceeding the receive buffer capacity, without storing it in the buffer. (After detecting the

BUSY signal, the host computer must stop transmission before the printer receive buffer

becomes full.)

● The RTS signal is always “High”.

3-5

Page 19

XON/XOFF (DC1/DC3) Protocol + READY/BUSY (DTR) Protocol

● When initialized after the power is turned on, this printer becomes ready to receive data

and turns the DTR signal to “High” level (READY). The printer also sends an XON code

(11H).

● When the free space in the receive buffer become 10 Kbytes or less, the printer turns the

DTR signal to “Low” level (BUSY) and sends an XOFF code (13H).

● When the free space in the receive buffer become 512 Kbytes or more, the printer turns

the DTR signal to “High” level (READY) and sends an XON code (11H).

● When there are no free space in the receive buffer, the printer discards data received

exceeding the receive buffer capacity, without storing it in the buffer. (After detecting the

XOFF code or BUSY signal, the host computer must stop transmission before the printer

receive buffer becomes full.)

● The printer sends an XOFF code (13H) when the power is off.

● The RTS signal is always “High”.

READY/BUSY (RTS) Protocol

● When initialized after the power is turned on, this printer turns the RTS signal to “High”

(READY).

● The printer turns the RTS signal to “Low” (BUSY) when the free space in the receive buffer

become 10 Kbytes or less.

● The printer turns the RTS signal to “High” (READY) when the free space in the receive

buffer become 512 Kbytes or more.

● When there are no free space in the receive buffer, the printer discards data received

exceeding the receive buffer capacity, without storing it in the buffer. (After detecting the

BUSY signal, the host computer must stop transmission before the printer receive buffer

becomes full.)

● The DTR signal is always “High” (READY).

● The DSR signal from the host shall be always “High”.

* When the flow control is performed with a Windows PC, “READY/BUSY (RTS) protocol” shall

be selected, and “Hardware” shall be selected for the flow control in the Windows

communication port setting.

NOTE: For “READY/BUSY (DTR) protocol”, data shall be sent after 200 ms from when the

DTR signal is turned to “High” (READY). For “READY/BUSY (RTS) protocol”, data

shall be sent after 200 ms from when the RTS signal is turned to “High” (READY).

3-6

Page 20

(14) Input/Output Signals

It is in the Low (Mark) state when no transmission is in

ate when no transmission is in

/BUSY (DTR) protocol or XON/XOFF

It is at “Low” level when the receive buffer is near full, and

C3) protocol or READY/BUSY

It is an input signal indicating whether or not the data

transmission to the host is possible. However, this

It is at “Low” when the receive buffer is nearly full, and at

Printer

(15) Connector Pin Assignment and Signal Description

N.C

TD

RD

DSR

SG

DTR

CTS

RTS

N.C

Host

Pin No.

Signal

Name

1 NC No Connection

2 TD Data line from the printer to the host

Logic 1 is a Low level, while logic 0 is a High level.

progress.

3 RD Data line from the host to the printer

Logic 1 is a Low level, while logic 0 is a High level.

It is in the Low (Mark) st

progress.

4 DSR Input signal from the host

For the printer to receive data, it must be at “High” level.

5 SG Ground line for all data and control signals

6 DTR Output signal to the host

For the READY

(DC1/DC3) protocol + READY/BUSY (DTR) protocol:

It indicates the ready state for the received data.

at “High” level when near empty.

For the XON/XOFF (DC1/D

(RTS) protocol:

After the power is turned on, it is always at “High”.

7 CTS

Function Signal Direction

Printer →

← Host

← Host

Printer →

← Host

printer does not detect this signal.

8 RTS Output signal to the host

For the READY/BUSY (RTS) protocol:

It indicates the ready state for the received data.

“High” when nearly empty.

For protocol other than the READY/BUSY (RTS) protocol:

After the power is turned on, it is always at “High” level.

9 NC No Connection

Printer →

3-7

Page 21

DSR

DTR

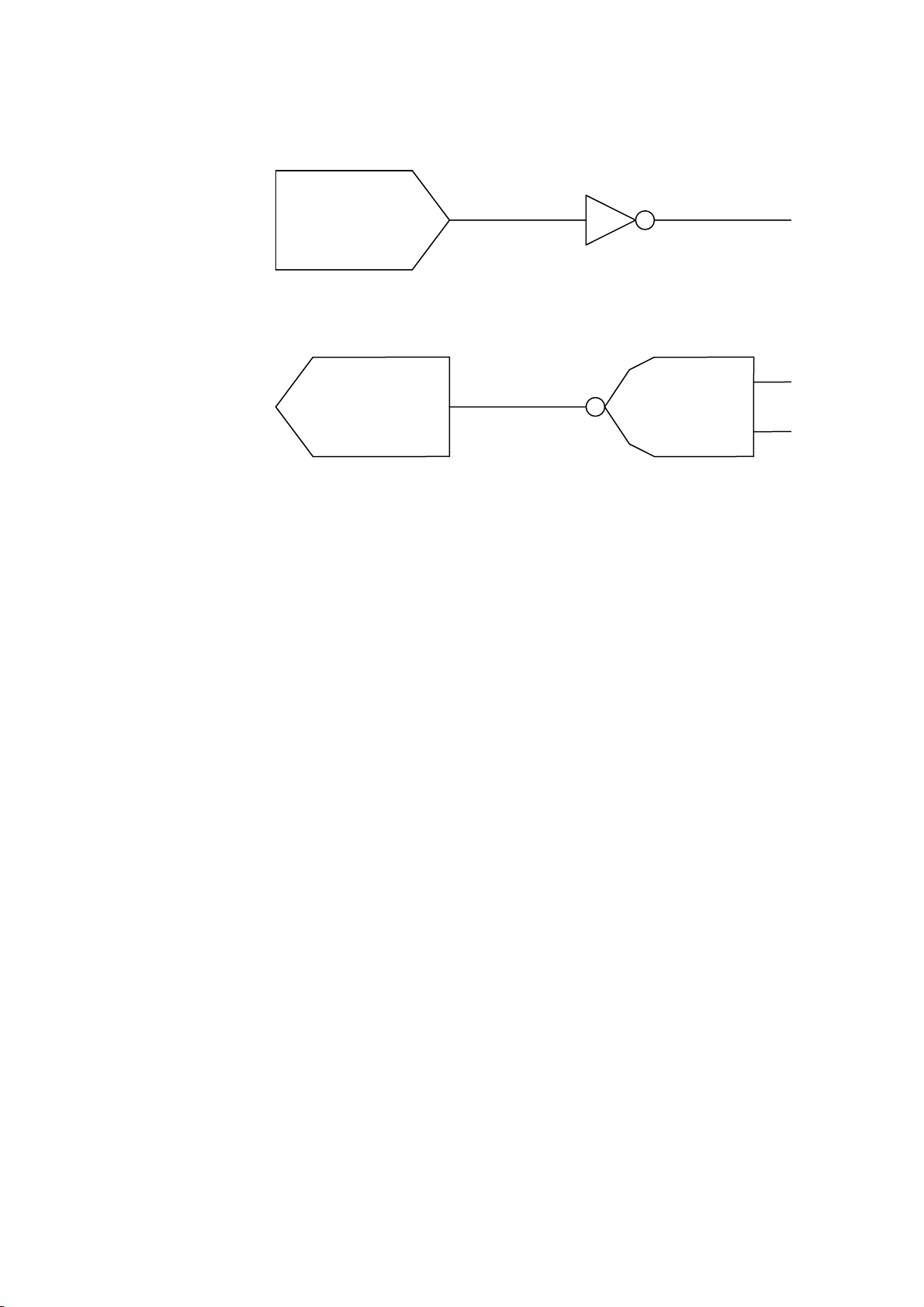

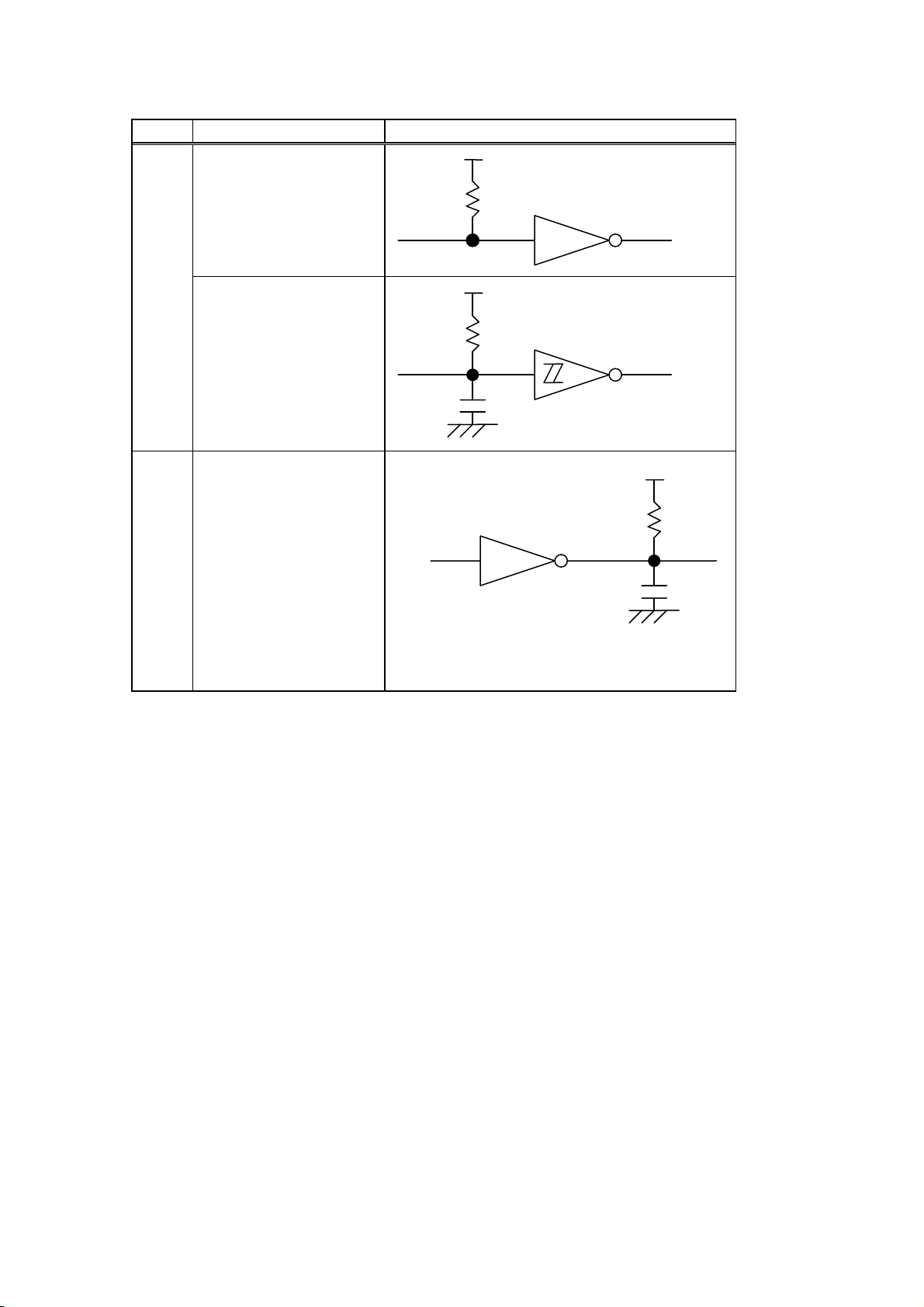

(16) Interface Circuit

Input Circuit

Output Circuit

Signal Levels

Input Voltage H ...... +3 to +15 V

Output Voltage H ......+6 to +13 V

RD

CTS

TD

RTS

L .......-3 to -15 V

L .......-6 to -13 V

SN75189 or equivalent

SN75188 or equivalent

3-8

Page 22

3.5 PARALLEL INTERFACE

(1) Type: Centronics

(2) Mode: Conforms to IEEE1284 Compatibility mode and Nibble mode

(3) Data Input Method: Parallel 8 bits (DATA1 to 8)

(4) Control Signals: Compatibility mode Nibble mode

nStrobe HostClk

nAck PrtClk

Busy PtrBusy

PError AckDataReq

Select Xflag

nAutoFd HostBusy

nInit nInit

nFault nDataAvail

nSelectIn IEEE1284Active

(5) Data Input Code: ASCII code

European character set 8 bit code

Graphics 8 bit code

JIS 8 code

Shift JIS Kanji code

JIS Kanji code

UTF-8

(6) Receive Buffer: 1 MB

* The receive buffer is shared with other interfaces.

3-9

Page 23

(7) Input/Output Circuit Configuration and Input/Output Conditions:

Signal Configuration

DATA1 to 8

+5V

1K

SN74LS245 or equivalent

Input nStrobe/HostClk/HostClk

nInit/nInit/

nReverseRequest

nAutoFd/HostBusy/

HostAck

nSelectIn/IEEE1284Active

/

IEEE1284Active

Busy/PtrBusy/PeriphAck

nFault/nDataAvail/

nPeriphRequest

nAck/PtrClk/PeriphClk

Select/Xflag/XFlag

Output

PError/AckDataReq/

nAckReverse

+5V

1K

100P

SN7406 or equivalent

SN74LS14 or equivalent

+5V

1K

100P

Logic level

(Input)

“1” = 2 to 5 V

“0” = 0 to 0.4

V

Logic level

(Input)

“1” = 2.4 to 5

V

“0” = 0 to 0.4

V

(8) Connector: Printer

Amp. Japan 552742-1 or equivalent

DDK 57RE-40360-73B or equivalent

Cable

Amp. Japan 552470-1 or equivalent

DDK 57E-30360 or equivalent

3-10

Page 24

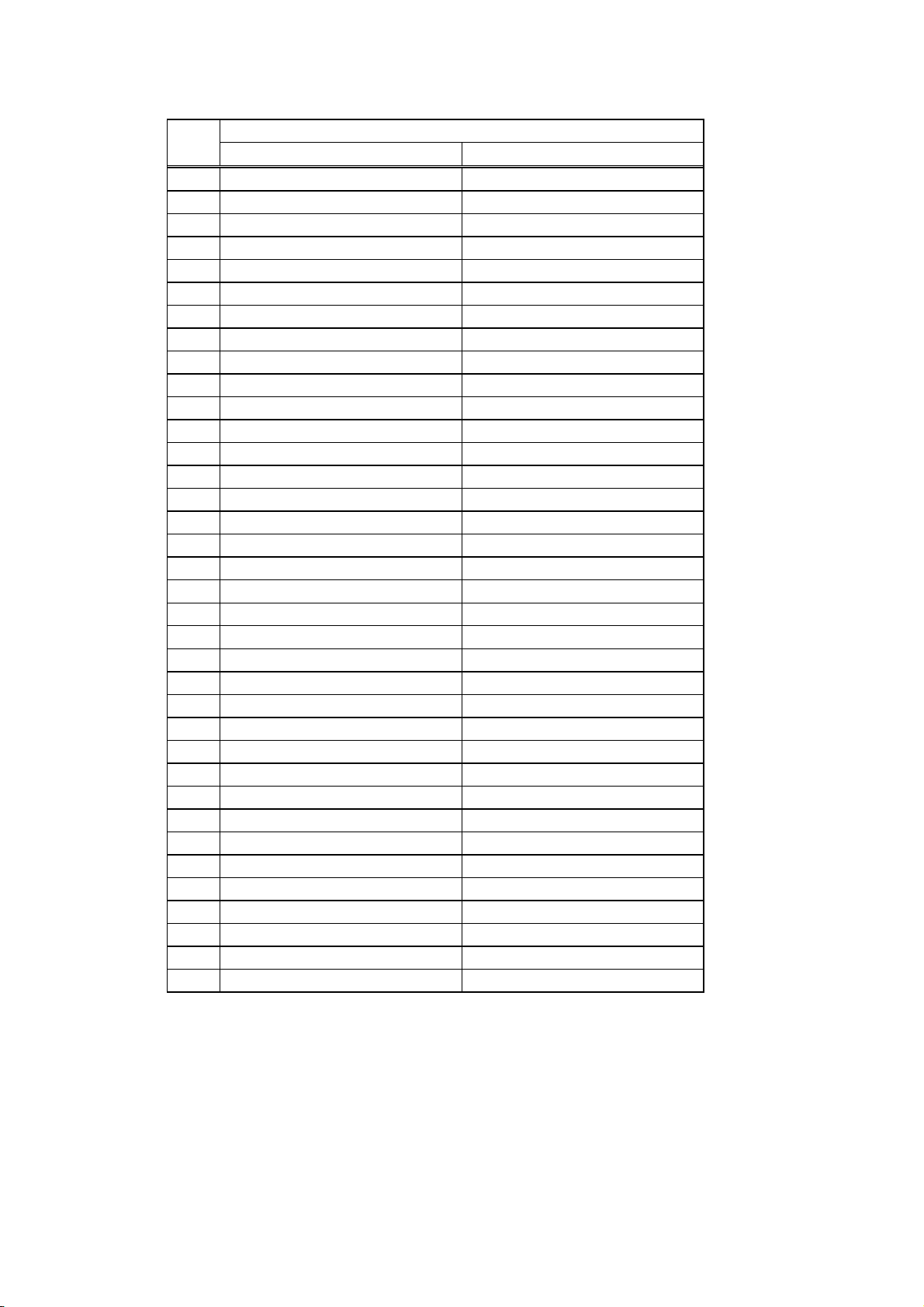

(9) Connector Pin Diagram (IEEE1284-B Connector):

Pin

Signal Name

No. Compatibility Mode Nibble mode

1

nStrobe HostClk

2

Data 1 Data 1

3

Data 2 Data 2

4

Data 3 Data 3

5

Data 4 Data 4

6

Data 5 Data 5

7

Data 6 Data 6

8

Data 7 Data 7

9

Data 8 Data 8

10

nAck PtrClk

11

Busy PtrBusy

12

PError AckDataReq

13

Select Xflag

14

nAutoFd HostBusy

15

NC NC

16

0V 0V

17

CHASSIS GND CHASSIS GND

18

+5V (for detection) +5V (for detection)

19

TWISTED PAIR GND (PIN1) TWISTED PAIR GND (PIN1)

20

TWISTED PAIR GND (PIN2) TWISTED PAIR GND (PIN2)

21

TWISTED PAIR GND (PIN3) TWISTED PAIR GND (PIN3)

22

TWISTED PAIR GND (PIN4) TWISTED PAIR GND (PIN4)

23

TWISTED PAIR GND (PIN5) TWISTED PAIR GND (PIN5)

24

TWISTED PAIR GND (PIN6) TWISTED PAIR GND (PIN6)

25

TWISTED PAIR GND (PIN7) TWISTED PAIR GND (PIN7)

26

TWISTED PAIR GND (PIN8) TWISTED PAIR GND (PIN8)

27

TWISTED PAIR GND (PIN9) TWISTED PAIR GND (PIN9)

28

TWISTED PAIR GND (PIN10) TWISTED PAIR GND (PIN10)

29

TWISTED PAIR GND (PIN11) TWISTED PAIR GND (PIN11)

30

TWISTED PAIR GND (PIN31) TWISTED PAIR GND (PIN31)

31

nInit nInit

32

nFault nDataAvail

33

0V 0V

34

NC NC

35

NC NC

36

nSelectIn IEEE1284Active

NOTE: The signal name starting with a lower case “n” indicates that it is a low active signal.

3-11

Page 25

(10) Input/Output Signals :

Compatibility mode

Data 1 to 8 (Printer ← Host)

● Input data signals for the 1st to 8th bits.

● Logic 1 is “High” level.

● Min. data pulse width of 2.5 µsec.

nStrobe (Printer ← Host)

● Synchronizing signal for reading the above data.

● Normally at “High” level. The data is read at the rise of the Low level pulse.

● Minimum data pulse width of 0.5 µsec.

Busy (Printer → Host)

● This signal indicates that the printer is in a Busy state.

● When initialized after the power is turned on, the printer becomes ready to receive data

and turns the signal to “Low” level.

● The signal turns to “High” level (in a Busy state) when data is set from the host (at the fall

of the nStrobe signal).

● The signal turns to “Low” level when the printer reads the data.

● When the free space in the receive buffer become 512 bytes or less, the printer keeps the

signal at “High” level (in a Busy state) for 10 seconds when data is set from the host, to

extend the data read interval.

● When there are no free space in the receive buffer, the printer stops reading data. Then,

it keeps the signal at “High” level (in a Busy state) until there are free space in the receive

buffer when data is set from the host.

● The signal is kept at “High” level (in a Busy state) until the current state (one of the

following states) is reset.

• PAUSE state caused by the [PAUSE] key

• Paper end state

• Ribbon end state

• Head open state

• Printer error state

• Initialization in progress upon receipt of the nInit signal

nAck (Printer → Host)

● This signal indicates that the printer has read the data set by the host and is ready to

receive the next data.

● The signal is normally at “High”. It is at “Low” for about 5 µsec. after the fall of the BUSY

signal. The host should usually set data after the ACK signal is turned from “Low” to

“High”.

● If the nAck signal is ignored and the next data is set while the nAck signal is Low, the

“LOW” level continues about further 5 µsec at the fall of the BUSY signal. However, the

data can be received properly.

3-12

Page 26

nInit (Printer ← Host)

● Reset request signal from the host.

● Normally at “High” level. A low on this input causes the printer to be initialized in the

same manner as when the power is turned on.

* When “Reset process when the nInit signal is ON” is set to “OFF” in the parameter setting

in the system mode, the printer is not initialized even if it receives a low signal.

● When the nInit signal is input during printing, the printer completes printing one tag/label

which is being printed, cancels the next processing, then is initialized in the same manner

as when the power is turned on.

* When “Reset process when the nInit signal is ON” is set to “OFF” in the parameter setting

in the system mode, the next process proceeds without being canceled.

● Minimum pulse width of 0.5 µsec.

Select (Printer → Host)

● This is an output signal which indicates whether the printer is in Pause state or placed

online. The printer can receive data while placed online.

● The signal is at “Low” level while the printer is in a Pause state.

● The signal is kept at “Low” level (in a Pause state) until the current state (one of the

following states) is reset.

• Pause state caused by the [PAUSE] key

• Paper end state

• Ribbon end state

• Head open state

• Printer error state

• Initialization in progress upon power on or receipt of the nInit signal

nFault (Printer → Host)

● Output signal indicating that the printer is in a Fault state.

● At “Low” level while the printer is in a Fault state.

● The signal is kept at “Low” level (in a Fault state) until the current state (one of the

following states) is reset.

• Pause state caused by the [PAUSE] key

• Paper end state

• Ribbon end state

• Head open state

• Printer error state

• Initialization in progress upon power on or receipt of the nInit signal

PError (Printer → Host)

● Output signal indicating a label end or ribbon end state.

● At “High” level when the printer is in a label end or ribbon end state.

● Turns to “Low” level when the label end or ribbon end state is reset.

+5 V

● This is not a signal but a +5 V power supply voltage.

● The maximum current of 500 mA can be taken out.

nSelectIn (Printer ← Host)

● Not used

11

nAutoFd (Printer ← Host)

● Not used

3-13

Page 27

Nibble mode

PtrClk (Printer → Host)

● Reverse data transfer phase: It is used for evaluating data sent to the host.

● Reverse idle phase: When the printer changes the signal from Low to High, an

interrupt informing the host that the data is available, occurs

PtrBusy (Printer → Host)

● Reverse data transfer phase: Data bit 3 is used for the first transfer. Data bit 7 is used for

the second transfer. Indicates the forward channel is in a

Busy state.

AckDataReq (Printer → Host)

● Reverse data transfer phase: Data bit 2 is used for the first transfer. Data bit 6 is used for

the second transfer.

● Reverse idle phase: This signal is set to high until the data transfer is requested

by the host. Then, the process is performed according to

the nDataAvail signal.

Xflag (Printer → Host)

● Reverse data transfer phase: Data bit 1 is used for the first transfer. Data bit 5 is used for

the second transfer.

HostBusy (Printer ← Host)

● Reverse data transfer phase: It indicates that the host can receive data from the printer by

setting the signal to low. Then, the host sets the signal to

high, and sends the Ack indicating that the nibble data is

received. When the signal is set to low after the reverse

channel data transfer is performed, the interface phase

changes to the idle phase. At that time, there is no

available data on the printer.

● Reverse idle phase: When this signal is set to high according to the low pulse of

the PtrClk signal, the host enters the reverse data transfer

phase again. If this signal is set to high when the

IEEE1284 Active signal is low, the IEEE1284 idle phase

stops, and the interface enters the Compatibility mode.

nDataAvail (Printer → Host)

● Reverse data transfer phase: When the signal is low, it indicates the printer has data to be

sent to the host. And it is used for sending data bits 0 and

4.

● Reverse idle phase: It is used for indicating that the data is available.

3-14

Page 28

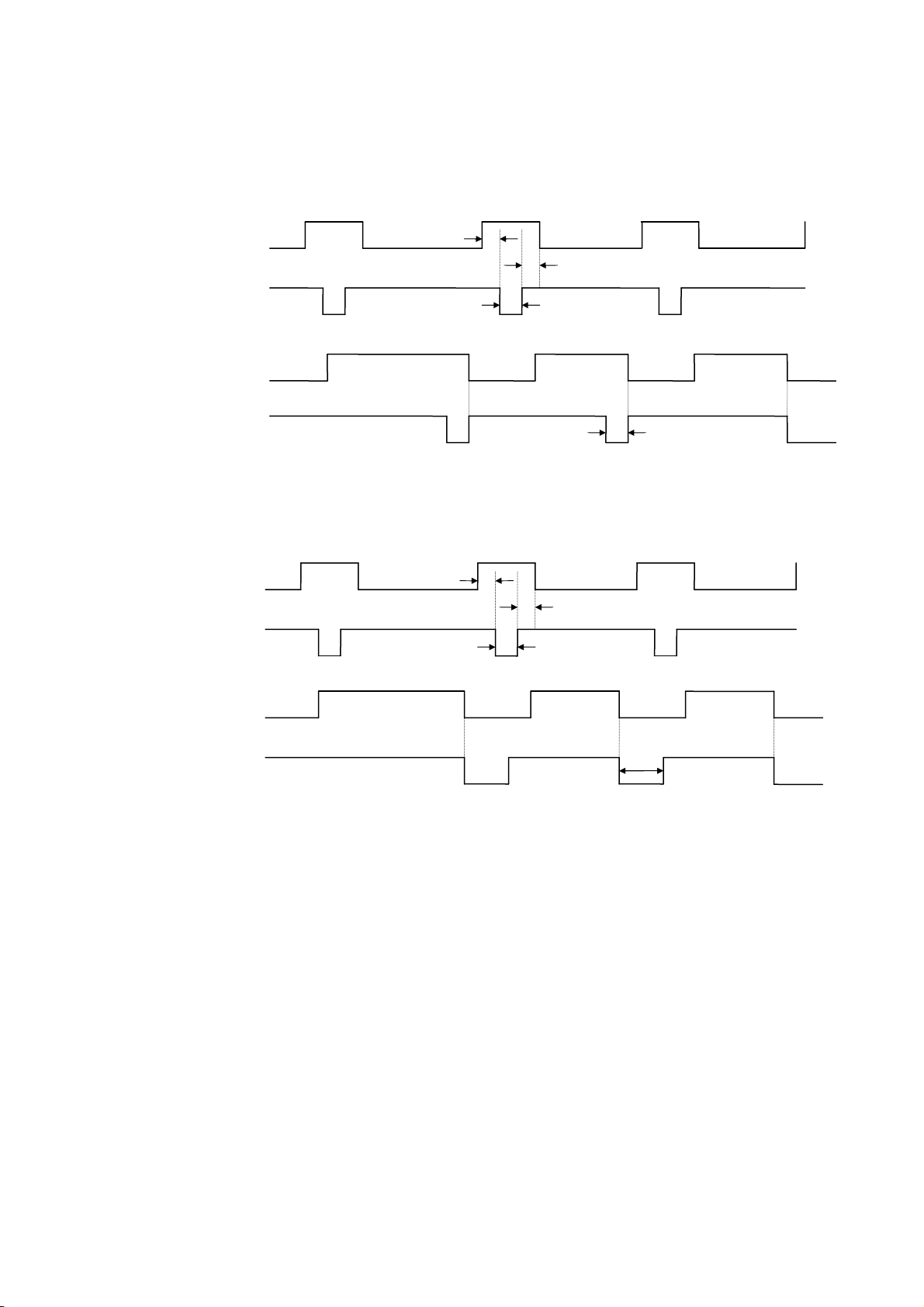

(11) Timing Chart

Approx. 5 µsec

Approx. 1 µsec

When receiving normal data:

For the Compatibility mode, one of two types of timing for BUSY-ACK can be selected.

a) Timing 1 (Default)

Data 1 to 8

(Host → Printer)

Min. 1 µsec

Min. 1 µsec

nStrobe

(Host → Printer)

Min. 0.5 µsec

Busy

(Host ← Printer)

nAck

(Host ← Printer)

b) Timing 2

Data 1 to 8

(Host → Printer)

Min. 1 µsec

Min. 1 µsec

nStrobe

(Host → Printer)

Min. 0.5 µsec

Busy

(Host ← Printer)

nAck

(Host ← Printer)

3-15

Page 29

Receiving data in the Compatibility mode when the free space in the receive buffer is 512

1 blank byte

bytes or less:

● When the free space in the receive buffer becomes 512 bytes or less, the printer stores all

of the already received data in the receive buffer, stays in a Busy state (Busy signal at

“High” level) for 10 seconds to extend the data read interval when data is set from the host,

then reads the data 10 seconds later.

● If the free space becomes 513 bytes or more while waiting for the data read, the printer will

receive the data with the normal data receive timing.

● When there is no free space in the receive buffer, the printer stops reading data. Then, it

stays in a Busy state (Busy signal at “High” level) until a free space is generated in the

receive buffer after data is set from the host.

Data 1 to 8

(Host → Printer)

nStrobe

(Host → Printer)

Busy

(Host ← Printer)

nAck

(Host ← Printer)

512 blank bytes

10 sec 10 sec

511 blank

0 blank byte

1 blank byte

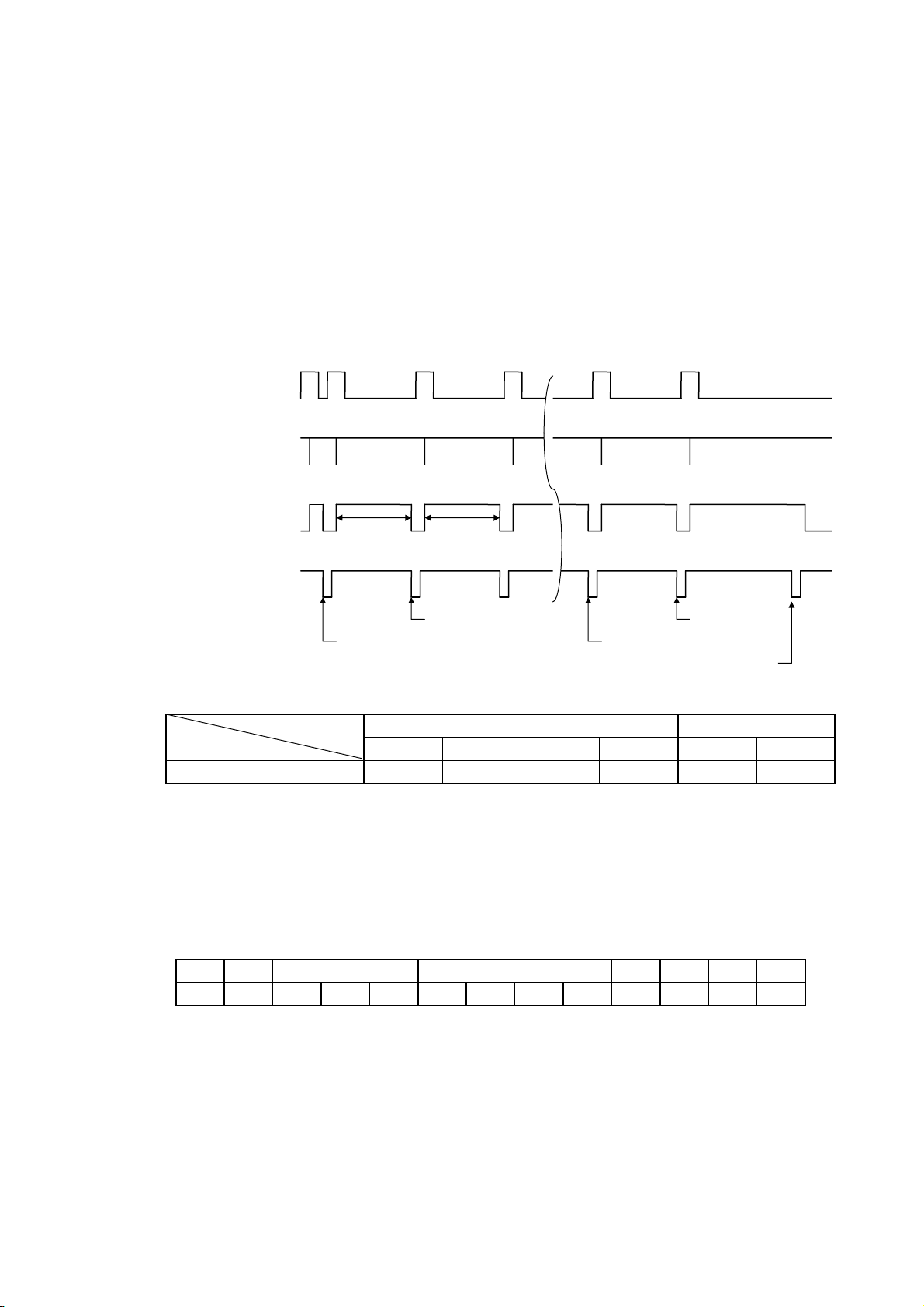

(12) Relationship between Printer Setting and PC Setting and Their Operation Modes

Host setting

Printer setting Compatibility

Windows95/98/Me WindowsNT4.0 Windows2000/XP

ECP

Compatibility

ECP

Compatibility

Compatibility mode (SPP) SPP SPP SPP SPP SPP SPP

* SPP mode operations include support of the Nibble mode.

* When SPP mode is selected for the printer setting, the printer returns a 13-byte status

(described at the top of the next page) to the Nibble mode negotiation immediately after [ESC]

WS [LF] [NUL] is received. The printer returns a 23-byte status with the receive buffer free

space information (described in (13) on the next page) to the Nibble mode negotiation

immediately after [ESC] WB [LF] [NUL] is received.

Status to be returned immediately after [ESC]WS[LF][NUL] is received (13 bytes):

SOX STX

Status Remaining count ETX EOT CR LF

01H 02H 3XH 3XH 3XH 3XH 3XH 3XH 3XH 03H 04H 0DH 0AH

ECP

3-16

Page 30

(13) Status with the receive buffer free space information

Indicates that the status includes the receive buffer free space

However, the maximum value differs depending on the models.

The printer returns a status along with the receive buffer free space information to the Nibble

mode negotiation immediately after [ESC] WB [LF] [NUL] is received, as described blow.

Status to be returned immediately after [ESC] WB [LF] [NUL] is sent (23 bytes):

SOH 01H Indicates the header of the status block

STX 02H

Status 3XH Printer status

3XH * Details are to be hereinafter described.

Status type 33H

information.

Remaining 3XH Remaining number of labels to be printed

count 3XH * Details are to be hereinafter described.

3XH

3XH

Length 3XH Total number of bytes of this status block.

3XH

Free space 3XH Free space of the receive buffer

of receive buffer 3XH “00000” (0 Kbyte) to “99999” (99999 Kbytes)

3XH However, the maximum value shall be the receive buffer

3XH capacity.

3XH

Receive buffer 3XH Receive buffer capacity

capacity 3XH “00000” (0 Kbyte) to “99999” (99999 Kbytes)

3XH

3XH

3XH

CR 0DH Indicates the terminator of the status block.

LF 0AH

3-17

Page 31

3.6 USB HOST INTERFACE

(1) Applicable standard: Universal Serial Bus V1.1

(2) Transfer Rate: Low speed (1.5 Mbps) and Full speed (12 Mbps)

(3) Others: Conforming to OpenHCI version 1.0 register set

Root hub

3-18

Page 32

3.7 WIRELESS LAN

3.7.1 Specification of Wireless LAN Module

(1) Applicable standard: IEEE802.11b/g

(2) Communication distance: 100 m/360° (Depending on conditions)

(3) Client protocol:

Physical layer 802.11b/g

Data link layer CSMA/CA

Network layer IP, ICMP, ARP

Transport layer TCP, UDP

Application layer SOCKET, LPR, SNMP agent, DHCP client, Web server, WINS

client

(4) Flow control TCP/IP flow control

(5) Antenna Built-in

(6) Parameter setting Via USB

(7) Parameter status monitoring Via HTTP

3.72 MAC address

When the wireless LAN module has been installed on the printer, the printer prints the MAC

address and wireless LAN module’s parameter settings.

[MAC address]

The MAC address is printed on the self-test result in the system mode.

For details, refer to LE840/LE850 Key Operation Manual.

3.7.3 Connection sequence

The connection sequence varies depending on the wireless LAN mode.

(1) Infrastructure Mode

The printer performs active scanning for all the supported channels at a power ON time using

the ESSID specified in advance. When the printer receives a valid active scanning response

from the access point, it enters the connection state.

The channel to be used is the one set on the access point.

The printer which is out of the connection state repeats the active scanning every 40 seconds

until it enters the connection state.

If the printer comes into a situation where it cannot receive the beacon from the access point for

a specified period of time after the connection due to weaker radio signals or other factors, the

printer goes out of the connection state. In this case, just as at a power ON time, the printer

waits for 40 seconds and then performs active scanning every 40 seconds until it is connected

again. This operation continues up to two hours.

When Supplicant is used, the 802.1x authentication is performed when the access point needs

to authenticate the printer which tries to connect to the access point (the timing differs

depending on the authentication method and access point specification.)

3-19

Page 33

when the same ESSID

is assigned.

If the printer failed in connection to an access point due

when the same ESSID

is assigned.

The

printer tries an active scanning, and connects to the

Channel 1

Roaming is enabled

Channel 2

(a) Example: Active scanning retry

to weak radio signals in spite of an active scanning with

ESSID “ABC”, the printer retries every 40 seconds.

ESSID (Extended Service Set ID): One of the identifiers

identifying a name of a wireless access point. It is named by a

user.

BSSID (Basic Service Set ID): One of the identifiers, generally

identifying the MAC address of an access point in the case of

BSS networks. It is not changeable by a user.

Note: Direct communication with wireless device is not allowed

when BSSID is different.

Channel 1

Roaming is enabled

Channel 2

network of BSSID: X1 when it receives a valid response

from the access point assigned with BSSID: X1.” The

channel to be used is the one used by the connected

access point.

(b) Example: Successful connection

3-20

Page 34

(2) Adhoc Mode

a joiner with ESSID:

ABC. When the printer cannot receive a valid response from

the creator, it becomes a creator and creates an IBSS network.

At this time, the printer refers to its own setup data for the

The printer performs active scanning for all the supported channels at a power ON time using

the ESSID set by a user in advance. When the printer receives a valid active scanning

response from the IBSS creator, the printer connects to the network as a joiner. The channel

set on the IBSS creator is used.

If the printer can receive no valid response after an approximately 3.5-second active scanning

for all the channels for , the printer becomes the IBSS creator and creates own BSS (a network

having a unique BSSID) for the channel specified for the printer.

The above operation enables a group of remotely-located wireless LAN clients (printers, handy

terminals, etc.) to share the same ESSID as well as each client of the group to become a

different network having unique BSSID. Since a communication is not allowed with the

network having different BSSID, wireless devices used in pairs are required to try connection

within a near area to avoid joining the network with different BSSID.

When the printer detects that there is a network having different BSSID but the same ESSID or

the IBSS creator exited from the network during periodic IBSS network monitoring, it tries reconnection to an optimum IBSS network. At this time, a connection may become unstable

temporarily.

Channel 1

ESSID (Extended Service Set ID): One of the identifiers,

identifying a name of a wireless access point. It is named by a

user.

BSSID (Basic Service Set ID): One of the identifiers, identifying

a wireless network. In the case of IBSS networks, it is named by

the creator.

Note: Direct communication with wireless device is not allowed

when BSSID is different.

The printer tries an active scanning as

channel to be used.

(a) Example: Joiner becomes creator

3-21

Page 35

Re-connection is

enabled when the same

ABC. When the printer receives a valid response from the

becomes a creator and creates an IBSS network.

At this time, the printer refers to its own setup data

After that, moving this n

ESSID is assigned

.

Channel 1

Channel 2

Move (Re-connection?)

The printer tries an active scanning as a joiner with ESSID:

creator, it connects to the IBSS created by the creator.

ESSID (Extended Service Set ID): One of the identifiers,

identifying a name of a wireless access point. It is named by a

user.

BSSID (Basic Service Set ID): One of the identifiers, identifying

a wireless network. In the case of IBSS networks, it is named by

the creator.

Note: Direct communication with wireless device is not allowed

when BSSID is different.

If the printer cannot receive a valid response from

the creator after performing an active scanning as

a joiner with ESSID “ABC”, the printer itself

for the channel to be used.

ew network into the cell of

BSSID: X1 network may cause the BSSID to

change to BSSID: X1.

Note: It depends on the device type.

(a) Example: Dynamic change of IBSS network

3.7.4 Received data handling when the printer enters the power save mode

Since the receive buffer has not been initialized, data sent before a timeout (power save mode)

remains in the receive buffer.

3-22

Page 36

4. TRANSMISSION SEQUENCE

<New>

flash ROM or USB

No

on the

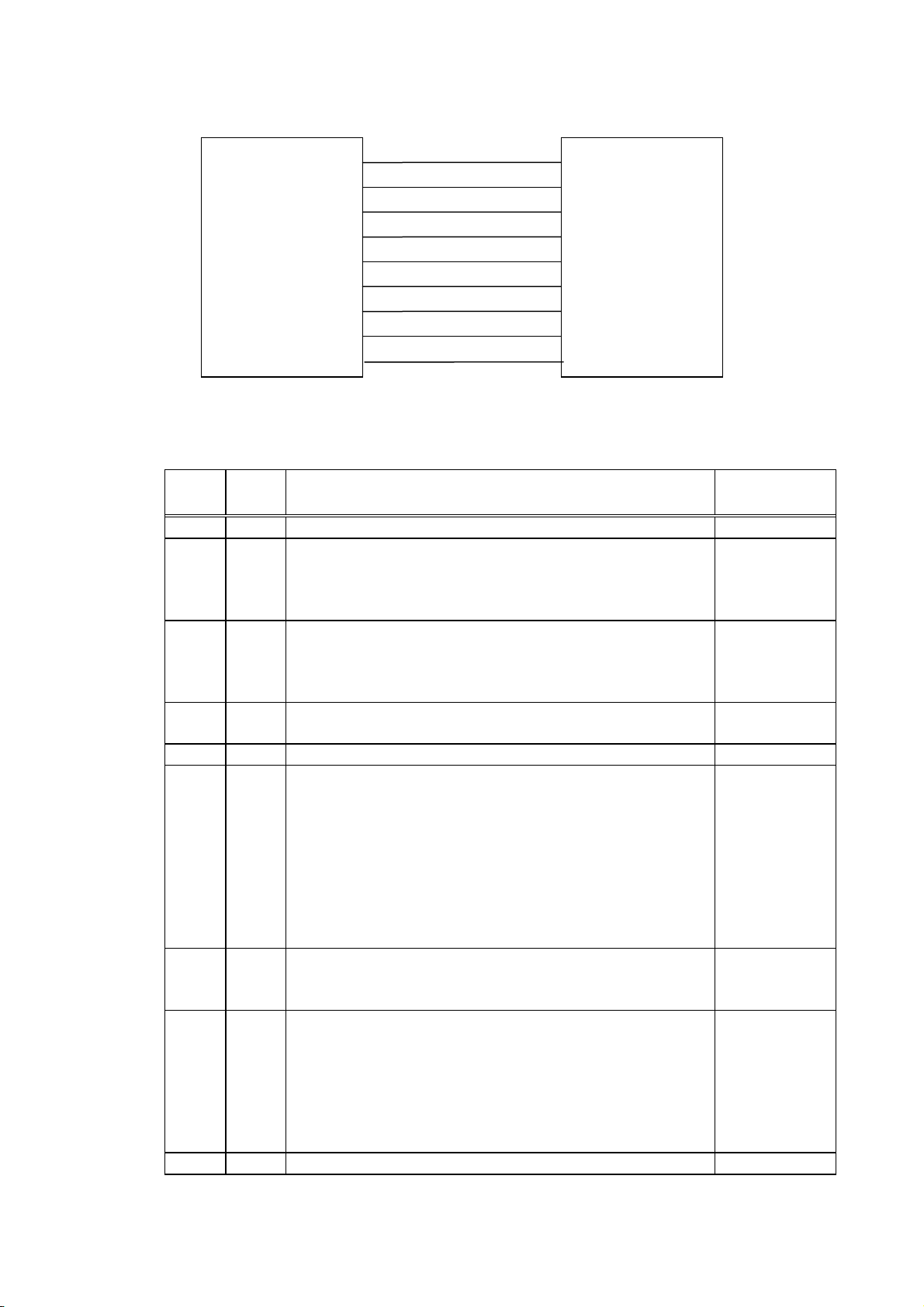

4.1 PREPARATORY SETTING

External characters, logos, and PC interface commands need be stored in the printer before

performing label issue operations.

(1) Storing writable characters and logos

(Add/change)

● Storing PC interface commands

● Label issue operation

Power ON

No

Yes

Format Command

Bitmap Writable

Character Command

Completion of storing

all characters

Yes

[ESC] J1/[ESC] JA:

Formats the on-board

memory.

[ESC] XD/[ESC] XA:

Stores writable characters or logos

on-board flash ROM or USB memory.

NOTES: (1) The storage of writable characters or logos is unnecessary when they are not used.

(2) When the on-board flash ROM is used for storage, the memory will be consumed each

time already stored writable characters or logos are saved unless the Format

Command is sent in advance.

(3) When another operation (storing PC interface commands or label issue operation) is

performed after storing writable characters or logos, the image buffer will be cleared

automatically.

(4) If a subsequent storage of writable characters or logos does not take place, the printer

automatically enters the online mode (label issue operation) in about 10 seconds. At

this time, the image buffer will be cleared automatically.

4-1

Page 37

(2) Storing PC interface commands

flash

●

Label issue operation

No

Declares the start of saving PC

Declares the termination of saving PC

(Add/change)

Power ON

No

<New>

Yes

Format Command

Save Start Command

Label Size Set Command

Position Fine Adjust Command

Print Density Fine Adjust

Command

Image Buffer Clear Command

[ESC] J1/[ESC] JA: Formats the on-board

ROM or USB memory.

[ESC] XO/[ESC] XV:

interface commands.

[ESC] D: Sets the label size.

[ESC] AX: Adjusts the feed length, cut position, and

back feed length.

[ESC] AY: Adjusts the print density.

[ESC] C: Clears the image buffer.

Line Format Command

[ESC] LC: Sets the line format and draws it.

Bit Map Font Format Command

Outline Font Format Command

Bar Code Format Command

[ESC] PC: Sets the bit map font format.

[ESC] PV: Sets the outline font format.

[ESC] XB: Sets the bar code format.

Bit Map Font Data Command

Save Terminate Command

● Storing writable characters or logos

Completion of

storage

Yes

[ESC] RC: Specifies the data for the bit map font.

[ESC] XP:

interface commands.

NOTES: (1) The storage of writable characters or logos is unnecessary when they are not used.

(2) When the on-board flash ROM is used for storage, the memory will be consumed each

time already stored PC interface commands are saved, unless the Format Command is

sent in advance.

(3) When a different operation (storing writable characters or logos or label issue operation)

is performed after storing PC interface commands, the image buffer will be cleared

automatically.

(4) Stored commands shall be selected as needed.

(5) If a subsequent storage of PC interface commands does not take place, the printer

automatically enters the online mode (label issue operation) in about 10 seconds. At

this time, the image buffer will be cleared automatically.

4-2

Page 38

4.2 LABEL ISSUE OPERATION

Adjust Command

Yes

An example of the label issue operation is shown below.

(1) When the Saved Data Call Command is not used:

Label Size Set Command

Position Fine Adjust Command

Image Buffer Clear Command

Bitmap Font Format Command

Outline Font Format Command

Bar Code Format Command

Power ON

Place paper

Print Density Fine

Feed Command

Line Format Command

[ESC] D: Sets the label size.

[ESC] AX: Adjusts the feed length, cut position, and

back feed length.

[ESC] AY: Adjusts the print tone.

[ESC] T: Feeds one label and aligns it with the print

start position.

[ESC] C: Clears the image buffer.

[ESC] LC: Sets the line format and draws it.

[ESC] PC: Sets the bit map font format.

[ESC] PV: Sets the outline font format.

[ESC] XB: Sets the bar code format.

NOTES: (1) Whenever a paper type is changed, the Label Size Set Command and the Feed

(2) After the power is turned off and on, the Bit Map Font Format Command, the Outline

Bitmap Font Data Command

Outline Font Data Command

Bar Code Data Command

Issue Command

Yes

<Data change>

No

<Format change>

Yes

<Label change>

Power OFF

Command must be sent. When the same paper continues to be used after the power

is turned off and on, the Label Size Set Command and the Feed Command may be

omitted.

Font Format Command, and the Bar Code Format Command shall be sent as occasion

demands because they are not backed up in the memory.

No

No

[ESC] RC: Draws bitmap font data.

[ESC] RV: Draws outline font data.

[ESC] RB: Draws bar code data.

[ESC] XS: Issues (prints) the label.

4-3

Page 39

(2) When the Saved Data Call Command is used:

Calls the label format stored in

board flash ROM or

and aligns it with the print

Saved Data Call Command

Bitmap Font Data Command

Outline Font Data Command

Bar Code Data Command

Yes

Yes

Power ON

Place paper

Feed Command

Issue Command

<Data change>

No

<Label change>

[ESC] XQ/[ESC]XT:

the onUSB memory.

[ESC] T: Feeds one label

start position.

[ESC] RC: Draws bitmap font data.

[ESC] RV: Draws outline font data.

[ESC] RB: Draws bar code data.

[ESC] XS: Issues (prints) the label.

NOTES: (1) Whenever a paper type is changed, the Feed Command must be sent. When the

(2) When “automatic call at power on” has been selected in the Saved Data Call

(3) When XML data is used, print data in XML format can be sent to the printer.

Power OFF

same paper continues to be used after the power is turned off and on, the Feed

Command may be omitted.

Command, the Saved Data Call Command may be omitted after the power is turned off

and on.

For details, refer to the XML Data Print Specification.

No

4-4

Page 40

5. INTERFACE COMMANDS

30 30 43 33 32 0A 00

5.1 GENERAL DESCRIPTION

5.1.1 Format of Interface Command

ESC

The length from [ESC] to [LF] [NUL] must be as specified by each command.

There are the following three kinds of control codes:

ESC (1BH), LF (0AH), NUL (00H)

{ (7BH), | (7CH), } (7DH)

Code set in the system mode

5.1.2 How to Use Reference

Function Describes the outline of the function of the command.

Format Shows the format of the command.

Command & Data LF NUL

The format designation method shall conform to the following rules:

Each set of small letters (such as aa, bbbb) indicates parameters.

An item enclosed in parentheses may be omitted.

“…” indicates the repetition of an item.

Brackets and parentheses are used only in coding, and must not be transmitted

in practice.

Other symbols must always be inserted at designated positions before being

transmitted.

Term Explains the term(s) used in the format.

* “0 to 999” described in the entry range indicates that up to 3-digit variable-length

entry is allowed. (Entry of “001” or “009” is also possible.) “000 to 999” indicates

that the entry must be fixed as 3 digits.

Explanation Explains the command in detail.

Note Supplementary explanation of the command

Refer to Related commands

Examples Explains the command examples.

The above corresponds to the transfer of the following:

[ESC] T20C30 [LF] [NUL]

1B 54

[ESC] T 2 0 C 3 0 [LF] [NUL]

5-1

Page 41

5.1.3 Precautions

•

The commands and parameters described in this specification must always be used.

•

If any other command or parameter than those covered in this specification are used, the printer

operation will not be guaranteed.

•

The commands shall be used in the online mode.

•

If any command is transmitted in the system mode, the printer will not operate.

NOTES:

(1) When a command cannot be recognized as a command, it will be ignored.

(Example) [ESC]H, [ESC]AA, etc.

(2) When an entered value does not meet the specified number of digits, a command error occurs.

(Example) A 5-digit value is entered for the parameter fixed to 4 digits.

(3) When an improper type of value was entered for a parameter, a command error occurs.

(Example 1) “000A” is entered though “0001” must be set.

(Example 2) “1” is entered though “A” must be set.

(Example 3) “3” is entered though a number must be selected from “0”, “1” and “2”.

(4) When an entered value exceeds the specified range, a command error occurs.

However, this is not applicable to the Label Size Set Command. See the section describing the

Label Size Set Command ([ESC]D.)

(5) When no data is set for non-omissible parameter, a command error occurs.

5-2

Page 42

5.1.4 List of Commands

(1) Commands related to setting

Label Size Set Command [ESC] D...................................5

(2) Commands related to fine adjustment

Position Fine Adjust Command [ESC] AX ..............................18

Print Density Fine Adjust Command [ESC] AY ..............................28

Ribbon Motor Drive Voltage Fine Adjust Command [ESC] RM..............................30

(3) Commands related to clear

Image Buffer Clear Command [ESC] C.................................31

Clear Area Command [ESC] XR ..............................32

(4) Commands related to drawing format setting

Line Format Command [ESC] LC...............................34

Bit Map Font Format Command [ESC] PC ..............................38

Outline Font Format Command [ESC] PV ..............................54

Bar Code Format Command [ESC] XB ..............................71

(5) Commands related to print data

Bit Map Font Data Command [ESC] RC............................135

Outline Font Data Command [ESC] RV ............................135

Bar Code Data Command [ESC] RB ............................138

(6) Commands related to issue and feed

Issue Command [ESC] XS ............................154

Feed Command [ESC] T...............................174

Eject Command [ESC] IB..............................184

Forward/Reverse Feed Command [ESC] U1, [ESC] U2 ...........186

(7) Commands related to writable characters

Storage Area Allocate Command [ESC] XF.............................189

Flash Memory Format Command [ESC] J1 .............................192

External Memory Format Command [ESC] JA .............................193

2-byte Writable Character Code Range Command [ESC] XE ............................194

Bit Map Writable Character Command (for flash memory) [ESC] XD ............................195

Bit Map Writable Character Command (for external memory) [ESC] XA ............................197

(8) Commands related to graphics

Graphic Command [ESC] SG............................208

(9) Commands related to PC command saving

Save Start Command (for flash memory) [ESC] XO............................216

Save Start Command (for external memory) [ESC] XV ............................217

Save Terminate Command [ESC] XP ............................219

Saved Data Call Command (for flash memory) [ESC] XQ............................220

Saved Data Call Command (for external memory) [ESC] XT.............................221

5-3

Page 43

(10) Commands related to check

Head Broken Dots Check Command [ESC] HD ............................222

(11) Commands related to display

Message Display Command [ESC] XJ .............................259

(12) Commands related to control

Reset Command [ESC] WR ...........................225

Batch Reset Command [ESC] Z0 .............................226

(13) Commands related to status

Status Request Command [ESC] WS ...........................227

Receive Buffer Free Space Request Command [ESC] WB ...........................228

Version Information Acquire Command [ESC] WV ...........................229

External Memory Information Acquire Command [ESC] WI.............................230

External Memory Writable Character Information

Acquire Command [ESC] WG...........................232

Printer Option Status Acquire Command [ESC] WN ...........................233

(14) Commands related to TCP/IP setting

IP Address Set Command [ESC] IP..............................234

Socket Communication Port Set Command [ESC] IS..............................235

DHCP Function Set Command [ESC] IH..............................236

(15) Commands related to internal serial interface

Pass-through Command [ESC] @002 .......................237

Internal Serial Interface Parameter Set Command [ESC] IZ..............................238

(16) Commands related to parameter setting

Parameter Set Command [ESC] Z2;1..........................239

Fine Adjustment Value Set Command [ESC] Z2;2..........................243

RFID Parameter Set Command [ESC] Z2;3 ..........................245

(17) Commands related to RFID

RFID Tag Position Adjustment Command [ESC] @003 .......................247

RFID Tag Read Command [ESC] WF............................249

RFID Void Pattern Print Command [ESC] @006 .......................253

RFID Data Write Command [ESC] @012 .......................254

(18) Commands related to Real Time Clock

Real Time Clock (RTC) Set Command [ESC] JT .............................263

5-4

Page 44

5.2 COMMANDS RELATED TO SETTING

5.2.1 LABEL SIZE SET COMMAND [ESC]D

Function Sets the size of a label or tag.

Format [ESC] Daaaa,bbbb,cccc(,dddd)[LF][NUL]

Term aaaa: Pitch length of the label or tag

4 or 5 digits (in 0.1 mm units)

4 digits: 0100 (10.0 mm) to 9999 (999.9 mm)

5 digits: 00100 (10.0 mm) to 15000 (1500.0 mm)

bbbb: Effective print width

Fixed to 4 digits (in 0.1 mm units)

0100 (10.0 mm) to 1040 (104.0 mm)

cccc: Effective print length

4 or 5 digits (in 0.1 mm units)

4 digits: 0060 (6.0 mm) to 9999 (999.9 mm)

5 digits: 00060 (6.0 mm) to 14980 (1498.0 mm)

dddd: Backing paper width (Omissible. When omitted, the initial value is used as the

effective print width.)

Fixed to 4 digits (in 0.1 mm units)

0300 (30.0 mm) to 1120 (112.0 mm)

5-5

Page 45

Explanation

[Print direction:

T

op first]

[Labels]

[

Print

direction:

B

ottom first]

[Tag

paper

]

[Print direction:

B

ottom first]

[Print direction:

T

op first]

Origin of

coordinates

(0, 0)

Effective

print length

0

Y

Origin of

coordinates

(0, 0)

Backing paper width

Backing paper

Label

Label

pitch

X

Effective

print width

Paper feed direction

Black mark

(Back side)

Tag

Effective

print length

X

Y

0

Backing paper width

Effective

print width

Paper feed direction

Backing paper

Label

Label

pitch

Origin of

coordinates

(0, 0)

Black mark

(Back side)

Tag

Effective

print length

0

Y

Tag

pitch

X

Effective

print width