LE840/LE850

Key Operation Manual

Technical Reference

Table of Contents

Page

1 SCOPE ....................................................................................................................................... 1

2 OUTLINE.................................................................................................................................... 1

3 OPERATION PANEL.................................................................................................................. 1

4 OUTLINE OF EACH MODE........................................................................................................ 2

4.1 ONLINE MODE............................................................................................................................... 2

4.1.1 Threshold setting mode ..................................................................................................................2

4.1.2 RFID calibration mode ....................................................................................................................2

4.1.3 Information mode ............................................................................................................................2

4.2 SYSTEM MODE ............................................................................................................................. 2

4.3 USER SYSTEM MODE.................................................................................................................. 3

5 GENERAL VIEW OF KEY OPERATION .................................................................................... 4

6 ONLINE MODE .......................................................................................................................... 6

6.1 KEY FUNCTION............................................................................................................................. 6

6.1.1 Online Mode Display.......................................................................................................................6

6.1.2 Help Display....................................................................................................................................7

6.1.3 Manual Threshold Setting Display ..................................................................................................7

6.2 LED FUNCTION ............................................................................................................................. 8

6.3 LCD FUNCTION............................................................................................................................. 8

6.4 ONLINE MODE LCD DISPLAY...................................................................................................... 8

6.4.1 Online Mode LCD Display Example................................................................................................8

6.4.2 Icon ...............................................................................................................................................10

6.4.3 Online Mode Display Transition, Operation example....................................................................11

6.5 HELP DISPLAY ............................................................................................................................ 12

6.5.1 Explanation of Help Display ..........................................................................................................12

6.5.2 Help Display Transition, Operation Example ................................................................................13

6.6 MANUAL THRESHOLD SETTING .............................................................................................. 14

6.6.1 Outline of Threshold setting ..........................................................................................................14

6.6.2 Threshold Setting Operation Example ..........................................................................................15

6.7 RFID CALIBRATION .................................................................................................................... 19

6.7.1 Outline of the RFID Calibration .....................................................................................................20

6.7.2 RFID Calibration Operation Example............................................................................................21

6.8 INFORMATION MODE................................................................................................................. 22

6.8.1 Outline of the Information Mode....................................................................................................22

6.8.2 Information Mode Operation Example ..........................................................................................23

6.8.3 Information Mode Print Sample ....................................................................................................24

6.9 JOB CANCELLATION.................................................................................................................. 25

6.9.1 Outline of the Job Cancellation .....................................................................................................25

6.9.2 Job Cancellation Operation Example............................................................................................25

6.10

Saving Log/Receive Buffer Data .............................................................................................. 26

6.10.1 Outline of Log Data Save..............................................................................................................26

6.10.2 Conditions .....................................................................................................................................26

6.10.3

6.10.4 Time Required ..............................................................................................................................26

6.10.5 Log Save Operation Example .......................................................................................................27

6.11

Data to be Saved ..........................................................................................................................26

LCD MESSAGES AND LED INDICATIONS ............................................................................ 28

7 DISPLAY PATTERN AND KEY OPERATION FOR SYSTEM MODE ANDUSER MODE......... 36

7.1 LIST BOX WITH SCROLLBAR .................................................................................................... 36

7.2 VALUE SETTING DISPLAY......................................................................................................... 40

7.3 INFORMATION DISPLAY ............................................................................................................ 42

7.4 SENSOR ADJUSTMENT DISPLAY ............................................................................................ 44

7.5 TEMPERATURE DISPLAY.......................................................................................................... 46

7.6 FILE SELECTION DISPLAY ........................................................................................................ 47

8 SYSTEM MODE ....................................................................................................................... 48

8.1 OUTLINE OF SYSTEM MODE .................................................................................................... 48

8.2 REFLECTING THE SYSTEM MODE SETTINGS IN THE PRINTER ......................................... 49

8.3 DIAG ............................................................................................................................................. 50

8.3.1 MAINTENANCE CONT.................................................................................................................50

8.3.2 AUTO DIAGNOSTIC.....................................................................................................................64

8.3.3 HEAD CHECK...............................................................................................................................71

8.4 PARAMETER SET ....................................................................................................................... 72

8.4.1 PRINTER SET ..............................................................................................................................72

8.4.2 SOFTWARE SET .........................................................................................................................76

8.4.3 PANEL ..........................................................................................................................................84

8.4.4 PASSWORD .................................................................................................................................85

8.5 ADJUST SET................................................................................................................................ 87

8.5.1 FEED ADJ.....................................................................................................................................88

8.5.2 CUT ADJ.......................................................................................................................................89

8.5.3 BACK ADJ.....................................................................................................................................94

8.5.4 X ADJUST.....................................................................................................................................95

8.5.5 TONE ADJ. (TRANS.)...................................................................................................................95

8.5.6 TONE ADJ. (DIRECT) ..................................................................................................................95

8.5.7 RBN ADJ.<FW>............................................................................................................................96

8.5.8 RBN ADJ.<BK>.............................................................................................................................97

8.5.9 THRESHOLD <REFL.>.................................................................................................................98

8.5.10 THRESHOLD <TRANS.> .............................................................................................................98

8.5.11 HDDWNADJ .................................................................................................................................99

8.6 TEST PRINT............................................................................................................................... 100

8.6.1 PRINT CONDITION ....................................................................................................................100

8.6.2 SLANT LINE (1DOT) ..................................................................................................................103

8.6.3 SLANT LINE (3DOT) ..................................................................................................................104

8.6.4 CHARACTERS ...........................................................................................................................105

8.6.5 BARCODE ..................................................................................................................................105

8.6.6 NON-PRINTING..........................................................................................................................105

8.6.7 FACTORY TEST.........................................................................................................................105

8.6.8 AUTO PRINT (TRANS.)..............................................................................................................107

8.6.9 AUTO PRINT (REFL.).................................................................................................................107

8.7 SENSOR ADJUST ..................................................................................................................... 108

8.7.1 TEMPERATURE.........................................................................................................................108

8.7.2

8.7.3 TRANS........................................................................................................................................108

8.7.4 PE REFL./TRANS.......................................................................................................................109

8.7.5 RIBBON ......................................................................................................................................109

8.8 RAM CLEAR............................................................................................................................... 110

8.8.1 NO RAM CLEAR.........................................................................................................................110

8.8.2 MAINTE.CNT CLEAR .................................................................................................................110

8.8.3 PARAMETER CLEAR.................................................................................................................111

8.9 INTERFACE ............................................................................................................................... 117

8.9.1 NETWORK..................................................................................................................................117

8.9.2 USB.............................................................................................................................................122

8.9.3 RS-232C .....................................................................................................................................123

8.9.4 CENTRO.....................................................................................................................................124

8.10

8.10.1 BASIC .........................................................................................................................................125

8.10.2 FILE MAINTENANCE .................................................................................................................125

8.10.3 TRACE........................................................................................................................................125

8.10.4 EXPAND MODE..........................................................................................................................125

8.11

8.11.1 HEAD UP ADJUST .....................................................................................................................126

8.11.2 PANEL TEST ..............................................................................................................................126

8.11.3 KEY TEST...................................................................................................................................127

8.12

8.12.1 TEST...........................................................................................................................................129

8.12.2 MODULE.....................................................................................................................................131

8.12.3 RETRY........................................................................................................................................132

8.12.4 UHF SETTING ............................................................................................................................134

8.12.5 OTHER........................................................................................................................................138

8.13

8.13.1 DATE TIME.................................................................................................................................141

8.13.2 BATTERY CHECK......................................................................................................................141

8.13.3 RENEWAL ..................................................................................................................................141

8.14

8.15

8.15.1 USB TO PRINTER......................................................................................................................144

8.15.2 PRINTER TO USB......................................................................................................................145

8.16

REFLECT....................................................................................................................................108

BASIC...................................................................................................................................... 125

FOR FACTORY ...................................................................................................................... 126

RFID........................................................................................................................................ 129

RTC......................................................................................................................................... 141

Z-MODE .................................................................................................................................. 142

USB MEMORY........................................................................................................................ 143

RESET .................................................................................................................................... 146

9 USER SYSTEM MODE........................................................................................................... 147

9.1 OUTLINE OF USER SYSTEM MODE....................................................................................... 147

9.2 RESET........................................................................................................................................ 148

9.3 PARAMETER SET ..................................................................................................................... 148

9.4 ADJUST SET.............................................................................................................................. 148

9.5 LAN/WLAN ................................................................................................................................. 149

9.5.1 LAN/WLAN..................................................................................................................................149

9.5.2 SNMP..........................................................................................................................................149

9.6 BASIC ......................................................................................................................................... 150

9.7 Z-MODE...................................................................................................................................... 150

9.8 AUTO CALIB .............................................................................................................................. 151

9.9 DUMP MODE ............................................................................................................................. 153

9.9.1 BUFFER......................................................................................................................................153

9.9.2 DUMP LIST.................................................................................................................................153

9.10

LOG......................................................................................................................................... 156

9.10.1 PRINTER TO USB......................................................................................................................156

10 POWER SAVE FUNCTION ................................................................................................. 159

1 SCOPE

This specification describes key operations using the keys and the LCD display of the LE840/LE850 series

high-end industrial general-purpose Label printers.

2 OUTLINE

Key operations are different depending on the printer mode: Online mode, in which operations are carried out

through the keys and error messages are displayed while the printer is connected to the host such as a PC, and

the system mode, in which self-test and setting of various parameters are performed.

This specification describes the key operation procedures with the printer keys and the LCD panel.

The names of the keys and LCD messages used in this specification are written in English

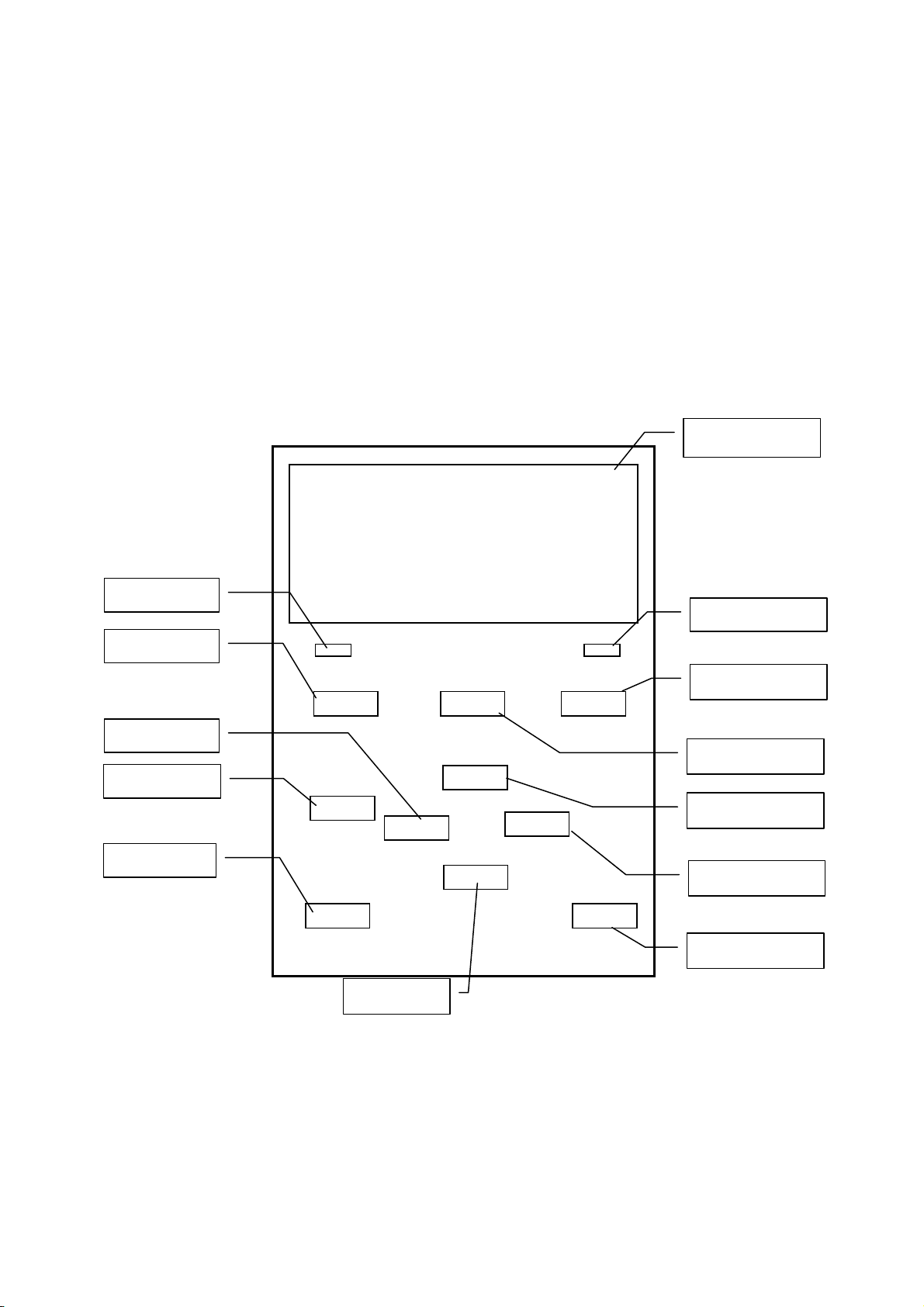

3 OPERATION PANEL

ONLINE LED

FEED key

LEFT key

MODE key

CANCEL key

DOWN key

Graphic LCD

ERROR LED

PAUSE key

RESTART key

UP key

RIGHT key

ENTER key

1

4 OUTLINE OF EACH MODE

This chapter describes the outline of each mode supported by the printer. Refer to each chapter for detailed

information.

4.1 ONLINE MODE

This mode is mainly used by users (operators).

The label or tag can be issued in the online mode. When an error occurs, the help function shows the

cause of an error, troubleshooting, and recovery from the error. The threshold setting, described below, is

also a part of the online mode.

4.1.1 Threshold setting mode

Threshold setting mode is provided to correct a print failure with pre-printed media.

When using pre-print label, detection of a print position may be disabled with the usual media sensor

threshold, depending on the ink type. Such error can be prevented by setting the threshold just for the

pre-printed media to be used. Since the threshold setting value is stored in the non-volatile memory, it is

unnecessary to set the threshold again as long as the same pre-print media is used.

4.1.2 RFID calibration mode

In the RFID calibration mode, the distance to the optimum tag write/read position and AGC value required

for properly writing/reading data on/from RFID tags are obtained through a calibration, the obtained values

are set on the printer automatically, and they are reflected in the printer operation.

To write/read data on/from RFID tags with the label printer, it was necessary to manually set a distance to

the write/read position and an AGC value, which controls the target tag, with @003 command and in the

system mode. These are automatically done in the RFID calibration mode.

4.1.3 Information mode

In the information mode, the total feed amount counted during feed and printing operations is displayed on

the LCD or printed in units of centimeter and inch.

Printing of the feed amount is performed on request.

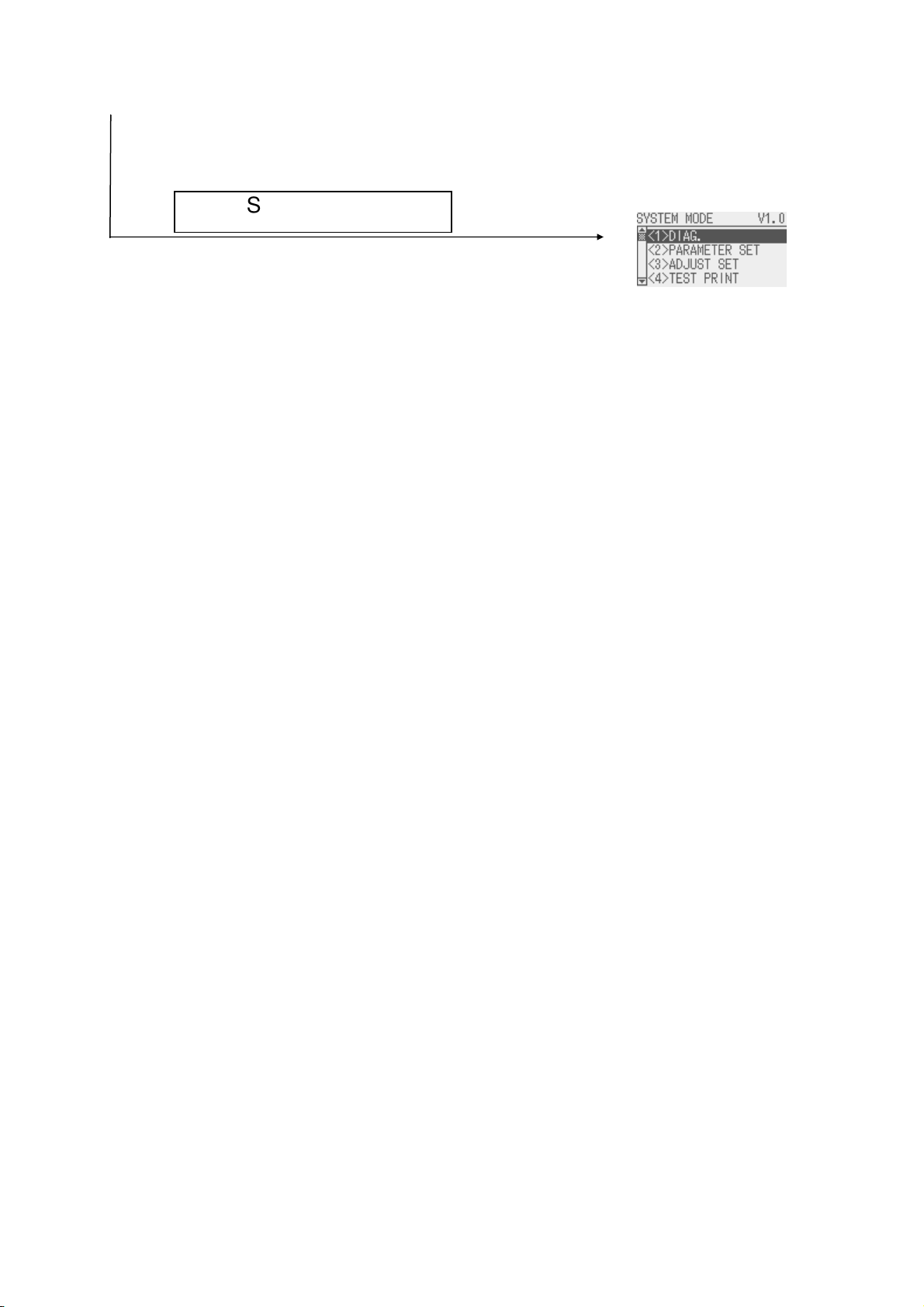

4.2 SYSTEM MODE

Turning the power on while holding down the both [FEED] and [PAUSE] keys, or the [MODE] key alone

activates the system mode. This mode is mainly used by service persons or the Production Dept. for

adjustment before shipment. The system mode contains the menus which might be changed not so

frequently.

In addition to the menus common to the User System Mode, such as parameter setting, fine adjustment,

and BASIC setting, there are sensor adjustment, interface, RFID and RTC setting menus.

Furthermore, self-diagnosis, test print, RAM clear to initialize the printer settings, pre-shipment adjustment

for factory use, and the menu which enables saving parameter settings, external characters, TPCL

commands to the external USB memory or copying the data from the USB memory to the printer are

provided. The values set in this mode are stored in the non-volatile memory.

2

4.3 USER SYSTEM MODE

The user system mode is accessible from the online mode. This mode, mainly used by users

(administrator) or service persons, contains the menus which might be frequently changed.

In addition to the menus common to the System Mode, such as parameter setting, fine adjustment, and

BASIC setting, there are LAN/WLAN setting, auto calibration, dump function which enables the printer to

dump received data.

The values set in this mode are stored in the non-volatile memory.

3

key for a few

or

Threshold setting mode

User mode

Online mode

key for a

key for a few

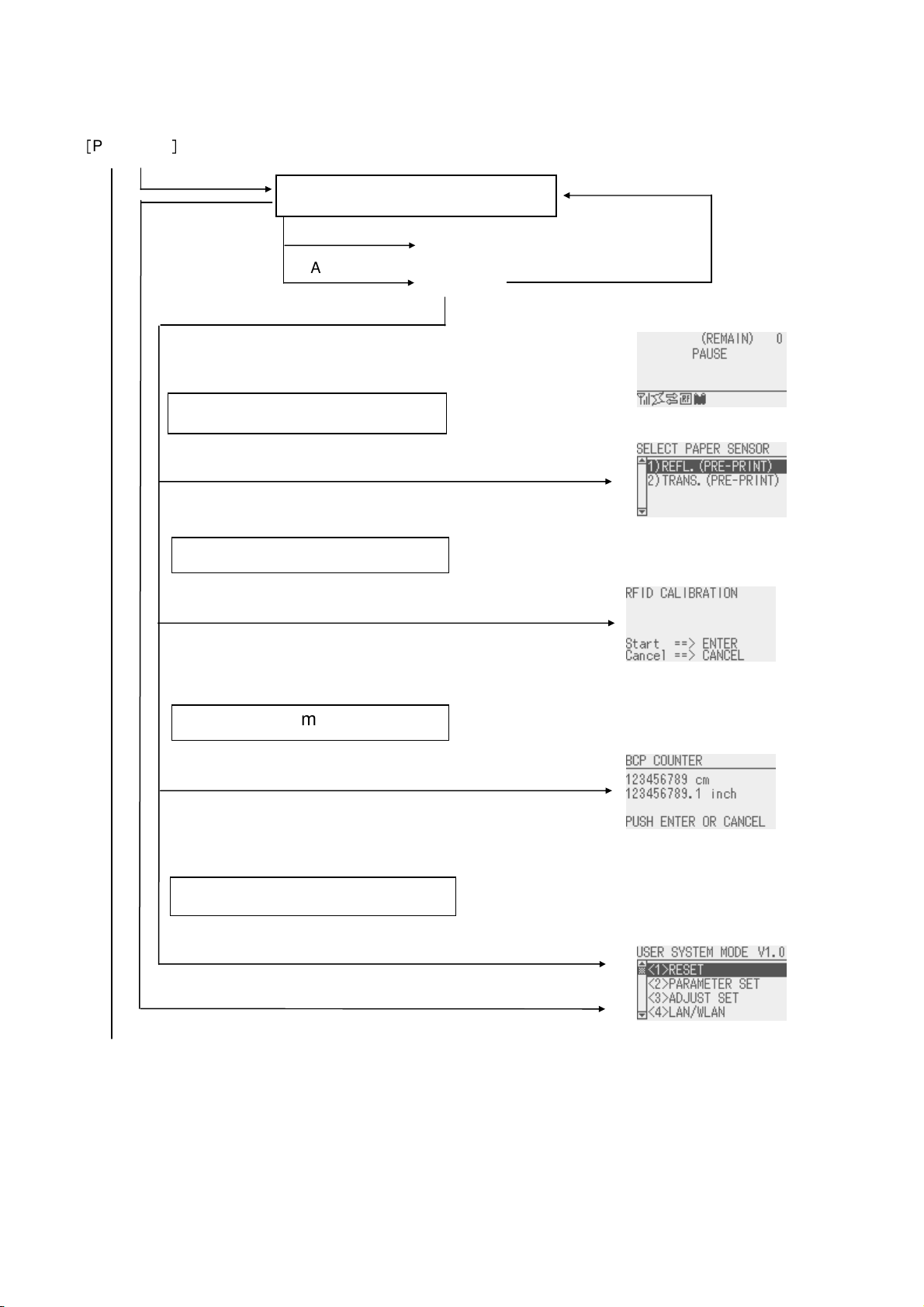

5 GENERAL VIEW OF KEY OPERATION

[

Power OFF]

Power on

[Online]

[FEED] key

[Feeds one label]

[PAUSE] key

[Pause]

Display

[RESTART] key

Hold down the [PAUSE]

seconds.

RFID calibration mode

Hold down the [ENTER]

seconds.

Information mode

Hold down the [UP] key for a few

seconds.

Hold down the [RESTART]

[MODE] key for a few seconds.

Hold down the [MODE]

few seconds.

<Continued on the next page.>

4

holding down the

keys at the same time or

System mode

<Continued from the previous page.>

Turn the power on while

[FEED] and [PAUSE]

holding down the [MODE] keys.

NOTES:

1. To enter the system mode, keep holding down the key until each display is shown.

2. Power off

When the power switch of the printer is turned off, the ONLINE and ERROR LEDs synchronously flash at a 500-ms

interval (ON: 250ms, OFF: 250ms). When the LEDs are unlit, the printer power turns off.

The power switch shall not be turned on again while these LEDs are flashing. Otherwise, “SYSTEM ERROR 02 POWER

FAILURE” message will be displayed, and the LCD message may corrupt before the error message is displayed.

5

6 ONLINE MODE

6.1 KEY FUNCTION

The printer behavior is not guaranteed when undefined key is operated.

6.1.1 Online Mode Display

Key Function

[FEED]

[RESTART]

[MODE] (1) Places the printer in the user system mode.

[CANCEL] (1) Clears the job.

[ENTER] (1) Displays help messages.

[UP] (1) Places the printer in the Information mode.

[DOWN] (1) No function.

[LEFT] (1) No function.

[RIGHT] (1) Displays help messages.

(1) Feeds one piece of media.

Ejects one piece of media.

Used to adjust the media to the proper position. If printing is attempted with the media

improperly positioned, printing is not performed at the proper position. One or two

pieces of media need to be fed to adjust the paper position before printing.

(2) Prints the data in the image buffer on one piece of media according to the system

mode setting.

NOTE: A Clear Command or a command for drawing shall not be sent while printing

caused by a depression of the [FEED] key. If it is sent, the layout will be destroyed,

and the media will not be printed properly. Also, if printing is performed by a

depression of the [FEED] key while the data is being drawn in the image buffer, the

layout may be destroyed.

* For details of the following cases, refer to the parameter setting section.

• How to issue the label stock having the label pitch of 25.4 mm or less in the cut issue

mode when the disc cutter is used.

• How to issue the label stock having the minimum label pitch or less for each print

speed in the cut issue mode when the rotary cutter is used.

* In the strip mode, feeds labels even when the peel-off sensor is detecting a label.

* When Media Load parameter is enabled, a media feed is performed to find the print

start position depending on the condition. For details, refer to Section 8.4.1.1 MEDIA

LOAD.

(1) Resumes printing after a temporary stop of printing or after an error.

(2) Places the printer in the usual initial state, which is obtained when the power is turned

on.

(3) Places the printer in the user system mode.

(1) Stops label printing temporarily. [PAUSE]

(2) Programs the threshold value.

(2) Saves the log/receive buffer data.

(3) Places the printer in the RFID calibration mode.

6

6.1.2 Help Display

Key Function

[FEED] (1) Ends help display.

[RESTART] (1) Ends help display.

[PAUSE] (1) Ends help display.

[MODE] (1) Ends help display.

[CANCEL]

[ENTER]

[UP] (1) Moves the cursor upward.

[DOWN] (1) Moves the cursor downward.

(1) Ends help display.

(2) Returns to the previous help page.

(3) Ends help display.

(1) Ends help display.

(2) Goes to the next help page.

(3) Ends help display.

(1) Returns to the previous help page. [LEFT]

(2) Ends help display.

(1) Goes to the next help page. [RIGHT]

(2) Ends help display.

6.1.3 Manual Threshold Setting Display

Key Function

(1) Moves the cursor upward. [FEED]

(2) Re-sets

[RESTART] (1) Moves the cursor downward.

(1) Sets the threshold. [PAUSE]

(2) Fixes the selection.

[MODE] No function.

[CANCEL] No function.

(1) Fixes the selection. [ENTER]

(2) Ends manual threshold setting.

[UP] (1) Moves the cursor upward.

[DOWN] (1) Moves the cursor downward.

(1) Goes to the judgment result page [LEFT]

(2) Goes to the fine adjustment setting menu

(1) Goes to the detail page. [RIGHT]

(2) Goes to the fine adjustment setting menu

7

6.2 LED FUNCTION

[ONLINE] LED

Indicates that the printer is in online state.

Flashes when the printer is communicating with the host.

Flashes at a 500-msec. interval (ON: 250ms., OFF: 250ms) in synchronization

with the [ERROR] LED when the printer is turned off.

[ERROR] LED

Indicates that the printer is in error state.

Flashes when a ribbon near end condition is detected.

Flashes when a system error occurs (at a 1-second interval (ON: 500 ms., OFF:

500 ms.)

Flashes at a 500-msec. interval (ON: 250ms., OFF: 250ms) in synchronization

with the [ONLINE] LED when the printer is turned off.

NOTE: If the wireless LAN is being linked at power off time, both [ONLINE] and [ERROR] LEDs turn on, not

flash.

6.3 LCD FUNCTION

The LCD displays the messages which indicate the printer status.

LCD

Type Graphics LCD

Size 128 dots (W) X 64 dots (H)

Display structure Maximum of 21 digits x 5 lines

6.4 ONLINE MODE LCD DISPLAY

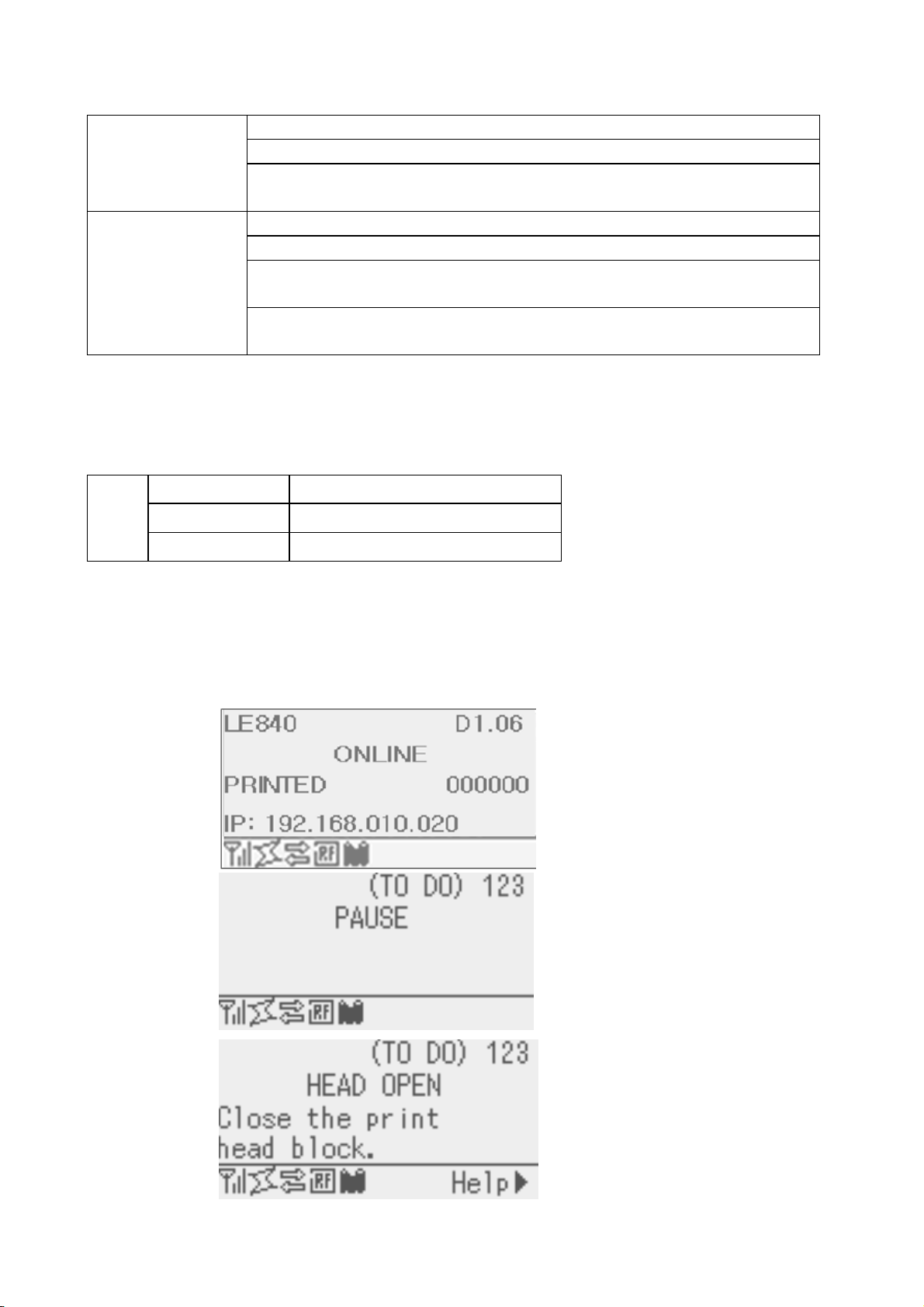

6.4.1 Online Mode LCD Display Example

Printer

condition

Online

Pause

Head open

LCD Display Display contents

← Model name, Firmware version

← Message

← The number of labels printed (*1)

← IP address etc. (*4)

← Icon

← The number of remaining labels to print (*2)

← Message

← 1st line of the error message

← 2nd line of the error message (*5)

← Icon

← The number of remaining labels to print (*2)

← Message

← 1st line of the error message

8

nd

← 2

line of the error message

← Icon, Help guide (*3)

st

* Whether to display or hide the 1

, 3rd and 4th lines of online mode display can be selected in the system mode.

* Refer to “Icon display” for Icon in detail.

(*1) The number of labels printed is the cumulative number of labels printed while the printer is activated. It is

reset to zero when the printer is turned on. During an issue with the cut interval specified, the number of

labels is updated when the label is cut normally.

(*2) [The number of remaining labels to print] = [Specified number of labels to print] – [The number of normally

printed labels before occurrence of an error or placing the printer in pause]

When the number of remaining labels to print is zero, it is not displayed. During an issue with the cut

interval specified, the number of remaining labels is updated when the label is cut normally.

(*3) The help guide is displayed only when applicable help message exists.

(*4) The message displayed in this area is IP address or supplemental information like ribbon near end.

•

When LAN/WLAN setting is disabled, the IP address is not displayed even if displaying IP address is

enabled in the system mode.

•

The ribbon near end message is displayed when a ribbon near end is detected, regardless of whether or

not displaying the ribbon near end message is enabled in system mode.

A ribbon near end is detected depending on diameter of the unused ribbon. The diameter of 38mm is

equivalent to 30-meter ribbon and the diameter of 43 mm is equivalent to 70-meter ribbon, respectively.

(*5) The ribbon near end message may be displayed on this line. The condition for display is the same as *4.

9

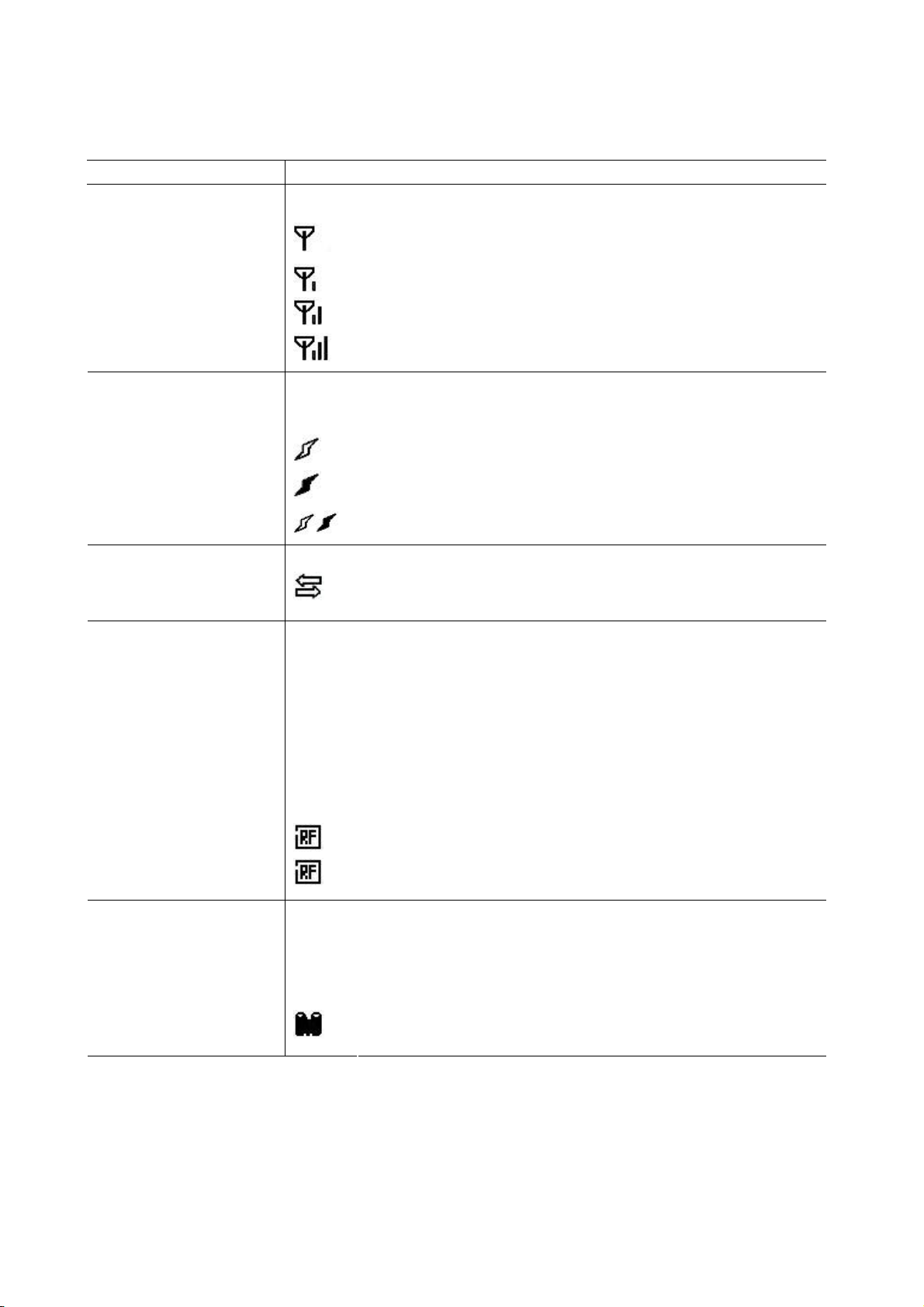

6.4.2 Icon

Five kinds of icon are displayed in the bottom line of the online mode display.

These icons are displayed only in the online mode display.

Icon Explanation

Wireless LAN icon

Displayed and used when the wireless LAN module is mounted.

The graph shows the strength of radio wave.

Graph 0: Outside the communication range

Graph 1: Strength of radio wave is weak.

Graph 2: Strength of radio wave is middle

Graph 3: Strength of radio wave is strong

Link icon

RFID icon

Displayed and used when the wireless LAN module is mounted.

Displayed while the printer is communicating by wireless LAN.

Blinks while roaming.

OFF: No connection

ON: Connecting to an access point

Blink: Roaming (*4)

Appears when a print job is present. Data transmission icon

ON: Print job is present.

Displayed and used when the RFID module is mounted.

Appears when a communication between the printer and the RFID

module is enabled.

Blinks during a communication with the RFID module.

- The communication includes the one without radio wave output.

- Blinks after radio wave output is instructed to the module even when no

radio wave is output.

(Blinks while the module stops outputting radio wave or changing the

channel under the influence of other carrier.)

ON: Module type is set and ready to communicate

⇔

Blink: Communicating

Ribbon near end icon

(*4) Icon blinks at a 1-second interval (ON for 500 msec. and OFF for 500 msec.)

Ribbon near end is detected.

Blinks when the ribbon is close to the end.

Ribbon near end is detected depending on the diameter of unused

ribbon. ∅38 mm is equivalent to 30-meter ribbon and ∅43 mm is

equivalent to 70-meter ribbon.

Blinking: Ribbon near end state (*4)

10

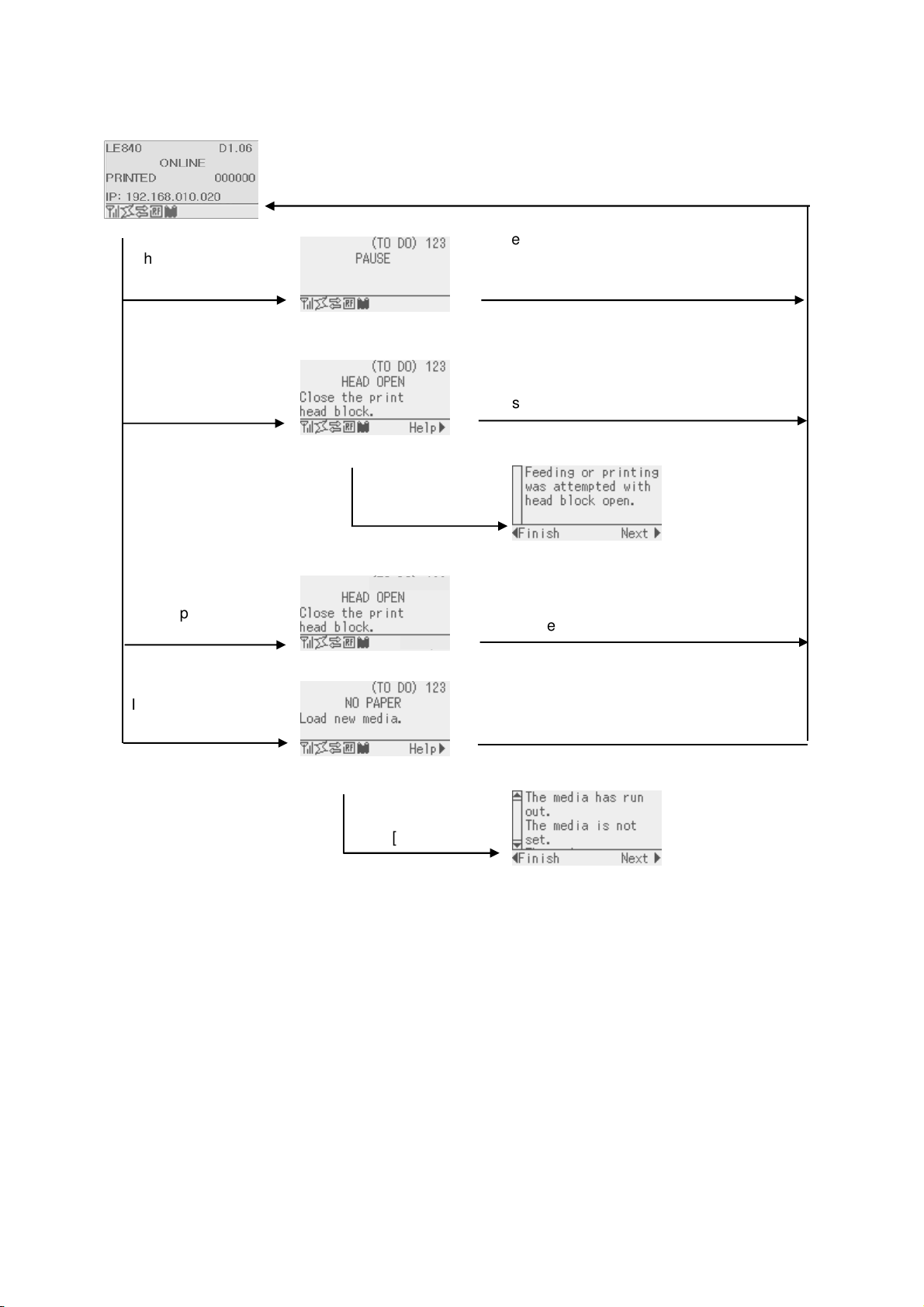

If the print head is

If an error occurs

is

When [RESTART] key is pressed, the

printer resumes printing if there is

If the print head is

6.4.3 Online Mode Display Transition, Operation example

Idling or normal issuing

When [PAUSE] key

pressed while printing:

remaining data

Printing is stopped

opened while printing:

opened while idling:

while printing:

Help guide is displayed.

Press [RIGHT] key.

Printing is stopped and Help

guide is displayed.

Close the print head.

Close the print head.

Help guide message for head open

(*1)

Load media.

When [RESTART] key is pressed, the

printer resumes printing if there is

remaining data.

Press [RIGHT] key.

(*1) Refer “HELP DISPLAY TRANSITION, OPERATION EXAMPLE” for help display.

Help message for NO PAPER (*1)

11

6.5 HELP DISPLAY

6.5.1 Explanation of Help Display

When “Help” is displayed at the lower right of the online mode display, pressing [RIGHT] or [ENTER] key

causes the help message to be shown.

Help message is displayed on the upper four lines. When the message exceeds four lines, the hidden lines

can be displayed by scrolling down. When scrolling is possible, the up and down arrows are provided on the

scrollbar on the left.

Display example:

← 1st line of help message

← 2nd line of help message

← 3rd line of help message

← 4th line of help message

← Help guide

Since the help message is within three lines, the scroll bar is not provided with up and down

arrows.

← 1st line of help message

← 2nd line of help message

← 3rd line of help message

← 4th line of help message

← Help guide

Since the help message exceeds four lines, the scroll bar is provided with the up and down

arrows.

12

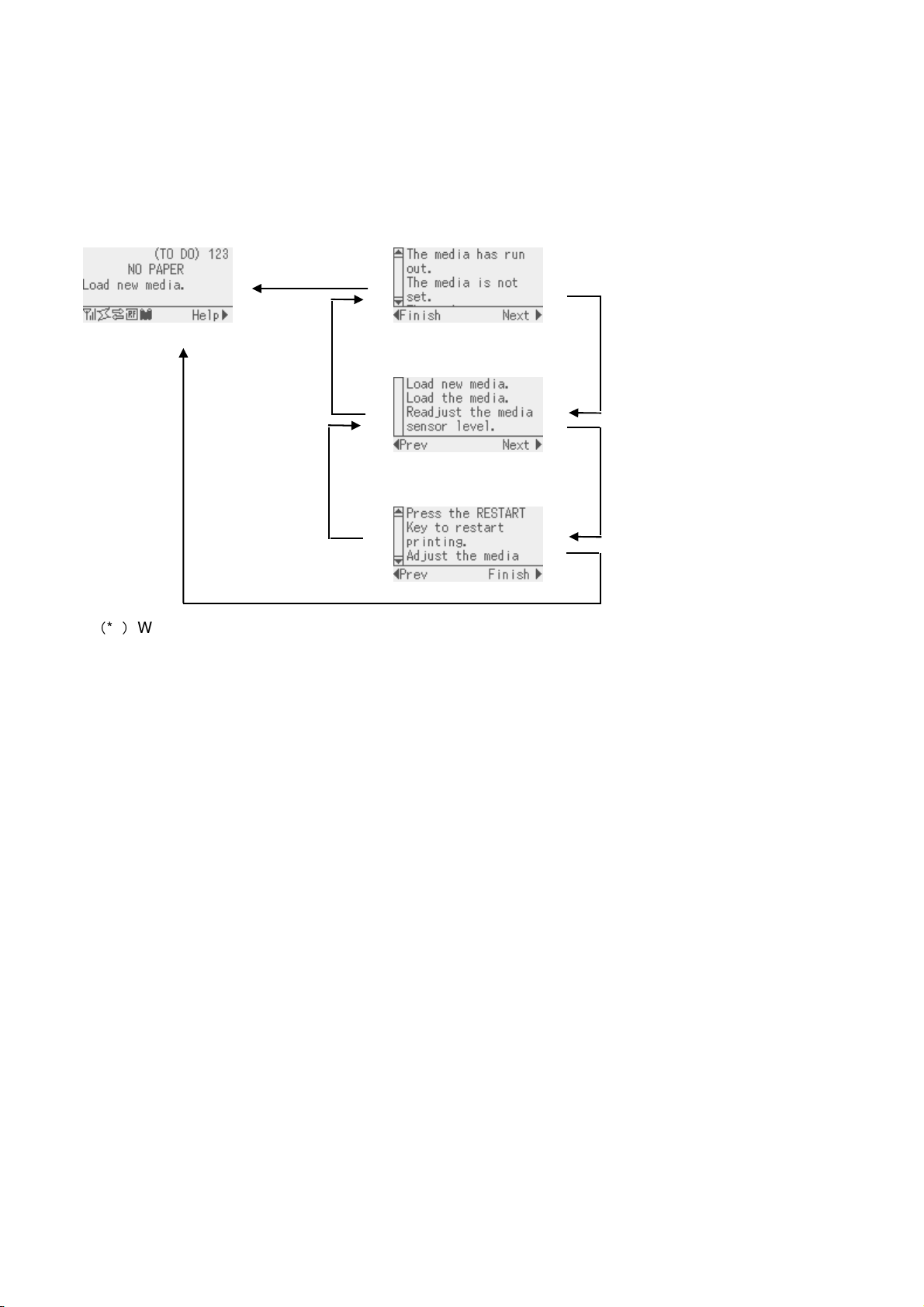

6.5.2 Help Display Transition, Operation Example

The help consists of three pages, which are Help1, Help2 and Help3.

Help1 shows the detail of the error, Help2 shows a troubleshooting, and Help3 shows how to recover from the

error.

Display transition

[LEFT] key

[CANCEL] key

Online mode Error detail

Troubleshooting

How to recover from error

(*5)

When a key other than above is pressed, the help display is ended and returned to the online m

ode display.

Display transition

[RIGHT] key

[ENTER] key

Scroll the display

with the [UP] or

[DOWN] key.

Scroll the display

with the [UP] or

[DOWN] key.

Scroll the display

with the [UP] or

[DOWN] key.

13

6.6 MANUAL THRESHOLD SETTING

6.6.1 Outline of Threshold setting

When a label stock is printed, the printer automatically corrects the print position by detecting gaps between

the labels using the transmissive sensor to maintain a constant print position. However, when a preprinted

label is used, some ink may prevent proper gap detection. In this case, it is required to manually program

the transmissive sensor threshold through key operations and store the value in the non-volatile memory.

Selecting “3: Transmissive Sensor (when using the preprinted label)” for the sensor type of the Issue

Command enables printing at a constant print position.

When the media with black marks printed on the back side is used, the printer automatically corrects the

print position by detecting the black marks by using the reflective sensor. However, if there is reflective rate

variation at a portion other than the black mark, the print position cannot be corrected properly. In this case,

it is required to manually program the reflective sensor threshold through key operations and store the value

in the non-volatile memory.

Selecting “4: Reflective Sensor (when using a manual threshold value)” for the sensor type of the Issue

Command enables printing at a constant print position.

14

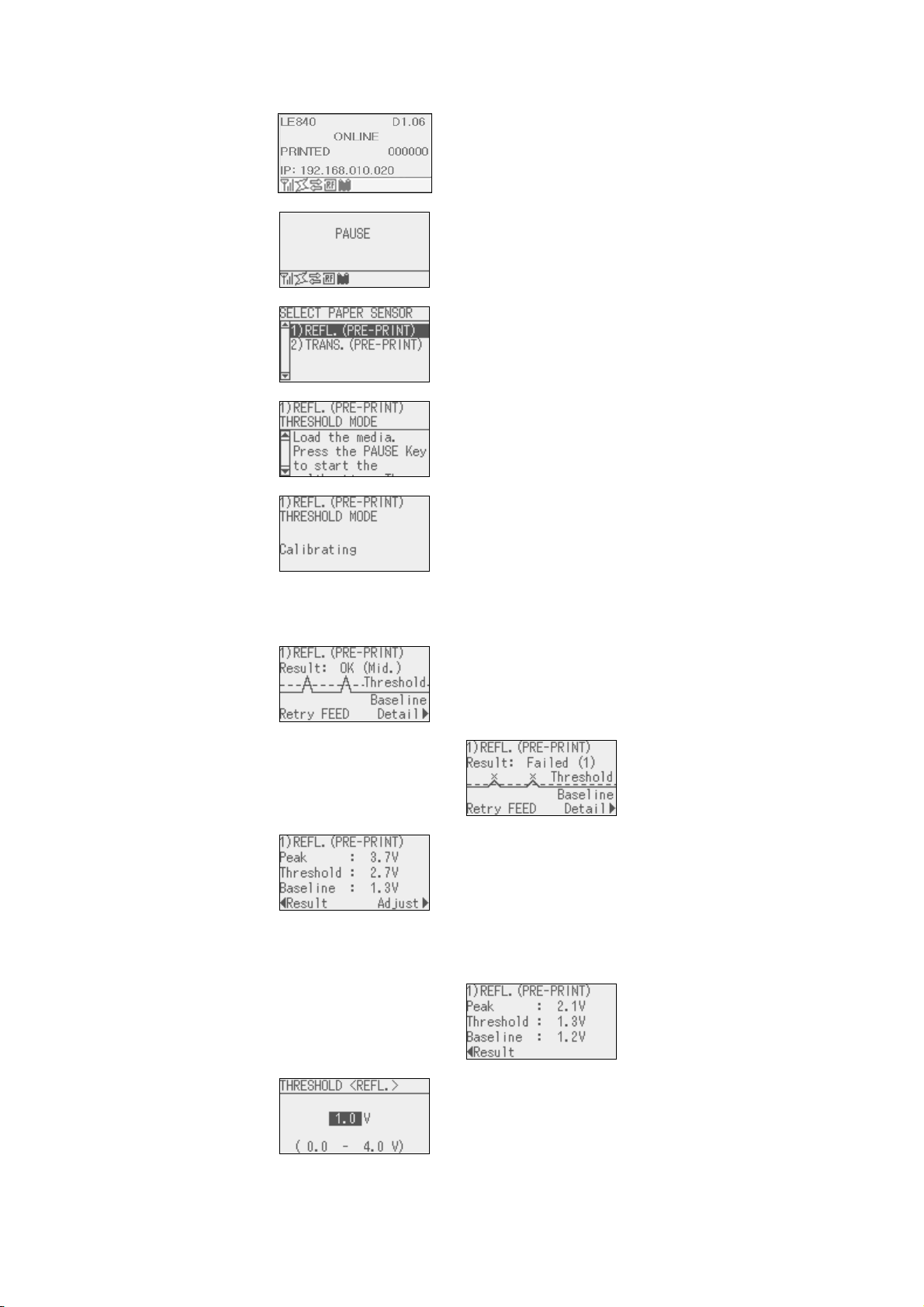

6.6.2 Threshold Setting Operation Example

[Online mode]

1. Normal state

[Online mode]

2. Pause state

[Threshold setting]

3.

Media sensor

selection

[Threshold setting]

4.

Waiting for the

media to be loaded

[Threshold setting]

5. Calibration

[Threshold setting]

6a.

Result: OK (Mid.)

[Threshold setting]

6b.

Result: NG (1)

[Threshold setting]

7a.

Detail: OK (Mid.)

[Threshold setting]

7b.

Detail: NG (1)

[Threshold setting]

8a. Sensor fine

adjustment

↓ Press [PAUSE] key

↓ Hold down [PAUSE] key for 3 seconds

Move the cursor with the

[UP] or [DOWN] key

↓ Press [ENTER] key

Scroll the display with the

[UP] or [DOWN] key

↓ Press [PAUSE] key

Hold down the [PAUSE]

key to keep feeding the

media

↓ Release [PAUSE] key.

↓ ↓

↓

↓

↓

↓

↓ ↓

↓

↓

↓

↓ Press [RIGHT] key

↓

↓

↓

↓

↓

↓

↓

↓ ↓

↓

↓

↓

↓ Press [RIGHT] key

Operation is same as 8.5.9

reflective sensor fine

adjustment

When the [PAUSE] key is

released, media feed

stops

Pressing the [FEED] key

returns the display to “3.

Media sensor selection.”

Pressing the [ENTER] key

returns the display to “2.

Pause condition.”

Pressing the [RIGHT] key

causes the display to go

to “7a/7b. Detail.

Pressing the [RIGHT] key

causes the display to go

to “8a. Sensor Fine

adjustment.”

Pressing the [LEFT] key

returns the display to “6a.

Judgment.”

Pressing the [LEFT] key

returns the display to “6b.

Judgment

Pressing the [PAUSE],

[ENTER] or [CANCEL]

key returns the display to

“6a. Judgment

15

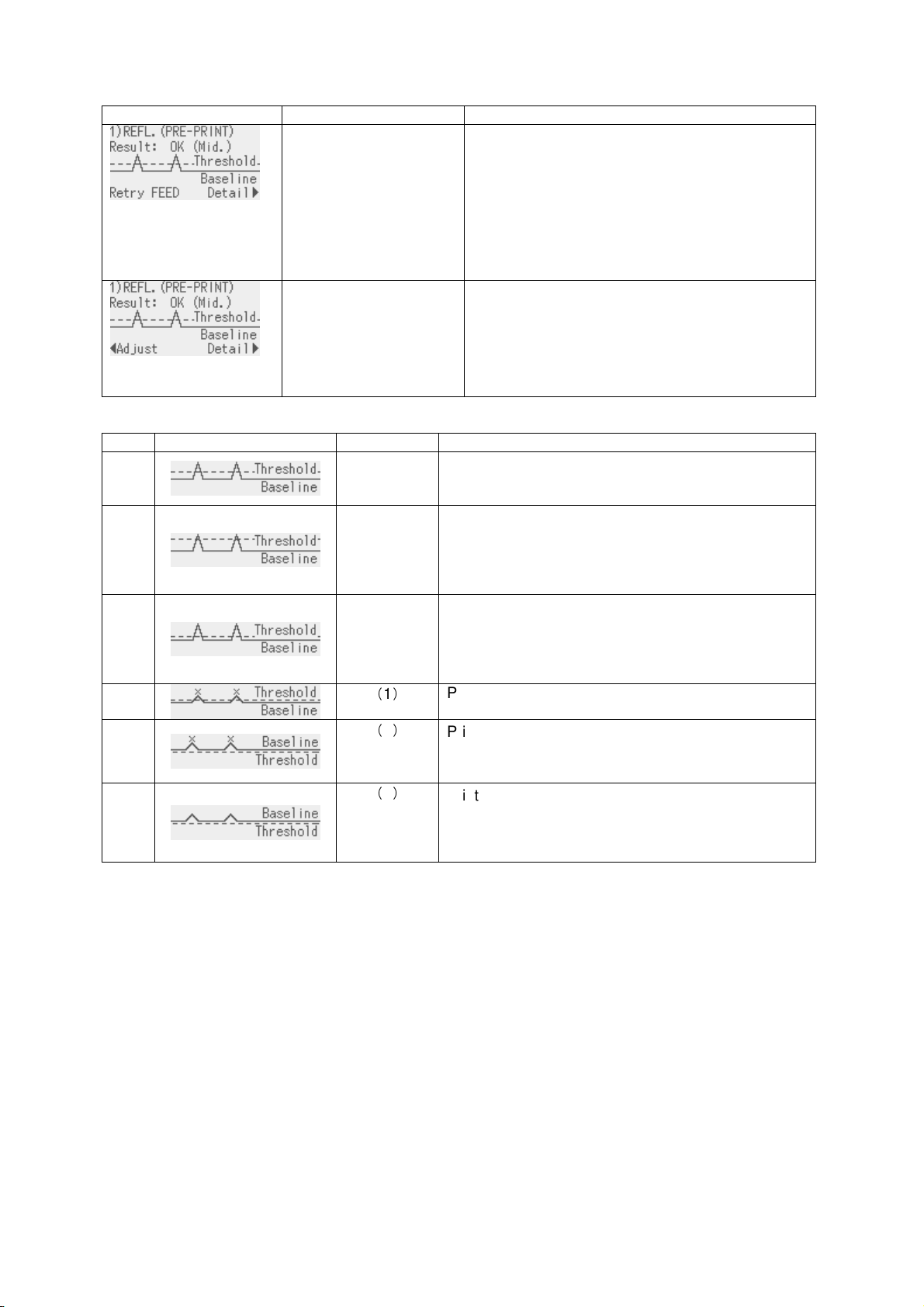

Judgment result

Display example Displayed item Explanation

•

Sensor type

•

Result (Text)

•

Result (Graph)

•

Key operation guide

The calibration result is shown.

Pressing the [FEED] key returns the display to

the media sensor selection and enables a

threshold setting.

Pressing the [RIGHT] key shows the measured

voltages.

Pressing the [ENTER] key terminates the

threshold setting.

•

Sensor type

•

Result (Text)

•

Result (Graph)

•

Key operation guide

The result of fine adjusted threshold setting is

shown.

Pressing the [LEFT] key returns the display to

the threshold fine adjustment.

The [RIGHT] and [ENTER] keys function in the

same way as above.

The threshold setting result is indicated with one of the following icon types.

No. Display example Icon name Explanation

1

2

OK (Mid.) Print position is detectable with the media sensor.

Threshold is at the midpoint between the peak and

the baseline.

OK (High) Threshold is near the peak voltage, so detection of a

gap/black mark may fail if the voltage difference is

very small. (Adjusting the threshold to the midpoint

between the peak and the baseline enables more

accurate detection.)

3

OK (Low) Threshold is near the baseline voltage, so detection

of a gap/black mark may fail if the voltage difference

is very small. (Adjusting the threshold to the

midpoint between the peak and the baseline

enables more accurate detection.)

4

5

6

NG (1)

NG (1)

NG (2)

Print position is not detectable with the media

sensor. Sensor adjustment is necessary.

Print position is not detectable with the media

sensor. Sensor adjustment is necessary.

(Threshold ≤ Baseline)

Print position is not detectable with the media

sensor.

(Calibration may enable print position detection, b

ut it is very difficult.)

16

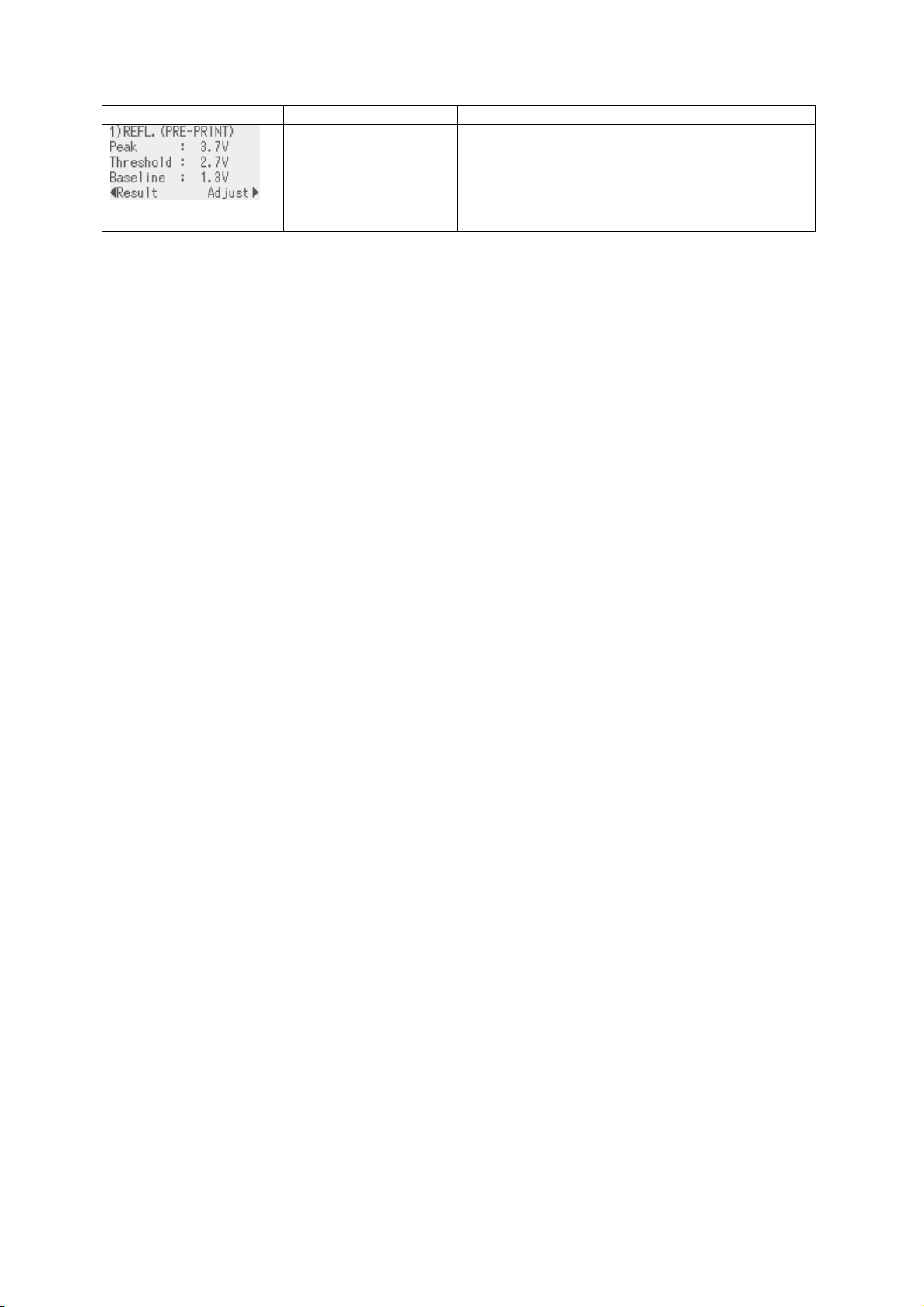

Detailed display

Display example Displayed item Explanation

•

Sensor type

•

Peak value

•

Threshold voltage

•

Baseline voltage

•

Key operation guide

The calibration result and the threshold voltage

are displayed.

Pressing the [RIGHT] key enables setting a

threshold fine adjustment value.

Pressing the [LEFT] key returns the display to the

calibration result display.

(Supplementary Explanation)

(1) When the [PAUSE] key is released within 3 seconds while the printer is paused, the [PAUSE] key is

invalid.

(2) To program the threshold, 1.5 pieces or more label shall be fed. (If the label feed amount is insufficient,

the threshold may not be properly programmed. In this case, the threshold setting is required again.)

(3) While the head is lifted, the [PAUSE] key is invalid even if the [PAUSE] key is held down for 3 seconds or

more.

(4) When the proper print position is not obtained even after threshold setting, the sensor may be improperly

adjusted. In this case, readjust the sensor in system mode, and program the threshold.

When the backing paper of the label is too thick, the transmissive sensor needs to be readjusted.

In addition, make sure that “3: Transmissive sensor (when using the preprinted label)” or “4: Reflective

sensor (when using a manual threshold value)” is selected for sensor type of the Feed Command and the

Issue Command.

(5) Paper end and ribbon end are not detectable during the threshold setting. (The setting continues as long

as the [PAUSE] key is held down even if the printer runs short of media or ribbon.)

(6) The detailed display is shown when the [RIGHT] key is pressed while the result is displayed. The

measured sensor level and the currently programmed threshold fine adjustment value can be checked.

Fine adjustment value = Peak voltage – Threshold voltage

(7) Pressing the [LEFT] key returns the detailed display to the result display. Pressing the [RIGHT] key

causes the display to go to threshold fine adjustment screen. This is the same menu with the threshold

fine adjustment menu in section 8.5.9 (Reflective sensor) or 8.5.10 (Transmissive sensor).

(8) After setting the threshold fine adjustment value, the screen returns to the result display.

(9) While the result of fine adjusted threshold setting is shown, pressing the [LEFT] key returns the display to

the threshold fine adjustment screen and pressing the [RIGHT] key goes to the detailed display.

(10) During threshold setting, the media is fed at the same speed with that for the previous issue.

(11) Whether the threshold setting succeeded or not can be checked with either of the following methods.

Media feed with the [FEED] key

1. While the judgment result is displayed, press the [FEED] key to terminate the threshold setting.

→ The printer is placed in the pause state.

2. Press the [RESTART] key to clear the pause state.

→ The printer is placed in the online state.

3. Hold down the [MODE] key.

→ The printer enters the user system mode.

4. Select “<2>PARAMETER SET”, “Software Set”, then “THRESHOLD SELECT” with the [UP], [DOWN] and

[ENTER] keys.

5. Select the applicable media sensor type (“REFLECT” or “TRANS.”) and press the [ENTER] key.

→ The selected sensor type display is shown.

6. Select “MANUAL SET”, press the [ENTER] key, then [MODE] key.

→ User system mode menu is displayed.

17

7. Select “<1> RESET” and press the [ENTER] key.

→ After the printer is reset, it is placed in the online mode.

8. Press the [FEED] key to feed the media.

→ If a paper jam occurs or the media does not stop at the print start position, retry the threshold setting.

Sending Issue command

1. Press the [FEED] key while the judgment result is displayed to terminate the threshold setting.

→ The printer is placed in the pause state.

2. Press the [RESTART] key to clear the pause state.

→ The printer is placed in the online state.

3. Hold down the [MODE] key.

→ The printer enters the user system mode.

4. Select “<2>PARAMETER SET”, “Software Set”, then “THRESHOLD SELECT” with the [UP], [DOWN] and

[ENTER] keys.

5. Select the media sensor type (“REFLECT” or “TRANS.”) depending on the sensor type specified by the

Issue Command, and press the [ENTER] key.

Sensor type in Issue Command Setting

0: No sensor Whether the threshold setting succeeded or not cannot be

checked.

1: Reflective sensor Select “REFLECT”.

When the selected sensor type display is shown, select

“MANUAL SET” and press the [ENTER] key.

* Select the media sensor type to the one for which the

threshold was set.

2: Transmissive sensor (when using

normal labels)

Select “TRANS.”

When the selected sensor type display is shown, select

“MANUAL SET” and press the [ENTER] key.

* Select the media sensor type to the one for which the

threshold was set.

3: Transmissive sensor (when using

No setting is necessary.

preprinted labels)

4: Reflective sensor (when using a

No setting is necessary.

manual threshold value)

6. Press the [MODE] key.

→ User system mode menu is displayed.

7. Select “<1> RESET” and press the [ENTER] key.

→ After the printer is reset, it is placed in the online mode.

8. Send an Issue Command to make the printer print.

→ If a paper jam occurs or the media does not stop at the print start position, retry the threshold setting.

18

6.7 RFID CALIBRATION

The supported RFID tag types are the following three, which are used at Decathlon. The others are

unusable.

UPM Web for Store

UPM Web for Warehouse

IER for Warehouse

19

6.7.1 Outline of the RFID Calibration

The RFID calibration is a function to automatically determine the distance to the optimum write/read

position and AGC value required for properly writing/reading data on/from RFID tags.

When the result of an RFID calibration is saved (by pressing the [ENTER] key) while the detected values are

shown on the screen, the value obtained through the RFID calibration is set for the CALIB. AGC and CALIB.

POSITION parameters in the system mode and the CALIB. MODE is turned on automatically.

NOTES:

1. Note that the optimum write/read positions and AGC value obtained through RFID calibration do not

guarantee a perfect write/read, so they should be used as a guide.

2. Prior to an RFID calibration, be sure to perform an automatic calibration (<7>AUTO CALIB. in the user

system mode) to place the media at the print start position.

3. If an RFID calibration is performed without placing the media at the print start position, an improper value

may be set, which may cause an error message, “RFID WRITE ERROR”, to be shown during

writing/reading data or data to be written on/read from a wrong tag.

4. If an error message, “RFID WRITE ERROR”, often appears while writing/reading data on/from RFID tags

with CALIB. MODE parameter enabled, perform an automatic calibration (<7>AUTO CALIB. in the user

system mode) or change the setting value for the POWER LEVEL parameter in the system mode, then

perform an RFID calibration again.

5. If an RFID calibration is performed while the actual antenna position is different from that set for the

ANTENNA POSITION parameter in the system mode, an improper value may be set, which may cause

an error message, “RFID WRITE ERROR”, to be shown during writing/reading data or data to be written

on/read from a wrong tag.

Actual antenna position

Rotation of antenna Wave director position

0° 0 mm FRONT

0° 9 mm CENTER

180° 12 mm REAR

Antenna position set in

the system mode

20

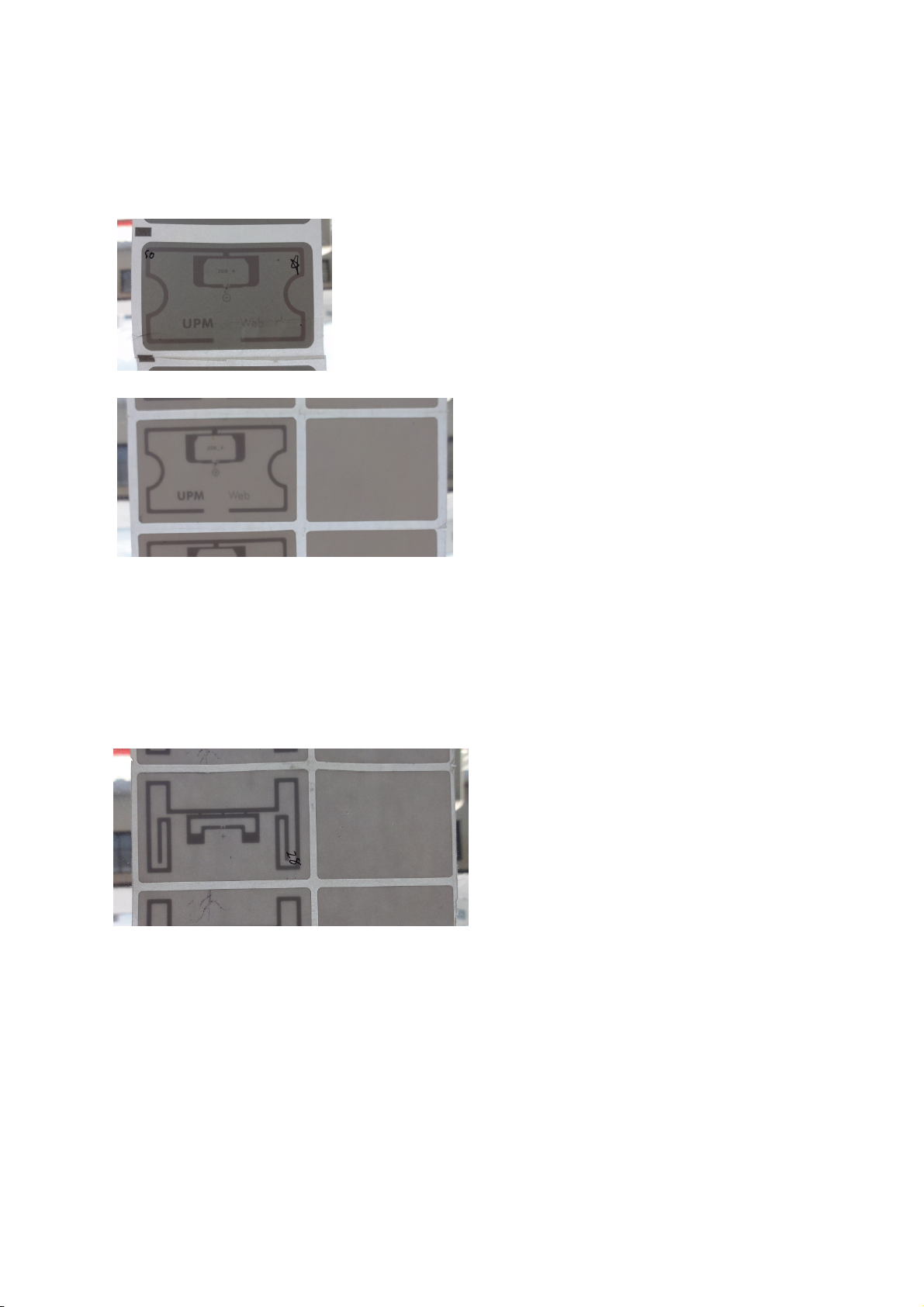

6.7.2 RFID Calibration Operation Example

NOTE: Be sure to place the RFID media at the print start position in advance by performing an automatic

calibration (<7>AUTO. CALIB.).

[Online mode]

1. Normal state

[Online mode]

2. Pause state

↓ Press [PAUSE] key.

[RFID Calibration]

3.

Calibration start

[RFID Calibration]

4. Calibration is being

performed.

[RFID Calibration]

5a. Result: Detected.

[

RFID Calibration

5a.

Result: Not found.

↓ Hold down [ENTER] key for 3 seconds.

Press [CANCEL] key to

return to the normal

state.

↓ Press [ENTER] key.

↓

Pressing the [ENTER] key returns the display to 1. Normal

state.

The value of “POSITION” is set for “CALIB. POSITION”, the

value of “AGC” is set for “CALIB. AGC”, and ”CALIB. MODE”

is turned ON.

Pressing the [CANCEL] key returns the display to 1. Normal

state.

Values of “POSITION” and “AGC” on the display are not

saved.

]

Pressing the [CANCEL] key returns the display to 1.

No value is saved.

(Supplementary Explanation)

(1) The position and AGC value obtained through an RFID calibration are calibrated with reference to the

media at the print start position.

(2) When the [ENTER] key is released within 3 seconds while the printer is paused, the [ENTER] key is

invalid.

(3) After performing an RFID calibration, the printer returns the RFID media to the print start position.

(4) An RFID calibration is enabled when the FORWARD WAIT parameter is set to ON. In this case, the

printer feeds the RFID media to the print start position temporarily, performs an RFID calibration, then

returns the media to the former position.

(5) If an engine-related error (such as print head open, paper end, ribbon end, and ribbon near end) occurs

during an RFID calibration, the printer stops at the moment the error occurs. Therefore, the media dos not

return to the print start position (or the forwarded position in the case the FORWARD WAIT parameter is

ON.) In this case, the LCD will show the display of 5a. Result Not detected.

(6) An RFID calibration is inoperable in the strip mode.

(7) Do not send a command to the printer while an RFID calibration is being performed. If a command is

sent during an RFID calibration, printer operation is not guaranteed.

21

6.8 INFORMATION MODE

6.8.1 Outline of the Information Mode

In the information mode, the total feed amount counted during feed and printing operations is displayed

on the LCD, and printed in units of centimeter and inch on request.

The feed amount is counted at the end of feed or printing, and saved in the non-volatile memory.

NOTES:

1. The effective range of the feed amount

the maximum value will be saved.

In unit of centimeter: 0 to 320000000

In unit of inch: 0.0 to 125984251.9

2. In the following cases, feed or printing is not counted in this feed amount

Reverse feed, Forward feed to the strip position, Pre-strip feed, Auto forward feed, Void printing on

RFID media, RFID tag position adjustment command (@003 command), Pre-reverse feed when an

expansion I/O device is connected, Printing in offline (Diag. test print, maintenance counter print, test

print, dump), printing in the information mode, manual threshold, automatic calibration, and RFID

calibration

3. Since the feed amount

(*1)

is counted based on the label pitch specified by the command, a large

margin of error may be generated if the command-specified label pitch differs from the

actually-measured label pitch.

(*1)

is as follows. When the feed amount exceeds the maximum,

(*1)

.

4. Since the counted feed amount is saved in the non-volatile memory (EEPROM), replacement of the

EEPROM is prohibited. (Except for the case the Main PC board is replaced with a service part.)

(*1): Feed amount counted in the information mode

22

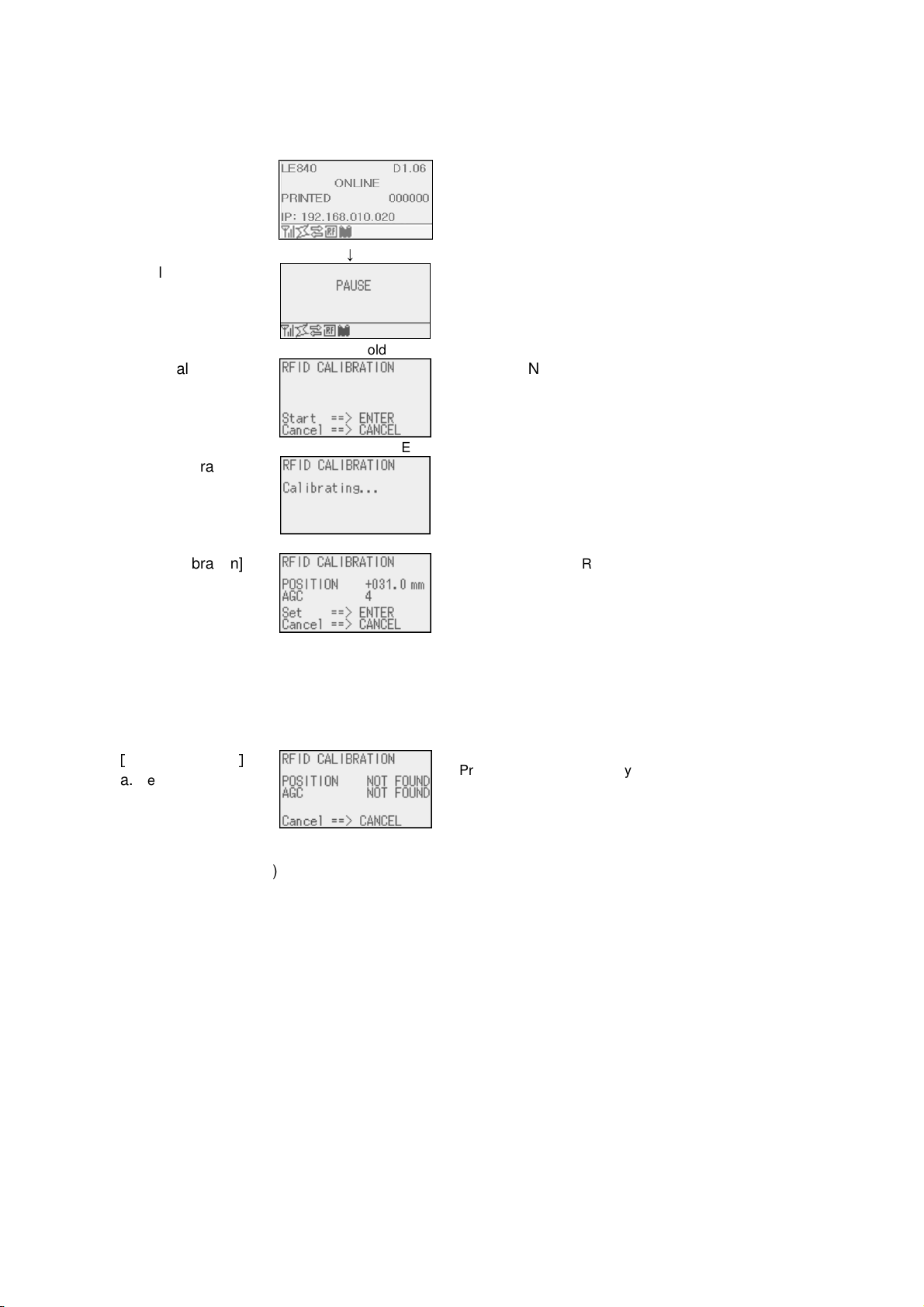

6.8.2 Information Mode Operation Example

[Online mode]

1. Normal state

[Online mode]

2. Pause state

↓ Press [PAUSE] key.

[Information mode]

3.

Feed amount is

displayed.

↓ Hold down [UP] key for 3 seconds.

Press [CANCEL] key to

return to 1. Normal state.

[Information mode]

4. Printing is

performed.

↓ Press [ENTER] key.

After printing is finished,

the display returns to 1.

Normal state.

(Supplementary Explanation)

(1) When printing is performed in this mode, a quick reset is performed.

Performing a quick reset causes the print count (number of labels issued) to be reset to zero and the

image buffer to be cleared. When the automatic calibration is enabled, a calibration is performed after

the quick reset.

When the automatic call at power on parameter is enabled in the Saved data call command, saved data

will be called after a quick reset.

(2) Previous print conditions are applied to the printing performed in this mode, except:

Printing direction

When the mirror printing has been specified, only the mirror printing is not performed. Therefore, the

bottom first mirror printing and top first mirror printing will be changed to bottom first printing and top first

printing, respectively.

Effective print width and X-coordinate fine adjustment

When the feed amount reaches the max. number of digits, the print position is left-aligned with a 25-mm

left margin.

(3) Before shifting to the Information mode, make sure that the printer has not received any commands

related to feed or drawing. If the printer has received such commands, printing will not be performed and

the printer will return to the normal state. At this time, a quick reset will not be performed.

(4) Do not send a command to the printer in the information mode.

23

320000000cm

6.8.3 Information Mode Print Sample

<Print sample>

125984251.9”

<Print data>

Item Information Range

1st line Feed amount in the information mode (Unit: cm) 0 to 320000000

2nd line Feed amount in the information mode (Unit: inch) 0 to 125984251.9

24

6.9 JOB CANCELLATION

6.9.1 Outline of the Job Cancellation

The [CANCEL] key enables cancellation of subsequent print jobs.

Holding down the [CANCEL] key for 3 seconds while the printer is in an error* or pause state causes the

printer to start a quick reset and shift to the online mode.

As long as the [CANCEL] key is held down, the data in the receive buffer is all discarded.

Job cancellation is finished when the [CANCEL] key is released, and the printer restores to the normal

condition.

*: Errors which can be recovered by a depression of the [RESTART] key.

For details, refer to Section 6.8 LCD MESSAGES AND LED INDICATIONS.

*: A command error may occur if the [CANCEL] key is released before the all received data has been

discarded.

6.9.2 Job Cancellation Operation Example

[Online mode]

1. Normal condition

[Online mode]

2. Pause or error

[Online mode]

3. Job cancellation

after quick reset

[Online mode]

4. Normal condition

condition

↓ Hold down [PAUSE] key for 3 seconds.

↓ Release the [CANCEL] key.

↓ Occurrence of an error of depression of

the [PAUSE] key.

As long as the [CANCEL]

key is held down, received

data is discarded.

The printer restores to the

online mode.

25

Loading...

Loading...