Page 1

LE810DT

RT322

User’s Guide

59320201 my.okidata.com

Page 2

Copyright Information

Copyright © 2010 by Oki Data. All Rights Reserved

Document Information

LE810DT User’s Guide

P/N 59320201

Revision 1.2

April, 2010

Disclaimer

Every effort has been made to ensure that the information in this document is

complete, accurate, and up-to-date. The manufacturer assumes no responsibility for

the results of errors beyond its control. The manufacturer also cannot guarantee

that changes in software and equipment made by other manufacturers and referred

to in this guide will not affect the applicability of the information in it. Mention of

software products manufactured by other companies does not necessarily constitute

endorsement by the manufacturer .

While all reasonable efforts have been made to make this document as accurate and

helpful as possible, we make no warranty of any kind, expressed or implied, as to

the accuracy or completeness of the information contained herein.

The most up-to-date drivers and manuals are available from the web site:

http://www.okiprintingsolutions.com

Trademark Information

Oki is a trademark of Oki Electric Industry Company Ltd.

Apple, Macintosh and Mac OS are registered trademarks of Apple Computers Inc.

Hewlett-Packard, HP, and LaserJet are registered trademarks of Hewlett-Packard

Company. Microsoft, MS-DOS and Windows are either registered trademarks or

trademarks of Microsoft Corporation in the United States and/or other countries.

Other product names and brand names are registered trademarks or trademarks of

their proprietors.

Note

The appearance of your printer may differ somewhat

from the illustrations in this manual, depending on the

model you purchased.

Page 3

Contents _________________________

Introduction . . . . . . . . . . . . . . . . . . . . . . 4

About This Manual . . . . . . . . . . . . . . . . . . . 4

General Printer Description . . . . . . . . . . . . . 5

Printer Components . . . . . . . . . . . . . . . . . . 6

Operator Panel . . . . . . . . . . . . . . . . . . . . . 7

Installation. . . . . . . . . . . . . . . . . . . . . . . 8

Parts Identification . . . . . . . . . . . . . . . . . . 8

Printer Installation . . . . . . . . . . . . . . . . . . . 8

Site Location . . . . . . . . . . . . . . . . . . . . . 8

Interface Connection . . . . . . . . . . . . . . . . 9

USB / RS232C / IEEE Models . . . . . . . 9

Ethernet (LAN) Models . . . . . . . . . . 10

USB Only Model . . . . . . . . . . . . . . . 10

Connect to Power . . . . . . . . . . . . . . . . . 11

Media Selection . . . . . . . . . . . . . . . . . . 12

Loading Media . . . . . . . . . . . . . . . . . . . . . 13

Roll-Type, with Liner Fed to Rewinder

Shaft . . . . . . . . . . . . . . . . . . . . . . . . . 13

Roll-Type, Front Exit with Liner Attached 20

Fanfold Type . . . . . . . . . . . . . . . . . . . . 26

Operational Mode Selection . . . . . . . . . . . . 32

Tear-off Mode. . . . . . . . . . . . . . . . . . . . 32

Continuous Mode . . . . . . . . . . . . . . . . . 32

Dispense Mode . . . . . . . . . . . . . . . . . . . 32

Specifications. . . . . . . . . . . . . . . . . . . . .49

Physical Characteristics . . . . . . . . . . . . . . 49

Power . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Environmental. . . . . . . . . . . . . . . . . . . . . 49

Processing . . . . . . . . . . . . . . . . . . . . . . . 49

Interfaces . . . . . . . . . . . . . . . . . . . . . . . 50

Print Specifications . . . . . . . . . . . . . . . . . 50

Sensing Specifications . . . . . . . . . . . . . . . 50

Media . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Commands . . . . . . . . . . . . . . . . . . . . . . 51

Character Font Capabilities . . . . . . . . . . . . 52

Bar Code Capabilities . . . . . . . . . . . . . . . 53

Printer Configuration . . . . . . . . . . . . . . 33

Basic Configuration Modes. . . . . . . . . . . . . 33

Normal Mode . . . . . . . . . . . . . . . . . . . . 33

Advanced Mode . . . . . . . . . . . . . . . . . . 34

Counters Mode . . . . . . . . . . . . . . . . . . . 35

Test Print Mode. . . . . . . . . . . . . . . . . . . 36

Default Setting Mode. . . . . . . . . . . . . . . 37

Hex Dump Mode . . . . . . . . . . . . . . . . . . 38

Menu Definition Tables . . . . . . . . . . . . . . . 39

Normal Mode . . . . . . . . . . . . . . . . . . . . 39

Advanced Mode . . . . . . . . . . . . . . . . . . 40

Counters Mode . . . . . . . . . . . . . . . . . . . 41

Test Print Mode. . . . . . . . . . . . . . . . . . . 42

Default Setting Mode . . . . . . . . . . . . . . 43

Hex Dump Mode . . . . . . . . . . . . . . . . . 43

Troubleshooting . . . . . . . . . . . . . . . . . . 44

Test Label Printing . . . . . . . . . . . . . . . . . . 44

Sample Test Print Label . . . . . . . . . . . . 45

Maintenance . . . . . . . . . . . . . . . . . . . . . 46

Cleaning the Printer . . . . . . . . . . . . . . . . . 46

Removing Debris. . . . . . . . . . . . . . . . . . 46

Cleaning the Print Head and Platen . . . . 47

Cleaning the Printer Housing . . . . . . . . . 48

LE810DT User’s Guide 3

Page 4

Introduction

About This Manual

This manual uses special information boxes. Examples of these boxes and the type

of information provided in each, are below.

Warning!

Provides information that, if unheeded, may

result in personal injury.

Caution!

Provides information that, if unheeded, may

result in equipment damage.

Attention!

Provides information that is deemed of special

importance but will not result in personal injury or

product damage if unheeded.

Note

Provides helpful hints to assist in performing the tasks

at hand.

LE810DT User’s Guide 4 Introduction

Page 5

General Printer Description

The LE810DT printer comes in several configurations which can differ by

• Connection ports on the back of the printer

• Default print mode

• Internal path for print media

Note

The appearance of your printer may differ somewhat

from the illustrations in this manual, depending on the

model you purchased.

LE810DT User’s Guide 5 Introduction

Page 6

Printer Components

1 Operator Panel

2 Print Assembly

3 Platen Roller

4 Dispenser Latch

5 Print Head Latch

6 Rewinder Shaft (only present on some models)

7 External Media Slot

8 Media Holder

LE810DT User’s Guide 6 Introduction

Page 7

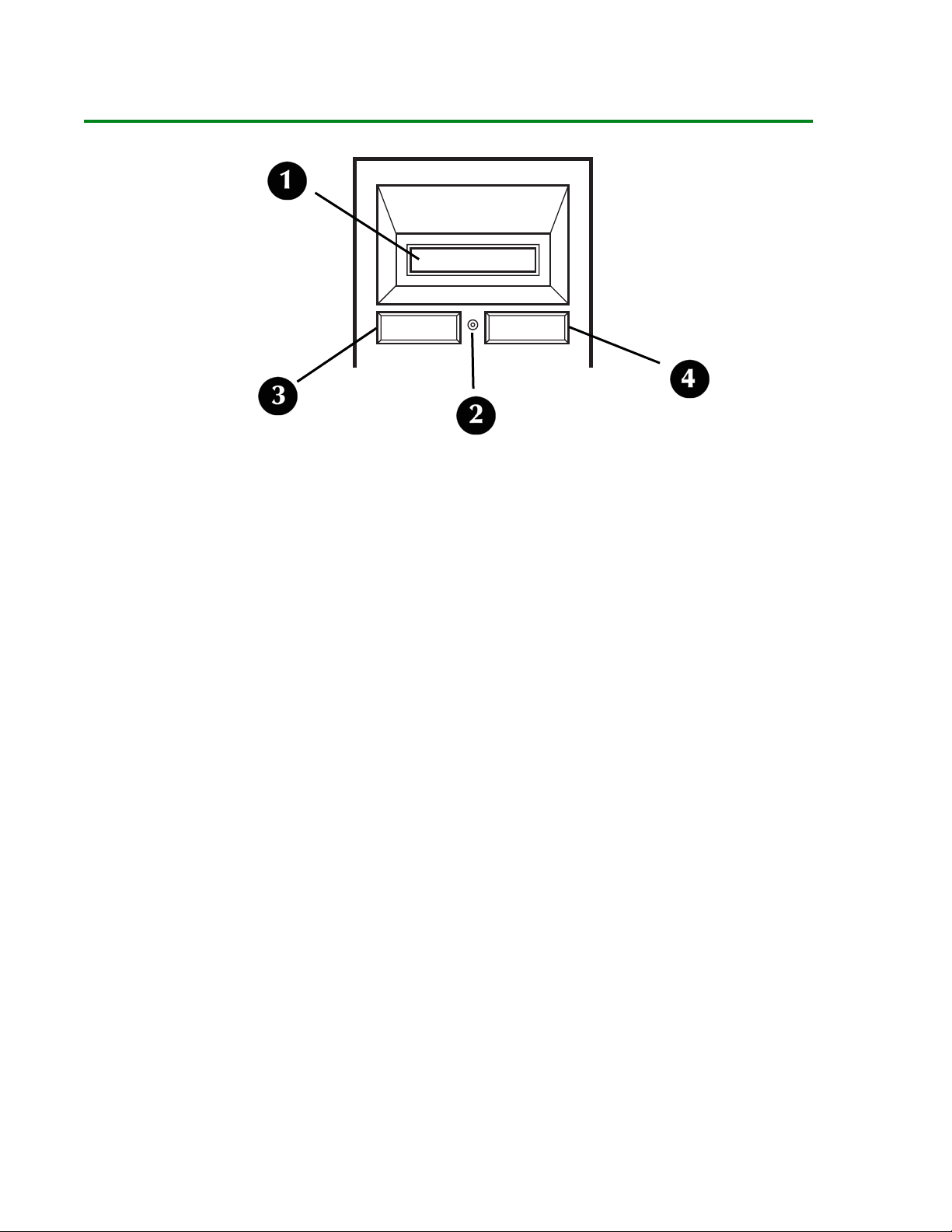

Operator Panel

1 LCD Display

2 Status LED

- Illuminates green when online and turns off when offline.

- Blinks green when receiving data or the buffer is near full.

- Illuminates or blinks red when detecting a printer error.

3 LINE button

- Press to switch back and forth between online and offline state.

- Press to scroll through menu options.

- Press to initiate other special functions as indicated later in this manual.

4 FEED button

- Press to advance the label media.

- Press to select menu options.

- Press top initiate other special functions as indicated later in this manual.

LE810DT User’s Guide 7 Introduction

Page 8

Installation

Parts Identification

1 CD-ROM

2 Power Cable

3 USB Cable (included only on models equipped with a USB port)

4 Printer (front view)

Printer Installation

Site Location

• Place the printer on a solid flat surface, away from hazardous materials.

• Make sure it is within operational distance of the host, based on interface

specifications.

LE810DT User’s Guide 8 Installation

Page 9

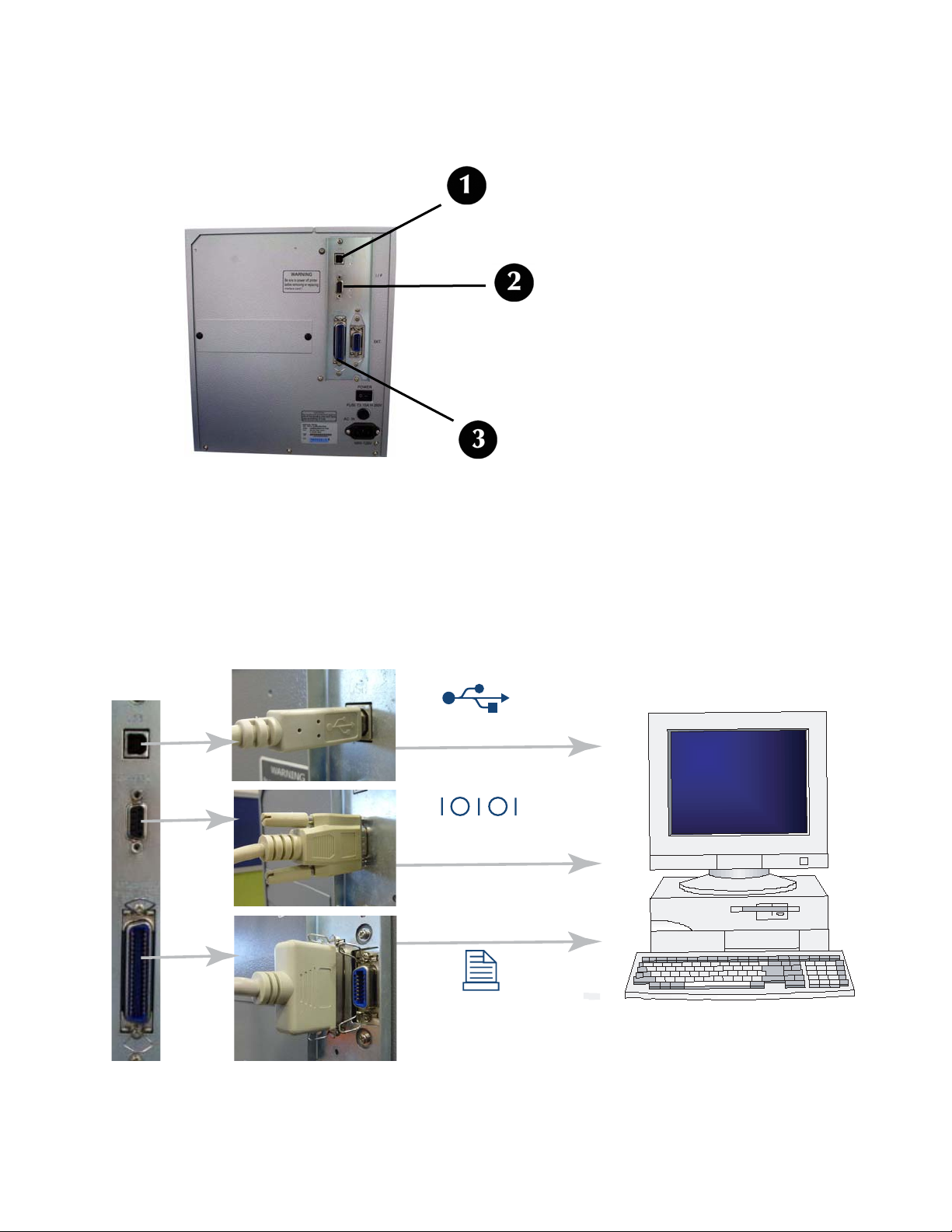

Interface Connection

USB / RS232C / IEEE Models

1. Locate the interface connection ports on the back of the printer.

1: USB

2: Serial (RS-232C)

3: IEEE Parallel

2. Connect the appropriate cable to the interface port, then connect it to the

computer.

USB

RS232C

IEEE

LE810DT User’s Guide 9 Installation

Page 10

Ethernet (LAN) Models

1. Locate the Ethernet port on the back of the printer.

2. Plug a 10/100Base T Category 5 Ethernet cable (not supplied) into the Ethernet

port on the printer and then into the computer.

USB Only Model

1. Locate the USB port on the back of the printer.

2. Plug the USB cable supplied with the printer into the USB port on the printer,

then into the USB port on the computer.

USB

LE810DT User’s Guide 10 Installation

Page 11

Connect to Power

1. Connect the power cable to the power socket on the back of the printer, then

connect it to a 120-volt, grounded power outlet.

2. Turn the printer on.

3. Set the interface option in the configuration menus of the operator panel. Refer

to the Configuration unit of this manual to configure the printer for host

computer interfacing.

Note

Multiple interface options may display in the printer’s

LCD menus, the desired option must be chosen.

LE810DT User’s Guide 11 Installation

Page 12

Media Selection

Caution

The media width should be equal to, or just

narrower than, the print head. Using media that

does not cover the print head will allow the

platen roller to tread on it and wear it out. The

media edge will also wear a groove in the platen

roller affecting print quality.

Both roll-type and fanfold media can be used with the printer. To use fanfold

media, you may need to remove the access plate on the back of the printer as

described under Loading Media, Fanfold Type.

LE810DT User’s Guide 12 Installation

Page 13

Loading Media

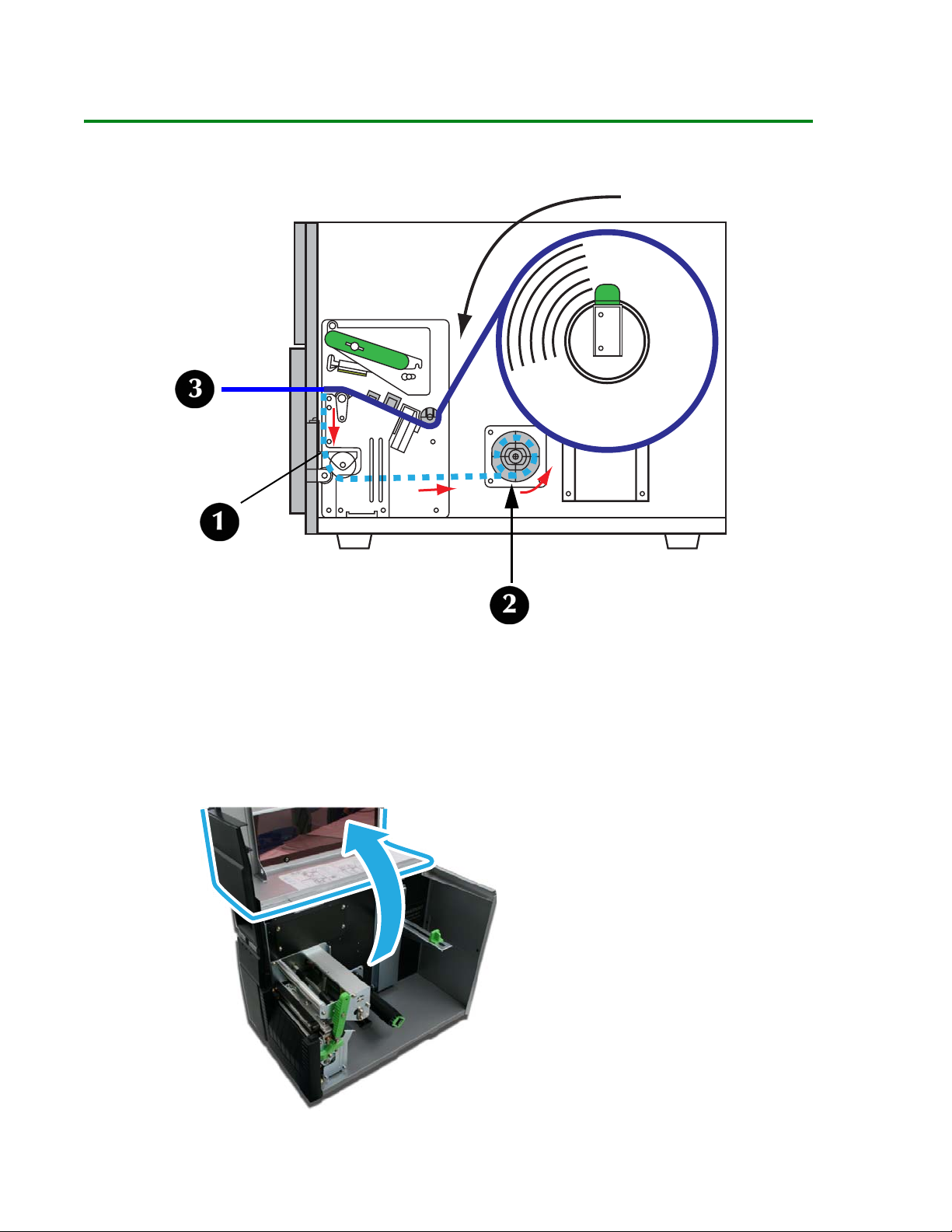

Roll-Type, with Liner Fed to Rewinder Shaft

With roll-type media loaded this way, the liner (1) automatically separates from the

media and is pulled back into the printer and wrapped around the rewinder shaft

(2). The self-adhesive label (3) without its liner moves out the front of the printer

for pickup and direct application. The printer will not print another label until the

printed label is removed.

1. Lift up the Top Access Cover.

LE810DT User’s Guide 13

Page 14

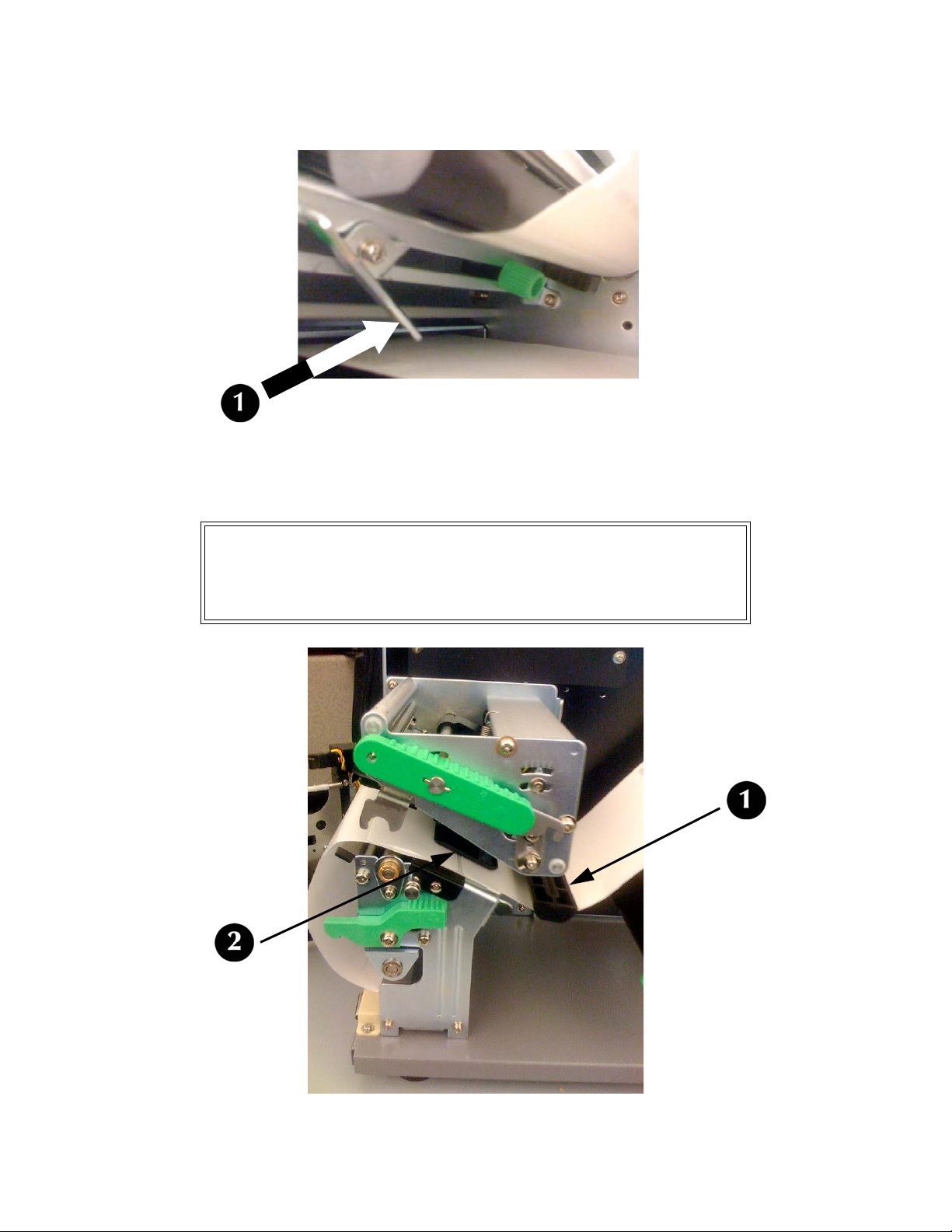

2. Open the printer front door: push down on the green dispenser latch (1) to

release the door, then swing it open (2).

3. Open the Print Head Assembly by rotating the Head Latch (1) counter clockwise.

LE810DT User’s Guide 14

Page 15

4. Pull the green Media Supply Guide (1) out as far as it will go, then angle the

label roll over it and push the roll back against the printer housing. Push the

Media Support Guide back in until it fits snugly against the media roll (2).

5. Locate the metal Outside Media Guide (1) under the print path and slide it

toward you as far as it will go.

LE810DT User’s Guide 15

Page 16

6. Push in on the bottom of the Outside Media Guide (1) to move the top out of the

way while you are loading the media.

7. Slide the media into the print path, making sure it goes under the Media

Hold-Down (1) and under the Sensor Assembly (2) Push it against the back of

the printer.

Attention!

If the media does not go under the Sensor Assembly,

the printer will not recognize that media is loaded.

LE810DT User’s Guide 16

Page 17

8. Adjust the media sensor to compensate for irregularities in the media (i.e.:

notch, tag hole, gap, perforation or markings). The proper position will be

media-dependent. To properly adjust the sensor position, loosen the green

Sensor Adjust Knob located on the bottom side of the Media Transport Assembly

and move the sensor in ¼-inch increments (or finer) until the sensor error is

cleared. After the error is cleared, retighten the Sensor Adjust Knob.

9. Pull out the bottom of the Outside Media Guide so that it is upright, then push

the guide inward until it barely contacts the outside edge of the media.

LE810DT User’s Guide 17

Page 18

10.Pull the media roll out until about 24 inches are exposed, then remove the labels

from that section. Feed the end of the liner back into the bottom of the printer,

under the Backing Drive Roller (1).

11.Pull out the green tab (1) on the front of the Take-Up Spindle (2). Notice the two

prongs (3) on the Take-Up Spindle. Pull the liner through the bottom of the

printer and pass the end under the two prongs, then use the green tab to rotate

the spindle until the liner is wrapped around it several times. When you are

done, swing the tab back into place.

LE810DT User’s Guide 18

Page 19

12.Swing the Head Latch back down to close the print head, then latch it in place.

13.Close the front door and lower the top access cover into place.

b

Attention!

These covers have interlock switches and the printer

will not operate if either is open.

LE810DT User’s Guide 19

Page 20

Roll-Type, Front Exit with Liner Attached

1. Lift up the Top Access Cover.

LE810DT User’s Guide 20

Page 21

2. Open the printer front door: push down on the green dispenser latch (1) to

release the door, then swing it open (2).

3. Open the Print Head Assembly by rotating the Head Latch (1) counter clockwise.

LE810DT User’s Guide 21

Page 22

4. Pull the green Media Supply Guide (1) out as far as it will go, then angle the

label roll over it and push the roll back against the printer housing. Push the

Media Support Guide back in until it fits snugly against the media roll (2).

5. Locate the metal Outside Media Guide (1) under the print path and slide it

toward you as far as it will go.

LE810DT User’s Guide 22

Page 23

6. Push in on the bottom of the Outside Media Guide (1) to move the top out of the

way while you are loading the media.

7. Slide the media into the print path, making sure it goes under the Media

Hold-Down (1) and under the Sensor Assembly (2) Push it against the back of

the printer.

Attention!

If the media does not go under the Sensor Assembly,

the printer will not recognize that media is loaded.

LE810DT User’s Guide 23

Page 24

8. Adjust the media sensor to compensate for irregularities in the media (i.e.:

notch, tag hole, gap, perforation or markings). The proper position will be

media-dependent. To properly adjust the sensor position, loosen the green

Sensor Adjust Knob located on the bottom side of the Media Transport Assembly

and move the sensor in ¼ inch increments (or finer) until the sensor error is

cleared. After the error is cleared, retighten the green Sensor Adjust Knob.

9. Pull out the bottom of the Outside Media Guide so that it is upright, then push

the guide inward until it barely contacts the outside edge of the media.

LE810DT User’s Guide 24

Page 25

10.Swing the Head Latch back down to close the print head, then latch it in place.

11.Close the front door and lower the top access cover into place.

b

Attention!

These covers have interlock switches and the printer

will not operate if either is open.

LE810DT User’s Guide 25

Page 26

Fanfold Type

1. Lift up the Top Access Cover.

LE810DT User’s Guide 26

Page 27

If the back plate is on your printer, perform the following step; other wise, skip to step 3.

2. Remove the back plate covering the access hole.

a. Press on the pin holders (1) inside the printer at either end of the bracket

until the pins extend from the outer housing.

b Carefully pull out the pins at either end of the cover plate and save them.

You will need the pins if you ever decide to reinstall the back plate.

c Remove the plate from the printer.

Save it with the pins: you will need them should you ever decide to reinstall

it.

LE810DT User’s Guide 27

Page 28

3. Place the stack of fanfold media behind the printer and feed the first label in

through the opening.

M

E

D

I

A

M

E

D

I

A

M

E

D

I

A

M

E

D

I

A

M

E

D

I

A

M

E

D

I

A

M

E

D

I

A

4. Locate the metal Outside Media Guide (1) under the print path and slide it

toward you as far as it will go.

LE810DT User’s Guide 28

Page 29

5. Push in on the bottom of the Outside Media Guide (1) to move the top out of the

way while you are loading the media.

6. Slide the media into the print path, making sure it goes under the Media

Hold-Down (1) and under the Sensor Assembly (2) Push it against the back of

the printer.

Attention!

If the media does not go under the Sensor Assembly,

the printer will not recognize that media is loaded.

LE810DT User’s Guide 29

Page 30

7. Adjust the media sensor to compensate for irregularities in the media (i.e.:

notch, tag hole, gap, perforation or markings). The proper position will be

media-dependent. To properly adjust the sensor position, loosen the green

Sensor Adjust Knob located on the bottom side of the Media Transport Assembly

and move the sensor in ¼ inch increments (or finer) until the sensor error is

cleared. After the error is cleared, retighten the green Sensor Adjust Knob.

8. Pull out the bottom of the Outside Media Guide so that it is upright, then push

the guide inward until it barely contacts the outside edge of the media.

LE810DT User’s Guide 30

Page 31

9. Swing the Head Latch back down to close the print head, then latch it in place.

10.Close the front door and lower the top access cover into place.

b

Attention!

These covers have interlock switches and the printer

will not operate if either is open.

LE810DT User’s Guide 31

Page 32

Operational Mode Selection

There are three modes of printer operation; Tear-off, Continuous, and Dispense.

Tear-off Mode

• For printing labels one at a time.

• The liner remains with the label as it exits the printer.

• Once the printed label has been removed from the printer, the unprinted media

will retract and position itself for printing the next label.

Continuous Mode

• For printing bulk quantities of labels.

• The liner remains with the label as it exits the printer.

• The media remains in position for printing at all times.

• A printed label is only available for removal when one to four additional labels

have been printed (quantity depends upon label size).

Dispense Mode

• For printing labels one at a time.

• The printer automatically peels the liner from the printed label as it exits the

printer.

• Once the printed label has been removed from the printer, the unprinted media

will retract and position itself for printing the next label.

LE810DT User’s Guide 32

Page 33

Printer Configuration

Basic Configuration Modes

Configuration is done using the operator panel buttons. However, many settings

may also be controlled via external software commands. In the case of conflict

between external software commands and control panel settings, the printer will

always use the last valid setting (the default is software commands).

See the Menu Definition Tables starting on page 39 for more information on the

modes below.

Normal Mode

For configuring print features that tend to change from job to job. See page 39.

POWER: ON

Scrolls

options

ONLI NE

QTY: 000000

LINE FEED

LINE + FEED

OFFLINE

QTY: 000000

LINE FEED

PRIN T DARKN ESS

12345

FEED

PRIN T SPEED

23456

LINE

PITC H OFF SET

LINE

FEED

+00MM

[Z]

Reprints

last lab el if

enabled.

Feeds

one label if

DSW3-3is

OFF.

Scrolls

options

CANC EL PRINT JOB

YES NO

LINE

NO

FEED

All

print jobs

saved

USER TEST PRINT

YES NO

LINE

NO

FEED

YES

FEED

All

print jobs

canceled

YES

FEED

TO

TEST PRINT

MENU

Scrolls

options

Selects

and

advances

LINE

LINE

FEED

LE810DT User’s Guide 33 Printer Configuration

Page 34

Advanced Mode

For making basic printer operational adjustments. Typically, once these adjustment

settings have been made, they will not require additional changes unless a new job

is downloaded.

LINE + POWER

ADVANCED MODE

Scrolls

options

Scrolls

options

Selects

and

advances

Only if

calendar is

installe d

SET CALENDAR

YES NO

LINE

Yes

FEED

CALENDAR

YY / MM/ DD HH : MM

LINE

FEED

No

FEED

Toggles

Service

Mode

Scrolls

options

Scrolls

options

Scrolls

options

Scrolls

options

Scrolls

options

FEEDLINE

DARKNESS RANGE

AB

LINE

AUTO ON LINE

YES NO

LINE

PRINT OFFSET

V: +XXXX H: +XXX

IGNORE CR/LF

YES NO

LINE

INTERFACE TYPE

IEEE RS232 USB

LINE

FEED

FEED

LINE

FEED

FEED

Selects

and

advances

Scrolls

options

Scrolls

options

Scrolls

options

Scrolls

options

Scrolls

options

DATA BIT SELECT

8BIT 7BIT

LINE

PARITY SELECT

EVEN ODD NON

LINE

STOP BIT SELECT

1BIT 2BIT

LINE

BAUD RATE SELECT

9600 19200 >>

BAUD RATE SELECT

<< 3800 S7600

LINE

PROTOCOL SELECT

RD/BSY XON/OF >>

PROTOCOL SELECT

<< BICOM3 BICOM4

LINE

FEED

FEED

FEED

FEED

FEED

IEE/USB

FEED

RS232

FEED

LE810DT User’s Guide 34 Printer Configuration

Page 35

Counters Mode

• Print Head Counter

The head counter records the length of the media that has been printed since

the print head was installed. It should be reset each time the print head is

replaced.

•Life Counter.

The life counter measures the length of media the printer as a whole has

printed. This counter would only be reset in case of circuitry replacement.

The printer’s Counter Mode allows the operator to view the accumulated

measurement and also allows the print head counter to be reset to zero.

LINE + POWER

ADVANCED MODE

Toggles

Advanced

Mode

SERVICE MODE

LINEFEED

Scrolls

options

HD

FEED

HEADCOUNTER

HEADCOUNT CLEAR

YES NO

LINE

X. X M

FEED

FEED

Toggles

Service

Mode

Toggles

Emulation

Mode

Scrolls

options

DSP

FEED

DISPENSE COUNT ER

DSP COUNT CLEAR

YES NO

LINE

X. X M

FEED LINE

COUNTERS MODE

LINE FEED

COUNTERS

HD DSP CUT LIFE

LINE

CUT COUNTER

CUT COUNT CLEAR

YES NO

FEED

LINE

CUT

FEED

FEED

LIFE

FEED

X

FEED

LIFE COUNTER

X. X M

FEEDFEED

LE810DT User’s Guide 35 Printer Configuration

Page 36

Test Print Mode

For printing a test label.

Test labels are designed to identify failures in configuration, adjustments problems,

and mechanical defects.

FEED + POWER

TEST PRINT MODE

CONFIGURATION

BARCODE

HEADCHECK

FACTORY

Scrolls

options

Scrolls

options

LINE

Conguration

Barcode

Headcheck

FEED

TEST PRINT SIZE

XXCM

LINE

PRESS FEED KEY

TO STOP PRINTING

FEED

Test

printing

begins

FEED

Test

printing

stops

Factory

FEED

PRINT SIZE

SMALL LARGE

LINE

Scrolls

options

USER TEST PRINT

YES NO

LINE

NO

FEED

YES

FEED

Scrolls

options

PRINT CONTINUE

Scrolls

options

YES NO

LINE

YES

FEED

NO

FEED

ONLINE MODE [Z]

QTY: XXXXXX

LE810DT User’s Guide 36 Printer Configuration

Page 37

Default Setting Mode

For resetting the printer to the default configuration state as received from the

factory. Use the printer’s buttons to select and enter the required options.

LINE + F EED + POWER

DEFAULT SETTING

YES NO

Scro lls

options

DEFAULT SETTING

Yes

FEED

Print er

returned to

default

settings

COMPLETED

Power printer off

and then on again

to exit.

LINE

No

FEED

No action,

no change

LE810DT User’s Guide 37 Printer Configuration

Page 38

Hex Dump Mode

The contents of the print buffer and the contents received before it may be

examined through the use of the Hex Dump Mode. Each line of the printed data is

enumerated in the first column, the second column contains the data in

hexadecimal format, and the right column contains the same data in ASCII format.

Send ~ESC+HX command

ONLINE [Z]

QTY: XXXXXX

Print er

receives

data

Print er

begins

Hex Dump

printing

Power printer o ,

to exit

LE810DT User’s Guide 38 Printer Configuration

Page 39

Menu Definition Tables

Normal Mode

Display Description

ONLINE

QTY XXXXXX

OFFLINE

QTY XXXXXX

PRINT DARKNESS

1 2 3 4 5

PRINT SPEED

2 3 4 5 6

PITCH OFFSET

+00MM

Displays the printer’s operational status. The ONLINE status is

displayed on the top line and the label quantity status is on the

bottom. The message will be changed to OFFLINE whenever the

printer is switched offline by pressing the LINE key. When a print

job is received, the quantity line will indicate the number of labels

to be printed. As the label job prints, the display status indicates

the quantity of labels remaining to be printed.

Displays the printer’s operational status. The OFFLINE status is

displayed on the top line and the label quantity status is on the

bottom. The message will be changed to ONLINE whenever the

printer is switched online by pressing the LINE key.

Permits the adjustment of print density. Higher print density

equates to darker pint images.

Permits the printer’s printing speed to be established based on

inches per second (IPS).

The label pitch is the distance from the leading edge (the edge that

comes out of the printer first) of a label and the leading edge of the

next label. Once the position has been set, it can be fine adjusted

using the PITCH potentiometer.

Positive (+) digit settings moves the leading edge forward and

away from the print head while a negative (-) setting moves the

label’s leading edge incrementally back into the mechanism.

CANCEL PRINT JOB

YES NO

USER TEST PRINT

YES NO

LE810DT User’s Guide 39 Printer Configuration

Print data that has previously been received, can be cleared. If YES

is selected, the print data will be deleted and then the printer will

go offline. If the NO option is selected, the printer will go offline

without deleting data in buffer.

Provides the specific sequence of events required by the operator,

the printer, and the printer’s software for a test label to be printed.

Select YES to enter User Test Print menu while select NO will

advance to Online mode.

Page 40

Advanced Mode

Display Description

ADVANCED MODE

DARKNESS RANGE

A B

AUTO ONLINE

YES NO

PRINT OFFSET

V: +XXXX H: +XXX

IGNORE CR/LF

YES NO

Is the first menu screen of the Advanced Mode. The Advanced Mode is

provided to make basic printer operational adjustments. Typically,

once these adjustments or settings have been made, they will not

require additional address unless a new job is downloaded.

Allows the darkness (print density) selection of the printed image.

Has two selection options.

The printer can be set to automatically go into the online mode when

powered on. Otherwise, theprinter starts in the offline state and must

be manually placed online before it is ready to print.

Print offset refers to the vertical and horizontal shifting of the entire

print area relative to the label and the print start position. The

movement is incremental by dots in the positive (+) or negative (-)

direction. Positive and negative vertical adjustment is toward and

away from the print head respectively. Positive and negative

horizontal adjustment is to the left and right of the reference point

respectively.

Determines whether the print data code requires deletion.

Hexadecimal graphic data will not be deleted. Select YES to delete all

carriage return (CR) and line feed (LF) commands in the data stream

- including graphics and 2D barcodes.

SET CALENDAR

YES NO

CALENDAR

00 / 00 / 00 00:00

INTERFACE TYPE

IEEE RE232 USB

The calendar is an optional feature that allows the date and time to

be manually set using the operator panel or through command codes.

This screen will not be displayed if the calendar chip (real-time clock)

is not installed.

This menu allows the operator to choose if the calendar settings are

to be altered.

• This menu screen allows the calendar settings to be altered. The

calendar is divided into five sets of two digits. The first two allows

for the year to be set, followed by the month, the day, the hour,

then the minute.

• This menu will display only when the standard Plug-in 3-in-1 combo

interface module is installed. Select the type of interface according

to the connection to the host. Either IEEE, RS232 or USB interface

can be selected.

• If the optional single interface board (LAN or USB) is installed, this

menu will not be displayed.

LE810DT User’s Guide 40 Printer Configuration

Page 41

Counters Mode

Display Description

ADVANCED MODE

SERVICE MODE

COUNTERS MODE

COUNTERS

HD LIFE

HEAD COUNTER

XXXM

LIFE COUNTER

XXXM

HEAD COUNTER CLEAR

YES NO

First transitional menu screen to access the Counters Mode.

Second transitional menu screen to access the Counters Mode.

Is the first menu screen of the Counters Mode. The Counters

Mode allows the printers various internal counters to be reset to

zero or to view count in meters printed thus far.

Allows the selection of which counter to be viewed to reset.

HD: Head counter

LIFE: Life counter

Is an informational screen that provides the printed length of

media using the existing print head.

The head counter must be reset each time the print head is

replaced.

Is an informational screen that provides the printed the length of

media since printer setup.

Resets the print head counter to zero.

LE810DT User’s Guide 41 Printer Configuration

Page 42

Test Print Mode

Display Description

TEST PRINT MODE

CONFIGURATION

BARCODE

HEADCHECK

FACTORY

TEST PRINT SIZE

XXCM

PRINT SIZE

SMALL LARGE

PRESS FEED KEY

TO STOP PRINTING

PRINT CONTINUE

YES NO

Is the initial screen of the Test Print Mode.

• CONFIGURATION: The printer’s configuration settings.

• BARCODE: The printer’s installed barcodes.

• HEAD CHECK: A pattern to check print head elements.

• FACTORY: A factory test label will be printed.

This menu screen only appears if CONFIGURATION, BARCODE, or

HEAD CHECK was chosen in the previous menu. The increments of

measure is 1cm.

For factory test prints, this screen appears instead of the previous

screen for setting print size.

Large (10cm) and small (4cm) are the only two options.

Is a directional screen prompting action on how to terminate print

activity. Press FEED to stop printing and press again to resume

printing.

A confirmation screen to stop test printing or to continue the label

test printing.

If YES is selected, the printer will goes back to TEST PRINT MODE

selection menu. If NO is selected, the test print mode will stop and

proceed to Online mode.

USER TEST PRINT

YES NO

ONLINE MODE (Z)

QTY: XXXXXX

Provides the specific sequence of events required by the operator, the

printer, and the printer’s software for a test label to be printed.

Select YES to enter User Test Print menu while select NO will advance

to Online mode.

Displays the printer’s operational status. The ONLINE status is

displayed on the top line and the label quantity status is on the

bottom.

Ready for print job.

LE810DT User’s Guide 42 Printer Configuration

Page 43

Default Setting Mode

Display Description

DEFAULT SETTING

YES NO

DEFAULT SETTING

COMPLETED

Is the first menu screen of the printer’s Default Setting Mode. The

Default Setting Mode allows the printer to be reset to the

programmed condition as received from the factory.

The selection of YES confirms the operator wants to proceed and the

selection of NO allows for exit without default reset. If YES is

selected, resetting will immediately begin.

Reboot the printer to return to normal operation.

Is an informational screen only indicating that reset activity is

complete.

Hex Dump Mode

Display Description

ONLINE (Z)

QTY: XXXXXX

Displays to indicate the printer is online and waiting to print HEX

interpretation of data received by the print buffer.

LE810DT User’s Guide 43 Printer Configuration

Page 44

Troubleshooting

Test Label Printing

The test label is designed to assist in the identification of print problems. The actual

content of the test label depends on the type of test label printed.

To print a test label:

1. To enter the Test Print mode, turn off the printer, then press and hold the FEED

button while turning the printer on.

TEST PRINT MODE appears on the display.

2. Press the LINE button to scroll to your choice of CONFIGURATION, BARCODE or

HEADCHECK, then press FEED to select it.

The display shows the current test print size.

3. To change the size, use the LINE button to scroll through the various choices.

4. Once the appropriate size is selected, press FEED to start printing the test label.

5. When the label has finished printing, press FEED to stop the test.

6. To exit the Test Print mode, turn the printer off, then on again.

LE810DT User’s Guide 44 Troubleshooting

Page 45

Sample Test Print Label

Note

The only print problem that the following sample test

label does not display is fading of print image from one

side of the label to the other. This type of fading is the

result of improper print head balance.

D S W 3D S W 2D S W 1

N O N E

1Compare this scale on each side to ensure the print is evenly spaced

horizontally.

2 Visually inspect these rows for voids indicating defective elements.

3 Line sharpness is determined by print speed and darkness.

4 Compare this scale on either side to ensure the print is evenly spaced vertically.

LE810DT User’s Guide 45 Troubleshooting

Page 46

Maintenance

Cleaning the Printer

Warning!

Disconnect the power cord and allow the printer

to cool to room temperature before cleaning.

Be careful when cleaning to prevent personal

injury.

Cleaning of the printer is a necessary maintenance activity to ensure print quality

and longer printer life. There are two basic types of cleaning involved; the removal

of loose debris and the removal of residue.

Removing Debris

Use a soft cloth and/or a pneumatic blower to remove debris from the printer. This

process should be performed prior to the removal of residue.

Caution

If you are using a pneumatic blower to remove

debris from the printer, be careful to stay away

from the print head to avoid damaging it.

LE810DT User’s Guide 46 Maintenance

Page 47

Cleaning the Print Head and Platen

Attention!

The print head should be cleaned after every other

label roll is loaded.

1. Turn the printer off and remove the power cable.

2. Open the Top Access Cover.

LE810DT User’s Guide 47 Maintenance

Page 48

3. Rotate the green Head Latch counter clockwise to open the print head.

4. Remove any print media from the print head.

5. The print head faces downward along the front edge of the print head assembly.

6. Apply some isopropyl alcohol (available at most pharmacies) to a cotton swab,

then gently run the swab across the full width of the print head.

7. Check the swab for any dark coloring or adhesive. If either is present, run a new

swab over the print head. Repeat until no residue is found on the swab.

8. Next, clean the platen roller by running a fresh cotton swab (with alcohol on it)

along the platen. Be sure to rotate the platen to clean all of its surface.

9. Allow the roller to dry, then reload the print media and close the top cover.

Cleaning the Printer Housing

Use a soft lint-free cloth dampened with a bit of water to wipe the printer housing

clean.

LE810DT User’s Guide 48 Maintenance

Page 49

Specifications

Physical Characteristics

Width 10.7 Inches (271 mm)

Height 12.7 Inches (322 mm)

Depth 16.9 Inches (428 mm)

Weight 32.6 Pounds (14.8 Kg)

Power

Input Voltage 100-120 Volts AC +/- 10%, 50/60 Hertz +/-5%

Power Consumption

Peak Time : 190VA 130W

Idle : 24VA 16W

Environmental

Operating Temperature 41 to 104°F (5° to 40°C)

Storage Temperature 23 to 140°F (-5° to 60°C)

Storage Humidity 30 to 90% RH Non-Condensing

Operating Humidity 30 to 80% RH Non-Condensing

Processing

CPU 32 Bit RISC

Flash ROM 2 Megabytes

Receive Buffer 2.95 Megabytes maximum, 2 Megabytes near full

LE810DT User’s Guide 49 Specifications

Page 50

Interfaces

Model Interface(s)

Combo Interface Board:

LE810DT- SER/PAR/USB

LE810DT- ETHERNET Ethernet: 10/100 Base-T

LE810 DT – PAR Parallel: IEEE1284 Enhanced Parallel Port

LE810 DT – SER Serial: RS232C (9600 to 57,600 bps)

LE810 DT – USB USB: Universal Serial Bus (USB Full Speed)

• Serial: RS232C (9600 to 57,600 bps)

• Parallel: IEEE1284 Enhanced Parallel Port

• USB: Universal Serial Bus (USB Full Speed)

Print Specifications

Method Direct Thermal

Maximum Speed (selectable) 2, 3, 4, 5, 6 Inches Per Second (50.8 - 152.4 mm)

Print Module (dot size) .0049 Inches (.125 mm)

Resolution 203 Dots Per Inch (8 dpmm)

Maximum Print Width 4.09 Inches (104 mm)

Maximum Print Length 15.75 Inches (400 mm)

Sensing Specifications

Gap Adjustable

Reflective I-Mark Adjustable

Media Out Constant

Cover Open Constant

LE810DT User’s Guide 50 Specifications

Page 51

Media

Width

• Media Width: 0.866 to 5.04 Inches (22-128 mm)

• Media Width with Backing Paper: 0.984 to 5.16 Inches (25131 mm)

Length

Length (Tear-Off)

Typ e

Thickness 0.003 to 0.010 inches (0.08-0.26 mm)

Roll Diameter Maximum: 8.6 inches (218 mm)

Core Diameter 3.0 Inches (76.2 mm)

Wind Direction Face Inward

Fan-Fold Height Maximum: 3.94 Inches (100 mm)

• Media Length: 15.63 Inches (397 mm)

• Media Length with Backing Paper: 15.75 Inches (400 mm)

• Media Length: 0.669 to 7.01 Inches (17-178 mm)

• Media Length with Backing Paper: 0.787 to 7.13 Inches (20181 mm)

• Roll or Fan-Fold

•I-Mark or Gap

• Direct Thermal

Commands

• ZEBRA emulation and ZPL command

Standard

Non-Standard N/A

LE810DT User’s Guide 51 Specifications

• SATO Barcode Printer Language (SBPL)

• Intelligent Command

Page 52

Character Font Capabilities

TTF fonts

0 15 dots H x 12 dots W

Bitmap fonts

A 9 dots H x 5 dots W

B 11 dots H x 17 dots W

C 18 dots H x 10 dots W

D 18 dots H x 10 dots W

E 28 dots H x 15 dots W

F 26 dots H x 13 dots W

G 60 dots H x 40 dots W

H 21 dots H x 13 dots W

P 20 dots H x 18 dots W

Q 28 dots H x 24 dots W

R 35 dots H x 31 dots W

S 40 dots H x 35 dots W

T 48 dots H x 42 dots W

U 59 dots H x 53 dots W

V 80 dots H x 71 dots W

Downloadable Fonts

N/A

Character Control

Expansion up to 12 x in either the X or Y coordinates.

Character Pitch Control

Line Space Control

Journal Print Facility

0, 90, 180, and 270 Degree Rotation

LE810DT User’s Guide 52 Specifications

Page 53

Bar Code Capabilities

Bar Code Capabilities

• UPC A/E

• JAN 8/13

•EAN 8/13

• Code 39

• Code 93

• Code 128

• Interleaved 2 of 5

Linear Bar Codes

• Industrial 2 of 5

•Matrix 2 of 5

• Bookland

•NW-7

•MSI

•POSTNET

• UCC/EAN 128

• NW-7 (Codabar)

•QR Code

• Data Matrix

Two Dimensional

Ratios 1:2, 1:3, 2:5, User definable bar widths

Bar Height 4 to 999 dots, User programmable

Rotation 0, 90, 180, and 270 Degrees

Sequential Numbering Sequential numbering of both numerics and bar codes

Expansion Ratio of

Character

Graphics Full dot addressable graphics, BMP or PCX formats

Form Overlay Form overlay for high-speed editing of complex formats

•Maxi Code

•PDF417

•Synthetic Symbol

• Height: 1 to 12 times

• Width: 1 to 12 times

LE810DT User’s Guide 53 Specifications

Loading...

Loading...