Page 1

LD670

Page 2

Every effort has been made to ensure that the information in this document is complete, accurate, and

up-to-date. The manufacturer assumes no responsibility for the results of errors beyond its control. The

manufacturer also cannot guarantee that changes in software and equipment made by other

manufacturers and referred to in this manual will not affect the applicability of the information in it.

Mention of software products manufactured by other companies does not necessarily constitute

endorsement by the manufacturer.

While all reasonable efforts have been made to make this document as accurate and helpful as possible,

we make no warranty of any kind, expressed or implied, as to the accuracy or completeness of the

information contained herein.

All rights are reserved by Oki Data Corporation. Unauthorized copying, transferring, translating, or

related actions are prohibited. You must obtain written permission from Oki Data Corporation before

doing any of the above.

© 2011 Oki Data Corporation

OKI is a registered trademark of Oki Electric Industry Co., Ltd.

Energy Star is a trademark of the United States Environmental Protection Agency.

Microsoft, Windows, Windows Server and Windows Vista are registered trademarks of Microsoft

Corporation.

Apple, Macintosh, Rosetta, Mac and Mac OS are registered trademarks of Apple Inc.

Other product names and brand names are registered trademarks or trademarks of their proprietors.

As an Energy Star Program Participant, the manufacturer has determined that this product

meets the Energy Star guidelines for energy efficiency.

This product complies with the requirements of the Council Directives 2014/30/EU (EMC) and

2014/35/EU (LVD), 2014/53/EU (RED) and 2011/65/EU(RoHS) as amended where

applicable, on the approximation of the laws of the member states relating to Electromagnetic

Compatibility, Low Voltage, Radio & Telecommunications Terminal Equipment, Energy

related Products and Restriction on the use of certain Hazardous Substances in electrical

and electronic equipment.

The following cables were used to evaluate this product to achieve EMC directive

2014/30/EU compliance and configurations other than this may affect that compliance.

&$%/(7<3( &25(CORE

CABLE TYPE

Power 2.0

USB 5.0

Serial (25pin)

LAN

Drawer 1.8

This is a class A product as defined in EN55022. In a domestic environment

this product may cause radio interference, in which case the user may be required to

take adequate measures.

LENGTH

(METRE)

15.0

10.0

CORE SHIELD

88

89

89

88

88

Page 3

M

ANUFACTURER

Oki Data Corporation,

4-11-22 Shibaura, Minato-ku,

Tokyo 108-8551,

Japan

For all sales, support and general enquiries contact your local distributor.

I

MPORTER TO THE

OKI Europe Limited (trading as OKI Printing Solutions)

Blays House

Wick Road

Egham

Surrey, TW20 0HJ

United Kingdom

For all sales, support and general enquiries contact your local distributor.

E

NVIRONMENTAL INFORMATION

EU/A

UTHORISED REPRESENTATIVE

Page 4

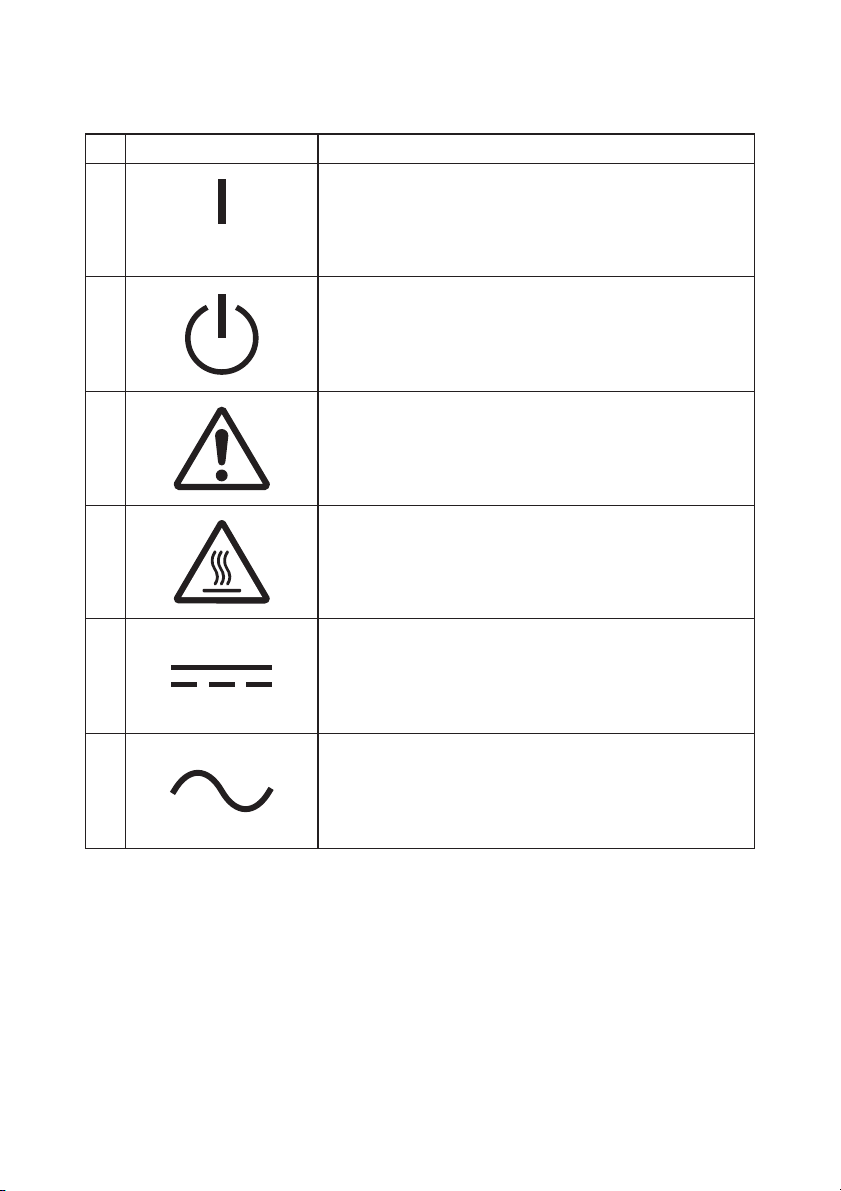

Description of Safety symbols displayed on the equipment

No. Symbol Description

1

"ON" (power)

To indicate connection to the mains, at least for

mains switches or their positions.

2

3

4

5

6

Stand-by

To identify the switch or switch position by means of

which part of the equipment is switched on in order

to bring it into the stand-by condition.

General warning/caution

To identify a general warning/caution.

Caution, hot surface

To indicate that the marked item can be hot and

should not be touched without taking care.

Direct current

To indicate on the rating plate that the equipment is

suitable for direct current only; to identify relevant

terminals.

Alternating current

To indicate on the rating plate that the equipment

is suitable for alternating current only; to identify

relevant terminals.

Page 5

Notes on Use

Notes on printing and the paper used

(1) Printing at a high rate might result in unclear printing. If this problem occurs,

adjust the printing rate. Alternatively, adjust the print speed and print density so

that there are no blurs.

(See Examples (1) and (2) in Section 10-2, "Setting Up the Printer.")

(2) Printing characters from a non-standard character set e.g. in a thin serif font will

result in the characters appearing very faint. Use a bold sans serif font.

(3) For quality printing that is free from uneven spacing and condensed or elongated

printing after paper is cut or printing is paused, resume printing following a paper

feed of at least 1 mm (8 dots).

(4) If the data transfer rate is too low, serial printing may result in uneven print

density (vertical white marks may appear on printouts) because of repeated

printing and pausing. If priority is placed on print quality, use batch printing

mode.

(See Example (8) in Section 10-2, "Setting Up the Printer.")

(5) The printer shipped from the factory is preset to the darkest print density

(130%). If this setting is inappropriate, specify a lighter print density.

(See Example (1) in Section 10-2, "Setting Up the Printer.")

(6) If roll paper with an outside core diameter of other than 32 mm is used, the

paper-near-end detection accuracy deteriorates.

If roll paper with an outside core diameter of less than 32 mm is used, a transport

error may occur when the cutter cuts the paper in full cutting mode and reaches

the core.

(7) Since the difference in hue between red and black or blue and black may not be

noticeable when two-color thermal paper is used, be sure to confirm in advance the

color of the printed characters.

(8) When roll paper with a width of 83 mm is used, characters that are too close to the

(left or right) edge of the paper may not be printed because of inaccuracies in

tracking. Be sure to set a margin of sufficient width.

(9) Do not switch from narrow paper to wide paper (e.g., from paper that is 58 mm

wide to paper that is 80 mm wide) during operation. When narrow paper is used,

the thermal head area where there is no paper comes in direct contact with the

platen roller, and the resulting wear on the head may lead to a deterioration in

print quality. Similarly, if the paper width is changed, the cutter blade will cut at

a location that has no paper, and the resulting wear on the blade may lead to

improper cuts. To switch from narrow paper to wide paper, exchange the thermal

head and the cutter blade.

3

Page 6

(10) If label paper is used, adhesive matter adhering to the cutter blade, thermal head,

paper transport, or paper holder may cause a cutting error, print error, or paper

transport error. Remove adhesive matter periodically (typically on a monthly

basis).

(11) If paper is left inserted in the printer for a long time, the paper may become

deformed and result in thin (faint) printed characters. Before starting printing

in such cases, feed the paper by 20 to 30 mm.

(12) If the type of paper used is other than the recommended ones, the print quality

and thermal head life are not guaranteed. In particular, if the type of thermal

paper contains Na+, K+, or Cl-, the thermal head life may be significantly

shortened.

(13) When using full-sheet label paper, note that the paper may adhere to the head

and cause noise if the top margin is less than 3 mm. You should therefore set

the top margin to 3 mm or a greater value when printing on this type of paper.

4

Page 7

Notes on using the cutter

(1) Note also that the paper length used per transaction must be at least

15mm.

(2) The maximum number of successive cuts by the cutter is 30 cuts per

minute (at least two seconds per cut). Using the cutter at a higher rate may

cause a failure.

(3) Do not pull the paper during cutting. Doing so may cause a paper jam or

another problem.

(4) Each time that 30 sheets of paper are printed, the paper must be removed.

Otherwise, the printed paper remains in the automatic cutter section and may

cause a cutting error.

Notes on printing of barcodes and two-dimensional codes

(1) Barcodes that are rotated 90 degrees or aligned vertically when printed may

not be readable. Verify the readability in advance.

(2) Printouts on label paper or thick paper may contain blurs, depending on

humidity and other environmental conditions. Adjust the print speed and

print density appropriate for the type of paper used, and verify the

readability in advance.

(See Examples (1) and (2) in Section 10-2, "Setting Up the Printer.")

(3) The recognition ratio of two-dimensional codes (QR codes, PDF417,

DataMatrix, MaxiCode and RSS) varies depending on various factors,

including the module width, print density, ambient temperature, thermal

roll paper type, and reader performance. Adjust the print speed and print

density appropriate to printing two-dimensional codes, and verify the

readability in advance.

(See Examples (1) and (2) in Section 10-2, "Setting Up the Printer.")

(4) The paper transport accuracy may be negatively affected by printing a

barcode in the Upper margin at the beginning of paper transport or in the

Lower margin at the end of paper transport. Verify the readability before

starting printing.

5

Page 8

Notes on using the printer through the USB interface

(1) The printer must be connected directly to the host computer.

(2) Before starting printing, turn on the power to the printer.

(3) If a printer error occurs during printing, recover the printer from the

error, and then retry printing.

(4) The host computer should not be set to any of the following modes: standby,

sleep, suspend, and pause.

If the host computer or printer does not work normally after the host

computer returns to normal operation mode from one of the above modes,

disconnect the USB cable once and then reconnect it, or turn off the printer

power switch once and then turn on the switch again. If the host computer

or printer cannot be restored to normal operation after the cable is

reconnected or power switch is turned on again, restart the host computer.

(5) The USB hub function cannot be used when the power to the printer is off.

(6) If a peripheral device connected to the USB hub is not recognized, perform

one of the following operations:

- Disconnect the USB cable from the peripheral device once, and then

reconnect it.

- Connect the peripheral device to the other port of the USB hub.

(7) The operation of connected USB devices is not guaranteed. Before using a

USB device, verify its operation yourself.

Note : Do not turn off the power to the printer during printing.

If you inadvertently turn off the power to the printer during printing and

the printer then fails to work normally, restart the host computer.

6

Page 9

Note on installation

(1) The printer must be used indoors. If used outdoors, the printer may fail

because of dust.

Note on the modular connector

(1) This product uses a modular connector as a dedicated connector for the cash

drawer or customer display terminal. The connector must not be connected

with a connector that leads to a public switched line or other such

destination.

Note on using the printer in special mode

(1) If a large diameter roll is used, paper may fold or unusual noises may be

heard. To prevent these problems, use a roll with a small diameter (50mm

or less). If a Windows PC is used as the host system, a utility program can be

used to make settings.

Windows® is a registered trademark of Microsoft Corporation in the United

States and/or other countries.

7

Page 10

TABLE OF CONTENTS

1. Appearance and Names of Components ·········································· 11

Appended goods·········································································· 12

2. AC Adapter ················································································ 13

2-1. AC adapter ·········································································· 13

3. Paper Specifications ···································································· 14

3-1. Paper Width········································································· 14

3-2. Paper Thickness ··································································· 14

3-3. Forms of Paper ····································································· 14

3-4. Paper Types ········································································· 16

3-4-1. Requirements for full-sheet label paper ··························· 18

3-4-2. Conditions for using black mark paper ···························· 19

3-4-3. Conditions for using die-cut label paper··························· 20

3-5. Recommended Thermal Paper················································· 21

4. Preparations ·············································································· 23

4-1. Connecting Interface Cable····················································· 23

4-2. Connecting the drawer kick cable ············································ 26

4-3. Connecting the AC Adapter ···················································· 27

4-4. Disconnecting the AC Adapter ················································ 29

4-5. Turning on the Power ···························································· 30

5. Inserting Paper for Printing·························································· 31

5-1. Opening the Top Cover ·························································· 31

5-2. Setting the Paper Width························································· 32

5-2-1. Mounting separator A··················································· 33

5-2-2. Removing separators A and B ········································ 34

5-2-3. Attaching separators A and B ········································ 36

5-3. Loading Paper ······································································ 38

5-3-1. Loading roll paper························································ 38

5-3-2. Loading fanfold paper··················································· 40

5-4. Setting the Paper Guide························································· 43

5-5. Closing the Top Cover···························································· 44

6. Setting Up the Printer ································································· 45

6-1. Paper Information Setting Using the Driver······························ 47

6-1-1. Paper layout································································ 48

6-1-2. Custom paper ······························································ 49

6-1-3. Printing from an application ·········································· 53

6-2. Paper information setting using the utility································ 54

6-2-1. Paper layout································································ 54

8

Page 11

6-2-2. Setting detailed paper layout information ························ 55

6-3. Setting Paper Information Using the Printer····························· 58

6-3-1. Automatic layout detection ············································ 58

6-3-2. Setting the Paper Width················································ 59

6-3-3. Automatic layout detection ············································ 61

6-4. Replacing paper ···································································· 64

6-5. Paper Layout Errors······························································ 65

6-6. Adjusting Sensors ································································· 66

6-7. Print Density Setting····························································· 67

6-8. Print Speed Setting ······························································· 68

6-9. Cutting Position Correction ···················································· 69

6-10. Other Settings ···································································· 70

6-11. Initializing the Printer Setup Information······························· 70

7. Control Panel ············································································· 71

7-1. Control Panel ······································································· 71

7-2. Error Indications ·································································· 73

8. Preventing and Clearing Paper Jams ············································· 75

8-1. Preventing Paper Jams·························································· 75

8-2. Clearing a Paper Jam ···························································· 75

9. Troubleshooting ·········································································· 76

9-1. Power-on Problems and Errors················································ 76

9-2. Cutter-related Problems························································· 76

9-3. Printing-related Problems ······················································ 77

10. Special Modes ··········································································· 78

10-1. Test Printing ······································································ 78

10-2. Setting Up the Printer ························································· 80

Example (1): Changing the Print Density ································· 81

Example (2): Changing the Max Speed····································· 89

Example (3): Changing the Print Color····································· 97

Example (4) Changing the Feed at Power On ···························104

Example (5) Initializing the printer settings ····························112

Example (6) Changing the PNE Detect····································116

Example (7) Changing the Paper Width ··································125

Example (8) Changing the Batch(OTHER IF)···························133

10-3. Setup Items·······································································142

10-4. Sensor Adjustment ·····························································151

10-4-1. Sensor adjustment mode·············································151

10-4-2. Black mark (BM) sensor adjustment·····························156

10-4-3. Adjusting the label sensor···········································158

10-4-4. Paper-near-end (PNE) sensor adjustment······················160

10-4-5. Paper end (PE) sensor adjustment ·······························162

9

Page 12

10-5. Data Analysis ····································································165

10-6. Sample Print ·····································································169

11. Regular Cleaning ·····································································174

11-1. Cleaning the Paper Holder and Paper Transport·····················174

11-2. Cleaning the Platen Roller···················································175

11-3. Cleaning the Thermal Head ·················································179

11-4. Cleaning the Cutter Blade and Frame ···································180

12. Interface ·················································································188

12-1. LAN Interface····································································188

12-2. Dual Interface····································································190

12-3. Drawer Kick Connector ·······················································191

12-4. Specifications of Power Supply ·············································194

13. Specifications···········································································195

13-1. General Specifications·························································195

13-2. Cutter Specifications···························································199

13-3. Paper Supply Specifications ·················································200

13-4. Interface Specifications ·······················································201

13-5. Environment Specifications··················································202

13-6. Specifications of Reliability ··················································203

14. Roll Paper Unit ········································································204

14-1. Outline ·············································································204

14-2. Nomenclature ····································································204

14-3. Paper Specifications····························································206

14-4. Roll Paper Feed Specifications··············································207

14-5. Roll Paper Unit Installation Procedure ··································208

14-6. Method of setting PNE sensor ··············································213

14-7. Method of setting guide plate ···············································214

14-8. Setting the Roll Paper ·························································215

14-9. Roll Paper Unit Appearance·················································220

10

Page 13

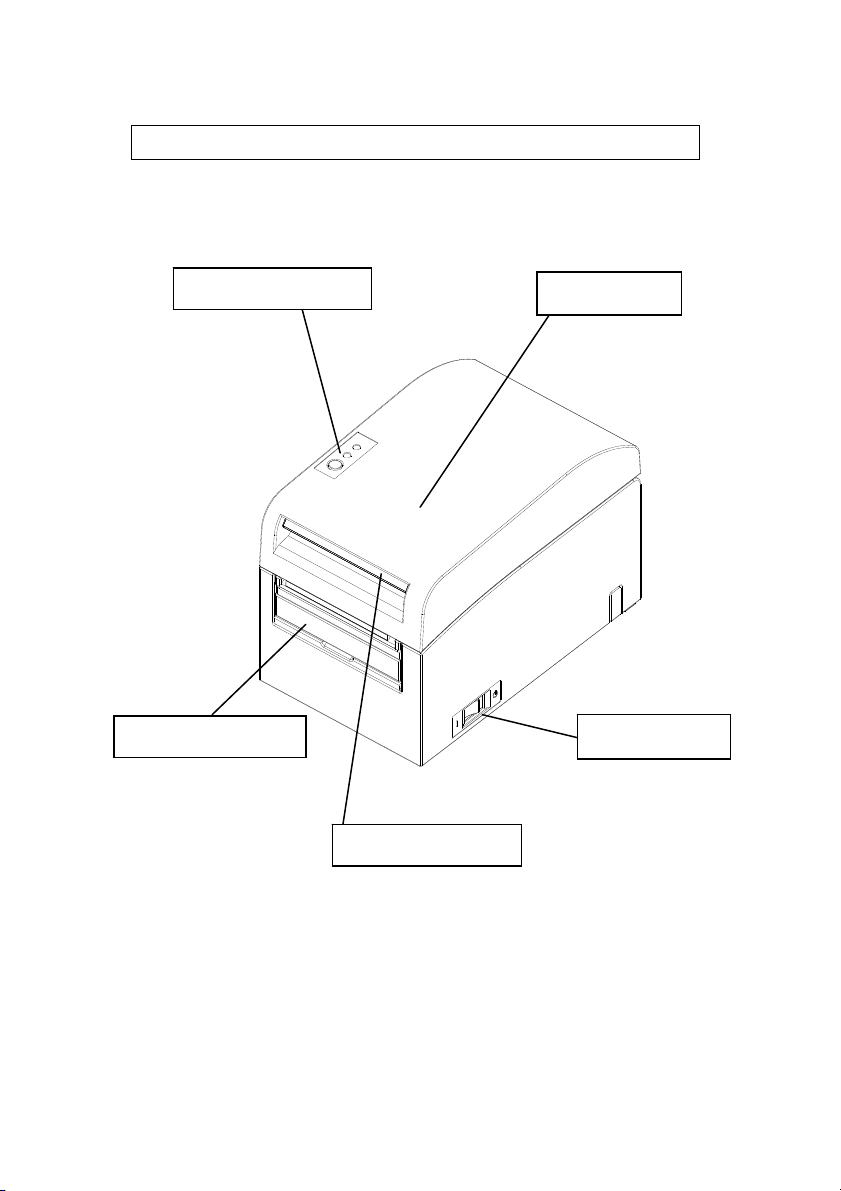

1. Appearance and Names of Components

Control panel

This panel

contains status

lamps and

operating

switches.

Top cover

Open and close this

cover to replace

forms.

Paper guide

Open the paper guide

when the expected

print length is longer

than 50 mm.

Power switch

This switch turns the

printer power on and off.

Release lever

Pull up the release lever to

open the top cover.

11

Page 14

Appended goods

Thermal paper CD

MANUAL

PRINTER DRIVER

UTILITY SOFT

Instruction sheet Safety warranty sheet

AC adapter Power cable

12

Page 15

2. AC Adapter

2-1. AC adapter

Only use the AC adapter specified below.

Model name: KA02951-0120

Input: 100 to 240V AC, 50/60HzOutput: DC24V±5%, 1.5A

Caution: Only use authorized AC adapters.

Caution: Do not use the bundled AC adapter and Power cable for any

electrical equipment other than this printer.

13

Page 16

3. Paper Specifications

3-1. Paper Width

(1) Paper width of 83 mm: 83

0

mm; paper width of 80 mm: 80

-1.0

(2) Paper width within a range of 70 to 25.4 mm (by units of 1 mm)

: 70 to 25.4

0

mm

-1.0

Note: Paper with a width within a range of 71 to 79 mm cannot be used.

3-2. Paper Thickness

: 75 to 150 m

3-3. Forms of Paper

(1) Roll paper

- Outside diameter: 1020.5 mm or less

With the large-diameter roll paper unit (option) attached, the printer can use

a roll with an outside diameter of up to 200 mm.

- Core dimension: Inside diameter of 1 inch

(inside diameter: 25.40.5 mm; outside diameter: 320.5 mm)

- Printed surface: Outside of the roll

- Treatment of end of paper:The roll paper must not be glued to the core.

The end of the paper must also not be folded back.

Note: Do not use rolls that have rough sides or sides from which pieces of paper

extrude. Using such rolls could cause a printer failure.

0

mm

-1.0

14

Page 17

(2) Fanfold paper

- Maximum stack height: 180 mm or less

- Fold length: 76.2 to 203.2 0.5 mm (3 to 8 inches)

- Perforation specifications: 3 (cuts):1 (tie)

15

Page 18

3-4. Paper Types

The printer supports the following paper types:

a. Plain paper (including full-sheet label paper)

b. Black mark paper

c. Die-cut label paper (including die-cut label paper with black marks)

When using black mark or die-cut paper, the printer can move the paper to the

start position, cutting position, peeling-off position, or tear-off position according

to the paper layout settings.

To use this function, provide the printer with paper layout information,

including the paper type and size, before printing. Use of the printer without

these settings may result in a paper layout error or unexpected printouts.

Therefore, set the paper layout when you:

(1) use label paper for the first time,

(2) change the paper type (plain paper, black mark paper, or die-cut label

paper),

(3) change the paper size, or

(4) switch to die-cut label paper of the same size as the current paper but with a

different base color or other specification.

You can set the paper layout automatically or manually. For details, see Chapter

6, "Setting Up the Printer."

16

Page 19

Note: Die-cut label paper is a type of label paper with a label sheet already cut

into segments of a certain size.

Note: Full-sheet label paper is a type of label paper with an uncut label sheet

that allows users to cut to any length by using a cutter.

Note: The same settings can be used when printing on full-sheet label paper or

plain paper (with no black marks).

Note: When printing on die-cut label paper with black marks, be careful

regarding the print position and cut position. Printing on base paper,

which is not covered with label sheet, may damage the thermal head.

Note: Note on preprinting on the recording side of thermal paper

Using thermal paper whose recording side is preprinted may result in the

thermal head sticking to the surface of thermal paper, causing a print error.

Therefore, you should avoid using this type of thermal paper as much as

possible. If such use is unavoidable, confirm beforehand that use of the

paper does not cause print errors, thin printing or other problems.

17

Page 20

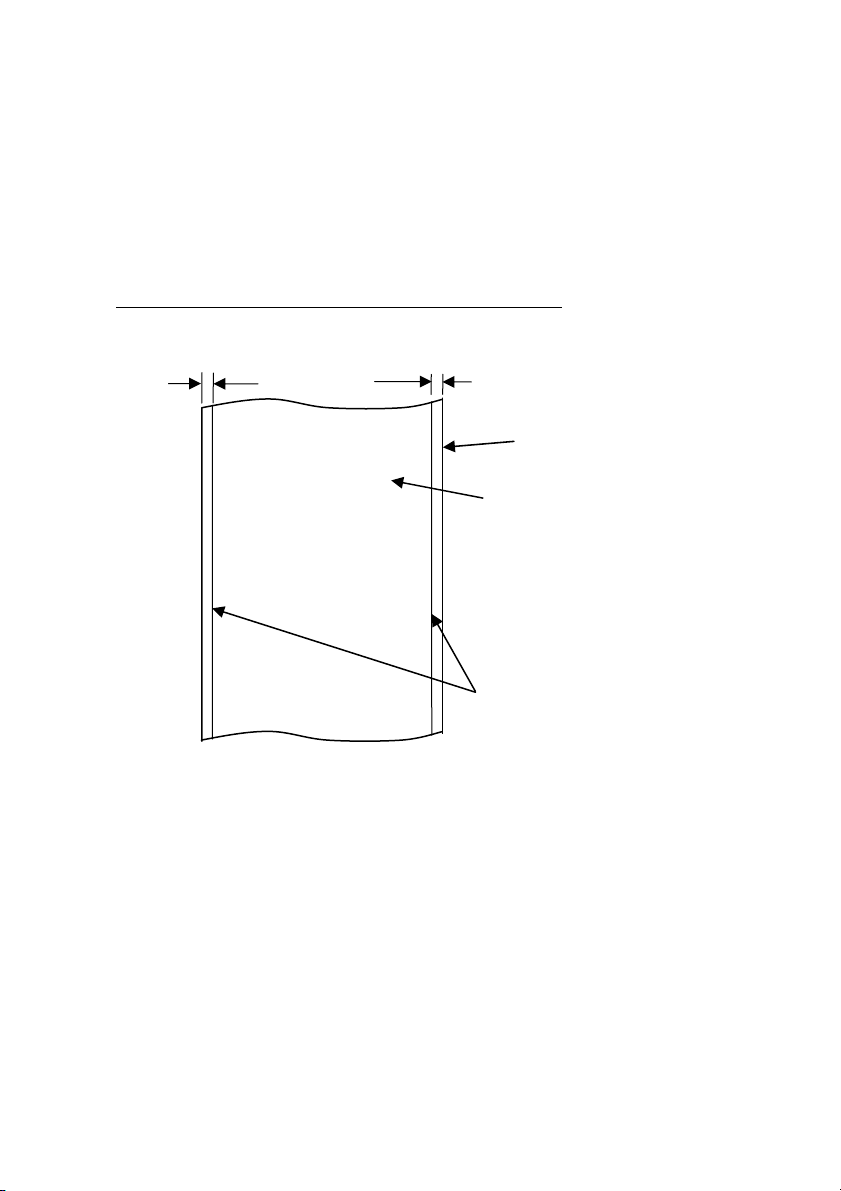

3-4-1. Requirements for full-sheet label paper

To prevent adhesive matter from sticking to the print head or paper guide,

use label paper that has undergone margin removal as shown below.

(Margin removal means cutting the margins at the time of

manufacturing.)

Slits on both sides on the printable side of paper

2 mm or less

2 mm or less

Base paper

Label

Slits

(for margin removal)

18

Page 21

A

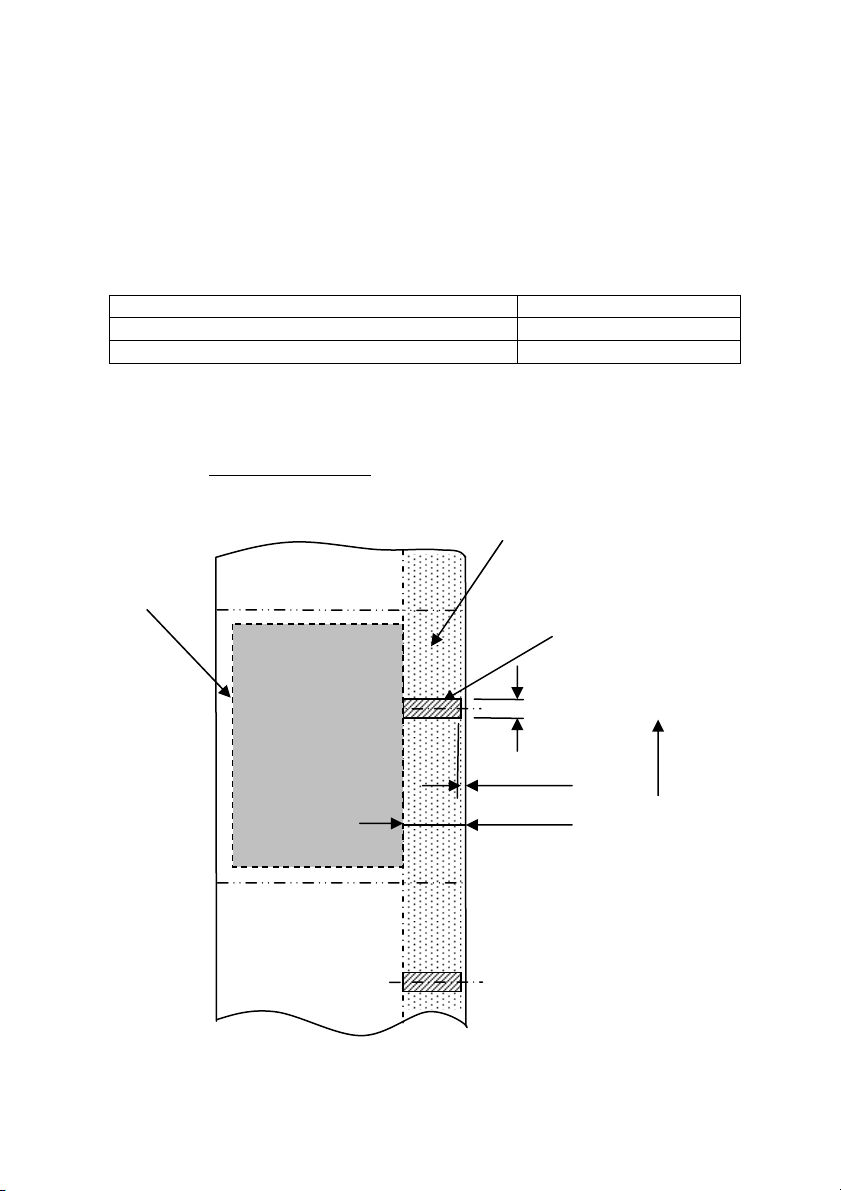

3-4-2. Conditions for using black mark paper

When using receipt paper or full-sheet label paper with black marks,

confirm that the following conditions are satisfied. The reflection factors at

locations A and B on the paper must be the combination of values specified

in the table below.

Reflection factor

A: Black mark area 8%

B: Margins above or below black marks 75%

Note: The reflectivity values were measured using a Macbeth PCM II

density meter (Filter C).

Print area

(seen from the

back side of

paper)

Back side of paper

(back of the coloring side of paper)

B

5.0 to 5.5 mm

0 to 1 mm

10 to 12 mm

Paper feed

direction

19

Page 22

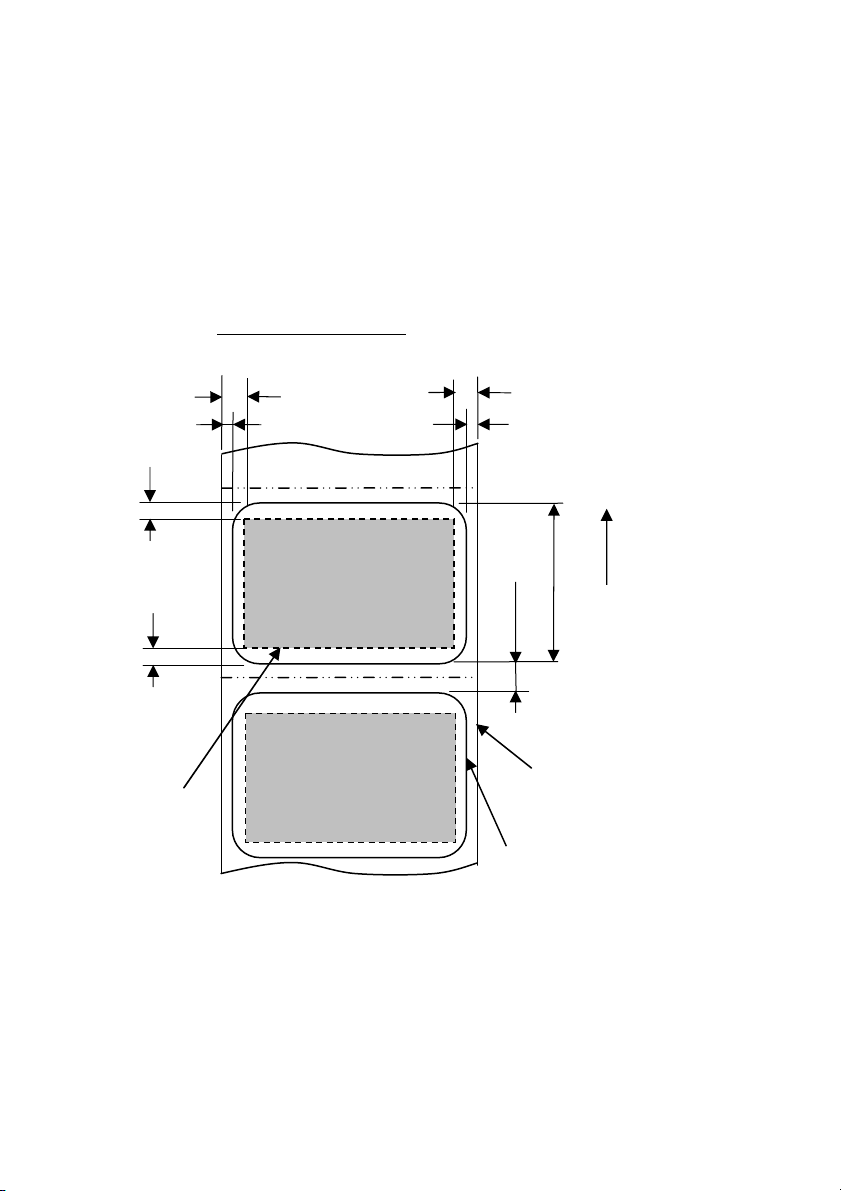

3-4-3. Conditions for using die-cut label paper

When using die-cut label paper, confirm that the following conditions are

satisfied. When using die-cut label paper with black marks, confirm that

the conditions stated in Section 3-4-2, "Conditions for using black mark

paper," are also satisfied.

Printable side of paper

4.5 mm or more

2 0.5 mm

4.5 mm or more

0.5 mm

2

1.5 mm or more

Paper feed direction

15 to 101.6 mm

3 to 10 mm

1.5 mm or more

Print area

Base paper

Label

Note: The base paper's opacity (ISO) must be equal to or less than 70%.

20

Page 23

3-5. Recommended Thermal Paper

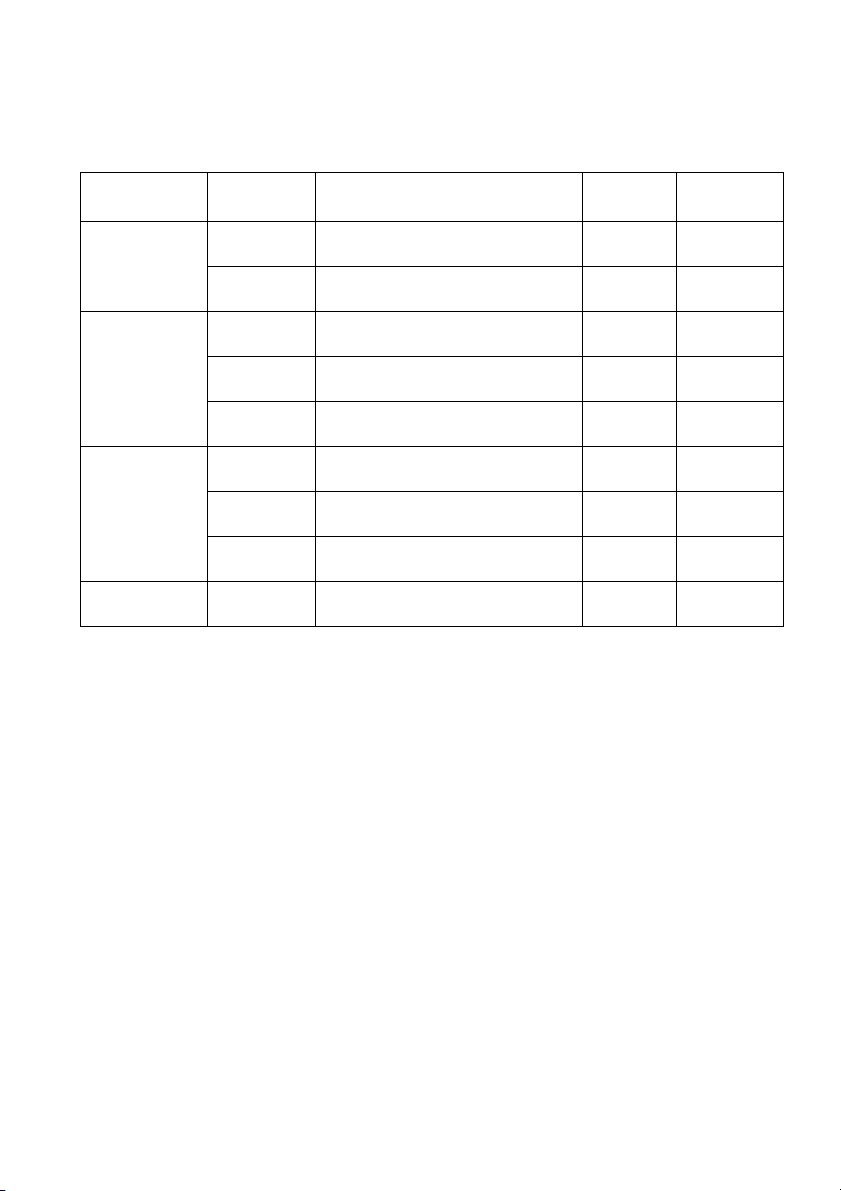

Manufacturer Product

Ltd.

Nippon Paper

Industries Co.,

Ltd.

Mitsubishi

Paper Mills

Limited

Ricoh Co.,

Ltd.

name

PD160R Monochrome receipt paper

PD190R Monochrome receipt paper

TF60KS-EX Monochrome receipt paper

TP60KS-FN Monochrome receipt paper

HD75 Monochrome label paper

P220AE-1 Monochrome thick paper

PB670 Two-color thermal paper

PB770 Two-color thermal paper

150LHB Monochrome label paper

Note : A recommended type of paper must be used. If a type of paper other than

a recommended one is used, head damage, printing irregularities, or

similar problems may occur.

Note : To use two-color thermal paper, set the print color to two colors from the

printer setup menu or using the setup tool contained on the CD-ROM

provided with the printer.

(See Example (3) in Section 10-2, "Setting Up the Printer.")

* By setting the appropriate property (use Color on the Graphics tab) for

printing with this printer driver, you can easily print in two-color mode

without having to change the printer setup.

Note : Ruled lines or characters containing fine lines (e.g. a serif typeface) tend to

have dull colors when they are printed on two-color thermal paper. For

printing on two-color thermal paper, a thick font (e.g., a sans serif font) is

recommended.

Quality characteristics Paper

(high-grade preservation type)

(mid-grade preservation type)

(normal type)

(mid-grade preservation type)

(normal type)

(normal type)

(red/black: normal type)

(blue/black: normal type)

(high-grade preservation type)

thickness

75m

75m

75m

75m

150m

150m

75m

75m

150m

specification

Density

100% Oji Paper Co.,

100%

100%

100%

130%

100%

105%

100%

130%

21

Page 24

Note : Red or blue printing on two-color thermal paper has an inferior preservation

characteristic that is equivalent to that of normal thermal paper.

Note : Printouts on label paper or thick paper may contain blurs or voids,

depending on the humidity and other environmental conditions.

Adjust the print speed and print density as appropriate for the type of paper

used.

(See Examples (1) and (2) in Section 10-2, "Setting Up the Printer.")

In particular, note that the paper transport accuracy may be negatively

affected by printing a barcode in the top margin at the beginning of paper

transport or in the Lower margin at the end of paper transport.

Note : The outside core diameter is assumed to be 32 mm.

If roll paper with an outside core diameter of other than 32 mm is used,

the paper-near-end detection accuracy deteriorates.

Note : If roll paper with an outside core diameter of less than 32 mm is used, a

transport error may occur when the cutter cuts the paper in full cutting

mode and reaches the core.

22

Page 25

4. Preparations

No printer cable is provided with the product. Obtain a printer cable suitable for

the product interface. If you have any questions, consult your dealer. Before

connecting or disconnecting cables, make sure of the following:

1) The power to the printer and all other devices connected to the printer

is turned off.

2) The AC adapter power cable has been unplugged from the outlet.

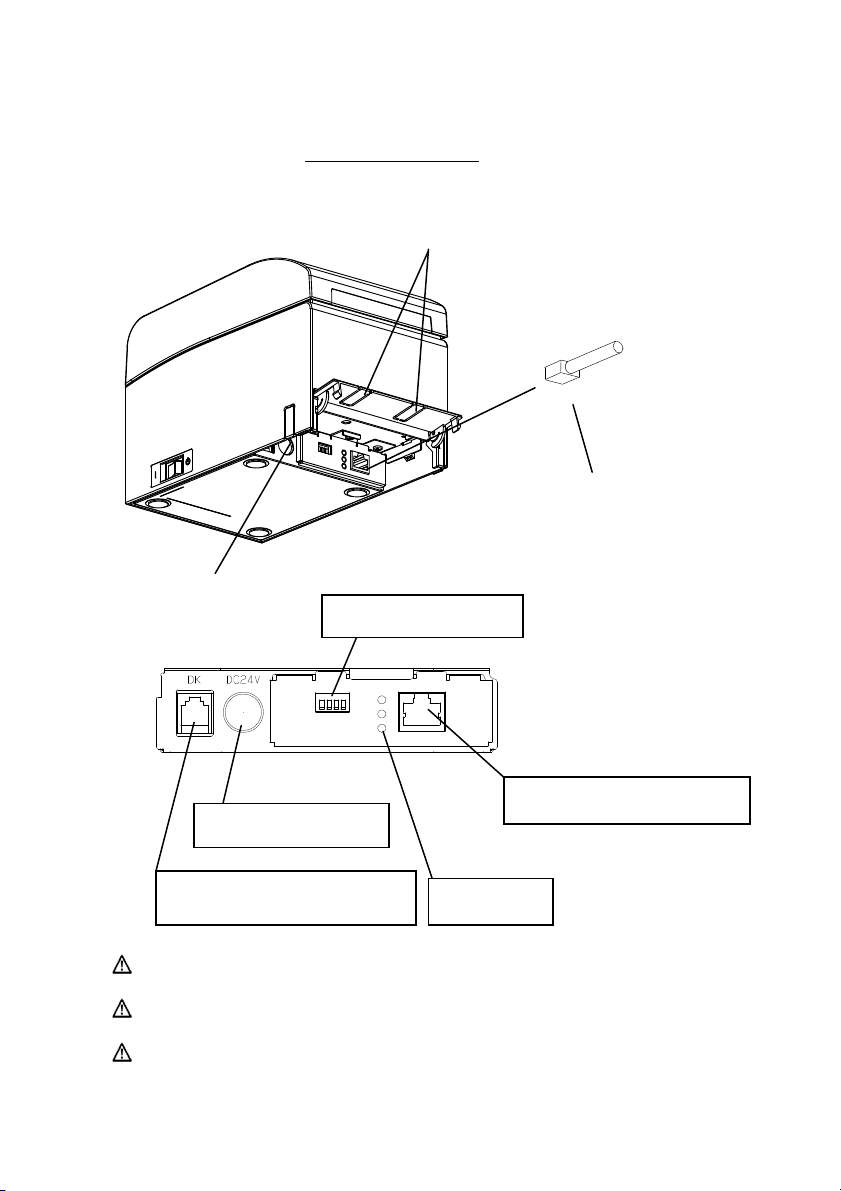

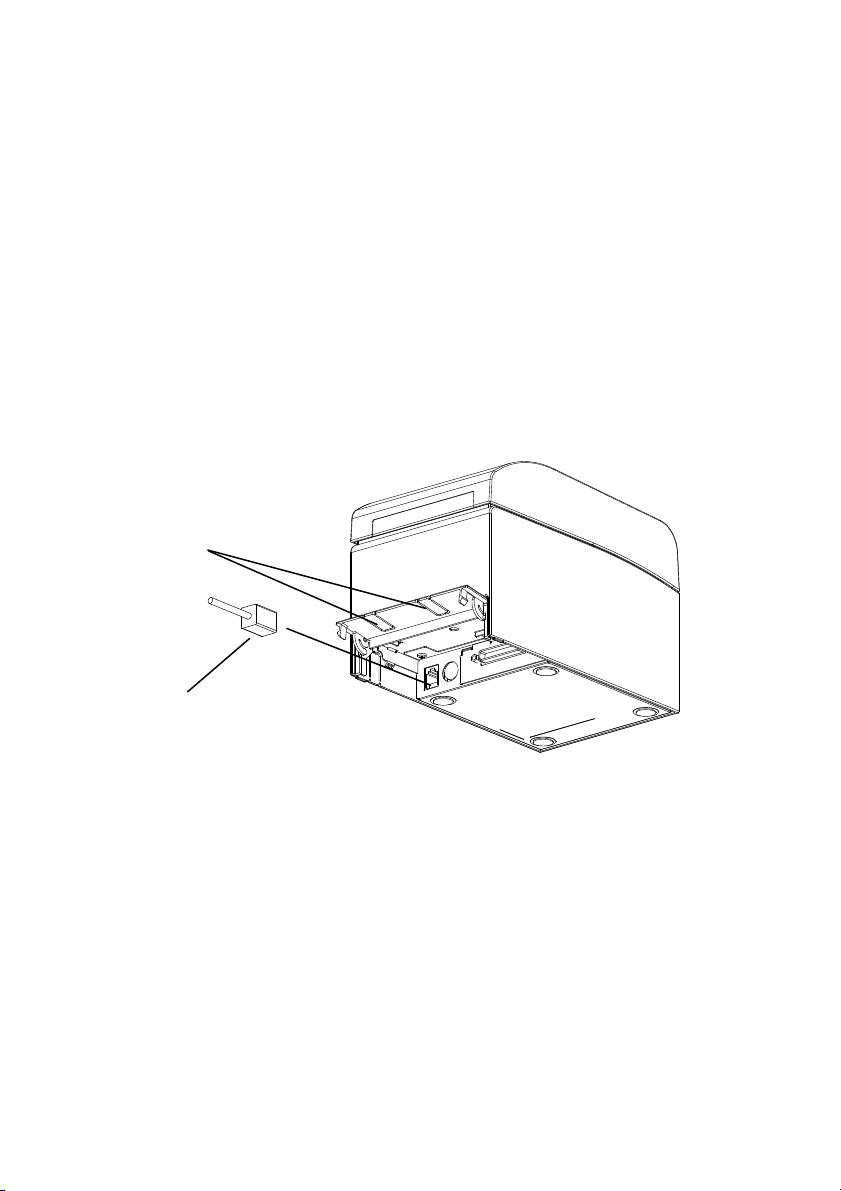

4-1. Connecting Interface Cable

Open the connector cover at the rear of the printer by pulling it up, and connect

the interface cable to its rear connector socket. Close the cover after connecting

the cable.

Note: If cables are arranged so that they extend from the rear or from the rear on

the right side, remove the inserts in the connector cover or the cover with

nippers or a similar tool. Unless the inserts are removed in this case, the

cables may be damaged and cause a failure.

23

Page 26

LAN interface model

Connector Cover

Insert

LAN interface cable

Insert

DIP switches

Power connector

LAN interface connector

Drawer kick connector

LEDs

Caution: Do not touch the DIP switches during normal use. This may

Caution: If the device is installed vertically, the LAN cable may not usable

Caution: The LAN interface cable must use the shield type.

change the network settings, disabling normal printing.

due to its shape. Please check before installing.

24

Page 27

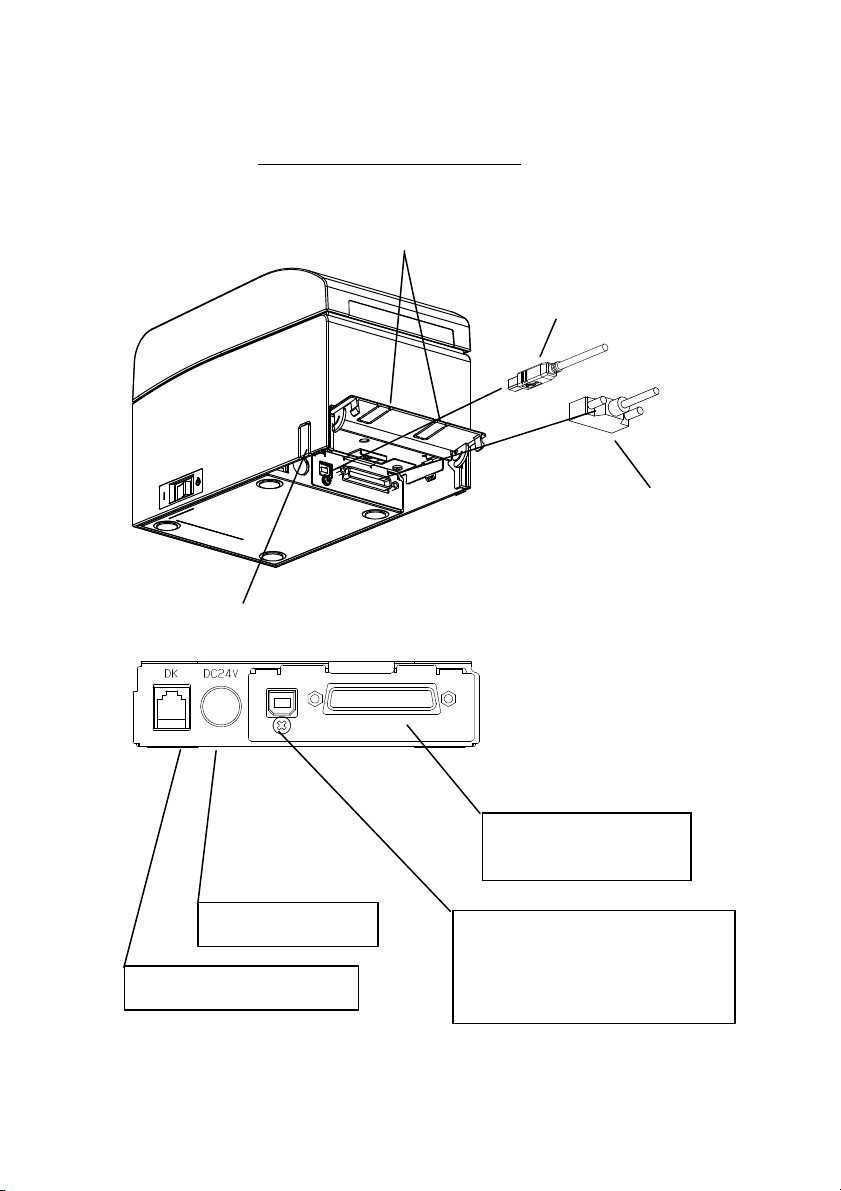

For a unit with Dual interface

Connector cover

Insert

USB Interface Cable

Type-B

* Connect the printer to a PC

through this connector.

Insert

Serial interface cable

* Secure the connector with

screws after making the

connection.

Interface connector

(Serial interface)

Power connector

Drawer kick connector

25

Interface Connector

(USB Interface Type-B)

* Connect the printer to a PC

through this connector.

Page 28

4-2. Connecting the drawer kick cable

Open the connector cover at the rear of the printer by pulling it up, and connect

the drawer kick cable to its rear connector socket. Close the cover after

connecting the cable.

Note : If the cable is arranged so that it extends from the rear, remove the inserts

in the connector cover with nippers or a similar tool. Unless the inserts are

removed in this case, the cable may be damaged and cause a failure.

Note : The drawer kick cable must not be used for a purpose other than for control

of the drawer.

Connector cover

Insert

Drawer kick cable

26

Page 29

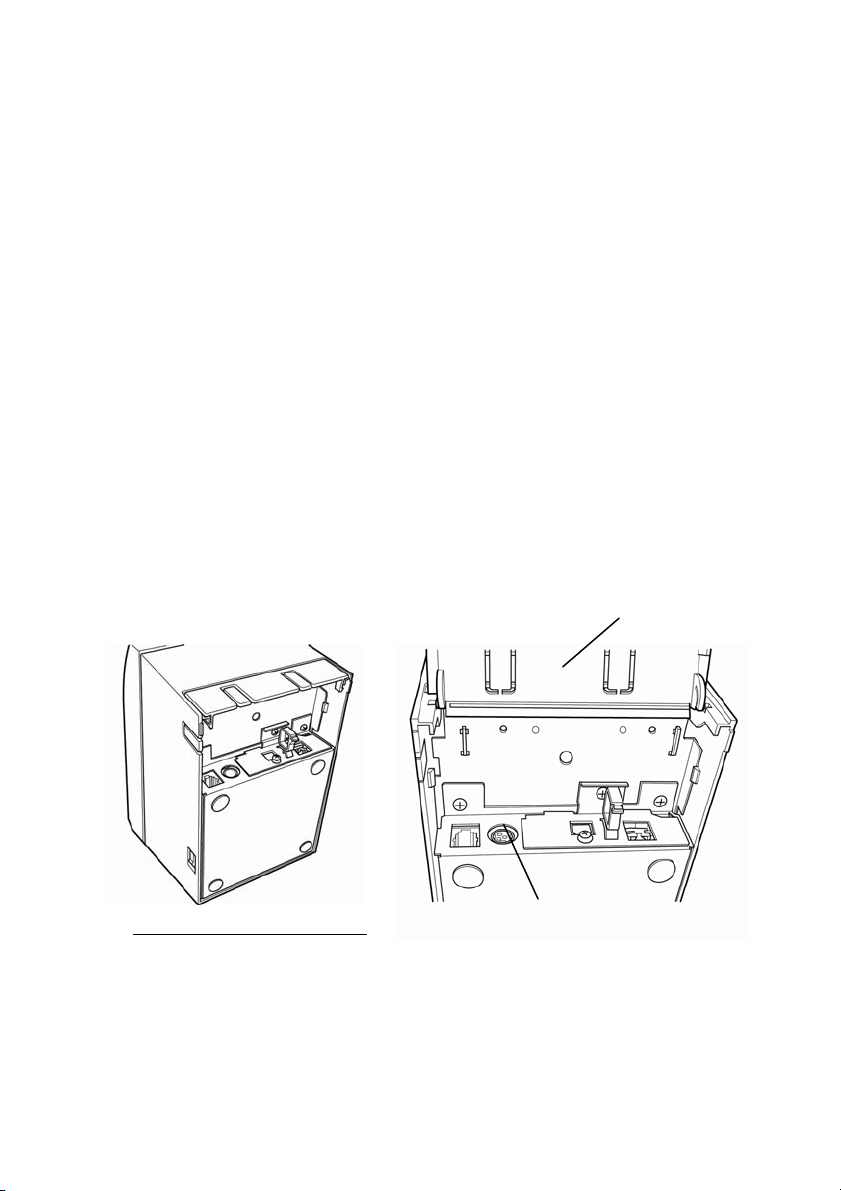

4-3. Connecting the AC Adapter

(1) Connect the AC adapter to the AC adapter power cable.

Note: To connect or disconnect the AC adapter, turn off the power switches of the

printer and all the devices to be connected to the printer. Then, unplug the

plug of the AC adapter power cable from the electrical outlet.

Note: Use only the specified AC adapter and specified AC adapter power cable.

(2) Open the connector cover at the rear of the printer by pulling it up, and

connect the AC adapter cable to the power socket.

Close the cover after connecting the cable.

Note: To connect the AC adaptor, place the printer on its side to make the

connection operation easier to perform.

Note: Remove notch of connector cover with Nipper, to maintain the space for the

cable of AC adapter.

Otherwise, the cable may be damaged and it way cause a failure.

Connector cover

Printer placed on its side

Power connector

27

Page 30

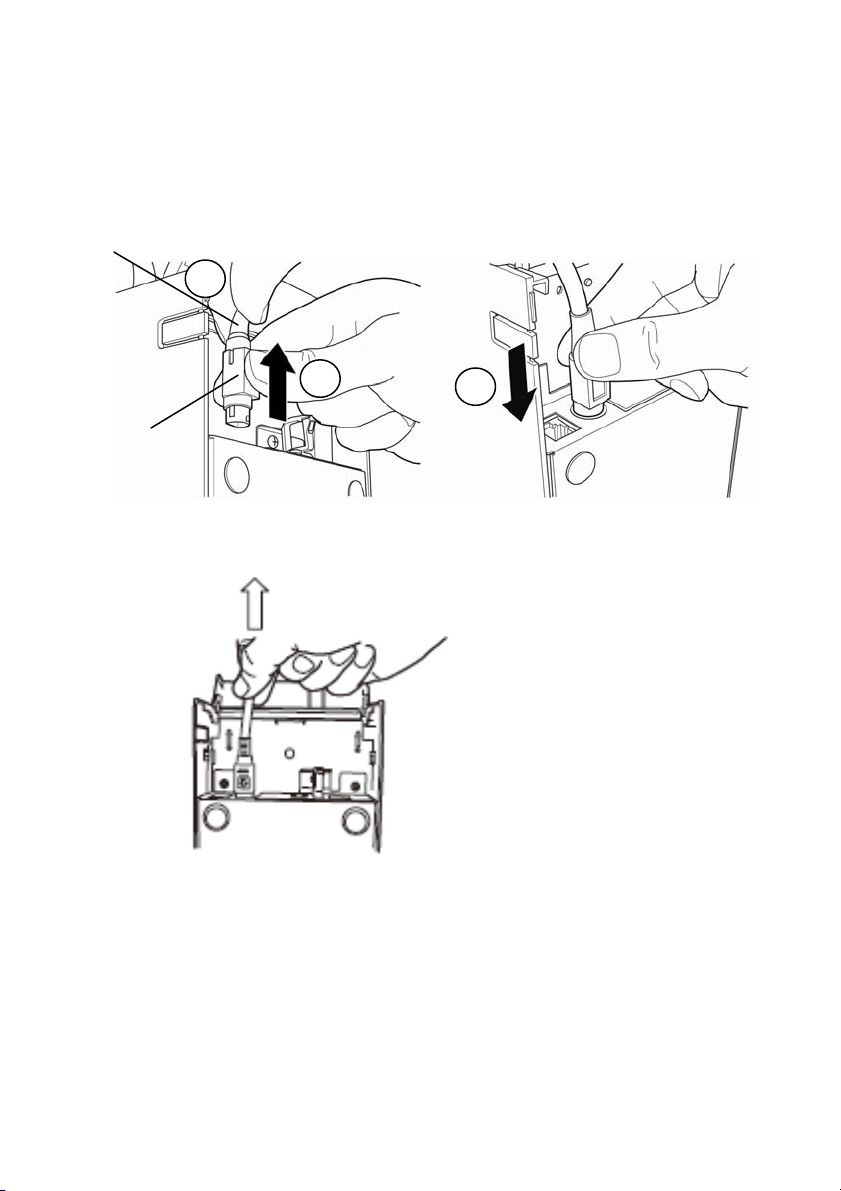

Note: To prevent the adaptor from slipping out, the connector section is

designed to be tight to fit. When inserting, (1) pinch the base of the cable,

(2) while sliding the outer section of the connector upwards, (3) and

insert the connector until it locks in place with a “click” sound.

Base of the cable

Outer section of

the connector

1

2

3

(3) Connect the plug of the power cable to electrical outlet.

(4) Plug the other end of the power cord into the power outlet.

28

Page 31

4-4. Disconnecting the AC Adapter

To unplug the AC adapter cable, grasp the connector as shown in the

picture below and pull it out. The lock mechanism of the connector will

then disengage, and the cable can be unplugged easily. Conversely,

forcibly pulling on the cable itself may damage the connector.

Note: Before disconnecting the AC adapter, switch off the printer and all devices

connected to the printer, and also disconnect the power cable of the AC

adapter from the outlet.

29

Page 32

4-5. Turning on the Power

After the AC adapter is connected, turn on the power switch at the side of the

printer. The POWER lamp on the control panel lights.

Control panel

Power switch

30

Page 33

5. Inserting Paper for Printing

5-1. Opening the Top Cover

(1) Grasp the top cover, pull up the cover release lever, and open

the top cover.

Top part of the top cover

Bottom part of the cover

release lever

(2) When manipulating the top cover, note that the cover seems to lock in

position before it is open completely. Make sure that the cover is really

open completely as shown in the picture below.

Note: If the top cover is not open completely during maintenance, it may close

inadvertently.

31

Page 34

5-2. Setting the Paper Width

Separator A is set to the position for a paper width of 70 mm at the time of

shipment from the factory.

- By adjusting the position of separator A, you can use paper with a width

within a range of 70 to 25.4 mm. (See "Section 5-2-1. Attaching separator A.")

- To use paper with a width of 80 mm, remove separator A.

(See "Section 5-2-2. Removing separators A and B.")

- To use paper with a width of 83 mm, remove separators A and B.

(See "Section 5-2-2. Removing separators A and B.")

Note : When replacing the separator, set a paper width appropriate to the

print area, referring to "Special Modes."

(See Examples (7) in Section 10-2, "Setting Up the Printer.")

Note : If the printer is using narrow paper (e.g., width of 70 mm), do not replace

the paper with wide paper (e.g., width of 80 mm). In printing with

narrow paper, part of the thermal head (the part where there is no

paper) comes in direct contact with the platen roller. The resulting wear

may lead to a deterioration in print quality. Similarly, if the paper width

is changed such that the cutter blade cuts at a location that has no paper,

the resulting wear on the blade may lead to improper cuts.

Note : Do not touch the thermal head except during cleaning. Doing so may

result in damage from static electricity.

Thermal head

32

Page 35

5-2-1. Mounting separator A

Holding separator A at locations a (lever) and b, slide the lever to the desired

position. Then, set the separator in place. Use the scale as necessary.

Note: Separator A must be set in place with an allowance of about 0.5 mm for

the maximum paper width.

Location b

Location a (lever)

1

Scale

2

Separator A

33

Page 36

5-2-2. Removing separators A and B

(1) Removing separator A

While holding part b on separator A with part a (lever) pushed in the

arrow-indicated direction, lift it to disengage the lock, and then remove the

rear bearing section.

Location b

Location a (lever)

Separator A

Lock

Rear bearing section

Separator A

34

Page 37

(2) Removing separator B

Holding separator B at location a, lift the s

Then, remove the separator at the rear bearing section.

eparator to disengage the lock.

Rear bearing section

Lock

Location a

Separator B

Separator B

35

Page 38

5-2-3. Attaching separators A and B

(1) Attaching separator A

Attach separator A from the rear bearing section.

Rear hook for the axis

Aligned horizontally

Note : Push the separator down until it engages with an audible click, and confirm

that the top of the separator is aligned horizontally.

36

Page 39

(2) Attaching separator B

Attach separator B from the rear bearing section.

Rear hook for the axis

Aligned horizontally

Note : Push the separator down until it engages with an audible click, and confirm

that the top of the separator is aligned horizontally.

37

Page 40

5-3. Loading Paper

5-3-1. Loading roll paper

(1) When using a new paper roll, remove the glued portion of the paper as

well as the part to which adhesive tape is affixed.

Note : Since the glued portion of the paper should not be printed on, remove about

one turn (about 40 cm) of the roll paper from the beginning so that none of

the remaining paper has glue on it.

Any adhesive or other matter remaining from the glue may adhere to the

thermal head and cause a problem, such as voids on printouts. Therefore,

do not forget to remove the glued portion of the paper.

(2) From the front of the printer, pull out the end of the paper as shown below.

Front cover of the printer.

Note: Pull the end of roll paper until it comes out from the front of the cover.

38

Page 41

Note : Before loading a new roll, make sure that an old core does not remain in

the roll holder. Leaving an old core will cause a paper-near-end error

condition.

Paper not protruding

from the front cover

e : The roll paper mus

Not

shown in the figure below may cause a paper jam, uneven printing, or other

printing problem.

t have no deformities. Using roll paper such as that

Roll paper inserted

upside down

Note : If the loaded roll paper is loose (slack) as shown below, take up the slack

before printing on the paper. Printing on roll paper that is loose may cause

a paper jam, uneven printing, or other printing problem, which will prevent

the printer from detecting paper near end conditions.

39

Page 42

5-3-2. Loading fanfold paper

(1) Load the fanfold paper with its thermo sensitive side facing up.

(2) Open the top cover, and then pass the fanfold paper through the paper

feed section at the rear of the printer.

Paper feed section

Load the paper with its

thermo sensitive side

facing up.

Note: Pull the end of fanfold paper until it comes out from the front of the cover.

40

Page 43

Figure 1

Max 180mm

20 mm or more

Figure 2

Max 80mm

Note: Fanfold paper must be placed at least 20 mm from the rear of the

printer. When this requirement is satisfied, paper can be stacked up to

180 mm (see Figure 1).

When fanfold paper is placed in contact with the rear of the printer,

paper can only be stacked up to 80 mm (see Figure 2).

Note: Also, the paper location must be confined to an area between the left

and right edges of the printer.

41

Page 44

Note: When using perforated paper, make sure that the printer does not

cut the paper at perforations or in an area that is 0 to 15 mm in

front of perforations (as viewed from the paper feed direction).

Otherwise, incorrect cutting may result. (See Figure 3.)

Note: When using perforated paper, be sure to prevent paper from being

caught, paper jams, paper from being cut during transport, and

other such problems. These problems may shorten the life of the

thermal head.

Area that is 0 to 15 mm in front of perforations

(cutting prohibited in this area)

Paper feed direction

Fold at perforations

Figure 3

Note: Should you find that the blinking ERROR lamp annoys you, perform

printer setup to change PNE DETECT to DISABLE.

(See Example (6) in Section 10-2, "Setting Up the Printer.")

42

Page 45

5-4. Setting the Paper Guide

When the print length per print session is longer than 50 mm, use the printer

with the paper guide open. When it is equal to or less than 50 mm, use the

printer with the paper guide closed.

Paper guide

For print length equal to or less than 50 mm:

Use the printer with the paper guide closed.

Paper guide

For print length longer than 50 mm:

Use the printer with the paper guide open.

43

Page 46

5-5. Closing the Top Cover

Place the paper in the correct orientation, and carefully close the top cover.

Release lever

Note : Place the paper in t

the paper is not correctly in place, a paper jam or misaligned printing

might occur.

Note : To close the top cover, press it down near its center (the location pointed

at in the figure below) until you hear the lock engage. If the cover is not

completely locked, printing might be impossible

Press

here

Top cover

he correct orientation. If the top cover is closed while

44

Page 47

6. Setting Up the Printer

Introduction to printer setup procedures

You can set the following items for this printer:

(1) Paper type and paper layout

- Die-cut label paper, black mark paper, or plain paper

- Paper width and other paper layout information

(2) Custom paper creation

(3) Sensor adjustment

(4) Print speed

(5) Print density

(6) Printer operation

Item (1), (2) is a required setting.

Items (3) to (6) are optional settings.

<Reference documents>

The CD-ROM that comes with the printer contains some PDF-formatted

online manuals.

For details on how to install and use each of the software programs

that come with the printer, see the following documents:

Document title Folder File name

Installation Guide \Manuals LD670_InstallGuide1_en.pdf

Windows Driver User’s Guide \Manuals LD670_WindowsDriverGuide_en.pdf

Utility User’s Guide \Manuals LD670_UtilityGuide_en.pdf

Status Monitor User’s Guide \Manuals LD670_StatusMonitorGuide_en.pdf

45

Page 48

Detection of paper layout information

The printer supports the following paper types:

a. Plain paper (including full-sheet label paper)

b. Black mark paper

c. Die-cut label paper (including die-cut label paper with black

marks)

When using black mark or die-cut paper, the printer can move the paper to the

start position, cutting position, peeling-off position, or tear-off position

according to the paper layout settings.

To use this function, provide the printer with paper layout information,

including the paper type and size, before printing. Use of the printer without

these settings may result in a paper layout error or unexpected printouts.

Therefore, set the paper layout when you:

(1) use label paper for the first time,

(2) change the paper type (plain paper, black mark paper, or die-cut label

paper),

(3) change the paper size, or

(4) switch to die-cut label paper of the same size as the current paper but

with a different base color or other specification.

You can set the paper layout automatically or manually. The next and

subsequent pages provide detailed information.

Note: The paper layout must be set under the same temperature

conditions as in the actual operating environment of the printer.

Otherwise, the cutting position may be outside the base area for

labels because of a temperature difference.

Note: - The printer provides a function that automatically detects the paper

layout. This automatic layout detection function obtains fixed

information on width settings. Therefore, OKI recommends that you

manually specify these settings.

Note: - There are two ways to manually set up the printer:

(1) Paper information setting using the driver

(2) Paper information setting using the utility

46

Page 49

6-1. Paper Information Setting Using the Driver

Printer setup flow

I. Installing the driver

↓ See "Chapter 3 Installation" in the

II. Paper layout detection

↓ Provide the printer with the paper layout information described in the

Manual Section 6-1-1, "Paper layout."

III. Custom paper creation

↓ Create your custom paper as described in the Manual Section 6-1-2,

"Custom paper."

IV. Printing from an application

Perform printing as described in the Manual Section 6-1-3,

"Printing from an application." (The use of WordPad is assumed for

the procedure described in Section 6-1-3.)

Installation Guide

.

47

Page 50

6-1-1. Paper layout

The printer shipped from the factory is configured to enable automatic

paper detection. Follow the procedure below to have the printer

automatically detect the paper layout information.

<<Procedure>>

(1) Turn on the printer power.

(2) Open the top cover.

(3) Load the paper that you want to use into the printer.

Leave the top cover open.

(4) Press and hold down the FEED switch. The POWER and ERROR lamps

blink alternately. Continue to hold down the FEED switch until the

POWER and ERROR lamps blink at the same time. At this time, release

the FEED switch.

(For details on how to initialize the paper layout, see "How to initialize

the paper layout" in Section 7-1, "Control Panel.")

(5) Close the top cover.

(6) The printer feeds the paper, automatically obtains paper layout

information, and saves the information.

Note: Automatic layout detection involves a paper feed of several tens of

centimeters. This is normal operation.

48

Page 51

6-1-2. Custom paper

The printer driver provides a function that allows you to set printer layout

information when creating a custom type of paper.

The layout information can be updated even with the printer in

paper-layout-error status.

Note: When changing the paper type to plain paper from another type, you

must initialize the layout information by following the procedure

described in "How to initialize the paper layout" in 7-1 Section,

"Control Panel."

Follow the procedure below to register layout information with the printer.

This procedure indicates how to create a custom paper type and send the

resulting information to the printer. The use of Windows XP Professional is

assumed for the screen shots used in the procedure.

1. Click [Start] and then [Printers and Faxes].

* The method of opening the printer folder varies depending on the

Windows version.

For details on how to open the printer folder, see "Section 3.1.1 How to

Display the Printer Properties" in the

2. Right-click [LD670 Raster], and then select [Properties].

3. Click the [Custom Paper] tab.

Windows Driver User's Guide

.

49

Page 52

(1) Creating a new custom paper type

<<Procedure>>

(1) Check the [Create a New Paper] check box and enter the paper name.

(2) Select [Paper Type] and enter the appropriate paper information ([S1] to

[S5]). Do not change [S5] (cut position) with its default value.

(3) Enter the left, right, top and bottom margins.

(4) Click the [Save] button.

This registers your custom paper settings in the printer driver as paper

size information.

(5) Click the [Transfer to Printer] button.

The selected paper layout information is sent to the printer and becomes

effective.

(6) Go to step 4.

50

Page 53

(2) Using an existing type of paper

<<Procedure>>

(1) Select the desired paper that has already been created.

(2) Click the [Transfer to Printer] button.

The selected paper layout information is sent to the printer and becomes

effective.

(3) Go to step 4.

51

Page 54

4 When a confirmation message appears, respond as instructed and then click

the [OK] button.

* You may encounter a paper layout error when attempting to replace paper

in one of the following patterns:

- Change from die-cut label paper to plain paper

- Change from black mark paper to plain paper

- Change from die-cut label paper to black mark paper

- Change to paper having a different paper layout

* If the error remains even after setting is completed, re-verify that the paper

loaded on the printer matches the custom paper setting.

* The [Transfer to Printer] button works even when the new paper is not

loaded. Before actually printing data, however, be sure to replace the

paper.

* If the newly set type of paper is not plain paper, the printer feeds paper up

to the top-of-form position.

5 In the LD670 Raster Properties window, click the [OK] button.

52

Page 55

6-1-3. Printing from an application

You can print a document from an application using paper information

registered in the printer driver.

The procedure below explains how to print a document to the LD670 printer

using WordPad as an example.

1. From the WordPad [File] menu, select [Page Setup].

2. The Page Setup window appears. Click the [Print Setup] button.

3. In the [Printer Name] field, specify [LD670 Raster] as the target

printer.

4. Click the [Properties] button to configure printing preferences for the printer

driver.

* The button used to open the printing preferences window varies from one

application to another. For example, the [Options] button is used for this

purpose in Excel.

* Some applications (including Word) also assume use of the Print window

for setting printing preferences, instead of providing a separate Page

Setup window.

For details on the Print window, see the description in step 10 later.

5. The LD670 Raster Properties (printing preferences) window appears. Specify

desired printing preferences, and then click the [OK] button.

6. Click the [OK] button in the Page Setup window to close the window.

7. In Page Setup window, specify the paper size, orientation and margins, and

then click the [OK] button.

8. Edit a document in the WordPad edit window.

9. Select [Print] from the [File] menu.

10. The [Print] window appears.

Click the [Advanced] button to specify printing preferences for the printer

driver.

11. Specify [Page Range] and [Copies] when necessary, and then click the [Print]

button.

12. Print data is sent to the printer and printing starts.

53

Page 56

6-2. Paper information setting using the utility

6-2-1. Paper layout

The printer shipped from the factory is configured to enable automatic

paper detection. Follow the procedure below to have the printer

automatically detect the paper layout information.

<<Procedure>>

(1) Turn on the printer power.

(2) Open the top cover.

(3) Load the paper that you want to use into the printer.

Leave the top cover open.

(4) Press and hold down the FEED switch. The POWER and ERROR lamps

blink alternately. Continue to hold down the FEED switch until the

POWER and ERROR lamps blink at the same time. At this time, release

the FEED switch.

(For details on how to initialize the paper layout, see "How to initialize

the paper layout" in Section 7-1, "Control Panel.")

(5) Close the top cover.

(6) The printer feeds the paper, automatically obtains paper layout

information, and saves the information.

Note: Automatic layout detection involves a paper feed of several tens of

centimeters. This is normal operation.

54

Page 57

6-2-2. Setting detailed paper layout information

The printer utility provides a function that allows you to set printer layout

information.

The layout information can be updated even with the printer in

paper-layout-error status.

Follow the procedure below to register layout information with the printer.

This procedure explains how to send layout information to the printer.

The use of Windows XP Professional is assumed for the screen shots.

1. Click [Start], [All Programs], [Okidata], and [LD670 Utility] in this order.

* The method of running the printer utility varies depending on the Windows

version. See "Section 3.1 Starting LBL32" in the

2. Select [LD670 Raster] and then click [OK].

3. Click the [Paper Layout] tab.

Utility User's Guide

.

55

Page 58

<<Procedure>>

(1) Uncheck the [Automatically set the paper layout] check box.

(2) Select [Paper Type] and enter the appropriate paper information ([S1]

to [S5]). Do not change [S5] (cut position) with its default value.

(3) Enter the left, right, top and bottom margins as required.

(4) Click the [Set Layout] button.

The paper layout information you entered in this window is sent to

the printer and becomes effective.

56

Page 59

4 When a confirmation message appears, respond as instructed and then click

the [OK] button.

5 A message appears, prompting you to replace the paper with paper targeted

by the layout setting. Replace the paper and click the [OK] button.

* If the error remains even after setting is completed, re-verify that the

paper loaded on the printer matches the paper setting.

* If the newly set type of paper is not plain paper, the printer feeds paper up

to the top-of-form position.

57

Page 60

6-3. Setting Paper Information Using the Printer

6-3-1. Automatic layout detection

The printer shipped from the factory is configured to enable automatic

paper detection. Follow the procedure below to have the printer

automatically detect the paper layout information.

<<Procedure>>

(1) Turn off the printer power.

(2) Open the top cover.

(3) Turn on the printer power.

(4) Load the paper that you want to use into the printer.

Leave the top cover open.

(5) Press and hold down the FEED switch. The POWER and ERROR

lamps blink alternately. Continue to hold down the FEED switch

until the POWER and ERROR lamps blink at the same time. At

this time, release the FEED switch.

(For details on how to initialize the paper layout, see "How to

initialize the paper layout" in Section 7-1, "Control Panel.")

(6) Close the top cover.

(7) The printer feeds the paper, automatically obtains paper layout

information, and saves the information.

Note: Automatic layout detection involves a paper feed of several tens of

centimeters. This is normal operation.

Note: The printer’s automatic layout detection function cannot obtain the

paper width setting as part of paper information. For details on how to

set the paper width, see Example 7) in Section 10-2, "Setting Up the

Printer."

Note: If you need to specify information other than the paper width, follow

the procedure described in Section 6-1, "Paper Information Setting

Using the Driver," or 6-2, "Paper Information Setting Using the

Utility."

58

Page 61

6-3-2. Setting the Paper Width

The printer utility provides a function that allows you to set a paper width on

the printer.

The paper width can be set even with the printer in paper-layout-error status.

Follow the procedure below to set a paper width on the printer.

This procedure explains how to send your paper width setting to the printer.

The use of Windows XP Professional is assumed for the screen shots.

1. Click [Start], [All Programs], [Okidata], and [LD670 Utility] in this order.

* The method of opening the printer folder varies depending on the

Windows version.

For details on how to open the printer folder, see "Section 3.1, Starting

LBL32" in the

2. Select [LD670 Raster] and then click [OK].

3. Click the [Paper Layout] tab.

Utility User's Guide

.

59

Page 62

<<Procedure>>

(1) Enter the paper width.

(2) Click the [Layout Auto Set] button.

4 When a confirmation message appears, respond as instructed and then

click the [OK] button.

5 A message appears, prompting you to replace the paper with paper

targeted by the layout setting. Replace the paper and click the [OK]

button.

Note: Automatic paper size setting involves a paper feed of several tens of

centimeters for layout detection. This is normal operation.

60

Page 63

6-3-3. Automatic layout detection

The automatic layout settings are configured as follows:

Black mark paper

L1: Length from the vertical reference position to the next reference

Position : Automatically detected

L2: Length of the detection area for the vertical reference position

: 5.0mm to 5.5mm

L3: Length from the vertical reference position to the start position

: 1.5mm

L4: Length from the vertical reference position to the cutting position

L5: Print area length : (L1 - 1.5 x 2) mm

L6: Length from the left edge of the paper to the left end of the print area

: 11.0 mm (for a paper width of 83 mm)

: 4.0 mm (for a paper width of 80 mm)

: 3.0 mm (for other paper widths)

L7: Print area width : 80.0 mm (for a paper width of 83 mm)

(Paper width - L6 x 2) mm (for other paper widths)

Note: L1 to L7 above are values detected by the printer sensor.

These values do not match the S1 to S5, L, R, T, and B parameter

values specified by the driver or utility.

Note: If the paper length (L1) of the loaded roll paper differs by 10% or

more from the initially set paper length (L1) or that set upon

automatic recognition, an error occurs because the type of loaded

roll paper is considered illegal.

L4

L3

L6

Print Area

L5

L7

: 0.0mm

Paper feed direction

L2

L1

Base Position

61

Page 64

Die-cut label paper

L1: Length from the vertical reference position to the next reference position

: Automatically detected

L2: Length of the detection area for the vertical reference position

: Automatically detected

L3: Length from the vertical reference position to the start position

: (L2/2 + 1.5) mm

L4: Length from the vertical reference position to the cutting position

: 0.0 mm

L5: Print area length : (L1 - L3 x 2) mm

L6: Length from the left edge of the paper to the left end of the print area

: 5.0 mm

L7: Print area width : (Paper width setting - L6 x 2) mm

Note: L1 to L7 above are values detected by the printer sensor.

These values do not match the S1 to S5, L, R, T, and B parameter

values specified by the driver or utility.

Note: If the paper length (L1) of the loaded roll paper differs by 10% or

more from the initially set paper length (L1) or that set upon

automatic recognition, an error occurs because the type of loaded

roll paper is considered illegal.

Paper feed direction

L5

L4

L3

L7

Print Area

L2

Base Position

L1

L6

62

Page 65

Plain paper (including full-sheet label paper)

L1: Length from the vertical reference position to the next reference position

: Not determined

L2: Length of the detection area for the vertical reference position

: Not determined

L3: Length from the vertical reference position to the start position

: Not determined

L4: Length from the vertical reference position to the cutting position

: Not determined

L5: Print area length : Not determined

L6: Length from the left edge of the paper to the left end of the print area

: 1.0 mm (for a paper width of 83 mm)

: 4.0 mm (for a paper width of 80 mm)

: 3.0 mm (for other paper widths)

L7: Print area width

: 80.0 mm (for a paper width of 83 mm)

(Paper width - L6 x 2) mm (for other paper widths)

Note: L1 to L7 above are values detected by the printer sensor.

These values do not match the S1 to S5, L, R, T, and B parameter

values specified by the driver or utility.

Paper feed direction

L7

Print Area

L6

63

Page 66

6-4. Replacing paper

The paper replacement procedure is as follows.

Automatic layout detection

<<Procedure>>

(1) Turn off the printer power, and open the top cover.

(2) Turn on the printer power.

(3) Load the paper that you want to use into the printer.

Leave the top cover open.

(4) Press and hold down the FEED switch. The POWER and ERROR

lamps blink alternately. Continue to hold down the FEED switch

until the POWER and ERROR lamps blink at the same time. At

this time, release the FEED switch.

(5) Close the top cover.

(6) The printer feeds the paper, automatically obtains paper

information, and saves the information.

Note: Automatic layout detection involves a paper feed of several

tens of centimeters. This is normal operation.

Updating the layout information

Re-specify paper information by following the procedure described in

Section 6-1-2, "Custom paper," or 6-2-2, "Setting detailed paper layout

information."

64

Page 67

6-5. Paper Layout Errors

When using black mark or die-cut label paper, the printer monitors the

paper length (L1) based on the set paper layout. If the detected paper

length does not match the set paper length, a paper layout error occurs.

(1) Error when paper is being loaded

Confirm that the paper being loaded is the same as the paper specified

in the paper layout information for the printer. If not, replace the paper

with paper that matches the paper layout information.

(2) Error during printing

If a paper layout error occurs during printing, open the top cover, check

whether label peeling, a paper jam or other problem has occurred,

reposition the paper, and then close the top cover.

(3) Error when paper is being replaced

Follow the procedure in "Section 6-4. Replacing paper."

Note: If the paper length (L1) of the loaded paper is 10% different from

your specified paper length or that set through automatic detection,

a paper layout error occurs.

65

Page 68

6-6. Adjusting Sensors

1) There are two ways to adjust sensors:

a. Automatic sensor adjustment (This mode is set at the time of shipment

from the factory.)

b. Manual sensor adjustment

■ Automatic sensor adjustment

1) With this mode enabled, the sensor is automatically adjusted in

parallel with automatic layout detection. This adjustment sets

optimal values based on the measured sensor input level.

Sensor adjustment values are not preset at shipping. However, when

you load paper on the printer and initially power on the printer, the

automatic layout detection function will set the sensor adjustment

values.

■ Manual sensor adjustment

1) You can start manual adjustment of a sensor by selecting the sensor in

sensor adjustment mode, which is a special mode. The printer prints

instructions for operations. Adjust the sensor by following these

instructions.

2) Automatic sensor adjustment is enabled at the time of shipment from

the factory. The printer as shipped need not be manually adjusted

because sensors are automatically adjusted at the same time as

automatic layout detection. Adjust sensors manually only if a paper

layout error frequently occurs.

66

Page 69

6-7. Print Density Setting

The printer can specify a print density for the paper to be used.

The print density is preset to 130% at shipping. You can change this setting to

the value appropriate for the paper to be used as described in Section 3-5,

"Recommended Thermal Paper."

There are three methods of changing the setting:

(1) Using the Windows printer driver

See "Section 4.4 [Graphics] Tab" in the

(2) Using the printer utility

See "Section 3.2.5 Customize Value" in the

(3) Setting up the printer

Change the setting as described in Example (1) in Section 10-2, "Setting Up

the Printer."

* If you have specified a print density using the Windows driver, the print

density specified by the driver will be used for printing. (The print density

specified by the driver takes precedence over print density specified by

the utility.)

Windows Driver User's Guide

Utility User's Guide

.

.

67

Page 70

6-8. Print Speed Setting

There are three methods of changing the setting:

(1) Using the Windows printer driver

See "Section 4.4 [Graphics] Tab" in the

(2) Using the printer utility

See "Section 3.2.5 Customize Value" in the

(3) Setting up the printer

Change the settings as described in Example (2) in Section 10-2, "Setting Up

the Printer."

* If you have specified a print speed using the Windows driver, the print

speed specified by the driver will be used for printing. (The print speed

specified by the driver takes precedence over print speed specified by the

utility.)

Note: The printer restricts the print speed when using paper with a width of

57 mm or less.

Up to 260 mm/s for a paper width within a range of 83 to 58 mm

Up to 180 mm/s for a paper width within a range of 57 to 38 mm

Up to 80 mm/s for a paper width within a range of 37 to 25.4 mm

Windows Driver User's Guide

Utility User's Guide

.

.

68

Page 71

6-9. Cutting Position Correction

This printer allows you to correct (upward or downward) the top-of-form

position, cut position, peeling-off position and tear-off position. Change the

setting as required.

You can use one of the following methods to change this setting.

(1) Using the Windows printer driver

See "Section 4.1 [Custom Paper] Tab" in the

(2) Using the printer utility

See "Section 4.3 Adjusting Cut Position or Tear Off Position" in the

User's Guide

.

Windows Driver User's Guide

.

Utility

69

Page 72

6-10. Other Settings

This printer allows you to specify whether to feed paper up to the top-of-form

position at power-on and whether to cut paper upon the closing of the cover.

There are two methods of changing the setting:

(1) Setting up the printer

Change the setting as described in Example (4) in Section 10-2, "Setting

Up the Printer."

(2) Using the printer utility

See "Section 3.2.4 Memory Switch settings" in the

Utility User's Guide

6-11. Initializing the Printer Setup Information

You can disable the settings you specified on the printer and restore the default

settings preset at shipping.

Initialize the settings as described in Example 5) in Section 10-2, "Setting Up

the Printer."

.

70

Page 73

7-1. Control Panel

7. Control Panel

POWER lamp (●)

Lights when the power switch is

turned on and power is supplied to

the printer.

ERROR lamp (●)

Lights or blinks to indicate errors.

FEED switch

- Plain paper (including full-sheet label

paper)

Pressing this switch once advances the

paper one line. Holding down this switch

adva

nces paper continuously.

- Paper type other than plain paper

(including full-sheet label paper)

Pressing this switch once feeds one

sheet of paper.

71

Page 74

* How to initialize the paper layout

Pressing the FEED switch with the top cover open initializes the paper layout

information. After initialization is completed, load the paper you want to use

and then close the top cover. The printer feeds paper, automatically retrieves

paper information, and retains the paper layout information.

(1) Initialization

- Initialization initializes the paper layout information. You can use

initialization when changing the layout information while using the same

type of paper.

- Procedure: Press and hold down the FEED switch for a while. The POWER

and ERROR lamps will start blinking alternately. At this time, release the

FEED switch.

(2) Full initialization

- Full initialization initializes the paper type setting in addition to paper

layout information. Use it when you change the type of paper.

- Procedure: Press and hold down the FEED switch for a while. The POWER

and ERROR lamps will start blinking alternately. When you continue

holding down the FEED switch, the POWER and ERROR lamps will blink

simultaneously. At this time, release the FEED switch.

72

Page 75

7-2. Error Indications

Recoverable errors

Error condition

No paper

(paper end)

Cover open

Head hot (*1)

LED LAMP

POWER (●)

ERROR (●)

POWER (●)

ERROR (●)

POWER (●)

ERROR (●)

Blinking pattern

Constantly on

Constantly on

Constantly on

Constantly on

Constantly on

Constantly on

*1 Printing is suspended because of a high thermal head temperature.

Error condition

Paper near end

Paper layout

error

LED LAMP

POWER (●)

ERROR (●)

POWER (●)

ERROR (●)

Constantly on

● ●――――● ●――――

Constantly on

●―●―――――●―●―――――

Repeated blinking of the amber lamp four

times in succession

Blinking pattern

73

Page 76

Unrecoverable errors

Error condition LED LAMP Blinking pattern

Internal error

Head not

installed

Low voltage

Over voltage

Cutter

functioning

abnormally

LF motor

functioning

abnormally

POWER (●)

ERROR (●)

POWER (●)

ERROR (●)

POWER (●)

ERROR (●)

POWER (●)

ERROR (●)

POWER (●)

ERROR (●)

POWER (●)

ERROR (●)

――●―●―

●―――――

Repeated pattern in which the green lamp

blinks twice and the amber lamp blinks once

――●―●―●―

●―――――――

Repeated pattern in which the green lamp

blinks three times and the amber lamp blinks

once

――●―●―●―●―

●―――――――――

Repeated pattern in which the green lamp

blinks four times and the amber lamp blinks

once

――●―●―●―●―●―

●―――――――――――

Repeated pattern in which the green lamp

blinks five times and the amber lamp blinks

once

――●―●―●―●―●―●―

●―――――――――――――

Repeated pattern in which the green lamp

blinks six times and the amber lamp blinks

once

――●―●―●―●―●―●―●―

●―――――――――――――――

Repeated pattern in which the green lamp

blinks seven times and the amber lamp

blinks once

74

Page 77

8. Preventing and Clearing Paper Jams

8-1. Preventing Paper Jams

Do not touch the paper while the paper is being ejected or cut.

Holding or pulling the paper by hand during ejection might cause a paper

jam, incorrect cutting, or a feed error.

8-2. Clearing a Paper Jam

If a paper jam occurs, remove the jammed paper as follows:

(1) Turn off the printer power by turning off the power switch.

(2) Press the cover open lever down, and open the top cover.

(3) Pull out the jammed paper slowly toward the top while holding down the

printer, as shown in the picture below.

Note: Do not pull the paper with excessive force.

Note: Do not touch the thermal head. Doing so may result in damage from static

electricity.

75

Page 78

9. Troubleshooting

This chapter describes the appropriate action to be taken in cases where

the printer is not operating correctly or fails to produce clean printouts.

9-1. Power-on Problems and Errors

Symptom Cause Corrective action

Although the power

has been turned on,

the POWER lamp on

the control panel does

not light and the

printer does not start

up.

The ERROR lamp on

the control panel is lit,

and the printer does

not work.

(1) The power cable is

disconnected.

(2) The connector of the

AC adapter is

disconnected.

(1) No paper is inserted.

(2) The top cover is not

closed completely.

(3) The thermal head is at

a high temperature.

9-2. Cutter-related Problems

Symptom Cause Corrective action

Paper cannot be cut. (1) The cutter blade is

The cutter does not

return to the correct

position.

damaged or worn, or it

has been used for too

long.

(2) Paper fragments or

other foreign matter is

stuck around the

cutter blade or paper

chute.

(3) Adhesive matter is

adhering to the cutter