LD670

POS Printer, Cash Drawer

Application Programmer's Guide

of

OPOS-OCX Driver

for

Serial/ Parallel/ USB/ LAN

Interface

Index

1. Outline............................................................................................................................1

1.1. Subject Scope of this document.......................................................................................1

1.2. OPOS Control Outline ..................................................................................................... 2

1) OPOS Control Configuration Drawing........................................................................ 2

2) Terminology................................................................................................................. 4

1.3. Restrictions....................................................................................................................... 5

1) POS Printer .................................................................................................................. 5

2) Common Restrictions on POS Printer.......................................................................... 6

3) Setting of Apartment ="0" with connecting LAN interface cable................................ 6

4) Setting of Apartment ="1" with connecting LAN interface cable................................ 6

5) About the "Found New Hardware Wizard" in Windows.............................................. 7

6) About parallel interface................................................................................................ 7

1.4. Connection Way to POS Printer....................................................................................... 8

2. Installation......................................................................................................................9

2.1. Installation Condition....................................................................................................... 9

2.2. Installation Media........................................................................................................... 10

2.3. Installation Procedure......................................................................................................11

Installation using installer...................................................................................................11

Installation using batch file................................................................................................ 15

2.4. Uninstallation Procedure................................................................................................ 16

Uninstallation when installing it with installer (Setup32.exe or Setup64.exe)................... 16

Uninstallation when OPOS is installed with batch file...................................................... 18

2.5. Installation File List....................................................................................................... 19

2.6. Setting Program Usage................................................................................................... 21

3. Using OPOS Control.................................................................................................... 39

3.1. Common......................................................................................................................... 39

3.2. POS Printer .................................................................................................................... 39

3.3. How to Implement the OPOS Control ........................................................................... 40

4. OPOS Interface Specifications (Printer)......................................................................47

4.1. List ................................................................................................................................. 47

4.2. Printi

ng Data and Escape Sequence............................................................................... 57

4.3. Common Properties........................................................................................................ 65

BinaryConversion Property R/W....................................................................................... 65

CapCompareFirmwareVersion Property............................................................................ 68

CapPowerReporting Property ............................................................................................ 68

CapStatisticsReporting Property........................................................................................ 68

CapUpdateFirmware Property............................................................................................ 69

CapUpdateStatistics Property............................................................................................. 69

CheckHealthText Property................................................................................................. 69

Claimed Property ............................................................................................................... 70

ControlObjectDescription Property.................................................................................... 70

ControlObjectVersion Property.......................................................................................... 71

DeviceDescription Property............................................................................................... 71

DeviceEnabled Property R/W............................................................................................ 72

DeviceName Property........................................................................................................ 74

FreezeEvents Property R/W............................................................................................... 74

OpenResult Property.......................................................................................................... 75

PowerState Property........................................................................................................... 77

ResultCode Property.......................................................................................................... 78

ResultCodeExtended Property........................................................................................... 79

ServiceObjectDescription Property.................................................................................... 81

ServiceObjectVersion Property .......................................................................................... 81

State Property..................................................................................................................... 81

4.4. Common Methods.......................................................................................................... 82

CheckHealth Method ......................................................................................................... 82

ClaimDevice Method......................................................................................................... 84

ClearOutput Method........................................................................................................... 85

Close Method..................................................................................................................... 85

CompareFirmwareVersion Method.................................................................................... 86

DirectIO Method................................................................................................................ 88

Open Method...................................................................................................................... 95

ReleaseDevice Method....................................................................................................... 96

ResetStatistics Method....................................................................................................... 96

RetrieveStatistics Method.................................................................................................. 96

UpdateFirmwareMethod.................................................................................................... 97

UpdateStatistics Method .................................................................................................... 98

4.5. Specific Property............................................................................................................ 99

AsyncMode Property R/W................................................................................................. 99

CapCharacterSet Property.................................................................................................. 99

CapCoverSensor Property.................................................................................................. 99

CapMapCharacterSet Property......................................................................................... 100

CapRec2Color Property................................................................................................... 100

CapRecBarCode Property................................................................................................ 100

CapRecBitmap Property................................................................................................... 100

CapRecBold Property....................................................................................................... 101

CapRecCartridgeSensor Property .................................................................................... 101

CapRecColor Property..................................................................................................... 101

CapRecDhigh Property .................................................................................................... 101

CapRecDwide Property.................................................................................................... 102

CapRecDwideDhigh Property.......................................................................................... 102

CapRecEmptySensor Property......................................................................................... 102

CapRecItalic Property...................................................................................................... 102

CapRecLeft90 Property.................................................................................................... 103

CapRecMarkFeed Property.............................................................................................. 103

CapRecNearEndSensor Property..................................................................................... 103

CapRecPageMode Property............................................................................................. 104

CapRecPapercut Property ................................................................................................ 105

CapRecPresent Property................................................................................................... 105

CapRecRight90 Property ................................................................................................. 105

CapRecRotate180 Property.............................................................................................. 105

CapRecStamp Property.................................................................................................... 106

CapRecUnderline Property .............................................................................................. 106

CapTransaction Property.................................................................................................. 106

CartridgeNotify Property R/W......................................................................................... 107

FlagWhenIdle Property R/W.............................................................................................111

FontTypefaceList Property................................................................................................111

MapCharacterSet Property................................................................................................111

MapMode Property R/W...................................................................................................112

PageModeArea Property...................................................................................................112

PageModeDescriptor Property..........................................................................................112

PageModeHorizontalPosition Property.............................................................................113

PageModePrintArea Property ...........................................................................................113

PageModeStation Property................................................................................................113

PageModeVerticalPosition Property .................................................................................113

RecBarCodeRotationList Property....................................................................................114

RecBitmapRotationList Property......................................................................................114

RecCartridgeState Property...............................................................................................115

RecCurrentCartridge Property R/W..................................................................................115

RecEmpty Property...........................................................................................................115

RecLetterQuality Property R/W........................................................................................116

RecLineChars Property R/W.............................................................................................117

RecLineCharsList Property...............................................................................................117

RecLineHeight Property R/W...........................................................................................118

RecLineSpacing Property R/W.........................................................................................118

RecLinesToPaperCut Property..........................................................................................119

RecLineWidth Property.....................................................................................................119

RecNearEnd Property........................................................................................................119

RecSidewaysMaxChars Property..................................................................................... 120

RecSidewaysMaxlLines Property.................................................................................... 121

RotateSpecial Property R/W............................................................................................ 121

4.6. Exclusive-Use Methods ............................................................................................... 123

BeginInsertion Method..................................................................................................... 123

BeginRemoval Method.................................................................................................... 123

ChangePrintSide Method ................................................................................................. 124

ClearPrintArea Method.................................................................................................... 124

CutPaper Method ............................................................................................................. 124

EndInsertion Method........................................................................................................ 126

EndRemoval Method ....................................................................................................... 126

MarkFeed Method............................................................................................................ 127

PageModePrint Method ................................................................................................... 128

PrintBarCode Method ...................................................................................................... 128

PrintBitmap Method......................................................................................................... 147

PrintImmediate Method ................................................................................................... 150

PrintMemoryBitmap Method........................................................................................... 152

PrintTwoNormal Method................................................................................................. 156

RotatePrint Method.......................................................................................................... 157

SetBitmap Method ........................................................................................................... 160

SetLogo Method............................................................................................................... 162

TransactionPrint Method.................................................................................................. 163

ValidateData Method........................................................................................................ 165

DrawRuledLine Method................................................................................................... 166

4.7. Event ............................................................................................................................ 167

DirectIOEvent Event........................................................................................................ 167

ErrorEvent Event.............................................................................................................. 168

OutputCompleteEvent Event ........................................................................................... 168

StatusUpdateEvent Event................................................................................................. 169

5. Registry Used by OCX ..............................................................................................171

5.1. POS Printer (Serial Interface) ...................................................................................... 172

5.2. POS Printer (Parallel Interface).................................................................................... 174

5.3. POS Printer (USB Interface)........................................................................................ 176

5.4. POS Printer (LAN Interface)........................................................................................ 178

5.5. The explanation of the registry item (POS Printer)...................................................... 179

6. Log Files .................................................................................................................... 185

7. Supplement.................................................................................................................187

7.1. When you change paper into the different layout ........................................................ 187

7.2. When you replace the printer....................................................................................... 187

8. Using Multiple Printers..............................................................................................189

Revision History........................................................................................................................ 190

1. Outline

POS Printer OPOS Control that control Label Printer "LD670" is OPOS Controls conforming to

OPOS 1.13 POS Printer Devise. When using OPOS Control, refer to "OLE for Retail POS

Application Programmer's Guide Instructions The 1.13 Version" (OPOS-APG V1.13), too.

In this guide, "OPOS Control" means same as "OPOS OCX".

1.1. Subject Scope of this document

These instructions (Application Programmer's Guide) aim for the main reference of programmers

who develop the application for the use of OPOS Control, and describe the following contents

necessary for that.

- Installation way of OPOS Control

- Usage of OPOS Control

- Restrictions of OPOS Control

- Interface (Property/Method/Event) Remarks of OPOS Control

- Item Setting Remarks of OPOS Control

1

r

1.2. OPOS Control Outline

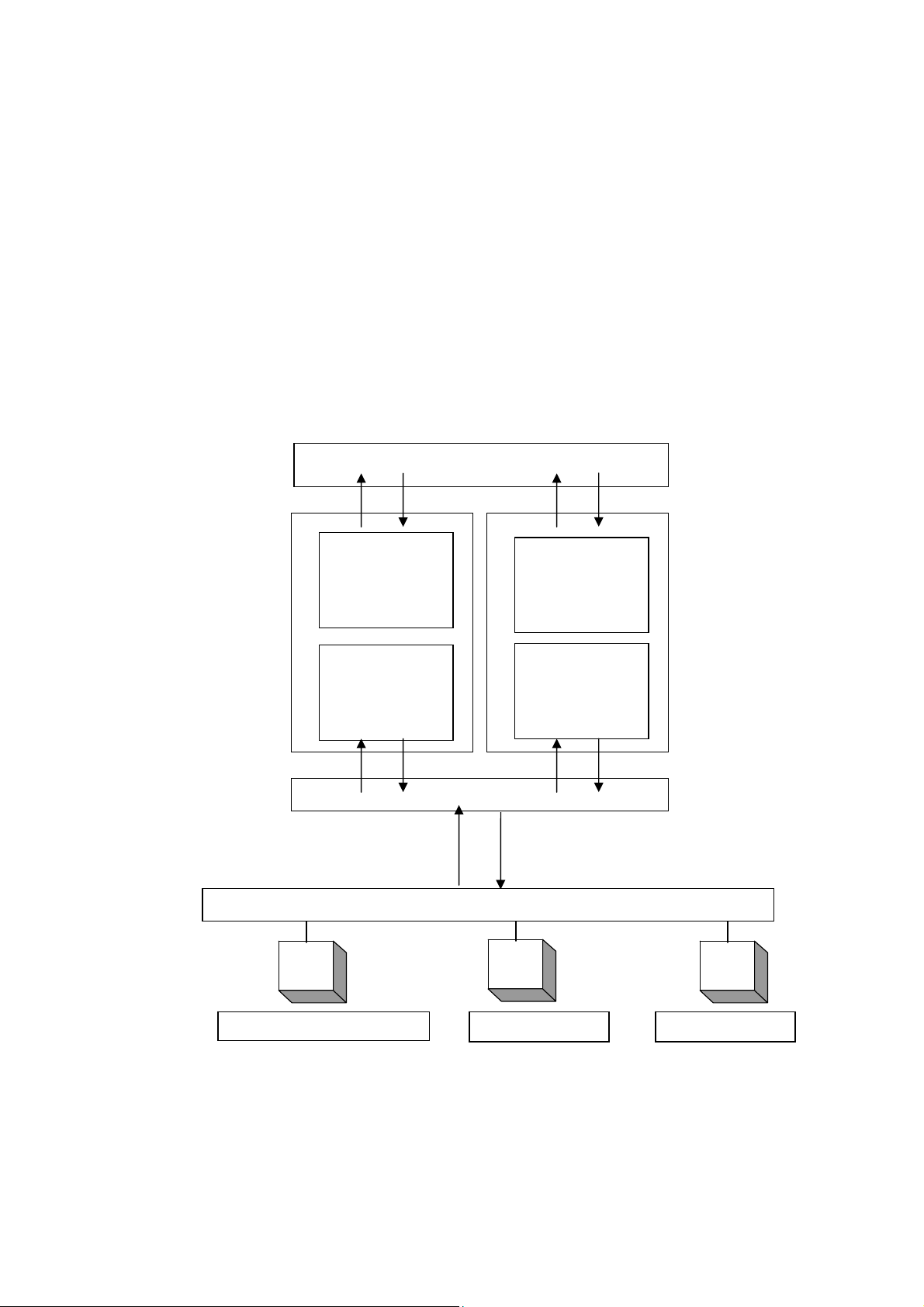

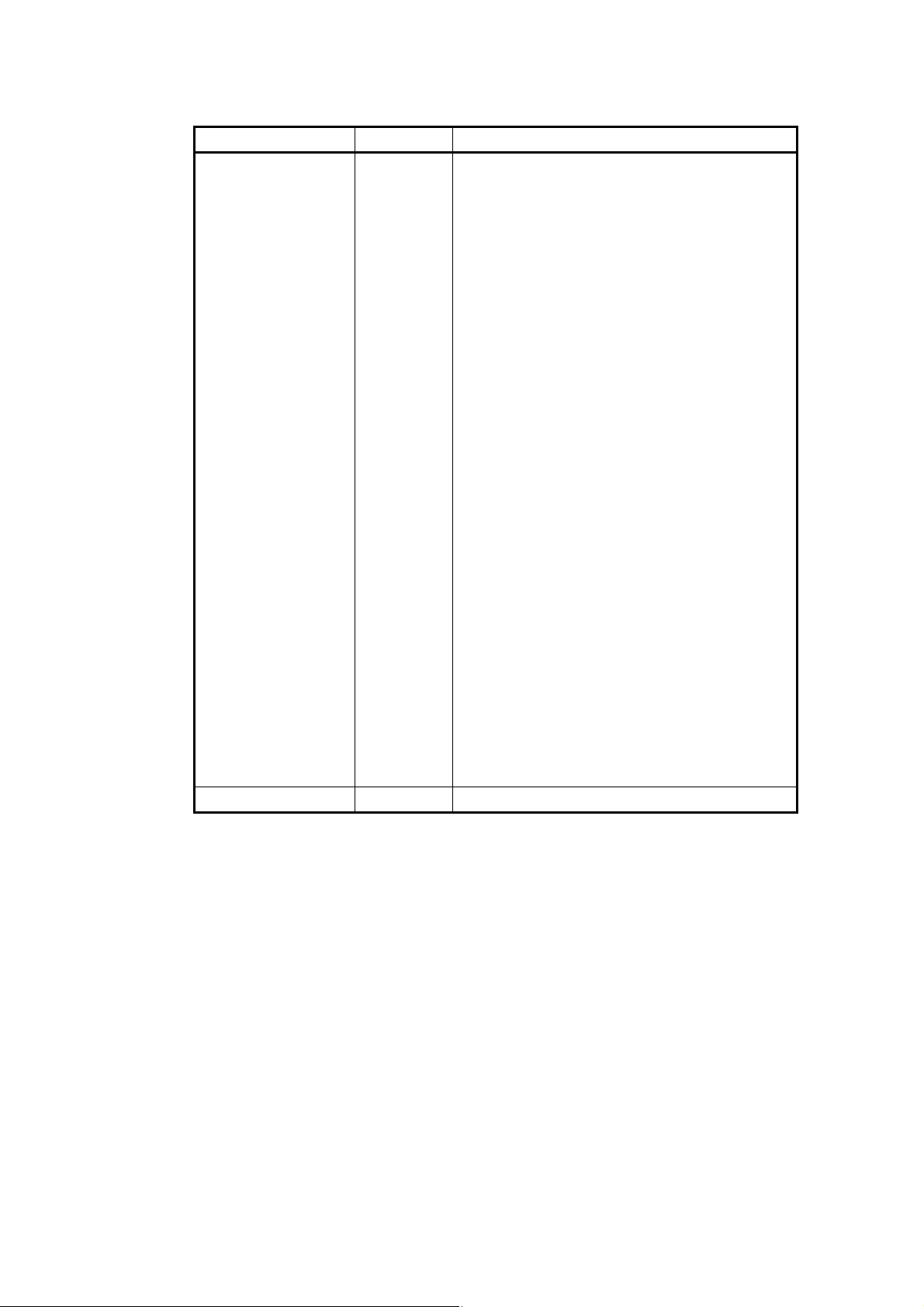

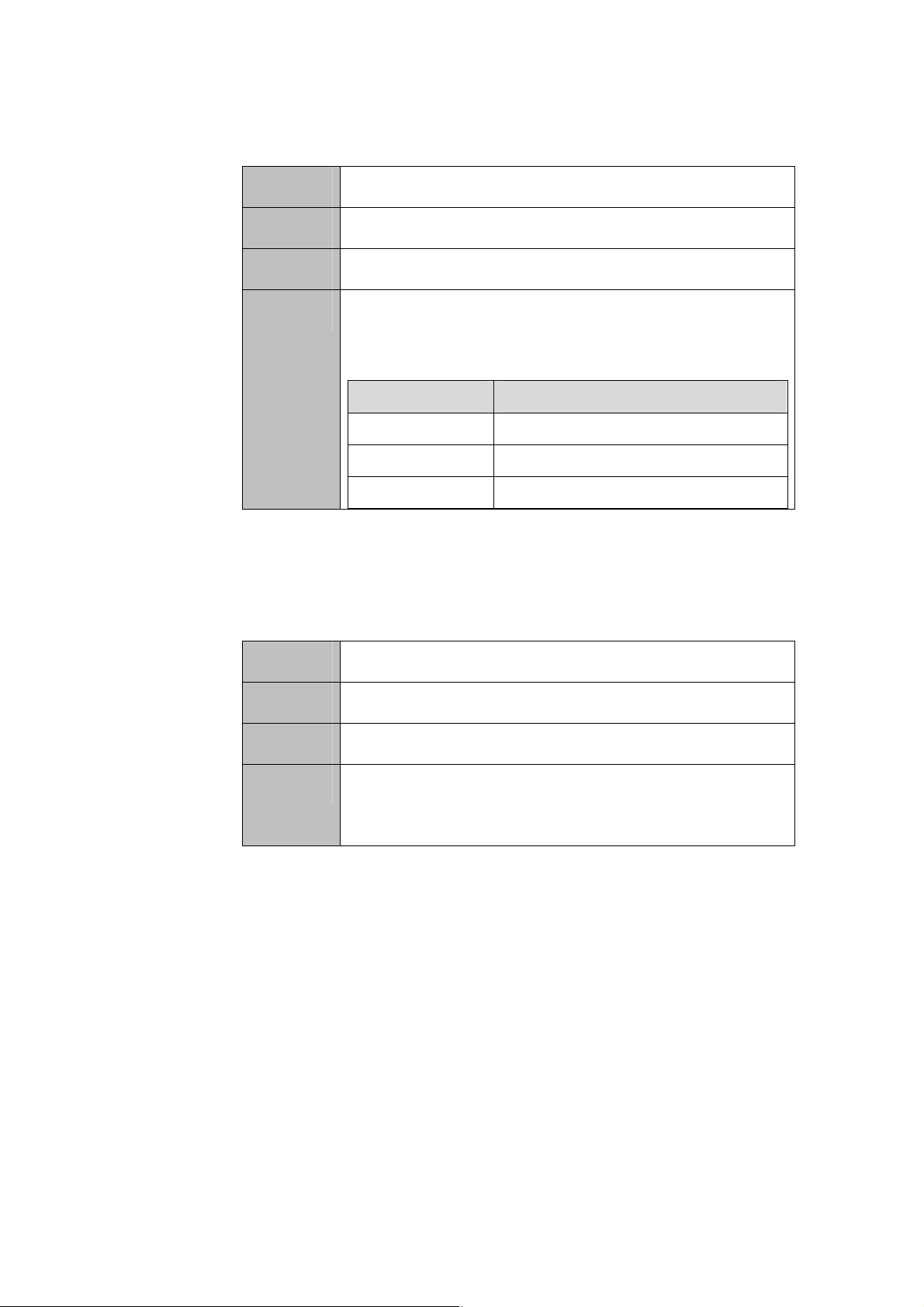

1) OPOS Control Configuration Drawing

OPOS Control co

nforms to ActiveX specifications and provides Property, Method, and Event to

application. Control cannot be seen on UI in application execution. Only application, which uses it,

requests to process through Method and Property. Application receives processing result through

Method return value, parameter, Property, and Event. This OPOS Control is implemented as

in-process server.

<Serial, Parallel, USB Interface>

Application

POSPrinter

Control

Object

CashDrawer

Control Object

POSPrinter

Service

Object

CashDrawer

Service Object

OPSharedPort.exe

OS / Device Drive

Printer

Printer

Printer

Serial Interface

Parallel Interface

USB Interface

2

n

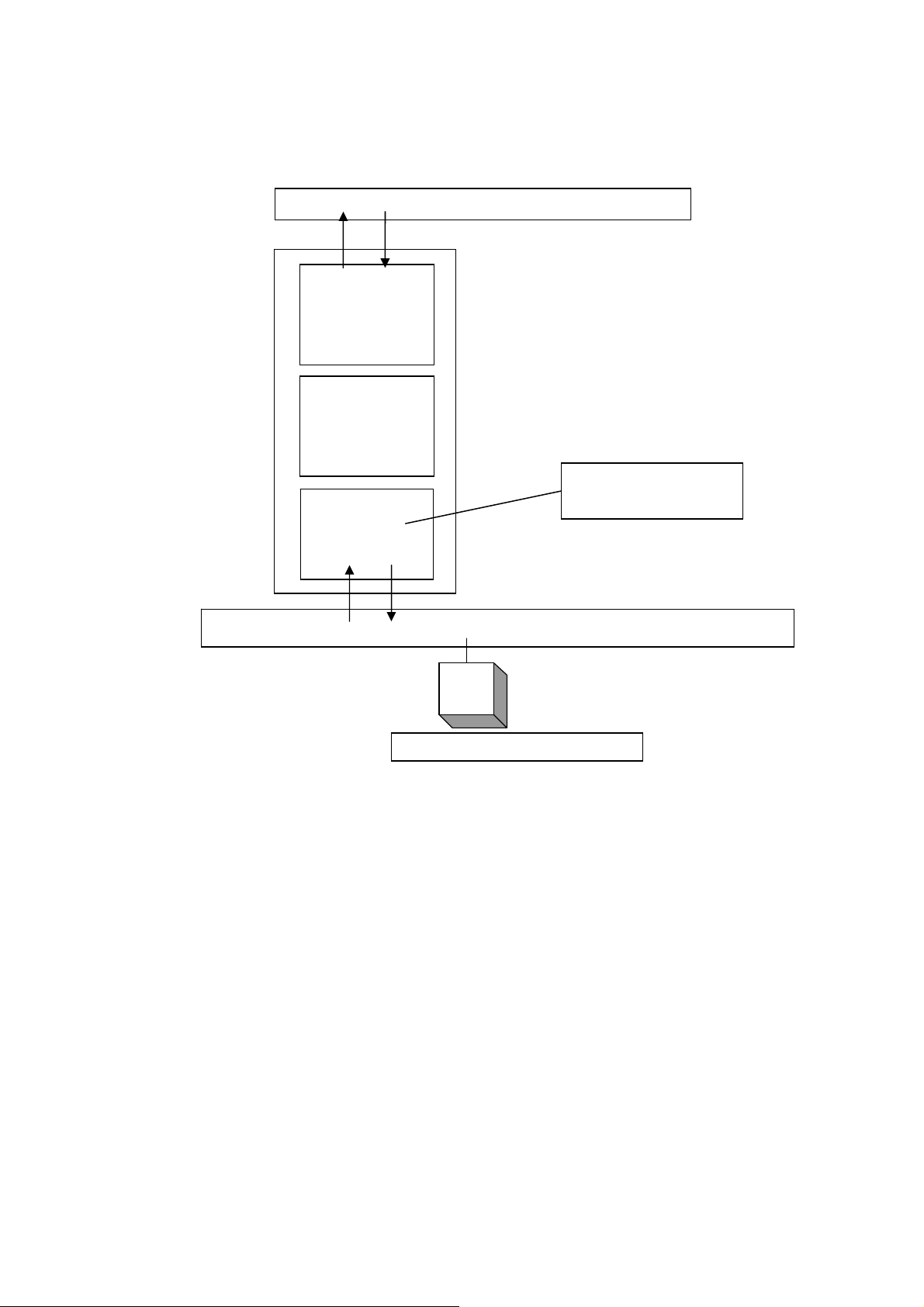

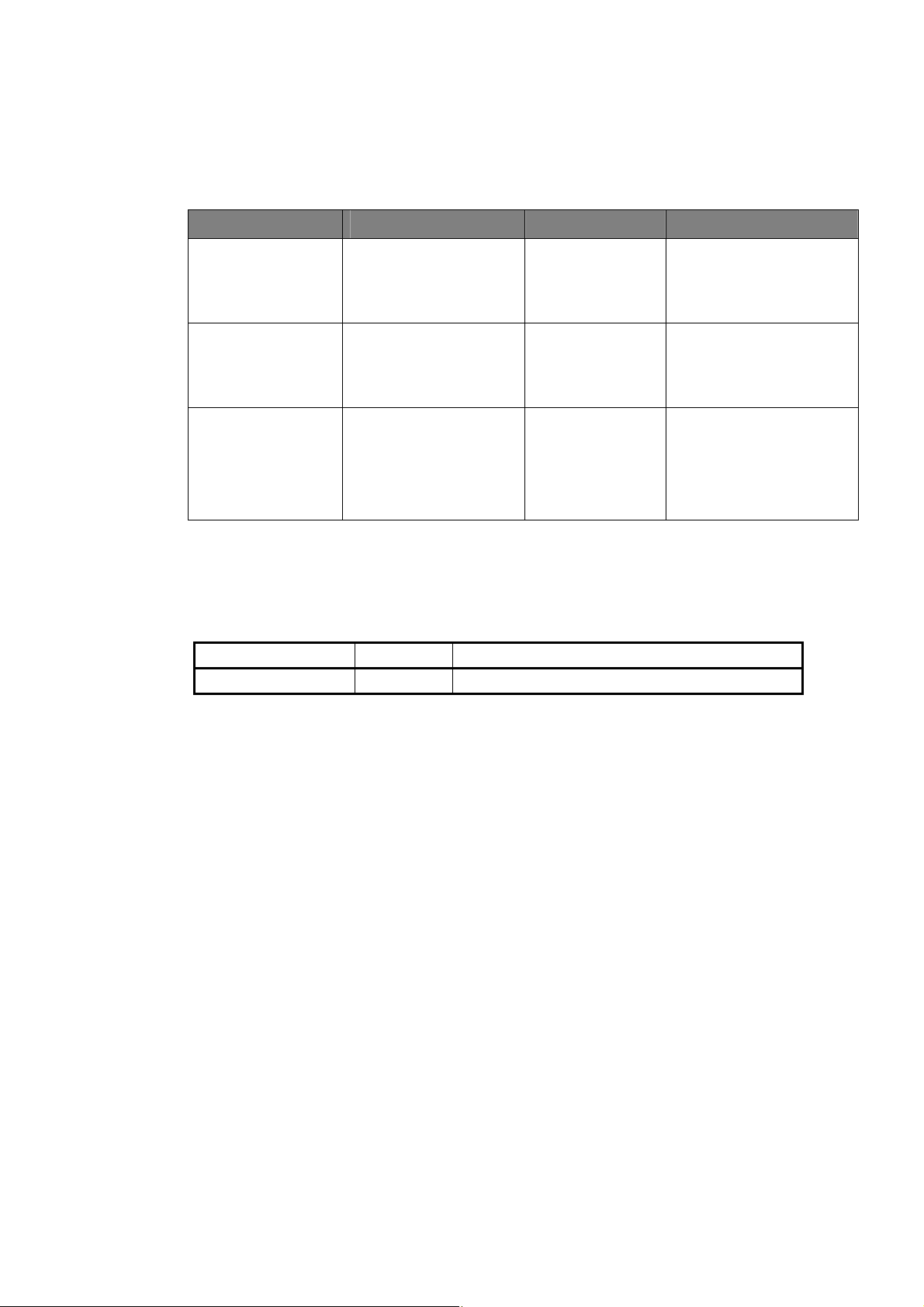

<LAN Interface>

Applicatio

POSPrinter Control

Object

POSPrinter Service

Object

SxJcp32.dll

DLL used to communicate

with printer in LAN

OS / Device Driver

Printer

LAN Interface(10Base-T, 100Base-T)

*This

S

Driver supports the control of Serial/Parallel/USB/LAN Interface Printer.

OPO

*Multiple numbers of interface and printers can be set to the driver. For details, refer to

Chapter 8 "Using Multiple Printers."

* In case of LD670, OPOS Driver doesn’t support drawer connection.

* In case of LAN Interface, OPOS Driver doesn’t support drawer connection.

*This OCX works with Thread Model of STA(Single, Thread or Apartment). To work with

several processes, the setting value of "Apartment" in Registry should be set as "1".

*Regarding LAN interface, Network Connection corresponds to 10Base-T, 100Base-T.

3

2) Terminology a. Control Obj

According to each device class, it provides application with the set of Property, Method, and Event.

This Document explains these API.

b. Service Ob ject (Service Object; SO)

It executes the function which is called from Control Object and which is prescribed by OPOS for

each device.

ect (Control Object; CO)

4

1.3. Restrictions

Followings are restrictions.

1) POS Printer

[Restriction

restrictions.

s on OPOS specifications]

All the interfaces of OPOS POS Printer Device are provided, but there are the following

a. It does not support property setting concerning journal printing and journal.

b. It does not support property setting concerning slip printing and slip.

c. It does not support functions of Italic, custom color, shading printing, and cartridge.

d. It does not support change of receipt printing character font. (Printing font change)

e. The following methods always return OPOS_E_ILLEGAL(106) after enabling.

PrintTwoNormal Method

BeginInsertion Method

EndInsertion Method

BeginRemoval Method

EndRemoval Method

ChangePrintSide Method

ResetStatistics Method

RetrieveStatistics Method

UpdateStatistics Method

(Limitation of Cable disconnection and connection)

There are conditions for disconnection and connection of LAN cable under printer

"enable" status:

1)When LAN cable is disconnected from PC, printer cannot support any actions. When the

cable is disconnected during "enable" status, OCX may fail to be "enable" even though the

application restarts.

2)When LAN cable is disconnected from Printer, and while OCX and printer is connecting,

printer cannot support any actions even if "disable" is sent. If "disable" is sent in above

situation, even though the application is restarted, OCX may fail to enable.

When the LAN cable is disconnected, connect the LAN cable again, and switch off and on

the power of Printer.

5

2) Common Restrictions on POS Printer

The OPOS Control is not

different thread, unexpected result may occur. In the multithread environment,

implementation of exclusive processing for the critical sections is required for accessing

the property and executing the method in order to avoid the method and property are

executed at the same time.

3) Setting of Apartment ="0" with connecting LAN interface cable

Apart

ment is set as "0" in Registry setting, one process can control several printers. But

the several processes do "Open" OCX (LAN Interface) at the same time, unexpected

results may happen.

4) Setting of Apartment ="1" with connecting LAN interface cable

Apartment is set as "

In this case, the number of printers (LAN interface) should be guaranteed that one process

should be less than one unit. If more than 2 printers per one process were used, unexpected

results might occur. The following chart shows the examples of the case that Apartment

="1" can work, and the case that Apartment ="1" cannot work. (OCX uses LAN interface.)

thread-safe. When the method or property is accessed from the

0" in Registry setting, several processes can control printers.

examples of the case that Apartment ="1" can work

ProcessA---PrinterOCX

ProcessB---PrinterOCX

examples of the case that Apartment ="1" cannot work---1

ProcessA---PrinterOCX, PrinterOCX

ProcessB---PrinterOCX

(Two PrinterOCX exis

t in ProcessA.)

6

5) About the "Found New Hardware Wizard" in Windows

When the printer is connected to PC in USB or Parallel interface and "Found New

Hardware Wizard" was displayed, set it in the following procedures.

For Windows 7 / Server 2008 R2

1. The message "Installing device driver software" is displayed in a balloon(lower right corner of the

screen).

2. After a while, the message "Device driver software was not successfully installed" is displayed.

This is not a problem.

For Windows Vista / Server 2008

1. The "Found New Hardware" is displayed, select [Don't show this message again for this device].

* When "User Account Control" screen is displayed, select [Continue].

For Windows XP / Server 2003 / WEPOS / WEPOS2009

1. The "Found New Hardware Wizard" screen is displayed. Select [No, not this time] and then click

[Next].

2. When "What do you want the wizard to do?" is displayed, select [Install from a list or specific

location] and then click [Next].

3. Select [Search for the best driver in these locations], clear all checkboxes and then click [Next].

4. When "Cannot Install this Hardware" is displayed, click [Don't prompt me again to install this

software] and then click [Finish].

For Windows 2000

1. The "Found New Hardware Wizard" screen is displayed, click [Next].

2. When "What do you want the wizard to do?" is displayed, select [Search for a suitable driver for my

device] and then click [Next].

3. When [Locate Driver Files] is displayed, clear all checkboxes and then click [Next].

4. When "Driver Files Search Results" is displayed, select [Disable the device] and then click [Finish].

6) About parallel interface

LD670 has not parall

el interface. So LD670 do not support parallel interface.

7

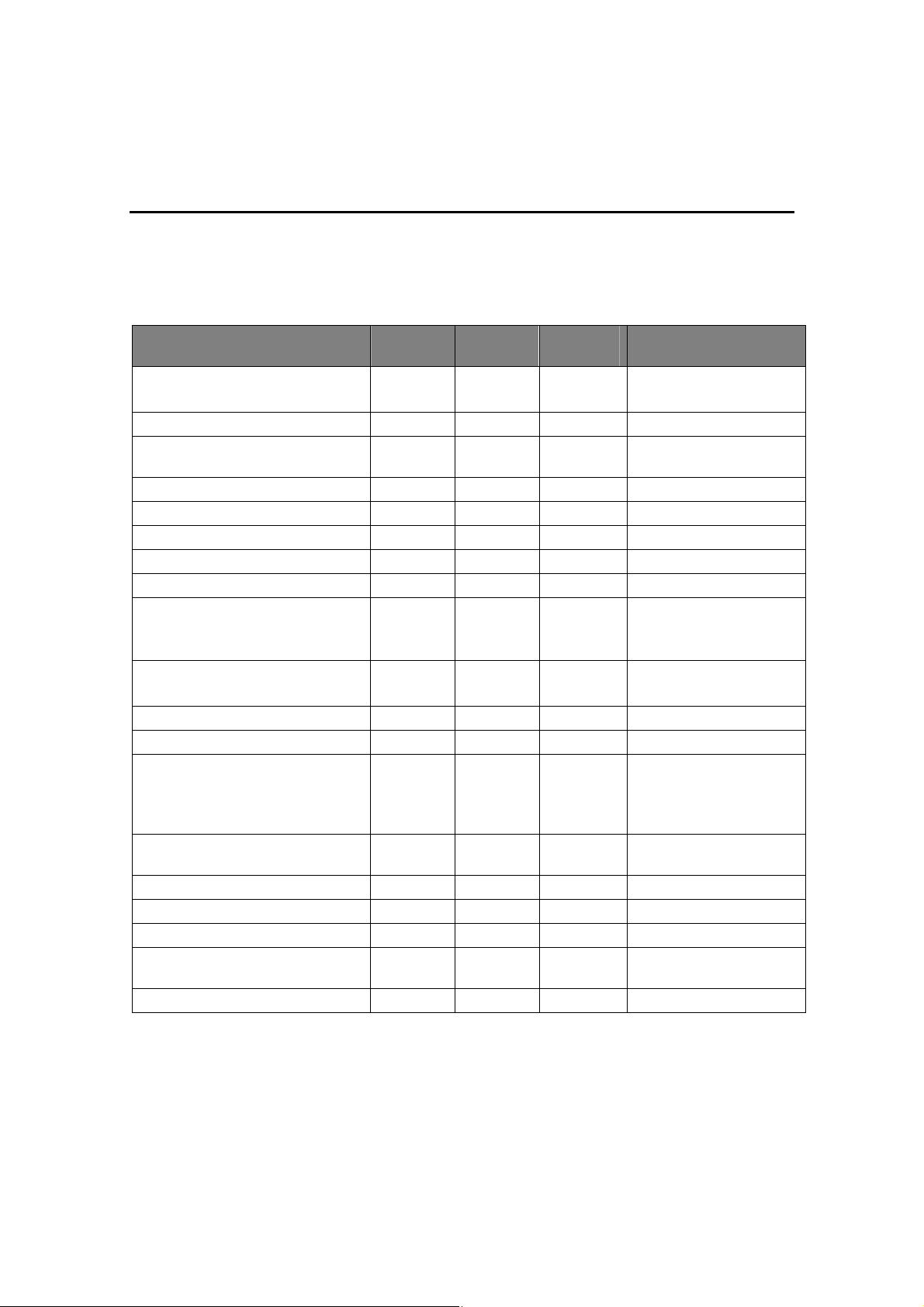

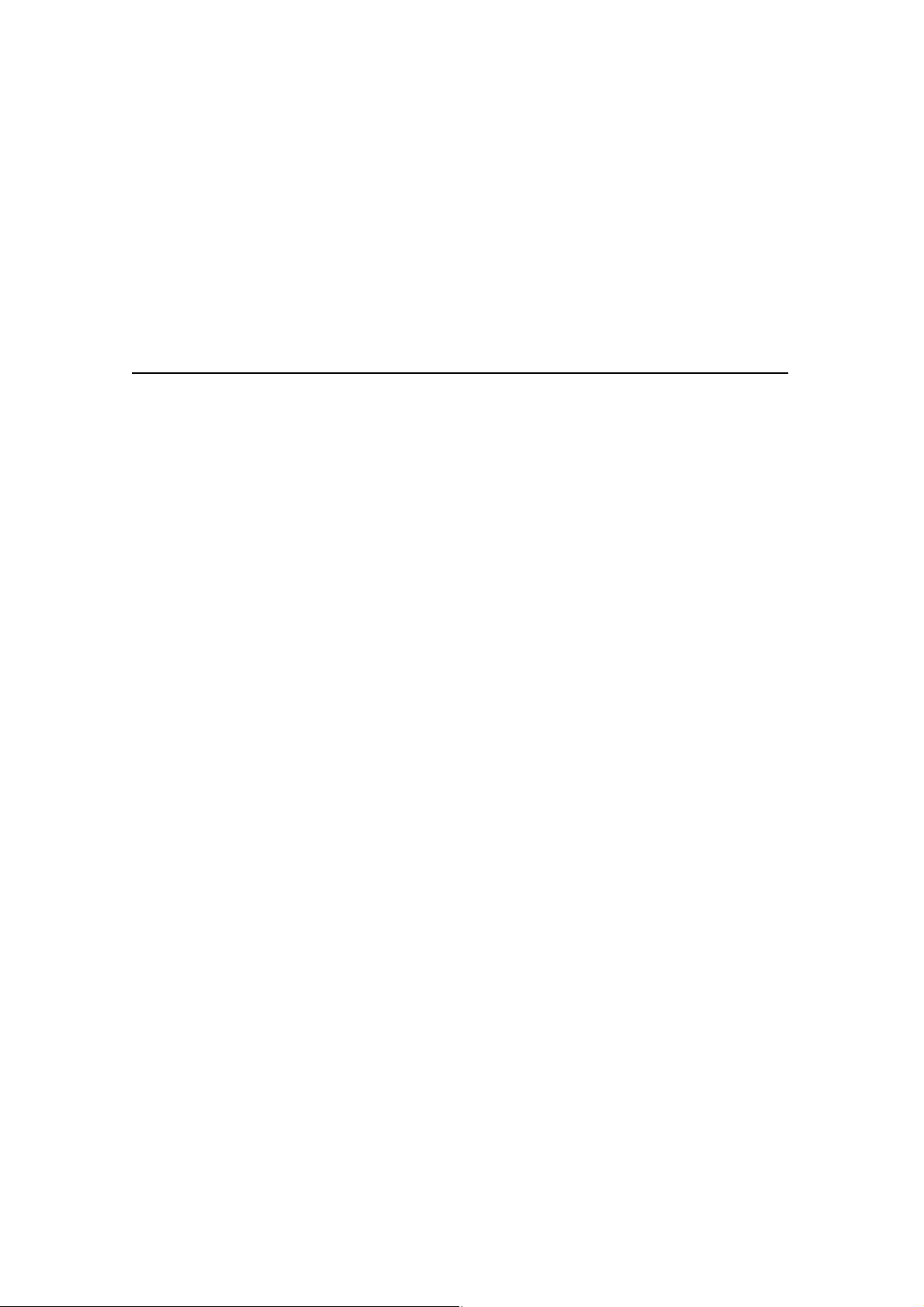

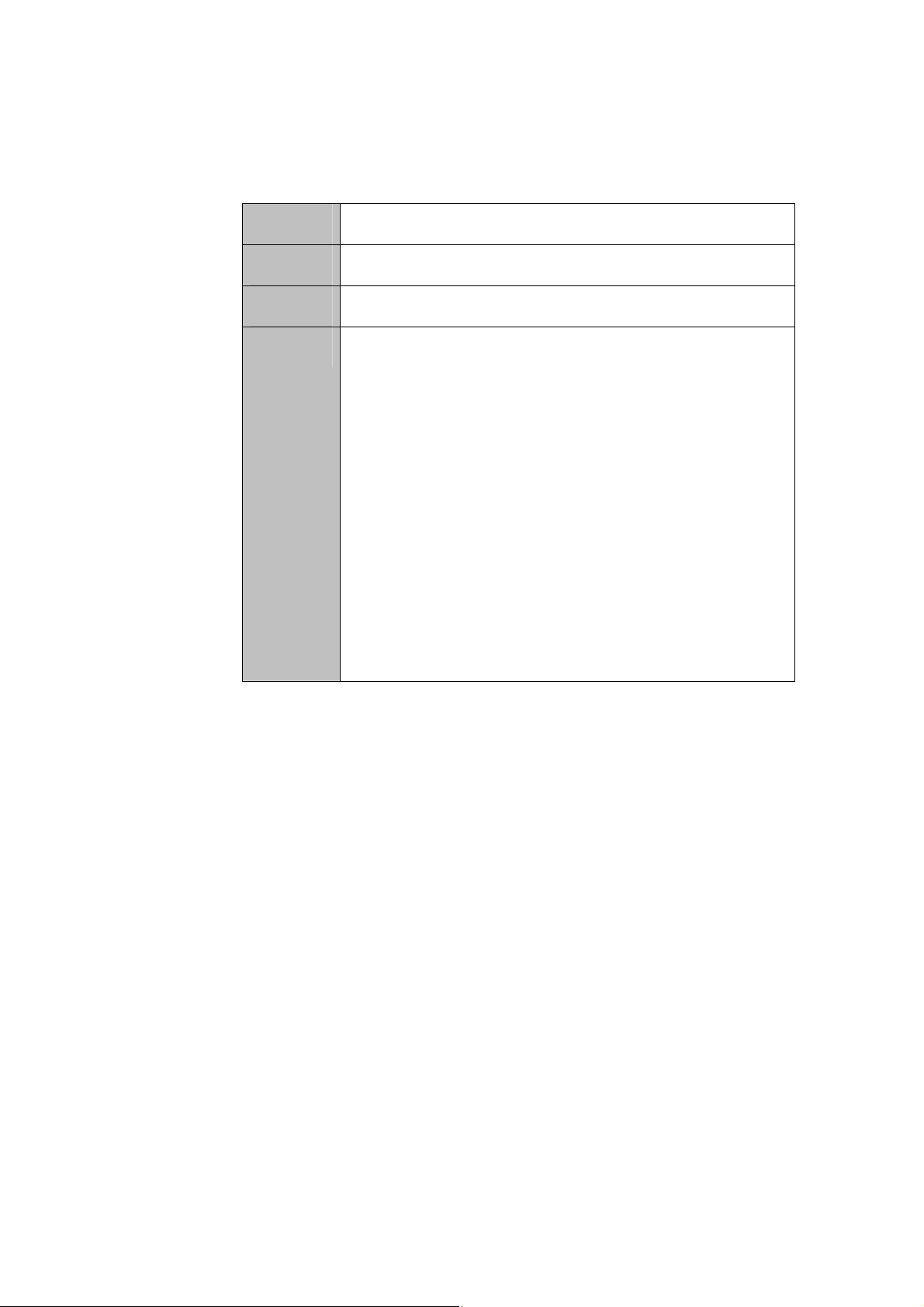

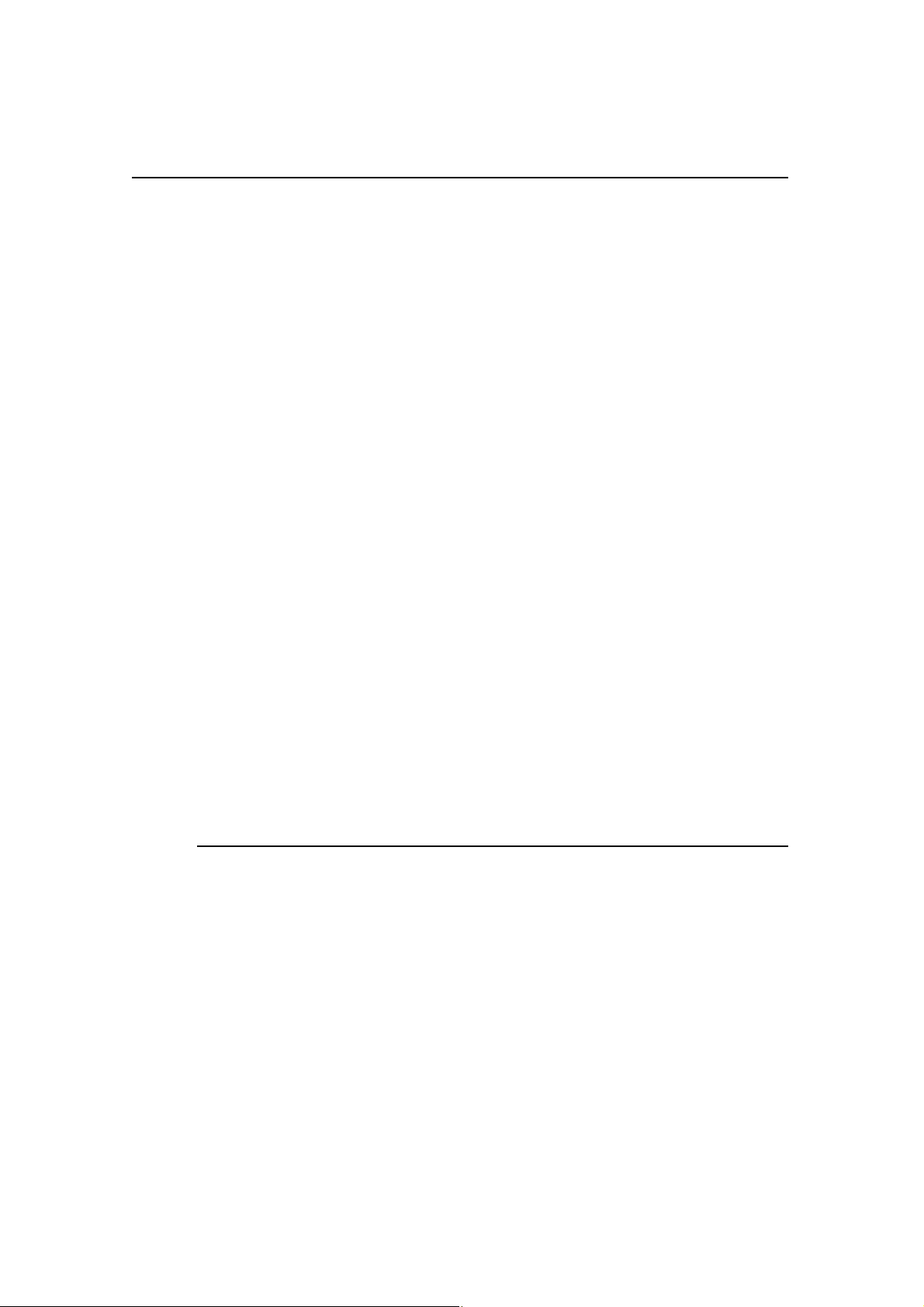

1.4. Connection Way to POS Printer

Set the POS Printer to the following settings (in gray highlight). Rest of the values can be set in the

registry or the setting program attached with installer.

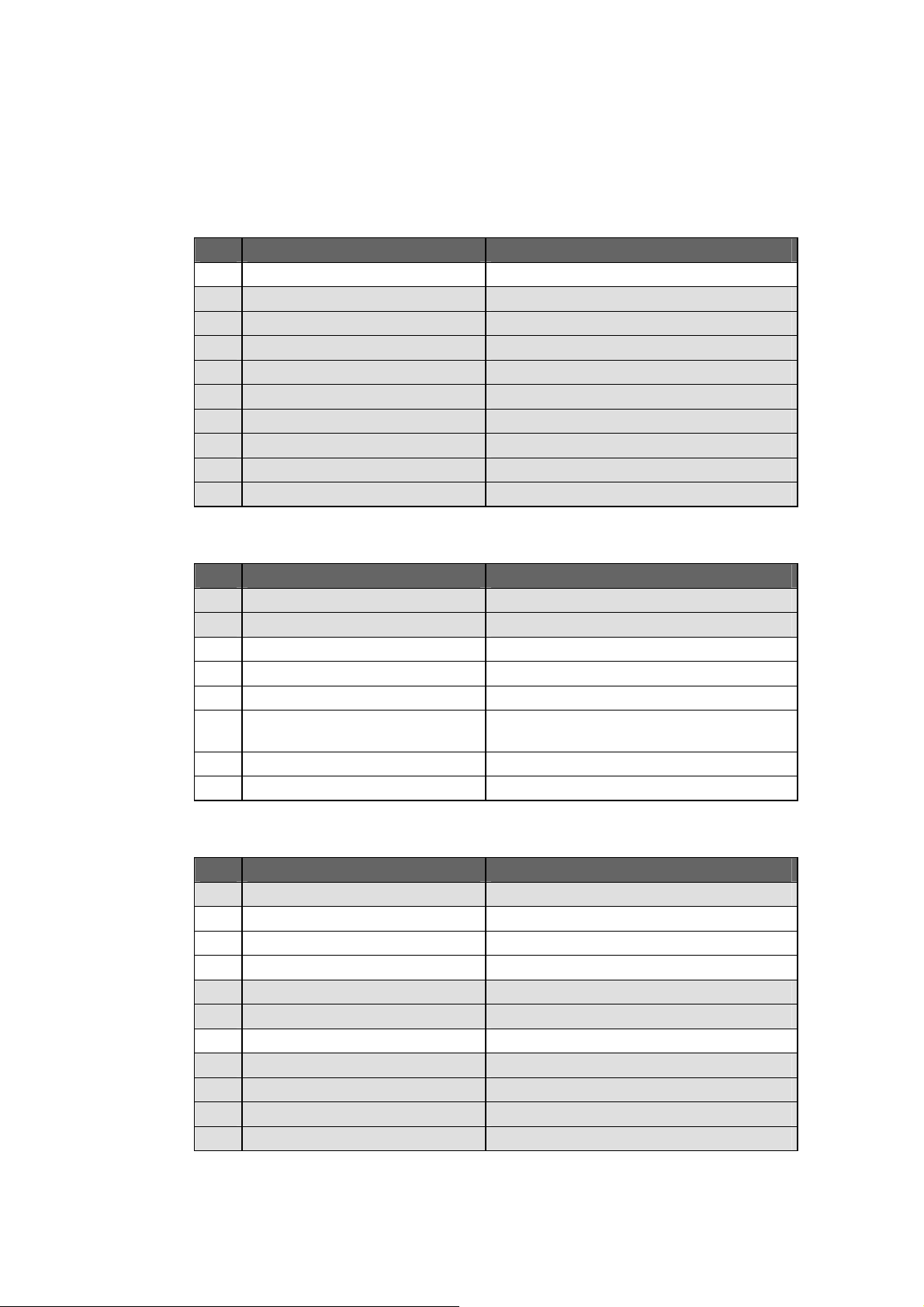

No. Setting Item Setting Contents

1 POWER ON STATUS *Set form the registry

2 RECEIVE BUFFER 4 KB

3 RECEIVE ERROR HANDLING Print ?

4 AUTO LINEFEED Not available at any time

5 DSR (#6) RESET Not available

6 INT (#25) RESET Not available

7 INT (#31) RESET Available

8 POSITIONING ON POWER ON Execute

9 COVER OPEN Auto Recover

10 BUSY CONDITION Bufferfull

Customize Value

No. Setting Item Setting Contents

1 USER NV MEMORY 192 KB

2 GRAPHIC MEMORY 384 KB

3 PAPER WIDTH *Set from the setting program

4 PRINT LEVEL *Set from the setting program

5 PRINTING COLOR *Set from the setting program

6 BACK LEVEL ON TWO COLOR

PRINT

7 PRINT SPEED *Set from the setting program

8 POWER SAVE *Set from the setting program

*Set from the setting program

Others

No. Setting Item Setting Contents

1 ACK PULSE WIDTH 1 microsecond

2 CUTTER MOVEMENT *Set from the setting program

3 BM SENSOR *Set from the setting program

4 CUT FOR POSITIONING *Set from the setting program

5 ERROR RECOVERY Command

6 PROCESS ID Normal

7 PNE DETECTION *Set from the setting program

8 FONT B Mode 1

9 USB Printer

10 BUZZAR It depends on the printer setting.

11 BATCH PRINT Disable

8

2. Installation

OPOS Control can be installed just like in the following procedures.

2.1. Installation Condition

Operation Environment

OS: Microsoft Windows 2000, XP, 2003Server, Vista, WEPOS, POSReady2009

Windows7, Server 2008, Server 2008 R2

CPU: Pentium3 550MHz and more is recommended

RAM: 128MB and more is recommended

HDD: Space 2MB and more

*To install on WEPOS, "Local Management Support" must be installed in the minimum

configuration of WEPOS.

* To install on POS Ready 2009 using Batch Installer, "Command-line Application" component

must be installed on POS Ready 2009.

(Note)

When OPOS control (POS PRINTER OPOS OCX) is already installed,

please install this OPOS control aft er uninstallation of OPOS control.

Please refer how to uninstall to 2.4. uninstallation procedures.

9

2.2. Installation Media

Installation media is provided as CD.

Configuration of CD is just the following.

\(root) \Drivers\OPOS

\ Driver........................ The root folder of the Installer (x32)

- setup32.exe : Installer for 32bit OS

- setup64.exe : Installer for 64bit OS

\Driver_x32................. The folder of the driver (x32)

* Use this when you do not use the installer for 32bit.

\Driver_x64................. The folder of the driver (x64)

* Use this when you do not use the installer for 64bit

10

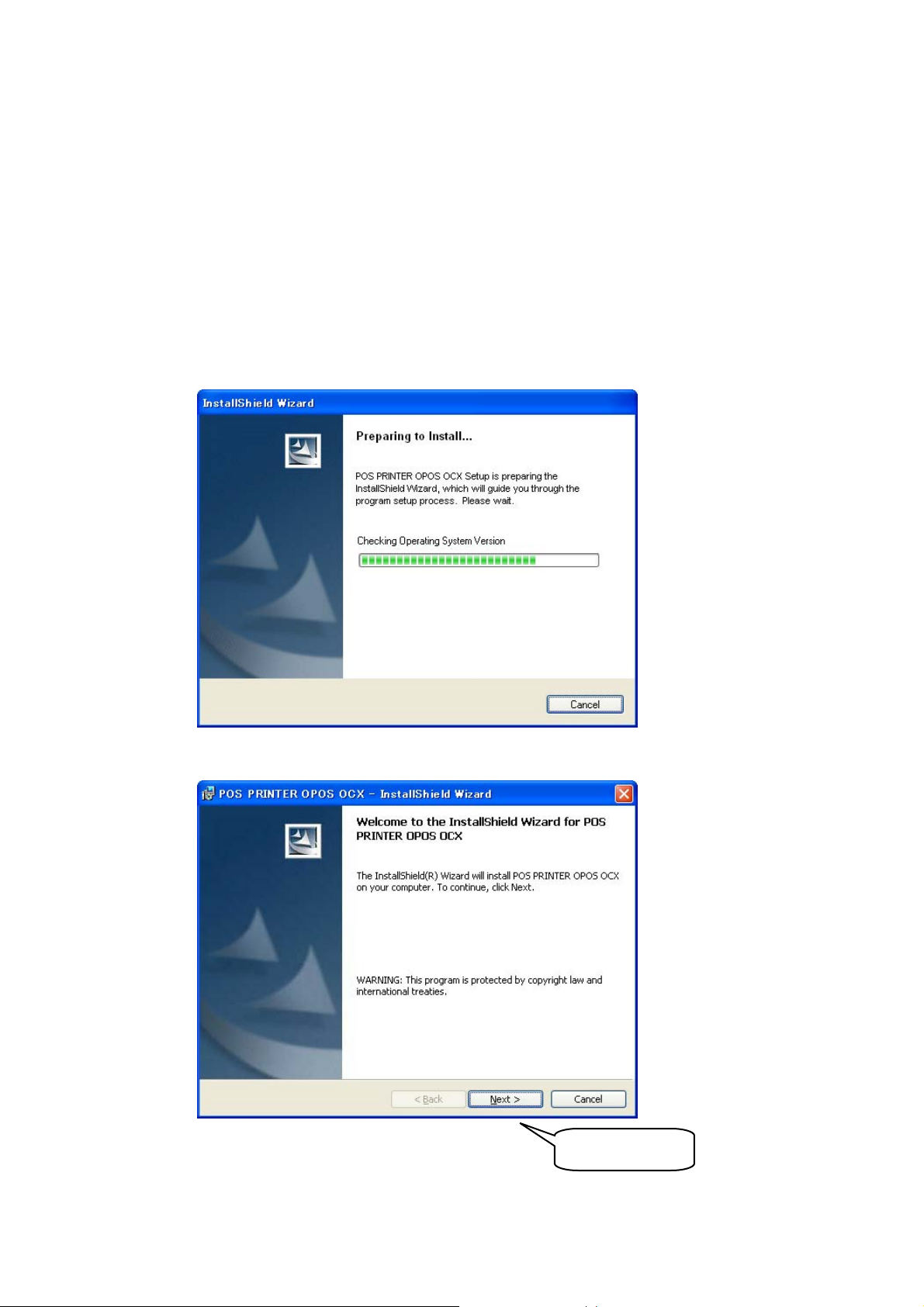

2.3. Installation Procedure

Installation using installer

1. Set the installation Media CD to the Drive. After that, start "My Computer" or "Explorer"

and refer to the Drive.

In case of CD: Open \Driver folder, and if OS is 32bit, double click Setup32.exe. If OS

is 64bit, double click Setup64.exe

2. After the dialogue below is shown, Setup Program starts.

click "Next"

11

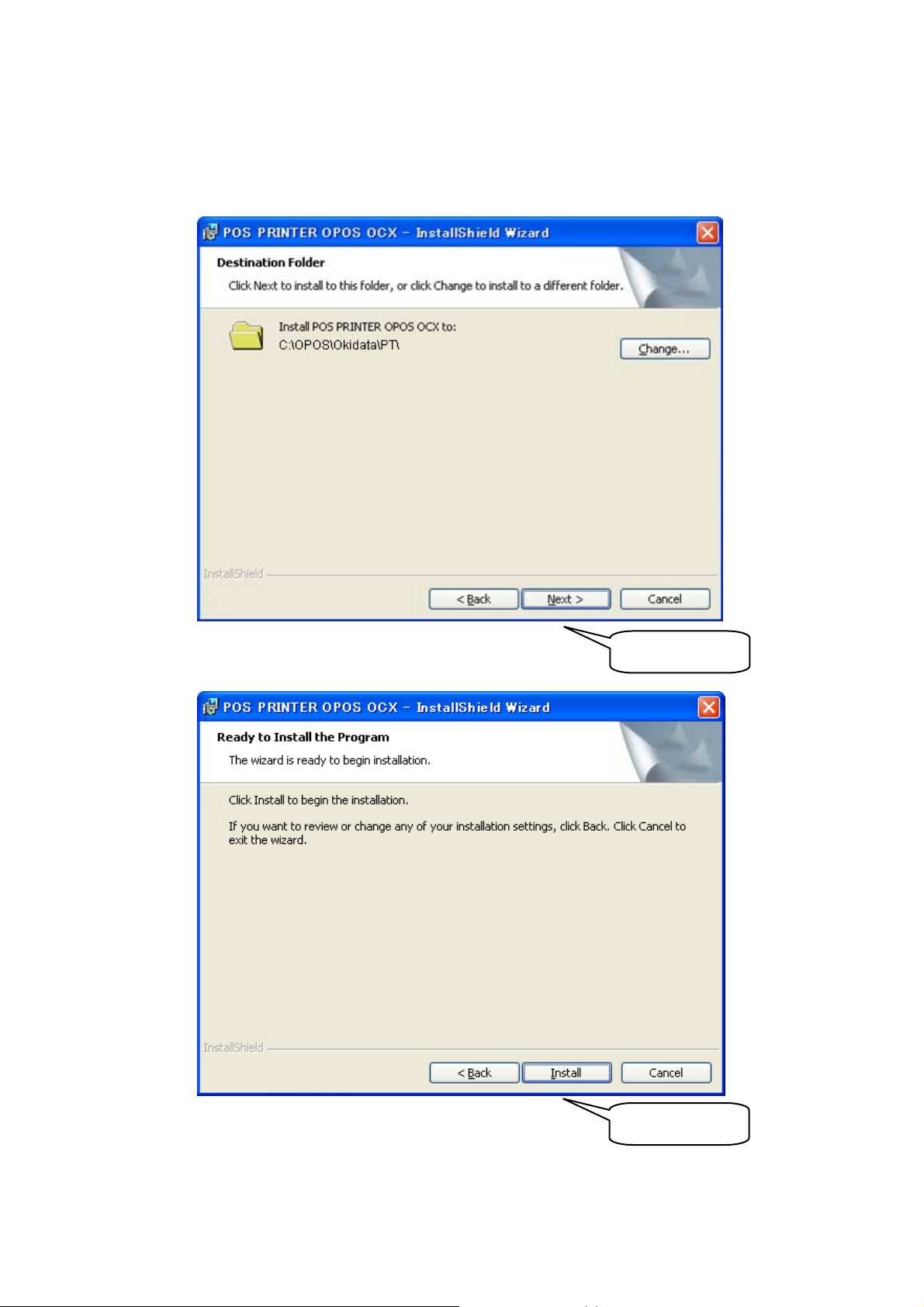

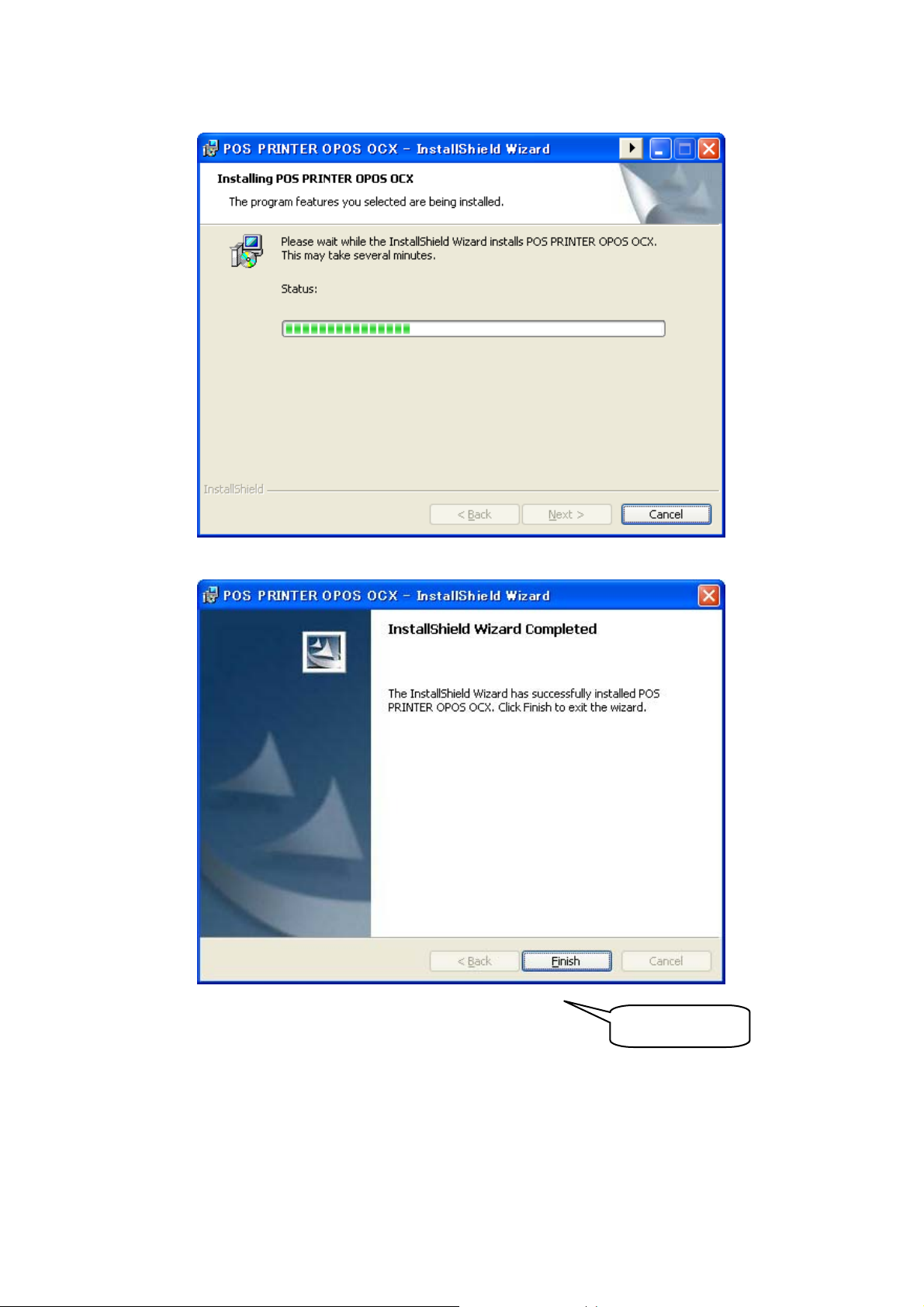

3. Installation

[System Drive]:\OPOS\Okidata\PT\

starts. Installation folder is:

click "Next"

12

click "Install"

click "Finish"

13

4. Start setting

If the [User Account Control] dialog box is displayed,

【For Windows 7 / Windows Vista】

1) Click the button indicated with the Windows logo

2) Go to [All programs] →

【For Windows XP / Windows Server 2008 R2 / Windows Server 2008 /

Go to [Start]→[All programs] →

program.

[Windows 7 / Server 2008 R2]

click [Yes].

[Windows Vista / Server 2008]

click [Allow].

desktop.

[Okidata]→[OPOS]→[Printer OPOS Setup].

Windows Server 2003 / WEPOS/POS Ready 2009】

[Okidata]→[OPOS]→[Printer OPOS Setup].

at the left bottom of the

【For Windows 2000】

Go to [Start]→[Program] →

[Okidata]→[OPOS]→[Printer OPOS Setup].

*As for how to use setting program, refer to 2.6. Setting Pr ogram Usage.

5. After setting, installation finishes.

14

Installation using batch file

* If OS is 32bit, us

folder

Installation method for Windows Vista or Windows 7

1. Copy driver folder ("\Driver_x64" or "\Driver_x32") onto an arbitrary folder.

2. The button that attaches the Windows logo under the left of a desktop screen is clicked.

3. Select [All Programs]->[Accessories]->[Command Prompt], and right-click in the icon of

the [Command Prompt], click "Run as administrator (A)", and execute the command

prompt by the administrator authority.

4. Change the current directory of the command prompt to the directory that copied by 1, and

execute the batch file "Install.bat".

5. The Registry Editor and additional confirmation message to the registry is displayed, and

click [yes]. The additional completion message to the registry is displayed when the

addition to the registry is completed, and click [OK].

6. The driver is installed in the folder "C:\OPOS\Okidata\PT\".

7. Please execute "C:\OPOS\Okidata\PT\OPPrinterSetup.exe", and execute the setup.

*As for how to use setting program, refer to 2.6. Setting Program Usage.

e batch file of \Driver_x32 folder. If OS is 64bit, use batch file of \Driver_x64

8. After setting, installation finishes.

Installation methods except Windows Vista and Windows 7

1. Driver folder ("\Driver_x64" or "\Driver_x32") onto an arbitrary folder.

2. The button that attaches the Windows logo under the left of a desktop screen is clicked.

3. Select [All Programs]->[Accessories]->[Command Prompt], and execute the command

prompt.

4. Change the current directory of the command prompt to the directory that copied by 1, and

execute the batch file "Install.bat". (Use "Install_Win2k.bat" for Windows 2000.)

5. The Registry Editor and additional confirmation message to the registry is displayed, and

click [yes]. The additional completion message to the registry is displayed when the

addition to the registry is completed, and click [OK].

6. The driver is installed in the folder "C:\OPOS\Okidata\PT\".

7. Please execute "C:\OPOS\Okidata\PT\OPPrinterSetup.exe", and execute the setup.

*As for how to use setting program, refer to 2.6. Setting Program Usage.

8. After setting, installation finishes.

15

2.4. Uninstallation Procedure

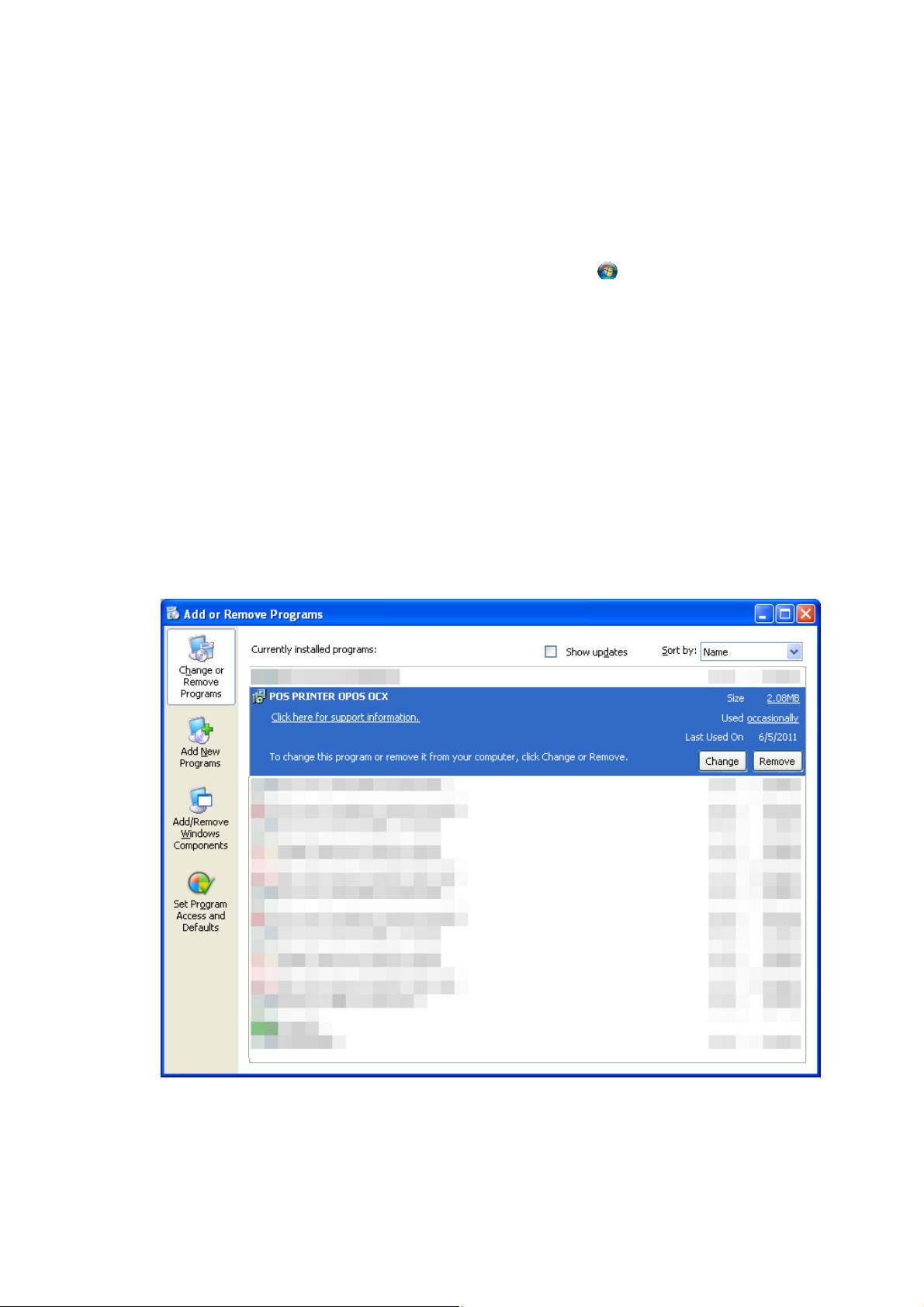

Uninstallation when installing it with installer (Setup32.exe or Setup64.exe)

1. Follow the steps blow to display the uninstalling screen.

【For Windows 7 / Windows Vista】

・Click the button indicated with the Windows logo

desktop.

・Go to [Control Panel]→[Uninstall program] or [Uninstall a program].

【For Windows Server 2008 R2】

・Go to [Start]→[Control Panel]→[Uninstall a program]

【For Windows Server 2008】

・Go to [Start]→[Control Panel]→[Programs and Functions].

【For Windows XP / Server 2003 / WEPOS】

・Go to [Start]→[Control Panel]→[Add or Remove Progra ms].

【For Windows 2000】

・Go to [Start]→[Settings]→[Control Panel]→[Add or Remove Programs].

at the left bottom of the

16

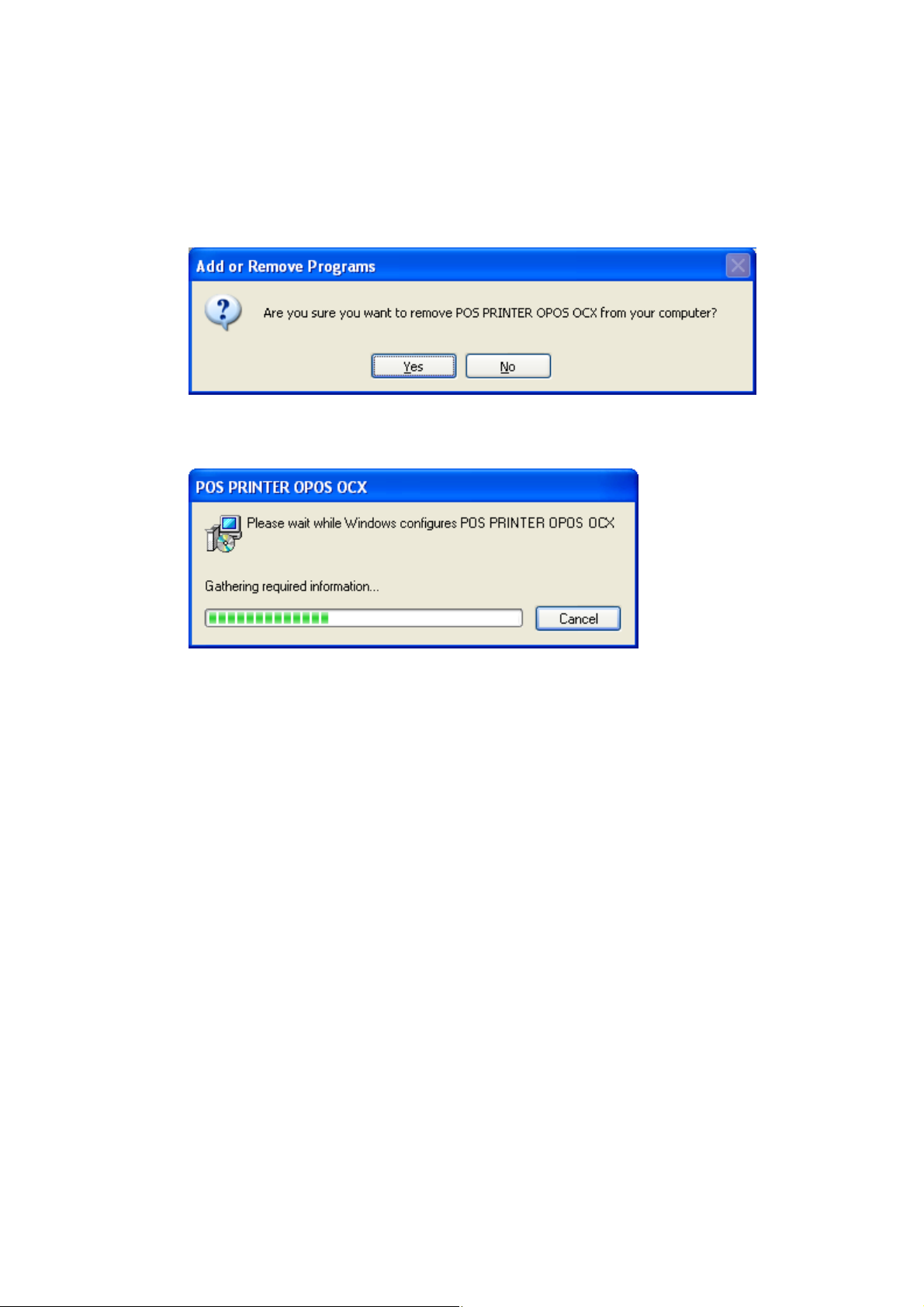

2. Select "POSPrint

3. The dialogue to confirm Uninstallation is displayed. Click [Yes].

4. Uninstallation is executed.

er OPOS OCX" and click "Uninstall" or "Remove".

5. Sometimes there are some files that could not be deleted by uninstaller in Installed folder

([System Drive]:\OPOS\Okidata\PT), so please delete manually.

That is all of uninstallation.

17

Uninstallation when OPOS is installed with batch file

Uninstall

1. The button that attaches the Windows logo under the left of a desktop screen is clicked.

2. Select [All Programs]->[Accessories]->[Command Prompt], and right-click in the icon of

the [Command Prompt], click "Run as administrator (A)", and execute the command

prompt by the administrator authority.

3. Execute batch file "uninstall.bat" with the folder of "C:\OPOS\Okidata\PT\".

4. Delete "C:\OPOS\Okidata\PT" folder manually.

5. It is an end.

Uninstallation methods except Win dows Vista and Windows 7

1. The button that attaches the Windows logo under the left of a desktop screen is clicked.

2. Execute batch file "uninstall.bat" with the folder of "C:\OPOS\Okidata\PT\".

3. Delete "C:\OPOS\Okidata\PT" folder manually.

4. It is an end.

ation method for Winodws Vista or Windows 7

18

2.5. Installation File List

File groups of POS Printer OPOS-OCX Control are arranged just like the following.

[System Drive]:\OPOS\Okidata\PT\

OPPOSPrinterCO.ocx POS Printer Control Object

OPPOSPrinterSO.dll POS Printer Service Object

OPPrinterSetup.exe Setting Program

oposdef.ini OPOS display string definition file

[System Drive]:\OPOS\Okidata\PT\Log

Folder to output Log File

[System Drive]:\OPOS\Okidata\PT\include

Include-File-Group defined by OPOS-OCX

Control.

Opos.h OPOS Shared-Definition-Constant Header

File

OposPtr.h OPOS POS Printer Definition-Constant

Header File

OposCash.h OPOS Drawer Definition-Constant Header

File

FitPtr.h Particular Definition-Constant Header File

for OPOS Printer.

OPOSPRN.BAS OPOS Definition-Constant Standard Module

(Shared-Definetion-Constant,

Printer and Drawer Definition-Constant)

(for V isual Basic)

OposFIT.BAS OPOS Printer Particular Definition Constant

Module (for Visual Basic)

[System Drive]:\WINDOWS\system32\

(64bit OS: [System Drive]:\Windows\SysWOW64\)

OPSharedPort.exe Shared Port Program

SxJcp32.dll DLL used to communicate with printer in

LAN

19

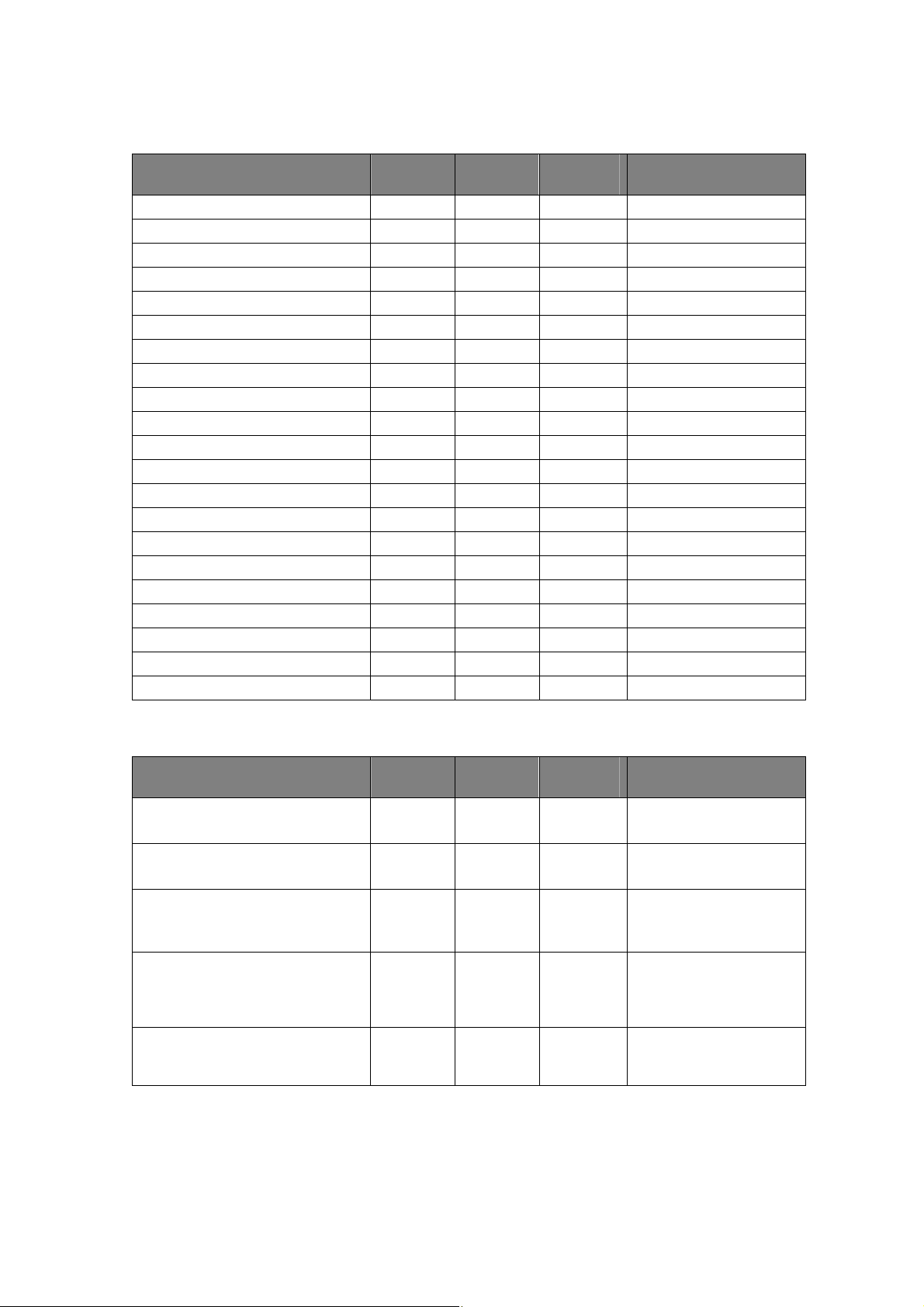

The module to be ins

File Version

Remarks

Copyright "Copyright (C) 2011 Oki Data Corporation"

Comment

Special Built Information (Not written specially)

Private Built Information (Not written specially)

Company "Oki Data Corporation"

Language "English (U.S.)"

Trademark (Not written specially)

Formal File Name (Object File Name of the subject)

Product Version Same as File Version

Product Name "OPOS POSPrinter"

Inside name (Formal File Name without extension)

talled has set property according to the following standard.

Item Remarks

OPOS Version (for each release, the third and the

forth characters are incremental numbers of version)

In case of files except CO/SO, successive increment

from 1.0.0.1

- In case of CO; "POSPrinter OPOS Control Object

Module".

- In case of SO; "POSPrinter OPOS Service Object

Module".

- The other cases; "[exe file name part without

extension] XXX (any wording)".

(Not written specially; If necessary, written

specially)

20

2.6. Setting Program Usage

Operation Conditions

OPOS must be installed

Screen and function

Setting Program is executed as the following procedure.

1. Execution

If the [User Account Control] dialog box is displayed,

[Windows 7 / Server 2008 R2]

click [Yes].

[Windows Vista / Server 2008]

click [Allow].

【For Windows 7 / Windows Vista】

1) Click the button indicated with the Windows logo

desktop.

2) Go to [All programs] →

[Okidata]→[OPOS]→[Printer OPOS Setup].

【For Windows XP / Windows Server 2008 R2 / Windows Server 2008 /

Windows Server 2003 / WEPOS/ POS Ready 2009】

Go to [Start]→[All programs] →

[Okidata]→[OPOS]→[Printer OPOS Setup].

【For Windows 2000】

Go to [Start]→[Program] →

[Okidata]→[OPOS]→[Printer OPOS Setup].

at the left bottom of the

21

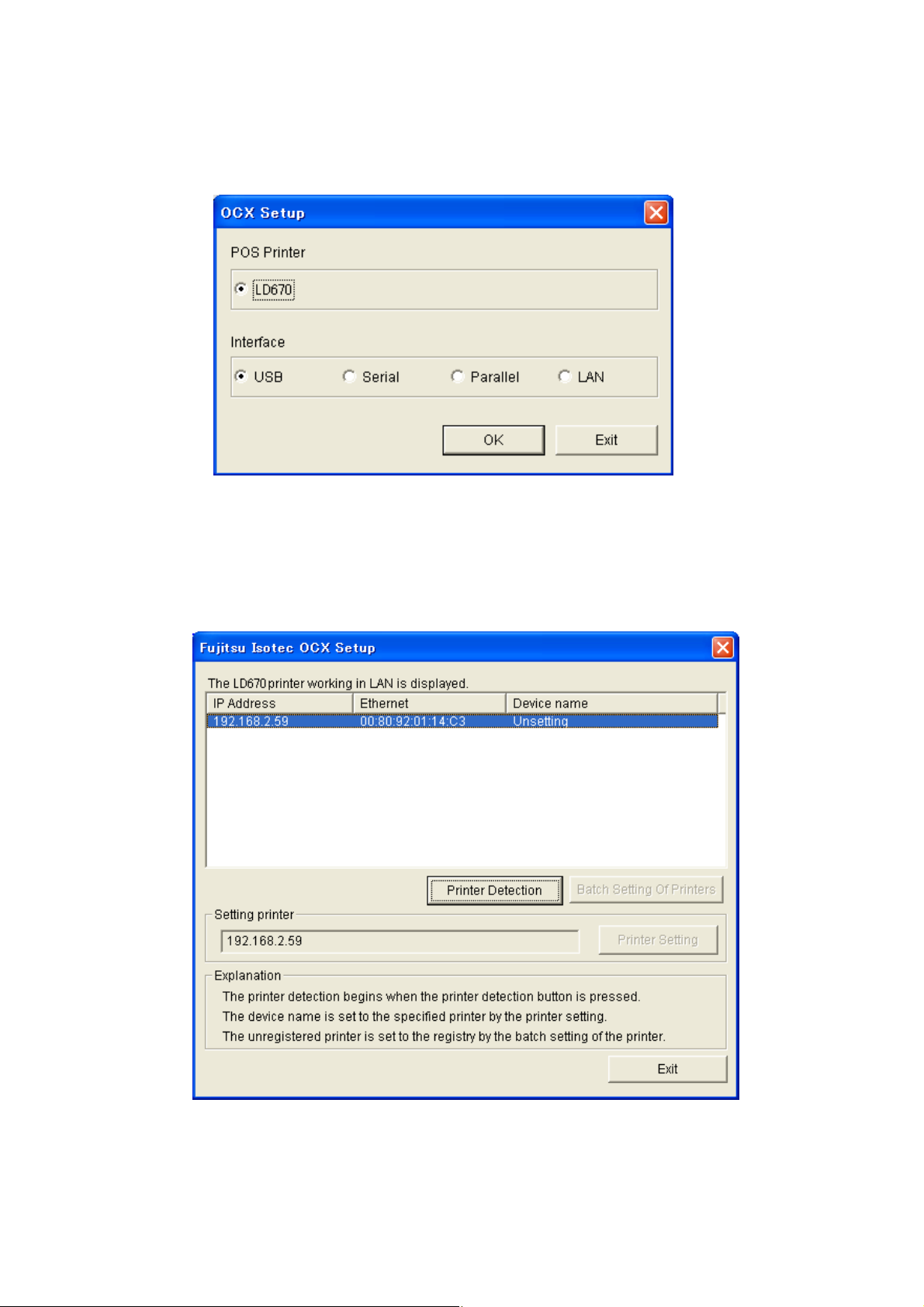

2. Selecting Pri

Select “POS Printer” and “Interface”, and then click [OK].

When LAN interface is selected, Searching printers screen is displayed.

When other interface is selected, POS printer detail setting screen is displayed.

3. Searching printers

nter and Interface

22

- Printer

- Batch Setting Of Printers

- Printer Setting

When POS printer is selected in the list, "Setting printer" shows own IP address, then

press "Printer Setting" button for moving to POS printer detail setting screen page.

Double click on a printer in the list for jumping to POS printer detail setting screen page

Detection

When "Print

name of the found POS printer is displayed. When Device name is "Unsetting", Printer is

disabled on OCX control. There are 2 solutions to enable Printer on OCX control. One is

to set all Unsetting POS printers to default setting by "Batch Setting Of Printers", and

another one is to entry Unsetting Printers one by one by "Printer Setting".

When "Batch Setting Of Printers" button is pressed, OCX gives "Device name" to every

single "Unsetting" printer. In that case, registry setting value will be the same as "5.

Registry Used by OCX ". IP address and Device name is set depending on each printer's

setting.

er Detection" is pressed, the list of IP address, MAC address and Device

directly.

23

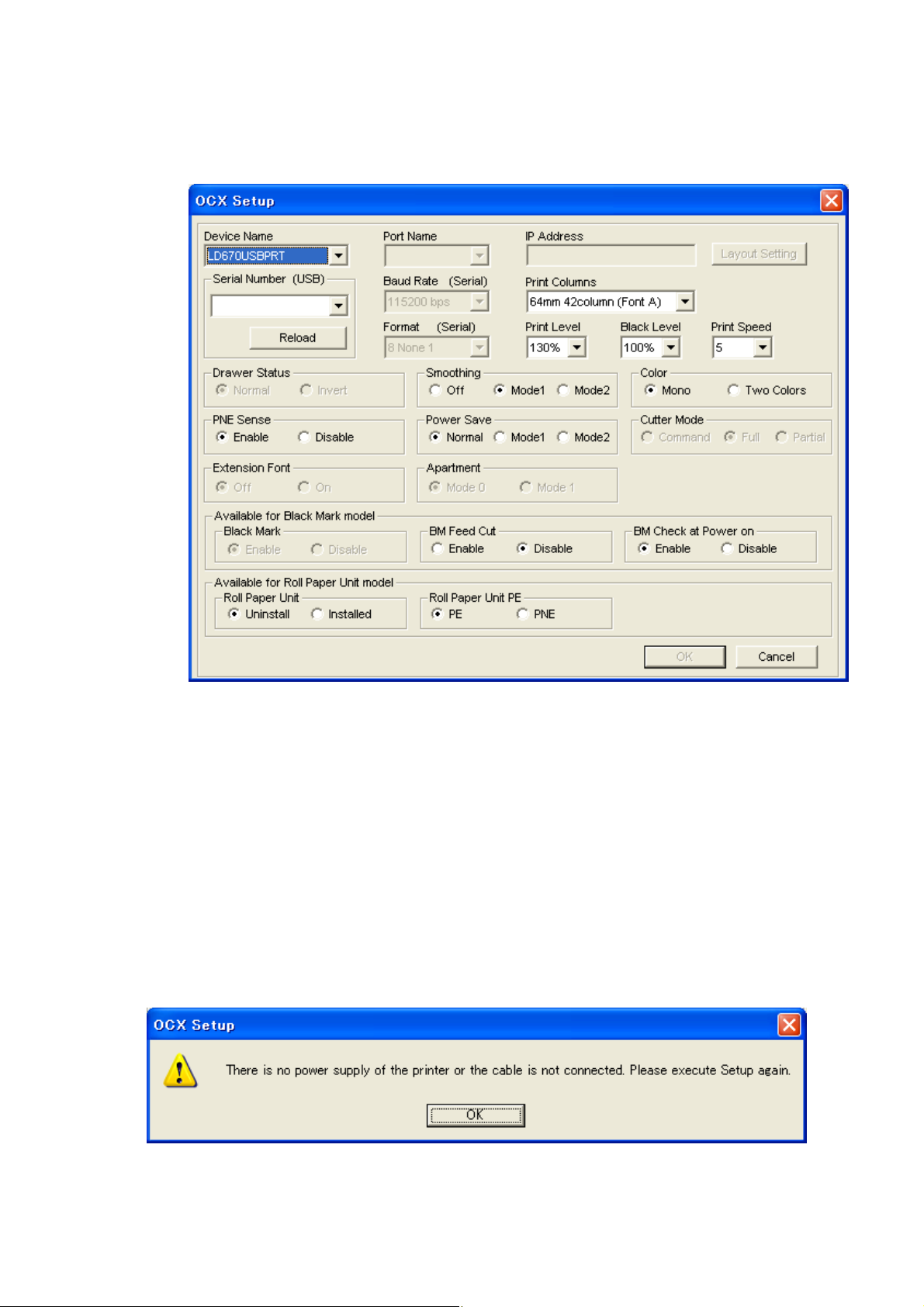

4. POS printer

detail setting

When an error occurred with [OK] clicked, the following messages are displayed.

Confirm an error factor, and setup again.

<An error factor>

A cable is not connected.

The printer is not switched on.

A cover opens.

There is not paper.

A port is already used in others.

A communication condition does not accord with a printer. (Serial connection)

Serial number input is wrong. (USB connection)

24

1) Device Name

Specify the device to be set which may differ depending on the OCX installed. The items to

be displayed is as follows:

Device Name Interface

LD670SERPRT For Serial Interface

LD670PARPRT For Parallel Interface

LD670USBPRT For USB Interface

LD670SER2PRT For Second Serial Interface

LD670PAR2PRT For Second Parallel Interface

LD670USB2PRT For Second USB Interface

LD670LANPRT_xxx.xxx.xxx.xxx For LAN Interface

2) Port Name

(xxx.xxx.xxx.xxx : IP Adress.)

For XXXSERPRT or XXXSER2PRT, the port can be selected from "COM1" to "COM9"

and for XXXPARPRT or XXXPAR2PRT, from "LPT1" to "LPT9." The port number other

than above can be entered into the Dropdown list. "COM1" or "LPT1" is set as the default

setting after installation.

3) IP Adress

IP address of the set device is displayed.

4) Serial Number

For XXXUSBPRT or XXXUSB2PRT, select the serial number of the printer from "Serial

Number" by all means.

When the serial number of the printer is set by "123456", please select "123456" from

"Serial Number".

5) Baud Rate

Perform the baud rate setting. This setting is available only when XXXSERPRT or

XXXSER2PRT is selected in the “Port Name”. Set the baud rate set in the Printer.

25

6) Format

rm the co

Perfo

XXXSER2PRT is selected in the “Port Name”. Set the communication format set in the

Printer.

The communication protocol is fixed to XON/XOFF.

* Special attention is required to perform the following settings:

1. Specifying 7bit Even (7bit Even 1) is not available from 8bit None (8 None 1) setting.

To perform this setting, specify Even (8 Even 1) first, and then specify 7bit Even.

2. Specifying 7bit Odd (7bit Odd 1) is not available from 8bit None (8 None 1) setting.

To perform this setting, specify Odd (8 Odd 1) first, and then specify 7bit Even.

3. To specify 8bit None (8 None 1) from 7bit Even (7 Even 1), specify 8bit Even (8 Even

1) first, and then specify 7bit Even.

4. To specify 8bit None (8 None 1) from 7bit Odd (7 Odd 1), specify 8bit Even (8 Odd 1)

first, and then specify 7bit Odd.

7) Print Columns

Set the width of receipt and the number of the characters to be set in a single line.

mmunication format. This setting is available only when XXXSERPRT or

8) Drawer Status

With some drawer, the drawer open/close event from the Drawer OCX may be reversed. To

acquire the event properly and avoid such behavior, change the setting to "Invert."

9) Smoothing

Select whether smoothing processing is performed when the RecLetterQuality property is

set to TRUE while printing double byte or more is specified for the font printing. When

Mode1 or Mode2 is selected, smoothing processing is performed. With smoothing

processing, the quality of double byte printing is improved, but printing performance may

be declined slightly.

10) Color

When red is specified in the escape sequence with special paper, printing in the second

color on the receipt is available. When "Mono" is specified, the second color printing is not

performed even the escape sequence setting is specified.

26

11) PNE Sence

Set whet

12) Print Level

Specifies the printing thickness.

The default's printing level of black is taken as 130 %. The percentage can be set from 70

to 130 by 5 %.

13) Black Level

Specifies the thickness of black when 2-color printing is set.

The default's printing level of black is taken as 130 %. The percentage can be set from 70

to 130 by 5 %.

14) Print Speed

Specifies the printing speed. It can be set to the numbers form 1 to 9. The default is set to

"5" that is highest printing speed.

15) Power Save

her to notify

the paper near end.

Set whether to reduce power consumption.

"Normal" is standard (the default value), and power consumption is not reduced.

"Mode1" reduces the power consumption setting to 80%.

"Mode2" changes the division numbers of strobe (The printing speed is declined)

16) Cutter Mode

This is valid only for the full cut model.

"Full" (a default value) sets movement of a full cut command on a full cut.

"Partial" sets movement of a full cut command on a partial cut.

17) Extension Font

Set whether to use Extension font.

This is valid only for the Extension font model.

"Off" uses normal size font.

"On" uses Extension font, which is larger than normal size font.

27

18) Apartment

The method of initialization and the termination of DLL is specified.

19) Black Mark

The setting is available only in the case of black mark specifications.

Set whether to mount the black mark sensor. The setting is valid when "Enable" is selected.

20) BM Feed Cut

This is valid only when the blackmark sensor is mounted.

When "Enable" is selected, cut operation is executed at black mark positioning.

When "Disable" is selected, cutting operation is not executed.

21) BM Check at Power on

This is valid only when the blackmark sensor is mounted.

"Enable" feeds the paper to black mark position, when the printer turns on.

22) Roll Paper Unit

This is valid only when the Roll Paper Unit is installed.

When "Uninstall" is selected, the Roll Paper Unit is invalid.

When "Installed" is selected, the Roll Paper Unit is valid.

23) Roll Paper Unit PE

This is valid only when the Roll Paper Unit is installed.

The sensor that detects PE of the Roll Paper Unit is specified.

When "PE" is selected, PE sensor detects PE.

When "PNE" is selected, PNE sensor detects PE.

24) Cancel, OK buttons

When the OK button is pressed, the settings are written into the registry and the command

to change the settings is sent to the Printer. To run this program, connect the printer and

turn on the power beforehand. (If the printer is not connected, the power is not turned on or

the printer is in the error status, the settings are not set in the Printer and only the registry is

set.)

25) Reload button

When the Reload button is pressed, the serial number of the printer connected with USB is

acquired again.

28

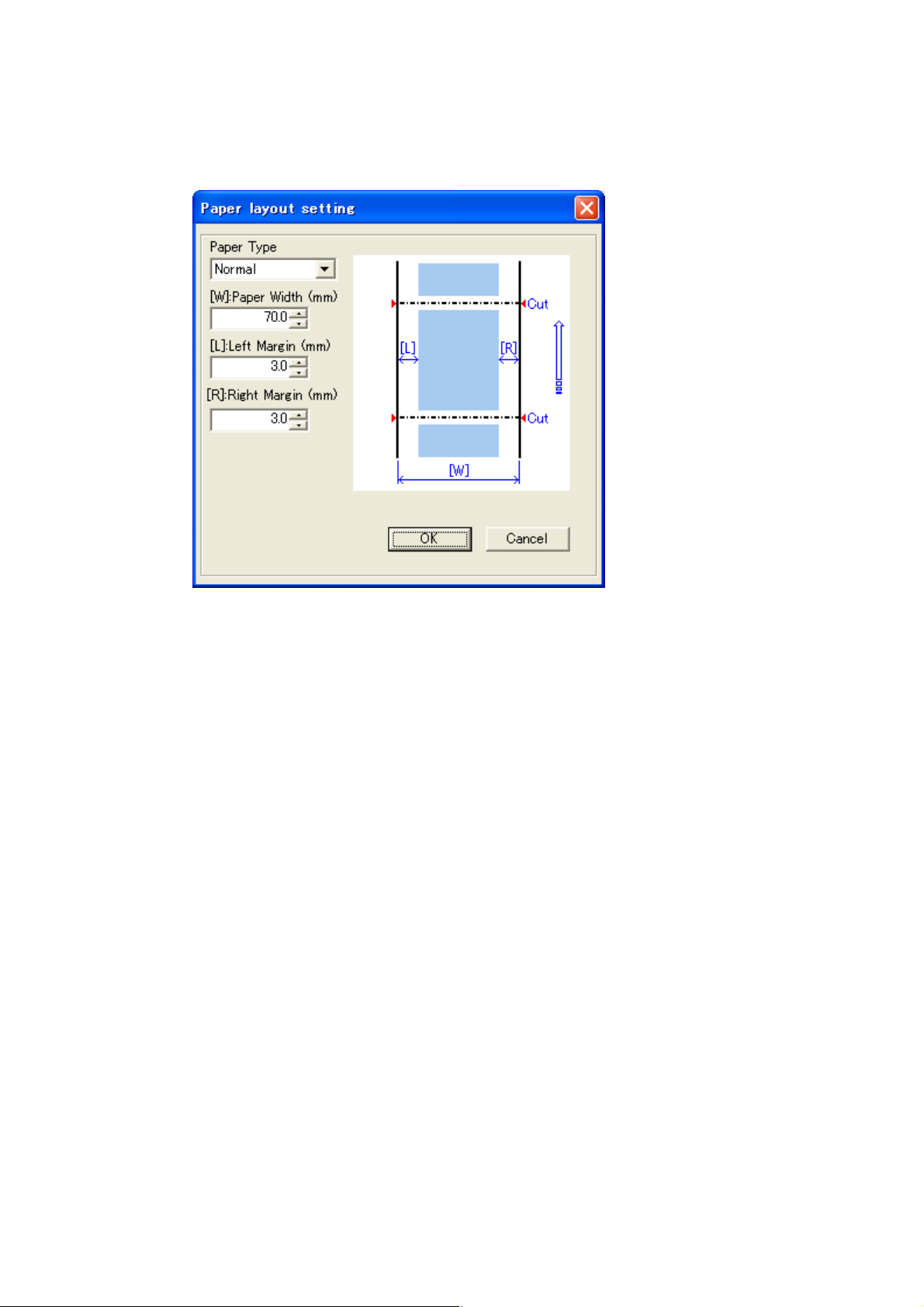

26) Layout Setting button

the Layout Sett

When

ing button is pressed, the Paper layout setting screen is displayed.

29

5. Paper

- Paper Type

layout setting

.

Specifies the paper type used by LD670.

Selection value: “Normal” / “Black Mark” / “Label”

Default value: “Normal”

- Paper Width

Specifies the paper width used by LD670.

Input range: 25.4 – 70, 80, 83mm *

Default value: 70mm

- Left Margin

Specifies the left margin of the paper used by LD670.

Input range: 1.0 – 69.0mm *

Default value: 3.0mm

30

- Right Margin

es the ri

Specifi

Input range: 2.0 – 70.0mm *

Default value: 3.0mm

* When [Print Width] of the following calculation comes off from the range from 12 to

80mm, the input value is corrected to a proper value.

[Print Width] = Paper Width – Left Margin – Right Margin

When focus comes off from each input box, the check and the correction of the input

value are done.

When the calculation value of [Print Width] becomes small more than 12mm, the input

value is corrected to the value that [Print Width] becomes 12mm.

When the calculation value of [Print Width] exceeds 80mm, the input value is corrected

to the value that [Print Width] becomes 80mm.

6. Paper layout setting screen useage

1) Select “Paper Type”, and input “Paper Width”, “Left Margin”, “Right Margin”

ght margin of the paper used by LD670.

according to the layout of the paper you want to use.

2) Click [OK].

3) When the following message is displayed, open the cover, and load the paper you use,

and close the cover, and click [OK].

4) The printer detects the paper layout automatically, and the layout data is set to the

printer. (If you selected "Black Mark" or "Label" the paper is fed.)

5) When the paper layout setting has been finished, this screen is closed.

31

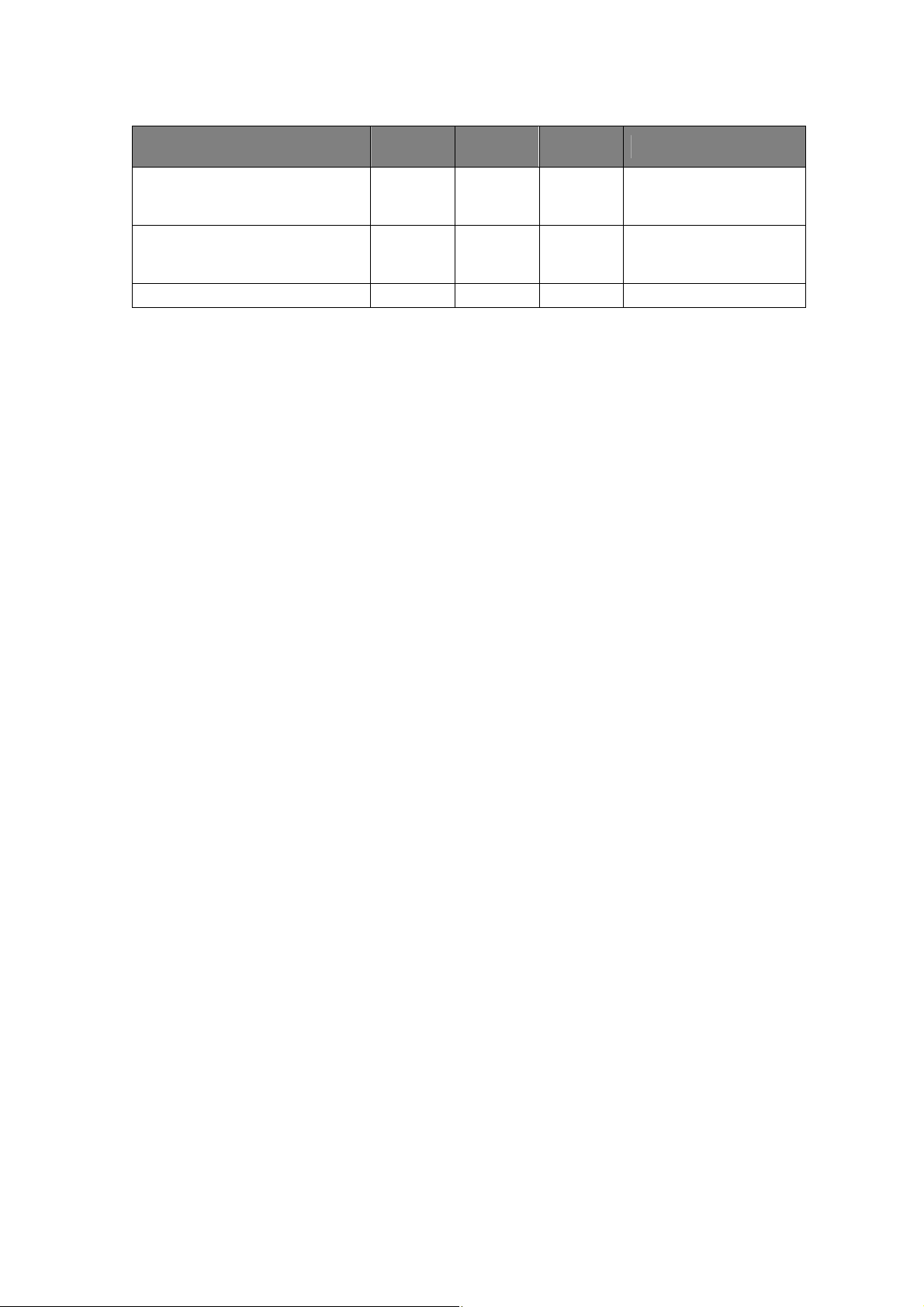

Operation C

Registry Setting

The valu

Change the value as follows acc ording to the printer in use. Wh en the setting is applicable

to the particular OCX, it is stated as so.

POS Printer (first) LD670SERPRT LD670PARPRT LD670USBPRT

POS Printer (second) LD670SER2PRT LD670PAR2PRT LD670USB2PRT

onditions

e to write into the registry may differ depending on the printer to be set.

Serial Interface Parallel Interface USB Interface

POS Printer

(IP Adress : xxx.xxx.xxx.xxx)

LD670LANPRT_xxx.xxx.xxx.xxx

Device Name

Device Name

LAN Interface

Port Name (Serial/Parallel)

The value specified is directly written into the following registry:

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\port

SerialNumber (USB)

Default Port of the USB is set by "USB", and the set value adds it after "USB" and writes

in it at the following registry. (Please set the serial number of the printer to connect)

(An example: When the serial number is set to "123456", "USB123456" is written in the

registry.)

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\port

32

Baud R

Based on the setting values, the combination of Baud Rate and Format is written to the

registry. For example, when Baud Rate = "19200" and Format = "8 None 1",

"19200,N,8,1,x" is written into the value. When Format = "7 Odd 1", "19200.O,7,1,x", and

when Format = "8 Even 1", "19200,E,8,1,x" are written into the following values:

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

IPAddress(LAN)

IP Address of the printer connected with the network is set.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Print Columns

Based on the setting values set, the number of the characters per line, available line

character width and paper width are set in the following values:

ate, Form

Printer]\Protocol

Printer]\IPAddress

at (For Serial only)

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\RecLineChars

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\RecLineCharsList

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\RecLineWidth

Drawer Status

When the value is set to Normal, "0" is written into the following registry, and when the

value is set to Invert, "1" is written.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\InvertDrawerStatus

33

Smoothing

When t

value is set to Mode2, "2" is written into the following registry, and when the value is set to

OFF, "0" is written.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Color

When the value is set to Mono, "F" is written into the following registry, and when the

value is set to Two Colors, "T" is written.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Power ON Status

When the value is set to Enable, "1" is written into the following registry, and when the

he valu

Printer]\Smoothing

Printer]\CapRec2Color

e is set to Mode1, "1" is written into the following registry , and when the

value is set to Disable, "0" is written.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\PowerOnNotify

Process ID

When the value is set to Standard, "S" is written in to the following registry, and when the

value is set to HighSpeed, "H" is written.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\ProcessID

PNE Sense

When the value is set to Enable, "E" is written into the following registry, and when the

value is set to Disable, "D" is written.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\PNESense

34

Print Level

The value specified is directly written into the following registry:

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\PrintLevel

Black Level

The value specified is directly written into the following registry:

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\BlackLevel

Print Speed

The value specified is directly written into the following registry:

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\PrintSpeed

Power Save

When the value is set to Normal, "S" is written into the following registry, and when the

value is set to Mode1, "1" is written, and when the value is set to Mode2, "2" is written.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\PowerSave

35

Batch Print

When the value is set to Enable, "E" is written into the following registry, and when the

value is set to Disable, "D" is written.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\BatchPrint

Cutter Mode

When the value is set to Full, "F" is written into the following registry, and when the value

is set to Partial, "P" is written.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\CutterMode

Apartment(LAN)

When the value is set to Mode0, "0" is written into the following registry, and when the

value is set to Mode1, "1" is written.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\Apartment

Black Mark

When the value is set to Enable, "T" is written into the following registry, and when the

value is set to Disable, "F" is written.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\BlackMarkEnabled

BM Feed Cut

When the value is set to Enable, "E" is written into the following registry, and when the

value is set to Disable, "D" is written.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\BMFeedCut

36

BM Check a

When the value is set to Enable, "E" is written into the following registry, and when the

value is set to Disable, "D" is written.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\BMCheckAtPowerOn

Extension Font

When the value is set to Off, "0" is written into the followi ng registry, and when the value

is set to On, "1" is written.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\ExtensionFont

AnkCharsSpacing and RecLineSpacing

If "Extension Font" value is set to On, "2" is written in "Ank.CharsSpacing" and "34" is

written in "RecLineSpacing".

t Power o

n

If "Extension Font" value is set to Off, "0" is written in "Ank.CharsSpacing" and "30" is

written in "RecLineSpacing".

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\AnkCharsSpacing

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\RecLineSpacing

RollPaperUnit

When the value is set to Uninstall, "0" is written into the following registry, and when the

value is set to Installed, "1" is written.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\RollPaperUnit

RollPaperUnitPE

When the value is set to PE, "0" is written into the following registry, and when the value is

set to PNE, "1" is written.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\RollPaperUnitPE

37

Paper Type

When Normal is selected, "48" is written into the following registry, and when Black Mark

is selected, "49" is written, snd when Label is selected, "64" is written.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\PaperType

Paper Width

The input value is converted into the unit of dot , and it is written into the following

registry.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\Paper

Left Margin

The input value x 10 is written into the following registry.

· HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\POSPrinter\[

Printer]\LeftMargin

38

3. Using OPOS Control

3.1. Common

The application uses the OPOS control in the steps as follows:

1. Open method: Called to link the control object to the service object.

2. ClaimDevice method: Called to enable exclusive access to the device. For the device of

exclusive use, this method is required, and foe the dev i ce of sharable use, it is opt io nal.

3. DeviceEnabled property: Set to TRUE to operate the device.

4. Use the device. (Each property, method, event)

5. DeviceEnabled property: Set to FALSE to disable the device.

6. ReleaseDevice method: Called to clear exclusive access to the device.

7. Close method: Called to release the service object from the control object.

For details of other usage, refer to "OPOS-APG V1.13" document.

3.2. POS Printer

The POS printer supports only "Receipt." For the methods and properties of other than that

(Journal or Slip), interface is supplied but behavior is not supported.

According to the general output model, synchronous and asynchronous output is available for the

POS printer.

The POS printer is the device to be used exclusively.

39

3.3. How to Implement the OPOS Control

The following steps describe how to implement the OPOS-OCX control in the application.

To Implement Using Visual Basic 6.0

1. Start Visual Basic 6.0 and select the type of the project to be created. In this example,

[Standard EXE] is selected. After selection, select [Project] from the menu, and select

[Component].

40

2. When the Co

OLE Control (1.13) module], and press the [OK] button.

3. Paste the OCX displayed in the toolbar on the form. After this procedure, use it in the

mponent dialog box is displayed, select the [Control] tab -> [POSPrinter

same manner as normal OCX.

41

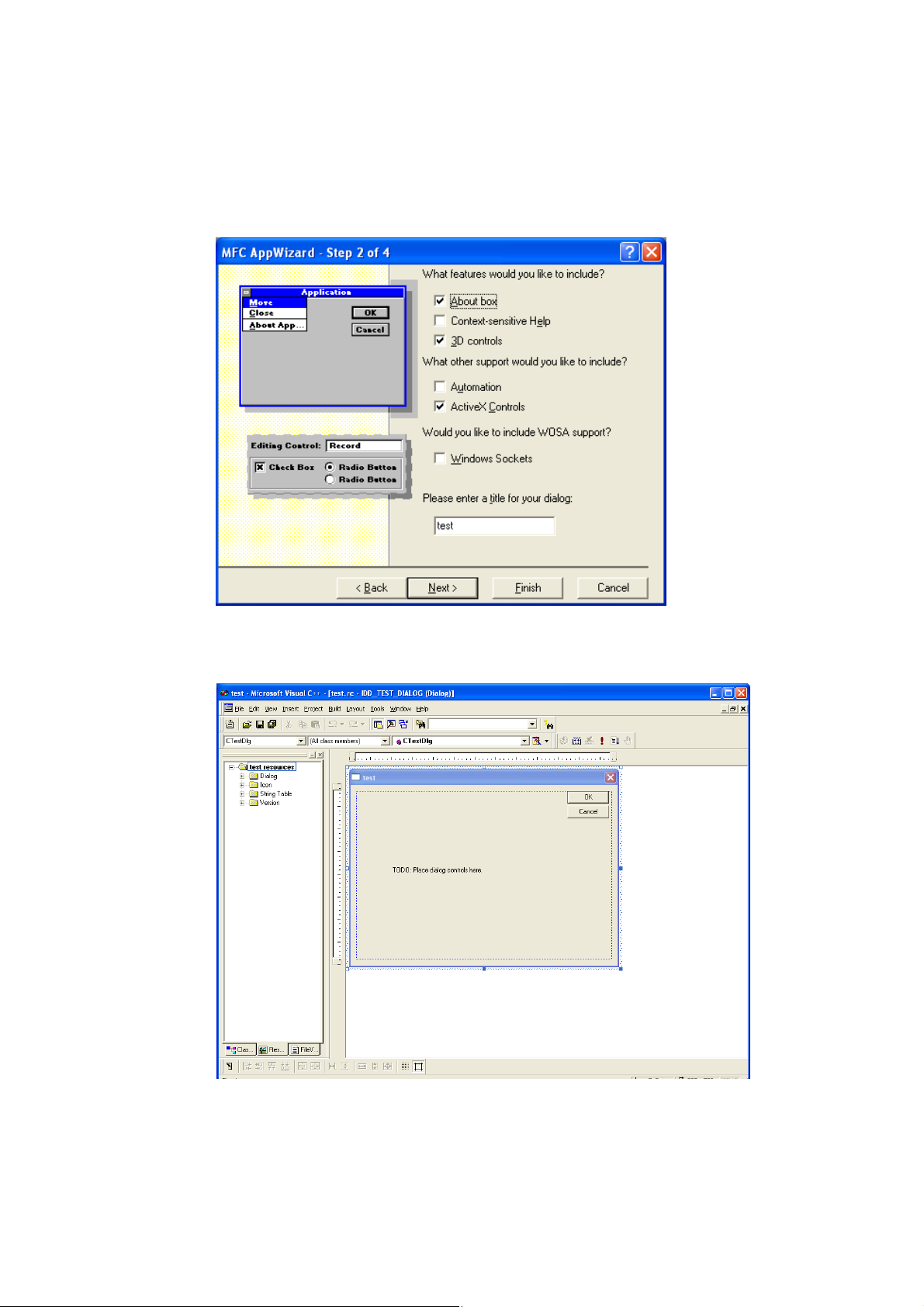

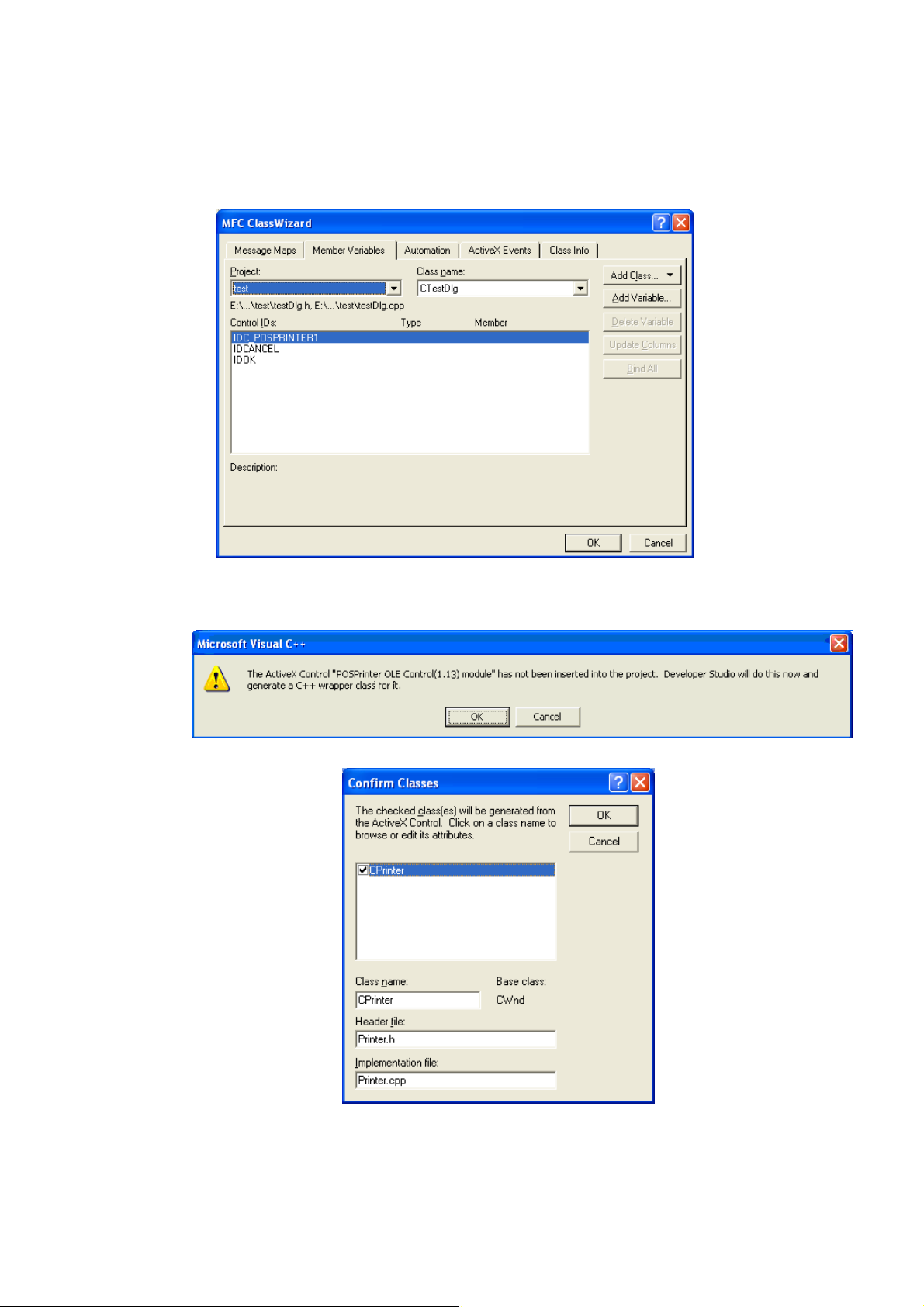

To Implement Using Visual C++ 6.0

1. Start Visual C++ 6.0, select [Create New] -> [MFC AppWizard(exe)], and press [OK].

2. In the MFC AppWizard Step 1, select [Dialog Base] and press the [Next] button.

42

3. Select the ActiveX

to the type of the project to be created. Select [Next] and perform appropriate setting

as required for the rest of the instruction.

Control checkbox to be supported. Change other settings according

4. When

n the proje

ct is created, select [Resource View] to display the main dialog box.

43

5. On the dialo

Control]. When the dialog box is displayed, select [POSPrinter OLE Control (1.13)

module] and select [OK].

6. When OCX is inserted on the dialog box, select the control and right-click it. From the

pop-up menu, select [Property]. Check the ID of the OCX. Clear the [Visible] and

g box, right-click to display the pop-up menu, and select [Insert ActiveX

[Tab Stop] check boxes.

44

7. Close [Property

Variable] tab, select the control ID checked in the step 6, and press [Add Variable].

8. When th

e

], repeat the step 6 and select [ClassWizard]. Select the [Member

wing dialog box is displayed, press [OK].

follo

45

9. Set the mem

Use this member variable for the properties and methods with the OCX.

Example: m_POSPrinter.Open(“LD670SERPRT”)

ber variable corresponding to the OPOS control, and exit Class Wizard.

46

4. OPOS Interface Specifications (Printer)

4.1. List

Properties

Common Type Access

BinaryConversion Long R/W Open OPOS_BC_NONE(0)

CapCompareFirmwareVersion Boolean R Open TRUE

CapPowerReporting Long R Open OPOS_PR_STANDARD(1

CapStatisticsReporting Boolean R Open FALSE

CapUpdateFirmware Boolean R Open TRUE

CapUpdateStatistics Boolean R Open FALSE

CheckHealthText String R Open ""

Claimed Boolean R Open FALSE

DeviceEnabled Boolean R/W Open &

FreezeEvents Boolean R/W

Open

OpenResult Long R None 0

OutputID Long R Open 1

PowerNotify Long R/W Open OPOS_PN_DISABLED(0)

PowerState Long R Open OPOS_PS_UNKNOWN(2

ResultCode Long R -- 0

ResultCodeExtended Long R Open 0

State Long R -- OPOS_S_CLOSED

ControlObjectDescription String R -- "POS Printer OPOS

ControlObjectVersion Long R -- 1013XXX

May Use

After

Claim

FALSE

Open

Initial Value, Conditions

Made writable after Open.

)

FALSE

Made writable after Open

and Claim.

FALSE

Made writable after Open.

Made writable after Open,

and unwritable after

Enabled.

000)

Control Object"

47

Common Type Access

ServiceObjectDescription String R Open "POS Printer OPOS

ServiceObjectVersion Long R Open 1013XXX

DeviceDescription String R Open "OP 1 Station Thermal

DeviceName String R Open "OP 1 Station Thermal

May Use

After

Initial Value, Conditions

Service Object"

POSPrinter"

POSPrinter"

Specific Type Access

CapCharacterSet Long R Open PTR_CCS_KANJI (11)

CapConcurrentJrnRec Boolean R Open FALSE

CapConcurrentJrnSlp Boolean R Open FALSE

CapConcurrentPageMode Boolean R Open FALSE

CapConcurrentRecSlp Boolean R Open FALSE

CapCoverSensor Boolean R Open TRUE

CapMapCharacterSet Boolean R Open TRUE

CapTransaction Boolean R Open TRUE

CapJrnPresent Boolean R Open FALSE

CapJrn2Color Boolean R Open FALSE

CapJrnBold Boolean R Open FALSE

CapJrnDhigh Boolean R Open FALSE

CapJrnDwide Boolean R Open FALSE

CapJrnDwideDhigh Boolean R Open FALSE

CapJrnEmptySensor Boolean R Open FALSE

CapJrnItalic Boolean R Open FALSE

CapJrnNearEndSensor Boolean R Open FALSE

CapJrnUnderline Boolean R Open FALSE

CapJrnCartridgeSensor Long R Open 0

CapJrnColor Long R Open 0

May Use

After

Initial Value, Conditions

48

Specific Type Access

CapRecPresent Boolean R Open TRUE

CapRec2Color Boolean R Open The initial value may vary

CapRecBarCode Boolean R Open TRUE

CapRecBitmap Boolean R Open TRUE

CapRecBold Boolean R Open TRUE

CapRecDhigh Boolean R Open TRUE

CapRecDwide Boolean R Open TRUE

CapRecDwideDhigh Boolean R Open TRUE

CapRecEmptySensor Boolean R Open TRUE

CapRecItalic Boolean R Open FALSE

CapRecLeft90 Boolean R Open TRUE

CapRecNearEndSensor Boolean R Open The initial value may vary

CapRecPapercut Boolean R Open TRUE

CapRecRight90 Boolean R Open TRUE

CapRecRotate180 Boolean R Open TRUE

CapRecStamp Boolean R Open FALSE

CapRecUnderline Boolean R Open TRUE

CapRecCartridgeSensor Long R Open 0

CapRecColor Long R Open 0

CapRecMarkFeed Long R Open Using LD670 : 15

CapRecPageMode Boolean R Open FALSE

CapRecRuledLine Boolean R Open FALSE

May Use

After

Initial Value, Condition

according to the contents

of the registry.

according to the contents

of the registry.

Others: 0

49

Specific Type Access

CapSlpPresent Boolean R Open FALSE

CapSlpFullslip Boolean R Open FALSE

CapSlp2Color Boolean R Open FALSE

CapSlpBarCode Boolean R Open FALSE

CapSlpBitmap Boolean R Open FALSE

CapSlpBold Boolean R Open FALSE

CapSlpDhigh Boolean R Open FALSE

CapSlpDwide Boolean R Open FALSE

CapSlpDwideDhigh Boolean R Open FALSE

CapSlpEmptySensor Boolean R Open FALSE

CapSlpItalic Boolean R Open FALSE

CapSlpLeft90 Boolean R Open FALSE

CapSlpNearEndSensor Boolean R Open FALSE

CapSlpRight90 Boolean R Open FALSE

CapSlpRotate180 Boolean R Open FALSE

CapSlpUnderline Boolean R Open FALSE

CapSlpBothSidesPrint Boolean R Open FALSE

CapSlpCartridgeSensor Long R Open 0

CapSlpColor Long R Open 0

CapSlpPageMode Boolean R Open FALSE

CapSlpRuledLine Boolean R Open FALSE

May Use

After

Initial Value, Condition

Specific Type Access

AsyncMode Boolean R/W Open FALSE

CartridgeNotify Long R/W Open PTR_CN_DISABLED(0)

CharacterSet Long R/W Open,

CharacterSetList String R Open "101.132,103,437,850,851,

CoverOpen Boolean R Open,

May Use

After

Claim &

Enable

Claim &

Enable

Initial Value, Condition

Made writable after Open.

Unwritable

998

Made writable after

Enabled

852,857,858,860,863,864,8

65,866,869,932,998,1252,2

8592,28597"

FALSE

50

Specific Type Access

ErrorLevel Long R Open 0

ErrorStation Long R Open 0

ErrorString String R Open “”

FontTypefaceList String R Open “”

FlagWhenIdle Boolean R/W Open FALSE

MapCharacterSet Boolean R/W Open TRUE

MapMode Long R/W Open PTR_MM_DOTS (1)

PageModeArea String R Open “”

PageModeDescriptor Long R Open 0

PageModeHorizontalPosition Long R/W Open 0

PageModePrintArea String R/W Open “”

PageModePrintDirection Long R/W Open 0

PageModeStation Long R/W Open 0

PageModeVerticalPosition Long R/W Open 0

RotateSpecial Long R/W Open PTR_RP_NORMAL (1)

May Use

After

Initial Value, Condition

Made writable after Open

Made writable after Open

Made writable after Open

Specific Type Access

JrnLineChars Long R/W Open,

JrnLineCharsList String R Open “”

JrnLineHeight Long R/W Open,

JrnLineSpacing Long R/W Open,

JrnLineWidth Long R Open,

JrnLetterQuality Boolean R/W Open,

JrnEmpty Boolean R Open,

JrnNearEnd Boolean R Open,

May Use

After

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Initial Value, Condition

0

Unwritable

0

Unwritable

0

Unwritable

0

FALSE

Unwritable

FALSE

FALSE

51

Specific Type Access

JrnCartridgeState Long R Open,

JrnCurrentCartridge Long R/W Open,

May Use

After

Claim &

Enable

Claim &

Enable

Initial Value, Condition

0

Unwritable

0

Unwritable

Specific Type Access

RecLineChars Long R/W Open,

RecLineCharsList String R Open The initial value may vary

RecLineHeight Long R/W Open,

RecLineSpacing Long R/W Open,

RecLineWidth Long R Open,

RecLetterQuality Boolean R/W Open,

RecEmpty Boolean R Open,

RecNearEnd Boolean R Open,

RecSidewaysMaxLines Long R Open,

RecSidewaysMaxChars Long R Open,

RecLinesToPaperCut Long R Open,

RecBarCodeRotationList String R Open “0,R90,L90,180”

RecCartridgeState Long R Open,

May Use

After

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Initial Value, Condition

The initial value may vary

according to the contents

of the registry

Made writable after Open.

according to the contents

of the registry.

The initial value may differ

according to the contents

of the registry

Unwritable

The initial value may vary

according to the contents

of the registry

Made writable after Open.

The initial value may vary

according to the contents

of the registry

TRUE

Made writable after Open.

FALSE

FALSE

The initial value may vary

according to the contents

of the registry

The initial value may vary

according to the xml

contents.

The initial value may vary

according to the xml

contents.

PTR_CART_UNKNOWN

(268435456)

52

Specific Type

RecCurrentCartridge Long R/W Open,

RecBitmapRotationList String

Access Initial Value, Condition

R Open

May Use

After

Enable

Claim &

Enable

Specific Type Access

SlpLineChars Long R/W Open,

SlpLineCharsList String R Open ""

SlpLineHeight Long R/W Open,

SlpLineSpacing Long R/W Open,

SlpLineWidth Long R Open,

SlpLetterQuality Boolean R/W Open,

SlpEmpty Boolean R Open,

SlpNearEnd Boolean R Open,

SlpSidewaysMaxLines Long R Open,

SlpSidewaysMaxChars Long R Open,

SlpMaxLines Long R Open,

SlpLinesNearEndToEnd Long R Open,

SlpBarCodeRotationList String R Open ""

SlpPrintSide Long R Open,

May Use

After

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

Claim &

Enable

0

Unwritable

“0,R90,L90,180”

Initial Value, Condition

0

Unwritable

0

Unwritable

0

Unwritable

0

FALSE

Unwritable

FALSE

FALSE

0

0

0

0

0

53

Specific Type Access

SlpCartridgeState Long R Open,

SlpCurrentCartridge Long R/W Open,

SlpBitmapRotationList String R Open ""

May Use

After

Claim &

Enable

Claim &

Enable

* In the Access column, R indicates Read-Only, R/W indicates Read/Write. The item in May

Use After is the method and property required for initialization, Open indicates the Open

method, Claim indicates the ClaimDevice method and Enable indicates setting the

DeviceEnabled property to TRUE. If required procedure is not executed, the error may be

set in the ResultCode property. When May Use After is Open & Claim or Open, Claim &

Enable, the property is available for acquisition after the Open method is executed, but the

value may not be initialized until all Open, Claim & Enable are executed. To acquire such

property, access it after the conditions are met.

Initial Value, Condition

0

0

Unwritable

54

List of Methods

Common Initialization

Open --

Close Open

ClaimDevice Open

ReleaseDevice Open, Claim

ClearOutput Open, Claim & Enable *1

CheckHealth Open, Claim & Enable

CompareFirmwareVersion Open, Claim & Enable

DirectIO Open, Claim & Enable *1

ResetStatistics Open, Claim & Enable

RetrieveStatistics Open, Claim & Enable

UpdateFirmware Open, Claim & Enable

UpdateStatistics Open, Claim & Enable

Specific Initialization

PrintNormal Open, Claim & Enable

PrintTwoNormal Open, Claim & Enable

PrintImmediate Open, Claim & Enable

BeginInsertion Open, Claim & Enable

EndInsertion Open, Claim & Enable

BeginRemoval Open, Claim & Enable

EndRemoval Open, Claim & Enable

CutPaper Open, Claim & Enable

RotatePrint Open, Claim & Enable

PrintBarcode Open, Claim & Enable

PrintBitmap Open, Claim & Enable

TransactionPrint Open, Claim & Enable

ValidateData Open, Claim & Enable

SetBitmap Open, Claim & Enable

SetLogo Open, Claim & Enable

ChangePrintSide Open, Claim & Enable

MarkFeed Open, Clai m & Enable

ClearPrintArea Open, Claim & Enable

PageModePrint Open, Claim & Enable

PrintMemoryBitmap Open, Claim & Enable

55

List of E

vents

Event Initialization

DirectIOEvent Open, Claim & Enable

ErrorEvent Open, Claim & Enable *1

OutputCompleteEvent Open, Claim & Enable

StatusUpdateEvent Open, Claim & Enable

*1: Items required for initialization are different from "OLE for Retail POS Application

Programmer's Guide Instructions The 1.13 Version".

56

4.2. Printing Data and Escape Sequence

This OCX supports the following Escape Sequence.

1) Escape Sequence which operates only when assigned time

Name Data Contents

Paper Cut ESC |#P It cuts the receipt paper. The character '#' is the

character string of ASCII decimal number which

shows the percentage of required cutting. It is

possible to omit '#'. When the value is between '1' to

'99', partial cutting is performed. When the value is

'100' or omitted, full cutting is performed. When the

value is other than any value between '1' to '100', it is

ignored

In addition to that, if there are data buffered to POS

Printer, (in the case that POS Printer does not print

even though printing request is done) it cannot do

cutting. To execute cutting, it must be at the head of

the line.

It is also unavailable in 90 degrees rotating to the left

or to the right by RotatePrint Method, and back in

operation after clearing 90 degrees rotating to the left

or to the right.

When PTR_MF_TO_CUTTER(2) is included in the

CapRecMarkFeed property, the cutting is executed

after the paper is fed to the cutter position, and the

paper is fed to the next mark position.

Feed and Paper Cut ESC |#fP It cuts the receipt paper after feeding the paper for

the lines of RecLinesToPaperCut. Character '#' is

defined by "Paper Cut" Escape Sequence. In addition

to that, if there are data buffered to POS Printer, (in

case that POS Printer does not print even though

printing request is done) it cannot do cutting. To

execute cutting, it must be at the head of the line.

It is also unavailable in 90 degrees rotating to the left

or to the right by RotatePrint Method, and back in

operation after clearing 90 degrees rotating to the left

or to the right.

When PTR_MF_TO_CUTTER(2) is included in the

CapRecMarkFeed property, the paper is fed for the

lines of RecLinesToPaperCut, and the cutting is

executed after the paper is fed to the cutter position,

and the paper is fed to the next mark position.

Feed, Paper Cut,

and Stamp

ESC |#sP It is not supported.

57

Name Data Contents

Print bitmap ESC |#B It prints the bitmap saved by SetBitmap Method. '#'