Page 1

LD630T/LD640T

User’s Guide

Page 2

P

REFACE

Every effort has been made to ensure that the information in this document is complete, accurate, and

up-to-date. The manufacturer assumes no responsibility for the results of errors beyond its control. The

manufacturer also cannot guarantee that changes in software and equipment made by other

manufacturers and referred to in this manual will not affect the applicability of the information in it.

Mention of software products manufactured by other companies does not necessarily constitute

endorsement by the manufacturer.

While all reasonable efforts have been made to make this document as accurate and helpful as possible,

we make no warranty of any kind, expressed or implied, as to the accuracy or completeness of the

information contained herein.

All rights are reserved by Oki Data Corporation. Unauthorized copying, transferring, translating, or

related actions are prohibited. You must obtain written permission from Oki Data Corporation before

doing any of the above.

© 2012 Oki Data Corporation

OKI is a registered trademark of Oki Electric Industry Co., Ltd.

Energy Star is a trademark of the United States Environmental Protection Agency.

Microsoft, Windows, Windows Server and Windows Vista are registered trademarks of Microsoft

Corporation.

Apple, Macintosh, Rosetta, Mac and Mac OS are registered trademarks of Apple Inc.

Other product names and brand names are registered trademarks or trademarks of their proprietors.

As an Energy Star Program Participant, the manufacturer has determined that this product

meets the Energy Star guidelines for energy efficiency.

This product complies with the requirements of the Council Directives 2004/108/EC (EMC) and

2006/95/EC (LVD) and 1999/5/ EC (R&TTE), as amended where applicable on the

approximation of the laws of the member states relating to electromagnetic compatibility, low

voltage and radio & telecommunications terminal equipment.

The following cables were used to evaluate this product to achieve EMC directive

2004/108/EC compliance and configurations other than this may affect that compliance.

CABLE TYPE LENGTH

CABLE TYPE CORE

(METRE)

Power

USB

Serial

Parallel

LAN

1.8

1.8

1.8

1.8

3.0

CORE SHIELD

-2-

Page 3

M

ANUFACTURER

Oki Data Corporation,

4-11-22 Shibaura, Minato-ku,

Tokyo 108-8551,

Japan

For all sales, support and general enquiries contact your local distributor.

I

MPORTER TO THE

OKI Europe Limited (trading as OKI Printing Solutions)

Blays House

Wick Road

Egham

Surrey, TW20 0HJ

United Kingdom

For all sales, support and general enquiries contact your local distributor.

E

NVIRONMENTAL INFORMATION

EU/A

UTHORISED REPRESENTATIVE

-3-

Page 4

- 4 -

LD630T/LD640T

■ Table of Contents

※ Manual Information & Usage Precautions .................................................................. 5

1. Content Confirmation .................................................................................................... 9

2. Product Part Names..................................................................................................... 10

3. Installation & Usage ..................................................................................................... 12

3-1 Power Connection .................................................................................................... 12

3-2 Interface Cable Connection ...................................................................................... 13

3-3 Paper Installation ...................................................................................................... 15

3-4 Ribbon Installation .................................................................................................... 16

3-5 Buttons and LED ....................................................................................................... 20

3-6 Test printing .............................................................................................................. 22

4. Self-Test ........................................................................................................................ 23

5. Detailed features .......................................................................................................... 24

5-1 Printer setting using utility program ........................................................................... 24

5-2 Stand-alone Configuration Mode .............................................................................. 25

5-3 Pause/Cancel ........................................................................................................... 26

5-4 Media Calibration ...................................................................................................... 27

5-5 Smart Media Detection ............................................................................................. 28

5-6 Gap Sensor Auto Calibration Mode .......................................................................... 28

5-7 Black Mark Sensor Auto Calibration Mode ............................................................... 29

5-8 Manual Calibration Mode .......................................................................................... 30

5-9 Cover Closing Mode ................................................................................................. 31

5-10 Data Dump Mode .................................................................................................... 31

5-11 Factory Reset .......................................................................................................... 32

5-12 The Peel-Off (Option).............................................................................................. 32

5-13 Using Fan-Fold Paper ............................................................................................. 34

5-14 Auto Cutter (Option) ................................................................................................ 35

5-15 Real-Time Clock (Option) ....................................................................................... 36

6. Cleaning Head .............................................................................................................. 37

6-1 Cleaning Head .......................................................................................................... 37

6-2 Cleaning Sensors, Roller or/and Paper Path ............................................................ 38

7. Appendix ....................................................................................................................... 39

7-1 Specifications ............................................................................................................ 39

7-2 Label Types .............................................................................................................. 39

Rev. 1.0

Page 5

- 5 -

LD630T/LD640T

1. Windows Driver Manual

This manual provides information on the installation instructions and main functions

of the Windows Driver.

2. Unified Label Utility-II Manual

This manual provides information on the usage of software for function selection of

this product, operating condition modification, etc.

3. Programming (SLCS) Manual

This manual provides information on label printer commands.

4. True Font Downloader Manual

This manual provides information on the usage of the font downloader that can

download True Fonts and facilitate their usage as Device Fonts.

5. Network Interface Manual

This manual provides information on the configuration and usage of Ethernet

interface.

6. Net Configuration Tool Manual

This manual provides information on the usage of the net configuration tool that can

configure Ethernet interface configuration on this product.

■ Manual Information

※ Manual Information & Usage Precautions

This user’s guide contains basic information for product usage as well as for emergency

measures that may be required.

※ The following separate manuals provide more detailed content on various technological

issues and areas.

We at Oki Data maintain ongoing efforts to enhance and upgrade the functions and quality

of all our products. In following, product specifications and/or user’s guide content may

be changed without prior notice.

Rev. 1.0

Page 6

- 6 -

LD630T/LD640T

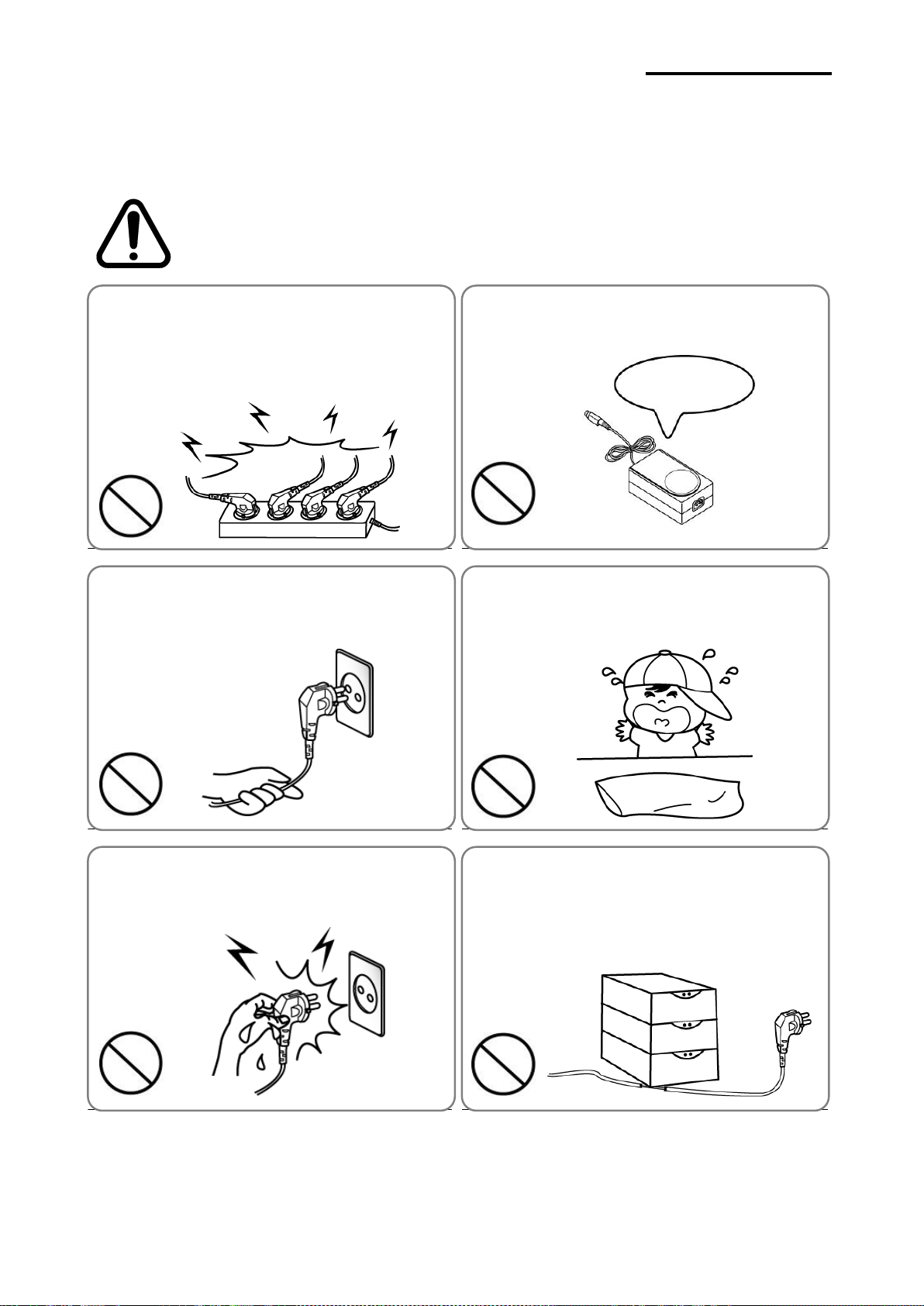

WARNING

Violating following instructions can cause serious injury or death.

Do not bend the cable by force or leave it under any

heavy object.

• A damaged cable can cause a fire.

Do not plug in or unplug with your hands wet.

• You can be electrocuted.

Keep the plastic bag out of children’s reach.

• If not, a child may put the bag on his head.

Do not pull the cable to unplug.

• This can damage the cable, which is the origin of a fire or a

breakdown of the printer.

You must use only the supplied adapter.

• It is dangerous to use other adapters.

Do not plug several products in one multi-outlet.

• This can provoke over-heating and a fire.

• If the plug is wet or dirty, dry or wipe it before usage.

• If the plug does not fit perfectly with the outlet, do not plug in.

• Be sure to use only standardized multi-outlets.

PROHIBIT

PROHIBIT

PROHIBIT

PROHIBIT

PROHIBIT

ONLY SUPPLIED ADAPTER

PROHIBIT

■ Safety Precautions

In using the present appliance, please keep the following safety regulations in order to

prevent any hazard or material damage.

Rev. 1.0

Page 7

- 7 -

LD630T/LD640T

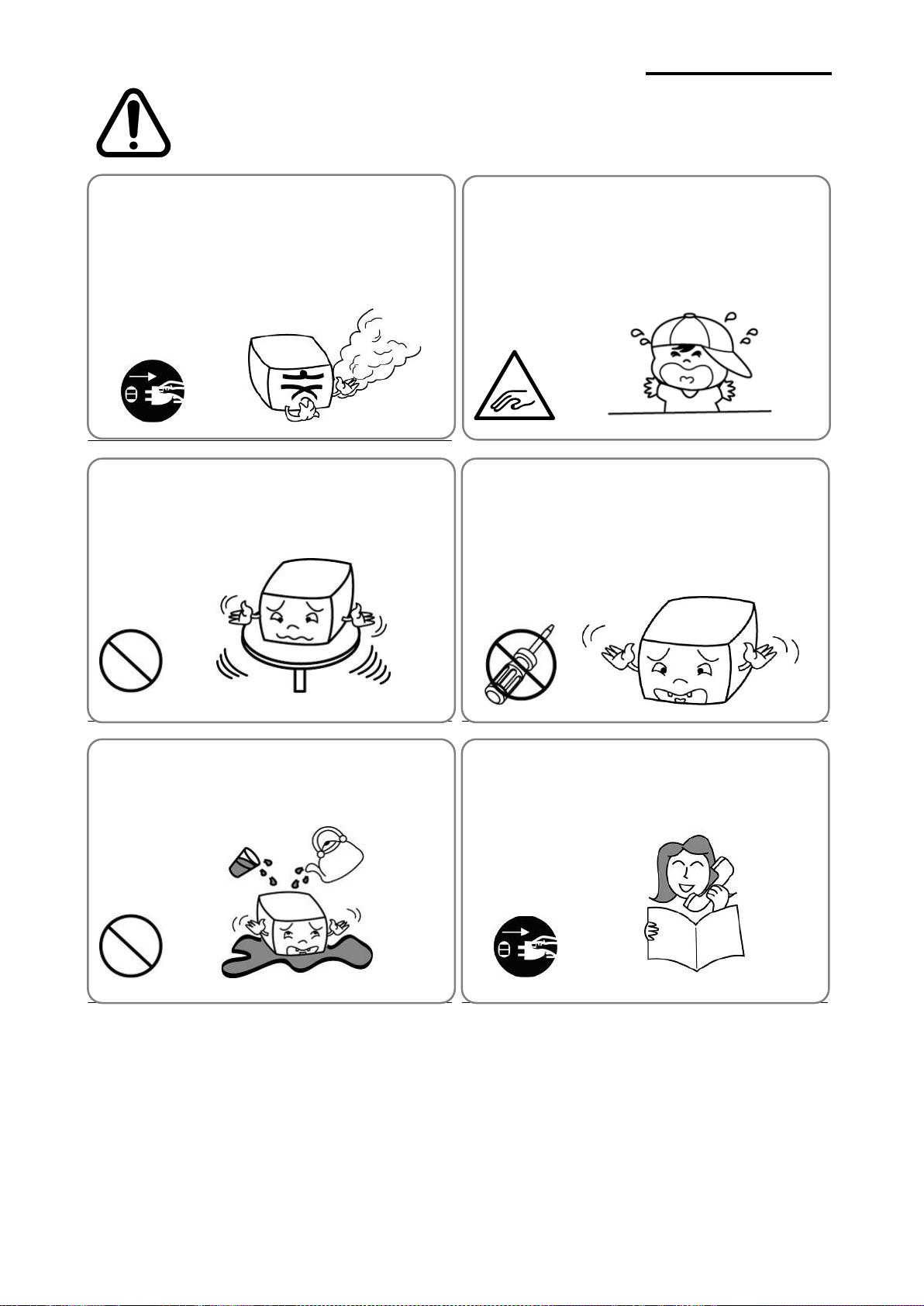

CAUTION

Violating following instructions can cause slight wound or damage the appliance

.

Be careful not to get your fingers pinched when

opening or closing the paper cover. Also be careful

the paper cover does not slip off and drop.

Do not use the printer when it is out of order. This

can cause a fire or an electrocution.

• Switch off and unplug the printer before calling your dealer.

Do not let water or other foreign objects in the

printer.

• If this happened, switch off and unplug the printer before

calling your dealer.

Use only approved accessories and do not try to

disassemble, repair or remodel it for yourself.

• Call your dealer when you need these services.

• Do not touch the blade of auto cutter.

Install the printer on the stable surface.

• If the printer falls down, it can be broken and you can hurt

yourself.

If you observe a strange smoke, odor or noise from

the printer, unplug it before taking following

measures.

• Switch off the printer and unplug the set from the mains.

• After the disappearance of the smoke, call your dealer to

repair it.

TO UNPLUG

DISASSEMBLING

PROHIBITED

PROHIBIT

PROHIBIT

TO UNPLUG

PRINTER

PRINTER

PRINTER

PRINTER

DEALER

PRINTER

MECHANICAL

HAZARD

Rev. 1.0

Page 8

- 8 -

LD630T/LD640T

■ Other Precautions

The copyright for this user’s guide and various other manuals is property of the Oki Data

Corporation. Any copying or conversion into electronic firm and saving of this material

without the express written permission of Oki Data Corporation. is strictly prohibited.

Use of the information contained in this manual is not subject to any patent liability. This

manual has been prepared with utmost care and attention to detail but may contain certain

errors and/or omissions.

Oki Data Corporation. is not legally liable for any damages resulting from the use of the

information in this manual.

Oki Data Corporation. and its affiliates are not legally liable (United States excluded) for

any damages, loss, costs, and/or expenses that result from the breakdown, malfunction,

and/or misuse of the product due to violation or neglect of the operation and maintenance

information and instructions provided by the Oki Data Corporation., as well as from the

unauthorized alteration, repair, and/or modification of the product by the user and/or third

party.

Oki Data Corporation. is not legally liable for any damages and/or issues resulting from the

use of options and/or parts that are not authentic Oki Data products or authorized products.

Rev. 1.0

Page 9

- 9 -

LD630T/LD640T

LD630T/LD640T

Power Cord

AC Adapter

1" Ribbon Core adapter

Ribbon take

up core

CD

User Documents

(Setup Guide, Safety, Warranty)

1. Content Confirmation

The following items should all be contained in the printer package.

Contact the dealer from which the purchase was made if any item is damaged and/or

missing.

Rev. 1.0

Page 10

- 10 -

LD630T/LD640T

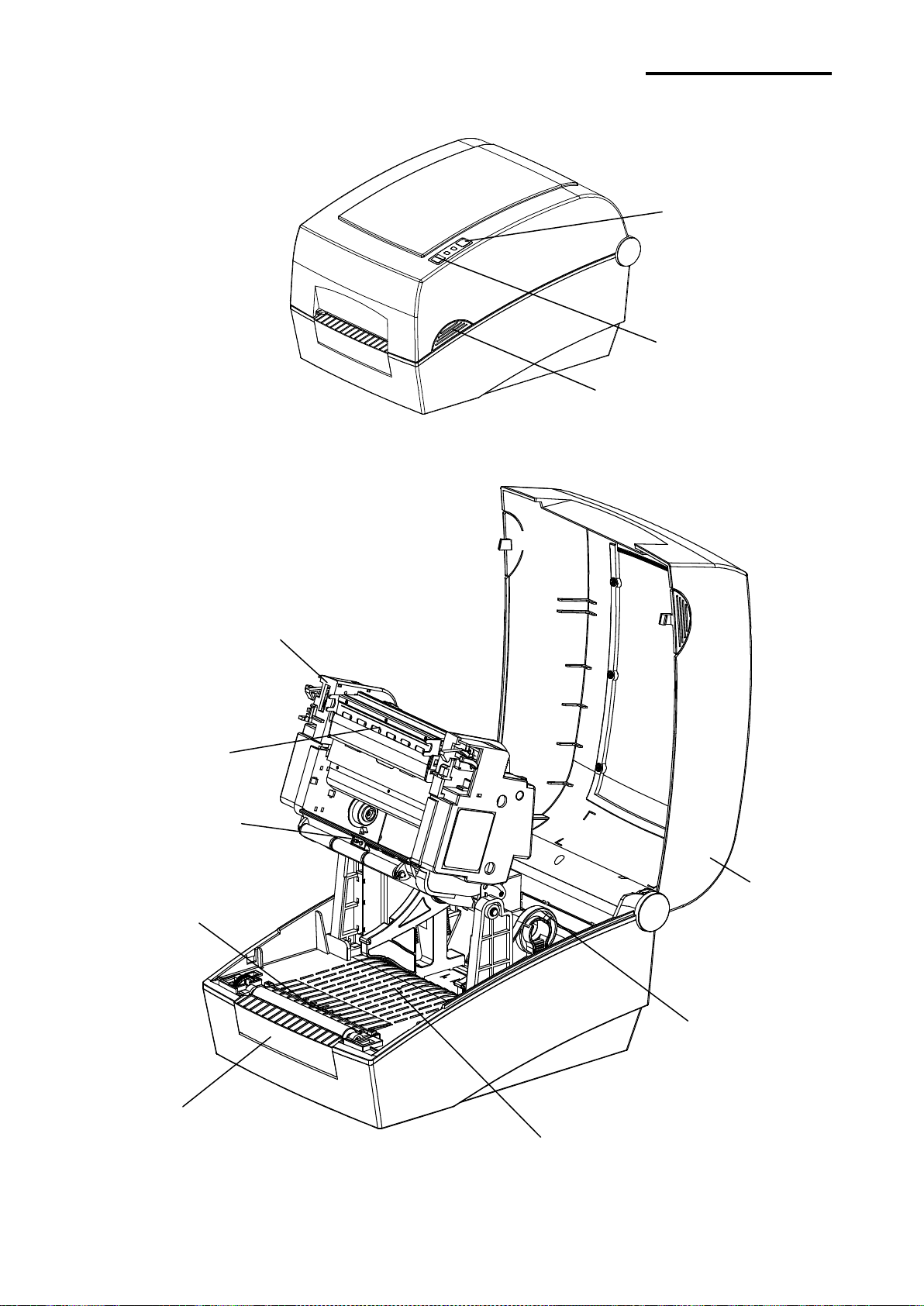

Feed Button

Cover Lever

Printer Head

Paper Holder

Upper Gap Sensor

Cover STD

Black-Mark &

Notch Sensor

Pause Button

Paper Cover

Ribbon Assembly

Lower Gap Sensor

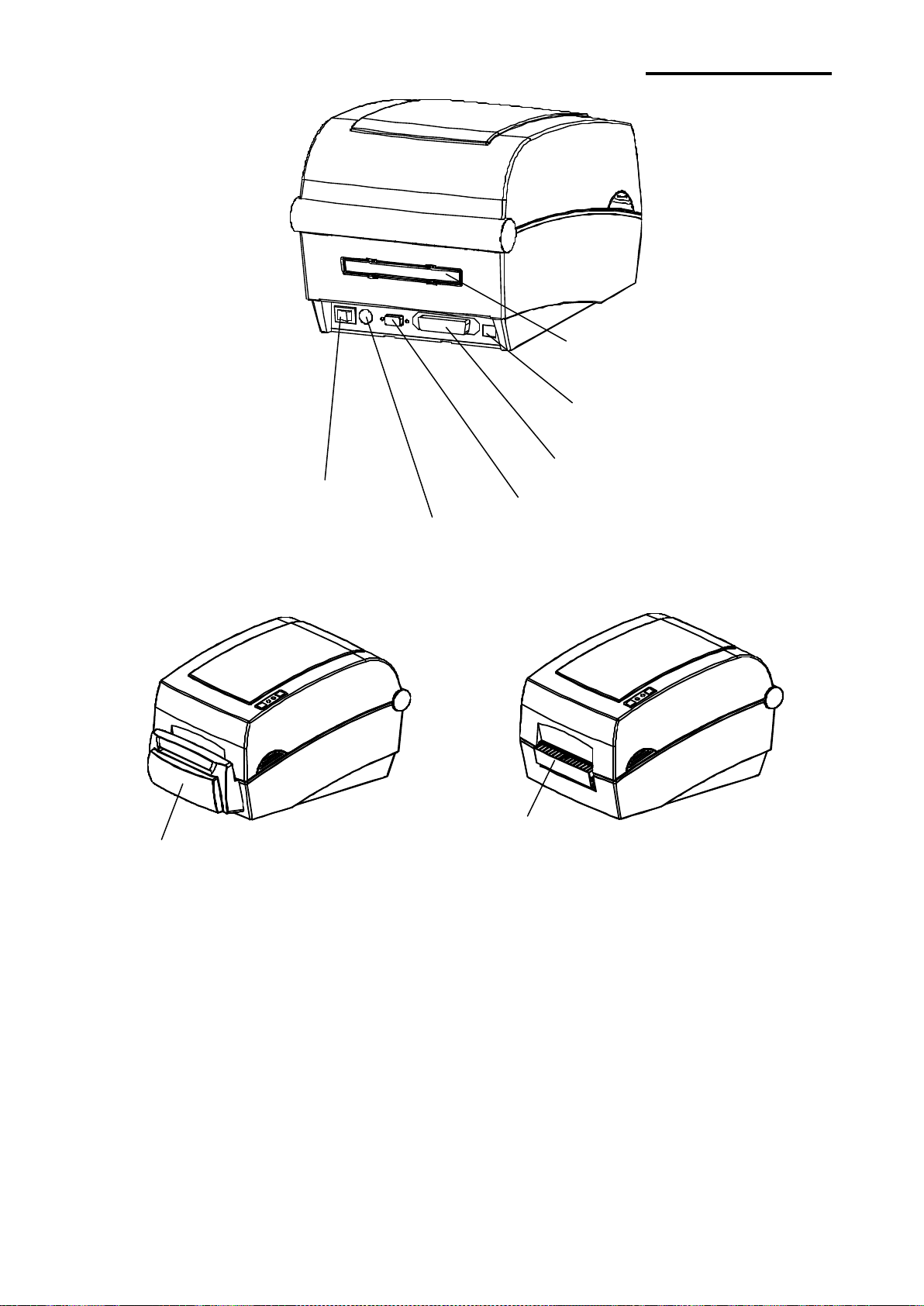

2. Product Part Names

Rev. 1.0

Page 11

- 11 -

LD630T/LD640T

Power Switch

IEEE1284(Parallel)

USB

Fan-Fold or External Paper Cover

Power Jack

RS-232C(Serial)

Auto Cutter

(Option)

Label Peel-off

(Option)

Rev. 1.0

Page 12

- 12 -

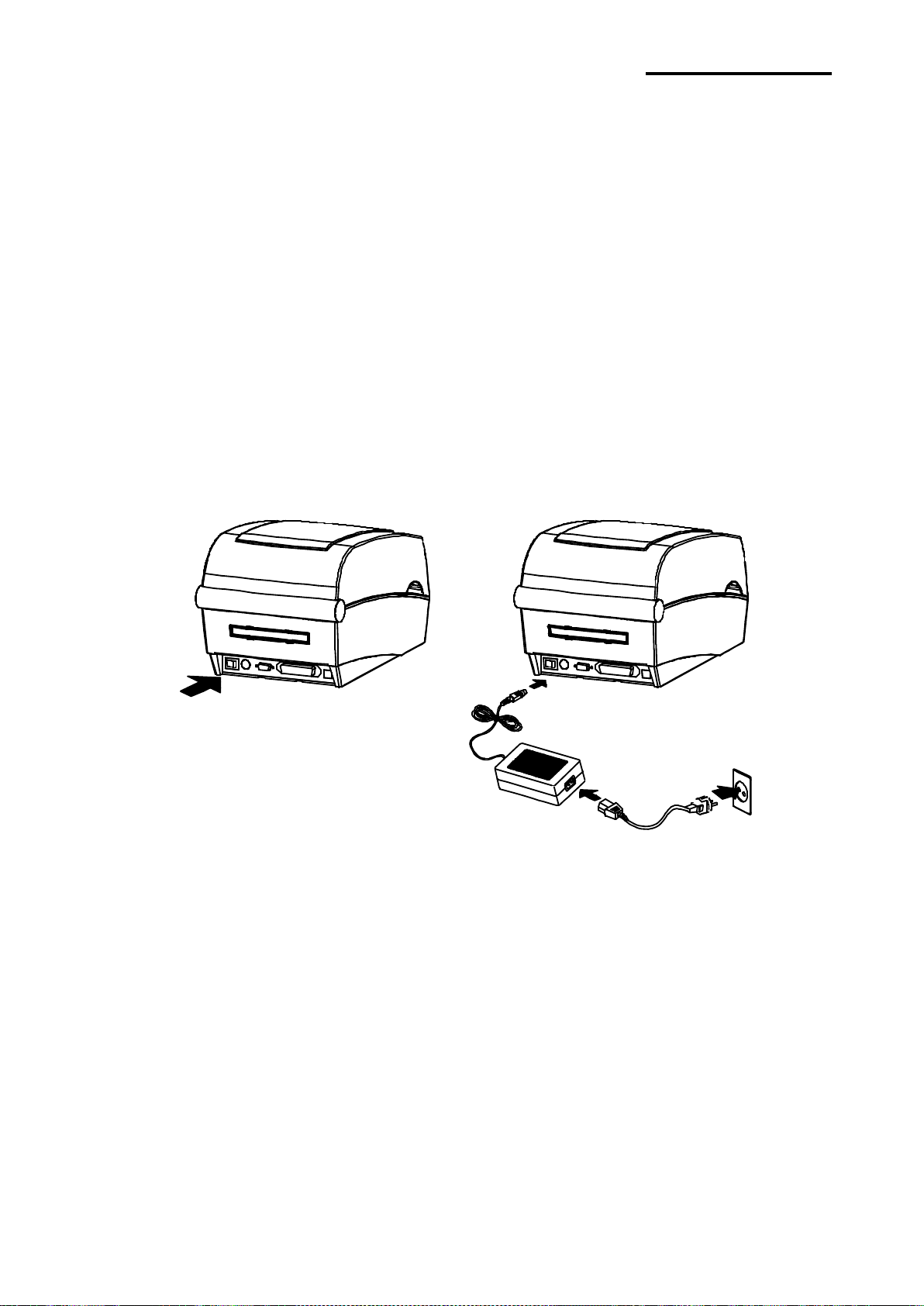

LD630T/LD640T

OFF

Power Switch

Power Cord

AC Adapter

3. Installation & Usage

※ CAUTION

- Be careful not to get your fingers pinched when opening or closing the paper cover.

Make sure to open the paper cover all the way until it locks into the open position.

- When loading roll paper, be careful not to get your fingers pinched between the paper roll

and the paper holder.

- Do not touch the cutter with your hands or do not put something into the cutter. Doing so

could result in an injury.

3-1 Power Connection

Connect power to the printer as shown below.

1) Turn off the printer power switch.

2) Check to see that the AC adapter voltage matches that of the power source.

3) Connect the AC adapter jack to the printer power connector.

4) Connect the power cord to the AC adapter.

5) Connect the power cord to a power source/outlet.

Rev. 1.0

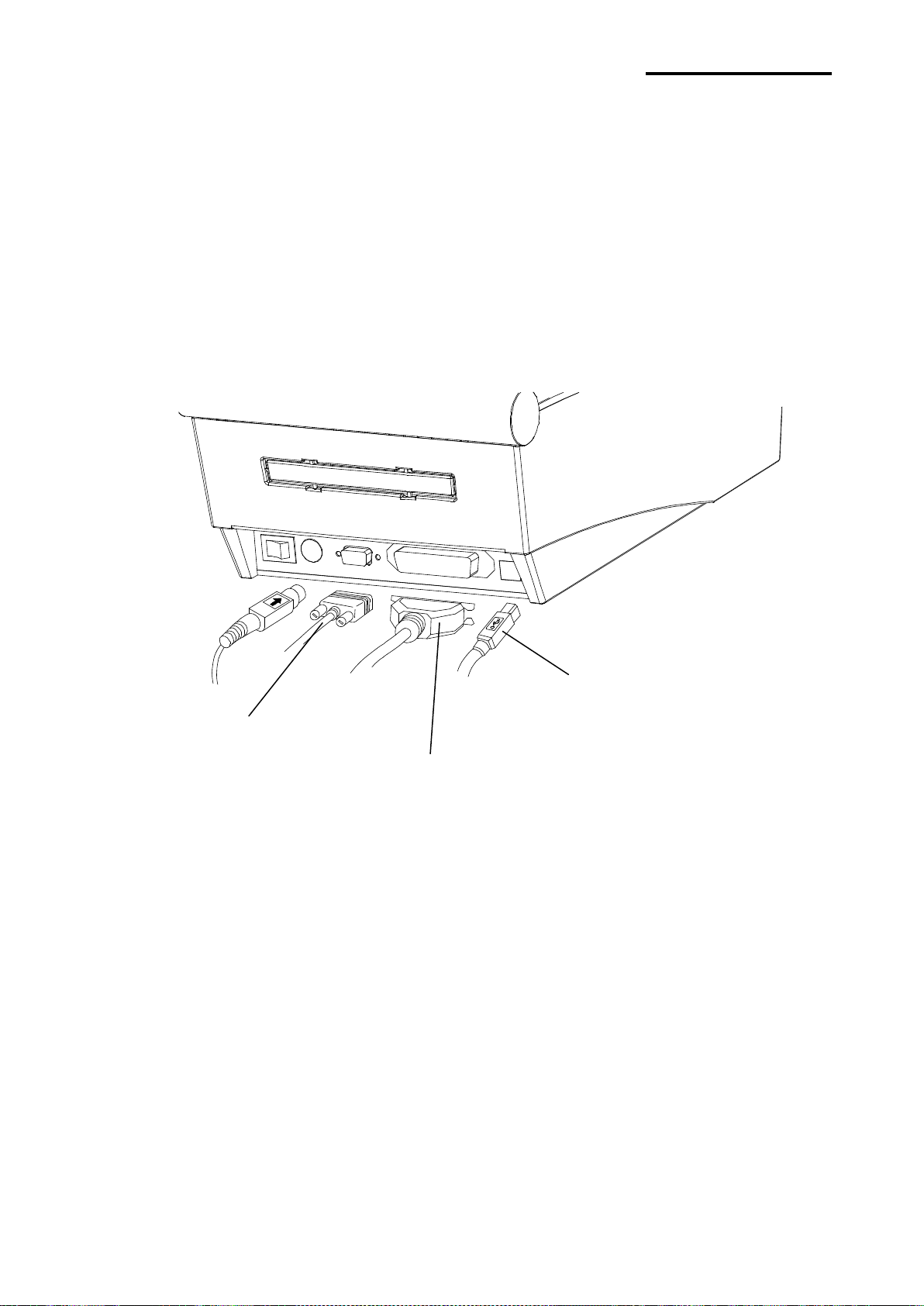

Page 13

- 13 -

LD630T/LD640T

USB Cable

RS-232C(Serial) Cable

IEEE1284(Parallel) Cable

3-2 Interface Cable Connection

3-2-1 Standard Model

Connect the interface cable as shown below.

This printer supports the following communications interface standards.

- RS-232C(Serial) Cable

- IEEE1284(Parallel) Cable

- USB B-Type Cable

1) Turn off the power switch.

2) Connect the communication cable to the printer communication port to be used.

- Connect the RS-232C(Serial) Cable to the SERIAL port.

and tighten the screw on both sides.

This port requires a shielded cable less then 1.8m long.

- Connect the IEEE1284(Parallel) Cable to the PARALLEL port.

and fasten the clips on both sides.

This port requires a shielded cable with ferrite core less then 1.8m long.

- Connect USB B-Type cable to the USB port.

This port requires a shielded cable less then 1.8m long.

Rev. 1.0

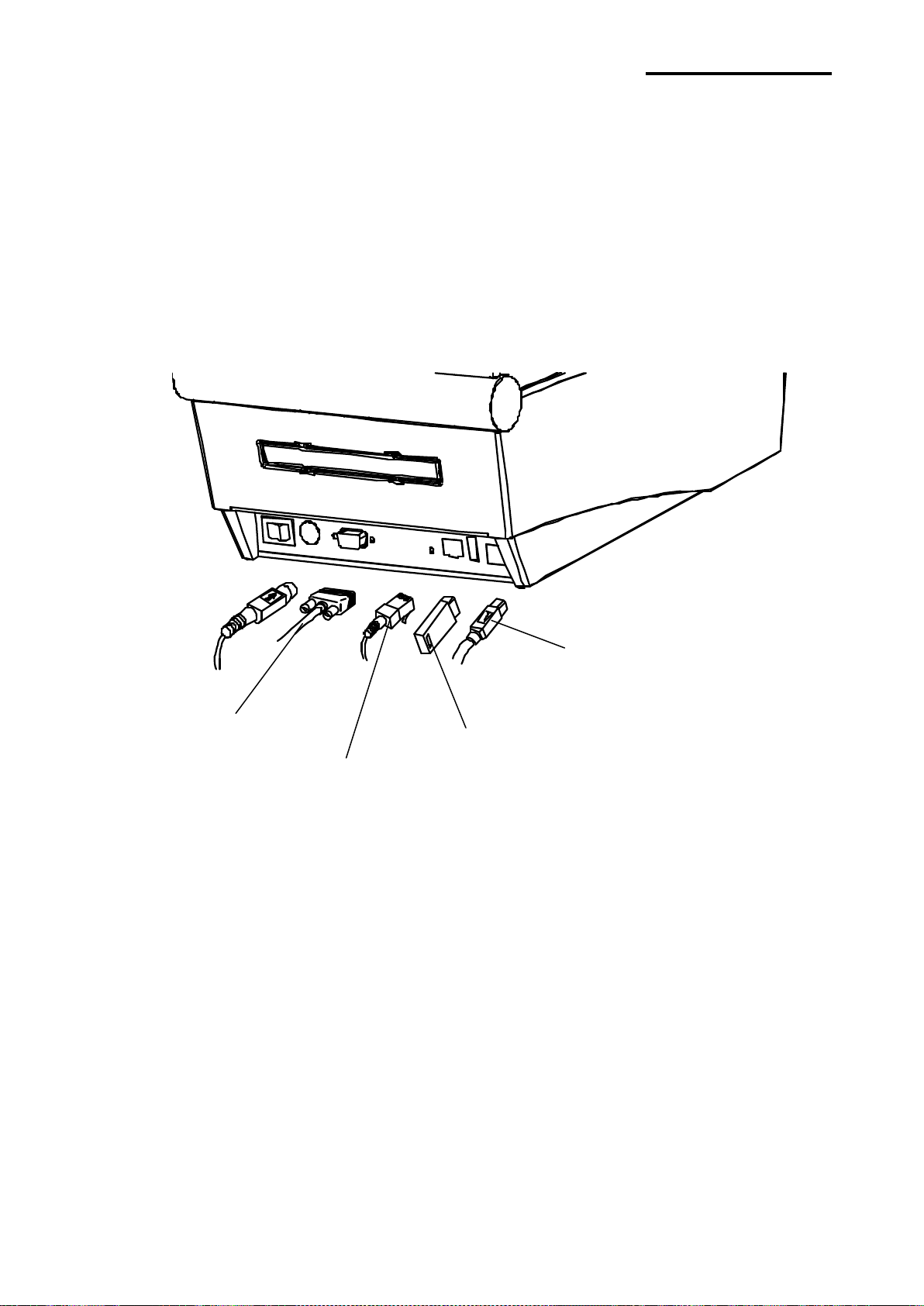

Page 14

- 14 -

LD630T/LD640T

USB B-Type Cable

RS-232C(Serial) Cable

LAN(Ethernet) Cable

USB A-Type

(WLAN Dongle only)

3-2-2 Ethernet Model

Connect the interface cable as shown below.

This printer supports the following communications interface standards.

- RS-232C(Serial) Cable

- LAN(Ethernet) Cable

- USB A-Type(WLAN Dongle only)

- USB B-Type Cable

1) Turn off the power switch.

2) Connect the communication cable to the printer communication port to be used.

- Connect the RS-232C(Serial) Cable to the SERIAL port.

and tighten the screw on both sides.

This port requires a shielded cable less then 1.8m long.

- Connect the LAN(Ethernet) Cable to the ETHERNET port.

This port requires a cable less then 3.0m long.

- Connect USB A-Type(WLAN Dongle only) to the HOST port.

- Connect USB B-Type Cable to the USB port.

This port requires a shielded cable less then 1.8m long.

Rev. 1.0

Page 15

- 15 -

LD630T/LD640T

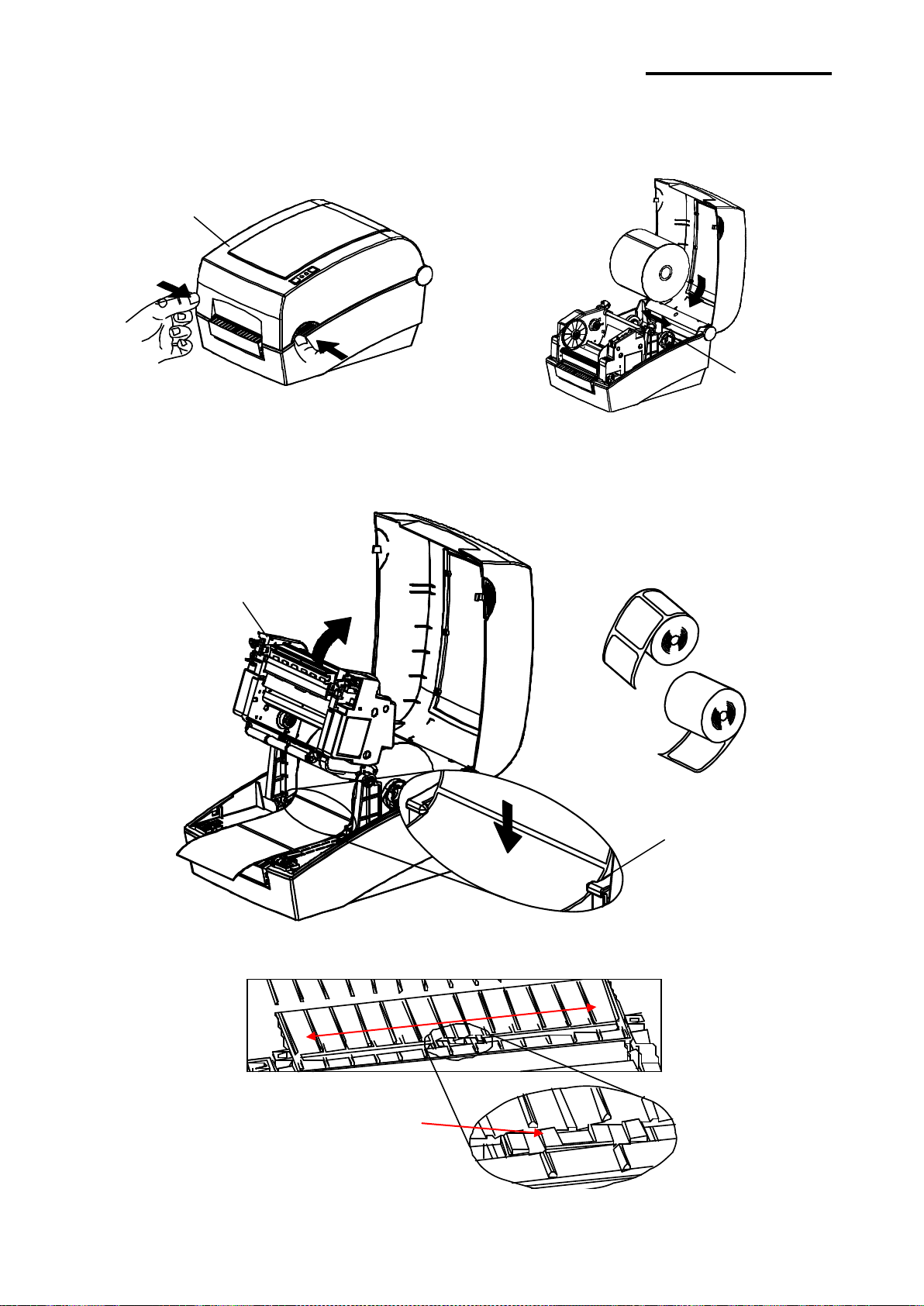

1) Open the Paper Cover.

2) Spread the Paper Holder and insert

paper roll.

3) Open the Ribbon Assembly and then pull the paper so that it extends out of the front

of the printer. Push the paper under both of the Paper Guide.

* Whether the paper label is wound inwards or outwards, its printing surface must

face up.

4) If you use Black-Mark or Notch paper roll, please lift up the paper and match the

sensor position adjust the black mark or notch hole.

5) Close the Ribbon Assembly until a click sound is heard, close the Paper Cover.

Moveable Black-Mark Sensor

and Notch Sensor

●

●

Paper Guide

Ribbon Assembly

Paper Cover

Paper Holder

3-3 Paper Installation

Rev. 1.0

Page 16

- 16 -

LD630T/LD640T

Outside Ribbon

Inside Ribbon

one-inch

half-inch

Coated Area

(Surface

to be printed)

Coated Area

(Surface to be printed)

( O )

( X )

3-4 Ribbon Installation

3-4-1 Type of Ribbon

1) Type by Film Coating Location

- Take note before ribbon purchase that only ribbons facing outward can be used.

※ Note

- Follow the procedure described below to determine the coating surface of the ribbon.

• Ribbon test using adhesive material

- Perform contact test in order to determine which side is coated if there are useable

labels.

• Complete the following steps to carry out the contact test

- Remove the liner from the label

- Put a piece of adhesive surface of the label on the outer/inner surface of the ribbon,

and apply pressure.

- Remove the label from the ribbon

- Check whether adhesive surface of the label is stained by black ink ribbon.

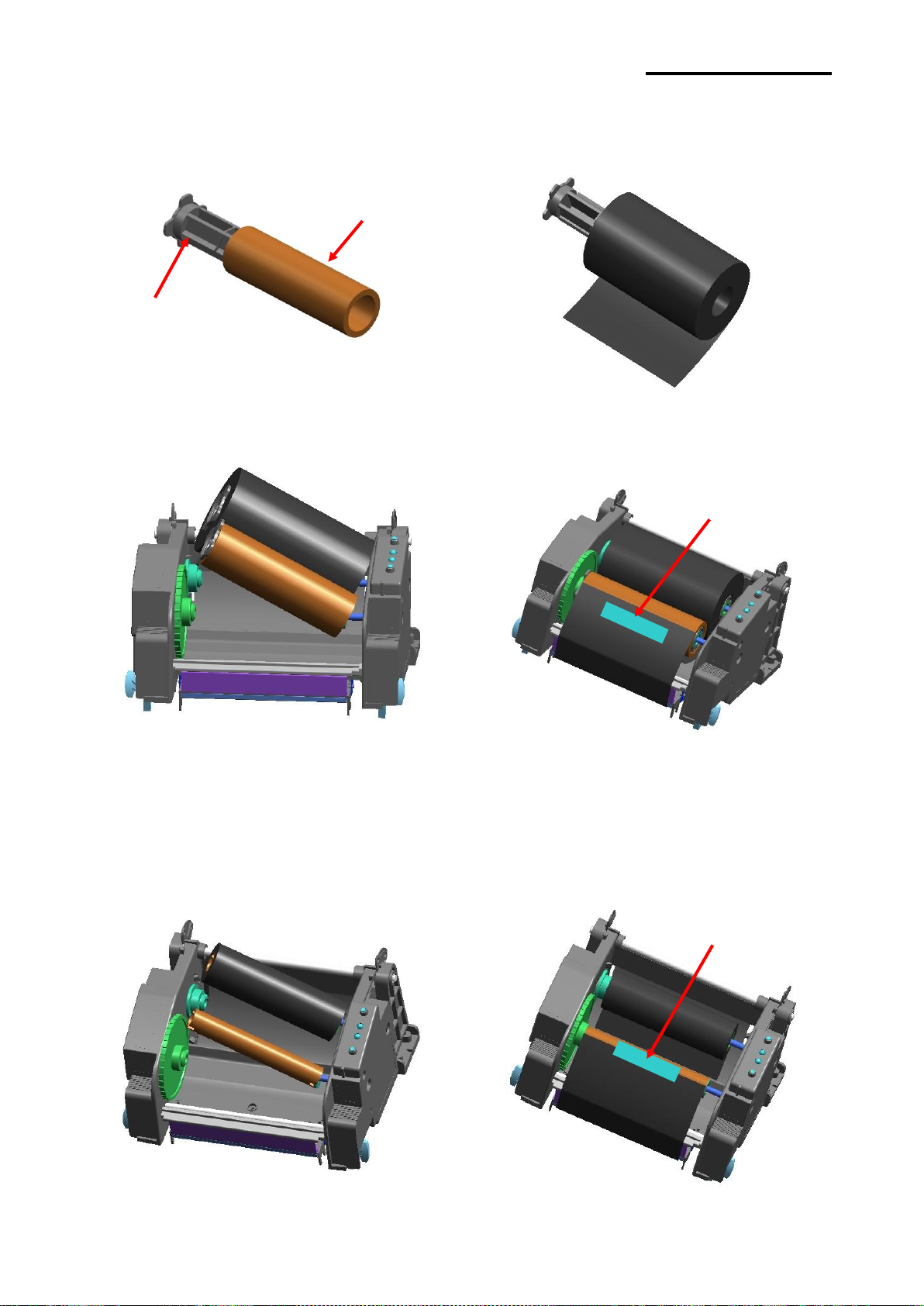

2) Ribbon core size adapter

- This printer can use a one-inch or half-inch core ribbon.

- For a 1 - inch core ribbon a ribbon core adapter must be used with the ribbon and the

used ribbon take up core. (Adapters and used ribbon take up core were shipped with

the printer).

- When replacing a used ribbon remove the core adapters (if they were used) and the

exposed ribbon core from the used ribbon. These items are required for use with the

new ribbon.

Do not discard.

Rev. 1.0

Page 17

- 17 -

LD630T/LD640T

1) Insert the ribbon core adapter into the new ribbon core and the used ribbon take up

core. (keep note of ribbon printing direction)

2) Open the ribbon assembly and insert the

ribbon and core by pushing from left to

right.

3) Apply tape to the leading edge of the

ribbon and fasten it to the used ribbon

take up core.

4) Press on both sides of the ribbon assembly to close it for printing.

1) Open the ribbon assembly and insert the

ribbon and the used ribbon take up core

by pushing from left to right. (keep note of

ribbon printing direction)

2) Apply tape to the leading edge of the

ribbon and fasten it to the used ribbon

take up core.

Tape

Tape

Core (one-inch)

Ribbon Core Adapter

3-4-2 Inserting a One - Inch Ribbon Core Adapter

3-4-3 Inserting a Half-Inch Core Ribbon

3) Press on both sides of the ribbon assembly to close it for printing.

Rev. 1.0

Page 18

- 18 -

LD630T/LD640T

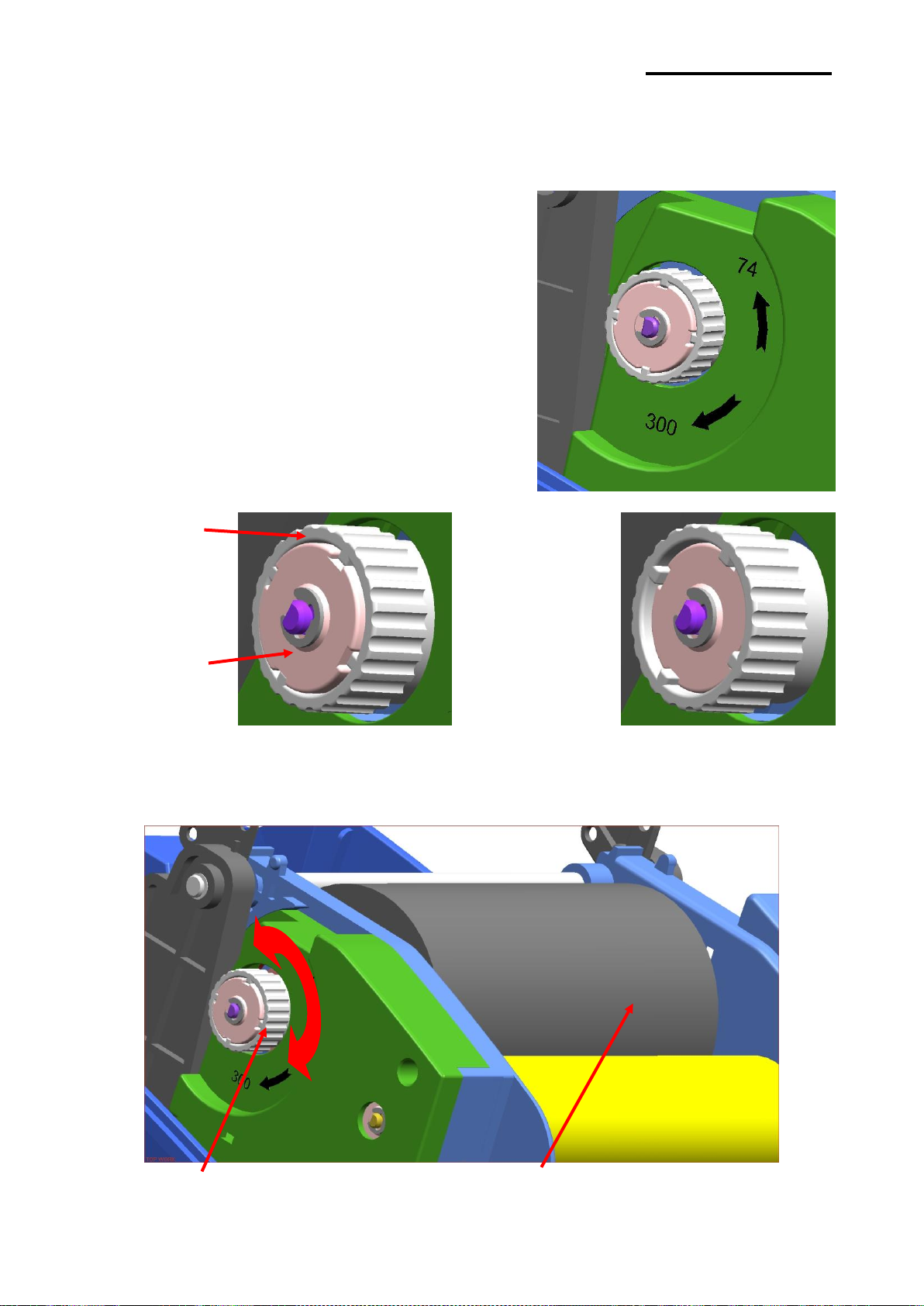

Ribbon lengths of 74m, 100m (0.5” core), and 300m (1” core) can all be used with this

product. Adjust the knob accurately according to the ribbon length (74 ~ 300 m).

Exercise care as print quality and operation can be affected.

The product is shipped with a default

setting for a ribbon length of 300m

(1” core). To use a 74m (0.5” core)

ribbon, adjust (rotate) the knob in the

direction of 74m prior to use.

When the cover is outside the knob

as shown in the image A, the ribbon

length is set to 74m. If the cover is

inside the knob as shown in Image

B, the ribbon length is set to 300m.

Image-A (74m)

Image -B (300m)

■ Knob Adjustment

- Grasp the ribbon while it is fitted and rotate the knob as shown in the image.

Knob

Cover

Knob

Ribbon

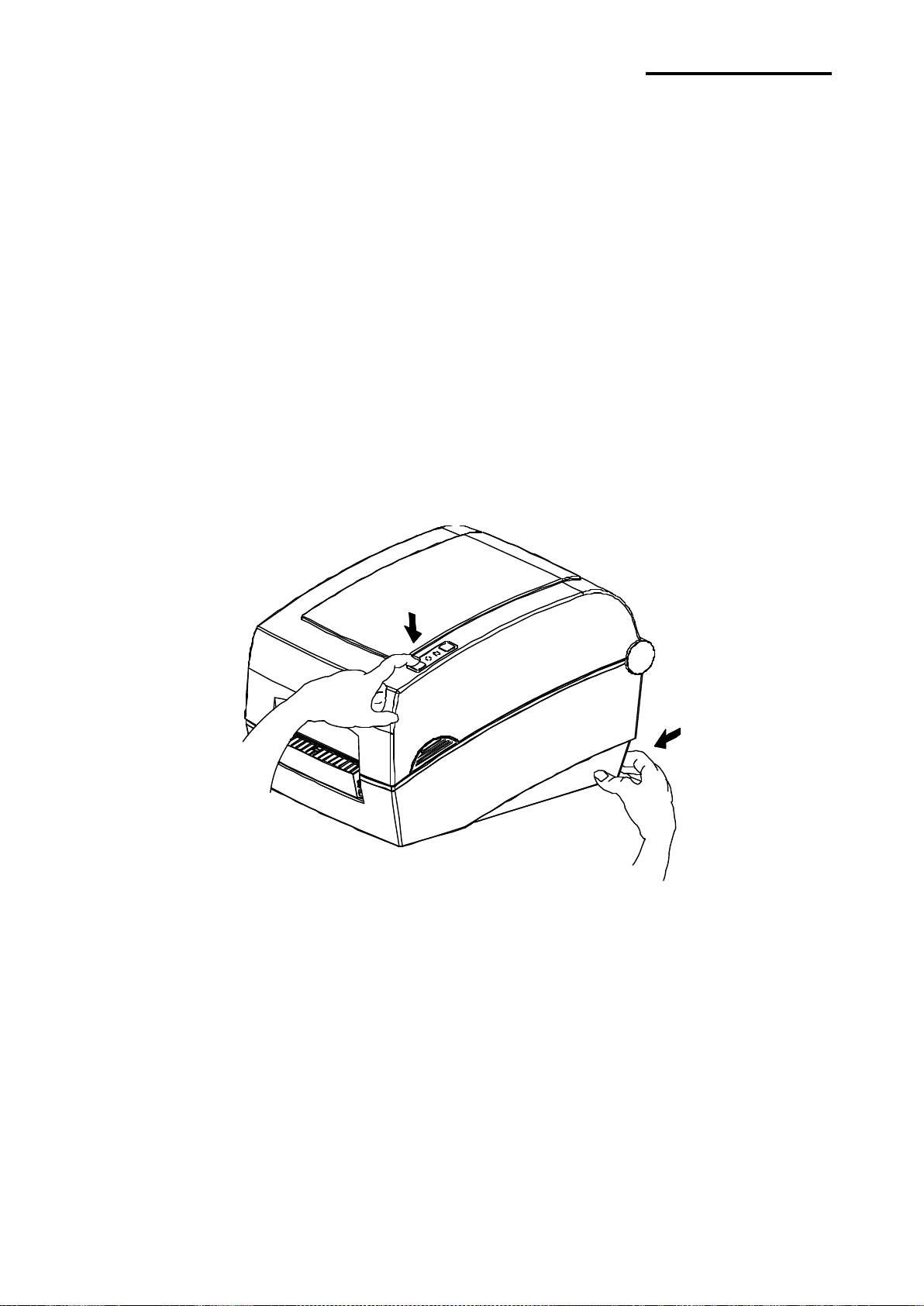

3-4-4 Knob Adjustment by Ribbon Length

Rev. 1.0

Page 19

- 19 -

LD630T/LD640T

When using ribbons of widths of 110mm or

smaller, install in a centered position on the

Ribbon Core Adapter.

1) Use a knife or other sharp-edged object to cut the ribbon.

(Take care not to injure hands)

2) Open the ribbon assembly and remove the ribbon and core by pushing from left to right.

3) Remove the ribbon core adapter from the ribbon and core.

Cutting

3-4-5 Narrow Ribbon Installation

3-4-6 Ribbon Removal

3-4-7 Ribbon Sensor Activation

Ribbon detection sensor is disabled by default factory settings. Check the settings related

to ribbon detection sensor if printing does not stop when the printer is out of ribbon or

ribbon is broken.

* Ribbon detection sensor can be enabled by command control. And default setting can

be changed by Unified Label Utility-II.

※ CAUTION

1. When replacing a ribbon, keep the now exposed core of the old ribbon as it will be

required for use as the used ribbon take up core for the new ribbon.

2. As the ribbon core adapter is required for continuous use, make sure not to misplace it.

Rev. 1.0

Page 20

- 20 -

LD630T/LD640T

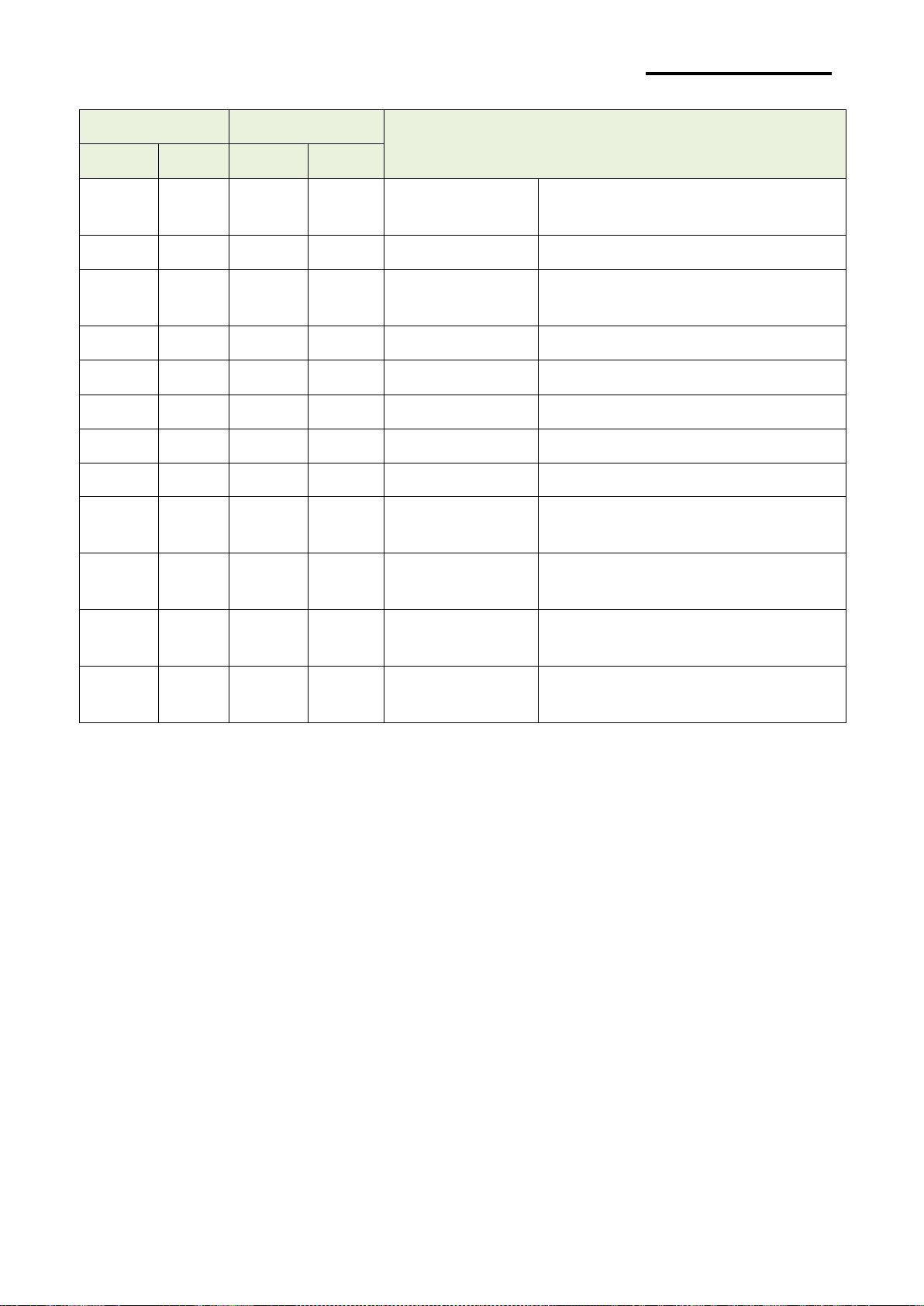

Printer state

before

operation

Button

Operation procedure

Printer operation mode

Feed/

Cancel

Pause

Power OFF

Depress

-

• Apply power while

depressing the button.

• Hold the button for about

five seconds.

Self-test Printing Mode.

Print

Standby

Depress

-

• Depress the button softly

and release it immediately

Feed Mode

Print

Standby

-

Depress

• Depress the button for two

seconds and continue to

hold

Stand-alone

configuration Mode

During

printing

Depress

-

• Depress the button softly

and release it immediately

Print Cancel Mode

During

printing

-

Depress

• Depress the button softly

and release it immediately

Print Pause Mode

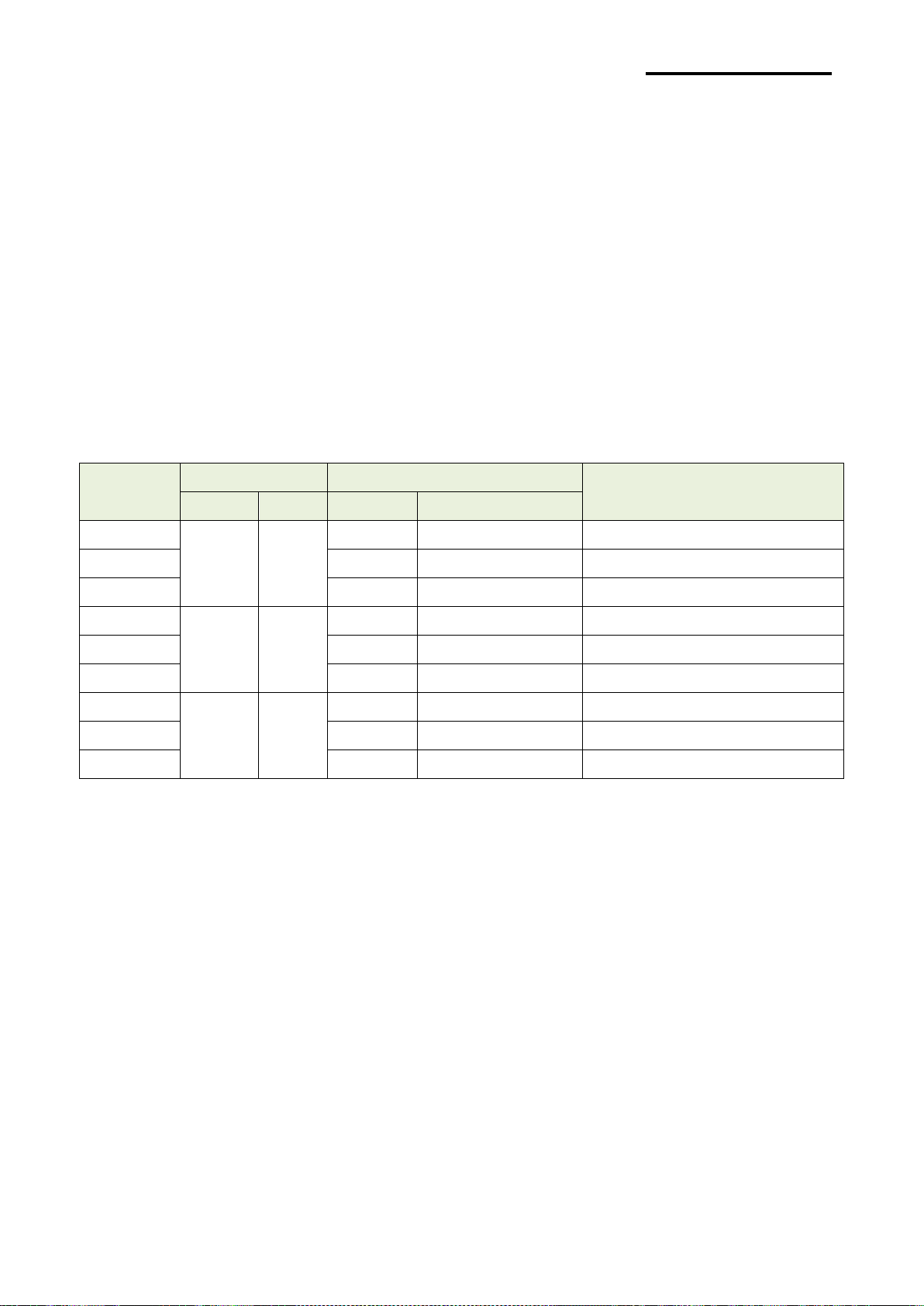

3-5 Buttons and LED

3-5-1 Button Operations

Rev. 1.0

Page 21

- 21 -

LD630T/LD640T

Status LED

Error LED

Printer Status

Color

Status

Color

Status

Green

On

Green

On

Print standby

mode

Print standby mode

Red

On

Red

On

Error mode

Ribbon is not detected

Red

On

Orange

On

Error mode

Paper jam (gap/black mark is

not recognized)

Red

On

Green

Blink

Error mode

Printer head overheating

Red

On

Red

Blink

Error mode

Cover open

Red

On

Orange

Blink

Error mode

No paper

Red

On - Off

Error mode

Media calibration failure

Red

Blink

Red

Blink

Error mode

Auto-Cutter error

Orange

On

Orange

On

Mode switching

notification

Mode switching notification

Green

Blink

Red

On

Wait for input

Print is paused temporarily.

Wait for button input

Green

Blink

Green

Blink

Wait for input

Cover Close Mode. Wait for

button input

Green

On

Red

Blink

Wait for input

Print Cancel Mode. Wait for

button input

3-5-2 LED indicator for various printer statuses

Rev. 1.0

Page 22

- 22 -

LD630T/LD640T

3-6 Test printing

3-6-1 Printing using Windows driver

1) Install the Windows driver.

Refer to the “Windows driver manual” in the CD for the installation procedure.

2) Set the “port” of Windows driver to the appropriate interface to be used. Refer to the

“Ethernet interface user’s manual” in the CD when using Ethernet interface.

3) Print the test page using the “Print test page” function of Windows driver.

3-6-2 Printing using label design program

- The label design program is included in the CD.

1) Install the label design program.

2) Refer to the “Label Design Program Manual” included in the CD and set the interface.

3) Print the test page after designing a label.

Rev. 1.0

Page 23

- 23 -

LD630T/LD640T

4. Self-Test

The self-test checks whether the printer has any problems.

(Users cannot perform this procedure if using the printer’s label peel-off option.)

If the printer does not function properly, contact an authorized dealer.

The self-test checks the following;

1) Make sure that the paper roll has been installed properly.

2) Turn on the power while holding down the FEED button. The self-test begins.

(It takes about 5 seconds before starting self-test)

3) The self-test prints the current printer configuration information.

4) After the self-test results are printed out, a printer enters into Print Standby Mode.

Rev. 1.0

Page 24

- 24 -

LD630T/LD640T

5. Detailed features

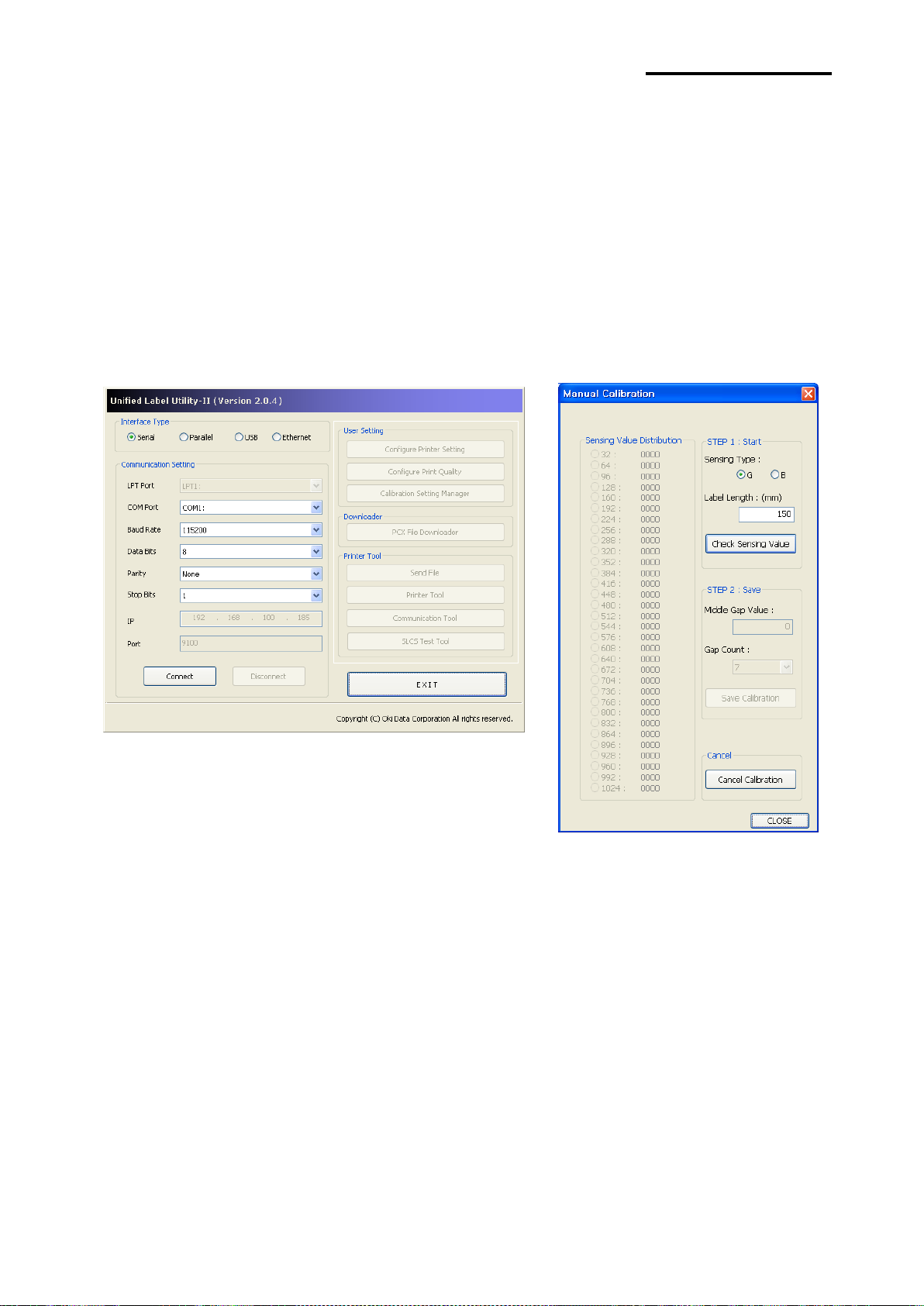

5-1 Printer setting using utility program

Various printer settings can be changed using the utility program (Unified Label Utility-II).

Functions that can be used with the utility program are as follows.

1) Serial communication settings

Handshake, Stop bit, Data bit, Parity, and Baud rate can be configured.

2) Basic printer settings

Paper size, printing speed and density, paper type, and use of ribbon can be

configured.

3) Language setting

Code page can be configured.

4) Media sensor manual calibration function

This function can be used to detect special type or special material paper that is not

detected through automatic calibration function. Refer to Manual Calibration mode

page for more details

5) Other functions for printer test are also provided.

Refer to the United Label Utility-II Manual contained in the CD for more detailed

information.

Rev. 1.0

Page 25

- 25 -

LD630T/LD640T

Sequence

number

Status LED

Error LED

Printer operation

Color

Status

Color

Status

1

Green

On

Green

Blink four times

Print Configuration Info.

2

Orange

Blink four times

Print File List

3

Red

Blink four times

Factory Reset

4

Orange

On

Green

Blink four times

Gap Sensor Auto Calibration

5

Orange

Blink four times

B/M Sensor Auto Calibration

6

Red

Blink four times

Data Dump Mode

7

Red

On

Green

Blink four times

Demo Mode

8

Orange

Blink four times

- 9 Red

Blink four times

Object Delete

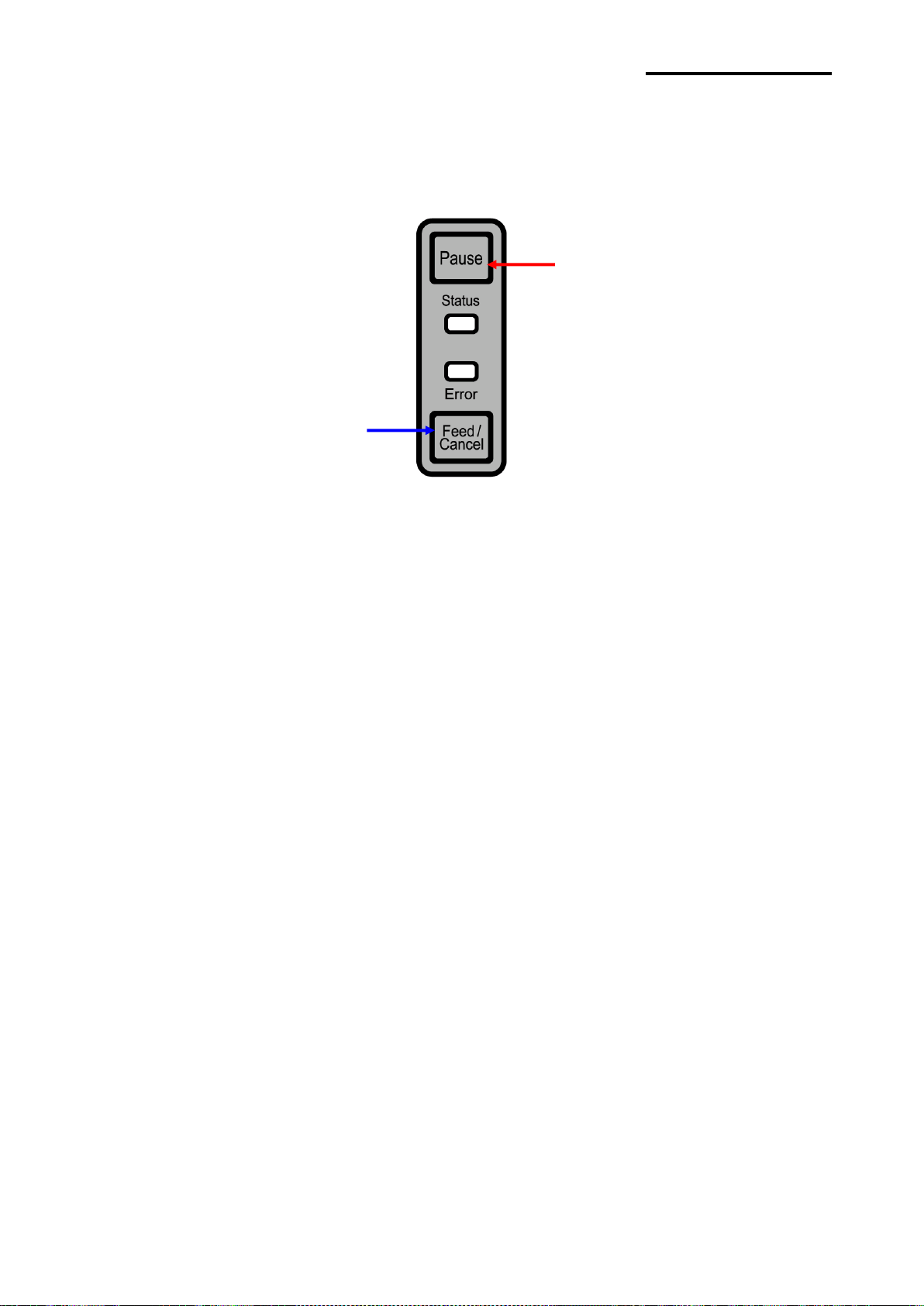

5-2 Stand-alone Configuration Mode

Various modes can be executed using buttons and LED only.

5-2-1 How to start stand-alone configuration mode

• The printer mode is set to Printer Setting Mode when the Pause button is depressed

for two seconds while in Print Standby Mode.

• Both LEDs will change to orange color and the printer will be set to Stand-alone

Configuration Mode.

• When the printer enters into this mode, the status of Status LED and Error LED

are changed sequentially.

• When the Feed button is depressed at specific LED color combination, the

corresponding printer operation will be selected.

5-2-2 List of supported functions

Rev. 1.0

Page 26

- 26 -

LD630T/LD640T

Print Pause/Resume

Print Cancel/Standby

5-3 Pause/Cancel

During multiple-page print jobs, the Pause and Cancel button can be used to temporarily

cease printing and cancel the print job altogether, respectively.

5-3-1 Pause/Resume Function

1) When printing labels, pressing the Pause button

2) The printer will pause after finishing the current label printing and the status of LED will

be as follows.

- Status LED: Green Blink

- Error LED: Red On

3) While the print job is paused, press the Pause button again to resume printing.

5-3-2 Print Cancellation

1) During label printing and/or pause mode, pressing the Cancel button enters the print

cancellation mode.

2) The following processes occur in the print cancellation mode.

- All label printing cancelled

- All data received in the printer communications buffer deleted.

- All received data deleted.

3) The LED Status in the print cancellation mode can be as follows.

- Status LED: Green On

- Error LED: Red Blink

4) While in the print cancellation mode, press the Cancel button again to return to print

standby mode.

Rev. 1.0

Page 27

- 27 -

LD630T/LD640T

5-4 Media Calibration

This printer has been designed to recognize the gaps with most print papers, but

sometimes it may not recognize the gap and keep feeding paper if a special type of paper

is used. In this case, run Auto Calibration function so that the printer can recognize the gap.

Oki Data printer provides various media calibration methods in order to accommodate

various special paper types.

5-4-1 About media calibration

• This function is for adjusting the sensitivity of the paper detection sensor for accurate

printing position control and measuring actual length of paper.

• Sensor sensitivity adjustment

- The purpose is to detect the identifier (gap/black mark/groove) of installed label

• Paper length measurement

- Accurate length is required to rotate the printing orientation.

- The purpose is to detect the change of paper type.

5-4-2 When is media calibration required?

• When the printer is installed first time

• When the newly installed paper is a different paper type

• When printer position is not accurate or printer does not stop in the right position

5-4-3 How to perform media calibration

• The following four methods of media calibration can be used depending on the

conditions.

- Smart Media Detection

- Gap Sensor Auto Calibration Mode

- Black Mark Sensor Auto Calibration Mode

- Manual Calibration Mode

• Why are several calibration methods provided?

- Multiple labels should be scanned for media calibration and more accurate

sensitivity calibration can be performed when more labels are scanned.

- The number of labels to scan for sensor sensitivity adjustment depends on various

conditions such as label paper material, color, surface status, thickness, gap length,

pre-printed pattern, etc.

- Four different media calibration modes are provided for compromise between

prevention of excessive use of paper and accuracy of sensor sensitivity adjustment.

- Smart media detection mode that allows for adjustment of sensitivity with minimum

amount of scanning should be good enough for most cases with general labels.

- Try various methods in order of Smart Media Detection Gap Sensor Automatic

Calibration / Black Mark Sensor Automatic Calibration Manual Calibration Mode.

Rev. 1.0

Page 28

- 28 -

LD630T/LD640T

5-5 Smart Media Detection

• Printer executes this function when necessary without user input and media

configuration can be completed with Smart Media Detection function for most print

papers.

• Papers with gap or black mark can be identified without separate settings.

• 3 ~ 5 pages of labels will be used depending on the type of paper.

• Smart Media Detection function is executed in the followings cases

- When the printer is installed first time, it is executed through Feed button or print

command.

- When paper length change is detected during feeding or printing.

- When the paper type entered by command is different from the configured paper type.

- After reset with factory settings

• Smart Media Detection function will be turned off after setting the sensor sensitivity using

Automatic Calibration Mode or Manual Media Calibration mode, and it will be enabled

again after resetting the printer with factory settings.

5-6 Gap Sensor Auto Calibration Mode

Use this mode when paper is not detected correctly with Smart Media Detection function.

Printer feeds paper and calibrates Gap Sensor automatically.

The printer will enter error mode if paper detection fails after feeding up to 1 meter of paper.

Error mode can be released by opening and closing the cover.

Use Manual Calibration Mode if paper detection fails in this mode.

Smart Media Detection will be disabled if paper detection is successful in this mode.

5-6-1 Procedure to run the calibration

• Depress the Feed button at 4th LED sequence as shown in section 5-2-2 (Status LED

is Orange and Error LED is blinking Green four times) to start Gap Sensor Automatic

Calibration Mode.

Rev. 1.0

Page 29

- 29 -

LD630T/LD640T

5-7 Black Mark Sensor Auto Calibration Mode

Use this mode when paper is not detected correctly with Smart Media Detection function.

Printer feeds paper and calibrates Black Mark Sensor automatically.

The printer will enter error mode if paper detection fails after feeding up to 1 meter of paper.

Error mode can be released by opening and closing the cover.

Use Manual Calibration Mode if paper detection fails in this mode.

Smart Media Detection will be disabled if paper detection is successful in this mode.

5-7-1 Procedure to run calibration

• Depress the Feed button at 5th LED sequence as shown in section 5-2-2 (Status LED

is Orange and Error LED is blinking Orange four times) to start Black Mark Sensor

Automatic Calibration Mode.

Rev. 1.0

Page 30

- 30 -

LD630T/LD640T

5-8 Manual Calibration Mode

Manual-calibration of media detection can be used when the printer cannot detect a media

gap (or black mark) even after auto-calibration has been executed.

Users can calibrate sensor parameters in detail by using the utility program provided by

the manufacturer.

The utility can be obtained from the enclosed CD.

Please make sure the printer is connected and execute the utility program.

Click on the Calibration Setting Manager Button after setting the interface type.

1) Select the sensing type and input the label length by millimeter and click on “Check

Sensing Value” button. Then printer starts to calibrate.

2) Printer will print the scanned values after calibration and the values will appear on the

Screen.

3) Optimal sensing values will appear in bold letters on the left of the utility screen. Select

one of the optimal sensing value by clicking on it's option button and then click on "Save

Calibration."

4) If chosen value does not work properly, please try the other values among the bold

letters.

5) To go back to the initial value, please click on “Cancel Calibration”

Rev. 1.0

Page 31

- 31 -

LD630T/LD640T

5-9 Cover Closing Mode

1. About Cover Closing Mode

• The printed area may become out of range of paper if the paper is not in the accurate

printing position when the cover is opened and closed.

• The printer is put into Cover Closing Mode instead of Print Standby Mode when the

cover is closed in order to prevent this problem, and it waits for user input.

• The status of LEDS are as follows in this mode.

- Status LED: Green Blink

- Error LED: Green Blink

• The data received during Cover Close Mode is not printed until the printer recovers

to Print Standby Mode.

2. How to switch the printer from Cover Close Mode to Print Standby Mode

• Depress the Pause button to switch to Print Standby Mode without feeding any paper.

• Depress the Feed button to feed one page to align the paper position and switch to the

Print Standby Mode.

5-10 Data Dump Mode

This function can be used to diagnose the communication issues when the printing does

not work correctly.

In this mode, the received data are not analyzed instead they are dumped in hex format

without processing.

Turn the printer off and on to recover to the Print Standby Mode.

5-10-1 How to start Data Dump Mode

1) Depress the Pause button for two seconds during Print Standby Mode.

2) Both LEDs will change to orange color and the printer will be set to Stand-along

Configuration Mode.

3) Depress the Feed button at the third LED sequence in 5-2-2 (Status LED Green /

Error LED Red – Blink four times) to enable Data Dump Mode.

Rev. 1.0

Page 32

- 32 -

LD630T/LD640T

LED

ON

5-11 Factory Reset

This function is used to reset the printer settings to factory default settings.

5-11-1 How to reset the printer

1) Depress the Pause button for two seconds during Print Standby Mode.

2) Both LEDs will change to orange color and the printer will be set to Stand-alone

Configuration Mode.

3) Depress the Feed button at the 3rd LED sequence as shown in section 5-2-2 (Status

LED is Green and Error LED is blinking Red four times) to reset the printer to factory

settings, and Smart Media Detection function will be executed.

5-12 The Peel-Off (Option)

As a function that is used to peel-off labels, it is used only with label paper.

1) Open the paper cover.

2) Open the Ribbon Assembly.

3) Open the label peel-off cover and set the peeler switch to the ON position.

- Check to see that the LED has turned on.

Rev. 1.0

Page 33

- 33 -

LD630T/LD640T

Remove

( O )

( X )

4) Remove one sheet of the label paper, and insert the paper as shown in the image below.

5) Adjust the paper guides and close the label peel-off cover.

6) Close the Ribbon Assembly until a click sound is heard, close the Paper Cover.

7) Turn the printer off and on.

Rev. 1.0

Page 34

- 34 -

LD630T/LD640T

Remove

Fix Tool

Paper Holder

5-13 Using Fan-Fold Paper

Supplying paper to the printer externally is done as follows.

5-13-1 Printer Preparation

Remove the rear paper supply cover on the back side of the printer with a knife or other

cutting instrument.

※ CAUTION

- Take care not to injure the hands and/or any other part of the body when performing

this step.

5-13-2 When Using Fan-Fold Paper

1) Insert the paper at the rear of the printer using the slot and guides.

2) Adjust Paper Holders to the paper width by using the Fix Tool.

Rev. 1.0

Page 35

- 35 -

LD630T/LD640T

5-14 Auto Cutter (Option)

For auto paper cutting, products equipped with auto cutter are available.

Auto-Cutter can be controlled by command. And default setting can be changed by Unified

Label Utility-II.

※ The paper installation method is the same as paper with no auto cutter.

Rev. 1.0

Page 36

- 36 -

LD630T/LD640T

Battery

Dip Cover

Close

5-15 Real-Time Clock (Option)

The function of the Real-Time Clock option is to print the time and date onto the label.

The date and time can be set in the printer by using the Unified Label Utility-II.

You can discern a low or depleted battery if printer provides a consistently incorrect time

and date. In this case, you need to replace the battery. When battery is changed, the time

and the date will need to be reset.

※ CAUTION

- For your safety, The access cover on the bottom of the printer should always be closed.

When changing the battery, please open the cover with your thumb and index finger.

Then close the cover after changing the battery.

- Wrap the battery when recycling or storing to avoid short circuit.

- Do not short circuit the battery. It may result in heat generation or fire.

- Do not disassemble or heat the battery.

Rev. 1.0

Page 37

- 37 -

LD630T/LD640T

6. Cleaning Head

Printing quality might be degraded by dust, foreign substance, adhesive substance, or

other pollution materials stuck in the printer head or inside the printer.

When dirty, clean the print head as follows:

※ CAUTION

- Make sure to turn the printer power off prior to cleaning.

- As the print head gets very hot during printing, if intending to clean the print head, turn

the printer power off and wait approximately 2~3 minute before commencement.

- When cleaning the print head, take care not to touch the heated portion of the print

head.

→ Printer Head is susceptible to damage from static electricity, etc.

- Take care not to allow the print head to become scratched and/or damaged in any way.

- Be careful not to get your fingers pinched when opening or closing the paper cover.

Make sure to open the paper cover all the way until it locks into the open position.

- When loading roll paper, be careful not to get your fingers pinched between the paper

roll and the paper holder.

- Do not touch the cutter with your hands or do not put something into the cutter. Doing

so could result in an injury.

6-1 Cleaning Head

1) Open the paper cover and Ribbon Assembly and then use the cleaning pen to clean the

head in the direction from the center of the head to the edges.

2) After cleaning the head, do not use the printer until the alcohol used for cleaning

evaporates completely (1~2 min) and the printer has completely dried.

※ Perform the cleaning process each time the paper roll is replaced to prevent print

quality deterioration.

Rev. 1.0

Page 38

- 38 -

LD630T/LD640T

Lower Gap Sensor

Black-Mark &

Notch Sensor

Paper Holder

Peel-off Sensor

(Option)

Platen Roller

Peel-off Roller

Ridges

Paper Roller

Head Cover

Ridges

Upper Gap Sensor

6-2 Cleaning Sensors, Roller or/and Paper Path

1) Open the paper cover and ribbon assembly, and remove the paper and ribbon.

2) Remove any dust or foreign substance using dry cloth or cotton swab.

3) Soak the cloth or cotton swab in alcohol for medical use and use it to remove adhesive

foreign substances or other pollution materials.

4) After cleaning the parts, do not use the printer until the alcohol evaporates completely

(1~2 min) and the printer has completely dried

※ Clean the parts when there is a degradation of performance in printing quality or paper

detection.

Rev. 1.0

Page 39

- 39 -

LD630T/LD640T

Item

Description

Printer

Printing Method

Thermal Transfer / Direct Thermal Printing

Dot Density

LD630T : 203 dpi (8 dot/mm)

LD640T : 300 dpi (11.8 dot/mm)

Printing Width

LD630T : Max. 108 mm (Max. 4.25”)

LD640T : Max. 105.7 mm (Max. 4.16”)

Printing Speed

LD630T : Max. 152 mm/sec (Max. 6ips)

LD640T : Max. 102 mm/sec (Max. 4ips)

Paper

Width

20 ~ 112 mm (0.79 ~ 4.41”)

Roll

Max 130mm (Max. 5.12”)

Core

25.4~38.1mm (1~1.5”)

Ribbon

Length / Width

Max 300m (Max. 11.8”) / 33 ~ 110mm(1.3~4.33”)

Type(Outside)

Wax, Wax/Resin, Resin

Core

0.5” / 1”

AC

Adapter

Input Voltage

AC 100~240V

Frequency

50/60 Hz

Output Voltage

DC 24V±5%

Output Current

2.5A

Usage

Conditions

Temperature

5 ~ 40 ℃ (Operating)

-20 ~ 60 ℃ (Storage)

Humidity

(except for paper)

10 ~ 80 % RH (Operating)

10 ~ 90 % RH (Storage)

7. Appendix

7-1 Specifications

※ Note

- Printing speed can vary depending on the data transmission speed and combination of

control commands.

- This equipment is for indoor use and all the communication wirings are limited to inside

of the building.

- The switch is the disconnecting device. Turn off switch from any hazard.

7-2 Label Types

The label types used with this printer are as follows.

• Control Labels: PP

• Other Labels: PET

Rev. 1.0

Page 40

OkicontactName. Oki Systems

(UK) Limited

OkicontactAddress.550 Dundee Road

Slough Trading Estate

Slough

Berkshire

SL1 4LE

Tel:+44 (0) 1753 819819

Fax:+44 (0) 1753 819899

http://www.oki.co.uk

Oki Systems Ireland Limited

The Square Industrial Complex

Tallaght

Dublin 24

Tel:+353 (0) 1 4049590

Fax:+353 (0)1 4049591

http://www.oki.ie

Oki Systems Ireland Limited Northern Ireland

19 Ferndale Avenue

Glengormley

BT36 5AL

Northern Ireland

Tel:+44 (0) 7767 271447

Fax:+44 (0) 1 404 9520

http://www.oki.ie

Technical Support for all Ireland:

Tel:+353 1 4049570

Fax:+353 1 4049555

E-mail: tech.support@oki.ie

OKI Systems (Czech and Slovak),

s.r.o.

IBC – Pobřežní 3

186 00 Praha 8

Czech Republic

Tel: +420 224 890158

Fax:+420 22 232 6621

Website: www.oki.cz, www.oki.sk

Oki Systems (Deutschland) GmbH

Hansaallee 187

40549 Düsseldorf

Tel: 01805/6544357**

01805/OKIHELP**

Fax: +49 (0) 211 59 33 45

Website:

www.okiprintingsolutions.de

info@oki.de

**0,14€/Minute aus dem dt. Festnetz

der T-Com (Stand 11.2008)

CPI S.A1 Rafailidou str.

177 78 Tavros

Athens

Greece

Tel: +30 210 48 05 800

Fax:+30 210 48 05 801

EMail:sales@cpi.gr

Oki Systems (Iberica), S.A.U

C/Teide, 3

San Sebastian de los Reyes

28703, Madrid

Tel:+34 91 3431620

Fax: +34 91-3431624

Atención al cliente: 902 36 00 36

Website: www.oki.es

Oki Systèmes (France) S.A.

44-50 Av. du Général de Gaulle

94246 L'Hay les Roses

Paris

Tel:+33 01 46 15 80 00

Télécopie:+33 01 46 15 80 60

Website: www.oki.fr

OKI Systems (Magyarország) Kft.

Capital Square

Tower 2

7th Floor

H-1133 Budapest,

Váci út 76

Hungary

Telefon: +36 1 814 8000

Telefax: +36 1 814 8009

Website: www.okihu.hu

OKI Systems (Italia) S.p.A.

via Milano, 11,

20084 Lacchiarella (MI)

Tel:+39 (0) 2 900261

Fax:+39 (0) 2 90026344

Website: www.oki.it

OKI Printing Solutions

Platinium Business Park II, 3rd Floor

ul. Domaniewska 42

02-672 Warsaw

Poland

Tel:+48 22 448 65 00

Fax:+48 22 448 65 01

Website: www.oki.com.pl

E-mail: oki@oki.com.pl

Hotline: 0800 120066

E-mail: tech@oki.com.pl

Oki Systems (Ibérica) S.A.

Sucursal Portugal

Edifício Prime Av. Quinta Grande 53

7º C Alfragide

2614-521 Amadora

Portugal

Tel:+351 21 470 4200

Fax:+351 21 470 4201

Website:www.oki.pt

E-mail : oki@oki.pt

Oki Service

Serviço de apoio técnico ao

Cliente

T

el: 80

8 200 197

E-mail : okiserv@oki.pt

OKI Europe Ltd. (Russia)

Office 702, Bldg 1

Zagorodnoye shosse

117152, Moscow

Tel: +74 095 258 6065

Fax: +74 095 258 6070

e-mail: info@oki.ru

Website: www.oki.ru

Technical support:

Tel: +7 495 564 8421

e-mail: tech@oki.ru

Oki Systems (Österreich)

Campus 21

Businesszentrum Wien Sued

Liebermannstrasse A02 603

22345 Brun am Gebirge

Tel: +43 223 6677 110

Drucker Support:

+43 (0) 2236 677110-501

Fax Support:

+43 (0) 2236 677110-502

Website: www.oki.at

OKI Europe Ltd. (Ukraine)

Raisy Opkinoy Street,8

Building B, 2

nd

Floor,

Kiev 02002

Ukraine

Tel: +380 44 537 5288

e-mail: info@oki.ua

Website: www.oki.ua

Harman sok Duran Is Merkezi,

No:4, Kat:6,

34394, Levent

İstanbul

Tel: +90 212 279 2393

Faks: +90 212 279 2366

Web: www.oki.com.tr

www.okiprintingsolutions.com.tr

Oki Systems (Belgium)

Medialaan 24

1800 Vilvoorde

Helpdesk: 02-2574620

Fax: 02 2531848

Website: www.oki.be

AlphaLink Bulgaria Ltd.

2 Kukush Str.

Building "Antim Tower", fl. 6

1463 Sofia, Bulgaria

tel: +359 2 821 1160

fax: +359 2 821 1193

Website: http://bulgaria.oki.com

Διανομέας των συστημάτων OKI

OKI Sistem ve Yazıcı Çözümleri

Tic. Ltd. Şti.

Oki contact details

Page 41

OKI Printing Solutions

Herstedøstervej 27

2620 Albertslund

Danmark

Adm.: +45 43 66 65 00

Hotline: +45 43 66 65 40

Salg: +45 43 66 65 30

Fax: +45 43 66 65 90

Website: www.oki.dk

Oki Systems (Finland) Oy

Polaris Capella

Vänrikinkuja 3

02600 Espoo

Tel: +358 (0) 207 900 800

Fax: +358 (0) 207 900 809

Website: www.oki.fi

Oki Systems (Holland) b.v.

Neptunustraat 27-29

2132 JA Hoofddorp

Helpdesk: 0800 5667654

Tel:+31 (0) 23 55 63 740

Fax:+31 (0) 23 55 63 750

Website: www.oki.nl

Oki Systems (Norway) AS

Tevlingveien 23

N-1081 Oslo

Tel:+47

Telefax:+47 (0) 63 89 36 01

Ordrefax:+47 (0) 63 89 36 02

Website: www.oki.no

General Systems S.R.L.

(Romania)

Sos. Bucuresti-Ploiesti Nr. 135.

Bucharest 1

Romania

Tel: +40 21 303 3138

Fax: +40 21303 3150

Website: http://romania.oki.com

Var vänlig kontakta din Återförsäljare

i första hand, för konsultation. I

andra hand kontakta

Oki Systems (Sweden) AB

Borgafjordsgatan 7

Box 1191

164 26 Kista

Tel. +46 (0) 8 634 37 00

e-mail:

info@oki.se

Oki produkter

support@oki.se för teknisk support

gällandes Oki produkter

Vardagar: 08.30 - 12.00,

13.00 - 16.00

Website: www.oki.se

(0) 63 89 36 00

för allmänna frågor om

Oki Systems (Schweiz)

Baslerstrasse 15

CH-4310 Rheinfelden

Support deutsch +41 61 827 94 81

Support français +41 61 827 94 82

Support italiano +41 061 827 9473

Tel: +41 61 827 9494

Website: www.oki.ch

Oki Data Americas Inc.(United

States)

2000 Bishops Gate Blvd.

Mt. Laurel, NJ 08054

USA

Tel: 1-800-654-3282

Fax: 1-856-222-5247

http://

http://my.okidata.com

Oki Data Americas Inc.(Canada •

Canadá)

4140 B Sladeview Crescent Units 7&8

Mississauga, Ontario

Canada L5L 6A1

Tél: 1-905-608-5000

Téléc: 1-905-608-5040

http://

Oki Data Americas Inc.(América

Latina (OTRO))

2000 Bishops Gate Blvd.

Mt. Laurel, NJ 08054

USA

Tel (Español): 1-856-222-7496

Fax: 1-856-222-5260

Email: LASatisfaction@okidata.com

Oki Data de Mexico, S.A. de C.V.

Mariano Escobedo #748, Piso 8

Col. Nueva Anzures

C.P. 11590, México, D.F.

Tel: 52-555-263-8

Fax: 52-555-250-3501

http://

Oki Data do Brasil, Ltda.

Rua Avenida Alfrefo Egidio de souza Aranha

100-4° andar-Bloco C Chacara Santo Antonio

Sao Paulo, Brazil 04726-170

Tel: 55-11-3444-6747 (Grande São

Fax: 5511-3444-3501

e-mail: okiserv@okidata.com.br

http://

Oki Data (Singapore) Pte. Ltd.

438A Alexandra Road #02-11/12,

Lobby 3, Alexandra Technopark

Singapore(119967)

WWW.OKIPRINTINGSOLUTIONS.COM

WWW.OKIPRINTINGSOLUTIONS.COM

1-856-222-5276

780

WWW.OKIPRINTINGSOLUTIONS.COM

Paulo)

0800-11-5577 (Demais

localidades)

WWW.OKIPRINTINGSOLUTIONS.COM

Oki Systems (Thailand) Ltd.

1168/81-82 Lumpini Tower,

27th Floor Rama IV Road

Tungmaha

Bangkok 10120

Tel:(662) 679 9235

Fax:(662) 679 9243/245

http://www.okisysthai.com

Oki Systems (Hong Kong) Ltd.

Suite 1908, 19/F, Tower 3,

China Hong Kong City

33 Canton Road, TsimShaTsui,

Kowloon, Hong Kong

Tel: (852) 3543 9288

Fax: (852) 3549 6040

http://

Oki Data(Australia) Pty Ltd.

Levwl1 67 Epping Road, Macquarie Park

NSW 2113, Australia

Tel: +61 2 8071 0000

(Support Tel: 1800 807 472)

Fax: +61 2 8071 0010

http://www.oki.com.au

Comworth Systems Ltd.

8 Antares Place Mairangi Bay,

Auckland, New Zealand

Tel:(64) 9 477 0500

Fax:(64) 9 477 0549

http://www.comworth.co.nz

Oki Data(S) P Ltd. Malaysia Rep

Office

Suite 21.03, 21st Floor Menara

Mid Valley City,

Lingkaran Syed Pura 59200,

Kuala Lumpur, Malaysia

Tel: (60) 3 2287 1177

Fax: (60) 3 2287 1166

mek, Sathorn

www.okiprintingsolutions.com.hk

IGB,

Tel:(65) 6221 3722

Fax:(65) 6594 0609

http://www.okidata.com.sg

Page 42

LD630T/LD640T

Guide de l'utilisateur

Page 43

P

RÉFACE

Tout a été mis en œuvre pour que les informations contenues dans ce document soient complètes,

précises et à jour. Le fabricant décline toute responsabilité quant aux conséquences d'erreurs échappant

à son contrôle. Le fabricant ne peut garantir que les changements dans les logiciels et les équipements

d'autres fabricants et mentionnés dans ce manuel n'affectera pas l'applicabilité de l'information de celuici. La mention de produits logiciels fabriqués par d'autres entreprises ne constitue pas nécessairement

l'approbation par le fabricant.

Toutes les mesures ont été prises pour que ce document vous apporte une aide précieuse, toutefois nous

ne pouvons garantir qu'il traite dans son intégralité toutes les informations contenus.

Tous droits réservés par OKI Data Corporation. Vous ne devez pas effectuer une copie non autorisée, le

transfert, la traduction, ou des actions apparentées. Vous devez obtenir l'accord écrit d'Oki Data

Corporation avant de pouvoir effectuer une des actions mentionnées ci-dessus.

© 2012 Oki Data Corporation

OKI est une marque déposée de Oki Electric Industry Co., Ltd.

Energy Star est une marque de l'Agence de protection de l'environnement des États-Unis.

Microsoft, Windows, Windows Server et Windows Vista sont des marques déposées de Microsoft

Corporation.

Apple, Macintosh, Rosetta, Mac et Mac OS sont des marques déposées de Apple Inc.

D'autres noms de produits et noms de fabriques sont des marques déposées ou marques déposées de

leur propriétaire.

En tant que participant au programme Energy Star, le fabricant a déterminé que ce produit

répond aux directives d'Energy Star concernant l'efficacité énergétique.

Ce produit est conforme aux exigences des directives du Conseil 2004/108/CE (CEM) et 2006/

95/CE (LVD) et 1999/5/CE (R&TTE), modifiées si applicables, sur le rapprochement des lois

des États membres concernant la compatibilité électromagnétique, basse tension et des &

équipements terminaux de télécommunications radio.

Les câbles suivants ont été utilisés pour évaluer ce produit et obtenir la conformité avec la directive EMC

le respect de normes 2004/108/EC et des configurations autres que celles-ci peuvent affecter leur

respect.

TYPE DE CÂBLE LONGUEUR

(MÈTRE)

Alimentation

USB

Série

Parallèle

LAN

1,8

1,8

1,8

1,8

3,0

COEUR BLINDAGE

-2-

Page 44

F

ABRICANT

OKI Data Corporation,

4-11-22 Shibaura, Minato-ku,

Tokyo 108-8551,

Japon

Pour toute question d'ordre général, sur les ventes et sur le support, contactez votre distributeur local.

I

MPORTATEUR VERS L

OKI Europe Limited (Solutions pour l'impression OKI)

Blays House

Wick Road

Egham

Surrey, TW20 0HJ

Royaume Uni

Pour toute question d'ordre général, sur les ventes et sur le support, contactez votre distributeur local.

I

NFORMATIONS RELATIVES À L'ENVIRONNEMENT

'UE/

REPRÉSENTANT AGRÉÉ

-3-

Page 45

- 4 -

LD630T/LD640T

■ Sommaire

※ Mode d'emploi et précautions d'usage ........................................................................ 5

1. Confirmation du contenu .............................................................................................. 9

2. Nom des pièces du produit ......................................................................................... 10

3. Installation et utilisation .............................................................................................. 12

3-1 Alimentation .............................................................................................................. 12

3-2 Connexion du câble d'interface ................................................................................. 13

3-3 Installation du papier ................................................................................................. 15

3-4 Installation du ruban ................................................................................................. 16

3-5 Boutons et voyants ................................................................................................... 20

3-6 Test d'impression ................................................................................................ ...... 22

4. Auto-test ....................................................................................................................... 23

5. Caractéristiques détaillées.......................................................................................... 24

5-1 Paramétrage de l'imprimante à l'aide de programme des utilitaires .......................... 24

5-2 Mode Configuration automatique .............................................................................. 25

5-3 Pause / Annuler ........................................................................................................ 26

5-4 Calibrage des médias ............................................................................................... 27

5-5 Détection intelligente des médias ............................................................................. 28

5-6 Mode Calibrage automatique du capteur d'espace ................................................... 28

5-7 Mode Calibrage automatique du capteur de marque noire ....................................... 29

5-8 Mode de calibrage manuel ....................................................................................... 30

5-9 Mode Capot fermé .................................................................................................... 31

5-10 Mode de transfert des données .............................................................................. 31

5-11 Réinitilisation Usine ................................................................................................. 32

5-12 Le détachement des étiquettes (Option) ................................................................. 32

5-13 Utilisation d'un papier plié en accordéon ................................................................ 34

5-14 Coupe automatique (Option) .................................................................................. 35

5-15 Horloge en temps réel (Option) ............................................................................... 36

6. Nettoyage de la tête d'impression .............................................................................. 37

6-1 Nettoyage de la tête d'impression ............................................................................. 37

6-2 Détecteur de nettoyage, roulis et/ou chemin du papier ............................................. 38

7. Annexe .......................................................................................................................... 39

7-1 Caractéistiques ......................................................................................................... 39

7-2 Types d'étiquettes ..................................................................................................... 39

Rev. 1.0

Page 46

- 5 -

LD630T/LD640T

1. Manuel du pilote Windows

Ce manuel fournit les consignes d'installation et explique les fonctions principales du

pilote Windows.

2. Manuel de l’Unified Label Utility II

Ce manuel fournit des consignes d'utilisation du logiciel pour a sélection du produit,

les modifications des conditions d'opération et de fonctionnement, etc.

3. Manuel de programmation (SLCS)

Ce manuel fournit des informations concernant les commandes de l'imprimante à

étiquette.

4. Manuel du logiciel de téléchargement des vraies polices (True Font)

Ce manuel fournit des informations concernant l'utilisation du logiciel de

téléchargement des polices pouvant télécharger de vraies polices (True Font) et

facilitant leur usage en tant que police de l'appareil (Device Fonts)

5. Manuel de l'interface Réseau

Ce manuel fournit les consignes de configuration et d'utilisation de l'Internet

Ethernet.

6. Manuel de l'outil de configuration du net

Ce manuel fournit les informations relatives à l'utilisation de l'outil de configuration du

net servant à configurer l'interface Ethernet du produit.

■ Mode d'emploi

※ Mode d'emploi et précautions d'usage

Ce mode d'emploi contient des informations basiques concernant l'utilisation d'un produit

ainsi que les éventuelles mesures d'urgence à prendre en cas de besoin.

※ Les modes d'emploi suivant fournissent davantage d'informations sur les divers

problèmes et contenus technologiques.

Oki Data s'engage à poursuivre ses efforts pour améliorer les fonctions et la qualité de ses

produits. Par conséquent, les caractéristiques du produit et/ou le contenu du manuel

d'utilisation peuvent être modifiés sans avis préalable.

Rev. 1.0

Page 47

- 6 -

LD630T/LD640T

AVERTISSEMENT

Violer les instructions suivantes peut entraîner des blessures graves ou la

mort.

Ne pas plier le câble et ne pas poser d’objet lourd dessus.

• Un câble endommagé peut entraîner un incendie.

Ne pas brancher ou débrancher avec vos mains humides.

• Vous pouvez vous électrocuter.

Veuillez tenir le sac plastique éloigné des enfants.

• Si tel n’est pas le cas, l’enfant risque de mettre le sac sur la

Tête.

Ne pas tirer le câble pour débrancher.

• Cela peut endommager le câble, ce qui peut être à l’origine

d’un incendie ou d’une panne de l’imprimante.

Uniquement utiliser l’adaptateur fourni.

• Il est dangereux d’utiliser d’autres adaptateurs.

Ne pas brancher plusieurs produits sur une même

multiprise.

• Cela peut entraîner une surchauffe ou un incendie Si la prise

est humide ou sale, la sécher ou la nettoyer avant de l’utiliser.

• Si la prise n’entre pas parfaitement dans la prise, ne pas la

Brancher.

• S’assurer de n’utiliser que des multiprises normalisées.

INTERDIT

INTERDIT

INTERDIT

MUITIPRISE ADAPTEE

FOURNIE UNIQUEMENT

INTERDIT

INTERDIT

INTERDIT

■ Consignes de sécurité

Lors de l’utilisation de cet appareil, veuillez suivre les consignes de sécurité suivantes afin

d'éviter tout danger ou endommagement du matériel.

Rev. 1.0

Page 48

- 7 -

LD630T/LD640T

PRECAUTION

Violer les consignes suivantes peuvent entraîner des blessures légères ou

endommager le produit.

Ne pas utiliser l’imprimante lorsqu’elle est hors service.

Il y a un risque d’incendie et d’électrocution.

• Eteindre et débrancher l’imprimante avant d’appeler le

fournisseur.

Ne pas laisser d’eau ou de corps étranger sur

l’imprimante.

• Si cela arrive, éteindre et débrancher l’imprimante avant

d’appeler le fournisseur.

N’utiliser que les accessoires agréés et ne pas tenter de

les démonter, réparer ou modifier vous-même.

• En cas de besoin, appelez votre fournisseur.

• Ne pas toucher la lame du coupeur automatique.

Installer l’imprimante sur une surface stable.

• Si l’imprimante tombe, elle peut se casser et vous pouvez

vous blesser.

Veillez à ne pas vous pincer les doigts en ouvrant et

fermant le couvercle du papier. Veillez également à ce que

le couvercle du papier ne vous échappe pas des mains et

ne tombe pas.

Si vous observez une fumée, une odeur ou un bruit

étrange provenant de l’imprimante, débranchez-la avant

de prendre les mesures suivantes.

• Eteindre l’imprimante et débrancher l’ensemble.

• Une fois la fumée dissipée, appeler le fournisseur pour qu’il

vienne ma réparer.

BRANCHER

DANGER

MECANIQUE

DEMONTAGE

INTERDIT

INTERDIT

INTERDIT

DEBRANCHER

IMPRIMANTE

IMPRIMANTE

IMPRIMANTE

FOURNISSEUR

IMPRIMANTE

IMPRIMANTE

Rev. 1.0

Page 49

- 8 -

LD630T/LD640T

■ Autres mises en garde

Les droits d'auteur du guide d'utilisation et des autres manuels et documents sont la

propriété d'Oki Data Corporation. Toute copie ou conversion sous format électronique et la

sauvegarde de ce document sans l'accord écrit et exprès d'Oki Data Corporation. est

strictement interdite.

L'utilisation des informations contenues dans le présent manuel n'est sujette à aucune

responsabilité de la société. Même si le plus grand soin a été apporté lors de la rédaction

de ce manuel, cependant ce dernier peut contenir quelques erreurs et/ou omissions.

Oki Data Corporation. n'est pas tenue responsable de tout dommage pouvant résulter de

l'utilisation des informations fournie par le présent manuel.

Oki Data Corporation. et ses filiales ne sont pas tenues responsables (hormis aux EtatsUnis) de tout dommage, de toute perte, de tout coût et/ou de toute dépendant résultant

d'une panne, d'un dysfonctionnement et / ou d'une mauvaise utilisation du produit,

causé(e) par une violation ou une non-observation des informations et consignes

d'utilisation et d'entretien fournies par Oki Data Corporation. ainsi que par une modification,

une réparation et/ou une modification non autorisée(s) du produit effectuée(s) par

l'utilisateur et/ou une tierce personne.

Oki Data Corporation.. n'est pas tenue responsable de tout dommage et/ou problèmes

pouvant résulter de l'utilisation d'options et/ou de pièces originales des produits Oki Data

ou de pièces non agréées.

Rev. 1.0

Page 50

- 9 -

LD630T/LD640T

LD630T/LD640T

Câble d'alimentation

Adaptateur CA

1 Adaptateur de ruban

de ruban

ruban de ruban

CD

Documentation Utilisateur

(Guide de paramétrage,

Sécurité, Garantie)

1. Confirmation du contenu

Les articles suivants doivent être fournis avec l'imprimante.

En cas de article endommagé ou manquant, contactez votre revendeur.

Rev. 1.0

Page 51

- 10 -

LD630T/LD640T

Bouton

Alimentation (Feed)

Levier du capot

Tête d'impression

Support du papier

Détecteur d'espace

supérieur

Capot principal

Détecteur de

marque noire

Bouton Pause

Capot Papier

Ensemble Ruban

Détecteur d'espace

inférieur

2. Nom des pièces du produit

Rev. 1.0

Page 52

- 11 -

LD630T/LD640T

Interrupteur

IEEE1284 (Parallèle)

USB

Capot du papier plié en

accordéon ou papier administré

par l'extérieur

Prise jack

d'alimentation

RS-232C (en série)

Coupe Auto

(en option)

Détachement des étiquettes

(en option)

Rev. 1.0

Page 53

- 12 -

LD630T/LD640T

OFF

Interrupteur

Câble d'alimentation

Adaptateur CA

3. Installation et utilisation

※ ATTENTION

- Veillez à ne pas vous pincer les doigts lorsque vous ouvrez et fermez le capot du papier.

Assurez d'ouvrir le capot en entier jusqu'à ce qu'il se bloque en position ouverte.

- Lorsque vous rechargez un rouleau de papier, veillez à ne pas vous pincez les doigts

entre le rouleau de papier et la fixation du rouleau.

- Ne touchez pas la lame avec les mains et ne placez rien sur la lame. Vous risqueriez

de vous blesser.

3-1 Alimentation

Mettez l'imprimante sous tension, comme indiqué ci-dessous.

1) Eteignez l'imprimante à l'aide de l'interrupteur.

2) Vérifiez que la tension de l'adaptateur CA corresponde bien avec celle de la source

d'alimentation/

3) Connectez la prise jack de l'adaptateur CA au connecteur d'alimentation de l'imprimante.

4) Connectez le câble d'alimentation à l'adaptateur CA.

5) Connectez le câble d'alimentation à la source/sortie d'alimentation.

Rev. 1.0

Page 54

- 13 -

LD630T/LD640T

Câble USB

Câble RS-232C (en Série)

Câble IEEE 1284 (Parallèle)

3-2 Connexion du câble d'interface

3-2-1 Modèle standard

Connectez le câble d'interface, comme indiqué ci-dessous.

L'imprimante est compatible avec les interfaces de communication standards suivantes.

- Câble RS-232C (en Série)

- Câble IEEE 1284 (Parallèle)

- Câble USB de type B

1) Eteignez l'imprimante à l'aide de l'interrupteur.

2) Connectez le câble d'alimentation au port de communication de l'imprimante à utiliser.

- Connectez le câble RS-232C (en série) au port SERIAL

puis servez-les vis des deux côtés.

Ce port nécessite un câble gainé d'une longueur inférieure à 1,8m.

- Connectez le câble IEEE1284 (en parallèle) au port PARALLEL

puis fermez mes clips des deux côtés.

Ce port nécessite un câble gainé avec un cœur en ferrite d'une longueur inférieure à

1,8m.

Connectez le câble USB de type B au port USB.

Ce port nécessite un câble gainé d'une longueur inférieure à 1,8m.

Rev. 1.0

Page 55

- 14 -

LD630T/LD640T

Câble USB de type B

Câble RS-232C (en Série)

Câble LAN (Ethernet)

USB de type A

(Dongle WLAN uniquement)

3-2-2 Modèle Ethernet

Connectez le câble d'interface, comme indiqué ci-dessous.

L'imprimante est compatible avec les interfaces de communication standards suivantes.

- Câble RS-232C (en Série)

- Câble LAN (Ethernet)

- USB de type A (Dongle WLAN uniquement)

- Câble USB de type B

1) Eteignez l'imprimante à l'aide de l'interrupteur.

2) Connectez le câble d'alimentation au port de communication de l'imprimante à utiliser.

- Connectez le câble RS-232C (en série) au port SERIAL

puis servez-les vis des deux côtés.

Ce port nécessite un câble gainé d'une longueur inférieure à 1,8m.

- Connectez le câble ILAN (Ethernet) au port ETHERNET

Ce port nécessite un câble d'une longueur inférieure à 3,0m.

- Connectez le câble USB de type A (Dongle WLAN uniquement) au port Hôte (Host).

- Connectez le câble USB de type B au port USB.

Ce port nécessite un câble gainé d'une longueur inférieure à 1,8m.

Rev. 1.0

Page 56

- 15 -

LD630T/LD640T

1) Ouvrez le capot du papier.

2) Sortez le support du papier puis

insérez le rouleau.

3) Ouvrez la partie Ruban puis tirez le papier pour qu'il sorte de l'avant de l'imprimante.

Placez le papier sous les deux guides de papier.

* Que le papier étiquette soit enroulé vers l'intérieur ou vers l'extérieur, sa surface

d'impression doit être orientée vers le haut.

4) Si vous utilisez un rouleau de papier Marque-Noire ou à broche, soulevez le papier

et placez le capteur en face de la marque noire ou du trou de la broche.

5) Fermez l'ensemble Ruban jusqu'au clic, fermez le capot du papier.

Détecteur de marque noire et

détecteur de broche mobile

●

●

Guide Papier

Ensemble Ruban

Capot Papier

Support du

papier

3-3 Installation du papier

Rev. 1.0

Page 57

- 16 -

LD630T/LD640T

Ruban extérieur

Ruban intérieur

Un pouce

Un demi-pouce

Zone enduite

(surface

à imprimer)

Zone enduite

(surface à imprimer)

( O )

( X )

3-4 Installation du ruban

3-4-1 Type de ruban

1) Type par emplacement du film enduit

- Remarque : avant tout achat du ruban, souvenez-vous que seuls les rubans tournés

vers l'extérieur peuvent être utilisés.

※ Note

Respectez la procédure décrite ci-dessous pour définit la surface enduite du ruban.

• Test du ruban utilisant une matériel adhésive

- Réalisez un test de contact afin de définir qu'elle est la partie enduire, s'il s'agit

d'étiquettes.

• Procéder aux étapes suivantes pour réaliser le test de contact

- Retirez le papier au dos de l'étiquette

- Placez une partie de la surface adhésive sur l'étiquette sur la surface extérieure /

intérieure du ruban, puis exercez une pression.

- Retirez l'étiquette du ruban.

- Vérifiez que la surface adhésive de l'étiquette est tachée par le ruban d'encre noire.

2) Adaptateur de taille de ruban de ruban

- Cette imprimante peut utiliser des rubans ayant un diamètre d'un pouce ou d'un demipouce.

- Pour un ruban d'un pouce, l'adaptateur de ruban doit être utilisé avec le ruban et le

ruban du ruban. (Les adaptateurs et le ruban utilisé sont livré avec l'imprimante).

- Pour remplacer un ruban, retirez les adaptateurs (s'ils ont été utilisés) ainsi que le

ruban du ruban utilisé. Ces éléments doivent être utilisés avec le nouveau ruban.

Ne les jetez pas.

Rev. 1.0

Page 58

- 17 -

LD630T/LD640T

- Insérez l'adaptateur de ruban du ruban dans le ruban du nouveau ruban et le ruban du

ruban utilisé . (Vérifiez le sens d'impression du ruban)

2) Ouvrez l'ensemble ruban puis insérez le

ruban et le rouleau en les poussant de la

gauche vers la droite.

3) Insérez de l'adhésif sur l'extrémité du

ruban puis fixez-le au rouleau du ruban

utilisé.

4) Appuyez sur les deux côtés de l'ensemble ruban pour le fermer et lancer l'impression.

1) Ouvrez l'ensemble ruban puis insérez le

ruban et le rouleau du ruban utilisé en les

poussant de la gauche vers la droite.

(Vérifiez le sens d'impression du ruban)

2) Insérez de l'adhésif sur l'extrémité du

ruban puis fixez-le au rouleau du ruban

utilisé.

Adhésif

Adhésif

ruban (Un pouce)

Adaptateur de ruban

de ruban

3-4-2 Insérer un adaptateur de ruban d'un pouce

3-4-3 Insérer un ruban avec un rouleau d'un demi-pouce

3) Appuyez sur les deux côtés de l'ensemble ruban pour le fermer et lancer l'impression.

Rev. 1.0

Page 59

- 18 -

LD630T/LD640T

Les longueurs de ruban de 74m, 100m (Rouleau 0,5") et 30 m (Rouleau 1") peuvent

utilisées avec ce produit. Réglez la bonne longueur à l'aide du bouton de réglage,

en fonction de a longueur du ruban (74 ~ 300 m). Soyez précis car, en cas de mauvais

réglage, la qualité d'impression peut être affectée et certaines options peuvent ne pas

fonctionner correctement.

Le produit est livré avec une

longueur par défaut de 300m

(Rouleau 1"). Pour utiliser une

longueur de 74m (0,5"), tournez le

bouton et placez sur la position 74m

avant toute utilisation.