Page 1

Page 2

PREFACE

Ev ery ef for t ha s be en m ade to ens ure tha t th e in for ma tio n in thi s do cum en t is com ple te,

accurate, and up-to-date. Oki assumes no respons ibility for the results o f errors beyond

its control. Oki also cannot guarantee that changes in softwar e and equipment made by

other manufacturers and referred to in this guide will not affect the applicability of the

information in it. Mention of software products manufactured by other companies does

not necessarily constitute endorsement by Oki.

While all reasonable efforts have been made to make this document as accurate and

helpful as possible, we make no warranty of any kind, expressed or implied, as to the

accuracy or completeness of the information contained herein.

For latest information please see the Oki Europe website:

http://www.okieurope.com

07043201 First edition 05/2003.

Copyright 2003 by Oki. All rights reserved.

Oki is a registered trademark of Oki Electric Industry Company Ltd.

Microsoft, MS-DOS and Windows are registered trademarks of Microsoft Corporation.

This product complies with the requirements of the Council

Directives 89/336/EEC (EMC) and 73/23/EEC (LVD) as amended

where applicable on the approximation of the laws of the member

states relating to electromagnetic compatibility and low voltage.

WARNING!

This is a Class A product. In a domestic environment this product may cause radio

interference, in which case the user may be required to take adequate measures.

2 < PREFACE

Page 3

CONTENTS

Preface .......................................................................... 2

Introduction................................................................... 7

How to use this Guide..................................................... 8

Identifying component items .......................................... 9

Finisher .................................................................... 9

Overall configuration............................................... 10

Using the Finisher ........................................................ 12

Before you begin ..................................................... 12

General.............................................................. 12

Stacker summary information............................. 12

Punching information ......................................... 13

Stapling information ..........................................15

Job offset information......................................... 17

Printing and “finishing” a document ........................ 18

Printer control panel settings.............................. 18

Setting your printer driver .................................. 19

Windows drivers ................................................ 21

Macintosh drivers .............................................. 33

Troubleshooting........................................................... 39

Counteracting paper curl ......................................... 39

Clearing a paper jam ............................................... 41

Removing jammed staples....................................... 48

Maintaining the Finisher...............................................52

Replenishing the staple cartridge unit...................... 53

Removing the punch chips....................................... 58

Appendix A - Specification............................................ 61

Main characteristics................................................ 61

Configuration diagram ....................................... 62

Appendix B - Paper feed and ejection details................. 63

Printer paper feed details........................................ 63

Paper ejection details.............................................. 65

Finisher Face Up stacker..................................... 65

Finisher Face Down stacker................................. 67

Printer Face Down stacker .................................. 68

Appendix C - Error and warning messages..................... 70

English

CONTENTS > 3

Page 4

Appendix D - Consumables ........................................... 71

Staples ................................................................... 71

Oki Contact Details....................................................... 73

Index ........................................................................... 75

4 < CONTENTS

Page 5

English

NOTES, CAUTIONS & WARNINGS

NOTE

A note appears in this manual like this. A note provides additional

information to supplement the main text which may help you to use and

understand the product.

CAUTION!

A caution appears in this manual like this. A caution provides

additional information which, if ignored, may result in equipment

malfunction or damage.

WARNING!

A warning appears in this manual like this. A warning provides

additional information which, if ignored, may result in a risk of

personal injury.

Only use genuine Oki Original consumables to ensure the best quality

and performance from your hardware. Non Oki Original products may

damage your printer's performance and invalidate your warranty.

Specifications subject to change without notice. All trademarks

acknowledged.

NOTES, CAUTIONS AND WARNINGS > 5

Page 6

6 < NOTES, CAUTIONS AND WARNINGS

Page 7

INTRODUCTION

The C9300/C9500 Finisher option adds document production

functionality to the C9300/C9500 colour printers by providing:

l on-line stapling

l on-line punching

l paper position offset capability for job and copy unit (collated

printing) separation

For use with the Finisher, the printer requires a total of five paper trays

and the Finisher is positioned on a Finisher Cabinet so that it aligns

with the printer paper output path.

NOTE

This document assumes that the Finisher has been mechanically

installed.

English

INTRODUCTION > 7

Page 8

HOW TO USE THIS GUIDE

This User’s Guide describes the C9300/C9500 Finisher. The printer

and Finisher Cabinet are described in separate documents.

The contents of this Guide are arranged to take you through the

following steps to make the best use of the Finisher:

l Being aware of safety issues

l Setting up the printer driver

l Using the Finisher

l Troubleshooting the Finisher

l Maintaining the Finisher

You are advised to read the sections of this document in the order in

which they are presented. Once you are familiar with the equipment

you can refer to specific sections in isolation via the Table of Contents

or Index.

8 < HOW TO USE THIS GUIDE

Page 9

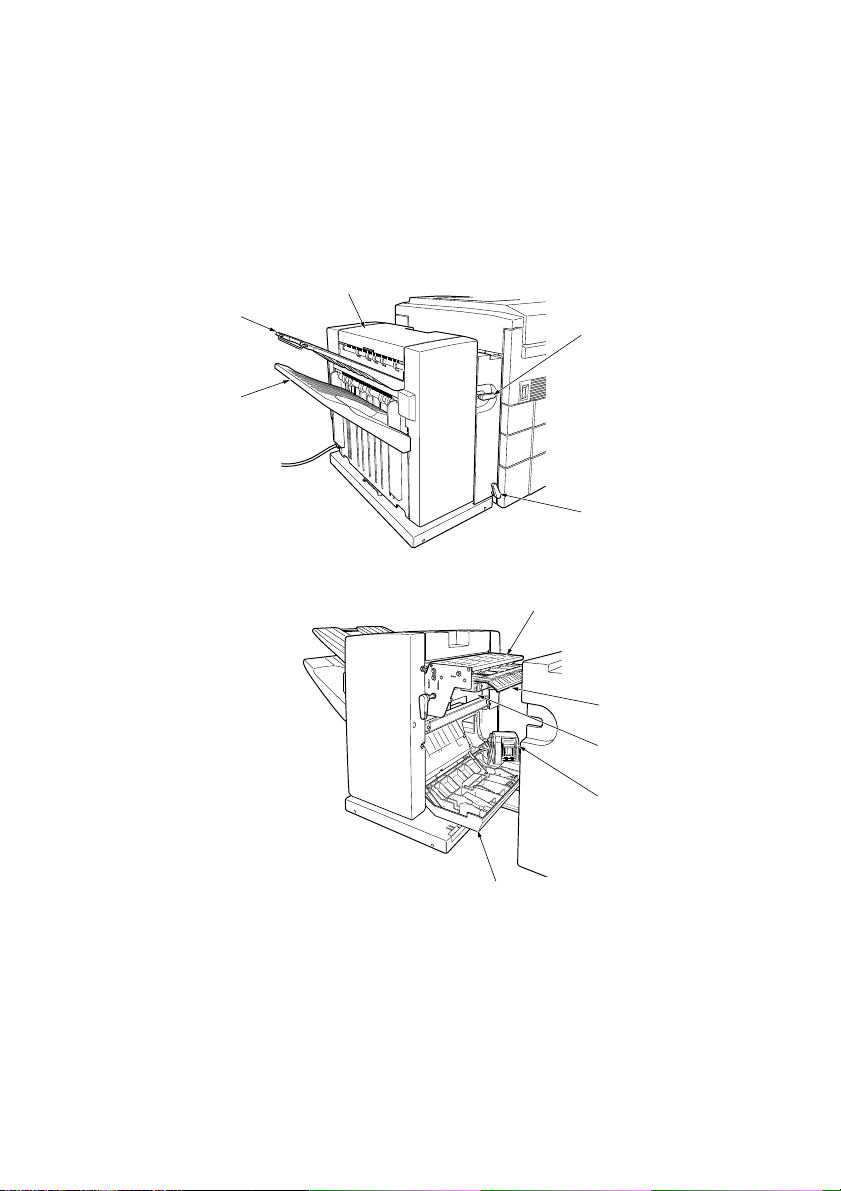

IDENTIFYING COMPONENT ITEMS

FINISHER

The component parts of the Finisher identified in the following

diagram are referred to as:

3

2

4

1

5

6

English

Face Down Stacker

1.

Face Up Stacker

2.

Finisher Cover

3.

Decurler Lever

4.

7

8

9

10

IDENTIFYING COMPONENT ITEMS > 9

Page 10

Release Lever

5.

Finisher Guide

6.

Finisher Entry Plate

7.

Chip Box (to catch the small circular paper punchings

8.

produced when the paper is punched)

Staple Unit

9.

Staple Cover

10.

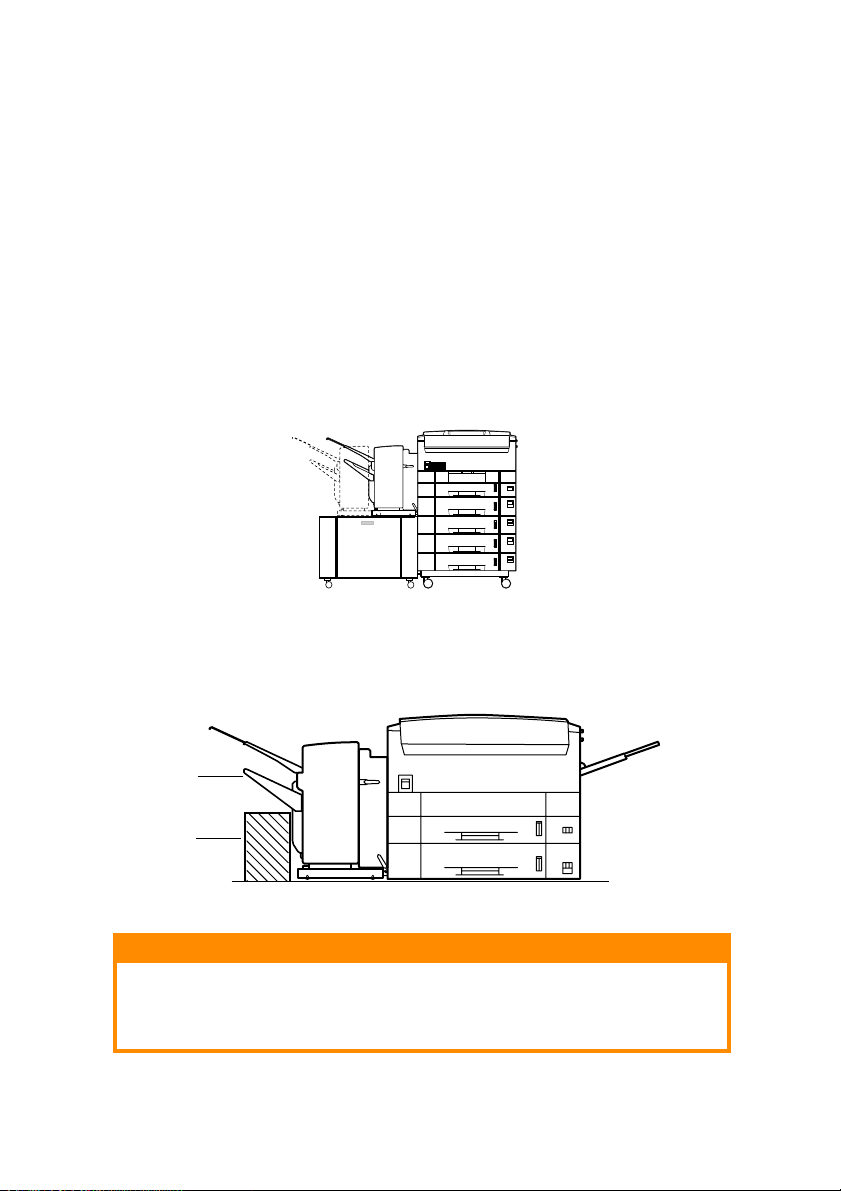

OVERALL CONFIGURATION

l For compatibility with the Finisher, the printer requires both a

second tray and an additional high capacity feed paper tray

unit. A Finisher Cabinet is required to support the Finisher.

1

2

CAUTION!

To avoid possible damage to the Finisher as the Face Down Stacker (1)

moves upwards or downwards, do not place any objects in the shaded

area (2) at any time.

10 < IDENTIFYING COMPONENT ITEMS

Page 11

English

When carrying out troubleshooting or maintenance work on the

Finisher, it can be detached from the printer.

l Paper trays are numbered from top to bottom:

Trays 1, 2, 3, 4, and 5 (where Tray 1 is the original tray supplied

with the printer, Tray 2 is the additional second tray and Trays

3 through 5 are part of the additional high capacity feed paper

tray unit).

NOTE

For simplicity, many of the illustrations in this manual do not show the

Finisher Cabinet.

IDENTIFYING COMPONENT ITEMS > 11

Page 12

USING THE FINISHER

BEFORE YOU BEGIN

The Finisher can handle only certain sizes, weights and types of media

in its punching, stapling and offsetting operations. Refer to the

following summary information to help you ensure that you make

correct use of the Finisher.

For detailed information, see “Appendix A - Specification” and

“Appendix B - Paper feed and ejection details”.

GENERAL

When the Finisher is being used:

l Custom width is 100 to 297mm and length is 149 to 1200mm.

Paper size must be set to Portrait.

l Envelope 1 (Portrait No 3), Envelope 2 (Portrait No 4), Envelope

3 (Landscape No 4), Com-9, Com-10, DL, C4 and Monarch

envelopes cannot be used.

l Error and warning messages that appear on the printer control

panel display are given in “Appendix C - Error and warning

messages”.

STACKER SUMMARY INFORMATION

TACKER

S

Face up (upper stacker)

Face down (lower stacker)

EATURES

F

Capacity: 100 sheets (at 80g/m

Size: A6 to A3

Punching, short or long side

Capacity: 1000 sheets (at 80g/m2)

Size: A4, Letter

Punching, long side

Stapling

Offsetting for job or copy unit separation

12 < USING THE FINISHER

2

)

Page 13

PUNCHING INFORMATION

Allowable paper sizes

For long-side binding:

l A4 (landscape) - 2-hole or 4-hole

l Letter (landscape) - 2-hole or 4-hole

l B5 (landscape) - 2-hole or 4-hole

For short side binding:

l A4 (portrait) - 2-hole

l Letter (portrait) - 2-hole

l B5 (portrait) - 2-hole

l Custom (width: 100 to 297mm, length: 149 to 1200mm)

(portrait) - 2-hole or 4-hole

l A3 (portrait) - 2-hole or 4-hole

l A5 (portrait) - 2-hole

l A6 (portrait) - 2-hole

English

l B4 (portrait) - 2-hole or 4-hole

l Legal (13in, 13.5in, 14in) (portrait) 2-hole

l Executive (portrait) - 2-hole

l Tabloid (portrait) - 2-hole or 4-hole

Allowable paper weight

l Upper tray (face up): 64 to 200g/m

2

104g/m

can be punched).

l Lower tray (face down): 64 to 104g/m

2

(only paper weights up to

2

, can be punched and

stapled.

l Post card, Envelope, Label stationery and OHP sheets cannot

be punched.

USING THE FINISHER > 13

Page 14

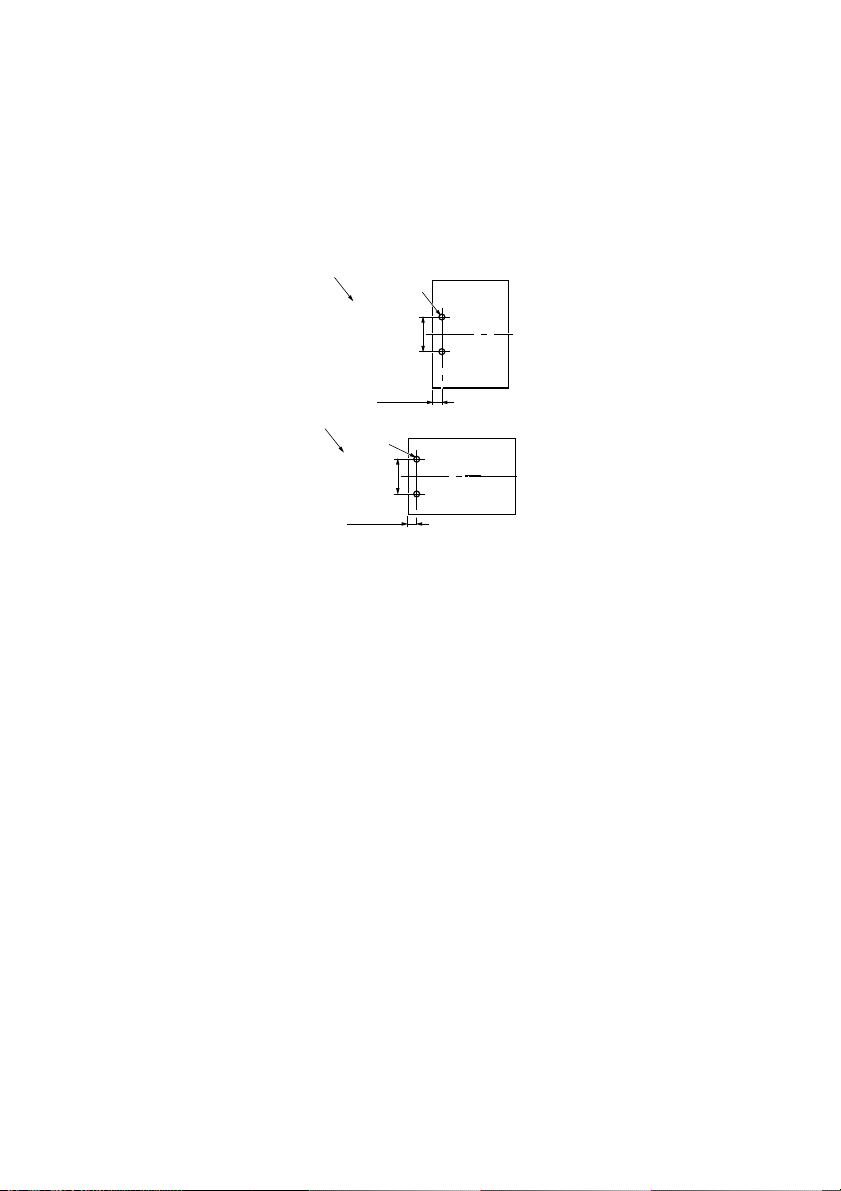

Hole positions

The Finisher is supplied with either 2-hole or 4-hole punching

capability.

The hole positions are shown below for 2-hole long-side binding (1)

and short-side binding (2):

1

f6+/-0.5mm

80+/-0.5mm

10.5+/-1mm

2

f6+/-0.5mm

80+/-0.5mm

10.5+/-1mm

l For 4-hole punching, two additional holes of the same

diameter are added, spaced 80+/-5mm on either side of the 2-

hole punching holes.

l Although punching always takes place at the same position on

the paper, by selecting paper orientation (portrait, landscape

or landscape with 180 deg rotation of printed data) in the

printer driver, the holes can effectively be placed at the left

side of a document for portrait use or at the top side or bottom

side of a document for landscape use.

Punching procedure

l Each sheet is punched individually.

14 < USING THE FINISHER

Page 15

English

STAPLING INFORMATION

Allowable paper sizes

l A4 (landscape)

l Letter (landscape)

Allowable paper weight

2

l Only normal paper of weight 64 to 104g/m

l Post card, Envelope, Label stationery and OHP sheets cannot

be stapled.

l Maximum paper per staple is 30 sheets or 3mm total

thickness. The number of sheets that can be stapled for

different paper weights is:

can be used.

APER WEIGHT

P

64 to 74g/m

75 to 90g/m

91 to 104g/m

2

2

2

UMBER OF SHEETS

N

30

25

22

l Face Down stacker full detection occurs when a maximum

number of stapled sets is reached (for example, 50 sets at 10

sheets per set). The printer control panel message is:

COULD NOT STAPLE. TOO MUCH PAPER

(See “Appendix C - Error and warning messages”.)

l Paper of weight greater than

104g/m2 is ejected without being

stapled.

USING THE FINISHER > 15

Page 16

Staple position

The staple (1) position is shown below:

6+/-2mm

6+/-2mm

1

l Although stapling always takes place at the same position on

the paper, by selecting paper orientation (portrait, landscape

or landscape with 180 deg rotation of printed data) in the

printer driver, the staple can effectively be placed at top left of

a document for portrait use or top right or bottom left of a

document for landscape use.

Stapling procedure

l Stapling is by print job or by copy unit.

l When stapling is enabled, single-sheet print jobs or copy units

are stapled.

l If paper sizes of A4 (landscape) and Letter (landscape) are

mixed in one print job, stapling will take place. Any other

paper size mixes will not be stapled and the paper will be

ejected to another stacker.

16 < USING THE FINISHER

Page 17

English

JOB OFFSET INFORMATION

Allowable paper sizes

l A4 (landscape)

l Letter (landscape)

Job offset position

Successive jobs are offset from each other by nominally 23mm (in a

direction orthogonal to paper travel).

Job offset procedure

l Job offset cannot be done along with stapling.

l Job offset is by print job or by copy unit.

USING THE FINISHER > 17

Page 18

PRINTING AND “FINISHING” A DOCUMENT

NOTE

This section deals only with additional settings required for Finisher

usage. Refer to your printer User’s Manual for other control panel and

printer driver settings such as paper source, type and size.

PRINTER CONTROL PANEL SETTINGS

For details on making settings at the printer control panel, refer to

your printer User’s Manual.

The additional functions associated with the Finisher that are

available on the printer control panel are accessed via:

l The PRINT MENU

l The LIFE SPAN MENU

PRINT MENU options

NOTE

Settings made from an application via the printer driver override the

following settings.

Output bin

Output bin: Set to define where to eject paper

Output binOutput bin

Standard bin

Standard bin: ejects to printer face down stacker at the top of

Standard binStandard bin

the printer (default setting)

Option bin 1

Option bin 1: ejects to Finisher face up stacker

Option bin 1Option bin 1

Option bin 2

Option bin 2: ejects to Finisher face down stacker

Option bin 2Option bin 2

Punching

Punching: Set to enable or disable punching

PunchingPunching

Off

Off: disables punching (default setting)

OffOff

On

On: enables punching

OnOn

Stapling

Stapling: Set to enable or disable stapling

StaplingStapling

Off

Off: disables stapling (default setting)

OffOff

18 < USING THE FINISHER

Page 19

English

On

On: enables stapling

OnOn

LIFE SPAN MENU options

Stapling count

Stapling count: displays the number of staples used in the format

Stapling countStapling count

nnnnnn (a 6-digit number)

Punching count

Punching count: displays the number of punch operations made in

Punching countPunching count

the format nnnnnn (a 6-digit number)

Finisher count

Finisher count: displays the number of sheets ejected to the Finisher

Finisher countFinisher count

in the format nnnnnn (a 6-digit number)

SETTING YOUR PRINTER DRIVER

The operating systems supported are as follows:

PostScript printing: Windows 95, 98, Me, 2000, NT4, XP, Macintosh

PCL printing: Windows 95, 98, Me, 2000, NT4, XP.

NOTE

The following instructions explain the driver settings involved to use the

Finisher. Other settings are explained in your printer User’s Manual.

Finisher-related settings

The settings you have to make for the Finisher are to:

Define that the Finisher is installed.

1.

Define the number of paper trays installed (a total of 5, i.e. 1

2.

original tray, 1 additional tray and 1 high capacity feed unit).

Define the paper orientation (Portrait, Landscape or

3.

Landscape with 180 deg rotation of printed data) to suit your

punching and/or stapling requirements.

ROTATION

NO

Portrait Staple top left

Punch left hand side

Landscape Staple top right

Punch top side

USING THE FINISHER > 19

DEG ROTATION

180

Not applicable

Staple bottom left

Punch bottom side

Page 20

Define the punching and/or stapling requirements (None,

4.

Staple, Staple + Punch (Long Edge), Punch (Long Edge), Punch

(Short Edge)).

NOTE

A graphic on some driver windows illustrates where punching and/or

stapling is located on the finished document to assist you in making

these settings.

Define where the finished documents are ejected:

5.

Stacker (Face-down)

Stacker (Face-down): paper is ejected at the top of the

Stacker (Face-down)Stacker (Face-down)

printer

Finisher (Face-up)

Finisher (Face-up): paper is ejected to the upper

Finisher (Face-up)Finisher (Face-up)

stacker of the Finisher

Finisher (Face-down)

Finisher (Face-down): paper is ejected to the lower

Finisher (Face-down)Finisher (Face-down)

stacker of the Finisher.

NOTE

An error message is displayed if an inappropriate combination of paper

size, stapling, punching, output destination has been selected.

20 < USING THE FINISHER

Page 21

WINDOWS DRIVERS

Windows 95/98/Me

Use [Start]-[Settings]-[Printers] to show the [Printers] window.

1.

Right click on the required printer and click [Properties] in the

2.

pop-up menu to show the Properties window.

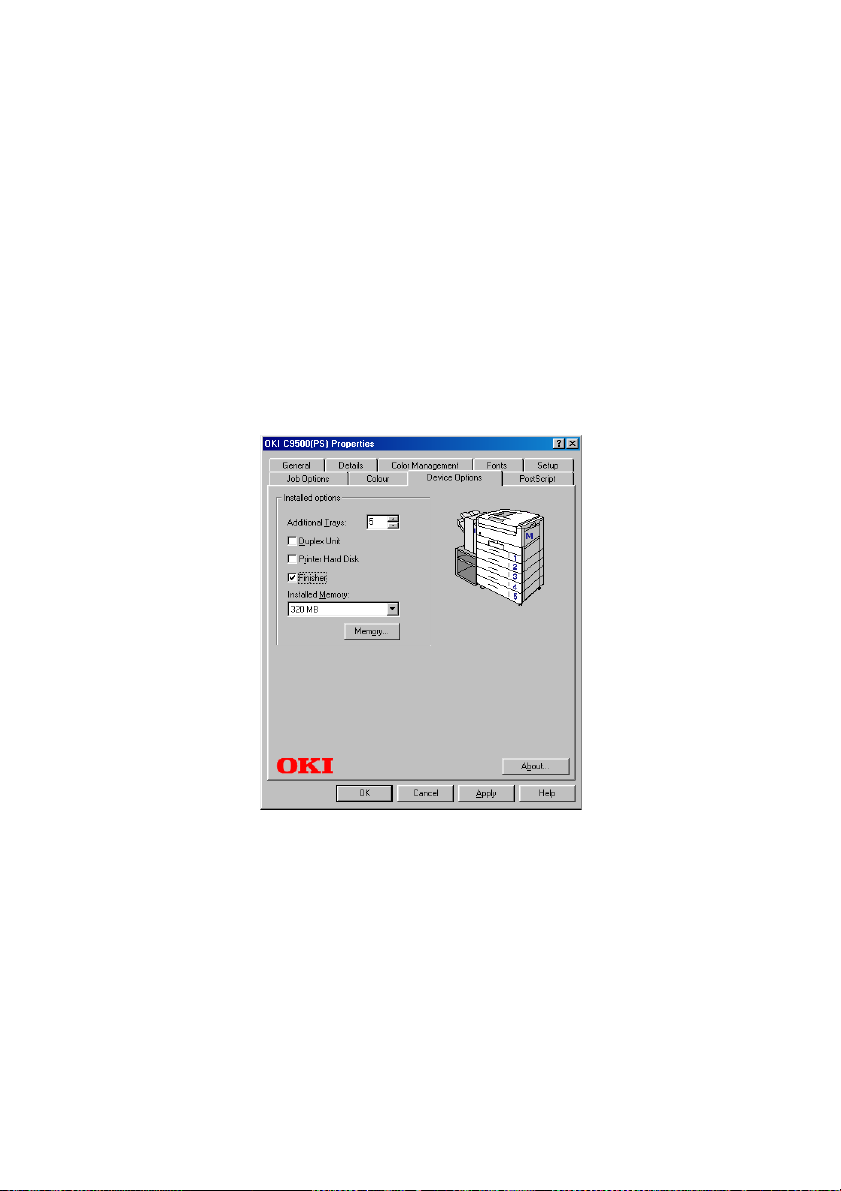

For PostScript printer driver:

3.

Click on the [Device Options] tab.

(a)

In [Additional Trays] select your tray configuration.

(b)

Check the [Finisher] checkbox then click [Apply].

(c)

English

USING THE FINISHER > 21

Page 22

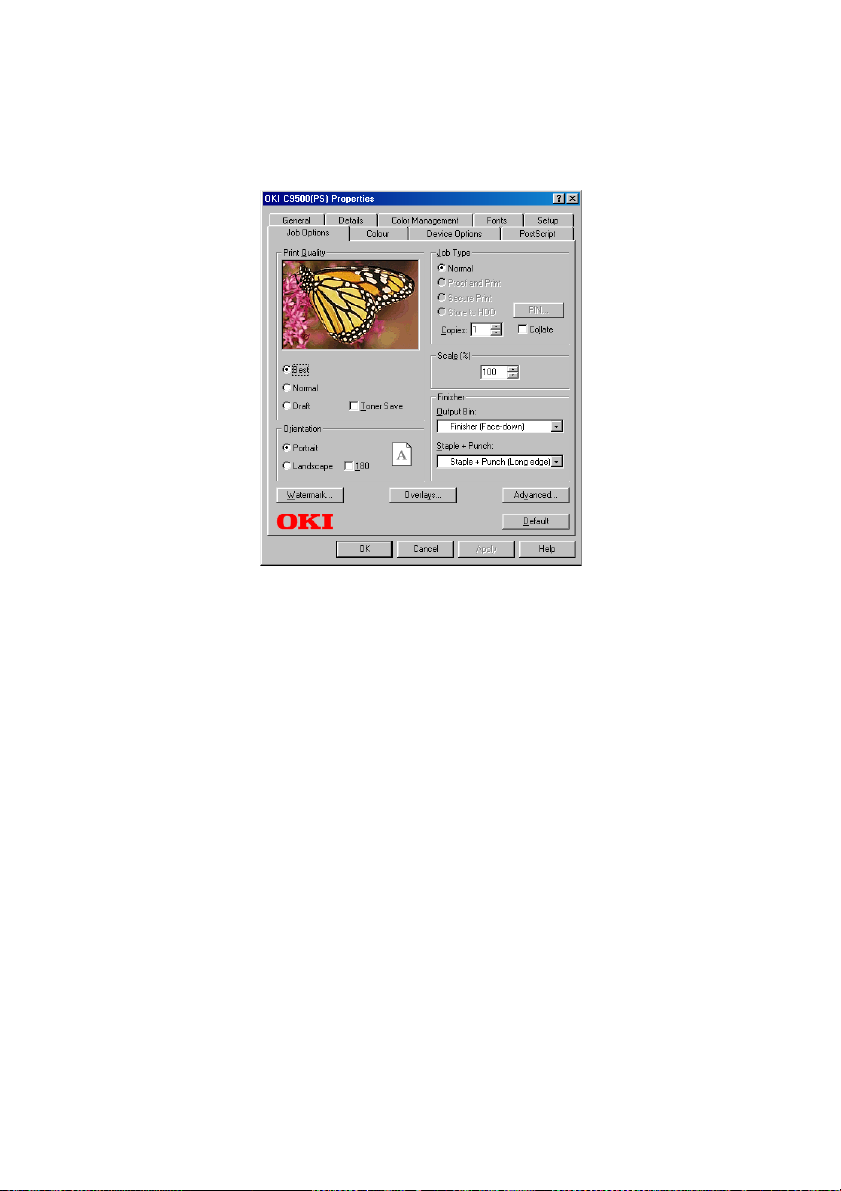

Click the [Job Options] tab, select the required [Output

(d)

bin], paper [Orientation] and stapling/punching

arrangement then click [Apply].

Click [OK] to close the driver user interface.

(e)

22 < USING THE FINISHER

Page 23

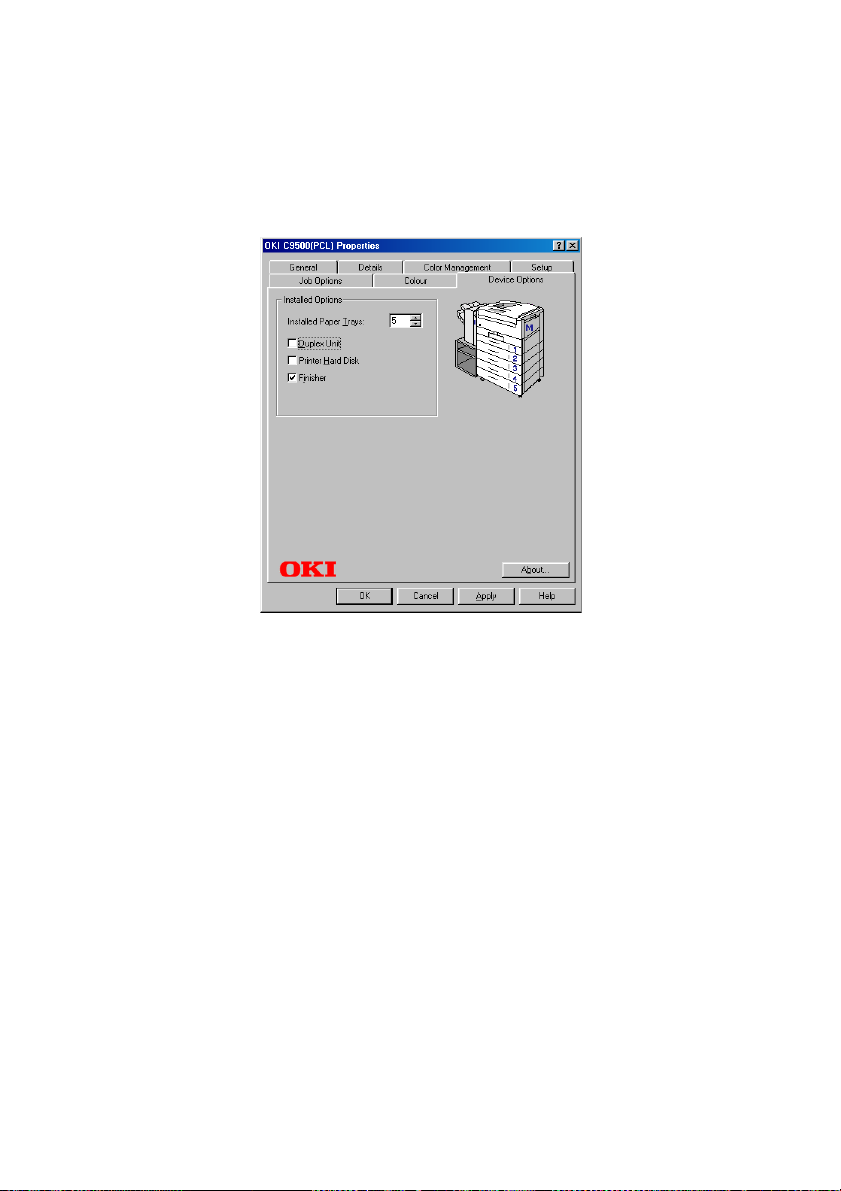

For PCL printer driver:

4.

(a)

(b)

English

Click on the [Device Options] tab.

Set the number of [Installed Paper Trays], check the

[Finisher] checkbox then click [Apply].

USING THE FINISHER > 23

Page 24

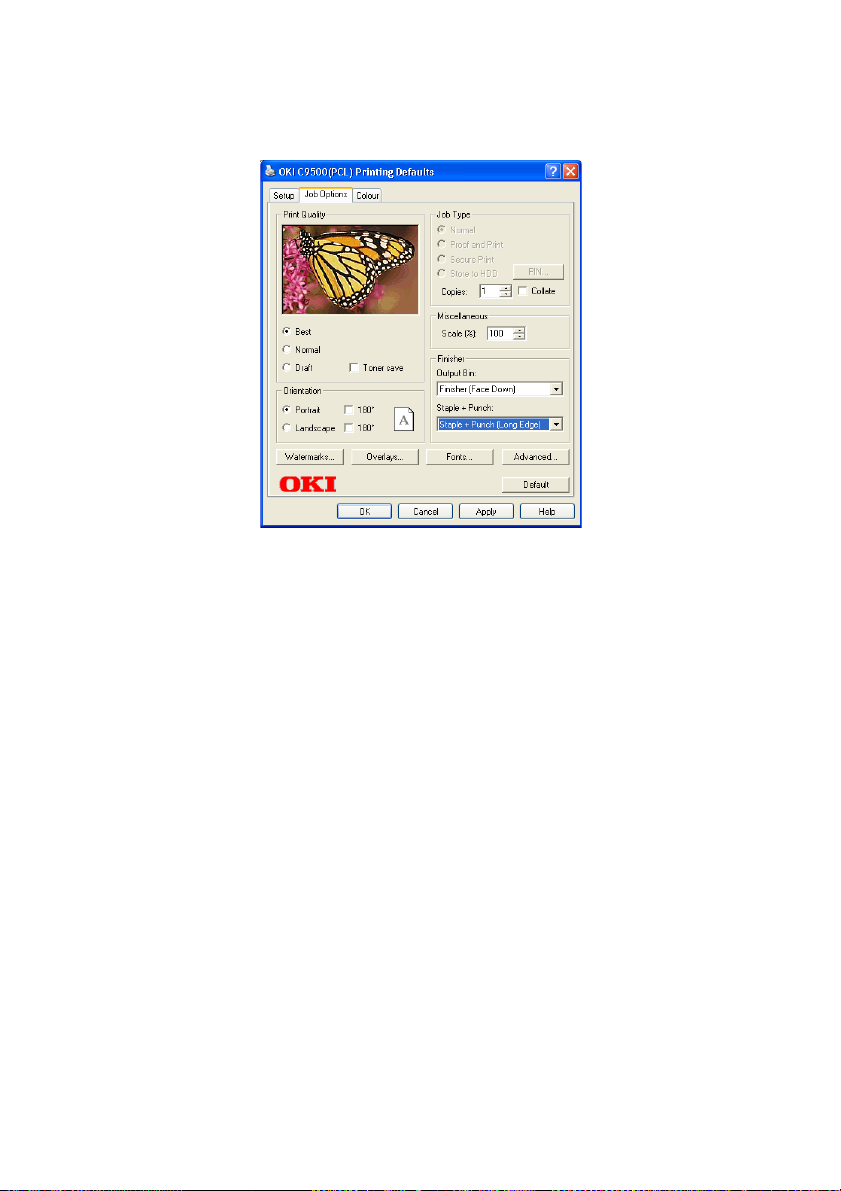

Click the [Job Options] tab, select the required [Output

(c)

bin], paper [Orientation] and stapling/punching

arrangement then click [Apply].

Click [OK] to close the driver user interface.

(d)

24 < USING THE FINISHER

Page 25

Windows 2000/XP (XP shown)

Use [Start]-[Settings]-[Printers/Printers and Faxes] to show the

1.

[Printers] window.

Right click on the required printer and click [Properties] in the

2.

pop-up menu to show the Properties window.

For PostScript printer driver:

3.

Click on the [Device Settings] tab.

(a)

English

Highlight [Finisher], then select [Installed].

(b)

Highlight [AvailableTray], select the number installed

(c)

and click [Apply].

USING THE FINISHER > 25

Page 26

Click [OK] to close the Properties dialog. Right click on

(d)

the printer icon and choose [Printing Preferences...].

On the [Layout] tab, select the required paper

(e)

[Orientation] and click [Apply].

Click the [Job Options] tab, select the required [Output

(f)

bin] and stapling/punching arrangement then click

[Apply].

26 < USING THE FINISHER

Page 27

(g)

For PCL printer driver:

4.

(a)

(b)

English

Click [OK] to close the driver user interface.

Click on the [Device Options] tab.

Set the number of [Installed Paper Trays], check the

[Finisher] checkbox then click [Apply].

USING THE FINISHER > 27

Page 28

Click on the [Advanced] tab the [Printing Defaults]

(c)

button then click on the [Job Options] tab.

Select the required paper [Orientation], [Output bin] and

(d)

stapling/punching arrangement then click [Apply].

Click [OK] twice to close the driver user interface.

(e)

28 < USING THE FINISHER

Page 29

Windows NT4.0

Use [Start]-[Settings]-[Printers] to show the [Printers] window.

1.

For PostScript printer driver:

2.

Right click on the required printer and click [Properties]

(a)

in the pop-up menu to show the Properties window.

Click on the [Device Settings] tab.

(b)

English

Highlight [Finisher] and select [Installed] from the list.

(c)

Highlight [Available Tray], then select the number

(d)

installed (i.e. 5) and click [OK].

USING THE FINISHER > 29

Page 30

Right click on the required printer and click [Document

(e)

Defaults...] in the pop-up menu to show the Default

window then click on the [Job Options] tab.

Select the required paper [Orientation], [Output bin] and

(f)

stapling/punching arrangement.

Click [OK] to close the driver user interface.

(g)

30 < USING THE FINISHER

Page 31

For PCL printer driver:

3.

(a)

(b)

English

Right click on the required printer and click [Properties]

in the pop-up menu to show the Properties window.

Click on the [Device Options] tab. Set the number of

[Installed Paper Trays], check the [Finisher] checkbox

and then click [OK].

USING THE FINISHER > 31

Page 32

Right click on the required printer and click [Document

(c)

Defaults...] in the pop-up menu to show the Default

window then click on the [Job Options] tab.

Select the required paper [Orientation], [Output bin] and

(d)

stapling/punching arrangement.

Click [OK] to close the driver user interface.

(e)

32 < USING THE FINISHER

Page 33

MACINTOSH DRIVERS

Macintosh (Mac OS)

Open the Chooser from the Apple menu.

1.

Depending on the driver you use, select either the AdobePS or

2.

LaserWriter 8 icon on the left-hand side of the Chooser. Click

on the [Setup...] button.

English

Click on [Configure].

3.

Change [Available Tray] to the required value.

4.

Change [Finisher] to [Installed].

5.

USING THE FINISHER > 33

Page 34

Click [OK] twice.

6.

Click [File] then [Page Setup...]. On the [Page Attributes] panel,

7.

set the page [Orientation] and on the [PostScript Options]

panel set the Visual Effects controls as required.

C9500

8.

C9500

Click [OK].

34 < USING THE FINISHER

Page 35

Click [File] and then click the application Print menu.

9.

On the [Printer Job Options] panel, set the required [Output

10.

Bin] option and [Staple & Punch] option.

Click [Save Settings].

11.

Macintosh (Mac OSX)

Mac OS X versions 10.1 - 10.1.5

English

For older versions of Mac OS X, it is not possible to manually change

the printer installable options. However, all of the printer options are

enabled by default in the PostScript Printer Description (PPD) file for

your printer. This may lead to some inappropriate options becoming

available for your printer model.

If you are using Mac OS X 10.1 - 10.1.5, please ignore Steps 1 to 7

below, and start at Step 8.

Mac OS X version 10.2 and greater

Launch the [Print Center] application which is located in the

1.

[Applications : Utilities] folder.

USING THE FINISHER > 35

Page 36

Select your printer from the list, and from the [Printers] menu

2.

select [Show Info].

From the pop-up menu, choose [Installable Options].

3.

Change [Available Tray] to the required value.

4.

Select the [Finisher] option.

5.

Click [Apply Changes].

6.

36 < USING THE FINISHER

Page 37

From the [Print Center] menu, select [Quit Print Center].

7.

From inside your application program, click [File] then [Page

8.

Setup].

From the [Format for:] menu, select your printer.

9.

Set the paper [Orientation] as required.

10.

English

11.

Click [OK].

USING THE FINISHER > 37

Page 38

Click [File] then [Print].

12.

On the [Printer Features] panel, set the required [Output Bin]

13.

and [Staple & Punch] options.

From the [Presets] menu, choose [Save As…] to save the

14.

settings as default.

38 < USING THE FINISHER

Page 39

TROUBLESHOOTING

For a full list of error and warning messages, refer to “Appendix C Error and warning messages”.

COUNTERACTING PAPER CURL

If the paper emerging from the Finisher displays significant curl (1) it

might not stack properly. Also, curled paper might cause jams to

occur in the Finisher.

1

To counteract such curl, you can adjust the position of the Decurler

Lever.

English

TROUBLESHOOTING > 39

Page 40

Setting the Decurler Lever

1.

Confirm that the Decurler Lever (1) is in the horizontal

(a)

position i.e. the setting for normal operation.

To counteract the curl, rotate the Decurler Lever

(b)

upwards as far as it will go.

1

1

NOTE

Depending on the direction and magnitude of paper curl, it is possible

that setting the Decurler Lever as above might cause a paper jam or

stacking error to occur. In this event, return the Decurler Lever to its

horizontal position.

40 < TROUBLESHOOTING

Page 41

CLEARING A PAPER JAM

When a paper jam occurs, the following message appears on the

printer control panel:

REMOVE FINISHER

nnn: PAPER JAM

where nnn is in the range 361 to 367.

NOTES

> Paper may be jammed in both the printer and the Finisher. For

details of clearing a paper jam in the printer, refer to the printer

User’s Manual.

> When a printer paper jam is cleared, recovery printing will reprint

the pages that were jammed. Provided the first page of a set to be

stapled is reprinted, stapling will take place: otherwise, the paper

will be ejected without stapling.

> When a Finisher unit paper jam is cleared, the pages that were

jammed will not be automatically reprinted. Remaining pages of a

set that was to be stapled will be ejected without stapling.

English

TROUBLESHOOTING > 41

Page 42

Use the paper jam identifying number on the printer display to

1.

locate the paper jam in the Finisher.

NOTE

The number (in the range 361 to 367 inclusive) identifies the first

position at which paper is jammed. If the paper is jammed in several

places, another number may be displayed after removing the jam at the

first location.

366

367

7

363

364

362

1

2

365

6

361

4

3

5

42 < TROUBLESHOOTING

Page 43

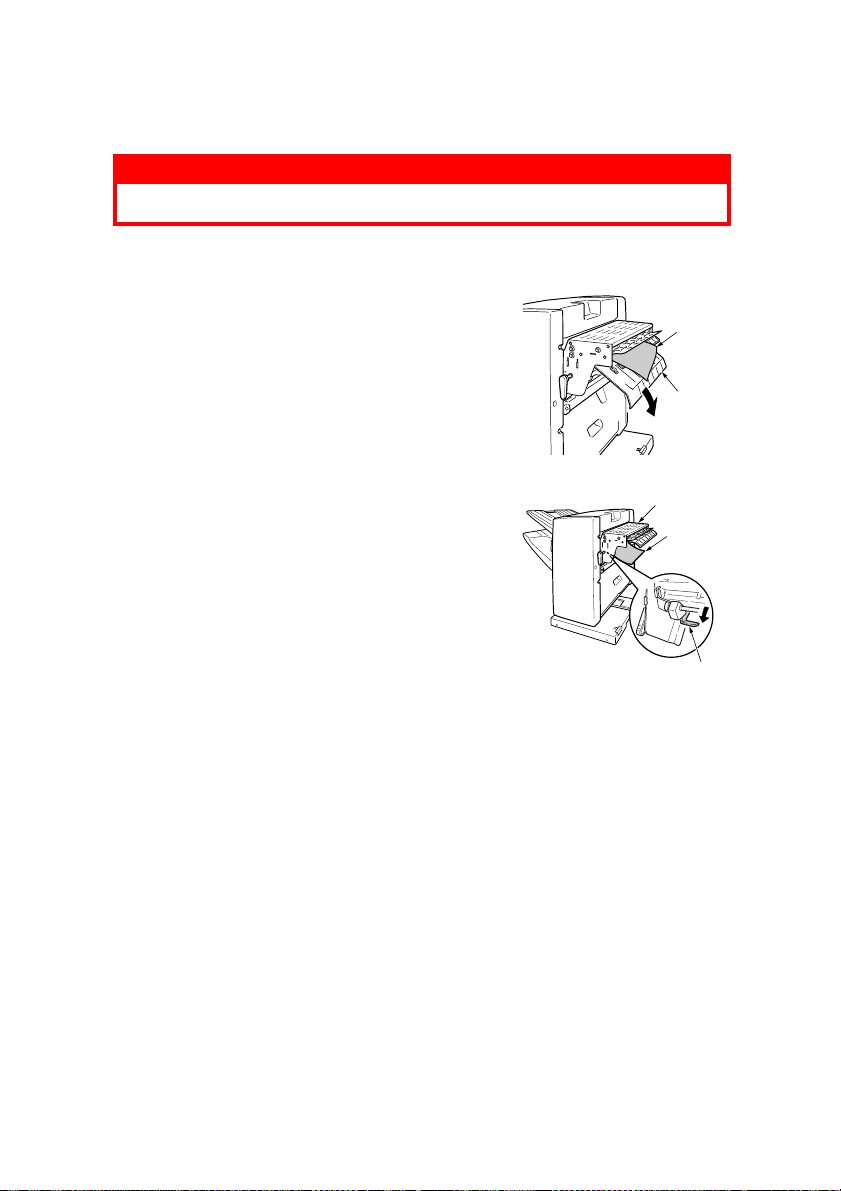

Detach the Finisher.

2.

WARNING!

Do not touch the Finisher Guide (2) as it may be hot.

Rotate the Decurler Lever (1)

(a)

to point downwards.

Rotate the Release Lever (3)

(b)

upwards and detach the

Finisher from the printer.

English

2

1

3

TROUBLESHOOTING > 43

Page 44

Remove the jammed paper.

3.

WARNING!

Be careful to avoid components and edges inside the Finisher.

Locations 361 and 362

Hold down the Finisher Entry

(a)

Plate (2) and remove the

paper (1).

Hold down the Loop Guide

(b)

(4) and remove the paper (1).

Raising the Finisher Guide

(3) may make the paper

removal easier.

1

2

3

1

4

44 < TROUBLESHOOTING

Page 45

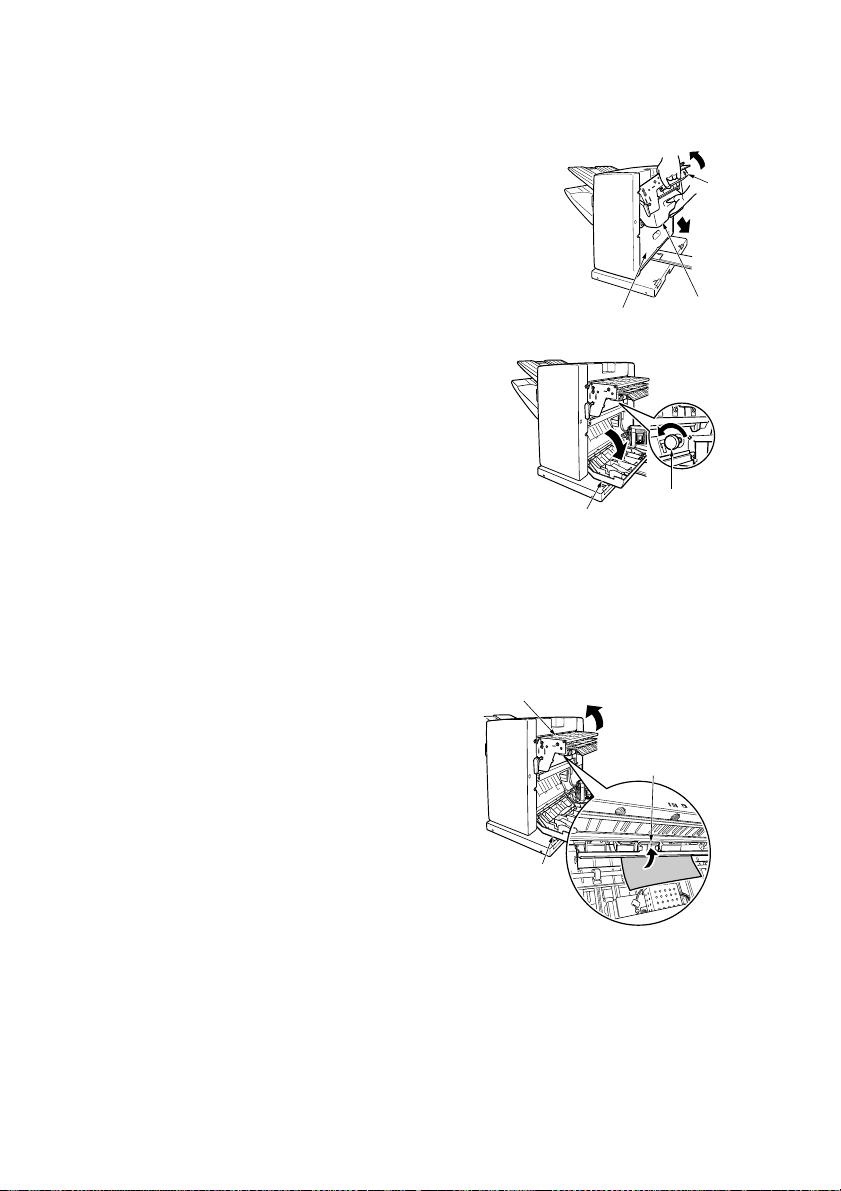

Locations 363 and 364

Hold up the Finisher Guide (1)

(c)

and carefully remove the Chip

Box (2). (You can empty the Chip

Box when you have removed it.)

English

1

Open the Staple cover (3).

(d)

Rotate the blue knob (4)

(e)

located in the Finisher

Guide in the direction of the

arrow and remove the

paper when it appears.

Raise and hold the blue

(f)

Guide Plate (5) in the

Finisher Guide and

remove the paper.

Raise and hold the

(g)

Finisher Guide (1) and

refit the Chip Box.

Close the Staple Cover

(h)

(3).

3

3

1

3

2

4

5

TROUBLESHOOTING > 45

Page 46

Locations 365 and 367

Open the Staple Cover

(i)

(2) and remove the

paper (3). Paper

removal may be easier

if you rotate the blue

knob (1) in the direction

of the arrow.

Close the Staple Cover

(j)

(2).

Location 366

Open the Finisher Cover (1)

(k)

and remove the paper (2).

Close the Finisher Cover (1).

(l)

1

23

1

2

46 < TROUBLESHOOTING

Page 47

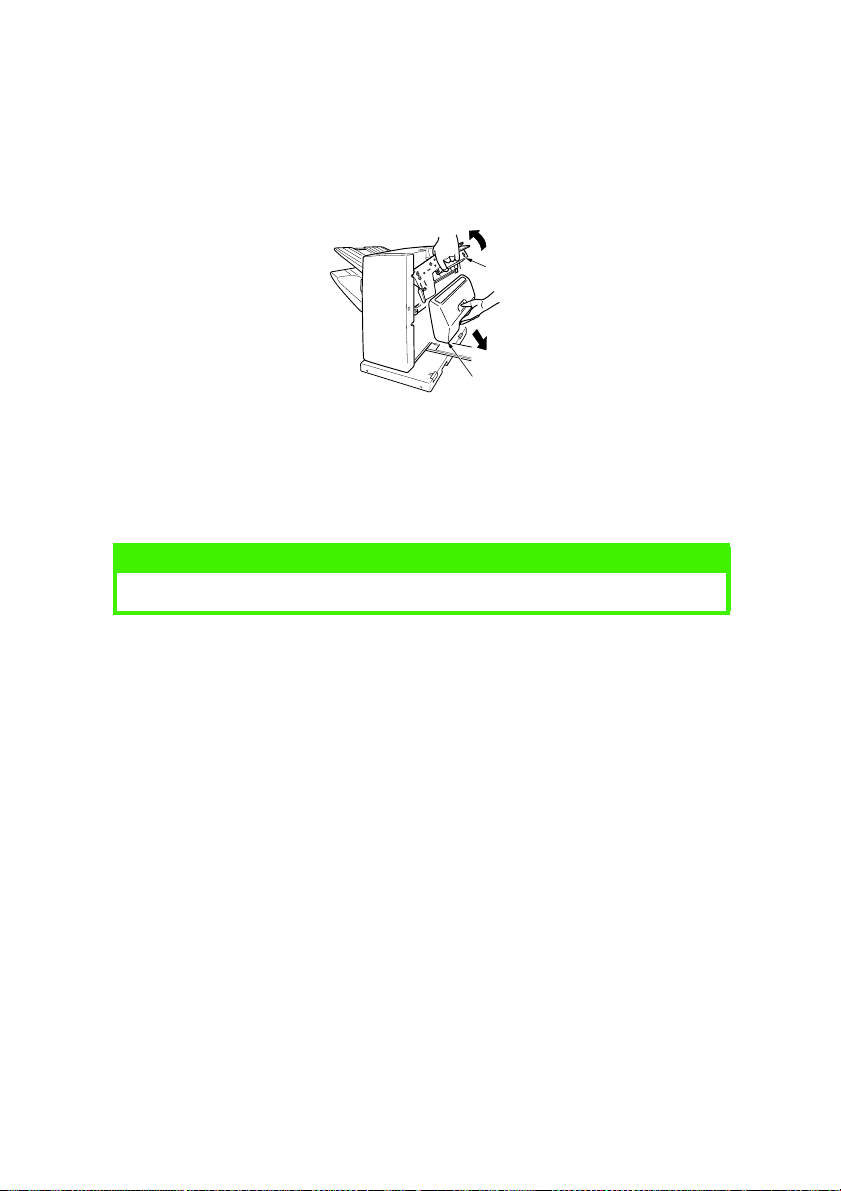

Attach the Finisher to the printer.

4.

Push the Finisher towards the printer until it clicks into

(a)

position.

Return the Decurler Lever (1) to the horizontal position.

(b)

English

1

NOTE

If the Decurler Lever is not returned to the horizontal position, it may

cause the paper to jam.

TROUBLESHOOTING > 47

Page 48

REMOVING JAMMED STAPLES

When stapling is not taking place as expected and there are still

staples in the staple cartridge unit, check for a staple jam.

Detach the Finisher.

1.

WARNING!

Do not touch the Finisher Guide (2) as it may be hot.

Rotate the Decurler Lever (1) to

(a)

point downwards.

Rotate the Release Lever (3)

(b)

upwards and detach the

Finisher from the printer.

Open the Staple Cover (1) to

(c)

expose the Staple Unit (2).

2

1

3

1

2

48 < TROUBLESHOOTING

Page 49

Remove the staple cartridge unit from the staple unit.

2.

WARNING!

Be careful to avoid components and edges inside the Finisher.

Do not touch the Staple Unit motor (3) which may be hot.

Lift the blue Lock Lever (1) and

(a)

rotate the Staple Unit (2) in the

direction of the arrow.

3

Holding the Staple Unit (3) as

(b)

shown, raise the light blue Knob

(1) and remove the Staple

Cartridge unit (2).

2

English

1

1

2

3

TROUBLESHOOTING > 49

Page 50

Remove the jammed staples.

3.

Use the handle (2) to open the

(a)

1

cartridge unit.

Remove and discard the jammed

(b)

staples (1).

Use handle (2) to close the

(c)

cartridge unit.

Fit the Staple Cartridge unit into the

4.

Staple Unit.

WARNING!

Be careful to avoid components and edges inside the Finisher.

Push the Staple Cartridge unit (1)

(a)

into the Staple Unit (2) until a

click is heard.

Rotate the Staple Unit (2) in the

(b)

direction of the arrow.

2

1

50 < TROUBLESHOOTING

2

Page 51

Attach the Finisher to the printer.

5.

Close the Staple Cover (2).

(a)

Push the Finisher towards the printer until it clicks into

(b)

position.

Return the Decurler Lever (3) to the horizontal position.

(c)

English

1

2

3

NOTE

If the Decurler Lever is not returned to the horizontal position, it may

cause the paper to jam.

TROUBLESHOOTING > 51

Page 52

MAINTAINING THE FINISHER

For a full list of error and warning messages, refer to “Appendix C Error and warning messages”.

The two tasks involved in maintaining the Finisher are:

l replenishing the staple cartridge unit when the staples are

(almost) exhausted

(See “Appendix D - Consumables” for details of ordering new

staples.)

l disposing of the punch chips (i.e. small circular punchings)

that accumulate in the punch Chip Box

52 < MAINTAINING THE FINISHER

Page 53

REPLENISHING THE STAPLE CARTRIDGE UNIT

NOTE

Your Finisher is supplied with a cartridge of staples pre-installed.

When the staple supply is almost exhausted, the following message

appears at the printer control panel:

NO STAPLE

Continue as follows:

Detach the Finisher.

1.

WARNING!

Do not touch the Finisher Guide (2) as it may be hot.

Rotate the Decurler Lever (1)

(a)

to point downwards.

Rotate the Release Lever (3)

(b)

upwards and detach the

Finisher from the printer.

2

1

English

Open the Staple Cover (1) to

(c)

expose the Staple Unit (2).

MAINTAINING THE FINISHER > 53

3

1

2

Page 54

Remove the Staple Cartridge unit from the Staple Unit.

2.

WARNING!

Be careful to avoid components and edges inside the Finisher.

Do not touch the Staple Unit motor (3) which may be hot.

Lift the blue Lock Lever (1) and

(a)

rotate the Staple Unit (2) in the

direction of the arrow.

3

2

Holding the Staple Unit (3) as

(b)

shown, raise the light blue

Knob (1) and remove the Staple

Cartridge unit (2).

1

1

2

3

54 < MAINTAINING THE FINISHER

Page 55

Fit the new staples.

3.

(a)

(b)

(c)

(d)

Remove the empty staple

cartridge from the Staple

Cartridge unit.

Remove the new cartridge of

staples from its packaging, but

do not yet remove the Tape (1).

Push the new cartridge of

staples into the Staple

Cartridge unit until a click is

heard.

Remove the Tape (1).

English

1

1

MAINTAINING THE FINISHER > 55

Page 56

Fit the Staple Cartridge unit into the Staple Unit.

4.

WARNING!

Be careful to avoid components and edges inside the Finisher.

Push the Staple Cartridge unit

(a)

(1) into the Staple Unit (2) until

a click is heard.

Rotate the Staple Unit (2) in

(b)

the direction of the arrow.

2

1

56 < MAINTAINING THE FINISHER

Page 57

Attach the Finisher to the printer.

5.

Close the Staple Cover (2).

(a)

Push the Finisher towards the printer until it clicks into

(b)

position.

Return the Decurler Lever (3) to the horizontal position.

(c)

English

1

2

3

NOTES

> If the Decurler Lever (3) is not returned to the horizontal position, it

may cause the paper to jam.

> If the Stapler Cartridge has not been properly fitted, the following

error message will occur at the printer control panel:

CHECK STAPLER CARTRIDGE

471: STAPLER CARTRIDGE MISSING

MAINTAINING THE FINISHER > 57

Page 58

REMOVING THE PUNCH CHIPS

When the punch Chip Box is almost full and requires to be emptied,

the following message appears at the printer control panel:

PUNCH CHIP OVERFLOW

Continue as follows:

Detach the Finisher.

1.

WARNING!

If the Finisher Guide (2) is hot, give it time to cool before proceeding.

Rotate the Decurler Lever (1)

(a)

to point downwards.

Rotate the Release Lever (3)

(b)

upwards and detach the

Finisher from the printer.

2

1

3

58 < MAINTAINING THE FINISHER

Page 59

English

Remove the punch Chip Box.

2.

Rotate the Finisher Guide (1) upwards and hold it in the

(a)

raised position while you carefully remove the Chip Box

(2).

1

2

Lower the Finisher Guide (1) back into position.

(b)

NOTE

Be careful not to spill the punch chips by tilting the Chip Box too much.

Dispose of the punch chips.

(c)

Refit the punch Chip Box.

3.

Rotate the Finisher Guide (1) upwards and hold it in the

(a)

raised position while you refit the Chip Box (2).

Lower the Finisher Guide (1) back into position.

(b)

MAINTAINING THE FINISHER > 59

Page 60

Attach the Finisher to the printer.

4.

Push the Finisher towards the printer until it clicks into

(a)

position.

1

Return the Decurler Lever (1) to the horizontal position.

(b)

NOTES

> If the Decurler Lever is not returned to the horizontal position, it may

cause the paper to jam.

> If the punch Chip Box has not been properly fitted, the following

error message will occur at the printer control panel:

CHECK PUNCH CHIP BOX

472: PUNCH CHIP BOX MISSING

60 < MAINTAINING THE FINISHER

Page 61

APPENDIX A - SPECIFICATION

MAIN CHARACTERISTICS

The main characteristics of the Finisher are specified in the following

table:

English

HARACTERISTIC

C

Overall function Mass stacking, stapling, punching, job offsetting

Stacking capacity

Paper size Face up stacker: A3, A4, A5, A6, B4, B5, Letter, Tabloid, Legal

Paper weight

Stapling paper size A4 (landscape), Letter (landscape)

Staple paper capacity Maximum 30 sheets or paper thickness 3mm (weight 64 to

Punch holes Either 2-hole or 4-hole punching

Punching paper size Long-side binding: A4 (landscape), Letter (landscape), B5

Punching paper weight

Power supply 100 - 240V +/- 10%, 50-60 +/- 3Hz AC

Power consumption During operation: 62W maximum, 30W average

Operating environment During operation: 10 to 32 deg C, 20 to 80%RH (max.wet

Normal usage Average power ON time: 220 hr/month

Consumabl es Staples

Weight Approximately 25kg

Face up stacker: about 100 sheets at 80g/m

Face down stacker: about 1000 sheets at 80g/m2 (with

stacker full detection)

(13in, 13.5in, 14in), Executive, Custom (width: 100 to

297mm, length: 149 to 1200mm)

Face down stacker: A4 (landscape), Letter (landscape)

Face up stacker: weight 64 to 200g/m2 (only paper up to

2

104g/m

Face down stacker: weight 64 to 104g/m

104g/m

(landscape)

Short side binding: A3, A4 (portrait), A5, A6, B4, B5 (portrait),

Letter (portrait), Tabloid, Legal (13in, 13.5in, 14in),

Executive, Custom (width: 100 to 297mm, length: 149 to

1200mm)

64 to 104g/m

Idling: 5W maximum

bulb temp. 25 deg C, max. wet bulb temp. difference 2 deg C)

Not in operation: 0 to 43 deg C, 10 to 90% RH (max.wet bulb

temp. 26.8 deg C, max. wet bulb temp. difference 2 deg C)

Average print quantity: 7000 sheets/month

can be punched)

2

)

2

PECIFICATION

S

2

2

APPENDIX A - SPECIFICATION > 61

Page 62

HARACTERISTIC

C

PECIFICATION

S

Compatible printers C9300/C9500 printers

Printer tray configuration Second tray + high capacity feed tray unit

See the following configuration diagram.

Dimensions See the following configuration diagram.

(Cabinet width = 560mm)

CONFIGURATION DIAGRAM

859mm

629mm

316mm

539mm

490mm

666mm

62 < APPENDIX A - SPECIFICATION

Page 63

English

APPENDIX B - PAPER FEED AND EJECTION DETAILS

PRINTER PAPER FEED DETAILS

MP: Multi-purpose tray

s: used for single-sided printing only

d: used for both single-sided and double-sided (optional) printing

x: cannot be used

IZE AND WEIGHT

S

Normal paper, 64 to 80g/m

Normal paper, 64 to 80g/m

Normal paper, 64 to 80g/mNormal paper, 64 to 80g/m

A4 (landscape), Letter (landscape) s s s

A4 (portrait), Letter (portrait) s s s

B5 (landscape) s s s

A5, B5 (portrait), B4, Legal (13in,

13.5in, 14in), Executive, tabloid

A3 s s s

A3 outsize, A3 wide (SRA3),

Tablo id extra

A6 x x s

Custom - Note 2 x x s

Normal paper, 81 to 104g/m

Normal paper, 81 to 104g/m

Normal paper, 81 to 104g/mNormal paper, 81 to 104g/m

A4 (landscape), Letter (landscape) d d s

A4 (portrait), Letter (portrait) d d s

B5 (landscape) d d s

A5, B5 (portrait), B4, Legal (13in,

13.5in, 14in), Executive, Tabloid

A3 d d s

A3 wide (SRA3), Tabloid extra d d s

A3 outsize s s s

A6 s x s

Custom - Note 2 x x s

Normal paper, 105 to 175g/m

Normal paper, 105 to 175g/m

Normal paper, 105 to 175g/mNormal paper, 105 to 175g/m

A4 (landscape), Letter (landscape) s s s

A4 (portrait), Letter (portrait) s s s

2222

2222

2222

RAY

T

1 T

sss

sss

d d s

RAYS

N

2 TO 5

OTE

1

ANUAL FEED

M

MP

APPENDIX B - PAPER FEED AND EJECTION DETAILS > 63

Page 64

IZE AND WEIGHT

S

A5, B5, B4, Legal (13in, 13.5in,

14in), Executive, Tabloid

A3 s s s

A3 wide (SRA3), Tabloid extra s s s

A3 outsize s s s

A6 s x s

Custom - Note 2 x x s

Normal paper, 176 to 198g/m

Normal paper, 176 to 198g/m

Normal paper, 176 to 198g/mNormal paper, 176 to 198g/m

A4 (landscape), Letter (landscape) x x s

A4 (portrait), Letter (portrait) x x s

A5, B5, B4, Legal (13in, 13.5in,

14in), Executive, Tabloid

A3 x x s

A3 outsize, A3 wide (SRA3),

Tabloid extra - Note 3

A6 x x s

Custom - Note 2 x x s

Post card

Post card

Post cardPost card

Post card, Double post card s x s

Envelope

Envelope

EnvelopeEnvelope

Envelope 1 (portrait No 3) - Note 4 x x x

Envelope 2 (portrait No 4) - Note 4 x x x

Envelope 3 (portrait No 4) - Note 4 x x x

Com-9, Com-10, DL, C4, Monarch

- Note 4

Envelope 4 (A4 size), C5 x x s

Label stationery

Label stationery

Label stationeryLabel stationery

A4, Letter x x s

OHP sheet

OHP sheet

OHP sheetOHP sheet

A4, Letter s x s

2222

RAY

T

1 T

sxs

x x s

x x x

xxx

RAYS

N

2 TO 5

OTE

1

ANUAL FEED

M

MP

Notes:

Trays (5 in total) are numbered from the top down.

1.

When feeding the Finisher, printer Custom dimensions are

2.

width 100 to 297mm and length 149 to 1200mm.

When feeding the Finisher, A3 outsize, A3 wide (SRA3) and

3.

²

Tabloid extra of weight 176 to 198g/m

64 < APPENDIX B - PAPER FEED AND EJECTION DETAILS

cannot be used.

Page 65

When feeding the Finisher, Envelope 1(portrait No 3), Envelope

4.

2 (portrait No 4), Envelope 3 (landscape No 4), Com-9, Com-10,

DL, C4 and Monarch cannot be used.

PAPER EJECTION DETAILS

FINISHER FACE UP STACKER

(No stapling possible)

EO: ejection only

PL: punched for long-side binding

PS: punched for short-side binding

s: used for single-sided printing only

d: used for both single-sided and (optional) double-sided printing

x: cannot be used

IZE AND WEIGHT

S

Normal paper, 64 to 80g/m

Normal paper, 64 to 80g/m

Normal paper, 64 to 80g/mNormal paper, 64 to 80g/m

A4 (landscape), Letter (landscape) s s x

A4 (portrait), Letter (portrait) s x s

B5 (landscape) s s x

A5, B5 (portrait), B4, Legal (13in,

13.5in, 14in), Executive, Tabloid

A3 s x s

A3 outsize, A3 wide (SRA3),

Tablo id extra

A6 s x s

Custom s x s

Normal paper, 81 to 104g/m

Normal paper, 81 to 104g/m

Normal paper, 81 to 104g/mNormal paper, 81 to 104g/m

A4 (landscape), Letter (landscape) d d x

A4 (portrait), Letter (portrait) d x d

B5 (landscape) d d x

A5, B5 (portrait), B4, Legal (13in,

13.5in, 14in), Executive, Tabloid

A3 d x d

A3 wide (SRA3), Tabloid extra x x x

A3 outsize x x x

2222

2222

EO PL PS

sxs

xxx

d x d

English

APPENDIX B - PAPER FEED AND EJECTION DETAILS > 65

Page 66

IZE AND WEIGHT

S

A6 s x s

Custom s x s

Normal paper, 105 to 175g/m

Normal paper, 105 to 175g/m

Normal paper, 105 to 175g/mNormal paper, 105 to 175g/m

A4 (landscape), Letter (landscape) s - Note 1 x x

A4 (portrait), Letter (portrait) s - Note 1 x x

A5, B5, B4, Legal (13in, 13.5in,

14in), Executive, Tabloid

A3 s - Note 1 x x

A3 wide (SRA3), Tabloid extra x x x

A3 outsize x x x

A6 s x x

Custom s x x

Normal paper, 176 to 198g/m

Normal paper, 176 to 198g/m

Normal paper, 176 to 198g/mNormal paper, 176 to 198g/m

A4 (landscape), Letter (landscape) s x x

A4 (portrait), Letter (portrait) s x x

A5, B5, B4, Legal (13in, 13.5in,

14in), Executive, Tabloid

A3 s x x

A3 outsize, A3 wide (SRA3),

Tablo id extra

A6 s x x

Custom s x x

Post card

Post card

Post cardPost card

Post card, Double post card s x x

Envelope

Envelope

EnvelopeEnvelope

Envelope 1 (portrait No 3) x x x

Envelope 2 (portrait No 4) x x x

Envelope 3 (portrait No 4) x x x

Com-9, Com-10, DL, C4, Monarch x x x

Envelope 4 (A4 size), C5 s x x

Label stationery

Label stationery

Label stationeryLabel stationery

A4, Letter s x x

OHP sheet

OHP sheet

OHP sheetOHP sheet

A4, Letter s x x

2222

2222

EO PL PS

s - Note 1 x x

s x x

x x x

Notes:

1.

105g/m

printing.

2

(maximum) paper can be used for double-sided

66 < APPENDIX B - PAPER FEED AND EJECTION DETAILS

Page 67

FINISHER FACE DOWN STACKER

The only possible paper usage is as follows:

EO: ejection only

PL: punched for long-side binding

PS: punched for short-side binding

ST: stapling

s: used for single-sided printing only

d: used for both single-sided and double-sided printing

x: cannot be used

IZE AND WEIGHT

S

Normal paper, 64 to 80g/m

Normal paper, 64 to 80g/m

Normal paper, 64 to 80g/mNormal paper, 64 to 80g/m

A4 (landscape), Letter (landscape) s s x s

Normal paper, 81 to 104g/m

Normal paper, 81 to 104g/m

Normal paper, 81 to 104g/mNormal paper, 81 to 104g/m

A4 (landscape), Letter (landscape) d d x d

2222

2222

EO PL PS ST

English

APPENDIX B - PAPER FEED AND EJECTION DETAILS > 67

Page 68

PRINTER FACE DOWN STACKER

EO: ejection only (no punching or stapling)

s: used for single-sided printing only

d: used for both single-sided and double-sided printing

x: cannot be used

IZE AND WEIGHT

S

Normal paper, 64 to 80g/m

Normal paper, 64 to 80g/m

Normal paper, 64 to 80g/mNormal paper, 64 to 80g/m

A4 (landscape), Letter (landscape) s

A4 (portrait), Letter (portrait) s

B5 (landscape) s

A5, B5 (portrait), B4, Legal (13in, 13.5in, 14in),

Executive, Tabloid

A3 s

A3 outsize, A3 wide (SRA3), Tabloid extra s

A6 x

Custom x

Normal paper, 81 to 104g/m

Normal paper, 81 to 104g/m

Normal paper, 81 to 104g/mNormal paper, 81 to 104g/m

A4 (landscape), Letter (landscape) d

A4 (portrait), Letter (portrait) d

B5 (landscape) d

A5, B5 (portrait), B4, Legal (13in, 13.5in, 14in),

Executive, Tabloid

A3 d

A3 wide (SRA3), Tabloid extra d

A3 outsize s

A6 x

Custom x

Normal paper, 105 to 175g/m

Normal paper, 105 to 175g/m

Normal paper, 105 to 175g/mNormal paper, 105 to 175g/m

A4 (landscape), Letter (landscape) s - Note 1

A4 (portrait), Letter (portrait) s - Note 1

A5, B5, B4, Legal (13in, 13.5in, 14in), Executive, Tabloid s - Note 1

A3 s - Note 1

A3 wide (SRA3), Tabloid extra s - Note 1

A3 outsize s

A6 x

Custom x

2222

2222

2222

EO

s

d

68 < APPENDIX B - PAPER FEED AND EJECTION DETAILS

Page 69

IZE AND WEIGHT

S

Normal paper, 176 to 198g/m

Normal paper, 176 to 198g/m

Normal paper, 176 to 198g/mNormal paper, 176 to 198g/m

A4 (landscape), Letter (landscape) x

A4 (portrait), Letter (portrait) x

A5, B5, B4, Legal (13in, 13.5in, 14in), Executive, Tabloid x

A3 x

A3 outsize, A3 wide (SRA3), Tabloid extra x

A6 x

Custom x

Post card

Post card

Post cardPost card

Post card, Double post card x

Envelope

Envelope

EnvelopeEnvelope

Envelope 1 (portrait No 3) x

Envelope 2 (portrait No 4) x

Envelope 3 (portrait No 4) x

Com-9, Com-10, DL, C4, Monarch x

Envelope 4 (A4 size), C5 x

Label stationery

Label stationery

Label stationeryLabel stationery

A4, Letter x

OHP sheet

OHP sheet

OHP sheetOHP sheet

A4, Letter x

2222

English

EO

Notes:

1.

105g/m2 (maximum) paper can be used for double-sided

printing.

APPENDIX B - PAPER FEED AND EJECTION DETAILS > 69

Page 70

APPENDIX C - ERROR AND WARNING MESSAGES

The following table summarises the error and warning messages that

can appear on the printer control panel when a Finisher is being used.

Each message is accompanied by the “Attention” LED flashing and

printing being stopped. Suggested remedial actions are given with

the messages below.

RROR/WARNING MESSAGESMEANING

E

NO STAPLE There are almost no staples

left.

PUNCH CHIP OVERFLOW The punch chip box is

COULD NOT STAPLE. TOO MUCH

PAP ER

REMOVE THE PAPER

482: FINISHER STACKER FULL

REMOVE FINISHER

nnn: PAPER JAM

CHECK STAPLE CARTRIDGE

471: STAPLE CARTRIDGE

MISSING

CHECK PUNCH CHIP BOX

472: PUNCH CHIP BOX MISSING

INSTALL FINISHER

473: FINISHER REMOVED

SERVICE CALL

nnn: FATAL ERROR

almost full and requires to

be emptied.

The number of stapled sets

exceeds a pre-determined

value.

The face down stacker is full. Remove all paper from the

Paper has jammed inside

the Finisher.

The staple cartridge is not

fitted properly or is missing.

The punch chip box is not

fitted properly or is missing.

The Finisher is not attached

correctly to the printer.

A serious error has occurred

and you should not attempt

to use the Finisher further

until the error has been

rectified.

EMEDIAL ACTION

R

See “Replenishing the

staple cartridge unit”

See “Removing the punch

chips”.

Remove all stapled copies

from the Finisher.

face down stacker.

See “Clearing a paper

jam”

(nnn values 361 to 367)

See “Replenishing the

staple cartridge unit”

See “Removing the punch

chips”

Check Finisher is attached

to printer.

Contact your Oki Service

Centre and quote the nnn

value (090 to 094 or 186).

70 < APPENDIX C - ERROR AND WARNING MESSAGES

Page 71

APPENDIX D - CONSUMABLES

NOTE

Use only genuine Oki consumables from your Oki dealer to avoid

possible damage to the Finisher.

STAPLES

English

RODUCT NAME

P

Box of Staples

(Finisher)

ESCRIPTION

D

Special staples for Finisher use.

(One box contains 3 cartridges, each

containing 3000 staples).

RDER CODE

O

01078301

APPENDIX D - CONSUMABLES > 71

Page 72

72 < APPENDIX D - CONSUMABLES

Page 73

OKI CONTACT DETAILS

English

Oki Systems (UK) Limited

550 Dundee Road

Slough Trading Estate

Slough, SL1 4LE

Tel: +44 (0) 1753 819819

Fax: +44 (0) 1753 819899

http://www.oki.co.uk

Oki Systems Ireland Limited

The Square Industrial Complex

Tallaght, Dublin 24

Ireland

Tel: +353 1 4049590

Fax: +353 1 4049591

http://www.oki.ie

OKI Systems (Ireland) Ltd

40 Sydenham Park

Belfast, BT4 1PW

Tel: +44 (0) 28 90 20 1110

http://www.oki.ie

Technical Support for all Ireland

Tel : +353 1 4049570

Fax: +353 1 4049555

E-mail: tech.support@oki.ie

Oki Systèmes (France) S.A.

44-50 Av. du Général de Gaulle

94240 L'Hay les Roses

Téléphone: 01 46 15 80 00

Télécopie: 01 46 15 80 60

http://www.oki.fr

OKI Systems (Italia) S.p.A.

c.c. “Il Girasole” - Lotto 3.05/B

20084 Lacchiarella (MI)

Tel. 02900261

Fax: 029007549

http://www.oki.it

Oki Systems (Deutschland) GmbH

Hansaallee 187

40549 Düsseldorf

Tel: +49 (0) 211 52 66-0

Fax: +49 (0) 211 59 33-45

BBS: +49 (0) 211 5266-222

(300-33600 bps, 8, N, 1)

http://www.oki.de

Oki Systems (Iberica),

S.A.C/Teide, 3-28700

(San Sebastian de los Reyes)

Madrid

Tel: 91-3431620

Fax: 91-3431624

http://www.oki.es

Oki Systems (Ibérica) SA

Sucursal em Portugal

Rua Quinta do Paizinho

Edificio Bepor-Bloco 2-1 Dto.

2795-651 Carnaxide

Tel: 21 424 67 40

Fax: 21 417 29 12

http://www.oki.pt

Oki Service (Portugal)

Serviço de apoio técnico ao cliente

Tel: 808 200 197

OKI CONTACT DETAILS > 73

Page 74

Oki Systems (Österreich)

IZ-NÖ-Süd, Str. 2/M7/1

A-2355 Wiener Neudorf

Österreich

Tel: +43 (0)223/677110

Fax: +43 (0)223/67711018

http:// www.oki.at

Oki Systems (Schweiz)

Zurlindenstrasse 29

CH-4133 Pratteln bei Basel

Schweiz

Tel: +41 (0)61/8279494

Fax: +41 (0)61/8279490

http: //www.oki.ch

OKI Systems (Norway) A/S

Hvamsvingen 9, P.O.Box 174

N-2013 Skjetten

Telefon: 63 89 36 00

Telefax: 63 89 36 01

Ordrefax: 63 89 36 02

http://www.oki.no

OKI Systems (Finland) Oy

Kutomotie 18 B, 5. krs,

00380 Helsinki

Puh. (09) 5404 420.

Int. +358 9 5404 420

Fax. (09) 5404 4223

Int. +358 9 5404 4223

Oki Systems (Danmark) a·s

Park Allé 382

2625 Vallensbæk

Tlf: 43 66 65 30

Fax: 43 66 65 90

http://www.oki.dk

OKI Systems (Sweden) AB

BOX 216

161 26 BROMMA

Telefonsupport: 0726-101 20

Vardagar: 09.00 - 11.30, 13.00 - 16.00

http://www.oki.se

74 < OKI CONTACT DETAILS

Page 75

INDEX

English

B

binding

long side...............................13

short side .............................13

C

component parts...........................9

Consumables..............................71

D

Decurler Lever.............................40

driver

Macintosh.............................33

Windows 2000 ......................25

Windows 95/98 ....................21

Windows NT4.0 .....................29

H

Hole positions ............................ 14

J

Job offset information .................17

M

maintenance...............................52

messages

error .....................................70

warning ................................70

P

paper

curl.......................................39

ejection.................................63

feed......................................63

jam .......................................41

Punch

information ...........................13

punch chips

removing ..............................58

S

Specification ..............................61

stacker

face down .............................12

face up..................................12

staple

cartridge ...............................49

jam .......................................48

position ................................16

replenishing..........................52

stapling details...........................15

T

troubleshooting

paper curl .............................39

paper jams............................41

staple jams ...........................48

INDEX > 75

Page 76

Loading...

Loading...