Oki C911, C931, C941, C942, ES9411 User's Manual Troubleshooting/Daily Maintenance Manual

...

1

Troubleshooting

User’s Manual

Troubleshooting/Daily

Maintenance

2

Maintenance Manual

Read for any points that

are not understood, or

for maintenance

Index

C911

C931

C941

C942

ES9411

ES9431

ES9541

ES9542

Pro9431

Pro9541

Pro9542

1

Manual Conguration

z

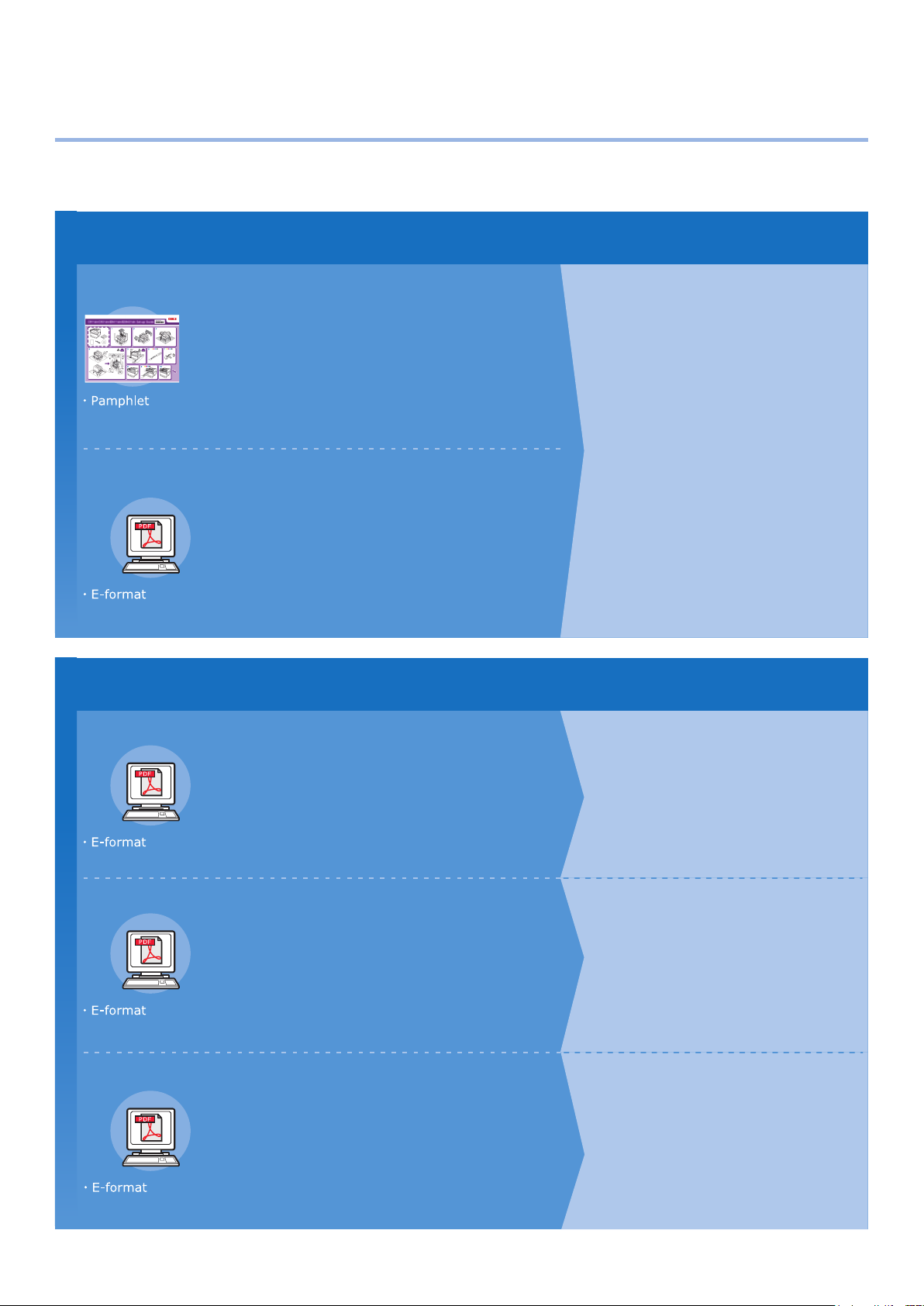

The following user manuals are enclosed with the product.

The e-manual is stored as software on DVD-ROM.

Step

Read this first

Opening the box and installing the printer

Set-up Guide

This guide uses illustrations to explain the

methods from opening the box to installation.

For the advanced setup guide, see the "Basic".

Preparing the printer to print

Basic

This guide describes the precautions for safe

use of the device. Make sure to read before use.

Further, basic uses from the device installation

methods to initial printing are also explained.

The device functions are described in the

appendix.

• Checking the product

• Parts nomenclature and functions

• Using the device to its fullest

• Installing the device

• Turning ON and OFF the power supply

• Test printing using the printer only

• Connecting to a PC

• Paper

• Printing

• Paper ejection

• Setting Power Save mode

• Setting auto power OFF

• Checking the print quantity,

consumables, remaining maintenance

unit quantity, and remaining service life

• Cancelling a print job

• Adding printers using LPD protocols

(TCP/IP)

• Table of control panel menu items

• Basic Windows procedures

• Printer specifications

Step

Read these guides as necessary

2

Try using various functions

Advanced

This guide explains the various paper print methods

and how to use useful functions. Read to optimize the

printing environment or to adjust the color, etc., using

the enclosed utility software.

Further, this guide also explains the items that can be

set from the control panel, and the network settings.

Read for any points that are not understood, or for maintenance

Troubleshooting/Daily

Maintenance Manual (This manual)

This manual explains the procedures for paper jams, and

troubleshooting method if an error message is displayed.

This manual also explains daily maintenance such as

now to replace consumables and maintenance units, and

cleaning, etc.

Using C941/C942/ES9541/ES9542/Pro9541/Pro9542

Separate Volume Spot Color Guide

This guide explains how to set up the Spot

Color kit and check the printer drivers, and

how to print using Spot Color. Make sure to

read before use.

• Useful print functions

• Adjusting the color

• Using utility software

• Network settings

•

Checking and changing printer settings

using the control panel

• Troubleshooting

• Maintenance

• Consumables, maintenance products,

options, color management server,

etc.

• Setting the Spot Color kit

• Control panel explanation

• Checking the printer drivers

• Table of printer driver functions

• Printing on color paper

• Printing on transparent film

• Specifying and printing Spot Color

toner using the applications

• Fine-tuning white

• Switching Spot Color kits

- 2 -

W

ARNING

CAUTION

Reading the Manual

z

Symbols

Note

These are cautions and restrictions for the correct operation of the device. Make sure to read to avoid misoperation.

z

Memo

Knowledge of the information before using the device is useful and can act as a reference. Reading is recommended.

z

Reference

These are the reference pages. Read to learn detailed information and relevant information.

z

Mishandling due to ignoring this display may cause death or serious injury.

z

Mishandling due to ignoring this display may cause personal injury.

z

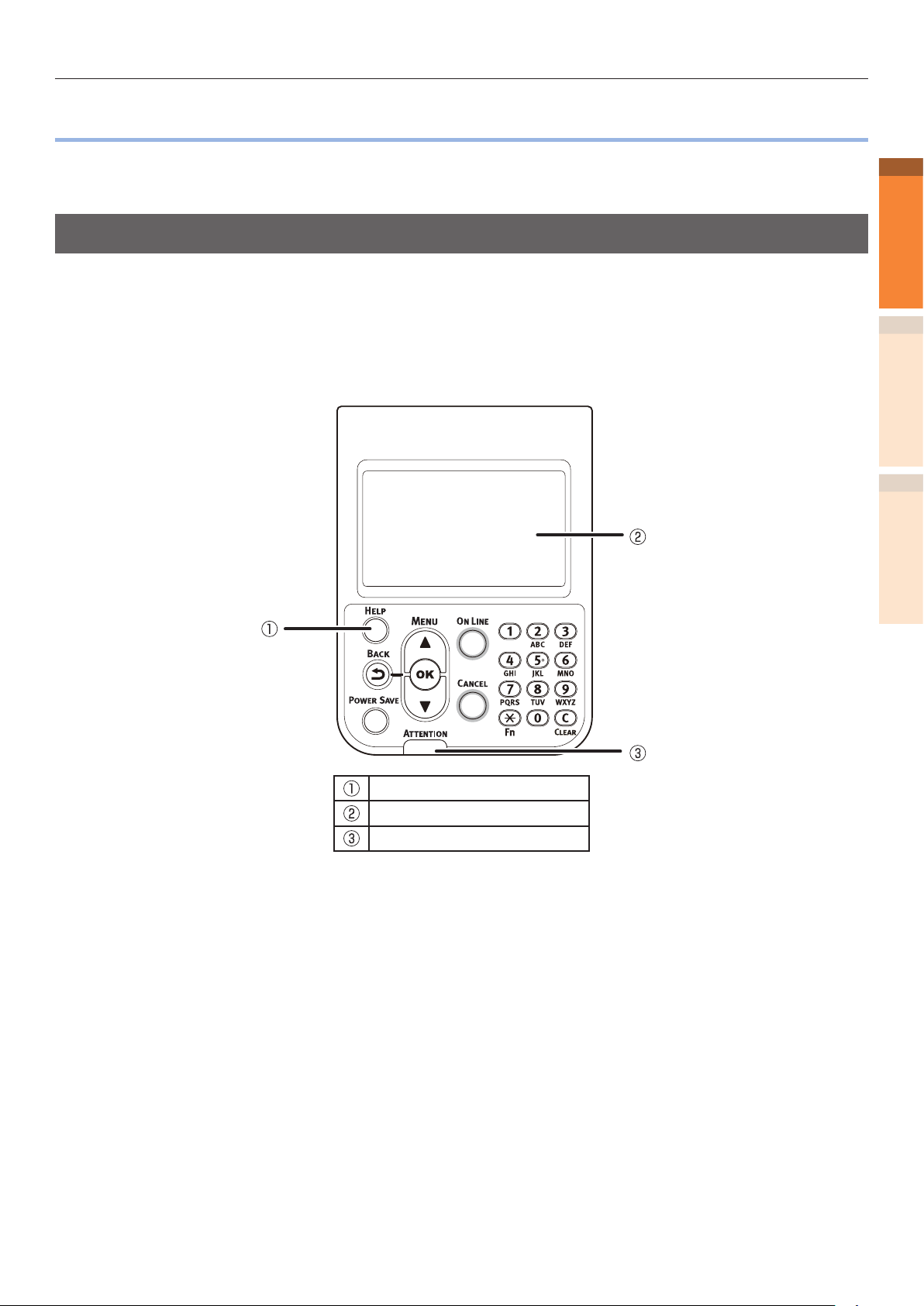

Keys, Buttons, and Symbols

This chapter described the following keys, buttons, and symbols.

Inscription Description

The control panel buttons and 10-key pad are described below.

z

E.g.:

[OK] button [BACK] button

[ ] button/key

[Fn] key [CLEAR] key

Indicates your PC keyboard.

z

Describes the menu name on the liquid crystal panel.

[ ]

" "

> Describes the menu level of the printer or PC.

z

Describes the PC menus, windows, and dialog box names.

z

Describes the messages and input text displayed in the liquid crystal

z

panel.

Describes the le and screen names on the PC.

z

Describes the reference title.

z

- 3 -

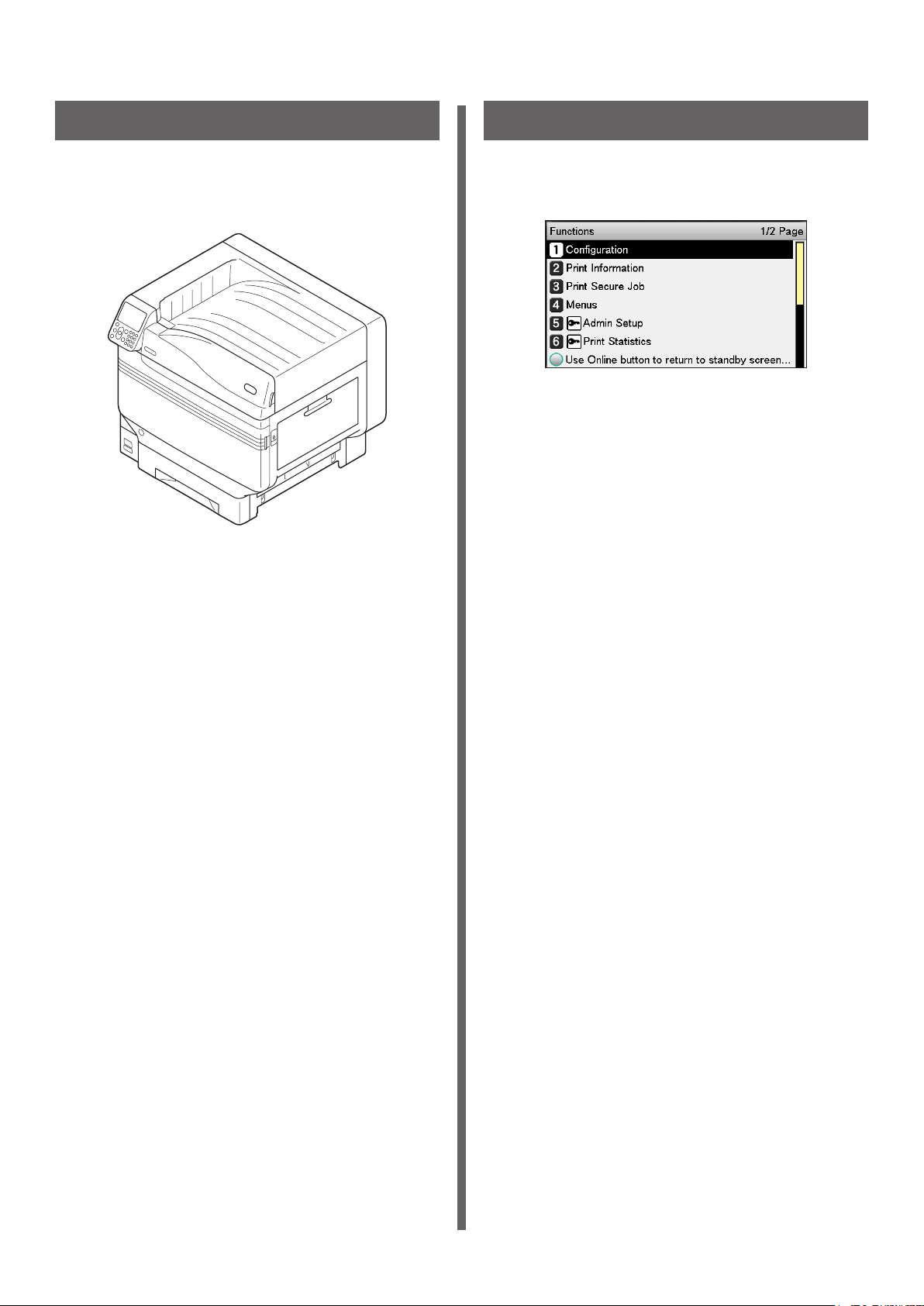

Illustrations

Screens

The printer illustrations used herein show the

C931 model unless otherwise specied.

Illustrations may differ from the actual product.

The images of the control panel and PC used

herein are examples. The images may differ

from actual products and screens.

- 4 -

Inscriptions

The following inscriptions are used in this manual.

C911dn → C911

z

C931dn → C931

z

C941dn → C941

z

C942dn → C942

z

ES9411dn → ES9411

z

ES9431dn → ES9431

z

ES9541dn → ES9541

z

Microsoft

z

Microsoft

z

Mac OS X10.3.9 or later → Mac OS X

z

The manuals enclosed with the printer use as examples Windows 7 in the case of Windows, and OS X

10.8 in the case of Mac OS X unless otherwise specied.

Depending on the OS and model used, descriptions in this manual may differ.

®

Windows® 7 64-bit Edition operating system → Windows 7 (64-bit Edition)

®

Windows® 7 operating system → Windows 7

- 5 -

Contents

Manual Conguration ........................................................................... 2

Reading the Manual

Symbols .................................................................................................................. 3

Keys, Buttons, and Symbols....................................................................................3

Illustrations

Screens...................................................................................................................4

Inscriptions

............................................................................................................ 4

............................................................................................................ 5

............................................................................. 3

1 Troubleshooting ................................................................... 9

Troubleshooting solutions procedure ................................................. 10

Paper jams

Checking messages (if a paper jam occurs) .......................................................... 11

Removing jammed paper

If paper messages are displayed ....................................................... 36

If replace consumables messages are displayed

If other messages are displayed

Printing Troubles

Unable to print ..................................................................................................... 46

........................................................................................ 11

...................................................................................... 14

............................... 38

....................................................... 40

............................................................................... 46

Printer driver malfunctions

Print quality is poor

Paper feed is poor

When image disturbance occurs

Adjusting the print result

.............................................................................................. 52

................................................................................................ 57

................................................................................... 50

........................................................................... 58

..................................................................................... 58

2 Maintenance ...................................................................... 59

Replacing consumables and maintenance unit ................................... 60

Consumables and maintenance unit service life ...................................................60

When the replacement period is approaching

Replacing toner cartridges.................................................................................... 63

Replacing Image Drums

Replacing belt units and transfer roller units

Replacing fuser units

Replacing waste toner boxes

Replacing paper feed rollers

....................................................................................... 66

............................................................................................ 75

................................................................................ 77

................................................................................. 79

Device Maintenance ........................................................................... 87

Cleaning device surfaces ...................................................................................... 87

....................................................... 62

........................................................ 69

Cleaning LED heads

Cleaning feed rollers

.............................................................................................. 87

............................................................................................. 93

- 6 -

Cleaning the Transfer Roller Unit and Paper Transfer Path ................................... 96

Cleaning the Pinch Roller

...................................................................................... 99

Moving and shipping the device ...................................................... 100

Moving the device ............................................................................................. 100

Shipping the device

.......................................................................................... 100

Index .................................................................................... 102

- 7 -

Memo

- 8 -

1

Troubleshooting

Troubleshooting solutions procedure … 10

1

Troubleshooting

2

Paper jams

If paper messages are displayed

If replace consumables messages

are displayed

If other messages are displayed

Printing Troubles

……………………………………… 11

……… 36

………………………………… 38

………40

…………………………… 46

IndexMaintenance

- 9 -

Troubleshooting solutions procedure

Troubleshooting solutions procedure

z

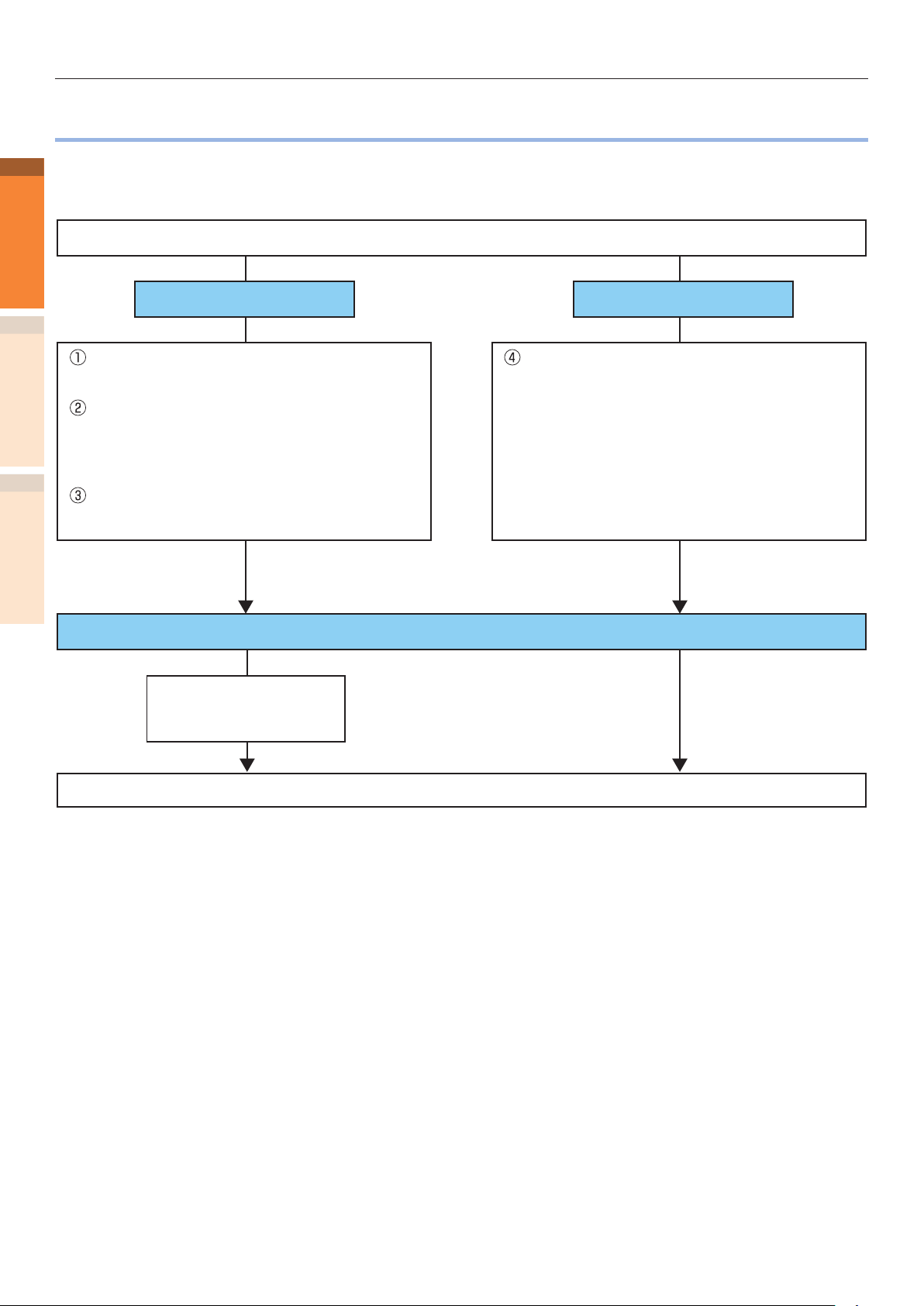

This chapter describes the procedure for solving the problems occurred while using the printer.

1

Troubleshooting

If you are unable to solve the problem with this procedure, contact your dealer.

Is error message or error code displayed on the control panel?

If it is displayed If it is not displayed

2

to the page 11 and solve it.

timing or service life of consumables and

maintenance items, refer to the page 60

and solve it.

refer to the page 36 and solve it.

IndexMaintenance

Call your designated help desk.

When there is a display of paper jam, refer

When there is a display of replacement

When there is a display of other errors,

When you cannot solve

Record the error

message displayed on

the control panel.

In the even to trouble refer to the

following pages for solution.

zUnable to print: page 46

zPrinter drivers cannot be installed: page 50

zUnable to print with ne quality: page 52

zAbnormal paper feeding: page 57

- 10 -

Paper jams

z

Paper jams

This section describes the procedure when a paper is jammed inside the printer, or when paper is

remaining inside the printer even after removing it.

Checking messages (if a paper jam occurs)

When a paper is jammed inside the printer, or when paper is remaining inside the printer even after

removing it, a message notifying paper jam will appear on the liquid crystal panel of the operation

panel, and the <ATTENTION> lamp will blink.

When "Please see HELP for details" is shown in the message, pressing the [HELP] button in the

operation panel will show the troubleshooting procedure, and you can easily solve the process according

to the guidance. For details, refer to “Operating the Help screen”(P.13).

1

Troubleshooting

2

IndexMaintenance

[HELP] button

Liquid crystal panel

<ATTENTION> lamp

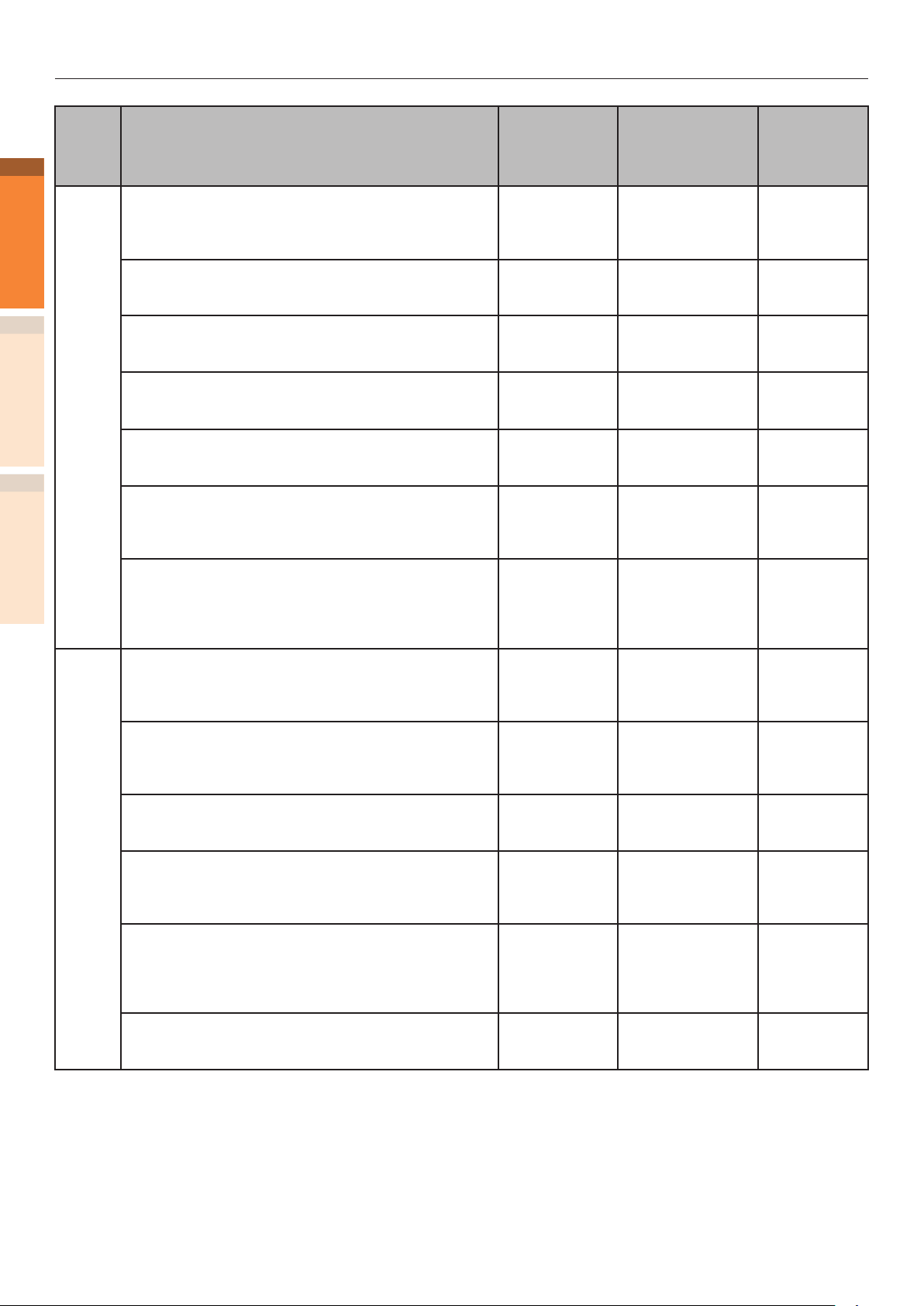

The following table shows the messages. Check the message, and remove the jammed paper according

to the procedure described in the reference.

- 11 -

Paper jams

Category

1

Troubleshooting

2

Paper

jam

(When a

paper is

jammed

inside

the

printer)

IndexMaintenance

Message

does not

disappear

(When the

message

does not

disappear

even after

removing

the jammed

paper)

Message displayed on the liquid crystal

panel

Open Right Side Cover

Paper Jam

Please see HELP for details

Open [TRAY]* Side Cover

Paper Jam

Please see HELP for details

Open Left Side Cover

Paper Jam

Please see HELP for details

Check Exit Unit

Paper Jam

Please see HELP for details

Check Exit Unit

Paper Jam

Please see HELP for details

Check Duplex Unit

Paper Jam

Please see HELP for details

Check the lower side of Duplex Unit

Paper Jam

Please see HELP for details

Open [TRAY]* Side Cover

Paper Remain

Please see HELP for details

Open Right Side Cover

Paper Remain

Please see HELP for details

Check Exit Unit

Paper Remain

Please see HELP for details

Check Duplex Unit

Paper Remain

Please see HELP for details

Check the lower side of Duplex Unit

Paper Remain

Please see HELP for details

Check Face Down Stacker

Paper Remain

Please see HELP for details

Location of

paper jam

Paper jam in

the vicinity

of Right Side

Cover

Paper jam in

the vicinity of

tray side cover

Paper jam in

the vicinity of

Left Side Cover

Paper jam in

the exit unit

Paper jam in

the vicinity of

the fuser unit

Paper jam in

the vicinity of

the 2-Sided

Printing unit

Paper jam in

the vicinity of

the lower side

of 2-Sided

Printing unit

Paper jam in

the vicinity

of TRAY Side

Cover

Paper jam in

the vicinity

of Right Side

Cover

Paper jam in

the exit unit

Paper jam in

the vicinity of

the 2-Sided

Printing unit

Paper jam in

the vicinity of

the lower side

of 2-Sided

Printing unit

Paper jam in

the vicinity of

Left Side Cover

Error code

displayed after

pressing the

[HELP] button

380, 390

391, 392, 393,

394, 395

384

381

382, 383, 389

370, 371, 373

375

631, 632, 633,

634, 635

637

638, 639

640, 641, 642

650

651

Reference

pages

page 14

page 24

page 34

page 15

page 20

page 25

page 30

page 24

page 14

page 15

page 25

page 30

page 34

*: Either of Tray 1 to Tray 5 will appear in [TRAY]. (Tray 2 to Tray 5 will be displayed when the option of additional tray units is

mounted.)

Either of Tray 1 Side Cover to Tray 5 Side Cover will appear in [COVER]. (Tray 2 Side Cover to Tray 5 Side Cover will be

displayed when the option of additional tray units is mounted.)

- 12 -

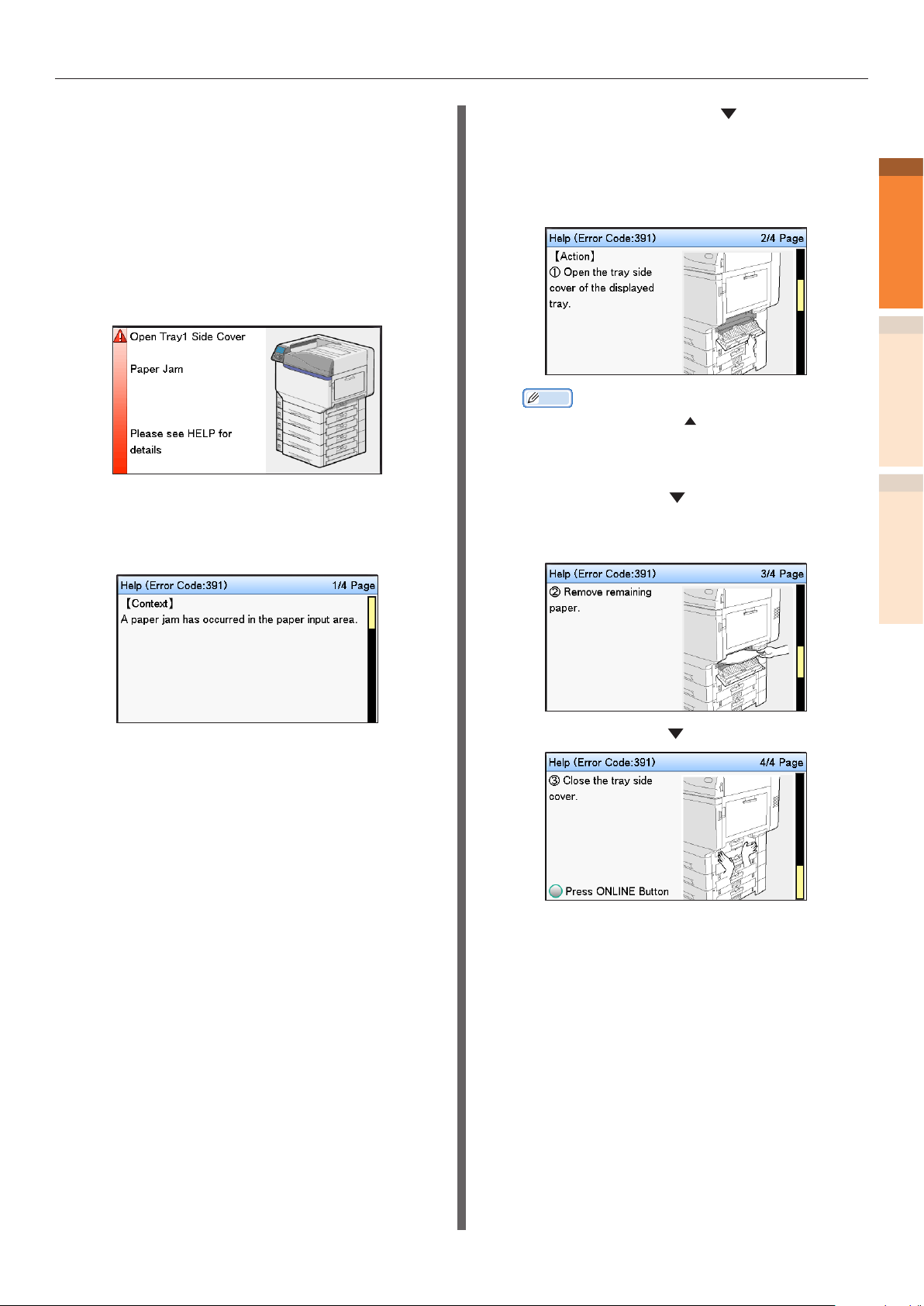

Paper jams

Operating the Help screen

Pressing the [HELP] button in the operation panel

will display the solution method. You can easily

remove the paper according to the guidance.

Example) Paper jam in the vicinity of Tray 1 Side

Cover

The following message will appear on the liquid

crystal panel, and the <ATTENTION> lamp will

blink.

Press the [HELP] button.

1

The error code will appear and the

condition of paper jam will be displayed.

Press the scroll button .

2

The next page will appear, and

solution procedure for paper jam

and corresponding animation will be

displayed.

Memo

Press the scroll button

z

page.

Scroll the pages of the Help screen with

3

the scroll button

paper according to the solution method

for paper jam displayed on the screen.

to return to the previous

, and remove the

1

Troubleshooting

2

IndexMaintenance

- 13 -

Removing the jammed paper will return

the display to the Standby screen and

the remaining printing will start.

Paper jams

Removing jammed paper

1

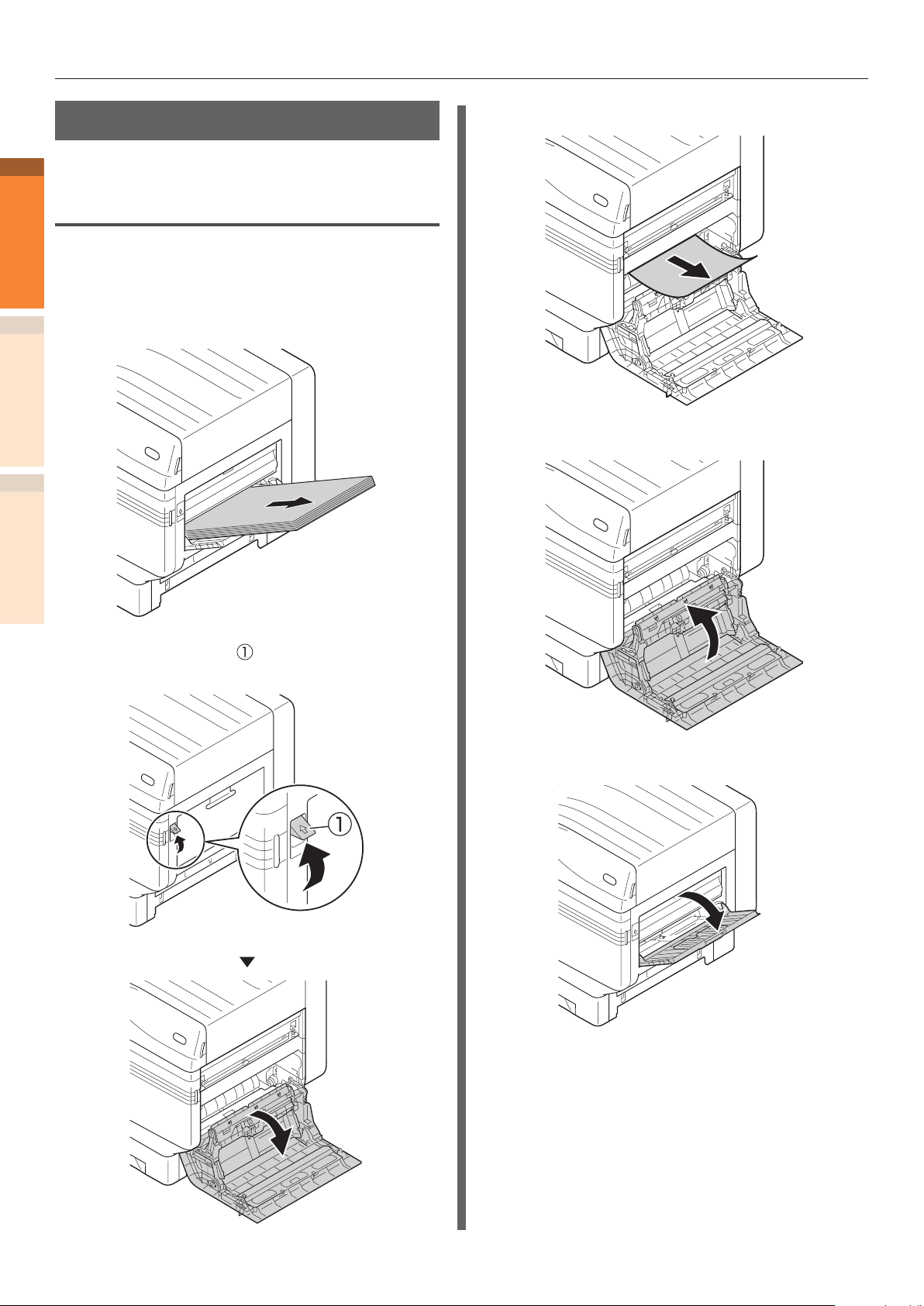

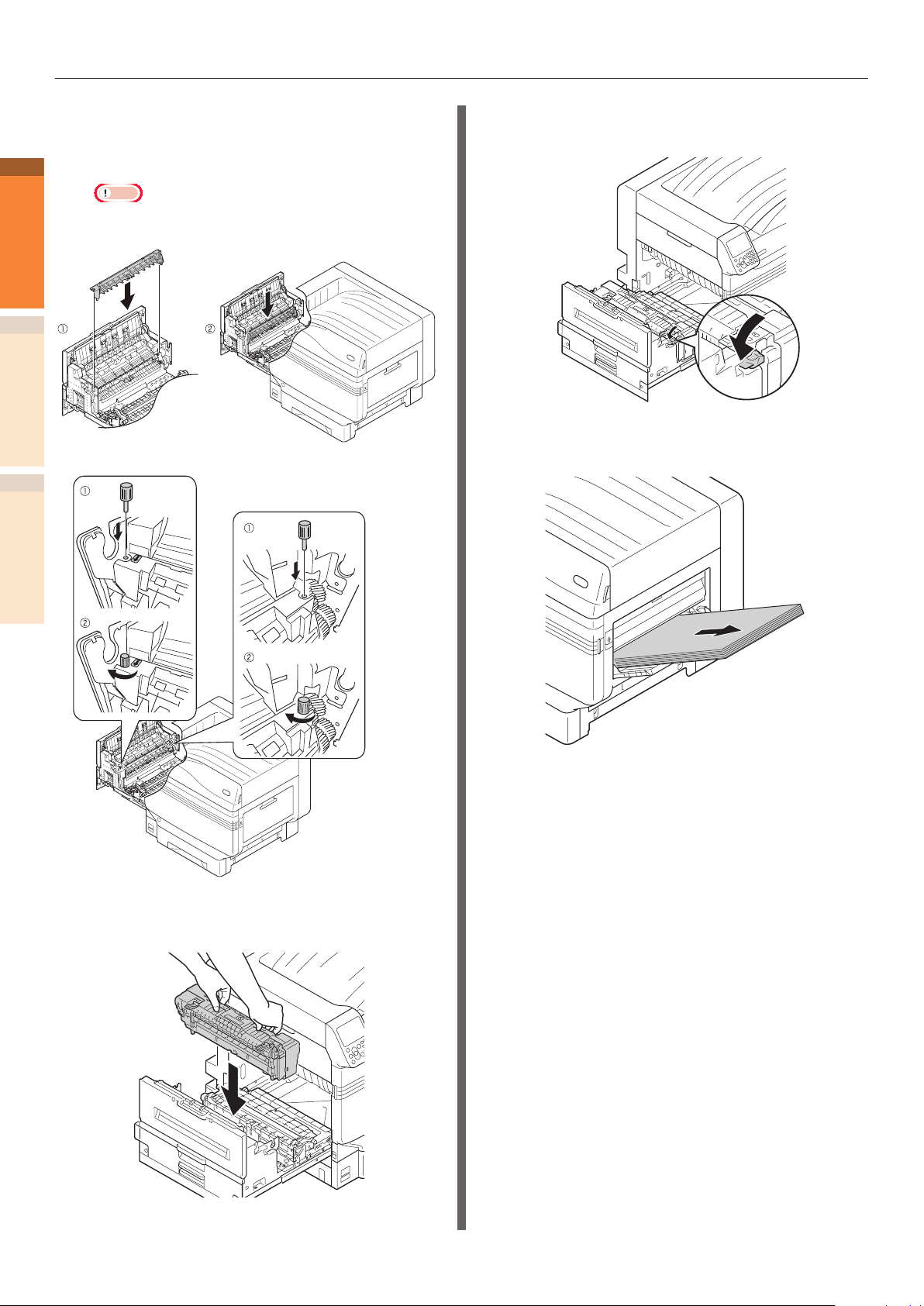

Removing paper jam in the

Troubleshooting

vicinity of Right Side Cover

Error code: 380, 390, 637

If paper is set in the MP tray, remove it

1

2

IndexMaintenance

and close the tray.

Slowly remove the remaining paper.

3

Close the right side cover.

4

Lift the opening( ), and open the right

2

side cover.

Open the MP tray.

5

- 14 -

Paper jams

CAUTION

Pull the set lever ( ) on the right side

6

of the paper supporter ( ) towards

yourself.

Set the print side for the removed

7

paper to face up.

Removing paper jam in the exit

unit

Error code: 381, 638, 639

Possible to get burned.

Work carefully as the temperature of fuser unit is

high. Ensure to hold the handle when lifting. When

it is hot, wait until it cools down before starting the

work.

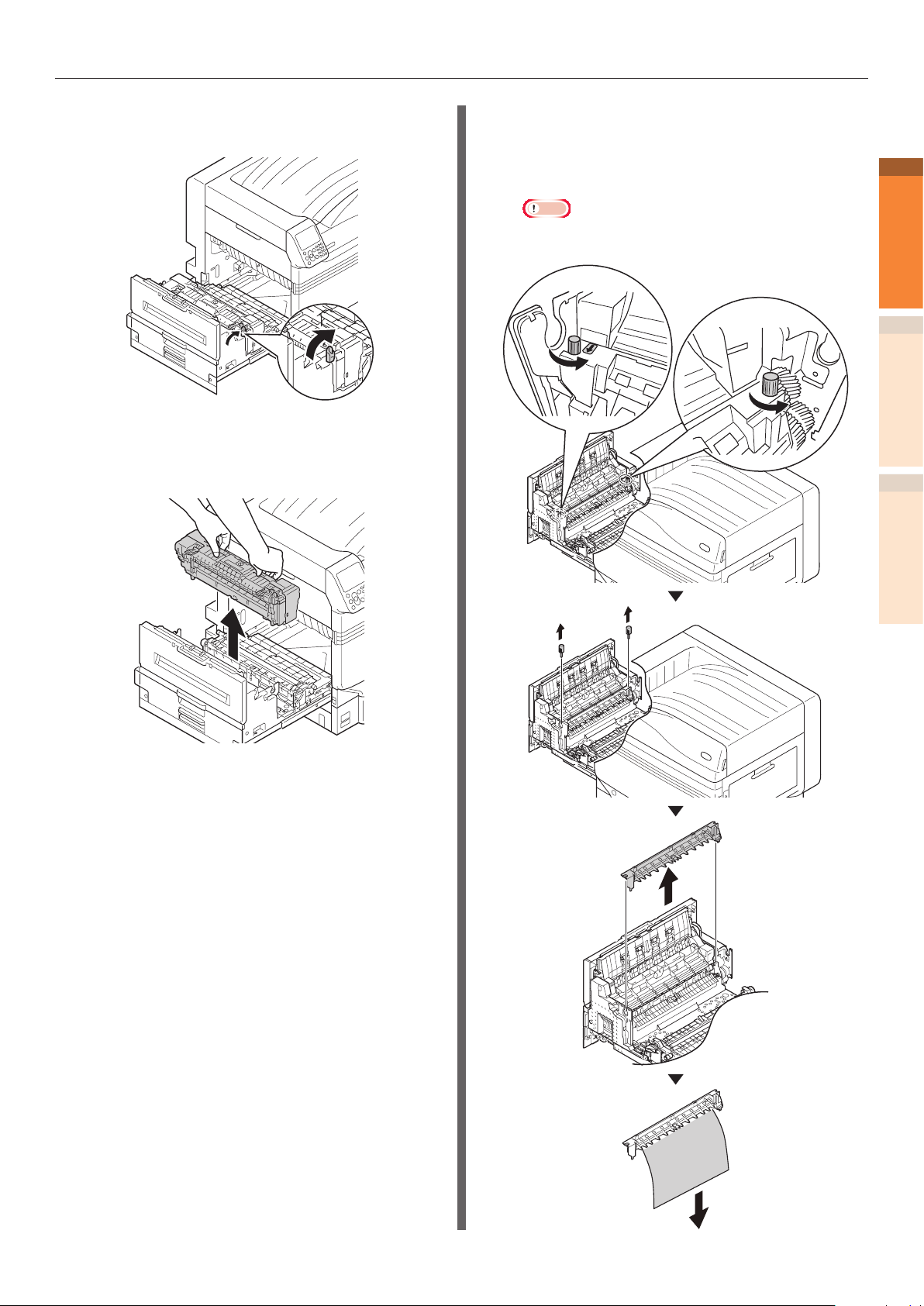

Lift opener ( ) of the exit unit, and pull

1

out the exit unit.

1

Troubleshooting

2

IndexMaintenance

Match the paper guide with the paper.

8

- 15 -

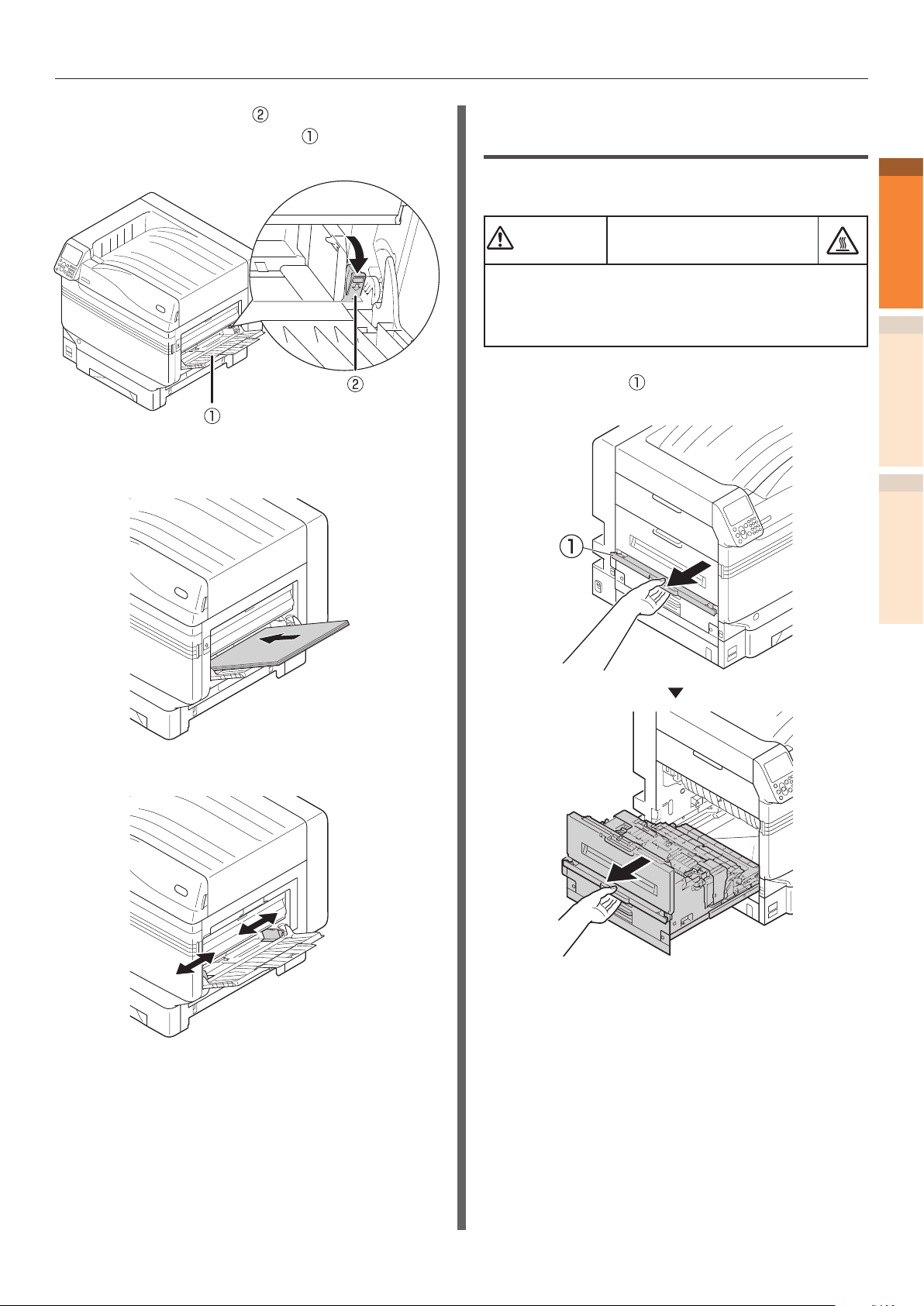

Paper jams

2

1

Troubleshooting

2

3

IndexMaintenance

Check inside of the printer, and slowly

remove the remaining paper.

If there is remaining paper in the fuser

unit then pull up the fuser unit's jam

release lever (blue).

Push down the fuser unit's jam release

5

lever (blue).

If there is no remaining paper in the

6

fuser unit then pull up the fuser unit's

lock lever (blue).

Ensure to slowly pull the remaining

4

paper towards the printer body

(opposite to the paper feeding

direction).

Hold the fuser unit handle with both

7

hands, and remove it onto a at

surface.

- 16 -

Paper jams

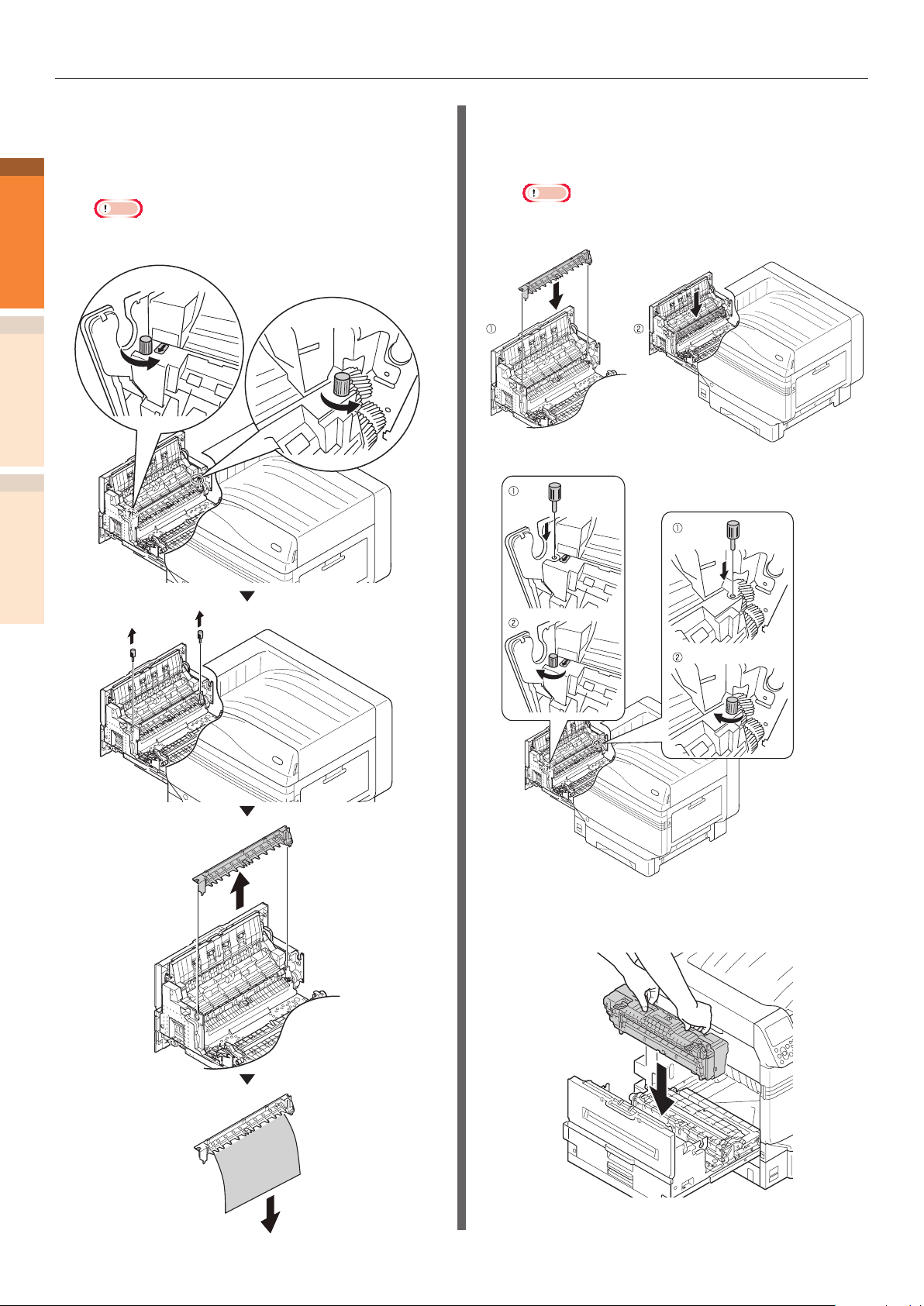

Raise the jam release lever of the fuser

8

unit.

Remove the remaining paper.

9

If the paper winds around the decal roller,

remove the decal unit by turning the

10

thumbscrews at both ends of the decal

unit to the left, and remove the paper.

Note

Be careful not to drop the thumbscrew into the

z

device when removing.

1

Troubleshooting

2

IndexMaintenance

- 17 -

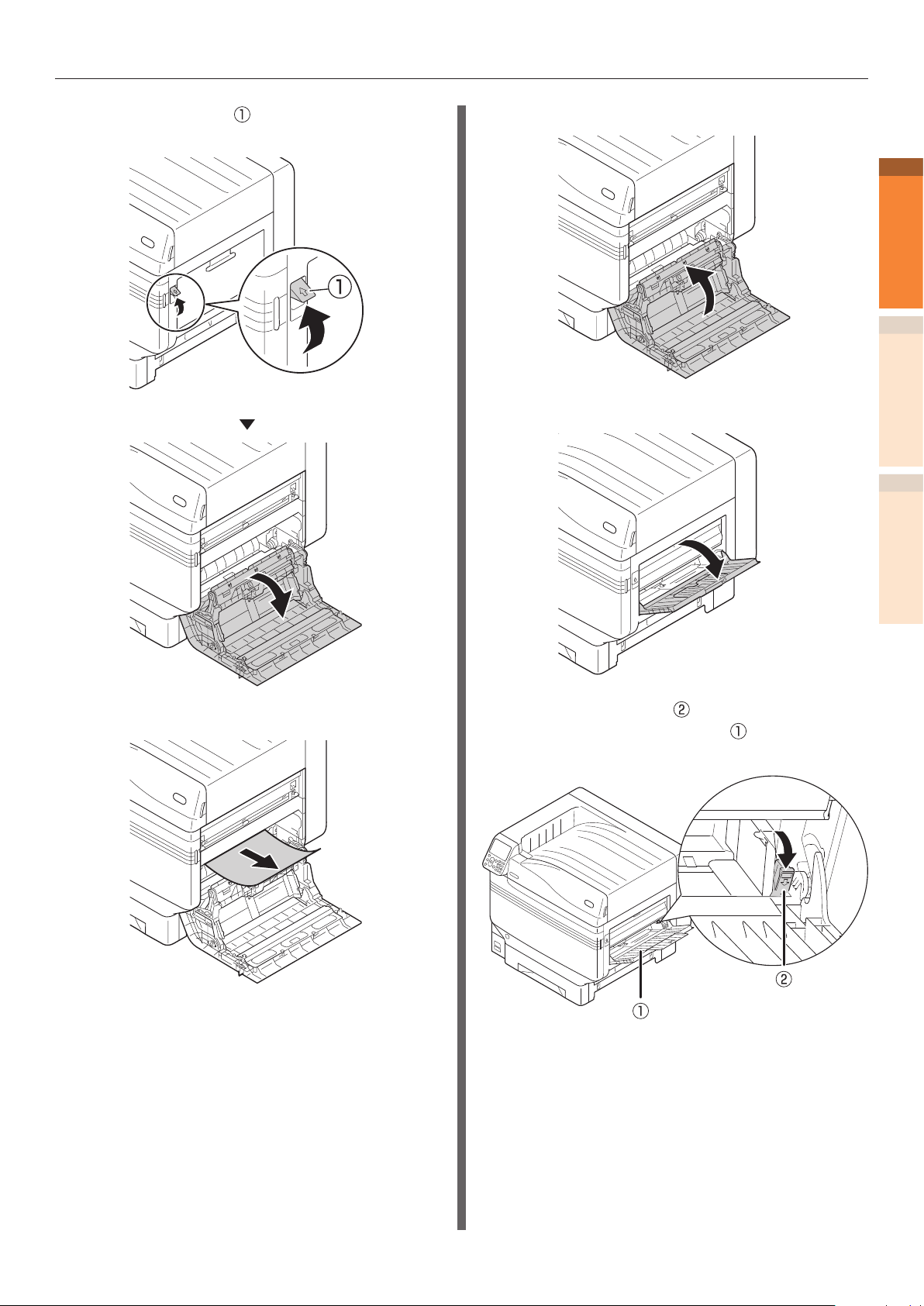

Paper jams

11

1

Troubleshooting

2

IndexMaintenance

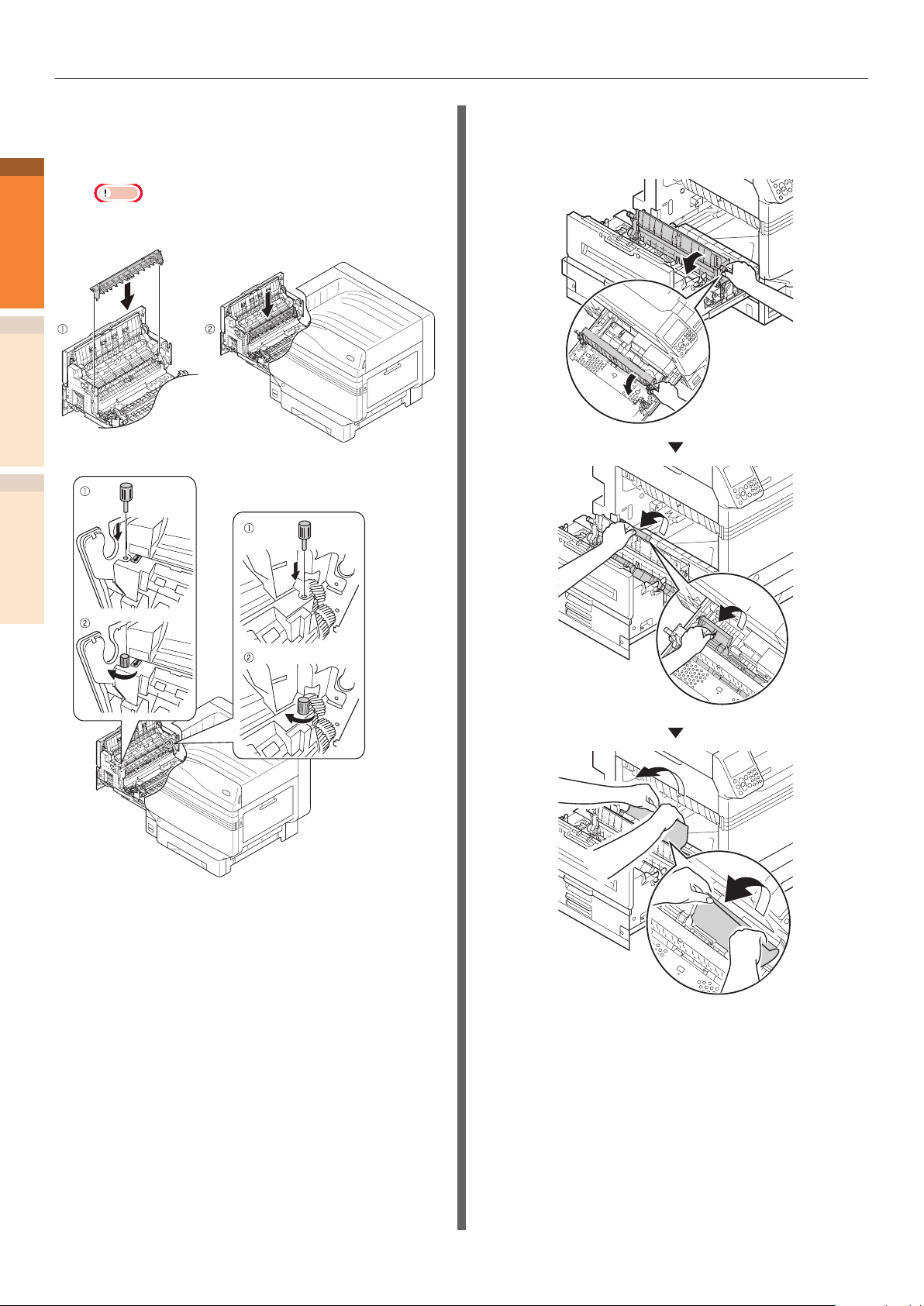

Return the decal unit to its original

position, and x it with two

thumbscrews.

Note

Be careful not to drop the thumbscrew into the

z

device when xing.

Push down the fuser unit's lock lever

13

(blue).

If paper is set in the MP tray, remove it

14

and close the tray.

Hold the fuser unit handle with both

12

hands, and set to the output unit.

- 18 -

Paper jams

Lift the opener ( ), and open the right

15

side cover.

Close the right side cover.

17

1

Troubleshooting

2

Open the MP tray.

18

IndexMaintenance

Slowly remove the remaining paper.

16

Pull the set leve ( ) on the right side

19

of the paper supporter ( ) towards

yourself.

- 19 -

Paper jams

CAUTION

20

1

Troubleshooting

2

21

IndexMaintenance

Match the paper guide with the paper.

Set the print side for the removed

paper to face up.

Removing paper jam in the

vicinity of the fuser unit

Error code: 382, 383, 389

Possible to get burned.

Work carefully as temperature of fuser unit is high.

Ensure to hold the handle when lifting. When it

is hot, wait until it cools down before starting the

work.

Lift opener ( ) of the exit unit, and pull

1

out the exit unit.

When you cannot see the jammed

paper, return the exit unit to the printer,

and go to “Removing paper from the

2-Sided Printing unit”(P.23).

Put the output unit back into the printer.

22

- 20 -

Paper jams

If there is remaining paper in the fuser

2

unit then pull up the fuser unit's jam

release lever (blue).

Ensure to slowly pull the remaining

3

paper towards the printer body

(opposite to the paper feeding

direction).

If there is no remaining paper in the

5

fuser unit then pull up the fuser unit's

lock lever (blue).

Hold the fuser unit handle with both

6

hands, and remove it onto a at

surface.

1

Troubleshooting

2

IndexMaintenance

Push down the fuser unit's jam release

4

lever (blue).

If a paper jam occurred in the fuser

7

unit, raise the jam release lever (blue),

and slowly pull the paper out in the

opposite direction from the paper

operation direction.

- 21 -

Paper jams

8

1

Troubleshooting

2

IndexMaintenance

If the paper winds around the decal roller,

remove the decal unit by turning the

thumbscrews at both ends of the decal

unit to the left, and remove the paper.

Note

Be careful not to drop the thumbscrew into the

z

device when xing.

Return the decal unit to its original

9

position, and x it with two

thumbscrews.

Note

Be careful not to drop the thumbscrew into the

z

device when removing.

- 22 -

Hold the fuser unit handle with both

10

hands, and set to the exit unit.

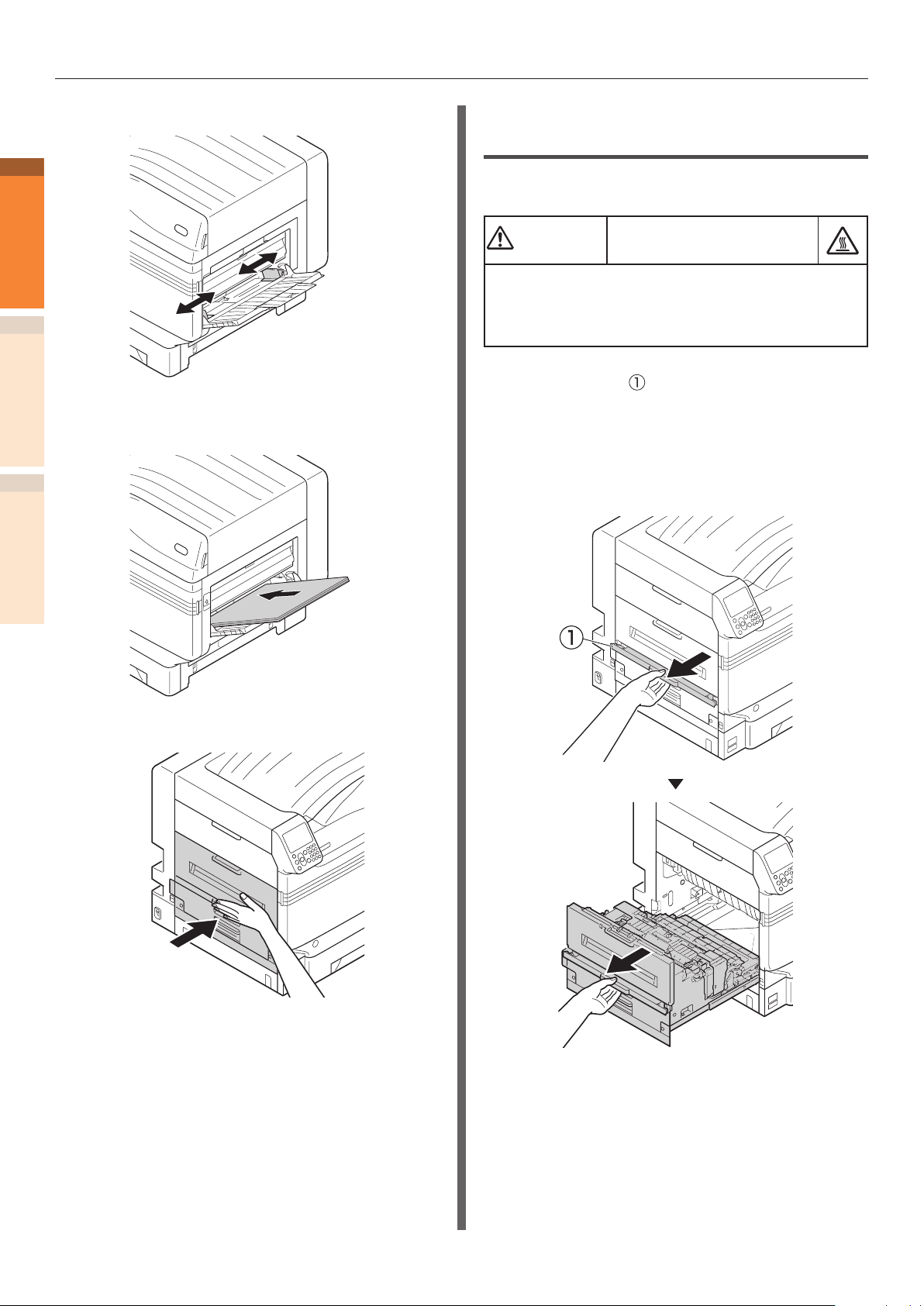

Paper jams

Push down the fuser unit's lock lever

11

(blue).

Put the exit unit back into the printer.

12

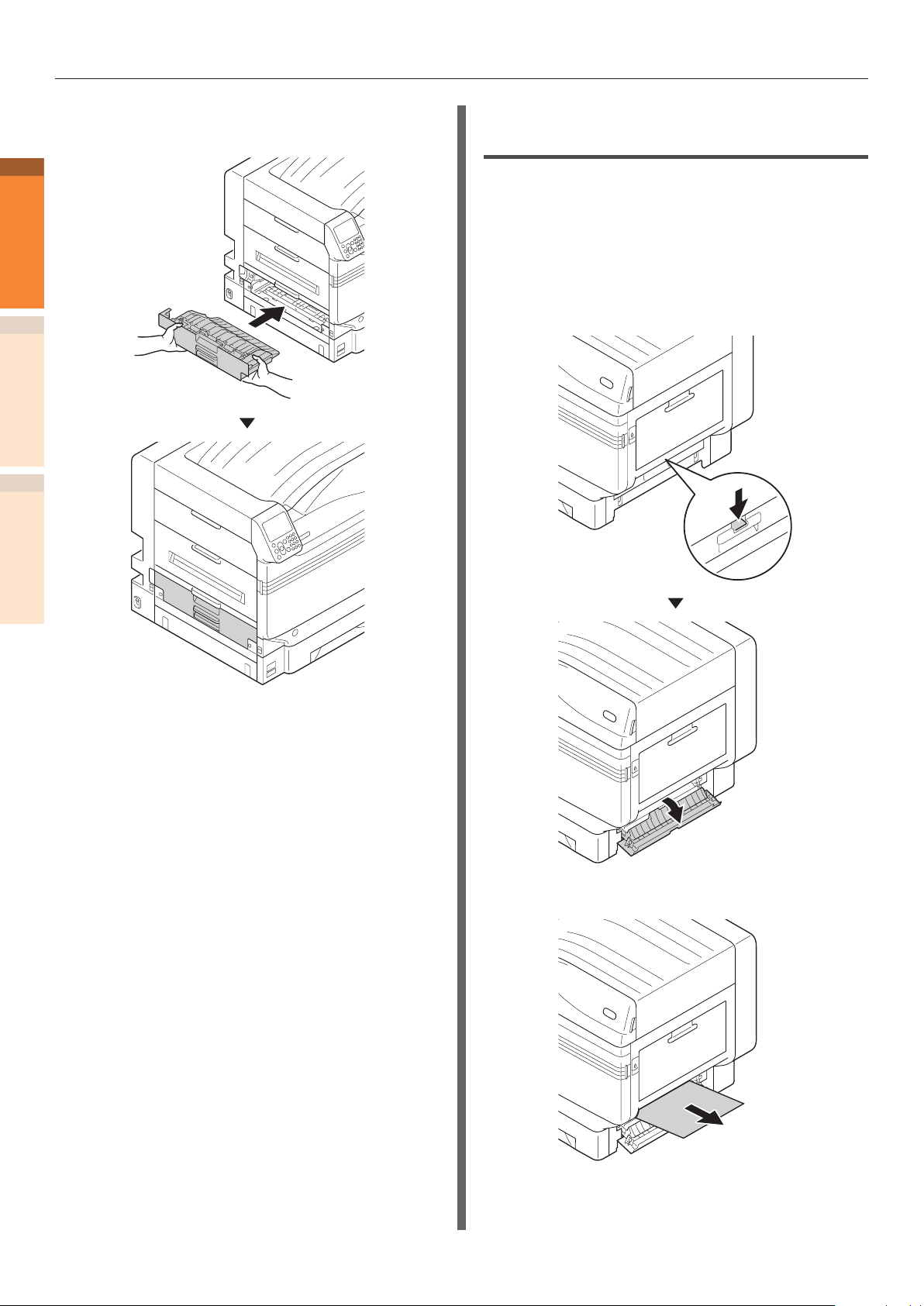

Removing paper from the 2-Sided

Printing unit

Pull out the 2-Sided Printing unit, lift it

1

up a little with both hands, and remove

it.

Note

Do not pull the 2-Sided Printing unit out in one shot.

z

2-Sided Printing unit may fall down if you pull it out

in one shot, which may damage it.

1

Troubleshooting

2

IndexMaintenance

Remove the remaining paper.

2

- 23 -

Paper jams

3

1

Troubleshooting

2

IndexMaintenance

Put the 2-Sided Printing unit back into

the printer.

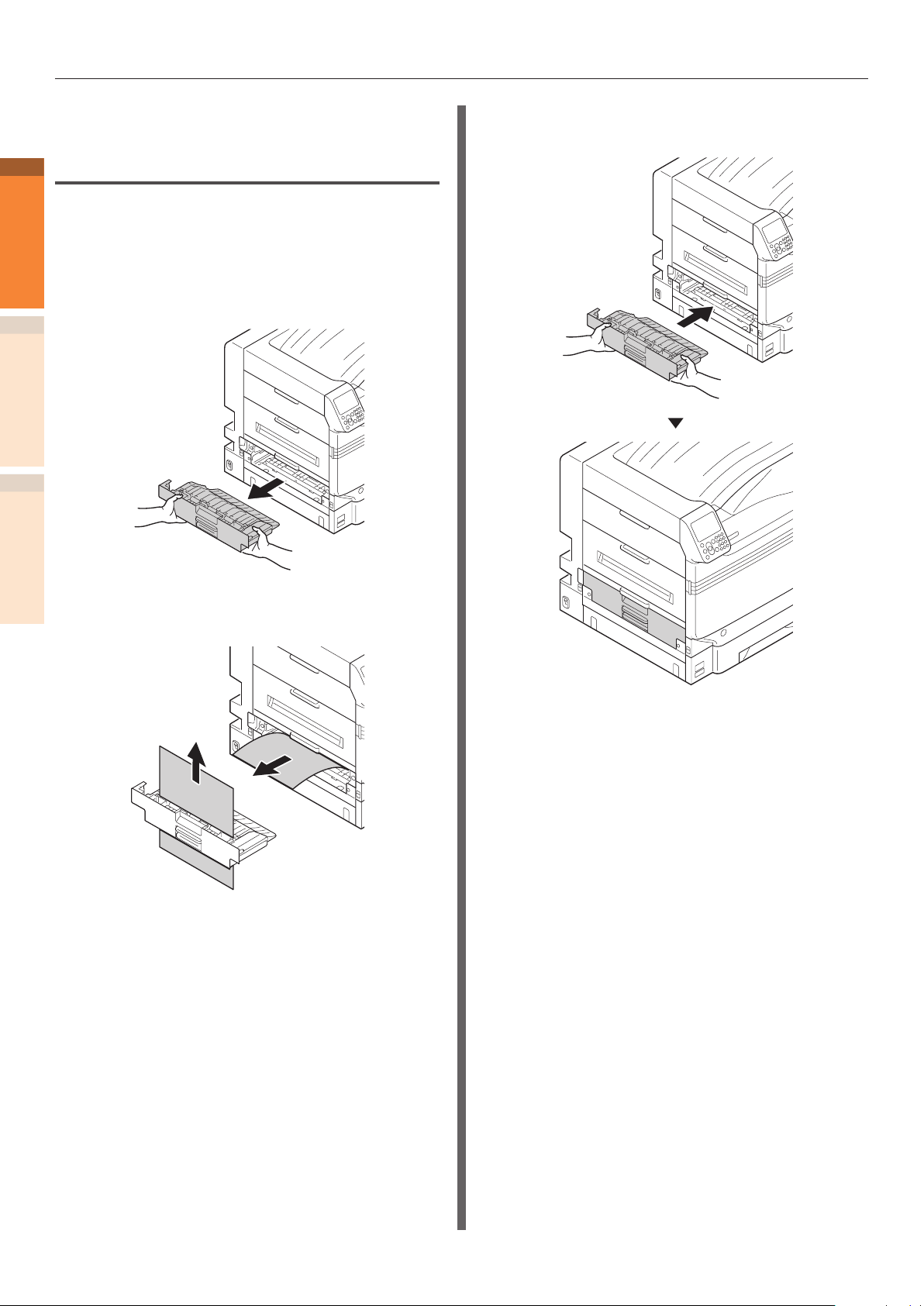

Removing paper from the vicinity

of Tray Side Cover

Error code: 391, 392, 393, 394,

395, 631, 632, 633, 634, 635

Example) In the case of Tray 1

Open the tray side cover where the

1

error is displayed.

- 24 -

Remove the remaining paper.

2

Paper jams

Close the Tray 1 side cover.

3

Removing paper from the vicinity

of the 2-Sided Printing unit

Error code: 370, 371, 373, 640,

641, 642

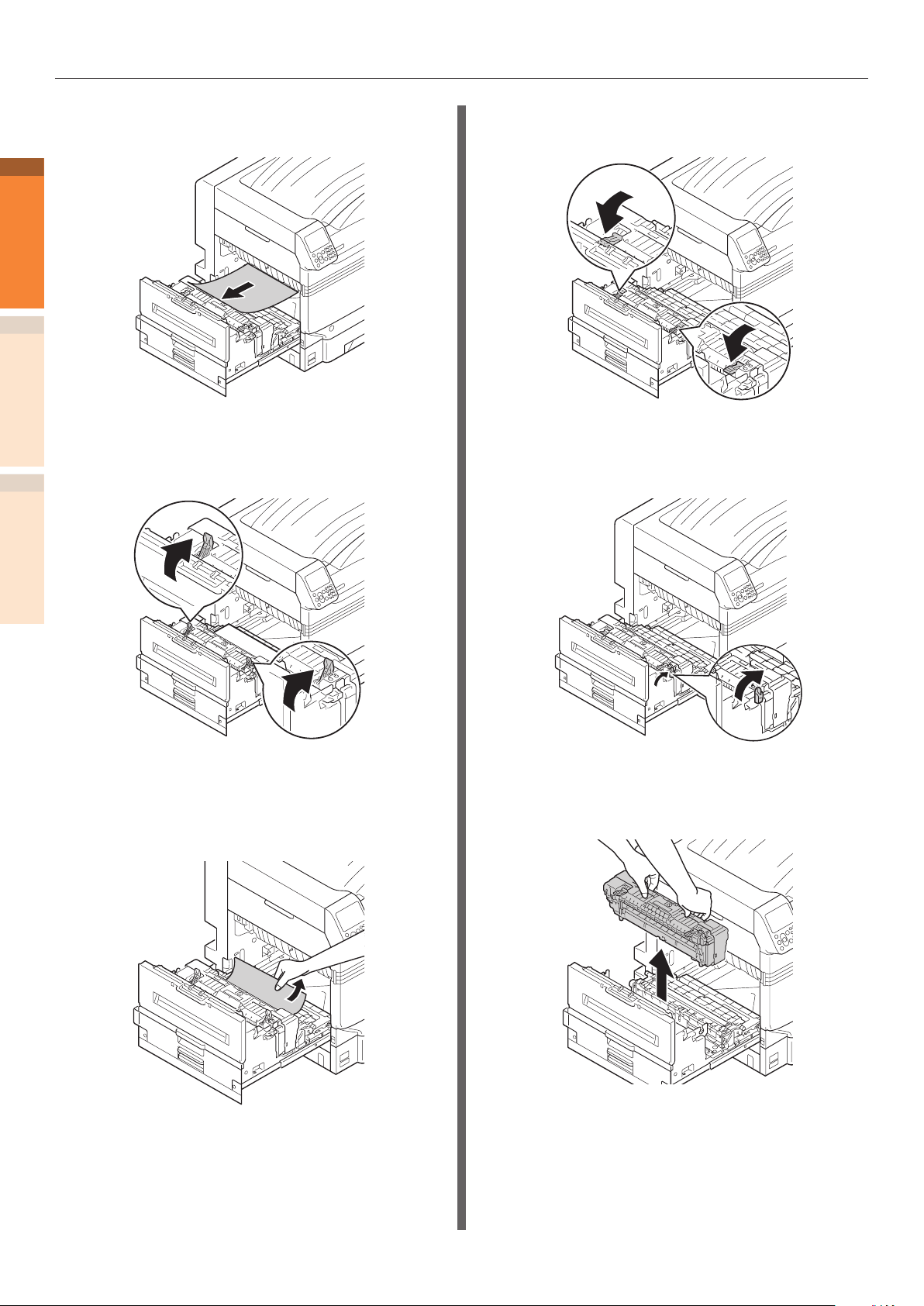

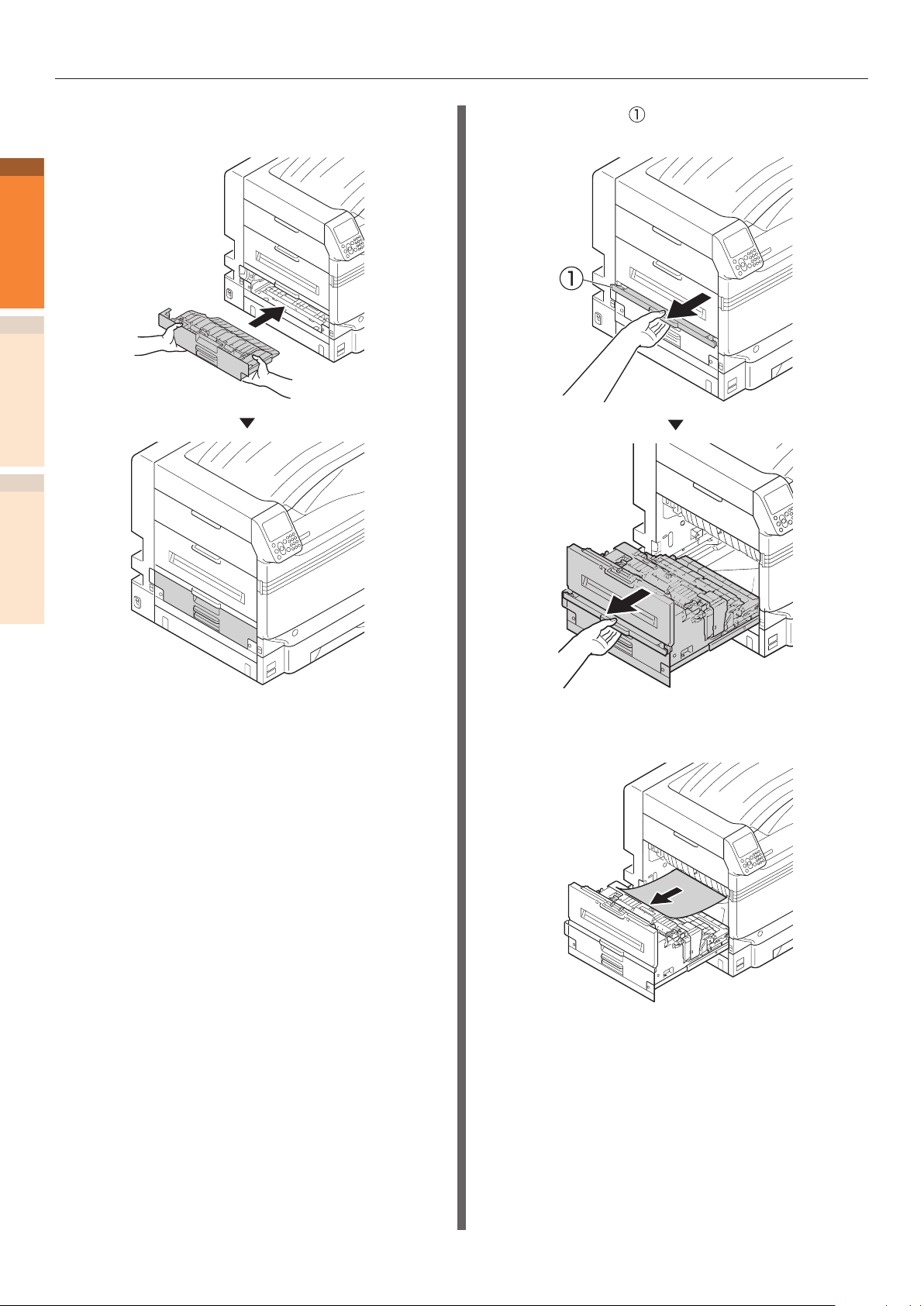

Pull out the 2-Sided Printing unit, lift it

1

up a little with both hands, and remove

it.

When you cannot see the jammed

paper in the 2-Sided Printing unit inside

the printer, put the 2-Sided Printing unit

back into the printer and go to Step 4.

1

Troubleshooting

2

IndexMaintenance

Remove the remaining paper.

2

- 25 -

Paper jams

3

1

Troubleshooting

2

IndexMaintenance

Put the 2-Sided Printing unit back into

the printer.

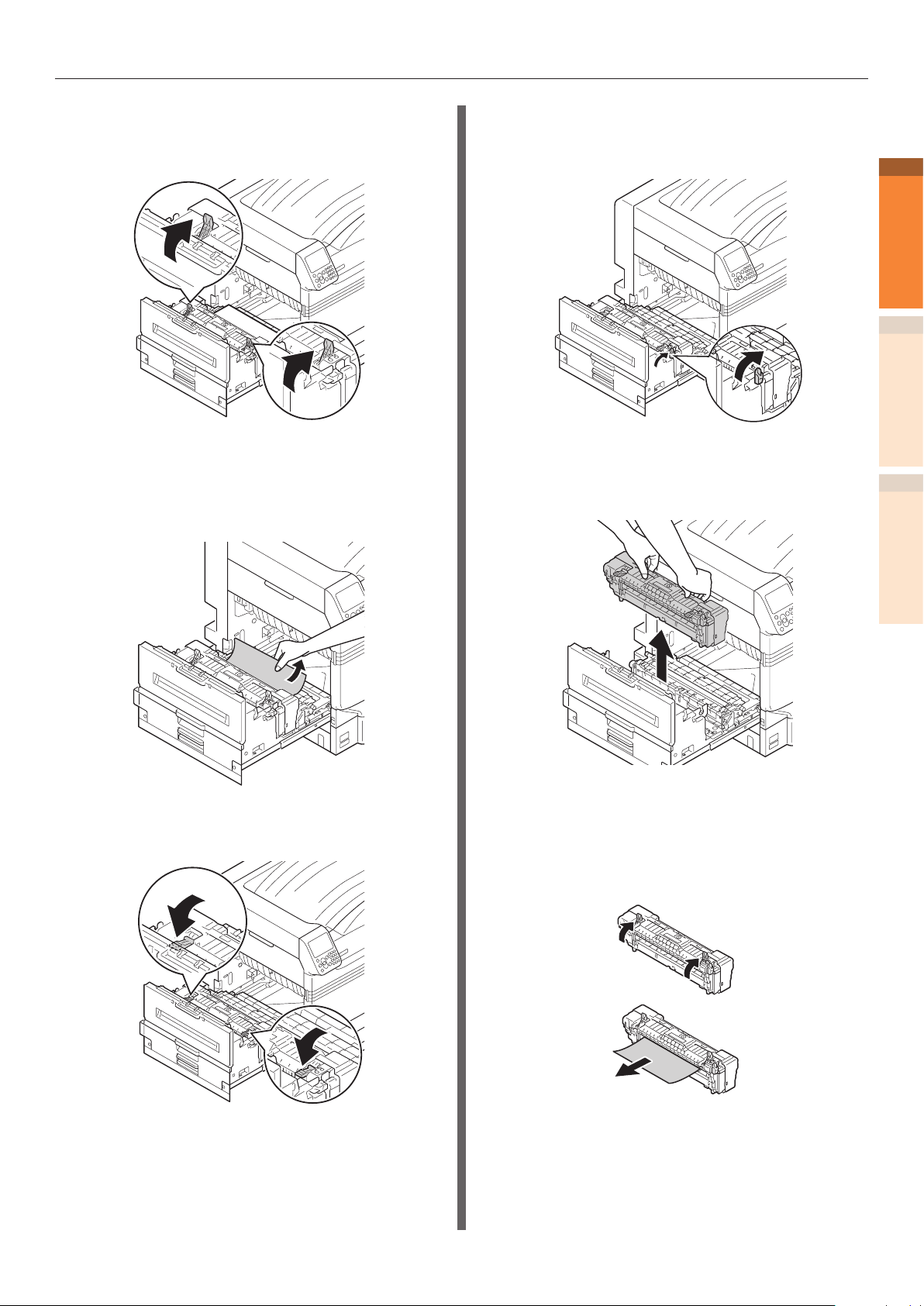

Lift opener ( ) of the exit unit, and pull

4

out the exit unit.

Check inside of the printer, and slowly

5

remove the remaining paper.

- 26 -

Paper jams

If the paper tip is not visible, pull up

6

the fuser unit's lock lever (blue).

Hold the fuser unit handle with both

7

hands, and remove it onto a at

surface.

If the paper winds around the decal roller,

8

remove the decal unit by turning the

thumbscrews at both ends of the decal

unit to the left, and remove the paper.

Note

Be careful not to drop the thumbscrew into the

z

device when removing.

1

Troubleshooting

2

IndexMaintenance

- 27 -

Paper jams

9

1

Troubleshooting

2

IndexMaintenance

Return the decal unit to its original

position, and x it with two

thumbscrews.

Note

Be careful not to drop the thumbscrew into the

z

device when xing.

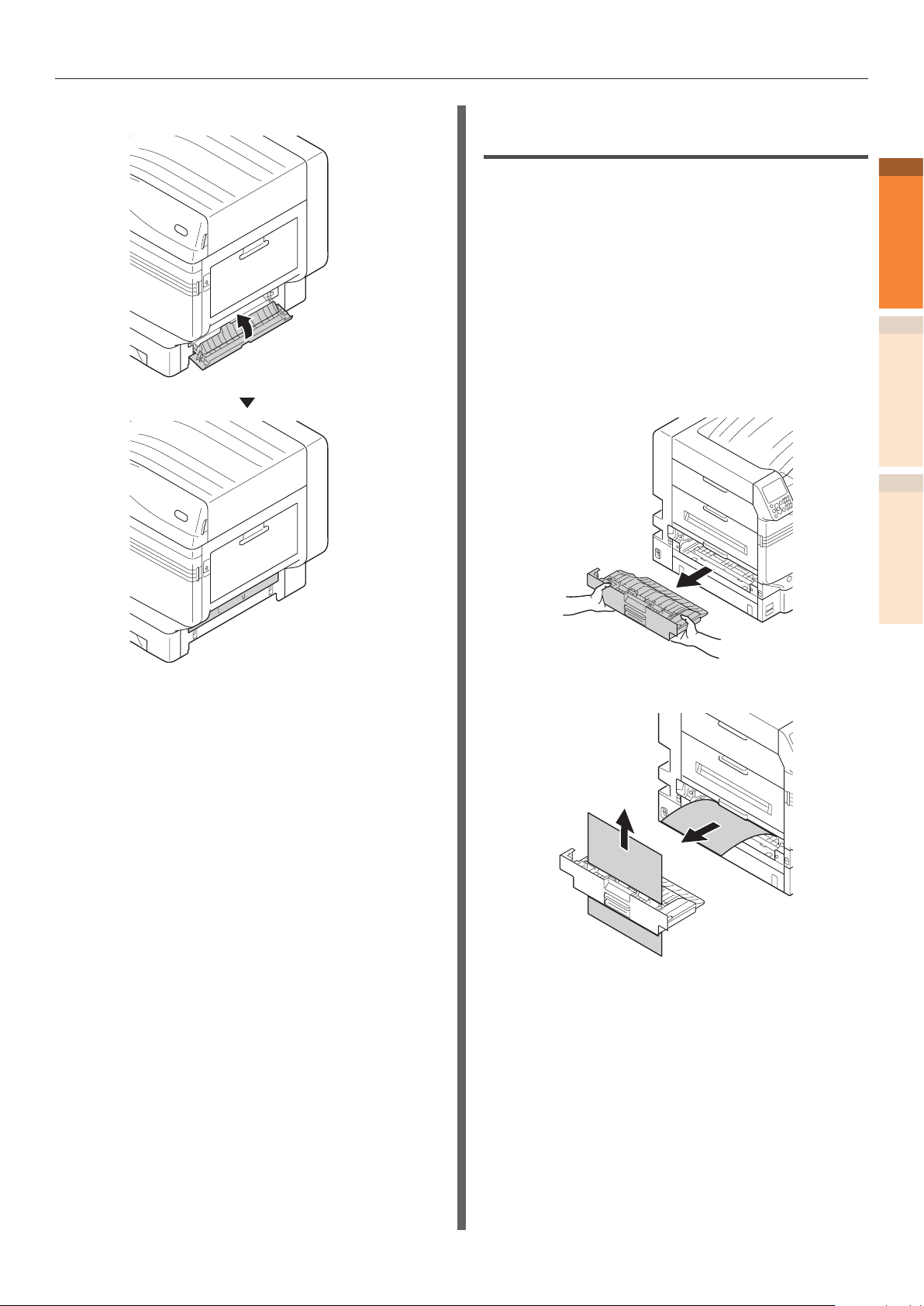

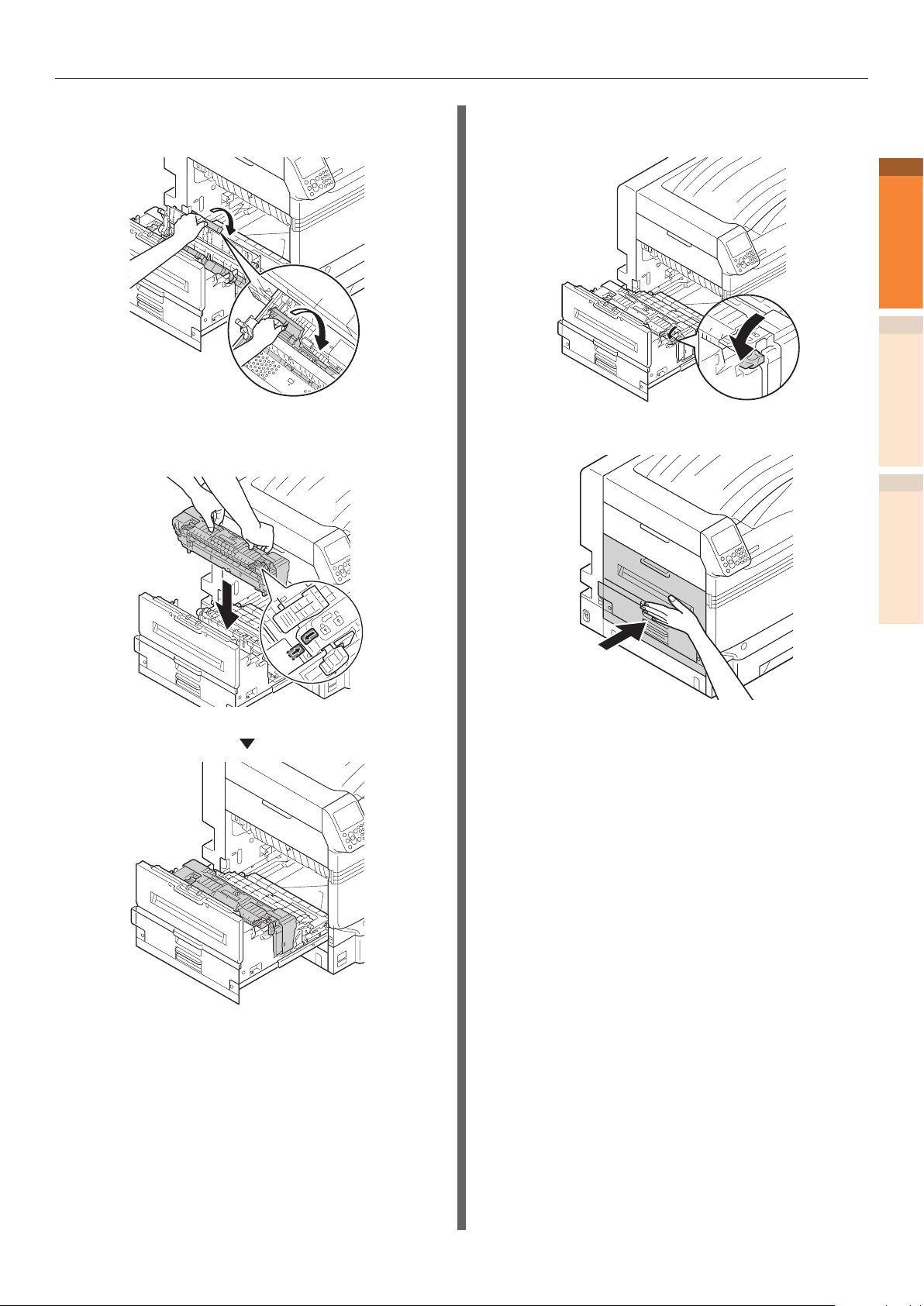

Hold the knob, pull up the transfer roller

10

unit, lift the paper guide, and remove

the remaining paper.

- 28 -

Paper jams

Hold the knob, push down the transfer

11

roller unit.

Hold the fuser unit handle with both

12

hands, and set to the exit unit.

Push down the fuser unit's lock lever

13

(blue).

Put the exit unit back into the printer.

14

1

Troubleshooting

2

IndexMaintenance

- 29 -

Paper jams

Removing paper from the

vicinity of the lower side of

1

2-Sided Printing unit

Troubleshooting

Error code: 375, 650

Pull out the 2-Sided Printing unit, lift it

1

up a little with both hands, and remove

it.

2

IndexMaintenance

Put the 2-Sided Printing unit back into

3

the printer.

Remove the remaining paper from the

2

printer.

If no paper remains in visible locations

in the printer, follow the procedure

given below.

- 30 -

Paper jams

Lift opener ( ) of the exit unit, and

4

remove the remaining paper.

If the paper tip is not visible, pull up

5

the fuser unit's lock lever (blue).

Hold the fuser unit handle with both

6

hands, and remove it onto a at

surface.

1

Troubleshooting

2

IndexMaintenance

- 31 -

Paper jams

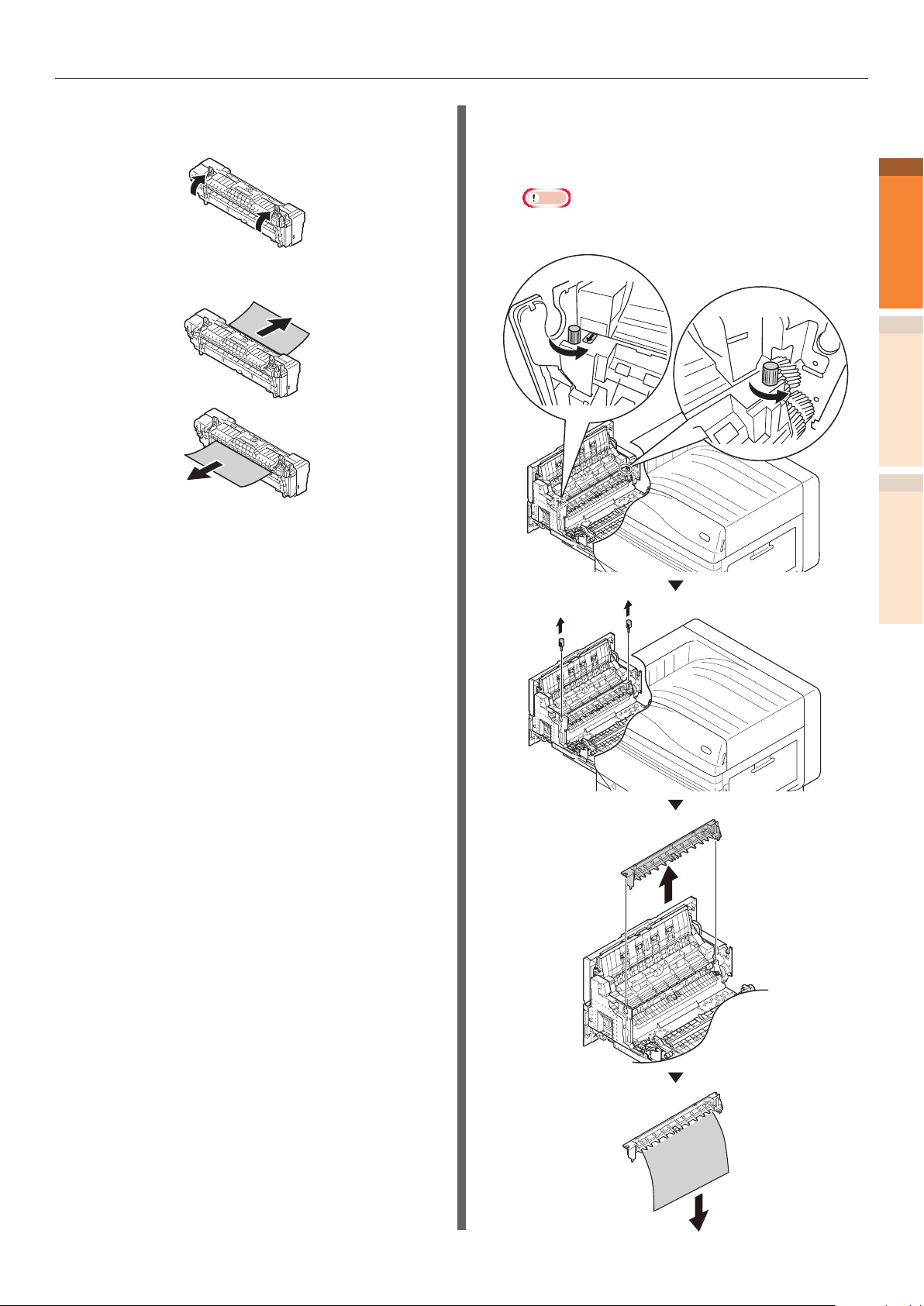

7

1

Troubleshooting

2

IndexMaintenance

If the paper winds around the decal roller,

remove the decal unit by turning the

thumbscrews at both ends of the decal

unit to the left, and remove the paper.

Note

Be careful not to drop the thumbscrew into the device

z

when removing.

Return the decal unit to its original

8

position, and x it with two

thumbscrews.

Note

Be careful not to drop the thumbscrew into the device

z

when xing.

- 32 -

Paper jams

Hold the knob, pull up the transfer roller

9

unit, lift the paper guide, and remove

the remaining paper.

Hold the knob, push down the transfer

10

roller unit.

Hold the fuser unit handle with both

11

hands, and set to the exit unit.

1

Troubleshooting

2

IndexMaintenance

Push down the fuser unit's lock lever

12

(blue).

- 33 -

Paper jams

13

1

Troubleshooting

2

IndexMaintenance

Put the exit unit back into the printer.

Removing paper from the

vicinity of Left Side Cover

Error code: 384, 651

Open the left side cover.

1

Slowly remove the remaining paper.

2

Close the left side cover.

3

- 34 -

When paper jam occurs frequently

Check the following when paper jam occurs very

frequently.

Paper jams

1

Is the feeding paper roller dirty? (“Cleaning

z

feed rollers”(P.93))

Is the paper guide set correctly? (Refer to

z

"Setting the Paper in the Basic")

Is the paper set after ipping through it

z

carefully? (Refer to "Setting the Paper in the

Basic")

Is the printer installed on a at and stable

z

surface?

Are you using the paper compatible with the

z

printer?

Are there any fragments of paper remaining

z

inside the printer?

Troubleshooting

2

IndexMaintenance

- 35 -

If paper messages are displayed

If paper messages are displayed

z

When paper type/size set in the printer tray differs from the printer driver specication, message such

1

as "Replace paper" and "Paper size error has occurred" will appear, and the <ATTENTION> lamp will

Troubleshooting

blink.

Messages related to paper and error codes, cause of errors and their resolutions, and status of the

<ATTENTION> lamp is described below.

Besides, when "Please see HELP for details" is shown in the message, pressing the [HELP] button in the

operation panel will show the solution procedure, and you can easily solve the process according to the

guidance. Refer to “Operating the Help screen”(P.13) for details.

2

Memo

Meanings of the symbols used in the error messages are as follows.

z

– [TRAY]: Tray 1, Tray 2 to Tray 5 (Displayed when the option of additional tray units is mounted.), either of the MP trays will

be displayed.

– [MEDIA_SIZE]: Paper size is displayed.

– [MEDIA_TYPE]: Paper type is displayed.

Category

IndexMaintenance

Load paper Please change [TRAY] paper

Empty Install [MEDIA_SIZE] in [TRAY]

Message displayed on the

liquid crystal panel

Ensure [MEDIA_SIZE], [MEDIA_TYPE]

is installed.

If printing fails, cancel and re-adjust

tray settings

Pressing OK will print using current

paper tray settings

Please see HELP for details

Change [MEDIA_SIZE], [MEDIA_TYPE]

in [TRAY]

Press OK button

Please see HELP for details

Change [MEDIA_SIZE], [MEDIA_TYPE]

in MPTray

Press OK button

Please see HELP for details

Please see HELP for details

Install [MEDIA_SIZE] in MPTray

Please see HELP for details

Error

code

461

462

463

464

465

661

662

663

664

665

660

460

491

492

493

494

495

490 Blinking The MP tray is empty.

<ATTENTION>

lamp

Blinking The size of the paper in the tray, or

Blinking The type of paper in the tray is

Blinking The type of paper in the MP tray

Blinking Tray shown in the message is empty.

Causes and Troubleshooting

the paper size and the paper type,

are different from the printer driver

specications.

Set the paper having size or type

shown in the message.

Printing will start if the paper size is

matching.

different from the specications of the

printer driver.

Set the paper having size or type

shown in the message.

is different from the print driver

specications.

Set the paper having size or type

shown in the message.

Set the paper having size or type

shown in the message.

Set the paper having size or type

shown in the message.

- 36 -

If paper messages are displayed

Category

Paper size

Error

Message displayed on the

liquid crystal panel

Remove Excess Paper and Reset Tray

[TRAY]

Please see HELP for details

Check Paper in [TRAY]

Paper Thick Error

Please see HELP for details

Check Paper in [TRAY]

Paper Multi Feed

Please see HELP for details

Check Paper in [TRAY]

Paper Size Error

Please see HELP for details

Reset Tray

[TRAY]

Please see HELP for details

Error

code

530

531

532

533

534

323

324

325

326

401 Blinking Multiple sheets of paper have been fed.

400 Blinking Printing has been conducted on paper

520

521

522

523

524

<ATTENTION>

lamp

Blinking The paper in the tray may exceed the

Blinking In the tray shown in the message,

Blinking Paper cannot be fed from the tray

Causes and Troubleshooting

maximum limit, or the paper tray may

need to be reset.

Please remove paper from the tray

shown.

paper of a different thickness is

detected.

To cancel printing, press the [CANCEL]

button. If multiple errors occur, you

can not cancel printing.

Press the [HELP] button, and solve

according to the guidance shown on

the Help screen.

To cancel printing, press the [CANCEL]

button. If multiple errors occur, you

can not cancel printing.

Press the [HELP] button, and solve

according to the guidance shown on

the Help screen.

which is of a different size from the

specications of the printer driver.

To cancel printing, press the [CANCEL]

button. If multiple errors occur, you

can not cancel printing.

Press the [HELP] button, and solve

according to the guidance shown on

the Help screen.

shown in the message.

Reset the paper in the tray shown in

the message.

1

Troubleshooting

2

IndexMaintenance

- 37 -

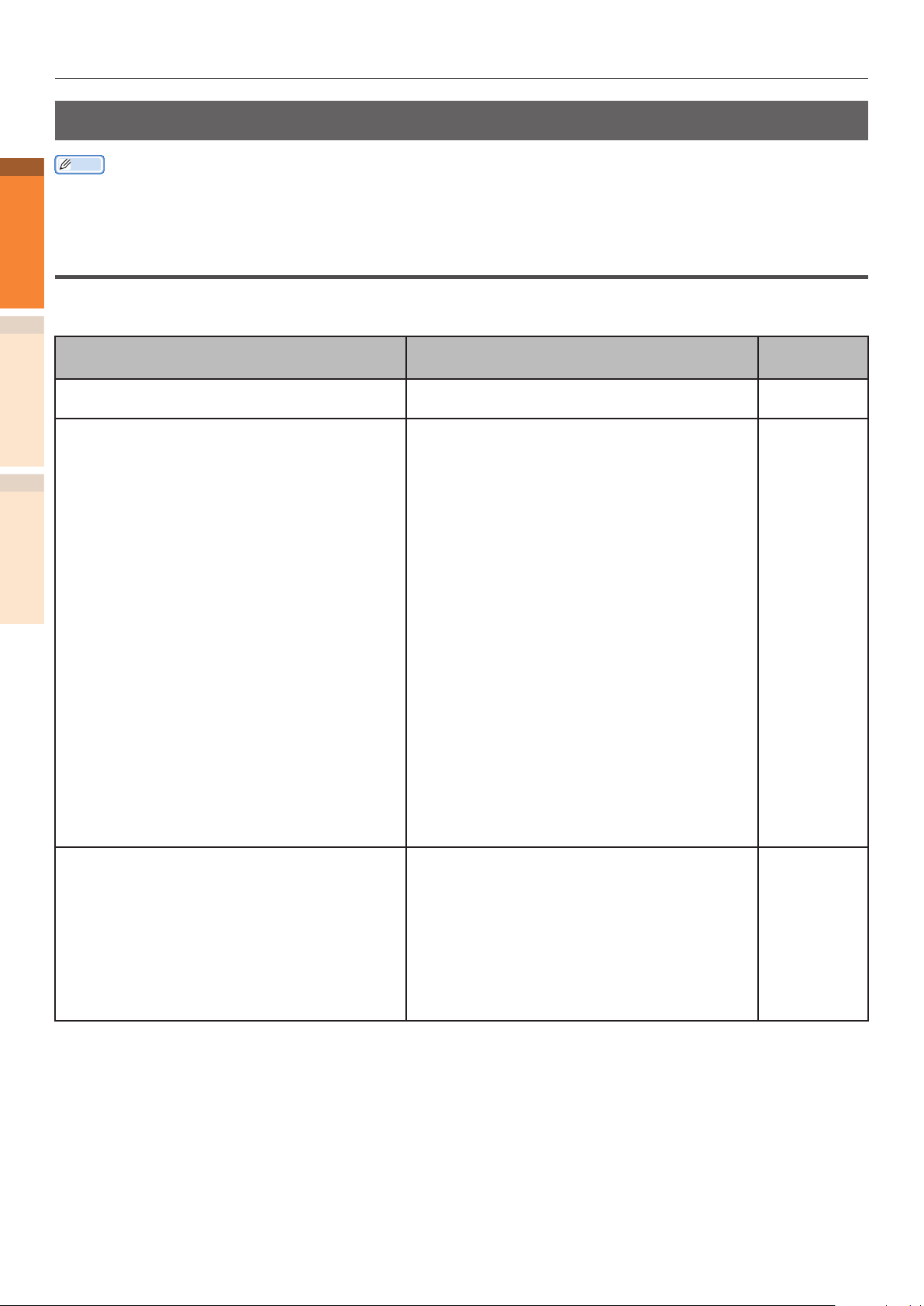

If replace consumables messages are displayed

If replace consumables messages are displayed

z

When timing for replacement of consumables and maintenance items approaches, or when the

1

replacement becomes necessary, message such as "Time for replacing ABC is approaching" and "ABC is

Troubleshooting

empty / Replace ABC" will appear, and the <ATTENTION> lamp will start blinking.

Messages related to replacement of consumable supplies and error codes, cause of errors and their

resolutions, and status of the <ATTENTION> lamp is described below.

Besides, when "Please see HELP for details" is shown in the message, pressing the [HELP] button in the

operation panel will show the solution procedure, and you can easily solve the process according to the

guidance. For details, refer to “Operating the Help screen”(P.13).

2

IndexMaintenance

Memo

Meanings of the symbols used in the error messages are as follows.

z

– [COLOR]: Either of Only Yellow, Only Magenta, Only Cyan, Only Black, White*1, and Clear*2 will be displayed.

*1: White will appear only for C941/C942/ES9541/ES9542/Pro9541/Pro9542.

*2: Clear will appear only for C941/ES9541/Pro9541.

Category

Toner

Cartridge

Image

Drum

Message displayed on the

liquid crystal panel

Install Toner

Black

Please see HELP for details

Install Toner

[COLOR]

Please see HELP for details

Install Toner Or Press OK Button

[COLOR]

Please see HELP for details

Install Toner Or Press OK Button

[White]/[Clear]

Please see HELP for details

Install [COLOR] New Image Drum

Image Drum Life

Please see HELP for details

Install [COLOR] New Image Drum

Image Drum Life To Exceed the

Life, Press OK Button

Please see HELP for details

Error

code

4103 Blinking Black Toner Empty

Printing

4100

4101

4102

4103*

4104

4105

Powering

on

4100

4101

4102

Powering

on

4104

4105

3500

3501

3502

3503

3504

3505

5600

5601

5602

5603

5604

5605

5640

5641

5642

5643

5644

5645

<ATTENTION>

lamp

Press the [HELP] button, and

solve according to the guidance

shown on the Help screen.

(C911/C931/C941/ES9411/ES9431/

ES9541/Pro9431/Pro9541 only)

Blinking Toner color shown in the

message is empty.

Press the [HELP] button, and

solve according to the guidance

shown on the Help screen.

If you switch the power back on,

please refer to the box below.

*: 4103 will appear only for

Blinking Toner Empty.

If you press the [OK] button,

only mono printing will continue.

Press the [HELP] button, and

solve according to the guidance

shown on the Help screen.

Blinking Toner Empty.

If you press the [OK] button, mono

or 4-color printing will continue.

Press the [HELP] button, and

solve according to the guidance

shown on the Help screen.

Blinking Lifespan of the image drum

shown in the message has

reached.

Press the [HELP] button, and

solve according to the guidance

shown on the Help screen.

Blinking The lifespan of the image drum

has been reached.

If you press [OK], printing will

continue, but the print quality

cannot be guaranteed.

Press the [HELP] button, and

solve according to the guidance

shown on the Help screen.

Causes and

Troubleshooting

C942/ES9542/Pro9542.

Reference

pages

page 64

page 64

-

-

page 66

page 66

- 38 -

If replace consumables messages are displayed

Category

Image

Drum

Waste

Toner Box

Fuser Unit Install New Fuser Unit

Belt Unit Install New Belt Unit

- Caution, unknown Consumable

Message displayed on the

liquid crystal panel

Install [COLOR] New Image Drum

Printing disabled due to low

threshold of Image Drum life

Please see HELP for details

Check Image Drum

[COLOR]

Please see HELP for details

Install New Waste Toner Box

Waste Toner Full

Please see HELP for details

Fuser Unit Life

Please see HELP for details

Belt Unit Life

Please see HELP for details

detected

Go to User Manual "Trouble

Shooting" to restore operation

Error

code

6800

6801

6802

6803

6804

6805

3400

3401

3402

3403

3404

3405

357 Blinking Waste toner is full.

354 Blinking Lifespan of the fuser unit has

355 Blinking Lifespan of the belt unit and

709 Blinking You can use any consumables

<ATTENTION>

lamp

Blinking The lifespan of the image drum

has been reached.

You cannot continue printing.

Press the [HELP] button, and

solve according to the guidance

shown on the Help screen.

Blinking Image drum shown in the

message has not been set

correctly.

Press the [HELP] button, and

solve according to the guidance

shown on the Help screen.

If you re-set and use a waste

toner box that is already used,

there is a risk of the waste toner

overowing, so please replace it

with a new waste toner box.

Press the [HELP] button, and

solve according to the guidance

shown on the Help screen.

reached

Press the [HELP] button, and

solve according to the guidance

shown on the Help screen.

the transfer roller unit has been

reached.

Press the [HELP] button, and

solve according to the guidance

shown on the Help screen.

in your product, but you must

accept the risks of using nongenuine consumables. If the use

of non-genuine consumables

causes damage to the product

or results in your product

not functioning to its full

specication, then such damage

or effect on the product is not

covered by warranty. To accept

these risks and to restore

function;

1. Turn off your product.

2. Press and hold the [CANCEL]

button and turn your product

on.

3. After start up, release the

[CANCEL] button.

Note

This operation will be recorded

for future reference.

Causes and

Troubleshooting

Reference

pages

page 66

-

page 77

page 75

page 69

-

1

Troubleshooting

2

IndexMaintenance

- 39 -

If other messages are displayed

If other messages are displayed

z

Other messages and error codes, cause of errors and their resolutions, and status of the <ATTENTION>

1

lamp are described below.

Troubleshooting

Besides, when "Please see HELP for details" is shown in the message, pressing the [HELP] button in the

operation panel will show the solution procedure, and you can easily solve the problem according to the

guidance. For details, refer to “Operating the Help screen”(P.13).

Memo

Meanings of the symbols used in the error messages are as follows.

z

2

– [COLOR]/[MENUCOLOR]: Either of Only Yellow, Only Magenta, Only Cyan, Only Black, White*, and Clear** will be displayed.

*: White will appear only for C941/C942/ES9541/ES9542/Pro9541/Pro9542.

**: Clear will appear only for C941/ES9541/Pro9541.

– [TRAY]: Tray 1, Tray 2 to Tray 5 (Displayed when the option of additional tray units is mounted.), either of the MP trays will

be displayed.

– [COVER]: Either front cover, Tray 1 side cover to Tray 5 side cover (Tray 2 side cover to Tray 5 side cover will be displayed

when the option of additional tray units is mounted.), or exit unit cover will be displayed.

– [CODE]: Detailed information of the error will be displayed.

IndexMaintenance

Message displayed on the

liquid crystal panel

Power Off/On

[ERRCODE]: Error

Image Drum Not Installed

[COLOR]

Please see HELP for details

Image Drum Sensor Error

Please check [COLOR] image

drum and reset

Please see HELP for details

Remove Paper

[STACKER]

Please see HELP for details

[STACKER]: Either Face Up Stacker or

Face Down Stacker will be displayed.

Press OK Button for Restoration

Memory Overow

Please see HELP for details

A spot color printing error has

occurred. Data will be erased.

Check the paper and paper

settings, then print again. To turn

off the display, press OK

Please see HELP for details

Error

code

6940

6941

6942

6943

6944

6945

5400

5401

5402

5403

5404

5405

480

484

420 Blinking Cannot print. Printing data has

459 Blinking

<ATTENTION>

lamp

- Blinking A fatal error has occurred.

Blinking The image drum shown in the

Blinking Sensor error has occurred in the

Blinking The paper stacker is full.

Causes and Troubleshooting

If the error is not resolved by

restarting the printer, contact your

designated help desk.

message has not been installed.

Press the [HELP] button, and solve

according to the guidance shown on

the Help screen.

image drum shown.

Sensor may be unclean or stopper is

installed.

Press the [HELP] button, and solve

according to the guidance shown on

the Help screen.

Remove Paper from stacker.

exceeded the memory capacity of

the printer.

In the Quality of printer driver, select

[Fine/Detail] or [Normal], and print

once again.

Press the [OK] button for deleting

the display of the liquid crystal

panel.

Printing is stopped because of print

request from an incompatible custom

media, and data is deleted.

Print once again.

Press the [OK] button for deleting the

display of the liquid crystal panel.

Reference

pages

-

-

-

-

[Advanced] >

[Print with

best quality]

-

- 40 -

If other messages are displayed

Message displayed on the

liquid crystal panel

Close Cover

[COVER]

Please see HELP for details

Non Genuine Image Drum

[COLOR]

Please see HELP for details

Incompatible Image Drum

[COLOR]

Please see HELP for details

Error

code

311

312

313

314

315

585

588

589

6840

6841

6842

6843

6844

6845

6900

6901

6902

6903

6904

6905

7000

7001

7002

7003

7004

7005

7040

7041

7042

7043

7044

7045

7100

7101

7102

7103

7104

7105

7200

7201

7202

7203

7204

7205

<ATTENTION>

lamp

Blinking The cover shown in the message is

Blinking The image drum is not intended for

Blinking The image drum is not intended for

Causes and Troubleshooting

open.

Close the cover.

use with this printer model.

Use an image drum intended for use

in this printer model.

use with this printer model.

Use an image drum intended for use

in this printer model.

Reference

pages

-

-

-

1

Troubleshooting

2

IndexMaintenance

- 41 -

If other messages are displayed

1

Troubleshooting

Incompatible Toner

[COLOR]

Please see HELP for details

2

IndexMaintenance

Non Genuine Toner

[COLOR]

Please see HELP for details

Non Genuine Fuser Unit

Please see HELP for details

Incompatible Fuser Unit

Please see HELP for details

Non Genuine Belt Unit

Please see HELP for details

Incompatible Belt Unit

Please see HELP for details

Fuser Unit Not Installed

Please see HELP for details

Message displayed on the

liquid crystal panel

Error

code

5540

5541

5542

5543

5544

5545

6140

6141

6142

6143

6144

6145

6200

6201

6202

6203

6204

6205

6240

6241

6242

6243

6244

6245

7140

7141

7142

7143

7144

7145

5500

5501

5502

5503

5504

5505

6981 Blinking Fuser unit not intended for use

6982

6983

6984

6985

6986

6987

6881 Blinking Belt unit not intended for use with

6882

6883

6884

6885

6886

699 Blinking

<ATTENTION>

lamp

Blinking Toner cartridge is not intended for

Blinking Toner cartridge is not intended for

Blinking Fuser unit not intended for use with

Blinking Belt unit not intended for use with

Causes and Troubleshooting

use with this printer model.

Use a toner cartridge intended for

use in this printer model.

use with this printer model.

Use a toner cartridge intended for

use in this printer model.

with this printer model.

Use a fuser unit intended for use

in this printer model.

this printer model.

Use a fuser unit intended for use in

this printer model.

this printer model.

Use a belt unit intended for use in

this printer model.

this printer model.

Use a belt unit intended for use in

this printer model.

The fuser unit is not installed

properly.

Press the [HELP] button, and solve

according to the guidance shown on

the Help screen.

Reference

pages

-

-

-

-

-

-

-

- 42 -

If other messages are displayed

Message displayed on the

liquid crystal panel

Check Fuser Unit

Please see HELP for details

Receiving Data Timeout

Press OK Button for Restoration

Please see HELP for details

Check Data

Message Data Write Error <[CODE]>

Install Transfer Roller Unit

Re-set the transfer roller unit

Please see HELP for details

A spot color printing error has

occurred. Data will be erased

Check the paper and paper

settings, then print again. To turn

off the display, press OK

Please see HELP for details

The data will be deleted due to an

overprint feature error

Mount the duplex printing unit

and print again. To turn off the

display, press OK

Please see HELP for details

The data will be deleted due to an

overprint feature error

Check the paper and paper

settings, then print again. To turn

off the display, press OK

Please see HELP for details

Spot Color has been replaced

Press OK to change the Spot Color

settings in the menu to [COLOR]

and restart the system

If you do not want to change

settings, return Spot Color toner,

image drum and Spot Color duct

settings to [MENUCOLOR].

Spot Color has been replaced

Check Spot Color menu settings

Current setting is [MENUCOLOR]

Press OK Button

Spot Color settings changes

Shut down and restart to enable

new settings

Error

code

348

320

519 Blinking A data receipt timeout occurred.

334 Blinking The transfer roller unit is not set

459 Blinking

458 Blinking

456 Blinking Paper used for printing is not

679 Blinking Spot Color has been exchanged

678 Blinking Spot Color has been exchanged

677 Blinking

<ATTENTION>

lamp

Blinking The fuser unit is not installed

- - Failed to write the message data to

Causes and Troubleshooting

correctly.

Install the fuser unit correctly.

Increase the length of timeout print

setting.

be updated. Check data.

correctly.

Press the [HELP] button, and solve

according to the guidance shown on

the Help screen.

Because of a print request for paper

unavailable to spot color printing, the

printing has been stopped, and the

data was deleted.

Check the paper and paper settings,

and print again.

Press the [OK] button for deleting the

display of the liquid crystal panel.

Spot Color over printing is specied,

but the 2-Sided Printing unit is not

there. Printing was stopped and the

print data was deleted.

Install the 2-Sided Printing unit and

print once again.

Press the [OK] button for deleting the

display of the liquid crystal panel.

(C941/ES9541/Pro9541 only)

compatible for Spot Color over

printing. Printing was stopped and

the print data was deleted.

Change the paper, or set to Normal

and print once again.

Press the [OK] button for deleting the

display of the liquid crystal panel.

(C941/ES9541/Pro9541 only)

Solve according to the message.

(C941/ES9541/Pro9541 only)

Solve according to the message.

(C941/ES9541/Pro9541 only)

Spot Color setting has been

changed.

Solve according to the message.

(C941/ES9541/Pro9541 only)

Reference

pages

-

[Advanced] >

[List of Setting

Items of

the Device

Settings

Screen] >

[Timeout

Printing]

-

-

-

-

-

-

-

-

1

Troubleshooting

2

IndexMaintenance

- 43 -

If other messages are displayed

1

Troubleshooting

2

IndexMaintenance

Spot Color Duct has not been

installed

Please install the Spot Color Duct

Please see HELP for details

Toner Duct has not been installed

Please install the Toner Duct

Please see HELP for details

Check Image Drum and Toner

Cartridge

[COLOR]

Please see HELP for details

Check Toner Duct

Please see HELP for details

Check Spot Color Duct

Please see HELP for details

Toner Not Installed

[COLOR]

Please see HELP for details

The toner replacement cover is

open

Please see HELP for details

Install Paper Cassette

[TRAY]

Please see HELP for details

Install Exit Unit

Please see HELP for details

Check Waste Toner Box

Please see HELP for details

Reset Waste Toner Box

Waste Toner Transfer Error

Please see HELP for details

Message displayed on the

liquid crystal panel

Error

code

676 Blinking

676 Blinking Toner Duct has not been installed.

5440

5441

5442

5443

5444

5440 Blinking The toner duct is not properly

5444

5445

6100

6101

6102

6103

6104

6105

586 Blinking The toner replacement cover is

430

431

432

433

434

333 Blinking The exit unit is missing.

331 Blinking The waste toner box is not set

359 Blinking A waste toner transfer error has

<ATTENTION>

lamp

*1

Blinking The toner cartridge shown in the

*2

Blinking The spot color duct is not properly

Blinking The toner cartridge shown in the

Blinking There is no paper cassette in the

Causes and Troubleshooting

Spot Color Duct has not been installed.

Please install the Spot Color duct.

(C941/ES9541/Pro9541 only)

Please install the Toner duct.

(C942/ES9542/Pro9542 only)

message is not set correctly.

Press the [HELP] button, and solve

according to the guidance shown on

the Help screen.

*1: 5440 will appear only for C942/

ES9542/Pro9542.

*2: 5444 will appear only for C941/

ES9541/Pro9541.

installed.

Reset the toner duct.

Press the [HELP] button, and solve

according to the guidance shown on

the Help screen.

(C942/ES9542/Pro9542 only)

installed.

Reset the spot color duct.

Press the [HELP] button, and solve

according to the guidance shown

on the Help screen. (C941/ES9541/

Pro9541 only)

message has not been installed.

Press the [HELP] button, and solve

according to the guidance shown on

the Help screen.

open.

Check that the toner cartridge is

pushed in rmly as far as it can go,

and close the toner cover.

tray shown in the message.

Set the paper cassette in the tray

shown in the message.

When the paper cassette is already

there in the tray, pull the cassette

out and set it correctly.

Please install the exit unit.

correctly.

Reset the waste toner box.

occurred.

Press the [HELP] button, and solve

according to the guidance shown on

the Help screen.

Reference

pages

-

-

-

-

-

-

-

-

-

-

-

- 44 -

If other messages are displayed

Message displayed on the

liquid crystal panel

Firmware Update Error

Please retry

If network doesn’t work, please

try rmware update over USB

Open Stacker

Face Up Stacker

Please see HELP for details

Belt Unit Not Installed

Please see HELP for details

Check Belt Unit

Please see HELP for details

Power Off and Wait for a while

126: Condensing Error

Install Duplex Unit

Please see HELP for details

The data was deleted because a

duplex printing error occurred

Check the paper and paper

settings, then print again. To turn

off the display, press OK

Please see HELP for details

Error

code

302 - Firmware update failed.

580 Blinking Face up stacker is closed.

689 Blinking The belt unit is not installed.

330 Blinking The belt unit is not set correctly.

360 Blinking The 2-Sided Printing unit is not set

455 Blinking

<ATTENTION>

lamp

- Blinking Condensation has occurred inside

Causes and Troubleshooting

Follow the contents of the message.

Please open the face up stacker.

Press the [HELP] button, and solve

according to the guidance shown on

the Help screen.

Press the [HELP] button, and solve

according to the guidance shown on

the Help screen.

the printer.

Restart the printer after some time.

If the error is not resolved by

restarting the printer, contact your

designated help desk.

correctly.

Install the 2-Sided Printing unit

correctly.

2-Sided printing cannot be done

because the paper is too thick or it is

small. Printing was stopped and the

print data was deleted.

Change the paper, or set to 1-Sided

Printing and print once again.

Press the [OK] button for deleting

the display of the liquid crystal panel.

Reference

pages

-

-

-

-

-

-

-

1

Troubleshooting

2

IndexMaintenance

- 45 -

Printing Troubles

Printing Troubles

z

This section describes the possible troubles that may occur while operating the printer, and their

1

solution procedure.

Troubleshooting

Memo

If the problem is not solved using the following methods, contact your dealer.

z

For problems arising from the applications, contact the application development company.

z

Unable to print

2

Basic reasons

Common for Windows/Mac OS X

Cause Solution procedure

Power supply of the printer is switched off. Switch on the power supply. Basic

Power supply was switched off due to the auto

power off function.

IndexMaintenance

Printer is in sleep mode.

LAN Cable/USB Cable is disconnected. Check that labels are correctly connected to the

Cables are defective. Replace with new cables. -

Printer is ofine.

Error message has appeared on the liquid

crystal panel of the operation panel.

NBT, EtherTalk, and WSP Print protocols are

used.

Interface settings are disabled. From [Admin Setup]>[Network Setup] on the

There is a problem with the print function. Check whether you can print the printer

Print will be automatically canceled. Print is not allowed when print job accounting

Switch on the power supply.

When you do not want to use the auto power off

function, disable it with [Admin Setup]>[Power

Setup]>[Auto Power Off] in the operation panel.

Touch the [POWER SAVE] button on the operation

panel, and change the status to the standby mode.

When you do not want to use the sleep mode,

disable the sleep mode from [Admin Setup]>[Power

Setup]>[Sleep] in the operation panel.

printer and the computer.

Press the [ON LINE] button on the operation panel.

Press “If paper messages are

displayed”(P.36),”If replace consumables

messages are displayed”(P.38),”If other

messages are displayed”(P.40), or the [HELP]

button on the operation panel.

When the sleep mode is enabled, disable it from

[Admin Setup]>[Power Setup]>[Sleep] in the

operation panel.

operation panel, enable the interface you are

using.

information or not.

client is used. Or, job accounting log buffer may

be full.

Reference

pages

Advanced

Basic

-

-

page 36

page 38

page 40

-

Advanced

Basic

Advanced

- 46 -

For Windows

Printing Troubles

Cause Solution procedure

This printer is not set as default printer. Set it to default printer. -

Output port of printer driver is incorrect. Select the output port where LAN cable/USB

cable is connected.

Printing from other interface is in progress. Wait until the printing is complete. -

Reference pages

Network Connection Problems

Common for Windows/Mac OS X

Cause Solution procedure

Cross cable is used. Arrange straight cable and hub, and connect

Compatibility problem with hub. Select [Admin Setup]>[Network Setup]>[Hub

There is a problem with hub. Insert network cable in the empty hub, or

Network cable is defective. Reconnect with a new or a different network

Incorrect IP address.

Duplicate IP address. Check that IP address of the printer does not

correctly.

Link Setting] from the operation panel, and

change the settings.

another port. If the problem is still not solved,

use another hub.

cable, and check again.

Check that IP address settings of the printer,

z

and IP address of the printer set in the

computer are matching.

If you are using OKI LPR Utility on Windows,

z

check IP address settings in OKI LPR Utility.

Check that IP address is not overlapping with

z

other device.

Check that correct address is set in IP

z

address, Subnet mask, and Gateway address.

overlap with other IP address.

Reference pages

Basic

Advanced

Advanced

1

-

Troubleshooting

2

-

-

-

IndexMaintenance

USB Connection Problems

Common for Windows/Mac OS X

Cause Solution procedure

Cable does not meet the standards. Use USB cable of USB 2.0 specications. Basic

USB hub is used. Directly connect the printer to the computer. -

Printer driver is not installed correctly. Please re-install the printer driver. Basic

For Windows

Cause Solution procedure

Printer is ofine. Right click the OKI C9xx icon in the [Devices and

Switch, buffer, extension cable, and USB hub

are used.

Another printer driver operated through USB

connection is installed.

Printers] folder, and select [See what’s printing]

(When multiple drivers are installed>[OKI C9xx

(*)]). Select the [Printer] menu in the dialog

displayed, and uncheck [Use Printer Ofine].

*: Select the type of required driver.

Directly connect the printer to the computer. -

From the computer, remove other printer

drivers.

Reference pages

Reference pages

Basic

-

- 47 -

Printing Troubles

Printer Troubles

1

Troubleshooting

Memo

If the problem is not solved using the following explanation, contact your dealer.

z

Symptom Cause Troubleshooting

Nothing is displayed in the

liquid crystal panel even after

switching on the power supply.

Power supply cord is

disconnected.

Power outage. Check if electricity is owing in

2

Does not function. Power supply cord is not

inserted rmly.

Power supply is not switched

on.

LED lamp of the power supply

switch is blinking at high speed

at about 0.3 seconds interval.

IndexMaintenance

The printer has broken down. Unplug the power cord

Reference

pages

Switch off the power supply, and

rmly insert the power supply

cord.

the power socket.

Firmly insert the power supply

cord.

Switch on the power supply. Basic

immediately, and then

contact your dealer.

Basic

-

Basic

-

Printing process does not start. Error is displayed. Check the error code, and follow

the instructions displayed on the

liquid crystal panel.

LAN Cable/USB Cable is not

connected.

LAN Cable/USB Cable is

defective.

LAN Cable/USB Cable does not

meet the standards.

There may be a problem with

the print function.

Interface is disabled. From [Admin Setup]>[Network

Printer driver is not selected. Set the printer driver to "default

Output port of printer driver is

incorrect.

Liquid crystal display of the

operation panel is blank.

Print data is not sent. LAN Cable/USB Cable is

Abnormal sound. Device is tilted. Install on a stable and a at

Printer is in sleep mode. Touch the [POWER SAVE]

damaged.

Computer had timed out. Increase the length of timeout. -

Firmly insert LAN Cable/USB

Cable.

Use another LAN Cable/USB

Cable.

Use a cable of USB 2.0

z

specications.

Use a cable of LAN Cable

z

1000 BASE-T Specications.

Check whether you can print the

printer information or not.

Setup] on the operation panel,

enable the interface you are

using.

printer".

Specify the output port where

LAN cable/USB cable is to be

connected.

button on the operation panel,

and change the status to the

standby mode.

Connect a new cable. -

surface.

page 36

page 38

page 40

Basic

-

Basic

Basic

Advanced

Basic

Basic

Basic

Basic

- 48 -

Printing Troubles

Symptom Cause Troubleshooting

Resonant sound. While temperature inside the

device has increased, printing

is done on a narrow paper or a

thick paper.

Printing does not start

immediately.

Printing stops in between. Temperature is adjusted

Not enough memory. Inadequate memory of the

Slow printing. Printing process is also done at

Display of the printer driver is

abnormal. (Mac OS X)

Device is warming up for

returning from the power

saving mode or auto power off.

Cleaning of image drum may

be in progress.

Temperature adjustment of the

fuser unit is under progress.

Processing of data from other

interface is in progress.

because temperature of the

fuser unit increased due to

continuous printing.

Temperature is adjusted

because temperature inside

the device increased due to

continuous printing for long

time.

printer due to large printing

data

the computer side.

Select [ProQ/High Quality] in

the [Job Options] tab of the

printer driver.

Complicated print data. Select simple print data. -

Printer driver may not be

functioning correctly.

Reference

pages

Device has not broken down.

Use the device as it is.

Please wait.

When you do not want to use

auto power off, select [Admin

Setup]>[Power Setup]>[Sleep]/

[Auto Power Off], and disable

both the modes.

Please wait. -

Please wait. -

Wait until the printing is

complete.

Please wait.

Printing will automatically

start again once temperature

of the fuser unit has become

appropriate.

Please wait.

Printing will automatically start

again once temperature of the

printer has become appropriate.

Print after lowering the quality

of printer driver.

User a computer with fast

processing speed.

In the [Advanced] tab of the

printer driver,

select [Fine/

Detail(1200x1200dpi)]

or [Normal (600x600dpi)].

Delete the printer driver once,

and re-install it.

Advanced

Advanced

-

1

Troubleshooting

2

-

-

IndexMaintenance

-

-

-

- 49 -

Printing Troubles

Printer driver malfunctions

1

Troubleshooting

Memo

If the problem is not solved using the following explanation, contact your dealer.

z

For problems arising from the applications, contact the application development company.

z

USB Connection Problems

For Windows

2

Cause Solution procedure

Icon of the printer is not created in the [Devices

and Printers] folder.

Even when installation of multiple printer drivers

is selected, only the initial printer driver is

installed.

IndexMaintenance

Reference

pages

Printer driver is not installed correctly. Basic

Install the second and subsequent printer

drivers according to the following procedure.

1. Insert the "Software DVD-ROM" in the

computer.

2. Click [Run Setup.exe], and follow the

instructions provided on the screen.

3. Select [Custom Install], select the printer

drivers you want to install on the [Install

Software] screen, and then click the [Install]

button.

4. When the [Installing] screen appears, click

[Install on other ports].

5. Select [FILE] on the [Select Port] screen, and

then click [Next].

6. Follow the instructions displayed on the

screen to nish the installation.

7. In [Devices and Printers], right click on the

icon of driver you installed, and select [Printer

properties] (or [OKI C9xx (*)] if installing

multiple printer drivers).

8. From the list of the [Port] tab, select

[USBxxx].

9. Click the [OK] button.

-

Error message such as "Printer driver installation

failed" appears.

*: Select the type of driver you would like to set.

Use plug and play. Follow the procedure given

below.

1. Check that power supply of the printer and

computer is turned off.

2. Connect the USB cable.

3. Turn on the power supply of the printer.

4. Turn on the power supply of the computer.

5. When the [Search new software] wizard

appears, set up according to the instructions

displayed on the screen.

- 50 -

-

Problems concerning restrictions of OS

Printing Troubles

Restrictions concerning Windows 7/Windows 8/Windows 8.1/Windows

Vista/Windows Server 2008 R2/Windows Server 2008/Windows Server

2012/Windows Server 2012 R2

Item Symptom Causes and Troubleshooting

Printer driver Help does not appear. The Help function is not supported by the PS printer driver.

The [User Account

Control] dialog appears.

Network Extension Help does not appear. The Help function is not supported.

The [User Account

Control] dialog appears.

The [Program

compatibility assistant]

dialog will appear.

Color Correct Utility The [User Account

Control] dialog appears.

The [Program

compatibility assistant]

dialog will appear.

Color sample print utility The [User Account

Control] dialog appears.

The [Program

compatibility assistant]

dialog will appear.

PS Gamma Adjuster The [User Account

Control] dialog appears.

The [Program

compatibility assistant]

dialog will appear.

When starting installer or utility, the [User Account Control]

dialog may appear. Click [Yes] or [go], and run installer or

utility as administrator. Clicking [No] or [Cancel] will not

start installer or utility.

When starting installer or utility, the [User Account Control]

dialog may appear. Click [Yes] or [go], and run installer or

utility as administrator. Clicking [No] or [Cancel] will not

start installer or utility.

When the [Program compatibility assistant] dialog appears

after completion of installation (including when installation

is aborted in the middle), ensure to click [This program

installed correctly].

When starting installer or utility, the [User Account Control]

dialog may appear. Click [Yes] or [go], and run installer or

utility as administrator. Clicking [No] or [Cancel] will not

start installer or utility.

When the [Program compatibility assistant] dialog appears

after completion of installation (including when installation

is aborted in the middle), ensure to click [This program

installed correctly].

When starting installer or utility, the [User Account Control]

dialog may appear. Click [Yes] or [go], and run installer or

utility as administrator. Clicking [No] or [Cancel] will not

start installer or utility.

When the [Program compatibility assistant] dialog appears

after completion of installation (including when installation

is aborted in the middle), ensure to click [This program

installed correctly].

When starting installer or utility, the [User Account Control]

dialog may appear. Click [Yes] or [go], and run installer or

utility as administrator. Clicking [No] or [Cancel] will not

start installer or utility.

When the [Program compatibility assistant] dialog appears

after completion of installation (including when installation

is aborted in the middle), ensure to click [This program is

successfully installed].

1

Troubleshooting

2

IndexMaintenance

- 51 -

Printing Troubles

Print quality is poor

1

Troubleshooting

Memo

If the problem is not solved using the following methods, contact your dealer.

z

Symptom Cause Troubleshooting

White stripe in perpendicular

direction.

2

Paper feeding direction

Printing is blurred in

perpendicular direction.

IndexMaintenance

Paper feeding direction

Printing is light.

Printing is blurred in some

parts. Solid printing will result

in the appearance of white dots

or lines.

Stripes in perpendicular

direction.

Reference

pages

LED head is unclean. Wipe LED head with a soft

tissue paper.

Low toner. Replace the toner cartridge. page 64

Deposit of foreign substances. Replace the image drum. page 66

Window lm of image drum is

unclean.

Image drum has not been set

correctly.

LED head is unclean. Wipe LED head with a soft

Low toner. Replace the toner cartridge. page 64

Paper not supported. Use recommended paper. Basic

The toner cartridge is not

installed correctly.

Low toner. Replace the toner cartridge. page 64

Paper is moist. Use paper stored at appropriate

Paper not supported. Use recommended paper. Basic

Paper not supported.

Type and thickness setting of

paper is inappropriate.

Recycled paper is used. Correct [Media Weight] in

Paper contains moisture. Dry it. Use paper stored at appropriate

Inappropriate settings of [Paper

Black Setting] or [Paper Color

Setting].

In the case of transparency

settings, [Trans. Black Setting]

or [Trans. Color Setting] is not

properly set.

There are dents on the image

drum.

Low toner. Replace the toner cartridge. page 64

Wipe window lm with a soft

tissue paper.

Please set the image drum

correctly.

tissue paper.

Re-install the toner cartridge. page 64

temperature and humidity.

Correct [Media Weight] in

the operation panel to the

appropriate value. Or, change

[Media Weight] to a thicker

value than the present value.

the operation panel to the

appropriate value. Or, change

[Media Weight] to a thicker

value than the present value.

temperature and humidity.

Change the value of [Printer

Setting]>[Paper Black Adjust]

or [Paper Color Setting].

In the case of transparency

settings, change the value of

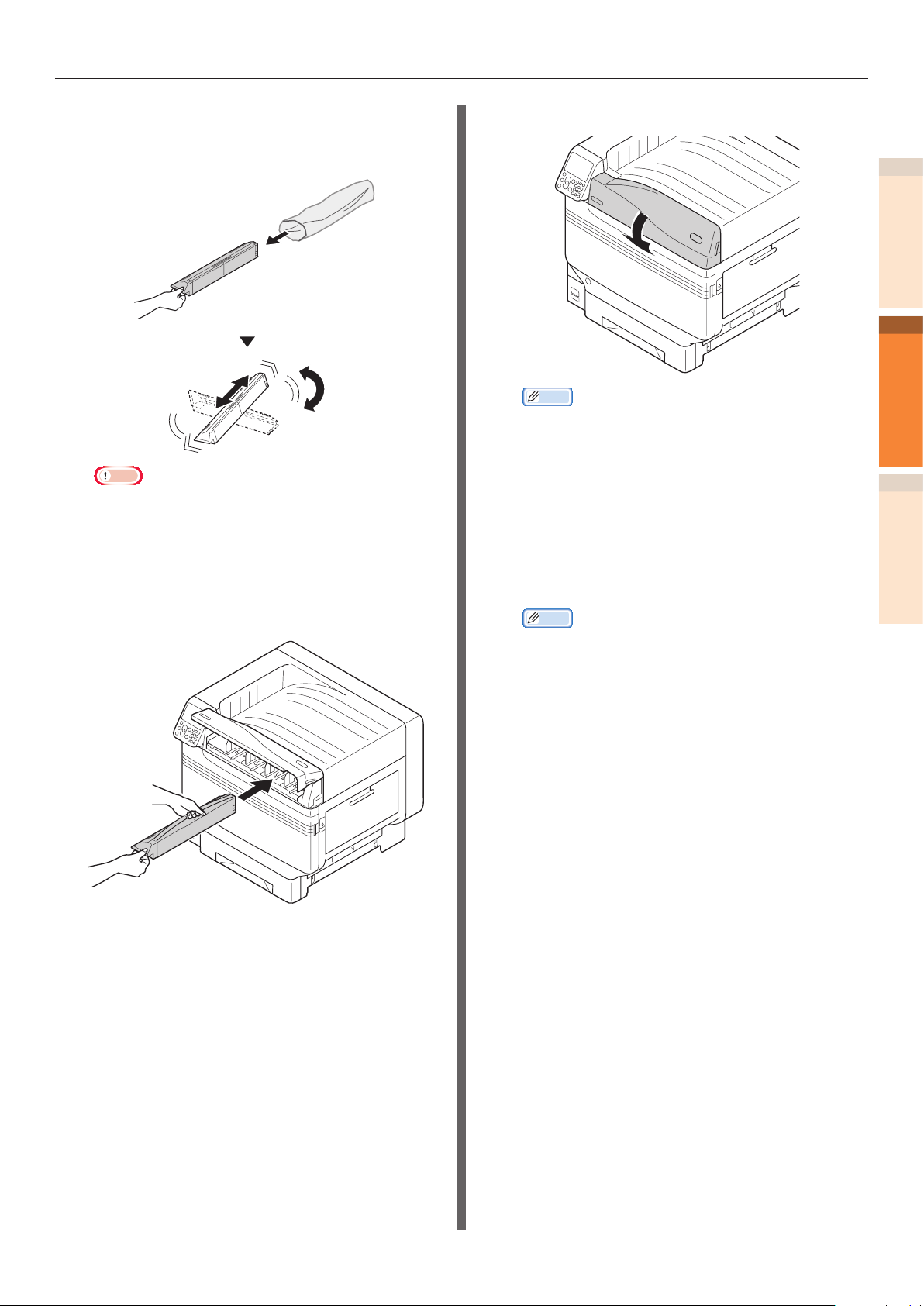

[Trans. Black Setting] or [Trans.