Page 1

BTX-208

Fume Extraction System

System User Guide

page

For Your Safety............................................................................ 2

Items Supplied ............................................................................. 2

Description ................................................................................... 2

Installation.................................................................................... 2

Operation and Maintenance ........................................................ 2

Maintenance ................................................................................ 2

Troubleshooting ........................................................................... 3

Technical Data............................................................................. 3

Part Numbers............................................................................... 4

Warranty ...................................................................................... 4

Contact Information ....................................................................... 4

www.okinternational.com

Page 2

For Your Safety

r

For safe and successful operation of the unit, read these instructions completely. If the instructions are not observed,

the manufacturer can assume no responsibility. Retain this manual for future reference.

Always disconnect the power supply before servicing the unit.

Do not operate the Unit without filter inserts. Contaminants in the extracted air will damage the blower. Use only

original equipment filters.

The BVX-208 is designed for the removal of solder fumes. Use filter unit only for this purpose. Consult your “safety

department” when using the unit on flammable gases. This unit is not explosion safe and can only be used for the

extraction of vapors, which have concentration levels well below the lower explosive limits.

This system is equipped with automatic reset overload protection, which may cause the unit to restart automatically.

While under warranty, the unit may be repaired only by an authorized Metcal Service Representative.

Items Supplied

1 Filter Unit with filters installed

1 32mm hose adapter

1 air inlet cover installed on second air inlet port

3

4

1 Power Cord

1 Operating Manual

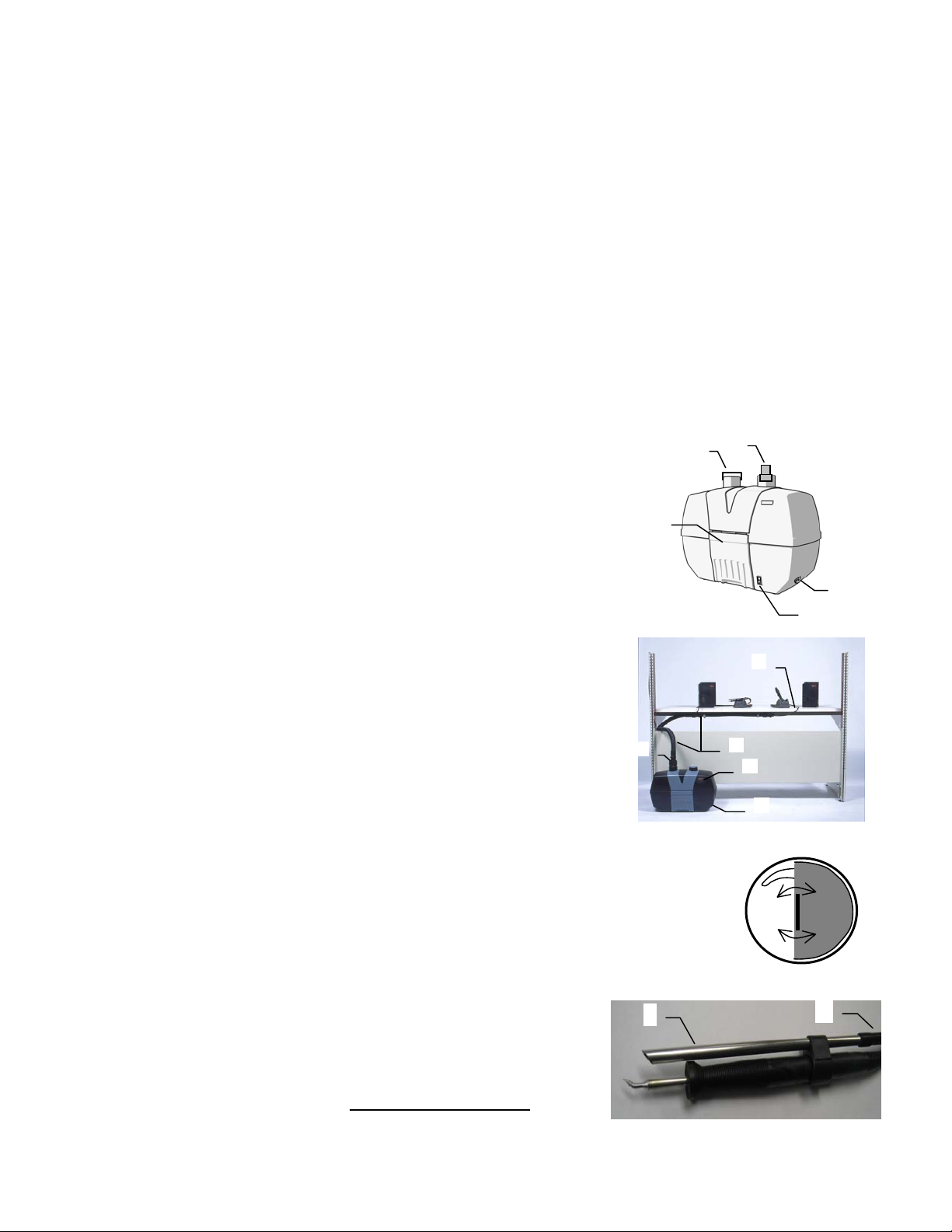

Description

5

(1) ON/OFF switch

(2) Power Output

(3) 32mm hose adapter

(4) air inlet cover with bypass valve

(5) latch (front and back)

2

1

Installation

4

• Place filter unit (1) at a location which minimizes length of ducting

• Screw supplied hose adapter into open air inlet port (2)

• Install ducting (3) as per duct installation instructions

• Install iron adapter kits (4)

• Connect filter unit to power supply (5)

2

3

1

5

Operation and Maintenance

• Turn unit ON.

• Check if the motor pump indicates an acoustical “fluttering” effect. If yes,

open air by-pass valve on air inlet cover until “fluttering” sound

disappears. Do not open too much as this will reduce the airflow

Air inlet cove

with bypass

valve

performance. The “fluttering” does not cause any damage to the system.

Maintenance

The airflow of the filter unit decreases during operation due to several

re ons: as

• Clogging of vacuum tubes and hoses attached to

Saturation of pre and main-filter inside filter unit

•

solder iron

1

2

Tip Extraction Accessories:

Clean stainless steel vacuum tubes (1) periodically and frequently

.

Cleaning brushes are supplied with the iron adapter kits. Inspect vacuum

oses (2) visually and clean if needed. h

2

Page 3

Replacement of filters:

If, after cleaning of accessories, the fumes are not extracted efficiently, replace filter(s) inside filter unit. Initially replace

the - is step does not sufficiently improve the airflow, then replace the main filter (HEPA/Carbon).

pre filter only. If th

1. Turn unit off.

2. Disconnect the power cord.

3. Unlatch the filter cove

r (1).

4. Remove filter cover.

5.

Replace the filters. (Pre-filter/main filter). Make sure

to place main filter inside the alignmen

t pins (2) so

1

that interlock switch (3) is depressed.

6.

Replace filter cover and ensure proper fit on bottom

h

ousing. Hook both latches into filter cover and press down carefully.

Caution! Do not use force. If latches do not close, check proper seating of

2

3

filter cover on bottom housing.

7. Reconnect power cord and turn system on.

8. If unit does not operate, refer to troubleshooting section.

otice: Always use new replacement filters!

N

or disposal of used filters follow local environmental and safety requirements.

F

roubleshooting

T

Problem Possibly C Solution

No air flow

No Power

Interlo

open

ause

ck switch

Check On/Off Switch

Check power outlet

Check powe

r cord

Check filter

Check safety interlock switch

Little air flow d tubes /

Clogge

hoses

A

ir leak

Clean extraction tube a

t solder iron

Clean vacuum hoses

Check duct connections for le

Housing not closed correctly

aks

Technical Data

Max. number of statio 8

Flow rate per s io > 28 lit/min

Noise Level: < 55 dBA

Dimensions (W x 508 x 254 x 38

Weight: 9 kg (20 lbs)

Voltage 100-240 VAC

Frequency 50 – 60 Hz

Power 85 Watt

ertification UL / CSA / CE

C

ns

tat n

xD H) 8 mm

3

Page 4

Part Num

bers

BTX-208 Filter Unit tip extraction for 8 stations, 100-240V / 50-60Hz

Replacement rs

FP-BVX200 Pre-filter (Pack of 5)

FM-BVX200 Main

Duct Connecti Kits

BTX-CK2-25 Hose connection kit 2-4 stations 2.5m (8’) long

TX-CK4-50 Hose connection kit 4-8 stations 5m (16’) long

B

BTX-CK4-75 Hose connection kit 2-4 stations 7.5m (25) long

or Iron Adapter Kits contact your OK International Sales Representative.

F

Filte

filter, HEPA 99.95% / Carbon

on

Warranty

OK International warrants the BTX-208 system against any defects in materials or workmanship for o

ne (1)

year from the date of purchase by the original owner. This Warranty excludes normal maintenance and shall

not apply to any opened, misused, abused, altered or damaged items. If the product should become

defective within the warranty period, OK International will repair or replace it free of charge at its sole o

The repaired or replacement item(s) will be shipped, freight pr

eriod will start from the date of purchase. If the date of purchase cannot be substantiated the date of

p

epaid, to the original purchaser. The warranty

ption.

manufacture will be used as the start of the warranty period.

or the repair or return of a unit, a Return Material Authorization Number (RMA #) needs to be obtained.

F

Contact Information

For Sales & Customer Care

North America

OK International

12151 Monarch Street

Garden Grove, CA 92841

USA

Tel: +1 714-799-9910

Fax: +1 714-799-9533

United Kingdom

OK International Ltd.

Eagle Close, Chandlers Ford

Hampshire, SO53 4NF

U.K.

Tel: +44 (0) 23 8048 9100

Fax: +44 (0) 23 8048 9109

France

OK International SA

Rue de la Saone

Zac De Folliouses-Les Echets

01706 Miribel Cedex

France

Tel: +33 (0) 4 72 26 20 30

Fax: +33 (0) 4 72 26 20 35

Germany

OK International GmbH

Frankfurter Strasse 74

D-64521 Gross-Gerau

Germany

Tel: +49 (0) 61 52-71 12-0

Fax: +49 (0) 61 52-71 12-22

Italy

OK International

Strada Statale 11 – No. 28,

20010 Vittuone (Milano)

Italy

Tel: +39 02 9025161

Fax: +39 02 90111147

Singapore

OK International (Sales Support Office)

10 Ang Mo Kio St.65

#03-18/19 Techpoint

Singapore 569059

Tel: +65-62810991

Fax: +65-62853473

China

OK Electronics (Beijing) Co., Ltd

No. 1 Bldi, A-10 Long Qing Street

Beijing Econ. & Tech. Developing Zone

Beijing, 100176

P.R. China

Tel: +86-10-67878490

Fax: +86-10-67878491

Japan

OK International Japan Co.

5-3-1 Heiwajima, Ota-ku

Tokyo 143-0006

Japan

Tel: +81-3-5753-0085

Fax: +81-3-3765-8855

4

Loading...

Loading...