Page 1

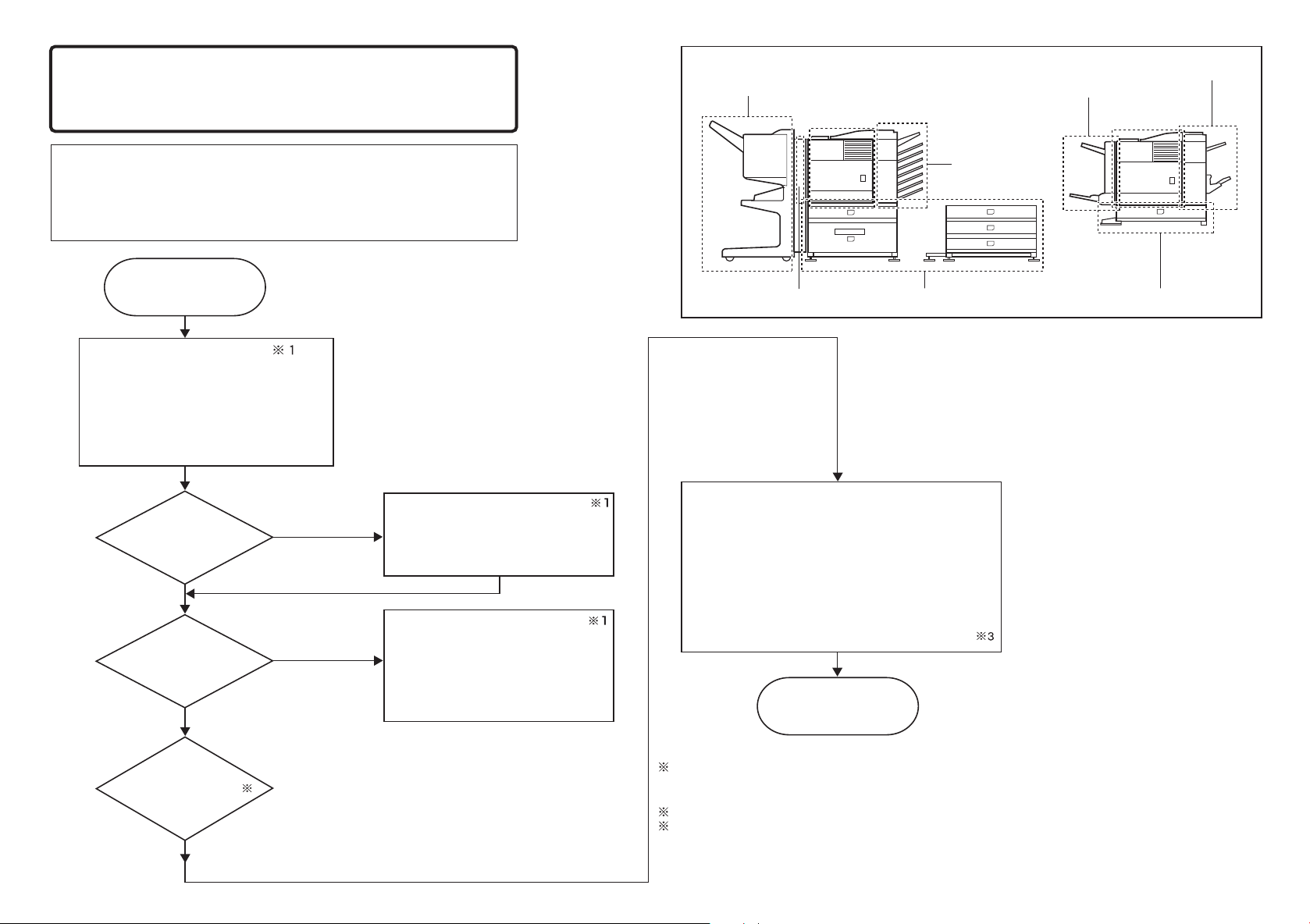

Page 2

1

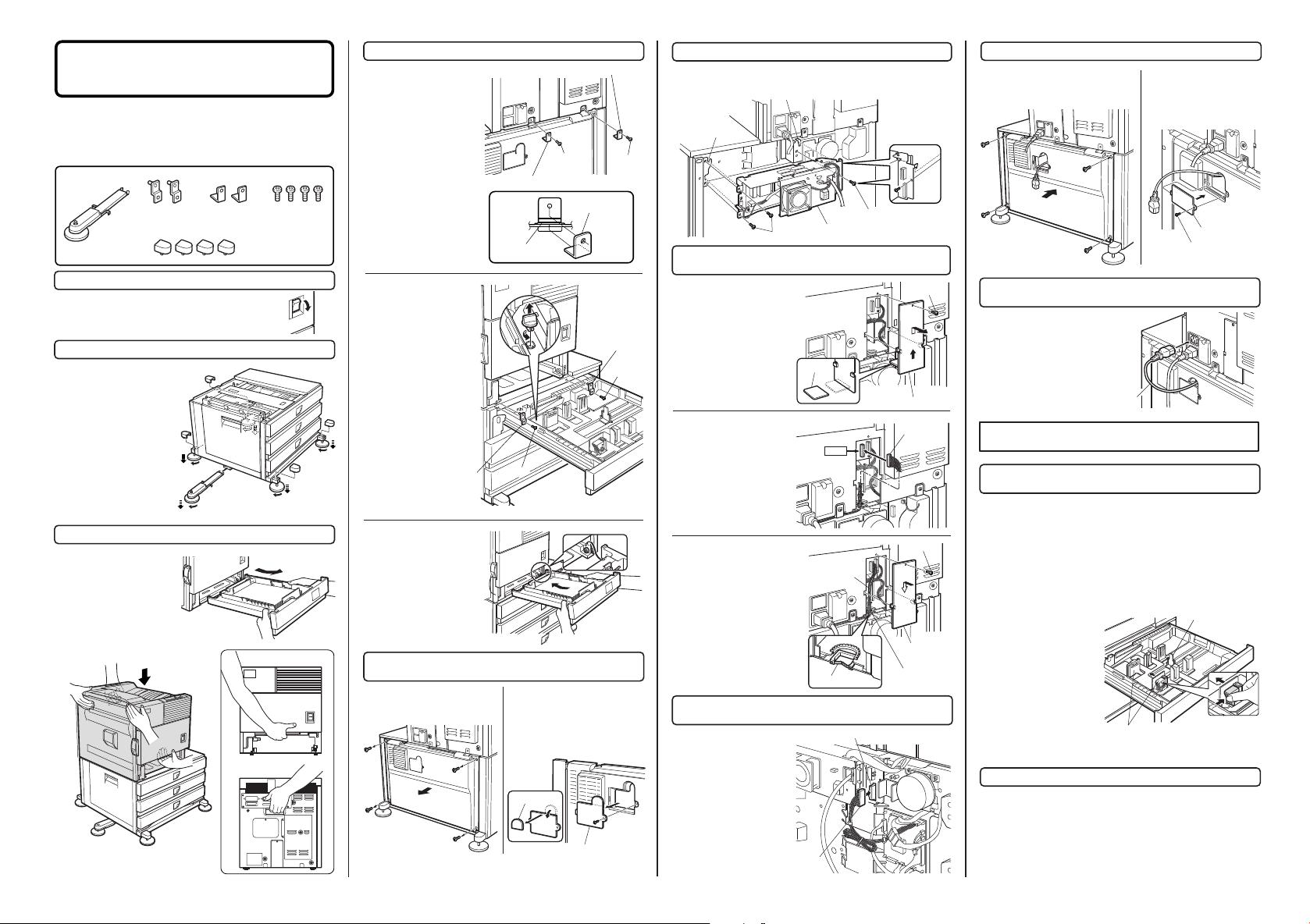

Installation Manual for B8300

and Its Peripheral Devices

To install the devices efficiently, follow the procedure below.

Some peripheral devices may have been installed as

standard devies depending on the main unit model.

Part of descriptions and illustrations may be different.

Start of installation

Main unit, paper feeding

device, and power supply

unit.

B83MP /

B83LT /

B83TT /

Main unit

Power Suply Unit

Power Suply Unit

Power Suply Unit

.................................. (P. 5)

Duplex/bypass

device installed?

... (P. 2)

..... (P. 3)

.... (P. 4)

Install duplex/pypass device.

Yes

B83D ....................(P. 7)

B83DB ................(P. 8)

Finishing device

Main unit

Paper feeding deviceDuplex device Paper feeding device

[Electrical setting/adjustment]

1) Installation of driver software, setting,

and operation check

Main unit / B83H..............

(P. 13)

Finishing device

Finishing device

Duplex/bypass device

Main unit

No

Finishing device

installed?

No

Hard

Disk

2)

Paper guide position adjustment/off center adjustment

Install finishing device.

Yes

2

B83MB/Power Suply Unit

B83F/Power Suply Unit

B83SS

....................................

B83THP / USP / FHP / FBP.(P. 12)

...

.......

(P. 9)

(P. 10)

(P. 11)

B83MP / B83LT / B83TT /

B83D / B83DB.................(P. 14 & 15)

End

1: When installing a paper feeding device, an optional power supply unit or a duplex/bypass device, be

sure to reattach the rear cabinet, the AC inlet cover, and the harness cover of the main unit at the end

of installation as needed.

2: When installing electrical devices, be sure to install them one at a time.

3: Only off center adjustment is needed for B83D.

Page 3

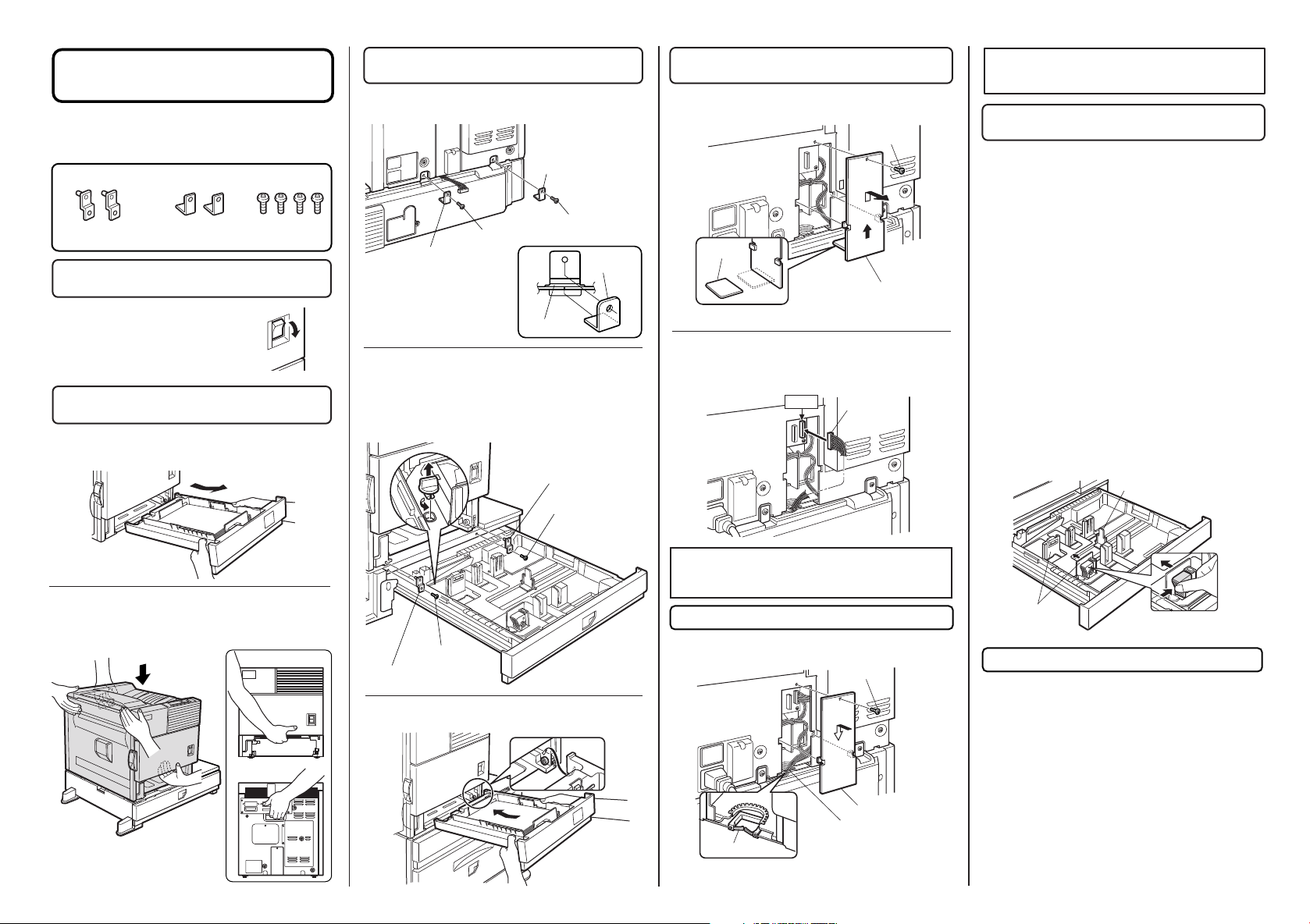

B83MP Installation Manual

FOR USE WITH COMPATIBLE OKI DIGITAL PRINTERS.

SEE OKI DIGITAL PRIN TER S ERVICE MANUA L OR

INSTALLATION MANUAL TO DETERMINE SUITABILITY.

<Before installation>

When installing a finisher or a mail-bin stacker with

B83MP, a power supply unit is needed.

<Parts included>

Front mounting plates:

2 pcs.

Rear mounting plates:

2 pcs.

Screws (M4x8):

4 pcs.

1. Turn off the main switch of the main unit

of the printer.

Turn the main switch located on the

front side of the main unit to the "OFF"

position.

Then, remove the power plug of the

main unit from the outlet.

"OFF"

2. Put the main unit of the printer on the

multi purpose drawer.

<1> Pull out the paper tray of the main unit until it stops

and then remove it by lifting both ends of the tray.

3. Connect the main unit of the printer to the

multi purpose drawer.

<1>Attach the two rear mounting plates using a supplied

screw for each.

Rear mounting plate

Screw

Screw

Rear mounting plate

[Caution]

Insert the mounting plate

under the tray frame.

Tray frame

<2> Pull out the multi purpose drawer until it stops and

attach the two front mounting plates using a supplied

screw for each.

Then, remove the lock of the paper tray and close the

tray.

Mounting

plate

Front mounting plate

Screw

4. Connect the harness to the main unit of

the printer.

<1> Remove the screw that fixes the harness cover of the

main unit of the printer and then slide the harness cover

up to remove it.

Screw

Cut out.

Harness cover

* Cut out the harness cover as shown in the illustration.

<2> Connect the connector of the relay harness of the

multi purpose drawer to CN10 (blue connector) of the

PCU PWB of the main unit of the printer.

CN10

Connector

2

* If another peripheral device must be installed,

carry out the following step at the end of the

installation work.

6. Adjust the position of the paper guides of

the paper tray.

<1> To use the setting mode, insert the power plug of the

main unit of the printer to the outlet and turn the main

switch on while pressing the [MENU] key and the [OK] key

of the operation panel of the main unit of the printer.

<2> Press the [MENU] key several times to display "SIZE

ADJUSTMENT A" and press the [OK] key.

<3> "MAXIMUM SIZE" is displayed.

Pull out the paper tray and extend the paper guides to the

maximum. Then, return the paper tray into the main unit

and press the [OK] key.

<4> "MINIMUM SIZE" is displayed.

Pull out the paper tray again and narrow the paper guides

to the minimum. Then, return the paper tray into the main

unit and press the [OK] key.

<5> Press the [BACK / CLEAR] key to exit the setting

mode.

[Caution]

If the setting above is not carried out, the paper detection

function will not operate.

Rear guide

<2> Hold the main unit of the printer at the positions

shown in the illustration and put the main unit on the multi

purpose drawer so that the front side and the left side of

the main unit are aligned to those of the multi purpose

drawer.

Front side

Rear side

[Caution]

For installation of the main unit, it

must be held by two persons and

installed carefully.

Screw

Front mounting plate

<3> Reattach the paper tray of the main unit of the

printer.

For installation of a finisher or a mail-bin stacker,

see its installation manual.

5. Attach the harness cover.

Reattach the harness cover to its original position and fix it

with the removed screw.

Screw

Harness cover

Wire saddle

Wire saddle

* Fix the harness securely to the wire saddle.

Paper guide

7. Carry out the off center adjustment.

Installation is now complete.

Page 4

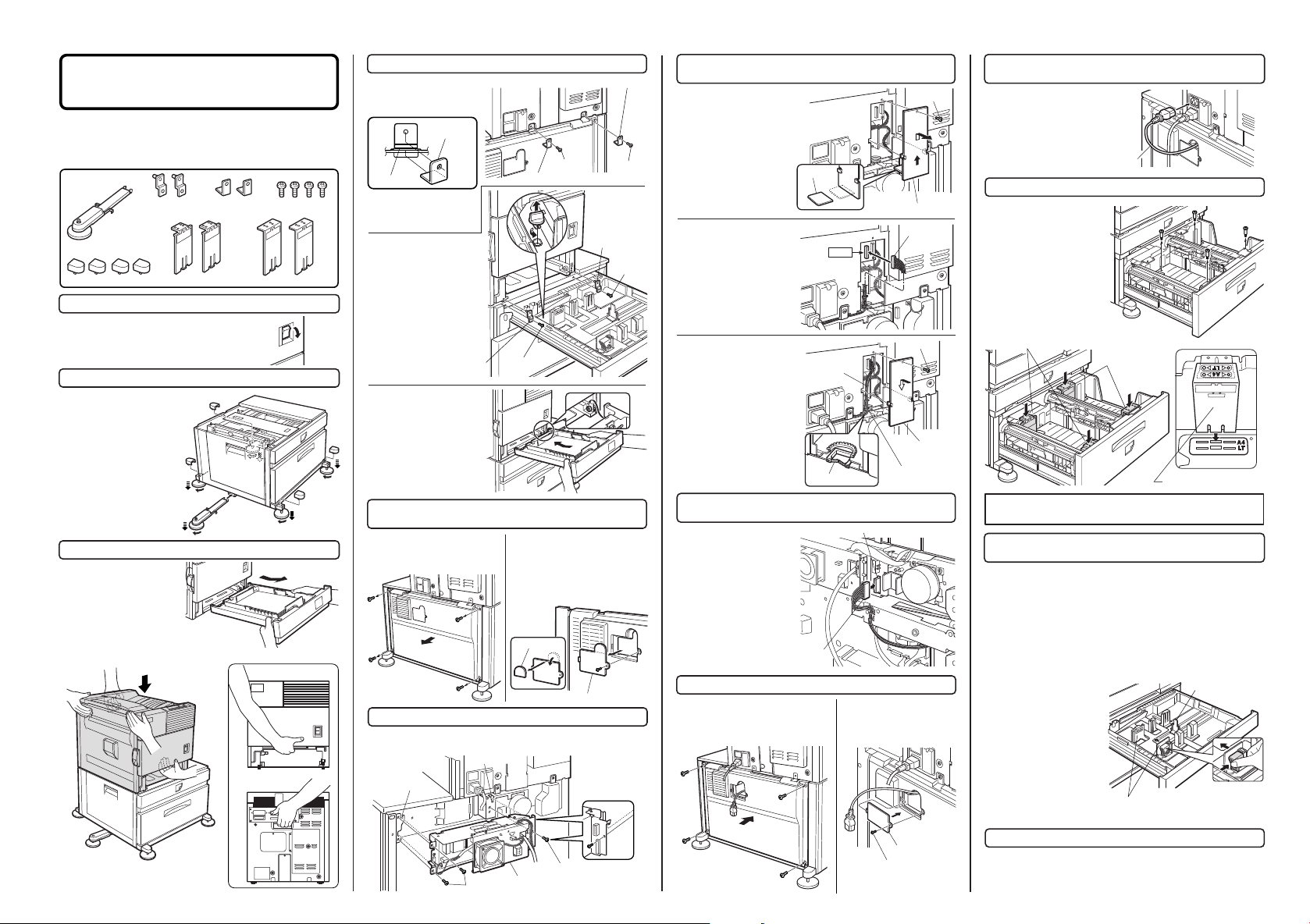

B83LT Installation Manual

FOR USE WITH COMPATIBLE OKI DIGITAL PRINTERS.

SEE OK I DIGI TAL PR INTER SERVICE MANUA L OR

INSTALLATION MANUAL TO DETERMINE SUITABILITY.

<Before installation>

• Start installation after checking that the DATA and

COMMUNICATION indicators on the operation panel are

neither lit nor blinking.

• For installation, a power supply unit is needed.

<Parts included>

Left adjuster: 1 pc.

Adjuster covers: 4 pcs.

Front mounting

plates: 2 pcs.

Left paper guides: 2 pcs. Right paper guides: 2 pcs.

Rear mounting

plates: 2 pcs.

Screws (M4x8):

4 pcs.

1. Turn off the main switch of the main unit of the printer.

Turn the main switch located on the front side of

the printer to the "OFF" position.

Then remove the power plug from the outlet.

"OFF"

2. Attach the adjusters and adjust them.

<1> Insert the left adjusters to

the stand/paper drawer.

<2> Tu rn eac h adj uster to

lower it until it touc hes the floor.

<3> Atta ch the four adjust er

covers.

Be su re to att ach t he le ft

adjuster to prevent overturning.

[Caut ion] The lower tray

cannot be pulled out unles s

the adjuster is lowered to the

specified position.

3

3

2

2

3

1

2

3. Put the main unit of the printer on the stand/paper drawer.

<1> Pull out the paper tray of

the main unit until it stops and

then remove it by lifting both

ends of the tray.

<2> Hold the main unit of the

printer at the positions shown

in the illustration and put the main unit on the

stand/paper drawer so that the front side and the

left side of the main unit are aligned to those of

the stand/paper drawer.

[Caution]

For installation of the main unit, it must be

held by two persons and installed carefully.

Front side

Rear side

4. Connect the main unit to the stand/paper drawer.

<1>A ttac h th e tw o re ar

mount ing plat es u sing a

supplied screw for each.

Rear

mounting plate

Stand frame

[Caution]

Insert the rear mounting

plates under the Stand frame.

<2>Pull out the upper tray

of the stan d/paper d rawer

until it stops, and attach the

two f ront mounting p lates

using a supplied screw for

each.

Then, r emove th e lock of

the paper tray and close the

tray.

Front mounting plate

<3> Reattach the paper tray

of the main unit.

Rear mounting plate

Screw

3

2

5. Remove the rear cabinet of the stand/paper drawer and

remove the AC inlet cover.

<1> Remove the four screws that

fix the r ear cabinet and then

remove the rear cabinet.

Rear cabinet

<2> Remove the screw that fixes the

AC inlet cover and then remove the

AC inlet cover.

<3> Cut out the AC inlet cover as

shown in the illustration.

Cut out.

6. Attach the power supply unit.

Attach the power supply unit to the brackets and secure it using the three

supplied screws.

Bracket

Bracket

Screws

Power supply unit

Rear mounting plate

Screw

Front

mounting plate

AC inlet cover

Screws

Screw

Screw

7. Connect the power supply unit harness to the PCU PWB

of the main unit of the printer.

<1> Rem ove th e screw that

fixes the harness cover of the

main un it of the printer and

slide the harness cover up to

remove it.

Cut out the harness cover as

shown in the illustration.

<2> C onnec t the opti onal

pow er sup ply har nes s

conne ctor t o CN11 (red

connector) of the PCU PWB of

the main unit of the printer.

<3> Reat tach the ha rness

cover to its original position

and fix i t with th e removed

screw.

At this tim e, ensure t hat the

optional power supply harness

are arranged as shown in the

illustration.

• Fix the harness securely to

the wire saddle.

8. Connect the relay harness of the stand/paper drawer to

the power supply unit.

Connect the relay harness of

the stand/paper drawer to the

connector of the power supply

unit.

Relay harness of the

stand/paper drawer

Cut out.

Harness cover

Connector

CN11

Screw

Optional power

supply harness

Harness cover

Wire saddle

Connector of the power supply connector

Wire saddle

9. Attach the rear cabinet of the stand/paper drawer.

<1> Pass the cord of the power supply

unit through the hole of the rear cabinet

and atta ch the rea r cabine t to the

stand/paper drawer.

Rear cabinet

<2> Attach the AC inlet cover

to the rear cabinet of the

stand/paper drawer and fix it

with the removed screw.

AC inlet cover

Screw

Screw

10. Connect the AC cord of the power supply unit to the

main unit of the printer.

Connect t he AC co rd of th e

power supply unit to the inlet

connector of the main unit of

the printer at t he location

shown in the illustration.

AC cord

11. Attach the paper guides to the lower tray.

Remove the four screws for

pack ing. (S ee the righ t

illustration.)

Insert the left paper guides and

right paper guides to the front

and re ar gui de sl ots fo r the

paper size to be used. (See the

illustration below.)

(For the AB system , set t he

guides to A4. For the inch

system, set the guides to LT.)

Left paper guides

Right paper guides

Paper guide

* If another peripheral device must be installed, carry out

the following step at the end of the installation work.

12. Adjust the position of the paper guides of the upper

paper tray of the stand/paper drawer.

<1> To use the setting mode, insert the power plug of the main unit of the

printer to the outlet and turn the main switch on while pressing the [MENU]

key and the [OK] key of the operation panel of the main unit of the printer.

<2> Press the [MENU] key several times to display "SIZE ADJUSTMENT

A" and press the [OK] key.

<3> "MAXIMUM SIZE" is displayed.

Pull out the paper tray and extend the paper guides to the maximum.

Then, return the paper tray into the unit and press the [OK] key.

<4> "MINI MUM SIZE " i s

displayed. Pull out the p aper

tray again and n arrow the

paper guides to the minimum.

Then, return the paper tray into

the unit and press the [OK] key.

(The rear gui de need not be

adjusted.)

[Caution] If the setting above

is not carried out, the paper

detec tion functi on will not

operate.

Paper guides

Rear guide

13. Carry out the off center adjustment.

Installation is now complete.

3

Page 5

B83TT Installation Manual

FOR USE WITH COMPATIBLE OKI DIGITAL PRINTERS.

SEE OKI DIGI TAL PRINTER SERVICE M ANUAL OR

INSTALLATION MANUAL TO DETERMINE SUITABILITY.

<Before installation>

•

Start installati on after check ing that the DATA and

COMMUNICATION indicators on the operation panel are

neither lit nor blinking.

• For installation, a power supply unit (AR-DC1) is needed.

<Parts included>

Rear mounting

plates: 2 pcs.

Left adjuster: 1 pc.

Front mounting

plates: 2 pcs.

1. Turn off the main switch of the main unit of the printer.

Turn the main switch located on the front side of the

printer to the "OFF" position.

Then remove the power plug from the outlet.

2. Attach the adjusters and adjust them.

<1> Insert the left adjusters to

the stand/paper drawer.

<2> Turn the five adjusters to

lower them until they touch the

floor.

<3> Attach th e four adjust er

covers.

• Be sure to attach the left

adj us ter to pr ev ent

overturning.

[Caution] The lo wer tray

cannot be pulled out unless

the adjuster is lowered to

the specified position.

4

3

2

1

3. Put the main unit of the printer on the stand/paper drawer.

<1> Pull out the paper tray of

the main unit until it stops and

then remove it by lifting both

ends of the tray.

<2> Hold the main unit of the

printer at the positions shown

in the illustration and put the main unit on the

stand/paper drawer so that the front side and

the left side of the main unit are aligned to

those of the stand/paper drawer.

Screws (M4x8):

4 pcs.

Adjuster covers: 4 pcs.

"OFF"

2

3

2

Front side

Rear side

2

4. Connect the main unit to the stand/paper drawer.

Attach the two rear mounting

plate s us ing a suppl ied

screw for each.

Rear mounting plate

[Caution]

Insert the rear mounting plates

under the Stand frame.

Stand frame

<2>Pull out the upper tray of

the stand/paper drawer until

it stops, and attach the two

front mounting plates using

a supplied screw for each.

Then, remove the lock of the

paper tray and close the

tray.

Remove the loc ks of the

middle tray and the lowe r

3

tray similarly.

Front mounting plate

<3> Reattach the paper tray

of the main unit.

5. Remove the rear cabinet of the stand/paper drawer and

remove the AC inlet cover.

<1> Remove the four screws that

fix the r ear cabinet and then

remove the rear cabinet.

Rear cabinet

Screw

<2> Remove the screw that fixes

the AC inlet cover and then remove

the AC inlet cover.

<3> Cut out the AC inlet cover as

shown in the illustration.

Cut out.

Rear mounting plate

Screw

Mounting plate

Front

mounting plate

Screw

Screw

6. Attach the power supply unit.

Attach the power supply unit to the brackets and secure it using the three

supplied screws.

Bracket

7. Connect the power supply unit harness to the PCU PWB

of the main unit of the printer.

<1> Rem ove the screw that

fixes the harness cover of the

main un it of the printer and

slide the harness cover up to

remove it.

Cut out the harness cover as

shown in the illustration.

<2> C onnec t the opti onal

pow er sup ply har nes s

conne ctor t o CN11 (red

connector) of the PCU PWB of

the main unit of the printer.

<3> Re attac h the harness

cover to its original position and

fix it with the removed screw.

At this time, ensure that the

option al powe r suppl y unit

harness is arranged as shown

in the illustration.

• Fix the harness securely to

the wire saddle.

8. Connect the relay harness of the stand/paper drawer

to the power supply unit.

Connect the relay harness of

the stand/paper drawer to the

connector of the power supply

unit.

Bracket

Screws

Screws

Power supply unit

Cut out.

CN11

Optional power

supply harness

Wire saddle

Connector of the power supply connector

Screw

Harness cover

Connector

Screw

Harness cover

Wire saddle

9. Attach the rear cabinet of the stand/paper drawer.

<1> Pass the cord of the power supply

unit through the hole of the rear cabinet

and atta ch the rea r cabine t to the

stand/paper drawer.

Rear cabinet

10. Connect the AC cord of the power supply unit to the

main unit of the printer.

Connect t he AC co rd of th e

power supply unit to the inlet

connector of the main unit of

the printer at t he location

shown in the illustration.

* If another peripheral device must be installed, carry out

the following step at the end of the installation work.

11. Adjust the position of the paper guides of the

upper paper tray of the stand/paper drawer.

<1> To use the setting mode, insert the power plug of the main unit of the

printer to the outlet and turn the main switch on while pressing the [MENU]

key and the [OK] key of the operation panel of the main unit of the printer.

<2> Af ter pr essing the [MENU ] key several times to display "S IZE

ADJUSTMENT A" in the message display and press the [OK] key.

<3> "MAXIMUM SIZE" is displayed.

Pull out the paper tray and extend the paper guides to the maximum.

Then, return the paper tray into the unit and press the [OK] key.

<4> "MINI MUM SIZE " i s

displayed. Pull out the p aper

tray again and n arrow the

paper guides to the minimum.

Then, return the paper tray into

the unit and press the [OK] key.

(The rear gui de need not be

adjusted.)

[Caution]

If the setting ab ove is not

carried out, the paper detection

function will not operate.

<2> Attach the AC inlet cover

to the rear cabinet of the

stand/paper drawer and fix it

with the removed screw.

AC cord

Paper guides

AC inlet cover

Screw

Rear guide

13. Carry out the off center adjustment.

Installation is now complete.

4

[Caution]

For installation of the main unit, it must be

held by two persons and installed carefully.

AC inlet cover

Relay harness of the

stand/paper drawer

Page 6

B8300 Digital Printer

Main Unit Installation Manual

FOR USE WITH COMPATIBLE OKI DIGITAL PRINTERS.

SEE OKI DIGITAL PRINTER S ERVICE MANUAL OR

INSTALLATION MANUAL TO DETERMINE SUITABILITY.

1. Select an installation location.

• Installation requirements

Selection of installation location is important to the performance of the machine. Consider the

following conditions.

• Environment

(1) Avoid locations subject to direct sunlight as plastic parts may be deformed.

(2) Avoid high temperature and high humidity locations or where temperatures change rapidly such as

near a heater or air conditioner. Rapid changes can cause paper to be become damp and condensation

to form within the machine resulting in misfeeds and deterioration of image quality.

Standard conditions: Conditions most adequate for

use of the machine

Acceptable temperature

and humidity range: 20%Å`85%

Max. 60% at 35Åé

Humidity

85

60

20

10 30

35

Temperature

2. Remove the main unit from the carton

(requires two people)

<1> Remove the cushioning materials from the right and

left of the front side.

<2>

Remove the locking

tape from the right and left

sidesof the tray.

Then,

remove the top of

the carton and lower the

plastic bag covering the

machin e whil e

the machine is

still on the carton

base.

<3> Remove the

packin g tape

from the paper

tray, pull out the

paper tray until it

stops and remove

it by tilting it

upward.

One person must lift by the empty front tray pocket with

the right hand and steady the machine with the left hand

placed at the upper left of the machine.

The other person must lift with the right hand by using

the lifting recess in the rear of the machine and also

steady the machine with the left hand as shown in the

illustration.

Front side

4. Install the main unit.

(Be sure to carry out this step after the paper

feeding device has been connected to the main

unit.)

<1> Remove the remainder of packing tape from the

operation panel.

<2> Raise the lever of the left door to unlock it and

open the left door.

<3> Open the front cover.

<4> Rotate the developer unit lock lever down.

5

(3) Avoid a dusty location and a location subject to vibration.

If dust enters the machine, deterioration of image quality or a failure may occur.

(4) Do not install the machine in a location that is not stable.

Be sure to install the machine on a level surface to maintain proper functions.

(5) Avoid poorly ventilated areas.

(6) Avoid areas near combustibles or any ammonia present.

• Space around the machine

Install the machine so that the rear side is at least 30 cm form any wall or other object to allow the

machine’ cooling fan and ventilation to be effective.

Allow sufficient space around the machine for operation and servicing.

• Stand

Ensure that the machine is leveled using a level or the like. If the machine is not placed on a level

surface, the toner density control may not function properly, resulting in poor image quality.

[Caution] If the machine is not placed on a level surface, the toner density control may not function

properly, resulting in bad influence on the quality.

• Grounding

(1) Be sure that the machine is properly grounded.

(2) Use a proper ground such as the grounding terminal on an outlet or according to local grounding

requirements.

Rear side

Caution

Removal of this machine and carrying it must be

always performed by two persons.

3. Check the parts included.

<1> Check that the following items are included with

this machine.

• Drum / Toner cartridge

• Developer cartridge

• CD-ROM

• Safety and Warranty information

• User Guide (may be on CD-ROM)

<5> Remove the protective covering from the

toner/drum cartridge.

<6> Shake the toner/drum cartr idge ho rizontally

approximately 5 times.

Page 7

<7> Insert the toner/drum cartridge into the main unit.

T

E

L

L

I

N

E

<8> Remove the drum protective paper in the direction

indicated by the arrow.

<9>

Remove the supplied developer cartridge from the

packing case and remove the protective materials A and B.

A

B

<10> Shake the developer cartridge horizontally

approximately 5 times and insert it into the machine.

<12> Remove the sealing tape from the developer

cartridge in the direction indicated by the arrow.

<13> Return the developer unit lock to its original

position.

<14> Close the front cover.

Gently close the cover.

<15> Apply pressure to the fusing roller.

Raise the right and left levers of the fusing unit in the

direction indicated by the arrow.

5. Load paper.

<1> Pull out the paper tray.

Gently pull out the paper tray until it stops.

<2> Load paper into the tray.

Do not exceed the maximum height line. (up to 500 sheets

of OKI recommended paper can be loaded)

6.

Connecting the machine to a computer.

<1> Connect the machine to the computer

• When connecting to a parallel port:

The parallel interface of this machine conforms to

IEEE-STD-1284-1983.

Use a commercially available shielded type parallel interface

cable conforming to the specifications of both the machine

and the computer.

The connector on this machine is a 36-pin Amphenol female

connector.

18

1

* If another peripheral device must be installed,

carry out the following step at the end of the

installation work.

<2> Insert the power plug into an outlet.

Caution

If the outlet is also used for lighting fixtures, the lighting

fixtures may flicker.

Use an outlet which is not connected to lighting fixtures.

<3> Turn on the main switch of the main unit.

Automatic level adjustment of toner density sensor will start

and a message indicating [WARMING UP] will appear on

the operation panel. After the level adjustment is complete,

the ready indicator will light up.

Caution

While automatic adjustment of the toner density sensor

is being done, do not turn the power to the machine off.

This will cause improper adjustment.

7. Check the printer operation

For installation of printer drivers on the computer refer to the

Operation manual (for printer operation and general

information) supplied with the machine.

After driver installation, execute a test print to ensure normal

printing.

6

<11> Remove the sealing tape from the toner/drum

cartridge by pulling it in the direction indicated by the

arrow.

<16> Close the left door.

<17> Turn the lock pin a 1/4 turn and remove it while

pressing down on the pressure plate.

Remove the lock pin

while holding down on

the paper pressure

plate and insert the

paper tray into the main

unit.

36

For the specifications of the connector on the computer, see

the operation manual of the computer.

Parallel interface connector

19

Page 8

B83D Installation Manual

"

OFF

"

Hook

Positioning boss

Positioning boss

Hook

Duplex module

FOR USE WITH COMPATIBLE OKI DIGITAL PRINTERS.

SEE OKI DIGITAL PRINTER SERVICE MANUAL OR

INSTALLATION MANUAL TO DETERMINE SUITABILITY.

<Before installation>

•

Carry out the installation after checking that the

DATA indicator on the operation panel is neither lit

nor blinking.

• For installing B83D, an optional desk (multi

purpose drawer, stand/3 x 500 sheet paper drawer

or stand/MPD & 2000 sheet drawer) must have

been installed.

• Ensure that the front mounting plates and the

rear mounting plates included with the optional

stand/paper drawer are securely attached.

•

Check that the left adjuster supplied with an

optional stand/drawer has been attached.

1. Turn off the main switch of the main unit of the printer.

Turn the main switch located on

the front side of the main unit of

the printer to the "OFF" position.

Then, remove the power plug of

the main unit of the printer from

the outlet.

Parts included

M4 Screws

(M4x8) : 1 pcs.

3.

Attach the duplex module to the main unit of the printer.

<1> Hang the hooks located at

the upper part of the duplex

module on the openings of the

left door of the main unit of the

printer.

<2> Push the lower part of the

duplex module to insert the

positioning bosses securely

into the main unit of the printer.

<3> Tighten the two screws

built in the duplex module.

4. Connect the harness to the main unit of the printer.

<1> Remove the screw that

fixes the harness cover of the

main unit of the printer and

then slide the harness cover

up to remove it.

<2> Cut out the harness cover

as shown in the illustration.

Harness cover

Screw

Harness cover

<6> Reattach the harness

Harness cover

cover to its original position

and fix it with the removed

screw.

Relay harness

* If another peripheral device must be installed, carry out

the following step at the end of the installation work.

5. Carry out the off center adjustment.

Installation is now complete.

7

Screw

Unlock the lock release

lever of the main unit of the

printer and then pull out the

left door.

Slide the two upper covers

up to remove them. Remove

the lower cover by inserting

a flat-blade screwdriver at

three locations ( ) shown in

the illustration.

Then, close the left door.

2.

Remove the left side cover of the main unit of the printer.

Top covers

Left door

Lower cover

Lock release lever

<3> Connect the connector of

the relay harness of the

duplex module to the CN12

(white connector) of the PCU

PWB of the main unit of the

printer.

<4> Insert the snap bands to

the locations shown in the

illustration and fix them.

<5>Secure the earth harness

using a supplied M4 screw.

Cut out.

Relay harness

connector

Snap bands

CN12

M4 Screw

PCU PWB

Ground harness

Page 9

B83DB Installation Manual

"

OFF

"

Hook

Positioning boss

Positioning boss

Hook

Duplex module

FOR USE WITH COMPATIBLE OKI DIGITAL PRINTERS.

SEE OKI DIG ITAL PRINTER SERVICE MANUAL O R

INSTALLATION MANUAL TO DETERMINE SUITABILITY.

<Before installation>

• Carry out the installation after checking that

the DATA indicator on the operation panel is

neither lit nor blinking.

• For installing B83DB, an optional desk (multi

purpose drawer, stand/3 x 500 sheet paper

drawer or stand/MPD & 2000 sheet drawer)

must have been installed.

• Ensure that the front mounting plates and

the rear mounting plates included with the

optional stand/paper drawer are securely

attached.

• Check that the left adjuster supplied with an optional stand/drawer

has been attached.

1. Turn off the main switch of the main unit of the printer.

Turn the main switch located on the front side of the

main unit of the printer to the "OFF" position.

Then, remove the power plug of the main unit of the

printer from the outlet.

2.

Remove the left side cover of the main unit of the printer.

Unlock the lock release lever of the

main unit of the printer and then pull

out the left door.

Slide the two upper covers up to

remove them. Remove the lower

cover by inserting a flat-blade

screwdriver at three locations ( )

shown in the illustration.

Then, close the left door.

3.

Attach the duplex module to the main unit of the printer.

<1> Hang the hooks located at

the upper part of the duplex

module on the openings of the

left door of the main unit of the

printer.

<2> Push the lower part of the

duplex module to insert the

positioning bosses securely into

the main unit of the printer.

<3> Tighten the two screws built

in the duplex module.

Top covers

Lower cover

Lock release lever

Left door

Parts included

Exit tray

M4 Screws :

1 pcs.

4. Connect the harness to the main unit of the printer.

<1> Remove the screw that

fixes the harness cover of the

main unit of the printer and

then slide the harness cover

up to remove it.

<2> Process the harness cover

as shown in the illustration.

<3> Connect the connector of

the relay harness of the

duplex module to the CN12

(white connector) of the PCU

PWB of the main unit of the

printer.

<4> Insert the snap bands to

the locations shown in the

illustration and fix them.

<5>Secure the earth harness

using the supplied M4 screw.

<6> Reattach the harness cover

to its original position and fix it

with the removed screw.

Harness cover

Cut out.

Relay harness

connector

Snap bands

CN12

M4 Screw

Harness cover

Relay harness

Screw

Harness cover

PCU PWB

Ground harness

Screw

5. Attach the exit tray.

* If another peripheral device must be installed, carry out

the following step at the end of the installation work.

6.

Adjust the position of the paper guides of the bypass tray.

<1> To use the setting mode, insert the power plug of

the main unit of the printer to the outlet and turn the

"ON"

main switch on while pressing the [MENU] key and

the [OK] key of the operation panel of the main unit of

the printer.

<2> After pressing the [MENU] key several times to

display "SIZE ADJUSTMENT A" in the message

display, press the [ ] key to display "SIZE ADJUSTMENT B" and press the

[OK] key.

<3> "MAXIMUM SIZE" is displayed.

Since "MAXIMUM SIZE" is displayed with a number, press the [ ] key or the

[ ] key to change the number so that the number is equal to the value of

[MAX] written on the label

( NOTE)

and then press the [OK] key.

<4> Since "P1 SIZE" is displayed with a number, press the [ ] key or the [ ]

key to change the number so that the number is equal to the value of [P1]

written on the label

( NOTE)

and then press the [OK] key.

<5> Since "P2 SIZE" is displayed with a number, press the [ ] key or the [ ]

key to change the number so that the number is equal to the value of [P2]

written on the label

( NOTE)

and then press the [OK] key.

<6> Since "MINIMUM SIZE" is displayed with a number, press the [ ] key or

the [ ] key to change the number so that the number is equal to the value of

[MIN] written on the label

( NOTE)

and then press the [OK] key.

[Caution]

If the setting above is not carried out, the paper detection function will not

operate.

( NOTE)

Illustration of label sticking position

(Back surface of the bypass tray

extension)

Label

MAX MINP1 P2

7. Carry out the off center adjustment.

Installation is now complete.

8

Page 10

B83MB Installation Manual

CN11

FOR USE WITH COMPATIBLE OKI DIGITAL PRINTERS.

SEE OKI DIGITAL PRINTER SERVICE MANUAL OR

INSTALLATION MANUAL TO DETERMINE SUITABILITY.

<Before installation>

• Start installation after checking that the DATA and

COMMUNIC ATION indicators on the operation panel are

neither lit nor blinking.

• For installation of B83MB, an optional stand/paper drawer

(stand/MPD & 2000 sheet paper drawer, stand/3 x 500 sheet

paper dr awer or multi purpos e drawer ) must h ave been

installed.

Also if a multi purpose drawer has been installed, a power

supply unit is needed additionally.

<Parts included>

Mounting plates: 2 pcs.

Tray: 1 pc.

Screws A (M4x8): 5 pcs.

Screw B: 1 pc.

1. Turn off the main switch of the main unit of the printer.

Turn the main switch located on the front side of the

main unit to the "OFF" position.

Then, remove the power plug of the main unit from the

outlet.

"OFF"

2. Remove the upper cabinet of the stand/paper drawer.

<1> Pull out the paper tray of

the stand/paper drawer.

Remove the four sc rews of

the ca binet attached t o the

right side of the main unit of

the p rinter and rem ove t he

cabinet.

Cabinet

<3> Hold the grip of the mailbin stacker and place the mailbin stacker on the stand/paper

drawer temporarily.

Then, push the lower part to

attach the mail-bin stacker by

sliding it toward the exit tray of

the main unit.

At this time, align the mail-bin

stacker with the exterior line of

the stand/paper drawer.

<4> Open the front cover of the

mail-b in stacker and fix th e

stacker with three screws A at

the pos itions shown in the

illustration.

Then, close the front cover and

close the pap er t ray o f the

stand/paper drawer.

(Front side)

Screw A

Screw A

4. Attach the tray.

Place.

Grip

<5> Attach the mounting plates to

the pos ition s shown in the

illust ration and fix them with

screws A.

(Rear side)

Mounting plate

Stand frame

[Caution ] Inse rt the mount ing

plate under the desk frame.

Grip

Push.

Screws A

Mounting plate

Push.

6. Attach the power supply unit.

Attach the power supply unit to the brackets and secure it using the

supplied three screws.

Bracket

Ç–Ç¡Ç©ÇØïî

7. Connect the power supply unit harness to the PCU PWB

of the main unit of the printer.

<1> Remov e the scr ew that

fixes the harness cover of the

main unit of the printer and

slide the harness cover up to

remove it.

<2> Connect the power supply

unit har ness con nector to

CN11 (red connector) of the

PCU PWB of the main unit of

the printer.

Bracket

Screws

Screw

Optional power supply unit

Screw

Harness cover

Connector

<2> Remove the AC cord of

the power supply unit from the

inlet connector of the main unit

of the printer.

Remove the four screws that

fix the rear cabinet and then

remove the rear cabinet.

Rear cabinet

(* Similar work for the multi purpose drawer)

9. Arrange the harness of the mail-bin stacker.

<1> Pass the harness of the

mail-bin stacker be tween the

power s upply unit and th e

frame o f the stand/ paper

drawer and connect it to the

connector of the power supply

unit.

<2> Fit t he s nap band

attac hed to the mail -bin

stacker at the position shown

in the illustrati on to fix the

harness.

(* Similar work for the multi purpose drawer)

Snap band

Mail-bin stacker harness

10. Attach the rear cabinet of the stand/paper drawer.

<1> Pass the AC cord of the pow er

supply unit as shown in the illustration

and f ix t he re ar c abine t of the

stand/paper drawer with the screws.

<2> Attach the AC inlet cover

to the r ear cabinet of the

stand/paper drawer and fix it

with the removed screw.

Power supply

unit connector

9

<2> Mount screw B to the

posit ion shown i n t he

illustration.

3. Attach the mail-bin stacker.

<1> Remove the paper exit

actuator from the main unit

of the printer.

<2> Raise the relay unit at the

side of the mail-bin stacker.

[Caution]

Do not press on the relay unit

while it is raised.

(Doing so may deform or

damage the unit.)

Relay unit

Screw B

Actuator

Tray

Steps 5 and after are the procedure to be carried out when a

multi purpose drawer has been installed.

If a stand/MPD & 2000 sheet paper drawer or a stand/3 x 500

sheet paper drawer has been installed, carry out steps 8 and

after.

5. Process the AC inlet cover attached to the rear cabinet

of the stand/paper drawer.

Remove the two screws that

secure the rear cabinet and

remove the rear cabinet.

Remove the screw that fixes

the AC inlet cover and then

remove the AC inlet cover.

Screw

Process the AC inlet cover as

shown in the illustration.

Screw

Cut out.

AC inlet cover

Screw

Rear

cabinet

<3> Re attach the harness

cover to its or iginal positi on

and fix it with the removed

screw.

At this time, ensure that the

power supply unit harness is

arrange d as shown in the

illustration.

• Fix the harness securely to

the wire saddle.

8. Remove the AC inlet cover and then remove the rear

cabinet of the stand/paper drawer.

<1> Remo ve the screw that

fixes the AC inlet cover and

then remove the A C inlet

cover.

Optional power

supply harnesses

Wire saddle

Wire saddle

AC inlet cover

(* Similar work for the multi purpose drawer)

Screw

Screw

Harness cover

Rear cabinet

Screw

AC inlet cover

(* Similar work for the multi purpose drawer)

11. Connect the AC cord of the optional power supply unit

to the main unit of the printer.

<1> Connect the AC cord of

the power supply unit to the

inlet connector of the main unit

of the printer a t the location

shown in the illustration.

AC cord

(* Similar work for the multi purpose drawer)

Installation is now complete.

Page 11

B83F Installation Manual

CN11

FOR USE WITH COMPATIBLE OKI DIGITAL PRINTERS.

SEE OKI D IGITAL P RINTER S ERVICE M ANUAL O R

INSTALLATION MANUAL TO DETERMINE SUITABILITY.

<Before installation>

• Star t installation after che cking that t he DATA an d COMMUNICATIO N

indicators on the operation panel are neither lit nor blinking.

• For installation of B83F, an optional stand/paper drawer (stand/MPD & 2000

sheet paper drawer, stand/3 x 500 sheet paper drawer or multi purpose drawer)

must have been installed.

Also if a multi purpose drawer has been installed, a power supply unit is

needed additionally.

<Parts included>

Tray 1: 1 pc.

Tray 2: 1 pc.

Screws A (M4x8): 5 pcs.

Screw B: 1 pc.

Mounting plates: 2 pcs.

Stapling position labels:

2 sheets

Staple cartridge: 1 pc.

1. Turn off the main switch of the main unit of the printer.

Turn the main switch located on the front side of the

main unit to the "OFF" position.

Then, remove the power plug of the main unit from

the outlet.

"OFF"

2. Remove the upper cabinet of the stand/paper drawer.

<1> Pull out the tray of the

stand/paper drawer.

Remo ve t he four scre ws

attached to the right on the top of

the stan d/pape r drawer and

remove the cabinet.

<2> Mount s crew B to th e

posit ion s hown in t he

illustration.

Cabinet

Screw B

<3> Hold the grip of the finisher

and place th e f inisher on t he

stand/paper drawer temporarily.

Then, push the lo wer part to

attach the f inisher by sl iding it

toward the exit tray of the main

unit.

At this time, align the finisher with

the exter ior lin e of the

stand/paper drawer.

Grip

<4> Open the front cover of the

finisher and fix the finisher with

three screws A at the positions

shown in the illustration.

Then, close th e fr ont cover and

close the p aper tray o f the

stand/paper drawer.

(Front side)

Screws A

Screws A

<5> Attach the mounting plates to the

positions shown in the illustration and

fix them with screws A.

Mounting plates

Stand frame

[Caution] Insert the moun ting plate

under the desk frame.

4. Insert the staple cartridge.

<1> Pull out the staple unit.

<2> Remove the sealing tape from the staple cartridge.

<3> Insert the staple cartridge.

<4> Slide the release lever to the left and return the staple unit.

Place.

(Rear side)

Push.

Mounting plate

Grip

Push.

Screws A

Steps 6 and after are the procedure to be carried out when a multi

purpose drawer has been installed.

If a stand/MPD & 2000 sheet paper drawer or a stand/3 x 500 sheet

paper drawer has been installed, carry out steps 9 and after.

6. Process the AC inlet cover attached to the rear cabinet

of the stand/paper drawer.

AC inlet cover

AC inlet cover

Screw

Rear

cabinet

Screw

Remove the two screws that

secure the rear cabinet and

remove the rear cabinet.

Remove the screw that fixes the

AC inlet cover and then remove

the AC inlet cover.

Process the AC inlet cover as

shown in the illustration.

Screw

Cut out.

7. Attach the power supply unit.

Attach the power supply unit to the brackets and secure it using the supplied

three screws.

Bracket

8. Connect the power supply unit harness to the PCU PWB

of the main unit of the printer.

<1> Remove the screw that fixes

the harness c over of the mai n

unit of the printer and slide the

harness cover up to remove it.

Process the harness cover as

shown in the illustration.

Bracket

Screws

Screws

Optional power supply unit

Screw

10. Remove the AC inlet cover and then remove the rear

cabinet of the stand/paper drawer.

<1> R emove the screw that

fixes the AC inlet cover an d

then remove the AC inlet

cover.

AC inlet cover

Screw

<2> Remove the AC cord of the power

supply unit from the inlet connector of the

main unit of the printer.

Remove the four screws that fix the rear

cabinet and then remove the rear cabinet.

Rear cabinet

(* Similar work for the multi purpose drawer)

10. Arrange the harness of the finisher.

<1> Pass the harness of the

finis her betwe en the power

supply unit and the frame of the

stand/paper drawer and connect

it to the connector of the power

supply unit.

<2> Fit the snap band attached to

the finisher at the position shown

in the illustra tion to fix the

harness.

(* Similar work for the multi purpose drawer)

Snap band

Finisher harness

Power supply unit

connector

11. Attach the rear cabinet of the stand/paper drawer.

<1> Pass the AC cord of the power supply

unit as shown in the illustration and fix the

rear cabinet of the stand/paper drawer with

the screws.

Rear cabinet

<2> Attach the AC inlet cover to

the rear ca binet o f the

stand/pap er dr awer and fix it

with the removed screw.

10

3. Attach the finisher.

<1> Remove the pa per exit

actuator from the main unit of

the printer.

<2> Raise the relay unit at the

side of the finisher.

[Caution]

Do not press o n the relay un it

while it is raised.

(Doing so may deform or damage

the unit.)

Relay unit

Actuator

5. Attach the trays .

Attach tray 1 and tray 2 to

the positions sh own in the

illustration.

Tray 1

Tray 2

<2> Connect th e power suppl y

unit harness connector to CN11

(red connector) of the PCU PWB

of the main unit of the printer.

<3> Reattach the harness cover

to its original position and fix it

with the removed screw.

At this time, ensur e that the

power suppl y unit harness is

arran ged as sho wn in t he

illustration.

• Fix the harness securely to the

wire saddle.

Optional power

supply harnesses

Wire saddle

Wire saddle

Harness cover

Connector

Screw

Harness cover

Wire saddle

Screw

AC inlet cover

(* Similar work for the multi purpose drawer)

12.

Connect the AC cord of the optional power supply unit

to the main unit of the printer.

<1> Connect the AC cord of

the power supply unit to the

inlet connector of the main

unit of the printer at the

locat ion sho wn in the

illustration.

AC cord

Installation is now complete.

Page 12

B83SS Installation Manual

FOR USE WITH COMPATIBLE OKI DIGITAL PRINTERS.

SEE OKI D IGITAL P RINTER S ERVICE M ANUAL O R

INSTALLATION MANUAL TO DETERMINE SUITABILITY.

<Before installation>

For inst allat ion of B8 3SS, an op tiona l stand /paper drawer

(stand/MP D & 20 00 shee t drawer or st and/3 x 500 sheet paper

drawer) and a duplex module B83D must have been installed. Also a

power supply unit is needed.

<Parts included>

Lock securing plate:

1 pc.

Staple unit: 1 pc.

Stapling position labels:

2 sheets

Rear grounding

plate: 1 pc.

Screws C

(M4x18):

7 pcs.

Connecting plate:

1 pc.

Screws D

(M4x10 with rosette):

1 pcs.

Front cover:

1 pc.

Screws A

(M4x6):

6 pcs.

Plate R: 1 pc.

Front grounding

plate: 1 pc.

Screws B

(M4x10):

2 pcs.

1. Turn off the main switch of the main unit of the printer.

Turn the main switch located

on the front side of the main

unit to the "OFF" position.

Then remove the power plug

of the main unit from the outlet.

"OFF"

2. Attach the lock securing plate to the duplex module.

<1> Remove the screw from the

right side of the duplex module.

<2> A ttach the lock secu ring

plate to th e du plex module

using the screws C and D (one

for each).

Screw

Screw D

Screw C

Lock securing plate

3. Work the stand/paper drawer.

Open the pawl of the left

adjuster to both sides to unlock

it that is located at the lower left

of the stand/paper drawer and

remove the left adjuster.

Pawl

Mounting

holes

Mounting

holes

Cut out the two mounting holes

of the stand/paper drawer using

a screwdr iver or the like and

remove burrs using a flat-blade

screwdriver or the like.

Left adjuster

4. Attach the grounding plate to the stand/paper drawer.

Remove the two screws

that fix the ex terior o f

the stand/paper drawer.

Then, attach t he fr ont

mounting plate and the

rear mount ing plate to

the stand/paper drawer

using screws C (two for

each).

Exterior

fixing screw

Screws C

Rear grounding plate

Exterior

fixing screw

Screws C

Front grounding plate

5. Install the staple unit to the finisher.

<1> Remo ve the t wo piece s of

packing ta pe from the location s

shown in the illustration.

Packing tape

Packing tape

<2> Open the front cover of the

finisher and insert the staple unit.

6. Attach the cover to the finisher.

<1> Attach the plate R to

the position show n in the

illustr ation and secure it

using two screws A.

<2> Attach the front cover

to the finisher, and secure

the upp er part using two

screws B and the lower

part using two screws A.

Front cover

Screws B

Screws A

Screws A

7. Connect the finisher to the stand/paper drawer.

<1> Remove the cover from

the finisher stand.

<2> Attac h the connectin g

plate to the finisher using two

screws A.

<3> Reattach the cover to its

original position.

Screws A

Cover

Finisher stand

Connecting plate

Plate R

<4> Cut out t he two moun ting

holes for the connecting plate at

the lower part of the stand/paper

drawer in a similar way to step 3.

<5> Attac h th e fi nis her

conn ecting plat e to the

stand/pa per drawer using two

screws C.

Screws C

Stand/paper drawer

Connecting plate

8. Check and adjust the height of the finisher.

Move the finisher toward the printer

and check to see if the guide pin of

the lock ing pla te is inser ted

smoothly to the connecting hole of

the finisher.

If it is not inserted smoothly, use

the following proced ure to adjust

the height.

1. If the guide pin of the lock securing plate is not aligned with the

connecting hole of the finisher:

<1> Loosen the scre w at

the rear adjusting portion.

<2> Remove the cap using

a flat-blade screwdriver or

the l ike a nd ad just t he

height adjusting pin so that

the guide pin is positioned

to the cente r of th e

connec ting ho le of th e

finisher.

<3> Loosen the scre w at

the front adjusting portion.

<4> Adjust t he height

adjusting pin so that the

exterior lines are align ed

as shown in the illustration.

<5> If the guide pin can be

inserted smo othly, tighte n

the screws at the front and

rear adjusting portions and

mount the caps.

2. If the guide pin of the locking plate matches to the connecting hole

of the finisher:

<1>Push the finisher into the

main unit.

<2>If the g ap between the

main unit of the print er and

the finisher is not uniform at

the top and th e bott om,

remove the cap s from the

front side and the rear side of

the finisher stand using a flatblade screwdriver or the like

and remove the screw of the

sub covers on the front side

and the rear side to remove

the sub covers.

<3>The n, loosen the four

screw s at the adj usti ng

porti ons indica ted in the

illustration and turn the height

adjusting screws on the front

side and the rear side so that

the gap becomes uniform.

Front side

Screw at

adjusting

portion

Screw at adjusting portion

Exterior lines

Front cover

Exterior lines

Height adjusting

screw

Finisher stand

Cap

Height

adjusting

screw

Connecting

hole

Guide pin

Cap

Rear side

Gap

Gap

<4>If the gap beco mes uniform, tight en the screws at the adjusting

portions and reattach the caps and sub covers.

Cap

Sub cover

Screw

Screw at adjusting portion

Rear side

Height

adjusting screw

Screw

Cap

Sub cover

Front side

Screw at adjusting portion

9. Paste the stapling position labels.

Paste the labels to the positions

shown in the illustration.

10. Remove the AC inlet cover from the rear cabinet of the

stand/paper drawer.

Remove the screw that fixes

the AC inlet cover and then

remove the AC inlet cover.

AC inlet cover

Screw

11. Connect the finisher connector.

<1> C onnec t the fini sher

connector to the stand/paper

drawer.

<2> Tighten the screw of the

connector.

Screw

Connector

12. Turn on the main switch of the main unit.

Insert the power plug of the

main unit to the outlet.

Turn on the main switch of the

main unit.

Installation is now complete.

"ON"

11

Page 13

Screws

Connector

AC cord

Screws B

Screws A

Front cover

B83THP / USP / FHP / FBP

Installation Manual

FOR USE WITH COMPATIBLE OKI DIGITAL PRINTERS.

SEE OKI D IGITAL P RINTER S ERVICE MA NUAL OR

INSTALLATION MANUAL TO DETERMINE SUITABILITY.

<Before installation>

For installation of B83THP / USP / FHP / FBP, a saddle stitch

finisher B83SS must have been installed.

Parts included

Harness A (purple): 1 pc.

Screw

(M4 x 6 with rosette)

: 1 pc.

Dust box label:

1 sheet

1. Turn off the main switch of the main unit of the printer.

Turn the main switch located

on the front side of the main

unit to the "OFF" position.

Then remove the power plug

of the main unit from the outlet.

Loosen the screw and remove

the connector of the finisher.

2.

Remove the front cover from the right front of the finisher.

Remove the screws A and B

(two for each) that secure the

finis her fro nt cover a nd

remove the front cover.

3. Remove the front cabinet and the rear cabinet from

the finisher.

<1> Open the front

door of the finisher and

rem ove t he jam

handling dial.

Harness B (orange): 1 pc.

Hole punch position label:

"OFF"

Jam handling dial

2 sheets

Screws

Connector

<2> Remove the fou r fr ont

cabinet securing screws, pull

out the staple unit until it stops,

then remove the pawl of the

front cabinet in the direction

indicate d by the arr ow an d

remove the front cabinet.

<3> Remove the three screws

that fix the rear cabinet and

remove the rear cabinet.

At this time, remove the relay

harness through the opening

of the rear cabinet.

<4> Rem ove the three rear

cabi net sec urin g scre ws,

remov e t he pawl in t he

direct ion ind icate d by the

arrow, a nd remov e the re ar

cabinet.

At this time, remove the relay

harness through the opening

of the rear cabinet.

Screw

Staple unit

Screws

Pawl

Front cabinet

Screws

Pawl

Rear

cabinet

Screw

Opening for

relay harness

Relay harness

4. Remove the top cover.

<1> Rem ove the four top cover

securing screws and remove the top

cover.

Screws

Top cover

<2> Remove the four pa wls

from the top c over and

separat e the cove r into the

upper an d l ower port ions.

Reuse the upper portion.

Pawl

Top cover

Pawl

5. Attach the punch module.

<1> Insert the two bosses of the punch unit into the boss holes of the

finisher and fix the punch module using three screws.

(Note)

For the screws, use a supplied screw and the two screws that have been

removed in step 4.

Boss hole

Boss

Screw

Punch module

Screw

Screw (with rosette) (supplied with this module)

Boss

Boss hole

6. Connect the harness of the punch module to the PWB

of the finisher.

Remove th e clamps that fix

the harness, handle the wiring

of harn ess A (purple ) and

harness B (orange) , and fix

them with the clamps.

Harness B (orange)

Harness A (purple)

Clamps

Harness B (orange)

Clamps

Harness A (purple)

7. Reattach the covers that have been removed.

<1> Hang the tw o pawls of

the to p cove r and secure

them using the two screws.

<2> Pass the relay harness to

the rear cabinet and se cure

the rear cabin et using the

three screws.

<3> Remove the lock release

lever that has been attached

to the front cabinet.

Reattach the front cabinet to

its origina l position, p ush in

the staple unit, and attach it

using the two screws.

Insert the protrusion (B) of the

lock release lever t hat has

been removed before to the

hole (C) of the latch arm.

After at taching i t, move the

lever to check that it moves

smoothly.

If the lever doe s not move

smoothl y, remov e the lock

release lever by releasing the

pawl at the lower part of the

lock release lever using a flatblade screwdriver or the like

and then insert it again.

Staple unit

Screws

Front cabinet

Pawl

Screws

Screw

Top cover

Latch arm

Lock release lever (A)

Projection (B)

Opening for

relay harness

Relay harness

Screw

Rear cabinet

Screw

Pawl (D)

(C)

<4> Re atta ch the jam

handling dial and close the

front cover.

Jam handling dial

8. Reattach the front cover to the right front of the finisher.

Attach the front cover using

the screws A and B (two for

each).

Front cover

Screws B

Screws A

9. Paste the dust box label to the top cover.

Paste the supplied dust bo x

label to the location indicated

in the illustration.

10. Connect the connector to the stand/paper drawer and

connect the AC cord of the power supply unit to the

main unit of the printer.

Connect the connector of the

relay harness of the finisher to

the sta nd/paper drawer and

tighte n th e s crews of the

connector.

Installation is now complete.

12

Page 14

"OFF"

"ON"

Screws

Grip

Grip

Screws

Screws

B83HD Installation Manual

FOR USE WITH COMPATIBLE OKI DIGITAL PRINTERS.

SEE OKI DIGITAL PRINTER SERVICE MANUAL OR

INSTALLATION MANUAL TO DETERMINE SUITABILITY.

<Before installation>

• Start installation after checking that the DATA and

COMMUNICATION indicators on the operation panel are

neither lit nor blinking.

Parts included

PWB fixing screws: 3 pcs.

Grounding plate

: 1 pcs.

1. Turn off the main switch of the main unit of the printer.

Turn the main switch

located on the front

side of the main unit to

the "OFF" position.

Then remo ve the

power plug from the

outlet.

2. Remove the cables connected to the control PWB unit.

Remove all the cables connected to the control PWB unit of the main unit of the

printer.

• In case of printer control PWB

• In case of MFP control PWB

screws: 1 pcs.

"OFF"

3. Remove the control PWB unit.

Remove the five screws that

fix the control PWB unit to

the main unit of the printer.

Then, hold the two grips and

pull out the printer control

PWB unit to remove it from

the main unit.

(Example) MFP control PWB

4. Mount the HDD expansion PWB to the control PWB.

• The procedure (shape of PWB) varies with the printer control PWB and

the MFP control PWB.

• In case of printer control PWB ..................................................................................

<1> Remove the screw at the position shown in the

illustration among the screws that secure the hard

disk to the HDD expansion PWB.

<2> Attach the supplied grounding plate to the HDD

PWB as shown in the illustration

and secure it using the screw that

has been removed in step <1>.

<3> Remove the three screws

shown in the illustration among

the screws that fix the printer

control PWB.

<4> Mount supplied three PWB

fixing screws to the positions from

which three screws have been

removed.

<5> Insert the HDD expansion

PWB to the connector of the

printer control PWB.

<6> Fix the HDD expansion PWB

to the PWB fixing screws using

the three screws that have been

removed in step 1.

<7> Secure the grounding plate that

has been attached to the HDD

expansion

PWB to the controller mounting

plate using the supplied screw.

• In case of MFP control PWB ......................................................................................

<1> Remove the three screws

shown in the illustration among

the screws that fix the MFP

control PWB.

<2> Mount supplied three PWB

fixing screws to the positions from

which three screws have been

removed.

<3> Insert the HDD expansion

PWB to the connector of the MFP

control PWB.

<4> Fix the HDD expansion PWB

to the PWB fixing screws using

the three screws that have been

removed in step 1.

HDD expansion PWB

HDD expansion PWB

5. Attach the control PWB.

Attach the control PWB unit to

the main unit of the printer and

fix it using five screws.

(Example) MFP control PWB

6. Connect the cables to the control PWB.

Connect all the cables that have been removed in step 2 to the original positions

of the printer control PWB unit.

• In case of printer control PWB

• In case of MFP control PWB

* If another peripheral device must be installed, carry out

the following step at the end of the installation work.

7. Turn on the main switch of the main unit of the printer.

Insert the power plug of the

main unit of the printer to the

outlet.

Then, turn the main switch

located on the front side of the

main unit to the "ON" position.

"ON"

8. Check the operation.

• For setting change of the printer drivers on the computer, see the supplied

operation manual.

Then, execute printing from the computer using the print hold function to check

for proper printing.

13

Page 15

Electrical Setting/ Adjustment/ Operation Check

[1]Installation of driver software,

setting, and operation check

Applied model: Main unit

•

Carry out installation of driver software and check

of printing

<1> Insert the power plug into an outlet.

Caution

If the outlet is also used for lighting fixtures, the lighting

fixtures may flicker.

Use an outlet which is not connected to lighting

fixtures.

<2> Turn on the main switch of the main unit.

Automatic level adjustment of toner density sensor will

start and a message indicating [WARMING UP] will

appear on the operation panel. After the level adjustment

is complete, the ready indicator will light up.

Caution

While automatic adjustment of the toner density

sensor is being done, do not turn the power to the

machine off. This will cause improper adjustment.

<3>Check the printer operation

For installation of printer drivers on the computer refer to

the Operation manual (for printer operation and general

information) supplied with the machine.

After driver installation, execute a test print to ensure

normal printing.

Applied model: B83HD

•

Carry out installation of driver software and

check of printing

For setting change of the printer drivers on the computer,

see the supplied operation manual.

Then, execute printing from the computer using the print

hold function to check for proper printing.

[2]Paper guide position adjustment

and off center adjustment

For Printer Models

B83MP/ B83LT / B83TT/ B83D / B83DB

Applied models: B83MP/ B83LT / B83TT

•

Adjust the position of the paper guides of the

paper tray of B83MP or the upper paper tray of

stand/paper drawer B84LT / B83TT.

<1> To use the setting mode, insert the power plug of the

main unit of the printer to the outlet and turn the main

switch on while pressing the [MENU] key and the [OK]

key of the operation panel of the main unit of the printer.

<2> Press the [MENU] key several times to display "SIZE

ADJUSTMENT A" and press the [OK] key.

<3> "MAXIMUM SIZE" is displayed.

Pull out the paper tray and extend the paper guides to the

maximum. Then, return the paper tray into the main unit

and press the [OK] key.

<4> "MINIMUM SIZE" is displayed.

Pull out the paper tray again and narrow the paper guides

to the minimum. Then, return the paper tray into the main

unit and press the [OK] key.

[Caution]

If the setting above is not carried out, the paper detection

function will not operate.

Paper guides

[Applied models]

Rear guide

Applied model: B83DB

•

Adjust the position of the paper guides

of the bypass tray.

<1> To use the setting mode,

insert the power plug of the main

unit of the printer to the outlet

and turn the main switch on

while pressing the [MENU] key

and the [OK] key of the operation

panel of the main unit of the

printer.

<2> After pressing the [MENU] key several times to

display "SIZE ADJUSTMENT A" in the message display,

press the [ ] key to display "SIZE ADJUSTMENT B" and

press the [OK] key.

<3> "MAXIMUM SIZE" is displayed.

Since "MAXIMUM SIZE" is displayed with a number,

press the [ ] key or the [ ] key to change the number so

that the number is equal to the value of [MAX] written on

( NOTE)

the label

<4> Since "P1 SIZE" is displayed with a number, press

the [ ] key or the [ ] key to change the number so that

the number is equal to the value of [P1] written on the

( NOTE)

label

<5> Since "P2 SIZE" is displayed with a number, press

the [ ] key or the [ ] key to change the number so that

the number is equal to the value of [P2] written on the

( NOTE)

label

<6> Since "MINIMUM SIZE" is displayed with a number,

press the [ ] key or the [ ] key to change the number so

that the number is equal to the value of [MIN] written on

the label

( NOTE)

[Caution]

If the setting above is not carried out, the paper detection

function will not operate.

( NOTE)

Illustration of label sticking position

(Back surface of the bypass tray

extension)

and then press the [OK] key.

and then press the [OK] key.

and then press the [OK] key.

and then press the [OK] key.

"ON"

14

Label

MAX

Then, carry out the off center adjustment.

MINP1 P2

Page 16

Applied models: B83MP / B83LT / B83TT / B83D / B83DB

•

Carry out the off center adjustment.

<1> To select the setting mode, insert the power plug of

the main unit of the printer into an outlet and turn on the

main switch while pressing the [MENU] key and the [OK]

key simultaneously.

When carrying out the off center adjustment after paper

guide position adjustment, this operation is not needed.

(For B83D, this operation is needed.)

<2> Press the [MENU] key repeatedly until "TEST PRINT

00" is displayed, and press the [OK] key.

<3> Use the [MENU] key to select "MULTI SETTING" and

enter "1" using the [ / ] key.

<4> Use the [MENU] key to select "PRINT PATTERN"

and enter "1" using the [ / ] key.

<5> Use the [MENU] key to select "CASSETTE" and

select the tray for which the off center adjustment is to be

carried out using the [ / ] key. (See the table below.)

<6> Use the [MENU] key to select "DUPLEX" and select

"USE" or "NO" using the [ / ] key. (See the table below.)

<7> Use the [MENU] key to select "** OFF CENTER ADJ"

corresponding to the option in the table below, press the

[OK] key, and check that the printed line is positioned at

the center of paper.

<8> If the off center is displaced, use the [ / ] key to

adjust the value so that the line is positioned at the center.

(Fig. 1 and 2)

Default: 50 (setting range: 0 to 99)

Increase of the value shifts the overall image toward the

rear side.

Value 1 corresponds to 0.1 mm.

<9> Turn off the main switch of the main unit of the printer

and then turn on the switch again after several seconds.

The setting is now complete.

(Fig. 1)

[Rear side of the main unit]

Top end of paper

Center line of image

(first print image)

In this case, increase the value.

(ADU)

BPT (MFT)

(ADU)

BPT (MFT)

LCC (T3)

(ADU)

BPT (MFT)

Example

of image

Center of paper

Main unit

Main unit

Main unit

(Fig. 2)

[Rear side of the main unit]

Top end of paper

Center line of image

(first print image)

In this case, decrease the value.

Center of paper

Example

of image

TRAY 1 (T1)

TRAY 2 (T2)

TRAY 1 (T1)

TRAY 2 (T2)

LCC (T4)

TRAY 1 (T1)

TRAY 2 (T2)

DESK 1 (T3)

DESK 2 (T4)

15

Setting example for each model

■

[MENU] key

1

TEST PRINT 00

2

MULTI SETTING

3

PRINT PATTERN

4

CASSETTE

5

DUPLEX

6

OFF CENTER ADJ

B83MP

•

1

1

TRAY 2

NO

T2

B83LT B83TT

•

1

1

LCC

NO

T2

•

1

1

LCC

NO

T3(*1)

•

1

1

LCC

NO

T4(*2)

•

1

1

TRAY 2

NO

T2

(*1) Load paper only in the left tray. (*2) Load paper only in the right tray.

•

1

1

DESK 1

NO

T3

•

1

1

DESK 2

NO

T4

B83D

•

1

1

TRAY 1

USE

ADU

•

1

1

BPT

NO

MFT

B83DB

•

1

1

TRAY 1

USE

ADU

Loading...

Loading...