Page 1

Owner’s Manual

Öhlins Superbike Front Fork FG 470

Page 2

Safety signals

Important information concerning safety is

distinguished in this manual by the

following notations:

!

This Safety alert symbol means: Caution!

Your safety is involved.

! WARNING!

Failure to follow warning instructions could

result in severe or fatal injury to anyone

working with, inspecting or using the suspension, or to bystanders.

CAUTION!

Caution indicates that special precautions

must be taken to avoid damage to the

suspension.

NOTE!

This indicates information that is of importance with regard to procedures.

Introduction

All of Öhlins advanced suspension products

are adapted to the brand and model. This

means that length, travel spring action and

damping charac teristics, are tested individually just for the motorcycle that you have

decided to fit with Öhlins suspension.

! WARNING!

1. Installing a suspension, that is not ap proved by the vehicle man u fac tur er, may

affect the stability of your ve hi cle. Öhlins

Rac ing AB cannot be held responsible for

any per son al in ju ry or dam age what so ev er

that may oc cur after fi t ting the sus pen sion.

Contact an Öhlins deal er or oth er qual i fi ed

person for advice.

2. Please study and make certain that you

ful ly un der stand all the mount ing in struc tions

and the owner´s man u als before han dling

this suspension kit. If you have any questions

regarding proper in stal la tion pro ce dures,

contact an Öhlins deal er or other qual i fi ed

per son.

3. The vehicle service manual must be

re ferred to when installing the Öhlins suspension.

NOTE!

Öhlins products are subject to con tin u al

improve ment and de vel op ment. Con se quent ly, although these in struc tions in clude

the most up-to-date in for ma tion available

at the time of print ing, there may be minor

dif fer enc es between your sus pen sion and

this manual. Please con sult your Öhlins

dealer if you have any ques tions with regard to the con tents of the manual.

Before installation

Öhlins Racing AB can not be held re spon si ble for any damage whatsoever to sus pen sion or vehicle, or injury to persons, if

the instruc tions for fitting and main tenance

are not fol lowed exactly. Similarly, the

warranty will be come null and void if the

instructions are not ad hered to.

© Öhlins Racing AB.

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Öhlins Racing AB is prohibited.

Printed in Sweden.

2

NOTE!

During storage and transportation, es pe cial ly at high ambient tem per a ture, the oil

and grease used for as sem bling may run

out inside the pack ing and dam age the expanded pol y sty rene pack ing ma te ri al. This

is not unusual and is in no way det ri men tal

to the suspension.

Page 3

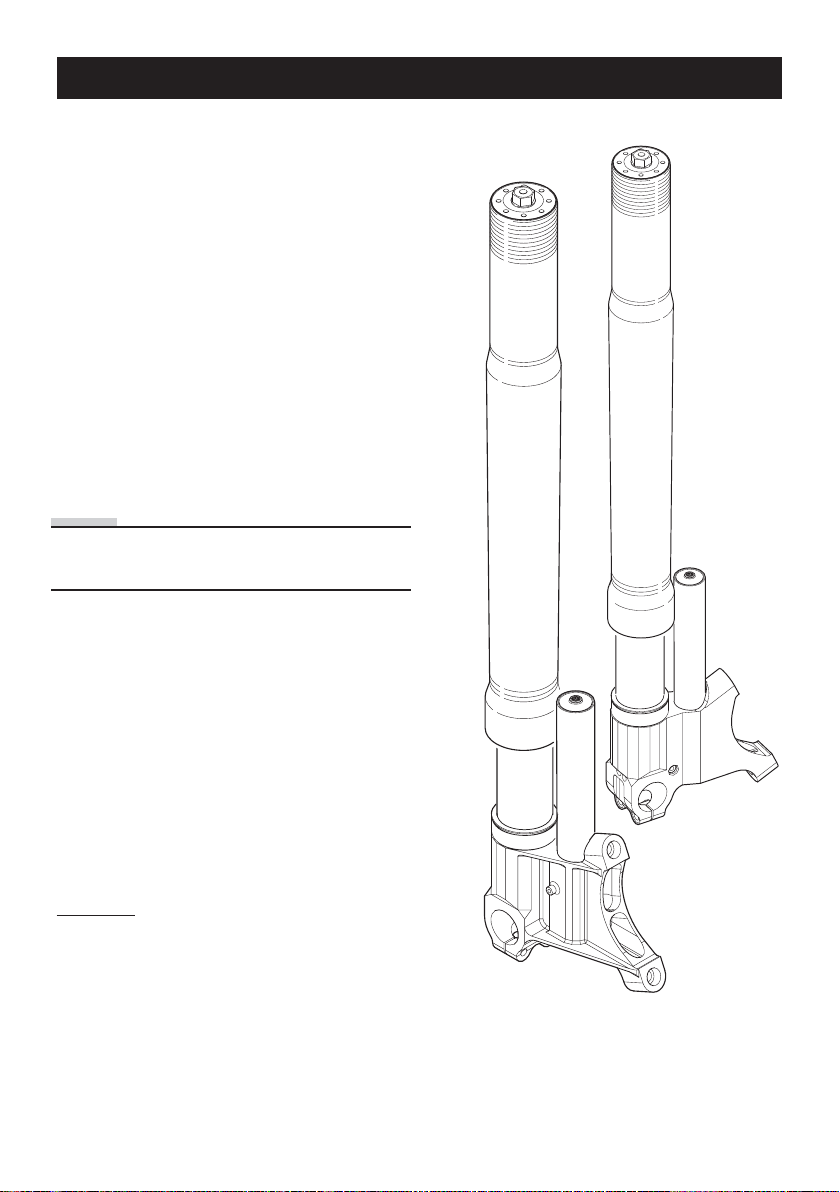

Öhlins Front Fork FG 470

This Super Bike front fork is an improved

version of FG 370 with pressurised damping system. FG 470 is based on 4 years

experience from factory road racing. The

pressurised damping system improves the

front fork function at high frequency movements. The immediate damping responses

improve the tyre feeling and also give more

possibilities for adjustments. Of course

the combination of spring and air-gap (oil

level*) still gives a possibility to adjust the

characteristic of the fork to suit different

tracks and riders.

For example a soft spring in combination

with a small air-gap (high oil level) gives a

more progressive action of the front forks.

NOTE!

Gas pressure should not be changed or

used as an alternative to adjust the damping.

For better understanding, please refer to

our oil level chart see page 17.

A telescopic front fork is depending on a

smooth friction-free action. Make sure your

front forks are serviced regularly and don’t

use strong solvents such as brake cleaner

to clean the front forks. This will dry out the

seals and cause friction.

For tighten torque, loctite and grease see

page 19.

Contents

Before installation

Öhlins front fork FG 470

...........................................................................4

Adjusters

Setting up your forks

Changing springs

Changing seals

Dismantling the forks

Assembly of the forks

Oil level adjustment

Troubleshooting

Technical information

Spare parts list

Service tools

...........................................................2

.................................................3

......................................................5

...........................................................6

...............................................................7

.....................................................8

..................................................12

......................................................17

............................................................18

...................................................19

.............................................................20

...............................................................23

*

Front fork 470 is equipped with an external reservoir, pressurized

with nitrogen. A dividing piston separates the oil from the gas.

3

Page 4

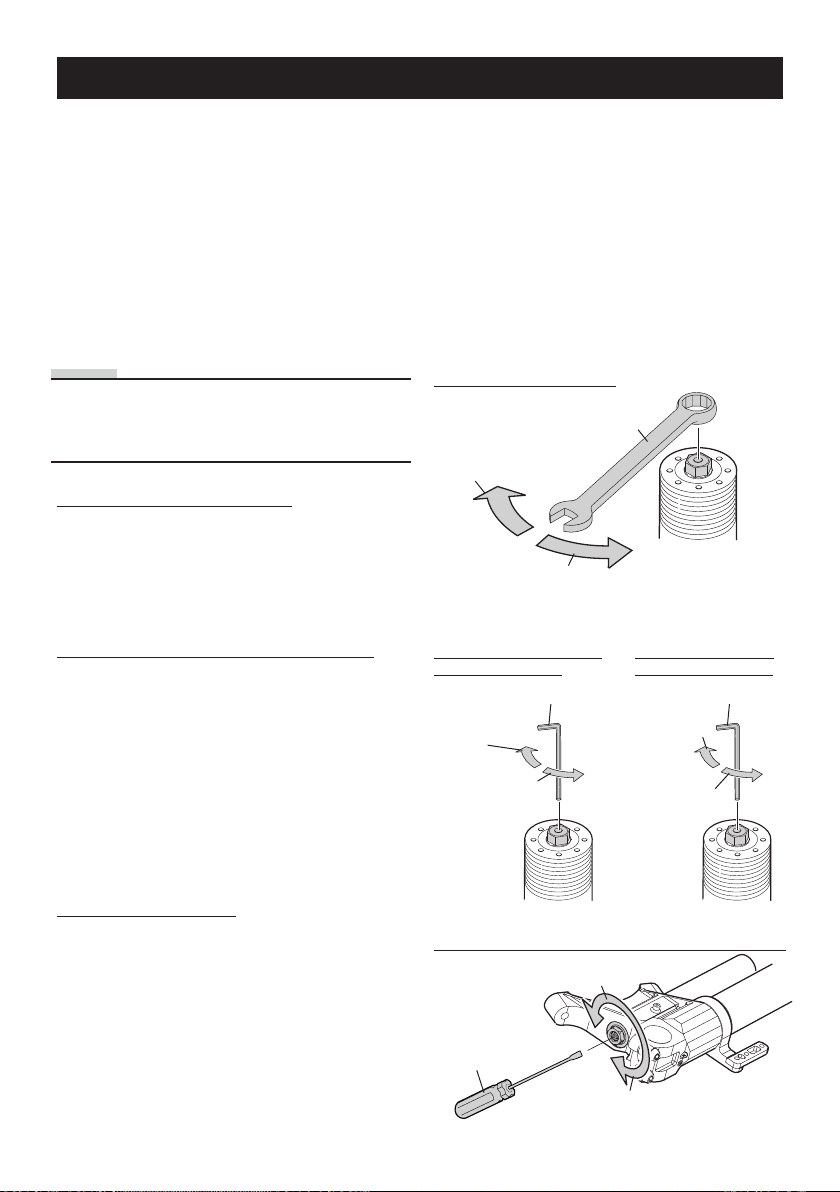

Adjusters

Your Öhlins super bike front fork is provided with the following external adjusters:

• Spring pre-load adjuster

• Rebound damping adjuster.

• Two type of compression

damping adjuster:

- Reservoir valve adjuster in the

lower part of the fork leg.

- Main valve bleed circuit.

NOTE!

The rebound damping adjuster is located at

the top of the right hand fork leg. The Main

valve bleed circuit (compression adjuster) is

located at the top of the left hand fork leg.

Spring pre-load adjustment

Use a 17-mm wrench to turn the upper

adjustment screw. The adjustment range

is 0-18mm. On the adjustment screw one

turn will change 1mm in spring pre-load.

Recommended static sag is 25-30 mm.

Compression adjustment main valve.

Adjust the compression damping on the

adjustment screw positioned at the top of

the left hand fork leg. Use a hex key with

spherical head (use tool 794-01).

Compression adjustment reservoir valve

(Base valve)

Adjust the compression damping (shaft

displacement) on the lower part of the fork

legs. Use a normal screwdriver. Adjustment

range from closed valve (clockwise) to

maximum open valve (counter clockwise)

is 20 “clicks”. Recommended adjustment

“clicks”, from closed position:

See specification card.

Spring pre-load adjustment

17 mm wrench

Increase spring pre-load

Top cap

Reduce spring pre-load

Compression adjustment

Left Hand Fork Leg

Clockwise turn

closes = increase

compression

damping

Tool 794-01

Rebound adjustment

Right Hand Fork Leg

Clockwise turn

closes = increase

rebound damping

Tool 794-01

Adjustment range from closed valve

(clockwise) to maximum open valve

(counter clockwise) is 20 “clicks”. Recommended adjustment “click”, from closed

position: See specification card.

Rebound adjustment

Adjust the rebound damping on the adjustment screw positioned at the top centre of

the right hand fork leg. Use a hex key with

a spherical head (use tool 794-01).

Adjustment range from closed valve (clockwise) until maximum open valve (counter

clockwise) is 20 “clicks”. Recommended

adjustment “click”, from closed position:

See specification card.

4

Counter clockwise

turn opens = reduced

compression damping

Compression adjusment reservoir valve (Base valve))

Counter clockwise turn opens =

reduced compression damping

Screwdriver

Counter clockwise

turn opens = reduced

rebound damping

Clockwise turn closes =

increase compression damping

Page 5

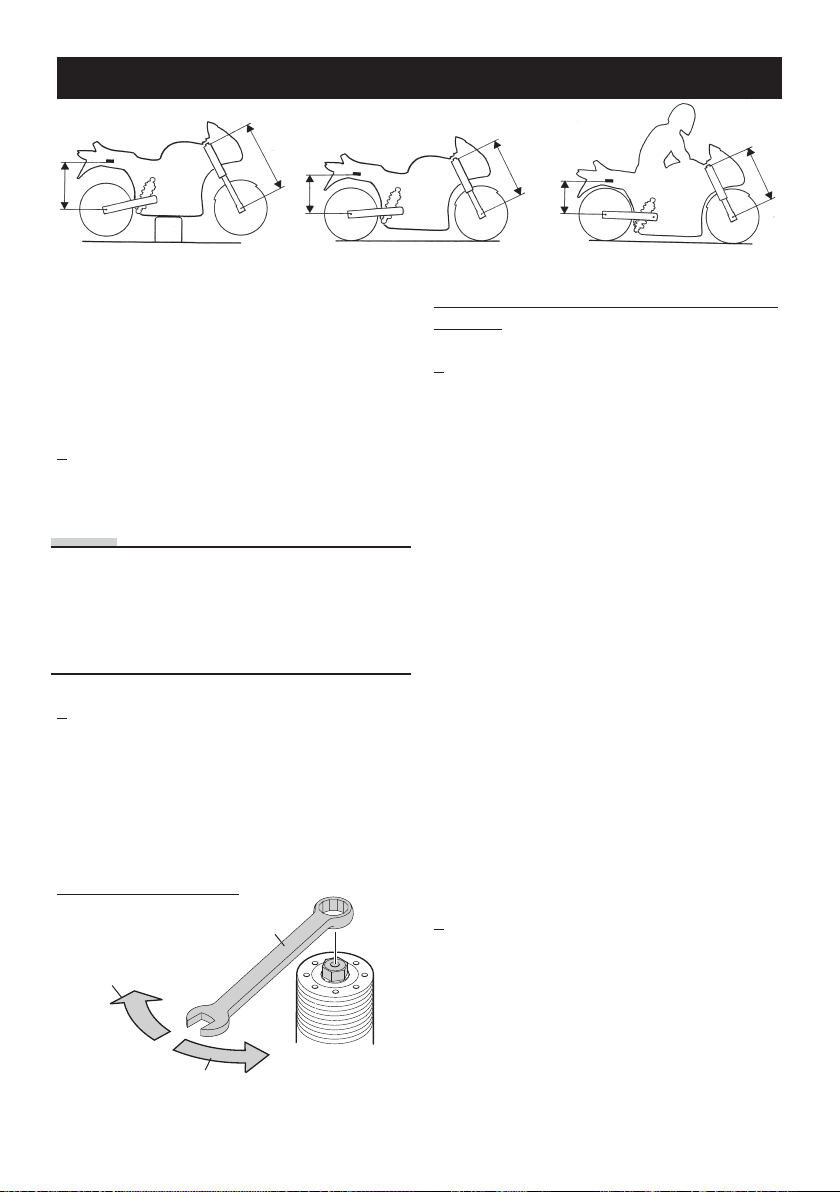

Setting up your forks

F1

R1

A-D. Bike on a stand

R2

E. Bike on the ground F. Bike with rider on

Here is some basic guidelines, how to set

up your Öhlins front forks. However you

must remember that the front forks are just

one part of your motorcycle and to get it to

work properly, the whole motorcycle has to

be set up according to your bikes manual.

1

Put your bike on a front stand and fit the

Öhlins front fork.

NOTE!

The lower triple clamp must not be tightened to more than 12-15 Nm. This is also

important for the steering damper bracket,

when located around the upper front leg.

To high torque might deform the front fork

leg.

2

Set your initial pre-load of the spring, by

using a 17mm socket or wrench, until you

get a static sag of 25-30 mm. Each turn

gives 1mm in pre-load, maximum pre-load

is 18mm.

Spring pre-load adjustment

F2

R3

F3

Setting the spring pre-load generally on

the bike

3

Pre-load on the spring/springs is very

important, since it affects the height of

the motorcycle and the fork angle. Consequently, handling characteristics can be

changed, even negatively.

Proceed as follows (it will be much easier if

done by two persons):

1 Place the motorcycle on a stand.

2 Lift up the rear end to a fully extended upper

position.

3 Measure the distance, e.g. from the ower edge of

the rear mud guard or from a point marked by a

piece of tape, immediately above the rear whee

axle, to the wheel axle. (R1)

4 Make a similar measurement on the front axle, e.g.

from the bottom of the upper fork crown to the

front wheel axle. The fork must be fully

extended. (F1)

5 Allow the motorcycle (without rider) to apply load

on the springs and repeat the measuring proce dure. (R2, F2)

6 Then take the same measurements with the rider

and equipment on the motorcycle. It is important

that the rider has a correct riding posture, so that

the weight is balanced on the front and rear wheel

in the same way as when riding. (R3, F3)

Increase spring pre-load

Reduce spring pre-load

17 mm wrench

4

The measurements may not differ from the

following sizes:

Without rider:

Rear: 5-15 mm (R1-R2)

Front: 25-30 mm (F1-F2)

With rider:

Rear: 30-40 mm (R1-R3)

Front: 35-50 mm (F1-F3)

5

Page 6

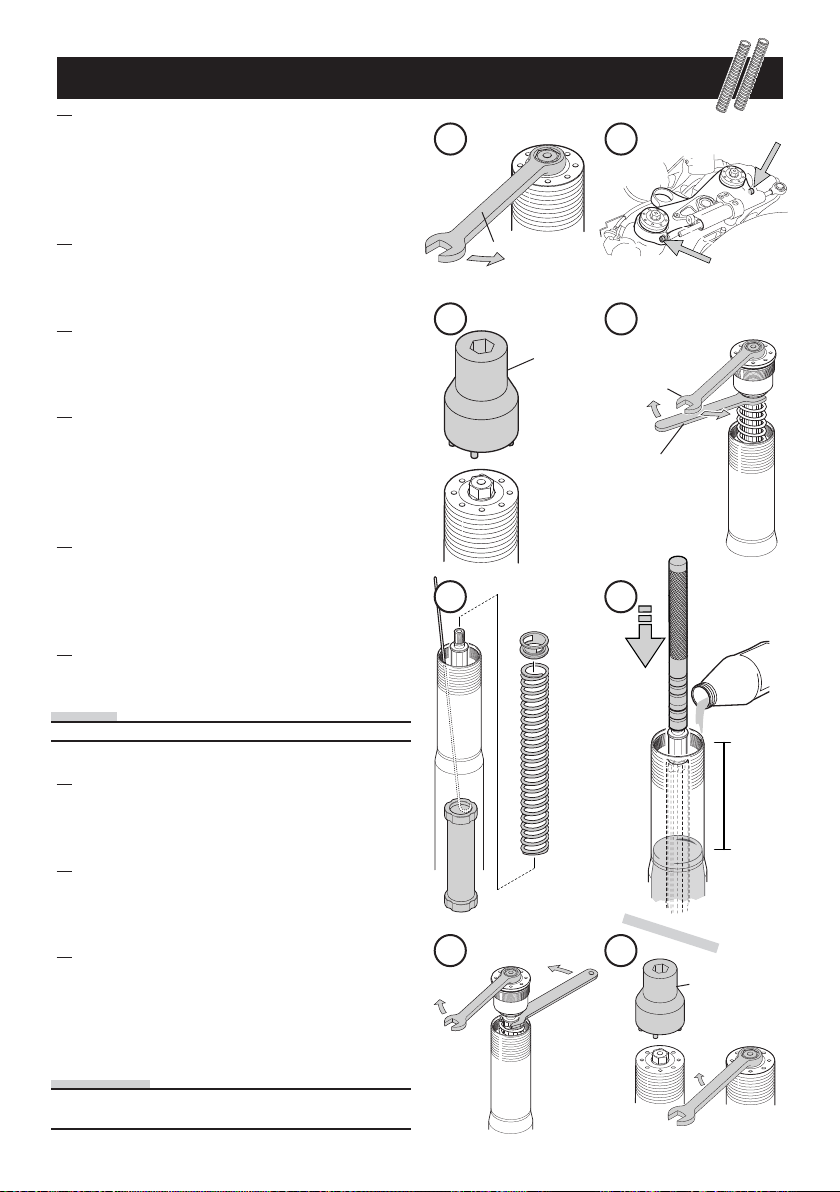

Changing springs

1.

Unload the spring pre-load completely

by turning the adjustment nut counter

clockwise as far as possible. Use a 17 mm

wrench or socket.

12

2.

Loosen the screws that hold the fork legs

in the upper tripple clamps.

3.

Remove the Top nut assembly. Use tool

797-01.

4.

Remove the top nut assembly from the

piston shaft. Use a 17 mm wrench to the

top and tool 4705-01 to hold the nut on the

lower side of the top nut.

5.

Remove the adjustment driver and the

spring. Use a wire with a hook and carefully pull out the preload tube.

6.

Check the oil level according to page 17.

NOTE!

Use Öhlins Front fork oil 1305-01 only.

7.

Refit the Pre-load tube. Install the new

spring and refit the adjustment driver.

17 mm socket

34

Tool 797-01

17 mm socket

Tool 4705-01

5 6

Adjustment driver

Spring

Tool 1765-03

1305-01

Check the oil level

8.

Refit the top nut assembly to the piston

shaft. Tighten the jam nut to 20 Nm.

9.

Refit the top nut into the fork leg, with

the front wheel off the ground (use tool

797-01). Tighten the upper triple clamps

and adjust the preload, compression and

rebound according to above instructions.

CAUTION!

The top nut should only be tightened by

hand into the fork leg.

6

Preload tube

8 9

20 Nm

CAUTION!

Tool 797-01

Page 7

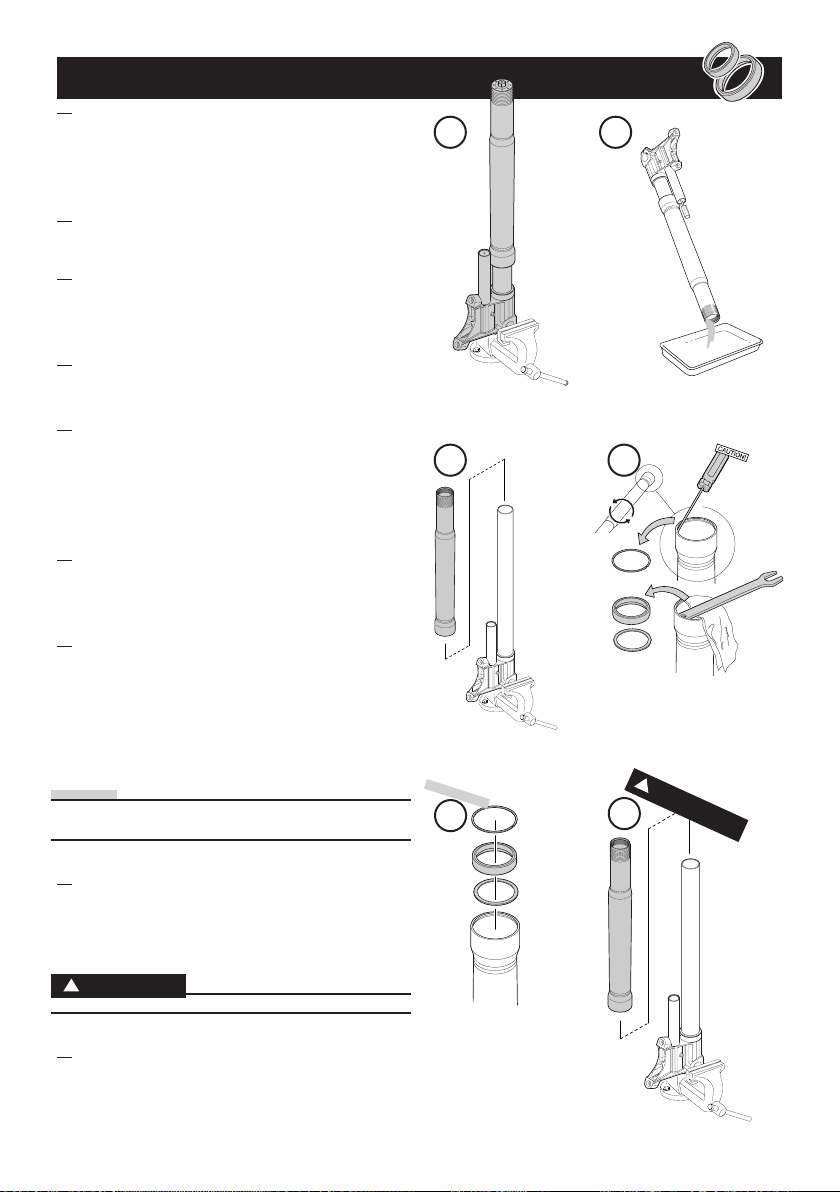

Changing seals

!

1.

Remove the fork legs from the motorcycle.

Put the fork legs in upright position for

about 5 minutes to allow the oil to settle.

2.

Fasten the fork leg in a vice. Use soft jaws.

3.

Carry out instructions 1 to 5 in “Changing

springs”, page 6.

4.

Drain the cylinder tube from oil.

5.

Remove the outer tube, clean the seal and

check the condition. If the seal is in good

condition apply some red grease (146-01)

to it. A damaged seal must be replaced!

6.

First remove the circlip, then the seal and

finally the washer.

2 4

5 6

180

1st, Circlip

2nd, Seal

0

7.

Apply a thin layer of Öhlins red grease

(146-01) to the washer and to the sealing

surfaces of the fork seal. Install the seal

and the washer in the outer tube. Fit the

circlip into the groove.

NOTE!

It is important to use the correct grease in

order to achieve optimum fork function.

8.

Apply some front fork oil (1305-01) to the

inner tube surface and carefully mount the

outer tube (slide it completely down).

! WARNING!

Be careful not to damage the fork seal!

9.

Repeat instructions 6 to 9 in “Changing

springs” on page 6. Refit the front fork.

NOTE!

7

Circlip

Seal

Washer

3rd, Washer

WARNING!

8

7

Page 8

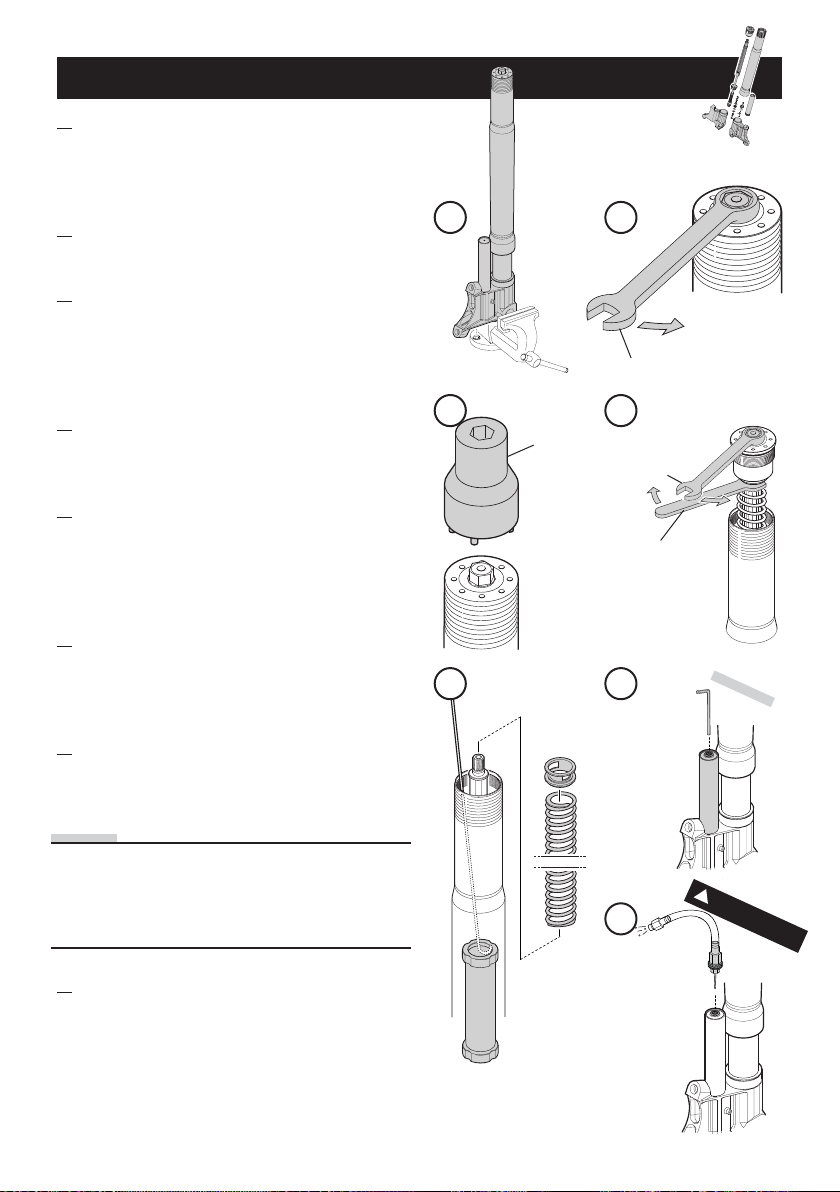

Dismantling the Forks

!

1.

Remove the fork legs from the motorcycle.

Put the fork legs in upright position for

about 5 minutes to allow the oil to settle.

2.

Fasten the fork leg in a vice. Use soft jaws.

3.

Unload the spring pre-load completely

by turning the adjustment nut counter

clockwise as far as possible. Use a 17 mm

wrench or socket.

4.

Loosen the top nut assembly. Use tool

797-04.

5.

Remove the top nut assembly from the

piston shaft. Use a 17 mm wrench to the

top and tool 4705-01 to hold the nut on the

lower side of the top nut.

6.

Remove the adjustment driver and the

spring. Use a wire with a hook and carefully pull out the preload tube.

23

17 mm socket

4 5

Tool 797-04

17 mm socket

Tool 4705-01

6 7

NOTE!

7.

Remove the screw and o-ring from the

reservoir end cap.

NOTE!

Before the gas pressure is relieved the

adjuster settings must be counted and

noted. Even check that the gas pressure is

correct. Follow that, the adjusters should

be set in a fully open position.

8.

Relieve the nitrogen gas by inserting an

injection needle into the reservoir end cap

through the rubber valve.

8

Adjustment driver

Spring

WARNING!

8

Preload tube

Page 9

!

WARNING!

Releasing high pressure gas from the

shock absorber can be hazardous. Do not

perform any kind of service until gas pressure is completely released.

9.

Remove the circlip.

10.

Use tool 720-03 to lift up the reservoir end

cap. Install the tool 720-02 into the gas

piston.

11.

Use tool 1797-04 and 1765-03 to unscrew

the seal head from the cartridge tube.

Remove the piston rod unit.

12.

Fasten the piston rod in a vice. Use soft

jaws (727-02). Remove the nut with a 13

mm wrench or socket. Remove the valve

from the piston rod.

Place all parts, including the shims, in their

correct position on the work bench. Clean

all parts thoroughly and dry with compressed air.

910

Tool 1765-03

Tool 720-03

11

Tool 1797-04 Piston rod unit

Seal head

Tool 720-02

NOTE!

The right hand fork leg is the rebound leg.

The left hand fork leg is the compression

leg.

Notes

12

NOTE!

13 mm socket

Nut

Soft jaws

(727-02)

Rebound Valve RH-Leg

Compression Valve LH-Leg

9

Page 10

13.

Remove the Piston holder. Use a 14 mm

wrench.

14.

Remove the Topout spring, the Sleeve, the

Spacer and the O-ring.

15.

Remove the Seal head. Check the O-ring

and the X-ring. Change them if necessary.

16.

Remove the needle and change the O-ring

if necessary.

17.

Drain the cylinder tube from oil.

18.

Remove the gas piston in the reservoir, use

tool 720-02.

19.

Drain the reservoir from oil.

20.

Use a 17 mm wrench to unscrew the

complete compression valve at the bottom

of the fork.

13

14 mm Wrench

14

Piston holder

Topout spring

Sleeve

Spacer

O-ring

15 16

X-ring

Seal head

O-ring

17

18

O-ring

Rebound neendle

21.

Remove the piston from the compression valve. Place the shims in their correct

position on the work bench. Clean all parts

thoroughly, change O-rings if necessary

and dry all parts with compressed air.

Notes

10

19

21

20

Page 11

22.

Remove the outer tube, clean the seal and

check the condition. If the seal is in good

condition apply some red grease (146-01)

to it. A damaged seal must be replaced!

23.

First remove the circlip, then the seal and

finally the washer.

24.

Heat the tube where the bushings are positioned. Use a heat air gun.

22 23

180

1st, Circlip

2nd, Seal

3rd, Washer

0

25.

Put the outer tube standing up on a soft

suface, seal side facing down. Remove the

bushings by pushing them out. Use attachment bar (1757-01) and dismantling sleeve

(1759-07) from the top nut side.

26.

Tap gently on the attachment bar with a

heavy hammer, until the bushings are free

and can be released from the seal side of

the outer tube.

27.

Check the innertube for damages, replace

if necessary. Use a heat gun to warm up

the fork bottom and tool 786-05 to unscrew the inner tube of the fork leg.

28.

Check the reservoir tube for damages,

replace if necessary. Use tool 786-07 to

unscrew the reservoir tube.

24 25

Heat air gun

26 27

Upper bushing

Lower bushing

Attachment bar

(1757-01)

Dismantling sleeve

(1759-07)

Rubber mat

Tool 786-05

28

Tool 786-07

11

Page 12

Assembly of the forks

1.

Use Tool 786-07 to refit the reservoir tube.

Tighten to 45 Nm.

2.

Use Tool 786-05 to refit the inner tube of

the fork leg. Tighten to 80 Nm.

3.

Put the outer tube standing up on a soft

surface, seal side up. Fit the bushings

from the seal side of the outer leg. Install

first the upper bushing then the lower one.

Use installing sleeve (1759-08), guide ring

(1758-04) and attachment bar (1757-01)

when installing the upper bushing. Apply Loctite 601 on the seat position of the

upper bushing, use a long brush. Tap the

attachment bar until it reaches the correct

position (stop against a shoulder).

12

Tool 786-07

Apply Red grease (146-01), No loctite!

3

Long brush

Lower bushing

Upper bushing

Tool 786-05

Guide ring

(1758-04)

4.

When the upper bushing is in position, the

lower bushing is to be installed the same

way. Apply some red grease (146-01) to

the bushing before installation.

5.

Apply a thin layer of Öhlins red grease

(146-01) to the washer and to the sealing

surfaces of the fork seal. Install the seal

and the washer in the outer tube. Fit the

circlip into the groove.

NOTE!

It is important to use the correct grease in

order to achieve optimum fork function.

Loctite 601

4

Outer tube

Attachment bar

(1757-02)

Installing sleeve

(1759-08)

Rubber mat

NOTE!

5

Circlip

Washer

Seal

12

Page 13

6.

!

Install the piston and the shims on the

compression valve. Tighten the 8 mm nut

with a torque of 7 Nm. Check the piston

ring and the O-rings for damages. Replace

if necessary.

Install the compression valve assembly into

the valve housing. Tighten to 20 Nm.

Compression valve assembly:

1675-01, Nut

153-01, Washer

641-02, Washer

Shim stack Comp.

1670-01, Piston

338-11, O-ring

530-22, Shims

1693-01, Spring

1669-01, Sleeve

1672-01, Collar

7.

Apply some front fork oil (1305-01) to the

inner tube surface and carefully mount the

outer tube (slide it completely down).

6

8 mm Nut,

7Nm

Comp. valve assembly,

20 Nm

1658-01, End piece

WARNING!

438-02, O-ring

1242-03, Needle

1474-01, Spring

87

884-02 x 2, Ball

338-53, O-ring

1473-02, Circlip

! WARNING!

Be careful not to damage the fork seal!

8.

Fill up with Öhlins front fork oil (1305-01) all

the way to the edge of the reservoir. Continue to fill until the oil level is the same in

both the reservoir and in the cylinder tube.

9.

Push the gas piston, with teflon band

and O-ring fitted, to the reservoir bottom

without allowing it to be pressed back over

the circlip groove, make sure that there is

no air between the piston and the oil. Use

tool 720-02.

Close the compression adjuster.

9

Tool 720-02

13

Page 14

10.

Grip the piston shaft with soft jaws 727-02.

Fit the O-ring on the adjustment needle.

Apply plenty of red grease on the O-ring so

that the needle slides easily into the piston

shaft.

11.

Check the X-ring and O-ring on the seal

head. Replace if necessary. Smear plenty

of white grease on the X-ring before you fit

it. Use tool 0715-01 to get the X-ring into

the right position.

10.

Wrap some teflon tape arond the thread

of the shaft to protect the seal and O-ring

from damages. Apply some red grease

(146-01) to the tape and the shaft end.

Mount the seal head and the O-ring.

10

10

11

11

X-ring

O-ring

Tool 0715-01

Piston holder

Topout spring

Sleeve

Spacer

11.

Use a brass wire brush to clean the piston

rod from tape. Mount Spacer, Sleeve, Topout spring and the Piston holder.

12.

Tighten the Piston holder to a torque of 15

Nm.

13.

Refit the Compression/Rebound valve. Use

the picture below to make it right. Tighten

the 8 mm nut with a torque of 7 Nm.

LEG (RH)

REBOUND

CAUTION!

1675-01, Nut

CAUTION!

LEG (LH)

COMPRESSION

2061-03, Piston

Shim stack

(rebound)

641-02, Washer

1675-01, Nut

1674-01, Washer

153-01, Washer

14

641-02, Washer

1674-01 4x,

Washer

Shim Stack

1447-02,

Piston ring

12

Shim stack

(rebound)

1618-01, Holder

(compression)

641-02, Washer

15 Nm

1447-02,

Pison ring

2061-03, Piston

530-22, Shims

520-20, Shims

1149-01, Wave

Shim stack

(compression)

641-02, Washer

1618-02, Cup

NOTE!

13

8 mm Nut (7 Nm)

1654-06,

1654-06,

338-19, O-ring

Piston holder

Piston holder

Page 15

CAUTION!

The Washers must be positioned correctly

(Notice that there is a difference between

the compression and the rebound valve).

Also make sure to fi t the Wave washer

(1149-01) in the correct position (convex

side facing piston).

NOTE!

The right hand fork leg is the rebound leg.

The left hand fork leg is the compression

leg.

14.

Fit the Seal head tool and the Top-out

spring tool on the piston rod. Pull the Topout spring tool and, at the same time, push

the Seal head tool to contract the Top out

spring. Install tool 2810-01 on tool 176503 to keep the contraction. Assemble the

complete piston rod into the cartridge tube

and tight it by hand (3-4 turns).

NOTE!

Make sure that the gas piston is pressed

down completely

NOTE!

14

15

Tool 1765-03

Tool 2810-01

Tool 1797-04

20 Nm

16

Tool 720-03

15.

Tighten the Seal head to 20 Nm. Use Seal

head tool (1797-04 and 1765-03).

16.

Check the O-ring on the reservoir cap

assy. Replace if necessary. Apply some red

grease on the O-ring and push the reservoir cap assy into the chamber using tool

720-03.

17.

Fit the circlip. Make certain that it enters its

groove properly.

18.

Once again contract the top out spring

using tool 2810-01, tool 1765-03 and tool

1797-04

NOTE!

Nitrogen (N2) gas. Use pressure gauge

(1781-01)

17

18

15

Page 16

! WARNING!

!

Use of infl ammable gas for pressurising

the soch absorber can be hazardous. Use

nitrogen gas (N2) only!

WARNING!

19

20

19.

Check the gas pressure stipulated in the

spec. card. Dip the needle of the gas tool

(1781-01) in red grease and insert the needle through the gas filler valve.

Charge with gas to the correct pressure,

according to the spec. card.

NOTE!

Ensure that there is no leakage of gas or

fl uid.

20.

Screw the gas filler screw with O-ring.

Remove tool 2810-01 and tool 1797-04 to

release the top-out spring.

21.

Push tool 1765-03 to a stop and check the

oil level according to page 17.

NOTE!

Use Öhlins Front fork oil 1305-01 only.

22.

Refit the Pre-load tube. Install the spring

and refit the adjustment driver.

NOTE!

21

3 Nm

22

Tool 1765-03

1305-01

Check the oil level

23

Refit the top nut assembly to the piston

shaft. Tighten the jam nut to 20 Nm.

24.

Refit the top nut into the fork leg (use tool

797-01). Adjust the preload, compression

and rebound.

CAUTION!

The top nut should only be tightened by

hand into the fork leg. The tightening force

of the triple clamp will hold it in locked

position.

16

23

20 Nm

CAUTION!

24

Tool 797-01

Page 17

Oil level adjustment

Compared with conventional type of front

forks, the upside down front forks are very

sensitive to variations in oil level. Therefore,

adjust the oil level with special care.

A change in the fork oil level will not affect

the spring force at the beginning of the fork

travel, but will have a great effect at the

end of the travel.

When the oil level is raised:

The air spring in the later half stage of

travel is stronger, and make the front forks

more progressive.

When the oil level is lowered:

The air spring of the travel is lessened, and

thus the front fork less progressive. The

oil level works most efficient at the end of

the fork travel. Air spring characteristics

shown, is a general card description to understand the difference when the oil level is

changed.

NOTE!

Adjust the oil level in mm according to the

fi gure with the fork leg fully compressed.

For the right oil-level, please see the specifi cation card.

Air spring characteristics

Air inside the front fork works as a spring.

The graph at the bottom of the page shows

the spring force related to stroke when the

oil level is changed between 140 mm and

200 mm. Standard oil level is 180 mm.

Öhlins front fork fl uid 1305-01

Push to a stop,

use tool 1765-03

Check the oil level

17

Page 18

Troubleshooting

Below are a few examples of how to adjust

for the most common road holding problems in Road Racing driving.

1.

The front wheel “chatters” entering a

corner, the problem goes away, as soon as

you let the brakes off, or when you get on

the power.

• This is caused by the fact that the fork is working

too low in the travel and reaches the progressive,

hard part at the end of the travel.

• Put on more pre-load.

• Change to a harder spring.

• If a lot of stroke remains after riding, drop the oil

level. See oil level chart.

• Make sure the front forks have no friction.

• Rear ride height is to high, too much rear spring

pre-load.

• Lower the rear end by taking off pre-loadfrom rear

shock spring.

2.

The front wheel is jumping during the last

part of braking.

• If a lot of stroke remains, the oil level is too high.

Lower the oil level.

• If the fork is bottoming, put in harder springs and

keep the oil level.

4.

The front end loses grip coming out of a

corner.

• Not enough rebound damping. Put on some more

rebound damping.

• Too much pre-load. Take off some pre-load.

• Rear end is too soft. Put on a harder rear spring.

• Front end is too high. Lower the front end by

pulling the fork legs through the triple clamps.

As mentioned in the beginning, the whole

bike setup affects the front forks. Try to

understand the feelings and work step by

step.

NOTE!

Our advice is to change only one thing at a

time and do everything step by step.

1

3.

The front end feels unpredictable and unsafe in the middle of the corner (between

braking and getting on power).

• Not enough rebound damping. Put on more

damping.

• Too much rebound damping. If it at the same time

feels harsh, take off some rebound damping.

• Too much compression damping. Also gives a

harsh feeling. Take off some compression

damping.

18

4

Page 19

Technical information

Fork length: 730 mm.

Stroke: 130 mm.

Free spring length: 260 mm.

Rebound adjustment:

Base setting 9-12 “clicks”.

Maximum open valve 20 “clicks”.

Compression adjustment:

Base setting 6-16 “clicks”.

Maximum open valve 20 “clicks”.

Compression adjustment (Base valve):

Base setting 6-16 “clicks”.

Maximum open valve 20 “clicks”.

Spring pre-load adjustment:

0-18 mm (0-18 turns).

Spring rate:

4744-95 9.5 N/mm (marking -95).

Optional springs supplied:

4744-10 10.0 N/mm (marking -10)

4744-90 9.0 N/mm (marking -90)

Optional springs:

4744-85 8.5 N/mm (marking -85)

4744-80 8.0 N/mm (marking -80)

Oil Capacity:

Please see specification card.

Use Öhlins high performance front fork

fluid No. 5 (1305-01) only.

Tighten torque, Loctite and Grease:

O-ring, No grease

Adjustment housing, By hand only

Upper bushing

Loctite 601

X-ring

White grease

Attach piston holder to rod

before assemble piston details!

Lower bushing

No loctite

Rod extensioner/bolt spring adjuster, 20 Nm

Piston shaft/rod extensioner, 15 Nm

Loctite 270

Piston rod/piston shaft, 15 Nm

Loctite 270

Seal head, 20 Nm

Screw, 3 Nm

Loctite 222

Nut, 7 Nm

Red grease on all other o-rings!

Reservoir tube, 45 Nm

Red grease

Tighten torque:

Lower triple clamp bolt 12-15 Nm.

Upper triple clamp bolt 18-22 Nm

Grease:

Öhlins front fork grease 146-01

(red grease).

Service interval:

Every 10 hours

Loctite 648

Fork leg, 140 Nm

Loctite 542

Screw, 3 Nm

Both fill-up points

Cylinder tube, 80 Nm

Base valve, 45 Nm

Inside of reservoir tube

White grease, thin film

Nut, 7 Nm

Loctite 222

19

Page 20

Spare parts list, FG 470

20

1

2

12

13

Pos. Part No. Pcs. Description Type/remarks

1 - 2 Top nut assembly See page 21

2 01408-04 2 Adjustment driver

3 04744-95

04744-10

04744-90

2

Spring

2

Option spring

2

Option spring

25.5/260/9.5

25.5/260/10.0

25.5/260/9.0

4 01438-04 4 Guide ring

5 01460-37 2 Preload tube

3

14

6 01900-05 2 Fork leg outer

7 01683-02 2 Bushing, upper

8 01684-02 2 Bushing, lower

9 04758-01 2 Washer

4

15

16

10 04720-02 2 Seal

11 04759-01 2 Circlip

12 02807-01 2 Adjustment rod

13 01901-03 2 Rod extensioner

5

4

6

17

18

19

20

21

22

23

24

25

26

14 02302-08 2 Guide sleeve

30

15 01499-01 2 Circlip

16 01440-01 2 Bump rubber

17 01651-04 2 Seal head

18 01027-04 2 X-ring

19 00438-02 2 O-ring

20 01056-04 2 Bushing

21 00438-41 2 O-ring

22 02803-01 2 Spacer

23 01653-05 2 Sleeve

24 01585-11 2 Topout spring

31

25 01698-30 2 Rebound needle

26 00338-14 2 O-ring

27 02367-06 2 Shaft

28 - 1 Compression valve (LH) See page 22

29 - 1 Rebound valve (RH) See page 22

27

7

8

9

10

11

37

39

41

40

42

46

2928

57

56

55

54

53

52

34

35

36

38

43

51

50

49

45

48

47

44

30 01656-02 2 Cylinder tube

31 01699-02 2 Fork leg inner

32 01565-04 2 Stroke indicator

33 00338-63 2 O-ring

32

34 00194-10 2 Sticker “Öhlins”

33

35 04759-02 2 Circlip

36 01682-28 2 Fender bracket ring

37 01678-14 2 Fender bracket

38 00382-08 2 Screw

39 01902-09

01902-1011

Fork bottom

Fork bottom

40 01050-01 2 Screw

41 00338-59 2 O-ring

42 01240-08 4 Bolt Titan

43 00438-33 2 O-ring

44 00382-07 2 Screw

45 05426-02 2 Plug Koenig

46 - 2 Base valve See page 21

47 00338-72 2 O-ring

48 02804-01 2 Reservoir tube

49 00338-25 2 O-ring

50 01447-02 2 Piston ring

51 02806-01 2 Gas piston

52 00604-01 2 Rubber valve

53 00338-25 2 O-ring

54 02805-01 2 Reservoir end

55 00338-59 2 O-ring

56 01050-01 2 Screw

57 01152-01 2 Circlip

Left

Right

Page 21

Top nut assey

1

2

3

4

3

5

6

7

Spare parts list, Top nut assey

Pos. Part No. Pcs. Description Type/remarks

1 04747-02 2 Cap

2 04756-01 2 Adjuster

3 00884-04 4 Ball

4 04727-01 2 Spring

5 04722-07 2 O-ring

6 04748-01 2 Bolt spring adjuster

7 04722-04 2 O-ring

8 04749-02 2 Plate, center

9 02801-01 2 Adjustment housing

10 00338-61 2 O-ring

11 04751-02 2 Washer

12 04752-01 2 Washer

13 04753-01 2 Washer

14 04762-03 2 Spring seat

8

9

Base valve

15

16

17

Spare parts list, Base valve

Pos. Part No. Pcs. Description Type/remarks

15 01675-01 2 Nut

16 00153-01 2 Washer

17 00641-02 2 Washer

18 - - Shim stack See spec. card

19 01670-01 2 Piston compression

20 00338-11 2 O-ring

18

21 00530-22 2 Shims

22 01693-01 2 Spring

23 01669-01 2 Sleeve

10

19

24 01672-01 2 Spring collar

25 01658-01 2 End piece

26 00438-02 2 O-ring

11

12

13

14

20

21

22

23

24

25

26

27

28

29

28

30

31

27 01242-03 2 Adjustment needle

28 00884-02 4 Ball

29 01474-01 2 Spring

30 00338-53 2 O-ring

31 01473-02 2 Circlip

21

Page 22

Compression valve

1

2

3

Rebound valve

Spare parts list, Compression valve (LH)

Pos. Part No. Pcs. Description Type/remarks

1 01654-06 1 Piston holder

2 00338-19 1 O-ring

3 01618-02 1 One way valve cup

4 00530-22 1 Shims

5 01149-01 1 Wave washer

6 00520-20 1 Shims

7 01618-01 1 Cup holder

8 00641-02 1 Washer

9 - - Shim stack (comp.) See spec. card

10 01447-02 1 Piston ring

11 02061-03 1 Piston rebound

12 - - Shim stack (reb.) See spec. card

13 00641-02 1 Washer

14 01674-01 1 Washer

15 00153-01 1 Washer

16 01675-01 1 Nut

4

17

Spare parts list, Rebound valve (RH)

5

6

7

8

9

10

11

12

13

14

15

18

19

20

21

22

23

24

24

24

24

Pos. Part No. Pcs. Description Type/remarks

17 01654-06 1 Piston holder

18 00641-02 1 Washer

19 - - Shim stack (comp.) See spec. card

20 01447-02 1 Piston ring

21 02061-03 1 Piston rebound

22 - - Shim stack (reb.) See spec. card

23 00641-02 1 Washer

24 01674-01 4 Washer

25 01675-01 1 Nut

22

16

25

Page 23

Service tools

1

4

10

2

5

11

12

16

Pos. Part No. Pcs. Description

1 00727-02 1 Soft jaws (one pair)

3

2 00786-05 1 Inner tube tool

3 00786-07 1 Cartridge tube tool

4 01781-01 1 Gas tool

5 00797-01 1 Top nut socket

6 01757-01 1 Attachment bar

7 01759-07 1 Dismantling bar

6-9

8 01759-08 1 Installing sleeve

9 01758-04 1 Guide ring

10 00720-02 1 Measure pin

14

11 00720-03 1 Pin tool

12 04705-01 1 Spanner

13 01765-03 1 Pull-up spring tool

14 01797-04 1 Seal head tool

15 02810-01 1 Pull-up spring tool holder

16 00715-01 1 Screwdriver

13

15

23

Page 24

More info

www.ohlins.com

Öhlins Racing AB, Box 722, S-194 27 Upplands Väsby, Sweden

Phone +46 8 590 025 00, Fax +46 8 590 025 80

07280-10, Issued 06 07 26. Öhlins Racing AB, Mattias Johansson, majo/ Update: Tiina Harakka

Loading...

Loading...