Page 1

Owners manual

Öhlins motocross front forks FG 012 GasGas

Including:

Setting up

your bike

Fine-tuning

Service

the fork

General

handling set-up

Technical info

Spare parts

& tools

1

Page 2

Safety signals

Important information concerning

safety is distinguished in this

manual by the following notations:

The Safety alert symbol means:

Caution! Your safety is involved.

WARNING!

Failure to follow warning instructions could result in severe or

fatal injury to anyone working

with, inspecting or using the suspension, or to bystanders.

CAUTION!

Caution indicates that special

precautions must be taken to

avoid damage to the suspension.

NOTE!

This indicates information that is

of importance with regard to procedures.

Öhlins motocross

front fork FG 012 GasGas

Before installation

Öhlins Racing AB can not be held

responsible for any damage whatsoever to shock absorber or vehicle,

or injury to persons, if the instructions for fitting and maintenance are

not followed exactly.

Similarly, the warranty will become

null and void if the instructions are

not adhered to.

WARNING!

1. Installing a front fork, that is not

approved by the vehicle manufacturer, may affect the stability of your

vehicle. Öhlins Racing AB cannot

be held responsible for any personal injury or damage whatsoever

that may occur after fitting the front

fork. Contact an Öhlins dealer or

other qualified person for advice.

2. Please study and make certain

that you fully understand all the

mounting instructions and the owners manuals before handling this

front fork kit. If you have any questions regarding proper installation

procedures, contact an Öhlins

dealer or other qualified person.

3. The vehicle service manual must

be referred to when installing the

Öhlins front fork.

Contents

Safety signals ............................. 2

Introduction................................ 3

Design ....................................... 3

Before you start ......................... 3

Marking...................................... 3

Recommended settings ............. 3

Mounting instructions ................. 4

Setting up the bike ..................... 4

Checking front sag ..................... 4

Checking rear sag ...................... 4

Checking front ride height .......... 5

Checking rear ride height ........... 5

Fine-tuning the bike ................... 5

Making adjustments ................... 6

Oil level adjustment .................... 6

Maintenance .............................. 6

General handling set-up ............. 7

Preload adjustment .................... 8

Changing springs ....................... 9

Dismantling the front fork ......... 10

Assembly of the front fork ........ 11

Service tools ............................ 13

Technical specifications ............ 13

Spare parts .............................. 14

© Öhlins Racing AB.

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Öhlins Racing AB is prohibited.

Printed in Sweden.

Öhlins products are subject to continual improvement and development. Consequently, although these

instructions include the most up-todate information available at the time

of printing, there may be minor differences between your suspension

and this manual. Please consult your

Öhlins dealer if you have any

questions with regard to the contents

of the manual.

NOTE!

During storage and transportation,

especially at high ambient temperature, the oil and grease used for

assembling may run out inside the

packing and damage the expanded

polystyrene packing material. This is

not unusual and is in no way detrimental to the shock absorber.

2

Page 3

Introduction

Öhlins Racing congratulates you on

your choice of front fork for your motocross bike.

All Öhlins products are designed

with just one aim; to win races. To

design a winner you need a concept

starting with a unique know-how.

You add engineering skill, precision

and the best material available. The

result is quality, endurance and winning performance.

Your new Öhlins front fork is developed from experience gained during

years of successful cooperation with

the World Championship winning

works motocross teams.

Spring rates and damping forces

are developed just for your bike. The

design and the settings are consequently the results of extensive testing and no guesswork!

Öhlins shock absorbers and front

forks have dominated the motorcycle scene for several years and have

captured more World Championship

titles than any other brand, over 80

titles!

A well equipped network of authorised Öhlins service centres around

the world, with specially trained mechanics, can help you with personally tuned settings, service, repairs

and spare parts.

Design

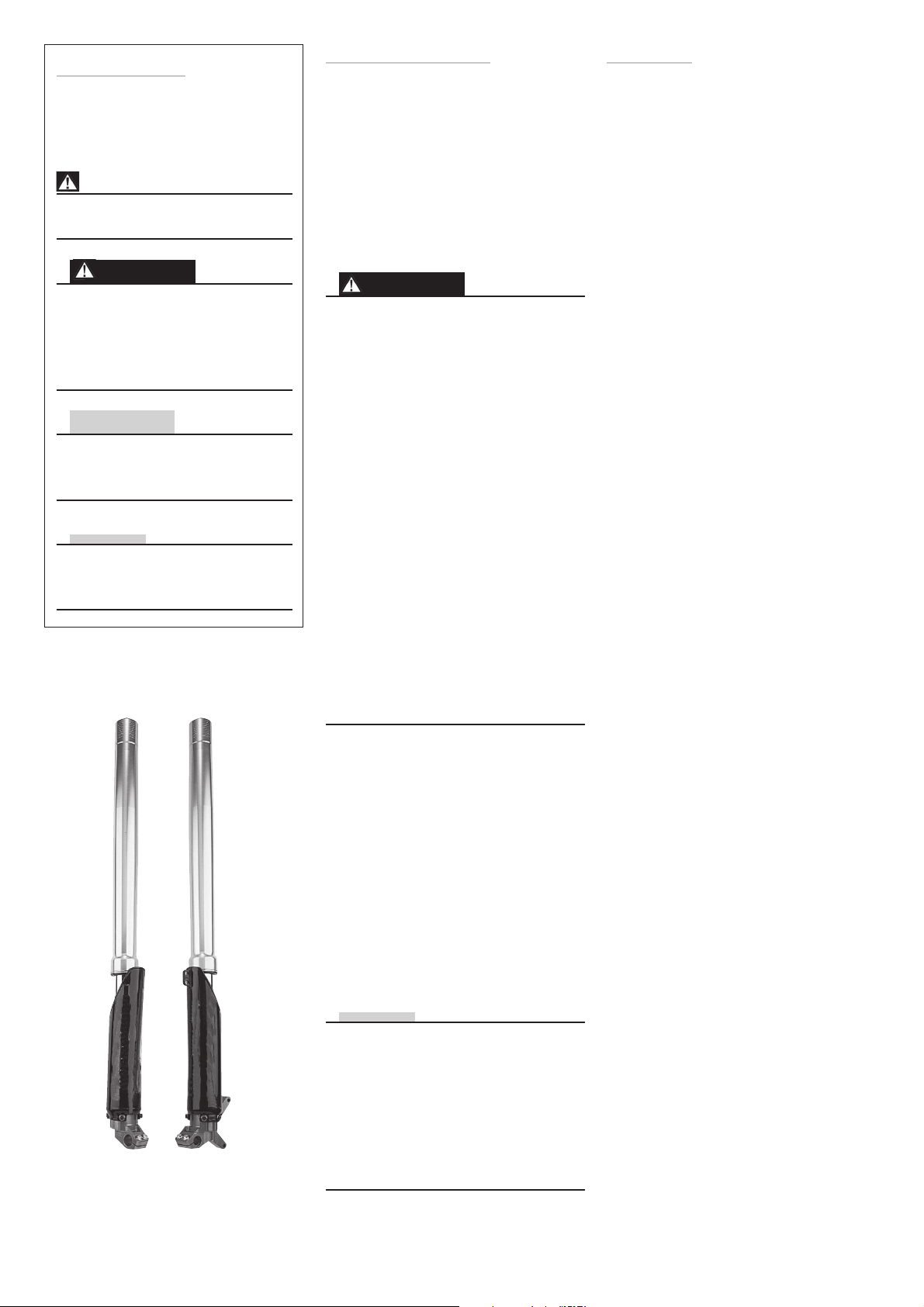

Öhlins new up-side-down (USD)

front fork is designed to combine the

advantages of comfortable, safe

conventional forks and rigid, light

USD forks. The result is a unique

combination of being rigid, precise

in corners and during hard braking

yet comfortable, forgiving when

“over-landing“ and in big bumps.

Your new Öhlins USD front fork has

aluminium outer legs and 46 mm

steel inner legs, with a polished surface for lowest possible friction.

The legs also feature a completely

new bushing design with fixed and

one sliding bushing.

The new USD fork features the

Öhlins championship winning cartridge damping system.

The fork is fully adjustable with

external adjuster for compressionand rebound damping.

The compression adjuster is lo-

cated at the bottom of the fork leg,

fig 1, the rebound adjuster at the top,

fig 2.

Spring preload is adjusted with

washers, fig 3, and optional springs

are available to suit different tracks

and riders.

In the legs there are also “airsprings“ (the air trapped above the

oil) that work together with the “real“

spring. You adjust the air-spring by

raising or lowering the oil level in the

legs.

By using different combinations of

springs and air-springs you can alter the characteristic of the fork. For

example, a soft spring in combination with a small air-spring (high oil

level) makes the fork progressive,

see “Fine-tuning the bike“.

Marking

All Öhlins front forks are marked. You

will find the part number on the inside of the fork bottom.

Your Öhlins front fork has the following marking:

FG 012 GasGas

Recommended settings

The front fork in your kit is adjusted

to the Öhlins recommended setting

for your bike, see “Making adjustments“. We advise you to use this

as your start setting.

Mounting instructions

WARNING

1. It is advisable to have an Öhlins

dealer or a qualified mechanic to

fit your front fork kit.

2. To install the kit you need your

motorcycle’s work shop manual.

3. When working on your motorcycle, support it securely so it does

not fall over.

The Öhlins front fork is designed to

fit your bike’s standard triple clamps

and to use the standard brake components and wheel.

A

Put your bike on a stand and remove

the front wheel, the front brake components and the fork legs from the

bike according to the work shop

manual.

CAUTION!

1. The outer legs, both left and right,

should be adjusted evenly in the

fork crown.

2. The Öhlins fork legs feature

grooves on top of the outer fork legs

to make adjustment of the fork

height easier. The distance between

the grooves is 4 mm.

B

Fit the Öhlins front fork legs. For recommended front fork mounting

height see mounting instruction.

C

Fit the brake components and the

front wheel according to the work

shop manual.

D

Tighten all screws. For maximum

torque, please see your bike’s work

shop manual.

3

Page 4

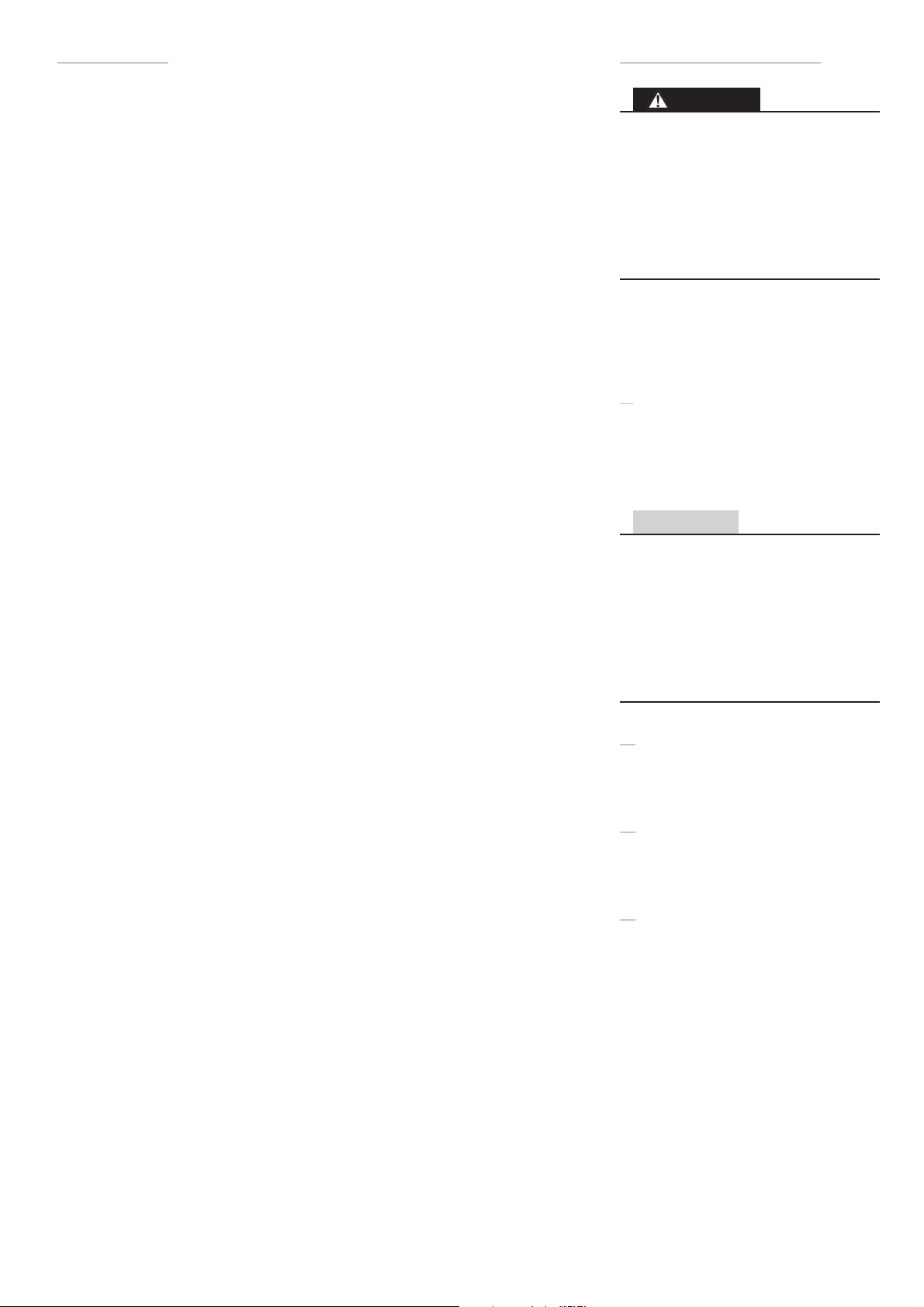

Compression adjuster

1.

The compression adjuster is located at the bottom of the fork leg.

Rebound adjuster

2.

The rebound adjuster at the top of

the fork leg.

Preload adjustment

3.

Spring preload is adjusted with

washers and optional springs are

available.

Setting up the bike

We would like to give you some basic guidelines how to set up your bike

with your new Öhlins front fork.

However, remember that the front

fork is just one part of your motorcycle and to get the fork to work properly the whole motorcycle has to be

set up according to standards.

Please follow the instructions below,

see also your bike’s work shop

manual.

Your new front fork is dialled-in to

the Öhlins recommended settings for

your bike. The same goes for the rear

shock absorber if you are using an

Öhlins unit.

All settings are based on a bike and

a rider of normal weight.

Depending on your own and your

bike’s actual weight minor differences, between the Öhlins recommended settings and the settings

you achieve, may occur. Therefore,

it is always wise to start the setting

up by checking!

The sag effects not just only the suspension but also the rake of the front

fork and therefore the overall behaviour of the bike.

Checking front static sag

A

Put your bike on a stand.

Arrange the stand so that the front

wheel is off the ground and the front

fork fully extended.

B

Measure the distance between the

upper fork crown and the front wheel

axle, fig 4 distance A. Make a note of

the measurement.

C

Remove the stand. With the wheels

on the ground measure the distance

again, fig 4 distance B.

The difference of the two measurements is the static sag.

D

The static sag should be 30 ± 10 mm.

E

If the static sag is less than 20 mm,

you need to reduce spring preload.

If the static sag is more than 40 mm,

you need to increase spring preload.

F

Spring preload is adjusted with spacers,

see “Preload adjustment“ on page 8.

Maximum allowed spring preload is

13 mm.

If you need to preload the springs more

than 13 mm, we recommend you to

change to a “stiffer“ spring.

Checking rear static sag

A

Put your bike on a stand. Arrange the

stand so that the rear wheel is off the

ground and the rear suspension fully

extended.

B

Measure the distance between the

rear wheel axle and a point near the

rear end of the seat, for example a

seat bolt, fig 4 distance A.

Make a note of the measurement.

C

Remove the stand. With the wheels

on the ground measure the distance

again, fig 4 distance B.

The difference of the two measurements is the static sag.

NOTE!

Refer to mounting instruction for

more specific set-up data.

D

The static sag should be 45 ±10 mm.

E

If the static sag is less than 35 mm,

you need to reduce spring preload.

If the static sag is more than 55 mm,

you need to increase spring preload.

F

Adjust the spring preload according to

your rear shock mounting instruction.

4

Page 5

Setting up the bike

4.

Checking sag and ride height.

Front sag:

A - B = 30 ± 10 mm.

Front ride height:

A - C = 50 ± 10 mm.

Rear sag:

A - B = 35 ±10 mm.

Rear ride height:

A - C = 100 ± 10 mm.

A: Fully extended.

B: On the ground.

C: Rider on.

A: Fully extended.

B: On the ground.

C: Rider on.

Checking front ride height

A

Put your bike on a stand.

Arrange the stand so that the front wheel

is off the ground and the front fork fully

extended.

Measure the distance between the upper fork crown and the front wheel axle,

fig 4 distance A. Make a note of the

measurement.

B

Race dressed sit on the bike, straight

above the foot pegs, with the feet barely

touching the ground.

Have somebody to measure between

the same point as before, fig 4 distance

C.

C

The difference of the two measurements

should be 50 ± 10 mm.

CAUTION!

Do not try to alter ride height by altering the spring preload. New springs

are needed.

D

If you need to change the springs, see

“Changing springs“ on page 9.

E

Stiffer springs are needed if the difference is more than 60 mm.

Softer springs if the difference is less

than 40 mm.

Consult your Öhlins dealer for the right

rate.

Checking rear ride height

A

Put your bike on a stand. Arrange the

stand so that the rear wheel is off the

ground and the rear suspension fully

extended.

Measure the distance between the rear

wheel axle and a point near the rear end

of the seat, for example a seat bolt, fig 4

distance A.

Make a note of the measurement.

B

Race dressed sit on the bike, straight

above the foot pegs, with the feet barely

touching the ground. Have somebody

to measure between the same point as

before, fig 4 distance C.

C

The difference of the two measurements

should be 115 ± 10 mm.

CAUTION!

Do not try to alter ride height by altering the spring preload. A new spring

is needed.

D

A stiffer spring is needed if the difference is more than 110 mm.

A softer spring if the difference is less

than 90 mm.

Consult your Öhlins dealer for a spring

of the right rate.

Should you still experience excessive

bottoming or that the bike feels much

to stiff and suspension travel is not fully

used, harder/softer than normal springs

may be needed for the track you are

testing on.

Consult your Öhlins dealer for advice!

Fine-tuning the bike

Learning how to use the adjusters will

take time but you quickly appreciate

them once you know the tricks. Even

the specialists sometimes need a

specialist!

With the adjusters you optimize the

suspension for your riding style and the

track you are competing on.

The same basic guide lines goes for

both the front fork and the rear shock

absorber.

Too much compression damping will

give you a harsh ride as your bike

“jumps“ along the track.

With too much rebound damping your

bike will have difficulties with several

bumps in a row. The suspension will not

extend fast enough between bumps,

your bike will ride lower and lower and

eventually the suspension will bottom!

External adjusters

On the Öhlins front fork the adjusters

are bleed valves, totally separated from

each other.

The compression bleed valve controls

the flow in the cartridge tube during the

compression stroke, the rebound bleed

valve the flow during the rebound stroke.

CAUTION!

Using too much force when closing

the adjusters will destroy important

sealing surfaces.

Both the adjusters have a normal righthand thread.

Click position zero (0) is when the adjusters are turned clockwise to fully

closed.

The adjustment range, from fully

closed until maximum open valve

(anticlockwise), is 20 clicks.

In order not to click in the wrong direction; always first close the adjuster,

then dial-in the new setting.

5

Page 6

Air spring

5.

A change in oil

level will effect

the damping

forces, not in

the early stage

of fork travel

but a great deal

in the later

stage.

Oil level 100 mm Oil level 110 mm Oil level 120 mm Oil level 130 mm

500

450

400

350

F

o

300

r

c

250

e

Force

200

k

g

150

f

100

50

0

0

20 40 60 80 100 120

Stroke

Stroke mm

Oil level

6.

Oil level is

measured from

the top of the

outer leg, with

the top nut

off,the fork fully

compressed

and no preload

washer nor

spring installed.

Oil level

Making adjustments

To make improvements using the

adjusters, it is important to understand the function of the front fork

and the shock absorber and through

testing learn how they effect the handling of your bike.

Make sure that you have the correct springs and the correct spring

preload before making any adjustments. And always start with the

Öhlins recommended settings:

NOTE!

See mounting instruction for recommended settings.

NOTE!

Higher click numbers give less

damping force.

When making adjustments; keep

notes, make adjustments one at a

time... and in small steps.

The adjusters should normally not

be adjusted in steps of more than 2

clicks at a time and not outside the

usable click range.

When you think you have made an

improvement, go back to what you

started with and double check to be

sure. Pay attention to changes in conditions like tires, temperatures etc.

In general, compression damping

changes should be used to influence

the bike’s stability and response,

while rebound damping changes

should be used to influence comfort

and traction.

6

When you need more damping

force, you should mainly try to increase compression damping and

use as little rebound damping as possible.

This usually means that you gain

comfort and performance in handling.

Oil level adjustment

As the air trapped between the oil and

the top nut acts as an air-spring, a

change in oil level will effect the

damping forces. Not in the early

stage of fork travel, but a great deal

in the later stage.

A general description of how the oil

level/air-spring effects the damping

forces are shown in fig 5.

The air-spring gives the Öhlins USD

fork a progressive spring rate, preventing it from bottoming out hard.

By using different combinations of

springs and oil levels/air-springs you

can alter the characteristic of the fork

and tailor it to suit different tracks and

conditions.

CAUTION!

The oil level must be the same in

both front fork legs.

Riding a bike with different oil levels will cause instability.

When the oil level is raised:

The air-spring in the later half of travel

is strong, and thus the front fork hard.

When the oil level is lowered:

The air-spring in the later half of travel

is soft, and thus the front fork soft.

CAUTION!

Adjust the oil level with the fork leg

fully compressed and no preload

washer nor spring installed.

NOTE!

See mounting instruction for recommended oil level.

The oil level is measured from the

top of the outer leg, with the top nut

off, see fig 6.

A change in oil level should be made

in small steps. We recommend a

change of 5 mm at a time and not

outside the range of 90-130 mm.

Maintenance

Telescopic front forks depend on a

smooth, friction free action.

Make sure your forks are regularly

serviced.

Do not use strong solvents, such

as brake cleaner, to clean the front

forks. This will dry out the seals and

the steel tubes and cause friction or

leakage.

After every race:

Clean externally and spray with an

all-purpose oil after washing with

detergent.

Check externally for damage.

Put a little Öhlins green grease (148-

01) on the steel tubes and work it in

by pushing the fork up and down.

Every 20 hours:

Dismantle the fork and check all

parts for wear and damage, replace

if necessary, see page 10.

Page 7

General handling set-up

A

Front end falls into the curves (oversteering) especially in sand.

Steep front fork angle. Front end too

low in comparison to rear end.

Increas the front fork

compression damping.

Change to harder springs.

Lower fork leg approximately

5 mm in the triple clamp.

B

Front end ”ploughs”, understeers.

Shallow front fork angle. Front end too

high in comparison to rear end.

Decrease the front fork

compression damping.

Raise the fork legs approximately

5 mm in the triple clamp.

Change to softer fork springs.

C

Front end unstable at high speed, unstable when accelerating out of curves.

Front fork angle too steep. Front end

too low in comparison to rear end.

Lower the fork legs approximately

5 mm in triple clamp.

Change the front fork springs to

harder ones.

D

Front end unstable during deceleration.

Front fork angle too steep during

braking. Front end too low or rear end

too high.

Increase the oil level in the

front fork.

Change to harder fork springs.

Increase the front fork

compression damping.

Front suspension.

A

Front fork travel is not used to its full

capacity. Harsh feeling, front wheel grip

is not satisfactory in bumpy turns.

Suspension too hard.

Decrease the front fork

compression damping.

Change to softer springs.

B

Suspension bottoming, too soft during

entire travel.

Spring too weak or compression

damping too soft.

Increase oil level 5 mm.

Increase compression damping.

Change to stiffer springs.

C

Suspension bottoming, but can handle

smaller bumps.

Damping force not progressive enough.

Increase the oil level.

D

Can handle smaller bumps but is too

hard during the last part of the travel.

Damping force is too progressive.

Decrease the oil level.

E

Front end feels low, initially feels soft,

but is not bottoming.

The initial spring rate is too soft or spring

preload is too low.

Increase the spring preload.

E

Feels harsh over small bumps, but using

full wheel travel.

Too much spring preload or too much

compression damping.

Increase the oil level or change

to softer springs.

Decrease the compression

damping.

Decrease the spring preload.

Clean the oil seals and scrapers.

Use Öhlins grease 148-01 for

regreasing.

F

Can handle the first in a series of bumps

but feels hard after a few more bumps.

Frontal grip insufficient in rough and

bumpy turns.

Too much rebound damping.

Decrease the rebound damping.

G

Front end rebound too fast after a bump.

Front wheel grip insufficient in bumpy

curves.

Not enough rebound damping, or too

much spring preload

Increase the rebound damping.

Decrease the spring preload.

Rear suspension.

A

Rear suspension stroke is not used to

its capacity. Suspension feels harsh.

Traction not satisfactory in bumpy

curves.

Suspension hard in general or too much

compression damping, too much spring

pre-load.

Decrease the compression

damping.

Decrease the spring preload.

Change to softer spring.

B

Suspension is bottoming, feels soft during the entire wheel travel.

Spring too soft, compression damping

too low.

Increase the compression

damping.

Change to harder spring.

C

Suspension is bottoming, feels harsh

and sags down too much with the rider

in the saddle.

Spring too soft or compression

damping too low.

Increase the spring preload,

check ride height. 95 +- 5 mm.

Change to harder spring if the

load is more than 100 mm.

Increase compression damping.

D

Rear wheel jumps over small bumps

during deceleration or when going

downhill. Traction not satisfactory in

washboard curves.

Too much spring preload, as the spring

is probably too soft, will cause the spring

to extend too fast.

Change to a harder spring in order

to achieve a balanced position

using less spring preoad.

Check the static sag and ride height.

E

Rear end kicks up over bumps with

sharp edges, but can handle bumps

with round edges.

Compression damping too hard.

Decrease the compression

damping.

F

Rear end becomes too low in series of

bumps. Traction not satisfactory in

washboard type curves or when

decelerating on washboard ground.

Rebound damping too slow.

Decrease the rebound damping.

G

Rear end very unstable. Shock does not

respond to adjustments.

Shock damping is gone, caused of low

gas pressure, bad oil is used, or

components are broken in the shock

absorber. Service is needed.

Gas filling required.

Change shock oil.

Repair or change the

shock absorber.

7

Page 8

1

Preload adjustment

4

1

Put the bike on a stand and loosen

the screws in the fork top crown that

hold the fork legs.

NOTE!

On most MX-bikes you have to take

of the handle bar before you can

unscrew the top cap.

Unscrew the top cap, use a

24 mm wrench.

2

3

2

Put a box under the front wheel so

that the springs are visible.

Remove the top cap from the

damper rod extender.

Use a 16 and 24 mm wrench.

Remove the spring support.

3

Install a new preload spacer to

achieve the right static sag.

Fit the spring support, top cap and

the handle bar.

Tighten all screws.

For tightening torques, please see

your bike's work shop manual.

5

6

8

Page 9

Changing springs

4

Loosen the screws that hold the fork

legs in the upper fork crown.

With the fork leg still tightened in

the lower fork crown unscrew the top

cap, use a 24 mm wrench.

Loosen the screws that hold the

fork legs in the lower fork crown.

Remove the fork legs from the

motorcycle.

7

7

NOTE!

Closing the compression- and the

rebound valves will keep the

damper rod extended making it

easier to install the new spring.

Pull out the damper rod as far as

possible.

Close the compression and the

rebound valve (clockwise).

5

Fasten the fork leg with soft jaws in

a vice and loosen the lock nut on the

top of the fork cap.

6

Remove the top cap from the

damper rod extender, use a 16 and

24 mm wrench.

Remove the spring support, the

preload washer and the spring.

For free spring length see technical

information on page 13.

8

9

8

Install the spring and the

preloadwasher.

9

Install the spring support fork top cap

and the lock nut.

Tighten the top cap and the lock

nut against each other, use a 16 and

24 mm wrench.

Adjust the compression- and the

rebound valves according to

specification card.

Fit the fork legs on the motorcycle.

For tightening torques, please see

your bike's work shop manual.

9

Page 10

1797-01

10

Dismantling

10

Perform steps 4-7 "Changing

springs" on page 9.

Loosen the bush head, on top of the

cartridge tube, with tool 1797-01.

Lift up the damper rod assembly

and drain the oil.

Pull up the scraper with a screw-

driver, release and remove the circlip.

13

15o mm

1702-02

11

12

11

CAUTION!

The fork legs have two fixed and

one sliding bushing. Be very careful when disassembling the fork

legs.

Fasten the fork leg horizontally with

soft jaws in a vice.

Use a hot air gun to warm up the

outer leg where the bushings are

located.

The first bushings is located at the

bottom end of the outer leg, the second approximately 150 mm further

up the leg.

Between them is a sleeve to maintain the distance.

12

Use the special tool 1702-02 to

remove the bushings.

Install the tool in the top of the in-

ner steel leg.

Screw the top cap onto the tool and

install the cap in the outer leg.

Rotate the tool to press out the

bushings.

If tool 1702-02 not is avaliable push

the inner steel leg to the bottom and

then pull it back quickly, so that the

fork is topping out hard.

Repeat this procedure until the seal

and the bushings can be pulled out

from the outer leg.

14

15

10

Page 11

13

Remove the seals and bushings and

check them for wear and damage.

Replace if necessary.

CAUTION!

When removing the oil seal and

bushings use a small plastic bag to

cover the bushing attachment

groove and edges of the inner tube,

to avoid damage to the seals.

Assembling

16

16

Apply a thin layer of Öhlins green

grease (148-01) on the scraper ring

and on the sealing surface of the fork

seal.

CAUTION!

When installing the oil seal and

bushings use a small plastic bag to

cover the bushing attachment

groove and edges of the inner tube,

to avoid damage to the seals.

Mount the scraper, circlip, fork seal,

support ring and the bushings

separated by the sleeve on the inner

steel leg.

14

Fasten the damper rod assembly

with soft jaws in a vice.

Remove all parts from the damper rod.

NOTE!

If the right order is lost, use the

specification card as a guide.

Put them in the right order on the

bench.

Inspect all parts for wear and

damage, replace if necessary.

Clean all parts thoroughly.

Assemble the damper rod.

15

Remove the compression valve

assembly from the fork bottom, use

a 17 mm socket.

Fasten the valve assembly with soft

jaws in a vice.

Remove all parts from the valve

body.

Put them in the right order on the

bench.

Inspect all parts for wear and

damage, replace if necessary.

Clean all parts thoroughly.

Assemble the

compression valve.

1799-02

17

17

Fasten the outer leg with soft jaws in

a vice.

Install the inner leg and mount the

upper bushing with tool 1799-02,

and the sleeve.

Mount the lower bushings.

18

18

Apply some Öhlins green grease on

the seals.

Again, use tool 1799-02 turn it around

to install the seal in the outer leg.

Install the circlip and the scraper.

CAUTION!

Make sure the circlip is fitted

correctly into the groove in the

outer leg.

1799-02

11

Page 12

19

Notes19

Fasten the fork leg, at the fork bottom,

with soft jaws in a vice.

Install the compression valve as-

sembly in the fork bottom.

Tightening torque 65 Nm.

Apply some front fork oil on the

outer surface of the inner leg, and

push the outer leg up and down a

few times.

Measure the correct amount of oil

according to the specification card.

First, fill up the cartridge tube, then

raise up the outer leg about 250 mm

and add the remaining oil.

20

21

20

Install the damper rod assembly into

the cartridge tube.

Use Lotite 542 on the cartridge top lid.

Tighten with tool 1797-01.

Tightening torque 65 Nm.

Pump the damper rod up and down

a few times to check that there is no

air left.

Pull out the damper rod as far as

possible and close the compressionand the rebound valves.

Install the spring and the preload

spacer.

21

Install the fork top cap and the lock nut.

Tighten the top cap and the lock nut

against each other, use a 16 and 24

mm wrench.

Fit the fork legs on the motorcycle.

For tightening torques, please see

your bike's work shop manual.

Adjust the compression- and the

rebound valves according to the

specification card.

12

Page 13

Service tools

3

2

1

4

Pos. Part No. Description

1 1799-02 Bushing/seal mounting tool

2 0786-03 Inner tube tool

3 1797-01 Tool-cylinder tube lid

4 0787-03 Cylinder tube tool (cartridge)

5 1702-02 Bushing remover tool

5

Technical specifications

Fork lengths and diameters

Front fork Motorcycle Length (L) ØA ØB

FG 012 GasGas 938 mm 53,9 mm 58,4mm

Rebound and compression adjustment

Refer to mounting instruction for set-up data.

70

ØA

Maximum open rebound and compression valve: 20

clicks.

Free Spring Length:

200

All forks: 467 mm (service limit 460 mm).

Spring preload:

300

Maximum allowed adjustment

range 3-13 mm (with washers).

ØB

Spring rate:

All forks: 2328-41 4,1 N/mm.

2328-43 4,3 N/mm supplied

Optional spring rate:

2328-39: 3,9 N/mm.

2328-45: 4,5 N/mm.

2328-47: 4,7 N/mm

Oil level:

L

See mounting instruction for recommended oil level.

Adjustment range 90-130 mm.

CAUTION!

Use only Öhlins high performance front fork fluid No.

5 (1305-01).

Loctite glue:

542 for fork bottom thread and cartridge top lid.

Tighten torque:

Triple clamp bolt: See your bike's work shop manual.

Compression valve: 65 Nm (Base valve).

Cylinder tube lid (cartridgetube): 65 Nm

Compression valve, 8 mm nut 8 Nm.

Rebound valve, 8 mm nut 8 Nm.

Grease:

Öhlins Front Fork grease 148-01

(Green grease).

Service Intervals:

Every 20 hours.

13

Page 14

Spare parts

Pos. Part No. Pcs. DescriptionType/remarks

1

2

3

4

5

6

7

8

11

17

9

1 02338-01 2 Nut

2 02306-02 2 Top cap

3 00438-17 2 O-ring

4 02337-01 2 Spring support

5 02319-01 Preload washersee spec. card

6 02328-39 2 Spring front fork 3,9 N/mm

02328-41 2 4,1 N/mm

02328-43 2 4,3 N/mm

02328-45 2 4,5 N/mm

02328-47 2 4,7 N/mm

7 02324-01 2 Fork leg outer

8 00329-02 2 Circlip

9 02021-01 4 Bushing lower

10 02325-01 2 Sleeve

11 02332-03 2 Cover Sticker Öhlins

12 01552-01 2 Washer

13 02336-01 2 Seal

14 02015-01 2 Circlip

15 02014-01 2 Scraper

17 02339-01 2 Cylinder tube cartridge

18 02022-01 2 Bushing upper

19 02315-83 2 Fork leg inner

20 02309-80 1 Cover fork leg pair

21 00438-30 2 O-ring

22 02314-01 6 Bolt

23 02372-01 1 Fork bottom left

24 02372-02 1 Fork bottom right

25 02314-02 4 Bolt fork bottom

- 00195-01 2 Sticker Öhlins

white / transparent

10

9

12

13

14

15

24

25

21

22

18

19

23

20

22

22

25

14

26

Page 15

1

4

5

6

7

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Spare parts

Pos. Part No. Pcs. Description Type/remarks

1 02338-01 2 Lock nut

2 01050-01 2 Screw

3 00338-59 2 O-ring

2

3

24

25

26

9

27

28

8

29

30

31

32

33

34

36

37

38

39

40

41

43

42

44

45

46

47

48

49

50

51

52

53

4 02306-02 2 Top cap

5 01473-02 2 Circlip

6 00338-53 2 O-ring

7 02321-02 1 Adjustment screw

8 01248-01 2 Spring

9 00884-04 4 Ball

10 02366-12 2 Adjustment rod

11 00338-76 2 O-ring

12 02301-03 2 Needle housing

13 02302-03 2 Guiding sleeve

14 02303-01 2 Sleeve

15 02304-01 2 Hydraulic stop

16 00131-05 2 Circlip

17 01499-02 2 Circlip

18 02305-03 2 Cylinder tube cap

19 02059-01 2 Bushing holder

20 00338-19 2 O-ring

21 00110-01 2 Bushing

22 02340-01 2 Washer

23 02307-01 2 Shaft

24 02063-02 2 Spring

25 00438-31 2 O-ring

26 02356-03 2 Rebound needle

27 02322-01 2 Spring

28 02320-03 2 Piston holder

29 00530-18 8 Shim washer see spec. card,

notes

30 01149-01 6 Wave washer see spec. card,

notes

31 - Shims see spec. card,

notes

32 02335-01 2 Rebound piston

33 01447-02 2 Piston ring

34 - - Shim see spec. card,

rebound

36 - 2 Clamp washersee spec. card,

rebound

37 00153-01 2 Washer

38 00430-05 2 Lock nut

39 01473-02 2 Circlip

40 00338-53 2 O-ring

41 01242-05 2 Adjustment needle

42 01248-01 2 Spring

43 00884-04 4 Ball

44 02054-02 2 End piece

45 00438-02 2 O-ring

46 - 2 Clamp washer see spec. card

compression

47 - - Shims see spec. card

compression

48 02334-01 2 Compression piston

49 00438-03 2 O-ring

50 00530-22 2 Shims

51 01149-01 2 Wave washer

52 00153-01 2 Washer

53 00430-05 2 Nut

15

Page 16

More info

www.ohlins.com

The ultimate suspension site.

Find out everything about your suspension.

Download mounting instructions, manuals and brochures.

And a lot more.

Öhlins Racing AB, Box 722, S-194 27 Upplands Väsby, Sweden

Phone +46 8 590 025 00, Fax +46 8 590 025 80

Your Öhlins dealer:

07295-08 Teknisk Illustration AB, OM Motocross front fork FG 012 GasGas, 02 02. 200 ex.

16

Loading...

Loading...