Ohaus T51XW, T51P User Manual

Visit us at www.TestEquipmentDepot.com

5000 Series Indicators

Instruction Manual

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

T51P Indicator

T51XW Indicator

i

ii

TABLE OF CONTENTS

1. INTRODUCTION ..........................................................................................................................................EN-5

1.1 Safety Precautions .....................................................................................................................................EN-5

1.1.1 Relay Option Safety Precautions ........................................................................................................EN-5

1.2 Overview of Parts and Controls ................................................................................................................... EN-6

1.3 Control Functions ..................................................................................................................................... EN-10

2. INSTALLATION .........................................................................................................................................EN-11

2.1 Unpacking ..............................................................................................................................................EN-11

2.2 External Connections ................................................................................................................................ EN-11

2.2.1 Scale Base with Connector to T51P .................................................................................................EN-11

2.2.2 RS232 Interface Cable to T51P........................................................................................................EN-11

2.2.3 AC Power to T51P ........................................................................................................................EN-11

2.2.4 AC Power to T51XW .......................................................................................................................EN-11

2.2.5 Battery Power to T51P ....................................................................................................................EN-11

2.2.6 Mounting Bracket ...........................................................................................................................EN-12

2.3 Internal Connections .................................................................................................................................EN-12

2.3.1 Opening the Housing .......................................................................................................................EN-12

2.3.2 Scale Base Without Connector to T51P or T51XW ............................................................................EN-12

2.3.3 RS232 Interface Cable to T51XW ...................................................................................................... EN-13

2.3.4 Footswitch to T51P or T51XW ..........................................................................................................EN-13

2.4 T51P Rear Housing Orientation .................................................................................................................EN-13

2.5 Mounting Bracket ..................................................................................................................................... EN-13

EN-15000 Series Indicators

3. SETTINGS ................................................................................................................................................EN-14

3.1 Menu Structure ........................................................................................................................................EN-14

3.2 Menu Navigation .....................................................................................................................................EN-15

3.3 Calibration Menu .....................................................................................................................................EN-15

3.3.1 Zero Calibration ............................................................................................................................EN-16

3.3.2 Span Calibration ...........................................................................................................................EN-16

3.3.3 Linearity Calibration ......................................................................................................................EN-17

3.3.4 Calibration Test ............................................................................................................................EN-18

3.3.5 Geographical Adjustment Factor .....................................................................................................EN-18

3.3.6 End Calibration .............................................................................................................................EN-18

3.4 Setup Menu ............................................................................................................................................. EN-20

3.4.1 Reset ...........................................................................................................................................EN-20

3.4.2 Range ......................................................................................................................................... EN-20

3.4.3 Capacity ......................................................................................................................................EN-20

3.4.4 Graduation ...................................................................................................................................EN-21

3.4.5 Power On Unit ..............................................................................................................................EN-21

3.4.6 Zero Range ..................................................................................................................................EN-21

3.4.7

3.4.8 Retain Weight Data .......................................................................................................................EN-22

3.4.9 Legal for Trade .............................................................................................................................EN-22

3.4.10 Beeper Volume .............................................................................................................................EN-23

Auto-Tare .....................................................................................................................................EN-22

EN-2 5000 Series Indicators

TABLE OF CONTENTS (Cont.)

3.4.11 Beeper Signal ...............................................................................................................................EN-23

3.4.12 Button Beeper ...............................................................................................................................EN-23

3.4.13 End Setup ....................................................................................................................................EN-23

3.5 Readout Menu .........................................................................................................................................EN-23

3.5.1 Reset ...........................................................................................................................................EN-24

3.5.2 Stable Range ................................................................................................................................EN-24

3.5.3 Filter ............................................................................................................................................EN-24

3.5.4 Auto-Zero Tracking ........................................................................................................................EN-24

3.5.5 Backlight .....................................................................................................................................EN-25

3.5.6 Auto Off Timer ..............................................................................................................................EN-25

3.5.7 Gross Indicator ..............................................................................................................................EN-25

3.5.8 End Readout .................................................................................................................................EN-25

3.6 Mode Menu ............................................................................................................................................. EN-25

3.6.1 Reset ...........................................................................................................................................EN-26

3.6.2 Weighing Mode ............................................................................................................................EN-26

3.6.3 Parts Counting Mode .....................................................................................................................EN-26

3.6.4 Parts Counting Optimize ................................................................................................................EN-26

3.6.5 Percent Weighing Mode .................................................................................................................EN-26

3.6.6 Dynamic Weighing Mode...............................................................................................................EN-26

3.6.7 Check Weighing Mode...................................................................................................................EN-27

3.6.8 End Mode ....................................................................................................................................EN-27

3.7 Unit Menu ...............................................................................................................................................EN-27

3.7.1 Reset ...........................................................................................................................................EN-27

3.7.2 Kilogram Unit ...............................................................................................................................EN-27

3.7.3 Pound Unit ...................................................................................................................................EN-27

3.7.4 Gram Unit ....................................................................................................................................EN-28

3.7.5 Ounce Unit ...................................................................................................................................EN-28

3.7.6 Pound Ounce Unit .........................................................................................................................EN-28

3.7.7 Tonnes Unit ..................................................................................................................................EN-28

3.7.8 Custom Unit .................................................................................................................................EN-28

3.7.9 End Unit ......................................................................................................................................EN-29

3.8 GMP Menu .............................................................................................................................................. EN-29

3.8.1 Reset ...........................................................................................................................................EN-29

3.8.2 Date Type ....................................................................................................................................EN-29

3.8.3 Date Set .......................................................................................................................................EN-30

3.8.4 Time Type ....................................................................................................................................EN-30

3.8.5 Time Set ......................................................................................................................................EN-30

3.8.6 User ID ........................................................................................................................................EN-31

3.8.7 Project ID .....................................................................................................................................EN-31

3.8.8 Scale ID .......................................................................................................................................EN-31

3.8.7 End GMP .....................................................................................................................................EN-31

3.9 Print1 and Print2 Menus ........................................................................................................................... EN-32

3.9.1 Reset .....

3.9.2 Print Stable data Only ....................................................................................................................EN-32

3.9.3 Auto Print .....................................................................................................................................EN-32

3.9.4 Print Content Sub-menu .................................................................................................................EN-33

......................................................................................................................................EN-32

EN-35000 Series Indicators

TABLE OF CONTENTS (Cont.)

3.9.5 Layout Sub-menu .........................................................................................................................EN-35

3.9.6 Output .........................................................................................................................................EN-35

3.9.7 List Menu Settings .........................................................................................................................EN-35

3.9.8 End Print1 or End Print2 ................................................................................................................EN-35

3.10 COM1 and COM2 Menus ......................................................................................................................... EN-35

3.10.1 Reset ...........................................................................................................................................EN-36

3.10.2 Baud ...........................................................................................................................................EN-36

3.10.3 Parity ..........................................................................................................................................EN-36

3.10.4 Stop Bit ........................................................................................................................................EN-36

3.10.5 Handshake ..................................................................................................................................EN-36

3.10.6 Address .......................................................................................................................................EN-36

3.10.7 Alternate Command Sub-menu .......................................................................................................EN-37

3.10.8 End COM1 or End COM2 ............................................................................................................... EN-37

3.11 I-O Menu ................................................................................................................................................EN-37

3.11.1 Reset ...........................................................................................................................................EN-37

3.11.2 External Input ...............................................................................................................................EN-38

3.11.3 Input Beep ...................................................................................................................................EN-38

3.11.4 Relay Output ................................................................................................................................EN-38

3.11.5 End I-O ........................................................................................................................................EN-39

3.12 Menu Lock Menu ...................................................................................................................................EN-39

3.12.1 Reset ...........................................................................................................................................EN-39

3.12.2 Lock Calibration ...........................................................................................................................EN-39

3.12.3 Lock Setup ...................................................................................................................................EN-40

3.12.4 Lock Readout ...............................................................................................................................EN-40

3.12.5 Lock Mode ...................................................................................................................................EN-40

3.12.6 Lock Unit .....................................................................................................................................EN-40

3.12.7 Lock Print1 ..................................................................................................................................EN-40

3.12.8 Lock Print2 ..................................................................................................................................EN-40

3.12.9 Lock COM1 ..................................................................................................................................EN-40

3.12.10 Lock COM2 ................................................................................................................................EN-40

3.12.11 Lock GMP ..................................................................................................................................EN-41

3.12.12 Lock I-O .....................................................................................................................................EN-41

3.12.13 End Lock ...................................................................................................................................EN-41

3.13 Key Lock Menu .......................................................................................................................................EN-41

3.13.1 Reset ...........................................................................................................................................EN-41

3.13.2 Lock All Buttons ............................................................................................................................EN-41

3.13.3 Lock Off Button .............................................................................................................................EN-41

3.13.4 Lock Zero Button ...........................................................................................................................EN-41

3.13.5 Lock Print Button ..........................................................................................................................EN-42

3.13.6 Lock Unit Button ...........................................................................................................................EN-42

3.13.7 Lock Function Button .....................................................................................................................EN-42

3.13.8 Lock Mode Button .........................................................................................................................EN-42

3.13.9 Lock Tare Button ...........................................................................................................................EN-42

3.13.10 Lock Menu Button .......................................................................................................................EN-42

3.13.11 End Lock ...................................................................................................................................EN-42

3.14 Security Switch .......................................................................................................................................EN-42

EN-4 5000 Series Indicators

TABLE OF CONTENTS (Cont.)

4. OPERATION ............................................................................................................................................. EN-43

4.1 Turning Indicator On/Off ............................................................................................................................ EN-43

4.2 Zero Operation ......................................................................................................................................... EN-43

4.3 Manual Tare ............................................................................................................................................ EN-43

4.4 Pre-Set Tare ............................................................................................................................................EN-43

4.5 Auto-Tare ................................................................................................................................................EN-43

4.6 Changing Units of Measure ....................................................................................................................... EN-44

4.7 Printing Data ...........................................................................................................................................EN-44

4.8 Application Modes ...................................................................................................................................EN-44

4.8.1 Weighing .....................................................................................................................................EN-44

4.8.2 Parts Counting .............................................................................................................................EN-44

4.8.3 Percent Weighing .........................................................................................................................EN-45

4.8.4 Check Weighing ...........................................................................................................................EN-46

4.8.5 Dynamic Weighing .......................................................................................................................EN-47

5. SERIAL COMMUNICATION ..........................................................................................................................EN-48

5.1 Interface Commands ................................................................................................................................ EN-48

5.2 Output Format .........................................................................................................................................EN-49

5.3 Printouts .................................................................................................................................................EN-49

6. LEGAL FOR TRADE ................................................................................................................................... EN-51

6.1 Settings ..................................................................................................................................................EN-51

6.2 Verification ..............................................................................................................................................EN-51

6.3 Sealing ...................................................................................................................................................EN-51

7. MAINTENANCE .........................................................................................................................................EN-53

7.1 Model T51P Cleaning ............................................................................................................................... EN-53

7.2 Model T51XW Cleaning ............................................................................................................................EN-53

7.3 Troubleshooting ....................................................................................................................................... EN-53

7.4 Service Information ..................................................................................................................................EN-54

8. TECHNICAL DATA .....................................................................................................................................EN-55

8.1 Specifications ..........................................................................................................................................EN-55

8.2 Accessories and Options ...........................................................................................................................EN-56

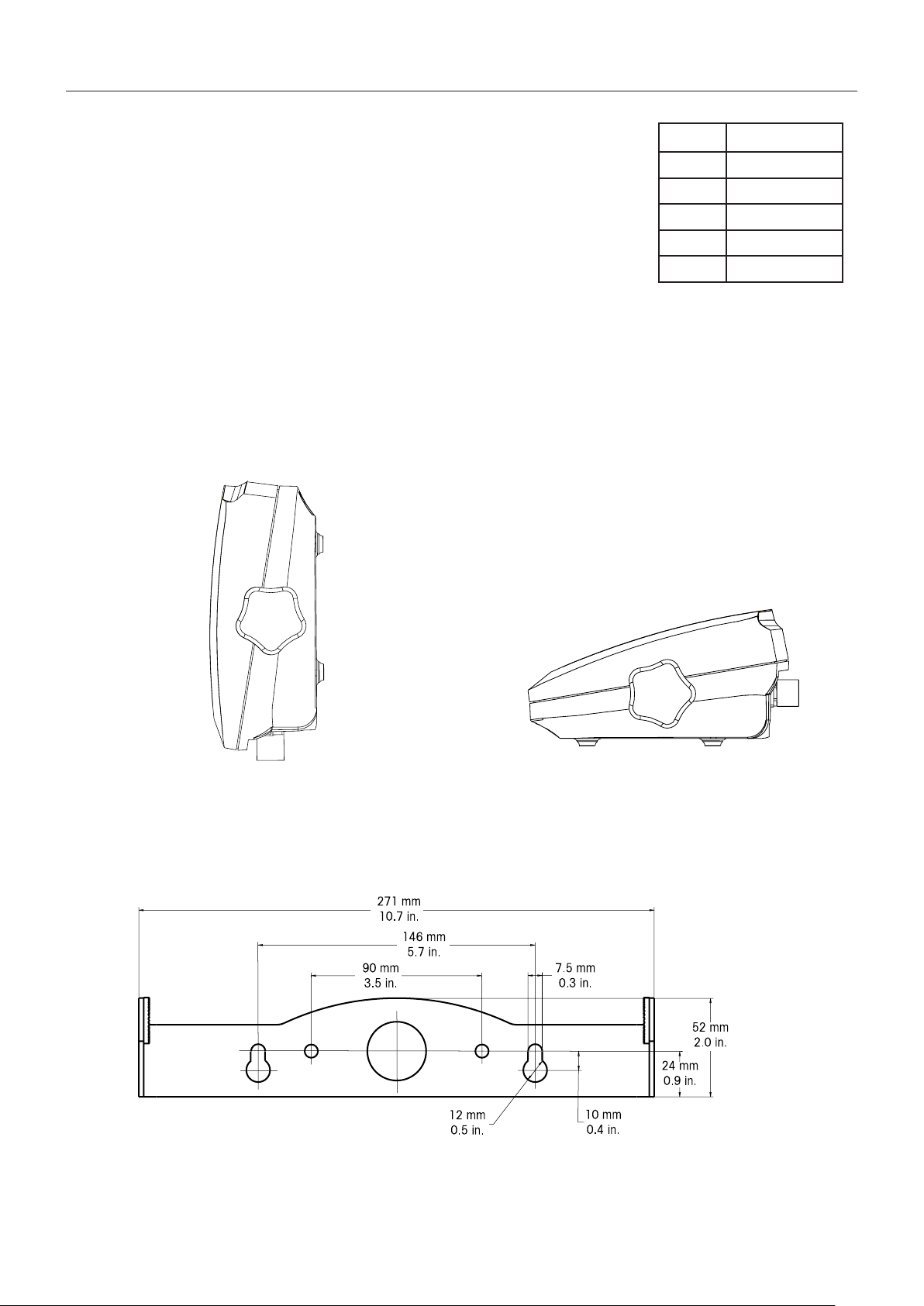

8.3 Drawings and Dimensions ........................................................................................................................ EN-57

8.4 Compliance.............................................................................................................................................EN-58

EN-55000 Series Indicators

1. INTRODUCTION

This manual contains installation, operation and maintenance instructions for the T51P and T51XW Indicators. Please read this

manual completely before installation and operation.

1.1 Safety Precautions

For safe and dependable operation of this equipment, please comply with the following safety precautions:

• Verify that the input voltage range printed on the data label matches the local AC power to be used.

• Make sure that the power cord does not pose a potential obstacle or tripping hazard.

• Use only approved accessories and peripherals.

• Operate the equipment only under ambient conditions specified in these instructions.

• Disconnect the equipment from the power supply when cleaning.

• Do not operate the equipment in hazardous or unstable environments.

• Do not immerse the equipment in water or other liquids.

• Service should only be performed by authorized personnel.

• The T51XW is supplied with a grounded power cable. Use only with a compatible grounded power outlet.

1.1.1 Relay Option Safety Precautions

This equipment may have an optional AC or DC Relay Option board installed. This option allows external devices to be

controlled by the Indicator.

CAUTION: ELECTRICAL SHOCK HAZARD. REMOVE ALL POWER CONNECTIONS TO THE INDICATOR

BEFORE SERVICING OR MAKING INTERNAL CONNECTIONS. THE HOUSING SHOULD ONLY BE OPENED BY

AUTHORIZED AND QUALIFIED PERSONNEL, SUCH AS AN ELECTRICAL TECHNICIAN.

Before making connections to the Relay terminals, remove power from the system. If the system contains an optional

rechargeable battery system, be sure that the ON/ZERO Off button is used to fully turn off the system after removing the AC power

plug.

More detailed installation instructions are included with the Relay Option Kit when purchased.

EN-6 5000 Series Indicators

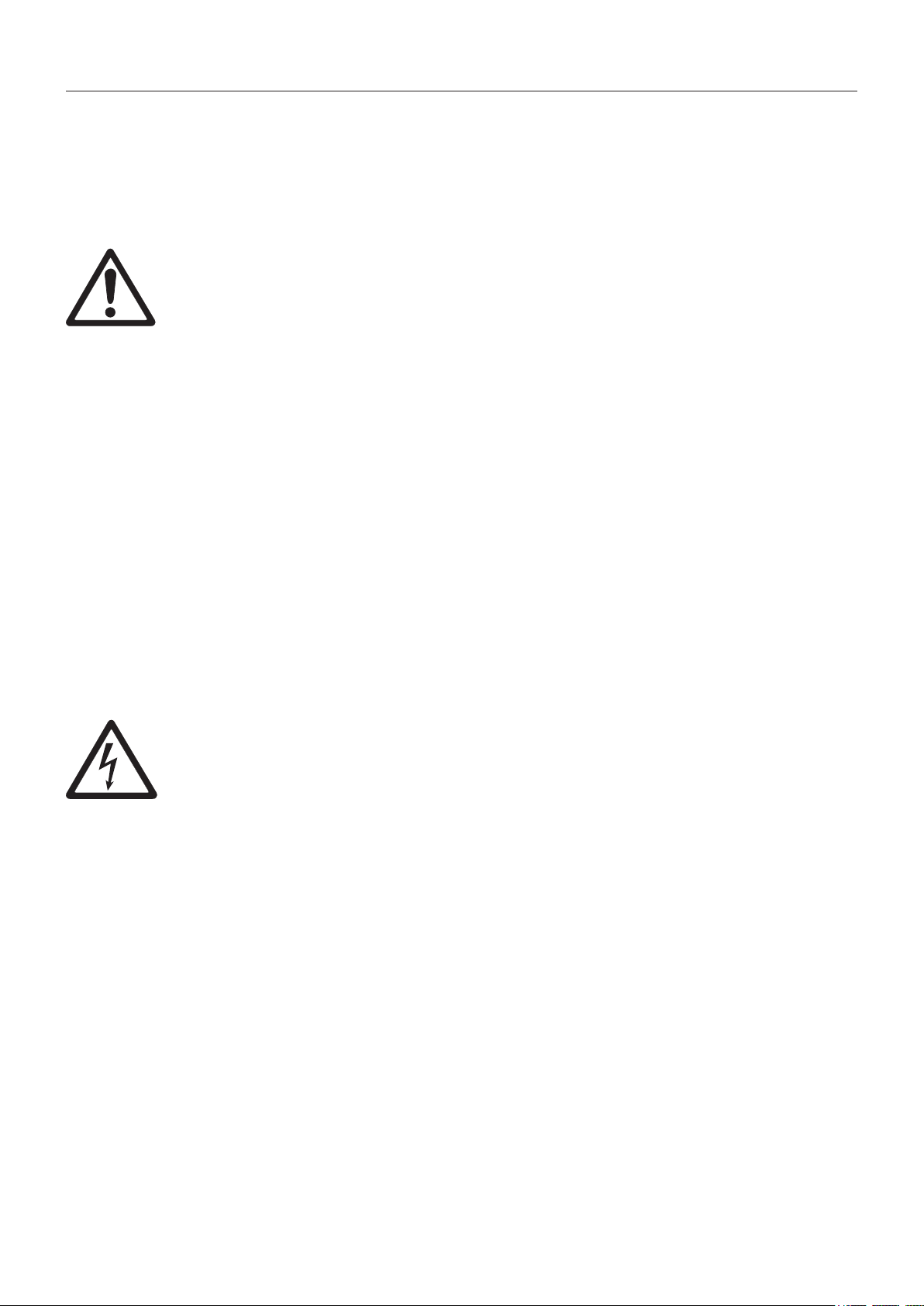

1.2 Overview of Parts and Controls

TABLE 1-1. T51P PARTS.

2

3

4

1

5

6

7

8

9

10

Item Description

1 Data Label

2 Front Housing

3 Control Panel

4 Adjusting Knob (2)

5 Mounting Bracket

6 Security Screw

7 Data Label

8 Rear Housing

9 Battery Cover

10 Screw (4)

11 Power Receptacle

12 Hole plug for option

13 Strain relief for alternate

load cell connection

14 Load Cell Connector

15 Hole plug for option

16 RS232 Connector

12 14 1611 13 15

Figure 1-1. T51P Indicator.

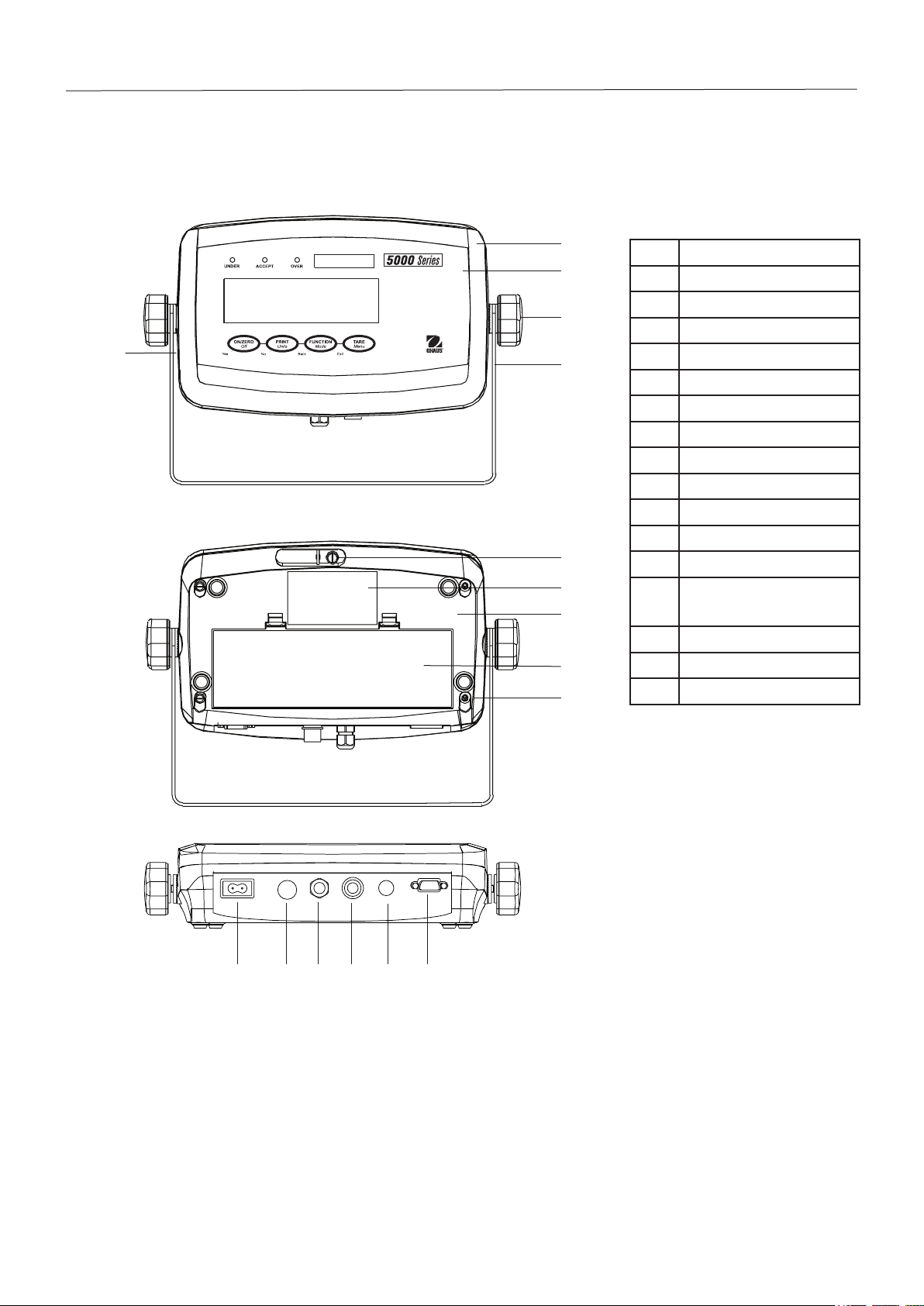

1.2 Overview of Parts and Controls (Cont.)

EN-75000 Series Indicators

1

2

3

4

5

6

7

TABLE 1-2. T51XW PARTS.

Item Description

1 Data Label

2 Front Housing

3 Control Panel

4 Adjusting Knob (2)

5 Mounting Bracket

6 Screw (4)

7 Rear housing

8 Data Label

9 Security Screw

10 Strain relief for option

11 Strain relief for RS232

12 Strain relief for option

13 Strain relief for option

14 Strain relief for Load Cell

Cable

15 Power cord

10 11 13 1412 15

Figure 1-2. T51XW Indicator.

8

9

EN-8 5000 Series Indicators

1.2 Overview of Parts and Controls (Cont.)

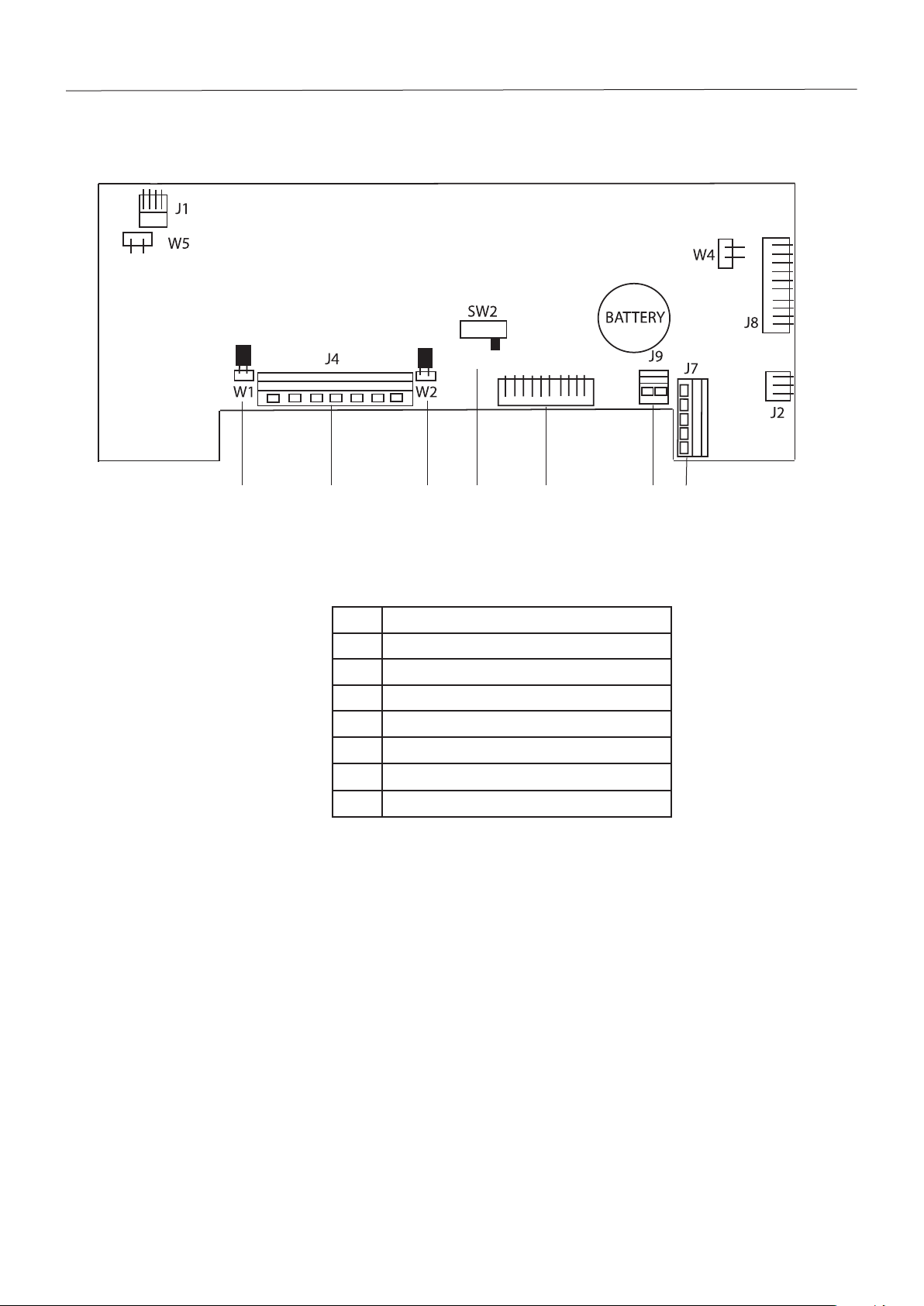

/./&&

1 2 3 4 5 6

Figure 1-3. Main PC Board.

TABLE 1-3. MAIN PC BOARD.

Item Description

1 Sense Jumper W1

2 Alternate Load Cell Terminal Block J4

3 Sense Jumper W2

4 Security Switch SW2

5 External input Terminal Block J9

6 RS232 Terminal Block J7 (T51XW only)

7 Load Cell Connector (T51P only)

7

1.2 Overview of Parts and Controls (Cont.)

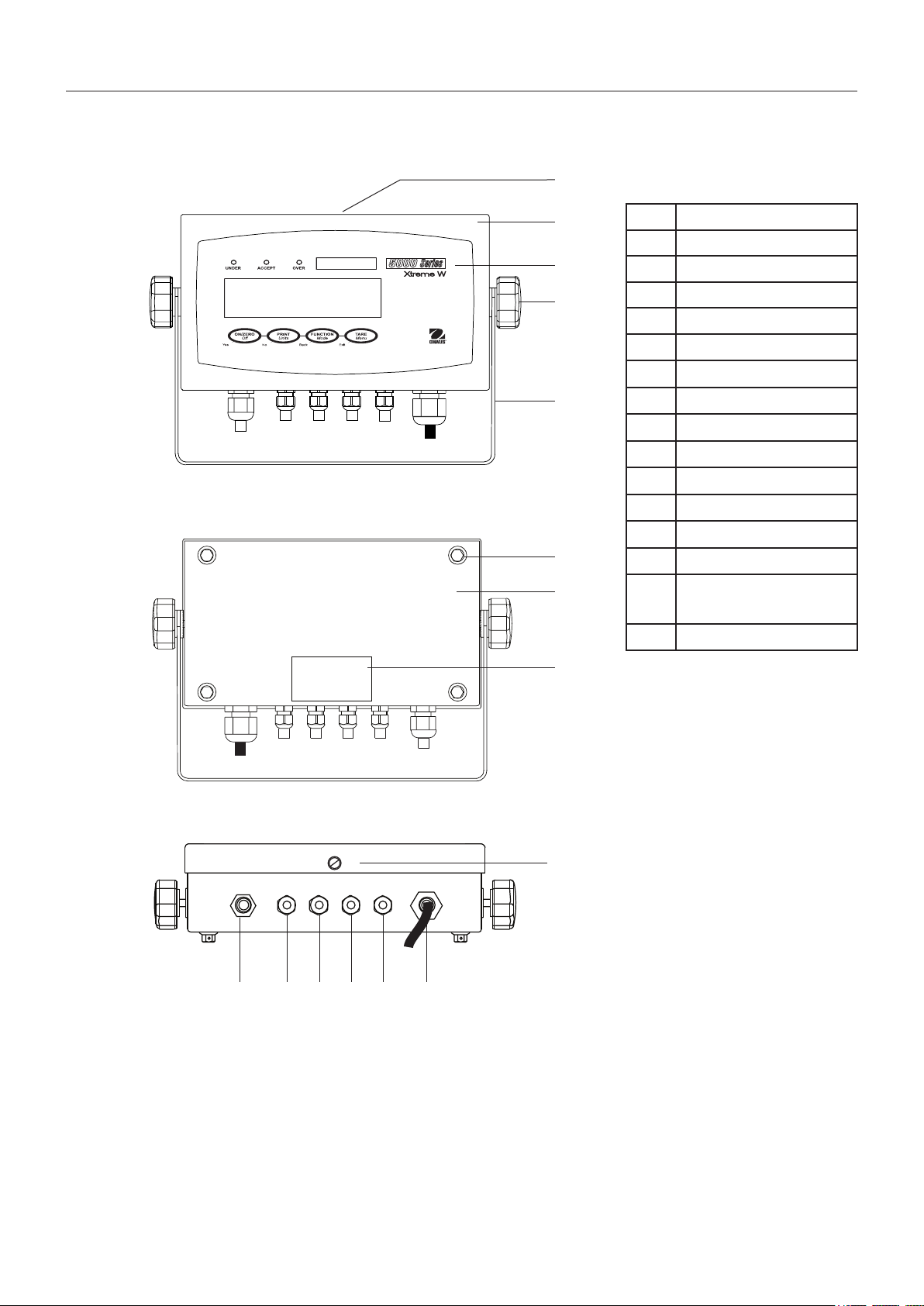

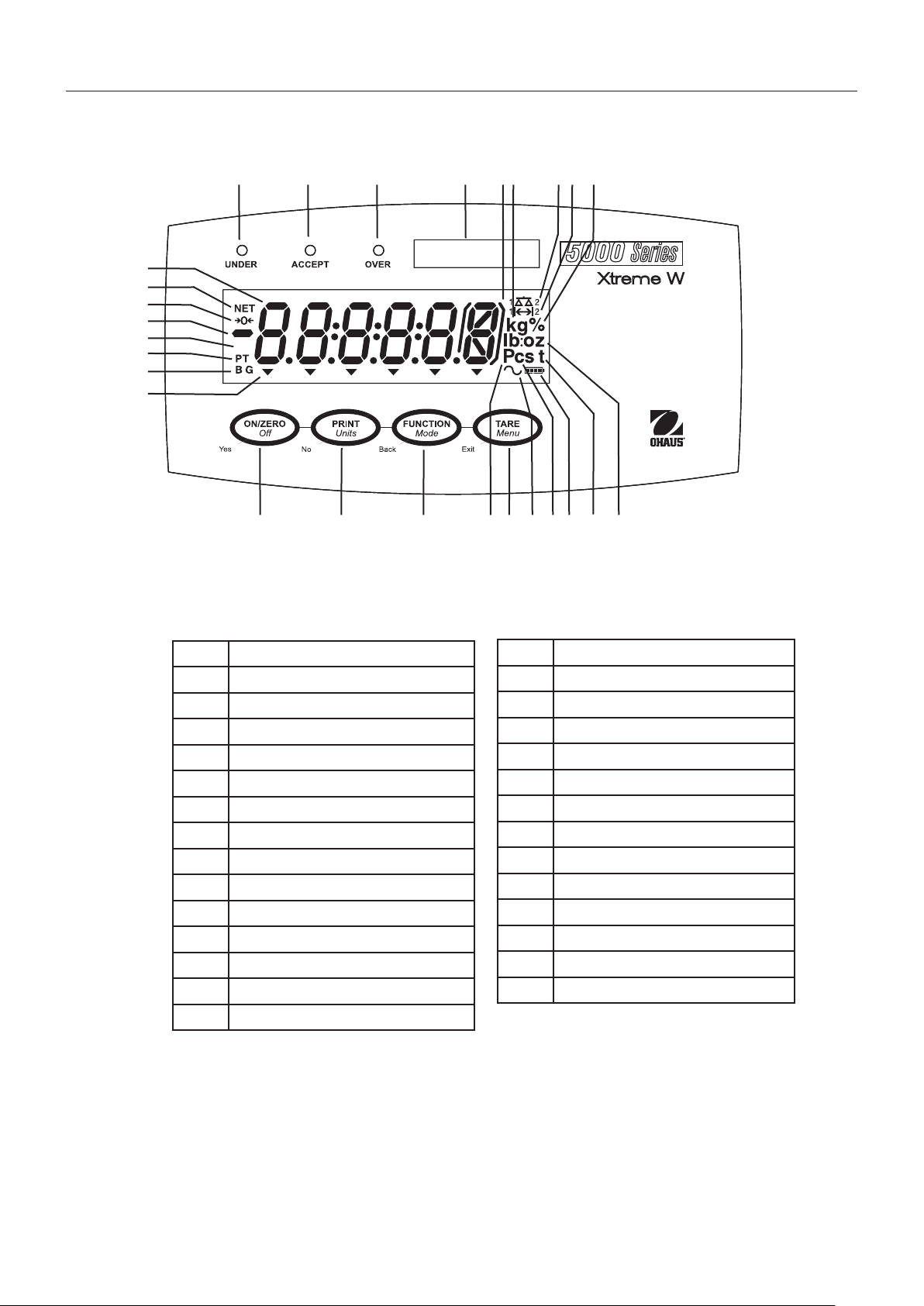

EN-95000 Series Indicators

27

26

25

24

23

22

21

20

1

2

3

Figure 1-4. Controls and Indicators.

4

5 6

16

7

9

8

1112131415171819

10

TABLE 1-4. CONTROL PANEL.

No. Designation

1 UNDER LED

2 ACCEPT LED

3 OVER LED

4 Capacity Label Window

5 Brackets (not used)

6 Kilogram, gram symbols

7 Scale symbol (not used)

8 Range symbol

9 Percent symbol

10 Pound, Ounce, Pound:ounce symbols

11 Tonne symbol

12 Battery charge symbol

13 Custom unit symbol

14 Dynamic symbol

No. Designation

15 TARE

16 Pieces symbol

17 FUNCTION

18 PRINT

19 ON/ZERO

20 Pointer symbols (not used)

21 Brutto, Gross symbols

22 Preset Tare, Tare symbols

23 Stable weight Indicator

24 Negative symbol

25 Center of Zero Indicator

26 NET symbol

27 7-segment Display

Menu

Units

Off

button

Mode

button

button

button

EN-10 5000 Series Indicators

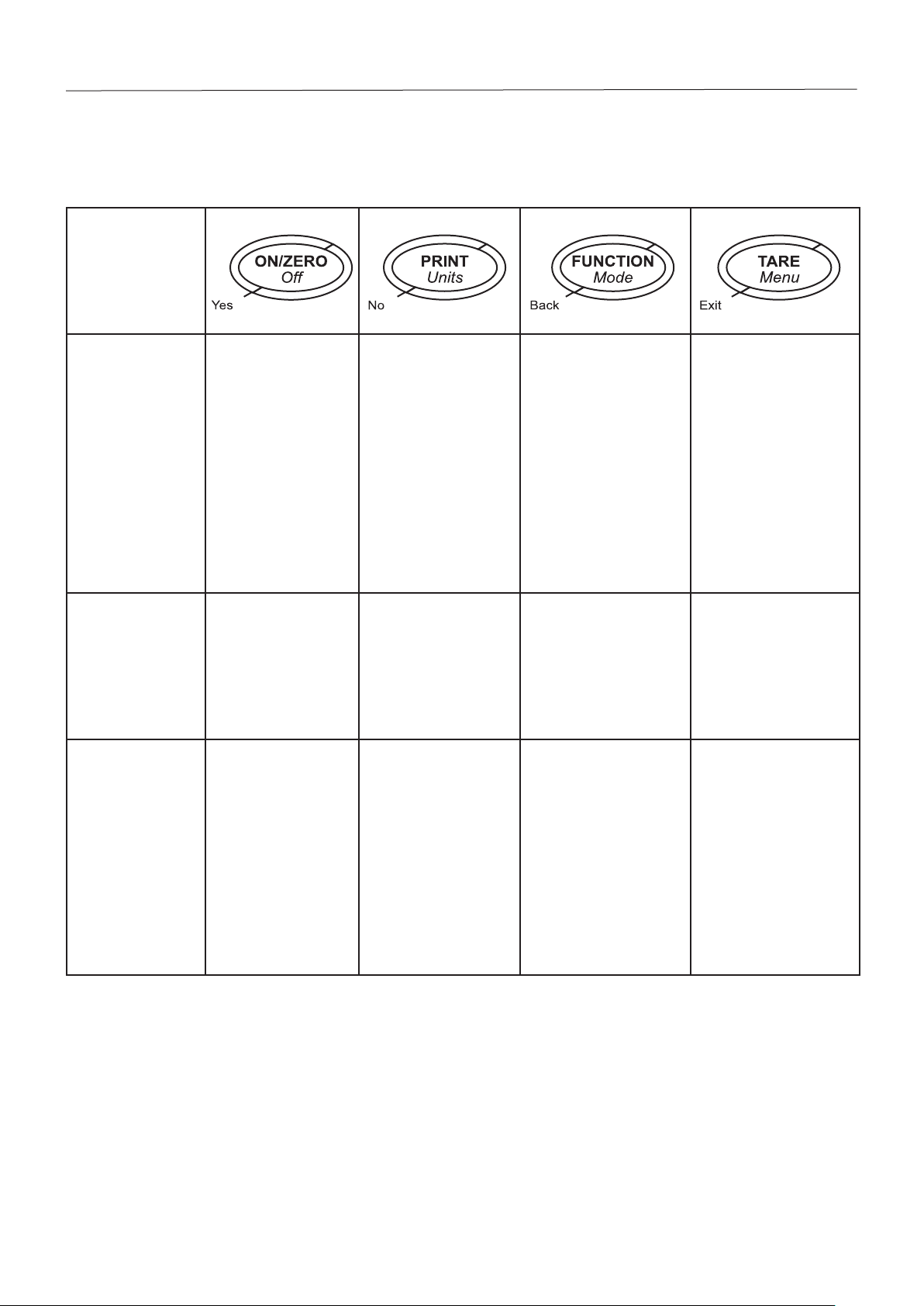

1.3 Control Functions

TABLE 1-5. CONTROL FUNCTIONS.

Button

Primary Function

(Short Press)

Secondary Function

(Long Press)

Menu Function

(Short Press)

ON/ZERO

Turns the Indicator

on.

If Indicator is On, sets

zero.

Off

Turns the Indicator off.

Yes

Accepts the current

setting on the display.

PRINT

Sends the current value

to the selected COM

ports if AUTOPRINT is

set to Off.

Units

Changes the weighing

Unit.

No

Advances to the next

menu or menu item.

Rejects the current

setting on the display

and advances to the

next available setting.

Increments the value.

FUNCTION

Initiates an application

mode.

Temporarily displays the

active mode’s reference

data.

In Weigh mode,

temporarily displays 10x

expanded resolution.

Mode

Allows changing the

application mode.

Press and hold allows

scrolling through modes.

Back

Moves Back to previous

menu item.

Decrements the value.

TARE

Performs a tare

operation.

Menu

Enter the User menu.

Exit

Exits the User menu.

Aborts the calibration in

progress.

EN-115000 Series Indicators

2. INSTALLATION

2.1 Unpacking

Unpack the following items:

• T51P or T51XW Indicator

• AC Power Cord (T51P only)

• Mounting Bracket

• Knobs (2)

2.2 External Connections

2.2.1 Scale Base with Connector to T51P

Ohaus bases with a connector can be attached to the external load cell connector (Figure 1-1, item 14). Refer to section 2.3.2

for bases without a connector. To make the connection, plug the base connector onto the external load cell connector. Then

rotate the base connector’s locking ring clockwise.

For connecting bases with a connector to a T51XW (which does not have the external connector), a Load Cell Cable Adapter

Kit p/n 80500736 is available as an accessory. This kit connects to the terminal block inside the T51XW and has an external

connector on the other end.

• Capacity Label Sheet

• LFT Sealing kit

• Instruction Manual CD

• Warranty Card

2.2.2 RS232 interface Cable to T51P

Connect the optional RS232 cable to the RS232 connector (Figure 1-1, item 16).

2

4

5

Figure 2-1. RS232 Pins.

3

9

1

78

6

Pin Connection

1 N/C

2 TXD

3 RXD

4 N/C

5 GND

6 N/C

7 CTS

8 RTS

9 N/C

2.2.3 AC Power to T51P

Connect the AC power cord (supplied) to the power receptacle (Figure 1-1, item 11), then connect the AC plug to an electrical

outlet.

2.2.4 AC Power to T51XW

Connect the AC plug to a properly grounded electrical outlet.

2.2.5 Battery Power to T51P

The indicator can be operated on alkaline batteries (not supplied) when AC power is not available. It will automatically switch

to battery operation if there is power failure or the power cord is removed. The indicator can operate for up to 80 hours on

battery power.

Remove the battery cover (Figure 1-1, item 9) and install 6 C-type (LR14)

alkaline batteries in the orientation specified. Re-install the battery cover.

During battery operation, the battery charge symbol indicates the battery status.

The indicator will automatically turn-off when the batteries are fully discharged.

EN-12 5000 Series Indicators

2.2.6 Mounting Bracket

Position the wall bracket over the threaded holes in the side of the indicator as shown in Figures 8-1 or 8-2 and install the

knobs. Adjust the indicator to the desired angle and tighten the knobs.

2.3 Internal Connections

Some connections require the housing to be opened.

2.3.1 Opening the Housing

CAUTION: ELECTRICAL SHOCK HAZARD. REMOVE ALL POWER CONNECTIONS TO THE INDICATOR

BEFORE SERVICING OR MAKING INTERNAL CONNECTIONS. THE HOUSING SHOULD ONLY BE OPENED

BY AUTHORIZED AND QUALIFIED PERSONNEL, SUCH AS AN ELECTRICAL TECHNICIAN.

T51P

Remove the four Phillips head screws from the rear housing.

Remove the front housing being careful not to disturb the internal connections.

Once all connections are made, reattach the front housing.

T51XW

Remove the four hex head screws from the rear housing.

Open the housing by carefully pulling the front housing forward.

Once all connections are made, reattach the front housing.

The screws should be tightened to 2.5 N•m (20-25 in-lb) torque to ensure a watertight seal.

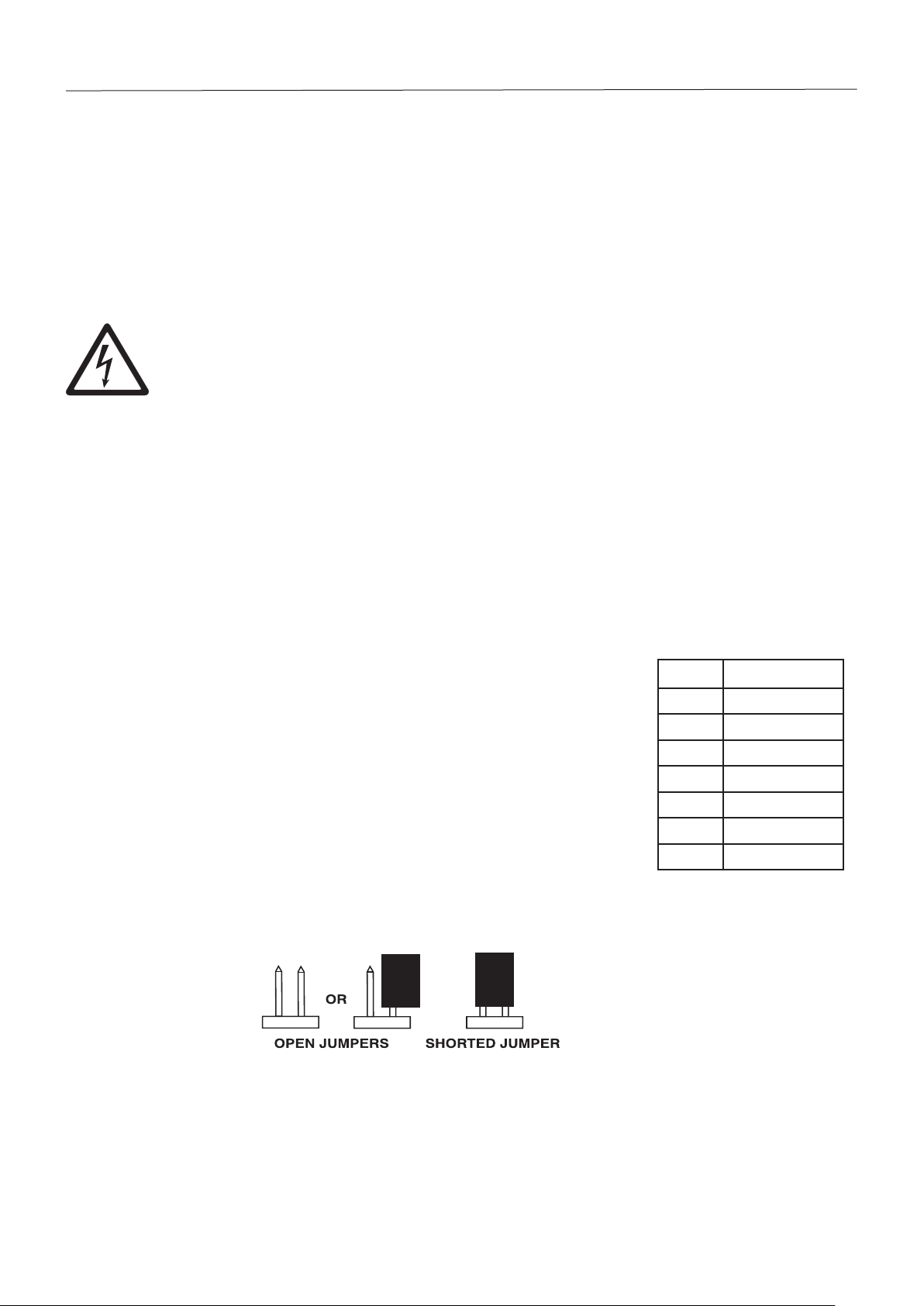

2.3.2 Scale Base Without Connector to T51P or T51XW

Bases without a connector must be attached to the internal load cell connector on the main

PC board. Pass the load cell cable through the strain relief (Figure 1-1, item 13 or Figure 1-2,

item 13) and attach it to terminal block J4 (Figure 1-3, item 2). Tighten the strain relief to

maintain a watertight seal.

Jumper Connections

For a 4-wire load cell with no sense wires: Jumpers W1 and W2 must be left in place shorting

the two pins.

For a 6-wire load cell that includes sense wires, Jumpers W1 and W2 must be removed.

For load cells with an extra ground shield wire: Connect the shield to the center position (GND)

of J4.

Pin Connection

J4-1 +EXE

J4-2 +SEN

J4-3 +SIG

J4-4 GND

J4-5 -SIG

J4-6 -SEN

J4-7 -EXE

Figure 2-2. Jumper Connections.

After wiring is completed and jumpers are in place, replace the indicator housing screws. Make sure the liquid-tight connector is

properly tightened.

EN-135000 Series Indicators

2.3.3 RS232 Interface Cable to T51XW

Pass the optional RS232 cable through the strain relief (Figure 1-2, item 10) and attach it to

terminal block J7 (Figure 1-3, item 6). Tighten the strain relief to maintain a watertight seal.

2.3.4 Footswitch to T51P or T51XW

Pass the optional footswitch cable through the strain relief (Figure 1-1, item 15 or Figure 1-2, item 11) and attach it to terminal

block J9 (Figure 1-3, item 5).

Pin Connection

J7-1 RTS

J7-2 TXD

J7-3 RXD

J7-4 CTS

J7-5 GND

2.4 T51P Rear Housing Orientation

The T51P is delivered in the wall mount orientation with the connections exiting below the display. The rear housing may be

reversed so the connections exit above the display when the T51P is placed horizontally on a bench. To reverse the rear housing,

remove the four Phillips head screws, carefully rotate the housing 180°, and reinstall the screws.

Figure 2-3. Wall Mount Configuration. Figure 2-4. Bench Top Configuration.

2.5 Mounting Bracket

Attach the bracket to a wall or table using fasteners (not supplied) that are appropriate for the type of mounting surface. The

bracket will accommodate up to 6 mm (1/4”) diameter screws. Locate the mounting holes as shown in Figure 2-5.

Figure 2-5 Mounting Bracket Dimensions.

EN-14 5000 Series Indicators

3. SETTINGS

3.1 Menu Structure

TABLE 3-1. MENU STRUCTURE.

CALIBRATIONSETUP

1)

• ZERO

• SPAN

1)

• RESET • RESET • RESET • RESET • RESET • RESET

• RANGE

2)

• LINEARITY 1)• CAPACITY

• CAL TEST • GRADUATION

• GEO

1)

• POWER ON UNIT 2)• BACKLIGHT • DYNAMIC

• END CAL • ZERO RANGE

• AUTO TARE

• RETAIN WEIGHT

• LEGAL FOR TRADE • END UNIT • PROJECT ID • HEADER

• BEEPER VOLUME • SCALE ID • USER ID

• BEEPER SIGNAL • END GMP • PROJECT ID

• BUTTON BEEPER • SCALE ID

• END SETUP • DIFFERENCE

READOUT

• STABLE RANGE

2)

2)

• FILTER • COUNT

2)

• AUTO ZERO

2)

• AUTO OFF TIMER • CHECK WEIGH 2)• POUND OUNCE 2) • TIME TYPE • GROSS

• GROSS INDICATOR • END MODE • TONNE

2)

• END READOUT • CUSTOM

MODE

2)

• WEIGH

2)

• PERCENT

2)

2)

UNIT

• KILOGRAM

2)

2)

• GRAM

• OUNCE

• POUND

2)

2)

2)

2)

GMP

2)

• DATE • STABLE ONLY

PRINT1

2)

• DATE TYPE • AUTO PRINT

• DATE SET • CONTENT

• TIME • RESULT

• TIME SET • NET

2)

• USER ID • TARE

• DATE TIME

• INFO

• MODE

• NAME

• LAYOUT

• FORMAT

• FEED

• LIST

• END PRINT1

PRINT2

COM1

COM2

I-O

LOCK MENU

LOCK KEY

• RESET • RESET • RESET • RESET • RESET • RESET

2)

• STABLE ONLY

• BAUD • BAUD • EXT. INPUT • LOCK CAL • LOCK ALL

• AUTO PRINT • PARITY • PARITY • INPUT BEEP • LOCK SETUP • LOCK OFF

• CONTENT • STOP BIT • STOP • RELAY OUTPUT • LOCK READOUT • LOCK ZERO

• RESULT • HANDSHAKE • ADDRESS

3)

• TYPE • LOCK MODE • LOCK PRINT

• GROSS • ALT. COMMAND • HANDSHAKE • SEQUENCE • LOCK UNIT • LOCK UNIT

• NET • PRINT • ALT. COMMAND • CONTACT • LOCK PRINT1 • LOCK FUNCTION

• TARE • TARE • PRINT • STABLE • LOCK PRINT2 • LOCK MODE

• HEADER • ZERO • TARE • END I-O • LOCK COM1 • LOCK TARE

• USER ID • END COM1 • ZERO • LOCK COM2 • LOCK MENU

• PROJECT ID • END COM2 • LOCK GMP • END LOCK KEY

• SCALE ID • LOCK I/O

• DIFFERENCE • END LOCK MENU

• DATE TIME

• INFO

• MODE

• NAME

• LAYOUT

• FORMAT

• FEED

• LIST

• END PRINT2

Notes:

1) Hidden when LEGAL FOR TRADE is ON.

2) Locked at current setting when LEGAL FOR TRADE is ON.

3) Visible only with RS485/RS422 option installed.

END

3.2 Menu Navigation

Enter the

the Legal for Trade status is displayed, followed by the first menu. Press the No or Back button to move to a

different menu. Press the Yes button to enter the menu. Once in the menu, press the Yes button to view the

menu item setting or press the No or Back button to move to the next menu item. When viewing the setting,

press the Yes button to accept the setting, or press the No or Back button to change the setting. Once all

settings have been made, press the Exit button to return to the current application mode.

For menu items with numeric settings such as Capacity, the current setting is displayed with all digits flashing.

Press the No button to begin editing.

The first digit is displayed flashing.

Press the No button to increment the digit or press the Yes button to accept the digit and move to the next digit.

Repeat this process for all digits.

Press the Yes button when the last digit has been set.

menu by pressing the TARE

Menu

button until MENU is displayed. When the button is released,

EN-155000 Series Indicators

The new setting is displayed with all digits flashing. Press the Yes button to accept the setting or press the No

button to resume editing.

This method also applies to setting Checkweigh under and over targets.

For End menu items, pressing the Yes button advances to the next menu, while pressing the No button returns

to the top of the current menu.

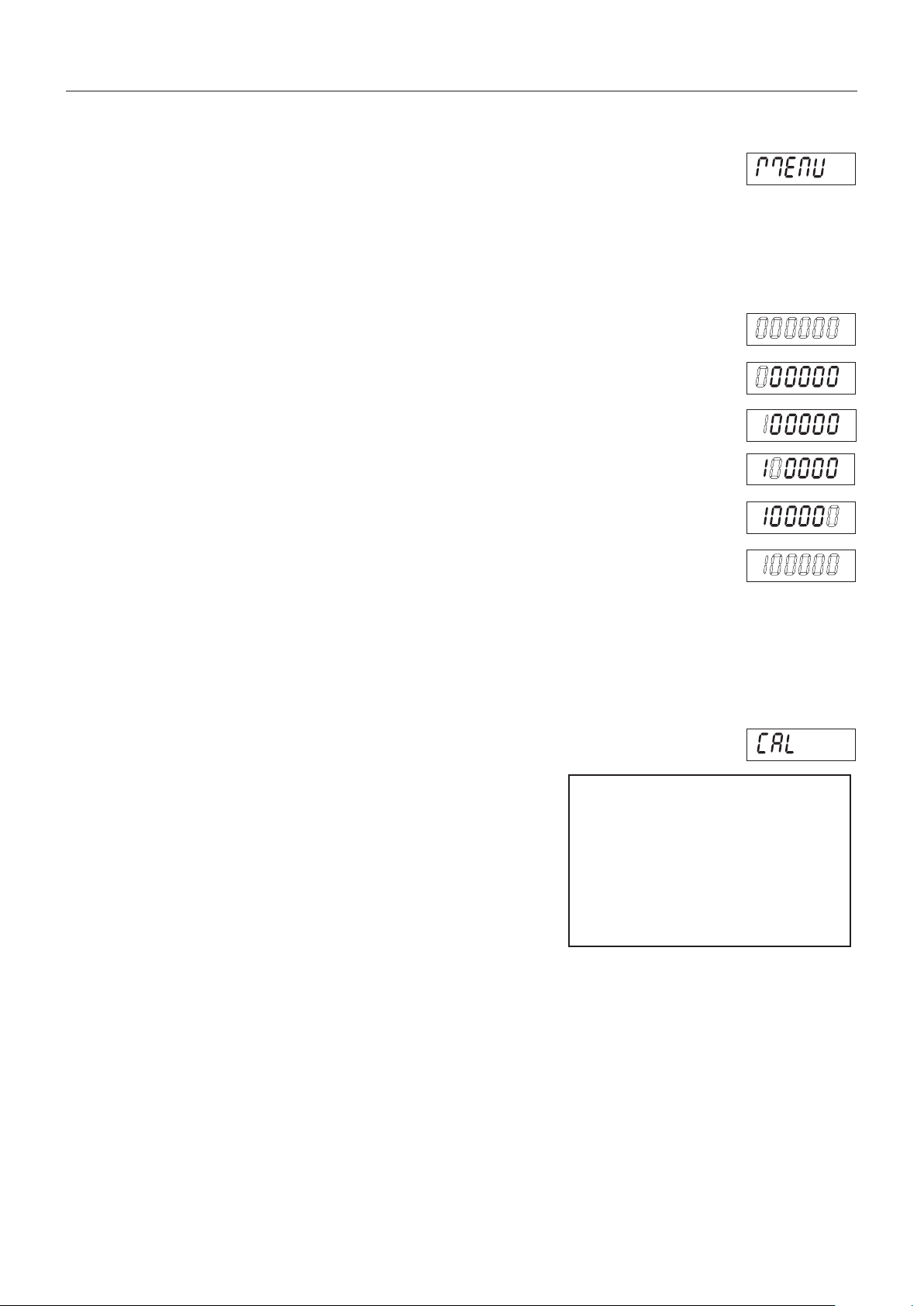

3.3 Calibration Menu

When CAL is displayed, press the Yes button to accept the Calibration menu

selection. Press the No button to advance to the desired calibration menu item.

Three calibration processes are available: Zero Calibration, Span Calibration and

Linearity Calibration. Default settings are bold.

NOTES:

1. Make sure that appropriate calibration masses are available before

beginning calibration.

2. Make sure that the scale base is level and stable during the entire

calibration process.

3. Calibration is unavailable with LFT set to ON.

4. Allow the Indicator to warm up for approximately 5 minutes after

stabilizing to room temperature.

5. To abort calibration, press the Exit button anytime during the calibration

process.

6. When any selection within the GMP menu is enabled, calibration results

are automatically printed.

Zero Perform

Span Perform

Linearity Perform

Cal Test Perform

Geographic

Adjustment Set 00…Set 12…Set 31

End Calibration Exit CALIBRATE menu

EN-16 5000 Series Indicators

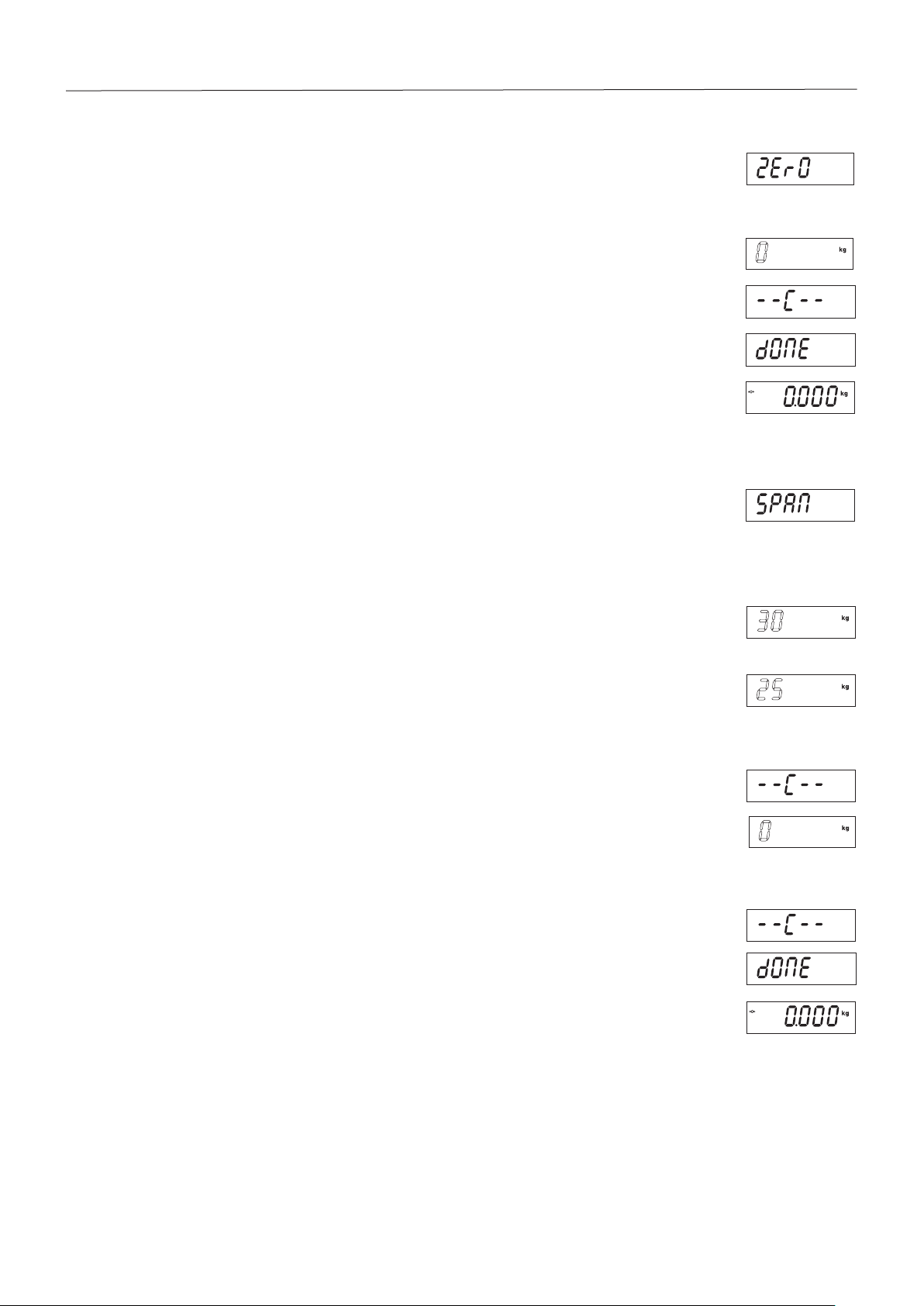

3.3.1 Zero Calibration

Zero calibration uses one calibration point. The zero calibration point is established with no weight on the

scale. Use this calibration method to adjust for a different pre-load without affecting the span or linearity

calibration. When ZErO is displayed, press the Yes button to initiate Zero Calibration.

The display flashes 0 and the calibration unit. Press the Yes button to establish the zero point.

The display shows --C-- while the zero point is established.

When zero calibration is completed, the display shows dONE.

Then the scale exits to the active weighing mode and displays the actual weight value.

3.3.2 Span Calibration

Span Calibration uses two points to adjust the scale. The span calibration point is established with a

calibration mass placed on the scale. The zero calibration point is established with no weight on the scale.

When SPAN is displayed, press the Yes button to initiate Span Calibration.

The display flashes the span calibration point. Place the specified weight on the scale and press the Yes

button.

To choose a different span point or calibration unit, edit the setting as explained in Section 3.2 Menu

Navigation. When the desired setting is displayed, place the specified weight on the scale and press the Yes

button.

The display shows --C-- while the span point is established.

The display flashes 0.

With no weight on the scale, press the Yes button to establish the zero point.

The display shows --C-- while the zero point is established.

When span calibration is completed, the display shows dONE.

Then the scale exits to the active weighing mode and displays the actual weight value.

3.3.3 Linearity Calibration

Linearity calibration uses 3 calibration points. The full calibration point is established with a weight on the

scale. The mid calibration point is established with a weight equal to half of the full calibration weight on

the scale. The zero calibration point is established with no weight on the scale. The mid calibration points

cannot be altered by the user during the calibration procedure.

When LINEAr is displayed, press the Yes button to initiate Linearity Calibration.

The display flashes the full calibration point and calibration unit. Place the specified weight on the scale and

press the Yes button.

To choose a different full point or calibration unit (kg or lb), edit the setting as explained in Section 3.2 Menu

Navigation. When the desired setting is displayed, place the specified weight on the scale and press the Yes

button.

The display shows --C-- while the full point is established.

The display flashes the mid calibration point.

EN-175000 Series Indicators

Place the specified weight on the scale and press the Yes button.

The display shows --C-- while the mid point is established.

The display flashes 0.

With no weight on the scale, press the Yes button to establish the zero point.

The display shows --C-- while the zero point is established.

When linearity calibration is completed, the display shows dONE.

Then the scale exits to the active weighing mode and displays the actual weight value.

EN-18 5000 Series Indicators

3.3.4 Calibration Test

Calibration test is used to compare a known calibration weight against the stored span calibration data.

NOTE: Calibration Test is always available (even when LFT is set to ON).

When tESt is displayed, press the Yes button to initiate Calibration Test.

The display flashes 0. With no weight on the scale, press the Yes button to record the current zero point.

The display shows --t-- while the zero point is recorded.

The display flashes the span calibration weight using the value from the last calibration. The example shows

test weight of 30 kg.

Place the specified test weight on the scale and press the Yes button.

The display shows --t-- while the data is processed.

The display flashes the actual difference between the calibration data and the test weight.

The example shows a 0.010 kg difference. The result of the Calibration Test is printed.

After 5 seconds, Calibration Test ends, the scale returns to the active weighing mode and displays the current

weight.

3.3.5 Geographical Adjustment Factor

Refer to Table 3-2 and set the GEO factor that corresponds to your location.

00 to 31

NOTE: Only an authorized manufacturer’s representative or certified verification personnel may make these

changes. Changing the geographical setting alters the calibration values.

3.3.6 End Calibration

Advance to the next menu.

•

•

•

Loading...

Loading...