Page 1

Model CW-11 Indicator

Instruction Manual

Indicador Modelo CW-11

Manual De Instrucciones

Indicateur Modèle CW-11

Manuel De L'utilisateur

Page 2

Ohaus Corporation, 19A Chapin Road, P.O. Box 2033 Pine Brook, New Jersey, 07058, USA

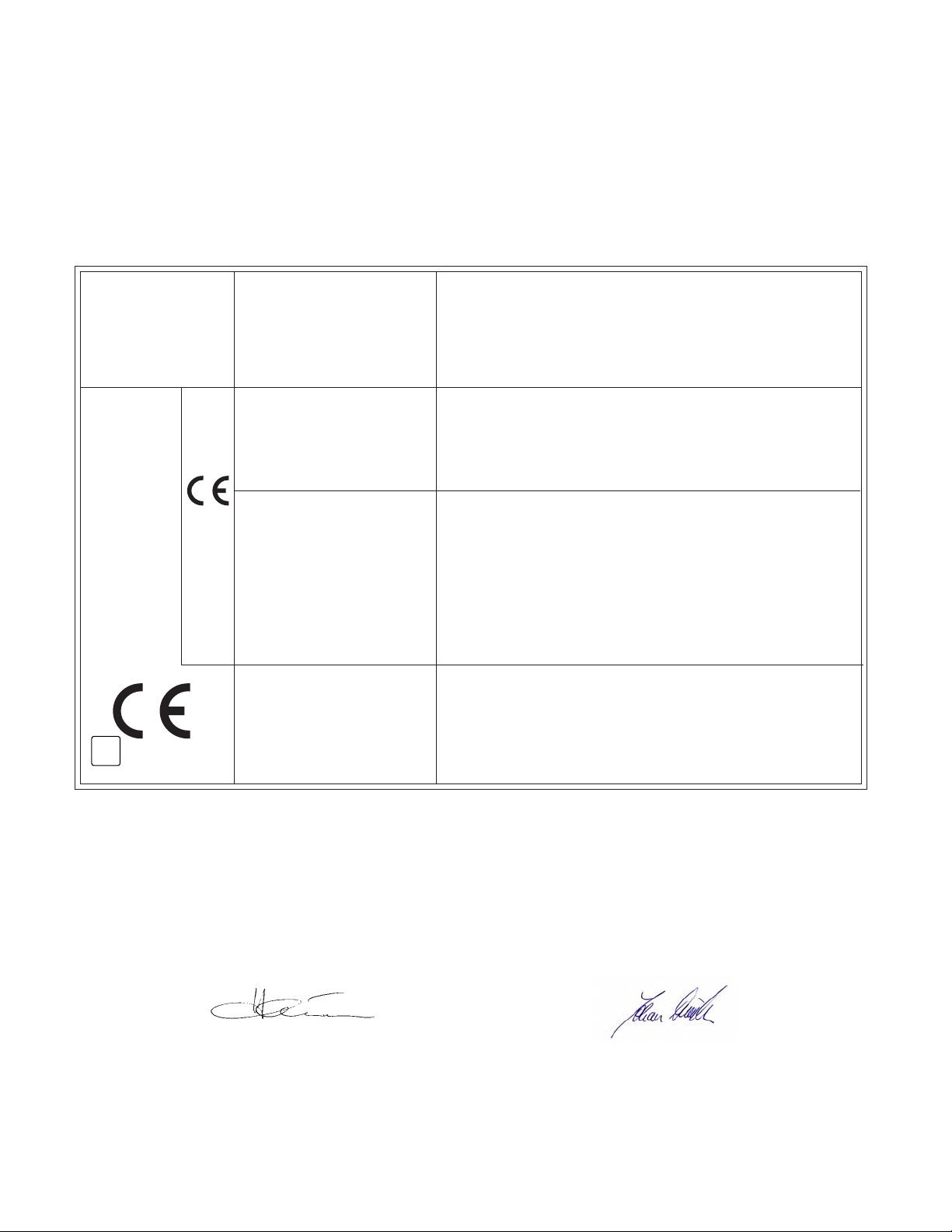

Declaration of Conformity We, Ohaus Corporation, declare under our sole responsibility that the balance models listed below marked with

CE - are in conformity with the directives and standards mentioned.

Konformitätserkärung Wir, die Ohaus Corporation, erklären in alleiniger Verantwortung, dass die untenstehenden Waagentypen,

gekennzeichnet mit CE - mit den genannten Richtlinien und Normen übereinstimmen.

Déclaration de conformité Nous, Ohaus Corporation, déclarons sous notre seule responsabilité, que les types de balance ci-dessous cité munis de la mention «CE» - sont conformes aux directives et aux normes mentionnées ci-après.

Declaración de Conformidad Nosotros, Ohaus Corporation, declaramos bajo responsabilidad exclusiva que los modelos de balanzas

indicados a continuación - con el distintivo ,CE - están conformes con las directivas y normas citadas.

Dichiarazione di conformità Noi, Ohaus Corporation, U.S.A, dichiariamo sotto nostra unica responsabilità, che i tipi di bilance specificati di

seguito - contrassegnati con la marcatura CE - sono conformi alle direttive e norme citate.

Instrument Type/Waagentyp/Type de instrument/Tipo de instrumento/Tipo di strumento: CW-11

Marked with: Directive Standard

Gekennzeichnet mit: Richtlinie Norm

Munis de la mention: Directive Norme

Con el distintivo: Directiva Norma

Contrassegnati con la Direttiva Norma

marcatura:

EU 73/23/EEC EN61010-1:1993 + A2: 1995

Low Voltage Safety Regulations

Niederspannung Sicherheitsbestimmungen

Basse tension Consignes de sécurité

Baja tensión Disposiciones sobreseguridad

Bassa tensione

Prescrizioni di sicurezza

EU 89/336/EEC EN55011: 1991 (class B) Emissions; EN61000-3-2

Electromagnetic compatibility EN50082-2:1995 Immunity; EN61000-3-3

Elektromagnetische EN55011: 1991 (class B) Funkstörungen; EN61000-3-2

Verträglichkeit EN50082-2:1995 Immunität; EN61000-3-3

Compatibilité électromagnétique EN55011: 1991 (class B) Emissions parasites; EN61000-3-2

Compatibilidad electromagnética EN50082-2:1995 Immunité; EN61000-3-3

Compatibilità elettromagnetica EN55011: 1991 (class B) Radiointerferencias; EN61000-3-2

EN50082-2:1995 Inmunidad; EN61000-3-3

EN55011: 1991 (class B) Radiointerferenze; EN61000-3-2

EN50082-2:1995 Immunità; EN61000-3-3

EU 90/384/EEC EN45501 1) 2)

NAWI Non Automatic Weighing Instruments

FNSW Für nicht selbsttätige Waagen

0103

M

1) Applies only to certified non-automatic weighing instruments

Betrifft nur zertifizierte nicht selbsttätige Waagen

Sapplique uniquement aux instruments de pesage à fonctionnement non automatique approuvés

Applicabile solamente a strumenti di pesatura a funzionamento non automatico

Aplicable solamente a instrumentos de pesaje aprobados de funcionamiento no automático

2) Valid only for CW-11 terminals in connection with approved load cells

Gültig nur für Anzeigegeräte in Verbindung mit eichzulässigen Wägezellen

Valable seulement pour les indicateurs CW-11 connectés à des cellules de pesée approuvées.

Valido soltanto per indicatori CW-11 collegati a celle di carico approvate

Válido solamente para terminales CW-11 en conexión con células de carga aprobadas

BFNA Balances à fonctionnement non automatique

PBNA Para balanzas no automátäcas

BFNA Per bilance a funzionamento non automatics

Date: March 28, 2003

Ted Xia

President

Ohaus Corporation

Pine Brook, NJ USA

Johan Dierbach

General Manager

Ohaus Europe

Greifensee, Switzerland

Page 3

ISO 9001 Registration for Ohaus Corporation. Ohaus Corporation, USA, was examined and evaluated in 1994 by the Bureau Veritas

Quality International, BVQI, and was awarded ISO 9001 registration. This certifies that Ohaus Corporation, USA, has a quality system that

conforms with the international standards for quality management and quality assurance (ISO 9000 series). Repeat audits are carried out

by BVQI at intervals to check that the quality system is operated in the proper manner.

ISO 9001-Zertifikat für Ohaus Corporation. Die Firma Ohaus Corporation, USA, wurde 1994 durch das Bureau Veritas Quality Interna-

tional BVQI geprüft, und erhielt das ISO 9001 Zertifikat. Dieses bescheinigt, dass Ohaus Corporation, USA über ein Qualitätssystem verfügt,

welches den internationalen Normen für Qualitätsmanagement und Qualitátssicherung (ISO 9000er-Reihe) entspricht. Anlässlich von

Wiederhol-Audits durch das BVQI wird periodisch überprüft, ob das Qualitätssystem zweckmässig gehandhabt wird.

Certificat ISO 9001 pour Ohaus Corporation. La société Ohaus Corporation, USA, a été contrôlée en 1994 par Bureau Veritas Quality

International BVQI et a obtenu le certificat, degré ISO 9001. Celui-ci atteste que Ohaus Corporation, USA, dispose dun système qualité

correspondant aux normes internationales pour la gestion de la qualité et pour Iassurance qualité (degré ISO 9000). Des audits réguliers

effectués par la BVQI vérifient si le système qualité est appliqué de facon appropriée.

Certificado ISO 9001 para Ohaus Corporation. La firma Ohaus Corporation, USA, ha sido inspeccionada por la Bureau Veritas Quality

International (BVQI) y ha obtenido el certificado ISO 9001. Esto acredita que Ohaus Corporation, USA, dispone de un sistema de calidad

que cumple las normas internacionales para gestión y garantfa de calidad (ISO serie 9000). Con ocasión de las inspecciones de

repetibilidad por parte de la BVQI, se comprueba periódicamente si el sistema de calidad se manipula de forma correcta.

Certificato ISO 9001 per la Ohaus Corporation. ll sistema di garanzia della qualità della Società Ohaus Corporation, USA è certificato ISO

9001 sin dal 1994 dal Bureau Veritas Quality International BVQI, e così fomisce la dimostrazione che il suo sistema di Garanzia Qualità

soddisfa i massimi requisiti. Verifiche periodiche del BVQI garantiscono che il sistema qualità opera correttamente.

NOTE: THIS EQUIPMENT HAS BEEN TESTED AND FOUND TO COMPLY WITH THE LIMITS FOR A CLASS A DIGITAL DEVICE, PURSUANT TO

PART 15 OF THE FCC RULES.

THESE LIMITS ARE DESIGNED TO PROVIDE REASONABLE PROTECTION AGAINST HARMFUL INTERFERENCE WHEN THE EQUIPMENT IS

OPERATED IN A COMMERCIAL ENVIRONMENT. THIS EQUIPMENT GENERATES, USES, AND CAN RADIATE RADIO FREQUENCY ENERGY

AND, IF NOT INSTALLED AND USED IN ACCORDANCE WITH THE INSTRUCTION MANUAL, MAY CAUSE HARMFUL INTERFERENCE TO RADIO

COMMUNICATIONS. OPERATION OF THIS EQUIPMENT IN A RESIDENTIAL AREA IS LIKELY TO CAUSE HARMFUL INTERFERENCE IN WHICH

CASE THE USER WILL BE REQUIRED TO CORRECT THE INTERFERENCE AT HIS OWN EXPENSE.

THIS DIGITAL APPARATUS DOES NOT EXCEED THE CLASS A LIMITS FOR RADIO NOISE EMISSIONS FROM DIGITAL APPARATUS AS SET OUT

IN THE INTERFERENCE-CAUSING EQUIPMENT STANDARD ENTITLED DIGITAL APPARATUS, ICES-003 OF THE DEPARTMENT OF COMMUNICATIONS.

CET APPAREIL NUMERIQUE RESPECTE LES LIMITES DE BRUITS RADIOELECTRIQUES APPLICABLES AUX APPAREILS NUMERIQUES DE

CLASSE A PRESCRITES DANS LA NORME SUR LE MATERIEL BROUILLEUR : APPAREILS NUMERIQUES, NMB-003 EDICTEE PAR LE MINISTRE

DES COMMUNICATIONS.

Unauthorized changes or modifications to this equipment are not permitted.

Page 4

TABLE OF CONTENTS

OVERVIEW OF CONTROLS AND INDICATOR FUNCTIONS ................................................................................................. 3

1. GETTING TO KNOW YOUR INDICATOR .......................................................................................................................... 4

1.1 Introduction ........................................................................................................................................................... 4

1.1.1 Features ......................................................................................................................................................... 4

2. INSTALLATION ........................................................................................................................................................... 5

2.1 Unpacking and Checking ............................................................................................................................................ 5

2.2 Selecting the Location ................................................................................................................................................ 5

2.3 Connecting the Indicator to a Scale Base ...................................................................................................................... 5

2.4 Communication connection ........................................................................................................................................ 7

2.5 Cautionary Notes ....................................................................................................................................................... 7

2.6 Connecting Power ..................................................................................................................................................... 7

2.6.1 Battery Installation ............................................................................................................................................ 7

2.6.2 AC Power......................................................................................................................................................... 7

2.6.3 Operating the Indicator ..................................................................................................................................... 8

2.7 Setup Protection ........................................................................................................................................................ 8

2.8 Initial Setup ........................................................................................................................................................... 8

2.8.1 Control Functions ............................................................................................................................................ 8

2.8.2 Menu Structure ................................................................................................................................................ 9

2.8.3 Load Cell Capacity Information........................................................................................................................ 10

2.8.4 Setup Menu .................................................................................................................................................. 11

2.8.5 Readout Menu ............................................................................................................................................... 13

2.8.6 Print menu.................................................................................................................................................... 18

2.8.7 Lockout Switch Menu ..................................................................................................................................... 20

3. CALIBRATION AND SEALING ...................................................................................................................................... 22

3.1 Legal for Trade (LFT) Operation and LFT Sealing ......................................................................................................... 24

4. OPERATION ......................................................................................................................................................... 26

4.1 Turning On Indicator ................................................................................................................................................ 26

4.2 Turning Off Indicator ................................................................................................................................................ 26

4.3 Zero Operation ........................................................................................................................................................ 26

4.4 Tare Operation ........................................................................................................................................................ 26

4.5 Gross/Net/Tare Recall Operation ................................................................................................................................ 27

1

Page 5

TABLE OF CONTENTS (Cont.)

4.6 Unit Switch Operation ............................................................................................................................................... 27

4.7 Parts Counting Operation.......................................................................................................................................... 27

4.8 Establishing a New Average Piece Weight .................................................................................................................. 28

4.9 Returning to a Weighing Mode .................................................................................................................................. 28

4.10 Returning to a Preset APW ...................................................................................................................................... 28

4.11 Animal Weighing ................................................................................................................................................... 29

4.12 RS232 Commands ................................................................................................................................................ 30

4.12.1 Output Formats............................................................................................................................................ 30

4.13 Printing Data......................................................................................................................................................... 30

5. CARE AND MAINTENANCE ........................................................................................................................................ 31

5.1 Troubleshooting ...................................................................................................................................................... 31

5.2 Error Codes List ....................................................................................................................................................... 33

5.3 Service Information .................................................................................................................................................. 33

5.4 Technical Data ........................................................................................................................................................ 33

2

Page 6

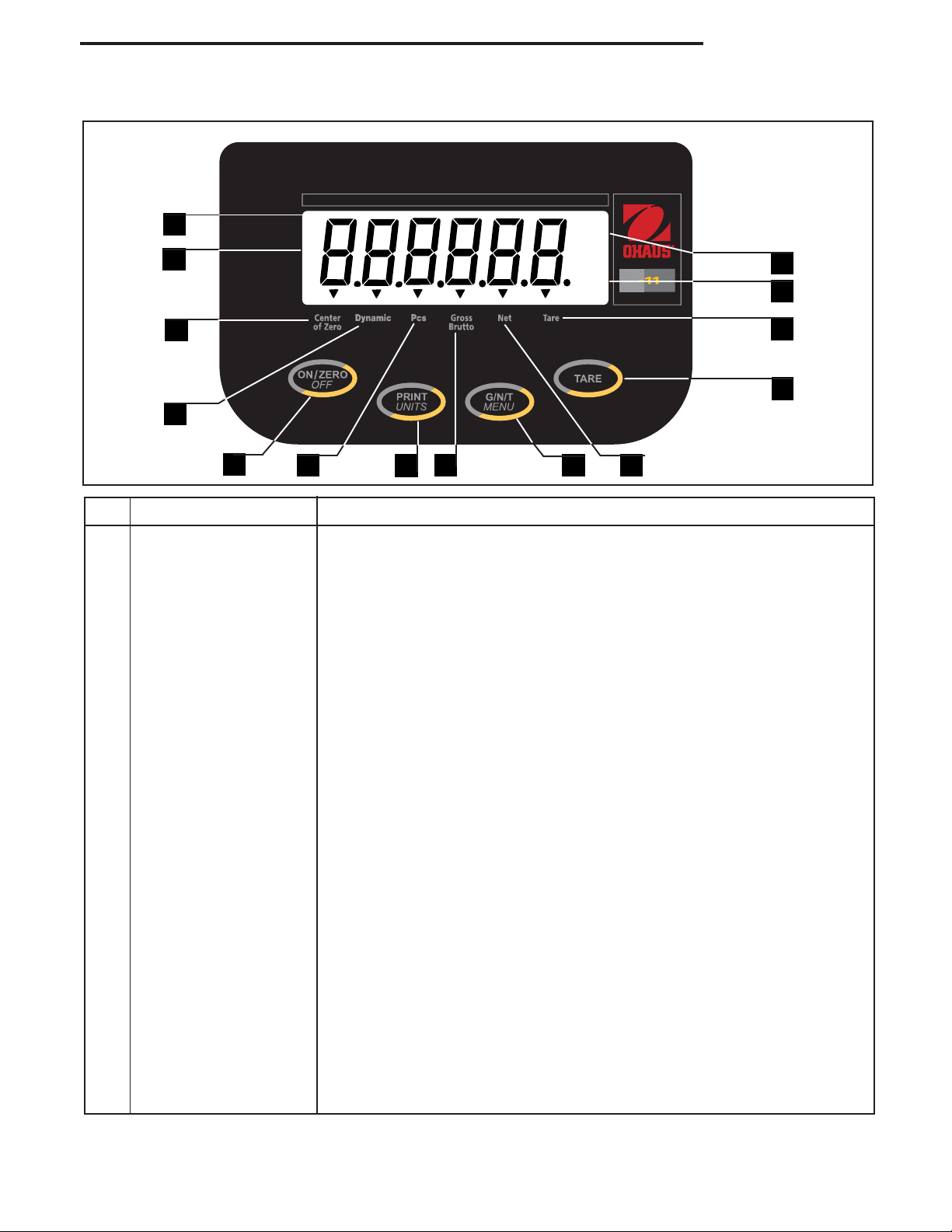

OVERVIEW OF CONTROLS AND INDICATOR FUNCTIONS

14

1

*

lb

oz

kg

BAT

C

W

CW-11 Indicator

13

12

2

3

4

No. Designation Function

1 Display LCD display, indicates weight, modes and setup information.

2 Center of Zero LCD indicator prompt, indicates center of zero when within +/- 0.25d.

3 Dynamic LCD indicator prompt, indicates that Indicator is in dynamic weighing mode.

4 ON/ZERO/OFF button Turns Indicator on or off. Secondary use, provides zero function.

5 Pcs LCD indicator prompt, indicates parts counting function.

6 Print/Units button Short press, prints data which is displayed on the Indicator.

5

Long press, changes unit of measure.

When in menus, each press advances horizontally through the menus.

Finalizes a menu selection.

6

7

8

9

11

10

7 Gross Brutto LCD indicator prompt, indicates gross weight.

8 G/N/T/Menu button Recalls Gross/Net/Tare. Long press allows entry into menus. When in

menus, advances through individual menu items.

9 Net LCD indicator prompt indicates net weight.

10 Tare button When pressed, enters tare value into memory.

11 Tare LCD indicator prompt indicates tare weight.

12 kg LCD indicator, when lit, indicates weight in kilograms.

g LCD indicator, when lit, indicates weight in grams.

13 lb LCD indicator, when lit, indicates weight in pounds.

oz LCD indicator, when lit, indicates weight in ounces.

14 * Stability indicator, when lit, indicates stable weight.

3

Page 7

CW-11 Indicator

1. GETTING TO KNOW YOUR INDICATOR

1.1Introduction

Thank you for deciding to purchase a CW-11 Indicator from Ohaus. The Ohaus CW-11 Indicator is a rugged,

reliable, electronic weight indicator in an IP65 washdown enclosure designed for easy operation in washdown

applications. The CW-11 Indicator can drive up to four 350 ohm load cells and provides capacity selections

up to 20,000 lb/kg with a maximum resolution of 1:20,000.

The CW-11 operates from AC power and can also be powered by six Alkaline C batteries internally. A six digit

LCD display is 1.0 inches/2.5 centimeters in height provides easy visibility when working at distances from the

indicator. Four switches mounted on the front panel enable simple set up procedures. A menu lockout switch

can be set to lock out various functions of the indicator to prevent settings from being changed. An RS232

Interface is built in. An adjustable mounting bracket permits the Indicator to be installed on a table or wall.

Behind your instrument stands OHAUS, a leading manufacturer of precision Indicators, Scales and Balances.

An Aftermarket Department with trained instrument technicians is dedicated to providing you with the fastest

service possible in the event your instrument requires servicing. OHAUS also has a Customer Service Department to answer any inquiries regarding applications and accessories.

To ensure you make full use of the possibilities offered by your CW-11 Indicator, please read the manual

completely before installation and operation.

1.1.1 Features

Major features include:

6 digits, 7-segments, 25 mm Numeric LCD display

4 membrane switches

Supports up to four (4) 350 ohm analog load cells

Suitable for 2mV/V and 3mV/V load cell with no jumper

Up to 20,000d display resolution

Push-button Tare/Clear

Flexible unit switching-lb/kg/oz/g

Enhanced digital filtering

Overload/Underzero display indication

3-wire RS232 Serial Communication in Ohaus RS-Interface

Up to 100 hours continuous battery operation with one 350 load cell

AC & DC power supply

Low - BAT warning comes on 20 minutes prior to low power point

Auto shut off for power saving

IP65 washdown SS enclosure

Either Animal weighing or parts counting function

4

Page 8

CW-11 Indicator

2. INSTALLATION

2.1 Unpacking and Checking

Open the package and remove the instrument and the accessories. Check the completeness of the delivery. The

following accessories are part of the standard equipment of your new Indicator.

Remove packing material from the instrument.

Check the instrument for transport damage. Immediately inform your Ohaus dealer if you have complaints or

parts are missing. Your Indicator package should contain:

Indicator CW-11

Warranty card

Capacity label

Screw driver for terminal connections

Instruction Manual

lead seal for weights and measures sealing

Store all parts of the packaging. This packaging guarantees the best possible protection for the transport of your

instrument.

2.2 Selecting the Location

The Indicator should be used in an environment which is free from corrosives, vibration or temperature extremes.

These factors will affect displayed weight readings. Scale bases used with the Indicator should be located on a

stable level surface and kept away from vibrating sources such as large machinery. Maximum accuracy will be

achieved when the area is clean and vibration free.

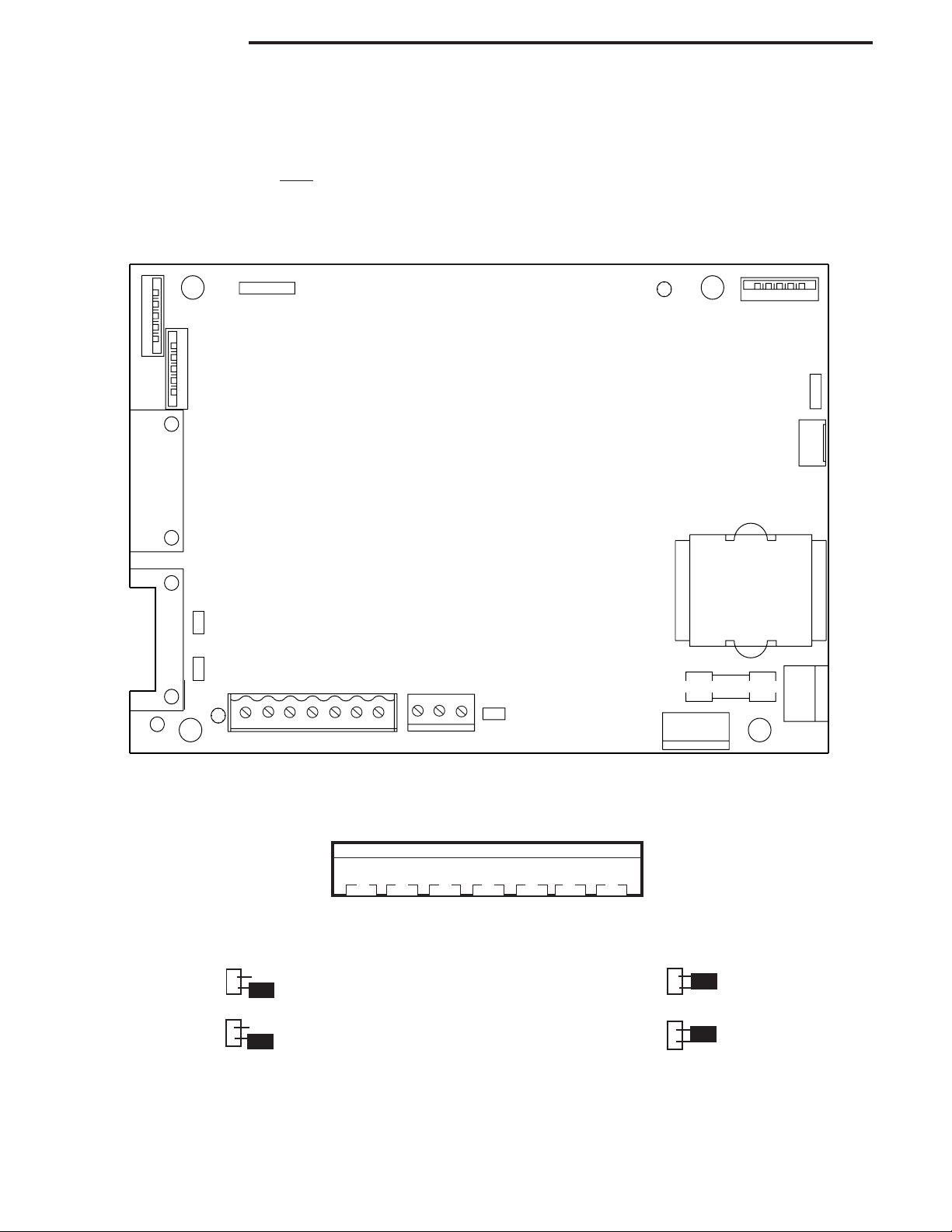

2.3 Connecting the Indicator to a Scale Base

At the bottom of the back cover of the Indicator are two slots. There is a spring clip at each slot location which

holds the cover in place. Insert the small scewdriver blade into each slot and press and work the back cover

off. With the cover removed, proceed as follows:

Remove the rear cover. Inside is the battery compartment which is wired to the PC board underneath.

Remove batteries if installed.

Remove the four corner screws from the battery board. One of the screws is crossed drilled to accept a wire seal

when used for legal for trade applications.

Carefully lift the battery board up and out of the indicator. The wires can be disconnected from the main PC

board by unplugging the connector.

Pass the load cell cable through the large or small liquid tight connector on the bottom of the housing. (Depending on cable size.)

5

Page 9

CW-11 Indicator

2.3 Connecting the Indicator to a Scale Base (Cont.)

Refer to the color code of the load cell cable and connect the wires to Terminal Strip J4. Tighten all screws

securely. The connections are shown for a 6 wire cable. When a 4 wire cable is used, the Jump 1 and Jump

2 jumpers on the PC board

For obtaining better performance, it is recommended to keep both JUMP 1 and JUMP 2 jumpers open when a

6-wire load cell is connected to the CW-11.

J5A

1

J5B

5

J2

1

6

J1

5

must be positioned as shown in the illustrations below.

15

CW11 MAIN BOARD

J5

5

1

J6

3

2

J7

4

1

9

5

J3

5

JUMP 1

6

1

JUMP 2

1

9

1

17

+EXE +SEN

J4

+SIG

CGND -SIG -SEN -EXE

J10

1

TXD RXD GND

3

CAL

T1

50m

A

250V

1

J9 3

NEUT 110V 220V

3

J8

0V

2

2

V

0

1

1

T

U

E

N

1

Printed Circuit Board Connector Locations.

12 3 4 5 6 7

J4

+EXE +SEN +SIG CGND -SIG -SEN -EXE

Connector J4 Terminations.

J3

6-Wire Jumper Connections.

4-Wire Jumper Connections.

J3

6

Page 10

CW-11 Indicator

2.4 Communication Connections

Provisions are made in the Indicator to communicate with an external computer or printer using an RS232

protocol. To connect, proceed as follows:

Pass the communication cable through one of the liquid seal connectors at the bottom of the Indicator.

Connect the cable to the J10 connector on the PC board. Observe the functions and connect correctly.

Connect the opposite end of the cable to the device.

After all connections have been made to the main PC board, replace the battery cover and lightly secure with

the four screws previously removed. If the Indicator is to be used in a legal for trade application, you will have

to gain access to the legal for trade switch on the main PC board again after all Indicator settings have been

made. Once this is done, the rear cover can be replaced.

2.5 Cautionary Notes

Model CW-11 Indicator must not be operated in hazardous areas.

Before connecting AC power, verify that the Indicator operating voltage corresponds to the local mains voltage.

If this is not the case, check terminal board J9 connections on the main PC board. There are provisions for

110V or 220V operation. Please contact your local Ohaus dealer if the voltages do not match.

Model CW-11 Indicator may be used in a washdown environment.

The CW-11 Indicator may be operated using the AC power cord , or 6 Alkaline C-type batteries (not supplied).

When the Indicator is plugged into a power source, the batteries are automatically disconnected. In the event

of a power failure, the batteries if installed will automatically continue to operate the balance.

2.6 Connecting Power

2.6.1 Battery Installation

With the back cover removed from the Indicator, insert 6 Alkaline C-type batteries into the battery holder

making sure that the batteries are properly orientated (correct polarity).

NOTE: It is recommended that when the CW-11 is operated from batteries, the Auto-Off Timer feature be

turned on to extend battery life. When setting up the Indicator, refer to Intial Setup,Readout menu,

paragraph 2.8.5.

2.6.2 AC Power

Connect the AC power cord from the Indicator and plug into a convenient power outlet.

NOTICE:

The socket/outlet must be installed near

the equipment and shall be easily accessible.

7

Page 11

CW-11 Indicator

2.6.3 Operating the Indicator

Once the Indicator and Scale Base are connected and installed, follow the setup procedure outlined below.

Power On/Off

With the Indicator connected to an appropriate power supply, press the ON/ZERO/OFF button. The Indicator

performs a self-test, indicates the software revision momentarily and then goes to a weighing mode. At this

point, the Indicator is on and ready for initial setup.

Stabilization

Before initially using the Indicator, allow time for it to adjust to its new environment. Recommended warm up

period is five (5) minutes.

2.7 Setup Protection

The CW-11 Indicator is equipped with menus which permit certain functions to be locked out (not changed)

during operation. If you intend to lock out changes to the setup selections you make, do not re-assemble the

indicator. You will need to access the cal jumper located on the main PC circuit board following the setup

procedure.

2.8 Initial Setup

For first time setup, step through all menus and set the parameters as desired. As the last step, enter the CAL

menu and calibrate the system.

The indicator has five menus; CAL, SETUP, READ, PRINT and LOCSW which are entered by pressing and holding

the G/N/T/MENU button until MENU is displayed, then releasing it. The display then switches to CAL. To access

the rest of the menus, the PRINT/UNITS button is repeatedly pressed until the desired menu is reached.

2.8.1 Control Functions

During setup, only the PRINT/UNITS and G/N/T/MENU buttons are used.

PRINT/UNITS Button

Change between menus horizontally or change sub-menu parameters.

G/N/T/MENU Button

Press and hold to enter menu. Enters menu and steps through sub-menus vertically.

8

Page 12

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

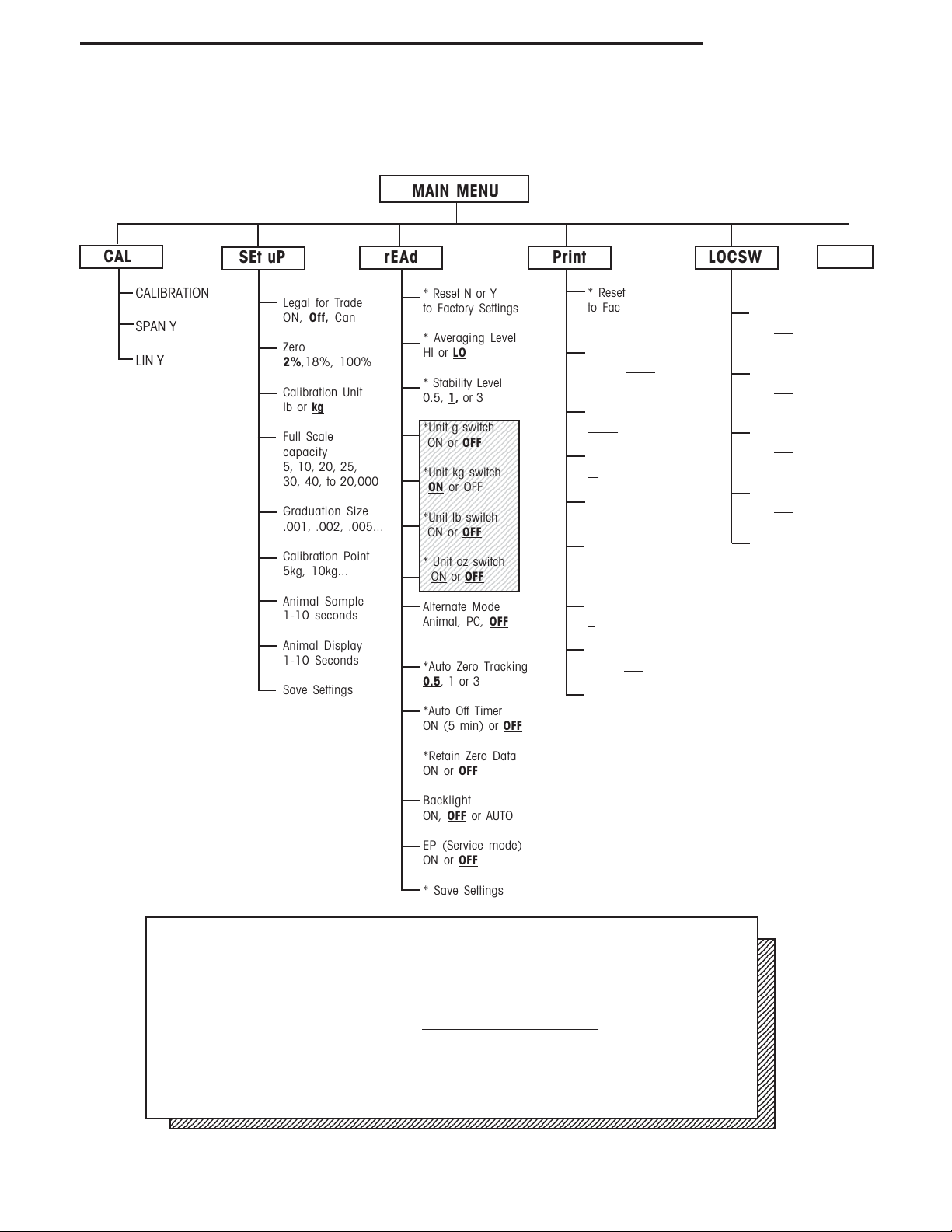

2.8.2 Menu Structure

The following table illustrates the menu structure in the CW-11 Indicator.

MAIN MENU

CW-11 Indicator

CAL

CALIBRATION

SPAN Y

LIN Y

SEt uP rEAd Print LOCSW

Legal for Trade

Off, Can

ON,

Zero

2%,18%, 100%

Calibration Unit

lb or

kg

Full Scale

capacity

5, 10, 20, 25,

30, 40, to 20,000

Graduation Size

.001, .002, .005...

Calibration Point

5kg, 10kg...

Animal Sample

1-10 seconds

Animal Display

1-10 Seconds

Save Settings

* Reset N or Y

to Factory Settings

* Averaging Level

HI or

LO

* Stability Level

0.5,

1, or 3

234567890123456789

234567890123456789

*Unit g switch

234567890123456789

234567890123456789

234567890123456789

ON or

OFF

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

*Unit kg switch

234567890123456789

234567890123456789

234567890123456789

ON or OFF

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

*Unit lb switch

234567890123456789

234567890123456789

ON or

OFF

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

* Unit oz switch

234567890123456789

234567890123456789

234567890123456789

ON or OFF

234567890123456789

Alternate Mode

Animal, PC,

OFF

*Auto Zero Tracking

0.5, 1 or 3

*Auto Off Timer

ON (5 min) or

OFF

* Reset

to Factory Settings

Yes or No

* Baud Rate set

1200,

2400, 4800

9600, 19,200

*Parity Bit set

NONE, Even, or Odd

*Data Length set

7 or 8

*Stop Bits set

1 or 2

Auto Print

ON,

OFF, cont,

Interval, On Stability

Interval

1 to 3600 seconds

Stable

ON or

OFF

* Save Settings

Quit

SETUP Lock

Switch set

ON,

OFF

* READOUT

Lockout Switch set

ON,

OFF

* PRINT Lockout

Switch set

ON,

OFF

CALIBRATION

Lockout Switch set

ON,

OFF

* Save Settings

NOTE: For details about units in shaded

area, refer to paragraph 4.7.

Press (G/N/T/MENU) to enter the display submenu or select a displayed setting.

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

Press (PRINT/UNITS) to change the displayed submenu or setting.

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

Factory default settings are shown in

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

When jumper (CAL) on the circuit board is opened, all of the menus can be reached

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

except CALIBRATION Menu, but only the submenus which are marked ' * ' can be

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

setup, see menu structure.

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

*Retain Zero Data

ON or

OFF

Backlight

ON,

OFF or AUTO

EP (Service mode)

ON or

OFF

* Save Settings

underlined and boldface type.

9

Page 13

CW-11 Indicator

2.8 Initial Setup (Cont.)

2.8.3Load Cell Capacity Information

Review the specifications of the scale base to be used with the Indicator. Make sure the settings you select in the

indicator are compatible with the scale base. Below is a Load Cell Scale Capacity (lb or kg) table. Use this table

to determine the settings of the Indicator based on the capacity and resolution of the scale base.

Grad

1000d 1200d 1500d 2000d 2500d 3000d 4000d 5000d 6000d 7500d 10000d 20000d 12500d 15000d

0.001 - - - 2 - 3 - 5 - - 10 20 - 15

0.002 - - - 4 - 6 - 10 - 15 20 40 25 30

0.005 5 - - 10 - 15 20 20 30 - 50 100 - 75

0.01 10 - - 20 25 30 40 50 60 75 100 200 - 150

0.02 20 - 30 40 50 60 - 100 120 150 200 400 250 300

0.05 50 60 75 100 - 150 200 250 300 - 500 1000 - 750

0.1 100 120 150 200 250 300 400 500 600 750 1000 2000 - 1500

0.2 200 - 300 400 500 600 - 1000 - 1500 2000 - 2500 3000

0.5 500 600 750 1000 - 1500 2000 2500 3000 - 5000 10000 - 7500

1 1000 1200 1500 2000 2500 3000 - 5000 - 7500 10000 20000 - 2 2000 - 3000 - 5000 - - 10000 - - 20000 - - 5 5000 - 7500 10000 - - 20000 - - - - - - -

LOAD CELL SCALE CAPACITIES (LB OR Kg)

10

Page 14

CW-11 Indicator

2.8 Initial Setup (Cont.)

2.8.4 Setup Menu

The CW-11 Indicator Setup Menu must be entered the first time the Indicator is used to set the scale base

parameters to match the Indicator. Do not attempt to calibrate the Indicator before setting up the Setup

Menu. All other menus should be entered and set up the first time the Indicator is used.

Procedure

With the Indicator ON, press and hold the G/N/T/

MENU button until MENU is displayed. When you

release G/N/T/MENU button, CAL is displayed when

the CAL jumper on the PC board is in place. When

the CAL jumper is removed, the Indicator will not

permitcalibration. This jumper should be in place

initially.

Press PRINT/UNITS button, SETuP is displayed.

Press G/N/T/MENU button, LFTOFF is displayed.

legal for trade selections are:

'LFT ON' - LFT is ON

'LFTOFF' - LFT is OFF

'LFTCAn' - LFT is set for Canada

kg

Press PRINT/UNITS button and select either ON ,

OFF or Canada.

Press G/N/T/MENU button, 0 2 is displayed. This

is the Zero 2%, 18% or 100% setting. 2% - zero

operation range is - 2% to + 2%. 18% - zero

operating range is -2% to +18%, 100% - zero

operation range is -2% to +100%.

NOTE: If LFT is ON, only 2% and 18% are available.

Press PRINT/UNITS button, and select either 2%,

18% or 100%.

Press G/N/T/MENU button, CAL Un kg is displayed.

This is the calibration unit setting. Selections are:

'lb' - calibration unit is lb

'kg' - calibration unit is kg.

Press PRINT/UNITS button, and select either kg or lb.

11

Page 15

CW-11 Indicator

2.8 Initial Setup (Cont.)

2.8.4 Setup Menu (Cont.)

kg

kg

Press G/N/T/MENU, F xx is displayed. This is full

scale capacity selections. xx= value last set.

Selections are:

5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120,

150, 200, 250, 300, 400, 500, 600, 750, 1000,

1200, 1500, 2000, 2500, 3000, 5000, 7500,

10000, 20000 (lb or kg).

Press PRINT/UNITS button until desired capacity

value is reached.

Press G/N/T/MENU button, Gd0.01 is displayed.

This is the graduation size. Refer to paragraph

2.8.3 Load Cell Capacity Information table. For

available selections, press PRINT/UNITS button until

desired graduation value is reached.

kg

Press G/N/T/MENU button, CP 30 kg is displayed.

This is the full scale calibration point setting. The

range is from 20% to 100% Full scale capacity.

Press PRINT/UNITS button until desired calibration

value is reached.

Press G/N/T/MENU button, AS 3 is displayed. This

is the duration of animal sample time which can be

set from 1 to 10 seconds.

Press PRINT/UNITS button until desired sample time

value is reached. See Note below.

Press G/N/T/MENU button, Ad 4 is displayed. This

is the duration of animal weighing display time

which can be set from 1 to 10 seconds. The default

is 10 seconds. See Note below.

Press PRINT/UNITS button until desired sample time

value is reached. See Note below.

Press G/N/T/MENU button to end this block, SAVE is

displayed.

Press G/N/T/MENU button, rEAD is displayed which

is the next menu or press PRINT/UNITS button to

return to Setup menu.

12

The Indicator is now matched up with the scale

base and the Indicator parameters may now be set

and calibrated.

NOTE: Not available if LFT is ON. Only available if ALT

is set to ANI.

Page 16

CW-11 Indicator

2.8 Initial Setup (Cont.)

2.8.5 Readout Menu

The Readout menu is used to adapt the Indicator to environmental conditions, set measuring units on/off, alternate modes - animal weighing & parts counting, auto zero tracking, timer on/off, retain zero data and backlighting. Review all of the settings available before proceeding.

Procedure

To select any of the items in the Readout menu,

proceed as follows: NOTE: If you have entered from

the preceeding menu, disregard the first step.

With the Indicator ON, press and hold the G/N/T/

MENU button until MENU is displayed. When you

release the G/N/T/MENU button, CAL is displayed,

then press PRINT/UNITS button, until rEAd is displayed.

Press G/N/T/MENU button, rESETn is displayed.

This allows resetting the readout menu to factory

defaults. rESETn = no and does not reset settings.

rESETy= yes and will reset the entire readout menu

as follows: AL Lo, StAb 1, Un Off g, Un On kg, Un Off,

lb, Un Off oz, Alternate Mode Off, AZt 0.5, Aot Off, rZd

Off and Backlight auto.

Press PRINT/UNITS button,and select N or Y.

AVERAGING LEVEL

Averaging level compensates for vibration or excessive air currents on the scale base. During operation,

the indicator continually takes weight readings from

the load cell. Successive readings are then digitally

processed to achieve a stabilized display. Using this

feature, you specify how much processing you need.

HI and LO settings are available.

HI setting:

More processing, greater stability and

slower stabilization time.

LO setting:

Less processing, less stability and faster

stabilization time.

13

Page 17

CW-11 Indicator

2.8 Initial Setup (Cont.)

2.8.5 Readout Menu (Cont.)

Procedure

AVERAGING LEVEL (Cont.)

Press G/N/T/MENU button, AL LO is displayed. This is

averaging level settings. Selections are:

'Lo' - Averaging level is low

'Hi' - Averaging level is high.

Press PRINT/UNITS button,and select LO or HI.

STABILITY

The stability range specifies the weighing results and

must be within a preset tolerance limit for a certain

time to turn the stability indicator ON. When a displayed weight changes beyond the allowable range,

the stability indicator turns OFF, indicating an unstable

condition. Factory default setting is shown in bold

type.

.5d Smallest range: stability indicator is

ON only when displayed weight is

within .5 divisions.

1d Normal setting. - Fixed for LFT

3d More stable course

Press G/N/T/MENU button, StAb1 is displayed.The

stability range specifies the weighing results and

mustbe within a preset tolerance limit for a certain

time to turn the stability indicator ON. When a

displayed weight changes beyond the allowable

range, the stability indicator turns OFF, indicating an

unstable condition. 0.5 d smallest range, stability

indicator is ON only when displayed weight is stable

within 0.5 divisions. 1 d-stable within 1 division. 3

d-largest range, stability indicator is ON even

though displayed weight changes 3 divisions.

Factory default setting is 1.

Press PRINT/UNITS button,and select 0.5, 1, or 3.

Normal 1d stability is default/recommended.

14

Page 18

2.8 Initial Setup (Cont.)

2.8.5 Readout Menu (Cont.)

CW-11 Indicator

Procedure

UNITS SELECTION

Press G/N/T/MENU button, Un OFF g is displayed.

g

lb

kg

oz

Press PRINT/UNITS button, and select ON or OFF.

OFF is the default setting.

Press G/N/T/MENU button, Un ON lb is displayed.

This is unit pounds which can be turned ON or OFF.

This will be displayed when CAL UNIT kg was

selected. When lb was selected as calibration unit,

kg will display.

Press PRINT/UNITS button,and select ON or OFF.

ON is the default setting.

Press G/N/T/MENU button, Un OFF oz is displayed.

This unit is ounces which can be turned ON or OFF.

Default setting is OFF.

Press PRINT/UNITS button,and select ON or OFF.

NOTE: If CAL Unit is kg, then UNIT kg is fixed to ON

menu not shown. The same if CAL Unit is set to lb.

ALTERNATE MODE - Not available if LFT is ON.

Press G/N/T/MENU button, ALtOFF is displayed.

This enables either animal weighing or simple parts

counting functions. The alternate mode can be

turned off so that neither mode is available. It is not

possible to have both modes activated at the same

time.

Press PRINT/UNITS button, and select either OFF,

ALtAn i (animal) or ALt PC (parts counting). OFF is

the default setting.

15

Page 19

CW-11 Indicator

2.8 Initial Setup (Cont.)

2.8.5 Readout Menu (Cont.)

AUTO ZERO

Press G/N/T/MENU button, AZt 0.5 is displayed.

This is the Auto Zero Threshold setting. Auto Zero

minimizes the effects of temperature changes and

small disturbances on the zero reading. The

Indicator maintains the zero display until the threshold is exceeded. Settings are shown as follows:

OFF

0.5d Sets threshold to 0.5 divisions. - Fixed in LFT

1d Sets threshold to 1 division.

3d Sets threshold to 3 divisions.

Factory default setting is 0.5d.

Press PRINT/UNITS button,and select either 0.5, 1 or

3.

AUTO POWER OFF

Press G/N/T/MENU button, AOtOFF is displayed. This

is the Auto Off Timer. When set ON, the Indicator will

shut off automatically after 5 minutes has elapsed

based on the condition that no button is pressed

and the scale base is stable during that period.

Press G/N/T/MENU button,and select ON or OFF.

OFF is the default setting.

RETAIN ZERO DATA

Press G/N/T/MENU button, Un rZdOFFis displayed.

This is Retain Zero Data which can be turned on or

off. When set On, the Indicator stores the current

zero point and restores it on the power-up.

Press PRINT/UNITS button, and select ON or OFF.

OFF is the default setting.

16

Page 20

2.8 Initial Setup (Cont.)

2.8.5 Readout Menu (Cont.)

CW-11 Indicator

LCD BACK LIGHT

Press G/N/T/MENU button, bLAutOis displayed. You

can select to have the LCD backlight either on

contiuously, off or in an automatic mode which

turns off the display in 5 seconds.

Press PRINT/UNITS button, and either select ON, OFF

or Auto. Auto is the default setting.

EP

This is service function and is not a user operated

command. OFF is the default setting.

Not available w/LFT ON.

SAVE

Press G/N/T/MENU button to end this block, SAVE is

displayed. All settings are retained.

Press G/N/T/MENU button, setting are saved and

PRINT is displayed which is the next menu or press

PRINT/UNITS button to go back to Setup menu

without saving.

NOTE:(If initial setup, go to the next paragraph. To

exit from the Setup, press PRINT/UNITS button to

skip to PRINT then to LOCKSW, then QUIT. Press

G/N/T/MENU button to go back to the weighing

mode).

17

Page 21

CW-11 Indicator

2.8 Initial Scale Setup (Cont.)

2.8.6 Print Menu

The Print menu provides data communication settings which can be entered. It contains 9 submenus: Reset,

Baud rate, Parity Bit, Data Length, Stop Bits, Auto Print, Interval, Stable and Save.

Procedure

PRINT

To select any of the items in the Print menu, proceed

as follows: NOTE: If you have entered from the

preceeding menu, disregard the first step.

With the Indicator ON, press and hold the G/N/T/

MENU button until MENU is displayed. When you

release the G/N/T/MENU button, CAL is displayed,

then press PRINT/UNITS button, until Print is displayed.

RESET

Press G/N/T/MENU button, rESEtn is displayed. This

allows resetting the Print menu to factory defaults.

rESETn = no does not reset settings. rESETy= yes

will reset the entire Print menu as follows:

Baud rate =2400, parity =none, data length=7,

stop bit=2.

Press PRINT/UNITS button, and select N or Y.

BAUD RATE

Press G/N/T/MENU button, bd2400 displayed.

Press PRINT/UNITS button, and select desired baud

rate. Baud rate selections are: 1200, 2400, 4800

9600 and 19200. 2400 is the default setting.

PARITY

Press G/N/T/MENU button, PAr NO is displayed.

This is the parity bit.

18

Press PRINT/UNITS button, and select desired parity

of NO=none, Odd=odd, E=even. Default setting is

none.

Page 22

2.8 Initial Scale Setup (Cont.)

2.8.6 Print Menu (Cont.)

CW-11 Indicator

Procedure (Cont.)

DATA

Press G/N/T/MENU button, dAtA 7 is displayed.

This is the data length.

Press PRINT/UNITS button, and select desired data

length of 7 or 8. Default setting is 7.

STOP BITS

Press G/N/T/MENU button, StOP 2 is displayed. This

is the stop bit.

Press PRINT/UNITS button, and select desired stop

bit of 1 or 2. Default setting is 2.

AUTO PRINT

Auto print has settings which enables data to a printer

or PC to be set Off, run continuously, at selected preset

intervals or on stability. On stability will print first stable

non-zero value after each change in weighing value.

Press G/N/T/MENU button, AP OFF is displayed.

Press PRINT/UNITS button, and select either Off,

Continous, Interval or On Stability. Default setting is

OFF.

INTERVAL - PRINTING

When interval has been selected in the previous step,

you may now set an interval from 1 to 3600 seconds.

Press G/N/T/MENU button, int is displayed, after a

few seconds, a second display appears which

allows you to set in the time in seconds.

Pressing the PRINT/UNITS button advances the zero

from left to right. Sample at left indicates 10 seconds.

NOTE: 0000 not valid.

19

Page 23

CW-11 Indicator

2.8 Initial Scale Setup (Cont.)

2.8.6 Print Menu (Cont.)

INTERVAL - PRINTING (Cont.)

Pressing the TARE button increments the digit from 1

to 0. When the desired number of seconds have

been entered, press the G/N/T/MENU button. Stb

OFF is displayed.

STABLE

When set ON, allows only stable weight values to be

printed. When set OFF, prints immediate value with an

indication of stability. In LFT, fixed to ON.

With Stb OFF displayed, press PRINT/UNITS button,

and select ON or OFF. Default setting is OFF.

SAVE

Press G/N/T/MENU button to end this block, SAVE is

displayed. All settings are retained.

Press G/N/T/MENU button to save settings, LOCSW

is displayed which isthe next menu or press PRINT/

UNITS button to go back to Read menu without

saving.

NOTE:(If initial setup, go to the next paragraph. To

exit from the Setup, press PRINT/UNITS button to

skip to LOCKSW, then QUIT. Press G/N/T/MENU

button to go back to the weighing mode).

2.8 Initial Scale Setup (Cont.)

2.8.7 Lockout Switch Menu

Lockout Switch menu (LOCSW) is a software controlled option which can lock the settings in the Calibration,

Setup, Readout, and Print menus to prevent tampering. When used in conjunction with the Lock Switch

(jumper) on the printed circuit board, the Calibration, Setup, Readout and Print menus can be read only and

not changed by an operator or the jumper can be left in place and the LOCSW menu is used to prevent accidental changes..

Procedure

To select any of the items in the Lockswitch menu,

proceed as follows: NOTE: If you have entered from

the preceeding menu, disregard the first step.

20

Page 24

2.8 Initial Scale Setup (Cont.)

2.8.7 Lockout Switch Menu (Cont.)

CW-11 Indicator

Procedure (Cont.)

With the Indicator ON, press and hold the G/N/T/

MENU button until MENU is displayed. When you

release the G/N/T/MENU button, CAL is displayed,

then press PRINT/UNITS button, until LOCSW is

displayed.

Press G/N/T/MENU button, LSTOFF is displayed.

This permits locking the Setup menu. OFF is unlocked, ON is read only (locked). This menu is

hidden if the CAL jumper is off.

Press PRINT/UNITS button, and select ON or OFF.

Press G/N/T/MENU button, LrdOFF displayed. This

permits locking the Readout menu. OFF is unlocked, ON is read only (locked).

Press PRINT/UNITS button, and select ON or OFF.

Press G/N/T/MENU button, LPtOFF is displayed.

This permits locking the Print menu. OFF is unlocked, ON is read only (locked).

Press PRINT/UNITS button, and select ON or OFF.

Press G/N/T/MENU button, LCLOFF is displayed.

This permits locking the Calibration menu. OFF is

unlocked, ON is read only (locked). This menu is

hidden if the CAL jumper is off.

Press PRINT/UNITS button, and select ON or OFF.

Press G/N/T/MENU button to end this block, SAVE

is displayed.

Press G/N/T/MENU , Quit is displayed..

Press PRINT/UNITS button to go to CAL or press

G/N/T/MENU button, Indicator returns to a weighing

mode.

Center

of Zero

Gross

Brutto

kg

NOTE: At this point, the Indicator must be calibrated

and the jumper removed from the CAL connector in

order to lock out the menus. The top cover of the

Indicator should be free to gain access to the CAL

jumper.

21

Page 25

CW-11 Indicator

3. CALIBRATION AND SEALING

Model CW-11 Indicator requires span calibration before using. Span calibration ensures that the Indicator

reads correctly within specifications using weight values from about 20% to 100% of capacity. For best

results, calibrate at or near full capacity. Calibration unit can be set to either kg or lb.

NOTE: When the Indicator is used in Legal for trade applications, the calibration menu is locked out and

is not accessable. This is to prevent unauthorized personnel from changing calibration. Before beginning

calibration, make sure masses are available. If you begin calibration and realize calibration masses are not

available, exit the menu. The Indicator will retain previously stored calibration data. Calibration should be

performed as necessary to ensure accurate weighing. Masses required to perform the procedures should be

in compliance with the requirements of the scale base being used with the Indicator. You have a choice of

either span or linearity calibration. Span calibration checks zero and full span calibration points. Linearity

calibration checks zero, mid span and full span points.

Procedure

SPAN CALIBRATION

With the Indicator ON, press and hold the button

G/N/T/MENU until MENU is displayed. When you

release the G/N/T/MENU button, CAL is displayed.

Press G/N/T/MENU button, SPAN Y is displayed.

Press G/N/T/MENU button, -C- is displayed. The

scale base MUST be stable during this period and is

establishing a zero point. After a few seconds, the

requested weight value is displayed. The sample illustration indicates a 10kg scale. (Cal Point CP

was set for 10kg)

kg

Place the indicated mass on the platform. Keep the

platform stable during this period.

Press G/N/T/MENU button, -C- is displayed while

the Indicator stores the reading and then displays

the weight of the mass.

*

kg

Gross

Brutto

If the calibration was successful, the calibration

mass is displayed and the calibration data is saved

automatically. If unsuccessful, refer to the troubleshooting section.

Remove calibration masses from platform.

NOTE: If the Indicator is to be used for legal for trade applications, it must be calibrated and the jumper removed

from the CAL connector in order to lock out the menus. The top cover of the Indicator should be free to gain

access to the CAL jumper. Refer to paragraph 3.1 for sealing for legal for trade use.

22

Page 26

3. CALIBRATION AND SEALING (Cont.)

CW-11 Indicator

Procedure

LINEARITY CALIBRATION

With the Indicator ON, press and hold the button

G/N/T/MENU until MENU is displayed. When you

release the G/N/T/MENU button, CAL is displayed.

Press G/N/T/MENU button, SPAN Y is displayed.

Press PRINT/UNITS button, Lin Y is displayed.

Press G/N/T/MENU button, -C- is displayed. The

scale base MUST be stable during this period and is

establishing a zero point. After a few seconds, the

display flashes LIN CP twice and the requested

weight value is displayed. The sample illustration

indicates a 5kg center point for a 10kg scale..

Place the indicated mass on the platform. Keep the

platform stable during this period.

kg

Press G/N/T/MENU button, -C- is displayed. The

scale base MUST be stable during this period and is

establishing a zero point. After a few seconds, the

display flashes FULLCP twice and the requested

weight value is displayed.

Place the indicated mass on the platform and press

*

kg

the G/N/T/MENU button -C- is displayed.

If linearity calibration was successful, the calibration

mass is displayed and the calibration data is saved

automatically. If unsuccessful, refer to the troubleshooting section.

*

Remove calibration masses from platform.

Gross

Brutto

kg

NOTE: If the Indicator is to be used for legal for trade applications, it must be calibrated and the jumper removed from the CAL connector in order to lock out the menus. The top cover of the Indicator should be free to

gain access to the CAL jumper. Refer to paragraph 3.1 for sealing for legal for trade use.

23

Page 27

CW-11 Indicator

3.1 Legal for Trade (LFT) Operation and LFT Sealing

Before this product can be used in legal-for-trade or legally controlled applications, it must be inspected in

accordance with local weights and measures or approval agency regulations. It is the responsibility of the

purchaser to ensure that all pertinent legal requirements are met. Please contact your local weights and

measures office or authorized manufacturer's representative for further details.

Legal for Trade (LFT) operation is possible through a Lock Switch ( CAL jumper) located on the PC board. The

Indicator MUST be set up and calibrated prior to performing this proceedure.

J5A

1

5

J2

J3

15

J1

J5B

5

1

6

9

5

5

JUMP 1

6

1

JUMP 2

1

9

1

J4

17

+SIG

+EXE +SEN

CGND -SIG -SEN -EXE

CW11 MAIN BOARD

J10

3

1

TXD RXD GND

CAL

PC Board Connections.

50mA

250V

1

J9 3

NEUT110V 220V

J5

1

J7

5

J6

3

2

4

1

Procedure

Set up Indicator, and calibrate. After this is done,

remove power from the Indicator.

At the bottom of the rear cover of the Indicator are

two slots. There is a spring clip at each slot location

T1

which holds the cover in place. Insert the small

scewdriver blade into each slot and press and work

the back cover off. With the cover removed, pro-

3

J8

NEUT 110V 220V

1

ceed as follows:

Remove the rear cover. Inside is the battery compartment which is wired to the PC board underneath.

Remove batteries if installed.

Remove the four corner screws from the battery

board. One of the screws is crossed drilled to

accept a wire seal when used for legal for trade

applications.

Carefully lift the battery board up and out of the

indicator making sure that that the wires are not

pulled off of the battery connector on the main PC

board.

CAL

J4

17

+SIG

+EXE +SEN

CGND -SIG -SEN -EXE

J10

1

TXD RXD GND

3

Refer to the illustrations at the left and note the

position of the CAL jumper. The first illustration

shows the jumper in place. To lock out the menus,

remove the jumper and position it on one pin as

shown in the second illustration. This removes the

jumper and stores it in the event it has to be repositioned.

24

Page 28

3.1 Legal for Trade (LFT) Operation and LFT Sealing (Cont.)

Replace the battery cover and four battery cover

screws. One of these screws is cross drilled and

can accept a wire seal.

NOTICE: The CW-11 has been tested and found to

comply with Class lll requirements of NIST Handbook

44.

After the Indicator has been tested and found to

comply with local applicable regulations by a local

weights and measures official, it may be sealed as

follows:

LEAD AND WIRE SEAL

See illustration at left. Place wire seal through the

holes in the screw and ribs as shown and com-

BATTERY COVER

press lead seal in place.

CW-11 Indicator

SEALING SCREW

Sealing the Indicator

PAPER SEAL

If an audit trail or paper seal will be used, install the

6-32 pan head screw to the battery cover and place

seal over the screw area.

PAPER SEAL

BATTERY HOLDER

SCREW

CLOSING THE INDICATOR

After the Indicator has been calibrated and sealed,

replace the rear cover and snap into place. Connect

power to the Indicator and verify operation.

25

Page 29

CW-11 Indicator

4. OPERATION

Before using the Indicator, make sure it has been properly set up and calibrated. Refer to Sections 2 and 3 and

review settings. Four buttons are used: ON/ZERO/OFF = power on or OFF, PRINT/UNITS = short press =prints

data, long press= changes unit of measure, G/N/T/MENU - short press = view gross net, or tare, long press =

enter setup menu, TARE - short press = enter tare.

*

kg

Center

of Zero

Gross

Brutto

4.1 Turning On Indicator

Press and hold ON/ZERO/OFF button until the LCD

display appears, then release ON/ZERO/OFF button.

The display momentarily displays segment check,

the software revision of the Indicator and then goes

into a weighing mode. If the Indicator has been

properly set upand connected, the display should

be as shown to the left. The decimal point position

may be different depending on the setup of the

Indicator.

4.2 Turning Off Indicator

To turn the Indicator off, press the ON/ZERO/OFF

button until OFF is displayed.

*

Center

of Zero

*

*

*

Center

of Zero

Gross

Brutto

Gross

Brutto

Gross

Brutto

Net

kg

kg

kg

kg

4.3 Zero Operation

Using a short duration press, press ON/ZERO/OFF

button to zero the Indicator. The display acknowledges by indicating the selected measuring unit

followed by a zeroed display.

NOTE: Stable cursor must be lit to accept zero

operation.

Place item to be weighed on the scale platform.

The display indicates a sample of 5kg, gross

weight.

4.4 Tare Operation

When weighing material or objects that must be held

in a container, taring stores the container weight in the

Indicators memory. To store the container weight,

proceed as follows:

Place the container on the scale. Sample shown is

2kg.

Press TARE button. Scale is tared and shows Net

weight.

26

Page 30

4. OPERATION (Cont.)

CW-11 Indicator

4.5 Gross/Net/Tare Recall Operation

*

kg

Gross

Brutto

*

kg

Net

When a container has been placed on the platform

and tared, it's weight is stored in memory. Adding

material to the container is shown as NET weight. The

gross weight is a combination of the tared weight and

the material. The G/N/T/MENU button allows switching between GROSS, NET and TARE weights.

Repeately press (short presses) the G/N/T/MENU

*

button to cycle through Gross, Tare and Net

readings.The sample illustrations indicate a tare

kg

Tare

weight of 2kg simulating a container, a net weight

of 8kg which would be the material in a container

and a gross weight of 10kg which is the total weight

of the container and material. After 3 seconds,

display returns to Net weight.

4.6 Unit Switch Operation

*

Net

*

Net

lb

lb

To switch measuring units, proceed as follows:

Press and hold PRINT/UNITS button until display

changes to selected measuring unit. Depending on

which units are enabled in the menu, you have a

choice of g, lb, kg or oz. The display sample

indicates 8kg load changed to lbs shown as a net

weight because a tared weight of 2kg was used

and stored in memory.

*

Center

of Zero

Pcs

Gross

Brutto

4.7 Parts Counting Operation

Parts counting is enabled only when turned ON in the

Readout menu. Refer to paragraph 2.8.4. In the

parts counting mode, the Indicator displays the

quanitity of parts placed on the platform. The Indicator determines the quanitity based on the average

piece weight of a sample. All parts must be reasonably uniform in weight for accurate measurements.

27

Page 31

CW-11 Indicator

4. OPERATION (Cont.)

*

Gross

PcsCenter

of Zero

*

*

*

Brutto

Pcs

Pcs

Net

Net

4.8 Establishing a New Average Piece Weight

(APW)

If the APW has not been calculated previously, proceed as follows:

Press and hold PRINT/UNITS button until Pcs cursor

is displayed.

Press and hold G/N/T/MENU until SEtPCS is dis-

played. This is displayed for about 1 second, then

SEt 5 is displayed.

Select an alternate sample size by pressing and

holding PRINT/UNITS button. Choices are 5, 10,

20, and 50. Place count samples on platform.

Press G/N/T/MENU button to accept current sample.

The new APW is established. Place parts on platform or in a container to count. If a container is

used, be sure to tare the empty container first.

*

*

*

Center

of Zero

*

Center

of Zero

Pcs

Pcs

Pcs Gross

Brutto

Gross

Brutto

Gross

Pcs

Brutto

Net

Net

kg

Additional parts may be added to the platform as

long as the same sample weight intially entered is

the same as the parts being weighed.

4.9 Returning to a Weighing Mode

Press PRINT/UNITS button until the display indicates

the desired measuring unit either kg, lb or g.

4.10 Returning to a Preset APW

If the APW has been calculated previously, the Indicator stores the value in memory. Proceed as follows to

use a previously set APW:

Press and hold PRINT/UNITS button until Pcs cursor

is displayed.

Place samples on the platform. The display indicates the number of pieces based on the previously

entered data. Sample shown at left indicates 100

pieces.

28

Stable

Pcs

Brutto

Gross

CAUTION

WHEN POWER IS TURNED OFF, APW

WILL ALWAYS RETURN TO DEFAULT APW 5.

Page 32

4. OPERATION (Cont.)

*

Center

of Zero

Gross

Brutto

kg

CW-11 Indicator

4.11 Animal Weighing

Animal weighing is enabled only when 'Ani' in the

Read menu under Alternate Mode is turned ON and

animal sample time and animal display time have

been set in the Setup menu. Refer to paragraphs

2.8.4. and 2.8.5. Those menus allows setting animal

sample time up to 10 seconds and to display the

averaged animal weight for up to 10 seconds. Longer

sampling times are used for highly active subjects.

*

kg

Gross

Brutto

Sample Container Weight

*

kg

Tared Container weight

*

kg

Dynamic

Net

Displayed Average Animal Weight

With the Indicator in a weighing mode, place a

holding container if used on the base. Press the

TARE button to tare the container weight.

Place the subject in the container and momentarily

press the PRINT/UNITS button. The display counts

down the number of seconds you have set, averages the subjects weight and then displays this for

the number of seconds you have selected. The

average weight shown is stable. The value is also

sent to the RS232.

At the end of the time out period, the actual weight is

shown as the Indicator reverts to a normal weighing

mode. If the subject is moving a lot, the displayed

weigh will fluctuate.

Press the TARE button to remove the container

weight from memory unless you intent to weigh

additional subjects using the same container. The

Indicator is now in a normal weighing mode.

29

Page 33

CW-11 Indicator

4. OPERATION (Cont.)

4.12 RS232 Commands

All communication is accomplished using standard ASCII format. Characters shown in the following table are

acknowledged by the Indicator. Invalid command response "ES" error indicates the Indicator has not recognized the command. Commands sent to the Indicator must be terminated with a carriage return (CR) or carriage return-line feed (CRLF). Data output by the Indicator is always terminated with a carriage return - line feed

(CRLF).

4.12.1 Output Formats

Data output can be initiated in one of two ways:

1. By pressing the PRINT/Units button, or

2. Sending a print command (P) from a computer.

Output Formats

The output format is as follows:

Weight* Spaces Unit Stable Legend CR LF

Length: 9 1 3 1 1 1 1

blank=stable G,N,T

"?"= not stable

* Displayed weight sent right justified with lead zero blanking. Nine characters (fixed) include:

decimal point (1), weight (7 max), polarity (1) : blank if positive, floating negative (1)

RS232 USER COMMAND TABLE

Command

Character Description

? Print current mode: kg, g, lb., oz.

P Same as pressing PRINT button.

T Same as pressing TARE button.

Z Same as pressing ZERO button.

xS Print Stable only. Where x=0 Off, and x=1 On

AS Automatically send data when stable after motion.

xxxxS Send at interval. Where xxxx=1 to 3600 seconds.

CS Send as fast as possible (continuous print)

M Increment to next enabled unit

To turn auto printing, interval printing or continuous printing off, send 1S or 0S to reset normal printing

mode.

4.13 Printing Data

Printing data to an external computer or printer requires that the communications parameters in the Print menu,

be set first. Refer to paragraph 2.8.6 Print Menu for proper set up.

To print data, press PRINT/UNITS button with a short press. The display acknowledges by momentarily

blinking off.

NOTE: If you hold this button down too long, the display will advance to another measuring unit.

30

Page 34

CW-11 Indicator

5 CARE AND MAINTENANCE

To keep the Indicator operating properly, the housing should be kept clean and free from foreign material. If

necessary, a cloth dampened with a mild detergent may be used.

5.1 Troubleshooting

SYMPTOM

Unit will not turn on.

Cannot zero Indicator, or will not

zero when turned on.

PROBABLE CAUSE(S)

Adapter not plugged in or properly

connected.

Batteries dead or not properly

installed.

Membrane switch failure.

Load on scale base exceeds

allowable zero % entered in ZERO

parameter of Setup menu.

REMEDY

Check power cord connections.

Make sure adapter connector

is plugged all the way into the

Indicator.

Check battery connector.

Check orientation of the

batteries.

Replace batteries.

Check functions of membrane

switch.

Remove load on scale base to

less than entered zero %.

Change allowable zero % in

ZERO parameter of Setup

menu.

Center of Zero display indicator

erratic or does not appear with

no load on scale base.

Retain Zero Data is enabled in

scale menu.

Scale base motion or disturbances exceed center of zero

criteria.

Normal operation when this

feature is disabled.

Remove disturbances or

reduce motion.

Increase AZT level in readout

menu.

Increase averaging level in

readout menu.

31

Page 35

CW-11 Indicator

5 CARE AND MAINTENANCE (Cont.)

5.1 Troubleshooting (Cont.)

SYMPTOM

Cannot display weight in desired

weighing unit.

RS232 not working.

Unable to calibrate unit.

PROBABLE CAUSE(S)

Desired unit not set to ON in Readout

menu.

RS232 communication parameters

set up incorrectly.

Improper or loose cable connections.

Scale base disconnected.

SETUP Lockout switch set to ON and

jump CAL on the circuit board set to

open position.

REMEDY

Enable desired unit in Readout

menu. See paragraph 2.8.5

Conversion too large (typically

in g).

Verify communication parameters.

Check cable connections.

Check connections.

Set LCL to OFF in the LocSW

menu, and set Jump CAL on

the circuit board to short

position. Refer to paragraphs

2.3 and 2.8.7.

32

Incorrect value for calibration mass.

Use correct calibration mass.

Page 36

CW-11 Indicator

5.2Error Codes List

The following list describes the various error codes and which can appear on the display and the suggested

remedy.

LoBat Is indicated when batteries are weak. Approximately 20 minutes of operating time

remain.

Error 1 Indicates an overload condition.

Error 2 Indicates an underload condition.

Error 7 EEPROM data incorrect.

Error 14 Zero exceeds

Err 21 Calibration data does not match current full scale, Grad and Cal Point settings. Settings

must be restored or the Indicator must be recalibrated using the current settings.

ZERO% and cannot be zeroed.

5.3 Service Information

If the Troubleshooting section does not resolve or describe your problem, you will need to contact an authorized

Ohaus Service Agent. For Service assistance in the United States, please call Aftermarket, Ohaus Corporation tollfree at (800) 526-0659. An Ohaus Product Service Specialist will be available to help you.

5.4 Technical Data

Materials

Housing stainless-steel

Keypad/display overlay polyester

Ambient conditions

The technical data is valid under the following ambient conditions:

Ambient temperature -10°C to 40C/ 14°F to113°F

Relative humidity 10%.......95%, noncondensing

Height above sea level up to 4000m

Operability is assured at ambient temperatures between 5 and 40° C.

33

Page 37

CW-11 Indicator

5.4 Technical Data (Cont.)

Capacity (lb or kg) 5 to 20,000*

Graduation (readability) lb or kg 0.001 to 5*

Displayed Resolution 1:5000 LFT or 1: 20,000 Non LFT*

Weighing modes lb, kg, oz, g*

Functions Parts counting, animal weighing

Over range capacity Capacity plus 9d

Stabilization time < 3 seconds

Auto-zero tracking capture range 0.5, 1, or 3 divisions*

Zeroing range 2%, 18%, or 100% of capacity*

Span calibration push-button (selectable from 20% to 100% of scale base capacity)

Weighing system Analog strain gauge load cell

Load cell excitation voltage 5V dc

Load cell input sensitivity Up to 3mV/V

Load cell drive 60 mA at 5V dc (drives up to 4 x 350 ohm load cells)

Display (in/cm) LCD (1.0/25.4)

Power AC 120 or 230 V ac and 240 Vac, 43-63 Hz or 6 alkaline C-type batteries

Typical battery life 100 hours with one 350 ohm load cell, 40 hours with four load cells

Operating temperature -10°C to 40°C (14°F to 113°F)

Keyboard 4 function membrane switches

Dimensions (WxDxH) (in/cm) 8.25 x 6.75 x 3/20.0 x 17.2 x 7.7

Shipping packing dimensions (in/cm) 7 x 9 x 12.5/17.7 x 22.8 x 31.7

Net weight (lb/kg) 4.3/1.9

Shipping weight (lb/kg) 7/3.1

* User selectable

NTEP Approved No: 99-100

Canada Weights and Measures Approved No: AM5340

LIMITED WARRANTY

Ohaus products are warranted against defects in materials and workmanship from the date of delivery through the

duration of the warranty period. During the warranty period Ohaus will repair, or, at its option, replace any