Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

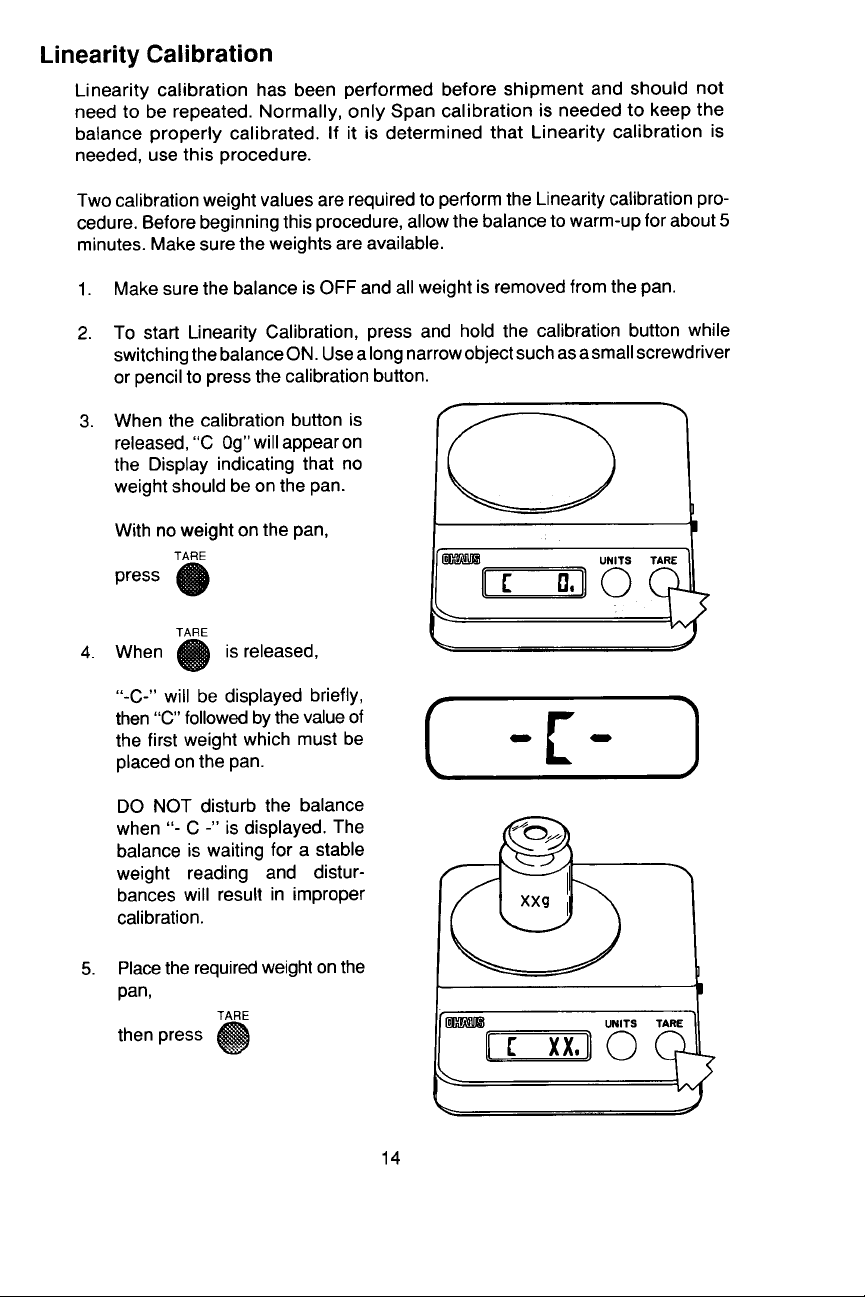

Page 14

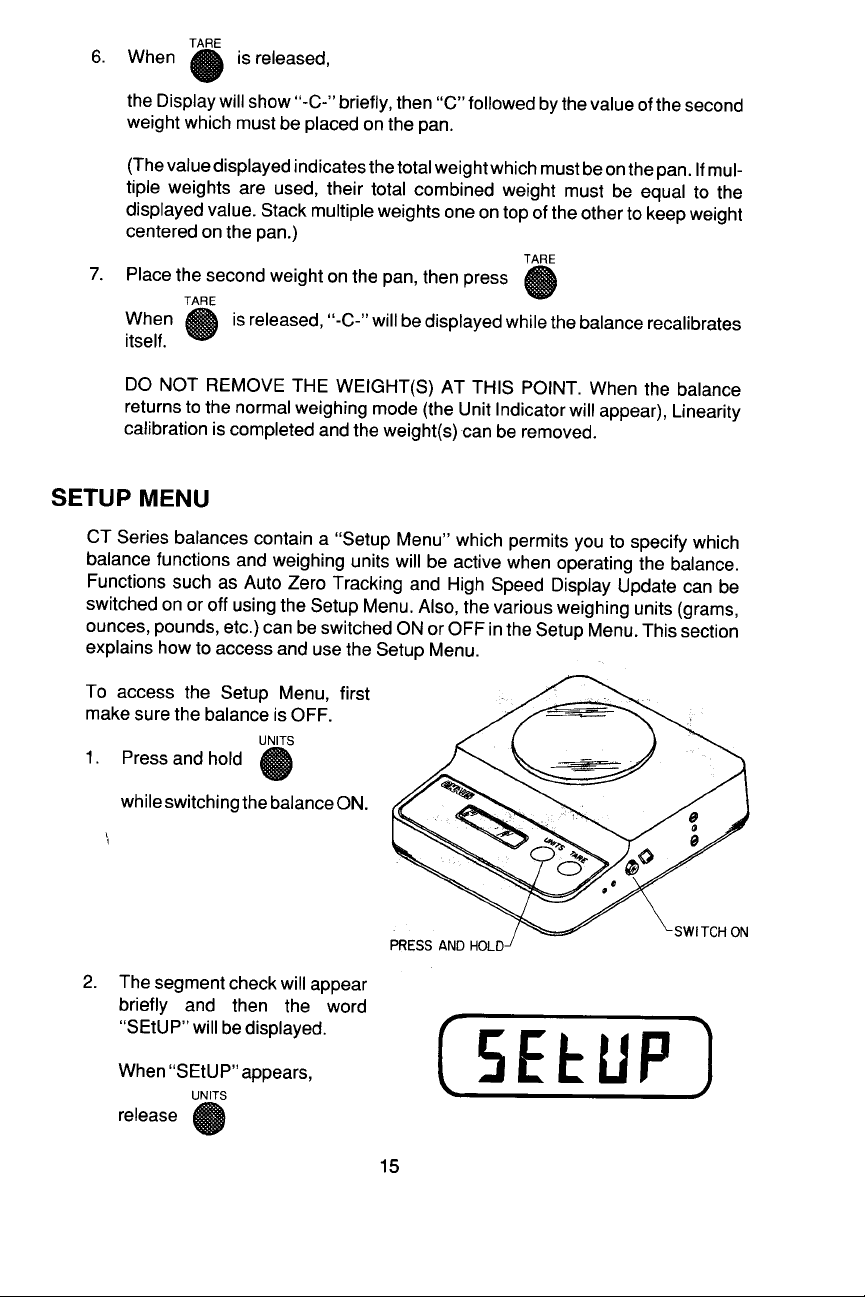

Page 15

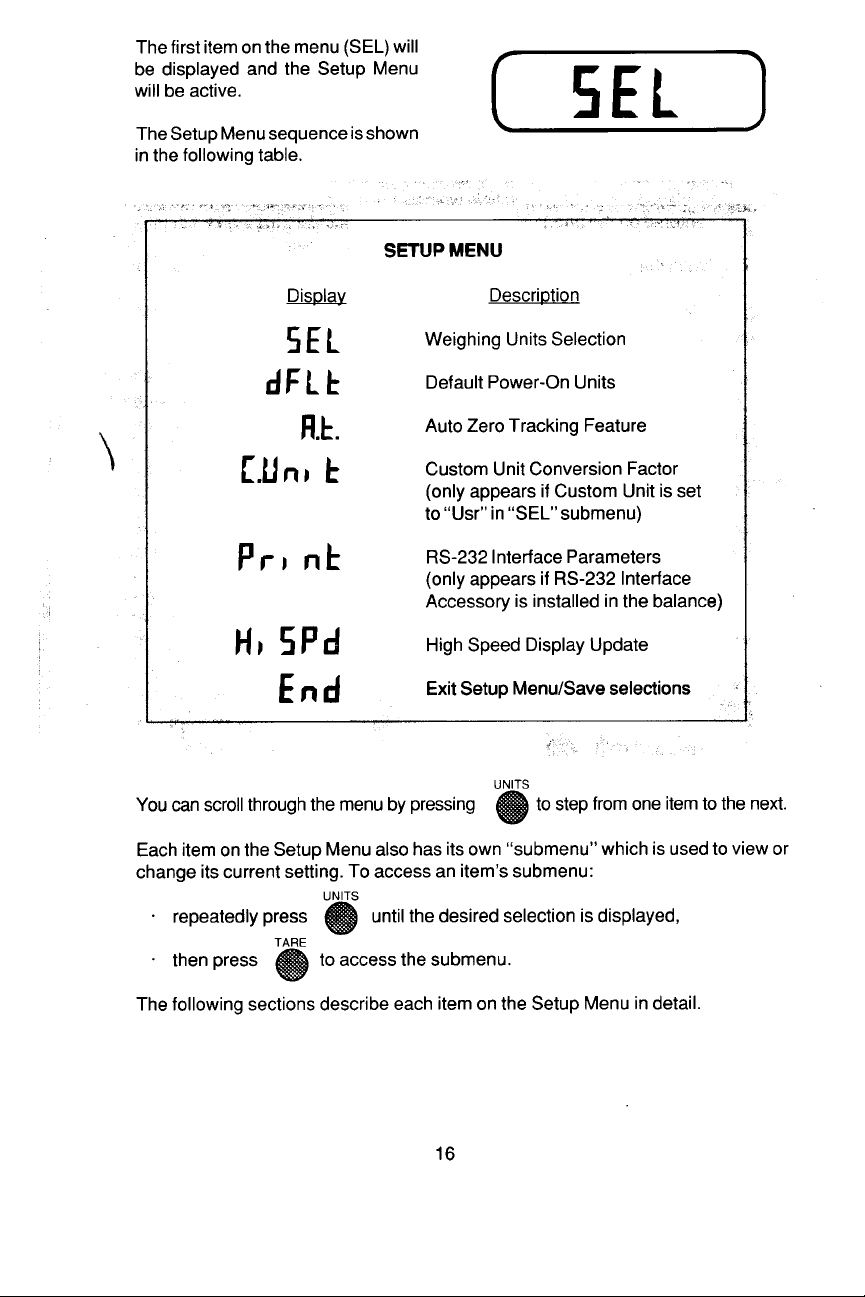

Page 16

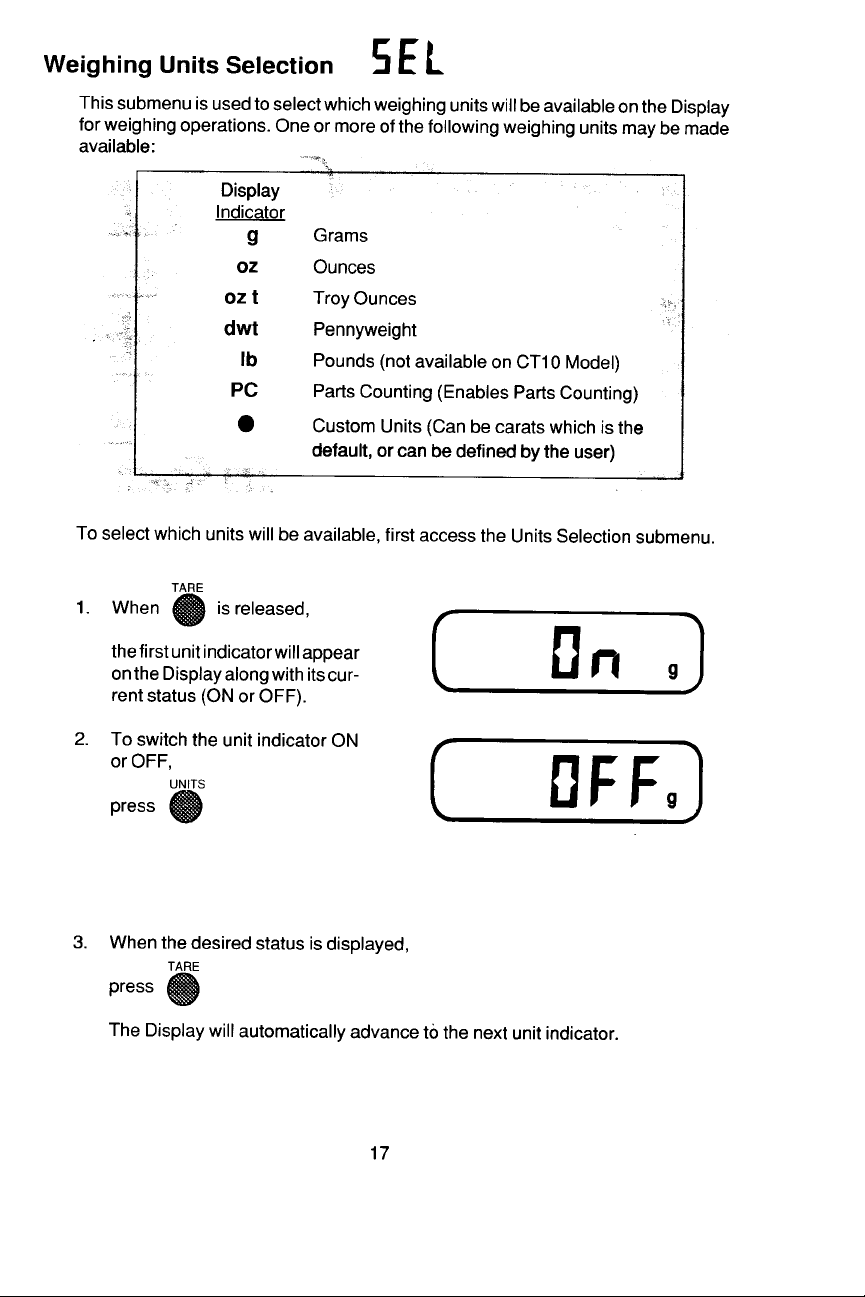

Page 17

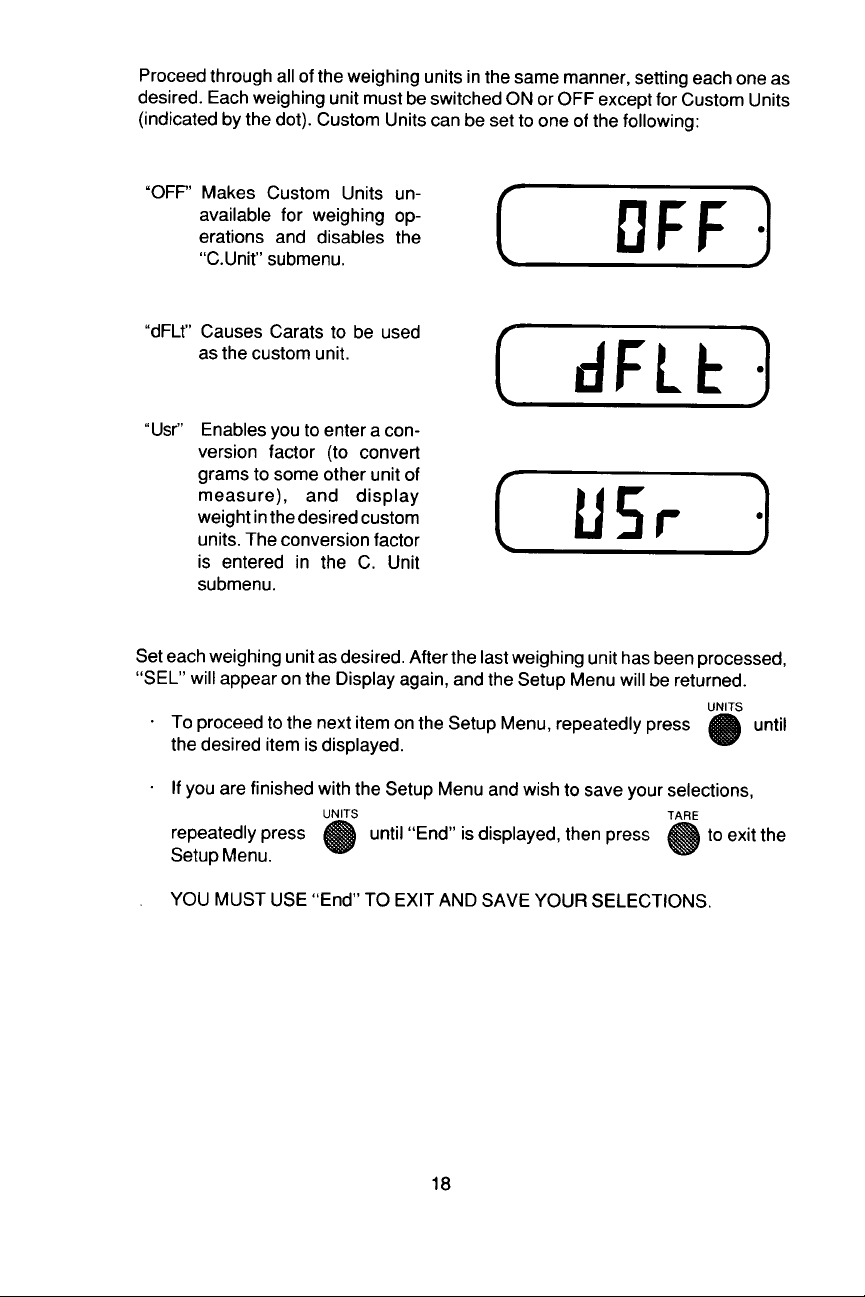

Page 18

Page 19

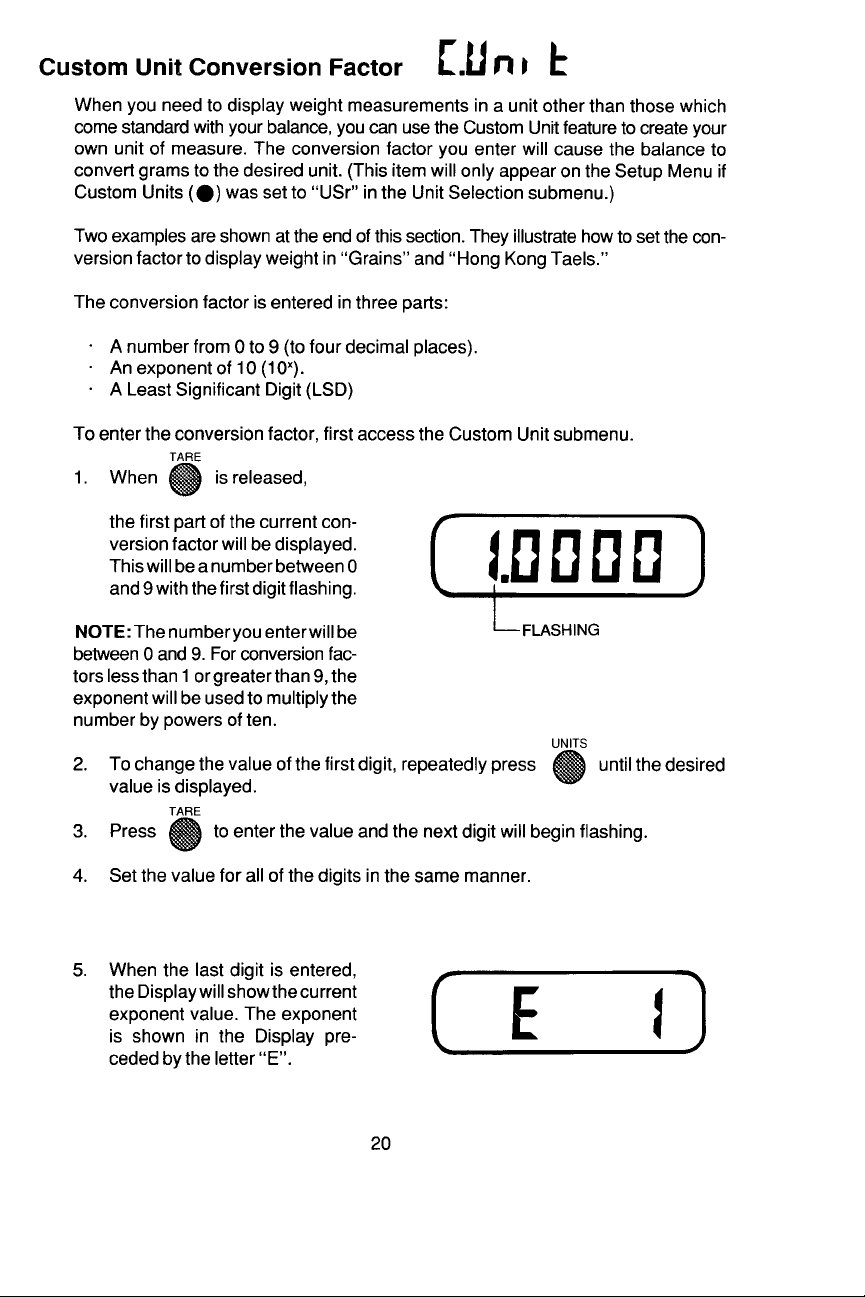

Page 20

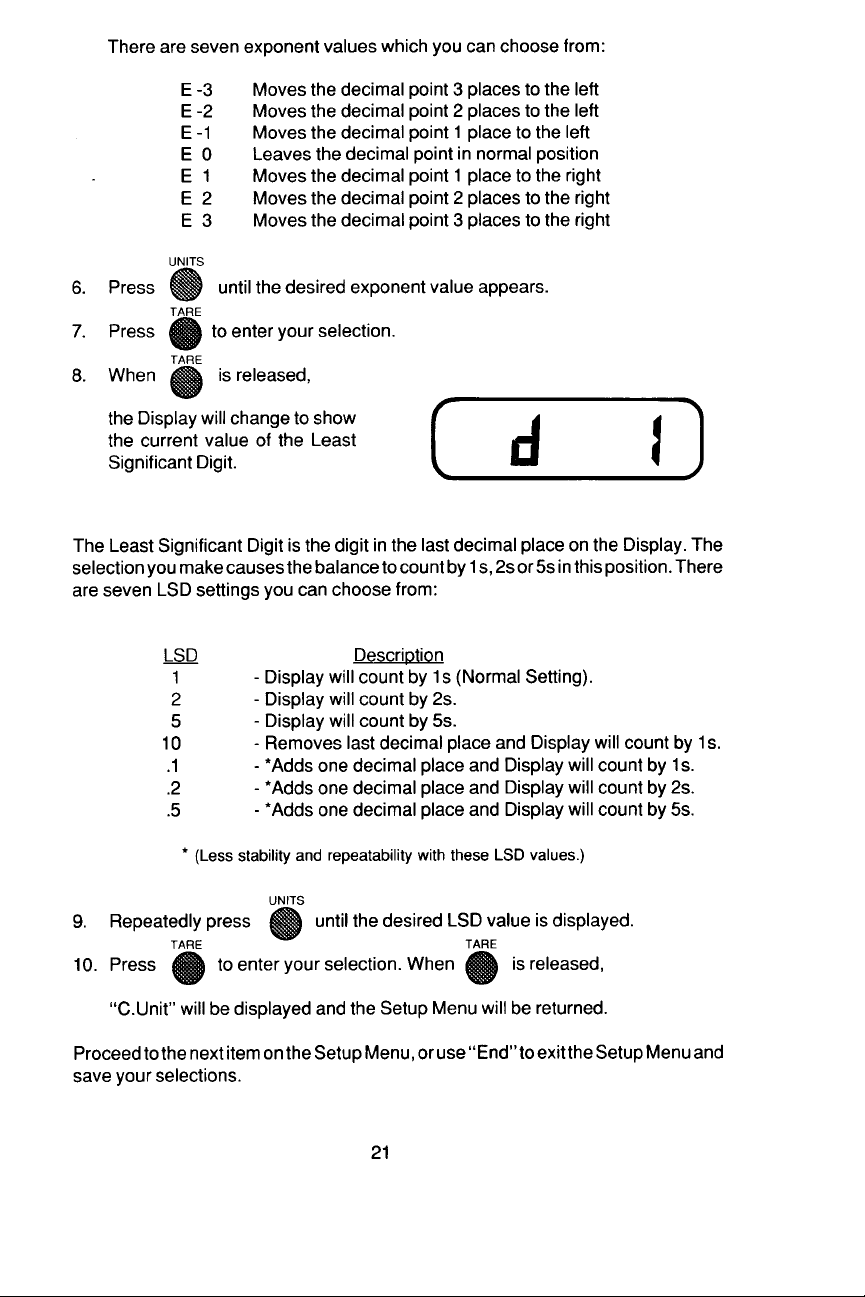

Page 21

Page 22

Page 23

Page 24

Page 25

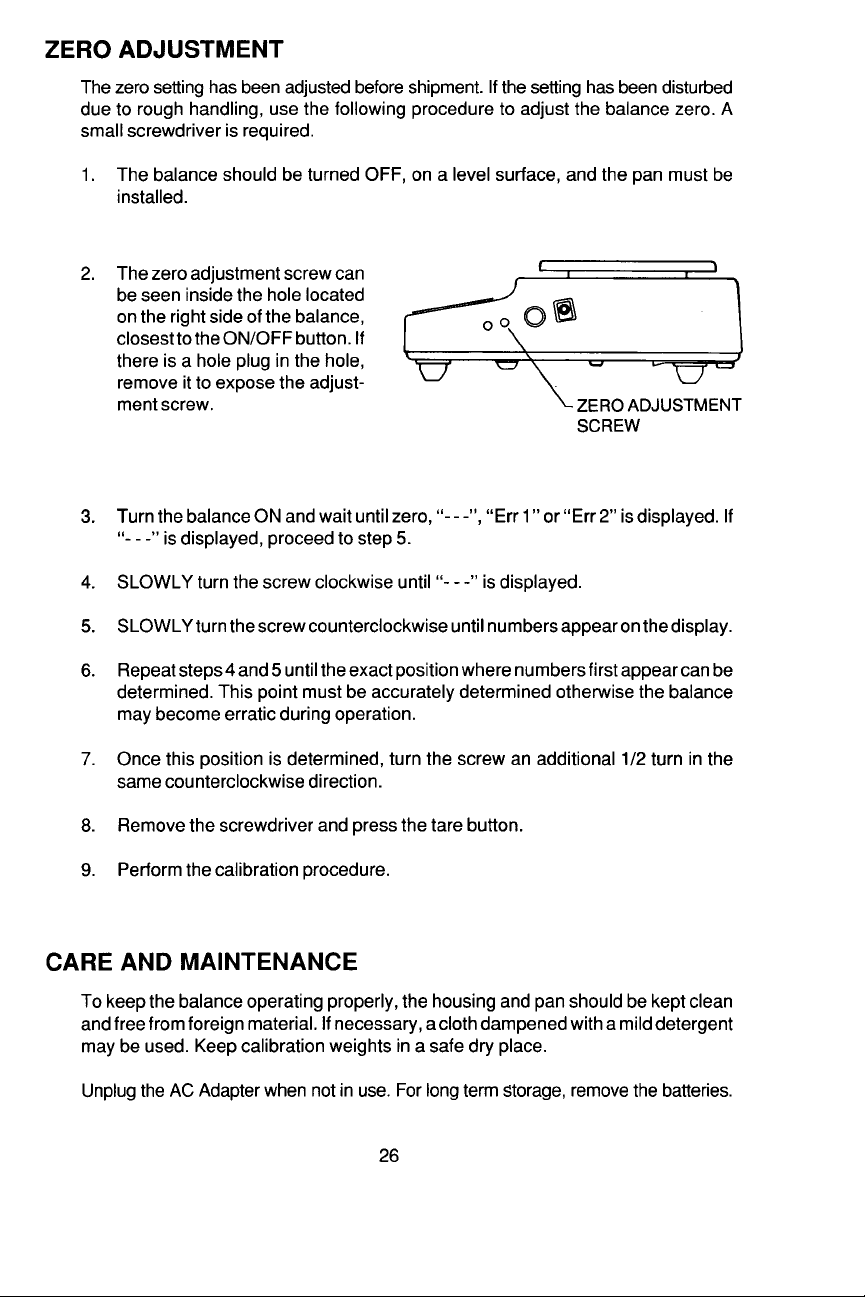

Page 26

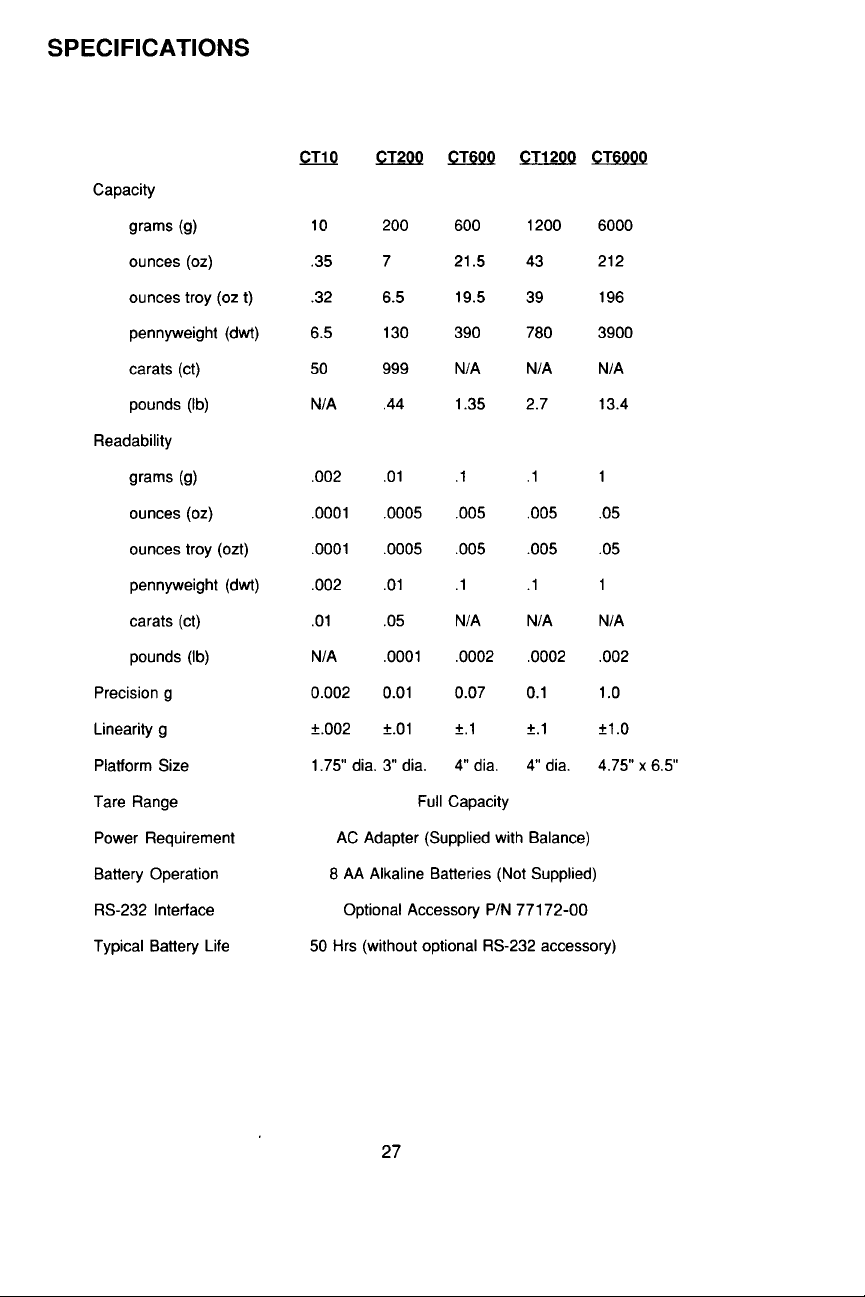

Page 27

Page 28

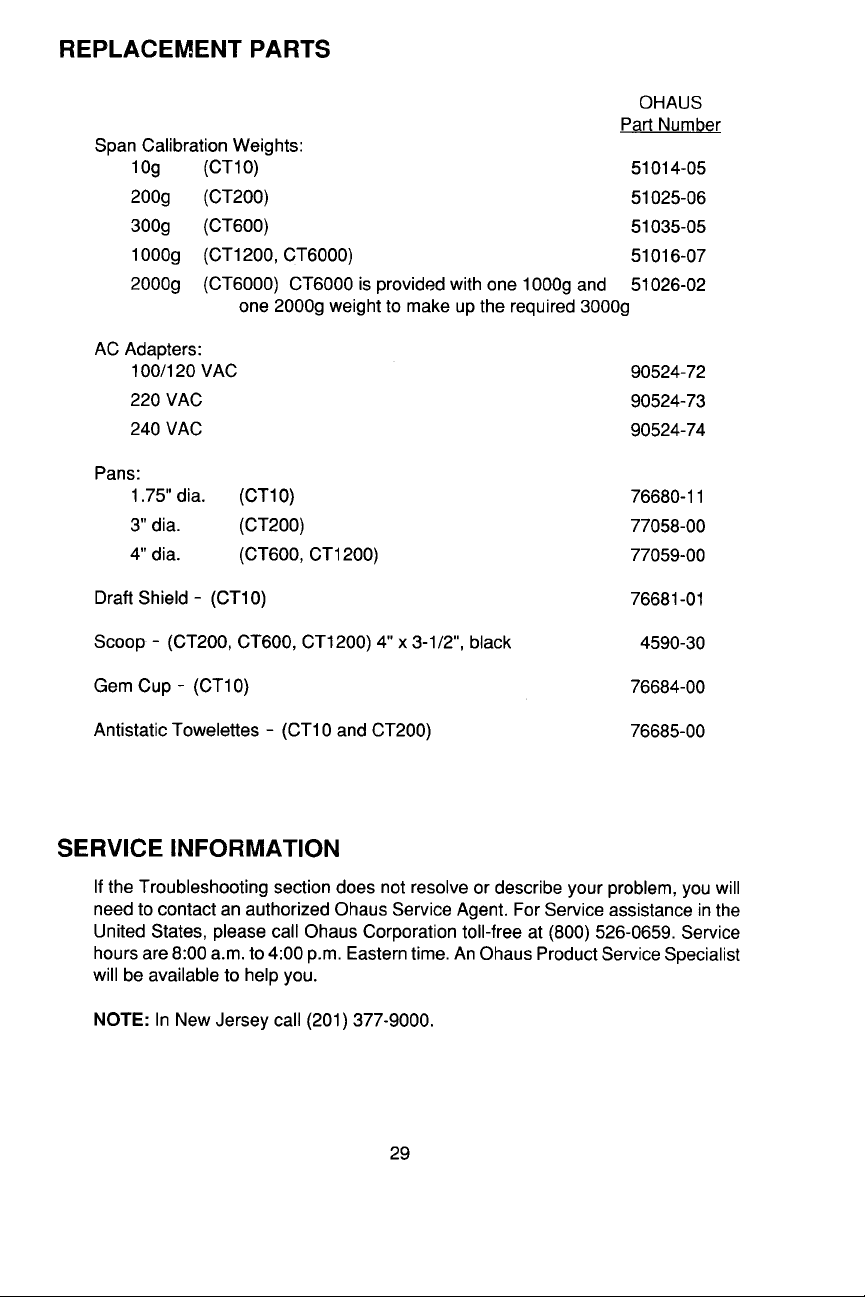

Page 29

Page 30

Page 31

Page 32

CT SERIESCT SERIES

CT SERIES

CT SERIESCT SERIES

RS-232 INTERFRS-232 INTERF

RS-232 INTERF

RS-232 INTERFRS-232 INTERF

KITKIT

KIT

KITKIT

AA

A

AA

CECE

CE

CECE

For use with Models

CT10, CT200, CT600, CT600L

CT1200, CT3000L and CT6000

Instruction ManualInstruction Manual

Instruction Manual

Instruction ManualInstruction Manual

WARNING:WARNING:

WARNING: THIS EQUIPMENT GENERATES, USES, AND CAN RADIATE RADIO

WARNING:WARNING:

FREQUENCY ENERGY AND IF NOT INSTALLED AND USED IN ACCORDANCE

WITH THE INSTRUCTION MANUAL, MAY CAUSE INTERFERENCE TO RADIO

COMMUNICATIONS. IT HAS BEEN TESTED AND FOUND TO COMPLY WITH CLASS

“A” REQUIREMENTS IN BOTH PART 15 OF FCC RULES AND THE RADIO INTERFERENCE REGULATION OF THE CANADIAN DOC. THIS EQUIPMENT DOES NOT

EXCEED THE LIMITS FOR RADIO NOISE EMISSIONS. OPERATION OF THIS

EQUIPMENT IN A RESIDENTIAL AREA MAY CAUSE UNACCEPTABLE INTERFERENCE TO RADIO AND TV RECEPTION REQUIRING THE OPERATOR TO TAKE

WHATEVER STEPS ARE NECESSARY TO CORRECT THE INTERFERENCE.

LE PRÉSENT APPAREIL NUMÉRIQUE N’EMET PAS DE BRUITS RADIOÉLECTRIQUES DEPASSANT LES LIMITES APPLICABLES AUX APPAREILS NUMÉRIQUES

DE CLASSE A PRESCRITES DANS LE REGLEMENT SUR LE BROUILLAGE RADIOÉLECTRIQUE EDICTÉ PAR LE MINISTERE DES COMMUNICATIONS DU CANADA.

©©

©

©©

Ohaus Corporation 1989, all rights reservedOhaus Corporation 1989, all rights reserved

Ohaus Corporation 1989, all rights reserved

Ohaus Corporation 1989, all rights reservedOhaus Corporation 1989, all rights reserved

Page 33

The CT Series RS-232 Accessory is a bidirectional interface which enables the balance

to communicate with a printer or computer that is equipped with an RS-232 serial port.

The Interface assembly is easily installed in the balance and all communication

parameters are configured using the Setup Menu (reference the CT Series Manual).

Before installing the Interface assembly, observe the following:

WARNINGWARNING

WARNING

WARNINGWARNING

To prevent damage to the balance, be certain that the power supply is

disconnected before removing the cover.

Even though the balance may have been switched OFF, voltage is present

inside the balance as long as the power supply is connected.

If the AC Adapter is being used, disconnect it.

If batteries are installed, remove them.

INSTALLATIONINSTALLATION

INSTALLATION

INSTALLATIONINSTALLATION

To install the RS-232 Interface Accessory, first remove the Pan from the balance, and turn the balance upside down.

(Do not remove Pan on CT3000L and

CT6000 Models.)

1. The bottom plate is held by four

screws, one located in each corner.

Remove the four screws and lift off

the bottom plate.

NOTE:NOTE:

NOTE: On earlier models the bot-

NOTE:NOTE:

tom plate is held by one screw located toward the center of the plate.

2. On the rear of the balance, a protec-

tive label is provided which covers

the hole for the 9-pin RS-232 connector.

Peel off the label to expose the hole.

3. Place the circuit board and connec-

2

Page 34

tor assembly in the balance so that

the 9-pin connector fits through the

hole.

4. Fasten the assembly using the two

screws provided.

5. Slide the ribbon connector onto the

edge of the main circuit board as

shown in the diagram.

Replace the bottom plate and install

the batteries or AC Adapter. Replace the pan if it was removed.

9-PIN CONNECTOR9-PIN CONNECTOR

9-PIN CONNECTOR

9-PIN CONNECTOR9-PIN CONNECTOR

The balance can now be interfaced with

other equipment utilizing the 9-pin connector which has been installed. The

diagram shows the pin-out and pin de-

scriptions for the connector.

The balance will not output any informa-

tion unless pin 5 (CTS) is held in an ON

state (+3 to +15 VDC). Interfaces not

utilizing the CTS handshake may tie pin

5 to pin 6 to defeat it.

NOTE:NOTE:

NOTE: This interface does not strictly

NOTE:NOTE:

adhere to the official RS-232 standard

(particularly in the connector used). However, it is compatible with what is commonplace in the microcomputer industry.

3

Page 35

SETUPSETUP

SETUP

SETUPSETUP

Once installation is completed, the interface parameters must be entered using the

Setup Menu (reference the CT Series Manual). When the interface is installed in the

balance, the Setup Menu will include an additional item, the Print submenu. Using the

Print submenu to enter the interface parameters includes:

• Selecting a Baud Rate

• Selecting a Data Frame Format (data bits, parity, stop bits)

• Selecting the Auto Print Interval (1-99 seconds)

• Enabling or Disabling the “Print Stable Data Only” feature

To begin, access the Setup Menu as explained in the CT Series manual, then repeatedly

press the UNITS button until “Print” is displayed. When “Print” is displayed, press the

TARE button to access the Print submenu selections. (On Legal for Trade models, the

RE-ZERO button replaces the TARE button.)

The first item displayed will be the RS-232 parameter selection. Pressing the UNITS

button repeatedly enables you to scroll through the Print submenu. Pressing the TARE

button lets you access the displayed selection.

r S232 - Used to select baud rate and data frame

A.P.- Used to set Auto Print Interval (1-99 seconds)

Print

Submenu

S tb. - Used to set “Stable Data Only” feature ON or OFF

End- Used to exit Print submenu and return to main

Setup Menu

Use the following procedures to set each of these parameters.

RS-232 ParametersRS-232 Parameters

RS-232 Parameters

RS-232 ParametersRS-232 Parameters

This selection is used to select the desired baud rate and data frame format. There are

five available baud rates (300, 1200, 2400, 4800, 9600), and nine data frame formats

(numbered 0-8) to choose from. Use the following procedure to set these parameters:

1. Access the RS-232 Parameters selection. When the TARE button is

released, the current baud rate setting will be displayed. The baud rate

is preceded by the letter “b”.

2. Press the UNITS button repeatedly

until the desired baud rate is displayed. Then press the TARE button

to select the displayed baud rate.

4

Page 36

3. Once the baud rate is entered, the

Display will change to show the current frame format selection. This will

be the letters “Fr” followed by a number from 0 to 8.

The number corresponds to one of the following data frames:

Fr. 0Fr. 0

Fr. 0 START 7 STOP STOP

Fr. 0Fr. 0

Fr. 1Fr. 1

Fr. 1 START 7 EVEN STOP

Fr. 1Fr. 1

Fr. 2Fr. 2

Fr. 2 START 7 ODD STOP

Fr. 2Fr. 2

Fr. 3Fr. 3

Fr. 3 START 7 EVEN STOP STOP

Fr. 3Fr. 3

Fr. 4Fr. 4

Fr. 4 START 7 ODD STOP STOP

Fr. 4Fr. 4

BIT DATA BITS BIT BIT

BIT DATA BITS PARITY BIT BIT

BIT DATA BITS PARITY BIT BIT

BIT DATA BITS PARITY BIT BIT BIT

BIT DATA BITS PARITY BIT BIT BIT

Fr. 5Fr. 5

Fr. 5 START 8 STOP

Fr. 5Fr. 5

Fr. 6Fr. 6

Fr. 6 START 8 ODD STOP

Fr. 6Fr. 6

Fr. 7Fr. 7

Fr. 7 START 8 EVEN STOP

Fr. 7Fr. 7

Fr. 8Fr. 8

Fr. 8 START 8 STOP STOP

Fr. 8Fr. 8

BIT DATA BITS BIT

BIT DATA BITS PARITY BIT BIT

BIT DATA BITS PARITY BIT BIT

BIT DATA BITS BIT BIT

Press the UNITS button repeatedly until the desired frame number is displayed.

Then press the TARE button to select the displayed frame number.

When the TARE button is released, “rS232” will be displayed and the Print submenu

is returned.

5

Page 37

Auto Print IntervalAuto Print Interval

Auto Print Interval

Auto Print IntervalAuto Print Interval

The Auto Print feature enables the scale to automatically send displayed data to a printer

or computer, at a specified time interval. The interval can be set from 1 to 99 seconds.

Setting the interval to 0 disables the Auto Print feature. Use the following procedure to

set the Auto Print interval:

1. Access the Auto Print selection. When the TARE button is released, the current

Auto Print interval will be displayed. The number is preceded by the letters “A.P.”

2. Press the UNITS button repeatedly to increase the setting. Holding the UNITS

button down will cause the value to increase more rapidly.

3. Press the TARE button to select the displayed value.

When the TARE button is released, “A.P.” will be displayed and the Print submenu

will be returned.

Print Stable Data OnlyPrint Stable Data Only

Print Stable Data Only

Print Stable Data OnlyPrint Stable Data Only

When enabled, this feature restricts the balance to sending only stable display data

when requested. (Display data is stable when the Unit Indicator is shown in the Display.)

To turn this feature ON or OFF:

1. Access the Stable Data selection. When the TARE button is released, the current

status will be displayed.

2. Press the UNITS button to switch the status ON or OFF as desired.

3. Press the TARE button to select the displayed status.

When the TARE button is released, “Stb.” will be displayed and the Print submenu

will be returned.

NOTE:NOTE:

NOTE: On Legal for Trade models, “Stb.” does not appear. The feature is always ON.

NOTE:NOTE:

Exit Print SubmenuExit Print Submenu

Exit Print Submenu

Exit Print SubmenuExit Print Submenu

When you are finished making your selections, “End” must be used to exit the Print

submenu. Use the following procedure:

1. Access the “End” selection. When the TARE button is released, “Print” will be

displayed and the Setup Menu will be returned.

2. Press the UNITS button repeatedly until End is displayed on the Setup Menu.

3. Press the TARE button to exit the Setup Menu and save your selections.

6

Page 38

DIRECT CONNECTION TO A PRINTERDIRECT CONNECTION TO A PRINTER

DIRECT CONNECTION TO A PRINTER

DIRECT CONNECTION TO A PRINTERDIRECT CONNECTION TO A PRINTER

The balance can be connected directly to a printer using the RS-232 Interface. Display

data can be sent to the printer in the format shown below, using one of three methods:

• using the Auto Print feature

• using the UNITS button (balances with version 2.0 software or later)

• using an external print switch

To send data to the printer using the UNITS button, press and hold the button for at least

three seconds. The word “Print” will be displayed and the current display data will be

sent. If only one weighing unit is enabled (in the Setup Menu), the UNITS button

becomes a dedicated PRINT button and does not have to be held for three seconds.

An external print switch may be connected between pins 9 (PRINT) and 7 (GND) of the

9-pin connector. This must be a normally open switch. When the switch is closed, the

current display data will be sent.

1234567891011121314

±XXX. XXSpXXXStb. Cr Lf

POLARITY

Field is Blank if

positive.

CONNECTION TO A COMPUTERCONNECTION TO A COMPUTER

CONNECTION TO A COMPUTER

CONNECTION TO A COMPUTERCONNECTION TO A COMPUTER

The balance can be connected to a computer using the RS-232 Interface. This

configuration enables full control of balance functions from the computer, except for

switching the scale ON and OFF. The balance will respond to commands sent as ASCII

characters followed by a Carriage Return (CR) or Carriage Return Line Feed (CRLF)

character. The following table defines the accepted commands. Any other control

characters or commands will be ignored.

COMMAND SENT

BY COMPUTER DESCRIPTION BALANCE RESPONSE

P Print Display Data The balance responds by sending the

DISPLAYED VALUE

Number is right justified

padded with zeroes.

displayed data in the format illustrated in

“DIRECT CONNECTION TO PRINTER”.

This includes Polarity, Displayed Value,

Weighing Units, Stability Status followed by

a CRLF.

UNITS

G

OZ

OZT

DWT

LBS

PCS

USR

CT

STABILITY

Blank if stable.

? if unstable.

COMMAND SENT

7

Page 39

BY COMPUTER DESCRIPTION BALANCE RESPONSE

? Print Display Units The balance responds by sending the

current unit indicator and stability status in

the following format:

(Field)

(# of Chars.)

Units Stability CR

3 1 1

M UNITS Button This command has the same effect as

pressing the UNITS button on the front

panel. No data is output.

T TARE Button This command has the same effect as

pressing the TARE button on the front

panel. No data is output.

E Extended UNITS This command has the same effect as

Button pressing and holding the UNITS button on

the front panel.

* L Start Linearity Starts Linearity Calibration procedure (see

Linearity Calibration in CT Series Manual).

* C Start Calibration Starts Span Calibration procedure (see

Span Calibration in CT Series Manual).

0D Turn OFF 1 Second Disables the 1 second delay the balance

Delay waits before responding to a “P” command.

When disabled, the balance responds

immediately.

1D Turn ON 1 Second Enables a 1 second delay in the balance’s

Delay response to a “P” command. This is

provided for computers requiring such a

delay.

* 0S Turn OFF Disables the Stable Data Only printing

"Stable Data Only" feature. When disabled, the balance will

send display data in response to a “P”

command, regardless of the stability status.

* 1S Turn ON Enables the Stable Data Only printing

"Stable Data Only" feature. When the feature is enabled, the

balance will only send stable display data in

response to the “P” command.

* Does not apply to Legal For Trade models.

COMMAND SENT

8

Page 40

BY COMPUTER DESCRIPTION BALANCE RESPONSE

nnA Set Auto Print Set the Auto Print Interval to “nn” seconds

Interval (nn = 0 to 99). Setting the interval to 00

disables the Auto Print function.

* 0Z Turn OFF Auto Zero Disables the Auto Zero Tracking feature

Tracking (see Setup Menu in CT Series Manual).

* 1Z Turn ON Auto Zero Enables the Auto Zero Tracking feature

Tracking (see Setup Menu in CT Series Manual).

** V Print PROM Causes the balance to respond with the

Revision Level revision level of the PROM installed in the

balance. Output is in the format: “CT V_._”.

** N Disable Automatic Permits you to disable the automatic printing

Error Message of error messages output by the balance.

Printing This command is reset on power-off.

** <esc>D Revert to Factory Sets all balance menu selections to the

Default Settings following factory defaults:

All available units enabled

Default units = Grams

* Auto-Zero Tracking is ON

High Speed Display Update is OFF

* Custom Unit = Carats

* Custom Unit Conversion Factor is set to:

1.0000, LSD = 1, Exponent = 0

“Stable Data Only” printing is ON

Auto Print feature is OFF

* Does not apply to Legal For Trade models.

** Available only on balances with version 2.0 software or later.

RS-232 Error MessagesRS-232 Error Messages

RS-232 Error Messages

RS-232 Error MessagesRS-232 Error Messages

If the balance is in an error condition when a request for output occurs, the current error

message number (Err0 - Err6) will be sent in the following format:

(Field)

(# of Chars.)

Error # CR LF

5 1 1

9

Page 41

OPTIONAL ACCESSORIESOPTIONAL ACCESSORIES

OPTIONAL ACCESSORIES

OPTIONAL ACCESSORIESOPTIONAL ACCESSORIES

Ohaus

Part Number

Interface Cables:

Blunt End (User Defined) 90641-01

IBM® - PC 90641-02

Apple® IIe 90641-03

Epson HX-20 90641-04

Apple® IIc 90641-05

®

Apple is a registered trademark of Apple Corporation.

®

IBM is a registered trademark of International Business Machines Corporation.

OHAUS® is the registered trademark of Ohaus Corporation as are the following

trademarks: AUTOGRAM® , BRAINWEIGH® , CENT-O-GRAM® , CHECK-O-GRAM® ,

CUBE-O-GRAM® , DEC-O-GRAM® , DIAL-O-GRAIN® , DIAL-O-GRAM® , DU-OMEASURE® , GALAXY® , LUME-O-GRAM® , PORT-O-COUNT® , PORT-O-GRAM® ,

PRACT-O-GRAM® , PRIMER® , STO-A-WEIGH® , TOUCH-N-WEIGH® , 5-0-5® , and 1010® .

OHAUS CORP.OHAUS CORP.

OHAUS CORP.

OHAUS CORP.OHAUS CORP.

29 Hanover Road Broad Lane, Cottenham

Florham Park, N.J. 07932 Cambridge CB4 4SW

Tel: 201-377-9000 ENGLAND

Telex: 6853191 OHAUS UW Tel: 0954-51343

Fax: 201-593-0359 Telex: 817285 OSCALE G

OHAUS EUROPE, LTD.OHAUS EUROPE, LTD.

OHAUS EUROPE, LTD.

OHAUS EUROPE, LTD.OHAUS EUROPE, LTD.

Fax: 0954-50205

P/N 77171-00 R1289

Page 42

Ohaus CorporationOhaus Corporation

Ohaus Corporation

Ohaus CorporationOhaus Corporation

29 Hanover Road

Florham Park NJ

07932-0900

PORTABLE

Advanced

Electronic Balances

CT Series

Instruction Manual

Page 43

NOTICE:NOTICE:

NOTICE: THIS EQUIPMENT HAS BEEN TESTED AND FOUND TO COMPLY

NOTICE:NOTICE:

WITH THE LIMITS FOR A CLASS A DIGITAL DEVICE, PURSUANT TO PART 15

OF THE FCC RULES.

THESE LIMITS ARE DESIGNED TO PROVIDE REASONABLE PROTECTION

AGAINST HARMFUL INTERFERENCE WHEN THE EQUIPMENT IS OPERATED

IN A COMMERCIAL ENVIRONMENT. THIS EQUIPMENT GENERATES, USES,

AND CAN RADIATE RADIO FREQUENCY ENERGY AND, IF NOT INSTALLED

AND USED IN ACCORDANCE WITH THE INSTRUCTION MANUAL, MAY CAUSE

HARMFUL INTERFERENCE TO RADIO COMMUNICATIONS. OPERATION OF

THIS EQUIPMENT IN A RESIDENTIAL AREA IS LIKELY TO CAUSE HARMFUL

INTERFERENCE IN WHICH CASE THE USER WILL BE REQUIRED TO CORRECT THE INTERFERENCE AT HIS OWN EXPENSE.

THIS DIGITAL APPARATUS DOES NOT EXCEED THE CLASS A LIMITS FOR

RADIO NOISE EMISSIONS FROM DIGITAL APPARATUS AS SET OUT IN THE

INTERFERENCE-CAUSING EQUIPMENT STANDARD ENTITLED “DIGITAL APPARATUS”, ICES-003 OF THE DEPARTMENT OF COMMUNICATIONS.

CET APPAREIL NUMERIQUE RESPECTE LES LIMITES DE BRUITS

RADIOELECTRIQUES APPLICABLES AUX APPAREILS NUMERIQUES DE CLASSE

A PRESCRITES DANS LA NORME SUR LE MATERIEL BROUILLEUR : “APPAREILS

NUMERIQUES”, NMB-003 EDICTEE PAR LE MINISTRE DES COMMUNICATIONS.

Unauthorized changes or modifications to this equipment are not permitted.

2

Page 44

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

INTRODUCTION.................................................................................................. 5

DESCRIPTION..................................................................................................... 5

FEATURES .......................................................................................................... 6

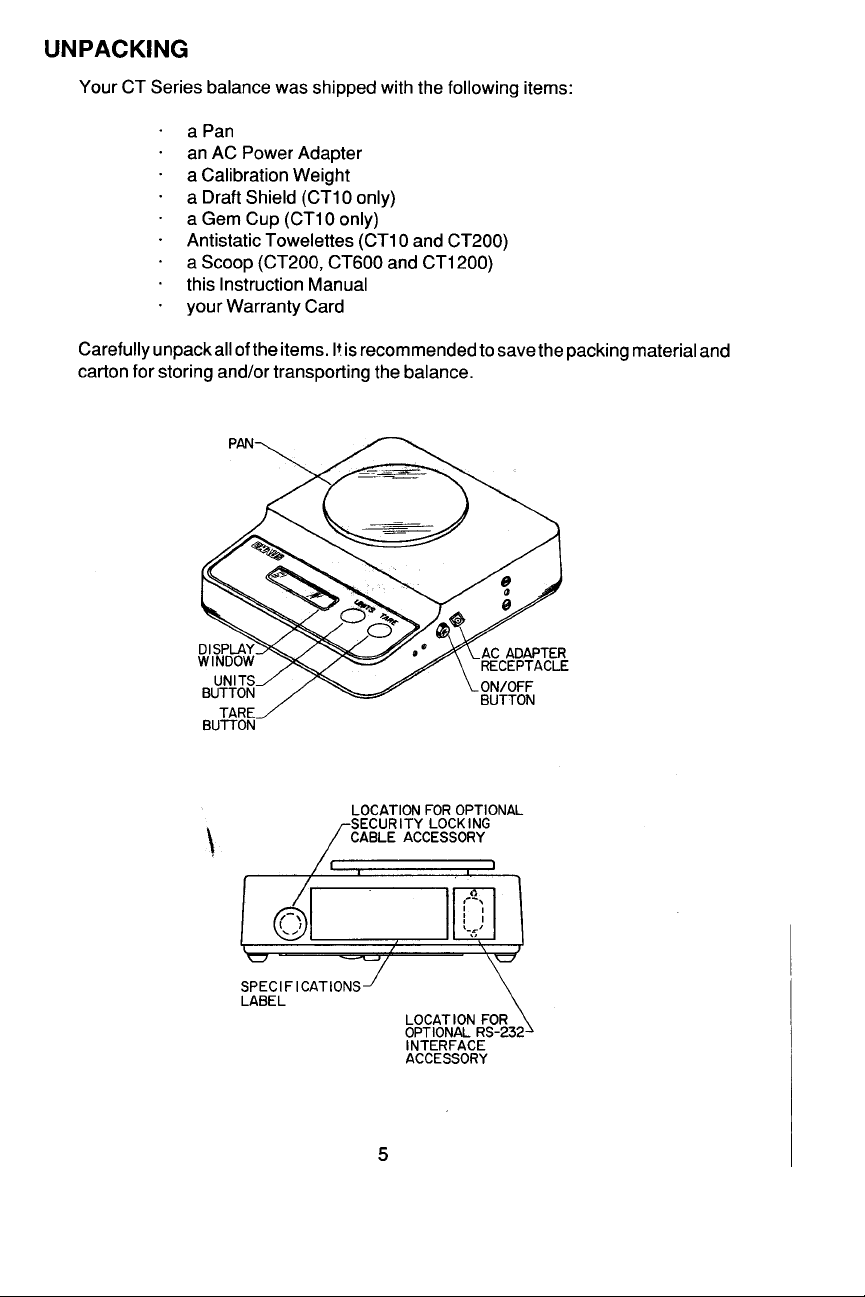

UNPACKING ........................................................................................................ 7

INSTALLATION.................................................................................................... 7

Environment .................................................................................................. 7

Power Options .............................................................................................. 8

Battery Installation ........................................................................................ 8

AC Adapter ................................................................................................... 8

Model CT200 Shipping Bracket .................................................................... 9

Platform Installation ...................................................................................... 9

Weigh Below Hook...................................................................................... 10

OPERATION ...................................................................................................... 10

Turning the Balance On and Off................................................................. 10

Checking Calibration ................................................................................... 11

Weighing ..................................................................................................... 1 1

Taring .......................................................................................................... 12

Parts Counting ............................................................................................ 13

Printing ........................................................................................................ 14

USING MENUS TO CONFIGURE THE BALANCE........................................... 15

CALIBRATION MENU ........................................................................................ 16

Calibration Menu Protection ....................................................................... 16

Calibration Masses ..................................................................................... 16

Span Calibration ......................................................................................... 17

Linearity Calibration .................................................................................... 1 8

End .............................................................................................................. 18

SETUP MENU.................................................................................................... 20

Accessing the Setup Menu ......................................................................... 21

Reset to Factory Settings ........................................................................... 21

Unit Selection .............................................................................................. 2 2

Taels ........................................................................................................... 22

Custom Units .............................................................................................. 23

3

Page 45

Custom Units Conversion Factor ................................................................ 24

Example ................................................................................................... 26

Averaging Level .......................................................................................... 27

Stability Range ............................................................................................ 28

Auto-Zero .................................................................................................... 29

Parts Counting Error Level ......................................................................... 30

Auto-Off ....................................................................................................... 31

End .............................................................................................................. 31

CALIBRATION LOCK-OUT PROTECTION ....................................................... 32

CARE AND MAINTENANCE ............................................................................. 33

TROUBLESHOOTING ....................................................................................... 33

Error Codes ................................................................................................. 34

SERVICE INFORMATION ................................................................................. 34

PARTS INFORMATION ..................................................................................... 35

REPLACEMENT PARTS ................................................................................... 35

SECURITY ......................................................................................................... 36

ACCESSORIES ................................................................................................. 36

SPECIFICATIONS ............................................................................................. 37

LIMITED WARRANTY ....................................................................................... 38

4

Page 46

INTRODUCTIONINTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

This manual covers installation, operation and troubleshooting for the OHAUS

Portable

CT6000. To ensure proper operation of the balance, please read this manual

completely.

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

Advanced

Electronic Balances, Models CT10, CT200, CT600, CT1200 and

®

The Ohaus Portable

signed to provide years of service with virtually no maintenance. The Portable

Advanced

one piece solid-state precision electronics PC board, and a five digit LCD display which

is 0.5 inches in height. All Portable

measure in grams and can be set to measure in other units of measure as desired.

Each balance operates through a series of menus which enable precise calibration and

the selection of various parameters which enhance operation. A built in lock switch

prevents calibration settings from being changed. Power is supplied through an AC

adapter or batteries. Accessories include: an RS232 Interface Kit which allows printing

of results through an external computer or printer, security device, calibration masses,

scoops and carrying cases. See accessory section.

housing is constructed of a material which is impact resistant, contains a

Advanced

balances are precision weighing instruments, de-

Advanced

balances are initially factory set to

Portable

Advanced

5

Balance

Page 47

FEATURES

Portable

and configure the balance for specific operating requirements. When an optional

RS232 Interface is installed, a third menu is available.

•

•

•

When the balance is first turned on, it can be used to weigh in grams or tare items

without setting the menus. Refer to the individual menus in this manual for detailed

descriptions and procedures for programming.

Advanced

CALIBRATIONCALIBRATION

CALIBRATION Menu - Allows the balance to be calibrated by using either Span or

CALIBRATIONCALIBRATION

Linearity calibration methods.

SETUPSETUP

SETUP Menu - Allows the balance to be set for environmental conditions and

SETUPSETUP

customized for specific weighing functions.

PRINTPRINT

PRINT Menu - When an

PRINTPRINT

of parameters under which the balance will interface with a computer or a printer.

Instructions for installing and using the interface are provided in a separate manual

which comes with the accessory.

balances contain two display menus which enable you to calibrate

optional

RS232 Interface is installed, allows the selection

6

Page 48

UNPACKINGUNPACKING

UNPACKING

UNPACKINGUNPACKING

All Portable

adapter, instruction manual and warranty card. Items checked below are supplied with

specific models as follows:

Calibration MassCalibration Mass

Calibration Mass

Calibration MassCalibration Mass

Draft ShieldDraft Shield

Draft Shield

Draft ShieldDraft Shield

Gem CupGem Cup

Gem Cup

Gem CupGem Cup

Weigh Below HookWeigh Below Hook

Weigh Below Hook

Weigh Below HookWeigh Below Hook

Antistatic TowelettesAntistatic Towelettes

Antistatic Towelettes

Antistatic TowelettesAntistatic Towelettes

ScoopScoop

Scoop

ScoopScoop

Hex KeyHex Key

Hex Key

Hex KeyHex Key

Carefully unpack all items. The platform for models CT200, CT600 and CT1200 is

packed in the upper portion of the packing material. Be sure to remove the platform

and do not discard the packing material. It is recommended to save the packing

material and carton for storing and/or transporting the balance. The packing material

may also be used as an insert for the Vinyl carrying case (optional accessory) listed

in the accessory section of this manual.

Advanced

balances are supplied with a weighing platform, AC power

CT10CT10

CT10

CT10CT10

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

CT200CT200

CT200

CT200CT200

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

✓✓

✓

✓✓

✓✓

✓

✓✓

CT600CT600

CT600

CT600CT600

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

CT1200CT1200

CT1200

CT1200CT1200

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

Location for optional

security device

CT6000CT6000

CT6000

CT6000CT6000

Display

Window

INSTALLATIONINSTALLATION

INSTALLATION

INSTALLATIONINSTALLATION

EnvironmentEnvironment

Environment

EnvironmentEnvironment

Balance performance can be affected by excessive air currents, corrosives, vibration,

temperature or humidity extremes.

DO NOTDO NOT

DO NOT use the balance:

DO NOTDO NOT

• Next to open windows or doors causing drafts or rapid temperature changes.

• Near air conditioning or heat vents.

• Near vibrating, rotating or reciprocating equipment.

• On an non-level work surface.

• Near corrosive vapors (example: nitric acid).

AC Adapter

Receptacle

Calibration Menu

Lockout Switch

Specifications Label

7

Location for optional

RS232 interface

Page 49

Power OptionsPower Options

Power Options

Power OptionsPower Options

The balance can be operated using 8 AA alkaline batteries (not included), or from any

AC electrical outlet by using the AC adapter supplied.

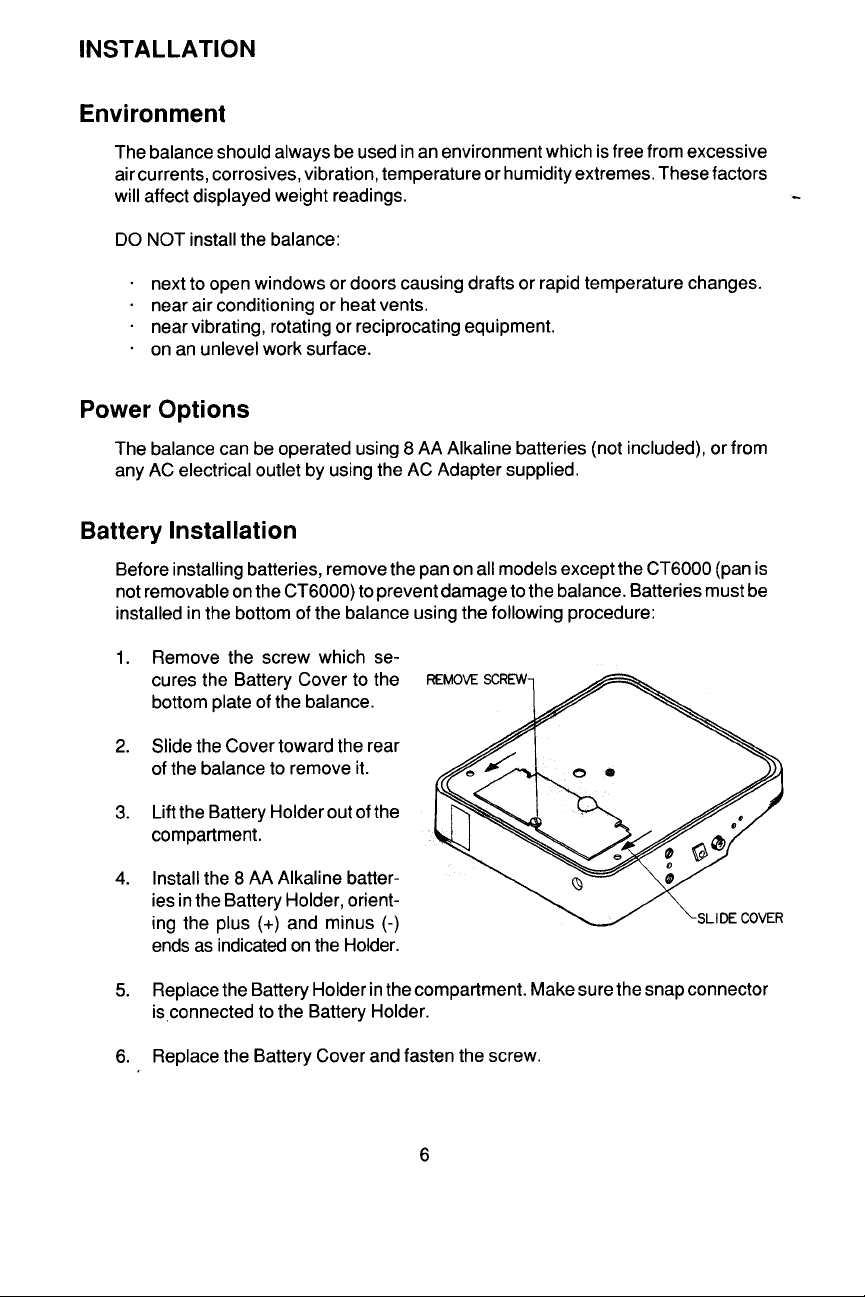

Battery InstallationBattery Installation

Battery Installation

Battery InstallationBattery Installation

1. Remove the platform on all models except the CT6000 (platform is not removable

on the CT6000).

2. Turn the balance over.

3. Press the tabs on the battery cover inward and lift the cover off.

4. Remove the battery holder.

5. Install the 8 AA alkaline batteries in the battery holder, orienting the plus (+) and

minus (-) ends as indicated on the holder.

6. Replace the battery holder in the compartment. Make sure the snap connector is

connected.

7. Replace the battery cover.

NOTENOTE

NOTE: The illustration shows a balance

NOTENOTE

with four feet. Certain models contain

only three feet.

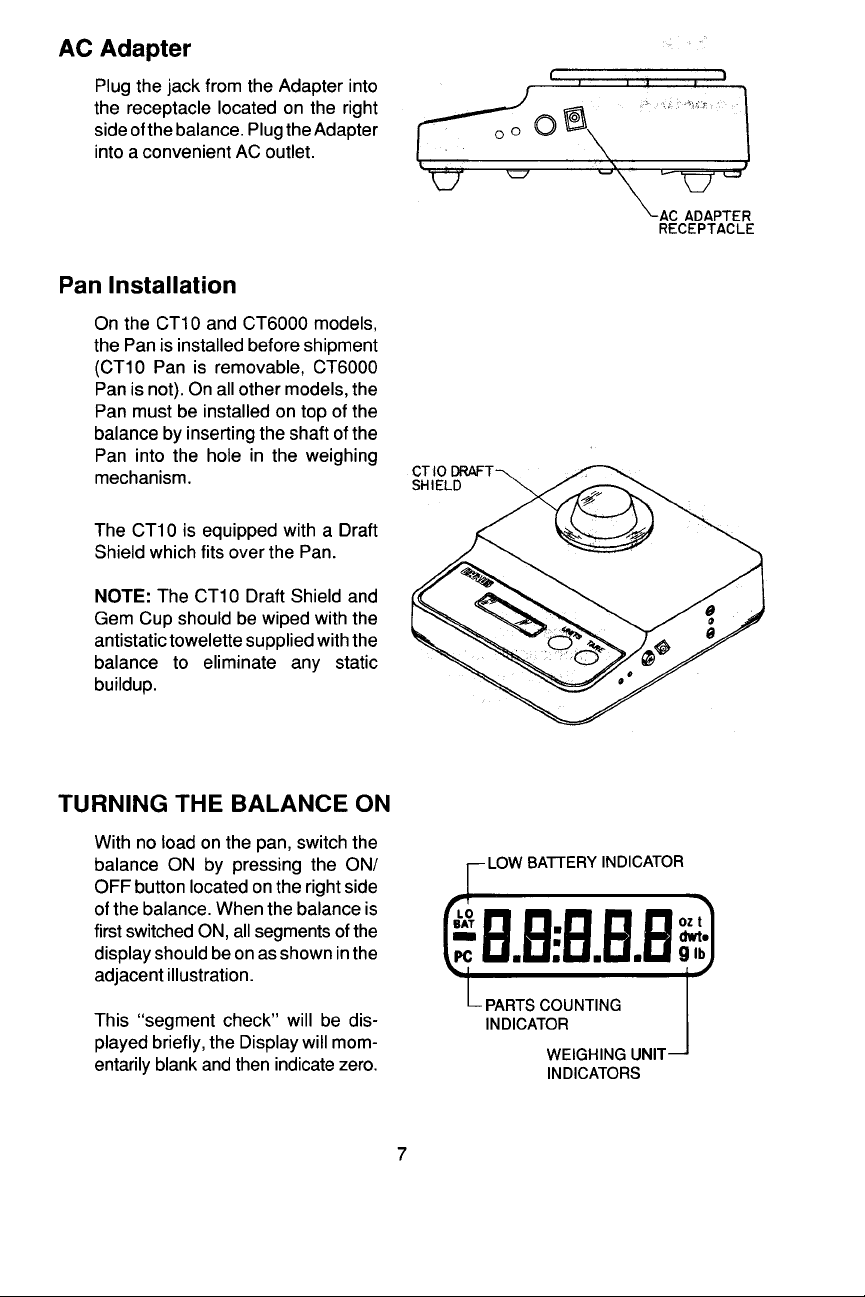

AC AdapterAC Adapter

AC Adapter

AC AdapterAC Adapter

Plug the jack from the adapter into the

receptacle located on the right side of the

balance. Plug the adapter into a convenient AC outlet.

Press tabs to

remove cover

8

Page 50

Model CT200 Shipping BracketModel CT200 Shipping Bracket

Model CT200 Shipping Bracket

Model CT200 Shipping BracketModel CT200 Shipping Bracket

The Model CT200 is factory packed

with a shipping bracket which must be

removed before installing the Platform.

1. Using the hex key provided, remove the screw which secures

the bracket to the transducer.

2. Slide the bracket out to remove it.

Platform InstallationPlatform Installation

Platform Installation

Platform InstallationPlatform Installation

On the CT10 and CT6000 models, the

platform is installed before shipment

(CT10 platform is removable, CT6000

platform is not). On all other models,

the platform must be installed on top of

the balance by inserting the shaft of the

platform into the hole in the weighing

mechanism.

CAUTION:CAUTION:

CAUTION: DO NOT ATTEMPT TO

CAUTION:CAUTION:

REMOVE THE DOWN STOP

ADJUSTMENT SCREW.

BRACKET

REMOVE SMALLER SCREW

(TURN COUNTERCLOCKWISE)

The CT10 is equipped with a draft

shield which fits over the platform.

NOTE:NOTE:

NOTE: The CT10 draft shield and gem

NOTE:NOTE:

cup should be wiped with the antistatic

towelette supplied with the balance to

eliminate any static buildup.

9

Page 51

Weigh Below HookWeigh Below Hook

Weigh Below Hook

Weigh Below HookWeigh Below Hook

A weigh below hook is provided with models CT200, CT600 and CT1200 for below

balance weighing applications.

To install the hook, turn the balance over

holding the platform in place. Screw the

hook into the platform shaft from the bottom of the balance. Tighten finger-tight.

Mount the balance on a suitable surface or

stand which permits below balance weighing.

OPERATIONOPERATION

OPERATION

OPERATIONOPERATION

Weigh Below Hook

Turning the Balance On and OffTurning the Balance On and Off

Turning the Balance On and Off

Turning the Balance On and OffTurning the Balance On and Off

With no load on the platform, press .

All segments of the display will turn on,

then the software version is displayed.

The display will momentarily blank and

then indicate zero.

NOTE: NOTE:

NOTE: Allow at least 5 minutes for the

NOTE: NOTE:

balance to temperature stabilize before

using. If the balance is moved to a different temperature environment, allow additional time to stabilize.

To turn the balance off, press and

hold until OFF is displayed, then

release it.

Low Battery Indicator

Parts Counting Indicator

Weighing Unit Indicators

&

Stability Indicators

10

Page 52

Checking CalibrationChecking Calibration

Checking Calibration

Checking CalibrationChecking Calibration

Before using the balance, its calibration

should be checked. The balance has

been calibrated before shipment, however, calibration is influenced by factors

such as:

• Variations in the earths gravitational

field at different latitudes of the world.

• Rough handling.

• Changes in work location.

• Height above sea level.

To check the balance’s calibration, place

a known mass on the center of the platform and read the displayed weight.

If the displayed weight differs from the

known mass by more than acceptable

limits, refer to the Calibration Menu and

the Specifications at the rear of the manual.

WeighingWeighing

Weighing

WeighingWeighing

1. Press to set the display to zero.

2. Place the object to be weighed on the

platform.

3. Wait until the unit indicator appears

before reading the displayed weight.

When the unit indicator appears, the

reading is stable.

11

Page 53

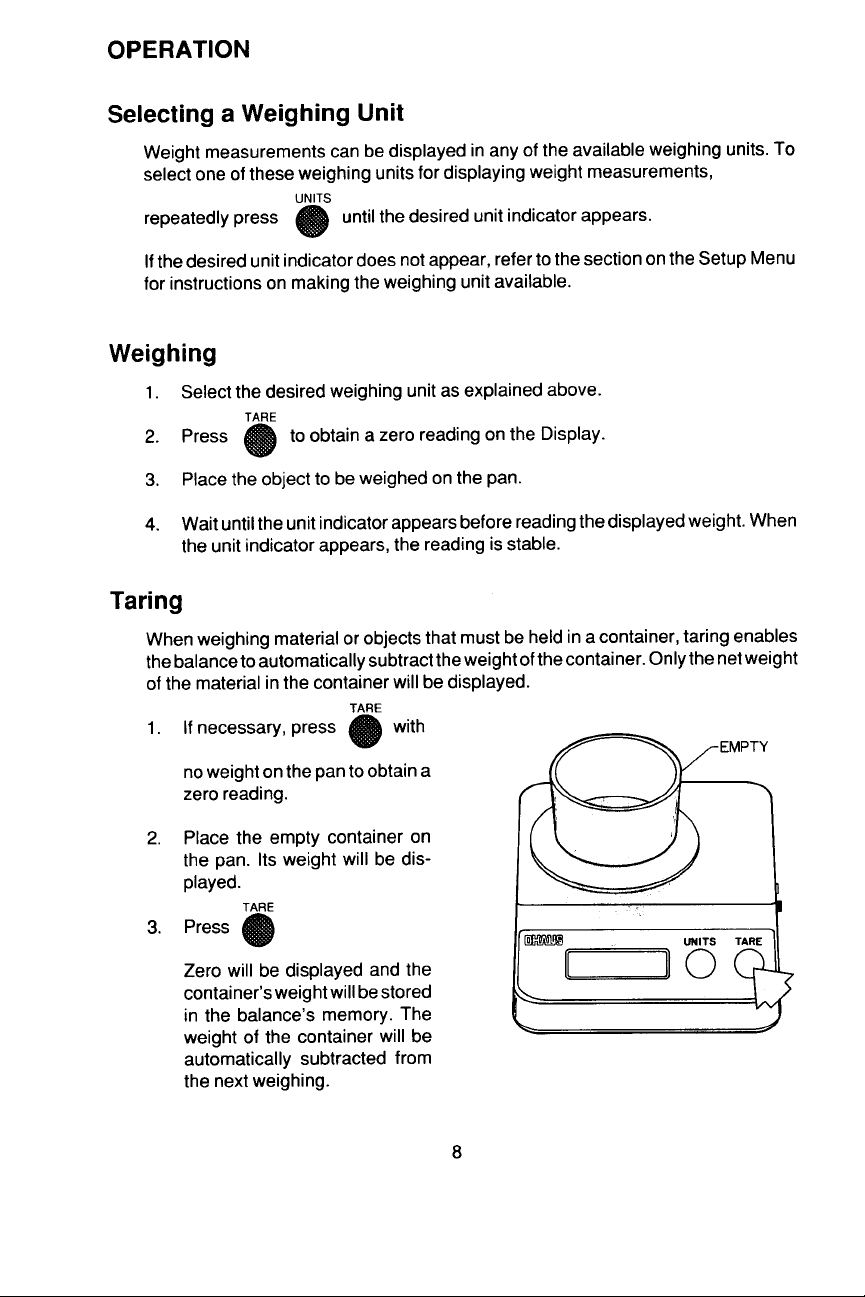

TaringTaring

Taring

TaringTaring

When weighing samples that must be held

in a container, taring enables the balance

to subtract the weight of the container and

display only the net weight of the sample.

1. Press

form to set the display to zero.

2. Place the empty container on the platform. Its weight will be displayed.

3. Press . Zero will be displayed

and the container’s weight will be stored

in the balance’s memory.

4. Add the sample to the container and

read its net weight on the display.

NOTE:NOTE:

NOTE: The combined weight of the con-

NOTE:NOTE:

tainer and the sample

capacity of the balance.

5. When the container and its con-

with no load on the plat-

must notmust not

must not exceed the

must notmust not

tents are removed, the container

weight will be displayed as a

negative number.

The tared weight will remain in

memory until is pressed

again or the balance is turned

off.

(Example)

12

Page 54

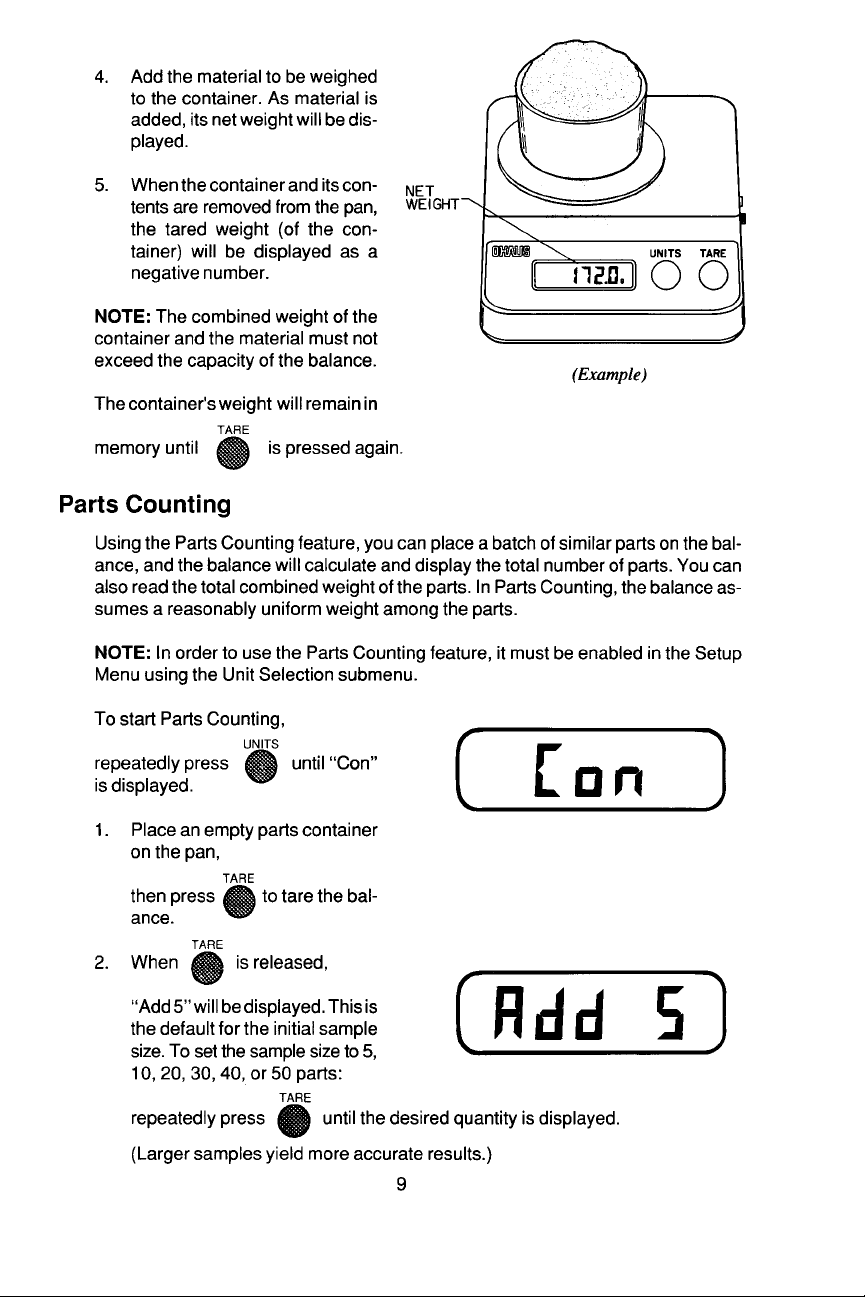

Parts CountingParts Counting

Parts Counting

Parts CountingParts Counting

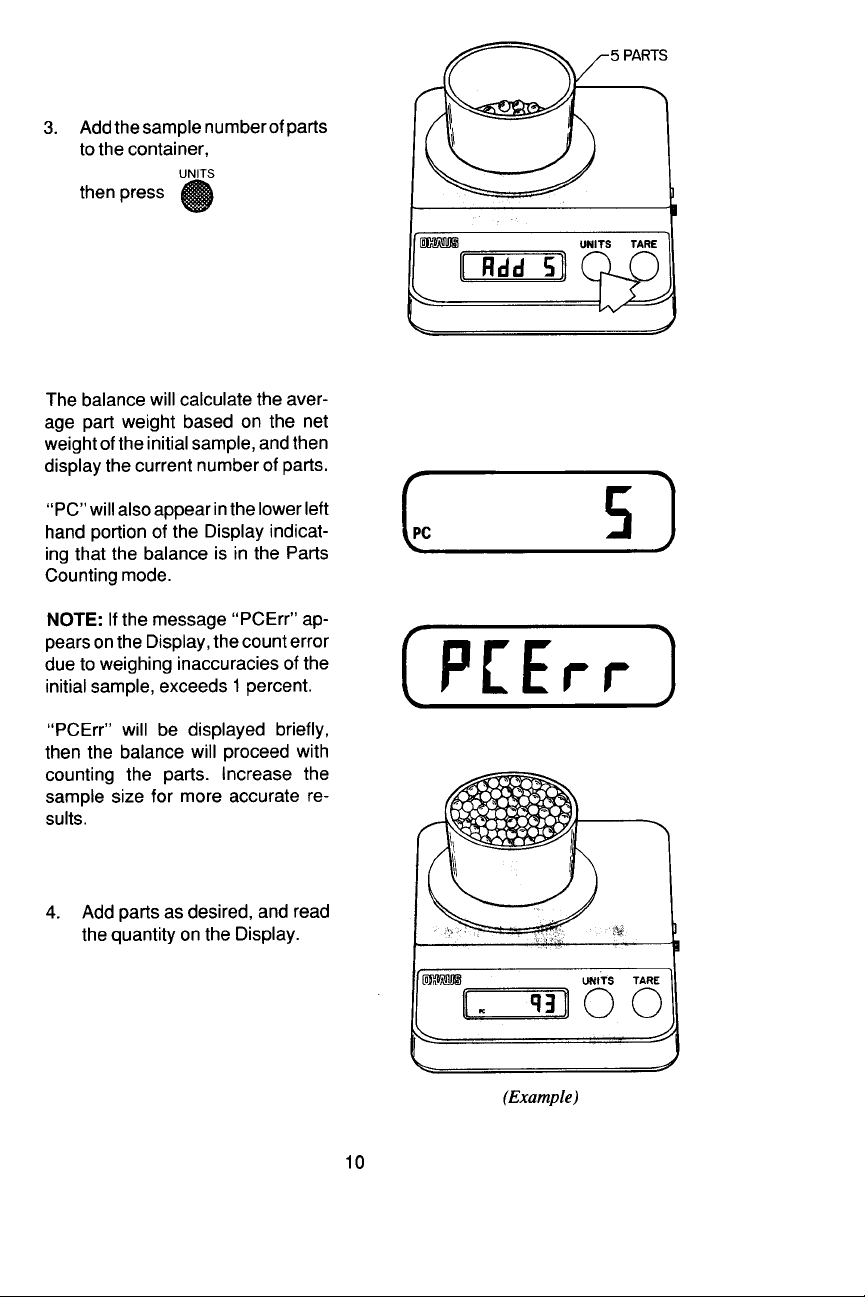

Parts Counting must be enabled in the

Setup menu before using this procedure.

The balance will count parts based on the

weight of a reference sample, 5, 10, 20,

30, 40 or 50 parts. For optimum results,

the parts should be uniform in weight.

until

1. Repeatedly press

PC

CON

is displayed.

2. Place a container on the platform,

then press

plays

ADD 5 which is the preset

PC

. The balance dis-

reference quantity.

3. To change the reference quantity,

repeatedly press until the desired quantity is displayed.

Parts Counting Factory SettingsParts Counting Factory Settings

Parts Counting Factory Settings

Parts Counting Factory SettingsParts Counting Factory Settings

Parts Counting Mode ........... Disabled

PC Err ......................................... OFF

NOTE: NOTE:

NOTE: If you need to exit or restart parts

NOTE: NOTE:

counting at any time, press and hold

until PC CON is displayed, then release it.

Return to step 2 to restart, or press

for other weighing functions.

4. Add the displayed number of parts to

the container, then press

. The

balance will display the current number of parts.

13

Page 55

NOTENOTE

NOTE: If PCErr is displayed, the sample is

NOTENOTE

too small to provide accurate results within

the selected parts counting error level (PC

Err of the Setup menu).

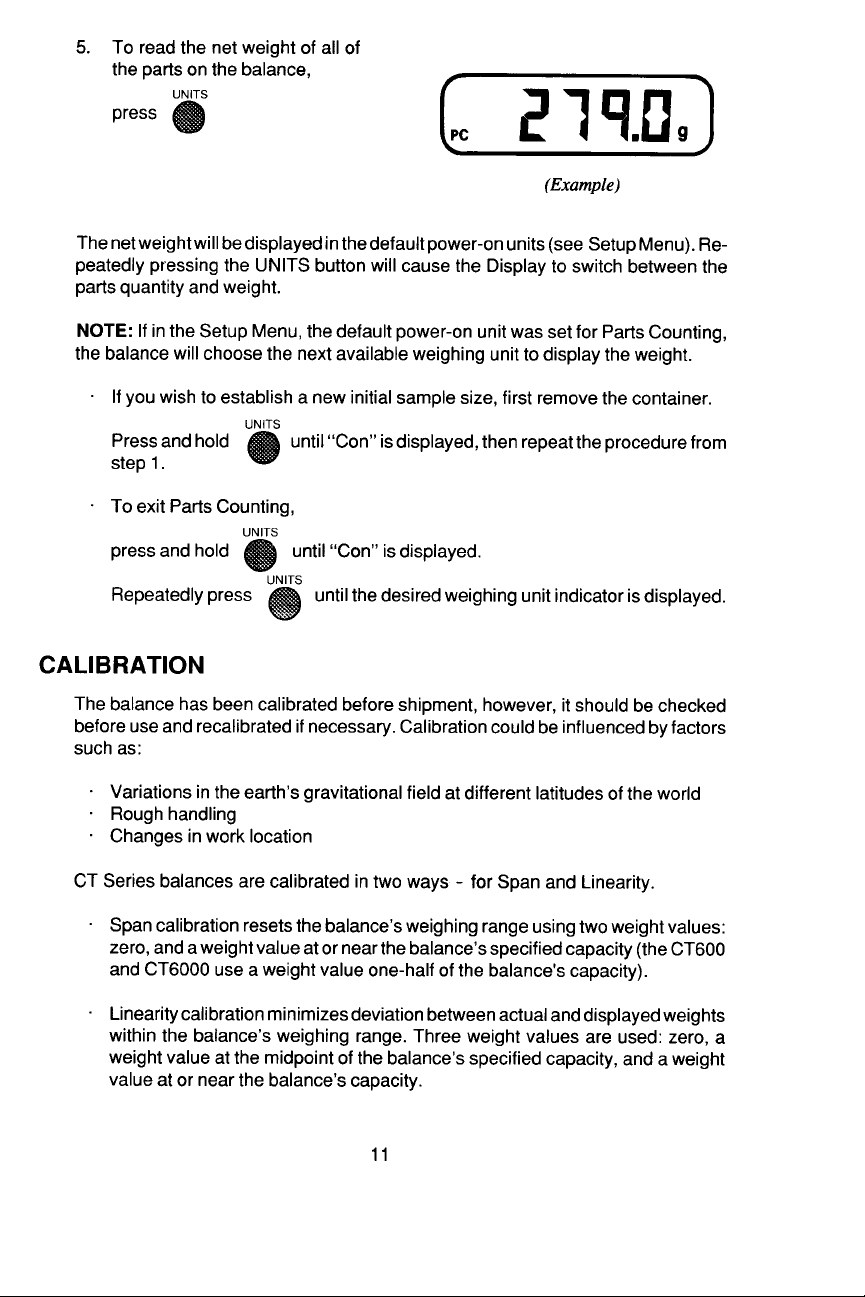

5. Add parts to the container as desired

and read the quantity on the display.

NOTENOTE

NOTE: The reference quantity will remain

NOTENOTE

in memory until it is changed or the balance is turned off.

6. To switch between viewing the quantity and weight of the parts,

press .

PrintingPrinting

Printing

PrintingPrinting

If the optional RS232 interface is installed,

(Example)

display data can be output from the balance. The

different manner depending upon if more

than one measuring unit is selected.

When only one measuring unit is enabled, a short press on

printing when -P- is displayed. A long

press will turn the balance off. When

more than one measuring unit is enabled,

a short press on

suring unit, a one-second press will initate

printing, a long press will turn the balance

off. To print data, press and

hold

quickly release it.

button operates in a

will enable

changes the mea-

until -P- is displayed, then

14

Page 56

USING MENUS TO CONFIGURE THE BALANCEUSING MENUS TO CONFIGURE THE BALANCE

USING MENUS TO CONFIGURE THE BALANCE

USING MENUS TO CONFIGURE THE BALANCEUSING MENUS TO CONFIGURE THE BALANCE

The following illustration identifies the items in each menu and the factory default

settings are shown in bold type.

CAL

SPAN

LINEARITY

END

SETUP

RESET

Yes,No

UNIT SELECTION

gg

g, oz, oz t, dwt, lb,

gg

t, • (custom), PC

DFLT/USR

AVERAGING LEVEL

11

0,

1, 2

11

STABILITY

1d1d

.5d,

1d, 2d, 5d

1d1d

AUTO ZERO

.5d.5d

OFF,

.5d, 1d,

.5d.5d

3d

CUSTOM UNIT

CONVERSION

FACTOR

Mantissa

1.00001.0000

1.0000

1.00001.0000

Exponent

E0E0

E0,E1, E2,E3,

E0E0

E -3,E -2, E-1

LSD

.1d, .2d, .5d,

2d, 5d, 10d

PARTS COUNTING

ERROR LEVEL

OFFOFF

OFF, 1, 2.5, 5

OFFOFF

AUTO OFF

OFFOFF

OFF, 60, 120, 180

OFFOFF

PRINT

NOTE: Refer to instructions

provided with the optional

RS232 interface kit.

1d1d

1d,

1d1d

END

To access a menu, press and hold until desired menu appears, then release it.

Use these buttons to step through menus and select submenus:

next

selection

select

displayed item

15

Page 57

CALIBRATION MENUCALIBRATION MENU

CALIBRATION MENU

CALIBRATION MENUCALIBRATION MENU

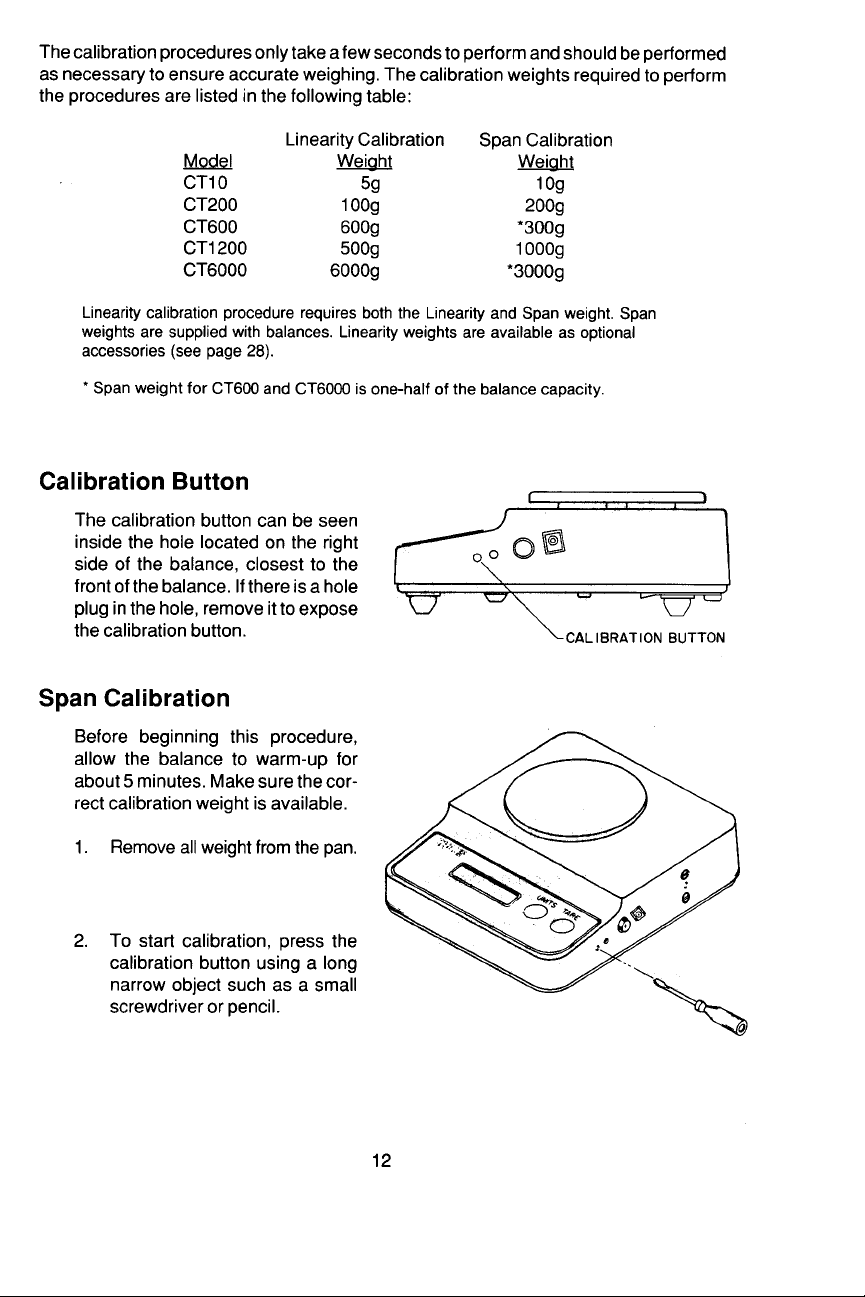

Portable

Linearity calibration. Span calibration resets the balance’s weighing range using two

points: zero and a calibrated mass value at or near the balance’s capacity. Linearity

calibration minimizes deviation between actual and displayed weights within the

balance’s weighing range using three points: zero, a calibrated mass value within the

balances weighing range, and a value at or near the balance’s specified capacity. The

illustration below indicates the sequence in which submenus appear on the Calibration

menu.

Calibration Menu ProtectionCalibration Menu Protection

Calibration Menu Protection

Calibration Menu ProtectionCalibration Menu Protection

The Calibration menu may be locked out

to prevent unauthorized access. To lock

out calibration menu, refer to the section

titled Calibration Lock-Out Protection.

Calibration MassesCalibration Masses

Calibration Masses

Calibration MassesCalibration Masses

Before beginning calibration, make sure

calibrated masses are on hand. If you

begin calibration and realize masses are

not available, either turn the balance off, or

go through the procedure without masses.

The balance will use previously stored

calibration data. Calibration should be

performed as necessary to ensure accurate weighing. Masses required to perform the procedures are listed in the adjacent table.

Advanced

balances can be calibrated in two ways: Span calibration or

CAL

SPAN

LINEARITY

END

Required Calibration MassesRequired Calibration Masses

Required Calibration Masses

Required Calibration MassesRequired Calibration Masses

Model Span LinearityModel Span Linearity

Model Span Linearity

Model Span LinearityModel Span Linearity

Masses Masses Masses Masses

Masses Masses

Masses Masses Masses Masses

CT10 10g 5g, 10g

CT200 200g 100g, 200g

CT600 300g (2) 300g

CT1200 1000g 500g, 1000g

CT6000 2000g (3) 2000g

1000g 1000g

16

Page 58

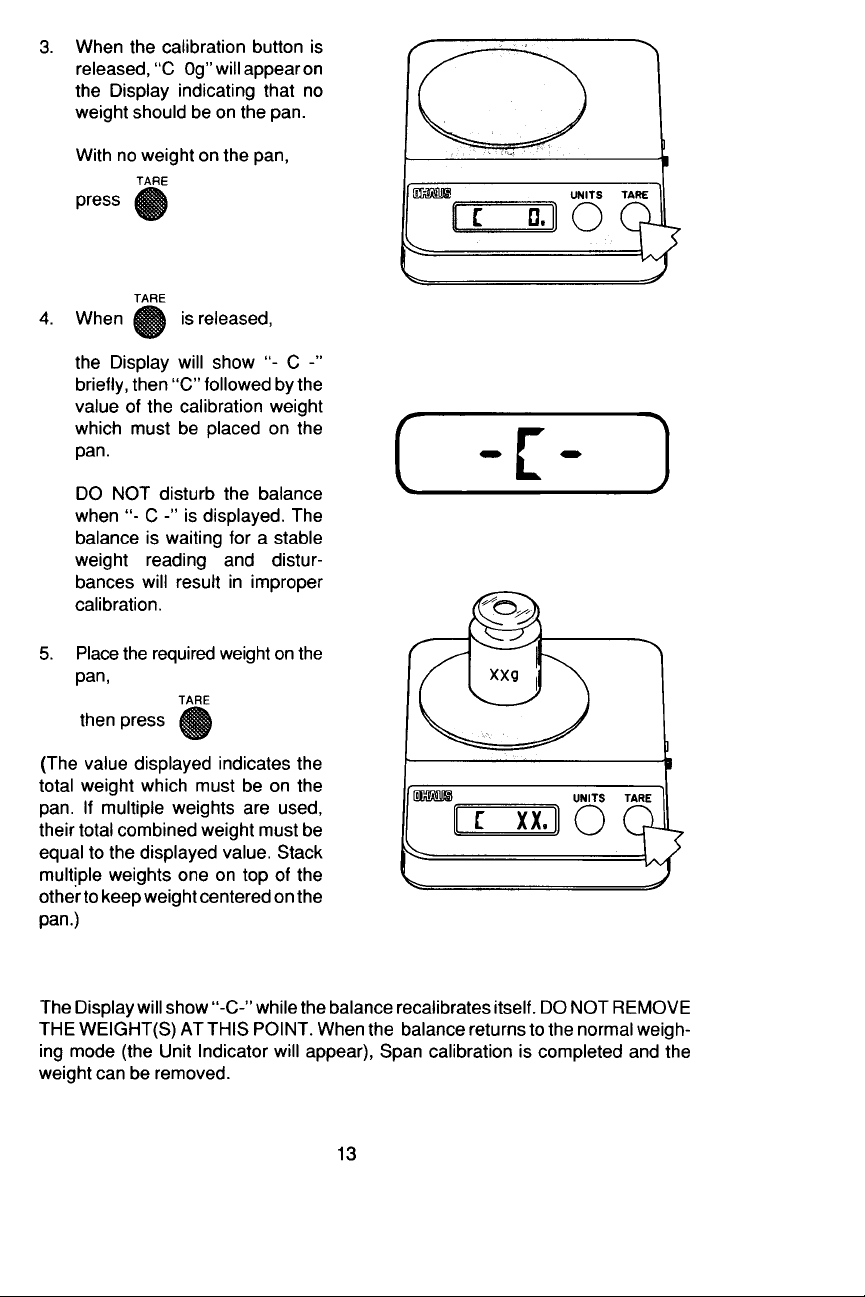

Span CalibrationSpan Calibration

Span Calibration

Span CalibrationSpan Calibration

1. Press and hold until CAL is displayed, then release it. Balance will

display SPAN.

2. Press

will be displayed indicating that no

mass should be on the platform.

3. Press

-C- followed by the value of the mass

which must be placed on the platform.

NOTE: NOTE:

NOTE: Do not disturb the balance when

NOTE: NOTE:

-C- is displayed. Disturbances will result

in improper calibration.

4. Place the required mass on the platform and press . The display will

show -C- while the balance recali-

brates. When the mass on the plat-

. When released, C 0g

. The display will show

form is displayed along with the current unit indicator, the balance is recalibrated.

17

Page 59

Linearity CalibrationLinearity Calibration

Linearity Calibration

Linearity CalibrationLinearity Calibration

1. Press and hold until CAL is

displayed, then release. Balance will

display SPAN.

2. Press

LIN.

3. Press . When released, C 0g

will be displayed, indicating that no

mass should be on the platform.

4. Press

-C- followed by the value of the mass

which must be placed on the platform.

5. Place the required mass on the platform.

and the display will show

. The display will show

18

Page 60

6. Press

-C- momentarily, then C followed by

the next mass to be placed on the

platform. Do not disturb the balance

when -C- is displayed. Disturbances

will result in improper calibration.

7. Place the required mass on the plat-

. The display will show

form, then press

will show -C- while the balance reca-

librates. When the mass on the platform is displayed along with the current unit indicator, the balance is recalibrated.

EndEnd

End

EndEnd

If you have entered the Calibration menu

and do not wish to calibrate the balance,

use END to return to normal weighing

operations.

1. Repeately press

displayed.

2. Press

ance will returned to normal weighing

operations.

. When released, the bal-

. The display

until END is

19

Page 61

SETUP MENUSETUP MENU

SETUP MENU

SETUP MENUSETUP MENU

The Setup menu is used to customize the operation of the balance for your specific

requirements. It contains submenus which enable you to turn features on or off, and

program balance parameters. The illustration below indicates the sequence in which

submenus appear on the Setup menu.

SETUP

RESET

Yes,No

UNIT SELECTION

gg

g, oz, oz t, dwt, lb,

gg

t, • (custom), PC

DFLT/USR

AVERAGING LEVEL

11

0,

1, 2

11

STABILITY

1d1d

.5d,

1d, 2d, 5d

1d1d

AUTO ZERO

.5d.5d

OFF,

.5d, 1d,

.5d.5d

3d

CUSTOM UNIT*

CONVERSION

FACTOR

Mantissa

1.00001.0000

1.0000

1.00001.0000

Exponent

E0E0

E0,E1, E2,E3,

E0E0

E -3,E -2, E-1

LSD

.1d, .2d, .5d,

2d, 5d, 10d

PARTS COUNTING**

ERROR LEVEL

OFFOFF

OFF, 1, 2.5, 5

OFFOFF

AUTO OFF

OFFOFF

OFF, 60, 120, 180

OFFOFF

1d1d

1d,

1d1d

END

* C.UNIT only appears in menu if custom unit is enabled in SEL submenu.

** PC ERR only appears in menu if parts counting is enabled in SEL submenu.

20

Page 62

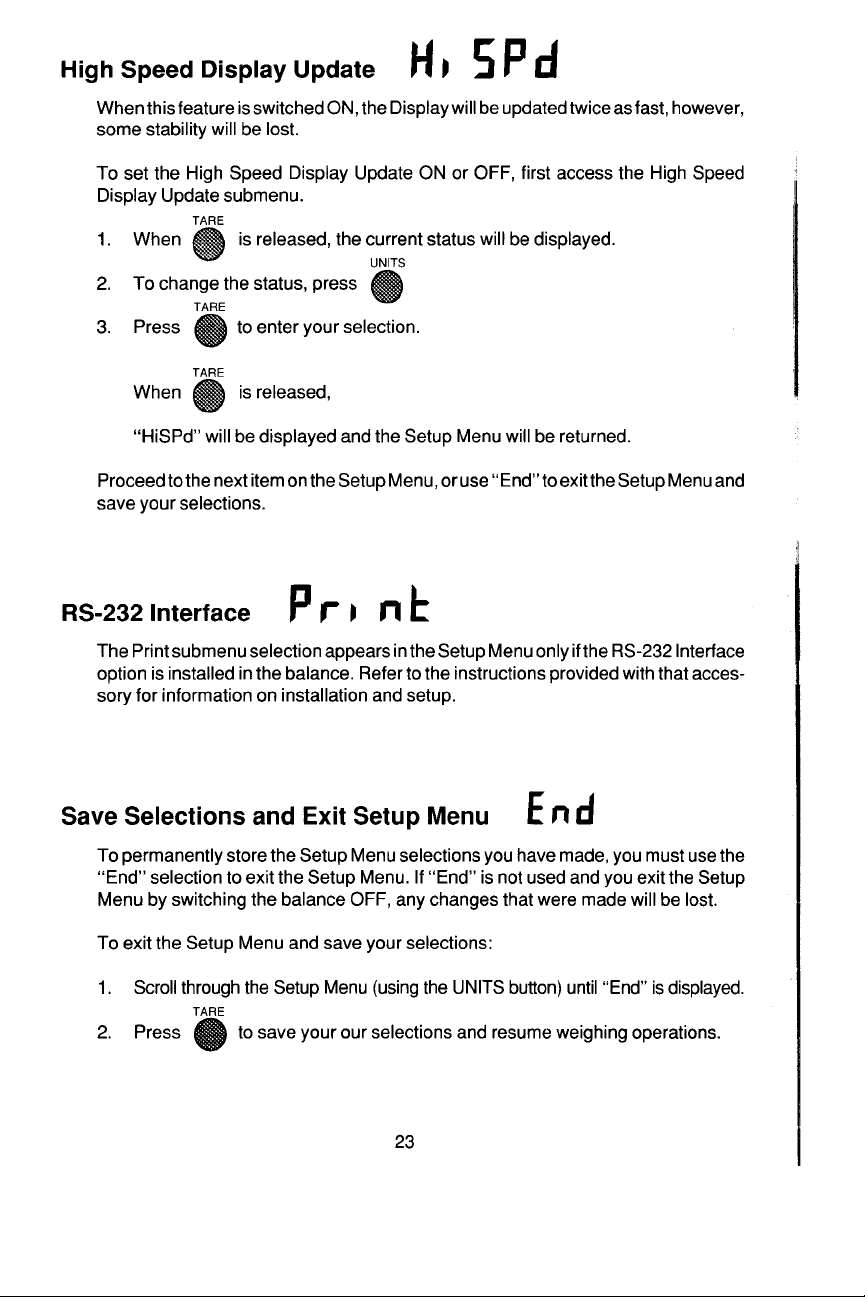

Accessing the Setup MenuAccessing the Setup Menu

Accessing the Setup Menu

Accessing the Setup MenuAccessing the Setup Menu

To access the Setup menu, press and hold

until SETUP is displayed, then re-

lease.

To access a submenu:

1. Repeatedly press

sired submenu is displayed.

2. Press

submenu.

NOTE:NOTE:

NOTE: You must use END to store any

NOTE:NOTE:

changes you make to the Setup menu.

The following sections describe each item

on the Setup menu in detail.

Reset to Factory SettingsReset to Factory Settings

Reset to Factory Settings

Reset to Factory SettingsReset to Factory Settings

This submenu enables you to reset all

Setup menu selections to the original factory settings outlined in the adjacent table.

To reset to factory settings:

1. Access the Reset submenu.

2. Press to enter RESET.

3. Press repeatedly to change the

setting from YES to NO. Selecting

YES resets the Setup menu to the

original factory settings.

to select the displayed

until the de-

SETUP MENUSETUP MENU

SETUP MENU

SETUP MENUSETUP MENU

FACTORY SETTINGSFACTORY SETTINGS

FACTORY SETTINGS

FACTORY SETTINGSFACTORY SETTINGS

Unit Selection g

Averaging Level 1

Stability 1d

Auto Zero .5d

Conversion Factor

Mantissa 1.0000

Exponent 0

LSD 1

PC Error Level OFF

Auto Off OFF

4. Press

setting.

to accept the displayed

21

Page 63

Unit SelectionUnit Selection

Unit Selection

Unit SelectionUnit Selection

The Unit Selection submenu permits you

to specify which weighing units and operating modes will be enabled for use during operation. The adjacent table lists the

units and modes available on Portable

Advanced

1. Access the Sel submenu.

2. Press , the display will show

balances.

the grams unit indicator (g) along

with the current status (ON/OFF).

Display Weighing Units and ModesDisplay Weighing Units and Modes

Display Weighing Units and Modes

Display Weighing Units and ModesDisplay Weighing Units and Modes

Indicator Indicator

Indicator

Indicator Indicator

g

oz ounces

ozt troy ounces

dwt pennyweight

lb pounds

t taels

• custom unit

pc parts counting

gramsgrams

grams

gramsgrams

3. Press

4. Press

status, when released, the display

will show the next unit indicator along

with the current status.

5. Set each unit or mode ON or OFF as

in steps 3 and 4.

TaelsTaels

Taels

TaelsTaels

If taels are enabled, you will be required

to choose one of three different taels:

Hong Kong, Singapore, or Taiwan.

1. When the display shows TAEL 1,

press

if desired.

2. Press to accept the displayed

tael.

to change the status.

to accept the displayed

to change to another tael

Hong Kong

Singapore

22

Taiwan

Page 64

Unit Selection (Cont.)Unit Selection (Cont.)

Unit Selection (Cont.)

Unit Selection (Cont.)Unit Selection (Cont.)

Proceed through all of the weighing units

in the same manner, setting each one as

desired.

Custom UnitsCustom Units

Custom Units

Custom UnitsCustom Units

Custom Units can be set to one of the

following:

DFLT Causes carats to be used as the

custom unit.

USR Enables you to enter a conversion

factor (to convert grams to some

other unit of measure), and display

weight in the desired custom units.

The conversion factor is entered in

the C. Unit submenu.

23

Page 65

Custom Unit Conversion FactorCustom Unit Conversion Factor

Custom Unit Conversion Factor

Custom Unit Conversion FactorCustom Unit Conversion Factor

When you need to display weight measurements in a weighing unit other than those

provided standard with the balance, this feature can be used to create your own custom

weighing unit. It permits you to enter a conversion factor which the balance will use to

convert grams to the desired unit of measure.

One example is shown at the end of this section. It illustrates how to set the conversion

factors to display weight in Grains.

Conversion Weight Weight

Factor x in = in

grams custom unit

Conversion factors are expressed in scientific notation and entered into the balance in three parts:

• A number between 0 and 9 to four

decimal places

• A power of 10 called the exponent.

• A least significant digit (LSD).

Use the following procedure to enter conversion factors:

1. Access the C.Unit submenu.

2. The mantissa of the current conversion factor will be displayed. This will

be a number between 0 and 9.9999

with the first digit flashing. For conversion factors outside of this range,

the exponent will be be used to move

the decimal point.

3. Press

to change the value of

SCIENTIFIC NOTATIONSCIENTIFIC NOTATION

SCIENTIFIC NOTATION

SCIENTIFIC NOTATIONSCIENTIFIC NOTATION

NumberNumber

Number

NumberNumber

BetweenBetween

Between

Conv.Conv.

Conv.

Conv.Conv.

FactorFactor

Factor

FactorFactor

BetweenBetween

0 and0 and

0 and

0 and0 and

9.99999.9999

9.9999

9.99999.9999

PowerPower

Power

PowerPower

of 10of 10

of 10

of 10of 10

Man-Man-

Man-

Man-Mantissatissa

tissa

tissatissa

Exp.Exp.

Exp.

Exp.Exp.

1234 = 1.234 x 1000 = 1.234 x 10

123.4 = 1.234 x 100 = 1.234 x 10

12.34 = 1.234 x 10 = 1.234 x 10

1.234 = 1.234 x 1 = 1.234 x 10

.1234 = 1.234 x .1 = 1.234 x 10

.01234 = 1.234 x .01 = 1.234 x 10

.00123 = 1.23 x .001 = 1.23 x 10

ExponentExponent

Exponent

ExponentExponent

FLASHING

3

2

1

0

-1

-2

-3

the first digit.

4. When the desired value is displayed,

press to accept it and the next

digit will begin flashing.

FLASHING

24

Page 66

5. Set the value of all digits in the same

manner.

6. After the last digit is entered, the display will show the current exponent.

The exponent is shown on the display

preceded by the letter E.

There are 7 exponent values which you

can choose from (see table).

7. Press

8. Press

to change the exponent.

to accept the displayed

exponent. When is released,

the display will show the current least

significant digit.

The least significant digit is the digit in the

last decimal place on the display. The

selection you make causes the balance to

count by 1’s, 2’s or 5’s in this position.

There are 7 LSD settings you can choose

from (see table).

9. Press to change the LSD.

10. Press

to accept the displayed

LSD. When is released, C.Unit

will be displayed again and the

Setup menu will be returned.

11. Proceed to the next item on the Setup

menu or use END to exit the Setup

menu and save your selections.

EXPONENTSEXPONENTS

EXPONENTS

EXPONENTSEXPONENTS

E-3 Moves decimal point 3

E-2 Moves decimal point 2

E-1 Moves decimal point 1

E0E0

E0

E0E0

E1 Moves decimal point 1

E2 Moves decimal point 2

E3 Moves decimal point 3

LSD .1 *Adds one decimal place

LSD .2 *Adds one decimal place

LSD.5 *Adds one decimal place

LSD 1 LSD 1

LSD 1

LSD 1 LSD 1

LSD 2 Display counts by 2’s.

LSD 5 Display counts by 5’s.

LSD 10 Removes last decimal

* Sensitivity to vibration is increased

places to the left.

places to the left.

place to the left.

Leaves decimal point inLeaves decimal point in

Leaves decimal point in

Leaves decimal point inLeaves decimal point in

normal position.normal position.

normal position.

normal position.normal position.

place to the right.

places to the right.

places to the right.

LSD’sLSD’s

LSD’s

LSD’sLSD’s

and Display counts by 1’s.

and Displayby counts by

2’s.

display counts by 5’s.

Display counts by 1’s.Display counts by 1’s.

Display counts by 1’s.

Display counts by 1’s.Display counts by 1’s.

(Normal Setting)(Normal Setting)

(Normal Setting)

(Normal Setting)(Normal Setting)

place and Display counts

by 1’s.

with this LSD setting.

25

Page 67

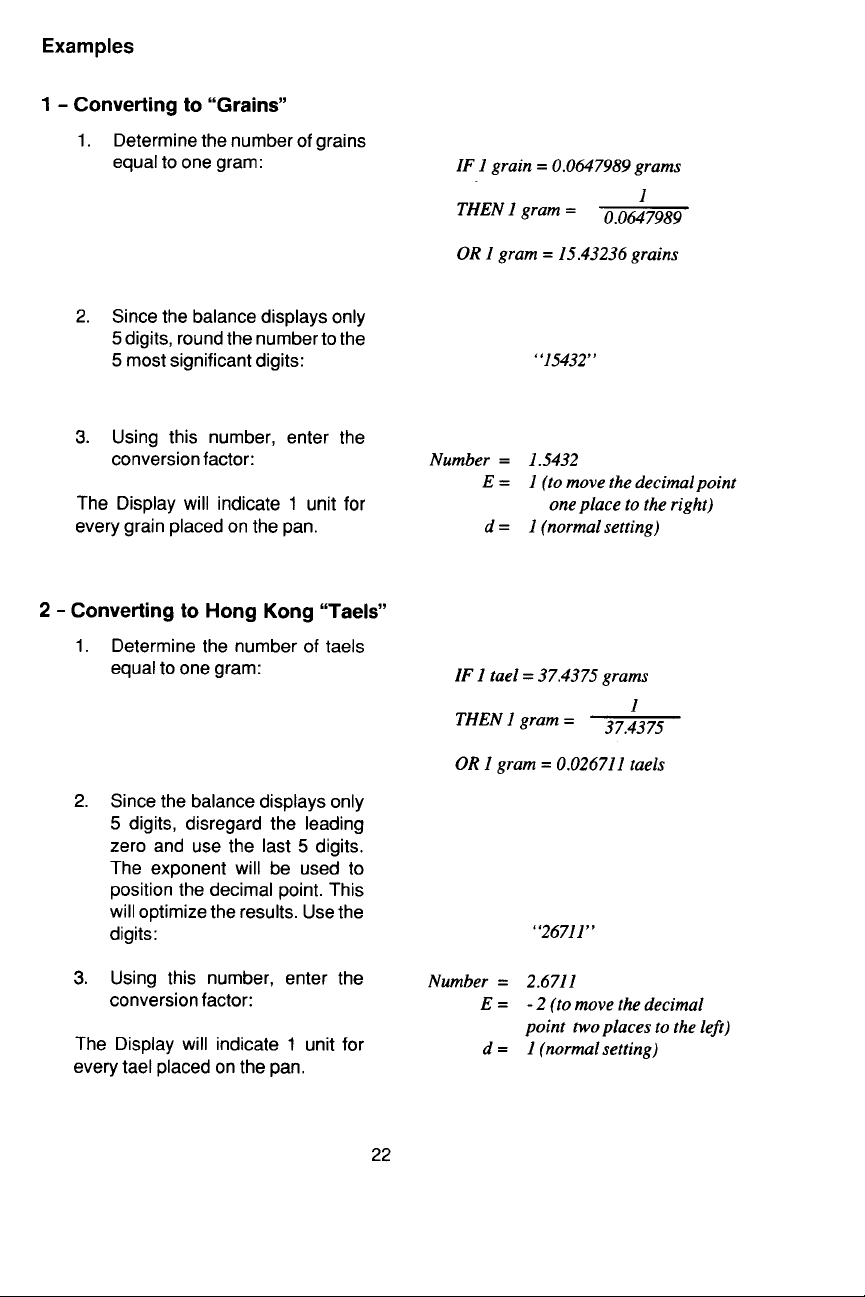

ExampleExample

Example

ExampleExample

Converting to “Grains”Converting to “Grains”

Converting to “Grains”

Converting to “Grains”Converting to “Grains”

1. Determine the number of grains equal

to one gram:

2. Since the balance displays only 5

digits, round the number to the 5 most

significant digits:

IF 1 grain = 0.0647989 grams

THEN 1 gram =

1

0.0647989

OR 1 gram = 15.43236 grains

3. Using this number, enter the conversion factor:

The display will indicate 1 unit for every

grain placed on the platform.

“15432”

Number = 1.5432

E = 1 (to move the decimal point

one place to the right)

d = 1 (normal setting)

26

Page 68

Averaging LevelAveraging Level

Averaging Level

Averaging LevelAveraging Level

Averaging level compensates for vibration or excessive air currents. During operation, the balance continually takes

weight readings from the weighing cell.

Successive readings are then digitally processed to achieve a stabilized display.

Use this submenu to specify how much

processing you need to obtain stable results.

NOTENOTE

NOTE: Averaging level does not affect

NOTENOTE

balance accuracy.

AVERAGING LEVELAVERAGING LEVEL

AVERAGING LEVEL

AVERAGING LEVELAVERAGING LEVEL

AL 0 Reduced stability, fastest

stabilization time.

AL 1AL 1

Normal stability, normalNormal stability, normal

AL 1

Normal stability, normal

AL 1AL 1

Normal stability, normalNormal stability, normal

stabilization timestabilization time

stabilization time

stabilization timestabilization time

..

.

..

Select one of three averaging levels using

the adjacent table as a guide.

To view or change the averaging level:

1. Access the AL submenu.

2. Press

ting.

3. Press

4. Press

setting, when released, AL will be

displayed again.

to display the current set-

to change the setting.

to accept the displayed

AL 2 More stability, slow

stabilization time.

27

Page 69

Stability RangeStability Range

Stability Range

Stability RangeStability Range

The stability range specifies how much a

displayed weight may change while the

stability indicator (unit indicator) remains

ON. When displayed weight changes

beyond the allowable range, the stability

indicator turns OFF indicating an unstable

condition. Portable

permit you to select one of four stability

ranges (in divisions) as shown in the table.

NOTENOTE

NOTE: When the RS232 interface is

NOTENOTE

configured to print stable data only, the

stability range also governs data output.

Displayed data will only be output if it is

within the selected stability range.

To view or change the stability range:

1. Access the Stb submenu to display

the current setting.

Advanced

balances

STABILITY RANGESTABILITY RANGE

STABILITY RANGE

STABILITY RANGESTABILITY RANGE

..

.5d Smallest range: stability indi-

..

cator is ON only when displayed weight is within .5 divisions.

1d1d

Normal range.Normal range.

1d

Normal range.

1d1d

Normal range.Normal range.

2d Increased range.

5d Largest range: stability indi-

cator is ON with displayed

weight changes up to 5 divisions.

2. Press to display the current setting.

3. Press

4. Press

setting, when released, Stb will be

displayed again.

to change the setting.

to accept the displayed

28

Page 70

Auto-ZeroAuto-Zero

Auto-Zero

Auto-ZeroAuto-Zero

Auto-Zero minimizes the effects of temperature changes and shift on the zero

reading. By defining a threshold level in

divisions, the balance maintains the zero

display until the threshold is exceeded.

This submenu permits you to select one of

three threshold levels, or turn the feature

OFF. Auto-zero only functions when the

display reads zero.

To view or change the auto-zero setting:

1. Access the Auto0 submenu.

AUTO ZEROAUTO ZERO

AUTO ZERO

AUTO ZEROAUTO ZERO

OFF Turns Auto-Zero OFF.

.5d.5d

Sets threshold to .5 divisions.Sets threshold to .5 divisions.

.5d

Sets threshold to .5 divisions.

.5d.5d

Sets threshold to .5 divisions.Sets threshold to .5 divisions.

1d Sets threshold to 1 division.

3d Sets threshold to 3 divisions.

2. Press

ting.

3. Press

4. Press

setting, when released, Auto0 will be

displayed again.

to display the current set-

to change the setting.

to accept the displayed

29

Page 71

Parts Counting Error LevelParts Counting Error Level

Parts Counting Error Level

Parts Counting Error LevelParts Counting Error Level

The parts counting error level is based on

the resolution (readability) of the particular

model balance and sample weight. The

adjacent table lists error levels that you

can choose from.

To view, change or disable the parts counting error level:

1. Access the PCErr submenu.

2. Press

to display the current set-

ting.

ERROR LEVELSERROR LEVELS

ERROR LEVELS

ERROR LEVELSERROR LEVELS

OFFOFF

OFF

OFFOFF

1 % ±1 % acceptable error.

2.5 % ±2.5 % acceptable error.

5 % ±5.0 % acceptable error.

Disables error level limits.Disables error level limits.

Disables error level limits.

Disables error level limits.Disables error level limits.

3. Press

4. Press

to change the setting.

to accept the displayed

setting, when released, PCErr will be

displayed again.

30

Page 72

Auto OffAuto Off

Auto Off

Auto OffAuto Off

Auto Off permits the selection of either

OFF, 60 seconds, 120 seconds or 180

seconds. When this function is selected,

the balance will turn off if it is idle for the

selected period of time (60, 120 or 180

seconds). This feature is especially useful

when the balance is operated from internal batteries.

To view, change or disable the auto off

feature:

1. Access the A. Off submenu.

TIMER SETTINGSTIMER SETTINGS

TIMER SETTINGS

TIMER SETTINGSTIMER SETTINGS

OFFOFF

OFF

OFFOFF

60 Turns off in 60 seconds.

120 Turns off in 120 seconds.

180 Turns off in 180 seconds.

Disables feature.Disables feature.

Disables feature.

Disables feature.Disables feature.

2. Press

to display the current set-

ting.

3. Press

4. Press

to change the setting.

to accept the displayed

setting. When is released,

A. Off will be displayed again.

EndEnd

End

EndEnd

You must use End to exit the Setup menu.

Changes you make in the Setup menuChanges you make in the Setup menu

Changes you make in the Setup menu

Changes you make in the Setup menuChanges you make in the Setup menu

are only stored in memory if you useare only stored in memory if you use

are only stored in memory if you use

are only stored in memory if you useare only stored in memory if you use

End.End.

End.

End.End.

To exit the Setup menu and store your

settings, press

played. When

when END is dis-

is released, the bal-

ance will be returned to normal weighing

operations.

31

Page 73

CALIBRATION LOCK-OUT PROTECTIONCALIBRATION LOCK-OUT PROTECTION

CALIBRATION LOCK-OUT PROTECTION

CALIBRATION LOCK-OUT PROTECTIONCALIBRATION LOCK-OUT PROTECTION

Access to the Calibration menu can be disabled using the lock out switch located on

the right side of the balance.

1. Turn the balance off and unplug the power cord.

2. Locate the access hole on the right side of the balance where the switch is located

and remove the plug from the hole.

3. Using a small screwdriver, slide the switch to the front of the balance for LOCKED

or towards the rear of the balance for UNLOCKED.

4. Replace the plug in the access hole.

5. Plug in the power cord and turn on the balance.

LOCK OUT

SWITCH

LOCK OUT SWITCH

ACCESS HOLE

UNLOCK

LOCK

32

Page 74

CARE AND MAINTENANCECARE AND MAINTENANCE

CARE AND MAINTENANCE

CARE AND MAINTENANCECARE AND MAINTENANCE

To keep the balance operating properly, the housing and platform should be kept

clean and free from foreign material. If necessary, a cloth dampened with a mild

detergent may be used. Keep calibration masses in a safe dry place.

Unplug the AC Adapter when not in use. For long term storage, remove the batteries.

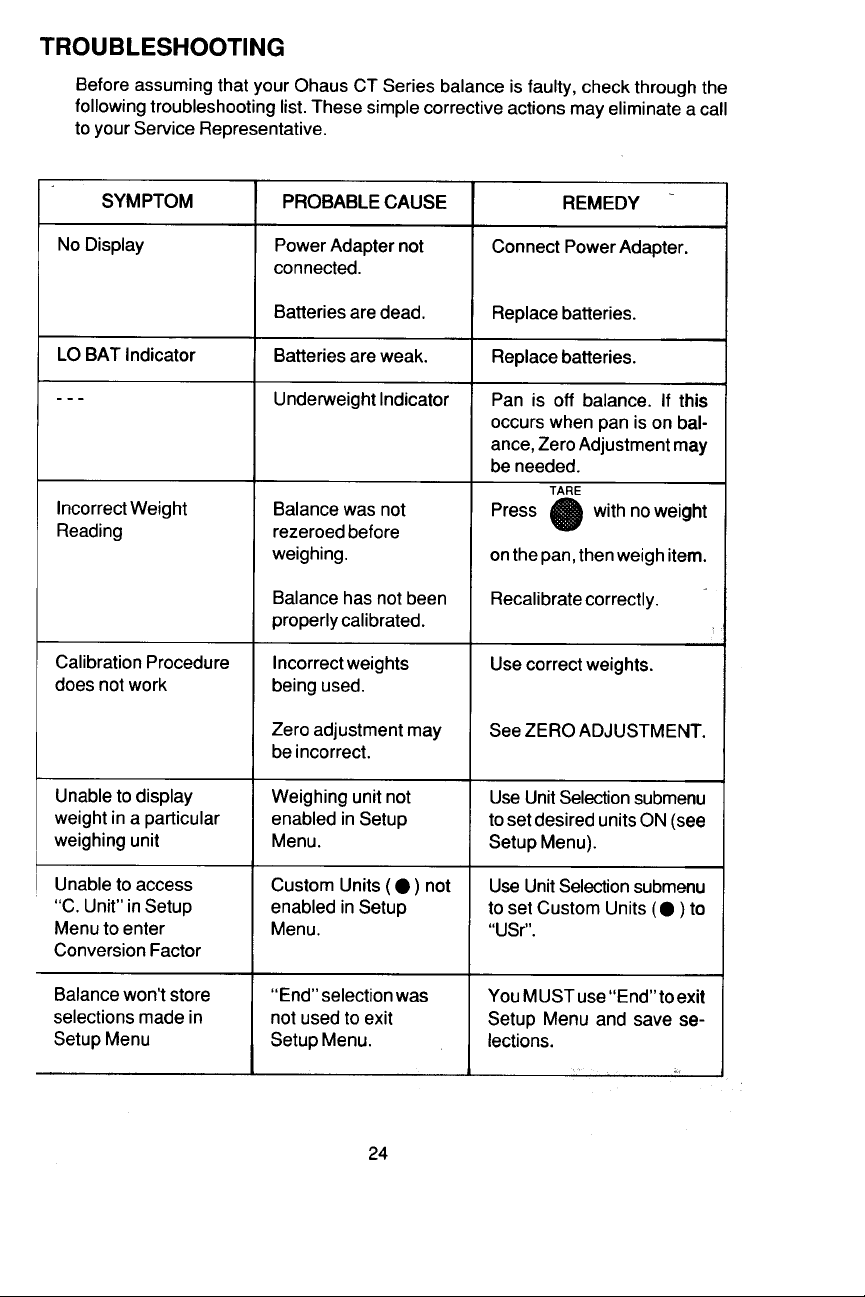

TROUBLESHOOTINGTROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTINGTROUBLESHOOTING

SYMPTOM

No Display

LO BAT Indicator

- - -

Incorrect Weight

Reading

Calibration Procedure does not work

Unable to display

weight in a particular weighing unit

PROBABLE CAUSE

Power Adapter not

connected.

Batteries are dead.

Batteries are weak.

Underweight Indicator,

platform may be off of

balance.

Balance was not

rezeroed before weighing.

Balance has not been

properly calibrated.

Incorrect weights being

used.

Weighing unit not

enabled in Setup menu.

REMEDY

Connect Power Adapter.

Replace batteries.

Replace batteries.

Replace platform.

Press ON TARE with no

weight on the platform,

then weigh item.

Recalibrate correctly.

Use correct weights.

Use Unit Selection submenu to set desired units

ON (see Setup menu).

Unable to access

C. UNIT in Setup

menu to enter

Conversion Factor

Balance won't store

selections made in

Setup menu

Custom Units ( ● ) not

enabled in Setup menu,

or not set to USR.

END selection was not

used to exit Setup menu.

33

Use Unit Selection submenu to set Custom Units

( ● ) to USR.

You MUST use END to

exit Setup menu and save

selections.

Page 75

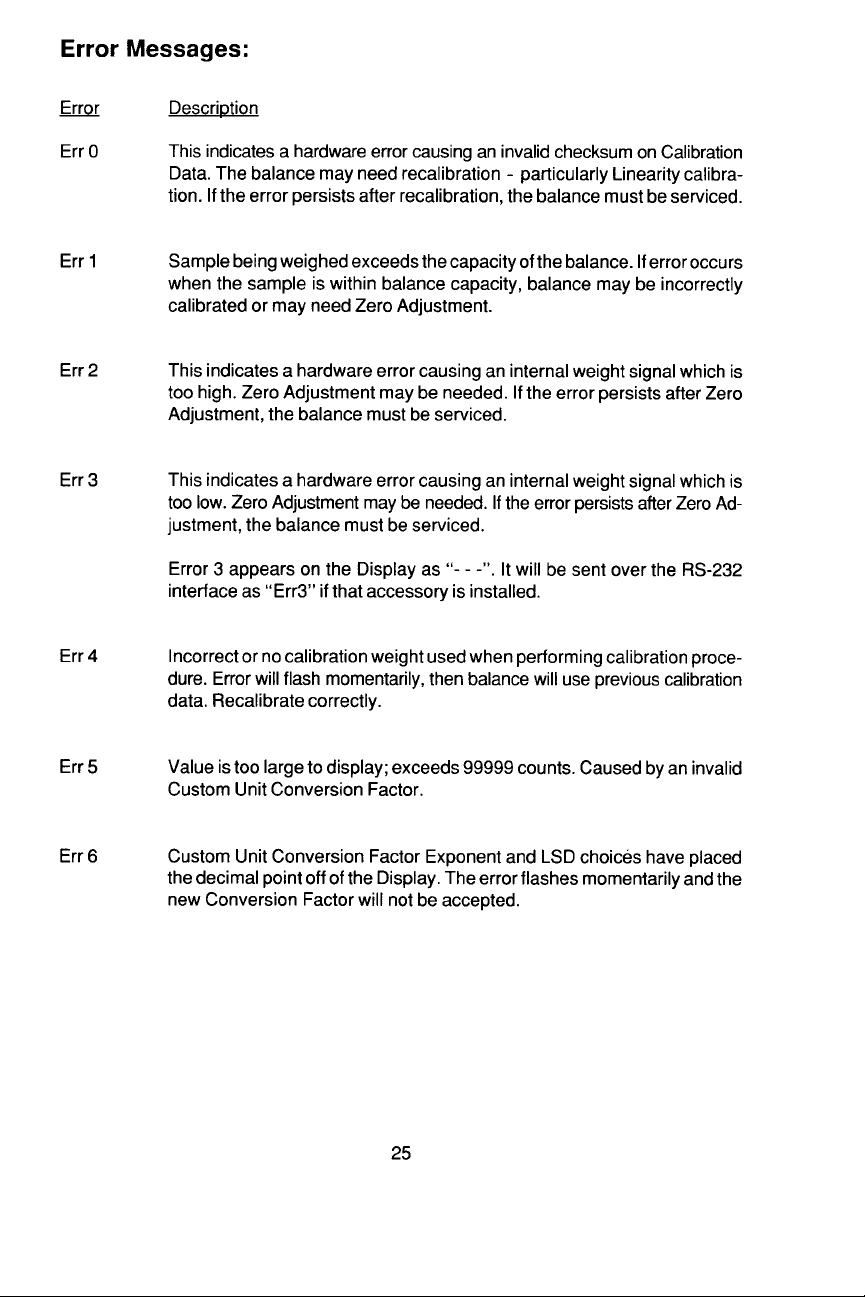

Error CodesError Codes

Error Codes

Error CodesError Codes

The following list describes the various error codes which can appear on the display

and the suggested remedy.

Display DescriptionDisplay Description

Display Description

Display DescriptionDisplay Description

Err 0Err 0

Err 0 This indicates a hardware error causing an invalid checksum on calibration

Err 0Err 0

data. The balance may need recalibration, particularly linearity calibration. If

the error persists after recalibration, the balance must be serviced.

Err 1Err 1

Err 1 Sample being weighed exceeds the capacity of the balance. If error occurs

Err 1Err 1

when the sample is within the balance capacity, balance may be incorrectly

calibrated. An underload such as the platform off of the balance could also

display Err1. Recalibrate the balance.

Err 2Err 2

Err 2 This indicates a hardware error causing an internal weight signal which is too

Err 2Err 2

high. The balance must be serviced.

Err 3Err 3

Err 3 This indicates a hardware error causing an internal weight signal which is too

Err 3Err 3

low. The balance must be serviced.

Error 3 appears on the display as "- - - ". It will be sent over the RS232 interface

as "Err3" if that accessory is installed.

Err 4Err 4

Err 4 Incorrect or no calibration weight used when performing calibration procedure.

Err 4Err 4

Error will flash momentarily, then balance will use previous calibration data.

Recalibrate correctly.

Err 5Err 5

Err 5 Value is too large to display; exceeds 99999 counts. Possibly caused by an

Err 5Err 5

invalid custom unit conversion factor.

Err 6Err 6

Err 6 Custom unit conversion factor exponent and LSD choices have placed the

Err 6Err 6

decimal point off of the display. The error flashes momentarily and the new

conversion factor will not be accepted.

Err 7Err 7

Err 7 Power-on load error caused by load on platform during power-up. The display

Err 7Err 7

appears for three seconds and the balance will use previously stored calibration

data. Remove load from platform and reapply power.

Err 9Err 9

Err 9 Internal data error. Return balance for servicing.

Err 9Err 9

SERVICE INFORMATIONSERVICE INFORMATION

SERVICE INFORMATION

SERVICE INFORMATIONSERVICE INFORMATION

If the Troubleshooting section does not resolve or describe your problem, you will need

to contact an authorized Ohaus Service Agent. For Service assistance in the United

States, please call Ohaus Corporation toll-free at (800) 526-0659, an Ohaus Product

Service Specialist will be available to help you.

NOTE:NOTE:

NOTE: In New Jersey call (201) 377-9000.

NOTE:NOTE:

34

Page 76

PARTS INFORMATIONPARTS INFORMATION

PARTS INFORMATION

PARTS INFORMATIONPARTS INFORMATION

If you require replacement parts or would like to purchase accessories, please call

Ohaus Corporation toll-free at (800) 526-0659, an Ohaus Product Parts Specialist will

be available to help you.

REPLACEMENT PARTSREPLACEMENT PARTS

REPLACEMENT PARTS

REPLACEMENT PARTSREPLACEMENT PARTS

OHAUS

Part Number

Span Calibration Masses:

10g (CT10) 51014-05

200g (CT200) 51025-06

300g (CT600) 51035-05

AC Adapters:

100/120 V ac US Plug 90524-77

230/240 V ac European Plug 90524-75

230/240 V ac UK Plug 90524-79

240 V ac Australian Plug 90524-76

Platforms:

1.75" dia. (CT10) 76680-11

4" dia. (CT200) 77521-00

4" dia. (CT200V) 77576-01

4.75" dia. (CT600) 77261-01

4.75" dia. (CT600V) 77577-01

4.75" x 6.5" (CT1200) 77467-02

Draft Shield - (CT10) 76681-01

Scoop - (CT200, CT600, CT1200) 4" x 3-1/2", black 4590-30

Gem Cup - (CT10) 76684-00

Antistatic Towelettes - (CT10 and CT200) 76685-00

Weigh Below Hook 5227-04

35

Page 77

SECURITYSECURITY

SECURITY

SECURITYSECURITY

The balance can be secured to a stationary object using the Security Locking Cable

Accessory. The locking cable is equipped with a fastener which must be inserted in

the plugged hole in the back of the balance. The cable can be passed through the

fastener and secured to a stationary object.

ACCESSORIESACCESSORIES

ACCESSORIES

ACCESSORIESACCESSORIES

OHAUS

Part Number

RS232 Interface 77172-01

Security Locking Cable 76288-00

Span Calibration Mass Sets for CT1200 and CT6000

CT1200 - set includes one 1000g weight 76527-02

CT6000 - set includes one 1000g and one 2000g Mass 76527-00

Linearity Calibration Masses:

CT10 5g 53053-00

CT200 100g 51015-05

CT600 300g (use with 300g span mass 51035-05

provided to make 600g.)

CT1200 500g (1000g span mass also required) 51055-06

CT6000 2000g - 2 required (1000g and 2000g span 51026-02

masses also required)

Scoops:

4" x 3-1/2", gold 4590-00

4" x 3-1/2", aluminum 4590-10

1-1/2" x 2", aluminum 5076-00

2-1/4" x 3", gold 5077-00

2-1/4" x 3", black 5077-01

12" x 6", Stainless Steel, footed, (tare 190g), for CT6000 1078-03

12" x 6", Polypropylene, footed, (tare 125g), for CT6000 1101-20

Vinyl Carrying Case (used with original foam packing) 76525-02

Deluxe Hard Carrying Case 77256-01

36

Page 78

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

MODELMODEL

MODEL

MODELMODEL

Capacity x Readability

grams (g) 10 x 0.002 202 x 0.01 602 x 0.1 1210 x 0.1 6010 x 0.5

ounces (oz) 0.35 x 0.0001 7.1 x 0.0005 21.2 x 0.005 42.6 x 0.005 212 x 0.02

ounces troy (oz t) 0.32 x 0.0001 6.5 x 0.0005 19.3 x 0.005 38.9 x 0.005 196 x 0.02

pennyweight (dwt) 6.4 x 0.002 130 x 0.01 387 x 0.1 778 x 0.1 3900 x 0.5

carats (ct) 50 x 0.01 999 x 0.05 3010 x 0.5 6050 x 0.5 30000 x 5

pounds (lb)

HK taels 0.2671/0.0001 5.396/0.0005 16.08/0.005 32.32/0.005 160.3/0.02

Singapore taels 0.2645/0.0001 5.344/0.0005 15.92/0.005 32.01/0.005 158.7/0.02

Taiwan taels 0.2666/0.0001 5.386/0.0005 16.05/0.005 32.26/0.005 160.0/0.02

Parts counting Standard

Custom unit Standard

Repeatability (std. dev.) (g)

Linearity (g) ±0.002 ±0.01 ±0.1 ±0.1 ±0.5

Tare range To capacity by subtraction

Over range capacity Capacity plus 9d

Stabilization time (Sec.) 3 3 2.5 2.5 2.5

Sensitivity drift (%/°C) ±0.005 ±0.003 ±0.01 ±0.003 ±0.005

Zero point drift (g/°C) ±0.002 ±0.02 ±0.2 ±0.2 ±1

Shift accuracy

(1/2 capacity, 1/2 distance) (g

Operating temperature 50° to 104°F/ 10° to 40°C

Calibration Auto calibration

Power requirements AC adapter (supplied with balance); 100, 120, 220, 240 V ac, 50/60 Hz

Typical battery life 50 hours (without optional RS232 accessory)

Display (in/cm) LCD (0.5/1.3 high)

Platform Size (in/cm) 1.75/4.4 dia. 4/10.2 dia. 4.75/12.1dia. 4.75 x 6.5/ 4.75 x 6.5/

Dimensions

(W x H x D) (in/cm) 7.0 x 2.5 x 7.7/17.8 x 6.3 x 19.6

Net weight (lb/kg) 2/0.9 1.5/0.7 1.7/0.8 2.3/1 2.3/1

Shipping weight (lb/kg) 3/2 4/2 4/2 4/2 4/2

CT10 CT10

CT10

CT10 CT10

0.002 0.01 0.07 0.1 0.5

)

±0.002 ±0.01 ±0.1 ±0.1 ±0.5

CT200CT200

CT200

CT200CT200

0.44 x 0.0001

or 8 AA Batteries (not included)

CT600CT600

CT600

CT600CT600

1.32 x 0.0002 2.6 x 0.0002 13.4 x 0.002

CT1200CT1200

CT1200

CT1200CT1200

12.1 x 16.5 12.1 x 16.5

CT6000CT6000

CT6000

CT6000CT6000

37

Page 79

LIMITED WARRANTYLIMITED WARRANTY

LIMITED WARRANTY

LIMITED WARRANTYLIMITED WARRANTY

Ohaus products are warranted against defects in materials and

workmanship from the date of delivery through the duration of the

warranty period. During the warranty period Ohaus will repair, or, at its

option, replace any component(s) that proves to be defective at no

charge, provided that the product is returned, freight prepaid, to

Ohaus.

This warranty does not apply if the product has been damaged by

accident or misuse, exposed to radioactive or corrosive materials, has

foreign material penetrating to the inside of the product, or as a result

of service or modification by other than Ohaus. In lieu of a properly

returned warranty registration card, the warranty period shall begin on

the date of shipment to the authorized dealer. No other express or

implied warranty is given by Ohaus Corporation. Ohaus Corporation

shall not be liable for any consequential damages.

As warranty legislation differs from state to state and country to

country, please contact Ohaus or your local Ohaus dealer for further

details.

38

Page 80

Ohaus Corporation

29 Hanover Road,

Florham Park, NJ 07932, USA

Tel: (973) 377-9000,

Fax: (973) 593-0359

With offices worldwide.

P/N 77145-03 R0698 © Ohaus Corporation 1998, all rights reserved.

39

Page 81

Ohaus Corporation

29 Hanover Road

Florham Park NJ

07932-0900

CT SERIESCT SERIES

CT SERIES

CT SERIESCT SERIES

RS232 INTERFRS232 INTERF

RS232 INTERF

RS232 INTERFRS232 INTERF

KITKIT

KIT

KITKIT

AA

A

AA

CECE

CE

CECE

For use with Models

CT10, CT200, CT600, CT600L

CT1200 and CT6000

Instruction ManualInstruction Manual

Instruction Manual

Instruction ManualInstruction Manual

NOTICE:NOTICE:

NOTICE: THIS EQUIPMENT HAS BEEN TESTED AND FOUND TO COMPLY WITH THE LIMITS FOR

NOTICE:NOTICE:

A CLASS A DIGITAL DEVICE, PURSUANT TO PART 15 OF THE FCC RULES.

THESE LIMITS ARE DESIGNED TO PROVIDE REASONABLE PROTECTION AGAINST HARMFUL

INTERFERENCE WHEN THE EQUIPMENT IS OPERATED IN A COMMERCIAL ENVIRONMENT.

THIS EQUIPMENT GENERATES, USES, AND CAN RADIATE RADIO FREQUENCY ENERGY AND,

IF NOT INSTALLED AND USED IN ACCORDANCE WITH THE INSTRUCTION MANUAL, MAY CAUSE

HARMFUL INTERFERENCE TO RADIO COMMUNICATIONS. OPERATION OF THIS EQUIPMENT IN