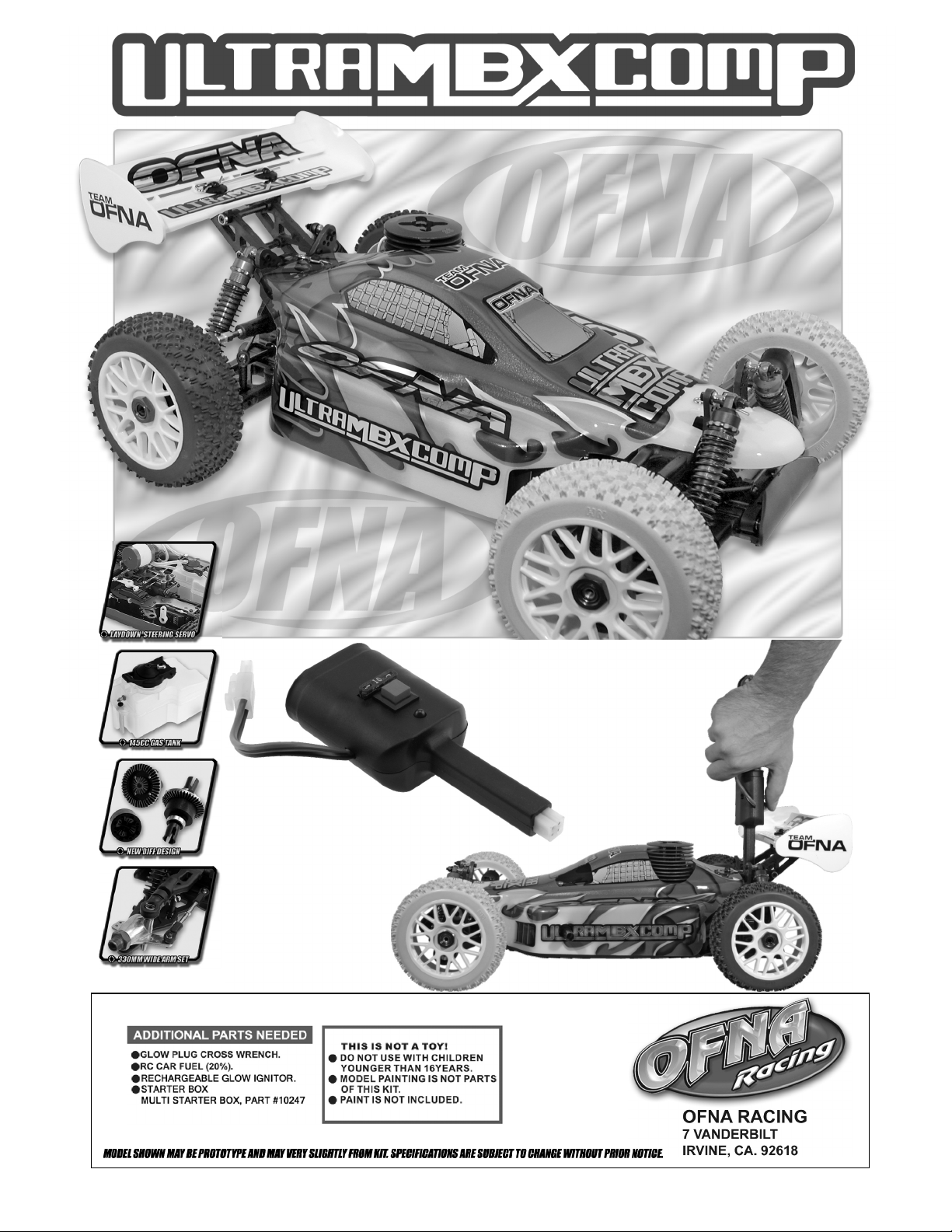

OFNA Racing Ultra MBX Comp User Manual

INSTRUCTION MANUAL

Ultra MBX Comp Rev:01

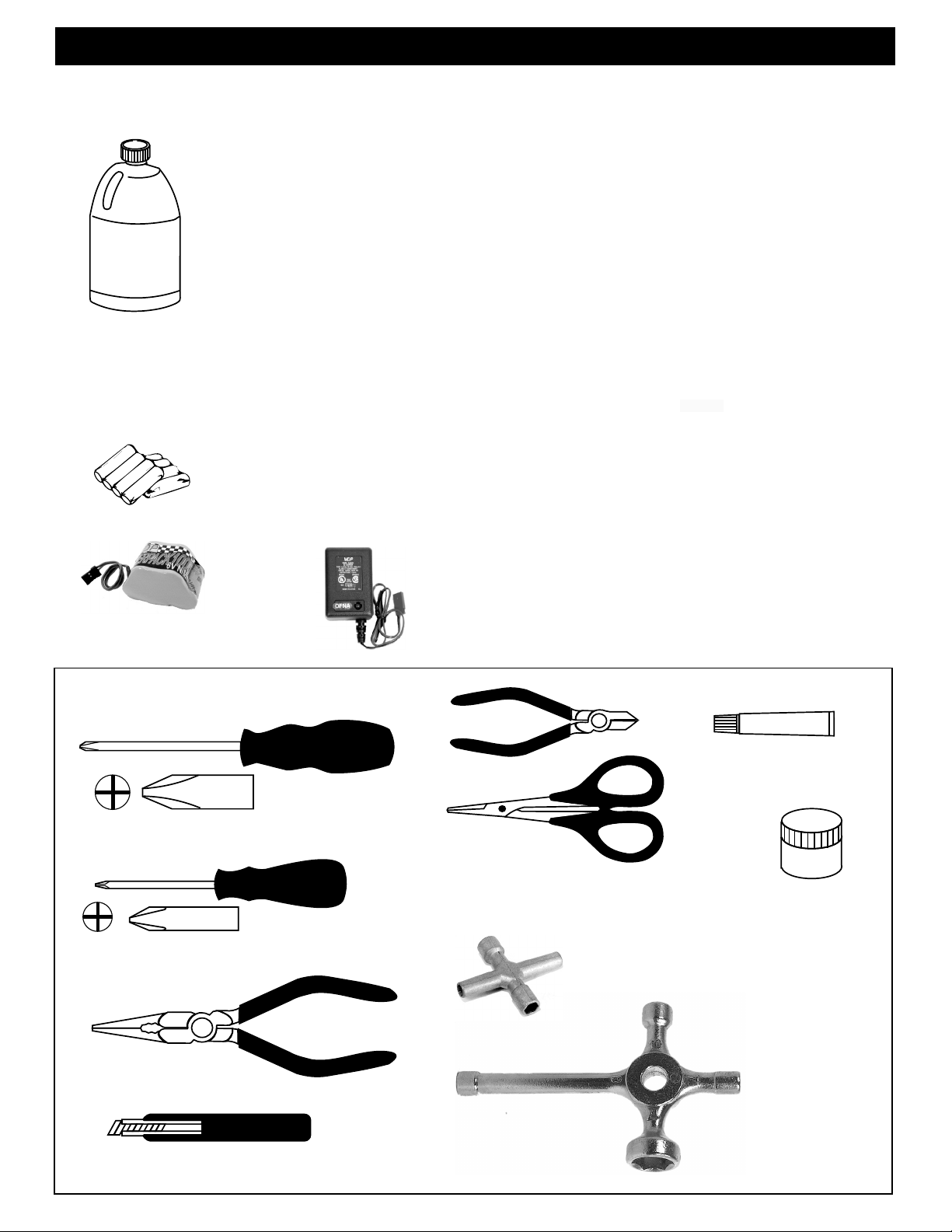

REQUIRED FOR OPERATION

THINGS NEEDED

Glow Fuel

20%

AA Batteries ( 12 pcs )

You will need to buy a few items to start the engine and run the car.

• Use 20% nitro CAR fuel. Do not use airplane or heli fuels, they will over

heat engine.

• Buy LONG glow plugs, like OFNA 51009 for auto start. Use plugs without

idle bar. Do NOT use plugs, like the MC-59 or OS-8 or any short plug

In your box you will find..

• #10162 - Bottle, 250cc

You need to get batteries for the radio transmitter and the car receiver packs.

7.2 volt pack for power start

• Radio TX needs (8) eight AA batteries.

• Car needs (4) four AA Ni-cad batteries, Alkaline type batteries will work, but

braking will be reduced. The best is to use a 5 cell hump pack for increased

voltage..

Recommended Option:

You may want to upgrade the car battery pack to a Ni-Cad or NiHm 5 cell

type(600AE). This will give more run time. OFNA #10212 1000NiMh Hump

10214

recv

pack

#10212 NiHm Hump Pack,

see charger 10214.

TOOLS NOT INCLUDED IN KIT,

BUT NEEDED TO MAINTAIN YOUR CAR.

Phillips Type Screw Drivers ( L )

Phillips Type Screw Drivers ( S )

10195

Battey

pack

7.2

Cutter

91009

Curved Scissors

$5.95

Cross Wrench

#17109 $3.95

#10796 $3.95

10239

Instant Cement

10620

Diff Gear

Grease

$9.95

Needle Nose Pliers

Knife

Glow Plug & 17MM Cross Wrench

#10801 $6.95

MUST READ THIS BEFORE RUNNING

Running a nitro kit is fun and easy, but to make this a safe rusting.

and good experience you must observe a few rules. This

kit is extremely fast, easily over 40MPH, and can seriously

injure someone if you are not careful.

Where to run car?

• Any running area you choose must be dry. Do not run

car near any water or wet dirt.

• Do not run on public streets. It is very easy to have the

car run over or damaged by hitting the curb.

• Do not operate car in tight confined places. The car is

very fast and will easily hit something.

• Do not run near people or animals.

and will too easily hit someone.

• Due noise, you will want to consider the surrounding

area when operating the car.

• Do not operate the car at night. You will not be able to

drive it without hitting something.

• Do not operate the car indoors. Engine exhaust is not

healthy.

Glow Fuel

• Glow fuel is poisonous!

• Glow fuel is flammable!

• Do not leave in fuel bottle with lid off at any time. label for additional precautions.

• Do not use any fuel other than glow fuel in this engine.

First Time Starting the Engine

Caution! When starting engine make sure the following is

observed. • Always turn off the car BEFORE turning off radio.

• Set engine Master needle to 3 turns (rich setting)

• Do not do this alone, get an experienced friend to help at • DAMAGE DUE CAR RUN AWAY IS NOT A WARRANTY

first. ISSUE.

• Fill fuel tank, try not to spill fuel. Do not spill fuel on

receiver

• Hold car off the ground, so it will not runaway when first

starts

• Turn on Radio and check the linkage before starting

engine.

• Turn on car receiver battery switch.

• Always have an air filter on the carburetor to keep dirt

out.

Engine Break-in

• See Engine Page.

The car is very fast

• Clean oil and dirt from chassis with a degreaser.

Precautions

• This kit is not a toy. Always run car with a second

person as a spotter and pitman.

• Hot Parts - The pipe, manifold, engine and head are very

hot and will cause burns.

• Rotating Parts - Keep hands away from the drive train,

wheels, and engine when engine is running.

• Radio - Check batteries life before running the car. If

radio does not have full control of the car with steering

and/or throttle/brake do not run until corrected. Failure to

correct this will result in possible injury and damage to the

car or property.

• Glow fuel - Do leave the glow fuel unattended with the lid

off. Fuel contains Methanol and Nitro Methane and is

flammable and poisonous.

Store fuel in cool ventilated location. Refer the glow fuel

• Car Fuel tank - Never store fuel in car tank, it will ruin the

engine if left in tank.

IF YOU DO NOT BREAK-IN ENGINE

CORRECTLY, MAINLY AT LOW RPM,

YOU WILL BREAK THE CONNECTING

ROD!

FAILURE TO NOT READ AND

FOLLOW BREAK-IN ENGINE

Emergency Stopping Engine When Running

• Remove air filter and cover carb. intake.

• Squeeze fuel line and hold until engine stops.

• With a rag, cover exhaust outlet.

Storing Car After Running

• Remove fuel from tank and fuel lines

• Turn off radio in car

• Put a few drops of after run in engine to keep it from

INSTRUCTIONS WILL VOID

WARRANTY!

CHECK RADIO SETTING AND

LINKAGE BEFORE STARTING

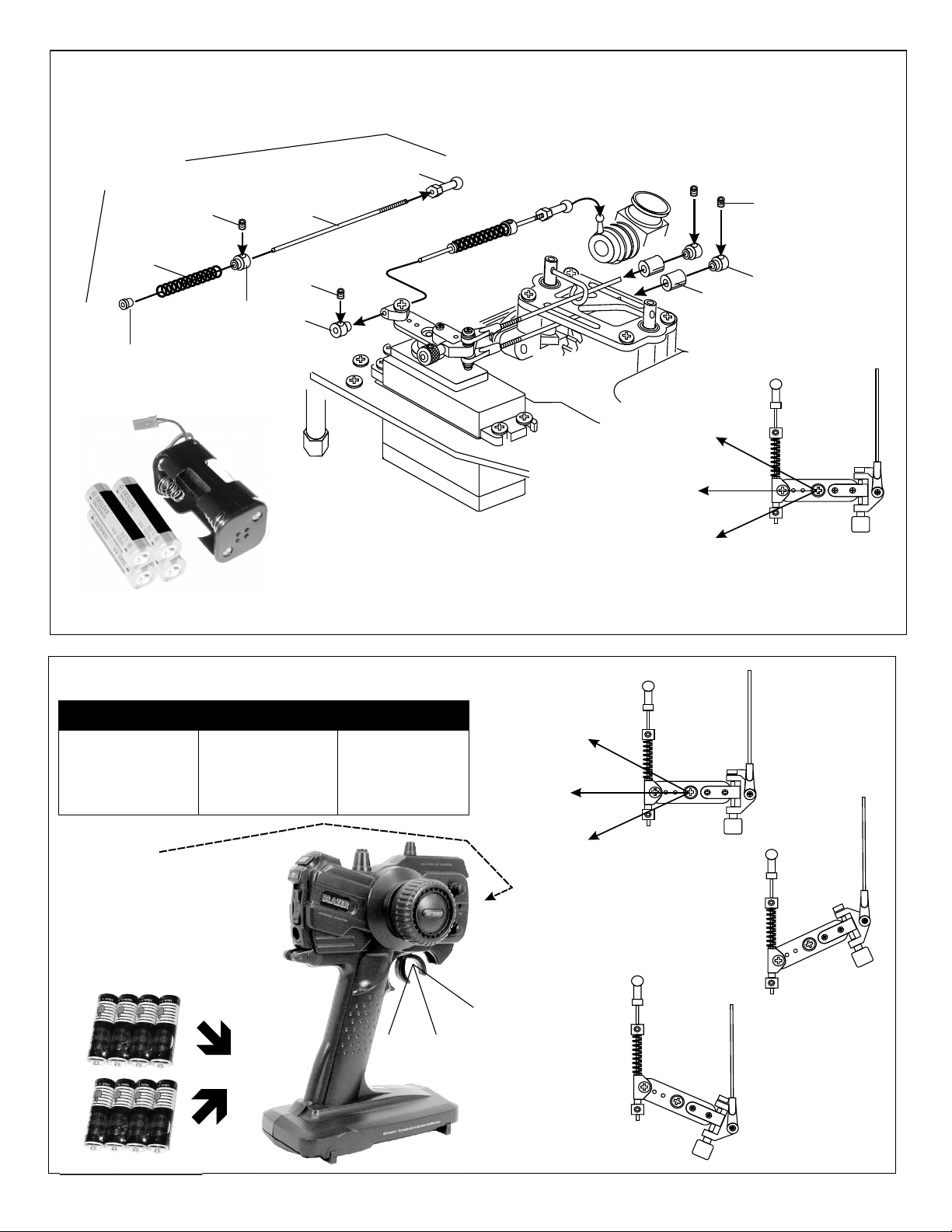

ASSEMBLY OF THE THROTTLE LINKAGE SYSTEM

#30800

Plastic Throttle

kit

Throttle

Spring

Plastic Collar

* Take the plastic collar

from brake system plastic

parts.

3X3mm

Set Screw

#30530

2mm Rod

3X3mm

Set Screw

Plastic Throttle

Ball Joint

* Snap On.

#10300

Alum.Stopper

Note:

Battery life is short when using Alkaline batteries. For safety, we recommend using

Alkaline batteries for only 30 minutes before testing; mostly changing. Battery strength

affects braking power and radio range. If voltage drops while running the car, you will

loose control and destroy your car! This is NOT covered under warranty.

To increase run time, upgrade receiver battery to a 5-cell hump pack. Also, install a

battery fail safe (OFNA # 91002) to further protect your car. But, the most important step

you can make, “is to always use fully charged or fresh batteries when running your car”.

Brake

Idle Position

Full Throttle

3X3mm

Set Screw

#10300

Alum.Stopper

Fuel

Tube

( 6mm )

* Align throttle servo same

as shown.

CHECKING ENGINE THROTTLE

A

1. Insert AA batteries into

transmitter (8 Pcs).

2.Turn on transmitter.

3.Turn on receiver.

4.Center throttle trims as

shown .

IMPORTANT

CHECK RADIO THROTTLE

AND STEERING SWITCHES

BEFORE RUNNING CAR

* Insert into transmitter.

1. Pull Full Throttle.

B

C

1. Push trigger to full

brake position.

2. Adjust alum. Stopper to

increase or decrease

the brake.

B

A

* Align throttle servo same

as shown.

Brake (C)

A

Idle Position (A)

Full Throttle (B)

• Full throttle arm position.

Spring rod pulls throttle

barrel open and brake

rods release pressure on

brake cams.

C

C

Radio shown, may be

different from what is in

your kit. OFNA

reserves the right to

change upon stock

availability.

B

• Full brake arm position.

Spring compresses

forward and brake rods

pull brake levers.

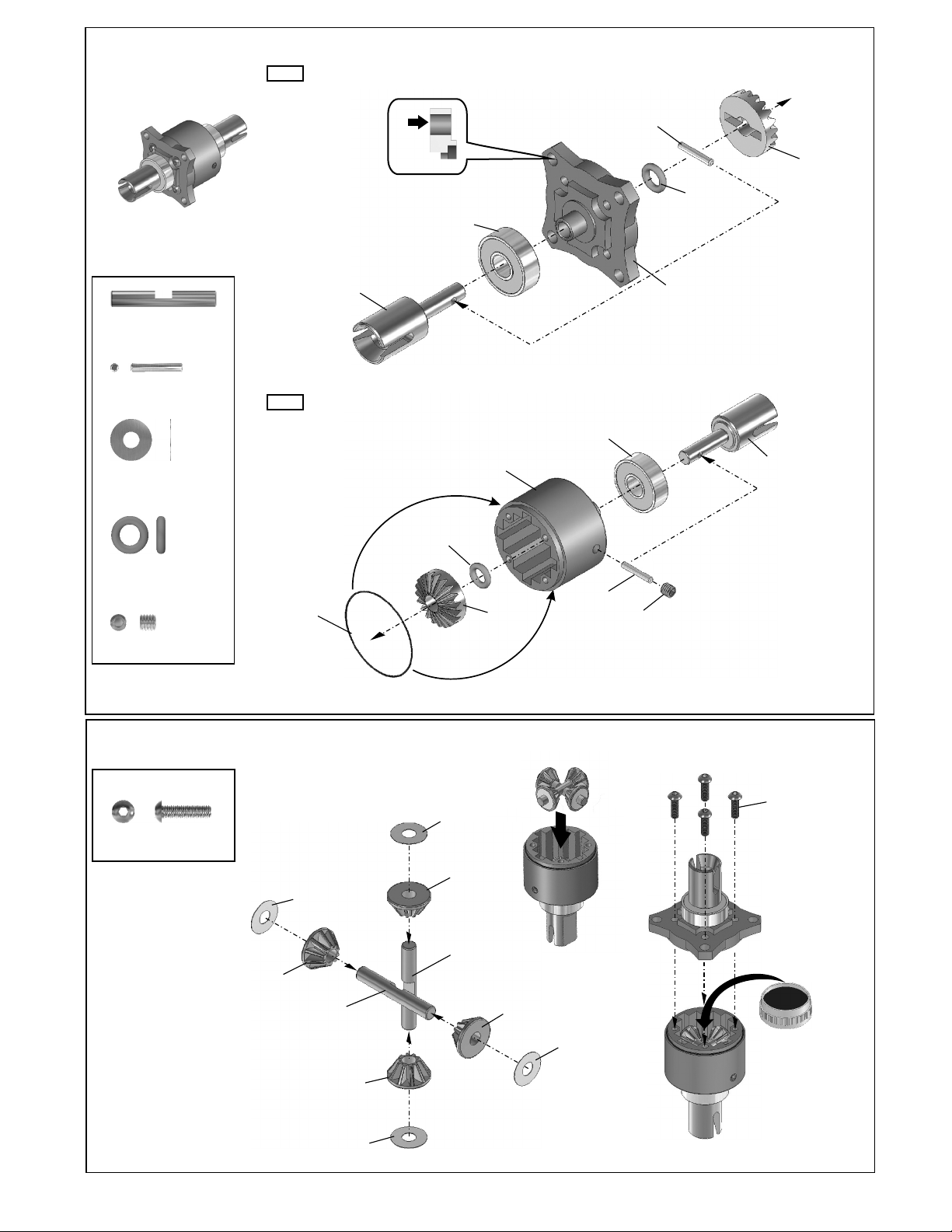

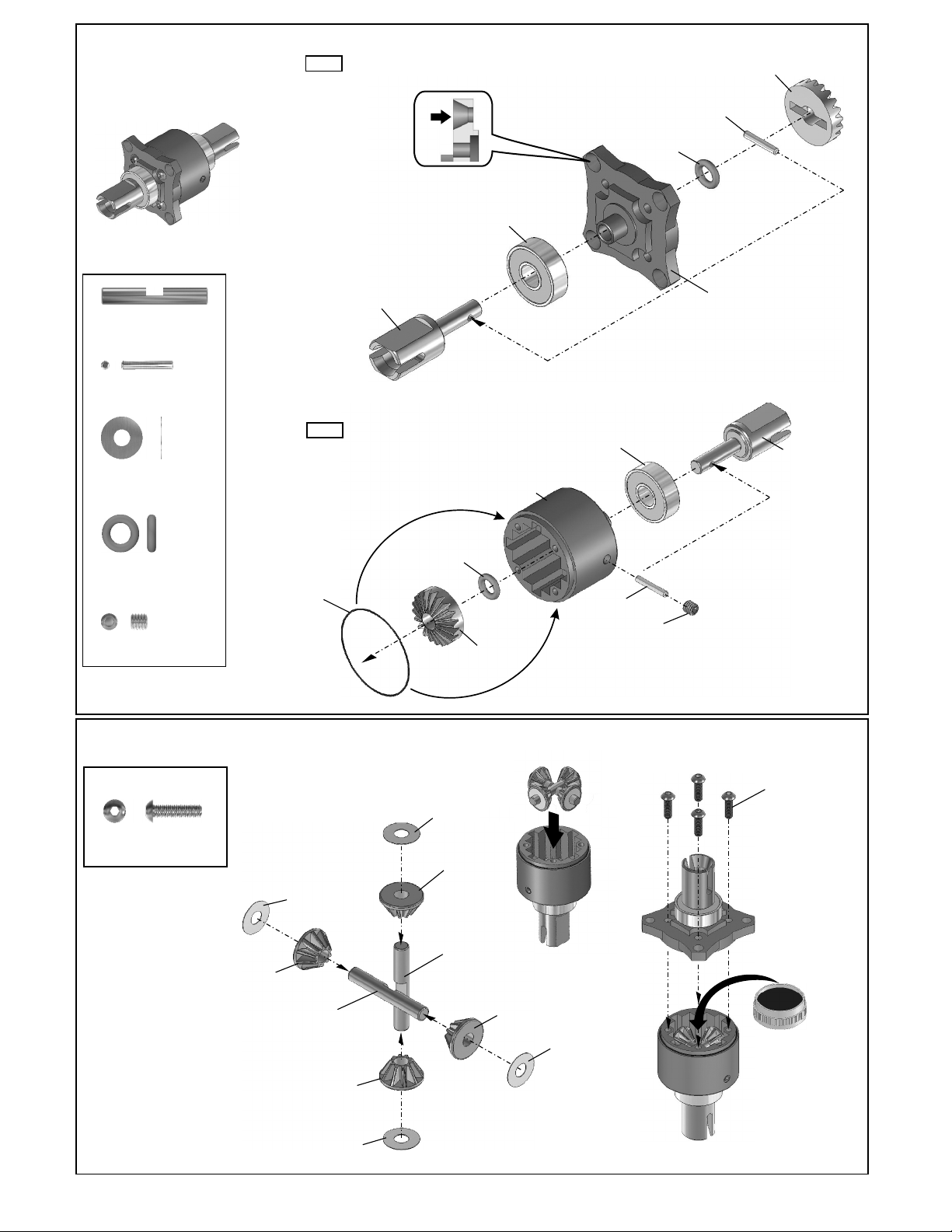

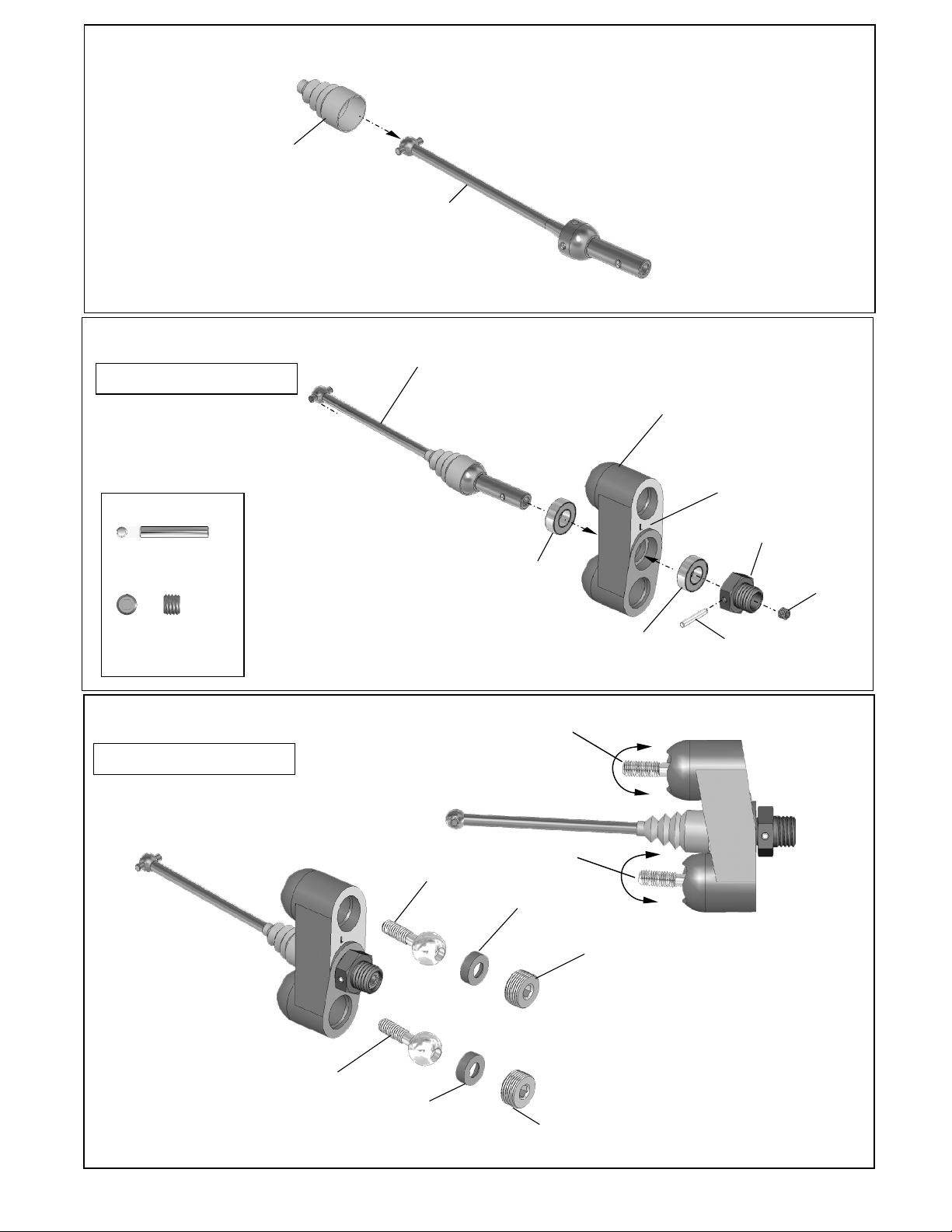

ASSEMBLY OF THE FRONT AND REAR DIFFERENTIAL

Step 1

*Builds two differentials for

font and rear.

*Notice the straight

holes are for the

front and rear only.

30620

7x19x6mm

Ball bearings

30779

2x12.8

30779

P5

O-Ring

30769

Diff. Gear

(Large)

30773

4x27mm

Cross Pin

30779

2x12.8mm

30779

4x10mm Washer

30779

P5 O-Ring

94034

Set Screw

X2

X2

X4

X2

X2

Step 2

30779

0.5x26mm

O-Ring

30901

Cap Joint

30779

P5

O-Ring

30751(Front/Rear)

30761(Center)

Diff. Case

30769

Diff. Gear

(Large)

30620

x19x6mm

Ball bearings

30779

2x12.8

94034

Set Screw

30751(Fro nt/Rear)

30761(Center)

Diff. Case

30901

Cap Joint

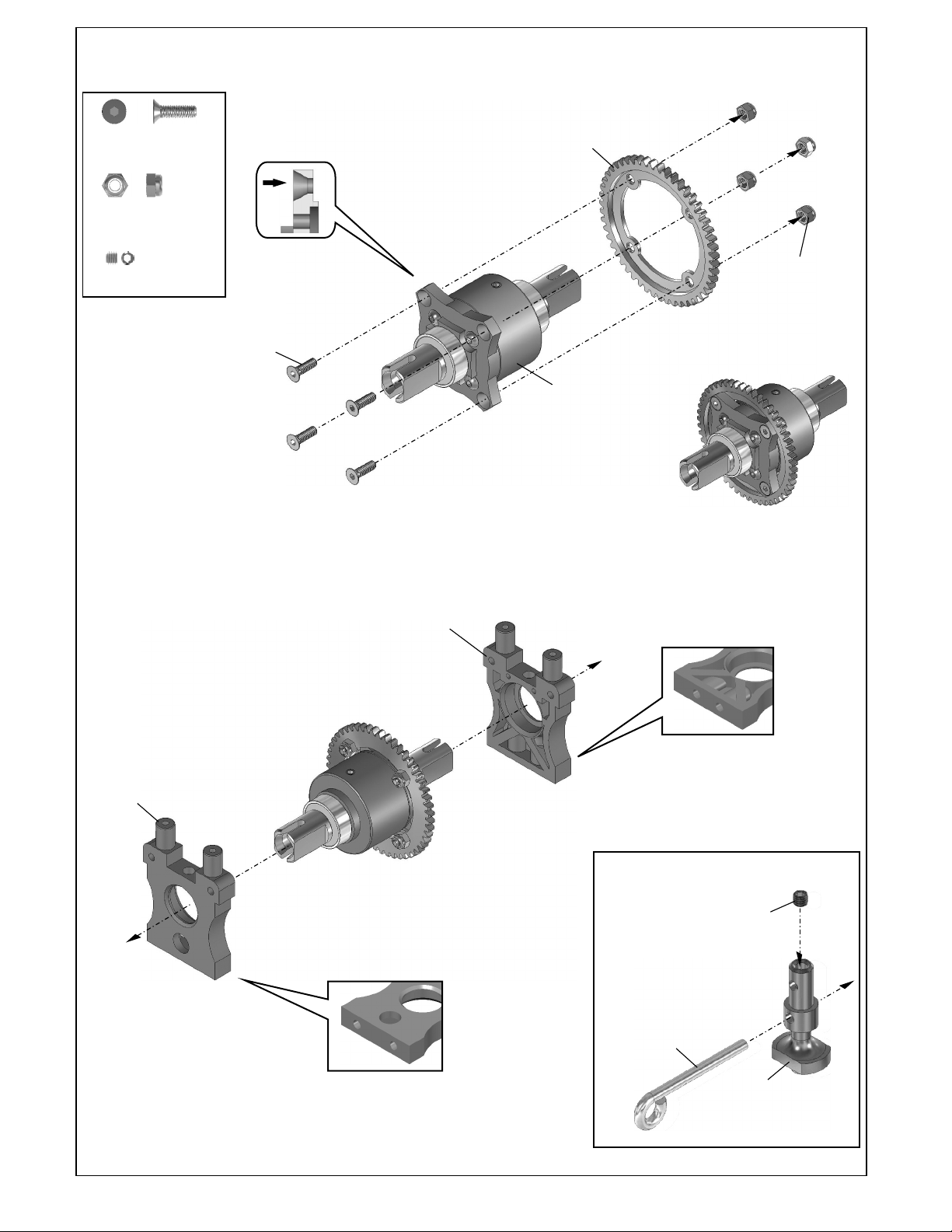

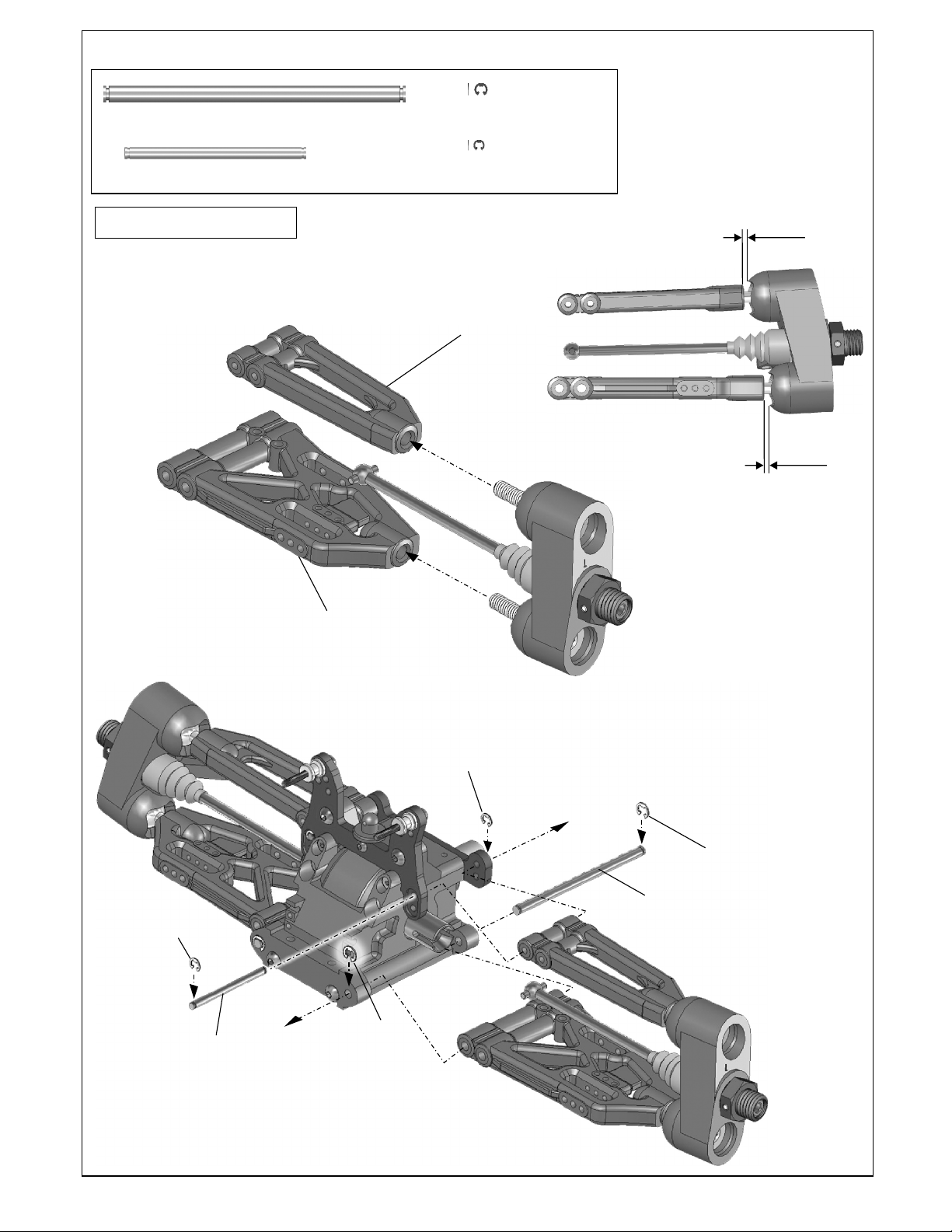

ASSEMBLY OF THE DIFFERENTIAL GEAR

94004

3X12mm

Hex Screw

X4

30779

4x10mm

Washer

30769

Diff. Gear

(Small)

30773

4mm

Cross Pin

30769

Diff. Gear

(Small)

30779

4x10mm

Washer

30779

4x10mm

Washer

30769

Diff. Gear

(Small)

30773

4mm

Cross Pin

* Put the differential gears

same as picture shown.

30769

Diff. Gear

(Small)

30779

4x10mm

Washer

94004

3X12mm

Hex Screw

*Apply diff. Gear grease

to the differential, during

assembly.

*Fill the dif. Case to

approx 80% with grease

ASSEMBLY OF THE CENTER DIFFERENTIAL

30773

4x27mm

Cross Pin

X2

Step 1

30911

Break Cap Joint

*Notice the tapered

holes are for the

center differential only.

30620

7x19x6mm

Ball bearings

30779

P5

O-Ring

30769

Diff. Gear

(Large)

30779

2x12.8

30761(center)

30751(F/R)

Diff. Case

30779

2x12.8mm

30779

4x10mm Washer

30779

P5 O-Ring

94034

Set Screw

X2

X4

X2

X1

Step 2

30779

0.5x26mm

O-Ring

O«¬Àô

ASSEMBLY OF THE DIFFERENTIAL GEAR

94004

3X12mm

Hex Screw

X4

30779

4x10mm

Washer

30779

P5

O-Ring

30779

4x10mm

Washer

30769

Diff. Gear

(Small)

30761(Center)

30751(F/R)

Diff. Case

30769

Diff. Gear

(Large)

* Put the differential gears

same as picture shown.

30620

7x19x6mm

Ball bearings

30779

2x12.8

94034

Set Screw

30911

Break Cap Joint

94004

3X12mm

Hex Screw

30769

Diff. Gear

(Small)

30773

4mm

Cross Pin

30769

Diff. Gear

(Small)

30779

4x10mm

Washer

30773

4mm

Cross Pin

30769

Diff. Gear

(Small)

30779

4x10mm

Washer

*Apply diff. Gear grease

to the differential, during

assembly.

*Fill the dif. Case to

approx 80% with grease

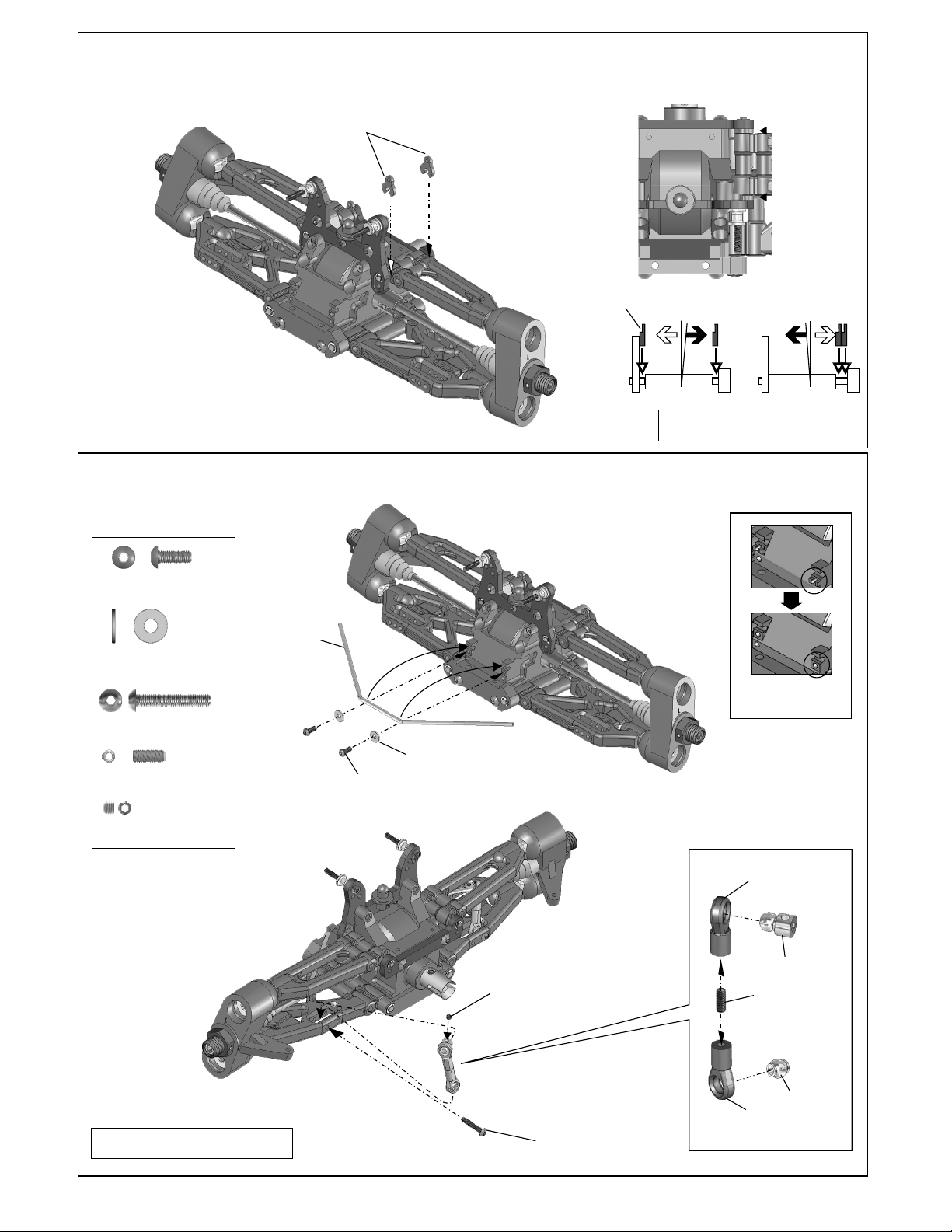

ASSEMBLY OF THE SPUR GEAR

30111

3x10mm

Flat Head Hex Screw

35313

M3 Nylon Nut

94033

M3x3 Set Screw

X4

X4

X4

30111

3x10mm

Flat Head

Hex Screw

*Notice the tapered

holes are for the

center diff. Only.

31040

51T Spur Gear

Center differential

assembly

35313

Nylon Nut

* The picture show are

center differential after

assembly.

30201

Center Diff. Mount

(Front)

Note

the holes for the rear

diff. Mount are wider

30201

Center Diff. Mount

(Rear)

* Note:

the holes for the rear

diff. Mount are closer .together

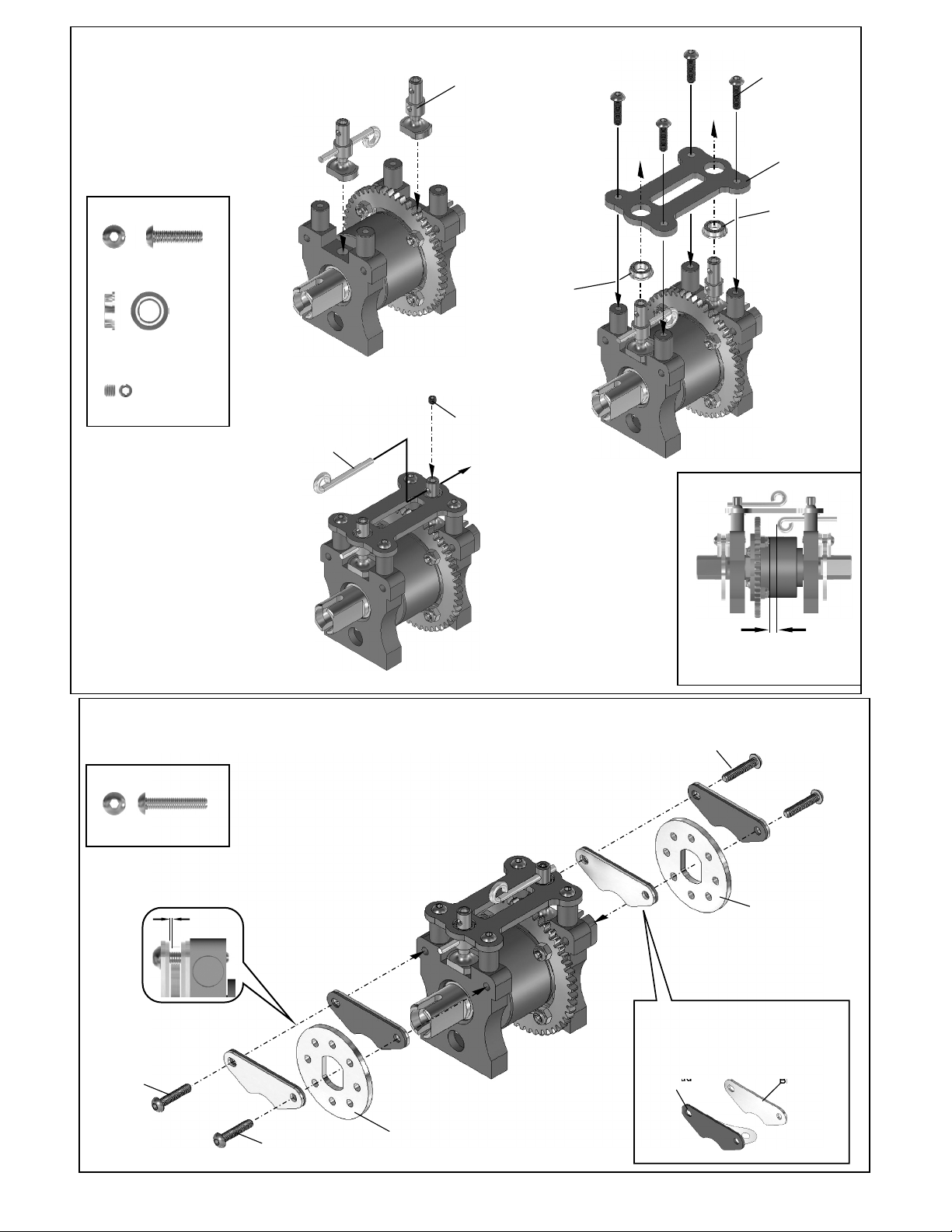

ASSEMBLY OF THE BRAKE CAM

94033

M3x3

Set Screw

30171

Brake Lever

30213

Brake Cam

ASSEMBLY OF THE BRAKE CAM AND BRAKE PADS

ASSEMBLY OF THE BRAKE CAM AND CENTER PLATE

30213

Brake Cam

94004

3X12mm

Hex Screw

30652

Center Diff.

Plate

30211

Plastic Bushing

30212

Ball Bearing

94004

3X12mm Hex Screw

30211

5x8x2.5mm

Plastic Bushing

94033

M3x3 Set Screw

X2

X2

X4

30171

Brake Lever

ASSEMBLY OF THE BRAKE PADS

94033

M3x3

Set Screw

30211

Plastic Bushing

30212

Ball Bearing

Note:

94005

3X15mm

Hex Screw

3mm

*Leave 3mm gap

between the brake cam

and nut.

94005

3X15mm Hex Screw

94005

3X15mm

Screw

X4

0.5mm

*Leave a 0.5mm space

between brake disk and

brake pad.

94005

3X15mm

Screw

36650

Brake Disk

Steel

36650

Brake Disk

Steel

* Remove the double-side tape

before assembly.

36661

Brake Pad

Linings

36660

Brake Pad

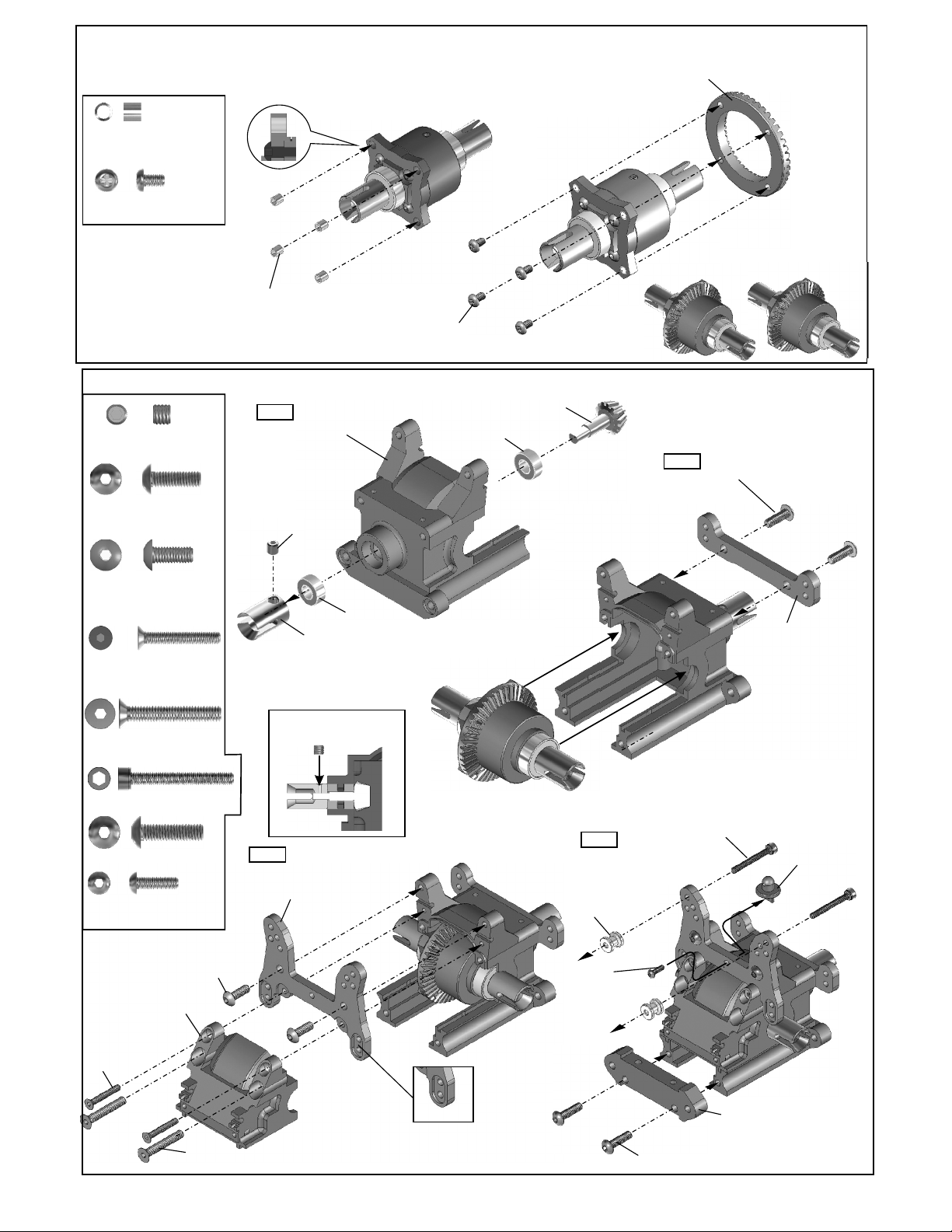

ASSEMBLY OF THE FRONT BEVEL GEARS

*Push 3mm tubes into the

holes of the diff. Case.

30120

Bevel Gear

(Large / Metal)

30121

4x3x3mm

Chromed Tube

3x5mm Hex Screw

X4

X430121

30121

3x4x4mm

Chromed Tube

ASSEMBLY OF THE FRONT GEAR BOX

94036

M5x5 Set Screw

94010

4x12mmHex Screw

Step 1

X1

X2

30010

Gear Box

94036

5x5mm

Set screw

30121

3x5mm

Hex Screw

30630

6x13x5mm

Ball Bearing

30130

Bevel Gear

(Small)

* Builds two differential for

front and rear.

Step 2

94010

4x12mm

Hex Screw

94009

4x10mm

Hex Screw

94022

3x18mm

Flat Head Hex Screw

94029

4x25mm

TP Flat Head

Hex Screw

90018

3X25mm

Cap Screw

94011

4X15mm

Hex Screw

94003

3X10mm

Hex Screw

30010

Gear Box

Front Cover

94022

3x18mm

Flat Head

Hex Screw

X2

X2

X2

X2

X2

X1

94009

4x10mm

Hex Screw

* Place 5x5mm

set screw in d cut.

Step 3

34018

Shock Tower

36730

Cap Joint

30630

6x13x5mm

Ball Bearing

Step 4

36610

Shock Support

Steel

36507

Shock Support

Alum

94003

3X10mm

Hex Screw

90018

3X25mm

Cap Screw

34021

Front Upper Arm

Holder

30102

Front body

Post

94029

4x25mm

Flat Head Hex Screw

* Notice the direction.

94011

4X15mm

Hex Screw

30160

Front Lower

Arm Holder

ASSEMBLY OF THE CVD DUST COVER

*Made two CVD joint.

10189

CVD Dust Cover

ASSEMBLY OF THE KNUCKLE ARMS

Assembly of the right and left hand side

are the same.

40105

CVD Joint

40105

CVD Joint

36901

Ball type

Knuckle Arm(Left)

* "L" mark for left side.

36055

2.5x16.8mm Pin

90026

5x4mm Set Screw

X2

X2

ASSEMBLY OF THE KNUCKLE ARMS

Assembly of the right and left hand side

are the same.

36903

14mm

Steering Ball

36053

8x16x5mm

Ball Bearing

Make steering

ball move

smooth.

Make steering

ball move

smooth.

36905

Plastic Washer

36053

8x16x5mm

Ball Bearing

36904

14mm

Alu m. Nut

36054

Wheel Hub

36055

2.5x16.8mm Pin

90026

5x4mm

Set Screw

36903

14mm

Steering Ball

36905

Plastic Washer

36904

14mm

Alu m. Nut

ASSEMBLY OF THE FRONT ARMS

30151

4mm Arm Shaft

36170

3mm Arm Shaft

Assembly of the right and left hand side

are the same.

X2

X2

3mm E-Ring

2.5mm E-Ring

36881

Front Upper Arm

X4

X4

*Approx. 2.6mm

*Approx. 3mm

90020

2.5mm

E-Ring

36170

3mm Upper

Arm Shaft

36881

Front Lower Arm

90021

3mm

E-Ring

90020

2.5mm

E-Ring

30151

90021

3mm

E-Ring

CLIP IN THE CASTER ADJUSTER

36905

Caster Adjuster

* o change

use adjuster t

the caster angle .

Caster Adjuster

Caster Adjuster

ASSEMBLY OF THE FRONT STABILIZER

94002

3x8mm Screw

3x8x0.8mm

Washer

94006

3x18mm Screw

94035

M3x8mm Set Screw

X2

X2

X2

X2

34027

Stabilizer

94002

3x8mm

Screw

3x8x0.8mm

Washer

Caster Adjuster

*Caster angle will

become bigger.

Assembly of the right and left hand side

are the same.

* Cut the plastic as shown.

*Caster angle will

become less.

A

B

94033

M3x3 Set Screw

Assembly of the right and left hand side

are the same.

X2

94033

M3x3

Set Screw

94006

3x18mm

Screw

40199

Stabilizer

Ball End

94035

M3x8mm

Set Screw

40199

Stabilizer

Ball End

30341

Stabilizer Ball

30403

6mm Ball

Loading...

Loading...