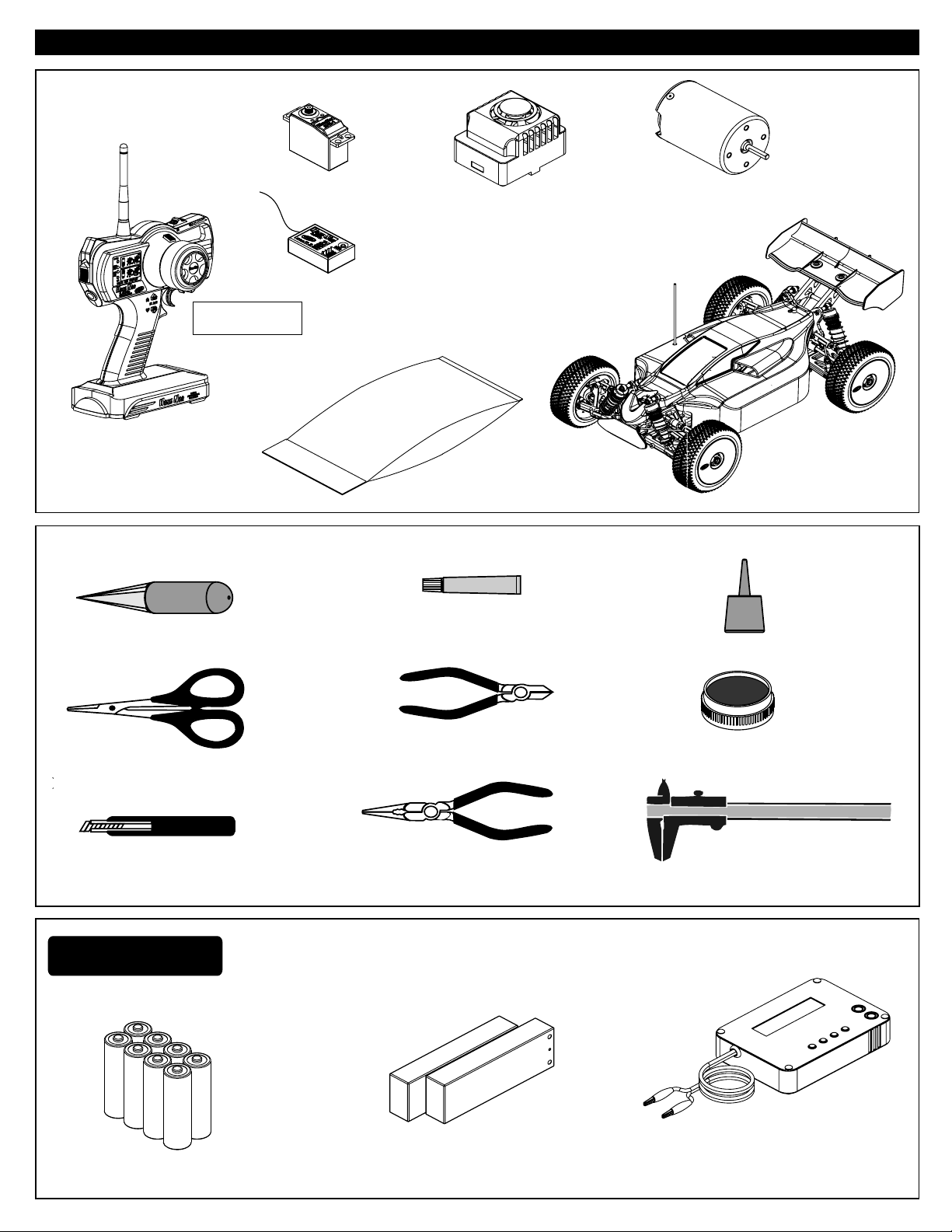

Components

OVERVIEW

Transmitter

Body Reamer

Radio System

40991

Servo

Receiver

Parts Bag

Brushless Electric

Speed Controller (30693)

Radio Control Car

TOOLS NOT INCLUDED IN THE KIT

Screw Cement

Screw Cement

Brushless Motor,1900KV

( 30694)

CA

Instant Cemment

Curved Scissors

Craft Knife

Equipment Needed

AA Batteries

( 8 pcs )

Cutter

Needle Nosed Pliers

7.4V L

i-Po Battery

(Hard Case x2 pcs)

GEAR

GREASE

Gear Grease

Precision Caliper

TOOLS NOT INCLUDED IN THE KIT

Included Item

s

1.5mm Allen Wrenc

h

2mm Allen Wrenc

h

2.5mm Allen Wrenc

h

Cutte

r

Curved Scissors

Craft Knife

Precision Caliper

Needle Nosed Pliers

Equipment Neede

d

L Battery Chargeri-Po

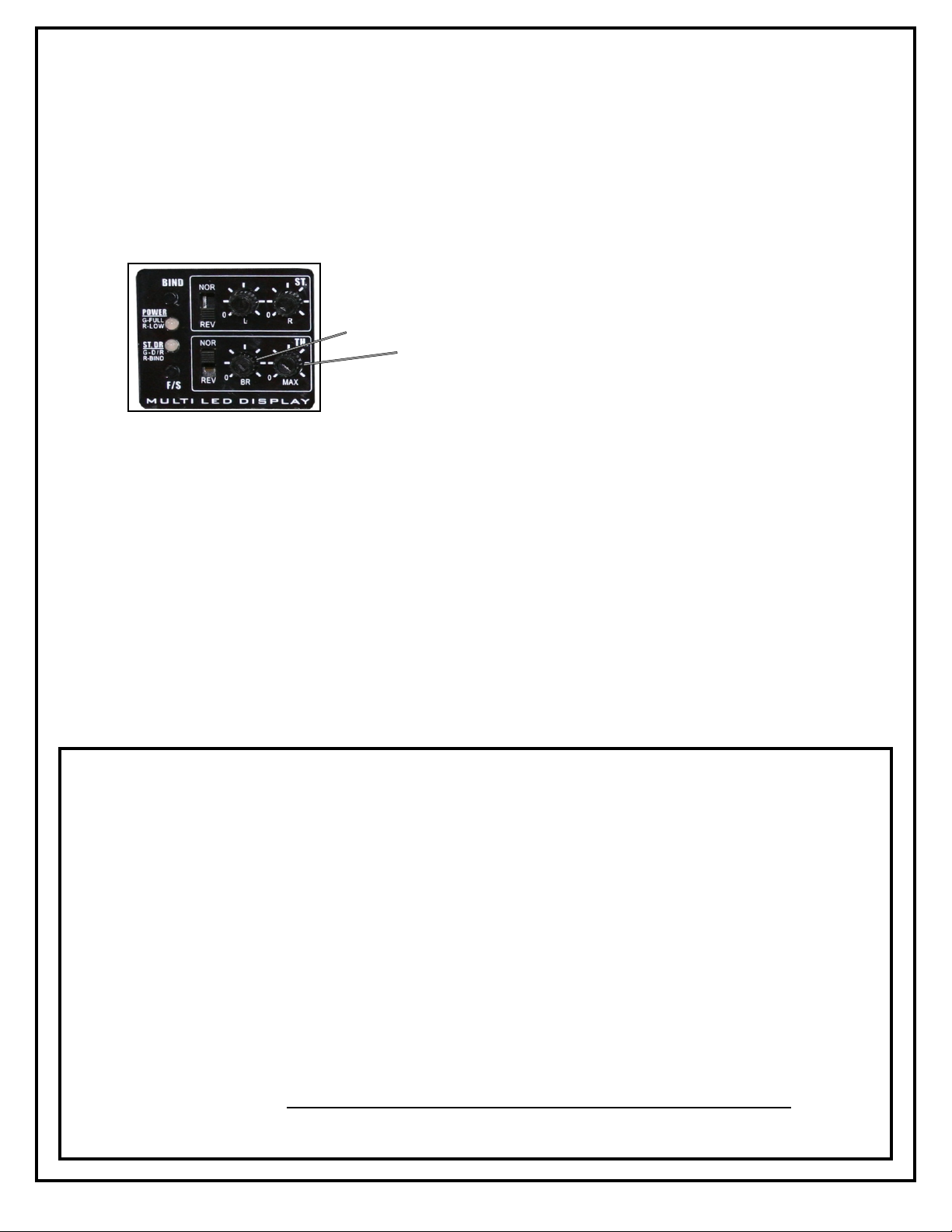

ATTENTION

•Before plugging in your batteries and turning on your radio

please read this page!

1. Check your brake and throttle dial on transmitter, and make sure it at MAX.

Brake

Forward

2. Turn on your transmitter.

3. Plug in your two 7.4v Lipo batteries.

4. Turn the switch to ON (Electronic Speed Control)

A. It will beep twice and LED will flash RED

B. Then the LED will go to solid Green on both LED

5. Now check your Throttle and Brake by slowly pulling the trigger.

(Make sure you don’t free wheel the buggy drive it around slowly)

6. Now everything should sync up you are ready to play.

For more instruction on all the function on your radio please refer to

pages 5-11 of this manual.

NOTE!

This model comes equipped with

a 14 tooth pinion gear. Do not

change the pinion gear to a higher

number tooth count. This can

cause motor and E.S.C. Damage

and will VOID THE WARRANTY!

5

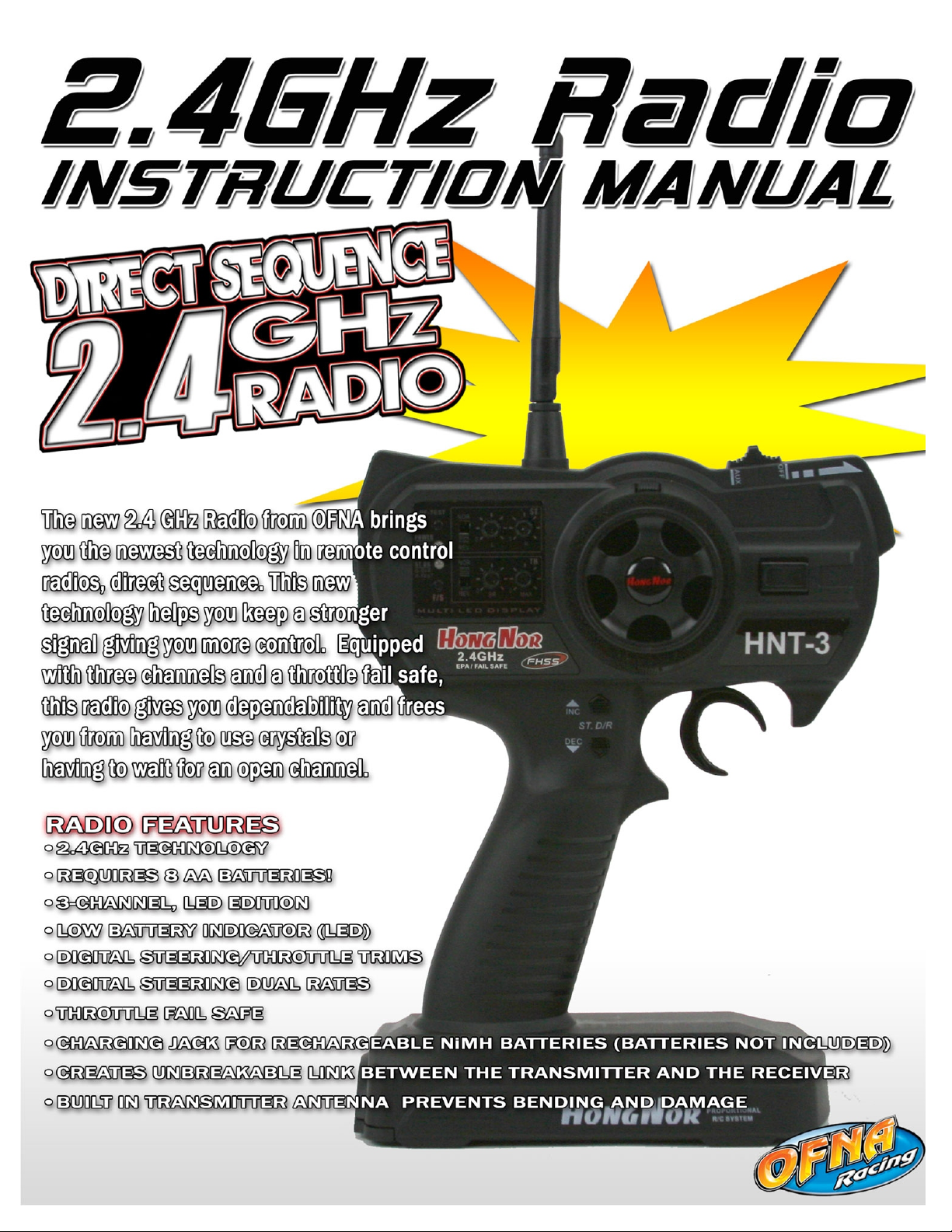

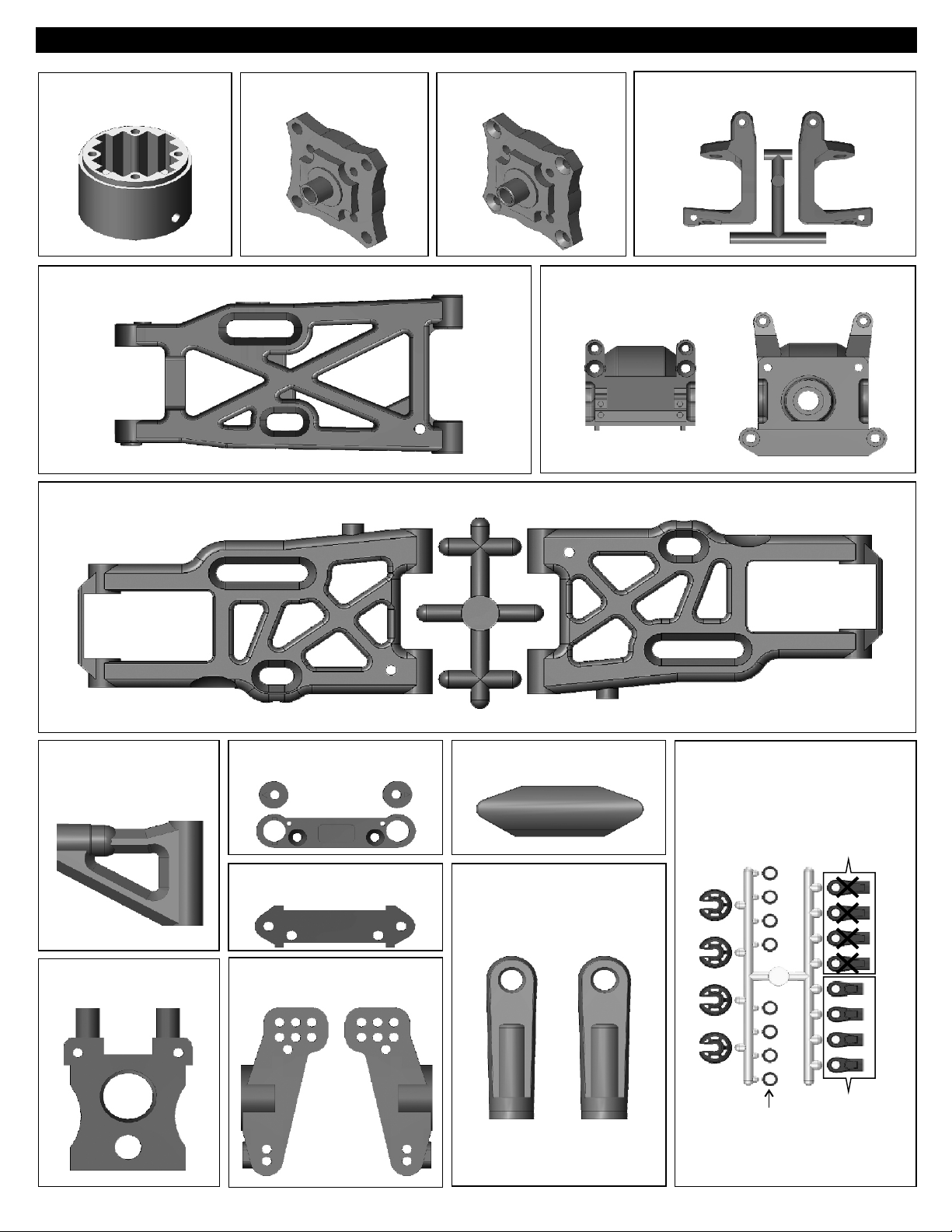

HNT-3 2.4GHz RADIO SYSTEM OVERVIEW

HNT-3 Transmitter

*Carefully read the instruction manual of your

radio controller before using and keep it in a

safe place as a reference introduction in the

future.

1

2

3

4

5

6

7

8

10

12

14

1.Transmitter Antenna

2.Servo Reverse Switches

3.TX RF Module And Binding Button

4.Power LED

5.Power Switch

6.Steering Dual Rate Trim LED

7.External Charging Jack

8.Fail Safe Button

9.Throttle End Point Adjustment Knob

10.Steering End Point Adjustment Knob

11.Steering Dual Rate Adjustment Button

12.Steering Trim

13.Throttle Trim

14.AUX Channel Switch

9

11

Receiver Connection Diagram

Bind Button

Battery Port

Auxiliary Channel

Throttle Channel

Steering Channel

15

16

13

17

15.Steering Wheel

16.Throttle Trigger

17.Battery Cover

Specification Data

•Transmitter

Channels: 3

Frequency: 2.4Ghz

Power DC: 9.6V - 12V

Measurement: 280 x 190 x 85mm

(Packing Meas.)

Net Weight: 510g

Specification:

Channels:3Ch

Frequency:2.4GHz

DC:12V/ 8 cell AA Type

Battery

Meas.:310*170*75mm

Net weight:530g

•Receiver

Channels: 3

Frequency: 2.4Ghz

Power DC: 4.8 - 5.6V

Net Weight: 13.5g

6

CAUTION

• To use your Radio with your models correctly and safely, read this manual carefully and keep it in a

safe place for future reference.

Warning:

1. This product is only equipped for radio controlled cars;

2. The usage of this product should be approved by local law or regulations;

3. We will not be responsible for the damages caused by unauthorized modification, adjustment

or replacement of parts on this product;

4. The manual may be change without prior notice. Please contact us if you have any corrections

or clarifications that should be made in the manual;

• Before turning on the transmitter, make sure the transmitter batteries are fresh. The voltage of the

transmitter batteries is should never be lower than 9.6V, and please check and confirm that the servos

are all well and properly connected.

• Keep the radio system away from moist, high temperature and strong vibrations. Do not clean radio

with any solvent.

• Make sure antenna does not touch anything when power switch is turned on. Do not leave this radio

in reach of small children.

• Please use this product according to your local laws and regulations, we are not responsible for any

incidents or damages.

2.4Ghz Binding

•Binding your RX to Transmitter

Turn on the transmitter, then turn on your ESC (speed control)

or receiver power switch. Then push the bind button located on

the receiver until LED light turns solid green which is about 3 sec.

Green which means the binding is successful. After that, it’s un necessary to bind again.

LED

BIND

Caution:

When binding make sure that the RX and TX is no more

than a yard or 3 feet from each other, also no other similar FHSS

system or device is being use within 10 yard of your RX and TX

or it could accidentally pair up or bind with your vehicle.

Reducing Power

• Reducing output power setting.

• Push the RF-TEST button, while holding it down turn on your transmitter,

the “ST-D/R” LED “RED” should light up. Now your output power of the

transmitter is reduce to a lower mode of 18dbm, which reduce the range

of the radio but save in battery consumption

.

•Now press the RF-TEST button again, the LED on the “ST-D/R should turn off, and

output power becomes normal 20dbm which can control your vehicle with more

range but more battery consumption.

STEP 1

STEP 2

Power Switch (turn on)

RF-TEST (Press and hold)

7

AUX Channel Function (CH3)

•This switch control the transmitter’s third channel. A servo plugged in this Channel 3 will move to full travel in one

direction when the switch is in the “AUX” position, then move the switch to the “OFF” position the servo will move

in the opposite position . This channel can be use to turn on all sort of things in your vehicle. For example, lights,

on board camera etc..... l

Steering Dual Rates Setup

INC

ST.DR

DEC

ST.D/R SW

•DEFINITION:

Steering Dual Rate (ST. DR): Is the adjustment that allows the dual rate value

(maximum servo travel) to be increased (INC) or decreased(DEC) with in a range

of 0% to 100% of the steering servo. This functions very useful in a race

conditions as it allows you to tailor the steering radius and sensitivity for the

current track conditions.

•ADJUSTMENT:

1.Press and hold the “INC” (Increase) button until the LED on the “ST.DR” blinking green

into a blinking red indicating maximum turning radius or value of 100%.

2.Press and hold the “DEC” (Decrease) button until the LED on the ‘ST.DR” start blinking green

and goes to a blinking red LED indicating minimum turning radius or value 0%.

Steering End Point Adjustment (EPA)

Steering End Point Adjustment (ST.EPA)

Left turn

Straight (neutral)

L R

Right turn

L R

*L/R Steering end point adjustment

(ST. EPA)knob.

Max Max

Use the "EPA" to adjust steering tie-rod to

the steering stopper.

Steering

Stopper

*After adjusting "D/R" to Max position then adjust

both "ST EPA" knob to the correct position as

picture shown.

*The steering stopper may vary for different

brand models. Follow the steering stopper

set-up for max position. The steering servo

may be damaged if it is overload.

8

CHECKING YOUR DUAL RATE

•To Check Your Dual Rate:

1. Turn your radio “ON” then turn “ON” your vehicle.

2. Check your steering on your radio by turning left and right several times.

3. Now turn your steering wheel all the way to the left or right whichever you choose

and hold it while pushing the “DEC” button ( see fig. 1) on the “ST-DR” and

hold it down, you should see that the wheel on your vehicle decrease in radius

(see fig. 2) and that the LED on “ST-DR” will start blinking Green and turn to a

blinking Red indicating it is at 0% or minimal steering radius

FIG. 1

INC

ST. D/R

DEC

FLASHING

.

4. To increase the dual rate turn the wheel left or right all the way and hold it while

pushing the “INC” button this will increase the turning radius of the and the LED

on ST-DR will start blinking Green and turning to the FIRST Blinking Red indicating

that the“Dual Rate” is at 80%, Holding the increase button past the FIRST Blinking

Red will turn to Blinking Green again then to the SECOND Blinking Red indicating

your “Dual Rate” is at 100%. When running your vehicle try to run the “Dual Rate”

at maximum radius (100%). Then if you have too much steering then decease as

needed.

FIG. 3

ST.DR

0%

%

001

INC

ST.D/R

DEC

100

%

FIG. 2

0

0

1

0%

%

10

0

%

0

0

1

0%

%

1

00

%

9

Steering Trim

Please turn on your transmitter, plug in your battery and turn on your esc while making the adjustment of these settings.

1.Connect the receivers, servos, and other components and then turn on the power switches of the transmitter and receiver.

2.Be sure the steering trim and throttle trim on the transmitter are at their neutral position.

3.When turning on your system make sure you turn on the transmitter first before turning on the receiver, while turning off the system

turn of receiver before turning off the transmitter.

•Steering Trim

Steering neutral adjustment can be made by moving the steering trim knob to the left or right.

•Finding Neutral position on the Steering

To find the center or neutral position on your transmitter, turn it on. Push the “ST-TRIM” left and notice the “ST-DR” will start flashing Green

then slowly turn to a flashing Red hold it there until you see a steady flashing Red, now you know you are at the end of left side trim. Now to

find the center or neutral position of the steering trim push the “ST-TRIM” to the right and hold it, you will notice that the “ST-DR” LED will start

flashing Green hold it their until you see that it will turn RED let go, now you are at center or neutral position, if you go past the RED light it

will start flashing GREEN again you are now off center or neutral and going toward the right.

•Racer Tip

Always check and be sure the servo is at it neutral position before installing a servo. Adjust the servo horn hole position and linkage so that

both are parallel. When a servo saver is used, place it as close to center position as possible. Be sure the steering trim on the transmitter is at

the neutral position.

•Trim Operation and Maximum Travel.

Changing the trim can effect the overall settings, when adjustments are made with the trims, please recheck your installation for maximum

servo travel. When Trim movement goes to extremes and your vehicle will not go straight.

That means if you make a lot of trim movement to get a servo to the neutral position, please reposition the servo horn or servo saver on the

servo and inspect your linkage installation.

1.When adjusting the ST-Trim button the ST-DR LED appears FLASHING GREEN.

2.When in the neutral position, the LED appears RED.

3.When in Max or Min position, LED appears FLASHING RED.

LEFT RIGHT

1

2

Throttle End Point Adjustment (EPA)

*Turn "BR" knob to set brake rate.

50%

0%

100%

100%

B

R

*We Suggest you to set the brake at 50%.

Too much brake may overheat and damage the

Electric Speed Controller and Motor.

*Turn "MAX" knob to maximize the throttle rate.

100%

M

X

A

10

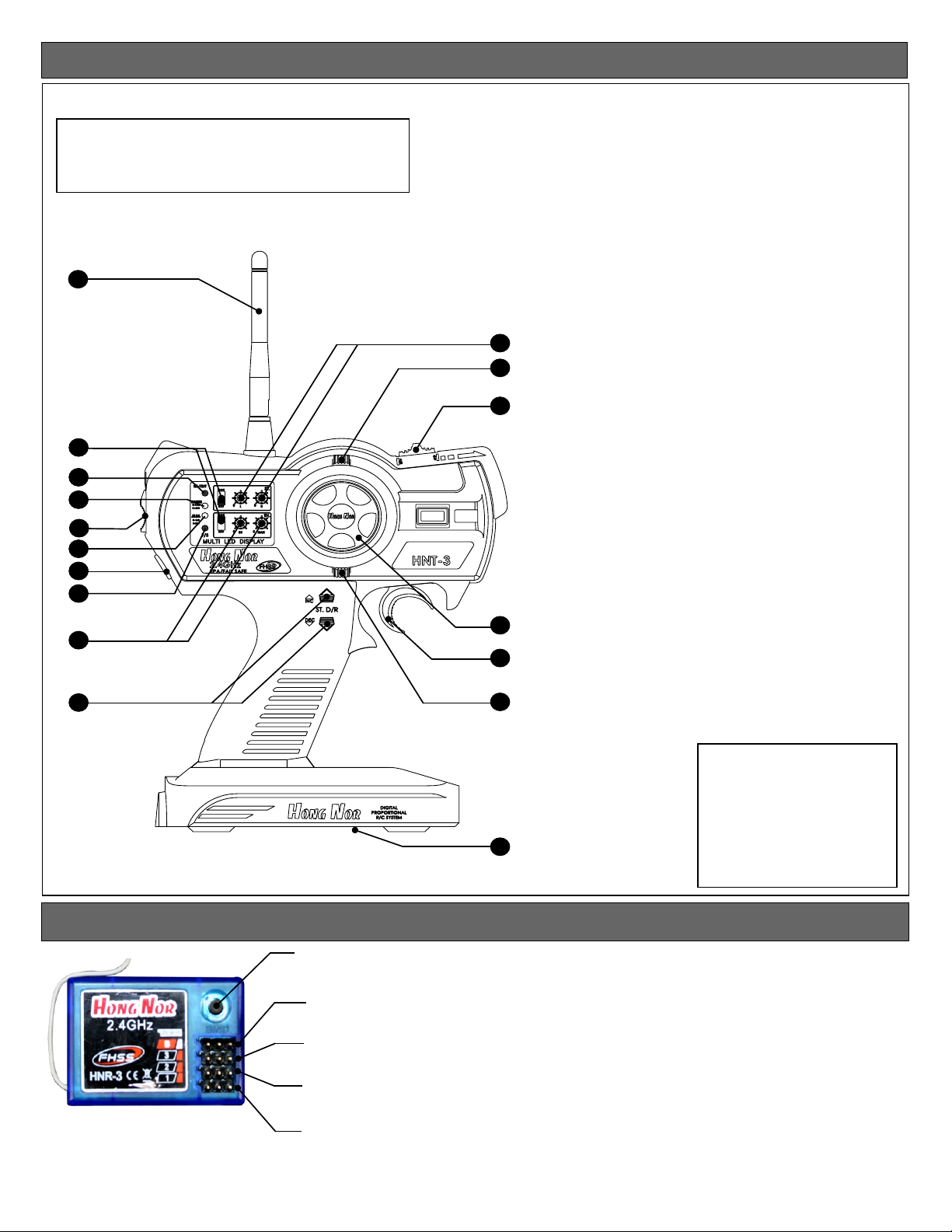

Handling Procedure For Batteries

Handling Procedure For Batteries

•Battery Replacement

1) Remove the battery cover from the transmitter by sliding it in the direction of the arrow.

2) Remove the used batteries.

3) Load the new 8 AA size alkaline, or Nickel Metal Hydride (NimH) rechargeable batteries,

and pay very close attention to the polarity marking on the batteries.

4) Slide the battery cover back onto the case.

5) If you use rechargeable batteries OFNA make this charger 10210 it will charge your Transmitter

9.6v at 100mA and Receiver battery 4.8v-6v at 100mA at the same time.

NOTICE THE DIRECTION OF BATTERY COVER

•Caution

Always make sure you reinsert the batteries are in the correct polarity order. If the batteries are loaded

incorrectly, the transmitter may not work or can be damaged.

When the transmitter is not used for a long period of time remember to remove the batteries. If the batteries

do happen to leak, clean the batteries case and contacts thoroughly and make sure the contacts are free of

corrosion.

•Battery Disposal

Some countries and state require special handling of used batteries, please contact the agencies responsible

for recycling hazardous wastes in your local area.

•Battery low voltage alarm indicator. LED Power light will flash.

Turning R/C Unit Off

1

*Turn off the receiver first, then turn off the transmitter.

OFF

CAUTION

2

*If you switch off the transmitter first

before the receiver, you may lose control

of the R/C car.

10210 - DUAL CHARGER, 4.8V-6V/9.6V TRANSMITTER AND RECEIVER

(Not included)

ON

FOR MORE SUPPORT PLEASE CALL US AT (949)586- 2910 OR CHECKOUT OUR WEBSITE

WWW.OFNA.COM .

11

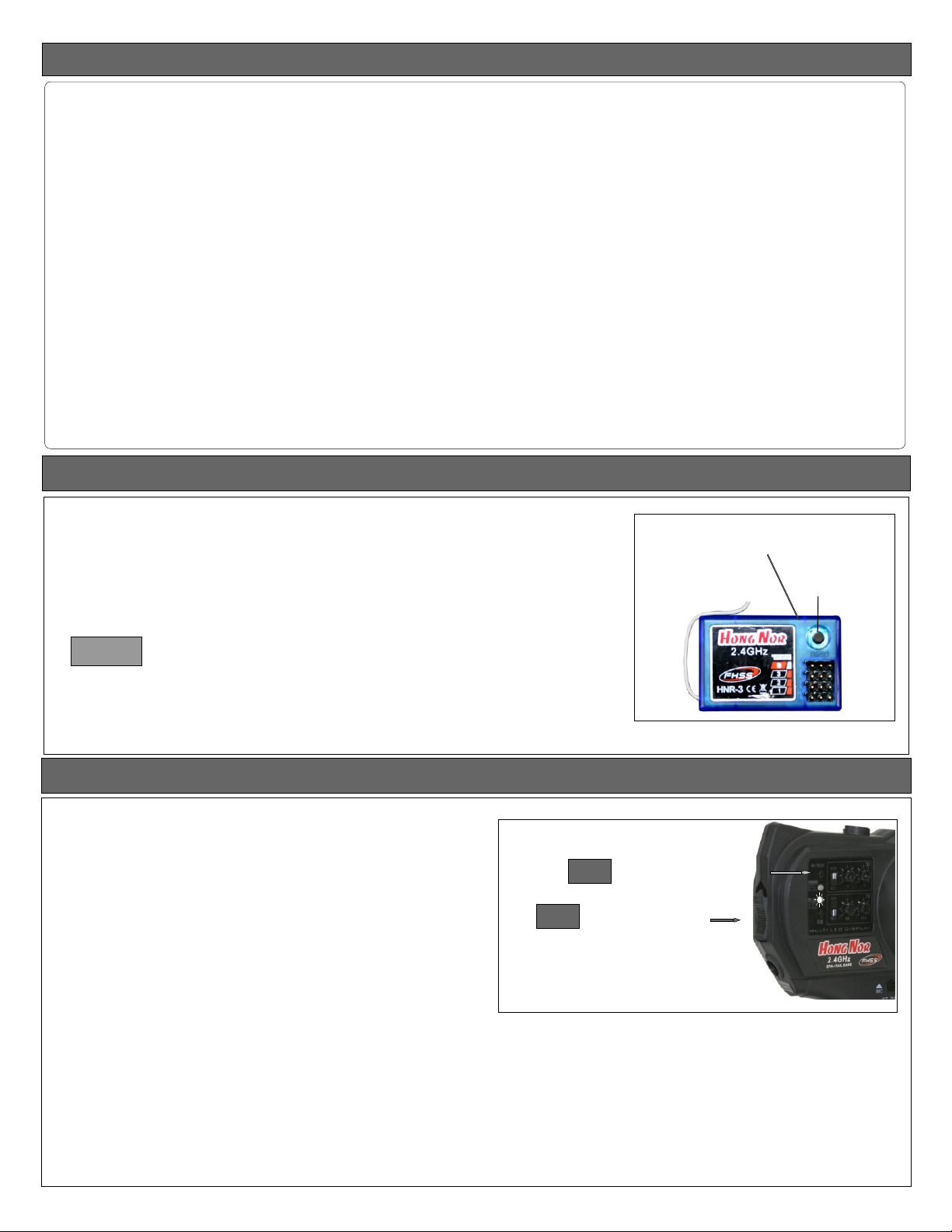

PLASTIC PARTS FOR USE

30751

DIFF. CASE

34063

REAR LOWER ARM

30657

FRONT LOWER ARM

30751

DIFF. CASE

FRONT & REAR

30761

DIFF. CASE

CENTER

40536

FRONT C HUB

30010

FRONT AND REAR GEAR BOX

36020

FRONT UPPER ARM

30201

CENTER DIFF. MOUNT

30351

REAR LOWER ARM HOLDER

30160

FRONT LOWER ARM HOLDER

36081

REAR WHEEL HUB

30240

BUMPER

40065

REAR UPPER ARM

PLASTIC ROD END

40643

SHOCK PLASTIC PARTS

40643

Shock Cap

Washer

40643

Shock Plastic

Ball End

(Long)

40643

Shock Plastic

Ball End

(Short)

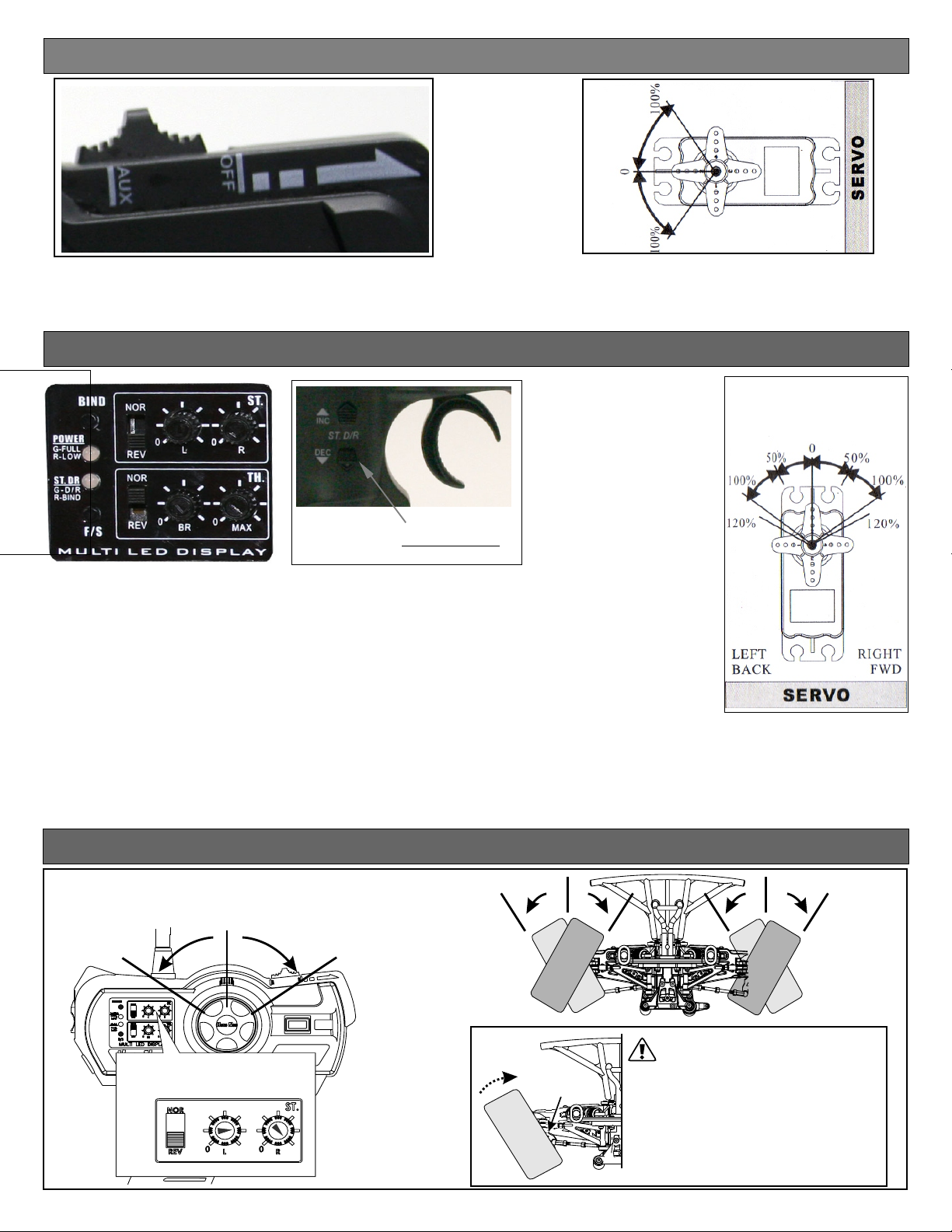

PLASTIC PARTS FOR USE

30674

SERVO SAVER

16015

WING

41033

STONE GUARD

30686

FRONT STIFFENER

30662BATTERY CASE

30270

WING STAY

SYMBOLS USED THROUGHOUT THE INSTRUCTION MANUAL

Degrease With

Motor Spray

Apply OilApply Screw

BAG

Screw

Cement

Parts Bag Used

Cement

Oil

Do Not

Over Tighten

Apply

Grease

Do Not

Over Tighten

Apply Lubricant

Tighten

1:1

Tighten

True-To-Scale

Ensure

Free

Movement

Time

Ensure Free

Movement

Contact

Adhesive

Contact Adhesive

Time Pay attention here

1

ASSEMBLY OF THE FRONT AND REAR DIFF.

Step 1

94034

4x4mm

Set Screw

30121

3x5mm Screw

94004

3x12mm

Hex Screw

30777

P5 O-Ring

30776

4x10mm Washer

30780

2x12.8mm Pin

.....x2

.....x8

.....x8

.....x4

.....x8

.....x4

30779

Step 3

Step 5

30769

30777

30751

30620

30773

30769

30901

30780

30776

Oil

4x4mm

30769

Notice the straight

holes are for the

front and rear only.

Step 2

30120

Build two differentials for front and rear.

30751

30777

Step 4

Apply diff. gear grease

to the differential, during

assembly.

Fill the diff. case to

approx 80% with grease.

Tighten the diff. screws

in this order.

30620

30901

Oil

30780

Tighten

3x12mm

30773

4mm Cross Pin

30121

3mm Tube

2

ASSEMBLY OF THE CENTER DIFF.

94034

4x4mm

Set Screw

94020

3x12mm

Flat Head Hex Screw

94004

3x12mm

Hex Screw

30777

P5 O-Ring

.....x4

.....x8

.....x1

.....x4

.....x4

.....x2

30779

Note: It is very important to remove

the 30776 washer if the gear

mesh is too tight.

*Push 3mm tubes into the

holes of the diff. case.

30121

30121

30911

30620

Step 1 Step 2

30769

Step 3

30777

30761

30773

30780

30769

4x4mm

30776

Oil

30769

Notice the tapered

holes are for the

center diff.

30777

1

3

30761

Apply diff. gear grease

to the differential, during

assembly.

Fill the diff. case to

approx 80% with grease.

30620

Step 4

4

2

30911

Oil

30780

Tighten

3x12mm

30776

4x10mm Washer

30780

2x12.8mm Pin

30773

4mm Cross Pin

.....x4

.....x2

.....x2

Step 5

3x12mm

30110

3mm

Tighten the diff. screws

in this order.

1

3

4

2

3

ASSEMBLY OF THE CENTER DIFF. MOTOR MOUNT

Note: The width of the

holes for front diff.

Mount.

94003

3x10mm

Hex Screw

94004

3x12mm

Hex Screw

4

ASSEMBLY OF THE FRONT GEAR CASE

.....x2

.....x2

Step 1 Step 2

94036

5x4mm

Set Screw

.....x1

30010

3x12mm

30653

3x10mm

30201

5x4mm

30630

C m

e

re

wSc

ent

Sc

em

C nt

30082

w

e

cr

S

t

en

e

C m

30675

er w

e

4x12mm

30673

94010

4x12mm

Hex Screw

.....x2

30630

30130

30630

6x13x5mm

Ball Bearing

5

ASSEMBLY OF THE FRONT GEAR CASE

.....x2

Apply

Grease

Step 1

94009

4x10mm

Hex Screw

94022

3x18mm

Flat Head Hex Screw

94029

4x25mm

Flat Head Hex Screw

41009

3x28mm

Cap Screw

.....x2

.....x2

.....x2

.....x2

4x10mm

3x18mm

30655

4x25mm

30010

Apply

Grease

Notice the direction.

41010

3x10mm

41010

Step 2

41009

30102

94003

3x10mm

Hex Screw

.....x1

94011

4x15mm

Hex Screw

.....x2

30160

4x16mm

6

ASSEMBLY OF THE KNUCKLE ARMS

Assemble both right and left side.

Step 1

94034

4x4mm

Set Screw

94042

4mm

Nylon Nut

40527

Knuckle Arm

Bushing

40528

King Pin Screw

36055

2.5x16.8mm Pin

7

ASSEMBLY OF THE FRONT SUSPENSION ARMS

36870

4x10mm

Set Screw

.....x2

.....x4

.....x4

.....x4

.....x2

.....x2

36053

Step 3

34053

40218

8x12x0.3mm Washer

Step 1 Step 2

.....x2

40520

8x12x0.3mm

36053

36055

30656

Step 2

40536

4x4mm

4mm

40528

4mm

ew cr

S

t

emen

C

Assemble both right and left side.

40527

40527

90020

2.5mm E-Ring

36850

7mm Ball

36861

5x35mm

Turnbuckle

36170

3x44.3mm Arm Shaft

8

ASSEMBLY OF THE FRONT SUSPENSION ARMS

94041

3mm Nylon Nut

94008

3x25mm

Hex Screw

90021

3mm E-Ring

.....x4

.....x2

.....x2

.....x2

.....x2

.....x2

.....x8

4x10mm

30657

2.5mm

36170

Step 1 Step 2

3mm

2.5mm

3mm

36020

1•1

Approx. 9.5mm

36861

36850

Assemble both right and left side.

3mm

3mm

36171

36690

36640

4x47mm Arm Shaft

36171

4x74.1mm Arm Shaft

.....x2

.....x2

3x25

36640

3mm

Insert the front drive shaft into

cap joint before assembly.

9

ASSEMBLY OF THE FRONT STABILIZER

Step 1 Step 2

94033

3x3mm

Set Screw

94035

3x8mm

Set Screw

94002

3x8mm

Hex Screw

.....x2

.....x2

.....x2

Assemble both right and left side.

3x3mm

94006

3x18mm

Hex Screw

94040

3x8x0.8mm

Washer

10

ASSEMBLY OF THE SERVO SAVER

94041

3mm Nylon Nut

94005

3x15mm

Hex Screw

36742

Servo Saver Bushing

36743

6mm E-Ring

40218

8x12x1mm Washer

.....x2

.....x2

.....x2

.....x2

.....x2

.....x4

.....x1

3x8x0.8mm

3x8mm

Step 1 Step 2 Step 3

8x12x1mm

3x8x0.8mm

30674

36741

30361

34027

36743

30674

36743

30674

30674

30361

36743

30674

36743

3x18mm

Makes two rods for left and right

hand-side

3x16mm

36742

30658

3mm

30341

40199

3x8mm

40199

30403

11

ASSEMBLY OF THE SERVO SAVER AND STEERING TIE-ROD

94003

3x10mm

Hex Screw

40038

7mm Ball

.....x3

.....x4

rew

30540

30380

Sc

em t

C en

Step 1 Step 2

3x10mm

e

Scr

C tem

34014

w

en

36700

40038

36790

Approx. 31mm

1•1

Make two steering rods

for left and right hand-side.

40038

36700

12

ASSEMBLY OF THE SERVO SAVER ONTO GEAR CASE

Step 1 Step 2

3x15mm

40039

94003

3x10mm

Hex Screw

.....x2

3x10mm

Screw

e

C

me

3x15mm

nt

40039

94021

3x15mm

Flat Head Hex Screw

40039

3mm

Tapered Washer(Alum.)

13

ASSEMBLY OF THE REAR GEAR CASE

.....x4

.....x4

Step 1

94036

5x4mm

Set Screw

.....x1

Apply

Grease

30630

30630

5x4mm

Screw

ment

Ce

30082

Screw

me

e

C

Step 2

3x15mm

nt

40039

30630

6x13x5mm

Ball Bearing

14

ASSEMBLY OF THE REAR GEAR CASE

.....x2

30130

Step 1 Step 2

94022

3x18mm

Flat Head Hex Screw

.....x2

3x18mm

94027

4x16mm

Flat Head Hex Screw

94029

4x25mm

Flat Head Hex Screw

.....x2

.....x2

4x25mm

30010

30010

30649

Apply

Grease

30351

4x16mm

30351

15

ASSEMBLY OF THE REAR GEAR CASE

Step 1 Step 2

41009

94019

3x10mm

Flat Head Hex Screw

94006

3x18mm

Hex Screw

94007

3x20mm

Hex Screw

41009

3x28mm

Cap Screw

16

ASSEMBLY OF THE WING STAY AND REAR WHEEL HUB

94036

5x4mm

Set Screw

94011

4x15mm

Hex Screw

90018

3x25mm

Cap Screw

.....x1

.....x2

.....x4

.....x2

.....x2

.....x2

.....x2

41010

3x10mm

41010

Step 1

3mm

4x15mm

34033

41009

3mm

3x20mm

3x18mm

Step 2

30270

36082

30270

36053

30270

30270

30270

30270

*Builds two rear wheel hubs for use.

36081

36055

30656

30270

3x20mm

3x18mm

94041

3mm Nylon Nut

36055

2.5x16.8mm

Pin

17

ASSEMBLY OF THE REAR WHEEL HUB AND UPPER ARM ROD

36870

4x10mm

Set Screw

94001

3x5mm

Hex Screw

34063

3x9.5x4mm

Plastic Washer

34055

3x42.6mm Arm Shaft

.....x2

.....x2

.....x4

.....x2

.....x2

.....x2

3x25mm

Step 1

4x10mm

4x15mm

34063

34063

34063

34055

3x5mm

Step 2

36850

36053

Assemble both right and left side.

40065

36861

36850

1:1

Approx. 18.9mm

5x4mm

40065

18

ASSEMBLY OF THE REAR LOW ARMS INTO GEAR BOX

Assemble both right and left side.

Step 1

94041

3mm Nylon Nut

90021

3mm E-Ring

94006

3x18mm

Hex Screw

94008

3x25mm

Hex Screw

19

ASSEMBLY OF THE REAR STABILIZER

.....x4

.....x4

.....x2

.....x2

3mm

Step 2

3x18mm

3mm

3x25mm

3mm

3mm

36171

34054

94002

3x8mm

Hex Screw

94040

3x8x0.8mm

Washer

20

ASSEMBLY OF THE REAR STABILIZER RODS

94033

3x3mm

Set Screw

94035

3x8mm

Set Screw

.....x2

.....x2

.....x2

.....x2

Makes two rods for left and right

hand-side

3x8x0.8mm

3x8mm

30341

3x8mm

3x8x0.8mm

40199

34027

Assemble both right and left side.

3x3mm

94006

3x18mm

Hex Screw

.....x2

40199

3x18mm

30403

21

ASSEMBLY OF THE FRONT GEAR CASE ONTO CHASSIS

94019

3x10mm

Flat Head Hex Screw

94023

3x25mm

Flat Head Hex Screw

94026

4x12mm

Flat Head Hex Screw

94027

4x16mm

Flat Head Hex Screw

22

ASSEMBLY OF THE CENTER DIFF. ONTO CHASSIS

.....x2

.....x2

.....x2

.....x4

30240

4x16mm

Insert drive shaft into cap

joint before assembly

center diff.

3x25mm

4x16mm

30676

4x12mm

3x10mm

94026

4x12mm

Flat Head Hex Screw

94027

4x16mm

Flat Head Hex Screw

.....x3

.....x2

36100 (90mm)

4x16mm

4x12mm

23

ASSEMBLY OF THE REAR GEAR CASE ONTO THE CHASSIS

Insert drive shaft into cap

joint before assembling

center diff.

94023

3x25mm

Flat Head Hex Screw

94027

4x16mm

Flat Head Hex Screw

.....x2

.....x4

36100 (86.5mm)

4x16mm

3x25mm

4x16mm

24

ASSEMBLY OF THE STONE GUARD

Assemble both right and left side.

41033

94019

3x10mm

Flat Head Hex Screw

.....x6

3x10mm

3x10mm

3x10mm

25

ASSEMBL OF THE REAR CENTER BRACEY

3x12mm

30686

30686

4x20mm

94042

4mm Nylon Nut

94004

3x12mm

Hex Screw

94012

4x20mm

Hex Screw

94027

4x16mm

Flat Head Hex Screw

26

ASSEMBLY OF THE MAGIC TAPE INTO BATTERY CASE

.....x2

.....x2

.....x1

.....x1

4mm

4x16mm

Step 1

Step 2

30662

30663

27

ASSEMBLY OF THE ELECTRIC SPEED CONTRTOL

Double side tape

28

ASSEMBLY OF THE BATTERY TRAY BRIDGE ONTO BATTERY CASE

3x8mm

30662

3x10mm

Electronic Speed Control

30693 90AMP ESC

94002

3x8mm

Hex Screw

94003

3x10mm

Hex Screw

29

ASSEMBLY OF THE ELECTRIC SPEED CONTROL WIRE INTO RADIO CASE

Step 1

.....x2

.....x2

30662

30662

Step 2

30

ASSEMBLY OF THE STEERING SERVO ONTO RADIO CASE

3x10mm

3x10mm

3x8x0.8mm

94003

3x10mm

Hex Screw

94040

3x8x0.8mm

Washer

31

ASSEMBLY OF THE SERVO WIRE INTO RADIO CASE

.....x4

30662

.....x4

3x8x0.8mm

Steering Servo

32

ASSEMBLY OF THE BATTERY CASE ONTO CHASSIS

94019

3x10mm

Flat Head Hex Screw

94026

4x12mm

Flat Head Hex Screw

94053

5x10mm

Flat Head Hex Screw

.....x3

.....x1

.....x2

4x12mm

5x10mm

3x10mm

3x10mm

33

ASSEMBLY OF THE RADIO CASE ONTO CHASSIS

94019

3x10mm

Flat Head Hex Screw

34

ASSEMBLY OF THE RECEIVER INTO RADIO CASE

Please carefully read the Receiver Instruction

Manuals before installation.

94002

3x8mm

Hex Screw

.....x4

*Plug in your speed controller

wire to CH2 and steering servo

wire to CH1 of your receiver.

.....x2

3x10mm

Receiver

3x10mm

Antenna Wire

40642

37410

30560

3x8mm

30662

30662

Do not cut or shorten antenna wire.

Step detail

Use a screwdriver to straighten the antenna wire so

it is easier to insert into antenna tube.

35

ASSEMBLY OF THE STEERING ROD ONTO STEERING SERVO

SAVOX

Sanwa/Airtronics

S J F

Choose the right servo horn adapter for your servo.

94004

3x12mm

Hex Screw

30411

6mm Ball Socket

JR

.....x2

.....x2

Futaba

HiTech

H

3x12mm

30401

30411

30661

30411

30401

38280(3x36mm)

3x12mm

30661

Approx. 19mm

13

36

MOTOR INSTALL

Electric Motor

(30694)

94034

4x4mm

Set Screw

37

MOTOR INSTALL

94038

3x12mm

Cap Screw

.....x1

.....x2

4x4mm

30665-(14T)

3x12mm

Do Not

Over Tighten

Step detail

*Approx. 20mm

94040

3x8x0.8mm

Washer

38

ADJUST MOTOR AND SPUR GEAR MAINTENANCE

.....x2

PUSH

Adjust the motor position to get proper gear mesh.

To get a perfect gear mesh , place a piece of notebook paper

between the gears and tighten the motor mount screws.

The spur gear will strip if the gear mesh is wrong.

Tighten

Tighten

3x8x0.8mm

30694

BRUSHLESS MOTOR

1900KV

EXTREMELY IMPORTANT

Notebook paper

Insert a piece of notebook paper between

spur gear and pinion gear to make correct

gear mesh.

Tighten the 3x12mm screw

temporary.

14

39

ASSEMBLY OF THE SHOCKS

40060

40060

2.6x6x0.5mm

41011

2.6x6x0.5mm

40054 (SHORT) 40055 (LONG)

2.6x6x0.5mm

2.6x6x0.5mm

41011

Step detail

Hold the shock rod at top of exposed

thread with side cutting needle nosed pliers.

Be careful not to damage the shock

shaft.

Assemble both left and right sides.

Do Not

Over Tighten

Use tools to tighten as shown.

40060

2.6mm

Nylon Nut

94059

2.6x6x0.5mm

Washer

40

ASSEMBLY OF THE SHOCKS

41012

1mm Washer

41012

2mm Washer

41012

3.5mm O-Ring

.....x2

.....x4

.....x4

.....x4

.....x8

FRONT SHOCK

Oil

Oil

REAR SHOCK

41008

41012(2mm)

41012

41012(1mm)

41012

40113

41003 (SHORT)

Step detail Step detail Step detail

41008

41012(2mm)

Oil

Oil

41012

41012(1mm)

41012

40113

41004 (LONG)

Assemble both left and right sides.

40113

P10 O-RING

41

ASSEMBLY OF THE SHOCKS

Oil

.....x4

(SHORT)

(SHORT)

REAR SHOCKFRONT SHOCK

Assemble both left and right sides.

(LONG)

Oil

Do not push the shock

shaft straight down;

O-ring can be damaged.

(LONG)

REAR SHOCKFRONT SHOCK

EXTREMELY IMPORTANT

Slowly twist the shock

shaft down to the

bottom.

15

42

ASSEMBLY OF THE SHOCKS

Assemble both left and right sides.

41007

P10 O-RING

43

ASSEMBLY OF THE SHOCKS

Step detail

.....x4

28mm

37.5mm

41007

Oil

Fit the o-ring into groove before

assembly.

40643

Do Not

Over Tighten

41006

30403

Step 2Step 1

Oil

Oil

Step detail

TOP

FRONT SHOCK

40643

Do Not

Over Tighten

30403

REAR SHOCK

Assemble both left and right sides.

Step detail

Attention distance.

30403

6mm Ball

44

SETTING THE SHOCK REBOUND TO 100% (HIGH REBOUND)

Step 1 Step 2

H

O K OILS

C

.....x4

3~5x

UP & DOWN

REAR SHOCKFRONT SHOCK

Step 3 Step 4

Leave the filled shock vertically for several

minutes with the shock shaft fully extended.

Time

The remaining air bubbles will release.

Step detail

41013

41005

14mm

Use tools to tighten as shown be

careful not to scratch the shock shaft.

Assemble both left and right sides.

TIGHTENED HALF WAY 50% TIGHTENED 100%

Step 5

Step 6

16

45

SETTING THE SHOCK REBOUND TO 50% & 0%

(MEDIUM REBOUND & LOW REBOUND)

TIGHTENED HALF WAY 50%

Step 1 Step 2

46

ASSEMBLY OF THE SHOCKS SPRING

Step 2 Step 3

50%

TIGHTENED 100%

Step 3 Step 1 Step 2 Step 3

50%

TIGHTENED HALF WAY 50% TIGHTENED 100%

Step 1 Step 2

Step 1

47

ASSEMBLY OF THE SHOCKS

40058

Cut 7mm

INTO THE SHOCK STAY

40643

94041

3mm Nylon Nut

.....x4

41015(SHORT)

41008

41015(LONG)

40058

REAR SHOCKFRONT SHOCK

41008

40643

94040

3x8x0.8mm

Washer

94007

3x20mm

Hex Screw

.....x4

.....x4

3mm

3x8x0.8mm

3x20mm

3x20mm

FRONT SHOCK REAR SHOCK

17

3mm

3x8x0.8mm

48

ASSEMBLY OF THE TIRES AND WHEELS

Step 1

Make four tires that are the same.

80025

IN

ST

G

AN

L E U

T

Step 2

Step detail

86056

49

ASSEMBLY OF THE TIRE ONTO THE FRONT

KNUCKLE AND REAR HUB

INST

G

A

L

NT

UE

Step 3

Use CA or “ Instant glue " and draw a round the

rim where it attaches the tire . When it is dry

glue the other side of the rim.

Repeat the step and ensure the rim and tire are

fully glued.

Agglutination place

Assemble both left and right sides.

40550

Wheel Nut

50

ASSEMBLY OF THE WING

94004

3x12mm

Hex Screw

.....x4

.....x2

26.5mm

26.5mm

Drill two 7mm holes for mounting.

16015 WHITE

16016 YELLOW

16017 RED

16018 BLACK

16019 ORANGE

40550

To tighten the Wheel Nut you can also

use 17mm Wheel Nut Tool.(10801)

3x12mm

30270

18

51

BATTERY INSTALL

Follow the manual instruction provided by ESC

manufacturer to install the wire.

52

MAKING HOLES AND CUTTING ON THE BODY SHELL

If use hard case battery , make a hole as picture shown.

15mm

8mm

Step 1 Step 2

Make 6mm hole

53

WASH THE INSIDE OF THE BODY SHELL

Step 1 Step 2

Body Reamet (not included)

10806 BLACK

10807 BLUE

Make 7.5mm holes on the body, Body Mount

as shown.

31143

For electric speed control cooling hole.

Cut the body shelll as shown.

Wash the inside of the body shell with mild detergent,

and then rinse and dry thoroughly.

54

PAINTING BODY SHELL

Mask the windows on the inside with masking tape.

55

PAINTING BODY SHELL

Paint the body with polycarbonate spray paints.

56

MOUNTING THE BODY SHELL

31159

31159

S

p

ra

y

Pa

i

n

t

When the paint is dry, remove the masking

tape.

When you have finished painting, peel off

the external protective films.

ULTRA LX2 ELECTRIC POWERED

EXPLODED VIEW

30540

41010

30655

30102

36740

36741

30361

30658

36742

30010

36743

36740

30380

30686

36740

30361

36742

36850

36700

36790

36740

40038

36700

40039

30151

30151

30689

30082

36171

30240

B-B

36171

34027

30403

30010

30160

A-A

30341

40528

40527

30657

30130

36850

40528

40527

30656

40520

40199

30403

36020

36861

36690

36170

34053

40536

C-C

40550

30560

40642

30662

38280(3x36mm)

30661

30401

30401

30411

30411

30661

37410

41033

30662

36100 (90mm)

30662

30662

30662

30653

30665-(14T)

36100 (86.5mm)

30675

E-E

30201

30676

E-E

30911

30110

30769

30620

30769

30761

30777

30777

30761

30620

30769

30773

30911

30662

30663

30662

30649

41010

30270

36171

A-A

30686

30901

34033

30082

30761

30751

30120

30121

30769

30779

30686

36171

36850

30769

40065

30773

30121

30130

30010

A-A

30769

36861

36850

30901

30403

D-D

30270

30351

34027

30341

30010

34054

40199

34063

34055

FRONT SHOCK ASSEMBLY

B-B

41015

41008

30403

41007

40643

30403

40113

41006

40102

41008

36082

36081

30270

30351

40058

41012

16015

41003

40102

41011

40054

41013

C-C

40550

30656

40643

41005

40060

C-C

B-B

80025

86056

REAR SHOCK ASSMEBLY

B-B

D-D

41015

41008

40113

30403

41008

41006

41007

40643

41012

40058

41004

40055

40643

41005

41013

41011

40060

Positive

+

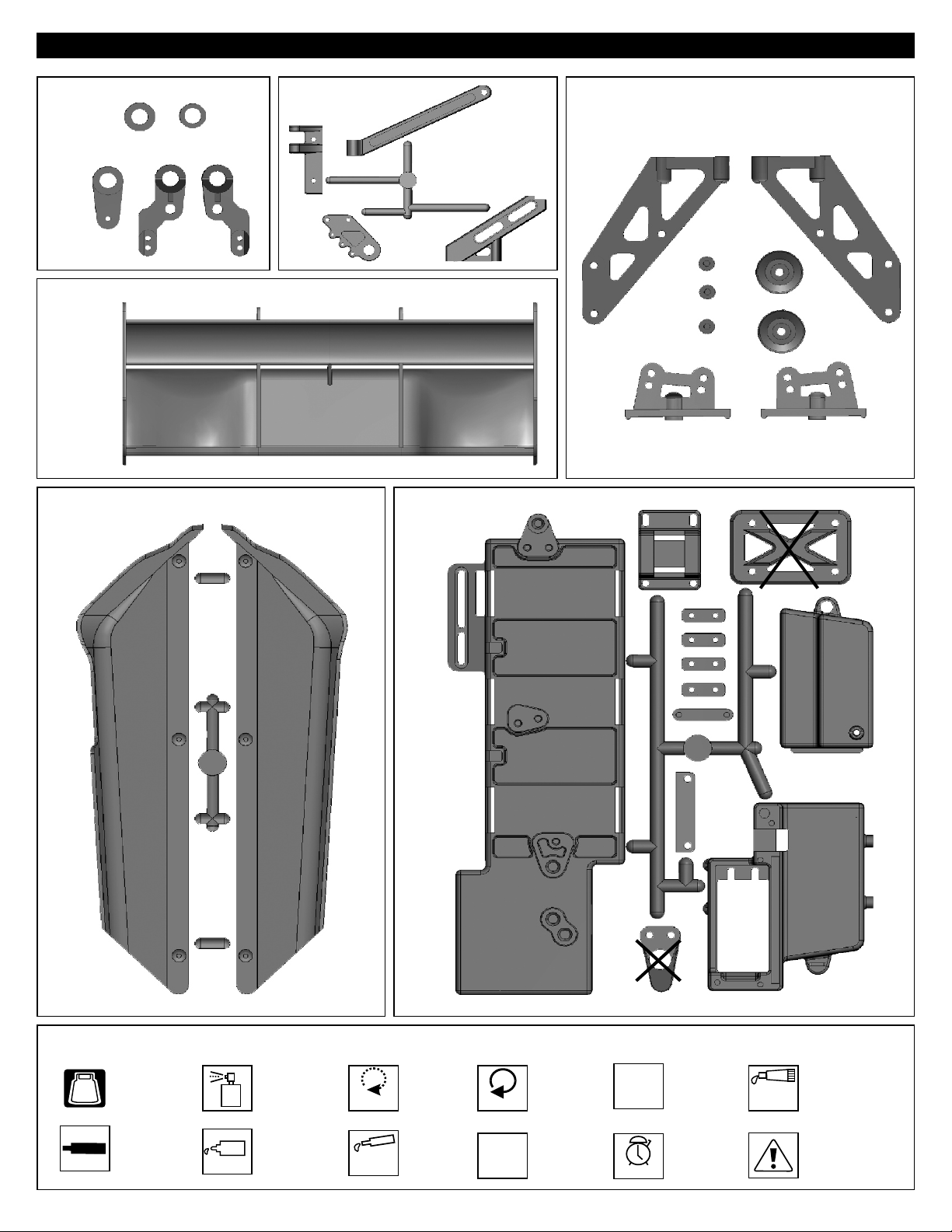

SETTING GUIDE

FRONT CAMBER ANGLE SETTING REAR CAMBER ANGLE SETTING

Positive

Negative

-

-

+

Negative

+

-

-

+

Turnbuckle

Place the model car on flat surface. Raise the chassis to its maximum clearance

before the wheels leave the ground.

Adjust the length of the front and rear upper arms so that the wheels are vertical to the

ground.

Adjust the camber angle by turning the turnbuckle rod on the upper arms clockwise or counter-clockwise.

(We suggest to use zero degree for the front and 1.5 degree for the rear.) negative

FRONT TOE-IN AND TOE-OUT SETTING

NEUTRAL POSITION

TOE-OUT TOE-OUT

TOE-IN

Steering Rod

Turnbuckle

Different shock positions will result in firmer or softer response of the

suspension system.

Install the shock in an inward angle will cause softer rebound. Softer or firmer

suspension system will lead to different steering response.

Adjust the shock angle positions according to track conditions.

FRONT SHOCK ANGLE SETTING

Soft

1 2 3

Firm

Adjust the length of front steering rod to

change the toe angle.

Making the tie rod longer will make front

tires toed in.

Response will be slower and may over steer.

Making the tie rod shorter will make front

tires toed out.

Response will be quicker and may under steer.

Firm front suspension, less steering.

Soft front suspension, more steering.

REAR SHOCK ANGLE SETTING

Firm rear suspension, over steering.

Soft rear suspension, under steering.

Soft

Soft

Soft

1 2 3

12

3

Firm

Firm

12

Firm

OFNA DESCRIPTIONS RETAIL OFNA DESCRIPTIONS RETAIL

16015 HI FORCE WING, 1/8 WHITE 15.95 34055 PINS, LOWER REAR ARMS 3x42.6mm 15.95

30010 GEARBOX, ULTRA SERIES 14.95 34063 FRONT & REAR LOWER ARMS 13.95

30082 CAP JOINTS, 6mm, 2 PCS. 9.95 36020 FRONT UPPER ARMS, 2 PCS. 5.95

30102 BODY MOUNT POSTS, 2 PCS. 0.95 36053 BEARING, 8x16mm, PAIR 12.95

30110 SPUR GEAR,(NYLON) ULTRA 7.95 36055 PIN, 2.5x17mm, HEX HUBS, 4PCS 3.95

30120 LARGE BEVEL GEAR,44T 10.95 36055 PIN, 2.5x17mm, HEX HUBS, 4PCS 3.95

30121 BEVEL MOUNTING HARDWARE,MISC 1.95 36081 REAR UP-RIGHT (8mm BEARING) PR 12.95

30130 PINION GEAR,14T ULTRA 14.95 36082 REAR AXLES, 8mm PAIR 10.95

30160 FRONT PLATE, ARM PIN HOLDERS 4.95 36100 CENTER DOGBONES,SET 86.5,90mm 16.95

30201 CENTER, DIFF MOUNT, NEW TYPE 13.95 36170 ARM PINS, 3mm 4PCS LX1 7.95

30240 FRONT BUMPER, ULTRA CHASSIS 7.95 36171 ARM PIN 4x74.1mm LX1 & X2T 5.95

30270 WING STAY,REAR,PLASTIC 13.95 36640 ARM SHAFT, 4mm, SHORT, 2PCS 9.95

30341 BALL END WITH COLLAR, 6mm 3.95 36700 STEERING BALL END, 7mm, 8PCS. 6.95

30351 REAR ARM HOLDER 3PCS 3.95 36741 SPRING, SERVO SAVER NEW HARD 3.95

30361 SERVO SAVER SHAFT 5.95 36742 BUSHING, SERVO SAVER 1.95

30380 SERVO SAVER POSTS, 2 PCS. 4.95 36743 E-CLIP, 6MM SERVO SAVER 2.95

30401 STEERING ENDS, PLASTIC 6 PCS. 2.95 36760 FRONT PLATE JOINT 9.95

30403 6mm BALL, STEEL (NO COLLAR) 4.95 36790 4x46MMTURNBUCKLES,4PCS. 10.95

30411 6mm BALLS w/COLLAR,STEERING 6P 4.95 36850 7mm BALL, 6 PCS. 3.95

30620 BEARING KIT, 7x19mm, 6 PCS. 29.95 36861 5x40mm TURNBUCKLES, 2 PCS BLK 6.95

30630 BEARING KIT, 6x13mm 12PCS. 59.95 37410 BODY CLIPS, 10 PCS. SMALL JL10 3.95

30649 SHOCK TOWER REAR LX1 H.C. 11.95 38280 TURNBUCKLES, 3X36MM 2PCS 5.95

30653 CENTER TOP PLATE LX1 H.C. 6.95 40038 BALLS, 7MM 4PCS. 9.95

30656 WHEEL HUB, LX1, PICCO 9.5 H.C. 11.95 40039 TAPPER CONE WASHERS,3MM 3.95

30657 LOWER ARM,FRONT, LX1 13.95 40053 SHOCK BODY REAR,THREADED,2PCS 59.95

30658 SERVO SAVER CONNECTOR H.C. LX1 6.95 40054 SHOCK SHAFTS,3.5m FR 13/16mm 7.95

30661 SERVO HORN HEAVY DUTY BLACK 4.95 40055 SHOCK SHAFTS,3.5m RR 13/16mm 7.95

30662 BATTERY CASE,RX BOX LX-1e 19.95 40058 SHOCK BOOTS,SILICON 9.95

30663 BATTERY VELCRO STRAPS LX-1e 9.95 40060 SHOCK PISTON LOCKNUT,2.5mm,4PC 4.95

30665 PINION 14T 5MM SHAFT 12.95 40065 BALL ENDS, PLASTIC, REAR UPPER 4.95

30673 FRONT ARM HOLDER,H.C. LX-1 12.95 40113 O-RING P-10 FOR X1-CR,9.5 SHCK 1.95

30674 SERVO SAVER PLASTIC SET LX-1 7.95 40199 BALL END,STEERING,PLASTIC,6mm 7.95

30675 MOTOR MOUNT,CNC, LX-1e 29.95 40520 KNUCKLE ARM, L & R LX-2 19.95

30676 CHASSIS H.C. LX-1e 89.95 40527 KNUCKLE ARM BUSHING LX-2 4.95

30686 CENTER BRACE LX-2 PLASTIC 9.95 40528 KING PIN SCREW LX-2,X1X,NEXX8 1.95

30693 SPEED CONTROL 90A LX2 RTR 219.95 40536 FRONT C HUB LX-2,X1X,X2,NEXX8 11.95

30694 BRUSHLESS MOTOR 1900KV 5MM SHT 119.95 40550 WHEEL NUT 17mm LX-2 4.95

30751 CASE, DIFF (K), FRONT or REAR 9.95 40642 ANTENNA , FIXING NUT 2.95

30761 CASE, DIFF CASE (K), CENTER 9.95 40643 PLASTIC SHOCK PARTS,13/16mmLX2 9.95

30769 DIFF GEAR,SILVER BEVEL,SET 4mm 14.95 41003 SHOCK BODY FRONT 16MM PAIR 29.95

30773 CROSS PIN AXLES, 4mm STEEL 3.95 41004 SHOCK BODY REAR 16MM PAIR 29.95

30776 WASHER, 4x10x0.2mm 4PCS. 1.95 41005 SHOCK CAP 16MM 4PCS. 22.95

30777 SEAL, O-RING DIFF CASE 3.95 41006 SHOCK SPRING ADJ. 16MM 4PCS. 14.95

30779 MISC. PARTS, ULTRA DIFF 9.95 41007 O-RING 19x1.5MM 16MM 4PCS. 4.95

30780 PINS, 2X12.8mm FOR DIF 2PCS 3.95 41008 PLASTIC SHOCK PARTS 16MM SET 12.95

30901 CAP JOINT W/SHAFT F/R DIFF 11.95 41009 CAP SCREWS 3X28MM 4PCS. 2.95

30911 CAP JOINT W/SHAFT, BRAKE 11.95 41010 SHOCK BALL END POST LONG 4PCS 11.95

31143 BODY, CLEAR ULTRA LX2e 39.95 41011 SHOCK PISTON 16MM 8PCS. 10.95

31158 BODY, LX2e PRINTED RTR 55.95 41012 REPAIR KIT FOR 16MM SHOCK 9.95

31159 BODY CLIPS, CHROME 4.95 41013 PRESSURE TOP ORANGE 16MM 4PCS. 7.95

34014 BRACE, FRONT CHASSIC,ULTRACOMP 3.95 41022 SPRING .58 REAR 16MM WHITE 9.95

34027 ANTI-ROLL BAR KIT, U.COMP,LX1 3.95 41033 STONE GUARDS X2T 15.95

34054 SHAFT, REAR DOG BONE 93mm PR. 15.95 80025 TIRES, TRIAD 1/8 BUGGY W/FOAM 24.95

86056 17mm TrueLITES DISH, WHT 6PACK 19.95

34301 ULTRA LX2e RTR PARTS LIST

OFNA DESCRIPTIONS RETAIL

10231 DIFF OIL,SILICON 1000 WT 8.95

10232 DIFF OIL,SILICON 3000 WT 8.95

10233 DIFF OIL,SILICON 5000 WT 8.95

10234 DIFF OIL,SILICON 7000 WT 8.95

10235 DIFF OIL,SILICON 10,000 WT 9.95

10236 DIFF OIL,SILICON 30,000 WT 9.95

10237 DIFF OIL,SILICON 50,000 WT 9.95

10238 DIFF OIL,SILICON 120,000 WT 9.95

10239 CA TIRE GLUE,Rubber to Plastic 5.95

10772 SERVO HORN,CNC,23T AIRTRONICS 10.95

10774 SERVO HORN,CNC,24T HITEC 10.95

10776 SERVO HORN,CNC,25T FUTABA 10.95

10994 SERRATED LOK NUT,17mm 1/8TH 4P 15.95

16016 HI FORCE WING, 1/8 YELLOW 15.95

16017 HI FORCE WING, 1/8 RED 15.95

16018 HI FORCE WING, 1/8 BLACK 15.95

16019 HI FORCE WING, 1/8 ORANGE 15.95

30774 CROSS PIN AXLES, 4mm ALUM 6PCS 9.95

33991 PCR REAR SHOCK TOWER ULTRA 24.95

33995 PCR STEERING LINK PLATE ULTRA 14.95

33996 PCR UPPER PLATE, FRONT DIFF UL 15.95

33997 PCR CENTER DIFF. TOP PLATE ULT 15.95

41014 SPRING 16MM SUPER SOFT YEL SET 17.95

41016 SPRING 16MM BUGGY SILVER SET 17.95

41017 SPRING 16MM HARD GRAY SET 17.95

41018 SPRING 16MM TRUGGY BLUE SET 17.95

41020 SHOCK BALL END POST L.W. LONG 14.95

41021 SPRING .52 REAR 16MM YELLOW 9.95

41023 SPRING .59 REAR 16MM BLUE 9.95

41024 SPRING .60 REAR 16MM SILVER 9.95

41025 SPRING .64 REAR 16MM GRAY 9.95

41026 SPRING .66 FRONT 16MM YELLOW 9.95

41028 SPRING .71 FRONT 16MM BLUE 9.95

41029 SPRING .74 FRONT 16MM SILVER 9.95

41030 SPRING .88 FRONT 16MM GRAY 9.95

41116 CNC ALUM. BALLS SET HARDCOATED 24.95

40570 STEERING KNUCKLE CNC H.C. 99.95

86057 17mm TrueLITES DISH, YEL 6PACK 19.95

86058 17mm TrueLITES DISH, ORG 6PACK 19.95

34301 ULTRA LX2e OPTION PARTS

TO: OFNA TECHNICAL SUPPORT

7 VANDERBILT, IRVINE, CA 92618

TODAY’S DATE: month________day______

1. Print out form.

2. Fill out the form completely.

3. Make a copy of purchase receipt. All replacements/repairs will not be processed,

unless accompanied by proof that item(s) was purchased in the last 30 days.

4. Call OFNA technical support at (949)586-2910 for assistance or fax (949) 583-9272

1. Your name

____________________________

2. Your address:

____________________________

6. Name of kit / part (on tag or end of box)

_____________________________

7. Kit/part number (on tag or end of box)

_____________________________

8. Purchased from (store name)

____________________________

3. Your Phone Number

(_____)______________________

_____________________________

a. Store phone: (_____) _________

b. _____Item was a gift?

4. Your e-mail address:

____________________________

9. If a part is missing form the kit, circle

the appropriate answers:

5. Summary of your problem (check lines):

a______part(s) is missing from my kit

b______part(s) seems to be defective

c______other problem

a. Yes / No: Is kit box damaged?

b. Yes / No: Factory Seal sticker was secure.

c. Yes / No: I am the original owner.

d. Yes / No: I have contacted the dealer first.

10. Describe your issue fully and include any part numbers:

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

Failure to fill out this form completely will cause a delay in processing!

11. Affix proof of purchase on second page. All replacement / repairs will not be processed

unless accompanied by proof that item(s) was purchased in the last 30 days.

A. If you lost the store receipt, ask the store if they will give you a new one.

B. We do not accepted the following as a substitute: Hand written receipts, ebay transaction numbers/forms or

credit card statements.

12. Send in form with your defective product, as instructed to do by the Ofna

technician,(Name)_________________ you spoke to. (949)586-2910 fax (949) 583-9272

Can’t find Proof of Purchase?

OWNER’S REGISTRATION CARD

OFNA Racing congratulates you on your purchase of our fine OFNA Product. With proper maintenance and handling this kit will provide many hours of enjoyment.

The registration card should be filled out and mailed to OFNA Racing within 10 days of purchase date.

IMPORTANT!

Please print or type, filling in the information listed below and mail immediately

MAIL TO:

OFNA RACING

7 VANDERBILT

IRVINE, CA. 92618

TEL: (949) 586-2910

Write in Your Model Name and Part Number

REGISTRATION CARD

RACER’S NAME TEL:( )

ADDRESS

CITY STATE ZIP

DEALER’S NAME TEL: ( )

ADDRESS

CITY STATE ZIP

OFNA

7 Vanderbilt

Irvine, Ca. 92618

Loading...

Loading...