OFNA Racing Nexx8 User Manual

IMPORTANT-READ THIS BEFORE RUNNING

1.Before Starting

•Please read manual carefulyl (With a parent, guardian or a responsible adult if necessary).

2.While Operating

•Any running area you choose must be dry. Do not run vehicle near any water or wet areas.

•Do not run on public streets. It is very easy to have the car run over or be damaged by hitting the curb.

•Do not operate the car in tight confined places. The vehicle is very fast and will easily hit something.

•Do not run near people or animals. The car is very fast and could easily seriously injured someone.

•Do not operate the car at night. You will not be able to drive it safely.

3.Before Operating

•Make sure that all screws and nuts are properly tightened.

•Always use fresh batteries for your transmitter and receiver before running the car. If the radio does

not have full control of the car with steering, throttle and brake. Do not run it until corrected. Failure

to correct this will result in possible injury and damage to the car or property.

We strongly recommend using a failsafe. But remember failsafe does not protect all power is lost

in vehicle.

•Please confirm the steering and throttle is at neutral position.

4.Check Your Vehicle After Runing

•Turn OFF receiver first, then turn OFF transmitter. This will prevent the car from losing control.

•After running radio controlled car, it is necessary to perform routine maintenance.

5.Battery Safety

•Please be careful when handling the battery. It will be hot after running. If the wire is frayed, a short

circuit can cause a fire.

WARNING: To avoid a possible fire hazard, always unplug the battery. Do not leave your vehicle

unattended with the battery plugged in.

OVERVIEW

Included Items

1.5mm Allen Wrench

2mm Allen Wrench

2.5mm Allen Wrench

Turnbuckle Wrench

Cross Wrench

Equipment Needed

TOOLS NOT INCLUDED IN THE KIT

•Can use 2 7.4V Li-Po battery (hard case). Other type of

batteries may cause damages to your electronic speed

controller and motor.

•It is important that you read all precautions and instructions

supplied by the charger and battery manufacturers. Make

sure you understand how to use your batteries correctly

and use them with required chargers.

CAUTION

•Be aware that OFNA shall not be liable for any indirect,

incidental or consequential damages caused by

inappropriate installation or use of batteries in OFNA models.

Phillips Type Screw Drivers ( L )

Phillips Type Screw Drivers ( S )

Needle Nosed Pliers

Cutter

Curved Scissors

Part# 91009

Precision Caliper

Craft Knife

Instant Cement

CA Part # 10239

Masking Tape

Ni-Mh/Lipo AC/DC 5amp

Battery Charger

Part# 91849

7.4V L i-Po Battery(Hard Case)

8 "AA" Type

Batteries

i-Po

L Battery Charger

Part# 91853

Power Supply

Part # 92135

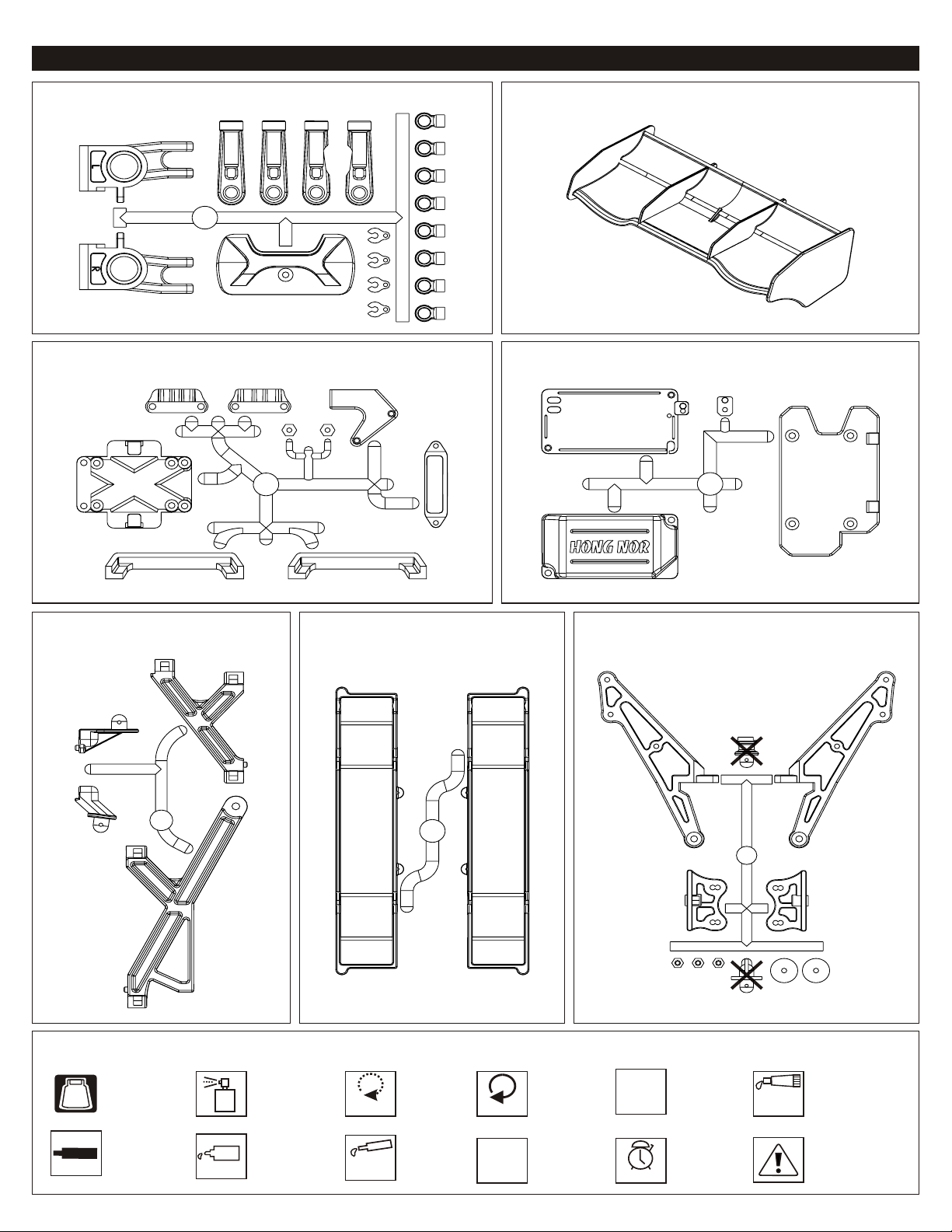

PLASTIC PARTS USED

40538

DIFF. CASE

41210

46t SPUR GEAR (PLASTIC)

40537

FRONT UPPER ARM

40536

FRONT C HUB

40535

FRONT AND REAR LOWER ARM

40643

PLASTIC SHOCK PARTS

40533

FRONT AND REAR GEAR BOX

40539

SERVO SAVER

41008

SHOCK HOLDER

40643

Shock Cap

Washer

40643

Shock Plastic

Ball End

(Short)

41036

CENTER DIFF. MOUNT

40534

ARM HOLDER

40643

Shock Cap

Washer

40643

Shock Plastic

Ball End

(Long)

PLASTIC PARTS USED

40540

REAR UPRIGHT & UPPER ARM

41207

CENTER DIFF. MOUNT PLATE & BODY PLANK

16015

WING

41206

PLANKRECEIVER CASE & ELECTRIC SPEED CONTROLLER

41205

CENTER BRACE & BODY POST

41204

BATTERY CASE

SYMBOLS USED THROUGHOUT THE INSTRUCTION MANUAL

40542

WING STAY

BAG

S

C

crew

emen

t

Parts Bag Used

Cement

Oil

Degrease With

Motor Spray

Apply OilApply Screw

Do Not

Over Tighten

Apply

Grease

Do Not

Over Tighten

Apply Lubricant

Tighten

1:1

Tighten

True-To-Scale

Ensure

Free

Movement

Time

Ensure Free

Movement

Contact

Adhesive

Contact Adhesive

Time Pay attention here

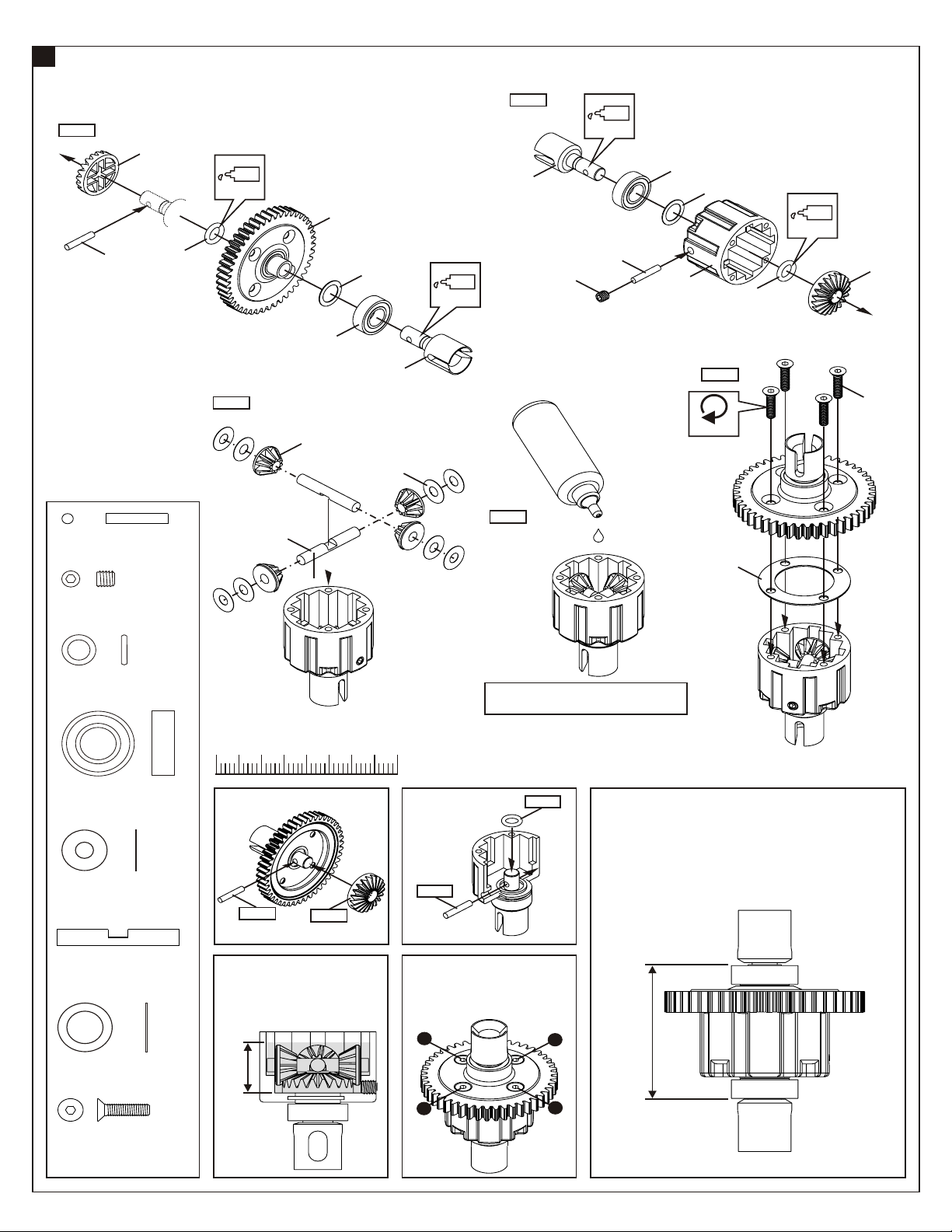

1

ASSEMBLY OF THE FRONT AND REAR DIFF.

Build two differentials for front and rear.

Step 2

Step 1

40010

Step 3

40513

40009

30773

Oil

40513

36053

30776

40517(43T)

40514

Oil

36053

40514

Oil

40010

Oil

4x4mm

40538

40009

Step 5

DI

F

F.

O

Tighten

40513

3x12mm

IL

Step 4

40011

40010

2.5x13.8mm Pin

94034

4x4mm

Set Screw

40009

P6 O-Ring

36053

8x16x5mm

Ball Bearing

30776

4x10x0.15mm

Washer

30773

4mm Cross Pin

.....x4

.....x2

.....x4

.....x4

.....x16

.....x4

•Use the Diff. Oil #5000 for front and #1000 for rear.

•Use A silver Sharpie to mark diff. Case front and rear.

2515

20

3010 355 400

Step detail

Step 1

Step detail Step detail

Fill the diff oil just level with the

top of the satellite gears.

Step 2

Step detail

Step 2

Repeat tightening in this order

1

80%

4

Step 1

After assembly the differential should be 34.5~34.6mm

measured from the ends of the installed ball-bearings.

If differential is longer, hold the bevel gear and

retighten the 4 screws.

3

34.5~34.6 mm

2

94020

3x12mm

Flat Head

Hex Screw

.....x8

2

ASSEMBLY OF THE CENTER DIFF.

Step 2

Step 1

40010

40010

2.5x13.8mm Pin

40513

40009

.....x2

Step 3

Oil

30773

36053

40513

41210

8x12x0.3mm

40514

30776

Oil

40514

Step 4

DI

4x4mm

FF

.

O

Oil

36053

8x12x0.3mm

Oil

40010

40538

I

L

40009

Step 5

Tighten

40011

40513

3x12mm

94034

4x4mm

Set Screw

40009

P6 O-Ring

36053

8x16x5mm

Ball Bearing

30776

4x10x0.15mm

Washer

30773

4mm Cross Pin

40218

8x12x0.3mm

Washer

94020

3x12mm

Flat Head

Hex Screw

.....x1

.....x2

.....x2

.....x8

.....x2

.....x2

.....x4

2515

20

3010 355 400

Step detail

Step 1

Step detail Step detail

Fill the diff oil just level with the

top of the satellite gears.

Step 2

Step detail

Step 2

Repeat tightening in this order

1

80%

4

Use the Diff. Oil #5000 for the center diff.

Step 1

After assembly the differential should be 35.6~35.7mm

measured from the ends of the installed ball-bearings.

If differential is longer, holding the bevel gear and

retighten the 4 screws.

3

35.6~35.7 mm

2

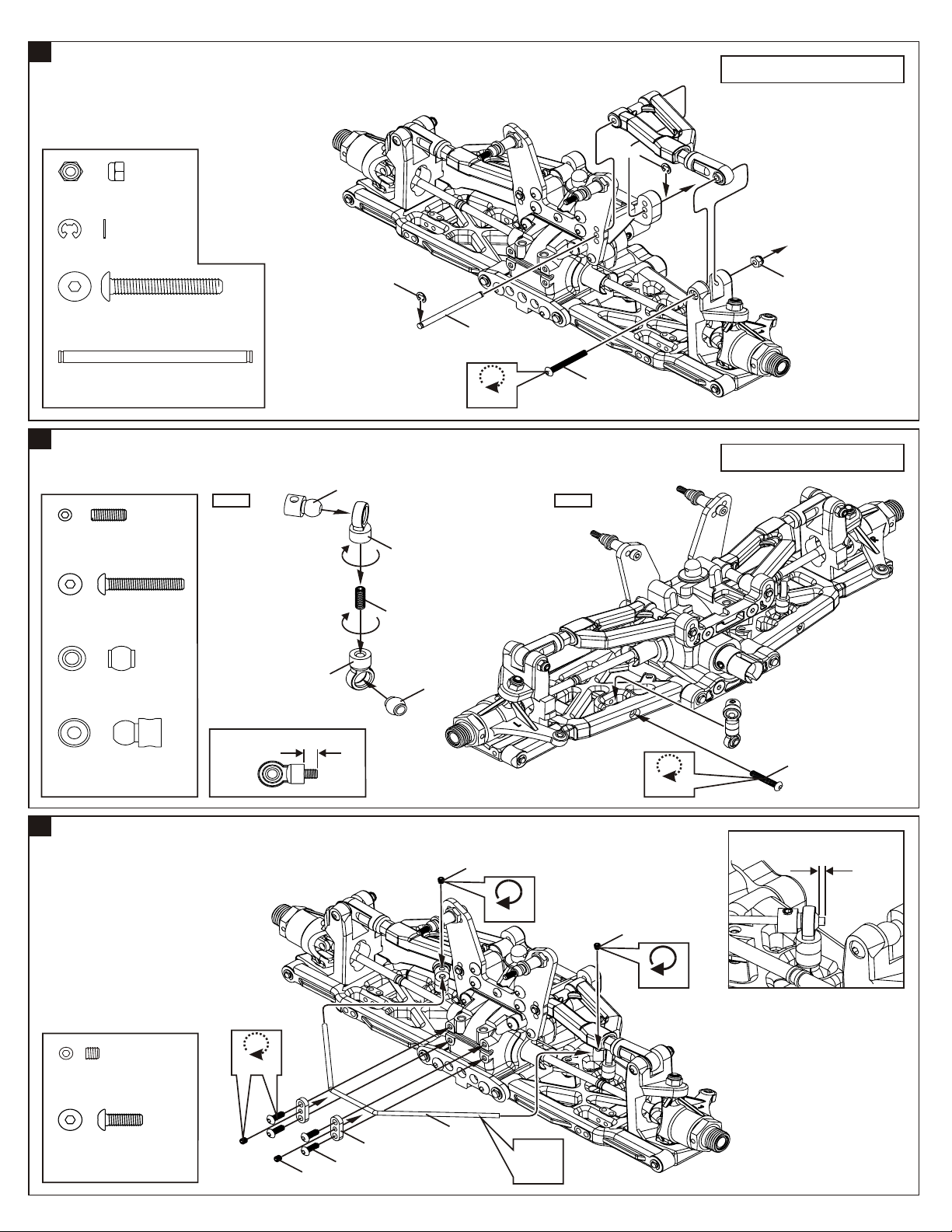

6

ASSEMBLY OF THE FRONT SHOCK TOWER

94003

3x10mm

Hex Screw

41009

3x28mm

Cap Screw

7

ASSEMBLY OF THE FRONT SHOCK TOWER

.....x1

.....x2

41010

Do Not

Over Tighten

41009

41205

Tighten

40502

3x10mm

4x10mm

94003

3x10mm

Hex Screw

94009

4x10mm

Hex Screw

8

ASSEMBLY OF THE STEERING KNUCKLE

LEFT SIDE

40527

Knuckle Arm

Bushing

.....x2

.....x4

.....x4

40536

Do Not

Over Tighten

Do Not

Over Tighten

40527

3x10mm

36053

Assemble both left and right sides.

Step 3Step 2Step 1

40520

36053

8x16x5mm

Ball Bearing

36053

40527

.....x4

9

ASSEMBLY OF THE STEERING KNUCKLE & C-HUB

Assemble both left and right sides.

LEFT SIDE

36055

2.5x16.8mm

Pin

94036

5x4mm

Set Screw

94042

4mm

Nylon Nut

40528

King Pin Screw

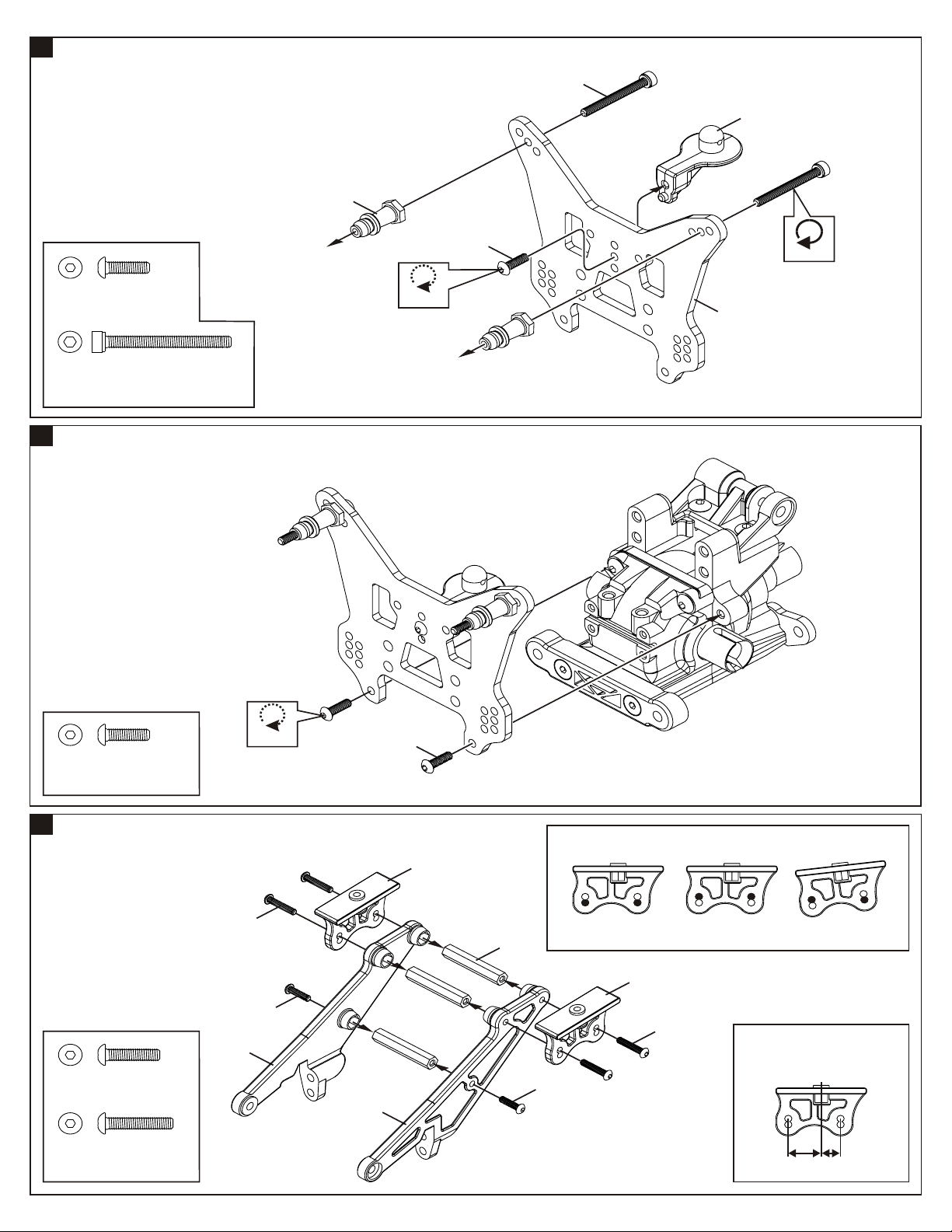

10

ASSEMBLY OF THE FRONT LOWER ARMS

36870

4x10mm

Set Screw

.....x2

4mm

.....x2

.....x4

.....x4

.....x2

Tighten

Tighten

4mm

40528

40528

40521

Step 2Step 1

3mm

40526

A 4x10mm set screw is used

to adjust ride-height.

5x4mm

S re

c

C

e

w

m

e

nt

36055

Right side

Assemble both left and right sides.

90020

2.5mm E-Ring

90021

3mm E-Ring

40546

3x42.7mm Arm Shaft

40524

4x73mm Arm Shaft

11

ASSEMBL OF THE FRONT UPPER ARMSY

36850

7mm Ball

LEFT SIDE

.....x4

.....x4

.....x2

.....x2

.....x2

40537

Approx. 7.5mm

3mm

40524 (4x73mm)

36860

4x10mm

2.5mm

40535

2.5mm

40546 (3x42.7mm)

Assemble both left and right sides.

Step detail

Note the locking direction!

TightenTighten

Step detail

36690

36860

5x35mm

Turnbuckle

.....x2

36850

2515

20

3010 355 400

Use tools to tighten as shown.

12

ASSEMBL OF THE FRONT UPPER ARMS Y

Assemble both left and right sides.

2.5mm

94041

3mm Nylon Nut

90020

2.5mm E-Ring

94013

4x25mm

Hex Screw

40546

3x42.7mm Arm Shaft

13

ASSEMBLY OF THE FRONT STABILIZER BAR

94035

3x8mm

Set Screw

94006

3x18mm

Hex Screw

.....x2

.....x4

.....x2

.....x2

.....x2

.....x2

30341

2.5mm

40540

3x8mm

40546(3x42.7mm)

Do Not

Over Tighten

3mm

3x35mm

Assemble both left and right sides.

Step 2Step 1

30403

30403

6mm Ball

30341

30341

Stabilizer Ball

14

ASSEMBLY OF THE FRONT STABILIZER BAR

94033

3x3mm

Set Screw

.....x2

.....x2

.....x4

Step detail

Do Not

Over Tighten

40540

4mm

30403

3x3mm

Tighten

3x3mm

Do Not

Over Tighten

Tighten

3x18mm

Step detail

*Approx. 3mm

94002

3x8mm

Hex Screw

.....x4

3x3mm

3x8mm

40533

40529

Ensure

Free

Movement

15

ASSEMBLY OF THE SERVO SAVER

40563

40037

Step 2Step 1

40539

40024

13x16x0.2mm

Shim

40539

4x8x2.5mm

Plastic

Flange

Ball Bearing

40037

Steering Plat

Hex Screw

16

ASSEMBLY OF THE FRONT PLATE ONTO SERVO SAVER

94041

3mm

Nylon Nut

94003

3x10mm

Hex Screw

94009

4x10mm

Hex Screw

.....x2

.....x2

.....x2

.....x3

.....x1

.....x2

94060

3x10x1.0mm

Washer

Scr

.....x2

emen

C

w

e

Oil

Oil

t

40505

3x10mm

S

cre

C

em

e

40539

40539

40539

40024

40621

40024

w

n

t

40539

40539

40034

Do Not

Over Tighten

Ensure

Free

Movement

* Notice the direction of the servo saver connecting plate.

Step 2Step 1

41205

Ensure

Free

Movement

40507

Over Tighten

3x10mm

3mm

Do Not

40539

6x10x3mm

Plastic Bushing

17

ASSEMBLY OF THE STEERING TIE-ROD

40038

7mm Ball

36790

4x46mm

Turnbuckle

.....x2

40038

Step detail

36700

.....x4

.....x2

Note the locking direction!

TightenTighten

36790(4x46mm)

2515

20

3010 355 400

40511

40038

36700

Step detail

1:1

3mm

3mm

Make two steering rods for left and right hand sides.

Step detail

Use tools to tighten as shown.

ヲpケマ・ワィマ・ホ、uィ翊コ。E

*Approx. 30mm

18

ASSEMBLY OF THE STEERING TIE-ROD

40548

3mm

Nylon Nut

(Thin Type)

40039

3mm

Tapered Washer

(Alum.)

.....x2

.....x2

Step detail

Face the anti-clockwise mark to the gear case and

make oposite direction for easy adjustment.

40548

40039

Assemble both left and right sides.

3.25mm

40548

3mm Nylon Nut

(Thin Type)

94021

3x15mm

Flat Head Hex Screw

19

ASSEMBLY OF THE SERVO SAVER ONTO

.....x2

THE FRONT GEAR BOX

Put the front plate spacer

in the right direction.

Front

40039

3mm

Tapered Washer

(Alum.)

94005

3x15mm

Flat Head Hex Screw

94009

4x10mm

Hex Screw

.....x2

.....x2

.....x4

LEFT SIDE

40533

Screw

Cement

Tighten

3x15mm

4x10mm

Do Not

Over Tighten

Tighten

Screw

Cement

Tighten

3x15mm

40039

20

ASSEMBLY OF THE FRONT BUMPER ONTO

THE FRONT GEAR CASE

94003

3x10mm

Hex Screw

.....x1

Do Not

Over Tighten

3x10mm

40540

21

ASSEMBLY OF THE REAR GEAR CASE

94036

5x4mm

Set Screw

.....x1

Adjust the backlash with the Shims.

40533

40519

30777

36053

w

e

r

Sc

Ceme

5x4mm

t

n

36053

8x16x5mm

Ball Bearing

40024

13x16x0.2mm

Shim

22

ASSEMBLY OF THE REAR GEAR CASE

94005

4x16mm

Hex Screw

.....x2

.....x4

.....x2

30777

P5 O-Ring

.....x1

40024

Over Tighten

4x40mm

Do Not

4x16mm

40516

36053

Step detail

No interval

40533

94031

4x40mm

Flat Head Hex Screw

23

ASSEMBLY OF THE REAR GEAR CASE

94004

4x12mm

Hex Screw

.....x2

.....x2

40562

Do Not

Over Tighten

4x42mm

)

40534 (2「X

Take the two degree rear lower arm holder

from 40534 Plastic Tree.

4x12mm

40539

24

ASSEMBLY OF THE REAR SHOCK TOWER

41009

41205

41010

94003

3x10mm

Hex Screw

41009

3x28mm

Cap Screw

25

ASSEMBLY OF THE REAR SHOCK TOWER

.....x1

.....x2

Do Not

Over Tighten

3x10mm

Tighten

40503

94003

3x10mm

Hex Screw

26

ASSEMBLY OF THE WING MOUNT

94004

3x12mm

Hex Screw

94005

3x15mm

Hex Screw

.....x2

.....x2

.....x4

Over Tighten

3x15mm

3x12mm

40542

Do Not

40542

3x10mm

40542

40542

The angle of the wing mount can become more aggressive or higher for more

traction.

3x12mm

High Position

40542

3x15mm

Low Position

Make both side wing mounts

in the same position.

Long

Big Angle

Short

27

ASSEMBLY OF THE WING MOUNT

94011

4x16mm

Hex Screw

28

ASSEMBL OF THE REAR CENTER BRACEY

94041

3mm Nylon Nut

94009

4x10mm

Hex Screw

94011

4x16mm

Hex Screw

.....x4

.....x2

.....x1

.....x1

4x16mm

4x16mm

4x10mm

41205

3mm

3mm

29

ASSEMBLY OF THE REAR WHEEL HUBS

RIGHT SIDE

40522

94036

5x4mm

Set Screw

36055

2.5x16.8mm

Pin

36053

8x16x5mm

Ball Bearing

.....x2

.....x2

.....x4

36053

40540

36053

40526

36055

5x4mm

Scr

Do Not

Over Tighten

Cem

Assemble both left and right sides.

Step detail

t

ew

en

2.5mm

Use tools to tighten 5x4mm set

screw as shown.

Loading...

Loading...