VER. 12-04-2008

MUST READ THIS BEFORE RUNNING

Running a nitro kit is fun and easy, but to make this a safe • Clean oil and dirt from chassis with a degreaser.

and good experience you must observe a few rules. This

kit is extremely fast, easily over 40MPH, and can seriously

injure someone if you are not careful.

Where to run car?

• Any running area you choose must be dry. Do not run

car near any water or wet dirt.

• Do not run on public streets. It is very easy to have the

car run over or damaged by hitting the curb.

• Do not operate car in tight confined places. The car is

very fast and will easily hit something.

• Do not run near people or animals.

and will too easily hit someone.

• Due noise, you will want to consider the surrounding

area when operating the car.

• Do not operate the car at night. You will not be able to

drive it without hitting something.

• Do not operate the car indoors. Engine exhaust is not

healthy.

Glow Fuel

• Glow fuel is poisonous!

• Glow fuel is flammable! label for additional precautions.

• Do not leave fuel bottle with lid off at any time.

• Do not use any fuel other than glow fuel in this engine. • Car Fuel tank - Never store fuel in car tank, it will ruin the

First Time Starting the Engine

Caution! When starting engine make sure the following is

observed.

• Set engine Master needle to 3 turns (rich setting) • DAMAGE DUE TO CAR RUN AWAY IS NOT A

• Do not do this alone, get an experienced friend to help at

first.

• Fill fuel tank, try not to spill fuel. Do not spill fuel on

receiver

• Hold car off the ground, so it will not runaway when first

starts

• Turn on Radio and check the linkage before starting

engine.

• Turn on car receiver battery switch.

• Always have an air filter on the carburetor to keep dirt

out.

The car is very fast

Precautions

• This kit is not a toy. Always run car with a second

person as a spotter and pitman.

• Hot Parts - The pipe, manifold, engine and head are very

hot and will cause burns.

• Rotating Parts - Keep hands away from the drive train,

wheels, and engine when engine is running.

• Radio - Check batteries life before running the car. If

radio does not have full control of the car with steering

and/or throttle/brake do not run until corrected. Failure to

correct this will result in possible injury and damage to the

car or property.

• Glow fuel - Do Not leave the glow fuel unattended with the

Lid off. Fuel contains Methanol and Nitro Methane and is

flammable and poisonous.

Store fuel in cool ventilated location. Refer the glow fuel

engine if left in tank.

• Always turn off the car BEFORE turning off radio.

WARRANTY ISSUE.

IF YOU DO NOT BREAK-IN ENGINE

CORRECTLY, MAINLY AT LOW RPM,

YOU WILL BREAK THE CONNECTING

ROD!

FAILURE TO NOT READ AND

Engine Break-in

• See Engine Page.

Emergency Stopping Engine When Running

• Remove air filter and cover carb. intake.

• Squeeze fuel line and hold until engine stops.

• With a rag, cover exhaust outlet.

Storing Car After Running

• Remove fuel from tank and fuel lines

• Turn off radio in car

• Put a few drops of after run in engine to keep it from

rusting.

FOLLOW BREAK-IN ENGINE

INSTRUCTIONS WILL VOID

WARRANTY!

RTR KITS - REQUIRED FOR OPERATION

THINGS NEEDED

Glow Fuel

20%

AA Batteries ( 12 pcs )

You will need to buy a few items to start the engine and run the car.

• Use 20% nitro CAR fuel. Do not use airplane or heli fuels, they will

over heat engine.

• Buy LONG glow plugs, like OFNA Plug (#51009).

Use plugs without idle bar. Do NOT use plugs, like the MC-59 or OS-8

In your box you will find..

• #10162- Bottle, 250cc

• #10219 - Red “D” size glow heater

10195

7.2 Volt

Over-nite

Charger

You need to get batteries for the radio transmitter and the car receiver packs.

• Radio TX needs (8) eight AA batteries.

• Shaft Starter requires a 7.2Volt battery pack and charger OFNA #10195

• Car needs (4) four AA Ni-cad batteries 2000Mah or higher or (4) Alkaline., Alkaline type

batteries will work, but braking will be reduced and 30 minute life. The best for car, is to use a 5

cell hump receiver pack for increased voltage and longer life..

10214

Rec’v Bat.

Over-nite

Charger

51009 OFNA GLOW PLUG #3 RTR

#10202 Rec’v Bat.

NiHm Hump Pack,

see charger 10214.

Recommended Option:

You may want to upgrade the car battery pack to a Ni-Cad or NiHm 5 cell type(600AE). This will

give more run time. OFNA #10212 1400NiMh Hump Pack and NiHm Battery Charger #10214

TOOLS NOT INCLUDED IN KIT

Glow Plug & 17MM Cross Wrench

#10801 $6.95

Cross Wrench

#17109 $3.95

Phillips Type Screw Drivers ( L )

Phillips Type Screw Drivers ( S )

Cutter

Curved Scissors

91009 $5.95

Precision Caliper

Instant Cemment

Masking Tape

INCLUDED WITH KIT

1.5mm Allen Wrench

2mm Allen Wrench

Needle Nose Pliers

2.5mm Allen Wrench

Hobby Knife

4mm'5mm Allen Wrench

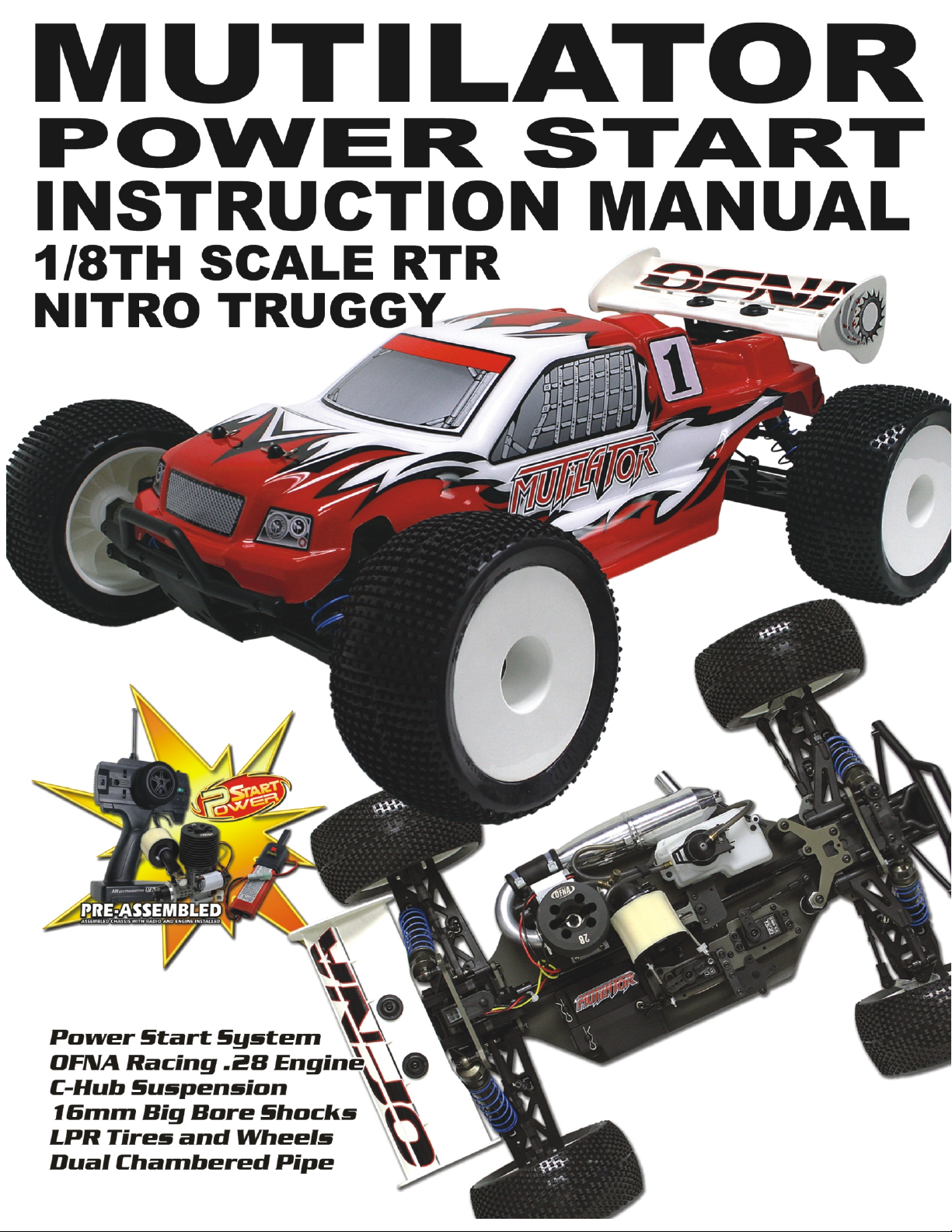

PLASTIC PARTS FOR USE

40017

GEAR BOX

40140

FRONT & REAR LOWER ARM

40003

DIFF. CASE

40536

FRONT C HUB

40015

ARM HOLDER

40540

REAR UPPER ARM & REAR WHEEL HUB

30802

THROTTLE LINKAGE

40015

FRONT UPPER ARM

40027

WING STAY

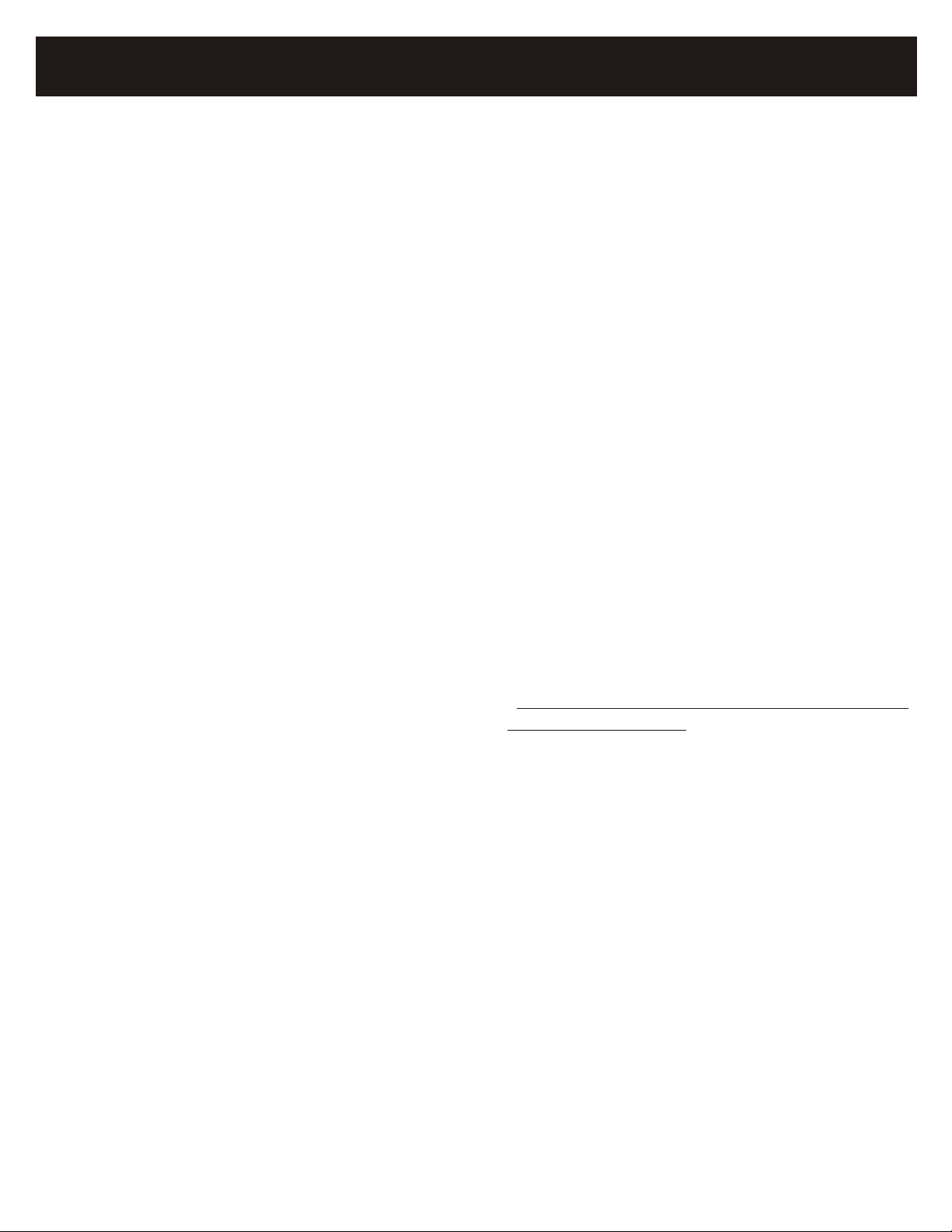

PLASTIC PARTS FOR USE

40031

SERVO SAVER

40040

CENTER DIFF. MOUNT

40541

RECEIVER BOX

40018/40029

CENTER BRACER

40137

BUMPER

40643

SHOCK PLASTIC BALL END

40643

Shock Plastic

Ball End

(Short)

40643

Shock Plastic

Ball End

(Long)

41008

SHOCK HOLDER

40643

Shock Cap

Washer

1

1

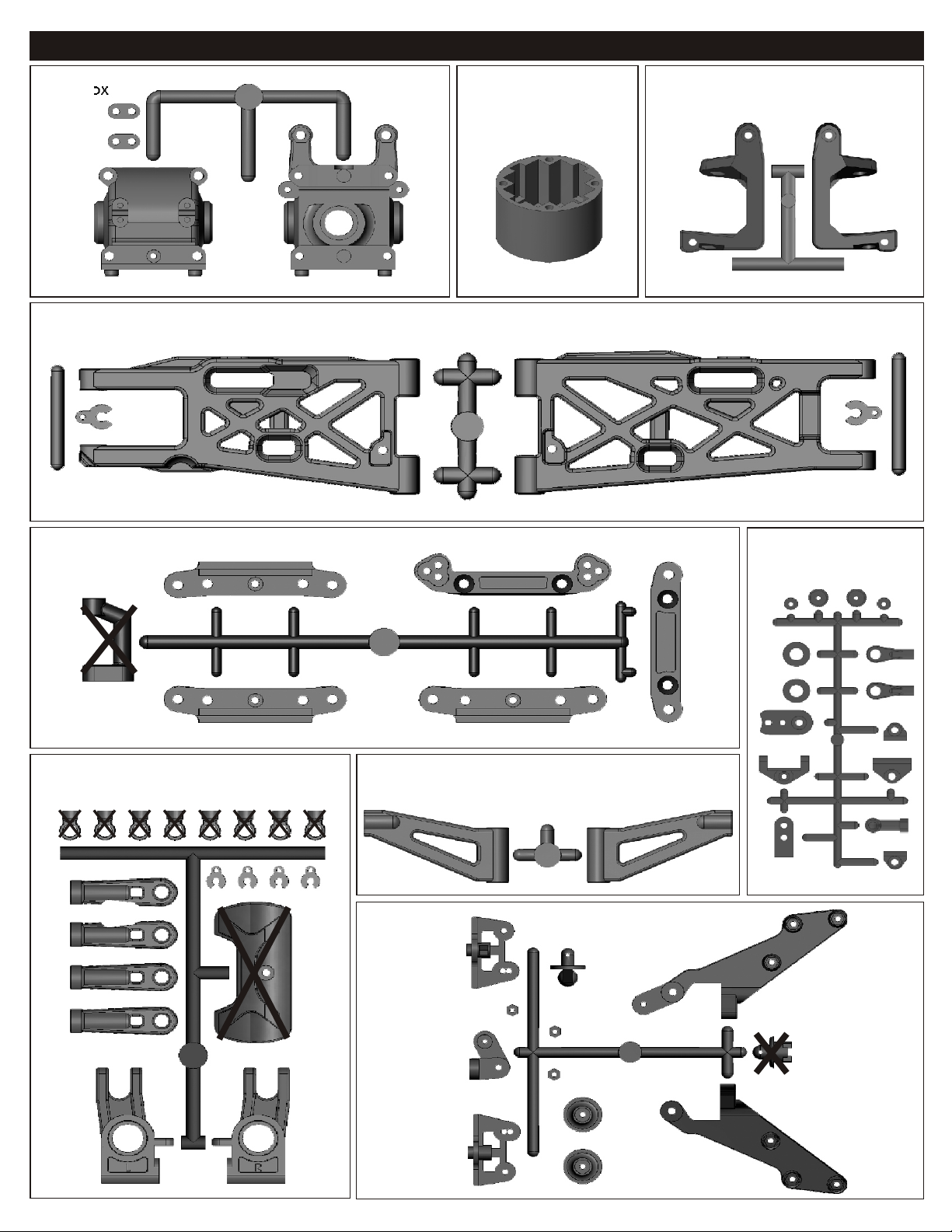

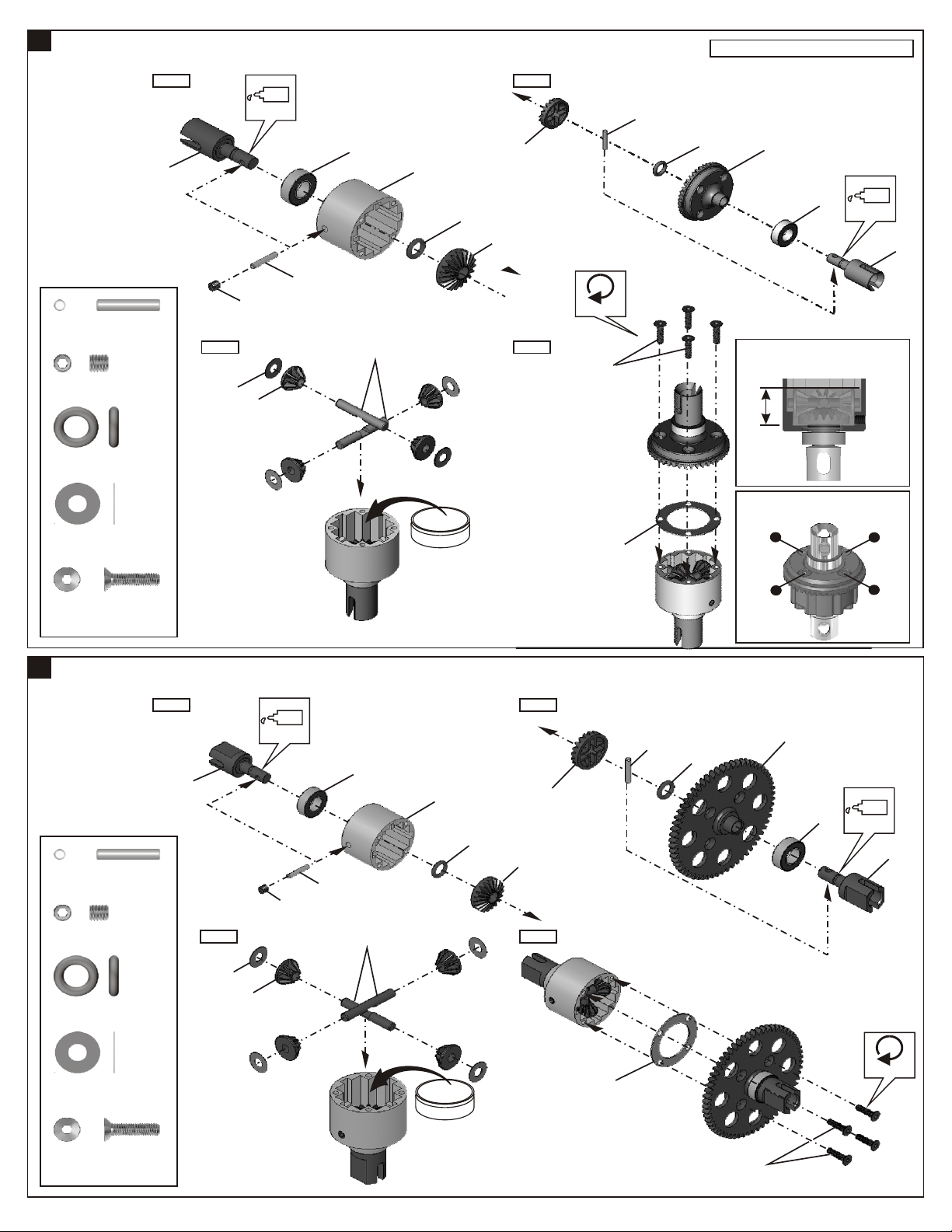

ASSEMBLY OF THE FRONT AND REAR DIFF.

Step 1 Step 2

Builds two differentials for front and rear.

40010

2.5x13.8mm

Pin

94034

4x4mm

Set Screw

40009

P6 O-Ring

30776

4x10mm

Washer

........x4

........x2

........x4

........x8

40006

Step 3

30776

4x4mm

40513

Oil

40010

36053

30773

40003

iff. O

40009

D

40010

40513

40513

Tighten

Step 4

3x12mm

il

40011

40009

49032

36053

Fill the diff oil just level with the

top of the satellite gears.

ョtウtェo・[、Jヲワョtウtセヲスウサ・ュュアォh・i。C

80%

Tighten the diff screws in this order.

スミィフケマ・ワカカァヌ、Wコチウオキ。C

1

Oil

40006

3

94020

3x12mm

Flat Head

Hex Screw

2

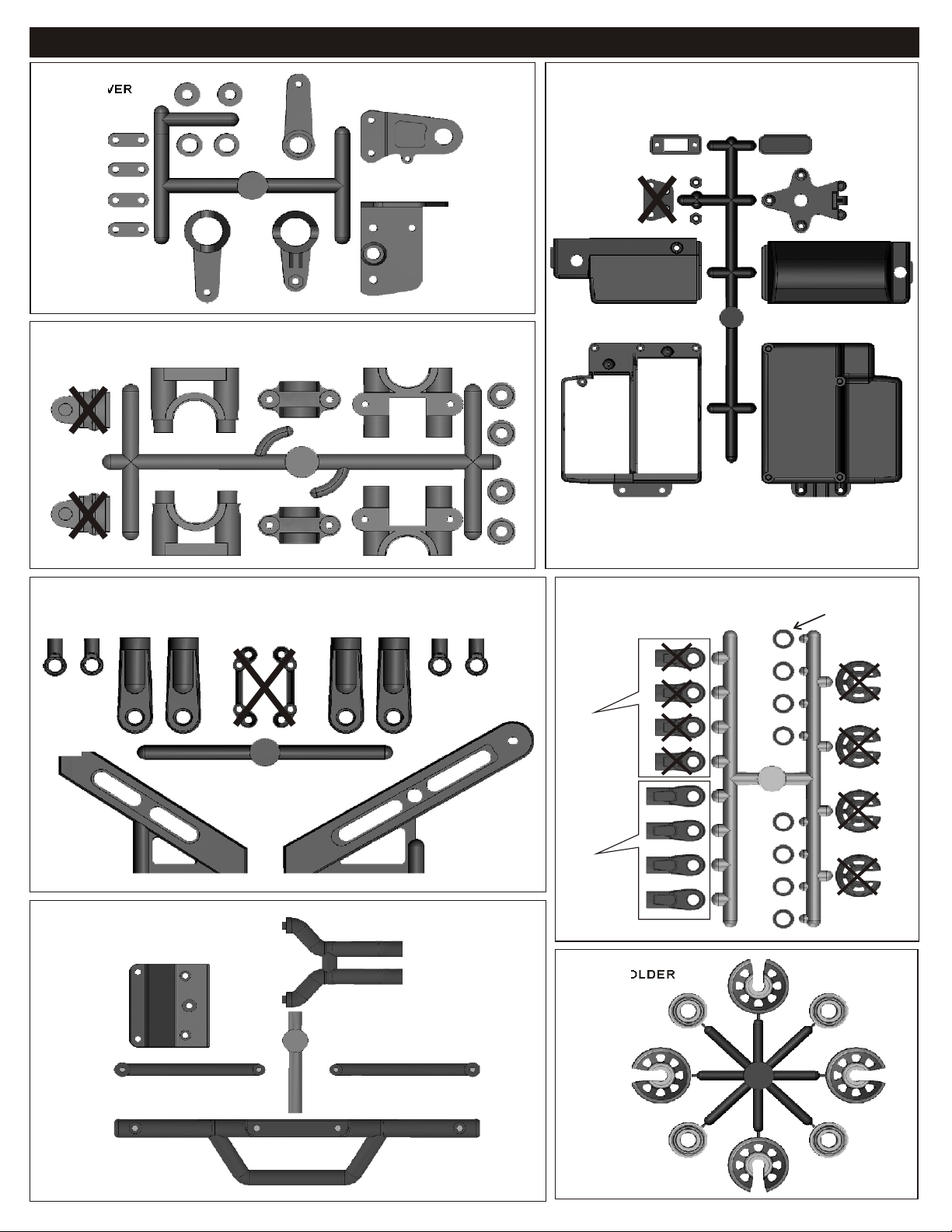

ASSEMBLY OF THE CENTER DIFF.

40010

2.5x13.8mm

Pin

94034

4x4mm

Set Screw

40009

P6 O-Ring

........x8

Step 1 Step 2

Oil

40005

........x2

4x4mm

........x1

........x2

Step 3 Step 4

30776

40513

40010

36053

30773

40003

40009

40513

40513

40010

40009

4

40134

36053

2

Oil

40005

30776

4x10mm

Washer

94020

3x12mm

Flat Head

Hex Screw

........x4

........x4

D f

Tighten

i

f .

Oi

l

40011

3x12mm

3

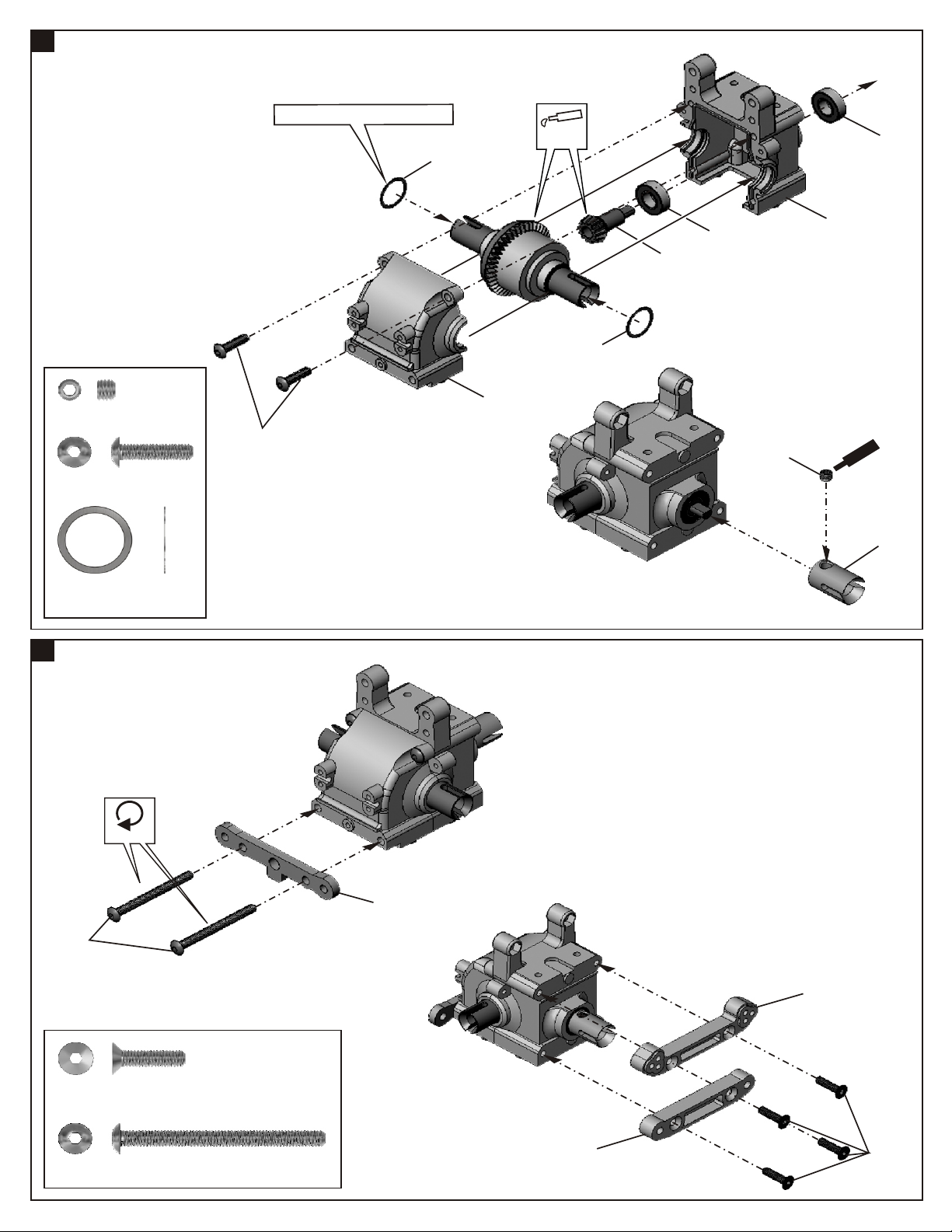

ASSEMBLY OF THE FRONT GEAR CASE

94036

5x4mm

Set Screw

94011

4x16mm

Hex Screw

........x1

........x2

。ッAdjust the backlash with the shims.

4x16mm

40024

40017

Apply

Grease

40024

49012

36053

5x4mm

40017

36053

nt

rew

e

m

Sc

Ce

36730

40024

13x16x0.2mm

Shin

4

ASSEMBLY OF THE FRONT ARMS HOLDER

4x45mm

........x2

Tighten

40022

40015

94027

4x16mm

Flat Head

Hex Screw

94014

4x45mm

Hex Screw

........x4

........x2

40015

4x16mm

5

ASSEMBLY OF THE FRONT SHOCK STAY

4x12mm

35313

3mm

Nylon Nut

35314

4mm

Nylon Nut

94004

3x12mm

Hex Screw

94010

4x12mm

Hex Screw

94012

4x20mm

Hex Screw

90018

3x25mm

Screw

........x2

........x2

.......x4

.......x4

.......x2

.......x2

40117

3mm

4x20mm

40117

40531

40116

3x12mm

3x25mm

4mm

6

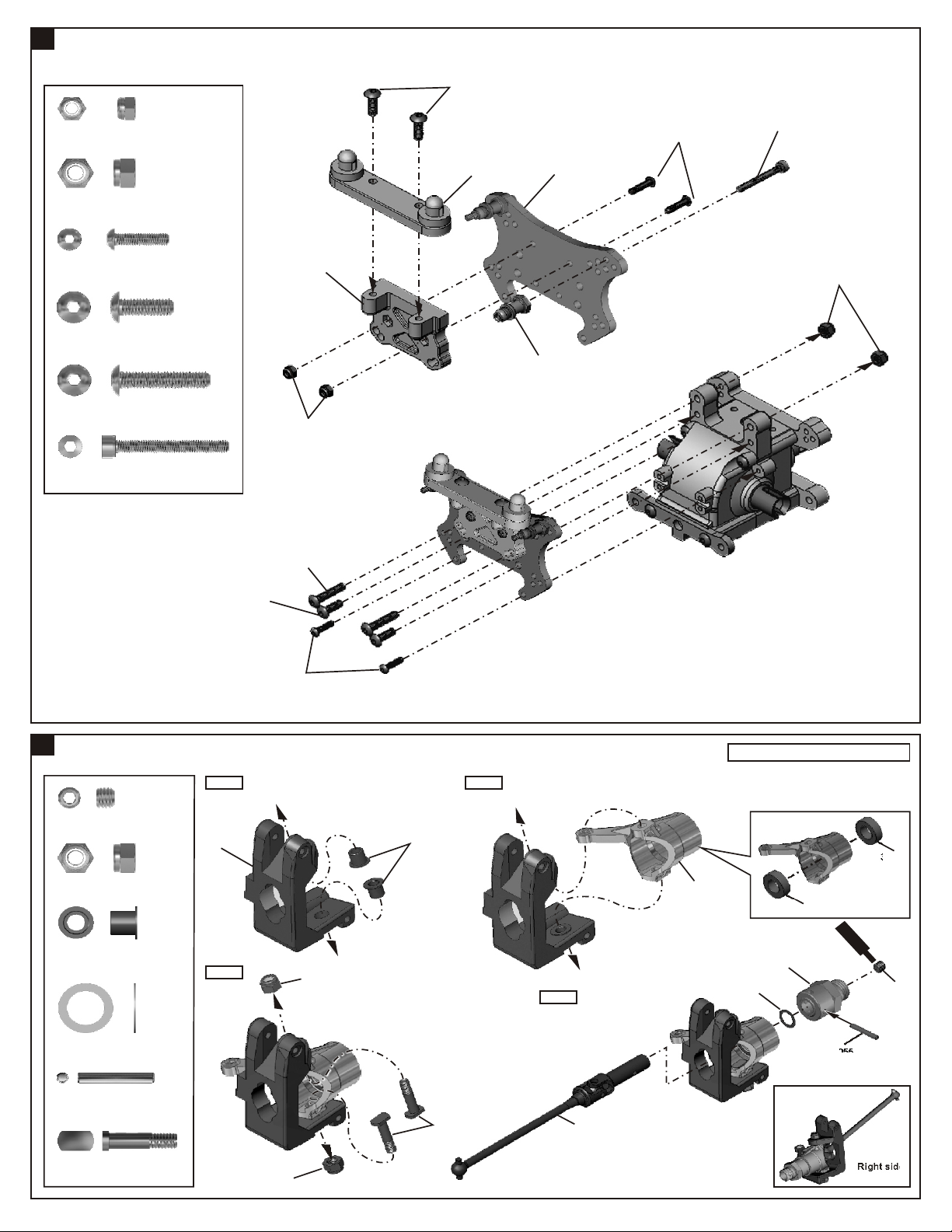

ASSEMBL OF THE KNUCKLE ARMSY

94034

4x4mm

Set Screw

35314

4mm

Nylon Nut

40527

Knukcle Arm

Bushing

40128

8x12x0.3mm

Washer

........x2

........x4

........x4

........x2

4x12mm

3x12mm

Step 1 Step 2

40536

Step 3

4mm

40527

Step 4

40520

Assembly for both right and left side

36053

Sc

Ce

r

ew

m

ent

30058

40128

8x12x0.3mm

36055

36053

4x4mm

36055

2.5x16.8mm

Pin

40528

King Screw

........x2

........x4

4mm

40528

40141

Right side

7

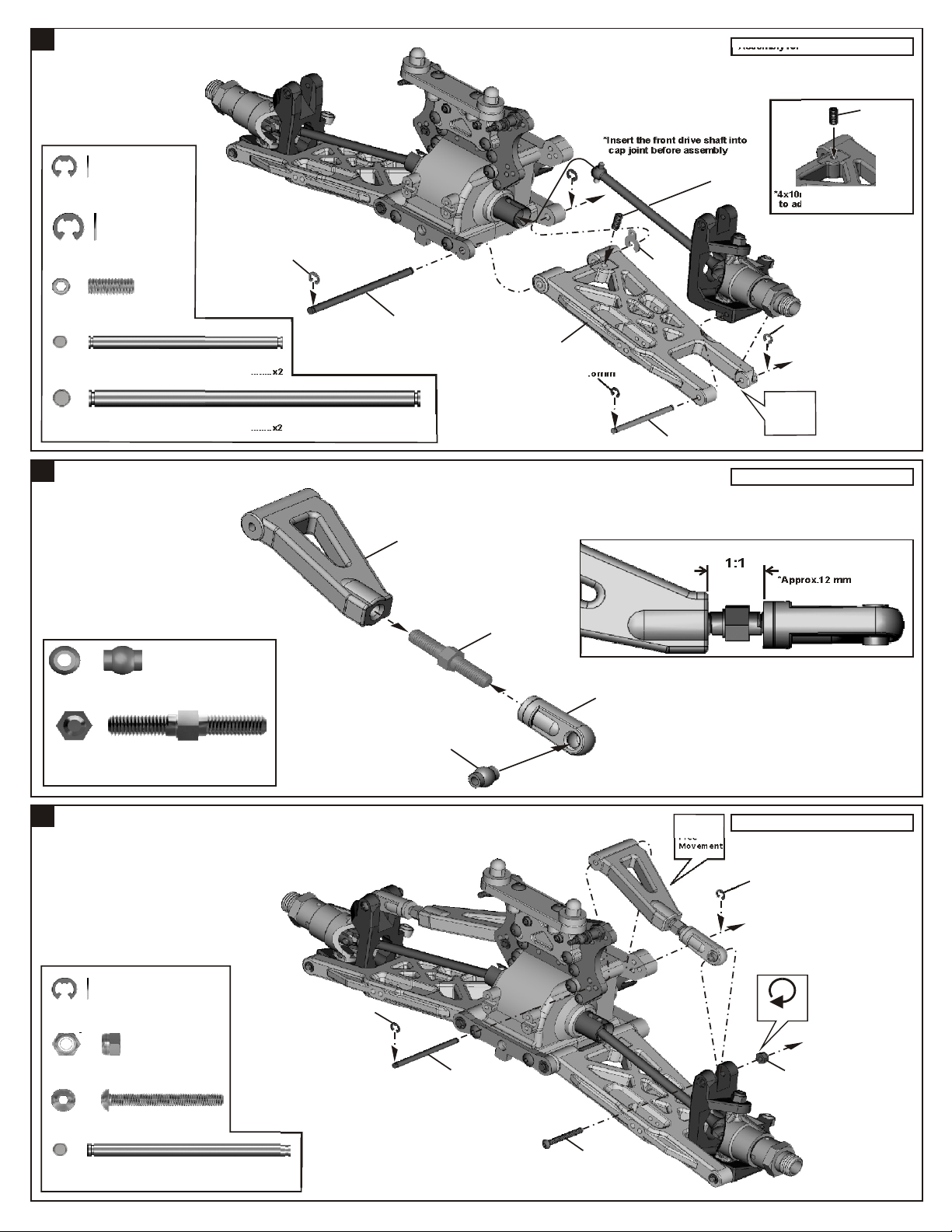

ASSEMBLY OF THE FRONT SUSPENSION ARMS

90020

2.5mm

E-Ring

........x2

*Insert the front drive shaft into

cap joint before assembly

4x10mm

Assembly for both right and left side

4x10mm

*4x10mm set screw is used

to adjust ride-height.

90021

3mm

E-Ring

36870

4x10mm

Set Screw

40546

3x42.7mm Arm Shaft

40524

4x73mm Arm Shaft

8

ASSEMBLY OF THE FRONT UPPER ARMS

36850

7mm Ball

........x2

........x2

........x2

3mm

........x2

........x2

40524

40139

36861

40140

2.5mm

36690

40140

40546

2.5mm

Ensure

Free

Movement

Assembly for both right and left side

1:1

*Approx.12 mm

36861

5X35MM

Turnbuckle

9

ASSEMBLY OF THE FRONT SUSPENSION ARMS

90020

2.5mm

E-Ring

35313

3mm

Nylon Nut

94008

3x25mm

Hex Screw

36170

3x44.3mm Arm Shaft

........x4

........x2

........x2

........x2

........x2

2.5mm

36850

36170

3x25mm

Ensure

Free

Movement

Assembly for both right and left side

2.5mm

Tighten

3mm

10

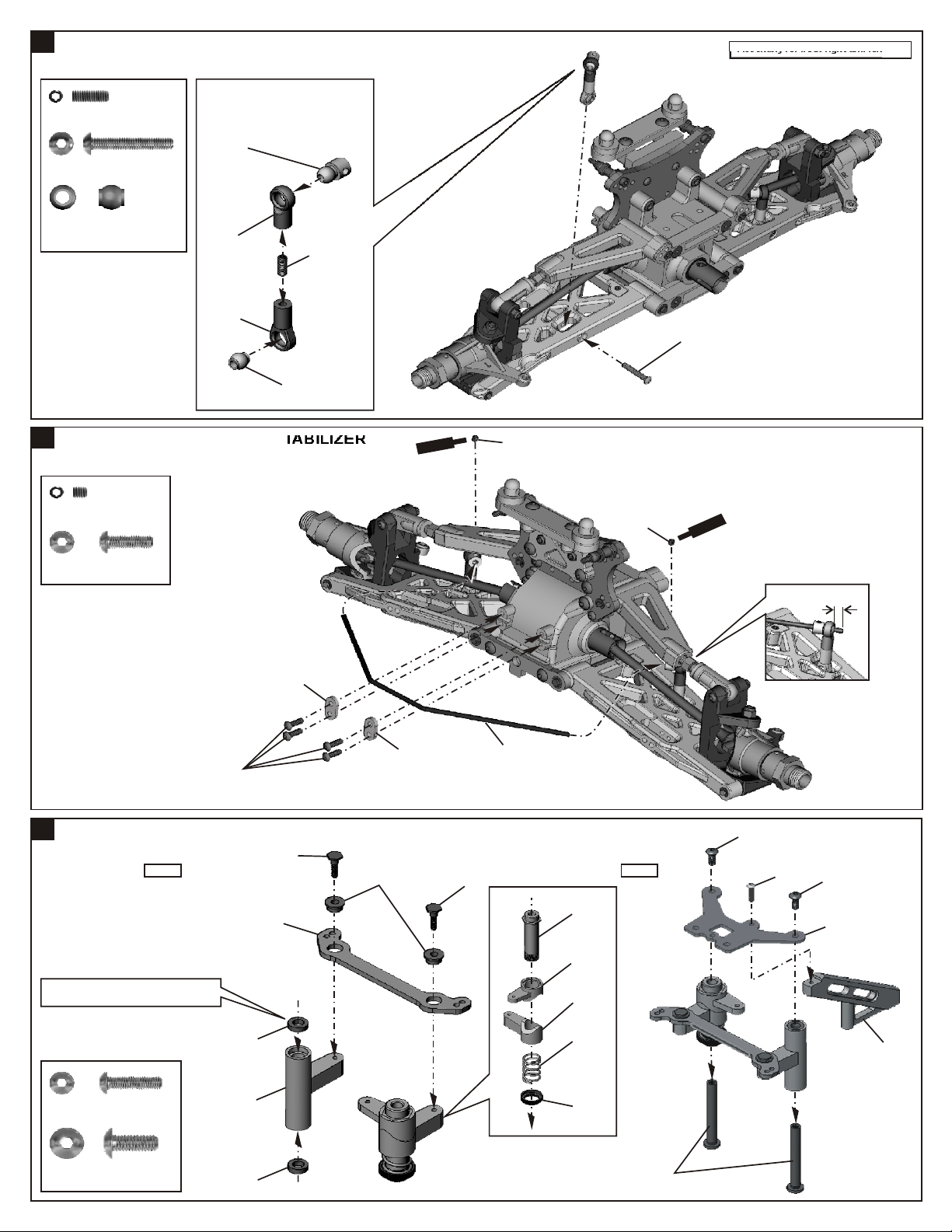

ASSEMBL OF THE FRONT STABILIZERY

9435

3x8mm

Set Screw

94006

3x18mm

Hex Screw

30403

6mm

Ball

11

ASSEMBL OF THE FRONT STABILIZERY

........x2

........x2

........x2

Makes two rods for left and right

hand-side.

30341

40029

40199

3x8mm

30403

Scre

Cem

Assembly for both right and left side

3x18mm

w

ent

3x3mm

94033

3x3mm

Set Screw

94003

3x10mm

Hex Screw

12

ASSEMBL OF THE SERVO SAVERY

........x2

........x4

40017

40017

3x10mm

40037

Step 1 Step 2

40032

*Do not tighten 40037

Hex Screw too tight.

40031

40019

40037

40035

3x3mm

w

tCeme

e

n

Scr

*Approx. 6mm

4x10mm

3x12mm

4x10mm

40030

*Take the plastic bushing from servo

saver plastic parts tree.

94004

3x12mm

Hex Screw

94009

4x10mm

Hex Screw

........x1

........x2

40031

40031

40031

40031

40031

40621

40018

40034

40036

13

ASSEMBL OF THE STEERING TIE-RODY

94041

3mm

Nylon Nut

94021

3x15mm

Flat Head

Hex Screw

94022

3x18mm

Flat Head

Hex Screw

........x2

........x2

........x2

3mm

Step 1 Step 2

40038

36700

40108

36700

40039

40038

3x15mm

40039

S

c ew

r

4x10mm

t

ew

en

cr

m

S

e

C

Cem nte

3x15mm

40039

94009

4x10mm

Hex Screw

14

ASSEMBL OF THE FRONT BUMPERY

3x10mm

94003

3x10mm

Hex Screw

........x2

1:1

*Approx. 45.8mm

Step 1 Step 2

40137

3x12mm

3x10mm

........x4

3x10mm

3x18mm

40137

40137

40137

3x12mm

3x12mm

40676

94004

3x12mm

Hex Screw

15

ASSEMBL OF THE REAR GEAR CASEY

40024

13x16x0.2mm

Shim

94011

4x16mm

Hex Screw

........x5

........x2

........x2

*Adjust the backlash with the shims.

40024

4x16mm

40017

Apply

Grease

36053

40017

36053

49012

40024

16

ASSEMBL OF THE REAR ARMS HOLDERY

94036

5x4mm

Set Screw

94003

3x10mm

Hex Screw

94009

4x12mm

Hex Screw

94030

4x45mm

Flat Head

Hex Screw

........x1

........x1

........x4

........x2

Step 1 Step 2

5x4mm

t

e

r w

c

e

S

em n

C

36730

40025

Tighten

40015

4x12mm

4x45mm

3x10mm

Do Not

Over Tighten

4x12mm

40027

17

ASSEMBL OF THE REAR SHOCK STAYY

Step 1 Step 2

40027

3x10mm

40145

Step 3

40531

40531

Screw

Cement

3x25mm

S

C t

3x25mm

c

e

r

men

e

w

94019

3x10mm

Flat Head

Hex Screw

94004

3x12mm

Hex Screw

90018

3x25mm

Cap Screw

........x1

........x2

........x2

3x12mm

18

ASSEMBL OF THE WING STAYY

Step 1 Step 2

40027

94042

4mm

Nylon Nut

94005

3x16mm

Hex Screw

94007

3x20mm

Hex Screw

........x2

........x2

........x4

Step 3

4x20mm

4x16mm

40027

40027

3x16mm

3x20mm

4x20mm

Step 4

40027

40027

3x20mm

3x16mm

4mm

4mm

4x20mm

94048

3x20mm

Cap Screw

94011

4x16mm

Hex Screw

94012

4x20mm

Hex Screw

19

ASSEMBL OF THE REAR WHEEL HUBSY

94036

5x4mm

Set Screw

36870

4x10mm

Set Screw

36055

2.5x16.8mm

Pin

........x2

........x2

........x2

........x1

........x3

........x3

40018

Step 1 Step 2

36053

36055

8x12x0.3mm

5x4mm

30058

2.5mm

3x20mm

4x10mm

Assembly for both right and left side

40140

2.5mm

*4x10mm set screw is used

to adjust ride-height.

4x16mm

4x10mm

Ensure

Free

Movement

40128

8x12x0.3mm

Washer

........x2

40522

40540

40525

40540

20

ASSEMBL OF THE REAR SUSPENSION ARMSY

Assembly for both right and left side

3mm

90021

3mm

E-Ring

40524

4x73mm Arm Shaft

21

ASSEMBL OF THE REAR SUSPENSION ARMSY

94041

3mm

Nylon Nut

94006

3x18mm

Hex Screw

94008

3x25mm

Hex Screw

........x4

........x2

........x4

........x2

........x2

3mm

40524

Step 1 Step 2

36850

40540

1:1

*Approx. 35mm

36880

40540

36850

3x18mm

40140

40142

(114mm)

Ensure

Free

Movement

Assembly for both right and left side

3mm

3mm

22

ASSEMBL OF THE REAR STABILIZERY

Step 1 Step 2

30341

40029

3x8mm

40199

30403

94033

3x3mm

Set Screw

94035

3x8mm

Set Screw

94003

3x10mm

Hex Screw

........x2

........x2

........x4

3x16mm

40017

3x25mm

3x3mm

3x3mm

94005

3x16mm

Hex Screw

........x2

3x10mm

Ensure

Free

Movement

40019

23

ASSEMBL OF THE BRAKE AND CENTER DIFF. MOUNTY

Step 1

40591

Step 4 Step 5

40676

Step 2

40040

40662

3x10mm

Step 3

40040

36660

3x12mm

3x3mm

40041

40040

40665

3x3mm

30171

40665

3x12mm

Step 7Step 6

40031

30171

94033

3x3mm

Set Screw

94003

3x10mm

Hex Screw

94004

3x12mm

Hex Screw

........x2

........x2

........x6

24

ASSEMBL OF THE RADIO TRAYY

3x10mm

94040

3x8mm Washer

94003

3x10mm

Hex Screw

........x8

........x6

40138

40143

Step 2 Step 3Step 1

3x20mm

3x8mm

40676

3x8mm

3x12mm

3x8mm

40031

3x10mm

40117

40541

3x25mm

3x8mm

40676

94004

3x12mm

Hex Screw

94007

3x20mm

Hex Screw

94008

3x25mm

Hex Screw

25

ASSEMBL OF THE RECEIVER BOXY

Step 1

10282

2x8mm

........x4

........x2

........x2

Switch

40541

40541

Step 2

37410

40541

37410

40031

30560

40541

40855

Battery

*Use the screw provide

with your switch.

Screw

40541

........x42x8mm

Receiver

26

ASSEMBL OF THE RADIO TRAY INTO RECEIVER BOXY

94004

3x12mm

Hex Screw

27

ASSEMBL OF THE FRONT GEAR CASE ONTO CHASSISY

3x12mm

........x2

4x10mm

4x12mm

4x16mm

4x10mm

Flat Head

Hex Screw

94026

4x12mm

Flat Head

Hex Screw

94027

4x16mm

Flat Head

Hex Screw

28

ASSEMBL OF THE REAR GEAR CASE ONTO CHASSISY

40133

........x2

........x2

........x4

4x12mm

4x16mm

94026

4x12mm

Flat Head

Hex Screw

94027

4x16mm

Flat Head

Hex Screw

........x2

........x4

29

ASSEMBL OF THE CENTER DIFF. ONTO CHASSISY

40136

(104mm)

4x10mm

Flat Head

Hex Screw

30

ASSEMBL OF THE RADIO TRAY ONTO CHASSISY

........x4

4x10mm

Radio Tray assembly

40136

(120mm)

*Insert the drive shaft into

the cap joint before assembly

center diff. onto chassis.

94019

3x10mm

Flat Head

Hex Screw

31

ASSEMBL OF THE FUEL TANK ONTO CHASSISY

94040

3x8mm Washer

94019

3x10mm

Flat Head

Hex Screw

94004

3x12mm

Hex Screw

........x8

Pressure Nipple

40109

........x2

........x2

........x2

3x12mm

3x8mm

40138

3x12mm

3x8mm

Pressure Nipple

3x10mm

Step 2Step 1

Do Not

Over Tighten

3x10mm

32

ASSEMBL OF THE CLUTCH AND ENGINE MOUNTY

Step 1 Step 2

*Fit the flywheel using a pair of the

plIer and cross wrench.

10098

* Only use this 10091 pilot shaft for threaded crank

shaft engine.

Sc

Ce n

w

re

e t

m

10040

Sc

Cem nt

10040

10091

10010

re

w

e

*Place the clutch shoes with the clutch

springs over the 3 pins of the flywheel.

*Using a phillips screw driver or needle

nose pliers and bend the small end in

10330

the clutch spring behind the pilot shaft

10102 than press down.

Step 3 Step 4

10102

3x16mm

Threaded

Crank Shaft

10330

34110

5x9x0.3mm

3x10mm

Cap Screw

........x1

3x8mm

10399

3x16mm

Cap Screw

33

ASSEMBL OF THE MANIFOLD AND MUFFLERY

........x4

3x10mm

Step 1 Step 2

31995

40674

10120

97500

14

31994

10185

ZIP TIES

34

ASSEMBL OF THE ENGINE ONTO CHASSISY

Note book Paper.

*Use note book paper to set gear backlash between

spur gear and clutch bell gear, applying pressure

while tightening the engine.

*If the space is not correct the spur gear will

be damaged.

94034

4x4mm

Set Screw

4x10mm

Flat Head

Hex Screw

........x2

........x1

3x12mm

4x4mm

40050

4x4mm

94004

3x12mm

Hex Screw

10114

5mm

Engine Mount

Screw

35

ASSEMBL OF THE FUEL TUBEY

........x2

40051

10114

4x10mm

........x4

Connect to carbulater.

10177

Connect to pressure nipple.

Connect to fuel tank nipple.

Connect to fuel nipple.

10177

36

ASSEMBL OF THE STEERING RODY

94003

3x10mm

Hex Screw

94004

3x12mm

Hex Screw

........x1

........x1

30661

30403

3x10mm

10759

30403

30401

38281

Use the screw

provided with

your servo.

3x12mm

1:1

*Approx. 28.5mm

37

ASSEMBL OF THE THROTTLE LINKAGEY

3x3mm

Step 1 Step 2

94033

3x3mm

Set Screw

2mm

Nut

2.5mm

Nylon Nut

2x8mm

Screw

94003

3x10mm

Hex Screw

........x4

........x2

........x1

........x2

........x1

3x3mm

10300

Step 3

Ce nt

me

2mm

30802

r

eSc

w

40664

3x3mm

10300

30531

2x8mm

30661

Cut off the servo saver as shown.

30802

Step 4

2.5mm

30802

30802

30802

2.5x18mm

Ensure

Free

Movement

40664

40617

Adjust the high

with3x6,4x1mm

washer

36140

3x3mm

36140

40664

2.5x18mm

Screw

38

ASSEMBL OF THE THROTTLE LINKAGEY

........x1

Use the screw

provided with

your servo.

3x10mm

3x3mm

10300

94033

3x3mm

Set Screw

10759

........x2

39

ADJUSTING THE ENGINE CONTROL LINKAGES

(Neutral)

Approx. 0.5mm

Turn on the Transmitter then Receiver and set the

Engine Control Servo Trim to the neutral position.

Adjust the idling adjusting screw on the Carburetor

to be open approx. 1mm gap.

Adjust both of the 10300 Engine Control and Brake linkage

accordingly.

Adjust the Engine while it is NOT RUNNING.

40

ASSEMBLY OF THE AIR FILTER

Step 1 Step 2

3x8mm

40127

40128

10300

Approx. 1mm gap

Idling Adjusting Screw

.

*Apply filter oil to the

foam before use.

(Throttle High)

Adjust the Servo-Horn mounting position for the

Carburetor to be full open.

Change the pivot mounting position on the servo

horn in case the Carburetor is not opening fully or

if it is opening excessively. Or if available on the

Transmitter, adjust the Throttle high end point.

ZIP TIES

Carburetor is

Opening fully

ZIP TIES

(Brake)

Spring Compress

10300

36140 Alum. Adjust Nut

Adjust 10300 so the brakes work smoothly.

If the brakes apply too much or not enough,

adjust 36140 accordingly. Or if available on the

Transmitter, adjust the High-End Brake

adjustment.

Adjust 36140 to Change the front or Rear Brake.

40128

94002

3x8mm

Hex Screw

41

ASSEMBLY OF THE FRONT SHOCK

Builds two front shocks.

2.6x5mm

Washer

40060

2.5mm

Nylon Nut

40090

3.5mm

O-Ring

40090

1mm

Washer

40090

2mm

Washer

........x4

........x2

........x4

........x2

........x2

........x1

Step 1

30403

41008

40090

40090

41019

41003

40127

40643

(Long)

40090

40090

40129

Fit the o-ring into groove

before assembly.

41007

41006

40054

(Short/Front)

2.6x5mm

41011

(1.4mmx6)

2.6x5mm

Step 2

1. Pull down piston and pour oil into shock cylinder.

2. To remove air bubbles by slowly moving piston up

and down.

3. Pull down piston, attach pressure top

and shock oil overflow with tissue

paper.

fill the shocks

with oil #50WT.

41013

41005

CORRECT SHOCK ASSEMBLY

56.7mm

28mm

OK

Carefully screw the shock

shaft into the bottom of the

plastic ball end untill the

distance between the ball end

and the shock body is 28mm

for the front .

N.B. Do not over tighten as the

plastic will strip.

30403

6mm

Ball End

........x2

40060

Do Not

Over Tighten

0 20

30

4010

42

ASSEMBL OF THE REAR SHOCKSY

Builds two rear shocks.

2.6x5mm

Washer

40060

2.5mm

Nylon Nut

40090

3.5mm

O-Ring

40090

1mm

Washer

40090

2mm

Washer

30403

6mm

Ball End

........x4

........x2

........x4

........x2

........x2

........x2

Step 1

30403

41004

41008

40090

40090

41019

40643

(Long)

40090

40090

Fit the o-ring into groove

before assembly.

41007

41006

40055

(Long/Rear)

2.6x5mm

41011

(1.4mmx6)

2.6x5mm

40060

Do Not

Over Tighten

Step 2

1. Pull down piston and pour oil into shock cylinder.

2. To remove air bubbles by slowly moving piston up

and down.

3. Pull down piston, attach pressure top

and shock oil overflow with tissue

paper.

fill the shocks

with oil .#50

41013

41005

0 20

CORRECT SHOCK ASSEMBLY

65.2mm

37.5mm

OK

Carefully screw the shock

shaft into the bottom of the

plastic ball end untill the

distance between the ball end

and the shock body is 37.5mm

for the rear .

N.B. Do not over tighten as the

plastic will strip.

30

4010

43

ASSEMBL OF THE FRONT SHOCK SPRINGSY

40058

m

u m

Ct7

45

ASSEMBL OF THE FRONT SHOCK ABSORBERY

Assembly for both right and left side

41028

41008

44

ASSEMBL OF THE REAR SHOCK SPRINGSY

40058

41023

41008

94041

3mm

Nylon Nut

94040

3x8mm

Washer

94007

3x20mm

Hex Screw

........x2

........x2

........x2

3mm

3x8mm

3x20mm

46

ASSEMBL OF THE REAR SHOCK ABSORBERY

Assembly for both right and left side

94041

3mm

Nylon Nut

94040

3x8mm

Washer

94007

3x20mm

Hex Screw

47

ASSEMBL OF THE TIRES AND WHEELSY

........x2

........x2

........x2

3mm

3x8mm

3x20mm

Step 1

80022

48

ASSEMBL TIRE ONTO FRONT KNUCKLE AND REAR HUBY

81106

Step 2

86106

Step 3

Apply instant glue into the groove of the wheel.

INST

GL

N

UE

TA

Tire and wheel assembly

40550

49

ASSEMBL OF THE WINGY

3x12mm

20

15

*Check the hole spacing on the underside.

3mm

Nylon Nut

3x12mm

Hex Screw

50

MOUNTING BODY

0

5

10

5

........x294041

........x294004

20

10

15

2525

40673RW

31159

40027

40083

3mm

51

STARTING OF THE ENGINE

How to start the engine:

1.Connect the Starter to the truck

*Connect the Starter control box to the connector

located in the rear shock stay mount.

*Caution : Before starting the engine ,review the

important-read this before running and operate

your model safety.

2.Start the engine

*With one hand ,hold the throttle half open using

the throttle trigger on the transmitter. With your

other hand ,press the red button on the Starter.

If the engine does not start ,release the red

button and try again in 5 sec. Interval.

*Follow the engine manufacturer instruction

manuals regarding engine set-up, carburetor

and maintenance.

7.2V Battery

(Not included)

Electric Starter

Electric Starter

SETTING GUIDE

FRONT CAMBER ANGLE SETTING REAR CAMBER ANGLE SETTING

Turnbuckle

+

Place the model car on flat surface. Raise the chassis to it's maximum clearance

before the wheels leave the ground.

Adjust the length of the front and rear upper arms so that the wheels are right angle to the

ground.

The camber angle adjustment can be moving the turnbuckle rod on the upper arms,

clockwise or anti-clockwise.

(We suggest use zero degree for the front and 2 degree for the rear.) negative

-

FRONT TOE-IN AND TOE-OUT SETTING

NEUTRAL POSITION

TOE-OUT

TOE-IN

-

+

TOE-OUT

+

-

NegativeNegative PositivePositive

FRONT SHOCK ANGLE SETTING

Soft

1

4

5

2

3

6

Turnbuckle

Firm

-

+

Adjust the length of front steering rod to change the

toe angle.

Making the tie rod longer will make the front tires

become toe-in.

Response will be slower and will over steer.

Making the tie rod shorter will make the front tires

become toe-out.

Response will be quicker and will under steer.

REAR TOE-IN SETTING

By change the rear toe-in block can be change

rear toe-in.

Steering Rod

Firm front suspension, less steering.

Soft front suspension, more steering.

REAR SHOCK ANGLE SETTING

Firm rear suspension, over steering.

Soft rear suspension, under steering.

REAR WHEELBASE

367.5mm 370mm365mm

0

Soft

1

4

5

2

Soft

6

3

Soft

Firm

12

Firm

12

Firm

1

1 Degree 2 Degree 3 Degree

2

3

Adjust the wheelbase by using the spacers on either side of the rear uprights (at the bottom pin).

IMPORTANT! Make equal adjustments on both left and right sides of the car.

Shorter wheelbase

less spacers in front of the rear upright.

- increases rearward weight transfer during acceleration.

- increases on-power traction.

- quicker off-power steering into corners.

- slight tendency to push on-power at corner exit.

- increases steering response.

- better on tighter, more technical tracks.

Longer wheelbase

more spacers in front of the rear upright.

- decreases off-power steering into sharp corners.

- increases stability.

- slower initial steering reaction (off-power).

- improves on-power steering at corner exit.

- better handling over bumps and ruts.

- better on more open tracks with high-speed corners.

MUTILATOR V3

SETTUP SHEET

DRIVER:

DATE:

TRACK:

SIZE:

OPEN

MEDUIM

TIGHT

TRACTION:

HIGH

MEDIUM

LOW

SURFACE:

SMOOTH

MEDIUM

BUMPY

FRONT SUSPENSION

TOE ANGLE

RIDHIEIGHT

CAMBER

SWAY BAR

OIL:

PISTON:

SPRING:

IN:

OUT:

mm

POS:

NEG:

2.5mm

OTHER

FRONT SHOCHS

W

STANDARD

DRLLRD

SOFT

MEDUIM

HARD

OTHER

mm x 1

mm x 2

WHEEL

NOTES:

1

2

3

4

5

6

1

2

3

1

2

REBOUND STOP:

A

B

mm

REAR SUSPENSION

REAR TOR-IN PLATE:

1

2

3

RIDHIEIGHT

CAMBER

SWAY BAR

REAR SHOCHS

OIL:

PISTON:

SPRING:

1 Degree

2 Degree

3 Degree

POS:

NEG:

2.5mm

OTHER

W

STANDARD

DRLLRD

SOFT

MEDUIM

HARD

mm

OTHER

mm x 1

mm x 2

WHEEL

NOTES:

1

2

3

4

5

6

1

3

4

5

2

1 2

1 2

REBOUND STOP:

WIN POSITION

A

B

mm

DIFF OIL TORSEN DIFF

ENGINE

FRONT: FRONT:

CENTER: CENTER:

REAR: REAR:

TYPE:

GASKET:

mm

PLUG:

MUFFLER:

FUEL:

TIRES

CLUTCH

TYPE: TYPE:

FRONT

INSERT: INSERT:

CLUTCH BELL

13T

14T

15T

CLUTCH SHOES

REAR

3 SHOE

4 SHOE

MUTILATOR V3

SETTUP SHEET

DRIVER:

DATE:

TRACK:

SIZE:

OPEN

MEDUIM

TIGHT

TRACTION:

HIGH

MEDIUM

LOW

SURFACE:

SMOOTH

MEDIUM

BUMPY

FRONT SUSPENSION

TOE ANGLE

RIDHIEIGHT

CAMBER

SWAY BAR

OIL:

PISTON:

SPRING:

IN:

OUT:

mm

POS:

NEG:

2.5mm

OTHER

FRONT SHOCHS

W

STANDARD

DRLLRD

SOFT

MEDUIM

HARD

OTHER

mm x 1

mm x 2

WHEEL

NOTES:

1

2

3

4

5

6

1

2

3

1

2

REBOUND STOP:

A

B

mm

REAR SUSPENSION

REAR TOR-IN PLATE:

1

2

3

RIDHIEIGHT

CAMBER

SWAY BAR

REAR SHOCHS

OIL:

PISTON:

SPRING:

1 Degree

2 Degree

3 Degree

POS:

NEG:

2.5mm

OTHER

W

STANDARD

DRLLRD

SOFT

MEDUIM

HARD

mm

OTHER

mm x 1

mm x 2

WHEEL

NOTES:

1

2

3

4

5

6

1

3

4

5

2

1 2

1 2

REBOUND STOP:

WIN POSITION

A

B

mm

DIFF OIL TORSEN DIFF

ENGINE

FRONT: FRONT:

CENTER: CENTER:

REAR: REAR:

TYPE:

GASKET:

mm

PLUG:

MUFFLER:

FUEL:

TIRES

CLUTCH

TYPE: TYPE:

FRONT

INSERT: INSERT:

CLUTCH BELL

13T

14T

15T

CLUTCH SHOES

REAR

3 SHOE

4 SHOE

OFNA DESCRI PTION RETAIL OFNA DESCRIPTION RETAIL

10010 CLUTCH SHOES, BLACK, 3 SHOES 13.95 40065 BALL ENDS, PLASTIC, REAR UPPER 4.95

10011 SHOES,ALUM BLUE-1.8g W /SPRING 24.95 40083 W IN G , 9.5 , W H ITE 15.95

10012 SHOES,ALUM PURPLE-2.0gW /SPRING 24.95 40090 SEALS,SHOCK REBU ILD, 9.5 X-1 7.95

10013 SHOES,ALUM SILVER-1.7gW /SPRING 29.95 40093 CAPS, SHOCK, HARD COATED LONG 15.95

10040 3 P IN FLYW H EEL, .21 CORN TYPE 14.95 40098 PISTONS, SHOCK, BLACK 9.5 & X1 5.95

10069 RED SEAL, SILICONE ROUND, 2PCS 6.95 40108 TURNBUCKLE, 4x56mm, 9.5V PAIR 7.95

10073 PIPE,INLINE,OFNA-095, POLISHED 79.95 40109 TAN K,FUEL,150cc VIO LATO R,X1CR T 13.95

10098 CLUTCH NUT, SG SHAFT 4.95 40116 SHOCK TOW ER FR/RR NEW BLAZER 9.95

10101 SPRINGS,CLUTCH,GOLD 1.1M 3PCS 4.95 40117 BLAZER TRUCK BODY MOUNT NEW 10.95

10114 FLAT HEAD ENGINE MOUNT SCREW S 7.95 40127 AIR FILTER SET, X-1 9.95

10120 SPRING, MANIFOLD, R.PORT .21 4.95 40128 FO AM, REPLACEMEN T FOR 40127 5.95

10177 FUEL LINE 3FT. G RAY/BLACK 1.95 40129 CONNECTOR, RUBBER FOR 40127 5.95

10185 SILIC ONE JOINT TUBE, SPL, BLACK 5.95 40133 C HAS SIS , M UTILAT OR 6061 3mm 79.95

10282 SW ITC H COVER, SILICONE BLACK 3.95 40134 SPUR, GEAR STEEL 62T MTL. 34.95

10300 ALUM . STOPPER KIT, 6 PCS. 4.95 40136 CENTER DRIVE SHAFT 104,120mm 16.95

10399 CLUTCH BELL W /BEARINGS, 13T 19.95 40137 BUM PER MUTILATOR 12.95

10765 SERVO HORNS, HD NYLON,BLUE SET 8.95 40138 RADIO TRAY POST, PLASTIC 4.95

30051 W HEEL HUB 17x6mm, BLUE PAIR 10.95 40139 ARM, FRONT UPPER MUTILATOR PRO 6.95

30058 W HEEL HUB EXTENSIO NS, 15mm 4PC 19.95 40140 ARM, FR & RR LOWER MTL PRO 12.95

30171 LEVER, BRAKE 1.95 40141 UNIVERSAL FRO NT MUTILATOR PRO 39.95

30341 BALL END W ITH COLLAR, 6mm 3.95 40142 DRIVE SHAFT REAR 114mm MTL PRO 12.95

30401 STEER ING EN DS, PLASTIC 6 PCS. 2.95 40143 RADIO TRAY MTL PRO H.C. 12.95

30402 3x30m m TIE RO D 2.95 40145 SHOCK TOW ER RR MTL AUTOSTART 14.95

30403 6m m BALL, ST EEL (NO COLLAR) 4.95 40199 STEERING BALL END,PLASTIC , 6mm 7.95

30530 THROTTLE JOINT KIT, NYLON END 3.95 40513 DIFF. GE AR (sm all & large)ALU M 16.95

30531 SPRING, THROTTLE LINKAG E 2.95 40520 KNUCKLE ARM, L & R 19.95

30560 ANT TUBE AND MOUNT 2.95 40525 SHAFT 3x48.1m m DM UPPER FRONT 6.95

30661 SERVO HORN HEAVY DUTY BLACK 4.95 40526 W HEEL HUB 5m m 11.95

30776 W ASHE R, 4x10x0.2m m 4PCS. 1.95 40527 KNUCKLE ARM BUSHING 4.95

30800 LINKAGE, BRAKE/THRO TTLE (98) 6.95 40528 KING PIN SCREW 1.95

30802 LINKAGE, 2 THROTTLE LINKAG E 7.95 40531 SHOC K BALL POST/O NE-PIECE/TOP 9.95

31994 PIPE, 9.5mm RTR POLISED 54.95 40536 FRONT C HUB 11.95

31995 MANIFOLD, SILVER MTL AUTOSTAR T 25.95 40540 REAR UP RHT & UPR ARM, BUMPER 9.95

34110 BEARING, 5x10, 2 PCS 6.95 40541 REC EIVER BOX, NEW TYPE 14.95

36053 BEARING, 8x16m m, PAIR 12.95 40546 FRONT ARM SHAFT 3x42.7mm 11.95

36055 PIN, 2.5x17mm , HEX HUBS, 4PCS 3.95 40550 W HEEL NUT 5mm 4.95

36081 REAR UP-RIGHT (8mm BEARING) PR 12.95 40556 ALUM. SHOCK SPRING ADJ. H.C. 21.95

36082 REAR AXLES, 8mm PAIR 10.95 40591 BRAKE DISK, FIBER X1-C R/CRT 14.95

36170 ARM PINS, 3mm 4PCS LX1 7.95 40617 W ASHER , PLASTIC, BLAC K 8PCS. 3.95

36660 BRAKE PAD, 4PCS. 3.95 40642 ANTENNA PIPE FIXING NUT 2.95

36690 UPPER BALL END, 7mm 6PCS 6.95 40662 CENTER DIFF. MOUNT POST 19.95

36700 STEER ING BALL END, 7mm , 8PCS. 6.95 40664 BRAKE ROD, 2x68mm 3.95

36730 JOINTS CAP, 6m m, 2PCS. 11.95 40665 BRAKE CAM 8.95

36850 7m m BALL, 6 PC S. 3.95 40673R W BODY, TRUGGY MUTILATOR RED/W H 69.95

36860 5x40mm TURNBUCKLES, 2 PCS. SIL 6.95 40674 ENGINE MOUNT (Tall) CR & CRT 18.95

36861 5x40mm TURNBUCKLES, 2 PCS BLK 6.95 40676 BODY PO ST AND SERVO MOUNT 9.95

36880 5x60mm TURNBUCKLES 6.95 40855 ANT. TUBE FIXING NUT (BROW N) 2.95

37410 BO DY CLIPS, 10 PCS. SMALL 3.95 41001 SHOCK BIG BORE FRO NT 16MM PAIR 79.95

38281 TURNBUCKLES, 3X40MM, 2PCS 5.95 41002 SHOCK BIG BORE REAR 16MM PAIR 79.95

38313 CONE, TAPER ED 7mm , SG 2.95 41003 SHOCK BODY FRONT 16MM PAIR 29.95

40003 CASE, DIFF, 1 PC 9.95 41004 SHOCK BODY REAR 16M M PAIR 29.95

40005 CAP JOINT, BRAKE, 2PCS 13.95 41005 SHO CK CAP 16MM 4PCS. 22.95

40006 CAP JOINT, FNT&RR DIFF, 2PCS. 13.95 41006 SHOC K SPRING ADJ. 16MM 4PCS. 14.95

40009 SEAL, P-6 O-RING, DIFF, 2PCS 2.95 41007 O -RIN G 19x1.5MM 16MM 4PC S. 4.95

40010 P IN , 2 .5X1 3 .8M M , D IFF , 2 P C S 2.95 41008 PLASTIC SH OCK PARTS 16MM SET 12.95

40011 G ASKET, DIFF 3PCS 3.95 41009 CAP SCREW S 3X28M M 4PCS. 2.95

40015 FRONT HOLDER, LOW ER ARMS 5PCS 14.95 41010 SHO CK BALL END PO ST LONG 4PCS 11.95

40017 M AIN G EAR BOX, FRONT&REAR, 1PC 18.95 41011 SHO CK PISTON 16MM 8PCS. 10.95

40018 BRACE, CENTER, NYLO N, 9.5 KIT 7.95 41012 REPAIR KIT FO R 16MM SHOCK 9.95

40019 ANTI-ROLL KIT (FRONT/REAR) 13.95 41013 PRESSURE TOP ORANGE 16MM 4PCS. 7.95

40022 FRONT, LOW ER ALUM. HOLDER 11.95 41014 SPRING 16MM SUPER SOFT YEL SET 17.95

40023 SHAFTS, LOW ER ARM S, 4MM , 4PCS. 17.95 41015 SPRING 16MM SOFT W HITE SET 17.95

40024 S H IM , 13 X 16 X O .2 M M , D IF F G E A R ,4 2.95 41016 SPRING 16MM BUGGY SILVER SET 17.95

40025 REAR, LOW ER ARM ALUM. HOLDER 11.95 41017 SPRING 16MM HARD GRAY SET 17.95

40027 W ING MOUNT SUPPORT SET 19.95 41018 SPRING 16MM TRU GGY BLUE SET 17.95

40028 DOG BONES, 93MM PAIR LX1 19.95 41019 O-RING 1OMMx1MM FOR 16MM SHOCK 2.95

40029 BALL ENDS, PLASTIC, ANTI-ROLL 3.95 41020 SHO CK BALL END POST L.W . LONG 14.95

40030 FRONT PLATE, ALUM. H.C. 8.95 41021 SP RING .52 REAR 16M M YELLOW 9.95

40031 SERVO SAVER HORN 15.95 41022 SPRING .58 REAR 16MM W HITE 9.95

34313 MUTILATO R AUTOSTART PARTS LIST

40032 PLATE, SERVO SAVER ,SLIDER H .C. 10.95 41023 SPRING .59 REAR 16MM BLUE 9.95

40033 SPRING, SERVO SAVER 3.95 41024 SPRING .60 REAR 16MM SILVER 9.95

40034 ALUM . RING, SERVO SAVER ADJ.RI 5.95 41025 SPRING .64 REAR 16M M GRAY 9.95

40035 AXLE TUBE, SER VO SAVER 35.95 41026 SPRING .66 F RONT 16M M Y ELLOW 9.95

40036 AXLE POSTS, SERVO SAVER 5.95 41027 SPRING .70 FRONT 16MM W HITE 9.95

40037 SCREW S, SERVO PLATE 5.95 41028 SPRING .71 FRONT 16M M B LUE 9.95

40038 BALLS, 7MM 4PCS. 9.95 41029 SPRING .74 FR ON T 16MM SILVER 9.95

40039 CONE, ALUM. 3MM, 4PCS. 3.95 41030 SPRING .88 FRONT 16MM GRAY 9.95

40040 CENTER DIFF MOUNT 4.95 50110 M OTOR, AUTO STAR T REPLACEMENT 9.95

40041 CENTER, ALUM . TOP PLATE, H.C . 8.95 50111 W IRE SET FOR AUT0 START 5.95

40050 PO ST, PIPE HOLDER 6.95 50114 GEAR ASLB W /O M OTOR MTL, ULTRA 33.95

40051 W IRE, PIPE MOUN T 4.95 52226 FORC E .28 AUTO START SYSTEM 299.95

40054 SHAFTS,3.5m FRONT SHOCKS, 2PCS 7.95 49012 GEAR, 13T PINION 7.95

40055 SHAFTS,3.5m REAR SHOCKS, 2PCS 7.95 49032 GEAR, BEVEL, 43 TOOTH 29.95

40057 ADJUSTERS, SPRING, BLUE, 4PCS 20.95 80022 TIRES, X LPR TRUGGY w/INSERTS 30.95

40058 COVERS, SH OCK SHAFTS, SILICONE 9.95 86106 W HEELS ,3.7 1/2O FFSET LPR W HT4P 28.95

40059 SEALS, 14.7mm O-RING, 4PCS 4.95 86107 W H EELS,3.7 1/2OFFSET LP R YEL4P 28.95

40060 NYLOK NUT, 2.5, PISTON NUT, 4 4.95 86108 W HEELS,3.7 1/2OFFSET LPR BLK4P 28.95

86109 W H EELS,3.7 1/2OFF SET LPR ORG4P 28.95

OWNER’S REGISTRATION CARD

OFNA Racing congratulates you on your purchase of our fine OFNA Product. With proper maintenance and handling this kit will provide many hours of enjoyment.

The registration card should be filled out and mailed to OFNA Racing within 10 days of purchase date.

In the event that the kit is incomplete or component parts are broken due to error in manufacturer, contact your

dealer from which you purchased the kit for replacement part or call OFNA at (949) 586-2910 for your nearest dealer

location. Other items such as radio and engine other covered by individual warranties.

IMPORTANT!

Please print or type, filling in the information listed below and mail immediately

MAIL TO:

OFNA RACING

7 VANDERBILT

IRVINE, CA. 92618

TEL: (949) 586-2910

Write in Your Model Name and Part Number

REGISTRATION CARD

RACER’S NAME TEL:( )

ADDRESS

CITY STATE ZIP

DEALER’S NAME TEL: ( )

ADDRESS

CITY STATE ZIP

OFNA

7 Vanderbilt

Irvine, Ca. 92618

Loading...

Loading...