Page 1

Halogen Light Source wit h RS 2 32 Inte nsi ty C on trol

HL-2000-HP-232

Installation and Operation Manual

Document Number 000-10000-140-02-201307

Offices: Ocean Optics, Inc. World Headquarters

830 Douglas Ave., Dunedin, FL, USA 34698

Phone 727.733.2447

Fax 727.733.3962

8 a.m.– 8 p.m. (Mon-Thu), 8 a.m.– 6 p.m. (Fri) EST

Ocean Optics Mikropack

Maybachstraße 11, D73760, Ostfildern, Germany

Phone +49 (0)711 34 16 96-0

Fax +49 (0)711 34 16 96-85

E-mail: Info@OceanOptics.com (General sal es inq u iries)

Info@Mikropack.de (Mikropack sales inquiries)

Orders@OceanOptics.com (Questions about orders)

TechSupport@OceanOptics.com (Technical support)

000-00000-000-02-A

Page 2

Copyright © 2009 Ocean Optics, Inc.

All rights reserved. No part of this publication may be reproduced, s t ored i n a retri e val system, or transmitted, by any means, electronic, mechanical,

photocopying, recording, or otherwise, without written perm iss i on from Ocean Optics, Inc.

This manual is sold as part of an order and subject to the condition that it shall not, by way of trade or otherwise, be lent, re-sold, hired out or otherwise

circulated without the prior c onsen t of Ocean Optics, Inc. in any form of binding or cover other than that in which it is published.

Trademarks

Microsoft, Windows, Wind ow s 95, Windows 98, Windows Me, Windows NT, Windows 2000, Wind ow s XP an d Excel are either registered trademarks or

trademarks of Microsoft Corporation.

Limit of Liability

Every effort h as been made to make this manual as complete and as ac cu rate as possible, but no warranty or fitness is imp lied . T he inf ormation provided is on

an “as is” basis. Ocean Optics, Inc. shall have n ei ther liability n or res ponsibility to any person or enti t y with r espect to any loss or damages arisin g from the

information contained in this m a nual.

Page 3

Important Safety Notices

1. Read all safe ty and operating instructions before using this equipment.

2. Use this equipment in a clean, dry environment. Place the unit away from heat sources and ensure

that nothing interferes with its ventilation.

3. Do not allow objects to fall, or liquids to spill into the unit through the en closure openings.

4. Do not use any power supply other than the type described in these instructions or as marked on

the unit.

5. Do not use the unit if it is dam aged in any wa y. Contact your dealer for repair or replacement

information.

Warranty

Mikropack Gmb H w arrants to the original user of th is in st ru men t that it shall be free of an y defects

resulting from faulty manu facture of this instrument f or a period of 12 months from the original data of

shipment.

This instrument should not be used for any Clinical or Diagnostic purposes. Data generated in thes e

areas is not warran t ed in any wa y b y Mikr op ac k Gmb H . An y def ec ts c ove r ed b y this W ar ran t y sh all be

corrected either by repair or by replacement, as determined by Mikropack GmbH.

There are no warranties that extend beyond the description herein.

This Warranty is in lieu of, and excludes, any and all other warranties or representations expressed,

implied, or statu tory, including merch an tab i lit y and fitn es s, as w ell as any and all other obligat ion s or

liabilities of Mikropack GmbH including, but not limited to, special or consequential damages. No

person, firm, or corporation is authorized to assum e for Mikropack GmbH. Any additional obli gation or

liability not expressed provided for herein except in writing duly executed by an officer of Mikropack

GmbH:

MIKROPACK GmbH

Maybachstraße 11

D-73760 Ostfildern

Tel.: +49 (0)711 34 16 96-51 • Fax.: +49 (0)711 34 16 96-85

e-mail: info@mikropack.de

internet: www.mikropack.de

000-10000-140-02-201307 A

Page 4

Important Safety Notices

B 000-10000-140-02-201307

Page 5

Table of Contents

About This Manual .............................................................................................................iii

Document Purpose and Intended Audience .............................................................................. iii

What’s New in this Document ................................................................................................... iii

Document Summary .................................................................................................................. iii

Product-Related Documentation ............................................................................................... iii

Upgrades ............................................................................................................................iv

Chapter 1: Setup ................................................................................... 1

Overview .............................................................................................................................1

Setting Up the HL-2000-HP-232 Light Source ..................................................................1

Unpacking the Light Source ...................................................................................................... 1

Package Contents ..................................................................................................................... 2

Set-Up ........................................................................................................................................ 2

Chapter 2: Operation ........................................................................... 5

Optimizing the Optical Power Output .................................................................................5

Shutter Diagram .................................................................................................................6

Chapter 3: Bulb Replacement ............................................................. 7

Overview .............................................................................................................................7

Bulb Replacement Procedure ............................................................................................7

Appendix A: ASCII Commands ........................................................... 9

Motion-Related Commands ...............................................................................................9

Configuration-Related Commands ....................................................................................10

External Limit Switch Configuration Commands ...............................................................11

Commands That Return Data ............................................................................................12

000-10000-140-02-201307 i

Page 6

Table of Contents

Appendix B: HL-2000-HP-232 Specifications .................................... 15

Specifications .....................................................................................................................15

Parts List .............................................................................................................................16

Index ...................................................................................................... 17

ii 000-10000-140-02-201307

Page 7

About This Manual

Document Purpose and Intended Audience

This document provides you with set-up and operation information to get your light source up and

running.

What’s New in this Document

This version of th e Halogen Light Source with RS232 Intensity Control HL-2000-HP-232 Installation and

Operation Manual updates the logo and the contact information.

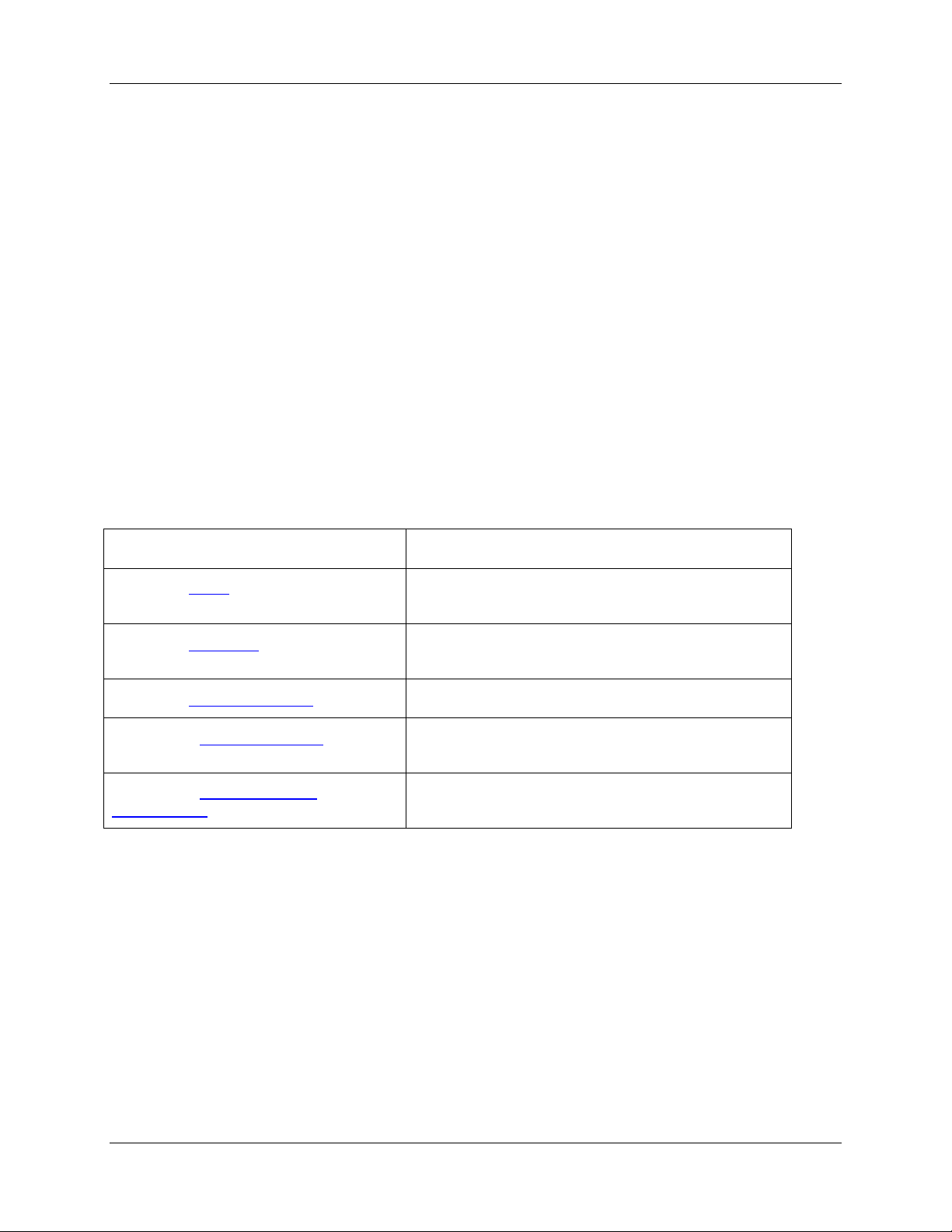

Document Summary

Chapter Description

Chapter 1: Setup

Chapter 2: Operation

Chapter 3: Bulb Replacement

Appendix A: ASCII Commands

Appendix B: HL-2000-HP-232

Specifications

Contains a list of package contents and unpacking

instructions.

Provides instructions for optimizing the optical power

output and a diagram of the shutter.

Provides instructions for replacing the bulb.

Contains a list of the ASCII command set used to

control the light source’s attenuator and shutter.

Contains operating environment specifications, as

well as other physical details of the product.

Product-Related Documentation

You can access documentation for Ocean Optics products b y visiting our website at

http://www.oceanoptics.com. Select Technical → Operating Instructions, then choose the appropriate

document from the avail able drop-down lists. Or, use the Search by Model Number field at the bottom

of the web page.

You can also access operating instru ctions for Ocean Optics product s on the Software and Technical

Resources CD included with the system.

Engineering-level docu mentation is located on ou r website at Technical → Engineering Docs.

000-10000-140-02-201307 iii

Page 8

About This Manual

Upgrades

Occasional l y, you may find that you need Ocean Optics to make a change or an upgrade to your system.

To facilitate these changes, you must first contact Customer Support and obtain a Return Merchandise

Authorization (RMA) number. Please contact Ocean Optics for specific instructions when returning a

product.

iv 000-10000-140-02-201307

Page 9

Chapter 1

Setup

Overview

The high-power Halogen Light Source with attenuator and shutter uses a 20-watt bulb for appli cations

requiring la rge-diameter optical fibers, or fiber and probe bundles. The attenuator and shutter can be

controlled by a series of ASCII commands issued by a host computer via RS-232.

Setting Up the HL-2000-HP-232 Light Source

Unpacking the Light Source

► Procedure

1. Unpack your new equipment carefully. Dropping this instrument can cause permanent damage.

000-10000-140-02-201307 1

Page 10

1: Setup

2. Inspect th e outside of the instrument and make sure that there is no damage. Do not use the

instrument if damage is present. Contact your dealer for repair or replacement information, if

necessary.

3. Use this instrument in a clean laboratory environment.

Package Contents

Your package should contain the following:

One HL-2000-HP-232 Light Source

One serial cable

One 24 VDC 1,2A power supply

HL-2000-HP-232 test software

One Ocean Optics Software and Technical Resources CD

In addition, you need an optical fiber (1000 μm diameter fiber is recommended).

Set-Up

Use the following procedure and diagrams to set up your light source.

2 000-10000-140-02-201307

Page 11

1: Setup

► Procedure

1. Plug the power sup p ly int o a wall ou tl et.

2. Plug the other end of the power supply cable into the socket of the light source.

3. Plug the serial cable (included) into the light source connector, and the other end into the COM

port on your PC.

4. Connect the SMA connector of your fiber optic cable to the SMA plu gs.

5. Turn on the Halogen lamp using the power switch on the front of the light source. The shutter

opens and the lamp flashes once.

Notes

The light can only be turned on via RS232 (see ).

To test the l ight source, u se the HL-2000-HP-232 test software included with your

equipment.

6. Configure your computer’s COM port to establish connection with your light source. The COM

port settings are as follows:

Baud Rate: 9600 (if 9600 does not work, try 19200)

Data Bits: 8

Parity: None

Stop Bits: 1

Flow Contro l: None

Note

If you are working with a termin al, th e Local Echo and CR When Sending options

should be activated.

000-10000-140-02-201307 3

Page 12

1: Setup

4 000-10000-140-02-201307

Page 13

Chapter 2

Operation

Optimizing the Optical Power Out put

The HL-2000-HP-232 is adjusted at the factory to provide maximum power into a 200µm fiber. If a lower

optical power is required or a different fiber (bundle) diameter is used, you can adjust the optical power of

the unit.

Procedure

►

Follow the steps below to adjust the optical power of the HL-2000-HP-232 Light Source:

1. Connect a fiber opt ic spe ctr o met er or an opt ic al po we r met e r to a fiber, an d th en con ne ct the other

end of the fiber to the HL-2000-HP-232’s SMA plug.

2. Loosen the blocking screw with the provided 1.3mm Allen wrench.

000-10000-140-02-201307 5

Page 14

2: Operation

3. Shift the SMA socket to optimize the optic al power of the light source.

4. Tighten the blocking screw to secure the SMA socket position.

Shutter Diagram

6 000-10000-140-02-201307

Page 15

Bulb Replacement

Overview

To order replace men t bulb s for th e H L-2000-HP-232, consult the Parts List.

WARNING

Before replacing the bulb in the lig ht source, disconnect the lamp from your power

source and allow the unit to cool for at least twenty min utes, if necessary.

Chapter 3

Bulb Replacement Procedure

► Procedure

1. Remove the 19-inch cassette from the rack.

2. Remove the four slotted screws and remove the side cover of the lamp enclosure.

3. Disconnect the two spare bulb cables from the connector.

000-10000-140-02-201307 7

Page 16

3: Bulb Replacement

4. Loosen the hex screw on the lamp housing.

5. Remove the bulb by pulling it back away from the connector.

6. Replace the spare bulb with a new one.

7. Replace the hex screw on the lamp hou sing.

8. Replace the cov e r.

8 000-10000-140-02-201307

Page 17

Appendix A

ASCII Commands

In serial communications mode, the motion controller is controlled via a series of ASCII instructions

issued by a host computer.

Motion-Related Commands

Command Function Description Example

M Initiate Motion Receipt of the "M" Move command initiates

motion using the values presently loaded to

determine the profile characteristics.

LA Load Absolute Position Allows programming of the desired target

position relative to the present zero or "home"

position.

LR Load Relative Position Allows programming of the desired tar ge t

position relative to the present position.

SP Load Command

Velocity

AC Load Command

Acceleration

V Select Velocity Mode Execution of this command causes the

This parameter should be loaded with the

desired maximum profile velocity in position

mode. This value should be selected to not

exceed the capabilities of the mechanical

system. Additionally, this command sets the

maximum velocity value in "velocity mode".

This parameter determines the acceleration and

deceleration rate to be calculated by the profiler

during execution. Argument in rpm/s

(Allowed value: 0 to 20000)

controller to switch into the Velocity control

mode. The motor will ramp the selected velocity

at the rate defined by the AC parameter.

2

M

LA 10000

LR 10000

SP 3000

AC 100

V 2200

HO Define Home-Position Define present position as zero HO

000-10000-140-02-201307 9

Page 18

A: ASCII Commands

Command Function Description Example

DI Disable Drive Execution of this command disables the drive

electronics and removes all current from the

motor

EN Enable Drive This instruction enables the drive electronics

and allows the servo controller to become

active, providing motor current as required.

LL Load Position Range

Limits

The range limit mechanism provides an

additional layer of protection. Both positive and

negative range limits are determined

independently using the sign of the limit

parameter. If the controller receives an

instruction from the host to move to a position

that is not within the range limit window, it will

stop at the set limit position.

DI

EN

LL 2000000

or

LL -5000000

Configuration-Related Commands

Command Function Description Example

POR Set Proportional Loop

Gain

The proportional gain determines the system's

proportional response to a given amount of

positional error. Increasing this parameter

provides a tighter and more dynamically

responsive system. (Allowed value 0 – 255)

POR 20

I Set Integral Loop Gain Unlike the proportional gain, where the

response remains constant if there is no

change in error, the integral term continues to

increase the effects of its response until it

becomes effective. This parameter determines

the rate of change of this response.

(Allowed value 0 – 255)

LPC Load Peak Current

Limit

LCC Load Continuous

Current Limit

RN Reset Node This command resets the gains and current

10 000-10000-140-02-201307

This command sets the Peak current limit. The

LPC argument is in milliamperes.

This command sets the continuous current limit.

The LCC argument is in milliamperes.

limits to the values stored in the controller ROM

(the defaults).

I 10

LPC 1000

LCC 500

RN

Page 19

A: ASCII Commands

Command Function Description Example

DCE Delayed Current Error This command sets the delay between current

limit condition and setting the Fault-Status

(Fault-Pin and Fault-Bit for the GFSCommand). The DCE argument is in

milliseconds.

SOR Source For Velocity This command defines the source for the

velocity of the motor.

SOR 0 defines that commanded velocity will

come from a serial command message using

RS232.

SOR 1 defines that the velocity value will be

an analog input voltage of +/-10 VDC at the

analog input. SOR 2 defines that the velocity

value will be a PWM signal at the analog input.

Note that the SP value dictates the Maximum

Velocity reached for the Maximum PWM signal

(SOR2) and the Maximum Velocity for 10 V at

the analog input (SOR1).

EEPSAV Save To EEPROM This command saves the current parameters

and configurations to EEPROM. The saved

parameters are recalled during power up so

that the motor is configured for use

immediately. After saving all configuration

parameters, a serial message "EEPROM

writing done" will be sent from the controller.

DCE 200

SOR 1

EEPSAV

NP Notify Position This command tells the motion controller to

send a "p" message when a particular position

is reached. In the example above, when 10,00 0

is reached a "p" message will be sent from the

controller.

NP 10000

External Limit Switch Configurati on Commands

Command Function Description Example

HA Arm the "HOME" input This command is used to arm the Home Arming

mode. It is used with the external limit or

reference switch to define the home position

(the Analog input serves as this digital input as

well).

000-10000-140-02-201307 11

HA 1

Page 20

A: ASCII Commands

Command Function Description Example

HL Home Limit Action This command is used to set the action that

occurs when the limit switch is activated. If HL

is set to 0, the motor will continue to run after

switch activation but will send an "h" message

signifying home switch was triggered. If HL is

set to 1, the motor will stop immediately after

switch activation.

HN Hard Notify If HN is set to 1, it configures the motion

controller to send a serial message "h" once the

external limit switch is triggered.

HP Define External Switch

Polarity

HS External Switch Status This command returns the state of the limit

This command defines the activation edge of

the external switch. If HP is 0 a falling edge at

the external limit switch is valid. If HP is 1 a

rising edge occurs actions due to HL, HN and

HA-commands.

switch. If the limit switch was active and an HS

request is sent, the controller will return a 1. If

the limit switch was not active since a HL, HN

or HA-command was sent an HS request will

return a 0 to the host.

HL 1

HN 1

HP 0

HS

Commands That Return Data

Command Function Description Example

GV Get Velocity

Commanded

GN Get Actual Velocity This command returns the actual velocity. GN

GI Get Integral Term This command returns the Integral gain setting. GI

GCL Get Current Limit This command returns the present current limit. GCL

POS Get Present Position This command returns the present motor

TEM Get Temperature This command returns the present coil

GAC Get Acceleration This command returns acceleration GAC

GSP Get Maximum Speed This command returns Maximum speed setting. GSP

This command returns the command velocity

sent.

position.

temperature (in °C)

GV

POS

TEM

12 000-10000-140-02-201307

Page 21

A: ASCII Commands

Command Function Description Example

GRC Get Real Current This command returns the current being used in

milliamperes

GST Get Status This command returns motion controller status.

Bit Description

Bit 0: 1... Position mode

0... Velocity mode

Bit 1: 1... Speed command is analog input

0... Speed command comes via RS232

Bit 2: 1... Speed command is PWM (SOR 2)

0... Speed command is analog voltage(SOR1)

Bit 3: 1... Amplifier En ab led

0... Amplifier Disabled

Bit 4: 1... In Position

GRC

GST

0... Not in Position

Bit 5: 1... Rising edge on external switch is

valid

0... Falling edge on external switch is

valid

Bit 6: 1... External switch now high level

0... External switch now low leve l

GFS Get Fault Status This command returns fault status.

Bit Description

(0 is normal, 1 is Fault present)

0 Over-temperature condition

1 Over-current condition

2 Under-voltage (< 15VDC)

3 Over-voltage (> 28VDC)

GFS

000-10000-140-02-201307 13

Page 22

A: ASCII Commands

Command Function Description Example

VER Get Version This command returns firmware version. VER

GPOR Get Proportional Term This command returns Proportional gain setting GPOR

14 000-10000-140-02-201307

Page 23

Appendix B

HL-2000-HP-232 Specifications

This section provides information on the operating environment, physical controls, and dimensions of the

HL-2000-HP-232. It also provides a parts list.

Specifications

Specification Criteria

Dimensions 60 mm x 130 mm x 190 mm

Weight 900 g

Pin description Pin 2: RX

Pin 3: TX

Pin 5: Ground

Output 20 watts

Output to bulb 1.6 A @ 24 VDC

Wavelength range 360–2400 nm

Spectral Range VIS - NIR

Stability 0.5%

Drift <0.3% per hour

Time to stabilize Approximately 5 minutes

Bulb lifetime 2,000 hours

Bulb color temperature 3,000 K

Temperature 5° C

Humidity 5–95% at 40° C

000-10000-140-02-201307 15

Page 24

B: HL-2000-HP-232 Spe cifications

Halogen high-power 20 W light source with RS232 control

HL-2000-HP-232

Halogen spare bulb High-Power

HL-2000-HP-B

Parts List

Spare Parts / Order Information Item Number

16 000-10000-140-02-201307

Page 25

Index

A

ASCII commands, 9

B

bulb replacement, 7

C

commands

configuration-related, 10

data-return ing, 12

external switch limit configuration, 11

motion-r elated, 9

D

document

audience, iii

purpose, iii

summary, ii i

O

optical power

optimizing output, 5

P

package contents, 2

parts list, 16

product-related documentation, iii

S

setup, 1

setup procedure, 2

shutter diagram, 6

specifications, 15

U

unpacking procedure, 1

upgrades, iii

W

warrant y, A

what's new, iii

000-10000-140-02-201307 17

Page 26

Index

18 000-10000-140-02-201307

Loading...

Loading...