Oasis Engineering Ltd

129 Birch Avenue, Tauranga, New Zealand.

T: +64 7 928 3808 F: +64 7 928 3809

E: info@oasisNGV.com

W: www.OasisNGV.com

SV100 Series

Actuated Sandwich Valve

Instruction Manual

Failure to follow these instructions or to properly install and maintain this equipment could result in gas leak-

age, fire or explosion causing property damage and personal injury or death.

Oasis products must be installed, operated and maintained by trained and competent personnel in

accordance with all applicable local codes, rules and regulations in addition to the Oasis Instructions.

Oasis Engineering Ltd. will not be held liable in such circumstances where installation, operation and

maintenance procedures were performed by incompetent personnel resulting in improper assembly, unsafe

operation, equipment damage or personal injury.

2

We reserve the right to modify product specifications without prior notice.

SV-INS-02 3317 © Oasis Engineering Limited

Safety

Warning!

High pressure gas and gas equipment can cause serious harm to

both infrastructure and personnel if safety precautions are not

followed.

Oasis recommends considering the use of the following PPE when

working with high pressure along with any other site specific health

and safety requirements:

Important for Canadian systems

The design has been confirmed and tested to standards not recognised by

Canadian authorities. For the purposes of installation of this design in

ASME B31.3 piping systems, the piping system designer should confirm

suitability and consider the following conditions:

Design pressure: 410 bar (6000 psi)

Design temperature: -40 to +85°C (-40 to + 185°F)

Corrosion allowance: 0mm (0in)

Ensure the system is clean of debris,

vented and isolated before any

installation or servicing work is carried

out.

3

We reserve the right to modify product specifications without prior notice.

SV-INS-02 3317 © Oasis Engineering Limited

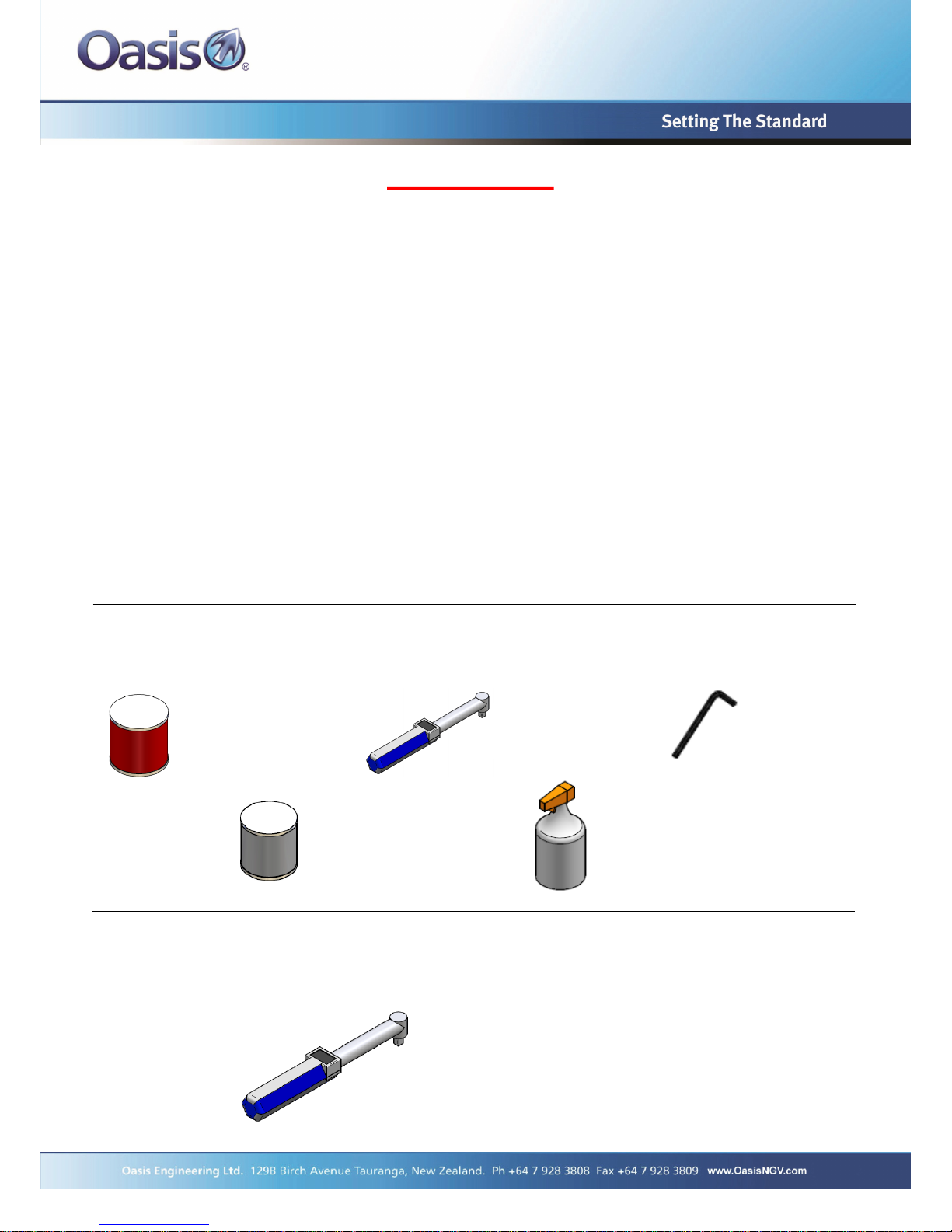

Tools Required

Silicone Grease

(Rocol MX22 or similar)

For all O-rings

Torque Wrench

Important

Oasis recommends the use of class 12.9 plain black socket

head cap screws with this product.

Some surface corrosion is normal on plain black cap screws

over time.

The use of zinc plated cap screws is NOT recommended by

Oasis due to potential weakening issues related to hydrogen

embrittlement during the plating process of zinc plated cap

screws.

SV103= 6mm

SV104= 6mm

SV106= 10mm

SV108= 12mm

Torque wrench hex sizes

Installation Instructions

Allen Key

Anti Seize Grease

- Swagelok Silver Goop

- Omega 99

- or similar

Spray bottle

(Snoop or soapy water)

4

We reserve the right to modify product specifications without prior notice.

SV-INS-02 3317 © Oasis Engineering Limited

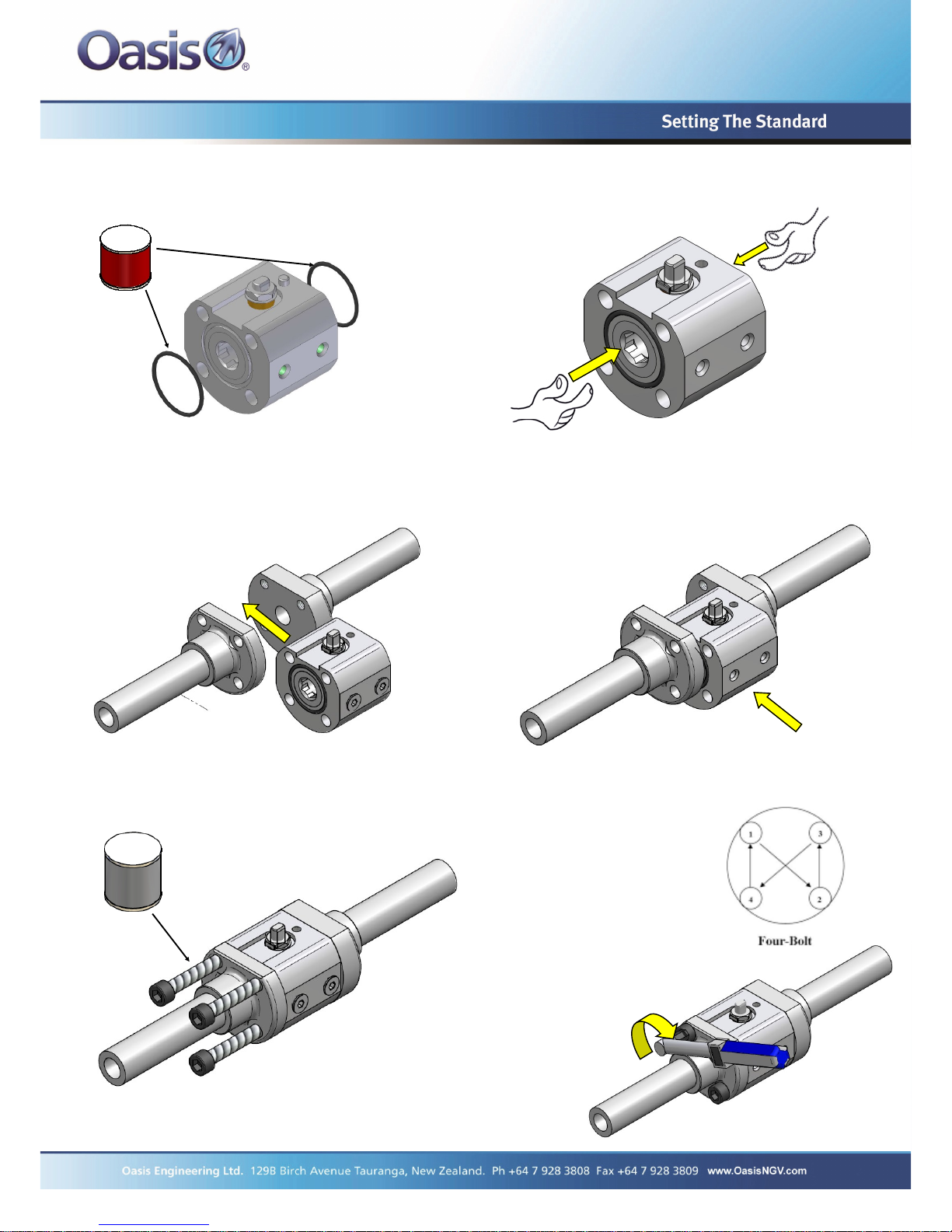

Installation Instructions

1. Grease O-rings. 2. Insert O Rings into grooves.

4. Place valve into position. 3. Line valve up with end caps.

6. Torque bolts. 5. Insert bolts.

Torque pattern

Recommended torque

with anti-seize grease:

SV103= 26 Nm

SV104= 26 Nm

SV106= 60 Nm

SV108= 70 Nm

Without anti-seize:

SV103= 37 Nm

SV104= 37 Nm

SV106= 60 Nm

SV108= 70 Nm

Loading...

Loading...