Model PWFSBF-K12 (retro fit) Bottle Filler

Installation Instructions

The Bottle Filler mounts directly above Versacooler® I and II products.

No additional electrical connections are required.

If installed onto a refrigerated cooler, then chilled water can be dispensed

through the Bottle Filler. Otherwise, room temperature water will be dispensed.

The Bottle Filler is shipped partially assembled.

When completed, the finished assembly will look like this:

OR

Section 1: Getting Started

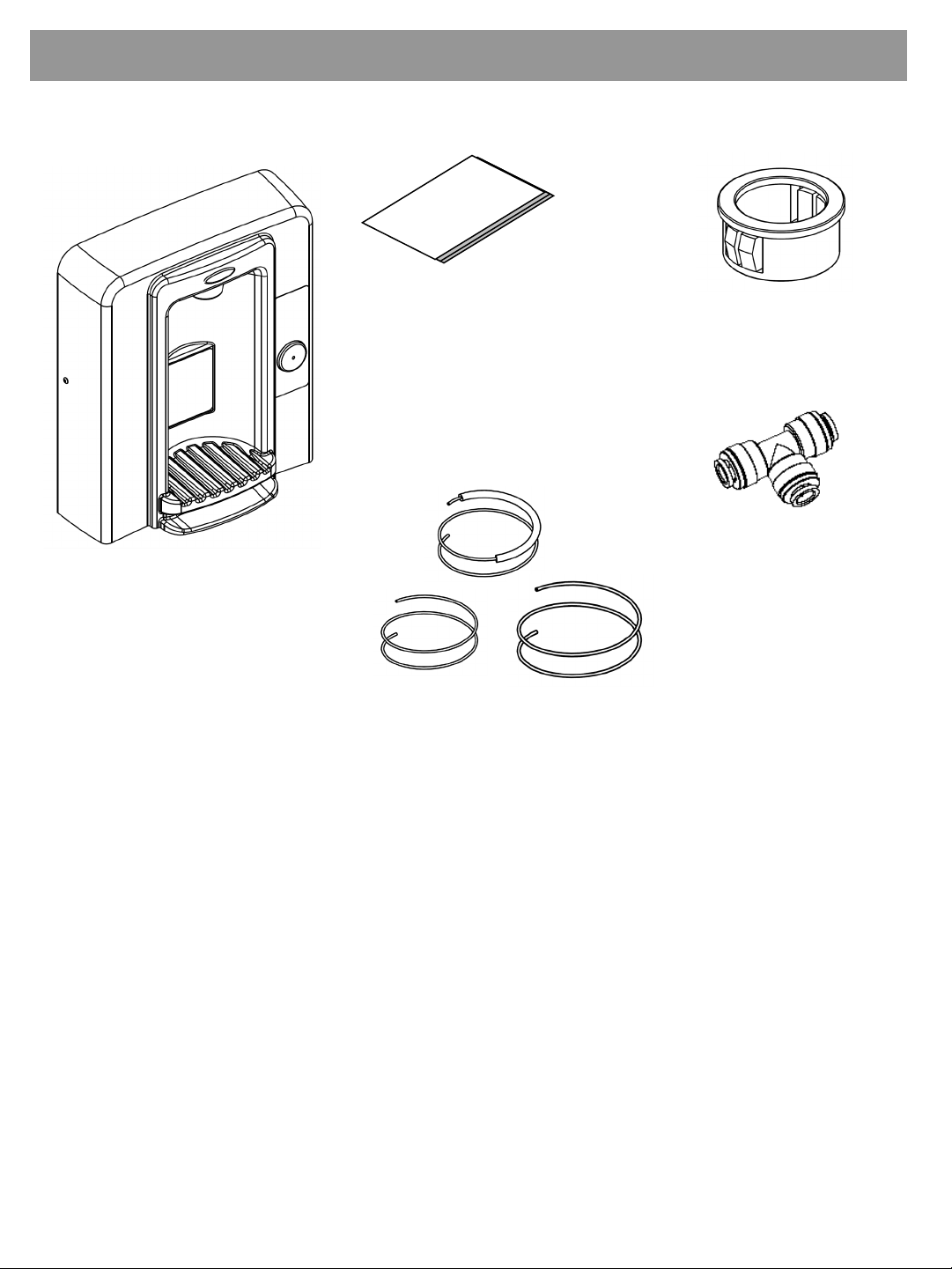

What’s Included:

Installation

instructions

K-12 Bottle Filler

with filter (installed

onto the wall

frame)

Snap bushing

Quick connect

tee fitting

1. One 38” of ¼ OD plastic tubing with

14” of sponge tubing insulation.

2. One 38” of ¼ OD plastic tubing.

3. One 48” of ¼ OD plastic tubing.

Tools required:

3/8” pilot drill and either a step drill bit up to 7/8” diameter that

will drill through SS top or 7/8” diameter punch die

Small tubing cutter for copper tube

1/4 “ nut driver

#15 torx bit driver

2

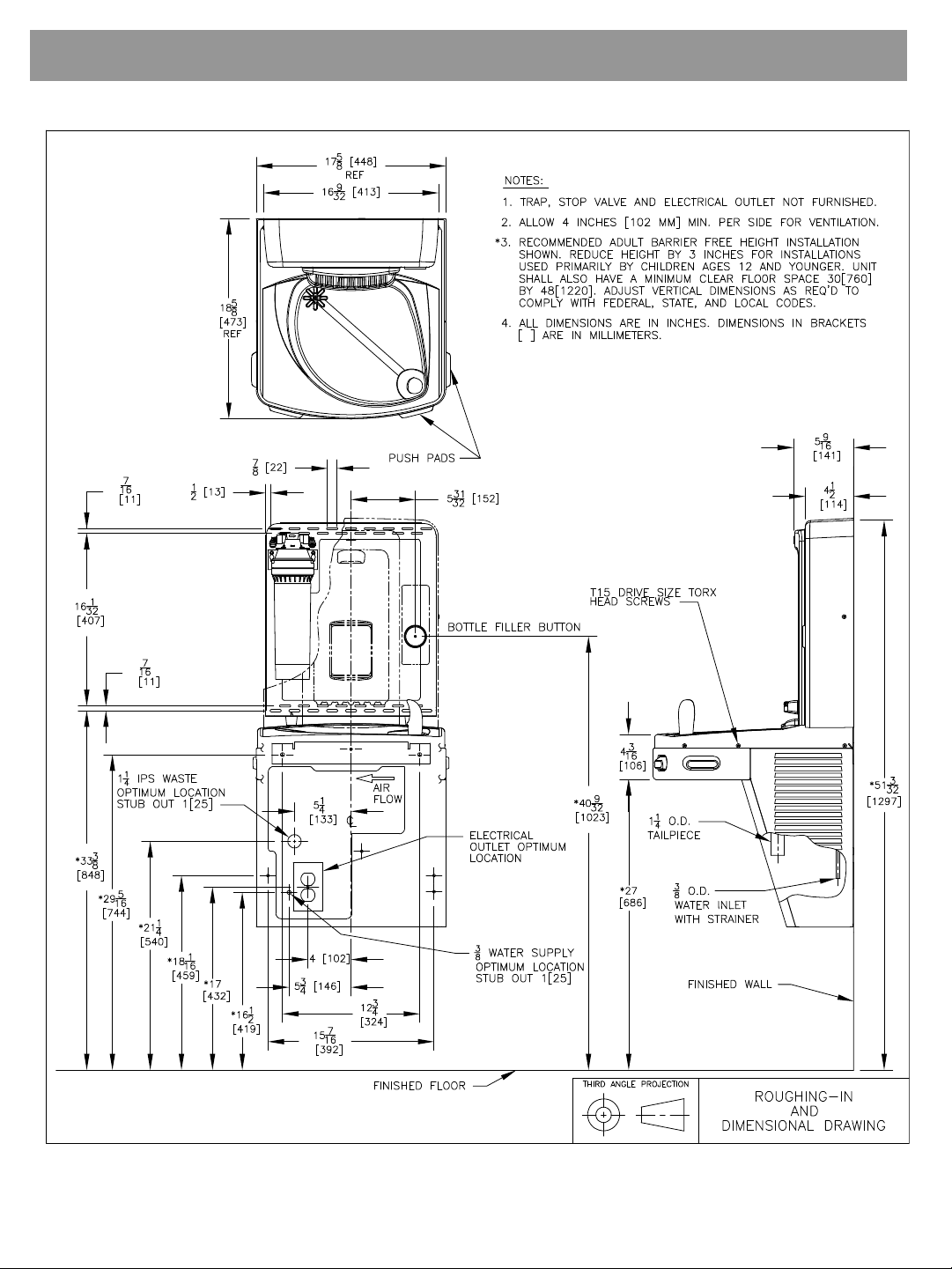

Section 2: Rough In Drawing

Oasis Versacooler® II Models PGAC, PG8AC with Bottle Filler

3

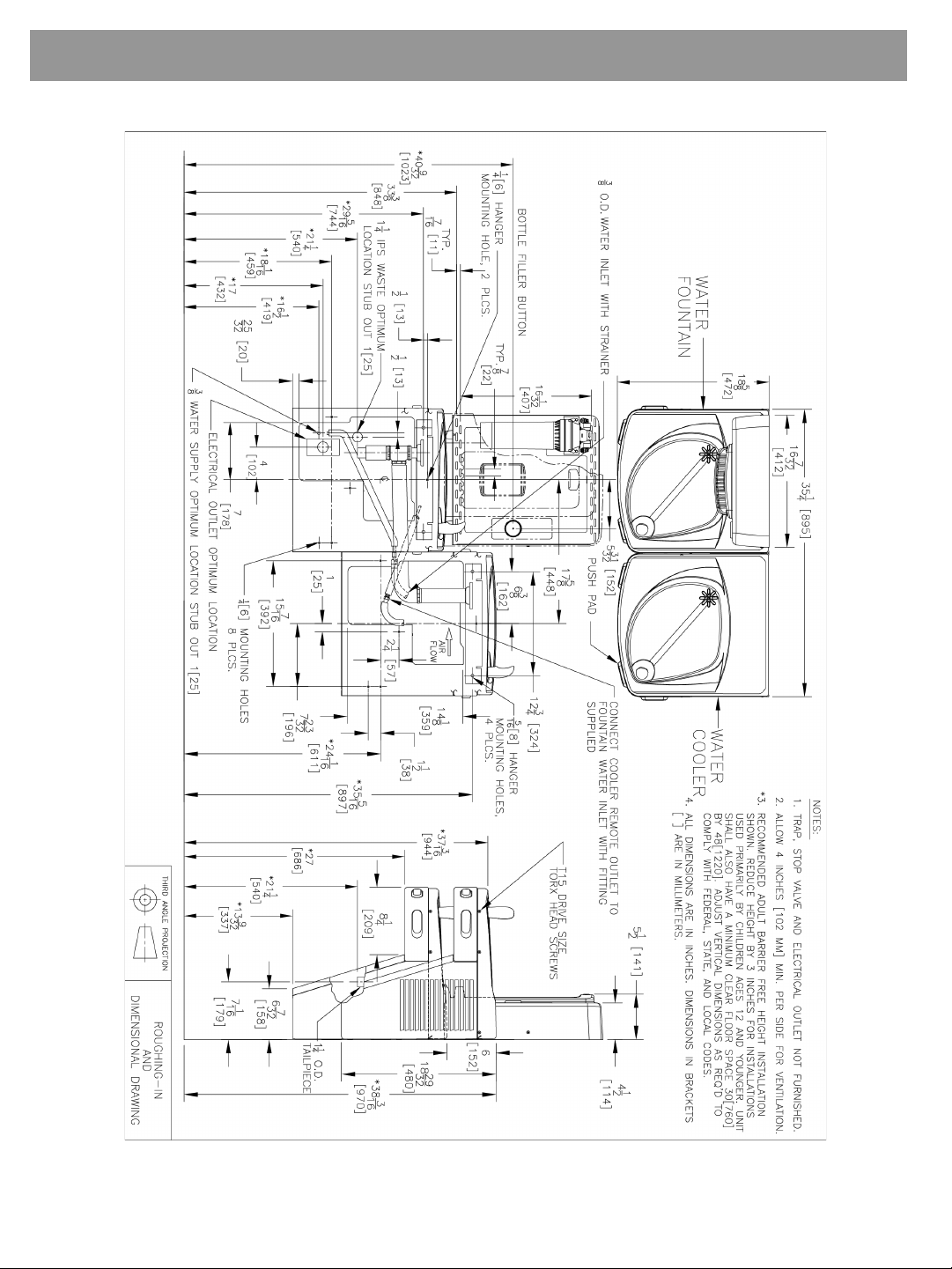

Section 2: Rough In Drawing

Oasis Versacooler® II Split Level Models with Bottle Filler

*On split level models, the Bottle Filler must be mounted on

the low unit in order to meet ADA guidelines.

4

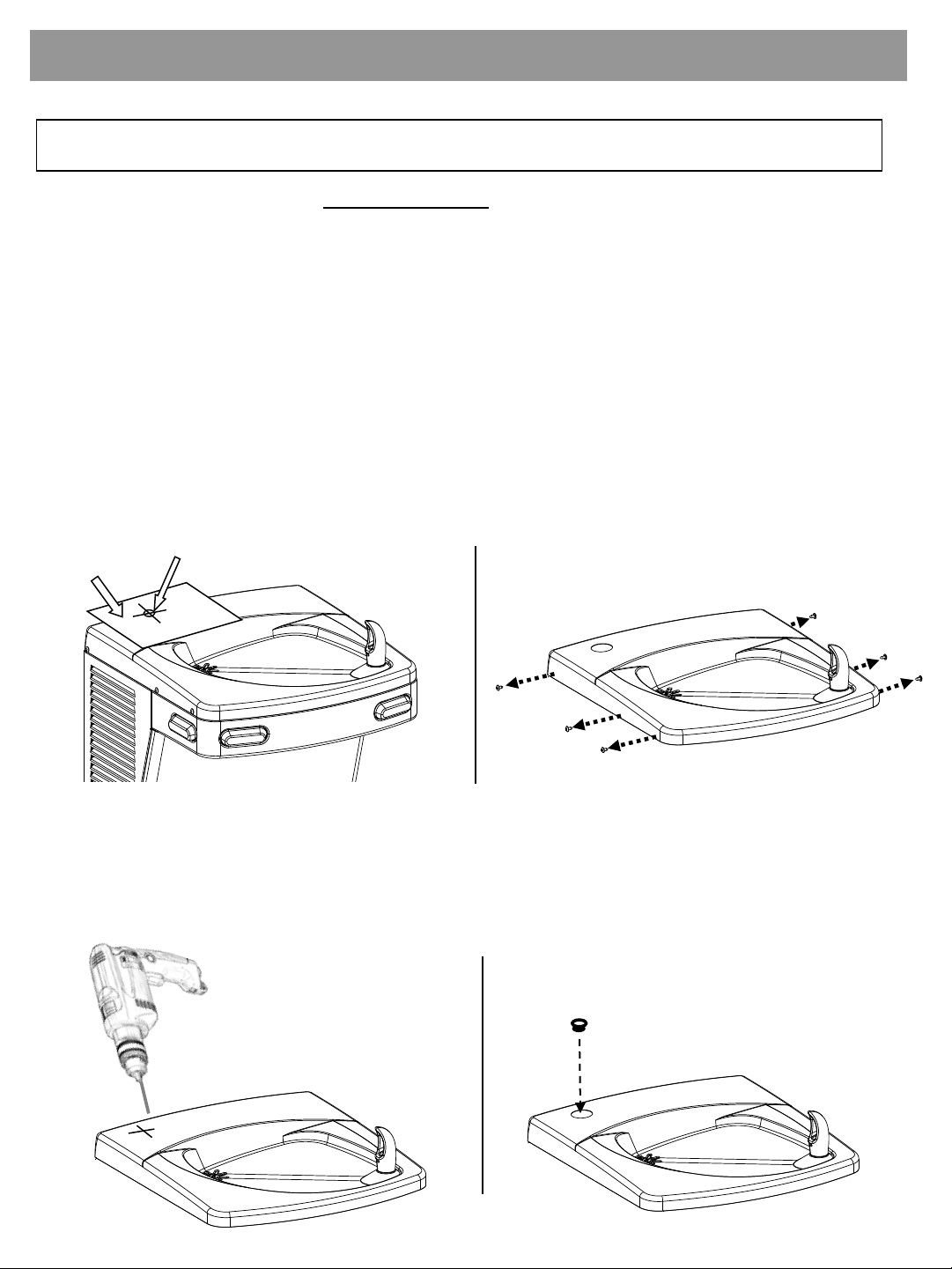

Section 3: Installation

A: Drilling Hole in the Top for Water Line Connections.

1. Disconnect power by UNPLUGGING unit. It might be necessary to

remove the front panel to get access to the power.

2. Turn OFF water supply to the unit. It might be necessary to remove the

front panel to access the water stop valve.

3. Place hole template onto cooler top so it is aligned with the left side of

unit and wall. SEE NEXT PAGE FOR TEMPLATE

4. Mark hole location

5. Remove top from unit.

Mark hole location.

Template

Remove top from cooler by

removing six, #15 torx head screws

on sides of top.

6. Using a step drill bit or 7/8” punch die, make a 7/8” hole through top. You

may want to drill a pilot hole to get these started.

7. Install snap bushing into hole to protect tubing from being cut.

Install bushing

Drill

5

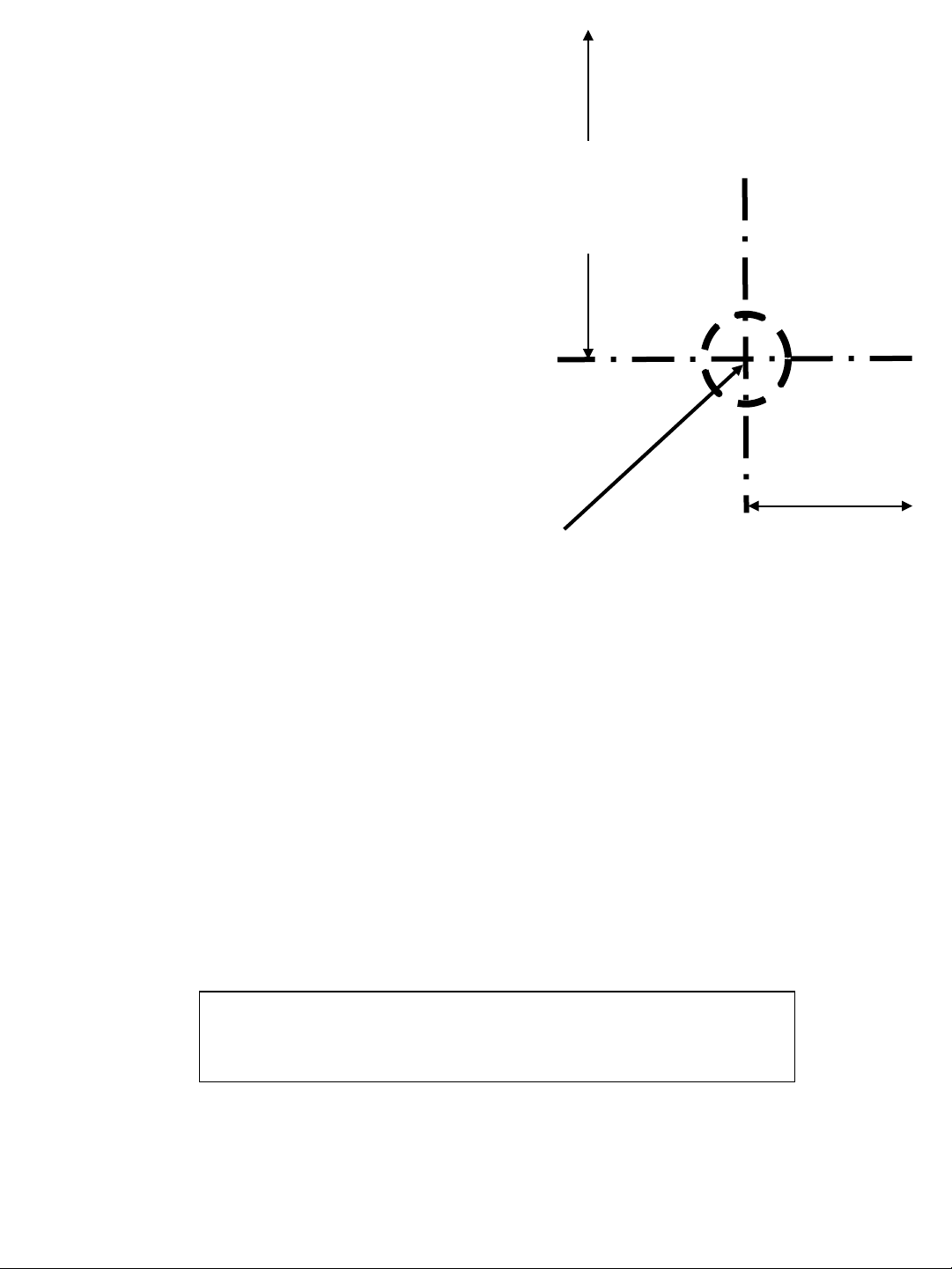

ALIGN THIS EDGE WITH LEFT EDGE OF COOLER TOP

Mark this center point on the

top. Remove the top from the

cooler. Then create a 7/8”

diameter hole through the top

3-1/4”

from

side

PLACE THIS EDGE AGAINST WALL

2-1/8”

from

back

at the marked center point

(step drill bit or punch die).

USE THIS TEMPLATE TO MARK THE

HOLE LOCATION ON COOLER TOP

6

Section 3: Installation

B: Connecting the Water Line

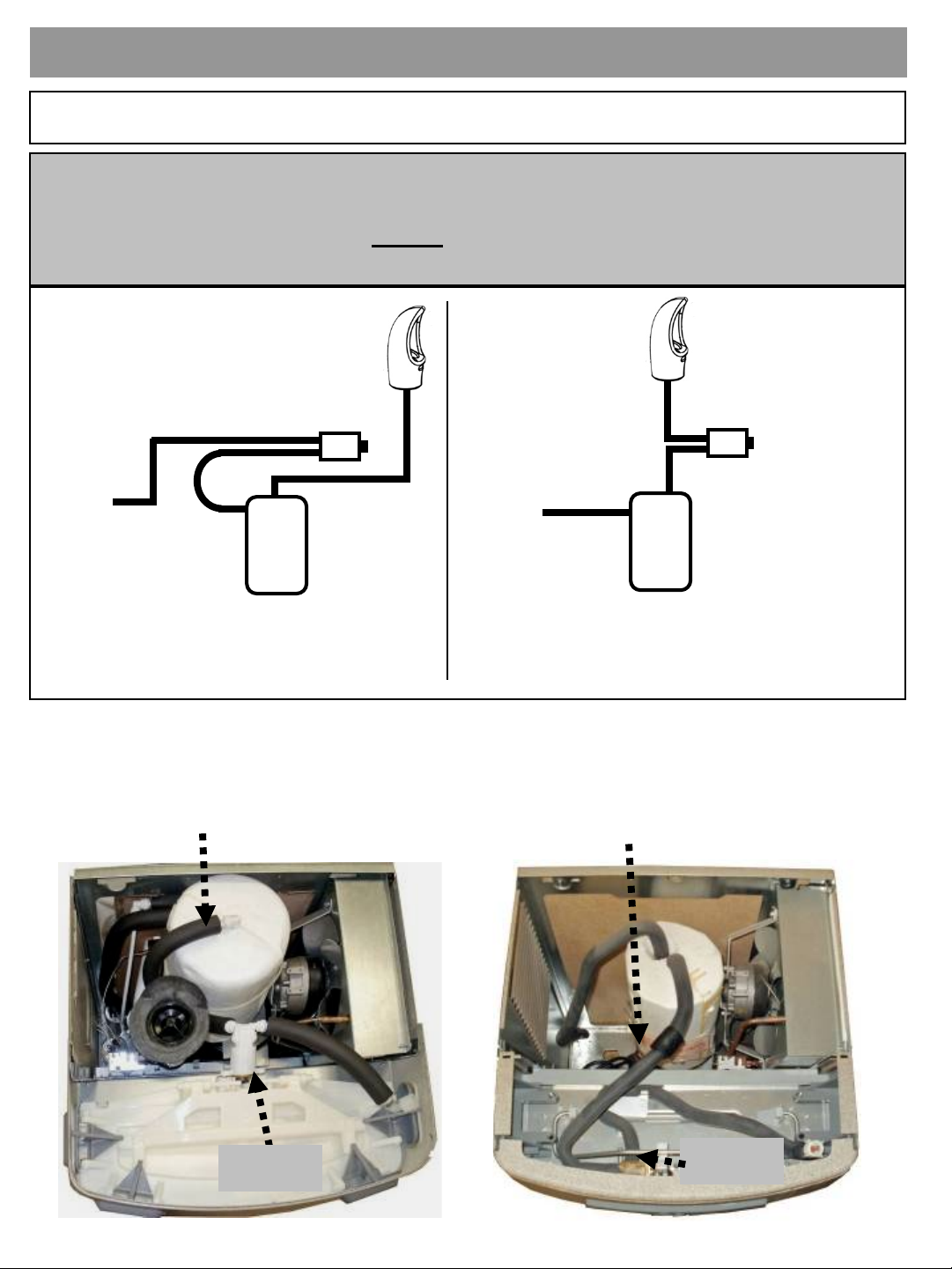

If the cooling tank is non-pressurized, then go to the “Pressurizing the

cooling tank” addendum section. Otherwise, proceed to step 1 below.

Non-pressurized units are single

Refer to the schematic below to identify the system that you have.

units made since December of 2009.

Water

valve/

regulator

tank

Supply

Water

Water

valve/

regulator

tank

Cooling

NON-

PRESSURIZED

COOLING TANK

Supply

Water

Cooling

PRESSURIZED

COOLING

TANK

1. With the cooler top removed, find the tube going from the cooling

tank outlet to the valve. The TEE fitting (supplied) will need to

connect between the cooling tank and valve.

Outlet Tube (insulated plastic)

Outlet Tube (insulated copper)

Valve

P8AC family

Valve

P8AM family

7

Section 3: Installation: For the P8AC Version: Versacooler II

2. Disconnect tubing from the

elbow on the valve.

3. Using the 38” piece

of tubing provided,

cut 6” and install it

on the end of the

TEE. Install the

remaining tubing

onto the branch of

the TEE. Connect

the other end of the

TEE to the tank

outlet tubing (tube

that was

disconnected from

the elbow).

TEE

32” tubing

6” tubing

4. Route the TEE and

tubing under the

waste drain and

connect the 6” length

to the water valve

elbow.

Go to Step 5 “Final steps for both product families:”

Water

valve

elbow

8

Section 3: Installation: For the P8AM Version: Versacooler I

2. Remove tar tape from

the insulation on the

outlet tube.

Remove tar tape

3. Pull back insulation and cut

the copper tube with a

tubing cutter. Cut where

there is at least 1 inch of

straight tubing on each side

of the cut.

4. Install TEE fitting by

connecting the copper

tubing to each end. Then

install the 32” piece of

plastic tubing to the TEE

branch.

32” plastic

tubing

(supplied)

9

Section 3: Installation: Final steps for both product families:

5. Feed tubing up through the top and attach the

top to the cooler.

To activation cartridge inlet.

TIP: For the P8AM, it is easier to

connect the outlet tube to the bubbler if

the front nose is removed.

10

Section 3: Installation

C: Mounting the frame to the wall

1. Set the wall frame onto the top. Center it left/right and push it against the

wall and mark hole locations for wall fasteners. The rubber feet will set the

frame at the proper height.

Use mounting slots that will

provide the proper securing

Make sure to pull

the plastic tubing

up through the hole

in the frame.

location.

2. Secure frame to the wall with fasteners (not provided). Pull plastic

tubing up through the hole in the frame.

11

Section 3: Installation

D: Bottle Filler Plumbing Connections

3.1. Install water line tubing as shown below.

ATTENTION: Shut off water and relieve water pressure through bubbler.

Supply water line In

Filtered water out

to cold tank

48” (trim excess)

Cold water out with

sponge tubing to

activation cartridge

inlet.

38”

Activation

Cartridge

Cold water out

of cooling tank.

Cut cold water out

tubing and insert tee

fitting before valve

cartridge holder inlet.

(Tee was installed per

Section 3B:

Connecting the water

line)

Front view of

cooler & bottle

filler.

12

Section 3: Installation

3.2. Install water line tubing as shown below.

ATTENTION: Shut off water and relieve water pressure through bubbler.

Filtered water out to cold tank

48” (trim excess)

Supply water

line In

Cold water out with

sponge tubing to

activation cartridge

inlet.

38”

Activation

Cartridge

Cold water out

(existing)

Cut cold water out tubing and

insert tee fitting before valve

cartridge holder inlet. (Tee

was installed per Section 3B:

Connecting the water line)

Front view of

cooler & bottle

filler.

13

Section 3: Installation

E: Attaching the Tether

4. Install bottle filler tether with the steps below.

Attach the tether line assembled to the bottle

filler dispense bracket to the cleat on the

mounting frame.

1.

Push loop through hole.

3.

2.

Put loop around one side

of the cleat.

4.

Pull loop around other

side of the cleat.

Pull tight.

14

Section 3: Installation

The tether keeps the bottle filler secured to the frame when changing the

filter. Make sure the tether is installed properly to avoid accidental

damage to the unit.

15

Section 3: Installation

F: Attaching Bottle Filler to Frame

5. Set the Bottle Filler cabinet into place.

6. Attach Bottle Filler assembly to the frame using the two (2) torx screws.

Torx screw

Torx screw

16

Section 3: Installation

G: Installation Completion

7. Turn ON water supply and check for leaks. Press the activation button

and release any trapped air from the system. Plug in the power cord and

replace the front panel IF it was removed earlier. Flush out filter as

directed on the filter cartridge label.

Press

INSTALLATION COMPLETE

17

Addendum Section: Pressurizing Cooling Tank

The water should

already be turned OFF

and the power

disconnected.

Unit as it appears with top

removed

STEP 1

Unplug un-insulated water

line from water valve inlet

(JG elbow located left side

of water valve facing the

front of the cooler). Set

tubing aside (careful to not

contaminate water contact

end).

STEP 2

Unplug tubing from JG

elbow leading to

cooling tank inlet.

18

STEP 3

Plug un-insulated tubing that

was removed in step 1 into

JG elbow leading to the

cooling tank from step 2.

STEP 4

Unplug tubing that is

connected to the

water valve outlet (JG

elbow located on the

right side of valve

facing the cooler).

STEP 5

Connect tubing

from step 4 to JG

elbow on the left

side of the valve.

19

Step 6

Unplug JG tubing

from the cooling

tank outlet. Do

not set it down.

Step 7

Using tubing

removed in step 6,

plug into JG elbow

on the right side of

the valve. (be sure

to rout the tubing

under existing

tubing installed in

step 4 as shown)

Step 8

Using tubing that is

connected to the JG

elbow left side of

valve (done in step

4), and plug the

other end to the JG

fitting at the top of

the cooling tank.

20

Return to Section 3 B

“Connecting the water line”

EXPLODED PARTS

ITEM QTY P/N Description ITEM QTY P/N Description

1 1 041080-001 CABINET, K12 BF 20 2 029994-103 FTG, PP ELBOW, PLUG IN

2 1 036790-001 BADGE, OASIS SMALL OVAL 21 4 026630-022 SCREW, PAN HD TAPPING #10

3 1 038031-009 LABEL, CABINET BUTTON 22 1 041072-001 FILTER HEAD, VERSAFILTER II

4 2 026642-023 SCREW, HEX HD TAPPING #8 23 2 026642-004 SCREW, HEX HD TAPPING #8

5 1 038031-010 LABEL, ALCOVE SBF K12 24 1 041073-001 BRKT, VERSAFILTER II

6 2 031875-003 SCREW, TRUSS HD TAPPING TORX 25 1 041071-001 FILTER, VERSAFILTER II

7 1 038636-001 PUSH BUTTON, AMC 26 2 041079-001 FOOT, RUBBER

8 1 038678-001 PLUG, BUTTON 27 2 026630-076 SCREW, PAN HD TAPPING #8

9 1 035990-001 HOLDER, CARTRIDGE STEM CON 28 38" 029959-006 TUBING, PE 1/4 OD WHITE

10 1 A020957 NUT, RETAINING PLASTIC 29 48" 029959-006 TUBING, PE 1/4 OD WHITE

11 1 029967-005 CARTRIDGE, 4.25# SPRNG 30 1 041076-001 BRKT, DISPENSE NOZZLE

12 2 026670-008 SCREW, HEX HD MACHINE #10 31 1 032459P008 LANYARD, BOTTLE FILLER

13 1 041075-001 BRKT, CARTRIDGE VALVE 32 2 031875-003 SCREW, TRUSS HD TAPPING TORX

14 11'' 028476-001 INSULATION, SPONGE TUBING 33 1 038032-001 FLOW NOZZLE ASSY

15 12" 029959-006 TUBING, PE 1/4 OD WHITE 34 1 038029-001 ADAPTER, FLOW NOZZLE

16 2 028481-101 FTG, PP UNION ELBOW WHT 35 1 028482-001 FTG, JG REDUC IN G ELBOW

17 38" 029959-006 TUBING, PE 1/4 OD WHITE 36 2 026642-003 SCREW, HEX HD TAPPING #8

18 14" 028476-001 INSULATION, SPONGE TUBING 37 1 027189-008 BUSHING, SNAP 7/8"

19 1 036687-003 FRAME, PWFSBF-K12 38 1 029199-103 FTG, PP UNION TEE WHITE

BREAKDOWN

P/N 030099-596 Date: 3/2019

© 2019 LVD Acquisition, LLC

Oasis, Versacooler are registered trademarks of LVD Acquisition, LLC.

Oasis International

222 East Campus View Blvd.

Columbus, OH 43235

614-861-1350

www.oasiscoolers.com

21

Loading...

Loading...