UM10741

Fm+ development kit OM13320

Rev. 1 — 1 April 2014 User manual

Document information

Info Content

Keywords I2C-bus, Fm+, development tool, PCA9672, PCA9955

Abstract User manual for the Fm+ development board (OM13260) kit (OM13320).

NXP Semiconductors

UM10741

Fm+ development kit OM13320

Revision history

Rev Date Description

1.0 20140401 User manual; initial release

Contact information

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 2 of 61

NXP Semiconductors

1. Introduction

UM10741

Fm+ development kit OM13320

The Fm+ Development Kit (OM13320) is intended for several different tasks: from a

hands-on introduction, understanding, and use of the I

bus), to I

shows and sales pitches).

The kit has a core Printed-Circuit Board (PCB) assembly, and three add-on PCBs. Other

PCBs are available for advanced use or to support newly-released I

as they are introduced to the market.

The Fm+ Development Kit (OM13320) is supported by a Graphics User Interface (GUI)

software program that runs on a Pe rsonal Com pute r ( PC) u nder the Microso ft Windows 7

Operation System. In some uses the GUI is not required, and the Fm+ Development Kit

(OM13320) can be run as a standalone demonstration, requiring only an external power

adapter (not included).

2. Key features

I2C-bus masters

2

2

C device evaluation, and as a simple product demonstration platfo rm (for trade

Self-contained PCB with two independent I

2

Bus 1: On-card I

C MCU master (NXP LPC1343)

2

C buses

C-bus (Inter-Integrated Circuit

2

C-bus components

Bus 2: NXP LPC Xpresso MCU module (not included), and NXP PCA9665 bus

controller

USB interface to on-card MCU (for connection to a PC running the GUI software)

2

C-bus slaves

I

General Purpose Input/Output (GPIO): PCA9672 (one each on Bus1 and Bus2)

LED driver, with 16 constant current outputs: PCA9955 (with four RGB and four White

LEDs on Bus1)

Accessory sockets

Connectors for up to four daughter cards, each providing power, Bus1 and Bus2 I

2

signals

Connector for the Bus Buffer Board OM13398 (supplied) containing two PCA9617A bus

buffers

2

Connector for a third-party I

C-bus logger or I2C-bus controller (Beagle and Aardvark,

from Total Phase)

2

C buses

I

2

C-bus voltage: jumper select 5 V (external) or 3.3 V (on-card 3.3 V regulator)

I

2

C-bus pull-up resistors: jumper select of ‘high’, ‘med’ or ‘low’ loading

I

C

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 3 of 61

NXP Semiconductors

Other features

SPI ports: One for on-card MCU, two more for LPC Xpresso

Serial Com Port: EIA232 with voltage level shifter and con nection to the LPC Xpresso

LED blinker: NXP PCA9901 one-wire with on-card LED

INT (Interrupt) and RST (Reset) Bus signal monitor LEDs (buffered)

Logic probe: Utility LEDs (buffered) to monitor signals by user jumper wire connection

External DC input (6 V DC maximum)

Prototype area: Uncommitted 8 × 8 100 mil pitch tie points for end user component

attachment

Test points and ground: for probe attachment to major signals

2

Connection of both I

C buses together (supplied 2-wire jumper)

3. Fm+ development kit quick tour

3.1 Kit contents

UM10741

Fm+ development kit OM13320

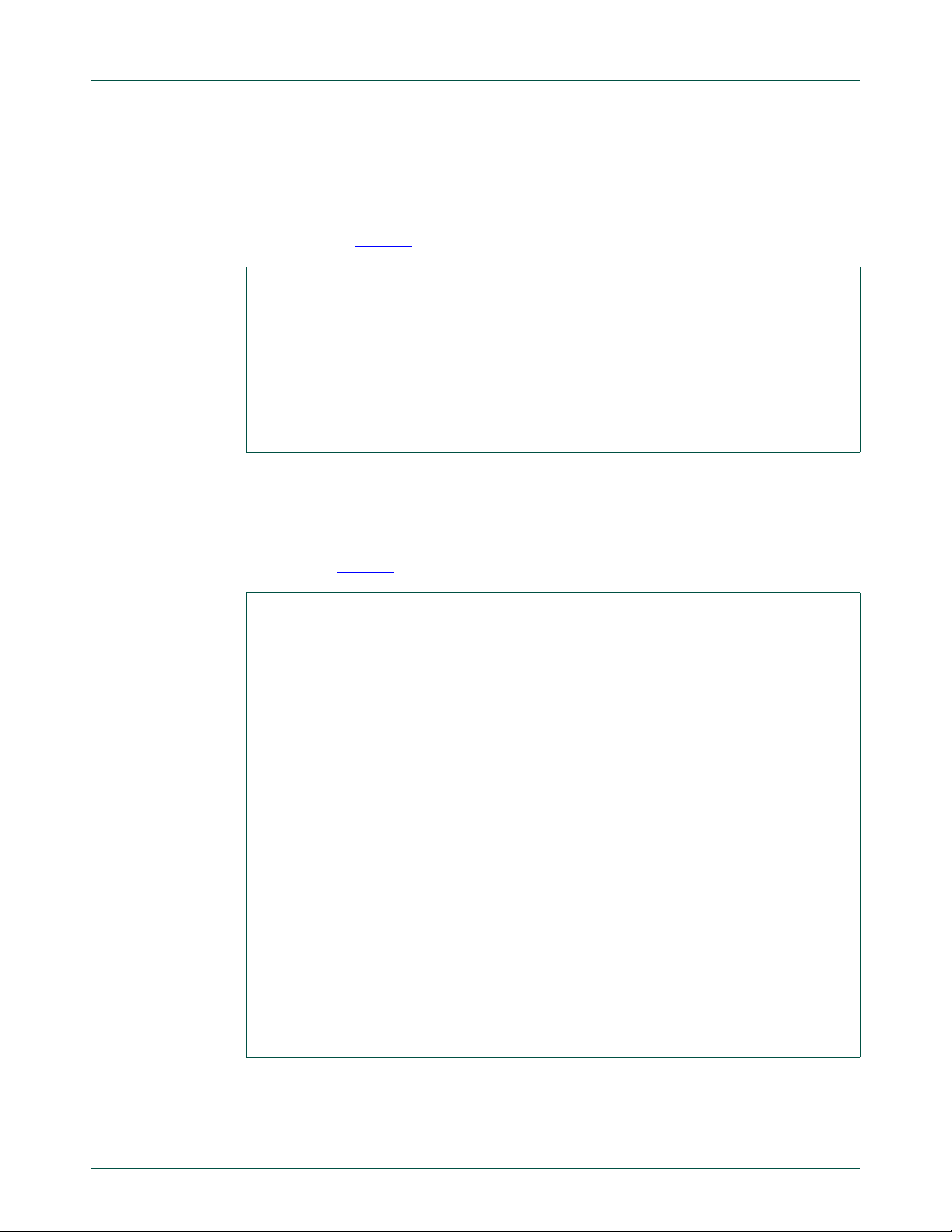

Before using the kit for the first time, please familiarize yourself with the various

components listed in Table 1

. See Figure 1.

Remark: Each PCB assembly is shipped in an anti-static bag. After the first use, these

may be discarded to simplify future storage.

a. Top layer b. Bottom layer

Fig 1. Fm+ development kit

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 4 of 61

NXP Semiconductors

Table 1. Fm+ development kit contents

Components

Fm+ development board (OM13260)

GPIO target board (OM13303)

PCA9617A bus buffer demo board (OM13398)

Bridge board (OM13399)

Cable, USB Type A to Type B

Ribbon cable, 10 position (bag of two)

Jumper wires with female terminals (bag of ten)

Shorting jumpers (bag of twenty)

Hardware (bag of M3 screws and standoffs)

3.1.1 Box contents

The Fm+ Development Kit (OM13320) contains four PCB assemblies, cables, and loose

hardware. These should be retained in the box for future access. Depending upon the

desired use, some of the PCB assemblies may be attached to each other, either by plug

connection or by ‘stacking’ the GPIO PCB assemblies above the Fm+ Development

Board (OM13260), using the supplied ribbon cables and hardware.

UM10741

Fm+ development kit OM13320

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 5 of 61

NXP Semiconductors

3.2 Supplied PCB assemblies

There are four PCB assemblies in the kit. Each has a spe cific function an d n ot all of th em

are used at the same time.

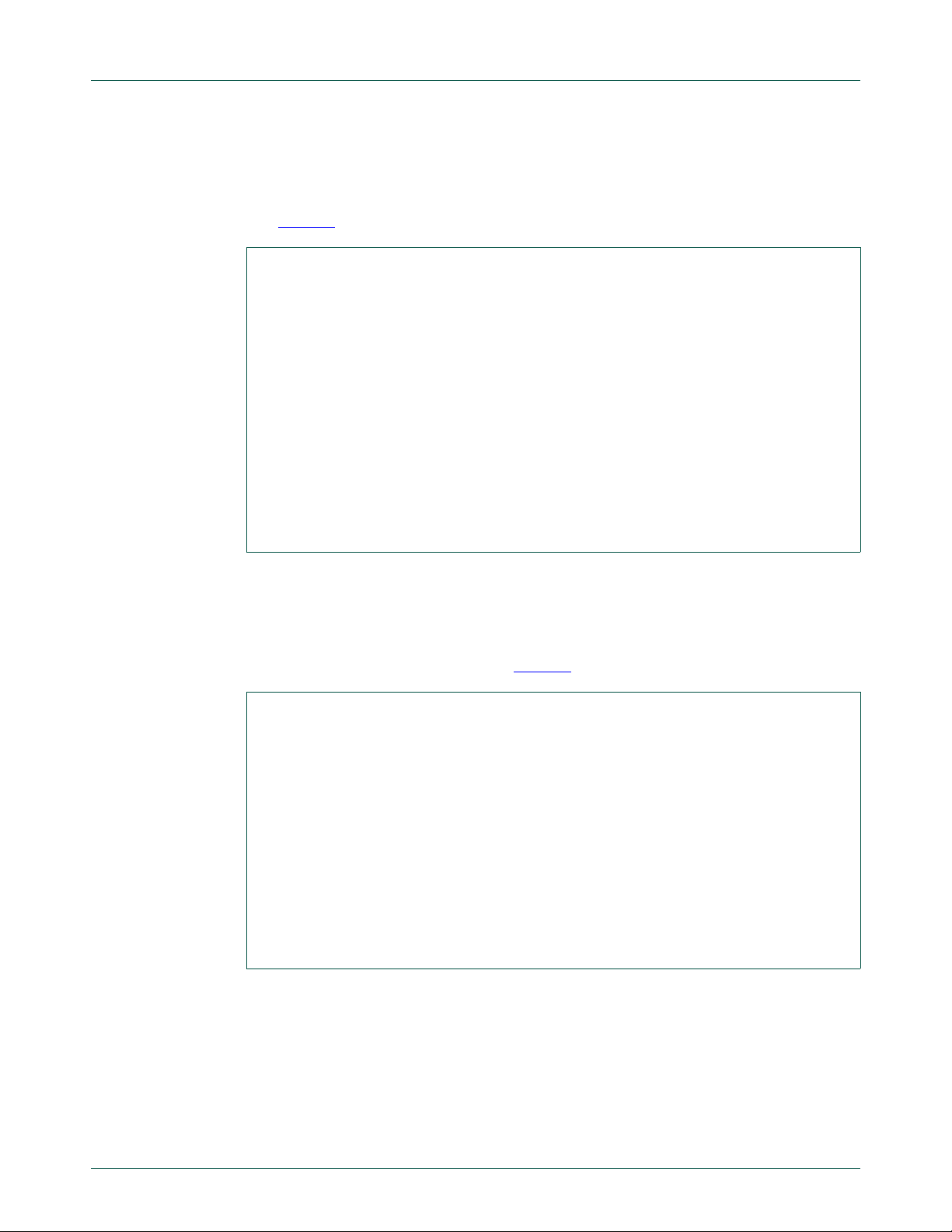

3.2.1 Fm+ Development Board (OM13260)

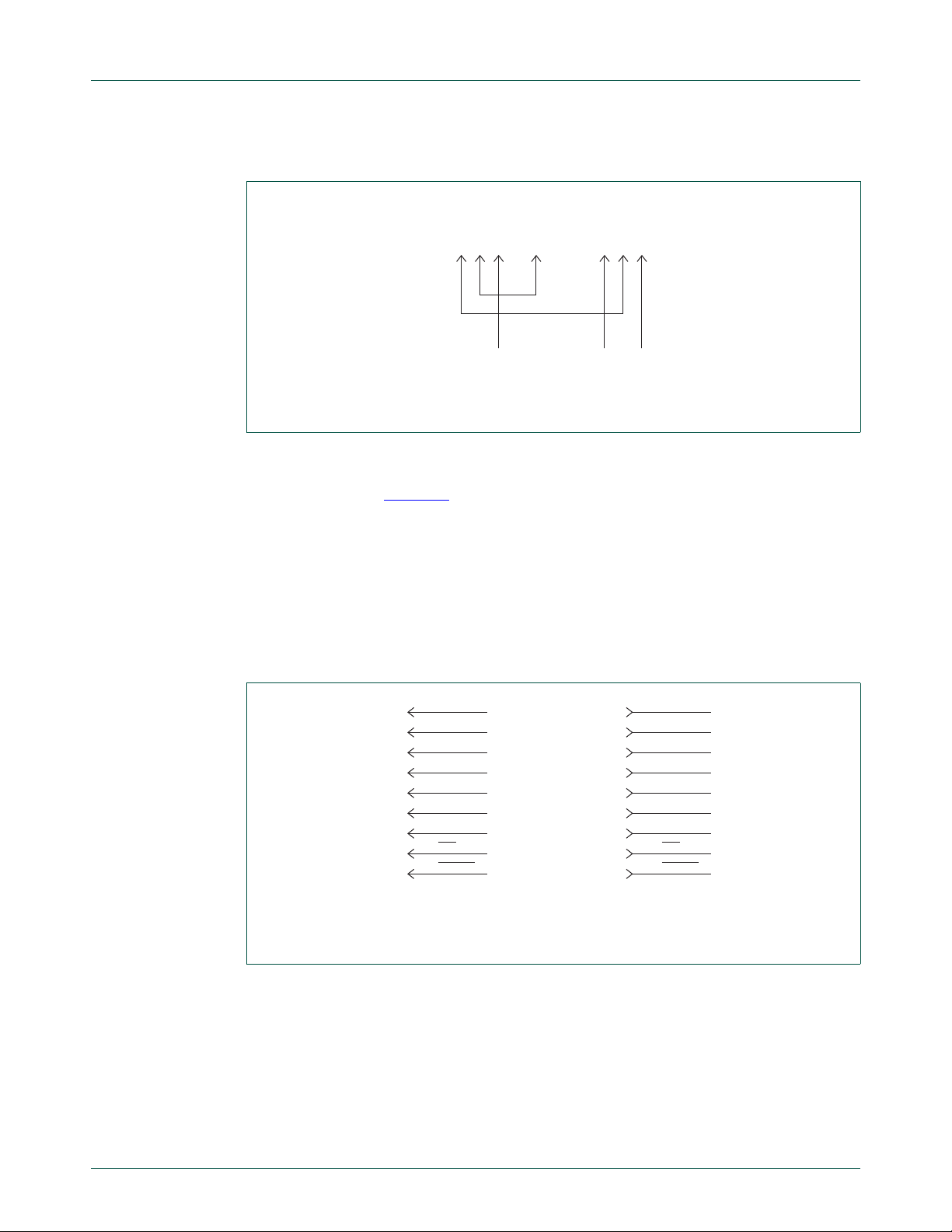

The large PCB, Figure 2, contains two separate I2C-bus structures, together with

supporting circuitry . Each bus has a bus master, one or more bus slaves, and user options

to change the bus voltage and bus pull-up resistors. Adjusting these changes the

operation of the buses to suit various goals. In addition, the two buses may be linked

together to operate a one I

(supplied) or the Bus Buffer Board OM133998 (supplied). See figure 3.5. Four identical

ports provide access for add-on boards that cont ain additional I

UM10741

Fm+ development kit OM13320

2

C-bus structure. This can be done with a two-wire jumper

2

C-bus devices.

Fig 2. OM13260 Fm+ development board PCB assembly

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 6 of 61

NXP Semiconductors

3.2.2 GPIO target board (OM13303)

Outputs from the GPIO devices on the Fm+ Development Board (OM13260), and those

when using GPIO daughter cards (not supplied in the kit), require the GPIO Target Board

(OM13303). Each one has eight channels of LED indicator and push-button switches for

user input. See Figure 3

Fig 3. OM13303 GPIO target board PCB assembly

3.2.3 PCA9617A bus buffer demo board (OM13398)

Bus buffers bridge two I2C-bus segments, which are provided on the Fm+ Development

Board (OM13260) by Bus1 and Bus2. Bus buffer daughter ca rd s, such as th e PCA9 617 A

Bus Buffer Demo Board (OM13398) (supplied in the kit) can be installed directly on Port E

(CN12). See Figure 4

UM10741

Fm+ development kit OM13320

.

.

Fig 4. OM13260 bus buffer PCB assembly

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 7 of 61

NXP Semiconductors

3.2.4 Bridge board (OM13398)

Some existing Demo Boards used a single row connector with nine pins. To use these

with the Fm+ Development Kit requires the Bridge Board (OM13399, supplied in the kit).

See Figure 5

UM10741

Fm+ development kit OM13320

.

Fig 5. OM13399 bridge board PCB assembly

3.2.5 Daughter cards (not supplied in the kit)

These are not in the OM13230 kit, and should be obtained separately. Daughter cards

hedge against obsolescence so that the Fm+ Development Kit (OM13320) can be used

with future devices by adding newly released daughter cards as they become available.

An example daughter card is shown in Figure 6

Fig 6. Example daughter card PCB assembly

.

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 8 of 61

NXP Semiconductors

Fm+ development kit OM13320

4. First time setup: Fm+ development board kit (OM13320)

4.1 Before you begin

To use the Fm+ Development Kit (OM13320) for the first time requires some hardware

setup and installation of both firmware (on the Fm+ Developmen t Board OM13260) and

software on the attached computer.

The following three steps must be completed:

UM10741

1. Install Jumpers on the Fm+ Development Board (OM13260) (see Section 4.3

2. Install Firmware on the Fm+ Development Board (OM13260) (see Section 4 .6

3. Install the NXP GUI Software on the computer to be used with the kit

(see Section 4.7

).

4.2 First time setup of the Fm+ development board (OM13260)

Several jumpers must be installed before using the Fm+ Develop ment Board (OM13260)

PCB. The on-board microcontroller (MCU) must contain the appropriate firmware.

To install the firmware requires the connection to a Personal Computer (PC) running

Microsoft Windows 7/64 Operating System and a USB port.

4.3 OM132680 jumpers

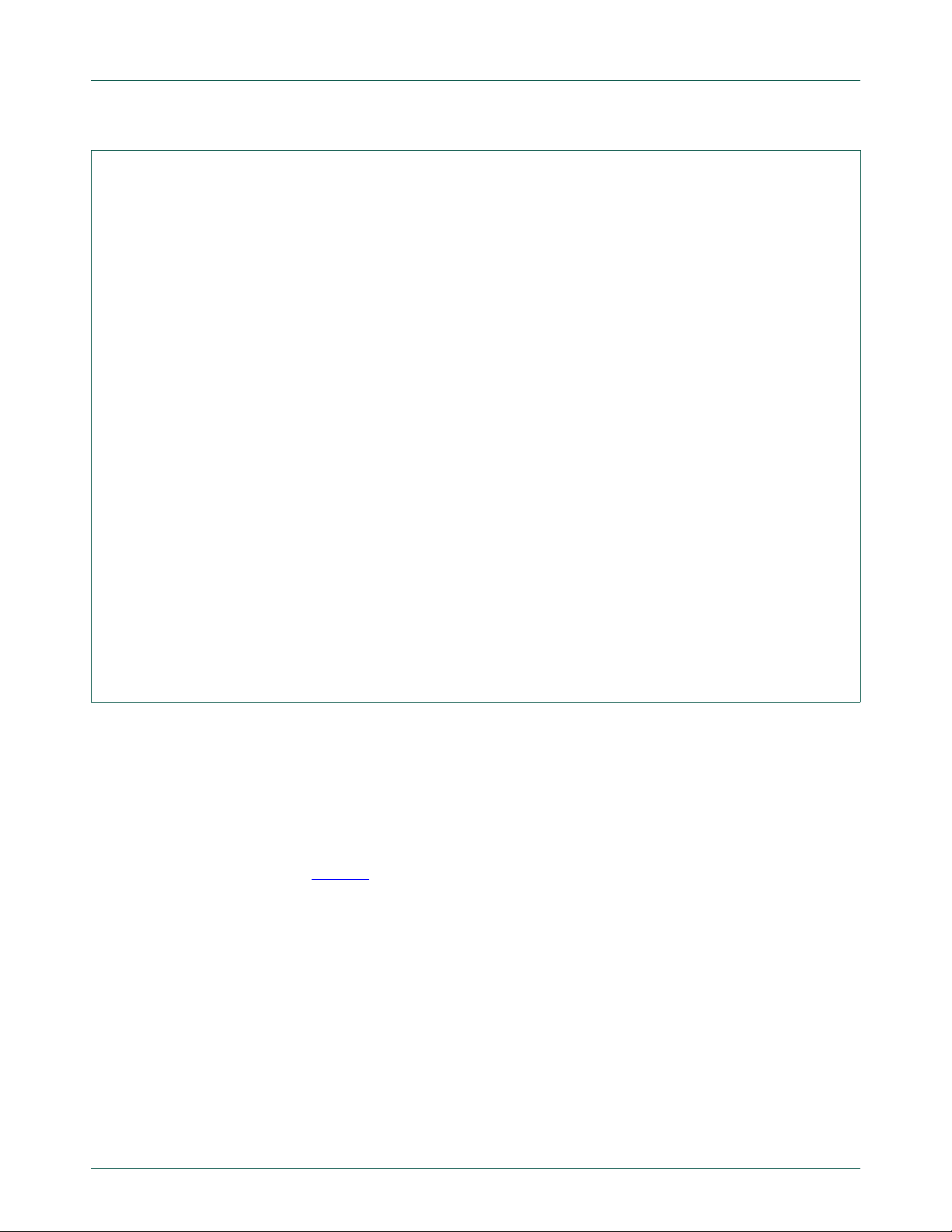

The jumpers and their function are shown in Table 2. Using Figure 7 and the table data,

install the jumpers.

Table 2. OM13260 jumpers

Jumper Label Function First time

JP1 XPRESSO POWER Close

JP2 HDD Open

JP3 CONNECT Close

JP4 RST Open

JP5 PCA9955 address GND

JP6 ISP Open

JP7 SPI SEL 1

JP10 PCA9672 address GND

JP11 SDA1 pull-up A

JP12 SCL1 pull-up A

JP13 Bus1 bus voltage 3V3

JP20 PCA9672 address GND

JP21 SDA2 pull-up A

JP22 SCL2 pull-up A

JP23 Bus2 bus voltage 3V3

).

).

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 9 of 61

NXP Semiconductors

UM10741

Fm+ development kit OM13320

Fig 7. OM13260 test point locations

4.4 OM13260 Port E bypass

Depending up the intended operation of the Fm+ Development Board (OM1326 0),

Port E (CN12) should be left open, or linked with a jumper wire, or for the attachm ent of a

Bus Buffer Board. The PCA9617A Bus Buf fer Demo Board (OM13398) is supplied in the

kit.

For the purpose of this quick setup section, install the two-wire jumper (supplied) as

shown in Figure 8

Remark: The two-wire jumper requires a twist, as shown. The diagonally opposite pins

are linked.

.

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 10 of 61

NXP Semiconductors

Fig 8. OM13260 Port E jumper

4.5 OM13260 mounting hardware

To prevent damage to the table surface, it is recommended that met a l hardware (supplied

in the kit) is installed in the four mounting holes. This raises the PCB assembly about

6mm. See Figure 9

UM10741

Fm+ development kit OM13320

.

Fig 9. OM13260 mounting hardware

Remark: Save the completed Fm+ Development Board, now install the NXP USB Driver.

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 11 of 61

NXP Semiconductors

4.6 NXP firmware installation

The micro on the Fm+ Development Board needs firmware running on it to interface with

the GUI running on a Windows 7 PC over USB. The board is shipped with a blank

microprocessor, so user action is necessary for proper operation.

UM10741

Fm+ development kit OM13320

An installation user manual UM10785 (Ref. 1

the process. A quick overview is presented here.

1. Download NXP_Fm+_Eval_Board_V1_0_firmware.zip from

www.nxp.com/demoboard/OM13320.html#documentation

2. Connect a USB cable from the PC USB port to CN5.

3. Install the Connect (JP3) jumper to connect the USB communications.

4. Install the ISP (JP6) jumper to put the MCU into In-System Programming mode.

5. Install and then remove RST (JP4) jumper to reset the MCU.

6. The MCU will enumerate on the PC as a disk drive called CRP_DISABLD.

7. Delete the file on the MCU (size may vary — up to 32 kB).

8. Copy the new firmware file NXP_Fm_Eval_Board_V1_0.bin, extracted from the

zip file to the MCU.

9. Remove the ISP (JP6) jumper.

10. Install and then remove RST (JP4) jumper to reset the MCU.

) is available at for a complete explanation of

4.7 NXP GUI installat ion

A Graphical User Interface (GUI) is provided which allows easy manipulation of the

devices included on the Fm+ Development Board and ma ny others that can be connected

to the board via daughter cards.

An installation user manual UM10785 (Ref. 1

the process. A quick overview is presented here.

1. Download NXP_Fm_Board_V1_0_Installation.zip from

www.nxp.com/demoboard/OM13320.html#documentation

2. Extract NXP Fm+ Board V1.0 Installation.exe and run.

3. Follow the instruction prompts. Select the default answers.

This GUI uses a USB Human Interface Driver (HID), so no driver installation is required.

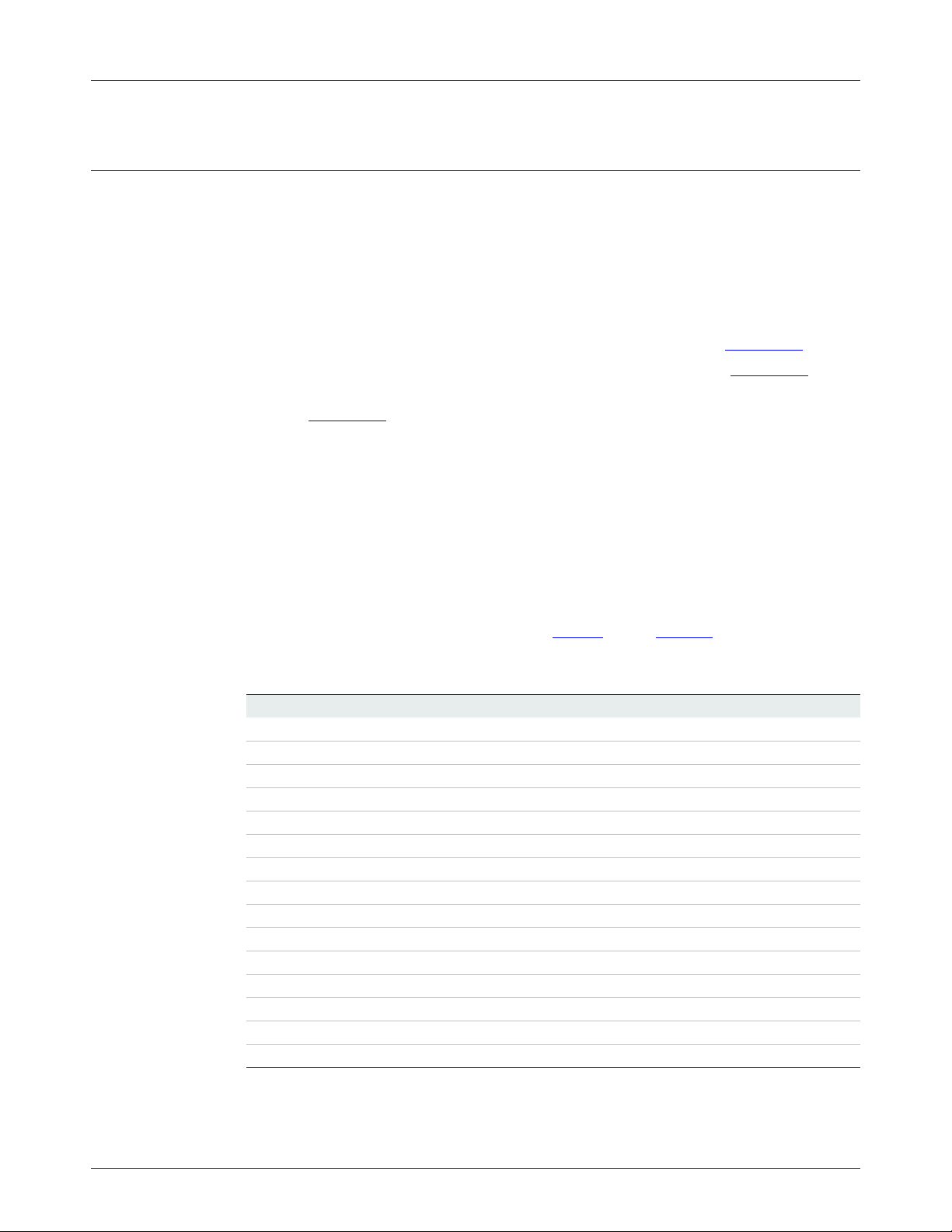

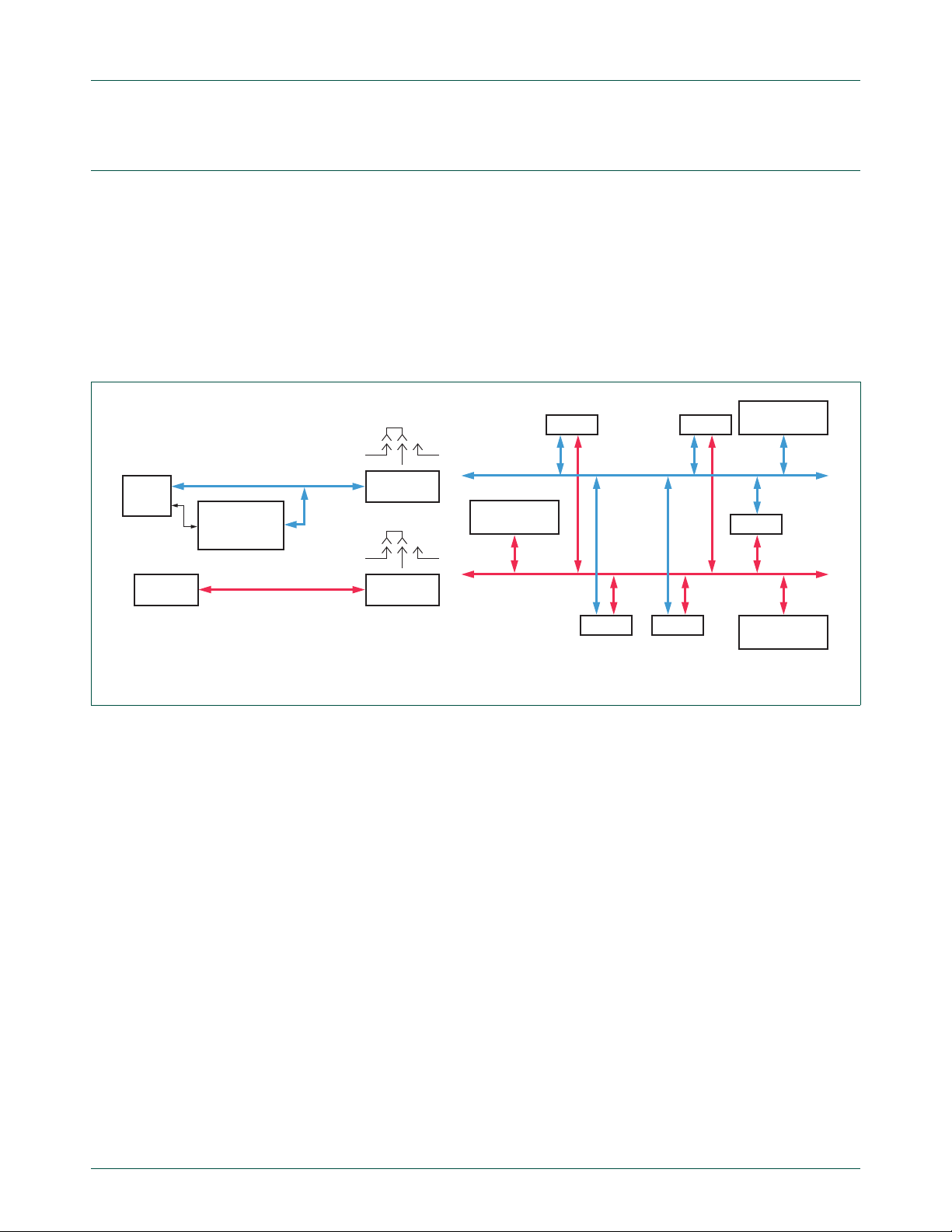

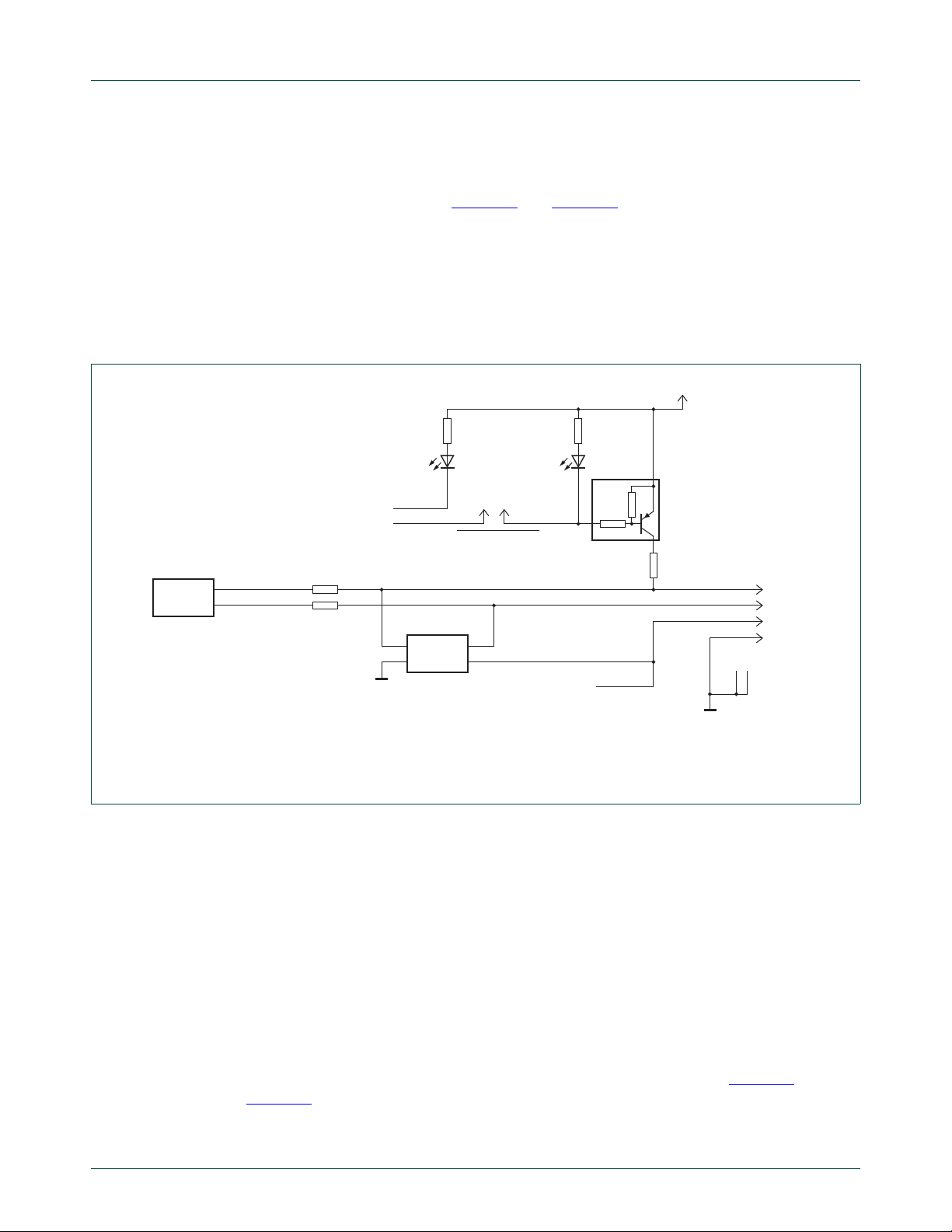

If the firmware and GUI installs are successful, an Fm+ Development Board block

diagram is displayed when the GUI executes (Figure 10

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 12 of 61

) is available for a complete explanation of

).

NXP Semiconductors

aaa-012039

PCA9672

8-channel GPIO

Port B

Port E

Port A

PCA9672

8-channel GPIO

I2C-bus 1

I

2

C-bus 2

5 V

5 V

Port C

Port D

PCA9955

16-channel LED

3.3 V

PULL-UP

RESISTORS

3.3 V

PULL-UP

RESISTORS

I2C-bus 1

PCA9665

BUS

CONTROLLER

LPC1343

MCU

I

2

C-bus 2

parallel port

LPC

XPresso

5. Fm+ development board (OM13260)

The Fm+ Development Board (OM13260) PCB assembly is self- contained, requiring only

DC power to operate. Depending upon the firmware installed on the Fm+ Development

Board (OM13260), it can also operate with a connected Personal Computer (PC) via a

USB cable.

The modular design of the kit and this board in par ticular allows accessory boards to be

easily connected.

5.1 Theory of operation

UM10741

Fm+ development kit OM13320

Fig 10. Fm+ development board bus structure

An I2C-bus requires a Master and one or more Slaves. The two bus signals, clock SCL

and data SDA, are wired-OR and require pull-ups to a DC power supply. Two similar but

separate I

2

C buses each support one Master and at least one Slave device on the bo ard .

The two buses may be linked by either a Bus Buffer Board (OM13398 supplied in the kit)

or a wire jumper, at the Port E connector (CN12).

The signals from both buses are available simultaneously at each of four connectors,

Port A through Port D (CN1 through CN4, respectively). These are intended for

2

attachment of accessory daughter cards, which will be made available as future I

C-bus

devices are released.

The size of the pull-up resistors can be changed by moving shorting jumpers (JP1, JP2,

JP1 1, and JP12), providing selection of ‘Low’ ‘Med’ and ‘High’ resistor values scaled to the

2

C-bus drive strength. When both buses are joine d by a jump er wire, the pull- ups

Fm+ I

are effectively in parallel, and have one-half the stated resistance values.

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 13 of 61

Operating voltage of the I

that select either 3.3 V or 5 V connected to the pull-up resistors. Compliant I

devices can tolerate 5.5 V (maximum), regardless of the device operating voltage.

2

C-bus depends upon the shorting jumpers (JP13 and JP23)

2

C-bus

NXP Semiconductors

Each bus has a GPIO 8-bit Slave device (PCA9672, IC10 an d IC2 0), an d Bus 1 also has

an LED Driver 16-channel device (PCA9955, IC6). All sixteen outputs are connected to

LEDs, for visual indication. The 8-bit GPIOs require connection of GPIO Target Boards

(OM13303, supplied in the kit) to both indicate the output using eight LEDs and a llow user

input from eight push switches.

An NXP LPC1343 Microcontroller (MCU) serves as both the Bus 1 Master, and the USB

link. The firmware on the MCU can be replaced by the In-System Programming (ISP)

mode, with data sent over the USB link (CN5).

Bus 2 has a Parallel to I

an optional NXP LPC Xpresso module (not supplied). That module is also an I

and connected to Bus 2.

Remark: Although Bus 2 has more than one I

The remaining circuitry is to support the I

PC over a USB link.

UM10741

Fm+ development kit OM13320

2

C-bus Controller device (PCA9665, IC6), which is to be driven by

2

C Master, only one is active at any time.

2

C devices, and provide communications with the

2

C Master

The main operating voltage on th e Fm+ Development Boa rd (OM13260) is 3.3 V supplied

2

from a linear regulator (IC1). Some circuits and the op tional I

C-bus pull-ups may run from

5 V derived either from the USB host (typically a PC) or an AC-DC power supply (not

supplied in the kit). The actual voltage is seldom 5 V, due to cable losses, plus an

additional drop in a series connected diode used to OR the two input s. Wh ichever has th e

highest voltage has priority.

A shunt Zener diode (6.2 V) protects the board from reverse polarity and overvoltage at

the DC Power connector (CN6).

To aid in understanding digital signal levels on the board, two ‘logic probe’ circuits are

provided. These are buffered LEDs (Green, D6 and Red, D7), which light if their

respective inputs (CN11) are grounded.

2

Two global digital signal nets, called INT (interrupt) and RST (reset) connect all I

C-bus

devices on the board and also the Port A – Port E Daughter Card connectors. These are

also connected to the Master (MCU, IC5) on Bus 1, the Master (Bus Controller, IC4), and

the LPC Xpresso module.

2

Remark: The I

only reset the I

The test points provide monitoring of interrup ts (usually generated by I

software reset of Fm+ class I

C global Reset is not the same as the MCU Reset. Resetting the MCU will

2

C-bus if the MCU firmware is intended to create a global reset.

2

2

C-bus devices that have that feature.

C-bus Slaves) and

Additional buffered LEDs are provided (D19, RST and D20, Interrupt) on the Fm+

Development Board (OM13260) for visual indication.

V arious MCU and LPC Xpresso signals are made a vailable through additional connectors.

These include a serial Port (CN7) with EIA232 volta ge level translation (I C2) and SPI Bus

signals (SP0, CN9 and SP1, CN8) from the LPC Xpresso module, together with SPI Bus

(SP2, CN16) from the MCU (IC5).

A prototyping area is provided for solder connection of components that may be required

by an application circuit beyond this board’s design. Power supplies and other sign als are

readily available.

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 14 of 61

NXP Semiconductors

UM10741

Fm+ development kit OM13320

On the Fm+ Development Board (OM13260) V3.0 there is an LED Blinker device

(PCA9901, IC3) and LED indicator (D10), while not strictly an I

one-wire protocol, it belongs to the NXP I

Remark: The PCA9901 will be made obsolete, and will not be present on future versions

of the Fm+ Development Board (OM13260).

The operation of the Fm+ Development Board (OM13260) is greatly enhanced by

third-party tools (not supplied in the kit) that may be attached to either I

dedicated connectors (Bus1, CN17 and Bus2, CN18), labeled ‘TESTER’.

5.2 Circuit description

The schematic diagram has multiple sheets. For clarification, only fragments of the

schematic are shown here. The full schematic should be downloaded if required. The

following pages are divided in to several sections covering the powe r supply, USB

interface, Bus1, Bus2, and support circuits.

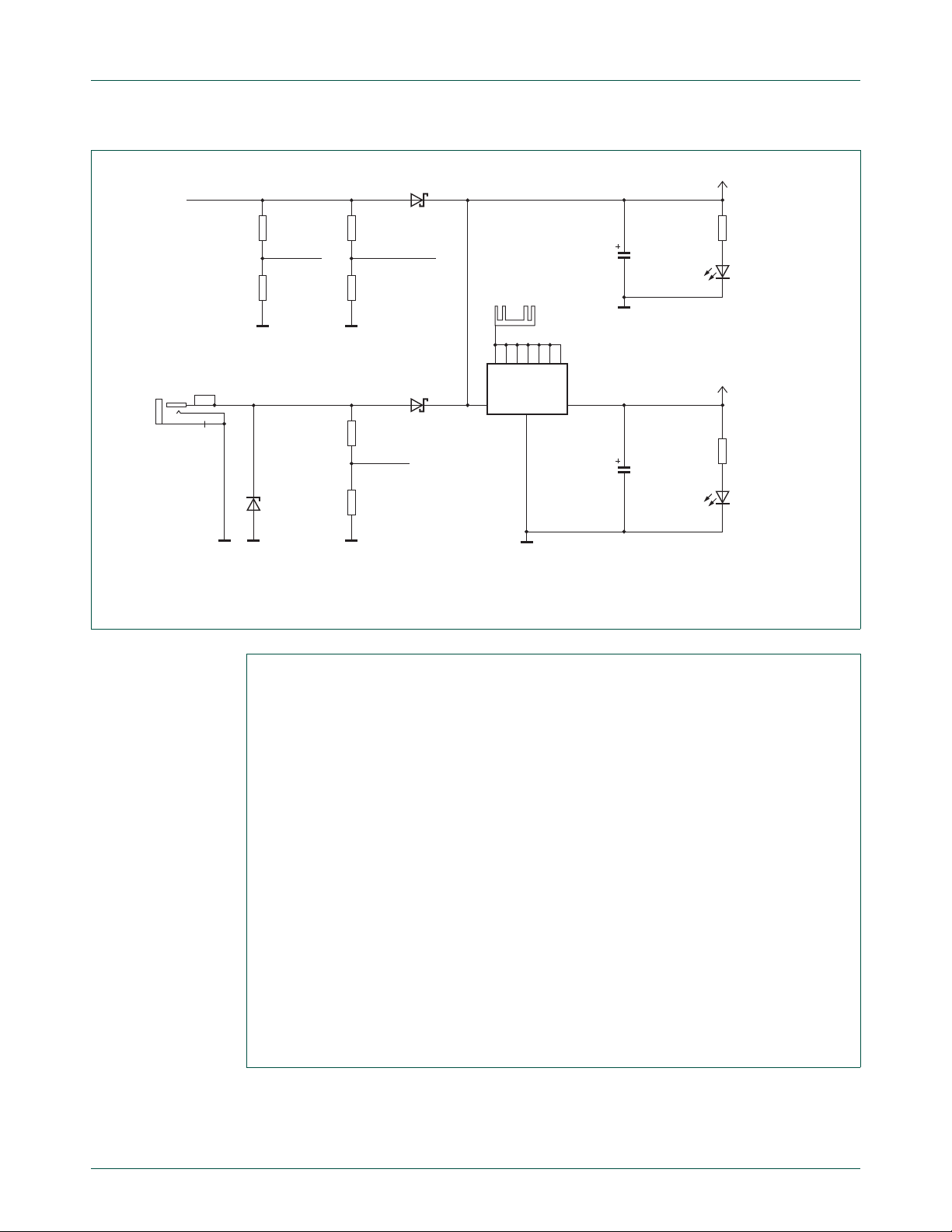

5.2.1 Power supply

The Fm+ Development Board (OM13260) operates from DC, either from the USB Host

connector (CN5) or an optional external AC-DC power adapter (not supplied in the kit) via

connector (CN6). See Figure 11

automatic, using ORing diodes (D1 and D2). The main power on the Fm+ Development

Board (OM13260) is 3.3 V from a linear regulator (IC1), but some of the circuits are

powered directly from the incoming supply, which is a nominal 5 V. Linear regulator (IC1)

uses the PCB bottom layer copper as a heat sink. The Fm+ Development Board

(OM13260) external DC input is protected against reverse polarity or overvoltage by

Zener diode (D3). Both input sources are scaled by resistor dividers (R1, R2 and R39,

R40) and fed to the MCU (IC5) Port1 ADC inputs for voltage leve l monitoring. The VBUS

from the USB Host is fed to the MCU Port 0 so that the MCU can detect that a USB

connection is available. Green LED (D4) confirms 5 V, and Green LED (D5) confirms

3.3 V.

2

2

C-bus product portfolio.

and Figure 12. Selection of the power source is

C device as it uses a

2

C-bus through

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 15 of 61

NXP Semiconductors

aaa-011872

VBUS

R2

10 kΩ

R1

10 kΩ

USB_V

GND

R4

10 kΩ

R3

10 kΩ

MCU_VBUS

GND

D2

STPS2L40U

GND

C2

100 pF/10 V

+5V

R5

820 Ω

D4

LTST-C170KGKT GRN

+5 V

5

HS1

PCBPAD

67489

10

1

23

HS1

HS6

HS5

HS4

ADVTAB

HS3

HS2

IN OUT

GND

IC1

ZLDO1117G33TA

C1

100 pF/10 V

+3V3

R6

820 Ω

D5

LTST-C170KGKT GRN

+3.3 V

GND

3V3 REGULATOR

R40

20 kΩ

R390

10 kΩ

EXT_V

GND

D1

STPS2L40U

Max input 6.2 V DC

GNDGND

EXT POWER

D3

1SMB5920BT3

6V2

CN6

DD-JACK-GMT

UM10741

Fm+ development kit OM13320

Fig 11. Power supply

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 16 of 61

Fig 12. Power supply and USB section

NXP Semiconductors

5.2.2 USB interface

The USB Host connector (CN5) provides DC power and USB connectivity using the MCU

(IC5) hardware interface, see Figure 12

resistors (R27 and R28) and protected by an ESD network (IC7). To signal to the host that

the USB connection is required, the USB signal DP is pulled to 3.3 V via a resistor (R18)

and a transistor (Q1). USB Connection is contro lled by the MCU (IC5) via signal CON_EN

and can be disabled by removing a jumper (JP3) ‘CONNECT’. Whe n the MCU requests a

USB connection, and the jumper (JP3) is installed, the green LED (D9) is ON. MCU

activity is displayed by the Heart Beat green LED (D8), which is set to blink at about

one per second.

UM10741

Fm+ development kit OM13320

and Figure 13. USB data lines are terminated by

+3V3

IC5G$8

USB_DP

USB_Dm

LPC134X_HVQFN32

14

13

Fig 13. USB interface

5.3 Bus one (Bus1)

R17

820 Ω

D9

10 kΩ

2.2 kΩ

SOFTCONNECT

VBUS

Q1

PDTA123YT

R18

1.5 kΩ

GND

DP

DM

VBUS

GND

GND

5

GND

6

CN5-3

CN5-2

CN5-1

CN5-4

LTST-C170KGKT GRN

R27

R28

33 Ω

33 Ω

GND

D8

CONFIG

USB_LED

CON_EN

IC7

2

IO1

1

GND

PRTR5V0U2X

R20

820 Ω

LTST-C170KGKT GRN

JP3-1

USB_CONNECT

3

IO2

4

VCC

CONNECT

JP3-2

USB PORTUSB INTERFACE

aaa-011873

There are two almost identical I2C buses on the Fm+ Development Board (OM13260),

called Bus1 and Bus2. These share a ground and power connection but may be operated

independently.

2

Remark: The bus voltage for each I

2

I

C-bus, 5 V for the other I2C-bus).

C may be different (for example 3.3 V for one

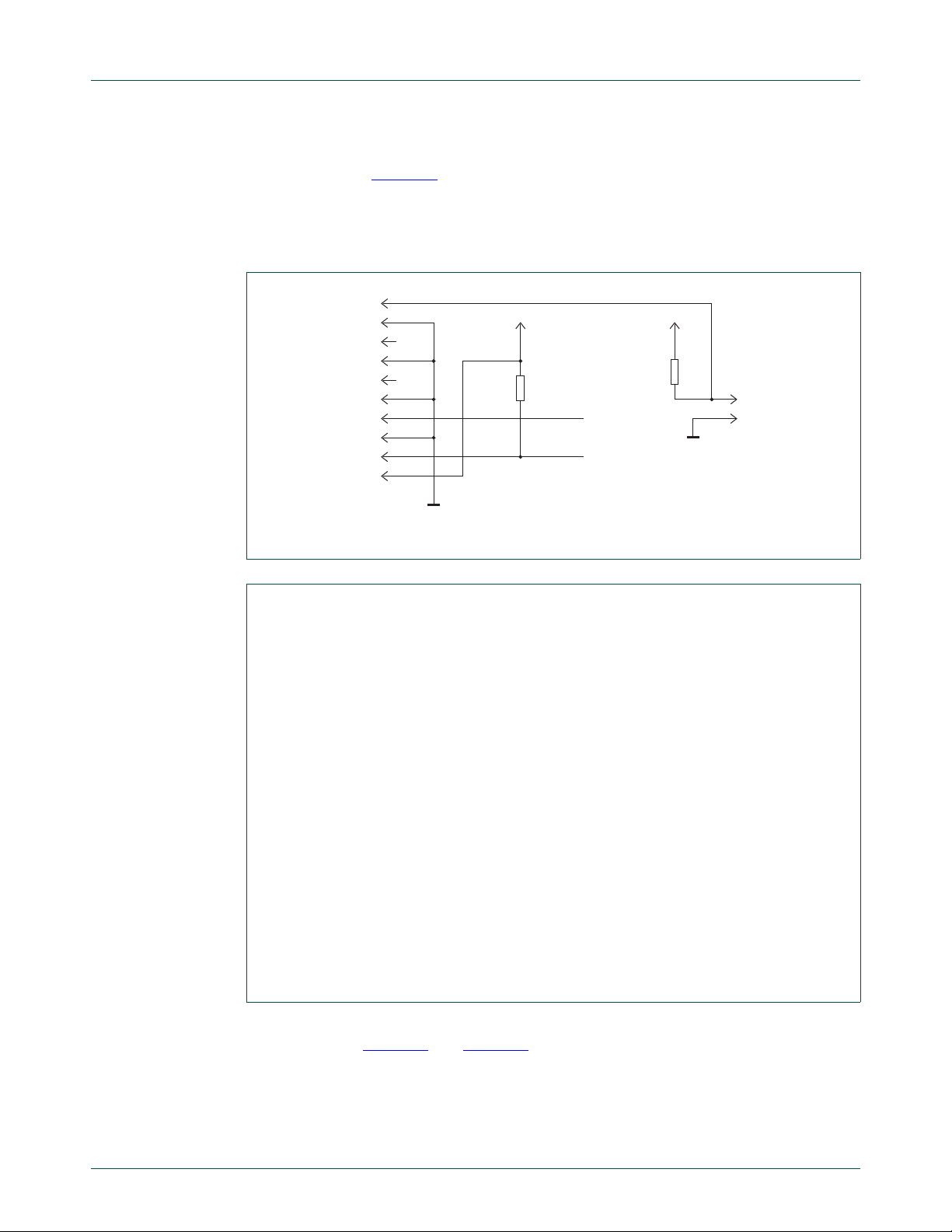

5.3.1 Bus1 master (MCU LPC1343)

Microcontroller (MCU) (LPC1343, IC5) serves as the Bus1 Master and the USB Bridge.

Firmware installed on the Fm+ Development Board (OM13260) is stored in non-volatile

memory, which has a limit of 32 kB. The MCU may be programmed through the USB por t

or the JTAG connector (CN 19), using Single Wire Debug (SWD), see Figure 14

Figure 15

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 17 of 61

.

and

NXP Semiconductors

aaa-011874

R38

10 kΩ

JP4-1

LPC SWD PROG CONNECTOR

R37

100 kΩ

JP4-2

RST

GND

+3V3+3V3

GND

MCU_SCLK

SWDIO

SWD_RESET

CN19-10

CN19-9

CN19-8

CN19-7

CN19-6

CN19-5

CN19-4

CN19-3

CN19-2

CN19-1

During programming or at other times it may be necessary to reset the MCU, by briefly

shorting JP4 (see Figure 15

Remark: An MCU Reset is not the same as an I

affect the I

it is reset.

UM10741

Fm+ development kit OM13320

).

2

2

C-bus, unless the MCU firmware is designed to issue an I2C Bus Reset when

C Bus Reset. Resetting the MCU will not

Fig 14. MCU SWD interface

Fig 15. MCU SWD interface section

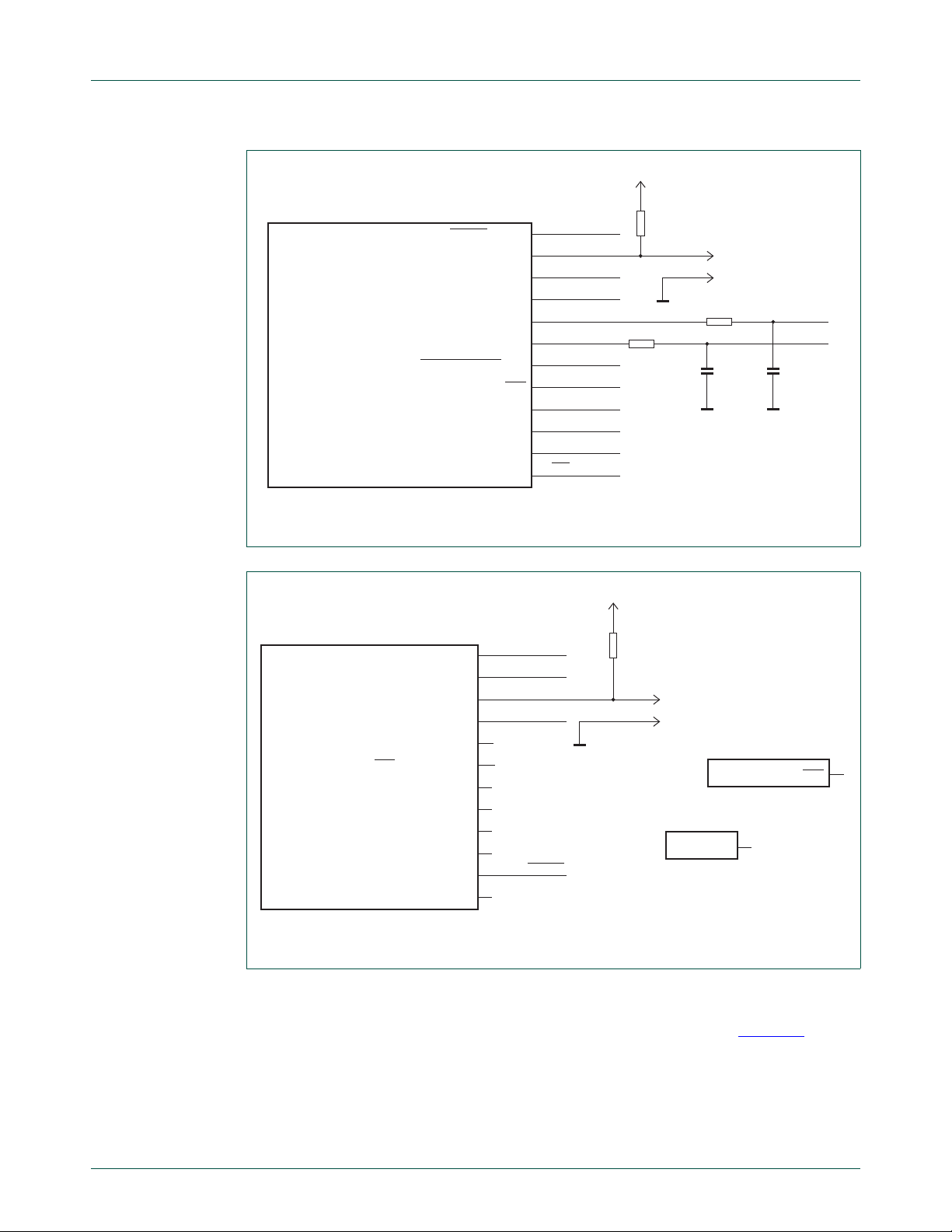

MCU Port0 and Port1 provide most of the signals used by the Fm+ Development Board

(OM13260), see Figure 16

and Figure 17. I2C Bus1 is connected to the MCU Port0 via

RC edge rate control networks that provide bus fall time control (SCL1: R42 and C18;

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 18 of 61

SDA1: R43 and C17).

NXP Semiconductors

aaa-011876

LPC134X_HVQFN32

IC5G$2

22

23

24

25

26

30

31

32

7

12

20

27

EXT_V

USB_V

SWDIO

RESET

+3V3

R41

10 kΩ

GND

JP2-1

JP2-2

HDD

R/PIO1_0/ADC1/CT32B1_CAP0

R/PIO1_1/ADC2/CT32B1_MAT0

R/PIO1_2/ADC3/CT32B1_MAT1

SWDIO/PIO1_3/ADC4/CT32B1_MAT2

PIO1_4/ADC5/CT32B1_MAT3/WAKEUP

PIO1_5/UART_RTS/CT32B0_CAP0

PIO1_6/UART_RXD/CT32B0_MAT0

PIO1_7/UART_TXD/CT32B0_MAT1

PIO1_8/CT16B0_CAP0

PIO1_9/CT16B1_MAT0

PIO1_10/ADC6/CT16B1_MAT1

PIO1_11/ADC7

LPC134X_HVQFN32

IC5G$4

28

PIO3_2

LPC134X_HVQFN32

IC5G$3

1

PIO2_0/UART_DTR

UM10741

Fm+ development kit OM13320

+3V3

LPC134X_HVQFN32

PIO0_1/CLKOUT/CT32B0_MAT2/USB_TOGGLE

PIO0_2/SSP_SSEL/CT16B0_CAP0

PIO0_3/USB_VBUS

PIO0_6/USB_CONNECT/SCK

PIO0_8/SSP_MISO/CT16B0_MAT0

PIO0_9/SSP_MOSI/CT16B0_MAT1/SWD

SWCLK/PIO0_10/SSP_CLK/CT16B0_MAT2

R/PIO0_11/ADC0/CT32B0_MAT3

IC5G$1

Fig 16. IC5 MCU Port0

RESET/PIO0_0

PIO0_4/I2C_SCL

PIO0_5/I2C_SDA

PIO0_7/CTS

2

SWD_RESET

3

8

MCU_SSN

9

MCU_VBUS

10

SCL1A

11

SDA1A

15

CON_EN

16

USB_LED

17

MCU_MISO

18

MCU_MOSI

19

MCU_SCLK

21

INT

R43

100 Ω

R33

10 kΩ

GND

100 Ω

GND

ISP

R42

C17

10 pF

JP6-1

JP6-2

TF EDGE RATE CONTROL

GND

SCL1

SDA1

C18

10 pF

aaa-011875

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 19 of 61

Fig 17. IC5 MCU Port1

The HVQN32 package has a thermal pad grou nd connection, and ope rates from the main

3.3 V supply. The MCU operates with a 12.00 MHz crystal controlled oscillator. The

frequency value and accuracy is necessary for correct USB timing (see Figure 18

).

NXP Semiconductors

LPC134X_HVQFN32

GND9

GND8

GND7

GND6

GND5

GND4

GND3

GND2

GND1

IC5G$7

UM10741

Fm+ development kit OM13320

LPC134X_HVQFN32

4

XTALIN

XTALOUT

41

40

39

38

37

36

35

34

33

GND

LPC134X_HVQFN32

VDDIO_EXT_1

VDDMAIN_EXT

IC5G$6

5

IC5G$5

15 pF

6

29

C8

GND

C9

100 nF

12 MHz

GND

XE1

NX5032GA

GND

+3V3

GND

aaa-011877

C7

15 pF

C6

100 nF

Fig 18. IC5 MCU Port1, oscillator and power supply

5.3.2 Bus1 pull-up resistors

The Bus1 is pulled up to either the 3.3 V or 5 V supplies via JP13. Three different value

pull-up resistors are provided by jumper selection, JP11 and JP12. The values of the

pull-up resistors are shown in Table 3

SDA signal lines. Bus2 has a similar arrangement. See Figure 19

+3V3

JP13-1

JP13-2

JP13-3

+5V

. Separate pull-ups are provided for the SCL and

and Figure 20.

1.1 kΩ

GND

R16

634 Ω

R15

324 Ω

R14

1.1 kΩ

R13

634 Ω

R12

324 Ω

R11

C10

100 nF

JP12-6

JP12-4

JP12-2

JP11-6

JP11-4

JP11-2

JP12-5

JP12-3

JP12-1

JP11-5

JP11-3

JP11-1

SCL1

SDA1

I2C BUS-1 PULL-UP RESISTOR NETWORK

aaa-011878

Fig 19. Bus1 pull-ups and bus voltage selector

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 20 of 61

NXP Semiconductors

UM10741

Fm+ development kit OM13320

Fig 20. Bus1 pull-ups section

T able 3. Bus pull-up resistors

Strength Position Value Bus1 SCL Bus1 SDA Bus2 SCL Bus2 SDA

LOW A 1.1 kΩ R16 R13 R26 R23

MID B 634 Ω R15 R12 R25 R22

HIGH C 324 Ω R14 R11 R24 R21

5.3.3 LED driver slave (PCA9955)

Bus1 is also used to control the LED Driver (PCA9955, IC6). Th e LED Driver has constant

current outputs and is directly connected to the LEDs, without customary series resistors.

The LEDs are powered directly from the 5 V supply, thus avoiding further power

dissipation in the 3.3 V linear regulator, IC1. The sixteen channels drive eight LED

clusters consisting of four White LEDs (LED12 – LED15) and four RGB LED clusters

(LED0 – LED11). The maximum current available for each channel is set by R35 and the

variable resistor R36. The LEDs use the PCB top metal for heat dissipation, the LED

driver is in the HTSSOP28 package has a thermal pad ground connection, and operates

from the main 3.3 V supply. See Figure 21

and Figure 22.

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 21 of 61

NXP Semiconductors

38

37

36

35

34

33

32

31

30

29

GND10

GND9

GND8

GND7

GND6

GND5

GND4

GND3

GND2

GND1

GND

IC6G$2

PCA9955PW

aaa-011879

GND

C5

22 pF/16 V

+3V3

R35

820 Ω

PCA9955 Address:

0xC0h or 0xD0h

GND

JP5-1

JP5-2

JP5-3

Iset

GND

R36

10 kΩ

GND

LED MAX BRT

1

2

3

4

5

6

7

8

9

10

REXT

A0

A1

A2

OE/A3

LED0

LED1

LED2

LED3

VSS

LED0

LED1

LED2

LED3

11

12

13

14

LED4

LED5

LED6

LED7

LED4

LED5

LED6

LED7

PCA9955PW

IC6G$1

LED[0..11]

PCA9955 16-ch CONSTANT

CURRENT LED DRIVER

VDD

SDA

SCL

RESET

VSS

LED15

LED14

LED13

LED12

VSS

LED11

LED10

LED9

LED8

28

27

26

25

24

23

22

21

20

19

18

17

16

15

GND

+3V3

SDA1

SCL1

RESET

LED15

LED14

LED13

LED12

LED11

LED10

LED9

LED8

GND

RGB LEDs

LED[12..15]

LED9

LED10

LED11

D14R

D14G

D14B

+5V

LED6

LED7

LED8

D13R

D13G

D13B

LED3

LED4

LED5

D12R

D12G

D12B

LED0

LED1

LED2

D11R

D11G

D11B

+5V

WHITE LEDs

LED15

D18

LED14

D17

LED13

D16

LED12

D15

+5V

UM10741

Fm+ development kit OM13320

Fig 21. Bus1 LED driver 16-channel

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

Operation of all sixteen LEDs at maximum current will overheat the LED driver, which is

protected by an internal thermal limiter. The device will shut down and recover when the

temperature has fallen.

When powered from the USB port (CN5) the USB Host is typically limited to 500 mA, and

it will shut down before the LEDs reach maximum current. Operation from an external DC

power supply connection (CN6) is required to drive the LEDs to the maximum current per

channel of 57 mA, for a total of approximately 1 A.

User manual Rev. 1 — 1 April 2014 22 of 61

Fig 22. Bus1 LED driv er 16-channel section

NXP Semiconductors

The recommended AC-DC adapter is Digikey PN: 62-1132-ND (not supplied).

See Figure 23

UM10741

Fm+ development kit OM13320

.

Fig 23. AC-DC adapter, 6 V, 2 A

The Slave address is set by JP5, summarized in Table 4.

Remark: The PCB is marked with hexadecimal (8-bit) address data, but data sheets and

the NXP GUI use the 7-bit address values. See Table 4

Table 4. LED driver address selection

JP5 connected to Hexad ecimal 8-bit address NXP 7-bit address

Address MSB LSB Address MSB LSB

GND 0xC0 1100 0000 0x60 110 0000

V

CC

0xD0 1101 0000 0x68 110 1000

5.3.4 GPIO slave (PCA9672)

The GPIO (PCA9672, IC10) is connected to Bus1, and provides eight input/output

channels at CN10. Jumper JP10 sets the device address to one of four options,

depending on whether the A0 pin is connected to GND, V

similar arrangement for a second GPIO (PCA9672, IC20). See Figure 24

Remark: The PCB is marked with hexadecimal (8-bit) address data, but data sheets and

the NXP GUI use the 7-bit address values. This is summarized in Table 5

.

, SCL, or SDA. Bus2 has a

CC

and Figure 25.

.

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 23 of 61

NXP Semiconductors

UM10741

Fm+ development kit OM13320

+3V3

JP10-1

JP10-3

JP10-5

JP10-7

GND

SDA1

SCL1

JP10-2

JP10-4

JP10-6

JP10-8

Fig 24. Bus1 GPIO 8-bit

Table 5. LED driver address selection

A0 connected to He xadecimal 8-bit address NXP 7-bit addres s

GND 0x44 0100 0100 0x22 010 0010

V

SCL 0x54 0101 0100 0x2A 010 1010

SDA 0x56 0101 0110 0x2B 010 1011

PCA9672 addresses:

VDD = 0x46h

SDA1 = 0x56h

SCL1 = 0x54h

GND = 0x44h

CC

+3V3

SDA1

SCL1

INT

RESET

15

SDA

14

SCL

13

INT

3

RESET

2

A1

1

A0

IC10

PCA9672PW

+3V3

16

8

GND

VDD

GND

IO0

IO1

IO2

IO3

IO4

IO5

IO6

IO7

4

5

6

7

9

10

11

12

GPIO1_0

GPIO1_1

GPIO1_2

GPIO1_3

GPIO1_4

GPIO1_5

GPIO1_6

GPIO1_7

GPIO1_[0..7]

GPIO1_7

GPIO1_6

GPIO1_5

GPIO1_4

GPIO1_3

GPIO1_2

GPIO1_1

GPIO1_0

+3V3

GND

PCA9672 8-bit GPIO (Bus1)

Address MSB LSB Address MSB LSB

0x46 0100 0110 0x23 010 0011

CN10-10

CN10-9

CN10-8

CN10-7

CN10-6

CN10-5

CN10-4

CN10-3

CN10-2

CN10-1

aaa-012040

Fig 25. Bus1 GPIO 8-bit section

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 24 of 61

NXP Semiconductors

5.4 Bus two (Bus2)

The second I2C bus on the Fm+ Development Board (OM13260) requires the addition of

an NXP LPC Xpresso Module (not included in the kit) to either be the Master, or drive the

bus controller (PCA9665, IC4).

There are two almost identical I

called Bus1 and Bus2. These share a ground and power connection, but may be o perated

independently.

Remark: The bus voltage for each I

5 V for the other I

5.4.1 Bus2 master (LPC Xpresso — MCU LPC1343)

The LPC Xpresso Module contains an NXP LPC1343 MCU (similar to the one on Bus 1)

and support circuits called LPC-Link. See Figure 26

that is loaded through either the LPC-Link and USB Bridge, or JTAG Single Wire Debug

(SWD) connector.

Remark: The LPC Xpresso is not compatible with the NXP GUI, and requires the

installation of an IDE for code development.

2

C bus).

UM10741

Fm+ development kit OM13320

2

C buses on the Fm+ Development Board (OM13260),

2

C maybe different (for example 3.3 V for one I2C bus,

. The LPC Xpresso requires firmware

Fig 26. Fm+ development board with LPC Xpresso installed

The LPC-Link may be powered from the Fm+ Development Board (OM13260), or from a

USB Host (connected to the LPC-Link port). There is a possible conflict that the LC P-Link

3.3 V supply will compete with the Fm+ Development Board (OM13260) 3.3 V supply.

To avoid this issue the LPC Xpresso Module can provide its own 3.3 V power by removing

jumper JP1 on the Fm+ Development Board (OM13260). See Figure 27

2

C Bus2 is connected to the MCU Port0 via RC edge rate control networks that provide

I

bus fall time control (SCL2: R45 and C23; SDA1: R44 and C19). See Figure 28

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 25 of 61

.

.

NXP Semiconductors

aaa-012041

GND

C23

10 pF

GND

C19

10 pF

SDA2

SCL2

100 Ω

100 Ω

R45

R44

TF EDGE RATE CONTROL

GND

SDA2A

SCL2A

A0

A1

RESET

INT

LPCXPRESSO

SOCKET

CN14-1

CN14-2

CN14-3

CN14-4

CN14-5

CN14-6

CN14-7

CN14-8

CN14-9

CN14-10

CN14-11

CN14-12

CN14-13

CN14-14

CN14-15

CN14-16

CN14-17

CN14-18

CN14-19

CN14-20

CN14-21

CN14-22

CN14-23

CN14-24

CN14-25

CN14-26

CN14-27

JP1-2

XPRESSO PWR

JP1-1

+3V3

GND

D6

D7

D4

D5

D3

CN13-1

CN13-2

CN13-3

CN13-4

CN13-5

CN13-6

CN13-7

CN13-8

CN13-9

CN13-10

CN13-11

CN13-12

CN13-13

CN13-14

CN13-15

CN13-16

CN13-17

CN13-18

CN13-19

CN13-20

CN13-21

CN13-22

CN13-23

CN13-24

CN13-25

CN13-26

CN13-27

RD

WR

CE

SSN1

D2

D1

D0

P0.7

RXD

TXD

SSN0

SCLK

MISO

MOSI

GND

Fig 27. LPC Xpresso power (JP1)

UM10741

Fm+ development kit OM13320

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

Fig 28. Bus2 master (LPC Xpresso)

User manual Rev. 1 — 1 April 2014 26 of 61

NXP Semiconductors

aaa-011880

GND

C21

10 pF

GND

C22

10 pF

SDA2

SCL2

100 Ω

100 Ω

R47

R46

TF EDGE RATE CONTROL

+3V3

GND

C11

100 nF

PIN20

PIN19

PIN18

SDA2B

SCL2B

GND

PIN9

PIN10

VDD

SDA

SCL

NC

VSS

PCA9665PW

IC4

D0

D1

D2

D3

D4

D5

D6

D7

CE

RD

WR

A0

A1

RESET

INT

D0

D1

D2

D3

D4

D5

D6

D7

CE

RD

WR

A0

A1

RESET

INT

PIN1

PIN2

PIN3

PIN4

PIN5

PIN6

PIN7

PIN8

PIN13

PIN12

PIN11

PIN14

PIN15

PIN17

PIN16

PCA9665 I2C BUS CONTROLLER

5.4.2 Bus2 bus master (PCA9665)

UM10741

Fm+ development kit OM13320

A second Bus Master is connected to Bus2 using a dedicated Bus Controller device

(PCA9665 Fm+ parallel bus to I

connected to the LPC Xpresso module (LPC1343 PIO2 and PIO3). The I

2

C-bus controller) (IC4). The parallel port side is

2

C side is

connected via RC edge rate control networks that provide bus fall time control (SCL2: R47

and C21; SDA2: R46 and C22). See Figure 29

and Figure 30. Note IC4 is physically

underneath the LPC Xpresso module.

Fig 29. Bus2 master (PCA9665)

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 27 of 61

Fig 30. Bus2 master (PCA9665) section

NXP Semiconductors

aaa-011881

I2C BUS-2 PULL-UP

RESISTOR NETWORK

GND

C10

100 nF

JP23-3

JP23-2

JP23-1

+3V3

+5V

1.1 kΩ

R26

634 Ω

R25

324 Ω

R24

1.1 kΩ

R23

634 Ω

R22

324 Ω

R21

JP22-2

JP22-4

JP22-6

JP21-2

JP21-4

JP21-6

JP22-1

JP22-3

JP22-5

JP21-1

JP21-3

JP21-5

SCL2

SDA2

5.4.3 Bus2 pull-up resistors

The Bus2 is pulled up to either the 3.3 V or 5 V supplies, via JP23. Three different value

pull-up resistors are provided by jumper selection, JP21 and JP22. The values of the

pull-up resistors are shown in Table 6

SDA signal lines. See Figure 31

Section 5.3.2

UM10741

Fm+ development kit OM13320

. Separate pull-ups are provided for the SCL and

and Figure 32. Bus1 has a similar arrangement (see

).

Fig 31. Bus2 pull-ups and bus voltage selector

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 28 of 61

Fig 32. Bus2 pull-ups section

NXP Semiconductors

T able 6. Bus pull-up resistors

Strength Position Value Bus1 SCL Bus1 SDA Bus2 SCL Bus2 SDA

LOW A 1.1 kΩ R16 R13 R26 R23

MID B 634 Ω R15 R12 R25 R22

HIGH C 324 Ω R14 R11 R24 R21

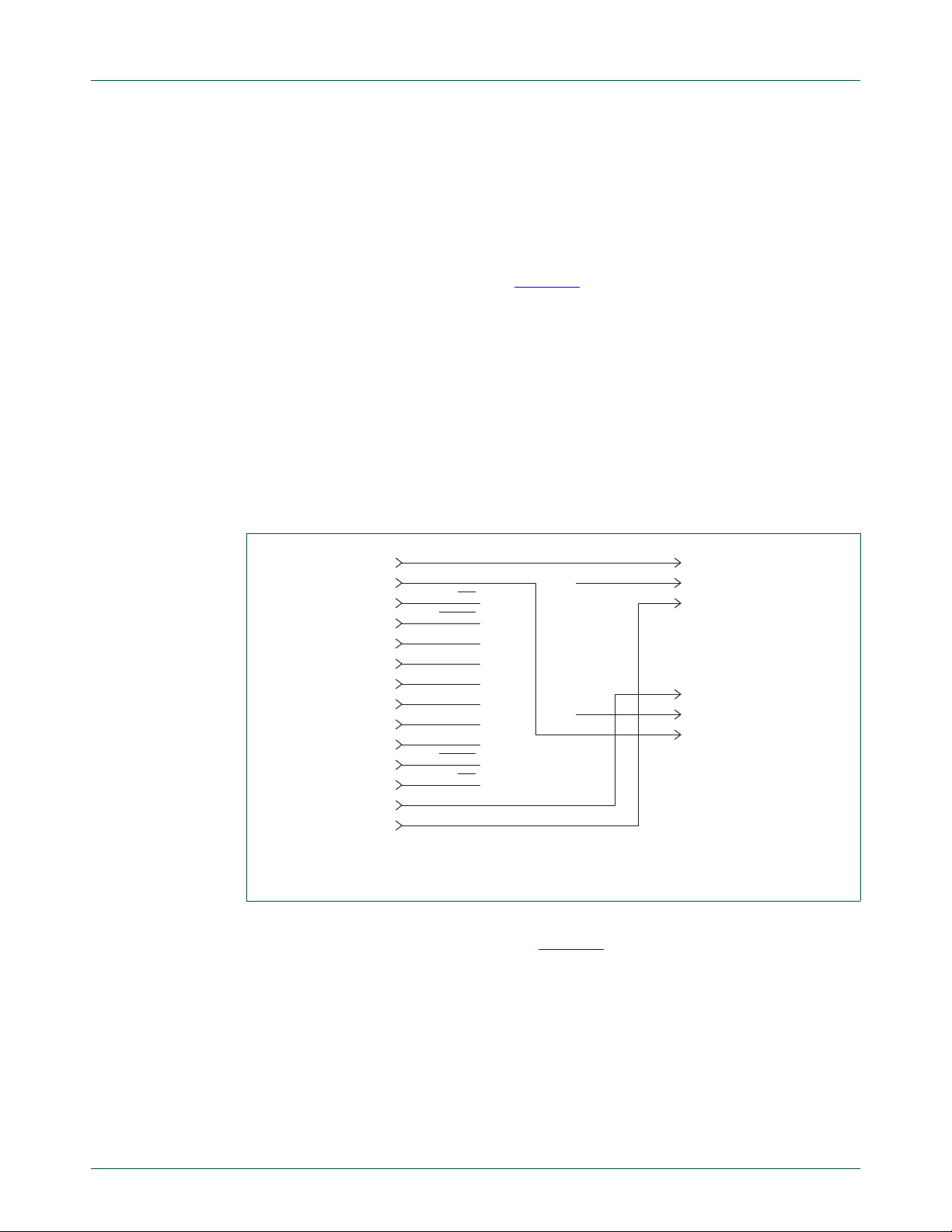

5.5 Daughter card ports

Accessory circuit cards called Daughter Cards may be att ached to any ports (P ort A – Port

D), connectors CN1 – CN4 respectively, see Figure 34

signals, regardless of physical location. Daughter Cards have jumpers to select whether

connection to Bus1 or Bus2 is required. Port A is shown in Figure 33

identical, and effectively in parallel.

UM10741

Fm+ development kit OM13320

. Each port carries the same

; Port B – Port D are

Fig 33. Port A

SCL1

SDA2

INT

RESET

+5V

+3V3

GND

GND

+3V3

+5V

RESET

INT

SDA1

SCL2

CN1-14

CN1-13

CN1-12

CN1-11

CN1-10

CN1-9

CN1-8

CN1-7

CN1-6

CN1-5

CN1-4

CN1-3

CN1-2

CN1-1

SCL BUS1

SDA BUS2

INT

RESET

+5V

+3V3

GND

GND

+3V3

+5V

RESET

INT

SDA BUS1

SCL BUS2

aaa-012042

Fig 34. Daughter ca rd connectors (Port A and Port B shown)

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 29 of 61

NXP Semiconductors

5.6 Port E

UM10741

Fm+ development kit OM13320

The two independent I2C Buses (Bus1 and Bus2) can be joined electrically to create a

single I

2

C-bus. The link may be made by wire jumper or by an add-on board with an I2C

Bus Buffer device installed. The PCA9617A Bus Buffer Demo Board (OM13398) (supplied

in the kit) is an example. The Fm+ Development Board (OM13260) may also be operated

with nothing connected to Port E (CN12).

The Port E signal pins are arranged to be symmetrical, permitting the card to be rotated

180°, effectively changing the direction of the signals th rough the ca rd. See Figure 35

Figure 36

.

Remark: When linked together by wire jumper, the pull-up resistors on each bus are

effectively in parallel. The resulting value is therefore one-half of the original value. Pull-up

2

resistors of low value will overload the I

C drivers, and effectively stop the bus from

operating.

5.6.1 Linking both buses together (with a jumper)

and

Fig 35. Port E with wire jumper

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 30 of 61

NXP Semiconductors

aaa-012043

JP7-1

JP7-2

JP7-3

SSN0

SSN1

BUS2 TEST BUS1 TEST

D21

GRN

CN18-10

GND

CN18-9

CN18-8

MOSI

CN18-7

SCLK

CN18-6

3V3_1

CN18-5

MISO

CN18-4

CN18-3

SDA2

CN18-2

GND

CN18-1

SCL2

R34

D22

GRN

CN17-10

GND

CN17-9

CN17-8

MCU_MOSI

CN17-7

MCU_SCLK

CN17-6

3V3_2

CN17-5

MCU_MISO

CN17-4

CN17-3

SDA1

CN17-2

GND

CN17-1

SCL1

R48

MCU_SSN

5.6.2 Linking both buses together (with a bus buffer board)

UM10741

Fm+ development kit OM13320

Fig 36. Port E with bus buffer card (OM13398) installed

5.7 Tester connectors (for third-party tools)

Bus1 may be connected to third-party test equipment via CN17. Bus2 has a similar and

independent connection at CN18. See Figure 37

Remark: Refer to Section 9 “

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 31 of 61

Fig 37. Bus1 and Bus 2 tester connectors

Third-party tools” of this user manual.

, Figure 38 and Figure 39.

NXP Semiconductors

Fig 38. Bus1 tester connectors

UM10741

Fm+ development kit OM13320

Fig 39. Bus2 tester connectors

5.8 Serial communication port

The LCP Xpresso module has a serial comms (communications) port, EIA232 standards

compliant using IC2, a voltage level translator. See Figure 40

connection to I

2

C Bridge devices that require Serial Communications.

To save space on the PCB, a small mini-DIN connector (CN7) replaces the standar d 9-pin

DE shell connector . For connection to standard serial comms cables an adapter is

required, see Figure 41

PN: AE1393-ND (not supplied) See Figure 42

. The recommended Mini-DIN to DE-9 Adapter is Digikey

.

. This is provided for

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 32 of 61

NXP Semiconductors

UM10741

Fm+ development kit OM13320

+3V3

C12

100 nF

C13

100 nF

TXD

RXD

+3V3

GND

IC2

2

C1+

4

C1−

5

C2+

6

C2−

11

T1IN

9

R1OUT

1

EN

16

FORCEOFF

12

FORCEON

ICL3221CVZ

SERIAL COMMS

Fig 40. Bus2 tester connectors

15

V+

VDD

V−

T1OUT

R1IN

INVALID

GND

14

GND

3

7

13

8

10

GND

C15

100 nF

GND

C14

100 nF

MINI-DIN6PTH

1

2

3

4

5

6

CN7

GND

aaa-012044

Fig 41. Serial Com section

Fig 42. Serial Com dongle

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 33 of 61

NXP Semiconductors

5.9 SPI ports

Both the Bus1 Master MCU and the Bus2 Master LPC Xpress o Mo d ule suppo rt SPI

communications. The Bus1 MCU has one SPI port (SPI2) (CN16) and the LPC Xpresso

has two SPI ports (SPI0 and SPI1) (CN9 and CN8, respectively). See Figure 43

Figure 44

the tester connector (for third-party tools) with the SPI ports.

UM10741

Fm+ development kit OM13320

,

and Figure 45. Also refer to Section 9 of this user manual for details on using

INT

GND

SSN0

RESET

SCLK

MOSI

+3V3

MISO

Fig 43. SPI connectors

CN9-8

CN9-7

CN9-6

CN9-5

CN9-4

CN9-3

CN9-2

CN9-1

INT

GND

SSN1

RESET

SCLK

MOSI

+3V3

MISO

SPI 0

SPI DAUGHTER CARD

EXPANSION CONNECTORS

CN8-8

CN8-7

CN8-6

CN8-5

CN8-4

CN8-3

CN8-2

CN8-1

SPI 1

INT

GND

MCU_SSN

RESET

MCU_SCLK

MCU_MOSI

+3V3

MCU_MISO

CN16-8

CN16-7

CN16-6

CN16-5

CN16-4

CN16-3

CN16-2

CN16-1

SPI 2

aaa-012046

Fig 44. SPI 2 (Bus1 MCU) connector

Fig 45. SPI 0 and SPI 1 (Bus2 LPC Xpresso) connectors

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 34 of 61

NXP Semiconductors

aaa-012047

UTILITY LED INDICATORS

GND

CN11-3

CN11-2

CN11-1

CN11-4

Q2

SI2325DS

R29

10 kΩ

R30

820 Ω

GND

R32

820 Ω

GND

D6

LTST-C170KGKT GRN

GRN

D7

LTST-C170CKT RED

RED

R31

10 kΩ

Q3

SI2325DS

+5V

5.10 Logic probe

Most of the I2C-bus slaves produce logic signals on their input/output ports. It is necessa ry

to know a logic state. To facilitate this test there are two LEDs with buffers that may be

used as a simple ‘logic probe’.

UM10741

Fm+ development kit OM13320

To prevent circuit loading the LEDs are buffered by FETs as shown in Figure 46

. Green

LED (D6) is driven by FET (Q2) when CN11-1 is at or near ground. When CN11-1 is open

(or logic 1) the FET is non-conducting, and the LED is off. Red LED (D7) is driven by FET

(Q3) when CN11-4 is at or near ground. When CN11-4 is open (or logic 1) the FET is

non-conducting, and the LED is off. See Figure 47

Note that the threshold voltage (V

) of the FET is 2.5 V to 4.5 V to ensure it operates

th

.

correctly on both 3.3 V and 5 V logic levels. The FET source is tied to 5 V, and the gate

must therefore be at 2.5 V or lower relative to ground, to turn on the FET and light the

LED.

Fig 46. Logic probe circuit

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 35 of 61

NXP Semiconductors

UM10741

Fm+ development kit OM13320

Fig 47. Logic probe section (shown monitoring two GPIO channels from Bus1)

5.11 INT and RST indicators

Two global digital signal nets, called INT (interrupt) and RST (reset), connect all I2C-bus

devices on the board and also the Port A – Port E daughter card connectors. These are

also connected to the Master (MCU, IC5) on Bus1, the Master (Bus Controller, IC4), and

the LPC Xpresso module. See Figure 48

Additional buffered LEDs are provided (D19, RST and D20, Interrupt) on the Fm+

Development Board (OM13260) for visual indication. These buffered LEDs operate in the

same fashion as the logic probe (see Section 5.10 “

+3V3

INT

10 kΩ

R9

Q4

SI2325DS

+5V

R8

820 Ω

D20

LTST-C170CKT RED

RED

INT LED

GND

and Figure 49.

Logic probe”).

+3V3

R10

10 kΩ

RESET

Q5

SI2325DS

+5V

R7

820 Ω

D19

LTST-C170CKT RED

RED

RST LED

GND

aaa-012048

Fig 48. INT an d RST indicators circuit

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 36 of 61

NXP Semiconductors

UM10741

Fm+ development kit OM13320

Fig 49. INT and RST indicators section

5.12 Prototype area

Additional circuits may be required to for an application beyond the intended scope of the

Fm+ Development Board (OM13260). For e xample, using dif f erent value p ull-up resistors

than those supplied, or other circuit experiments.

The prototype area is available, and consists of pads and holes on a 100 mil (2.54 mm)

grid. Power for these components is made available at several connector points (CN15 is

ground, CN21 is +3.3 V, and CN22 is +5 V). See Figure 50

and Figure 51.

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 37 of 61

NXP Semiconductors

aaa-012049

UTILITY POWER

+5V

CN22-4

CN22-2

CN22-3

CN22-1

+3V3

CN21-4

CN21-2

CN21-3

CN21-1

CN15-4

CN15-2

CN15-3

CN15-1

GND

UM10741

Fm+ development kit OM13320

Fig 50. Prototype area circuit

Fig 51. Prototype area section

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 38 of 61

NXP Semiconductors

5.13 LED blinker (PCA9901)

UM10741

Fm+ development kit OM13320

On the Fm+ Development Board (OM13260) V3.0 there is an LED Blinker device

(PCA9901, IC3) and LED indicator (D10). While not strictly an I

one-wire protocol, it belongs to the NXP I

2

C-bus product portfolio.

2

C-bus device, as it uses a

Remark: The PCA9901 will be made obsolete, and will not be present on future versions

of the Fm+ Development Board (OM13260).

Refer to the PCA9901 data sheet for det ails of th is device. Note that it is not connected to

2

either I

C Bus on the Fm+ Development Board (OM13260). It is connected to the LPC

Xpresso module (PIO_0.7), and that module must be present (and programmed) to drive

the PCA9901 device. See Figure 52

GND

D10

LTST-C170CKT RED

GND

and Figure 53.

IC3

1

GND

2

LEDOUT

4

ISET

R19

PCA9901DP

47 kΩ

GND

PCA9901 LED BLINKER

VDD

TEST1

CTRL

8

7

5 P0.7

GND

aaa-012137

Fig 52. LED blinker (PCA9901)

Fig 53. LED blinker (PCA9901) section

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 39 of 61

NXP Semiconductors

6. GPIO target board (OM13303)

The GPIO Target Board (OM13303) is used to monitor the Input/Output (I/O) signals from

a GPIO. The board has eight channels, each with a push switch and an LED indicator.

See Figure 54

Fig 54. OM13303 GPIO target board PCB assembly (front side)

6.1 Theory of operation

.

UM10741

Fm+ development kit OM13320

Each of the eight channels operates independently and in the same way. The voltage

applied to the input pin is compared in a Windows comparator, which in tur n drives a d ua l

color LED. The thresholds for the comparators are set to one-third (logic zero) and

two-thirds (logic one) of the supply voltage. These values correspond to the I

threshold voltages for the I

2

C-bus specification.

2

C-bus logic

When a push button is pressed, a logic zero is applied the channel, which can be r ead by

the GPIO device to which the GPIO Target Board is attached. A 2 × 5 header is used to

connect to the Fm+ Development Board (OM13260) or a GPIO daughter card with a flat

ribbon cable (supplied in the kit).

Two connectors are installed, one on each end of the board, and on opposite sides of the

PCB to aid in connection without the cables blocking the buttons or LEDs.

There are no option jumpers and no adjustments on the GPIO Target Board (OM13303).

Unlike other PCB assemblies in the Fm+ Development Kit (OM13320), the GPIO Target

Board (OM13303) has components on both sides of the PCB. See Figure 55

.

Fig 55. OM13303 GPIO target board PCB assembly (back side)

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 40 of 61

NXP Semiconductors

6.2 Circuit description

The schematic diagram has multiple sheets. For clarification, only fragments of the

schematic are shown here. The full schematic should be downloaded if required. The

following pages are divided in to several sections covering the win dow comparator, push

switches, bias circuit, and connectors.

6.2.1 Window comparator

Channel 0 is shown; channels 1 through 7 are identical. The input signal is applied to two

comparators, (IC01A and IC01B).

UM10741

Fm+ development kit OM13320

If the input (IO0) is higher than the threshold set by V

and resistor divider (R03 and

IH

R04), the output of the comparator (IC01A) switches to near ground. This turns on the

green LED (D01). Resistor (R04) applies positive feedback hysteresis (about 150 mV) to

the comparator, shifting the trip point to a slightly lower voltage, to stop the circuit from

oscillation around the switch point.

The input (IO0) is attenuated slightly by a resistor divider (R07 and R08), if the resulting

voltage is lower than the threshold set by V

, the output of the comparator (IC1B)

IL

switches to near ground. This turns on the red LED (D01). Resistor (R08) applies positive

feedback hysteresis (about 125 mV) to the comparator, shifting the trip point to a slightly

higher voltage, to stop the circuit from oscillation around the switch point.

LED current is limited by resistors R05 and R09, which are selected to give approximately

equal brightness to the green and red LED elements. See Figure 56

.

The operation of the window circuit is shown by applying a ramp waveform, see Figure 57

and Figure 58

.

+3V3

R02

VH

IO0

VL

10 kΩ

R03

51 kΩ

R06

10 kΩ

R07

51 kΩ

2

3

6

5

R04

1 MΩ

LMV358MM

1

IC01A

LMV358MM

1

IC01B

R05

330 Ω

GR

DUAL_LEDLTST

D01

R08

1 MΩ

R09

820 Ω

aaa-012138

Fig 56. Window comparator (Channel 0 shown)

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 41 of 61

NXP Semiconductors

Fig 57. Input ramp (yellow trace), green LED drive (green trace)

UM10741

Fm+ development kit OM13320

Fig 58. Input ramp (yellow trace), red LED drive (green trace)

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 42 of 61

NXP Semiconductors

6.2.2 Push switches

Each channel has a push switch (S01 through S71) that connects the appropriate IO pin

to ground when pressed. Series resistors (R01 th rough R71) lim it the current, in the event

that the IO pin is being driven HIGH (by the connected GPIO device) when the push

switch is closed. Each input is biased to VC (one-half the supply volt age), in the event that

the IO pin is left open. This extinguishes both the green and red LEDs of that channel,

preventing false readings. See Figure 59

UM10741

Fm+ development kit OM13320

.

VC

R102

IO0

R01

1

2

3

4

S01

GND

Fig 59. Push switches

6.2.3 Bias circuit

Each channel requires three reference voltag es (VL, VC, and VH), from the bias circuit.

A resistor divider chain (R01, R02, R0 3, and R04) divides the supply voltage to produce

one-third (VL), one half (VC) and two-thirds (VH). Each value is buffered by an op amp

(sections of IC80). Test points are provided as PCB pads for VH (high), VC (center), and

VL (low). The fourth section of the quad op amp (IC80) is not used. Noise spikes on each

bias supply are removed by capacitors (C89, C90, and C91), powe r supply variations are

removed by capacitors (C86 and C87). See Figure 60

10 kΩ

270 Ω

S11

IO1

R112

R11

1

3

GND

10 kΩ

270 Ω

S31

IO3

R132

R31

1

3

GND

2

4

R122

10 kΩ

IO2

R21

270 Ω

1

S21

3

GND

2

4

2

4

10 kΩ

270 Ω

S41

IO4

1

3

GND

R142

R41

2

4

10 kΩ

270 Ω

S51

IO5

R152

R51

1

3

GND

2

4

10 kΩ

270 Ω

S61

IO6

R162

R61

1

3

GND

2

4

10 kΩ

270 Ω

R172

IO7

R71

1

2

3

4

S71

GND

aaa-012139

10 kΩ

270 Ω

.

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 43 of 61

NXP Semiconductors

+3V3

R81

R82

R83

R84

GND

10 kΩ

5.1 kΩ

GND

5.1 kΩ

10 kΩ

GND

13

12

C87

4.7 μF, 6.3 V

C86

4.7 μF, 6.3 V

VL

10

6

5

2

3

9

14

IC80D

LMV324MZ

7

IC80B

LMV324MZ

1

IC80A

LMV324MZ

8

IC80C

LMV324MZ

UM10741

Fm+ development kit OM13320

TP3

VH

VH

C89

100 nF

GND

TP4

VC

VC

C90

100 nF

GND

TP2

VL

VL

C91

100 nF

GND

aaa-012140

Fig 60. Bias circuit

6.2.4 Connectors

The GPIO Target Board (OM13303) is intended to be connected to the Fm+ Development

Board (OM13260) (or other GPIO daughter cards) via a 10-pin ribbon cable. There are

two identical connectors, one on each end of the GPIO Target Board to allow connection

without blocking the push switches or the LEDs. See Figure 61

Fig 61. Connectors

GND

+3V3

+3V3

GND

IO0

IO1

IO2

IO3

IO4

IO5

IO6

IO7

CN1-1

CN1-2

CN1-3

CN1-4

CN1-5

CN1-6

CN1-7

CN1-8

CN1-9

CN1-10

GND

+3V3

+3V3

GND

IO0

IO1

IO2

IO3

IO4

IO5

IO6

IO7

, Figure 62 and Figure 63.

CN2-1

CN2-2

CN2-3

CN2-4

CN2-5

CN2-6

CN2-7

CN2-8

CN2-9

CN2-10

aaa-012141

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 44 of 61

NXP Semiconductors

UM10741

Fm+ development kit OM13320

Fig 62. Ribbon cables attached to underside of the GPIO target board (OM13303)

Fig 63. Ribbon cables attached to the topside of the GPIO target board (OM13303)

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 45 of 61

NXP Semiconductors

7. Bus buffer demo board (OM13398)

The Bus Buffer Board (OM13398) (supplied in the kit) provides a method to link both the

2

I

C buses on the Fm+ Development Board (OM1326 0) by attachment to Port E, in place

of the wire jumper used earlier (see Section 5.6.1 “

jumper)”. See Figure 64 and Figure 65.

UM10741

Fm+ development kit OM13320

Linking both buses together (with a

Fig 64. Bus buffer board (OM13398)

Fig 65. Bus buffer board (OM13398) attached to the Fm+ development board (OM13260)

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 46 of 61

NXP Semiconductors

7.1 Theory of operation

Two identical bus buffer devices are connected in series between the Bus1 and Bus2

segments on the Fm+ Development Board (OM13260). Ea ch Bus Buf fer has two identica l

channels, one for I

will be described in detail.

UM10741

Fm+ development kit OM13320

2

C clock (SCL) and the second for I2C data (SDA). Only one channel

Each PCA9617A bus buffer device has two p ower supply conn ections, V

to allow voltage level shifting between one I

2

C-bus segment and another I2C-bus

CC(A)

segment. Jumpers on the Bus Buffer Boar d ( OM133 98 ) select th e voltage source of each

of the two device power supplies. To demonstrate the voltage level translator ability the

link between the two bus buffers is supplied from a variable voltage regulator, which in

turn can be set by the user anywhere between 1.0 V and 3.2 V.

The pull-up resistor on the Low Voltage Bus section is selected by jumpers.

7.2 Circuit description

The schematic diagram has multiple sheets. For clarification, only fragments of the

schematic are shown here. The full schematic should be downloaded if required. The

following pages are divided in to several sections covering the Bu s1 Bus Buf fer, Bus2 Bus

Buffer, Supply select jumpers, Adjustable Voltage Regulator , and Connectors. A block

diagram will assist understanding. See Figure 66

5 V

ADJUSTABLE

VOLTAGE

REGULATOR

1.0 V to 3.2 V

V

CC(B)

V

V

CC(A)

JP2

CC(A)

3.3 V

PULL-UP

RESISTORS

V

CC(A)

.

5 V

JP1

3.3 V

V

CC(B)

V

CC(A)

V

CC(B)

and V

CC(B)

,

BUS1

BA

PCA9617A

low

voltage

bus

AB

PCA9617A

BUS2

aaa-012142

Fig 66. Block diagram for the bus buffer board (OM13398)

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 47 of 61

NXP Semiconductors

7.2.1 Bus1 bus buffer (PCA9617A)

I2C-bus signals from the Fm+ Development Board (OM13260), called SCL1 an d SDA1,

are applied to the high voltage or ‘B’ Side of IC1 (PCA9617A). The required pull-up

resistors on this section of Bus1 are on the Fm+ Development Board (OM13260).

Signals on the low voltage or ‘A’ Side of IC1 are connected to a selection of pull-up

resistors selected by either JP5 (for SCL) or JP3 (for SDA), and the low voltage or ‘A’ Side

of the second PCA9617A, IC3.

Loading capacitors, C31 for SCL and C51 SDA, can be place d on the low voltage section

of the bus. To accommodate two different footprints IC1 (TSSOP8) and IC2 (HWSON8)

are connected in parallel, but only one part is installed. Installing JP4 disables the Bus

Buffer. See Figure 67

UM10741

Fm+ development kit OM13320

.

V

DD(A)

TP1

SCL1

SDA1

TSSOP8

HWSON8

SDA VDD(A) PULL-UP

C7

100 nF

TP2

6

SCL1

7

SDA1

C9

100 nF

SCL1

SDA1

4

5

DO NOT PLACE

SDAB

SCLB

SDAB

SCLB

V

DD(A)

V

DD(B)

1

8

VDD(B)

VDD(A)

GND

4

PCA9617ADP

GND

V

DD(A)

V

DD(B)

7

6

VDD(B)

VDD(A)

GND

2

PCA9617ATP

GND

SDAA

SCLA

EN

SDAA

SCLA

EN

IC1

32SCLA

5

IC2

1

8

3

C52

100 nF

C8

GNDGND

C10

GNDGND

GND

100 nF

SDAA

100 nF

R51

JP3-2

JP3-1

SCLA

SDAA

R52

240 Ω

GND

ENABLE

524 Ω

JP3-4

JP3-3

R53

JP4-1

JP4-2

3.0 kΩ

JP3-6

JP3-5

JP3-8

JP3-7

C51

100 pF

GND

aaa-012143

Fig 67. Bus1 bus buffer

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 48 of 61

NXP Semiconductors

7.2.2 Bus2 bus buffer (PCA9617A)

I2C-bus signals on the low voltage bus are also connected to the A side of the second

PCA9617A Bus Buffer device, IC3. To accommodate two different footprints, IC3

(TSSOP8) and IC4 (HWSON8) are connected in parallel, but only one device is installed.

Installing JP6 disables the bus buffer. See Figure 68

2

C-bus signals from the high voltage or ‘B’ side of IC3 (PCA9617A) are passed back to

I

the Fm+ Development Board (OM13260). The required pull-up resistors on this section of

Bus1 are on the Fm+ Development Board (OM13260).

V

DD(A)

UM10741

Fm+ development kit OM13320

.

TP3

SCLA

C32

100 nF

SDAA

GND

TP4

R31

240 Ω

JP5-2

JP5-1

R32

524 Ω

JP5-4

JP5-3

JP6-1

JP6-2

ENABLE

R33

3.0 kΩ

JP5-6

JP5-5

GND

SCL VDD(A) PULL-UP

C31

JP5-8

JP5-7

SCLA

SDAA

100 pF

GND

GND GND

SCLA

SDAA

GND GND

V

DD(A)

C4

100 nF

IC3

3

SDAA

2

SCLA

5

EN

PCA9617ADP

V

DD(A)

C6

100 nF

IC4

1

SDAA

8

SCLA

3

EN

PCA9617ATP

V

DD(B)

1

VDD(A)

GND

V

DD(B)

7

VDD(A)

GND

8

SDAB

VDD(B)

SCLB

GND

4

6

SDAB

VDD(B)

SCLB

GND

2

DO NOT PLACE

C3

6

7

C5

4

5

100 nF

SCL2

SDA2

TSSOP8

100 nF

SCL2

SDA2

HWSON8

TP5

SCL2

TP6

SDA2

aaa-012144

Fig 68. Bus2 bus buffer

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 49 of 61

NXP Semiconductors

aaa-012145

GND

JP1-1

JP1-2

JP1-3

V

DD(B)

+5V

+3V3

SEL VDD(B) VOLTAGE

JP2-1

JP2-2

JP2-3

V

DD(A)

+3V3

+5V +5V

SEL VDD(A) VOLTAGE

D2

LTST-C170TBKT(BLU)

10 kΩ

R6

820 Ω

R2

V

DD(A)

TP7

51 kΩ

R3

C1

22 pF/16 V

1.64 kΩ

R7

BLU

GND

Q1

BSH111

VDD(A) ON

+5V

R4

50 kΩ

22 kΩ

R5

GND

GND

IC5

FAN2558ADJ

1

3

2

VIN

EN

GND

VOUT

ADJ

PG

6

5

4

VDD(A) LDO

1.0 V to 3.2 V

VAR ADJ

7.2.3 Supply select jumpers

The ‘B Side’ (high voltage side of the voltage level translator) of each PCA9617A can be

either 3.3 V or 5 V as selected by JP1. The ‘A Side’ (low voltage side of the voltage level

translator) of each PCA9617A can be either 3.3 V or a var iable voltage between 1.0 V and

3.2 V as selected by JP2. See Figure 69

UM10741

Fm+ development kit OM13320

.

UM10741 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2014. All rights reserved.

User manual Rev. 1 — 1 April 2014 50 of 61

Fig 69. Supply select jumpers

7.2.4 Variable voltage regulator

.

The low voltage bus bias is generated by an LDO (Low Drop Out) voltage regulator, IC5.

The output voltage is set by resistor divider R3, R4, and R5, and provides a range of 1.0 V

to 3.2 V. The LDO provides a ‘Power Good’ signal, which is pulled HIGH by R6, and

buffered by Q1. When the LDO is working correctly, the blue LED (D2) is turned ON.

See Figure 69

NXP Semiconductors

aaa-012146

CN1-14

SCL1

CN1-13

CN1-12

INT