Page 1

MCSPTR2A5775E 3-phase PMSM Motor

NXP Semiconductors

Document Number: AN13038

Application Note

Rev. 0

,

10/2020

Contents

1. Introduction ........................................................................ 1

2. System concept ................................................................... 2

3. PMSM field-oriented control.............................................. 3

3.1. Fundamental principle of PMSM FOC ................... 3

3.2. PMSM model in quadrature phase synchronous

reference frame ...................................................................... 5

3.3. Output voltage actuation and phase current

measurement ......................................................................... 7

3.4. Rotor position/speed estimation .............................. 9

3.5. Field weakening .................................................... 10

4. Software implementation on the MPC5777E ................... 13

4.1. eTPU ..................................................................... 13

4.2. MPC5777E – Key modules for PMSM FOC control

17

4.3. MPC5775E Device initialization ........................... 19

4.4. Software architecture ............................................. 34

5. FreeMASTER and MCAT user interface ......................... 47

5.1. MCAT Settings and Tuning .................................. 48

5.2. MCAT application Control ................................... 51

6. Conclusion ........................................................................ 52

7. References ........................................................................ 52

Control Kit with MPC5775E

Featuring Motor Control Application Tuning (MCAT) Tool

by: NXP Semiconductors

1. Introduction

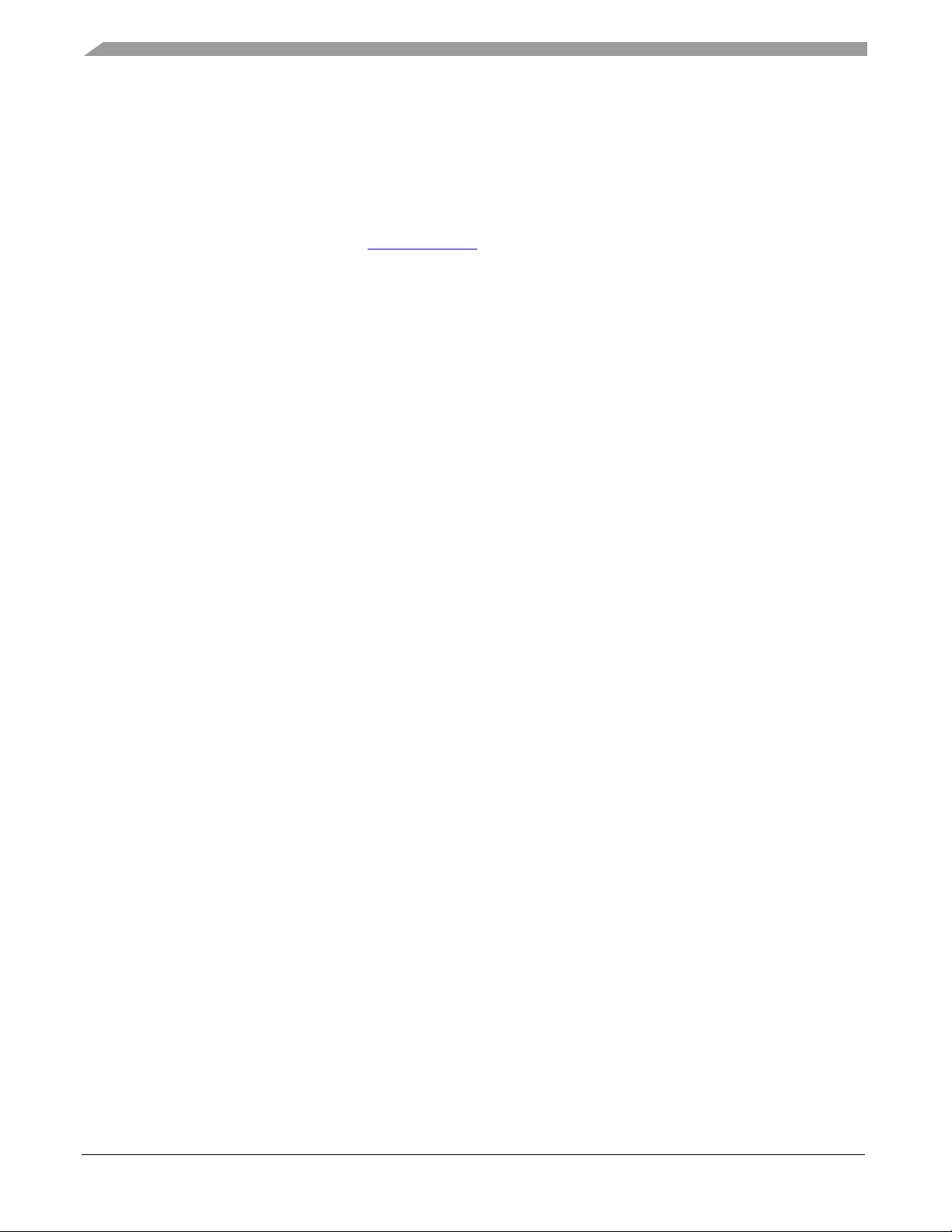

This application note describes the design of a 3-phase

Permanent Magnet Synchronous Motor (PMSM) vector

control drive with 3-shunt current sensing and resolver

position sensing. The design is targeted for automotive

motor control (MC) applications.

This design serves as an example of motor control design

using NXP family of automotive motor control MCUs

based on a 32-bit Power Architecture technology

optimized for a full range of automotive applications.

Following are the supported features:

• 3-phase PMSM speed Field Oriented Control.

• Current sensing with three shunt resistors.

• Application control user interface using

FreeMASTER debugging tool.

• Motor Control Application Tuning (MCAT) tool.

• Rotor position and speed measurement using

resolver transducer

Page 2

System concept

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

2 NXP Semiconductors

2. System concept

The system is designed to drive a 3-phase PM synchronous motor. The application meets the following

performance specifications:

• Targeted at the MPC5775E-EVB Evaluation Board (refer to dedicated user manual for

MPC5775E-EVB available at www.nxp.com). See References for more information

• S32 Design Studio (see References)

• MC33937 MOSFETs pre-driver with extensive set of functions and condition monitoring (see

References)

• Control technique incorporating:

o Field Oriented Control of 3-phase PM synchronous motor with resolver position sensor

o Closed-loop speed control with action period 1 ms

o Closed-loop current control with action period 100 µs

o Bi-directional rotation

o Flux and torque independent control

o Field weakening control extending speed range of the PMSM beyond the base speed

o Position and speed are computed by Enhanced Time Processing Unit eTPU

o Sensing of three-phase motor currents

o FOC state variables sampled with 100 μs period

• Automotive Math and Motor Control Library (AMMCLIB) - FOC algorithm built on blocks of

precompiled SW library (see section References)

• Use of eTPU Motor control function set to offload CPU

• FreeMASTER

o FreeMASTER software control interface (motor start/stop, speed setup)

o FreeMASTER software monitor

o FreeMASTER embedded Motor Control Application Tuning (MCAT) tool (motor

parameters, current loop, speed loop) (see section References)

o FreeMASTER software MCAT graphical control page (required speed, actual motor

speed, start/stop status, DC-Bus voltage level, motor current, system status)

o FreeMASTER software speed scope (observes actual and desired speeds, DC-Bus

voltage and motor current)

o FreeMASTER software high-speed recorder (reconstructed motor currents, vector control

algorithm quantities)

• DC-Bus over-voltage and under-voltage, over-current, overload and start-up fail protection

Page 3

PMSM field-oriented control

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

NXP Semiconductors 3

Figure 1 MCSPTR2A5775E 3-phase PMSM Development Kit with MPC5775E

3. PMSM field-oriented control

3.1.

Fundamental principle of PMSM FOC

High-performance motor control is characterized by smooth rotation over the entire speed range of the

motor, full torque control at zero speed, and fast acceleration/deceleration. To achieve such control,

Field Oriented Control is used for PM synchronous motors.

The FOC concept is based on an efficient torque control requirement, which is essential for achieving a

high control dynamic. Analogous to standard DC machines, AC machines develop maximal torque

when the armature current vector is perpendicular to the flux linkage vector. Thus, if only the

fundamental harmonic of stator magnetomotive force is considered, the torque Te developed by an AC

machine, in vector notation, is given by the following equation:

Equation 1

where pp is the number of motor pole-pairs, is is stator current vector and ψs represents vector of the

stator flux. Constant 3/2 indicates a non-power invariant transformation form.

Page 4

PMSM field-oriented control

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

4 NXP Semiconductors

In instances of DC machines, the requirement to have the rotor flux vector perpendicular to the stator

current vector is satisfied by the mechanical commutator. Because there is no such mechanical

commutator in AC Permanent Magnet Synchronous Machines (PMSM), the functionality of the

commutator has to be substituted electrically by enhanced current control. This reveal that stator current

vector should be oriented in such a way that component necessary for magnetizing of the machine (flux

component) shall be isolated from the torque producing component.

This can be accomplished by decomposing the current vector into two components projected in the

reference frame, often called the dq frame that rotates synchronously with the rotor. It has become a

standard to position the dq reference frame such that the d-axis is aligned with the position of the rotor

flux vector, so that the current in the d-axis will alter the amplitude of the rotor flux linkage vector. The

reference frame position must be updated so that the d-axis should be always aligned with the rotor flux

axis.

Because the rotor flux axis is locked to the rotor position, when using PMSM machines, a mechanical

position transducer or position observer can be utilized to measure the rotor position and the position of

the rotor flux axis. When the reference frame phase is set such that the d-axis is aligned with the rotor

flux axis, the current in the q-axis represents solely the torque producing current component.

What further resulted from setting the reference frame speed to be synchronous with the rotor flux axis

speed is that both d and q axis current components are DC values. This implies utilization of simple

current controllers to control the demanded torque and magnetizing flux of the machine, thus

simplifying the control structure design.

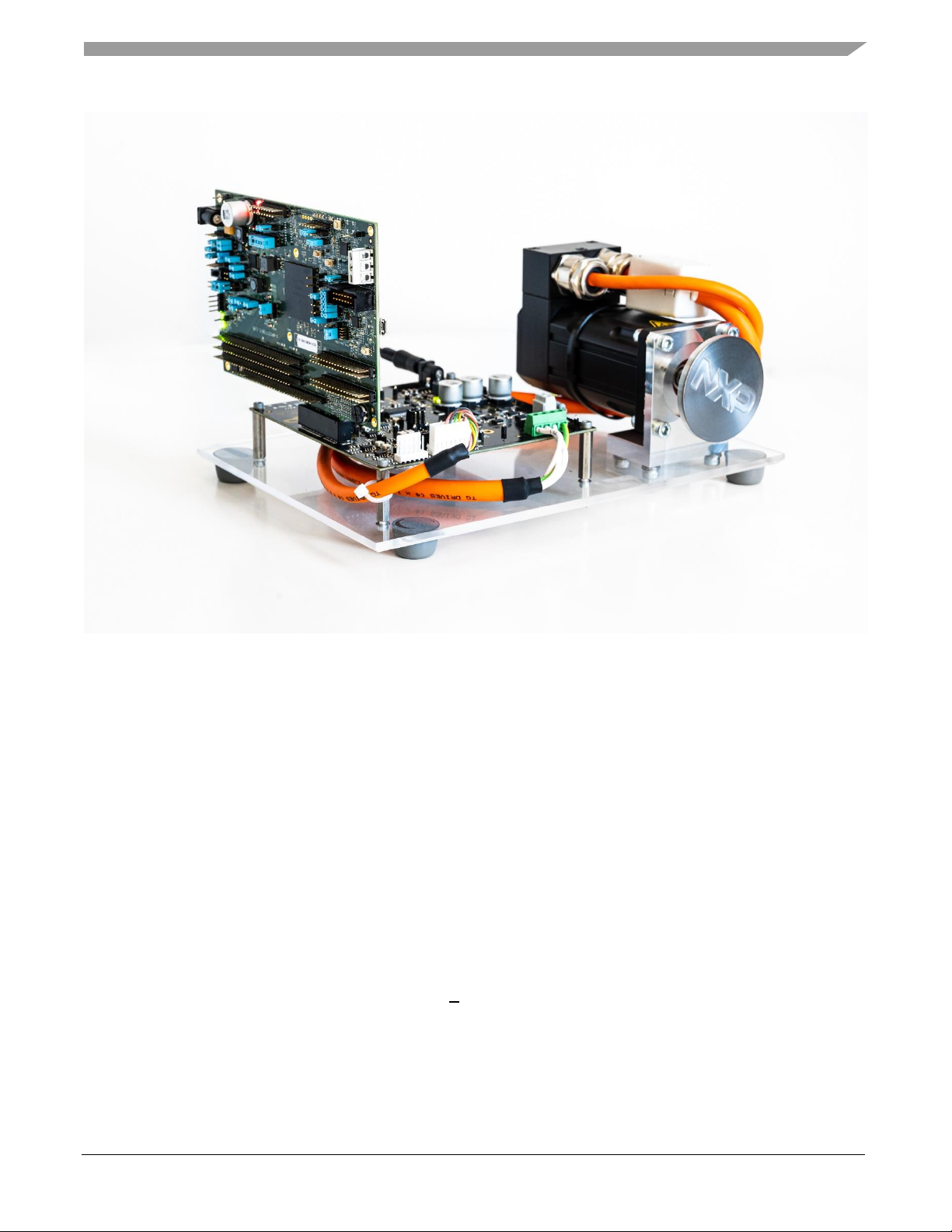

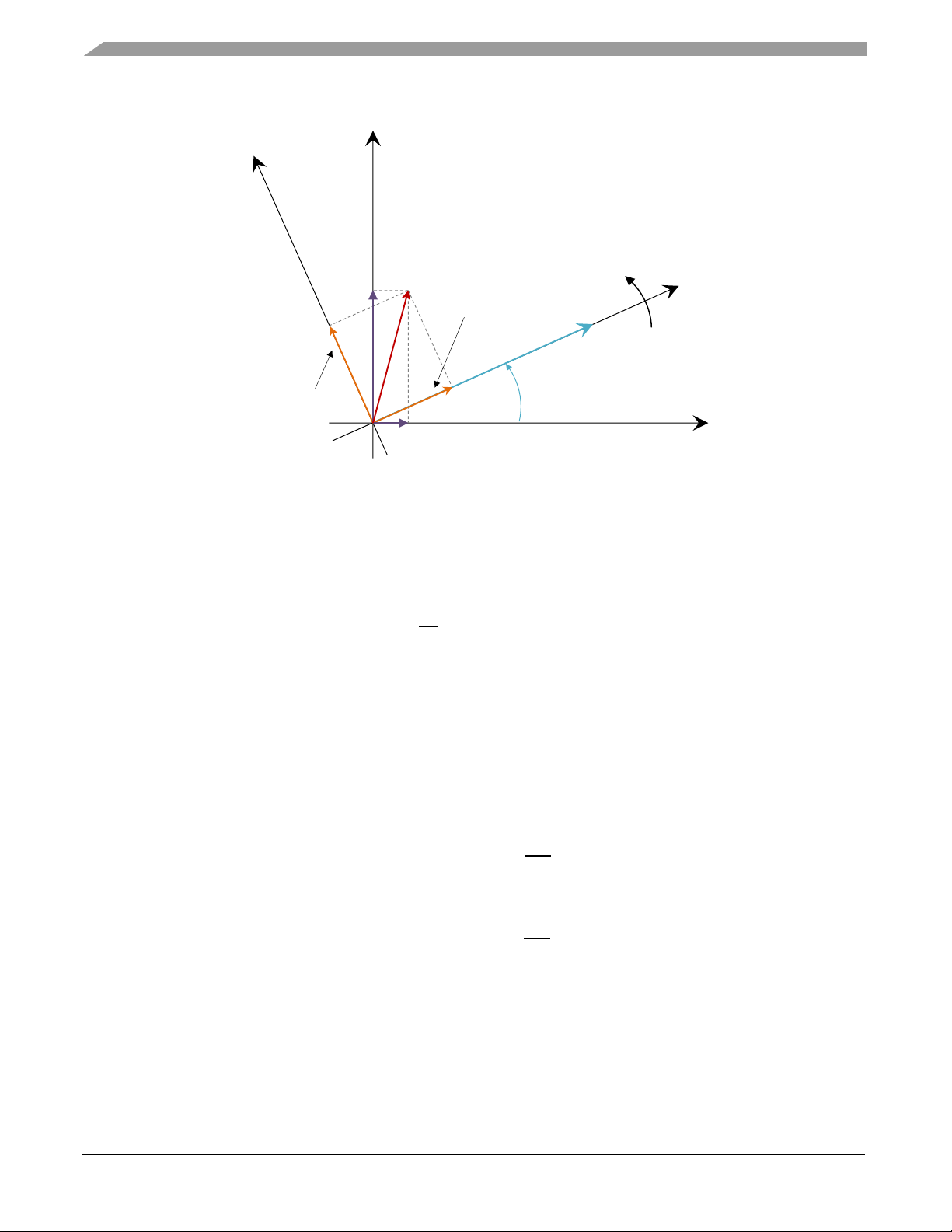

Figure 2 shows the basic structure of the vector control algorithm for the PM synchronous motor. To

perform vector control, it is necessary to take following four steps:

1. Measure the motor quantities (DC link voltage and currents, rotor position/speed).

2. Transform measured currents into the two-phase orthogonal system (α, β) using a Clarke

transformation. After that transform the currents in α, β coordinates into the d, q reference frame

using a Park transformation.

3. The stator current torque (i

sq

) and flux (isd) producing components are separately controlled in d,

q rotating frame.

4. The output of the control is stator voltage space vector and it is transformed by an inverse Park

transformation back from the d, q reference frame into the two-phase orthogonal system fixed

with the stator. The output three-phase voltage is generated using a space vector modulation.

Clarke/Park transformations discussed above are part of the Automotive Math and Motor Control

Library set (see section References).

To be able to decompose currents into torque and flux producing components (isd, isq), position of the

motor-magnetizing flux has to be known. This requires knowledge of the accurate rotor position as

being strictly fixed with magnetic flux. This application note deals with the sensor based FOC control

where the position and velocity are obtained by position/velocity estimator executed by eTPU. Position

and speed are processed by eTPU co-processor that runs independently on system core.

Page 5

PMSM field-oriented control

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

NXP Semiconductors 5

Figure 2 Field oriented control transformations

3.2.

PMSM model in quadrature phase synchronous reference frame

Quadrature phase model in synchronous reference frame is very popular for field-oriented control

structures, because both controllable quantities, current and voltage, are DC values. This allows to

employ only simple controllers to force the machine currents into the defined states. Furthermore, full

decoupling of the machine flux and torque can be achieved, which allows dynamic torque, speed and

position control.

The equations describing voltages in the three phase windings of a permanent magnet synchronous

machine can be written in matrix form as follows:

Equation 2

where the total linkage flux in each phase is given as:

Equation 3

where Laa, Lbb, Lcc, are stator phase self-inductances and Lab=Lba, Lbc=Lcb, Lca=Lac are mutual

inductances between respective stator phases. The term ΨPM represents the magnetic flux generated by

the rotor permanent magnets, and θe is electrical rotor angle.

Page 6

PMSM field-oriented control

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

6 NXP Semiconductors

Figure 3 Orientation of stator (stationary) and rotor (rotational) reference frames, with current

components transformed into both frames

The voltage equation of the quadrature phase synchronous reference frame model can be obtained by

transforming the three phase voltage equations (Equation 2) and flux equations (Equation 3) into a two

phase rotational frame which is aligned and rotates synchronously with the rotor as shown in Figure 3.

Such transformation, after some mathematical corrections, yields the following set of equations:

Equation 4

where ωe is electrical rotor speed. It can be seen that Equation 4

represents a non-linear cross dependent system with cross-coupling terms in both d and q axis and back-

EMF voltage component in the q-axis. When FOC concept is employed, both cross-coupling terms shall

be compensated in order to allow independent control of current d and q components. Design of the

controllers is then governed by following pair of equations, derived from Equation 4 after

compensation:

Equation 5

Equation 6

Those equations describe the model of the plant for d and q current loop. Both equations are structurally

identical, therefore the same approach of controller design can be adopted for both d and q controllers.

The only difference is in values of d and q axis inductances, which results in different gains of the

controllers. Considering closed loop feedback control of a plant model as in either equation, using

α

β

d

q

ω

e

αβ frame – stator coordinates

dq frame – rotor coordinates

θ

e

i

S

i

Sd

i

Sq

i

Sα

i

Sβ

torque

component

flux

component

PM

Page 7

PMSM field-oriented control

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

NXP Semiconductors 7

standard PI controllers, then the controller proportional and integral gains can be derived, using a poleplacement method, as follows:

Equation 7

Equation 8

where ω0 represents the system natural frequency [rad/sec] and ξ is the Damping factor [-] of the current

control loop.

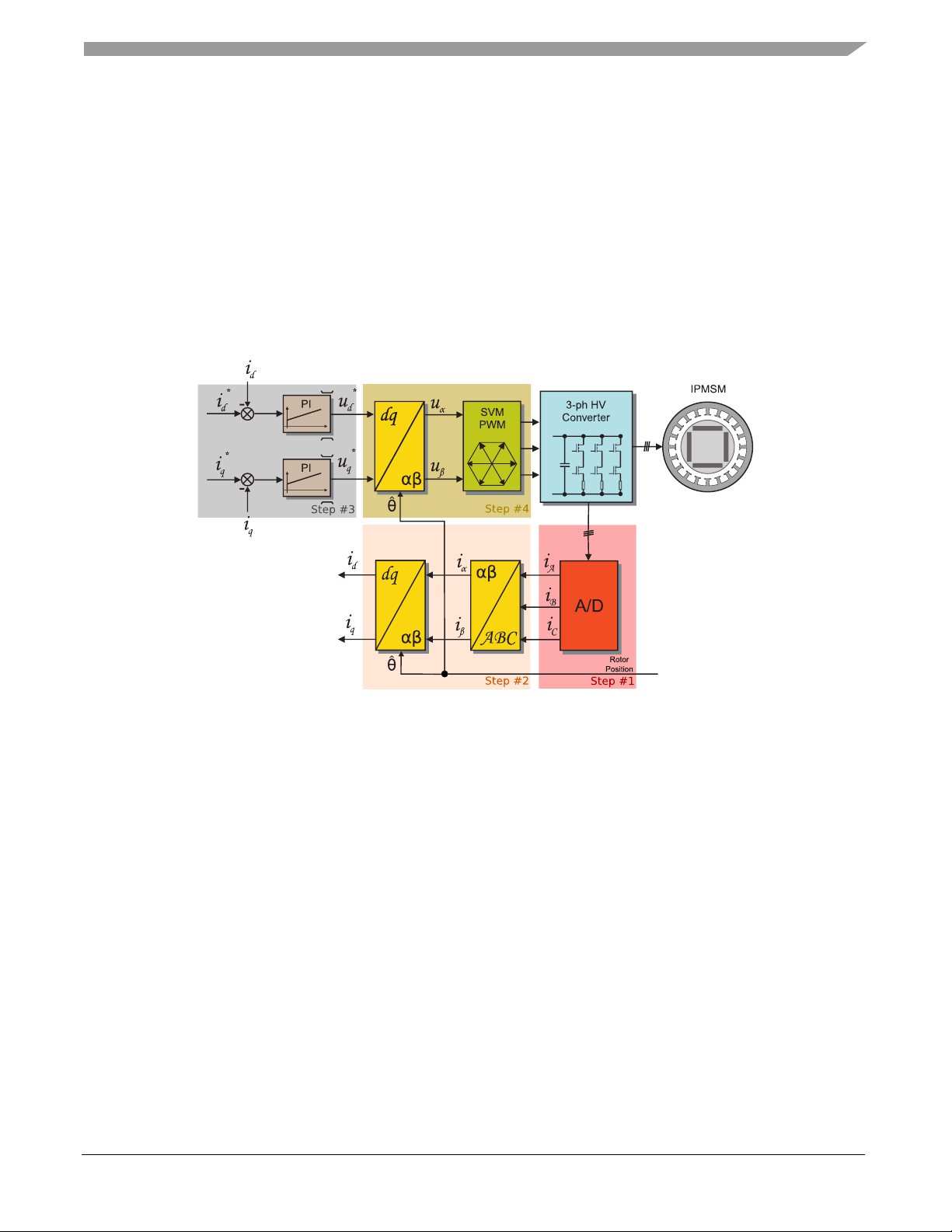

Figure 4 FOC Control Structure

3.3.

Output voltage actuation and phase current measurement

The 3-phase voltage source inverter shown in Figure 5 uses three shunt resistors (R38, R39, R40) placed

in three legs of the inverter as phase current sensors. Stator phase current which flows through the shunt

resistor produces a voltage drop which is interfaced to the AD converter of microcontroller through

conditional circuitry (refer to MCSPTR2A5775E Schematic available at nxp.com).

Page 8

PMSM field-oriented control

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

8 NXP Semiconductors

Figure 5 Three-phase DC/AC inverter with shunt resistors for current measurement

Figure 6 shows a gain setup and input signal filtering circuit for operational amplifier which provides the

conditional circuitry and adjusts voltages to fit into the ADC input voltage range.

Figure 6 Phase current measurement conditional circuitry

The phase current sampling technique is a challenging task for detection of phase current differences

and for acquiring full three phase information of stator current by its reconstruction. Phase currents

flowing through shunt resistors produces a voltage drops which need to be appropriately sampled by the

AD converter when low-side transistors are switched on. The currents cannot be measured by the shunt

resistors at an arbitrary moment. This is because the current only flows through the shunt resistor when

the bottom transistor of the respective inverter leg is switched on. Therefore, considering Figure 5, phase

A current is measured using the R38 shunt resistor and can only be sampled when the low side transistor

Q4 is switched on. Correspondingly, the current in phase B has to be measured when the low side

transistor Q5 is switched on, and the current in phase C can only be measured if the low side transistor

Q6 is switched on. To get an actual instant of current sensing, voltage waveform analysis has to be

performed.

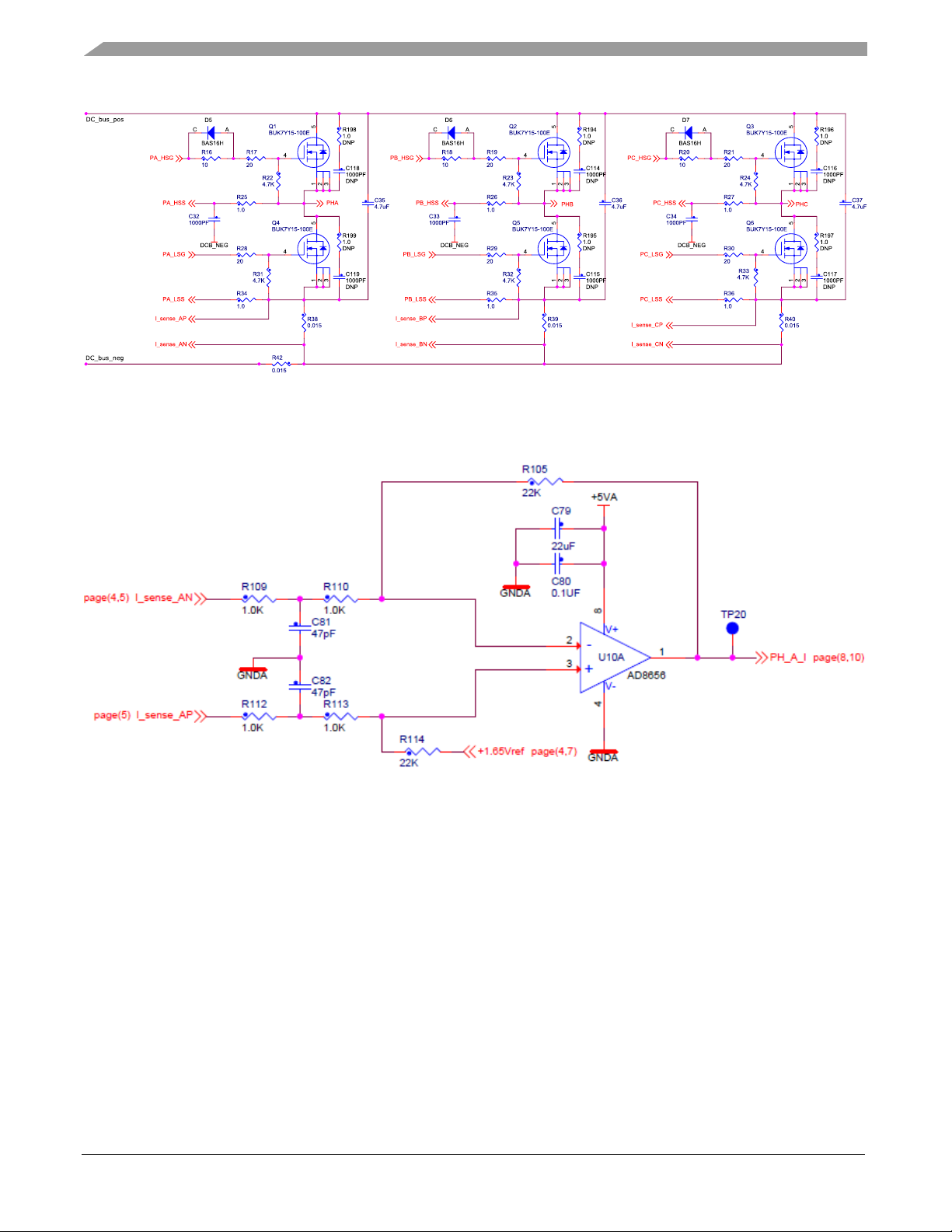

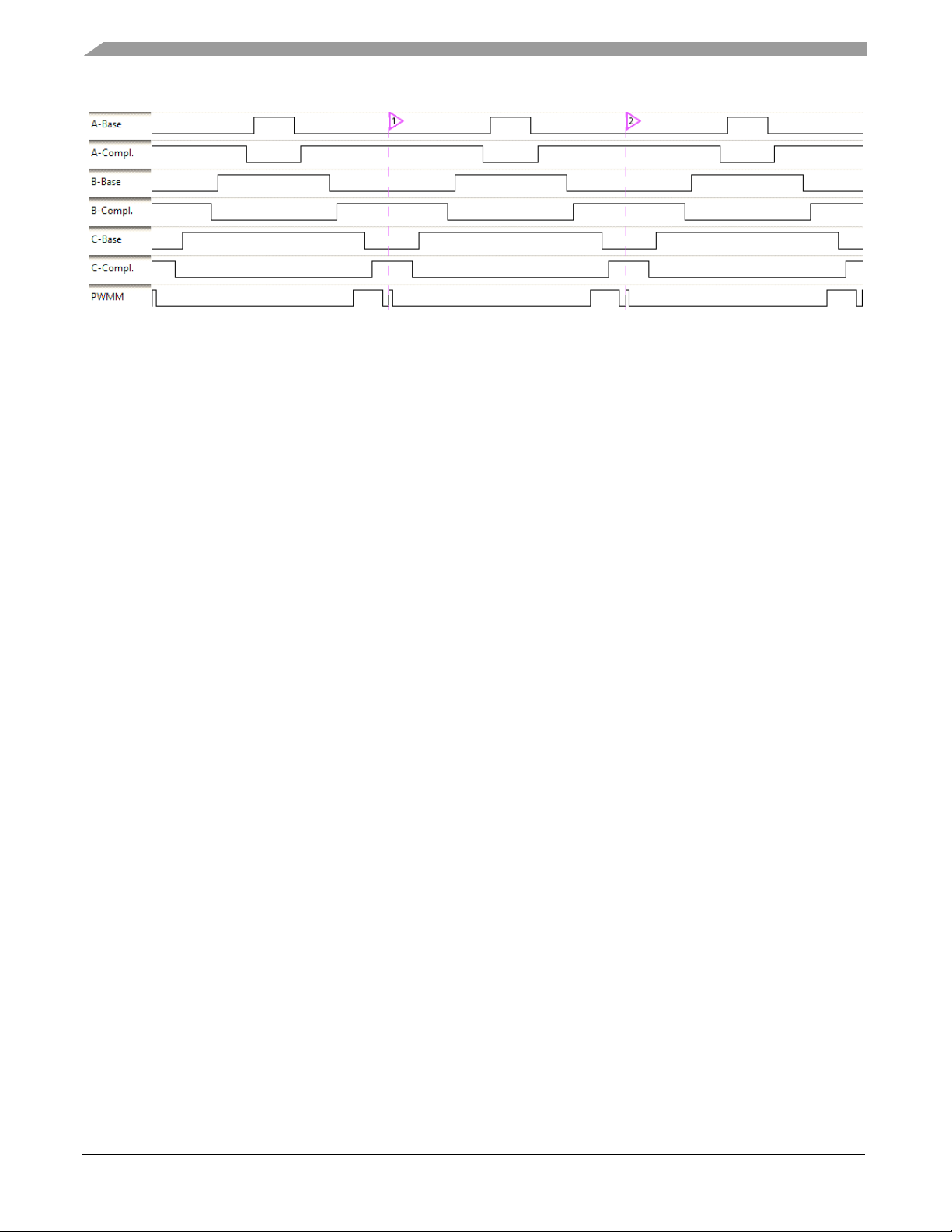

Generated duty cycles (phase A, phase B, phase C) for two consecutive PWM periods are shown in

Figure 7. These phase voltage waveforms correspond to a center-aligned PWM with sine-wave

modulation. As shown in the following figure, (PWM period I), the best sampling instant of phase

Page 9

PMSM field-oriented control

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

NXP Semiconductors 9

current is in the middle of the PWM period, where all bottom transistors are switched on. However, not

all three currents can be measured at an arbitrary voltage shape. PWM period II in the following figure

shows the case when the bottom transistor of phase A is ON for a very short time. If the ON time is

shorter than a certain critical time (depends on hardware design), the current cannot be correctly

measured.

Figure 7 Generated phase duty cycles in different PWM periods

In standard motor operation, where the supplied voltage is generated using the space vector modulation,

the sampling instant of phase current takes place in the middle of the PWM period in which all bottom

transistors are switched on. If the duty cycle goes to 100%, there is an instant when one of the bottom

transistors is switched on for a very short time period. Therefore, only two currents are measured and the

third one is calculated from equation:

Equation 9

NOTE

MPC5775-EVB is using eTPU timer for generation the PWMs signals.

The default limit of the PWM duty cycle is 98% which allows in whole

range of duty cycle measure all three currents. This default setting and

also type of motor control modulation can be changed. Refer to eTPU

PWMM: Center-aligned PWM mode

3.4.

Rotor position/speed estimation

Different sensor type might require different approach to evaluate the speed and position of the motor.

The NXP approach for resolver systems utilizes an Angle Tracking Observer (ATO), see Figure 8 which

is based on the Phase Lock Loop technique. The ATO input is a position error between the position

given by the sensor and estimated ATO position. The PI controller in the ATO loop minimizes the input

error by adjustment of a control variable, in this case the control variable is equivalent to a motor speed.

Integration of the speed leads to the estimated position.

Page 10

PMSM field-oriented control

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

10 NXP Semiconductors

Figure 8 ATO for Resolver systems

The ATO for resolver system is characterized by the position error calculation. The observer error

corresponds to the following formula:

Equation 10

The coefficients of ATO PI controller, Integrator and filter can be tuned by MCAT tool. The ATO

function is a member of the motor control SW library (see References) and is available as

AMCLIB_TrackObsrv.

The alignment algorithm applies DC voltage to d-axis resulting full DC voltage applied to phase A and

negative half of the DC voltage applied to phase B, C for a certain period. This will cause the rotor to

move to "align" position, where stator and rotor fluxes are aligned. The rotor position in which the rotor

stabilizes after applying DC voltage is set as zero position. Motor is ready to produce full startup torque

once the rotor is properly aligned.

NOTE

MPC5775E-EVB is using eTPU for resolver feedback signal

demodulation. eTPU based resolver o digital converter is described in

chapter Software implementation on the MPC5777E.

3.5.

Field weakening

Field weakening is an advanced control approach that extends standard FOC to allow electric motor

operation beyond a base speed. The back electromotive force (EMF) is proportional to the rotor speed

and counteracts the motor supply voltage. If a given speed is to be reached, the terminal voltage must be

increased to match the increased stator back-EMF. A sufficient voltage is available from the inverter in

the operation up to the base speed. Beyond the base speed, motor voltages ud and uq are limited and

cannot be increased because of the ceiling voltage given by inverter. Base speed defines the rotor speed

at which the back-EMF reaches maximal value and motor still produces the maximal torque.

As the difference between the induced back-EMF and the supply voltage decreases, the phase current

flow is limited, hence the currents id and iq cannot be controlled sufficiently. Further increase of speed

would eventually result in back-EMF voltage equal to the limited stator voltage, which means a

complete loss of current control. The only way to retain the current control even beyond the base speed

is to lower the generated back-EMF by weakening the flux that links the stator winding. Base speed

Page 11

PMSM field-oriented control

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

NXP Semiconductors 11

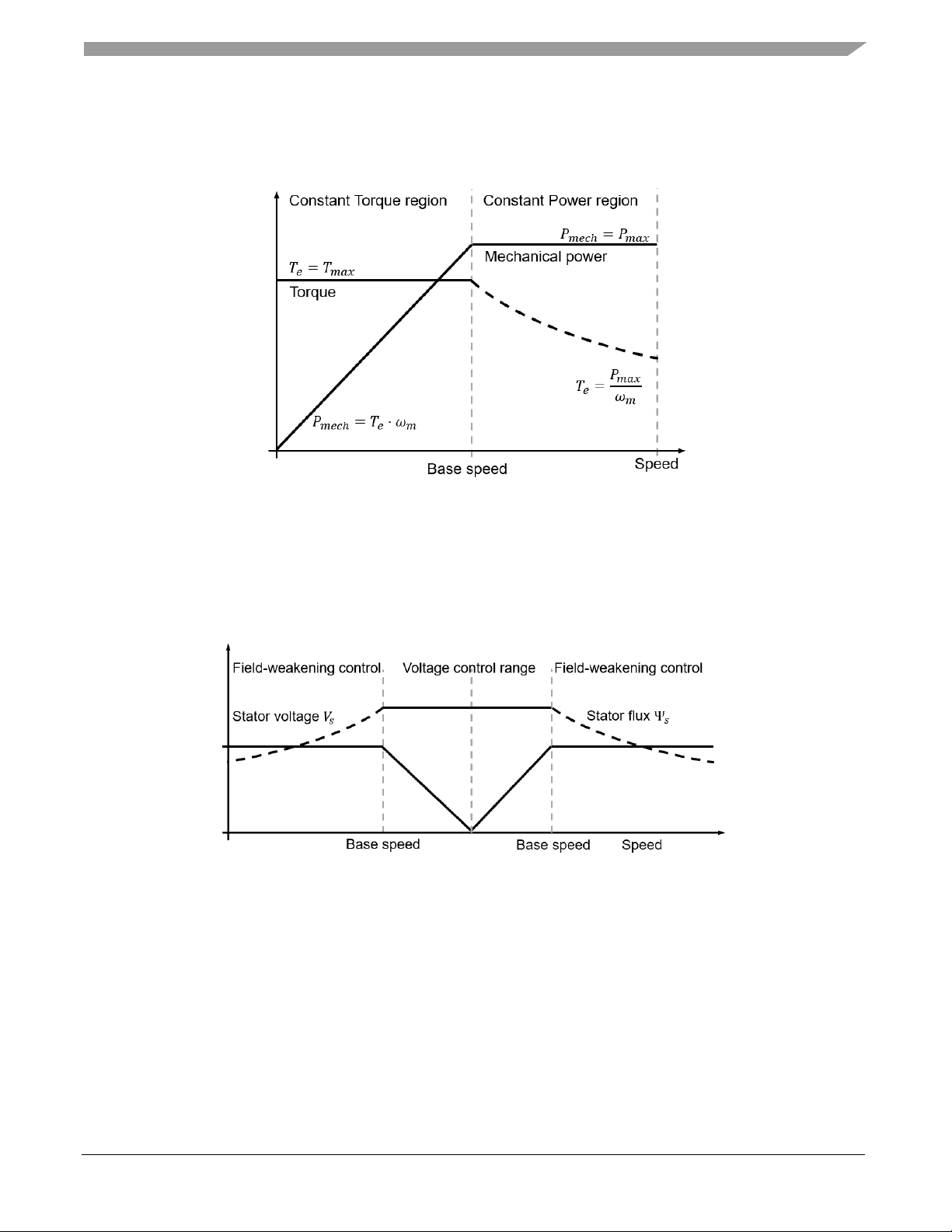

splits the whole speed motor operation into two regions: constant torque and constant power, see the

following figure.

Figure 9 Constant torque/power operating regions

Operation in constant torque region means that maximal torque can be constantly developed while the

output power increases with the rotor speed. The phase voltage increases linearly with the speed and the

current is controlled towards its reference. The operation in constant power region is characterized by a

rapid decrease in developed torque while the output power remains constant. The phase voltage is at its

limit while the stator flux decreases proportionally with the rotor speed, see the following figure.

Figure 10 Constant flux/voltage operational regions

FOC splits phase currents into the q-axis torque component and d-axis flux component. The flux current

component Id is used to weaken the stator magnetic flux linkage ΨS. Reduced stator flux ΨS yields to

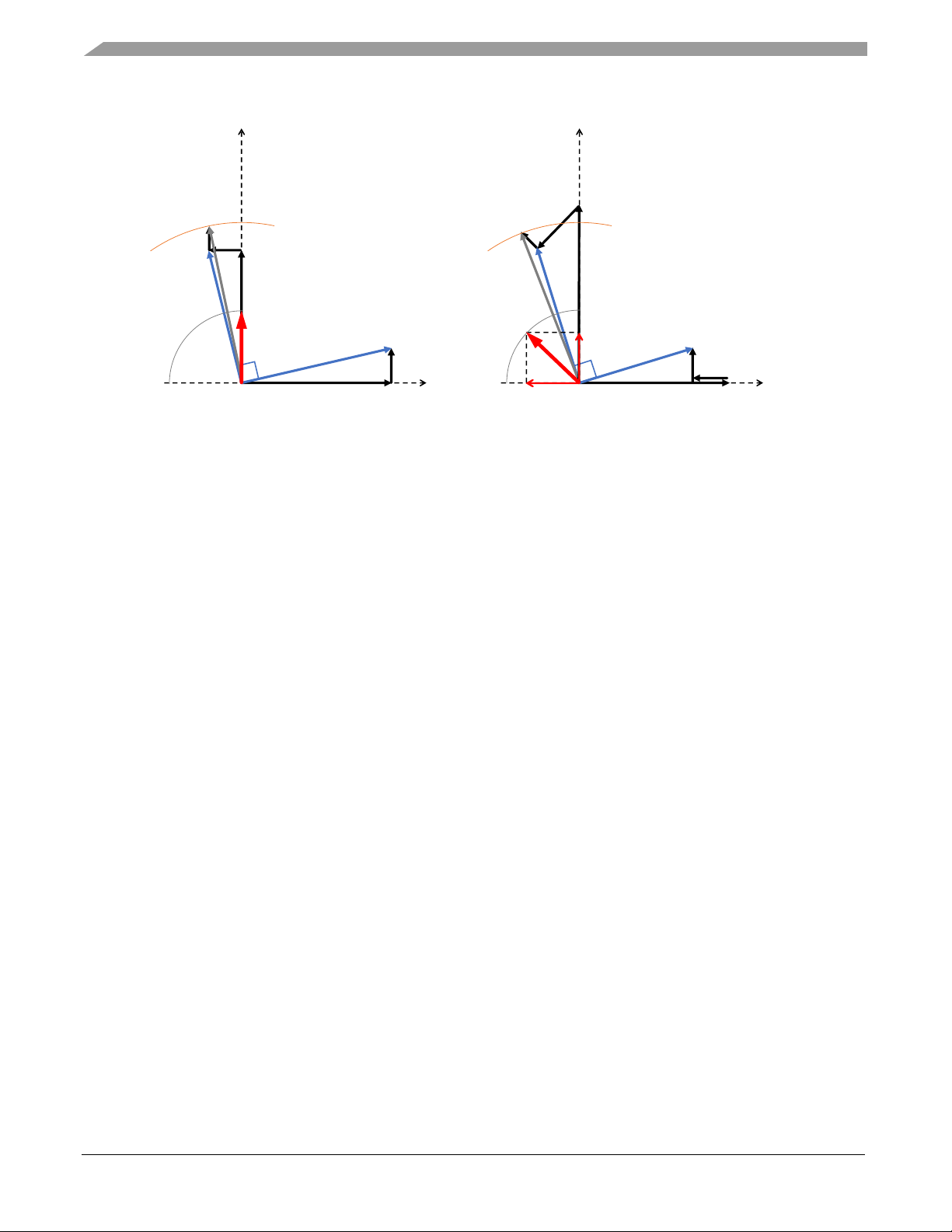

lower Back-EMF and condition of Field Weakening is met. More details can be seen from the following

phasor diagrams of the PMSM motor operated exposing FOC control without (left) and with FW (right),

Figure 11.

Page 12

PMSM field-oriented control

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

12 NXP Semiconductors

Figure 11 Steady-state phasor diagram of PMSM operation up to base speed (left) and above speed (right)

FOC without FW is operated demanding d-axis current component to be zero (Id=0) to excite electric

machine just by permanent magnets mounted on the rotor. This is an operation within constant torque

region (see Figure 9), since whole amount of the stator current consists of the torque producing

component Iq only (see Figure 11, left). Stator magnetic flux linkage ΨS1 is composed of rotor magnetic

flux linkage ΨPM, which represents the major contribution and small amount of the magnetic flux

linkage in q-axis LqIq produced by q-axis current component I

q

. Based on the Faraday’s law, rotor

magnetic flux linkage ΨPM and stator magnetic flux linkage ΨS1 produce back-EMF voltage

E

PM1=ωe1ΨPM

perpendicularly oriented to rotor magnetic flux ΨPM in q-axis and back EMF voltage

ES1=ω

e1ΨS1

perpendicularly oriented to stator magnetic flux ΨS1, respectively (see Figure 11, left). Both

voltages are directly proportional to the rotor speed ωe1. If the rotor speed exceeds the base speed, the

back-EMF voltage ES1=ω

e1ΨS1

approaches the limit given by VSI and Iq current cannot be controlled.

Hence, field weakening has to take place.

In FW operation, Id current is controlled to negative values to “weaken” stator flux linkage ΨS2 by -LdId

component as shown in Figure 11, right. Thanks to this field weakening approach, back-EMF voltage

induced in the stator windings ES2 is reduced below the VSI voltage capability even though E

PM2

exceeds it. Iq current can be controlled again to develop torque as demanded. Unlike the previous case,

this is an operation within constant power region (see Figure 9) where Iq current is limited due to Is

current vector size limitation (see Figure 11, right). In FW operation, stator magnetic flux linkage ΨS

consists of three components now: rotor magnetic flux linkage ΨPM, magnetic flux linkage in q-axis Ψq=

LqIq produced by q-axis current component Iq and magnetic flux linkage in d-axis Ψd= -LdId produced by

negative d-axis Id current component that counteracts to ΨPM.

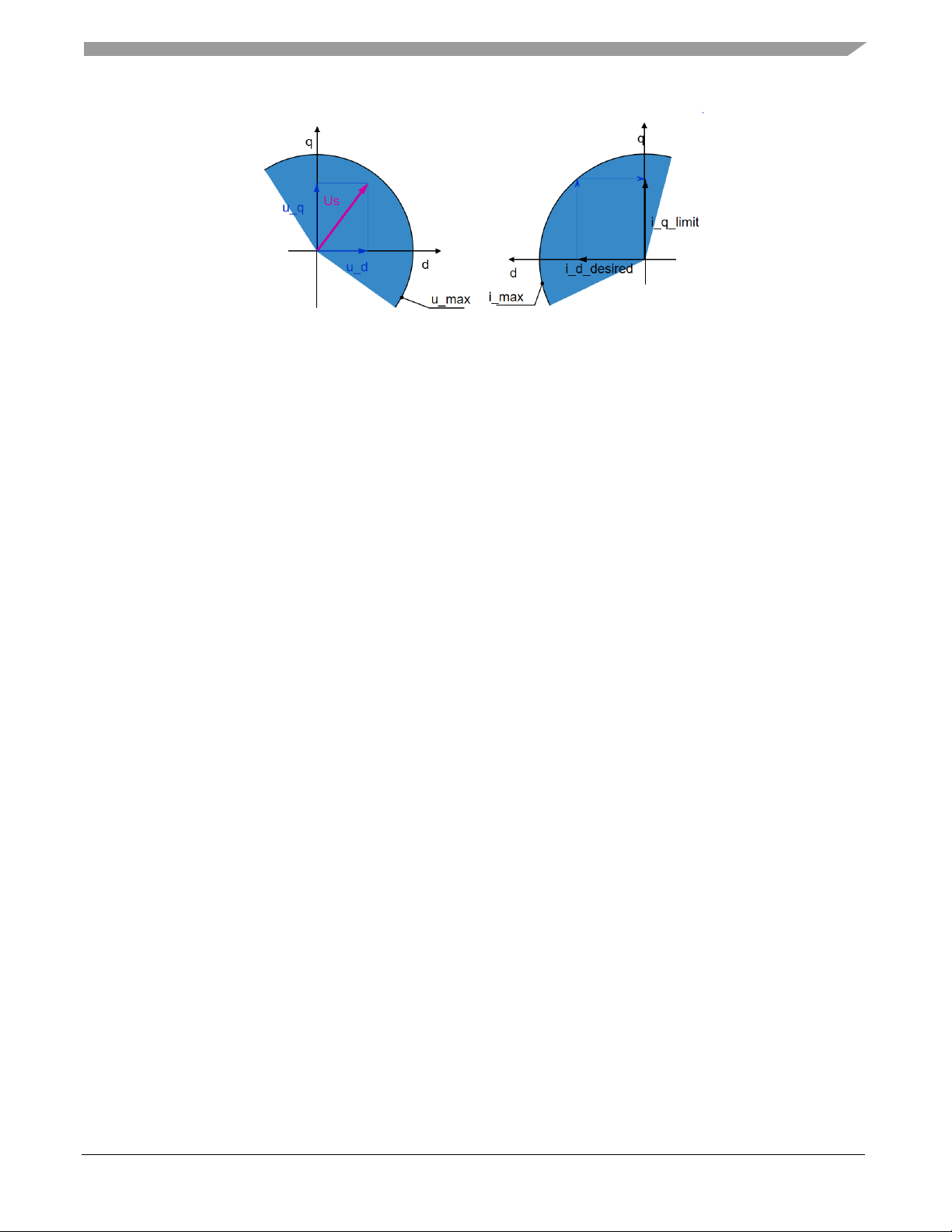

There are some limiting factors that must be taken into account when operating FOC control with field

weakening:

• Voltage amplitude u_max is limited by power as shown in Figure 12, left

• Phase current amplitude i_max is limited by capabilities of power devices and motor thermal

design as shown in Figure 12, right

• Flux linkage in d-axis is limited to prevent demagnetization of the permanent magnets

q- axis

d- axis

IS= I

q

E

PM1

=

e1

PM

V

S1

S1

RS I

S

jXSI

S

q- axis

d- axis

I

S

I

q

I

d

V

S2

S2

RS I

S

jXSI

S

-LdI

d

I

MAX

I

MAX

ES2=

e2

S2

ES1=

e1

S1

LqI

q

LqI

q

VSI voltage capability

VSI voltage capability

E

PM2

=

e2

PM

PM

PM

e1

<

e2

E

PM1

< E

PM2

Page 13

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

NXP Semiconductors 13

Figure 12 Voltage (left) and current (right) limits for PMSM drive operation

NXP’s Automotive Math and Motor Control library offers a software solution for the FOC with field

weakening respecting all limitations discussed above. This library-based function is discussed in section

AMMCLIB integration.

4. Software implementation on the MPC5777E

4.1.

eTPU

The Enhanced Time Processing Unit (eTPU) is a programmable I/O controller with its own core and

memory system, allowing it to perform complex timing and I/O management independently of the CPU.

The eTPU is used as a co-processor, specialized for advanced timing functions, such as handle complex

engine control, motor control, and communication tasks independently of the CPU.

A new complex library of eTPU functions enabling the eTPU to drive motor control applications was

developed. This library represents a step forward compared to its predecessor – the motor control

function sets (set3 and set4). The new Motor Control eTPU Library benefits from NXP eTPU

development tools from CodeWarrior. The eTPU(2) Development Suite is based on Eclipse IDE and

includes the C and assembly compiler, simulator and debugger.

4.1.1.

eTPU PWMM:

The Motor Control PWM eTPU function (PWMM) uses either three eTPU channels to generate three

PWM output signals, or six eTPU channels to generate three complementary PWM output signal pairs,

used to drive a 3-phase electrical motor. One extra channel PWMM Master is used to synchronize all the

outputs and is responsible for all the necessary calculation. Master channel does not generate any

PWMM output, but the output is used for debugging and visualization of PWMM function processing.

An example of eTPU PWMM function can be seen on Figure 13.

Page 14

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

14 NXP Semiconductors

Figure 13 Center aligned 3 phase PWM output with complementary channels and one Master channel

(PWMM).

Features:

• Generates three phases of PWM signals to drive an electrical motor.

• Based on the selected phase type, either single PWM outputs or complementary PWM pairs with

dead-time are generated for each motor phase.

• The PWM polarity can be separately configured for the base and the complementary PWM

outputs.

• The synchronous update of all PWM phases can happen either once or twice per PWM period:

o Frame update

o Frame and Center update (half-cycle update)

• The PWMM inputs are transformed into PWM output duty-cycles by a selected modulation. It

can be one of:

o Unsigned voltages

o Signed voltages

o Standard Space Vector Modulation

o Space Vector Modulation With O

000

Nulls

o Space Vector Modulation With O

111

Nulls

o Inverse Clark Transformation

o Sine Table Modulation

• There are four PWM modes supported. Switching between the PWM modes in run-time is also

supported:

o Left-aligned

o Right-aligned

o Center-aligned

o Inverted center-aligned

• The PWM period can be changed in run-time. The new period value is always applied at frame

update only, not at the center update.

Page 15

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

NXP Semiconductors 15

• Generation of short pulses can be limited by a minimum pulse width – a threshold for pulse

deletion.

4.1.2.

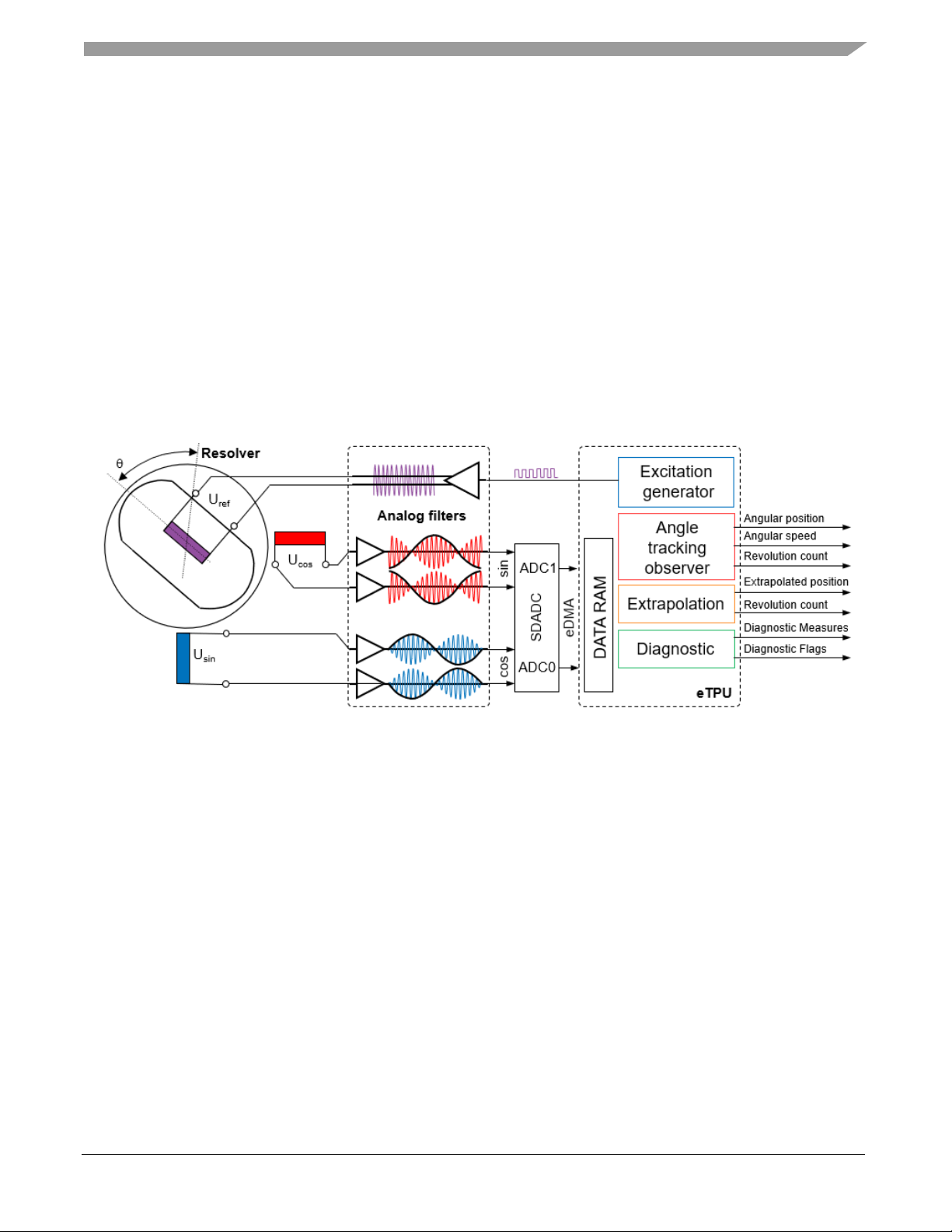

eTPU based Resolver to digital converter (RDC)

The Resolver Digital Interface eTPU function (RESOLVER) uses one eTPU channel to generate a 50%

duty-cycle PWM output signal to be passed through an external low-pass filter and used as a resolver

excitation signal. In the resolver position sensor, this excitation signal is modulated by sine and cosine of

the actual motor angle. The feedback Sine and Cosine signals are sampled by an on-chip ADC and the

conversion results can be transferred to eTPU DATA RAM by eDMA. Then, the eTPU function

RESOLVER can process the digital samples of resolver output signals. Motor angular position, angular

speed, a revolution counter, and diagnostics are results of the Sine and Cosine feedback signal

processing (see the following figure).

Figure 14 eTPU Resolver Digital Interface block diagram

Processing of the feedback signals is executed on a separate channel. Another channel is used to perform

linear extrapolation of the last updated position from ATO to any other time. This is important feature

since ATO updates come with a certain period (~50 µs) which most likely is not aligned with control

loop frequency.

Optionally, another eTPU channel can be used to process diagnostics either on the same eTPU engine

after the feedback signal processing is finished or on the other eTPU engine in parallel to the motor

angle and speed calculation. This enables the CPU application to read the new motor angle and, at the

same time, check the diagnostic results to ensure the motor angle is correct.

The Sine and Cosine analogue feedback signals need to be converted to a digital representation and

transferred to eTPU data RAM. This should be done independently of the CPU using an on-chip ADC

and eDMA. Although any of the ADC modules can be used, the described configuration adopts the

Sigma-Delta ADC (SDADC).

Page 16

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

16 NXP Semiconductors

Two SDADC modules are used to continuously sample the Sine and Cosine signals in parallel (Figure

15). They are configured to obtain 32 samples of each signal per period instead of one sample at the

presumed peak as it is implemented in most of the SW resolver applications. This oversampling method

together with demodulation and filtration brings more robustness towards the induced noise.

Furthermore, the position is evaluated twice per resolver excitation period.

Figure 15 Oversampling and demodulation of Resolver feedback signals

4.1.3.

eTPU Analog Sensing function (AS)

The Analog Sensing eTPU function (AS) uses one eTPU channel to generate adjustable ADC trigger

pulses. On the selected eTPU channels the trigger signal generated by the AS function can be internally

routed to an ADC module. Using eDMA, the A/D conversion results can be moved back to the eTPU

data RAM for further processing by the AS eTPU function. Those pre-processed analog samples are

then available for consequential processing by e.g. an eTPU function handling the closed loop motor

control. It can run either independently with a given period (periodic mode) or it can be synchronized

with any other eTPU function (synchronized mode).

Features:

• Generates one or two adjustable trigger pulses per period:

o Frame pulse

o Center pulse

• Generates interrupts, DMA requests and eTPU links at none, one, or more of selected time-

positions:

o Frame pulse start

o Frame pulse end

Page 17

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

NXP Semiconductors 17

o Center pulse start

o Center pulse end

• Pre-process a defined number of analog signals (ADC conversion results) using:

o Gain

o DC-offset

o Forgetting factor (low-pass EWMA filter).

• Supports processing phase currents – calculation of one phase current value using the other two-

phase current values, based on a SVM sector value.

• When working with eQADC (MPC5777C/MPC5775E), supports CPU-independent modification

of command queues.

4.2.

MPC5777E – Key modules for PMSM FOC control

The key module for motor control on MPC5775E device is Enhanced Time Processing Unit (eTPU).

Using the eTPU Motor control library function set this programmable timer co-processor is capable of

generation 3 phase PWM complementary output, analog signal measurement triggering and

synchronization signal as well as Resolver feedback signal processing. To enable full eTPU Resolver

functionality it is crucial to utilize sigma-delta Analog to digital converters together with Enhanced

Direct Memory Access module. For phase current sensing the Enhanced Queued Analog to Digital

Converters are used.

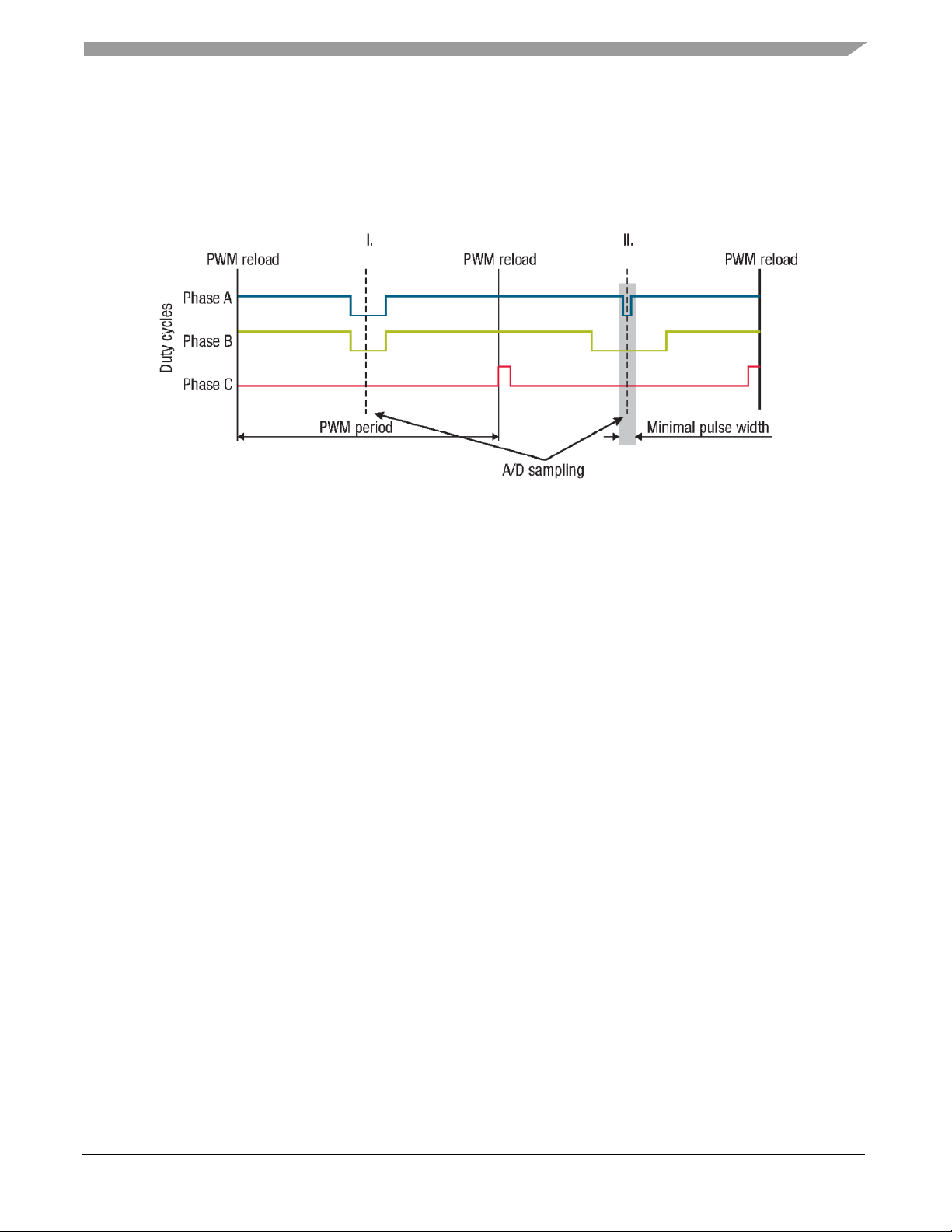

Figure 16 shows module interconnection for a typical PMSM FOC application working in sensor-based

mode using shunt current sensing with eTPU Motor Control Library functions involvement.

Figure 16 MPC5775E module interconnection block diagram

Page 18

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

18 NXP Semiconductors

4.2.1.

MPC5777E and FETs pre-driver interconnection

Excitation of power FETs is ensured by NXP MC33937 pre-driver. This analog device is equipped with

charge pump that ensures external FETs drive at low power supply voltages. Moreover, three external

bootstrap capacitors provide gate charge to the high-side FETs (see section References).

Configuration of MC33937 pre-driver is realized via SPI module. The MC33937 allows different

operating modes to be set and locked by SPI commands. SPI commands also report condition of the

MC33937 based on the internal monitoring circuits and fault detection logic. MPC5775E detects fault

state of the MC33937 by means of fault signal MC33937 pins. Integrated current sensing amplifier with

analog comparator allow to measure DC bus current and detect overcurrent. Interconnection between

MC33937 and MPC5775E is briefly depicted in Figure 16.

4.2.2.

Module involvement in PMSM FOC control

This section will discuss timing and modules synchronization to accomplish PMSM FOC on the

MPC5775E and the internal hardware features.

The time diagram of the automatic synchronization between PWM and ADC in the PMSM application

is shown in Figure 17.

Figure 17 Time Diagram of PWM and ADC Synchronization

The PMSM FOC control with shunt current measurement is based on static timing; meaning the trigger

point instances of the ADC conversions are located at same place within one control loop cycle.

Page 19

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

NXP Semiconductors 19

Each control cycle starts at beginning of the PWM cycle as shown in Figure 17. PWMM function runs

with a certain period that corresponds to control loop frequency. AS function is configured to run in

sync with PWMM and generates trigger pulse at the beginning of the PWMM period. This pulse rising

edge triggers eQADCs to sample phase currents and DC bus voltage. Phase currents are measured

simultaneously when bottom transistors of both inverter legs are closed, and currents flow through shunt

resistors. The rising edge of the pulse triggers also Resolver position sampling. The pulse width is

configurable and is configured for 4 µs. The falling edge of the AS pulse triggers an IRQ where the FOC

is calculated. Result of the FOC calculation is new duty cycles that has to be applied for next period. In

order to apply the new updated duty cycles for the next period the update (new duty cycle inputs) has to

come before so called “update time”. This is the time configured in PWMM function that is needed for

applying duty cycles by eTPU PWMM function for the next period, see Figure 18. If new inputs come

after the “update time” happens, then new inputs are not applied for next period and will be applied in

second next period. In that case PWMM function does not stop outputting the PWM signal and

continues with the last duty cycle values configured. Missing update IRQ is generated from eTPU

PWMM Master channel in case no new input comes before update time threshold.

Figure 18 PWMM update input values for frame update

4.3.

MPC5775E Device initialization

To simplify and accelerate application development, embedded part of the PMSM motor control

application has been created. Peripherals are initialized at beginning of the main() function. For each

MPC5775E module there is a specific configuration function:

• mcu_mode_clock_init() – MCU clock configuration

• xcptn_xmpl() – MCU interrupt routine initialization

• my_interrupt_init() – custom application interrupt initialization

• esci_init() – eSCI initialization for UART

• SIU_init() – PINs and PORT modules configuration

• my_system_etpu_init() – eTPU initialization

• edma_init() – eDMA initialization

• sdadc_init() – SDADC initialization

Page 20

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

20 NXP Semiconductors

• eqadc_init() – eQADC initialization

• dspi_init() – DSPI initialization

4.3.1.

Clock configuration

The clock architecture of MPC5775E device contains two clock domains coming from separate PLLs.

The first one is the system clock for the cores, cross-bar switch, peripheral bridges, memories, debug

logic and memory mapped portion of peripherals. The second one feeds the state machines and protocol

engines of communication and timer peripheral modules. These two clock domains can be configured to

be completely asynchronous between each other.

PLL0 module is supplied from 40 MHz external Crystal oscillator (XOSC). PLL0 circuit multiplies the

input XOSC frequency by 10 and divides by 2 for PHI output to be 200 MHz further used as eTPU

clock, SDADC clock and further divided by 2 used as peripheral clock. Second output of PLL0 PHI1 is

divided by 4 to be 50 MHz, further used as input clock for PLL1 module.

PLL1 module is used to generate 260 MHz system clock and 130 MHz platform clock. Clocking

configuration within this application is listed in Table 1.

Table 1 MCP5775E clocking configuration

clock

frequency

core_clk

260 MHz

plat_clk

130 MHz

etpu_clk

200 MHz

per_clk

100 MHz

The configuration of overall system clock is performed within function call mcu_mode_clock_init(), see

the code example below.

void mcu_mode_clock_init(void)

{

/* 0 The crystal oscillator (XOSC) is the clock source for PLL0 */

/* 1 The internal RC oscillator (IRC) is the clock source for PLL0 */

SIU.SYSDIV.B.PLL0SEL = 0;

/* Configure PLL0 Dividers from 40Mhx XOSC */

/* phi = 200 MHz */

/* phi1 = 50 MHz */

PLLDIG.PLL0DV.B.RFDPHI1 = 4;

PLLDIG.PLL0DV.B.RFDPHI = 2;

PLLDIG.PLL0DV.B.PREDIV = 1;

PLLDIG.PLL0DV.B.MFD = 10;

/* Check whether crystal is 40MHz, if not forever loop here TODO:implement error reporting */

while (!(SIU.RSR.B.XOSCHIGH)){};

/* Ensure SIU_RSR[XOSC] is 1 to confirm that XOSC is stable. */

while (!(SIU.RSR.B.XOSC)){};

PLLDIG.PLL0CR.B.CLKCFG = 3; /* Enable PLL0 by putting PLL into Normal mode */

while (!PLLDIG.PLL0SR.B.LOCK){}; /* Test PLL0 lock */

/* Select the source clock for PLL1 */

/* 0 The crystal oscillator (XOSC) is the clock source for PLL1 */

/* 1 The PHI1 output of PLL0 is the clock source for PLL1 */

SIU.SYSDIV.B.PLL1SEL = 0;

/* Configure PLL1 Dividers - 260MHz from 40Mhx XOSC */

PLLDIG.PLL1DV.B.RFDPHI = 2;

PLLDIG.PLL1DV.B.MFD = 26;

PLLDIG.PLL1CR.B.CLKCFG = 3; /* Enable PLL1 by putting PLL into Normal mode */

while (!PLLDIG.PLL1SR.B.LOCK){}; /* Test PLL1 lock */

…

}

Page 21

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

NXP Semiconductors 21

4.3.2.

eSCI configuration

Enhanced Serial Communication Interface (eSCI) module is used for communication between the

MPC5775E MCU and FREEMASTER runtime debugging and visualization tool. Function esci_init()

configures module A for UART functionality with baud rate 115200. See the following code example.

/* Initialize eSCI for UART */

esci_init(ESCIA_MODULE,MODE_SCI);

void esci_init(uint8_t module, uint8_t mode)

{

switch(module){

case ESCIA_MODULE:

eSCI_A.LCR1.B.LIN = mode; /* Select between LIN or SCI functionality */

eSCI_A.CR2.R = 0x2000; /* Enable ESCI and set all bits to reset value */

eSCI_A.CR1.B.TE = 1; /* Transmitter enable */

eSCI_A.CR1.B.RE = 1; /* Receiver enable */

eSCI_A.CR1.B.PT = 0; /* Parity is even */

eSCI_A.CR1.B.PE = 0; /* Parity control disable */

eSCI_A.BRR.B.SBR = 54; /* Baud rate = 115200:

MCLK = (200MHz/2), Txclk = MCLK/(16*SBR) */

break;

…

}

}

4.3.3.

eTPU configuration

eTPU function configuration is performed within so called GCT files (etpu_gct.c/.h). First there is

performed general eTPU engine configuration for both engine A and B, then eTPU functions are

assigned to selected channels and those channels are configured for that particular eTPU functionality.

The parameters for eTPU engine configuration are held in my_etpu_config structure, see part of the

structure in the following example.

/** @brief Structure handling configuration of all global settings */

struct etpu_config_t my_etpu_config =

{

/* etpu_config.mcr - Module Configuration Register */

FS_ETPU_GLOBAL_TIMEBASE_DISABLE /* keep time-bases stopped during intialization (GTBE=0) */

| FS_ETPU_MISC_DISABLE, /* SCM operation disabled (SCMMISEN=0) */

/* etpu_config.misc - MISC Compare Register*/

FS_ETPU_MISC, /* MISC compare value from etpu_set.h */

/* etpu_config.ecr_a - Engine A Configuration Register */

FS_ETPU_ENTRY_TABLE_ADDR /* entry table base address = shifted FS_ETPU_ENTRY_TABLE from etpu_set.h */

| FS_ETPU_CHAN_FILTER_2SAMPLE /* channel filter mode = three-sample mode (CDFC=0) */

| FS_ETPU_FCSS_DIV2 /* filter clock source selection = div 2 (FSCC=0) */

| FS_ETPU_FILTER_CLOCK_DIV2 /* filter prescaler clock control = div 2 (FPSCK=0) */

| FS_ETPU_PRIORITY_PASSING_ENABLE /* scheduler priority passing is enabled (SPPDIS=0) */

| FS_ETPU_ENGINE_ENABLE, /* engine is enabled (MDIS=0) */

…

}

The entire eTPU initialization and function configuration is then performed in my_system_etpu_init()

function call. See the following example code.

int32_t my_system_etpu_init(void)

Page 22

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

22 NXP Semiconductors

{

int32_t err_code;

/* Initialization of eTPU DATA RAM */

fs_memset32((uint32_t*)fs_etpu_data_ram_start, 0, fs_etpu_data_ram_end - fs_etpu_data_ram_start);

/* Initialization of eTPU global settings */

err_code = fs_etpu_init(

my_etpu_config,

(uint32_t *)etpu_code, sizeof(etpu_code),

(uint32_t *)etpu_globals, sizeof(etpu_globals));

if(err_code != 0) return(err_code);

#ifdef FS_ETPU_ARCHITECTURE

#if FS_ETPU_ARCHITECTURE == ETPU2

/* Initialization of additional eTPU2-only global settings */

err_code = fs_etpu2_init(

my_etpu_config,

#ifdef FS_ETPU_ENGINE_MEM_SIZE

FS_ETPU_ENGINE_MEM_SIZE);

#else

0);

#endif

if(err_code != FS_ETPU_ERROR_NONE) return(err_code);

#endif

#endif

/* Initialization of eTPU channel settings */

err_code = fs_etpu_pwmm_init(&pwmm_instance, &pwmm_config);

if(err_code != FS_ETPU_ERROR_NONE) return(err_code + (ETPU_PWMM_MASTER_CH<<16));

err_code = fs_etpu_as_init(&as_instance, &pwmm_instance, &as_config);

if(err_code != FS_ETPU_ERROR_NONE) return(err_code + (ETPU_AS_CH<<16));

err_code = fs_etpu_resolver_init(&resolver_instance, &resolver_config);

if(err_code != FS_ETPU_ERROR_NONE) return(err_code + (ETPU_RESOLVER_EXC_CHAN<<16));

return(0);

}

4.3.3.1.

eTPU PWMM: Center-aligned PWM mode

The Motor Control PWM eTPU function (PWMM) uses either three eTPU channels to generate three

PWM output signals, or six eTPU channels to generate three complementary PWM output signal pairs,

used to drive a 3-phase electrical motor.

In this application complementary pairs of PWM are used with center aligned configuration, frame

update only (parameters are updated once per PWM period, on a frame) and signed voltage modulation.

Period is configured for 100 µs, dead-time configuration is 1 µs as well as minimum pulse width.

Update time is configured for 7 µs which ensures enough time to perform update of all the three phases

for next period.

PWMM function configuration is performed within etpu_gct.c file. Part of the configuration is held in

pwmm_instance where PWMM channels are assigned, complementary channel mode, function priority

and polarity of the PWM outputs are configured. Other parameters, those that can be changed during

runtime, are held in pwmm_config structure and can be changed using fs_etpu_pwmm_config() function

call. Parameters are applied in upcoming PWMM update. The change of parameters is then visible in

next period after the PWMM update. See the timing of the updates illustrated on Figure 18.

struct pwmm_config_t pwmm_config =

{

FS_ETPU_PWMM_FM1_FRAME_UPDATE_ONLY, /**< selection of PWM update position. */

FS_ETPU_PWMM_MODULATION_SIGNED, /**< Selection of modulation */

Page 23

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

NXP Semiconductors 23

FS_ETPU_PWMM_MODE_CENTER_ALIGNED, /**< PWM Mode selection */

NSEC2TCR1(100000), /**< PWM period as a number of TCR1 cycles. */

USEC2TCR1(1), /**< PWM dead-time as a number of TCR1 cycles.*/

USEC2TCR1(1), /**< Minimum pulse width as number of TCR1 cycles. */

USEC2TCR1(7) /**< A time period (number of TCR1 cycles) that is needed to

perform an update of all PWM phases. */

};

NOTE

Use predefined macros to configure intended functionality. All the

possible options are listed in etpu_pwmm.h in comments and described in

PWMM-doxydoc.chm file. Note that parameters in pwmm_instance can be

configured only once at the eTPU initialization and cannot be changed

during runtime.

4.3.3.2.

eTPU Resolver configuration

Resolver function is designed so it cooperates closely with SDADC modules. SDADCs are configured

to provide 32 per one period of resolver feedback signal. Having considered the resolver excitation

frequency to be 10 kHz it means 320 kHz output data rate is required for SDADC. With a given

limitations of SDADC clocking and oversampling rate configurations the closest possible output data

rate that can be configured is 320.512 kHz (see Table 2). This determines the resolver excitation

frequency to be 10.016 kHz, 99.84 µs period respectively. Resolver bandwidth configuration can be

changed modifying ATO P and I gains. Current configuration of ATO is for 1 kHz bandwidth.

Excitation P and I gains are tuned for balanced phase-shift reaction, thus it is recommended to use this

configuration. For more information about eTPU Resolver implementation and its configuration please

refer to eTPU RDC and RDC Checker User Guide (References).

struct resolver_config_t resolver_config =

{

FS_ETPU_RESOLVER_SEMAPHORE_0,

FS_ETPU_RESOLVER_OPTIONS_CALCULATION_ON +

FS_ETPU_RESOLVER_OPTIONS_DIAG_MEASURES_ON +

FS_ETPU_RESOLVER_OPTIONS_EXC_ADAPTATION_ON +

FS_ETPU_RESOLVER_OPTIONS_EXC_GENERATION_ON, /* Resolver function options */

NSEC2TCR1(99840), /* Excitation signal period */

SFRACT24(0.070597541), /* ATO P-gain */

SFRACT24(0.002492006), /* ATO I-gain */

SFRACT24(0.00000), /* Excitation P-gain */

SFRACT24(0.00012), /* Excitation I-gain */

SFRACT24(0.9) /* Speed EWMA filter coefficient */

};

4.3.3.3.

eTPU AS: triggering output pulse

AS function is capable of generation periodical trigger pulses, one or two per period: Frame and Center

pulse. The position of the pulses (relative to AS period frame time and center time) is configurable as

well as the length.

In this application AS function is configured to work in synchronization mode adopting the period of

PWMM function. In that case AS period is configured to zero and pointer to the PWMM period is

provided in etpu_as.c file. The polarity of the AS signal is configured as high for the pulse. Those

Page 24

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

24 NXP Semiconductors

configurations are held in as_instace structure (defined similarly like PWMM in etpu_gct.c) and are not

a subject of change during the runtime. AS is configured to output one Frame pulse at the beginning of

the PWMM period (on a Frame time) and length is configured to be 4 µs which is enough for all the

feedback sampling and DMA transfer to eTPU data RAM. The AS pulse is internally gated to eQADC

to trigger conversion. AS pulse is also used to trigger Resolver Extrapolation. For this purpose there

need to be a HW connection between the eTPU AS channel output and eTPU Resolver Sample channel

input. If fulfilled rising edge of the AS pulse triggers extrapolation of the position - in other words

sampling the position and speed at the same time point as the feedback current measurement. IQR is

generated at the falling edge of the trigger pulse eTPU_AS_Isr() where all the feedback values are

processed and state machine is executed.

Also, configuration for measured signals triggered by AS function is present in etpu_gct.c in structure

called as_signal_config. This structure holds one sub-configuration structure per signal, number of the

signals to be processed by AS is defined in as_instance at the AS function initialization. The signal

configuration structure holds parameters like gain, DC offset and filter factor. The processing of the

signals may and may not be used. Within this application the processing of feedback signals is

performed by CPU, not eTPU AS function.

The following example code with AS configuration and AS signal configuration structures.

/** A structure to represent a single AS signal processing configuration.

* It includes both static and dynamic values. */

struct as_signal_config_t as_signal_config[4] =

{

{

0, /* Result queue offset of the signal */

1, /* Gain bit */

0x2000, /* DC offset */

SFRACT24(0) /* Forget factor of the EWMA filter */

},

…

};

/** A structure to represent a configuration of AS.

* It includes AS configuration items which can mostly be changed in

* run-time. */

struct as_config_t as_config =

{

0, /* Start offset */

0, /* Period */

USEC2TCR1(4), /* Pulse width */

FS_ETPU_AS_FM0_FRAME_PULSE_ON, /* Pulse selection */

0, /* Frame pulse adjustment */

0, /* Center pulse adjustment */

FS_ETPU_AS_IRQ_FRAME_PULSE_END, /* IRQ and DMA options */

0, /* Link options */

0, /* Link channels numbers at frame pulse start */

0, /* Link channels numbers at frame pulse end */

0, /* Link channels numbers at center pulse start */

0, /* Link channels numbers at center pulse end */

(uint32_t *)(0xC3FC8000 + 0x1000), /* Pointer to eTPU data RAM where signals from ADC are stored */

&as_signal_config[0], /* Pointer to a signal configuration structure */

0xF, /* Mask determining signals to be processed at frame pulse end */

0x0, /* Mask determining signals to be processed at center pulse end */

FS_ETPU_AS_PHASE_CURRENTS_OFF, /* Phase current processing option */

0, /* Phase A current index in result queue */

1, /* Phase B current index in result queue */

2, /* Phase C current index in result queue */

…

};

Page 25

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

NXP Semiconductors 25

4.3.4.

SDADC configuration

The Sine and Cosine analog feedback signals need to be converted to a digital representation and

transferred to eTPU data RAM for Resolver function processing. This should be done independently of

the CPU using an on-chip ADC and eDMA. Although any of the ADC modules can be used, the

described configuration adopts the Sigma-Delta ADC (SDADC).

Two SDADC modules are used to continuously sample the Sine and Cosine signals in parallel. They are

configured to obtain 32 samples of each signal per period. The following table details the configuration

for a 10 kHz excitation signal and a 320 kHz sampling frequency.

Table 2 SDADC configuration for Resolver

Configuration Item

Value

SDADC clock

200 MHz / 13 = 15.38 MHz (available range 4 – 16 MHz)

ADC decimation rate

24

Resulting output data rate

200 MHz / 13 / (2 * 24) = 320,512.8 Hz

Input mode

Single-ended

High-pass filter

enabled

FIFO size

16 words

FIFO threshold

8 words

DMA request on FIFO full

selected and enabled

NOTE

In this application single-ended mode is configured for SDADC to sense

resolver feedback signals (sine and cosine). This results from the Low

voltage power stage circuitry allowing single ended measurement for

position feedback. However, it is recommended to use differential

configuration for SDADC (and of course corresponding circuitry) when

using SDADCs for eTPU Resolver signal digitization. This brings the

advantage of noise rejection.

Using the function call sdadc_init() two instances of SDADC, namely SDADC1 and SDADC4 are

configured for continuous sampling with a given output data rate as listed in Table 2.

SDADC1 is started by software. SDADC1 trigger output is selected as a HW trigger to start SDADC4.

This configuration enables to start both modules of SDADC synchronously. Both SDADC modules are

configured so they generate DMA request as soon as FIFO sample count reaches the value 8. It means

that quarter of sine wave is moved by DMA from SDADC result FIFO to eTPU data RAM at once, four

times per period. See the following code example.

/* SDADC init*/

sdadc_init(OSR_24, GAIN_1, FTHLD_8, SINGLE);

void sdadc_init(uint8_t pdr, uint8_t gain, uint8_t fifo_thld, uint8_t inp_mode)

{

/* SD ADC 1 CONFIGURATION */

SDADC_1.SFR.R = 0x1B; /* Clear all the status flags */

SDADC_1.FCR.B.FRST = 1; /* Generate reset to flush FIFO */

SDADC_1.FCR.B.FTHLD = fifo_thld; /* FIFO threshold - overcome generates FIFO full event flag */

Page 26

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

26 NXP Semiconductors

SDADC_1.FCR.B.FSIZE = 3; /* FIFO size: 0 - 1 word, 1 - 4 words, 2 - 8 words, 3 - 16 words */

SDADC_1.FCR.B.FOWEN = 0; /* Disable FIFO overwrite */

SDADC_1.FCR.B.FE = 1; /* Enable FIFO */

SDADC_1.RSER.B.DFFDIRS = 1; /* DMA request on data FIFO full */

SDADC_1.RSER.B.DFFDIRE = 1; /* Data FIFO full request enable */

SDADC_1.MCR.B.MODE = inp_mode; /* Input mode: 0 - differential, 1 - single-ended */

SDADC_1.MCR.B.PDR = pdr; /* Over sampling rate */

SDADC_1.MCR.B.PGAN = gain; /* Digital gain */

SDADC_1.MCR.B.HPFEN = 1; /* High-pass filter enabled */

SDADC_1.MCR.B.EN = 1; /* Internal SDADC modulator enabled */

SDADC_1.OSDR.B.OSD = 1; /* Set the output settling delay */

SDADC_1.CSR.B.ANCHSEL = 0; /* Analog input channel AN[x] selection */

SDADC_1.MCR.B.TRIGEN = 1; /* Enable HW trigger */

…

SDADC_4.MCR.B.TRIGSEL = 0; /* SDADC_1 trigger output selected as an input trigger for SDADC4 */

SDADC_4.MCR.B.TRIGEDSEL = 1; /* Rising edge of trigger input selected */

SDADC_4.MCR.B.TRIGEN = 1; /* Enable HW trigger */

}

void sdadc_start(void)

{

/* start the SDADC_1 by SW trigger */

SDADC_1.STKR.R = 0xFFFF;

}

4.3.5.

eQADC configuration

MPC5775E features two instances of Enhanced Queued ADCs (eQADC), each module having two

independent ADCs, total four independent on-chip ADC modules. The eQADC transfers commands

from multiple Command FIFOs (CFIFOs) to the on-chip ADCs. The multiple Result FIFOs (RFIFOs)

can receive data from the on-chip ADCs or from an on-chip DSP module. The eQADC supports

software and external hardware triggers from other blocks to initiate transfers of commands from the

CFIFOs to the on-chip ADCs. It also monitors the fullness of CFIFOs and RFIFOs, and accordingly

generates DMA or interrupt requests to control data movement between the FIFOs and the system

memory, which is external to the EQADC.

In this application all the four on-chip ADCs are utilized to sample simultaneously Phase A, Phase B

and Phase C currents and DC bus voltage. This is achieved by utilizing of four command FIFOs, one per

ADC channel. External HW trigger is configured to trigger CFIFOs, namely eTPUA_28 channel is

selected as a trigger input for all CFIFOs. This eTPU channel is assigned to AS function. ADCs are

configured for single scan mode. Results are stored in Result FIFOs, one RFIFO per ADC channel.

FIFO Drain DMA requests are enabled for all the CFIFOs as well as RFIFOs. On a CFIFO Drain DMA

request respective eQADC command is transferred from system memory to CFIFO. Commands for all

the channels have the end Of Queue bit (EOQ) configured. This results in repeated write of a single

command to the CFIFO after CFIFO is triggered. Result FIFO drain DMA request evokes respective

DMA channel that performs transfer from RFIFO to eTPU data RAM. See the configuration of the

DMA channels in Table 5 and Table 6. See the following code example of the EQADC initialization.

void eqadc_init(void)

{

uint32_t tmp;

/* AN24 - Phase A current

* AN25 - Phase B current

* AN26 - Phase C current

* AN28 - DC bus voltage */

Page 27

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

NXP Semiconductors 27

/* SIU config of CFIFO trigger source selection:

* eTPU28_A selected to trigger all the FIFOs at one time */

SIU.ISEL5.B.CTSEL0_A = 0xC; /* eTPU28_A selected as trigger for eQADC_A Command FIFO 0 */

SIU.ISEL5.B.CTSEL1_A = 0xC; /* eTPU28_A selected as trigger for eQADC_A Command FIFO 1 */

SIU.ISEL7.B.CTSEL0_B = 0xC; /* eTPU28_A selected as trigger for eQADC_B Command FIFO 0 */

SIU.ISEL7.B.CTSEL1_B = 0xC; /* eTPU28_A selected as trigger for eQADC_B Command FIFO 1 */

/* Enable EQADC_A ADC0 and ADC1 and set ADC clock prescaler, via commands */

EQADC_A.CFCR0.B.CFINV0 = 1; /* invalidate CFIFO */

EQADC_A.CFCR0.B.CFINV1 = 1; /* invalidate CFIFO */

EQADC_A.CFPR[0].R = 0x80800301 + (0 << 25); /* push ADC0_CR configuration command to CFIFO_0 */

EQADC_A.CFPR[1].R = 0x80800301 + (1 << 25); /* push ADC1_CR configuration command to CFIFO_1 */

EQADC_A.CFCR0.R = 0x04100410; /* set software triggered single scan mode and enable single scan for both

ADC0 and ADC1 */

while (EQADC_A.FISR[0].B.EOQFX != 1) {} /* wait for end-of-queue flag */

while (EQADC_A.FISR[1].B.EOQFX != 1) {} /* wait for end-of-queue flag */

EQADC_A.FISR[0].R = ~0UL; /* clear all flags */

EQADC_A.FISR[1].R = ~0UL; /* clear all flags */

}

4.3.6.

DSPI configuration

DSPI module is used as a communication interface between MPC5775E MCU and FET pre-driver

MC33937. DSPI B module is configured for that purpose within this application using function call

dspi_init(). DSPI is configured as master mode SPI interface with 6.25 MHz frequency derived from

100 MHz PER_CLK. See the following configuration code.

/* DSPI initialization */

dspi_init(DSPI_B_MODULE, DSPI_MASTER, DSPI_SPI, CTAR0);

void dspi_init(uint8_t module, uint8_t mode, uint8_t com_mode, uint8_t ctar)

{

switch(module){

…

case DSPI_B_MODULE:

DSPI_B.MCR.B.HALT = 0x1; /* Module is set to HALT mode to perform initialization */

DSPI_B.MCR.B.MDIS = 0x1; /* Module is disabled during initialization */

DSPI_B.MCR.B.MSTR = mode; /* Select module mode: MASTER or SLAVE */

DSPI_B.MCR.B.PCSIS = 0x3F; /* The chip select inactive state is high */

DSPI_B.MCR.B.DIS_RXF = 0x1; /* RX FIFO disabled */

DSPI_B.MCR.B.DIS_TXF = 0x1; /* TX FIFO disabled */

DSPI_B.MCR.B.CLR_TXF = 0x1; /* Clear the TX FIFO counter */

DSPI_B.MCR.B.CLR_RXF = 0x1; /* Clear the RX FIFO counter */

DSPI_B.MODE.CTAR[ctar].B.FMSZ = 0x7; /* Frame size is FRMSZ + 1 = 8bit per frame */

DSPI_B.MODE.CTAR[ctar].B.DBR = 0x0; /* Duty cycle of the SCK is 50/50 */

DSPI_B.MODE.CTAR[ctar].B.CPOL = 0x0; /* Clock polarity: inactive state value of SCK is low */

DSPI_B.MODE.CTAR[ctar].B.CPHA = 0x1; /* Clock phase: Data is changed on leading edge of SCK */

DSPI_B.MODE.CTAR[ctar].B.LSBFE = 0x0; /* LSB first: Data is transferred MSB first */

DSPI_B.MODE.CTAR[ctar].B.CSSCK = 0x3; /* PCS to SCK Delay Scaler set to 16 */

DSPI_B.MODE.CTAR[ctar].B.ASC = 0x3; /* After SCK Delay Scaler set to 16 */

DSPI_B.MODE.CTAR[ctar].B.DT = 0x7; /* Delay After Transfer Scaler set to 128 */

DSPI_B.MODE.CTAR[ctar].B.BR = 0x3; /* Baud rate scaler is set to be 8, resultant DSPI clock

is 100 MHZ/(2x8) = 6.25 MHz */

DSPI_B.RSER.R = 0x0; /* No interrupts or DMA transfers enabled */

break;

…

}

}

Page 28

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

28 NXP Semiconductors

DSPI routines are used within MC33937.c/.h driver. Also PIT timer is utilized here for timing. With all

of this MC33937 driver provides access to all features of MC33937 FET driver chip such as

reading/writing status registers, dead-time configuration and fault handling. See the following example

code.

tBool MC33937_configure( MC33937_T *ptr)

{

volatile uint8_t cnt;

uint8_t empty_data;

uint16_t command;

volatile tBool statusPass;

statusPass = TRUE;

statusPass &= ClearRESET();

statusPass &= ClearEN();

statusPass &= SetRESET();

/* start the PIT to count 2 ms */

pit_start_wait_ns(2000000);

while(!pit_read_flag());

pit_stop();

/* initiate the DSPI */

statusPass &= dspi_start();

/* Clear all faults */

statusPass &= MC33937_clear_faults(ptr);

/* Initialize MASK register 0 */

command = (uint16_t)ptr->data.mc33937mask0;

statusPass &= dspi_master_data_tx(SINGLE_CS,CS3,CTAR0, command, &empty_data);

…

}

4.3.7.

DMA transfer configuration

Within this application eleven DMA channels are utilized to speed up the control loop operation and

offload the CPU. DMA is used to transfer:

• Samples of Resolver feedback sine and cosine signals from SDADC to eTPU data RAM

• eQADC commands to command FIFO for phase current and DC bus voltage measurement

• eQADC measurement from result FIFO to eTPU data RAM

All the channels used in this application are listed in the following table together with respective DMA

request sources.

Table 3 eDMA channel usage in application

Module

DMA chan.

Requesting source

Description

eDMA A

0

EQADC_A_FISR0[CFFF0]

EQADC_A Command FIFO 0 Fill Flag (Phase A current

measurement commands)

1

EQADC_A_FISR0[RFDF0]

EQADC_A Receive FIFO 0 Drain Flag (Phase A current values)

2

EQADC_A_FISR1[CFFF1]

EQADC_A Command FIFO 1 Fill Flag (Phase B current

measurement commands)

3

EQADC_A_FISR1[RFDF1]

EQADC_A Receive FIFO 1 Drain Flag (Phase B current values)

eDMA B

0

EQADC_B_FISR0[CFFF0]

EQADC_B Command FIFO 0 Fill Flag (Phase C current

measurement commands)

1

EQADC_B_FISR0[RFDF0]

EQADC_B Receive FIFO 0 Drain Flag (Phase C current values)

2

EQADC_B_FISR1[CFFF1]

EQADC_B Command FIFO 1 Fill Flag (DC bus voltage

measurement commands)

3

EQADC_B_FISR1[RFDF1]

EQADC_B Receive FIFO 1 Drain Flag (DC bus voltage values)

36

SDADC0

SDADC_0 result ready (sine positive resolver feedback signal)

Page 29

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

NXP Semiconductors 29

Module

DMA chan.

Requesting source

Description

39

SDADC3

SDADC_3 result ready (cosine positive resolver feedback signal)

48 - This channel is linked by eDMA B 36

NOTE

The numbering of SDADC instances differs in MPC5775E Reference

manual in various chapters. SDADC instances are numbered 1-4 whereas

the source signals from SDADCs to trigger eDMA operation are

numbered 0-3. Note that eDMA trigger signal SDADC_0 result ready

originates in SDADC1 module and similarly SDADC_3 result ready

originates in SDADC4 module.

For the purpose of eTPU Resolver function operation three eDMA channels are used to ensure Resolver

feedback signals are delivered to eTPU data RAM and to trigger eTPU processing once all the data are

transferred. Two eDMA B channels 36 and 39 are configured to transfer SDADC results after SDADC

result FIFO count reaches 8. Channel 36 is configured to link another eDMA B channel (channel 48) on

major loop completion (after all the results are transferred into eTPU data RAM) which causes a

subsequent transfer of constants into eTPU Resolver ATO channel HSR register. The array of the

constants defined in edma.c source file and is as follows:

const uint32_t link_cnst[] = {0,

FS_ETPU_RESOLVER_HSR_UPDATE_1ST,

0,

FS_ETPU_RESOLVER_HSR_UPDATE_2ND};

It means that after first quarter of sine wave samples is transferred into eTPU data RAM zero is written

into Resolver ATO eTPU channel HSR register. Writing a zero does not initiate any eTPU operation. On

the second quarter transfer end the FS_ETPU_RESOLVER_HSR_UPDATE_1

ST

constant is written to HSR register. This

write initiates eTPU service request for processing first half period of the sampled sine and cosine wave.

Similar applies for the second half period with FS_ETPU_RESOLVER_HSR_UPDATE_2

ND

that evokes processing of the

second half period. Detailed configuration for DMA channels used by eTPU Resolver function can be

found in Table 4.

Table 4 DMA configuration for eTPU Resolver

Configuration Item

Sine ADC FIFO DMA

channel

Cosine ADC FIFO DMA

channel

Linked HSR DMA channel

Source address

&SDADC_x.CDR.R

&SDADC_y.CDR.R

&link_const[0]

Destination address

resolver_instance.

.signals_pba

resolver_instance.

.signals_pba + 64

&ETPU.CHAN[resolver_instanc

e.chan_num_exc].HSRR.R

Source transfer size / modulo

32-bits / 0 bytes

32-bits / 0 bytes

32-bits / 0 bytes

Destination transfer size /

modulo

32-bits / 0 bytes

32-bits / 0 bytes

32-bits / 0 bytes

Source address offset

0 bytes

0 bytes

4 bytes

Destination address offset

4 bytes

4 bytes

0 bytes

Minor loop byte count

32 bytes

32 bytes

4 bytes

Major loop iteration count

4 4 4

Last source address adjustment

0 bytes

0 bytes

-16 bytes

Page 30

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

30 NXP Semiconductors

Configuration Item

Sine ADC FIFO DMA

channel

Cosine ADC FIFO DMA

channel

Linked HSR DMA channel

Source address

&SDADC_x.CDR.R

&SDADC_y.CDR.R

&link_const[0]

Destination address

resolver_instance.

.signals_pba

resolver_instance.

.signals_pba + 64

&ETPU.CHAN[resolver_instanc

e.chan_num_exc].HSRR.R

Source transfer size / modulo

32-bits / 0 bytes

32-bits / 0 bytes

32-bits / 0 bytes

Destination transfer size /

modulo

32-bits / 0 bytes

32-bits / 0 bytes

32-bits / 0 bytes

Source address offset

0 bytes

0 bytes

4 bytes

Last destination address

adjustment

-128 bytes

-128 bytes

0 bytes

Channel to channel linking

enabled

disabled

disabled

Linked channel

HSR DMA channel

-

-

See the code example below where the configuration of DMA_B channel 36 for transferring sine signal

samples from SDADC1 to eTPU data RAM is shown, according to Table 4.

void edma_init(void)

{

uint8_t hsr_ch = 48;

/* DMA B ch 36 - SDADC0 result ready

DMA B ch 39 - SDADC3 result ready */

/* DMA settings for SDADC_0 request */

DMA_B.TCD[36].SADDR.R = (uint32_t)&SDADC_1.CDR.R;/* Source address */

DMA_B.TCD[36].ATTR.B.SMOD = 0; /* Source address modulo*/

DMA_B.TCD[36].ATTR.B.SSIZE = 2; /* Source data size: 32bit */

DMA_B.TCD[36].ATTR.B.DMOD = 0; /* Destination address modulo */

DMA_B.TCD[36].ATTR.B.DSIZE = 2; /* Destination data size: 32bit */

DMA_B.TCD[36].SOFF.R = 0; /* Source address signed offset */

DMA_B.TCD[36].NBYTES.MLNO.R = 32; /* Inner "minor" byte count (8*4) */

DMA_B.TCD[36].SLAST.R = 0; /* TCD Last Source Address Adjustment */

DMA_B.TCD[36].DADDR.R = (vuint32_t)resolver_instance.signals_pba; /* Destination address */

DMA_B.TCD[36].CITER.ELINKYES.B.ELINK = 1; /* Enable chan-to-chan linking on minor-loop complete */

DMA_B.TCD[36].CITER.ELINKYES.B.LINKCH = hsr_ch; /* Minor Loop Link Channel Number */

DMA_B.TCD[36].CITER.ELINKYES.B.CITER = 4; /* Current major iteration count */

DMA_B.TCD[36].DOFF.R = 4; /* Signed destination address offset */

DMA_B.TCD[36].DLASTSGA.R = -128; /* Last destination address adjustment /scatter gather

address */

DMA_B.TCD[36].BITER.ELINKYES.B.ELINK = 1; /* Enable chan-to-chan linking on minor loop complete */

DMA_B.TCD[36].BITER.ELINKYES.B.LINKCH = hsr_ch; /* Minor Loop Link Channel Number */

DMA_B.TCD[36].BITER.ELINKYES.B.BITER = 4; /* Beginning major iteration count */

DMA_B.TCD[36].CSR.B.MAJORELINK = 1; /* Enable chan-to-chan linking on major loop complete */

DMA_B.TCD[36].CSR.B.MAJORLINKCH = hsr_ch; /* Major Loop Link Channel Number */

…

}

Another four eDMA channels are used to transfer eQADC commands from system memory to eQADC

command FIFO. The DMA transfer is requested when the command FIFO is empty. eQADC

commands can be seen below.

const uint32_t eqadc_commands[] =

{

0x80001800, /* Phase A: EQADC_A ADC 0, channel 24, EOQ */

0x82101900, /* Phase B: EQADC_A ADC 1, channel 25, EOQ */

0x80001A00, /* Phase C: EQADC_B ADC 0, channel 26, EOQ */

0x82101C00, /* DCB : EQADC_B ADC 1, channel 28, EOQ */

};

Page 31

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

NXP Semiconductors 31

Detailed configuration for DMA channels used by eQADC can be found in the following table.

Table 5 eDMA configuration for eQADC command FIFO

Configuration Item

EQADC_A Command

FIFO 0 DMA channel

EQADC_A Command

FIFO 1 DMA channel

EQADC_B Command

FIFO 0 DMA channel

EQADC_B Command

FIFO 1 DMA channel

Source address

&eqadc_commands[0]

&eqadc_commands[1]

&eqadc_commands[2]

&eqadc_commands[3]

Destination address

&EQADC_A.CFPR[0].R

&EQADC_A.CFPR[1].R

&EQADC_B.CFPR[0].R

&EQADC_B.CFPR[1].R

Source transfer size /

modulo

32-bits / 0 bytes

32-bits / 0 bytes

32-bits / 0 bytes

32-bits / 0 bytes

Destination transfer size /

modulo

32-bits / 0 bytes

32-bits / 0 bytes

32-bits / 0 bytes

32-bits / 0 bytes

Source address offset

0 bytes

0 bytes

0 bytes

0 bytes

Destination address

offset

0 bytes

0 bytes

0 bytes

0 bytes

Minor loop byte count

4 bytes

4 bytes

4 bytes

4 bytes

Major loop iteration count

1 1 1

1

Last source address

adjustment

0 bytes

0 bytes

0 bytes

0 bytes

Last destination address

adjustment

0 bytes

0 bytes

0 bytes

0 bytes

Channel to channel

linking

disabled

disabled

disabled

disabled

Linked channel

- - -

-

See the code example below where the configuration of DMA_A channel 0 for transferring eQADC

commands to measure Phase A current by eQADC are transferred from system memory to eQADC

command FIFO is shown, according to Table 5.

/* DMA settings for eQADC command FIFO */

/* phaseA - DMA_A source: 0 EQADC_A Command FIFO 0 Fill Flag */

/* phaseB - DMA_A source: 2 EQADC_A Command FIFO 1 Fill Flag */

/* phaseC - DMA_B source: 0 EQADC_B Command FIFO 0 Fill Flag */

/* DCB Voltage - DMA_B source: 2 EQADC_B Command FIFO 1 Fill Flag */

DMA_A.TCD[0].SADDR.R = (uint32_t)&eqadc_commands[0];/* Source address */

DMA_A.TCD[0].ATTR.B.SMOD = 0; /* Source address modulo */

DMA_A.TCD[0].ATTR.B.SSIZE = 2; /* Source data size: 32bit */

DMA_A.TCD[0].ATTR.B.DMOD = 0; /* Destination address modulo */

DMA_A.TCD[0].ATTR.B.DSIZE = 2; /* Destination data size: 32bit */

DMA_A.TCD[0].SOFF.R = 0; /* Source address signed offset */

DMA_A.TCD[0].NBYTES.MLNO.R = 4; /* Inner "minor" byte count */

DMA_A.TCD[0].SLAST.R = 0; /* TCD Last Source Address Adjustment */

DMA_A.TCD[0].DADDR.R = (uint32_t)&EQADC_A.CFPR[0].R;/* Destination address CFIFO */

DMA_A.TCD[0].CITER.ELINKNO.B.ELINK = 0; /* Disable chan-to-chan linking on minor-loop complete */

DMA_A.TCD[0].CITER.ELINKNO.B.CITER = 1; /* Current major iteration count */

DMA_A.TCD[0].DOFF.R = 0; /* Signed destination address offset */

DMA_A.TCD[0].DLASTSGA.R = 0; /* Last destination address adjustment /scatter gather

address */

DMA_A.TCD[0].BITER.ELINKNO.B.ELINK = 0; /* Disable chan-to-chan linking on minor loop complete */

DMA_A.TCD[0].BITER.ELINKNO.B.BITER = 1; /* Beginning major iteration count */

DMA_A.TCD[0].CSR.B.MAJORELINK = 0; /* Disable chan-to-chan linking on major loop complete */

Page 32

Software implementation on the MPC5777E

MCSPTR2A5775E 3-phase PMSM Motor Control Kit with MPC5775E, Rev. 0, 10/2020

32 NXP Semiconductors

Last set of four eDMA channels are used to transfer results from eQADC Result FIFO to eTPU data

RAM for further processing. Detailed configuration for DMA channels used by eQADC result FIFO is

shown in Table 6.

Table 6 eDMA channel configuration for eQADC Result FIFO

Configuration Item

EQADC_A Receive

FIFO 0 DMA channel

EQADC_A Receive

FIFO 1 DMA channel

EQADC_B Receive

FIFO 0 DMA channel

EQADC_B Receive

FIFO 1 DMA channel

Source address