Page 1

Magnetoresistive sensors for rotational,

angle and weak-fi eld measurement

The sixth sense for

automotive applications

Page 2

Accuracy and reliability

are key to NXP sensors

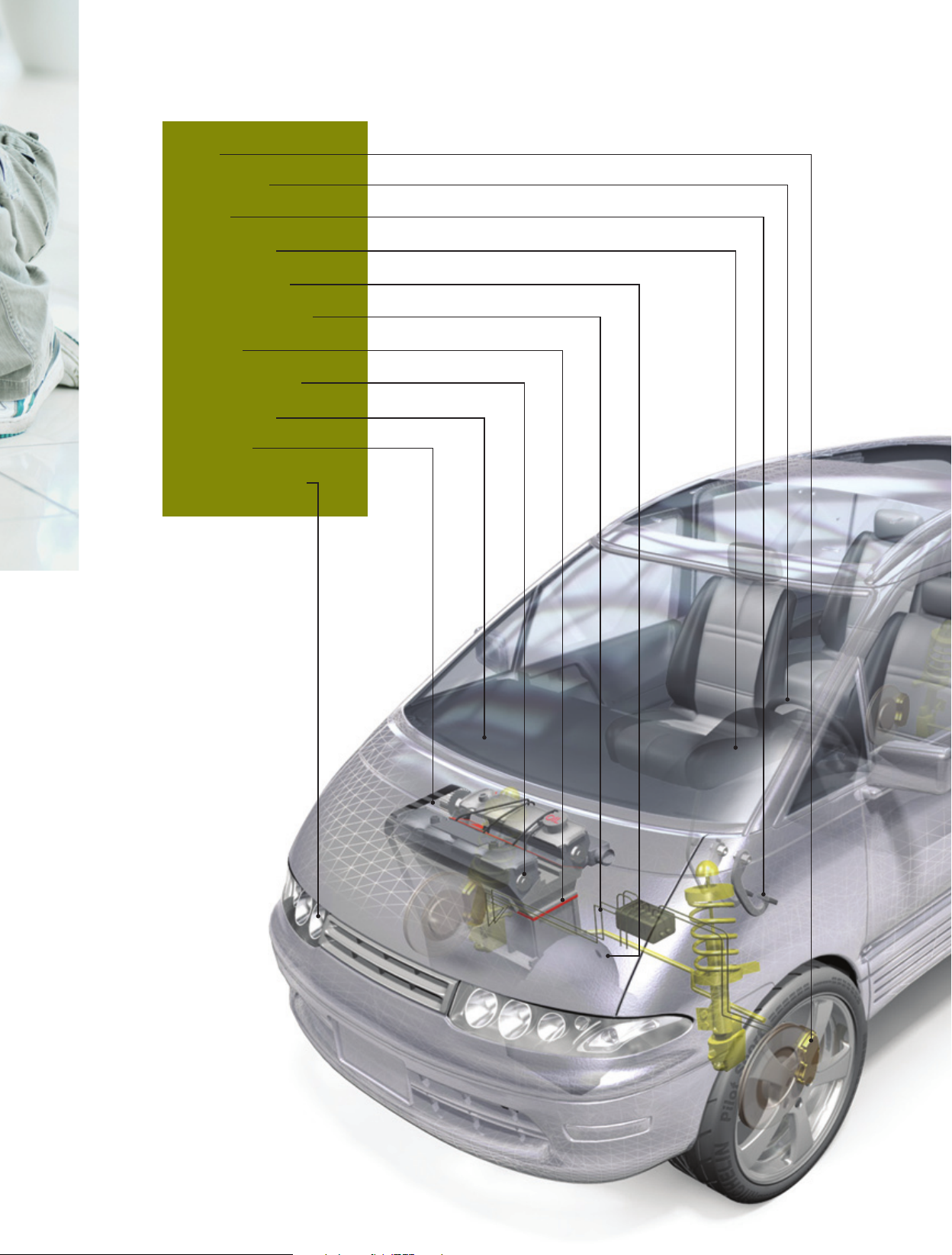

Engine management and ABS, variable valve timing and electronic throttle

control, active suspension and electronic steering – just some of automotive

applications vital in ensuring today’s cars are safer, more comfortable and

less fuel hungry. The majority of these systems depend on an accurate

and reliable supply of information and NXP Semiconductors provides an

extensive portfolio of high-performance sensor solutions to deliver just that.

Additionally, as you would expect from a leading supplier of automotive

semiconductors, all NXP’s sensors have the ruggedness and reliability needed

to meet the exacting automotive quality standards.

You can choose from a proven range of magnetoresistive (MR) sensors

for angle, rotation and weak-field measurements. They all offer precise

measurement, reliable operation and long lifetimes – exactly the qualities

needed for automotive use. With numerous options available to match a

wide variety of applications, you are sure to find the perfect part for your

application.

Page 3

Magnetoresistive sensors - suited to a host of applications

ABS

Steering angle

E-Gas

Steering torsion

Active transmision

EPAS motor positioning

E-throttle

Variable Valve Timing

Window wipers

Crankshaft

Headlight adjustment

Page 4

Page 5

Page 6

Page 7

NXP’s automotive sensors portfolio

Magnetoresistive rotational speed sensors

Compact and easy to design in, our KMI rotational speed sensors

provide a simple and cost-effective rotational sensing solution.

They are ready to use and include the sensor,

an advanced signal conditioning IC and a choice of three

back-biasing magnets, all housed in a special multi-chip package.

Magnetoresistive angle sensors

Highly accurate, NXP’s angle sensors are ideal for a variety of

demanding automotive and industrial applications.

These easy-to-use devices provide an output signal virtually

independent of magnet tolerances, magnet temperature

coefficients, magnet-sensor distance and positioning tolerances,

guaranteeing reliability and simplifying your manufacturing

process.

Magnetoresistive weak field detection sensors

Capable of detecting weak magnetic fields such as the Earth’s,

the KMZ5x range are ideal for navigation and traffic detection

applications. These devices consist of four magnetically sensitive

permalloy resistors arranged in a Wheatstone bridge configuration,

maximizing sensitivity while minimizing temperature influences.

Page 8

www.nxp.com

NXP Semi conduc tors is i n th e pr ocess of being esta blished as a separa te le gal entity in

vari ous coun tries wo rldwid e. This pro cess wil l be fi nalized in the cou rse of 20 06.

© 20 06 Konink lijke Phi lips Elec tronic s N.V.

All rights reserv ed. Repr oducti on in w hole or in par t is pro hibited withou t the pr ior wri tten

cons ent of the cop yright ow ner. The infor mation pre sented in t his docum ent does not

form part of any quotat ion or contra ct, is believe d to b e accur ate and reliab le and may be

chan ged wit hout not ice. No l iabilit y will be accept ed by the publish er for a ny conse quence

of it s use. P ublicat ion the reof doe s not co nvey nor imply an y licens e under patent- o r other

indu strial o r intelle ctual p ropert y right s.

Date o f release: Septemb er 200 6

Docu ment ord er numbe r: 9397 750 15728

Prin ted in the N etherla nds

Page 9

Magnetoresistive angle

Rotating shaft

S N

A

sensor systems

Cover all the angles in your

automotive systems

NXP’s magnetoresistive sensor technology is the superior choice for automotive measurement systems.

Features such as lack of wear, long term stability and direct measurement combine to deliver highly

accurate and robust sensors. With stand-alone sensors, companion signal conditioning ICs and complete

single-package sensing solutions our range of cost-effective angle sensors covers all your application needs.

Key benefi ts

Ñ

Contactless angle measurement up to 180°

Ñ

Measurement independent of magnetic drift caused by life

time and temperature changes

Ñ

Operation independent of mechanical tolerances and magnet

shifts caused by thermal stress

Ñ

High temperature range

Ñ

Automotive qualifi cation

Ñ

Highly fl exible solutions that measure any automotive angle

effectively

Ñ

Fully stable operation over long life-cycle

Key applications

Ñ

Electronic throttle control (ETC)

Ñ

Variable valve control (VVC)

Ñ

Pedal and wiper positioning

Ñ

Active suspension

Ñ

Automatic headlight adjustment

Ñ

Electronic steering

Ñ

Seat positioning

Offering many technical benefi ts over other technologies, our

magnetoresistive (MR) angle sensors provide car manufacturers

with a more reliable and accurate solution for automotive angle

measurement – reducing the risk of mechanical breakdown and

improving overall vehicle safety. This is an increasingly important

area within automotive electronics as the industry moves closer to

incorporating advanced X-by-wire networks and control systems,

such as FlexRay, that rely on accurate measurement data.

MR sensors use magnetic fi elds to

conduct measurement information

between physical value and sensor.

This contactless principle allows isolation

of all rotating components, making the

entire sensing system robust with respect

to pollution and mechanical degradation.

Also, MR sensors evaluate the direction

of the magnetic fi eld and not the fi eld

strength. As a result, MR sensors can

tolerate variations in fi eld strength caused

by ageing, mechanical fl uctuations or

temperature sensitivity of the magnet.

Rotating shaft

MR-sensor set-up

Page 10

Magnetoresistive angle sensors KMZ41/KMZ43 and UZZ900x

14

bra159

KMZ41 UZZ9000

ADC1

14

ALGORITHM

RC-OSCILLATOR &

CLOCK GENERATOR

TEST AND TRIM

MODE

RESET

DAC V

out

ADJUSTMENT

OF

OUTPUT CURVE

CHARACTERISTIC

+ V

O1

- V

O1

+ V

O2

- V

O2

ADC2

BUFFER

BUFFER

13 13

Our KMZ41 and KMZ43 sensor bridges contain eight MR resistors, connected as two individual Wheatstone bridges aligned at 45°.

Possessing different sensitivities, our KMZ41 and KMZ43 angle sensors are designed to work with the UZZ900x conditioning ICs.

Ensuring maximum flexibility, we offer MR sensor bridges both as standalone devices in SO8 package and as bare die for spacecritical solutions.

KMZ41, KMZ43T and X3T-KMZ43

(bare die) key specifications

Property KMZ41

Operating voltage max. 9 V max. 9 V

Angle range 180° 180°

Output signal sin/cos sin/cos

KMZ43T

X3T-KMZ43

Saturation field

strength

Operating

temperature range

100 kA/m 25 kA/m

-40 ....+150 °C -40 ....+150 °C

KMZ43T chip layout, showing the two 45º aligned bridges

Companion signal conditioning ICs for sensor bridges

Designed and developed specifically to complement the KMZ family of angle sensors, the UZZ9000 series provides optimized

single-chip signal conditioning solutions with either analog or 13-bit SPI interfacing. Incorporating all conditioning electronics they

also offer an adjustable measurement range and zero point to maximize design flexibility.

UZZ9000 and UZZ9001 key specifications

Property UZZ9000 UZZ9001

Supply voltage 5 V +/- 10 % 5 V +/- 10 %

KMZ4x and UZZ900x

Maximum angle

range

Angle range

variation

Zero point offset

cancellation

Output

Measurement

resolution

Accuracy

(ideal input)

0° to 180° 0° to 180°

0°- 30 °... 0°- 180° in

10° steps

fixed to 0°- 180°

+/- 5° in 0.5° steps fixed to 0

ratiometric analog

voltage

digital (SPI) with 13-Bit

< 0.1° < 0.05°

< +/- 0.4° < +/- 0.3°

Package SO24 (SOT137-1) SO24 (SOT137-1)

range

Temperature

-40°C to +150°C -40°C to +150°C

Page 11

Single package angle sensor systems with on-chip diagnostics - KMA200 and KMA199

bra900

EEPROM

ONLINE

DIAGNOSIS

R-DAC

DIGITAL PART

HV-

Protection

V

DD

Out1/Data

Buffer

Out2/CLK

GND

CS

MC

Amplifier $3-ADC

TEMP

SENSOR

SERIAL

INTERFACE

MR-

Bridges

bra901

V

DD

V

SS

V

out

EEPROM

DIGITAL PART (STATE MACHINE)

ONE-WIREINTERFACE

MPX

SAR-ADC

R-DAC Buffer

Protection

OFFSET

CALCULATION

ANGULAR/

RANGE

ADJUSTMENT

CORDIC

ALGORITHM

LOW-PASS

DIGITAL

FILTER

4 V-REGULATOR

MR-

Bridges

Amplifier

The KMA200 and KMA199 are pre-aligned, ready-to-use sensor systems. They consist of a magnetoresistive element

containing two independent MR sensor bridges and a signal conditioning IC in a special multi-chip package that allows

90º bending of the MR-element.

Magnetoresistive MR-element

Angle Sensor Chip

Signal Processing IC

The KMA 200 sensor system

KMA200 key features

Ñ

Digital SPI for programming (customer settings and calibration)

Ñ

4 analog and 2 digital output modes, selectable

Ñ

Reverse supply voltage protection up to 16.5 V

Ñ

Over voltage protection up to 26.5 V (32 V for 400 ms)

Ñ

On-line diagnosic of all main functional blocks

Magnetoresistive MR-element

Angle Sensor Chip

Signal Processing IC

The KMA199 sensor system

KMA199 key features

Ñ

Single-wire digital interface for programming

Ñ

3-lead device with analog output

Ñ

Transient protection circuit

Ñ

Active power-loss functionality

KMA200 sensor system KMA199 sensor system

Key specifications

Property KMA200 KMA199

Angular measurement range 180º 180º

Output mode 4 analog/2 digital, selectable ratiometric analog

Maximum error from reference line -1.65º…+1.65º

Linearity error ± 1º

Temperature drift (-25…+125 ºC) -0.64º…+0.64º

Temperature drift related to room temperature 0.55º

Microlinearity -0.1º…+0.1º -0.1º…+0.1º

Temperature range -40…+160 ºC -40…+140 ºC

Supply voltage 5 V + - 10% 5 V + - 10%

Page 12

Magnetoresistive angle sensors and conditioning ICs

Portfolio overview

Type Product Package

Supply

voltage (V)

Angle

range

Output value Output type

Operating

temperatures °C

KMZ41 sensor SO8 5.0 ... 9.0 180° 78 mV peak (5 V) sin/cos -40 ...+150

KMZ43 sensor SO8 5.0 ... 9.0 180° 67 mV peak (5 V) sin/cos -40 ...+150

X3T-KMZ43 sensor die 5.0 ... 9.0 180° 67 mV peak (5 V) sin/cos -40 ...+150

UZZ9000 signal conditioning unit SO24 4.5 ... 5.5 180° 0.5 ... 4.5 V analog linear -40 ...+150

UZZ9001 signal conditioning unit SO24 4.5 ... 5.5 180° 0.5 ... 4.5 V digital -40 ...+150

KMA199 sensor system SOT880 4.5 ... 5.5 180° 0.5 ... 4.5 V analog linear -40 ...+140

KMA200 sensor system SOT637 4.5 ... 5.5 180° 0.5 ... 4.5 V 4 analog linear/2 digital -40 ...+160

www.nxp.com

NXP Sem iconducto rs is in the proc ess of being e stablishe d as a separate l egal entit y in various co untries wor ldwide. Thi s process will b e finalized in th e course of 20 06.

© 2006 Konin klijke Philip s Electroni cs N.V.

All rights r eserved. Reproduc tion in whole or in pa rt is prohibited withou t the pr ior wri tten con sent of the cop yright o wner. The

infor mation pr esented i n this d ocument does no t form p art of any quot ation or contrac t, is b elieved to be acc urate an d reliable

and may be chang ed with out no tice. No liabil ity wi ll be accepted by the pu blisher for an y cons equence of it s use. Public ation

there of does not conv ey nor imply any l icense unde r patent- or othe r industria l or intellec tual proper ty right s.

Date of rel ease: Septem ber 2006

Docum ent order num ber: 9397 750 1572 9

Printe d in the Nether lands

Page 13

Rotational speed sensor

Constantly aware of that

speed sensation

Compact and easy to design in, our KMI magnetoresistive sensors provide simple and

cost-effective solutions for all your rotational speed measurement needs. They meet the high

EMC, reliability and temperature range requirements of the automotive sector, and are available

in a range of options to maximize design freedom.

Key benefi ts

Ñ

Wide air gap between sensor and target

Ñ

Speed detection down to 0 Hz

Ñ

Very low jitter

Ñ

Wide frequency range

Ñ

Insensitive to vibrations

Ñ

Temperature range: -40 to +150 ºC

Ñ

Prepared for injection moulding

Key applications

Ñ

ABS

Ñ

Engine management

Ñ

Gearbox

Ñ

Transmission systems

Ñ

Vehicle speed

Ñ

DC motor commutation

Accurate rotational speed measurement is a vital component

in maintaining performance, safety and reliability in modern

vehicles. It forms the basis of numerous applications from anti-lock

braking to engine management systems, and opens the way for

embedding intelligence throughout the car with the introduction

of advanced X-by-wire networks and control systems.

NXP’s KMI family of magnetoresistive (MR) rotational speed

sensors provides a solution for all applications. Designed

specifi cally to meet the needs of automotive systems,

they are complete, ready-to-use modules comprising sensor,

back-biasing magnet and advanced signal conditioning IC.

Enabling maximum design fl exibility, the devices are available

with a choice of output signals and individually magnetized

back-biasing magnets.

“ Ears “ to fi x the position

of the sensor chip during

moulding process

Extra thick leadframe material

for robustness, bendable

Conditioning IC

Component detail of the KMI20

MR-sensor

Conditioning IC

Page 14

How to measure rotation with MR sensors

gear wheel or rack

(a)

V

(b) (c) (d)

t

MBE073

magnet

sensor

magnetic field lines direction of motion

amplifier,

comparator

sensor

magnetic field lines

magnetized target

msc655

position

current

14 mA

7 mA

N

N

S

S

mbh777

KMIXY/2

mbh779

KMIXY/4

mbh778

KMIXY/1

The KMI sensors are designed to sense the motion of ferrous gear wheels or of magnetized targets. A periodic magnetic field

stemming from the effect of flux bending by ferrous gear wheels or directly from magnetized targets will be transformed by

a MR sensor into an analog electrical signal. The frequency of this signal is proportional to the rotational speed of the target.

A subsequent integrated circuit transforms the analogue into a digital output signal. The output level is independent of the sensing distance within the

measurement range.

Back-biasing magnets, individually magnetized

for each sensor

Ñ

Large (8.0 x 8.0 x 4.5 mm) – for maximum air gap

between sensor and ferrous targets

Ñ

Medium (5.5 x 5.5 x 3.0 mm) – for use with ferrous

targets where space is limited

Ñ

Small (3.8 x 2.0 x 0.8 mm) – for magnetized targets,

stabilizing the inherently bi-stable MR sensor

Output signals

For high flexibility in the design of the subsequent signal

conditioning electronics, the KMI sensors are available

with:

Ñ

a digital current output signal (2-wire)

Ñ

an open collector output signal (3-wire)

Page 15

mbl238

SMART

COMPARATOR

OFFSET

CANCELLATION

Fc = 0 Hz

ADJUSTABLE

AMPLIFIER

SENSOR

DIGITAL CONTROL UNIT

ON-CHIP

OSCILLATOR

VOLTAGE CONTROL

SWITCHABLE

CURRENT

SOURCE

VCC

V-

CONSTANT

CURRENT

SOURCE

SCHMITT

TRIGGER

AMPLIFIERSENSOR

VOLTAGE CONTROL

V

CC

mra958

SWITCHABLE

CURRENT

SOURCE

V-

CONSTANT

CURRENT

SOURCE

SCHMITT

TRIGGER

AMPLIFIERSENSOR

VOLTAGE CONTROL

V

CC

GND

V

out

open collector

output

mgl348

I

CC

T

t

p

mra960

14 mA

7 mA

KMI15 – 7/14 mA current output (2-wire)

KMI18 – open collec tor output (3-wire)

The MR sensor signal is amplified, temperature compensated and passed to a Schmitt trigger.

KMI20 – 7/14 mA current output (2-wire), extended air gap

The MR sensor signal is fed into the conditioning IC. The of fset, gain and

7/14 mA output signal as a func tion of time

hysteresis are digitally adapted to ensure an exceptional air gap capability.

Product overview

Sensor type typ. sensing distance (mm) Tooth frequency (Hz) Target Interface Magnet size (mm)

KMI15/1 0.9 - 2.9 0 - 25.000 note 1 Current 8 x 8 x 4.5

KMI15/2 0.5 - 2.7 0 - 25.000 note 2 Current 3.8 x 2 x 0.8

KMI15/4 0.5 - 2.3 0 - 25.000 note 1 Current 5.5 x 5.5 x 3

KMI18/1 0.9 - 2.9 0 - 25.000 note 1 Open collector 8 x 8 x 4.5

KMI18/2 0.5 - 2.7 0 - 25.000 note 2 Open collector 3.8 x 2 x 0.8

KMI18/4 0.5 - 2.3 0 - 25.000 note 1 Open collector 5.5 x 5.5 x 3

KMI20/1 0.9 - 3.5* 0 - 2.500 note 1 Current 8 x 8 x 4.5

KMI20/2 0.5 - 3.2* 0 - 2.500 note 2 Current 3.8 x 2 x 0.8

KMI20/4 0.5 - 2.8* 0 - 2.500 note 1 Current 5.5 x 5.5 x 3

* + 1 mm dynamic reserve | note 1 - ferrous target | note 2 - magnetized target

Page 16

mlc127

I

Magnetization

Permalloy

H

Current

A

R = R0 $ R0cos2A

Advantages by design

The magnetoresistive ef fect in permalloy

The MR sensor consists of four sensitive resistors in a

Wheatstone bridge configuration, with each resistor arranged

to maximize sensitivity and minimize temperature influences.

Such a Wheatstone bridge design along with the inherent

benefits of MR technology provides several advantages:

Ñ

reduction of temperature drift

Ñ

independent of mechanical assembly tolerances / shifts

Ñ

maximum signal output

Ñ

reduction of non-linearity

MR sensors offer a uniquely versatile combination of features

and important cost benefits. Based on the MR effect,

specifically designed sensors for angle and linear displacement

measurements are also available from NXP, as are solutions for

weak field detection.

NXP sensors are based on the MR effect, where the resistance

of a current-carrying magnetic material, for example a permalloy

(19% Fe, 81% Ni) changes under the influence of an external

magnetic field. If an external field is applied, in the plane of the

current flow, the internal magnetization vector will rotate by the

angle of this field, changing the resistance of the material.

www.nxp.com

Tipical sensor bridge structure

NXP Sem iconducto rs is in the proc ess of being e stablishe d as a separate l egal entit y in various co untries wor ldwide. Thi s process will b e finalized in th e course of 20 06.

© 2006 Konin klijke Philip s Electroni cs N.V.

All rights r eserved. Reproduc tion in whole or in pa rt is prohibited withou t the pr ior wri tten con sent of the cop yright o wner. The

infor mation pr esented i n this d ocument does no t form p art of any quot ation or contrac t, is b elieved to be acc urate an d reliable

and may be chang ed with out no tice. No liabil ity wi ll be accepted by the pu blisher for an y cons equence of it s use. Public ation

there of does not conv ey nor imply any l icense unde r patent- or othe r industria l or intellec tual proper ty right s.

Date of rel ease: Septem ber 2006

Docum ent order num ber: 9397 750 15731

Printe d in the Nether lands

Loading...

Loading...