Page 1

AN12868

Camera Interface in LPC55(S)xx

Rev. 1 — 10/2020

1 How to read this application note

This application note introduces a parallel interface for the camera solution

for LPC55(S)xx. It includes the introduction of camera interface, features and

API routines, and demo.

2 Target application

The camera interface can be used as important part of many camera usage

as below:

• Object detection

• Gesture recognition

• Color recognition

• QR code scanning, and so on

3 Introduction of camera interfaces

A typical camera interface supports at least one parallel interface, although

nowadays many camera interfaces begin to support the MIPI CSI interface.

The camera interface's parallel interface consists of the following lines:

• Data line (D[0:11]):

These are parallel data lines that carry pixel data. The data transmitted on

these lines change with every Pixel Clock (PCLK).

Application Note

Contents

1 How to read this application note.... 1

2 Target application............................1

3 Introduction of camera interfaces....1

4 Features of camera interface.......... 1

5 Function description........................ 2

5.1 Camera interface engine............. 2

5.2 Camera driver library................... 2

5.3 LCD display..................................2

5.4 System clock................................2

5.5 Clock source of camera............... 2

5.6 I2C interface................................. 2

5.7 Memory usage............................. 2

5.8 Other supported camera modules

.....................................................2

6 Pin description.................................3

6.1 Connection of interface................4

6.2 Requirement of interface............. 4

7 Library and API routine................... 4

7.1 Library..........................................4

7.2 API routine................................... 4

7.3 API routine description.................5

7.4 Code detail description................ 5

8 Demonstration.................................7

9 Revision history...............................8

A Purchasing LCD module used in this

demo............................................... 8

• Horizontal Sync (HSYNC)

This is a special signal that goes from the camera sensor. An HSYNC indicates that one line of the frame is transmitted.

• Vertical Sync (VSYNC)

This signal is transmitted after the entire frame is transferred. This signal is often a way to indicate that one entire frame

is transmitted.

• Pixel Clock (PCLK)

This is the pixel clock and it changes on every pixel.

The application note only focuses on Digital-Video-Port (DVP) interface which is parallel interface.

4 Features of camera interface

• Supported formats (8-bit): RGB565

• Maximum image transfer rate: 30 fps for QVGA(320 × 240). For small RAM parts, reduce the size of image and frame

rate.

Page 2

NXP Semiconductors

Function description

• Camera module tested : OV7673

• Other camera modules can be supported as long as they provide the same signal timing.

5 Function description

5.1 Camera interface engine

There is a hidden co-processor in LPC55S69 which can handle the signals of camera.

It reads the data from camera and stores the data in the RAM which can then be accessed by ARM core. Before using the

co-processor, some configurations need to be made, which includes pin configuration, clock enable, processor enable, interrupt

enable and so on.

5.2 Camera driver library

The instructions of co-processor use the type of machine code. The code implements the function of camera interface protocol

and is released in lib. Some API routines are provided in this application. User can use API routines to initialize the engine and

configure the pins.

5.3 LCD display

The application note uses LCD to display the video stream from camera in real time. The high-speed SPI port is used for LCD

driving port. The max speed on the SPI bus is 50 Mbps, so it can display the 320 × 240 resolution LCD up to 30 fps.

5.4 System clock

The camera engine shares the system clock with Arm® core. To speed up the processing time, the system clock must be

configured to 150 MHz. For those below 150 MHz, such as, 96 MHz system clock part, reduce the frequency of pixel clock.

5.5 Clock source of camera

The camera needs a 50 MHz clock source which can be provided by CLKOUT signal from MCU.

5.6 I2C interface

The camera is configured through I2C interface which can be connected with I2C peripheral port in the MCU.

5.7 Memory usage

The 320 × 240 resolution picture requires 150 K bytes RAM space. The solution uses the space address from 0x20010000

to 0x20035800.

Additionally, the instruction codes of camera engine need be run in the RAM for high performance. This solution uses the space

address from 0x20040000 to 0x20043FFF to store camera engine code.

5.8 Other supported camera modules

Other camera modules can be supported as long as they provide the same signal timing.

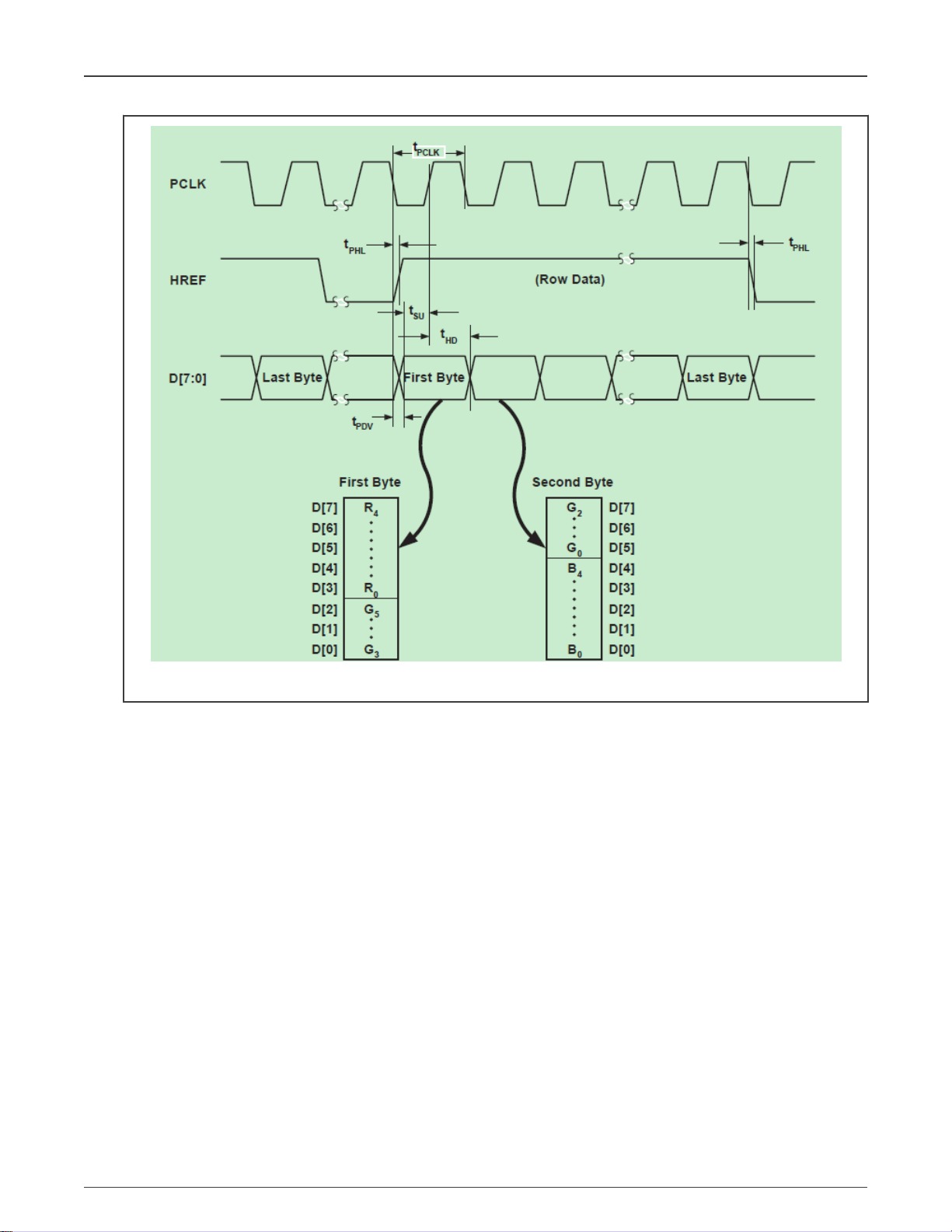

1. The camera module need to be configured as RGB565 mode with the timing diagram, as shown in Figure 1.

Camera Interface in LPC55(S)xx, Rev. 1, 10/2020

Application Note 2 / 9

Page 3

NXP Semiconductors

Pin description

Figure 1. Camera module configuration

2. The resolution should be configured as QVGA (320 × 240).

6 Pin description

Camera Interface in LPC55(S)xx, Rev. 1, 10/2020

Application Note 3 / 9

Page 4

NXP Semiconductors

6.1 Connection of interface

Library and API routine

Figure 2. Connection of interface

6.2 Requirement of interface

• The D0-D7 must be connected to P0.0-P0.7 for byte reading the data.

• SIOC and SIOD must be connected to the I2C interface of MCU for configuration.

• The VSYNC, HREF, PCLK must be connected to pins of Port0.

• XCLK needs to be connected to a clock output pin of MCU.

7 Library and API routine

7.1 Library

The library is named by camera engine lib. It includes the instructions which will be handled by co-processor.

The library can support Keil, MCUXpresso IDE, but not IAR.

7.2 API routine

The main purposes of the API routines include:

• Enable the clock of engine.

• Configure the IO as camera interface function.

• Initial the I2C interface.

• Enable the interrupt of engine for telling the Arm core data is ready.

Camera Interface in LPC55(S)xx, Rev. 1, 10/2020

Application Note 4 / 9

Page 5

NXP Semiconductors

• Initialize and start the engine.

7.3 API routine description

Table 1. API routine

Routine Description

Reserved46_IRQHandler Interrupt routine for camera engine

OV7670_Init Camera module initialization

Camera_Init(); Camera engine initialization

Camera_Start(); Camera engine start running

LCD_Init(); LCD module initialization

LCD_Refresh(); LCD refresh

7.4 Code detail description

7.4.1 System clock

Library and API routine

Camera engine need short time to store the data when every pixel edge comes. If the clock frequency of engine is higher, the time

cost is shorter. In this solution, the system clock must be set at 150MHz when engine is running. The code to configure system

clock is shown as below:

BOARD_BootClockPLL150M();

7.4.2 I2C interface

The flexcomm4 is used as I2C function for initializing the Camera before the video starts.

7.4.3 Pin function

Table 2. Pin function

Pin Function number Input/output Description

P0_0 15 Input Camera engine function

P0_1 15 Input Camera engine function

P0_2 15 Input Camera engine function

P0_3 15 Input Camera engine function

P0_4 15 Input Camera engine function

P0_5 15 Input Camera engine function

P0_6 15 Input Camera engine function

P0_7 15 Input Camera engine function

P0_18 15 Output Camera engine function

p0_13 0 Input GPIO as VSYNC input

P0_15 0 Input GPIO as Pixel clock input

Table continues on the next page...

Camera Interface in LPC55(S)xx, Rev. 1, 10/2020

Application Note 5 / 9

Page 6

NXP Semiconductors

Table 2. Pin function (continued)

Pin Function number Input/output Description

P0_16 2 Output CLKOUT

P1_20 5 Input/output FC4_I2C_SCL

P1_21 5 Output FC4_I2C_SDA

P1_2 6 Output LSPI_HS_SCK

P0_26 9 Output LSPI_HS_MOSI

P1_3 6 Input LSPI_HS_MISO

P1_1 5 Output LSPI_HS_SSEL1

Library and API routine

p1_11

P0_29 1 Input FC0_USART_RX

P0_30 1 Output FC0_USART_TX

0 Output GPIO

From P0_0 to P0_7 are the low eight bits, they can be read by engine at one read instruction which only takes one system

clock cycle.

P0_18 is set as camera engine function. It can be operated by engine directly such as set logic high level, clear zero, toggle and

so on. P0_18 will be toggled by engine after every VSYNC edge.

P0_13 and P0_15 are input function pins which can receive the VSYNC and pixel signals. The Pixel clock is 1/4 of clock source,

it is 12.5 Mhz.

As clock output pin, P0_16 will provide 50 MHz clock to camera as its clock source.

The LSPI_HS is high speed SPI interface which will be used to drive the LCD TFT screen.

7.4.4 LCD function

LCD is used to display the video of camera in real time. High-speed SPI is used to drive the LCD. The routine named by

LCD_Refresh() is a very high efficiency routine, it can refresh a 320 × 240 picture in about 24 ms, up to 40 fps. The bus clock of

high speed SPI can reach up to 50 MHz. The DMA isn’t used to drive the LCD. Instead, only software is used to drive LCD where

the Arm core writes the SPI FIFO data write register once it is empty.

Figure 3. LCD function

Camera Interface in LPC55(S)xx, Rev. 1, 10/2020

Application Note 6 / 9

Page 7

NXP Semiconductors

Demonstration

7.4.5 OV7670 camera module

The camera module is set as QVGA RGB565 mode. The 16-bit data will be received with two pixel edges (high-byte first and

low-byte follows).

At the beginning, the MCU initializes the camera through I2C interface. Then, the video stream data will be stored in the RAM by

camera engine.

7.4.6 Reserved 46_IRQHandler

Same with other peripheral handler, camera engine handler will be implemented by Arm core when engine finishes the

storage operation.

In the handler, a flag will be set as one. In the while(1) routine, the refreshing operation can be allowed when flag turns to

logic one.

7.4.7 Data buffer

There needs 150 KB space for one frame of video and LPC55S59 has about 300 KB RAM space. Double buffer isn’t possible.

Only one buffer is used. Because the LCD refresh time (24 ms) is shorted than data storage time (33 ms), so Arm always reads

the data for LCD refresh is earlier than storage operation by engine. Therefore, the media data won’t be lost.

7.4.8 Timing

The LCD always displays the previous frame data from the camera. Before displaying, the data stored needs to be optimized by

co-processor for exchanging the high and low bytes of every pixel. Because the speed of LCD module displaying is higher than the

speed of camera interface reading data, the single data buffer is used in this application. While the current frame data is stored,

the LCD displays the previous frame data.

8 Demonstration

1. Build and compile the project.

2. Plug one side of USB cable in PC USB port and another side in the debug link port in the EVK board, and then

download the image in the MCU.

3. Connect camera to MCU by referring to connection of interface in Chapter 4.

4. Connect the LCD panel with Arduino port on the LPCXpresso55s69 EVK board.

5. Connect one side of USB cable to USB power socket and the other to 5 V Power only USB port P5.

6. The LCD will display the video frame from camera as shown in Figure 4.

Camera Interface in LPC55(S)xx, Rev. 1, 10/2020

Application Note 7 / 9

Page 8

NXP Semiconductors

Revision history

Figure 4. Video frame

9 Revision history

Table 3. Revision history

Rev. Date Description

0 05/2020 Initial release

1 10/2020 Replaced LPC55(S)xx for LPC55S69

A Purchasing LCD module used in this demo

Purchase the LCD board at these links:

• https://www.waveshare.com/2.8inch-tft-touch-shield.htm

• http://www.waveshare.net/shop/2.8inch-TFT-Touch-Shield.htm

Camera Interface in LPC55(S)xx, Rev. 1, 10/2020

Application Note 8 / 9

Page 9

How To Reach Us

Home Page:

nxp.com

Web Support:

nxp.com/support

Information in this document is provided solely to enable system and software implementers

to use NXP products. There are no express or implied copyright licenses granted hereunder

to design or fabricate any integrated circuits based on the information in this document. NXP

reserves the right to make changes without further notice to any products herein.

NXP makes no warranty, representation, or guarantee regarding the suitability of its products

for any particular purpose, nor does NXP assume any liability arising out of the application

or use of any product or circuit, and specifically disclaims any and all liability, including

without limitation consequential or incidental damages. “Typical” parameters that may be

provided in NXP data sheets and/or specifications can and do vary in different applications,

and actual performance may vary over time. All operating parameters, including “typicals,”

must be validated for each customer application by customer's technical experts. NXP does

not convey any license under its patent rights nor the rights of others. NXP sells products

pursuant to standard terms and conditions of sale, which can be found at the following address:

nxp.com/SalesTermsandConditions.

While NXP has implemented advanced security features, all products may be subject to

unidentified vulnerabilities. Customers are responsible for the design and operation of their

applications and products to reduce the effect of these vulnerabilities on customer’s applications

and products, and NXP accepts no liability for any vulnerability that is discovered. Customers

should implement appropriate design and operating safeguards to minimize the risks associated

with their applications and products.

NXP, the NXP logo, NXP SECURE CONNECTIONS FOR A SMARTER WORLD, COOLFLUX,

EMBRACE, GREENCHIP, HITAG, I2C BUS, ICODE, JCOP, LIFE VIBES, MIFARE, MIFARE

CLASSIC, MIFARE DESFire, MIFARE PLUS, MIFARE FLEX, MANTIS, MIFARE ULTRALIGHT,

MIFARE4MOBILE, MIGLO, NTAG, ROADLINK, SMARTLX, SMARTMX, STARPLUG, TOPFET,

TRENCHMOS, UCODE, Freescale, the Freescale logo, AltiVec, C‑5, CodeTEST, CodeWarrior,

ColdFire, ColdFire+, C‑Ware, the Energy Efficient Solutions logo, Kinetis, Layerscape, MagniV,

mobileGT, PEG, PowerQUICC, Processor Expert, QorIQ, QorIQ Qonverge, Ready Play,

SafeAssure, the SafeAssure logo, StarCore, Symphony, VortiQa, Vybrid, Airfast, BeeKit,

BeeStack, CoreNet, Flexis, MXC, Platform in a Package, QUICC Engine, SMARTMOS, Tower,

TurboLink, UMEMS, EdgeScale, EdgeLock, eIQ, and Immersive3D are trademarks of NXP

B.V. All other product or service names are the property of their respective owners. AMBA,

Arm, Arm7, Arm7TDMI, Arm9, Arm11, Artisan, big.LITTLE, Cordio, CoreLink, CoreSight, Cortex,

DesignStart, DynamIQ, Jazelle, Keil, Mali, Mbed, Mbed Enabled, NEON, POP, RealView,

SecurCore, Socrates, Thumb, TrustZone, ULINK, ULINK2, ULINK-ME, ULINK-PLUS, ULINKpro,

µVision, Versatile are trademarks or registered trademarks of Arm Limited (or its subsidiaries)

in the US and/or elsewhere. The related technology may be protected by any or all of patents,

copyrights, designs and trade secrets. All rights reserved. Oracle and Java are registered

trademarks of Oracle and/or its affiliates. The Power Architecture and Power.org word marks and

the Power and Power.org logos and related marks are trademarks and service marks licensed

by Power.org.

©

NXP B.V. 2020. All rights reserved.

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

Date of release: 10/2020

Document identifier: AN12868

Loading...

Loading...