Nuvo V1350 User and service manual

Nuvo Surgical Light

User, Installation, & Maintenance

Manual

Model V1350 Series

For Parts or Technical Assistance

USA and CANADA (800) 663-1152

INTERNATIONAL (814) 899-4220

S2Z00124-05

This page left blank intentionally

S2Z00124-05

- 3 -

Nuvo Surgical Light

Revision Letter

Pages Affected

Date

Original Issue

May, 2003

Revision 01

16,23.25.28

September 2003

Revision 02

5, 24

April 2004

Revision 03

Cover, 1, 3, 4, 5, 9, 14,

20, 21, 22, 23, 24, 25, 26,

27, 28, 29, 30, 31,

July 2004

Revision 04

All (combined with user

& service manuals)

October 2009

User, Installation & Maintenance

Manual

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 4 -

© 2003 by Nuvo, Inc. ALL RIGHTS RESERVED.

No part of this text shall be reproduced or transmitted in any form or by

any means, electronic or mechanical, including photocopying, recording,

or by any information or retrieval system without written permission from

Nuvo, Inc. (Nuvo).

First Printing 2003

Printed in the USA

The information contained in this manual is subject to change without

notice.

Nuvo makes no commitment to update or keep current, the information

contained in this manual.

This manual is not applicable to monitor ready light systems.

The only product warranty intended by Nuvo is the express, written

warranty accompanying the bill of sale to the original purchaser. Nuvo

makes no other warranty, express or implied, and in particular, makes no

warranty of merchantability or fitness for a particular purpose.

Additional copies of this manual can be obtained from Nuvo.

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 5 -

Table of Contents

1.0 User Information .............................................................................................................................. 6

2.0 Installation of the Nuvo Surgical Light ..........................................................................................18

2.1 Check the ceiling structure............................................................................................................. 20

2.2 Ceiling Mounting Plate ...................................................................................................................22

2.3 Base Plate Alignment .....................................................................................................................24

2.4 Vertical Tube Installation ...............................................................................................................27

2.5 Ceiling Control/Transformer Box Installation ................................................................................29

2.6 Optional Wall Control.....................................................................................................................31

2.7 Counterbalance Arm Assembly ......................................................................................................34

2.8 Voltage Adjustments .......................................................................................................................36

2.9 Ceiling Shroud Installation .............................................................................................................39

2.1.0 Final Installation Verification ........................................................................................................40

3.0 Preventive Maintenance ..................................................................................................................41

4.0 Post-installation Inspection ............................................................................................................ 42

5.0 Maintenance ....................................................................................................................................42

5.1 Operator Interface ..........................................................................................................................43

5.2 Electrical System ........................................................................................................................... 44

6.0 Troubleshooting Procedures .......................................................................................................... 50

6.1 Initial Action .................................................................................................................................. 51

6.2 Function Checks............................................................................................................................. 52

6.3 Final Actions .................................................................................................................................. 54

6.4 Surgical Light Does Not Turn On (Lamp Control ) ...................................................................... 54

6.5 Surgical Light Does Not Turn On ( Wall Control ) ....................................................................... 56

6.6 Intensity Level Does Not Adjust ( Lamp Control ) ....................................................................... 58

6.7 Intensity Level Does Not Adjust ( Wall Control ) ......................................................................... 60

6.8 Surgical Light Does Not Turn Off ( Lamp Control ) .................................................................... 62

6.9 Surgical Light Does Not Turn Off ( Wall Control ) ...................................................................... 63

6.0.1 Transformer Control ......................................................................................................................64

6.0.2 Suspension Arm Drift Horizontal ..................................................................................................65

6.0.3 Counterbalance Arm Drift Vertical ...............................................................................................66

6.0.4 Yoke Drift Horizontal ....................................................................................................................67

6.0.5 Lighthead Drift Horizontal ............................................................................................................68

7.0 Lens Removal ...................................................................................................................................69

7.1 Lens Replacement .............................................................................................................................71

7.2 Counterbalance Arm Assembly ........................................................................................................72

7.3 Brakes ................................................................................................................................................75

7.4 Counterbalance Arm Adjustment .....................................................................................................76

7.5 Lighthead Assembly Adjustment ......................................................................................................80

8.0 Replacement Parts .............................................................................................................................81

9.0 Technical Specs ................................................................................................................................90

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 6 -

Positioning_______

Suspension arms rotate

continuously Lighthead

rotates continuously

Sterile Handle Control

Drift free positioning

Reduction of visual

Clutter Minimal airflow

disturbance

Illumination

Performance_____

Lighting control from inside

the sterile field

Computer modeled reflector

Shadow-free Illumination

Excellent color rendition

Low heat output

Maintenance

Features__________

Built-in backup lighting

Spare bulb storage in

wall control box

Sterile Handle Control

is easily sterilizeable.

1.0 User Information

Intended Use

The Nuvo Surgical Light is intended to provide a field of illumination in surgical,

diagnosis or treatment applications. The single light head configuration is intended for

minor surgical, diagnosis, and/or treatment applications and may be used in the situation

where the treatment or procedure can be interrupted. The dual and triple light head

configurations may be used in operating rooms for all surgical applications and where a

fail safe condition is required; alternatively, two singles, or a dual plus a single, are often

installed.

Introduction

This manual provides the information required for normal operation of the Nuvo Surgical

Light from Nuvo. Before operating the Nuvo Surgical Light, be sure that you have read

and understood in detail the contents of this manual. It is important that you read and

strictly adhere to the aspects of safety contained in this manual.

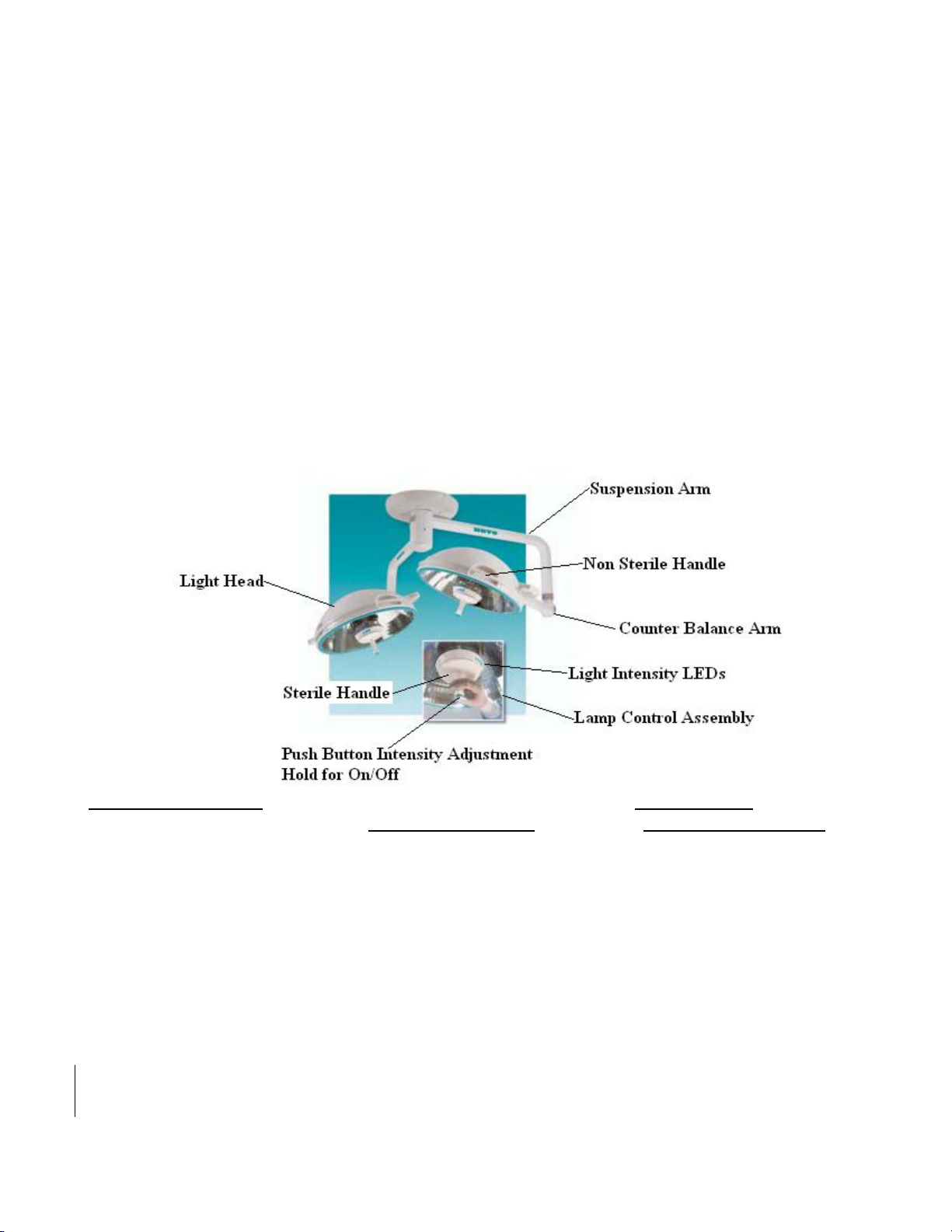

Product Overview

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 7 -

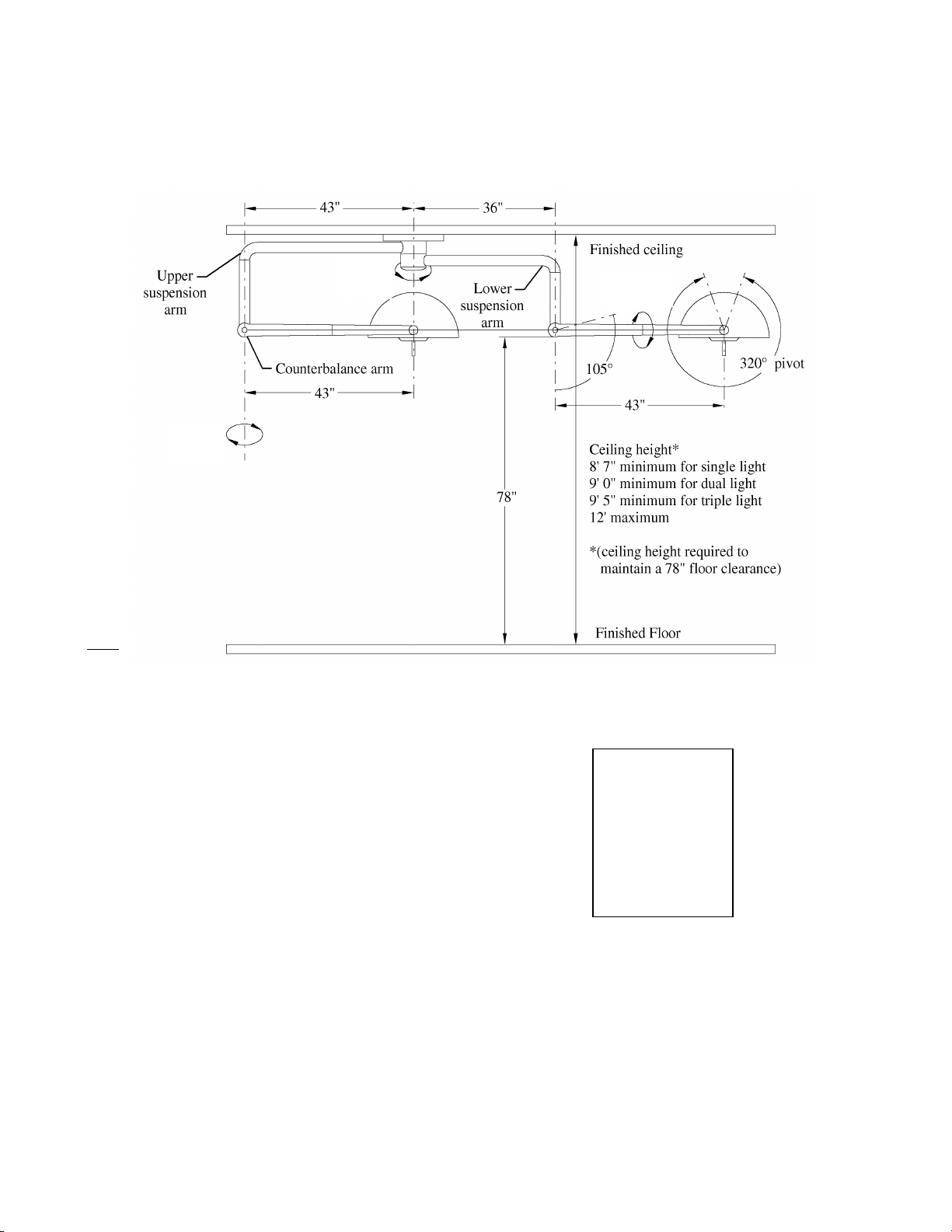

Positioning

The Nuvo Surgical Light provides the surgeon with a suspension system that is perfectly

balanced and can be guided effortlessly into any position.

The upper and lower suspension arms can rotate continuously around the ceiling mount.

The longer upper arm allows both arms to be positioned independently without

interfering with one another.

The counterbalance arms also rotate continuously around their vertical extensions. These

extension pieces are custom sized according to the ceiling height, assuring adequate head

clearance.

The yoke assembly, which holds the light head, turns continuously around the end of the

counterbalance arm. The light head pivots 320° inside the arms of the yoke.

The combination of these individual elements allows medical personnel to move the light

freely into an infinite variety of positions using only slight pressure on the Sterile Handle

Control. Once positioned, the system remains stable, without drifting, allowing focus to

remain where it belongs...on the patient.

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 8 -

Illumination Performance

• The Sterile Handle Control gives the user full command of the Nuvo Surgical Light.

Positioning, intensity, and pattern size can all be easily controlled from inside the sterile

field. A second set of intensity controls is conveniently located on a wall mounted panel.

• The Nuvo Surgical Light’s compact, 23" (58.4 cm) diameter light head combination

provides color-correct, shadow free illumination well suited to a wide variety of

procedures.

• The perfectly-honed inner reflective surface of the light head features 1890 reflective

facets computer designed for maximum light intensity and shadow reduction.

• With the generation of so many individual light rays, a large percentage of the projected

light can be blocked before any shadow is evident.

• Deep cavity illumination negates the need to refocus midway through a procedure. The

minimum depth of field, without refocusing, is 20" (50.8 cm).

• Each light head delivers 137,000 lux (12700 foot candles) and the color temperature of

the lamp has been optimized at 4300°K to ensure the color clarity of the surgical site.

• The use of a custom designed IR filter reduces emitted IR to a 3.8 μW/cm2fc average.

This low heat output ensures maximum comfort during long procedures.

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 9 -

Easy Maintenance Features

Backup Lighting and Bulb Replacement

To assure that the Nuvo Surgical Light will offer peak performance on demand, each

Light head is equipped with two bulbs. In the event that the primary bulb burns out

during normal operation, the backup will take over immediately. The changeover

happens so quickly that it is transparent to the user.

The quartz tungsten-halogen bulbs employed in the lamp provide as many as 1000 hours

of uninterrupted light before they need to be replaced. Spare bulbs are conveniently

housed in the wall control box. When necessary, fast, simple bulb replacement can be

accomplished in minutes between cases and without the need for special tools.

Cleaning and Sterilization

Special attention has been given to the aesthetics of the Nuvo Surgical Light. The

smooth, clean lines are visually appealing and aid in the prevention of dust particle buildup. Enhanced streamlining greatly reduces air turbulence over the surgical field.

The Sterile Handle Control is compatible with a wide range of sterile covers. It can also

be easily removed for steam sterilization or cold sterilization.

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 10 -

Instructions for Use

WARNING:

Do not operate the light if the glass filter is broken or removed. Operation without

the glass filter or with a broken glass filter could cause high levels of ultraviolet

and infrared radiation resulting in injury to the patient or user.

To identify a broken glass filter, inspect for the following:

1. Changes in the light pattern.

2. Loose particles under the lens.

3. Rattling noise when moving the light.

WARNING:

Not for use in areas of explosion hazard. This apparatus is neither approved nor

certified for use in areas where combustible or explosive gas mixtures are likely

to occur.

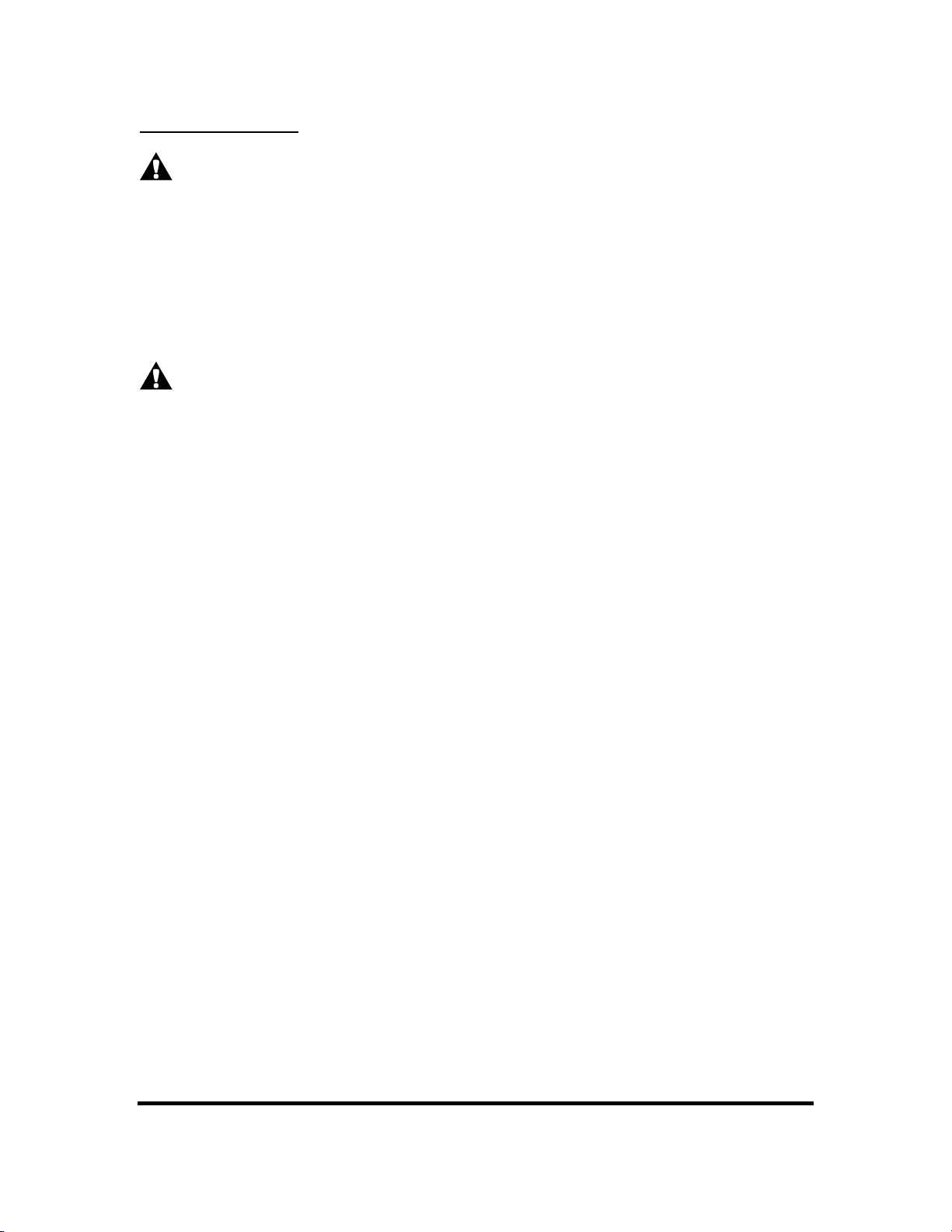

The light can be turned on or off by the use of the push button located at the center of the

sterilizable handle, or by the push button mounted on the wall control unit (both operate

in the same order). The push button on the sterilizable handle overrides the wall control

unit, thereby enabling medical personnel to operate the light in the general vicinity of the

sterile area.

The push button turns the light ON/OFF, and also controls the intensity level of the light.

When the light is turned on, LED’s located on the side of the sterile handle collar, and on

the wall control, illuminates to indicate the intensity level.

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 11 -

To Turn ON:

Push the button in once, and release. The blue LED’s located on the side of the handle

collar, and on the wall control, illuminate to indicate the intensity level.

NOTE:

After a power outage, the light automatically comes on at the intensity level that it was at

when the power was disconnected.

To Decrease/Increase Brightness Intensity:

Push the button in once, and release. Each time the button is pushed, the level of intensity

is decreased, until only one blue LED is illuminated. The brightness intensity goes back

to full intensity if the button is pushed and released again.

NOTE:

If the button is depressed and held for three seconds, the light goes off.

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 12 -

On / Off

Button

To Turn OFF:

Push the button in, and hold for three seconds.

The light goes off and all five blue LED’s located

on the side of the handle collar go off.

To Change the Light Pattern:

Grasp the handle, and rotate clockwise

to enlarge the light pattern. Rotate

counterclockwise to reduce the light

pattern.

To Remove the Sterile Handle and

Reinstall:

To Remove:

1. Grasp the handle, and rotate

counterclockwise. Remove handle.

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 13 -

To Install:

1. Inspect the O-ring for wear

or aging and replace if

necessary.

2. Install the handle onto the

light core

3. Rotate the handle

clockwise until fully seated

Step: 1

Step: 2

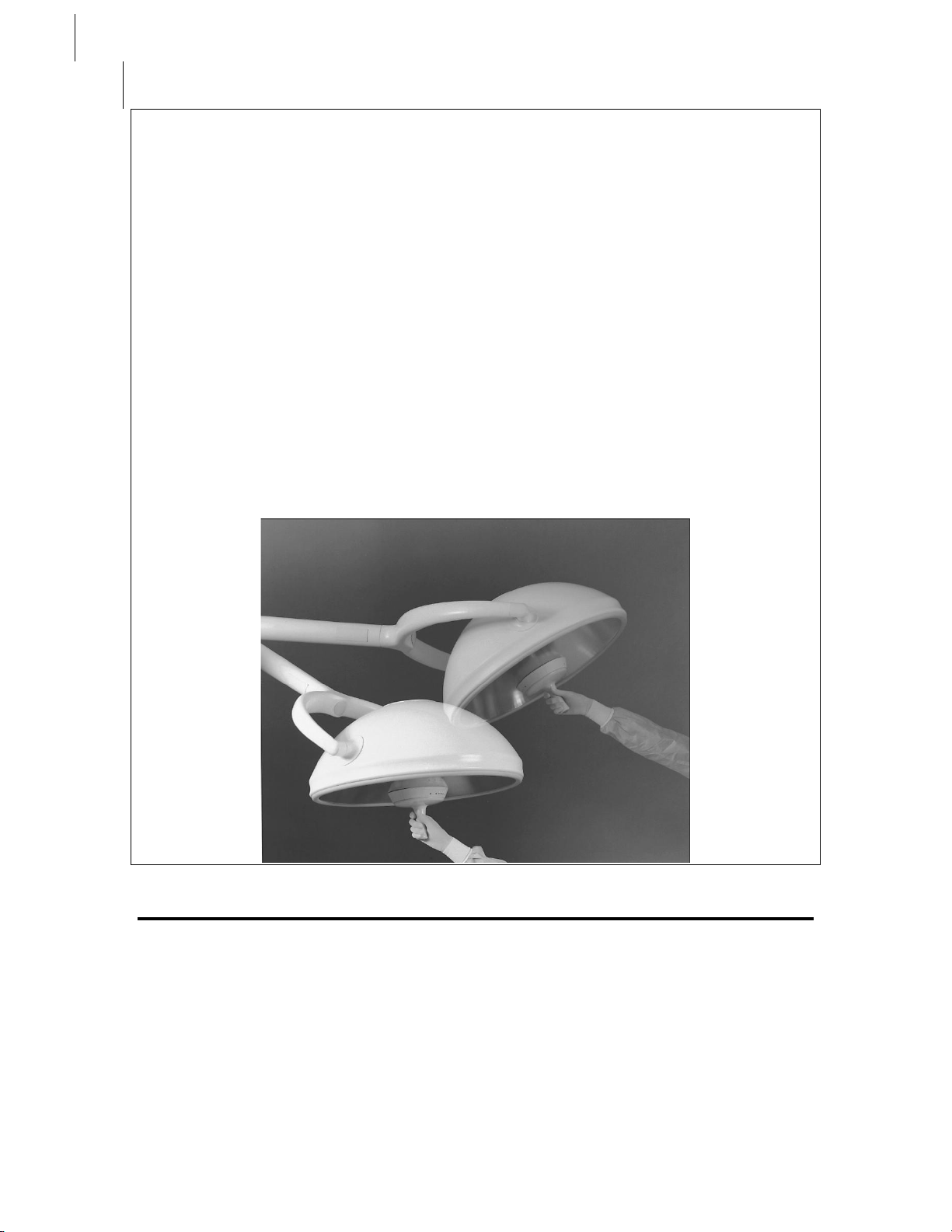

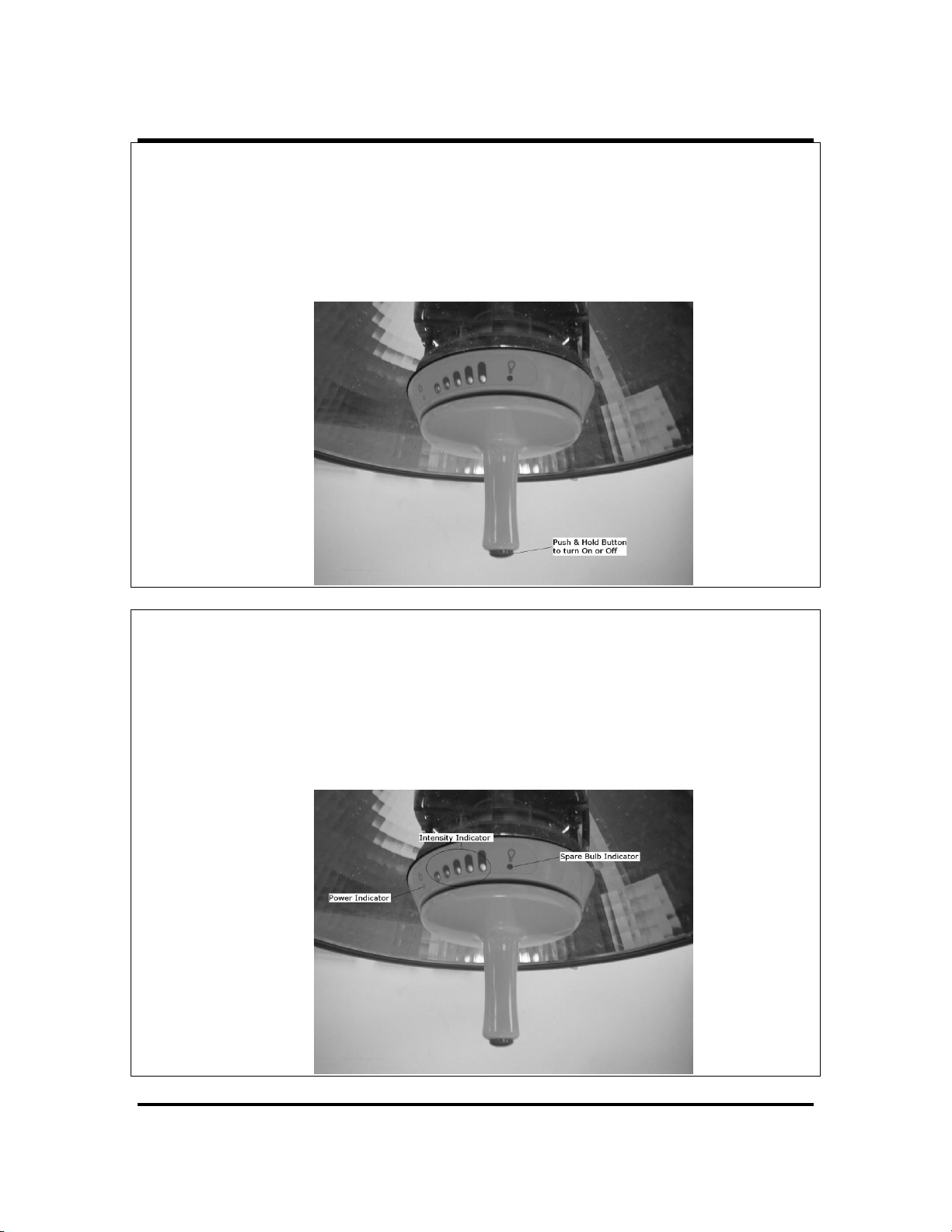

To Position the Lighthead:

CAUTION:

Do not hang equipment or other

unauthorized items on any part of the

light such as the arms and yoke. This

could cause the light to drift

unnecessarily. Damage to equipment

can occur

Using Central Sterile Handle

Grasp either the central sterile handle or one

of the four non-sterile handles set into the

lighthead cover, and position the lighthead

assembly in the desired position. A nominal

2 lb to 4 lb

(2.7 N·m to 5.4 N·m) force on either handle

produces up and down movement of the

suspension arm and counterbalance arm.

NOTE:

When positioned at any point, the lighthead

assembly moves quietly and smoothly

throughout its range of maneuverability

without drifting.

Using Non-sterile Handle

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 14 -

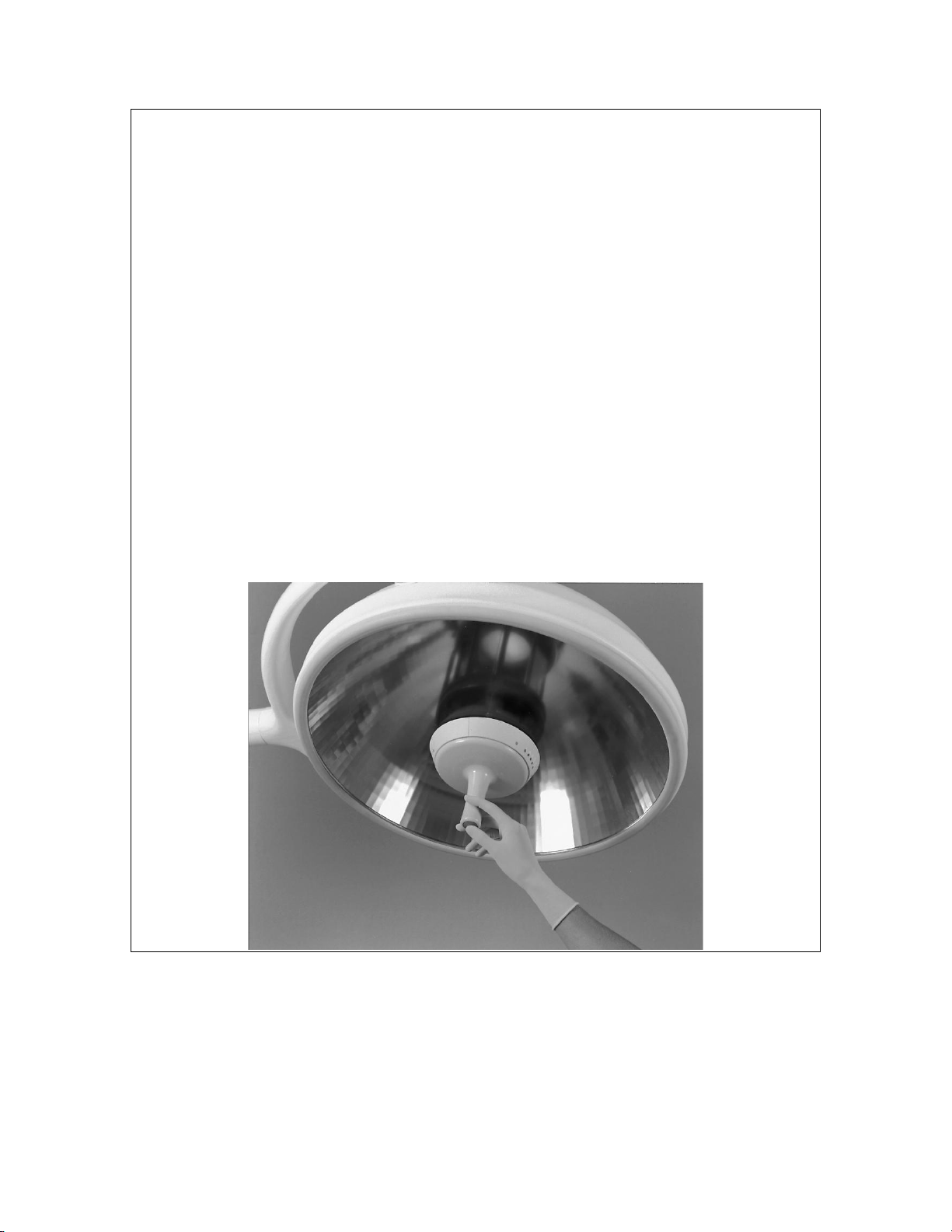

Lamps

Two quartz tungsten-halogen lamps are provided for each light head assembly. Only one lamp is

energized at a time. The primary lamp is on the optical center of the light head, while the backup lamp

is displaced slightly from the optical center.

Yellow spare bulb light located on the wall control and on the lamp control assembly illuminate when

the primary lamp is not working. If the yellow lamp is on, replace the primary bulb as soon as possible.

CAUTION:

Use only Nuvo lamp S2Q00006. If other lamps are used, damage to equipment can occur

and performance will be compromised.

Lamp Removal and Installation:

WARNING:

The lamp is HOT while in operation. Make sure sufficient time is allowed for the lamp to cool

completely before removal, or personal injury can occur.

CAUTION:

Make sure the light head assembly is supported when loosening the four thumbscrews.

Damage to equipment can occur if not done properly.

CAUTION:

Do not touch the lamp bulb. Always grasp the ceramic base, being careful not to touch

the glass of the bulb. Touching the glass could result in damage to the bulb and could

decrease the bulb life. If bulb is touched use alcohol pad to wipe off.

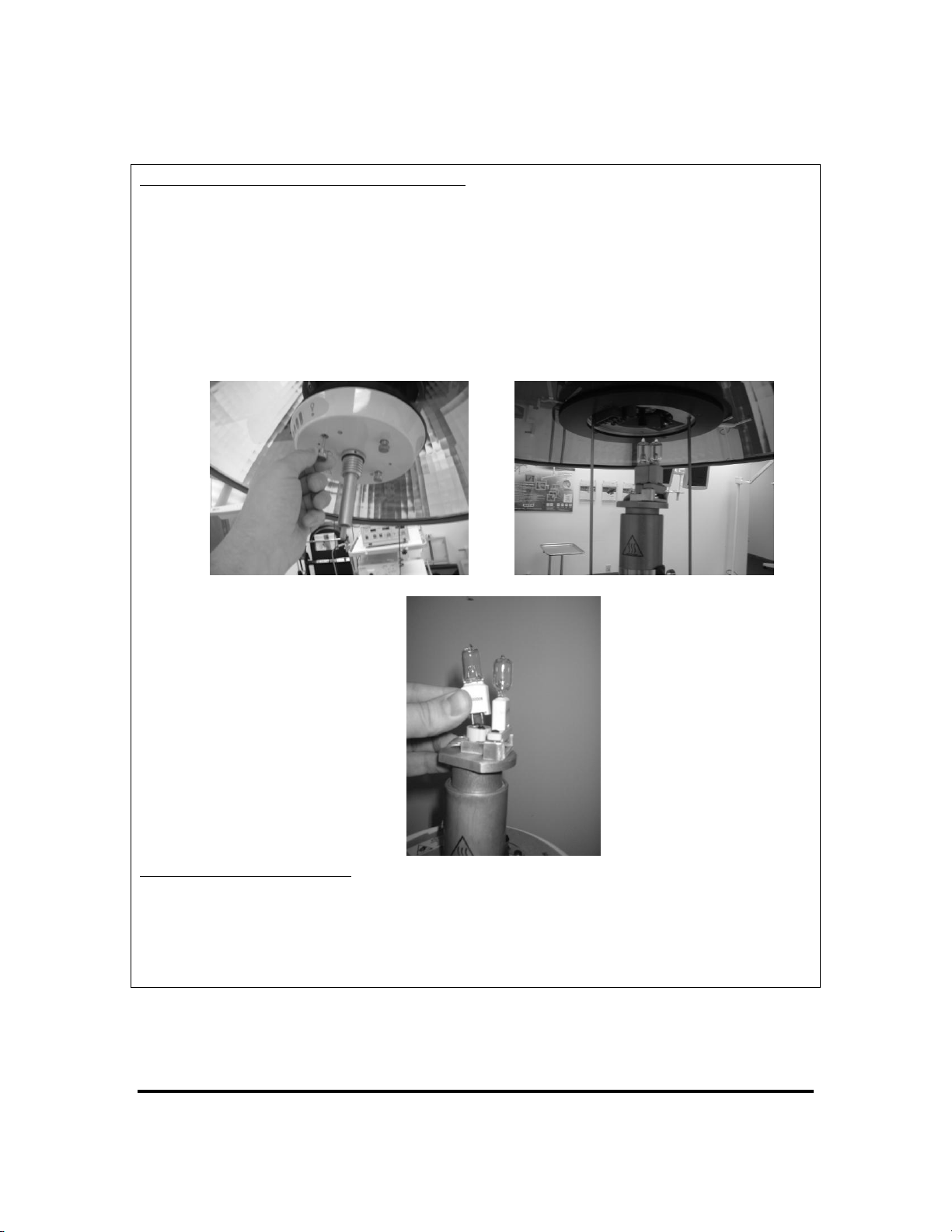

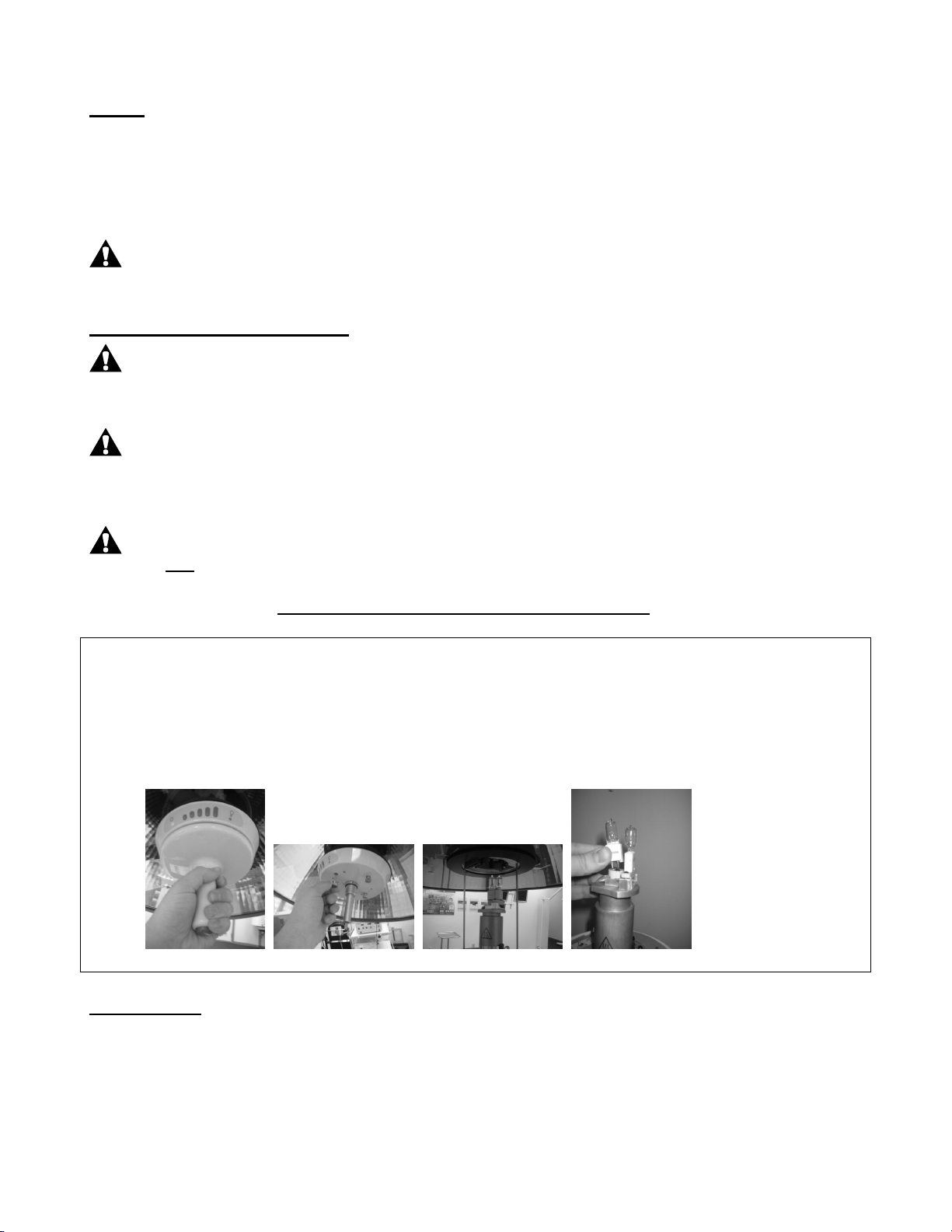

To Remove:

1. Grasp the sterilizable handle, and rotate counterclockwise. Remove the handle.

2. Support the light head by temporarily holding the light head assembly by the yoke or by one of the

four non-sterile handles set into the light head cover.

3. Loosen the four thumb-screws from the light head assembly.

4. Gently lower the light core assembly, leaving it hanging from the four tether rods.

5. Remove and replace the lamp.

Step: 1 Step: 3 Step: 4 Step: 5

To Reinstall:

1. Raise the lamp control assembly, and secure with the four thumbscrews.

2. Inspect the O-ring for wear or aging and replace if necessary.

3. Install the handle, and rotate clockwise until fully seated. Refer to previous steps.

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 15 -

Cleaning/Sterilization

Sterilize Cycle

Temperature

Exposure

Time

Dry Time

Gravity Displacement

270-274◦ @30psi (132-134◦ C

@207 kPa)

4 min

1 min Flash

20-25 wrapped

Pre-Vacuum

270-274◦ @30psi (132-134◦ C

@207 kPa)

4 min

1 min Flash

20-25 wrapped

Cleaning: Using enzymatic detergents aids in the decontamination process. All detergents should be

measured carefully and used in accordance with the manufacturer’s instructions.

Care should be taken to avoid the use of cleaning materials that contain high concentrations of alcohol

or chlorine as these may lead to premature aging of the lens.

Sterilization: Sterilization can be accomplished by using any FDA approved sterile liquid (USA only).

In areas outside the USA, individual facility policies addressing the use of sterile liquids should be

employed.

Sterilizable Handle

After every surgical operation:

• Remove the handle from the light head

• Wipe with a disposable cloth

• Clean and disinfect in a suitable cleaning and disinfecting machine

• Sterilize the handle

The sterilizable handle can be sterilized three ways:

• Cold by using cleaners recommended for hospitals and authorized by a competent health authority.

• Steam

• Flash in either gravity displacement or pre-vacuum sterilizers.

The minimum flash exposure times are shown in the following table: (Or refer to local codes / facility

your procedures.)

Handle Cleaning and Sterilization

The sterilized handle should only be fitted immediately before use.

NOTE:

Service Life of Sterilizable Handle: Frequent sterilization causes natural degradation to the replaceable

handle. If signs of material fatigue such as cracking or discoloration occur, the handle should be

replaced.

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 16 -

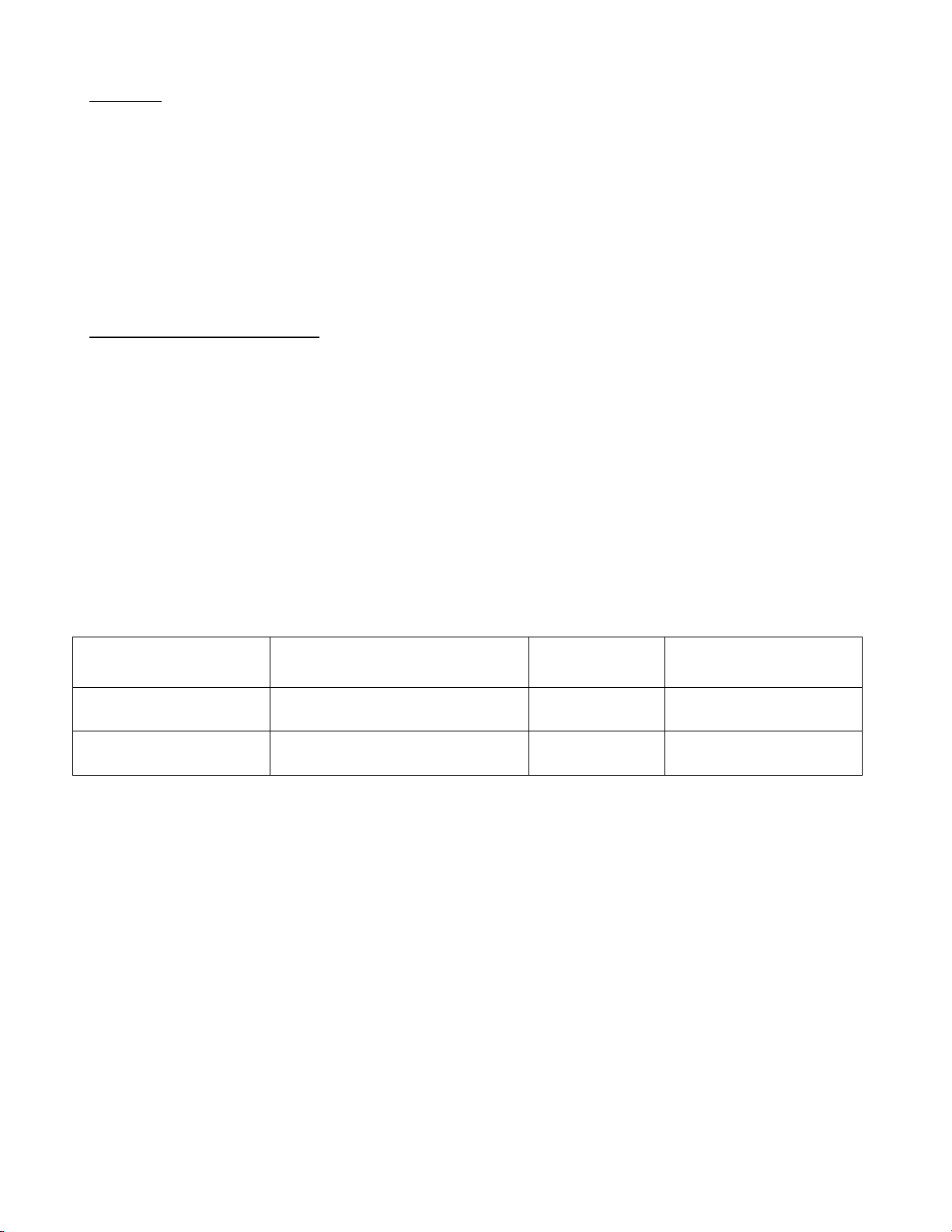

Optional Sterile Handle Covers

The sterile handle accepts the use of the Devin®1 LiteGlove flexible light handle cover, or equivalent

products from Medical Action or DeRoyal.

To install the handle cover, take the cover from its packaging. Unfold the cover as needed.

Install the cover over the sterilizable handle.

NOTE:

Care must be taken to prevent the cover from interfering with the intensity control button located on

the sterilizable handle.

Handle without the cover installed. Handle with cover installed.

1. Devin® is a registered trademark of Devin Industries, Inc.

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 17 -

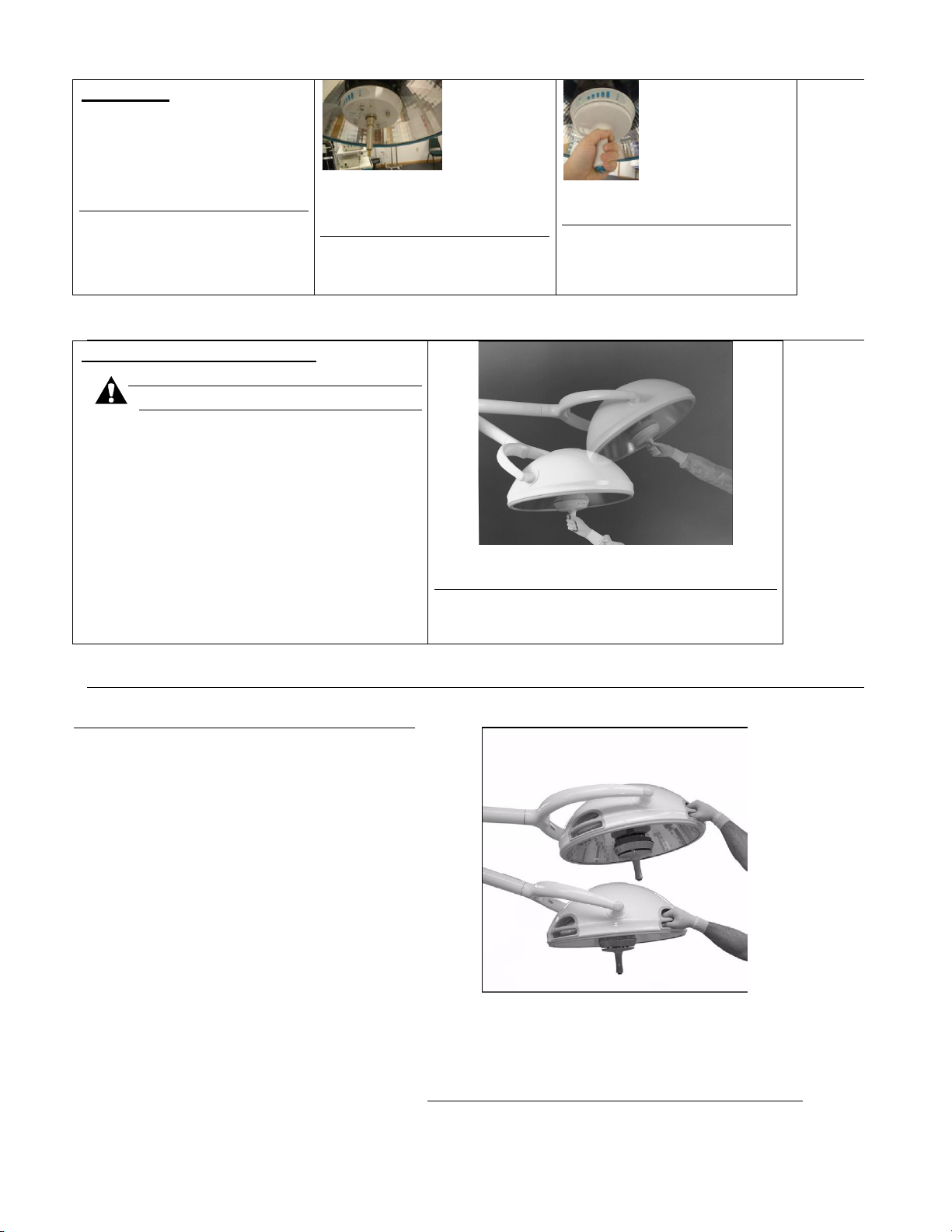

2.0 Installation of the Nuvo Surgical Light

WARNING:

Only facility-authorized personnel should install the Nuvo Surgical Light. Installation performed by unauthorized personnel could result in personal injury or

equipment damage

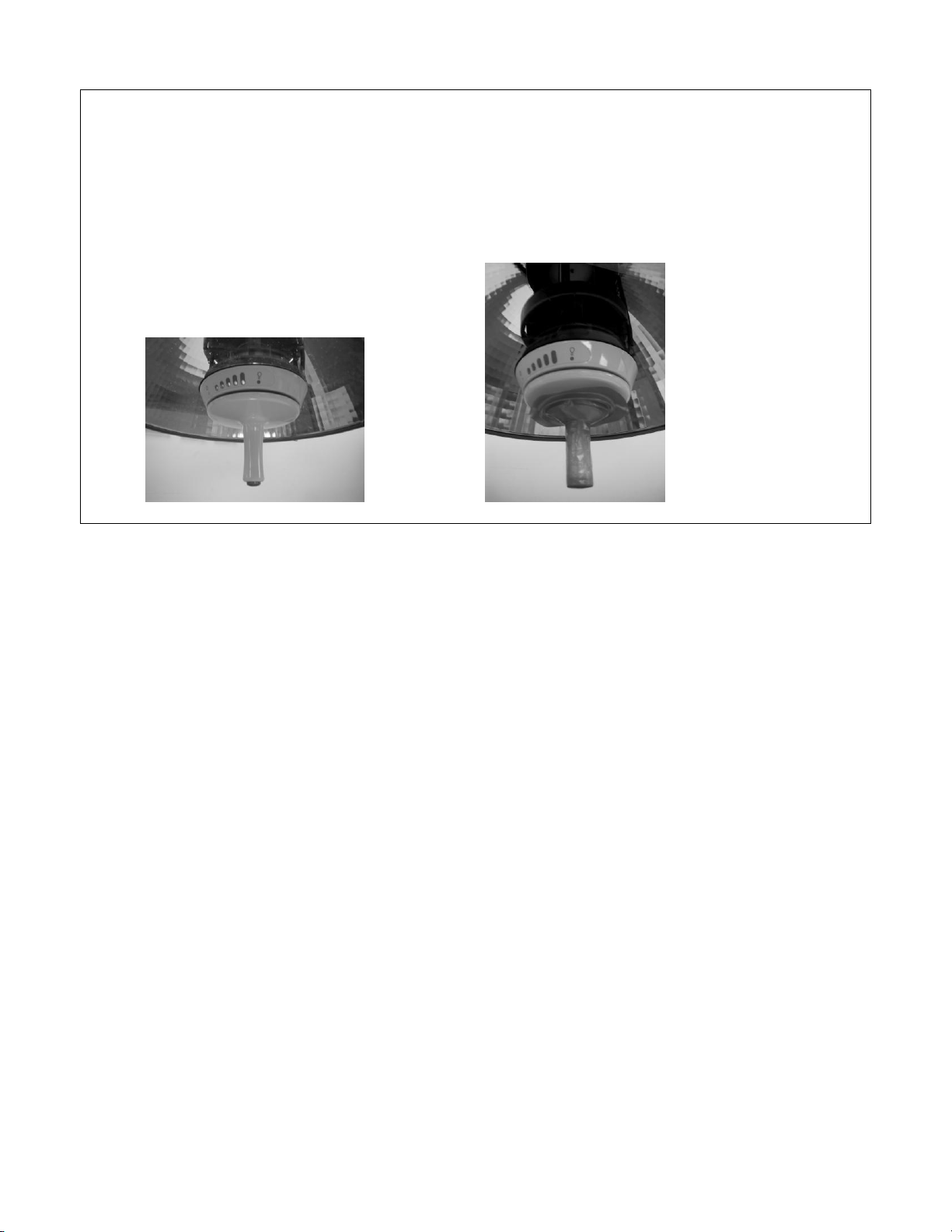

Introduction

This part of the User, Installation & Maintenance manual describes how to install the Nuvo Surgical

Light. Prior to installation, carefully read through and understand all of the installation instructions for

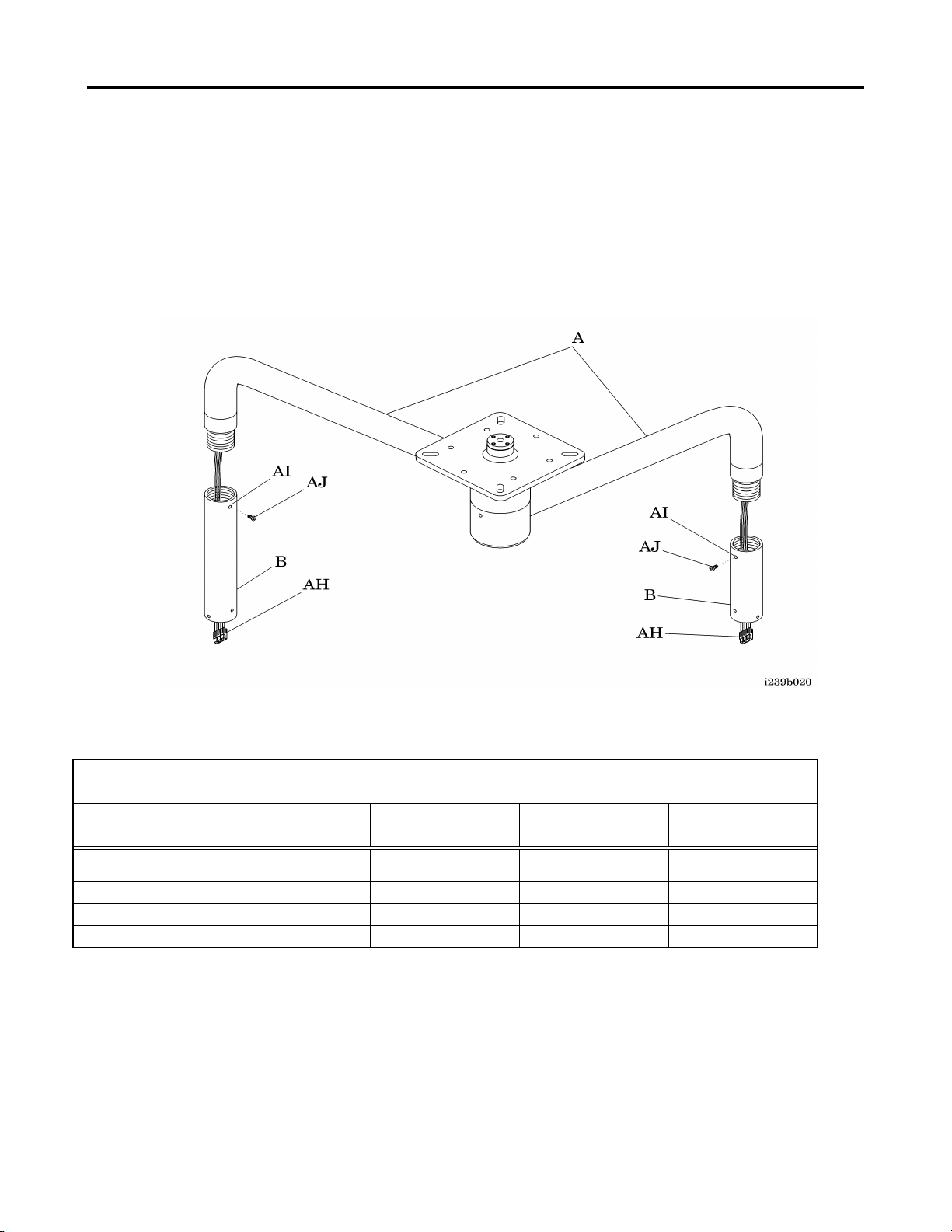

the Nuvo Surgical Light components: the suspension arm assemblies (A), with vertical tubes (B) and

the counterbalance arm assemblies (C) with lighthead/yoke assemblies (D) (see figure below), and

ceiling Control / transformer Box (see figure 12 on) and Wall Control Box (see pages 20 through page

22).

This User, Installation & Maintenance manual is for all models of the Nuvo Surgical Light: 100V,

120V, 220V, and 230/240V.

Figure 2.0.1. Nuvo Surgical Light Components

!

NOTE:

The Nuvo surgical Light must be wired to an emergency power circuit, so in the event of power

interruption, there will be a change over to emergency operation within 5 seconds

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 18 -

Checklist

Tools required: 1/2"(12.7 mm) drive ratchet 15/16"(24 mm) deep socket

Allen™1 wrench set Phillips head screwdriver

Precision level Tape

(2) Step ladders 3/4"(19 mm) wrenches

3/4"(19 mm) deep socket 15/16"(24 mm) wrenches

Jeweller’s screwdriver True RMS Multimeter

Before installing please check the following:

Height of finished ceiling, and floor to ceiling clearance requirements are met.

Contractor supplied ceiling structure is installed and leveled correctly.

Ceiling structure meets moment and vertical load requirements.

Ceiling structure will not deflect significantly when load is applied.

Clearance requirements for locating the control box above the finished ceiling are met.

Conduit from the wall control box to the ceiling control box.

Access to power is available.

NOTE:

The hole in the ceiling should not exceed 18” diameter on center of the light hub. The ceiling shroud is

20” diameter.

Nuvo Surgical Light Installation

1

Allen™ is a trademark of Industrial Fasteners, Inc.

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 19 -

Continuous

Rotation

Continuous

Rotation

Continuous

Rotation

78” = 198 cm

43” = 109 cm

36” = 91 cm

8’7” = 257 cm

9’0” = 274 cm

9’5” = 287 cm

12’ = 366 cm

Conversion Table from inches to

Centimeters.

Before you install the light, check the Clearances.

Figure 2.02. Circular Motion Range

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 20 -

Configuration

Moment Load

Vertical Load

Single Lighthead

410 ft-lb (556 N-m)

155 lb (71 kg)

Single Lighthead – Monitor Ready

720 ft-lb (976 N-m)

275 lb (125 kg)

Dual Lighthead

795 ft –lb (1078 N-m)

260 lb (118 kg)

Dual Lighthead – Monitor Ready

1105 ft-lb (1498 N-m)

380 lb (172 kg)

Triple Lighthead

1160 ft-lb (1573 N-m)

365 lb (166 kg)

WARNING:

The contractor-installed ceiling structure must not deflect more than 0.062" (1.57mm)

when the load is applied. Improper installation could result in personal injury or

equipment damage.

WARNING:

Verify the minimum finished ceiling height requirement of 8’ 7" (262 cm) for a single

light, 9’ (274cm) for a dual light, and 9’5" (287 cm) for a triple light.

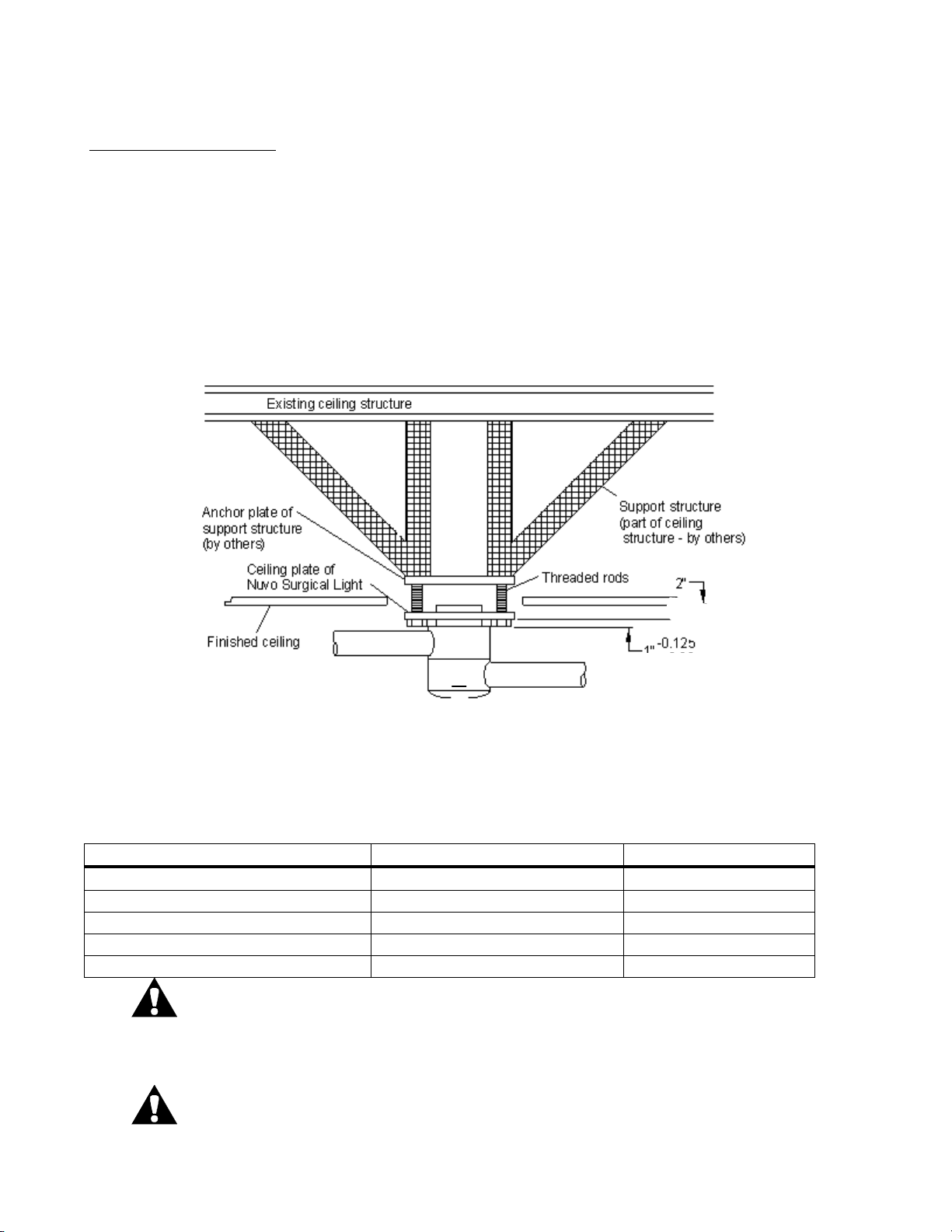

2.1 Check the Ceiling Structure

Ceiling Bearing Strength

The medical facility is required to supply a ceiling structure that is capable of sustaining the load

requirements for the contractor installed lighting system. To accomplish this, it may be necessary to

contract with an architect and certify that the Nuvo Surgical Light can be installed safely. The

following table shows calculated worst case load conditions for mounting single, dual, and triple

lighthead configurations. Worst case is defined as having all arm, monitor, and lighthead assemblies on

the same side of the ceiling plate with the lightheads fully extended from the ceiling plate. Improper

installation could result in personal injury or equipment damage. The contractor-installed ceiling

structure and mounting studs must be capable of supporting the following moment loads and vertical

weights (see figure 2.1.1and table 2.1.1):

Figure 2.1.1. Ceiling Bearing Strength

Ceiling Bearing Strength

Table 2.1.1. Load Requirements for the Nuvo Surgical Light

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 21 -

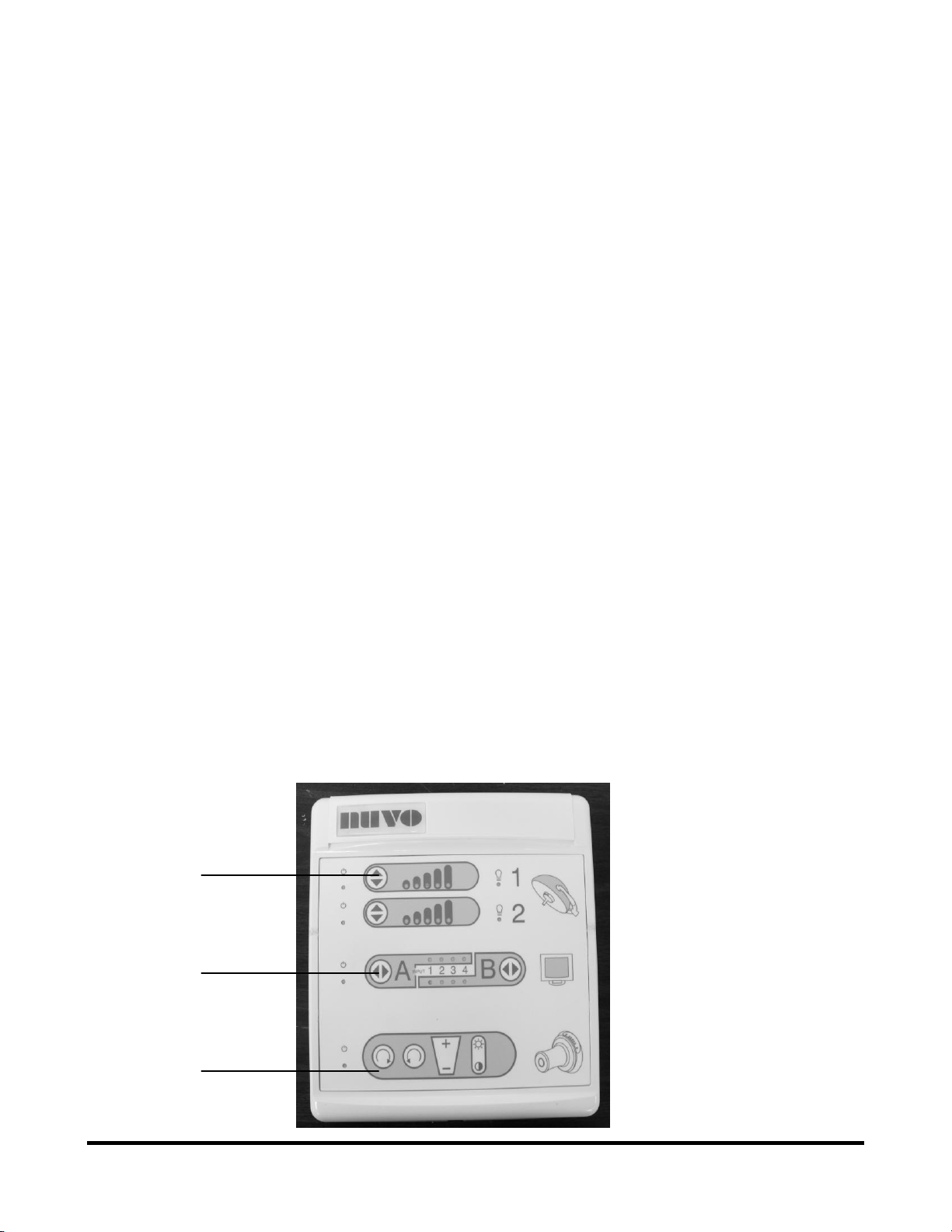

Ceiling control / Transformer Box

Monitor Controls

Light Control

Camera Control

Select a suitable location to mount the Ceiling Control Box (if not installed previously) within 50 feet

(15.24 meters) of the Nuvo Surgical Light. The selected location should provide room for a technician

to be able to remove the cover and access the voltage adjustment.

Typical locations include:

above the ceiling next to an access panel,

above the ceiling next to a removable lighting fixture,

above the ceiling of an adjacent hallway with removable panels,

in an electrical cabinet on the wall either inside or adjacent to the OR

The control box for single and dual lights measures 8½"(22 cm) x 16"(41 cm), and for a triple light

8½"(22 cm) x 21 ¼(54 cm). Sufficient room above the box is required to remove the cover and adjust

the voltage. A total height of at least 18" is preferred.

If the ceiling control / transformer box is to be located more than 4’ (four feet) from the mounted light

hub, an extension cable must be ordered. These extension cables are available in 6’, 12’, 18’, 25’ and

48’ lengths.

Wall Control Box

The wall control box measures 10" x 10 1/2"(25.4 cm x 26.7 cm) square and is 1 3/4"(4.4 cm) deep. It

connects to a standard two gang 4"(10.2 cm) x 4"(10.2 cm) back box recessed into the wall at

approximately 60” from the floor. A location where this control will be readily accessible to the

circulating nurse should be selected. The wiring harness (35′ 10.67 meters Standard), (50′ 15.24 meters

optional) is then routed from the wall box to the ceiling control box.

Single, dual, or triple light configurations can be operated from a single wall control box. The wall

control contains a discrete set of controls for each lighthead in the configuration. Each is numbered to

correspond to the labels on the suspension arms.

Figure 2.1.2. Wall Control Box

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 22 -

2.2 Ceiling Mounting Plate Alignment Installation

1. Check the serial numbers on the shipping containers to make sure that the correct Nuvo Surgical

Light is in the correct room.

2. Make sure that the contractor-installed ceiling structure has been properly installed and leveled

(see figure 5 )

3. Use one of the following mounting hole pattern measurements ( see figure 9 ) to position the

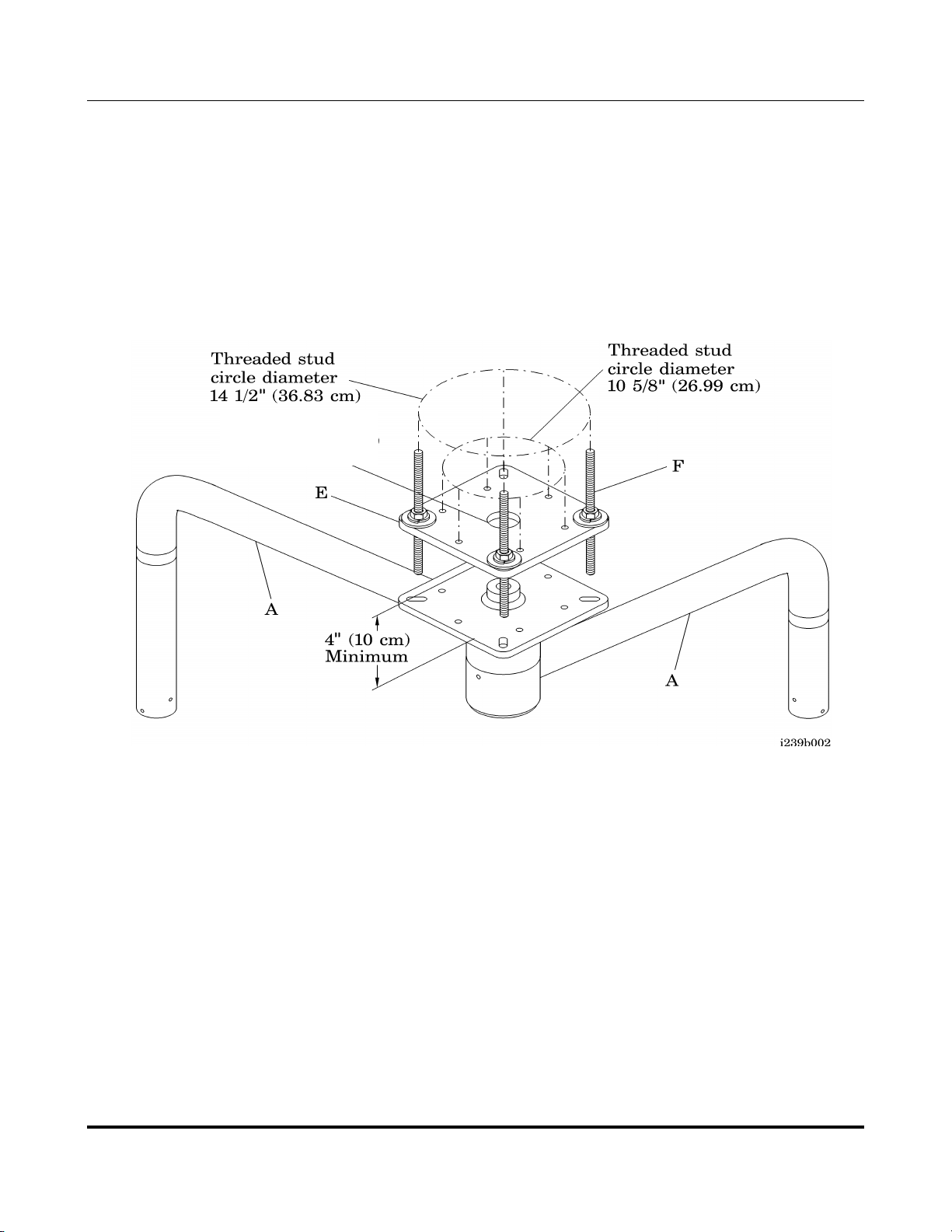

threaded studs (F) for installation of the suspension arm assemblies (A):

Threaded stud circle diameter of 10 5/8" (26.99 cm) for 6 mounting holes

NOTE:

For installation with 6 threaded rods, use a minimum threaded rod size of ½"(12.7 mm) diameter x 13

threads/inch, heat-treated, 4140 alloy steel that is corrosion resistant with a black oxide finish, 125,000

psi tensile strength, and Rockwell C hardness 28-32.

Threaded stud circle diameter of 14 ½" (36.83 cm) for 4 mounting holes (Preferred)

NOTE:

For installation with 4 treaded rods, use a minimum threaded rod size of 5/8"(15.88 mm) diameter x 11

threads/inch, heat-treated, 4140 alloy steel that is corrosion resistant with a black oxide finish, 125,000

psi tensile strength, and Rockwell C hardness 28-32.

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 23 -

Part Description

Quantity

Anchor plate

1

5/8″(1.6 cm) Threaded rod (min. length 8″(20.3 cm))

(max. length 14″(35.6 cm))

4

5/8″(1.6 cm) x 1 1/2″(3.8 cm) hardened washer

16

5/8″(1.6 cm) nut

16

Bottom Surface of the

base plate

2 1/4" (5.72 cm)

Mounting Plate Alignment Installation

Table 2.2.1 Recommended Ceiling Mounting Plate Configuration Installation Parts

NOTE:

The ceiling structure, treaded rods, nuts, lockwashers, and washer are to be supplied by others.

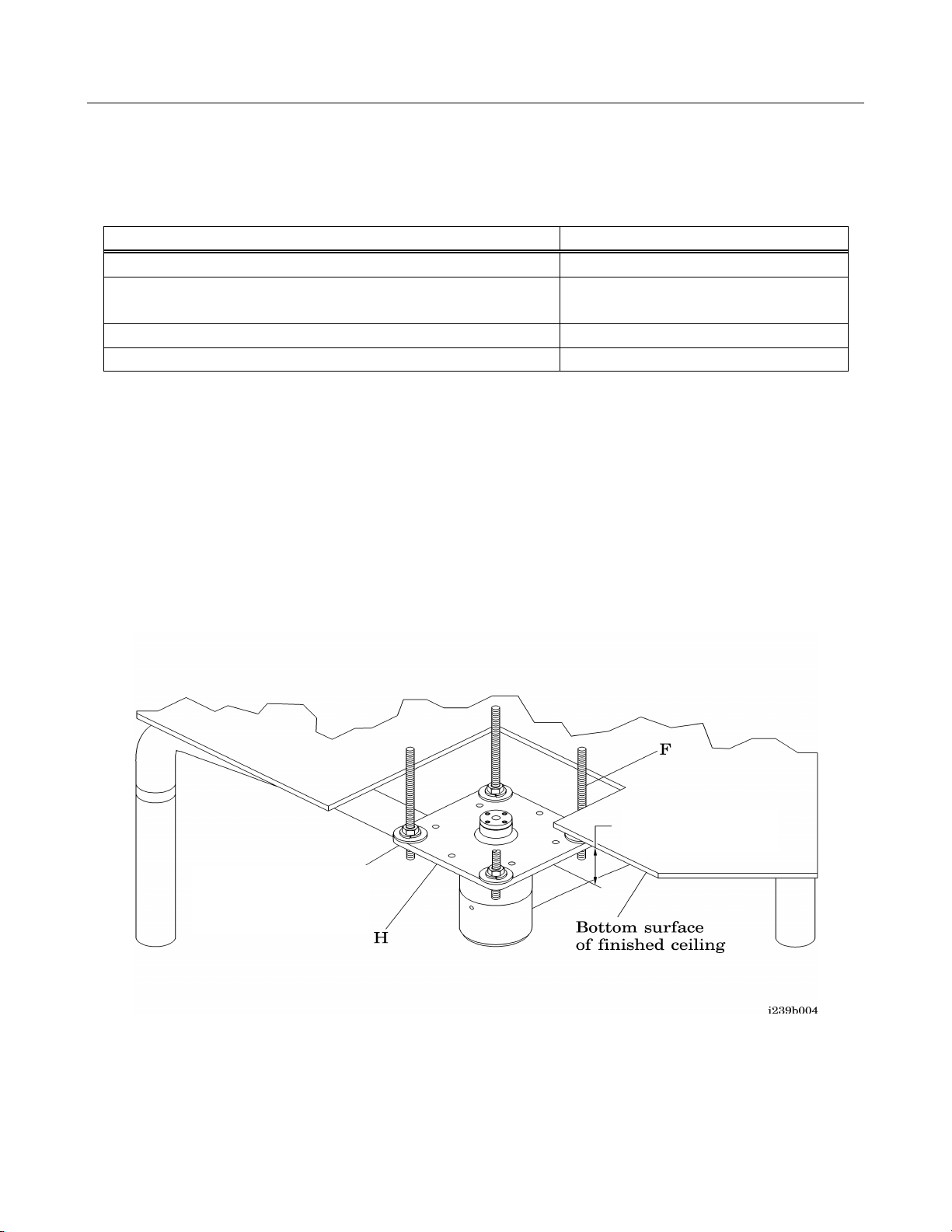

4. Ensure that the suspension arm assembly ceiling base plate (H) will be installed with the bottom

surface 2 1/4" (5.72 cm) below the bottom of the finished ceiling. Or 2 7/8" (7.11 cm) from the

bottom of the finished ceiling to the bottom of the threaded rod (F) to ensure access to the

leveling nuts on both sides of the ceiling base plate (H) (see figure 2.2.1).

Figure 2.2.1. Base Plate Alignment

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 24 -

7” ( 17.78 cm)

Hole

2.3 Base Plate Alignment Installation

5. Make sure that the studs will protrude no more than 1" (2.6cm) from the bottom surface of the

suspension arm assembly ceiling base plate (H) to allow clearance for the ceiling shroud. The

minimum distance between plates after installation is 4" (10cm), and the maximum distance is

7" (18 cm). The threaded rods must protrude below the finished ceiling by 2 7/8" (7.11 cm)

Figure 2.3.1. Mounting Pattern

NOTE:

When mounting the ceiling base plate to the anchor plate, Nuvo recommends that the installation

contractor use the four slotted bolt pattern holes.

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 25 -

Suspension Arm Assembly Installation

WARNING:

Use a lift capable of safely raising the suspension arm assembly to the ceiling mounting point.

Failure to use an appropriate lift could result in personal injury or equipment damage.

P

Weights of Suspension systems are: Single 105 lb (47.6 kg)

(without light heads attached) Single – Monitor Ready 135 lb (61.2 kg)

Dual 155 lb (70.3 kg)

Dual – Monitor Ready 185 lb (84 kg)

Triple 205 lb (93 kg)

1. Remove the top cover of the shipping container, and remove the bag of loose hardware.

2. Place the suspension arm assembly (A) (see figure 6) on the portable lift.

3. Install the threaded rods (F) (figure 6) so they protrude below the finished ceiling by 2 7/8" (7.11

cm)

Figure 2.3.2. Suspension Arm Assembly

`

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 26 -

Suspension Arm Assembly Installation

WARNING:

Follow safety precautions provided by the lift manufacturer when lifting

the suspension arm assembly. Improper operation could result in personal

injury or equipment damage.

WARNING:

Do not work under unsupported lift fixtures. Personal injury could occur.

CAUTION:

The ceiling plate must be level in two directions. Improper operation of the suspension

arm assembly could result in equipment damage.

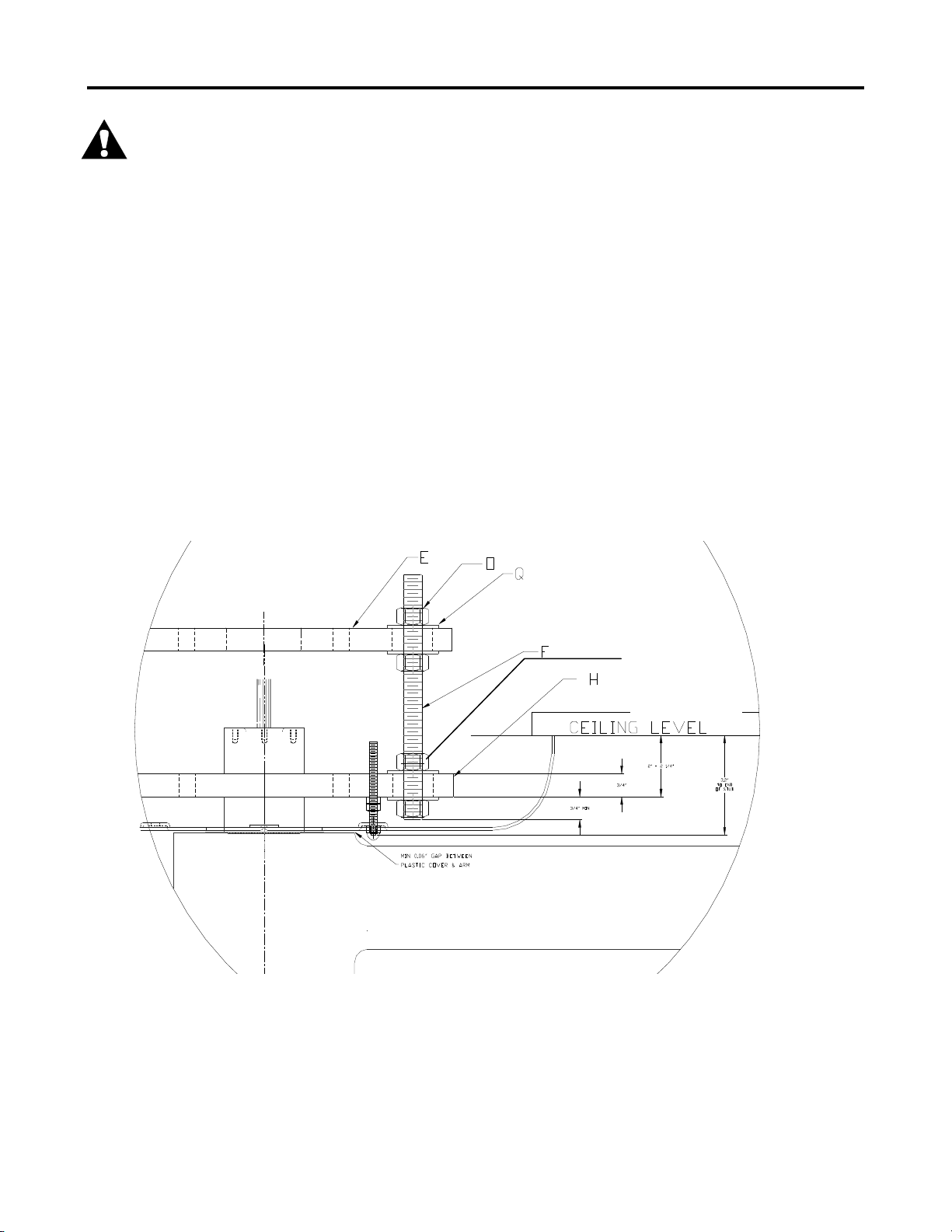

4. Install the serrated flanged nuts (P) (figure 7) on the threaded studs (F) below the field installed

mounting plate.

5. Install the serrated flanged nuts (P) upside down on the threaded studs (F), below the nuts

installed in step 4, flush to the finish ceiling.

6. Raise the suspension arm assembly (A) up to the ceiling.

7. Support the lift with blocks, as needed, while working under the raised suspension arm

assembly (A).

8. Lift the suspension arm assembly (A) until the base plate (H) contacts the flanged nuts.

9. Install the lower washers (Q) and nylon locknuts (O) on the threaded studs (F) to level the

ceiling mounting plate (H).

10. Tighten the nuts (P&O) on the top and bottom of the ceiling base plate (H) and on the top and

bottom of the anchor plate (E) using a pair of ¾” (19 mm) or 15/16” (24 mm) wrenches or

sockets.

Torque to: 80-107 ft-lb (.04-.05 kgf/cm2) for ½″ nuts

160-200 ft-lb (.08-.10 kgf/cm2) for 5/8″ nuts

11. Check the mounting plate (H) for level in two directions (90° from each other) using a

precision level.

12. Adjust and tighten the nuts (O) again, anchoring the suspension arm assembly (A), using a pair

of ¾” (19 mm) or 15/16” (24 mm) wrenches.

13. Make sure the bottom surface of the base plate (H) maintains a distance of 2 1/4 ”

(5 cm) below the finished ceiling line.

14. Remove the blocks under the lift.

15. Remove the lift from under the suspension arm assembly (A)

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 27 -

2.4 Vertical Tube Installation

Table 2.4.1. Finished Ceiling Height

Type

8′ 7″(262 cm) -

8′ 11″(272 cm)

9′ 0″(274 cm) -

9′ 4″(284 cm)

9′ 5″(287 cm) -

9′ 9″(297 cm)

9′ 10″(300 cm) -

10′ 2″(310 cm)

Tube Length

Tube Length

Tube length

Tube Length

SINGLE LIGHT

5″(12.7 cm)

10″(25.4 cm)

15″(38.1 cm)

20″(50.8 cm)

DUAL LIGHT

N/A

5″ & 10″

10″ & 15″

15″ & 20″

TRIPLE LIGHT

N/A

N/A

5″,10″ & 15″

10″, 15″ & 20″

The suspension system may have the vertical tubes pre-installed at the Nuvo factory, if this is the case

then this section does not apply.

1. Remove the vertical tubes (B) from the shipping container, and all of the parts included with the

vertical tube kit box (see figure 2.4.1).

Figure 2.4.1. Vertical Tube Installation

2. Ensure that the vertical tubes (B) you are installing are the proper length for the

Nuvo Surgical Light installation that you are performing (see table 2.4.1).

NOTE:

The longest vertical tube should be installed on the suspension arm assembly closest to the ceiling. The

shorter vertical tube should be installed on the suspension arm assembly closest to the floor.

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

- 28 -

Vertical Tube Installation

3. Test fit the threads on each vertical tube (B) by temporarily screwing it onto the appropriate

suspension arm assembly (A).

NOTE:

The threads may need to be cleaned if the vertical tubes do not screw onto the suspension arm

assemblies smoothly, and without any binding.

4. Ensure that the wiring (AH) extending from the suspension arm assemblies (A) is long enough

to go through the vertical tube (B), and extend slightly out of the end of the vertical tube (B)

when it is screwed onto the suspension arm assembly (A) all of the way.

5. Screw the vertical tube (B) onto the suspension arm assembly (A) until it bottoms out.

6. Unscrew and back-off the vertical tube (B) until the hole (AI) in the vertical tube (B) lines up

with the threaded hole in the suspension arm assembly (A).

NOTE:

This procedure should give you approximately 1/32” (0.8mm) of clearance between the rotating tube

and the stationary portion of the arm.

7. Test the rotation of the suspension arm assemblies (A), and ensure the arm moves smoothly

without any binding.

SIM-S2Z0001 Rev 05 Effective Date 10/25/09

Loading...

Loading...